Method for realizing nitride semiconductor device inter-active-area isolation utilizing boron ion injection

A technology of nitride semiconductors and boron ions, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting interconnection connection and device yield, so as to save production steps, improve performance and finished products rate, lowering the height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

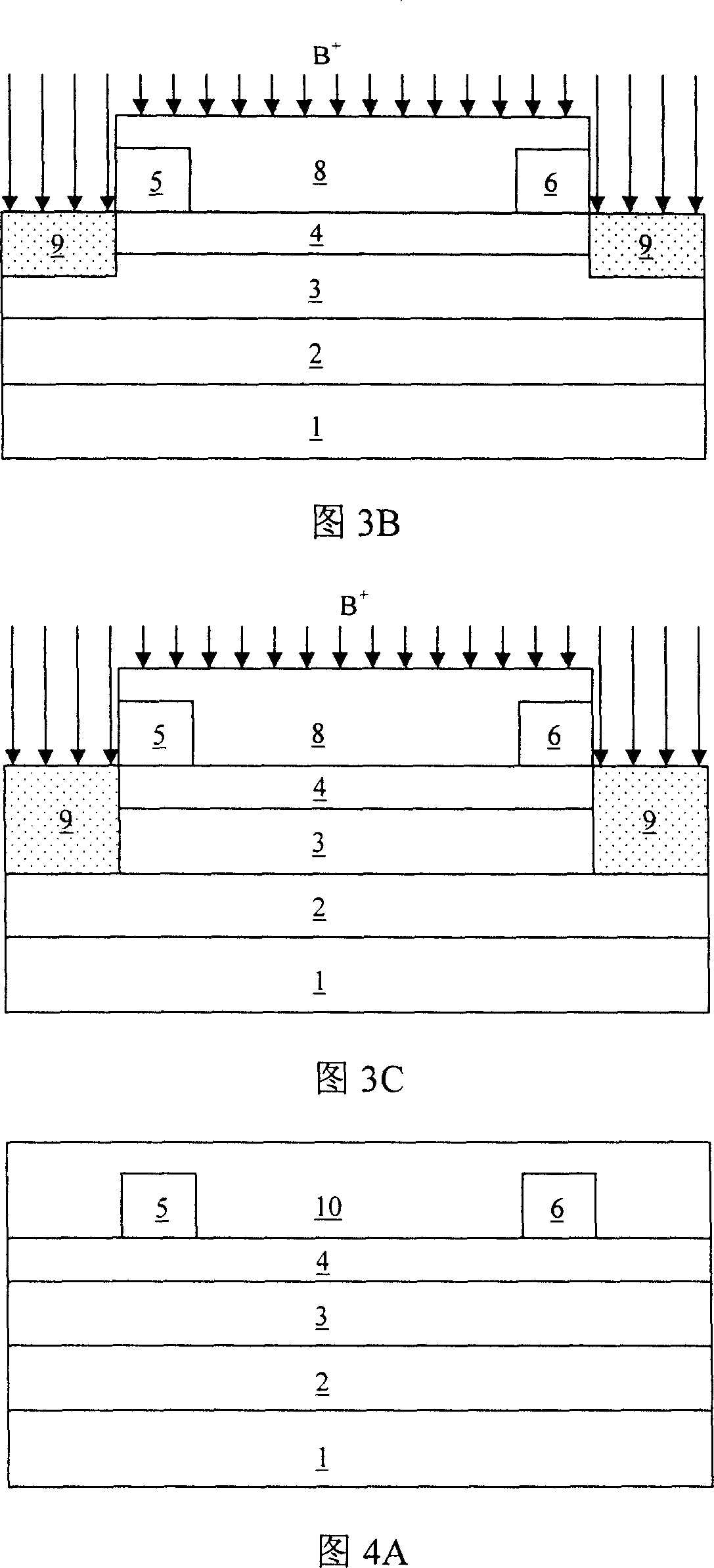

[0027] As shown in Figure 2, 3A-3C, 5.

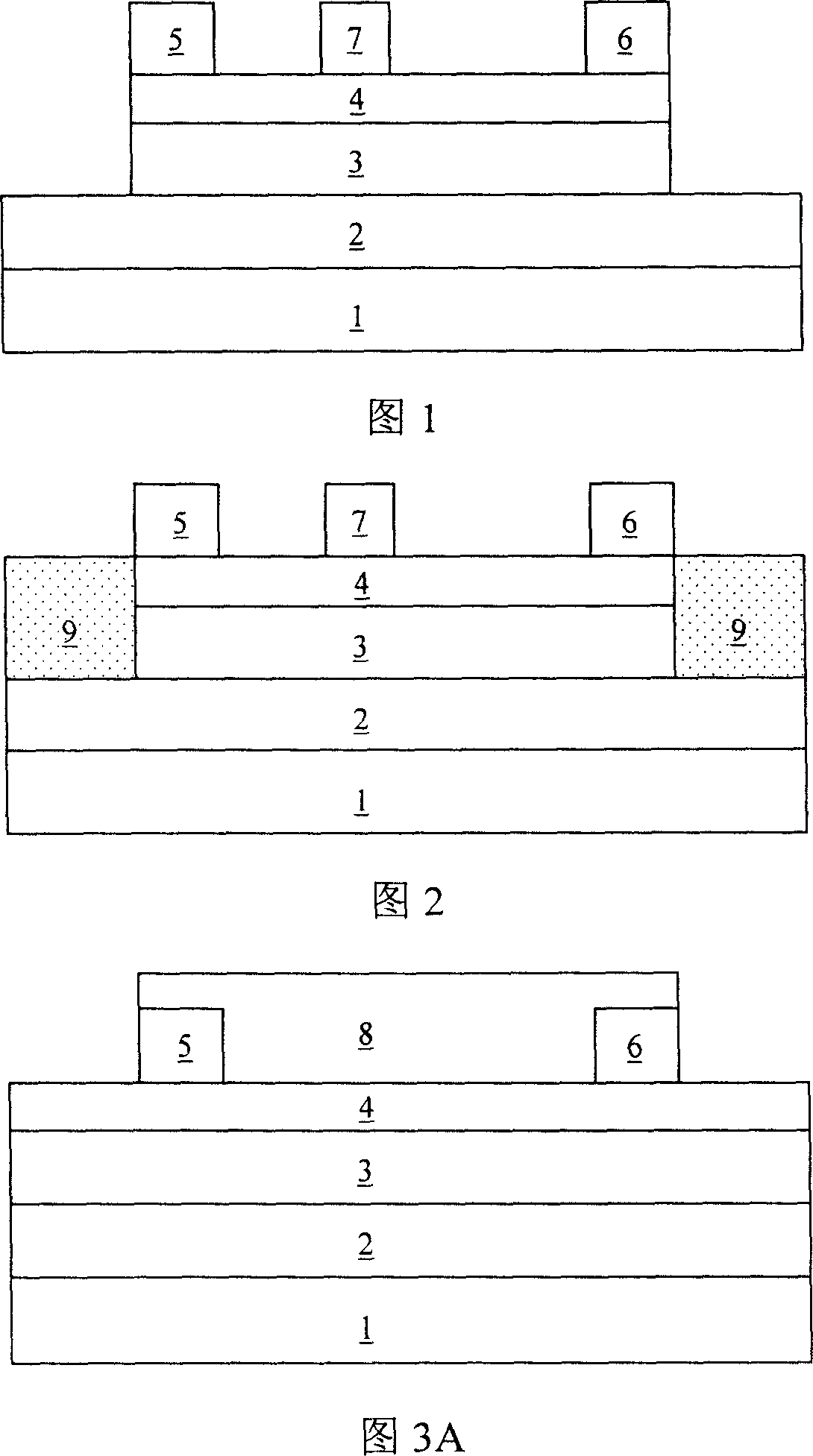

[0028] The AlGaN / GaN heterojunction material in Fig. 2 includes substrate 1, buffer layer 2, channel layer 3 and barrier layer 4, channel layer 3 and barrier layer 4 between devices, between AlGaN / GaN HEMT The intervening channel layer 3 and barrier layer 4 are bombarded by high-energy ion beams to form a high-resistance damaged layer 9, which realizes electrical isolation between devices. The specific production process is:

[0029] As shown in Figure 3A, the first ohmic contact region 5 is formed on the barrier layer 4 of the AlGaN / GaN heterojunction material as the source electrode, and then the barrier layer 4 is separated from the first ohmic contact region by 2 micrometers to 5 micrometers. The method of forming the second ohmic contact region 6 as the drain electrode and forming the ohmic contact with the AlGaN barrier layer is well known in the art and will not be repeated here. A mask 8 is used to protect the AlGaN / GaN hetero...

Embodiment 2

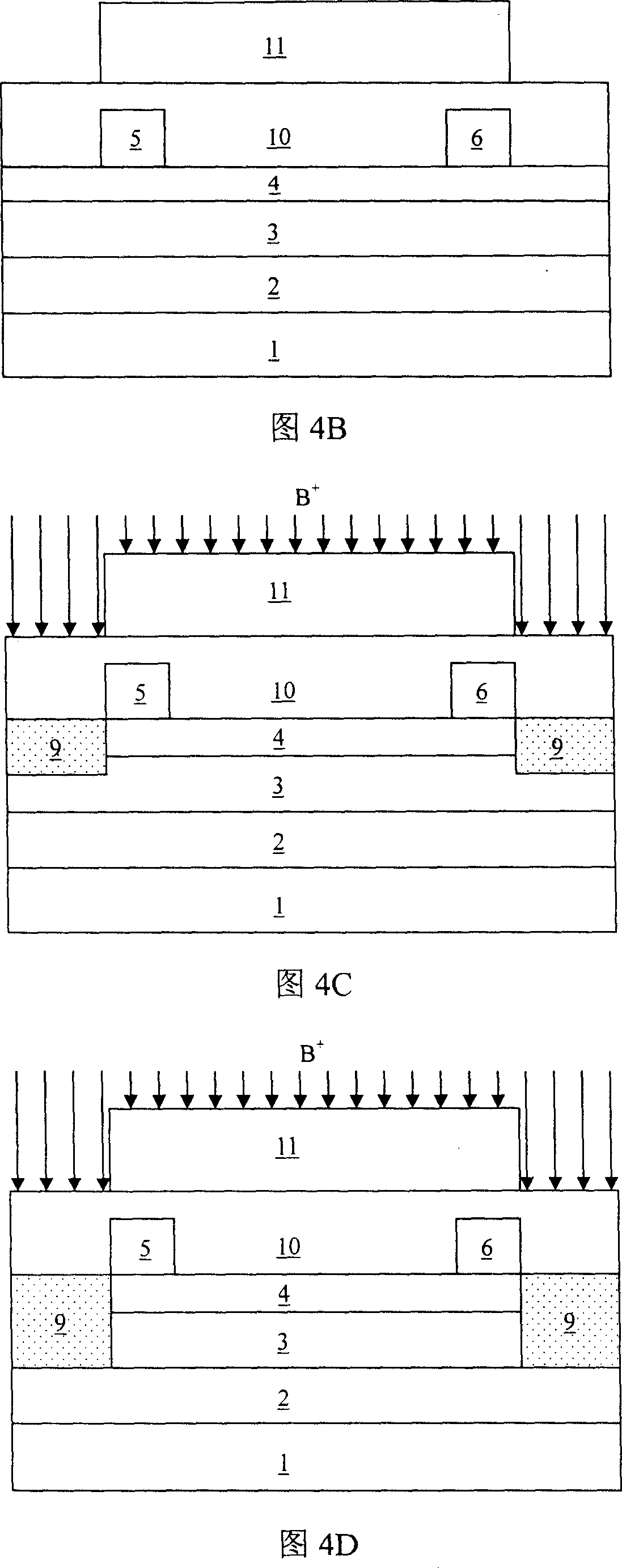

[0035] As shown in Figures 2, 4A-4D.

[0036] As shown in FIG. 4A, a source ohmic contact 5 and a drain ohmic contact 6 are formed on the AlGaN / GaN heterojunction as in Example 1, and a dielectric layer 10 is deposited on the exposed surface of the barrier layer 4, the source electrode 5 and the drain electrode. On pole 6, optional materials for the dielectric layer include but are not limited to silicon nitride (SiN), silicon oxide (SiO 2 ), aluminum nitride (AlN), aluminum oxide (Al 2 o 3 ), the dielectric layer deposition methods include but not limited to sputtering, electron beam evaporation, plasma enhanced chemical vapor deposition (PECVD), and the thickness of the dielectric layer is about 100nm. As shown in FIG. 4B , a mask 11 is used to protect the AlGaN / GaN heterojunction material and parts of the device that do not require ion implantation, and the preferred material of the mask 11 is photoresist.

[0037] As shown in Figure 4C, boron ions with an implantation e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com