System and method for achieving ultra-low emission of dust and NOx at high temperature

A dust and high temperature technology, applied in the field of multi-pollutant integrated dry removal, can solve the problems of no low-temperature catalyst available and the denitration efficiency is reduced, which is beneficial to the utilization of flue gas waste heat, occupies a small area, and shortens the purification process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

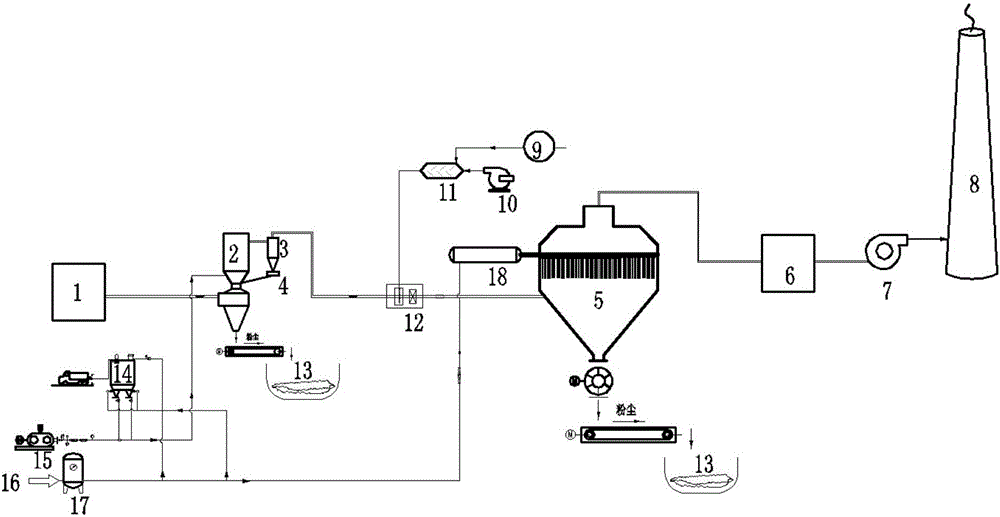

[0026] Such as figure 1 As shown, the present invention includes an economizer 1, a fluidized bed reactor 2, a cyclone dust collector 3, an ammonia injection grid 12, a denitrification and dust removal tower 5, an air preheater 6, an induced draft fan 7 and a chimney 8 connected in sequence. The denitrification and dust removal tower 5 is arranged in the flue behind the boiler economizer 1, and the fluidized bed reactor 2, the cyclone dust collector 3 and the ammonia injection grid 12 are arranged on the flue between the economizer 1 and the denitration and dust removal tower 5. The purified flue gas discharged from the denitrification and dust removal tower 5 enters the air preheater 6 and the induced draft fan 7 in turn, and finally is discharged to the atmosphere through the chimney 8 . D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com