Method for preparing battery-grade anhydrous iron phosphate from industrial ammonium phosphate clear liquid or industrial ammonium phosphate mother liquid

An industrial ammonium phosphate and anhydrous phosphoric acid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficult control of process links, difficult to realize industrialization, complex process, etc., and achieve large-scale industrialization. The effect of easy control of production and reaction conditions and simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

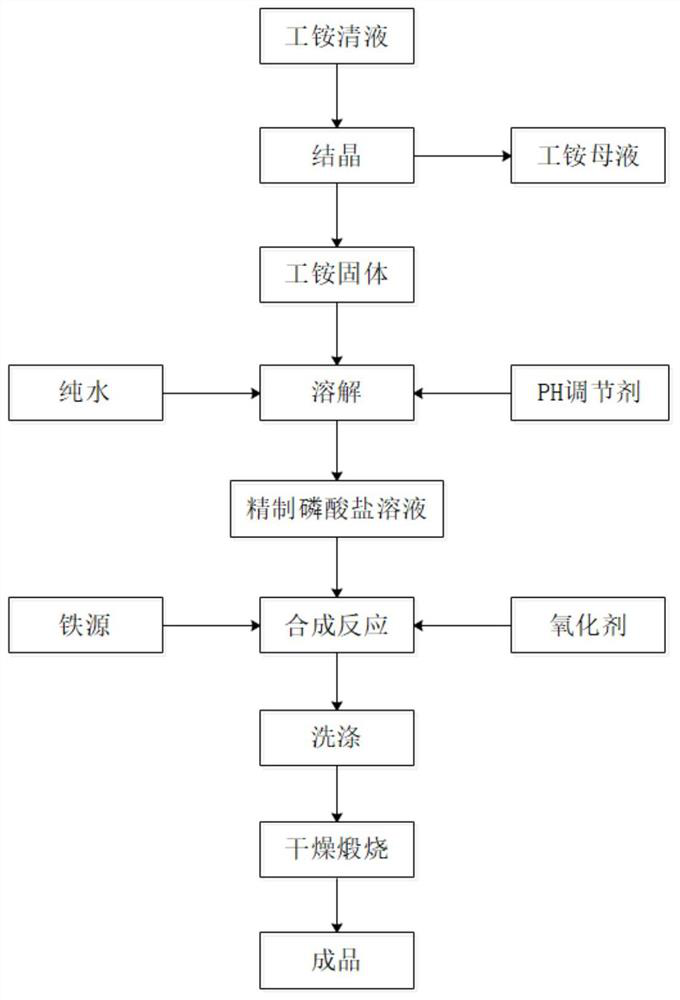

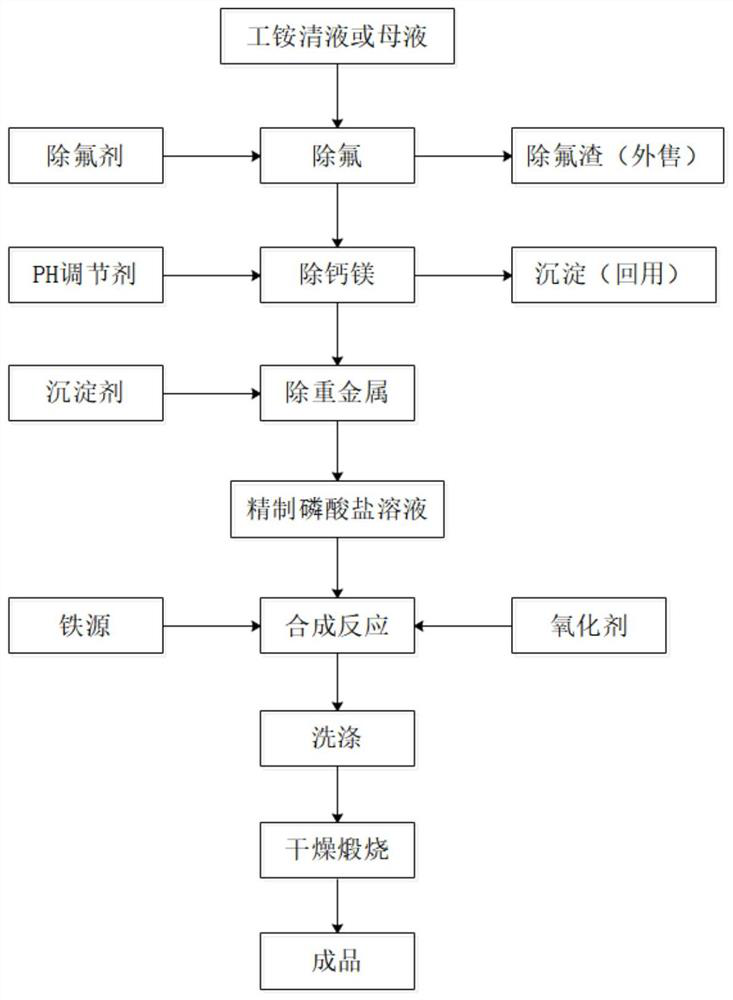

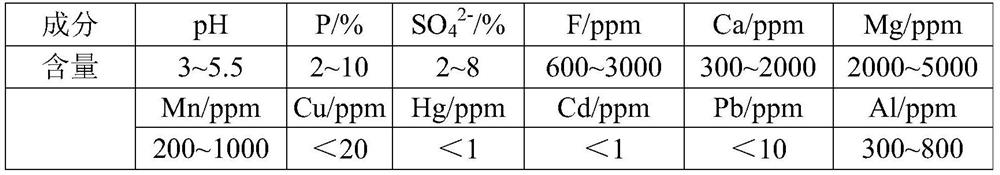

Method used

Image

Examples

Embodiment 1

[0082] S1. Fluoride removal: Add 1% diatomaceous earth and 1% sodium carbonate solution to the industrial ammonium phosphate clear solution to react for 5 hours, and then filter to obtain a phosphorus-containing solution after fluoride removal.

[0083] S2. Refining: adjust the pH value of the phosphorus-containing solution prepared in step S1 through ammonia gas, adjust the pH value to 6.8, remove impurities such as calcium, magnesium, manganese, aluminum through precipitation reaction, and obtain a phosphorus-containing solution with low impurity ion content .

[0084] S3. Removing heavy metals: adding an appropriate amount of sodium sulfide to the phosphorus-containing solution with low impurity ion content prepared in step S2 to remove heavy metal impurities and obtain a refined phosphate solution.

[0085] S4. Synthesis of ferric phosphate dihydrate: the refined phosphate solution obtained in step S3 is diluted with pure water, and the pH is adjusted to obtain the require...

Embodiment 2

[0088] S1. Defluorination: add 2% diatomaceous earth and 2.5% sodium carbonate solution to the industrial ammonium phosphate mother liquor to react for 3 hours, and then filter to obtain a phosphorus-containing solution after defluorination.

[0089] S2. Refining: adjust the pH value of the phosphorus-containing solution prepared in step S1 through ammonia gas, adjust the pH value to 7.05, remove impurities such as calcium, magnesium, manganese, aluminum, etc. by precipitation reaction, and obtain a phosphorus-containing solution with low impurity ion content .

[0090] S3. Removing heavy metals: adding an appropriate amount of sodium sulfide to the phosphorus-containing solution with low impurity ion content prepared in step S2 to remove heavy metal impurities and obtain a refined phosphate solution.

[0091] S4. Synthesis of ferric phosphate dihydrate: the refined phosphate solution obtained in step S3 is diluted with pure water, and the pH is adjusted to obtain the required...

Embodiment 3

[0094] S1. Fluorine removal: add 1.5% diatomite and 2.2% sodium carbonate solution to the industrial ammonium phosphate clear liquid to react for 2 hours, and then filter to obtain a phosphorus-containing solution after fluoride removal.

[0095] S2. Refining: adjust the pH value of the phosphorus-containing solution prepared in step S1 through ammonia gas, adjust the pH value to 7.10, remove impurities such as calcium, magnesium, manganese, and aluminum by precipitation reaction, and obtain a phosphorus-containing solution with low impurity ion content .

[0096] S3. Removing heavy metals: adding an appropriate amount of sodium sulfide to the phosphorus-containing solution with low impurity ion content prepared in step S2 to remove heavy metal impurities and obtain a refined phosphate solution.

[0097] S4. Synthesis of ferric phosphate dihydrate: the refined phosphate solution obtained in step S3 is diluted with pure water, and the pH is adjusted to obtain the required phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com