Patents

Literature

2586 results about "Sodium acid carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stable solid block metal protecting warewashing detergent composition

InactiveUS6410495B1Easy to cleanImprove decontamination abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

Owner:ECOLAB USA INC

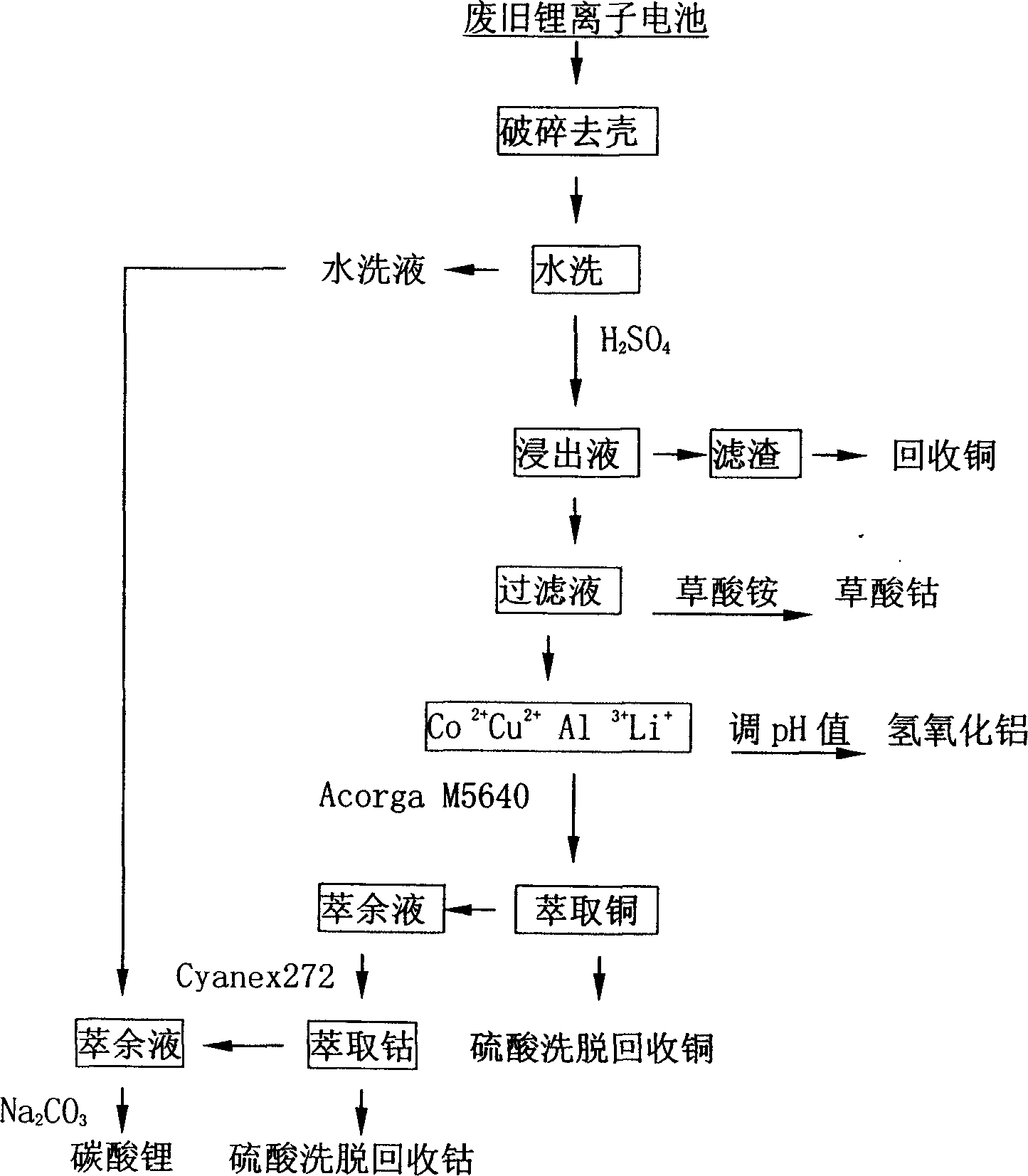

Recovery and treatment method for waster lithium ion cell

InactiveCN1601805AAvoid it happening againEasy to recycleSolid waste disposalWaste accumulators reclaimingSolventCobalt

The method for recycling and processing worn-out lithium ion battery includes steps: (1) taking out pack of worn-out battery; (2) using crushing facilities to open up case of battery, and segregation through magnetic method; (3) dissolving wastes of pole core of battery by using acid, and separating out most of cobalt through ammonium oxalate depositing method; (4) cobalt and copper deposited in residual liquid is extracted through solvent extraction method. Adding sodium carbonate generates deposition to retrieve lithium. Advantages are: simple technique, on solving pollution of worn-out batteries, and reclaining resources at same time.

Owner:SOUTH CHINA NORMAL UNIVERSITY

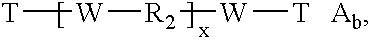

Composition comprising a surface deposition enhancing cationic polymer

InactiveUS20060052272A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOligomerIonic polymerization

The present invention relates to a detergent auxiliary composition comprising: (i) a liquid or liquefiable active component; and (ii) a water-insoluble solid support component and (iii) a water-soluble and / or water dispersible encapsulating material; and (iv) optionally one or more adjunct components, characterised in that the composition further comprises (v) a surface deposition enhancing cationic polymer or oligomer having cationic groups such that fewer than 50% are de-activated when a 1% by weight solution of the polymer or oligomer (prepared in deionised water and then adjusted to pH 7.0 with sodium carbonate or citric acid) is stored at 25° C. for ten days (ten day storage test), wherein the surface deposition enhancing cationic polymer is adsorbed onto the water-insoluble solid support component, and wherein the water-soluble and / or water dispersible encapsulating material encapsulates the liquid or liquefiable active component, the water-insoluble solid support component and the surface deposition enhancing cationic polymer.

Owner:THE PROCTER & GAMBLE COMPANY

A method for recovering lithium and iron from electric vehicle lithium iron phosphate power battery

ActiveCN102285673ASimple processIron oxides/hydroxidesLithium carbonates/bicarbonatesPower batteryLithium iron phosphate

The invention discloses a method for recovering lithium and iron from a lithium iron phosphate power battery for an electromobile. The method comprises the following steps: 1) disassembling the lithium iron phosphate power battery so as to obtain a positive electrode material, smashing and screening so as to obtain a powder material; 2) adding an alkali solution in the powder material to dissolve aluminum and oxide of aluminum, and filtering so as to obtain filter mud; 3) lixiviating the filter mud with a mixed solution of an acid and a reducing agent so as to obtain lixivium; 4) adding an alkali to regulate the pH value of the lixivium to 1.5-3, precipitating to separate out iron hydroxide, and filtering so as to obtain filtrate; 5) firing iron hydroxide obtained in the step 4) so as to obtain iron oxide; 6) regulating the pH value of the lixivium to 5.0-8.0 with an alkali, precipitating impurities in the lixivium, and filtering so as to obtain filtrate; and 7) adding a solid sodium carbonate in the filtrate, and concentrating and crystallizing the obtained solution so as to obtain lithium carbonate. The recovering method disclosed by the invention has simple process, can be used for simultaneously recovering iron and lithium and can be directly used for production, and the purity of prepared lithium carbonate can reach above 98.5%.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Full vanadium ion fluid cell electrolyte and preparing process thereof

InactiveCN1719655ASimple production processLow costConductive materialRegenerative fuel cellsIonChemistry

This invention relates to an electrolyte of a full-vanadium ionic fluid-flow battery composed of V salt sulfate, H2So4, water, alcohol and additives, which are Na2SO4, Na pyrophosphate, salufer and hydrogen peroxide. This invention also provides a preparation method: pumping qualified V liquid from a V-plant into a reaction tank, regulating the PH value of the solution and inletting liquid SO2 into it to be recovered, then the PH value of the solution is regulated with Na2SO4 to deposit VO2 to be dissolved in the solution containing H2SO4, water and alcohol to be added with the additives to be electrolyzed in the tank to get the V electrolyte with 50% of 3valence and 4 valence V separately and density of 1.0mol / L~4.2mol / L .

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Acidified zeolite

The invention discloses an acidified zeolite. The technical scheme is as follows: the acidified zeolite is composed of zeolite, attapulgite clay, magnesia, hydrochloric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate. The acidified zeolite materials are input into a mill and milled, and the milled powder is the acidified zeolite. The production method of acidified red mud adopts acidification before composite proportioning, thereby avoiding the chemical reaction between the sulfuric acid and the instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate; and the acidified zeolite can effectively remove ammonia, iron, fluorine, phosphides and micro pollutants in domestic sewage, and can be used for removing or recovering heavy metal ions and treating radioactive waste. The acidified rear has the characteristics of favorable thixotropy, favorable heat stability, favorable plasticity and favorable binding property, and is suitable for producing drying agents, adsorptive separation agents, molecular sieves, catalysts, defluorination soil improvers, deodorizers and firefighting products.

Owner:江苏世澳非金属应用科技有限公司

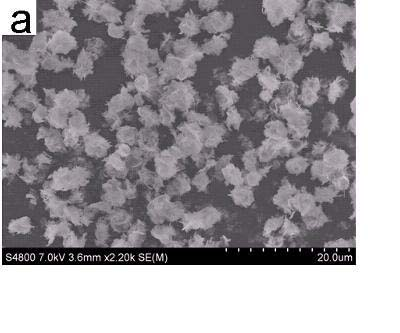

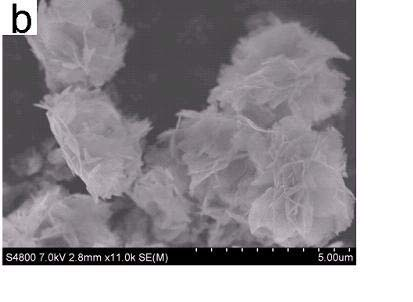

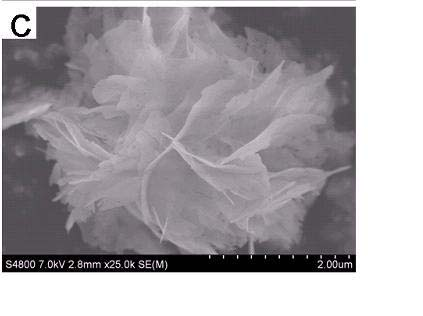

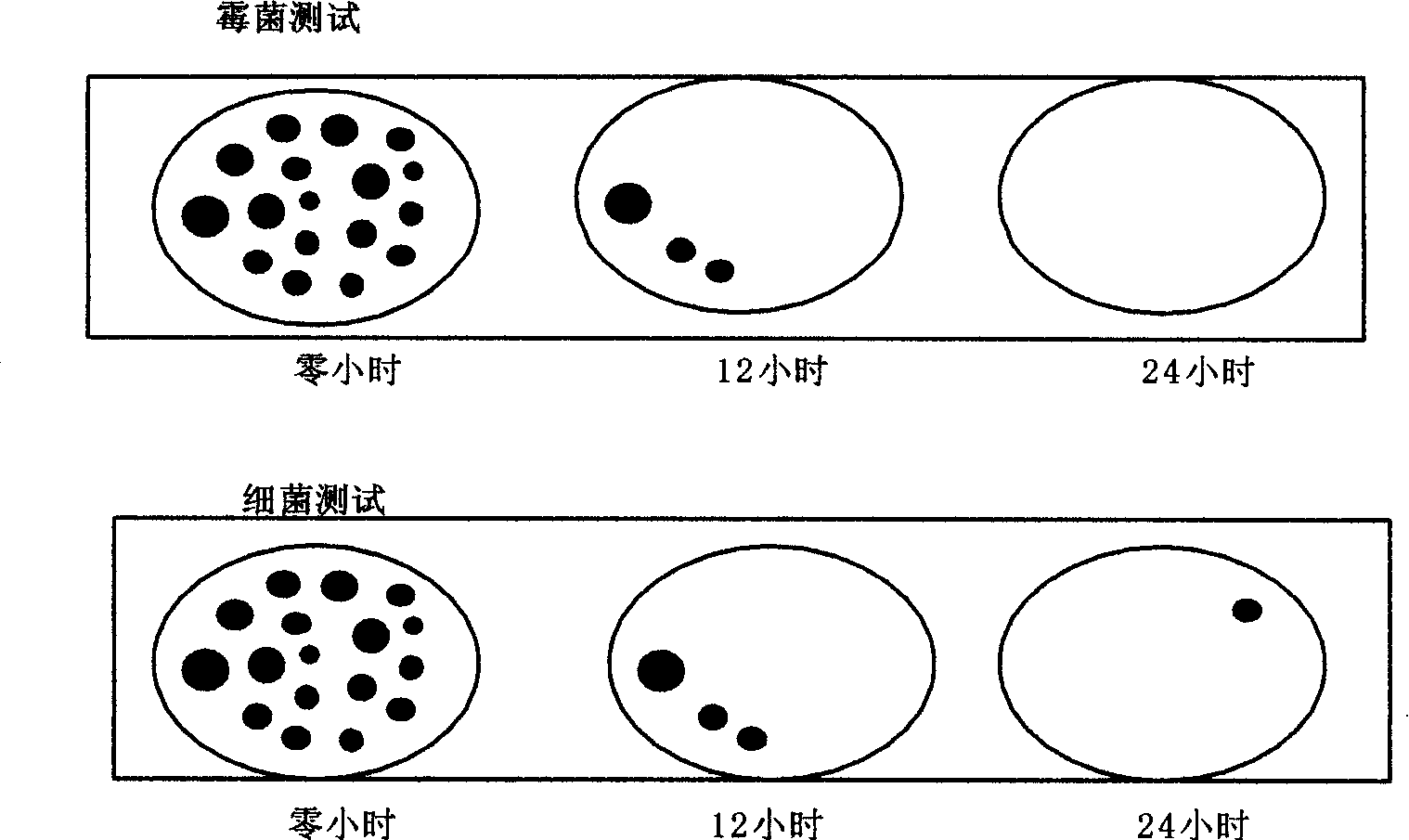

Bismuthyl carbonate micro flowery material with graded structure and preparation method thereof

The invention relates to a bismuthyl carbonate micro flowery material with a graded structure, which is structurally characterized in that two-dimensional nano flakes are staggered to form a flower shape, and the average diameter of the flakes is 3 to 4 microns. The material is prepared by fist dissolving bismuth nitrate into dilute nitric acid and then gradually dripping the dilute nitric acid into excessive sodium carbonate solution and reacting the solution. A preparation method can be implemented at the low temperature and the normal pressure, and has the advantages of short time consumption, low cost, simple equipment, easy operation and large-scale production. Because of a large specific surface area, the prepared bismuthyl carbonate micro flowery material with the graded structure has important practical application in the aspects of pharmacy and sterilization; and meanwhile, the material with the large specific surface area has good performance in the aspect of degrading organic pollutants by photocatalysis.

Owner:SHANDONG UNIV

Hydrophilic block polyether amino silicone oil with amino branched chain, and preparation method and application thereof

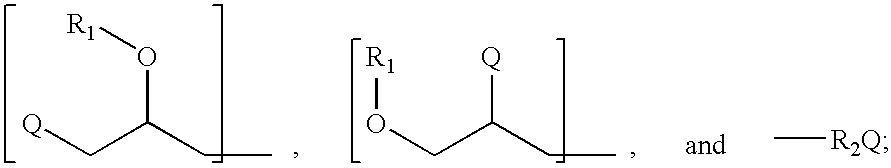

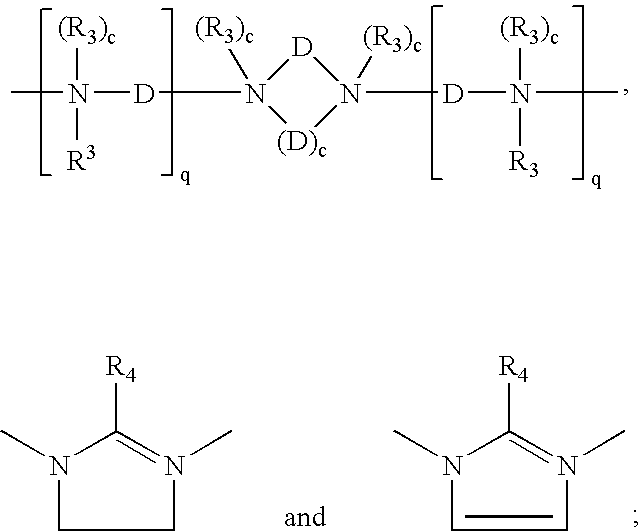

The invention discloses hydrophilic block polyether amino silicone oil with an amino branched chain and a preparation method thereof. The hydrophilic block polyether amino silicone oil with the amino branched chain has the following structure as shown in the specification, wherein R1 is represented by formulas shown in the specification. The preparation method comprises the following steps: carrying out mixing reaction of tetramethyl dihydro disiloxane, polysiloxane and concentrated sulfuric acid, neutralizing with anhydrous sodium carbonate, carrying out reduced pressure pumping to remove a low-boiling-point substance, and thus obtaining silicone oil with the end containing hydrogen; carrying out mixing reaction of the silicone oil with the end containing hydrogen, allyl epoxy polyether and a catalyst, and thus obtaining epoxy silicone oil; carrying out mixing reaction of the epoxy silicone oil, polyether amine and a solvent, and thus obtaining block polyether amino silicone oil; and carrying out mixing reaction of the block polyether amino silicone oil, a silane coupling agent hydrolysate and an alkali catalyst, neutralizing with glacial acetic acid, and thus obtaining the hydrophilic polyether amino silicone oil with the amino branched chain.

Owner:江阴市诺科科技有限公司

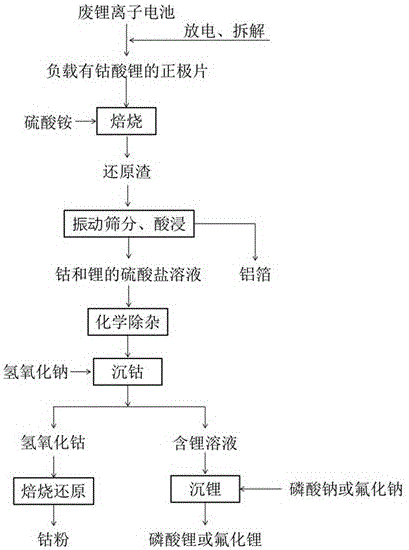

Method for recycling cobalt and lithium from positive plate of waste lithium ion battery

ActiveCN106505270AGuaranteed RecoveryHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementSlagLithium-ion battery

The invention provides a simple and high-efficiency method for recycling cobalt and lithium from a positive plate of a waste lithium ion battery, and relates to a method for recycling cobalt and lithium from the positive plate of the waste lithium ion battery. The method is characterized by comprising the following processes of ammonium sulfate roasting, in which the positive plate of the waste lithium battery is mixed with ammonium sulfate, and high-temperature roasting is performed to obtain reduction roasting slag; screening, in which the reduction roasting slag is vibrated and is screened by a vibration screening machine, and an aluminum foil is separated and removed to obtain reduction slag containing cobalt and lithium; acid leaching, in which the aluminum foil is separated and removed from the reduction roasting slag, is leached in sulfuric acid and is filtered to obtain a sulfate solution containing cobalt and lithium; impurity removal, in which pH of the solution is adjusted by sodium carbonate, and a precipitant is filtered and removed to obtain a lithium-cobalt sulfate mixture solution; cobalt deposition, in which sodium hydroxide is added into the lithium-cobalt sulfate mixture solution, the pH of the solution is controlled to be 7.5-9.5, and filtering is performed to obtain the precipitant, the precipitant is washed with deionized water at 85-95 DEG C, cobalt hydroxide is dried, cobalt hydroxide after being dried is placed in a reduction furnace, and H2 is introduced for reduction to obtain cobalt powder; and lithium deposition, in which pH of a lithium-containing solution is adjusted to 7-8, and an excessive amount of a lithium deposition agent is added to a lithium salt product.

Owner:JINGMEN GEM NEW MATERIAL

Particulate laundry detergent compositions containing nonionic surfactant granules

InactiveUS6262010B1Inorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsOrganic acidWater soluble

A particulate free-flowing laundry detergent composition comprises at least two different granular components: a granular component containing anionic surfactant, and a granular nonionic surfactant component comprising from 20 to 30 wt % of nonionic surfactant on a non-spray-dried particulate carrier material comprising sodium sesquicarbonate. The nonionic surfactant component is preferably prepared by in-situ neutralisation of sodium carbonate with a water-soluble organic acid in the presence of the nonionic surfactant, in a high- or moderate-shear mixer.

Owner:HENKEL IP & HOLDING GMBH

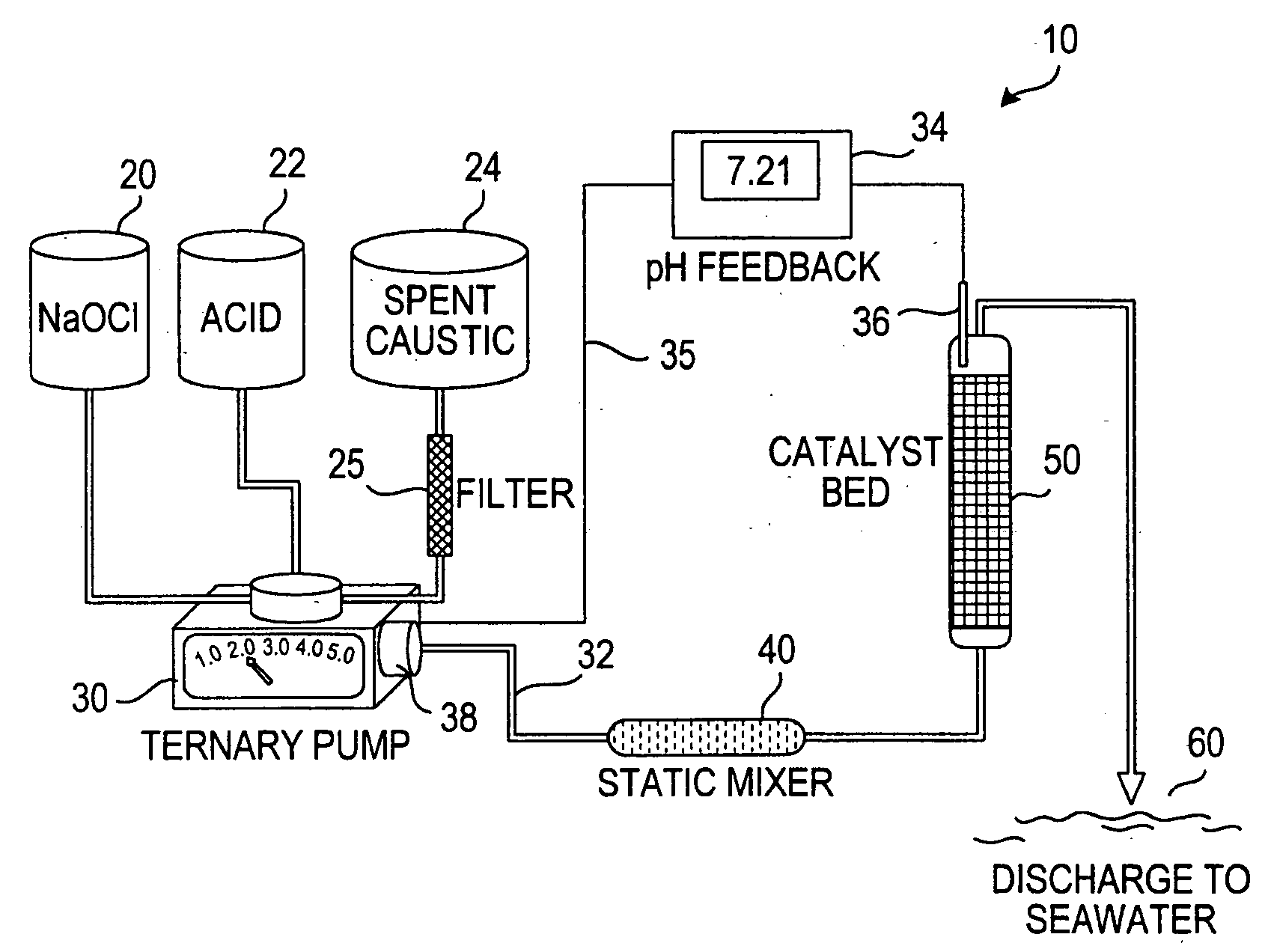

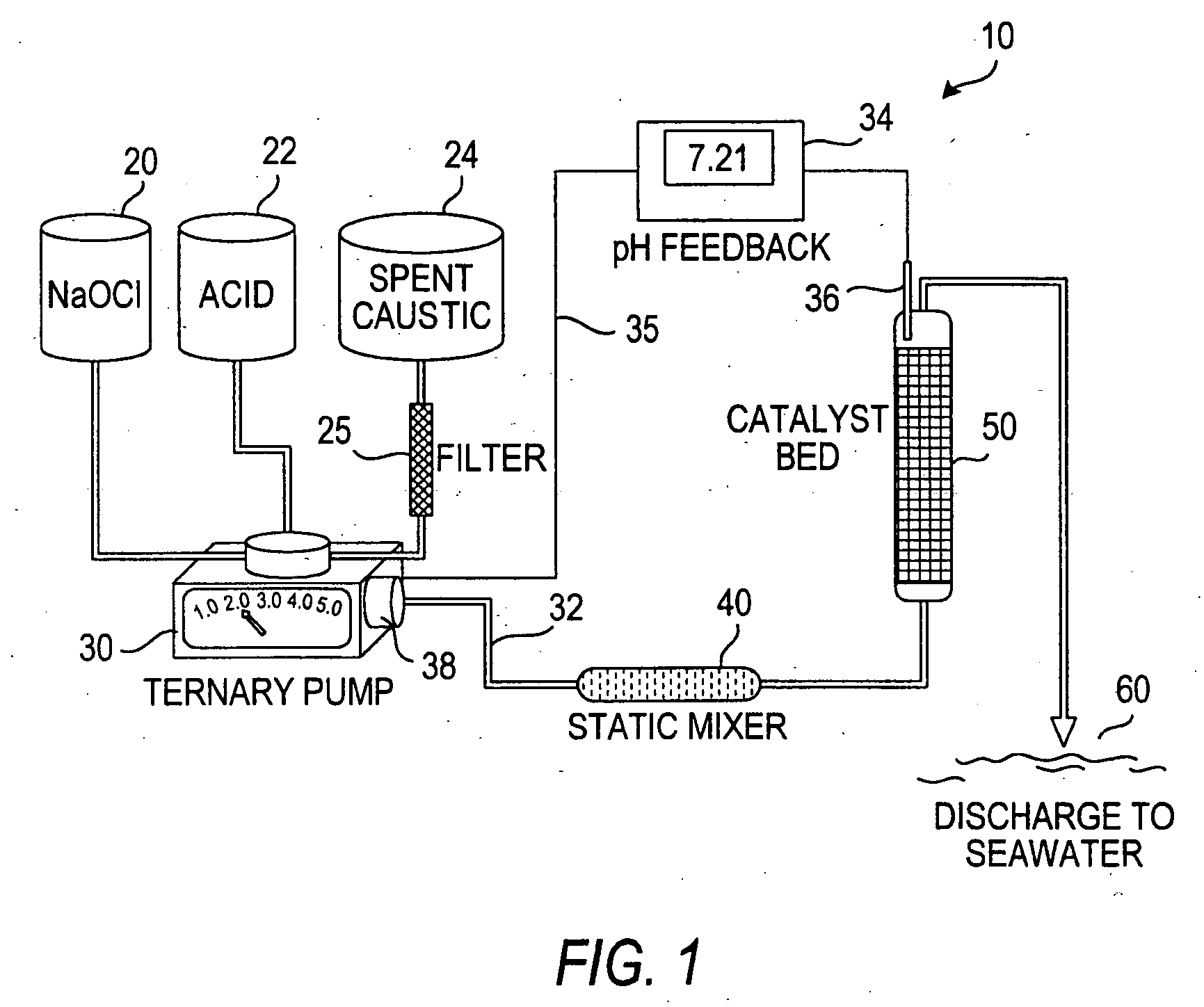

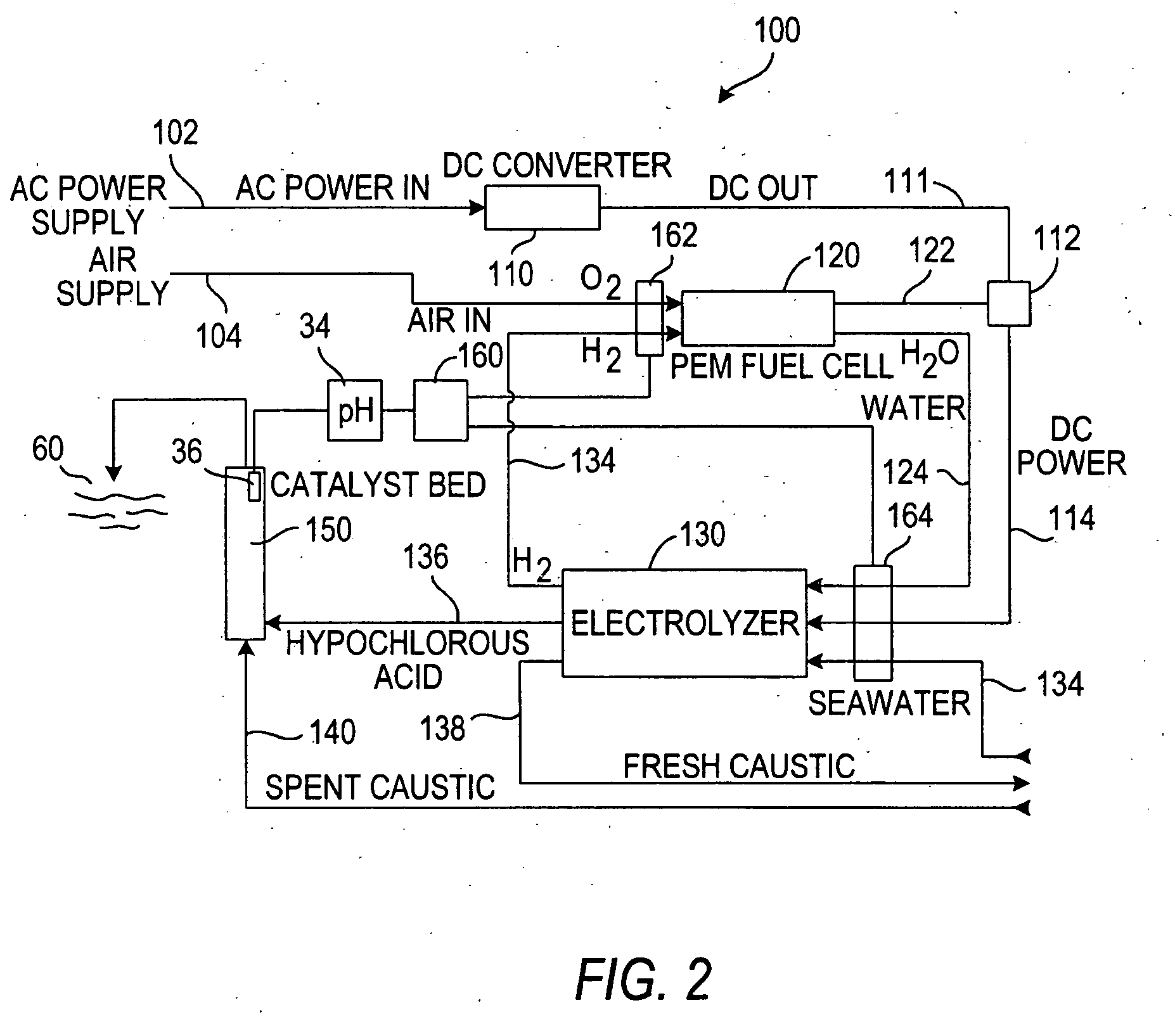

Process for treating a sulfur-containing spent caustic refinery stream using a membrane electrolyzer powered by a fuel cell

ActiveUS20060254930A1Simple and inexpensive and effectiveReduce investmentPhotography auxillary processesElectrolysis componentsSodium sulfateSulfur containing

A continuous method for the treatment of a spent aqueous caustic stream used to scrub a hydrocarbon process stream to remove oxidizable sulfur-containing compounds includes: a. mixing an oxidizing hypochlorous acid stream produced from an aqueous brine solution with the aqueous caustic stream to form a reactive mixed feedstream; b. contacting the reactive mixed feedstream with at least one catalyst to promote the oxidation of the sulfur-containing compounds and the neutralization of the sodium hydroxide; and c. recovering a neutral treated product stream comprising aqueous sodium sulfate, sodium carbonate and sodium chloride that is odorless, non-toxic and environmentally acceptable for discharge into the sea or into a conventional sewage treatment system. Preferably, the hypochlorous acid is produced by an electrolyzer that also produces a (1) hydrogen stream that is directed to a PEM fuel cell to generate at least a portion of the electrical power requirement of the electrolyzer, and (2) water that is combined with fresh sodium hydroxide from the electrolyzer to form a fresh caustic stream for use in scrubbing the hydrocarbon process stream.

Owner:SAUDI ARABIAN OIL CO

Preparation method of spherical high-capacity lithium-rich positive electrode material

ActiveCN103956479AEffective control of granularityIncrease energy densityCell electrodesSecondary cellsManganese oxideMaterials science

The invention discloses a preparation method of a spherical high-capacity lithium-rich positive electrode material. A sintering process is improved through regulating a coprecipitation reaction mode. The preparation method comprises the following steps: 1, preparing a nickel-cobalt-manganese sulfate solution; 2, performing a coprecipitation reaction on the nickel-cobalt-manganese sulfate solution and a mixed solution of a carbon carbonate solution and ammonia water at a pH value of 7-9 to obtain a solid-liquid mixture of a precursor; 3, filtering, separating, washing and drying to obtain a carbonate precursor; 4, performing gradient temperature rise on the carbonate precursor in a tubular furnace and keeping the temperature, cooling, crushing and sieving to obtain a nickel-cobalt-manganese oxide; and 5, mixing the nickel-cobalt-manganese oxide with lithium carbonate powder, and performing multi-section ventilation roasting in the tubular furnace to obtain the target object. The preparation method has the advantages that the sintering process is improved through regulating the coprecipitation reaction mode, the granularity of the precursor is effectively controlled, and the high-capacity lithium-rich lithium ion positive electrode material with a layered crystal structure, which is high in energy density, good in rate capability, low in cost, good in safety and long in service life, is prepared, and the market demand is met.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Cleaning agent for ceramic film and its preparation method

InactiveCN1837341AReduce concentration polarizationReduce cleaning frequencySemi-permeable membranesSurface-active detergent compositionsCelluloseCleansing Agents

The invention discloses a ceramic film abluent and preparing method, which comprises the following parts: 50-75 percent NaOH, 3-15 percent sodium polyphosphate, 5-15 percent sodium alkyl benzene sulphonate, 2-8 percent diatomite, 1-8 percent liquid glass, 0-5 percent sodium sulfate, 0-20 percent sodium carbonate, 0-5 percent methylol cellulose and 0-5 percent ethylene diamine tetraacetic acid tetrasodium salt. These components are added int the stirring and grinding corrosion-proof reactor sequently, which is stirred and grinded evenly at room temperature at 4-8 h to obtain the product. The invention shortens the system cleaning time and reduces the system consumption, which doesn't damage ceramic film.

Owner:JIANGSU JIUWU HITECH

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Method of processing meat to enhance moisture retention

InactiveUS20090004353A1Good moisturizing effectIncrease productionMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsAdditive ingredientSodium carbonate

The present invention is in the field of processing and treating meat. More particularly, the present invention relates to a method of processing meat to enhance moisture retention both during storage and cooking by administering a composition containing sodium carbonate and other ingredients.

Owner:QST INGREDIENTS & PACKAGING

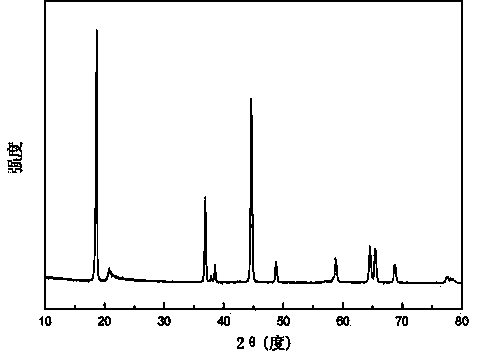

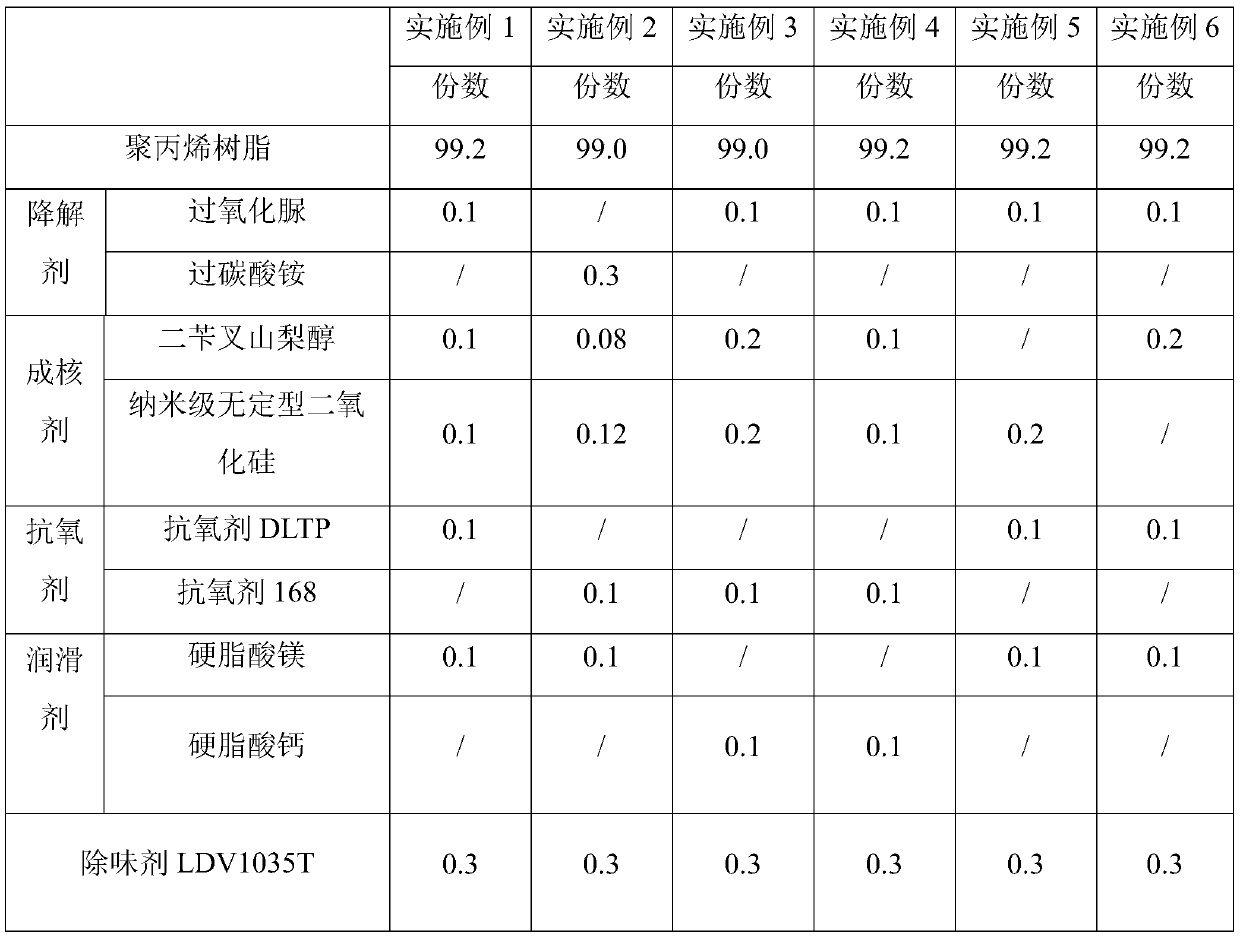

Melt-blown polypropylene as well as preparation method and application thereof

The invention discloses melt-blown polypropylene as well as a preparation method and application thereof. The melt-blown polypropylene comprises following raw polypropylene resin, a degradation agent,an antioxidant and a lubricant, wherein the degradation agent is selected from one or more of hydrogen peroxide, sodium percarbonate, ammonium percarbonate and urea peroxide. The melt-blown polypropylene also comprises a nucleating agent selected from one or more of dibenzylidene sorbitol, aryl phosphate and nano scale amorphous silicon dioxide, wherein the degradation agent and the nucleating agent respectively account for 0.05-0.5% of the mass percentage of the raw materials. The preparation method comprises the following steps: premixing raw materials, stirring, then selectively adding a deodorant; and melting and granulating by an extruder to obtain the product. The invention also discloses an application of the melt-blown polypropylene in manufacturing melt-blown non-woven fabrics, melt-blown filter elements and sound-absorbing cotton. The melt-blown polypropylene has the advantages of low odor, high electret charge stability and the like.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Crack-resistant waterproof cement-based permeable composite repairing material and method for preparing same

InactiveCN101531497AEffective protectionPromotes secondary hydrationSolid waste managementFiberSuperplasticizer

The invention discloses a crack-resistant waterproof cement-based permeable composite repairing material and a method for preparing same. The crack-resistant waterproof cement-based permeable composite repairing material of the invention comprises the following components by the mass fraction: 20% to 40% of Portland cement clinker, 3% to 20% of fly ash, 2% to 10% of gypsum, 2% to 10% of high-alumina cement, 1% to 4% of sodium silicate, 0.1% to 1.5% of high-efficiency naphthalene-based water-reducing agent, 0.1% to 2.0% of sodium carbonate, 40% to 70% of shaping quartz sand, 0.1% to 3.0% of polypropylene staple fiber and 0.05% to 1.0% of sodium carboxymethyl cellulose. The high-performance material of the invention is free from toxicity and pollution, and further has the characteristics of solid cementation, good penetration depth, good waterproof, anti-permeability and crack-resistant effects and the like; and meanwhile, the invention has the advantages of low production cost, simple preparation process and construction method and wide applicable range.

Owner:TIANJIN URBAN CONSTR COLLEGE

Ultrafine lead oxide prepared from desulfurated lead plaster by means of three-stage process and method thereof

InactiveCN103374658ALead volatility is smallReduce soot rateReclaiming serviceable partsLead oxidesLead carbonateLead oxide

The invention discloses ultrafine lead oxide prepared from desulfurated lead plaster by means of three-stage process and a method for preparing the ultrafine lead oxide. The method comprises the following steps of: carrying out a desulfurization and lead plaster acid leaching process by causing the desulfurated lead plaster to react with acid, simultaneously adding a reducing agent, and carrying out solid-liquid separation after the reaction is ended to obtain a plumbic acid containing solution; carrying out a lead carbonate preparation process by causing the plumbic acid containing solution to react with sodium carbonate, carrying out solid-liquid separation, washing and drying to obtain the lead carbonate; carrying out a roasting process by preparing the ultrafine lead carbonate by roasting the lead carbonate, wherein the ultrafine lead oxide can be PbO, Pb3O4, or the mixture of the PbO and the Pb3O4, the mean particle granularity of the ultrafine lead oxide is less than 2 mu m, and the nanocrystalline grain size is less than 500nm. Compared with the prior art, the preparation method of the ultrafine lead oxide disclosed by the invention has the following beneficial effects: the active material of the ultrafine lead oxide powder compound for the production of a storage battery enterprise can be directly prepared, lead volatilize quantity is small, the ash rate is low, the direct lead yield is high, the energy consumption is low, pollutants of sulfur dioxide and the like are not generated, and the like.

Owner:湖北金洋冶金股份有限公司 +1

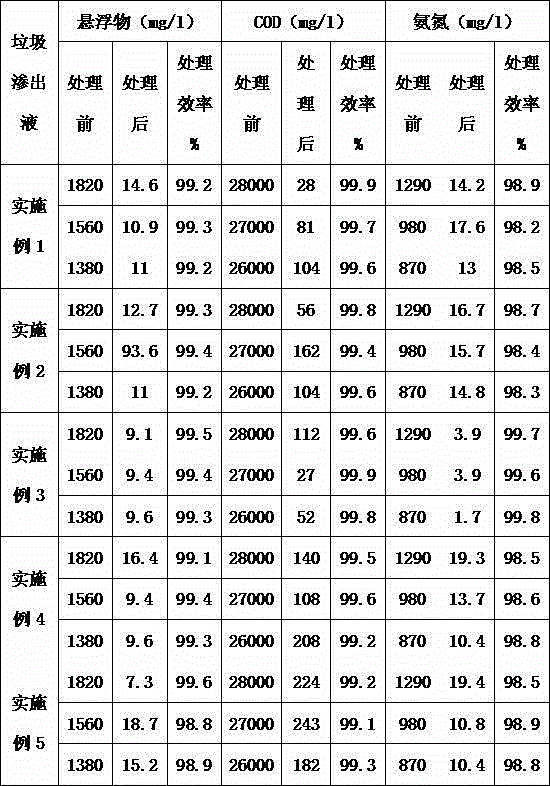

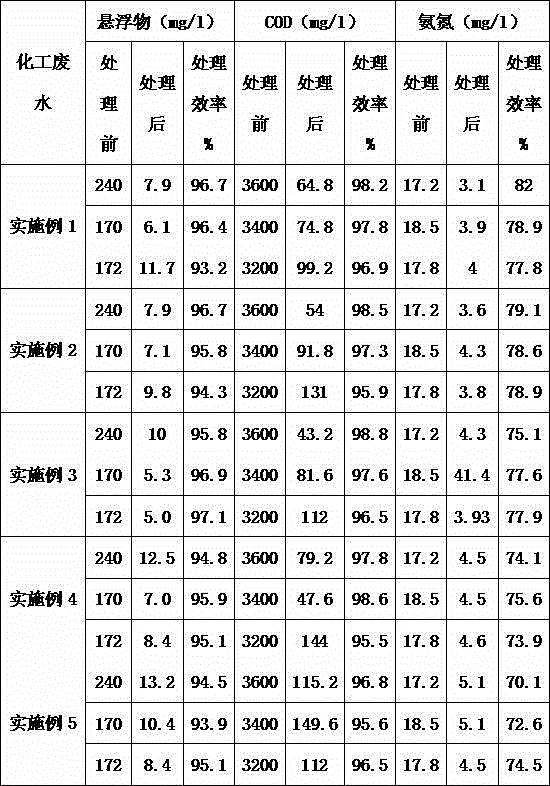

Industrial wastewater treating agent

InactiveCN104591362AGood effectImprove water qualityWater/sewage treatment by flocculation/precipitationSodium bicarbonateIron sulfate

The invention relates to the technical field of sewage treatment and particularly relates to an industrial wastewater treating agent. The industrial wastewater treating agent comprises the following components in parts by mass: 0.8-3 parts of polyacrylamide, 25-35 parts of aluminium polychlorid, 25-55 parts of alums, 3-8 parts of iron trichloride, 0.8-3.4 parts of polymeric ferric sulfate, 1.2-2.5 parts of a coagulant aid, 2-10 parts of plant fiber, 10-30 parts of coal ash, 0.8-2.5 parts of sodium silicate, 2.5-5 parts of sodium sulfite, 0.5-3.5 parts of sodium hypochlorite, 5-10 parts of hydrogen peroxide, 8-15 parts of a sodium carbonate-sodium bicarbonate buffer system and 10-20 parts of sodium-based bentonite. The treating agent has the beneficial effects of wide treated pollutant range, good effect, wide production raw material source, environmental friendliness, no toxicity, good discharged water quality, short process flow, and high process operating safety. The treating agent disclosed by the invention can treat various kinds of wastewater such as chemical wastewater produced in oil fields, mining, steel, electroplating wastewater, dyes, pesticides, wine-making and chemical engineering, and sanitary sewage, papermaking wastewater, river and lake water, rubbish seeping water, leather-making wastewater, and the like; and the treating agent is good in treatment effect.

Owner:湖北源绿高科技节能环保有限公司

Silk-reeling technology by utilization of tussah fresh cocoon live pupae

The invention relates to a silk-reeling technology by the utilization of tussah fresh cocoon live pupae. The technology includes the steps that vacuum low-temperature permeation is performed on tussah fresh silkworm cocoons of the live pupae after refrigeration and freshness retaining in a vacuum environment at water temperature of 26 DEG C-40 DEG C, wherein the pH value is 6.5-8; according to vacuum low-temperature chemical cocoon reeling, water, sodium carbonate, sodium silicate, sodium borate, hydrogen peroxide and N-coconut oil-potassium glutamate form a reeling solution, and at temperature of 30 DEG C-46 DEG C, vacuumizing is performed for reeling in the pH value of 4-14; according to constant-temperature cocoon blanching, the cocoons are soaked in the reeling solution at temperature of 30 DEG C-40 DEG C for blanching; low-temperature silk reeling is performed, and raw silks are reeled again to be arranged to obtain a finished product. Pupa linings are manually removed from the silkworm pupae after silk reeling, so that the silk-reeling live pupae are obtained. The cocoons are not dried and cooked, silk reeling is directly performed, cost and energy consumption are reduced, and the survival rate of the by-products silk-reeling silkworm pupae is over 95%. Protein, amino acid and other kinds of nutrient active substances of pupa bodies are not affected, the utilization rate of the silk-reeling silkworm pupae is increased, breeding cocoons are provided for a sericulture department to perform orientated breeding, fine-breed breeding is accelerated, and the technology has great significance.

Owner:辽宁柞蚕丝绸科学研究院有限责任公司

Environmental-friendly micro emulsion cutting fluid

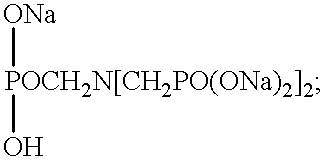

InactiveCN102533418AImprove the lubrication effectEasy to cleanLubricant compositionPhosphoric Acid EstersChemical industry

The invention relates to an environmental-friendly micro emulsion cutting fluid, which belongs to the field of chemical industry. The invention aims to provide the environmental-friendly micro emulsion cutting fluid, which not only is capable of protecting the environment but also is capable of performing cooling and lubrication actions in the metal cutting abrasive machining process. The environmental-friendly micro emulsion cutting fluid comprises 10# industrial white oil, sodium petroleum sulfonate, oleic acid, triethanolamine, alkylphenol polyoxyethylene OP-10, alkyl alcohol amido phosphate ester 6503, an antirusting agent monomer, tetradecyl alcohol or stearyl alcohol, benzotriazole, sodium tetraborate, sodium carbonate, triazine compound / benzisothiazolinone bactericide (NEUF652), a defoaming agent MS-455 and water. The environmental-friendly micro emulsion cutting fluid not only has the advantages of good lubricity of an emulsion-type cutting fluid and strong cleaning capacity of synthetic cutting fluid but also is capable of overcoming the defects that the emulsion-type cutting fluid is easy to go bad and stink and has a short service life and the synthetic cutting fluid has poorer lubricating property, and has the characteristics of good lubricity, strong cooling and cleaning capacity, long service life and the like.

Owner:FAW GROUP

Preparation method of superabsorbent resin used for high-molecular gel extinguishing agent, and extinguishing agent using superabsorbent resin

ActiveCN103483752APreparation Process GreenThe preparation process is environmentally friendlyFire extinguisherPolymer scienceCross linker

The invention provides a preparation method of a superabsorbent resin used for a high-molecular gel extinguishing agent. The preparation method comprises: mixing acrylic acid and a sodium carbonate aqueous solution to prepare a neutralization solution; successively adding a cross-linking agent, an initiator and an adhesion promoter into the neutralization solution to prepare a polymerization solution; performing polymerization to prepare the superabsorbent resin; and cutting into particles with a diameter of 10-20 mm to further prepare superabsorbent resin particles with a particle size of 40-150 meshes. The preparation method is simple, and the superabsorbent resin prepared by the method is convenient to used and excellent in fire extinguishing effect.

Owner:LANGFANG ZHONGAN FIRE PROTECTION TECH CO LTD

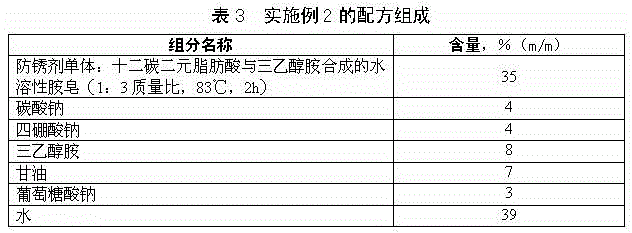

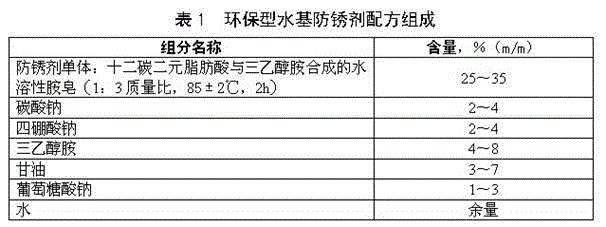

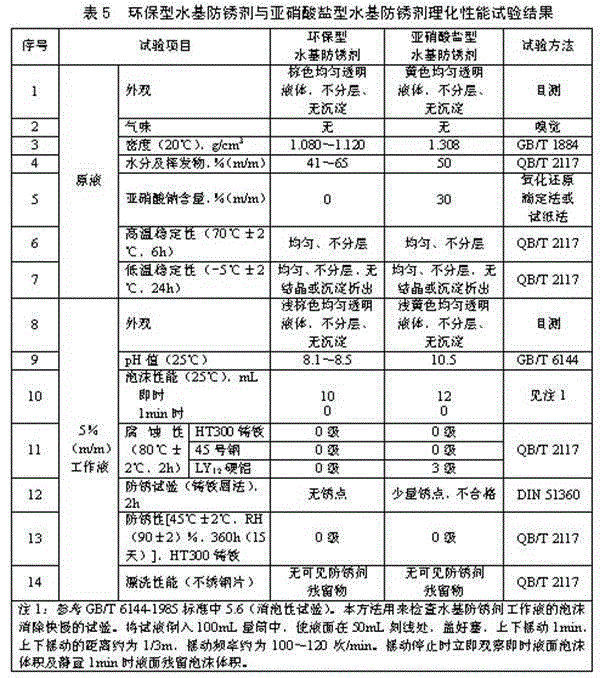

Environment friendly water-base anti-rusting agent

InactiveCN102747359AGood water solubilityImprove rust resistanceMetallic material coating processesGlycerolFatty acid

The invention relates to an environment friendly water-base anti-rusting agent which is characterized in that the preparation method comprises the following steps: mixing, stirring and heating dodec dibasic fatty acid and triethanolamine at a mass ratio of 1:3 in a reaction vessel at the constant temperature of 83-87 DEG C for 2 hours to synthesize a water-soluble amine soap used as an anti-rusting agent monomer; decreasing the temperature of the anti-rusting agent monomer to 80 DEG C or lower, adding water which is 1 / 4 of the predetermined amount, and stirring and dissolving uniformly; heating the left 3 / 4 water to 40-45 DEG C, adding sodium tetraborate, sodium carbonate and sodium gluconate slowly in sequence according to the proportion showed in table 1, and stirring to dissolve completely; adding triethanolamine and glycerol to the solution slowly in sequence according to the proportion showed in table 1, adding a liquid formed by mixing the anti-rusting agent monomer with water, and stirring dissolve completely. The main synthesized anti-rusting agent monomer is dissolved in water, and an inhibitor, a film forming agent and additives which can take a synergistic effect are added, so that a uniform, transparent and non-layered liquid without precipitates is formed. The liquid is good in cast-iron and steel component rusting resistance and good in aluminum, aluminum alloy, copper and copper alloy corrosion resistance, can be used for resisting rusting for metal parte interprocess and warehouse storage and has a rusting resisting period of 40-60 day in summer in normal circumstances.

Owner:CHINA FIRST AUTOMOBILE

Alkali metal magnesium phosphate hydrate buffering feed mineral

InactiveUS6451361B1Improve buffering effectAnimal feeding stuffAccessory food factorsMagnesium phosphateMagnesium orthophosphate

A bioavailable water soluble animal feed mineral composition which provides buffering of animal digestive fluids to near-neutral pH comprising an alkali metal magnesium phosphate hydrate providing a total of between 1.5 and 4.7 equivalent weights of alkali metal and magnesium per molecule of phosphorus. Water of hydration amounting to between 6 and 12 percent is required for effectiveness. An effective composition, Na2Mg(PO4) 0.8 H2O, is prepared by stepwise reaction of sodium carbonate and magnesium oxide with orthophosphoric acid in a rotating pan equipped for high intensity mixing.

Owner:AGRINUTRIENTS TECH GRP INC

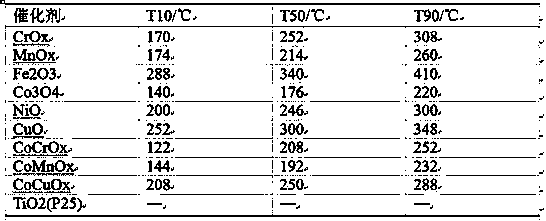

Propane complete oxidation catalyst as well as preparation method and application thereof

InactiveCN103990460AHigh reactivityEasy to makeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention discloses a preparation method of propane complete oxidation catalyst. The preparation method comprises the following steps: dropwise dripping 1 mol / L transition metal salt solution into 1 mol / L sodium carbonate solution which is in a stoichiometric ratio to the transition metal salt solution; reacting for 1 to 3 hours at 20 to 80 DEG C; washing a reaction product to neutral, drying at 60 to 100 DEG C, and roasting for 3 to 6 hours at 300 to 500 DEG C to obtain the propane complete oxidation catalyst, wherein the stoichiometric ratio is as follows: the molar ratio of Co<2+>, Mn<2+>, Cu<2+> and Ni<2+> to CO3<2-> is respectively 1:1, and the molar ratio of Fe<3+> and Cr<3+> to the CO3<2-> is respectively 2:3. The transition metal oxide obtained by the invention can be applied to the complete catalytic oxidation reaction of various types of hydrocarbons of C3H3, C3H6, CH4 and the like, and has good reactivity.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

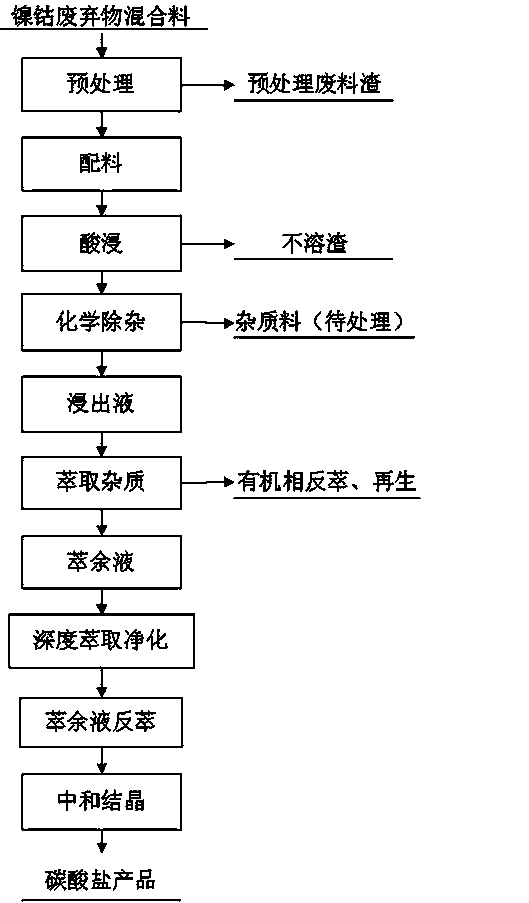

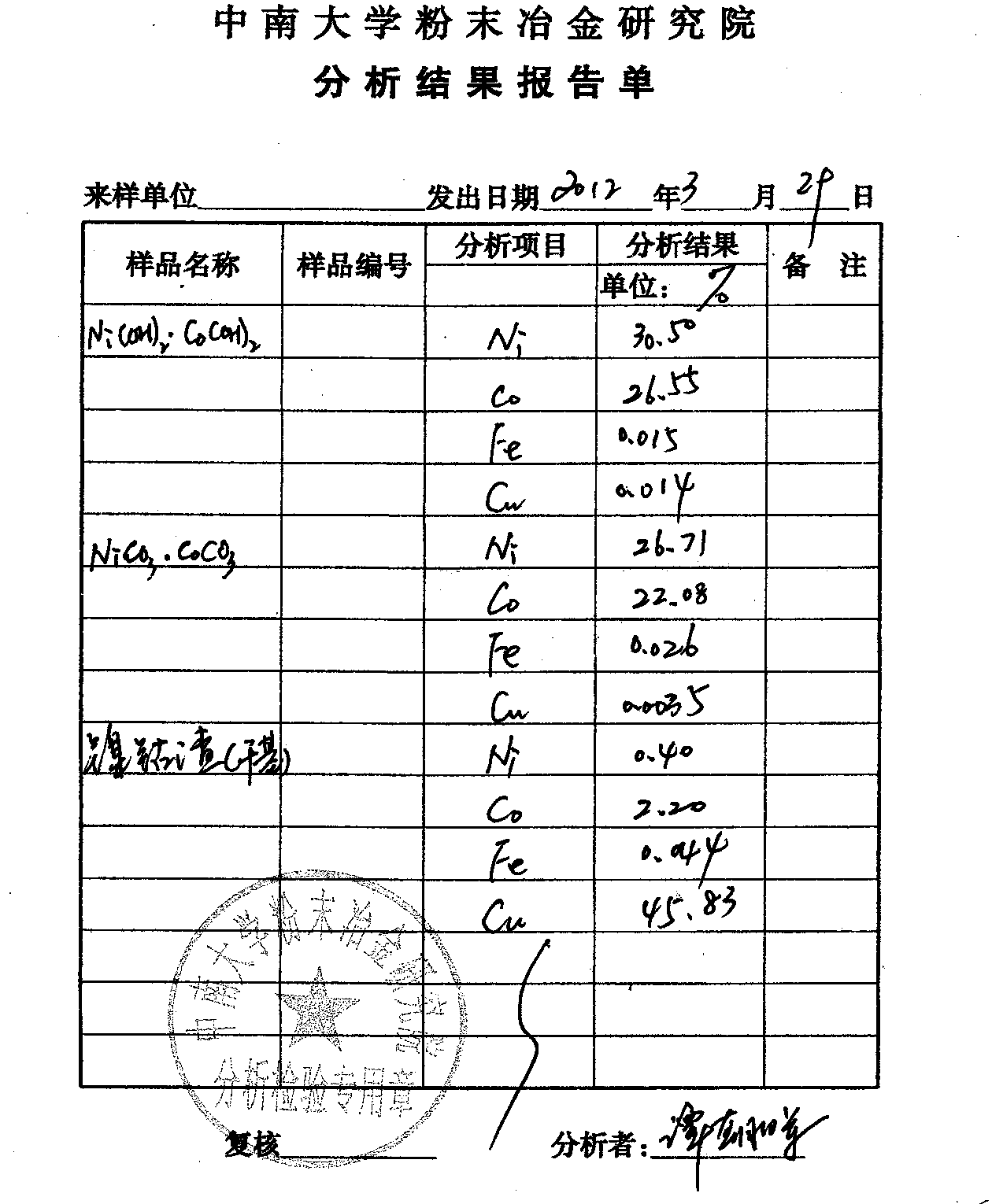

Method for preparing electronic ternary material precursor from Ni-Co residues

ActiveCN103384002AShorten the purification processConducive to hydrometallurgical processCell electrodesEngineeringElectronic materials

The invention discloses a method for preparing an electronic ternary material precursor from Ni-Co residues. The method realizes combination of one or more physical and chemical methods. The method comprises the following steps of pre-treating Ni-Co-containing waste or waste residues so that Ni and Co are preliminarily separated from other substances, adjusting a mole ratio of Ni to Co in the Ni-Co-containing waste or waste residues to 1: (1-0.2), carrying out deep purification of other elements except Ni and Co by an extraction method, treating an Ni-Co group, carrying out separation purification to remove other impurities, wherein Ni and Co is not separated, and directly preparing the Ni-Co oxide precursor of the electronic ternary material by a metallurgical technology, and adding sodium carbonate or sodium hydroxide into a Ni and Co sulfuric acid solution to directly produce an Ni-Co carbonate or an Ni-Co hydroxide. An important characteristic or an innovation point of the method comprises that Ni and Co are combined in an ion level. The method improves environment influence, can produce a novel Ni-Co product and is conducive to resource recycle and environment-friendly development.

Owner:HUNAN KEFEITE HIGH TECH CO LTD

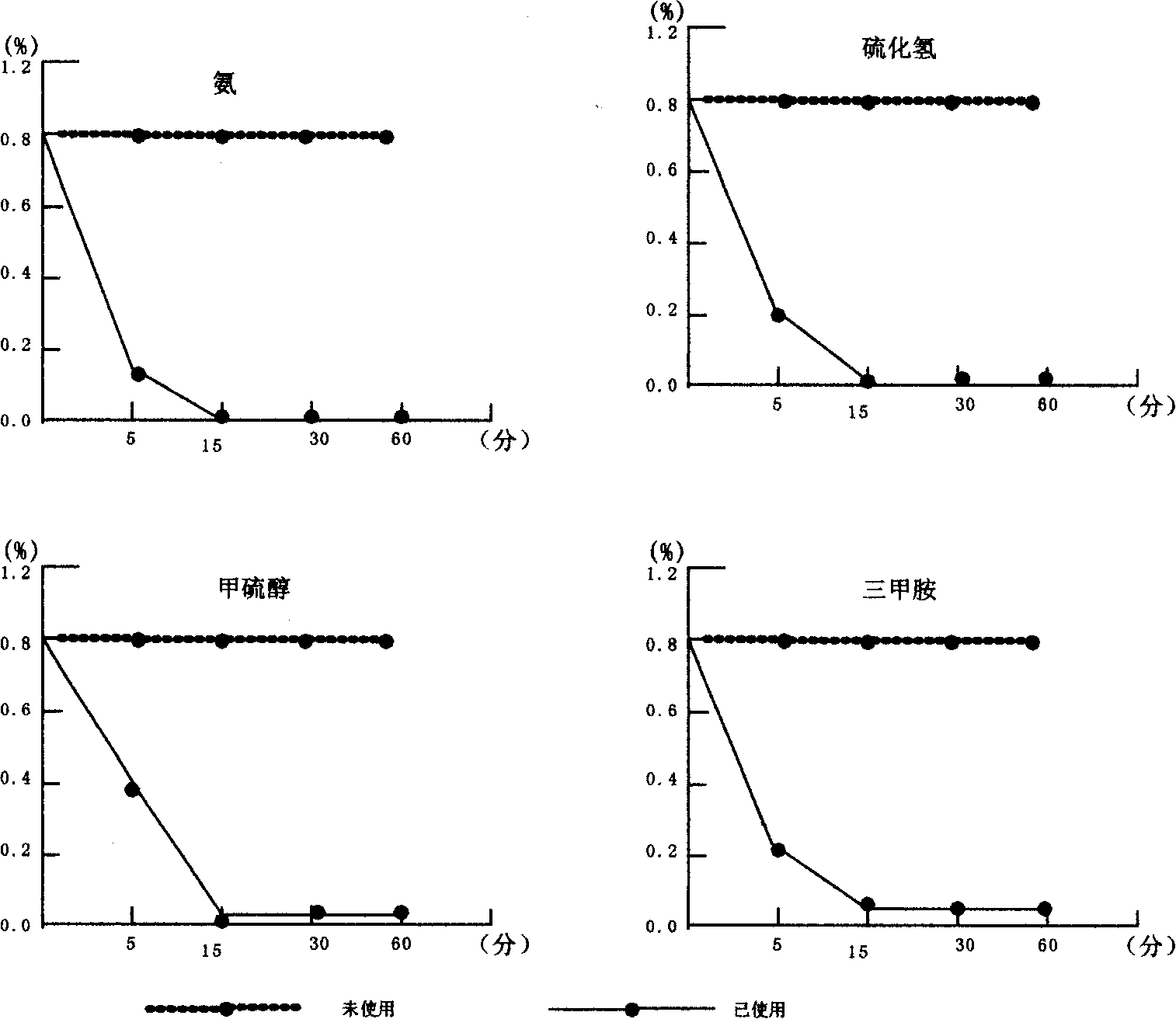

Disinfecting and foreign flavor removing sustained-release agent in small space

InactiveCN101194627AHigh removal rateImprove disinfection efficiencyBiocideDisinfectantsBenzeneMethyl aldehyde

The invention provides a small-space disinfecting and peculiar smell-removing slow release agent, which comprises chlorine dioxide liquid which is dissolved in the water, and is characterized in that solid adsorbent is filled in stable chlorine dioxide liquid whose thickness is set to form a gelatin system. The invention further comprises stabilizing agent and pH conditioning agent, wherein the stabilizing agent and pH conditioning agent can be citric acid and sodium percarbonate, and the solid adsorbent can be high water-absorbing resin. The invention has the advantage of solving the problems of dynamic constant disinfection, sterilization, and removing peculiar smell in small space, which has high disinfecting efficiency and plays a role in removing peculiar smell and bad odor momentarily, and the removing rate of harmful gases such as methyl aldehyde and benzene reaches more than 90%.

Owner:深圳市罗奇环保科技有限公司

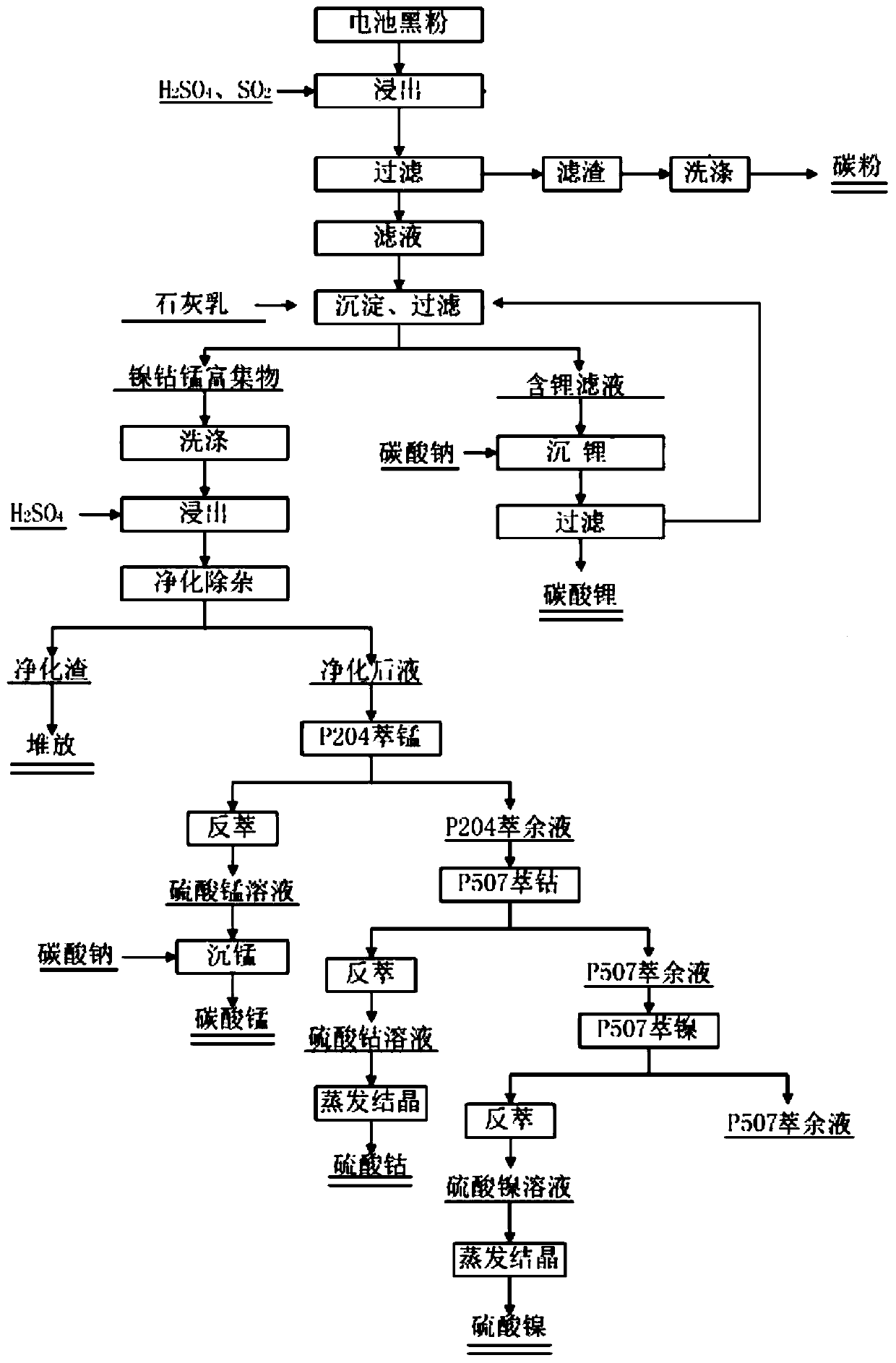

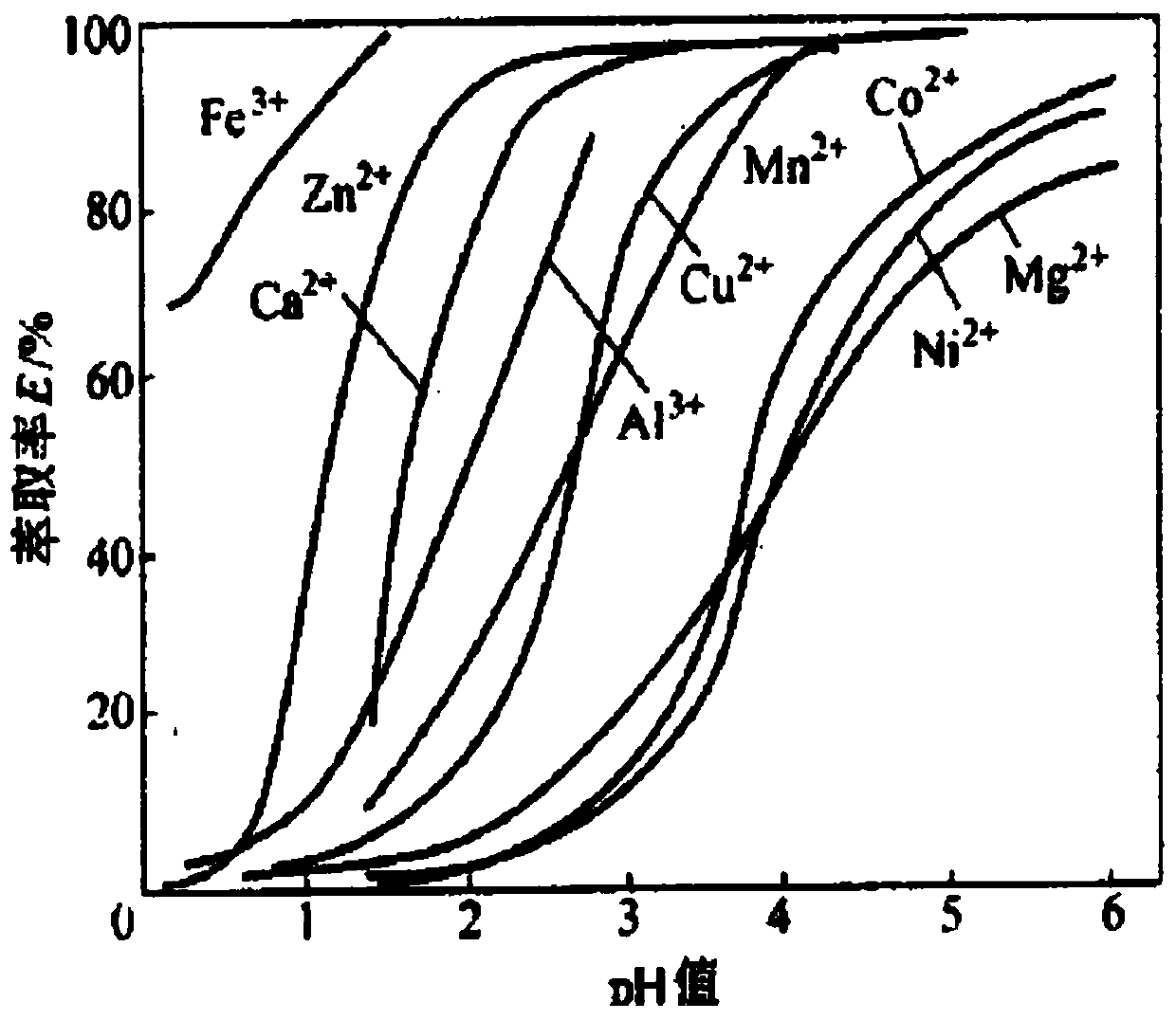

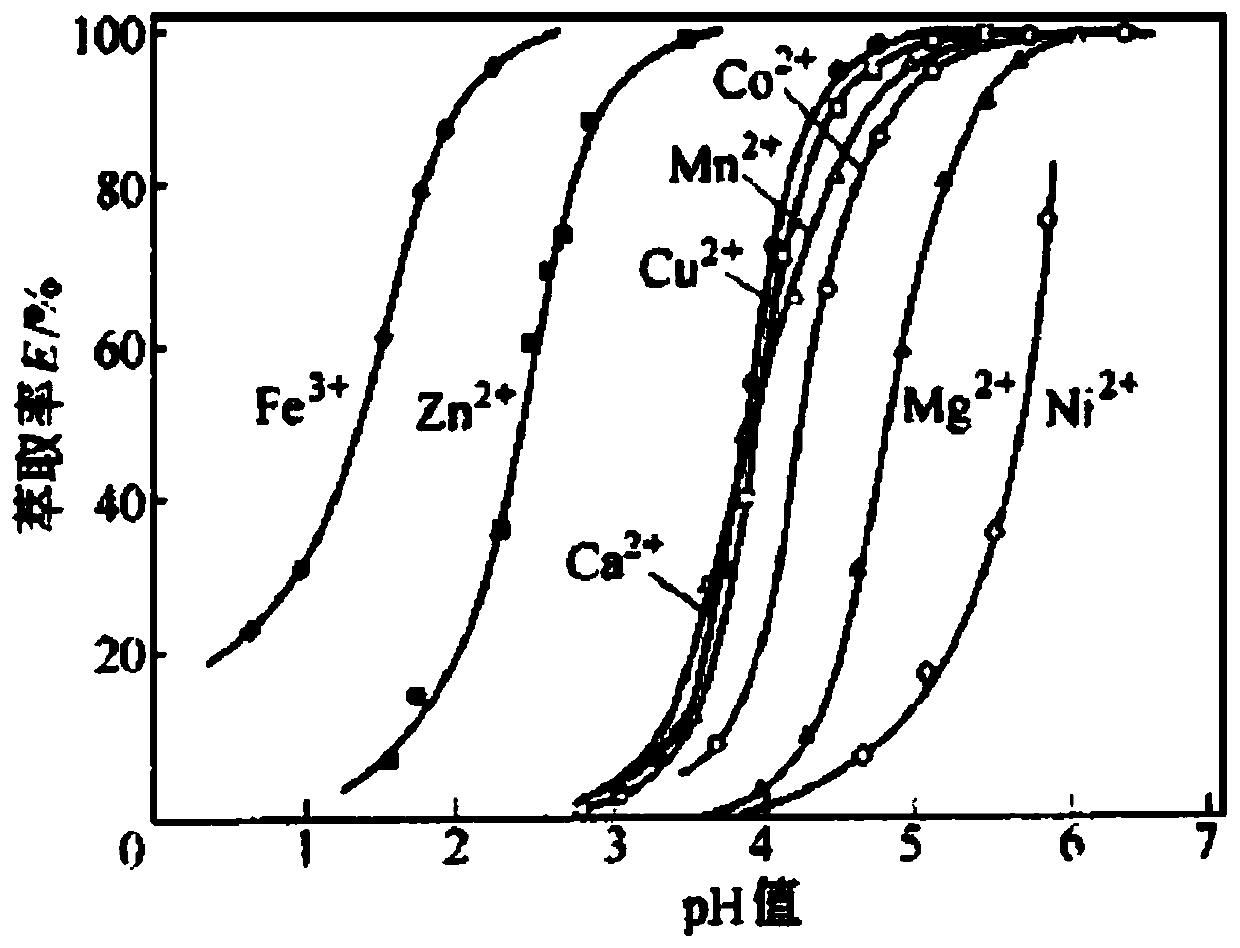

Method for recycling nickel-cobalt-manganese-lithium from waste power lithium ion battery black powder

ActiveCN111519031AHigh recovery rateImprove recycling ratesWaste accumulators reclaimingBattery recyclingLithium carbonateManganese

The invention discloses a method for recycling nickel-cobalt-manganese-lithium from waste power lithium ion battery black powder. The method comprises the steps of conducting leaching and filtering through a sulfuric acid and sulfur dioxide system, adding lime milk into filtrate, adjusting the pH to 10-12, controlling precipitation, and conducting filtering to obtain a nickel-cobalt-manganese enriched product and lithium-containing filtrate; conducting purifying and impurity removal on the lithium-containing filtrate, adding a sodium carbonate solution for precipitation of lithium to obtain lithium carbonate; leaching the nickel-cobalt-manganese enriched product through sulfuric acid, adjusting the pH to 4-6, removing impurity iron and aluminum, and conducting solid-liquid separation to obtain purified slag and purified liquid; and adjusting the pH of the purified liquid to 4-5, conducting manganese extraction with P204 as an extraction agent, conducting cobalt extraction with P507 asan extraction agent, and conducting nickel extraction with P507 as an extraction agent. Through the method provided by the invention, the lithium recovery rate is greatly increased; moreover, sodium hydroxide generated from precipitation of lithium can be returned and continuously used in the lime milk nickel-cobalt-manganese enrichment process; and meanwhile, the yield of nickel sulfate, cobalt sulfate and manganese carbonate is increased.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST

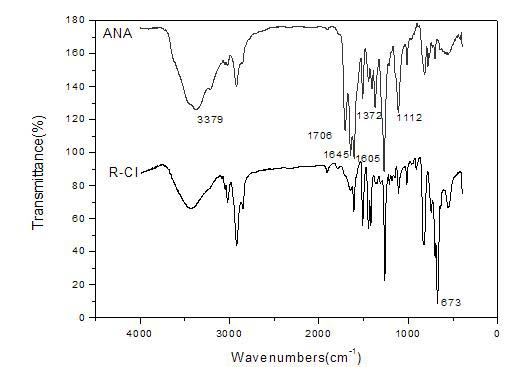

A kind of 6-aminopyridine-3-carboxylic acid chelating resin and preparation method thereof

ActiveCN102295723AHigh stability constantGood choiceOther chemical processesPolymer scienceChloromethyl Ether

The invention discloses a 6-aminopyridine-3-carboxylic acid chelating resin and its preparation method, which belongs to the field of chelating resin. The resin has a following structural unit: a functional group is 6-aminopyridine-3-carboxylic acid, wherein the color is yellowish, the particle size is 0.45-0.6 mm, the content of the functional group is 1.37-2.38 mmol / g. The preparation method comprises the following steps: using styrene as a monomer, employing a suspension polymerization method to prepare a low crosslinking degree macroporous styrene-divinylbenzens copolymer, air-flow dryingto obtain low crosslinking macroporous polystyrene-divinylbenzens resin (white ball for short); immersing the white ball in chloromethyl ether, adding zinc chloride as a catalyst, carrying out a chloromethylation reaction to obtain chloromethylated low crosslinking polystyrene-divinylbenzens resin (chlorine ball for short); taking N,N-dimethyl formamide as a swelling agent, taking DMF as a swelling agent to swell the chlorine ball, dissolving 6-aminopyridine-3-carboxylic acid and sodium carbonate in N, N-dimethyl formamide for reaction, then adding the above swelled chlorine ball, stirring for reacting to prepare 6-aminopyridine-3-carboxylic acid chelating resin. The resin prepared by the invention is suitable for selectively absorbing and separating heavy metal ions of copper and the like.

Owner:NANJING UNIV

Method for preparation of nano-cellulose whiskers from garlic skins

ActiveCN103643577AAvoid harmEfficient and reasonable usePaper material treatmentFreeze-dryingPolysaccharide

The invention relates to a method for preparation of nano-cellulose whiskers from garlic skins. Taking garlic skins as raw materials, the method includes the steps of: 1) conducting dipping swelling in a sodium carbonate solution; 2) performing cooking degumming by an alkali solution; 3) carrying out polysaccharide extraction; 4) implementing bleaching treatment; 5) conducting sanding treatment; 6) performing acidification hydrolysis; and 7) carrying out washing dialysis and freeze drying, etc. The garlic skin raw materials undergo component separation and conversion to be made into a nano-cellulose dispersion liquid with certain concentration, and the dispersion liquid is subjected to freeze drying to remove water, thus obtaining the nano-cellulose whiskers. The nano-cellulose whiskers prepared by the method provided by the invention is needle-shaped, presents good dispersion, and has a high length-diameter ratio, a diameter of 20nm-30nm, and a length of 300nm-2micrometers. The method provided by the invention adopts garlic skins as the raw materials to remove pectin and other impurities. After functional compounding, the prepared nano-cellulose whiskers have wide application value in the fields of optics, electrics, magnetics, biology and semiconductors, etc.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com