Flue gas cleaning system and flue gas cleaning process for integrated multi-pollutant removal by dry method

A flue gas purification system and pollutant technology, applied in the field of flue gas purification system, can solve the problems of large overall resistance, large floor space, ammonia escape, etc., and achieve the effects of no waste water discharge, small floor space, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

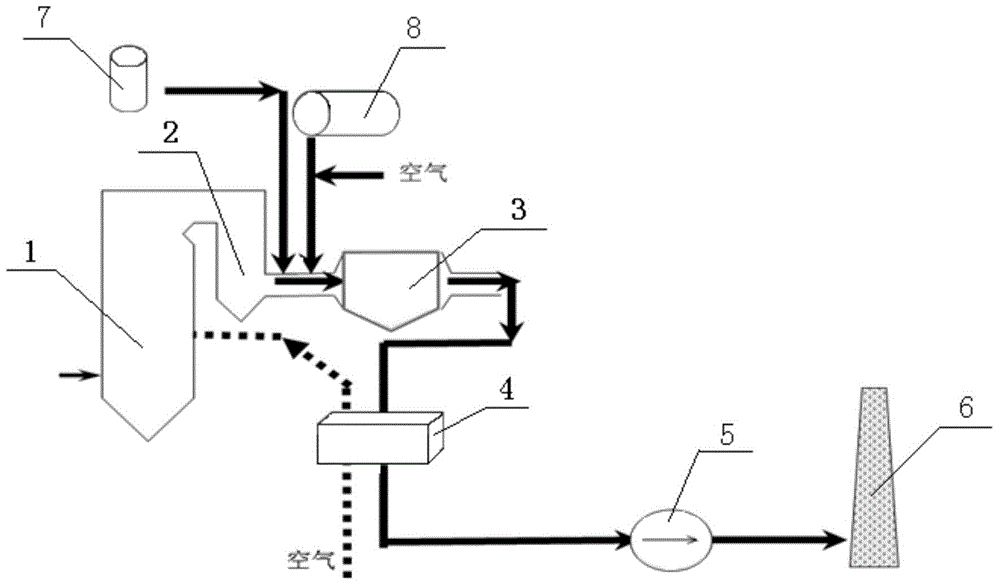

[0025] (1) see figure 1 , the system of the present invention includes an economizer 2 arranged at the tail of the boiler 1, and the outlet flue of the economizer 2 is sequentially connected with the integrated removal tower 3, the air preheater 4, the induced draft fan 5 and the smoke exhaust device, And the air preheater 4 is not only used to preheat the air entering the boiler 1 but also to preheat the purified flue gas, the induced draft fan 5 provides power for the whole system, and the smoke exhaust device is the chimney 6; the economizer 2 is integrated with On the flue between the removal towers 3, the first injection system for injecting the desulfurizer into the flue and the NO xThe second injection system in which the reducing agent is injected into the flue; in order to ensure a stable and efficient desulfurization effect, the desulfurizer uses C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com