Zoned testing method for surrounding rock damage zone

A testing method and technology for surrounding rock, which are applied in the testing of basic structures, measuring devices, and earth-moving drilling and mining, etc., can solve problems such as difficulty in direct promotion, and achieve the effect of low technical threshold, avoiding incompatibility, and ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation scheme of this embodiment is as follows:

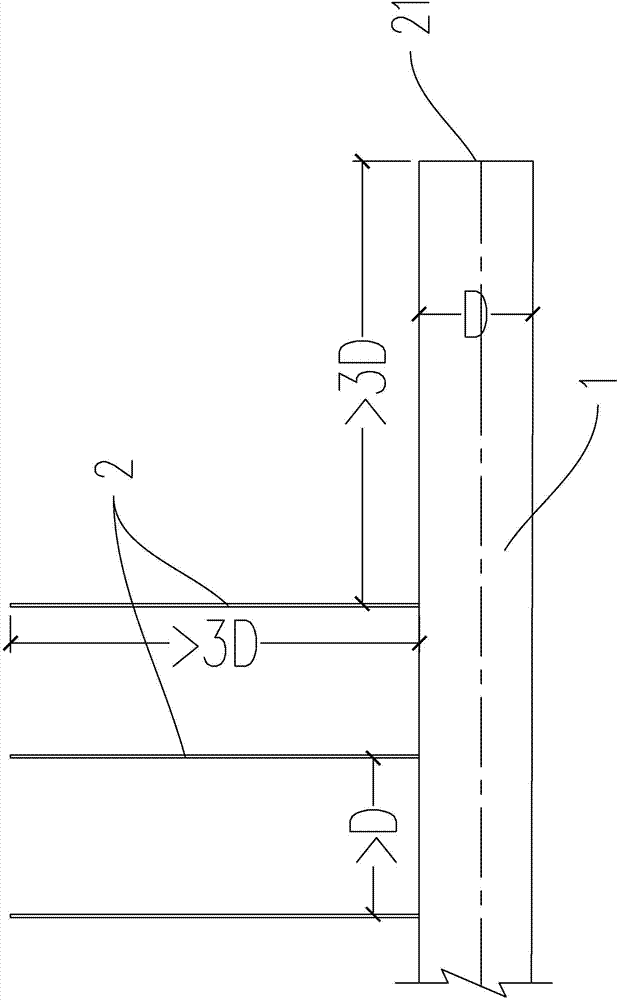

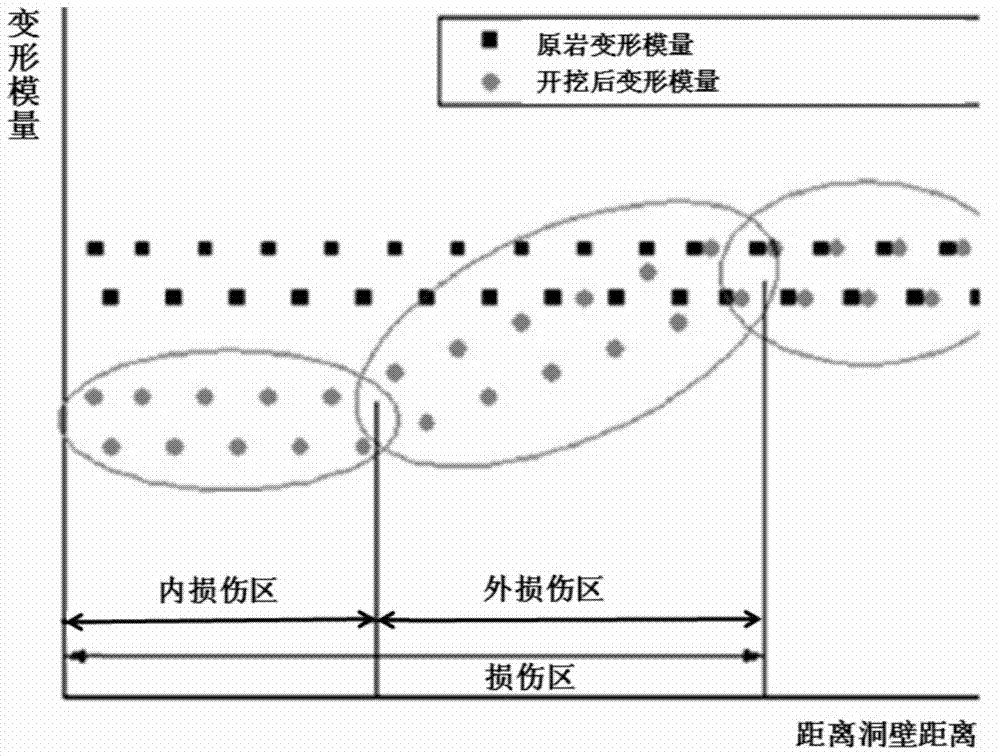

[0017] The test hole 2 is arranged vertically to the excavated cavern 1, and the length of the test hole 2 is required to exceed 3 times the diameter D of the excavated cavern (see figure 1 ) to ensure a complete test of the influence range of the damaged area; the test hole 2 requires a cavity diameter D that is more than 3 times the distance from the face 21 to ensure that the influence of the face effect is eliminated; the diameter of the test hole 2 must reach 60mm The above is to ensure that the core can be drilled and processed into a standard rock sample of 100mm×50mm. Since the core in the damaged area is easily affected by the unloading effect during the sampling process, it is discrete or the core cake cannot take out a complete core, it is required to arrange at least 3 test holes (arranged along the axial direction of the cavern) , and the spacing is greater than the cavern diameter D. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com