Method for preparing hexangular ordered FePt nano particle array

A nanoparticle array and array technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of not preparing bimetallic nanoparticle arrays, and achieve easy control of particle size and spacing, uniform distribution, and size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

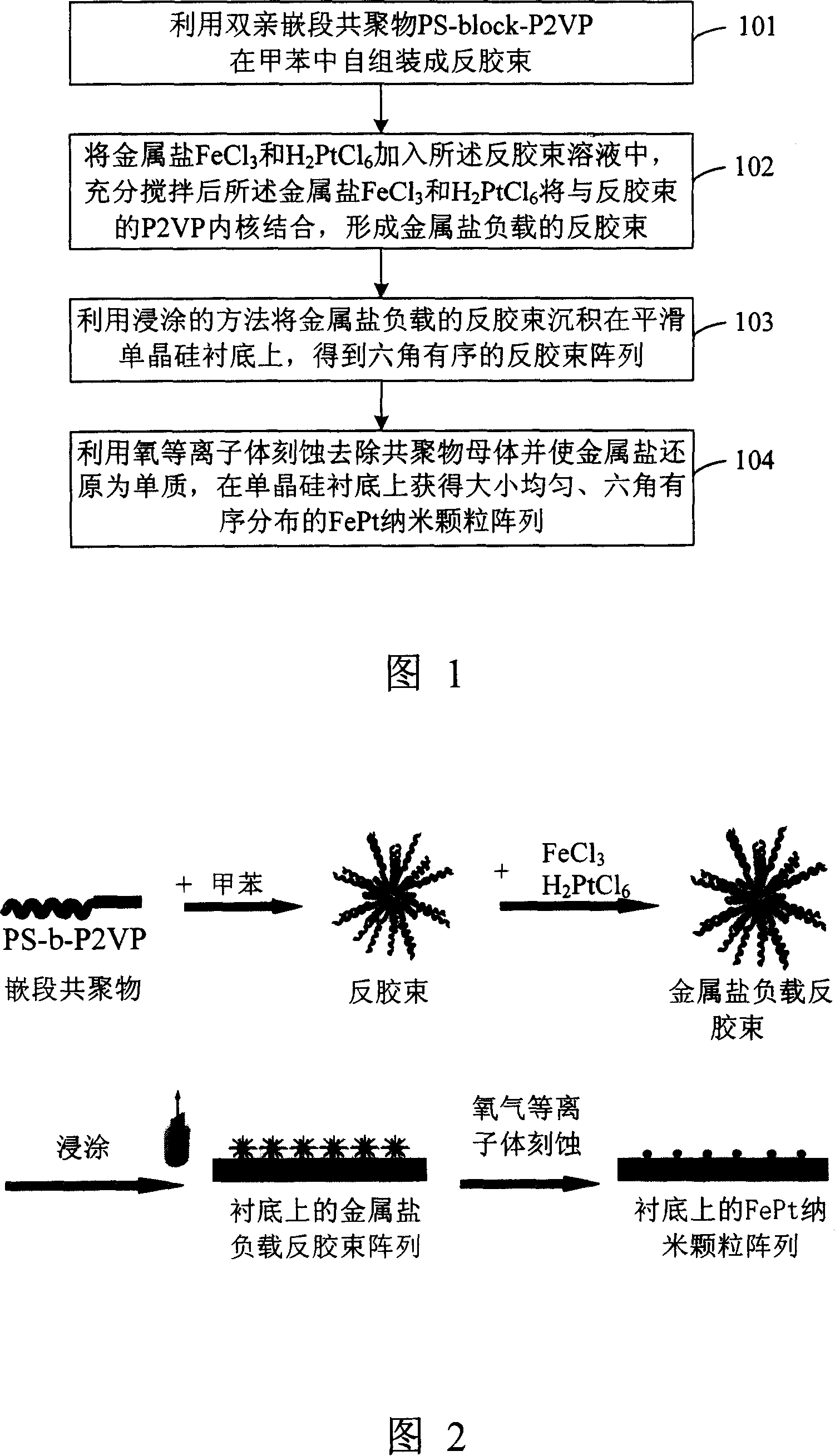

[0051] As shown in Figure 2, Figure 2 is a schematic diagram of the process flow for preparing a hexagonal ordered FePt nanoparticle array according to an embodiment of the present invention, which specifically includes the following steps:

[0052] 1) Add 5 mg of amphiphilic block copolymer PS(1760)-block-P2VP(700) into 5 mL of toluene. After sufficient stirring (more than 24 hours), the copolymer will self-assemble into uniformly sized, monodisperse reverse micelles in toluene.

[0053] 2) Add metal salt 2.77mgFeCl to the above reverse micellar solution 3 and 8.52mgH 2 PtCl 6 , after fully stirring, the metal salt will occupy the inner core of the reverse micelles to form metal salt-loaded reverse micelles.

[0054] 3) Immerse the cleaned and dried (100) silicon substrate vertically into the above-mentioned reverse micelles solution at a certain rate, and pull it out vertically at a constant and controllable rate of 12 mm / min, and a layer will be obtained on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com