Patents

Literature

669 results about "Refractive index matching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Index matching generally refers to a reduction in refractive index contrast through the application of an intermediate substance - not necessary a complete removal of the refractive index contrast all together.

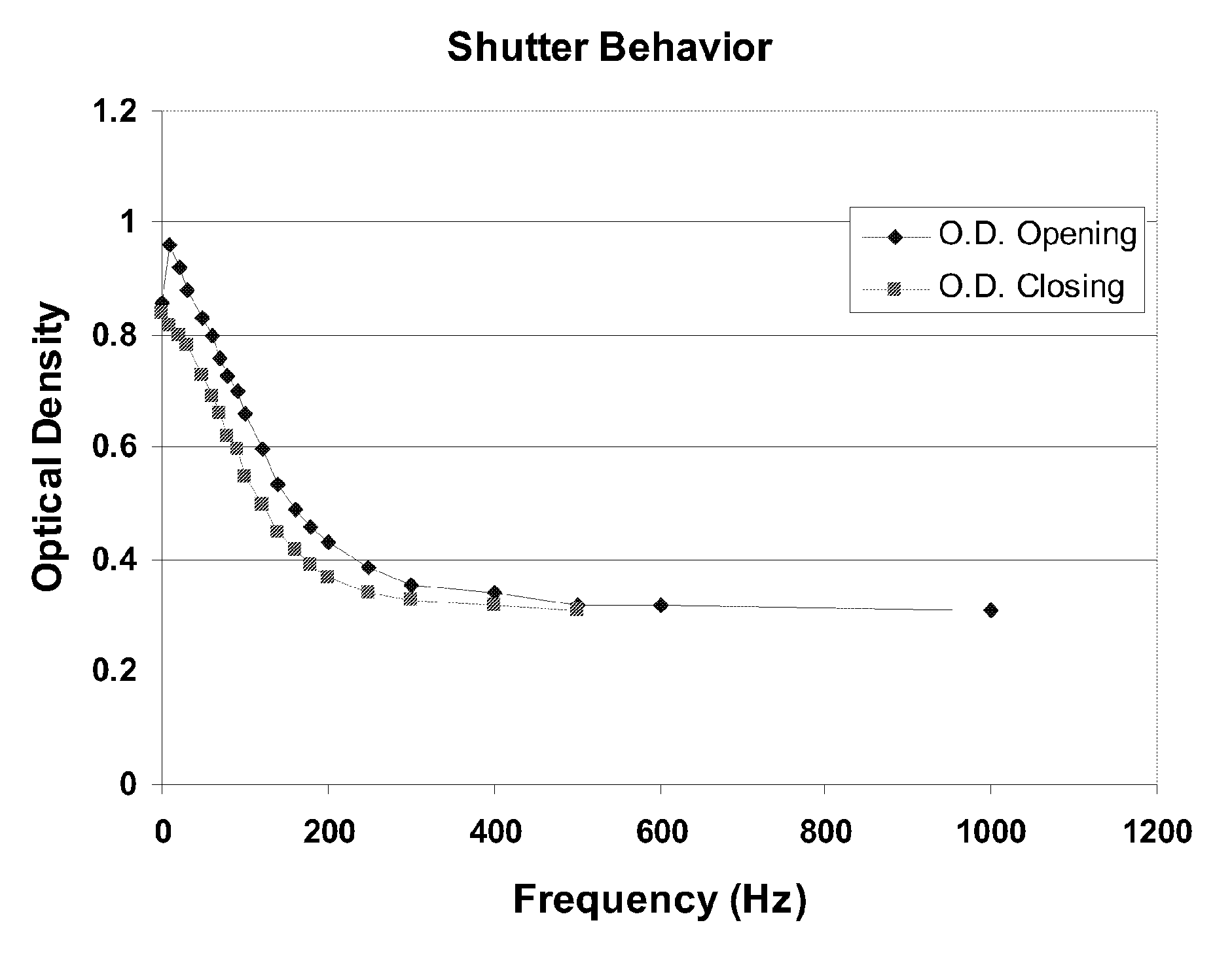

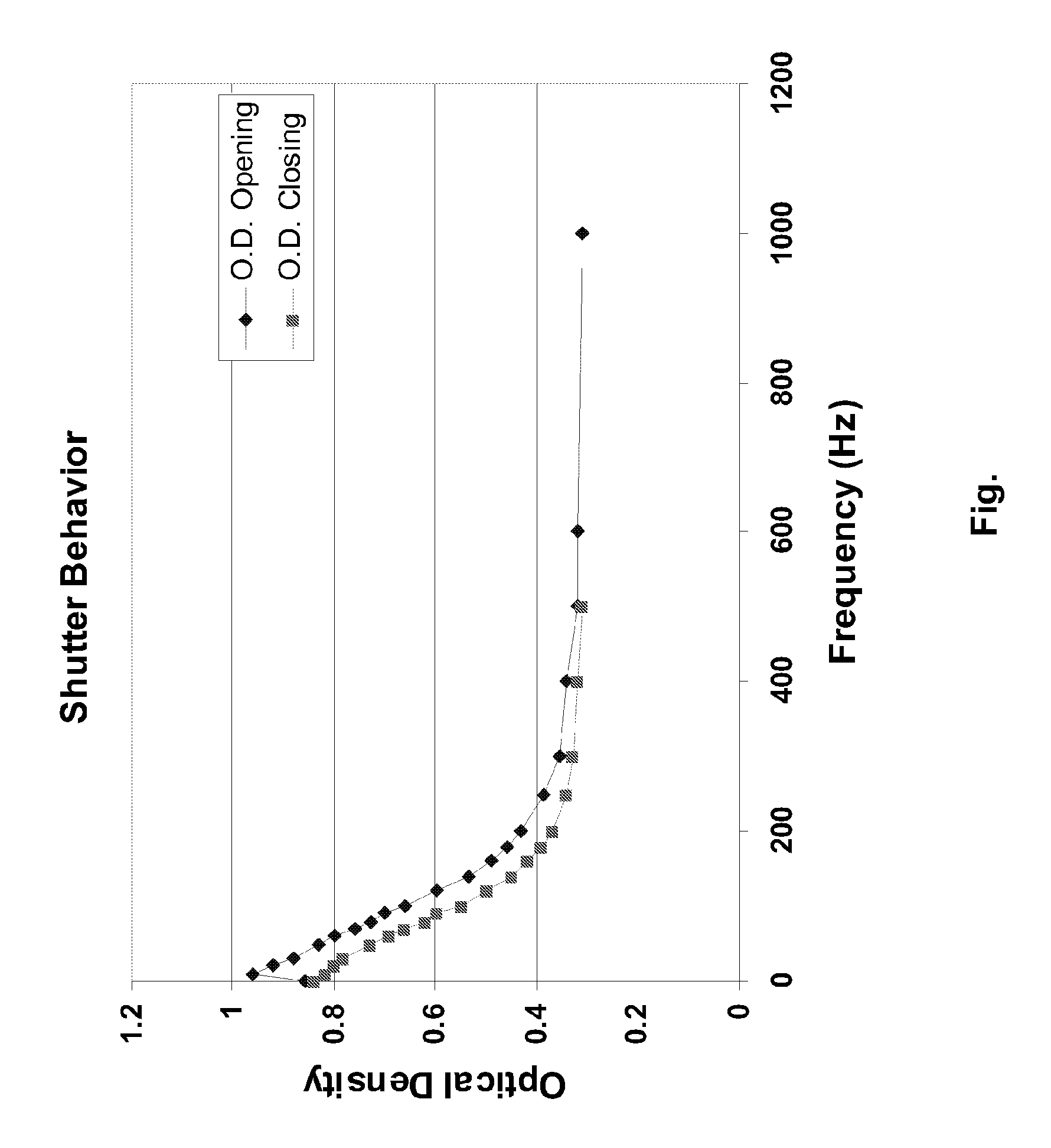

Light modulators

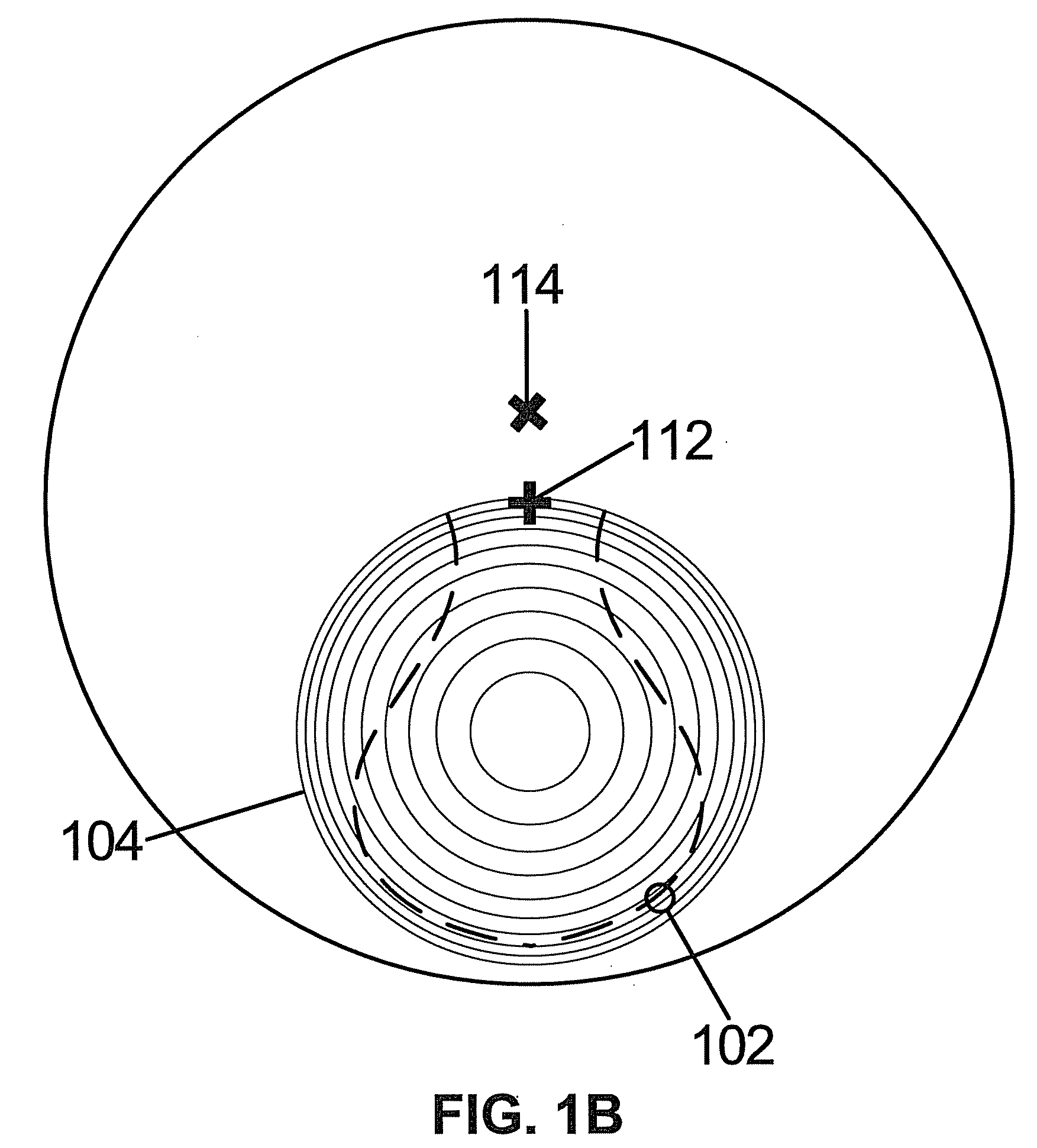

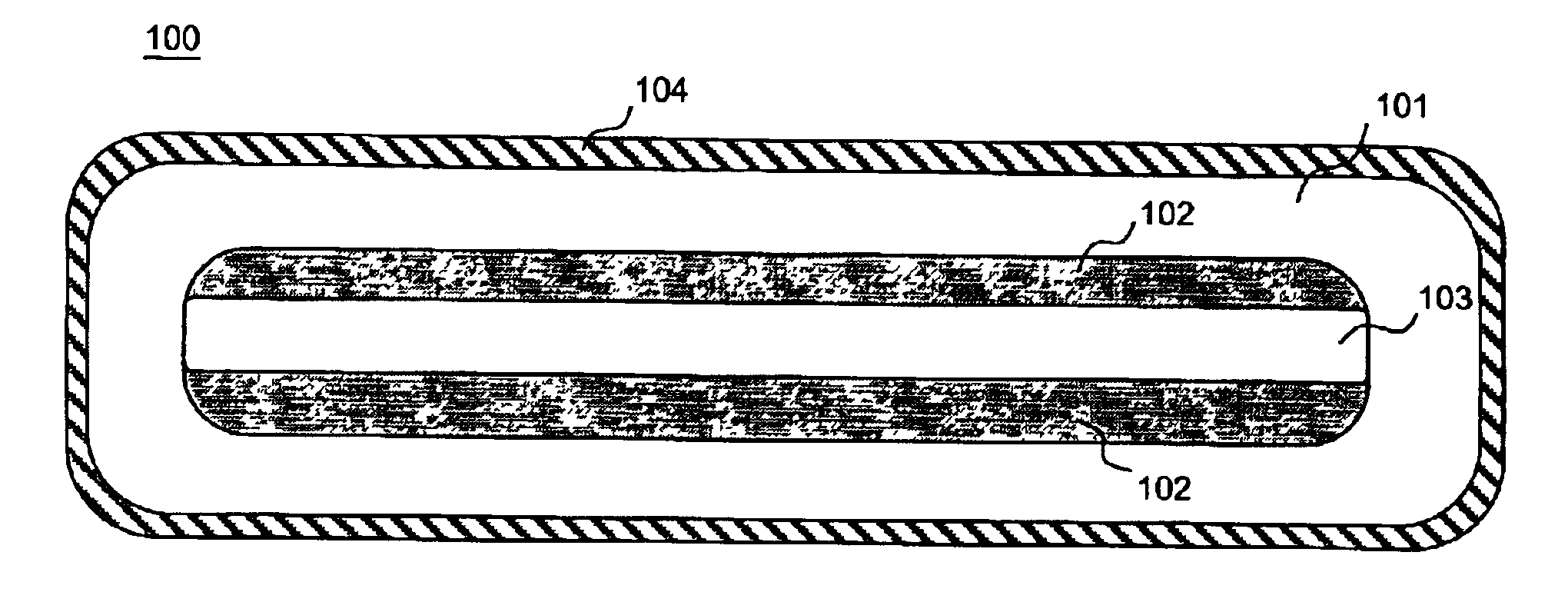

ActiveUS7327511B2Door/window protective devicesStatic indicating devicesElectrophoresisDisplay device

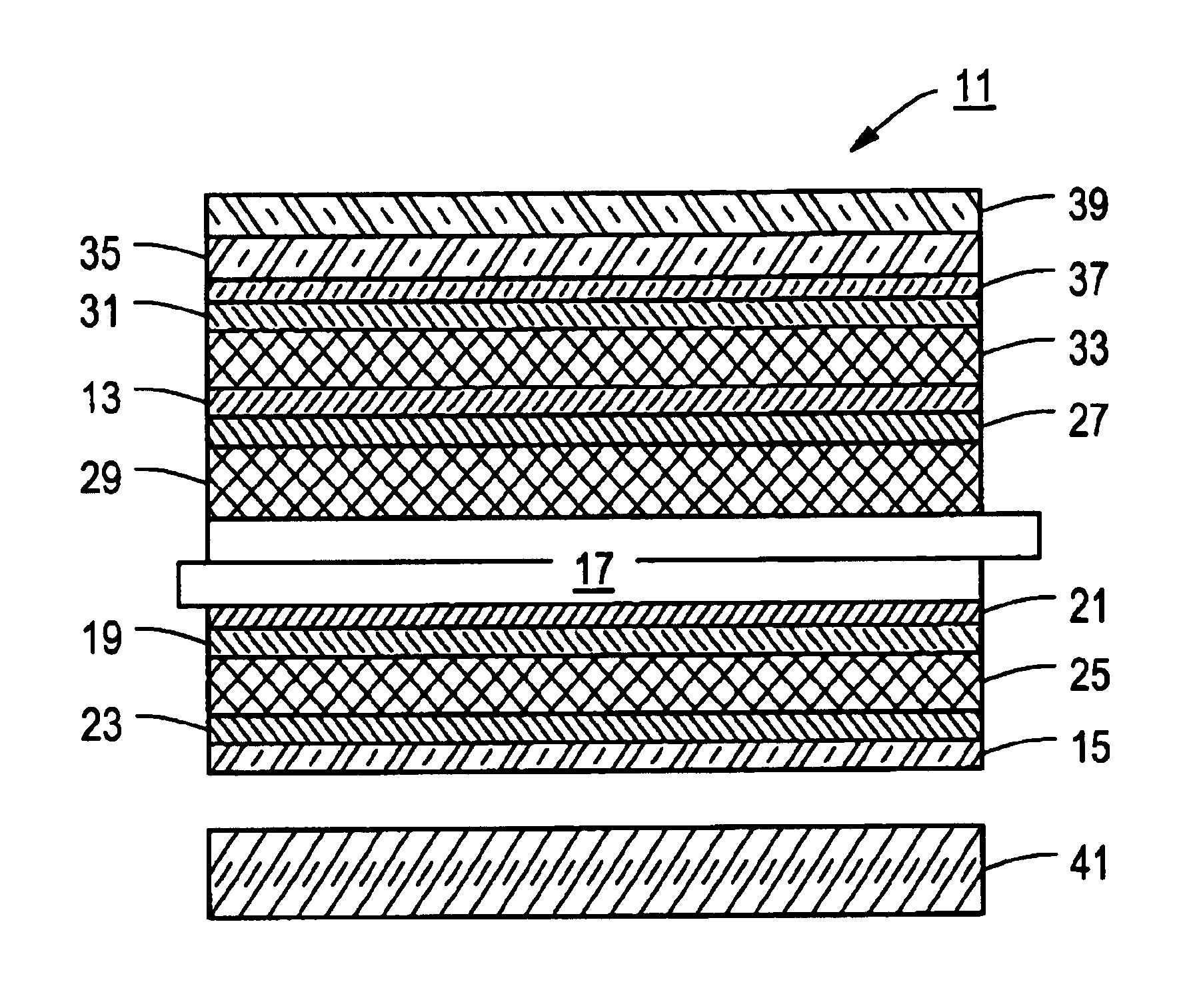

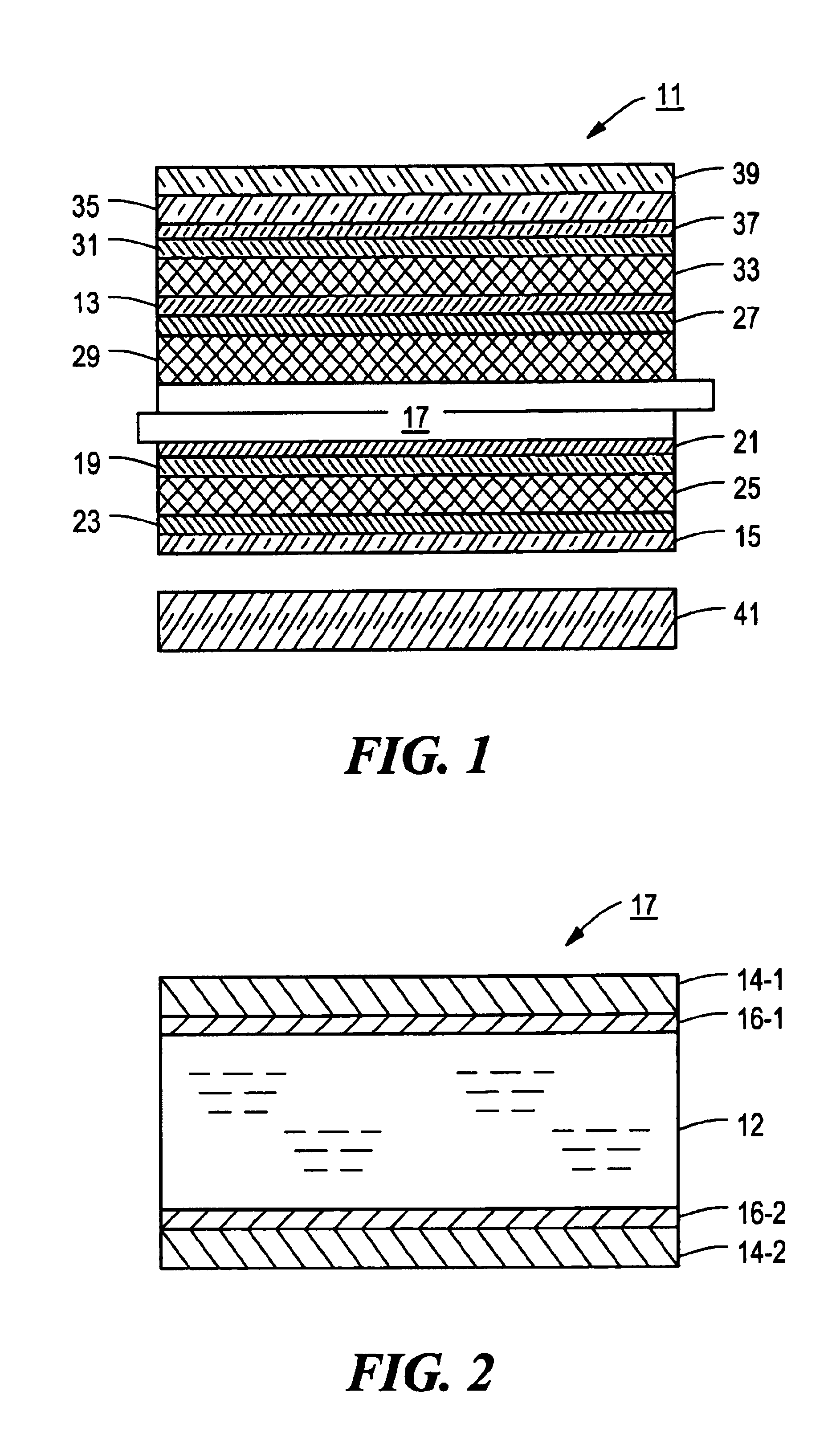

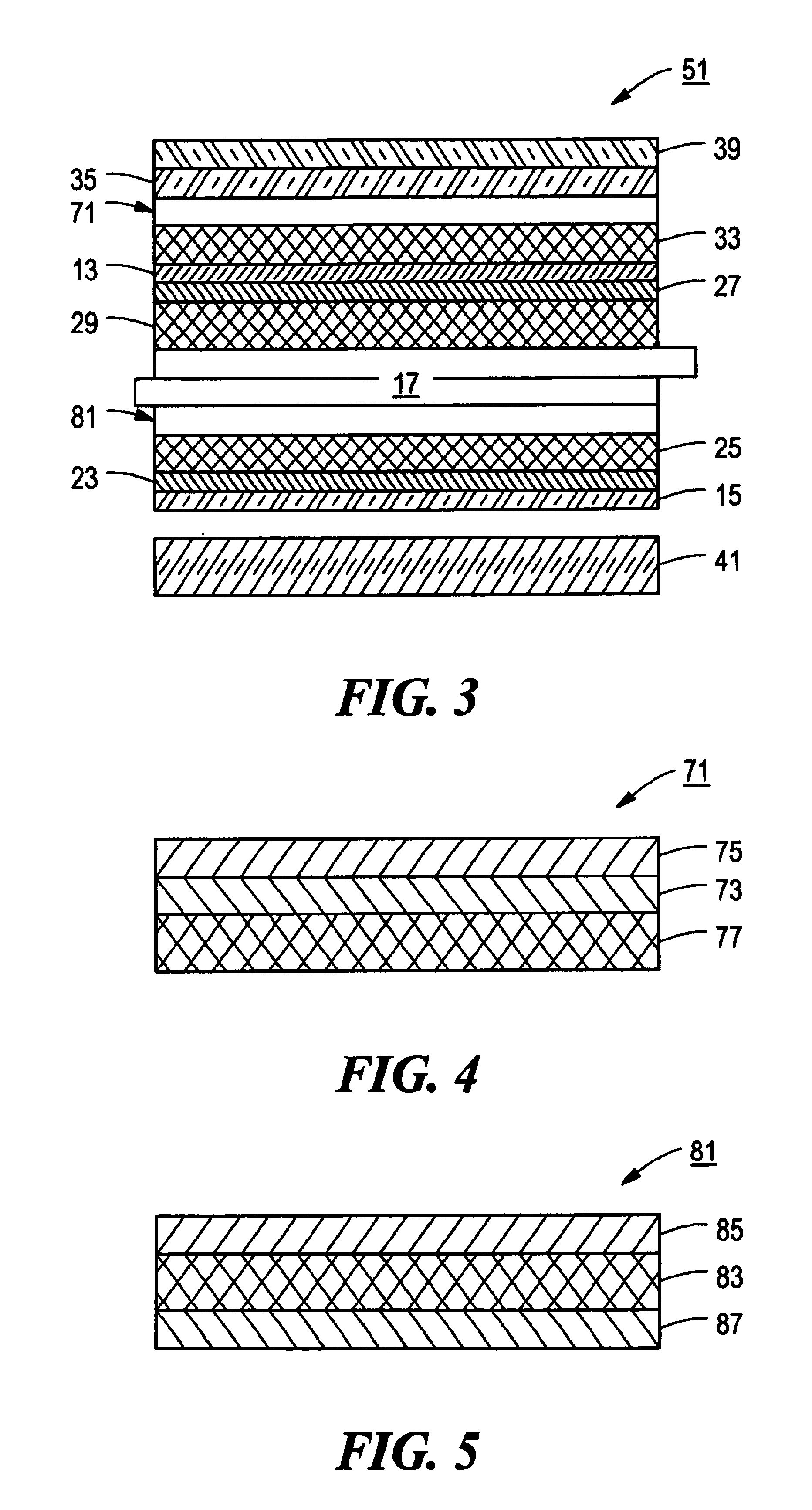

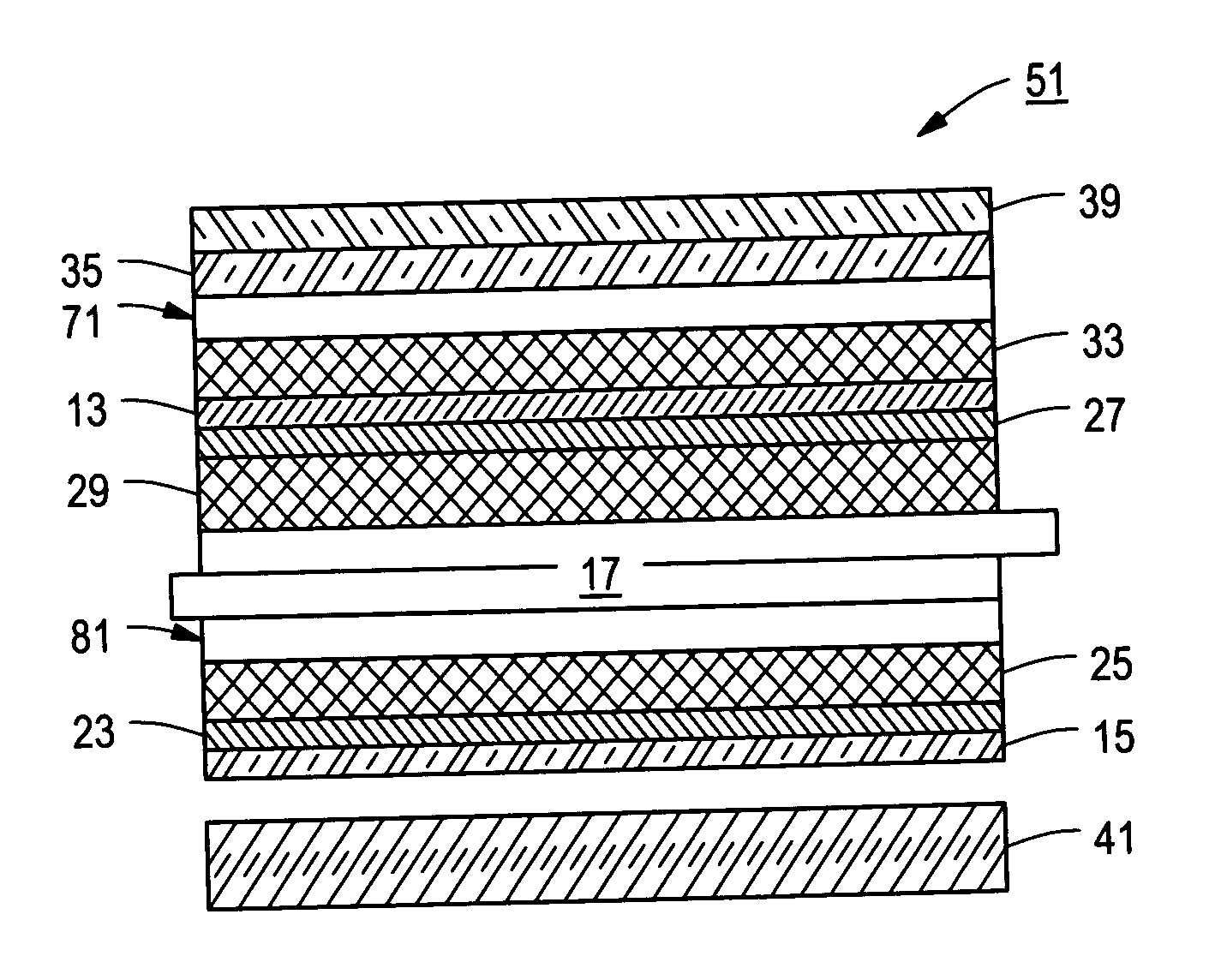

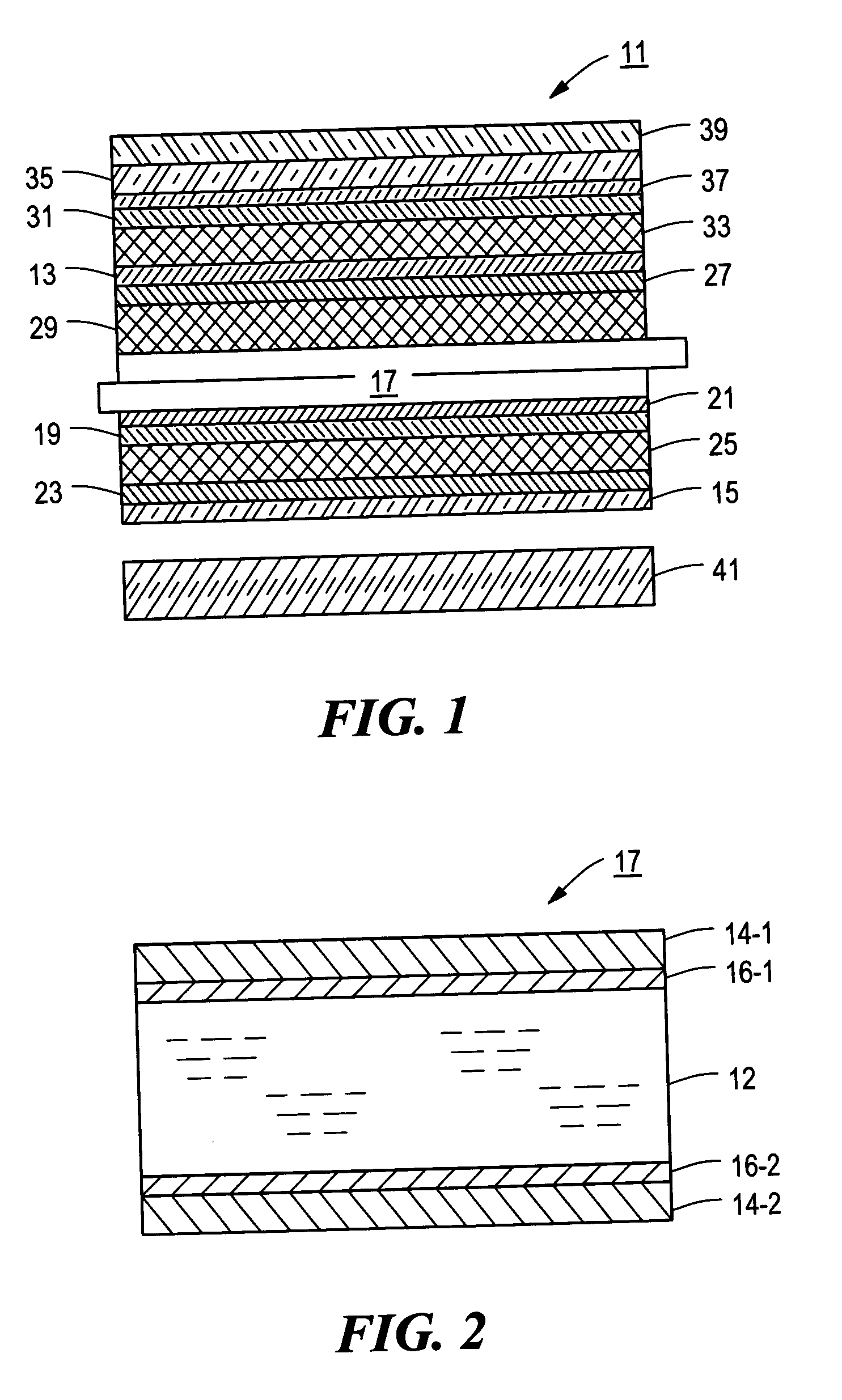

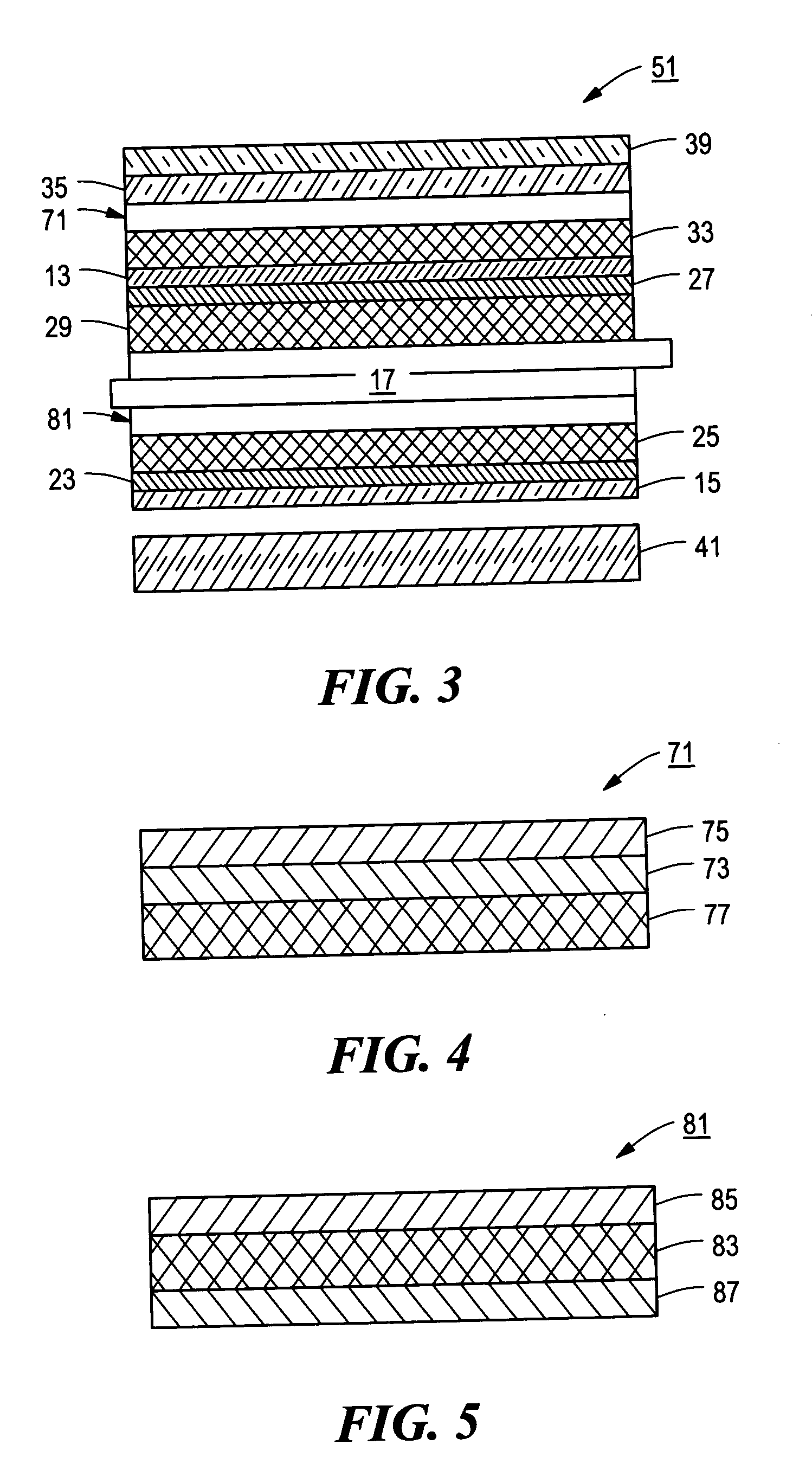

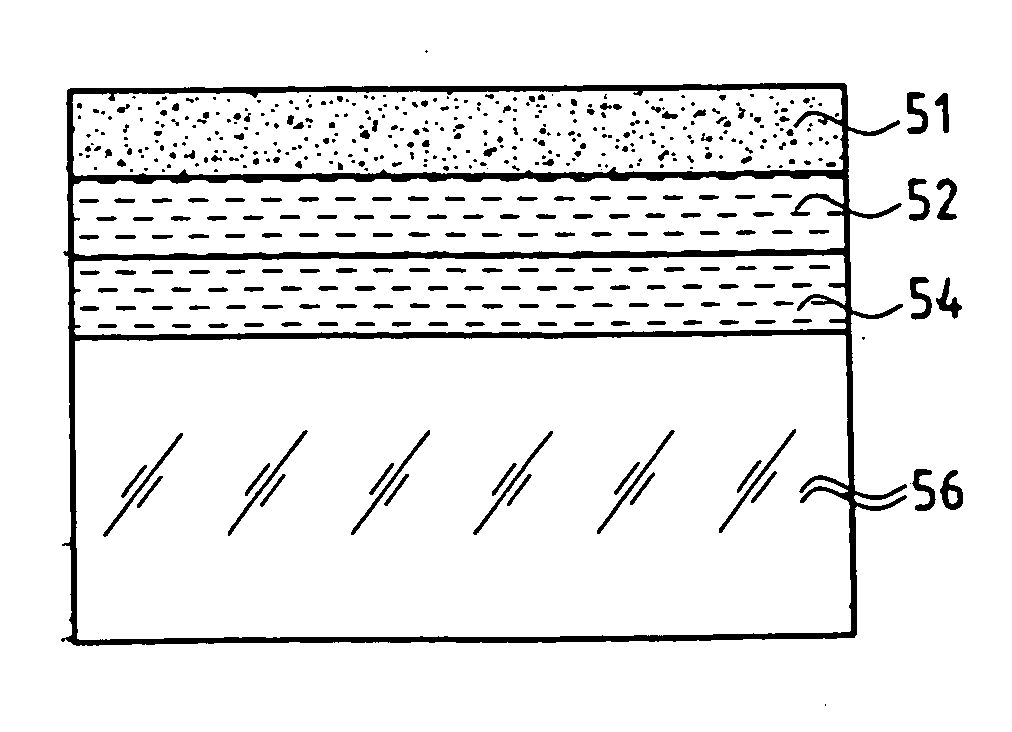

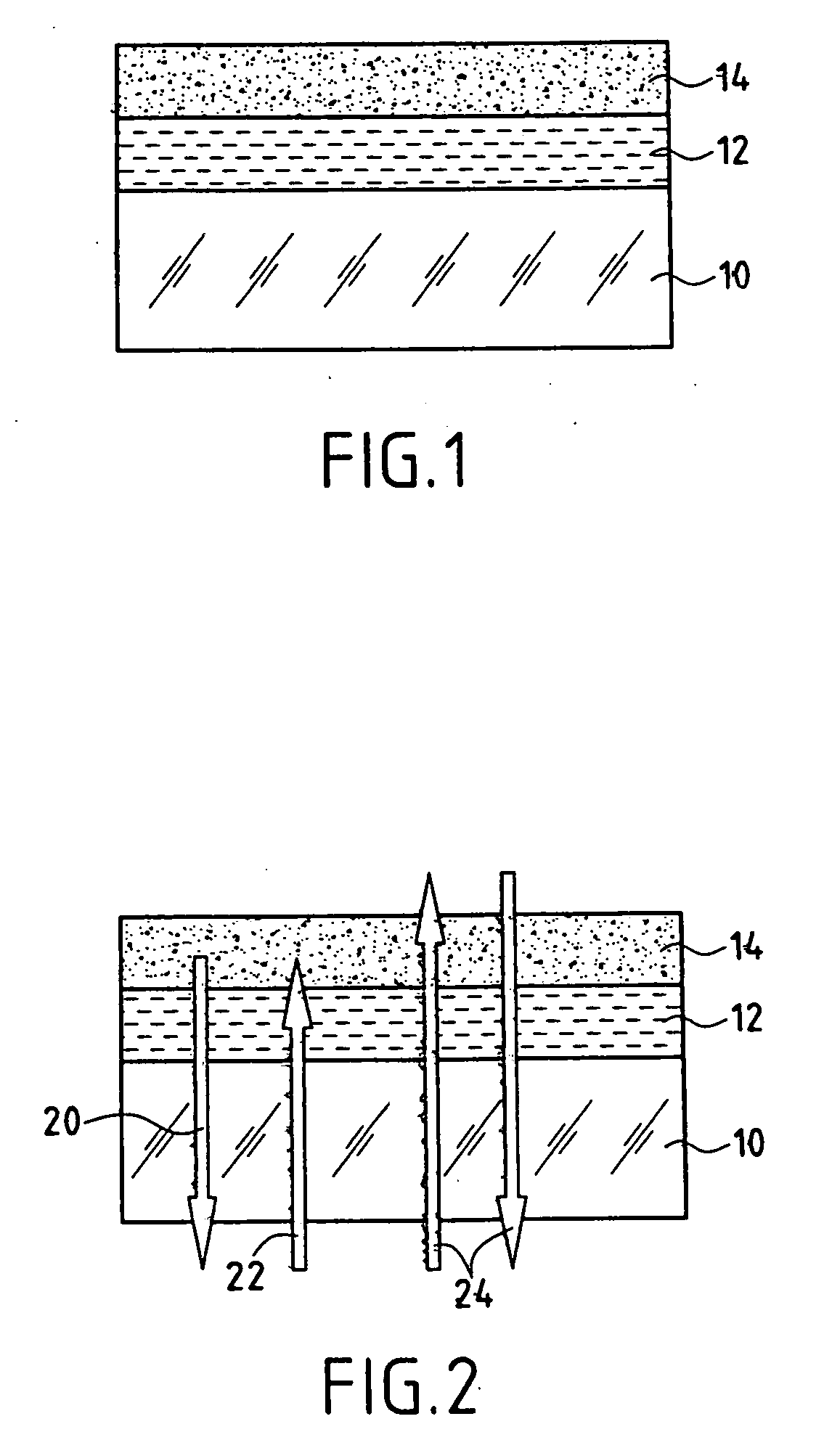

Various improvements in electrophoretic media and displays intended for use in light modulators are described. These improvements include index matching of the suspending fluid to a continuous phase surrounding the fluid, index matching of a capsule wall to a binder, planarization of a layer containing electrophoretic capsules before application of adhesive thereto, methods for concentrating electrophoretic particles into limited areas of sidewalls of electrophoretic capsules or microcells in the light-transmissive state of the display, and, in the case of light modulators comprising an electrophoretic layer sandwiched between two transparent plates, forming at least one of the plates so as to absorb electromagnetic radiation which adversely affects the electrophoretic layer.

Owner:E INK CORPORATION

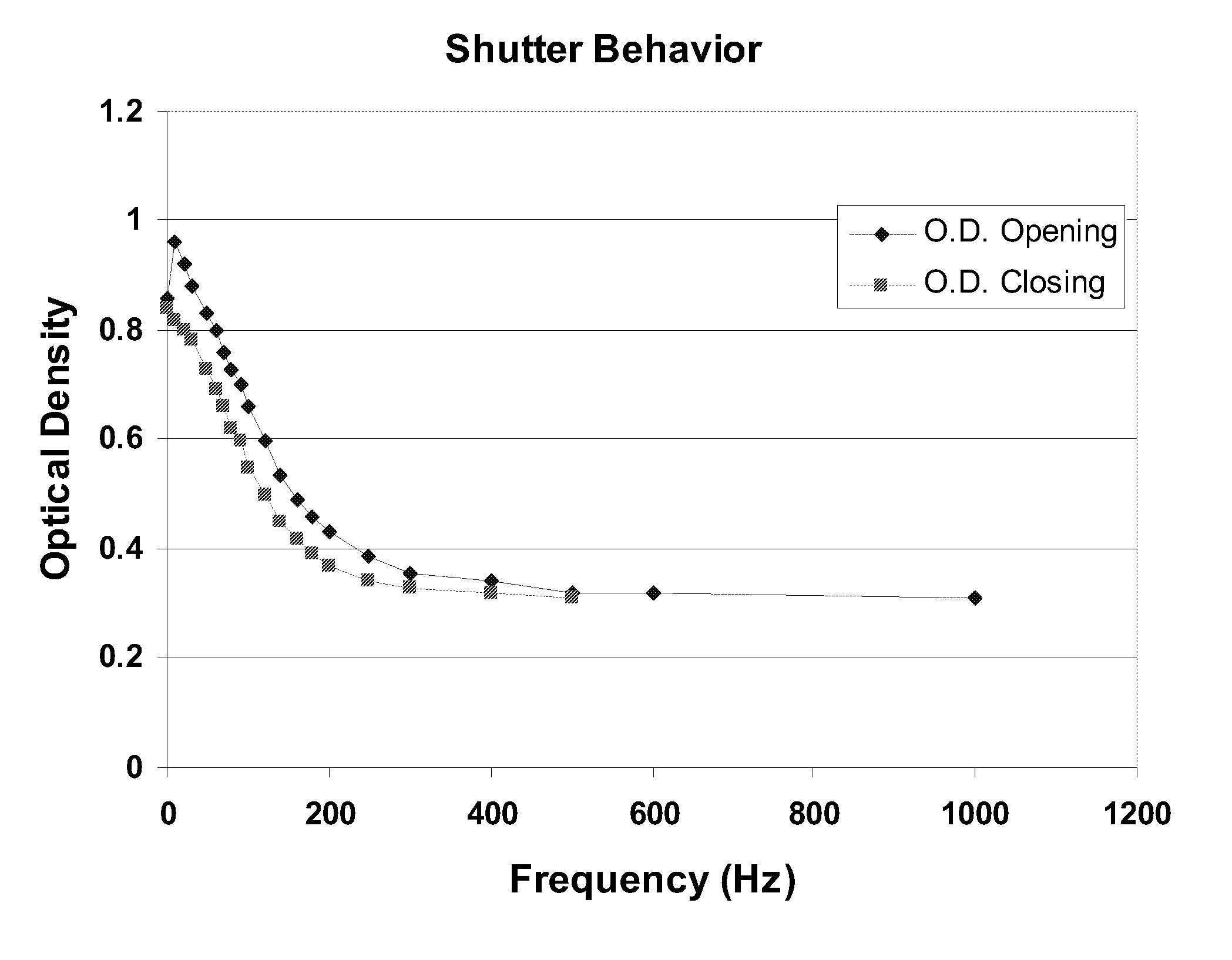

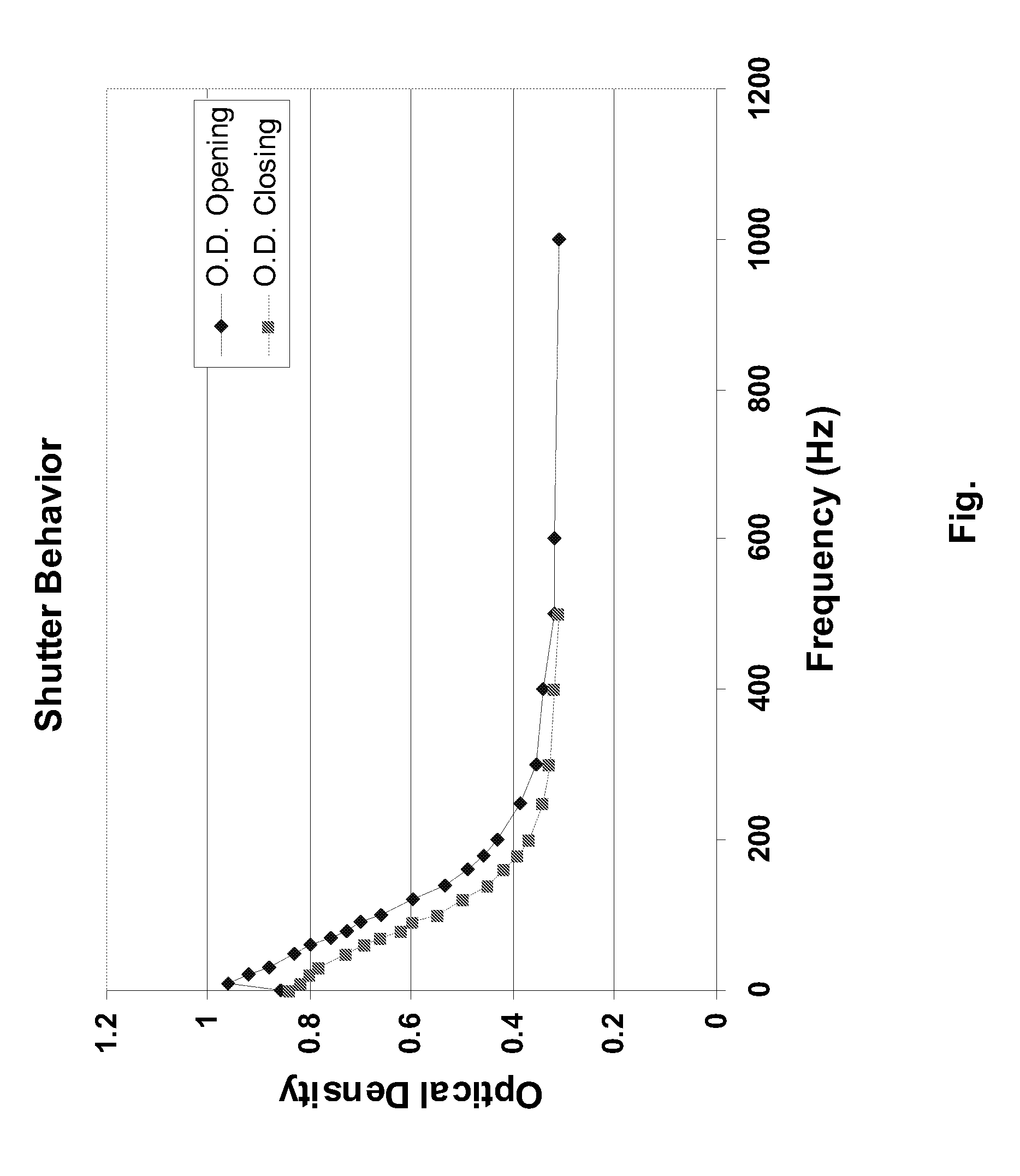

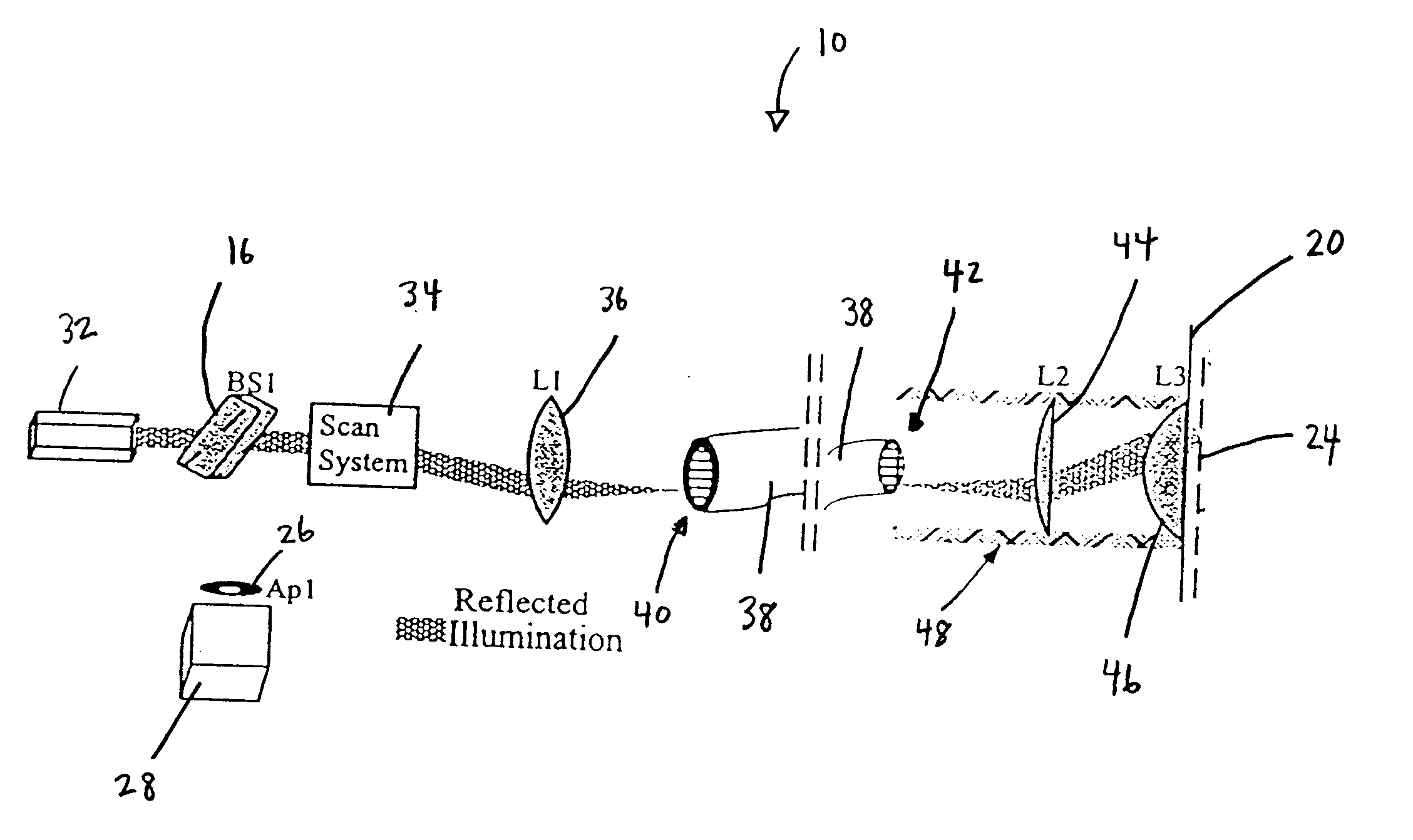

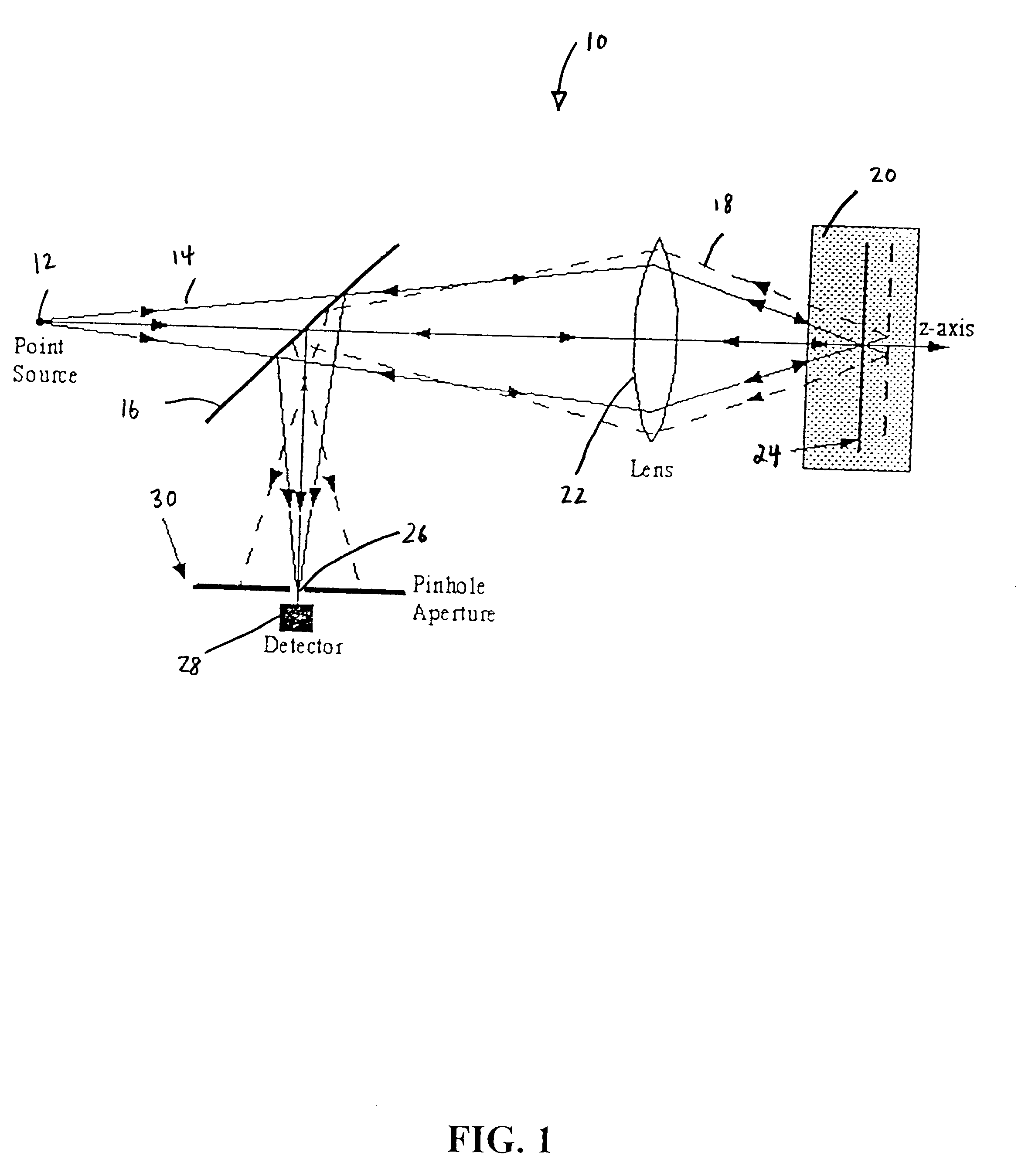

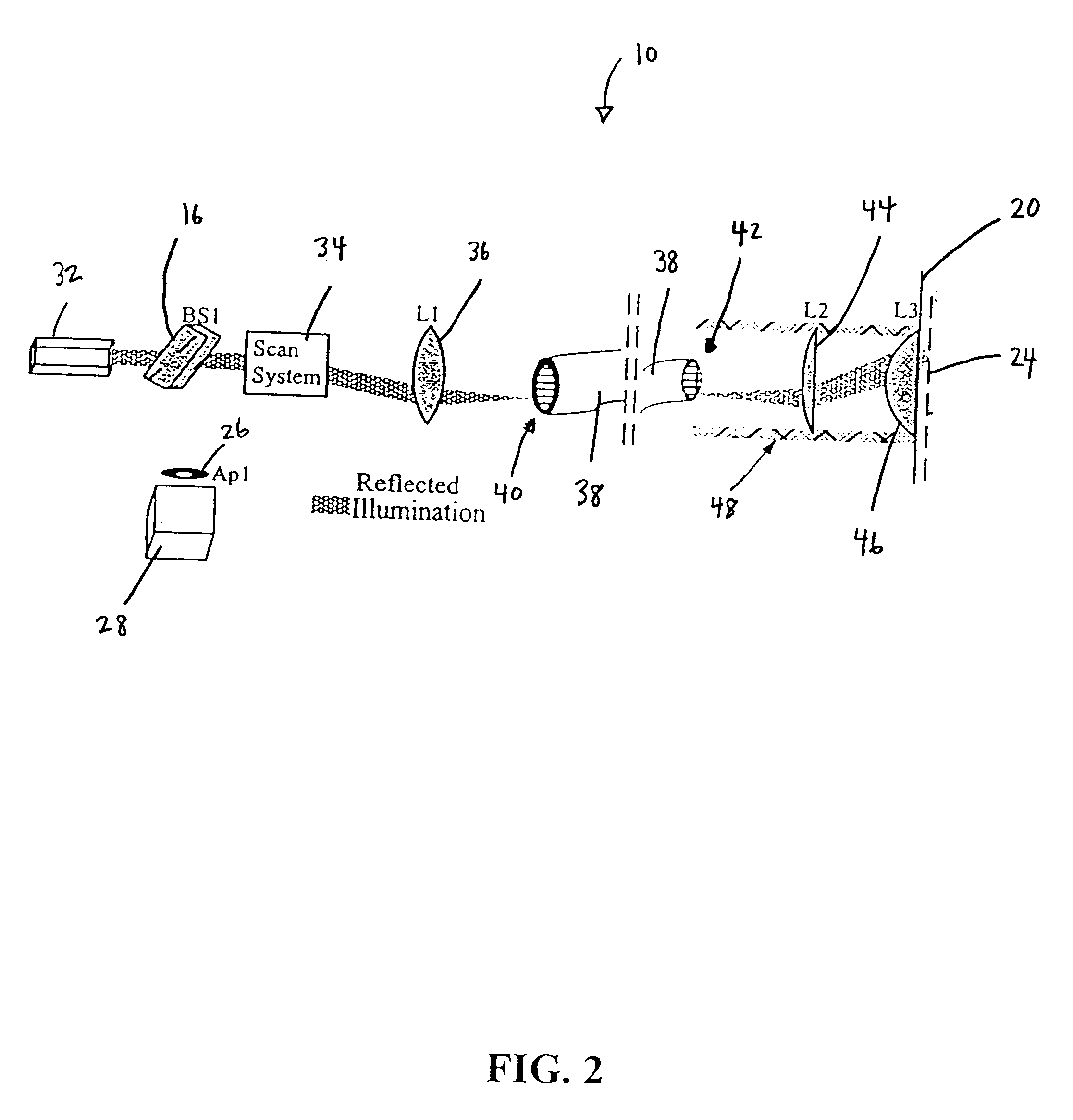

Fiber-optic confocal imaging apparatus and methods of use

InactiveUS6370422B1Reduce specular reflectionIncrease contrastEndoscopesSurgical instrument detailsFiberGrating

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

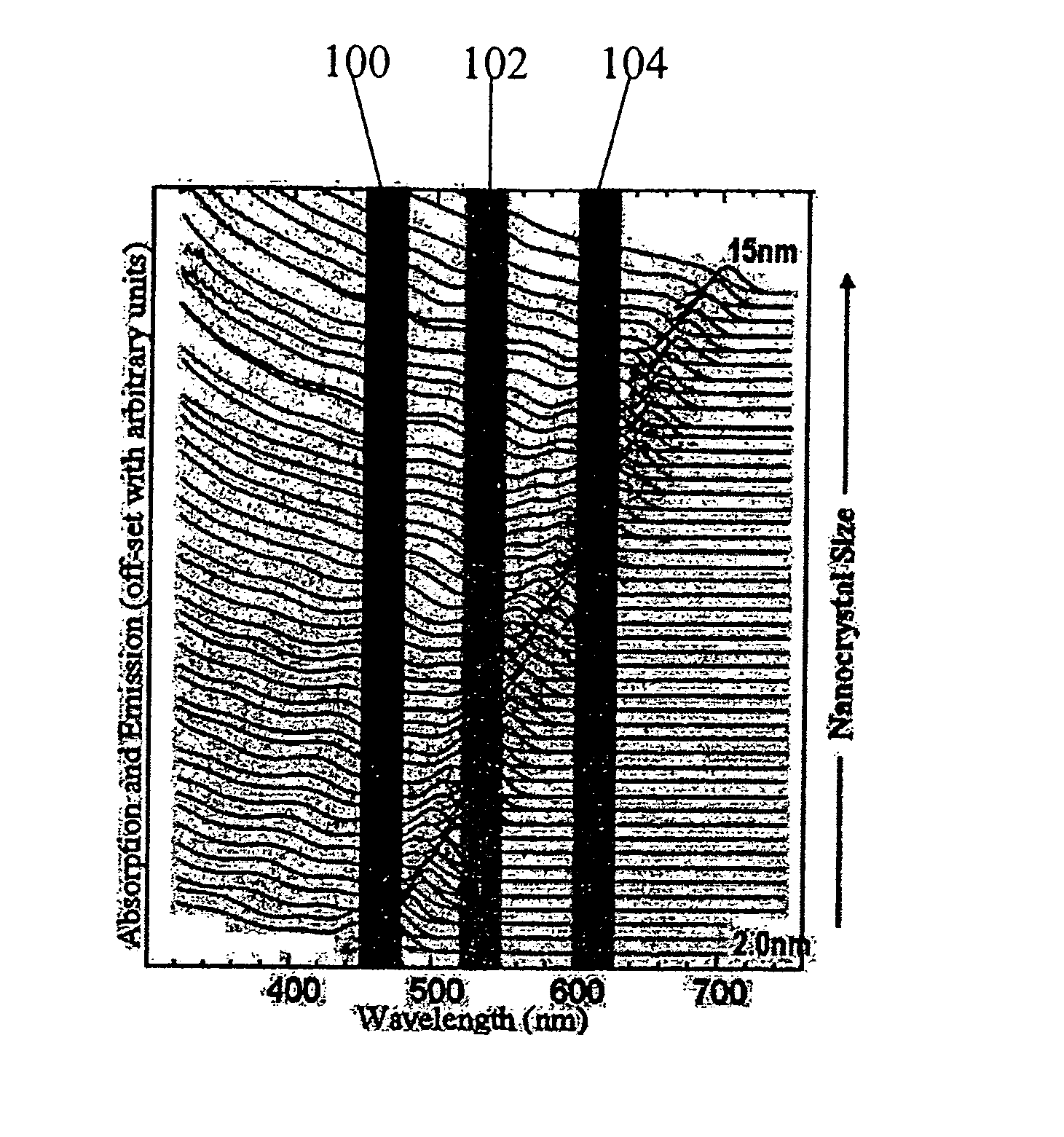

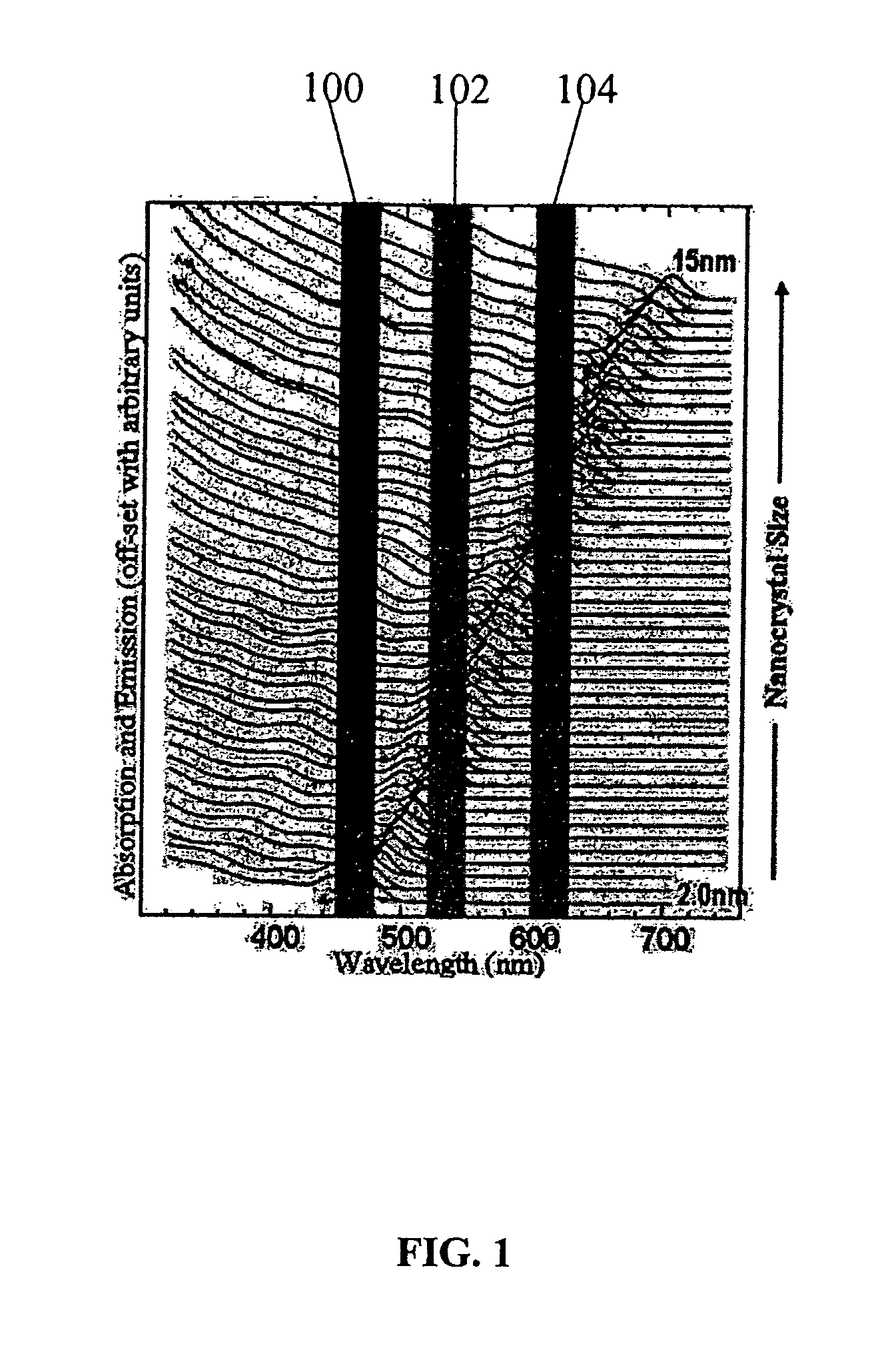

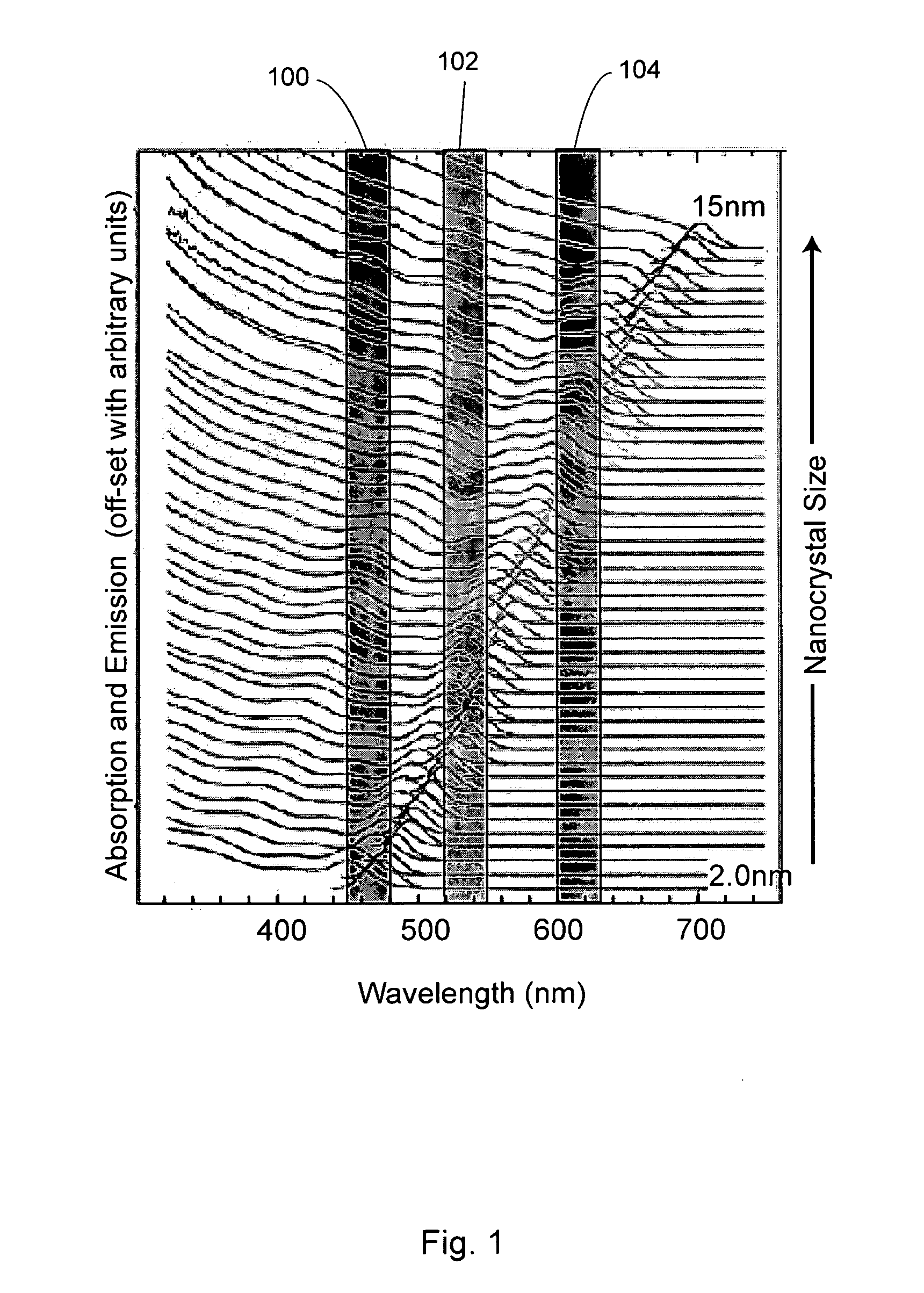

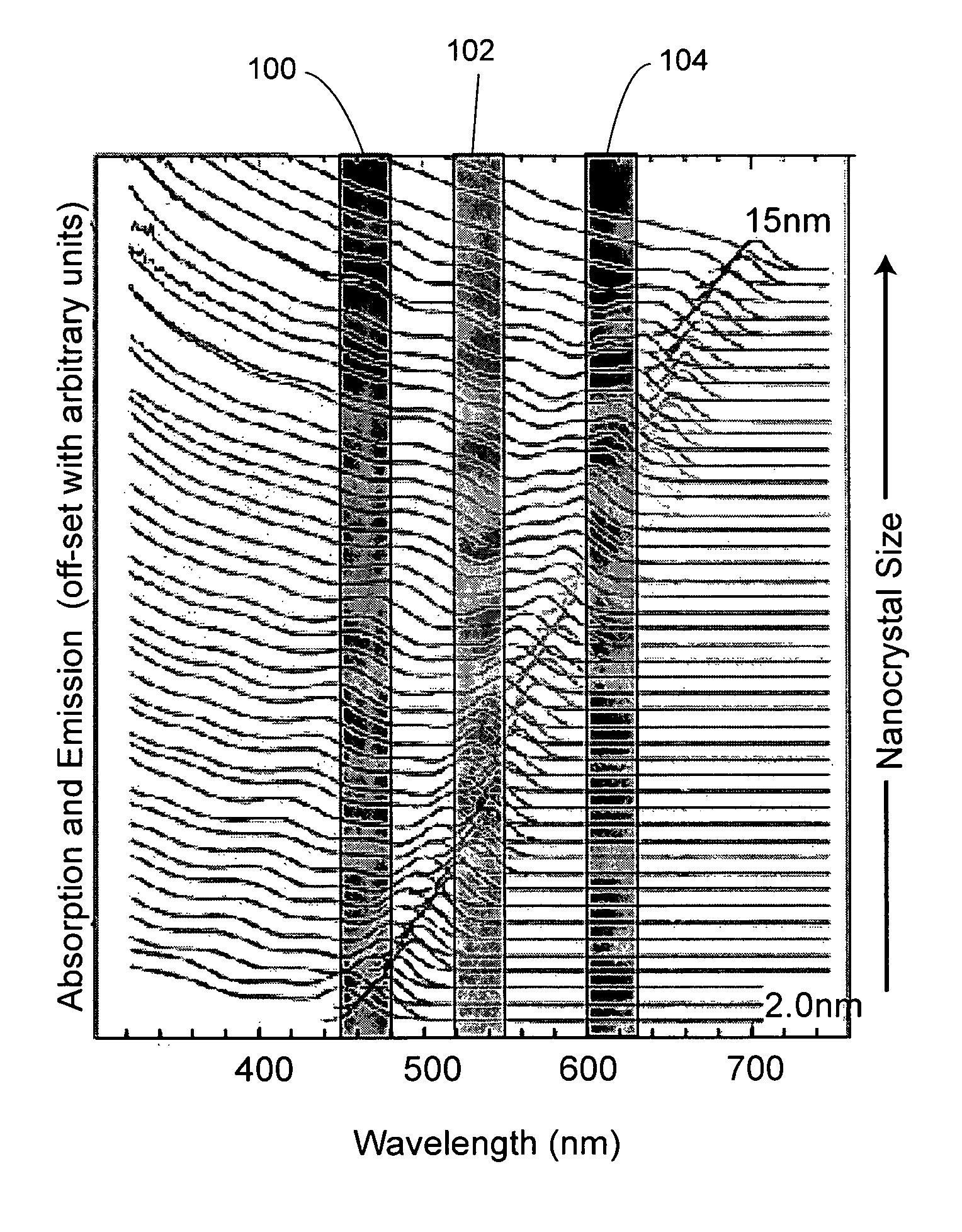

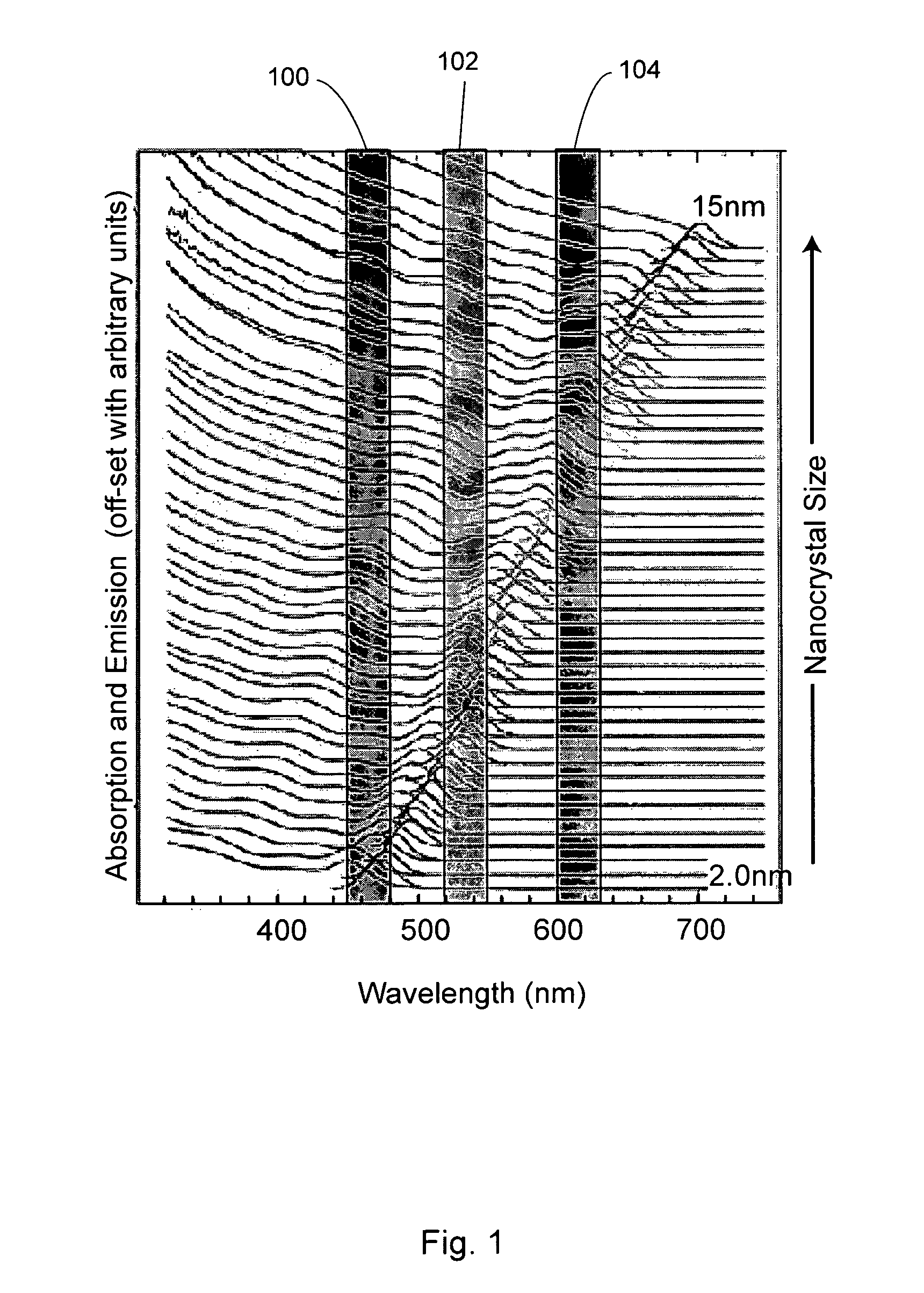

Nanocrystal doped matrixes

ActiveUS20070034833A1Good miscibilityInhibit aggregationMaterial nanotechnologyIndividual molecule manipulationAnti-reflective coatingSemiconductor nanocrystals

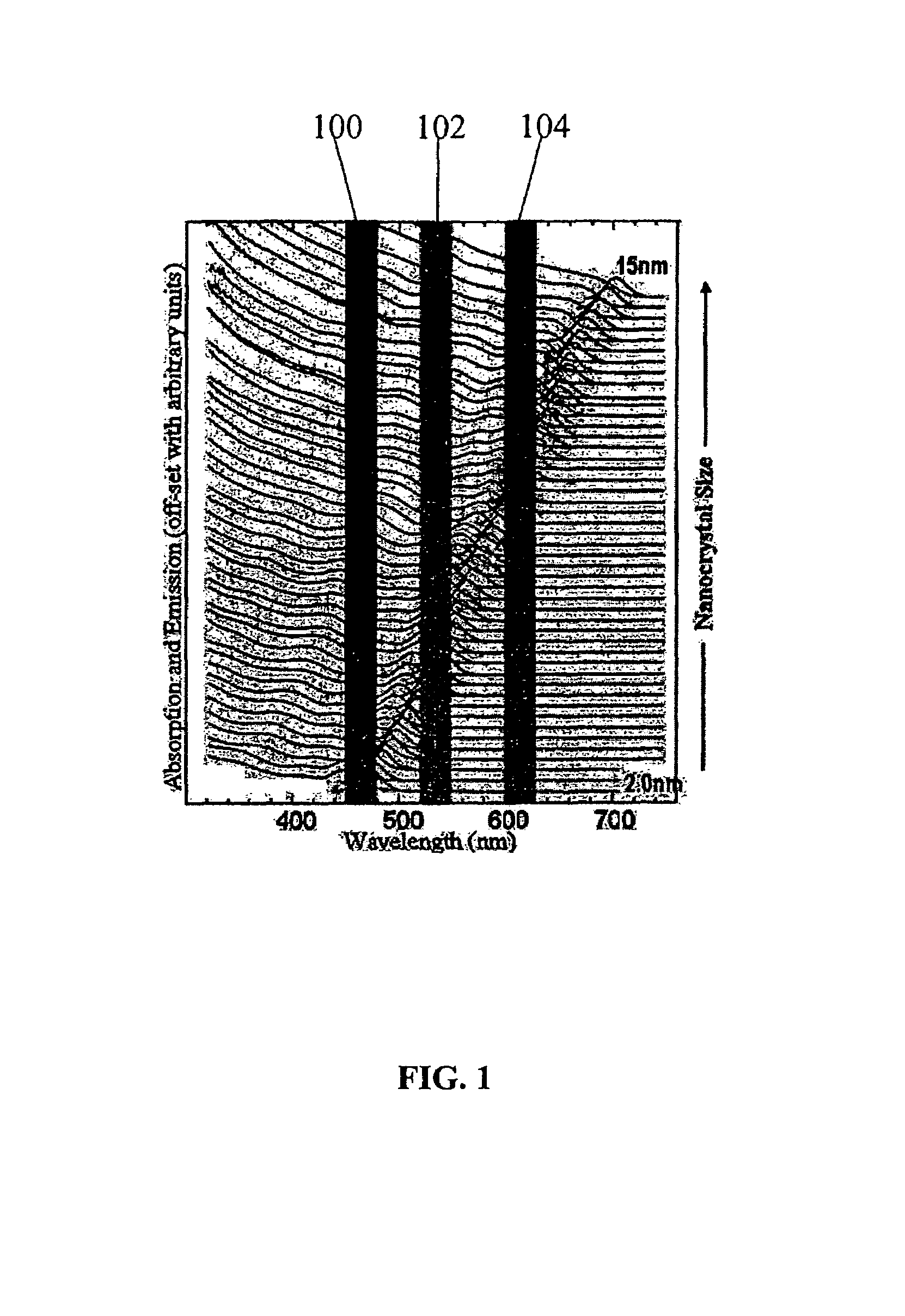

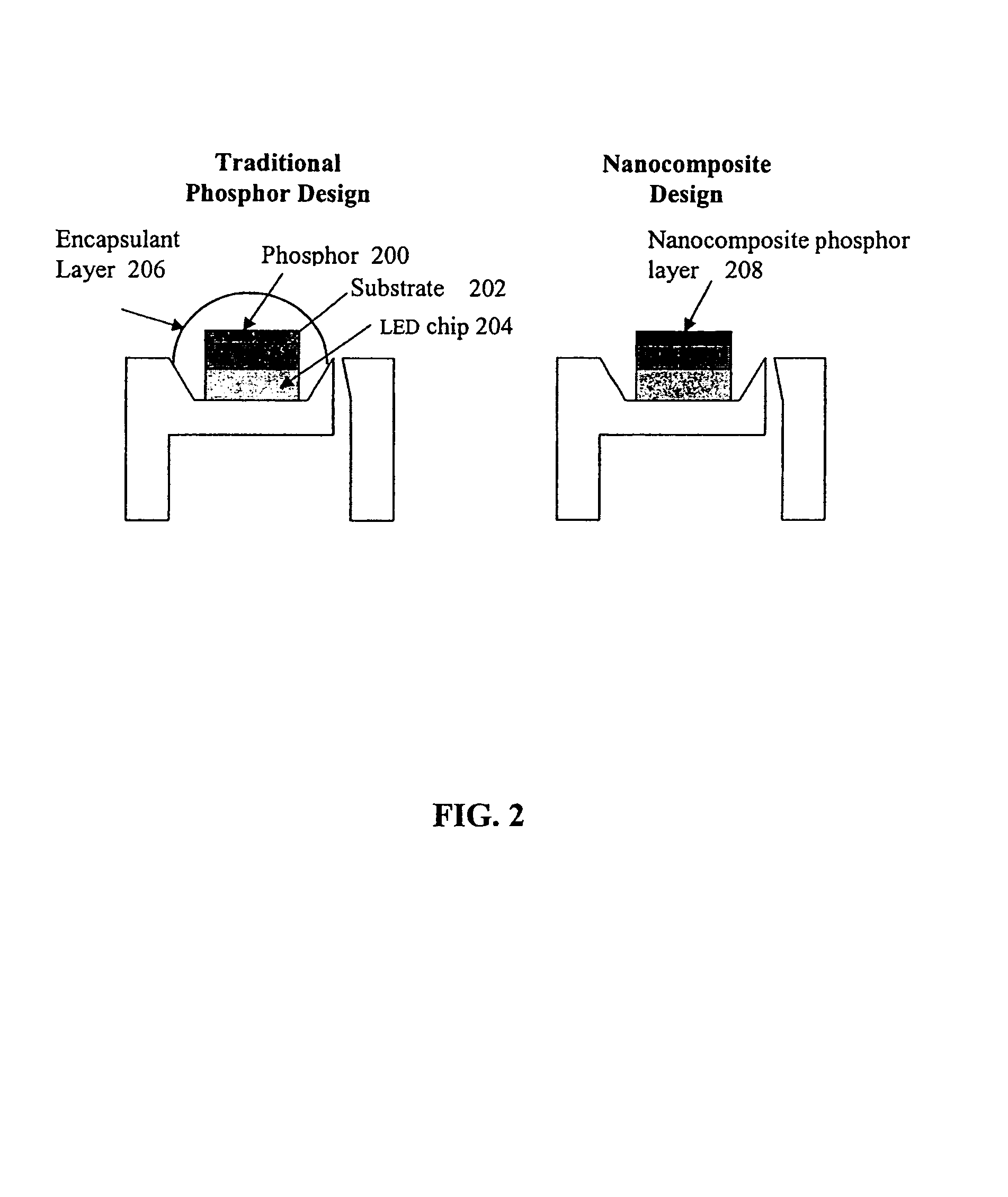

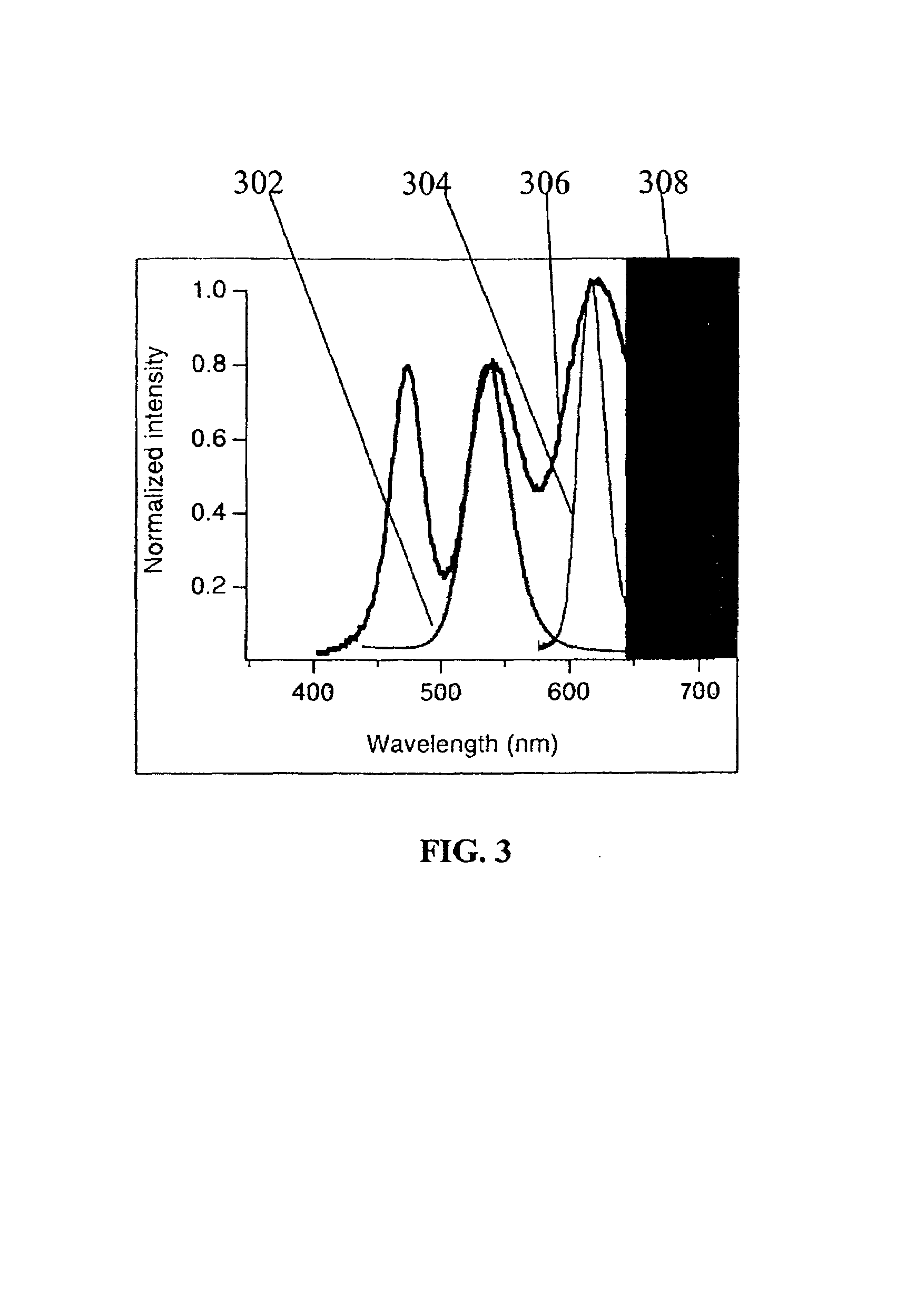

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:SAMSUNG ELECTRONICS CO LTD

Nanocrystal doped matrixes

ActiveUS7645397B2Good miscibilityInhibit aggregationMaterial nanotechnologyIndividual molecule manipulationAnti-reflective coatingQuantum efficiency

Owner:SAMSUNG ELECTRONICS CO LTD

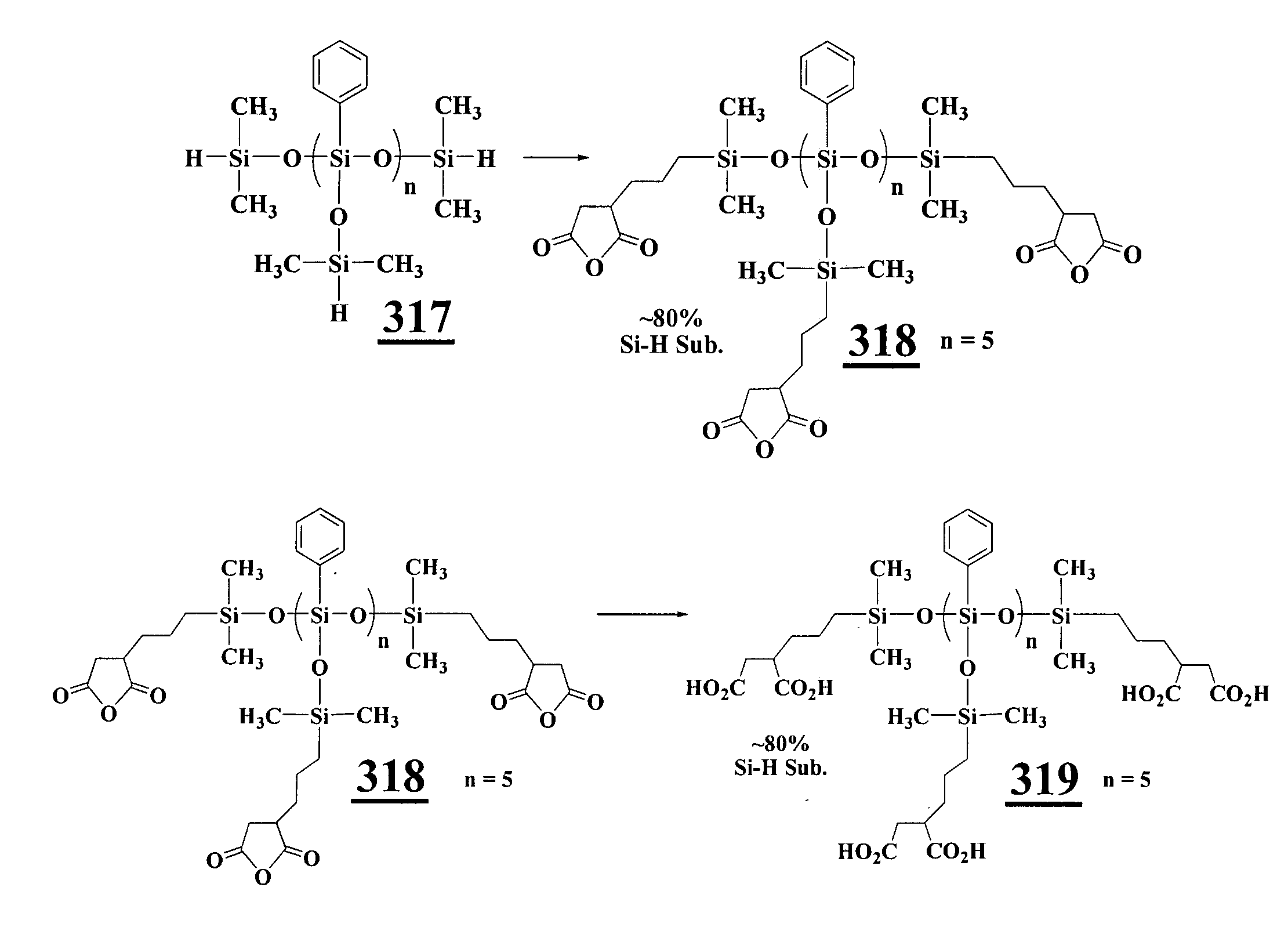

Functionalized matrixes for dispersion of nanostructures

ActiveUS20100276638A1High quantum yieldFacilitate device fabricationMaterial nanotechnologyGroup 4/14 element organic compoundsAnti-reflective coatingVolumetric Mass Density

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes are optionally formed from the ligands. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:NANOSYS INC

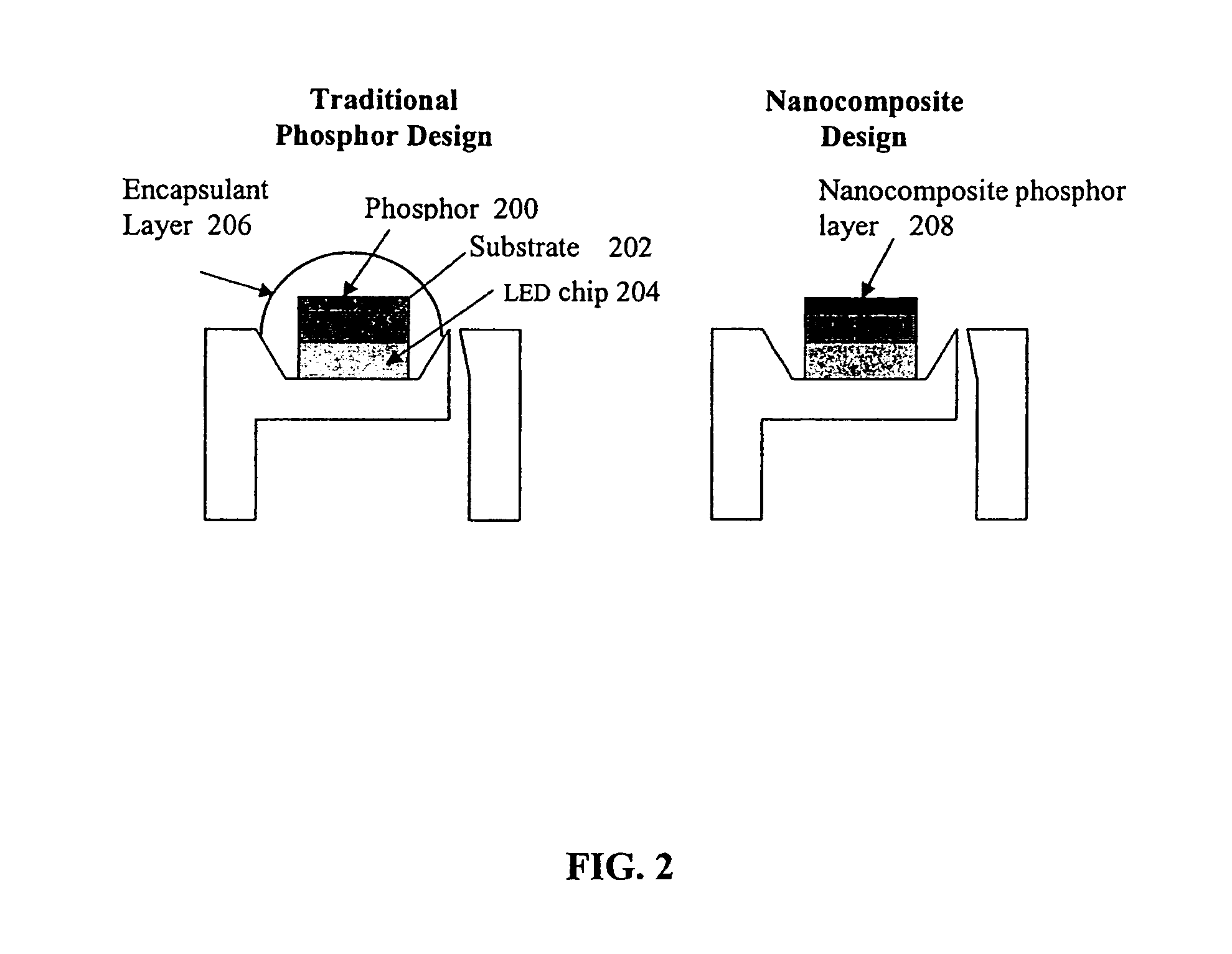

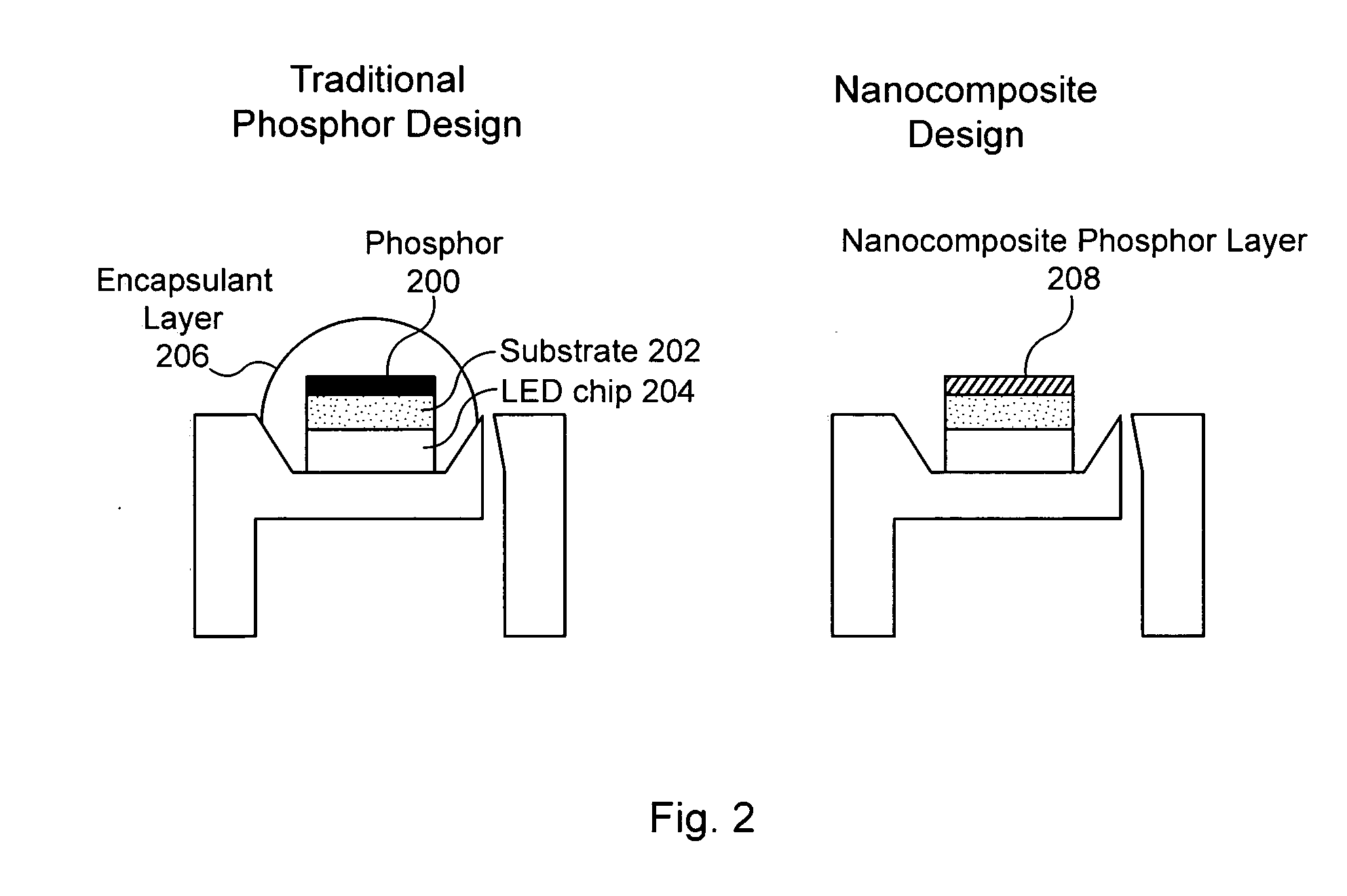

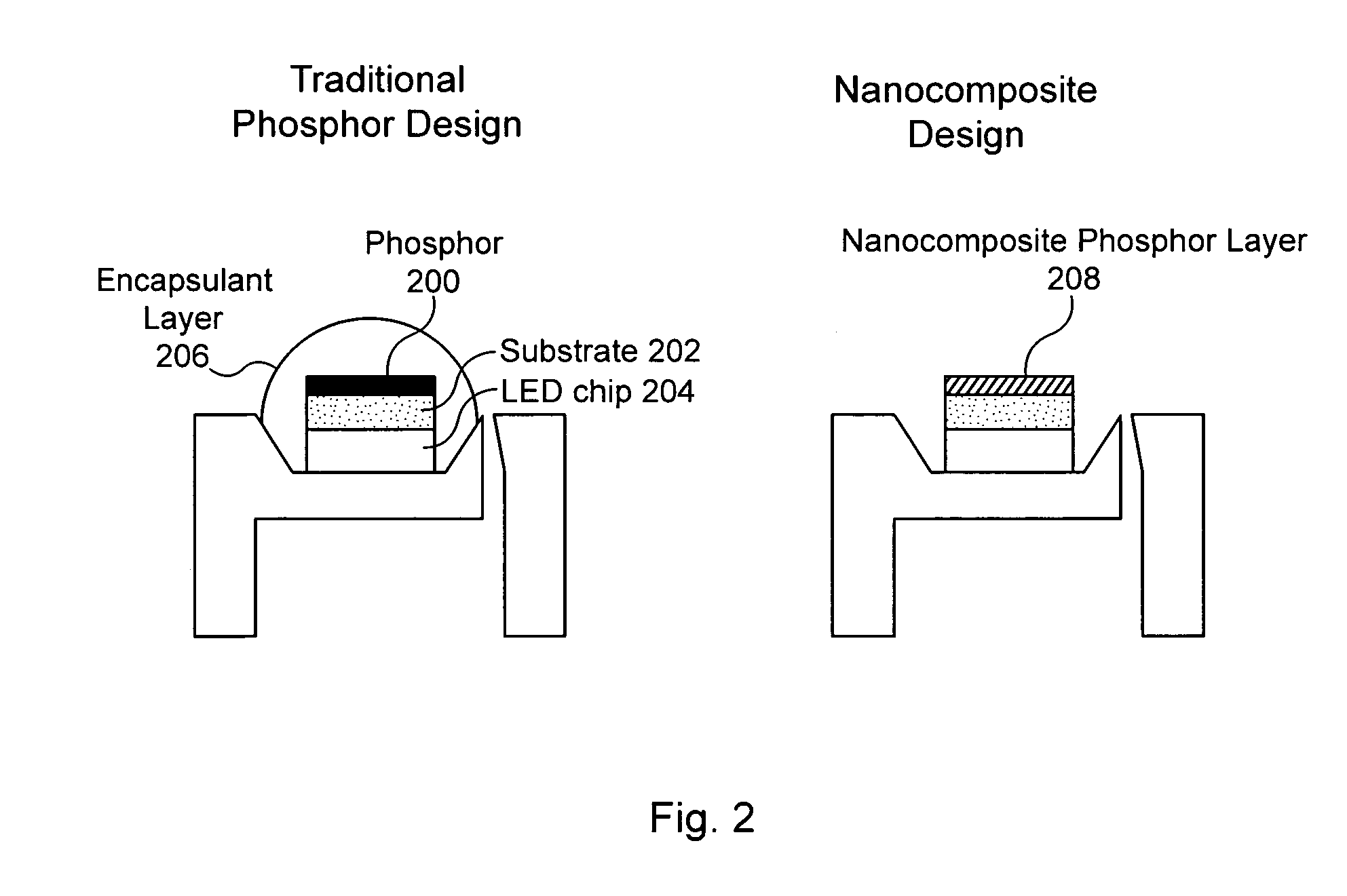

Light emitting device with a thermal insulating and refractive index matching material

ActiveUS20060091788A1Reduce heat transferPrevent thermal degradationDischarge tube luminescnet screensLamp detailsThermal insulationPhosphor

A light emitting device has a light emitting diode (LED) encapsulated by an encapsulant member. The encapsulant member includes a luminescent material, such as a phosphor, and a thermal insulating material. The thermal insulating material effectively insulates the luminescent material from the heat generated by the LED. A thermal conducting material is desirably placed in thermal contact with a back side of the LED to assist heat dissipation. The encapsulant member may be formed in two separate layers with the luminescent material forming a luminescent layer, and the thermal insulating material forming a thermal insulation layer disposed between the luminescent layer and the LED.

Owner:LED ENGIN

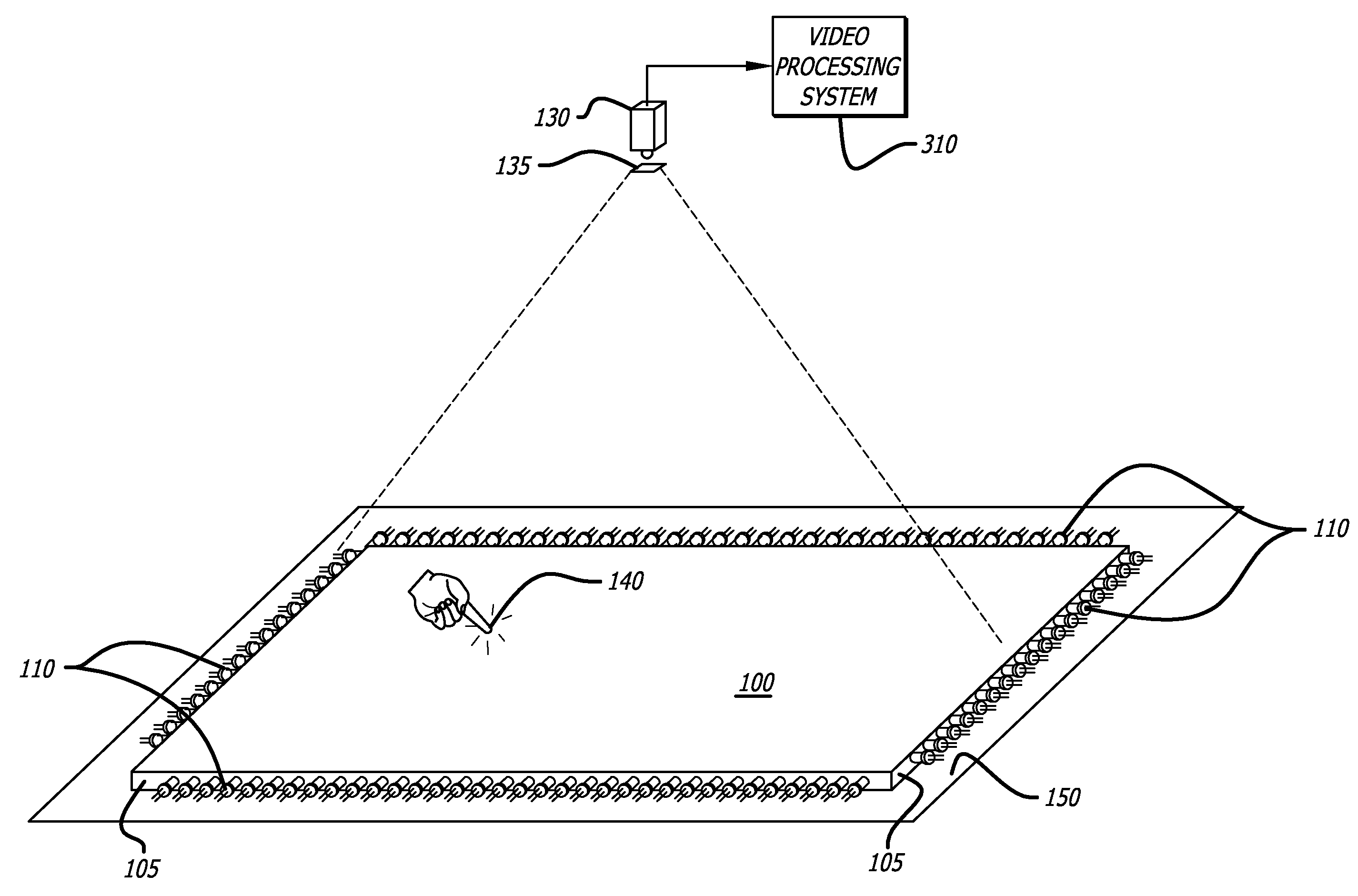

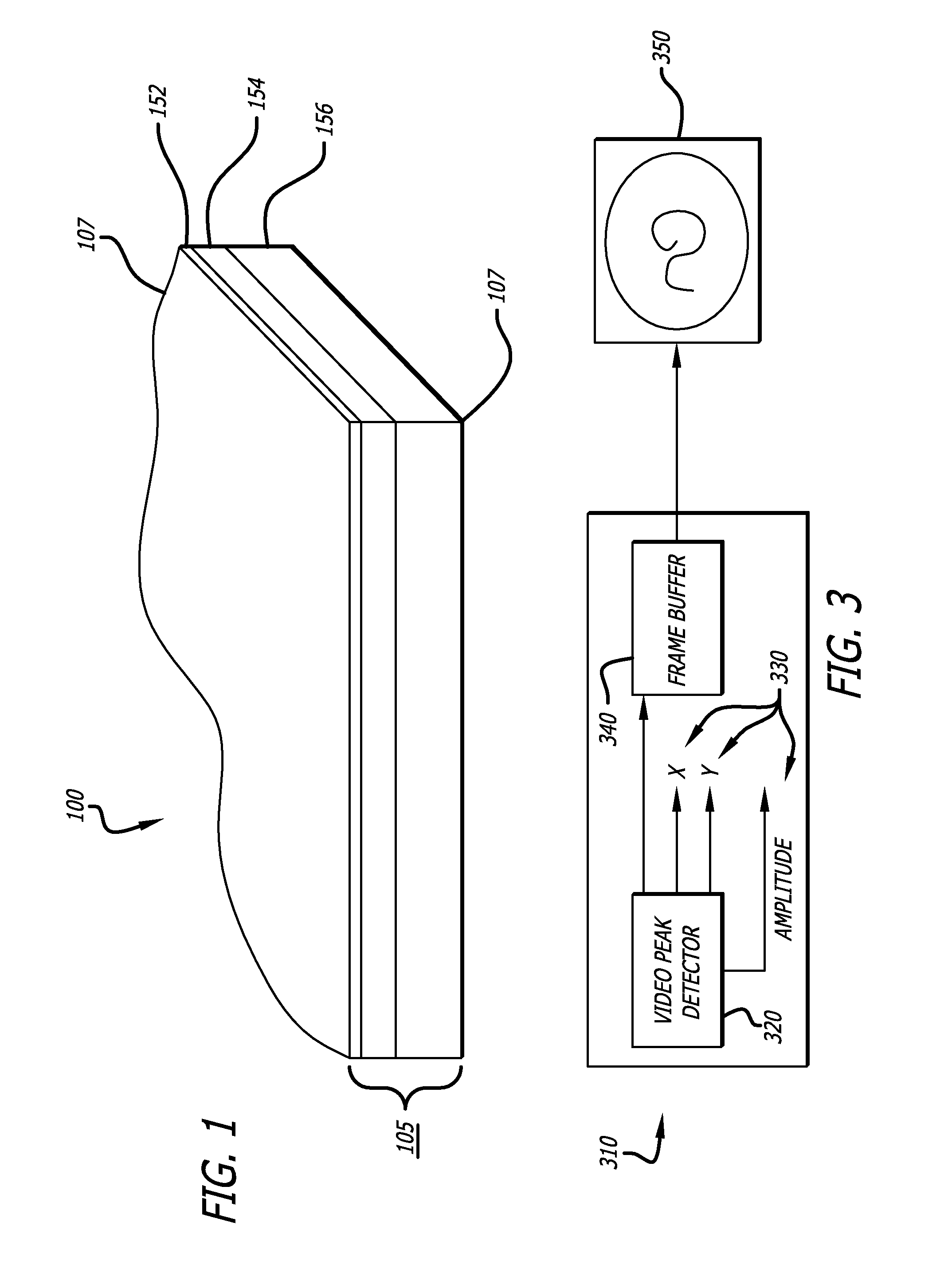

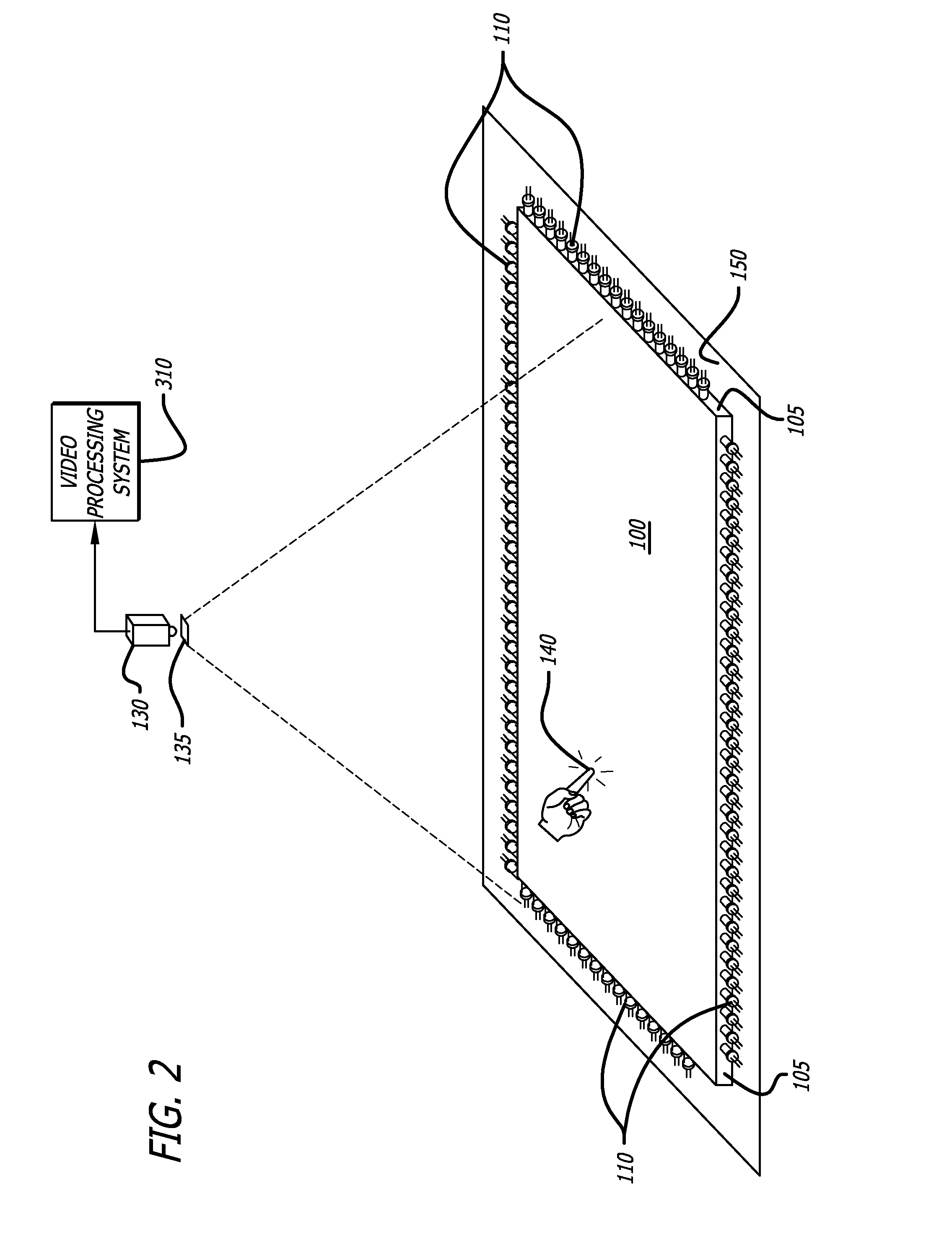

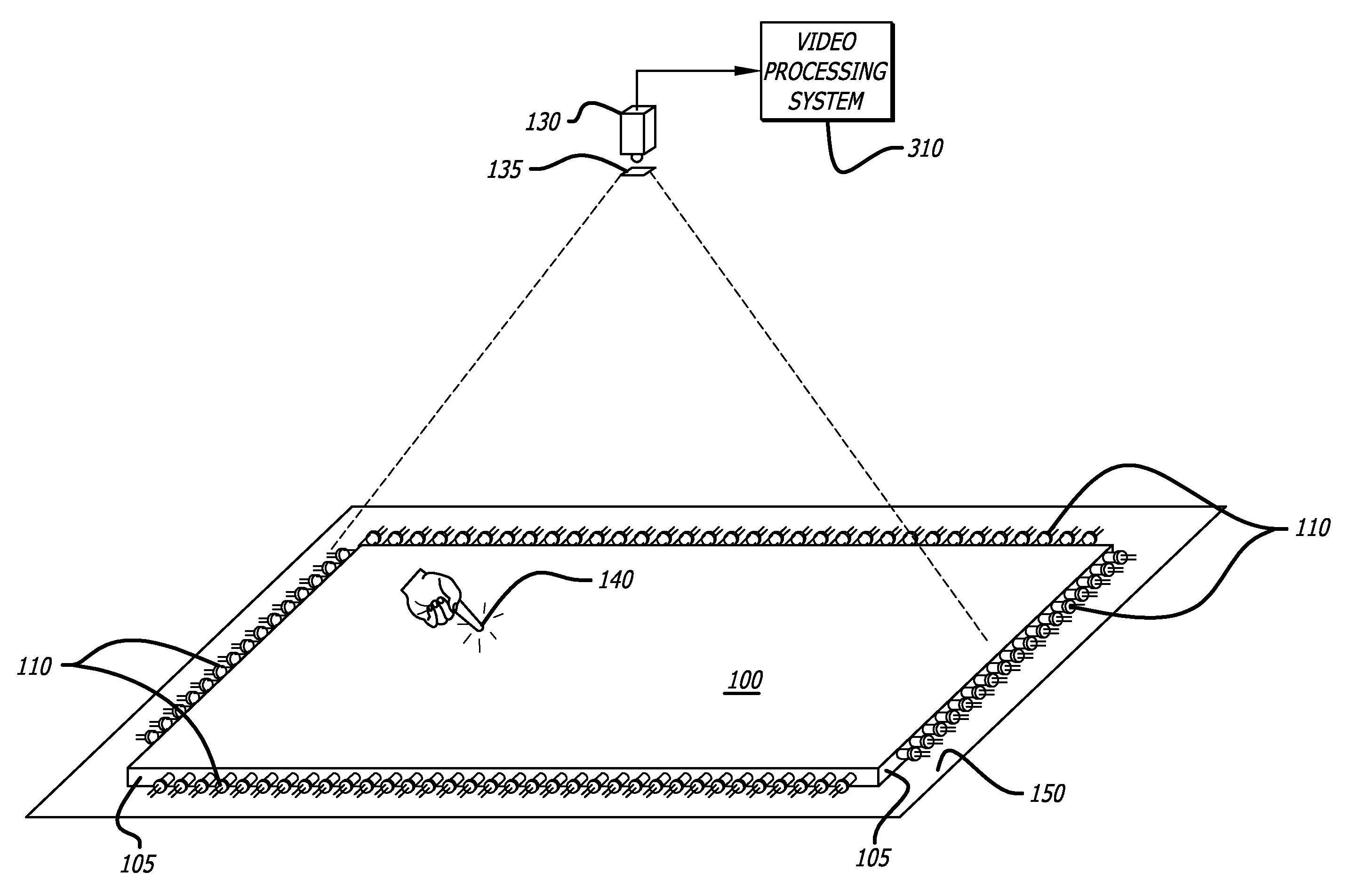

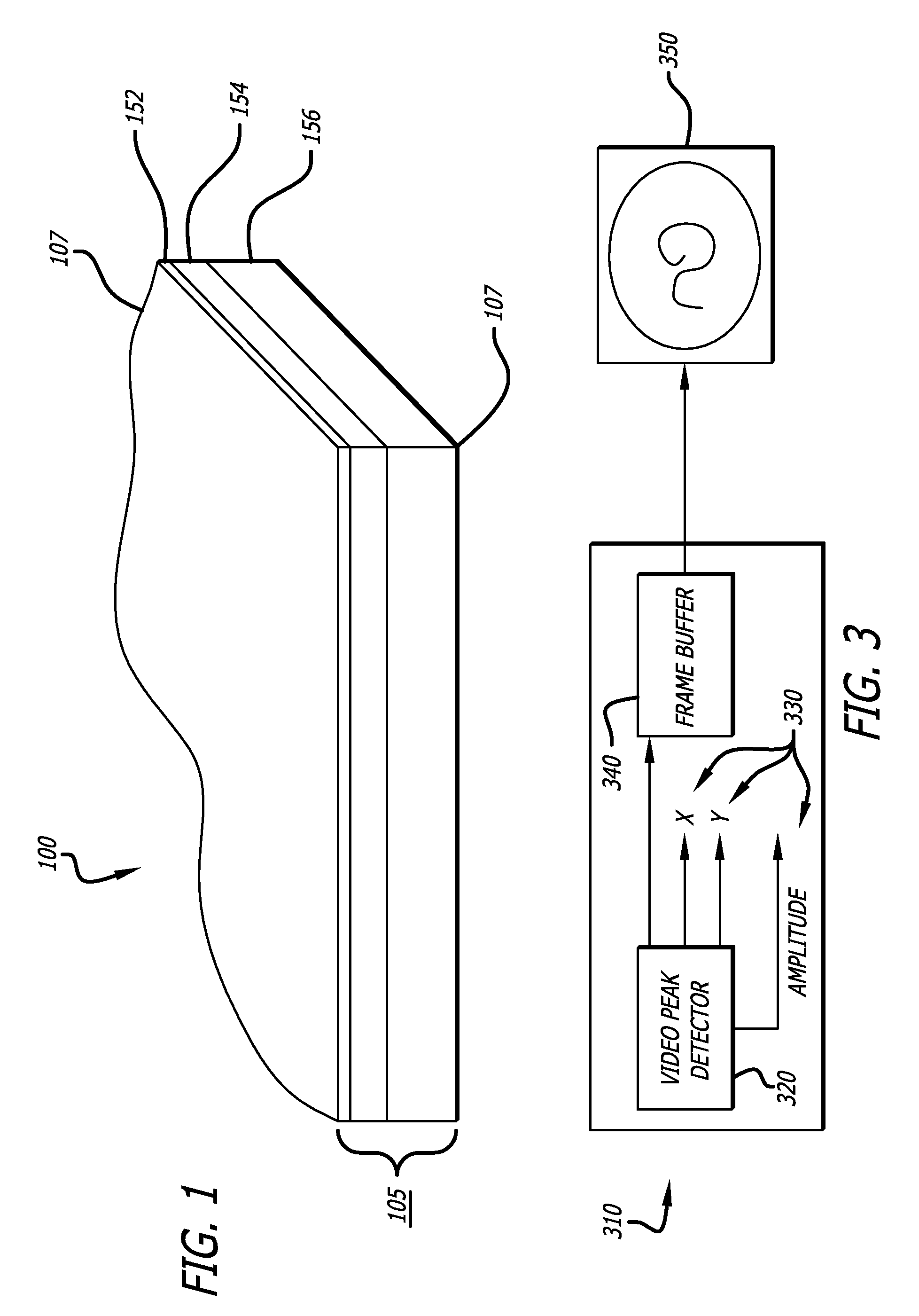

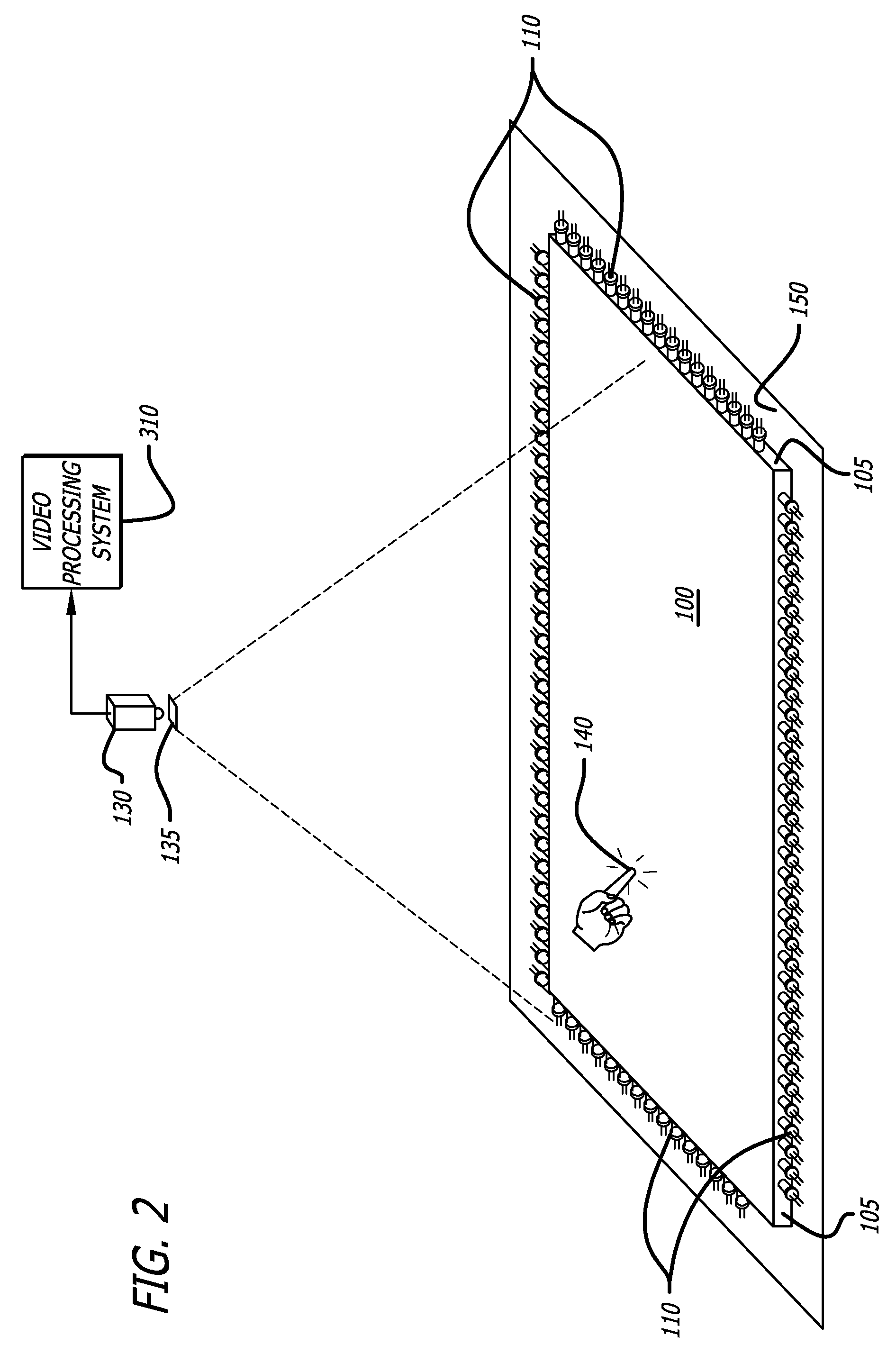

Multi-user touch screen

A multi-user touch-responsive viewing screen is described which uses frustrated total internal reflection in a slab of transparent material to illuminate the contact point between the slab and a finger or other object substantially matching the slab's index of refraction. Light, coupled upon touch, can be detected with a video camera, and used to determine both the position and pressure of the touch. Multiple touches can be accommodated and each touch accurately located. Projected images can be applied to the slab and a diffuser to construct an interactive touch screen.

Owner:DISNEY ENTERPRISES INC

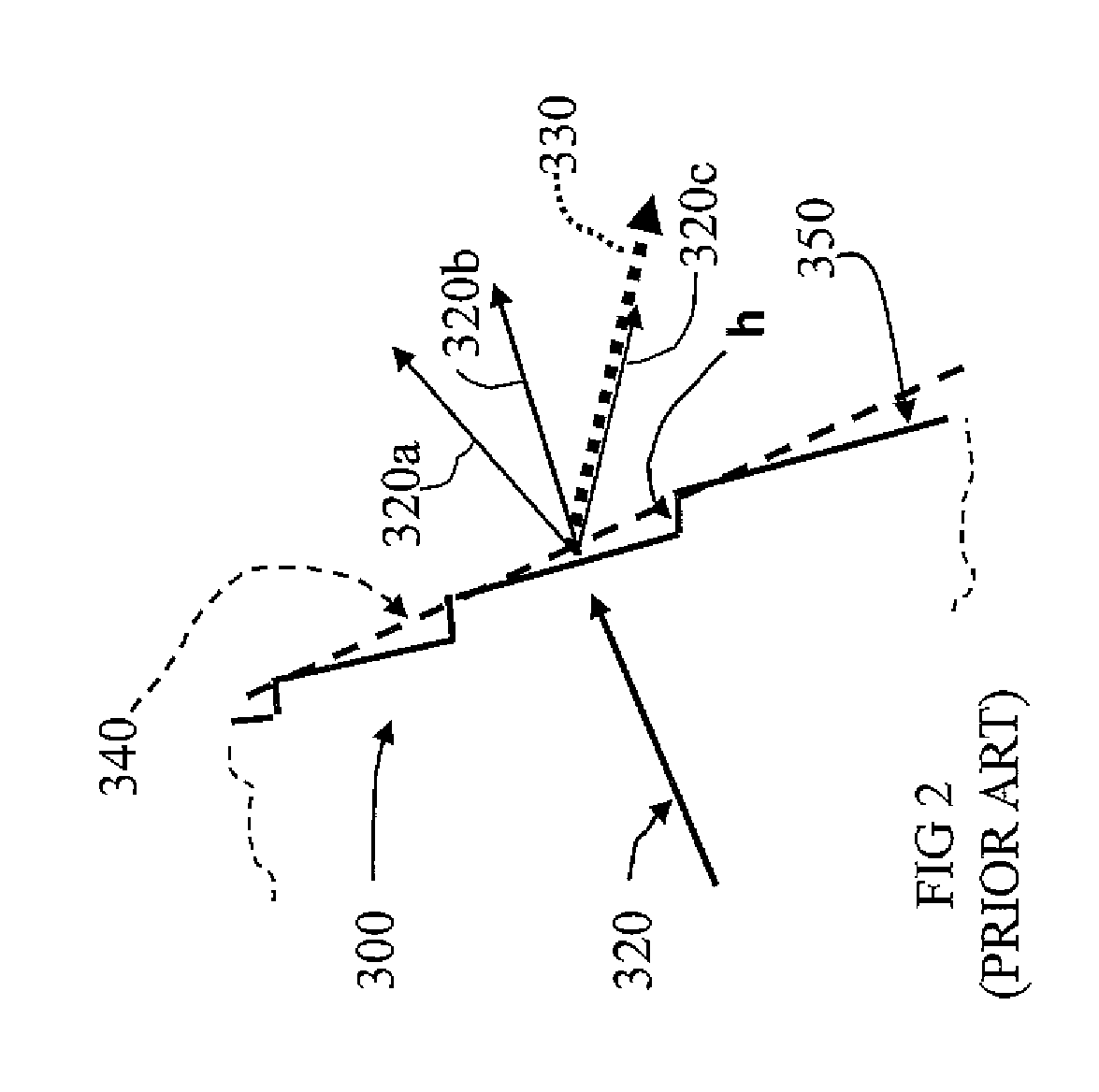

Optical switch and method for assembling the same

An optical switch includes a substrate having therein optical waveguides made of silicon and a silicon layer deposited on its top surface. A space is formed in the crossing portion of the optical waveguides which is covered with a lid, preferably made of low alkali borosilicate glass, and which is bonded to the silicon layer by anodic bonding. Preferably, a groove is formed in a surface of the optical waveguide substrate or a bonding surface of the lid. The groove, after the lid has been bonded, makes a passage which communicates between the space and an outside. The passage is a pouring slit for pouring an index-matching liquid and is connected to the space which acts as a driving slit in which the index-matching liquid moves. In one embodiment, the width of the pouring slit is smaller than that of the driving slit. The optical switch can be manufactured by providing an optical waveguide substrate and a lid substrate, one of which is formed with a groove in its surface on which the two substrates are bonded. The optical waveguide substrate and the lid substrate are bonded together by anodic bonding to make a passage which communicates between the space formed in a crossing portion of the optical waveguides and an outside. The regulation of the volume of the index-matching liquid is time-, temperature-, or pressure-based regulation.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

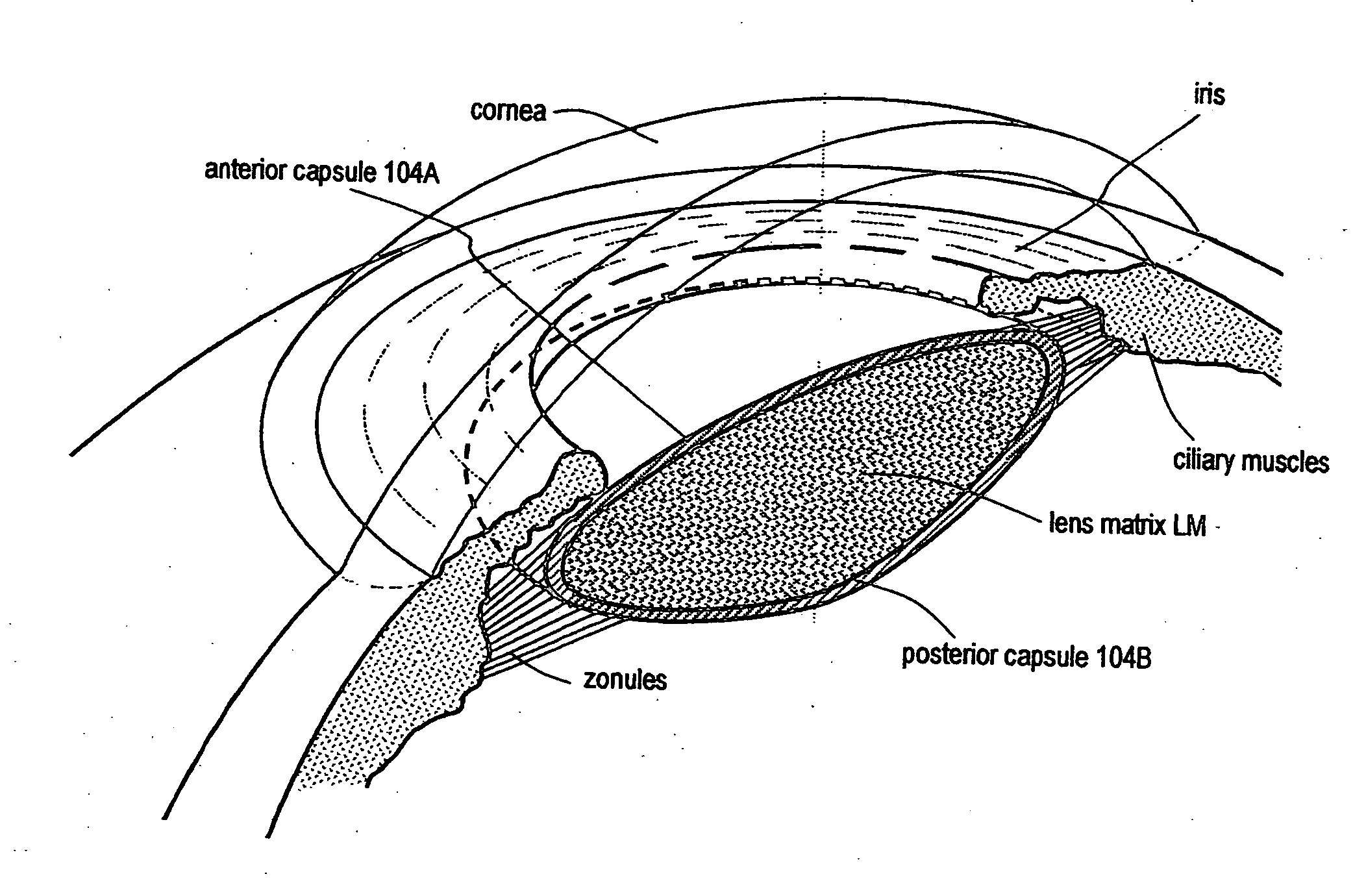

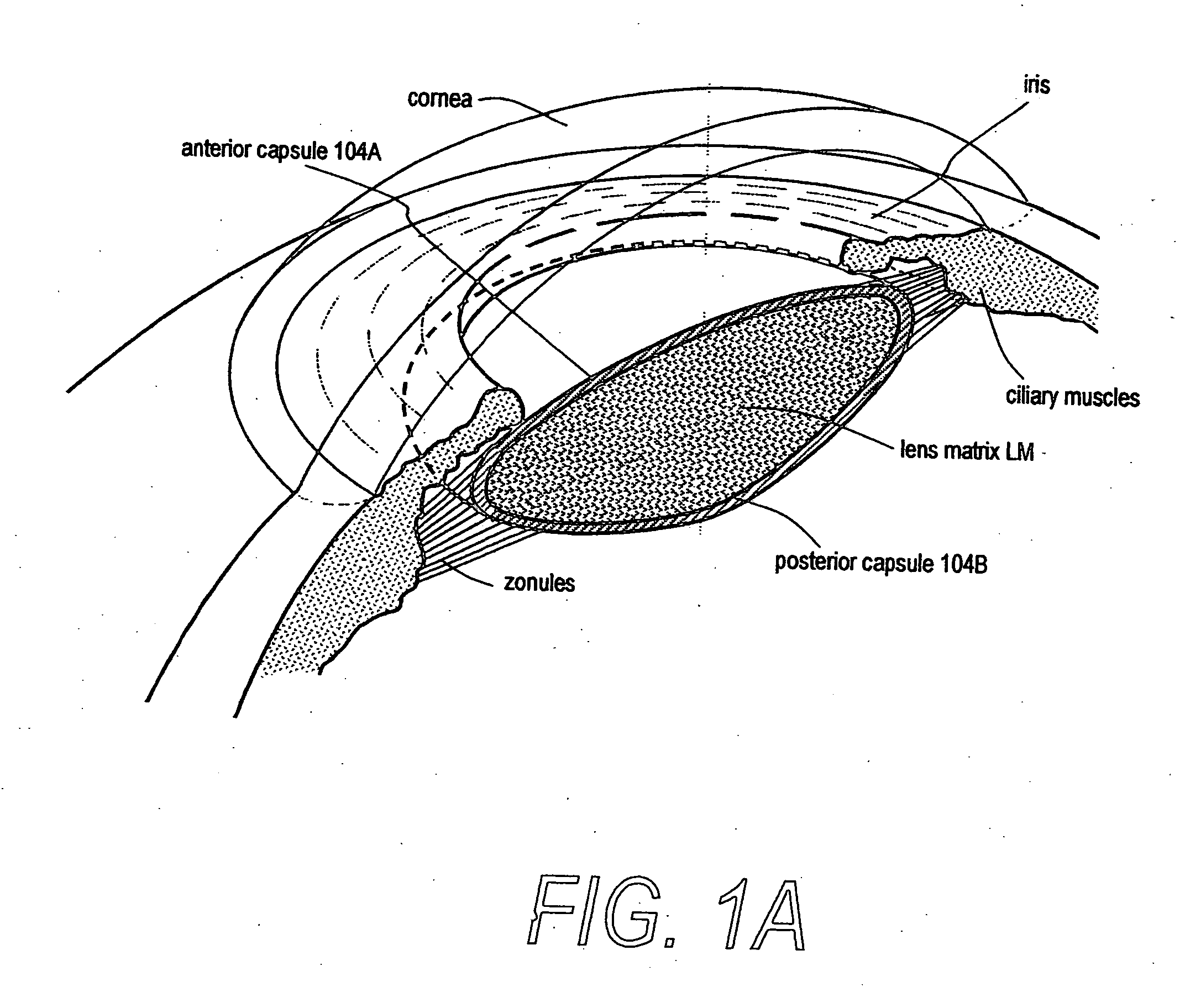

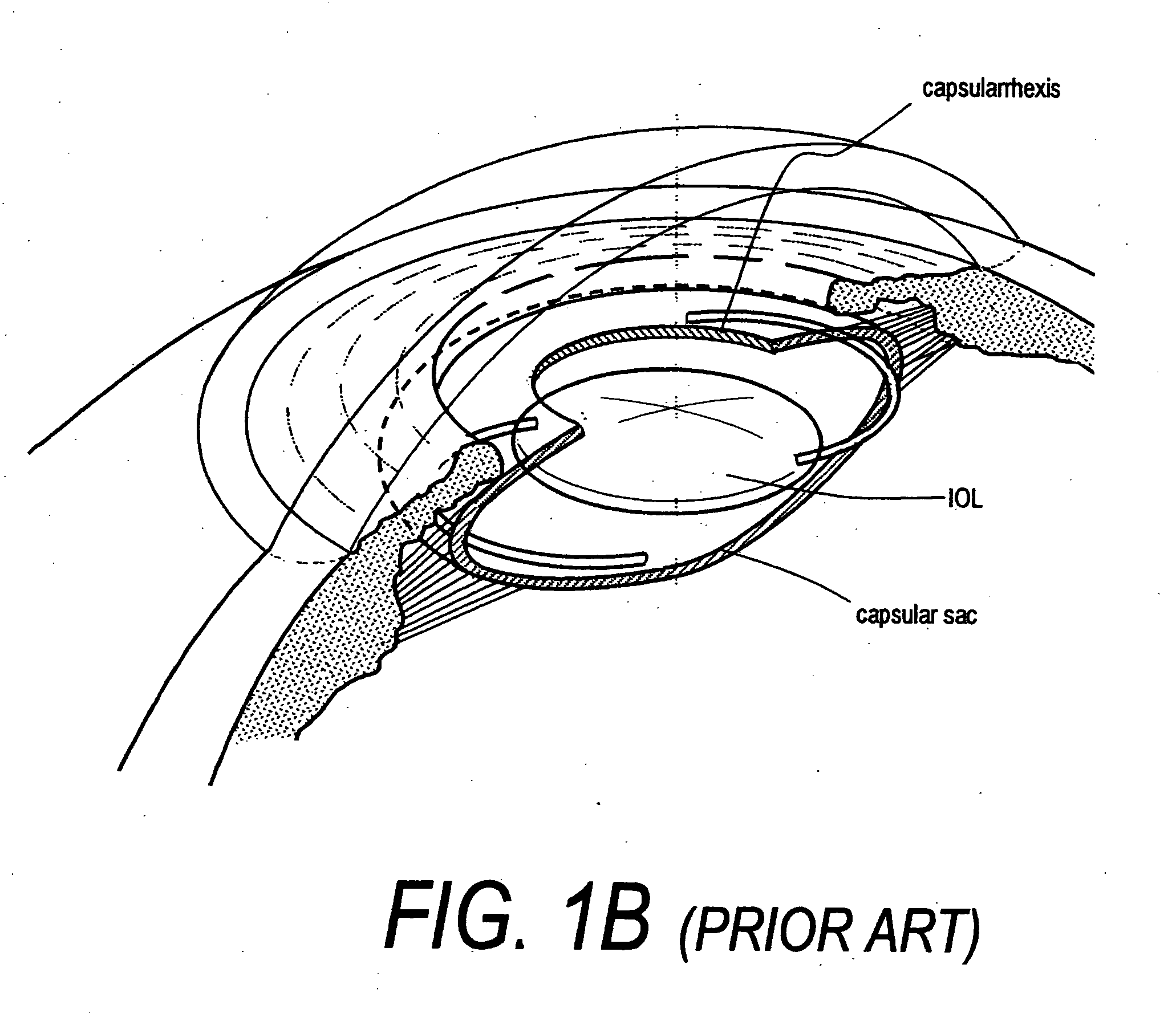

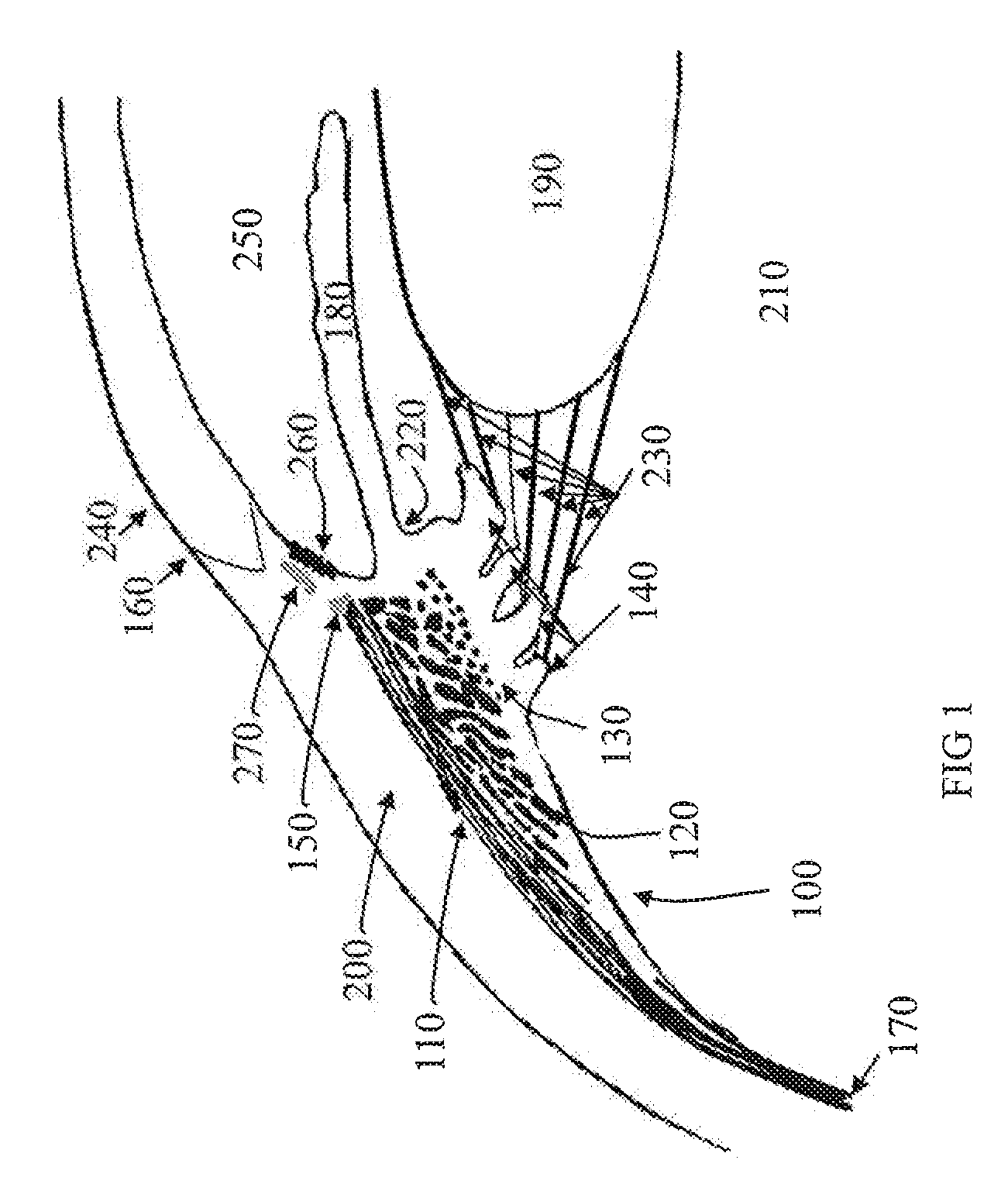

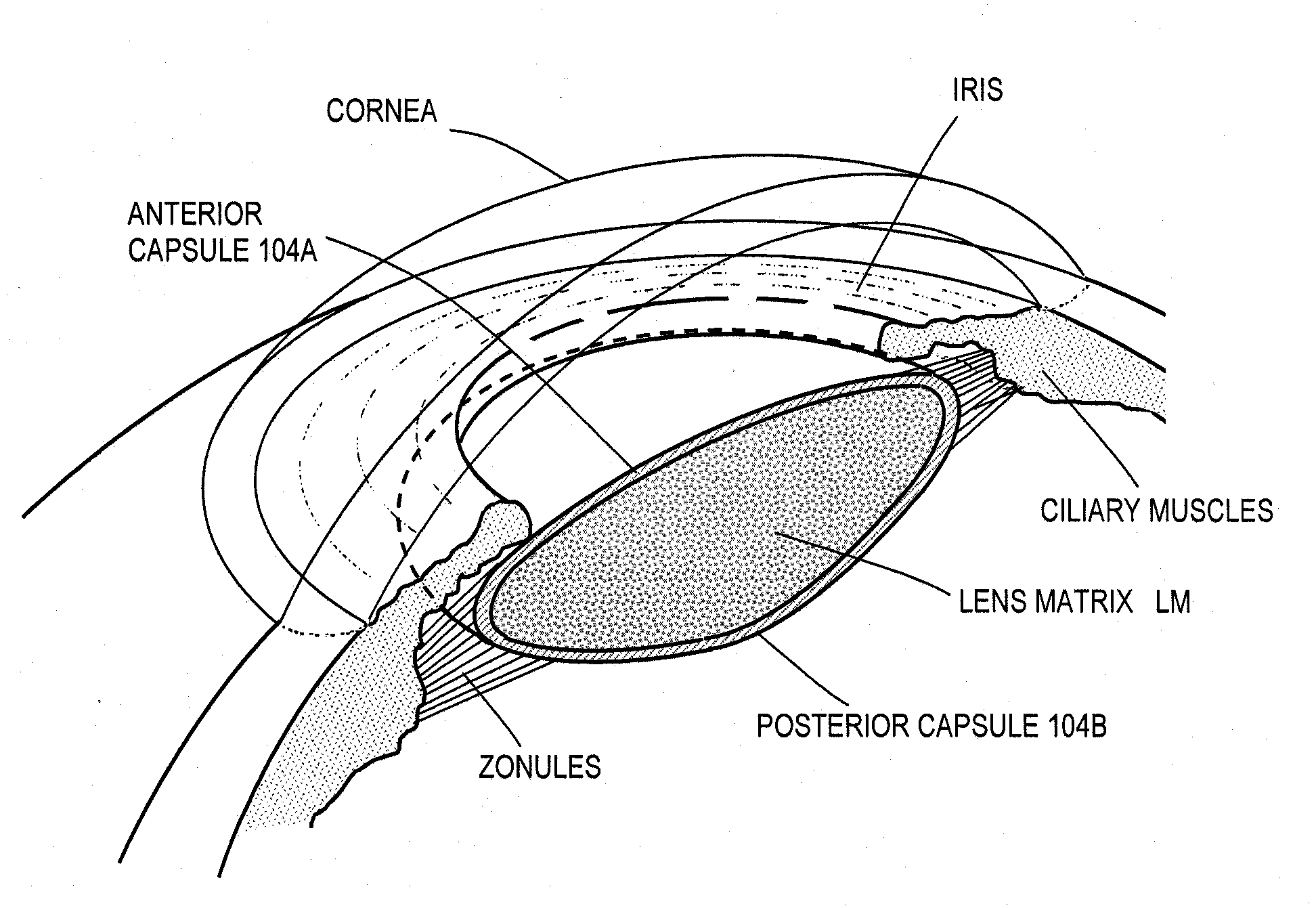

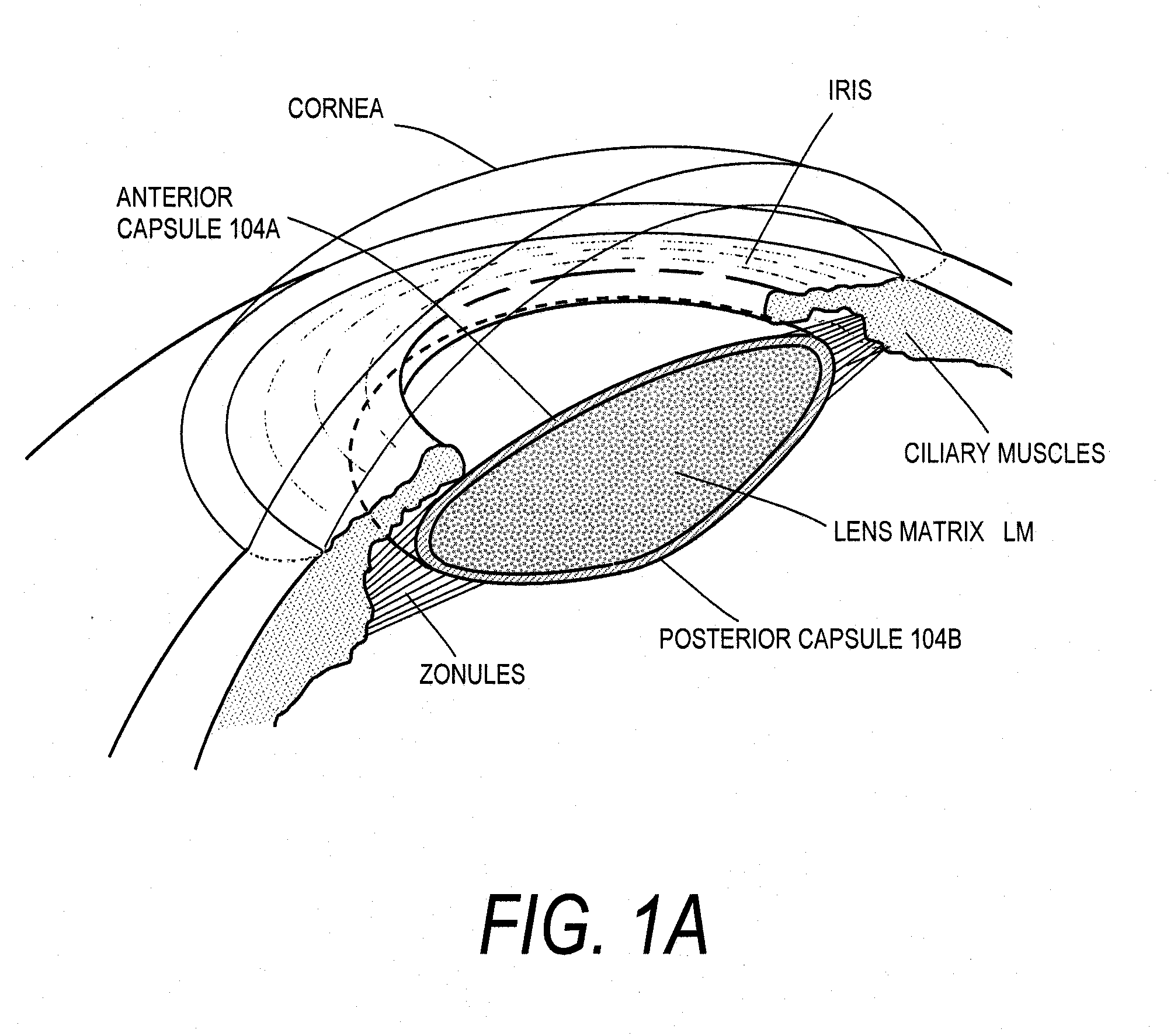

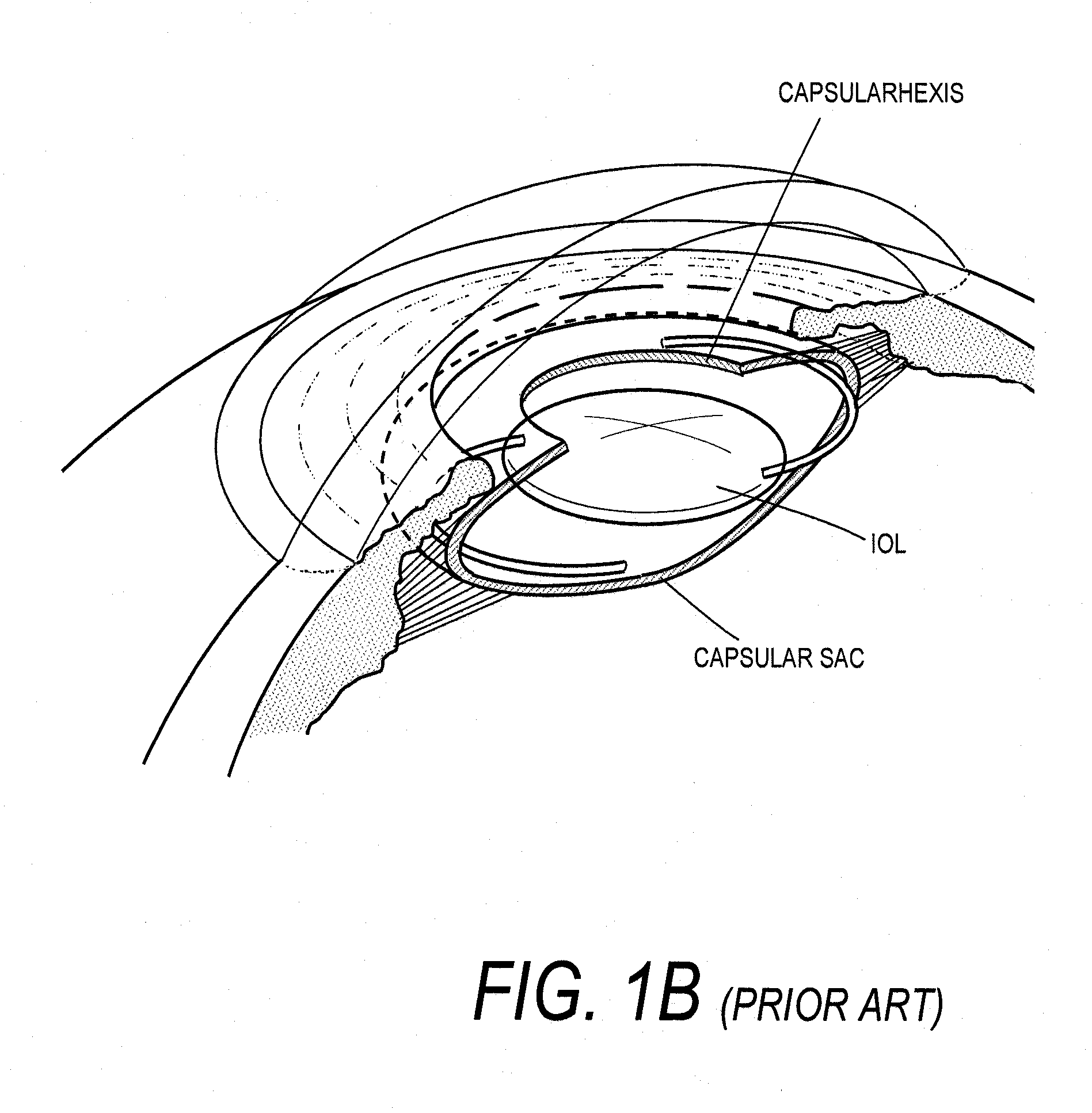

Intraocular lenses and business methods

An intraocular accommodating lens comprising a resilient polymer monolith with a peripheral component that has a Young's modulus and an equilibrium memory shape that imparts to the capsular sac's periphery the natural shape of the capsule in an accommodated state. The intraocular lens includes a central deformable optic that provides accommodated and disaccommodated shapes. The peripheral component is deformable to a disequilibrium, stressed shape in responsive to equatorial tensioning-and is capable of applying restorative forces to move the lens toward the accommodated shape from a disequilibrium disaccommodated shape. In one embodiment, the central optic portion includes a displaceable media than can be displaced by very low forces of zonular excursion, wherein the displaceable media can comprise a very low modulus polymer or an index-matched fluid.

Owner:POWERVISION

Functionalized matrices for dispersion of nanostructures

ActiveUS8283412B2Good miscibilityInhibit aggregationMaterial nanotechnologyGroup 4/14 element organic compoundsAnti-reflective coatingSemiconductor nanocrystals

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes are optionally formed from the ligands. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:SHOEI CHEM IND CO LTD

Light modulators

Various improvements in electrophoretic media and displays intended for use in light modulators are described. These improvements include index matching of the suspending fluid to a continuous phase surrounding the fluid, index matching of a capsule wall to a binder, planarization of a layer containing electrophoretic capsules before application of adhesive thereto, methods for concentrating electrophoretic particles into limited areas of sidewalls of electrophoretic capsules or microcells in the light-transmissive state of the display, and, in the case of light modulators comprising an electrophoretic layer sandwiched between two transparent plates, forming at least one of the plates so as to absorb electromagnetic radiation which adversely affects the electrophoretic layer.

Owner:E INK CORPORATION

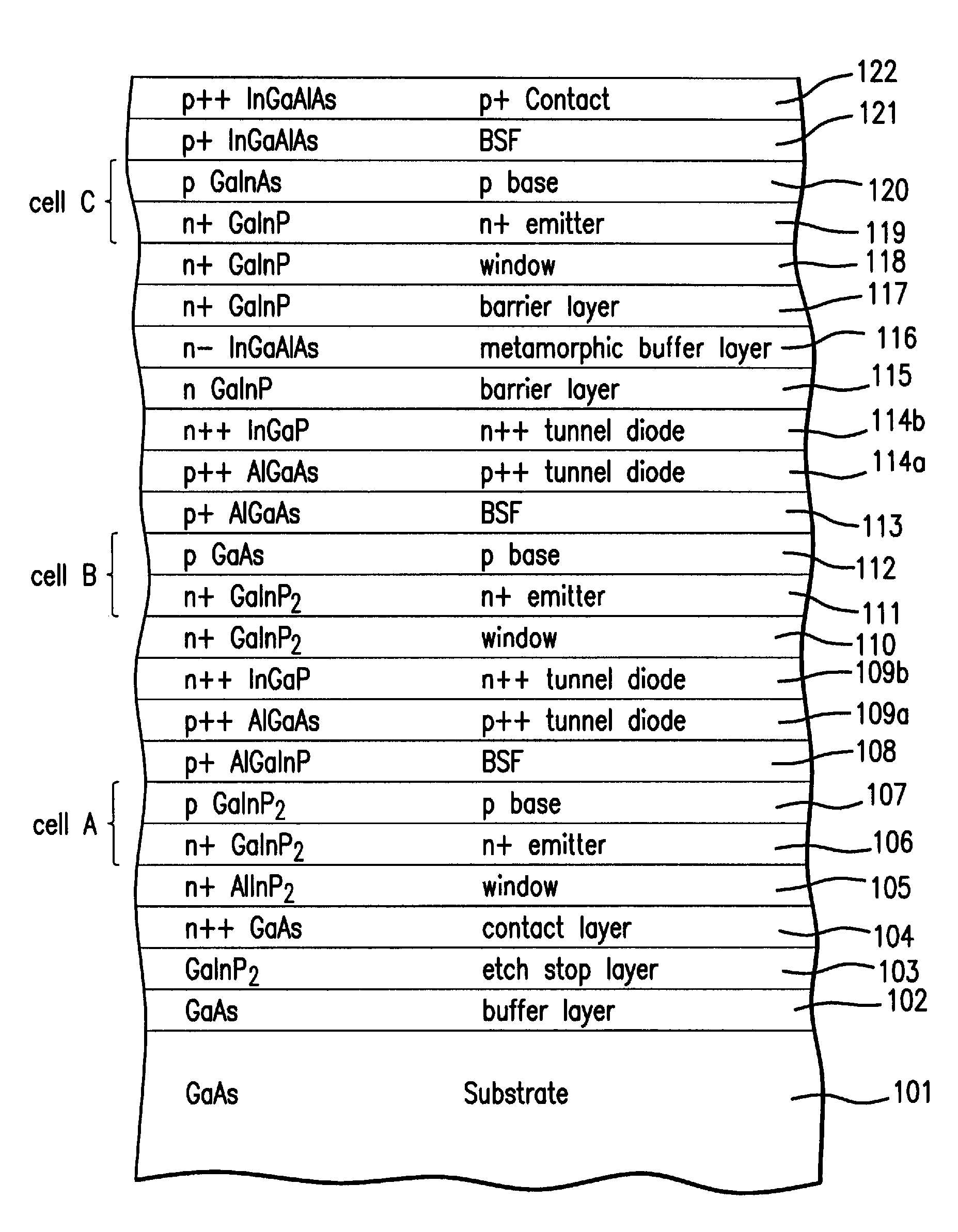

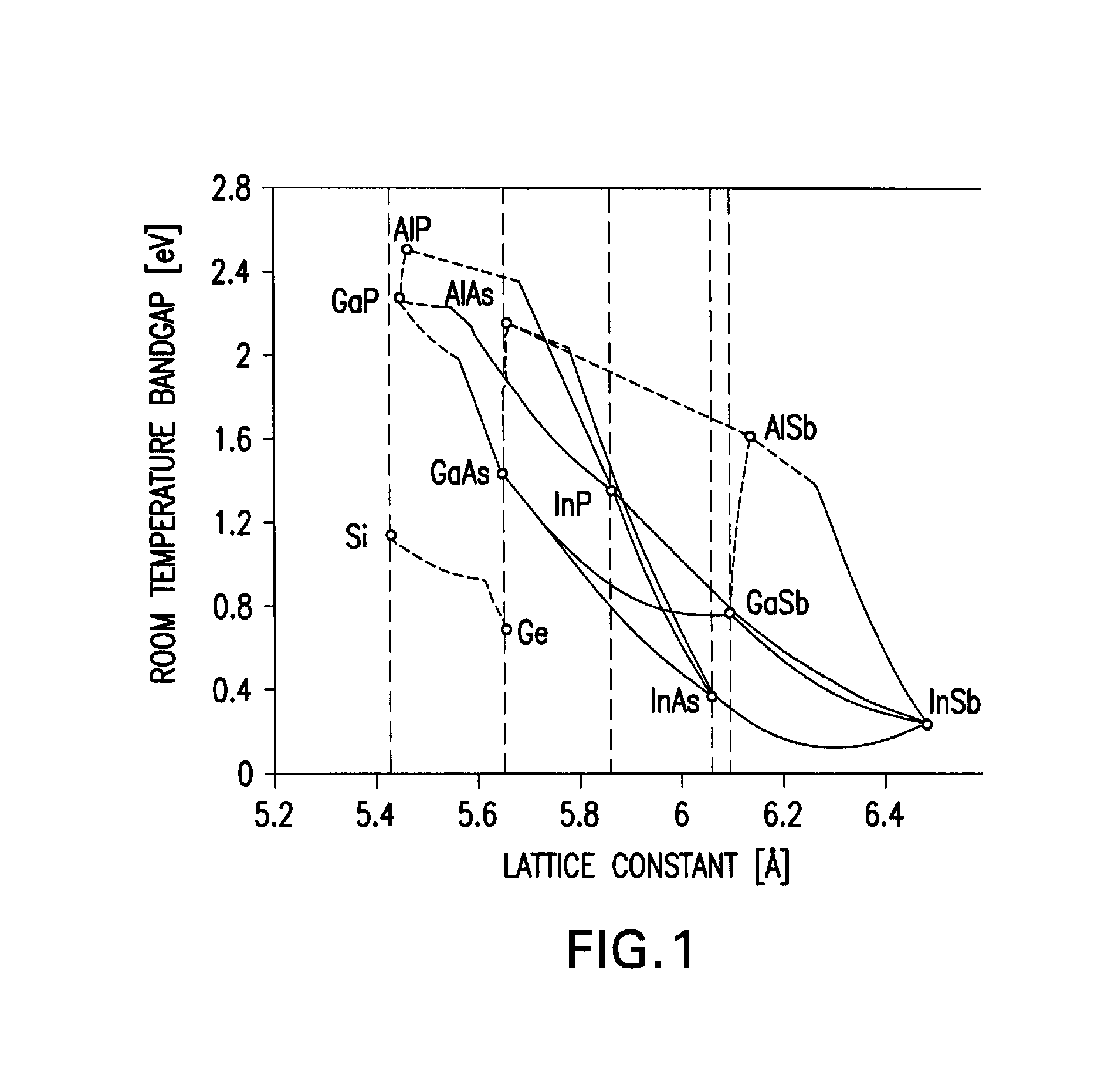

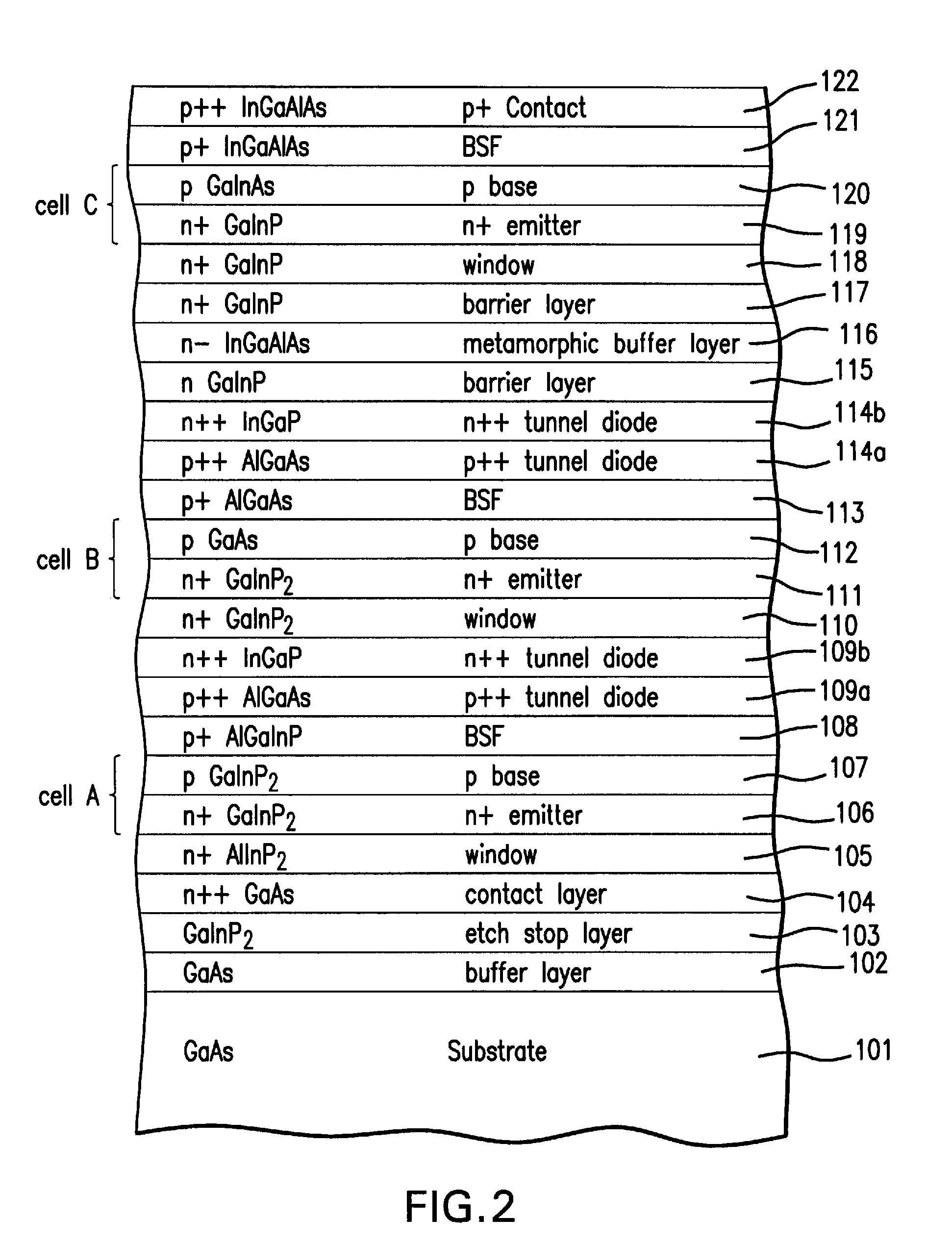

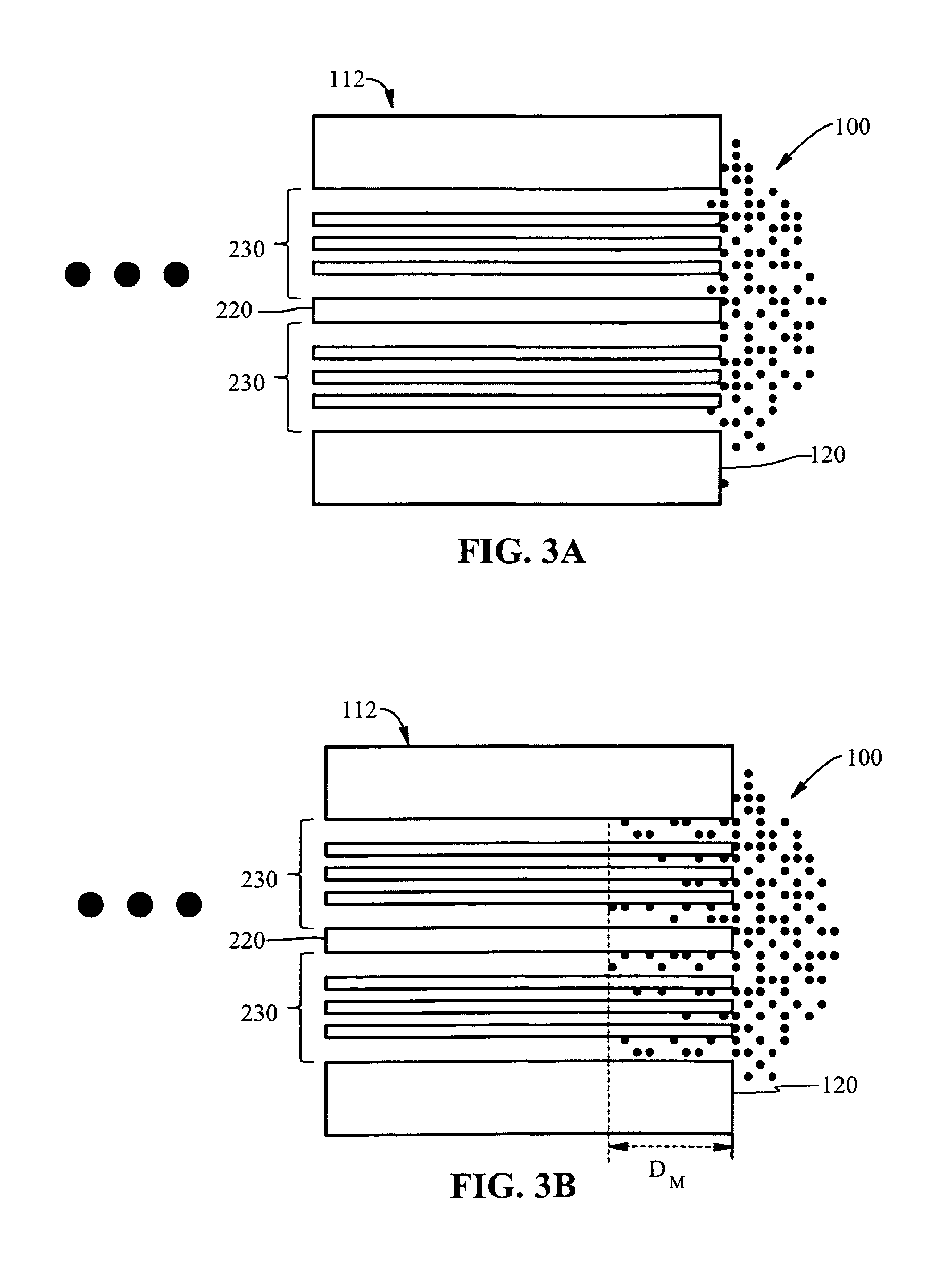

Refractive Index Matching in Inverted Metamorphic Multijunction Solar Cells

InactiveUS20090272430A1Final product manufactureSemiconductor/solid-state device manufacturingLattice mismatchRefractive index matching

A multijunction solar cell including an upper first solar subcell having a first band gap; a middle second solar subcell adjacent to the first solar subcell and having a second band gap smaller than the first band gap and having a base layer and an adjacent emitter layer, wherein the other layer adjacent to the emitter layer has an index of refraction substantially equal to that of the emitter layer; a graded interlayer adjacent to the second solar having a third band gap greater than said second band gap; and a lower solar subcell adjacent to the interlayer, and having a fourth band gap smaller than the second band gap, the third subcell being lattice mismatched with respect to the second subcell.

Owner:EMCORE SOLAR POWER

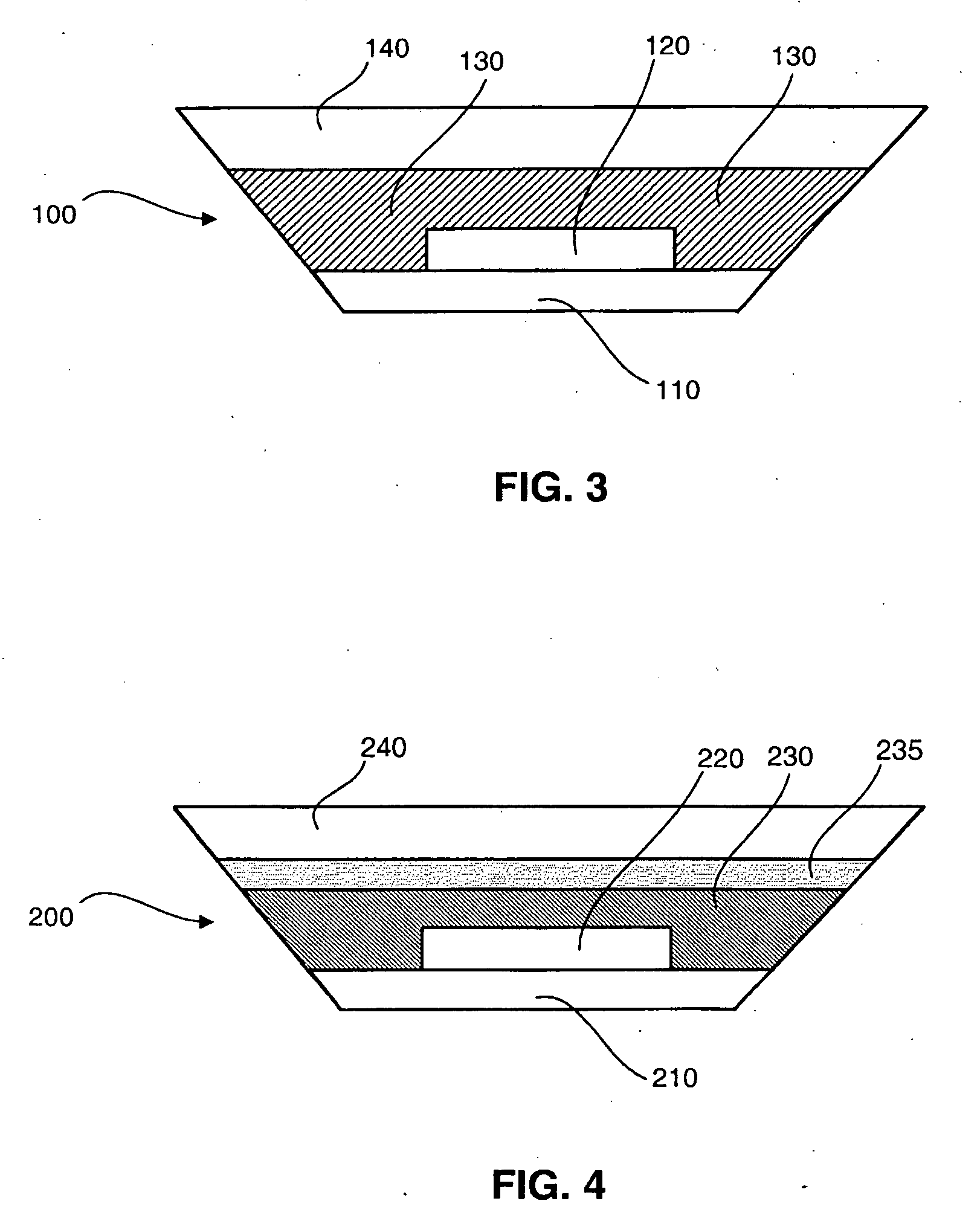

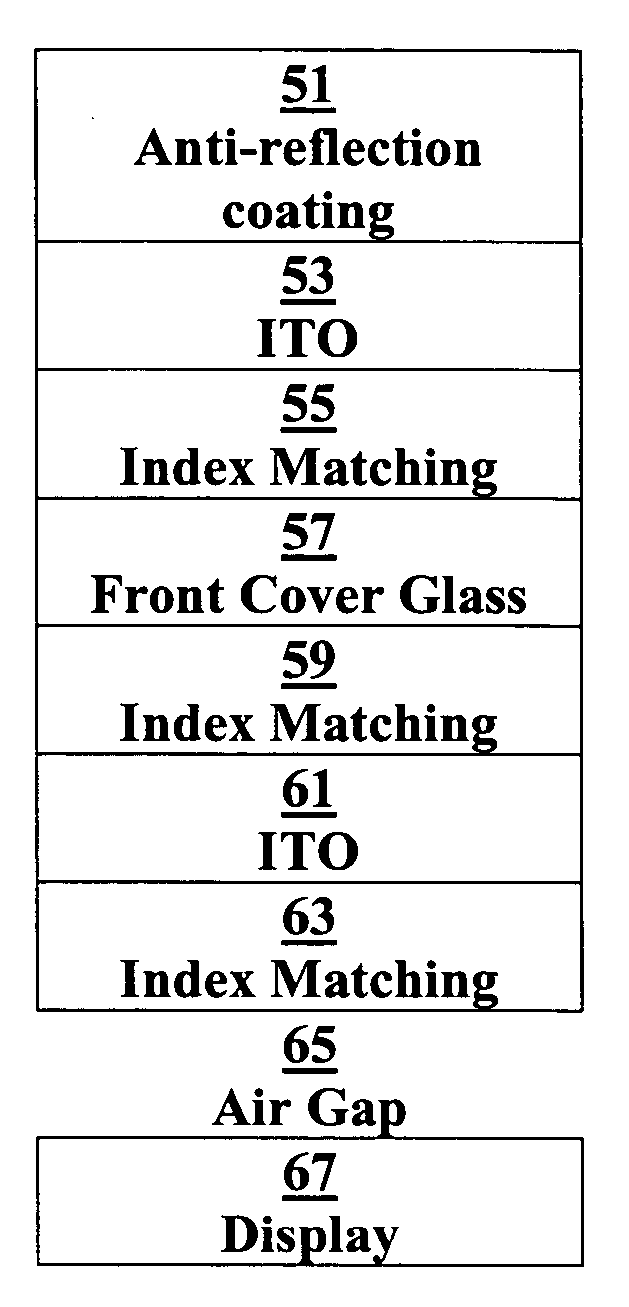

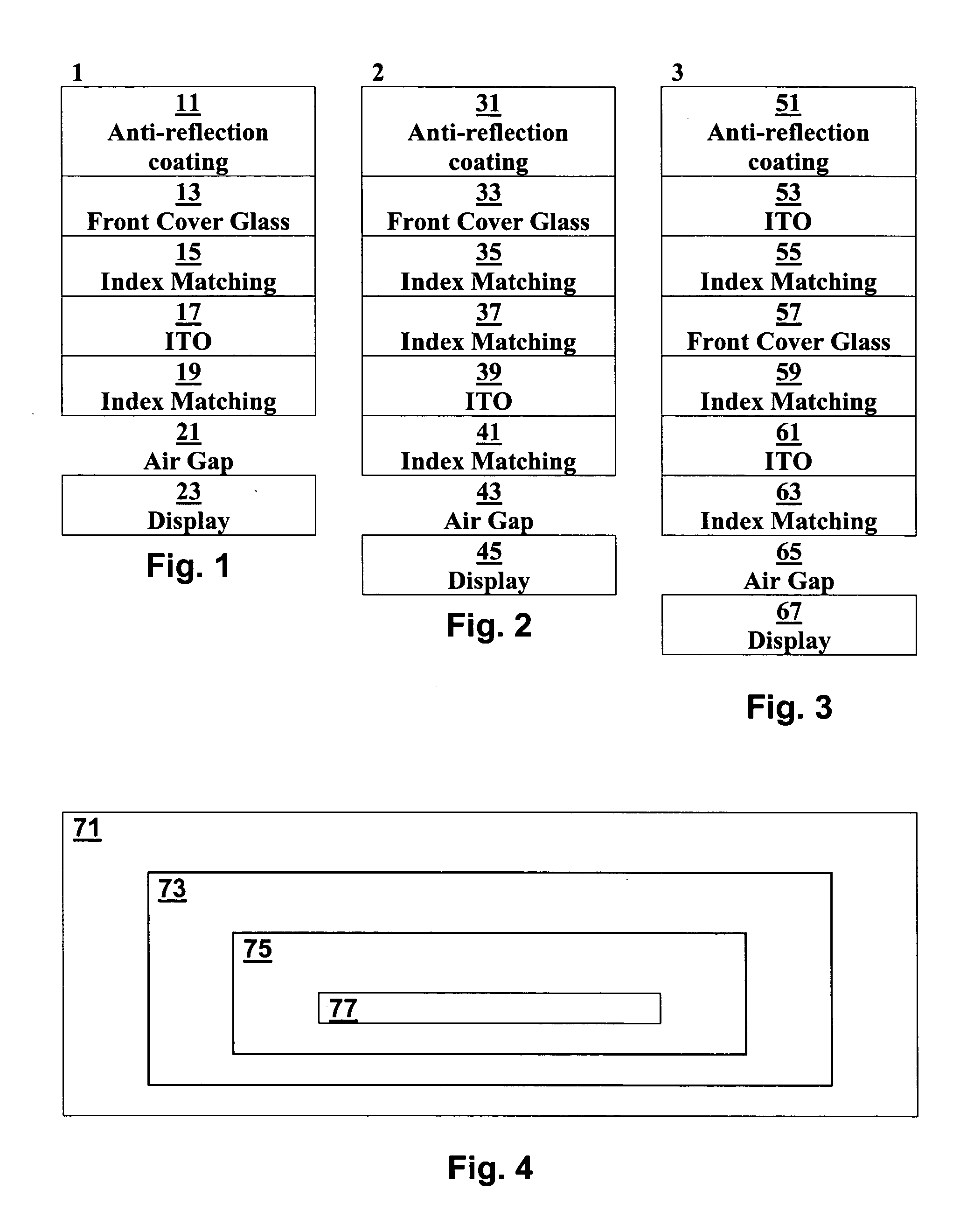

Optical compensation of cover glass-air gap-display stack for high ambient lighting

Apparatus and methods relating to display stacks wherein one or more index matching layers are utilized to minimize reflectance at the boundaries of otherwise adjacent layers. More particularly, the present invention is directed to methods and apparatus relating to a multilayer display stack comprising a glass layer, a first index matching layer, a first intermediate layer, a second index matching layer, a second intermediate layer, and a light emitting display panel wherein: the glass layer, first index matching layer, first intermediate layer, second index matching layer, and second intermediate layer are each transparent or translucent, and comprise an index of refraction; the index of refraction of the first index matching layer is between the index of refraction of the glass layer and the first intermediate layer; and the index of refraction of the second index matching layer is between the index of refraction of the first intermediate layer and the second intermediate layer. Alternative embodiments may comprise additional index matching layers, additional non-index matching layers, as well as layers other than those described herein.

Owner:NORTHROP GRUMMAN SYST CORP +1

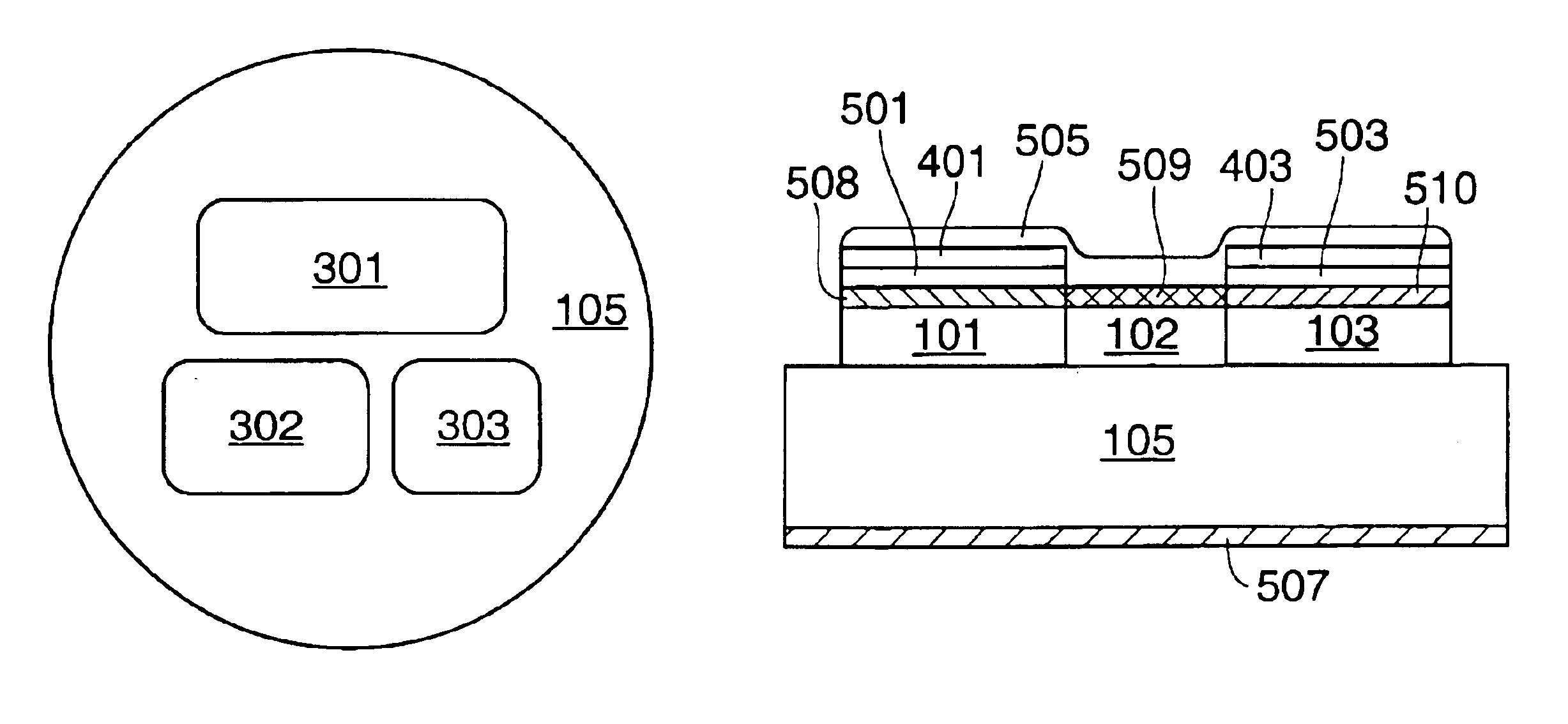

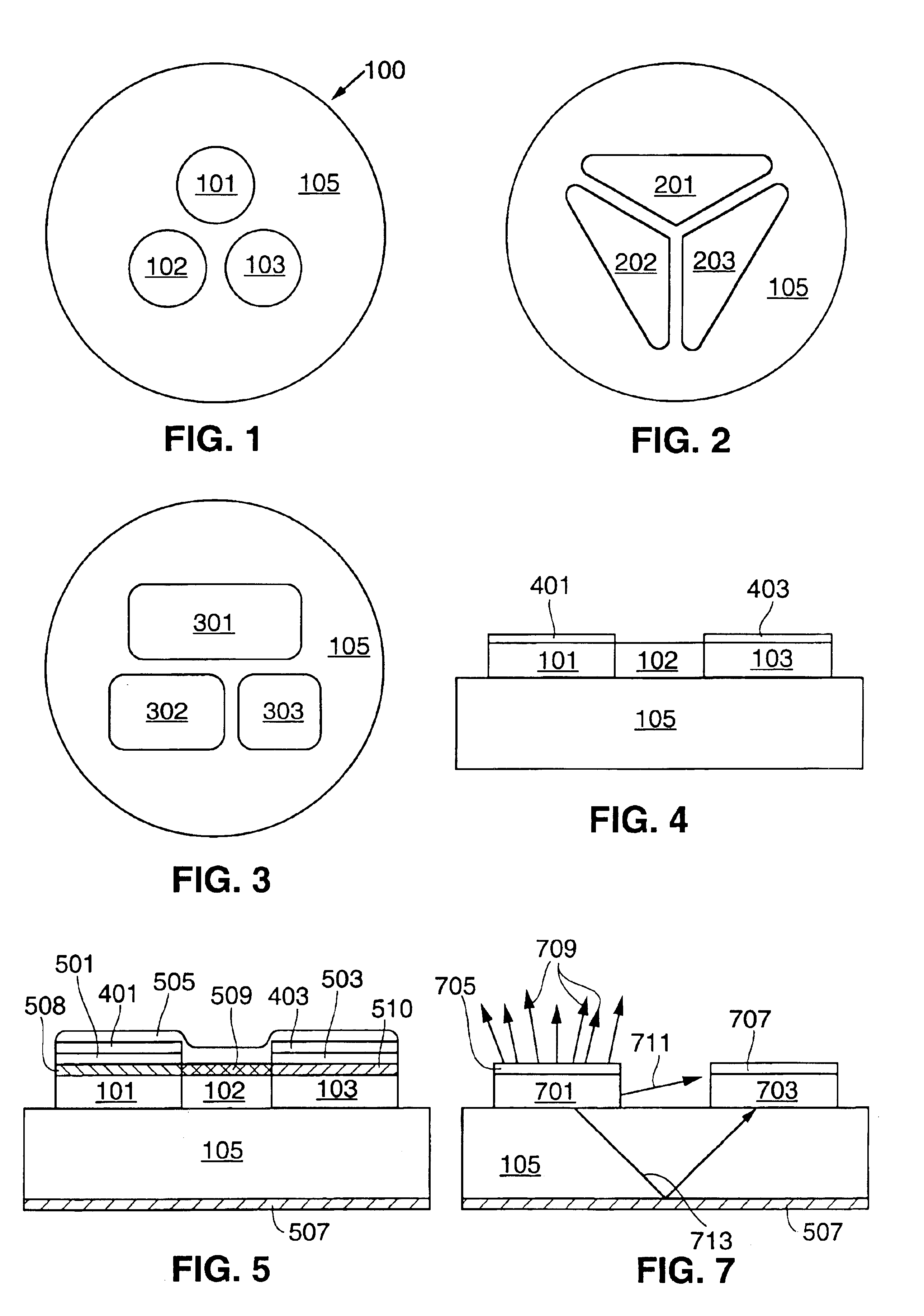

Integrated color LED chip

InactiveUS6882101B2Minimize cross-talkIncrease contrastIncadescent screens/filtersDischarge tube luminescnet screensEngineeringCrosstalk minimization

A method and apparatus for achieving multicolor displays using an integrated color chip is provided. The integrated color chip contains one or more multicolor generation sites on a single substrate. Each multicolor generation site is comprised of two or more light emitting regions in close proximity to one another, the number of light emitting regions per site dependent upon the number of required colors. The active light generation system for each light emitting region, e.g., an LED, is preferably identical in device structure although size and shape may vary. In order to achieve the desired colors, one or more light conversion layers are applied to individual light emitting regions. Each light emitting region may also include index matching layers, preferably interposed between the outermost surface of the light emitter and the light conversion layer, and protective layers. In order to minimize cross-talk and achieve improved contrast, opaque material is preferably deposited between adjacent light emitting regions. Cross-talk may also be minimized by locating the light emitting regions on a substantially non-reflective substrate.

Owner:KYMA TECH

Super bright low reflectance liquid crystal display

InactiveUS6933991B2Reduce the amount requiredImprove viewing characteristicsStatic indicating devicesPolarising elementsOptical bondingPolarizer

A liquid crystal display (LCD) exhibiting enhanced optical viewing performance. In a preferred embodiment, the LCD comprises a liquid crystal display panel, the liquid crystal display panel comprising a pair of transparent substrates, liquid crystal material sandwiched between the transparent substrates and transparent electrodes positioned between the liquid crystal material and the transparent substrates. The LCD also comprises a rear polarizer assembly comprising a compensation film, a polarizer mounted on the rear surface of the compensation film, and a first index-matched, pressure sensitive adhesive (PSA) mounted on the front surface of the compensation film, the PSA being adhered to the rear surface of the LCD panel. The LCD also comprises a front polarizer assembly, the front polarizer assembly comprising a front polarizer, a compensation film mounted on the rear surface of the front polarizer and an index-matched PSA mounted on the front surface of the front polarizer. The front polarizer is crossed relative to the rear polarizer. The front polarizer assembly may be adhered to the front of the LCD panel with a second index-matched, optical bonding material or may be spaced therefrom by an air gap. A transparent cover is mounted on the second index-matched PSA. The transparent cover is preferably a plastic plate. The plastic plate may be textured to reduce glare or may have an anti-reflection coating or an anti-reflection film applied to the front surface thereof. Instead of a plastic plate, the transparent cover may be a glass plate or a touch panel.

Owner:VIA OPTRONICS

Super bright low reflectance liquid crystal display

InactiveUS20060001800A1Reduce the amount requiredImprove viewing characteristicsStatic indicating devicesPolarising elementsOptical bondingAnti-reflective coating

A liquid crystal display (LCD) exhibiting enhanced optical viewing performance. In a preferred embodiment, the LCD comprises a liquid crystal display panel, the liquid crystal display panel comprising a pair of transparent substrates, liquid crystal material sandwiched between the transparent substrates and transparent electrodes positioned between the liquid crystal material and the transparent substrates. The LCD also comprises a rear polarizer assembly comprising a compensation film, a polarizer mounted on the rear surface of the compensation film, and a first index-matched, pressure sensitive adhesive (PSA) mounted on the front surface of the compensation film, the PSA being adhered to the rear surface of the LCD panel. The LCD also comprises a front polarizer assembly, the front polarizer assembly comprising a front polarizer, a compensation film mounted on the rear surface of the front polarizer and an index-matched PSA mounted on the front surface of the front polarizer. The front polarizer is crossed relative to the rear polarizer. The front polarizer assembly may be adhered to the front of the LCD panel with a second index-matched, optical bonding material or may be spaced therefrom by an air gap. A transparent cover is mounted on the second index-matched PSA. The transparent cover is preferably a plastic plate. The plastic plate may be textured to reduce glare or may have an anti-reflection coating or an anti-reflection film applied to the front surface thereof. Instead of a plastic plate, the transparent cover may be a glass plate or a touch panel.

Owner:VIA OPTRONICS GMBH

Switchable diffractive accommodating lens

InactiveUS20130035760A1Improve image contrastReduces halo and glareSpectales/gogglesIntraocular lensPressure differenceRefractive index matching

A lens in accordance with the present invention includes an accommodating cell having two chambers with at least one chamber filled with optical fluid with the refractive index matching the refractive index of the accommodating element separating them. The accommodating element has a diffractive surface with surface relief structure that maintains its period but changes its height due a pressure difference between the chambers to redirect most of light that passes through the lens between different foci of far and near vision. The invention also includes a sensor cell that directly interacts with the ciliary muscle contraction and relaxation to create changes in pressure between the accommodating cell chambers that results in changing surface relief structure height and the lens accommodation.

Owner:PORTNEY VALDEMAR

Light modulators

ActiveUS20050213191A1Reduce light transmittanceDoor/window protective devicesNon-linear opticsElectrophoresisDisplay device

Various improvements in electrophoretic media and displays intended for use in light modulators are described. These improvements include index matching of the suspending fluid to a continuous phase surrounding the fluid, index matching of a capsule wall to a binder, planarization of a layer containing electrophoretic capsules before application of adhesive thereto, methods for concentrating electrophoretic particles into limited areas of sidewalls of electrophoretic capsules or microcells in the light-transmissive state of the display, and, in the case of light modulators comprising an electrophoretic layer sandwiched between two transparent plates, forming at least one of the plates so as to absorb electromagnetic radiation which adversely affects the electrophoretic layer.

Owner:E INK CORPORATION

Intraocular Lenses and Business Methods

An intraocular accommodating lens comprising a resilient polymer monolith with a peripheral component that has a Young's modulus and an equilibrium memory shape that imparts to the capsular sac's periphery the natural shape of the capsule in an accommodated state. The intraocular lens includes a central deformable optic that provides accommodated and disaccommodated shapes. The peripheral component is deformable to a disequilibrium, stressed shape in responsive to equatorial tensioning—and is capable of applying restorative forces to move the lens toward the accommodated shape from a disequilibrium disaccommodated shape. In one embodiment, the central optic portion includes a displaceable media than can be displaced by very low forces of zonular excursion, wherein the displaceable media can comprise a very low modulus polymer or an index-matched fluid.

Owner:POWERVISION

Multi-user touch screen

A multi-user touch-responsive viewing screen is described which uses frustrated total internal reflection in a slab of transparent material to illuminate the contact point between the slab and a finger or other object substantially matching the slab's index of refraction. Light, coupled upon touch, can be detected with a video camera, and used to determine both the position and pressure of the touch. Multiple touches can be accommodated and each touch accurately located. Projected images can be applied to the slab and a diffuser to construct an interactive touch screen.

Owner:DISNEY ENTERPRISES INC

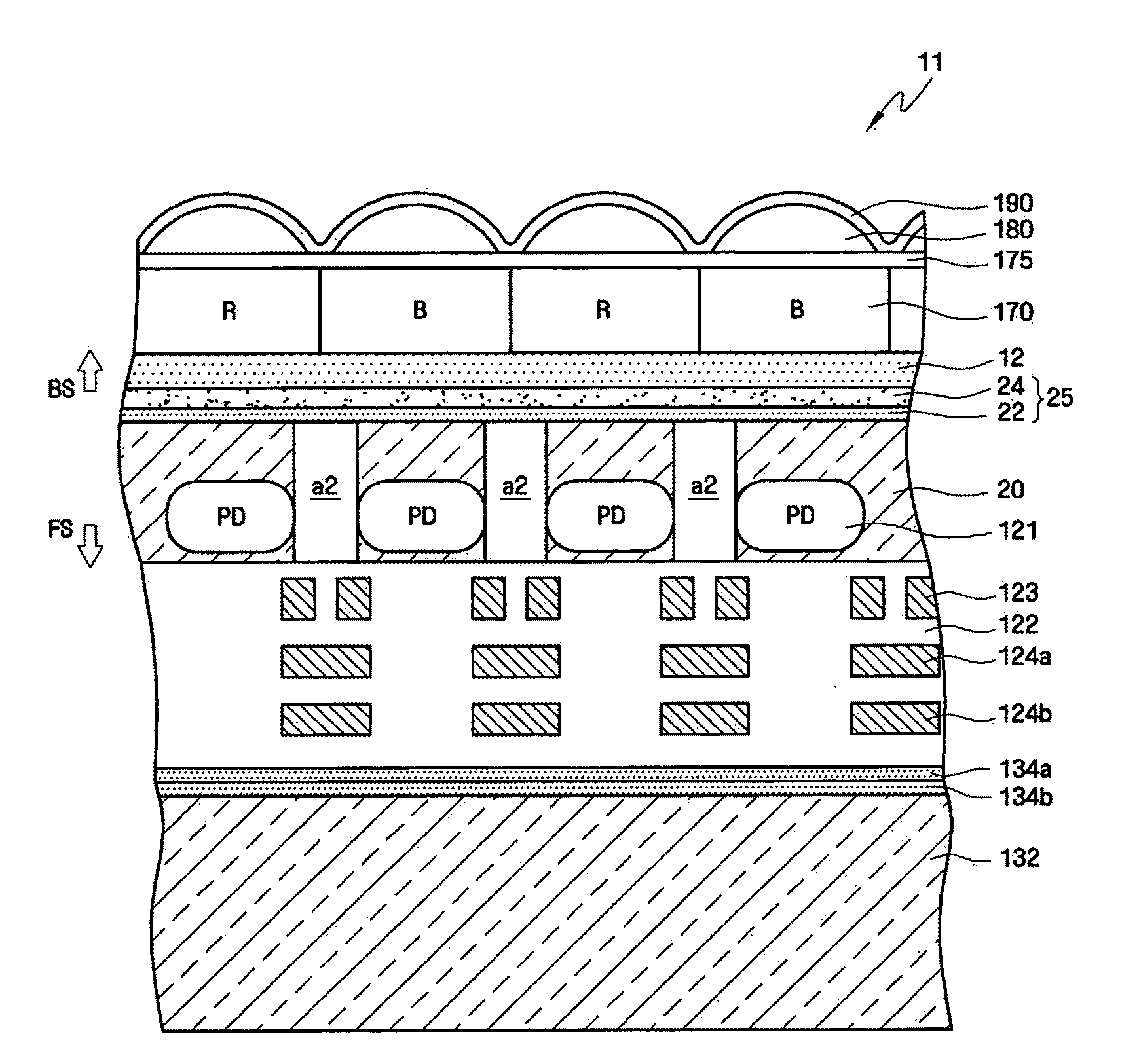

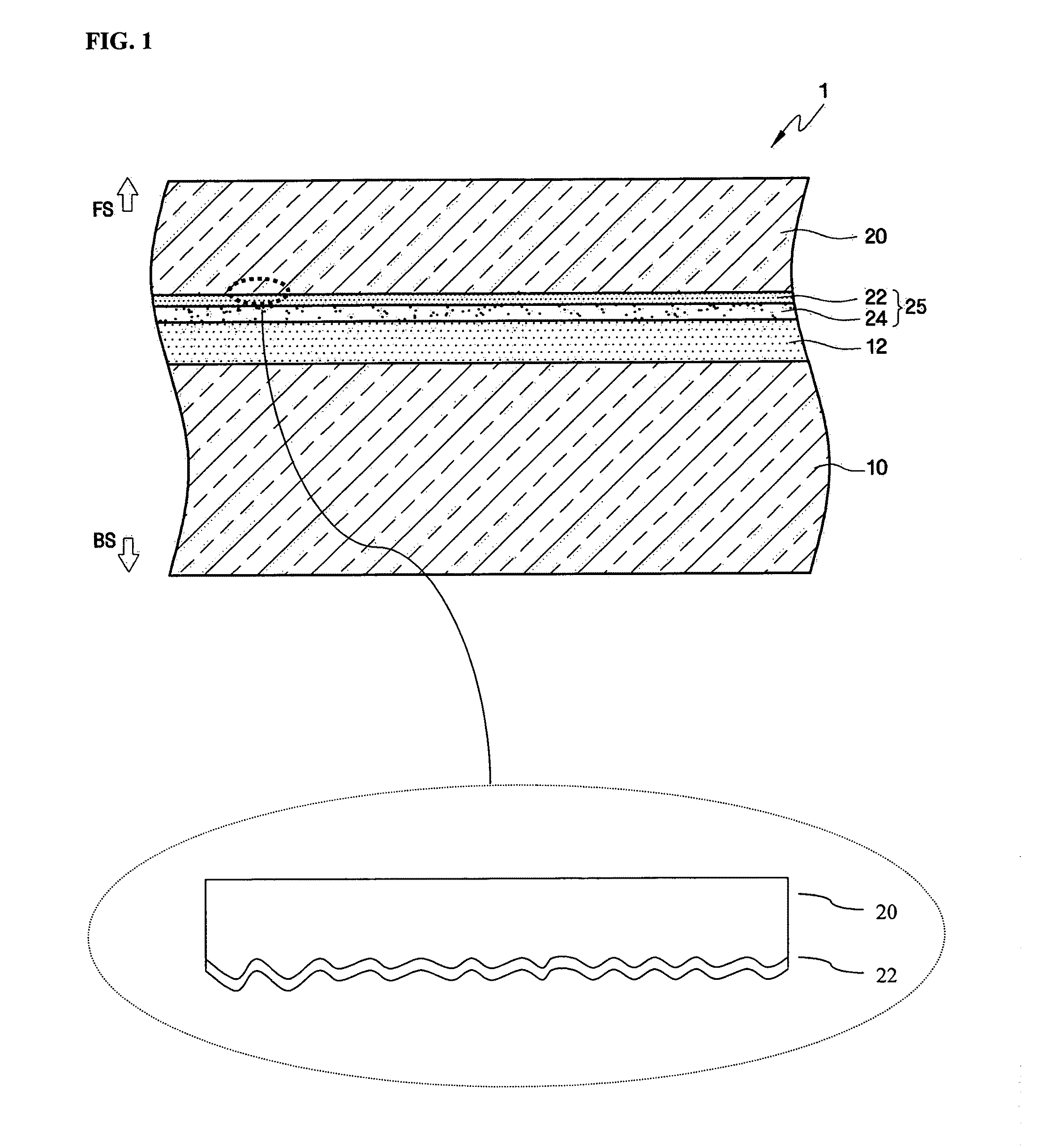

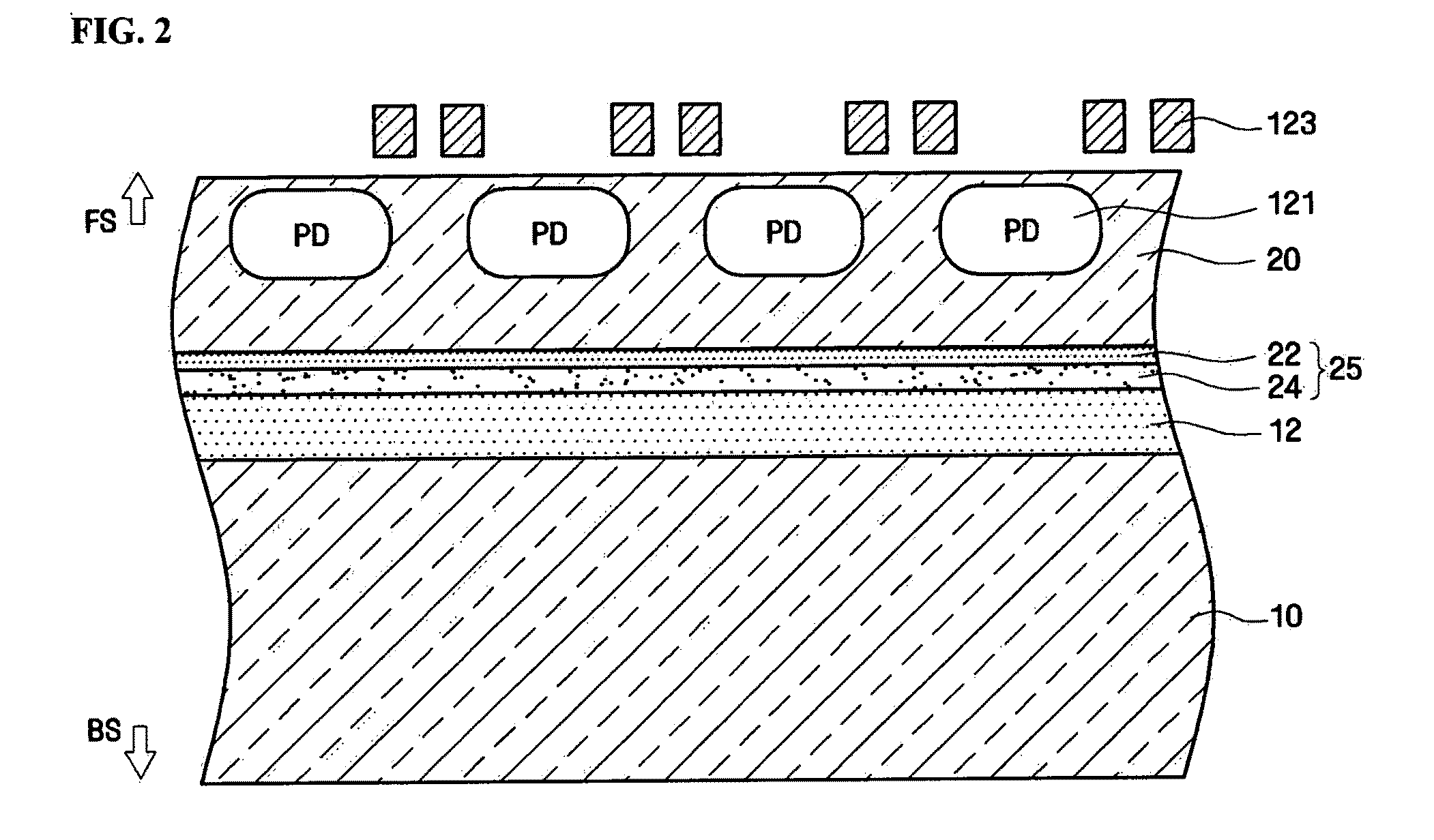

Image sensor, substrate for the same, image sensing device including the image sensor, and associated methods

InactiveUS20100006969A1Total current dropHigh light sensitivitySemiconductor/solid-state device detailsSolid-state devicesCMOSLight sensing

A method of fabricating a CMOS image sensor includes forming a substrate structure that includes a first substrate, a second substrate, and an index matching layer containing nitrogen and an oxide layer between the first and second substrates, and, forming at least one light-sensing device in the second substrate, and after forming the substrate structure, forming a metal interconnection structure on a first surface of the second substrate, the first surface facing away from the first substrate, such that the at least one light sensing device is between the metal interconnection structure and the index matching layer and the oxide layer, the metal interconnection structure being electrically connected to the at least one light-sensing device.

Owner:SAMSUNG ELECTRONICS CO LTD

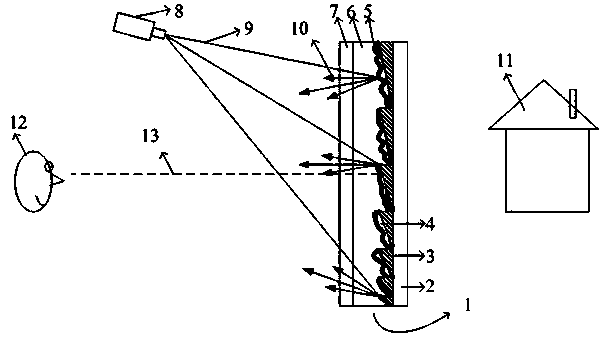

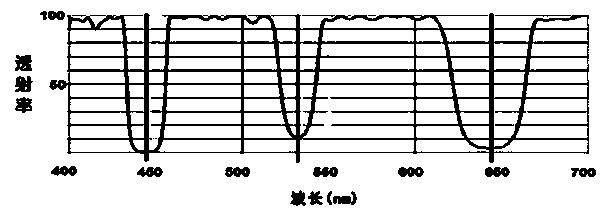

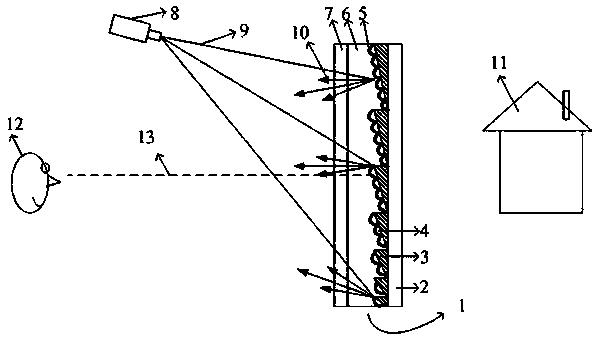

Transparent projection screen

ActiveCN104298063AIncrease profitEasy to mass manufactureProjectorsCoatingsProjection screenProjection image

The invention discloses a transparent projection screen. The transparent projection screen comprises base material layers, wherein focusing structures and diffusing structures are distributed on the lower surface of the first base material layer and combined with the first base material layer, light rays from a projection system are focused on the position where an observer is located through the focusing structures and are diffused into an observation area on the position where the observer is located by the diffusing structures, the focusing structures and the diffusing structures are plated with a partial reflection film structure, a reflective index matching layer is combined with the surface of the partial reflection film structure and covers the surface of the partial reflection film structure, the reflective index of the reflective index matching layer is identical with the reflective index of materials of the focusing structures and the diffusing structures, and the second base material layer is combined with the surface of the reflective index matching layer and covers the surface of the reflective index matching layer. By the adoption of the projection screen, the observer can see a high-brightness projection image and an object behind the screen clearly at the same time, the transparent effect is good, and the energy utilization rate is high.

Owner:SUZHOU UNIV

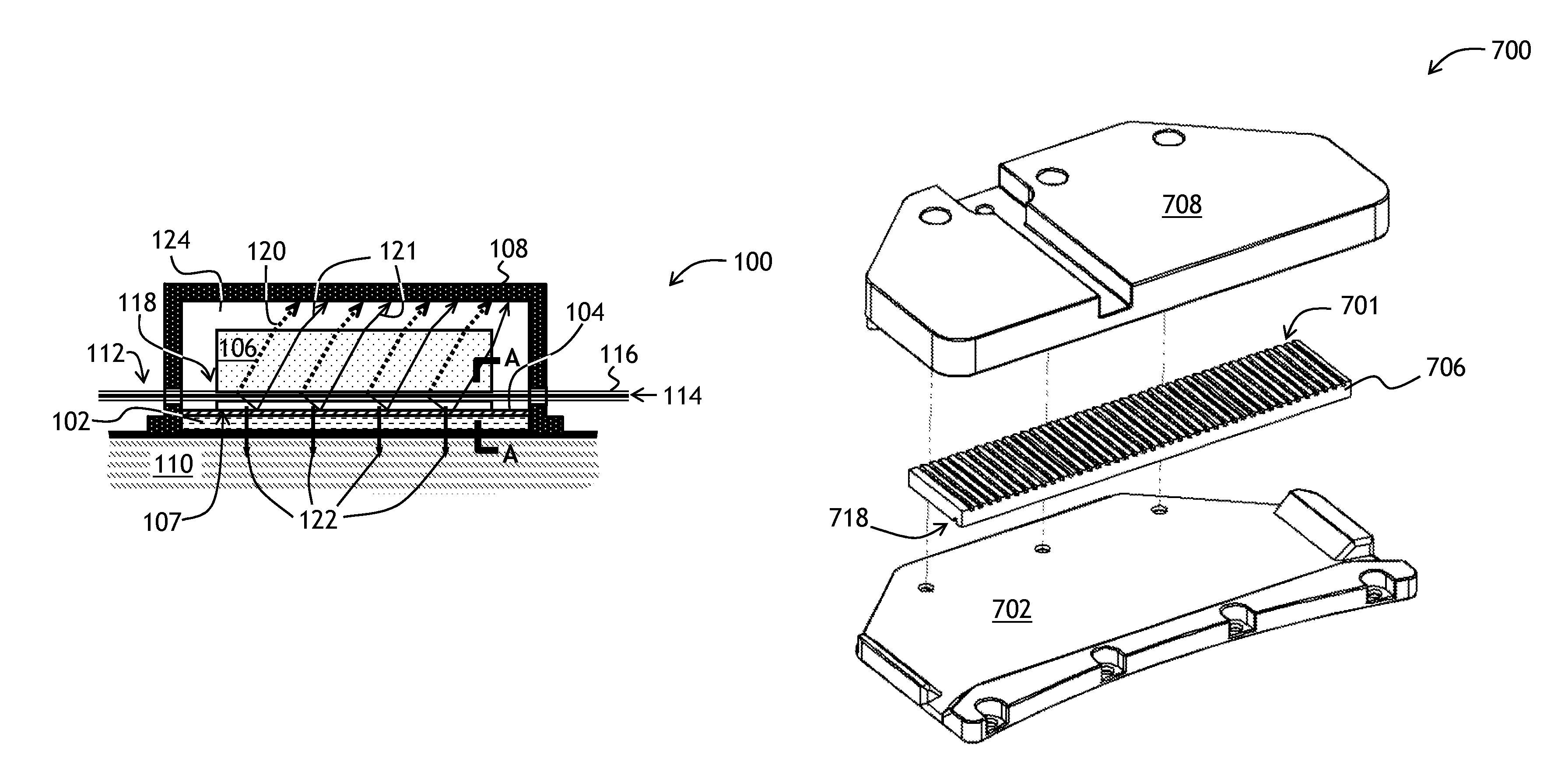

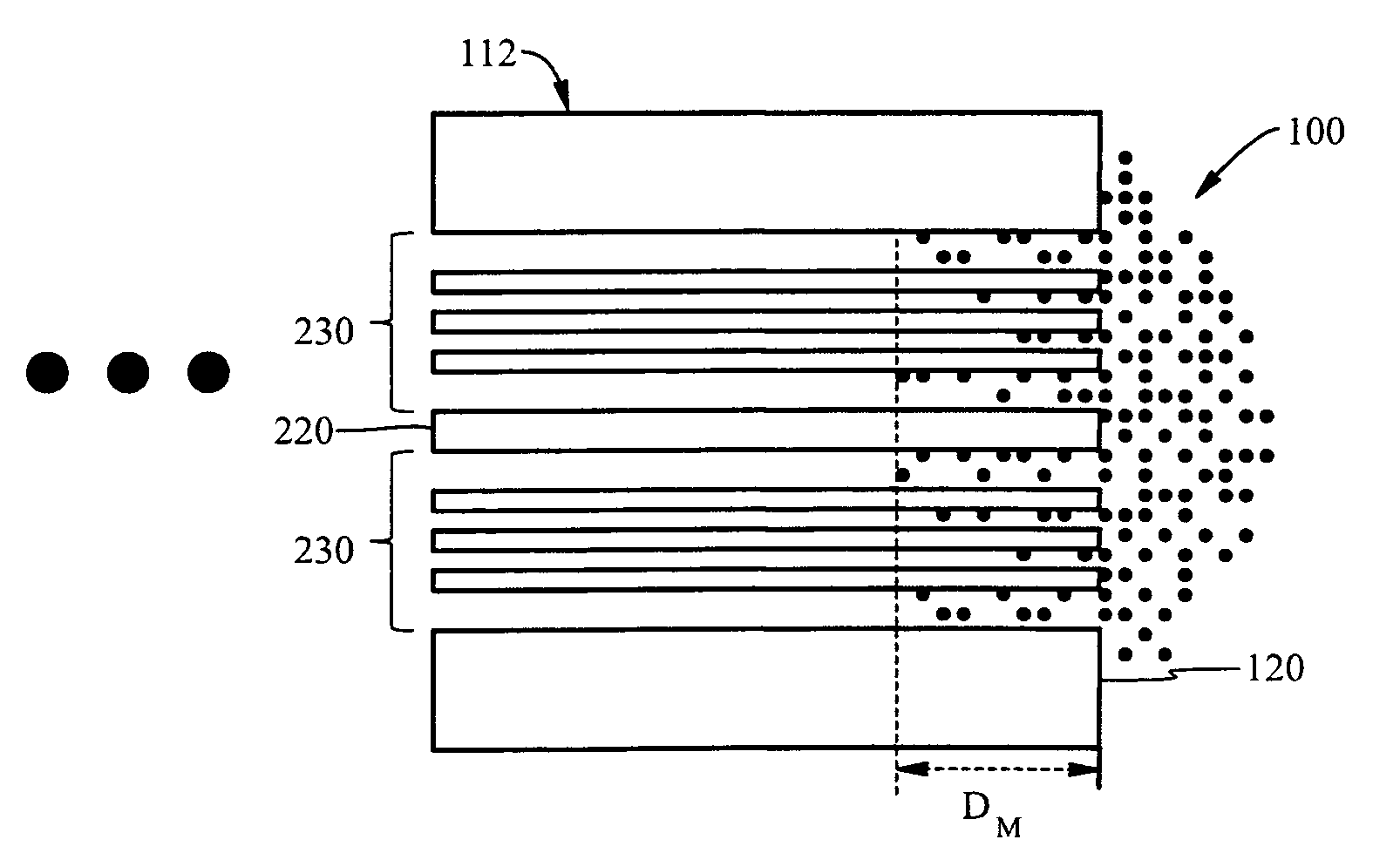

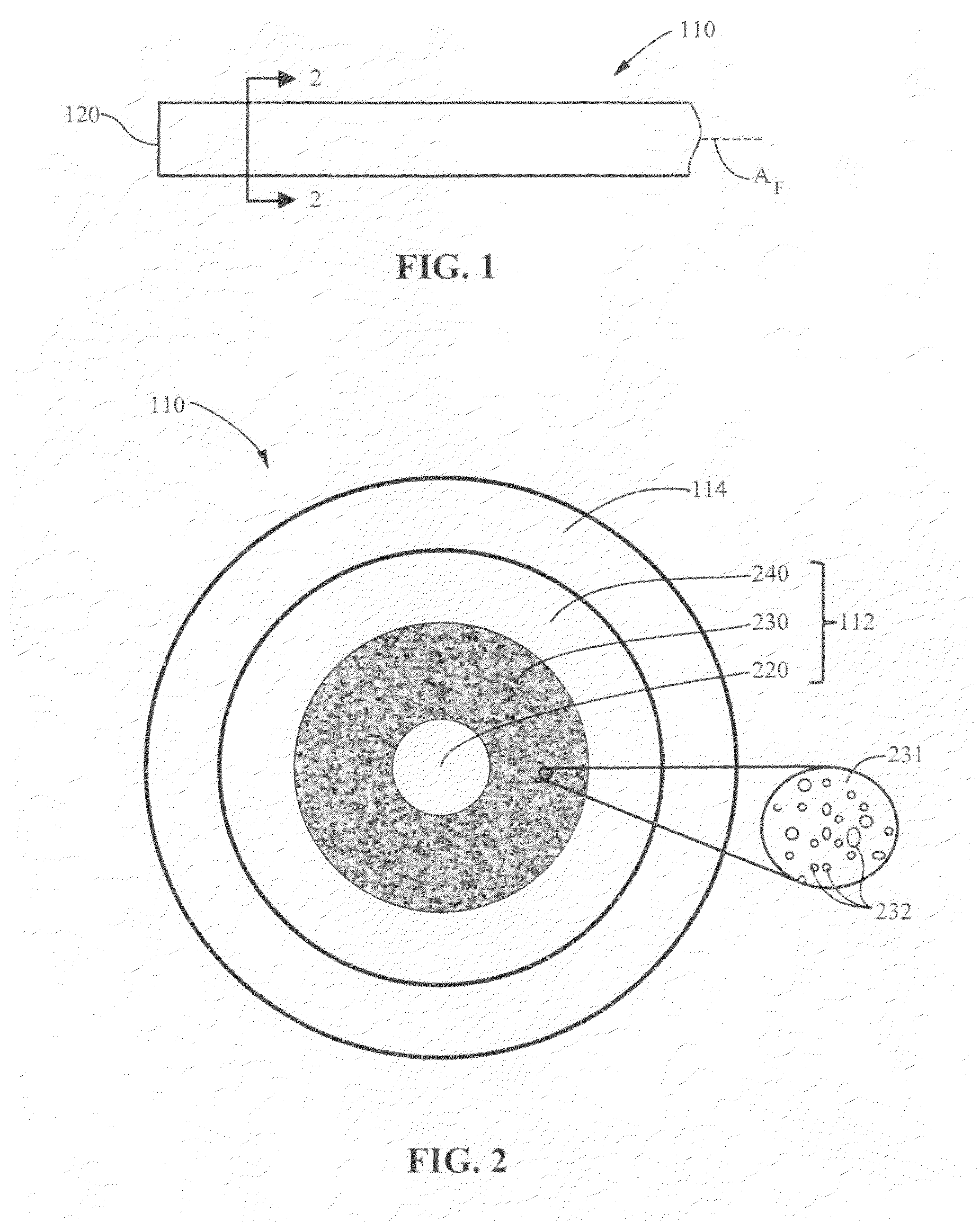

Scalable cladding mode stripper device

A cladding mode stripper for stripping cladding modes from an optical fiber is disclosed. The cladding mode stripper includes a reflective base and a block of a transparent material disposed on the reflective base. The block of the transparent material has a groove in its bottom surface for the fiber. The fiber is thermally coupled to the base and optically coupled to the groove in the block, for example using an index matching gel. The cladding mode light is reflected from the reflective base and is absorbed in a cover enclosing the block. An additional thin block of transparent heat-conductive material can be placed between the fiber and the reflective base, to prevent the index matching gel from contacting the reflective surface of the base.

Owner:LUMENTUM OPERATIONS LLC

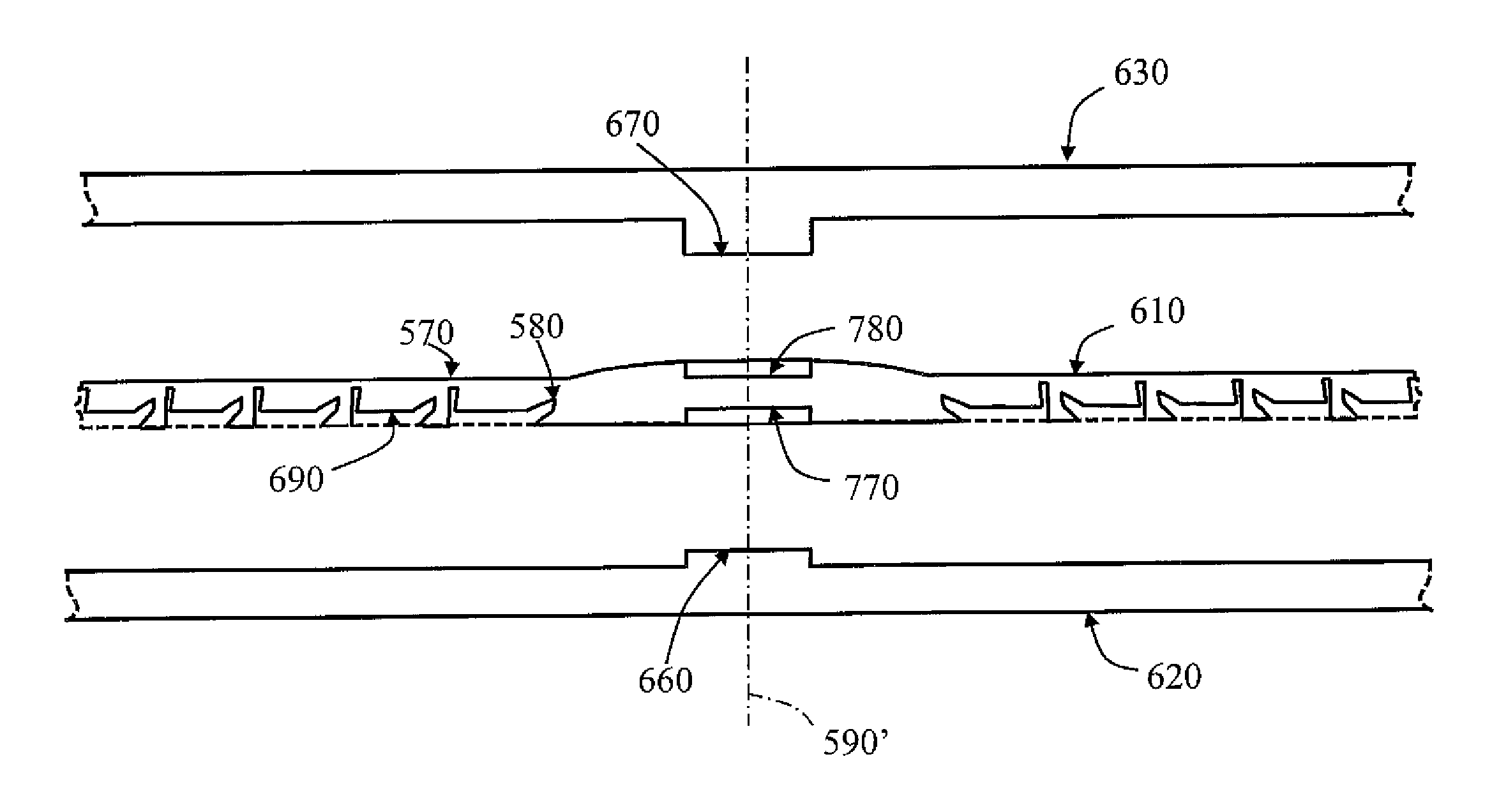

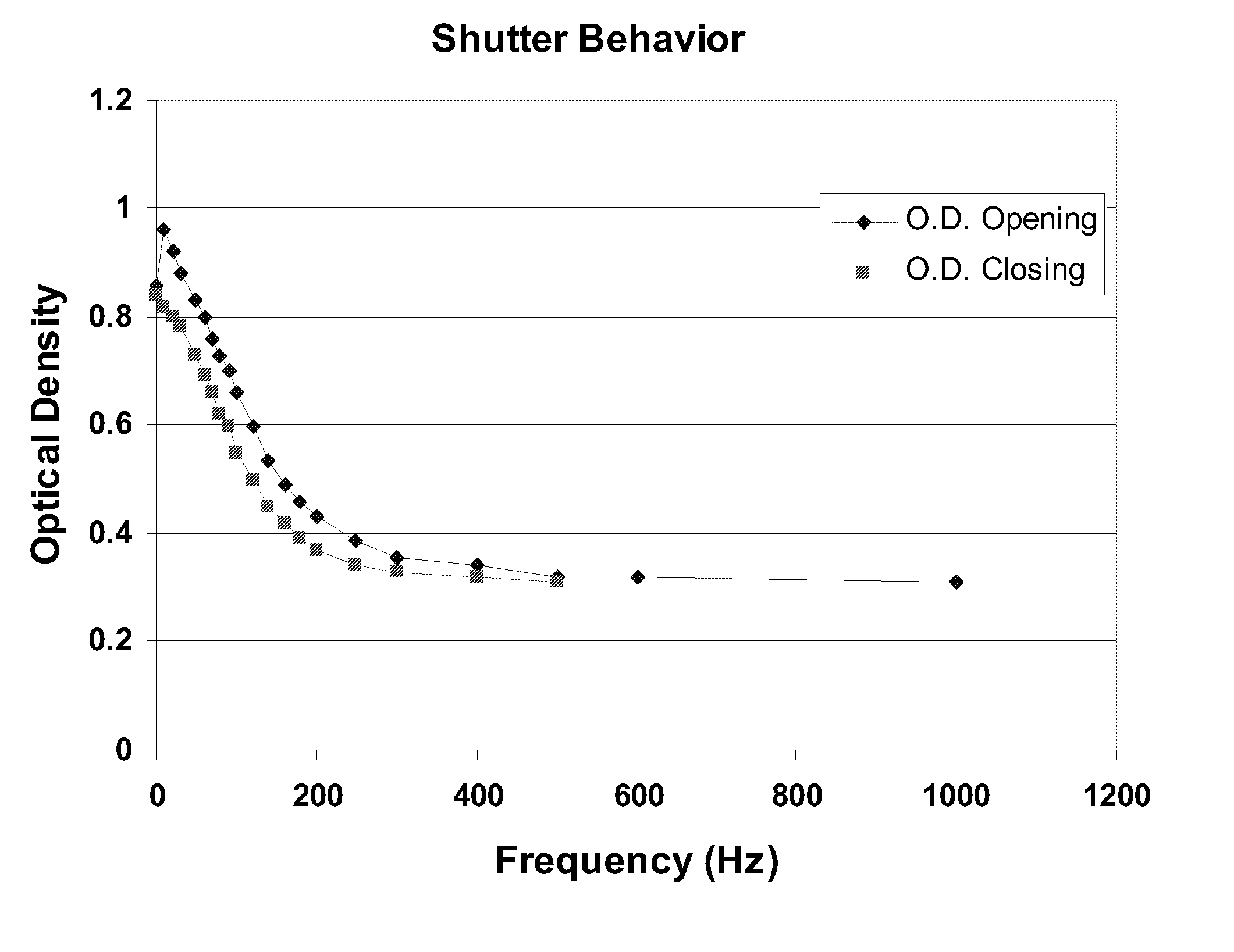

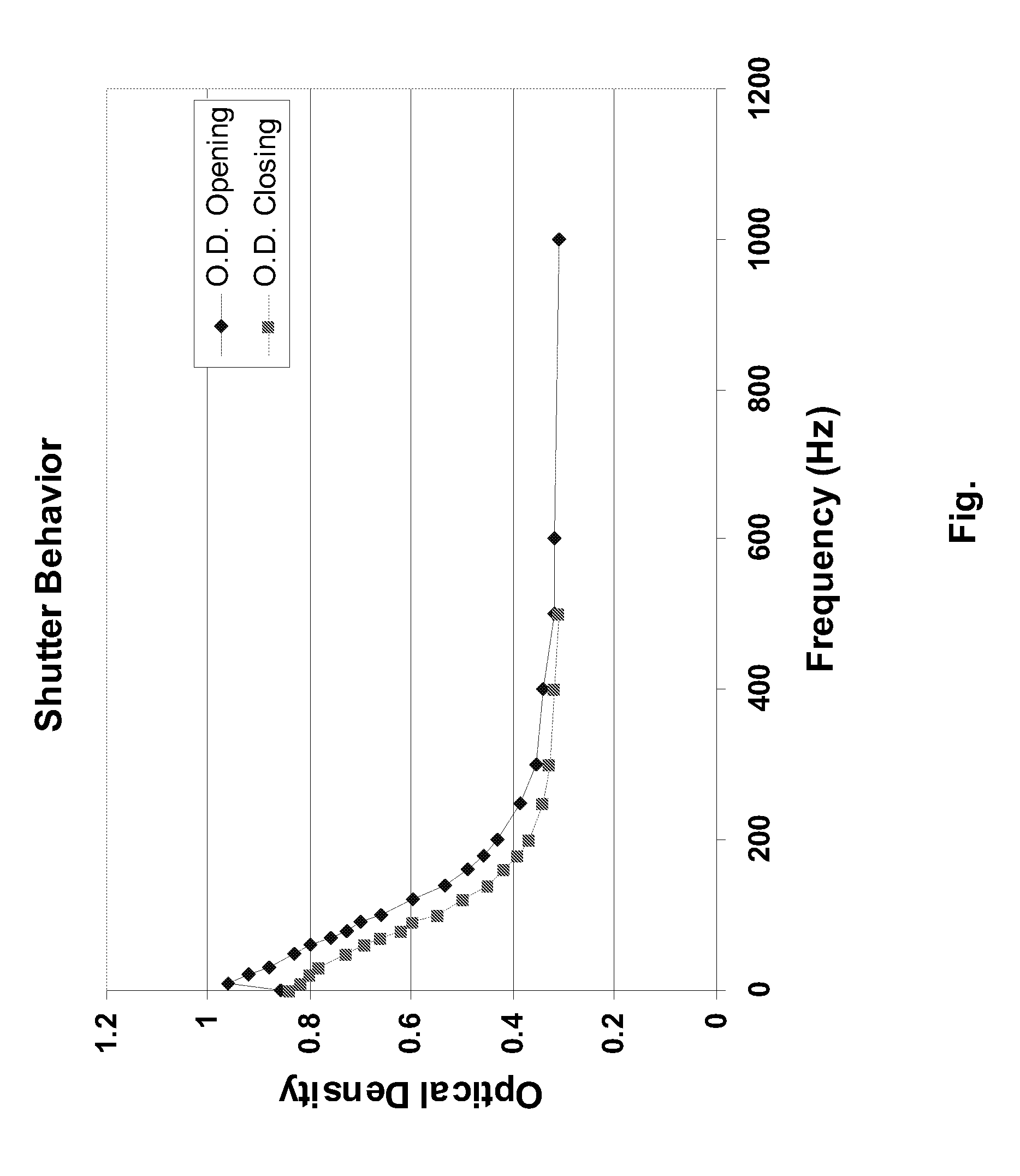

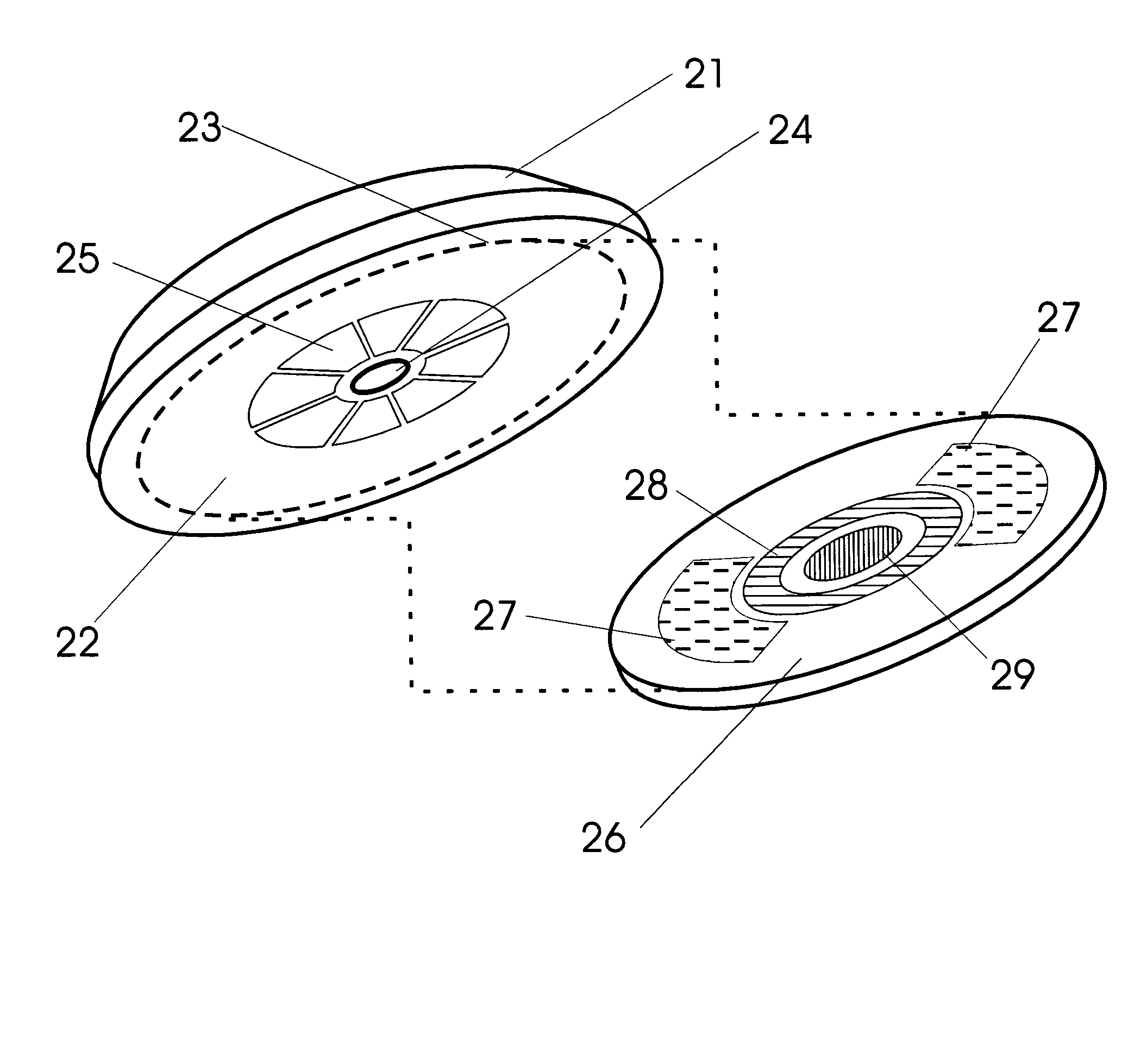

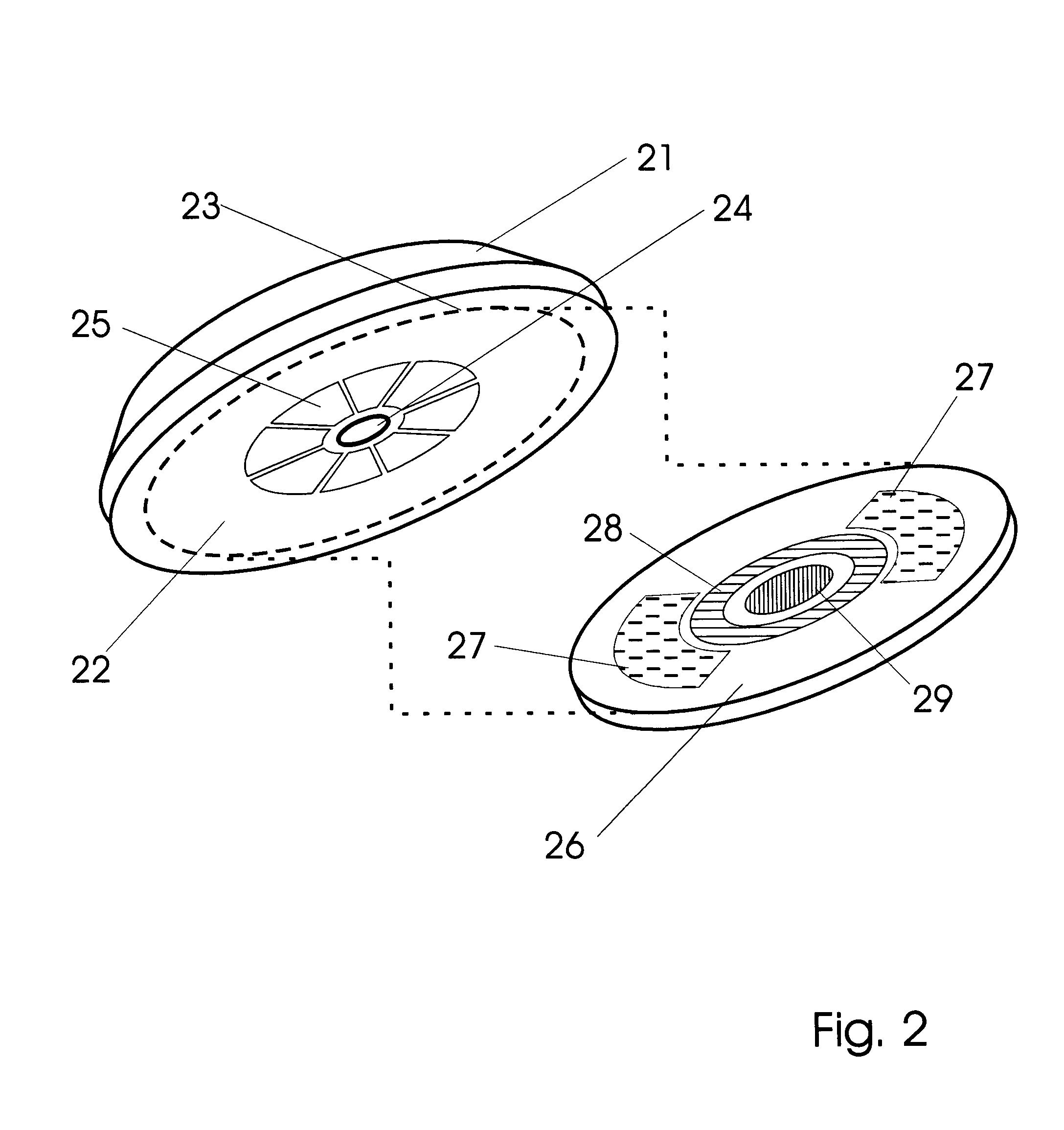

Electro-active insert

Aspects of the present invention provide multi-focal electro-active lenses having one or more multi-focal electro-active inserts. The electro-active inserts can provide multiple optical power regions each capable of providing a desired optical power. An electro-active power region of the insert is capable of providing a variable optical power upon application of an electrical signal such as a time-varying voltage waveform. Electro-active inserts can be fabricated from any type of material and can be inserted into any type of bulk lens material. The electro-active inserts can be thin and flexible and can function independently of other optical components of the overall electro-active lens. Consequently, the electro-active inserts can be fabricated according to a uniform design using uniform materials, independent of the supplementing portions of the final lens. Index matching layers of the present invention can be used to reduce reflection losses between bulk lens material and electro-active insert interfaces.

Owner:PIXELOPTICS

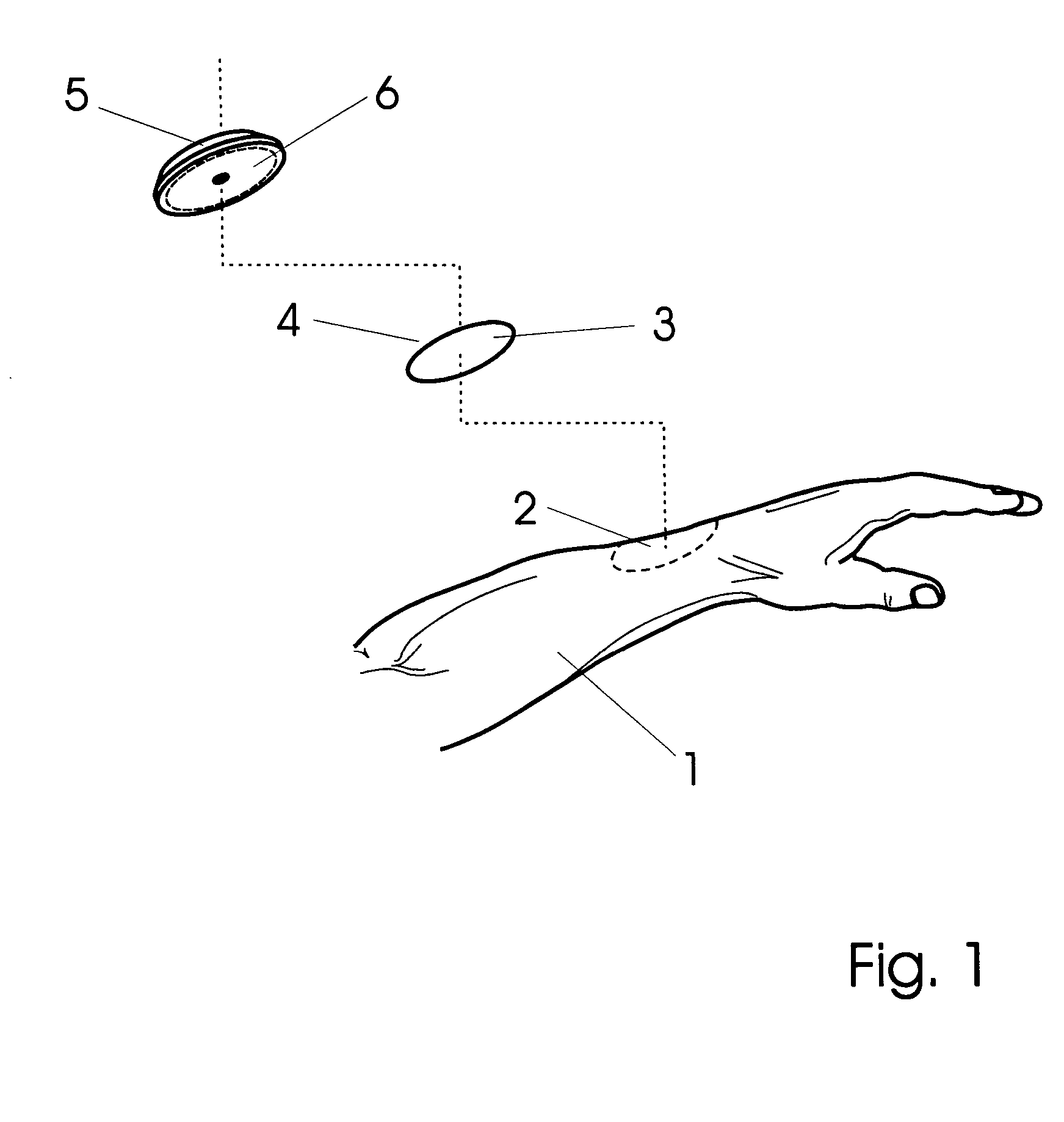

Disposable couplings for biometric instruments

InactiveUS20050090725A1Improve energy transferGood of laser lightUltrasonic/sonic/infrasonic diagnosticsDiagnostics using lightAcoustic energyOpto electronic

Photoacoustic measurement system are configured with a special view towards efficient coupling of optical and acoustic energy between respective transducers and a tissue test site. In particular, a disposable substrate provides support for advanced optical paths including, for example, windows, lenses, and index matching gels or fluids. In addition, substrates may also accommodate arrays of coupling sites corresponding to a plurality of acoustic detectors spatially separated. These substrates may additionally include means to affix and secure the device to a measurement head having optoelectronic and electromechanical transducers therein. Further, these substrates include mechanisms which help to affix the substrates to test sites in stabile and secure fashion.

Owner:PAGE JOSEPH +1

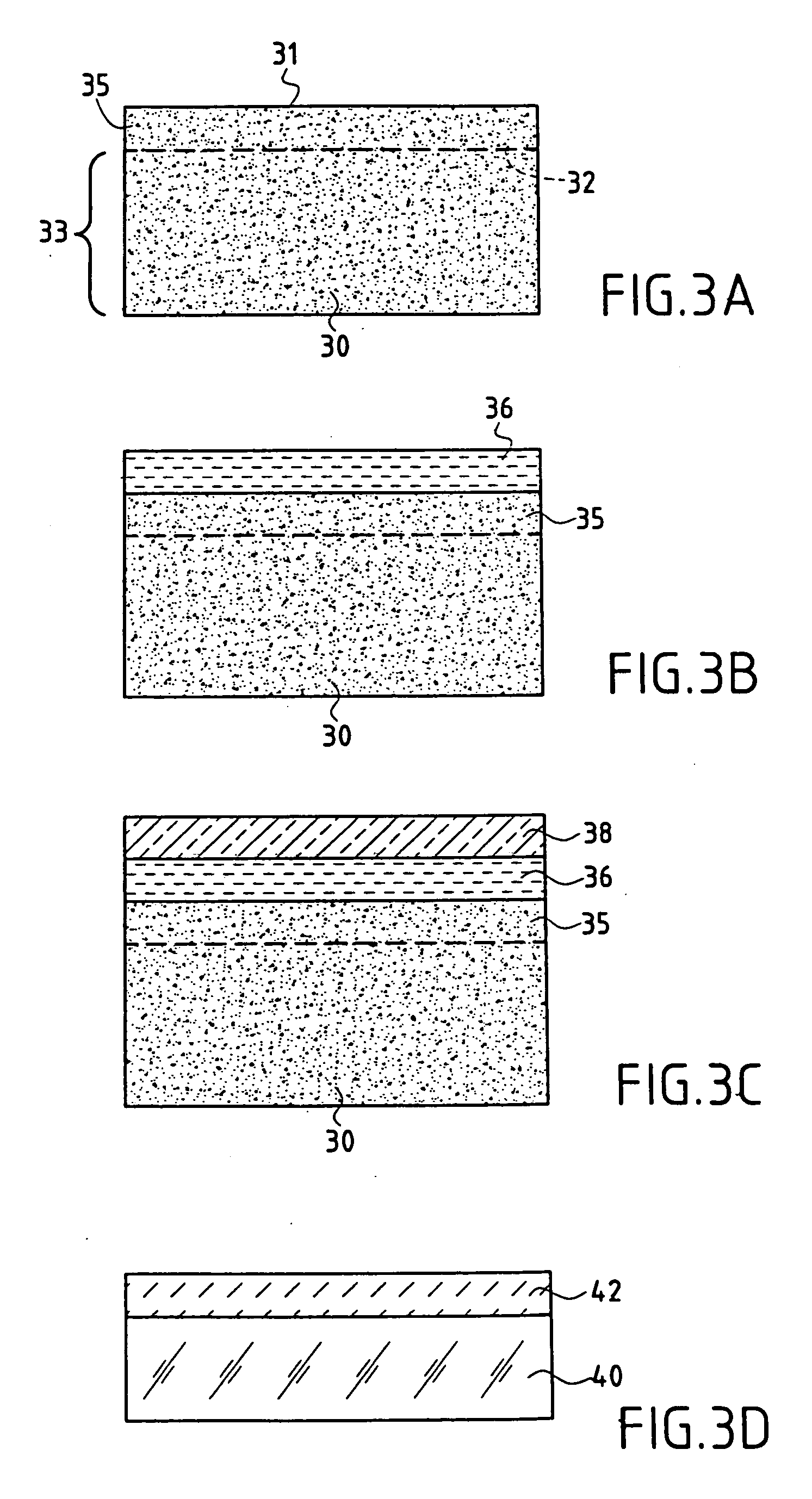

Substrate with refractive index matching

InactiveUS20060197096A1Solid-state devicesSemiconductor/solid-state device manufacturingThin layerComposite substrate

This invention provides a composite substrate that has a transparent mechanical support, for example of glass or quartz, a film or thin layer of monocrystalline semi-conductive material and an intermediate antireflective layer located between the thin layer or the semi-conductive film and the support. The composition of the intermediate antireflective layer varies between the support and the semi-conductive film, so that the refractive index similarly varies.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

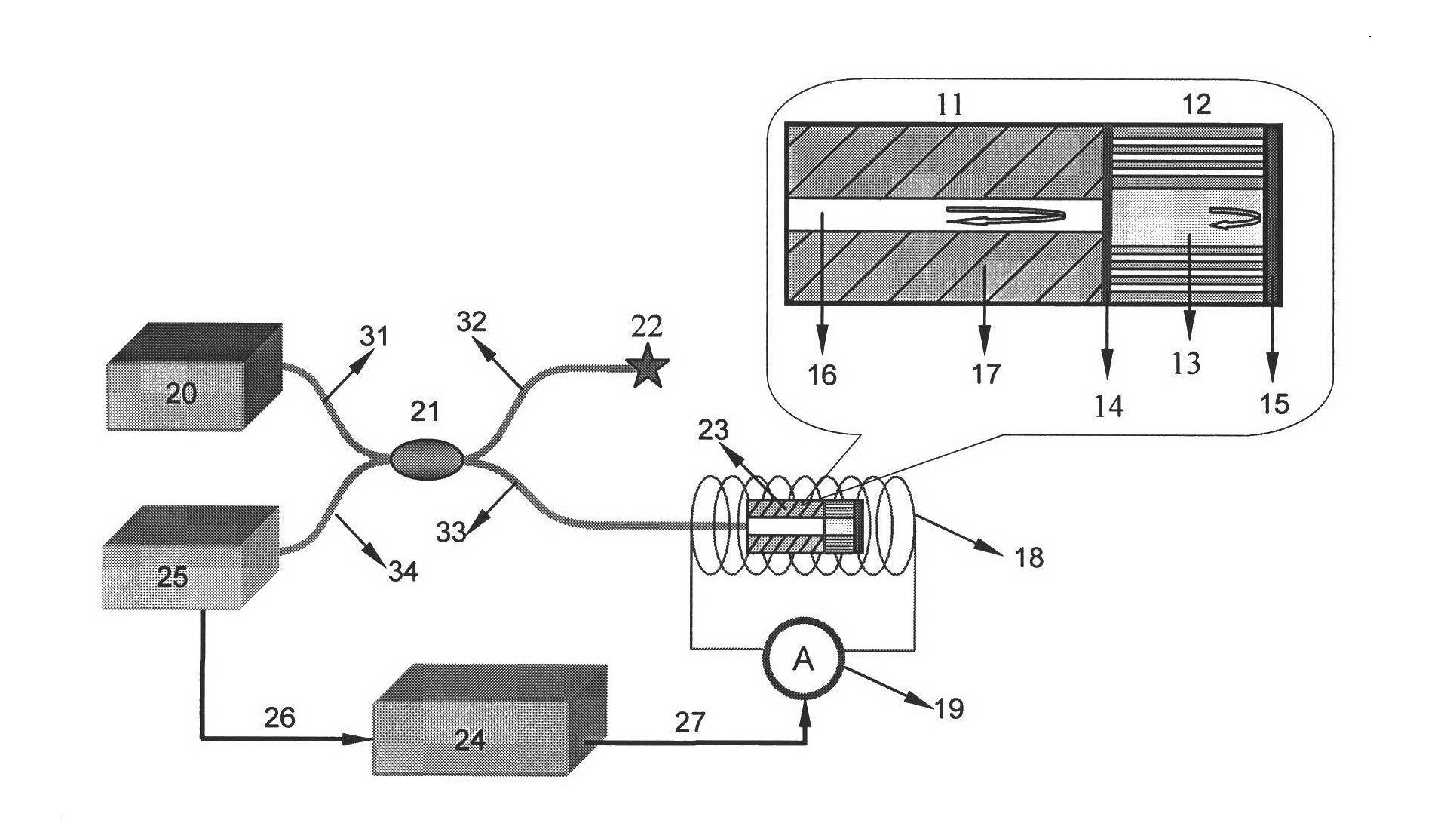

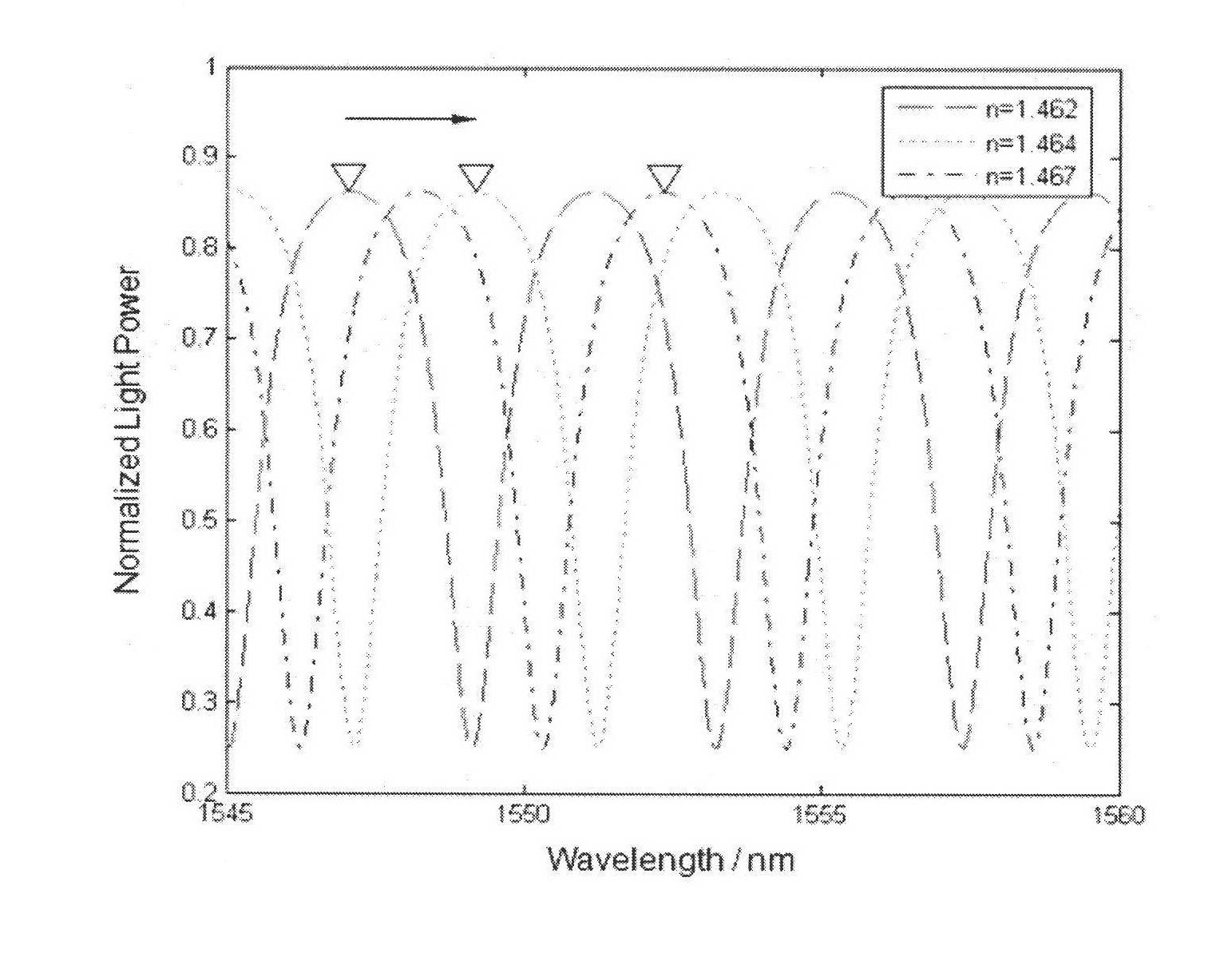

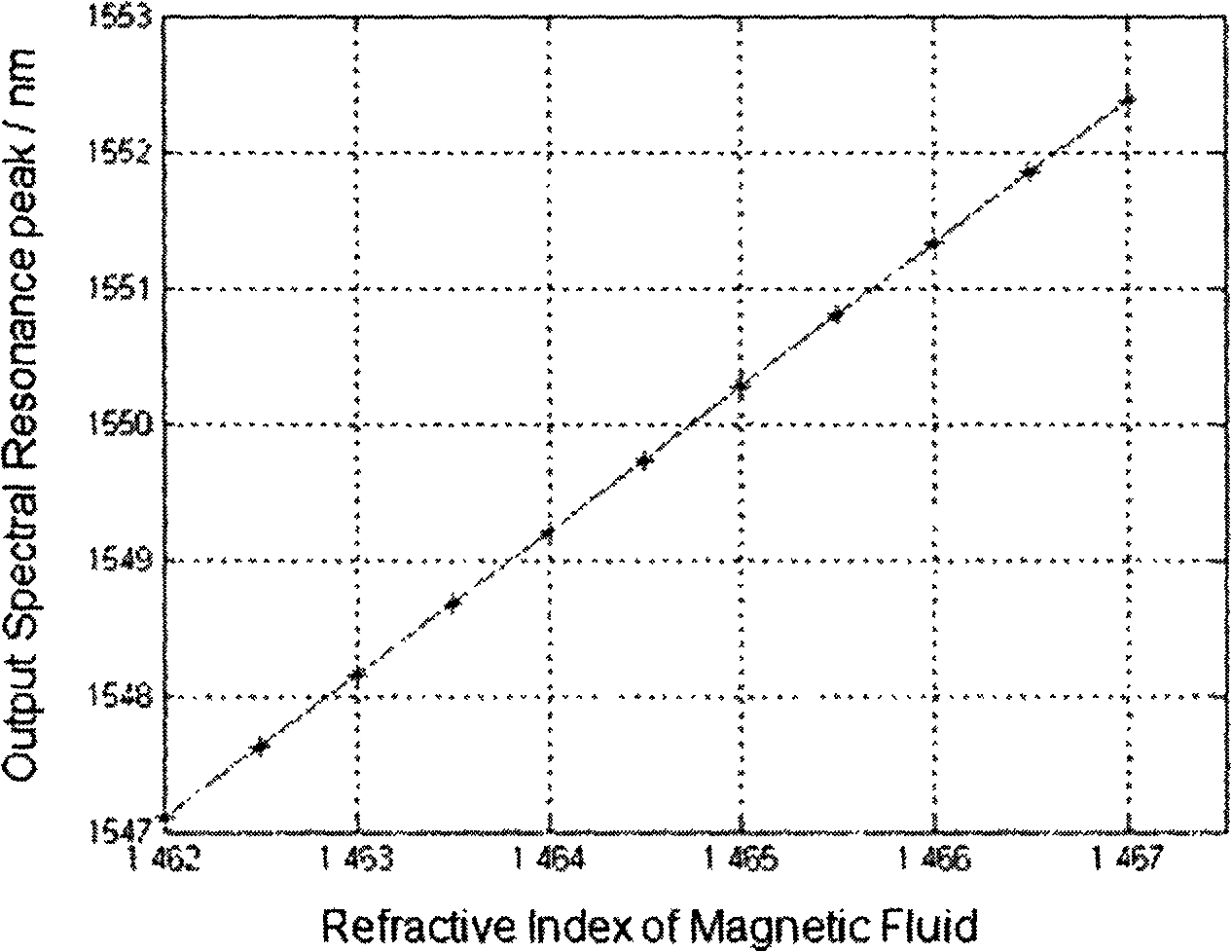

Magnetofluid filling photonic crystal optical fiber F-P magnetic field sensor

InactiveCN102221679ASimple structureInnovative designCladded optical fibreMagnetic field measurement using magneto-optic devicesSpectrum analyzerOptical fiber coupler

The invention discloses a magnetofluid filling photonic crystal optical fiber F-P magnetic field sensor, which belongs to the technical field of optical fiber sensing, and consists of a broadband light source 20, an optical fiber coupler 21 and optical fiber links (31, 32, 33 and 34) of the optical fiber coupler 21, a refractive index matching fluid 22, a sensor probe 23, an electromagnetic coil 18 and a current driving system 19 of the electromagnetic coil, a spectrum analyzer, a computer 24 as well as a connecting cable 26 and a connecting cable 27. The magnetofluid filling photonic crystal optical fiber F-P magnetic field sensor is characterized in that the sensor probe is formed by fusing a section of hollow photonic crystal optical fiber 12 filled with a magnetofluid 13 and a simple module optical fiber 11; the two ends of the hollow photonic crystal optical fiber are respectively stuck by a partial reflection film 14 and a total reflection mirror 15 to form an optical fiber F-P interferometric cavity structure; and the reflection rate of the magnetofluid serving as a medium in the F-P interferometric cavity is changed due to a magnetic field generated by the electromagnetic coil after conducted with a current, thereby causing the change of output spectrums so as to realize magnetic field measurement. The magnetofluid filling photonic crystal optical fiber F-P magnetic field sensor has the advantages of being low in temperature influences, simple in structure, small in size and easy to realize multi-point distribution type sense.

Owner:NORTHEASTERN UNIV

Index-matching gel for nano-engineered optical fibers and mechanical splice assemblies and connectors using same

An index-matching gel for use with nano-engineered optical fibers is disclosed. The index-matching gel is cross-linked, which prevents the gel from wicking into the voids and down the nano-engineered optical fiber to a depth where the fiber performance and / or device performance is compromised. The formulation comprises a non-reactive constituent A, two reactive constituents B and C, and a catalyst D. The gel is pre-cured and forms a cross-linked internal network that results in a single-component gel that does not require meter mixing of an additional constituent or heat curing. The gel is suitable for use in the mechanical splicing of optical fibers when at least one of the optical fibers is a nano-engineered optical fiber. The gel is also suitable for use in fiber optic connectors wherein at least one of the optical fibers constituting the connection is a nano-engineered optical fiber.

Owner:CORNING OPTICAL COMM LLC

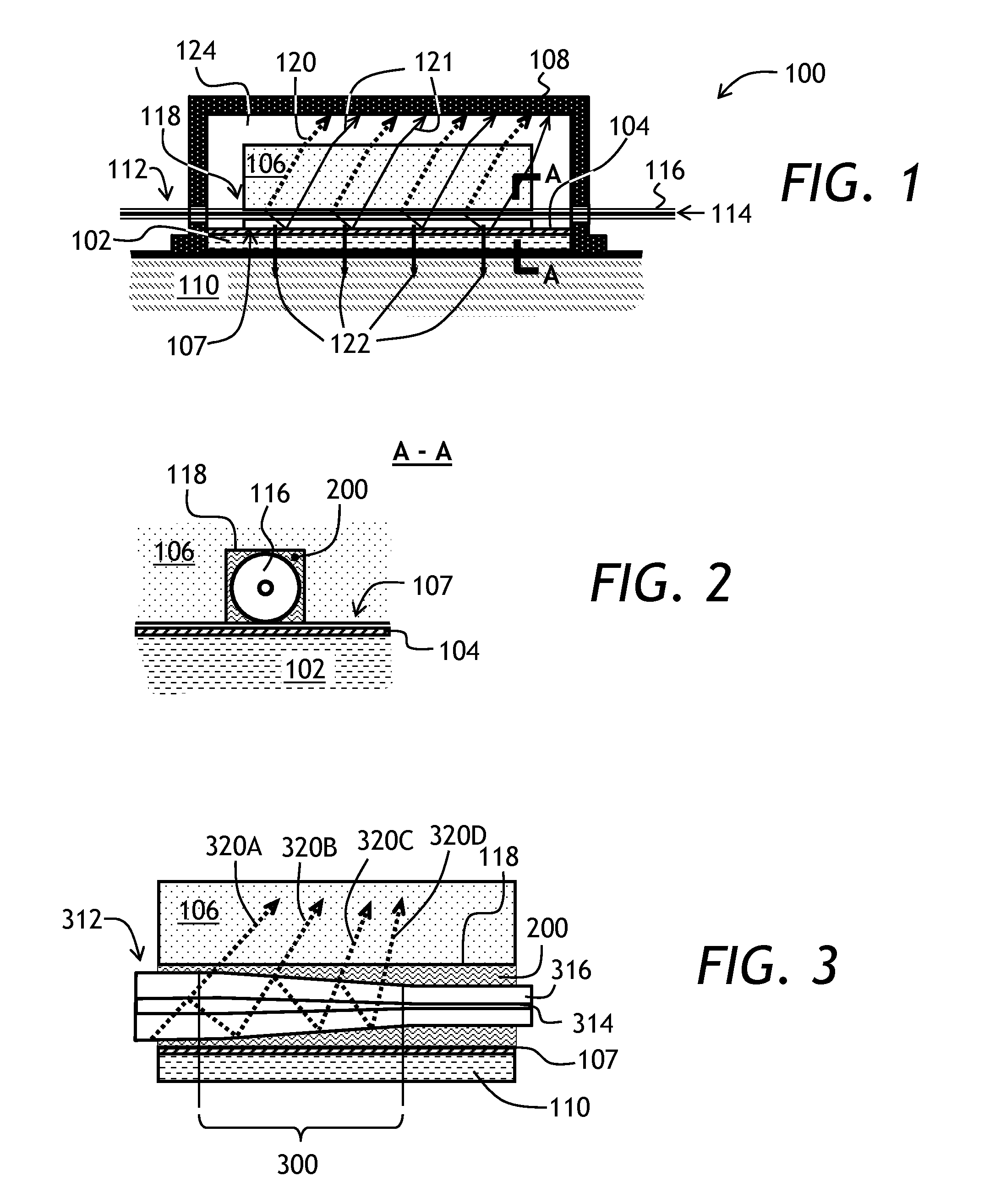

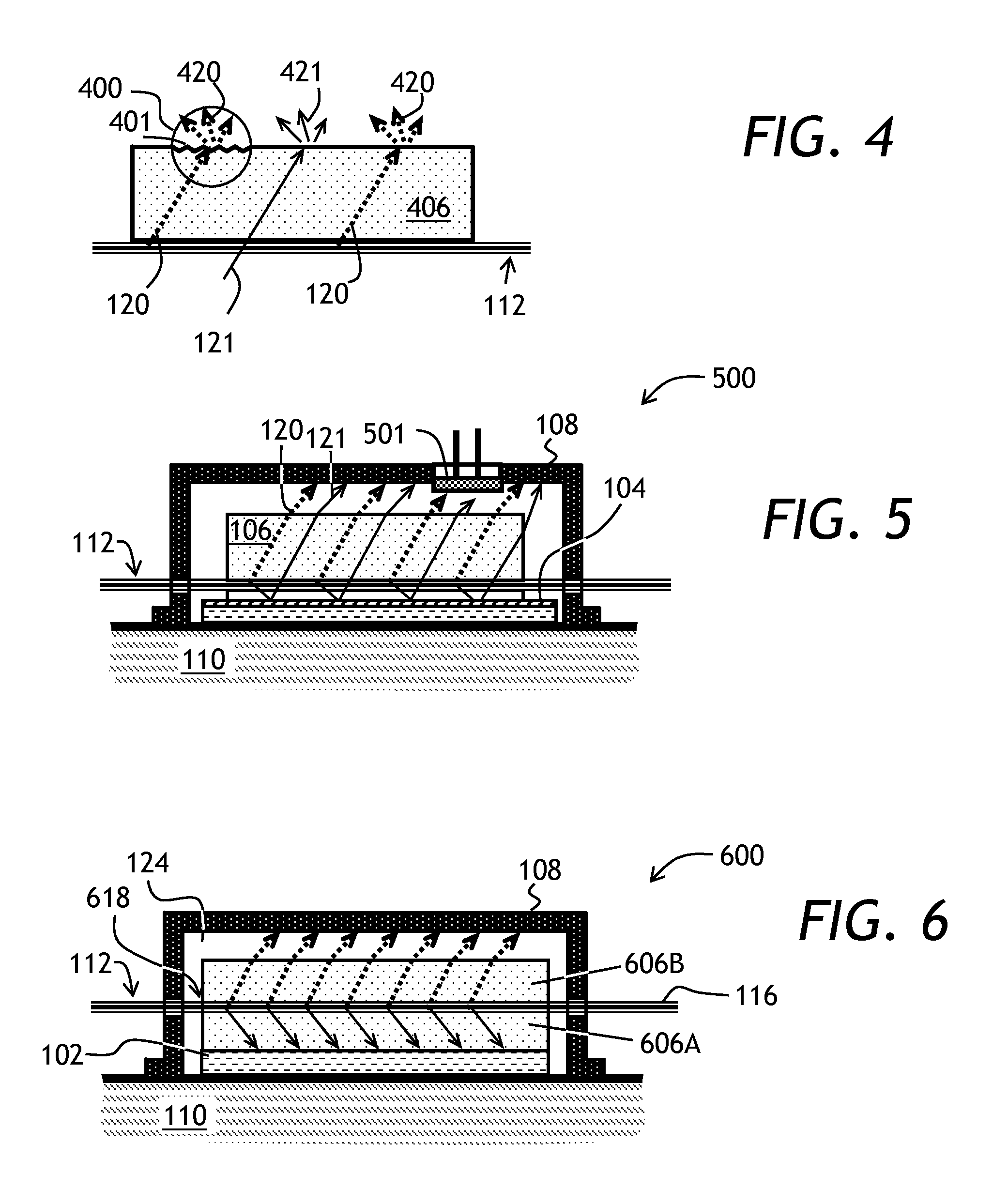

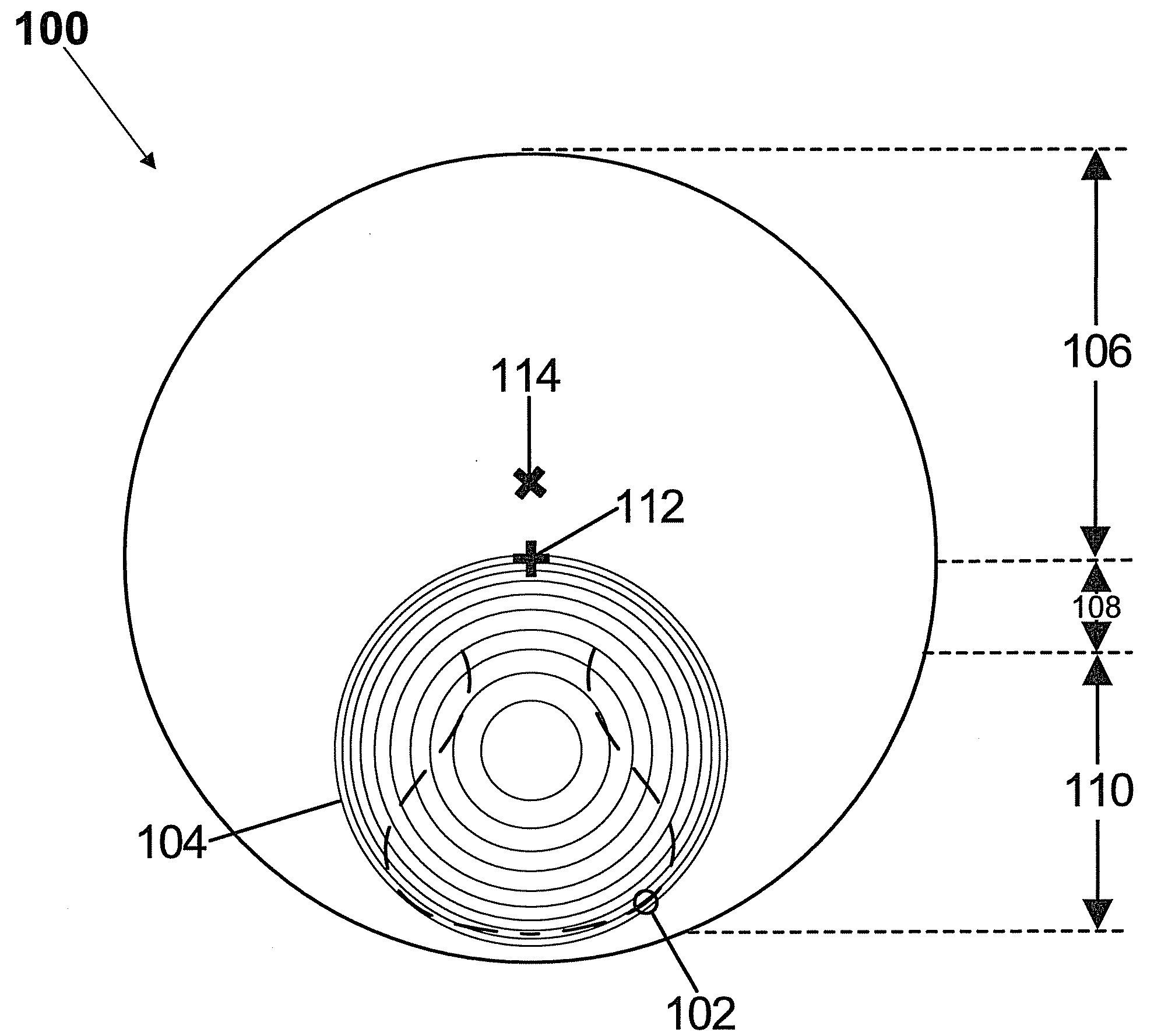

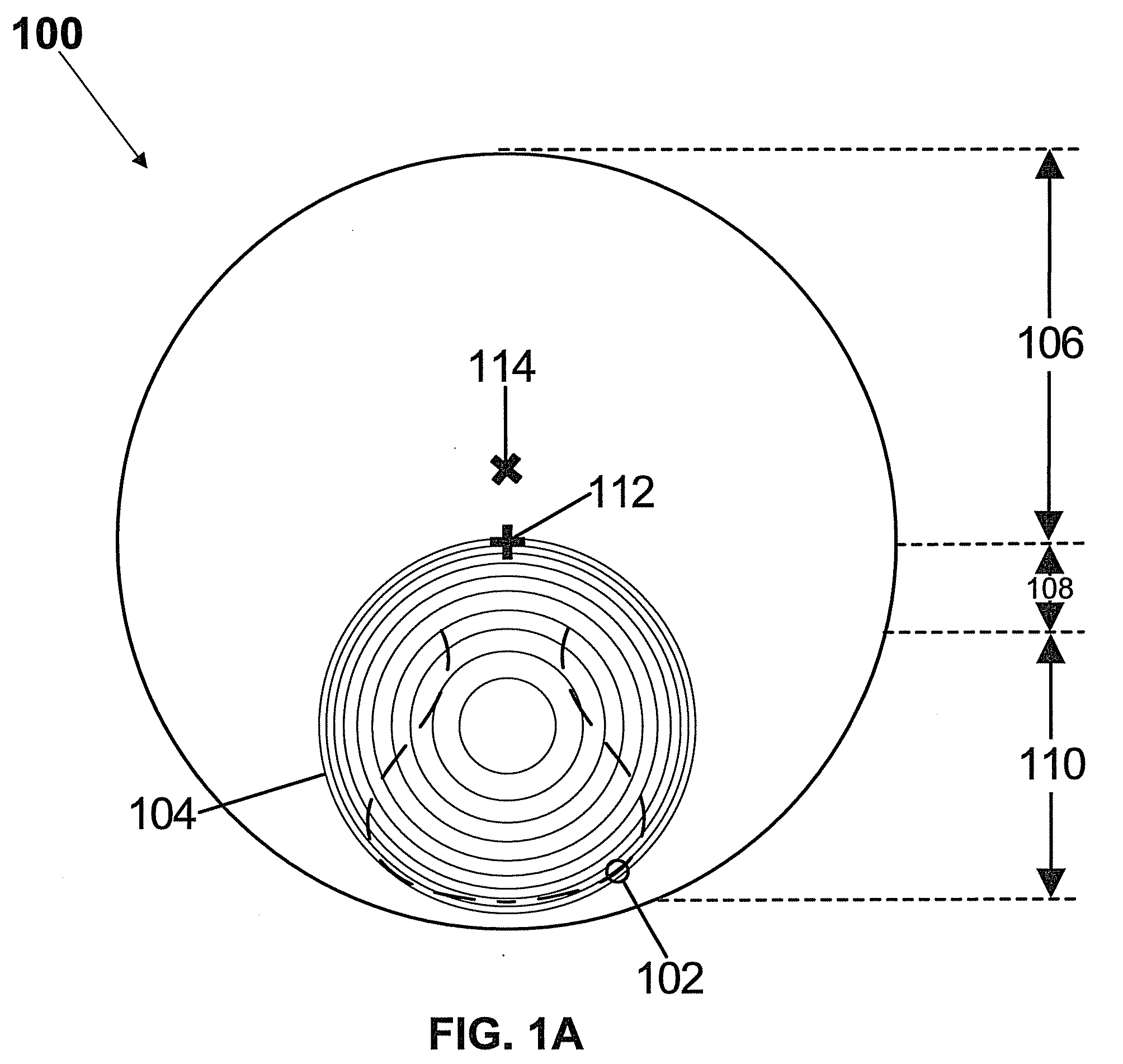

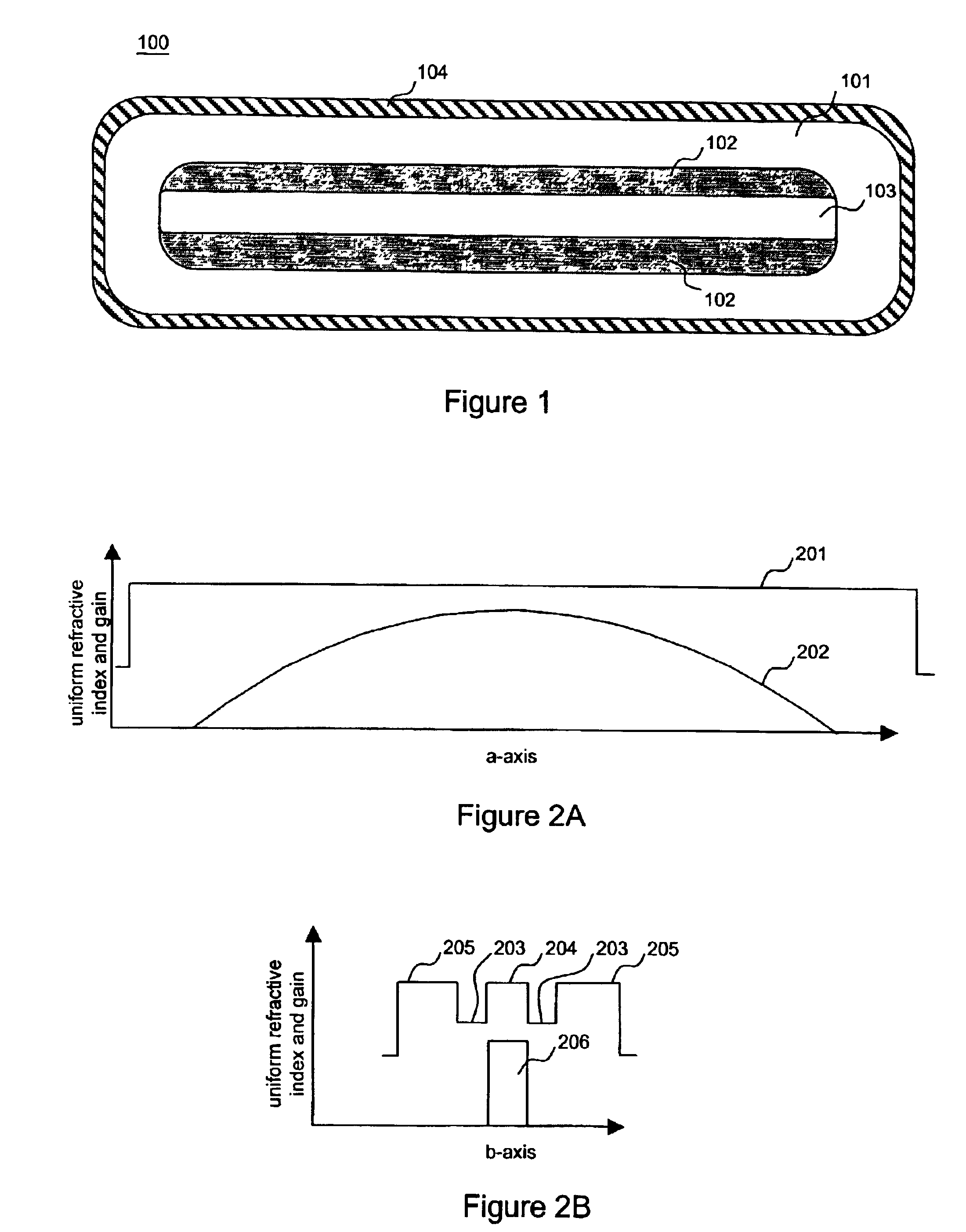

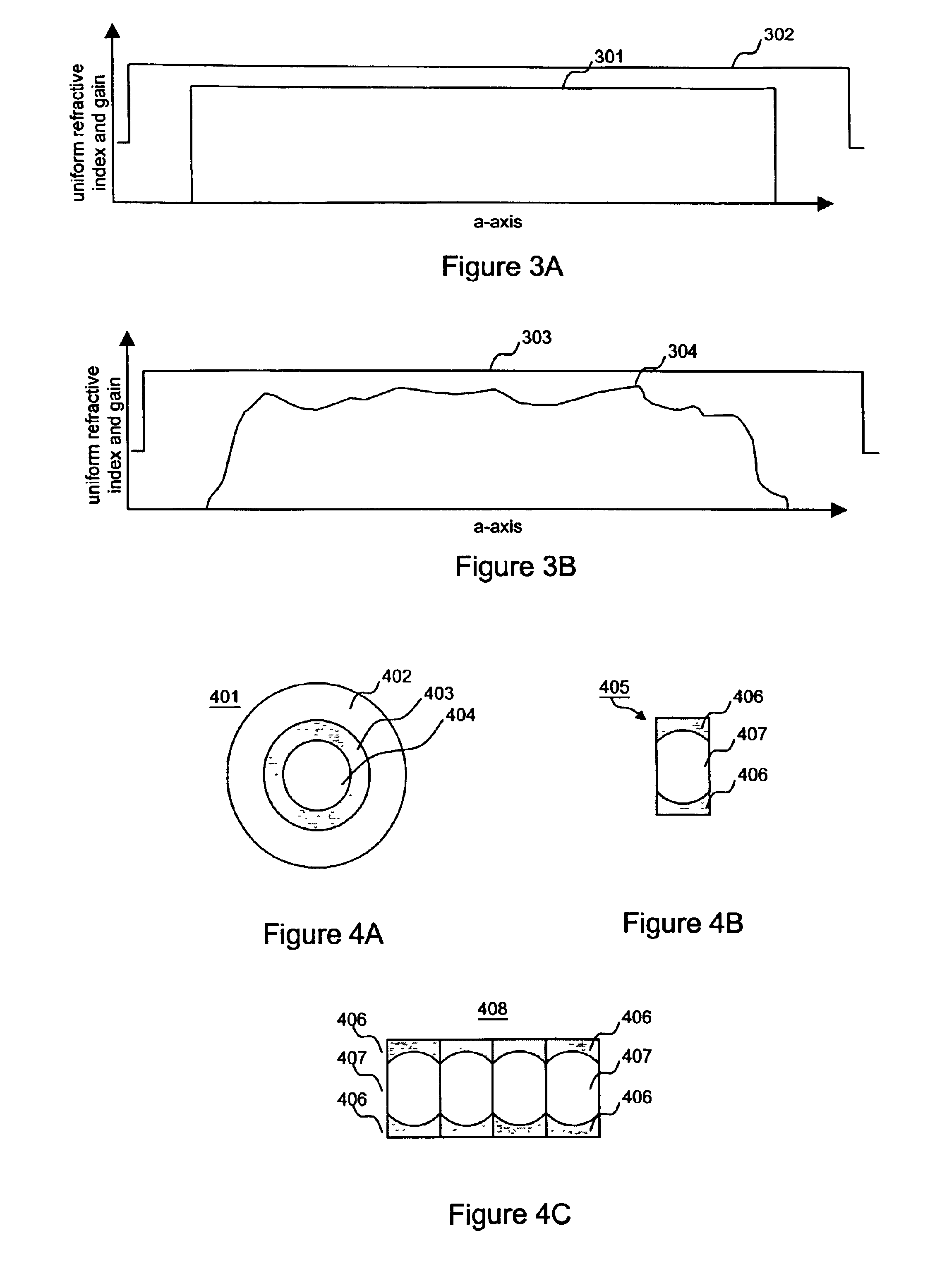

Ultra high-power continuous wave planar waveguide amplifiers and lasers

InactiveUS6904219B1Avoid bend lossesLaser detailsOptical fibre with multilayer core/claddingWaveguide amplifierHigh power diode laser

Double clad large mode area planar lasers or amplifiers comprising rare-earth or transition metal doped planar core regions are used to generate near-diffraction-limited optical beams of ultra-high power. The amplified light is guided in the core using different guiding mechanisms in two orthogonal axes inside the core. Waveguiding along a first long core axis is obtained substantially by gain-guiding or thermal lensing. Waveguiding along a second short core axis is obtained by index guiding. This is accomplished by surrounding the planar core region with regions of different refractive index. The long sides of the planar core region are surrounded with a depressed refractive index cladding region. The short sides of the planar core region are surrounded with a cladding region substantially index-matched to the core region. The whole structure is surrounded by an outer cladding region with a low refractive index to enable cladding pumping of the planar waveguide with high-power diode lasers. The rare-earth or transition metal doping level inside the planar core can be constant and can also vary substantially without negatively affecting the waveguiding properties. To avoid bend losses along the long axis of the planar waveguide, the planar core region and the planar waveguide are aligned parallel to each other and the planar waveguide is coiled with the long side of the planar waveguide mounted to a drum. The drum can also be used as a heat sink. A planar waveguide comprising a planar core region can be manufactured using conventional fiber fabrication methods.

Owner:BOSTON LASER

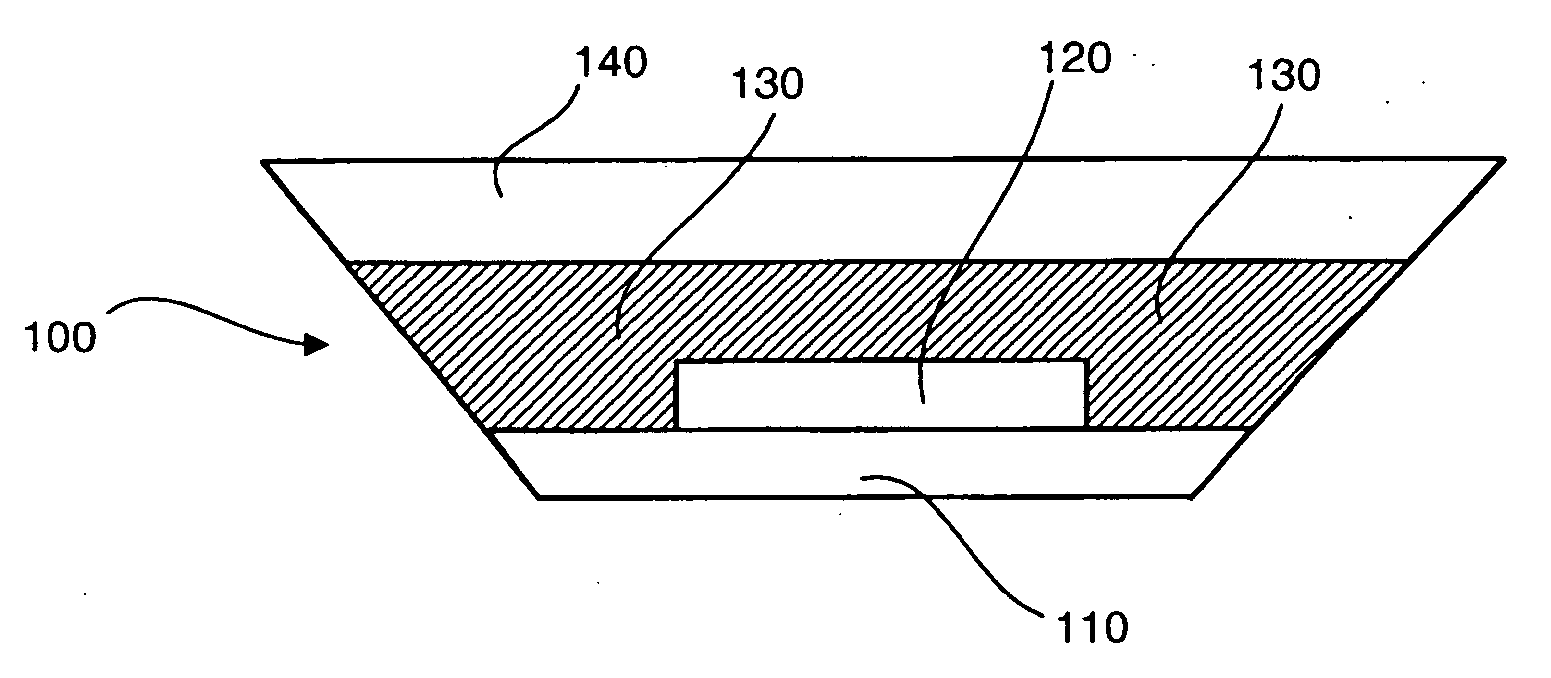

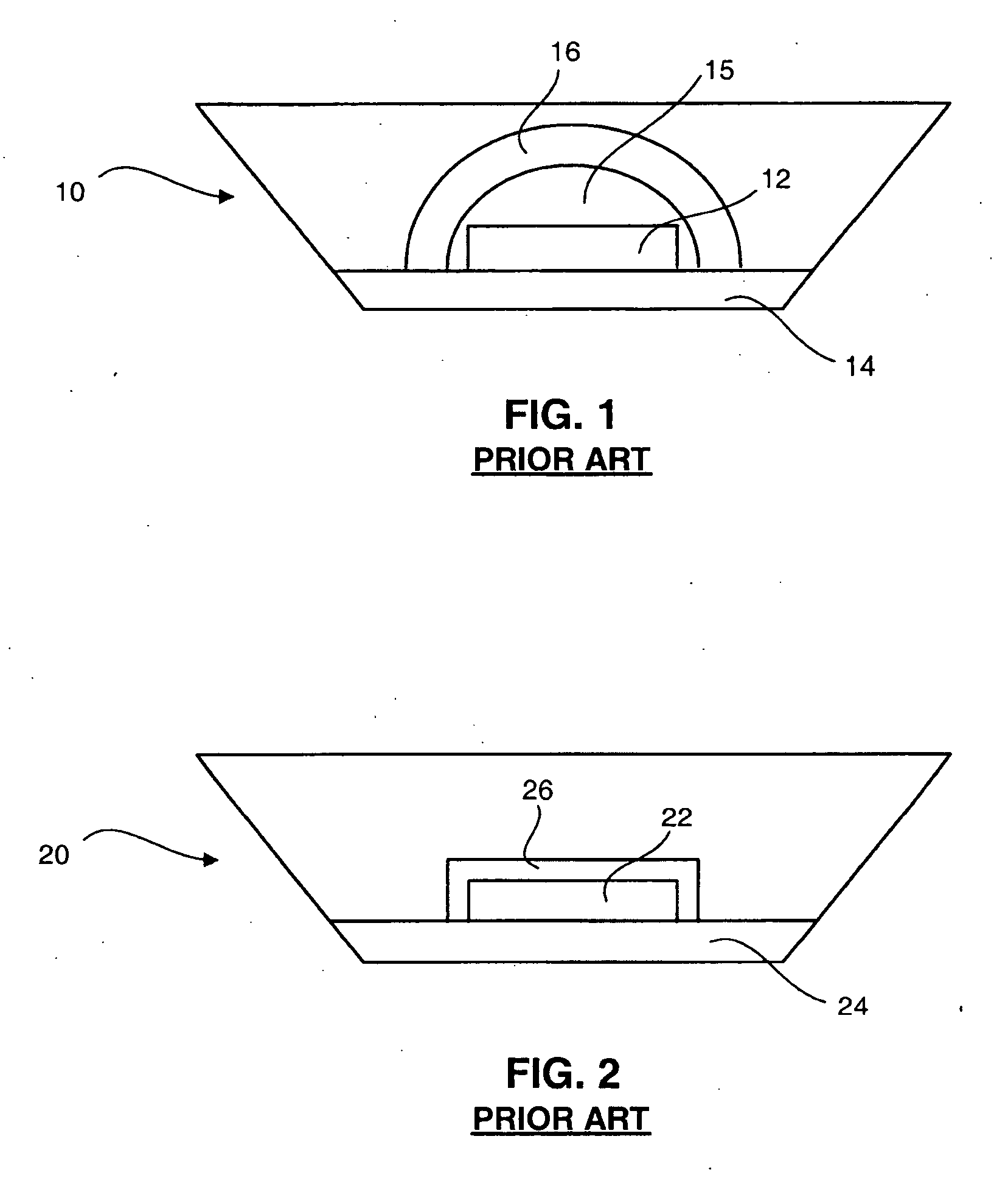

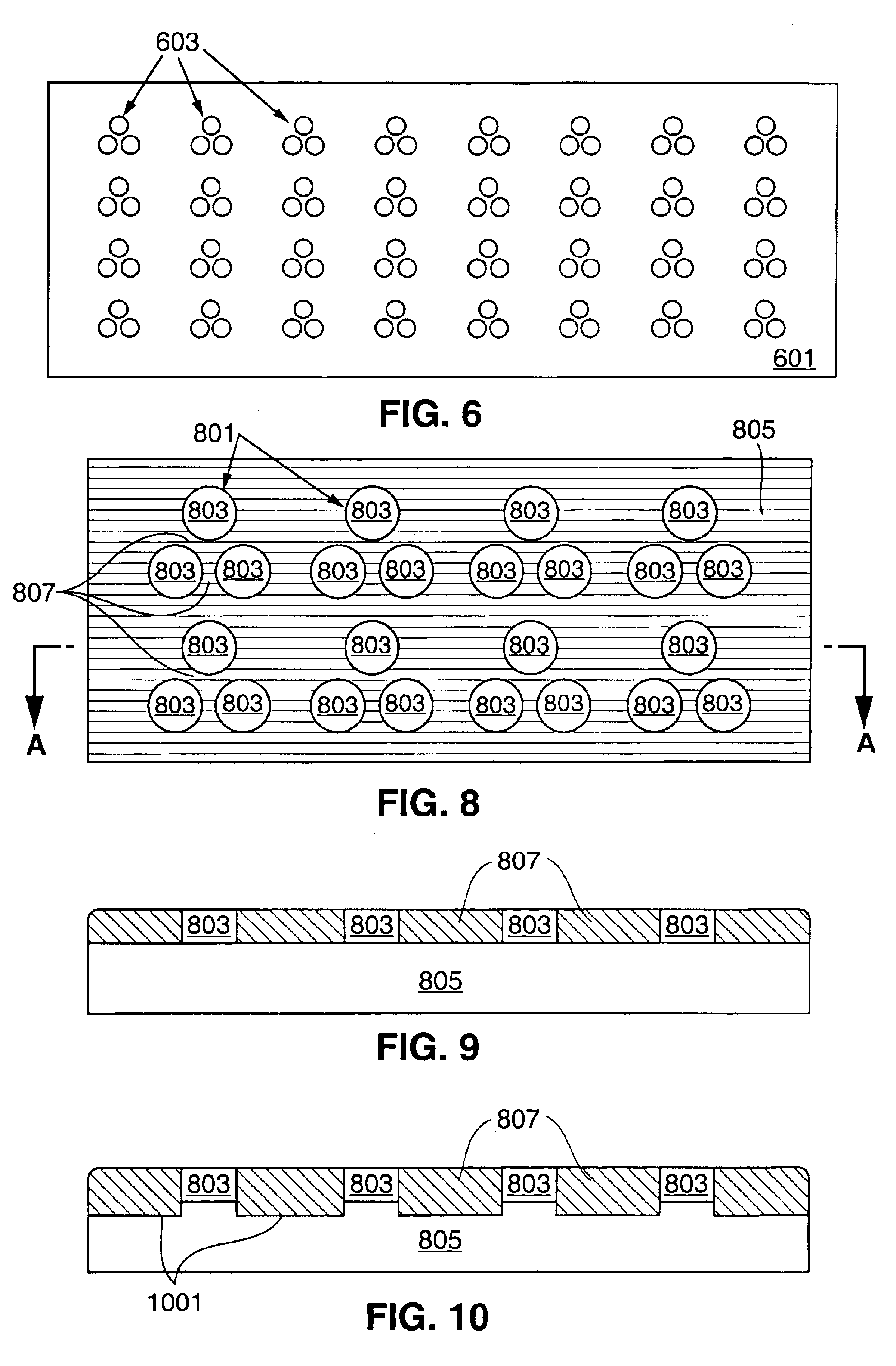

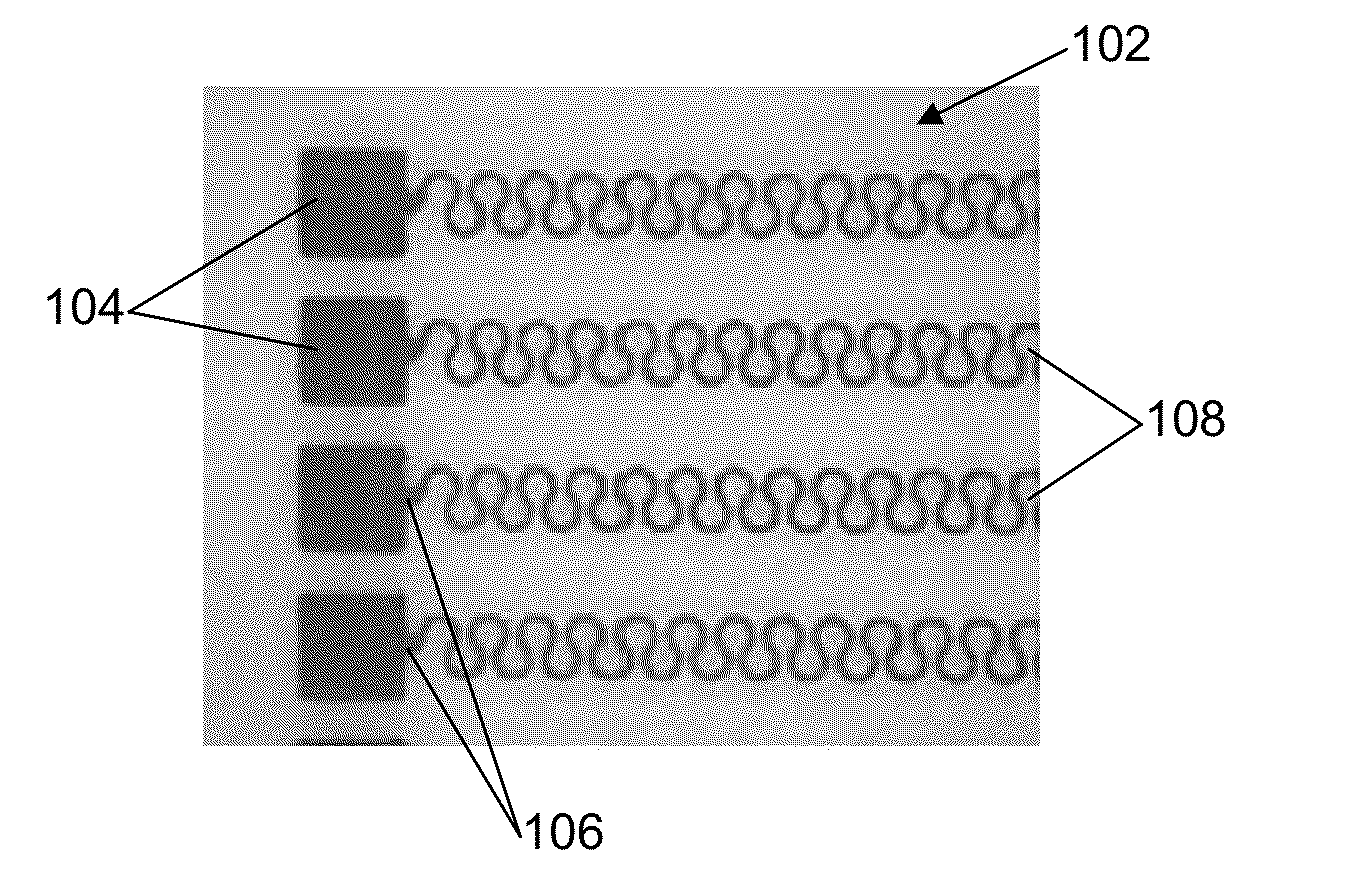

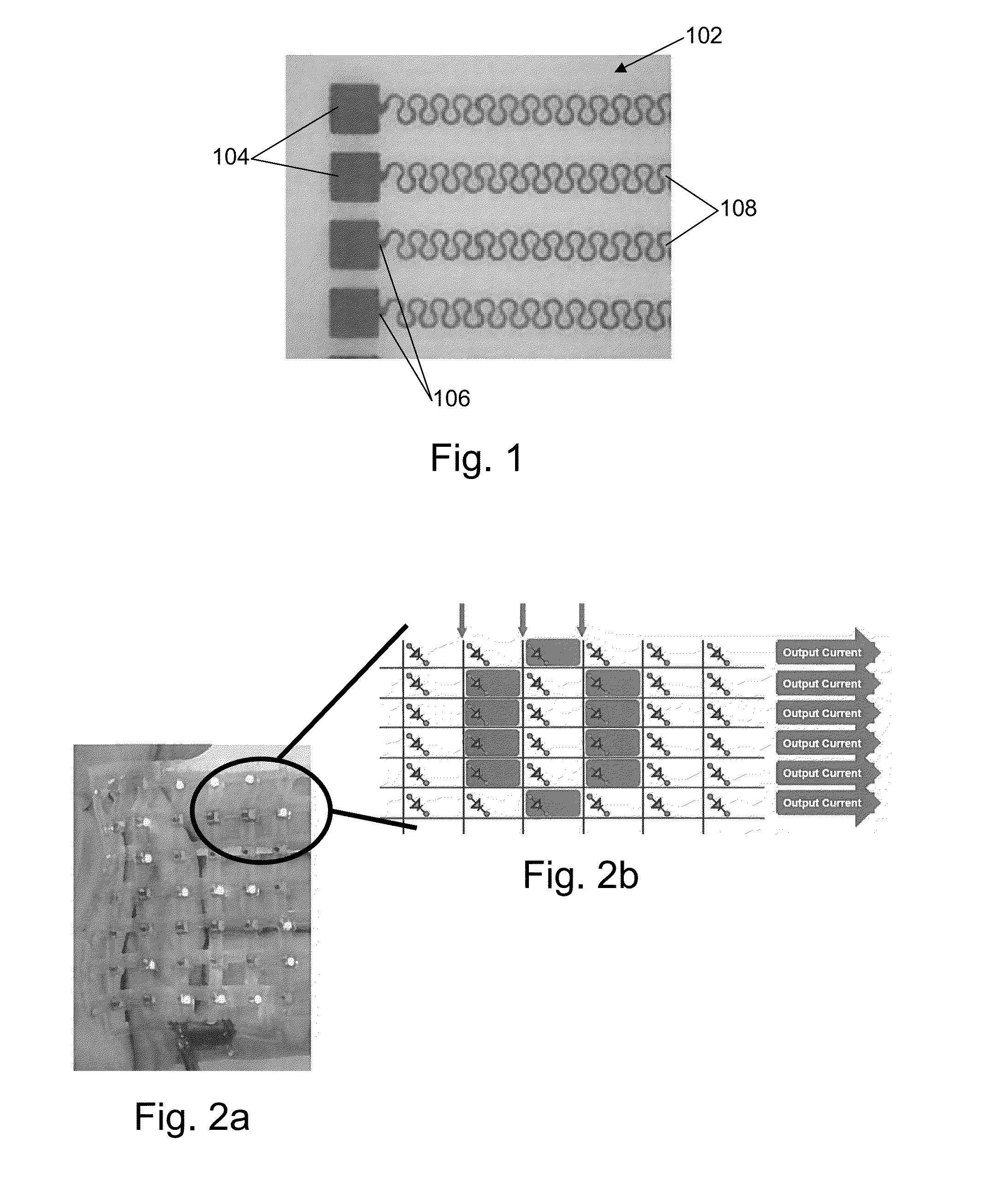

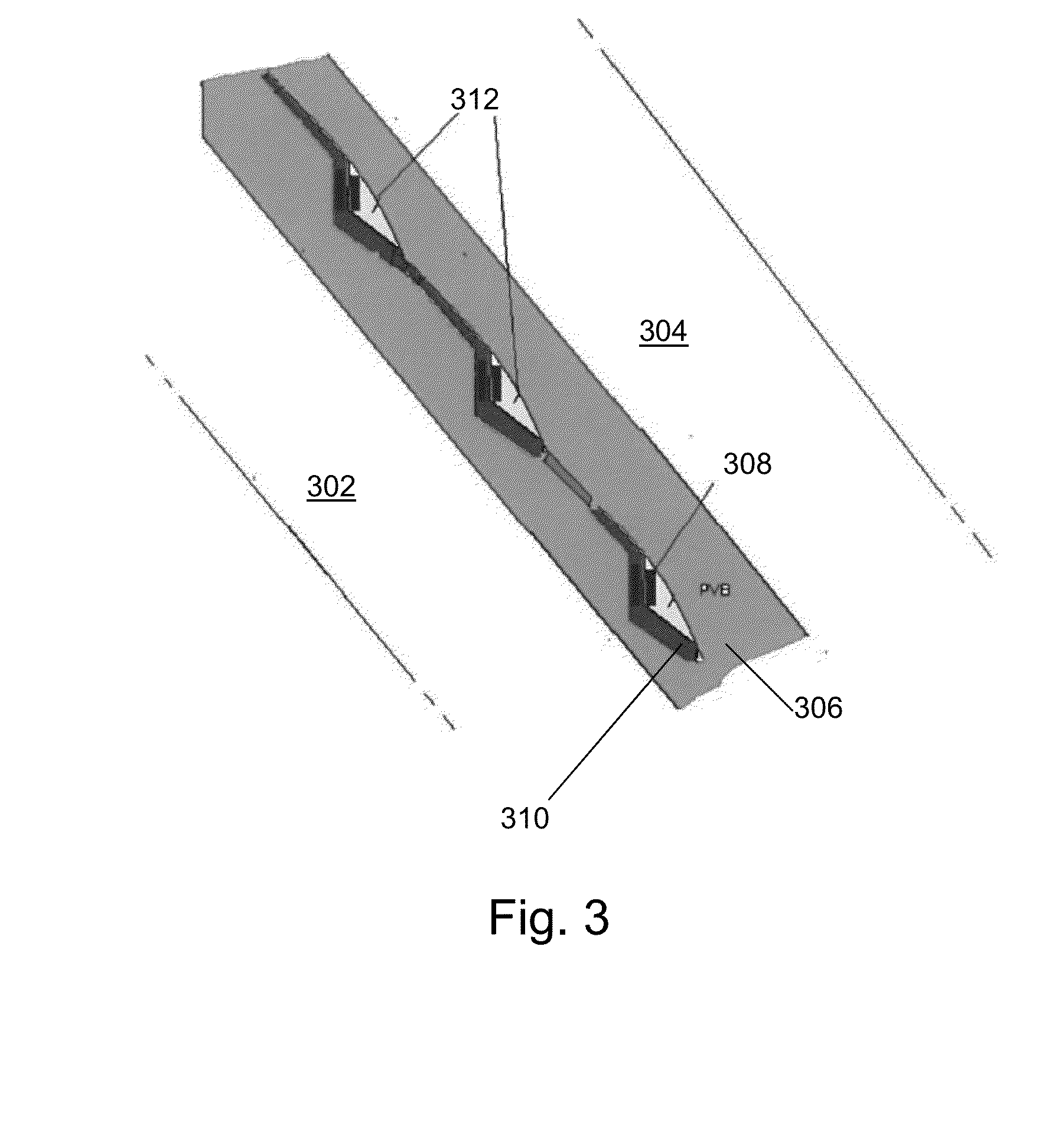

Laminated LED array and/or products including the same

InactiveUS20140098557A1Improve luminous efficiencyLighting support devicesOptical signallingElectricityLed array

In certain example embodiments, light emitting diodes (LEDs) may be disposed on a deformable and flexible backbone sheet and chained together in an array, e.g., via flexible wiggle wires. Such flexible wiggle wires may also provide an electrical connection to an external power source. An optical out-coupling layer stack (OCLS) system may help serve as an index matching layer, heat sink, étendue conserver, etc. The backbone may be formed to a shape tailored to its ultimate application. Applications may include, for example, automotive (such as Center High Mounted Stop Lamp (CHMSL) applications), lighting, signage, and / or other applications. In an example CHMSL application, the deformable sheet with the LED array thereon has a step, sinusoidal, or other shape matched to the angle and / or curvature of the glass such that the LEDs produce light primarily in a direction parallel to a surface on which a vehicle is located.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com