Patents

Literature

72results about How to "Reduce calcium concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous liquid pharmaceutical composition comprised of gatifloxacin

InactiveUS6333045B1Prevent from colorationReduce calcium concentrationAntibacterial agentsSenses disorderDisodium EdetateChemistry

There is provided an aqueous liquid pharmaceutical composition which comprises Gatifloxacin (chemical nomenclature: (±)-1-cyclopropyl-6-fluoro-1,4-dihydro-8-methoxy-7-(3-methyl-1-piperazinyl)-4-oxo-3-quinoline carboxylic acid) or its salt and disodium edetate. Further, there are provided a method for raising corneal permeability of Gatifloxacin, a method for preventing precipitation of Gatifloxacin crystals, and a method for preventing coloration of Gatifloxacin by incorporating disodium edetate into an aqueous liquid preparation containing Gatifloxacin or its salt.

Owner:SENJU PHARMA CO LTD +1

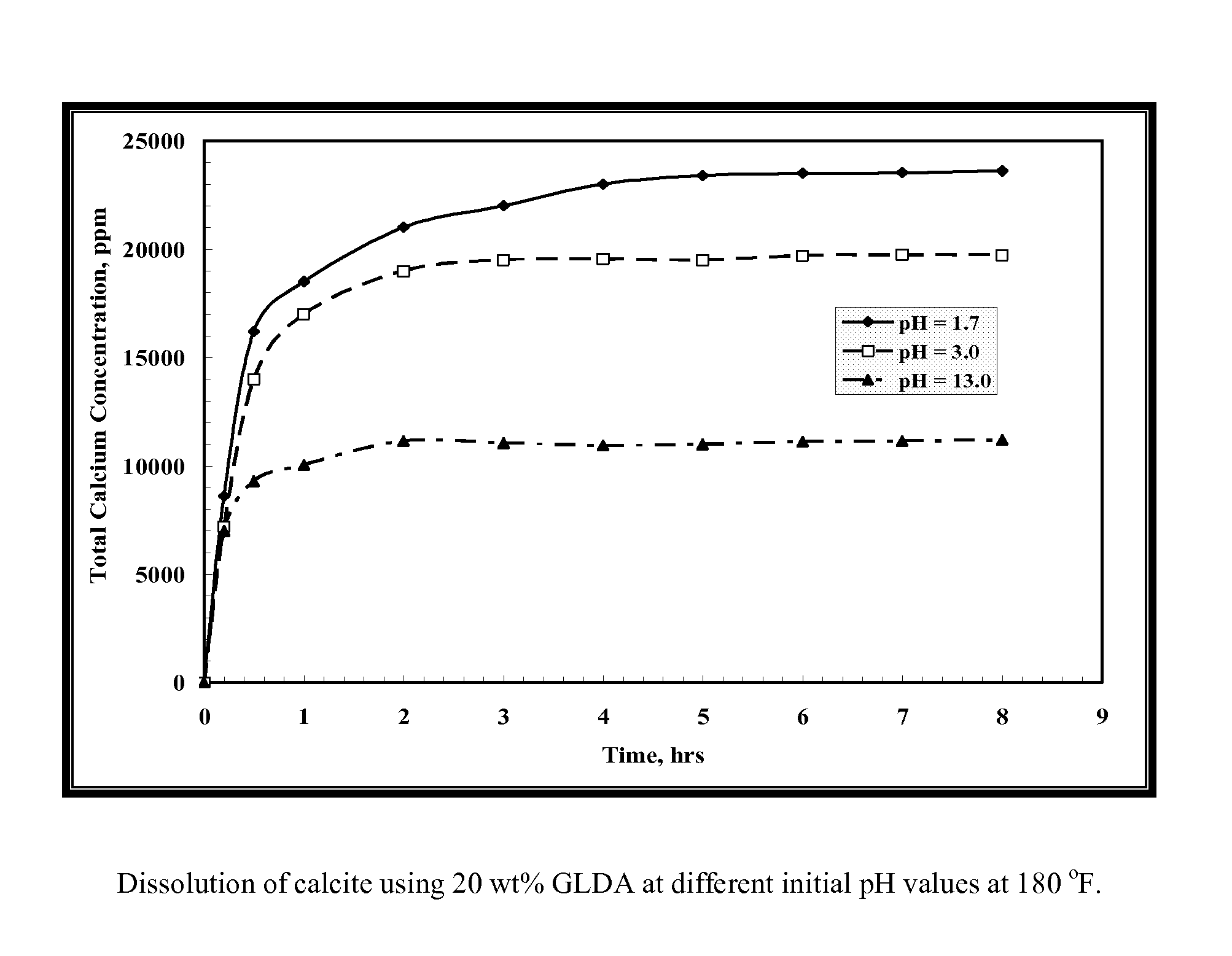

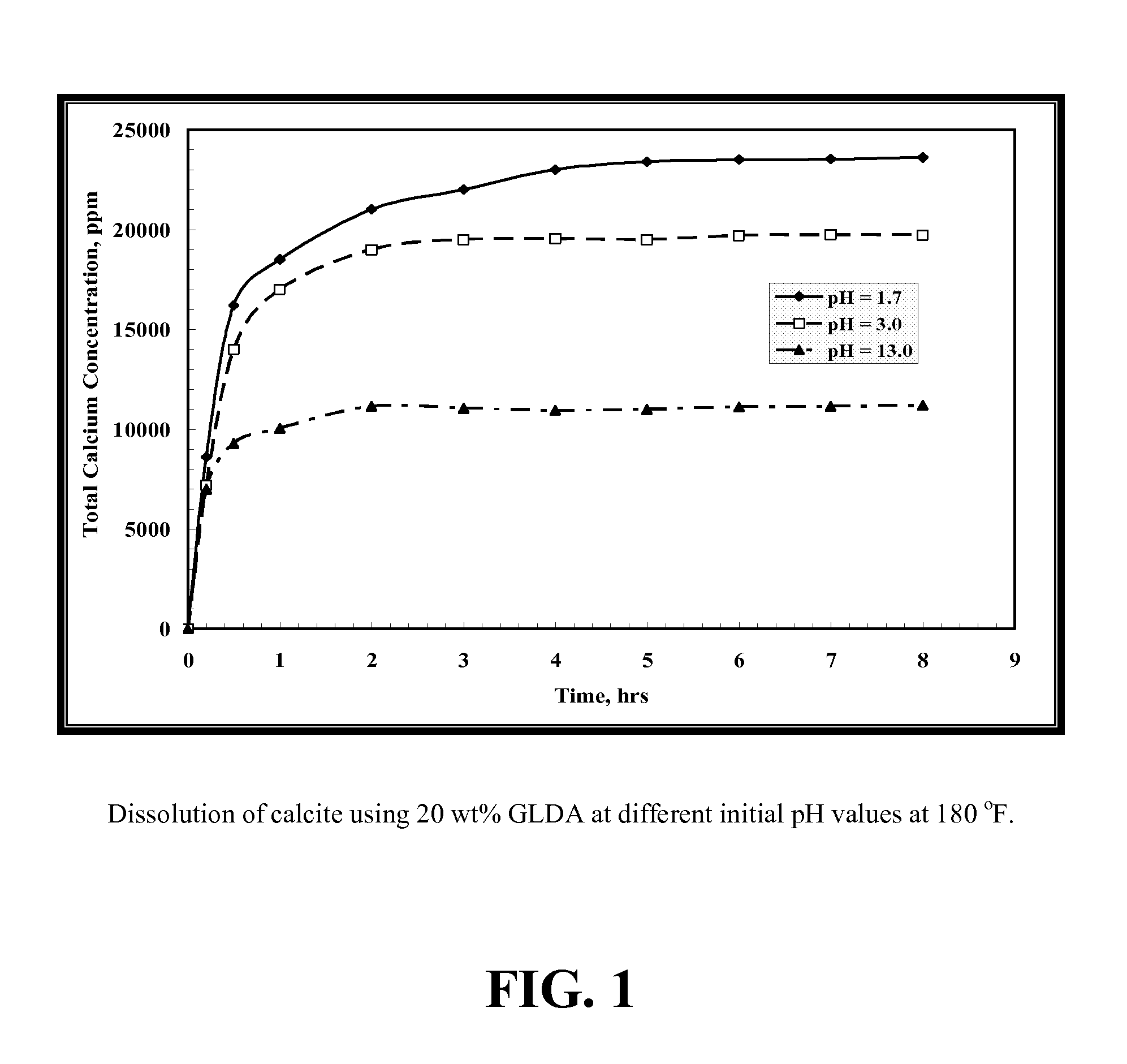

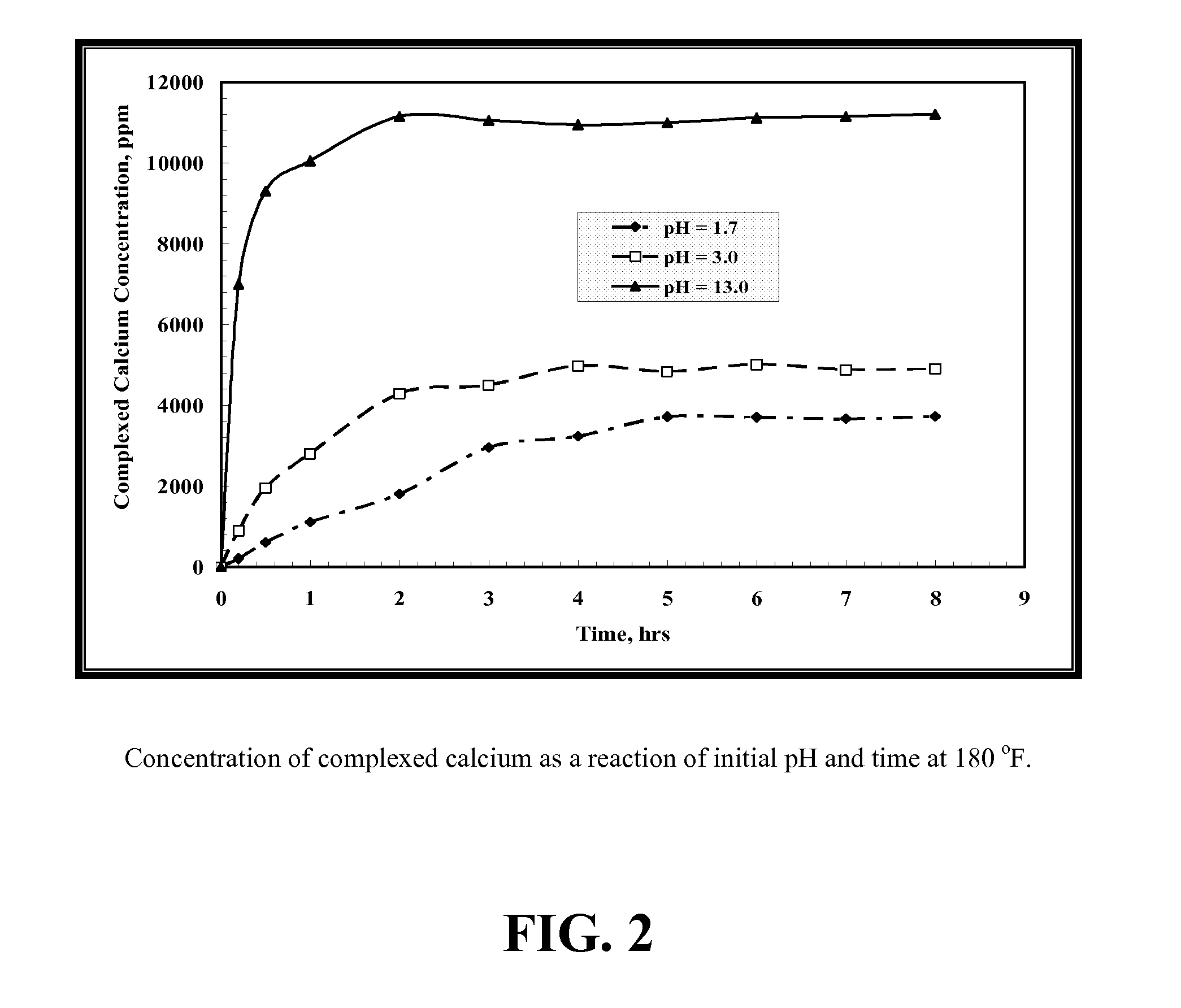

Environmentally friendly stimulation fluids, processes to create wormholes in carbonate reservoirs, and processes to remove wellbore damage in carbonate reservoirs

ActiveUS20120202720A1Reduce calcium concentrationChelating ability decreasedFlushingDrilling compositionDamage zoneWormhole

The present invention includes processes to create wormholes in carbonate reservoirs by contacting a formation with a solution comprising glutamic acid N,N-diacetic acid (GLDA) and / or a salt thereof, methylglycine-N,N-diacetic acid (MGDA) and / or a salt thereof, or a combination thereof. The present invention also includes processes to remove wellbore damage in a carbonate reservoir by contacting a damaged zone of the carbonate reservoir with a solution comprising GLDA and / or a salt thereof, methylglycine-N,N-diacetic acid (MGDA) and / or a salt thereof, or a combination thereof. The present invention further includes solutions comprising a salt and further comprising GLDA and / or a salt thereof, methylglycine-N,N-diacetic acid (MGDA) and / or a salt thereof, or a combination thereof.

Owner:AKZO NOBEL CHEM INT BV

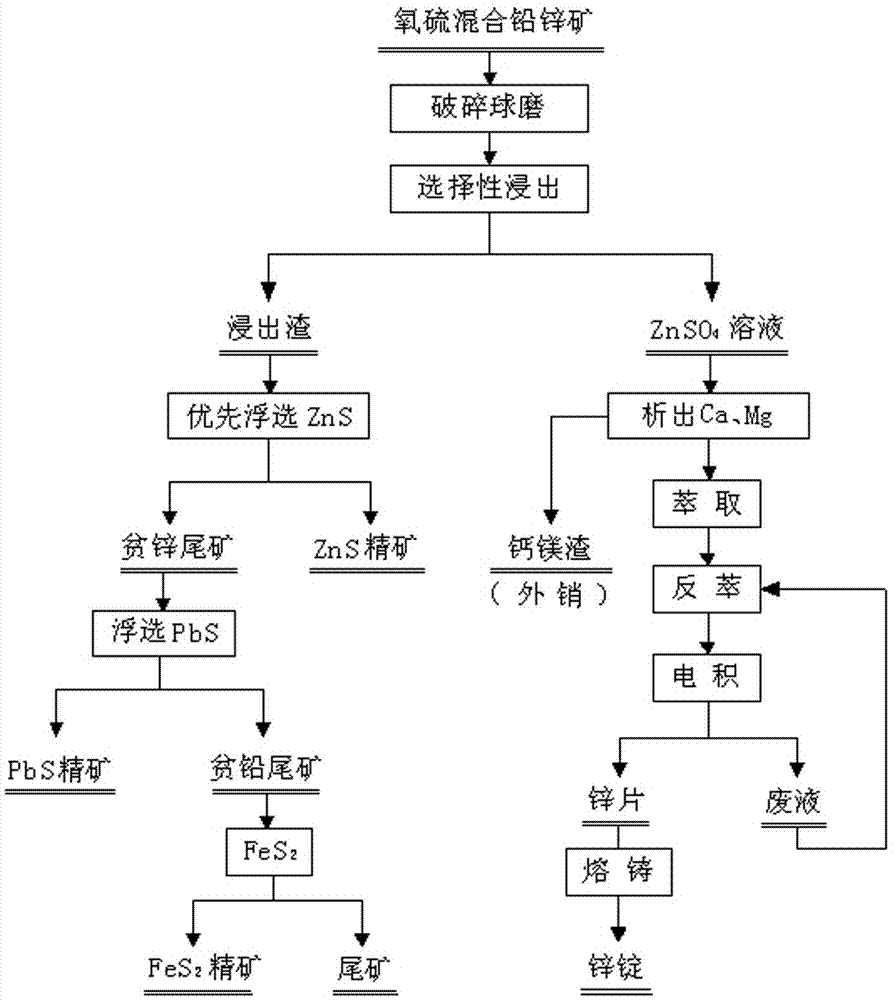

Selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process

ActiveCN103301929AReduce calcium concentrationHarm reductionFlotationWet separationOxygenTotal recovery

The invention discloses a selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process. For oxygen and sulfide mixed lead zinc ore, a zinc wet-method smelting process and a zinc flotation process are combined, zinc oxide in the ore is partially and selectively leached out by the first wet-method smelting process, and then zinc sulfide in the ore is floated out by the flotation process. In order to overcome the difficulty in treating the oxygen and sulfide mixed lead zinc ore, the invention provides the smelting and selection combining process which is short in process flow, reliable in technology, easy to operate and control, relatively low in material consumption and energy consumption for production, high in metal reclaiming efficiency, relatively good in economic benefit and high in practicability, the recovery of lead and zinc in the low-grade complex difficultly-selected oxygen and sulfide mixed lead zinc ore can be greatly improved, and the total recovery of lead and zinc can be up to over 90 percent.

Owner:云南金鼎锌业有限公司

Coronary artery medicinal-coating stent

InactiveCN1935274AIncrease cAMP contentInhibit biosynthesisStentsSurgeryPhosphorylcholinePercent Diameter Stenosis

The present invention discloses a coronary artery medicine coating scaffold for inhibiting endometrial hyperplasia and preventing restenosis in the scaffold. It includes dilating scaffold base body and inner coating layer coated on the dilating scaffold base body, the above-mentioned inner coating layer is formed from medicine carrier and ligustrazine, their mass ratio is 3:1-1:3, the above-mentioned inner coating layer is one of methyl acrylate, methyl methacrylate copolymer, polylactic acid, polyglycollic acid, polymonoracemic lactic acid, polylactide-diglycolide polymer, phosphorylcholine, ethyl polyurethane inorganic micropore aluminium oxide and cellulose or their composite.

Owner:SOUTHEAST UNIV

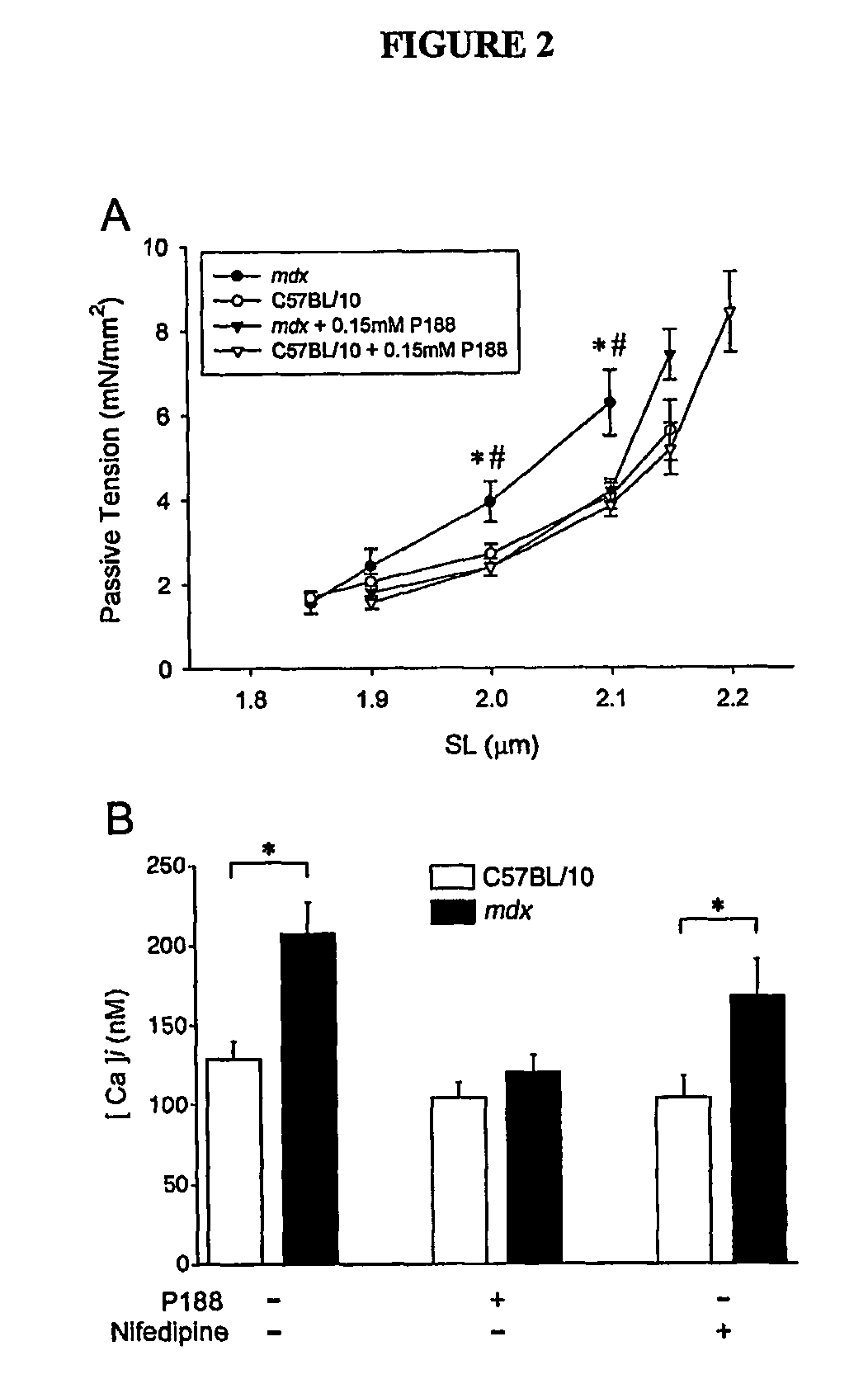

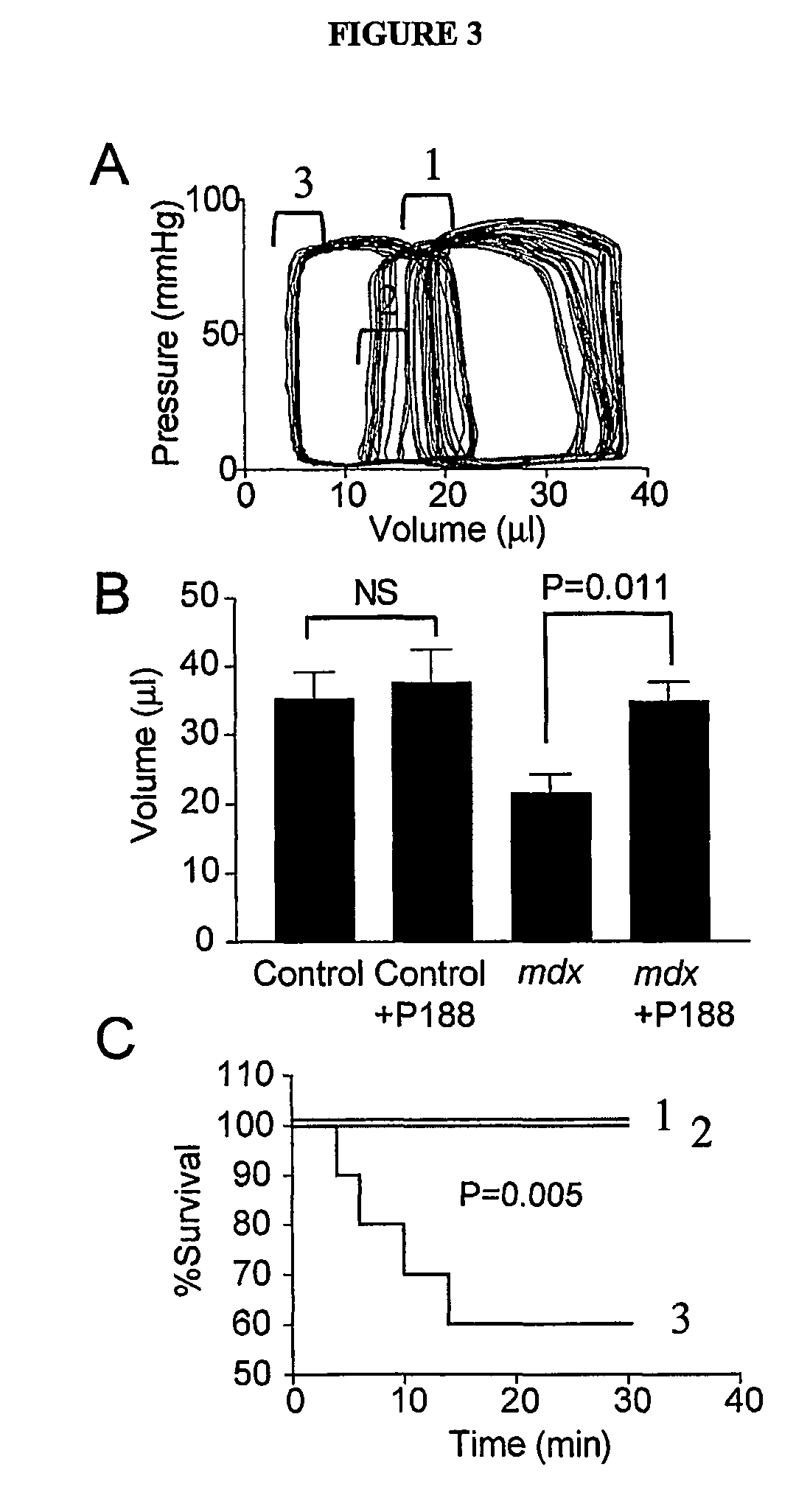

Compositions and methods for treating and preventing cardiomyopathy and heart disease

ActiveUS7846426B2Reduce concentrationReduces susceptibility to calcium overloadMuscular disorderTissue cultureMuscular dystrophyHeart disease

The present invention relates to compositions and methods for treating and preventing heart disease. In particular, the present invention provides compositions comprising poloxamers (e.g., poloxamer 188—P188) and methods of using the same for treating and preventing heart disease (e.g., in subjects with muscular dystrophy) and for treating cells and tissue damage caused by ischemia and cell death (e.g., for treating dystrophin-deficient cells (e.g., myocytes)).

Owner:RGT UNIV OF MICHIGAN

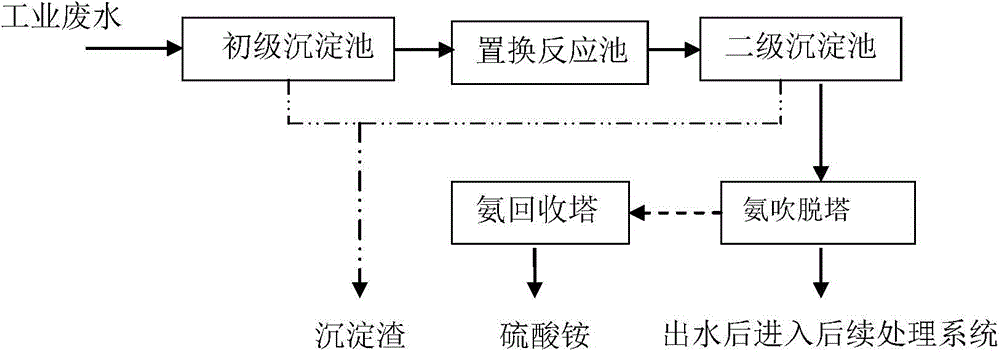

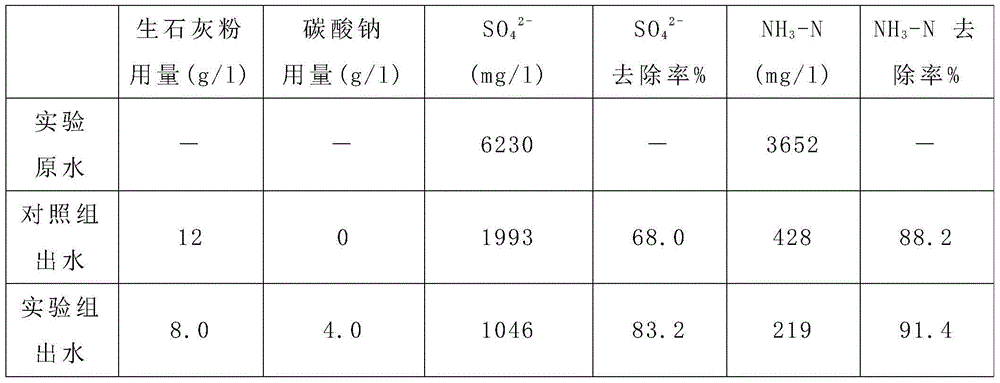

Treatment method for industrial wastewater

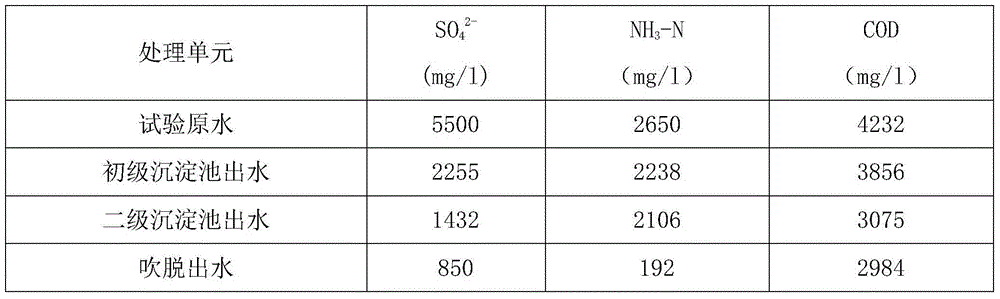

ActiveCN104591435AReduce the concentration of ammonia nitrogenReduce dosageMultistage water/sewage treatmentAmmonia compoundsHigh concentrationSulfate radicals

The invention belongs to the field of sewage treatment, and relates to a treatment method for industrial wastewater. The method comprises steps of primary precipitation, replacement reaction, secondary precipitation, ammonia stripping and ammonia recycling; removal rate to sulfate radicals in industrial wastewater is up to 80%, removal rate to ammonia nitrogen is up to 90%; the method is particularly applicable to treatment of high-concentration ammonium sulfate wastewater, meanwhile, solves the difficult problem that calcium sulphate scaling blocks equipment and pipelines and increases operation load in the conventional precipitation methods.

Owner:北京潮白环保科技股份有限公司

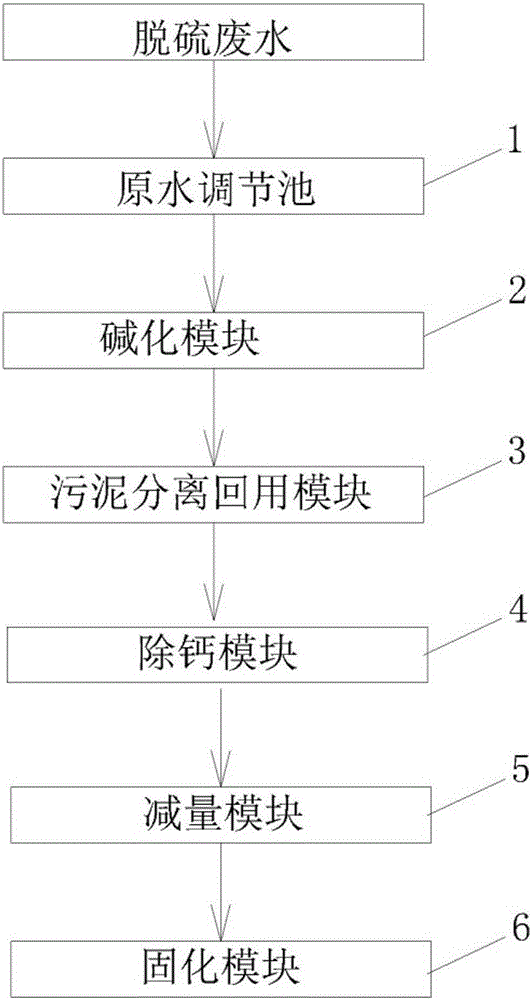

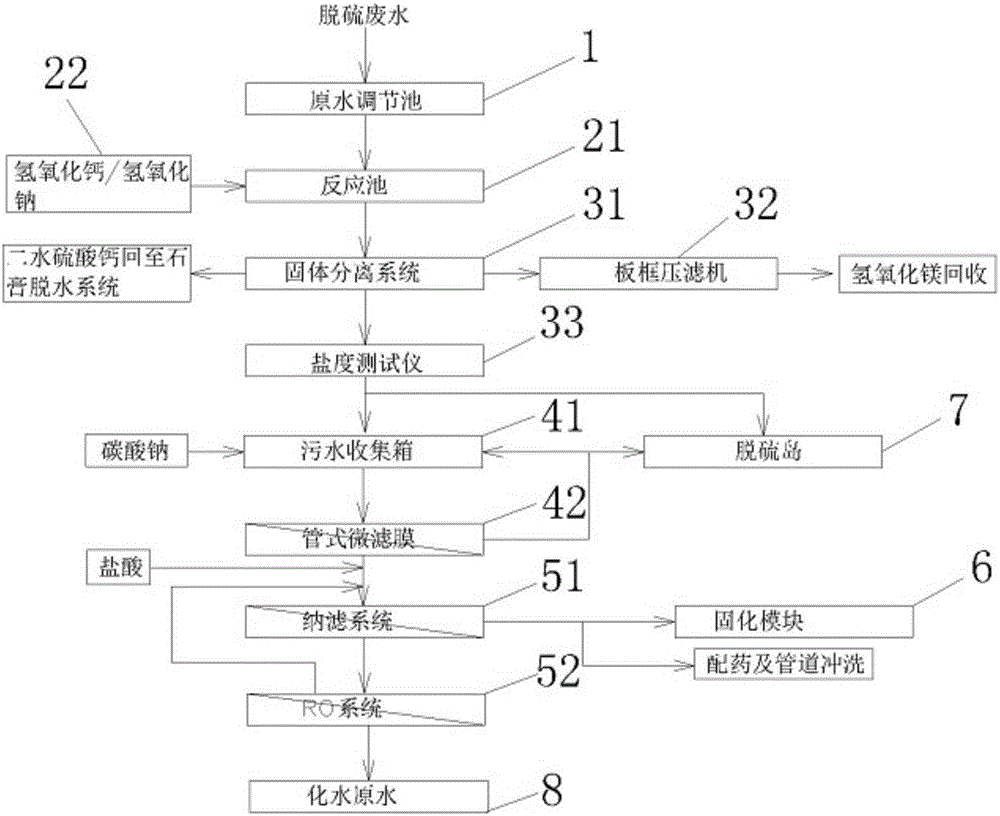

Device capable of realizing zero discharge of desulfurization wastewater

ActiveCN106396233AProtect the environmentAchieving zero emissionsSludge treatment by de-watering/drying/thickeningGeneral water supply conservationNanofiltrationMagnesium

The invention belongs to the technical field of zero discharge of desulfurization wastewater from power plants. A device capable of realizing zero discharge of desulfurization wastewater is characterized by comprising a raw water regulating pond, an alkalization module, a sludge separating and recycling module, a calcium removal module, a reduction module and a curing module; the desulfurization wastewater flows into the alkalization module for a flocculation reaction after the volume is adjusted by the raw water regulating pond, magnesium and sulfate radical ions in the desulfurization wastewater are deposited to form floccule, the flocculated desulfurization wastewater flows into the sludge separating and recycling module for sludge sorting, the sorted sludge is treated separately, the sorted desulfurization wastewater is subjected to salinity testing, the low-salinity desulfurization wastewater flows back to a desulphurization island, the high-salinity desulfurization wastewater flows into the calcium removal module, so that the concentration of calcium ions in the desulfurization wastewater is reduced, and water is softened; the pH of outflow water from the calcium removal module is regulated until the water is neutral, and the water flows into the reduction module which adopts a nanofiltration system and a reverse osmosis system for desalination. The device can realize zero discharge of the desulfurization wastewater.

Owner:SHENGFA ENVIRONMENT PROTECTION TECH XIAMEN CO LTD

'Xianlinggubao' new preparation, its preparing method and application

InactiveCN1634293ADisintegrates quicklyPromote dissolutionSkeletal disorderUnknown materialsAdjuvantAdditive ingredient

The invention discloses a compound traditional Chinese medicinal extract, which comprises (by weight ratio) epimeddium 1167, dipsacus root 167, root of red rooted saliva 83, anemarrhena rhizome 83, psoralea fruit 83, dried rehmannia root 83, and right amount of pharmaceutically acceptable adjuvant or base material. The compound can be prepared into the dosage form of soft capsule, emulsifying tablet and dressed dispersing tablet, which can be used for treating women's climacteric osteoporosis and senile dementia.

Owner:叶耀良

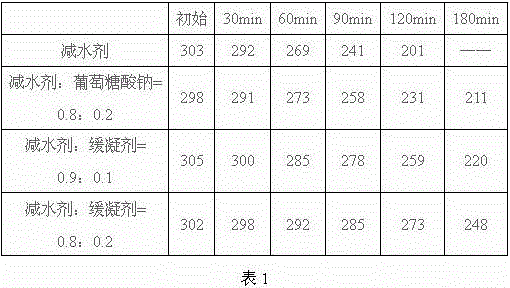

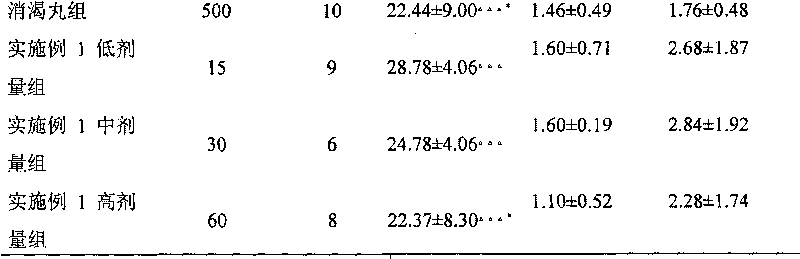

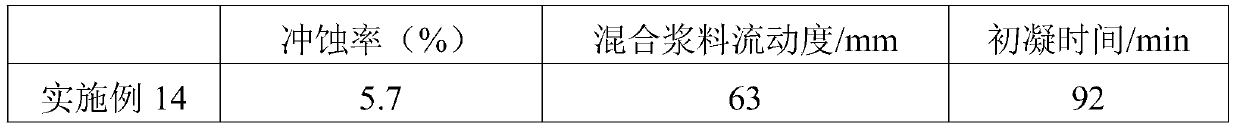

Polyaspartic-acid-containing architectural retarder and preparation method thereof

The invention provides a polyaspartic-acid-containing architectural retarder and a preparation method thereof. The preparation method comprises the following steps: carrying out esterification reaction on polyaspartic acid and unsaturated alcohol, and carrying out copolymerization reaction on the esterification reaction product, unsaturated carboxylic acid, unsaturated sulfonic acid and the like to obtain the architectural retarder. The architectural retarder has the aspartic acid structure, and thus, can lower the calcium ion concentration in the concrete system and inhibit the ettringite structure from formation, thereby achieving the effects of setting retarding and plasticity maintaining.

Owner:SHANGHAI TAIJIE CHEM

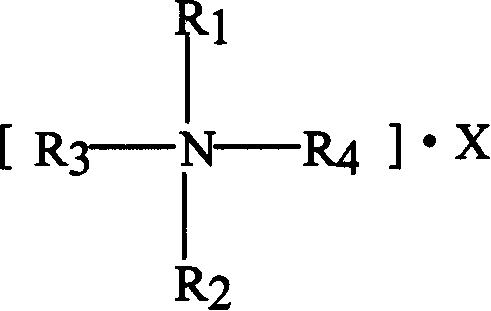

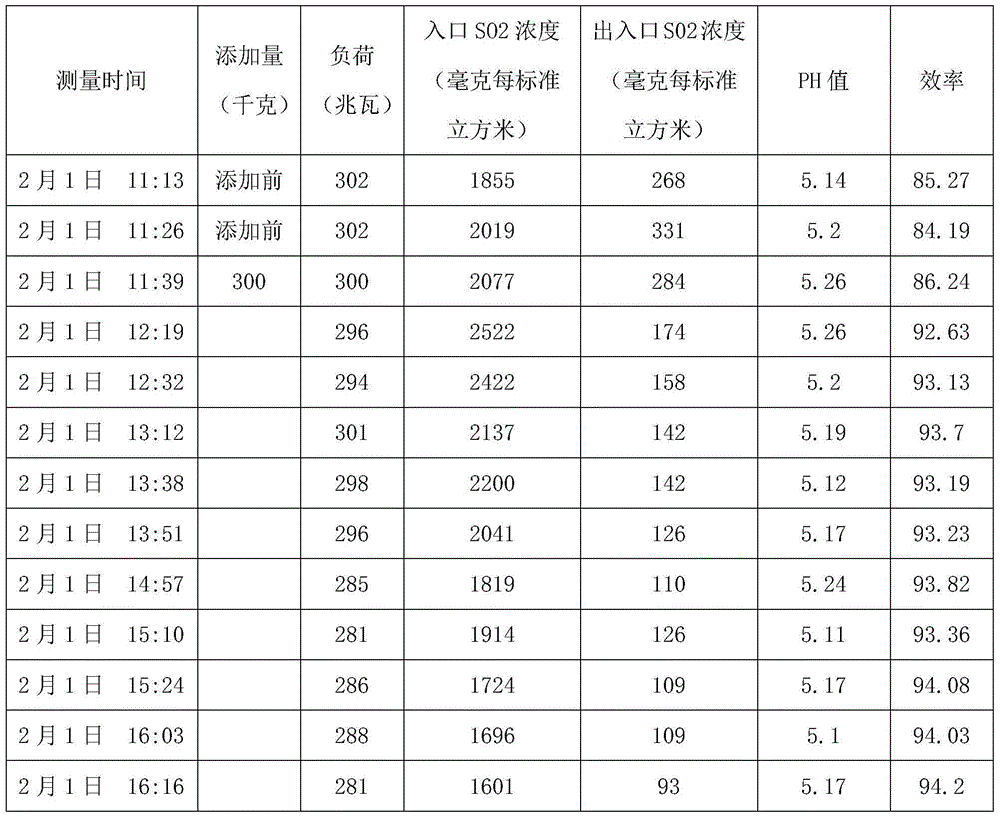

Method for decalcifying hydrocarbon oil raw material using quaternary ammonium salt

InactiveCN1611568AReduce calcium concentrationReduce consumptionHydrocarbon oils refiningDemulsifierElectricity

This invention involves the method of adopting quaternary ammonium salt to decalcify hydrocarbon oil material and mainly solves such problems existing in previous technology as too much consumption of electricity in electric desalting technology and actual low decalcification rate. By technological scheme of uniform mixing at least hydrocarbon oil, precipitant, quaternary ammonium salt, water and optional demulsifier to separate oil from water and get decalcified hydrocarbon oil material from aqueous solution, this invention can solve this problem well and can be applied in crude decalcification industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating and extracting myocardial cells of grown-up rats by adopting one-step enzyme digestion process

InactiveCN102911909AReduce calcium concentrationIncreased chance of calcium imbalanceArtificial cell constructsVertebrate cellsEnzyme digestionBovine serum albumin

The invention discloses a method for separating and extracting the myocardial cells of grown-up rats by adopting a one-step enzyme digestion process. The method comprises the steps of: carrying out reverse perfusion through aorta by adopting a Langendorff perfusion device, sequentially perfusing by using a calcium-containing solution, a calcium-free EGTA (Ethylene Glycol Tetraacetic Acid) solution and a II collagenase solution, collecting a II collagenase circulating solution to be added into a 10% BSA (Bovine Serum Albumin) solution, placing the ventricle in a constant-temperature shaker for shaking and digesting, blowing and beating the circulating solution by using a suction tube until the circulating solution is completely digested to obtain a digestion solution, filtering, naturally settling the filtrate, collecting cell sediments, and suspending in an enzyme eluant and repeatedly settling to obtain the myocardial cells. 75-93 percent of the rat myocardial cells obtained by adopting the method have activity, and the yield of living cells of the heart of each rat can reach up to about (5-8)*10<8>. According to the invention, the myocardial cells are separated by adopting single digestive enzyme and are settled by adopting a step-by-step gradient recalcification method, thus the experimental steps are simplified and the survival rate of the myocardial cells is greatly increased. The method is simple and economic, and is used for effectively separating the myocardial cells of grown-up rats.

Owner:AFFILIATED HOSPITAL OF ZUNYI MEDICAL COLLEGE

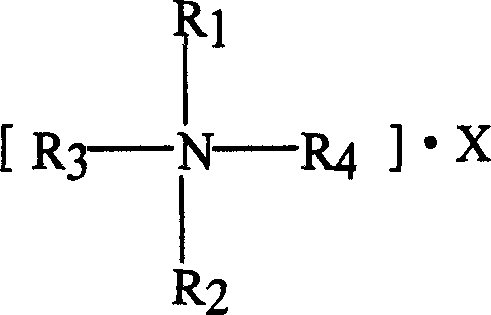

Method for comprehensive treatment and recycling of ammonium sulfate wastewater of rare-earth smelting

ActiveCN106396163ANo foulingGuarantee continuous and stable operationMultistage water/sewage treatmentAluminum IonFiltration

The invention discloses a method for comprehensive treatment and recycling of ammonium sulfate wastewater of rare-earth smelting and belongs to the technical field of environmental protection. The method comprises the steps: adding a neutralizer into the ammonium sulfate wastewater of rare-earth smelting so as to remove calcium, magnesium, iron and aluminum ions, and introducing carbon dioxide gas into the wastewater so as to further remove the calcium ions; enabling clarified liquor to enter a stripping deamination tower, and carrying out distillation so as to remove ammonia nitrogen from the clarified liquor and recover condensed weak aqua ammonia; and adjusting the pH of the ammonia-nitrogen-removed clarified liquor, carrying out filtration by a reverse osmosis membrane, and recycling purified water obtained through filtration to production. According to the method, the pollution problem of the high-hardness, high-alkalinity, high-ammonia-nitrogen and high-salinity ammonium sulfate wastewater of rare-earth smelting is solved, and the treatment cost of the ammonium sulfate wastewater of rare-earth smelting is reduced through recovering byproducts such as high-purity water, weak aqua ammonia and calcium carbonate, so that the method has good social and economic benefits.

Owner:JIANGSU WODEKAI ENVIRONMENTAL PROTECTION TECH CO LTD

Dialysis agent a containing acetic acid and acetate salt, and a two-part dialysis agent using thereof

ActiveUS20140097386A1Good storage stabilityReduce acetic acid odorOther chemical processesDialysis systemsAcetic acidAcetate ion

The purpose of the present invention is to provide a dialysis agent A, which is able to set the total acetate ion content in the dialysate to a low value, excellent in storage stability of glucose, able to reduce the acetic acid odor, and able to suppress the corrosion of the dialysate delivery system and the dialysis machine, as well as to provide a two pack type dialysis agent utilizing the dialysis agent A.In the dialysis agent A used in the preparation of a bicarbonate dialysate, which is used as one part of a two pack type dialysis agent, it becomes possible to prepare a bicarbonate dialysate having the total acetate ion concentration of between 2 mEq / L or more and less than 6 mEq / L by allowing to include glucose, acetic acid and acetate salt and to satisfy the molar ratio of 1:0.5 to 2 of acetic acid and acetate salt, and include acetic acid and acetate salt in a total amount of between 2 mEq or more and less than 6 mEq in the dialysis agent A required to prepare 1 L of the bicarbonate dialysate. Moreover, according to the dialysis agent A, in addition to the excellent stability of glucose, it is possible to reduce the acetic acid odor, and furthermore possible to suppress the corrosion of the dialysate delivery system and the dialysis machine.

Owner:TOMITA PHARMA

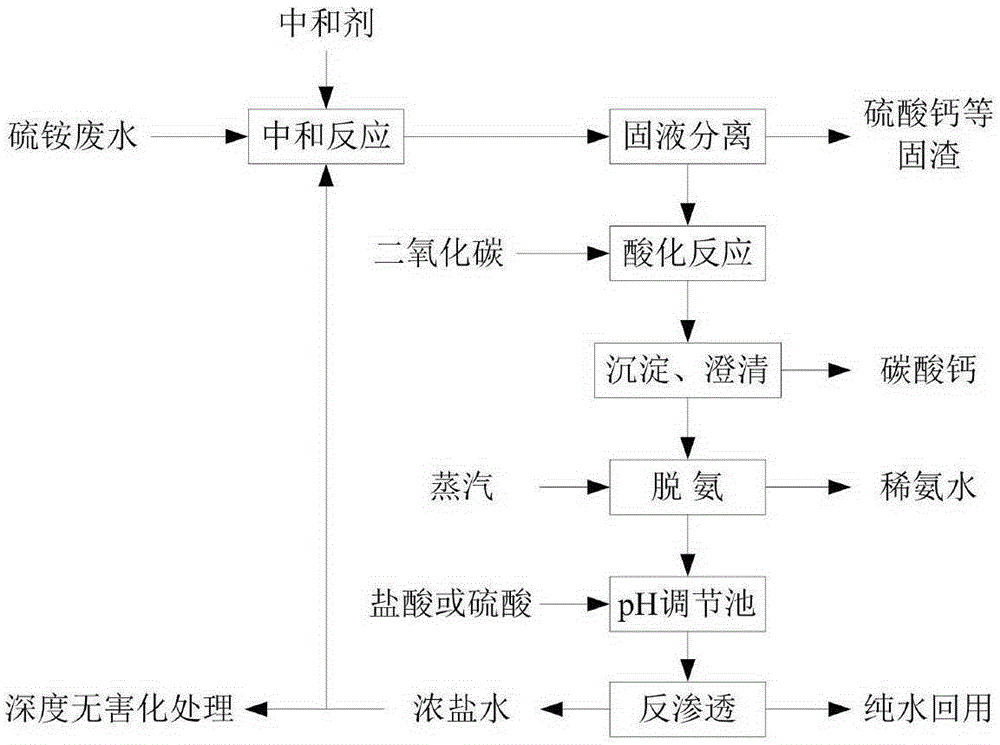

Limestone-gypsum wet flue gas desulfurization synergist and preparation method thereof

InactiveCN105251335AIncrease profitGood pH buffering capacityDispersed particle separationOrganic acidFood additive

The present invention discloses a limestone-gypsum wet flue gas desulfurization synergist, which comprises, by weight, 70-90 parts of an organic acid salt, 5-20 parts of an organic anhydride, and 5-15 parts of a surfactant. According to the present invention, the type of the component of the desulfurization synergist is simplified while the obtained synergetic desulfurization effect is good; due to the excellent and stable desulfurization effect, under the same conditions, the used raw materials are less, the production cost of the enterprise is low, and the performance price ratio is high; and the sodium diacetate accounting for the absolute proportion in the desulfurization synergist components is the internationally-recognized efficient, safe and inexpensive food additive, and has characteristics of good safety and good environmental protection during the production process, the storage and transportation process, the use process and other processes.

Owner:麦适(上海)化工有限公司

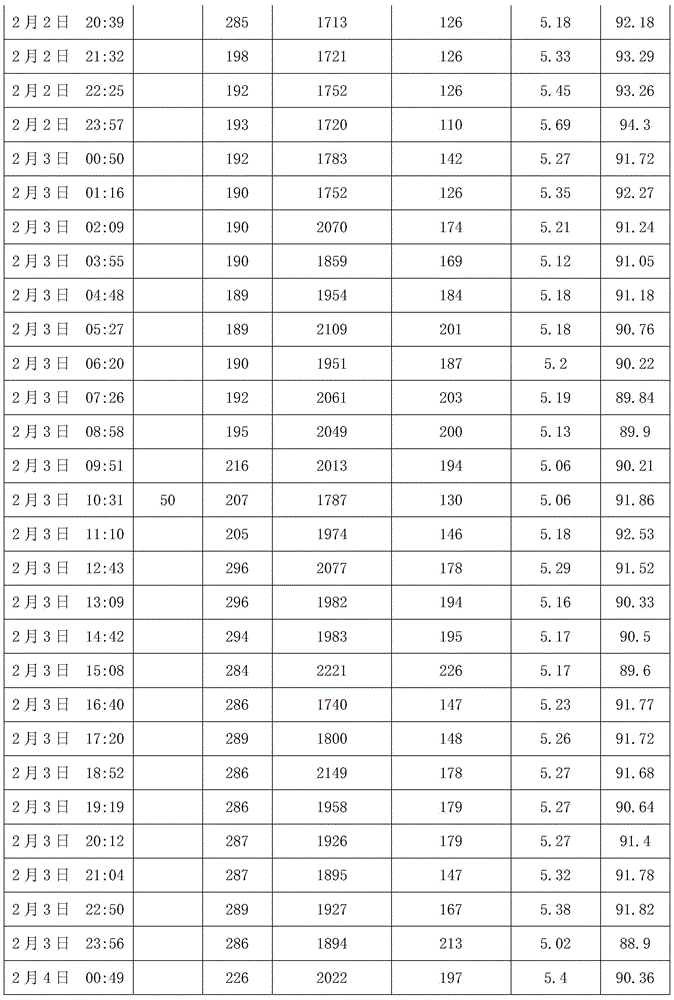

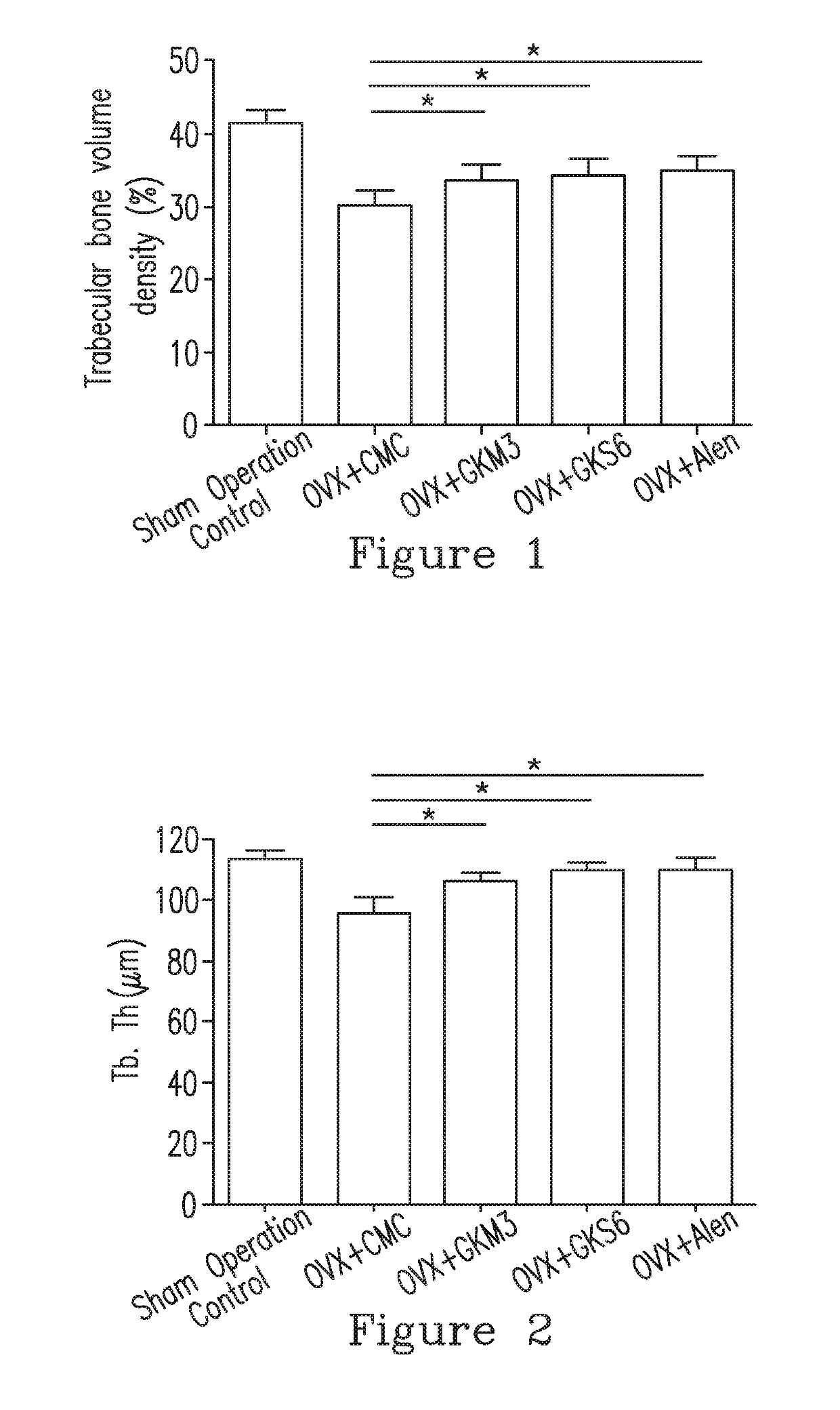

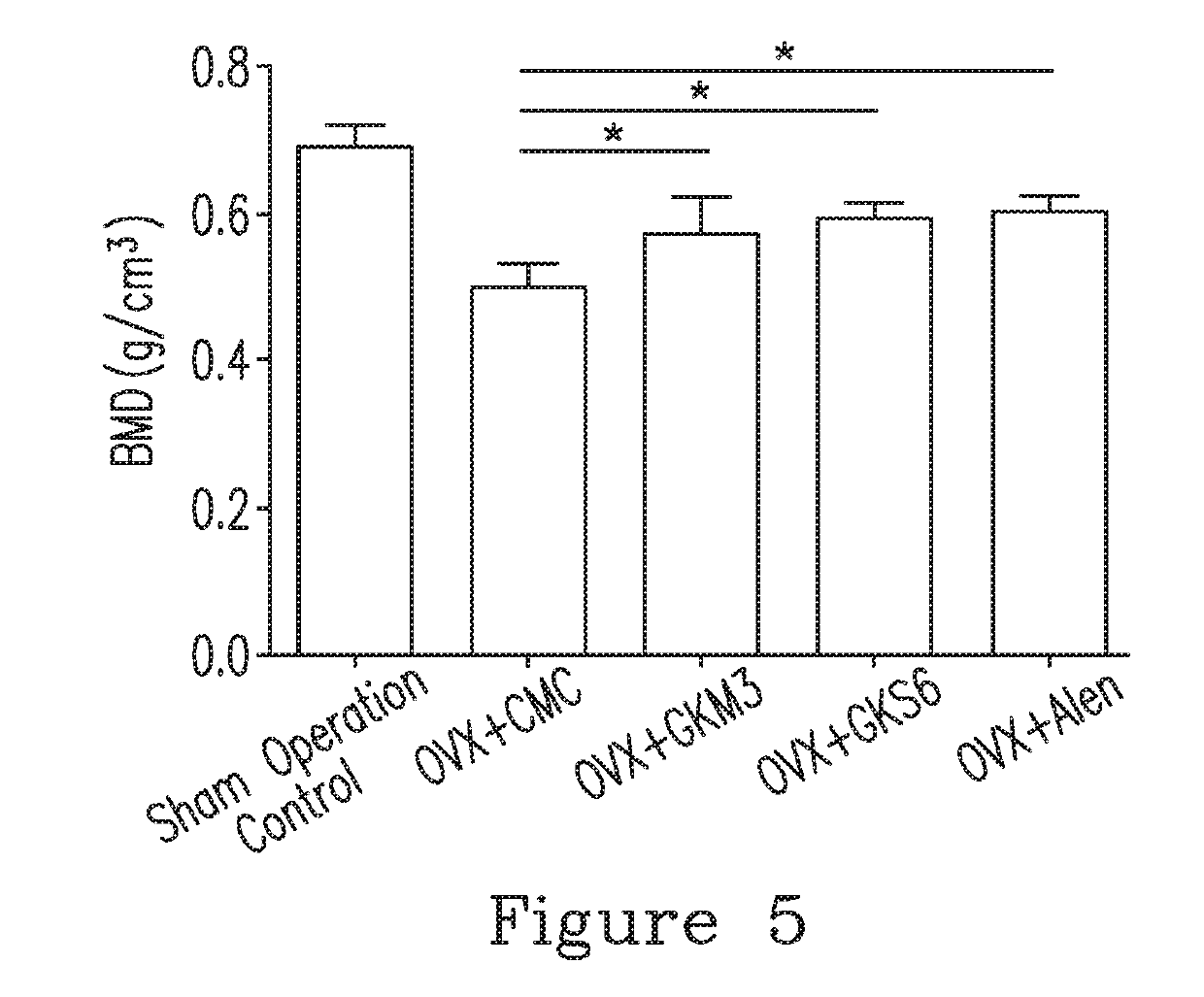

Method and composition for preventing, treating or relieving bone diseases

ActiveUS20190321420A1Increase in calcium concentrationImproves the bone parameterLactobacillusPharmaceutical delivery mechanismMedicineLactobacillus paracasei

The present invention discloses uses of treating, preventing or improving bone diseases by Lactobacillus or a composition including the Lactobacillus. The Lactobacillus and compositions can increase the blood calcium concentration, the trabecular bone volume density (BV / TV ratio), the trabecular thickness (Tb.Th), the trabecular number (Tb.N) and the bone mineral density (BMD) of a subject, and reduce trabecular spacing (Tb.Sp) of the subject. Further, the present invention discloses a method for treating a subject diagnosed with a bone disease, comprises steps of identifying the subject having the bone disease, and administering to the subject an effective amount of a composition including at least one of Lactobacillus plantarum GKM3 and Lactobacillus paracasei GKS6, wherein the Lactobacillus plantarum GKM3 is deposited in China General Microbiological Culture Collection Center (CGMCC) with a deposition number of CGMCC 14565 on Aug. 25, 2017, and the Lactobacillus paracasei GKS6 is deposited in CGMCC with a deposition number of CGMCC 14566 on Aug. 25, 2017.

Owner:GRAPE KING

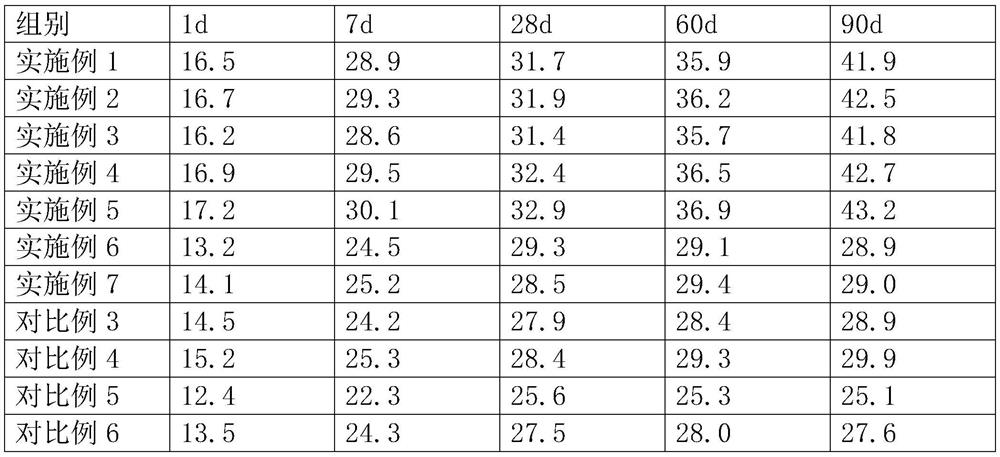

Modified aluminate cement and preparation method thereof

ActiveCN112209642AImprove corrosion resistanceImprove water resistanceSolid waste managementAluminateSilicic acid

Provided modified aluminate cement is prepared from the following raw materials: aluminate cement, titanium-silicon micro-nano capsules, magnesium oxide, a phosphate, fly ash, modified acrylic emulsion and an activating agent, wherein the titanium-silicon micro-nano capsule is prepared from orthosilicate and titanate under the conditions of a surfactant and alkalinity. The aluminate cement prepared by the invention is wide in raw material source and simple in preparation method, has good high-temperature resistance, wear resistance, sulfate corrosion resistance, adhesion, crack resistance, freezing resistance, seepage resistance, corrosion resistance and aging resistance, also has good effects of adsorbing and degrading formaldehyde and organic pollutants due to the TiO2 structure, plays agood role in environmental protection, ensures the safety as a structural part, and has a wide application prospect.

Owner:山东山铝环境新材料有限公司

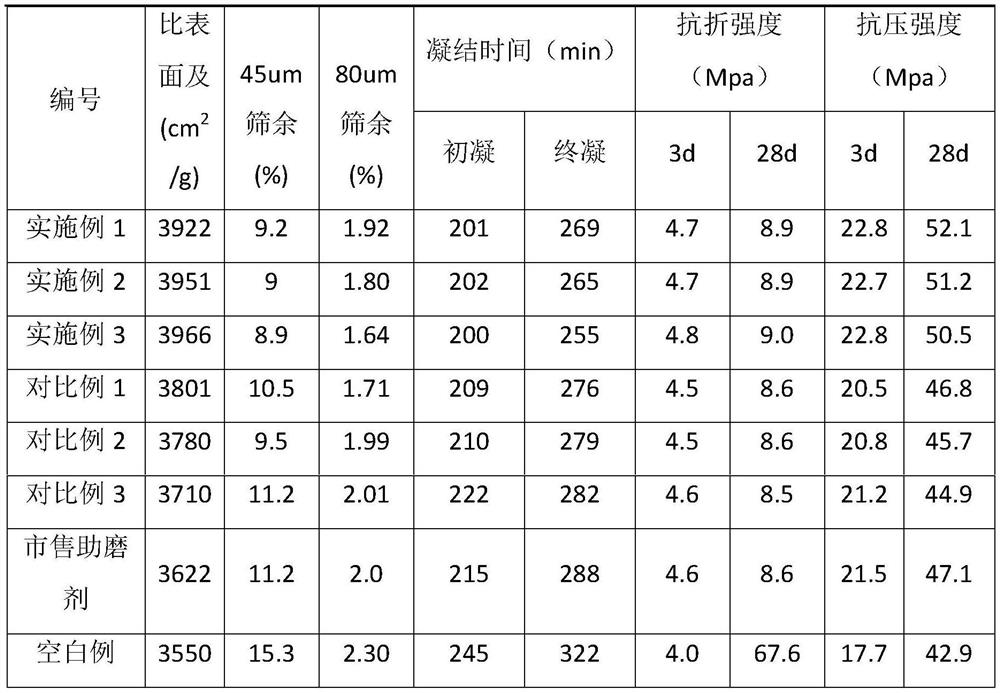

Application of pseudo-ginseng and extract thereof in preparing medicament for curing and/or preventing diabetic neuropathies

ActiveCN101700264APrevent inflowReduce calcium concentrationNervous disorderMetabolism disorderPANAX NOTOGINSENG ROOTPanax notoginseng extract

The invention relates to a new application of pseudo-ginseng, pseudo-ginseng extract, panax notoginseng saponins, and panax notoginseng saponins composite, namely, a new application in preparing medicament for curing and / or preventing diabetic neuropathies.

Owner:许淑清

Modified triethanolamine grinding aid

The invention relates to a modified triethanolamine grinding aid. The modified triethanolamine grinding aid comprises the following components: first modified triethanolamine, second modified triethanolamine, molasses, silicone emulsion, sodium pyrophosphate and water. The modified triethanolamine grinding aid is absorbed on surfaces of solid particles, changes the structural property of particlesurfaces, prevents particle agglomeration, improves the flowability of materials, can effectively prevent closure of new cracks, accelerates expansion of material cracks, can rapidly eliminate or weaken aggregation and adhesion among particles, and ensures that the grinding efficiency is improved by 12 percent or more, the 3d strength is improved by greater than or equal to 5MPa, 28d strength is improved by greater than or equal to 6MPa, the initial setting time is greater than or equal to 200min, and the final setting time is smaller than or equal to 300min.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for desulfurizing sintering machine flue gas by magnesium strengthened line-gypsum

InactiveCN102000494AHigh activityReduce calcium concentrationCalcium/strontium/barium sulfatesDispersed particle separationSolubilityMagnesium salt

The invention discloses a method for desulfurizing sintering machine flue gas by magnesium strengthened line-gypsum, comprising the following steps of: purifying the sintering machine flue gas by an electric precipitator and importing the sintering machine flue gas into an absorption tower by a draught fan; causing the flue gas to make reverse convection contact with the atomized desulfurization liquid sprayed by a nozzle in the tower to form a favorable atomized absorption area and complete the desulfurization absorption of the flue gas; demisting the desulfurized flue gas by a demister at the top of the tower and then directly discharging the flue gas from a chimney at the top of the tower; and prolonging the contact time between the flue gas and the slurry by adopting secondary impact technology in the absorption tower so as to improve the desulfurization rate. Lime slurry and MgO slurry are mixed in the desulfurization liquid, and MgO occupies 1-3% of the weight of the lime slurry; and the absorption tower is internally provided with a tower kettle agitator. In the invention, 1-3% of lime slurry is replaced by magnesium hydroxide solution, and the magnesium salt has stronger dissolubility to ensure that the alkalinity of the solution is 10-15 times higher than calcium-based technology; therefore, the desulfurization rate is as high as 95% when the gas-liquid interface is relatively faster in equivalent gas to liquid ratio.

Owner:秦皇岛双轮环保科技股份有限公司

Composite cement admixture

The invention discloses a composite cement admixture, and belongs to the technical field of cement process admixtures. The grinding aid is prepared from the following raw materials in parts by weight:20-30 parts of a compound alcohol amine component, 10-15 parts of isooctyl alcohol phosphate, 4-8 parts of molasses, 4-8 parts of an emulsifying dispersant, 5-10 parts of triethylene glycol, 3-5 parts of an accelerant and 50-70 parts of water. The isooctanol phosphate and the composite alkylol amine component are in synergistic interaction, so that the grinding aid is small in mixing amount and good in grinding aid effect, and the 3d and 28d compressive and flexural strength of cement can be remarkably improved under the mixing amount of 0.01%; in addition, the raw materials are easy to obtain, and the preparation method is simple and suitable for popularization and application.

Owner:安徽海螺材料科技股份有限公司 +1

BAPTA and application of derivant thereof in preparing analgesic drugs

The invention discloses a BAPTA and an application of a derivant thereof, in particular to an application of the derivant in preparing analgesic drugs. Clinical indications include headache, prosopalgia, dysmenorrheal, postoperative pain, cancer pain, viscera pain, postherpetic neuralgia, phantom limb pain, HIV, pathologic pain related to multiple sclerosis, morphine class medicine tolerance or addiction patient pain and serious chronic intractable pain or usual clinical pain diseases.

Owner:HENGXING PHARMA INST HEFEI

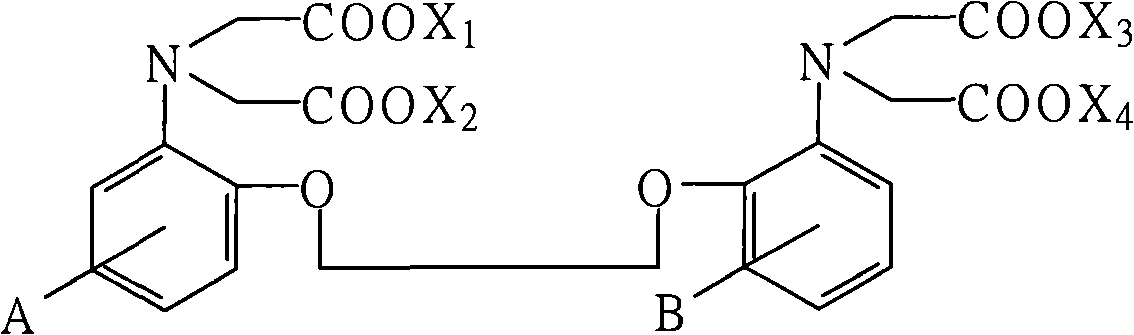

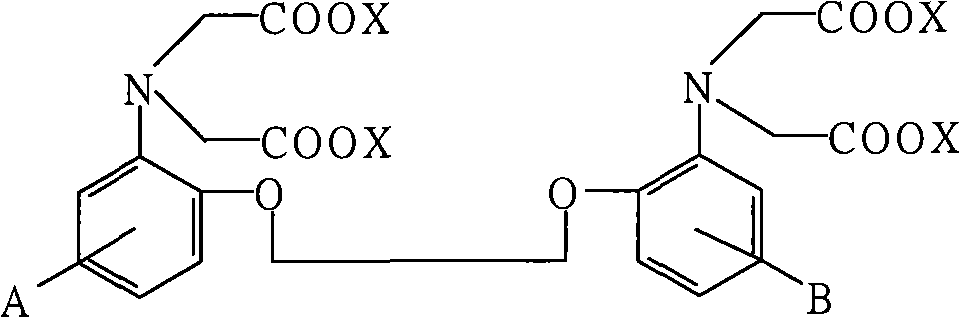

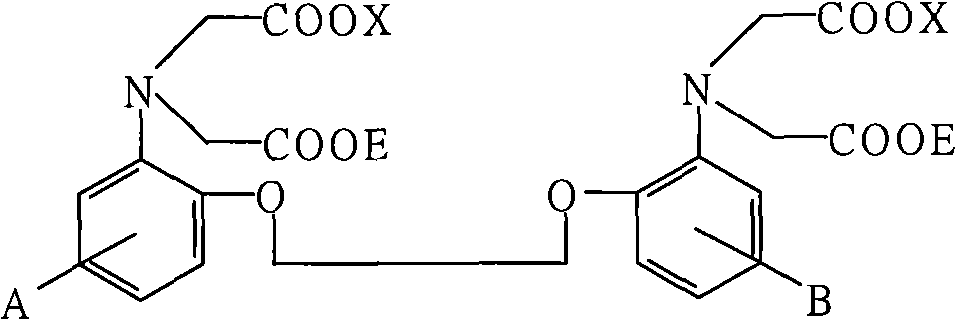

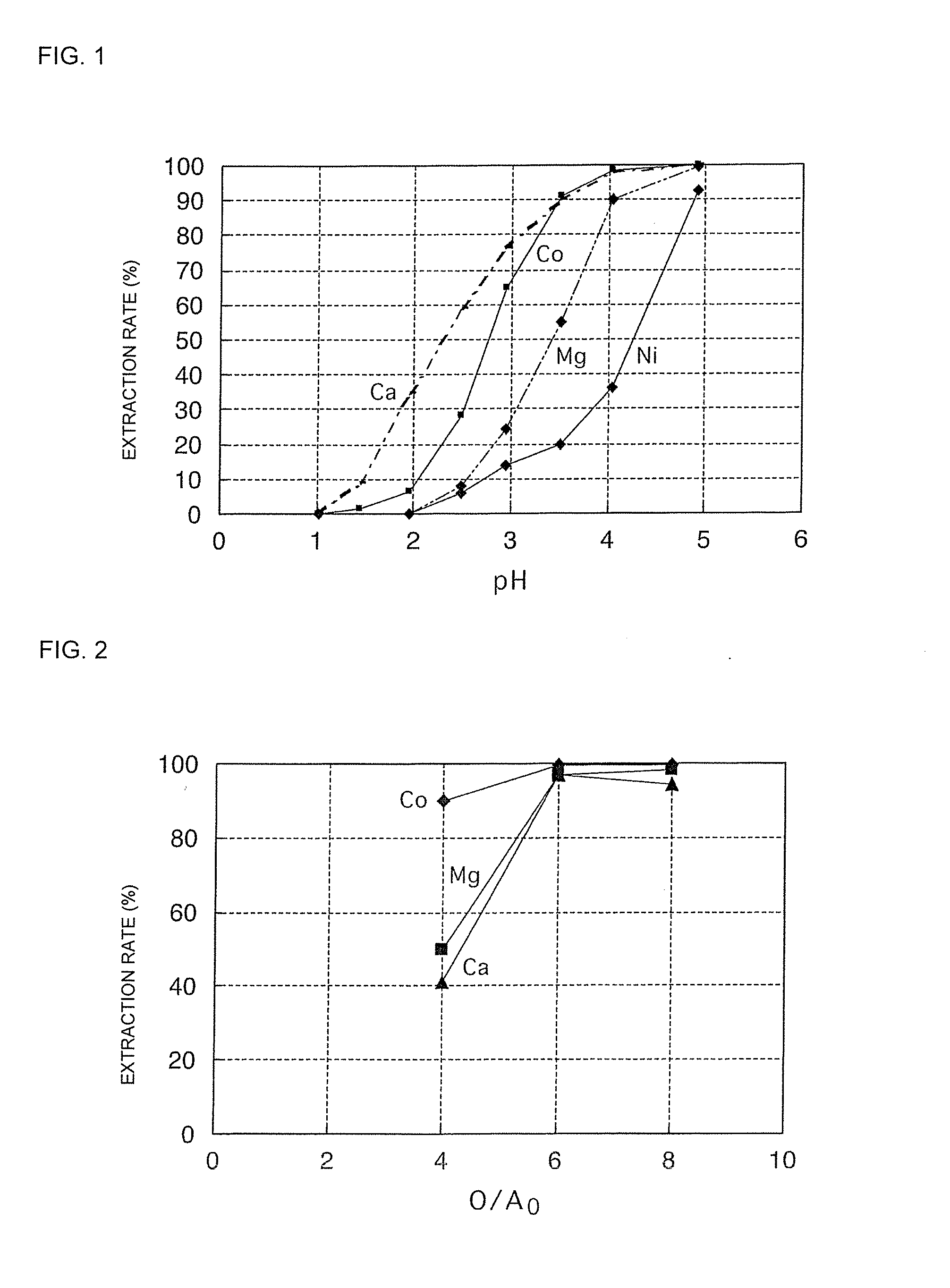

Method for producing cobalt sulfate

ActiveUS20140348731A1Reduce calcium concentrationHigh puritySolvent extractionIron compoundsDiluentSolvent

Provided is a method for producing cobalt sulfate, wherein, on the occasion of separating an acidic solution containing calcium, magnesium and sodium as impurities from a cobalt chloride solution by solvent extraction, when a diluent is added to the extractant to be used to dilute the extractant by 10% to 30% by volume; in Step 1, the operational pH is maintained in the range of 4.0 to 5.0 and the liquid volume ratio of organic phase / liquid phase is maintained in the range of 5.0 to 7.0; in Step 2, the operational pH is maintained in the range of 4.0 to 4.5 and the liquid volume ratio of organic phase / liquid phase is maintained in the range of 5.0 to 10.0; and in Step 3, the pH is maintained in the range of 0.5 to 1.0.

Owner:SUMITOMO METAL MINING CO LTD

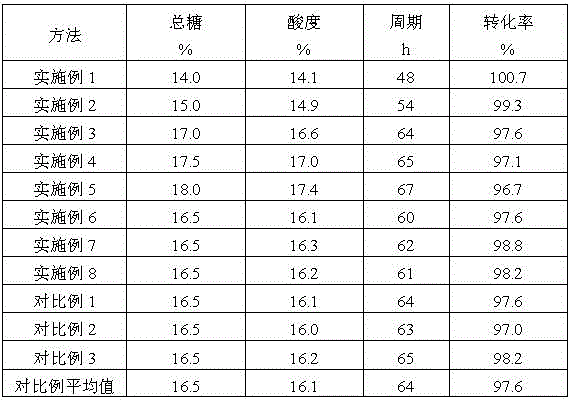

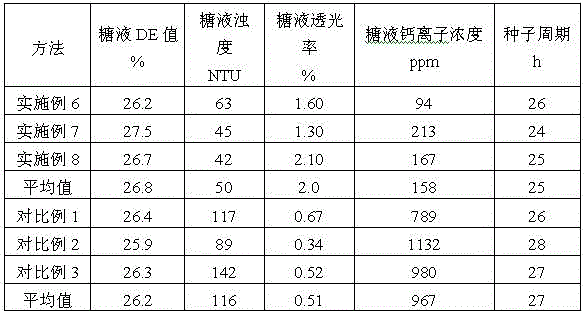

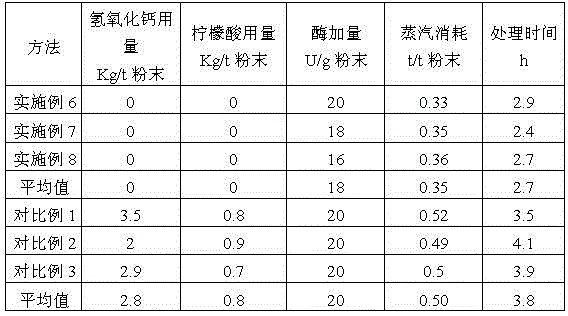

Processing method for starchiness materials and application of processing method in citric acid preparing industry

InactiveCN105567749AGood flocculation effectReduce dosageMicroorganism based processesFermentationAmylaseSide effect

The invention discloses a processing method for starchiness materials. According to the processing method, citric-acid waste water is utilized as a raw material. The processing method comprises the steps of material smashing, pulp mixing, once enzyme supplementation, once spraying, flashing and solid-liquid separation; and the enzyme is selected from acid-resisting alpha- thermostable amylase. The processing method is suitable for low-pH liquefying conditions. According to the processing method, the operation is greatly simplified, the energy consumption and producing cost are reduced, the ideal protein flocculating and purifying effect is guaranteed, and the side effects caused to following fermentation and purification are reduced. When the processing method is applied to the critic acid preparing industry, the seed growing speed is obviously increased, the seed cultivating period is shortened, the fermentation index is further improved, the fermentation period is shortened, and the converting rate is improved. Thus, the processing method has important industrial application value.

Owner:JIANGSU GUOXIN UNION ENERGY CO LTD +1

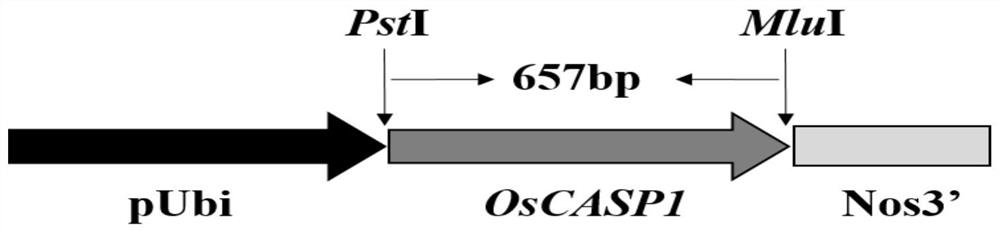

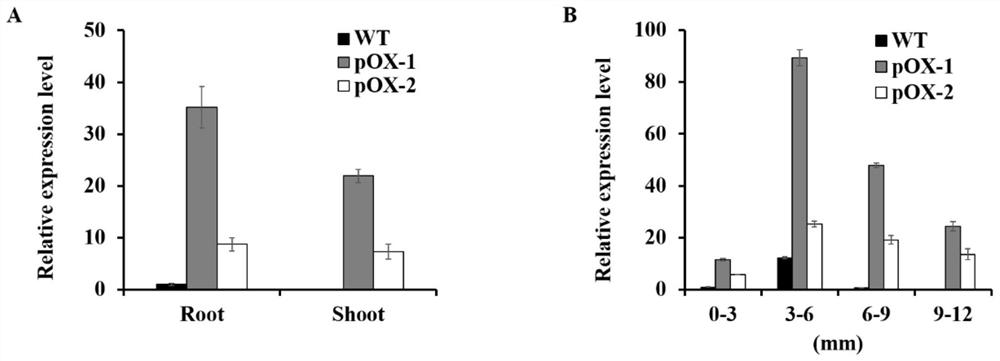

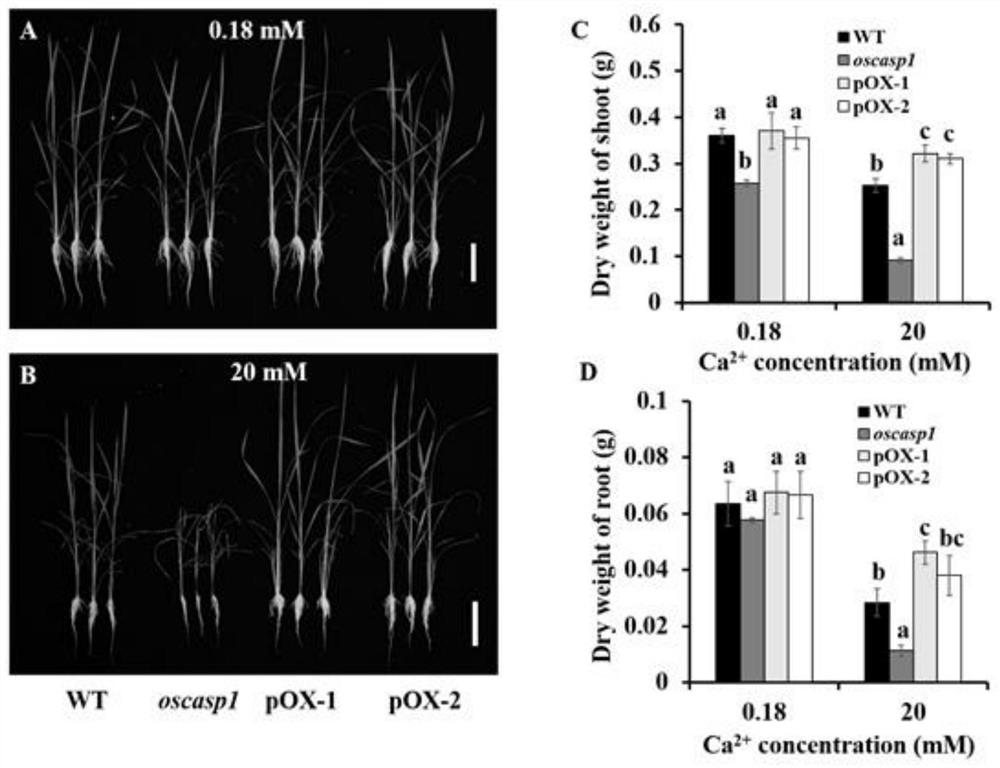

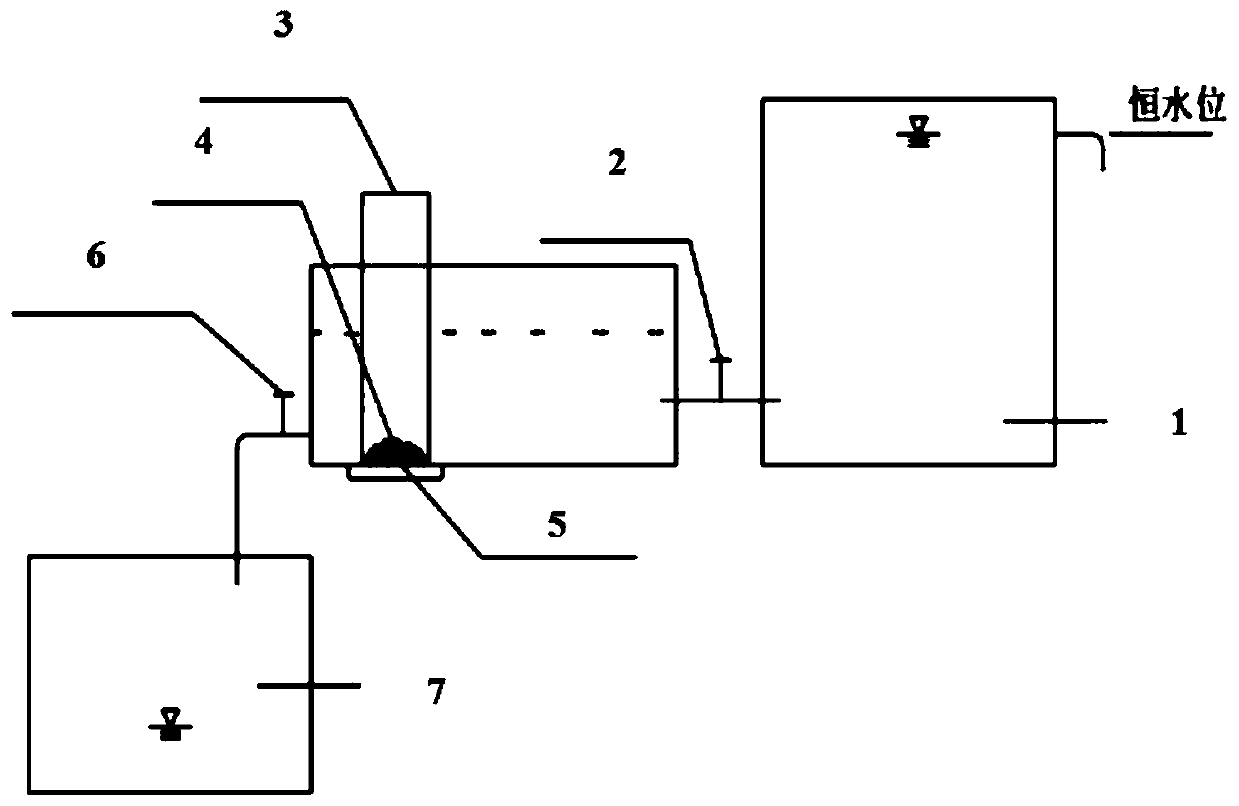

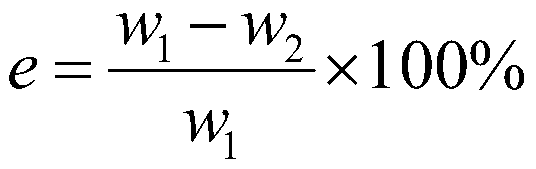

Rice OsCASP1 gene and application thereof

InactiveCN112011548AReduce accumulationImprove adaptabilityPlant peptidesFermentationBiotechnologyTransmembrane domain

The invention discloses a rice OsCASP1 gene; the sequence of the gene is shown as SEQ ID NO.1; the encoded protein of the rice OsCASP1 gene contains four transmembrane structural domains; and the sequence of the encoded protein is shown as SEQ ID NO.2. In the technical scheme of the invention, an OsCASP1 over-expressed transgenic strain is constructed; and the fact that the over-expressed strain enhances the calcium tolerance under a high-calcium condition is found. OsCASP1 over-expression can induce early-stage formation of a root tip casparian band; accumulation of calcium in stems is selectively reduced; and therefore the adaptability of rice to the high-calcium environment is improved. According to the invention, the understanding of the relationship among the formation of the casparian band, calcium absorption and calcium tolerance in rice is enhanced; and a method for obtaining a high-calcium-tolerance material is provided for preventing and treating heavy metals.

Owner:GUANGXI UNIV

Cement anti-erosion agent for high-pressure jet grouting and use method thereof

The invention discloses a cement anti-erosion agent for high-pressure jet grouting and a use method thereof. The cement anti-erosion agent is prepared by mixing the following raw materials in parts byweight: 65-93 parts of aluminum-containing inorganic salt, 5-12 parts of a thickening agent, 2-5 parts of a mineral admixture and 7-18 parts of an excitant. The anti-erosion performance of cement slurry with a high water-cement ratio can be improved under a low mixing amount by the cement anti-erosion agent; the cement slurry has low fluidity and long initial setting time, a large-diameter cement-soil pile can be formed in a large-gap loose stratum, the long initial setting time facilitates construction operation of inserting a precast pile after the cement-soil pile is formed, loss of cementmaterials can be effectively avoided, and the construction is easy.

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

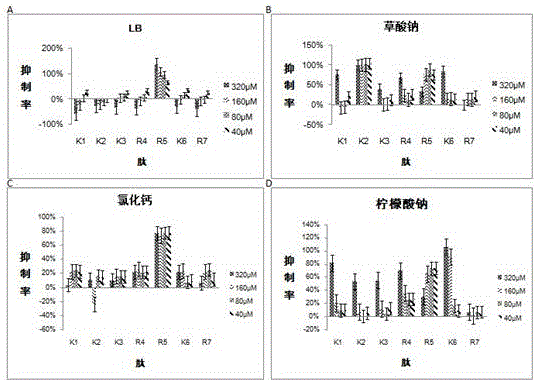

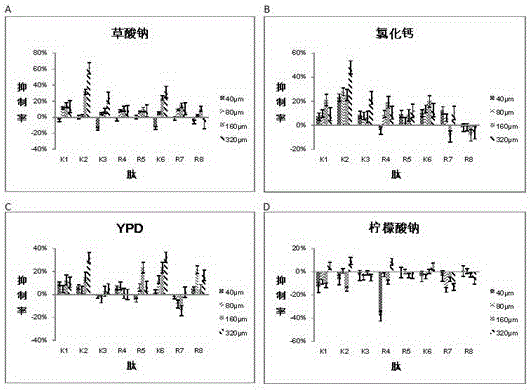

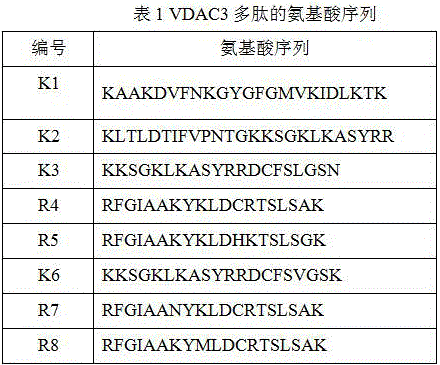

Application of VDAC protein to cell growth inhibition by utilizing oxalic acid or calcium salt and earthquake prediction

InactiveCN106432461AAccurate forecastPrevention and Mitigation of Natural DisastersAntibacterial agentsAntimycoticsWater birdEarthquake prediction

According to the invention, the affinity of VDAC3 protein on oxalic acid or calcium salt is proved by experiments. The calcium concentration can be reduced due to formation of organic acid calcium, such as calcium oxalate and the like, and related phenomena, such as spasm and the like, can be caused by reduction of the calcium concentration and the hard and insoluble organic acid calcium salt. Continental or offshore earthquake can be predicted accurately according to inhibition behavior activities and abnormal phenomena that animals suffer from spasm, refuse food, cannot stand and are easy to capture, water birds refuse to go in the water, and seabirds fear spasm and fly towards the mainland; therefore, the invention also provides application of the VDAC3 polypeptide to earthquake prediction, and a simple, convenient and effective earthquake prediction method is established and has great benefit of preventing and reducing natural hazard in the country and even the world.

Owner:SUN YAT SEN UNIV

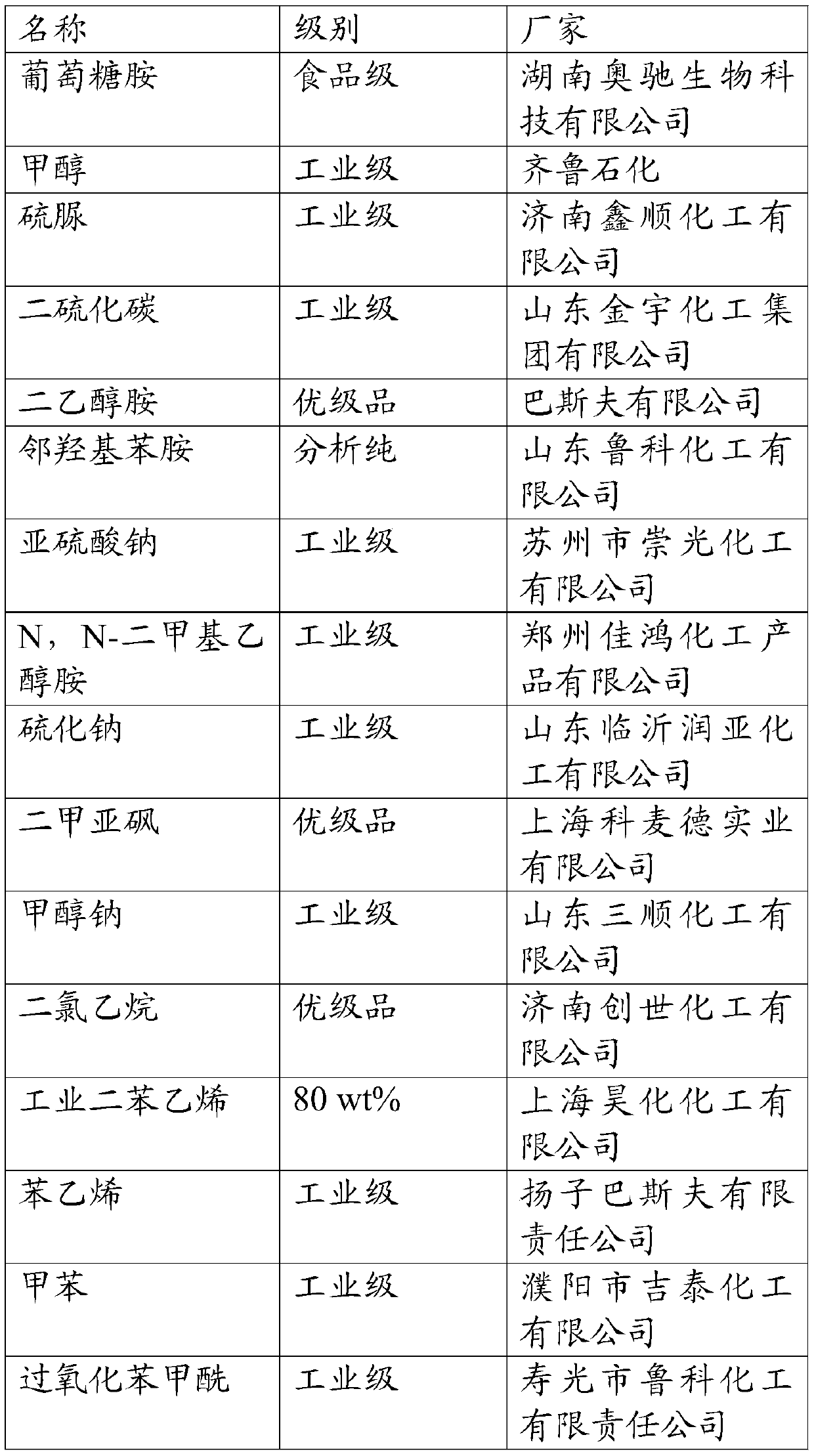

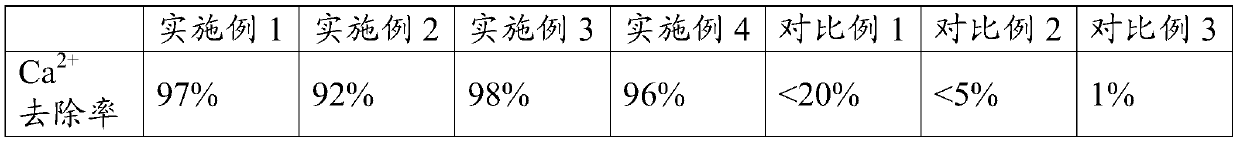

A kind of preparation method of calcium-removing resin

ActiveCN107602750BImprove chelation abilityReduce calcium concentrationAluminium chloridesAluminium chlorideChelating resin

The invention provides a preparation method of a chelating resin for removing calcium ions from an aluminum chloride solution. The method comprises the following steps: 1) performing a chloromethylation reaction by using resin dry white balls and a chloromethylation reagent to obtain chlorine balls; 2) performing a nucleophilic substitution reaction on the chlorine balls obtained in the step 1) and an organic amine solution containing hydroxy groups according to a mass ratio of (1:4)-(1:6), and performing drying to obtain a resin containing amino and hydroxy groups; 3) uniformly mixing the resin containing amino and hydroxy groups obtained in the step 2) with a sweller, and performing swelling to obtain a swelling product; and 4) performing an addition reaction on the swelling product obtained in the step 3), an alkaline matter and a sulfur compound to obtain the calcium-removing resin containing amino and hydroxy groups and sulfur. The resin obtained by the method has different functionalized structures, and greatly enhances the adsorption quantity of calcium ions. The obtained calcium-removing resin can satisfy the technical requirements for industrial preparation of aluminum oxide, creates favorable conditions for the resource reutilization of fly ash, and has great economic benefits and social values.

Owner:CHINA SHENHUA ENERGY CO LTD +1

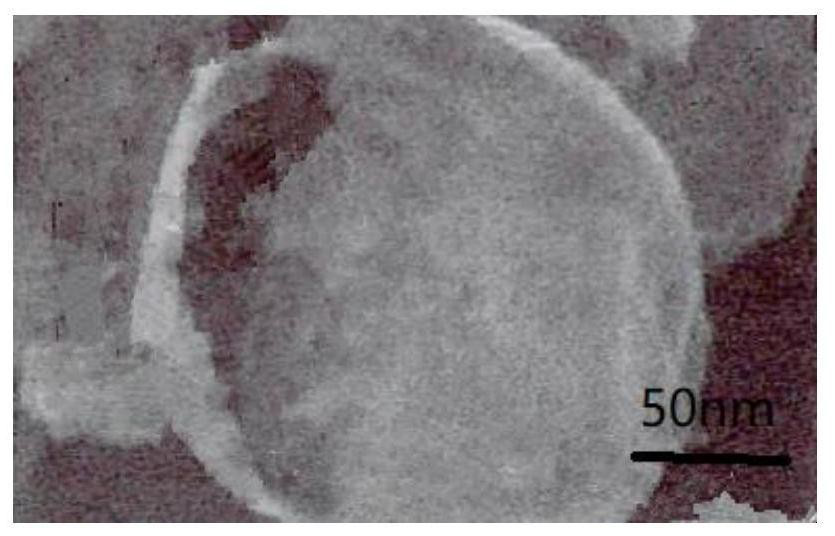

Preparing method of nano-hydroxyapatite

InactiveCN107473194AReduce calcium concentrationChange kinetic constantNanotechnologyPhosphorus compoundsIonChemistry

The invention relates to the technical field of nano-material preparing, in particular to a preparing method of nano-hydroxyapatite. According to the preparing method, firstly birch bark fiber is decomposed through alkali boiling, later microorganism degradation intake is better facilitated, acetobacter xylinum is cultured, bacterial cellulose is obtained, and a calcium ion precursor is anchored to nano bacterial fiber; next, under the effect of ammonium hydroxide, phospholipid and lecithin are hydrolyzed, the hydrolysis product, calcium ions anchored to the surface of a bacterial cellulose template, nano-hydroxyapatite ions and hydroxyl groups are slowly combined to generate crystal nucleuses, as time passes, the crystal nucleuses gradually grow, the nanoscale space of the bacterial cellulose template can stop agglomeration of the nano-hydroxyapatite ions, by controlling the pH and adding citric acid, the purpose of lowering the concentration of calcium ions is achieved, the aqueous phase homogeneous precipitation kinetic constant is changed, in the in-situ crystallization process, nano-hydroxyapatite with a small size tends to be formed, and nano-hydroxy calcium phosphate is obtained after calcination. The preparing method of nano-hydroxy calcium phosphate is wide in application prospect.

Owner:周益铭

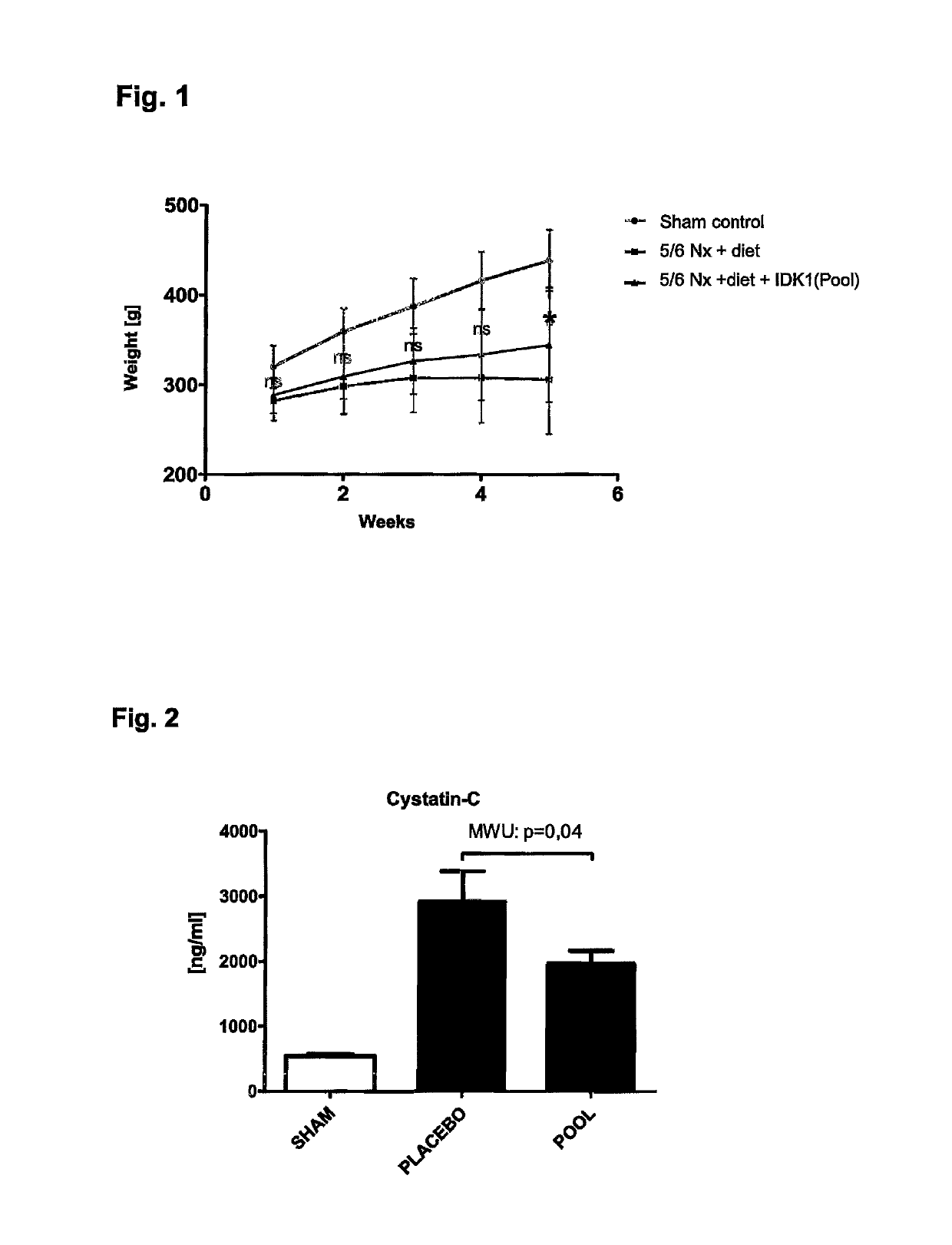

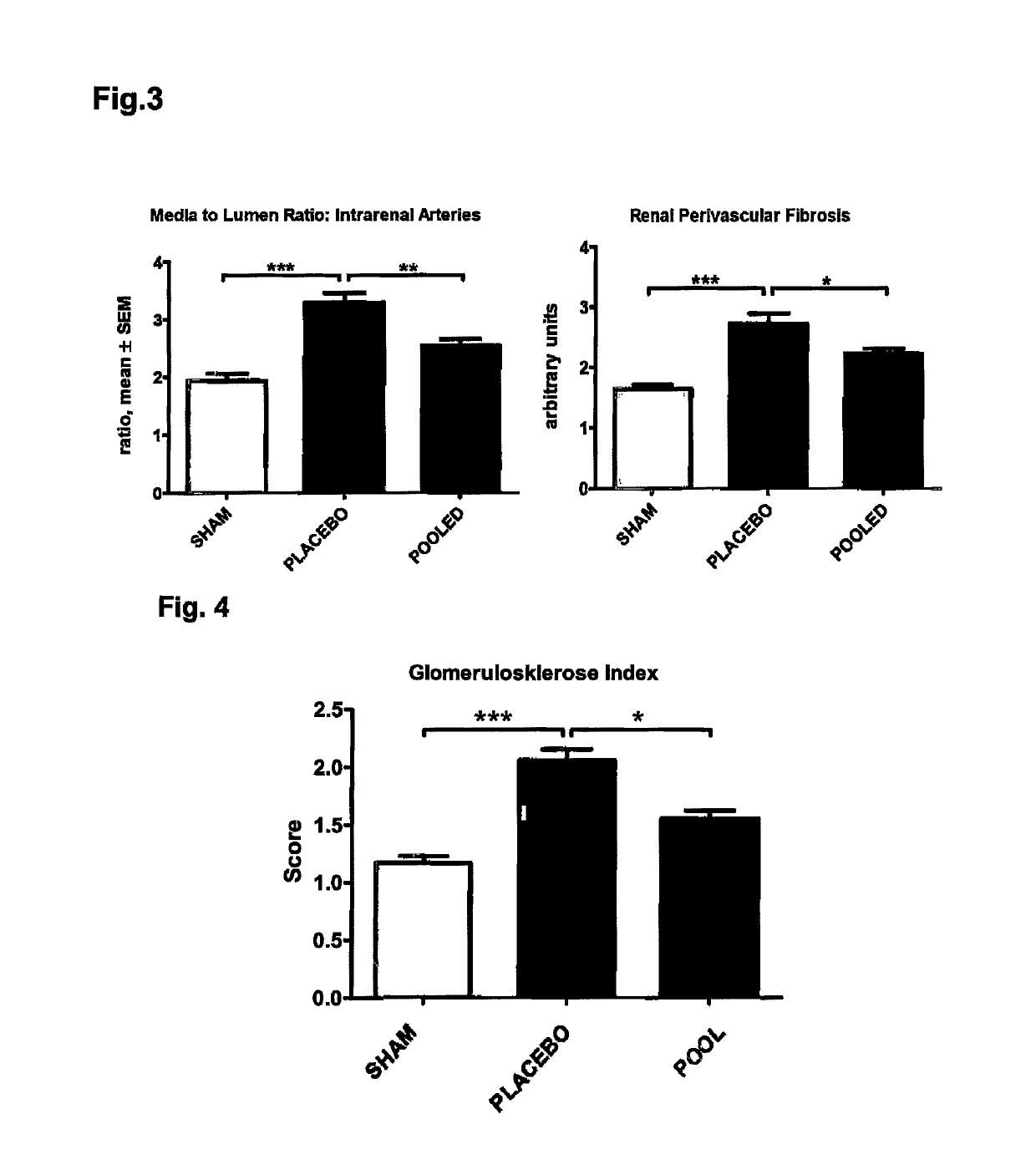

Medicament and apparatus for treating chronic kidney disease

ActiveUS10253092B2Reduce concentrationReduce calcium concentrationHaemofiltrationImmunoglobulins against cytokines/lymphokines/interferonsBone sialoproteinMortality rate

Owner:IMMUNDIAGNOSTIK AG

Medicament and apparatus for treating chronic kidney disease

ActiveUS20170204172A1Reduce concentrationReduce calcium concentrationHaemofiltrationImmunoglobulins against cytokines/lymphokines/interferonsBone sialoproteinSalivary Proteins

The present invention provides a novel therapy concept based on a removal of circulation BSP (bone sialoprotein) from the plasma of patients with chronic kidney disease (CKD), preferably by plasmapheresis or an administration of antibodies against BSP in plasma. The present invention further provides a BSP absorber material for plasmapheresis and a pharmaceutical composition namely in form of anti-BSP antibodies for direct administration which are biocompatible in humans. The beneficial effects of this therapy have been proven by the observed correspondence between levels of circulating free BSP levels and mortality of CKD patients.

Owner:IMMUNDIAGNOSTIK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com