Patents

Literature

92 results about "Damage zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

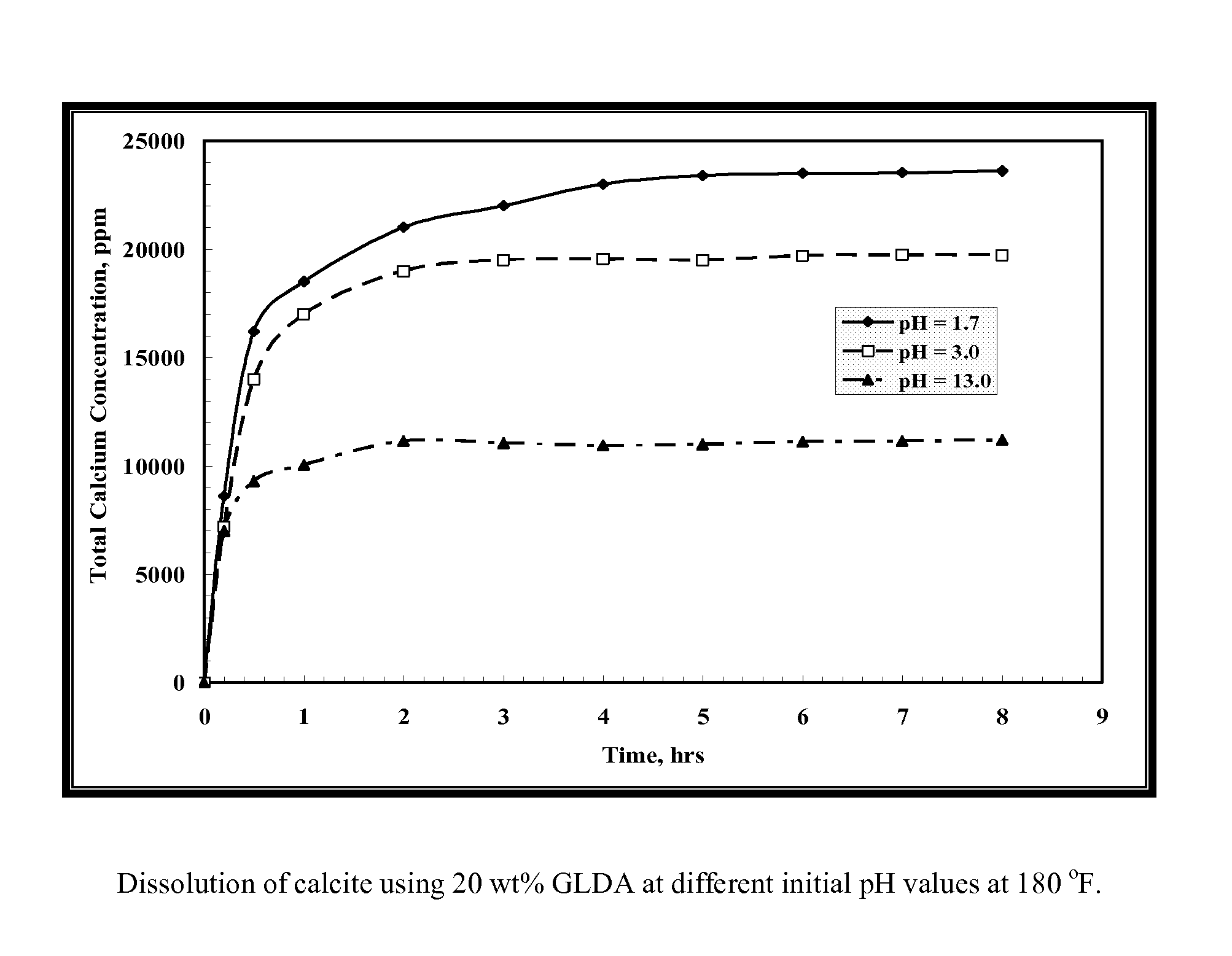

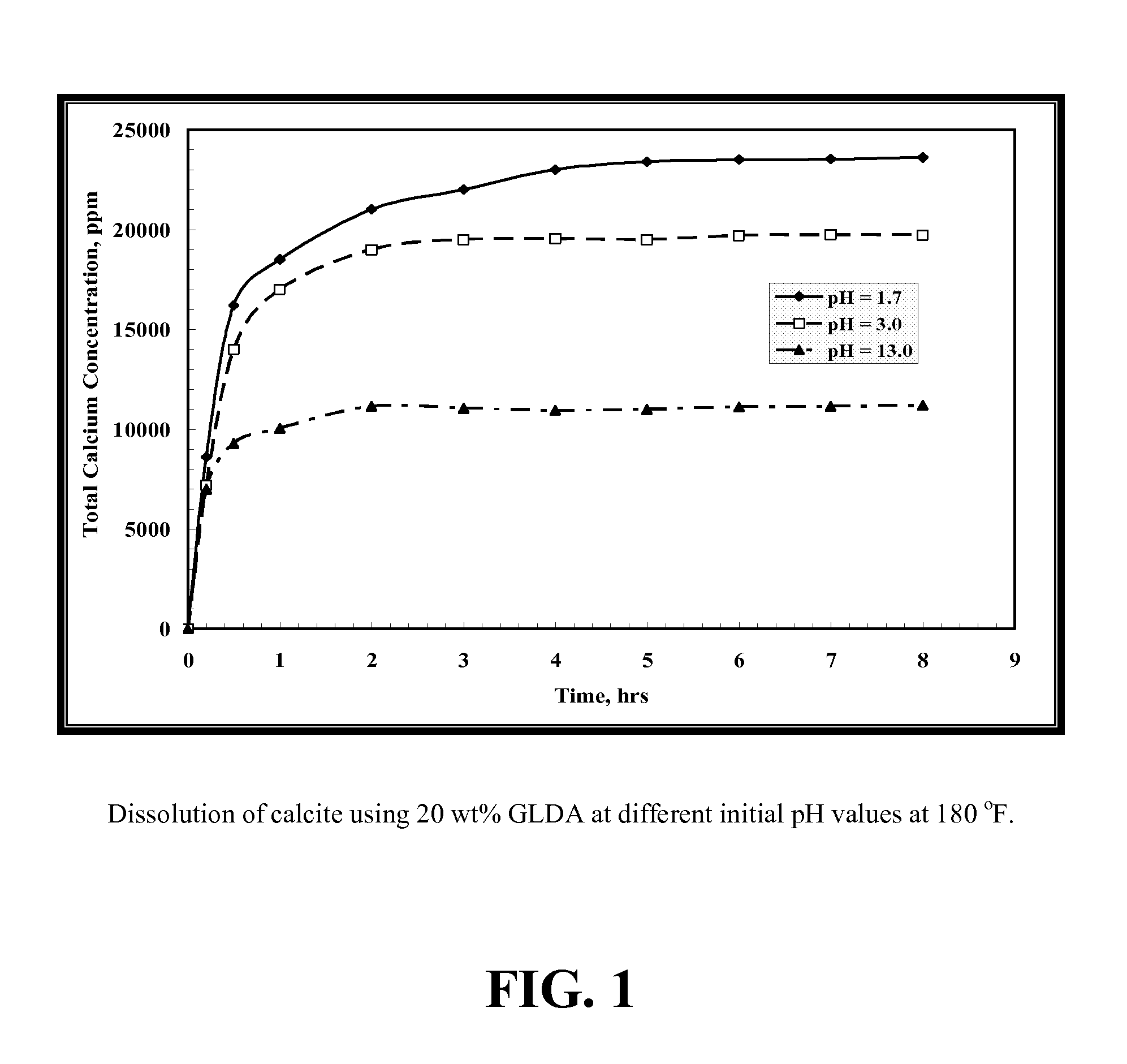

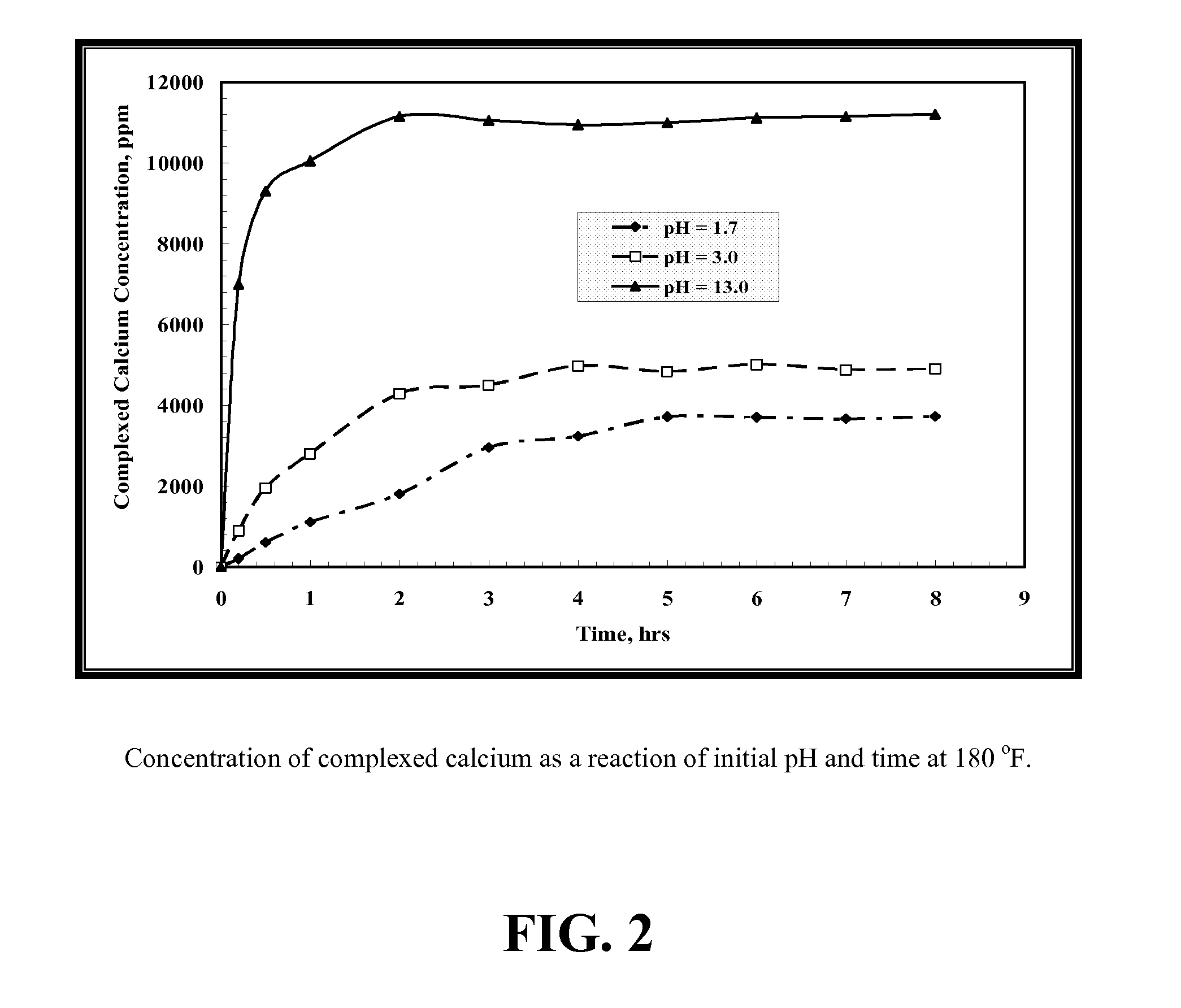

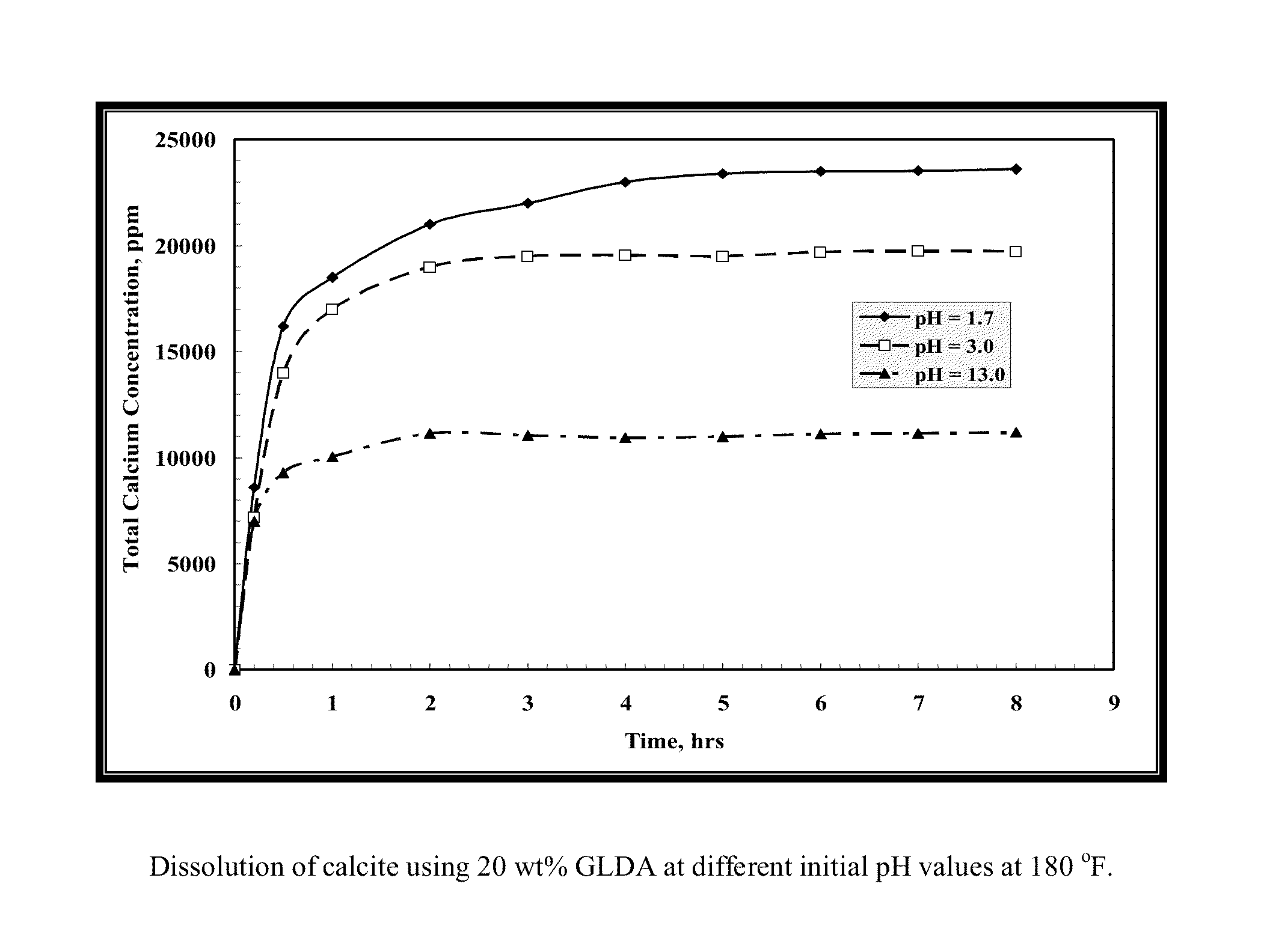

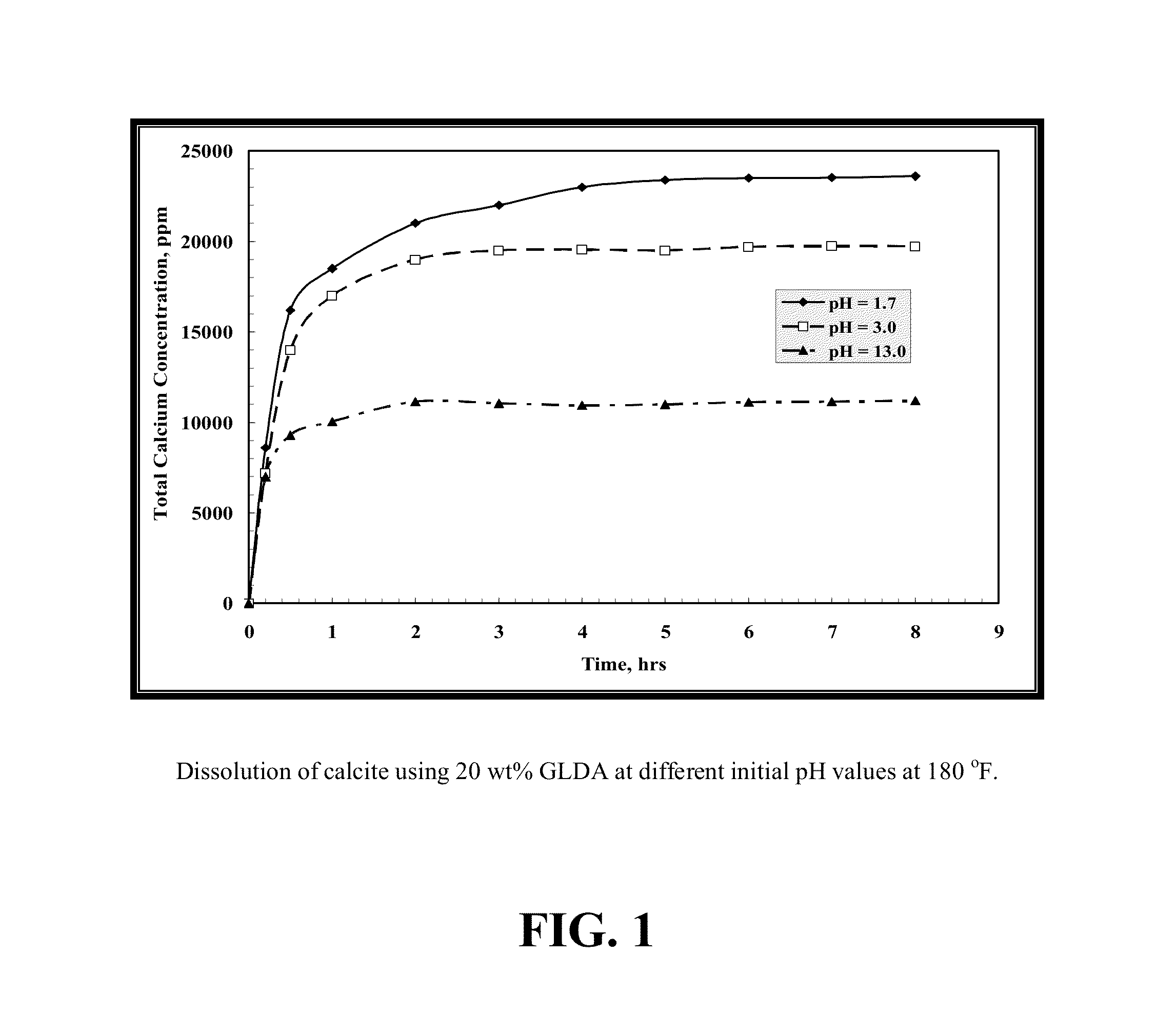

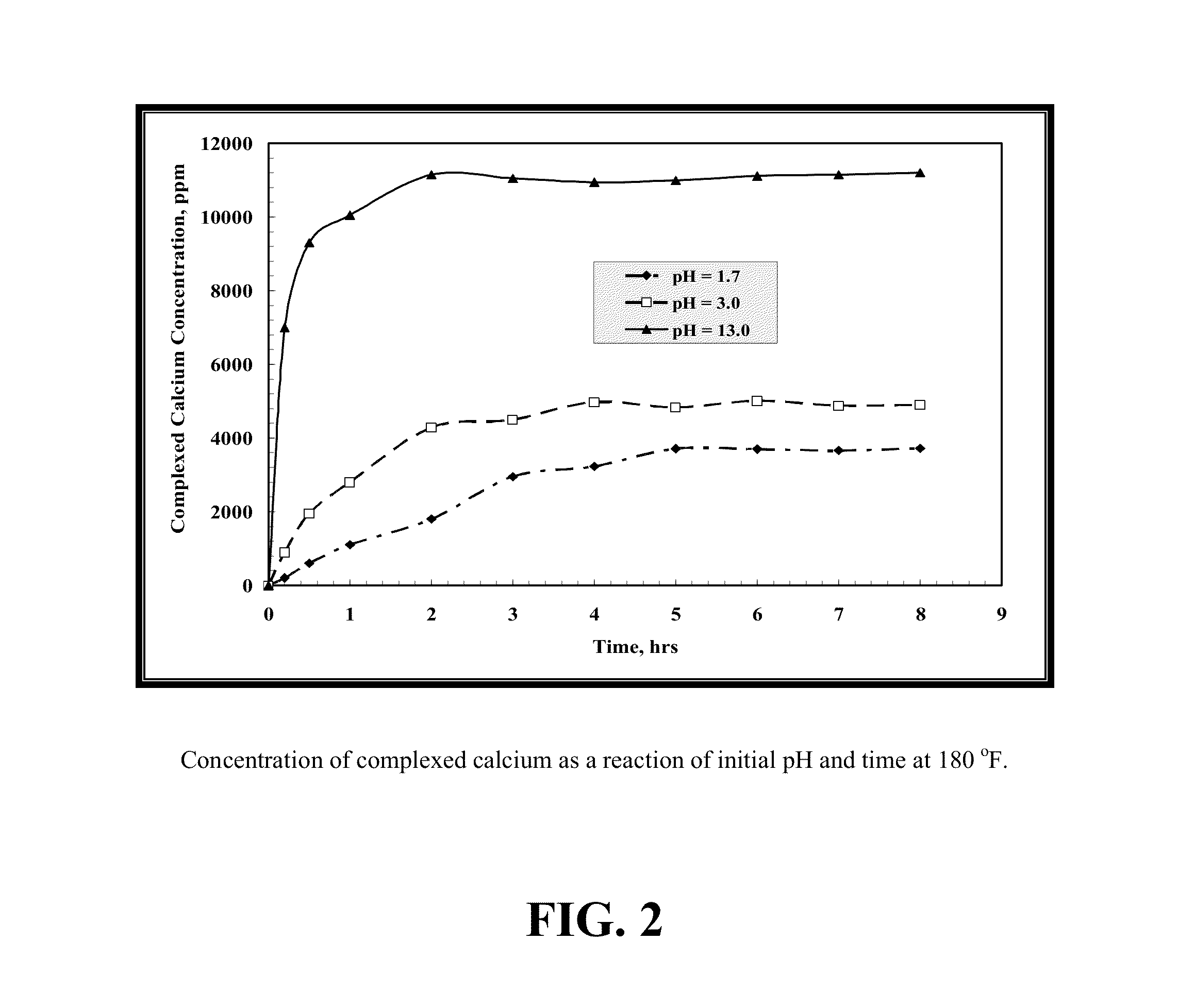

Environmentally friendly stimulation fluids, processes to create wormholes in carbonate reservoirs, and processes to remove wellbore damage in carbonate reservoirs

ActiveUS20120202720A1Reduce calcium concentrationChelating ability decreasedFlushingDrilling compositionDamage zoneWormhole

The present invention includes processes to create wormholes in carbonate reservoirs by contacting a formation with a solution comprising glutamic acid N,N-diacetic acid (GLDA) and / or a salt thereof, methylglycine-N,N-diacetic acid (MGDA) and / or a salt thereof, or a combination thereof. The present invention also includes processes to remove wellbore damage in a carbonate reservoir by contacting a damaged zone of the carbonate reservoir with a solution comprising GLDA and / or a salt thereof, methylglycine-N,N-diacetic acid (MGDA) and / or a salt thereof, or a combination thereof. The present invention further includes solutions comprising a salt and further comprising GLDA and / or a salt thereof, methylglycine-N,N-diacetic acid (MGDA) and / or a salt thereof, or a combination thereof.

Owner:AKZO NOBEL CHEM INT BV

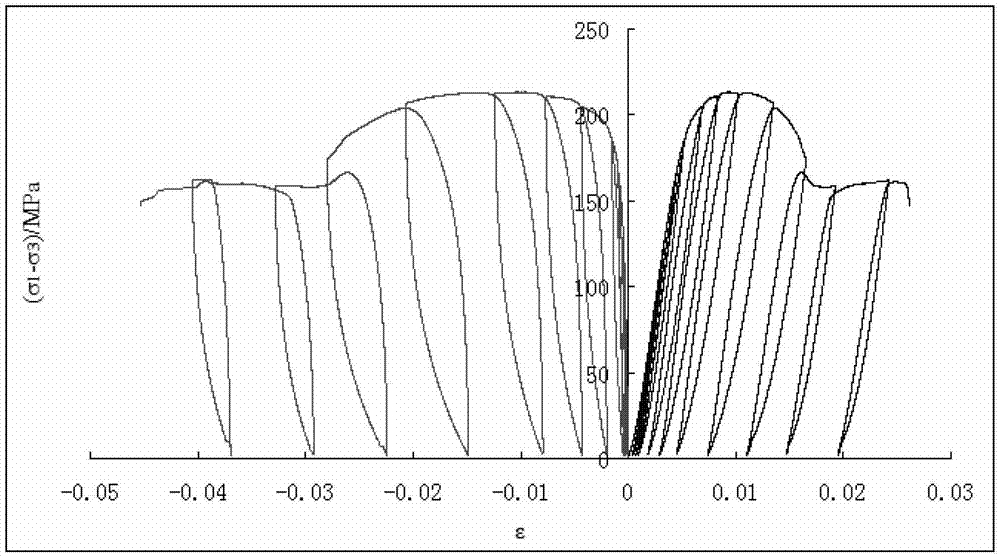

Method for measuring change law and values of deep-buried hard rock mechanical parameters

ActiveCN103076245ASolve the law of changeSolve the technical problem of measuring the valueMaterial strength using repeated/pulsating forcesDamage zoneRock mechanics

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

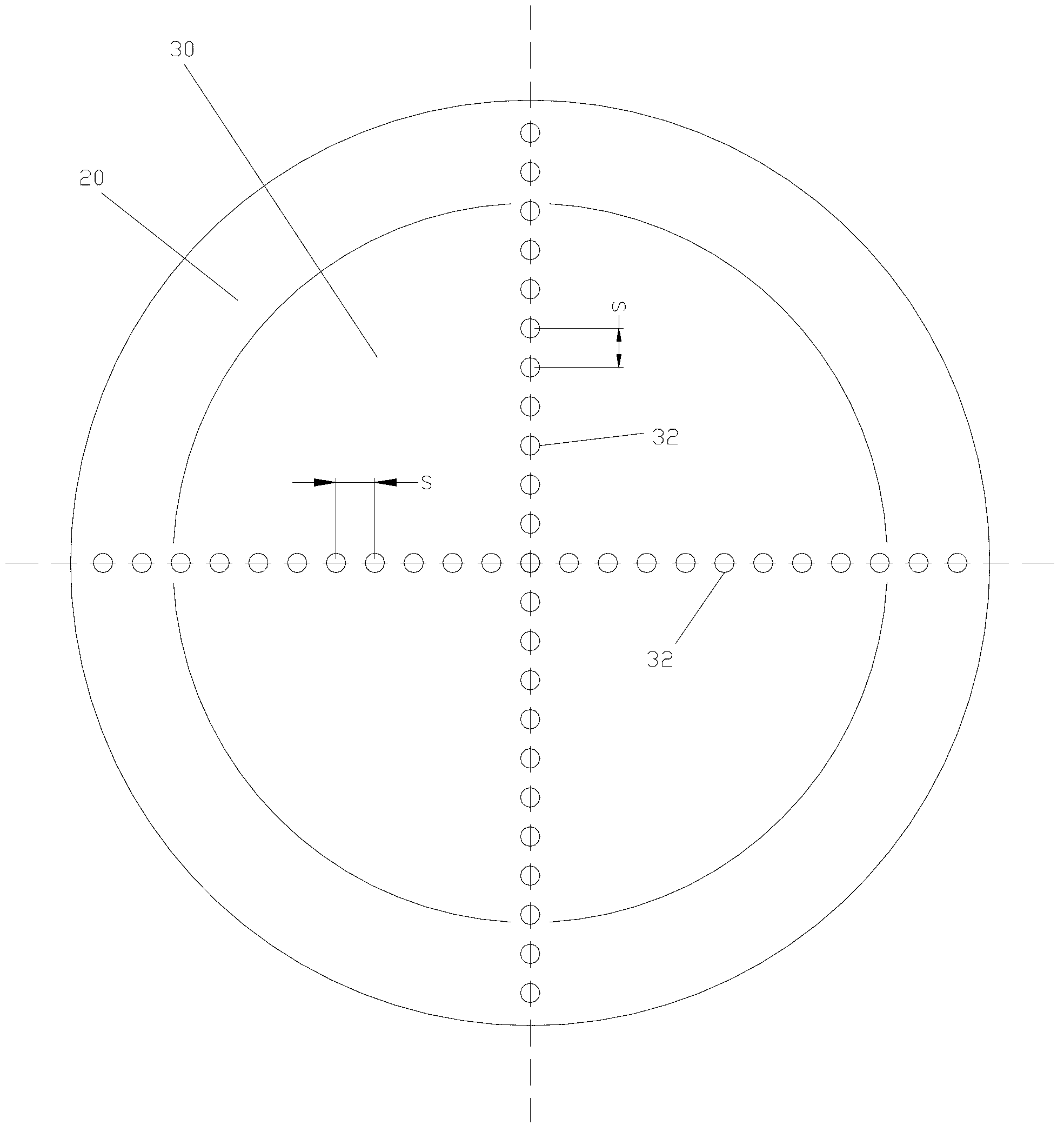

Method of determining by numerical simulation the restoration conditions, by the fluids of a reservoir, of a complex well damaged by drilling operations

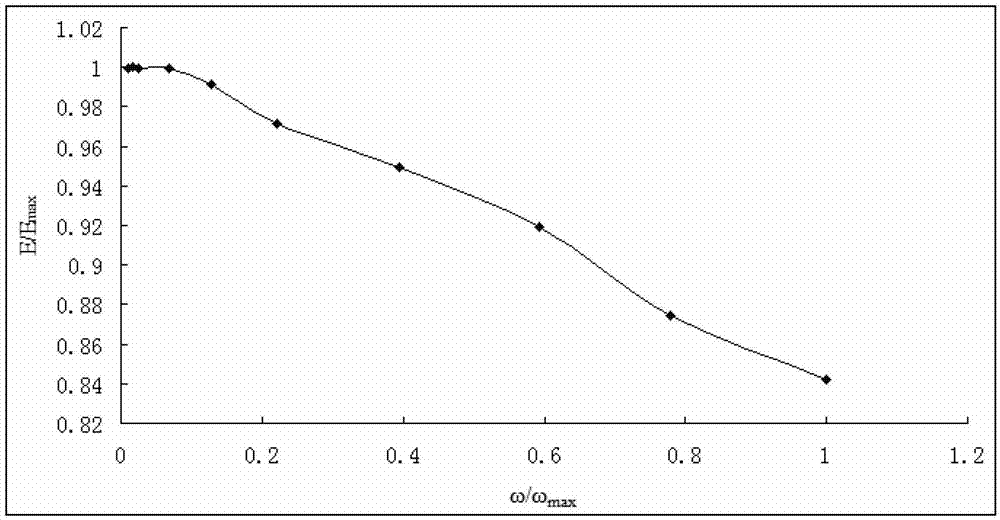

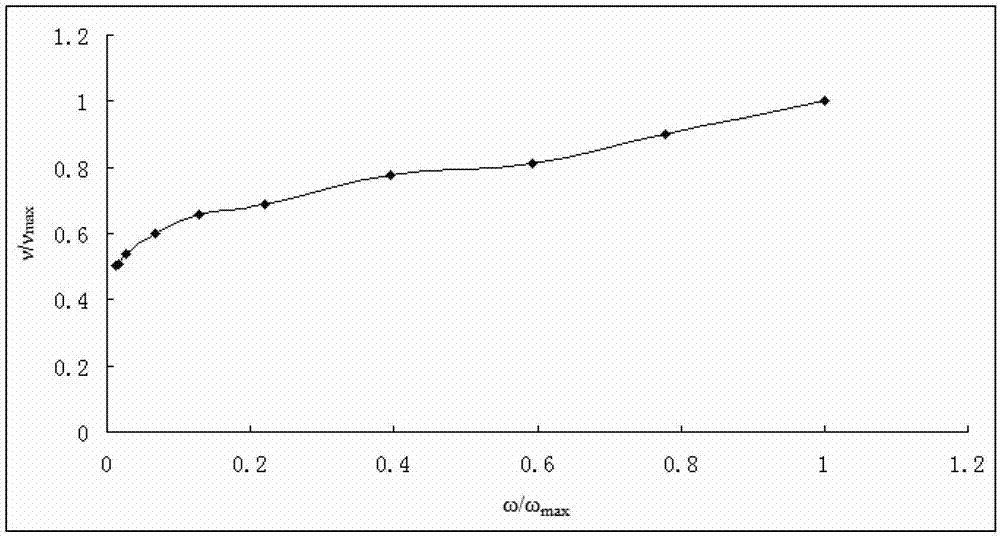

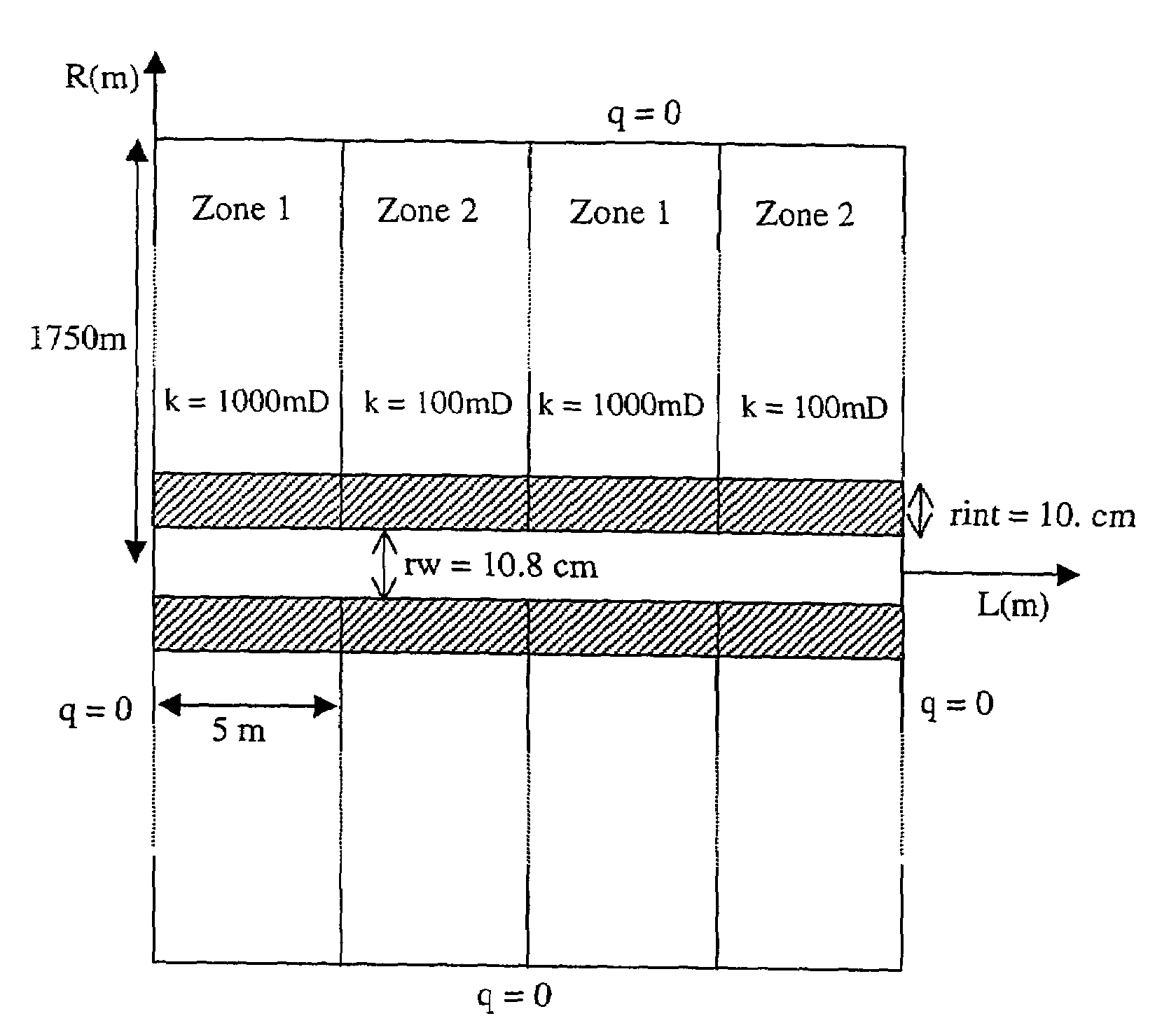

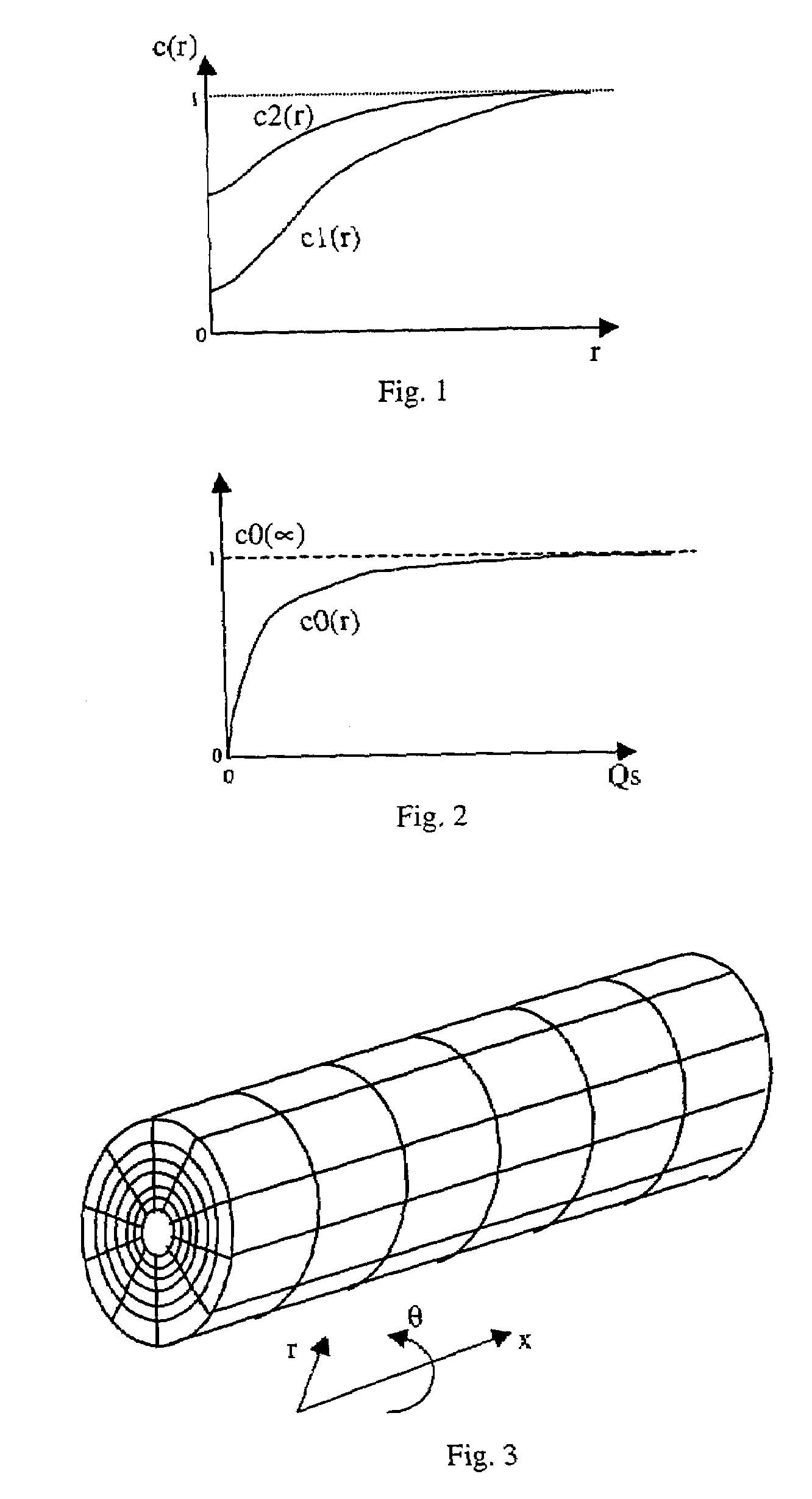

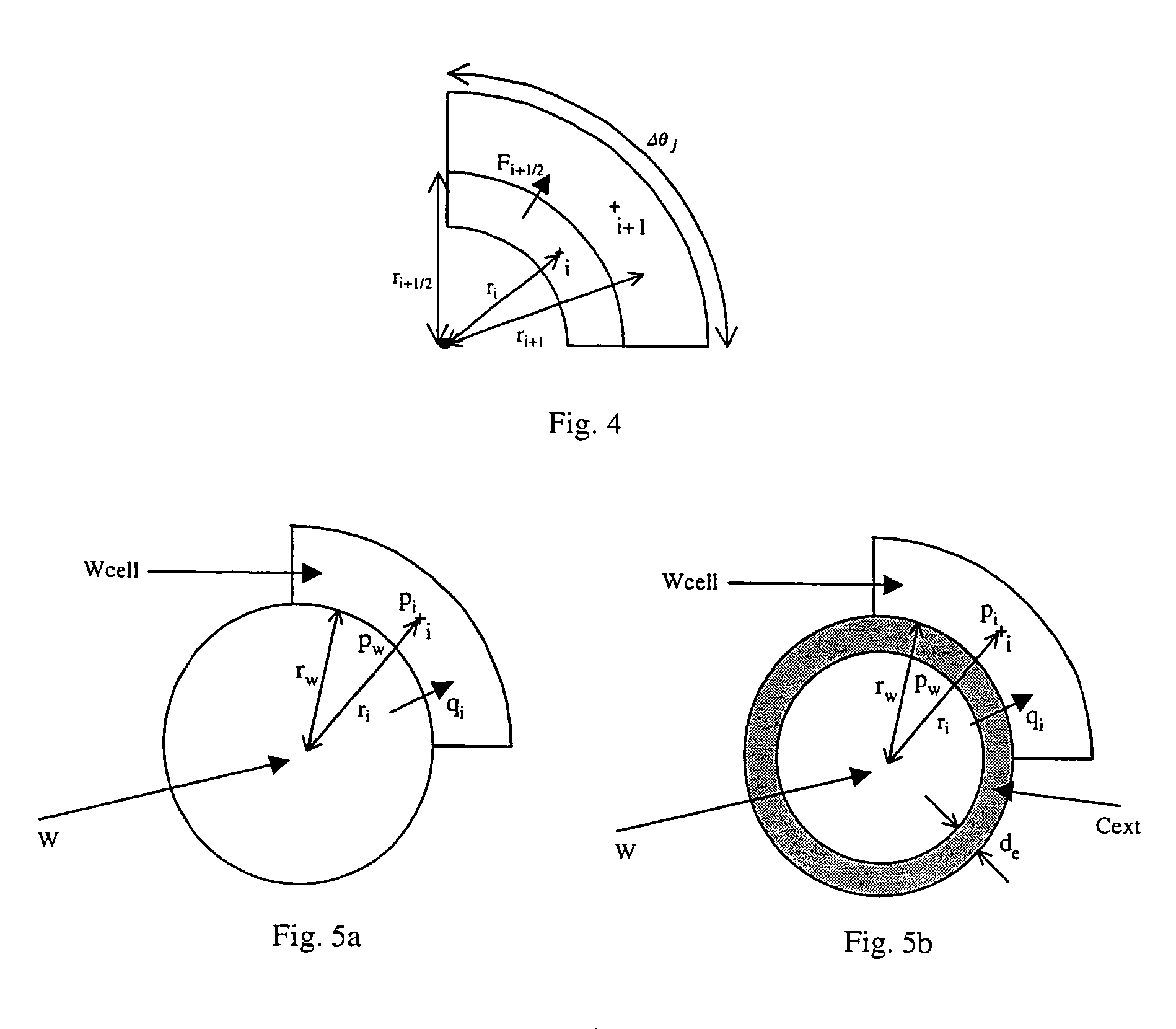

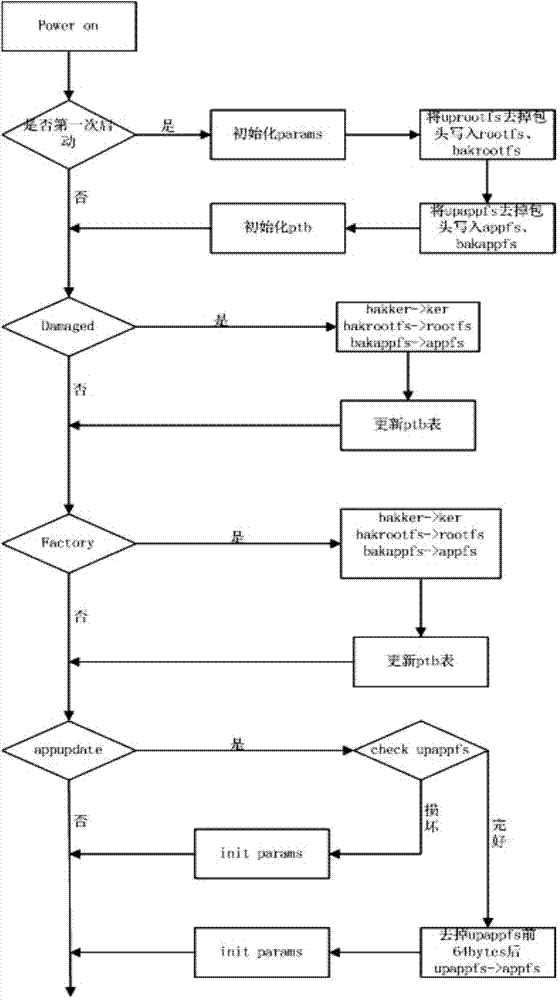

The method essentially comprises acquiring initial data obtained by laboratory measurements of the values, according to the initial permeability of the formations surrounding the well, of the thickness of the cakes and of the damaged permeability and restored permeability values of this zone, as a function of the distance to the wall of the well. Then the damaged zone is discretized by a 3D cylindrical grid pattern forming blocks of small radial thickness in relation to the diameter of the well, and the diffusivity equation, modelling the flow of the fluids through the cakes, is solved in this grid pattern by taking account of the measured initial data. Finally, the evolution of the permeability is modelled as a function of the flow rates of fluids flowing through the cakes, so as to deduce therefrom the optimum conditions to be applied for producing the well.

Owner:INST FR DU PETROLE

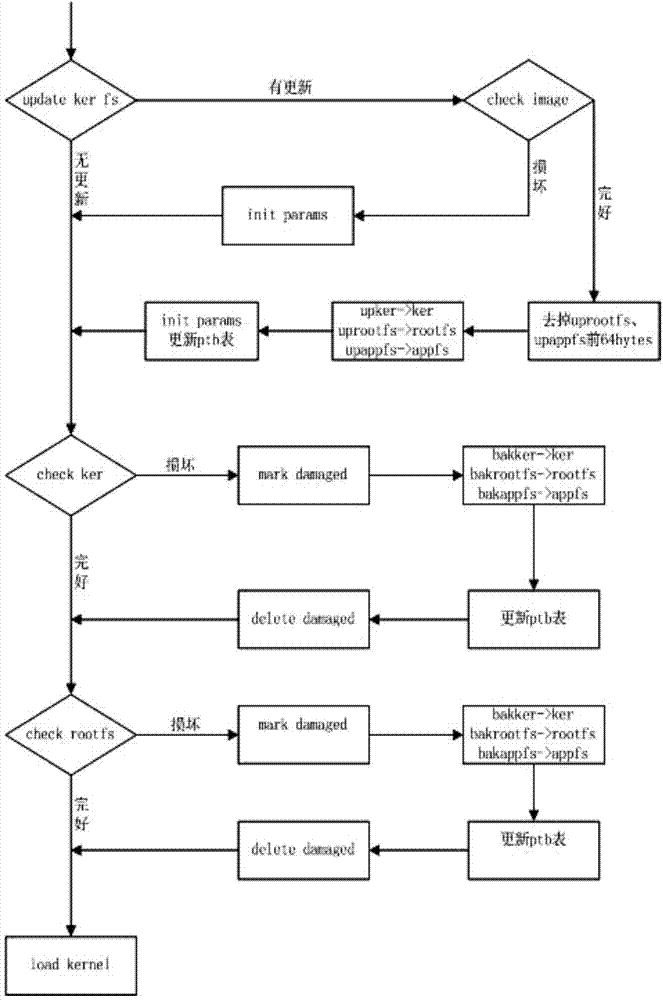

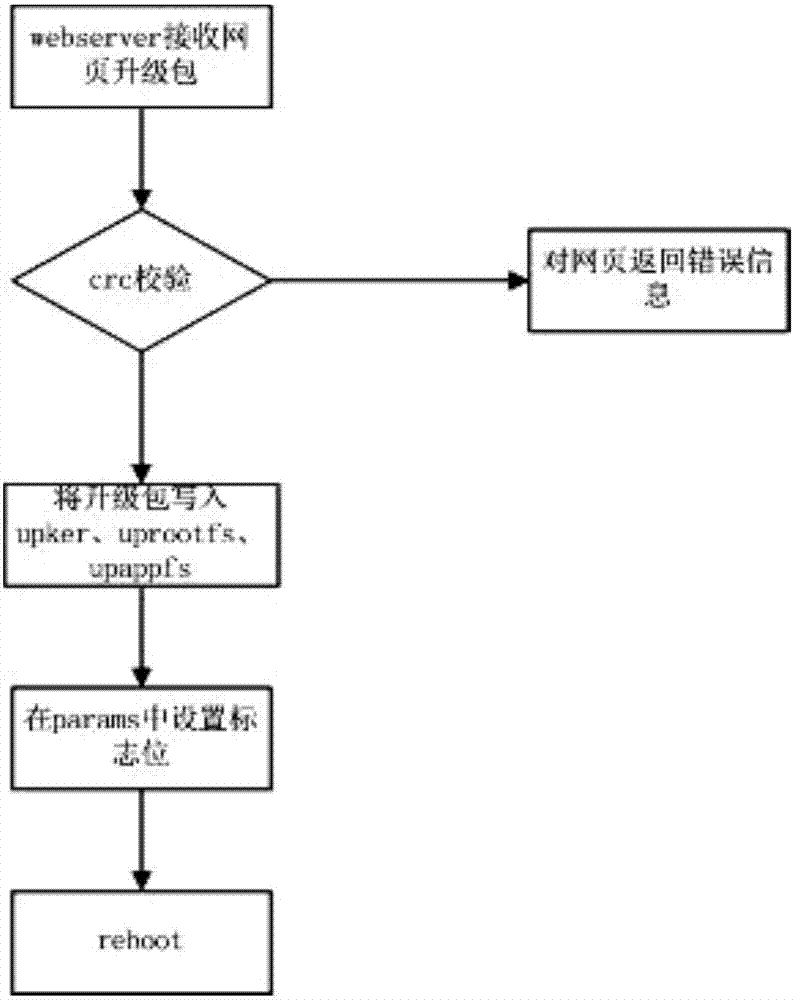

Equipment dual-system protection method and equipment dual-system upgrading method on basis of linux

ActiveCN103677947AImprove stabilityProgram loading/initiatingSpecial data processing applicationsFile systemGNU/Linux

The invention discloses an equipment dual-system protection method and an equipment dual-system upgrading method on the basis of the linux. The equipment dual-system protection method on the basis of the linux comprises the following steps: S01, establishing a backup system in a storage space of a linux file system; S02, judging whether the linux system is started for the first time; S03, judging whether a damaged zone bit in a params partition is set, recovering a kernel partition and a rootfs partition from the backup system if yes, and executing the step S04 if no; S04, judging whether an appupdate zone bit in the params partition is set; S05, judging whether kernel, rootfs and appfs updating zone bits in the params partition are simultaneously set; S06, checking whether a mirror image of the kernel partition is undamaged; S07, checking whether a mirror image of the rootfs partition is undamaged; and S08, loading the kernel partition and enabling the linux system to start to work. By carrying out backup on the important partitions of a system, the equipment dual-system protection method is used for recovering the integral system when detecting damage.

Owner:SHENZHEN INFINOVA

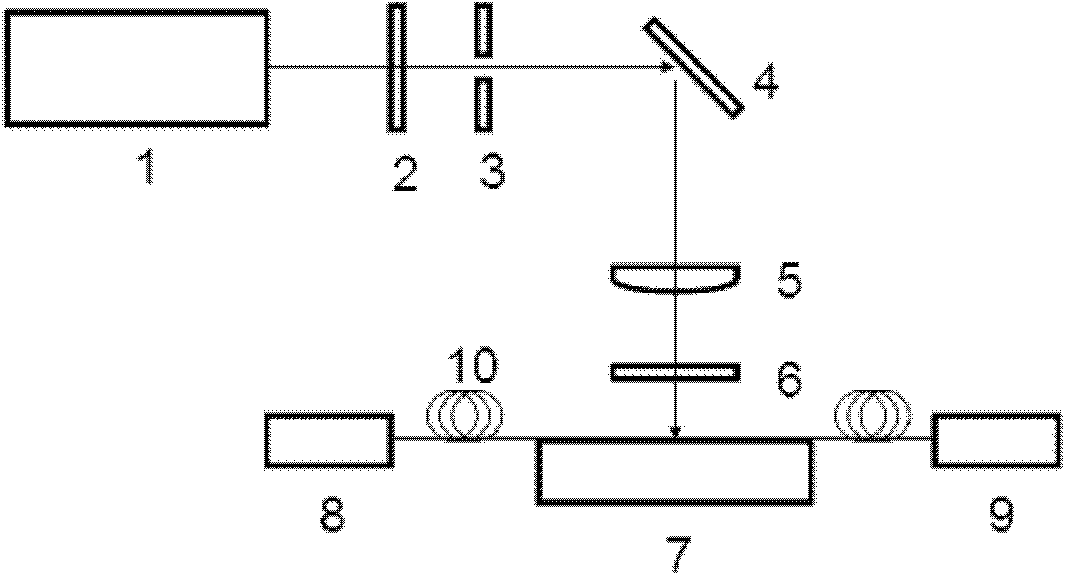

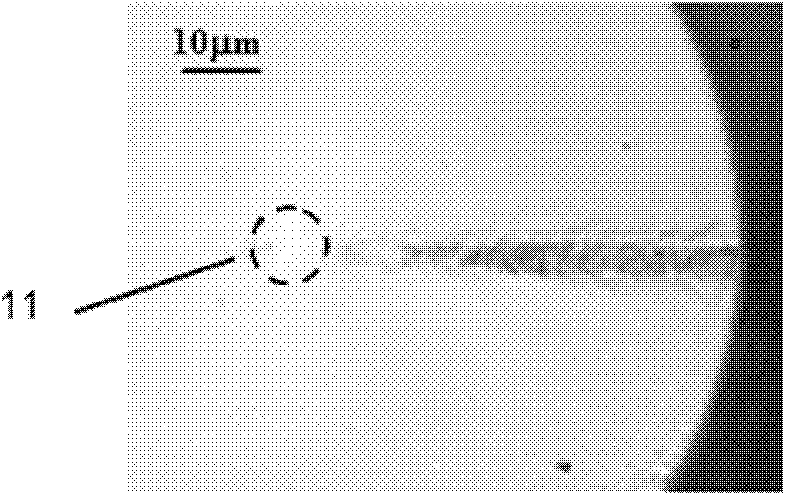

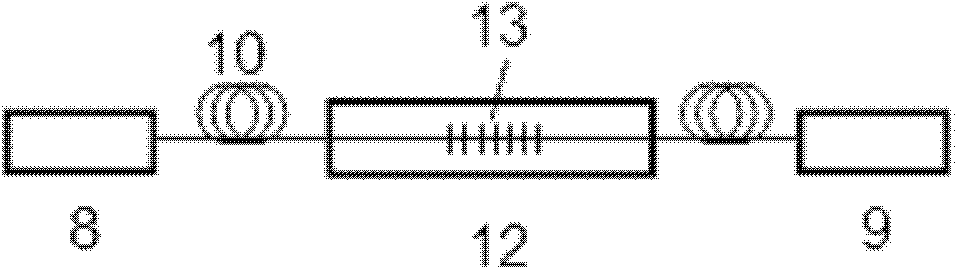

Method for preparing micropore array fiber bragg grating

The invention discloses a method for preparing a micropore array fiber bragg grating, belongs to the technical field of fiber bragg grating sensors and particularly relates to a method for preparing the micropore array fiber bragg grating by combining laser processing with a chemical corrosion technology. The method comprises the following steps of: producing a section of fiber bragg grating of which a damage zone extends to the outer edge of a coating from a fiber core on an optical fiber by a focusing laser beam with power of 0.5 to 1.5W; carrying out chemical corrosion on the section of fiber bragg grating at the temperature of between 10 and 50 DEG C by using 1 to 40 volume percent hydrofluoric acid; and carrying out neutralization by using alkaline solution and carrying out ultrasonic cleaning by using deionized water so as to obtain a micropore array fiber bragg grating structure of which the grating damage zone extends to the fiber core from the outer edge of the coating. By the method, the grating zone extends to the surface of the optical fiber from the inside of the optical fiber and the corroding process is mainly carried out along the damaged grating zone, so that the corroded structure has high mechanical strength, the sensing sensitivity is improved and the micropore array fiber bragg grating has high temperature stability.

Owner:JILIN UNIV

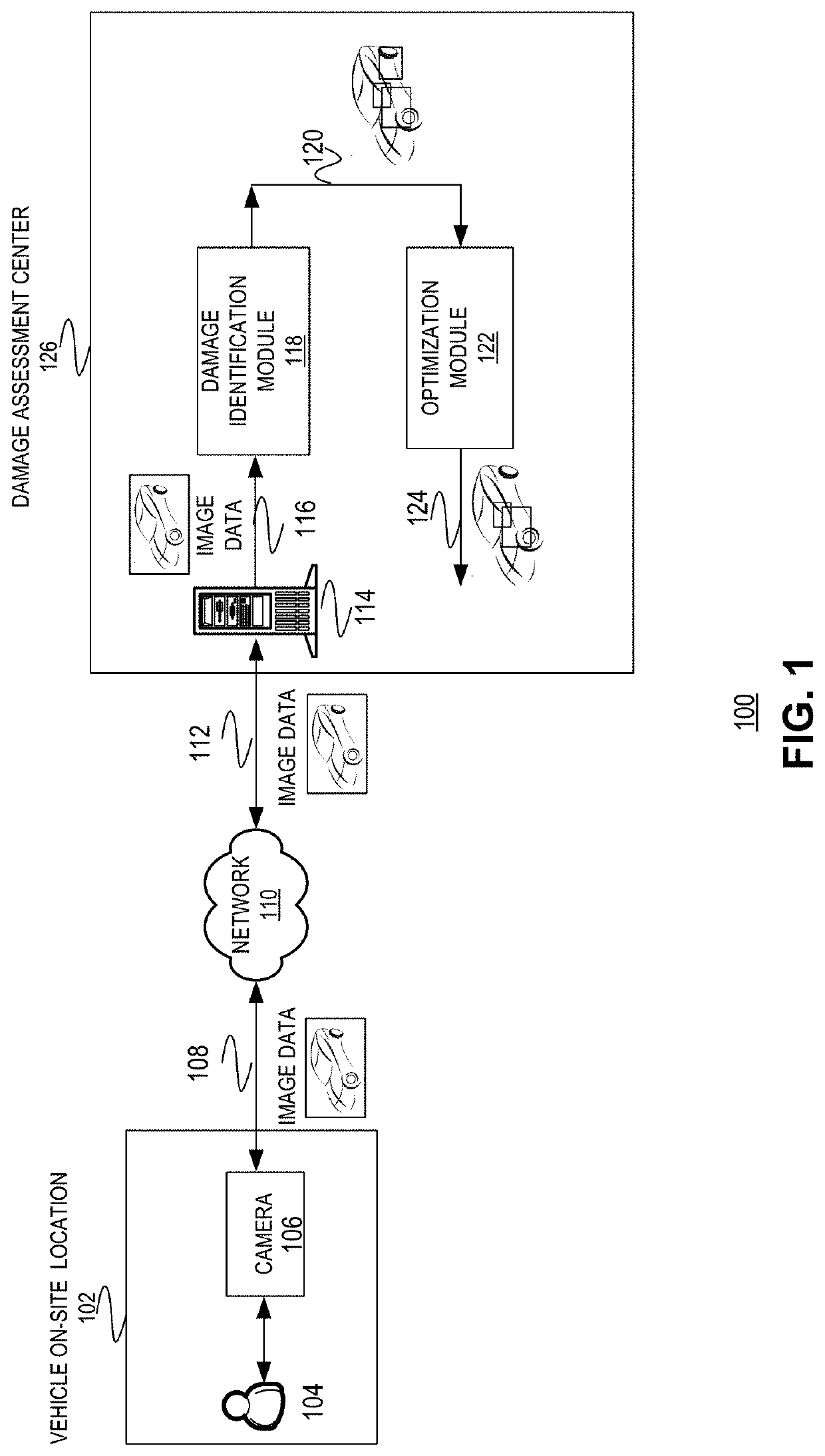

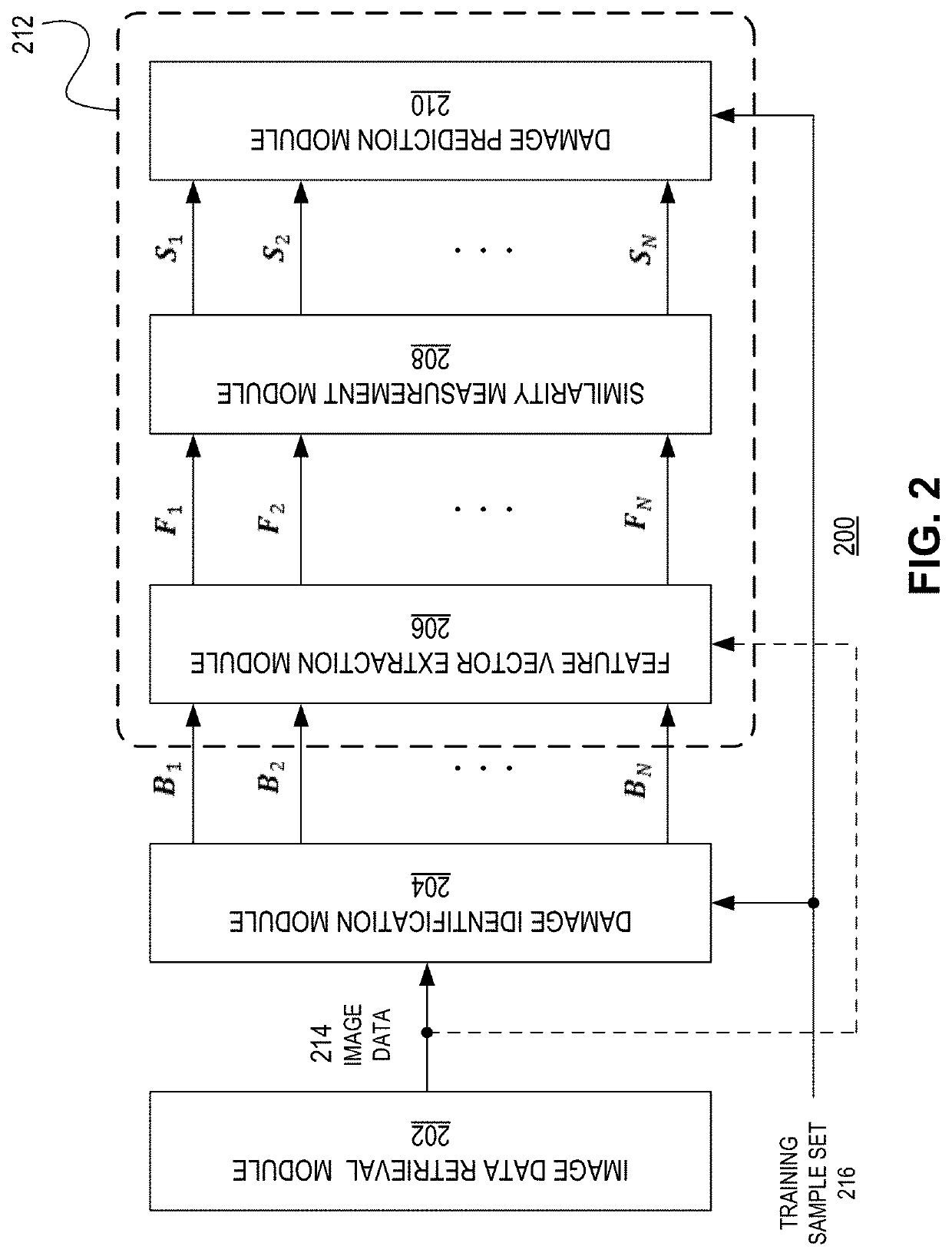

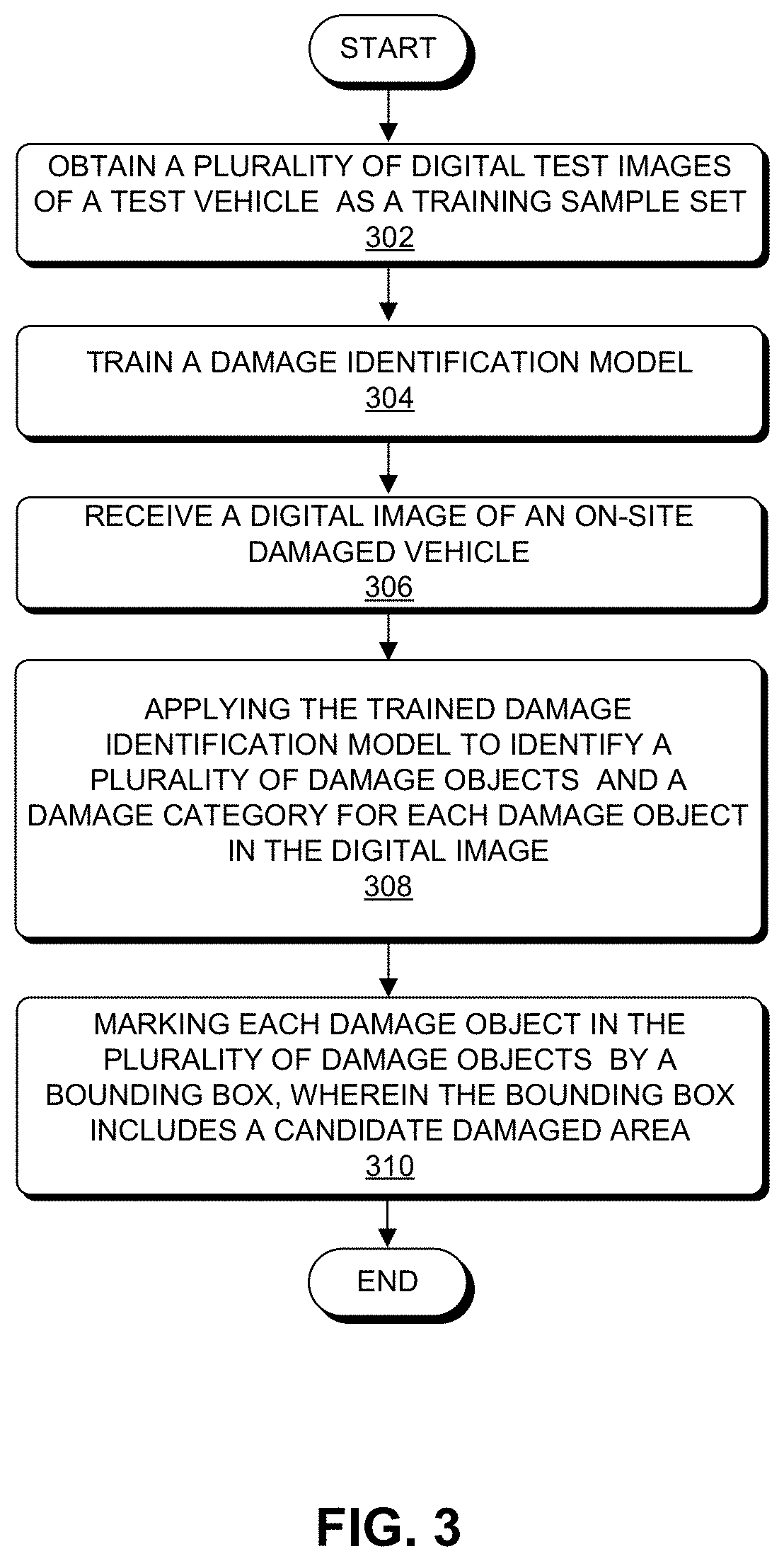

System and method for optimizing damage detection results

ActiveUS20200074560A1Damage detection resultImage enhancementImage analysisFeature vectorEngineering

One embodiment can provide a system for detecting optimizing a damage detection result. During operation, the system can obtain a digital image of a damaged vehicle, identify a set of candidate damaged areas from the digital image as the damage detection result. The system can then extract a set of feature vectors corresponding to the set of candidate damaged areas For each candidate damaged area, the system can calculate a set of similarity features between the candidate damaged area and other candidate damaged areas in the set of candidate damaged areas based on the set of feature vectors. The system can input the set of similarity features to a damage prediction module. The system can then determine whether the candidate damaged area is an exceptional area based on an output of the damage prediction module to optimize the damage detection result.

Owner:ADVANCED NEW TECH CO LTD

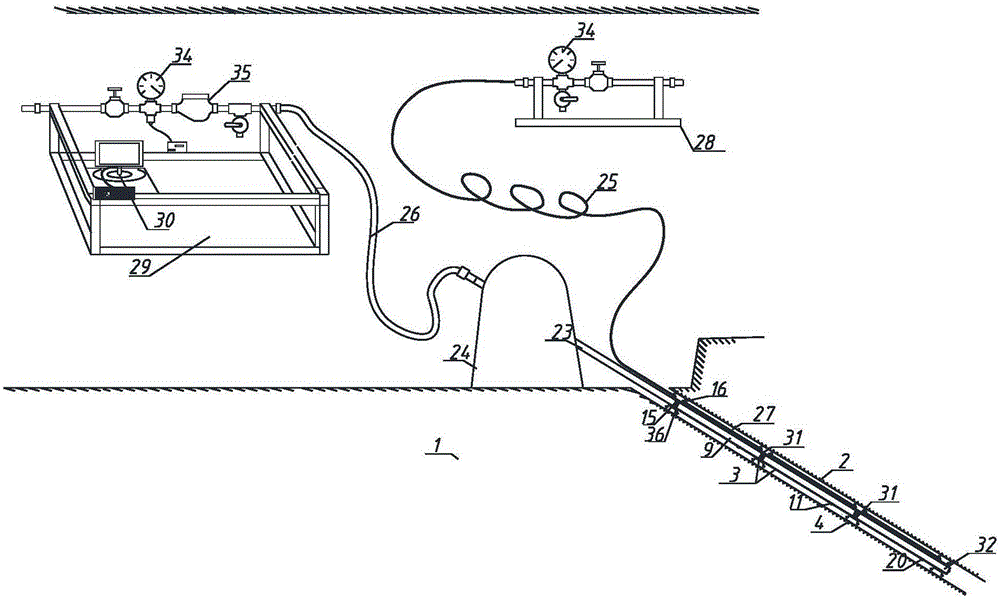

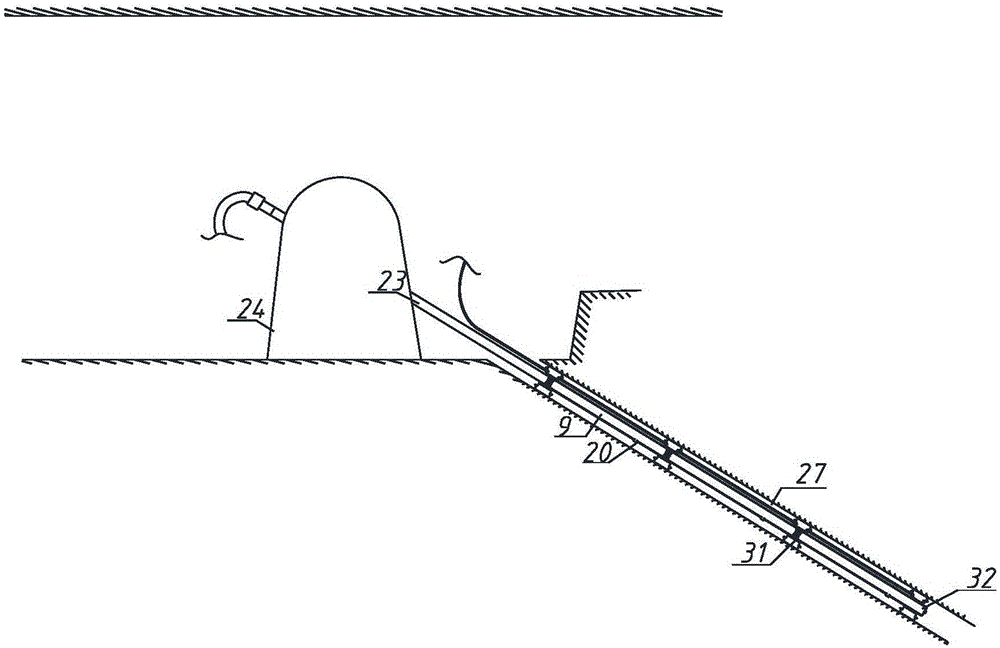

Floor mining damage zone multi-section blocking synchronous leakage detection method

ActiveCN105003255AReduce the number of movesReduce workloadSurveyConstructionsWater sourceEngineering

The invention discloses a floor mining damage zone multi-section blocking synchronous leakage detection method, which comprises the following steps of: forming a downward drill hole in a roof rock layer from a coal rock roadway, and cleaning the drill hole; installing a detection system, wherein a test probe of the detection system is formed by sequentially connecting a plurality of detection units, and the adjacent detection units are detachably connected through clamp groove joints; conveying the detection system to the initial position of the drill hole by using a drill pipe and a drilling machine in a supply measuring system; using a blocking system to seal the drill hole; using a water injection operation platform to convey a water source at the specific pressure to a water inlet pipe; processing and analyzing the collected data, then, forming a corresponding flow water vector diagram of the test section, and the like. The method provided by the invention has the advantages that the multi-section and synchronous measurement of a floor mining damage zone can be realized; the test section number in one test can be properly increased according to the length of the drill hole; the workload is exponentially reduced; and the measurement precision is improved.

Owner:SHANDONG UNIV OF SCI & TECH

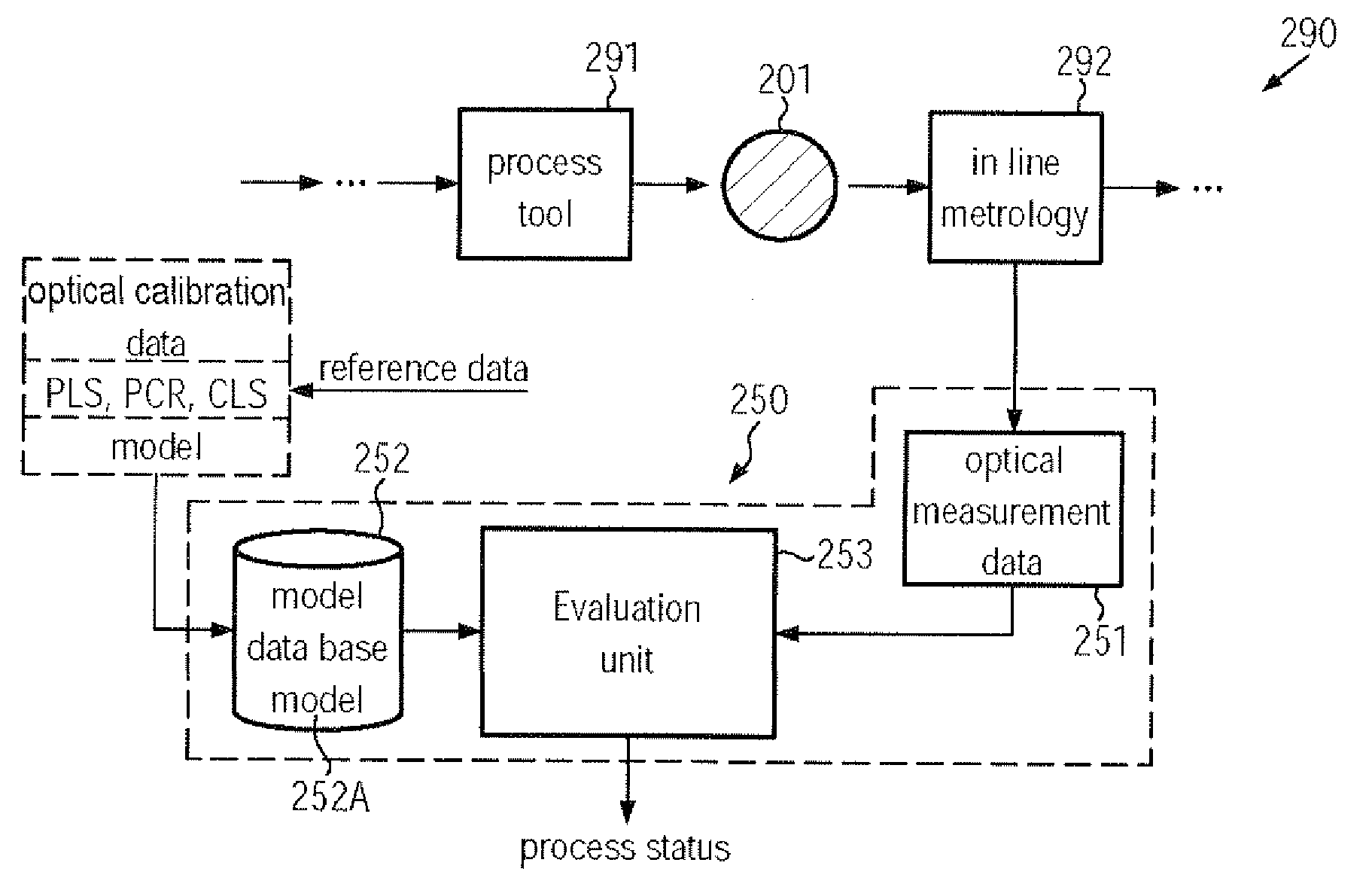

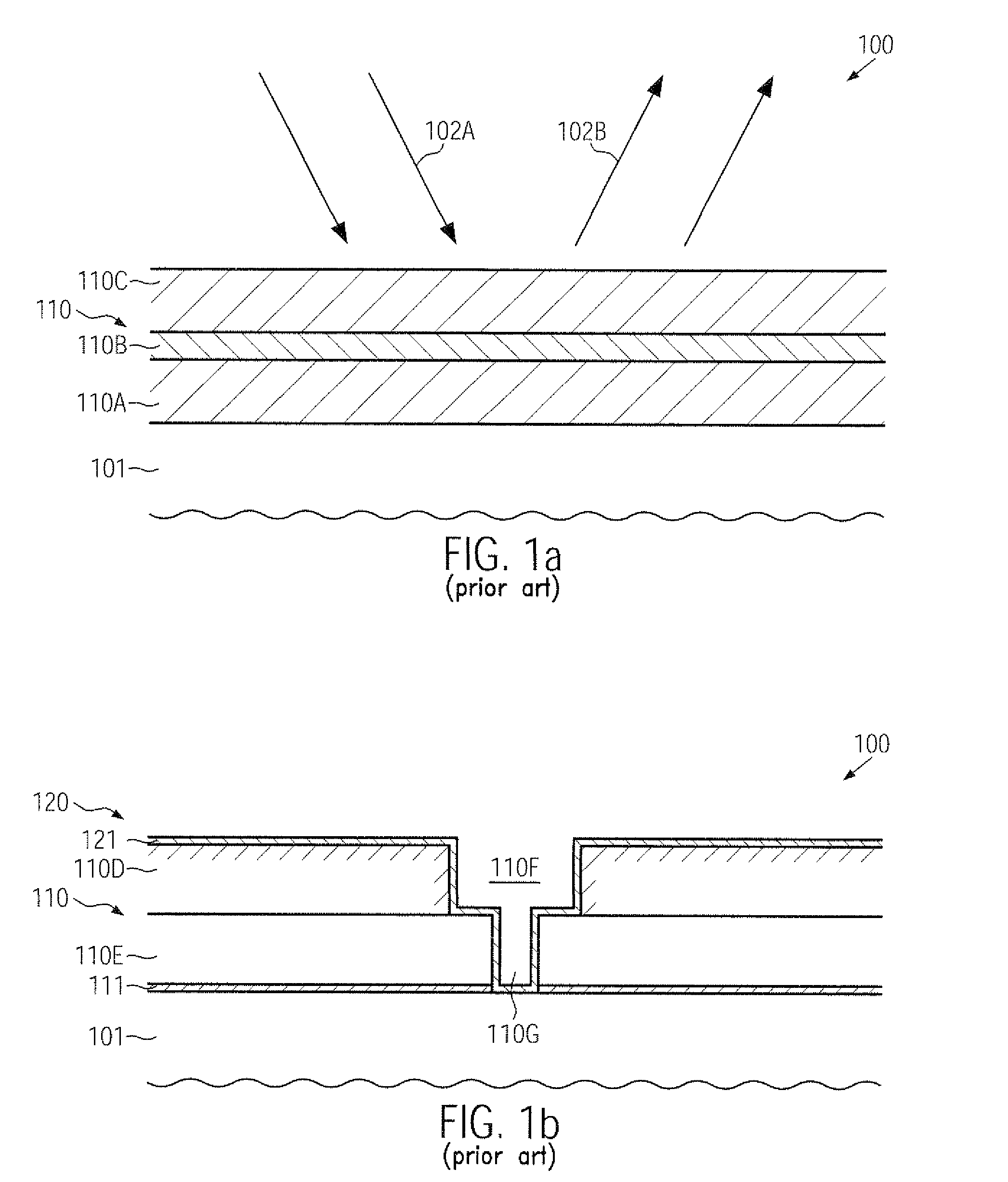

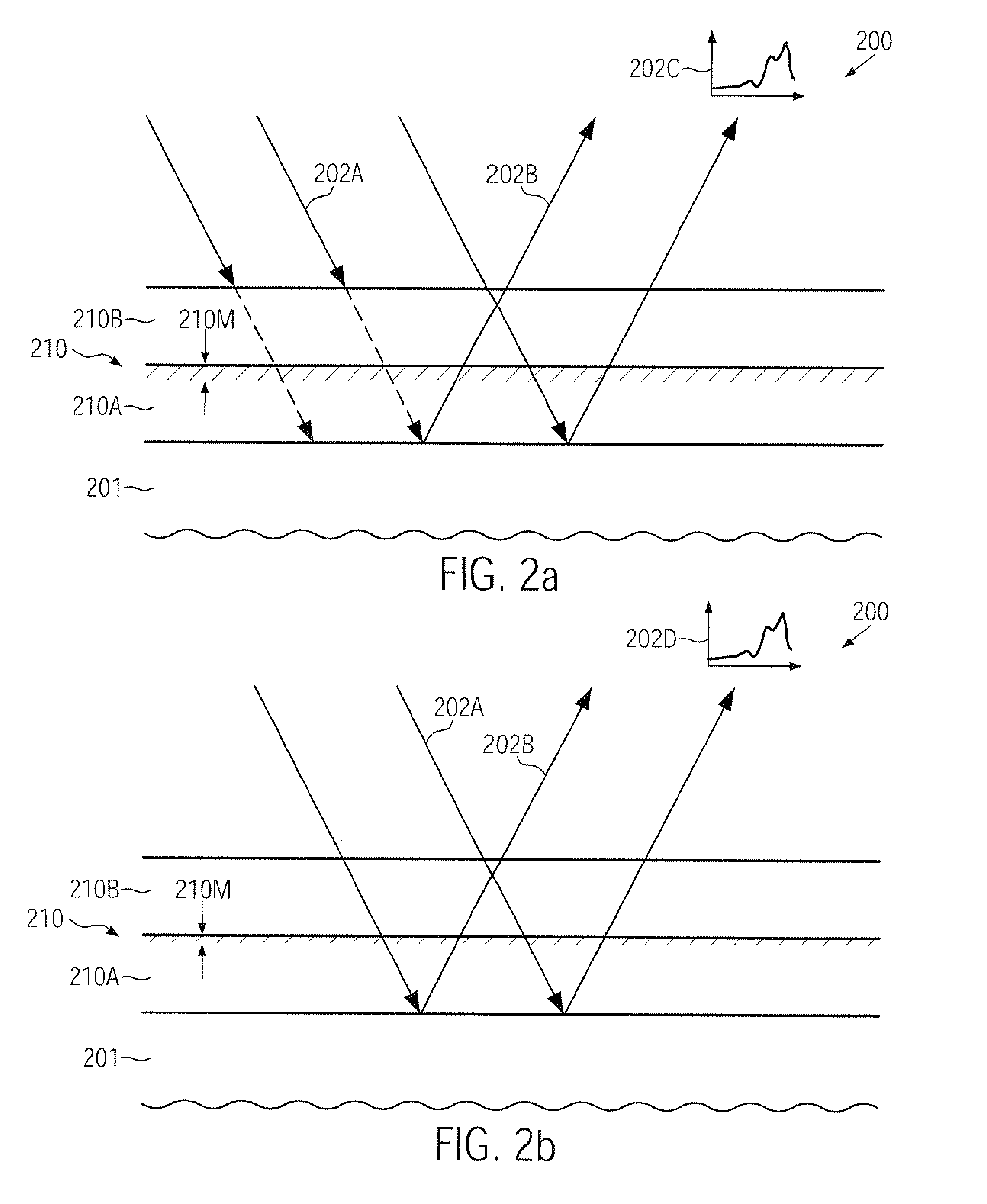

Method and system for quantitative inline material characterization in semiconductor production processes based on structural measurements and related models

ActiveUS20090319196A1Easy to monitorReduce delaysSemiconductor/solid-state device testing/measurementMaterial analysis by optical meansEngineeringDamage zone

By using powerful data analysis techniques, such as PCR, PLS, CLS and the like, in combination with measurement techniques providing structural information, gradually varying material characteristics may be determined during semiconductor fabrication, thereby also enabling the monitoring of complex manufacturing sequences. For instance, the material characteristics of sensitive dielectric materials, such as ULK material, may be detected, for instance with respect to an extension of a damage zone, in order to monitor the quality of metallization systems of sophisticated semiconductor devices. The inline measurement data may be obtained on the basis of infrared spectroscopy, for instance using FTIR and the like, which may even allow directly obtaining the measurement data at process chambers, substantially without affecting the overall process throughput.

Owner:ADVANCED MICRO DEVICES INC

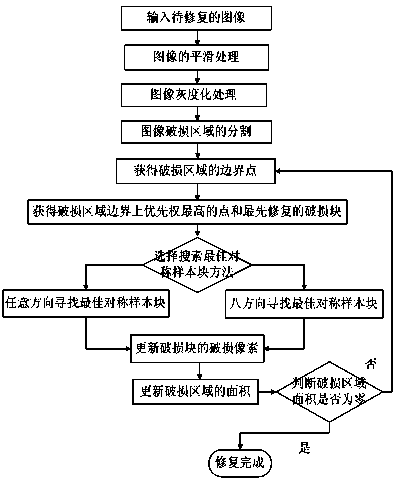

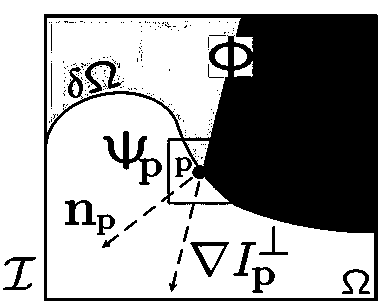

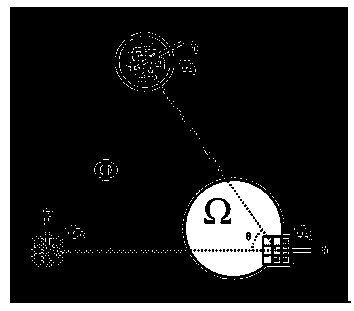

Image restoring method based on symmetric sample pieces

The invention provides an image restoring method based on symmetric sample pieces. The image restoring method comprises the following steps: original damaged image pre-processing, damaged zone segmentation and damaged zone restoration, wherein the original damaged image pre-processing comprises image Gauss smoothening, image graying processing; then damaged zone segmentation and damaged zone restoration are conducted; the damaged zone restoration is a recycling process which comprises the following steps: acquiring boundary points in the damaged zone, acquiring a point with highest priority in the boundary of the damaged zone and the first restored damaged piece as well as selecting a method for searching optimal symmetric sample pieces; the method for searching the optimal symmetric sample pieces comprises two methods, namely, searching symmetric sample pieces at any direction or searching symmetric sample pieces in eight directions, and each of the two methods comprises the following steps: updating pixel of the damaged pieces, updating area of the damaged zone and judging whether the area of the damaged zone is zero, if the area of the damaged zone is zero, stopping the restoration; if the area of the damaged zone is not zero, returning to the acquired boundary points for conducting the recycling process. The restoring experiment shows the effectiveness of the image restoring method.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

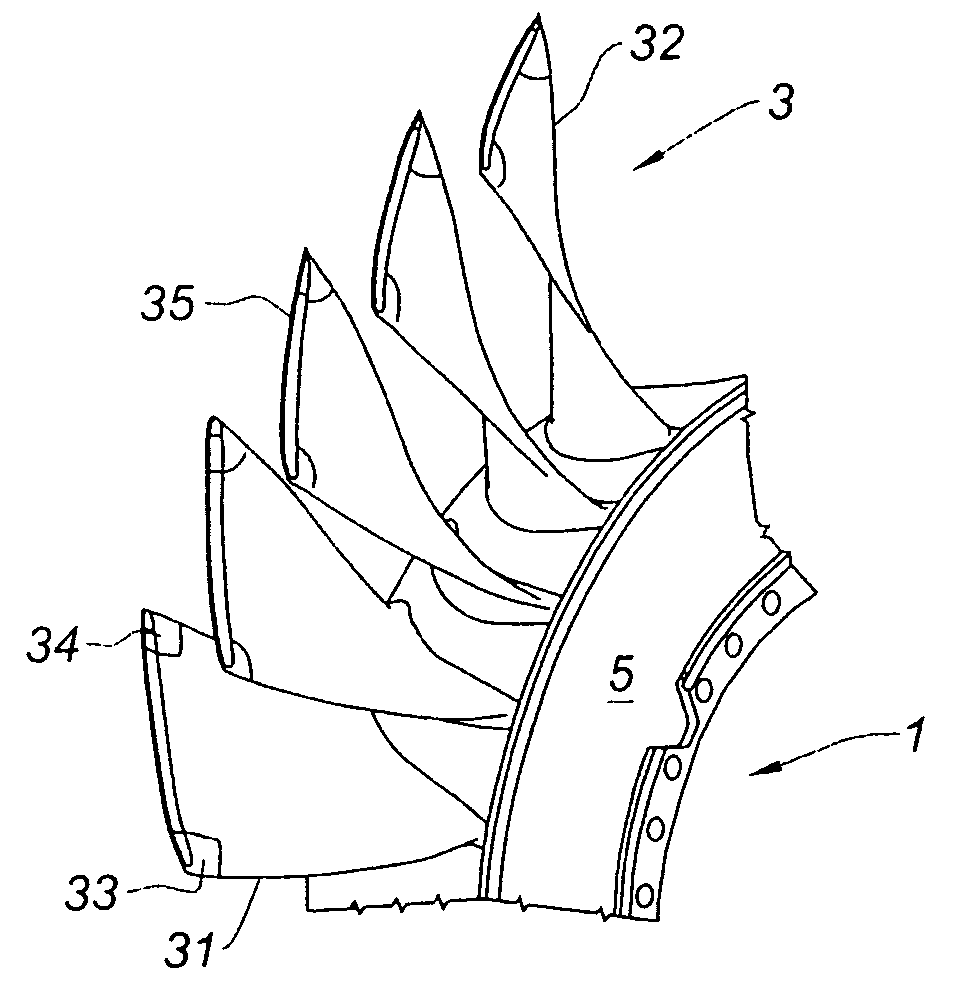

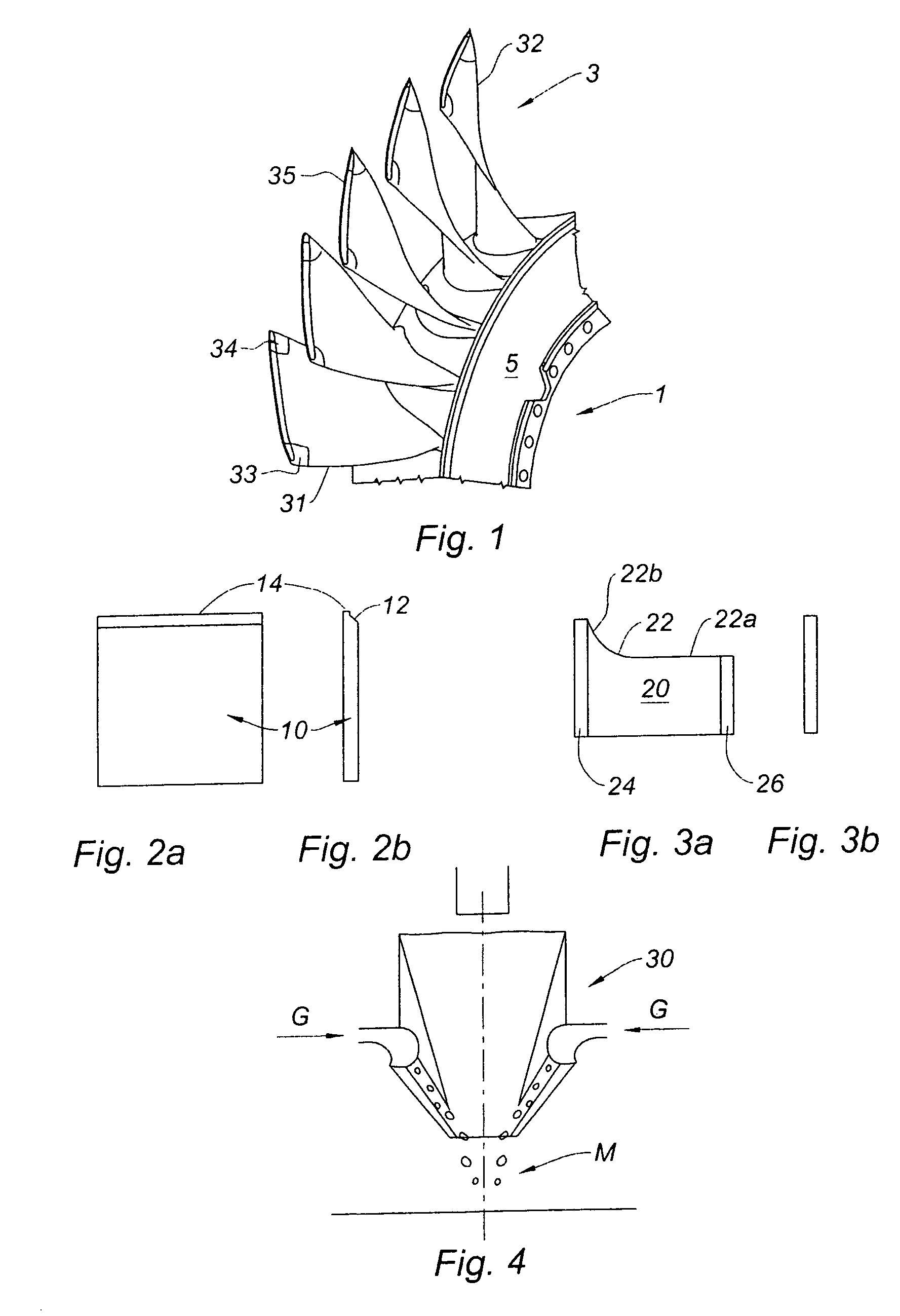

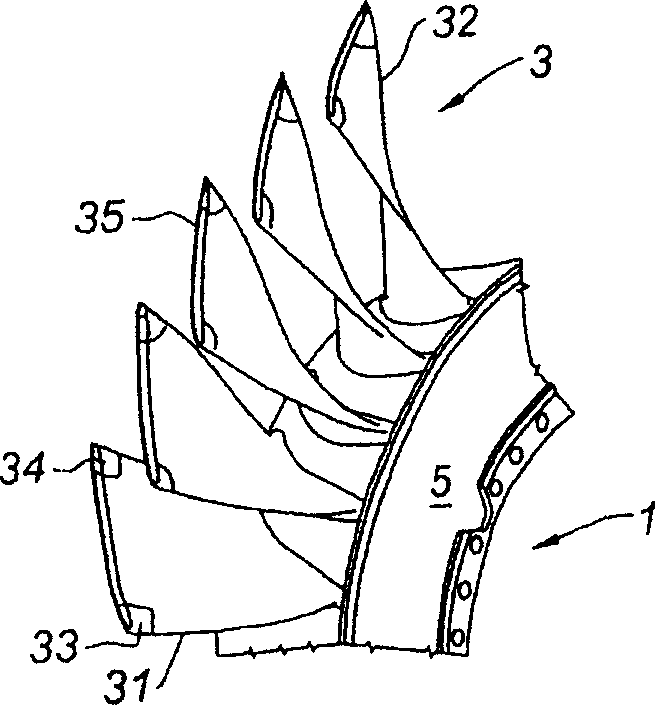

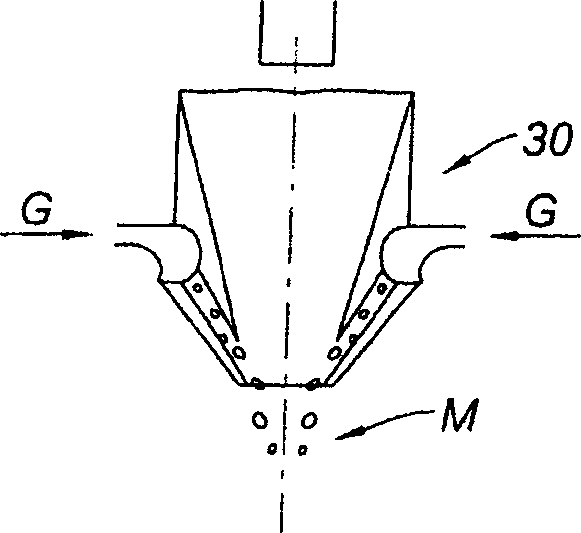

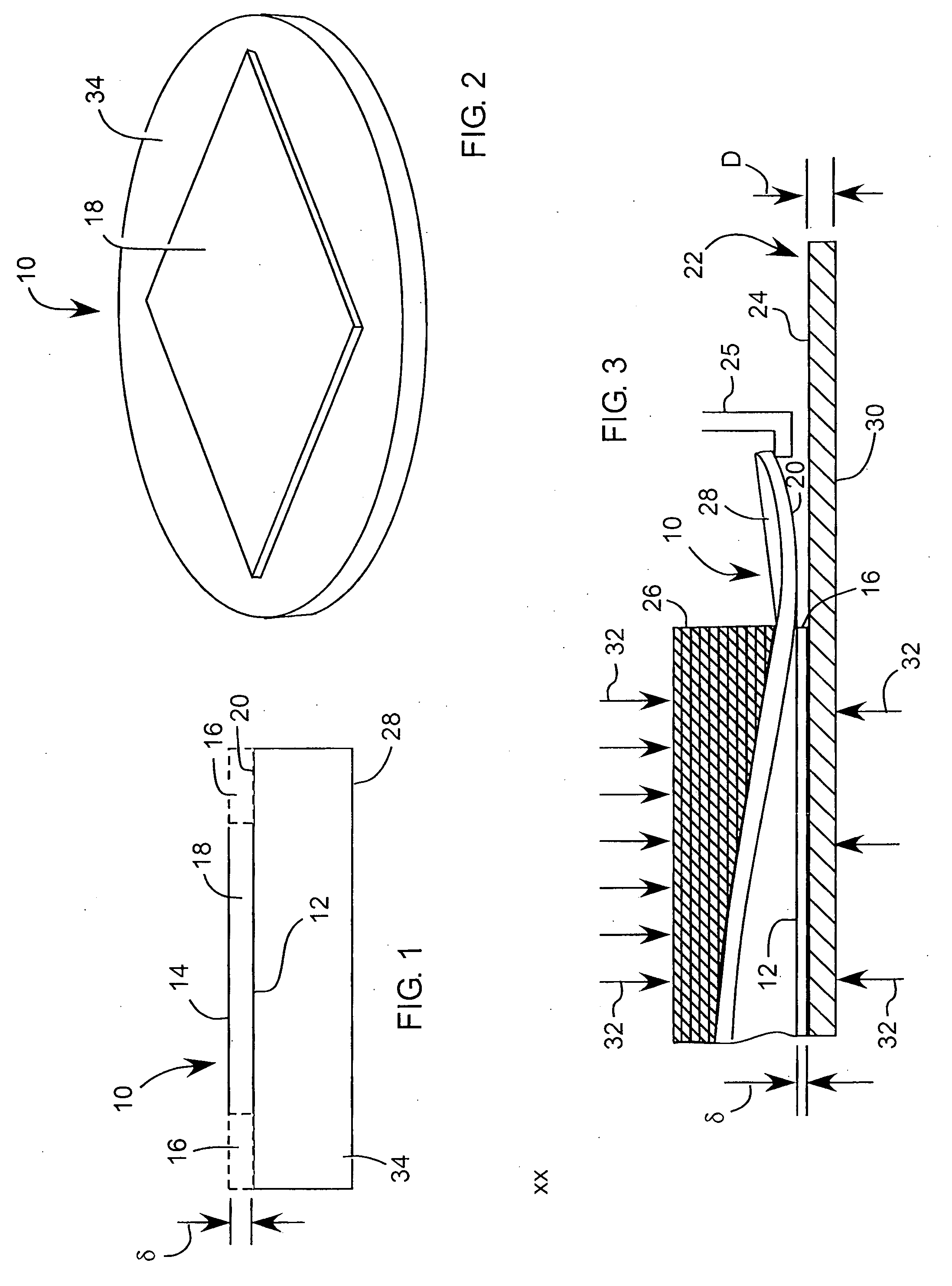

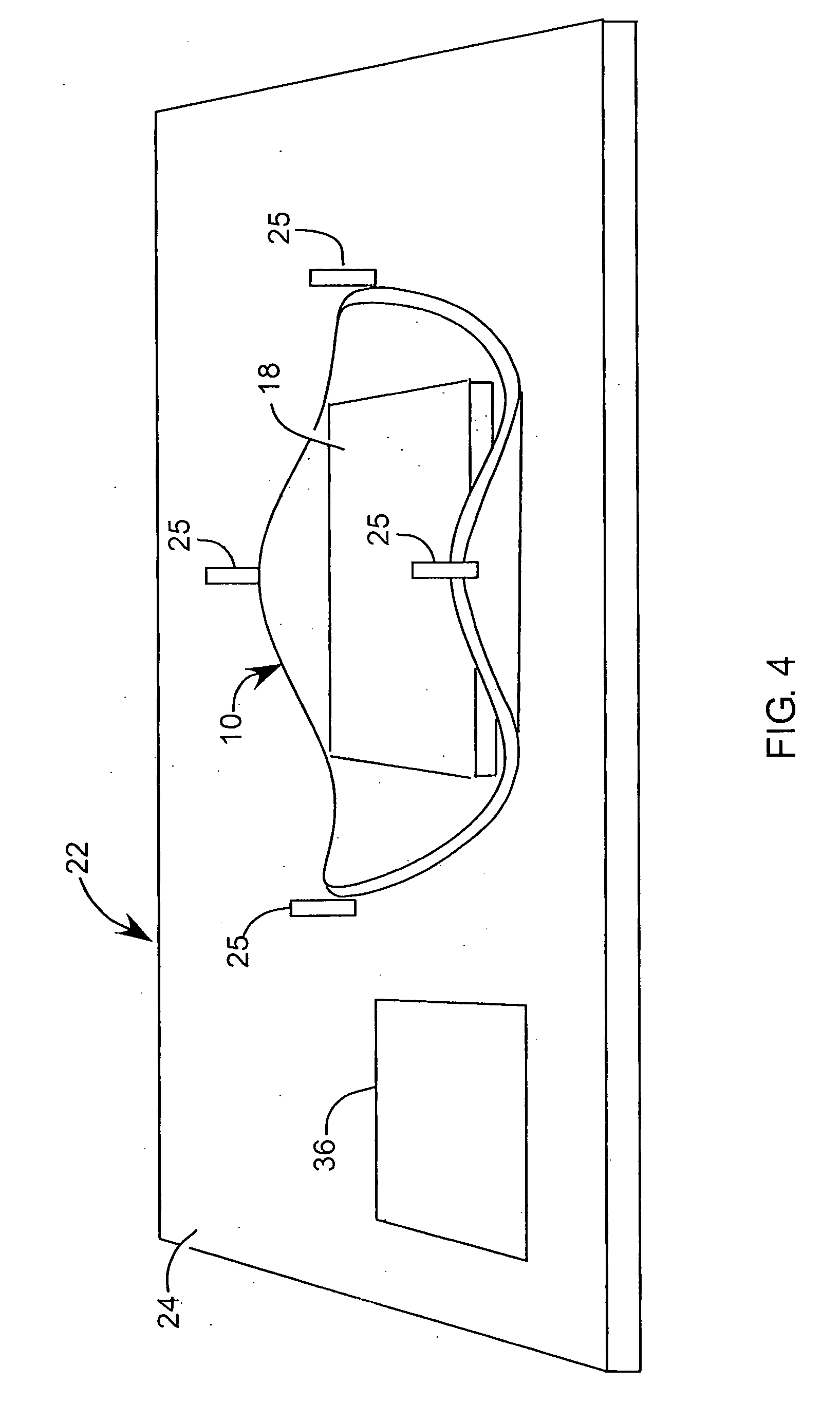

Method of repairing a blisk and test pieces by welding

ActiveUS8049132B2Improve reliabilityBlade accessoriesEfficient propulsion technologiesEngineeringDamage zone

A method of repairing a turbomachine blisk having at least one damaged zone by build-up of metal in the damaged zone using a laser build-up welding machine is disclosed. The method includes preparing the damaged zone by machining the damaged zone to obtain a zone of defined profile to be repaired, build-up welding of a start-of-run test piece that includes the defined profile using the laser build-up welding machine, checking geometric and metallurgical quality of the test piece, and build-up welding the zone to be repaired of the blisk using the laser build-up welding machine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

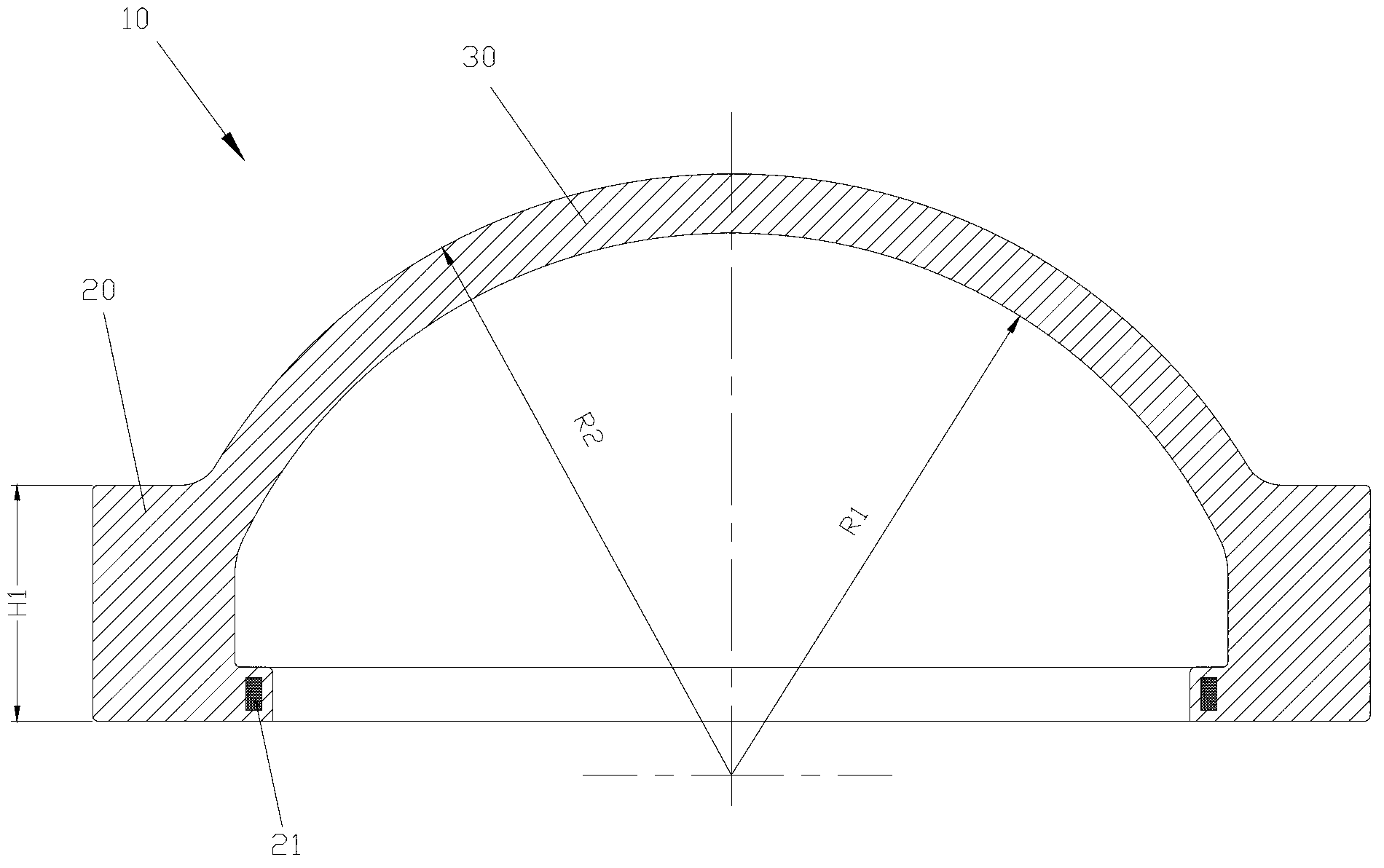

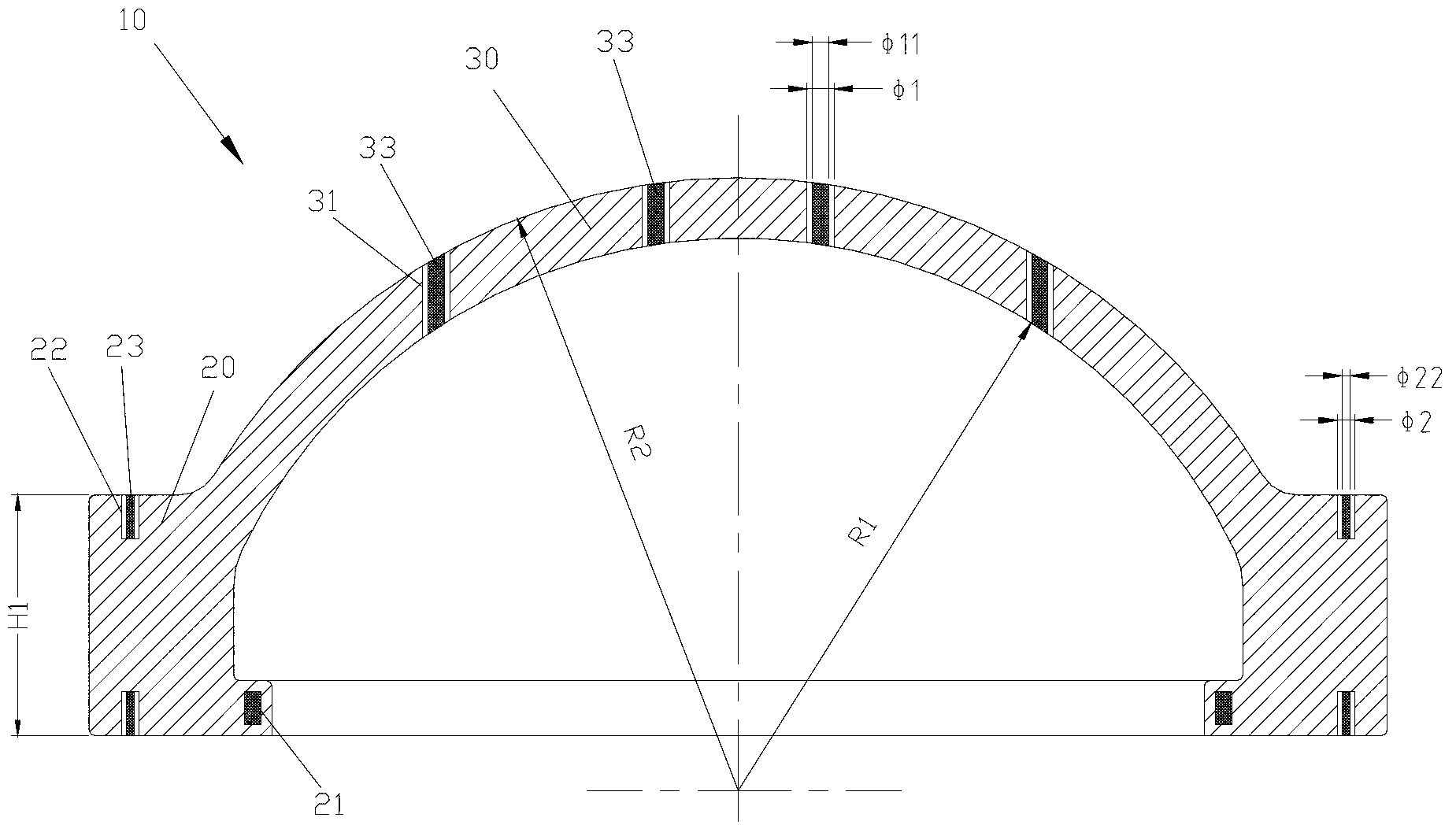

Sampling method for quality detection of entire top cover forging of reactor pressure vessel

ActiveCN102798543AComprehensive quality inspectionComply with process evaluation requirementsWithdrawing sample devicesChemical compositionReactor pressure vessel

The invention provides a sampling method for quality detection of entire top cover forgings of reactor pressure vessels. The sampling method includes: first pre-designing chemical composition analysis positions and sulfur print inspection regions of the entire forging surface before cutting; then performing inner-hole nesting sampling from preset installation holes of an end closure portion and bolt holes of a flange portion of the entire top cover forging; and cutting to obtain an inside test ring, a connection area test ring, a maximum damage zone test ring and a dome center test block from the entire top cover forging and cutting samples therefrom respectively. The sampling method of the present invention not only can inspect the overall quality of the entire top cover forging of the reactor pressure vessel and perform a complete assessment for the manufacturing process of the entire top cover forging in line with the procedure qualification requirements of the RCC-M nuclear power specification, but also does not require complete destruction of the entire top cover forging, so the flange portion still can be used as a flange product after sampling, thereby reducing the cost of sampling.

Owner:SUZHOU NUCLEAR POWER RES INST +1

Design method of a rig

A design method for design of a rig is presented. The rig comprises a hollow tubular shell, and the interior of said shell defines at least first and second intersecting cylinders. The design method comprises identifying a damage area, presenting a 3D view of identified damage area and generating a 3D model of a virtual rig. The generating comprises virtually placing in 3D view a shape covering or partly covering damage area, and creating, based on the position of the virtually placed shape, a position of hollow tubular rig shell of the virtual rig. The method further comprises selecting the at least first and second intersecting cylinders of the virtual rig, based on the size and form of the virtually placed shape, and creating a positioning surface of the virtual rig which is a bone and / or cartilage-engaging end of hollow tubular shell. The positioning surface is adapted to follow the surface surrounding the virtually placed shape when the virtual rig is placed in a virtual model of the joint. The method comprises producing a rig according to the virtually created rig.

Owner:EPISURF IP MANAGEMENT

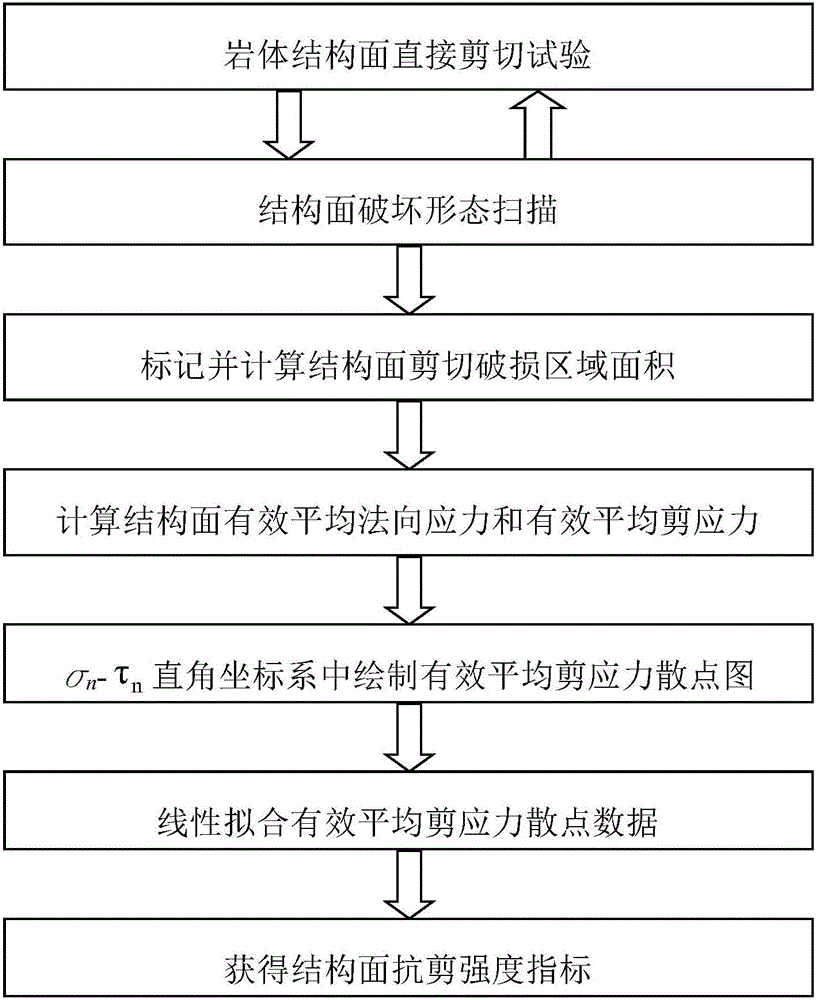

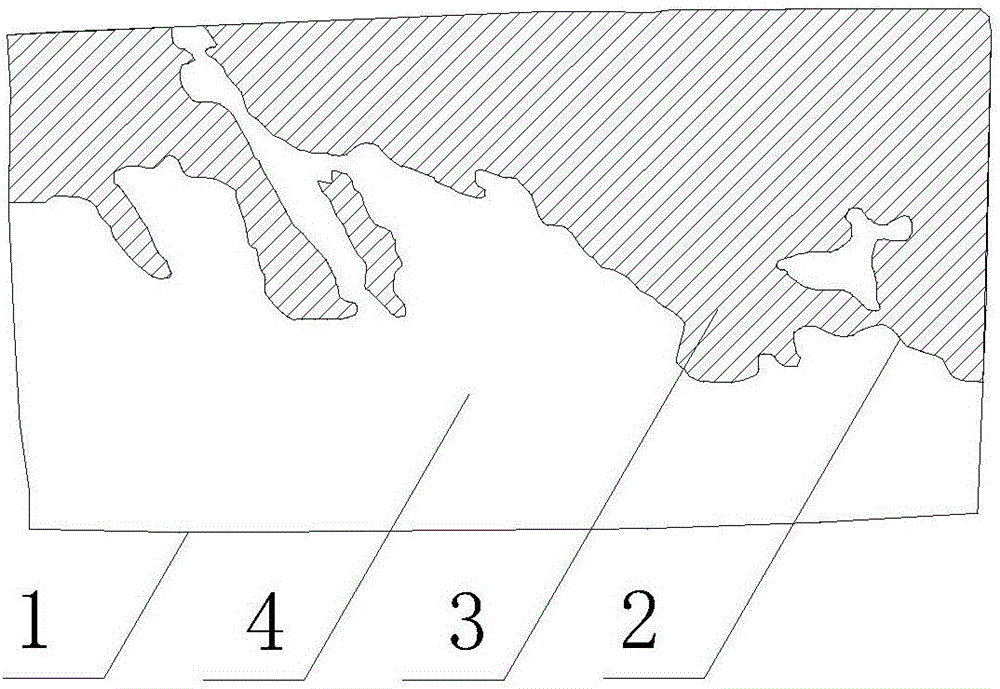

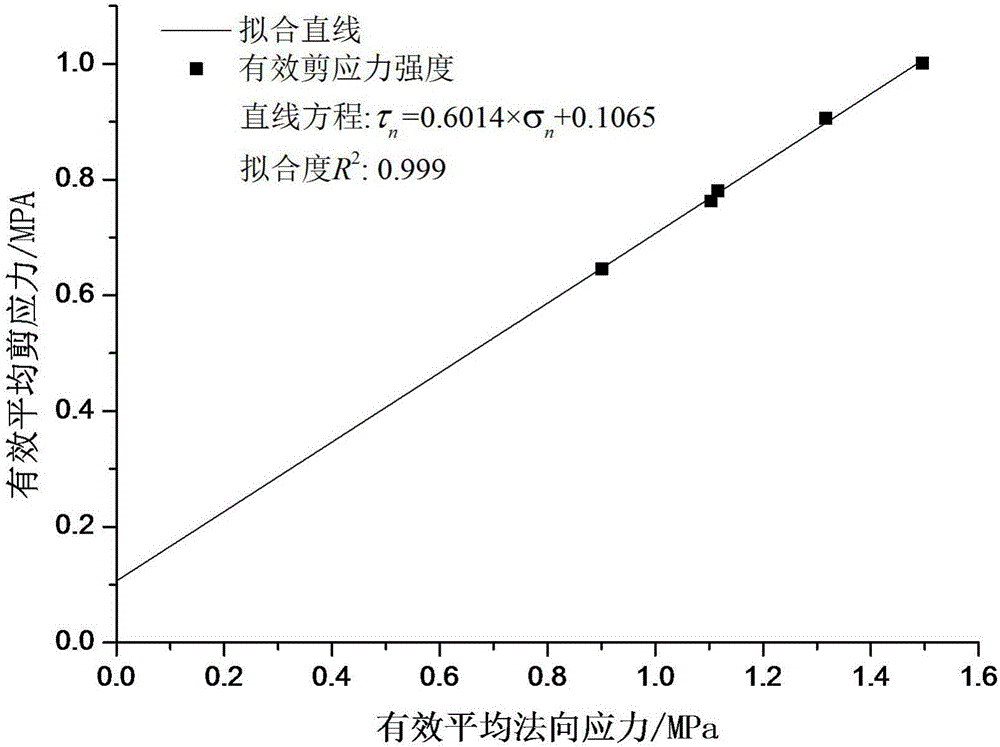

Method for calculating shear strength index of rock mass structural plane

InactiveCN106053256ATrue Shear Strength PropertiesIncreased testing effortMaterial strength using steady shearing forcesRectangular coordinatesGreek letter sigma

The invention discloses a method for calculating shear strength index of rock mass structural plane. The rock mass structural plane undergoes multiple direct shear tests under different normal stresses; shear damage zone of the structural plane is scanned and effective area of the shear damage zone is calculated; according to a formula, effective average normal stress sigma n and effective average shear stress tau n under different normal stresses are calculated, and a scatter diagram of effective average shear stress under different effective average normal stresses is drawn in the rectangular coordinate system of sigma n-tau n; scatter data of the effective average shear stress undergoes linear fitting; according to a value of fitting straight slope, internal friction angle of the rock mass structural plane is calculated; and according to the point of intersection between the fitting line and vertical coordinate of the rectangular coordinate system, cohesion force of the rock mass structural plane is obtained. By measuring the shear strength index of the structural plane on the basis of the effective shear area, shear strength characteristic of the rock mass structural plane can be truly reflected. The design for geotechnical engineering construction and hidden danger management scheme has more reliable safety and economy.

Owner:NANHUA UNIV

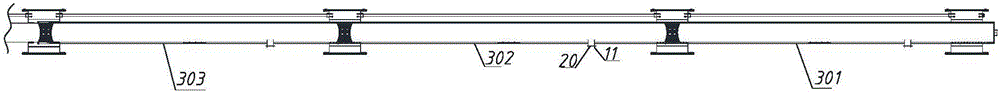

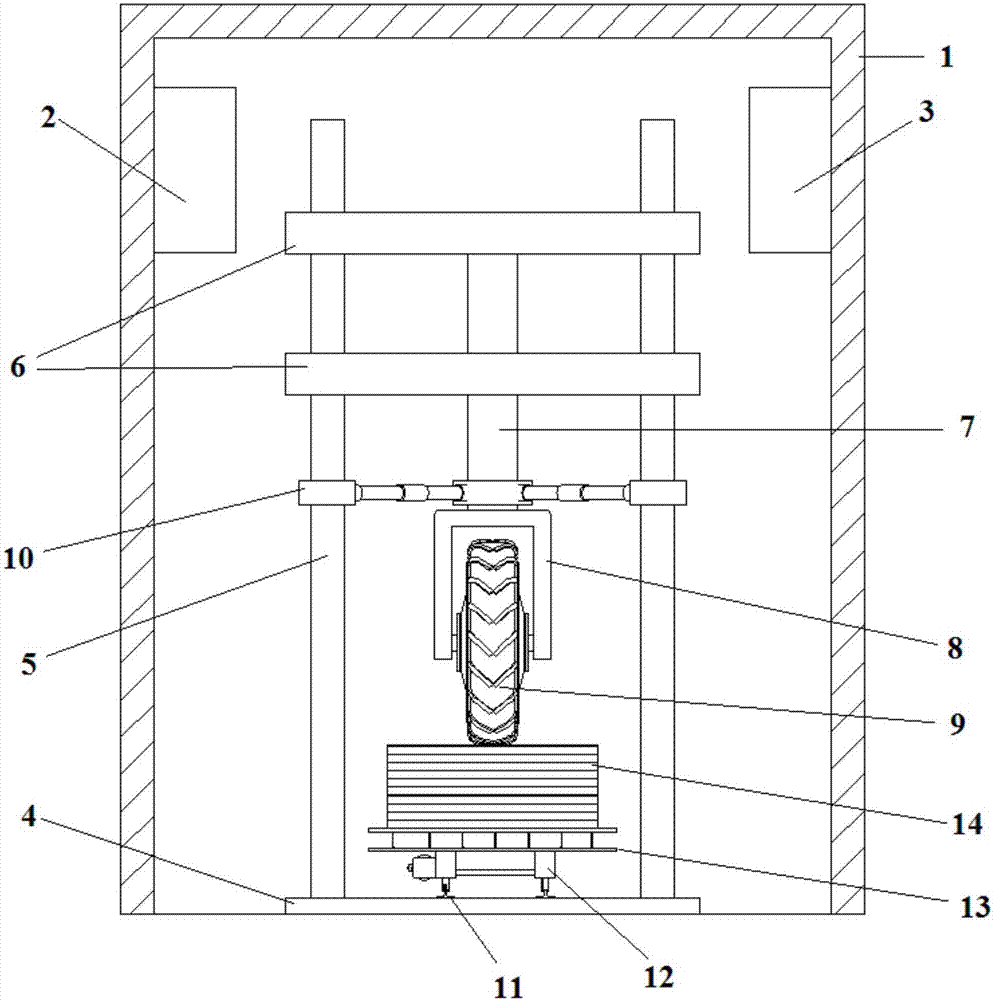

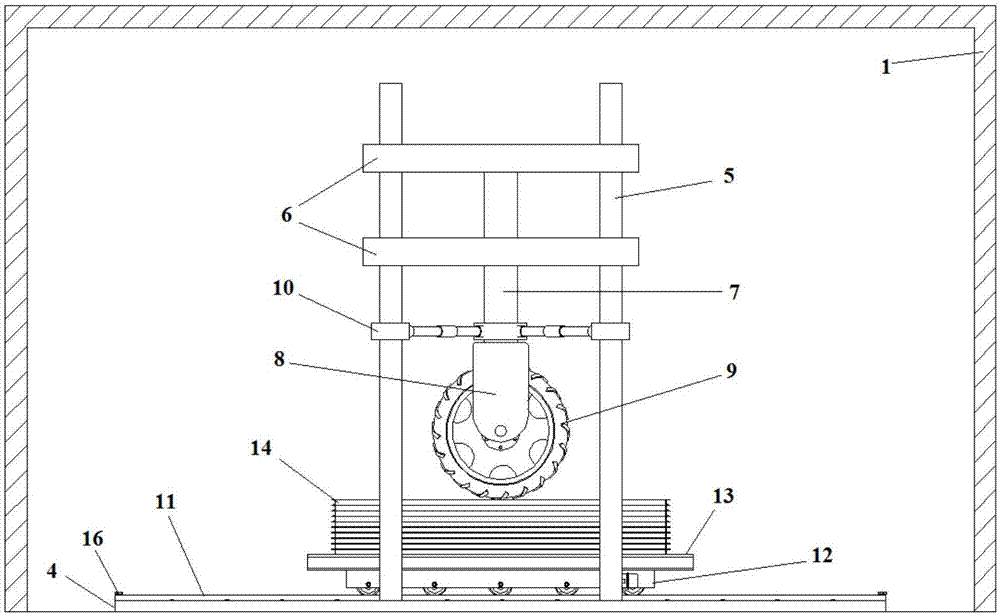

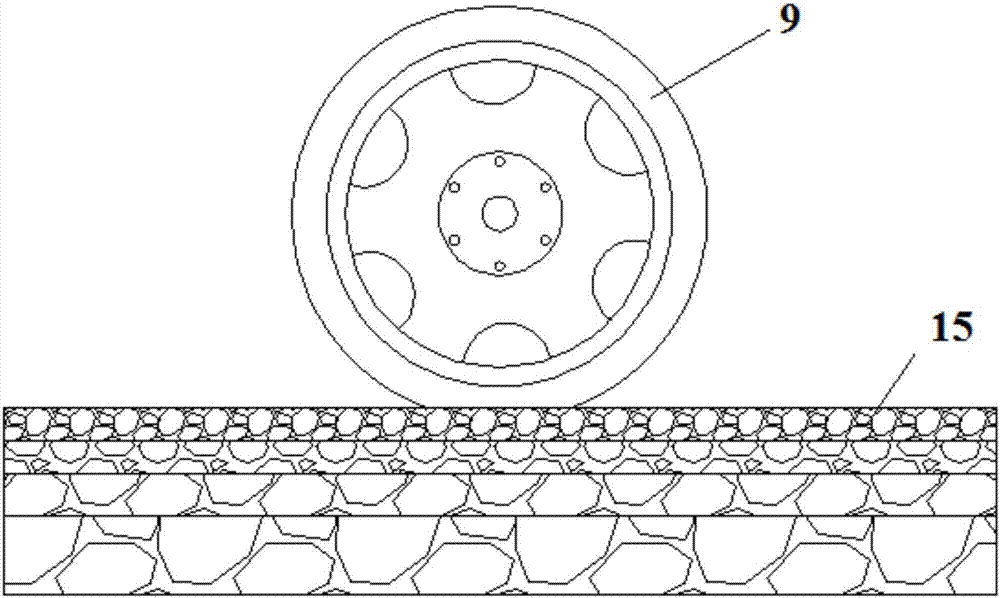

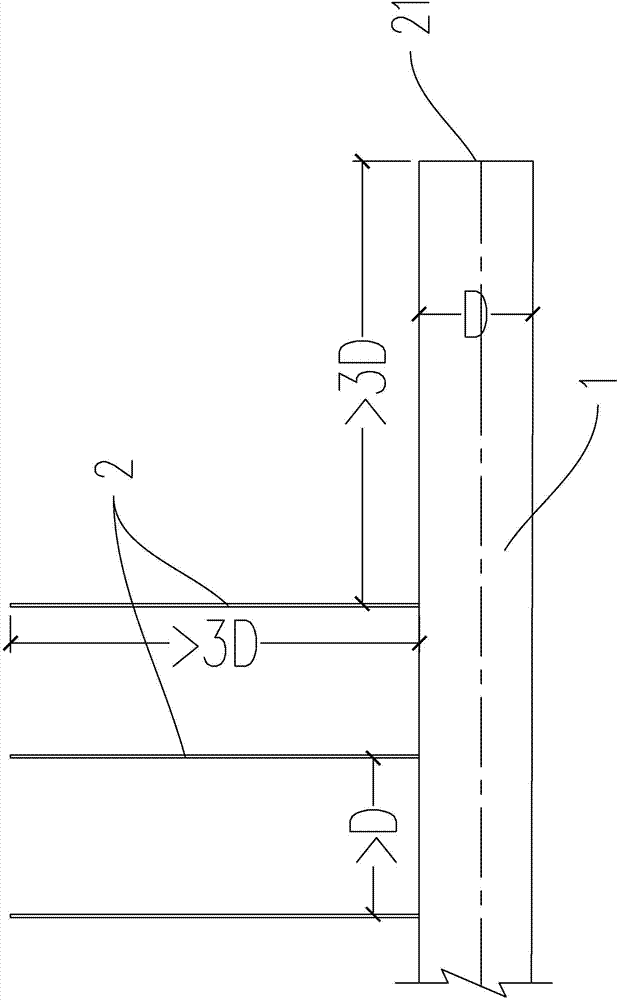

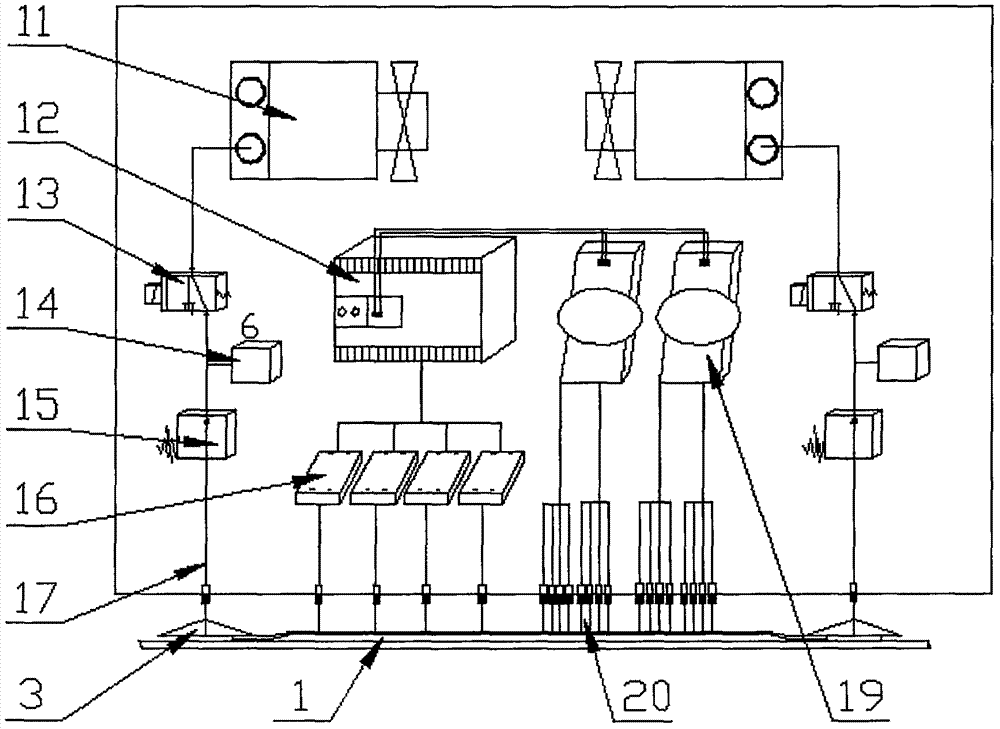

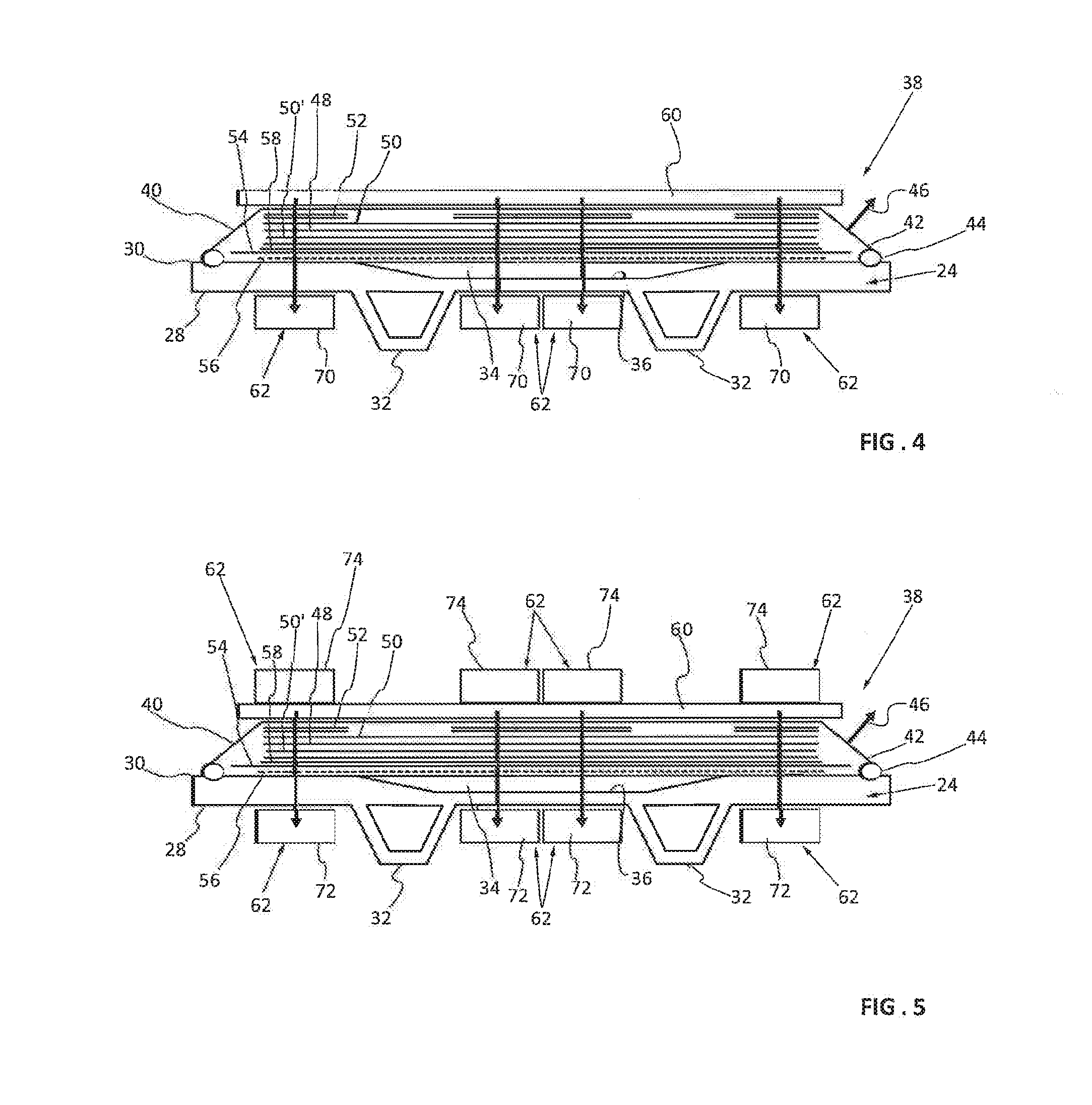

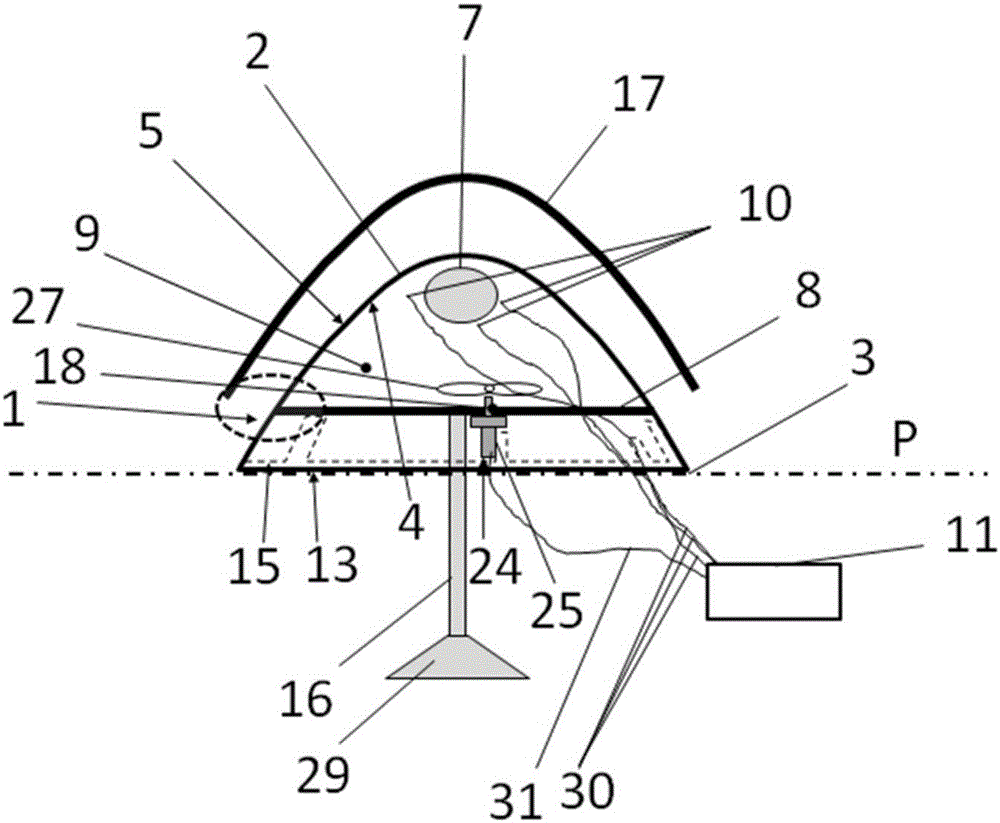

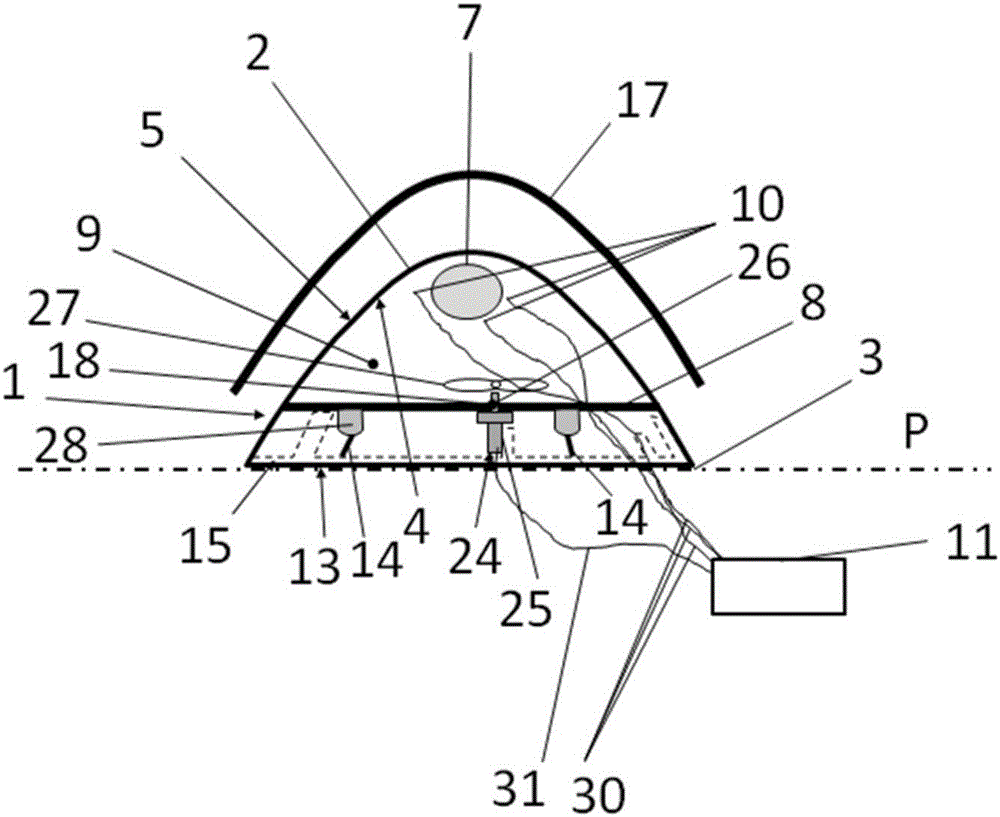

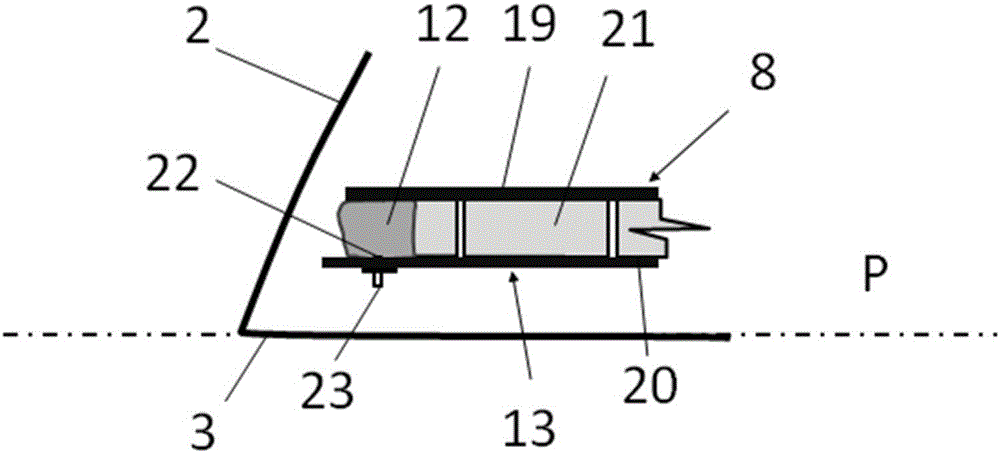

A pavement structural mechanical behavior testing device and method

InactiveCN107478802ATrue and effective reflectionGuaranteed accuracyEarth material testingEngineeringRoad surface

A pavement structural mechanical behavior testing device and method are provided. The bottom inside an insulating building is provided with a pedestal. The pedestal is provided with a group of vertical pillars. Lifting and descending platforms capable of being lifted and descending along the vertical pillars are mounted to the vertical pillars. A telescopic cylinder protruding out of the bottoms of the lifting and descending platforms is mounted to the lifting and descending platforms, and is perpendicular to the pedestal. The bottom of the telescopic cylinder is provided with a loading mechanism. A tyre is mounted to the loading mechanism. The vertical pillars and the telescopic cylinder are provided with a tyre positioning mechanism. A pair of guide rails are paved on the pedestal below the tyre. A roller box moving along the guide rails is mounted on the guide rails. A supporting platform is mounted to the top surface of the roller box. A test specimen box used for accommodating a pavement test specimen is mounted on the top surface of the supporting platform. According to the device and the method, restraint functions of pavement surrounding structures to critical damage zones are simulated by adopting a steel structure, and therefore the restraint state of pavement surrounding structures to critical damage zones in natural environment of an actual pavement can be simulated furthest.

Owner:CHANGAN UNIV

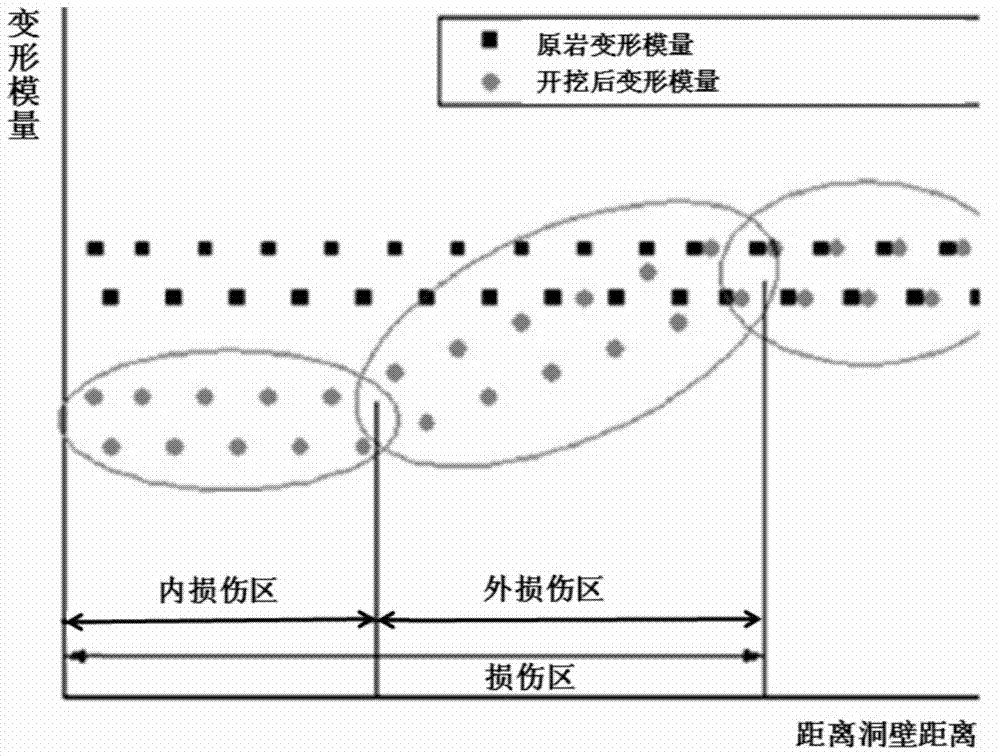

Zoned testing method for surrounding rock damage zone

InactiveCN104264721ARealistic evaluation of carrying capacityEvaluate carrying capacityMeasurement devicesFoundation testingRock coreDeformation modulus

The invention relates to a zoned testing method for surrounding rock damage zones and aims at providing a conveniently-operated, accurate and effective zoned testing method for the surrounding rock damage zones. The surrounding rock damage degree is judged through deformation modulus testing, and a damage zone partitioning limit is established. The technical scheme is that the zoned testing method for the surrounding rock damage zone is characterized in that a testing hole is formed and is perpendicular to an excavated grotto, a rock core is taken out of the testing hole, and the depth of the testing hole corresponding the rock core is recorded; a deformation modulus testing instrument is adopted to test the rock core and summarize deformation modulus testing results and performs tabulation statistics, a transverse shaft represents a distance away from the wall of the grotto, a longitudinal shaft represents deformation modulus, the testing results and original deformation modulus are compared, the testing results lower than the original deformation modulus in a table are damage zones, gentle sections lower than the original deformation modulus are internal damage zones, and rising sections are external damage zones. The zoned testing method for the surrounding rock damage zones is suitable for the field of underground engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

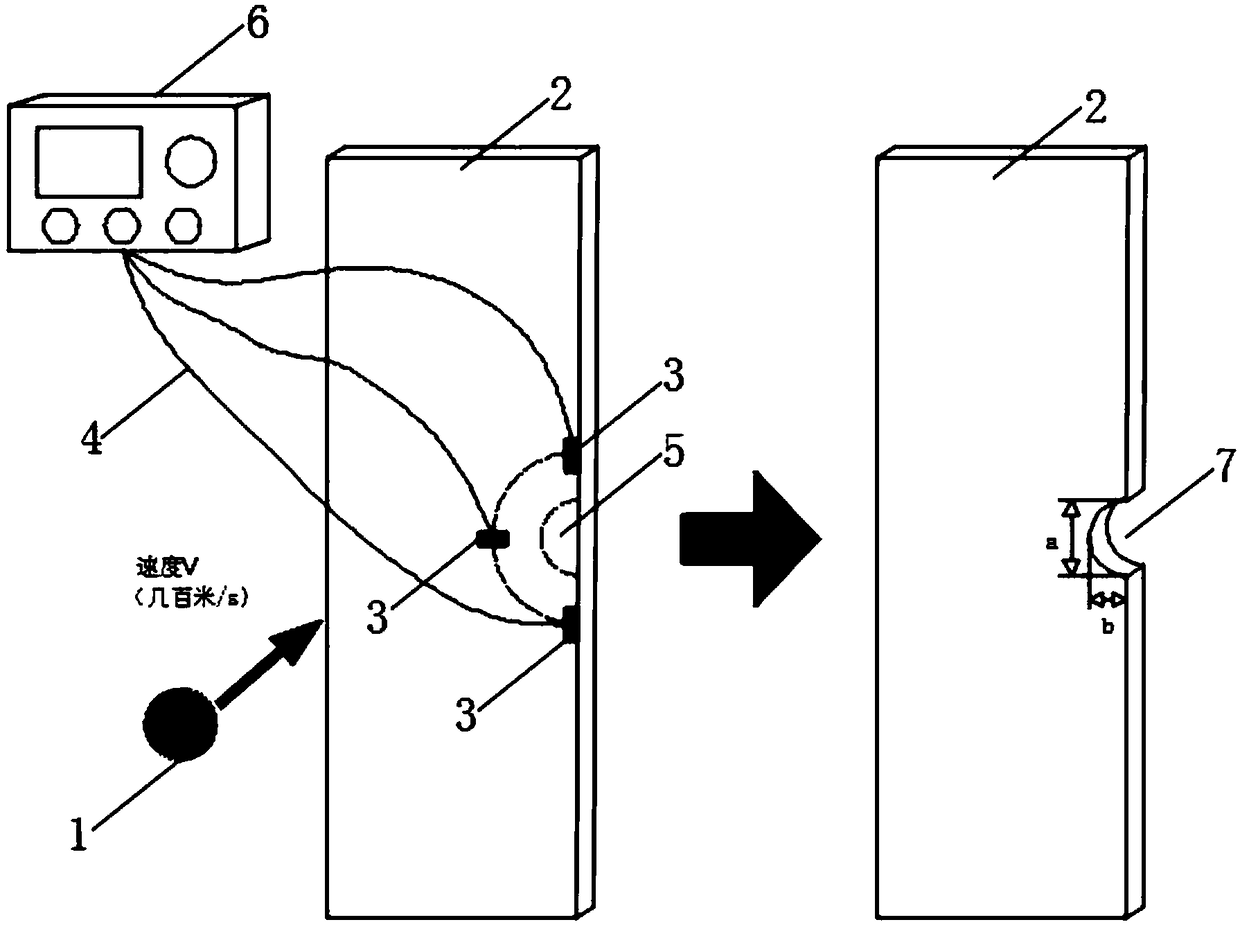

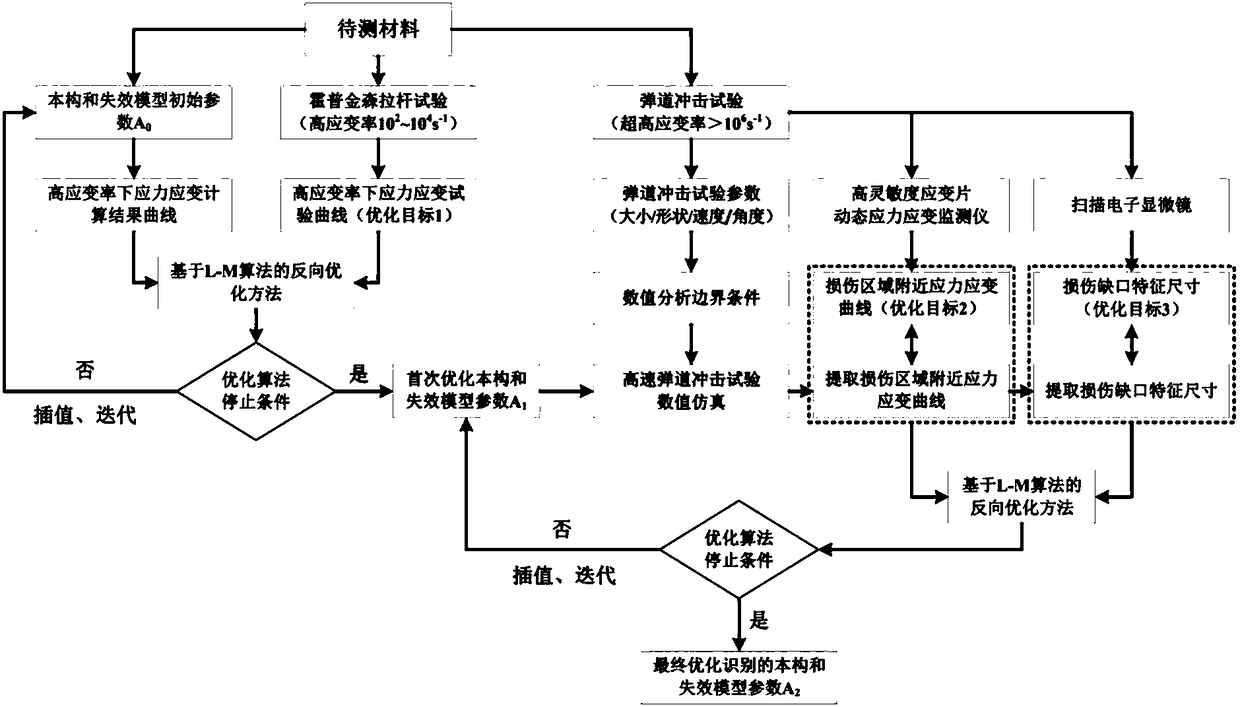

Parameter identification method for constitution and failure model of material under ultra-high strain rate

InactiveCN108169040AAddressing the lack of experimental dataAccurate Kinetic Response Behavior CharacterizationStrength propertiesEngineeringModel parameters

The invention discloses a parameter identification method for a constitution and failure model of a material under an ultra-high strain rate. A dynamic stress-strain curve of the deformation and failure process of the material under a high strain rate is obtained through Hopkinson pull rod test, and the dynamic stress-strain curve of the material under the high strain rate is used as a target forreverse optimization fitting to obtain parameters of the constitution and failure model after the first optimization are obtained; a light gas gun system is used to perform high-speed ballistic impacttests on the material, a high-sensitivity strain gauge is used to monitor the dynamic stress-strain curve of the material near a damage zone, and the feature size of a damage notch can be measured bya scanning electron microscopy; ballistic impact test parameters are used as boundary conditions for ballistic impact numerical simulation, and the dynamic stress-strain curve of the material corresponding to the position of the high-sensitivity strain gauge and the feature size of the damage notch can be extracted; the actually tested dynamic stress-strain curve of the material and the actuallytested feature size of the damage notch are used as targets for reverse optimization fitting to finally obtain the parameters of the constitution and failure model of the material under the ultra-highstrain rate.

Owner:AIR FORCE UNIV PLA

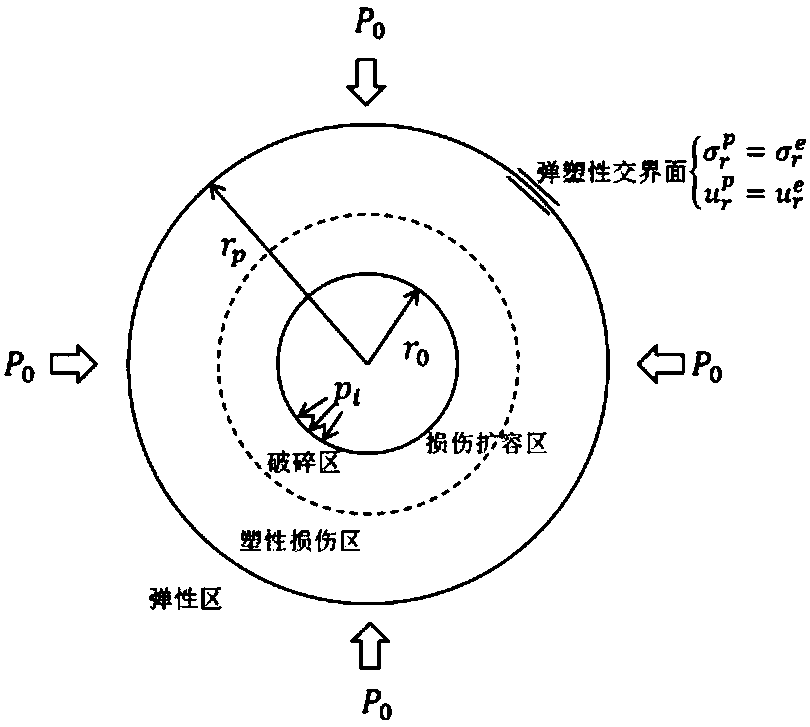

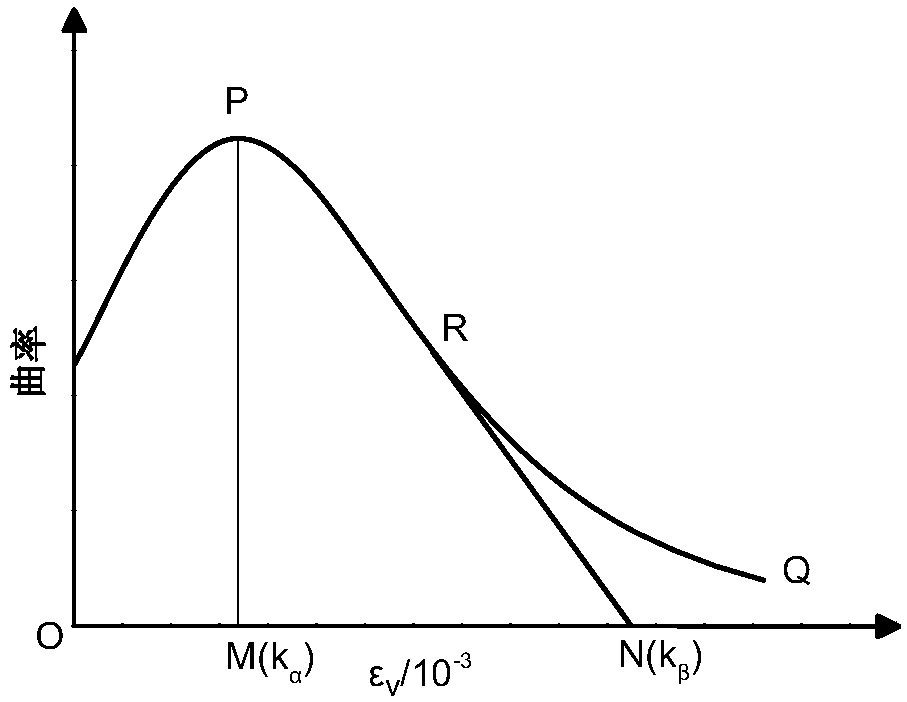

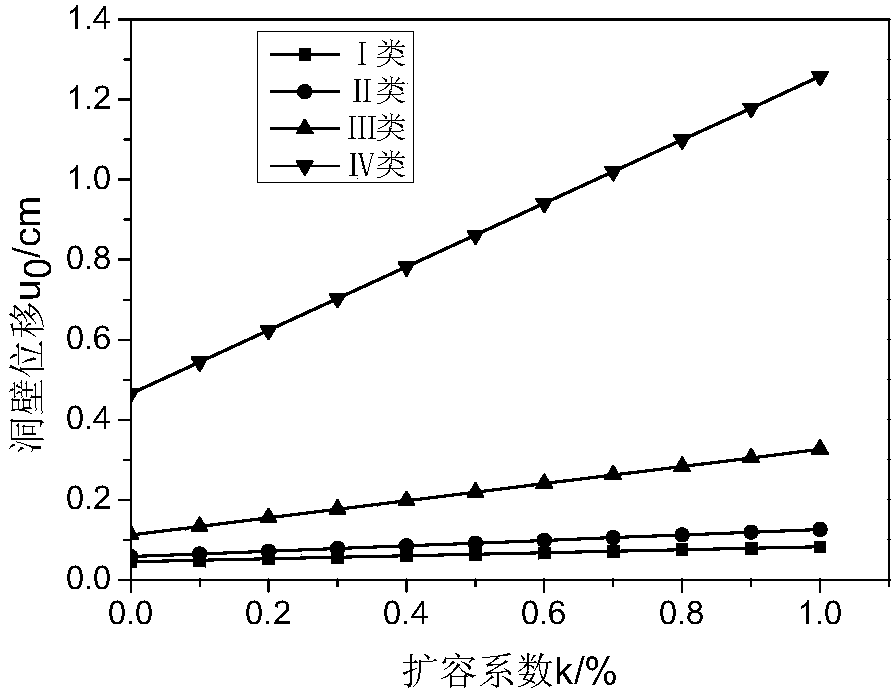

Surrounding rock displacement early-warning method based on damage dilatancy theory

ActiveCN107798195ADisplacement value of scientific first-level safety warningScientific safetyGeometric CADSpecial data processing applicationsThree levelSafety control

The invention discloses a surrounding rock displacement early-warning method based on a damage dilatancy theory. The surrounding rock displacement early-warning method comprises the following steps that 1, a calculation formula of surrounding rock pressure pi is obtained based on a traditional Fennar formula through elastic mechanical solution, a dilatancy coefficient k is introduced, the dilatancy effect of the damage dilatancy and deformation of a surrounding rock along with the excavation process is considered, and a formula, giving consideration to the dilatancy effect of a surrounding rock damage zone, of cavity wall displacement u0 is obtained; 2, hierarchical displacement calculation considering the dilatancy effect is conducted on the surrounding rock in the damage dilatancy zone;3, according to stress-strain curve characteristics in the rock damage dilatancy process, a three-level early warning safety management design system is established, and construction safety control isguided. A surrounding rock three-level damage dilatancy early-warning state is established so that the cavity wall displacement situation can be more really and accurately predicted, and the influence of a supporting structure is considered, therefore, the method can be also carried out according to the characteristics of different design stages such as preliminary design and construction design,is very easy to popularize and has an engineering application value.

Owner:HOHAI UNIV

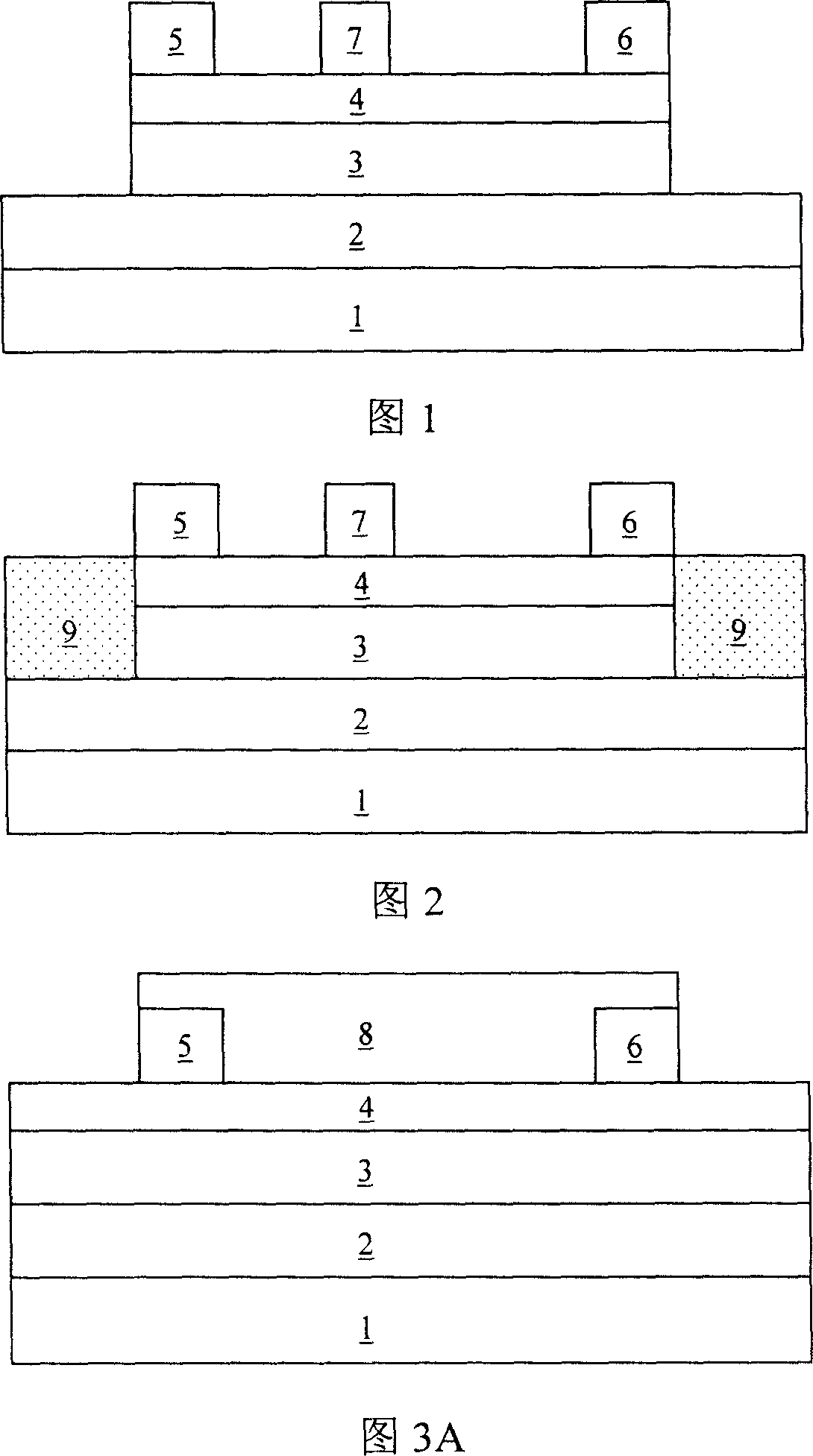

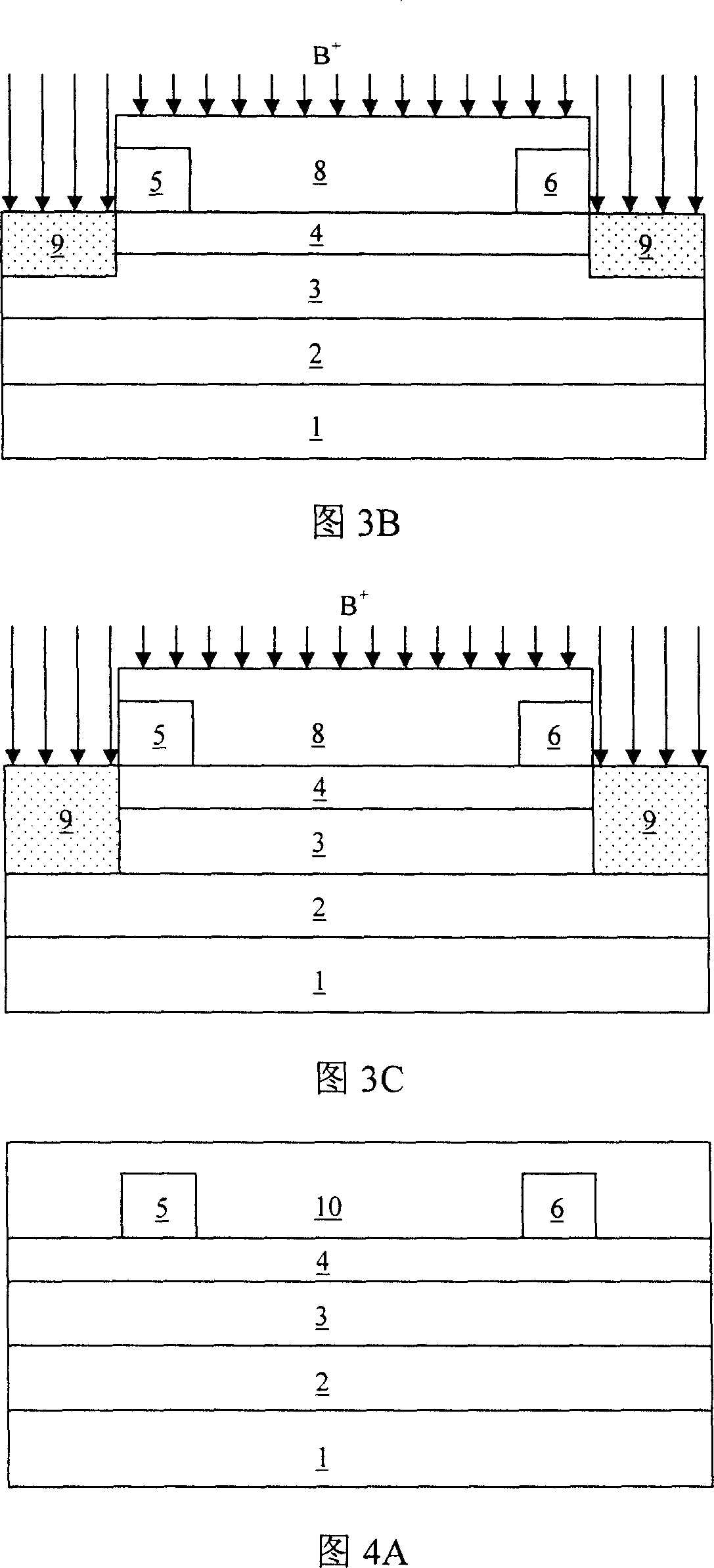

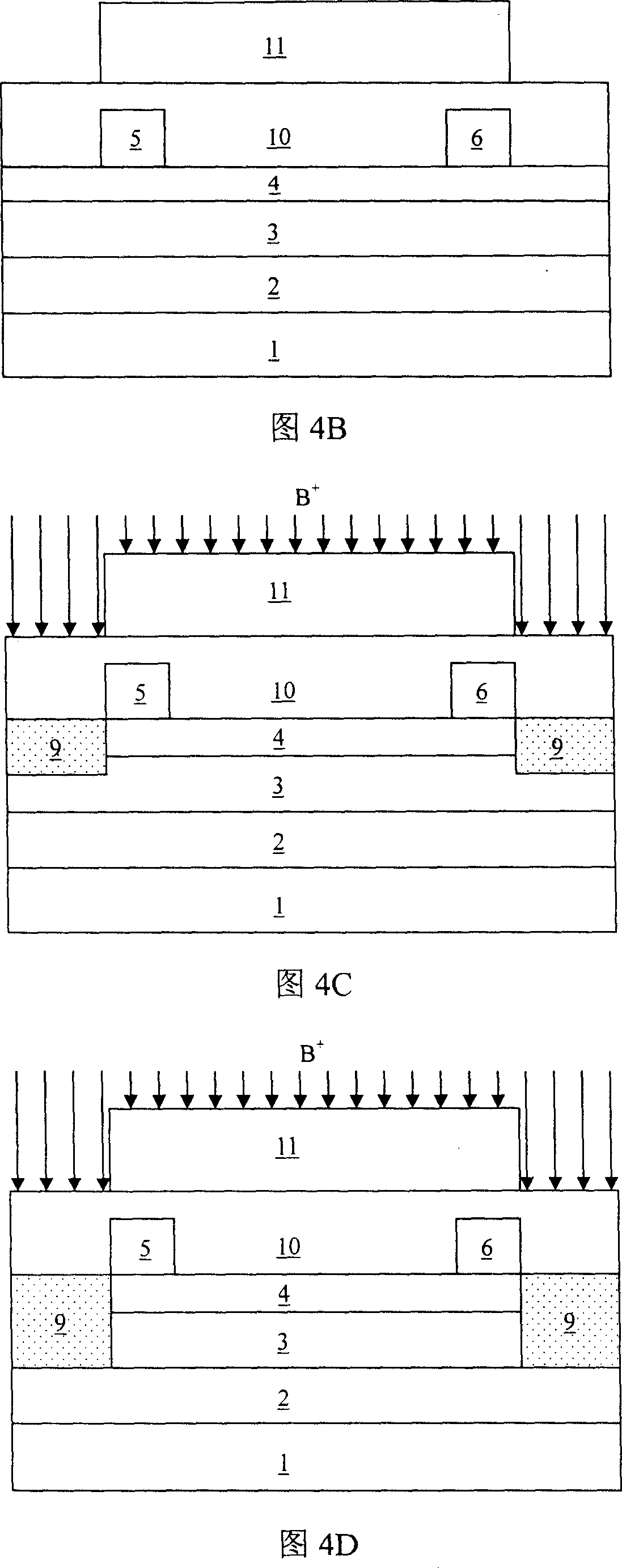

Method for realizing nitride semiconductor device inter-active-area isolation utilizing boron ion injection

InactiveCN1937206AReduce manufacturing stepsLower the altitudeSemiconductor/solid-state device manufacturingHigh resistanceIon bombardment

Aiming at issues of influencing on connection of interconnection line caused by height of tabletop and low yield existed in insulation of tabletop adopted by nitride semiconductor device, the invention discloses method of electrics insulation between active areas of nitride semiconductor device by using boron ion implantation. The method includes steps: after forming source ohmic contact and drain ohmic contact on AlGaN / GaN hetero junction, the method protects place, where ion implantation is not needed to carry out, of surface of AlGaN / GaN hetero junction material and device by using mask; forming high resistance damage zone on the said place not protected by using boron ion bombardment one or two times. Ensuring electrics insulation for device, the invention raises performance of device and is in favor of raising yield.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Satellite geodesy and reservoir performance

Satellite geodesy can identify fault-related surface deformation above onshore oil and gas fields through the use of radar interferometry (InSAR). The method provides an independent and cost-effective approach to identifying faults and damage zones that can be associated with increased reservoir performance beyond traditional tools of subsurface imaging and reservoir evaluation.

Owner:CONOCOPHILLIPS CO

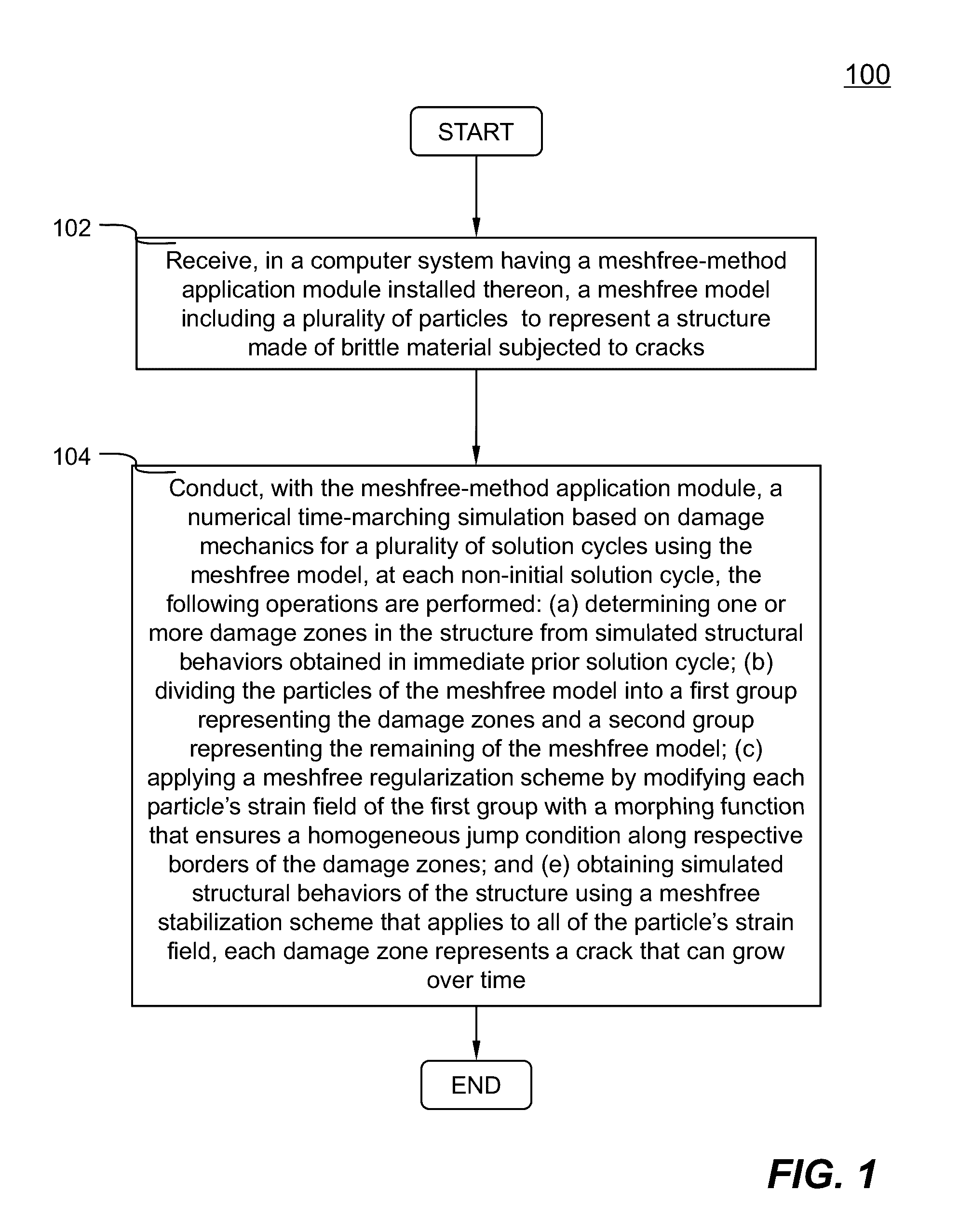

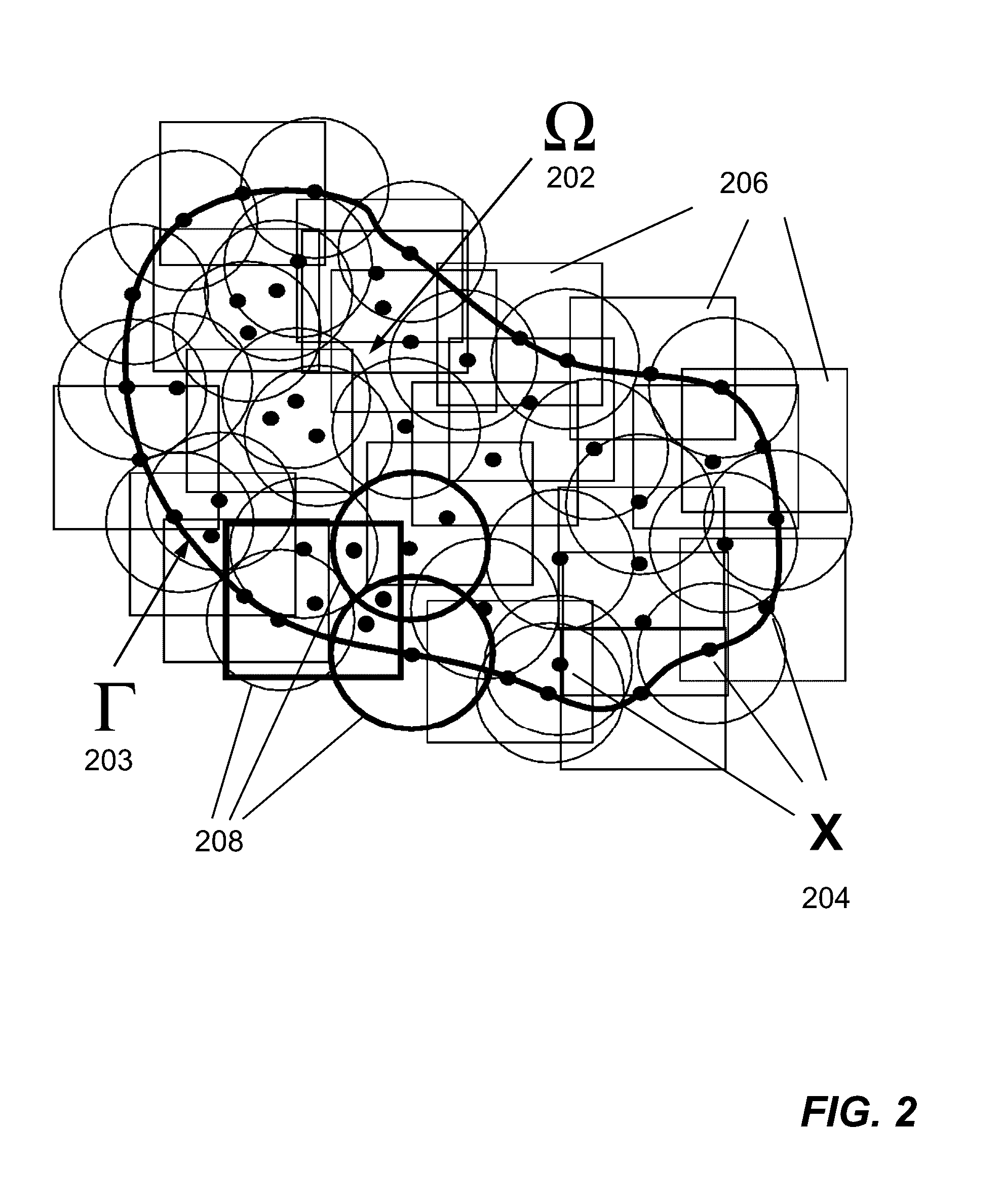

Meshfree Method And System For Numerically Simulating Brittle Material Based On Damage Mechanics

Meshfree model containing a number of particles to represent a structure made of brittle material is defined. At each non-initial solution cycle of a numerical simulation using the meshfree model based on damage mechanics, the following operations are performed: (a) determining one or more damage zones in the structure from simulated structural responses obtained in immediate prior solution cycle; (b) dividing the particles into a first group representing the damage zones and a second group representing the remaining of the meshfree model; (c) applying a meshfree regularization scheme by modifying each particle's strain field of the first group with a morphing function that ensures a homogeneous jump condition along respective borders of the damage zones; and (e) obtaining simulated structural behaviors of the structure using a meshfree stabilization scheme that applies to all of the particle's strain field. Each damage zone represents a crack that can grow over time.

Owner:ANSYS

Monitoring and repairing method for curing and cementing of composite material

PendingCN107538771AUniform temperature fieldAvoid excessive temperature differenceDomestic articlesField conditionsDamage zone

The invention provides a method for monitoring and repairing composite material curing adhesive bonding, which belongs to the field of composite material adhesive bonding repair equipment. The method is based on a composite material curing adhesive repair instrument, which includes a body, and a curing source module is provided at the adhesive repair working surface of the body, and the curing source module provides energy for the composite material prepreg to cure, and the curing The source module is surrounded by multiple temperature zones from the inside to the outside. Each temperature zone is equipped with an independent curing source for providing energy to the temperature zone. The multiple temperature zones are used alone or in conjunction with each other, and according to The shape of the damaged area of the structure is determined, and the temperatures of multiple temperature zones are the same or different. The present invention is based on multi-area curing source control, establishes a uniform and stable temperature field under external field conditions, and solves the problem of avoiding excessive temperature differences. Based on the principle of heat conduction, the multi-area temperature field control technology is used to achieve uniform and stable bonding repair areas. temperature field while avoiding excessive temperature differences.

Owner:青岛东正浩机电科技有限公司

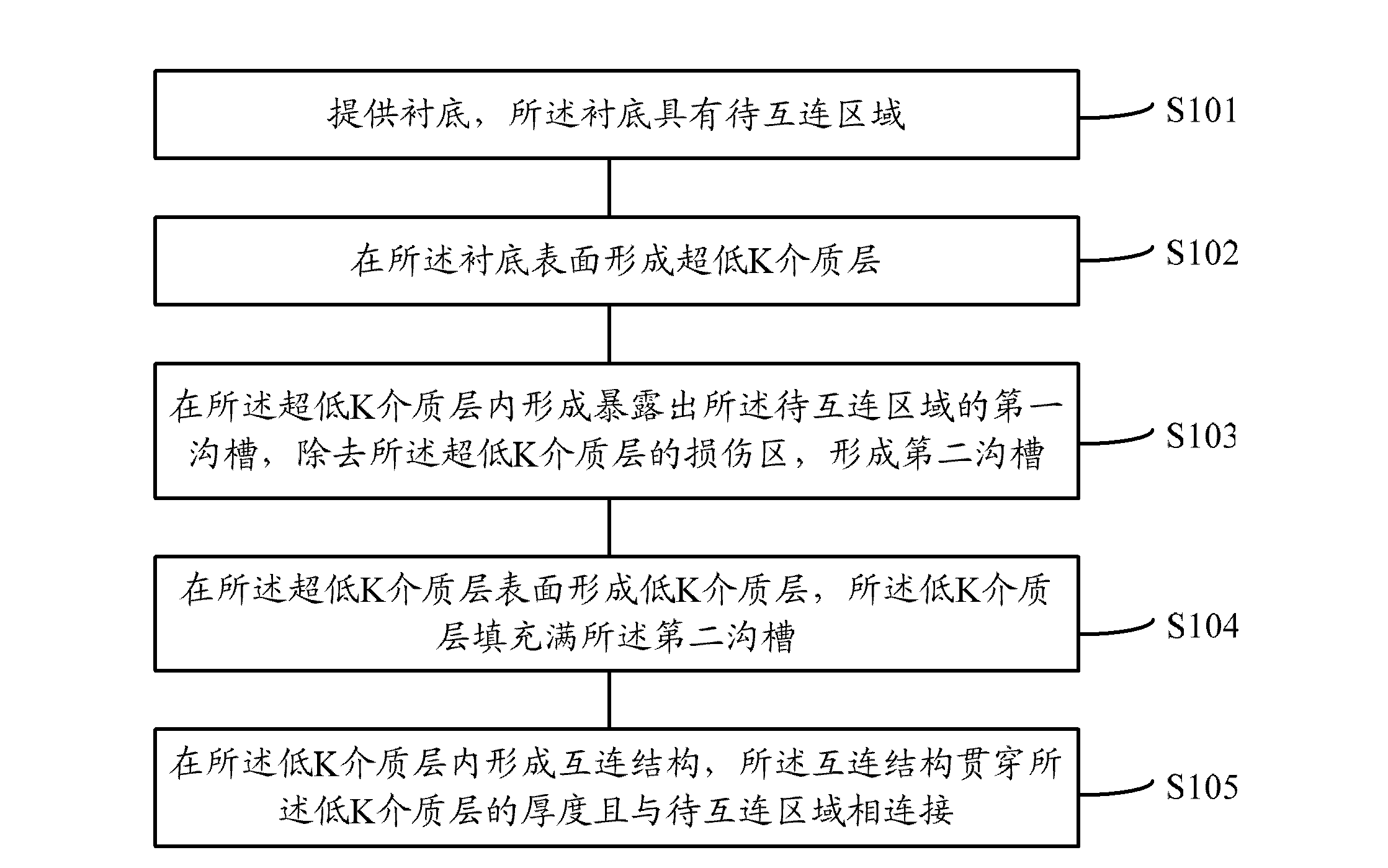

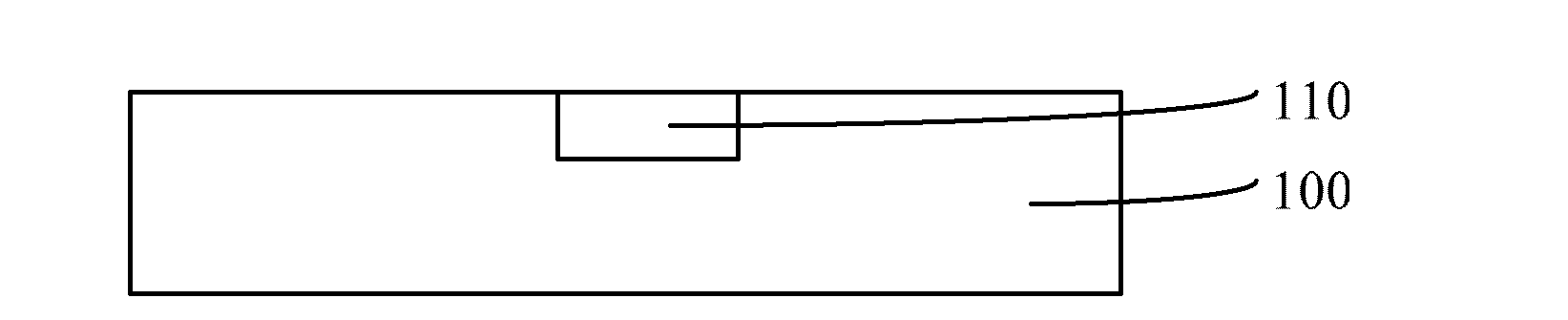

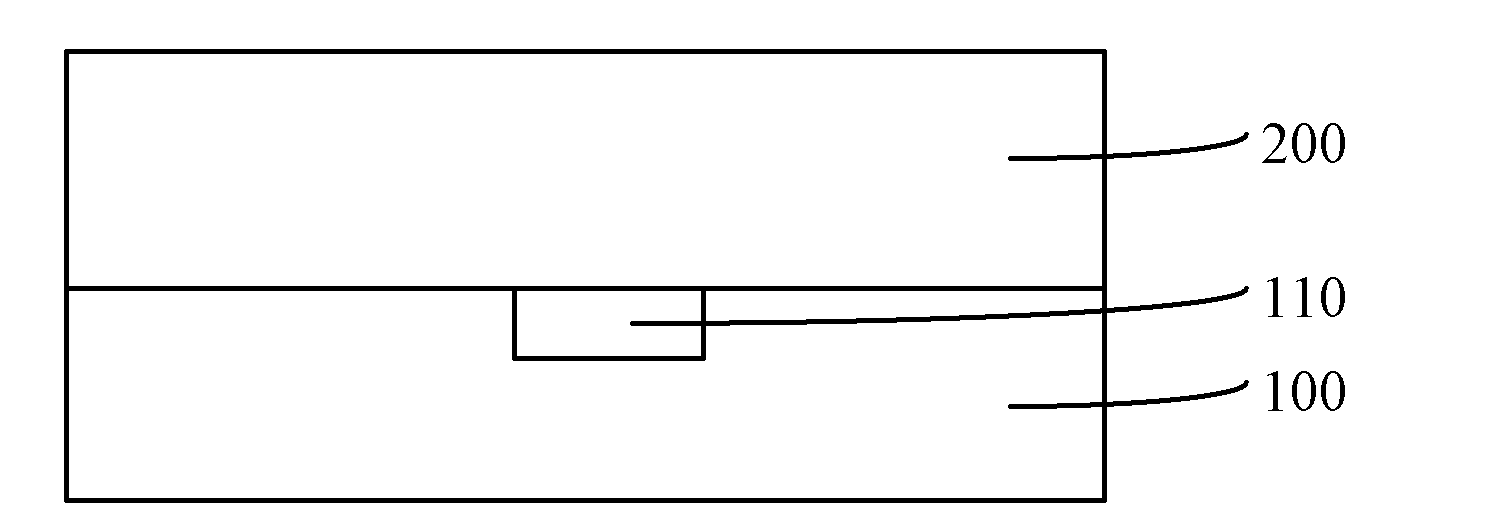

Semiconductor structure and forming method thereof

ActiveCN103165514ADoes not affect the dielectric constantSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureInterconnection

The invention discloses a semiconductor structure and a forming method thereof. The forming method particularly comprises the steps: providing a substrate which is provided with a to-be-interconnected region; forming an ultralow K medium layer on the surface of the substrate; forming a first groove in the ultralow K medium layer, removing a damage zone of the ultrlow K medium layer and forming a second groove, wherein the to-be-interconnected region is exposed of the first groove; forming a low K medium layer on the surface of the ultralow K medium layer, and filling the second groove by the low K medium layer; and forming an interconnection structure in the low K medium layer, wherein the interconnection structure penetrates through the thickness of the low K medium layer and is connected with the to-be-interconnected region. Due to the fact that the damage zone is removed, the damage zone cannot affect a dielectric constant of the ultralow K medium layer, the low K medium layer is formed in the second groove, the interconnection structure is formed in the low K medium layer subsequently, and a dielectric constant of a whole medium layer is not affected.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for mechanical characterization of a metal material

A method of repairing a turbomachine blisk having at least one damaged zone by build-up of metal in the damaged zone using a laser build-up welding machine is disclosed. The method includes preparing the damaged zone by machining the damaged zone to obtain a zone of defined profile to be repaired, build-up welding of a start-of-run test piece that includes the defined profile using the laser build-up welding machine, checking geometric and metallurgical quality of the test piece, and build-up welding the zone to be repaired of the blisk using the laser build-up welding machine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

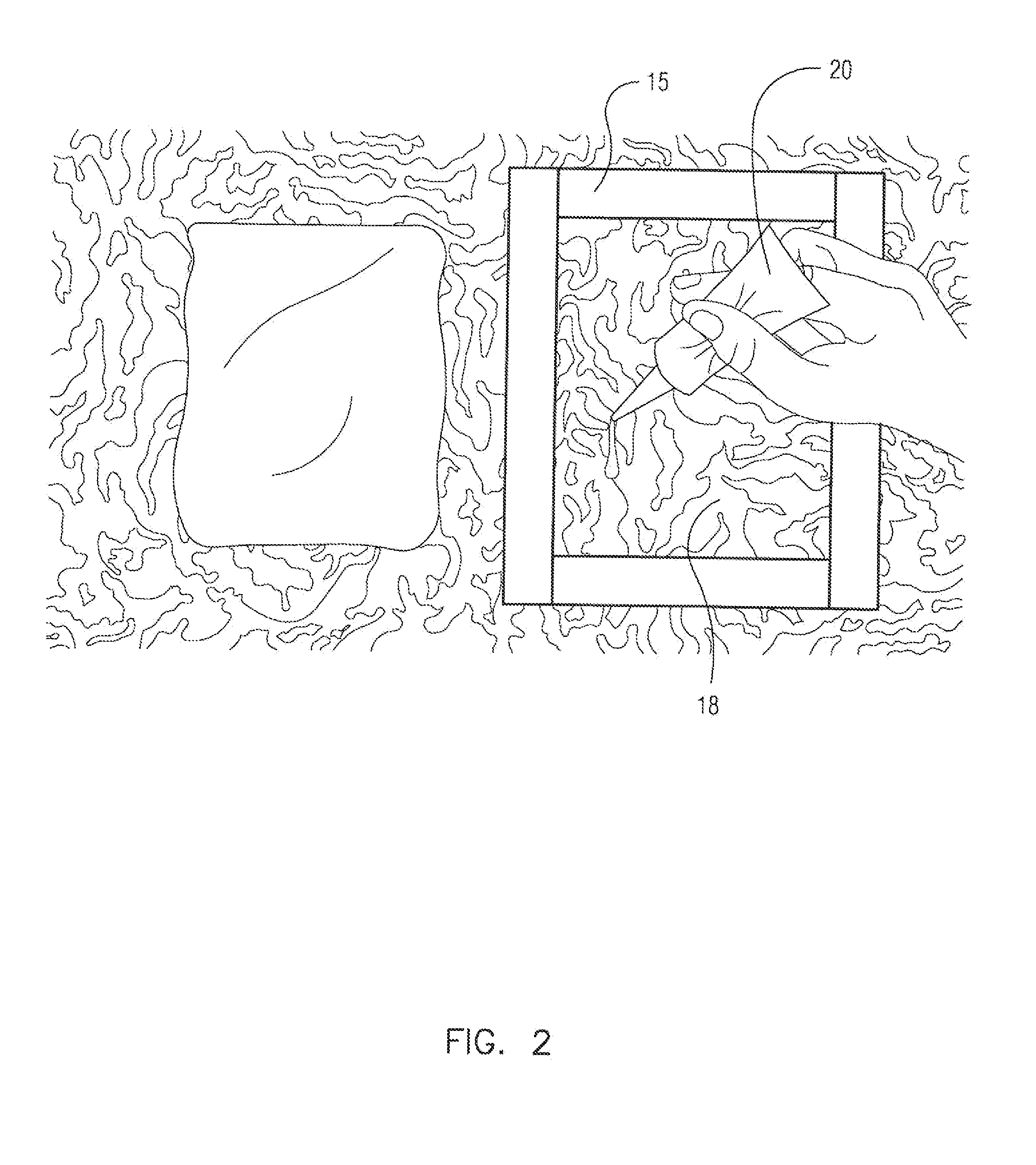

Method to apply texture to a wall surface

Owner:KOCHIS JOHN

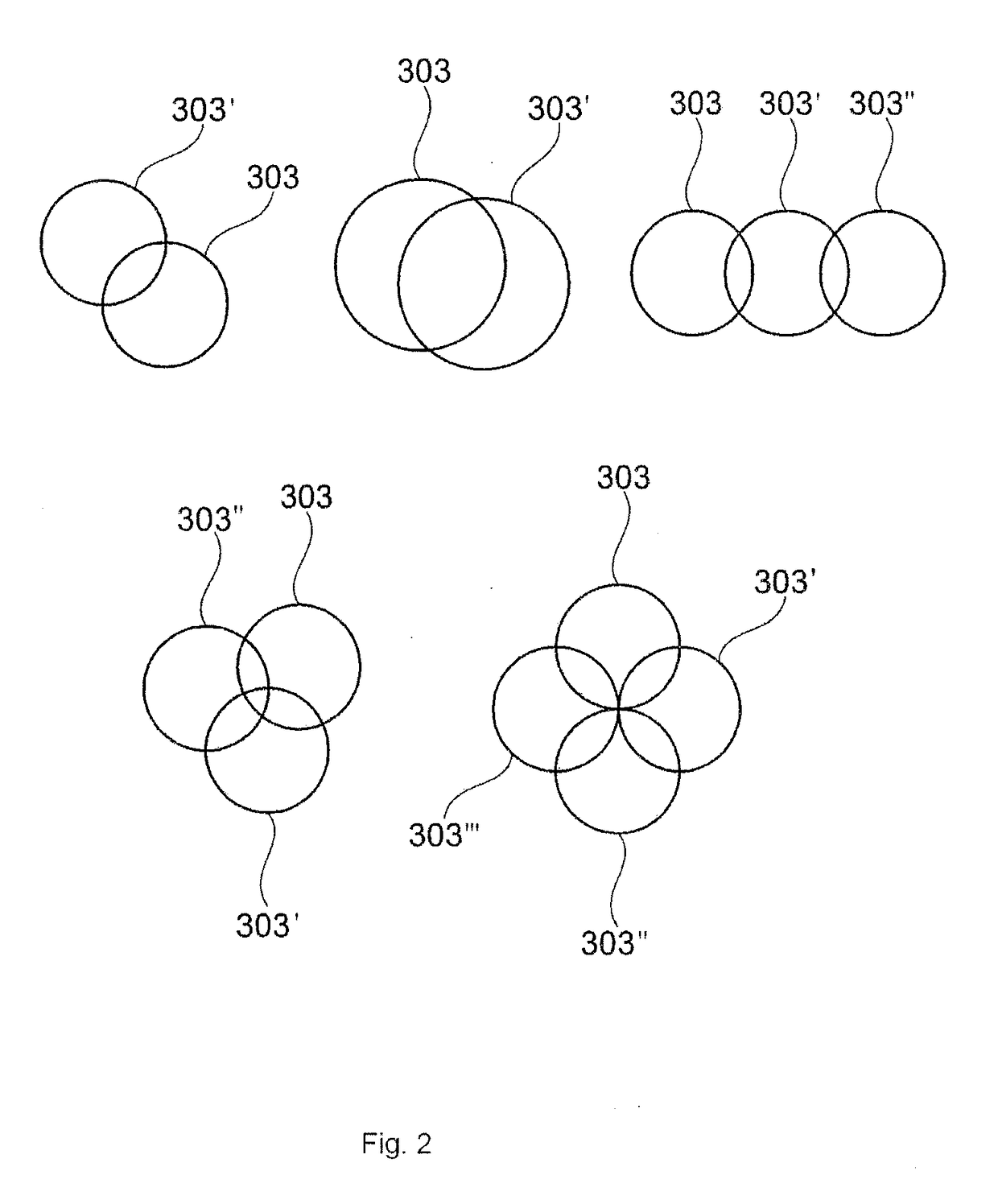

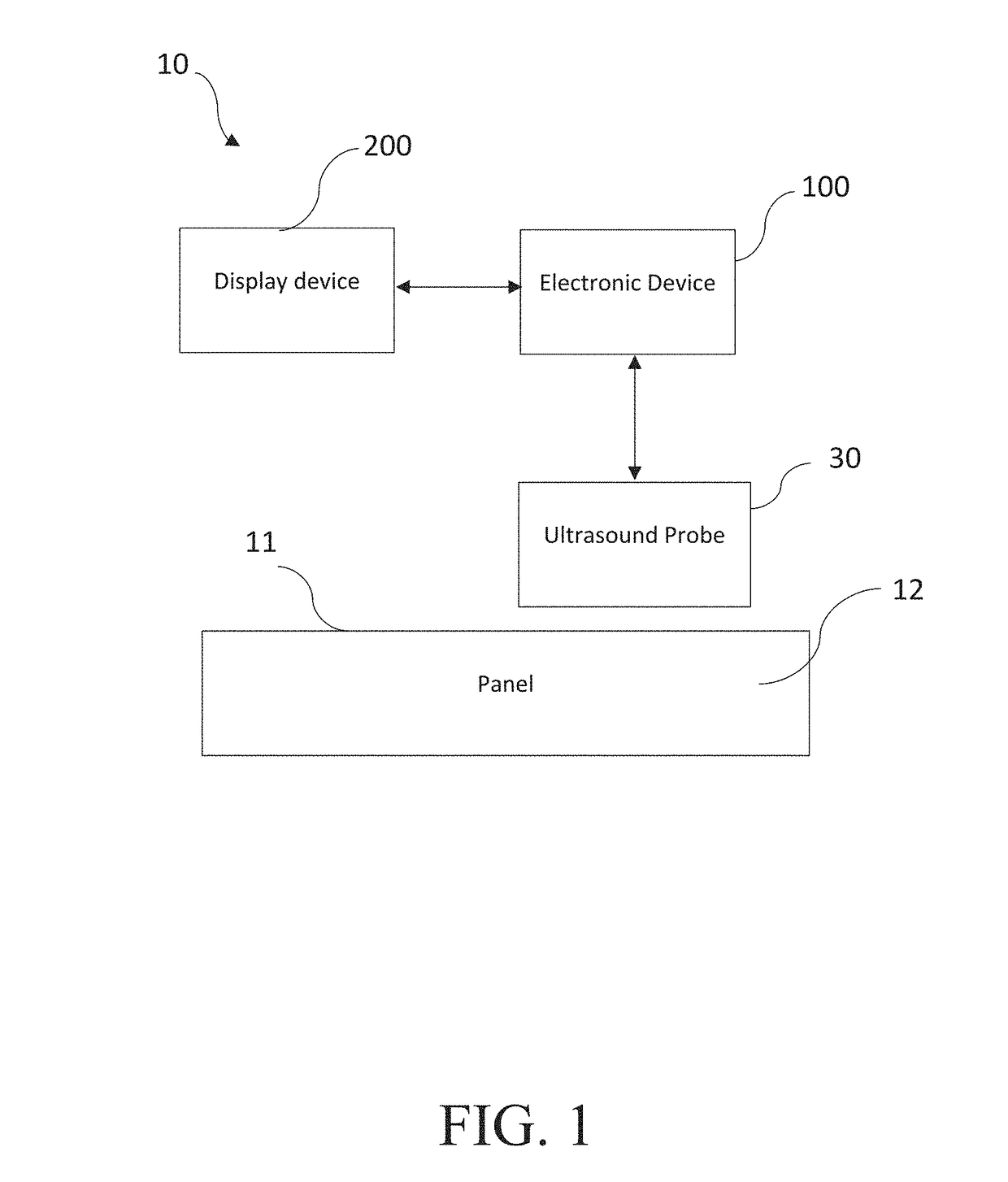

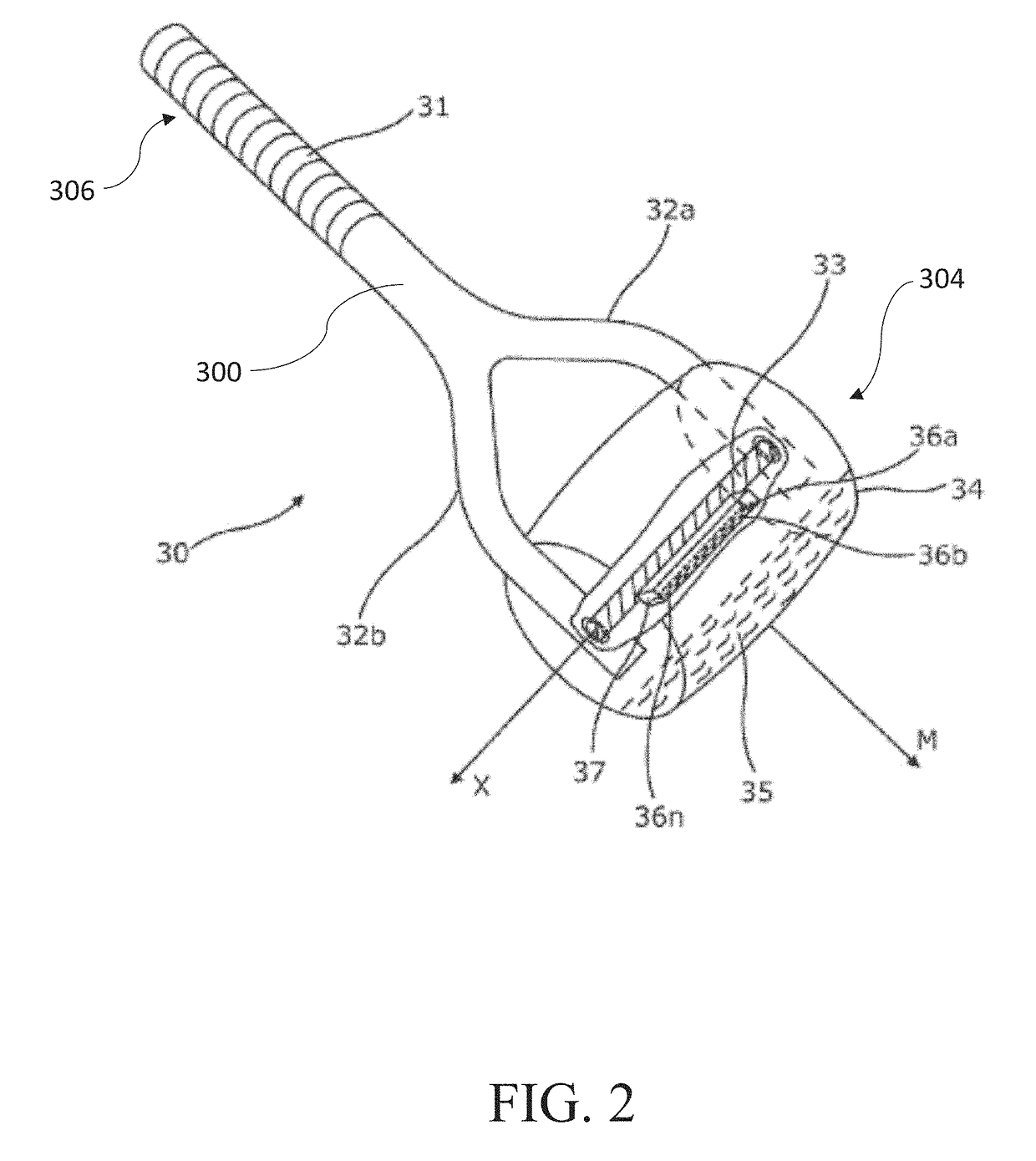

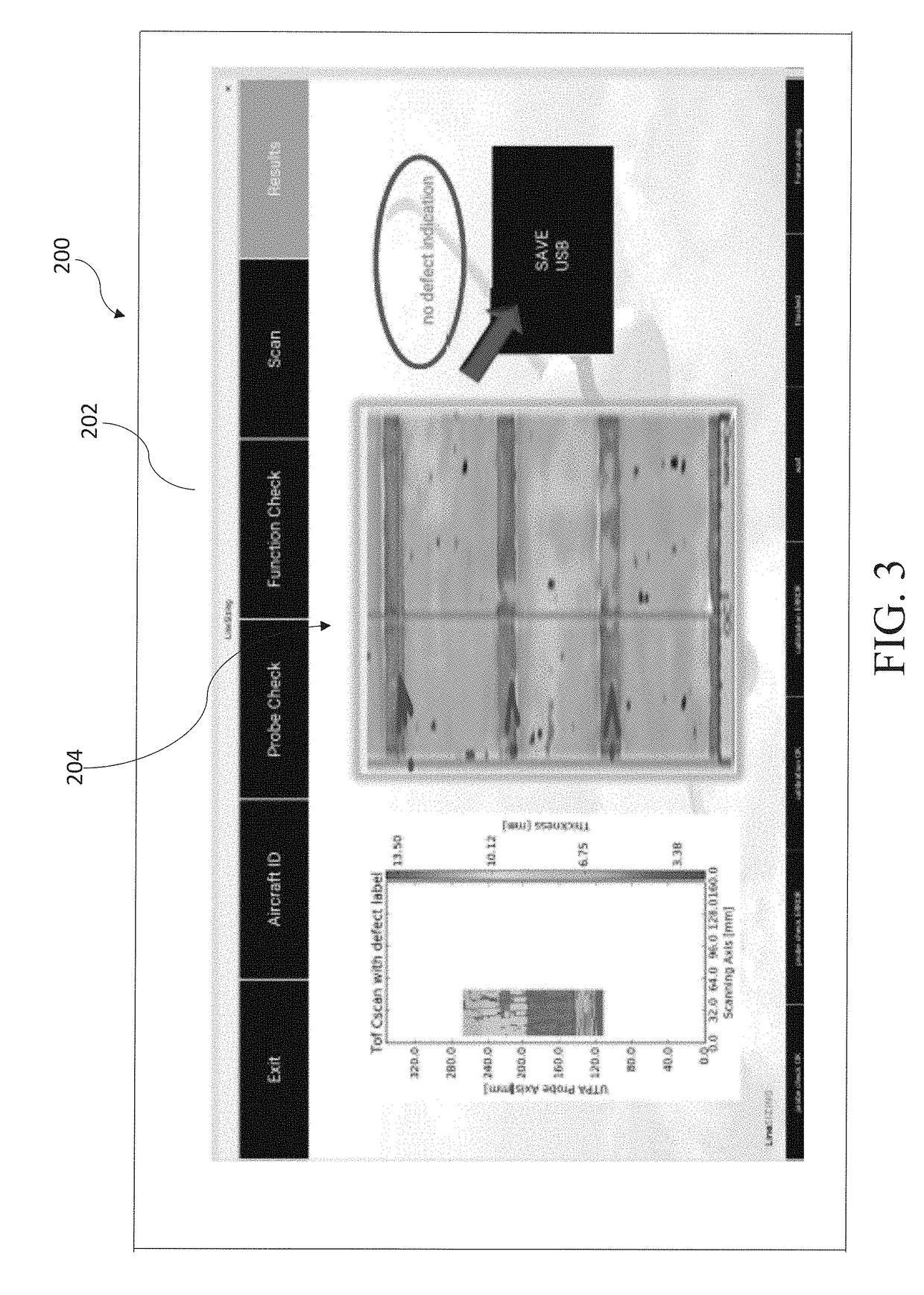

Device and method for non-destructive ultrasound inspection of structures made of composite material

ActiveUS20190025258A1Enhanced couplingGood ultrasound couplingAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansNon destructiveTransducer

A device and method for detecting delamination in a panel of laminated composite. The device comprises an ultrasonic probe with a plurality of elementary transducers, an electronic device in communication with the elementary transducers, and a display device. The transducers emit an ultrasonic pulse and receive a pulse reflected by an element in the panel. The received pulses are grouped into clusters of healthy, or non-damaged, zones and damaged zones. The dimensions of the damaged zones are based upon the limits formed by healthy zones. A display of the defect with dimensions is produced on the display device. A scale image of the defect with dimensions, via paper or digital overlay, can be placed on the panel.

Owner:AIRBUS SAS

Device for simulating harm of activities of ground fissures to high-speed rail bridge

InactiveCN103837359APredict hazardStructural/machines measurementSupporting systemEngineering controls

The invention discloses a device for simulating harm of activities of ground fissures to a high-speed rail bridge, and belongs to the field of geological disaster analysis. The device comprises a lifting system used for controlling lifting of a ground fissure hanging wall and footwall and the lifting speed of a settlement platform and simulating the activities of the ground fissures, a supporting system used for supporting the lifting system to carry out lifting on the ground fissure hanging wall and footwall, and a monitoring system used for monitoring dislocation, deformation and bridge foundation stress characteristics of a high-speed rail bridge model. Changes of stress in the high-speed rail bridge, bridge deformation and damage zone ranges and unstability and interaction between the bridge and a rail are taken into consideration under the action of different activities of the ground fissures, scientific bases are provided for engineering control measures for sections crossing the ground fissures of the high-speed rail bridge, and meanwhile the harm of the ground fissures to the high-speed rail bridge can be more accurately forecasted.

Owner:CHANGAN UNIV

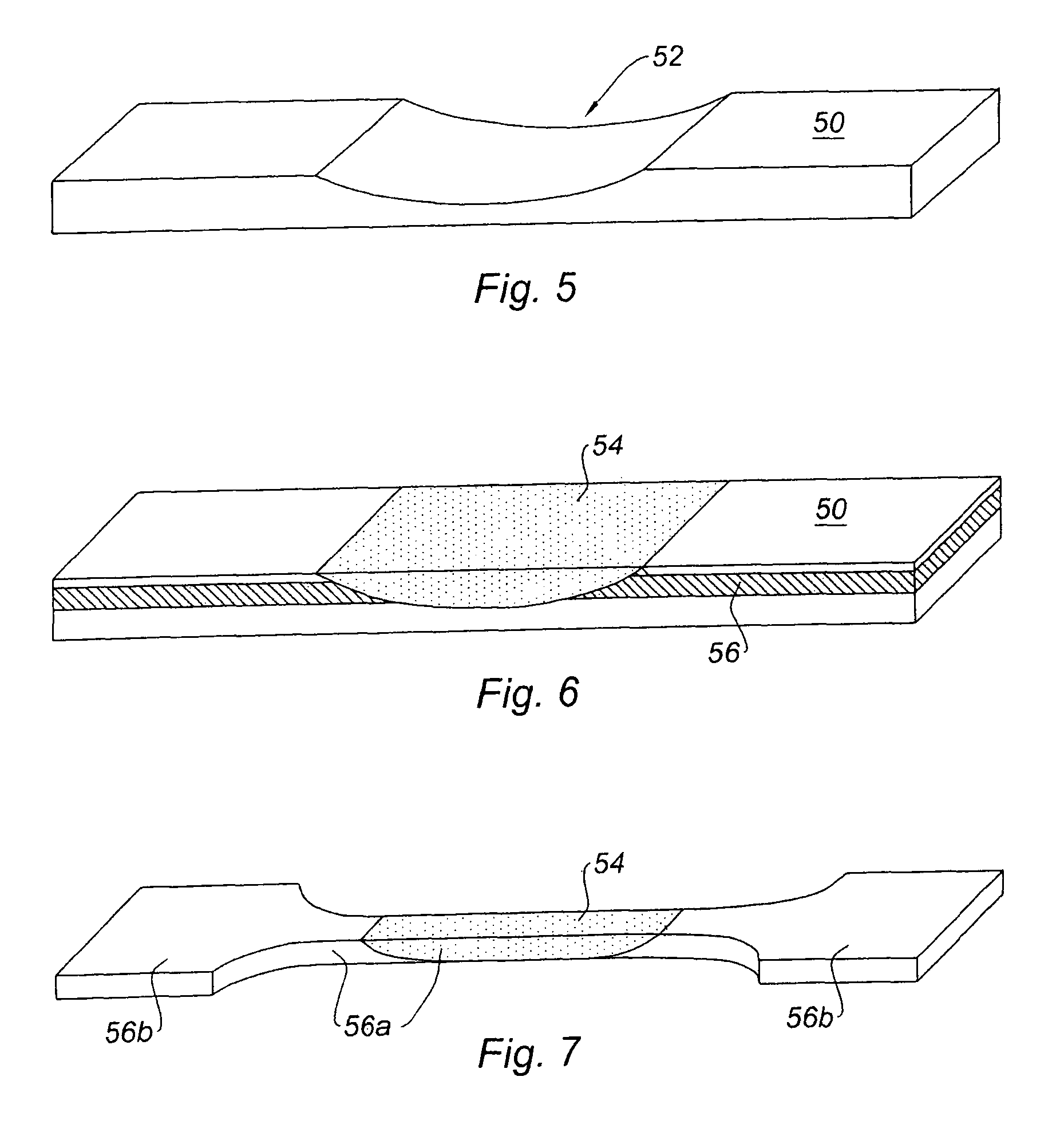

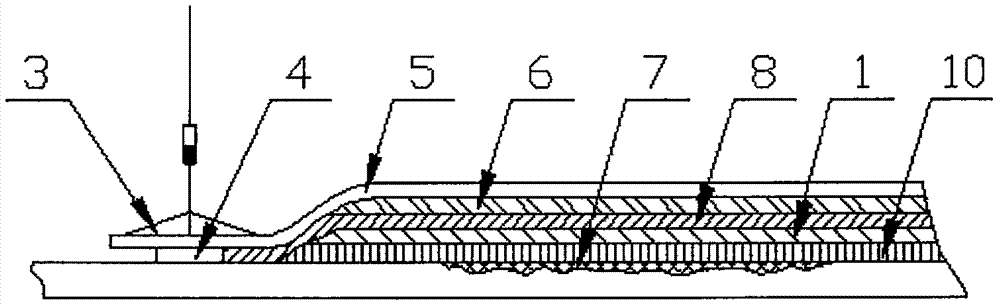

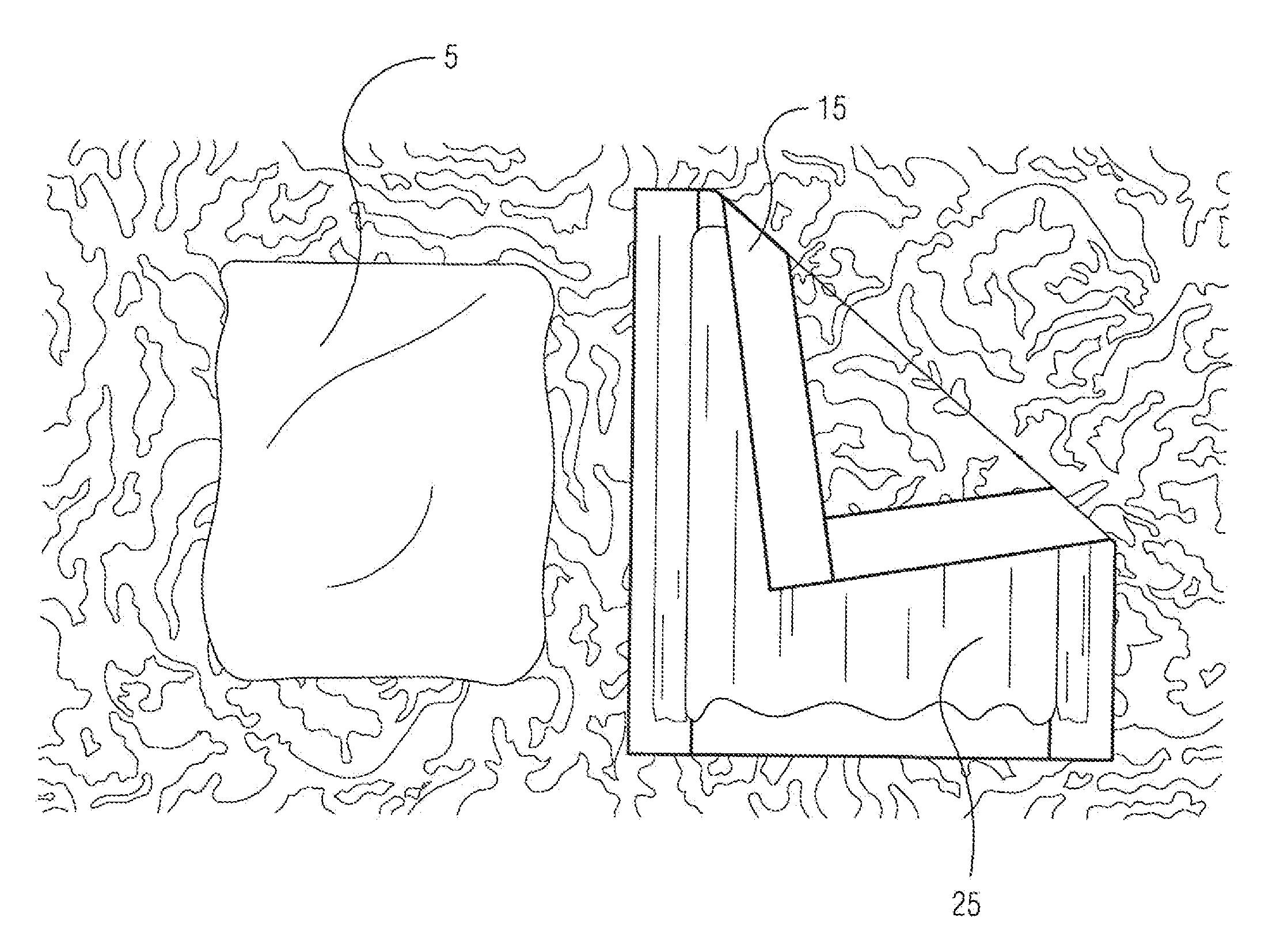

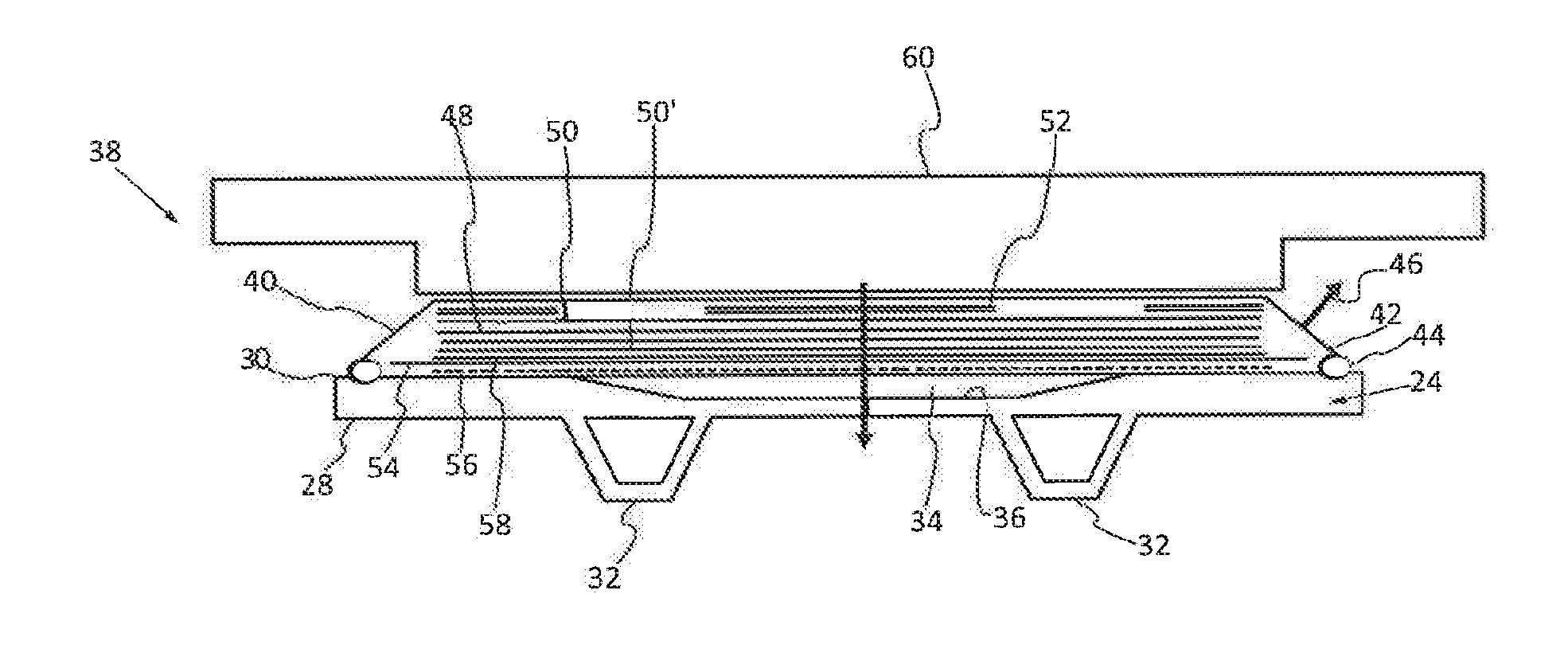

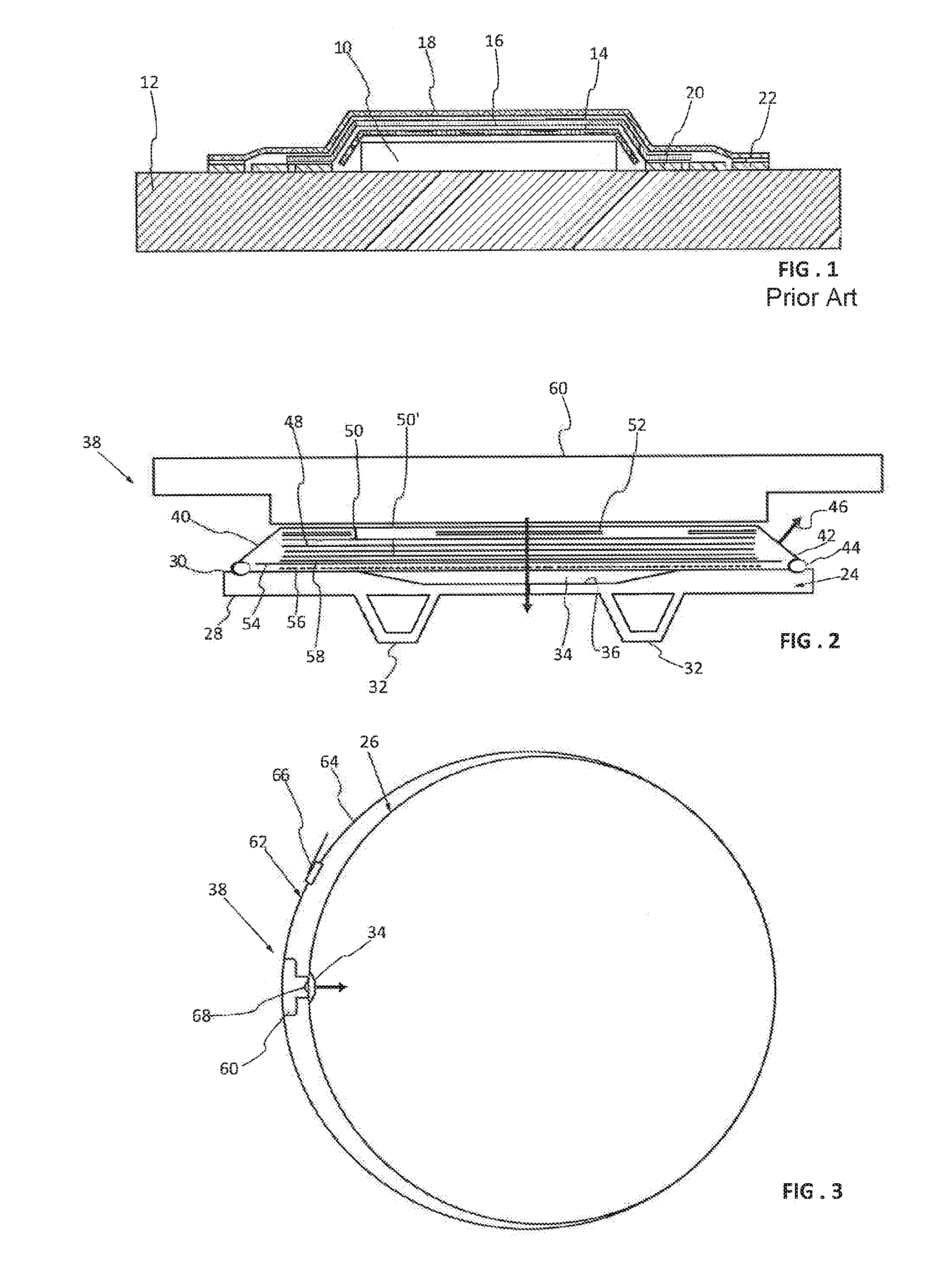

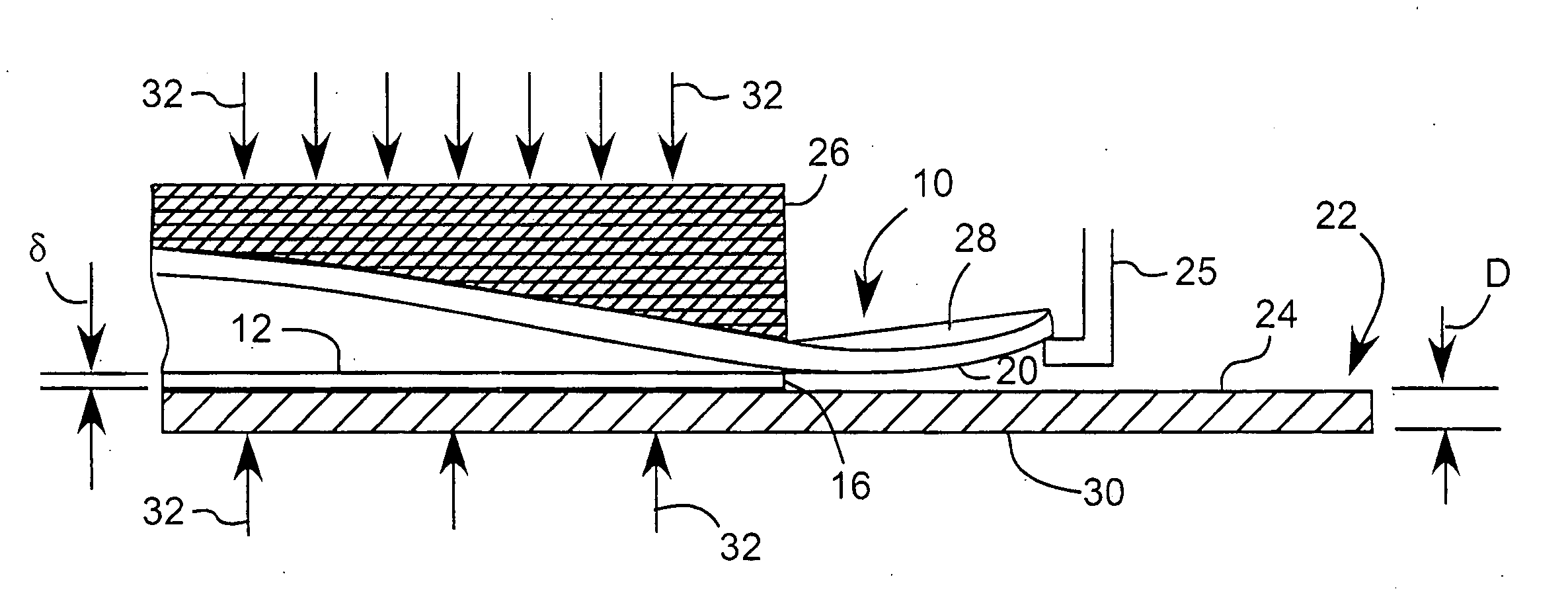

Method for repairing a composite-material panel of an aircraft and tool for implementing said method

A method and a tool for repairing a composite-material panel of an aircraft with at least one repair part made of composite material without using an autoclave. The repair method includes the steps of preparing the panel, placing at least one repair part made of composite material on the second face to cover a damaged zone, positioning a vacuum bag configured to sealingly cover the repair part, polymerizing or consolidating the repair part, compressing the vacuum bag against the repair part using a compression plate concomitantly with the step in which the repair part is polymerized or consolidated.

Owner:AIRBUS SAS +1

Environmentally friendly stimulation fluids, processes to create wormholes in carbonate reservoirs, and processes to remove wellbore damage in carbonate reservoirs

The present invention includes processes to create wormholes in carbonate reservoirs by contacting a formation with a solution comprising glutamic acid N,N-diacetic acid (GLDA) and / or a salt thereof, methylglycine-N,N-diacetic acid (MGDA) and / or a salt thereof, or a combination thereof. The present invention also includes processes to remove wellbore damage in a carbonate reservoir by contacting a damaged zone of the carbonate reservoir with a solution comprising GLDA and / or a salt thereof, methylglycine-N,N-diacetic acid (MGDA) and / or a salt thereof, or a combination thereof. The present invention further includes solutions comprising a salt and further comprising GLDA and / or a salt thereof, methylglycine-N,N-diacetic acid (MGDA) and / or a salt thereof, or a combination thereof.

Owner:AKZO NOBEL CHEM INT BV

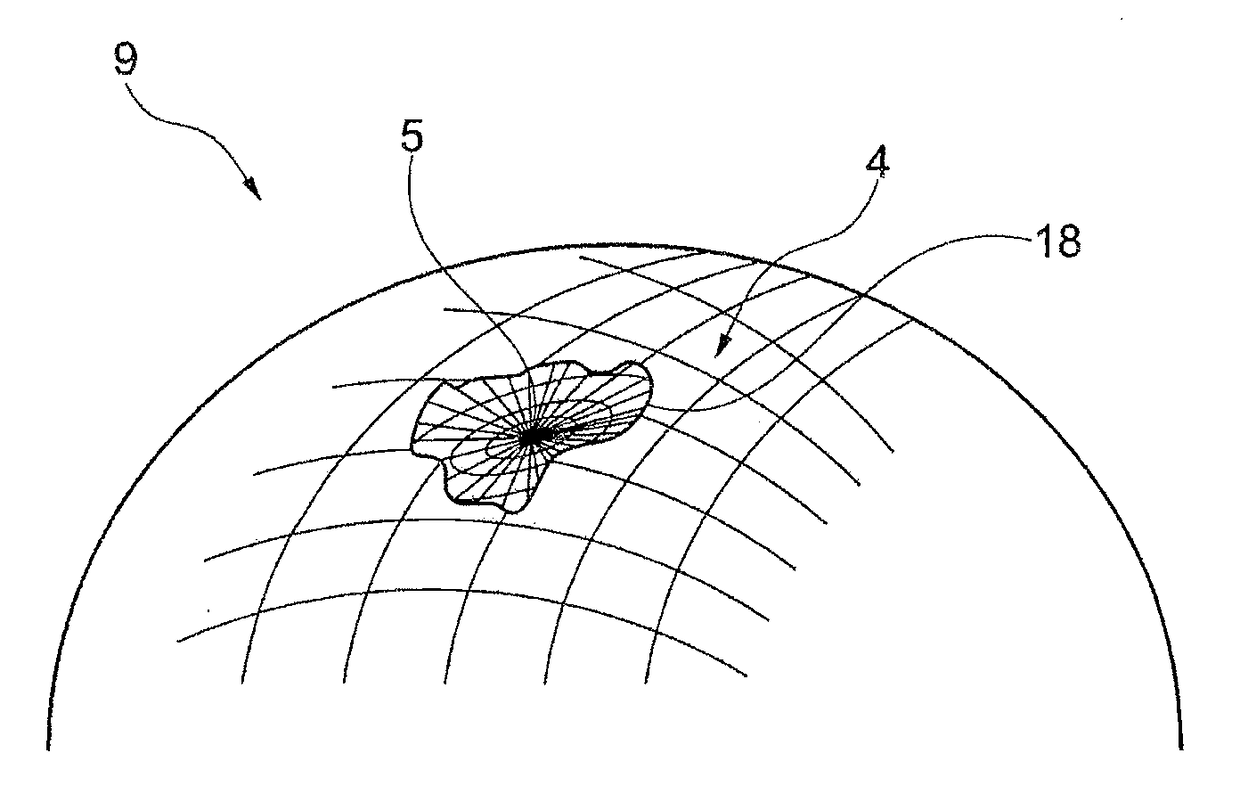

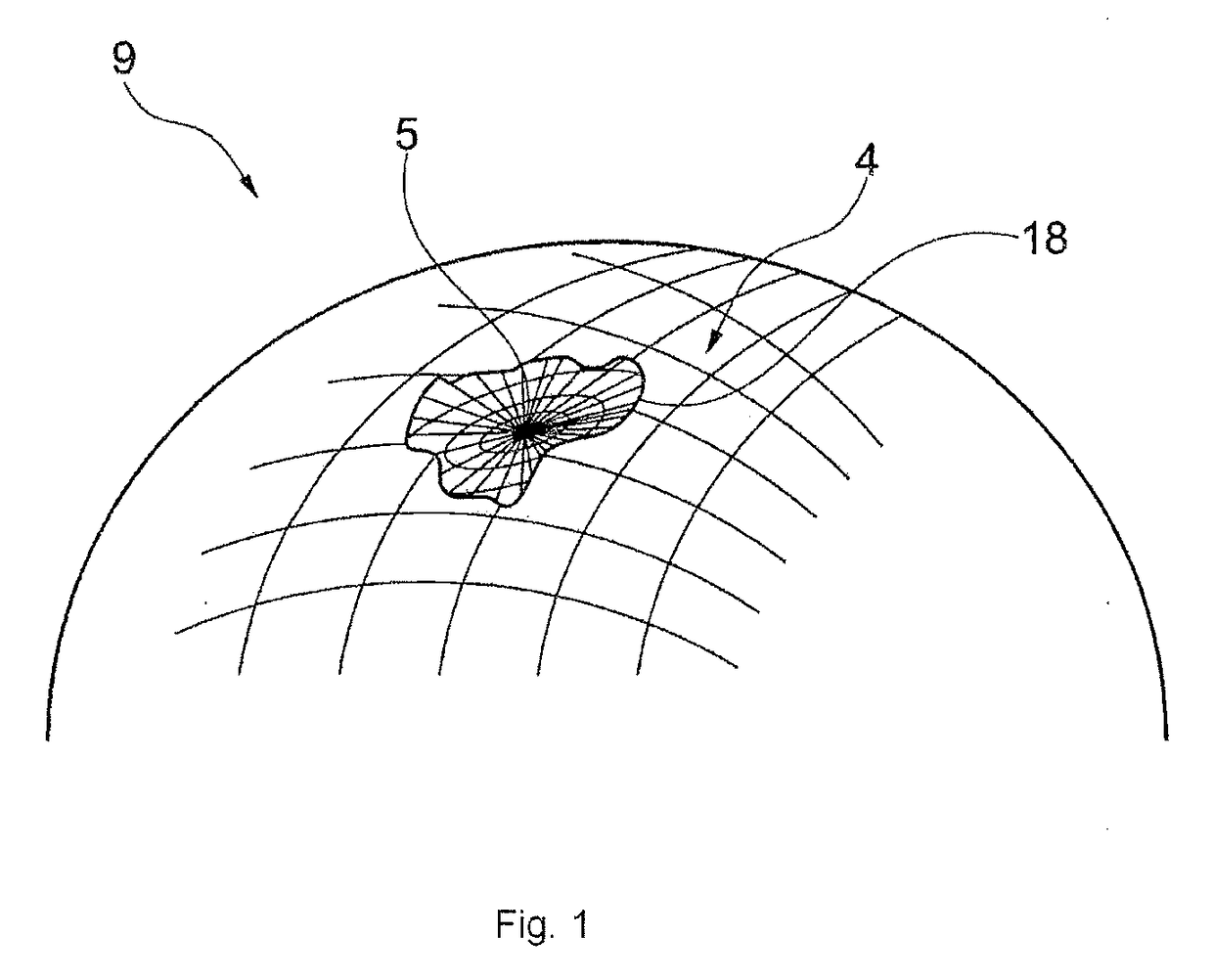

Method for repairing radome and tool for implementing same

A method for repairing a radome and a tool for implementing the same are provided. The method and tool for repair a damaged zone of an aircraft radome, solidifies a replacing member in a high pressure autoclave, using the actual radome itself as a heating chamber to avoid resorting to an autoclave and the removal of certain parts of the radome which cannot withstand the curing temperature needed for the repair. The radome (1) comprises a panel (2) exhibiting a double curvature forming a dome, the panel comprising at least one damaged zone (7). The method comprises the steps of closing an interior space of the panel (2) using a cap (8) to form a repair chamber (9). The surface of the panel (2) forms the repair chamber (9) containing the damaged zone (7). Another step is heating the space inside the repair chamber to form a heating chamber allowing the curing expected for repairing the damaged zone.

Owner:AIRBUS OPERATIONS (SAS) +1

Method for forming a semiconductor on insulator structure

InactiveUS20070264796A1Easy to understandSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

A method of bonding a thin semiconductor film onto a rectangular substrate is disclosed. The method makes it possible to exfoliate rectangular semiconductor films from a round precursor semiconductor wafer, thereby providing for efficient tiling of the substrate with semiconductor film. The method includes the steps of creating a damage zone in the precursor wafer by ion implantation of the wafer, removing a portion of the wafer to formed a raised portion, bonding the raised portion of the wafer to the substrate, and exfoliating the bonded raised portion.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com