Patents

Literature

2641 results about "Metal mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

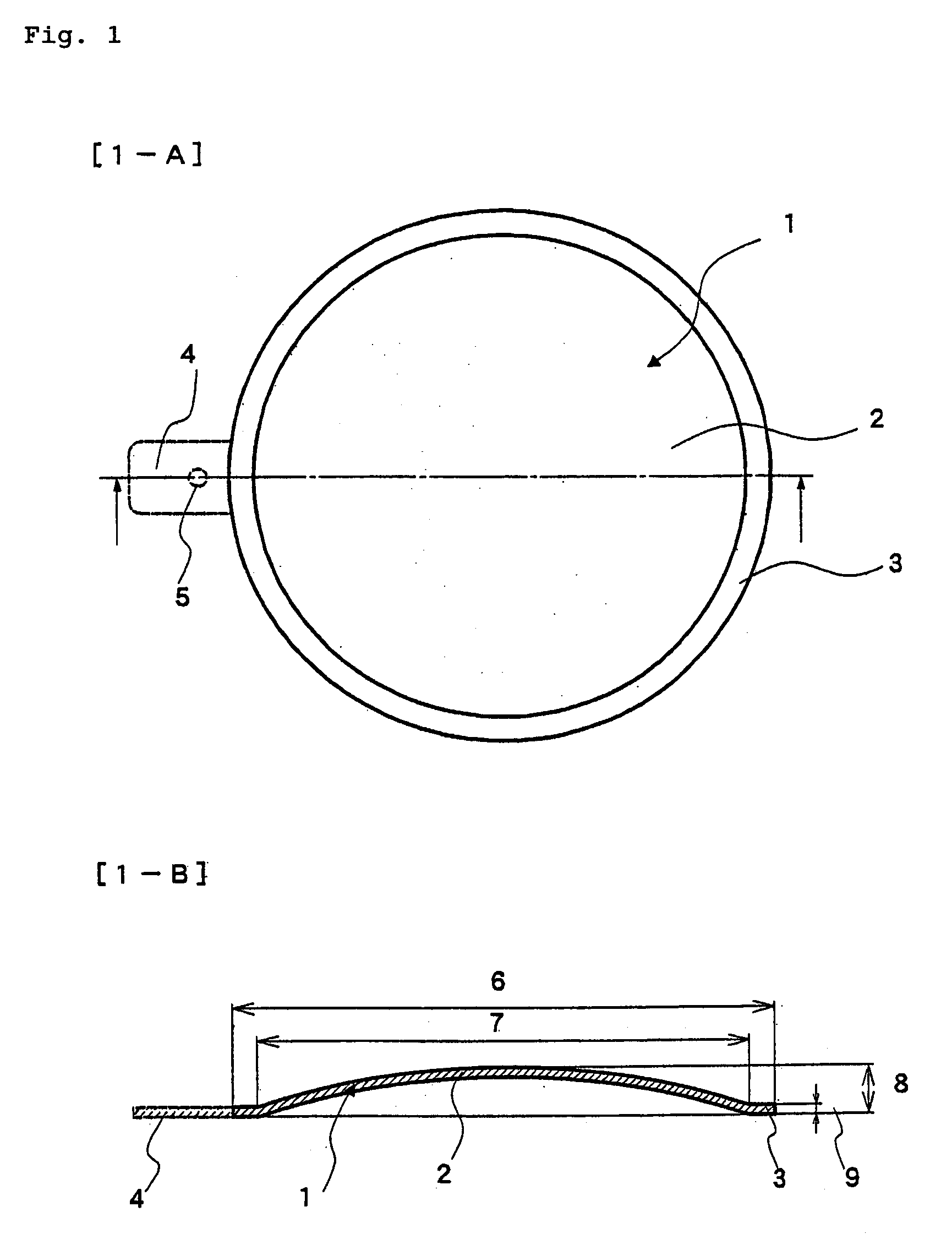

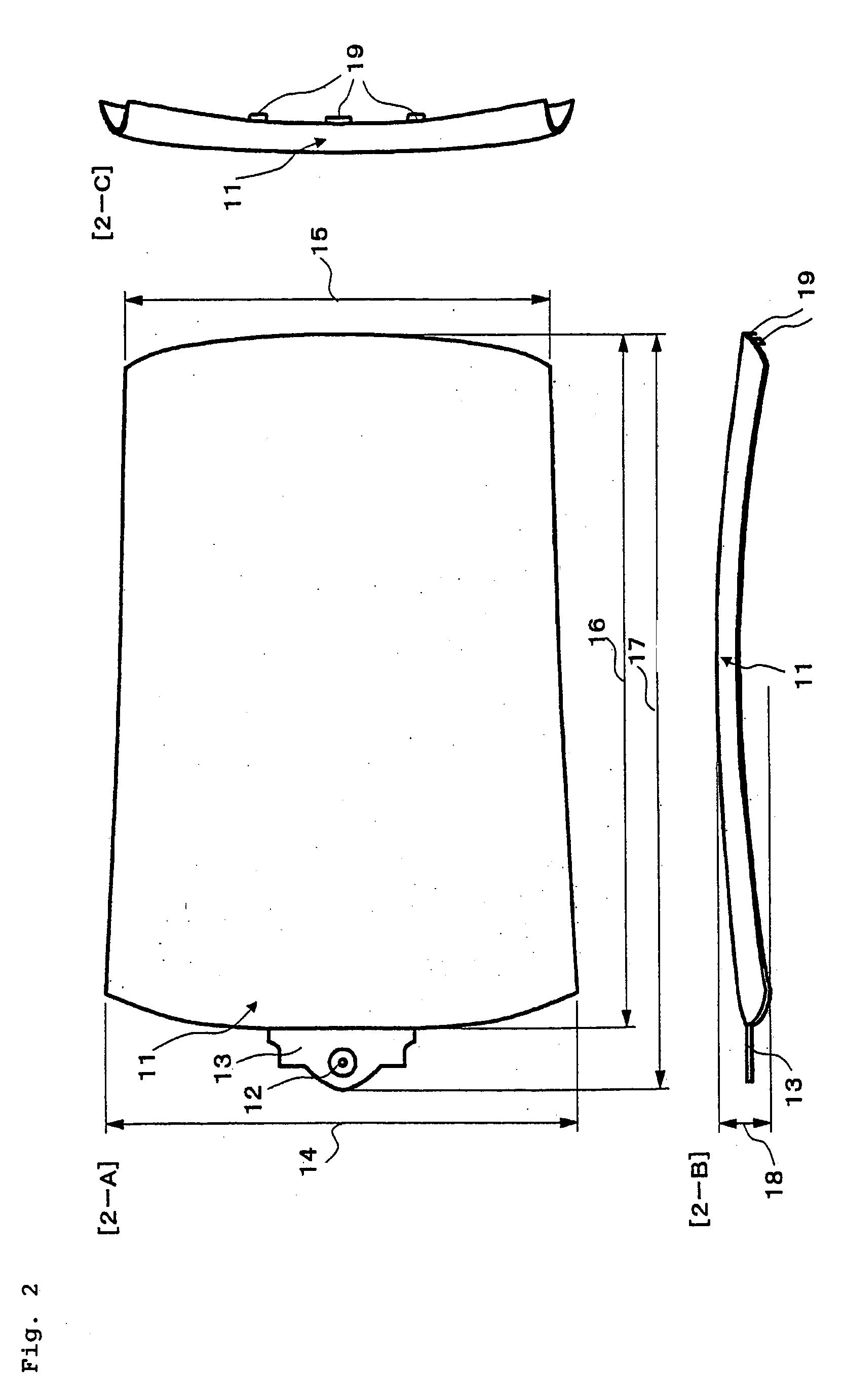

Compound tooling system for molding applications

ActiveUS7972129B2Easy to modifyEvenly heatedAdditive manufacturing apparatusConfectioneryShell moldingMetal mold

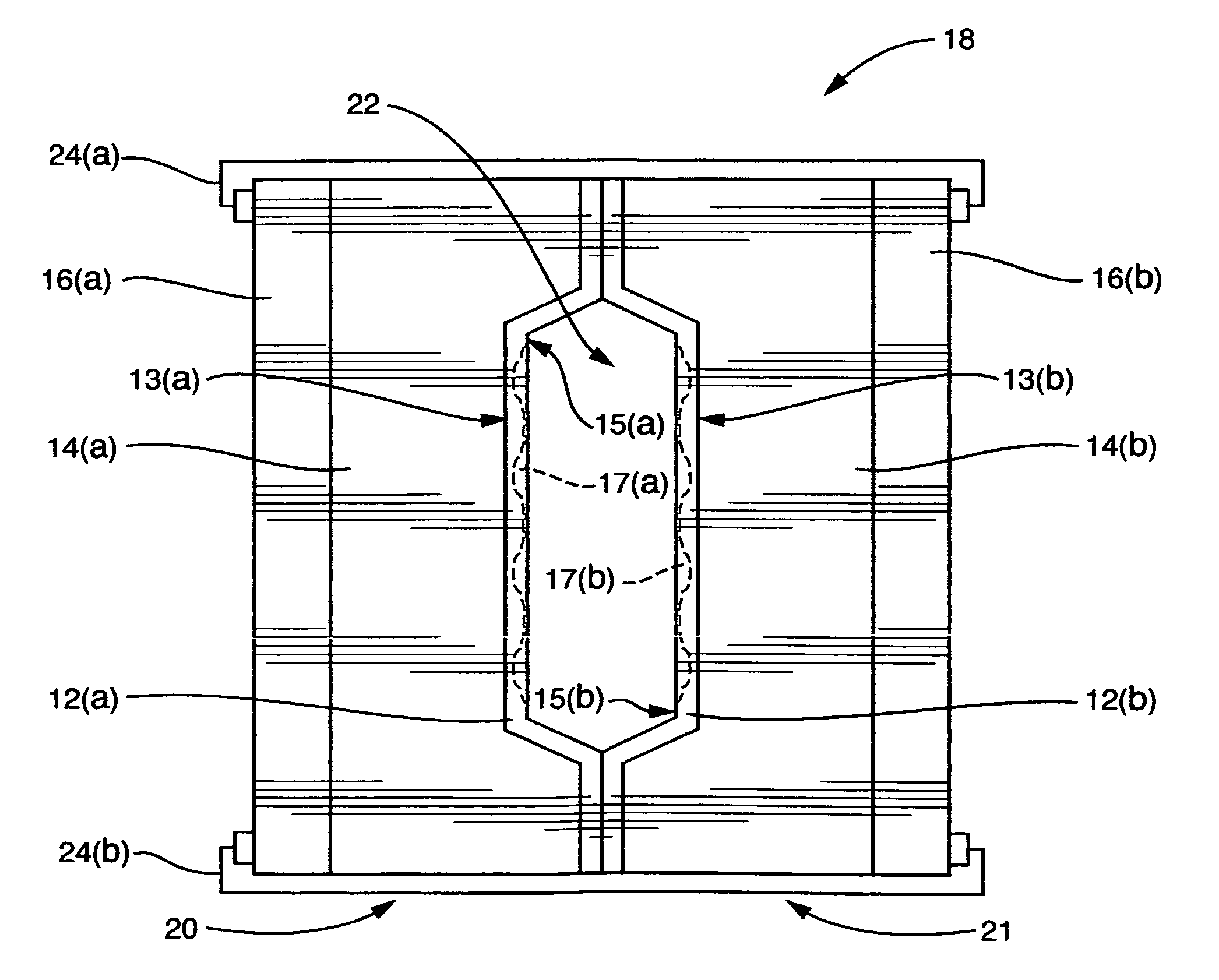

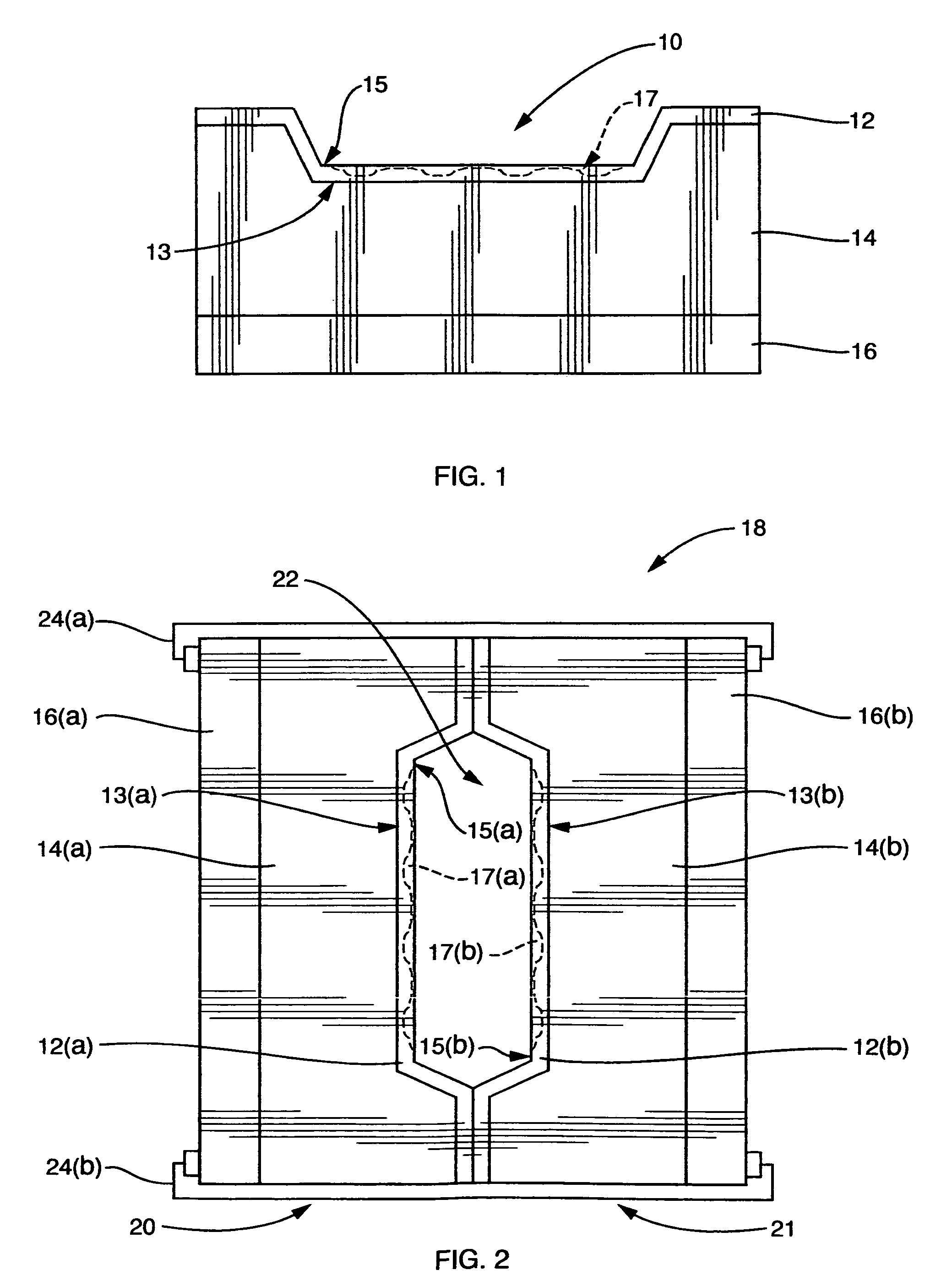

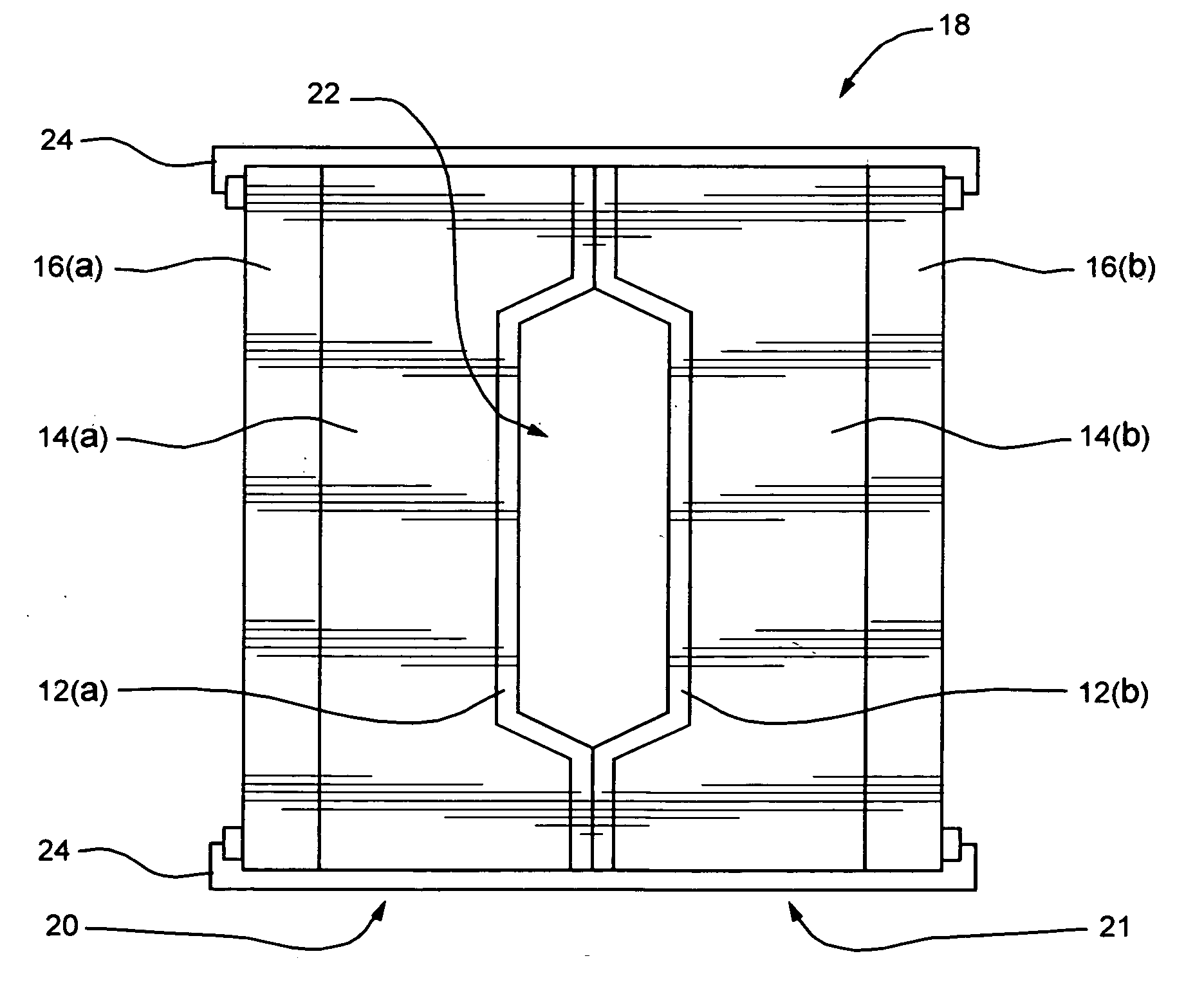

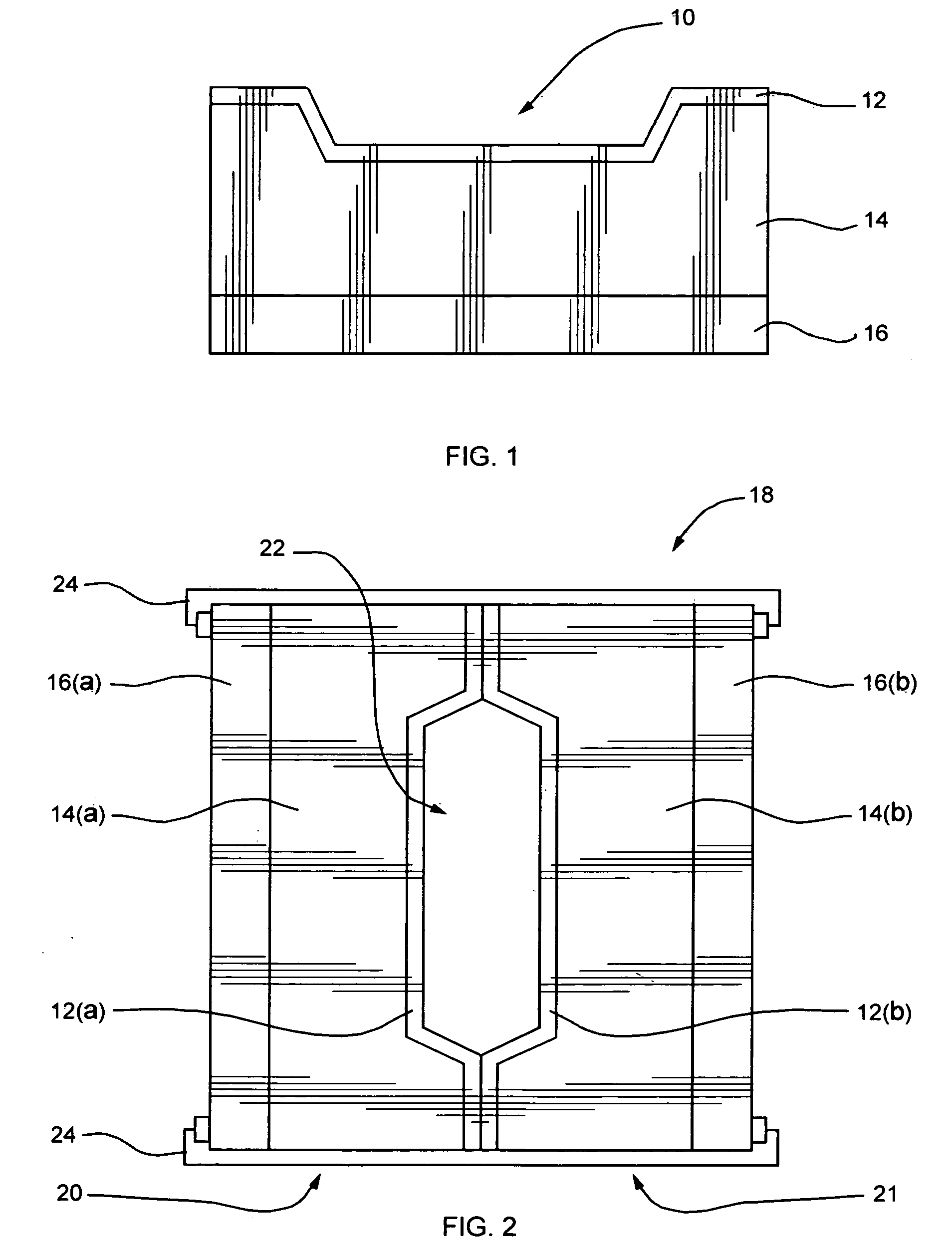

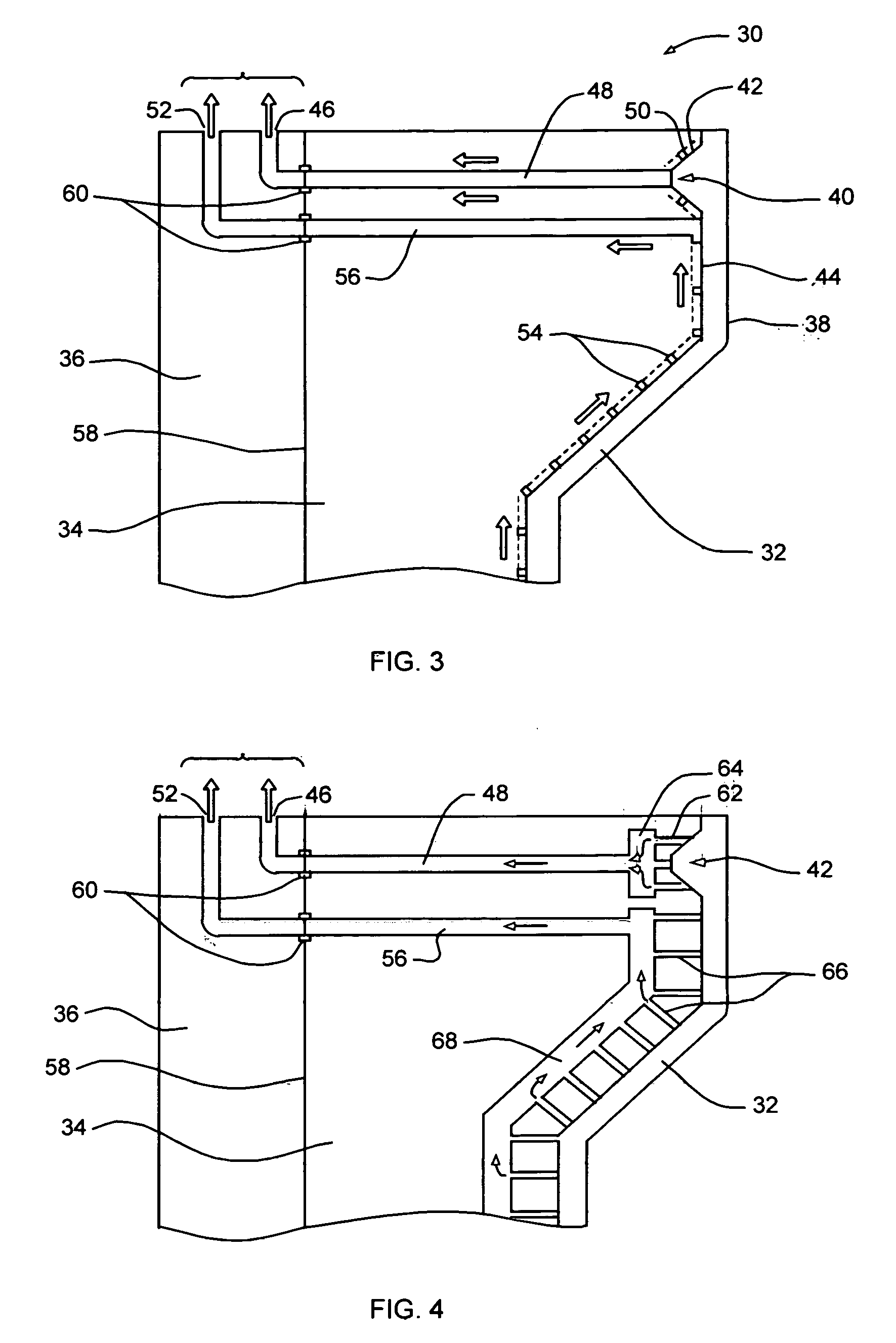

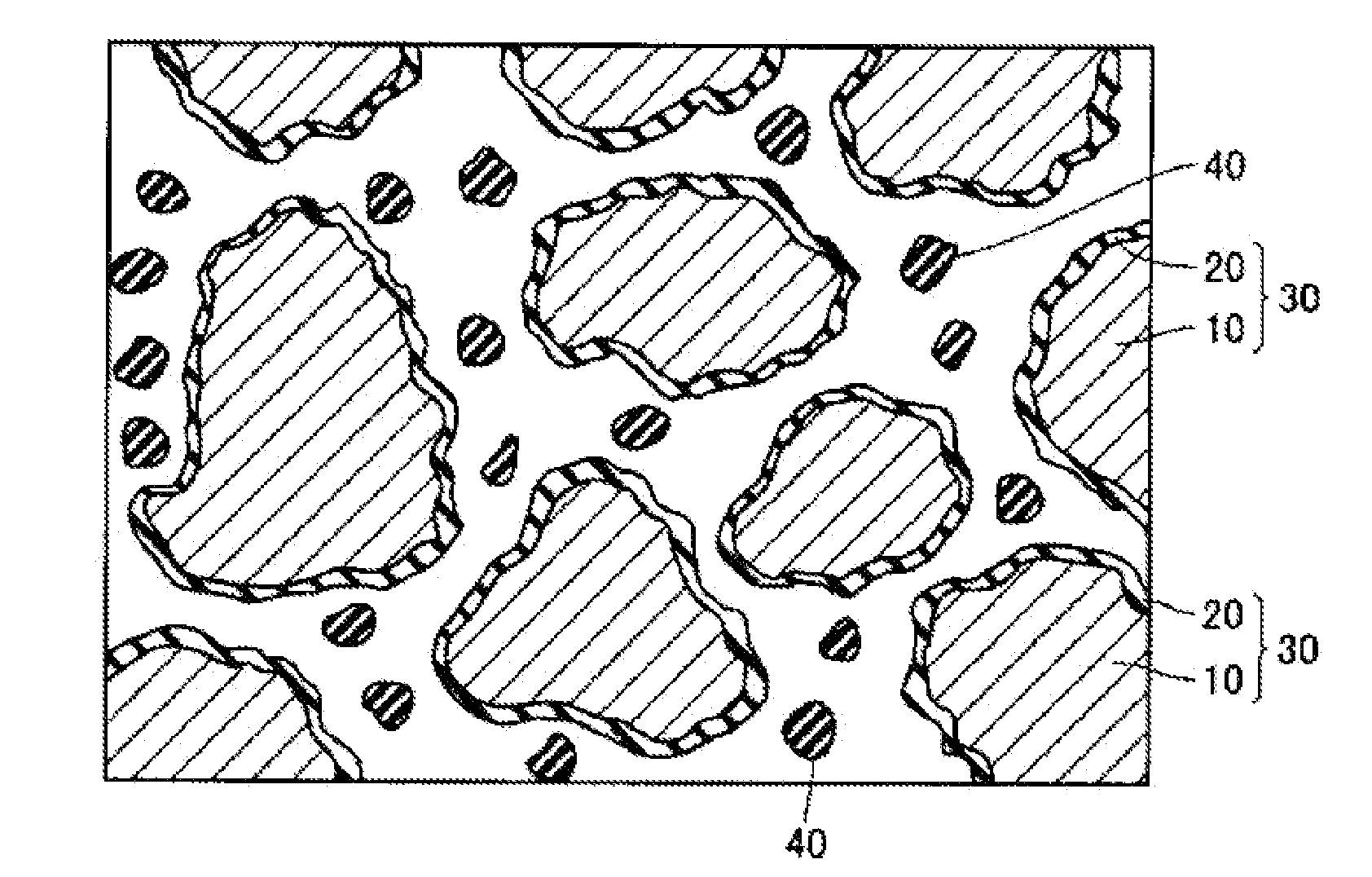

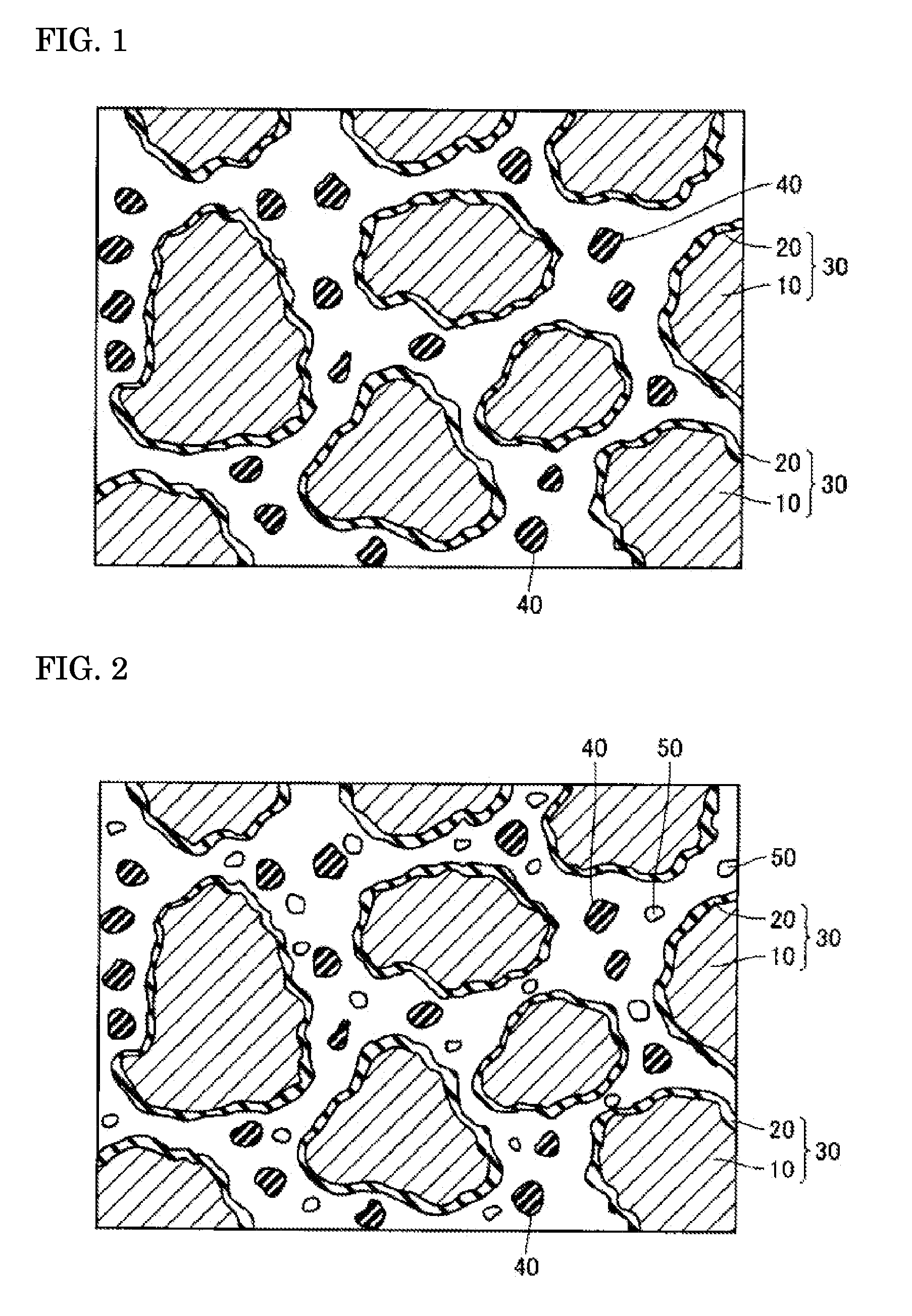

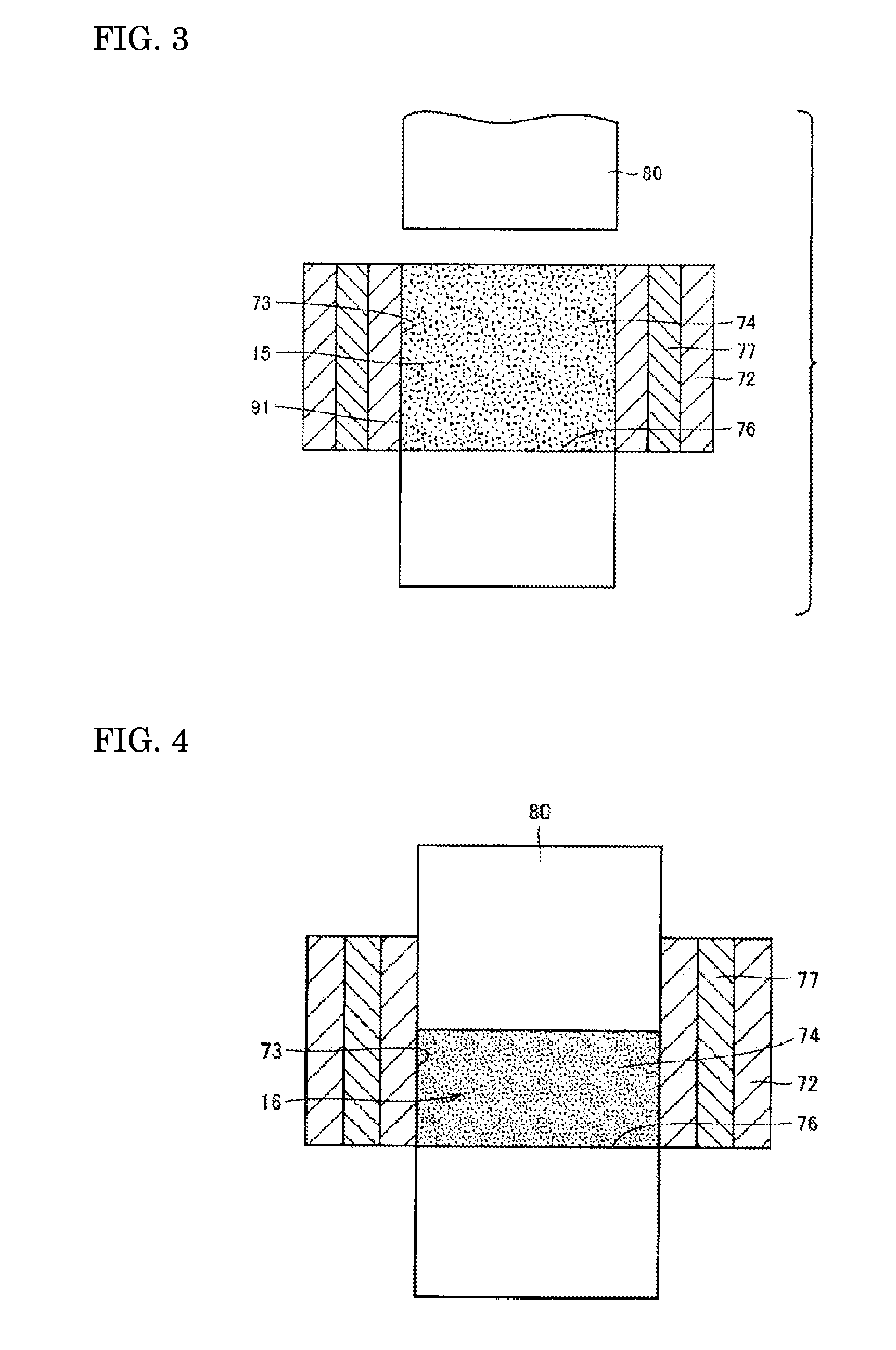

A compound mold or tooling system is designed to provide an alternative to conventional, expensive, metal molds for various plastics molding applications. The compound mold comprises a replaceable thin-walled liner, or skin-mold, defining the mold surface, temporarily bonded by vacuum means or mechanical means to a conforming backing-mold mold body supported by a rigid backing-plate. Both skin- and backing-molds are composed of suitable polymers with or without additives, fillers, reinforcements or other inclusions depending on mold requirements. The backing-plate contains standard features and fixtures common to all molds used in the particular process or of a particular geometry.

Owner:ODONOGHUE JOSEPH

Compound tooling system for molding applications

ActiveUS20070063378A1Accurate operationFacilitate partial removalAdditive manufacturing apparatusConfectioneryShell moldingMetal mold

A compound mold or tooling system is designed to provide an alternative to conventional, expensive, metal molds for various plastics molding applications. The compound mold comprises a replaceable thin-walled liner, or skin-mold, defining the mold surface, temporarily bonded by vacuum means or mechanical means to a conforming backing-mold mold body supported by a rigid backing-plate. Both skin- and backing-molds are composed of suitable polymers with or without additives, fillers, reinforcements or other inclusions depending on mold requirements. The backing-plate contains standard features and fixtures common to all molds used in the particular process or of a particular geometry.

Owner:ODONOGHUE JOSEPH

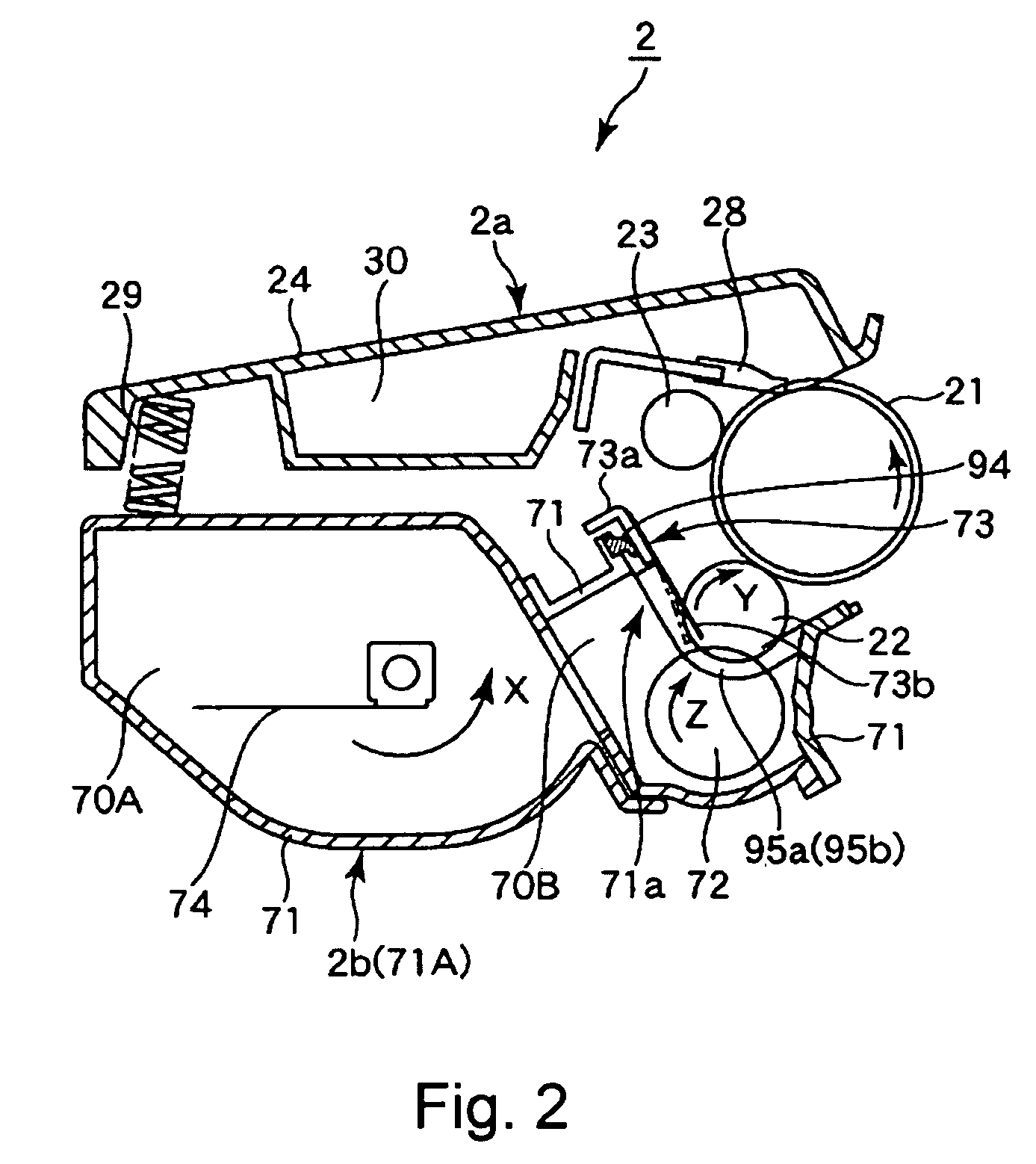

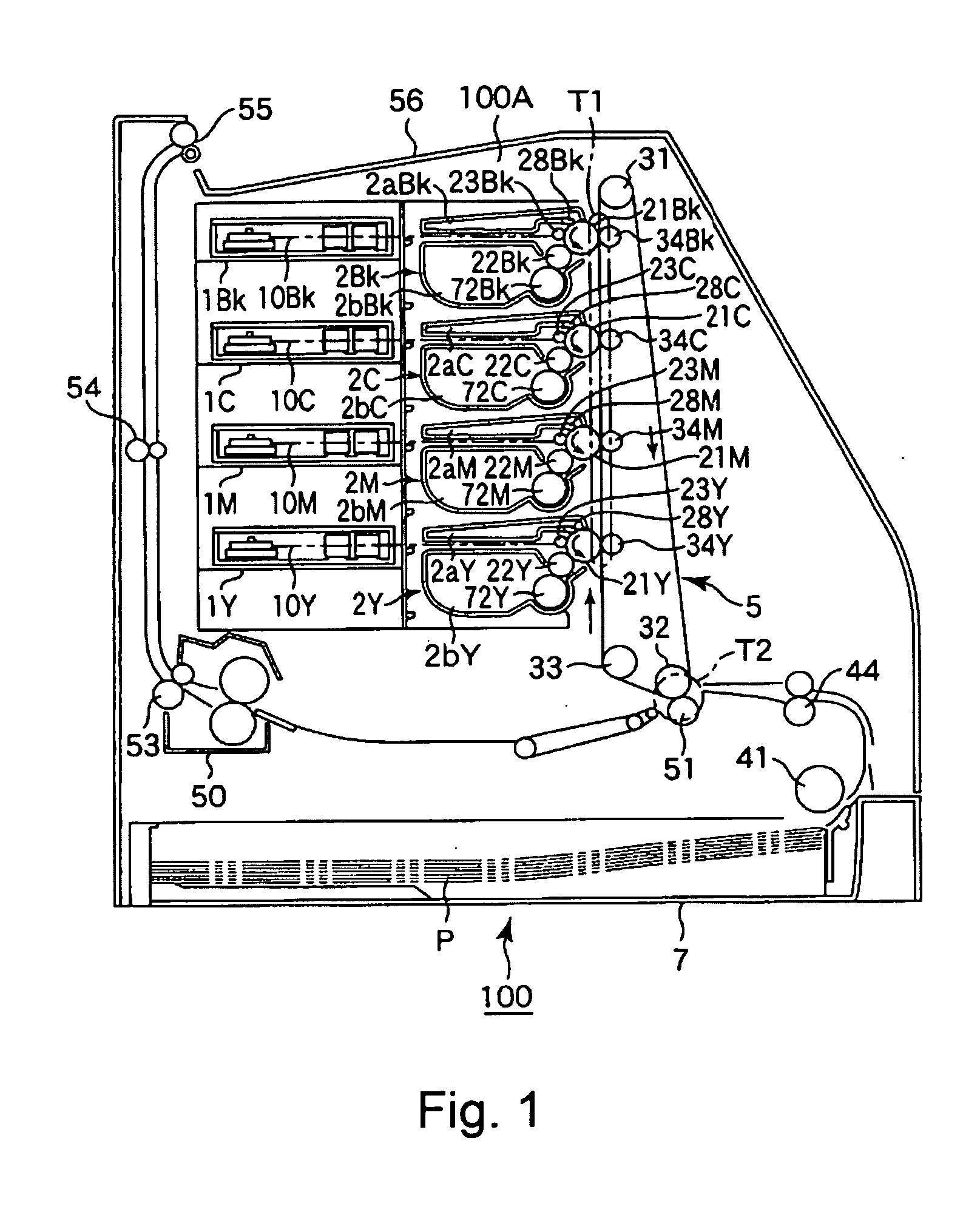

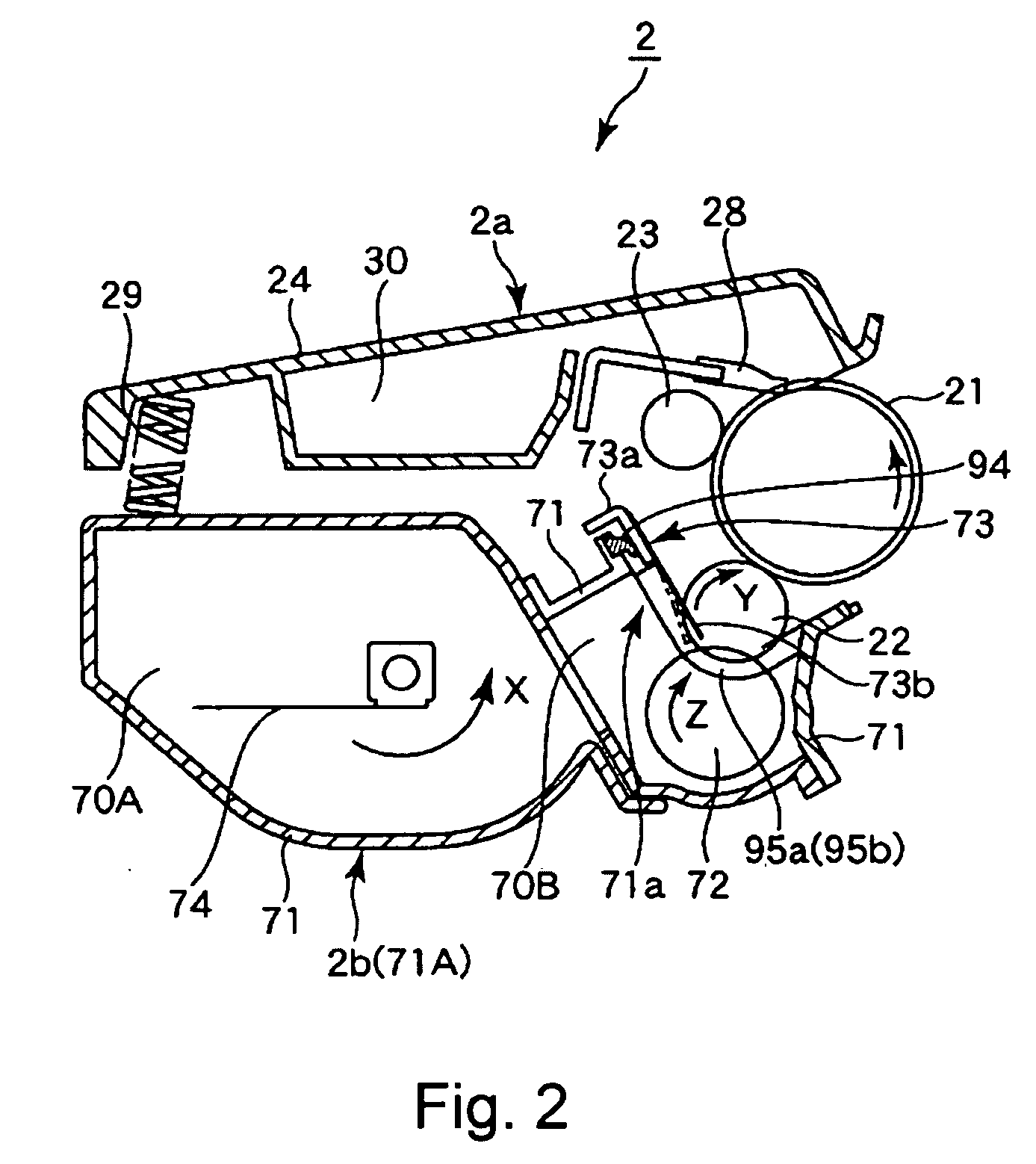

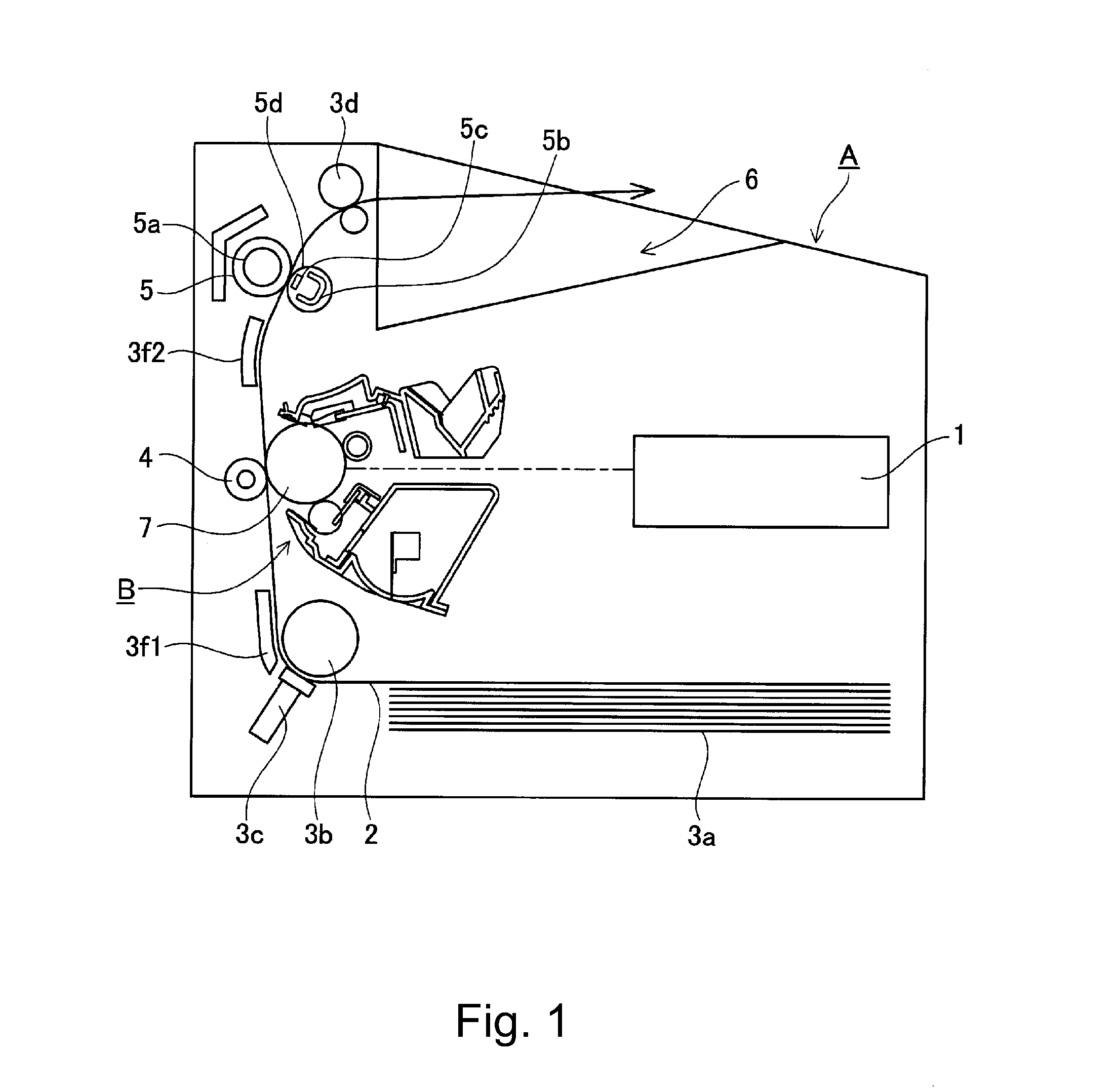

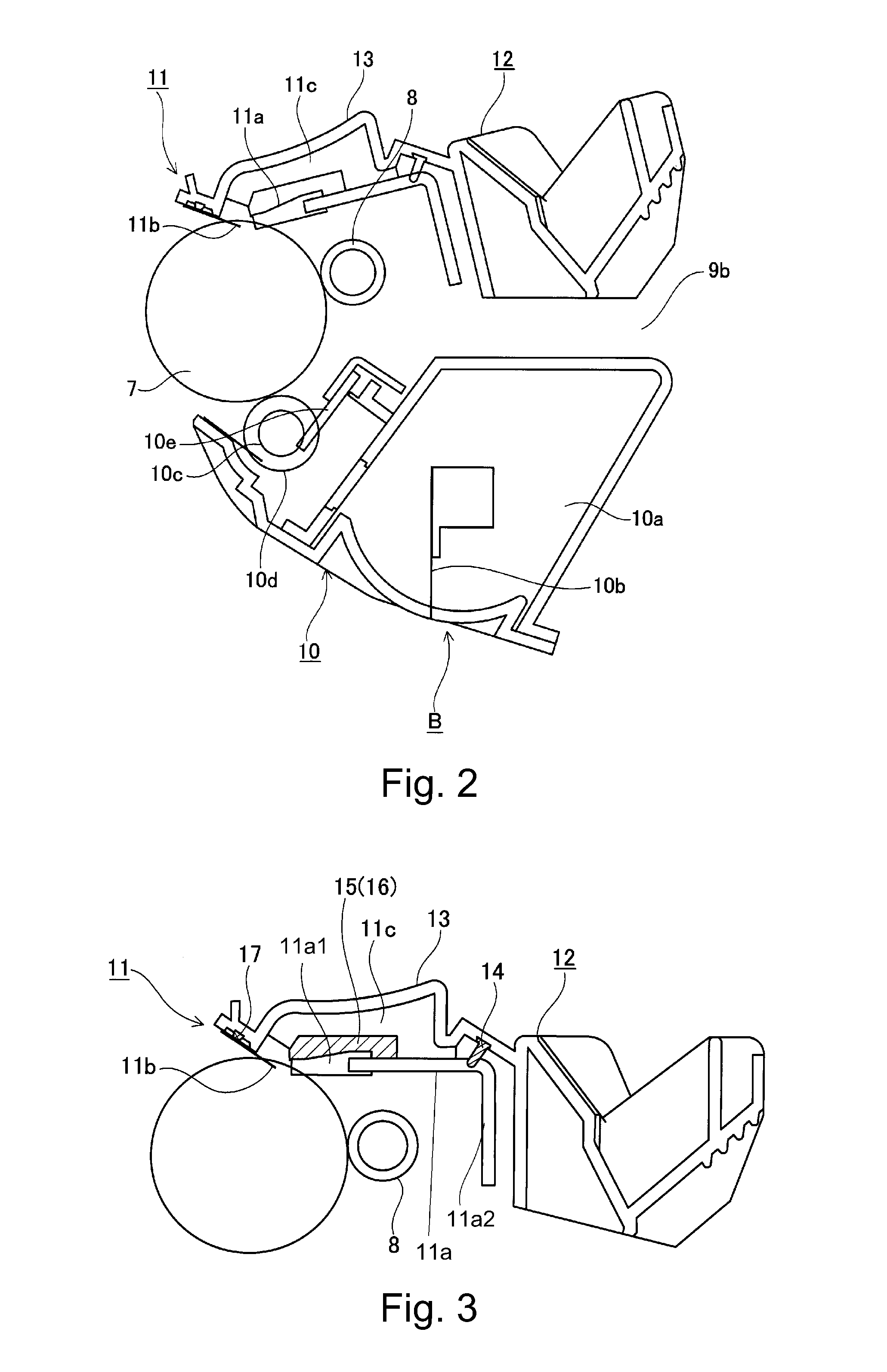

Developing device frame unit, developing device, process cartridge, and manufacturing method of the developing device frame unit

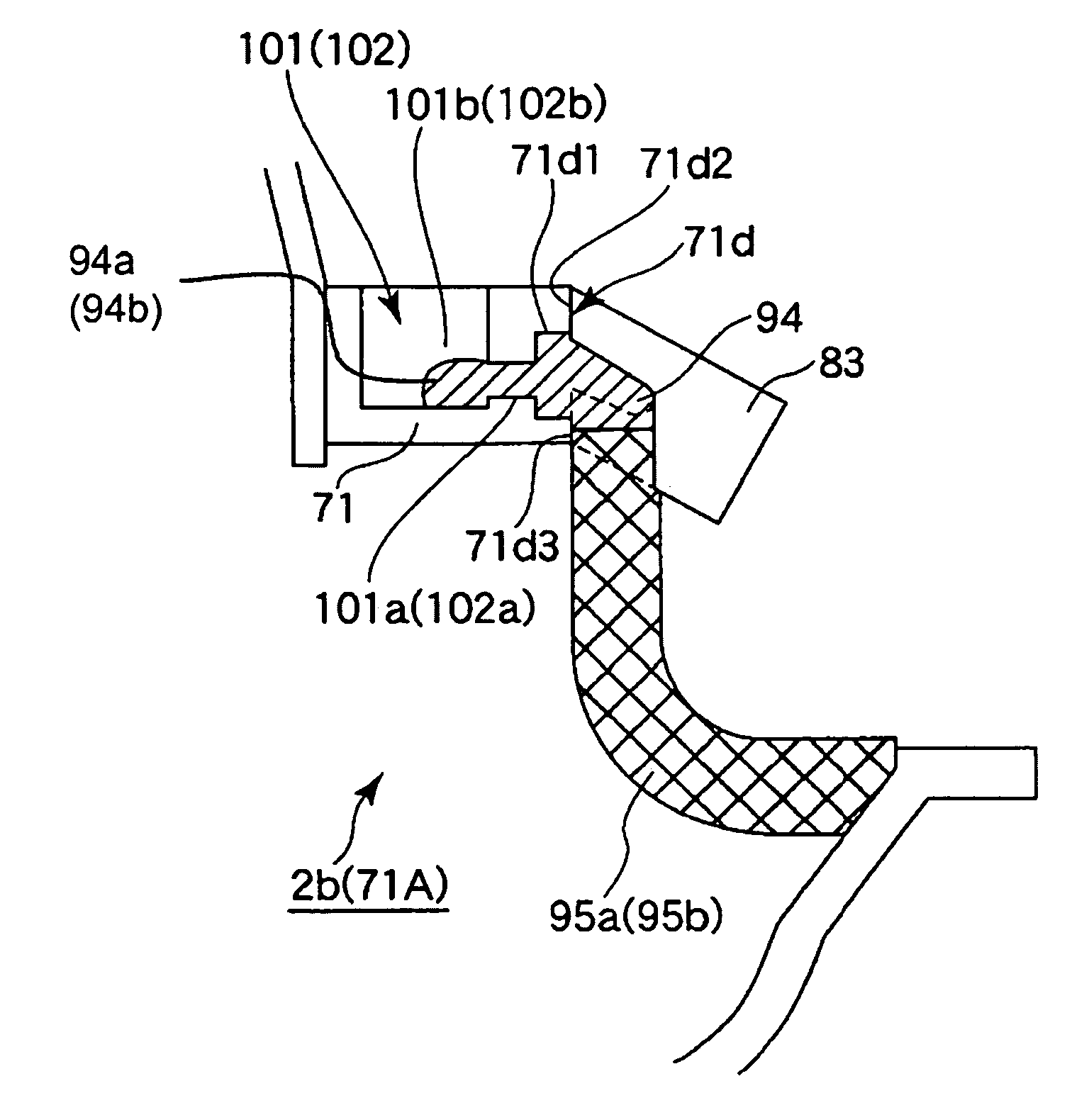

ActiveUS7933534B2Improve sealingReduce component countElectrographic process apparatusElastomerEngineering

A developing device frame unit supporting a regulating member regulating the layer thickness of developer on a developer carrier. The unit includes a frame having a seal forming portion, first and second, first and second end seals contactable to the carrier surface to prevent carrier-axial-direction leaking of the developer, and a blade sealer sealing between the regulating member and the frame to prevent developer leaking when the regulating member is mounted. The blade sealer is an elastomer resin material which is injection-molded with a metal mold and in the seal forming portion where the end seals are provided. The blade sealer connects the end seals with each other, and a protrusion provided by a squeezed-out portion of the resin material is provided by injecting, into a space defined by the metal mold, the seal forming portion, and the end seal seals, a resin material volume larger than a volume of the space.

Owner:CANON KK

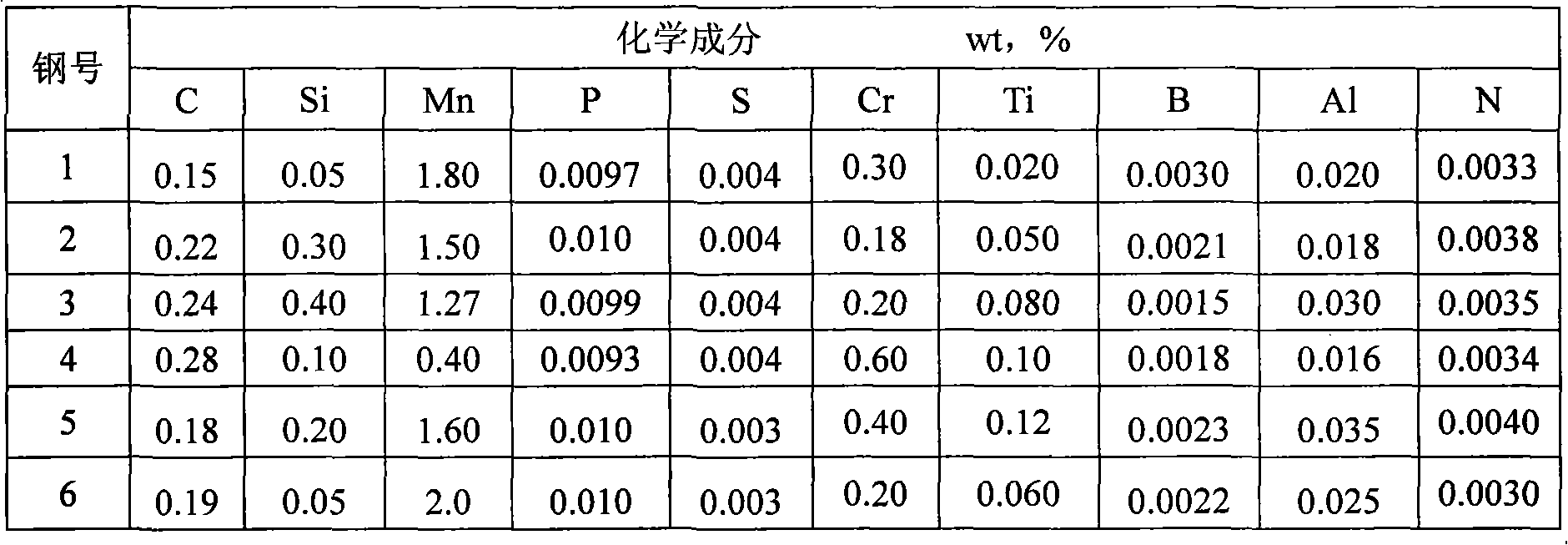

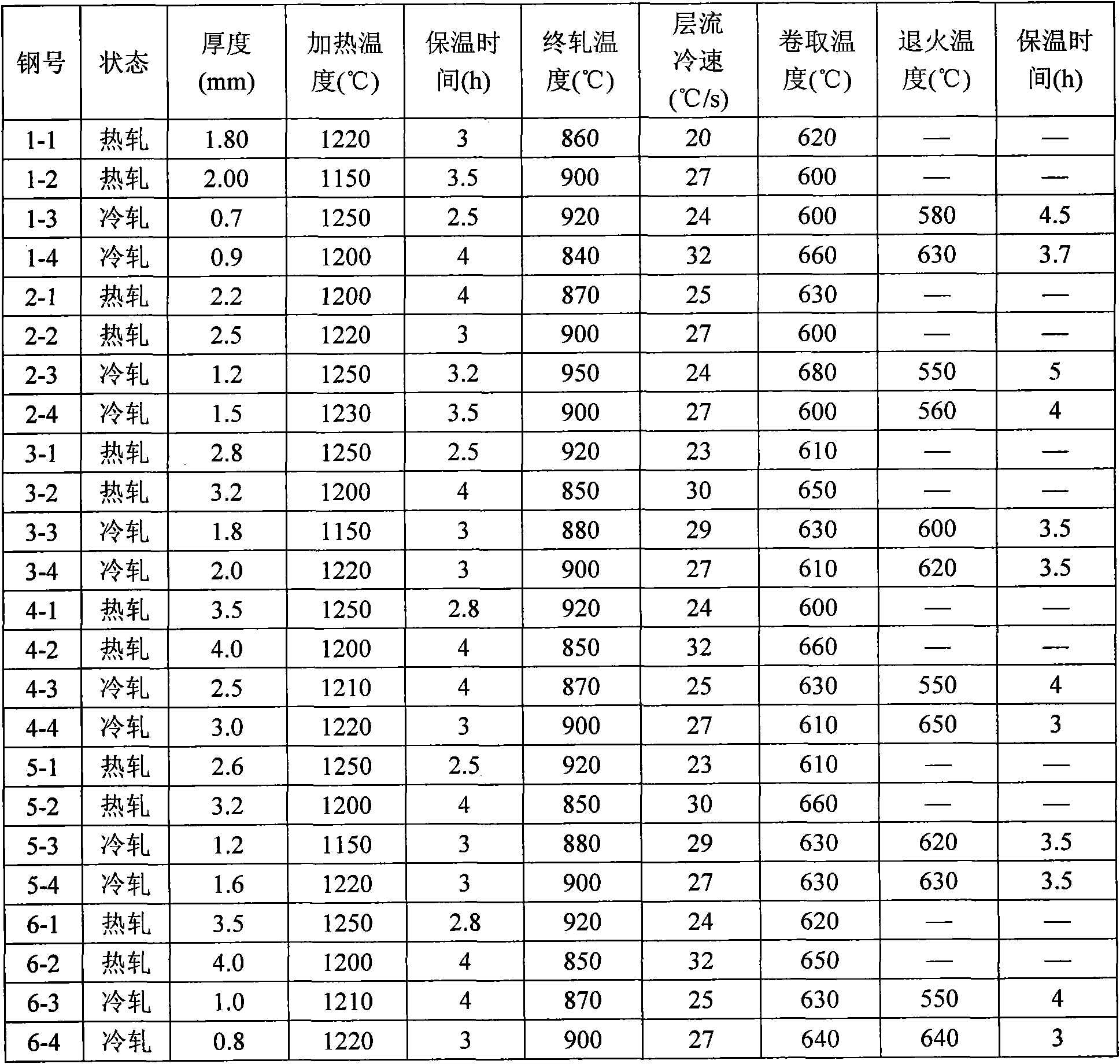

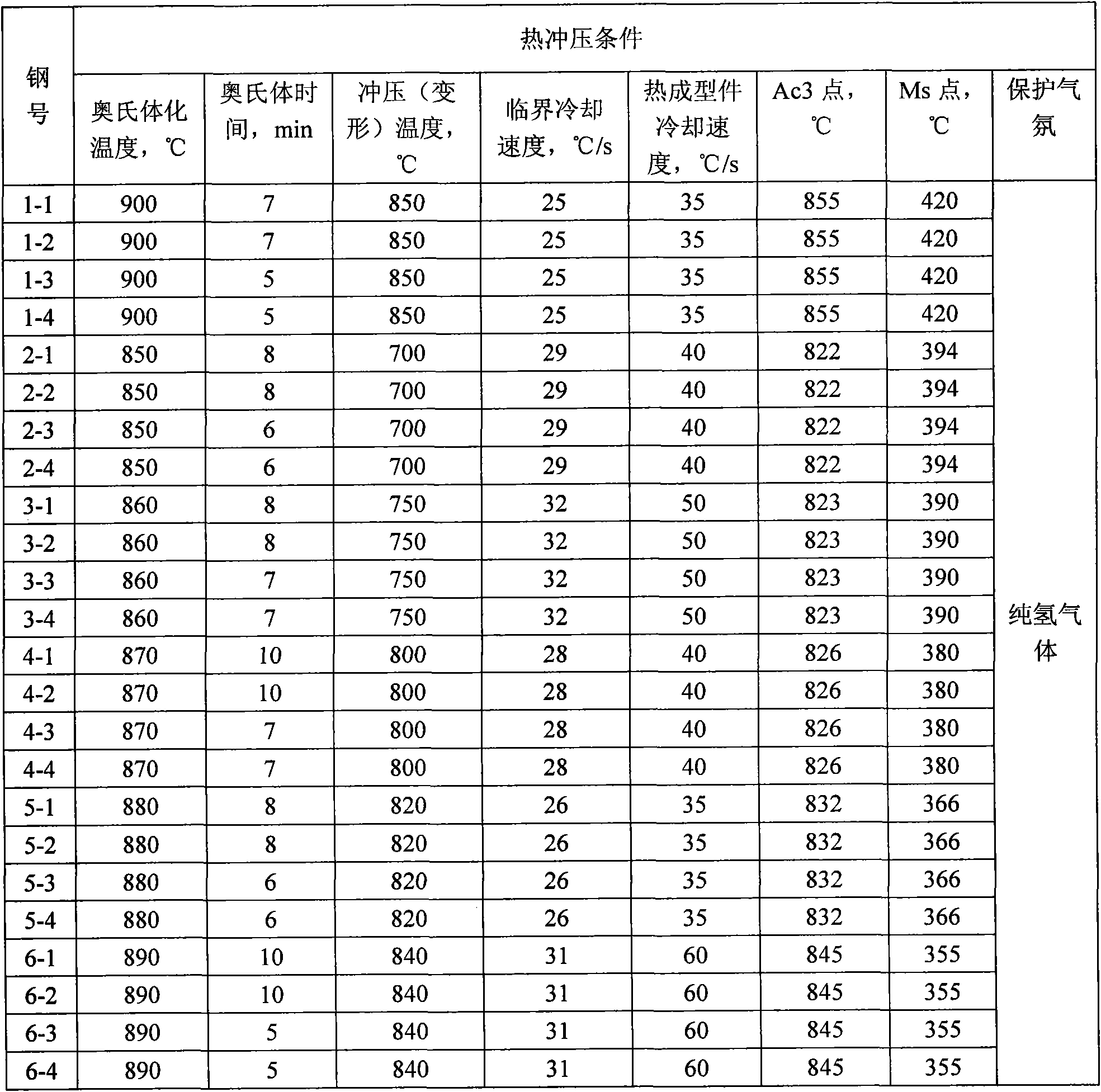

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

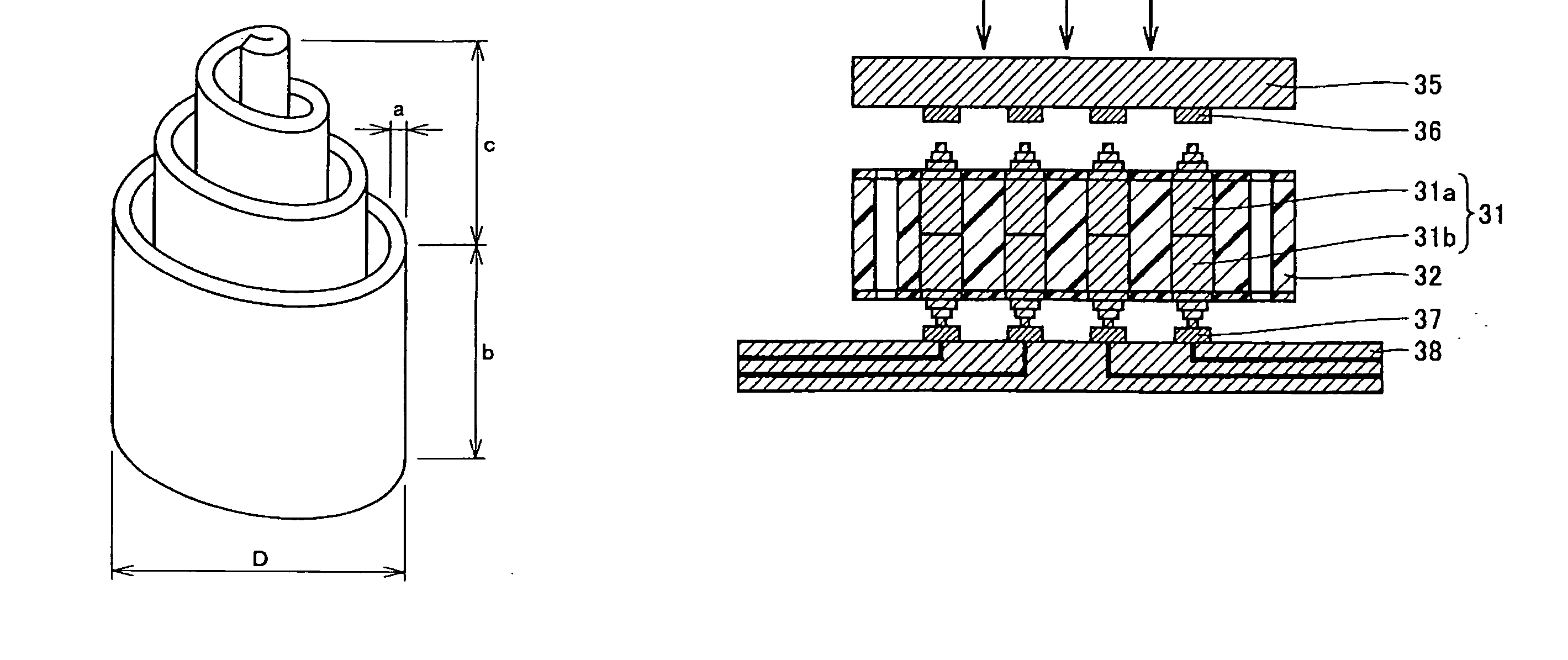

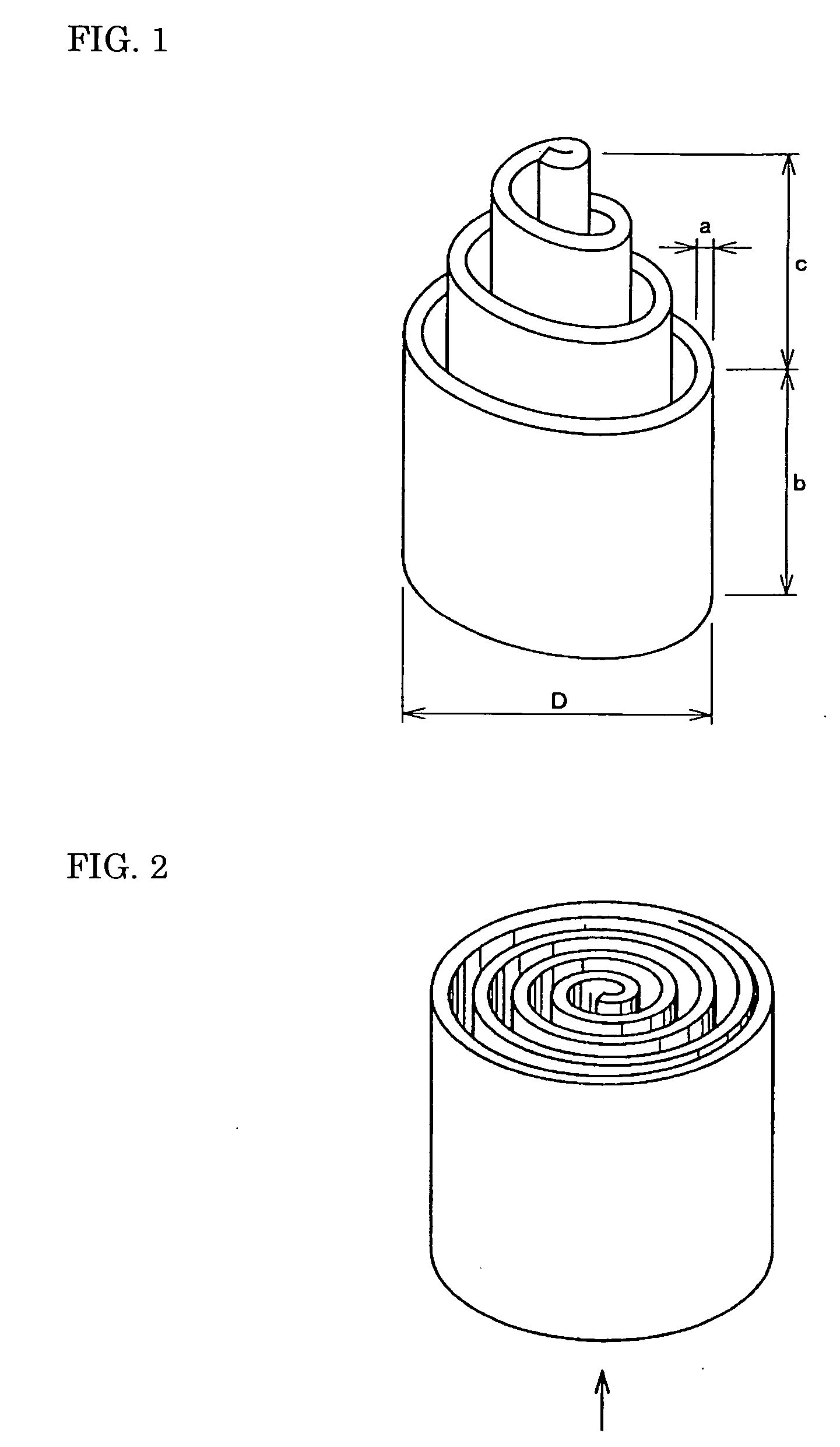

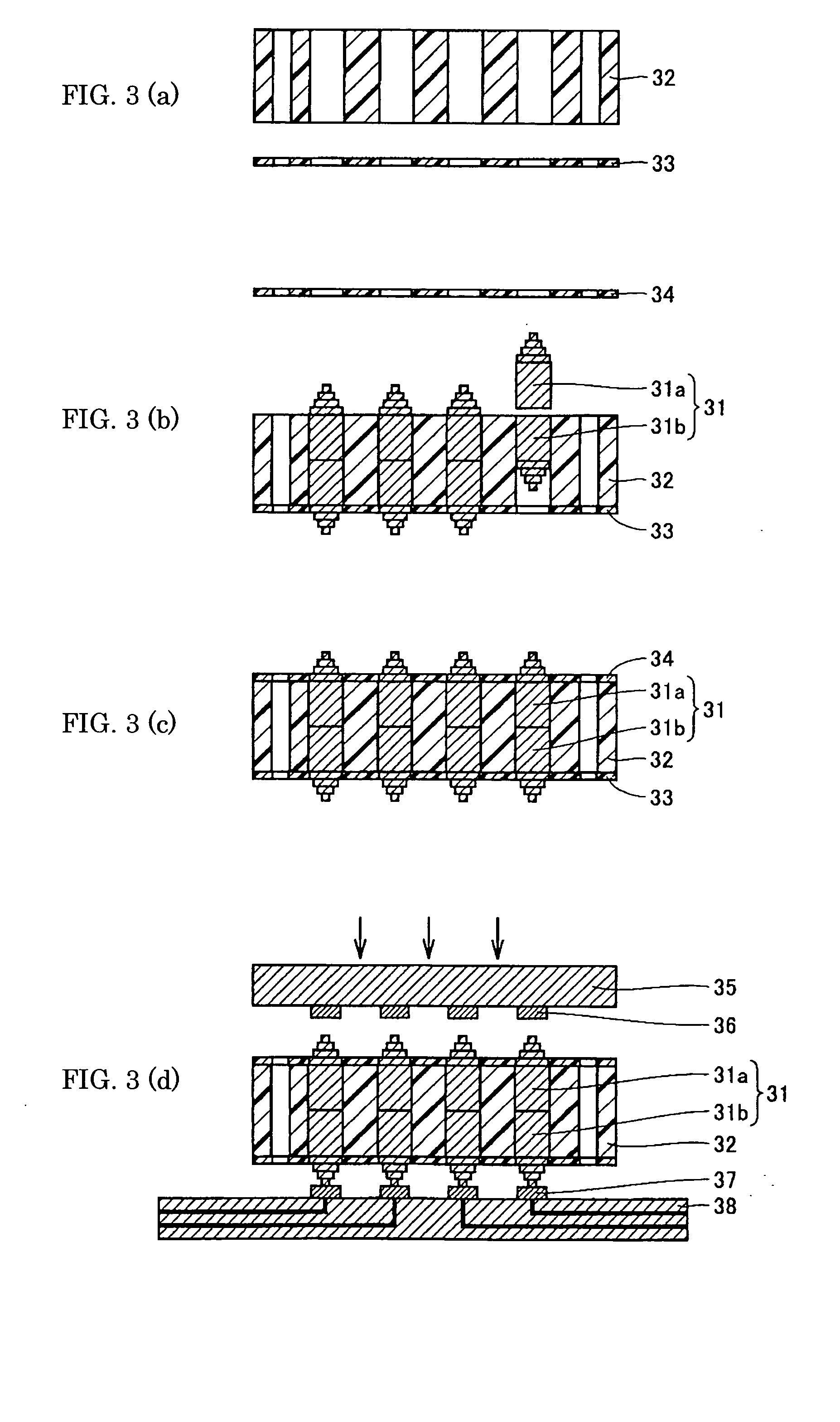

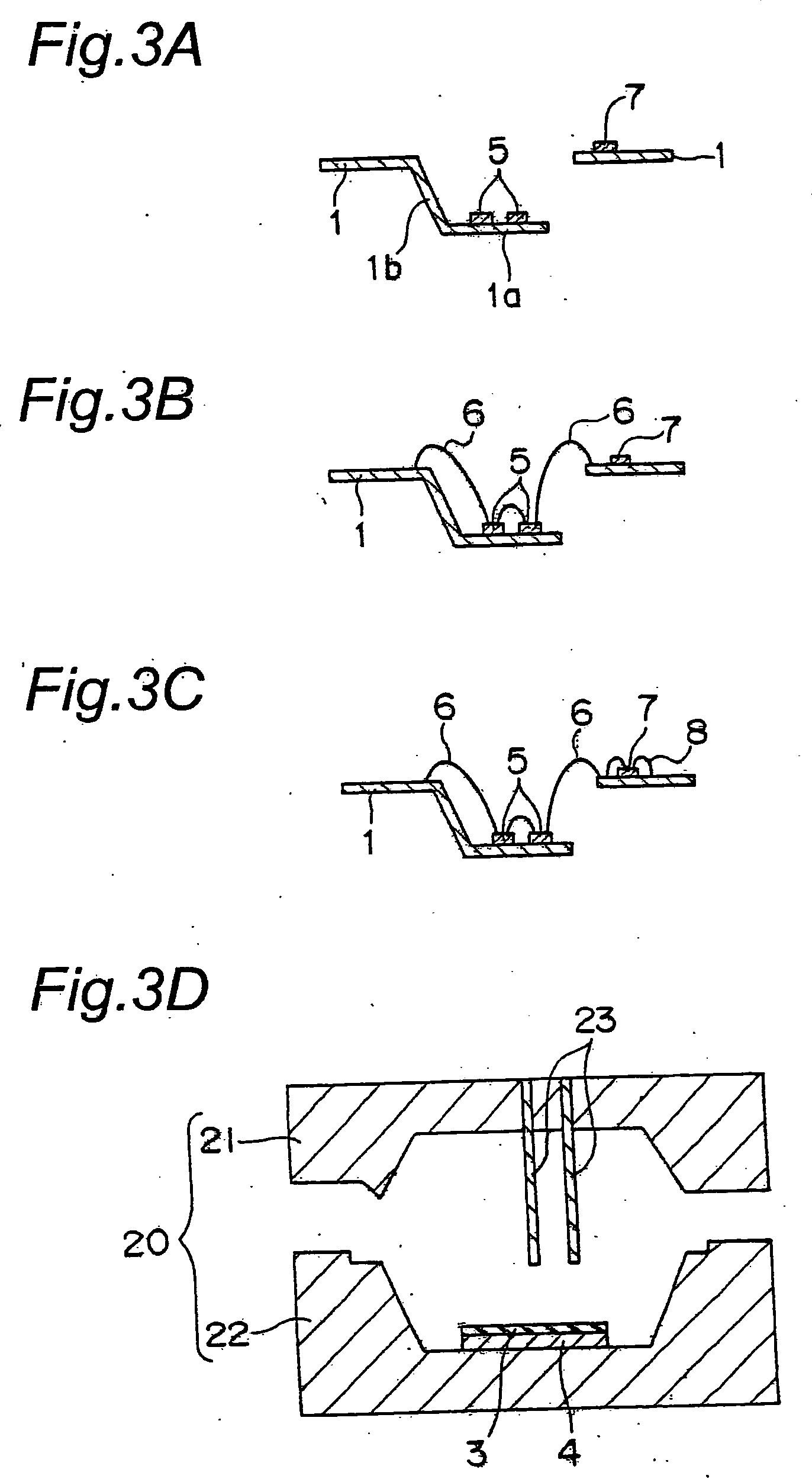

Method of manufacturing protruding-volute contact, contact made by the method, and inspection equipment or electronic equipment having the contact

InactiveUS20050088193A1Low costImprove reliabilityContact member manufacturingManufacture of electrical instrumentsCouplingCoil spring

A method of manufacturing a protruding-volute contact for attaining electrical continuity with an electrode of electronic equipment or inspection equipment, the method comprising the steps of forming a plastic mold (resist structure) with a metal mold; forming a layer consisting of metallic material on the plastic mold (resist structure) by means of electroforming; and performing convex formation of a metal microstructure made from the layer consisting of metallic material so as to form a spiral spring that protrudes volutedly outward. With such method, an inspection contact or coupling contact having high reliability and capable of attaining electrical continuity of large electric current can be produced at low cost.

Owner:SUMITOMO ELECTRIC IND LTD

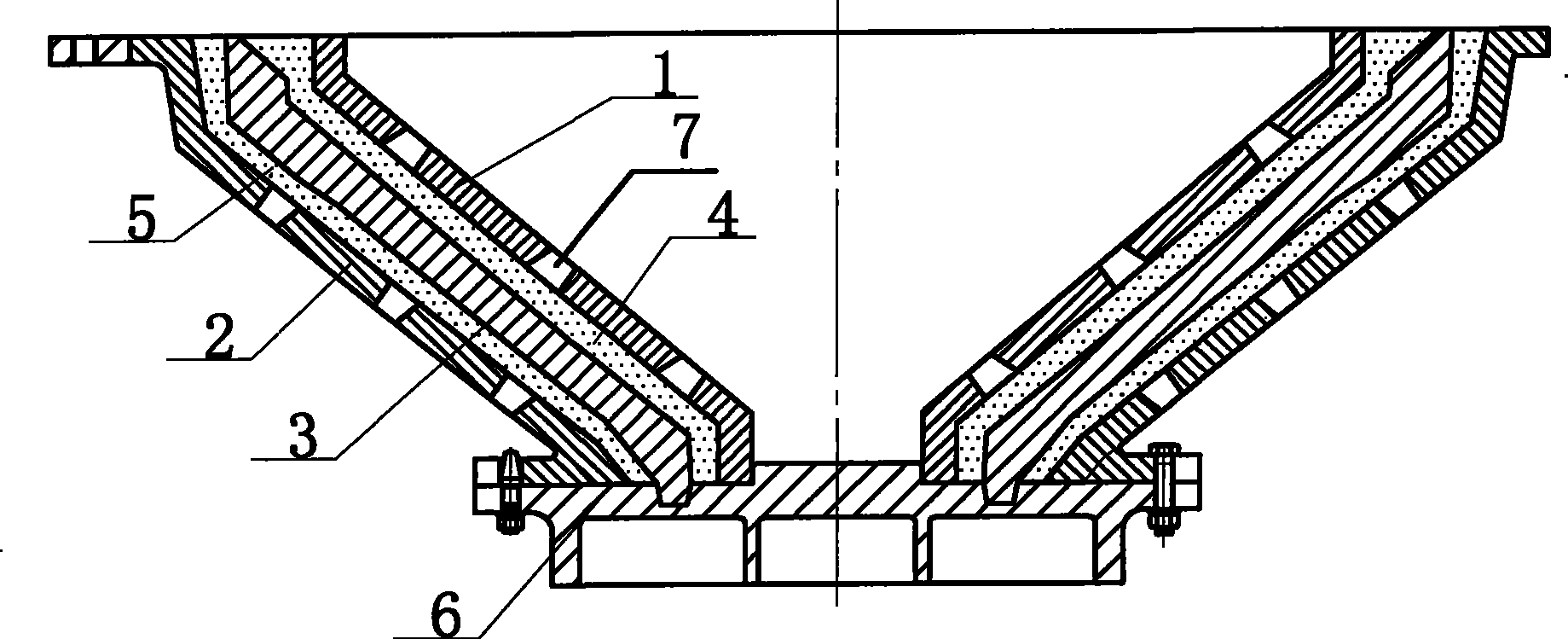

Production method for sand-lined metal mold casting cylinder body

ActiveCN102319873AEliminate tissue shrinkageEliminate defects such as porosityFoundry mouldsFoundry coresMetal moldMaterials science

The invention relates to a production method for a sand-lined metal mold casting cylinder body. In the method, the inner cavity of a metal mold is formed in a mold-following mode according to the shape of the cylinder body, the thickness of a mold-following sand-lined layer is 10 to 30mm, and a closed pouring gate is used; vent wires are arranged in a jet hole on the highest part and a core head part of an upper half mold, and gas exhaust slots are formed on a mold separating plane of the metal mold; heating devices are arranged in the middles of the lower mold base plate and the upper mold base plate of an outer mold, and sand is jetted after the temperature meets a requirement; and a sand core is made and loaded, a box is closed, pouring is performed, and the box is opened. By the method, yield is increased from 69 percent in the conventional sand mold casting to over 83.75 percent in metal mold casting, the defects of subsurface pinholes, a loose structure and the like are substantially overcome, the problem that the cylinder body leaks when working under pressure is solved, the overall mechanical performance is improved, sand treatment equipment, fields and a sand using quantity are reduced, and the severe environment of casting is improved. The production method is easy to control, the process flow is simple, and the production cost of the production method is 30 to 50 percent lower than that of a sand mold casting method.

Owner:广西玉柴铸造有限公司

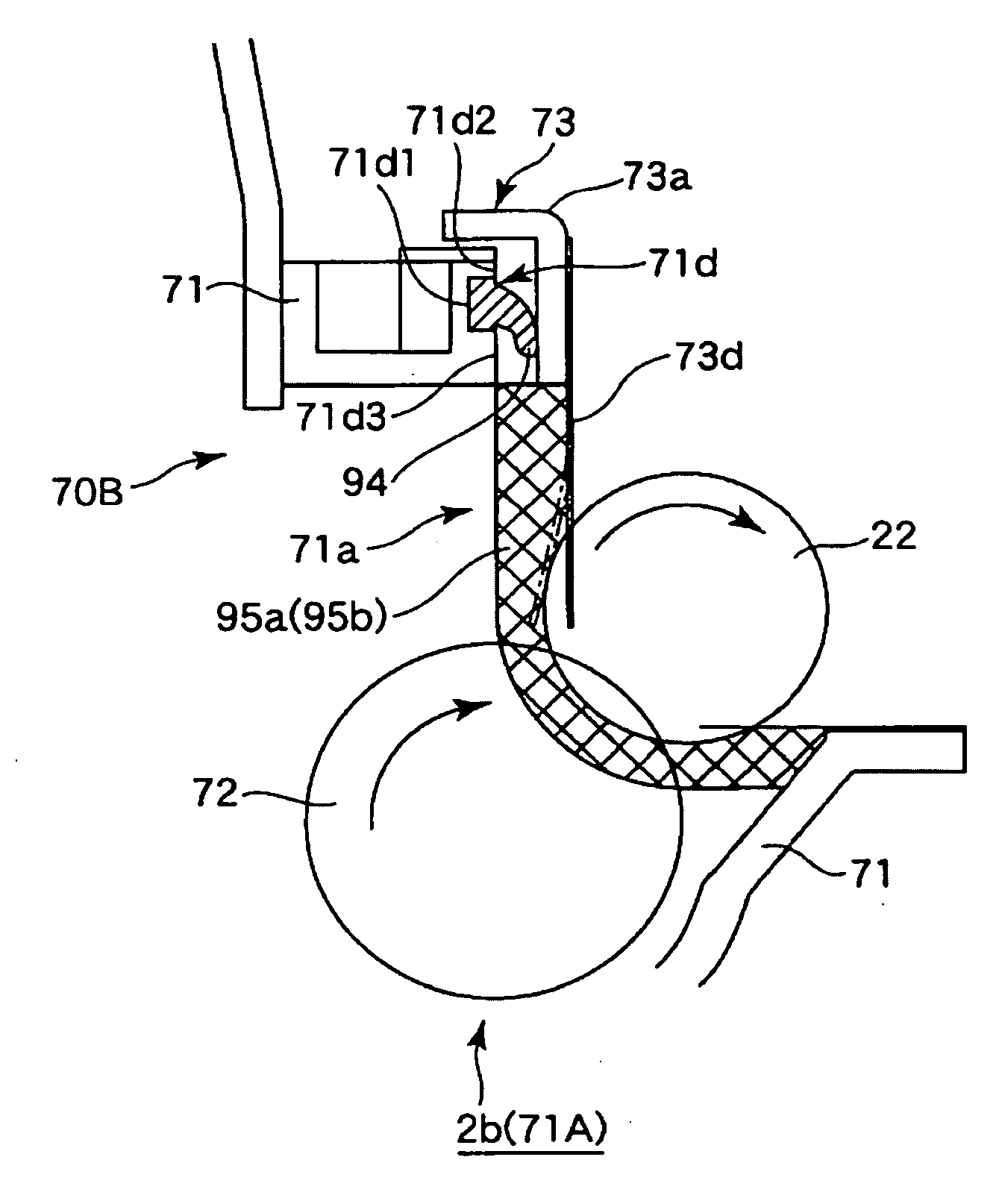

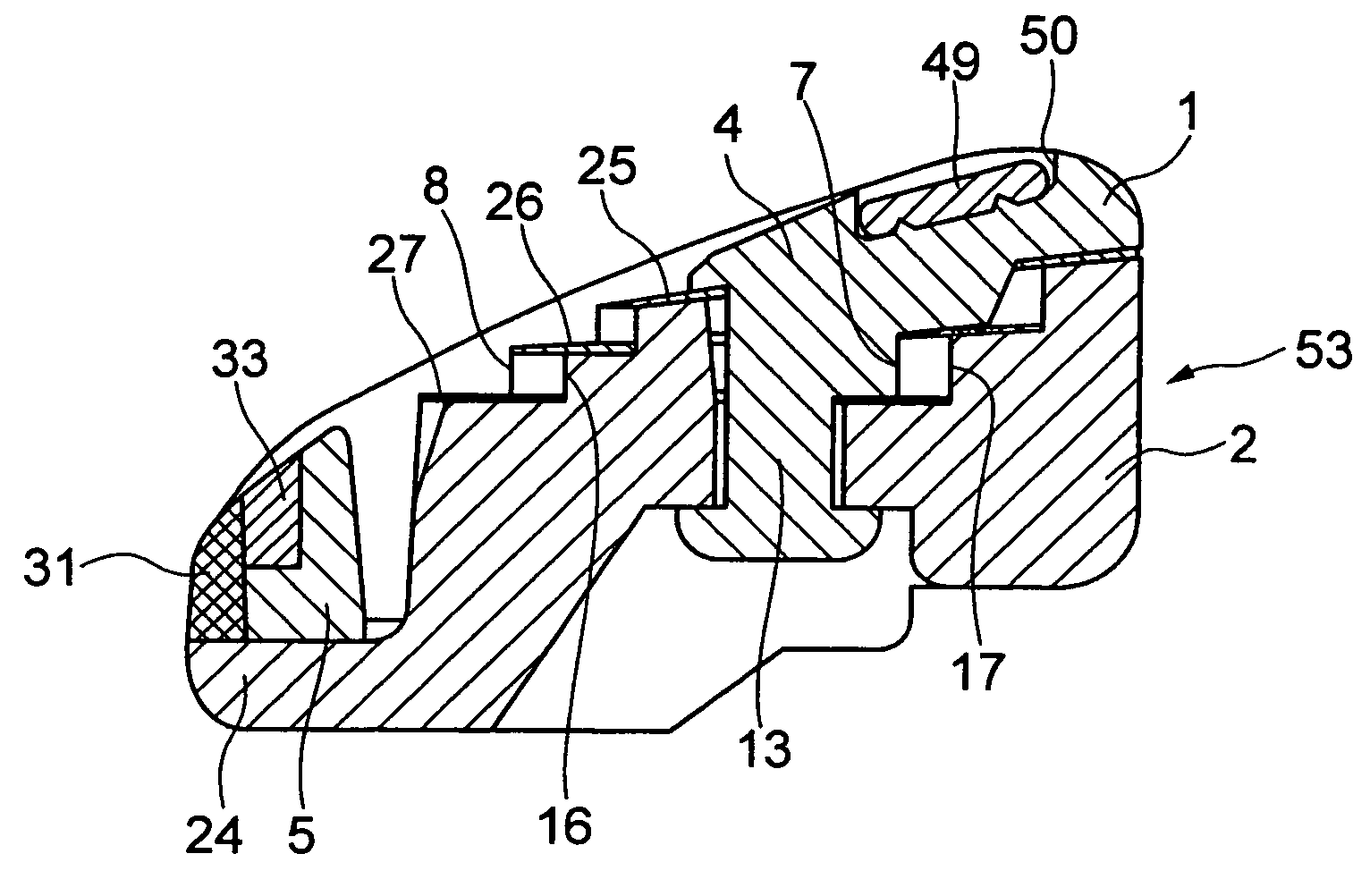

Developing device frame unit, developing device, process cartridge, and manufacturing method of the developing device frame unit

ActiveUS20090245851A1Improve sealingReduce component countElectrographic process apparatusElastomerEngineering

A developing device frame unit supporting a regulating member regulating the layer thickness of developer on a developer carrier. The unit includes a frame having a seal forming portion, first and second end seals contactable to the carrier surface to prevent carrier-axial-direction leaking of the developer, and a blade sealer sealing between the regulating member and the frame to prevent developer leaking when the regulating member is mounted. The blade sealer is an elastomer resin material which is injection-molded with a metal mold and in the seal forming portion where the end seals are provided. The blade sealer connects the end seals with each other, and a protrusion provided by a squeezed-out portion of the resin material is provided by injecting, into a space defined by the metal mold, the seal forming portion, and the end seals, a resin material volume larger than a volume of the space.

Owner:CANON KK

Polycarbonate resin composition and molded articles thereof

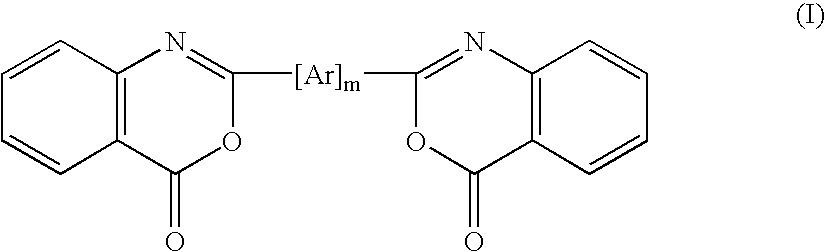

ActiveUS20050215750A1Improve heat stabilityExcellent releasabilityCeramic shaping apparatusAlcoholPolyol

A polycarbonate resin composition comprising 100 parts by weight of a polycarbonate resin (component A), 0.01 to 10 parts by weight of at least one ultraviolet light absorber (component B) selected from the group of a specific cyclic imino ester, and 0.01 to 1 part by weight of a fatty acid ester compound (component C) which is an ester of a polyhydric alcohol and an aliphatic carboxylic acid and has a molecular weight of 500 to 2,000 g / mol, as well as molded articles thereof. The polycarbonate resin composition provides molded articles having excellent transparency, color and resistance to ultraviolet radiation, is excellent in heat stability at the time of molding and releasability and fully suppresses the production of a deposit on a metal mold.

Owner:TEIJIN CHEM LTD

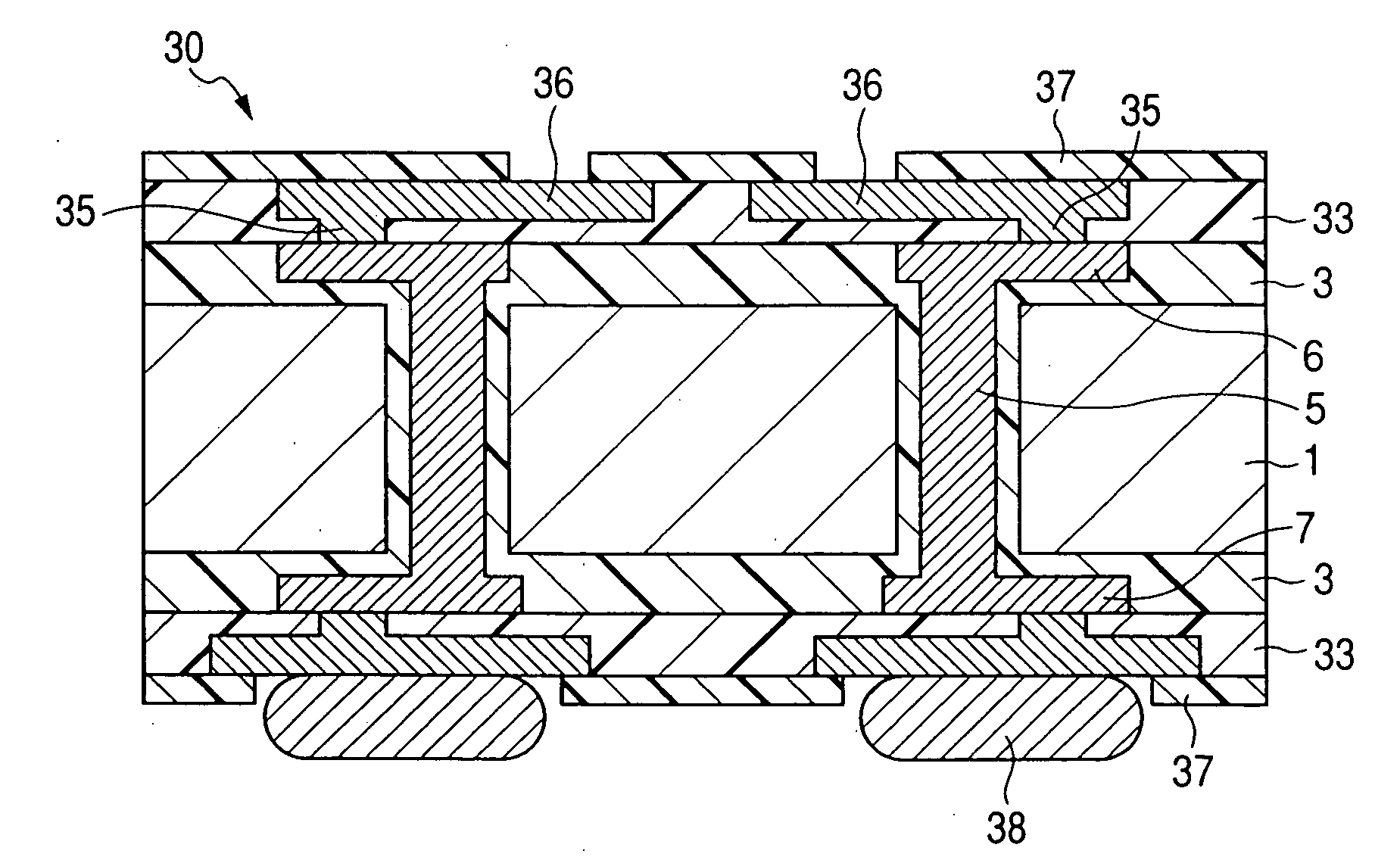

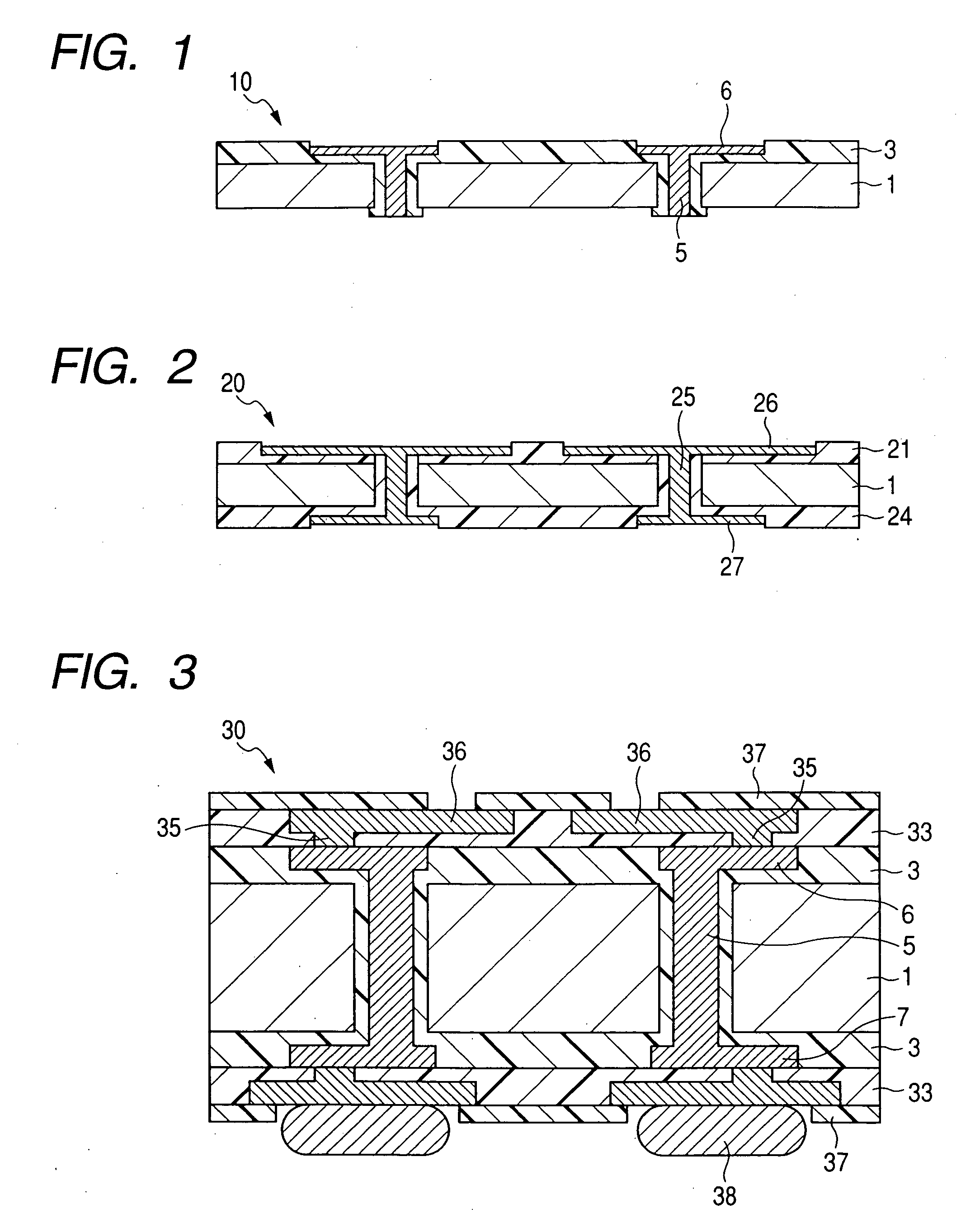

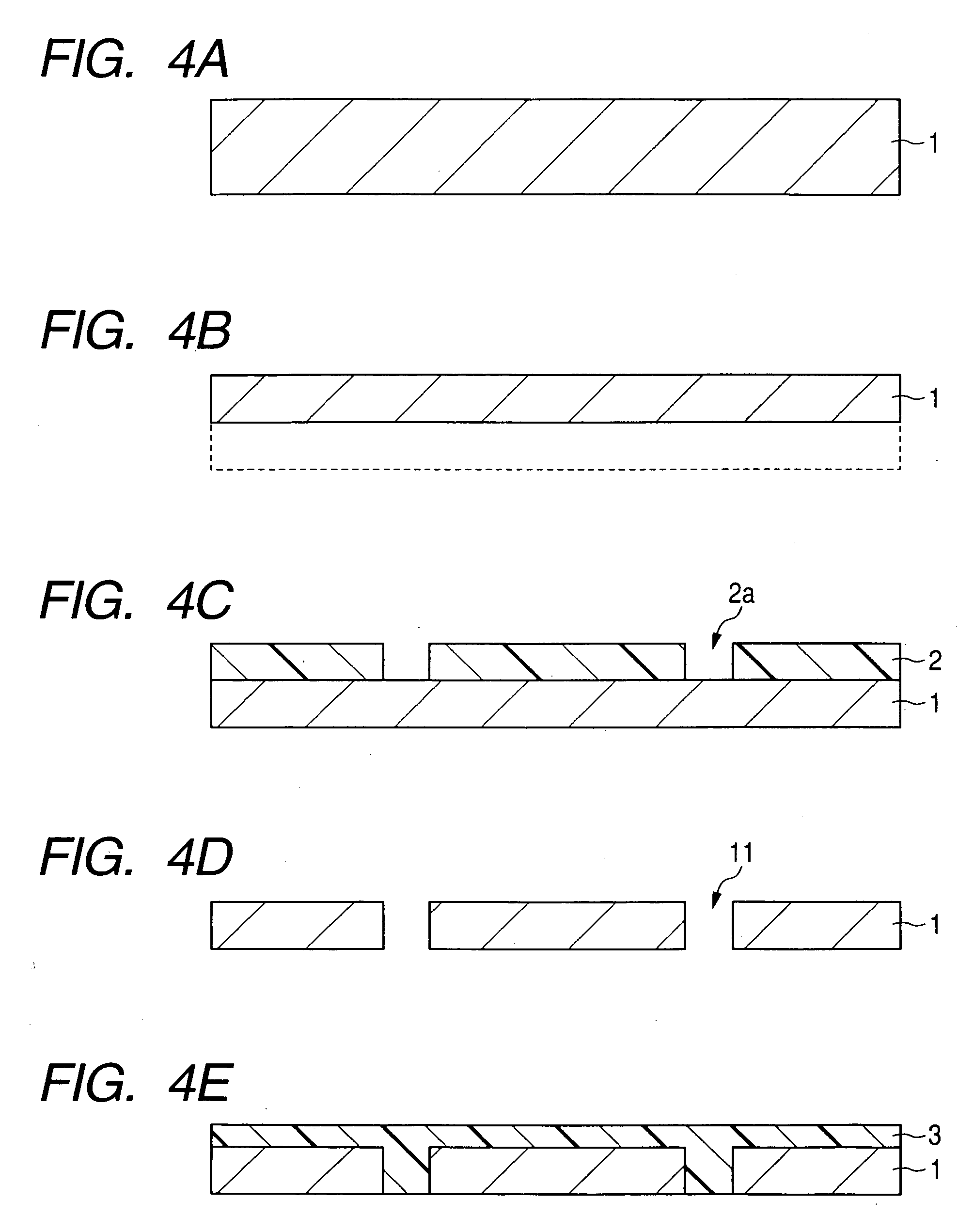

Interposer and method for producing the same and electronic device

InactiveUS20080241997A1Easily realizedServiceably miniaturizedSemiconductor/solid-state device detailsSolid-state devicesFine structureElectrical conductor

An interposer includes a substrate made of an inorganic material; a through wiring including conductors embedded in through holes; and an upper wiring and (or) a lower wiring. The through wiring, the upper wiring and the lower wiring are respectively formed on preliminary wiring patterns that are additionally simultaneously or sequentially formed on layers made of an insulating material applied to at least wiring forming parts of the substrate, and are formed with a metal mold itself used for forming the preliminary wiring patterns or layers made of a wiring material applied by a printing operation, a plating operation or a deposition on the preliminary wiring patterns formed on the layers of the insulating material by transferring a fine structure pattern of the metal mold.

Owner:SHINKO ELECTRIC IND CO LTD

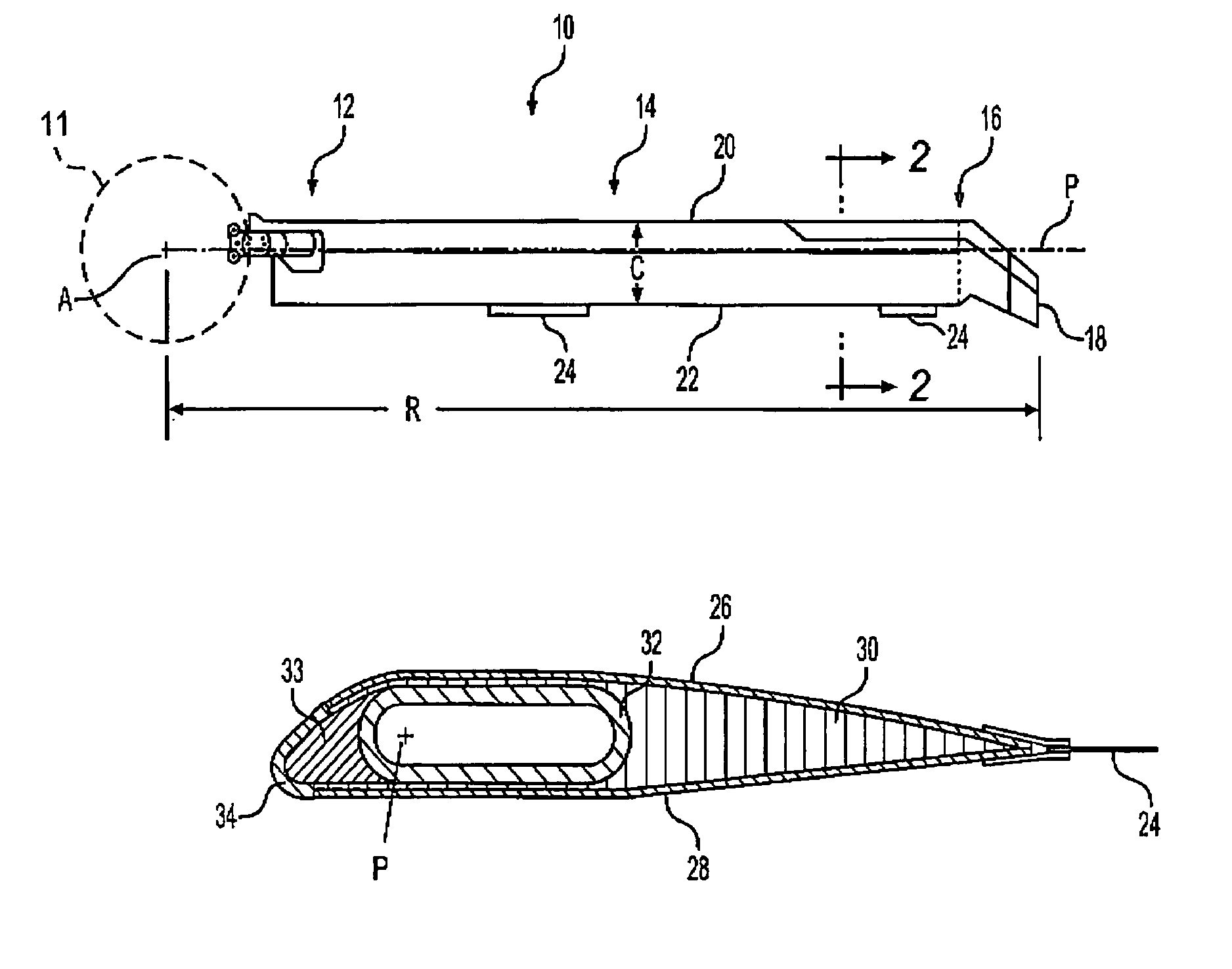

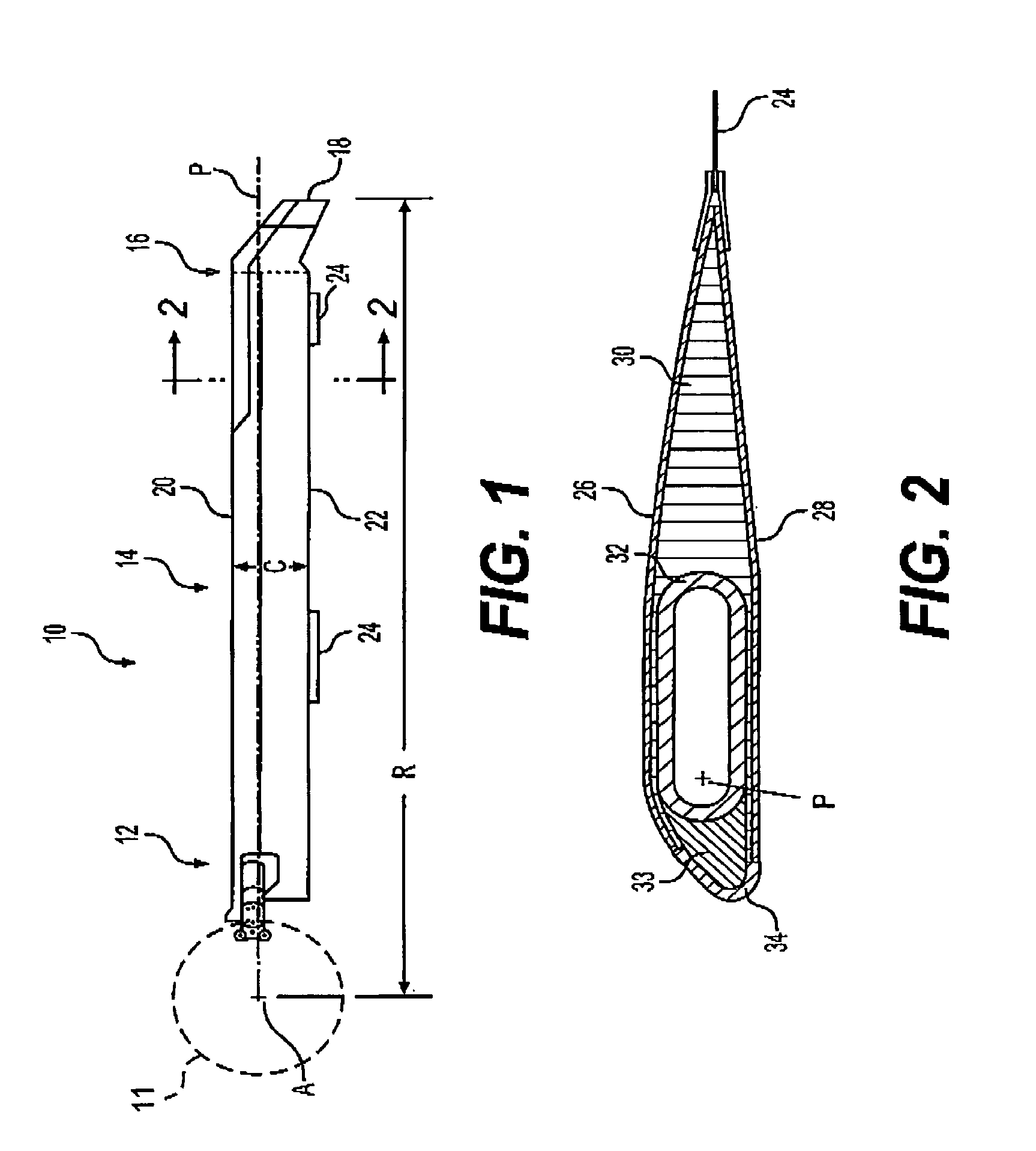

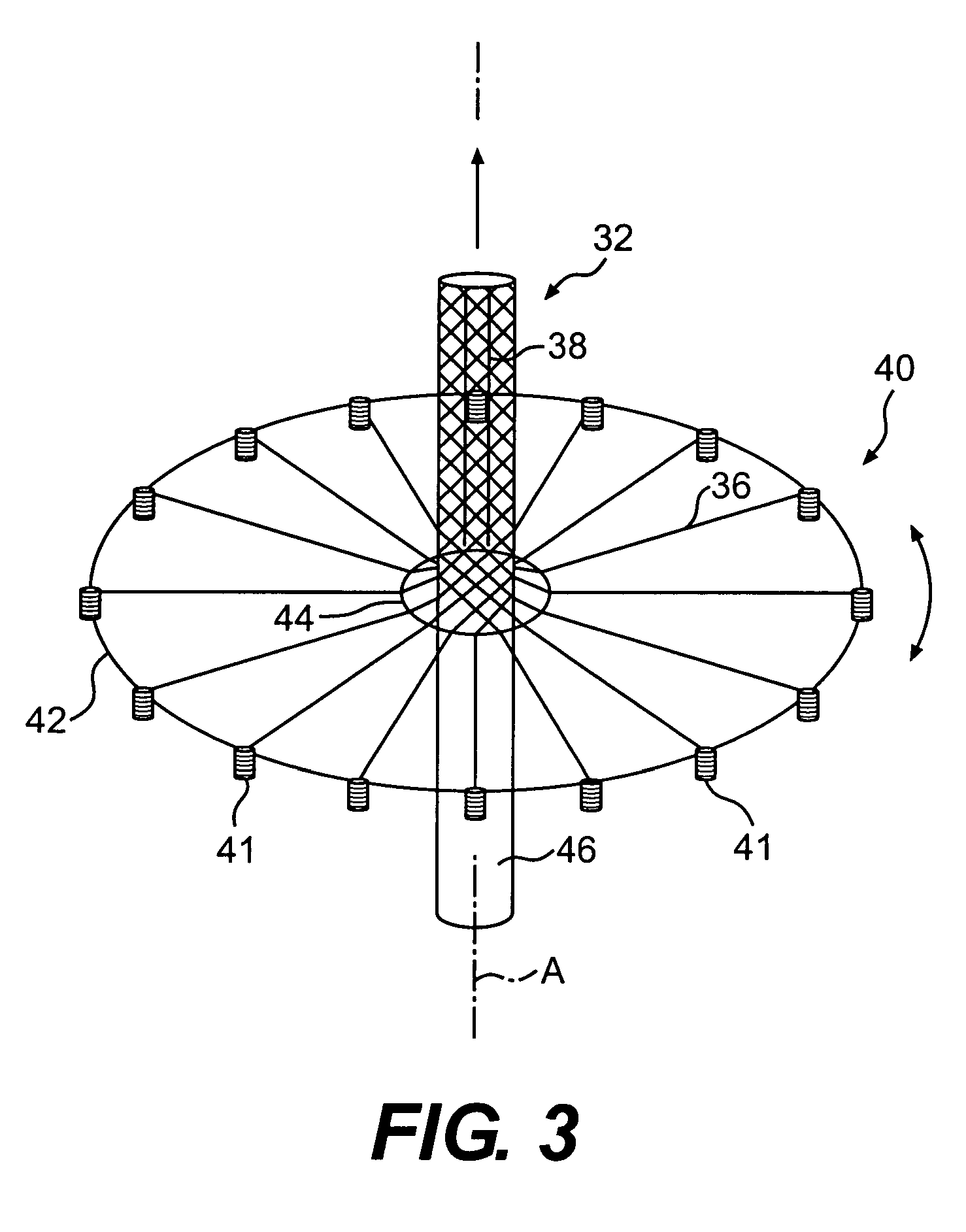

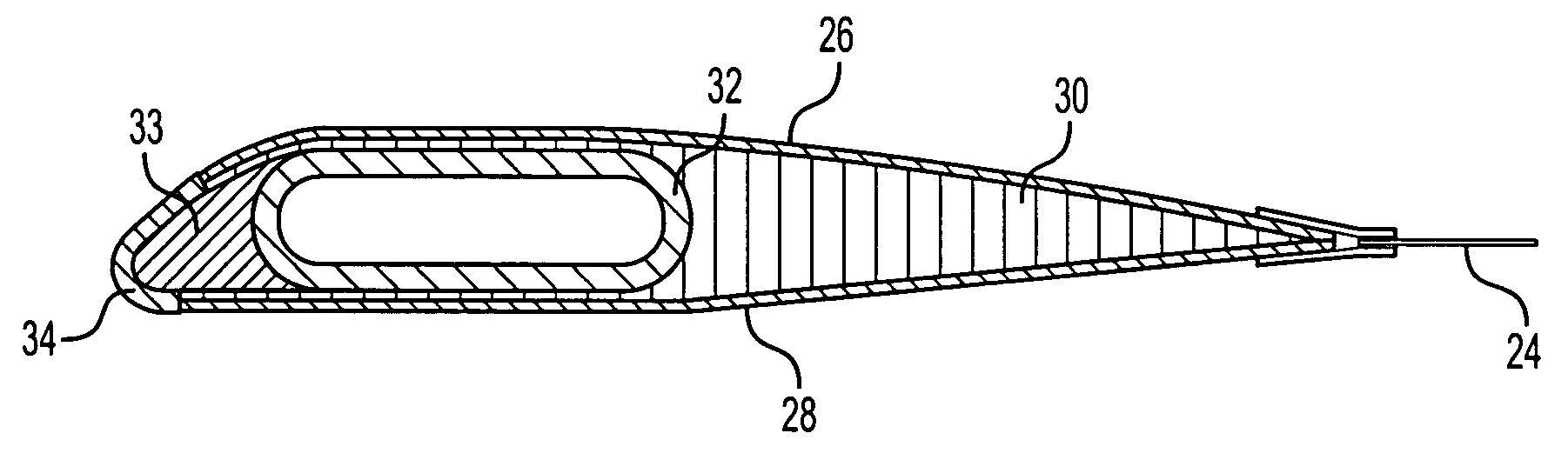

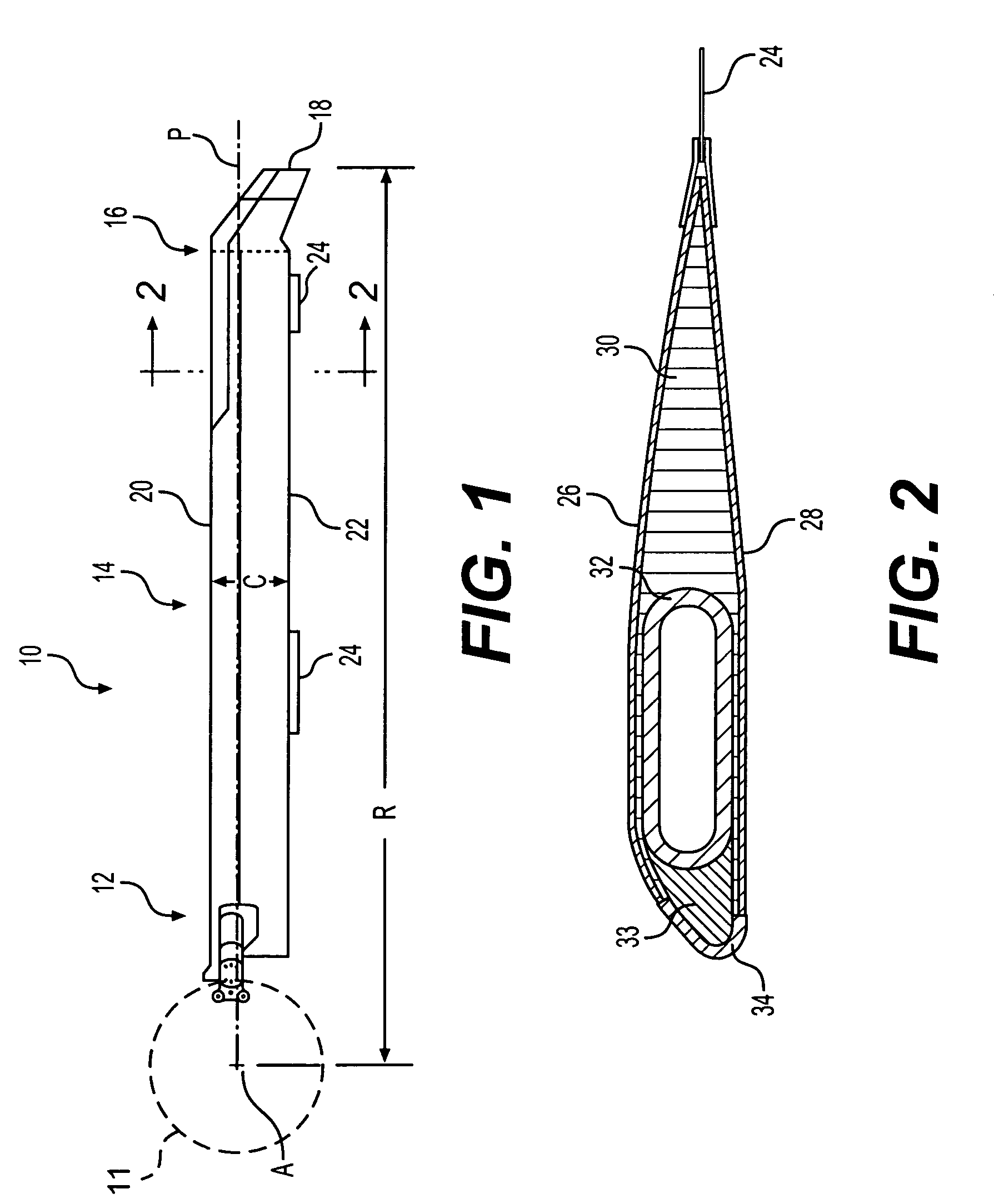

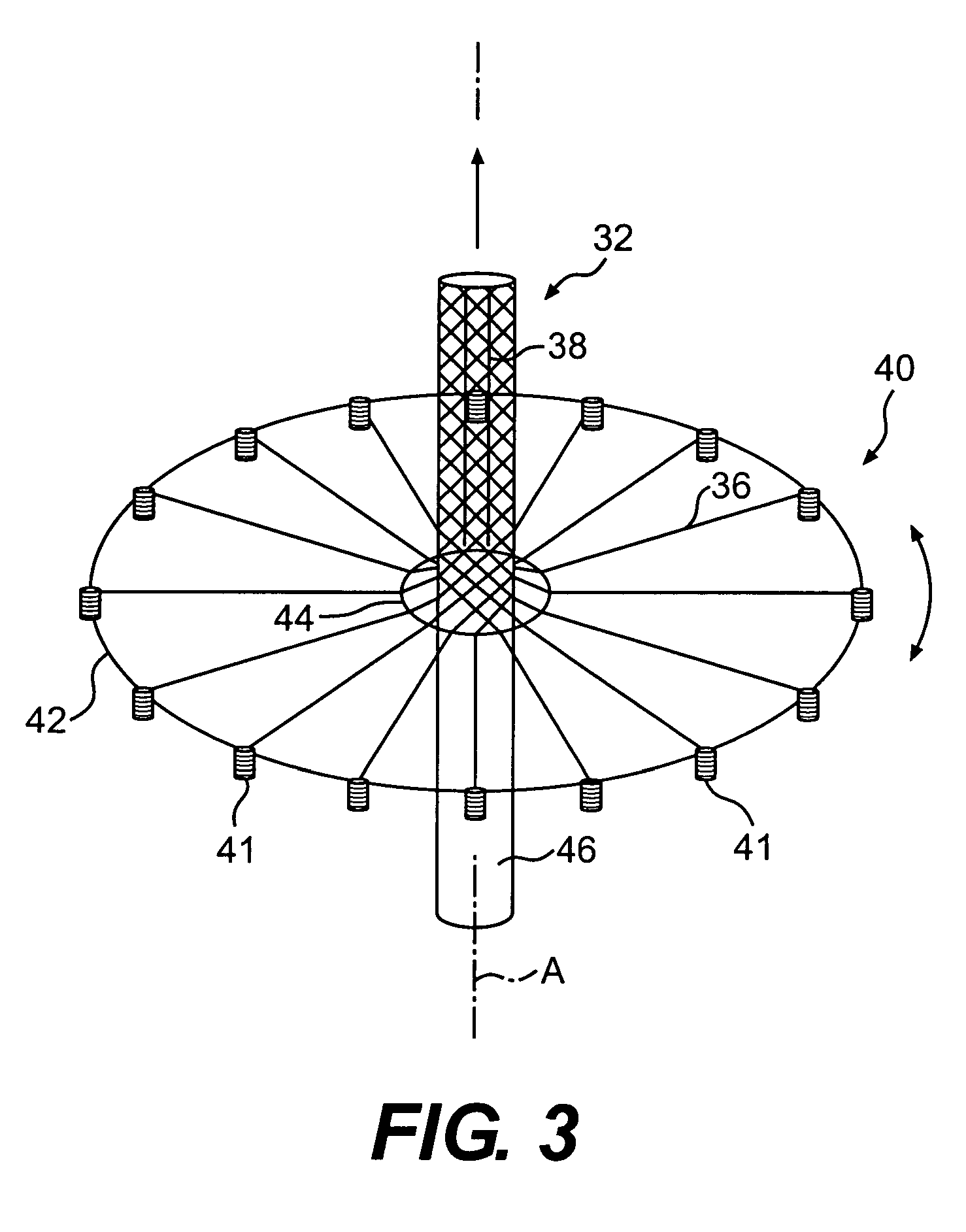

Braided spar for a rotor blade and method of manufacture thereof

ActiveUS7165945B2Increases ballistic toleranceMinimize delaminationPropellersPump componentsFiberEngineering

Owner:SIKORSKY AIRCRAFT CORP

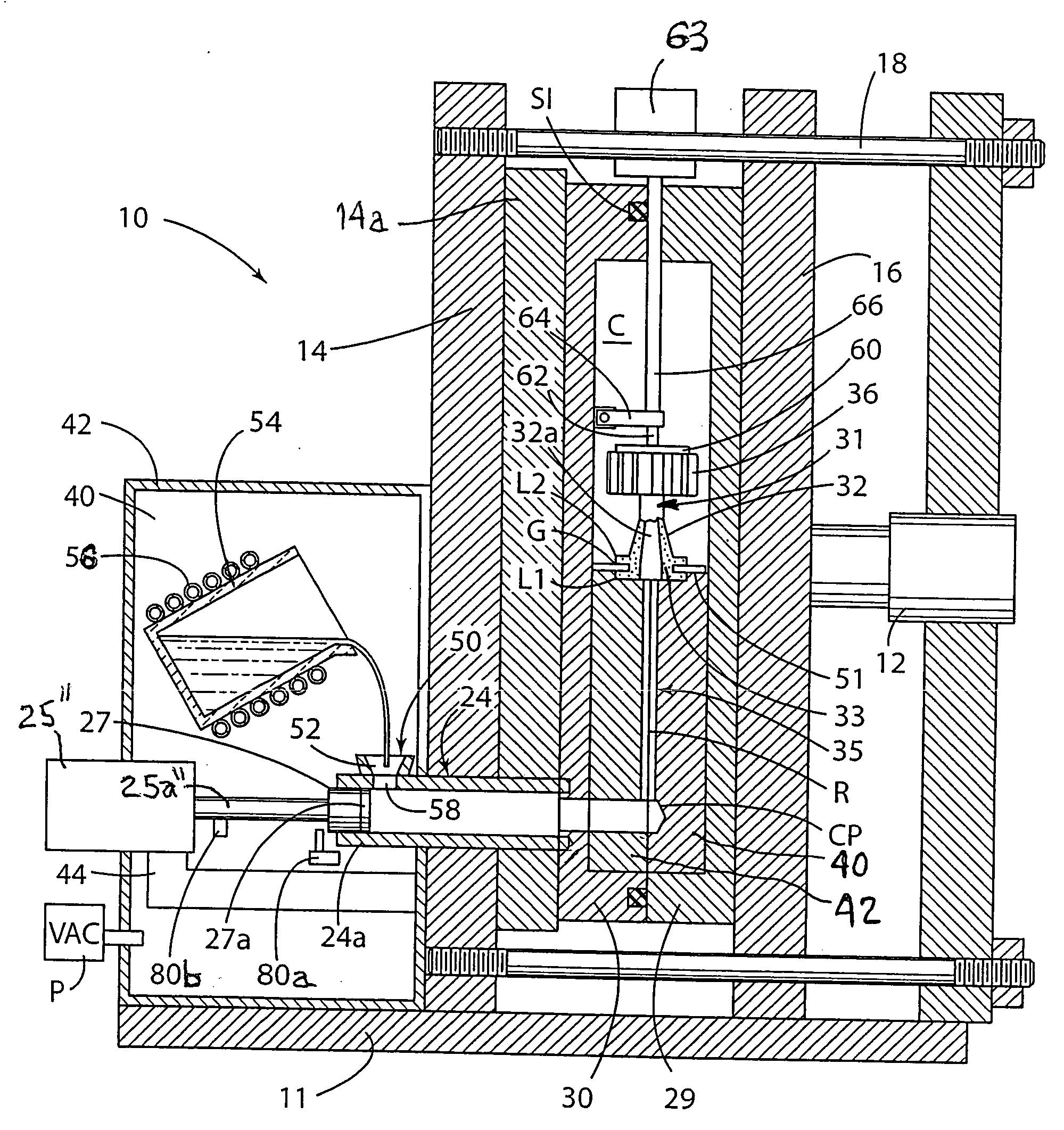

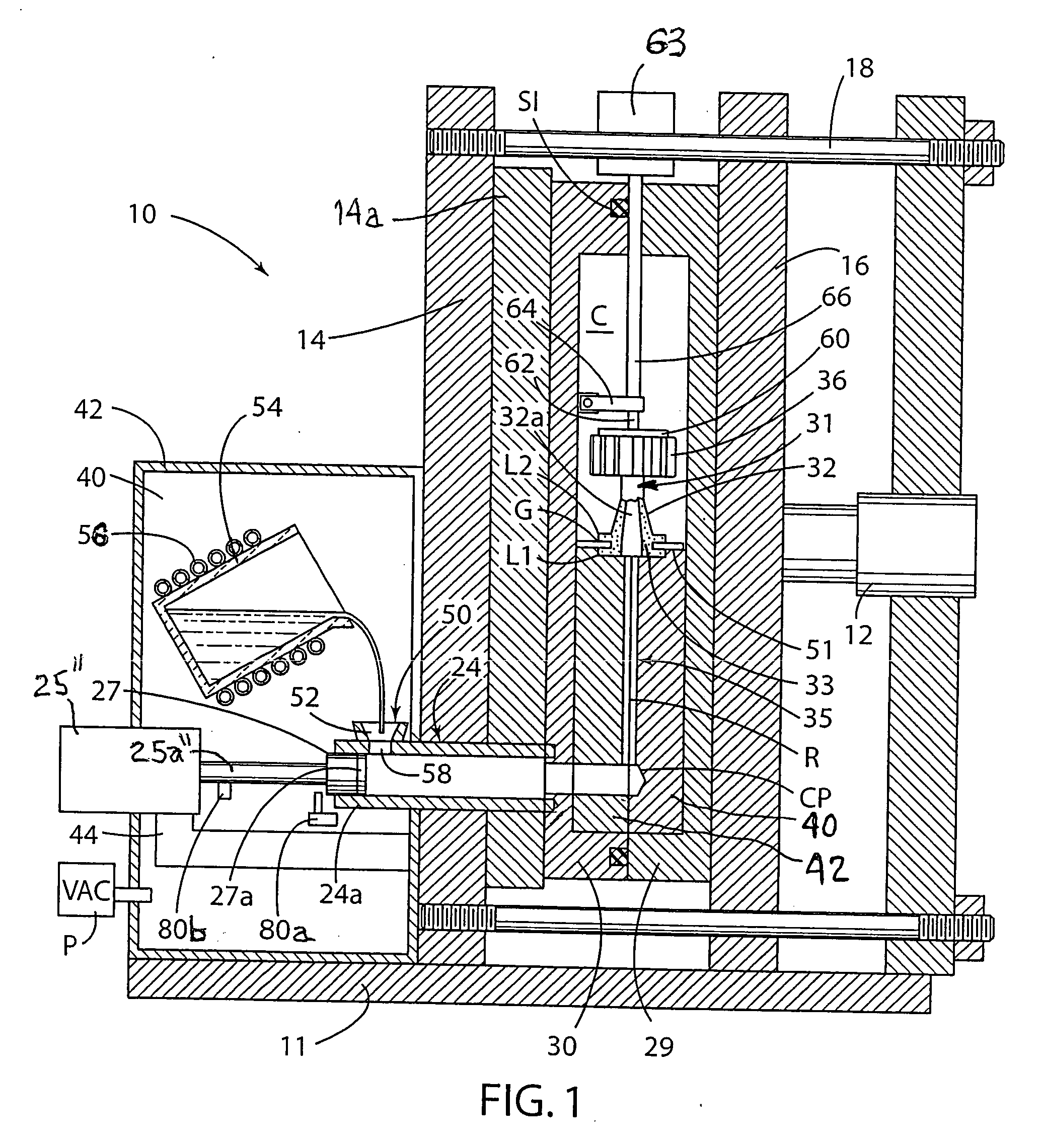

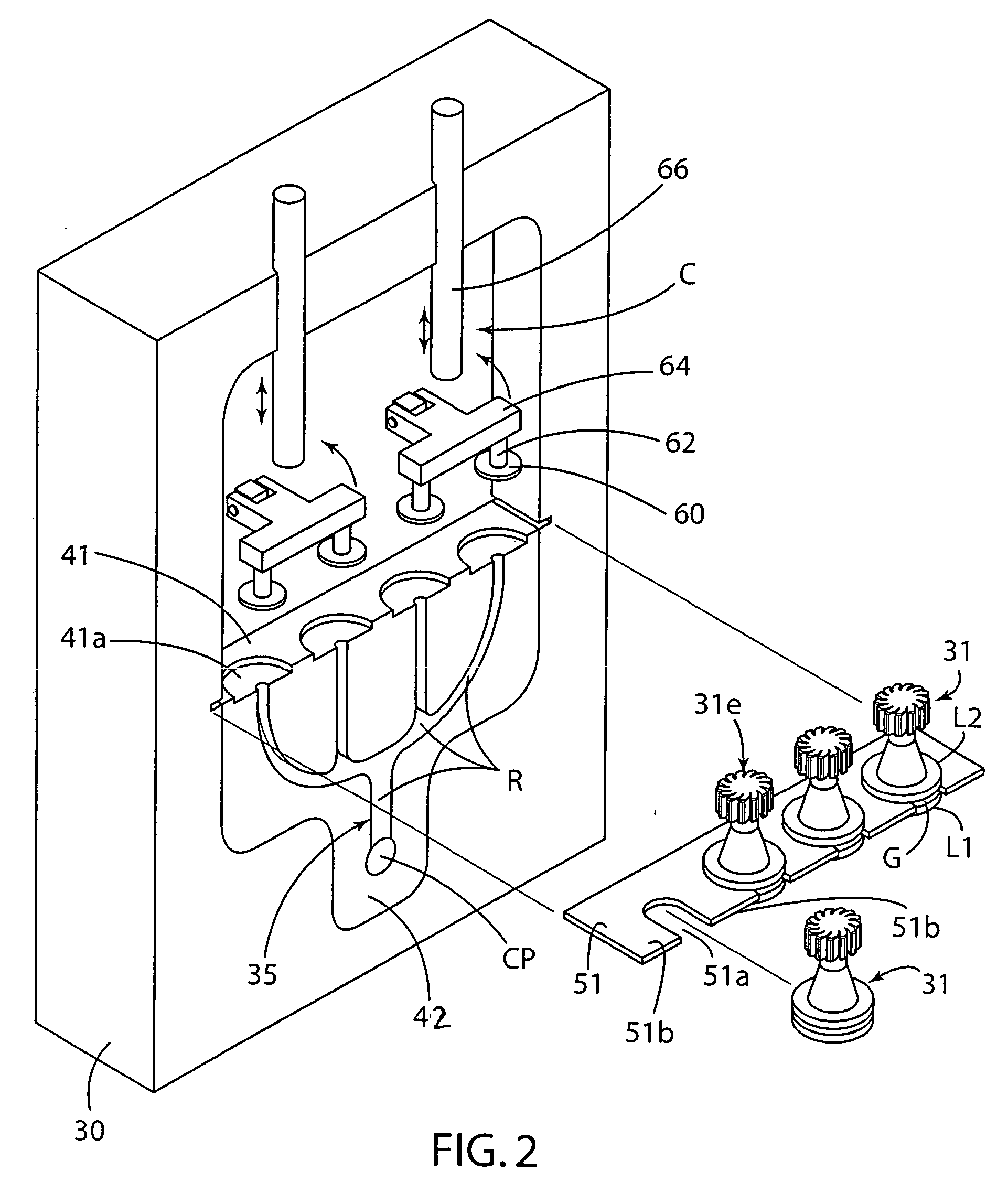

Braided spar for a rotor blade and method of manufacture thereof

ActiveUS20050042109A1Increases ballistic toleranceMinimize delaminationPropellersPump componentsFiberEngineering

A braided rotor blade spar includes a tri-axle braid in which braided bias angled fibers are located non-parallel to a longitudinal axis of the spar. Zero degree fibers are located parallel to the axis and are positioned to be on the upper and lower surfaces of the spar. The bias angle fibers are braided around the zero degree fibers. In a method of manufacture of the braided spar, a braided sleeve is formed dry over a mandrel by a multi-axial braiding machine. Once the braided sleeve is formed upon the mandrel, the mandrel is located within a matched metal mold, resin impregnated, and cured. The mandrel is then removed from the finished braided spar.

Owner:SIKORSKY AIRCRAFT CORP

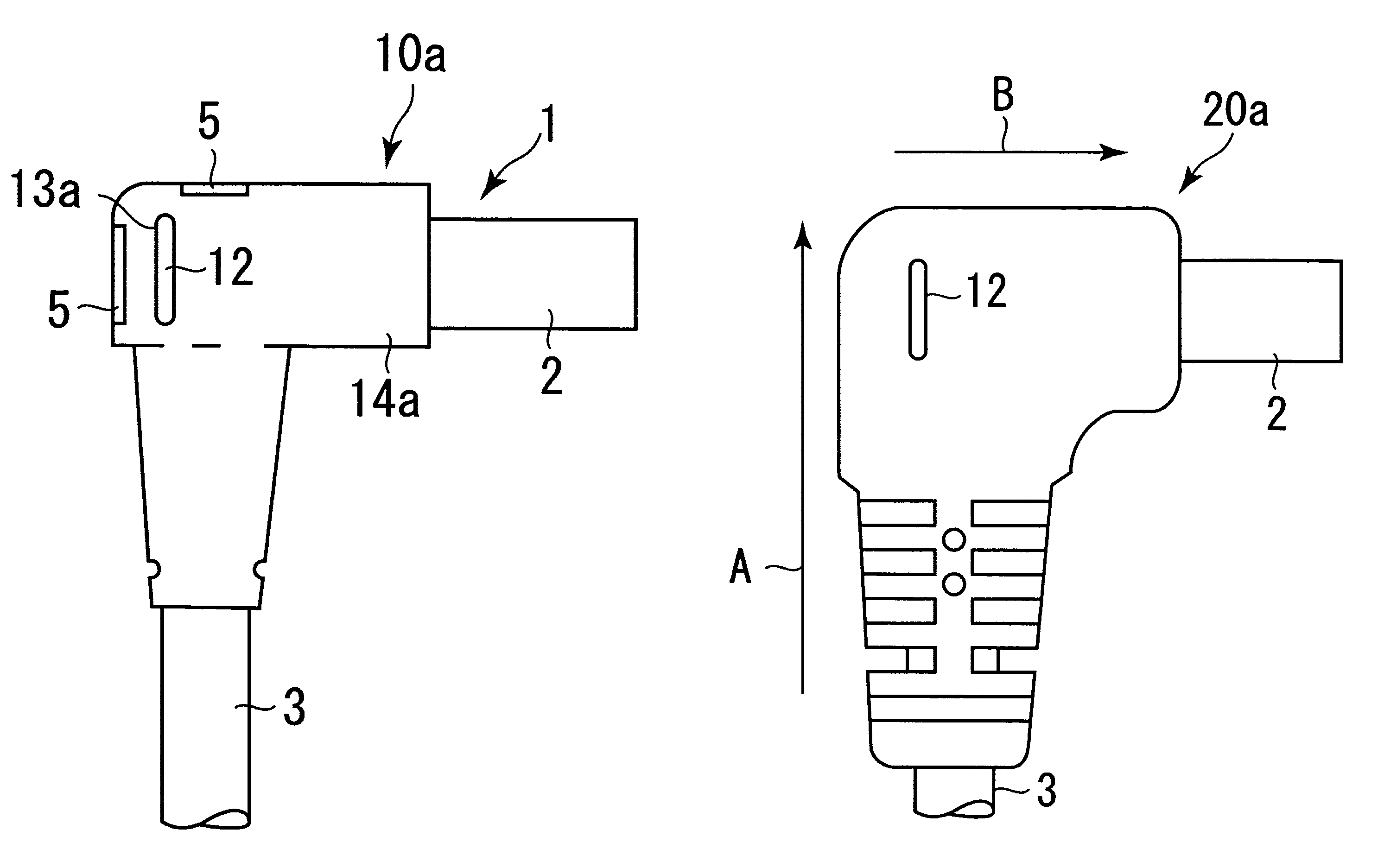

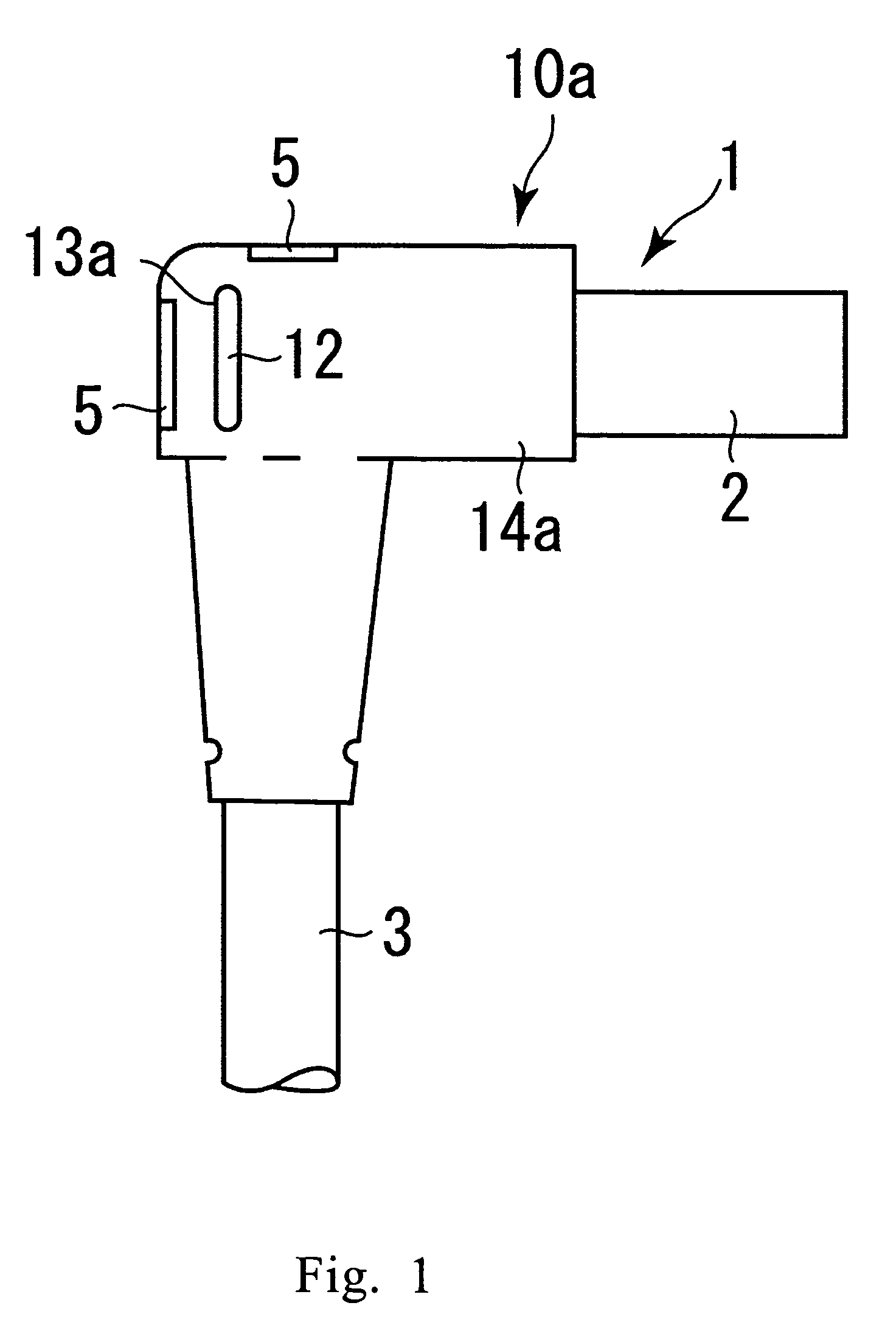

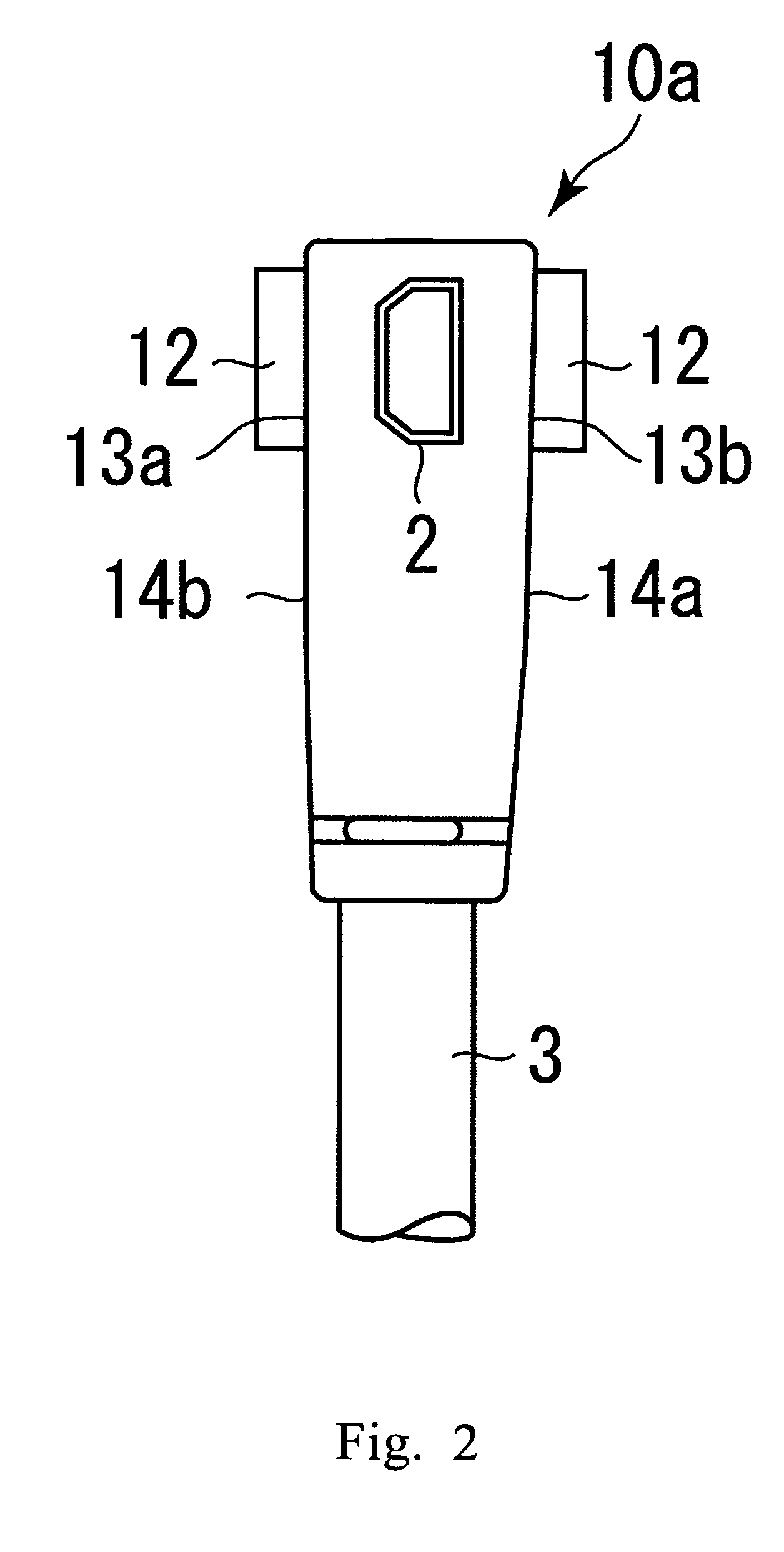

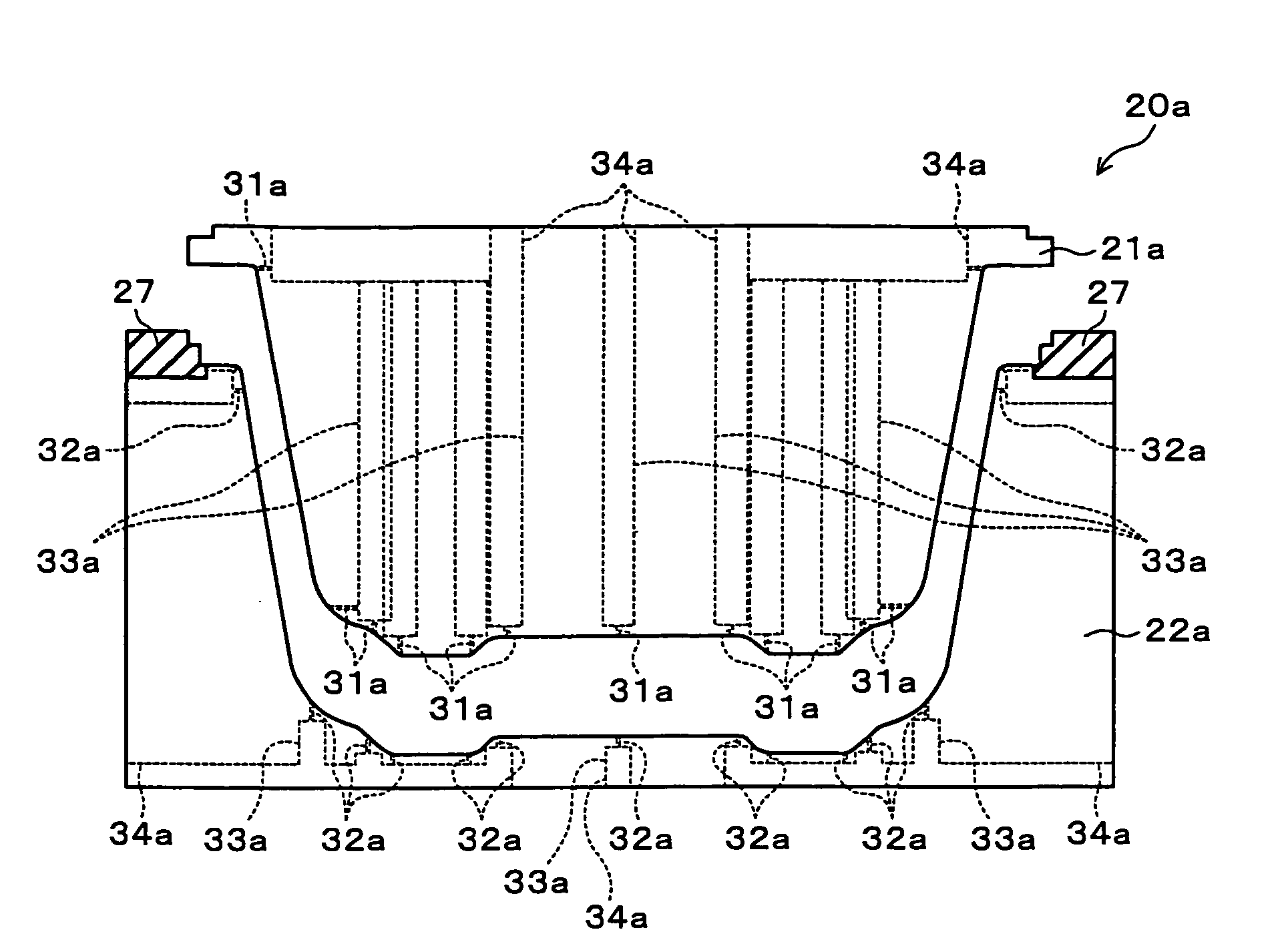

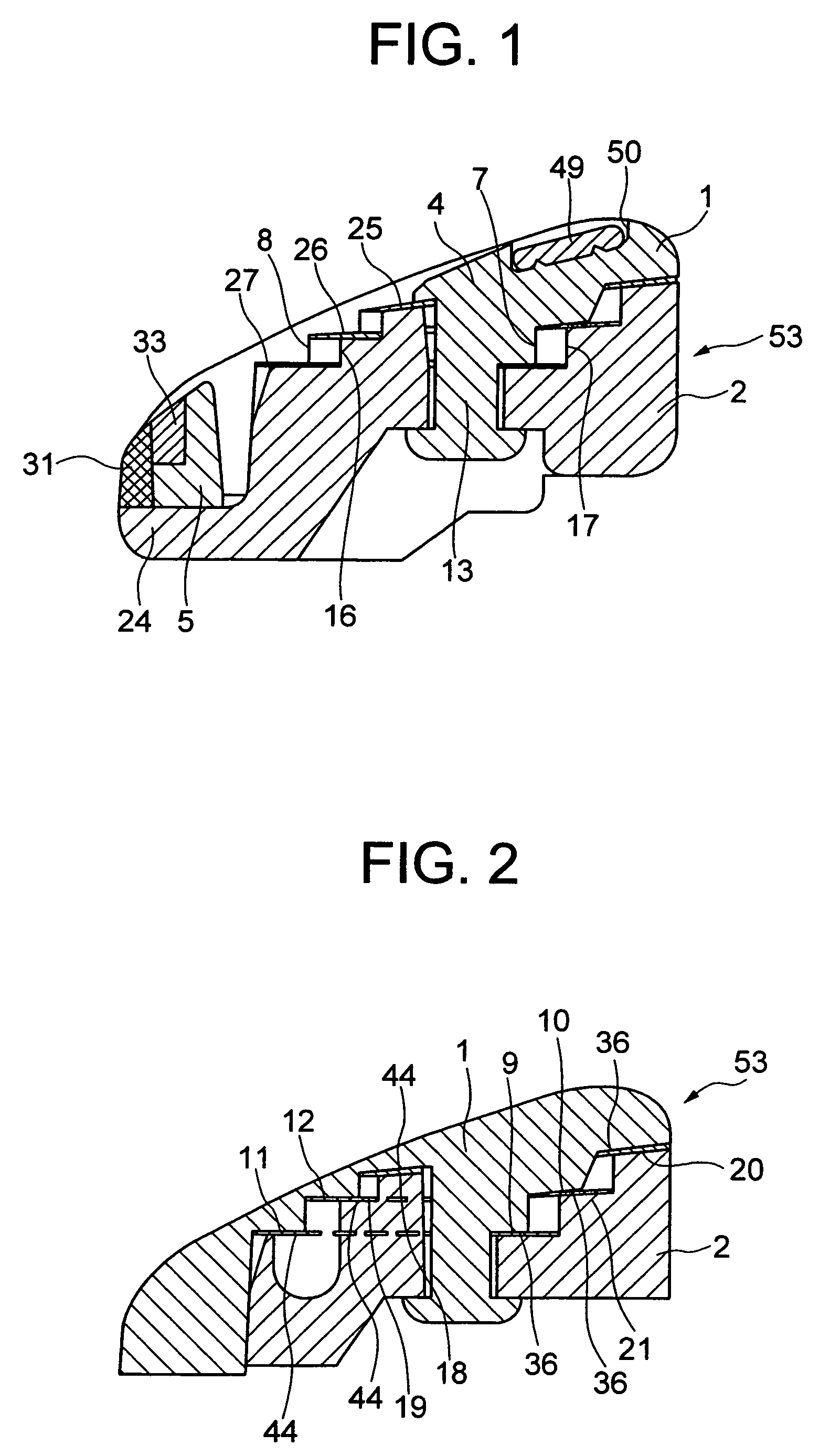

Connector with resin molded portion

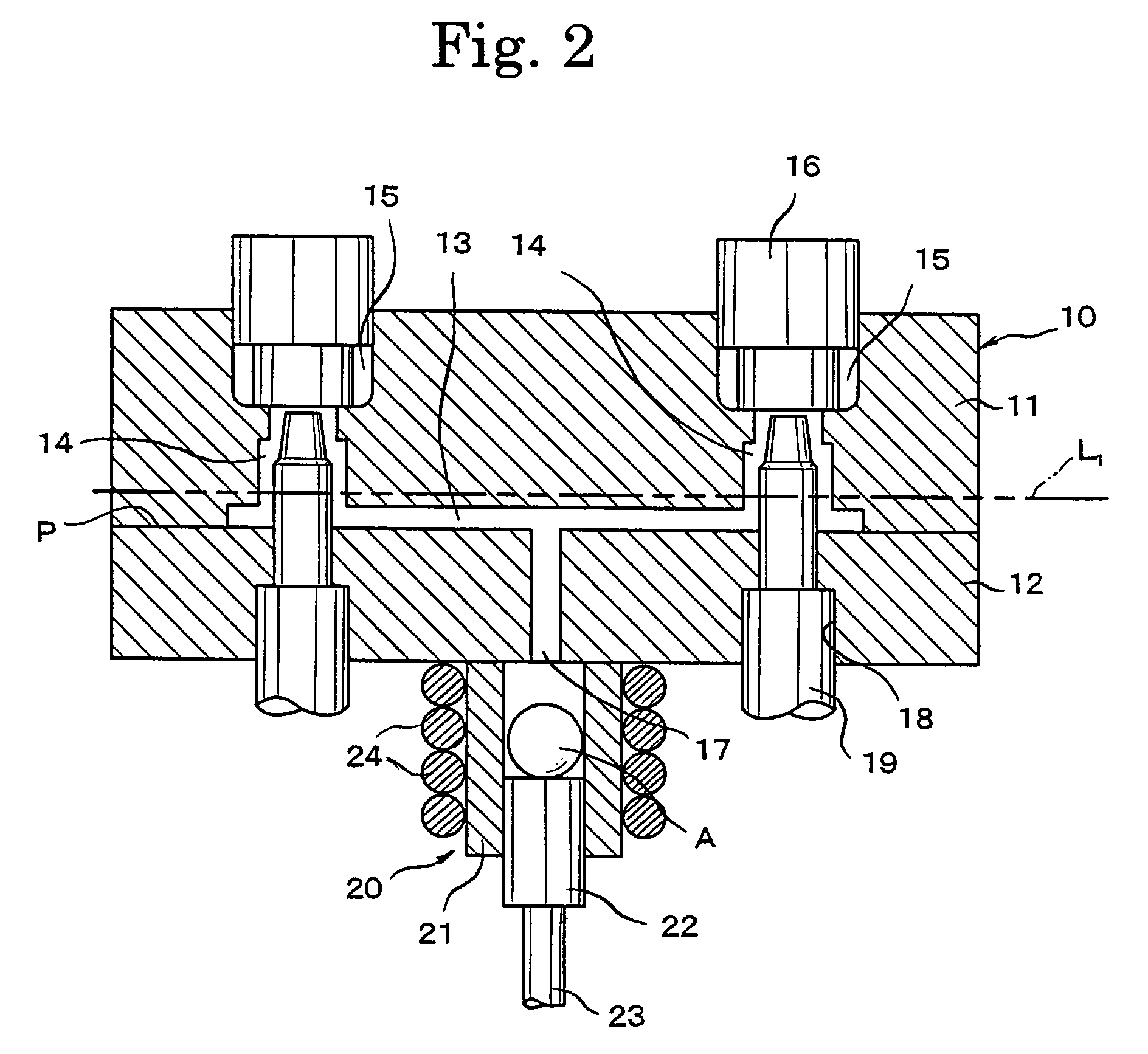

InactiveUS7018236B2Avoid misalignmentAvoid problemsRelieving strain on wire connectionContact member assembly/disassemblyShell moldingEngineering

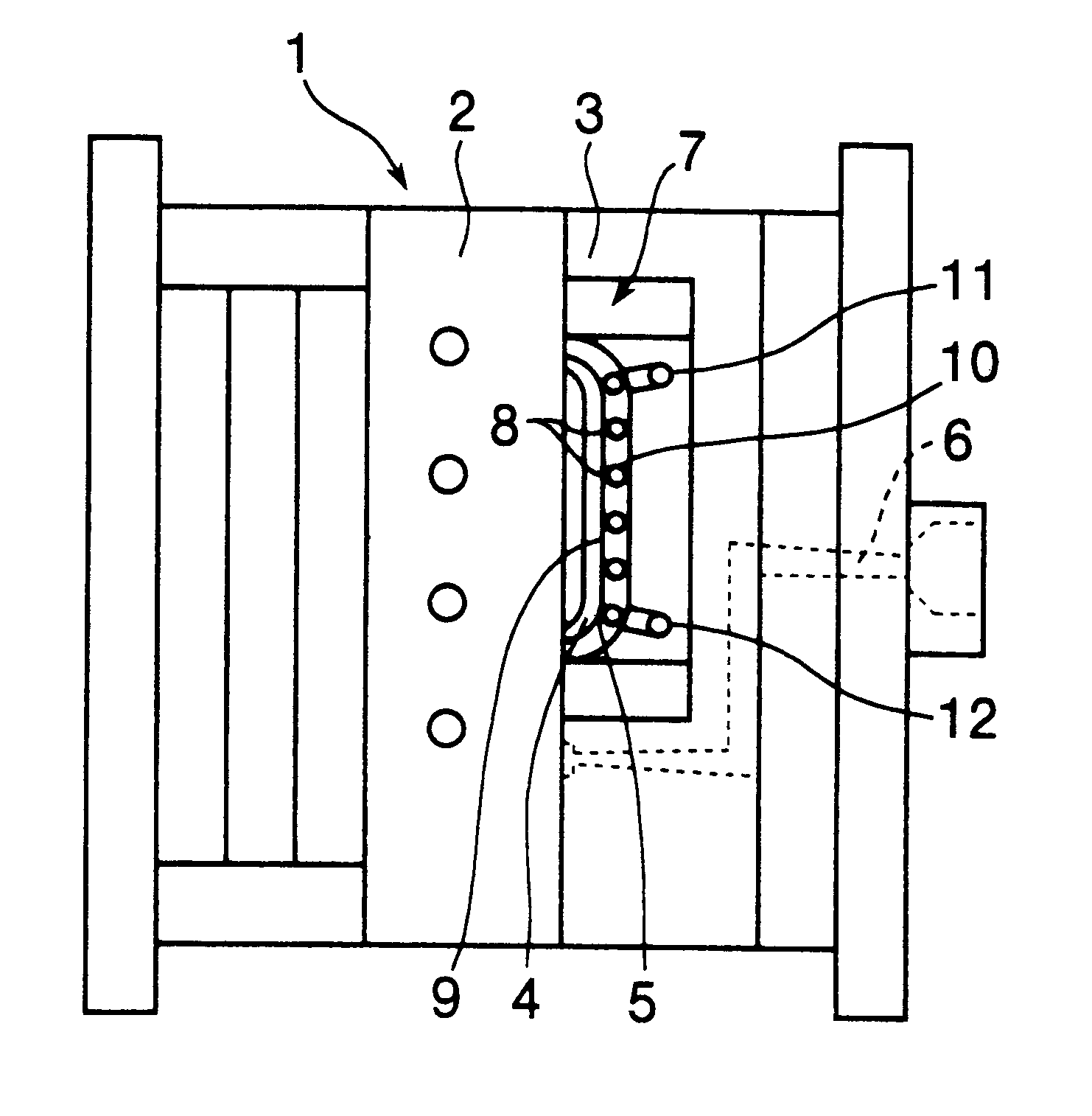

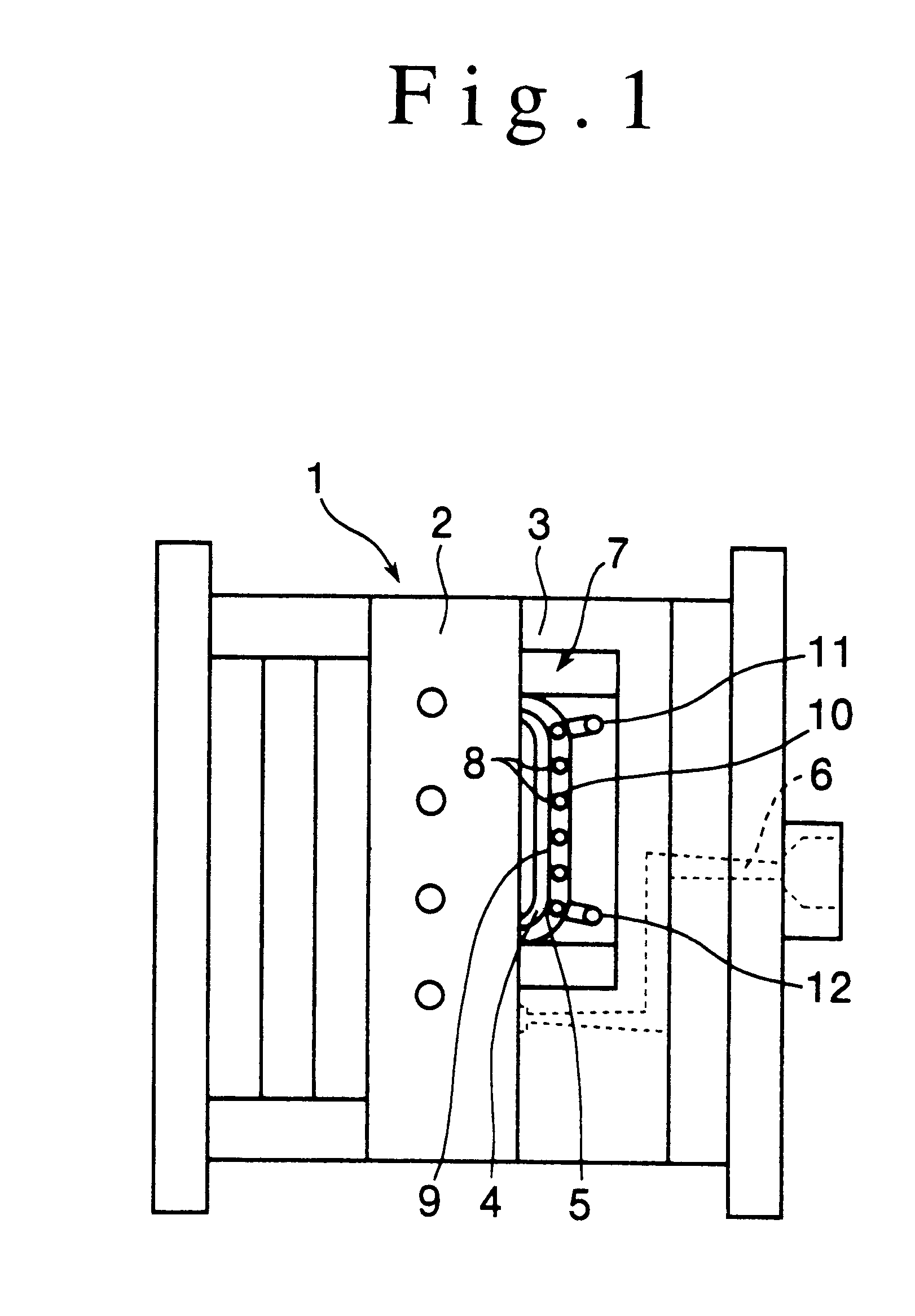

A connector includes a connector main body 1 having a metallic electrical connecting portion 2, an inner molded portion 10a provided outside the connector main body and having a pair of protrusions 12 which are integrally formed on the opposite surfaces of the inner molded portion 10a, and an outer molded portion 20a provided outside the inner molded portion so that the protrusions 12 are partially exposed on the outer surface of the outer molded portion 20a. The pair of protrusions 12 protrude toward a pair of metal molds for molding the outer molding portion, respectively.

Owner:MITSUMI ELECTRIC CO LTD

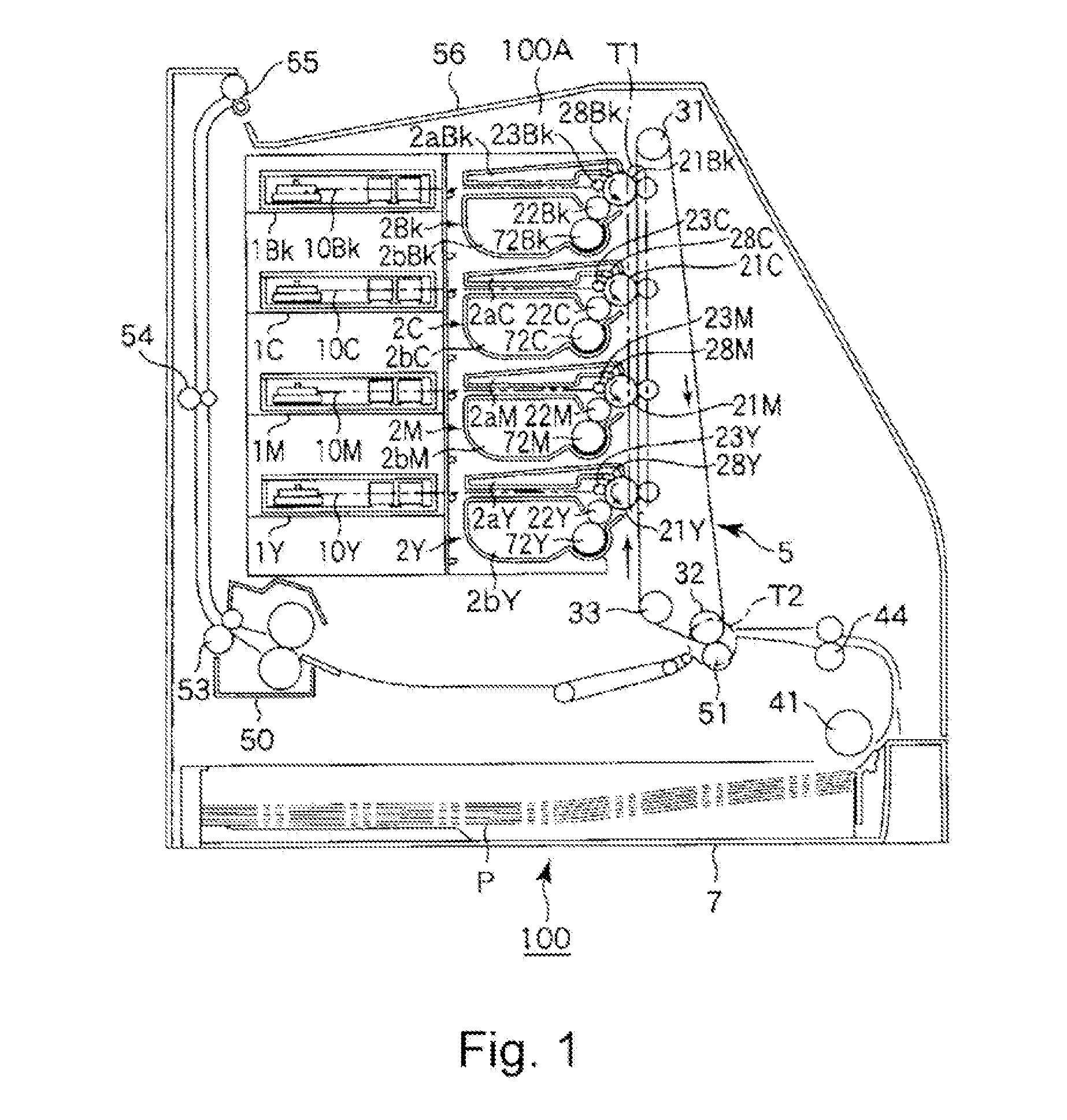

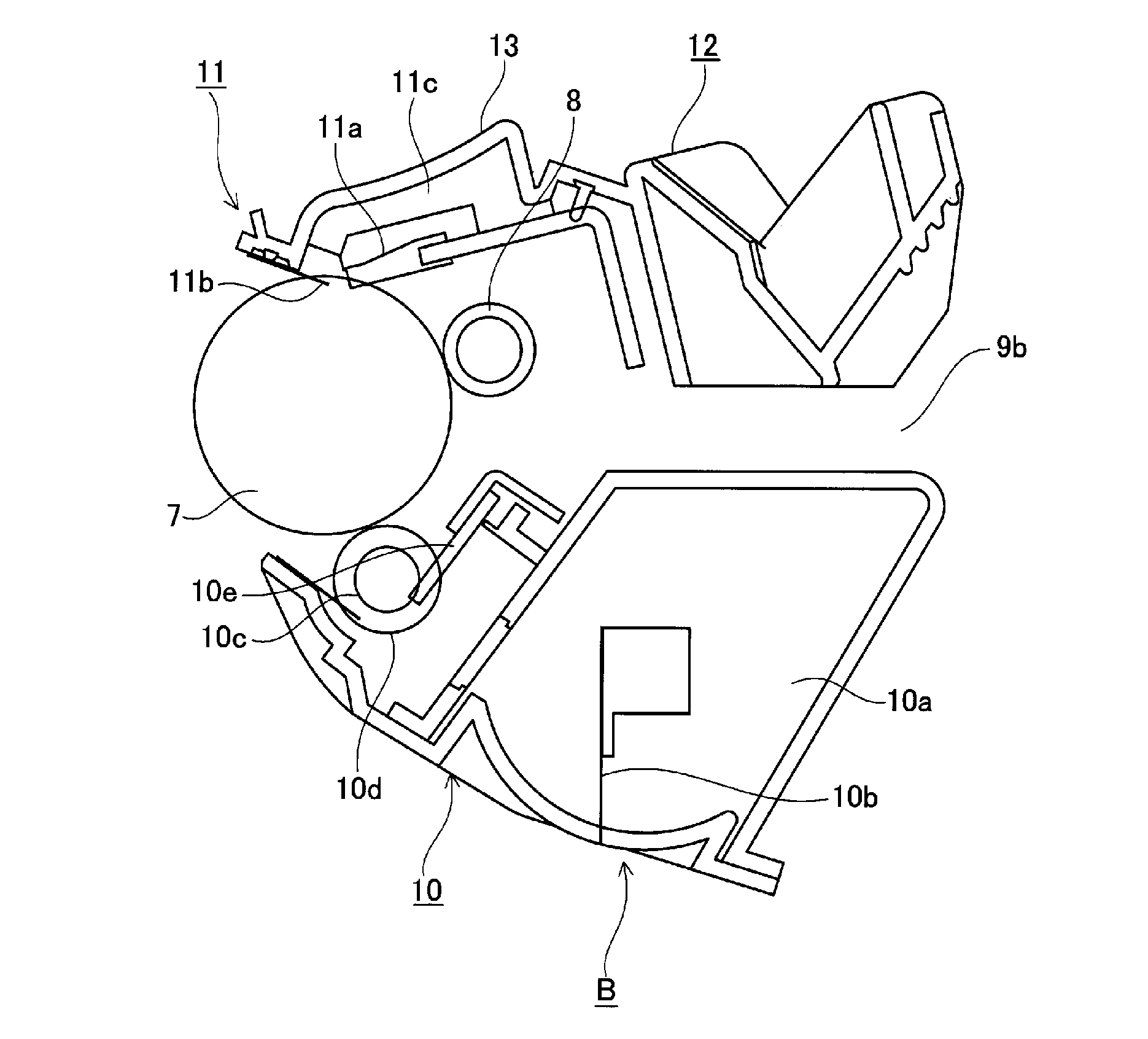

Cartridge and unit

ActiveUS20130121720A1Assembly property can be improvedImprove accuracyElectrographic process apparatusEngineeringMetal mold

A cartridge detachably mountable to a main assembly of an image forming apparatus includes a cartridge frame formed of a resin material; a plurality of resin members molded on the cartridge frame by injection molding of a resin material different from that of the cartridge frame; a plurality of contact surfaces, provided on the cartridge frame, to which metal molds corresponding to the resin members are to be contacted from the same side when the resin members are molded; and a plurality of resin material inlet ports, provided in an opposite side of said cartridge frame from a side where the contact surfaces are provided. The resin material has been flowed into the cartridge frame when the resin members are molded.

Owner:CANON KK

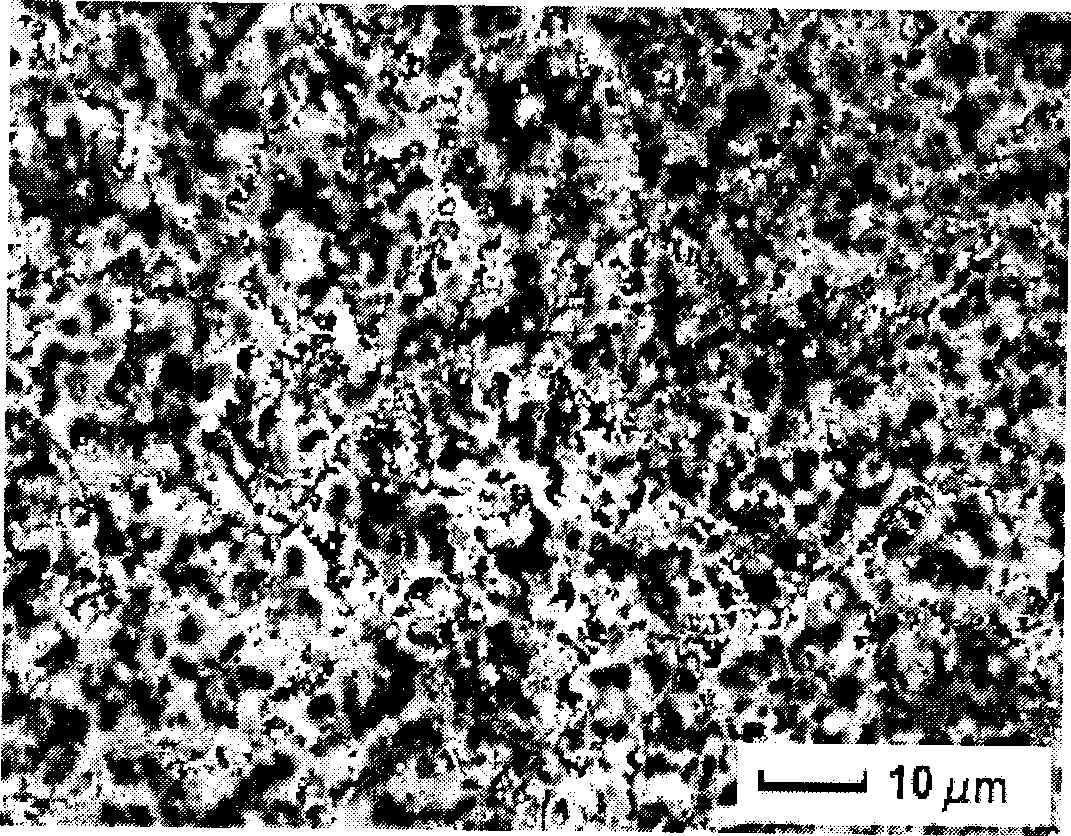

Soft Magnetic Material, Compressed Powder Magnetic Core and Method for Producing Compressed Powder Magnetic Core

InactiveUS20070290161A1Improve surface conditionAvoid residueTransportation and packagingMetal-working apparatusMetal moldMetal

A soft magnetic material has an iron based powder that has an insulating coating on the surface and an ester wax. The ester wax is added in an amount not less than 0.02% by weight and not more than 0.6% by weight in relation to the soft magnetic material. Consequently, seizure between a metal mold and a material to be molded at the time of molding can be suppressed and the arising of a black residue can be prevented.

Owner:SUMITOMO ELECTRIC IND LTD

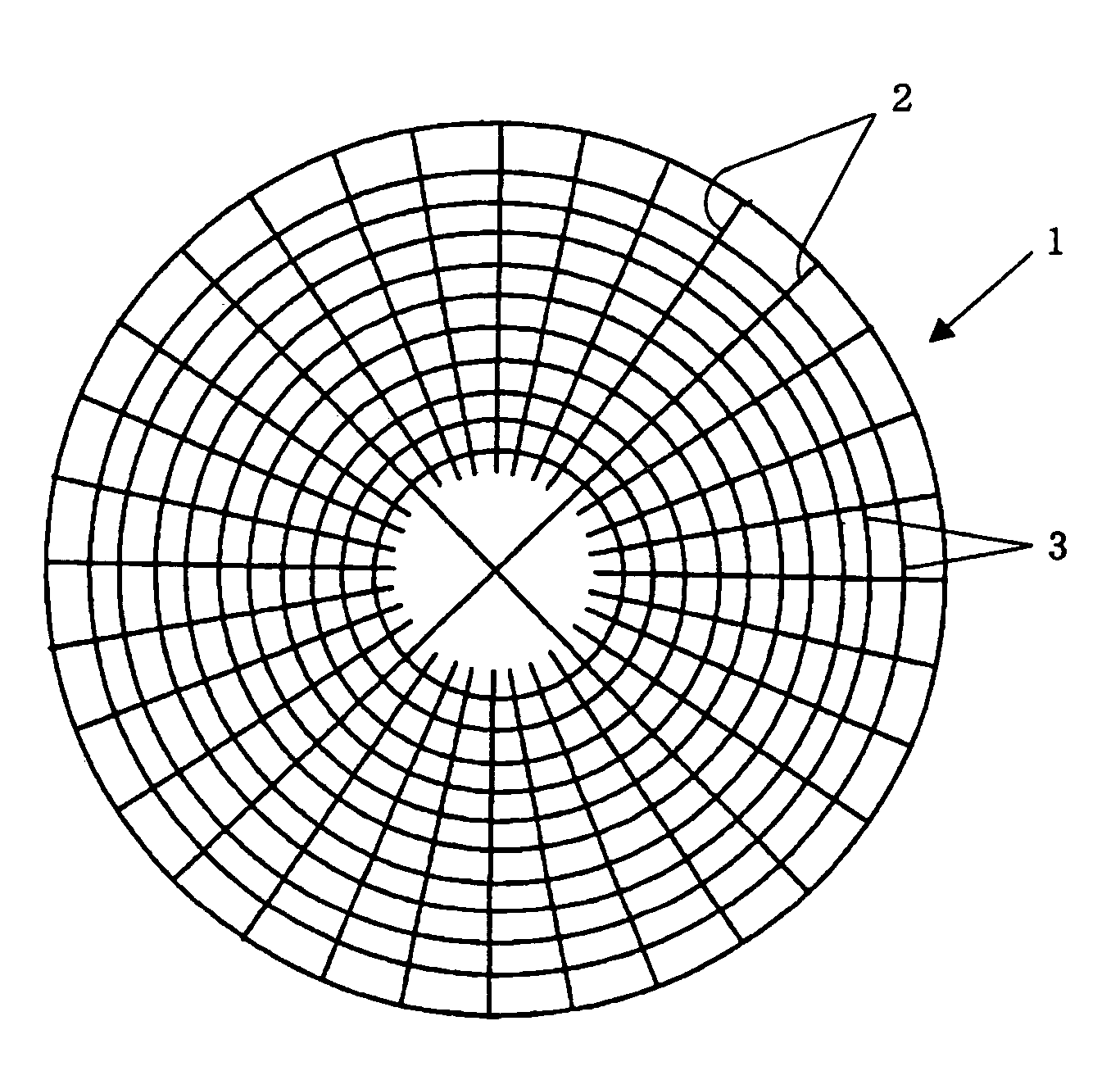

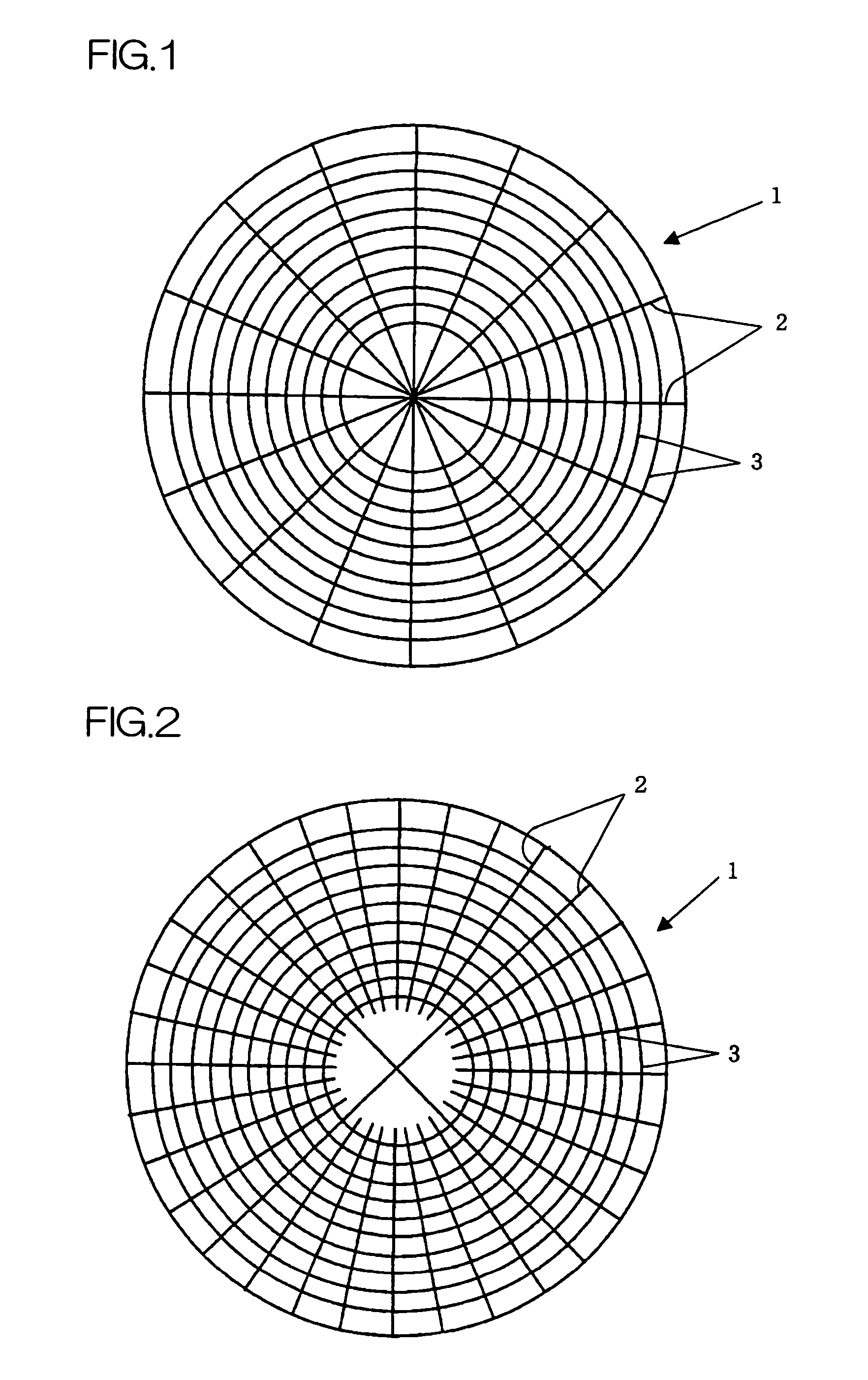

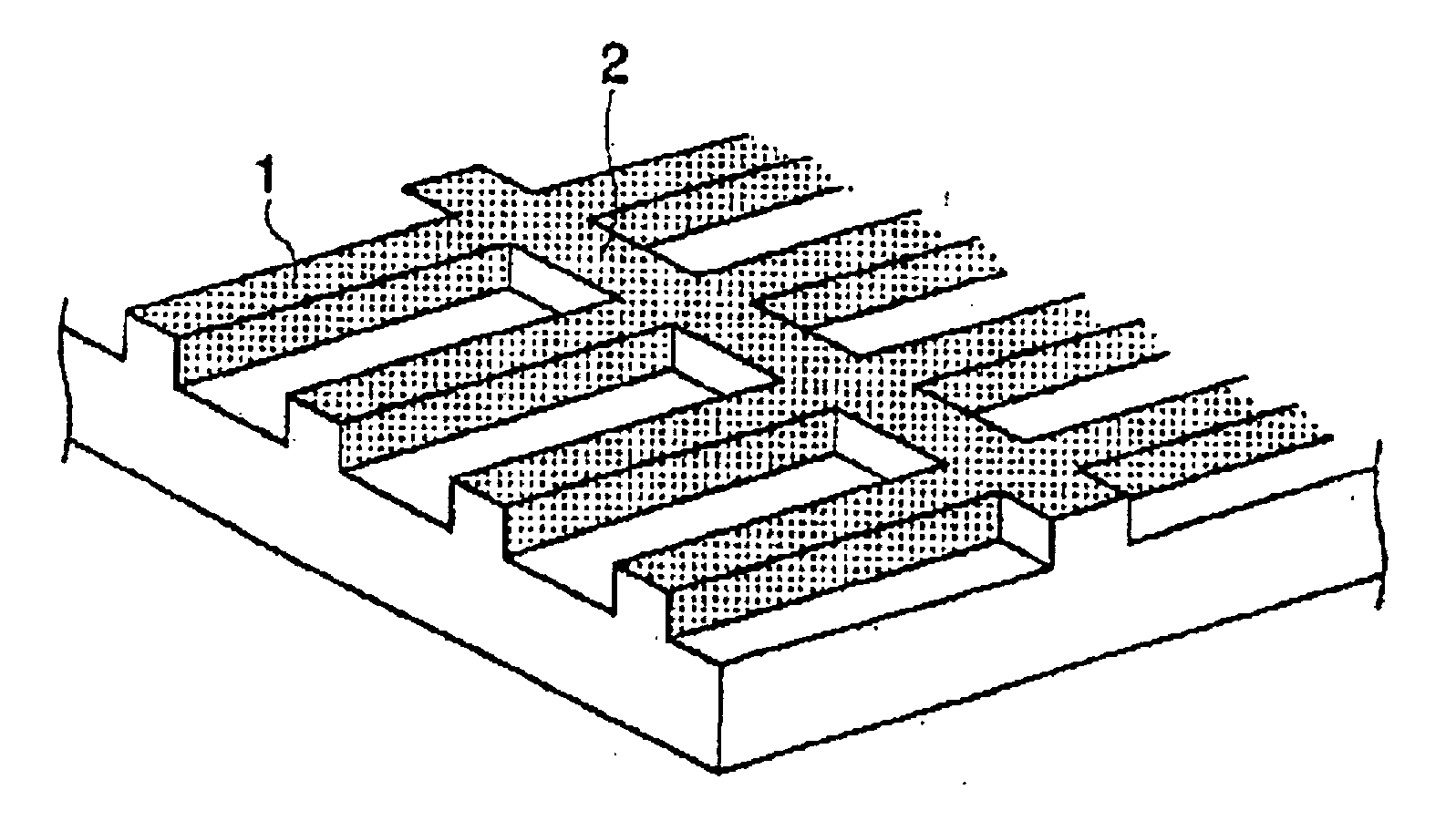

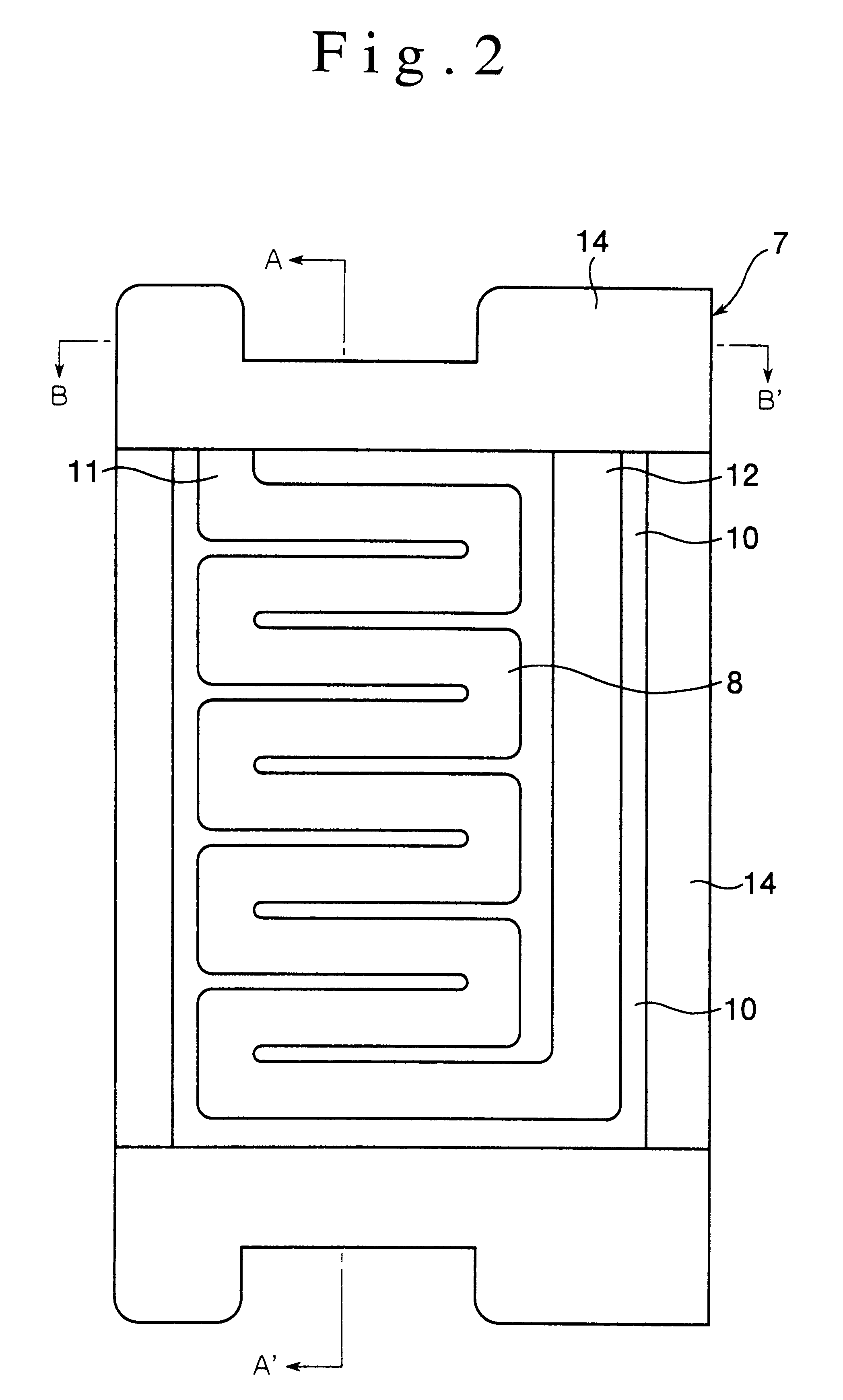

Method of manufacturing chemical mechanical polishing pad

ActiveUS7329174B2InhibitionIncrease ratingsFlexible-parts wheelsGrinding devicesRound tableMilling cutter

The present invention relates to a method of manufacturing a chemical mechanical polishing pad which provides a chemical mechanical polishing pad which fully suppresses the occurrence of a scratch on the polished surface and has an excellent polishing rate.The method comprising either one of a group of steps (A) and a group of steps (B), the group of steps (A) including(A1) the step of preparing a composition for forming a chemical mechanical polishing pad;(A2) the step of molding the composition for forming a chemical mechanical polishing pad into a pad-like form;(A3) the step of mounting the pad-like form on the round table of a cutting machine having at least a milling unit equipped with a milling cutter, a drive unit capable of angle indexing and positioning and a round table journaled by the drive unit;(A4) the step of forming the second group of grooves with the milling cutter; and(A5) the step of forming the first group of grooves, and the group of steps (B) including(B1) the step of preparing a composition for forming a chemical mechanical polishing pad;(B2) the step of molding the composition for forming a chemical mechanical polishing pad into a pad-like form having the second group of grooves by using a metal mold having projections corresponding to the shapes of the second group of grooves; and(B3) the step of forming the first group of grooves.

Owner:JSR CORPORATIOON

Method for evaporative pattern precise composite casting

InactiveCN101590513APrevent shrinkageAvoid shrinkage defectsFoundry mouldsFoundry coresSurface layerPolystyrene

The invention discloses a method for evaporative pattern precise composite casting. The method comprises the following steps: making a mould by polystyrene foam to form a casting system; coating a surface modifying agent on the surface of the mould; preparing a mould shell including a surface layer mould shell, a transitional layer mould shell and a back layer mould shell; taking the mould out after placing the mould in a pre-wetting agent for 2 to 3s, dipping the mould in a container filled with surface layer coating, turning the mould so as to evenly coat the mould, sprinkling zircon sand on the mould, and drying the mould for 4 to 6h to prepare a surface layer mould shell; dip-coating the surface layer mould shell by a transitional layer coating, sprinkling and drying the sand for 8 to 12h; preparing the transitional layer mould shell and the back layer mould shell by the similar method; sealing pulp by the back layer coating, and drying for 14 to 18h; roasting the mould at a temperature of between 950 and 1,050 DEG C, and keeping warm for 30 to 60min; and pouring the molten metal in the mould shell to form a casting. The method has the advantages of preparing the metallic mould without the conventional precise casting, saving processing time, lowering cost and simultaneously ensuring the product quality.

Owner:郑州神牛铸造有限公司

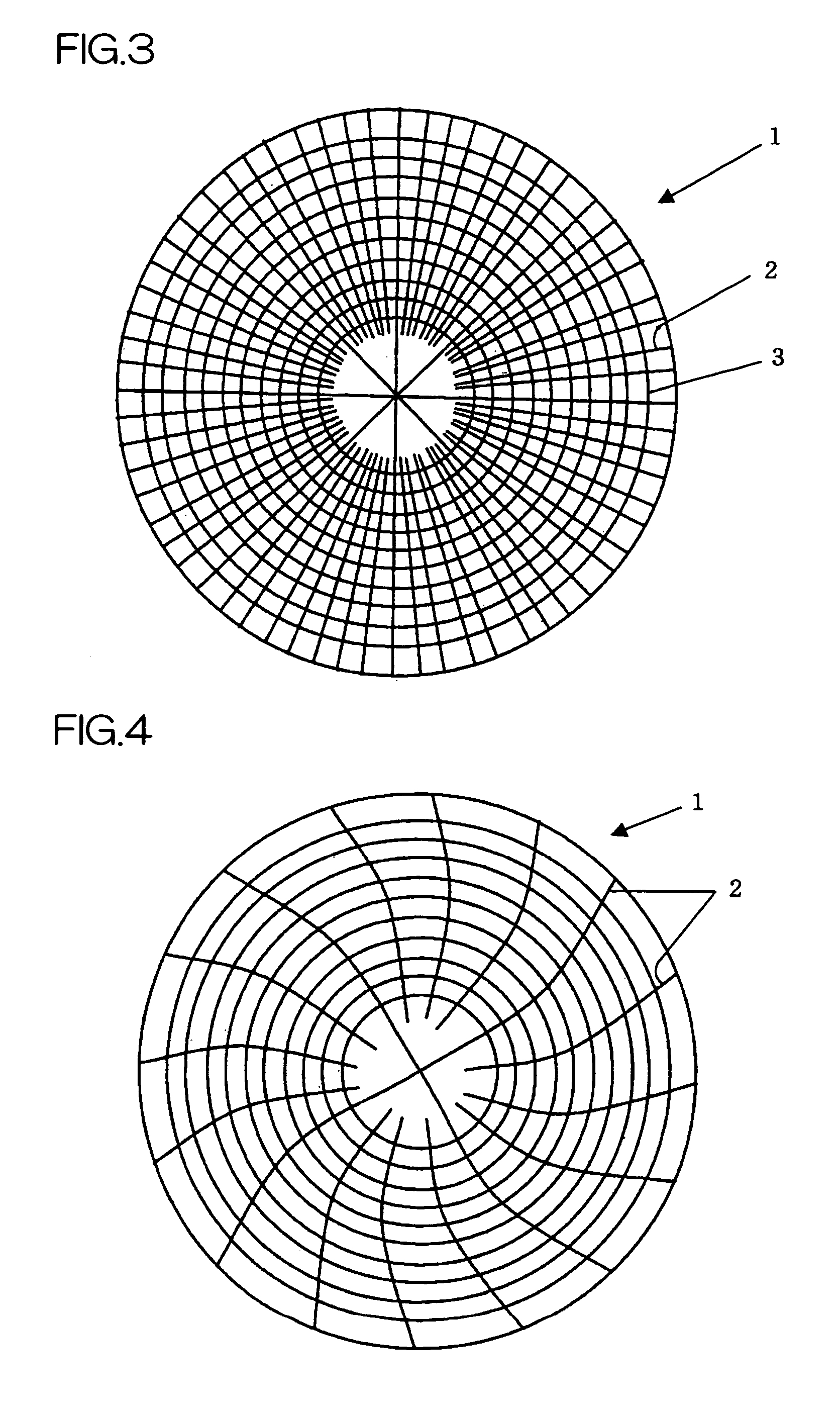

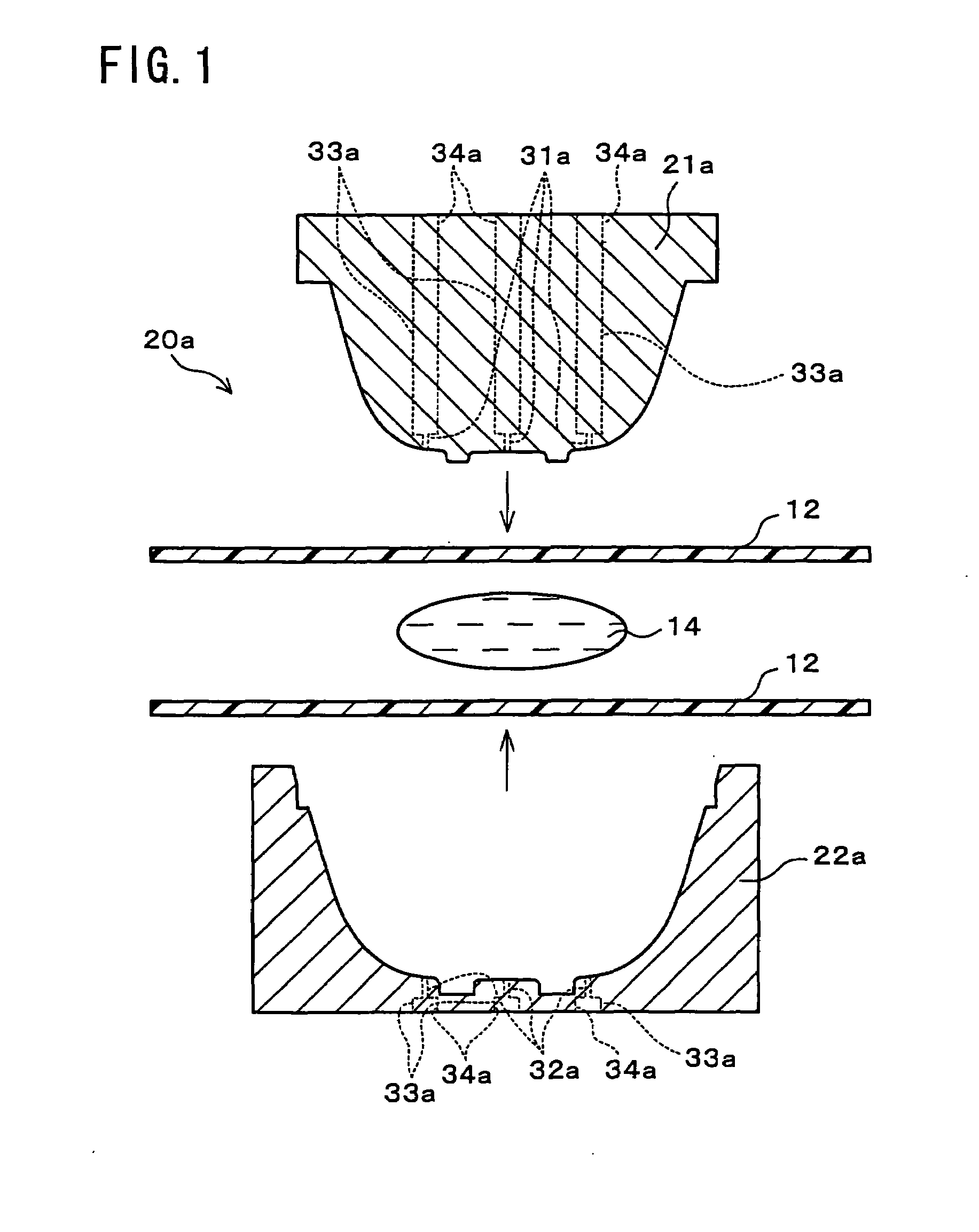

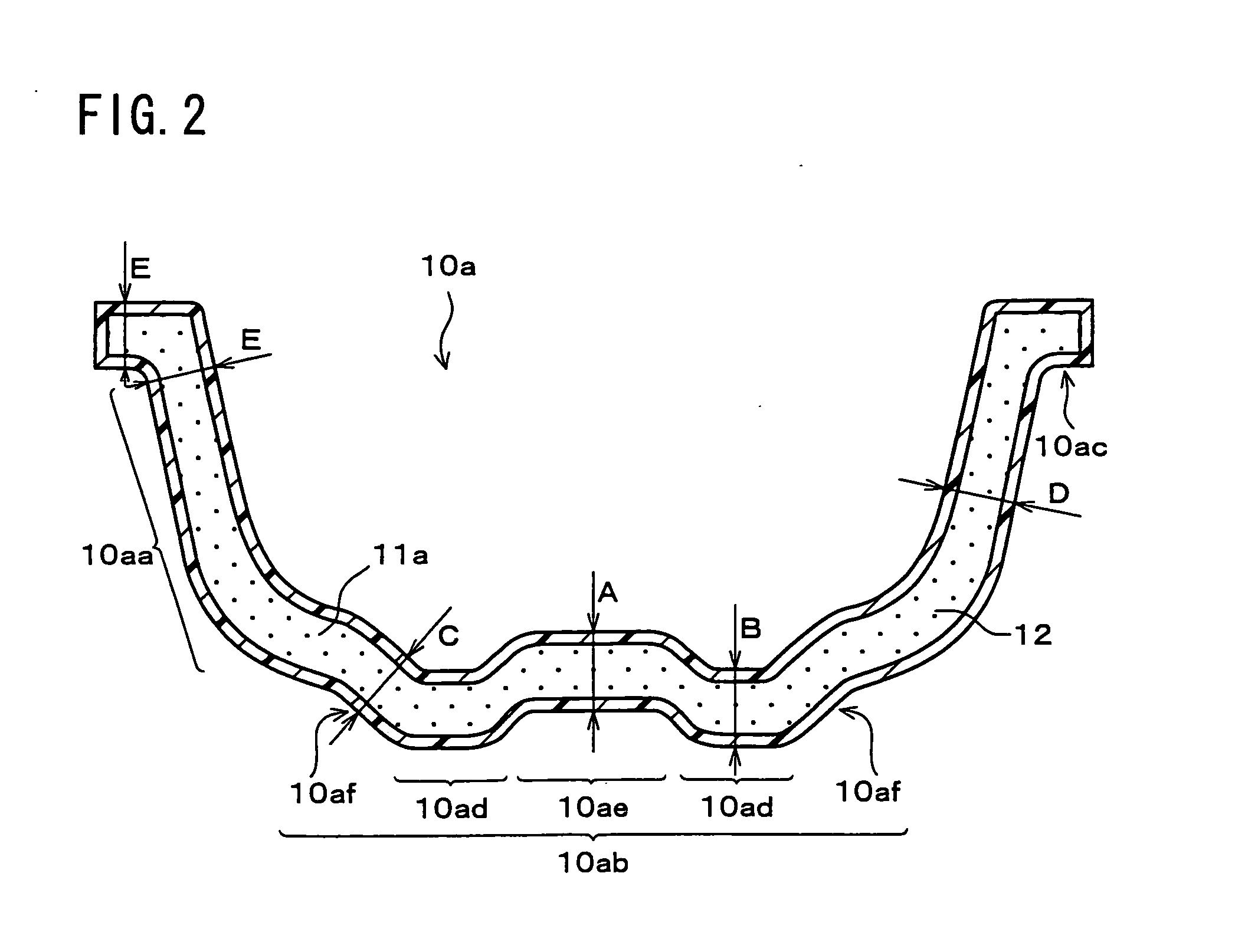

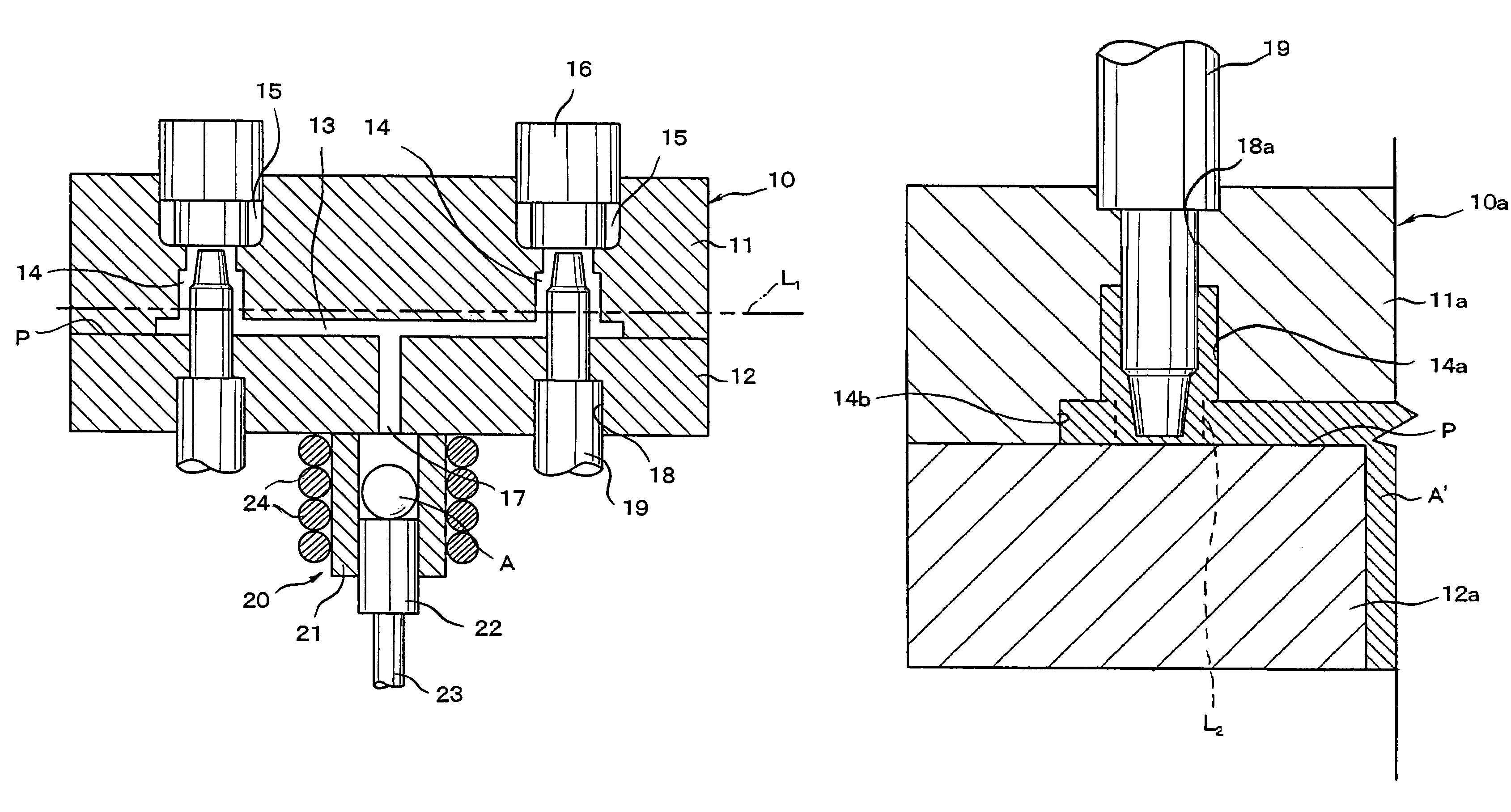

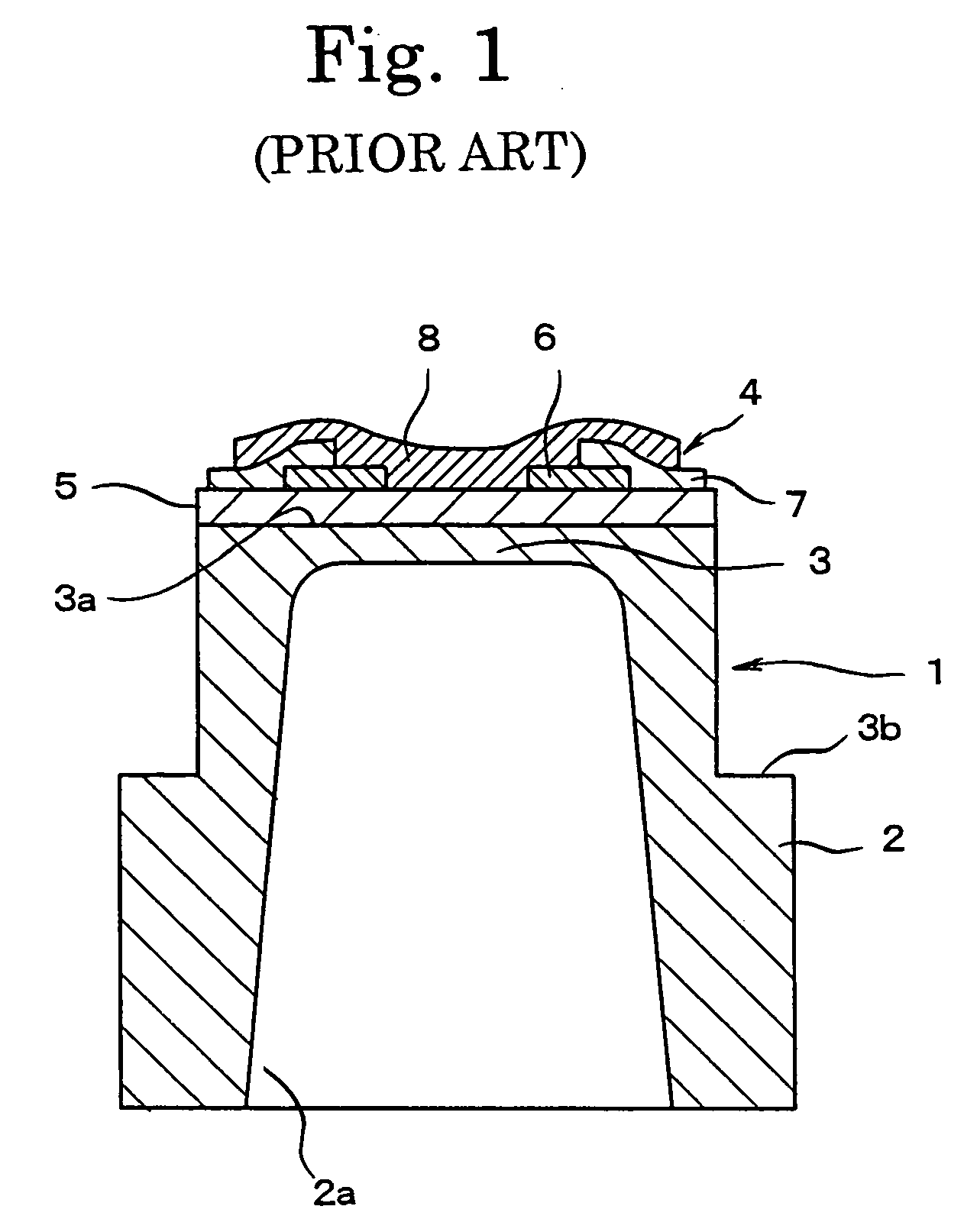

Method and mold for manufacturing biodegradable molded articles

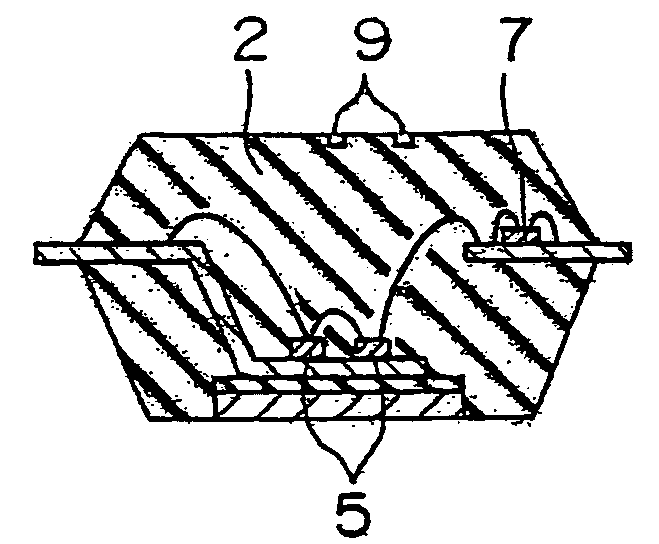

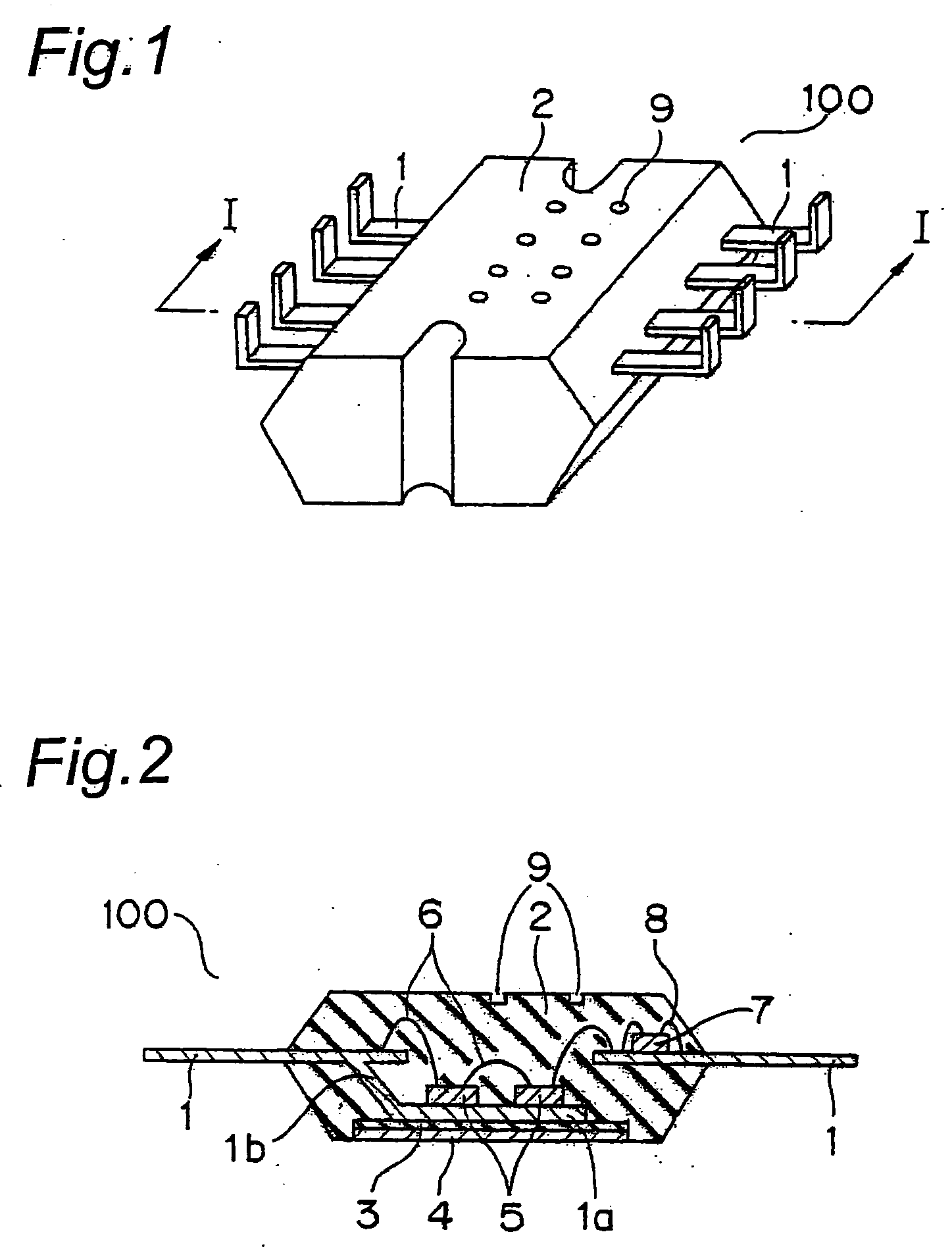

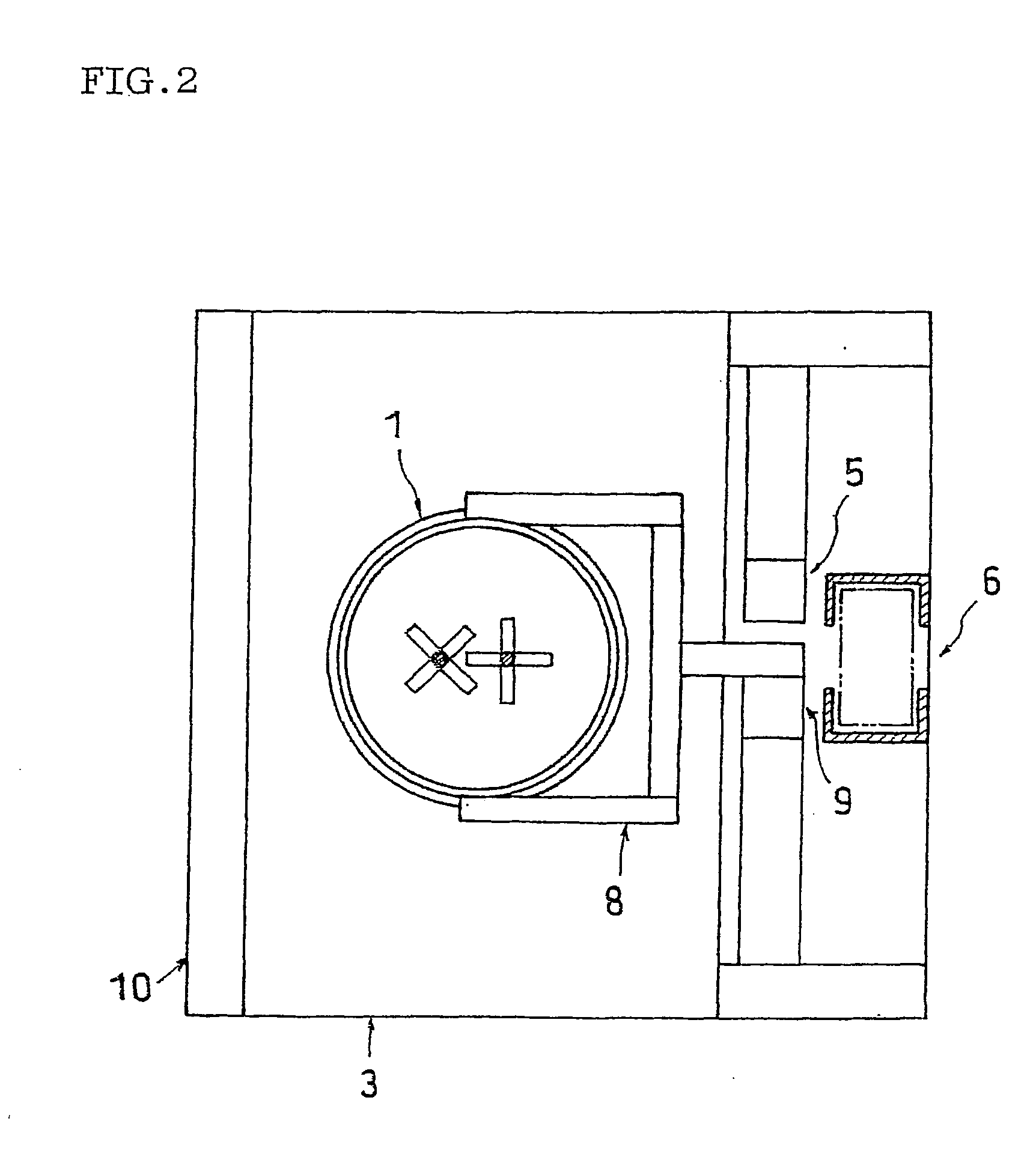

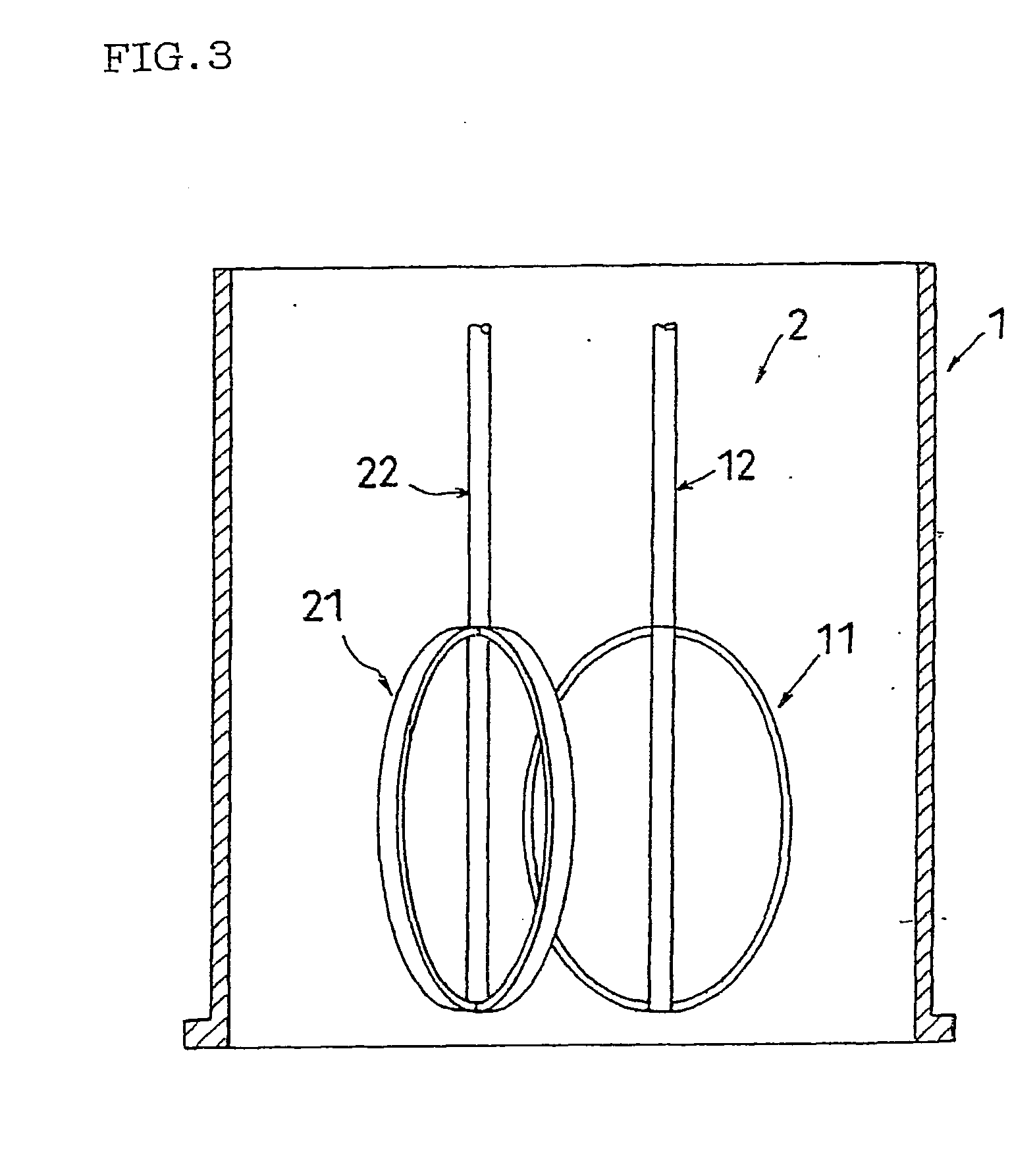

Using a metal mold (20a) consisting of a convex mold part (21a) and a concave mold part (22a), a molding material (14) is placed between a pair of coating films (12), and after claming, the molding material (14) and the coating film (12) are heated and molded to make a biodegradable expanded molded article, and at the same time, the coating film (12) is softened and pressure-bonded to a surface of the biodegradable expanded molded article. An exhaust hole (31a) and (32a) are provided on the convex mold part (21a) and the concave mold part (22a), respectively. At the time of heating and molding, gaseous matter existing between the coating film (12) and a surface of the metal mold (20a) is discharged out of the metal mold (20a) through the exhaust holes (31a) and (32a). Accordingly, it is possible to provide a method and a mold to manufacture a biodegradable expanded molded article easily and with excellent accuracy of dimension, having enough strength, enough water resistance, very excellent biodegradability and excellent surface smoothness even if the biodegradable molded article has a complicated shape.

Owner:NISSEI CO LTD

Die casting in investment mold

Method and apparatus for casting a metallic material involves the steps of providing a non-metallic mold in a mold-receiving chamber disposed in at least one of relatively movable first and second members, communicating a mold cavity in the mold to a gating passage disposed in at least one of the first and second metallic members, communicating the gating passage to a shot sleeve, and flowing metallic material from the shot sleeve to the gating passage and into the non-metallic mold.

Owner:HOWMET CORPORATION

Method for manufacture of a physical quantity detector

InactiveUS7708051B2High dimensional accuracyImprove surface smoothnessFluid pressure measurement by electric/magnetic elementsMetallic material coating processesMetal moldPressure sensor

Owner:NAGANO KEIKI

Electromagnetic Wave Shielding Grid Polarizer and Its Manufacturing Method and Grid Polarizer Manufacturing Method

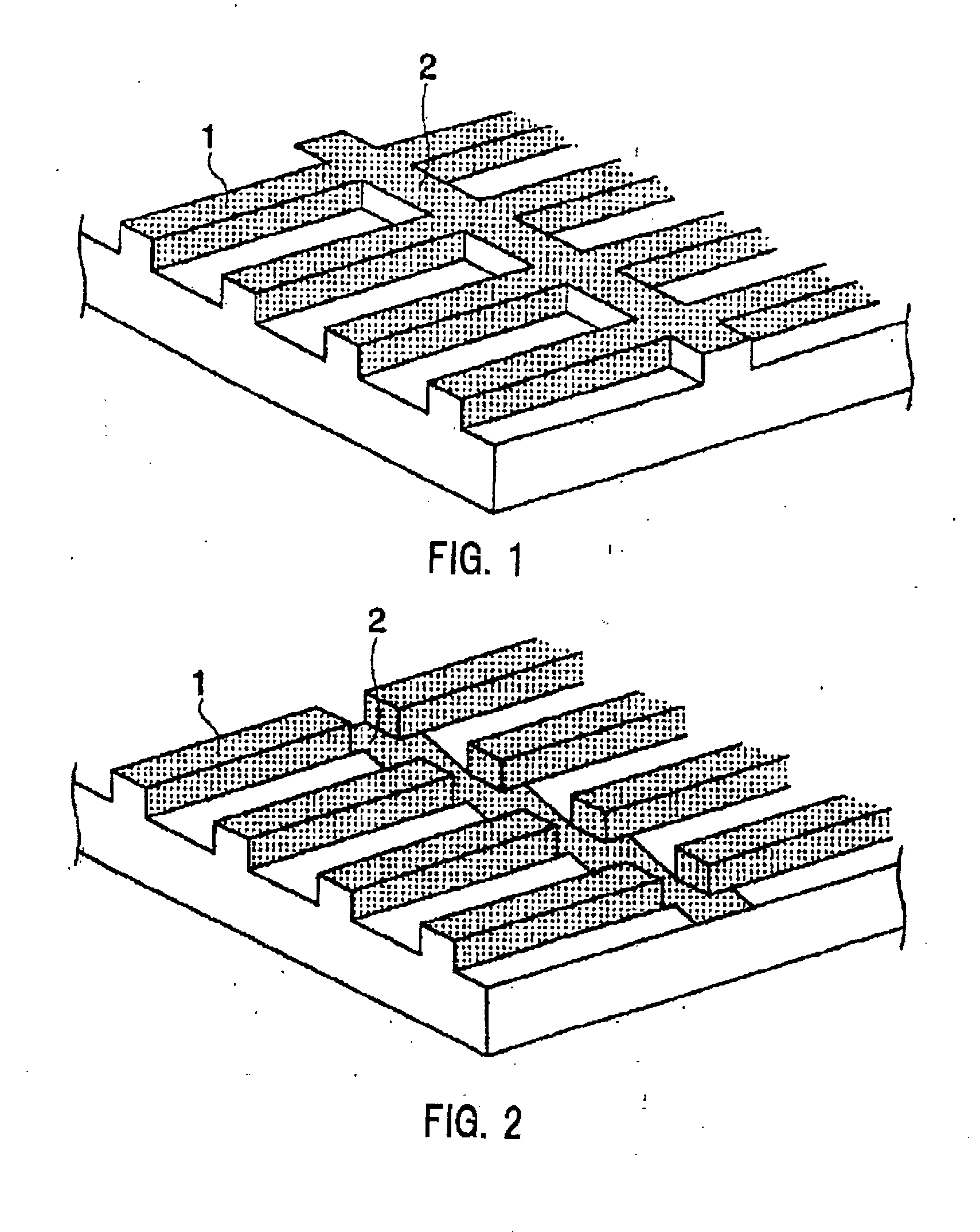

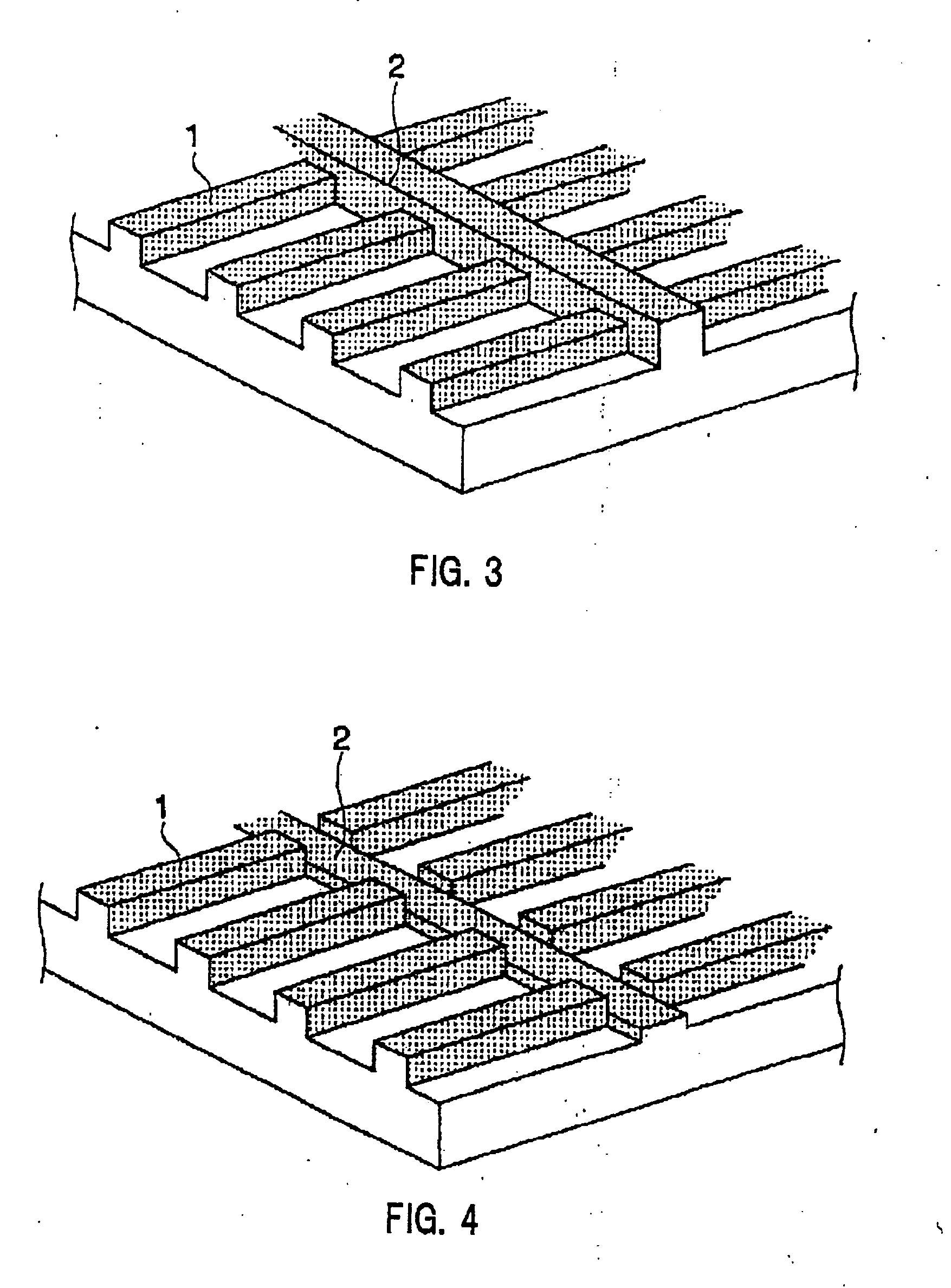

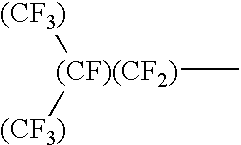

An electromagnetic wave shielding grid polarizer wherein a fine grating shape (1) consisting of linear, parallel projecting gratings and a grating shape (2) consisting of parallel gratings crossing fine grating shape (1) and having 0.1-500 μm width and 1 μm-100 nm pitch are formed; the total length of portions having lengths 10−5 to l0−1 times the wavelength of electromagnetic wave is at least 80% out of the projecting gratings of fine grating shape (1) segmented by the gratings of grating shape (2); and fine grating shape (1) is electrically interconnected with grating shape (2) by a conductive reflective material. The grid polarizer is made by a method of transferring linear, parallel grooves of a metal mold or a metal film to a transparent resin shaped article, and vapor-depositing a conductive reflective material on the shaped article, or by a method of formation of a conductive reflective material layer on a transparent base, coating with a resist, exposure to active radiation, development and etching.

Owner:ZEON CORP

Mold for nano imprinting

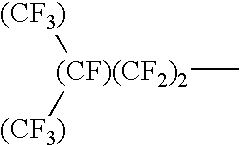

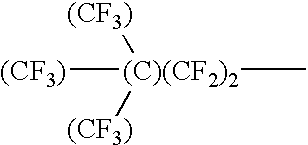

InactiveUS6923930B2Avoid reactionSimplified representationMechanical working/deformationDecorative surface effectsOrganic sulfide compoundMetal mold

A metal mold for use in a nano-imprinting process comprises a firmly adhering monomolecular non-sticking layer. The layer was obtained by subjecting the mold to a reaction with a fluoroalkyl compound having a mercapto group. As a result of said reaction, the layer comprises an organic sulfide of said metal.

Owner:OBDUCAT AB SE

Method for manufacturing metal molds used for casting manganese steel crushing walls or rolling motor walls of cone crushers

ActiveCN101954456ARealize the mechanization of modelingStandardize workFoundry mouldsFoundry coresCasting moldCrusher

The invention discloses a method for manufacturing metal molds used for casting manganese steel crushing walls or rolling motor walls of cone crushers. The method is characterized by comprising the following steps of: (1) manufacturing cast molds according to different sizes, specifications and models of the manganese steel crushing walls or the rolling motor walls of the cone crushers; (2) respectively designing and manufacturing near inner metal molds and near outer metal molds which have corresponding thicknesses and overall structures according to the shapes of the cast molds; and (3) distributing trumpet-shaped vent holes on the near inner metal molds and the near outer metal molds. Castings produced by using the method do not produce fragmentation; the metal molds can accelerate the cooling speed of the castings so that the surfaces of the castings have fine grain structures; and the mold cavities have the characteristics of high size precision, bright and clean surface and no distortion.

Owner:广西长城机械股份有限公司

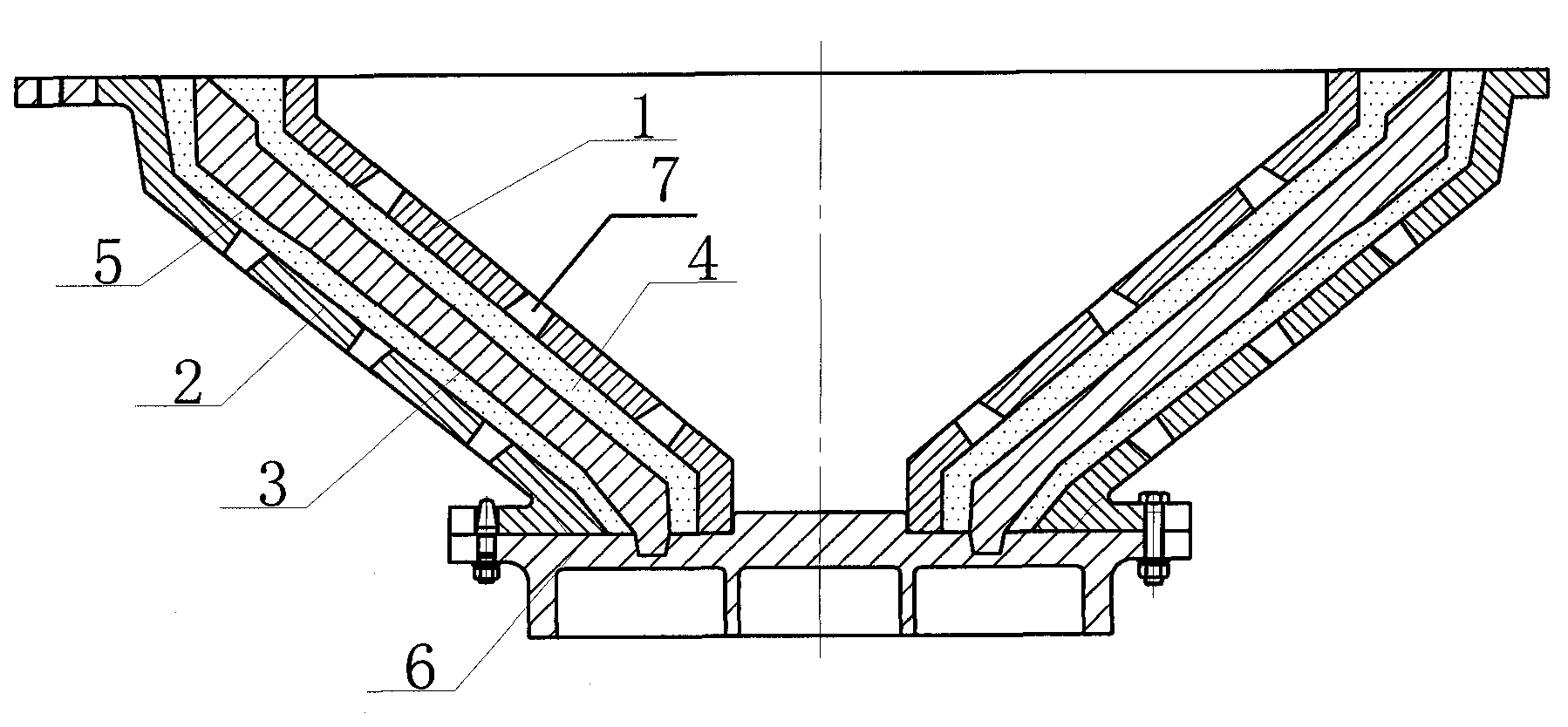

Metal die for coining super-hydrophobic micro-nanometer surface and laser manufacturing method thereof

ActiveCN103521929AHigh structural fidelityIncrease flexibilityNanotechnologyLaser beam welding apparatusPicosecond laserOptoelectronics

The invention discloses a metal die for coining a super-hydrophobic micro-nanometer surface and a laser manufacturing method thereof. The laser manufacturing method comprises the following steps that an ultra-short pulse laser is used for ablating a metal base material, a symmetrical negative structure of a lotus leaf micro-nanometer structure is obtained on the surface of the metal base material through laser ablating removing, and then the metal die is obtained; the symmetrical negative structure of the lotus leaf micro-nanometer structure is a micrometer-level pit and a nanometer-level substructure on the inner surface of the micrometer-level pit. The invention provides the micro-nanometer coining metal die for coining a non-metal material or a light-metal material so as to form the lotus leaf micro-nanometer structure with the surface being super hydrophobic and the laser manufacturing method of the metal die, and particularly relates to the micro-nanometer coining metal die which is manufactured efficiently in a large area by the utilization of high-power picosecond lasers and the manufacturing method of the metal die. The metal die for coining the super-hydrophobic micro-nanometer surface and the laser manufacturing method of the metal die have the comprehensive advantages that the manufacturing efficiency is high, the micro-nanometer coining die is high in temperature resistance, high in pressure resistance and wide in coning material range, the micro-nanometer structure is precise and adjustable in parameter and the lotus structure is vivid. Moreover, the manufacturing method is far superior than other methods.

Owner:TSINGHUA UNIV

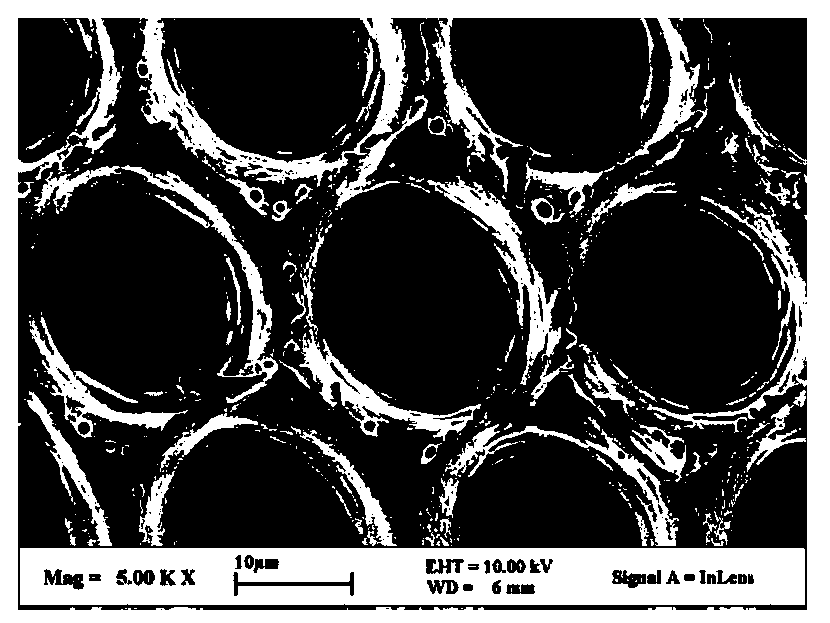

Wide temperature domain damping polyurethane micropore elastomer material and preparation method thereof

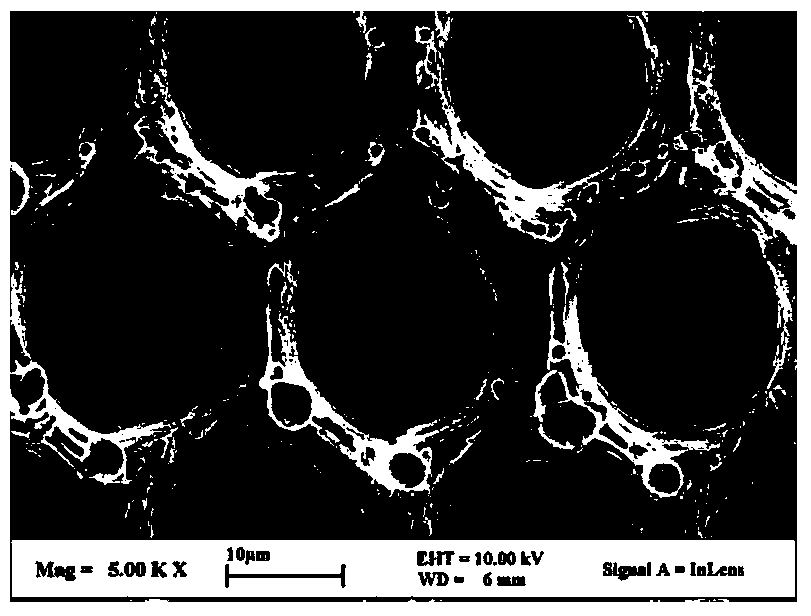

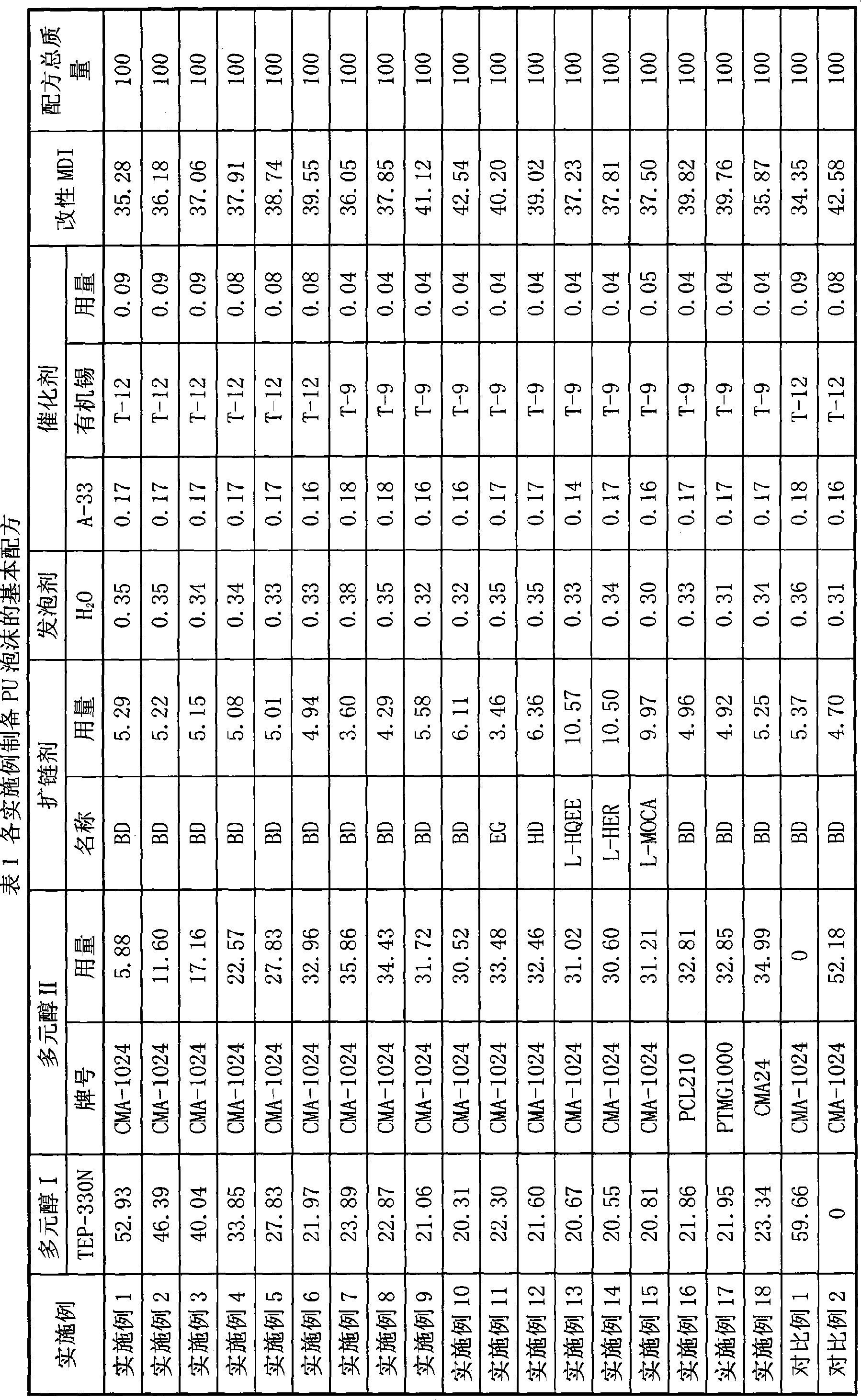

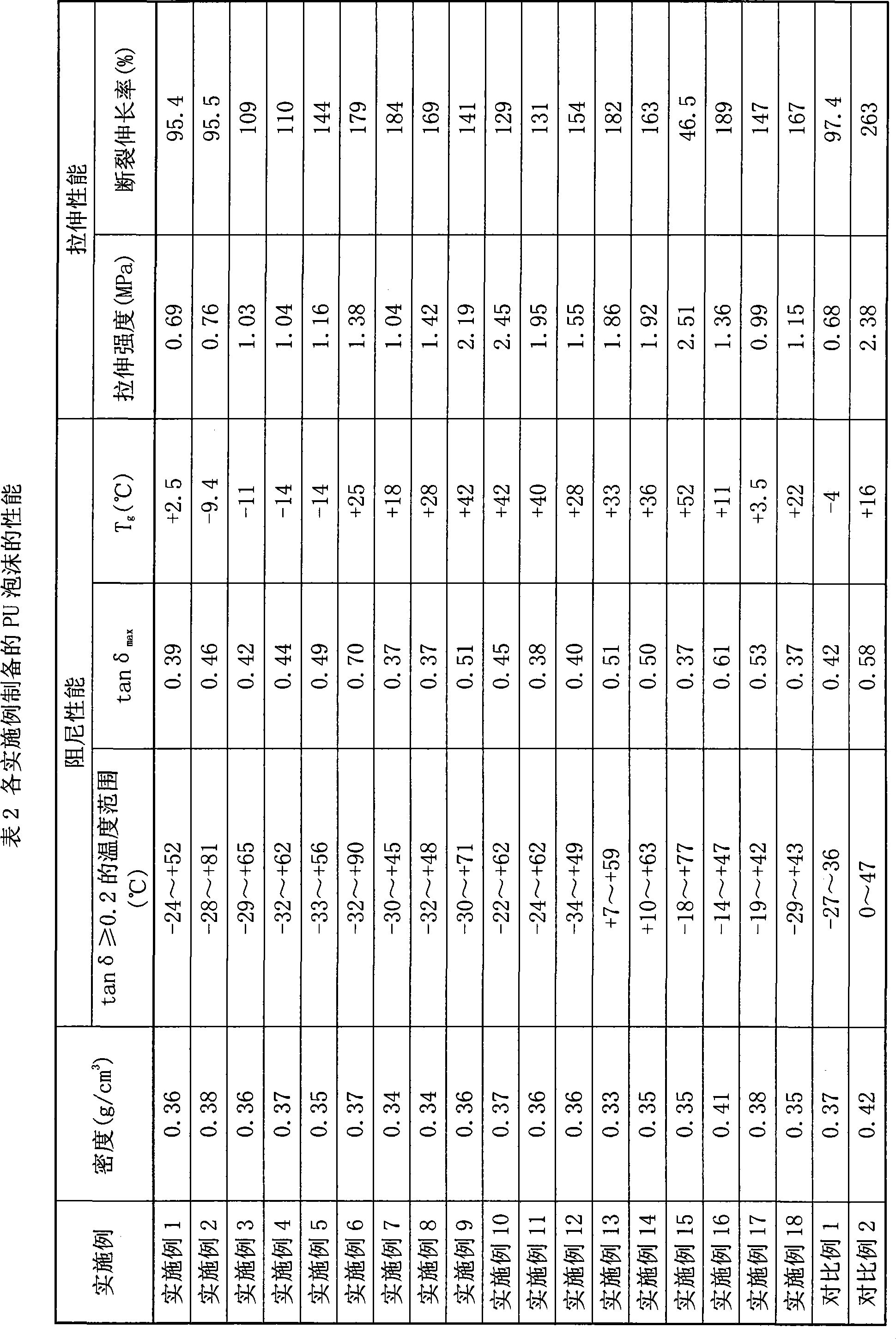

The invention provides a wide temperature domain damping polyurethane micropore elastomer material and a preparation method thereof; the formulation comprises 20 percent to 55 percent of polylol I, 5 percent to 38 percent of polylol II, 32 percent to 44 percent of isocyanate, 3.0 percent to 12.0 percent of chain extender, 0.10 percent to 0.30 percent of composite catalyst and 0.1 percent to 0.5 percent of foaming agent. The preparation method comprises the following steps: the polylol I and the polylol II are evenly mixed; the chain extender, the composite catalyst and foaming agent and other additives are added; the inner wall of a metal mold is coated with a releasing agent, heating and drying are carried out; and the mixture is added with isocyanate, is stirred with strong force, and the obtained mixture is cast into the mold, sealed, cured, cooled and demoulded so as to obtain the polyurethane micropore elastomer material. The invention adopts two types of polylol with large distance of molecular weight as polyurethane soft segment, leads the material to have excellent damping performance in the temperature range of -20 DEG C to 50 DEG C and can meet the use requirements under normal temperature condition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

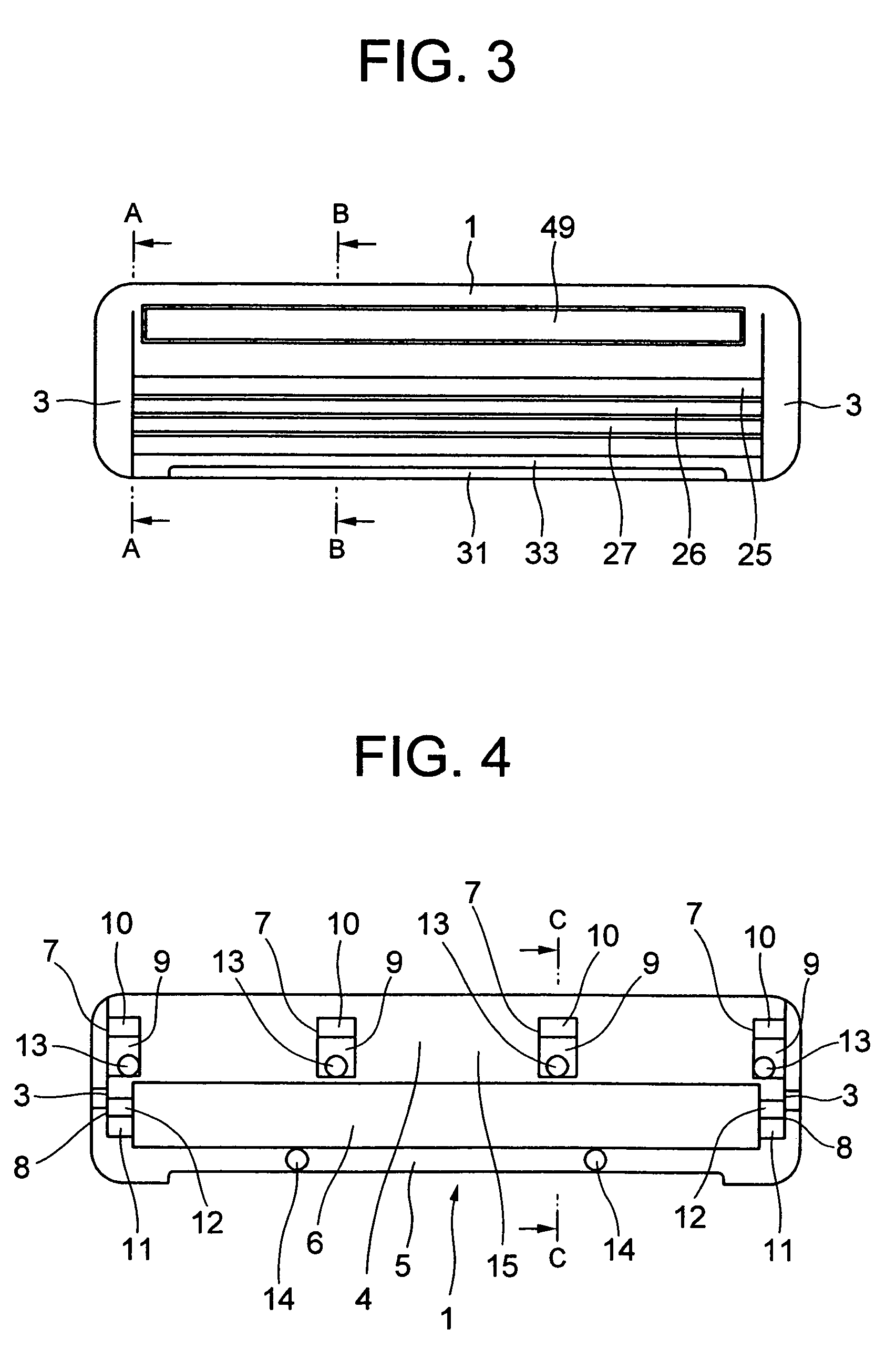

Safety razor

InactiveUS7191523B2Efficient ejectionSurely and simply fixedMetal working apparatusRazor stropMetal mold

A safety razor with a plurality of blades comprising a head provided with a plurality of vertically adjacent blades, which do not wholly overlap one another, and blade support parts supporting the respective blades apart from one another in order to retain the respective blades at spaces, and wherein non-overlapping portions, which do not overlap one another, are formed on supported portions of the respective blades and the blade support parts are held to the non-overlapping portions of the blades to support the blades. A support structure can be divided into two members to be manufactured and mechanically assembled, metal molds are not so much complicated, and mechanical assembly of blades is made possible to prevent degradation in yield.

Owner:KAI R&D CENT CO LTD

Method for preparing in-situ particle reinforced magnesium base compound material

ActiveCN101381829AImprove mechanical propertiesGood physical propertiesMagnesium matrix compositeMetal mold

The invention relates to a method for preparing in-situ particle reinforced magnesia-based composite materials, which particularly comprises the following steps: magnesium aluminum alloy raw materials are completely smelt under the protective condition of gas mixture of SF6 and CO2; aluminum-silicon intermediate alloy is pressed into a magnesium aluminum fused mass, and the temperature is raised and maintained, so as to guarantee complete reaction between silicon and magnesium in the magnesium aluminum alloy fused mass, and simultaneously an ultrasonic probe is inserted into the fused mass for treatment; and after the treatment is finished, surface scum is removed and the fused mass is cast into a metal die, and the in-situ Mg2Si particle reinforced magnesia-based composite materials are obtained. The method has the characteristics of good interference compatibility of Mg2Si particles and substrates, controllable particle size of reinforced phases, uniform distribution of the reinforced phase and so on; and the magnesia-based composite materials prepared have good mechanical property.

Owner:JIANGSU UNIV

Method for producing semiconductor device and semiconductor device

ActiveUS20050082690A1Improve cooling effectImprove insulation performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialMetal foil

The method of producing a semiconductor device in which chips are resin-molded, including steps of: preparing frames having front and back surfaces and die pads; preparing an insulation resin sheet having a first and a second surfaces; preparing a resin-sealing metal mold having cap pins; mounting the resin sheet inside the resin-sealing metal mold in such a manner that the second surface of the resin sheet contacts an inner bottom surface of the resin-sealing metal mold; mounting power chips on the surfaces of the die pads; positioning the frames on the first surface of the resin sheet in such a manner that the back surfaces of the die pads contact the first surface of the resin sheet; pressing the die pads toward the resin sheet using the cap pins and fixing the die pads; injecting a sealing resin in the resin-sealing metal mold and hardening the sealing resin; and removing the semiconductor device in which the power chips are molded with the sealing resin out from the resin-sealing metal mold. The resin sheet may include a metal foil which is disposed to the second surface.

Owner:MITSUBISHI ELECTRIC CORP

Method of producing polishing pad-use polyurethane foam and polyurethane foam

InactiveUS20050222288A1Avoid it happening againSpeed up the flowSemiconductor/solid-state device manufacturingFlexible-parts wheelsFoaming agentHydrogen

A production method comprising the step of charging prepolymer, a foaming agent and an active hydrogen-containing compound in specified amounts into a tank and foaming / mixing them for a specified time by a mixer, and the subsequent step of pouring the mixture liquid into a metal mold.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Method for injection molding of plastic products having excellent transcription properties

If the surface of metallic mold should not be highly transcribed to the surface of product in injection molding the plastic products, the transcription defects such as weld, shrinkage, etc. are caused to the surface of product. Further, if the resin should be exposed to the surface of high temperature metallic mold more than necessary during the molding, the filler and the like of glass and so forth are contained into the resin, and in this case, they are left over on the surface of metallic mold, resulting in the transcription defect. These problems can be solved by heating the surface temperature of metallic mold higher than the glass transfer temperature of resin if the resin is non-crystal and higher than the fusion point temperature if the resin crystal, with the temperature raising speed of more than 2° C. every second, maintaining this temperature during the resin charging, and by cooling at the lowering speed of more than 2° C. every second after the completion of charging. This temperature control shall be conducted with the feed back control while detecting the surface temperature of metallic mold by the temperature detection sensor mounted at the position close to the surface of metallic mold.

Owner:MUNEKATA TAKATUKI OSAKA JP

Preparation method of large quartz ceramic crucible

The invention discloses a preparation method of a large quartz ceramic crucible, which is formed based on the method of gel casting molding, and particularly comprises the following steps: a) taking fused quartz with purity of 99.0-99.9% according to the mass percent as a raw material, and carrying out granular grading on the grains of the fused quartz; b) uniformly mixing the raw material proportioned by the step a), adding gel solution, preparing into pulp in a ball mill or a blender; c) injecting or pressure-injecting the prepared pulp prepared by the step b) into a preheated metal mold, and taking out from the metal mold after the pulp is solidified into green bodies; d) naturally drying the green bodies; and e) putting the dried green bodies into a high-temperature furnace, baking toobtian the large quartz ceramic crucible. Raw material grain proportioning and the preparation method, optimized by the invention, can product the quartz ceramic crucible with larger overall dimension and thin wall for fusion of special glass, casting of polycrystalline and calcining of rear earth material.

Owner:洛阳北苑新材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com