Wide temperature domain damping polyurethane micropore elastomer material and preparation method thereof

A technology of microporous elastomer and elastomer material, which is applied in the field of polyurethane microporous elastomer material and its preparation, can solve the problems of low damping factor and limited application range, achieve excellent damping and vibration reduction performance, and meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the wide temperature range damping polyurethane microcellular elastomer material of the present invention comprises the steps of following order:

[0046] (1). Vacuumize polyol I and polyol II in a vacuum oven at 140°C for 2 hours, cool to room temperature, then mix the two in proportion and stir evenly.

[0047] (2). Add the chain extender, catalyst, and blowing agent to the mixture obtained in step (1), stir evenly, and adjust the temperature of the mixture to 40°C;

[0048] (3). Weigh the isocyanate and heat it to 40°C;

[0049](4). Evenly coat the inner wall of the metal mold with a release agent, dry the release agent, and heat the metal mold to 45°C;

[0050] (5). Add the isocyanate in step (3) to the mixture obtained in step (2), stir for 15 seconds at a speed of 2000 rpm with a strong mixer, and then quickly pour the stirred mixture into the mold in step (4) , seal the mold after the material fills the mold;

[0051] (6). Put the mol...

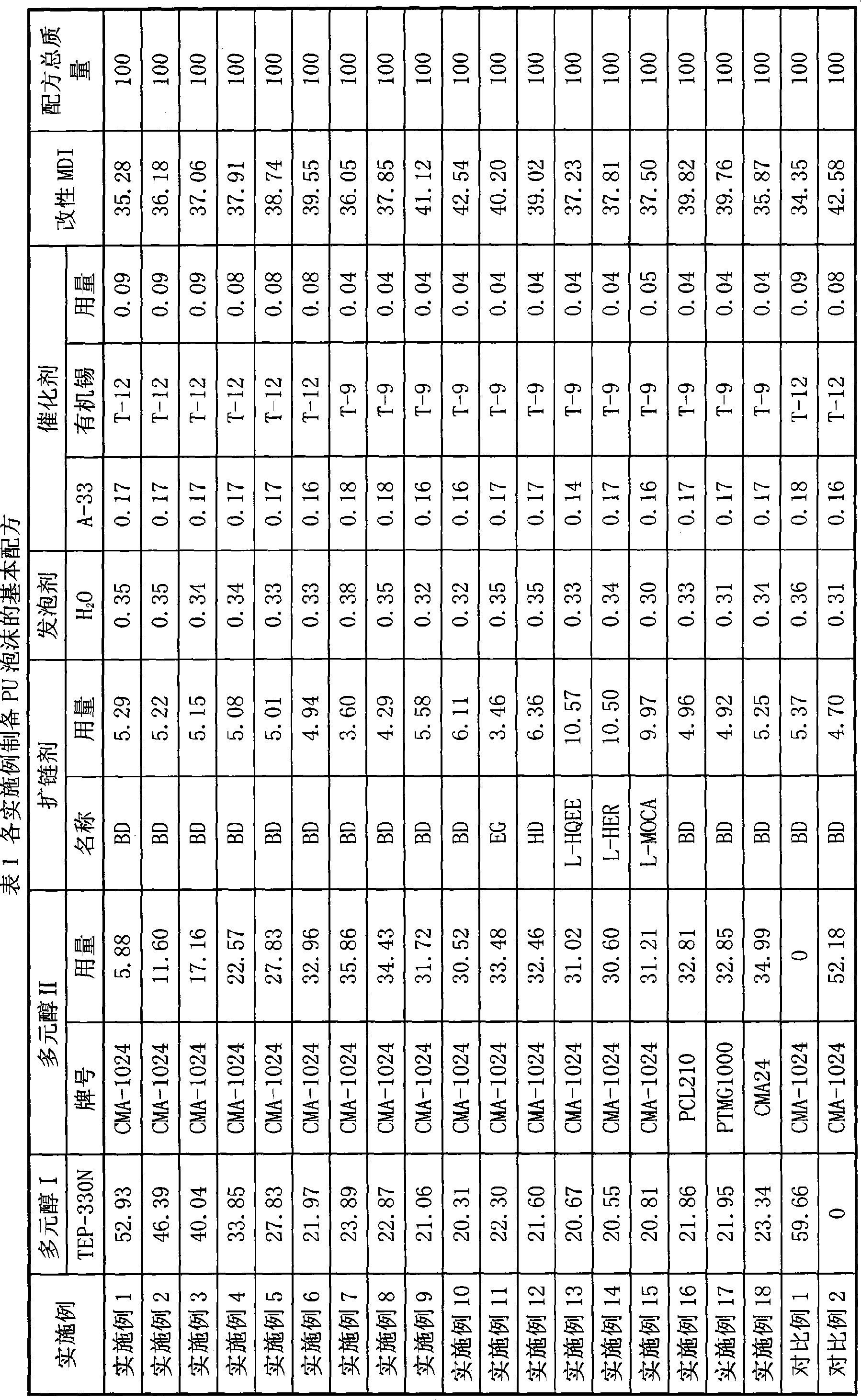

Embodiment 1

[0053] After melting polyethylene adipate polyol (CMA-1024) with a molecular weight of 1000, it was placed in a vacuum oven at 140°C for 1 hour of vacuum treatment, cooled to room temperature, and set aside. Polyoxypropylene ether polyol with a molecular weight of 4000 (abbreviated as polyether polyol, TEP-330N) was vacuum-treated in a vacuum oven at 140°C for 1 hour, cooled to room temperature, and set aside. Take 52.93 parts of TEP-330N, add 5.88 parts of CMA-1024, then add 5.29 parts of 1,4-butanediol (BD), 0.35 parts of H 2 O, 0.17 parts of A-33, 0.09 parts of T-12 to form a resin mixture. The above resin mixture was mixed evenly at a speed of 2000 rpm. Add 35.28 parts of modified MDI to the above mixture, quickly stir the mixture evenly, pour it into a mold at 45°C, mature it at 100°C for 2 hours, and demould after cooling to obtain a light yellow polyurethane microcellular elastomer material.

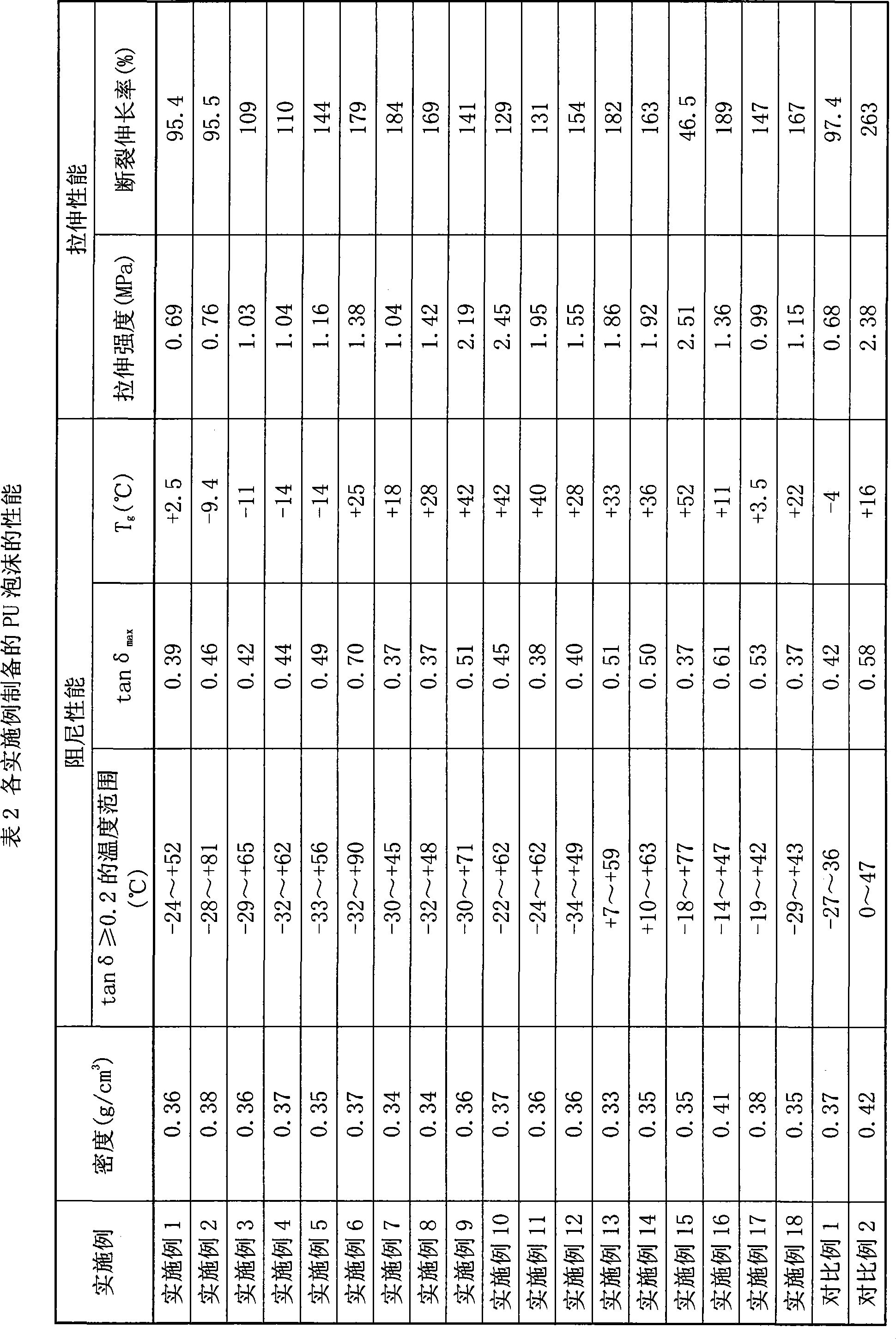

[0054] The prepared material has a density of 0.36 g / cm 3 , the temperatur...

Embodiment 2

[0056] The rest of this example is the same as Example 1, the difference is: take 46.39 parts of TEP-330N, add 11.60 parts of CMA-1024, and then add 5.22 parts of BD and 0.35 parts of H 2 O, 0.17 parts of A-33, 0.09 parts of T-12 to form a resin mixture. The above resin mixture was mixed evenly at a speed of 2000 rpm. Add 36.18 parts of modified MDI to the above mixture, quickly stir the mixture evenly, pour it into a mold at 45°C, mature it at 100°C for 2 hours, and demould after cooling to obtain a light yellow polyurethane microcellular elastomer material.

[0057] The prepared material has a density of 0.38 g / cm 3 , the temperature range of its damping factor (tanδ) greater than 0.2 is -28℃~+81℃, and its maximum damping factor (tanδ max ) is 0.46, tanδ max The corresponding temperature is -9.4°C, the tensile strength is 0.76MPa, and the elongation at break is 95.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com