Patents

Literature

166results about How to "Shorten the purification process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing functional nanocarbon and hydrogen by direct decomposition of lower hydrocarbon

ActiveUS20060257310A1Reduce conversionReduce purification costsMaterial nanotechnologyHydrogenHydrogenDecomposition

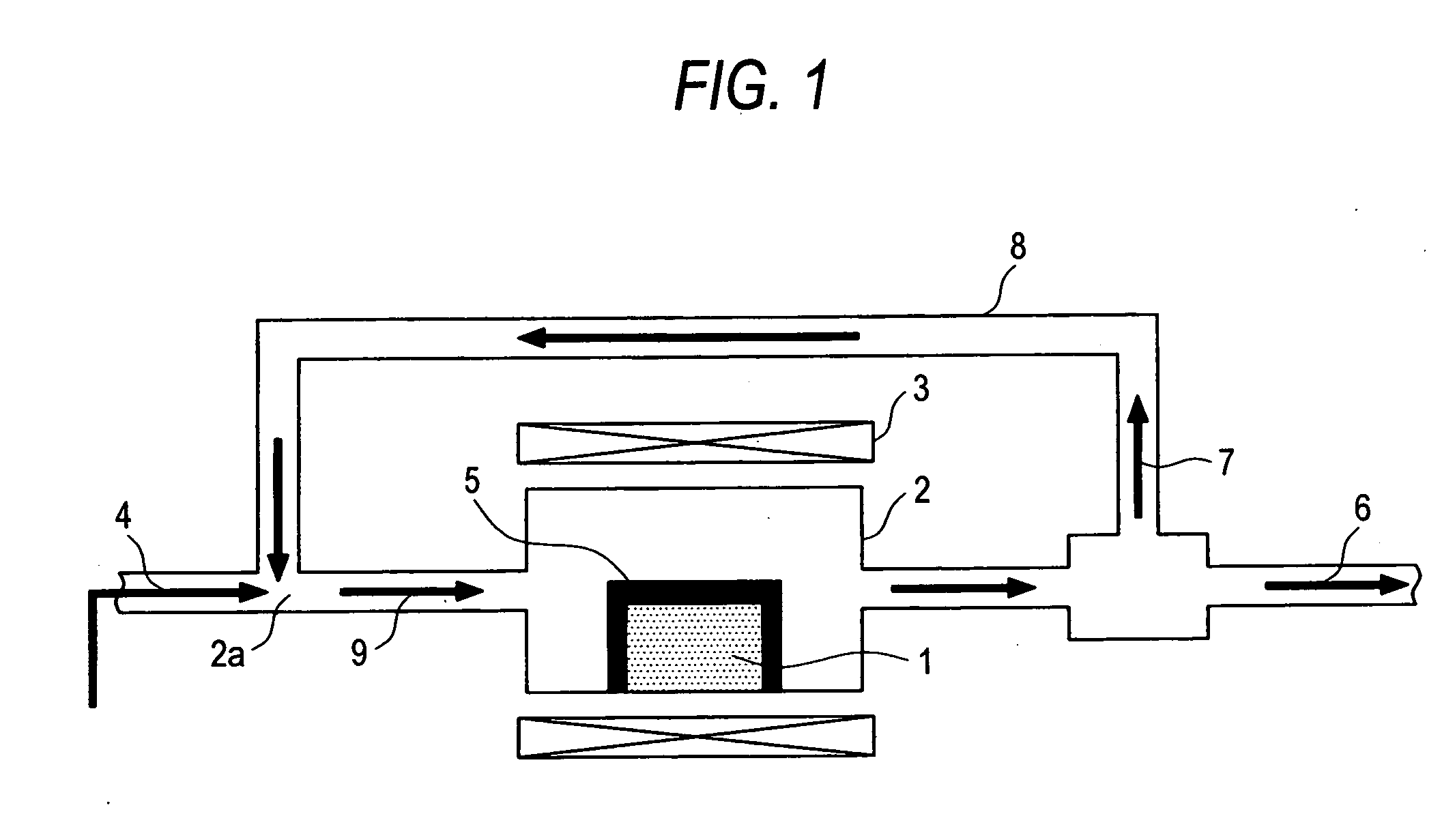

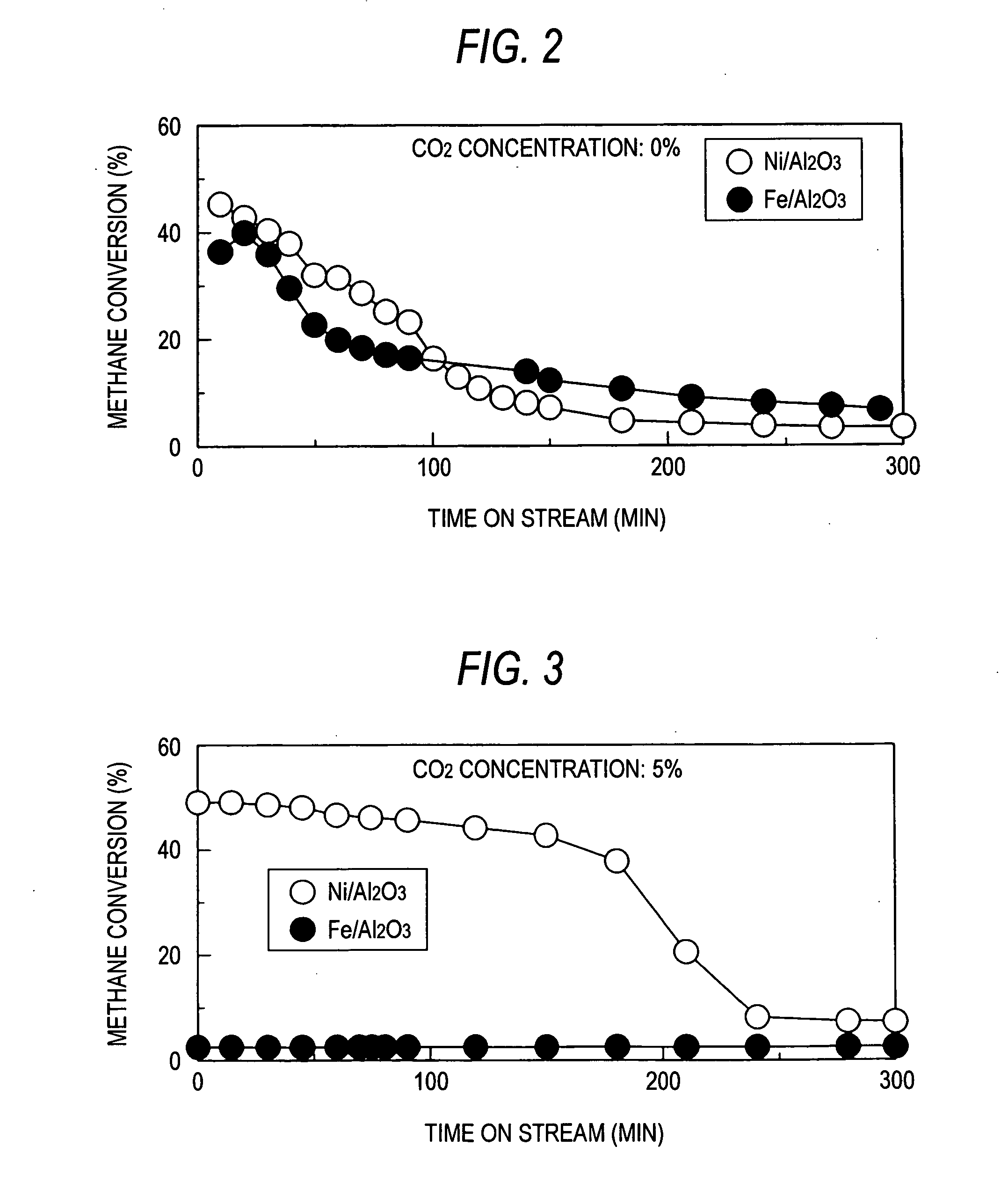

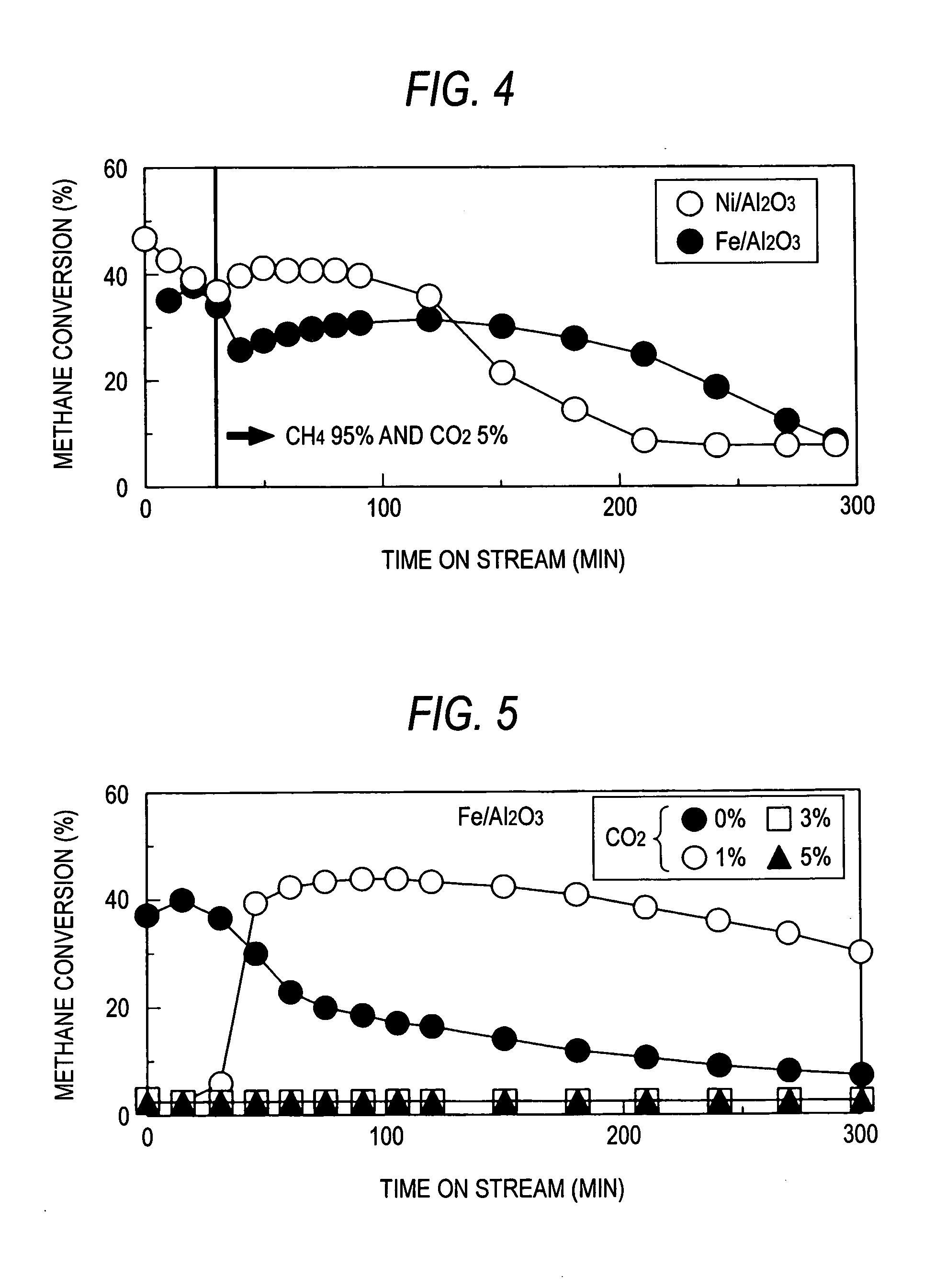

In a reaction where a lower hydrocarbon is subjected to direct decomposition by using a catalyst to produce a functional nanocarbon and hydrogen, the lower hydrocarbon is subjected to the reaction in an coexistent gas comprising low concentration of oxidizing gas, reducing gas or a mixture thereof. The precursor of functional nanocarbon produced on the catalyst and amorphous carbon secondarily produced on the catalyst react with the coexistent gas so that being removed from the catalyst, making it possible to prevent the drop of conversion with time on stream due to the inhibition of the reaction by the precursor and by-product. In the case where the raw material of lower hydrocarbon is biogas, the coexistent gas can be easily contained in methane by lowering purification degree of methane. Further, hydrogen can be obtained as one of decomposition products of lower hydrocarbon thus can be contained in methane during the reaction.

Owner:JAPAN STEEL WORKS LTD +1

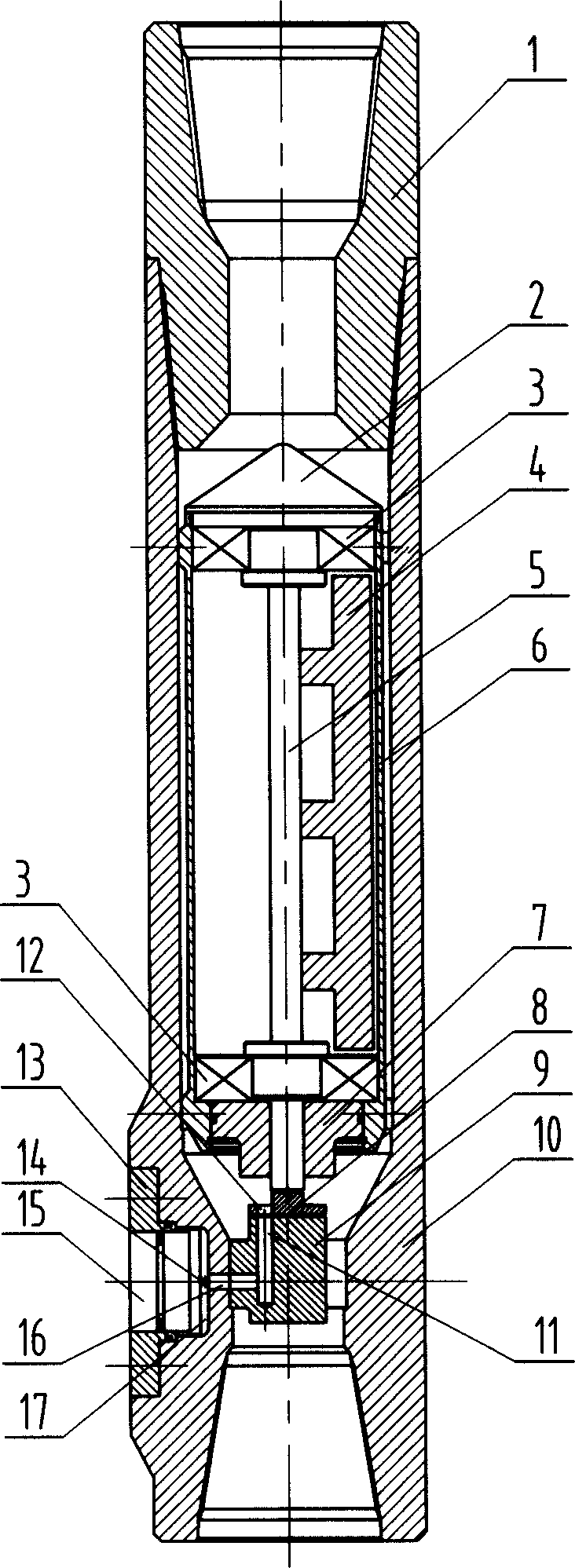

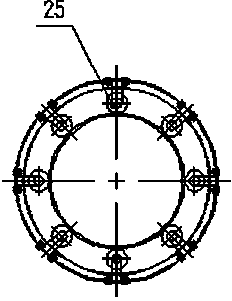

Mechanical automatic vertical drilling tool

InactiveCN1676862AIncrease drilling speedShorten the purification processDirectional drillingWell drillingDifferential pressure

One kind of mechanical type automatic vertically well-drilling tool, including turner, the conduction current head, the bearing, the counterweight, the spindle, in-tube, the back plate, above plate-valve, gets down plate-value, the shell, the piston cylinder back plate and the piston, its principle is at the right moment induces the well slanting gravity signal, by the gravity-actuates in the organization, the establishment drills inside and out the column high-low pressure channel between the fluid, uses two between the differential pressure, actuates the piston at the right moment to push depends on the wall of a well is high side, the wall of a well reacting force then pushes the drill bit to is low side, but in well-eye other positions, the piston does not push depends on the wall of a well, drills the column revolves, this process circulation reciprocation, the well is slanting namely is unceasingly induced and the revision, this invention realization is initiative, At the right moment guards against slanting at the same time, but also can effectively liberate distilling, largely enhances drills fast and well-eye the quality, reduces the construction risk, this invention has the structure is simple, reliable, is suitable to the many kinds of well drilling platform, the processing makes the maintenance cost is low and so on the characteristic.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

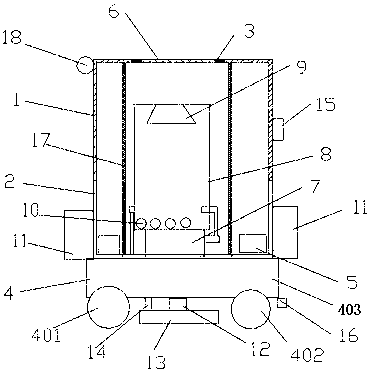

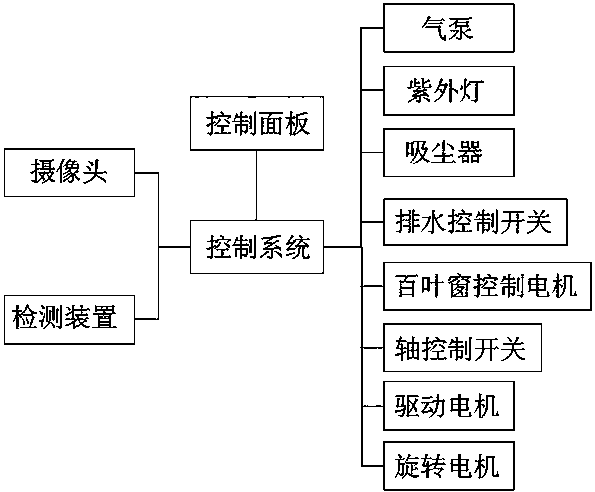

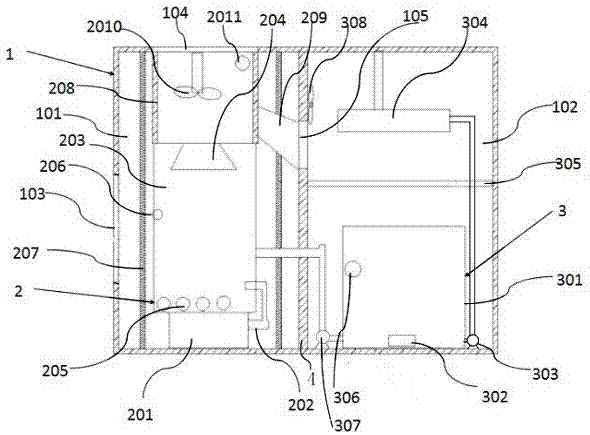

Sweeper with air purification function

InactiveCN108030449AEasy to cleanImprove purification effectAutomatic obstacle detectionMechanical apparatusWater dischargeAir purifiers

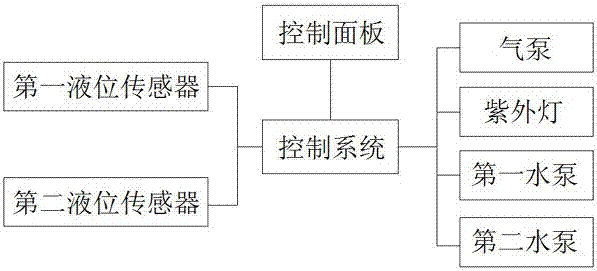

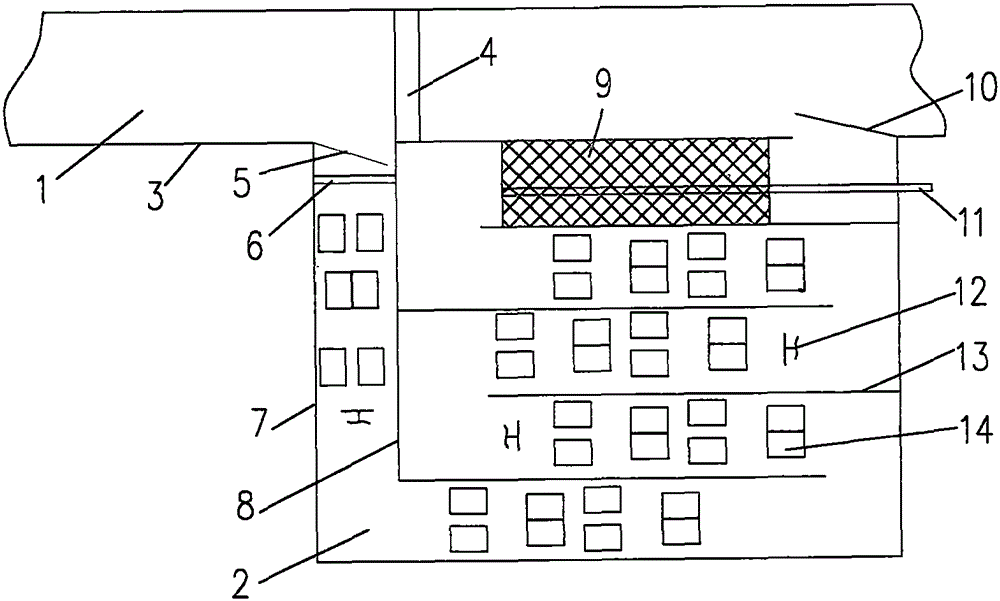

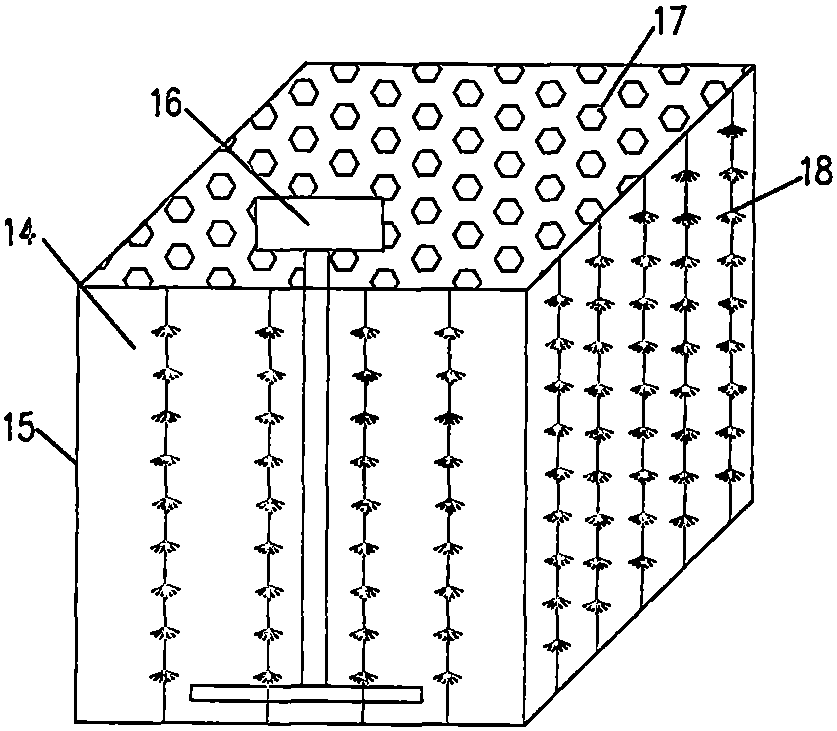

The invention relates to a sweeper with an air purification function. The sweeper comprises a shell, a dust collection device, a mopping device, an air purification device and a traveling device, an air inlet and an air outlet are formed in the shell, a filtering screen is arranged in the shell, the air purification device is arranged in the filtering screen and comprises an air pump, a water tankand an ultraviolet lamp, water solution and photocatalyst active balls are arranged in the water tank, the dust collection device comprises a dust collector and a dust storage chamber, the mopping device comprises a mopping plate, a water discharging pipe and a water discharging control switch, and the mopping plate is connected with the traveling device through a telescopic connecting shaft. According to the sweeper, indoor air purification and floor sweeping functions can be simultaneously achieved, so that the sweeper is richer in function, soluble organic pollutants in air are dissolved and adsorbed by the water solution, photocatalytic degradation is performed on dissolved matters by the photocatalyst active balls in the water solution, so that the air purification function of the sweeper is achieved, and an air purifier is high in efficiency.

Owner:柳州若思纳米材料科技有限公司

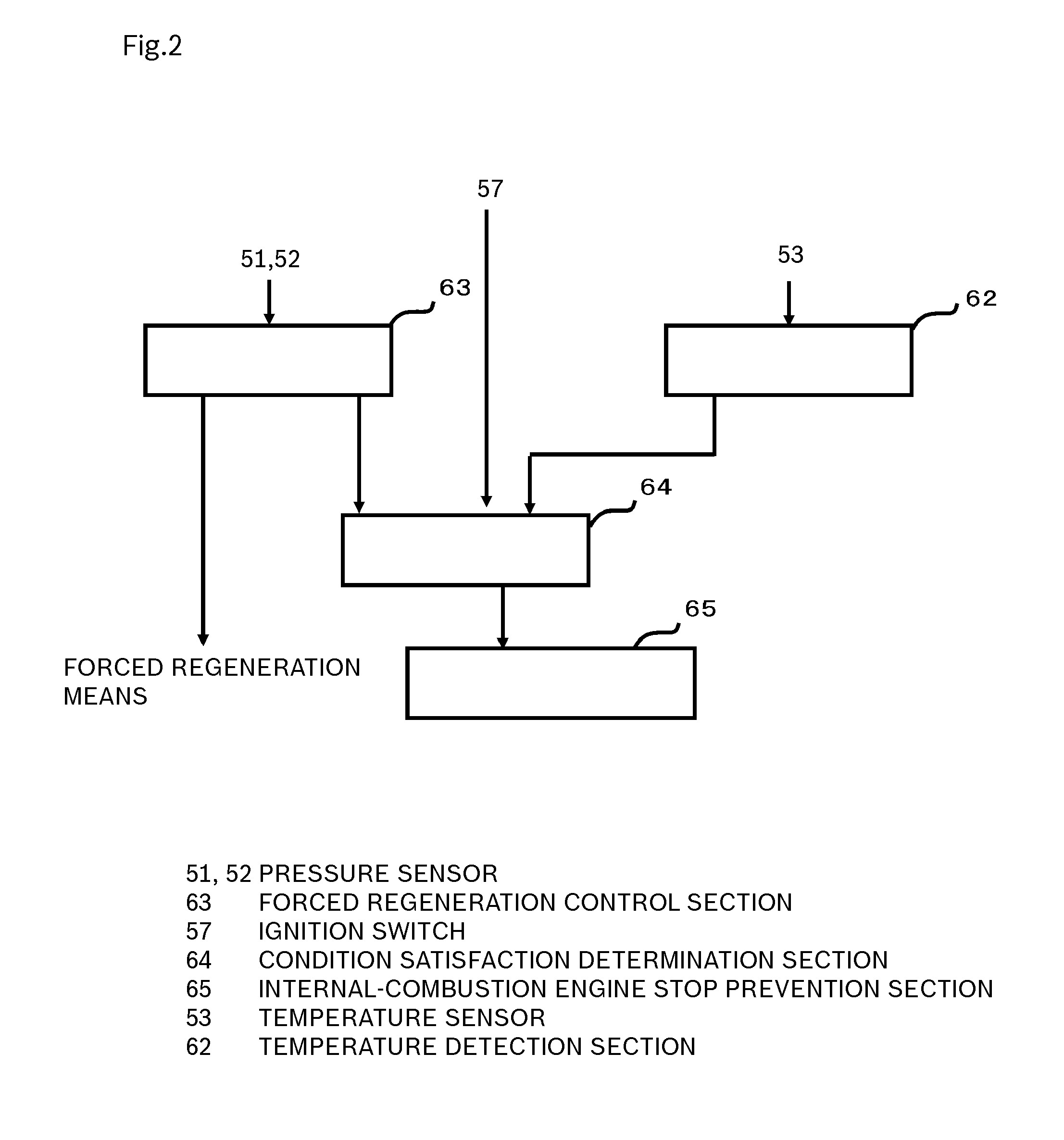

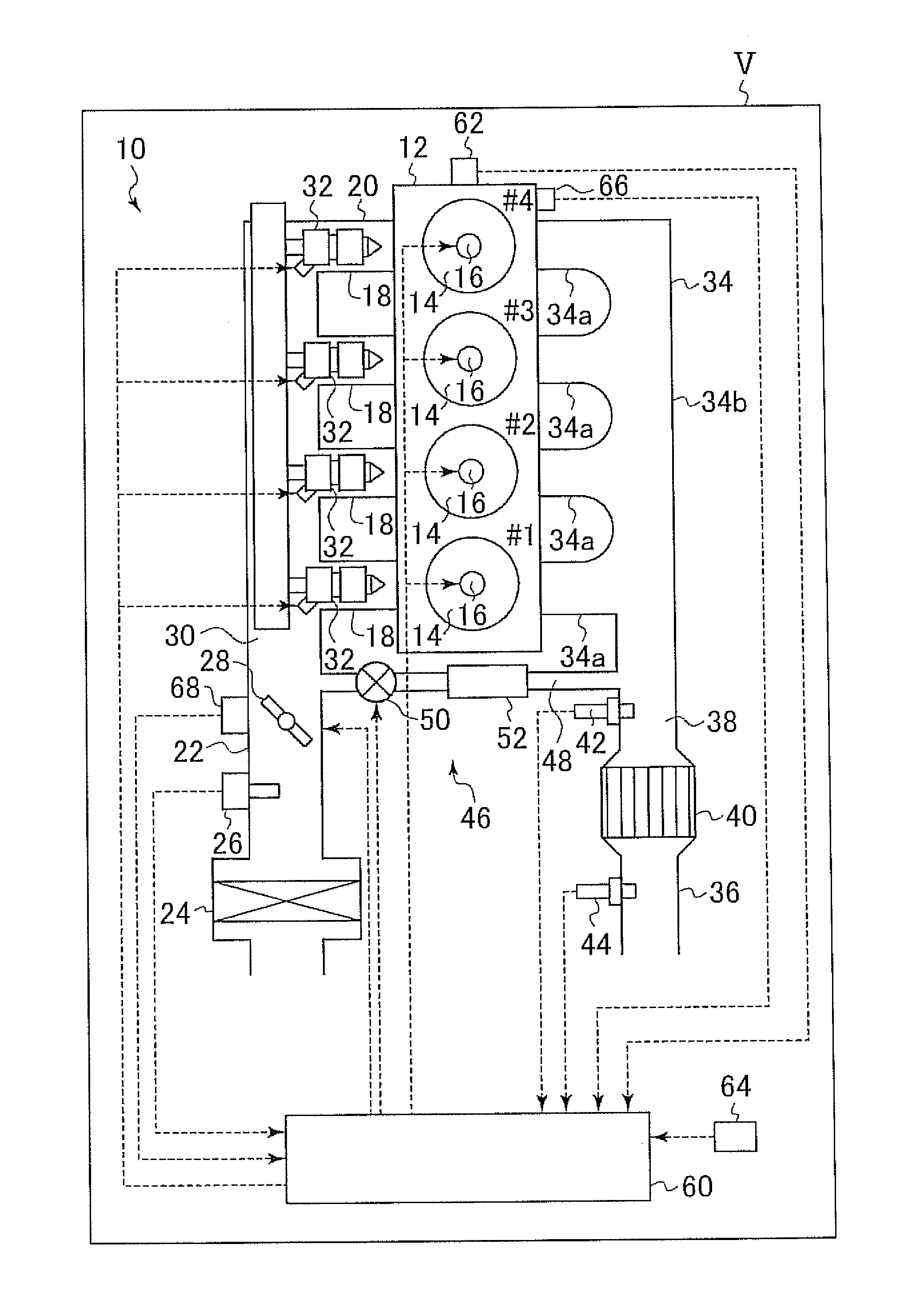

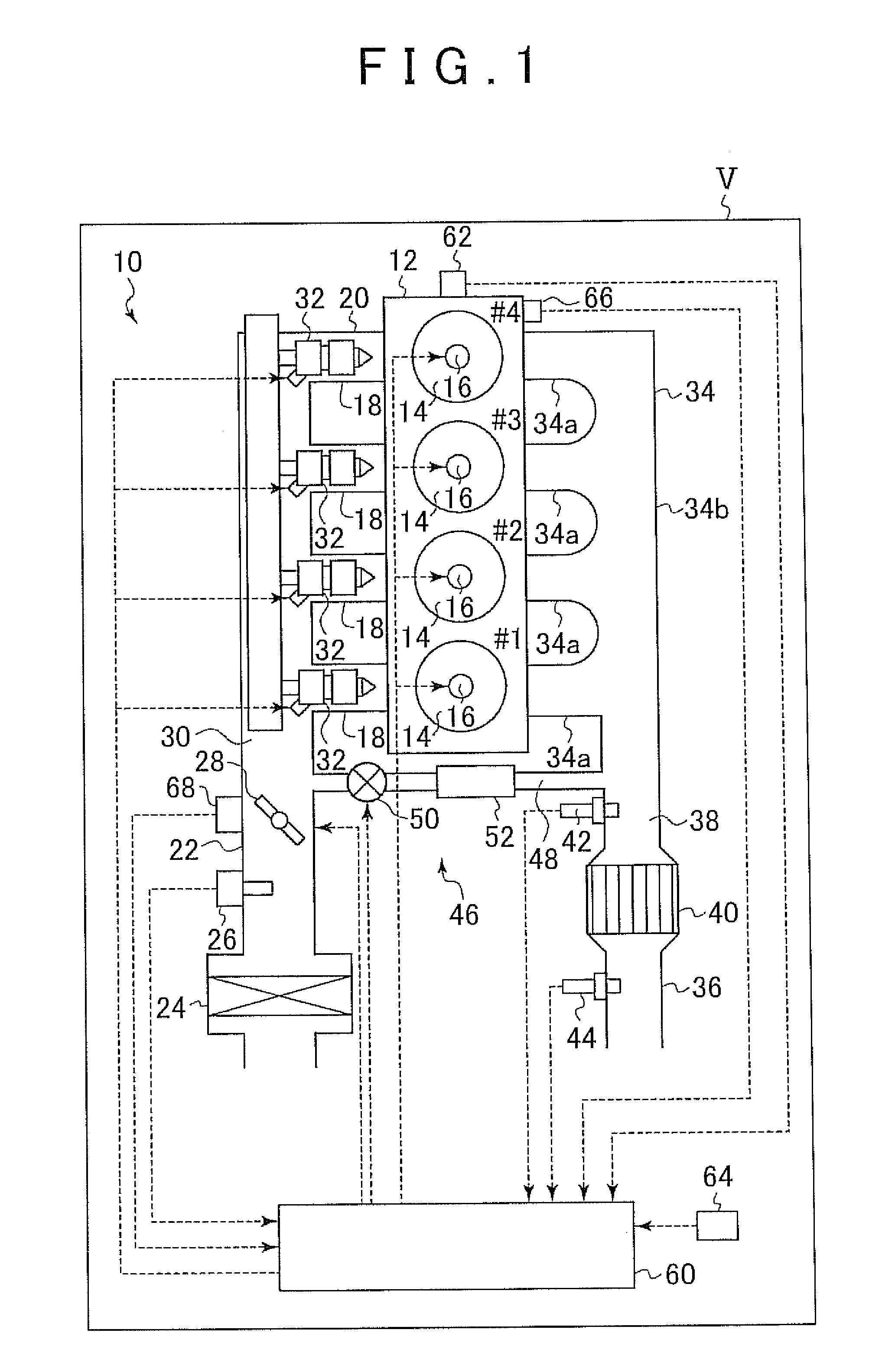

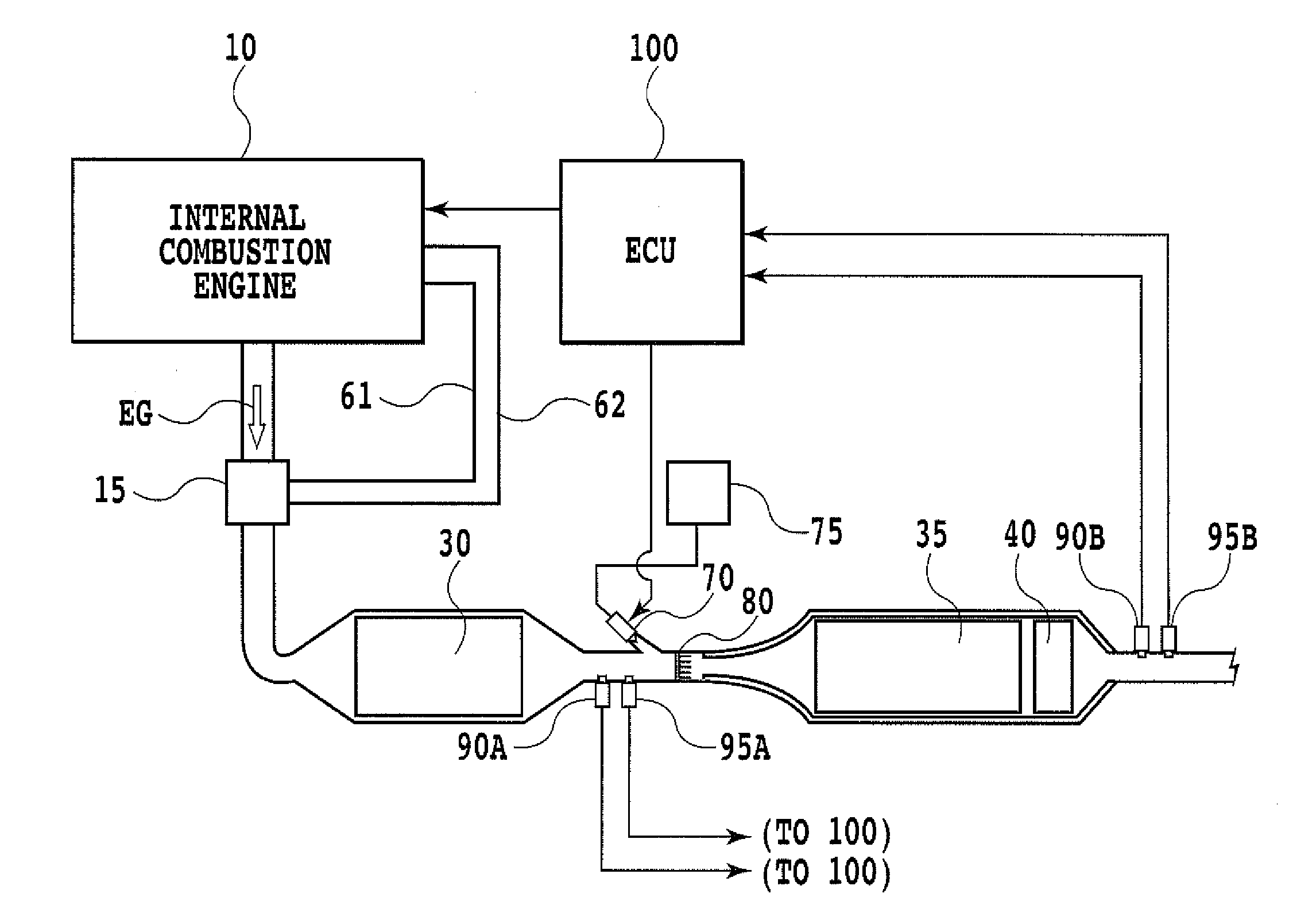

Exhaust gas purification system and method for controlling the same

ActiveUS20130283769A1Accurate estimateDecrease in exhaust gas purification efficiency can be preventedInternal combustion piston enginesExhaust apparatusExhaust fumesExhaust gas recirculation

[Problem] To provide an exhaust gas purification system capable of preventing clogging of a reducing agent injection valve due to solidified urea aqueous solution to prevent decrease in the exhaust gas purification efficiency of an internal-combustion engine.[Means for Resolution] An exhaust gas purification system including a DPF, a reducing agent injection valve and an SCR catalyst in this order from the exhaust upstream side includes: a condition satisfaction determination section for determining whether or not urea aqueous solution is likely to be solidified when detecting that an ignition switch is turned off; and an internal-combustion engine stop prevention section for preventing the internal-combustion engine from being stopped, based on a determination by the condition satisfaction determination section.

Owner:BOSCH CORP

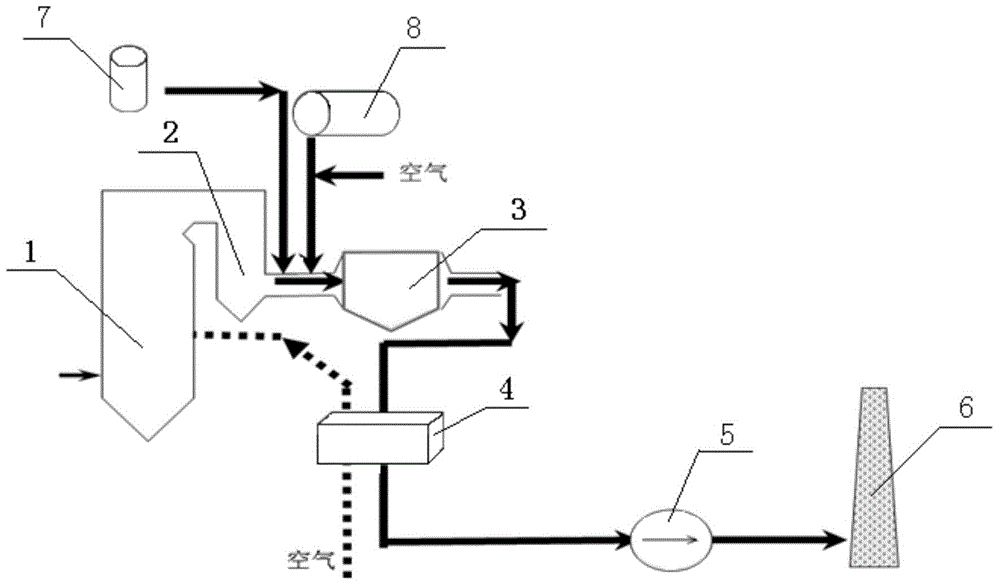

Flue gas cleaning system and flue gas cleaning process for integrated multi-pollutant removal by dry method

ActiveCN103604133ANo emissionsSmall footprintDispersed particle filtrationLighting and heating apparatusAir preheaterMulti pollutant

Disclosed are a flue gas cleaning system and a flue gas cleaning process for integrated multi-pollutant removal by a dry method. The flue gas cleaning system comprises an economizer arranged at the tail of a boiler, and an outlet of the economizer is sequentially communicated with an integrated removal tower, an air preheater and a flue gas extractor; a first injection system and a second injection system are sequentially arranged on a flue between the economizer and the integrated removal tower; a catalytic ceramic filter bag is arranged in the integrated removal tower. After flue gas comes out from the flue at the tail of the economizer, SOx and HC1 in the flue gas react with desulfurizing agents, the desulfurizing agents and deacidified products which are not fully reacted and carried in the flue gas are mixed with ammonia gas prior to entering the integrated removal tower to have dust the unreacted desulfurizing agents, the deacidified products and NOx in a mixed system removed, and the flue gas is cleaned and discharged through the flue gas extractor. The flue gas cleaning system is small in occupied area, low in operation energy consumption, shortened in cleaning process and free of wastewater discharge.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

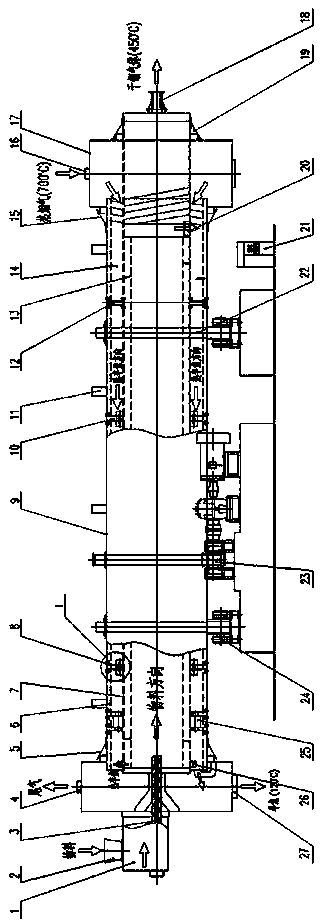

Multilayer rotary kiln based small granular material destructive distillation method

ActiveCN103952165ALow running costGuaranteed concentrationEnergy inputIndirect heating destructive distillationGranularityFlue gas

The invention relates to a multilayer rotary kiln based small granular material destructive distillation method. The method comprises the following steps: adding oil shale granules (with the granularity of 0-20mm) with the water content of below 5% to a bunker from a kiln head, sending to the inner cylinder of a rotary kiln by a spiral conveying device, heating the material in the inner cylinder to 500DEG C through the circulation of high temperature hot flue gas (with the temperature of 700DEG C) from a hot blast stove in an annular channel between an outer cylinder and the inner cylinder to pyrolyze the oil shale material in order to generate a destructive distillation gas and semicoke, and carrying out purifying recovery on the destructive distillation gas to obtain gas and shale oil; and adding the semicoke into the annular channel from the inner cylinder, allowing the semicoke to run along a direction opposite to the material running direction in order to carry out heat exchange of the material in the inner cylinder and absorb the waste heat of the semicoke, discharging parts of the semicoke from the stove, and adding a small amount of the semicoke to the inner cylinder for the mixing of the small amount of the semicoke with a normal temperature mixture in order to further utilize the waste heat of the semicoke. The method has the advantages of simple technology, low energy consumption, no pollution, high product quality, realization of the industrial large-scale production, and easy large-area popularization.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

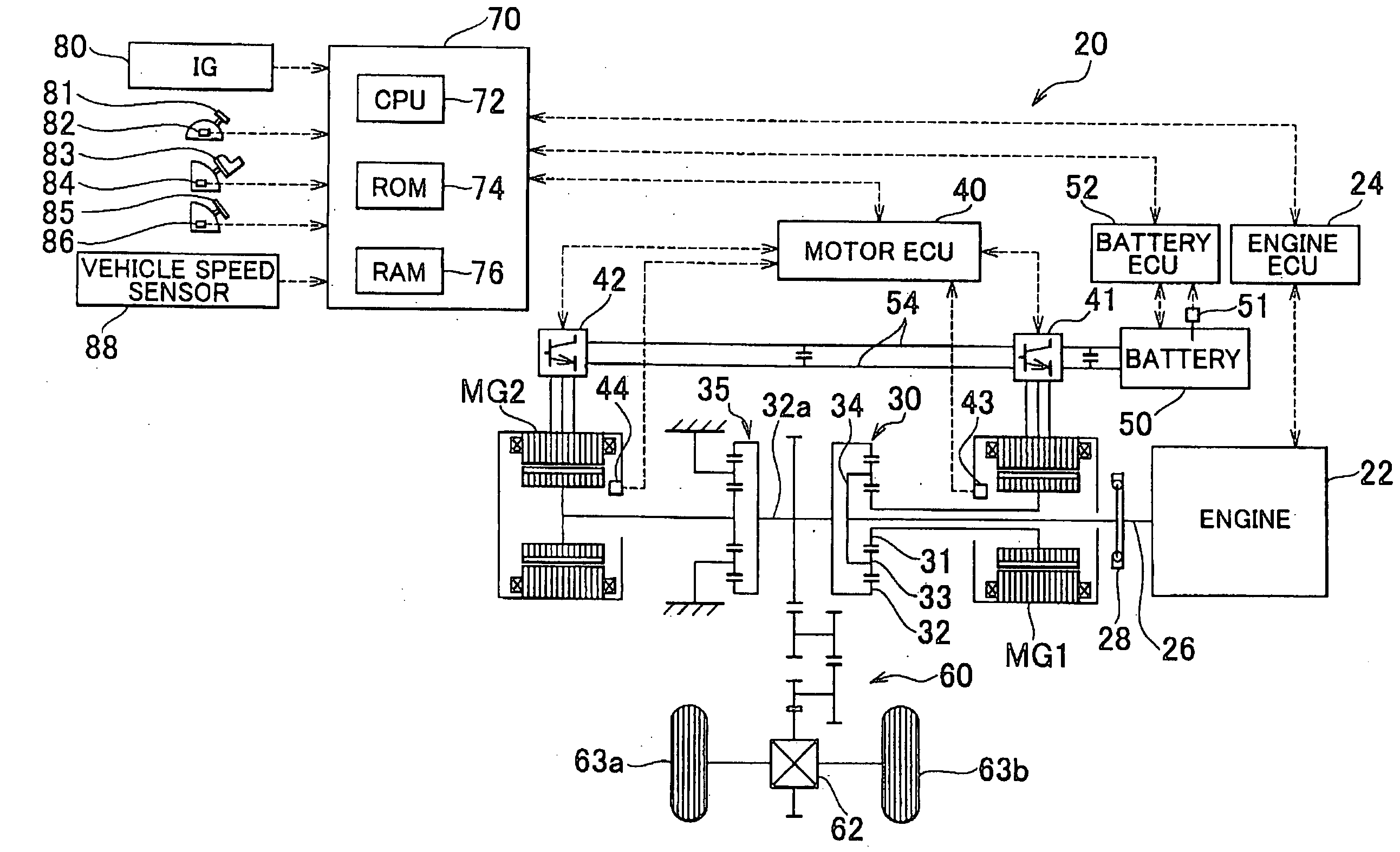

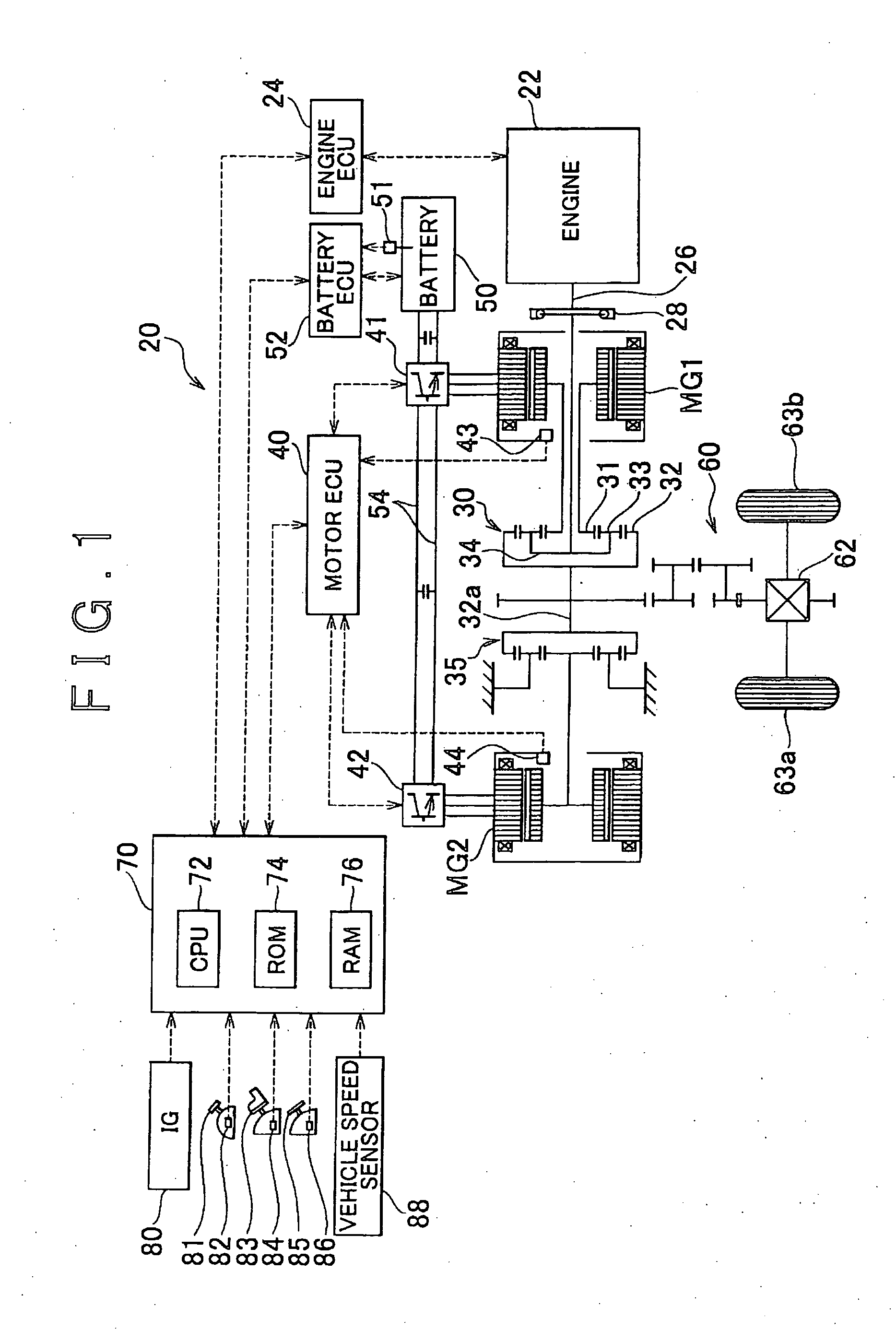

Hybrid vehicle and method for controlling hybrid vehicle

ActiveUS20070163540A1Reduction in NOx purification efficiency is suppressedReduce purification efficiencyHybrid vehiclesElectrical controlDriver/operatorAir–fuel ratio

In a hybrid vehicle, when the shift position SP is set to the S position at which a driver is allowed to select any one of the shift positions SP1 to SP6, and it is determined that warm-up of a purifying device has not been completed, the target air-fuel ratio AF* is set based on the S position / low coolant temperature-time target air-fuel ratio setting map. The air-fuel ratio AF* set based on the S position / low coolant temperature-time target air-fuel ratio setting map tends to be richer than the target air-fuel ratio AF* set based on any one of the normal-time target air-fuel ratio setting map and the D position / low coolant temperature-time target air-fuel ratio setting map that are used when the D position is selected.

Owner:TOYOTA JIDOSHA KK

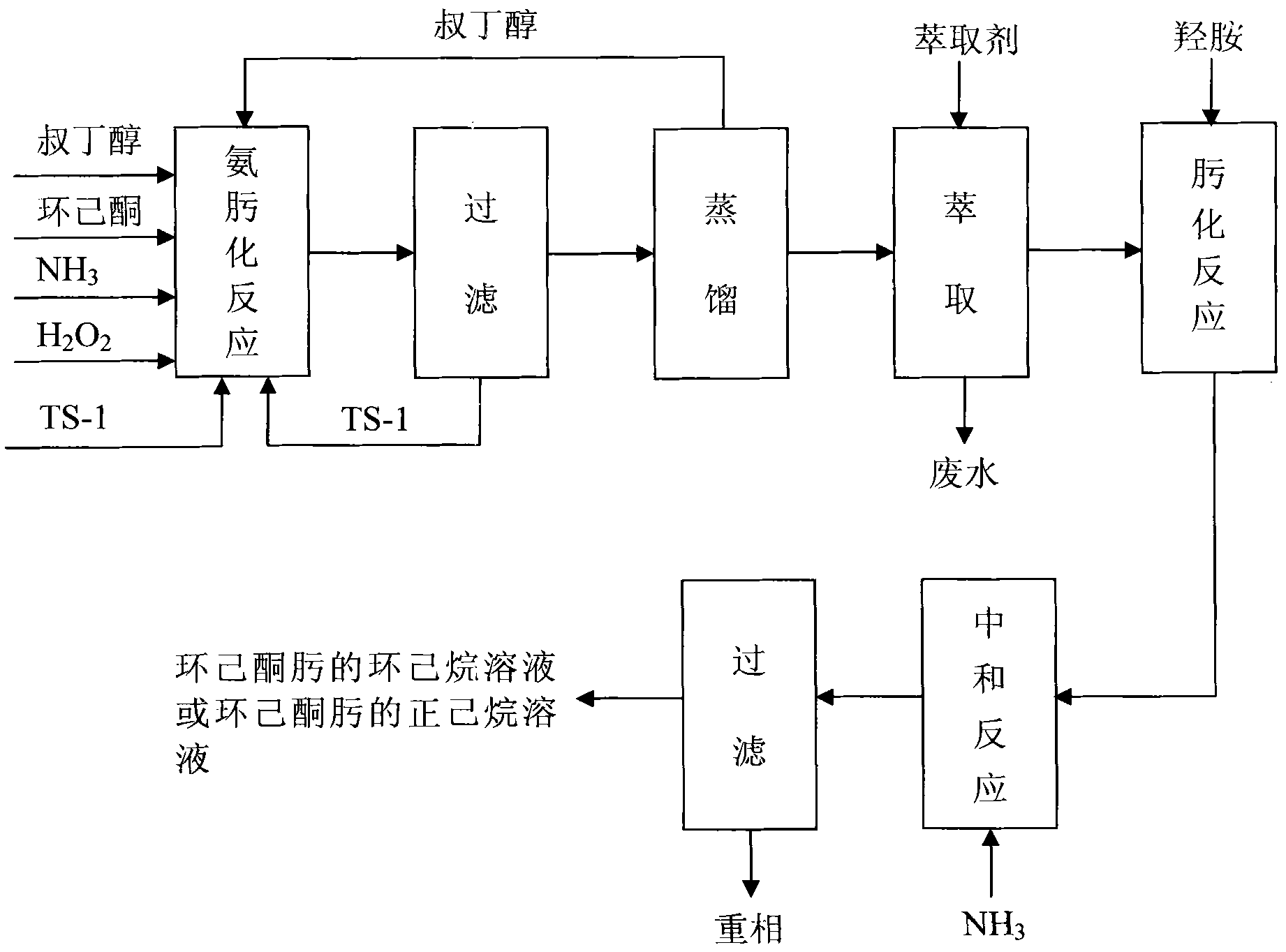

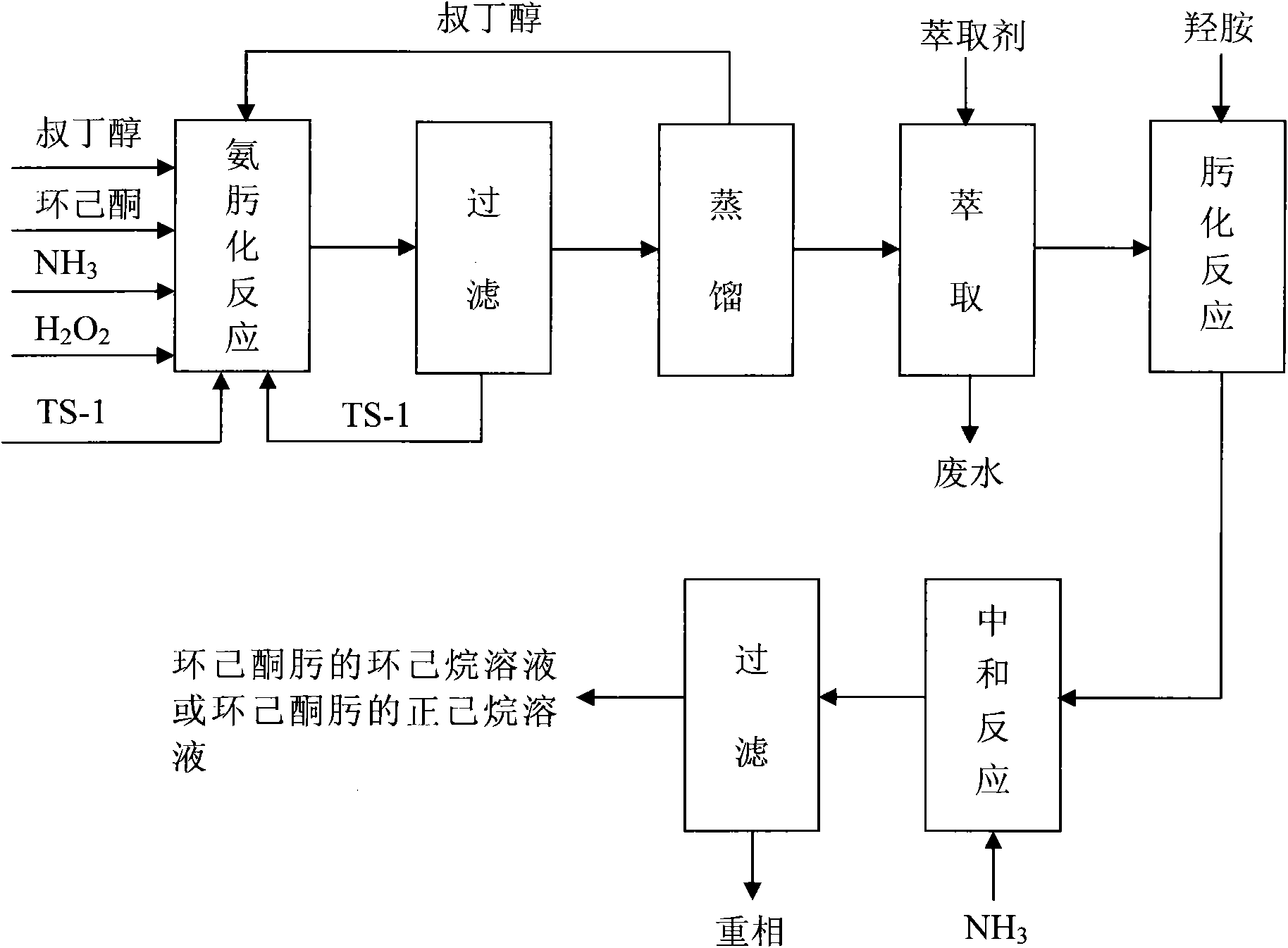

Preparation process of cyclohexanone-oxime

InactiveCN101781232AReduce consumptionEliminate safety and environmental hazardsOximes preparationChemical recyclingSolventHydroxylamine Hydrochloride

The invention discloses a preparation process of cyclohexanone-oxime. The process comprises the following steps: carrying out ammoximation under the condition of the existence of catalyst and tertiary butanol solvent, and filtering, distilling and leaching when the conversion ratio of cyclohexanone is 99.5% in the ammoximation; then adding hydroxylamine for performing oximation reaction; and finally neutralizing and filtering to obtain the cyclohexanone-oxime solution when the conversion ratio of the cyclohexanone is 100%. The process combines two different kinds of the oximation reactions to ensure that the conversion ratio of the cyclohexanone reaches to 100%, solves the defect that the cyclohexanone can not be fully converted in the existing ammoximation process, reduces the consumption of hydrogen peroxide and eliminates safety hidden troubles brought by excessive hydrogen peroxide. Compared with the traditional process, the process of the invention abrogates working procedures such as regenerating extractant by rectification, removing ketone, dealcoholization tower, regenerating cyclohexanone-oxime by rectification and the like, saves equipment investment and reduces energy consumption; and as for a device by which the annual cyclohexanone-oxime yield is 100,000 tons, the saved equipment investment is close to ** million yuan, and the saved energy sources such as water, electricity, steam and the like are close to ** yuan.

Owner:河北美邦工程科技股份有限公司

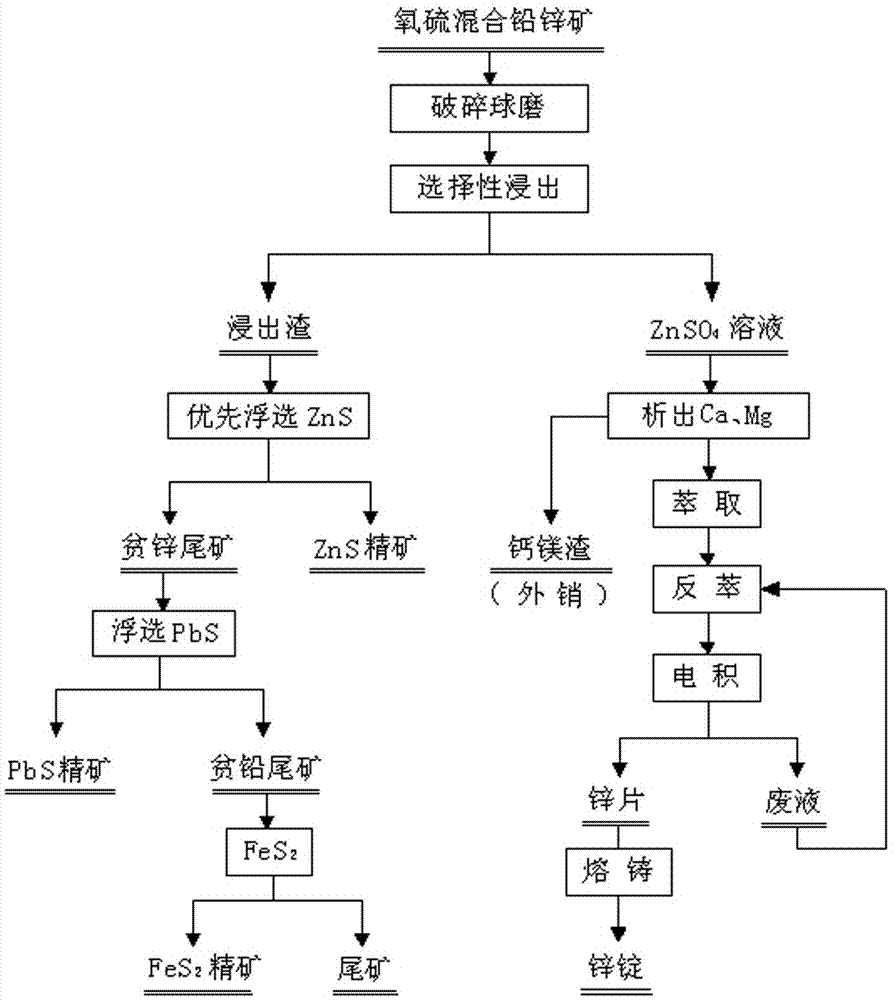

Selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process

ActiveCN103301929AReduce calcium concentrationHarm reductionFlotationWet separationOxygenTotal recovery

The invention discloses a selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process. For oxygen and sulfide mixed lead zinc ore, a zinc wet-method smelting process and a zinc flotation process are combined, zinc oxide in the ore is partially and selectively leached out by the first wet-method smelting process, and then zinc sulfide in the ore is floated out by the flotation process. In order to overcome the difficulty in treating the oxygen and sulfide mixed lead zinc ore, the invention provides the smelting and selection combining process which is short in process flow, reliable in technology, easy to operate and control, relatively low in material consumption and energy consumption for production, high in metal reclaiming efficiency, relatively good in economic benefit and high in practicability, the recovery of lead and zinc in the low-grade complex difficultly-selected oxygen and sulfide mixed lead zinc ore can be greatly improved, and the total recovery of lead and zinc can be up to over 90 percent.

Owner:云南金鼎锌业有限公司

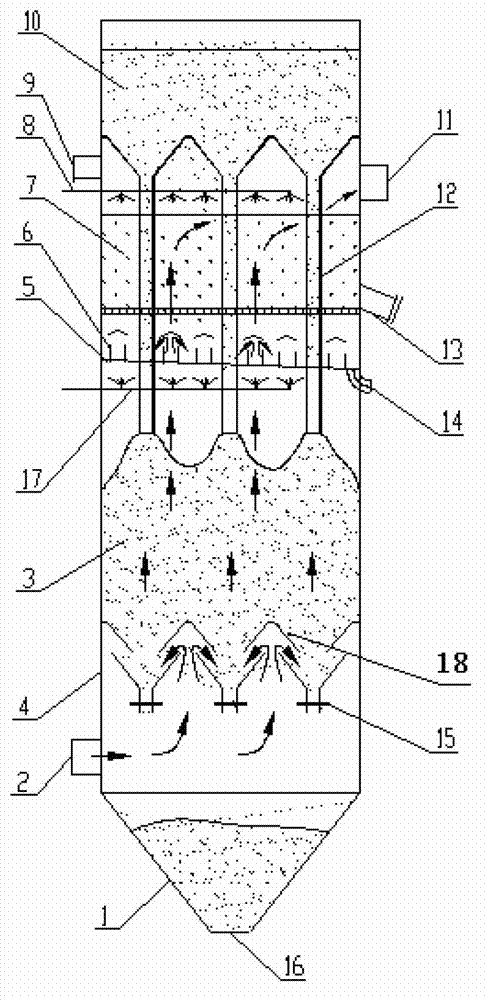

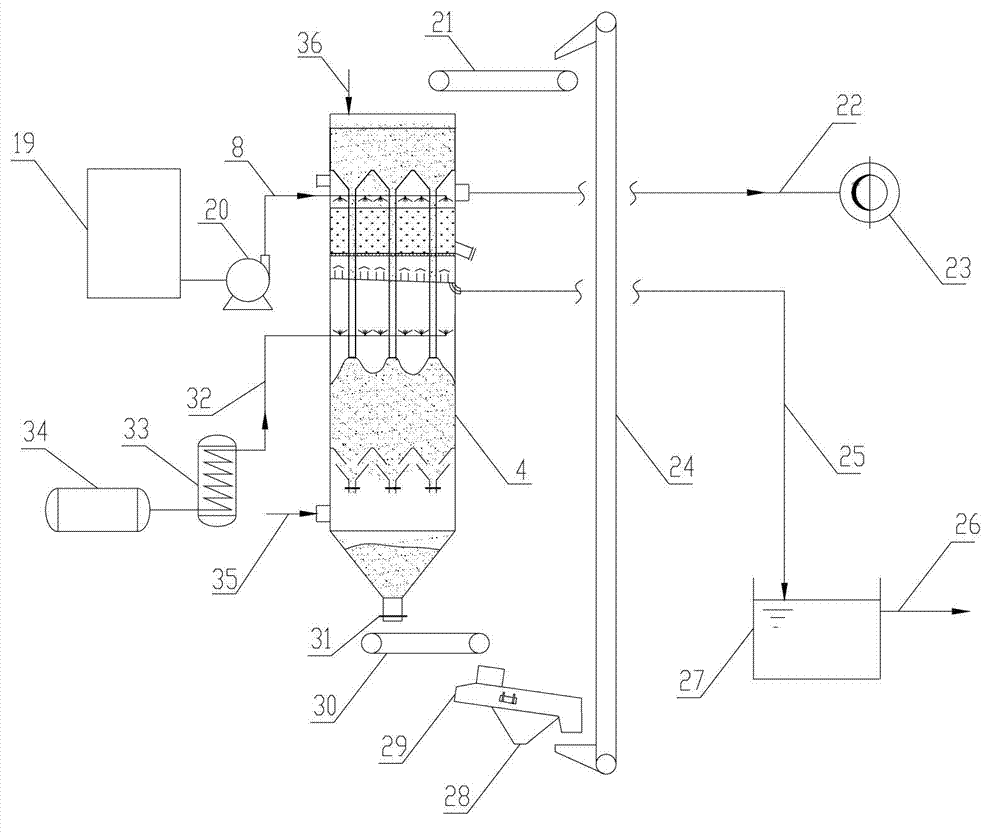

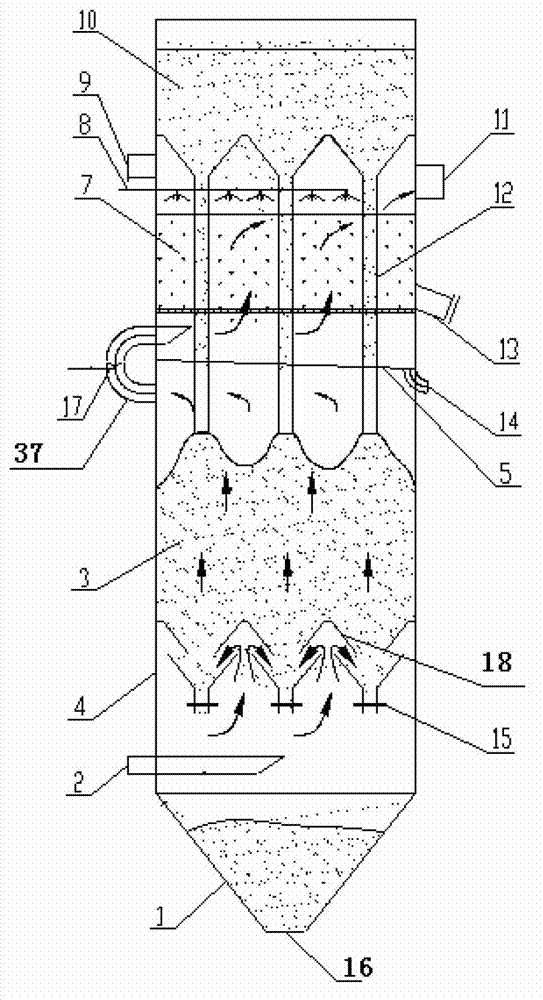

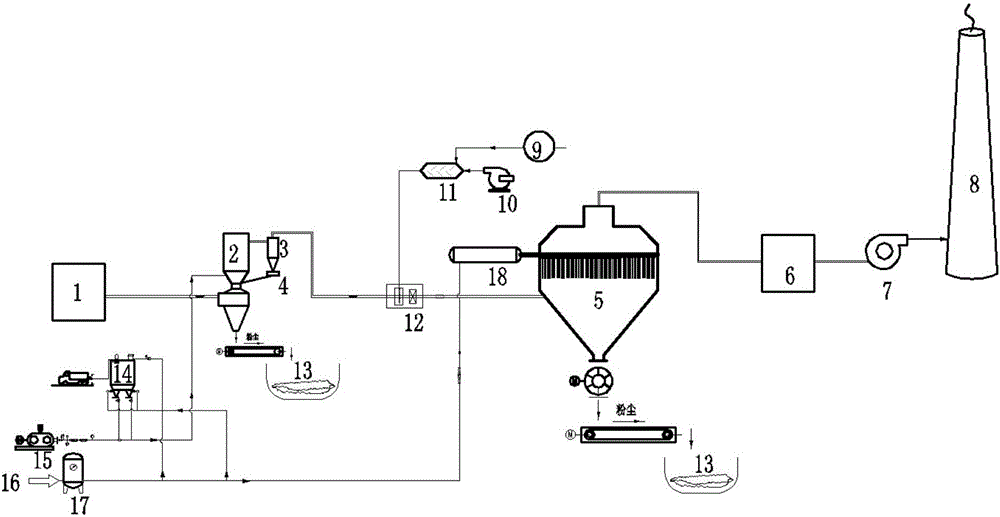

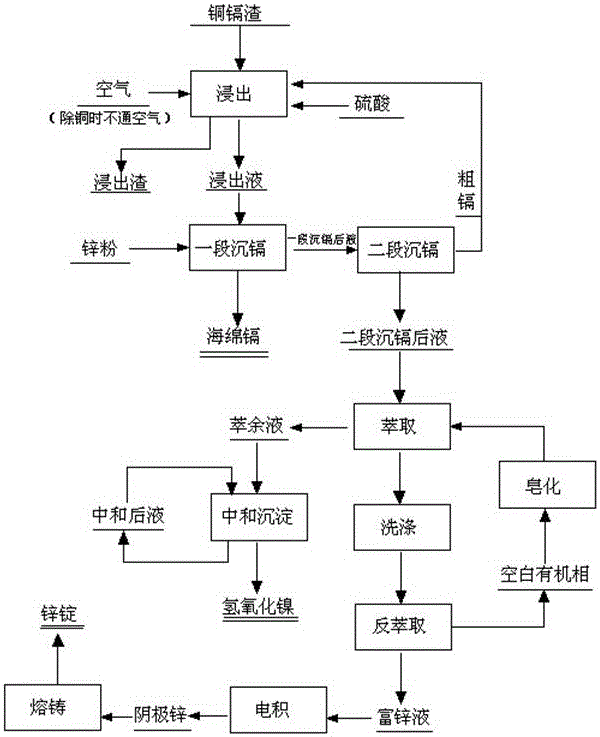

Device and method for performing integrated purification on smoke

ActiveCN102895839AShorten the purification processAvoid corrosionDispersed particle separationCalcium hydroxideDistributor

The invention provides a device and a method for performing integrated purification on smoke. The device comprises an adsorption column. The adsorption column comprises a smoke inlet, a smoke outlet, a calcium hydroxide bed, an activated coke bed, a gas uniform distributor and an ammonia distributor, wherein the calcium hydroxide bed is located at the lower part of the adsorption column; the activated coke bed is located at the upper part of the adsorption column; the smoke inlet is located below the calcium hydroxide bed; the smoke outlet is located above the activated coke bed; the ammonia distributor is located between the calcium hydroxide bed and the activated coke bed; and the gas uniform distributor is located between the smoke inlet and the calcium hydroxide bed. The device for performing the integrated purification on the smoke is convenient in running and maintenance. The method for performing the integrated purification on the smoke is simple in process step. The integrated purification is realized by the device and the method.

Owner:BEIJING ZHONGNENG NUOTAI ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

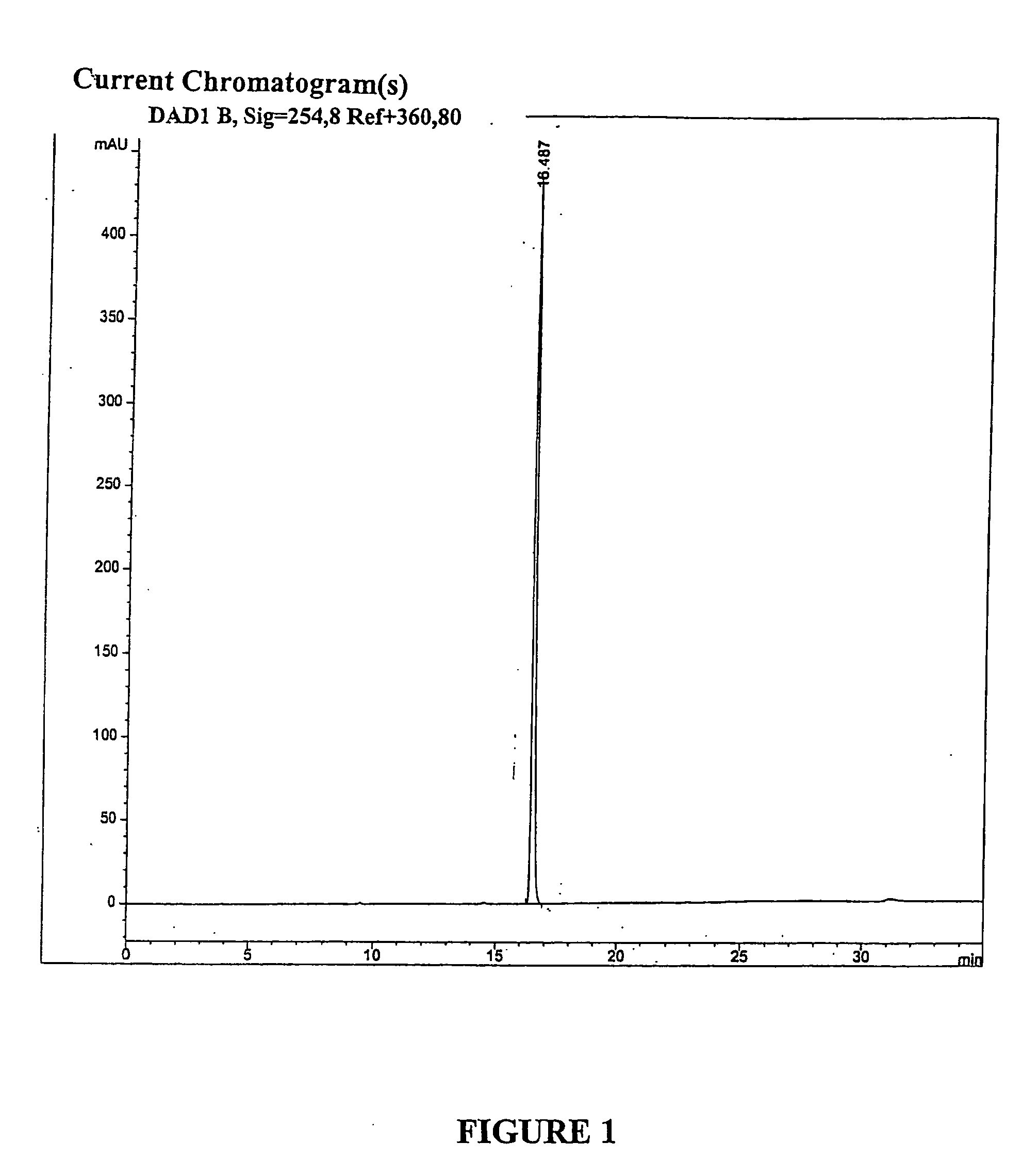

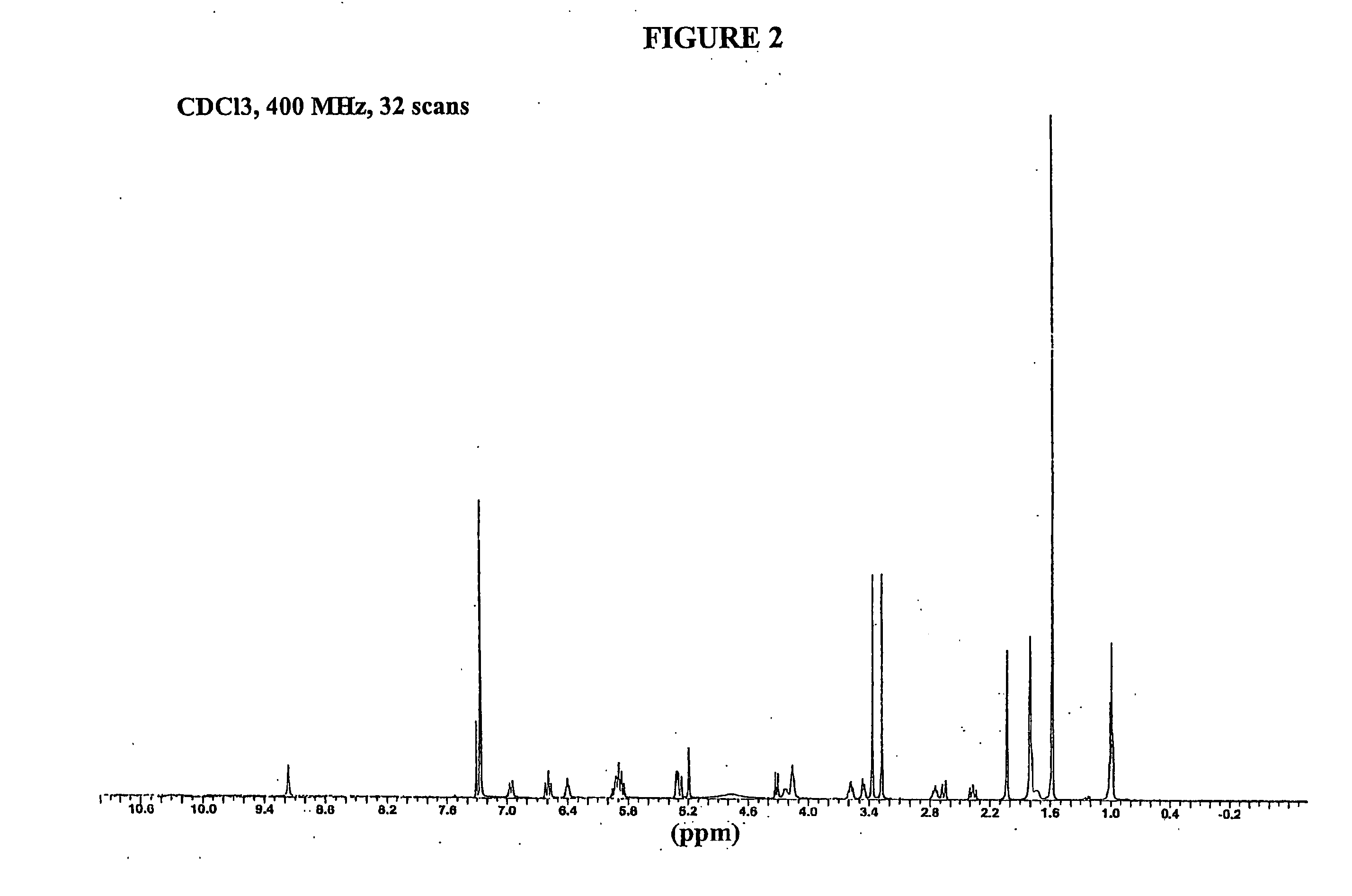

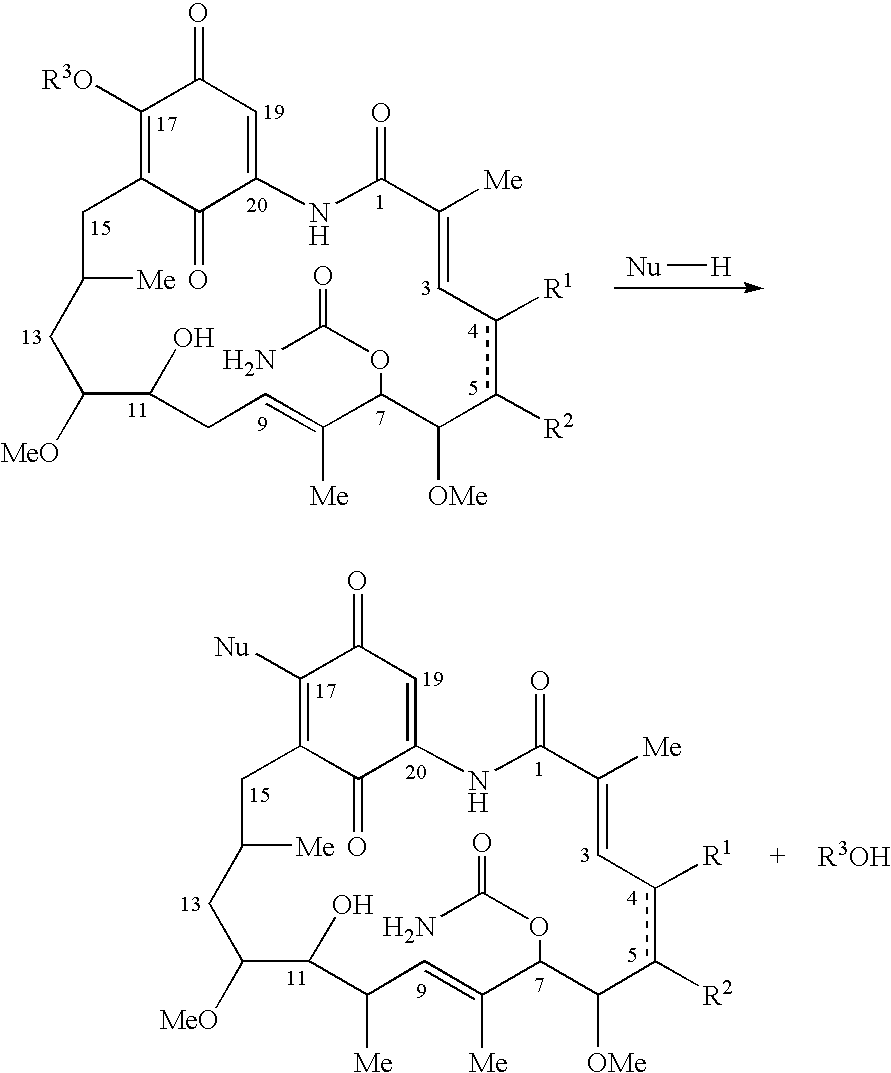

Process for preparing 17-allyl amino geldanamycin (17-aag) and other ansamycins

InactiveUS20050176695A1High yieldReduce the environmentBiocideOrganic chemistryGeldanamycinCompound (substance)

Efficient chemical processes for preparing high yields, purities, and different polymorphic forms of 17-allyl amino geldanamycin (17-AAG) and other ansamycins are described and claimed.

Owner:CONFORMAL THERAPEUTICS CORP (US)

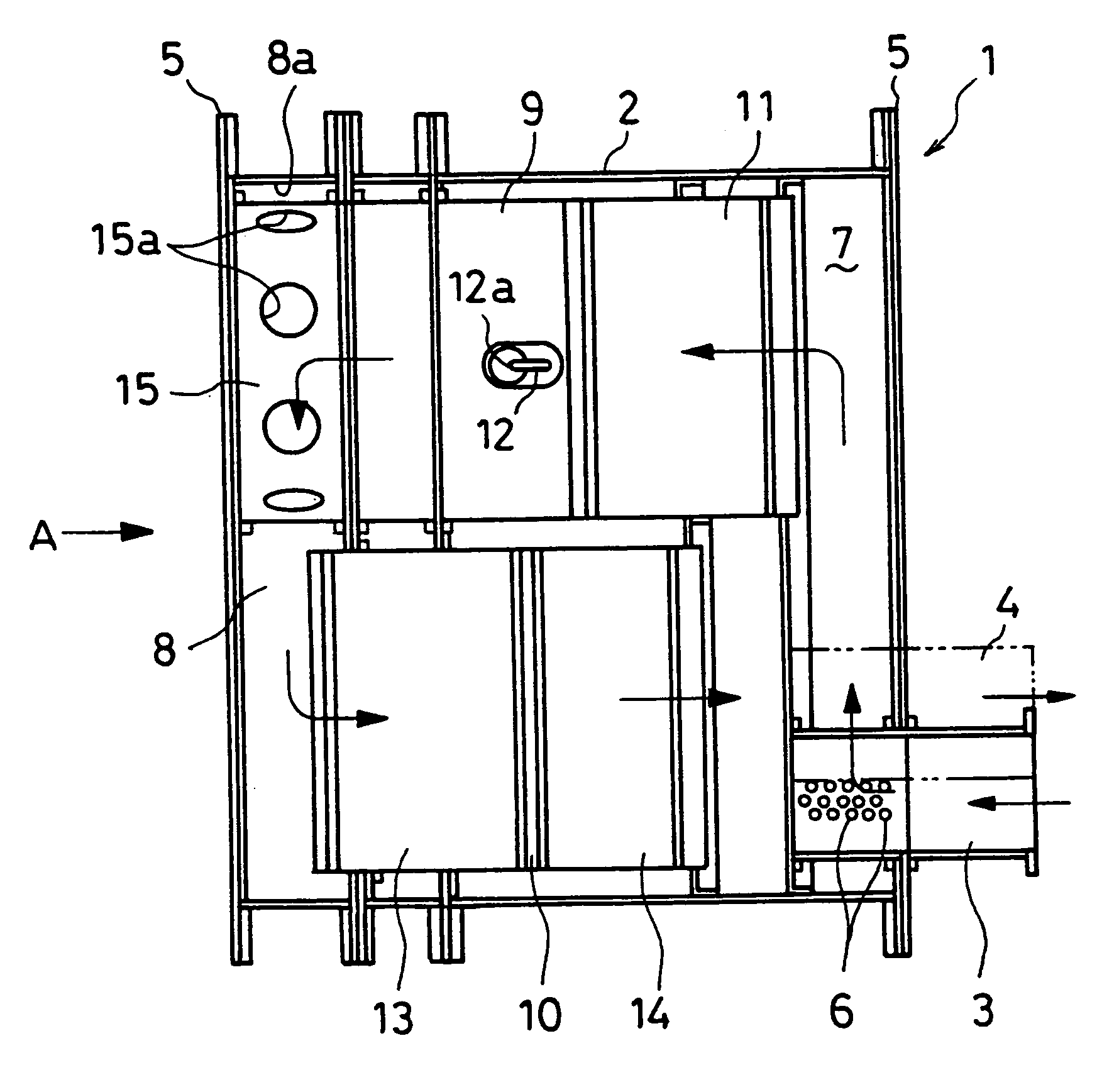

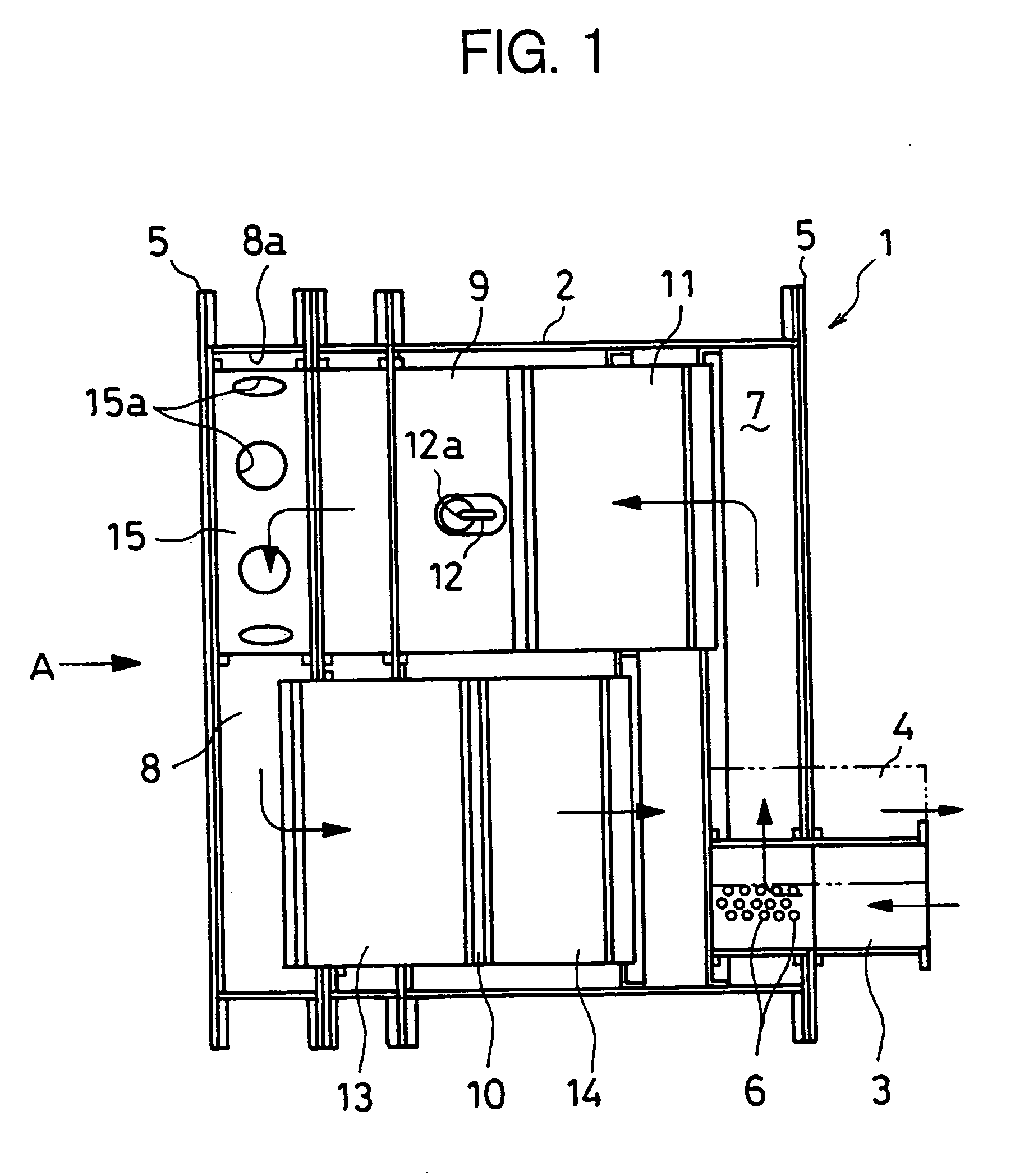

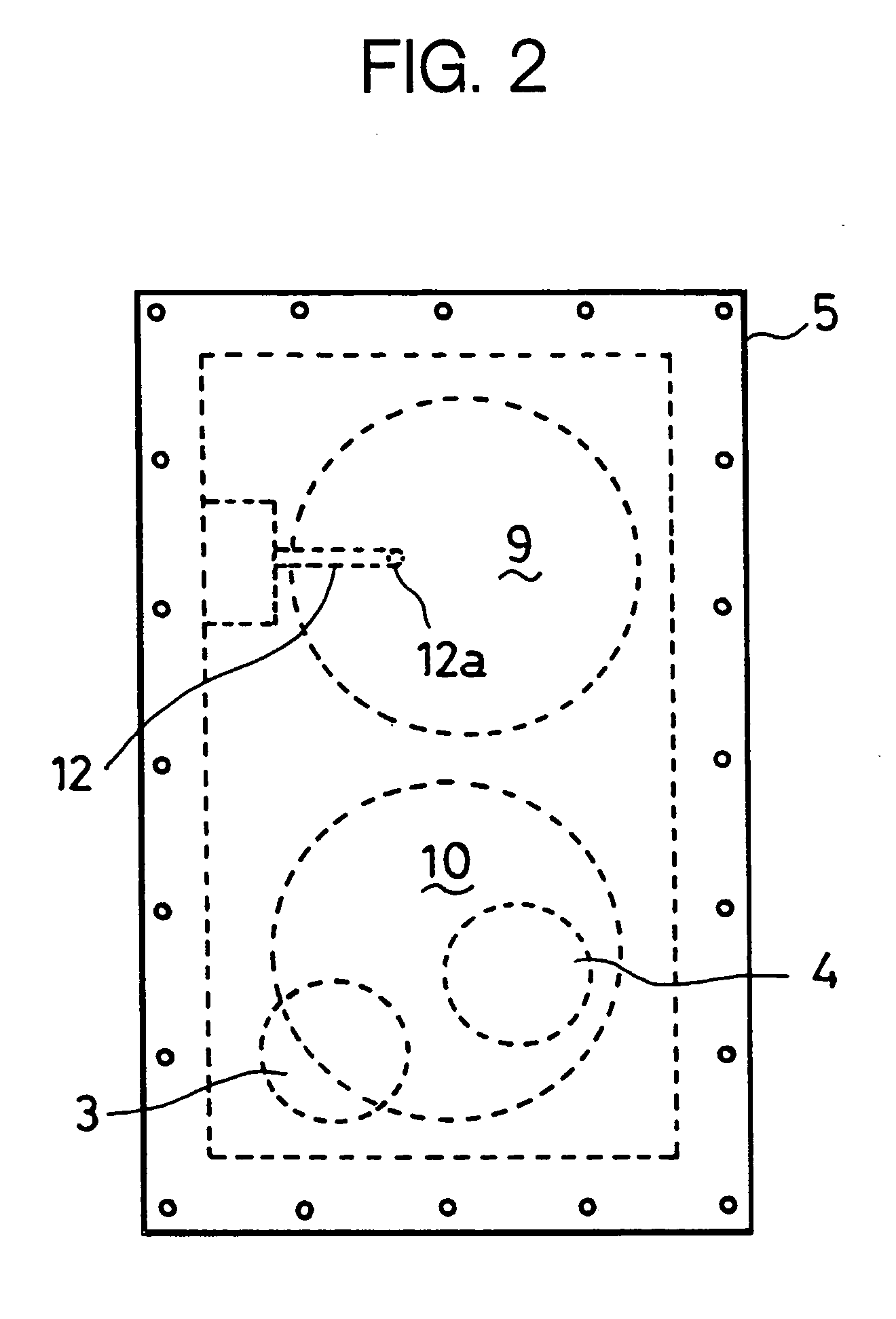

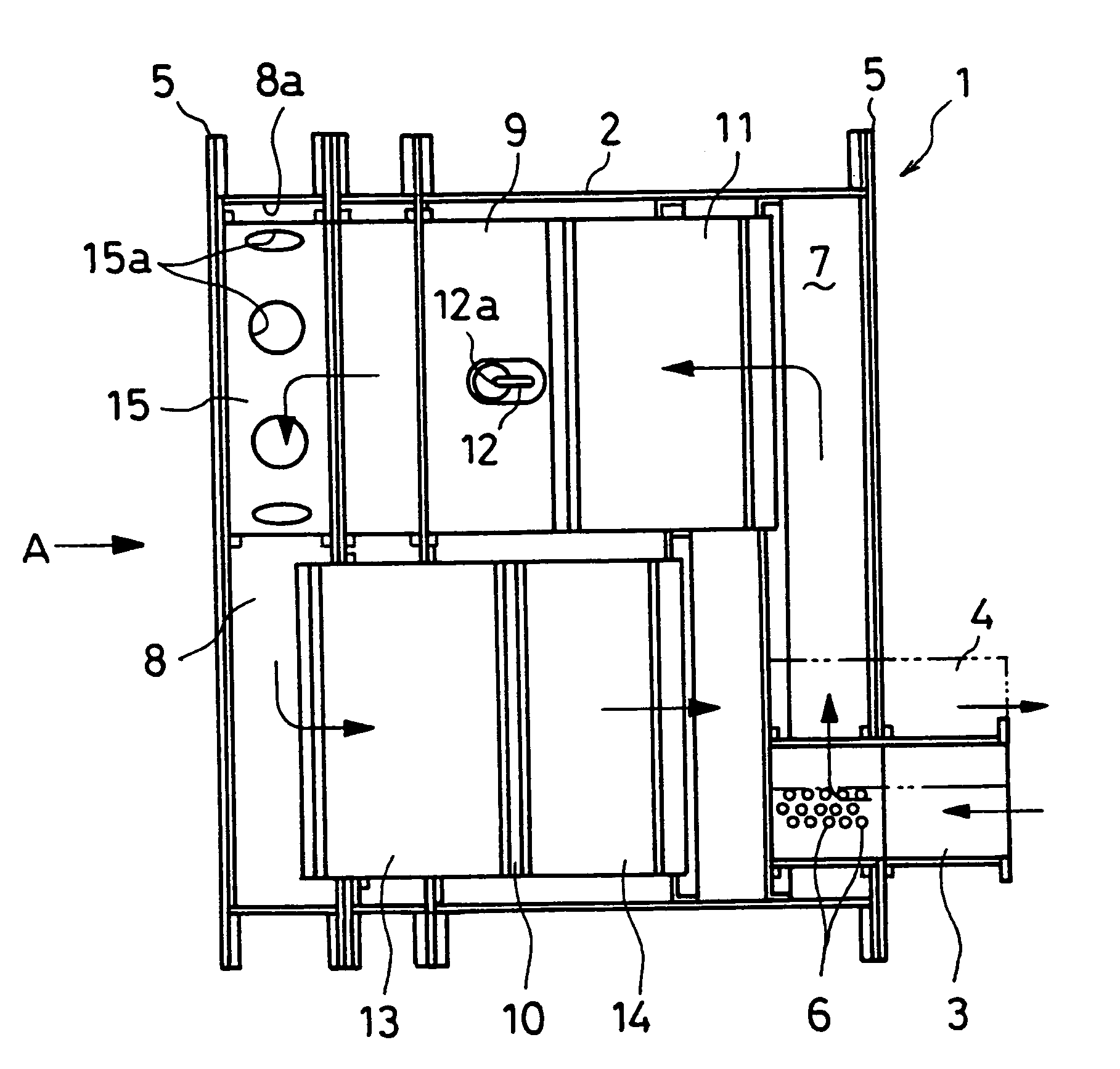

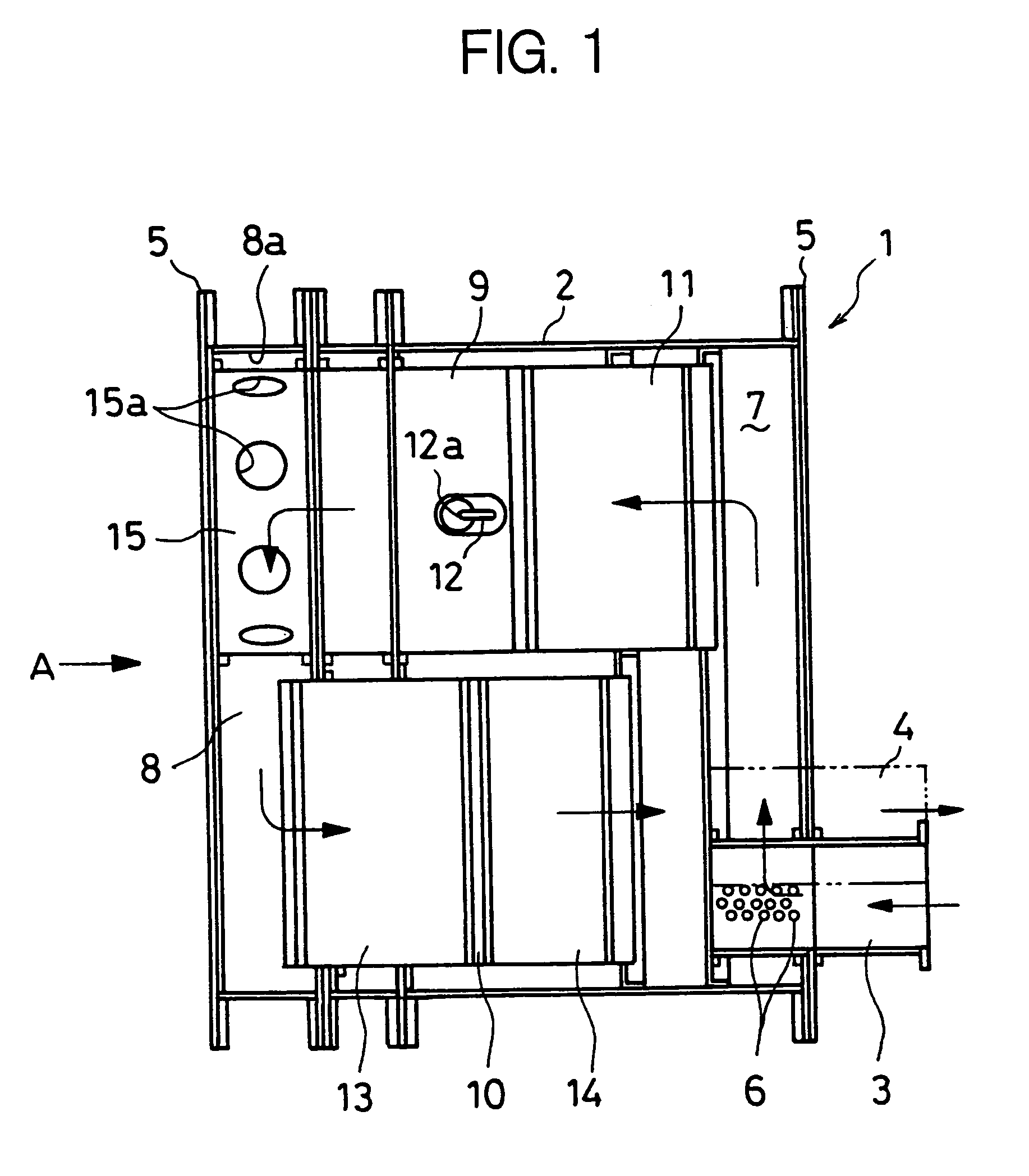

Muffling apparatus having exhaust emission purifying function

ActiveUS20070012035A1Reduction purification of NOxExcellent NOx purification performanceInternal combustion piston enginesSilencing apparatusVertical planeNitrogen oxides

A muffling apparatus 1 of the present invention having an exhaust emission purifying function, including a turning portion 8 in an inside of an exhaust gas flow passage, and having an injection nozzle 12 disposed in an upstream side exhaust gas flow passage 9 of the turning portion 8, for injection-supplying a liquid reducing agent; and a reduction catalytic converter 13 disposed in a downstream side exhaust gas flow passage 10 of the turning portion 8, for reductively purifying nitrogen oxides with the liquid reducing agent. The apparatus further includes a diffusing member 15, which generates a vortex flow of a gas traveling in a vertical plane of the turning portion 8 to diffuse the liquid reducing agent.

Owner:VOLVO LASTVAGNAR AB +2

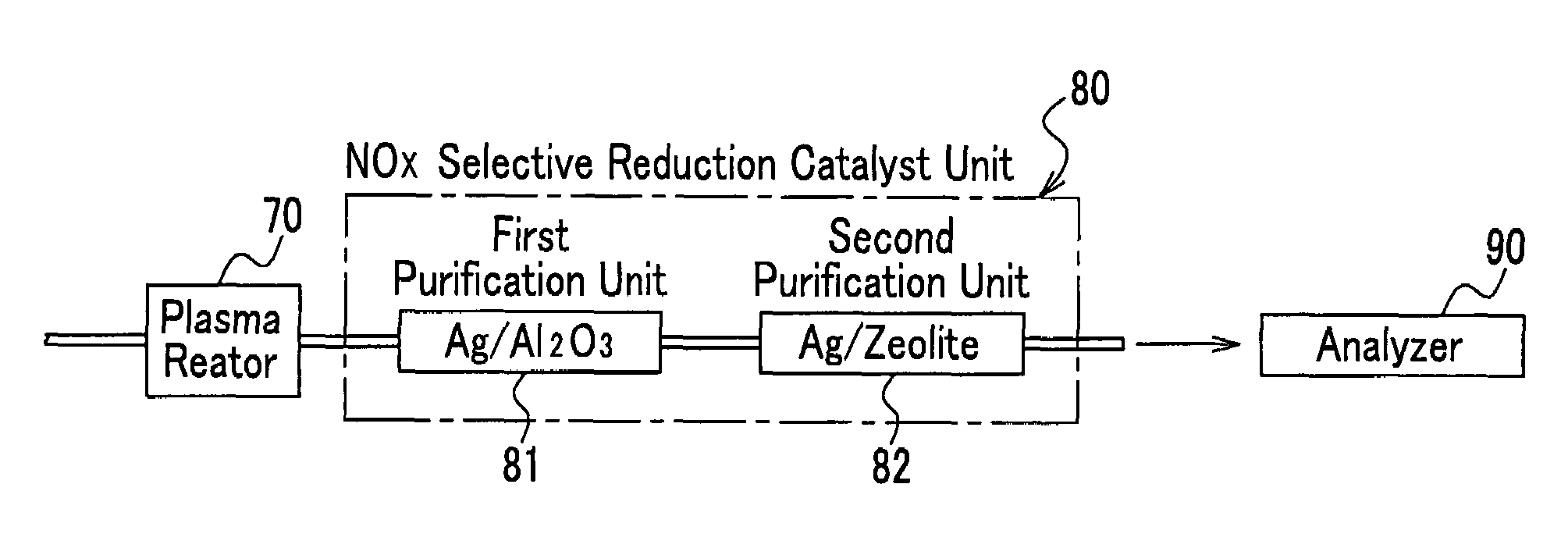

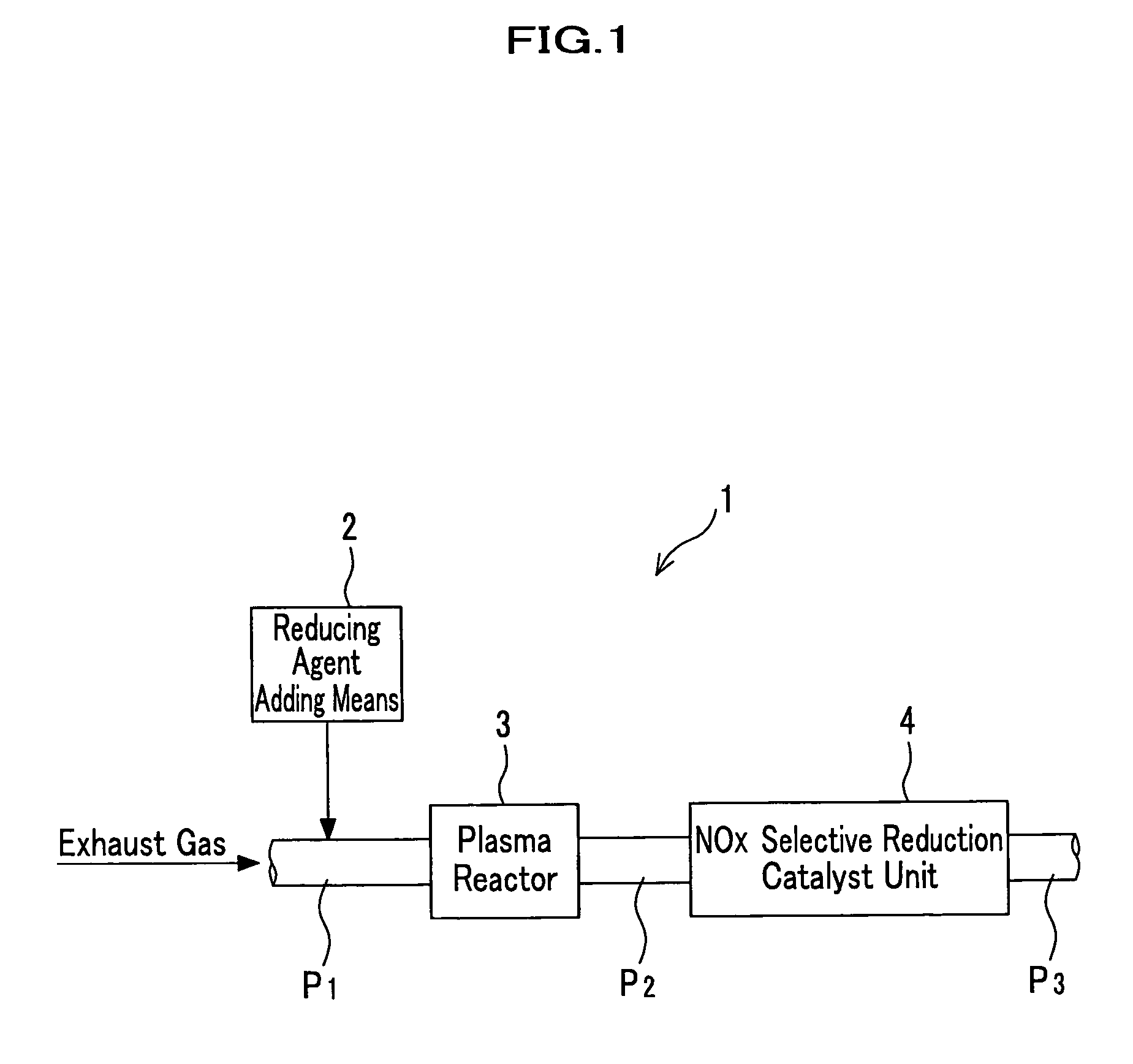

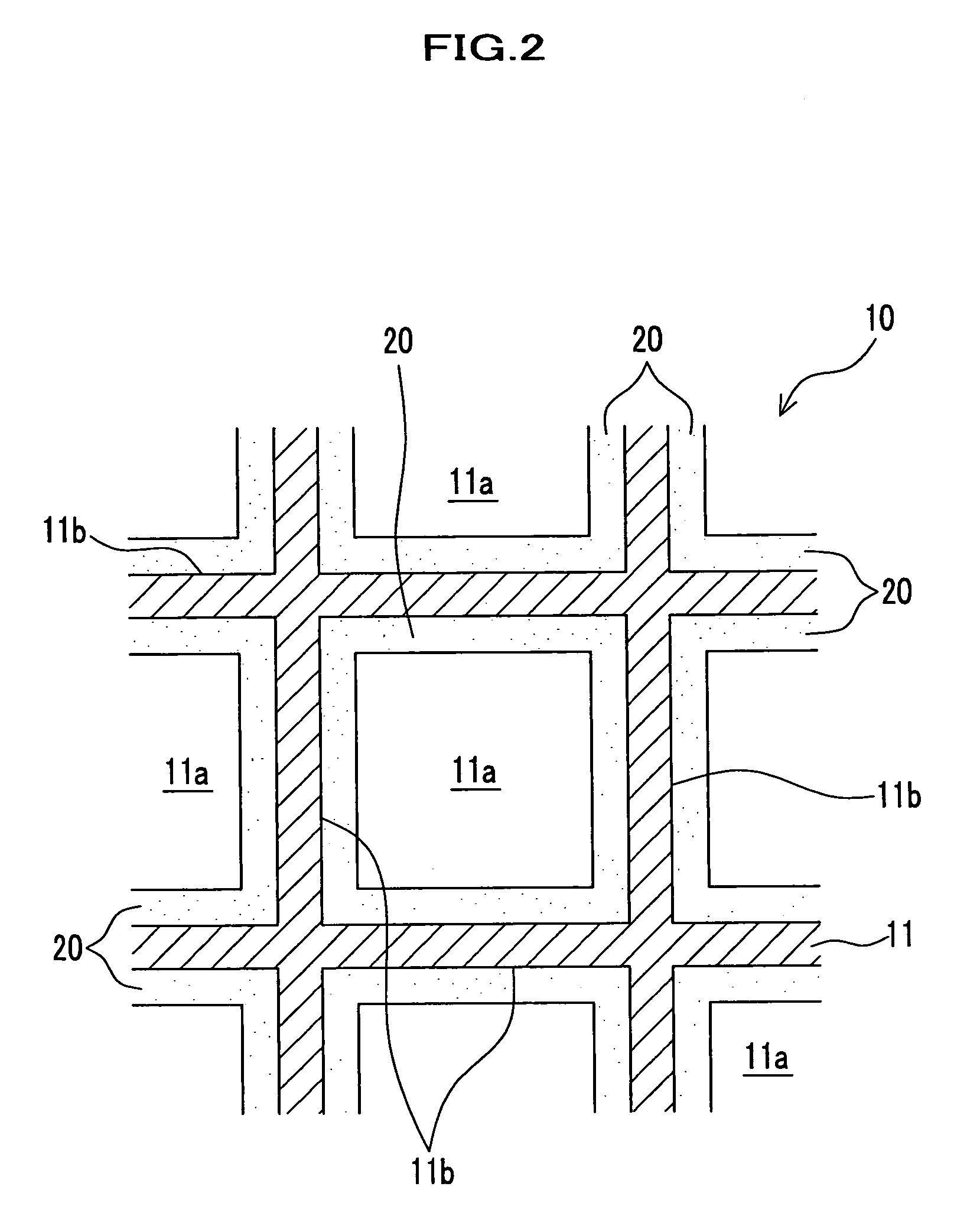

Exhaust gas purification system

InactiveUS7374728B2Improve oxidation capacityShorten the purification processCombination devicesMolecular sieve catalystsExhaust fumesEnvironmental engineering

An exhaust gas purification system that is equipped, from an upstream side toward downstream side through which an exhaust gas flows, with a plasma reactor and a NOx selective reduction catalyst unit having a NOx selective reduction catalyst layer acting on the exhaust gas, and which system provides a reducing agent adding means adding a reducing agent to the exhaust gas at an upstream side of the plasma reactor, wherein the NOx selective reduction catalyst layer comprises nickel and a NOx selective reduction catalyst or wherein the NOx selective reduction catalyst layer contains γ-alumina that supports magnesium or wherein the NOx selective reduction catalyst unit comprises a first purification unit where an exhaust gas via the plasma reactor is introduced, and a second purification unit where an exhaust gas via the first purification unit is introduced.

Owner:HONDA MOTOR CO LTD

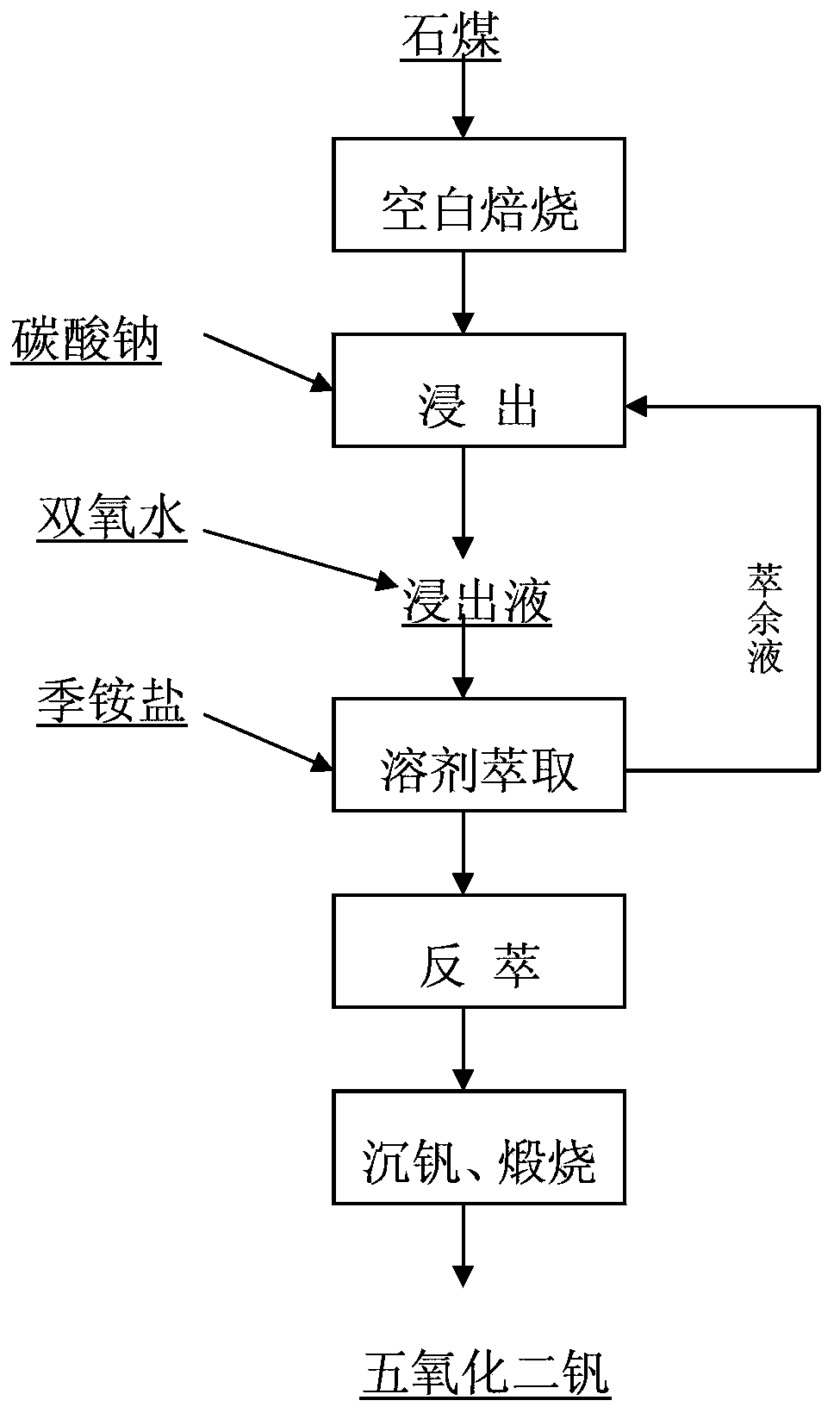

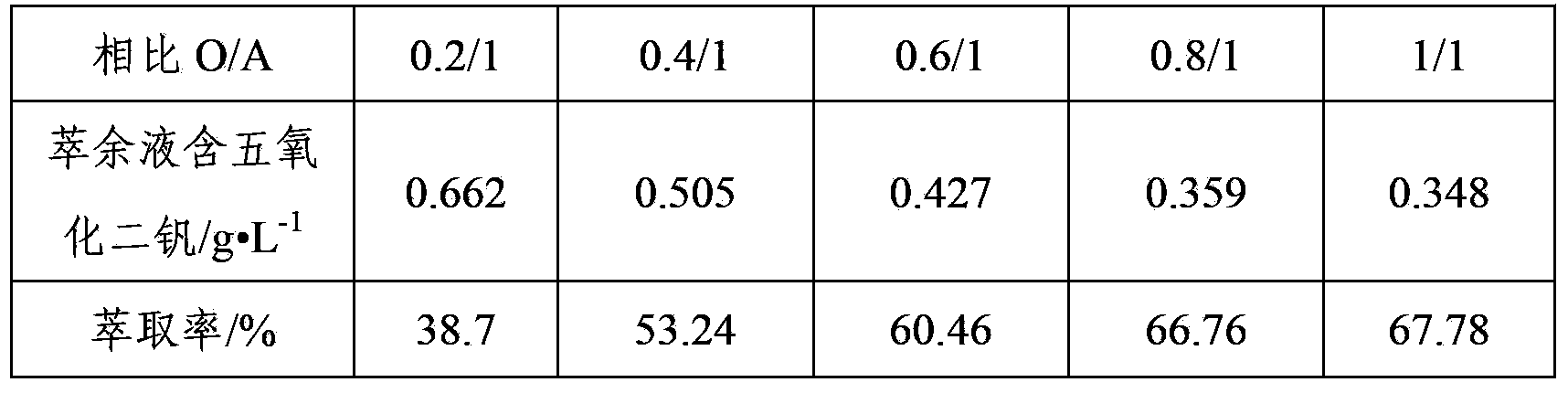

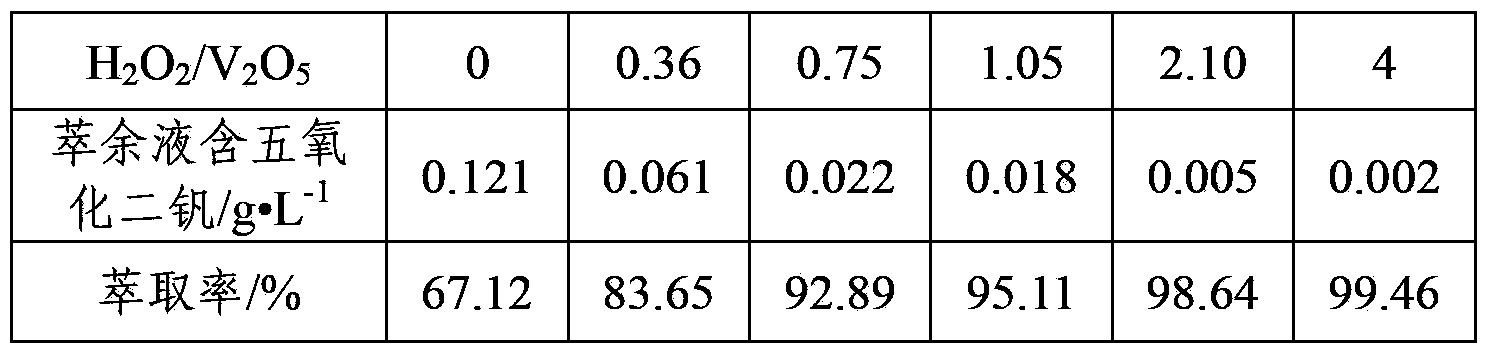

Method of extracting vanadium from stone coal

ActiveCN103436715AShorten the purification processReduce the leachateProcess efficiency improvementIon exchangeRaffinate

The invention discloses a method of extracting vanadium from stone coal. The method comprises the following steps: 1) using sodium carbonate and sodium hydroxide mixed solution to soak stone coal calcined material to obtain lixivium; 2) adding hydrogen peroxide; 3) using organic composition 40-60% A + 10-30% B + 20-40% C to extract the lixivium with hydrogen peroxide; 4) using sodium carbonate or odium carbonate and sodium hydroxide mixed solution to reextract out organic phase. Due to usage of direct extraction, the raffinate containing sodium carbonate and sodium hydroxide can be recycled for soaking; and the raffinate is used for preparing vanadium pentoxide. Compared with the existing alkaline leaching-ion exchange technology, a lixivium neutralizing procedure, a reextraction purifying procedure and a procedure of processing and discharging the raffinate are reduced, thus the production cost of vanadium pentoxide is greatly reduced, and the wastewater discharge is reduced. The extraction agent is better in selectivity, so that during the extraction process, vanadium is separated from impurities, and the reextraction liquid can be processed with vanadium precipitation-calcining to obtain the vanadium pentoxide product.

Owner:CENT SOUTH UNIV

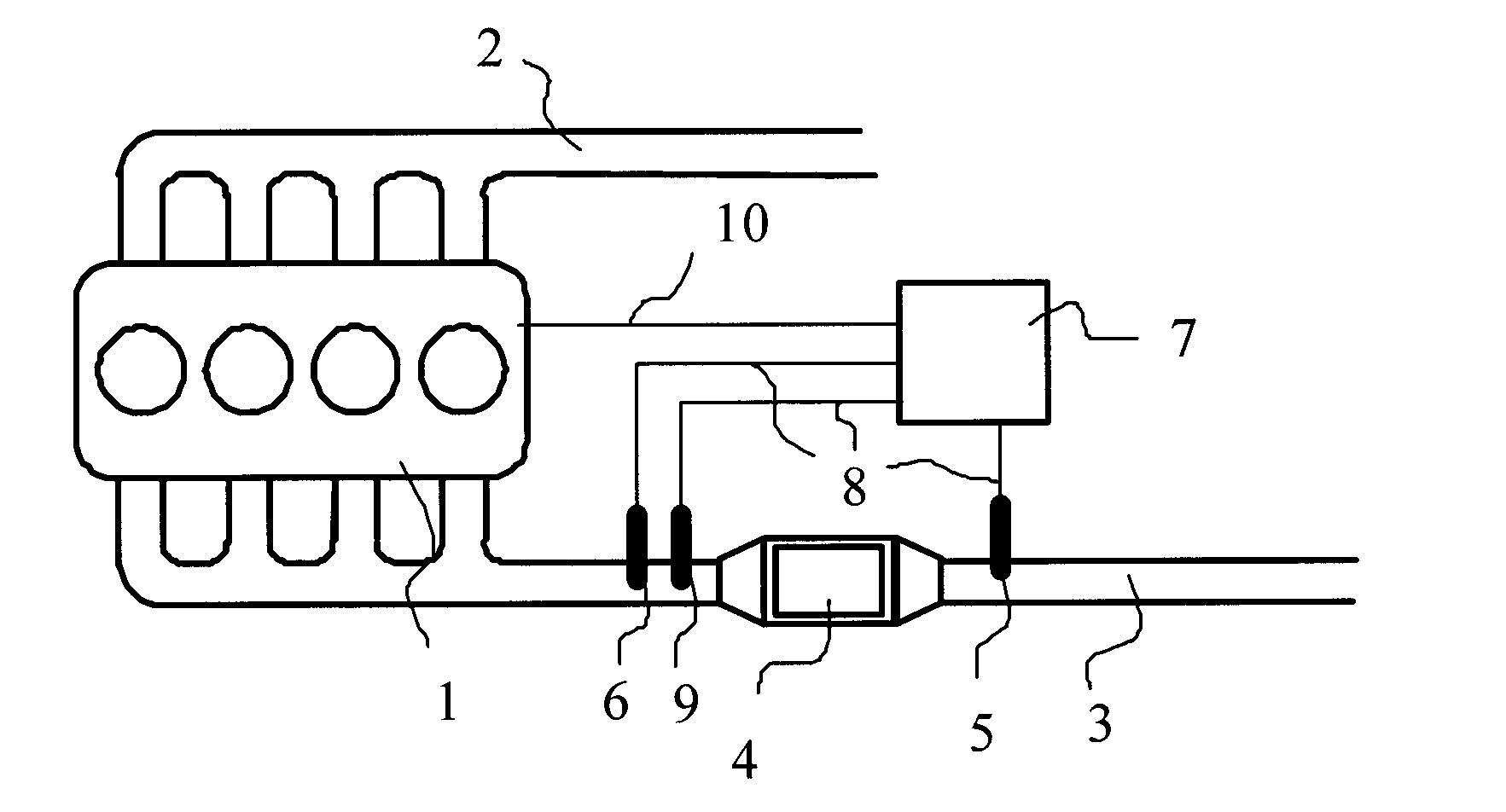

Control apparatus and control method for internal combustion engine

InactiveUS20130261936A1Purification rate is reducedReduce rateElectrical controlDigital data processing detailsAir–fuel ratioAutomotive engineering

A control apparatus for an internal combustion engine is configured to execute an air-fuel ratio control based on an output of an air-fuel ratio detector provided in an exhaust passage through which exhaust gas from a plurality of cylinders flows. The control apparatus includes an abnormal lean deviation detection portion configured to detect whether an abnormal lean deviation is occurring in at least one specific cylinder among the plurality of cylinders, the exhaust gas from the at least one specific cylinder influencing the air-fuel ratio detector more strongly than the exhaust gas from each of a rest of the plurality of cylinders; and an enriching control portion configured to execute an enriching control for the at least one specific cylinder when the abnormal lean deviation detection portion detects that the abnormal lean deviation is occurring in the at least one specific cylinder.

Owner:TOYOTA JIDOSHA KK

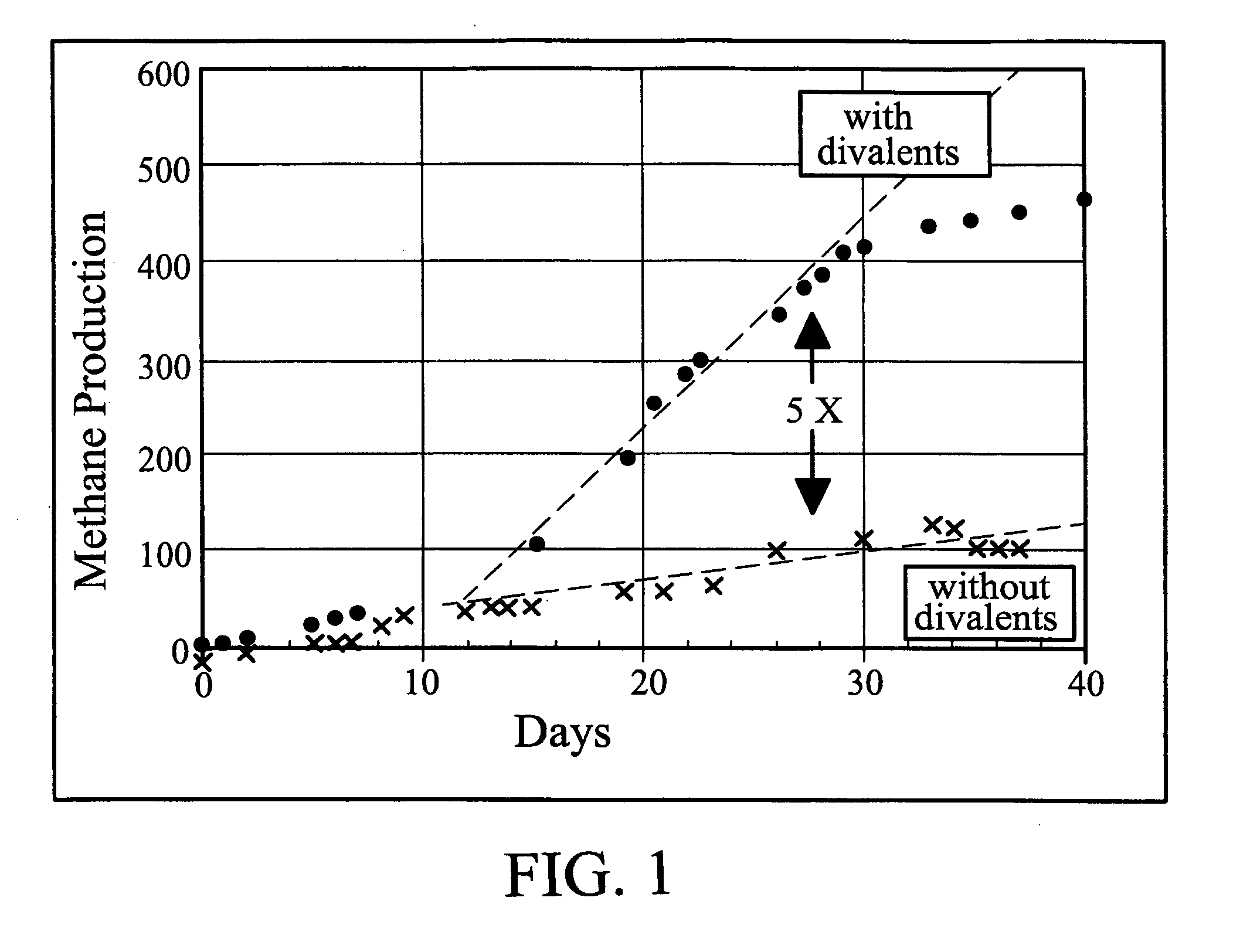

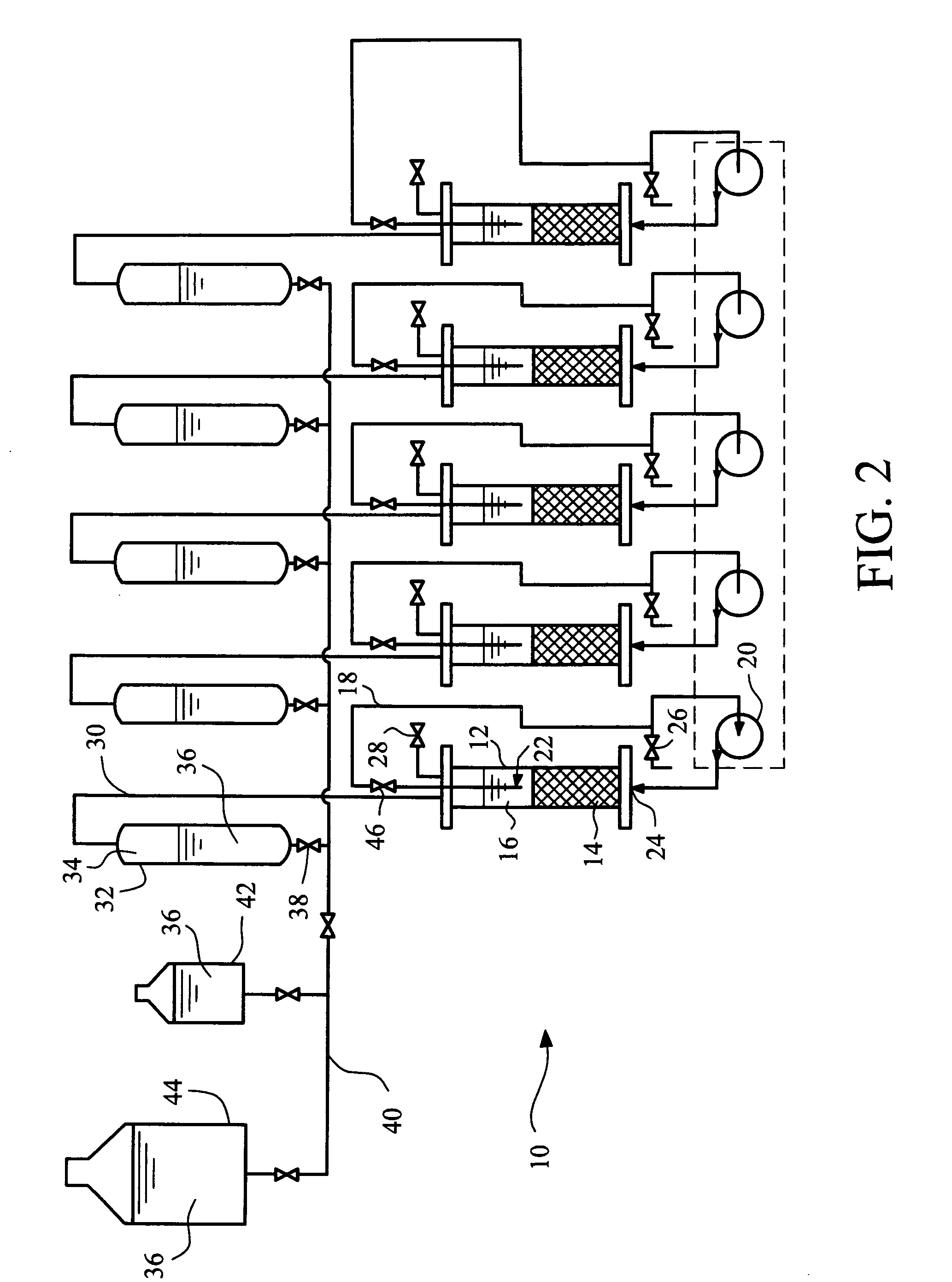

Biological methane production from coal, manure, sludge, wastes, or other carbonaceous feedstocks with simultaneous sequestration of co2

ActiveUS20100093049A1Reduce capacityReduce gas contentProductsGas treatmentParticulatesAlkaline earth metal

The present invention provides a method for generating methane from a carbonaceous fuel source with simultaneous sequestration of carbon dioxide, the method comprising anaerobically incubating a particulate alkaline earth metal salt in contact with a particulate and / or dissolved carbonaceous feedstock in a neutral or alkaline aqueous culture medium containing a culture of methanogenic bacteria consortia and collecting methane generated therefrom. At least a portion of carbon dioxide produced during the incubation reacts with the alkaline earth metal salt to form an alkaline earth metal carbonate, thereby sequestering the carbon dioxide.

Owner:UCHICAGO ARGONNE LLC

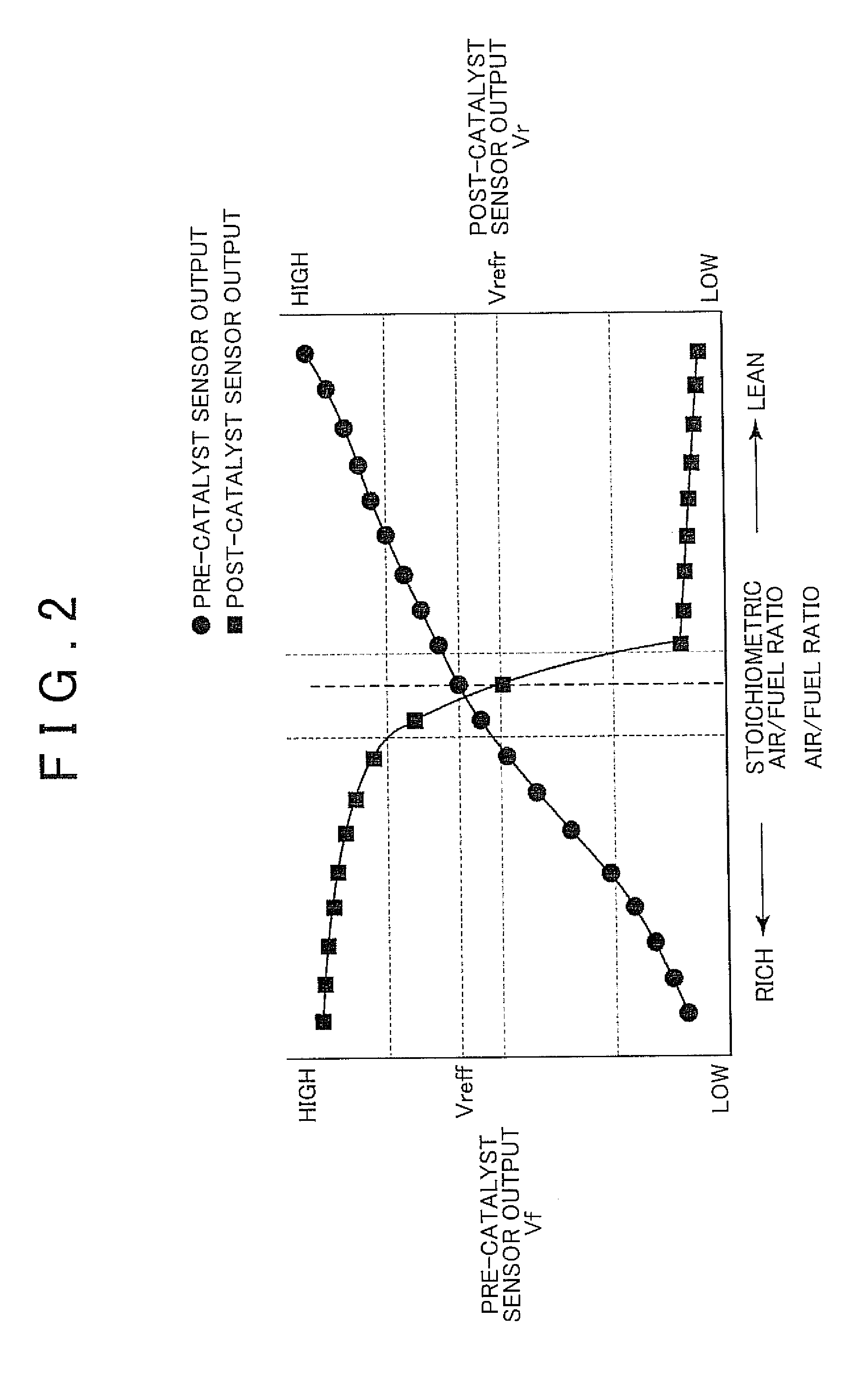

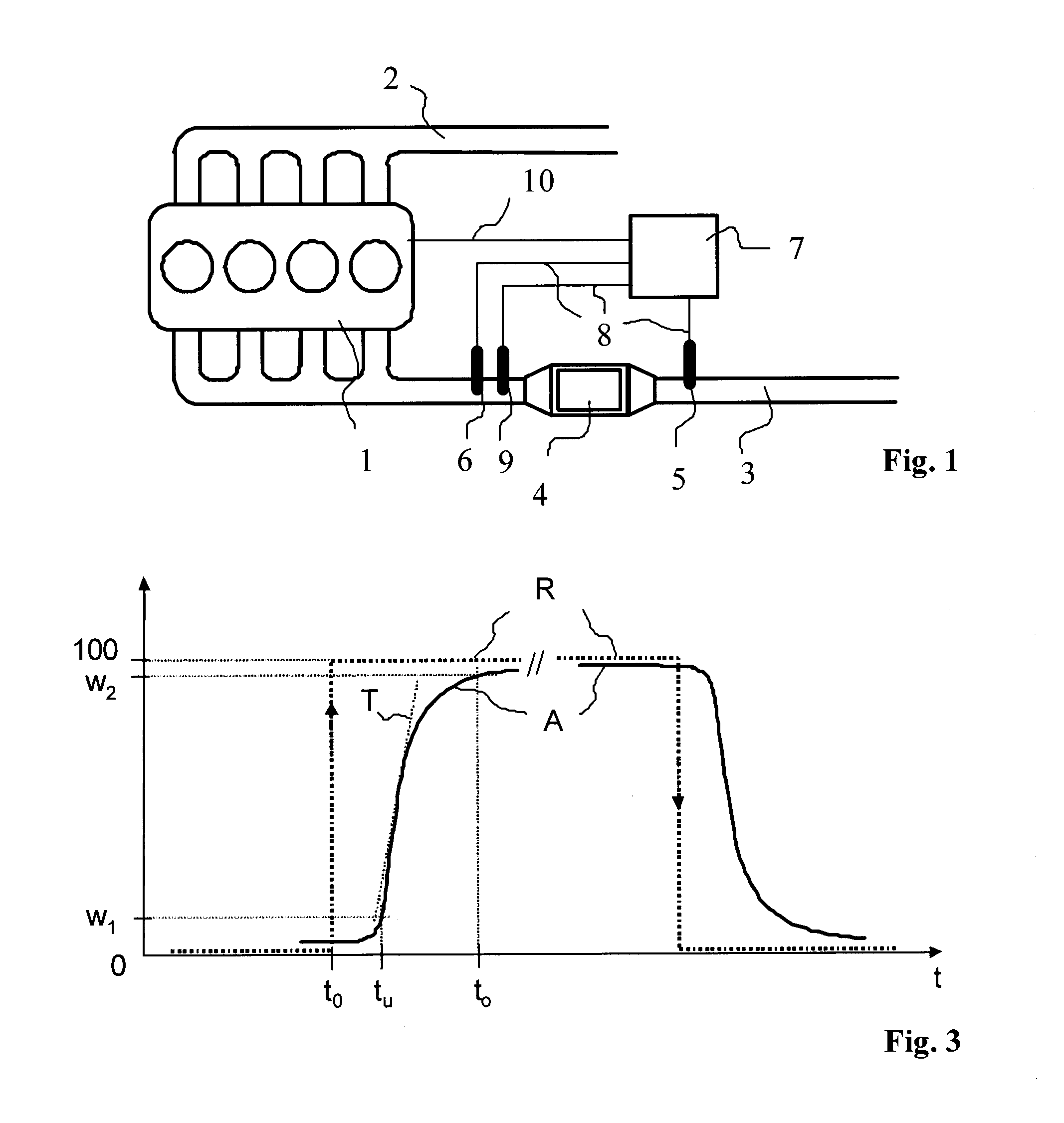

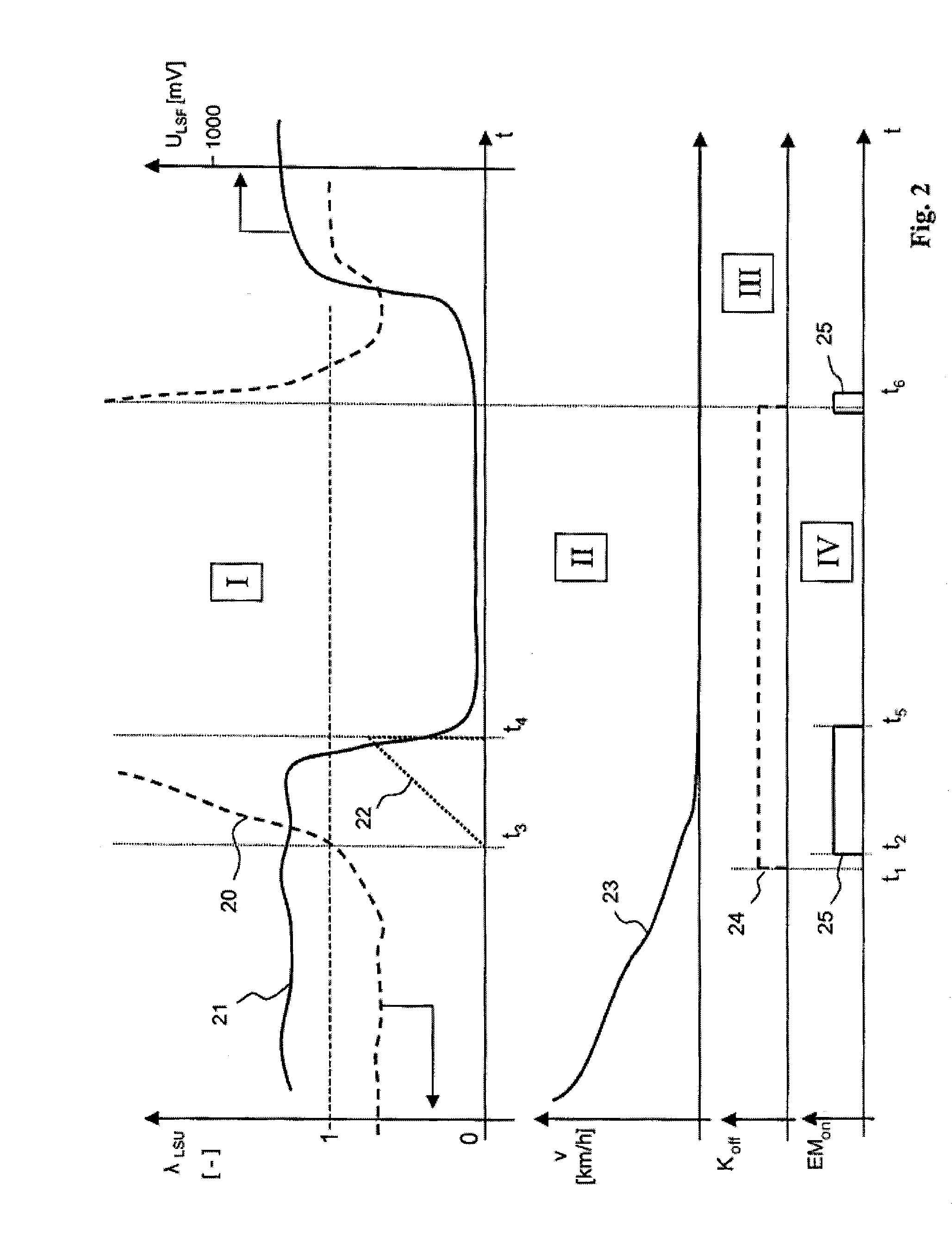

Method for Diagnosing an Exhaust Gas Catalytic Converter and/or an Exhaust Gas Sensor of a Motor Vehicle Internal Combustion Engine

InactiveUS20130297192A1Reduce harmful emissionsEmission reductionAnalogue computers for vehiclesElectrical controlMobile vehicleExhaust fumes

A method for diagnosing an exhaust gas catalytic convertor and / or an exhaust gas sensor arranged downstream and / or upstream of the exhaust gas catalytic convertor in an exhaust gas system of a motor vehicle internal combustion engine. The internal combustion engine is operated with an air / fuel mixture having a substoichiometric air / fuel ratio. The internal combustion engine is switched off and an unfired towed operation with disabled fuel supply is performed in which air drawn in by the internal combustion engine is conveyed through the exhaust gas system to the exhaust gas catalytic convertor and exhaust gas sensor. The internal combustion engine is then operated with a substoichiometric air / fuel ratio and a signal of the exhaust gas sensor is evaluated with regard to a predefinable evaluation criterion, the signal being provided at least in a period of time between switch-off and the subsequent self-running of the internal combustion engine.

Owner:DAIMLER AG

System and method for achieving ultra-low emission of dust and NOx at high temperature

ActiveCN105833689AImprove removal efficiencyImprove efficiencyCombination devicesGas treatmentAir preheaterHigh concentration

The invention provides a system and method for achieving ultra-low emission of dust and NOx at high temperature. Ultra-low emission of the dust and NOx in a high-concentration dust environment can be achieved, SO2, SO3, HCl and HF can be efficiently removed, the floor space is small, the operating energy consumption is low, no wastewater is drained, and the environmental indexes are advanced. The system comprises a coal economizer, a fluidized bed reactor, a cyclone dust collector, an ammonia injection grid, a denitration dust collection tower, a air preheater, an induced draft fan and a chimney which are communicated through flues, a desulfurizing agent supplying system and an ammonia supplying system; a gas inlet of the fluidized bed reactor is connected with the upstream flue, a solid inlet of the fluidized bed reactor is connected with the output end of the desulfurizing agent supplying system, and a flue gas outlet of the fluidized bed reactor is connected with a gas inlet of the cyclone dust collector; an ash discharging port of the cyclone dust collector is connected to the solid inlet of the fluidized bed reactor through a middle ash bin ash discharging device; the ammonia injection grid is arranged in one flue, and the input end of the ammonia injection grid is connected with the ammonia supplying system. Accordingly, ultra-low emission of NOx and the dust in the high-concentration dust environment can be achieved through secondary dust collection.

Owner:HUANENG POWER INT INC +2

Muffling apparatus having exhaust emission purifying function

ActiveUS7430855B2Improve the NO<sub>xPurification performanceInternal combustion piston enginesSilencing apparatusNitrogen oxidesVertical plane

A muffling apparatus 1 of the present invention having an exhaust emission purifying function, including a turning portion 8 in an inside of an exhaust gas flow passage, and having an injection nozzle 12 disposed in an upstream side exhaust gas flow passage 9 of the turning portion 8, for injection-supplying a liquid reducing agent; and a reduction catalytic converter 13 disposed in a downstream side exhaust gas flow passage 10 of the turning portion 8, for reductively purifying nitrogen oxides with the liquid reducing agent. The apparatus further includes a diffusing member 15, which generates a vortex flow of a gas traveling in a vertical plane of the turning portion 8 to diffuse the liquid reducing agent.

Owner:VOLVO LASTVAGNAR AB +2

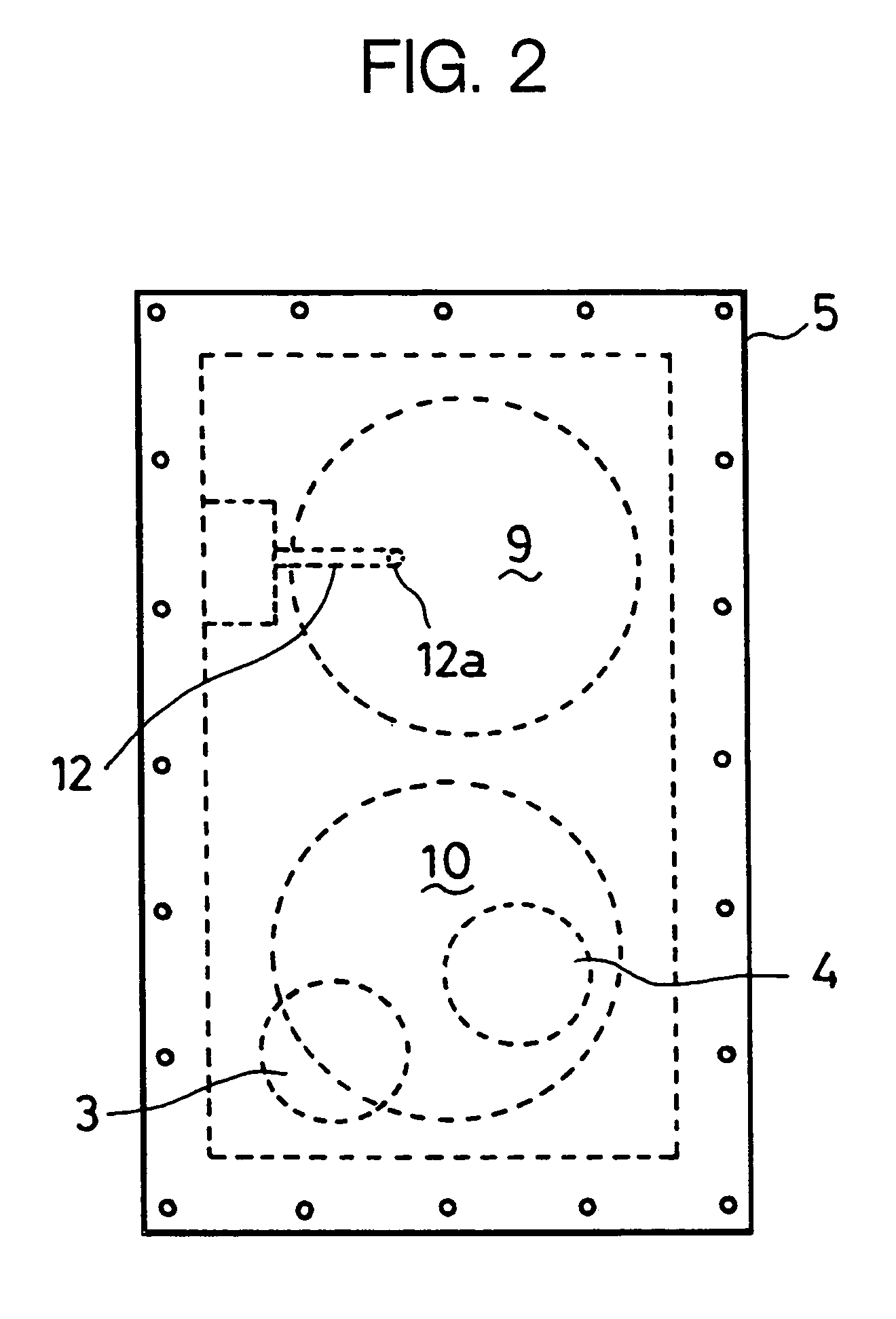

Method for comprehensively recovering zinc nickel cadmium from copper cadmium residues

InactiveCN106435213AAvoid leachingAchieve removalProcess efficiency improvementPregnant leach solutionNickel cadmium

The invention relates to a method for comprehensively recovering zinc nickel cadmium from copper cadmium residues. The method is characterized by including the steps: A leaching and purifying: simultaneously leaching and purifying the copper cadmium residues and filtering the copper cadmium residues to obtain leach liquor; B primary cadmium settling: adding zinc powder into the leach liquor in the step A to obtain primarily cadmium settled liquor and a sponge cadmium product; C secondary cadmium settling: adding substitute zinc powder into the primarily cadmium settled liquor in the step B to obtain secondarily cadmium settled liquor and crude cadmium; D zinc ingot production: performing 'extraction-washing-back extraction-electrodeposition-casting' procedures for the secondarily cadmium settled liquor obtained by the step C to produce a zinc ingot product; E nickel hydroxide neutralization and precipitation: precipitating and neutralizing nickel in zinc extraction raffinate obtained in the step D to obtain a nickel hydroxide product. The method is simple in process, low in cost and high in metal recovery rate, has the advantages of short process cycle, high efficiency and easiness in realizing automation and continuity, and is a clean pollution-free production process.

Owner:江西自立环保科技有限公司

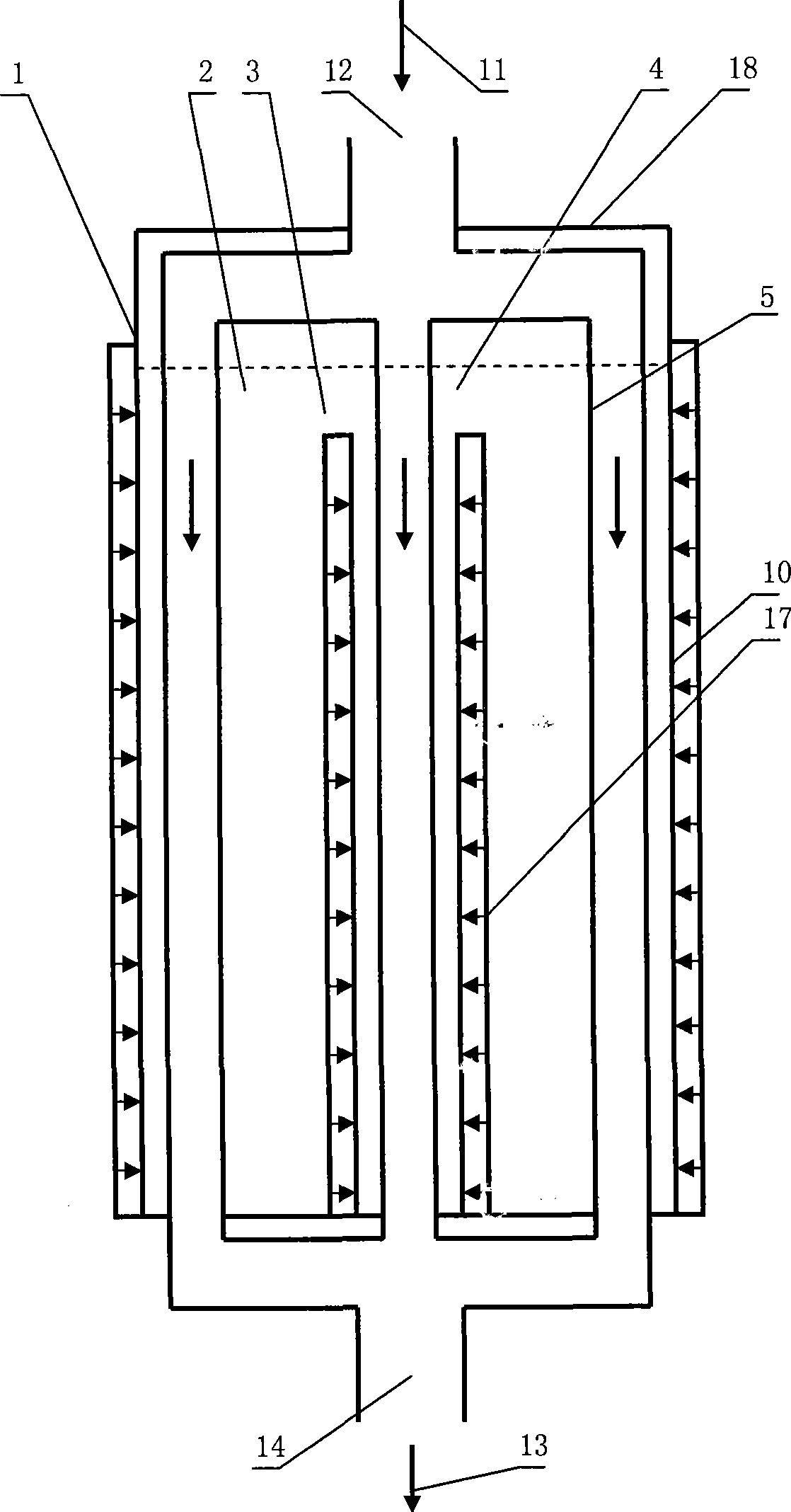

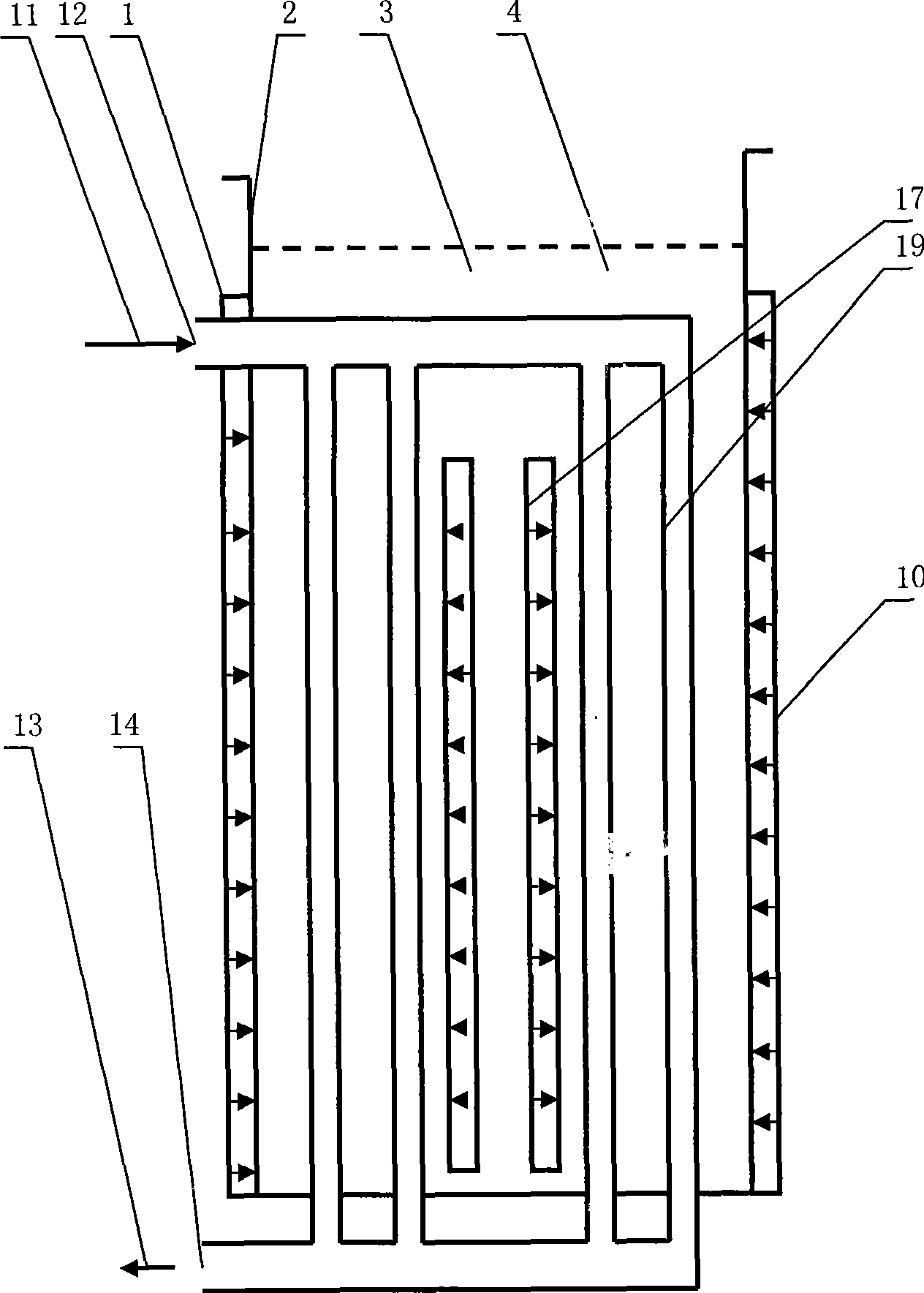

Tubular purification method and tubular purification tank

InactiveCN101476038ASmall volumeReduce in quantityProcess efficiency improvementLiquid mediumPurification methods

The invention provides a pipe type purifying method, the set purifying process of the solution to be purified is completed in a nonconservative pipe type purifying groove.The solution to be purified is a solution containing at least one granular solute; the pipe type purifying groove comprises a cavity full of liquid medium, at least one ultrasound wave source apparatus immersed in the liquid medium and at least one coiled apparatus full of the solution to be purified; the purifying process is that in the nonconservative flow process, the solution to be purified is irradiated in a insulation state by effective ultrasonic wave.

Owner:佛山市兴民科技有限公司

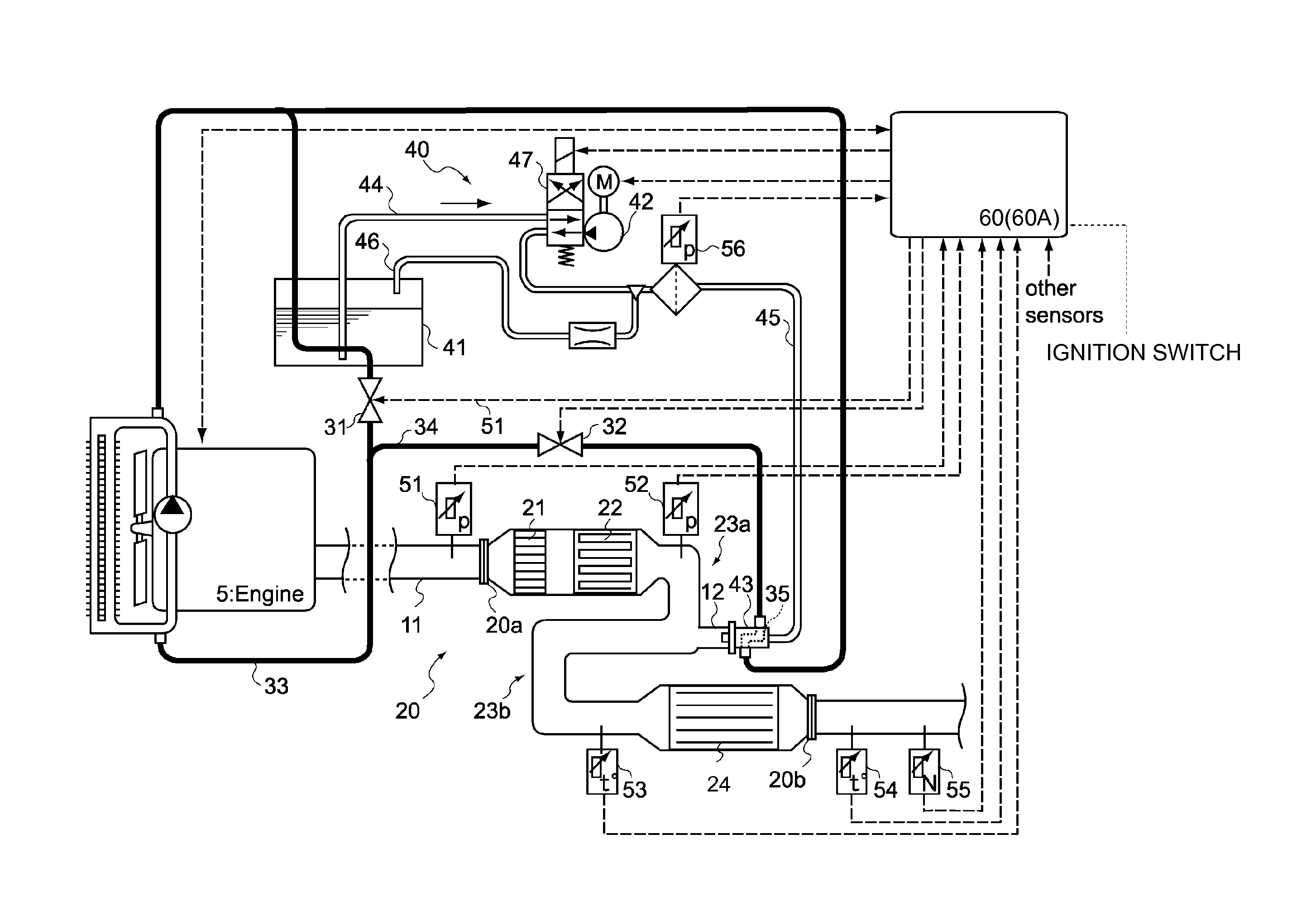

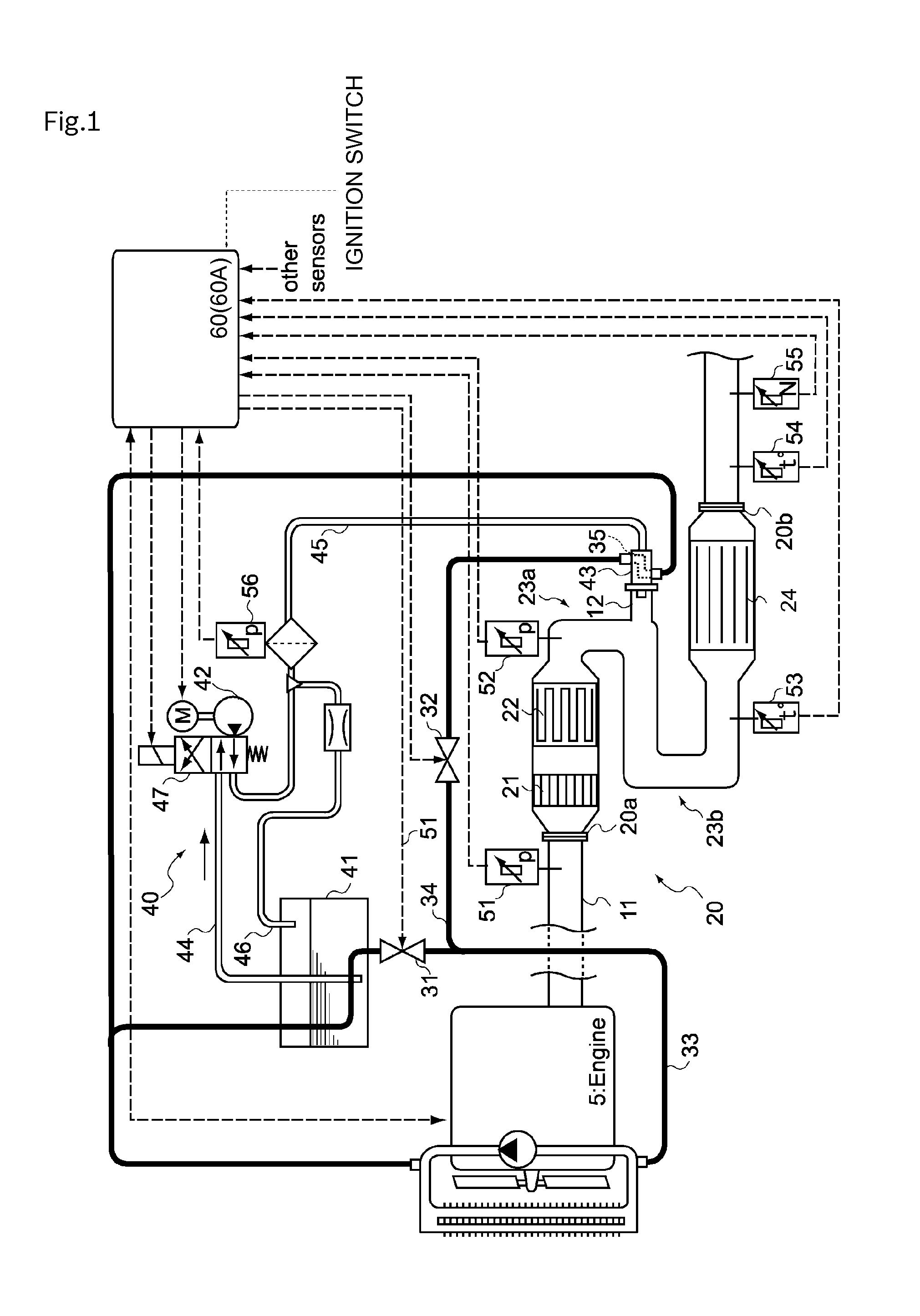

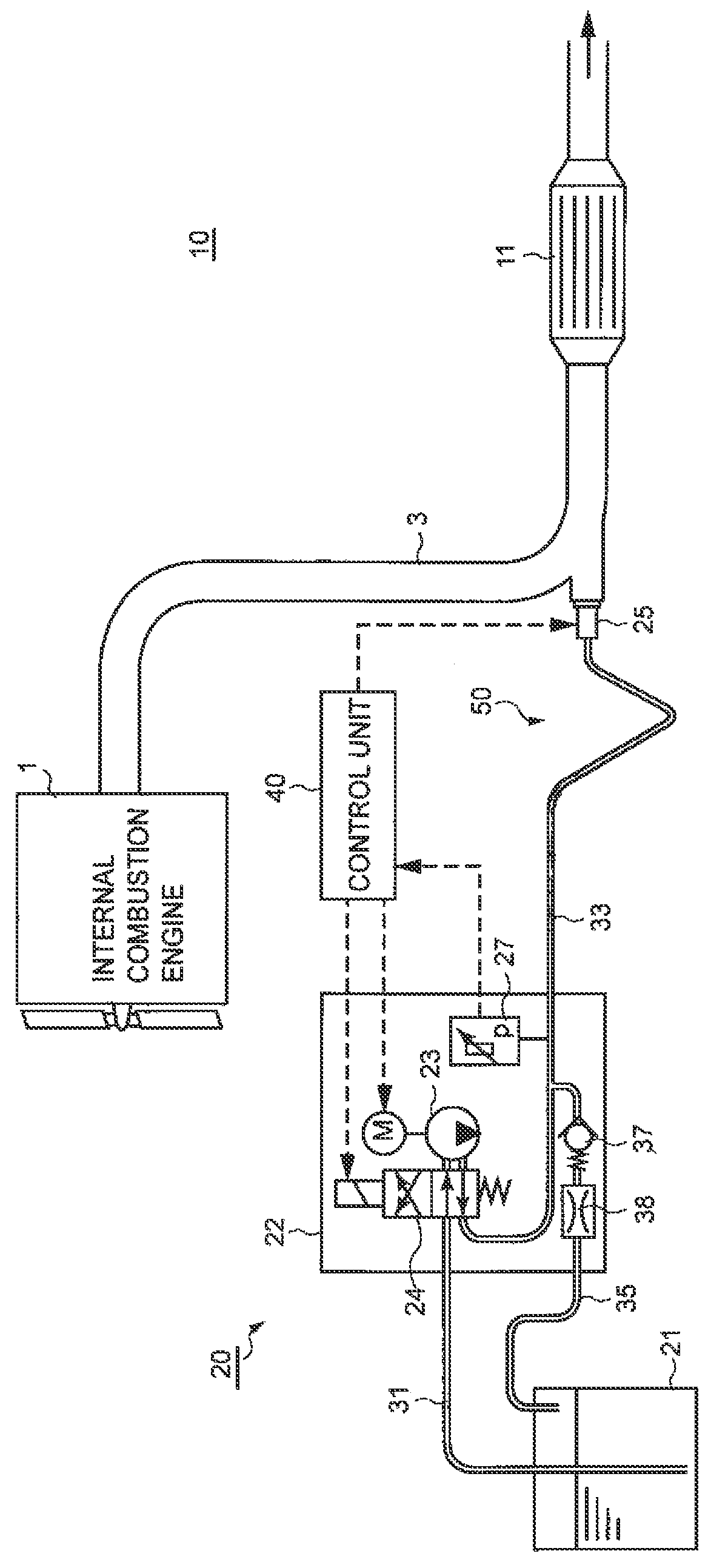

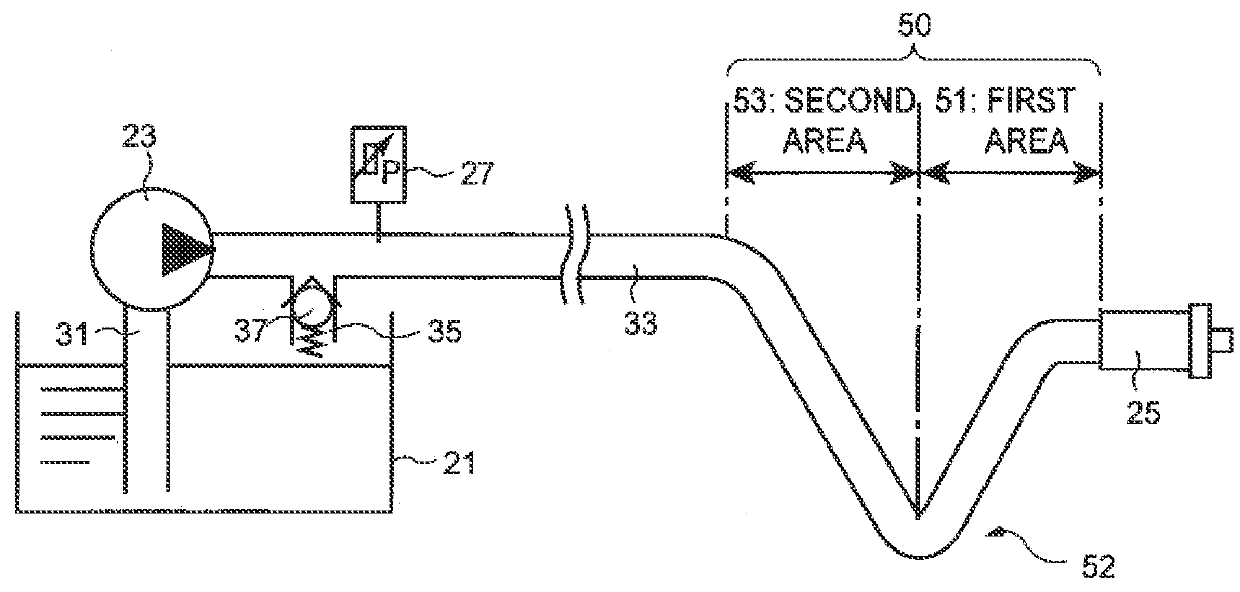

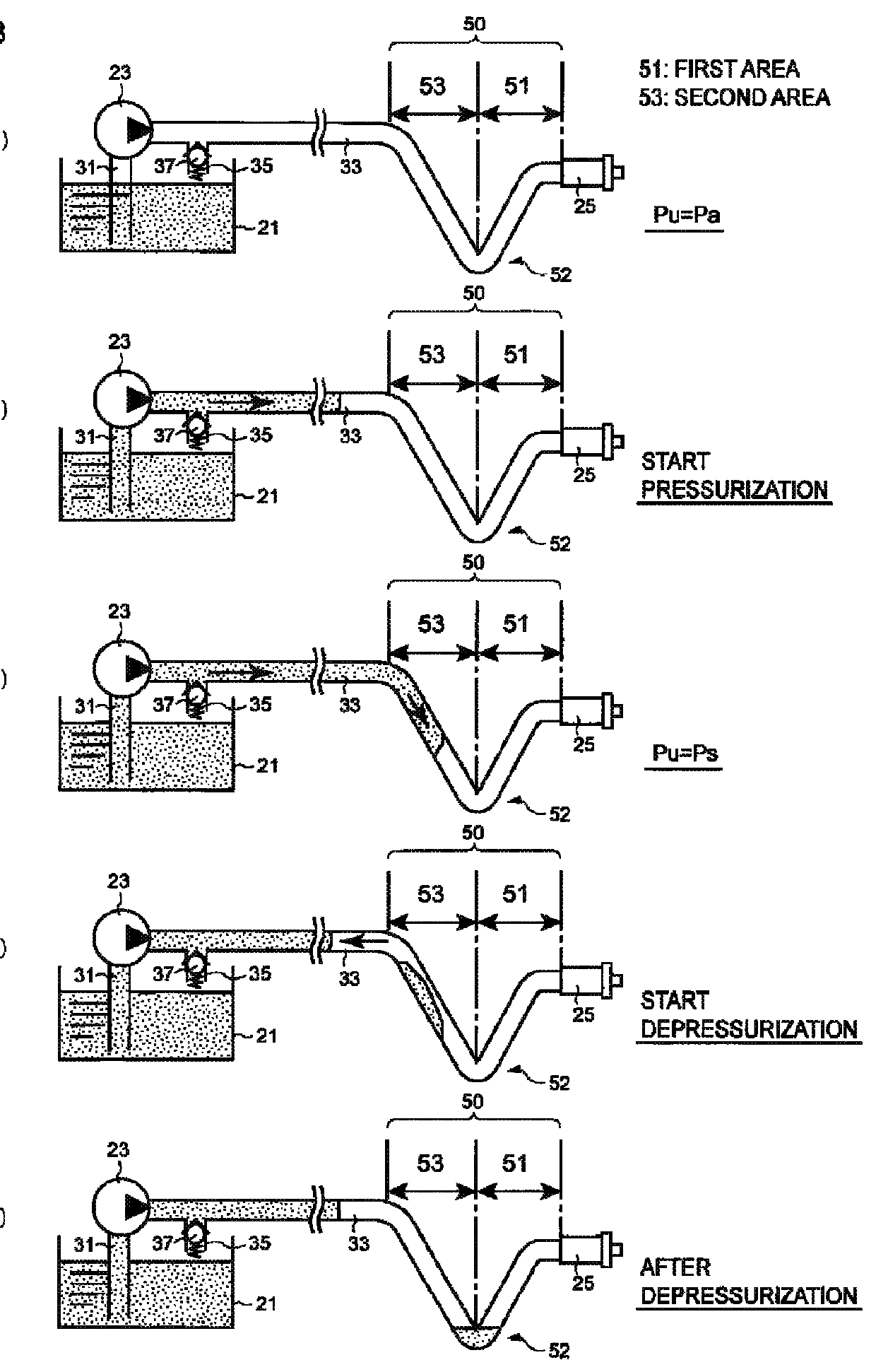

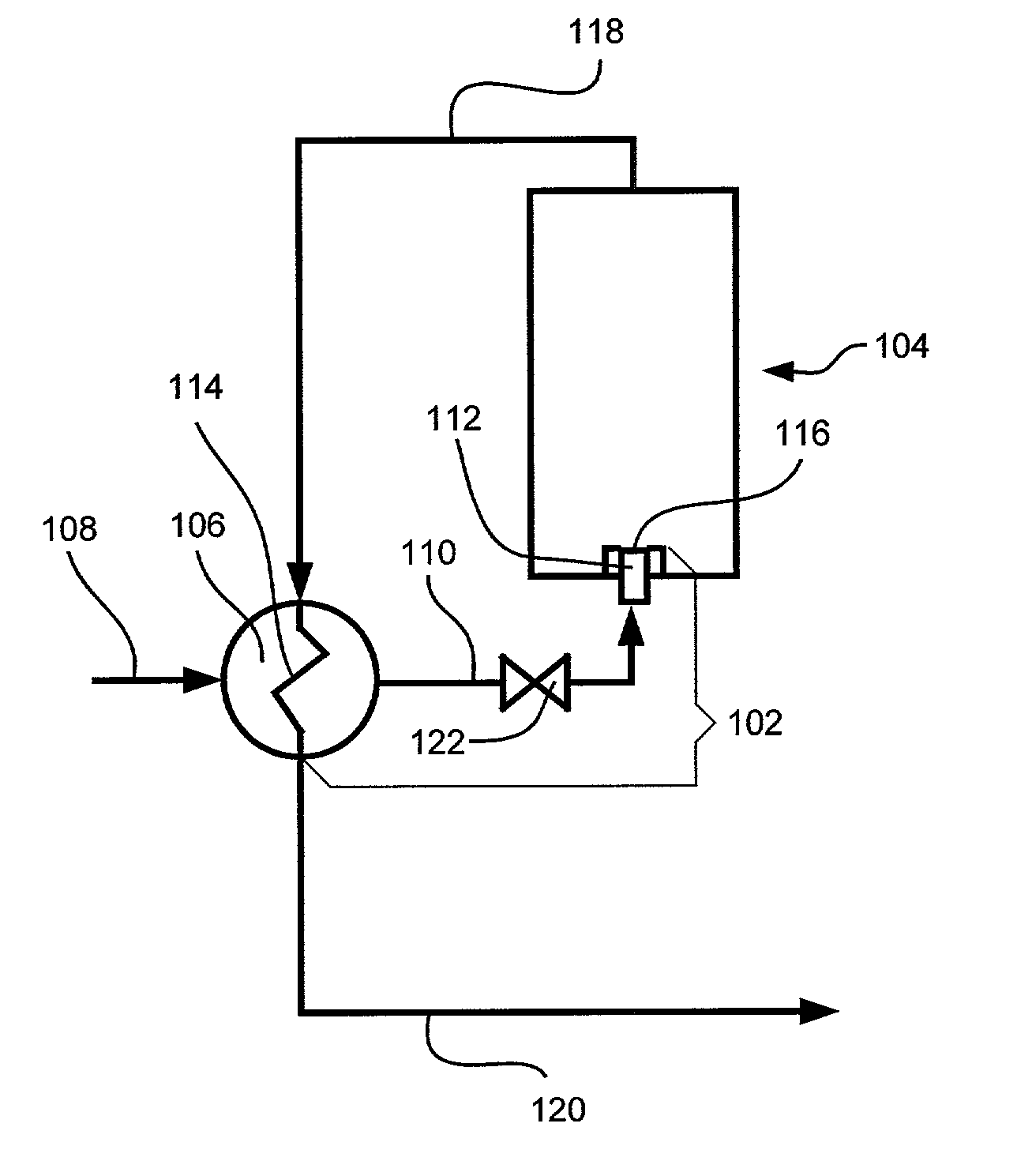

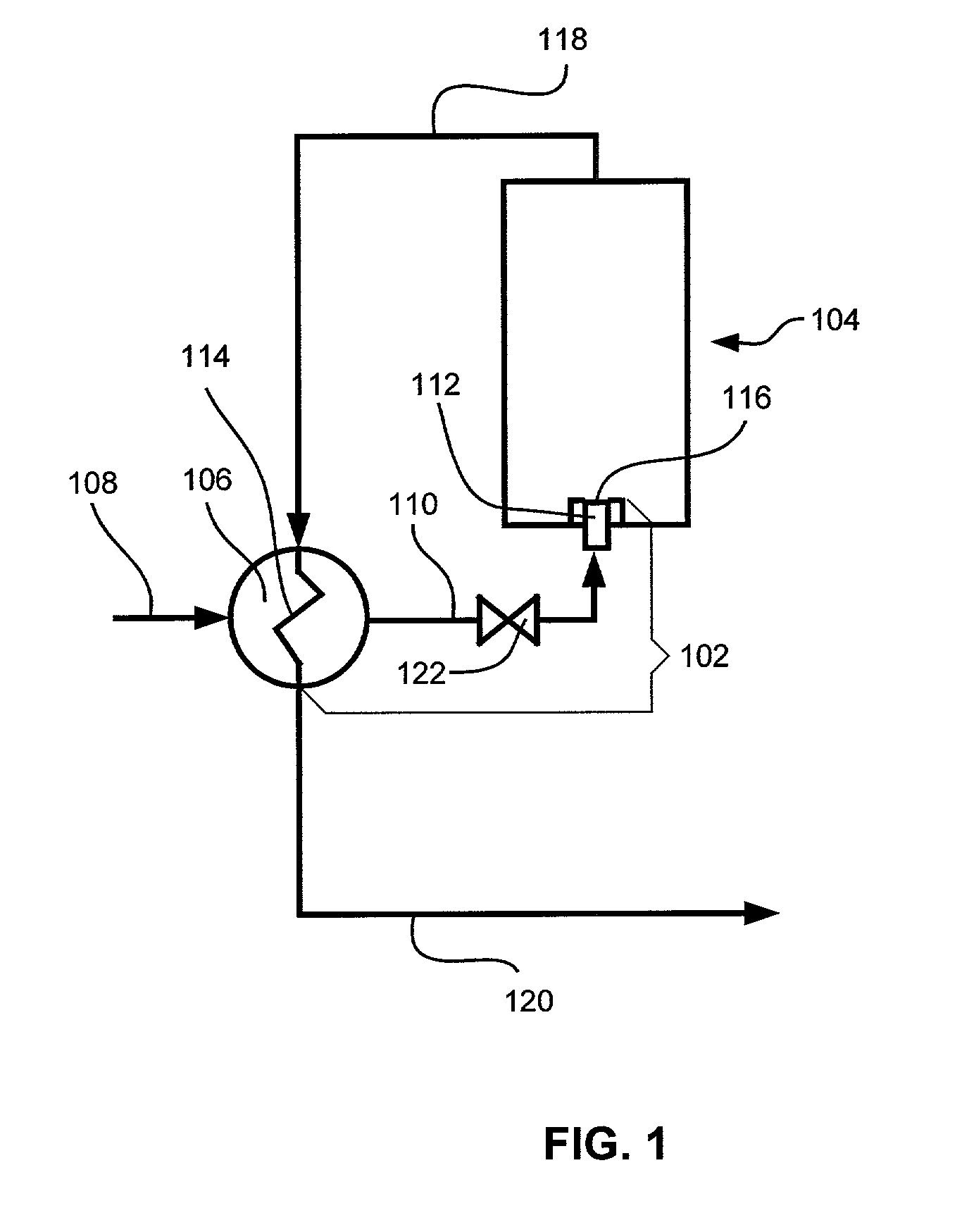

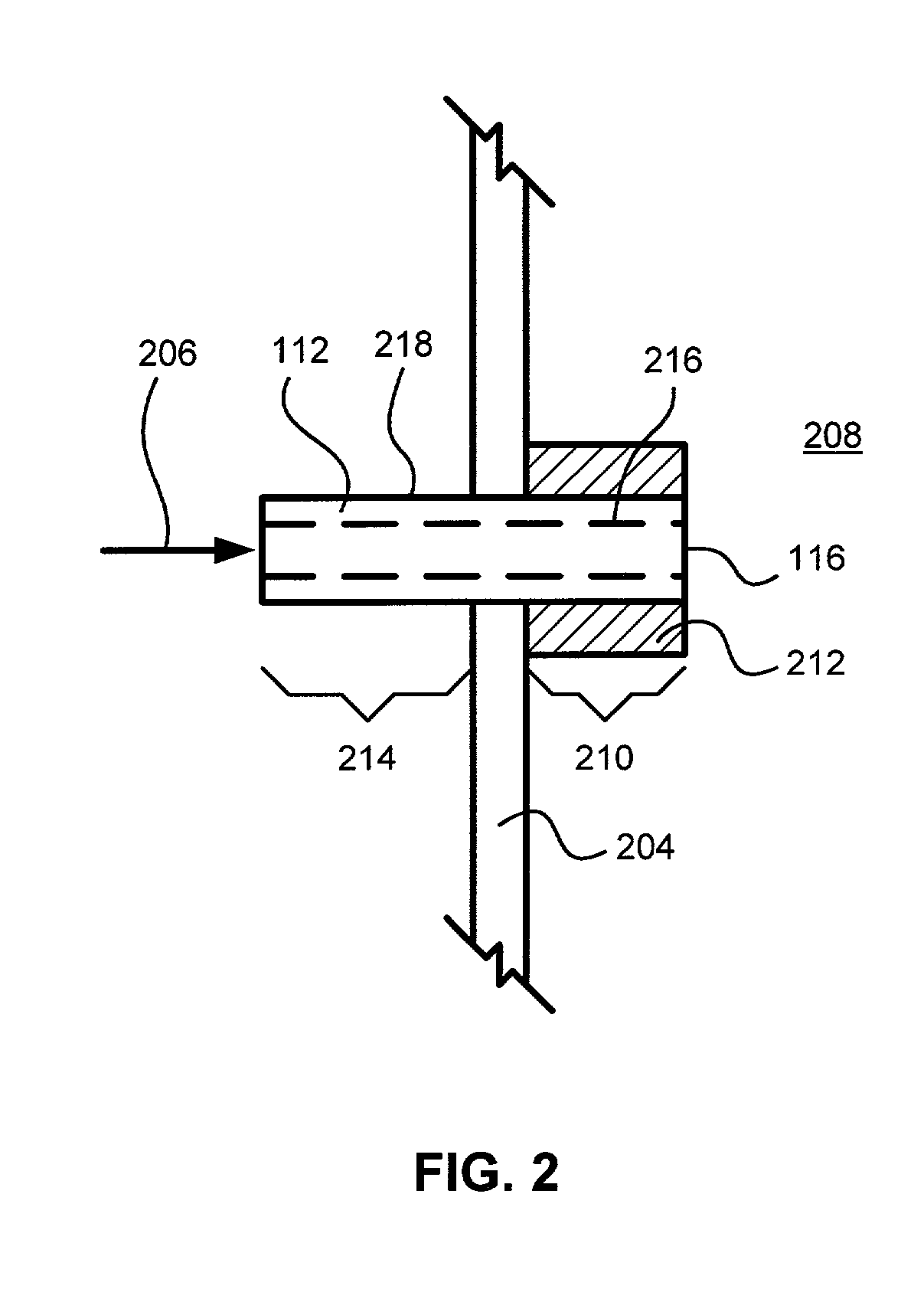

Reducing agent supply apparatus, method for controlling the same, and exhaust gas purification apparatus

ActiveUS8893480B2High freezing pointShorten the purification processInternal combustion piston enginesExhaust apparatusSiphonEngineering

[Problem] To provide a reducing agent supply apparatus that can quickly melt urea aqueous solution solidified in a reducing agent injection valve to allow early start of the injection control of urea aqueous solution, a method for controlling the reducing agent supply apparatus, and an exhaust gas purification apparatus.[Means for Resolution] A reducing agent supply apparatus, including: a storage tank for storing liquid reducing agent; a pump for pumping the reducing agent; a reducing agent injection valve for injecting the reducing agent pumped by the pump in an exhaust pipe of an internal combustion engine; and a reducing agent passage connecting the pump to the reducing agent injection valve, wherein, when the internal combustion engine stops, a purge process of collecting the reducing agent in the reducing agent passage into the storage tank is performed, and wherein, on part of the reducing agent passage, a siphon function portion is provided for, even when, at the start of the internal combustion engine, the reducing agent injection valve is in injection failure due to solidification of the reducing agent in the reducing agent injection valve, causing some of the reducing agent to reach the reducing agent injection valve after the start of the pump to cause the solidified reducing agent to melt.

Owner:BOSCH CORP

Method and apparatus for reducing decomposition byproducts in a methanol to olefin reactor system

InactiveUS7034196B2Reduce eliminateSuitable for usePhysical/chemical process catalystsHydrocarbon from oxygen organic compoundsReactor systemDecomposition

Disclosed is a method and apparatus for reducing the amount of metal catalyzed side-reaction byproducts formed in the feed vaporization and introduction system of a methanol to olefin reactor system by monitoring and / or maintaining the temperature of at least a portion of the feed vaporization and introduction system and / or of the feedstock contained therein below about 400° C., 350° C., 300° C., 250° C., 200° C. or below about 150° C. The temperature can be maintained in the desired range by jacketing at least a portion of the feed vaporization and introduction system, such as at least a portion of the feed introduction nozzle, with a thermally insulating material or by implementing a cooling system.

Owner:EXXONMOBIL CHEM PAT INC

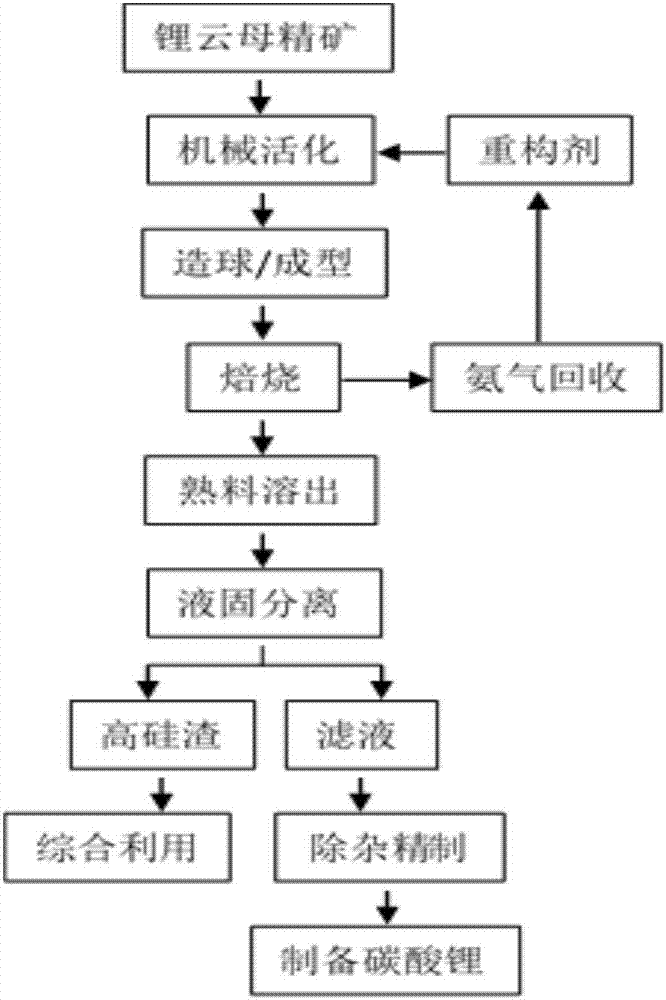

Method for extracting metallic elements by treating lepidolite

ActiveCN108004391ASmall granularityLarge specific surface areaProcess efficiency improvementRubidiumMass ratio

The invention discloses a method for extracting metallic elements by treating lepidolite. The method comprises the following steps of 1, conducting mechanical activation on lepidolite concentrate; 2,uniformly mixing lepidolite powder with a restructuring agent and a binding agent according to the mass ratio of 1: (1-2): (0.2-0.5), and then conducting molding; 3, firstly, conducting low-temperature restructuring on a blank body obtained in step 2, and then conducting medium-temperature decomposition, so that clinker is obtained; 4, conducting water logging treatment, wherein firstly, leachingseparation is conducted on the clinker obtained in step 3 in a leaching agent at the temperature of 0-30 DEG C, so that a lithium salt solution is obtained, and then, leaching separation is conductedin the leaching agent at the temperature of 70-100 DEG C, so that a salt solution containing sodium, potassium, rubidium, caesium and aluminum is obtained; and 5, implementing a washing process on filter residues obtained after secondary leaching in step 4, so that high-silicon residues are obtained. By means of the method, the metallic elements in the lepidolite concentrate can be converted intodiffluent salt to be separated and extracted to the greatest extent; the utilization rate and economic benefits of the lepidolite concentrate are remarkably increased; and the method is easy to operate, low in process cost and high in recycling rate of the metallic elements.

Owner:湖南吉新锂业科技有限公司

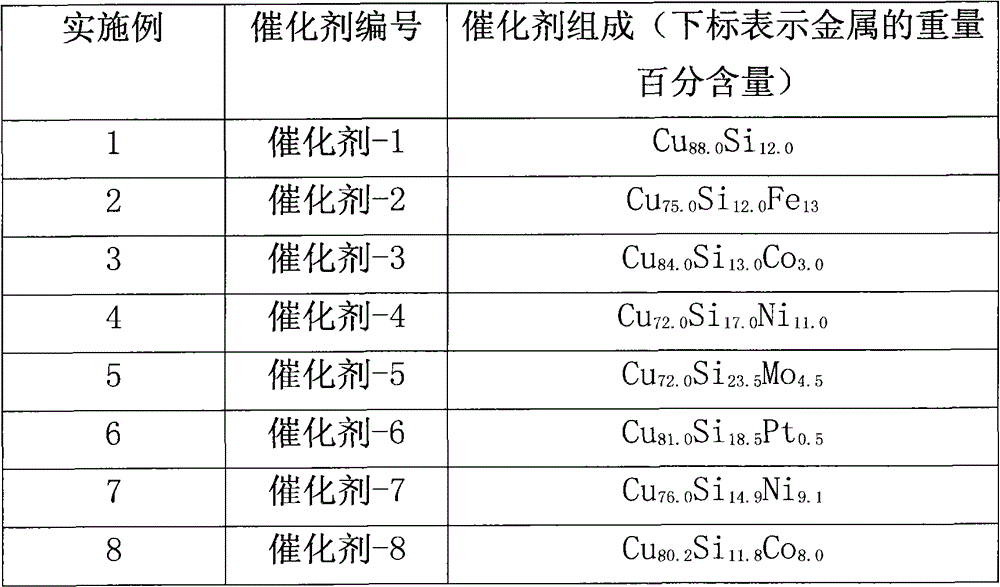

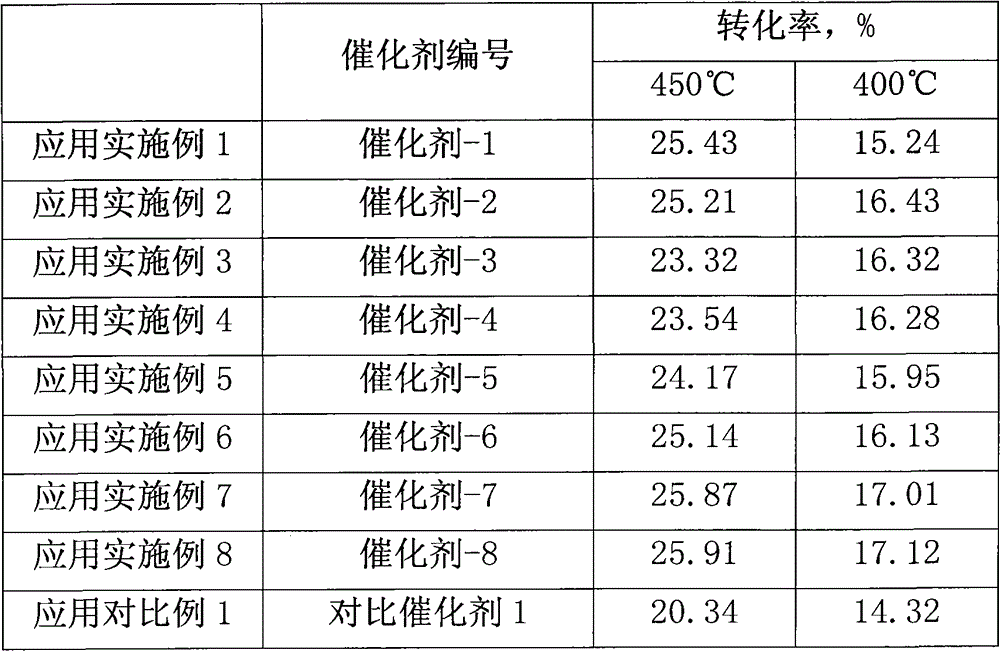

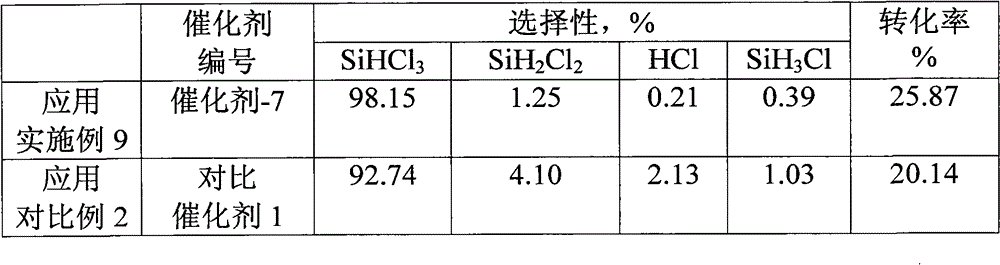

Copper catalyst and preparation method and application thereof

ActiveCN103055861AHigh activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsHalogenated silanesHydrogenation reactionAlloy

The invention discloses a copper catalyst. The copper catalyst is characterized by containing 20-95wt% of copper and 0.5-70wt% of silicon. The catalyst is obtained by heating copper, silicon and / or transition metals until the components are molten, cooling and curing the melt and carrying out extraction treatment on the alloy obtained after curing with an alkali-acid solution to extract part of silicon. The catalyst has higher activity and selectivity than conventional copper catalysts and has good stability when used in the silicon tetrachloride hydrogenation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

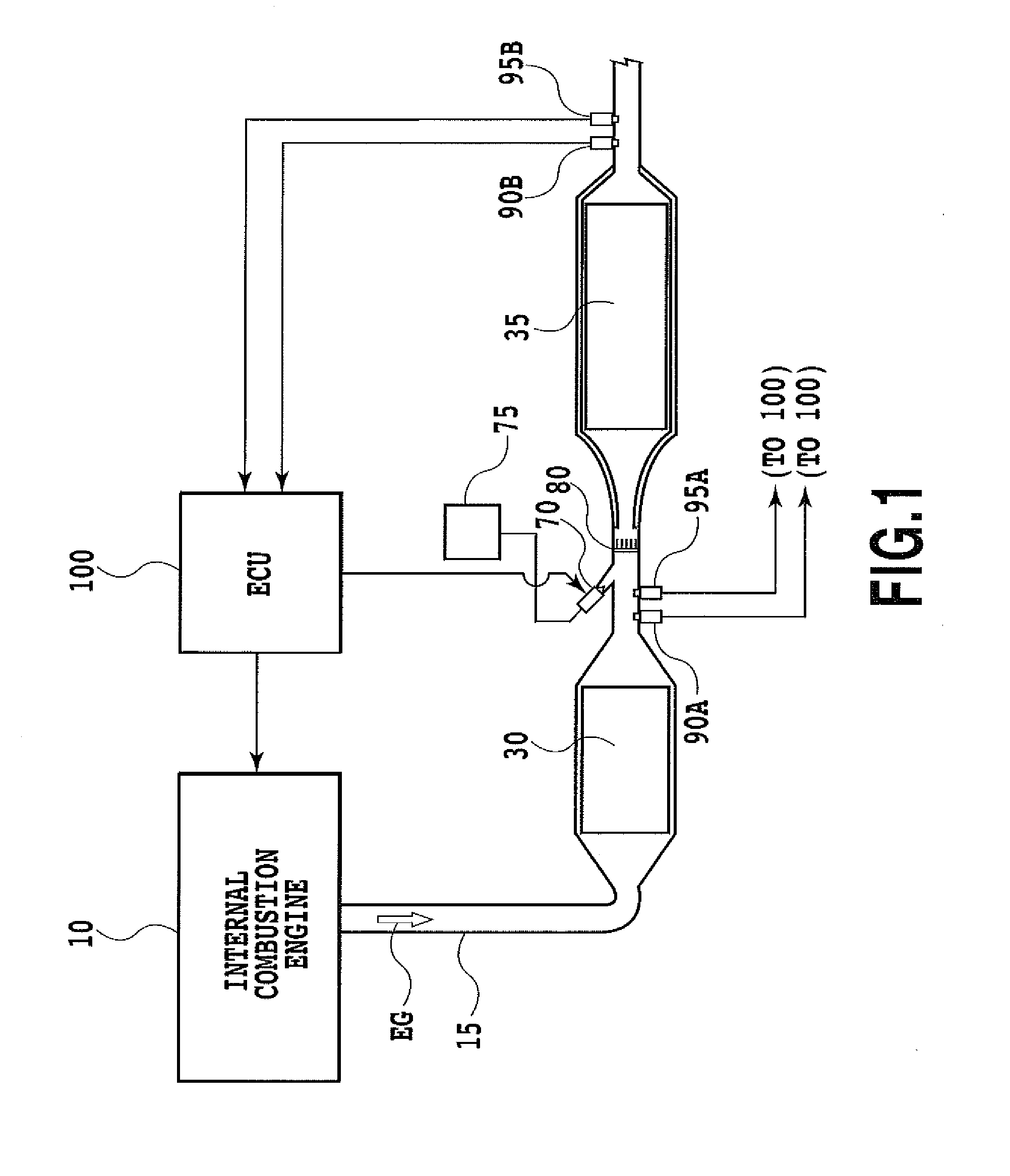

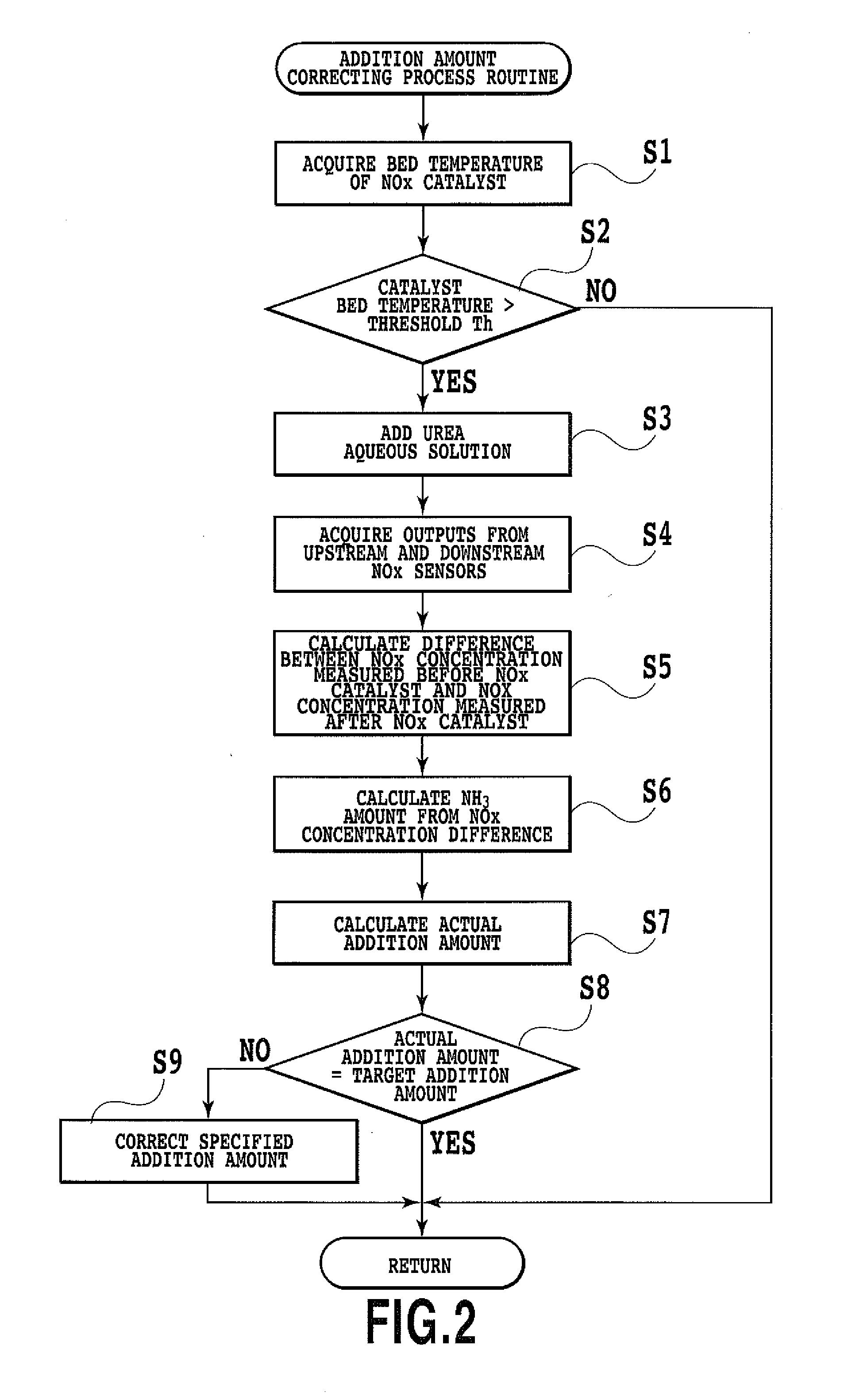

Exhaust purification apparatus for internal combustion engine

InactiveUS20110056188A1Decrease in NOx purification rateShorten the purification processInternal combustion piston enginesExhaust apparatusExternal combustion engineInternal combustion engine

The present invention provides an exhaust purification apparatus for an internal combustion engine which enables a decrease in NOx purification rate and possible ammonia slip to be inhibited. The apparatus includes an NOx catalyst, a urea aqueous solution addition valve serving as reducing agent adding means, and NOx sensors provided an inlet and an outlet of the NOx catalyst, respectively. When the bed temperature of the NOx catalyst is in a predetermined high-temperature region in which the amount of ammonia converted into NOx increases relatively and an NOx purification rate decreases relatively, the apparatus uses outputs from the NOx sensors to perform correction such that the actual addition amount of the urea aqueous solution addition valve reaches a target addition amount.

Owner:TOYOTA JIDOSHA KK

Double-cavity air purifier

InactiveCN107883476AImprove efficiencyReduce pollutionMechanical apparatusLighting and heating apparatusPhotocatalytic degradationPollutant

The invention relates to a double-cavity air purifier. The double-cavity air purifier comprises a shell, an air purification device and an air humidification device; the shell comprises a first innercavity, a second inner cavity, an air inlet and an air outlet; the first inner cavity is internally provided with a first filter net, and the air purification device is arranged in the first filter net; the air purification device comprises an air pump, a first water trough and an ultraviolet lamp, the first water trough is internally provided with a water solution and photocatalyst active balls,and the top of the first water trough is connected and communicates with the air outlet through an exhaust funnel; and the air humidification device is arranged in the second inner cavity and comprises a second water trough, a heater, a first water pump, a second water pump, a water distributor and an evaporator. According to the double-cavity air purifier, soluble organic pollutants in air are dissolved and adsorbed through the water solution, then, photocatalytic degradation is conducted on dissolved matter through the photocatalyst active balls in the water solution so that the efficiency of the air purifier can be improved, and the humidification function of the air purifier is additionally achieved through the double-cavity design.

Owner:柳州若思纳米材料科技有限公司

River course black foul water biological purification treatment device

InactiveCN105152352AEasy accessPromote growth and reproductionBiological water/sewage treatmentImpellerSludge

The invention discloses a river course black foul water biological purification treatment device which comprises a river course and river embankments, wherein the river course between the river embankments is provided with a cut-off dam; the outer side of the river embankment corresponding to the cut-off dam is provided with a biological tank; the biological tank comprises a water inlet gate, a water outlet gate and a tank body; the water inlet gate is communicated with the upper course of the cut-off dam; the water outlet gate is communicated with the lower course of the cut-off dam; the back of the water inlet gate is provided with a guide plate; the tank body and the river embankments form a closed space; longitudinal isolation walls and transverse isolation walls are arranged in the tank body and divide the tank body into a multistage purification tank; a biological island is arranged in the purification tank; the bottom of the purification tank is provided with a low-speed submersible water impeller; an inclined tube sedimentation tank is arranged in the last purification tank stage; the bottom of the inclined tube sedimentation tank is provided with a sludge discharge pipe; and the sludge discharge pipe is communicated with the outside of the biological tank. The device implements unpowered oxygenation by enabling river course black foul water to flow into the biological tank in a water fall mode; and the fixed biological island arranged in the biological tank purifies the river course black foul water.

Owner:朱学红

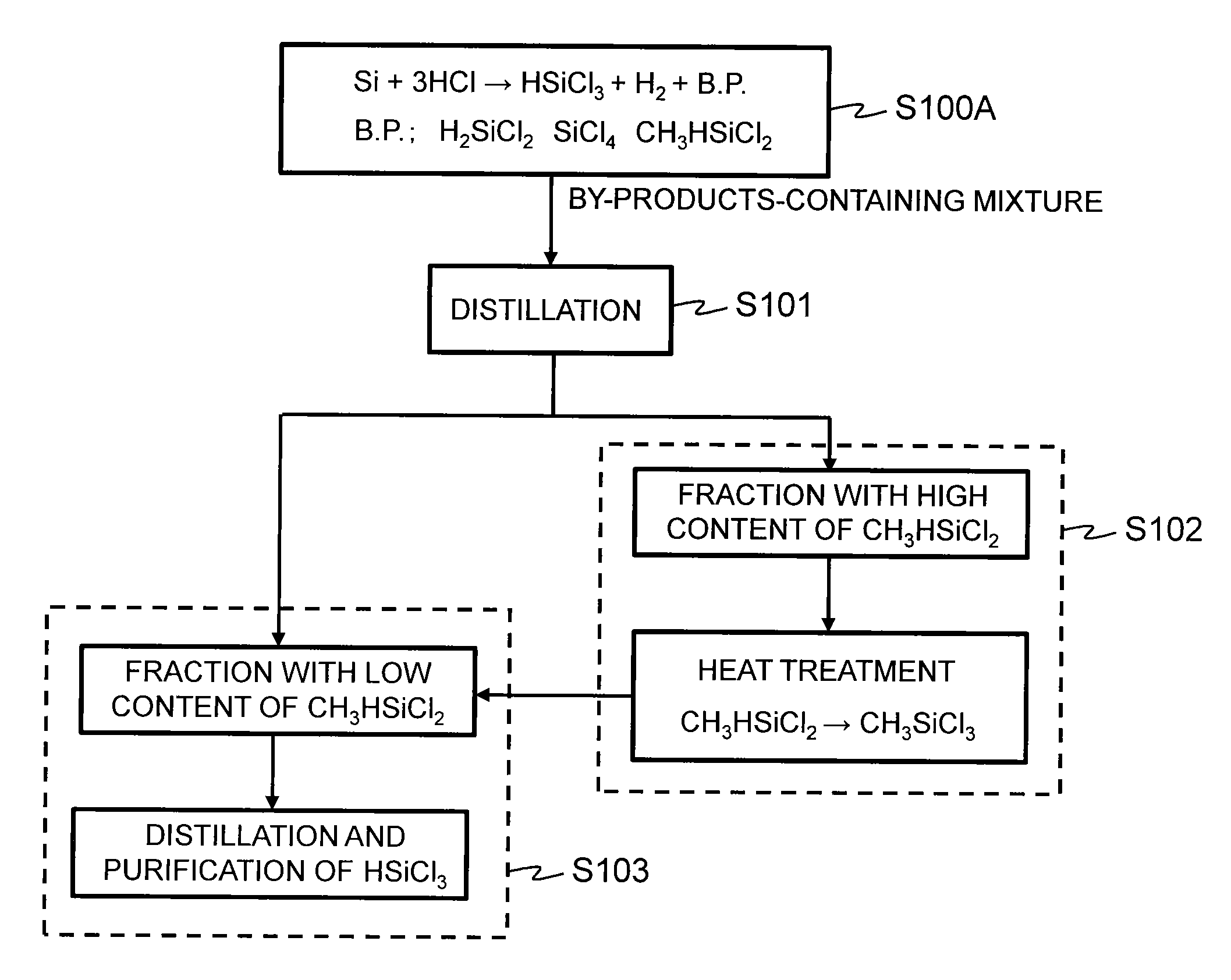

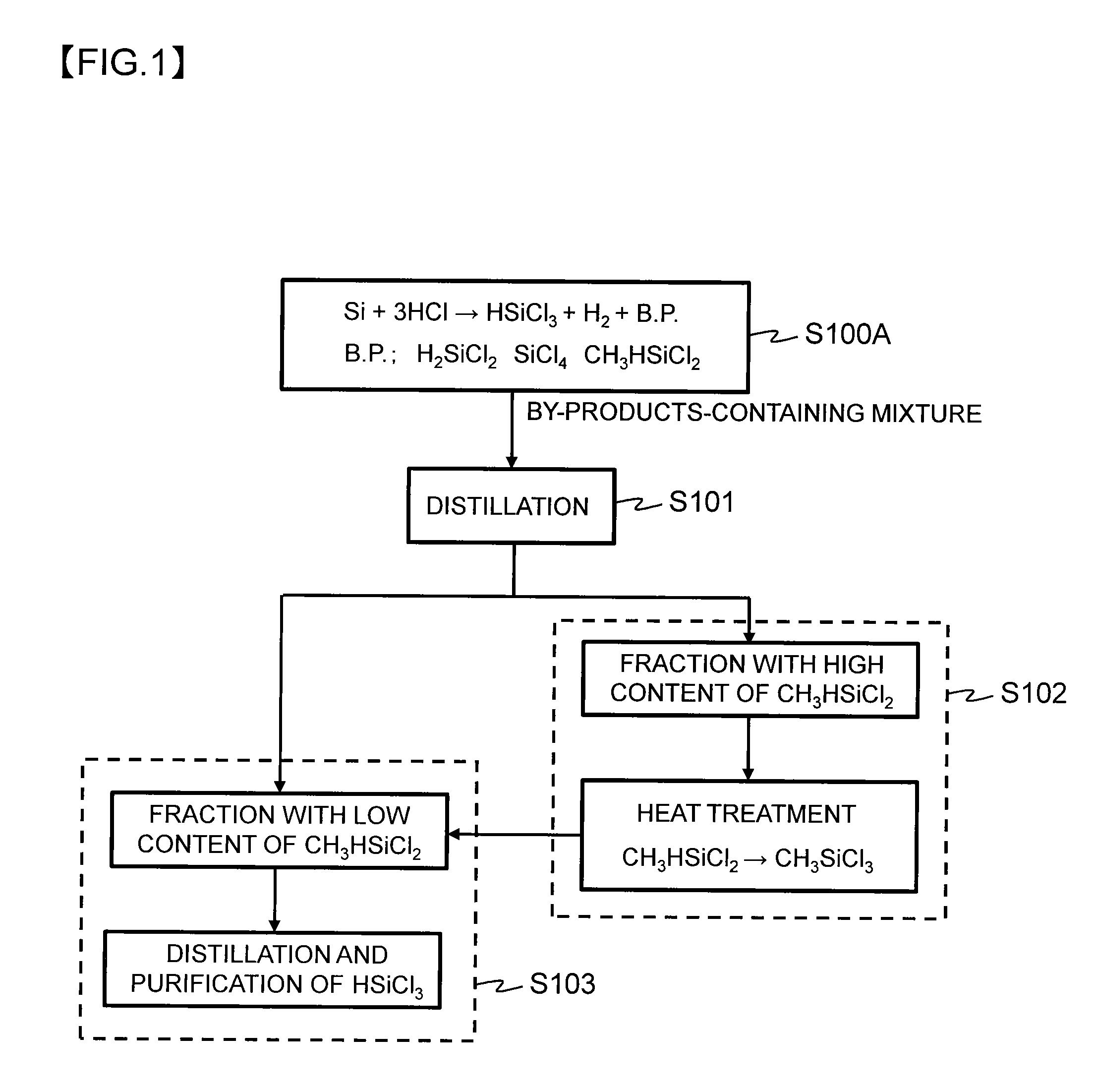

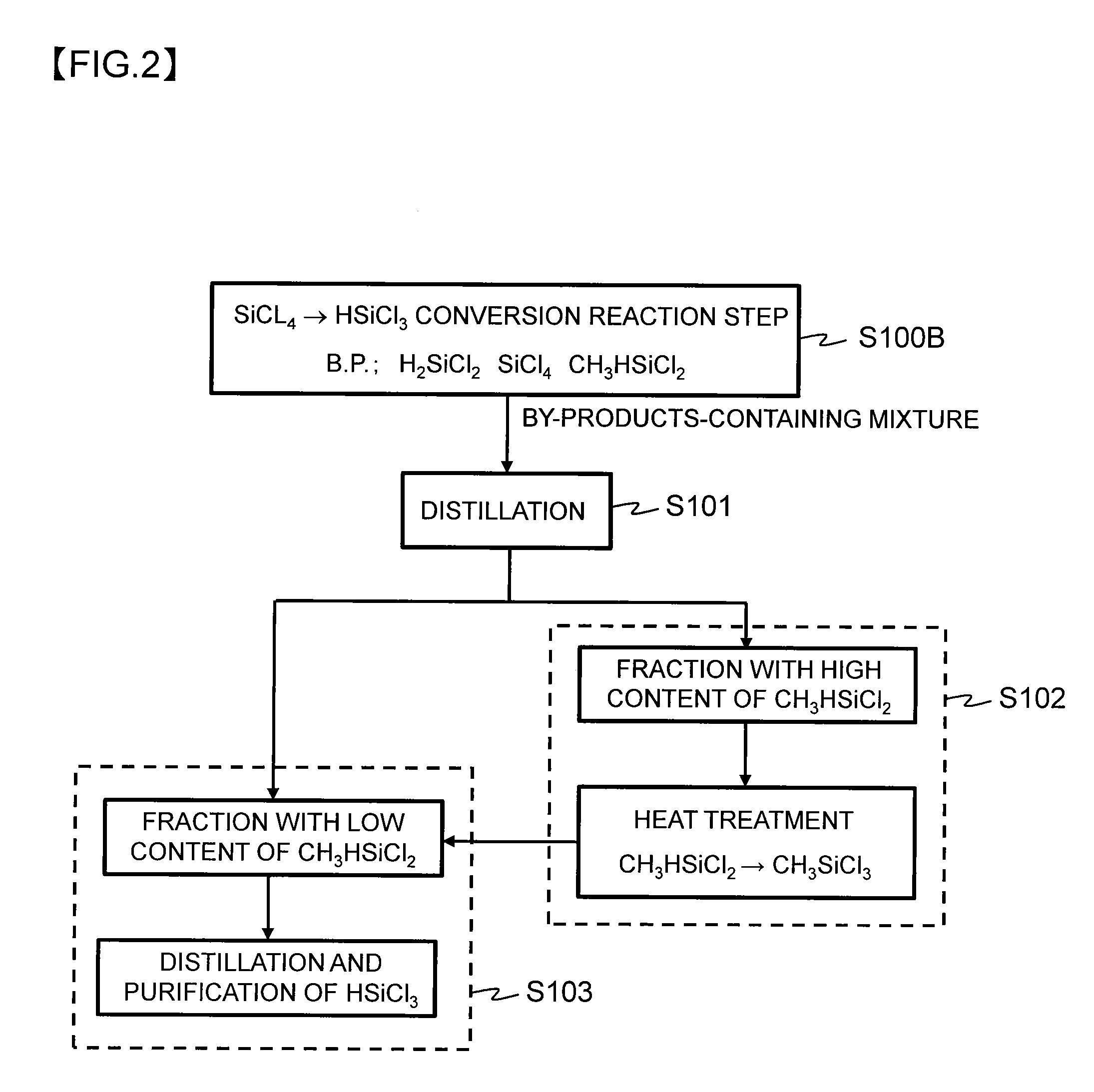

Method for producing trichlorosilane

ActiveUS20130001063A1Easy to disassembleShorten the purification processSilicon compoundsFractional distillationBoiling pointDistillation

A mixture containing methyldichlorosilane, tetrachlorosilane, and trichlorosilane is distilled to fractionate a fraction with a higher content of methyldichlorosilane than the mixture before distillation. Subsequently, the fraction thus fractionated is heated to disproportionate chlorine between methyldichlorosilane and tetrachlorosilane to disproportionate methyldichlorosilane into methyltrichlorosilane. Subsequently, the fraction after disproportionation containing methyltrichlorosilane is purified by distillation to separate high-purity trichlorosilane. Having a close boiling point to that of trichlorosilane (32° C.), which is a target product to be purified by distillation, removal of methyldichlorosilane (boiling point of 41° C.) has been difficult. The present invention removes methyldichlorosilane more easily by converting it into methyltrichlorosilane (boiling point of 66° C.) through disproportionation of chlorine between methyldichlorosilane and tetrachlorosilane.

Owner:SHIN ETSU CHEM IND CO LTD

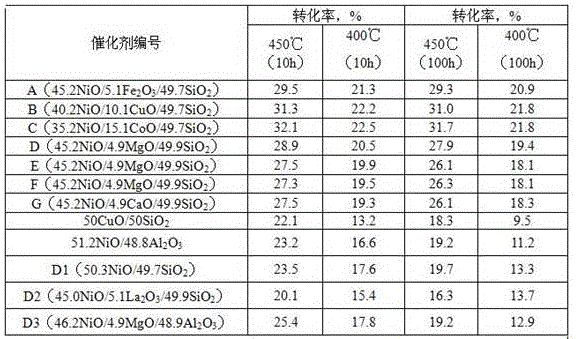

Catalyst, preparation method and application thereof

InactiveCN105944728AShorten the purification processEasily brokenHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsSolventSilicon dioxide

The invention discloses a catalyst and a preparation method thereof. The method comprises: contacting a soluble nickel salt, a soluble salt compound of metal M, a silicon source able to provide silica with a precipitant able to precipitate nickel and / or metal M ions in a solvent, filtering the contact product, and drying and roasting the obtained solid in order, wherein the M is selected from one or more of I B, II B, II A and group VIII metals except Ni. The catalyst prepared according to the method provided by the invention can be applied in preparation of trichlorosilane by hydrogenation of silicon tetrachloride. Compared with conventional aluminum-based catalysts, the catalyst prepared by the method provided by the invention has the advantages that: in the reaction atmosphere of preparation of trichlorosilane by hydrogenation of silicon tetrachloride, the SiO2 carrier is stable, the catalyst skeleton is not easily damaged as the carriers in traditional hydrogenation catalysts, therefore the service life can be longer, and compared with nickel salt and copper salt catalysts commonly used in the prior art, the activity is enhanced.

Owner:HENAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com