Patents

Literature

158 results about "Metal precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical precipitation using metal precipitants is a very common treatment modality used to remove dissolved, cationic, metals from solutions such as metal finishing and plating streams. The dissolved metals are converted to an insoluble form, a suspended solids that is, by the chemical reaction between the Tramfloc 900 Series Metal Precipitants and the metallic cation.

Methods for removing heavy metals from water using chemical precipitation and field separation methods

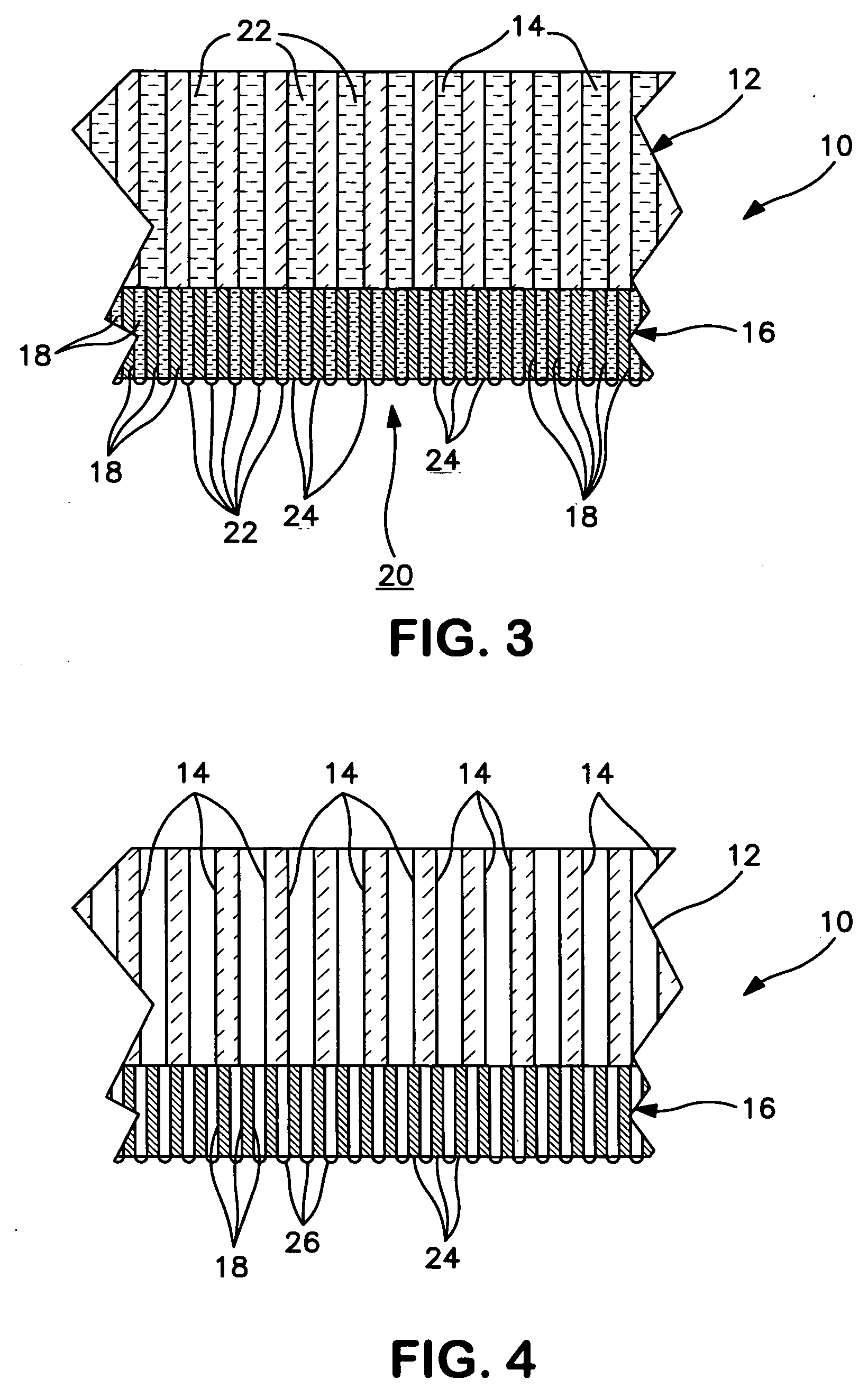

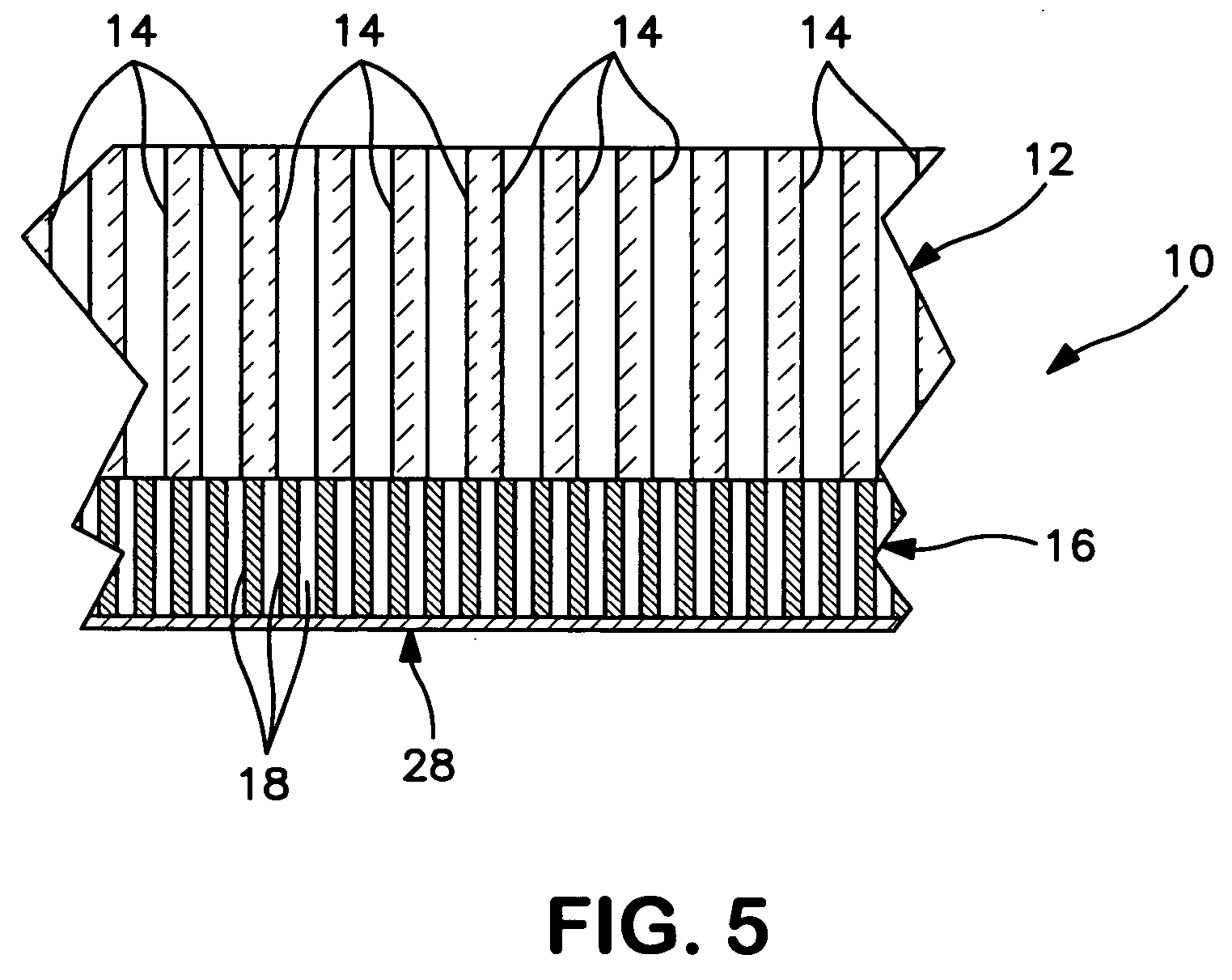

InactiveUS20050258103A1Efficient removalEasy to disassembleSedimentation separationDifferential sedimentationParticulatesSulfide

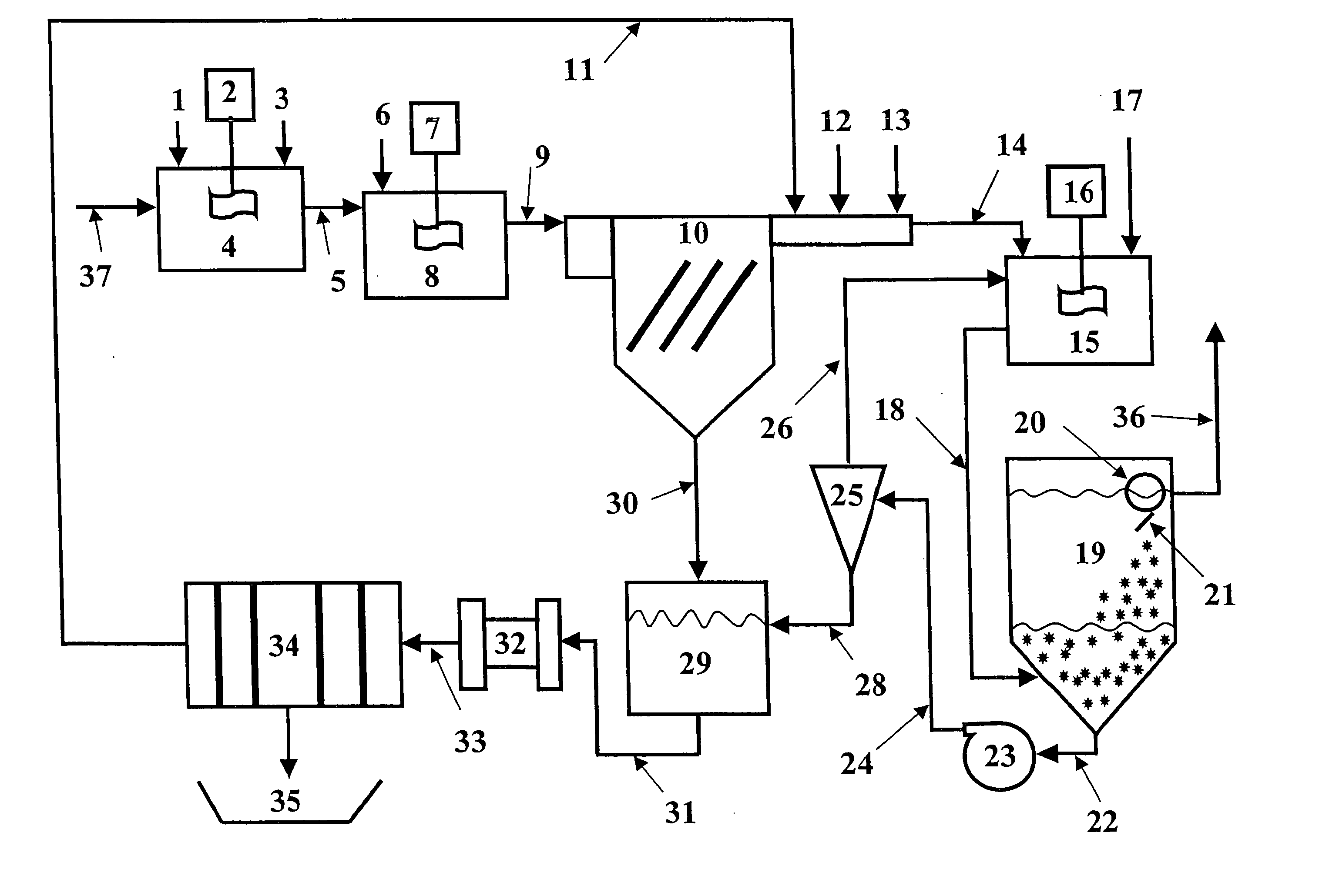

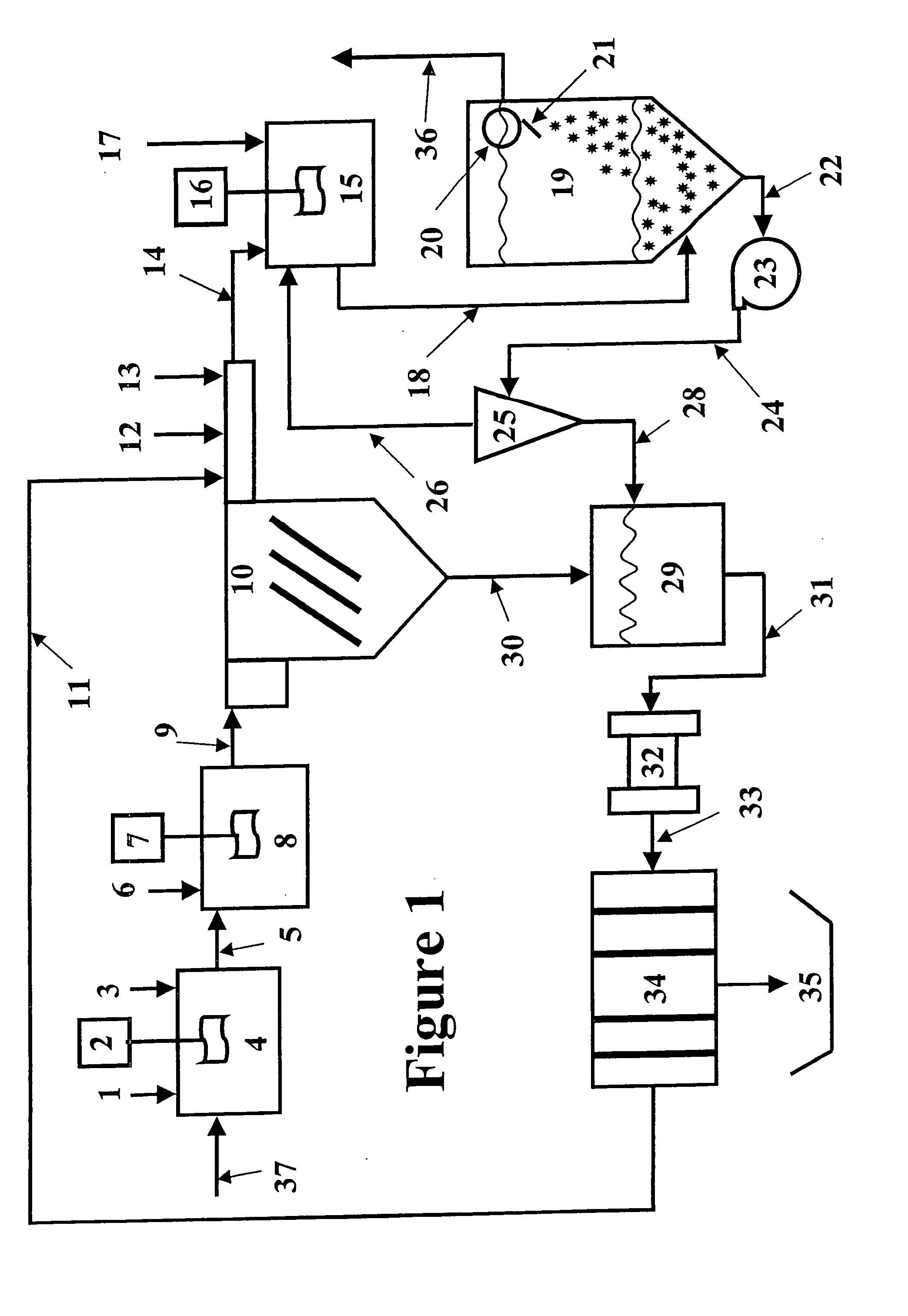

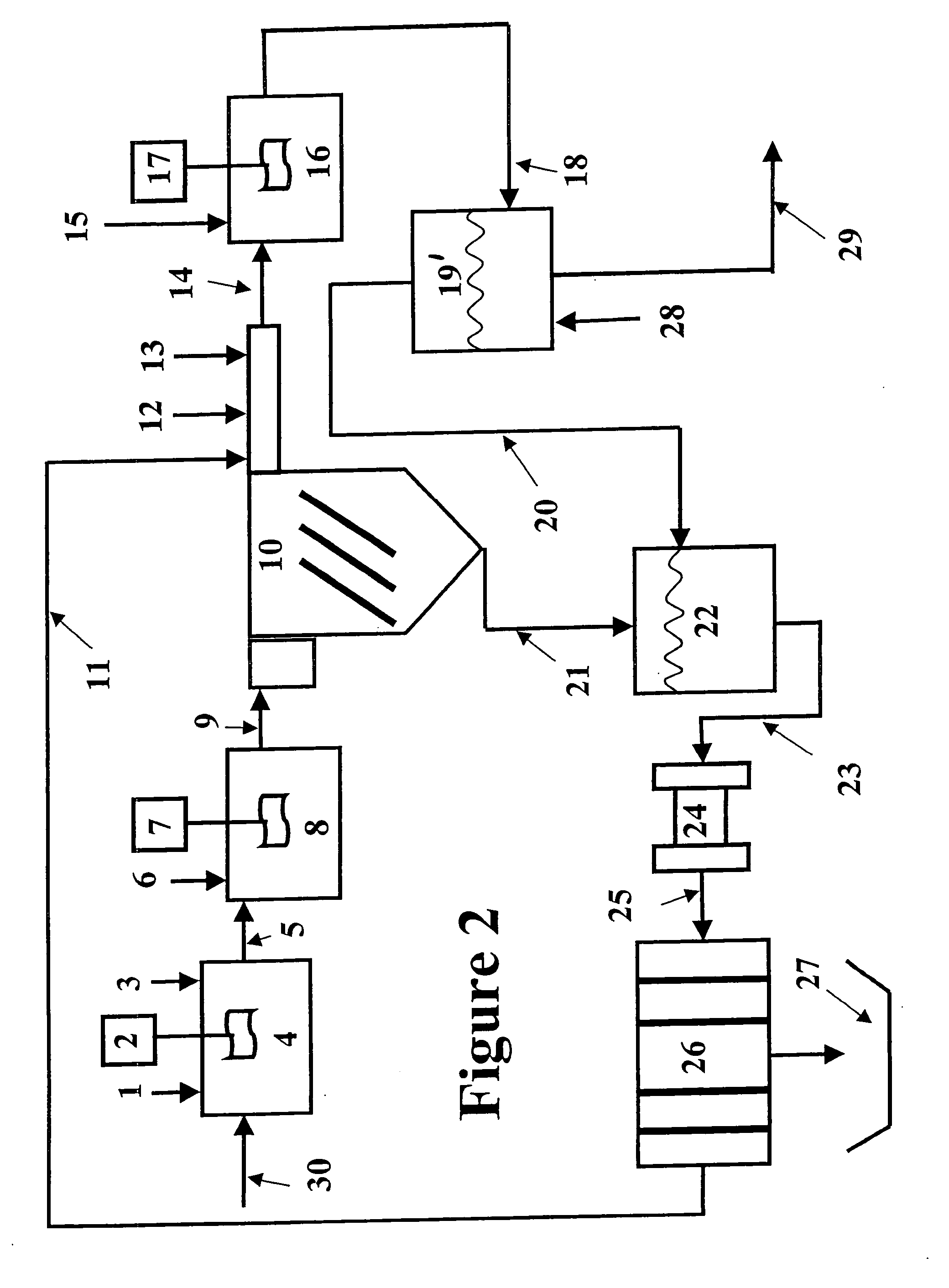

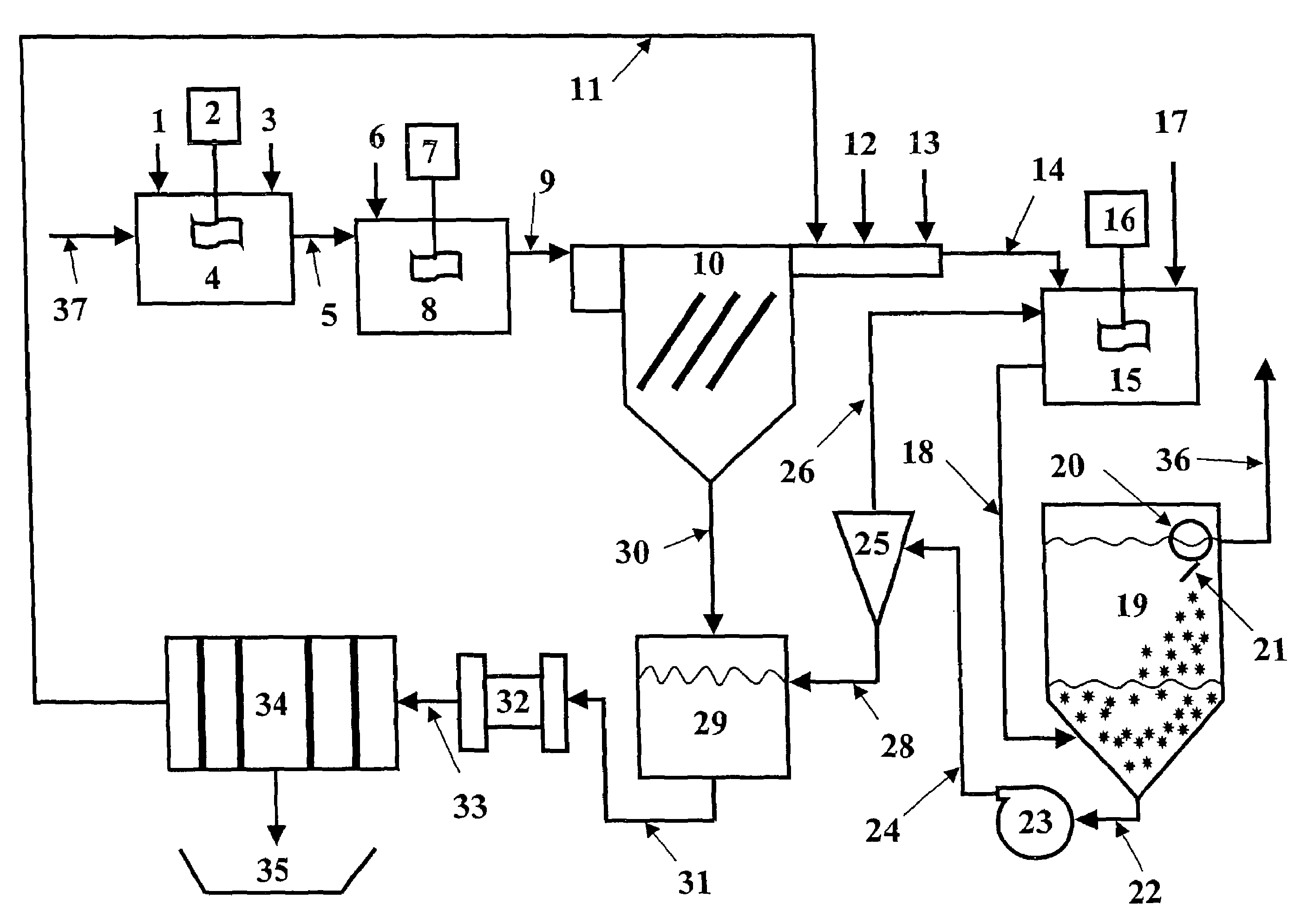

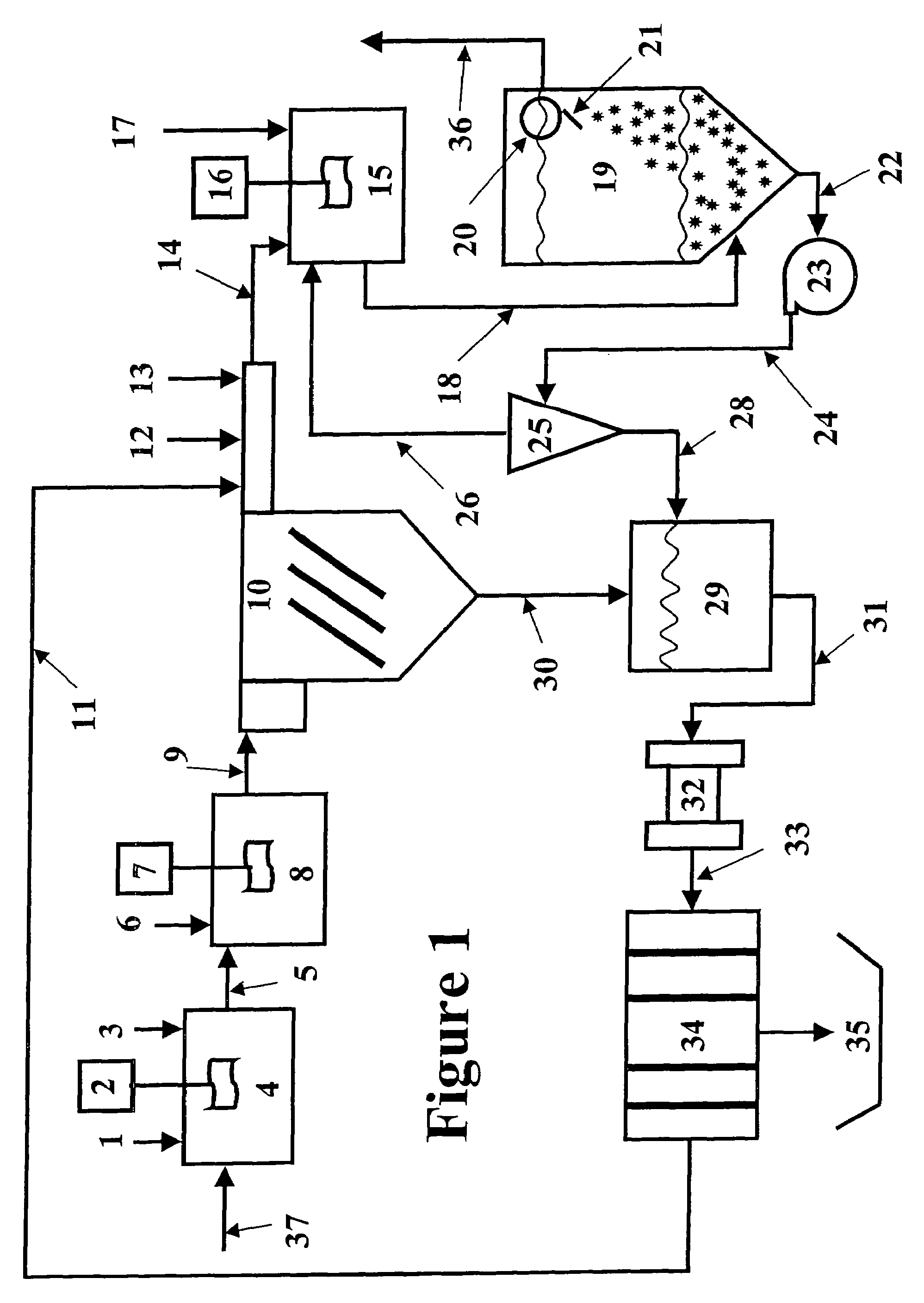

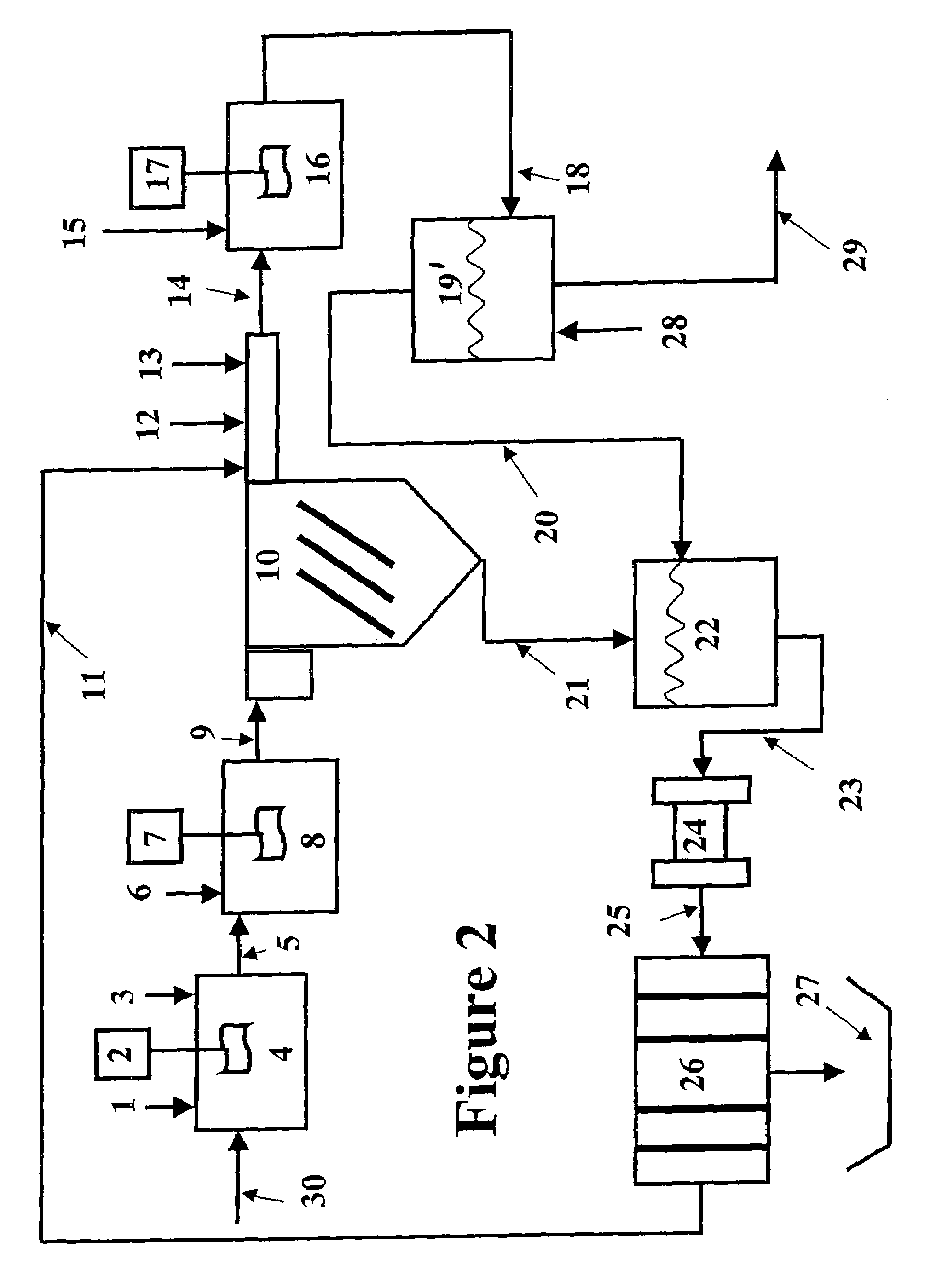

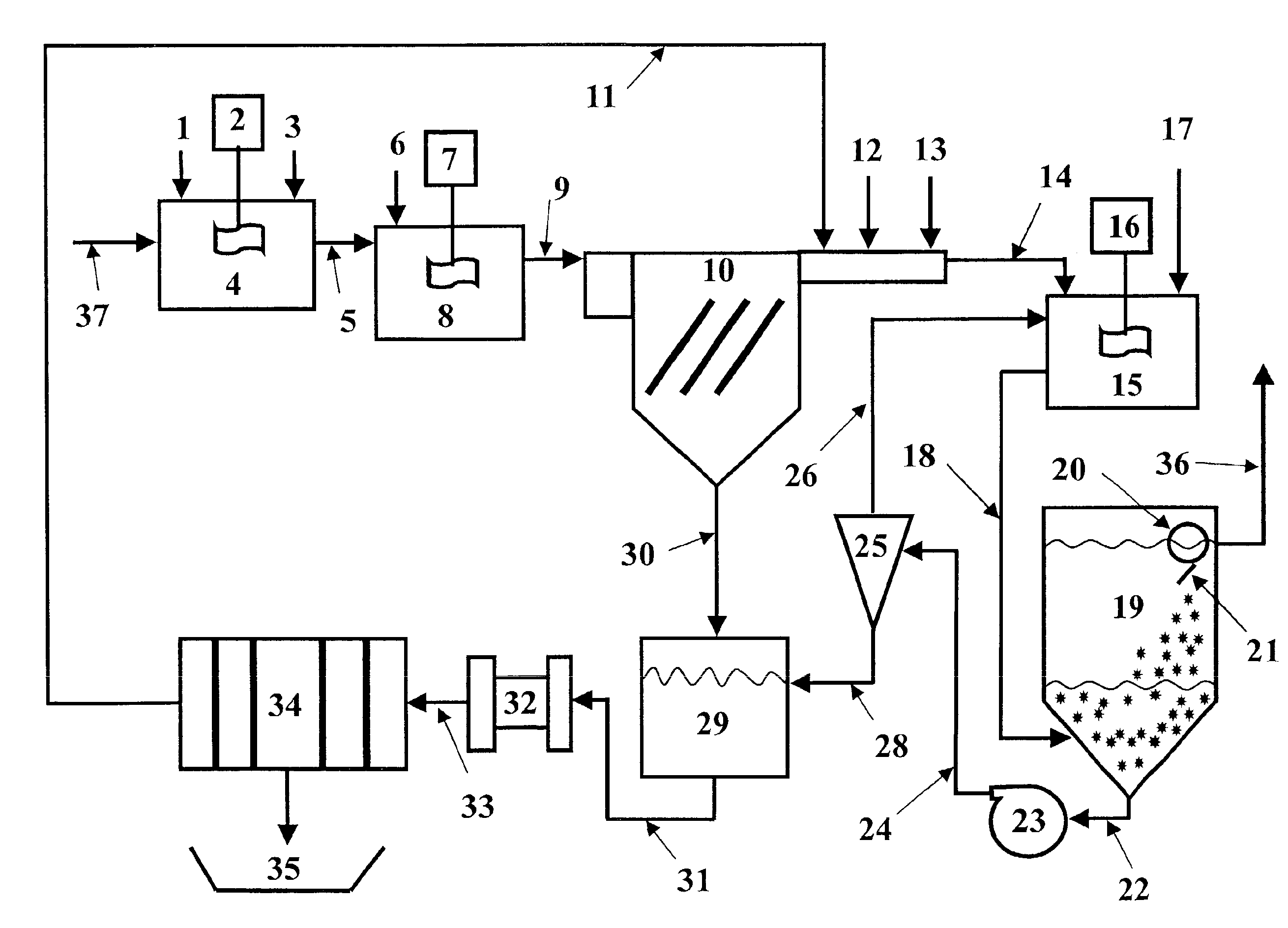

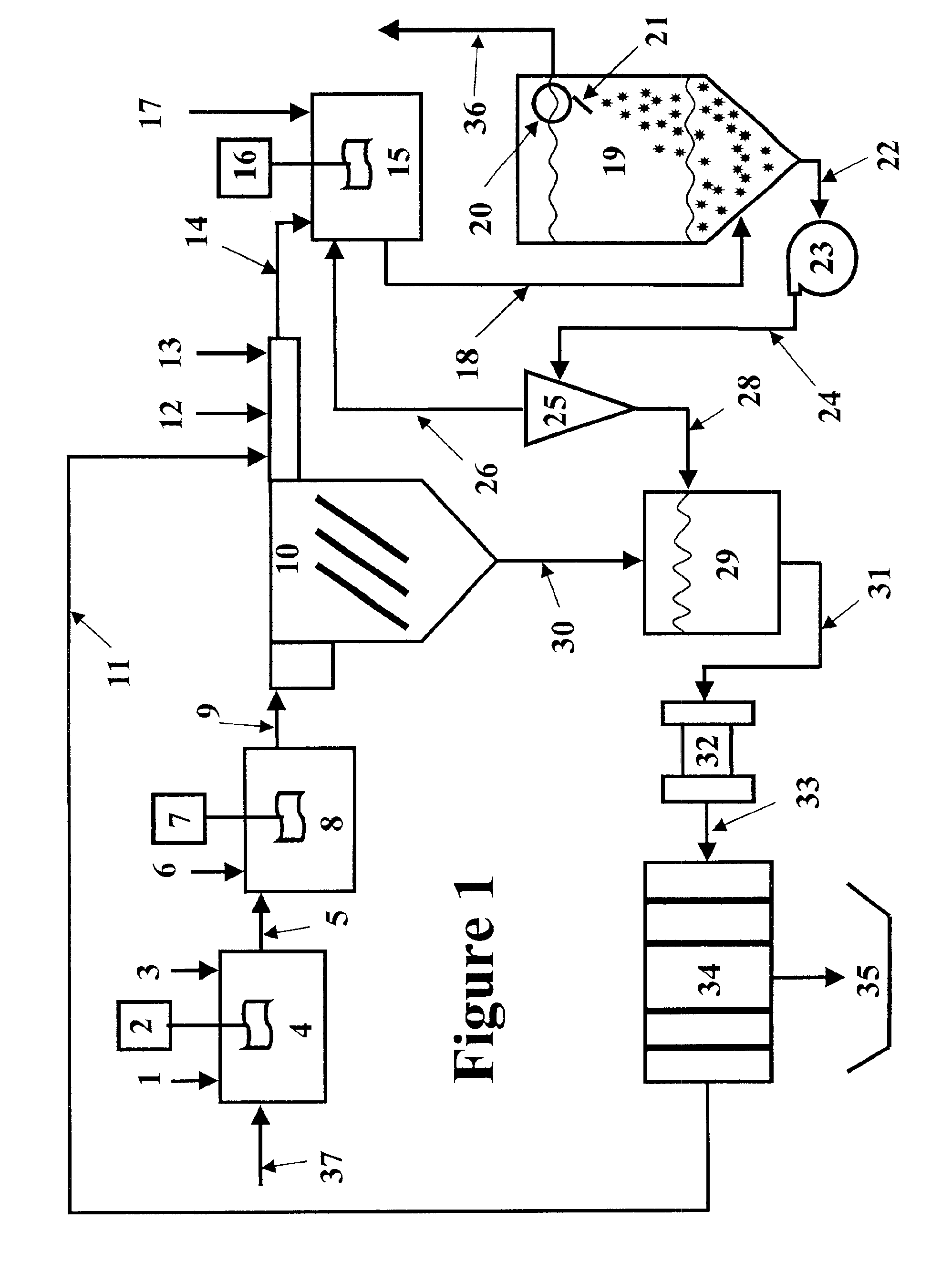

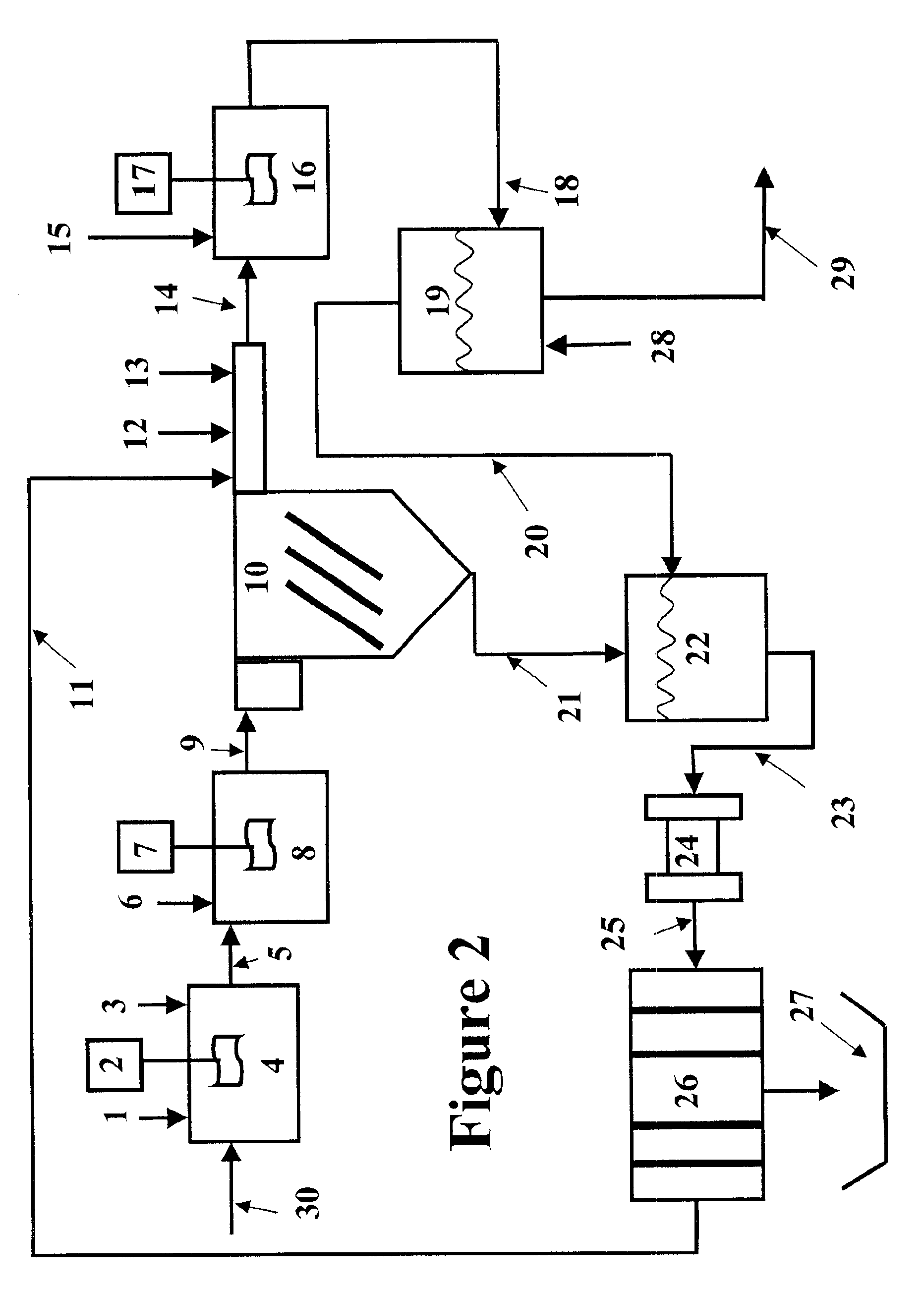

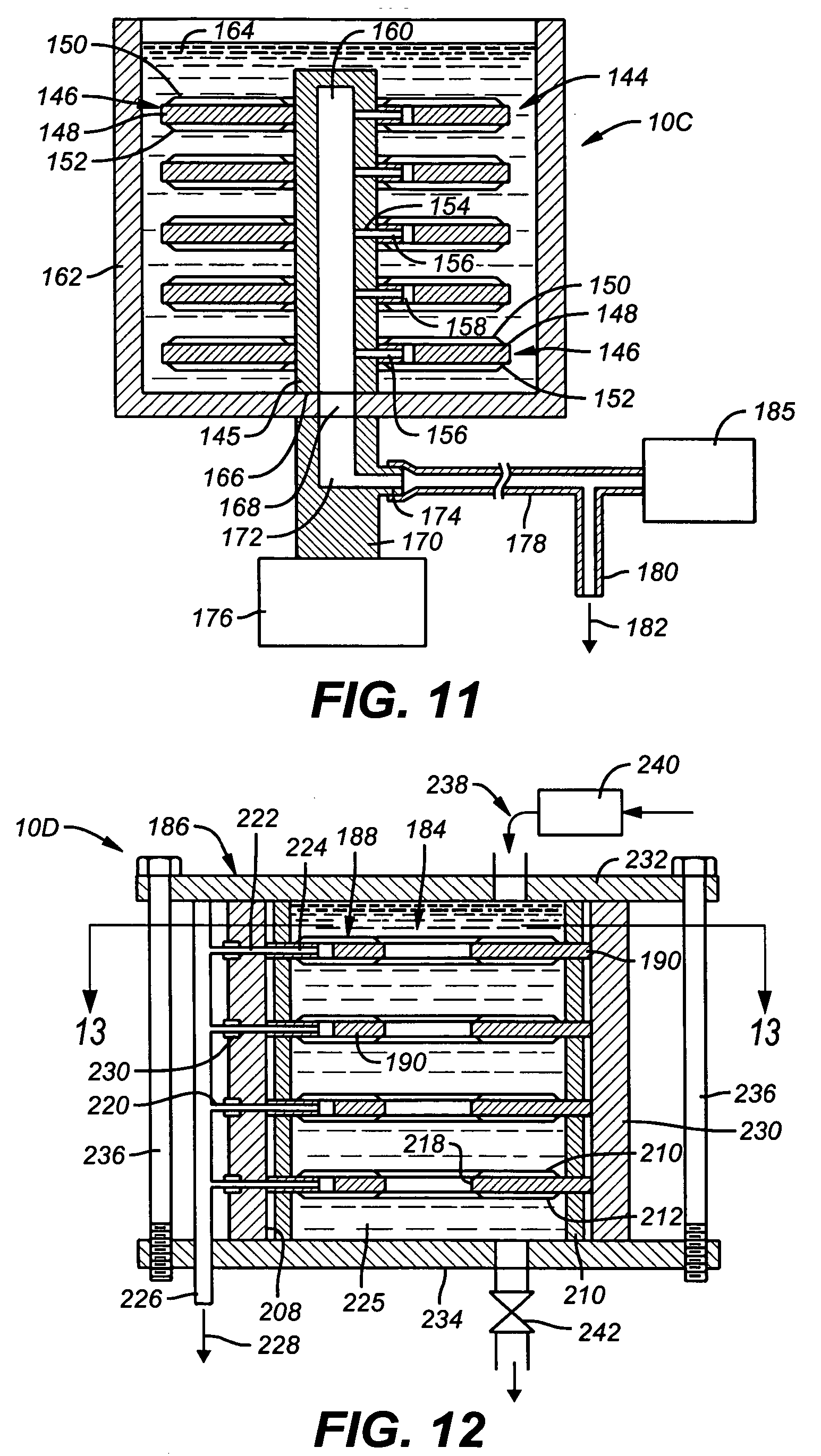

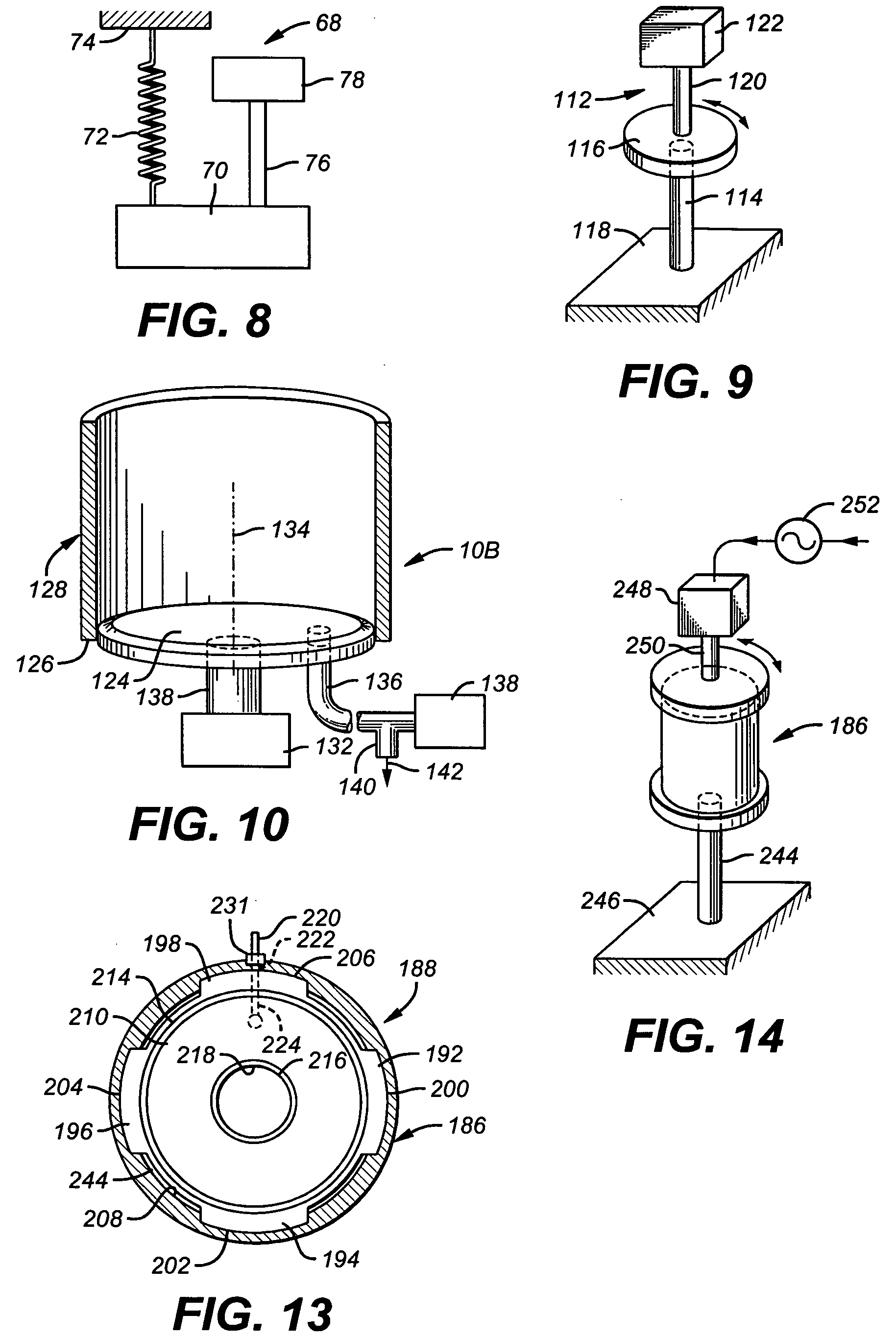

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation ” technology such as magnetic separation, dissolved air flotation, vortex separation, or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment. Magnetic separation is preferred for the separation of particles precipitated in the second stage. Similar methods can be employed for separation of other particulates from water. Particulates can also be removed by causing them to adhere to particles of expanded plastic, forming a floc lighter than water, so that the floc can be removed by flotation.

Owner:CORT CHERYL J

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS7255793B2Cost- and chemically-effectiveSedimentation separationWater/sewage treatment by neutralisationParticulatesSulfide

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation ” technology such as magnetic separation, dissolved air flotation, vortex separation, or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment. Magnetic separation is preferred for the separation of particles precipitated in the second stage. Similar methods can be employed for separation of other particulates from water. Particulates can also be removed by causing them to adhere to particles of expanded plastic, forming a floc lighter than water, so that the floc can be removed by flotation.

Owner:CORT CHERYL J

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS6896815B2Small sizeChemical cost reductionSolid sorbent liquid separationGold compoundsWater useSludge

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation” technology such as magnetic separation, dissolved air flotation, vortex separation or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment.

Owner:CORT STEVEN L

Heavy-metal-polluted site soil leaching remediation method and device

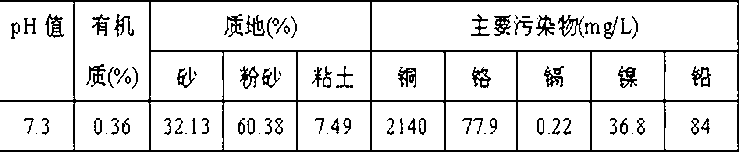

The invention relates to a heavy-metal-polluted site soil leaching remediation method and a heavy-metal-polluted site soil leaching remediation device. The method comprises the steps that: (1) soil pollutant types, densities, particle composition, pH value and organic matter content are detected; (2) the polluted soil is flushed by using water; a leaching agent is added, and the soil is leached; (3) separation is carried out by using a roller screen; on-screen substances are backfilled, and under-screen substances are subjected to fine separation; (4) under-screen substances are processed by using a hydrocyclone separation device; when obtained sand reaches a test standard, the sand can be backfilled; (5) alkali is added for regulating the pH value, and a heavy metal precipitating agent Na2S is added, such that heavy metal is converted into metal sulfide precipitate; (6) after the heavy metal precipitation reaction, a flocculant is added, such that coagulating sedimentation is carried out; after coagulating sedimentation, solid-liquid separation is carried out by using a plate-and-frame filter press; and (7) pH value of wastewater produced by solid-liquid separation is regulated by adding sulfuric acid, and is recycled in the leaching step. The method provided by the invention has the technical effects that: after heavy-metal-polluted soil is processed, heavy metal pollutants can be separated with physical separation (particle separation) and chemical extraction methods; and the leaching liquid (water) can be repeatedly utilized.

Owner:DONGJIANG ENVIRONMENTAL

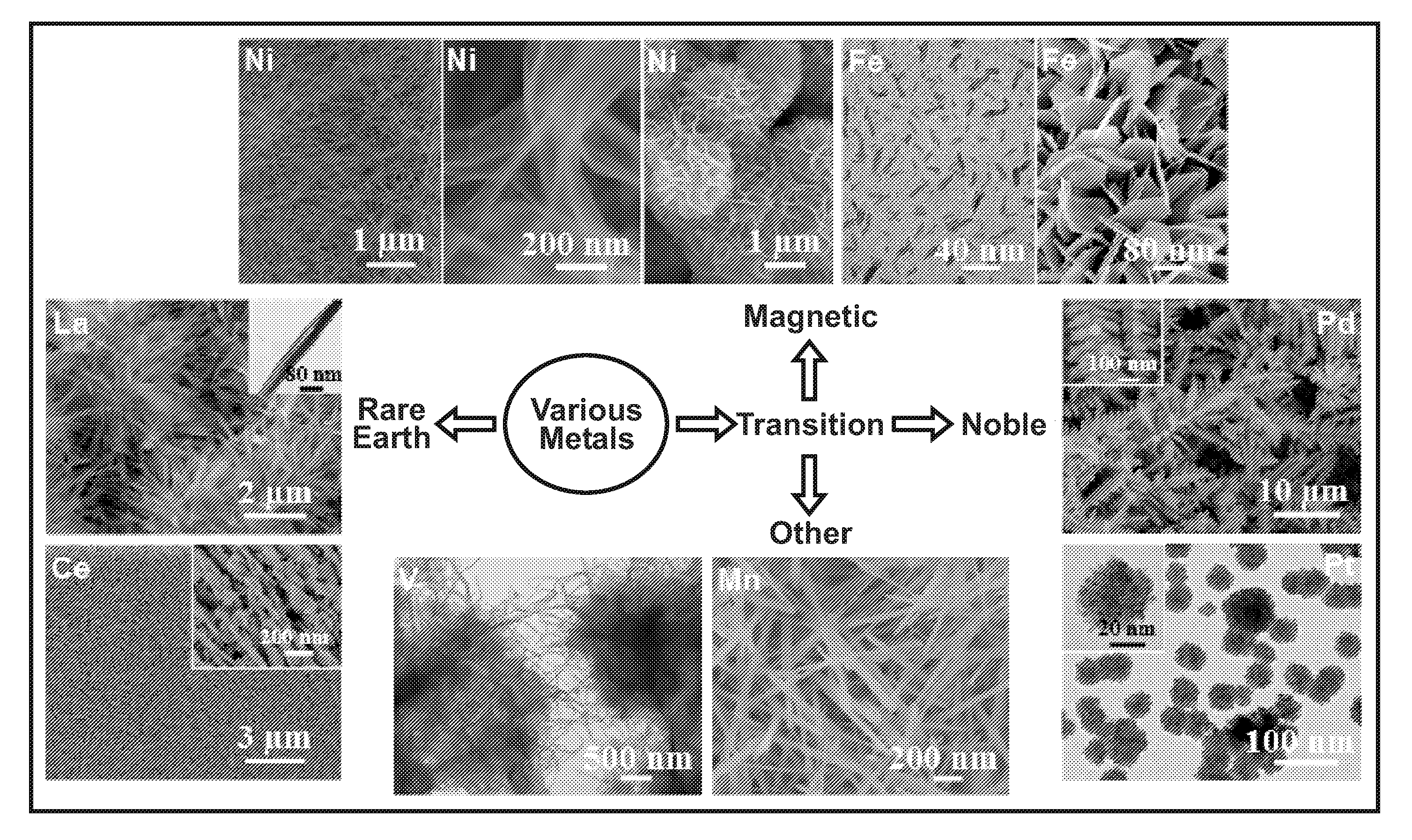

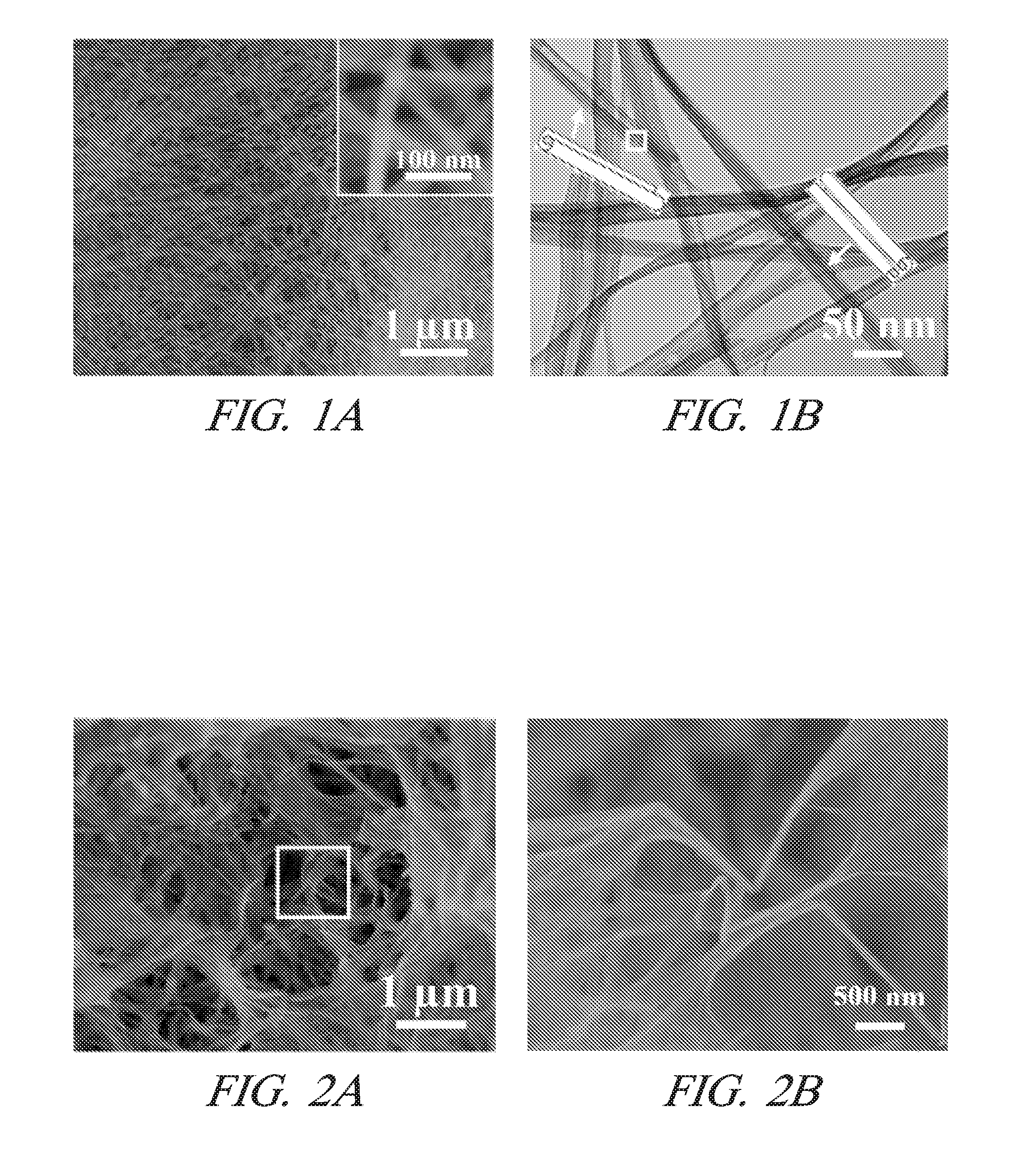

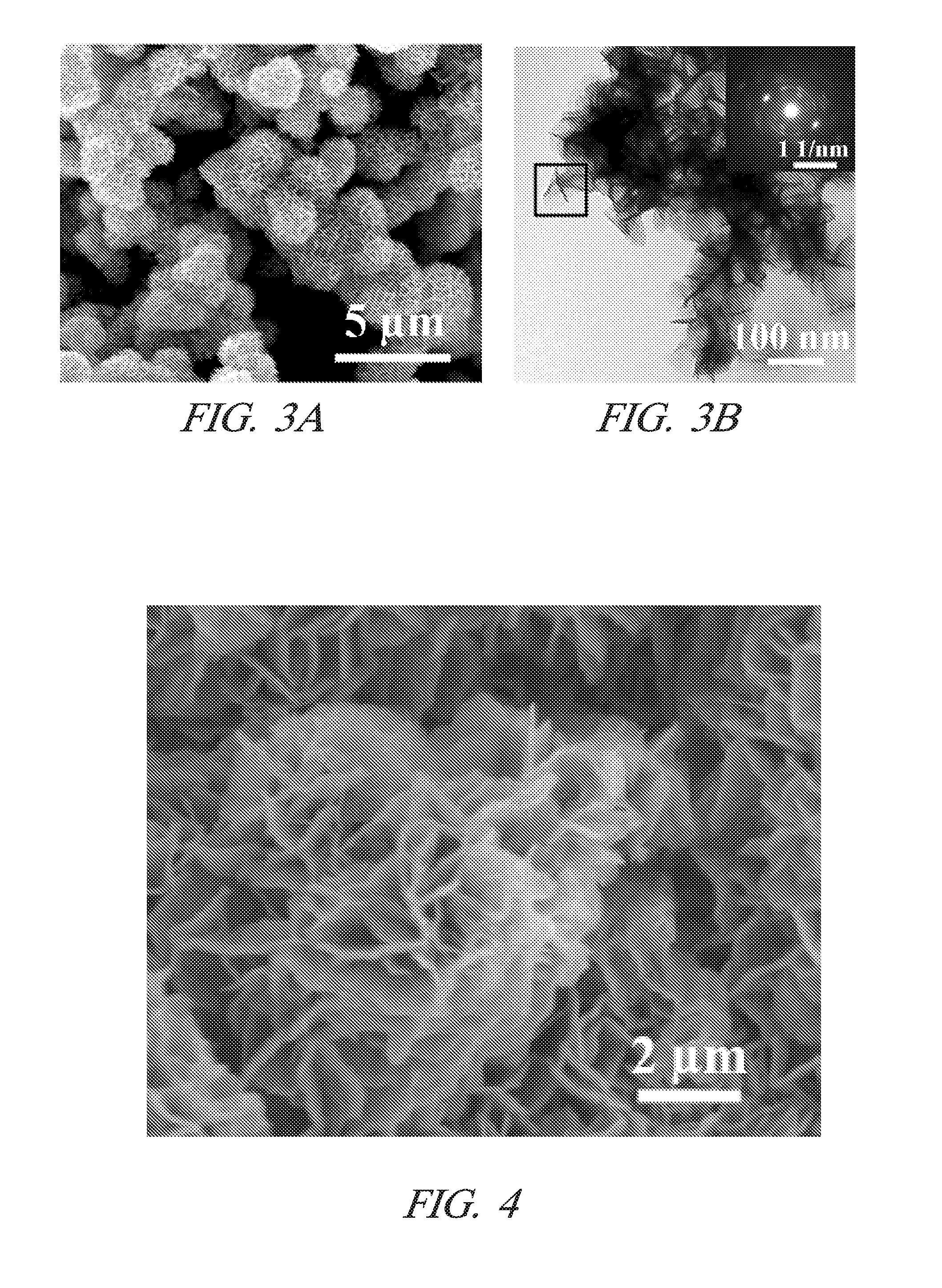

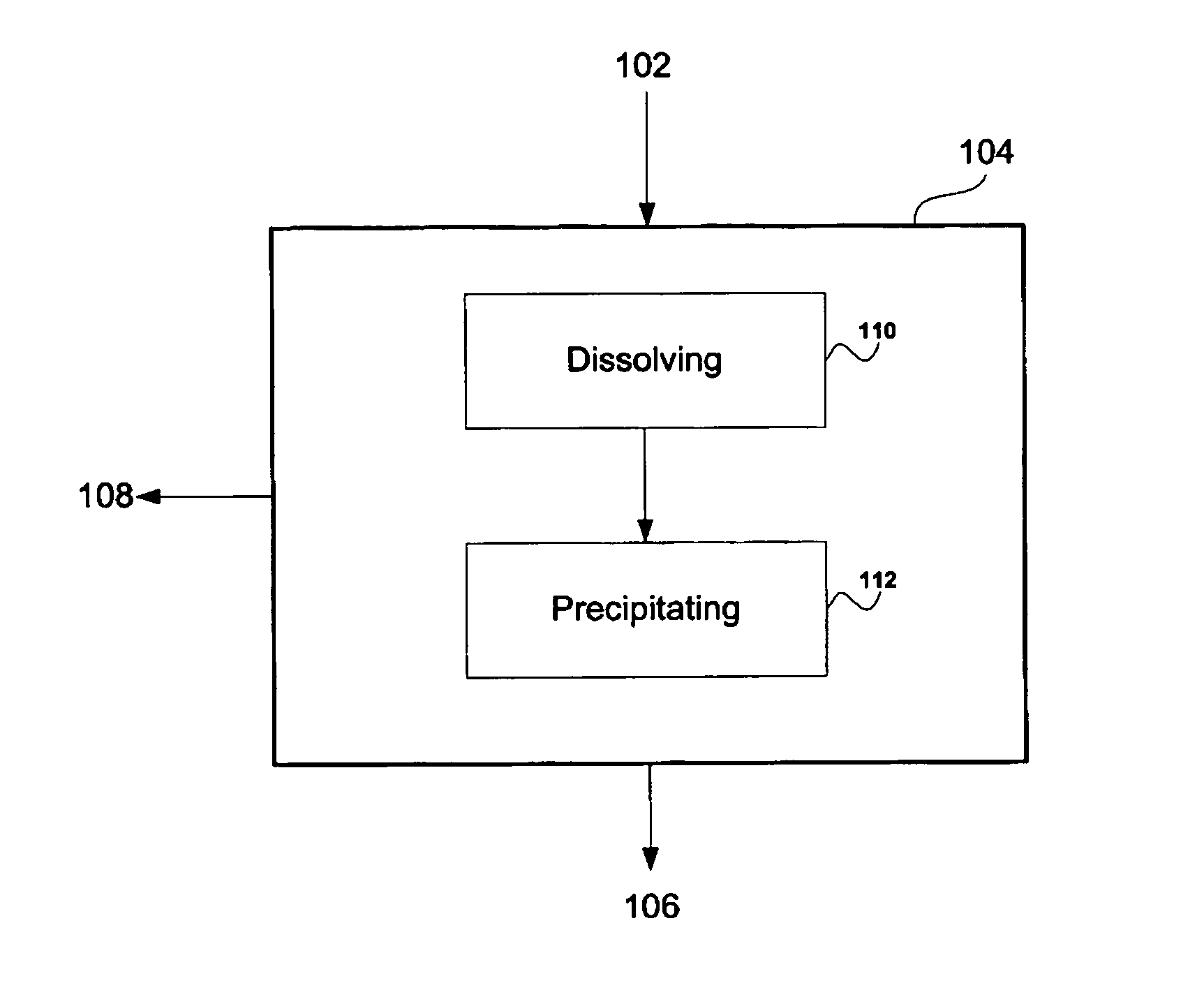

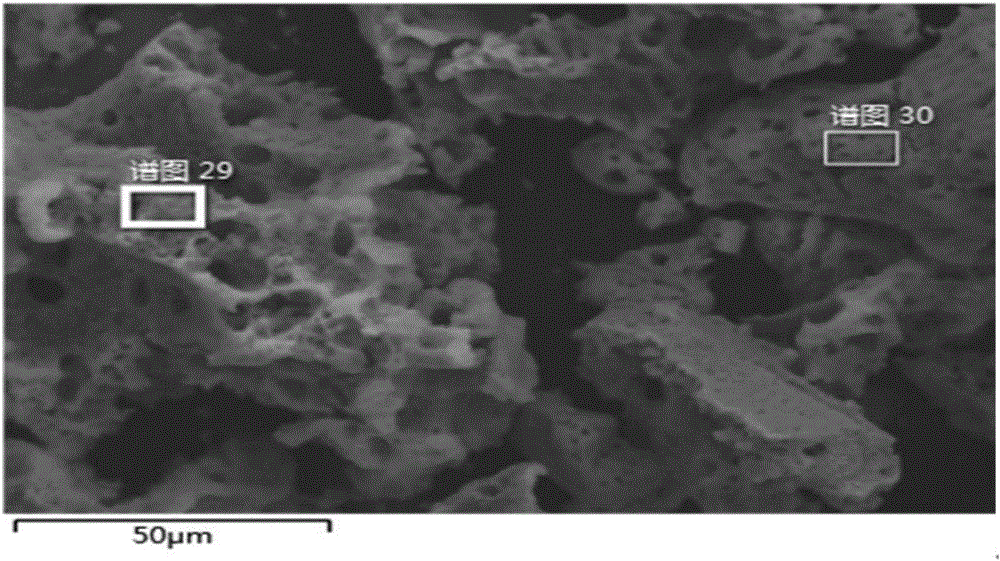

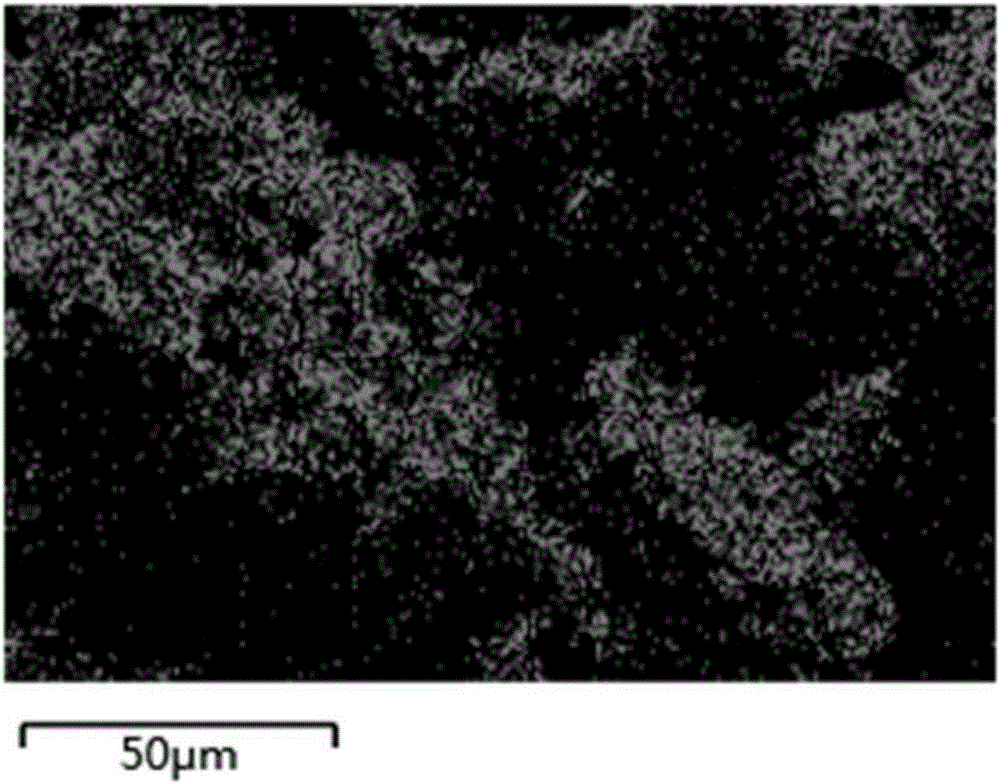

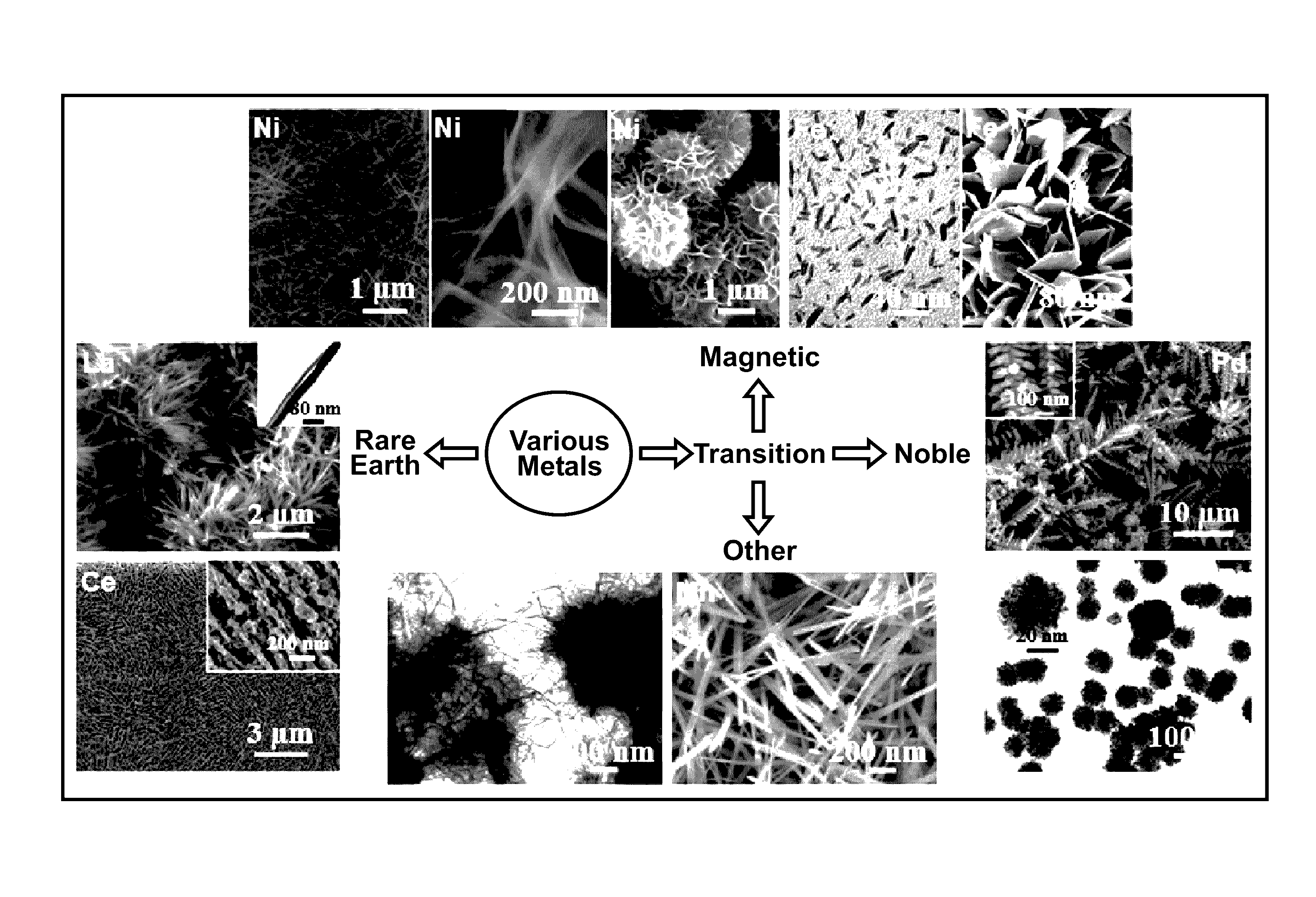

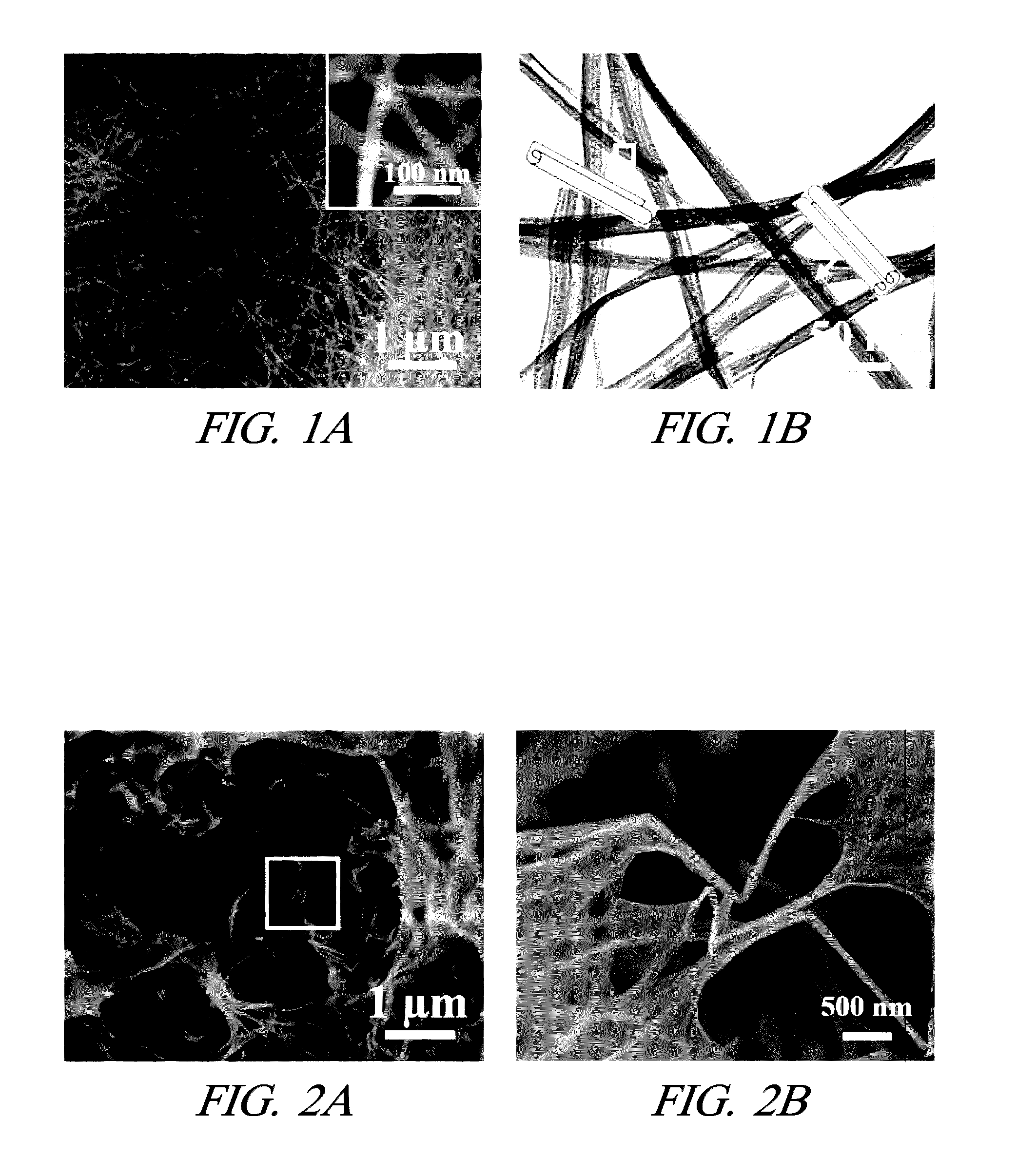

Making metal and bimetal nanostructures with controlled morphology

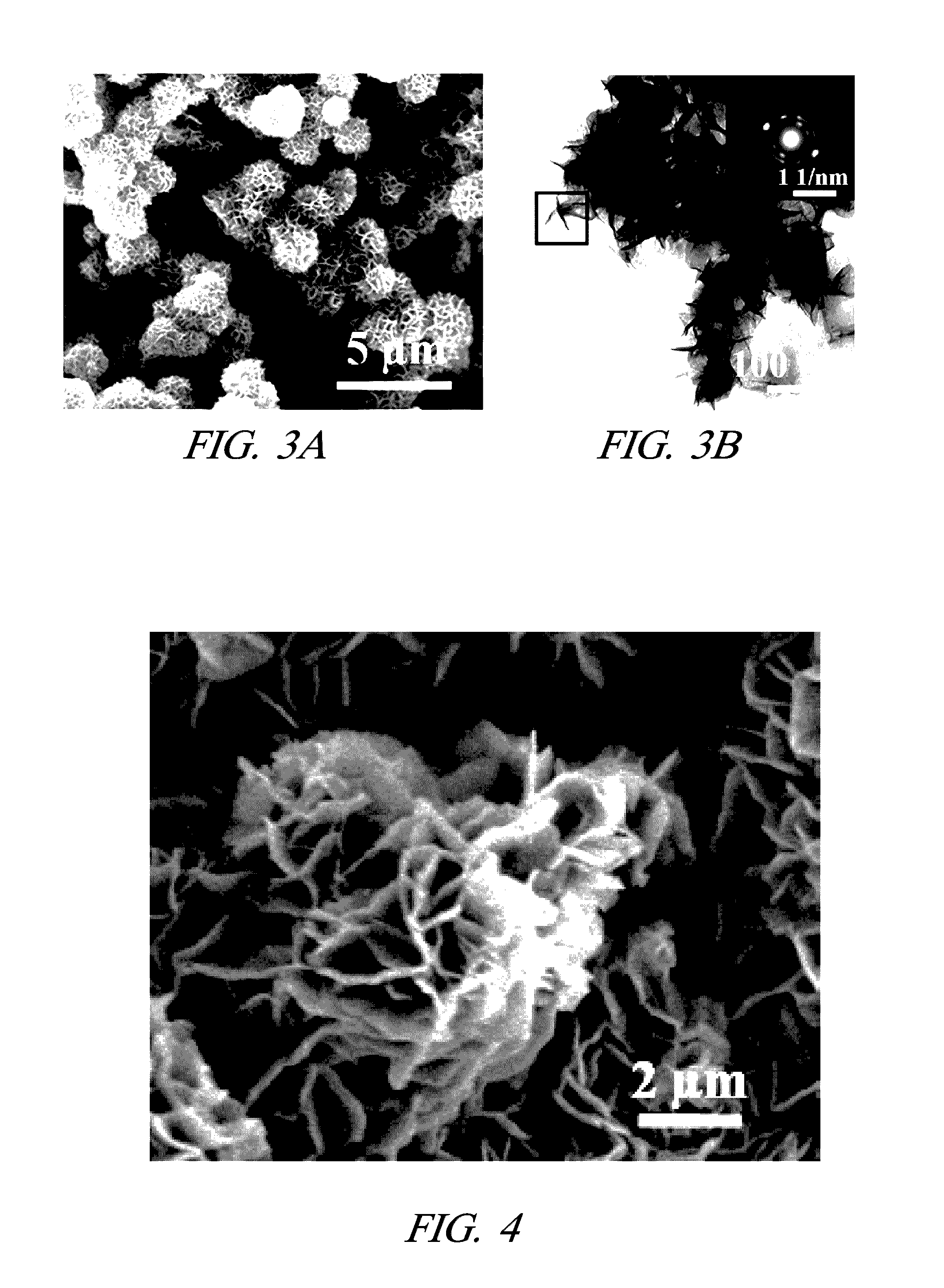

ActiveUS20110197710A1Ease of mass productionEfficiently conductedTransportation and packagingMetal-working apparatusDendriteAqueous solution

A method of making metal nanostructures having a nanometer size in at least one dimension includes preparing an aqueous solution comprising a cation of a first metal and an anion, and mixing commercial elemental powder particles of an elemental second metal having a greater reduction potential than the first metal with the aqueous solution in an amount that reacts and dissolves all of the second metal and precipitates the first metal as metal nanostructures. The temperature and concentration of the aqueous solution and the selection of the anions and the second metal are chosen to produce metal nanostructures of a desired shape, for example ribbons, wires, flowers, rods, spheres, hollow spheres, scrolls, tubes, sheets, hexagonal sheets, rice, cones, dendrites, or particles.

Owner:GM GLOBAL TECH OPERATIONS LLC

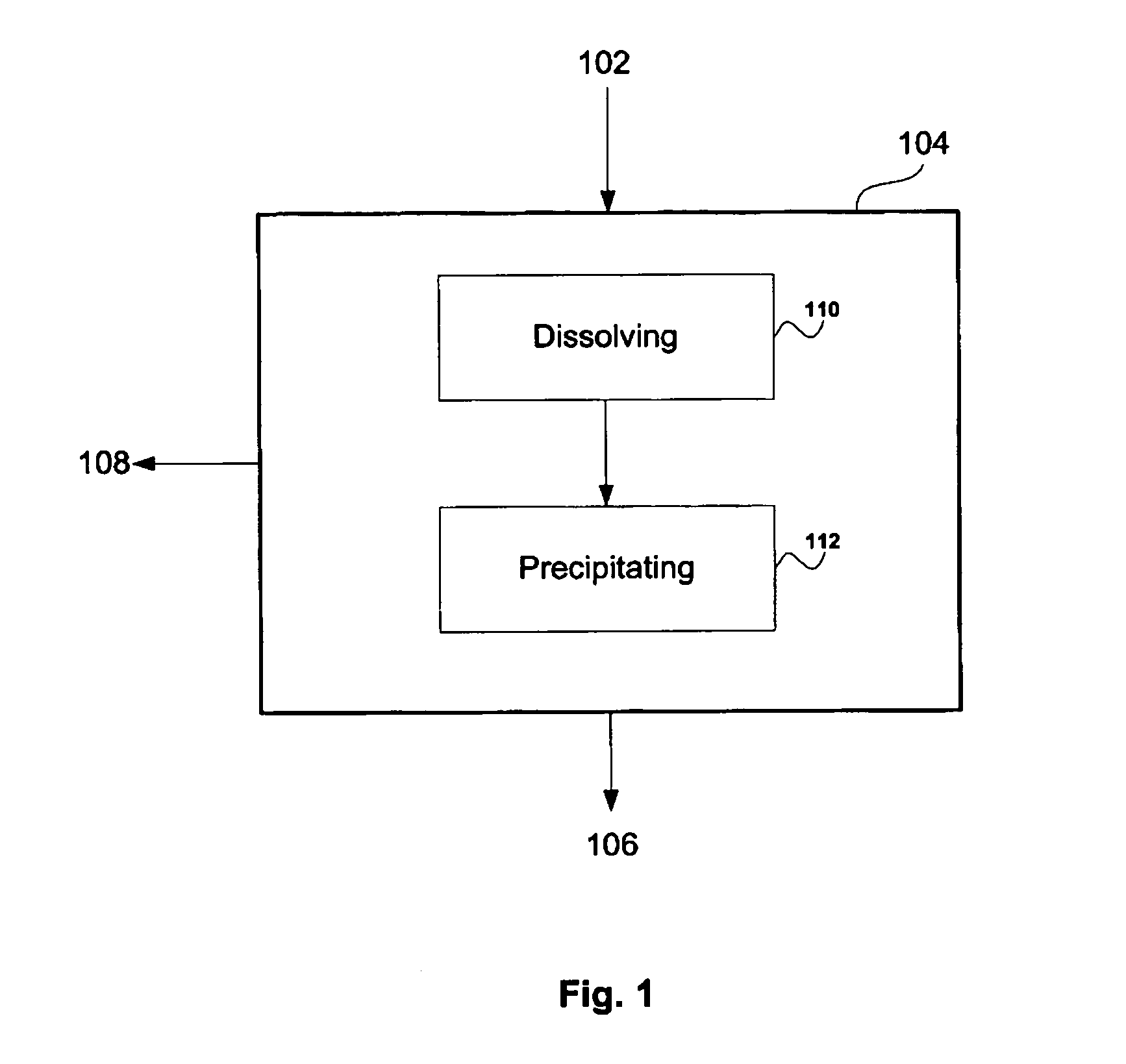

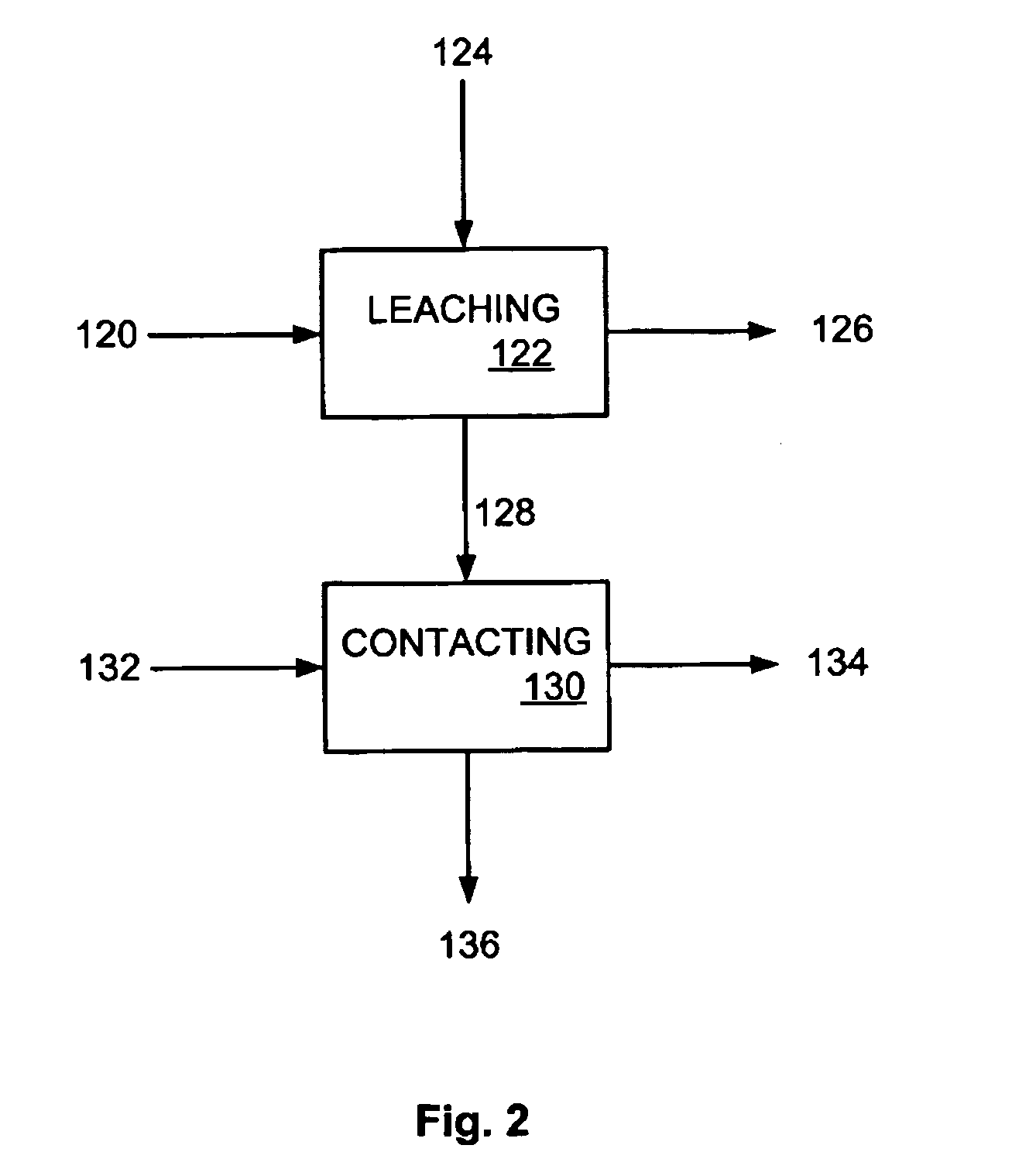

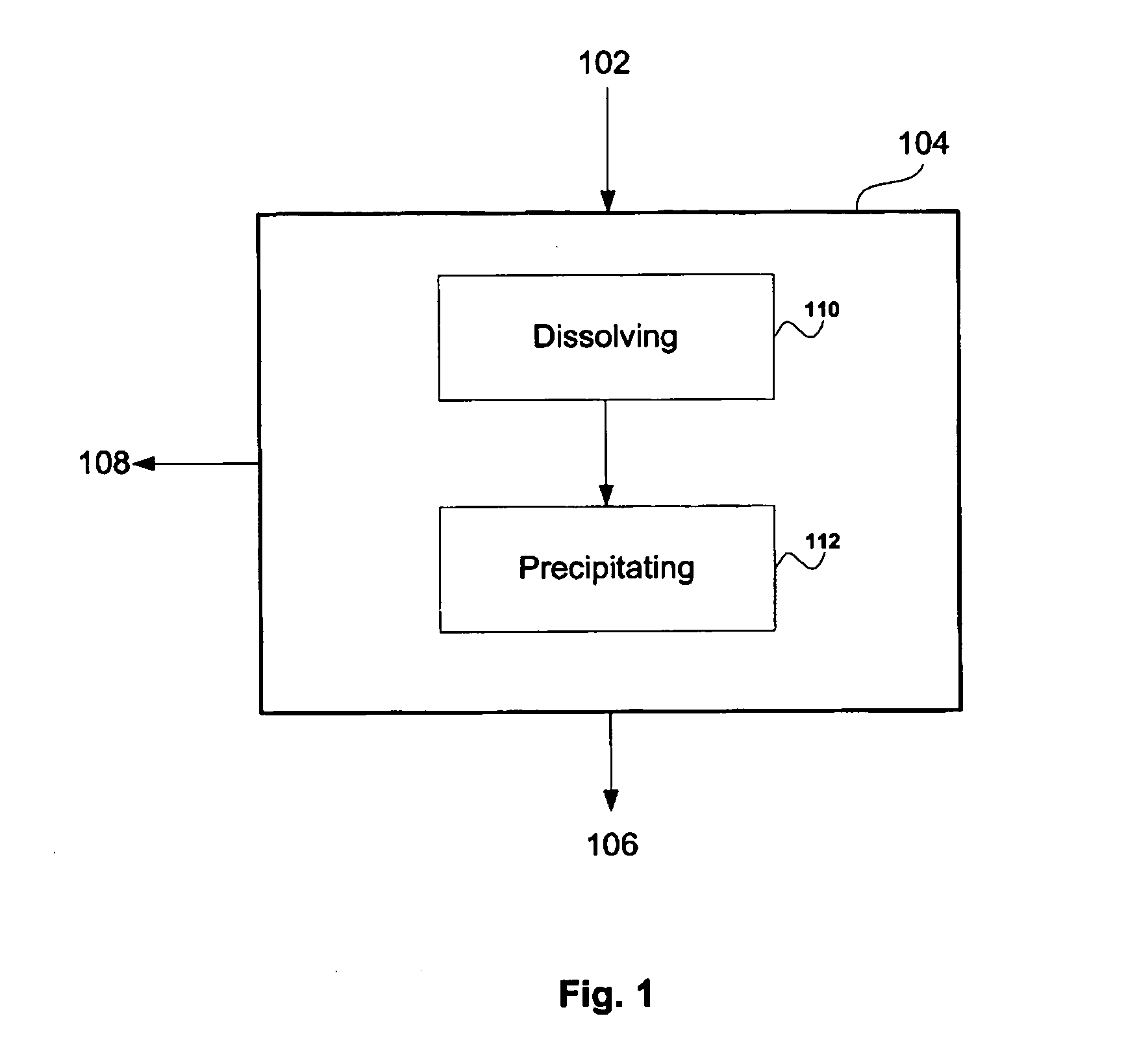

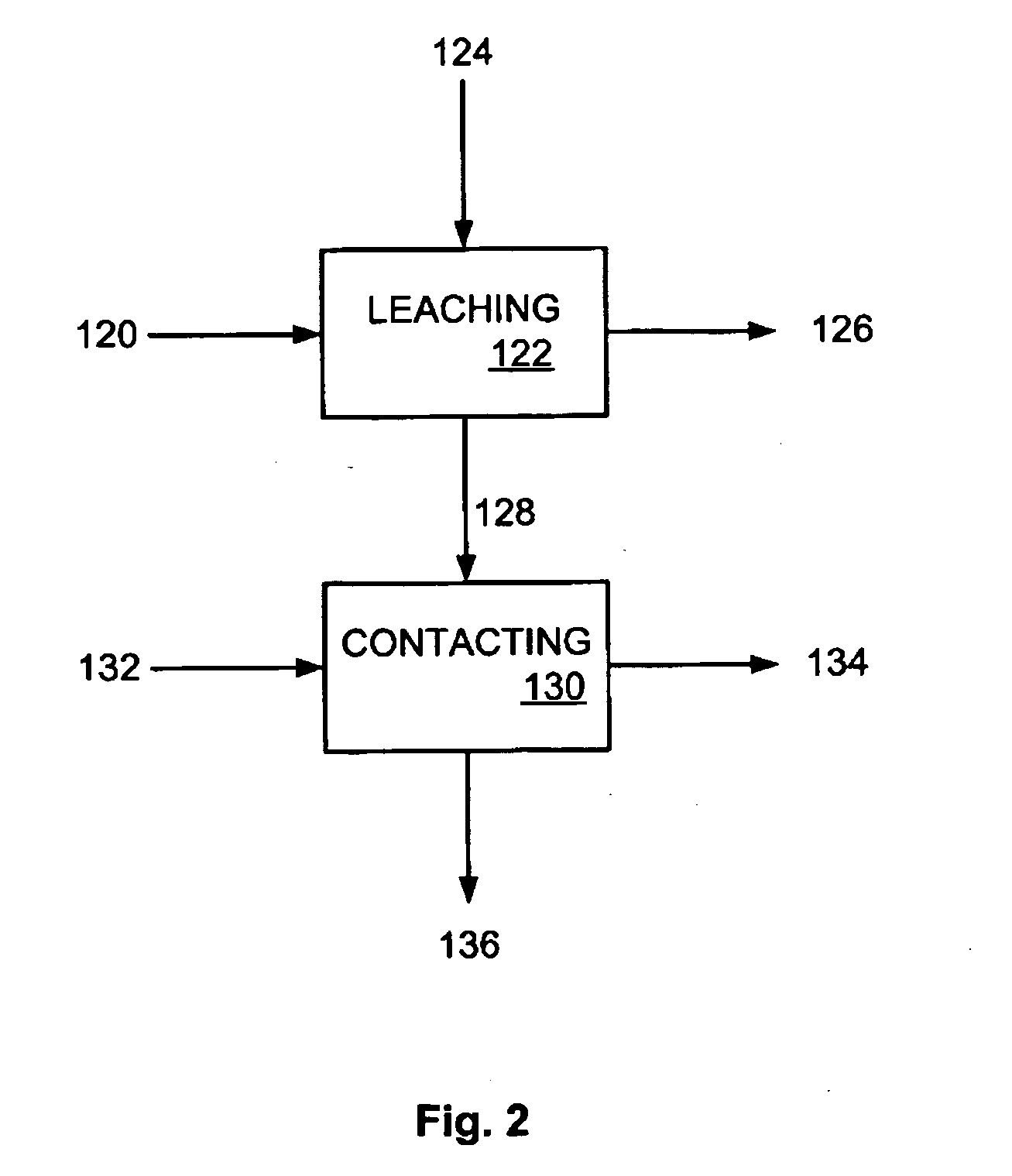

Flotation processing including recovery of soluble nonferrous base metal values

A method of flotation processing ores and other mineral materials containing soluble nonferrous base metal and sulfide minerals involves dissolving the soluble nonferrous base metal and precipitating the soluble nonferrous base metal in the form of a floatable precipitate that is collected as part of a sulfide concentrate. The use of an oxygen-deficient flotation gas, such as nitrogen gas, promotes the precipitation of the floatable precipitate. A method for removing dissolved nonferrous base metal from solution involves contacting the solution with a particulate containing sulfide minerals under conditions promoting precipitation of the nonferrous base metal onto the sulfide mineral.

Owner:NEWMOST USA

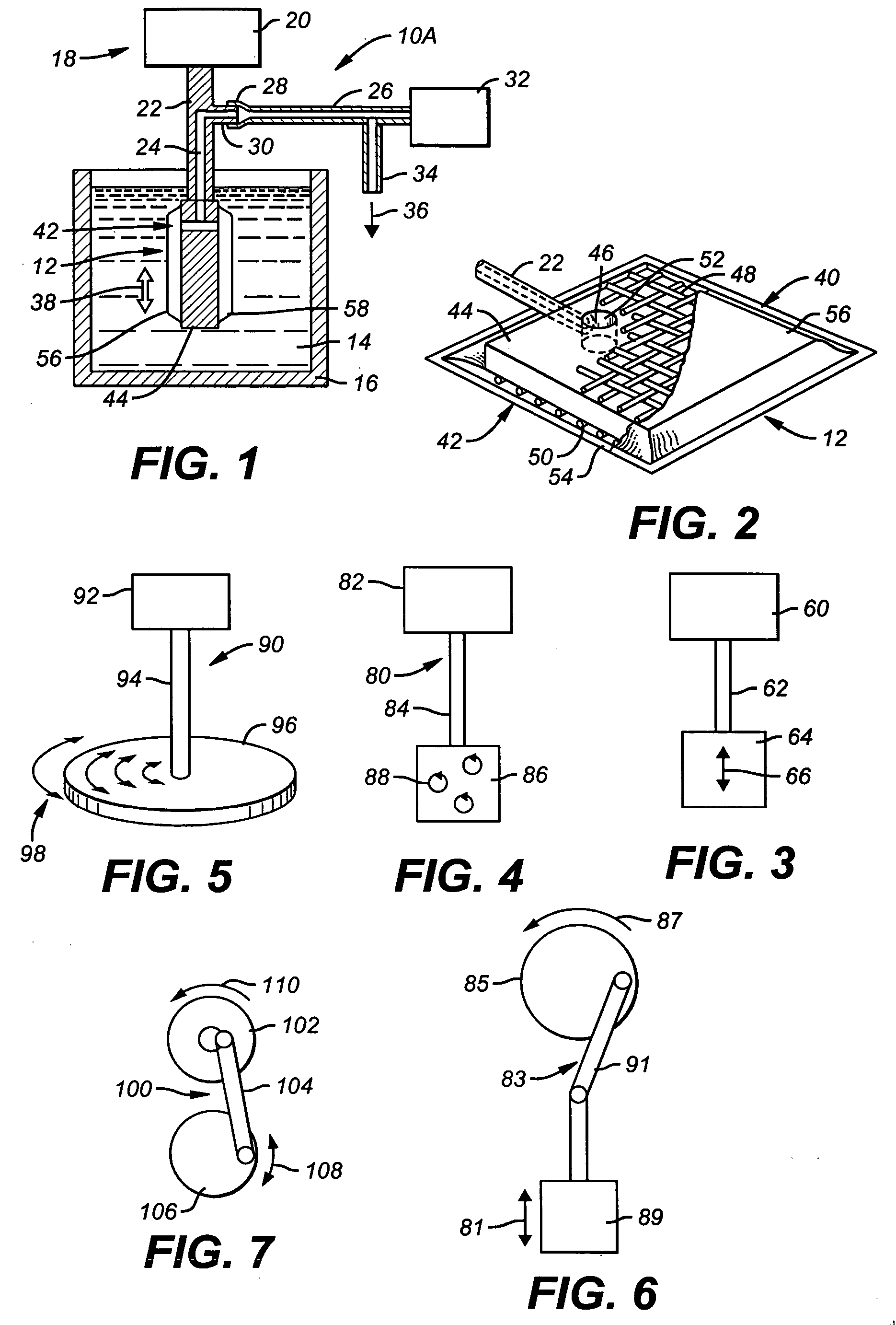

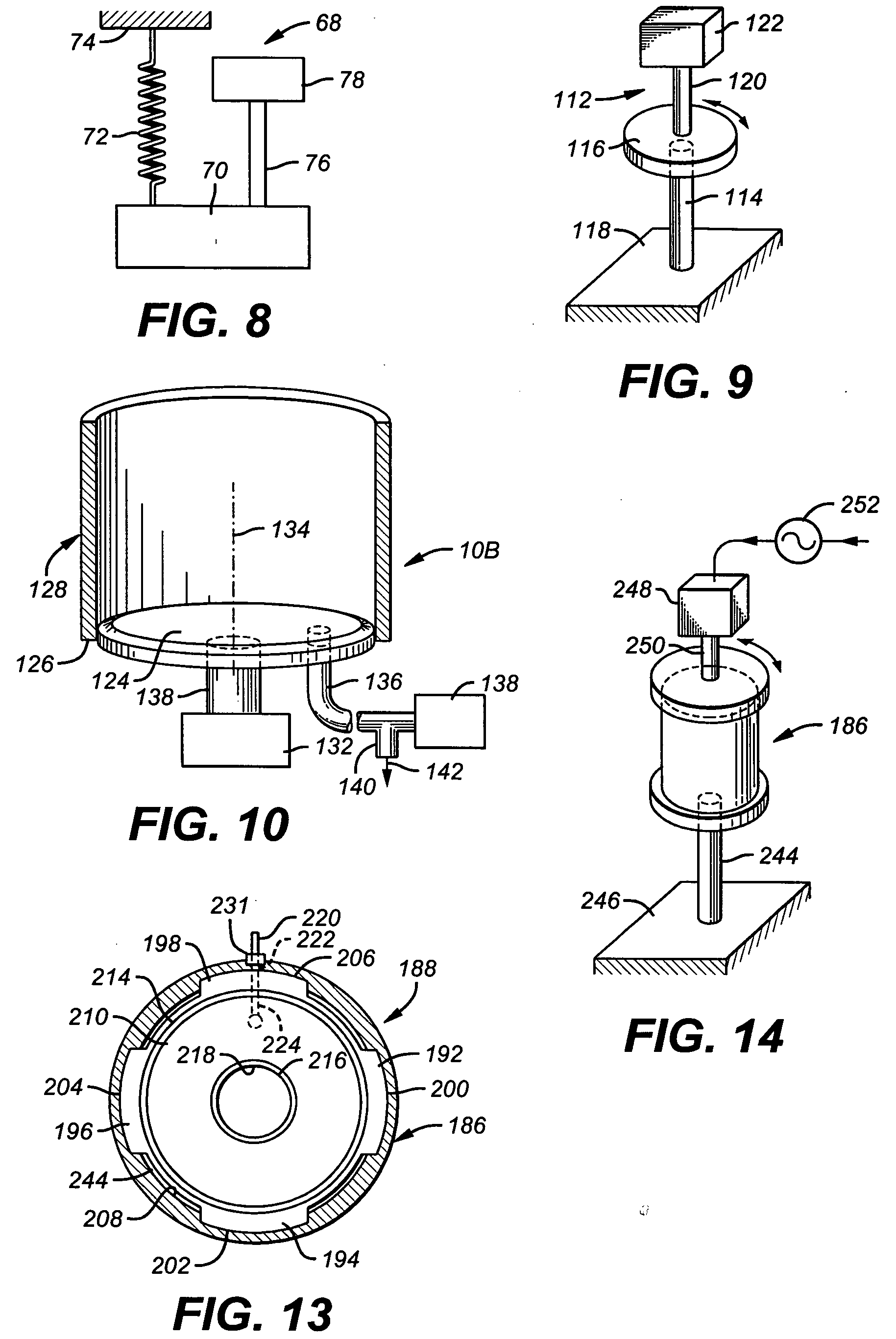

Methods for removing metals from water

InactiveUS20060108289A1Improve filtration rateImprove concentrationMembranesUltrafiltrationPositive pressureEngineering

A device for separating metal components from a colloidal suspension or solution uses a vessel for holding the colloidal suspension or solution. A membrane impermeable to the selected metal components of a colloidal suspension or solution is sealed over a support to form a leaf element. The leaf element includes an outlet for the selected components of the colloidal suspension or solution and is extended into the colloidal suspension or solution. The leaf element is controllably vibrated simultaneously with application of a negative or positive pressure which is used to motivate permeation of the membrane by the liquid of the colloidal suspension or solution to purify it. Metals removed by the method include metals with an atomic number greater than 10 including and / or silicon. The colloidal suspension or solution may optionally contain a metal precipitator such as a dithiocarbamate and / or trithiocarbamate to aid in the separation.

Owner:BAKER HUGHES INC

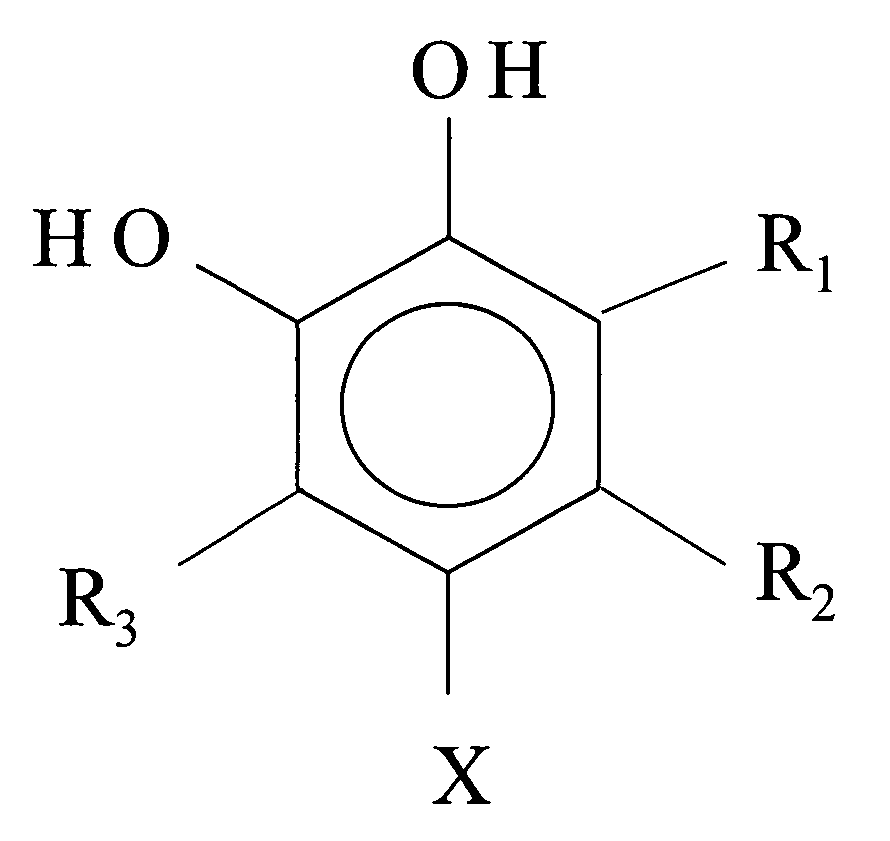

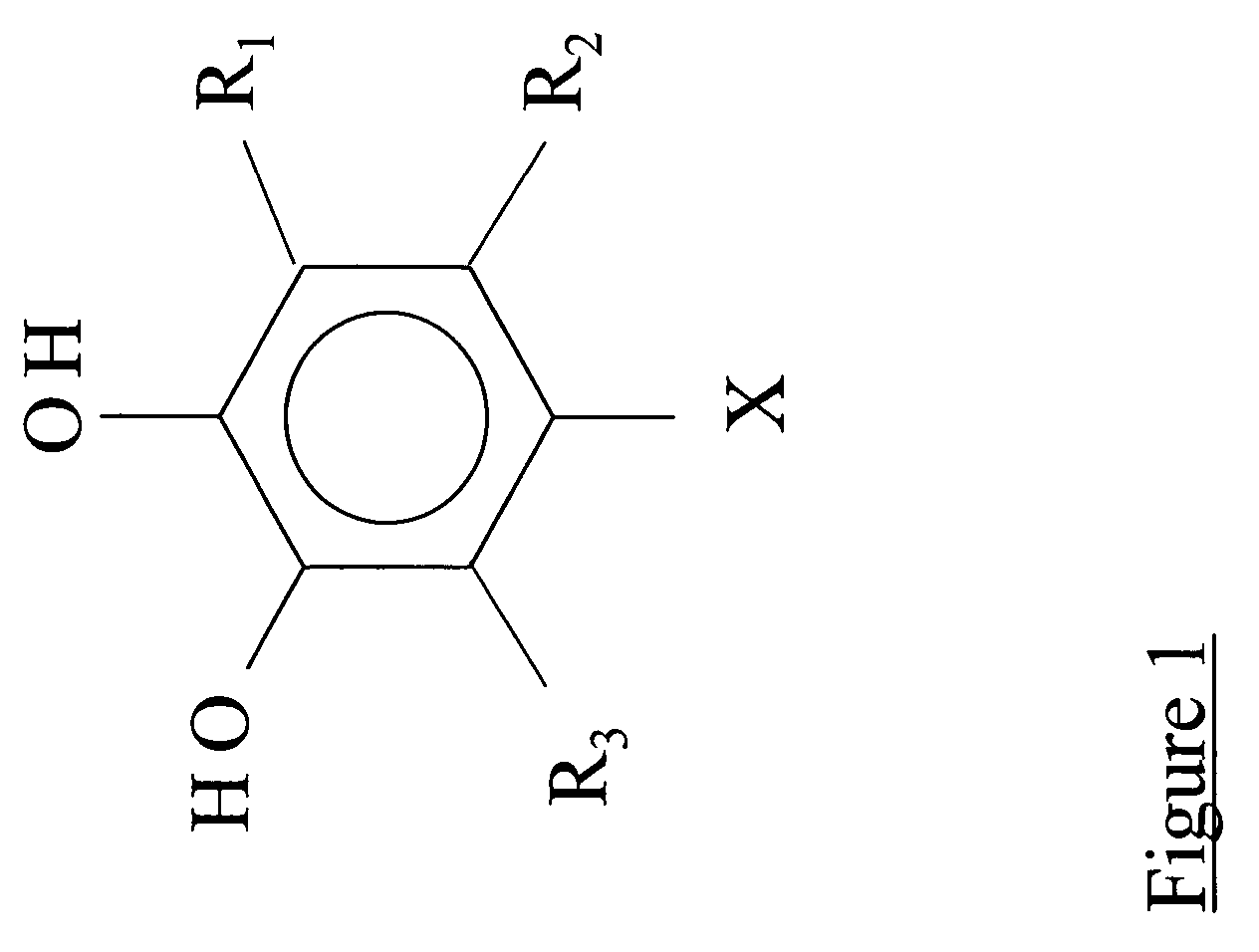

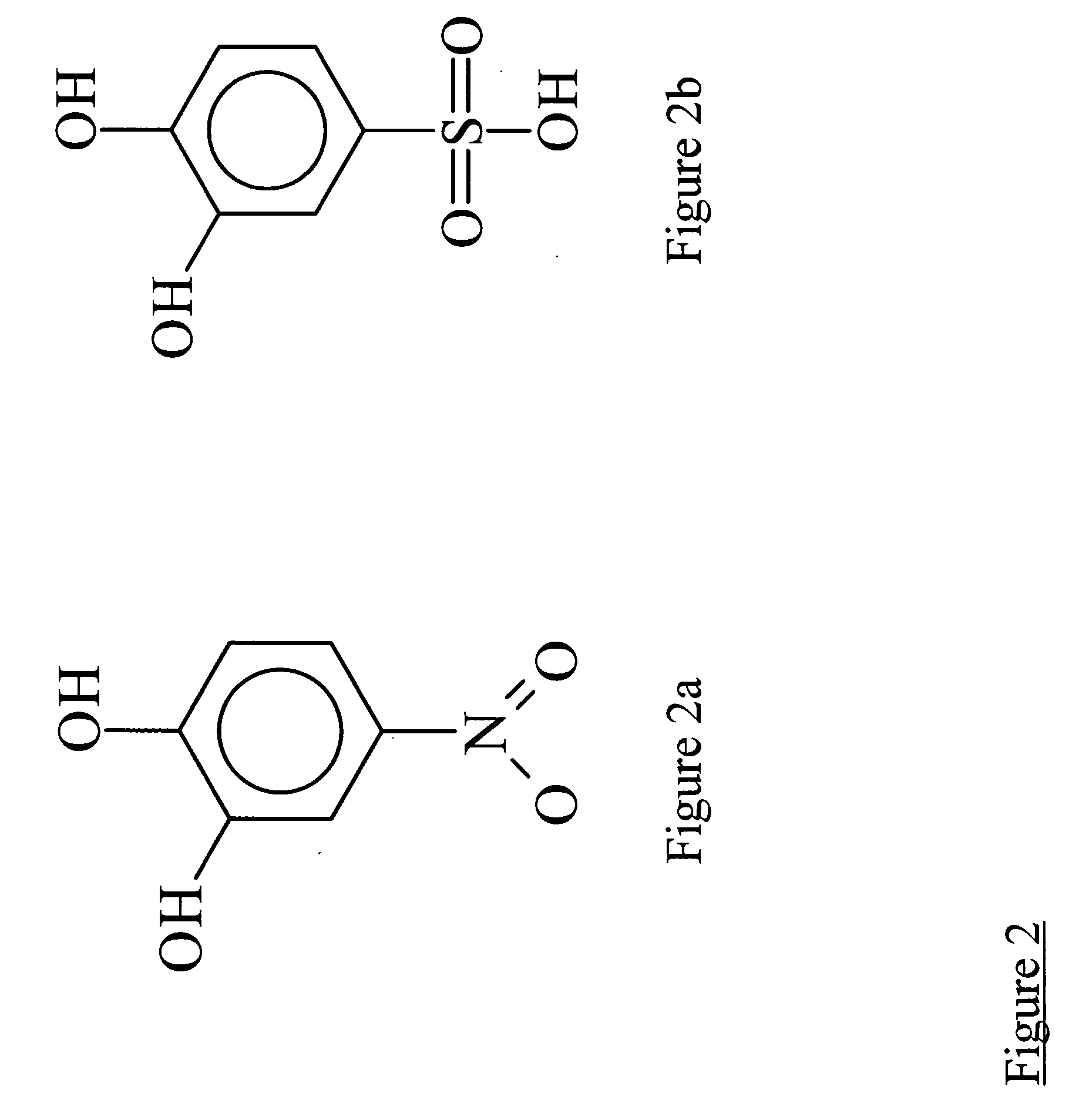

Composition and method for treating a semiconductor substrate

ActiveUS20050159323A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParticulatesPhysical chemistry

The invention relates to a method for cleaning semiconductor surfaces to achieve to removal of all kinds of contamination (particulate, metallic and organic) in one cleaning step. The method employs a cleaning solution for treating semiconductor surfaces which is stable and provokes less or no metal precipitation on the semiconductor surface.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

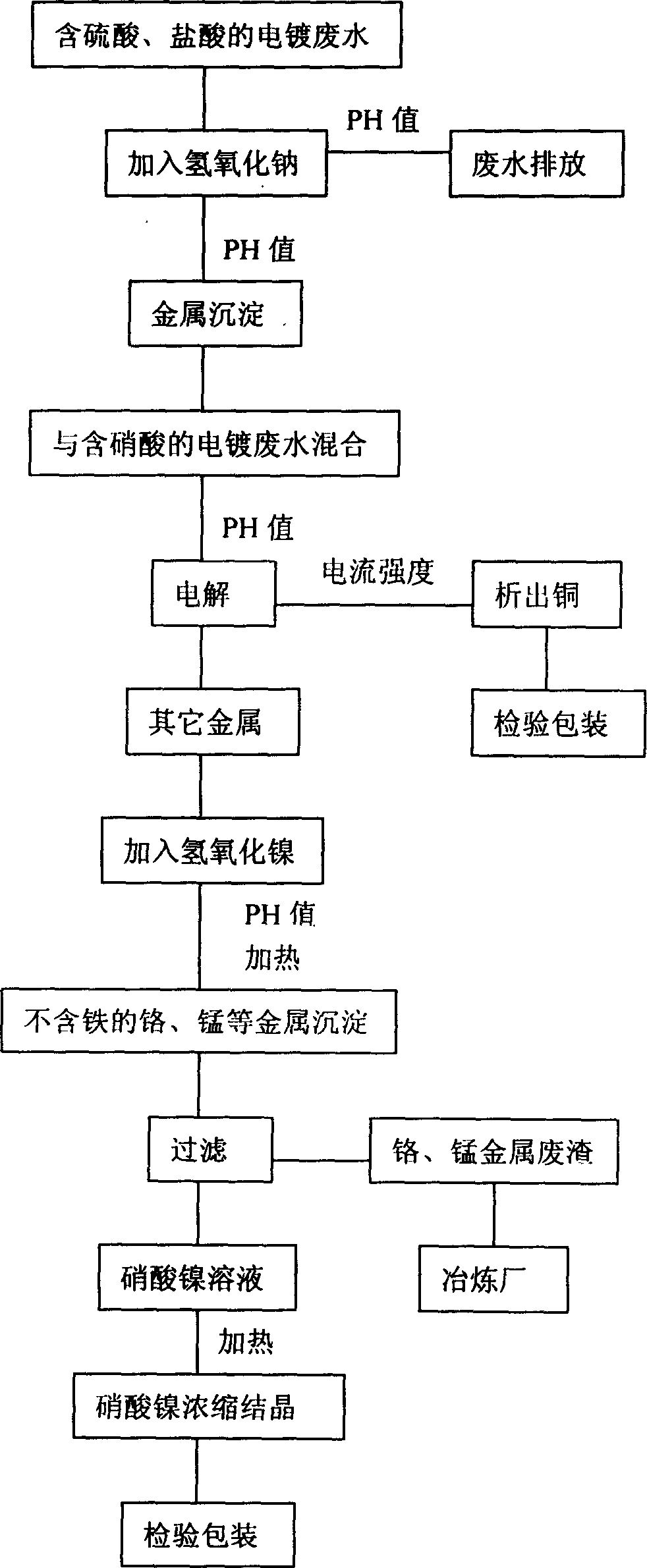

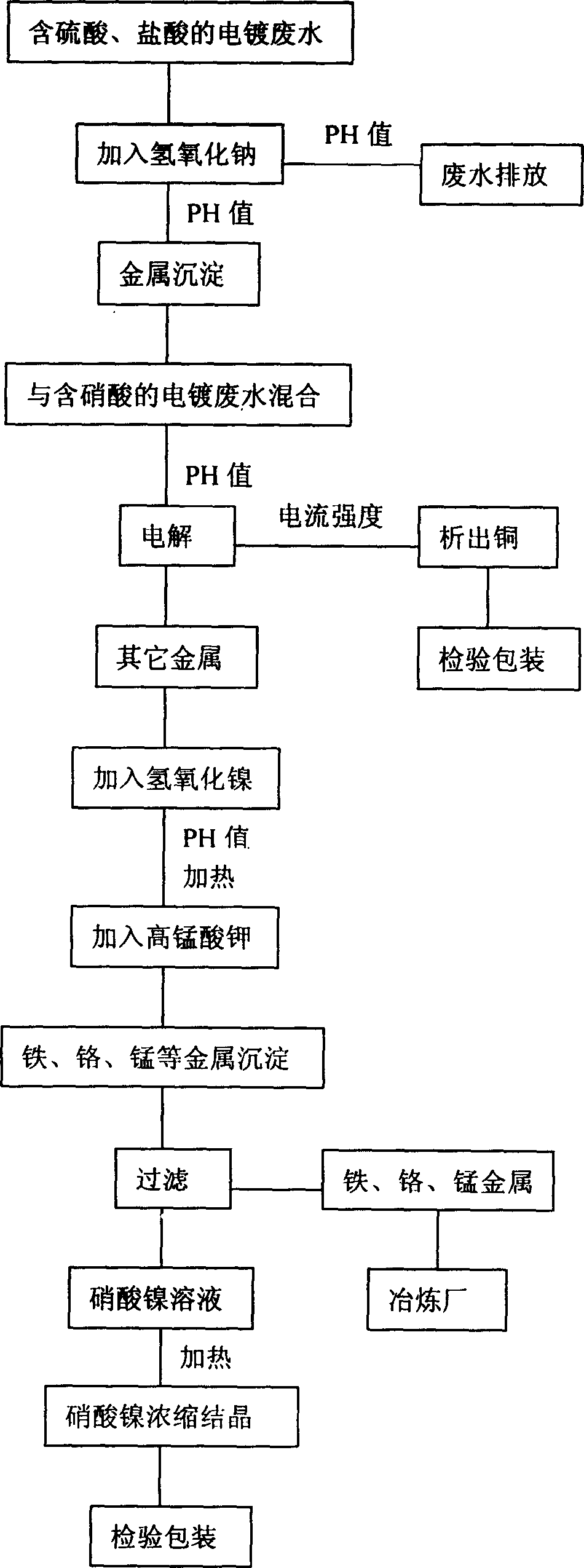

Method for recovering copper and nickel nitrate by electrolysis of electroplating waste water

InactiveCN1804148AGood workmanshipEasy to operateCellsPhotography auxillary processesRecovery methodSodium hydroxide

The electrolysis recovery method for Cu and Ni(NO3)3 from electroplating sewage comprises: adding NaOH into the sewage with at least H2SO4 or HCl to adjust pH till technical request and deposit metal; mixing the sewage contained metal and HNO3; with proper pH value, electrolyzing and controlling current to separate Cu; adding Ni(OH)3 into the liquid without Cu; with proper pH value, heating to deposit; filtering the precipitate, and obtaining the Ni(NO3)3 solution; heating and condensing to obtain the Ni(NO3)3 crystal. This invention is simple and low cost.

Owner:赵小毛

Metal catalyst preparation method and preparation method of carbon nanotube

InactiveCN105964268AUniform particle sizeHigh yieldHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsOrganic acidSimple Organic Compounds

The invention provides a metal catalyst preparation method which comprises the following steps: I, providing a metal salt solution, wherein a raising agent, carrier metal and active metal ions with a carbon nanotube preparation activation function are dissolved in the metal salt solution; the raising agent comprises one or more of organic acid, organic alcohol, organic aldehydes, nitrogenous organic compounds and sugar; II, adding a precipitator into the metal salt solution, and stirring so as to obtain composite metal precipitation; III, heating and calcining the composite metal precipitation, and cooling after calcining, and screening, thereby obtaining a metal catalyst. Meanwhile, the invention further discloses a carbon nanotube prepared from the metal catalyst. Problems that the metal catalyst finished product rate of a nanotube catalyst preparation method is low, the particle size is not accordant, and the quality of carbon nanotubes can be affected are solved.

Owner:徐丽丽

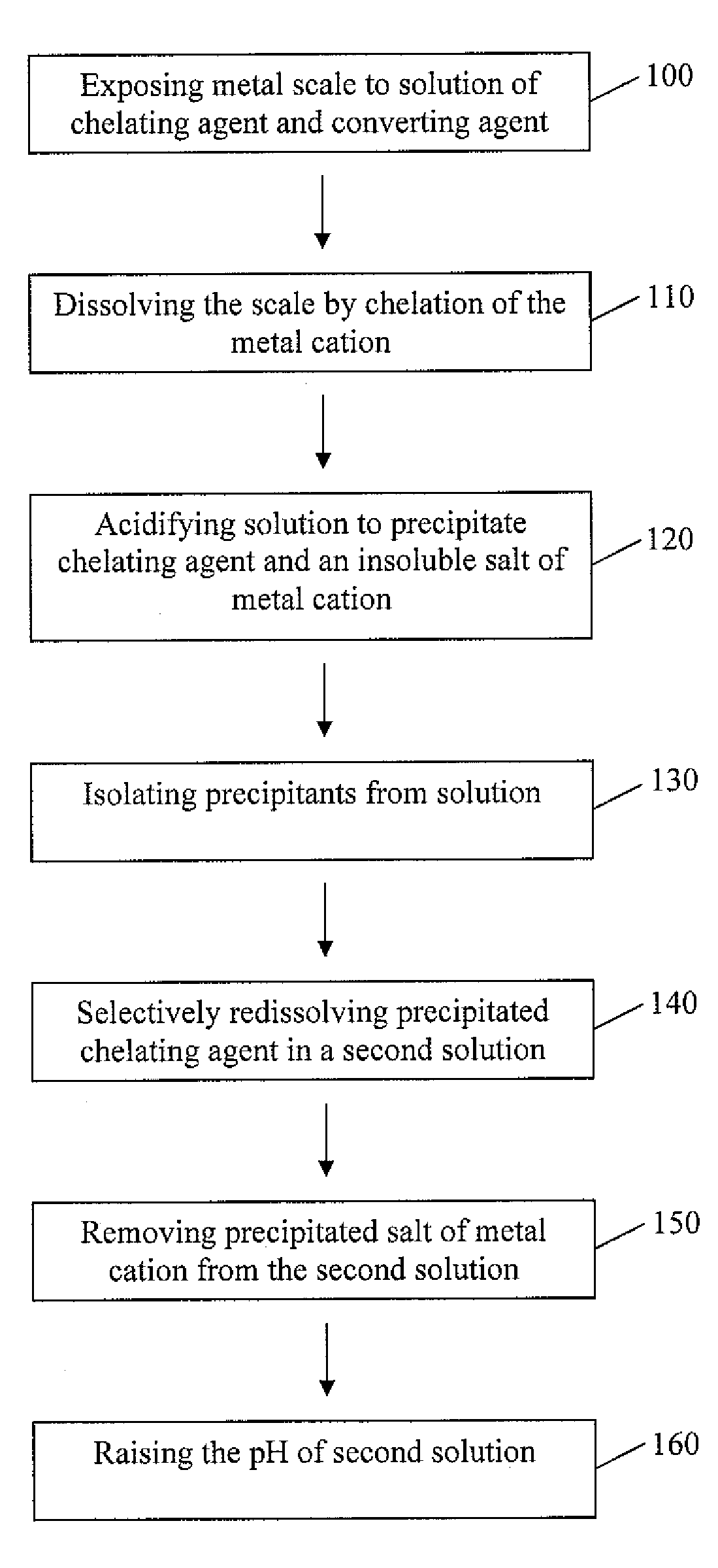

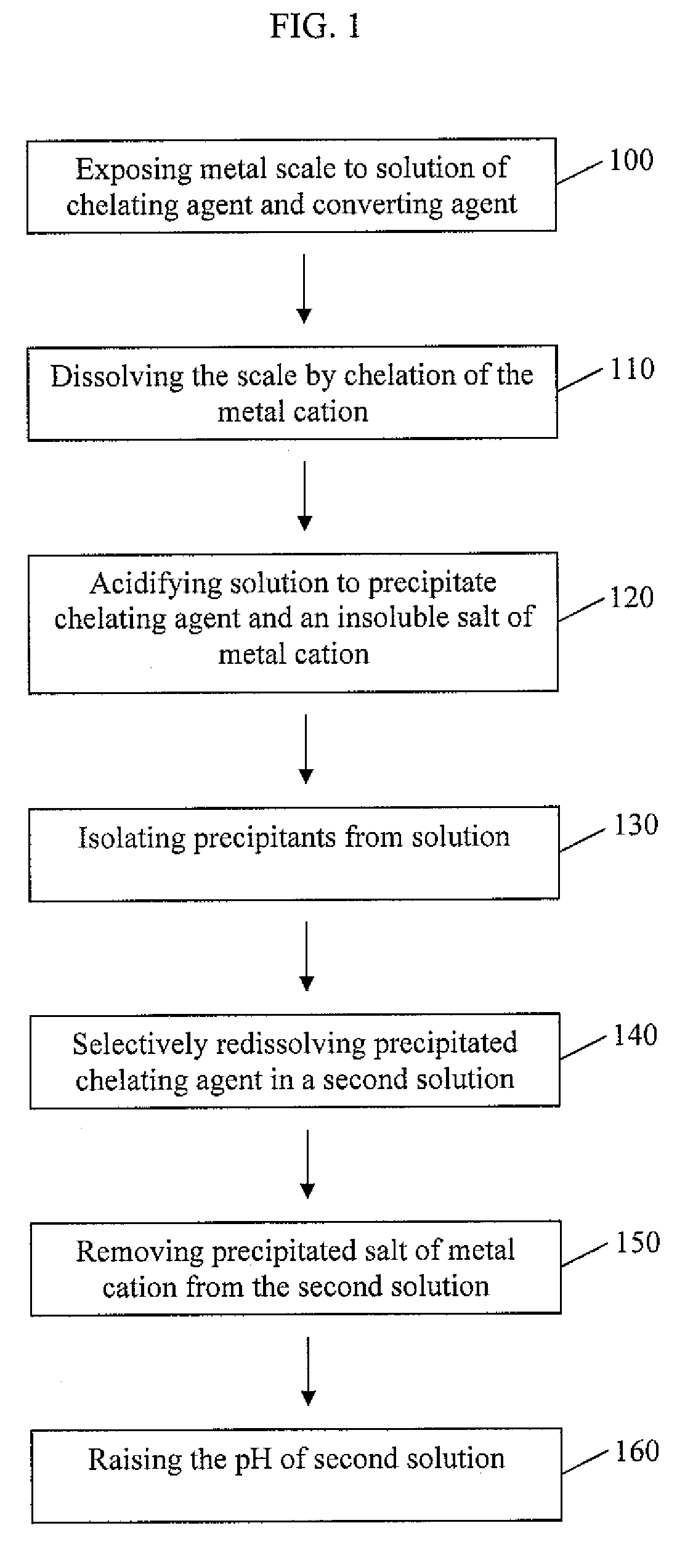

Method for dissolving oilfield scale

ActiveUS7470330B2Waste water treatment from quariesScale removal and water softeningAqueous solutionChemistry

Owner:M I DRILLING FLUIDS U K LTD +1

Technology for preparing cobalt hydroxide from cobaltous sulfate solution

The impurity content of cobaltous sulfate solution obtained after preliminary purification is high, and the conventional method is to sediment metals of cobalt and the like by using sodium salt. Because the alkalinity of the sodium salt is high and partial over-alkali occurs easily, a large proportion of impurities in the solution also form sediments and the cobalt content in finished cobalt hydroxide products is reduced. The invention provides a technology for preparing cobalt hydroxide from cobaltous sulfate solution, which is characterized by the following steps of carrying out first cobalt sedimentation on cobaltous sulfate solution by using cobalt hydroxide in a first cobalt sedimentation channel; processing the first cobalt sedimentation slurry obtained after the reaction by using a cobalt sedimentation buffer channel, then returning 30 to 50% of the obtained slurry to the first cobalt sedimentation channel, and carrying out filter pressing on the rest slurry; drying filter cakes obtained by filter pressing to obtain the dried cobalt hydroxide which is the finished products; and finally carrying out second cobalt sedimentation on the filtrate by using magnesium hydroxide. in the invention, the partial over-alkali is avoided and the cobalt content of cobalt sediments is increased because the magnesium hydroxide slurry of weak alkalinity is used as a precipitant.

Owner:ZHEJIANG HUAYOU COBALT

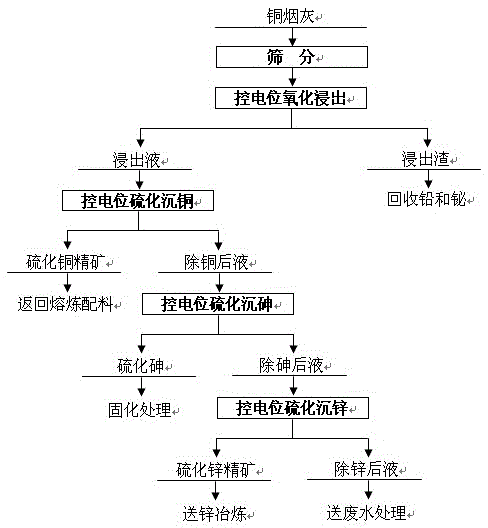

Method for potential controlled selection separation of copper refinery ash

InactiveCN105567984AIncrease sedimentation rateEasy to separateProcess efficiency improvementSlurryCopper sulfide

The invention relates to a method for potential controlled selection separation of copper refinery ash. The copper refinery ash is screened and then subjected to oxidizing leaching in a sulfuric acid system. An oxidizing agent is added to control the metal ion mixed potential of slurry, copper, arsenic, zinc and other metal are dissolved into a solution, and lead, bismuth and other metal precipitate and enter leaching residues. The metal ion mixed potential and the pH value of a leachate are simultaneously controlled, so that copper sulfide concentrate is produced through precipitation. The metal ion mixed potential and the pH value of copper-removed liquid are simultaneously controlled, so that arsenic sulfide products are produced through precipitation. The metal ion mixed potential and the pH value of arsenic-removed liquid are simultaneously controlled, so that zinc sulfide concentrate is produced through precipitation. Zinc-removed liquid is subjected to wastewater treatment and then discharged after reaching the standard. According to the method, the potential controlled oxidizing leaching and potential controlled sulfide precipitation ways are simultaneously adopted for recovering valuable metal step by step, the selection separation effect, which cannot be achieved by independently using the ways, of the valuable metal in the copper refinery ash is achieved, and the leaching rates of copper, arsenic and zinc are larger than 98.0%.

Owner:CENT SOUTH UNIV

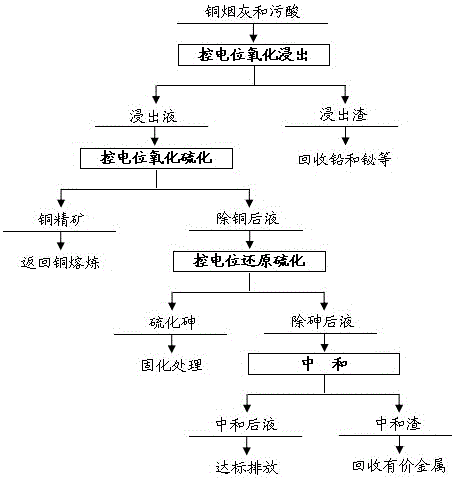

Combined treatment method for copper smelting soot and polluted acid

InactiveCN105950874AEasy to separateAvoid consumptionProcess efficiency improvementCopper sulfideSoot

The invention discloses a combined treatment method for copper smelting soot and polluted acid. The method includes the steps that after the copper smelting soot and the polluted acid are mixed for pulp conditioning, an oxidizing agent is added for controlled-potential oxidization leaching, so that copper, arsenic, zinc and other metal in the copper soot are dissolved to enter leachate, and lead, bismuth and other metal are precipitated to enter a reaching residue; then an oxidizing agent is added into the leachate so that As(III) in the solution can be completely oxidized into As(V); afterwards, sodium sulphide is added, so that the copper in the solution is precipitated in the form of copper sulphide to produce copper concentrate, and a reducing agent is added into the copper-removed solution so that the As(V) in the solution can be completely reduced into As (III); then sodium sulphide is added so that the arsenic in the solution can be precipitated in the form of arsenic sulfide; and finally the arsenic-removed solution is neutralized with alkaline and then is discharged after reaching the standard. By the adoption of the combined treatment method, controlled-potential oxidization leaching, controlled-potential oxidization sulfurization and reduction sulfurization are simultaneously combined to be used for step-by-step separation and recovery of valuable metal in the copper smelting soot and polluted acid, and therefore waste in the system can be recycled, and the purpose of using waste to treat waste is achieved.

Owner:CENT SOUTH UNIV

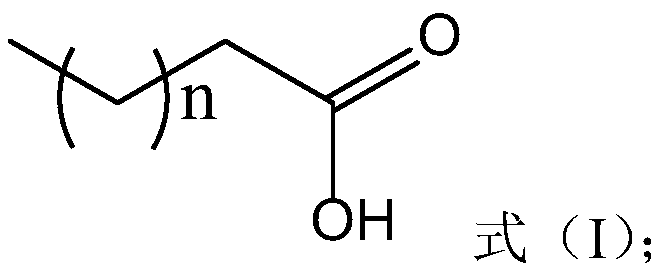

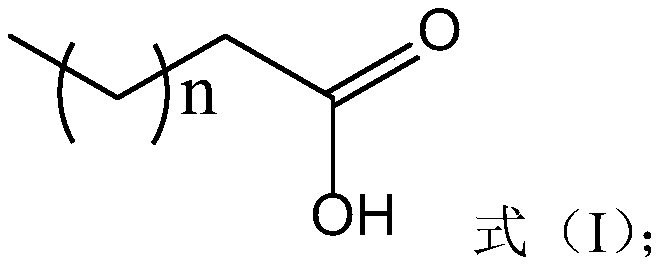

Method for extracting metal ions from fatty acids

ActiveCN110408777ABalanced utilizationImprove leaching efficiencyProcess efficiency improvementRare earthFatty acid

The invention relates to the field of enrichment of metal ions, and discloses a method for extracting metal ions from fatty acids. The method comprises the following steps that (1) saponification is carried out on a fatty acid extraction agent through alkali; (2) the saponification-treated fatty acid extraction agent and an extraction mother solution are mixed, react with each other, are stirred uniformly and precipitated and are then subjected to solid-liquid separation to obtain a metal precipitate, and rare-earth metal ions or non-rare-earth metal ions in the mother solution are extracted;and (3) the metal precipitate is eluted through an acid liquid, and a metal-enriched solution and a regenerative fatty acid extraction agent are obtained after liquid separation. The fatty acid extraction agent used in the method can be directly extracted from animals and plants, can be acquired from numerous sources at low price, is convenient to convey and store, good in biological compatibilityand easy to degrade and causes less pollution to water bodies, the precipitates formed in the precipitation process are large in particle size, solid-liquid separation is easy, the recovery rate of metal ions is high, the enrichment factor is large, and the fatty acids can be recycled.

Owner:厦门熙途科技有限公司

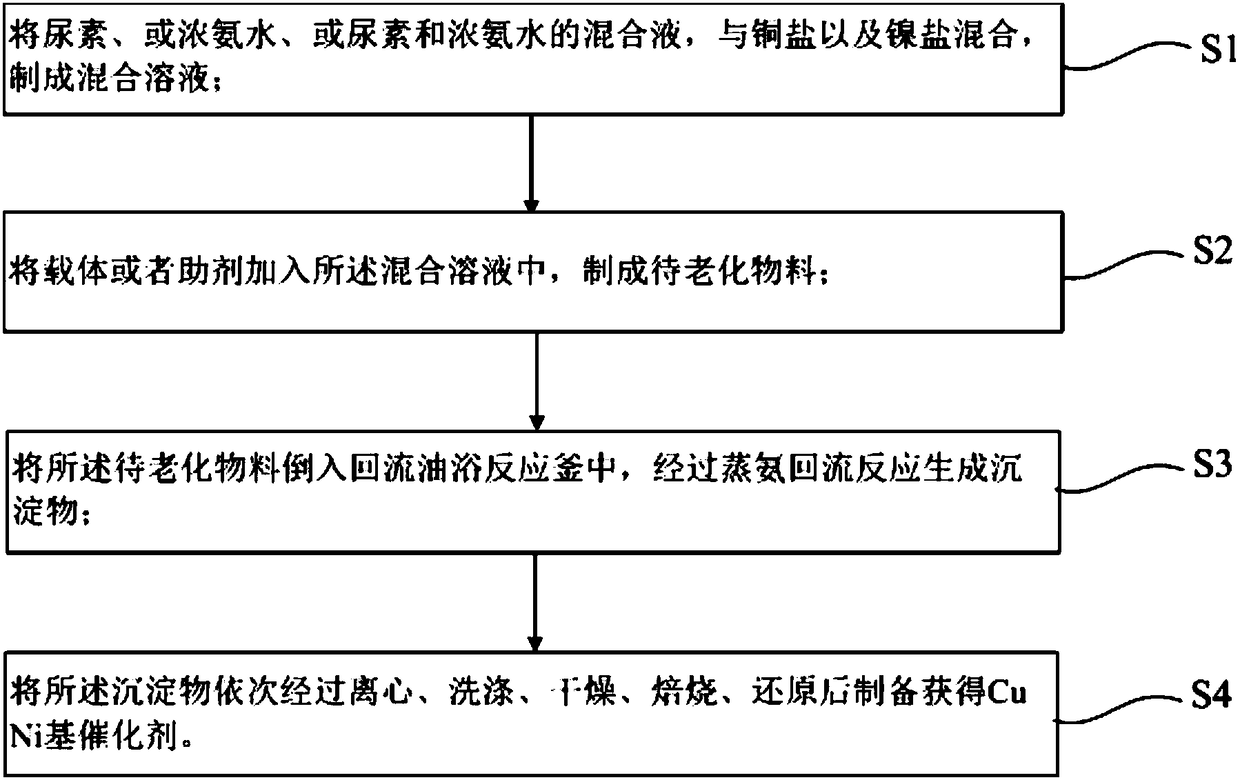

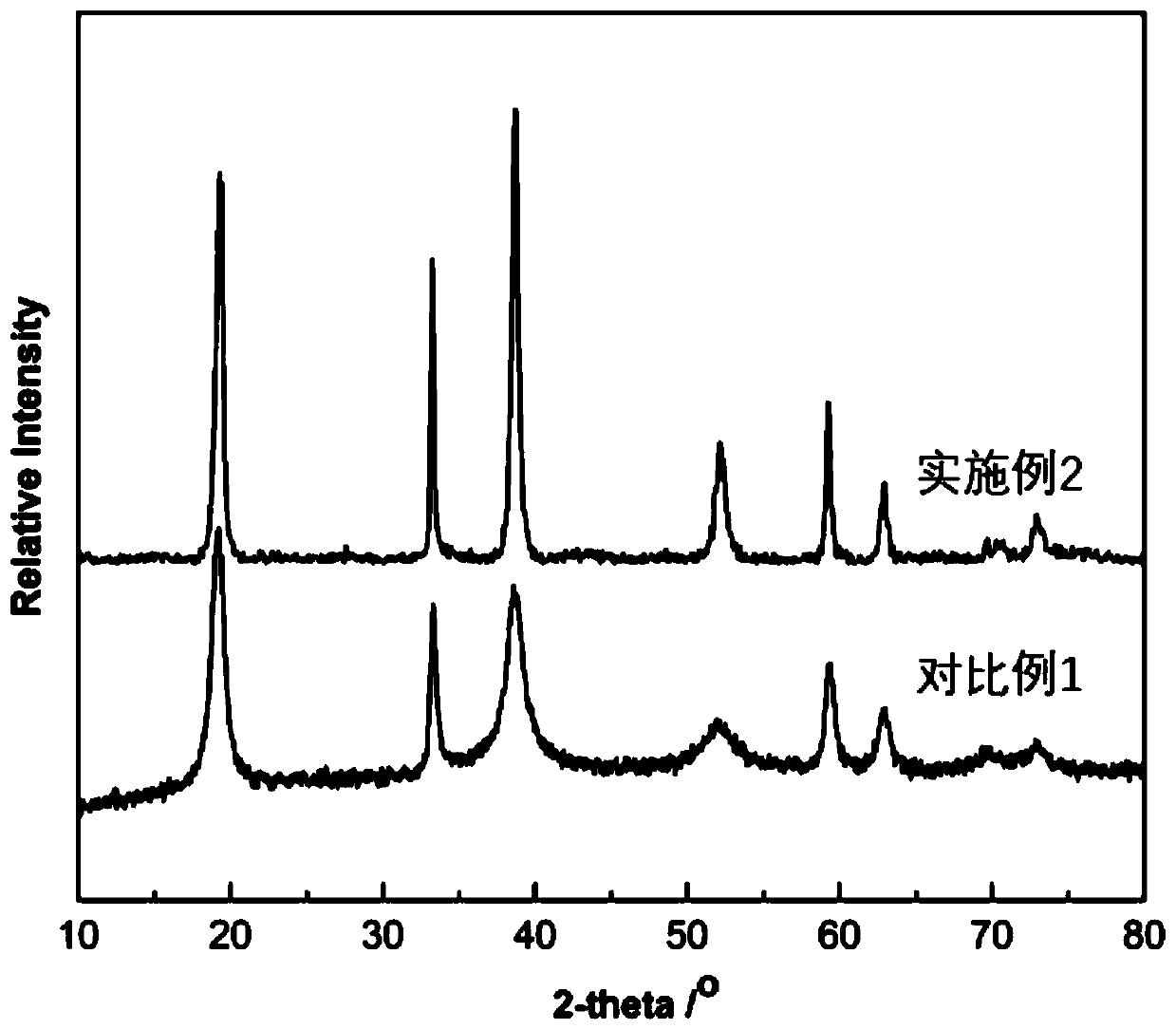

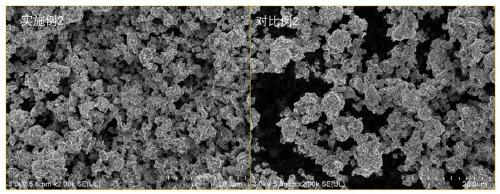

Preparation method and application of CuNi-based catalyst

InactiveCN108499566AImprove performanceHigh yieldOrganic compound preparationHeterogenous catalyst chemical elementsNickel saltDistillation

The invention provides a preparation method and application of a CuNi-based catalyst. The preparation method comprises the following steps: uniformly mixing urea or concentrated ammonia or a mixture of urea and concentrated ammonia with a copper salt, a nickel salt and a carrier or auxiliary agent in a reflux device under stirring; carrying out ammonia distillation to obtain a metal precipitate; and then successively carrying out centrifugation, washing, drying, calcination and reduction so as to obtain the CuNi-based catalyst. The CuNi-based catalyst comprises, by mass, 30-50% of CuO, 5-25% of NiO and 30-60% of a carrier or auxiliary agent. The CuNi-based catalyst prepared in the invention is free of active component loss and stable in catalytic performance; when the CuNi-based catalyst is applied to CO2 hydrogenation and HN(CH3)2(DMA) reaction for synthesis of DMF, the yield of DMF is high, and required raw materials are cheap and easily available; and the preparation method is simple in process, easy to operate, low in process cost and high in repetitive rate, and thus has good application prospects.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

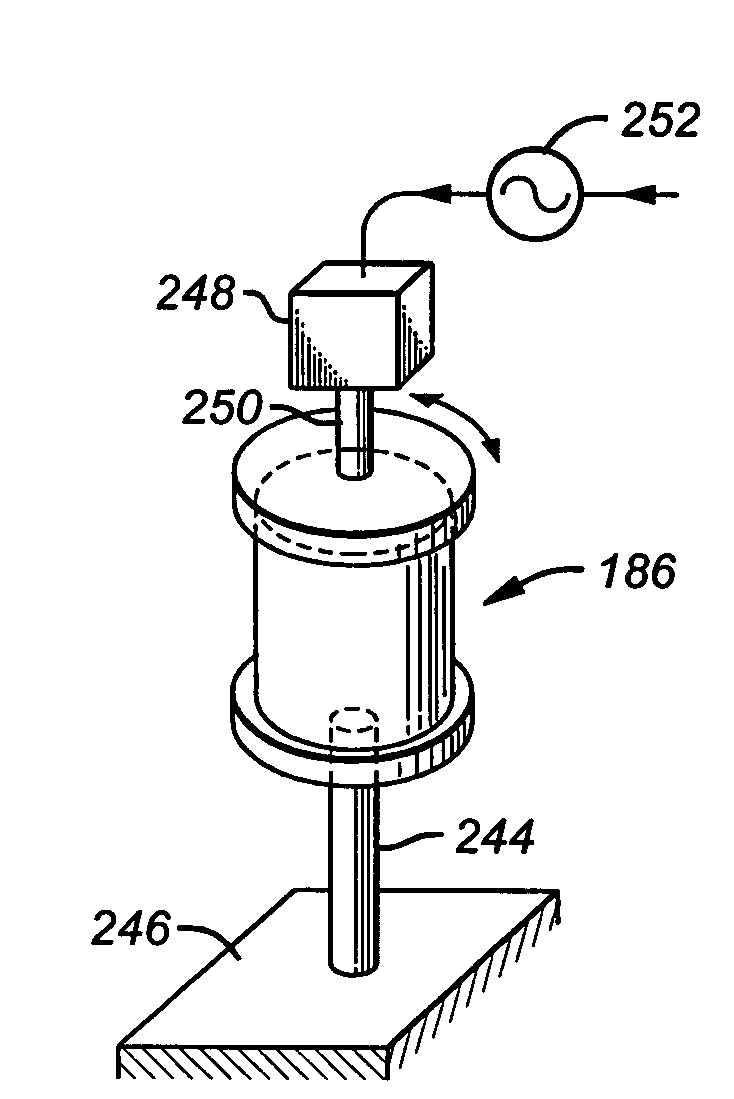

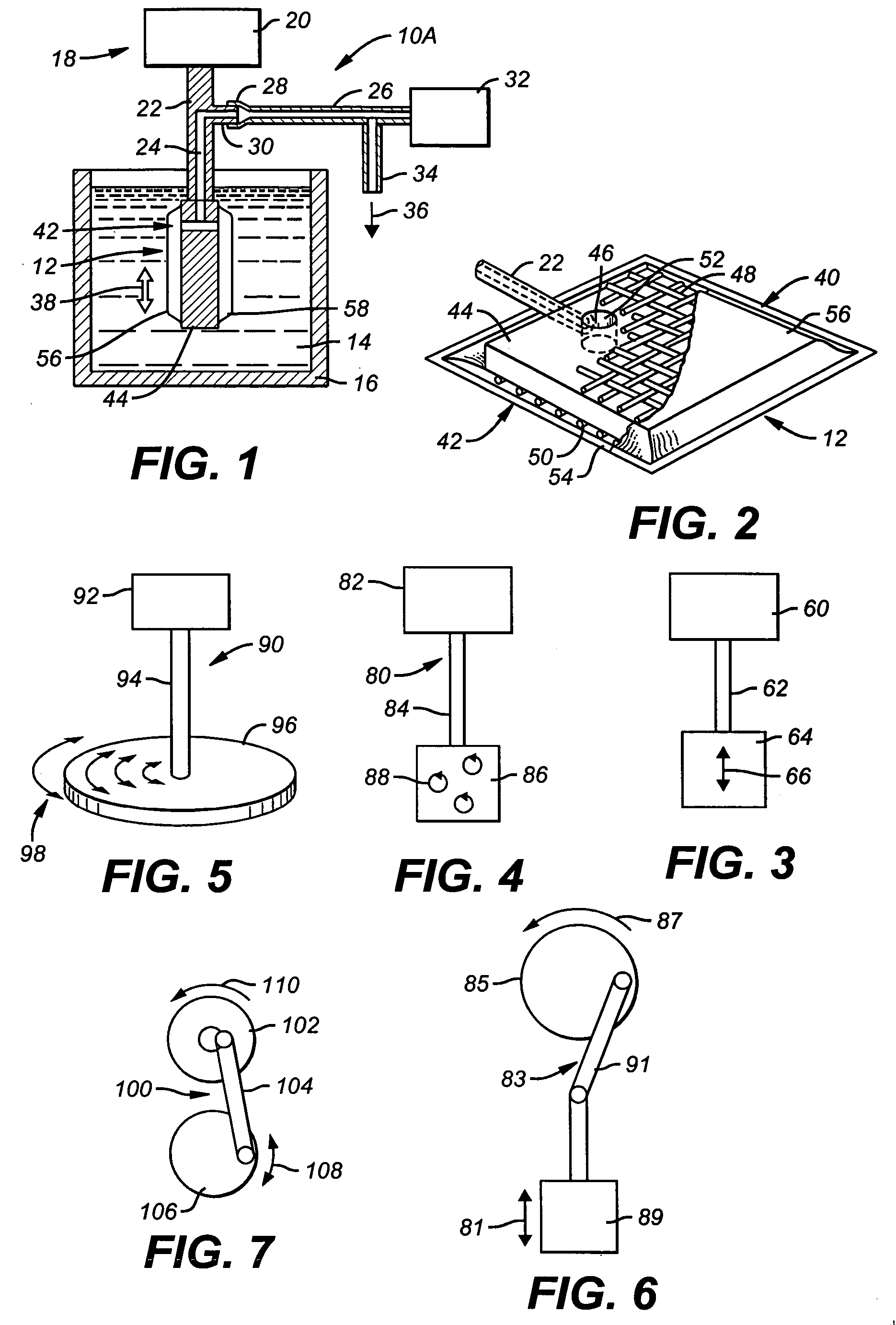

Methods for removing metals from water

A device for separating metal components from a colloidal suspension or solution uses a vessel for holding the colloidal suspension or solution. A membrane impermeable to the selected metal components of a colloidal suspension or solution is sealed over a support to form a leaf element. The leaf element includes an outlet for the selected components of the colloidal suspension or solution and is extended into the colloidal suspension or solution. The leaf element is controllably vibrated simultaneously with application of a negative or positive pressure which is used to motivate permeation of the membrane by the liquid of the colloidal suspension or solution to purify it. Metals removed by the method include metals with an atomic number greater than 10 including and / or silicon. The colloidal suspension or solution may optionally contain a metal precipitator such as a dithiocarbamate and / or trithiocarbamate to aid in the separation.

Owner:BAKER HUGHES HLDG LLC

Treatment of organic materials

InactiveUS6521809B1Loss in efficiencyIncrease ratingsRadioactive decontaminationRadioactive contaminationOxidation state

Processes for the treatment of solutions used for the decontamination of radioactively contaminated surfaces wherein the solution contains radioactive metal ions and organic complexing agents are described herein. The processes include treating the solutions with a reagent suitable for the destruction of the complexing agent and contains a metal capable of existing in more than one oxidation state, and raising the pH of the resultant solution to a level at which the metal of the reagent precipitates or flocs out of the solution. Processes in which the contaminated solutions are treated with electromagnetic radiation, treated with UV or visible radiation, and treated at an ambient temperature are also described herein.

Owner:NUCLEAR DECOMMISSIONING AUTHORITY

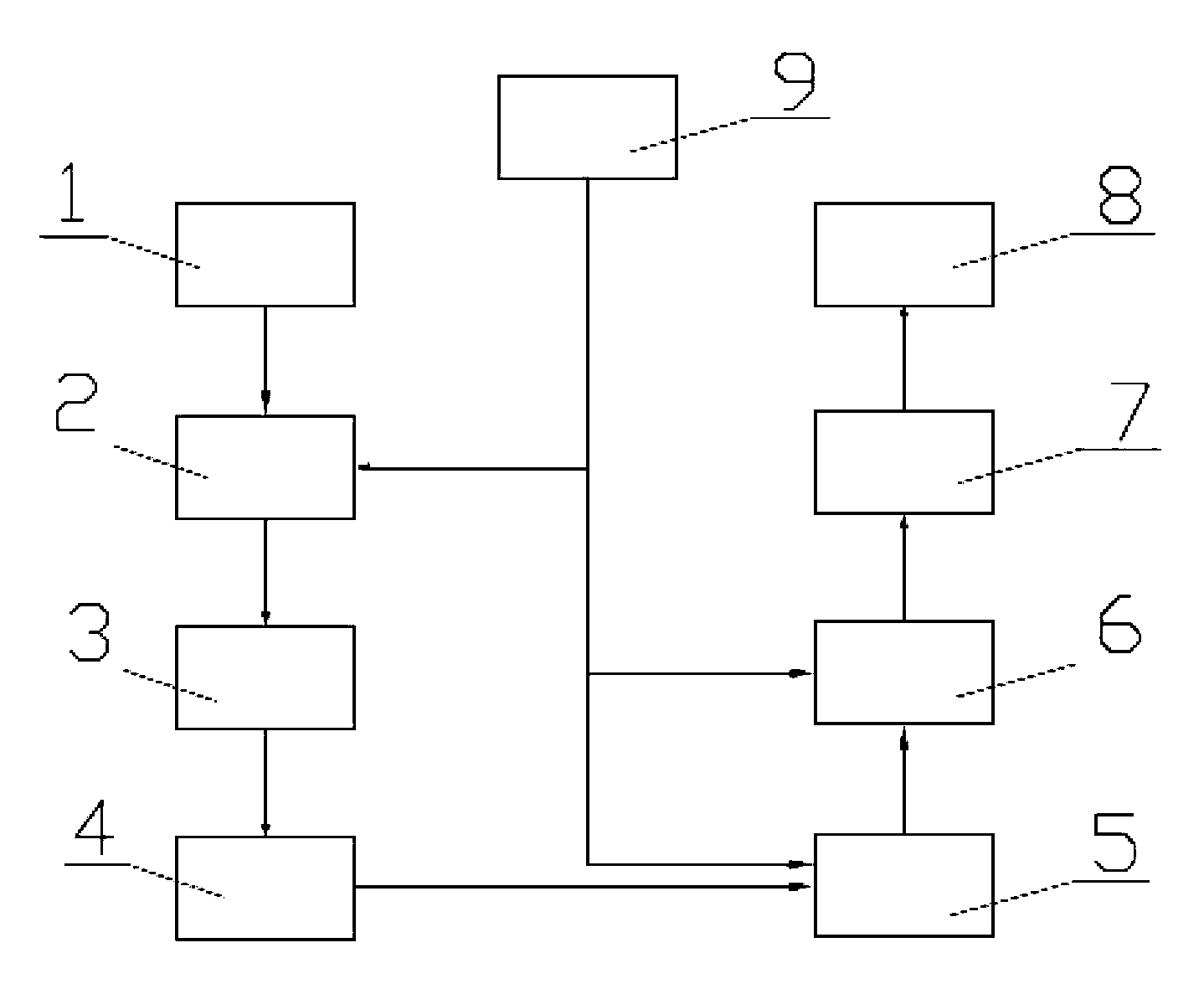

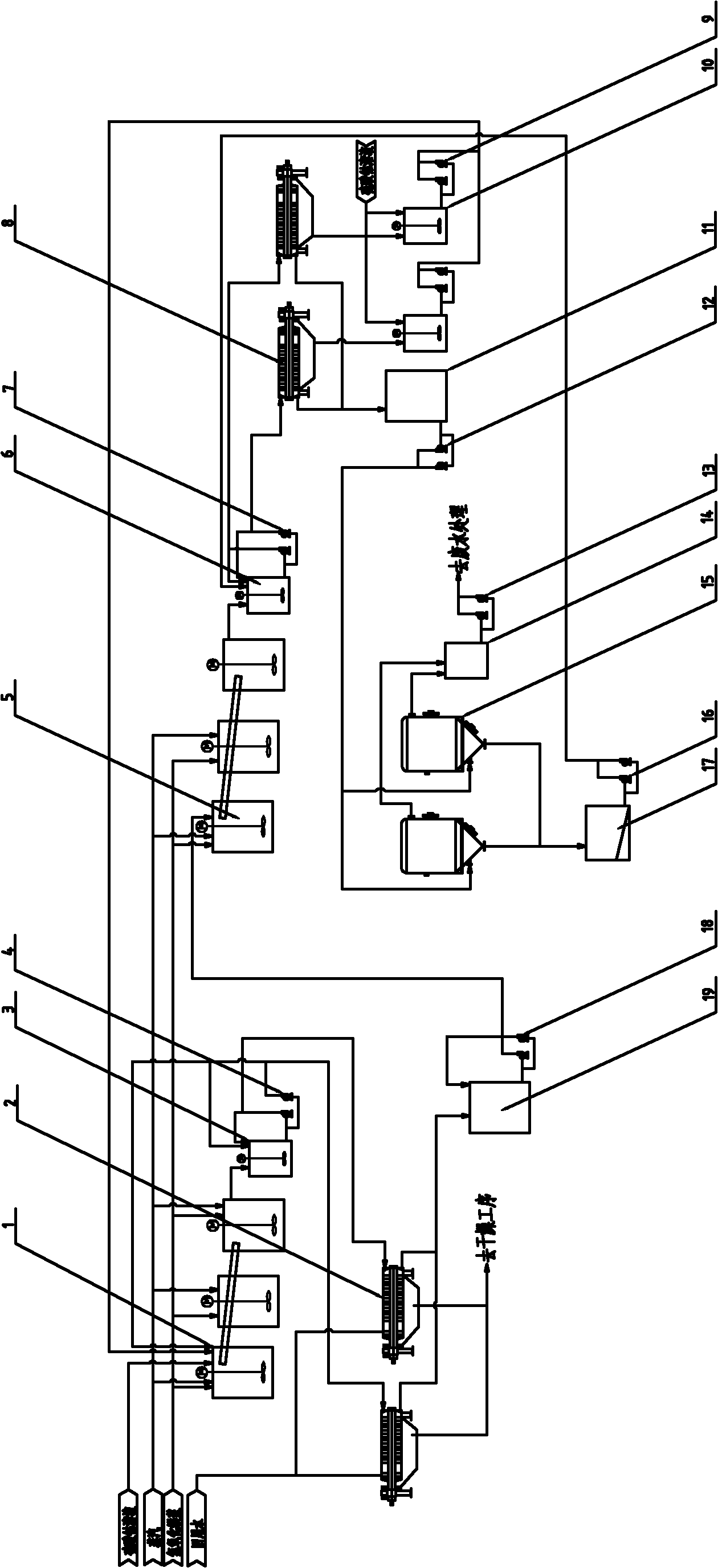

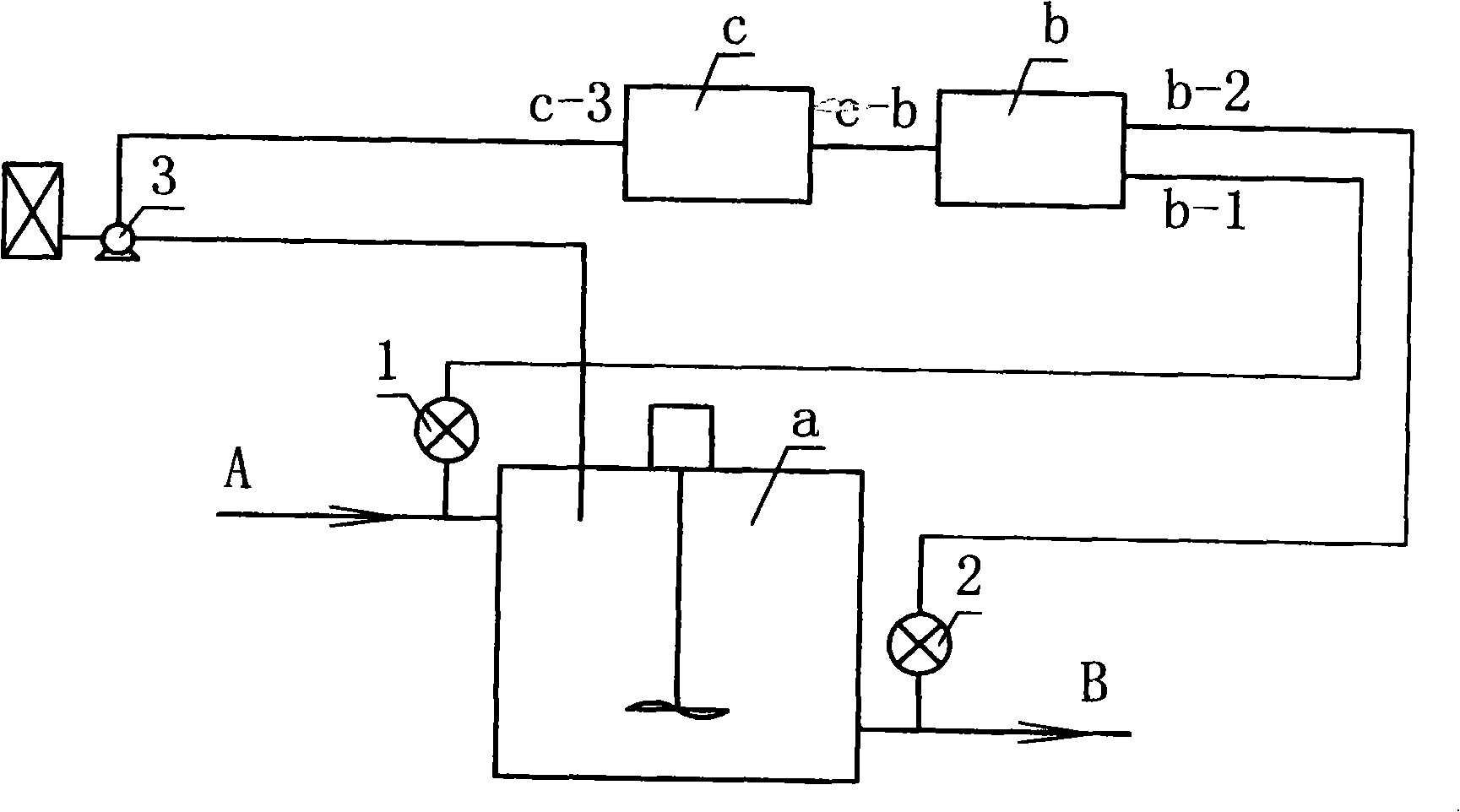

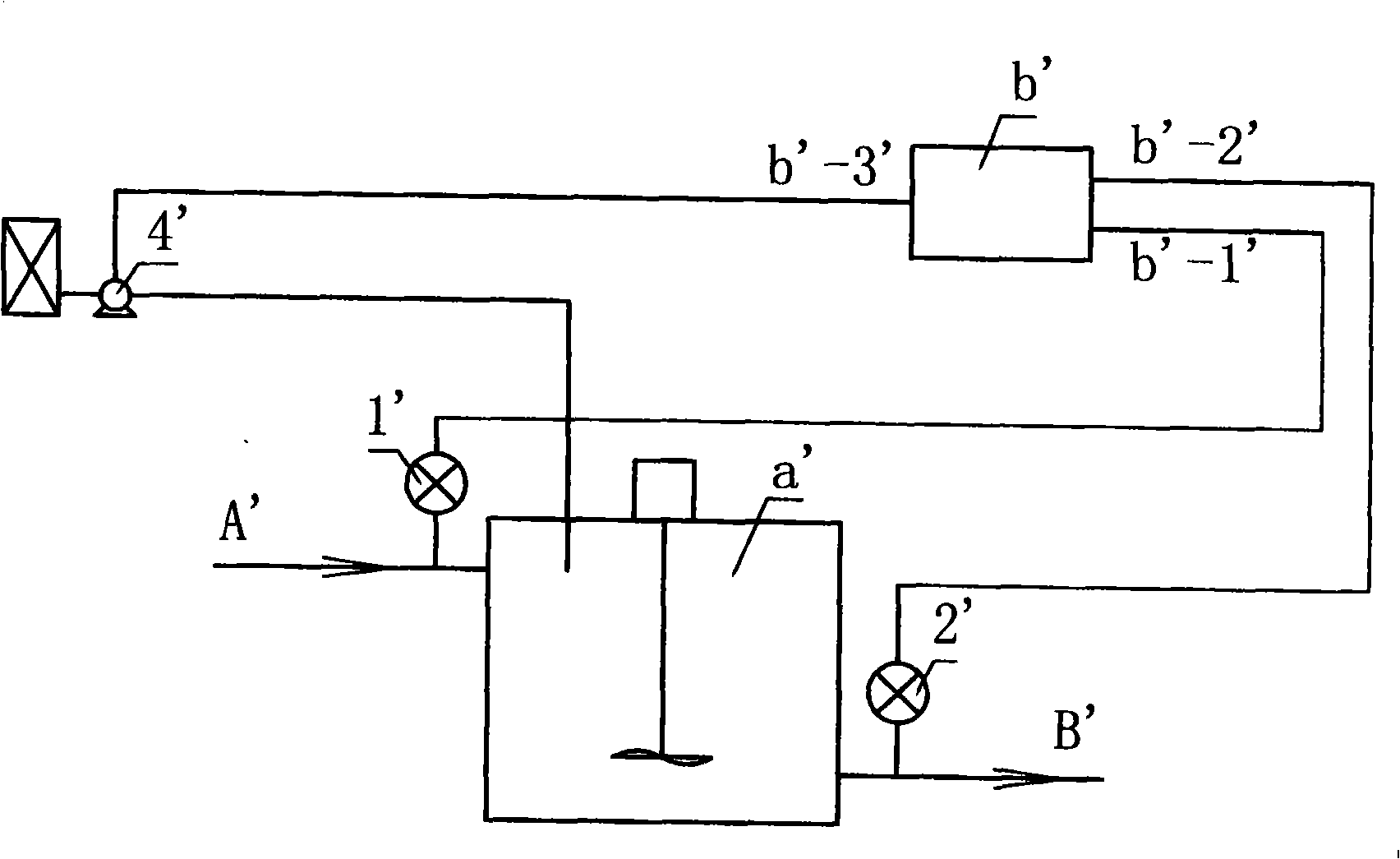

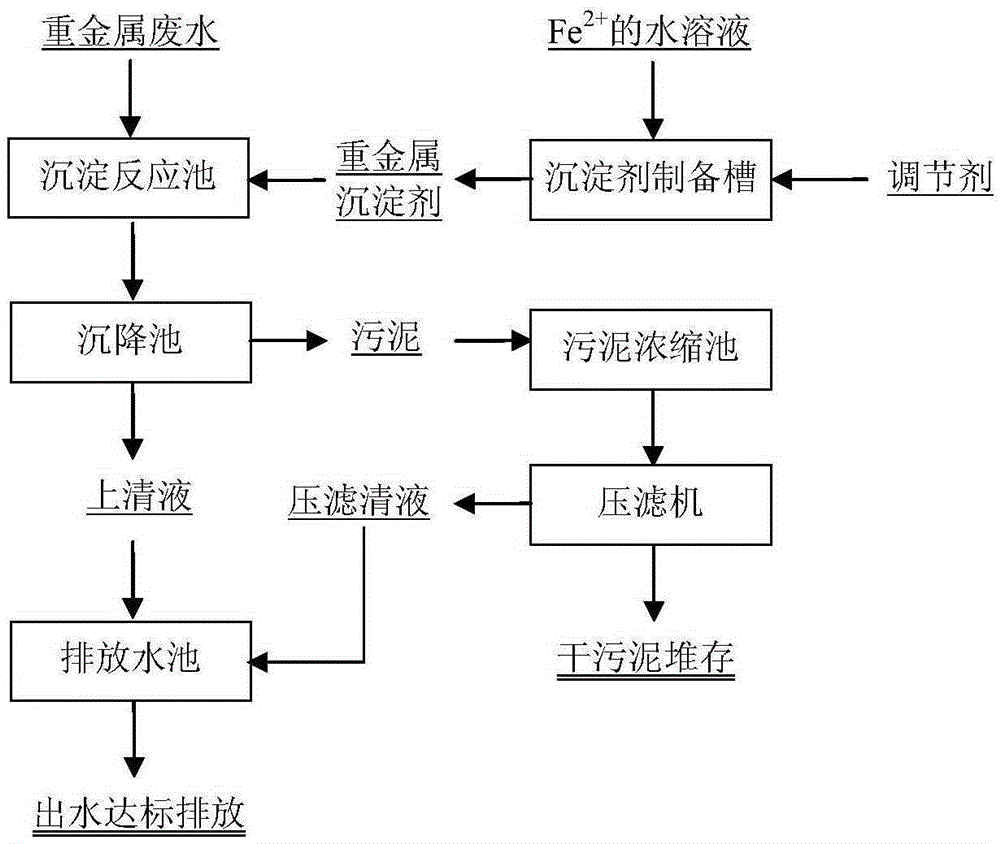

Automatic control method and apparatus for delivering medicine to process heavy metal ion containing wastewater

InactiveCN101314494AAutomatic control of continuous and stable dosingEnsure continuous and stable complianceWater contaminantsWater/sewage treatment by neutralisationAutomatic controlIon

The invention provides an automatic dosing control method for removing heavy metal ions in wasterwater containing the heavy metal ions and a device thereof. The method and the device are mainly suitable for automatic dosing control during treating the wastewater containing the heavy metal ions by adopting the chemical precipitation method. The control method comprises the following steps of: 1. detecting an ORP1 value with a certain pH value before heavy metal precipitator is added; 2. detecting an ORP2 value after the heavy metal precipitator is added and a heavy metal complete precipitation reaction is generated; 3. automatically controlling the dosage and the dosing process of the heavy metal precipitator according to an ORP difference value (ORP1 minus ORP2) between the ORP1 which is detected before the heavy metal ion precipitation is completed and the ORP2 which is detected after the heavy metal ion precipitation is completed. The control device comprises two sets of online detecting ORP meters, an automatic control system adopting the PID technology and the PLC technology and a plurality of dosing pumps. The invention is an automatic continuous dosing control technology for the heavy metal ion precipitation reaction in the treatment for the wastewater containing the heavy metal ions through combining the ORP technology and the PID / PLC technology into a whole, can effectively solve the continuous precise dosing problem during the treatment of the wastewater containing the heavy metal ions, and ensure that the treated water which can meet the standard is discharged continuously and stably.

Owner:陈德琪

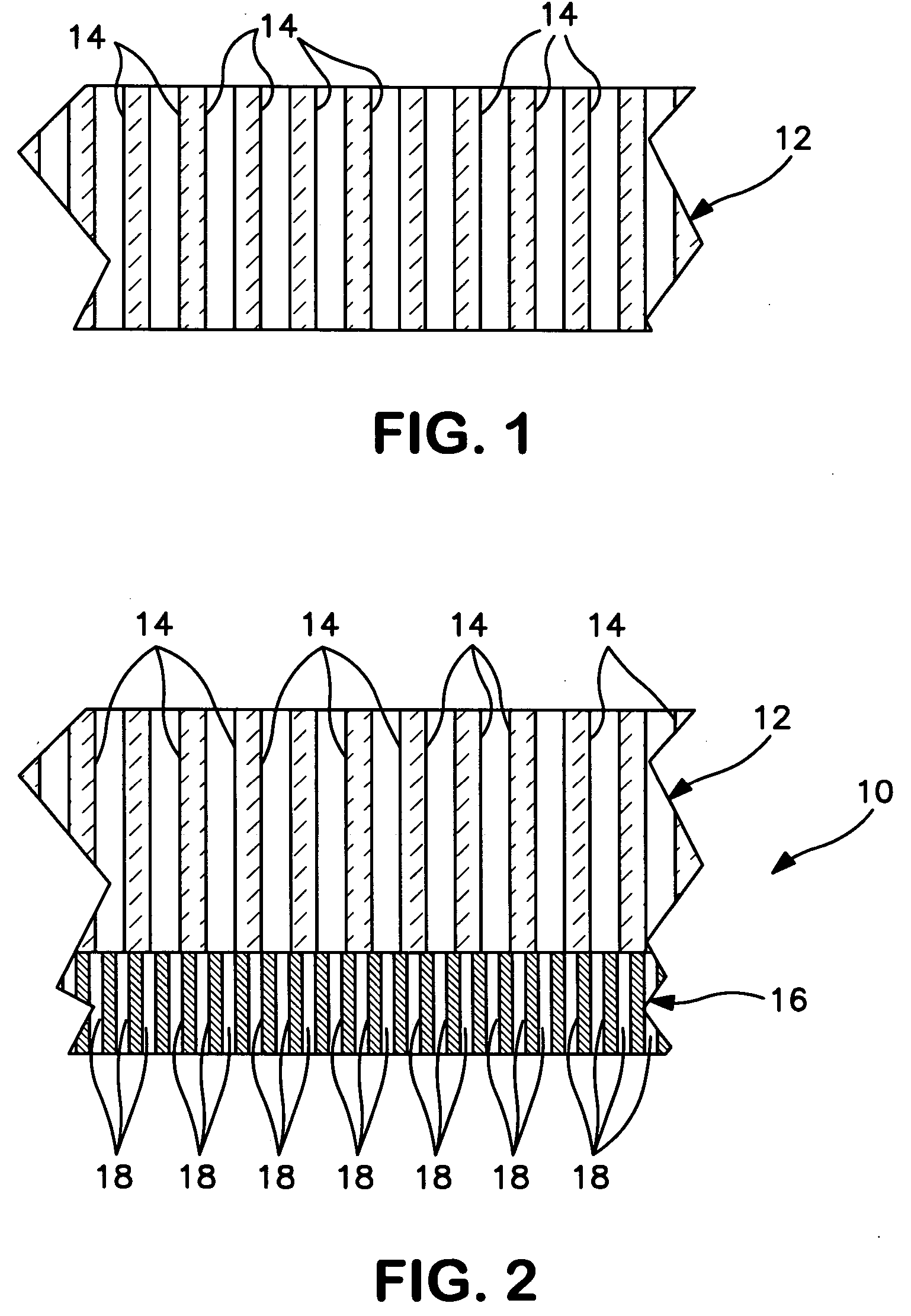

Hydrogen transport membrane fabrication method

InactiveUS20070110991A1Inhibits the formation of defectsMembranesSemi-permeable membranesAlloySalt solution

A method of forming a hydrogen transport membrane to separate hydrogen from a hydrogen containing feed in which a porous ceramic support is formed to support a dense layer of palladium or an alloy of palladium serving as a hydrogen transport material. Isolated deposits of palladium, a palladium alloy or a component of such alloy are produced on a surface of the porous ceramic support that bridge pores within the porous ceramic support without penetrating the pores and without bridging regions of the surface defined between the pores. The isolated deposits of the metal are produced by an electroless plating process that involves contacting the porous ceramic support with a precipitating agent so that the precipitating agent fills the pores but does not seep out of the pores onto the regions of the surfaces defined between the pores. The surface is then contacted with a salt solution containing a salt of the metal so that said metal precipitates and produces the isolated deposits of the metal. Thereafter, the dense layer is formed on the surface having the isolated deposits.

Owner:PRAXAIR TECH INC

Pickling waste liquid treatment process of steel industry

InactiveCN104445720ASimple and fast operationLow costFatty/oily/floating substances removal devicesTreatment involving filtrationLiquid wasteWater use

The invention discloses a pickling waste liquid treatment process of the steel industry. The pickling waste liquid treatment process comprises the following technical steps: a, primarily filtering a pickling waste liquid so as to filter off solid impurities and grease; b, adding alkali into the filtrate to adjust the pH value; c, feeding the solution obtained in the step b into a heavy metal capturer, and performing reaction on various metal ions in the solution and a heavy metal capturing agent, thereby forming a heavy metal precipitate; d, feeding the reactant obtained in the step c into a filter, filtering and recycling the heavy metal precipitate, and collecting the filtrate for later use; and e, feeding the filtrate obtained in the step d into a reverse osmosis device, and deeply treating, thereby obtaining water which almost meets the standard of pure water and can be recycled for production of washing water, wherein the thick water can be recycled to be used as primary pickling water used in a pickling process. The pickling waste liquid treatment process is simple and convenient to operate, low in cost, and applicable to industrialization popularization and application; the pickling waste liquid can be thoroughly treated, the recycling rate of heavy metal ions is high, and no secondary pollution is caused as the waste liquid is circulated and reused in a completely sealed manner after being treated.

Owner:WUXI EPIC TECH

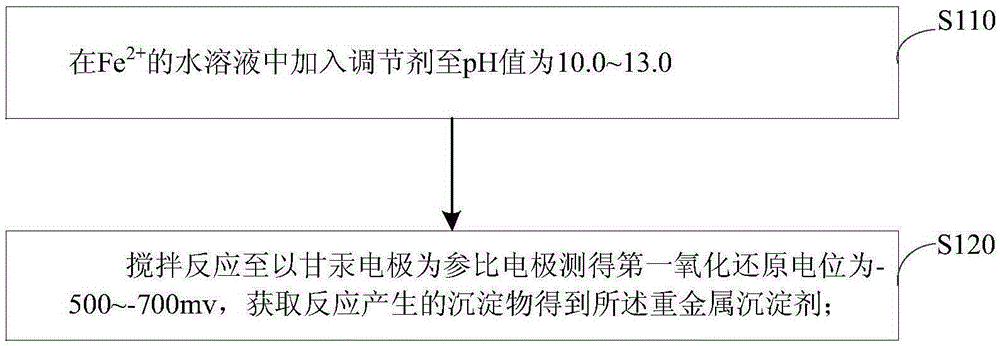

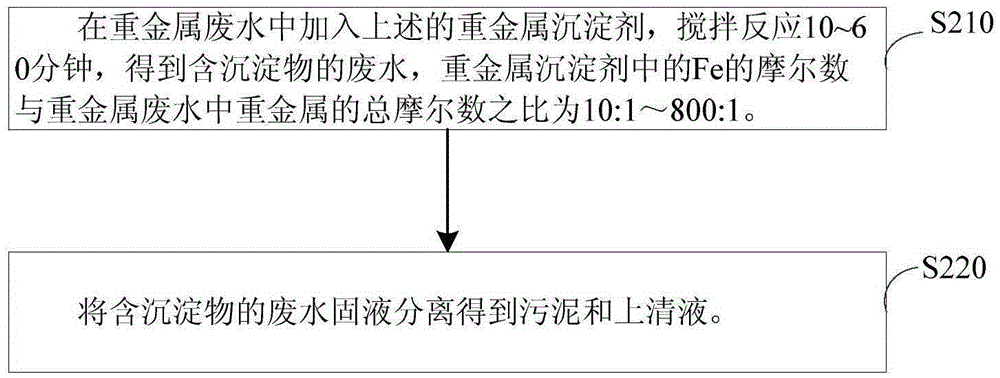

Heavy metal precipitant, preparation method thereof and heavy metal wastewater treatment method

InactiveCN105236543AGood removal effectReduce manufacturing costWater contaminantsWater/sewage treatment by flocculation/precipitationFerrous saltsWastewater

The invention discloses a heavy metal precipitant, a preparation method thereof and a heavy metal wastewater treatment method. The preparation method of the heavy metal precipitant comprises the steps that modifiers are added into Fe2+ water solution to regulate the pH value between 10.0 and 13.0; the mixture is stirred and subjected to reaction until calomel electrodes are adopted as reference electrodes to measure the first oxidation-reduction potential between minus 500mv and minus 700mv; sediment produced in reaction is acquired, and then the heavy metal precipitant is obtained, wherein the modifiers include one or more of NaOH, KOH and Ca(OH)2. According to the preparation method of the heavy metal precipitant, only relatively cheap ferrous salt is adopted as an iron source needed for preparing the heavy metal precipitant, so that the preparation cost of the heavy metal precipitant is greatly lowered; moreover, the oxidation-reduction potential and the pH value are used as control parameters in the preparation process, so control is easy and convenient, and stable quality of the heavy metal precipitant can be guaranteed.

Owner:湖南中金岭南康盟环保科技有限公司

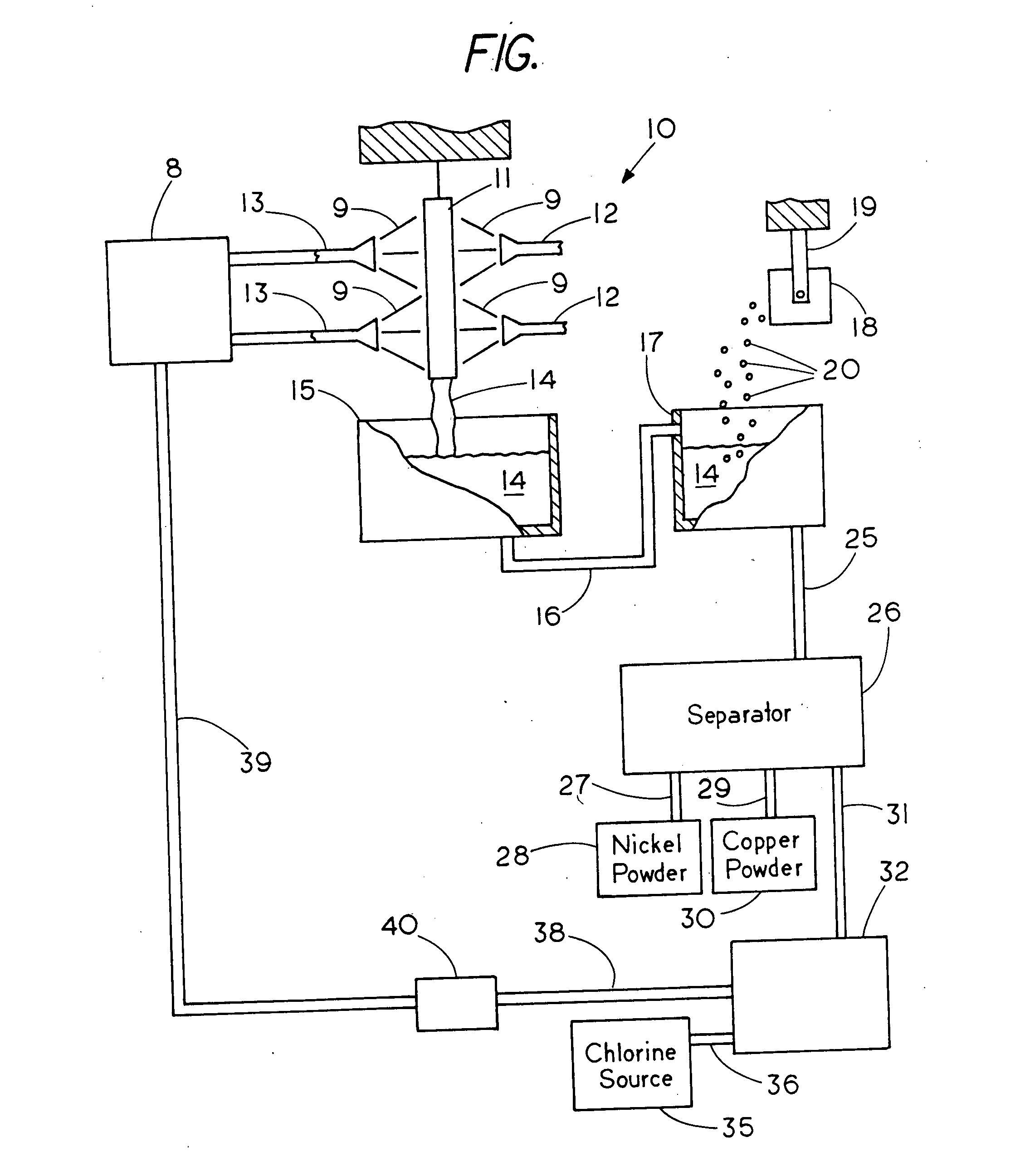

Method of recovery of metals from etching solutions

A method of etching and a method of regenerating a spent etching solution comprising adding metal particles to a spent etching solution to precipitate the residue metal or metals in the spent etching solution in the form of metal powders, removing the metal powders from the spent etching solution and recovering the metals in the metal powders for future use. The remaining portion of the spent etching solution can then be regenerated to produce a fresh batch of etching solution.

Owner:DEMMINER MASCHEN TECHN

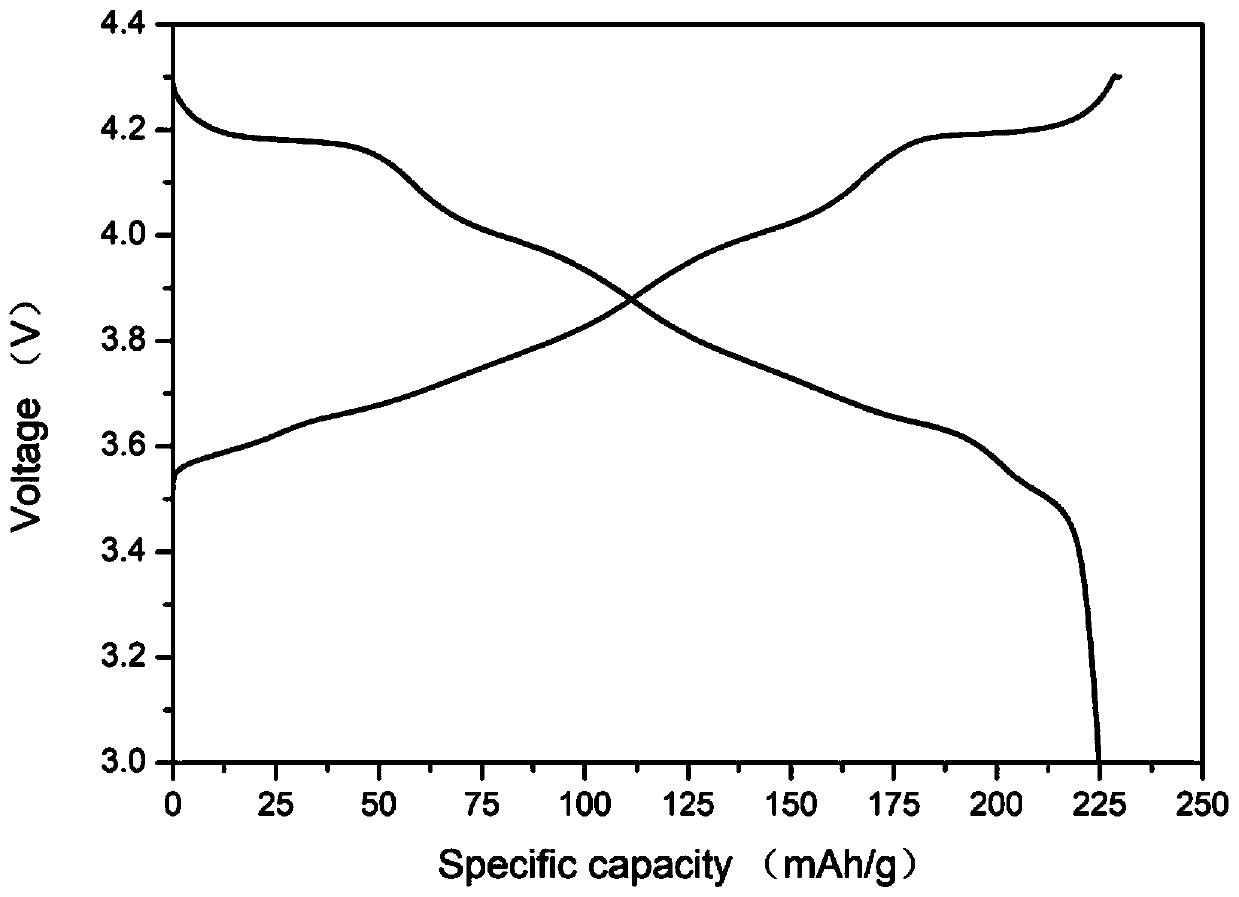

Preparation method of monocrystal-like lithium nickel cobalt manganate

ActiveCN111370683AIncrease ion concentrationReduce the effect of crystallinityCell electrodesSecondary cellsManganatePhysical chemistry

The invention provides a preparation method of monocrystal-like lithium nickel cobalt manganate, which comprises the following steps: 1. preparing a transition metal salt solution, adding a complexingagent or preparing a complexing agent solution, and preparing a pH regulating solution; 2, preparing a nickel-cobalt-manganese metal precipitate; continuously pumping various solutions prepared in the first step into a reaction kettle at the same time through different feeding pipes; connecting a reactor filled with manganese salt with a feed port of a reaction kettle, introducing protective gas,heating, continuously adding an oxidant into the reactor, reacting, adjusting the flow of the protective gas, introducing manganese oxide generated by the reaction into the reaction kettle, controlling the pH value in the reaction kettle, and carrying out precipitation reaction to obtain nickel-cobalt-manganese metal precipitates after the reaction is finished; 3, pre-sintering to prepare a nickel-cobalt-manganese precursor; and 4, performing lithiation sintering, such that the monocrystal-like lithium nickel cobalt manganate positive electrode material is obtained.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

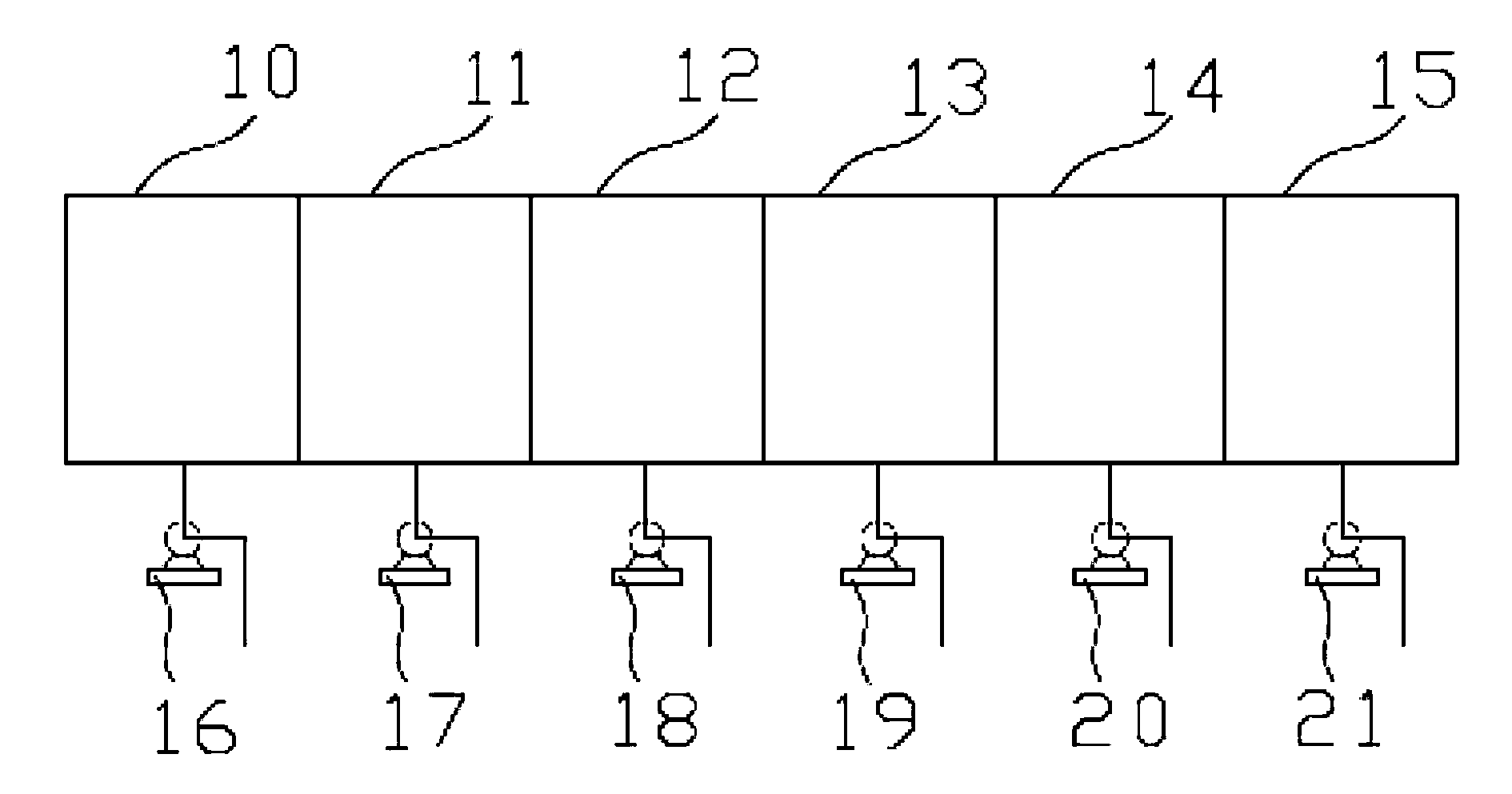

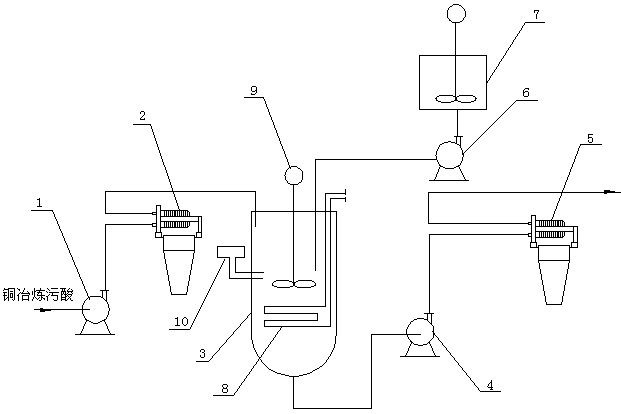

Comprehensive recovery device and method for valuable metal in copper smelting acidic wastewater

InactiveCN104017996AAvoid churnSimple structureProcess efficiency improvementSolid particleChemistry

The invention provides a comprehensive recovery device and method for valuable metal in copper smelting acidic wastewater. The device comprises an acidic wastewater pump, a first filter press, a reaction tank, a reaction liquid pump and a second filter press which are sequentially connected, wherein the top of the reaction tank is connected with the first filter press and the bottom of the reaction tank is connected with the reaction liquid pump; the reaction tank is internally provided with a steam heating coil and a stirring, and the top of the reaction tank is further connected with a reagent tank through a metering pump. The method mainly comprises the following steps: (1) carrying out press-filtering in the first press filter to remove solid particles in acidic wastewater; (2) adding a sodium thiosulfate solution in the reagent tank by the metering pump into the reaction tank and controlling the heating temperature of the reaction tank at 60-70 DEG C; and (3) feeding the solution after reaction into the second press filter to be press-filtered and discharging the filtrate after neutralizing treatment. According to the device and method, the recovery rate of metal precipitates such as copper, rhenium, silver and bismuth in the acidic wastewater reaches up to over 90%, so that the loss of valuable metals in the acidic wastewater is effectively solved.

Owner:BAIYIN NONFERROUS GROUP

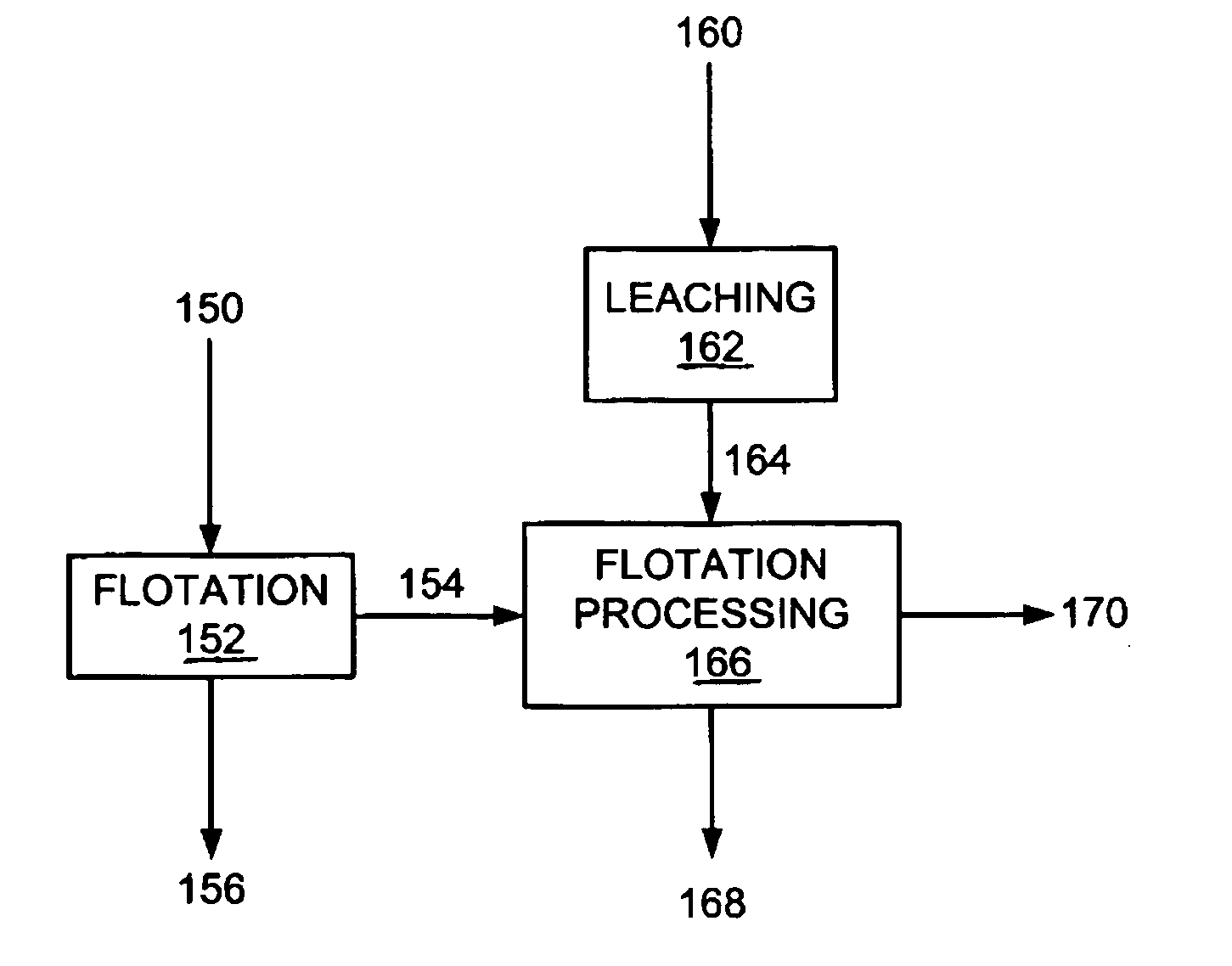

Flotation processing including recovery of soluble nonferrous base metal values

ActiveUS20050045528A1Reduce the amount requiredReduce presenceSolvent extractionGold compoundsParticulatesSulfide minerals

A method of flotation processing ores and other mineral materials containing soluble nonferrous base metal and sulfide minerals involves dissolving the soluble nonferrous base metal and precipitating the soluble nonferrous base metal in the form of a floatable precipitate that is collected as part of a sulfide concentrate. The use of an oxygen-deficient flotation gas, such as nitrogen gas, promotes the precipitation of the floatable precipitate. A method for removing dissolved nonferrous base metal from solution involves contacting the solution with a particulate containing sulfide minerals under conditions promoting precipitation of the nonferrous base metal onto the sulfide mineral.

Owner:NEWMOST USA

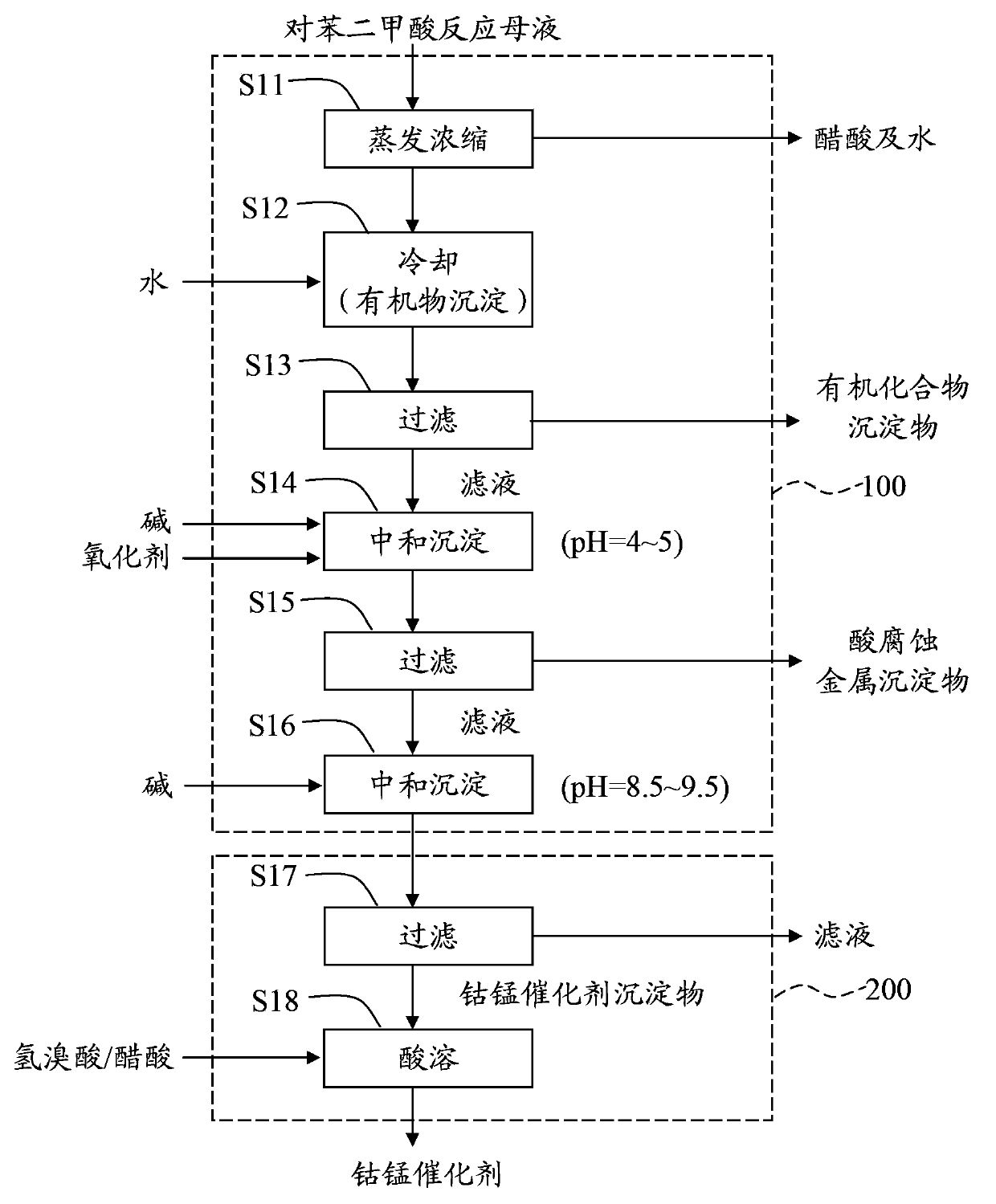

Method for recovering cobalt manganese catalyst from terephthalic acid reaction mother solution

InactiveCN103861650AReduce loadEasy to handleOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst regeneration/reactivationEvaporationManganese

A disclosed method for recovering a cobalt manganese catalyst from a terephthalic acid reaction mother solution comprises the following steps: recovering acetic acid form the reaction mother solution by evaporation; adding water to concentrated mother solution, and cooling to precipitate organic compound precipitation from the reaction mother solution; separating and recovering the organic compound precipitation; heating the solution and adding alkali and an oxidant, so as to enable metal ions such as iron, chromium and the like in the solution to form acid-corroding metal precipitation and precipitate; removing the acid-corroding metal precipitation, and continuing to add alkali into the solution, so as to enable metal ions such as cobalt, manganese and the like to precipitate and form a cobalt manganese catalyst precipitation; and performing filtering and water washing on the cobalt manganese catalyst precipitation, adding into hydrobromic acid or acetic acid, so as to dissolve the cobalt manganese catalyst precipitation and recover the precipitation as the cobalt manganese catalyst. Therefore, the purpose of recovering the cobalt manganese catalyst efficiently for reutilization is realized.

Owner:兴忠行股份有限公司 +1

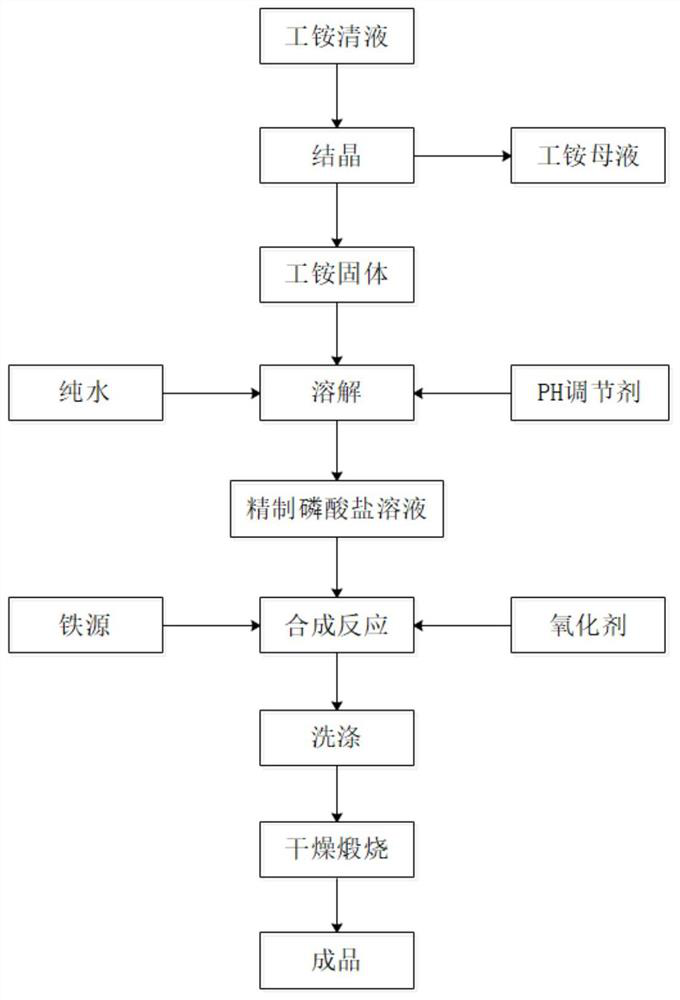

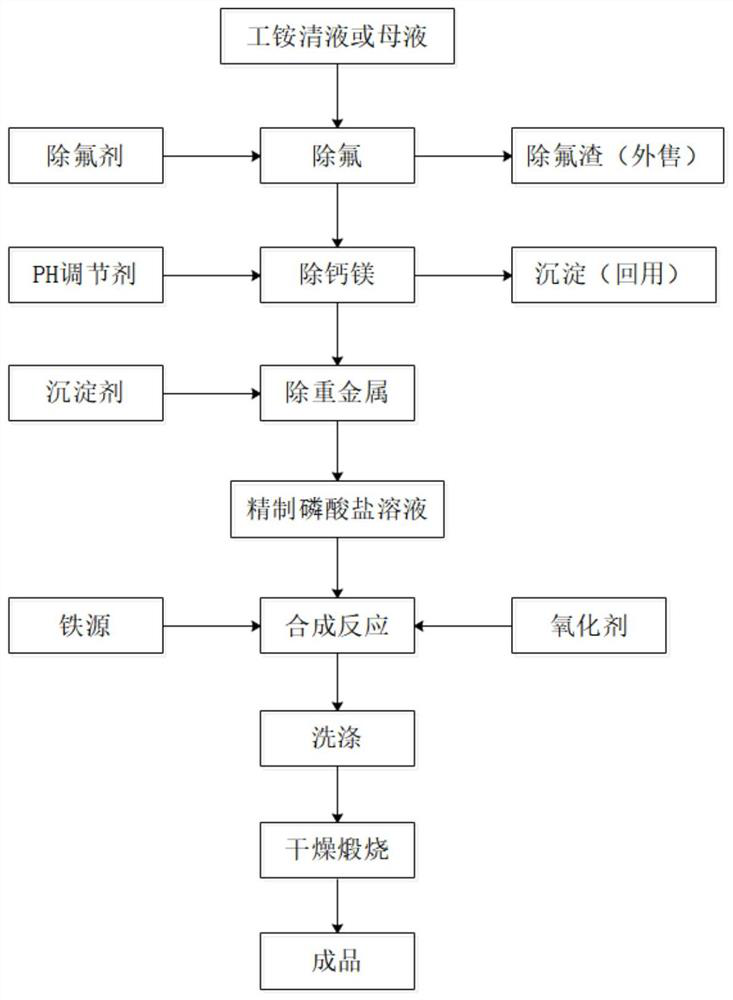

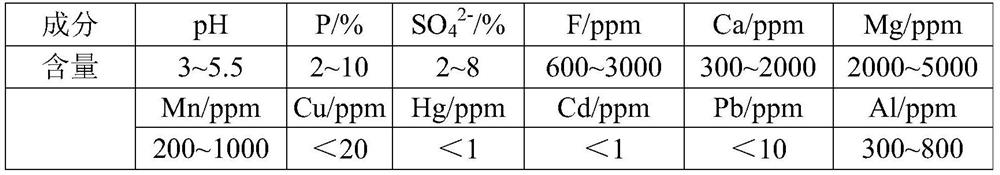

Method for preparing battery-grade anhydrous iron phosphate from industrial ammonium phosphate clear liquid or industrial ammonium phosphate mother liquid

ActiveCN113104827AReduce manufacturing costAvoid pollutionPhosphorus compoundsPhosphateElectrical battery

The invention discloses a method for preparing battery-grade anhydrous iron phosphate from industrial ammonium phosphate clear liquid or industrial ammonium phosphate mother liquor. The method comprises the following steps: S1, fluorine removal: adding diatomite and sodium carbonate into the industrial ammonium phosphate clear liquid or the industrial ammonium phosphate mother liquor to remove fluorine; S2, refining: adjusting the pH value of the phosphorus-containing solution in the step S1, and removing impurities such as calcium, magnesium, manganese, aluminum and the like; S3, heavy metal removal: adding a heavy metal precipitant into the phosphorus-containing solution with low impurity ion content in the step S2 to remove heavy metal impurities; S4, synthesis of iron phosphate dihydrate: fully reacting the refined phosphate solution obtained in the step S3 with ferrous sulfate under the action of an oxidizing agent to prepare the iron phosphate dihydrate; and S5, preparation of battery-grade anhydrous iron phosphate: calcining the iron phosphate dihydrate prepared in the step S4 to prepare the battery-grade anhydrous iron phosphate. The method provided by the invention is simple in technological process and low in overall cost, and has relatively high industrial application value and economic value.

Owner:湖北云翔聚能新能源科技有限公司

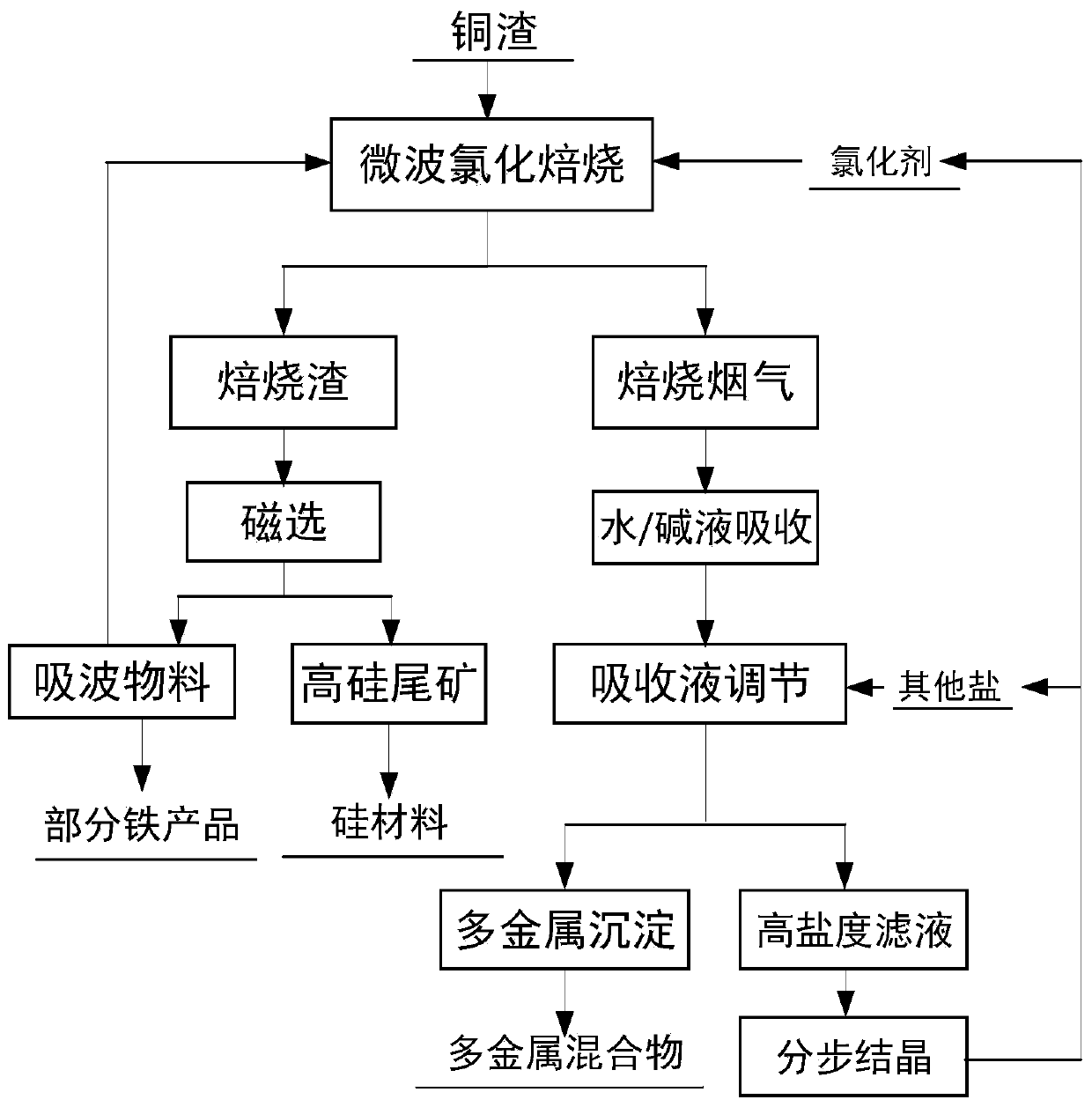

Method for recovering valuable metals from copper slag

ActiveCN111270079AHigh recovery rateWide adaptabilityMagnetic separationProcess efficiency improvementAlkaline waterFlue gas

The invention provides a method for recovering valuable metals from copper slag. The recovery method comprises the steps that under the microwave condition, the copper slag, a chlorinating agent and awave absorbing material are roasted, roasted slag and roasted flue gas are obtained, in the roasting process, the microwave frequency is 2450 MHz, and the microwave power is 2-75 KW; and the roastedflue gas, a flue gas absorbent and a metal ion precipitator are subjected to a precipitation reaction, metal precipitates are obtained, and the flue gas absorbent is water or an alkaline aqueous solution. By the adoption of the method, the iron element and other valuable metal elements in the copper slag can be effectively separated, then targeted treatment can be carried out, and the effect of greatly increasing the recovery rate of valuable metals in the copper slag is achieved; and in addition, the recovery method has the advantages of being wide in adaptability to the copper smelting slag,simple in technological process, high in recovery rate of valuable metal and the like.

Owner:CHINA ENFI ENGINEERING CORPORATION

Making metal and bimetal nanostructures with controlled morphology

ActiveUS9539643B2Ease of mass productionHigher reduction potentialTransportation and packagingMetal-working apparatusDendriteReduction potential

A method of making metal nanostructures having a nanometer size in at least one dimension includes preparing an aqueous solution comprising a cation of a first metal and an anion, and mixing commercial elemental powder particles of an elemental second metal having a greater reduction potential than the first metal with the aqueous solution in an amount that reacts and dissolves all of the second metal and precipitates the first metal as metal nanostructures. The temperature and concentration of the aqueous solution and the selection of the anions and the second metal are chosen to produce metal nanostructures of a desired shape, for example ribbons, wires, flowers, rods, spheres, hollow spheres, scrolls, tubes, sheets, hexagonal sheets, rice, cones, dendrites, or particles.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com