Method for preparing micropore array fiber bragg grating

A fiber grating, micro-hole array technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems of weakening the mechanical strength, increasing the sensitivity, and failing to reflect the selective corrosion of the type II damage zone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

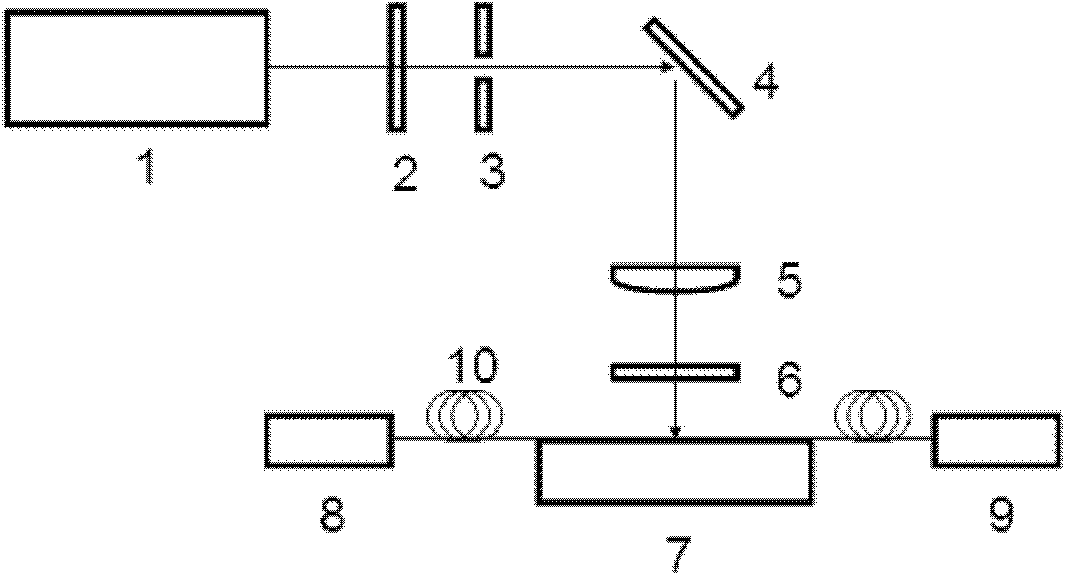

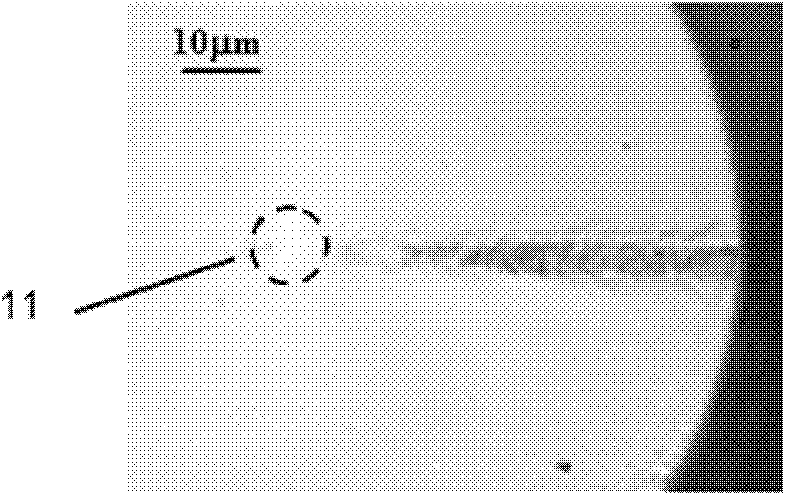

[0028] Infrared femtosecond laser combined with phase mask method (preparation method refers to "Formation of Type I-IR and Type II-IR gratings with an ultrafast IR laser and a phase mask", Christopher W.Smelser, Optics Express, 2005, 13, 5377 -5386) A type II Bragg fiber grating with a damage zone extending from the core to the outer edge of the cladding was prepared in a single-mode fiber for communication (SMF-28e). Preparation device such as figure 1 As shown, the laser light source 1 used in this embodiment is a titanium-doped sapphire femtosecond pulse laser manufactured by Spectra-Physics Corporation of the United States, with an operating wavelength of 800 nm and a repetition rate of 1 kHz. The attenuator 2 is adjusted so that the incident single pulse energy is 0.87 mJ. The femtosecond laser pulse passes through the shutter 3, is reflected by the total reflection mirror 4, is focused by the cylindrical lens 5 with a focal length of 40 mm, and passes through the phase ...

Embodiment 2

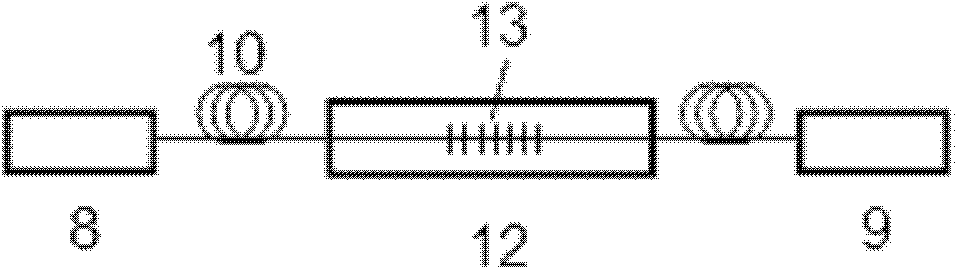

[0030] Utilize the method described in embodiment 1 to prepare a section of Bragg fiber grating 13, it is fixed on image 3In the shown plastic container 12 for fiber grating etching, hydrofluoric acid is sealed in the container. The optical fiber 10 connected to both ends of the Bragg fiber grating is respectively connected to a light source 8 and a spectrum analyzer 9 to monitor the spectral changes during the corrosion process of the fiber Bragg grating. In this embodiment, hydrofluoric acid with a volume concentration of 4% is used to etch the grating at room temperature (20° C.). After about 40 minutes of corrosion, it can be seen from the spectrum analyzer that the resonance peak of the transmission spectrum of the Bragg fiber grating has moved to the short wave direction obviously. At this time, take out the fiber grating, stop the corrosion, and rinse it with saturated sodium bicarbonate solution to neutralize the residual hydrofluoric acid, and then put it into an ul...

Embodiment 3

[0032] Using the method described in Example 1 and Example 2, a section of microhole array type Bragg fiber grating was prepared, and its environmental refractive index, stress response test and high temperature annealing research were carried out. Figure 6 The variation of the central wavelength of the microhole array Bragg fiber grating under different environmental refractive indices is given. The points in the figure represent the experimental results, and the curve is the fitting of the experimental data. The first point represents the device in air (refractive index 1), and the other points represent the device in the refractive index matching liquid. The matching liquid is made of glycerin and water in different volume ratios, and its refractive index is calibrated by an Abbe refractometer. From the results shown in the figure, it can be seen that the Bragg resonance peak moves to the long-wavelength direction with the increase of the environmental refractive index, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com