Magnetofluid filling photonic crystal optical fiber F-P magnetic field sensor

A technology of photonic crystal fiber and magnetic field sensor, which is applied in the direction of using magneto-optical equipment for magnetic field measurement, cladding fiber, optical waveguide and light guide, etc., to achieve the effect of simple instrument structure, novel design, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

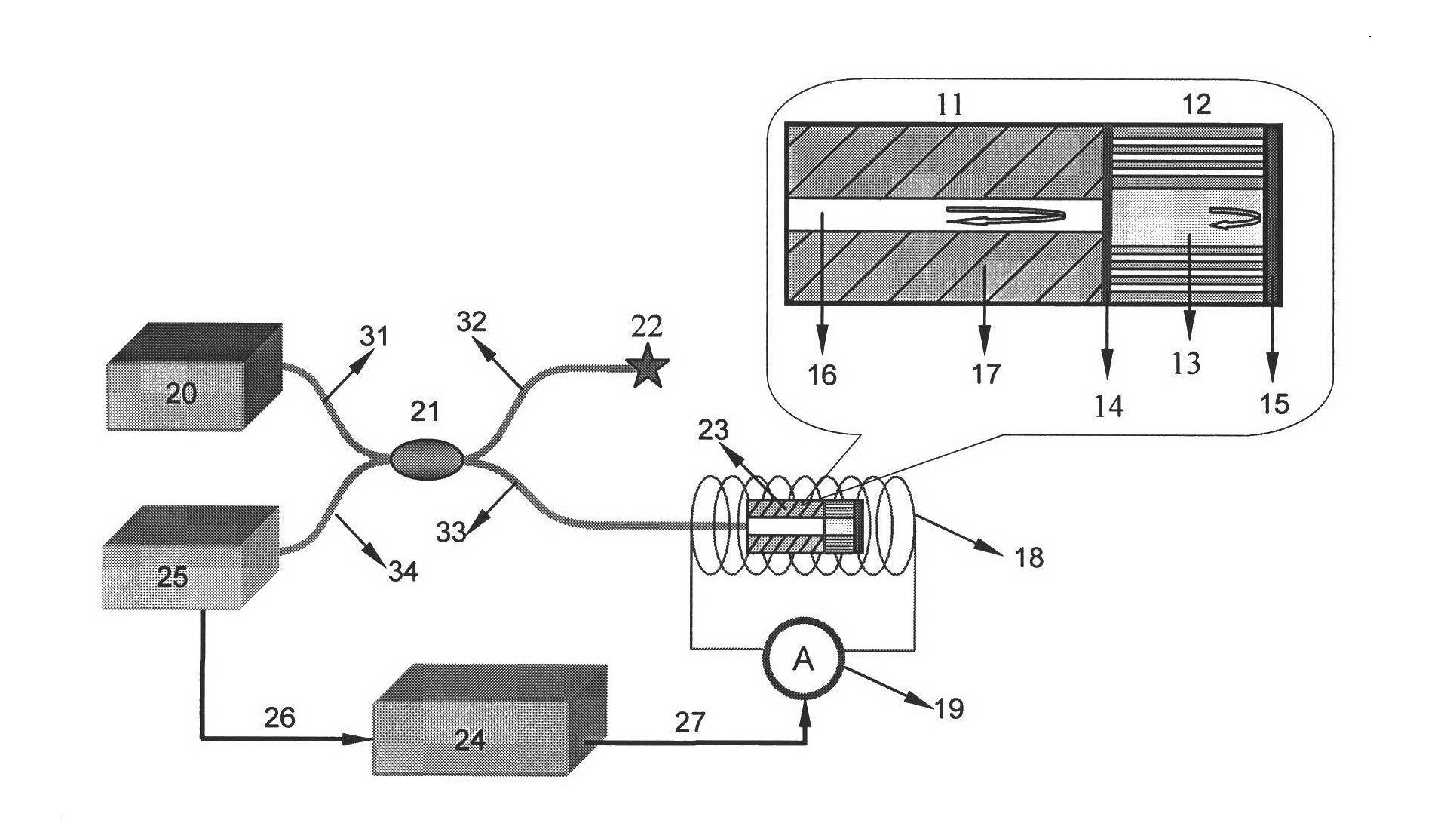

[0014] The specific structure, principle and measurement process of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] The F-P magnetic field sensor based on ferrofluid-filled hollow-core photonic crystal fiber consists of a hollow-core photonic crystal fiber (HC-PCF) and a standard single-mode fiber (SMF), such as figure 1 shown. As a reflective sensor design structure, a total reflection mirror is pasted on one end of the photonic crystal fiber, and the other end is passed through a partially reflective Ti 2 o 3 The film is fused with the single-mode optical fiber to form a reflective optical fiber F-P interference cavity structure.

[0016] The purpose of placing a partial reflection film between the hollow-core photonic crystal fiber and the single-mode fiber is to increase the light reflection effect here. For a fiber optic F-P sensor, the contrast of the interference fringe signal plays a crucial role in pract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com