Method for preparing in-situ particle reinforced magnesium base compound material

A particle-reinforced and composite material technology is applied in the field of in-situ particle-reinforced magnesium-based composite material preparation. , to avoid the effect of limited size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

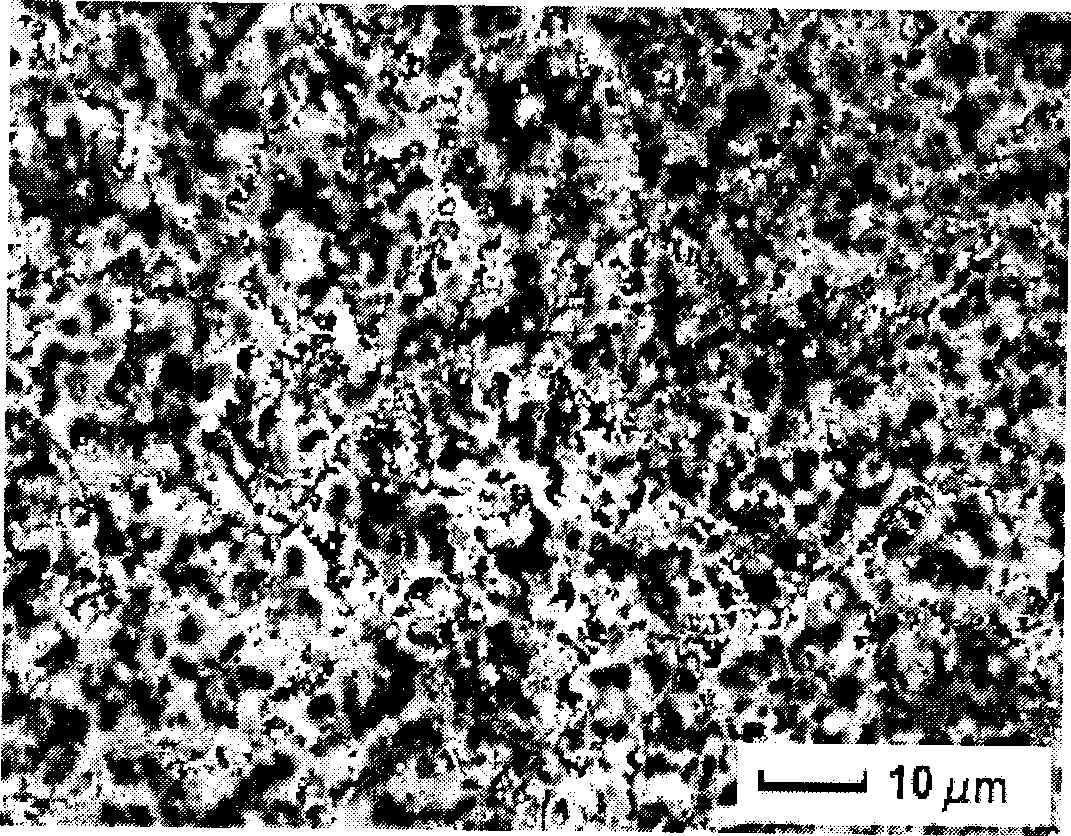

[0020] at 3vol.%SF 6 +97vol.%CO 2 Under the condition of mixed gas protection, the AZ91D alloy ingot (80wt.%) was completely melted at 680°C, and then the Al-Si master alloy (20wt.%) was pressed into the melt, and then the temperature was raised to 700°C, and Keep warm for 20 minutes, insert an ultrasonic probe into the melt for processing, set the ultrasonic power to 2KW, and continue processing for 5 minutes. Finally remove the scum on the surface and cast it in a metal mold to get 11vol% Mg after solidification 2 Si / AZ91D composite material. The obtained in situ Mg 2 The microstructure photos of Si particle reinforced magnesium matrix composites are as follows: figure 1 , the tensile strength at room temperature is 230MPa, and the tensile strength at 150°C is 202MPa.

Embodiment 2

[0022] at 2vol.%SF 6 +98vol.%CO 2 Under the condition of mixed gas protection, the AZ91D alloy ingot (85wt.%) was completely melted at 700°C, and then the Al-Si master alloy (15wt.%) was pressed into the melt, and then the temperature was raised to 720°C, and Keep warm for 15 minutes, insert an ultrasonic probe into the melt for processing, set the ultrasonic power to 1.6KW, and continue processing for 8 minutes. Finally remove the scum on the surface and cast it in a metal mold to get 8vol% Mg after solidification 2 Si / AZ91D composite, the resulting Mg 2 The room temperature tensile strength of the Si particle reinforced magnesium matrix composite is 215MPa, and the tensile strength at 150℃ is 188MPa.

Embodiment 3

[0024] at 1vol.% SF 6 +99vol.% CO 2 Under the condition of mixed gas protection, the AZ91D alloy ingot (90wt.%) was completely melted at 720°C, and then the Al-Si master alloy (10wt.%) was pressed into the melt, and then the temperature was raised to 740°C, and Keep warm for 10 minutes, insert an ultrasonic probe into the melt for processing, set the ultrasonic power to 0.4KW, and continue processing for 15 minutes. Finally remove the scum on the surface and cast it in a metal mold to get 5vol% Mg after solidification 2 Si / AZ91D composite, the resulting Mg 2 The tensile strength of Si particle reinforced magnesium matrix composite is 208MPa at room temperature and 175MPa at 150℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com