Transparent projection screen

A projection screen and transparent technology, applied in optics, instruments, projection devices, etc., can solve problems such as complex manufacturing process, high cost of liquid crystal materials, and restriction of display brightness diffraction efficiency, and achieve cost reduction, easy batch production, and increase light energy The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

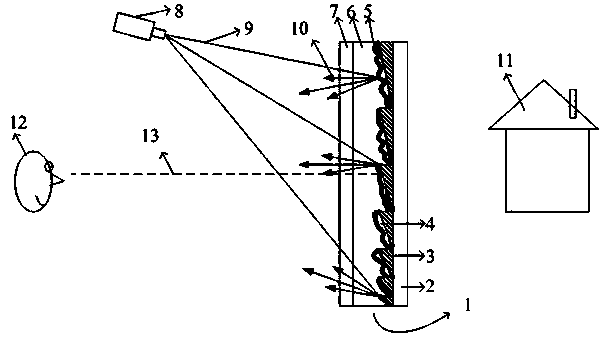

[0022] See attached figure 1 , which is a schematic diagram of a random diffusion transparent projection screen and its projection display structure in this embodiment.

[0023] The transparent projection screen 1 is composed of a first base material layer 2 , a focusing structure 3 , a diffusion structure 4 , a partially reflective film structure 5 , a refractive index matching layer 6 and a second base material layer 7 . The focusing structure 3 is a prism structure located on the lower surface of the first substrate layer 2, the diffusion structure 4 is a random phase structure located on the surface of the focusing structure 3, the partially reflective film structure 5 is a dielectric film structure coated on the surface of the random phase structure 4, and the refractive index matching layer 6 is filled between the second substrate layer 7 and the partially reflective film structure 5, and the refractive index of the material is consistent with that of the materials of t...

Embodiment 2

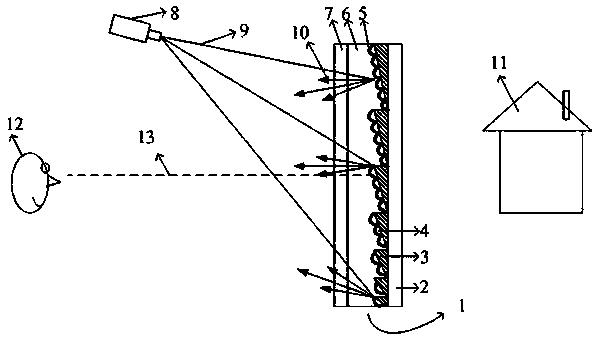

[0030] See attached image 3 , is a schematic diagram of a microlens diffusion transparent projection screen and its projection display structure in this embodiment.

[0031] The transparent projection screen 1 is composed of a first base material layer 2 , a focusing structure 3 , a diffusion structure 4 , a partially reflective film structure 5 , a refractive index matching layer 6 and a second base material layer 7 . The focusing structure 3 is a V-groove structure located on the lower surface of the first substrate layer 2, the diffusion structure 4 is a microlens array structure located on the surface of the focusing structure 3, and the partially reflective film structure 5 is a metal film coated on the surface of the microlens structure 4. The matching layer 6 is filled between the second substrate layer 7 and the partially reflective film structure 5 , and the refractive index of its material is consistent with that of the materials of the focusing structure and the di...

Embodiment 3

[0038] See attached Figure 4 , is a schematic diagram of an anti-reflection random diffusion transparent projection screen and its projection display structure in this embodiment.

[0039] The transparent projection screen 1 is composed of a first substrate layer 2 , a focusing structure 3 , a diffusion structure 4 , a partially reflective film structure 5 , a refractive index matching layer 6 , a second substrate layer 7 , and an antireflection structure 14 . The focusing structure 3 is a prism structure located on the lower surface of the first substrate layer 2, the diffusion structure 4 is a random phase structure located on the surface of the focusing structure 3, and the partially reflective film structure 5 is a dielectric film structure coated on the random phase On the surface of the structure 4, the refractive index matching layer 6 is filled between the second substrate layer 7 and the partially reflective film structure 5, and the refractive index of its material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com