Recovery and treatment method for waster lithium ion cell

A lithium-ion battery, recycling and processing technology, applied in the field of waste resource recovery and processing, can solve problems such as lithium-ion battery pollution, and achieve the effects of simple method, improved recovery rate, and economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A recovery example of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the used lithium-ion battery is a square-shaped iron-cased lithium-ion battery.

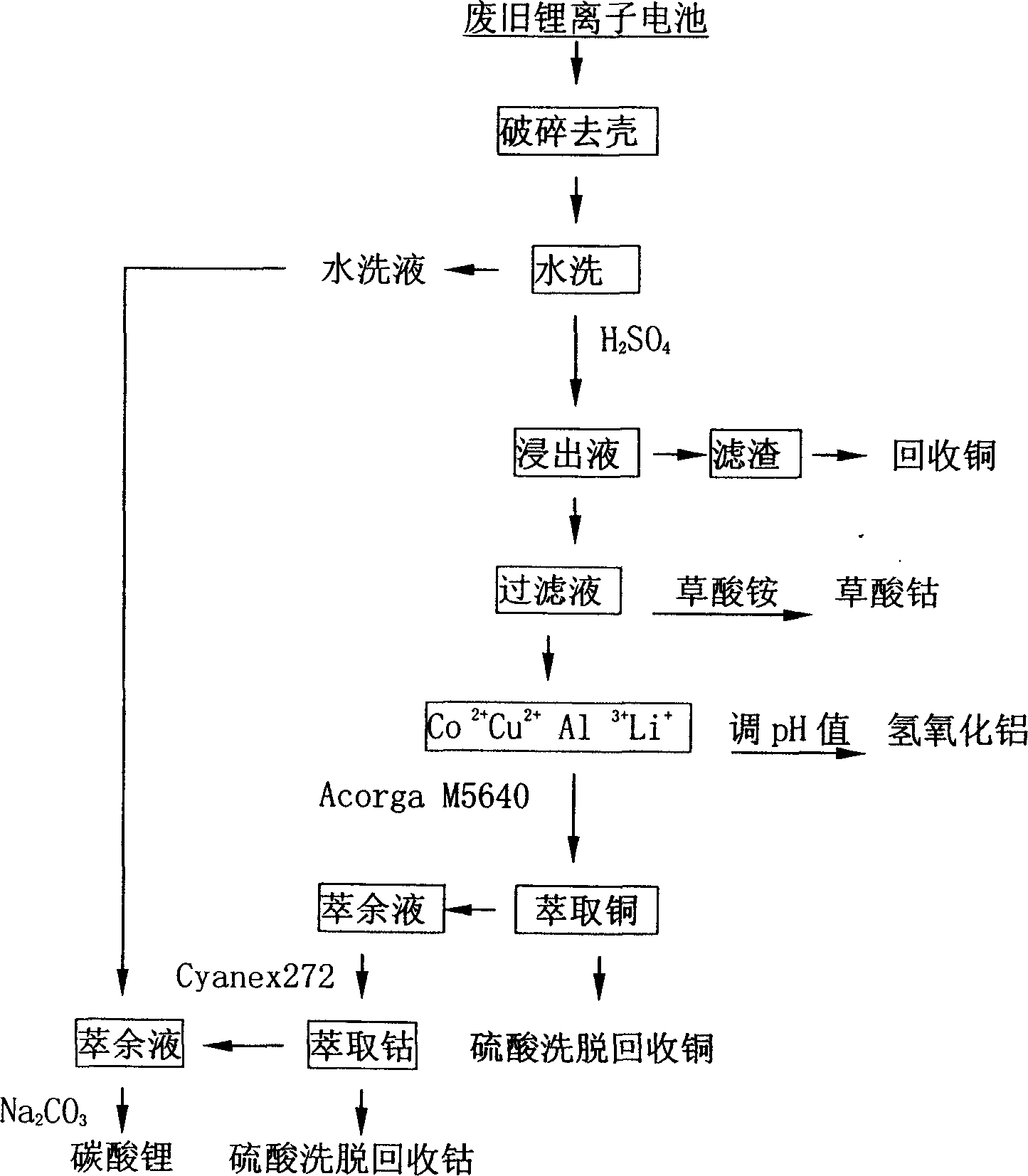

[0024] attached figure 1 It is a process flow diagram of the present invention. With reference to the accompanying drawings, the process of recycling waste lithium-ion batteries is as follows:

[0025] (1) By means of a shearing machine and a pulverizer, remove the outer packaging plastic shell of the waste lithium-ion battery to obtain a single battery. In this process, the charger control circuit board and connecting metal sheet are recovered, and the intact circuit board is reused after passing the inspection.

[0026] Since waste batteries generally have a certain amount of residual power, in order to avoid the danger caused by the short-circuit discharge of the positive and negative plates when the battery case is opened, these single batteries are put...

Embodiment 2

[0038] Other contents and operations are the same as in Example 1, except that carbon powder and iron powder are used as conductive agents in step (1). In step (3), when dissolving the battery waste, the concentration of sulfuric acid used is 1mol / L, the selected solid-liquid ratio is 1:30, the temperature is 95°C, and the reaction time is 6h, which can completely dissolve most of the substances to be dissolved; The concentration of hot sulfuric acid for dissolving copper in the filter residue is 8 mol / L, the amount added is 1.1 times the number of moles of copper, and the temperature is 85°C. In step (4), when adding ammonium oxalate to precipitate cobalt, the amount of ammonium oxalate added is 5 times of the theoretical value. In step (5), aluminum is precipitated at a pH value of 5.0; copper is extracted with a concentration of 5% Acorga M5640 at a pH value of 1.5, and Cyanex272 with a concentration of 0.5 mol / L is used at a pH value of 6.0. For cobalt extraction, the str...

Embodiment 3

[0040] Other contents and operations are the same as those in Example 1, except that carbon powder, iron powder and copper powder are used as conductive agents in step (1). In step (3), when dissolving the battery waste, the concentration of sulfuric acid used is 4mol / L, the selected solid-liquid ratio is 1:8, the temperature is 95°C, and the reaction time is 1h; the hot sulfuric acid concentration for dissolving copper in the filter residue is 8mol / L L, the amount added is 1.5 times the number of moles of copper, and the temperature is 75°C. In step (4), when adding ammonium oxalate to precipitate cobalt, the amount of ammonium oxalate added is 1 times of the theoretical value. In step (5), aluminum is precipitated at a pH value of 4.0; copper is extracted with a concentration of 20% Acorga M5640 at a pH value of 0.5, and extracted with Cyanex272 at a concentration of 3 mol / L at a pH value of 5.0 Cobalt, the stripping agent is 5.0mol / L sulfuric acid, which can realize the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com