Method for preparing CuCrS2 nano powder

A nano-powder and ball-milling tank technology, applied in the field of nano-materials, can solve problems such as high temperature and atmosphere protection, harsh reaction conditions, and long preparation cycle, and achieve the effects of easy operation, simple preparation process, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

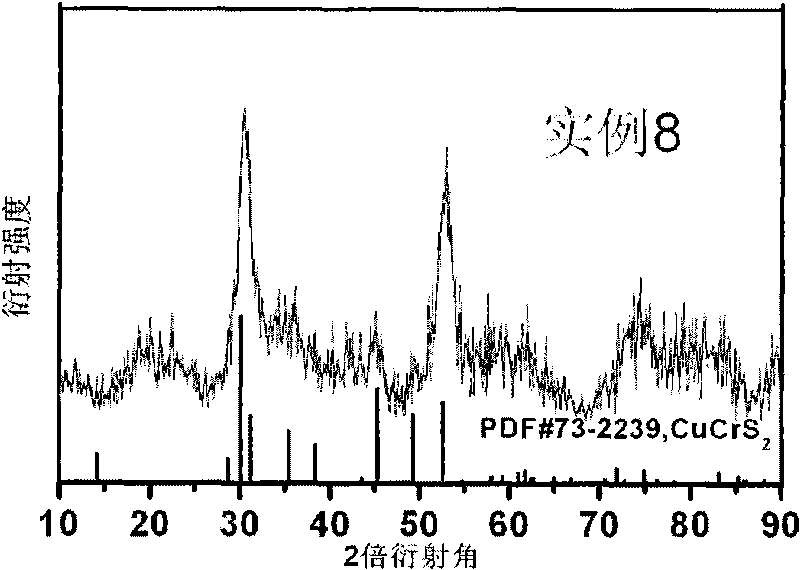

Image

Examples

Embodiment Construction

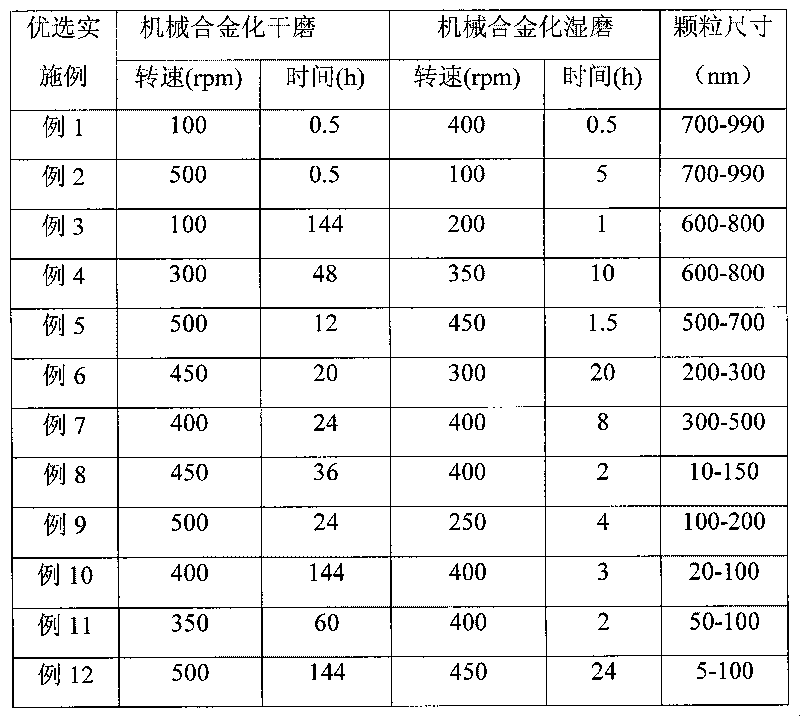

[0016] Preparation of CuCrS by Mechanical Alloying 2 Nano powder, the method is to Cu powder (mass percentage ≥ 99.9%), Cr powder (mass percentage ≥ 99.9%) and S powder (mass percentage ≥ 99.5%) according to the chemical formula CuCrS 2 Proportioning, mixing and putting into planetary ball mill, mechanical alloying under the protection of inert gas, dry grinding to synthesize compound, then wet grinding, and drying to obtain CuCrS 2 Nano powder. Table 1 has provided the present invention (CuCrS 2 ) of several preferred embodiments:

[0017]

[0018] In summary, the present invention synthesizes CuCrS by mechanical alloying 2 Nano-powder, the particle size of the powder can be controlled by adjusting the ball milling time and rotating speed, which is suitable for large-scale production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com