Environment friendly water-base anti-rusting agent

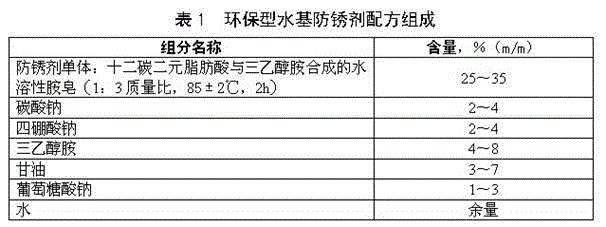

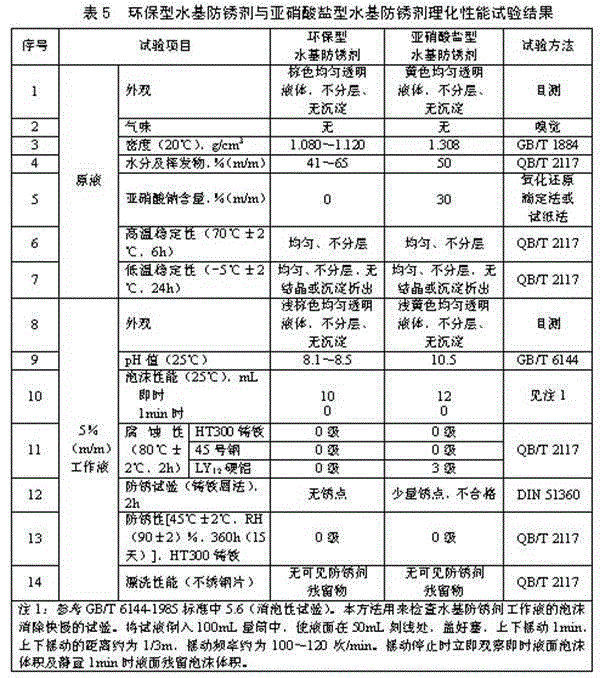

A water-based antirust agent, an environmentally friendly technology, applied in the coating process of metal materials, etc., can solve the problems of prominent corrosion, serious claims, high cost, etc., and achieve good rust resistance, good effect, and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) First, mix and heat the twelve-carbon dibasic fatty acid and triethanolamine in a reaction vessel at a mass ratio of 1:3. The heating temperature is controlled at 87°C, and the temperature is maintained at this temperature for 2 hours to synthesize water-soluble amines. Soap is used as the antirust agent monomer; (2) When the temperature of the synthesized antirust agent monomer drops to 80°C, add 1 / 4 of the specified amount of water, stir and dissolve evenly; (3) add the remaining 3 / 4 Heat the water to 45°C, slowly add sodium tetraborate, sodium carbonate, and sodium gluconate in sequence, the proportions are shown in Table 2, and stir to dissolve them completely; after stirring and dissolving completely, slowly add triethanolamine and glycerin in sequence, the proportions are shown in Table 2 Add the liquid in step (2) and stir to dissolve completely.

[0014]

Embodiment 2

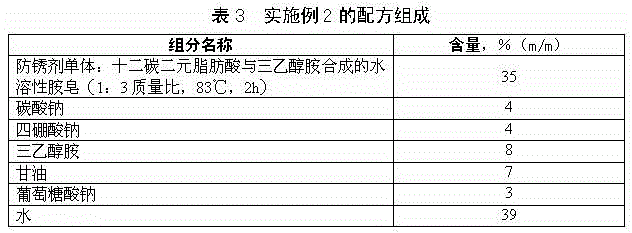

[0016] (1) First, mix and heat the twelve-carbon dibasic fatty acid and triethanolamine in a reaction vessel at a mass ratio of 1:3. The heating temperature is controlled at 83°C, and the temperature is maintained at this temperature for 2 hours to synthesize water-soluble amines. Soap is used as the antirust agent monomer; (2) When the temperature of the synthesized antirust agent monomer drops to 80°C, add 1 / 4 of the specified amount of water, stir and dissolve evenly; (3) add the remaining 3 / 4 Heat the water to 40°C, slowly add sodium tetraborate, sodium carbonate, and sodium gluconate in sequence, the proportions are shown in Table 3, and stir to completely dissolve; after stirring and dissolving completely, slowly add triethanolamine and glycerin in sequence, the proportions are shown in Table 3, Add the liquid in step (2) and stir to dissolve completely.

[0017]

Embodiment 3

[0019] (1) First, mix and heat the twelve-carbon dibasic fatty acid and triethanolamine in a reaction vessel at a mass ratio of 1:3. The heating temperature is controlled at 85°C, and the temperature is maintained at this temperature for 2 hours to synthesize water-soluble amines. Soap is used as the antirust agent monomer; (2) When the temperature of the synthesized antirust agent monomer drops to 80°C, add 1 / 4 of the specified amount of water, stir and dissolve evenly; (3) add the remaining 3 / 4 Heat the water to 43°C, slowly add sodium tetraborate, sodium carbonate, and sodium gluconate in sequence, the proportions are shown in Table 4, and stir to dissolve them completely; after stirring and dissolving completely, slowly add triethanolamine and glycerin in sequence, the proportions are shown in Table 4 Add the liquid in step (2) and stir to dissolve completely.

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com