Patents

Literature

156results about How to "Particle size is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

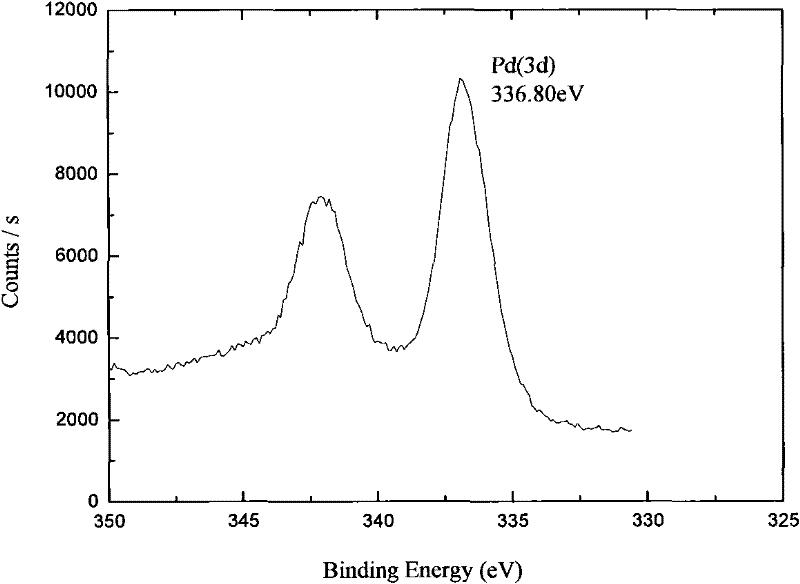

C4 selective hydrogenation catalyst and preparation method thereof

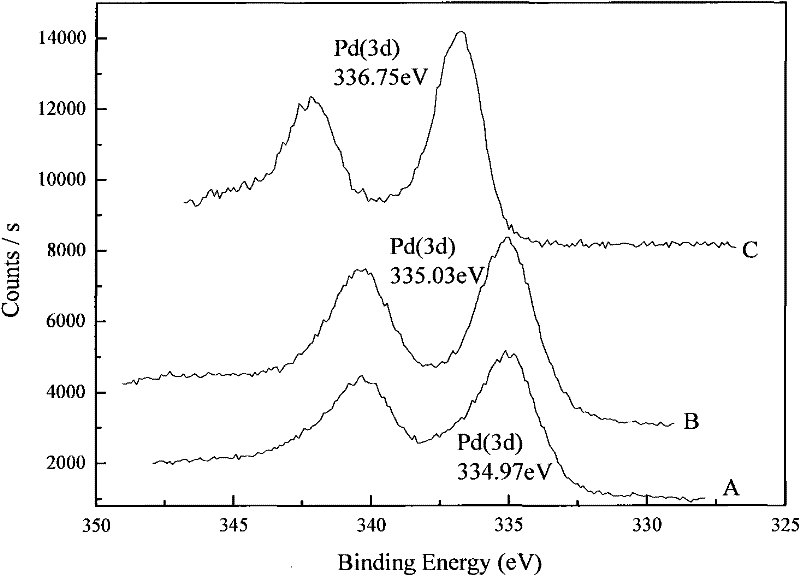

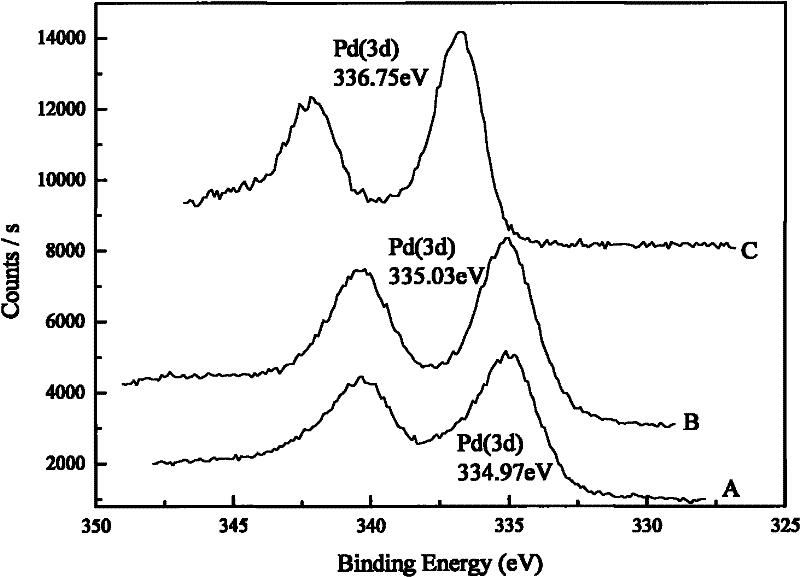

ActiveCN102240547AHigh activityHigh crystallinityHydrocarbon purification/separationCatalyst activation/preparationHydrogenActive component

The invention discloses a C4 selective hydrogenation catalyst and a preparation method and use thereof. The saturated hydrocarbon hydrogenation catalyst is prepared by ionizing radiation reduction of a primary metal active component precursor and a secondary metal active component precursor, which are supported by a carrier, wherein the primary metal active component is Pd monomer; and the average diameters of particles of the primary metal active component and the particles of the secondary metal active component are both smaller than 10 nanometers. The catalyst disclosed by the invention has the advantages of avoiding being reduced by hydrogen in advance, along with high activity and selectivity, direct use and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

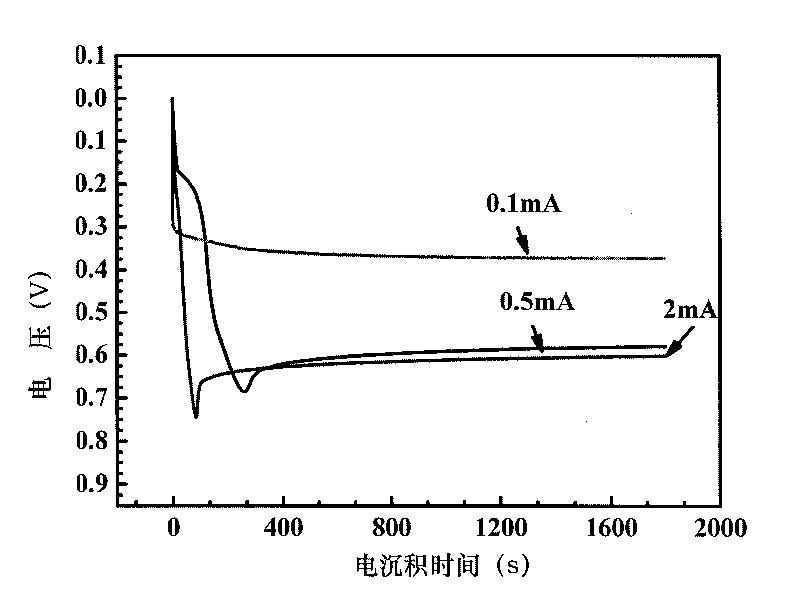

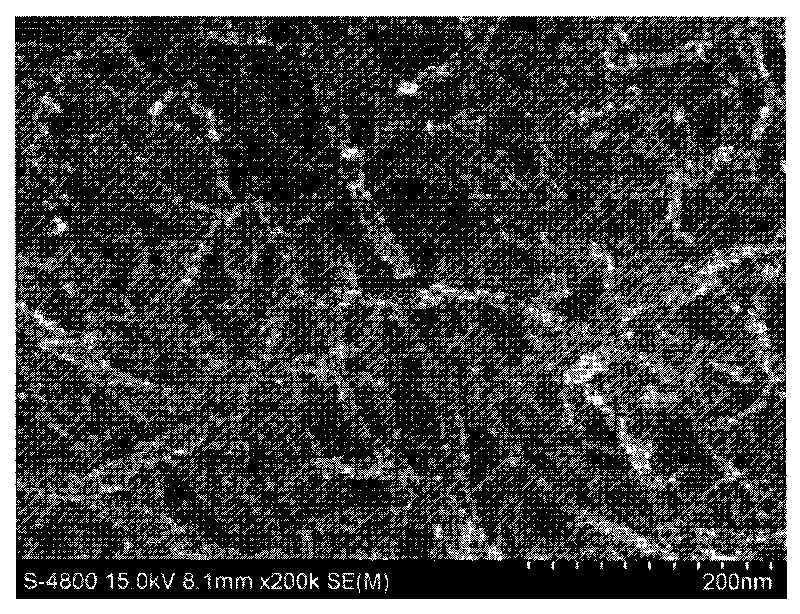

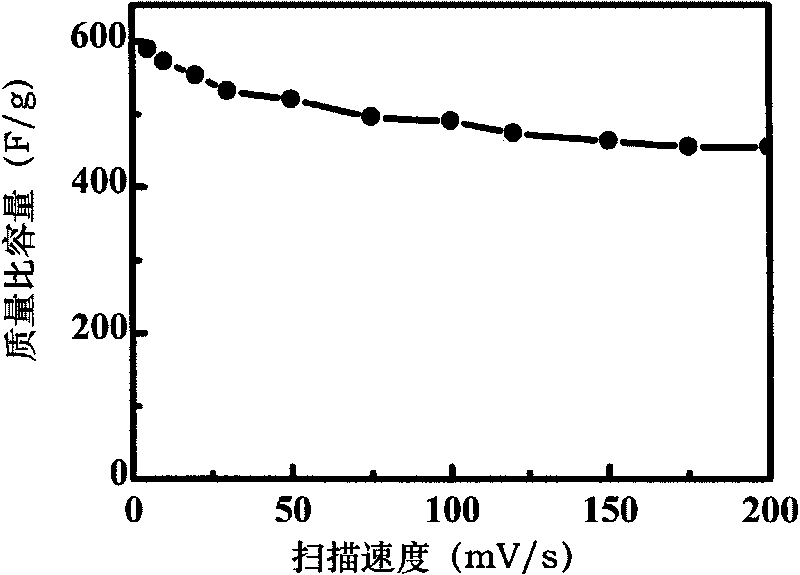

Method for preparing stannic oxide battery anode material on carbon nano tube by using electro-deposition process

The invention discloses a method for preparing a stannic oxide battery anode material on a carbon nano tube by using an electro-deposition process. The method comprises the steps of: making electro-deposition solution, treating the solution with water bath, preparing the carbon nano tube pole piece, pressing on a foam nickel base, putting the base carrying the carbon nano tube pole piece into the electro-deposition solution so as to perform vacuum treatment, and then perform the electro-deposition treatment under a constant current on the vacuumized pole piece so as to acquire the battery anode material on the carbon nano tube carrying the stannic oxide. The battery anode material prepared by using the method has higher power property and has a quality specific capacity kept between 350 and 450 F / g under a high scanning speed of 200 mV / s. The material applied in a super capacitor has higher volumetric properties, excellent cycling stability and long cycling life, first discharging specific capacity ranged between 410 and 588 F / g under a constant current density of 15 A / g, cycling times more than 5000 times and specific capacity retention rate ranged between 90 to 95 percent.

Owner:BEIHANG UNIV

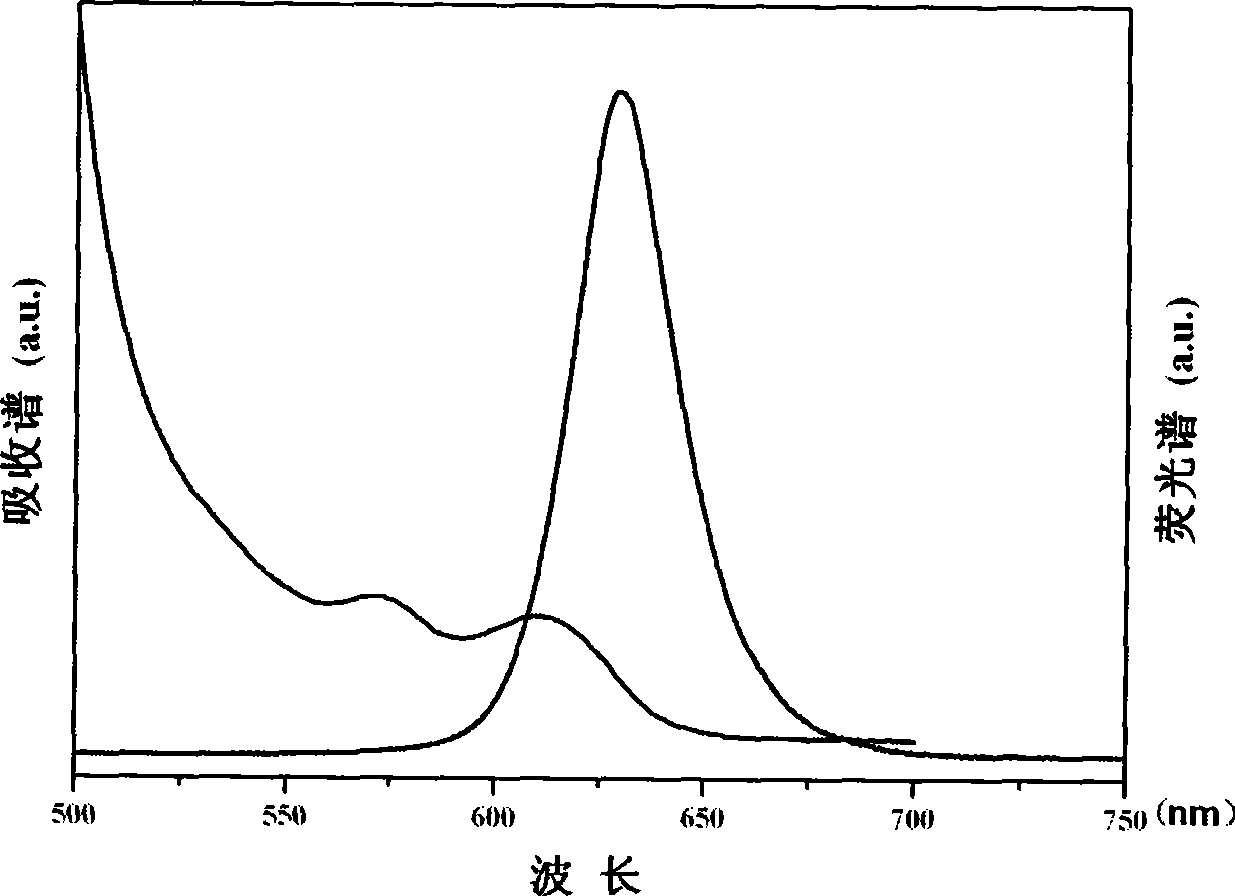

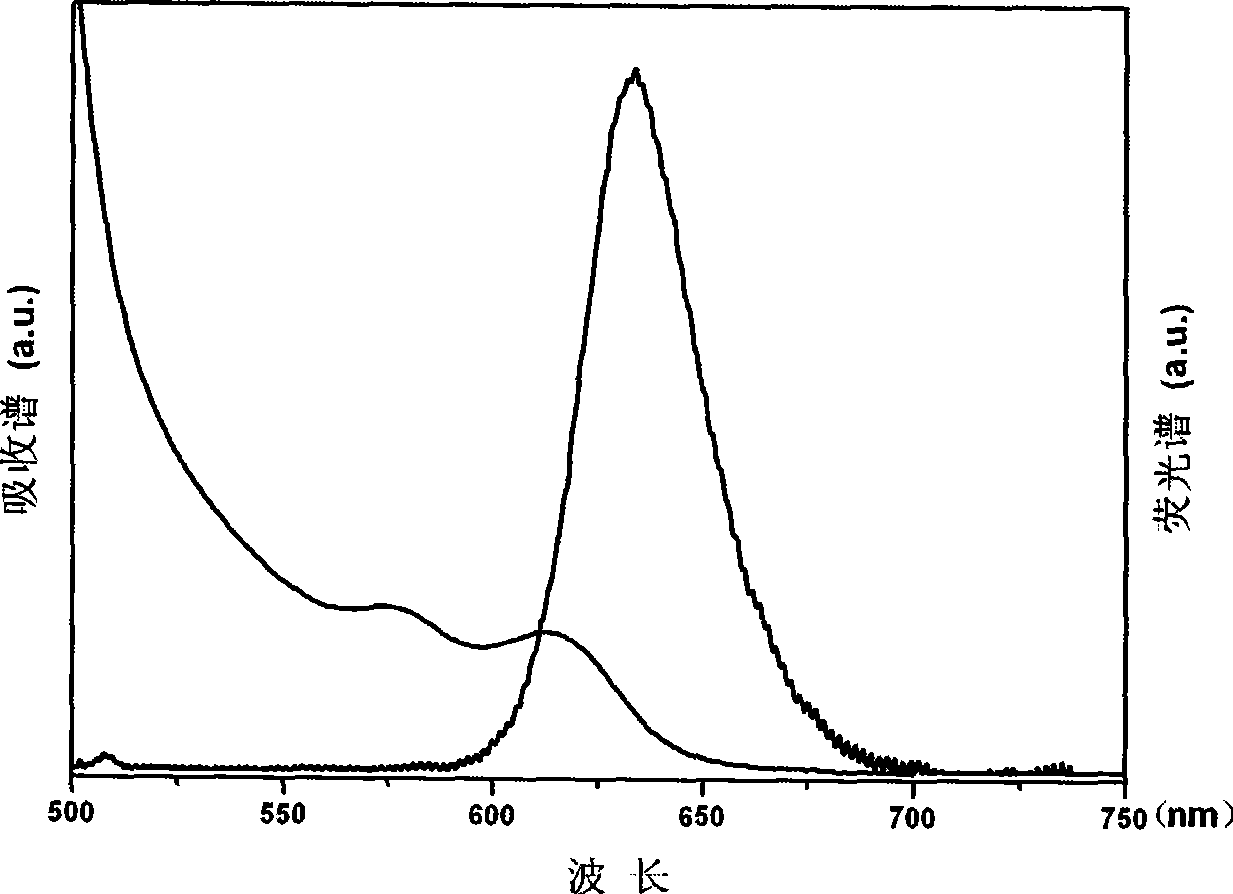

Preparation method of biocompatible aqueous phase quantum point

InactiveCN101381600AHigh fluorescence efficiencyGood stabilityLuminescent compositionsBiological macromoleculeOrganic molecules

The invention discloses a method for preparing a biocompatible aqueous quantum dot. The method comprises the following steps: a high-quality quantum dot and a nucleocapsid structure thereof are prepared; a surface modification technology is combined; the nucleocapsid structure is utilized to improve the stability of the quantum dot; through mutual action of intermolecular force, an organic molecular chain on the surface of the quantum dot is changed; an organic molecule of a long chain on the surface of an oil-phase quantum dot is changed into a small molecule which contains sulfhydryl and carboxyl or amidocyanogen and has biocompatibility and is water-soluble or a derivative of a large biological molecule; and finally, the biocompatible aqueous quantum dot which can be directly dissolved in phosphate buffer and the like is obtained. The method has the advantages: the preparation and surface modification method of the quantum dot are simple and easy to control the quality, the dimension and the surface property of the quantum dot; the obtained aqueous quantum dot has the advantages of higher fluorescent efficiency, even distribution of particle diameter, strong stability and the like; and the aqueous quantum dot prepared by the method can be used for biological detection, medical diagnosis, energy transferring and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

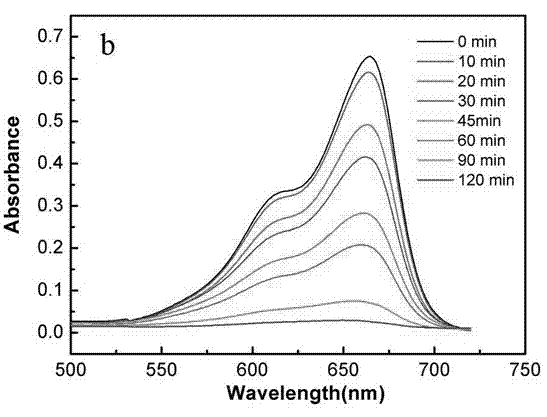

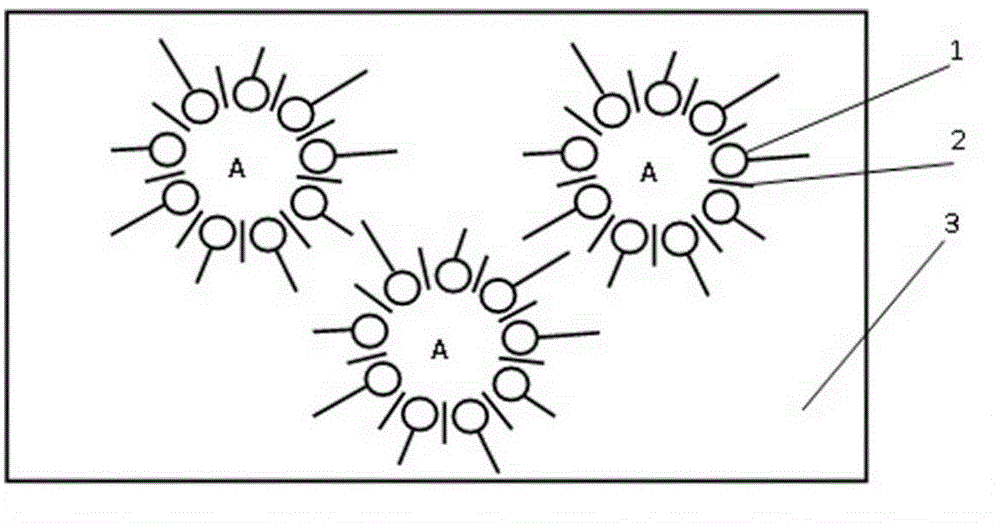

Polydopamine microcapsules and preparation method thereof

InactiveCN101966441ASimple and fast operationRaw materials are easy to getMicroballoon preparationMicrocapsule preparationEthylene diamineOrganic solvent

The invention relates to polydopamine microcapsules and a preparation method thereof. The polydopamine microcapsules are prepared from dopamine serving as a raw material and calcium carbonate particles serving as templates in a mass ratio of 0.1:1-10:1. The preparation method comprises the following steps of: preparing the calcium carbonate particles serving as the templates; adsorbing the dopamine on the templates so as to form polydopamine membranes on the templates by the self-polymerization of the dopamine; reacting for a certain period of time; and removing a calcium carbonate kernel by using ethylene diamine tetraacetic acid disodium after the polydopamine membranes on the templates reaches a certain thickness. For the microcapsules prepared by the method, a preparation process is simple and is convenient to operate, an acid-base catalyst and an organic solvent are saved, the raw material is readily available, the thickness of each membrane is easy to control through the assembly of different layers, the size of each particle is controllable, stability and repeatability are high and a wide application range is achieved.

Owner:TIANJIN UNIV

Method of improving coercivity of sintering Nd-Fe-B magnetic material

ActiveCN103056370AImprove crushing efficiencyImprove particle size uniformityMagnetic materialsHydrogenShielding gas

The invention discloses a method of improving the coercivity of sintering Nd-Fe-B magnetic materials. The method includes the following steps of using hydrogen to crush Nd-Fe-B alloy, powder processing, compression moulding, sintering and tempering under the protection of vacuum or protective gases. The sintering condition consists of heating to 300 to 600 DEG C, keeping the temperature for 5 to 6 hours to dehydrogenize, heating once again to 1060 to 1120 DEG C, sintering for 1 to 60 minutes under high temperature, finally decreasing the temperature to 1000 to 1050 DEG C, keeping sintering for 1 to 4 hours under the temperature and cooling. The method adopts the steps of sintering for a short period under high temperature to precipitate the liquid phase and then sintering under lower temperature. The liquid phase is rapidly precipitated under high temperature, thereby improving the sintering process of the magnetic materials, promoting the performance of sintering process, controlling the grain size through sintering under lower temperature, inhabiting grain growth and benefiting obtaining an excellent coercivity of magnetic materials.

Owner:ZHEJIANG ZHONGHANG NEW MATERIAL

In situ self-generation aluminum nitride enhanced magnesium-base composite material and preparation method thereof

InactiveCN101148723AEvenly distributedImprove mechanical propertiesMagnesium matrix compositeGraphite

The Mg-base composite material with in-situ autogeneous reinforcing AlN phase contains Mg alloy base in 80-95 wt% and reinforcing AlN ceramic grain in 5-20 wt%. Its Mg alloy base contains Al in 0-9 wt%. The Mg-base composite material is prepared through the following steps: 1. melting Mg-Al alloy material under the protection of mixed gas comprising SF6 in 10 vol% and CO2 in 90 vol%; 2. pressing aluminum foil coated Mg3N2 powder into the Mg-Al melt; 3. maintaining the temperature for the Mg3N2 powder and the Al in the melt to react completely; and 4. stirring the melt and skimming the scum with a graphite disc, casting into metal mold and solidifying to obtain the composite material. The composite material has the features of light weight, high strength, high modulus, high heat resistance, etc. and may be applied widely.

Owner:SHANGHAI JIAO TONG UNIV

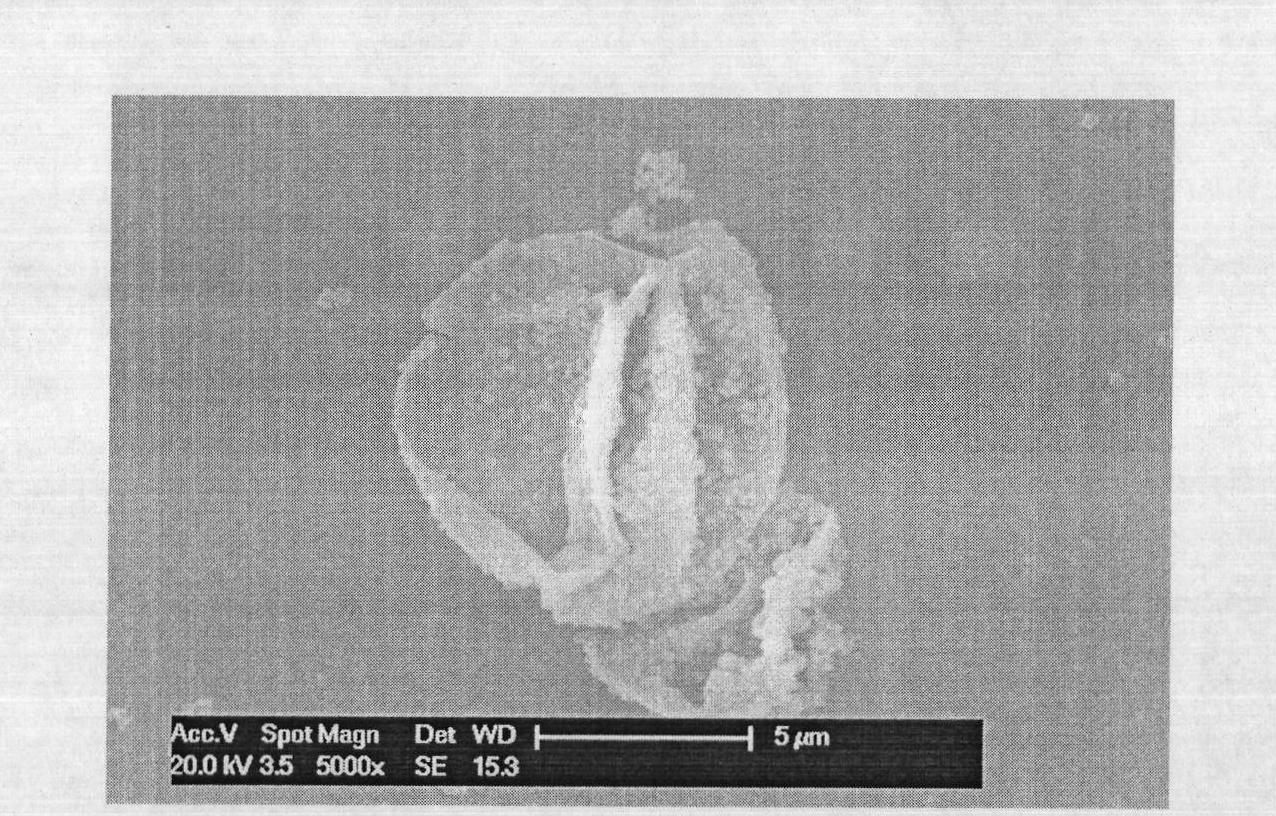

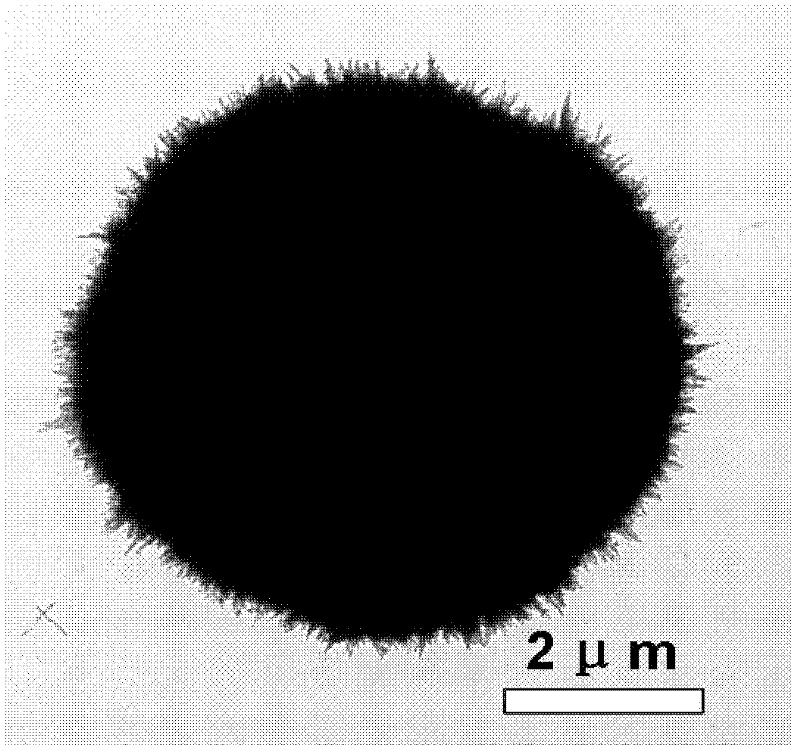

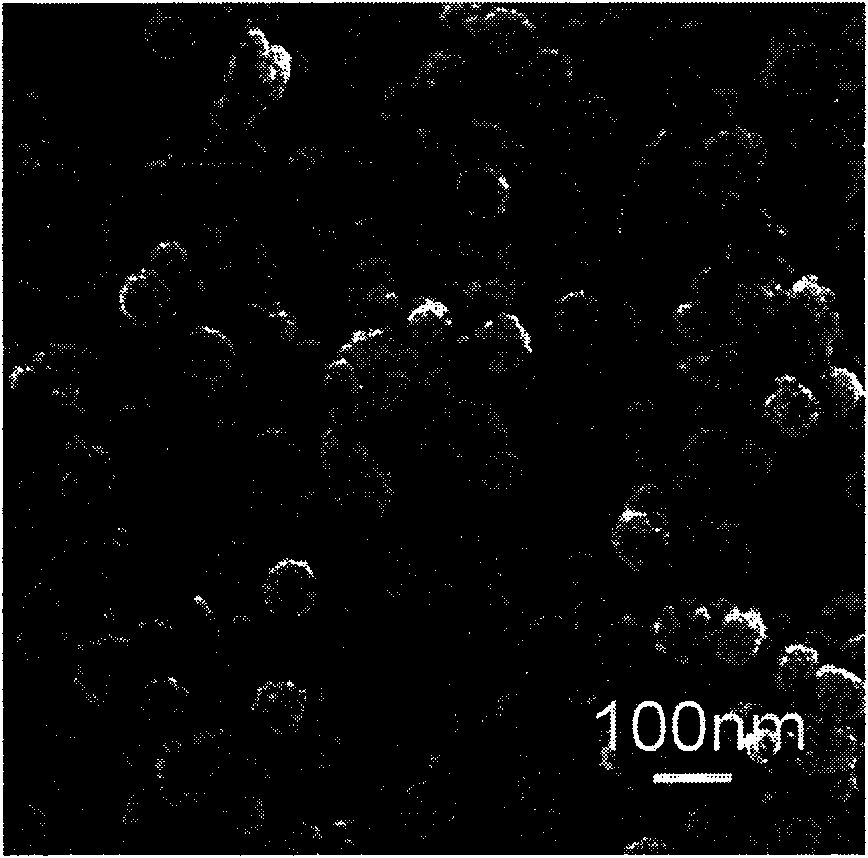

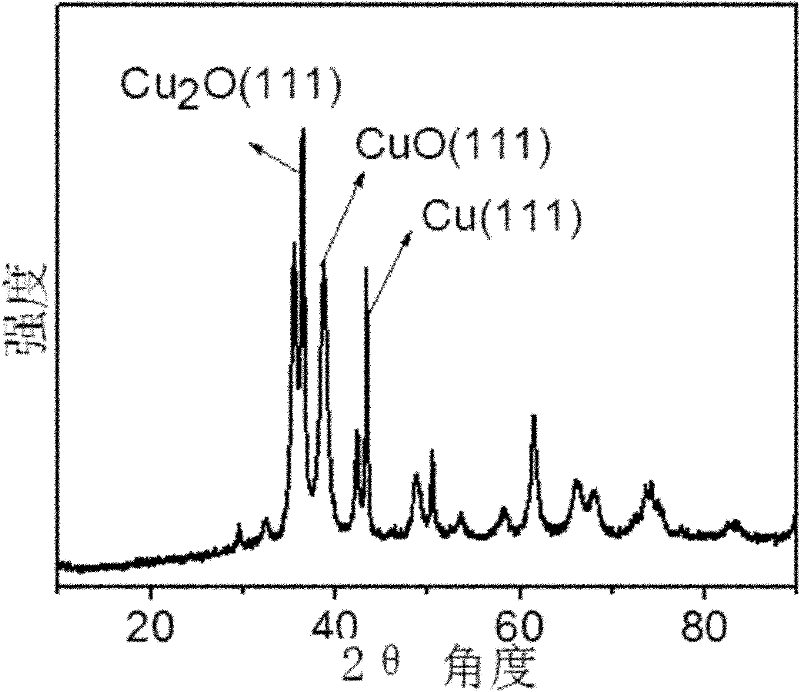

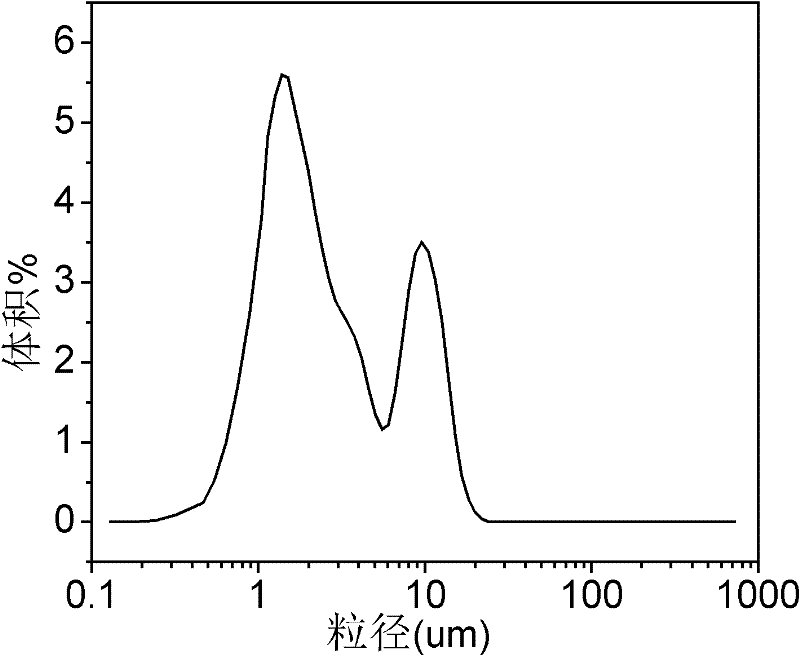

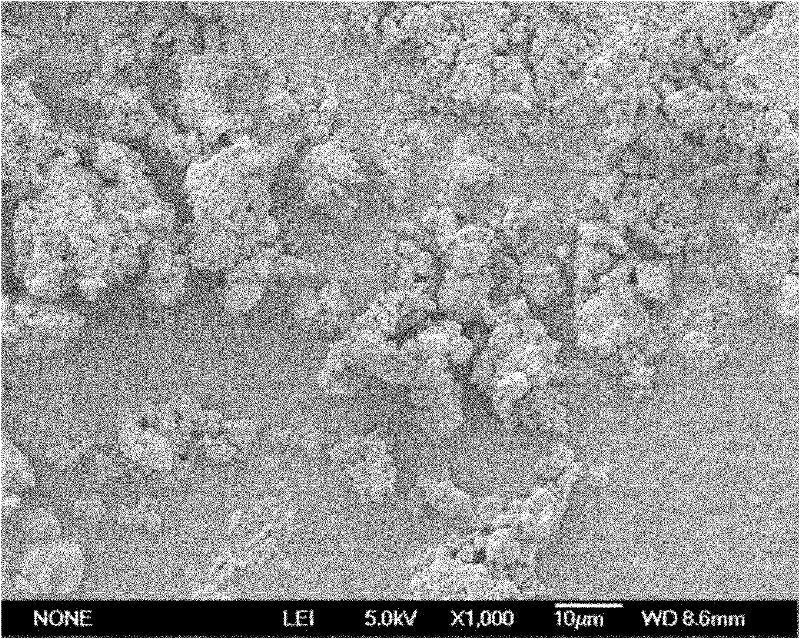

Sea urchin shaped copper oxide catalyst, as well as preparation method and application thereof

InactiveCN102641736ASimple processSimple and fast operationGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsOrganic solventCopper oxide

The invention relates to a sea urchin shaped copper oxide catalyst, as well as a preparation method and application thereof, and belongs to the field of catalysts. The preparation method for the sea urchin shaped copper oxide catalyst comprises the following steps of: dissolving a copper salt and a dispersant into an organic solvent, performing solvent heat reaction in an alkali environment, and thus obtaining the sea urchin shaped copper oxide catalyst. The method for preparing the sea urchin shaped copper oxide is concise, easy and convenient to operate, efficient, low in price and environment-friendly, and realizes large-scale preparation. The sea urchin shaped copper oxide catalyst prepared by the method is controllable in shape and granular size, and can be used for synthesizing organic silicon monomers.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

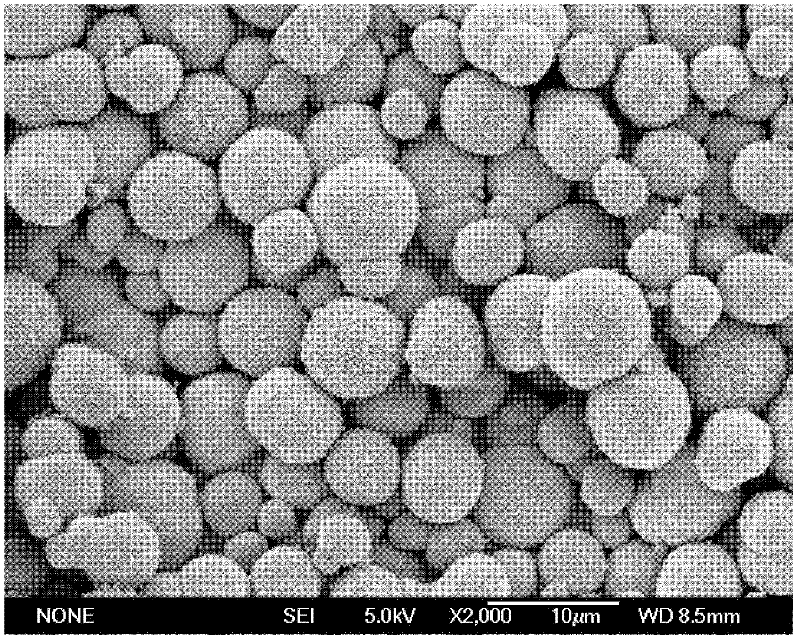

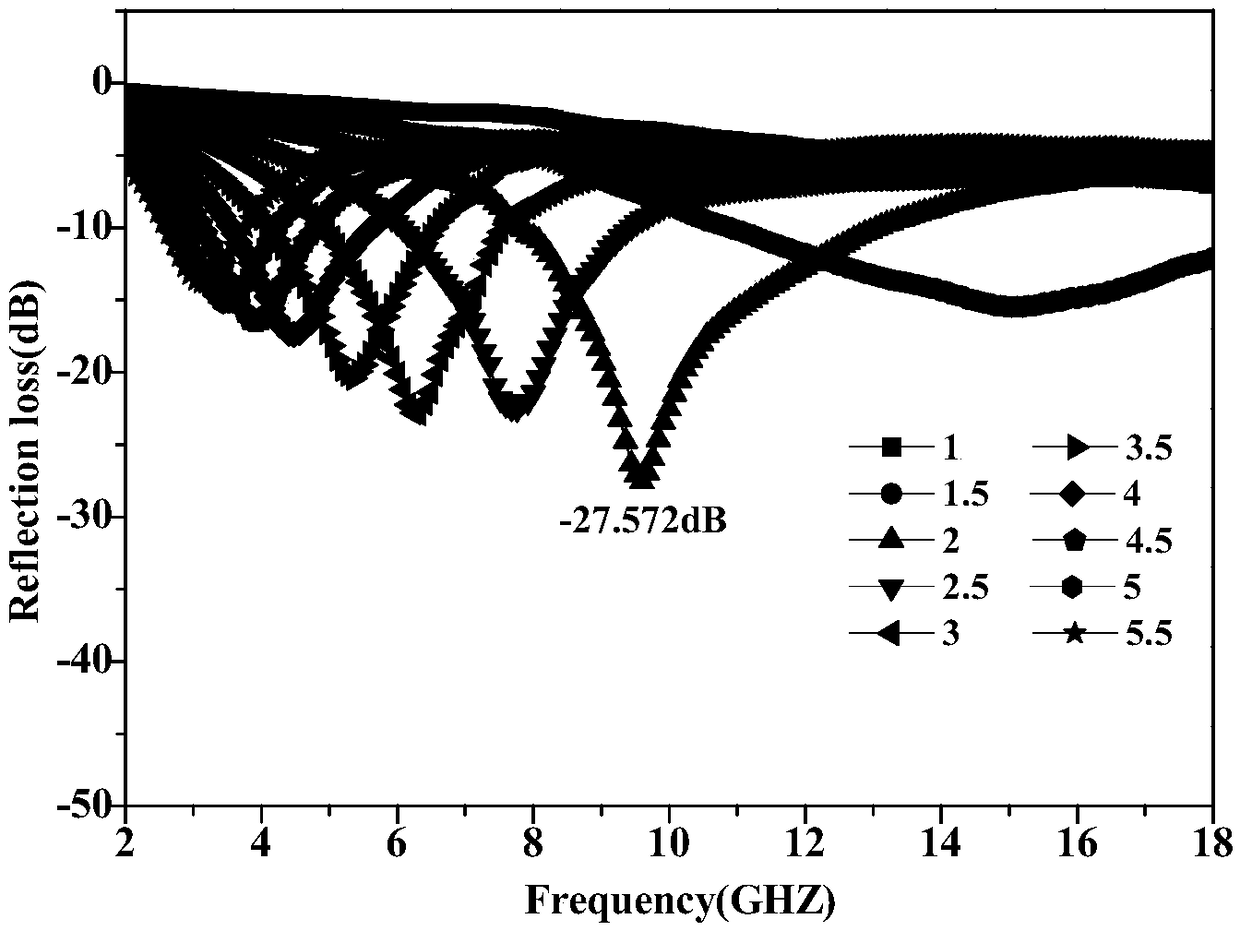

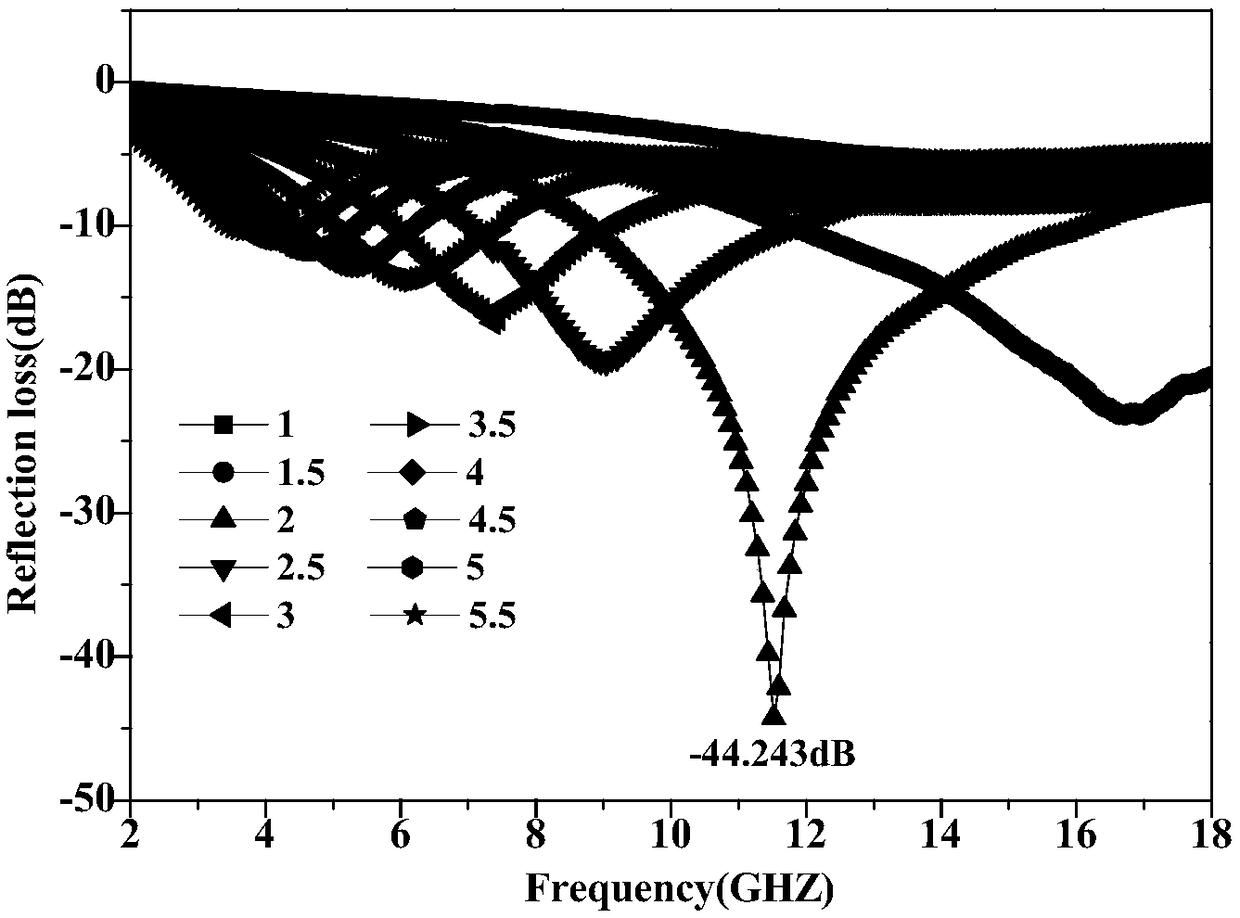

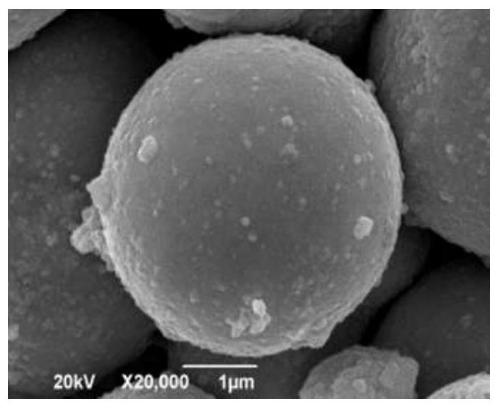

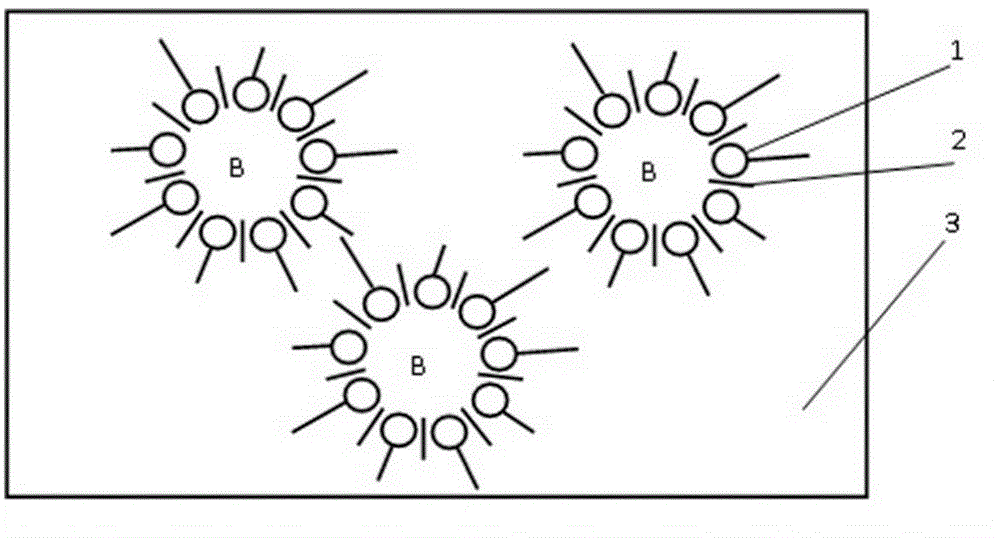

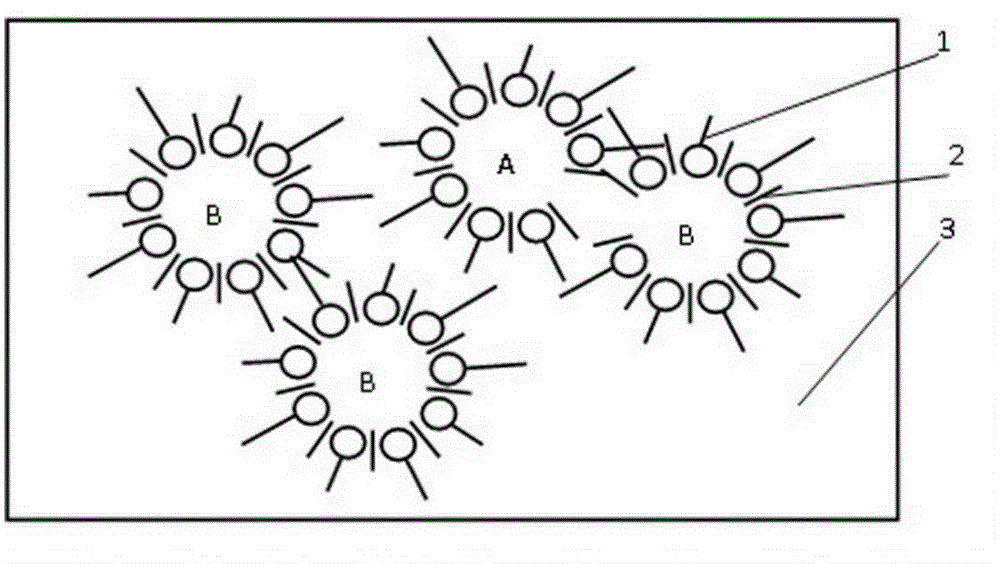

Double-shell-structure carbonyl iron powder composite wave-absorbing material and preparation method thereof

ActiveCN109207123ACoated evenlyControllable thicknessOther chemical processesMagnetic/electric field screeningCoprecipitationMagnetic layer

The invention discloses a double-shell-structure carbonyl iron powder composite wave-absorbing material and a preparation method thereof, wherein the composite wave-absorbing material is of a double shell layer core-shell structure, the core is carbonyl iron powder, the inner layer of the double-shell layer is an insulating layer, and the outer layer of the double-shell layer is a magnetic layer;the thickness of the insulating layer is 1 nm-1 [mu] m; and the thickness of the magnetic layer is 1nm-5 [mu] m; the preparation method comprises the following steps: coating the surface of the carbonyl iron powder with the insulating layer and coating the surface of a core-shell structure precursor by a chemical coprecipitation method. The surface of the carbonyl iron powder is coated with the double-shell layer by the chemical coprecipitation method. The impedance matching characteristic of the material is greatly improved, meanwhile, a large amount of nano-interface heterojunction is formedat the interfaces of the inner core and the double-shell layer, so that interface polarization is effectively induced, the scattering effect is formed for electron migration, and electromagnetic waveloss mechanisms such as multi-reflection absorption, strong ] ferromagnetic resonance and eddy current loss and the like of the material are greatly improved, so that the wave absorbing performance of the material is remarkably improved; the composite wave-absorbing material is simple in preparation method, is uniform and compact in coating and controllable in coating layer thickness and particlesize.

Owner:CENT SOUTH UNIV

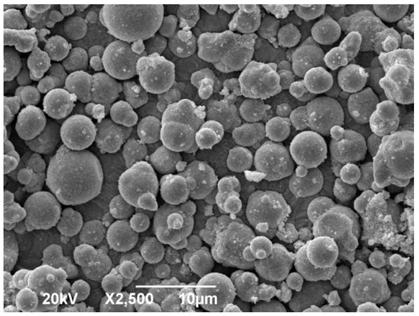

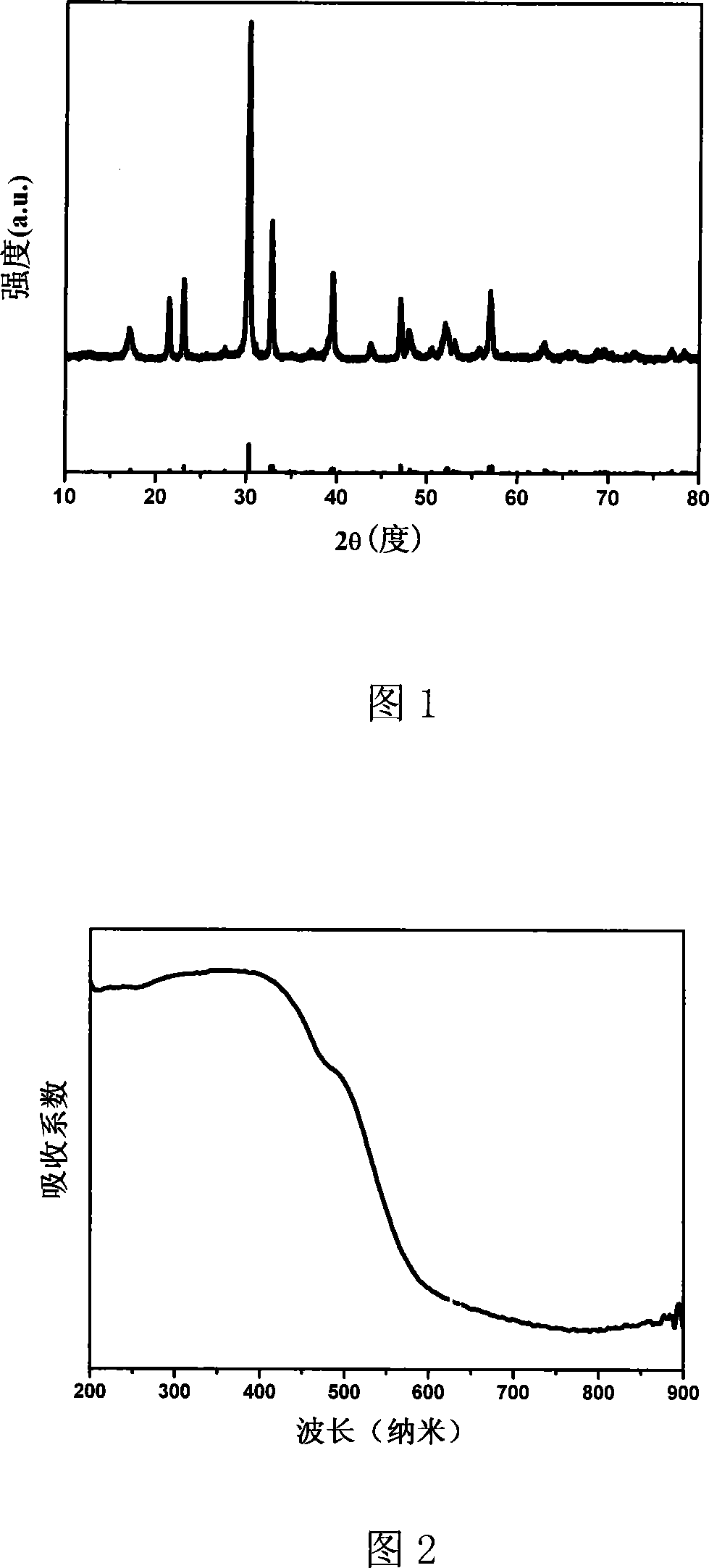

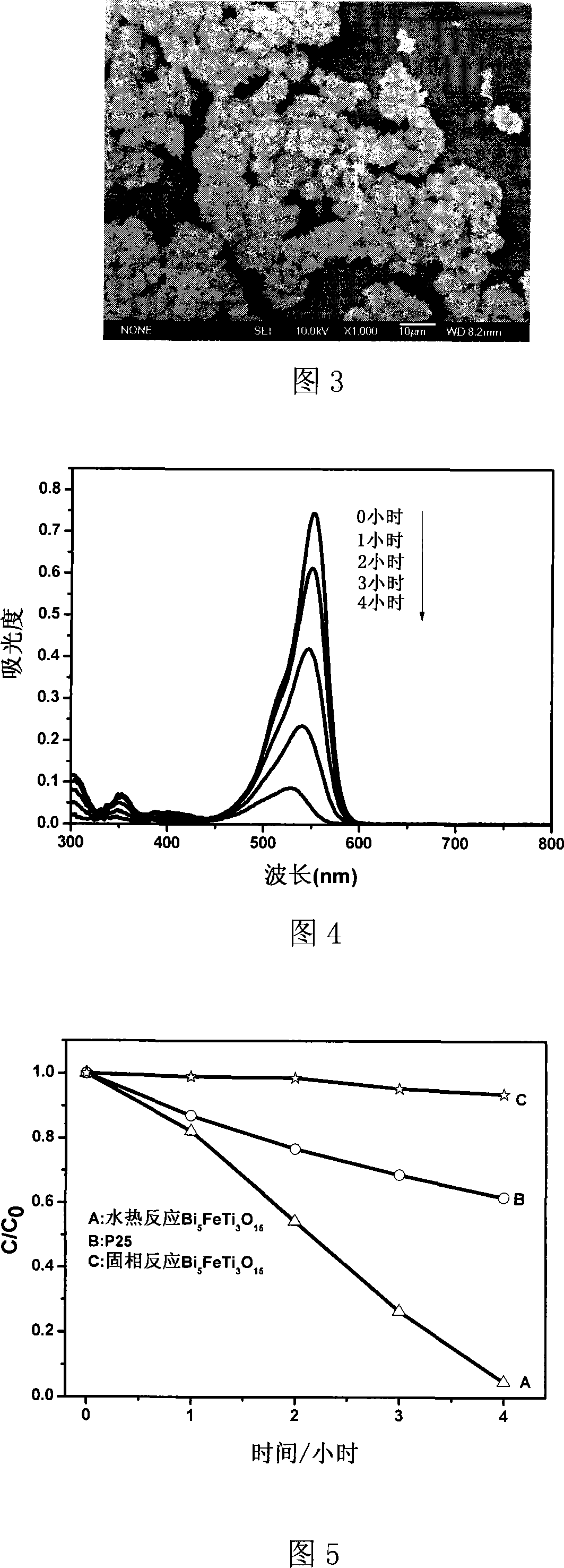

Preparation method of titanium barium ferrum series photocatalyst

InactiveCN101214441AAchieve the purpose of purificationVisible light catalytic activity is highMetal/metal-oxides/metal-hydroxide catalystsCentrifugationTitanium

The invention relates to a barium titanium iron series phhotocatalyst and a preparation method thereof, and belongs to the field of phhotocatalyst. In accordance with the chemical formula Bi5FeTi3O15, the invention adds titanium salt or titanate, malysite, bismuth salt into deionized water or acidic solution to dissolve and mix evenly, adds in aqueous alkali to produce settlings, and then adds the settlings into a water heat retort; after water heat reaction, the Bi5FeTi3O15 catalyst material is obtained after centrifugation, washing and drying. The invention reduces energy consumption of synthesization, and the product has even components, controllable grain size, quite high specific surface area, and good photocatalytic performance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

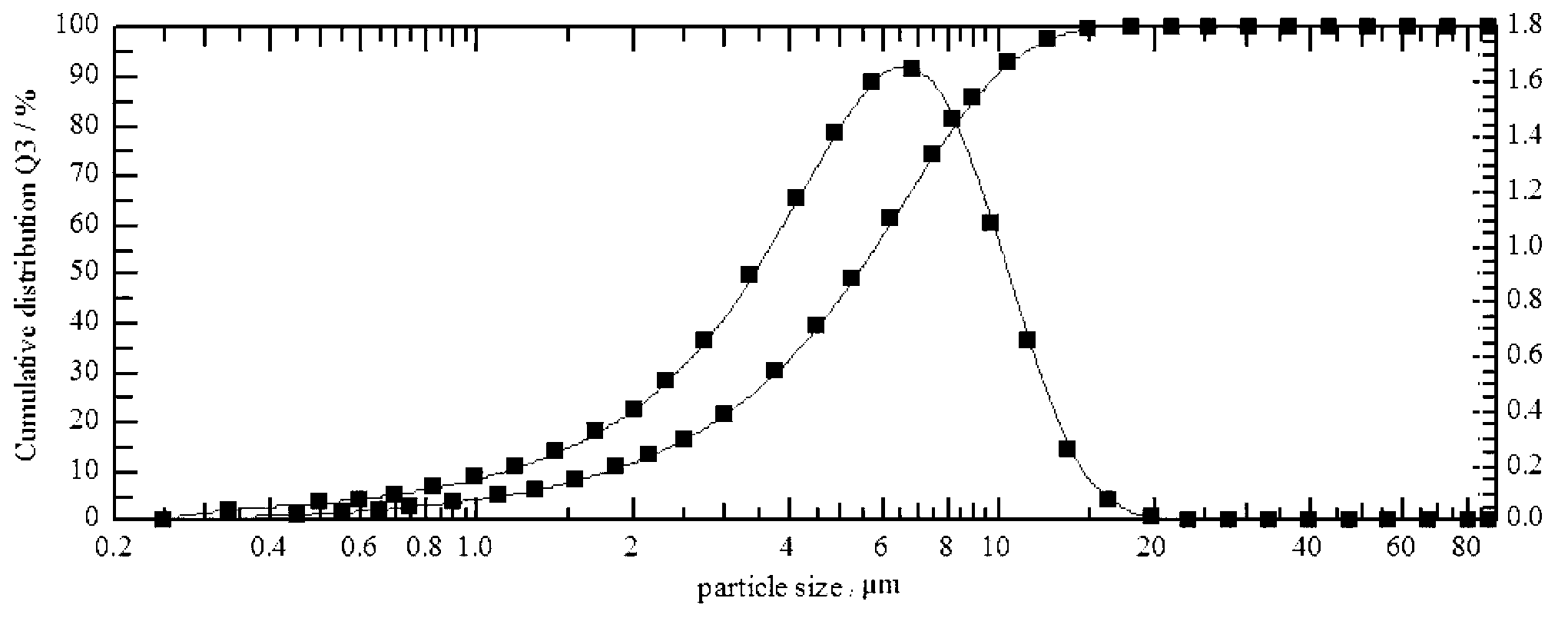

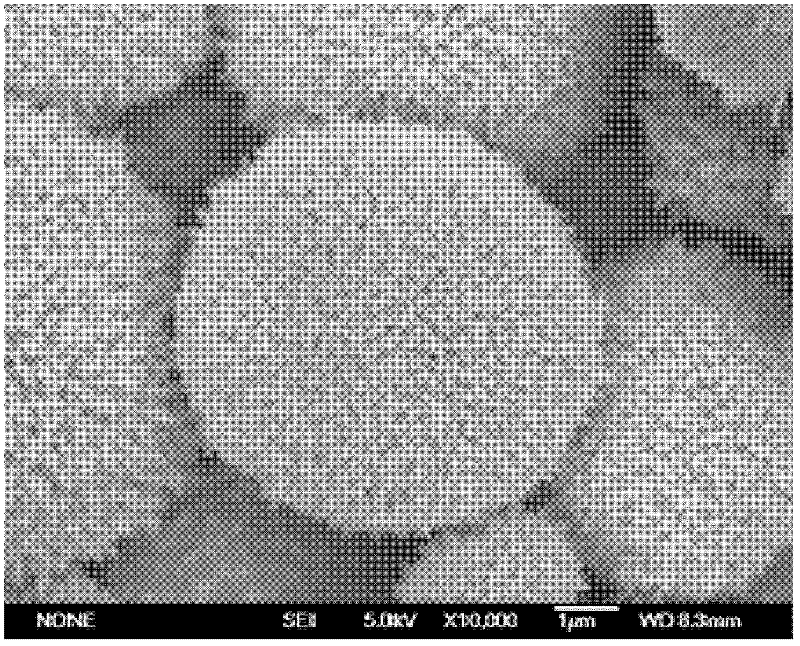

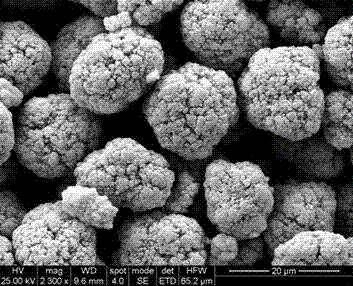

Spherical cobaltosic oxide and preparation method thereof

ActiveCN103359794ANo emissionsGranularity controllableCobalt oxides/hydroxidesFluid phaseCobalt(II,III) oxide

The invention discloses spherical cobaltosic oxide and a preparation method thereof. Salt, a precipitator and an oxidant are adopted in a liquid-phase synthesis process; the salt, the precipitator and the oxidant simultaneously flow inside a reaction kettle to react; and the spherical cobaltosic oxide is continuously prepared by adopting the methods of ageing, centrifuging, washing, secondary centrifuging and burning. The particle size is controllable; D50 is 2-20 microns; the spherical cobaltosic oxide is even in distribution of particle size, high in compactness, high in product consistency, and simple in preparation method; a complexing agent does not need to be added; and no harmful substance is discharged in the process, so that the preparation method is safe and friendly.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

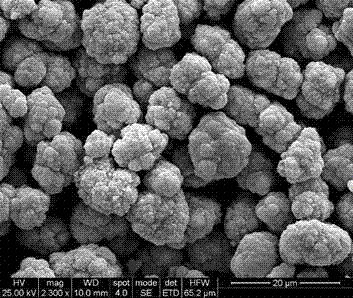

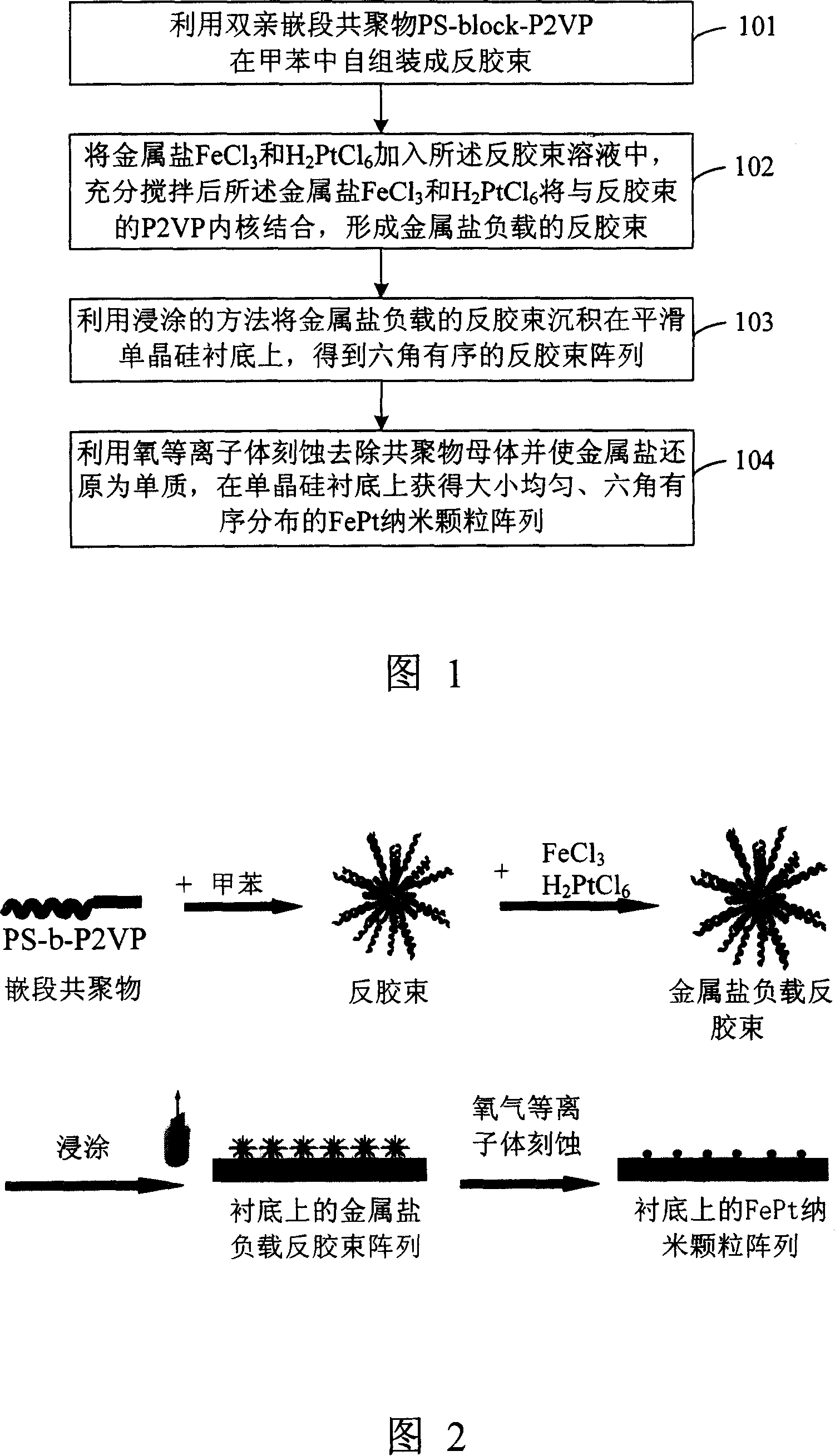

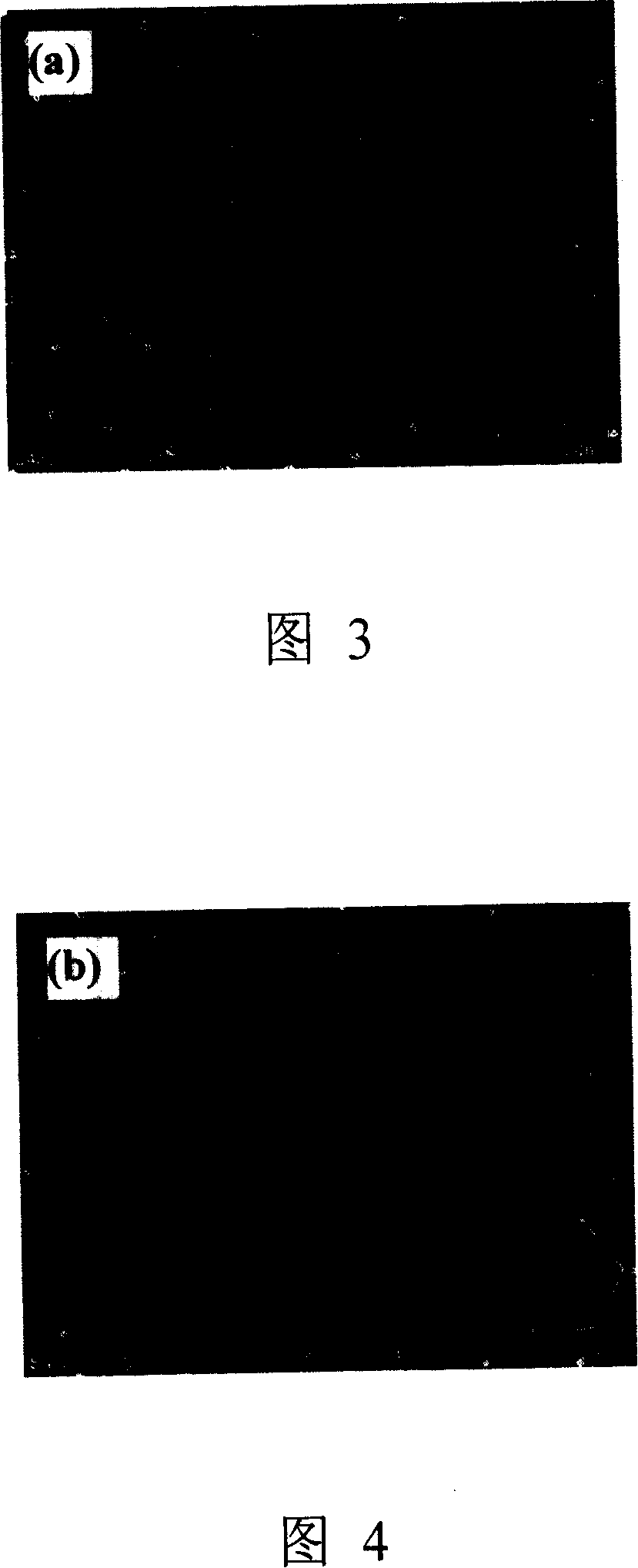

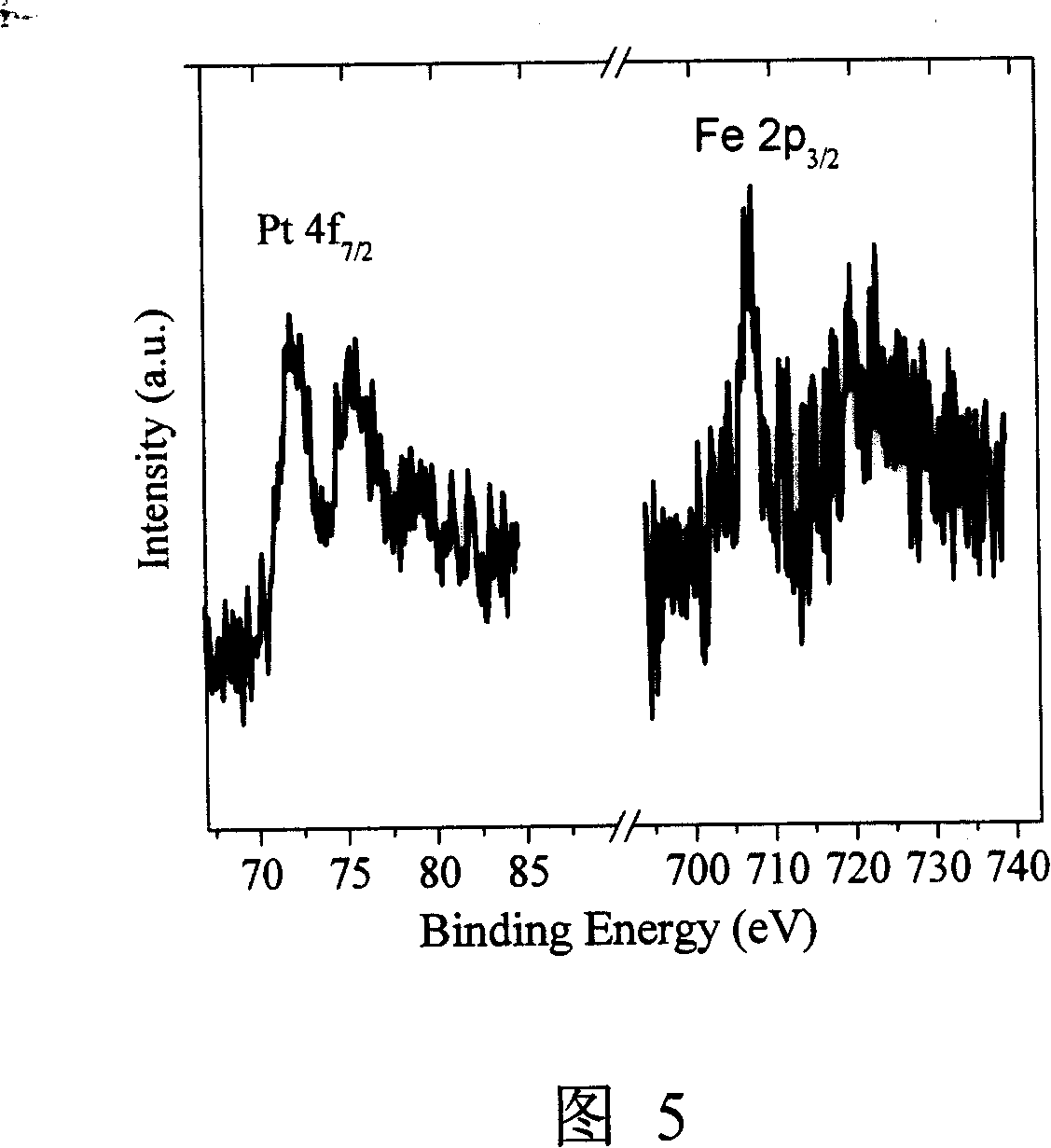

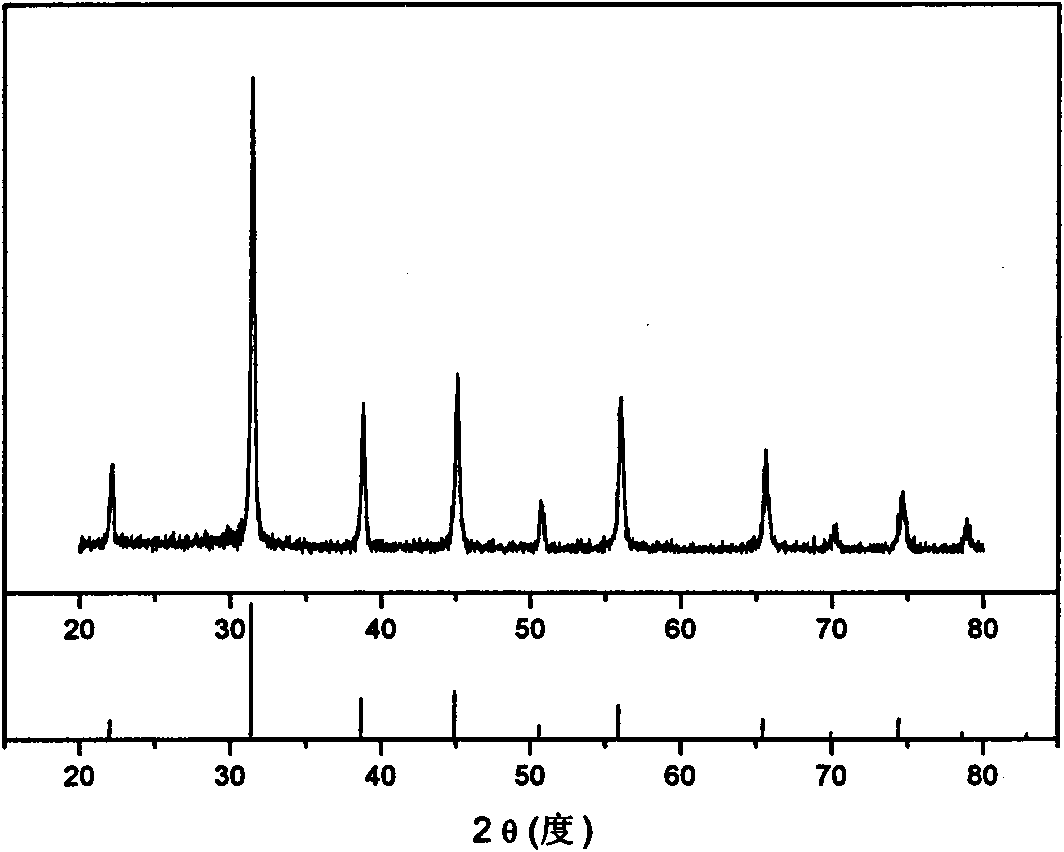

Method for preparing hexangular ordered FePt nano particle array

InactiveCN101148710AEvenly distributedParticle size is easy to controlInductances/transformers/magnets manufactureNanoparticleDip-coating

The process of preparing ordered hexagonal nanometer FePt particle array includes the following steps: 1. self-assembling inverse micelle with amphiphilic block copolymer PS-block-P2VP intoluene; 2. adding metal salts FeCl3 and H2PtCl6 into the inverse micelle solution through stirring for the metal salts FeCl3 and H2PtCl6 to be combined with the P2VP kernel of the inverse micelle to form inverse micelle with supported metal salts; 3. depositing the inverse micelle with supported metal salts onto smooth monocrystalline substrate through dip coating to obtain ordered hexagonal inverse micelle array; and 4. oxygen plasma etching to eliminate copolymer substrate and reduce metal salt into simple substance so as to obtain homogeneous ordered hexagonal nanometer FePt particle array on the monocrystalline substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

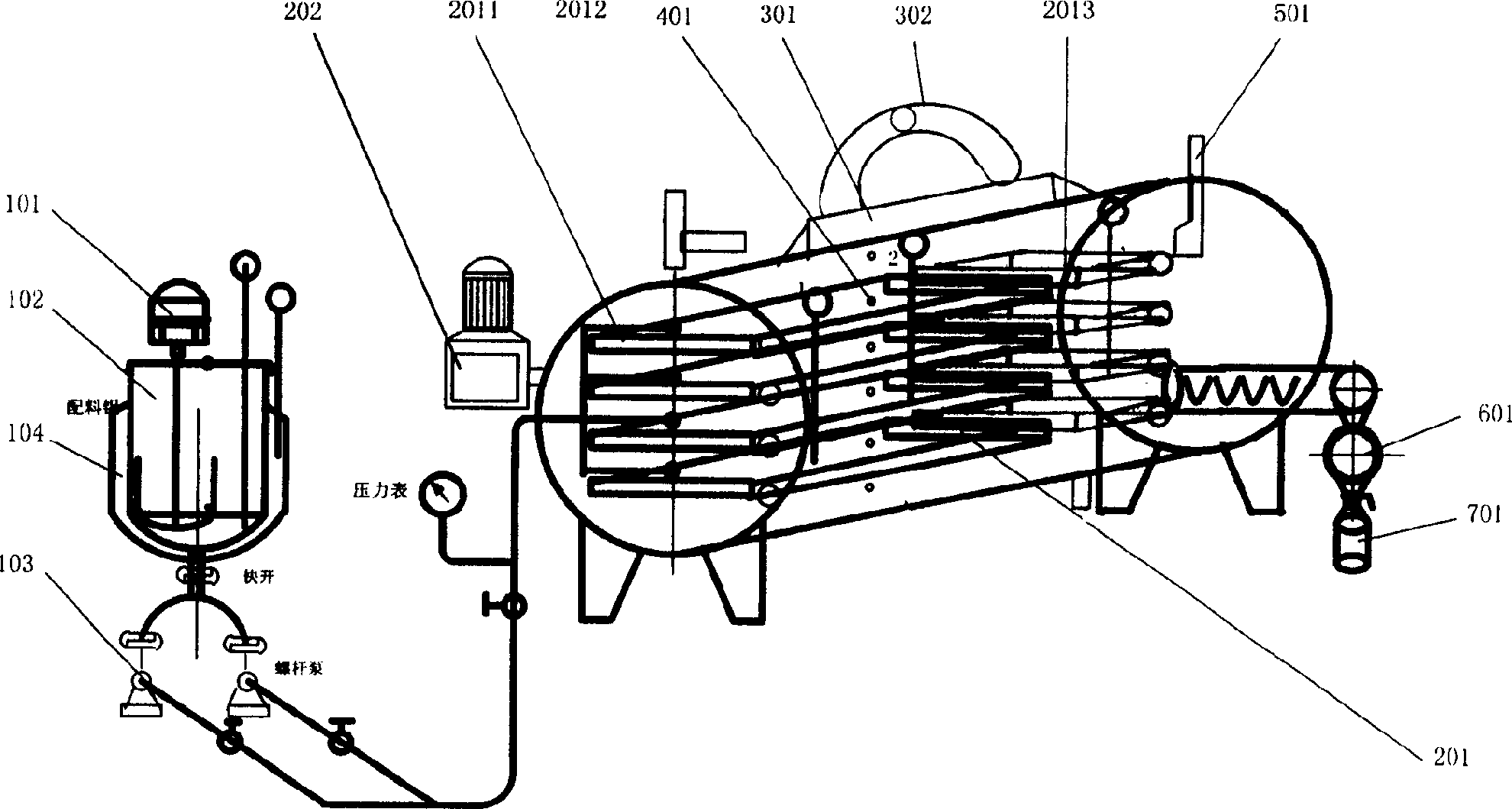

Automatic continuous-band freezing drier at vacuum low temperature

InactiveCN1854657AImprove product qualityPerfect solubilityDrying solid materials without heatDrying machinesEngineeringDistributor

The invention comprises a charging device, a drying belt driving device and a vacuum plant. The charging device includes a charger mixer, a dosage pot and a single-screw pump mounted one by one. The drying belt driving device is disposed in an enclosed vacuum chamber and has several layers of drying belts with the driving device inside. The vacuum plant includes a vacuum distributor and vacuum pipelines.

Owner:上海华琪实业有限公司

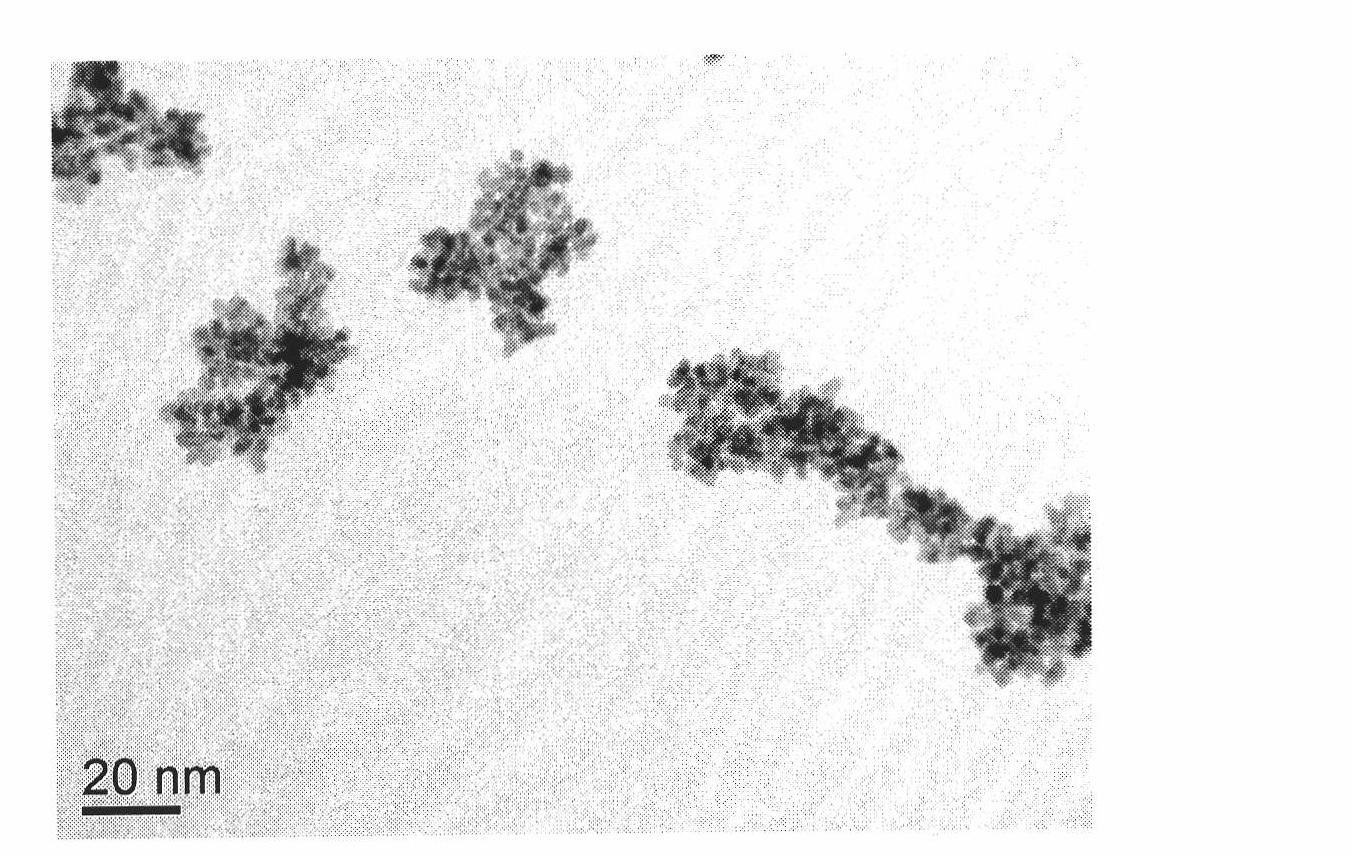

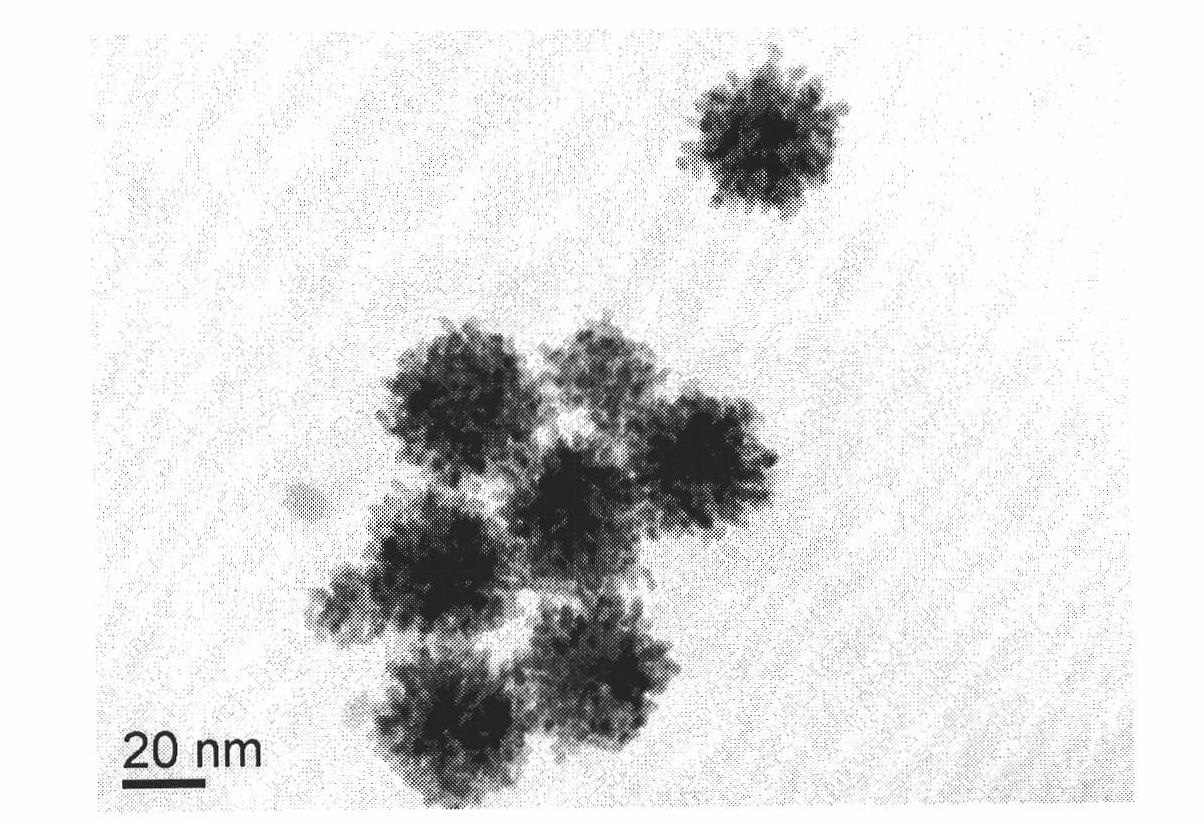

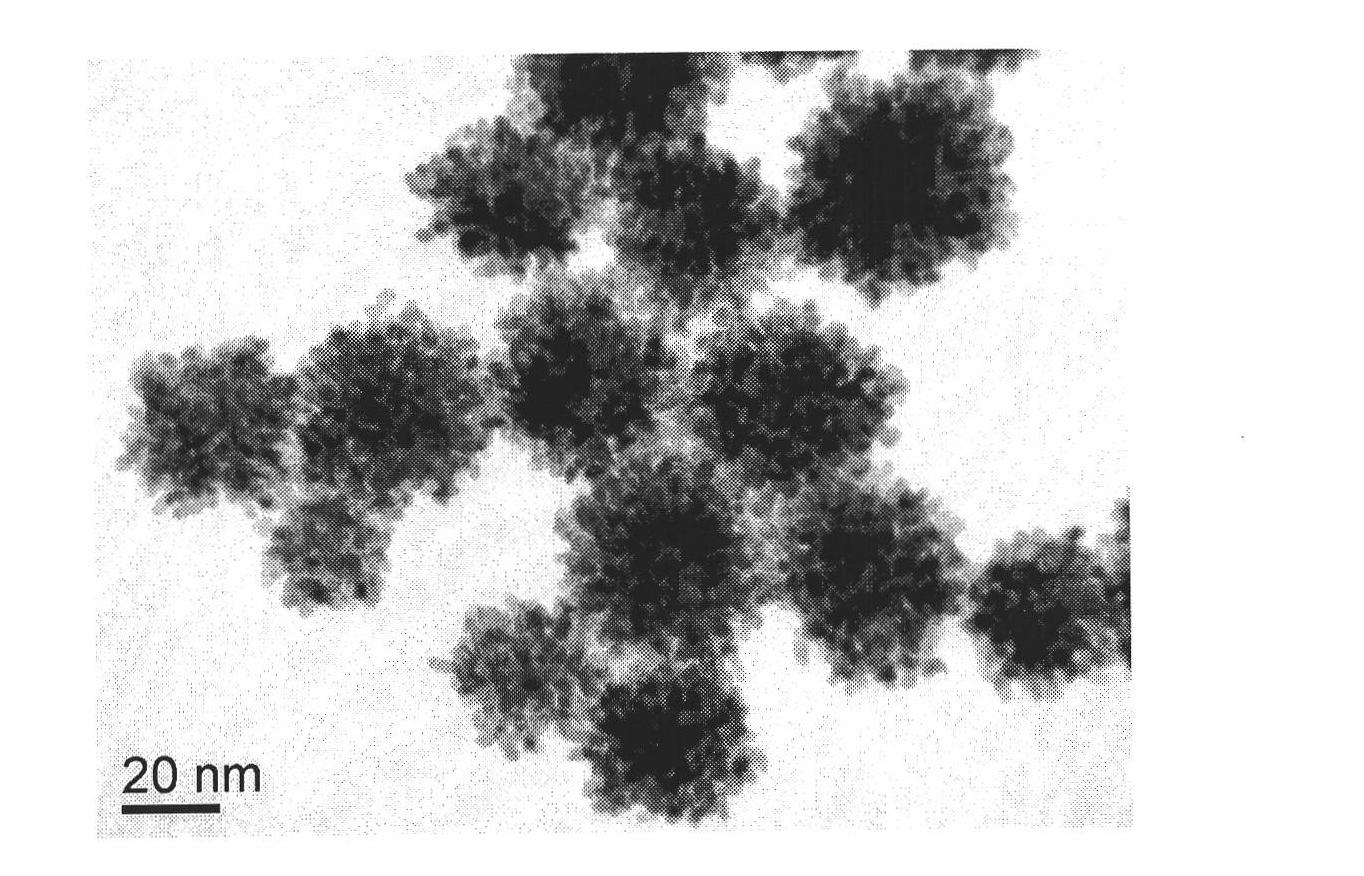

Preparation method of platinum nanoparticles

InactiveCN101875131AChange water bath durationParticle size is easy to controlWater bathsPlatinum nanoparticle

The invention discloses a preparation method of platinum nanoparticles, which comprises the following steps: dissolving glucose and ascorbic acid in water, wherein the concentration of the ascorbic acid is 0.01-0.2mol / L, and the molar ratio of the glucose to the ascorbic acid is 1-15:1; then, adding chloroplatinic acid in a water bath at 60-90 DEG C and reacting for 3-60 minutes to obtain platinum nanoparticles, wherein the molar ratio of the chloroplatinic acid to the ascorbic acid is 1:25-200; and transferring the obtained platinum nanoparticles into a water bath at 50-55 DEG C, adding the chloroplatinic acid of which the molar weight is 0.3-2 times the molar weight of the chloroplatinic acid added in the first time, and regulating the duration time of the water bath to regulate and control the sizes of the platinum nanoparticles. Platinum nanoparticles which have good dispersibility can be prepared under optimal conditions by adopting the method of the invention, and the average particle diameter of the platinum nanoparticles is less than 10nm; the reagents used are nontoxic and harmless; and the invention has the advantages of mild reaction conditions and low cost and can realize regulation and control of the sizes of the nanoparticles.

Owner:WUHAN UNIV

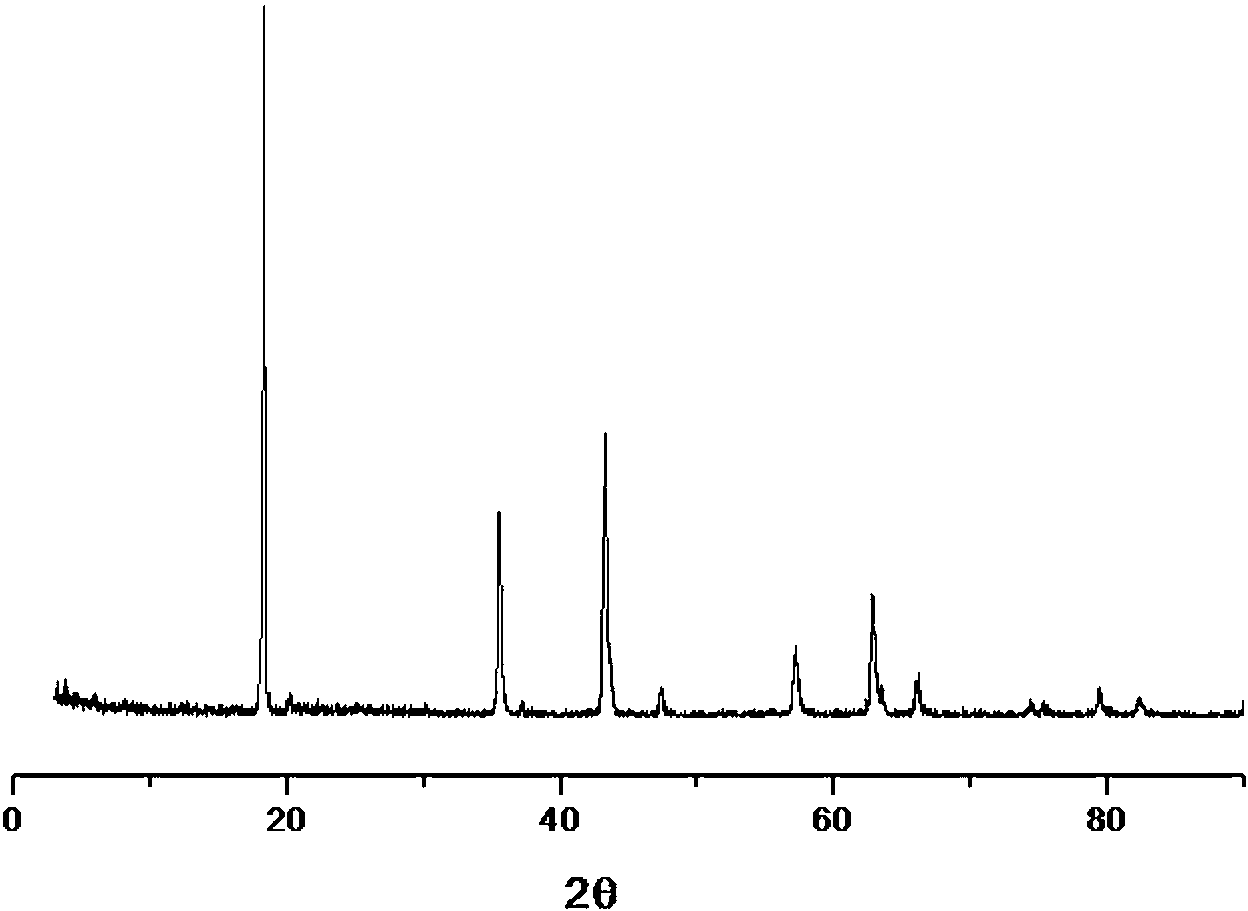

Preparation method of lithium titanate

ActiveCN103290426AControl stoichiometric ratioParticle size is easy to controlElectrolysis componentsElectrolysisElectrical battery

The invention discloses a preparation method of lithium titanate. The preparation method is characterized by comprising the following steps of: combining TiO2 powder which is wrapped by using a carbon source or is mixed by using a carbon material or a tabletting with a metal current collector so as to be used as a cathode; by taking graphite as an anode and taking a molten alkali halide as an electrolyte, electrolyzing for 1-5 hours in an argon atmosphere at an electrolysis temperature of 400-700 DEG C under an electrolysis voltage of 2.0-3.2V, cooling down to be the normal temperature and taking out, subsequently washing in distilled water or an organic solvent, and drying in vacuum so as to obtain LiTiO2 which is wrapped by using the carbon source or is mixed by using the carbon material; washing an electrolysis product, drying the electrolysis product in vacuum, and subsequently firing for 1-3 hours at 600-900 DEG C in air so as to obtain Li4Ti5O12. By utilizing the method, product grain size controllability is realized, and the problems of product batch stability and consistence caused by in-scale production are solved. The lithium titanate prepared by using the method can be used as an energy material to be directly applied to lithium ion secondary batteries and super-capacitors.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Preparation methods of spherical lithium manganate for lithium-ion power battery and precursor of spherical lithium manganate

ActiveCN103326012ALow impurity contentHigh discharge platformCell electrodesManganates/permanganatesWater bathsPower battery

The invention discloses preparation methods of a spherical lithium manganate for a lithium-ion power battery and a precursor of the spherical lithium manganate. The preparation method for the precursor is carried out as the following steps: (1) preparing a manganese salt water solution; (2) preparing a precipitant water solution; (3) injecting the prepared solutions in the step (1) and the step (2) to a reaction kettle with a stirrer and a constant-temperature water bath; (4) mixing the obtained MnCO3 and a compound containing an element M based on a mol ratio of M to Mn described in the invention, sintering and obtaining the precursor. The preparation method of the spherical lithium manganate is carried out as the following steps: mixing the precursor and Li2CO3, sintering and obtaining an M-doped spherical spinel lithium manganate. Compared with the prior art, the method of the invention has the advantages that: (1) impurity content is low, discharge plateau is high, specific capacity is high, cycle performance is good, high-temperature performance is good and tap density is high; and (2) raw material price and production cost are low, powder particle size can be controlled, microscale additive disperses uniformly, particle size distribution is concentrate, and microscopic morphology is spherical or spheroidic.

Owner:QINGDAO HUAGUAN HENGYUAN LI TECH

Graphene-loaded nanometer Fe<3>O<4>/ZnO composite and preparation method thereof

ActiveCN105384146AImprove conductivityEvenly distributedZinc oxides/hydroxidesMagnetic/electric field screeningSolubilityElectromagnetic shielding

The invention relates to a graphene-loaded nanometer Fe<3>O<4> / ZnO composite with an electromagnetic shielding function and a preparation method thereof. Te preparation method includes the steps that firstly, ferric chloride hexahydrate and Zn powder are mixed to be uniform after no sediment exists, an alkaline solution and a graphene oxide solution are added, and after the mixture is stirred to be uniform, suspension liquid is obtained; then, the suspension liquid is placed in a reaction kettle to be subjected to constant temperature heat treatment, centrifugal separation is conducted, and obtained paste-shaped solid is placed in a tube-shaped furnace to be subjected to thermal recovery under the mixed atmosphere of H<2> / Ar after being refrigerated and dried; finally, the graphene-loaded nanometer Fe<3>O<4> / ZnO composite is obtained. The graphene-loaded nanometer Fe<3>O<4> / ZnO composite prepared through the method is high in degree of dispersion and good in water solubility, the magnetic property and the electromagnetic shielding property are remarkably enhanced, the operation process is simple and efficient, and industrialized production and application is achieved easily.

Owner:TANGSHAN JIANHUA TECH DEV

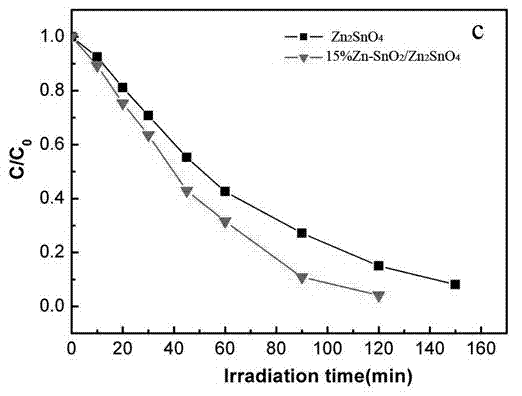

Method for synthesizing nanometer zinc-doped tin oxide/zinc stannate heterojunction

InactiveCN102527370ALow costHigh purityWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionUltraviolet lights

The invention relates to a method for thermally synthesizing a nanometer zinc-doped tin oxide / zinc stannate heterojunction by utilizing a solvent. The method comprises the following steps: 1) selecting a certain amount of tin oxide, zinc nitrate and sodium hydroxide, and respectively dissolving in a mixed solvent of water and absolute ethyl alcohol, thereby obtaining a uniform solution; 2) dropwise adding a NaOH solution into a mixed solution of SnC14 and Zn(NO3)2, stirring, and then placing into a reaction kettle, keeping the temperature at 180 DEG C for 15 hours, and separating, washing anddrying the obtained Zn-SnO2; 3) weighting a certain amount of Zn-SnO2, SnC14, Zn(NO3)2 and NaOH, adding into the mixed solvent of water and absolute ethyl alcohol, and continuously and fully stirring; 4) dropwise adding the NaOH solution into a mixed solution of SnC14, Zn(NO3)2 and Zn-SnO2, fully stirring, and then placing into a hydro-thermal reaction kettle, and keeping the temperature at 200 DEG C for 20 hours; and 5) separating, washing and drying, thereby obtaining an end product. The synthesizing technology of the product is simple; the product is 20-30nm spherical grains; the product has the characteristics of a mesoporous structure and has a bigger specific surface area; and the product has an excellent photocatalytic property under an ultraviolet light condition.

Owner:LUOYANG INST OF SCI & TECH

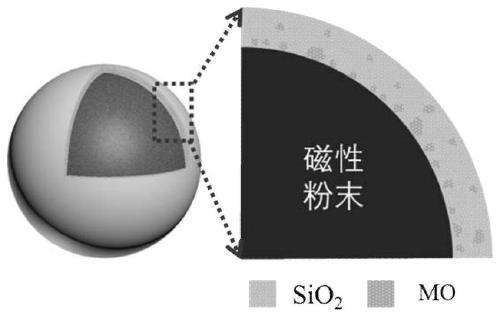

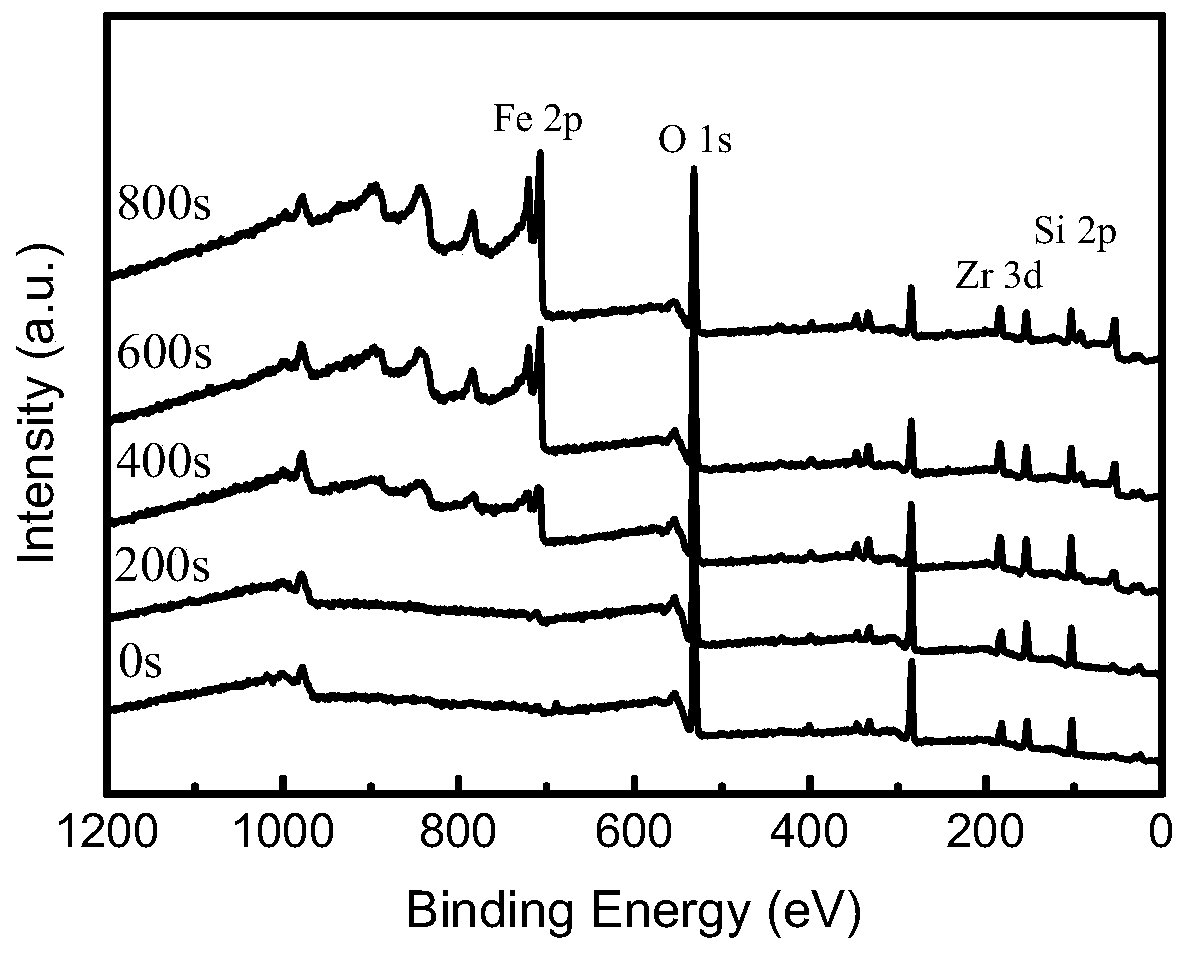

Magnetic powder surface gradient coating structure and coating method and soft magnetic composite

ActiveCN110405201ACoated evenlyCover tightlyTransportation and packagingMetal-working apparatusHigh resistivityThermal expansion

The invention relates to a magnetic powder surface gradient coating structure and coating method and a soft magnetic composite. The gradient coating structure is prepared from a coating layer which isformed on the surface of ferromagnetic powder by silicon dioxide and other coated components, and the contents of the silicon dioxide and other coated components in the coating layer are gradiently distributed. The coating method comprises the step of depositing the silicon dioxide and other coated components on the surface of the ferromagnetic powder in one step by adopting a chemical coprecipitation method, wherein the pH value of the system is adjusted in the deposition process. The soft magnetic composite is obtained by sectionally annealing the ferromagnetic powder with the coating layeron the surface after being pressed and formed. The coefficient of thermal expansion of the coating layer prepared by using the method can be controlled, the prepared soft magnetic composite has the advantages of low eddy current loss, high magnetic conductivity, high resistivity and high saturation magnetization, and the defects of low resistivity, mismatching of the coefficient of thermal expansion between coating layers and the like of the material in the prior art are overcome; in order to solve the problems of the reduction of the medium-high frequency magnetic conductivity, high eddy current loss, serious heating and the like of an existing magnetic powder core, a good method is provided.

Owner:CENT SOUTH UNIV

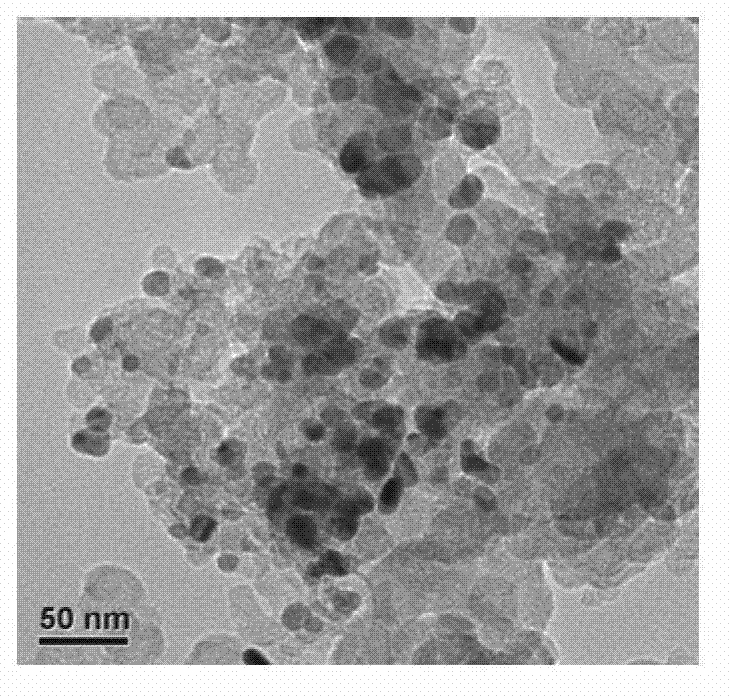

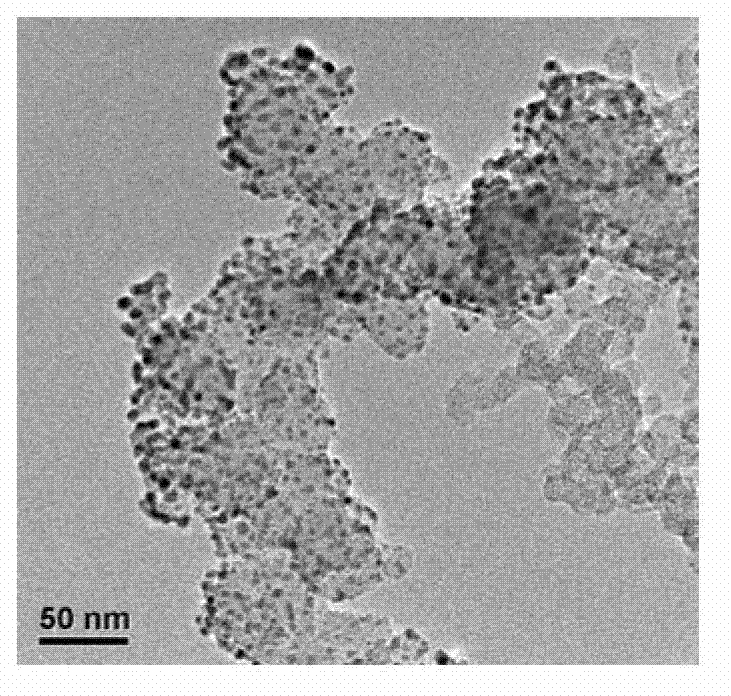

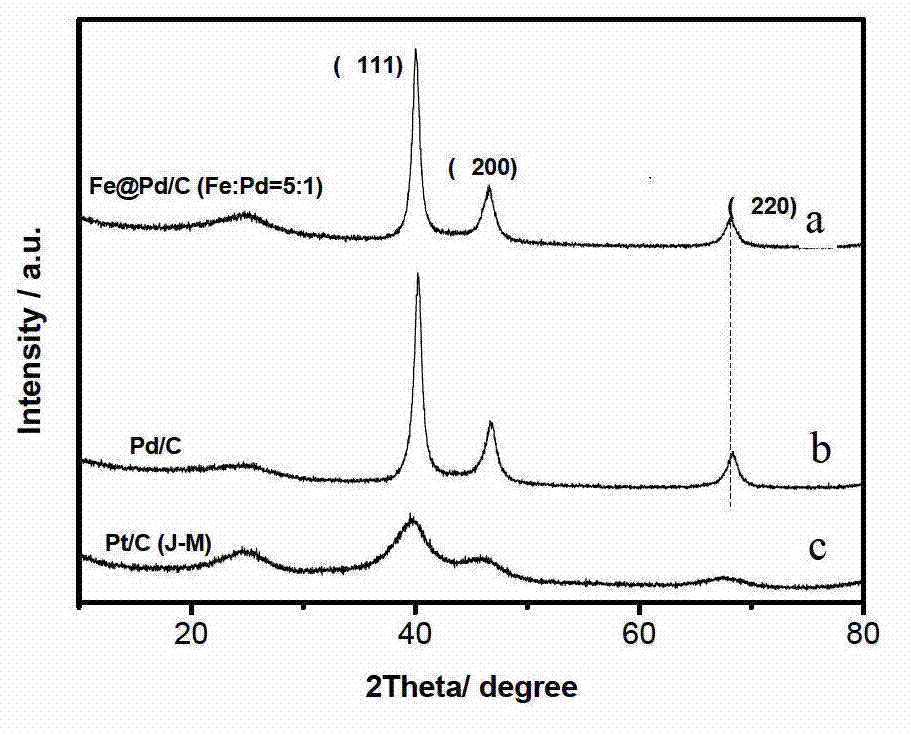

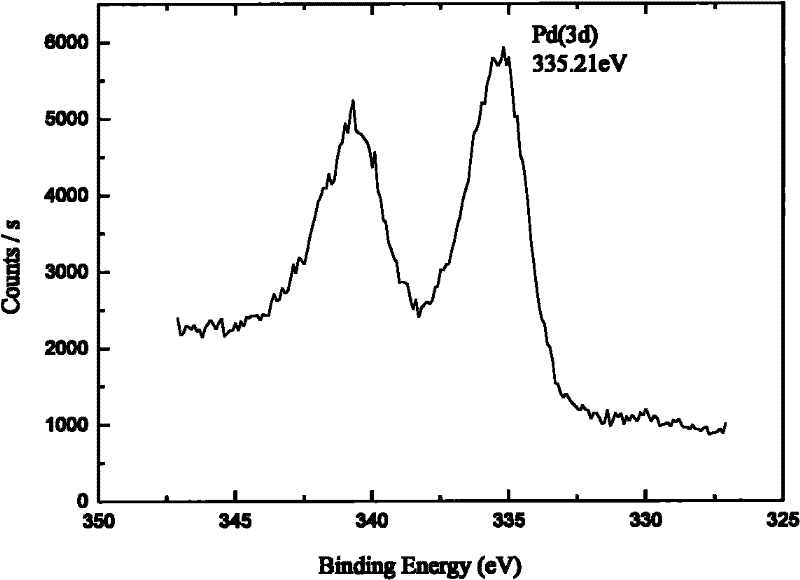

Fuel-cell catalyst with non-platinum core-shell structure and preparation method of fuel-cell catalyst

InactiveCN102903939ALow costSimple manufacturing methodCell electrodesMetal/metal-oxides/metal-hydroxide catalystsShielding gasNon platinum

The invention provides a fuel-cell catalyst with a non-platinum core-shell structure and a preparation method of the fuel-cell catalyst, and relates to a fuel-cell catalyst. A carrier of the catalyst is activated carbon, the active ingredient of the carrier is Fe-coated Pd, the molar ratio of nanocrystalline iron of the active ingredient Fe-coated Pd to palladium of the active ingredient Fe-coated Pd is 5:1, and the active ingredient Fe-coated Pd accounts for 40%-50% of the total mass of the fuel-cell catalyst with the non-platinum core-shell structure. The preparation method comprises the followings steps of: dissolving the activated carbon into water; performing ultrasonic treatment on the mixture; leading shielding gas in the mixture; adding reducing agents in the mixture; then adding a ferric salt aqueous solution in the mixture; reacting and then adding a palladium chloride aqueous solution in the mixture to perform replacement reaction; and filtering, washing and drying the mixture after the replacement reaction so as to obtain a product. The electrocatalytic activity of the catalyst is 10.63 times that of the traditional carbon load palladium nanocrystal Pd / C catalyst, and is 23.05 times that of a commercial Pt / C catalyst. The cost is low, the preparation method is simple and practicable, the particle size of the catalyst is easy to control, and the fuel-cell catalyst is suitable for large-scale industrial production.

Owner:XIAMEN UNIV

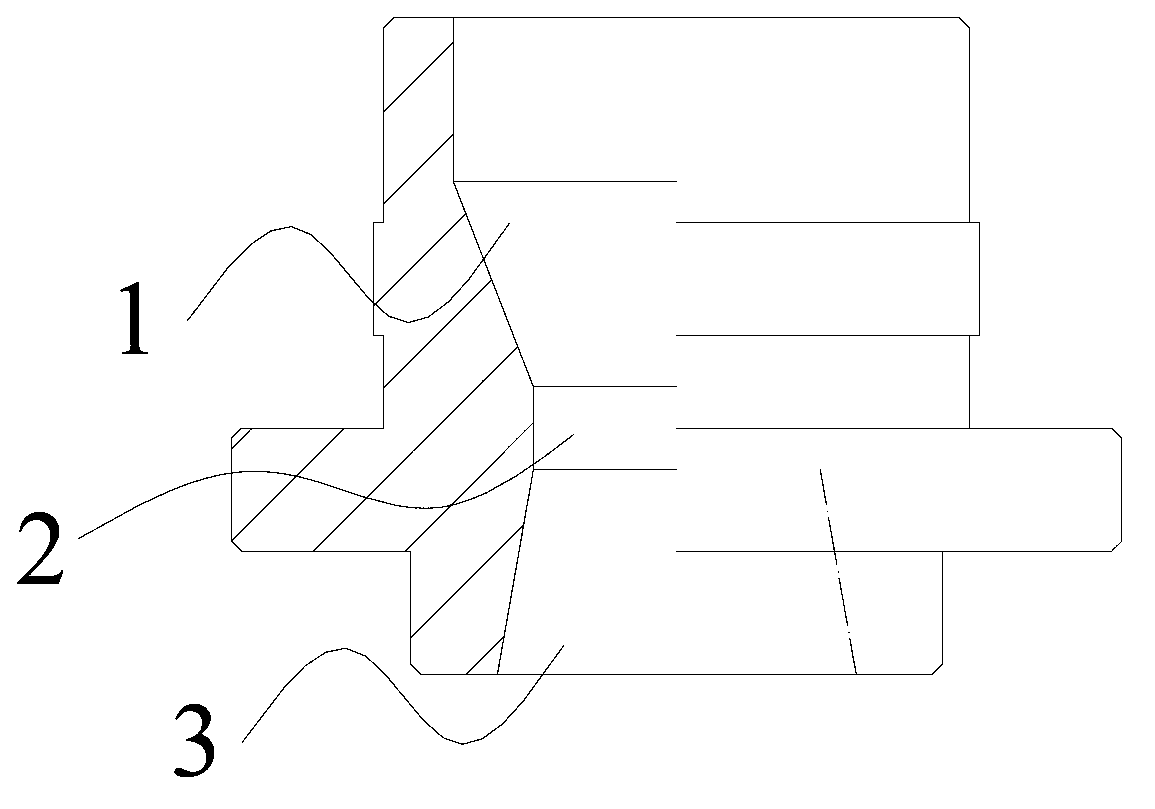

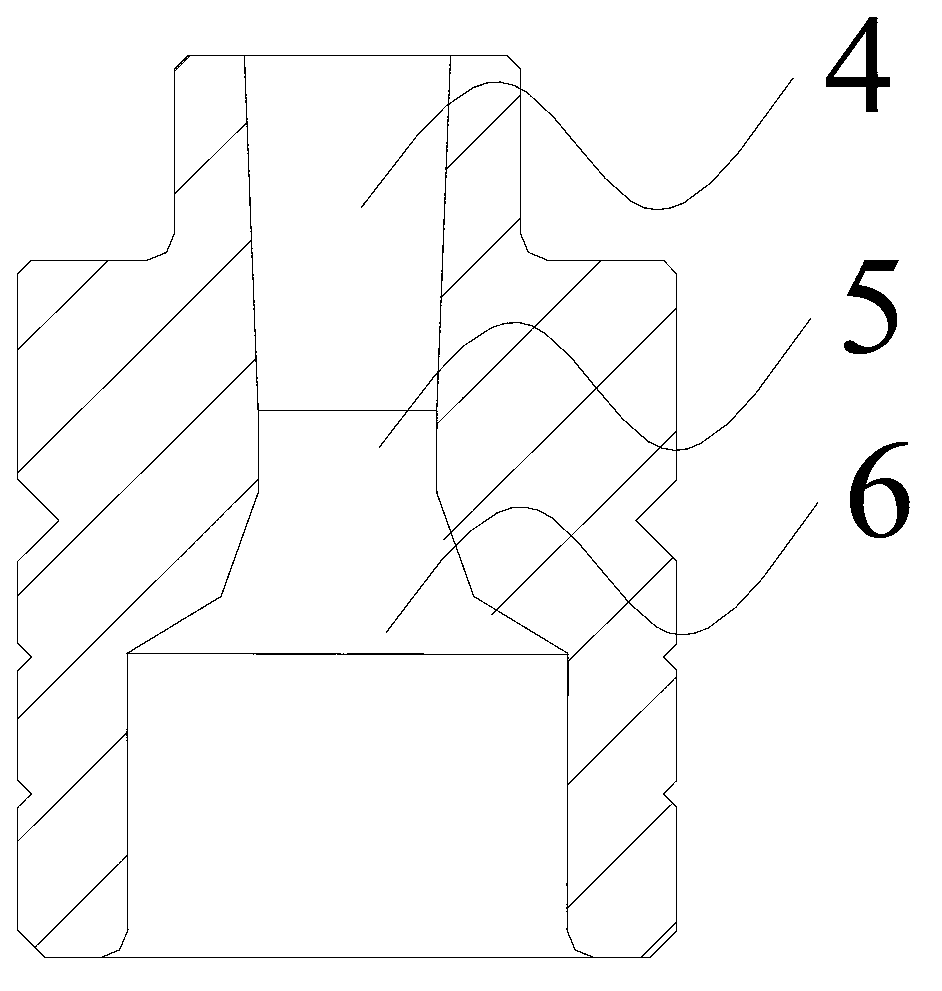

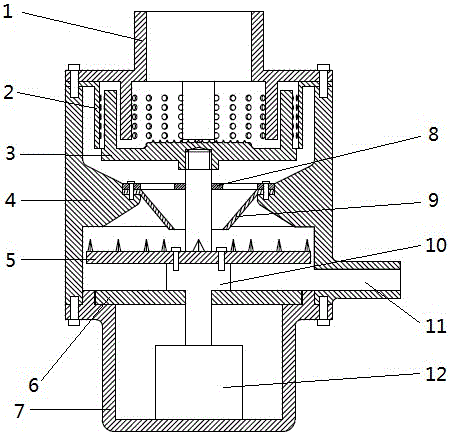

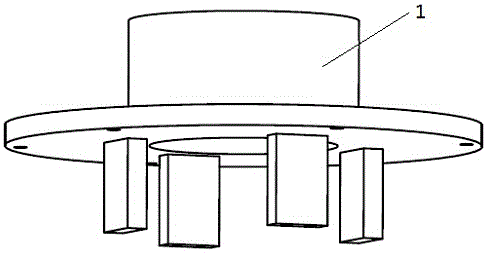

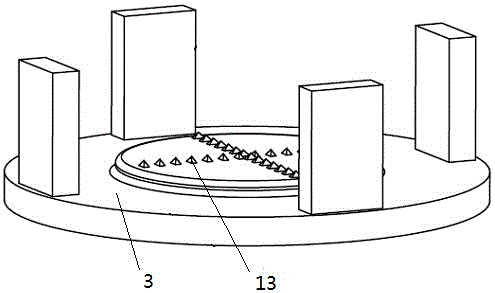

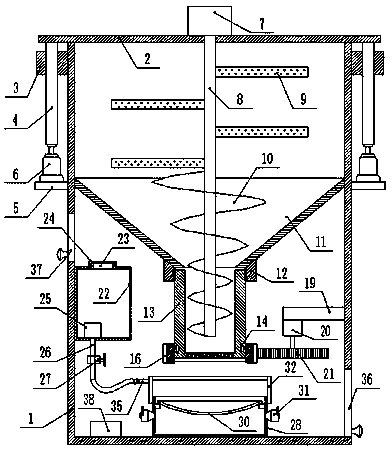

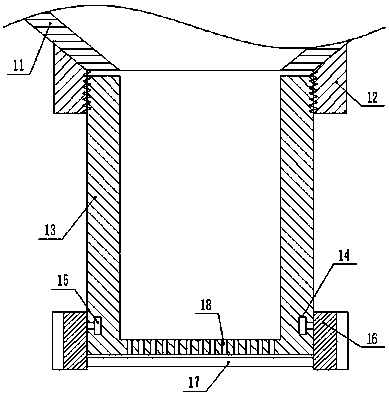

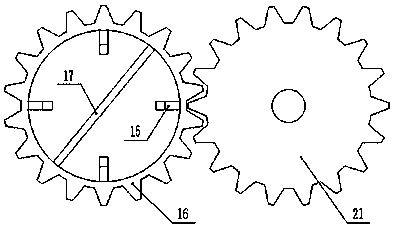

Kitchen garbage disposer capable of realizing two-stage crushing

InactiveCN106733018APlay the role of auxiliary crushingImprove crushing efficiencyDomestic plumbingGrain treatmentsDrive shaftEngineering

The invention relates to a kitchen garbage disposer capable of realizing two-stage crushing. The kitchen garbage disposer comprises an end cover, an upper cavity body, a lower cavity body, a crushing cutter disc and a drill bit cutter disc, wherein the end cover is mutually connected with the upper cavity body through a screw, and the upper cavity body is mutually connected with the lower cavity body through a screw; a screen drum is installed between the end cover and the upper cavity body; the crushing cutter disc is mutually matched with a rectangular tool at the lower end of the end cover and arranged in the screen drum; the upper end of a transmission shaft is in threaded connection with the crushing cutter disc, and the lower end of the transmission shaft penetrates through a circular tray and is connected with a motor in the lower cavity body; a support disc is mutually bonded with a funnel, and fixed to the middle part of the upper cavity body through a screw; the drill bit cutter disc is fixed to a large circular table of the transmission shaft through a screw; a circular tray is in threaded connection with the lower cavity body; and a waste discharge port is formed in the lower end of the upper cavity body. The kitchen garbage disposer disclosed by the invention has the following advantages: the garbage crushing efficiency is increased due to the design of a multi-stage crushing device; and the kitchen garbage disposer is ingenious in overall structure and convenient to use.

Owner:SOUTHWEST PETROLEUM UNIV

Fish feed stirring device

ActiveCN108201803AStir wellUniform particle sizeFeeding-stuffRotary stirring mixersSpiral bladeEngineering

The invention discloses a fish feed stirring device. The fish feed stirring device comprises a stirring barrel, a top cover is covered on the upper end of the stirring barrel, sleeves are fixed on theside wall of the upper end of the stirring barrel, a vertical rod fixed with the lower end of the top cover is inserted into each of the sleeves, the vertical rods and the sleeves are connected in asliding manner, a fixing plate fixed with the stirring barrel is arranged at the lower end of each of the sleeves, a jack for lifting the vertical rod is fixed on the upper end of each of the fixing plate, a motor A is fixed at the center of the upper end of the top cover, a rotating shaft is vertically inserted into the middle of the top cover and is connected with the top cover in a rotating manner, the rotating shaft is fixed to an output shaft of the motor A, a plurality of stirring rods are horizontally fixed to the upper end of the rotating shaft, spiral blades are fixed to the lower endof the rotating shaft, a conical partition plate is fixed in the inner wall of the stirring barrel, a cylinder A is fixed to the lower end of the conical partition plate, and a cylinder B is arrangedin the cylinder A through threaded connection. According to the fish feed stirring device, grease is sprayed to prevent feed from sinking into water and dissolving to cause waste, and to make the feed float on water surface to facilitate observation of feeding conditions of fish, so that feeding amount is timely adjusted to facilitate feeding management, and the feed can be picked up and reused after being sun dried when the feed is not ate completely by fish.

Owner:乳山市福强水产食品有限公司

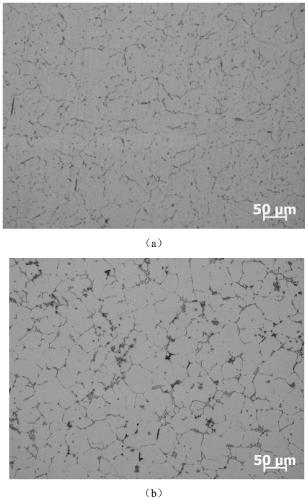

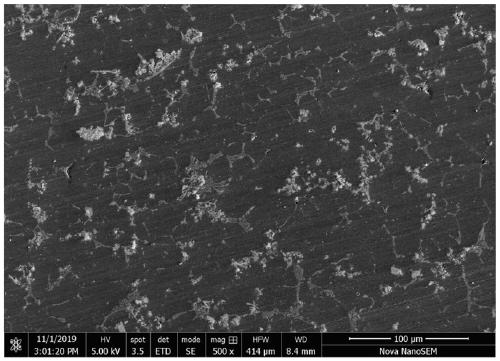

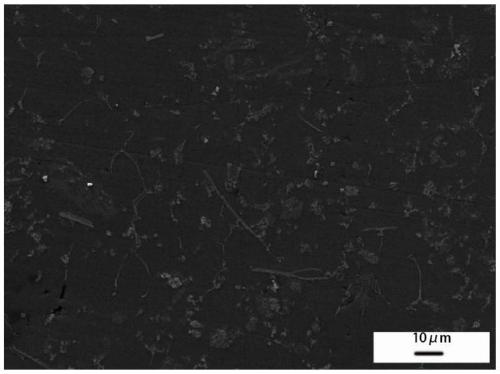

Preparation method of in-situ ternary nanoparticle reinforced aluminum-based composite material

The invention provides a preparation method of an in-situ ternary nanoparticle reinforced aluminum-based composite material. According to the method, an in-situ reaction generation technology is adopted, powder containing a generation reinforcing particle forming element is used as a reactant, a low-frequency rotating magnetic field / ultrasonic field control technology is combined, and a nano-particle intermediate alloy is remelted to prepare the aluminum-based composite material. According to the ternary nanoparticle reinforced AA6016-based composite material prepared by the invention, the average particle size is 65 nm, and a comparison unit and biphase nanoparticles have an obvious thinning phenomenon. The room temperature mechanical property test shows that compared with a matrix aluminum alloy, the tensile strength of the ternary nanoparticle reinforced AA6016-based composite material prepared by the invention is improved by 27.46%-33.5%, the elongation rate is increased by 23.56%-30.89%, and the ternary nanoparticle reinforced AA6016-based composite material has great application potential in the fields such as aviation, aerospace, advanced weapons, automotive industry, precision instruments and other civil industries.

Owner:JIANGSU UNIV

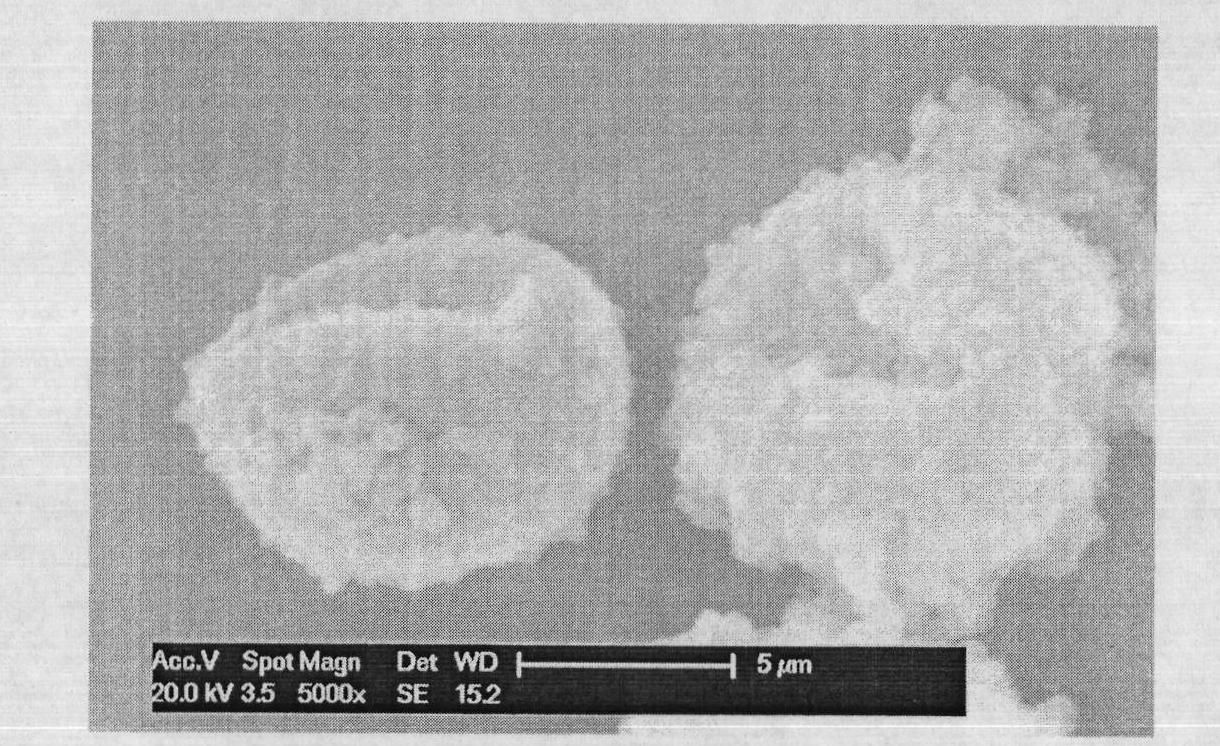

Synthetic method of porous BaTiO3 nano particle balls

InactiveCN101602521AReduce the temperatureHigh purityNanostructure manufactureTitanium compoundsDispersityBarium dichloride

The invention discloses a synthetic method of porous BaTiO3 nano particle balls. The invention comprises the following steps: dripping tetrabutyl titanate into surface active agent, stirring and mixing uniformly to form solution A; blending and mixing uniformly barium chloride and deionized water to form solution B; blending solution A and solution B and mixing uniformly with the volume ratio of 6:1 to 1:6, and then adding sodium hydroxide, carrying out the hydrothermal reaction for 0.3 to 50 hours at the temperature of 100 to 200 DEG C to obtain the porous BaTiO3 nano particle balls. The invention adopts the hydrothermal method to synthetize the porous BaTiO3 nano particle balls and the synthetic method is simple; compared with other wet-chemical methods, the synthetic method in the invention has the advantages of environmental friendliness, low temperature, no calcination and the like; the porous BaTiO3 nano particle balls obtained by the method have high purity, large specific surface area, controllable and uniform particle size, good dispersity, and no further surface treatment when used.

Owner:SUN YAT SEN UNIV

Method for preparing neodymium iron boron powder by means of hydrothermal method

The invention discloses a method for preparing neodymium iron boron powder by means of a hydrothermal method. The method comprises the steps of (1) dissolving neodymium nitrate, ferric nitrate, nitrate of metal M, boric acid and a surface active agent into water; (2) adjusting the PH value, heating the mixture in a reaction kettle, and preserving the temperature in the reaction kettle to obtain sediment; (3) cleaning and drying the sediment, and obtaining powder in the air by means of heat treatment; (4) uniformly mixing the powder with calcium powder, carrying out high-temperature reduction heat treatment on the powder inside a vacuum-tube-type furnace, and obtaining the neodymium iron boron powder after the powder is cleaned. According to the method for preparing the neodymium iron boron powder, the sizes of granules of the sediment obtained and prepared by means of the hydrothermal method can be controlled, dispersion of the granules is good, the size of grains of the neodymium iron boron powder obtained after reduction heat treatment is from 0.2 micrometer to 20 micrometers, and the magnetic performance is higher.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Low-temperature sintering nano-silver paste and preparation process thereof

ActiveCN105127435AReduced impact on sintering propertiesImprove sintering performanceNanotechnologySilver pasteSlurry

The invention discloses a process for preparing low-temperature sintering nano-silver paste. The process comprises the following steps: 1) preparing blank reverse microemulsion and making a pseudoternary phase diagram; 2) preparing the reverse microemulsion containing nano-silver particles; 3) performing centrifugal separation: performing centrifugal separation on the reverse microemulsion containing the nano-silver particles 2-4 times, separating oil phase organic matter and aqueous phase solution, and obtaining the nano-silver particles adsorbed by mixed surfactants; 4) causing the nano-silver particles adsorbed by the mixed surfactants obtained in the step 3) to be mixed with organic carriers, adjusting the viscosity, and preparing the low-temperature sintering nano-silver paste. The process has the advantages that the nano-silver particles are wrapped with the surfactants from nucleation growth to the formation of final slurry, the hard aggregation of the nano-silver particles is greatly reduced, the nano-silver particles prepared through the process are controllable in size, and the preparation process is simplified.

Owner:GUILIN UNIV OF ELECTRONIC TECH

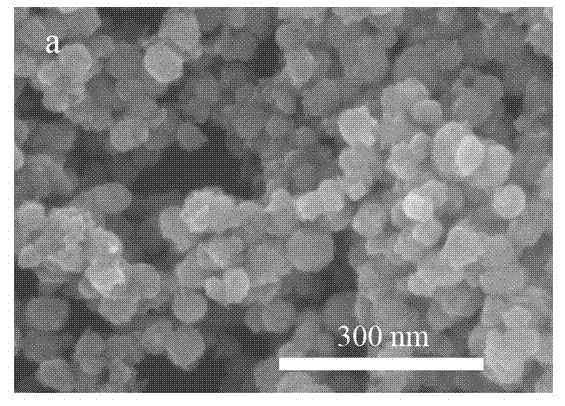

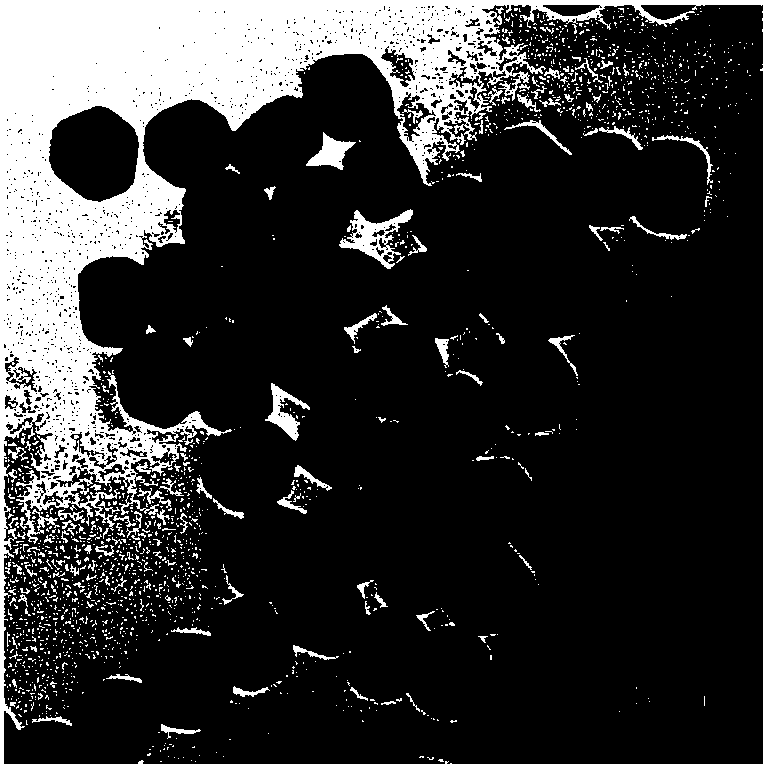

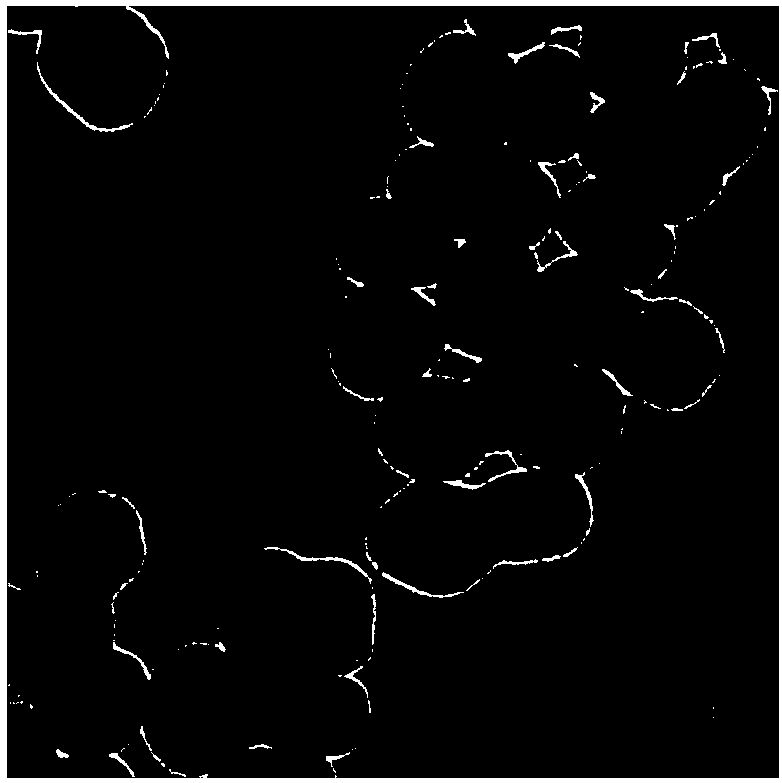

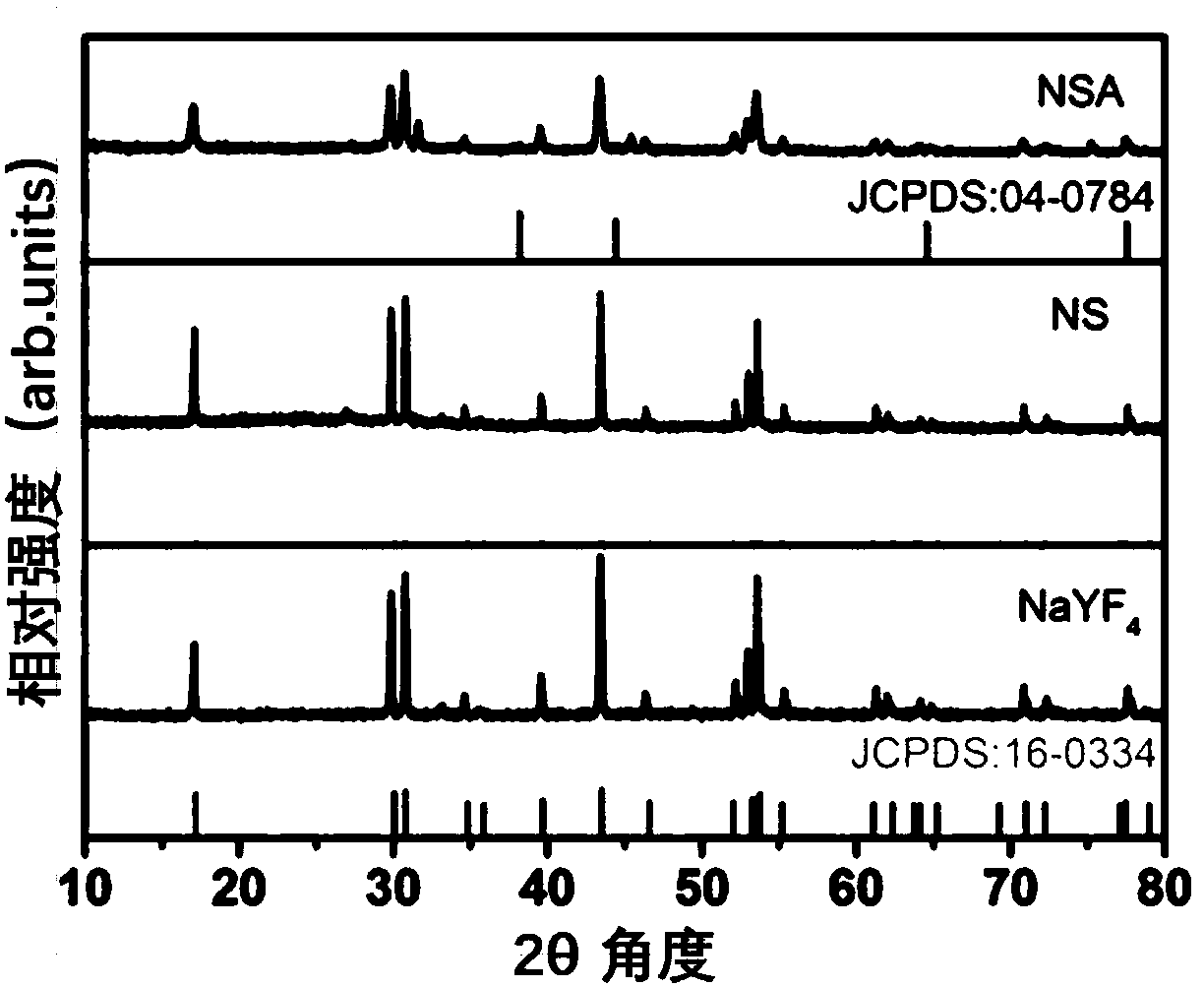

Nanogold shell coated upconversion nanocrystal composite structure material and preparation method thereof

InactiveCN108165270ASmall particlesMorphological rulesNanoopticsLuminescent compositionsBiological tissueBiocompatibility Testing

The invention belongs to the technical field of luminous materials and relates to a nanogold shell coated upconversion nanocrystal composite structure material and a preparation method of the material. The material solves the technical problems of large nano particle size, low fluorescence intensity, incomplete core-shell structure and poor biological tissue penetration capacity of the existing rare-earth upconversion luminescent material. The invention provides the nanogold shell coated upconversion nanocrystal composite structure material in a fluoride and oxide upconversion nano core-shellstructure. The invention further provides the preparation method of the composite structure material. Compared with the upconversion luminescent material prepared by the traditional method, the nanogold shell coated upconversion nanocrystal composite structure material is small in particle size, regular in pattern, good in dispersity, good in biocompatibility, and easy in surface biological functionalization; a gold shell is ultrathin, complete and consecutive; and selectively reinforced fluorescence emission is obtained by adjusting a position of an SPR (surface plasmon resonance) absorptionpeak. The preparation method of the material has the advantages of good controllability, low reaction temperature, low equipment requirements, simple in-situ synthesis operation technology and the like.

Owner:CHANGCHUN UNIV OF TECH

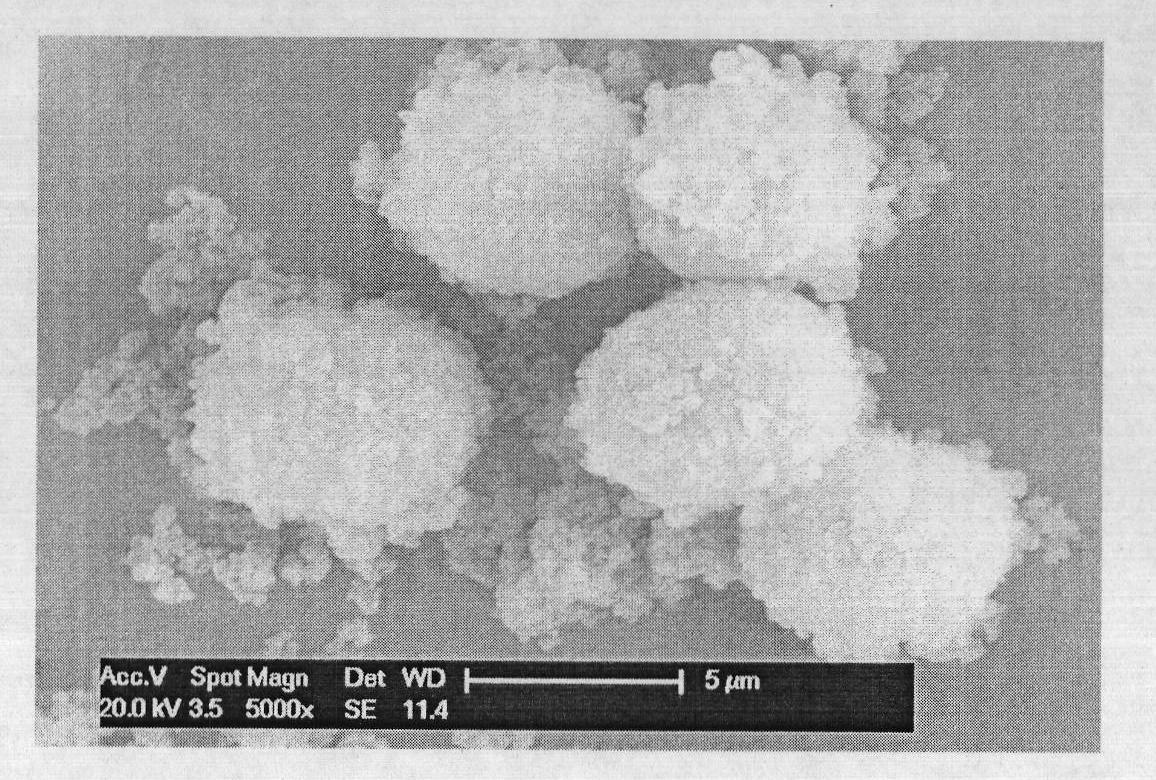

Ternary copper catalyst used in synthesis of dimethyl dichlorosilane and preparation method of ternary copper catalyst

InactiveCN102649061AEvenly dispersed and relatively livelyGood dispersionGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsSolventCopper salt

The invention relates to the field of a catalyst used in synthesis of dimethyl dichlorosilane, in particular to a ternary copper catalyst used in synthesis of the dimethyl dichlorosilane and a preparation method of the ternary copper catalyst. The preparation method according to the invention comprises the following steps of: (1) dissolving a copper salt into a mixed solvent of polybasic alcohol and water to obtain solution with copper ion concentration of 0.0025-0.25 g / mL; and (2) dropwise adding pH regulator aqueous solution into the solution obtained by the step (1) under a stirring condition, transferring the solution into a reaction kettle after the pH value of the solution is 6-13, reacting at 100-250 DEG C for 2-30 hours to obtain brown precipitate, and washing and drying the precipitate to obtain the ternary copper catalyst. The ternary copper catalyst prepared by the invention has the advantages of simple experimental process route, convenience in operation, entire process performed in the reaction kettle, no need of any complex experimental equipment, high reaction speed, easiness for large-scale production and capability of showing higher selectivity for the dimethyl dichlorosilane and higher conversion rate for a silicon powder raw material.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

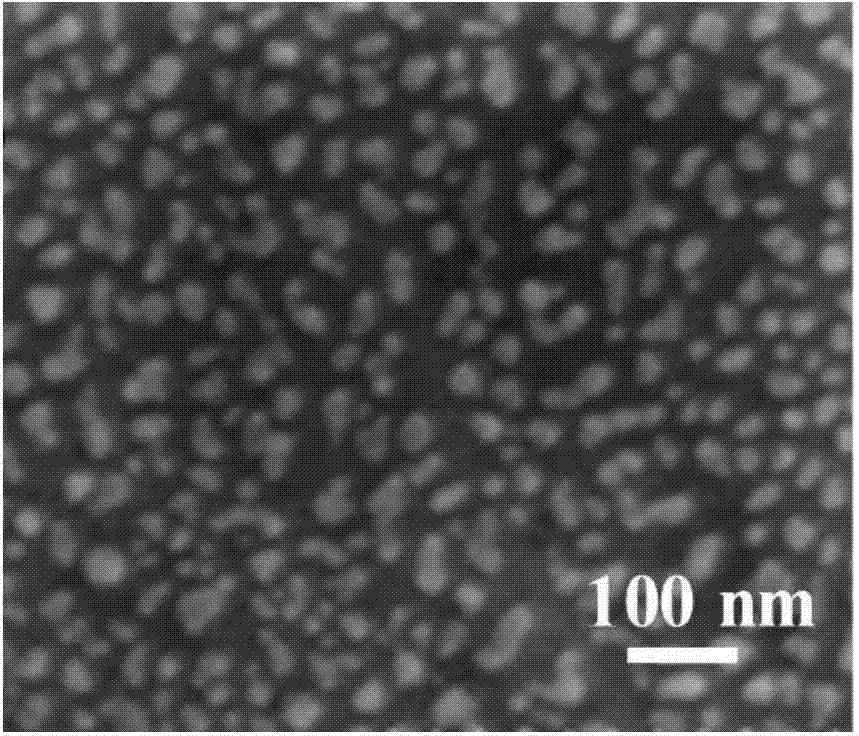

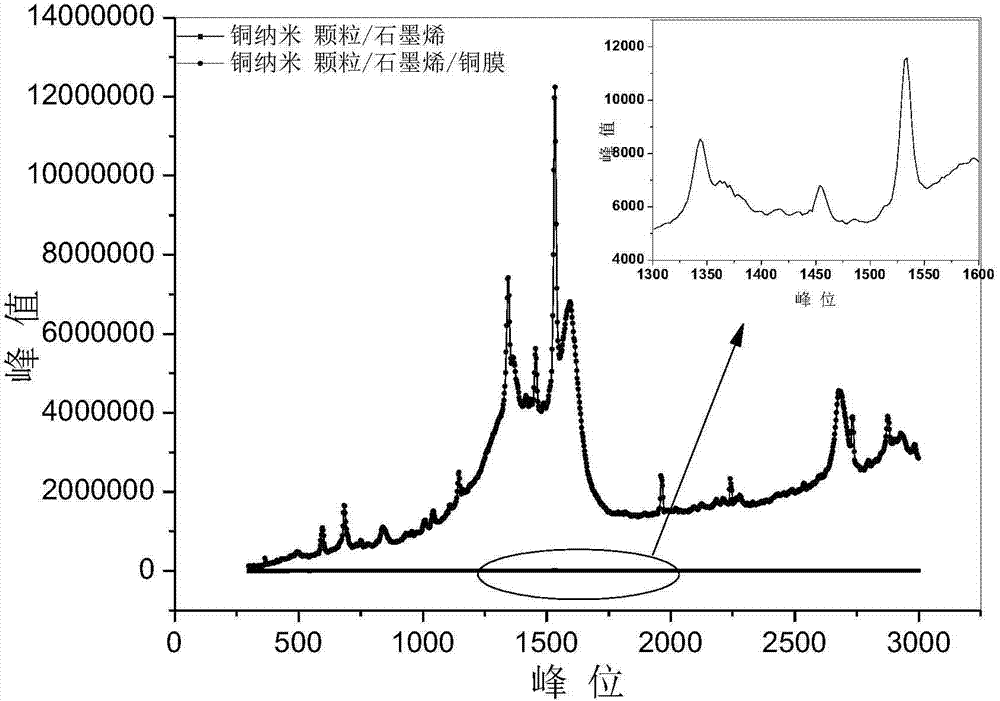

Ultra-sensitive SERS substrate and preparation method thereof

InactiveCN104777151AIncreased sensitivityAdjustable coverage densityRaman scatteringPlasmonic couplingGraphene

The invention relates to an ultra-sensitive SERS substrate and a preparation method thereof. A superstrong plasma coupling effect is produced while the Cu nanometer particles are separated from a Cu film by use of graphene, so that the sensitivity of the SERS based on copper can be obviously promoted. By use of full copper material, the cost of the structure is greatly lowered. The Cu nanometer particles are directly paved on the Cu film growth with graphene on the surface by virtue of a chemical vapor deposition (CVD) method in the preparation process, and the complex graphene transferring process is omitted. Furthermore, the coverage density of the Cu nanometer particles of the structure is adjustable, and sandwich structure substrates with different Cu nanometer particles coverage densities can be obtained after the Cu film is soaked in the acetone for a certain time. The preparation method is convenient and fast.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

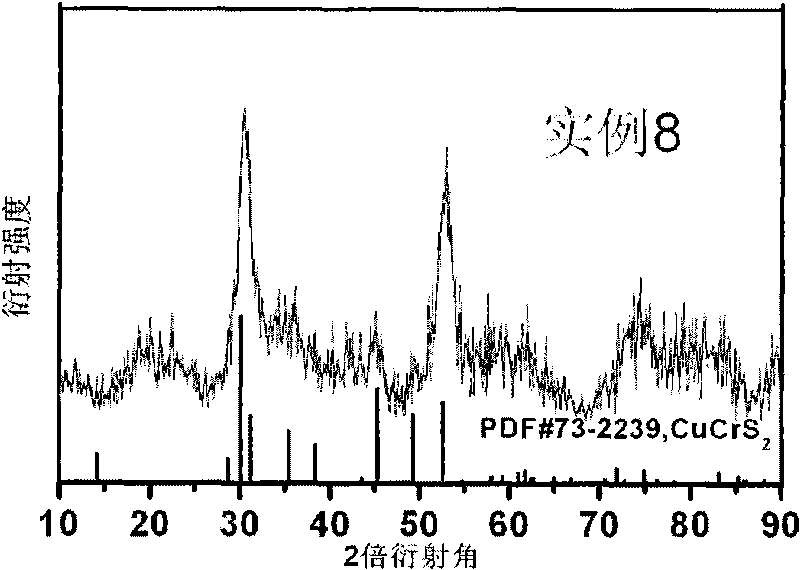

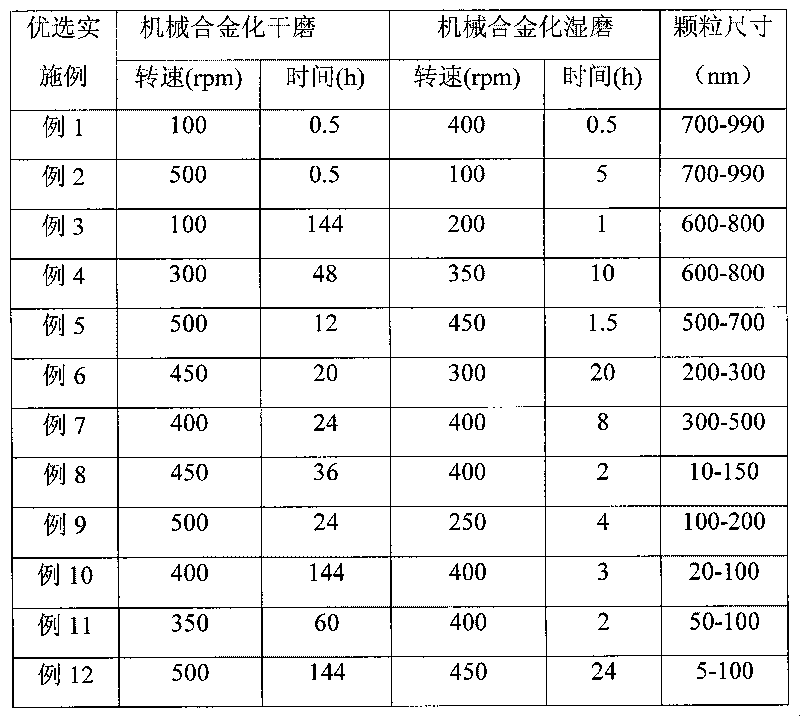

Method for preparing CuCrS2 nano powder

InactiveCN101717118AEasy to manufactureEasy to operateNanostructure manufactureChromium compoundsBall millRaw material

The invention discloses a method for preparing CuCrS2 nano powder and belongs to the technical field of nano materials. In the method, Cu powder (more than or equal to 99.9 mass percent), Cr(more than or equal to 99.9 mass percent) and S powder (more than or equal to 99.9 mass percent), serving as raw materials, are mixed according to a stoichiometric molar ratio of Cu to Cr to S of 1:1:2 of the final product and then put in a planetary ball mill to be milled at a certain rotation speed to form compound powder, then a certain amount of absolute ethanol is added into the compound powder for wet milling, and drying a resulting product to obtain the CuCrS2 nano powder which has a uniform particle size of 5 to 990 nano meters. The preparation method has the advantages that: the raw materials are cheap and readily available; the preparation process is simple, quick and easy in operation; and the requirements on equipment and preparation environment are low; and the particle size of the powder is uniform and controllable.

Owner:UNIV OF SCI & TECH BEIJING

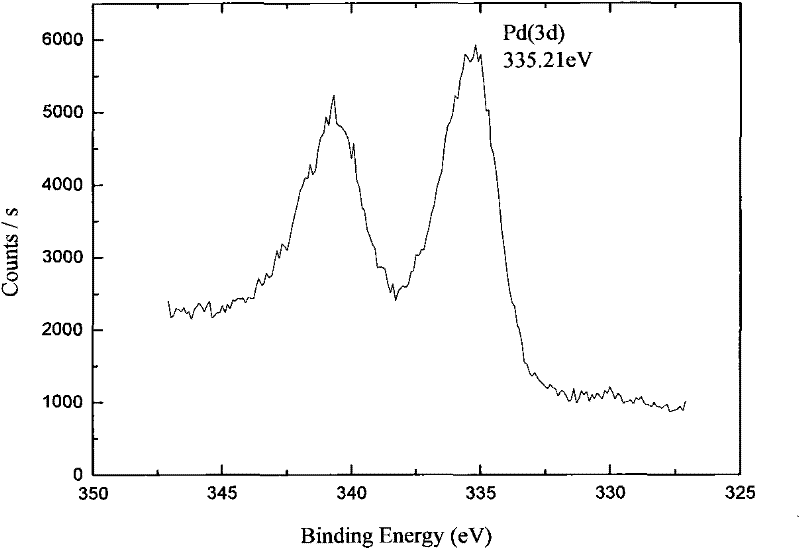

Catalyst for C4 fraction selective hydrogenation and removal of alkyne, and preparation method thereof

InactiveCN102240548ASmall particle sizeUniform particle sizeHydrocarbon purification/separationCatalyst activation/preparationHydrogenActive component

The invention discloses a catalyst for C4 fraction selective hydrogenation and removal of alkyne, and a preparation method thereof. A main metal active component precursor loaded on a carrier and assistant metal component precursors loaded on the carrier are reduced through ionizing radiation to prepared the unsaturated hydrocarbon hydrogenation catalyst provided by the present invention. The main metal active component precursor comprises Pd, wherein the Pd content is 0.01 (wt)%-2.00 (wt)% of the total weight of the carrier. The assistant metal component precursors comprise: (1) at least one selected from Cu, Co, Ag, Cr, Bi, Sn, Pb, Ga, Zn, Sb and Tl, wherein the metal content is 0.005 wt%-30.0 wt% of the total weight of the carrier; (2) optional one or a plurality of metals selected from Na, K, Mg, Ca and Ba, wherein the metal content is 0.005 wt%-5.0 wt% of the total weight of the carrier. The catalyst has advantages of high activity, high selectivity, no requirement of pre-reduction through hydrogen, direct use and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com