Patents

Literature

37results about How to "There will be no reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of low-percolation graphene/macromolecule electromagnetism shielding material

InactiveCN103087386ALow percolation valueReduce manufacturing costNon-conductive material with dispersed conductive materialPolymer scienceElectromagnetic shielding

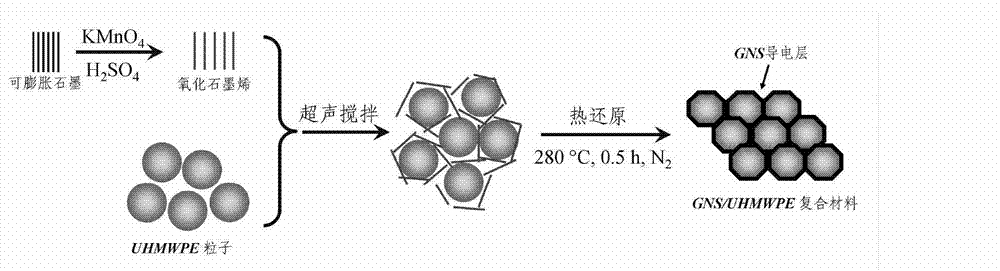

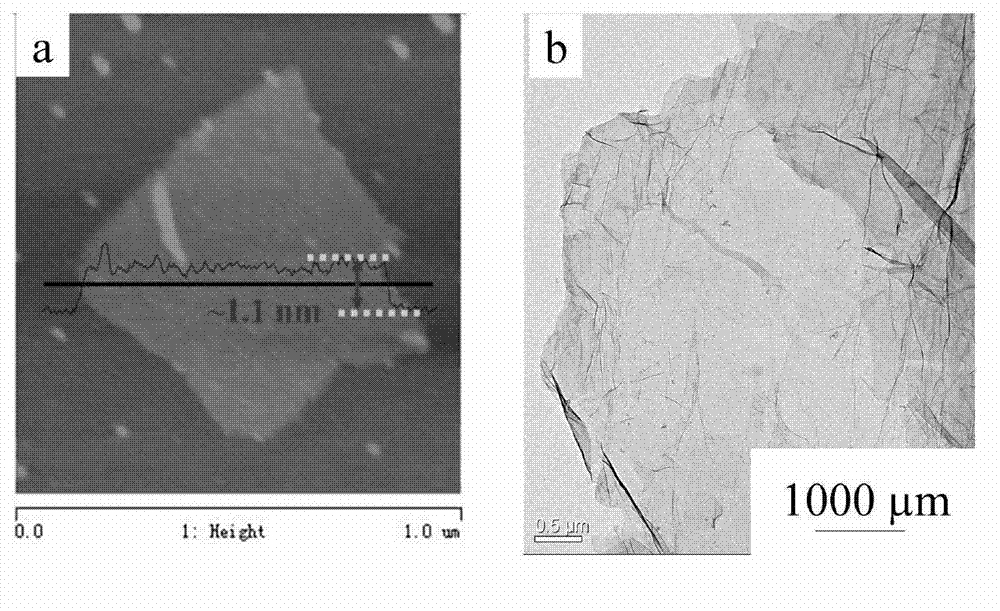

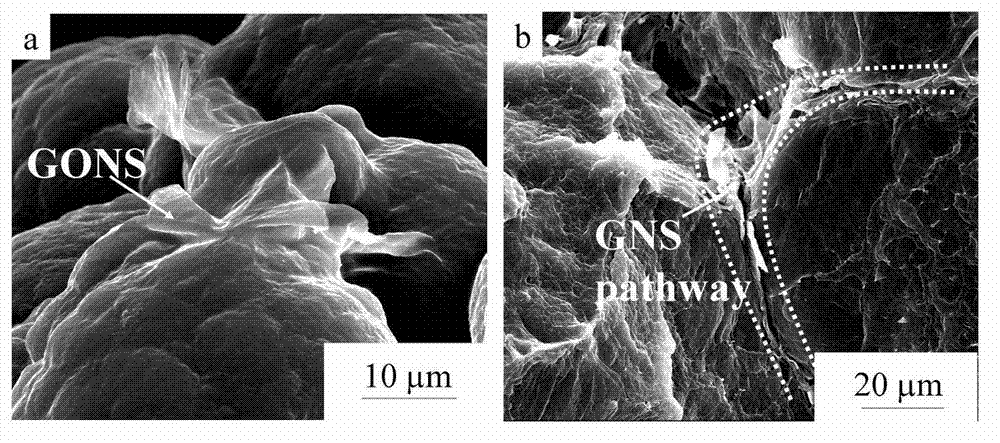

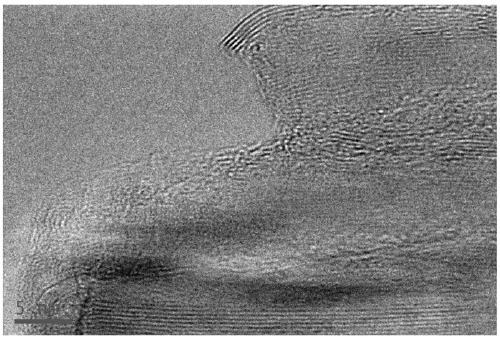

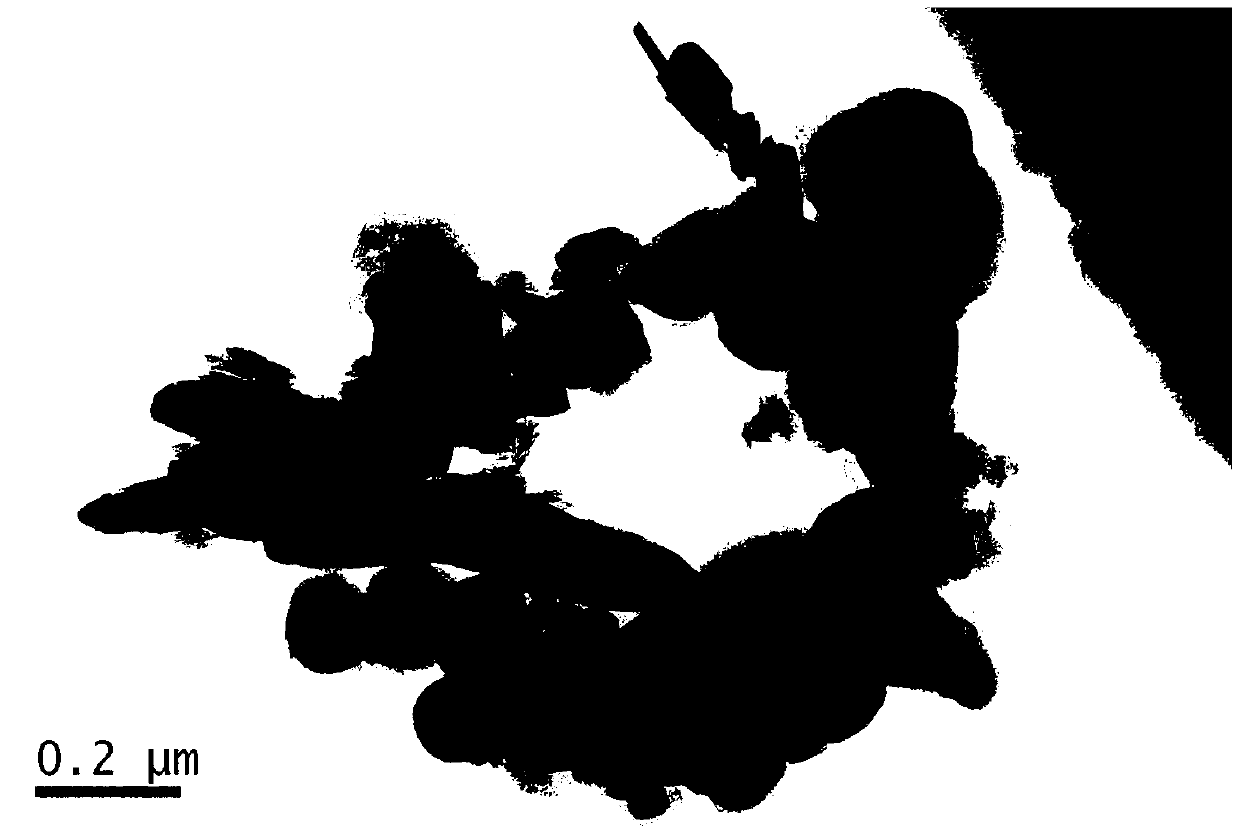

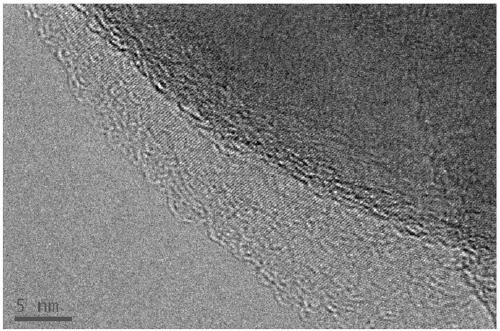

The invention relates to a preparation method of a low-percolation graphene / macromolecule electromagnetism shielding material. The composite material comprises the following main raw materials by weight percent: 94-99.7wt% of ultra-high molecular weight polyethylene (UHMWPE) and 0.3-6wt% of graphene oxide GONS. The preparation process comprises the following steps: (1) drying the raw materials; (2) preparing GONS / UHMWPE conductive particles; and (3) pressing and forming at high temperatures. According to the invention, the graphene oxide is reduced in situ at high temperatures in a hot pressing preparation process, so that the agglomeration of the graphene oxide in a chemical reduction process is avoided, the composite material has lower conductive percolation value, higher conductivity and higher electromagnetism shielding performance; and the preparation process is simple and low in production cost, the process is easy to master and mass production is easy to achieve.

Owner:SICHUAN UNIV

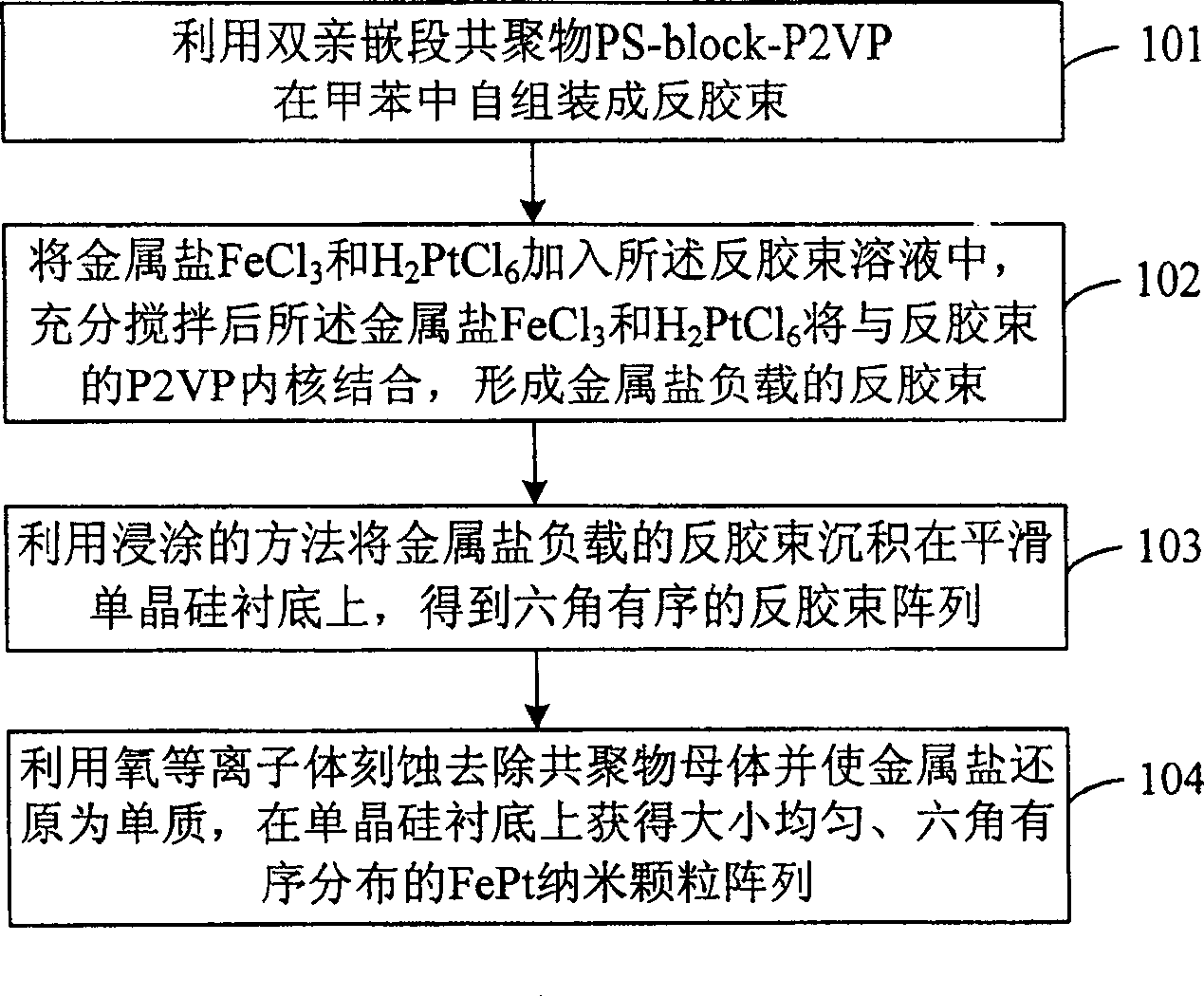

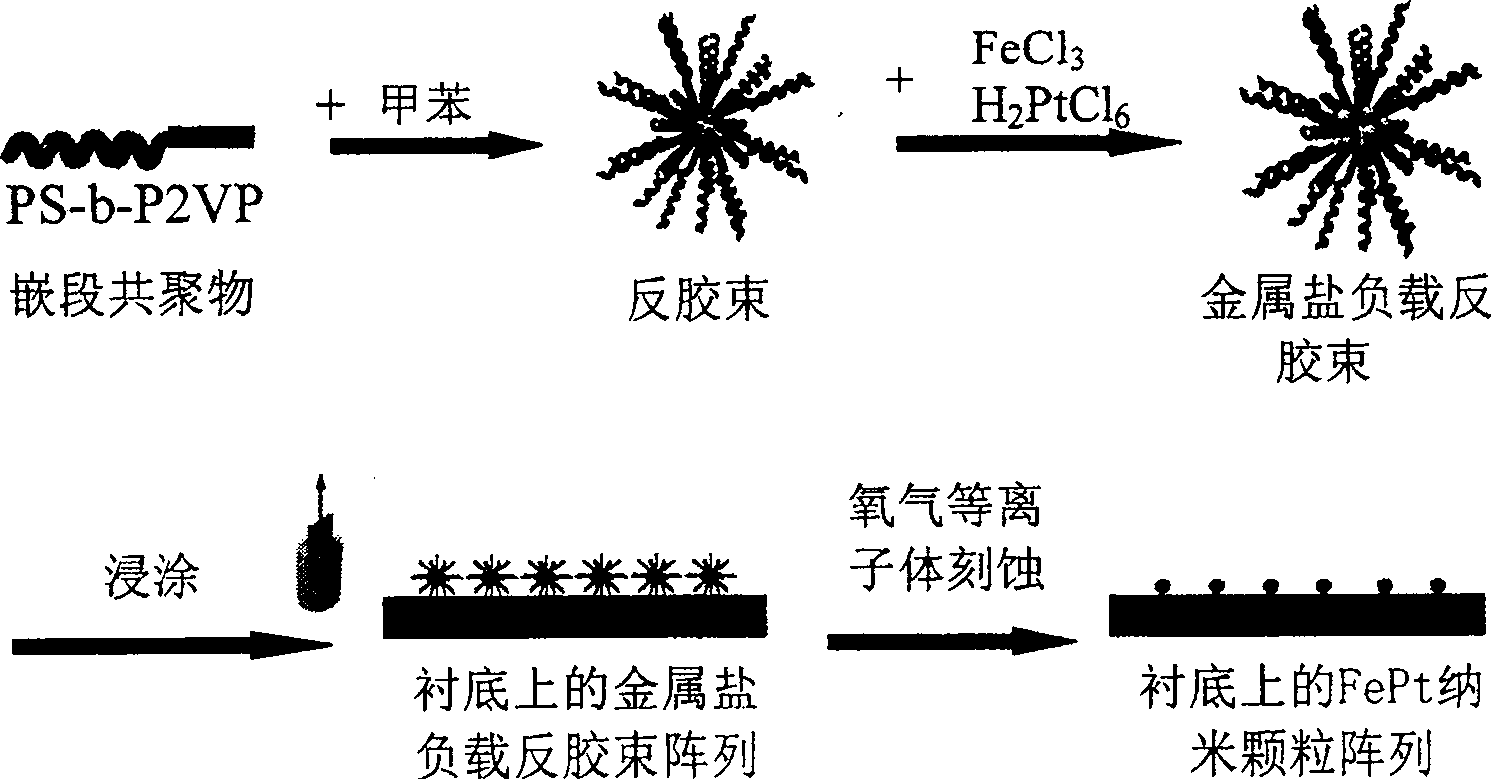

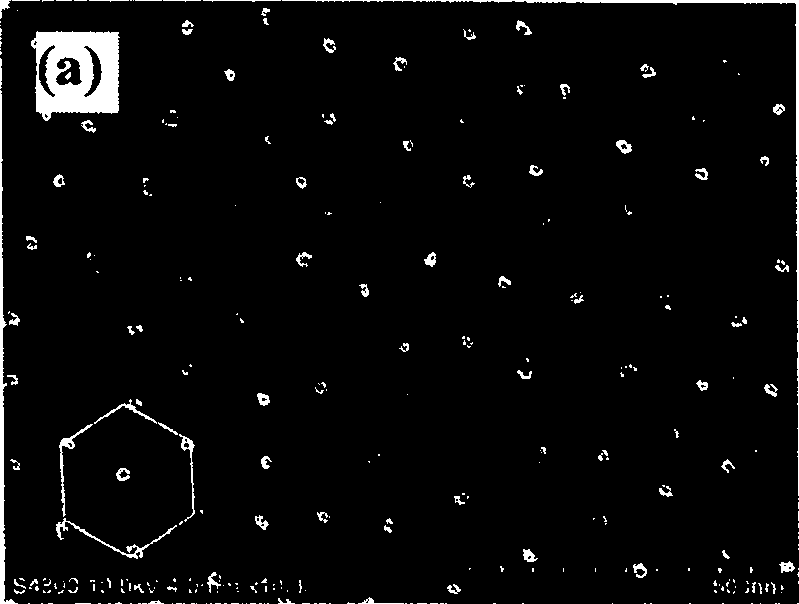

Method for preparing hexangular ordered FePt nano particle array

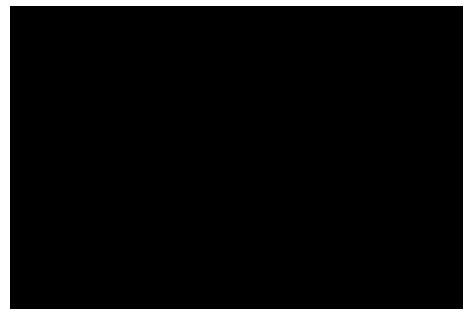

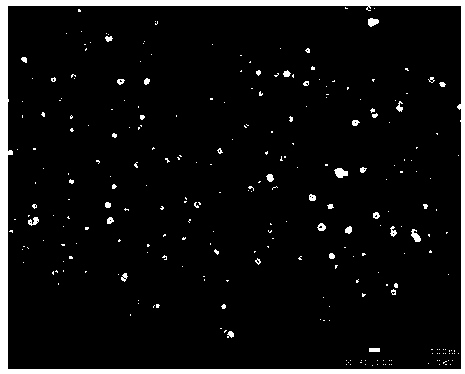

InactiveCN101148710AEvenly distributedParticle size is easy to controlInductances/transformers/magnets manufactureNanoparticleDip-coating

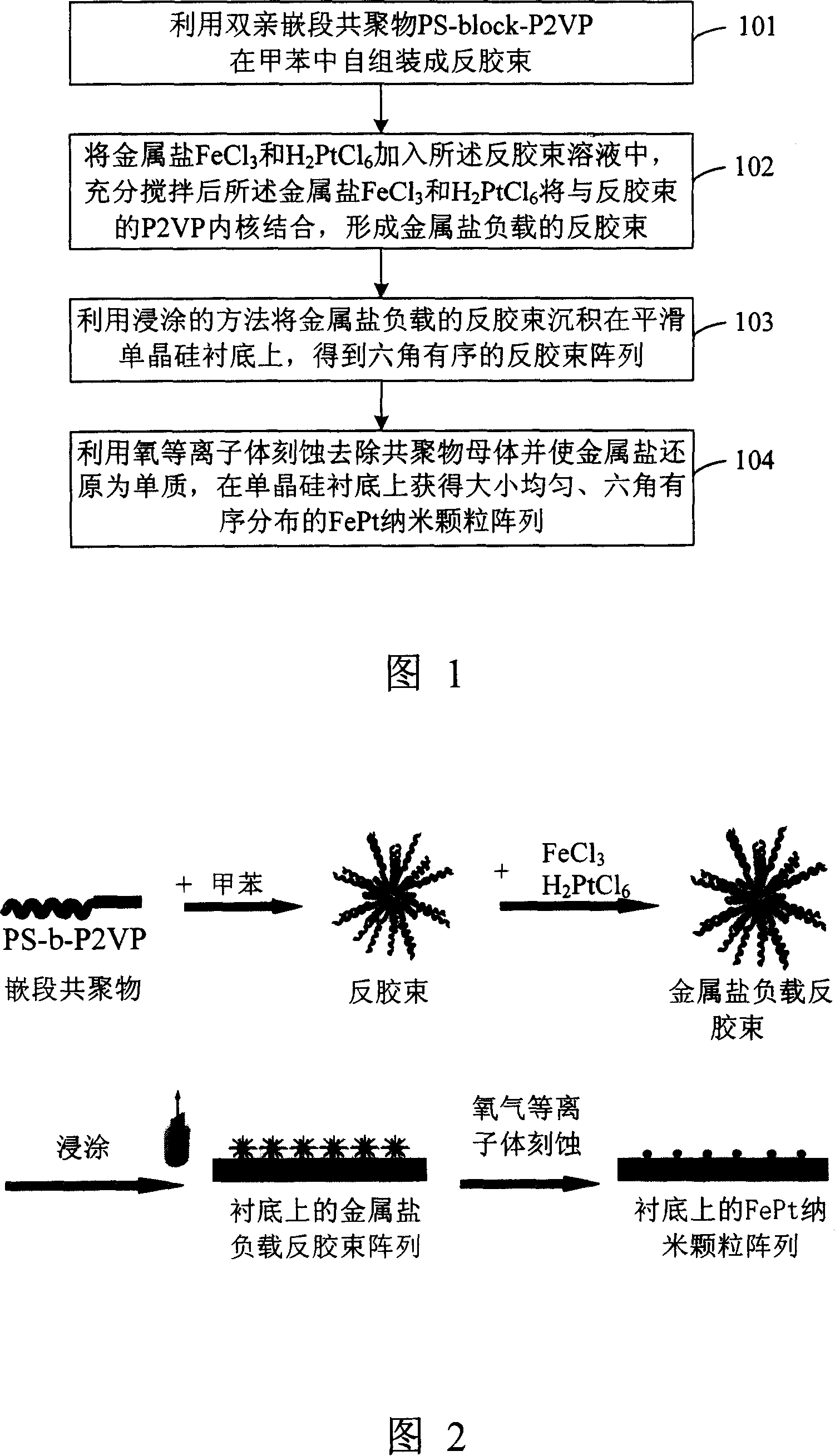

The process of preparing ordered hexagonal nanometer FePt particle array includes the following steps: 1. self-assembling inverse micelle with amphiphilic block copolymer PS-block-P2VP intoluene; 2. adding metal salts FeCl3 and H2PtCl6 into the inverse micelle solution through stirring for the metal salts FeCl3 and H2PtCl6 to be combined with the P2VP kernel of the inverse micelle to form inverse micelle with supported metal salts; 3. depositing the inverse micelle with supported metal salts onto smooth monocrystalline substrate through dip coating to obtain ordered hexagonal inverse micelle array; and 4. oxygen plasma etching to eliminate copolymer substrate and reduce metal salt into simple substance so as to obtain homogeneous ordered hexagonal nanometer FePt particle array on the monocrystalline substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for preparing nano Ag/polymer antimicrobial film by utilizing irradiation method

The invention discloses a method for preparing nano Ag / polymer antimicrobial film by utilizing <60>Co-gama ray or electronic beam irradiation. The method comprises the steps of: dissolving an NVP (N-vinylpyrrolidone) monomer in one or any two of ethanol, methanol, water and acetone, then adding AgNO3 solution, evenly stirring, putting a polymer film into the mixed solution, vacuumizing, irradiating in a closed reaction container, taking out the polymer film, washing with water and drying to obtain the nano Ag / polymer antimicrobial film. No initiator or reductant needs to be added in the irradiation process, NVP is polymerized on the surface of the polymer when Ag<+> is reduced into nano Ag, the method has the advantages that the technology is simple, the process is controllable, the yield is high, the prepared nano Ag / polymer antimicrobial film has good hydrophilicity and safety, the antimicrobial rate to Escherichia coli 107CFU / ml in 24 hours can reach 97.7%-100%.

Owner:SICHUAN INST OF ATOMIC ENERGY

Preparation method of hydrophilic polyethersulfone microfiltration membrane

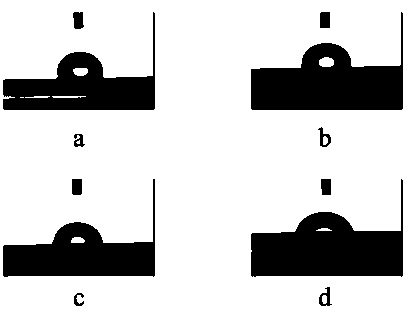

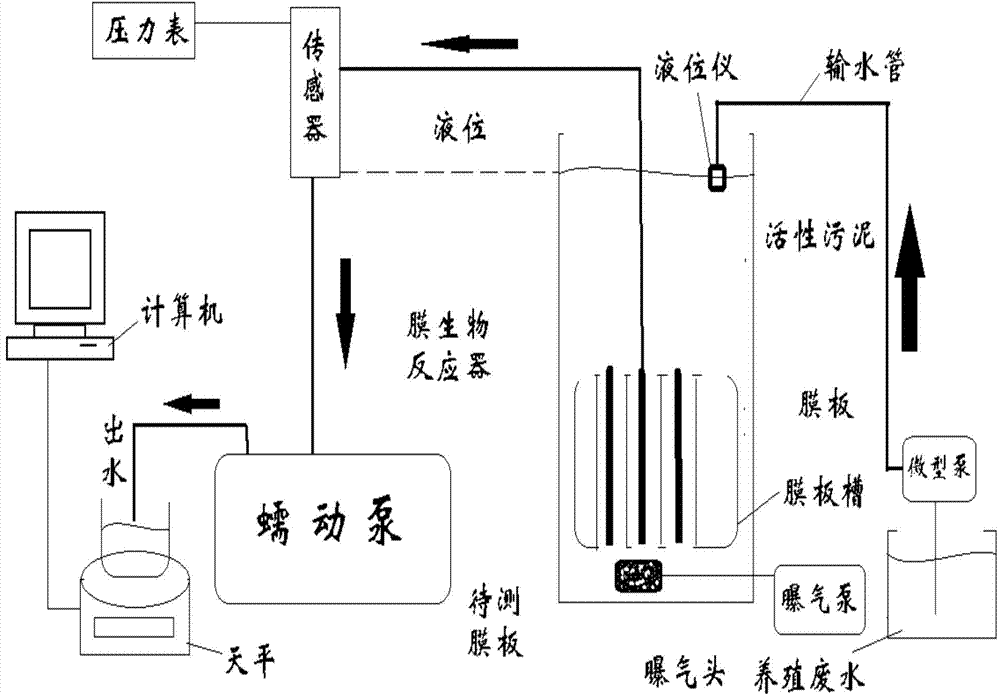

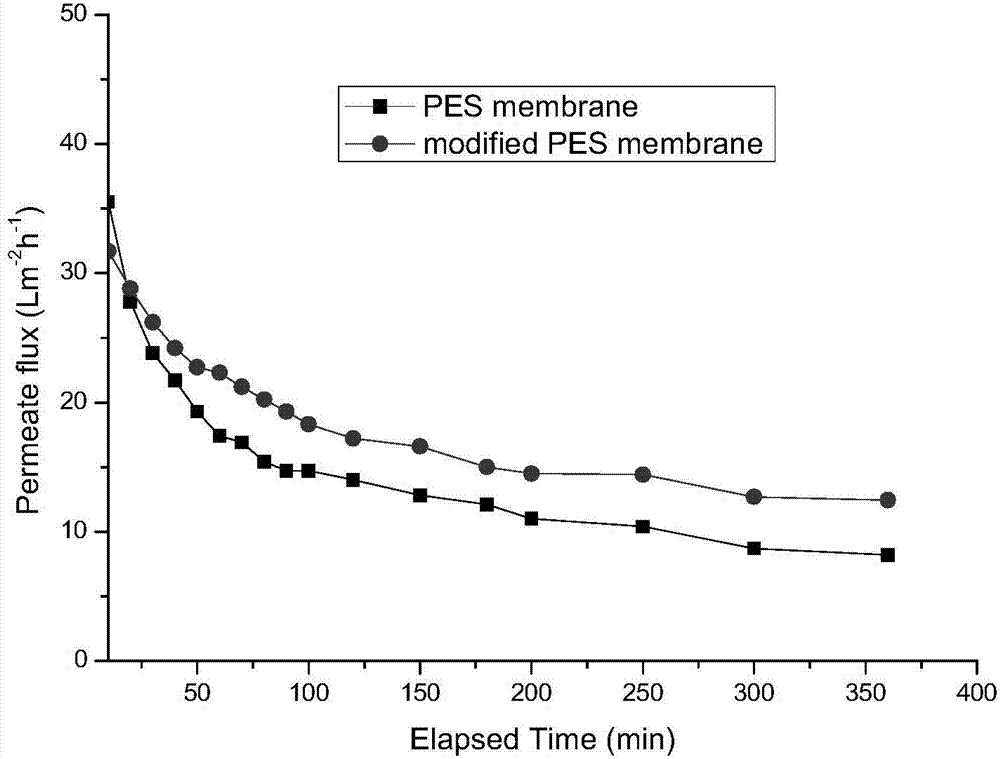

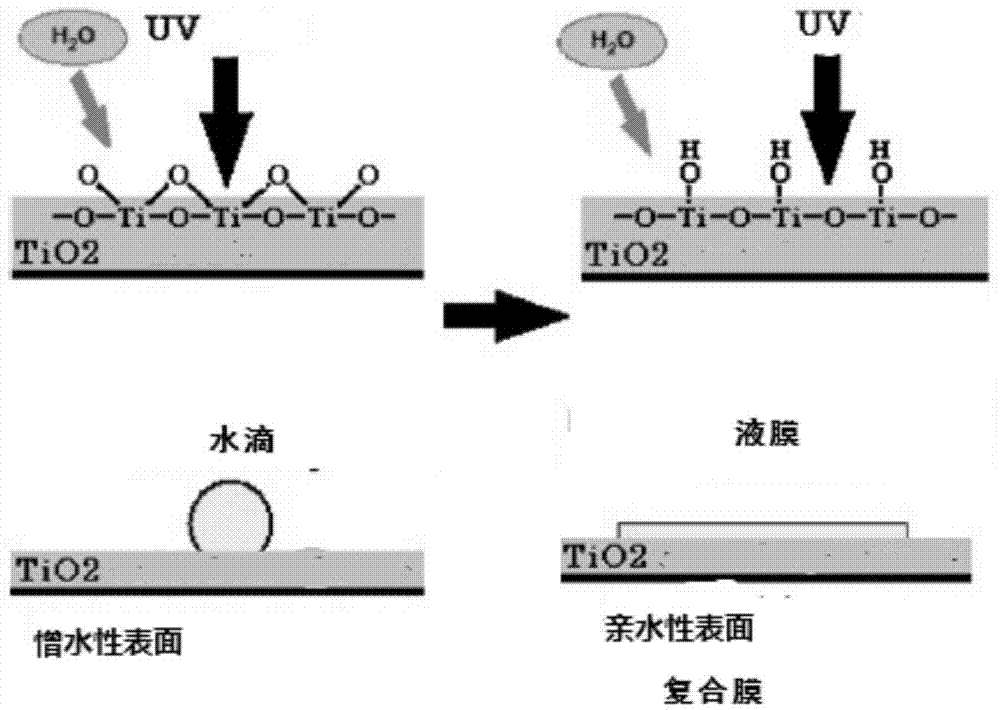

InactiveCN104258745AThere will be no reunionImprove hydrophilicitySemi-permeable membranesMicrofiltration membraneNanoparticle

The invention discloses a preparation method of a hydrophilic polyethersulfone microfiltration membrane. The preparation method comprises the following steps: 1, uniformly mixing polyethersulfone, an organic solvent, a non-solvent, a surfactant, an additive and hydrophilic nanoparticles into a membrane casting solution; 2, scraping the casting solution in the step 1 into a liquid membrane with the thickness of 0.2-0.4mm; 3, evaporating the liquid membrane in the step 2 in air for 6-60s at the room temperature; 4, immersing the liquid membrane in the step 3 into a coagulation bath for phase inversion to complete a preparation process. By the preparation method, the hydrophilic polyethersulfone microfiltration membrane is good in hydrophilic effect, high in flux and low in cost.

Owner:NANJING SHUISI ENVIRONMENTAL PROTECTION TECH

Core-shell-type optical diffusion hybrid microsphere and preparation method thereof

The invention relates to a core-shell-type optical diffusion hybrid microsphere and a preparation method thereof. The hybrid microsphere is obtained by carrying out a copolymerization reaction, a hydrolysis reaction and a condensation reaction on a cerium complex, a vinyl unsaturated monomer, a siloxane monomer containing double bonds and a sulfur-containing initiator, wherein an inner core of the hybrid microsphere is formed by a nanometer ceria hybrid copolymer; the nanometer ceria is from 30nm to 40nm in size; and a shell layer of the hybrid microsphere is formed by a polysiloxane condensation polymer. The white hybrid microsphere is from 350nm to 500nm in size and can be used for preparing an optical diffusion film in a liquid crystal display backlight module and ensuring that the good mechanical and abrasion-resistant performance of the optical diffusion film is obtained as well as the heat stability and the transparency of the optical diffusion film are improved. Thus, the hybrid microsphere is especially suitable for preparing an ultra-thin scratch-resistant optical diffusion film with good flexibility.

Owner:SOUTHEAST UNIV

Preparation method of carbon/carbon-boron nitride anti-friction composite material

ActiveCN109665855AImprove mechanical propertiesImprove friction and wear propertiesFiberCarbon fibers

The invention discloses a preparation method of a carbon / carbon-boron nitride anti-friction composite material. The preparation method comprises acidizing a graphitized C / C blank, washing the acidizedC / C blank to be neutral to obtain a preprocessed C / C blank, immersing the preprocessed C / C blank into a solution containing modifier for reaction to obtain a functionalized C / C blank, impregnating the functionalized C / C blank with h-BN (hexagonal boron nitride) slurry, then drying the impregnated C / C blank to obtain a C / C-BN precursor, and performing carbonizing densification and graphitization on the C / C-BN precursor with a carbon source to obtain the C / C-BN anti-friction composite material; the modifier is selected from silane coupling agent or polyvinyl alcohol (PVA). According to the preparation method of the carbon / carbon-boron nitride anti-friction composite material, a slurry impregnation method is applied for the first time to produce a BN matrix, and after the C / C blank is functionalized, a slurry impregnation process can effectively introduce BN powder into the C / C blank. The preparation method of the carbon / carbon-boron nitride anti-friction composite material can effectively avoid damage of carbon fiber and ensure excellent structural strength of the C / C-BN composite material; the prepared C / C-BN composite material has excellent friction-wear properties.

Owner:CENT SOUTH UNIV

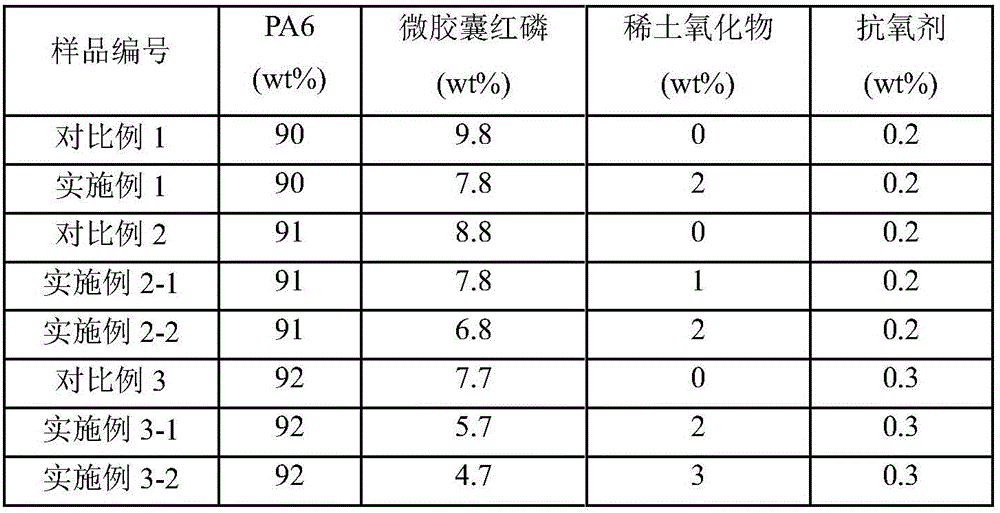

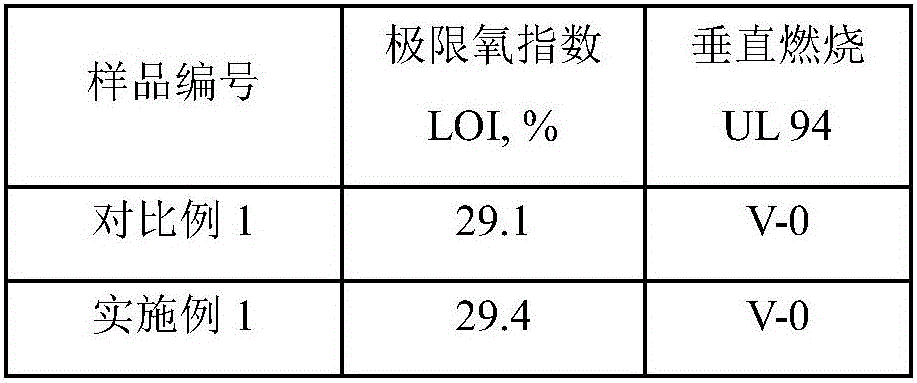

Rare-earth oxide and microencapsulated red phosphorus synergic flame retardance PA6 composite and preparation method thereof

ActiveCN106751778AImproved Density and ContinuityCondensed phase flame retardant effect is goodChemistryMass transfer

The invention provides a rare-earth oxide and microencapsulated red phosphorus synergic flame retardance PA6 composite and a preparation method thereof. The rare-earth oxide and microencapsulated red phosphorus synergic flame retardance PA6 composite is characterized by being prepared from PA6, microencapsulated red phosphorus and rare-earth oxide. Rare-earth oxide is introduced into a red phosphorus flame-resistant polymer material system, rare-earth oxide can catalyze dehydrated carbonization of red phosphorus, a more compact and continuous charcoal layer structure can be formed, the mass transfer process of volatile products generated by polymer degradation to a gas phase is blocked, feedback of heat generated by gas phase combustion to a condensed phase is also blocked, and flames are prevented from propagating and spreading.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

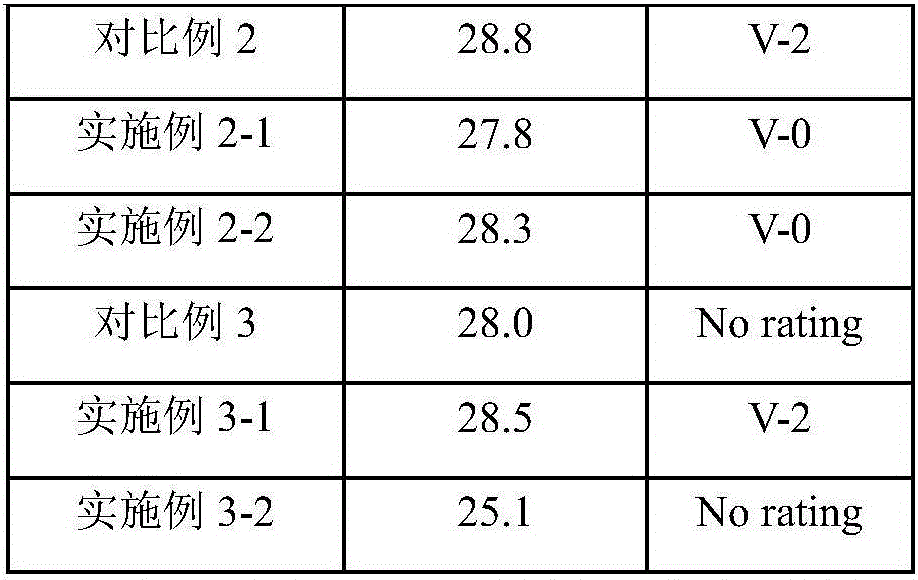

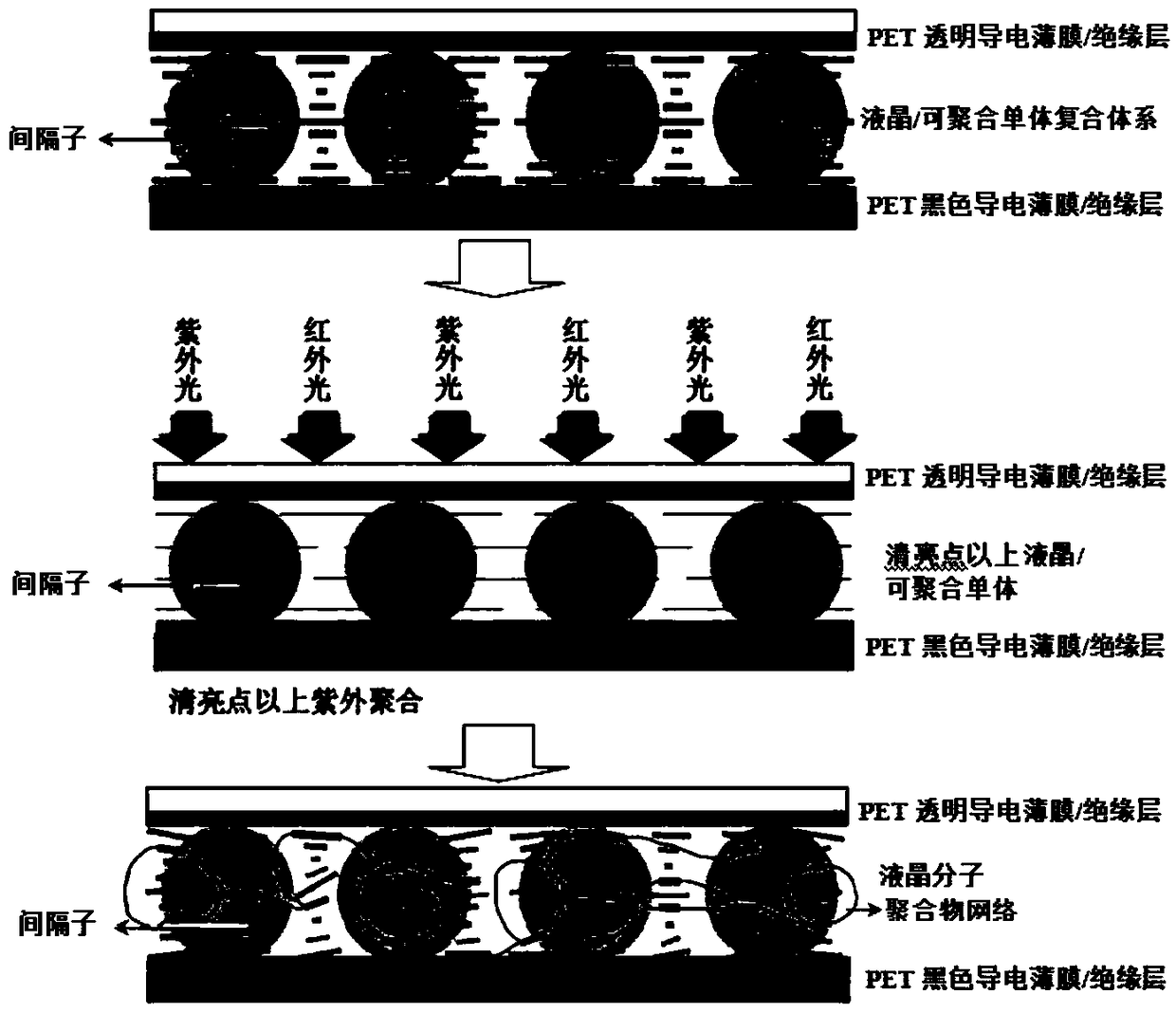

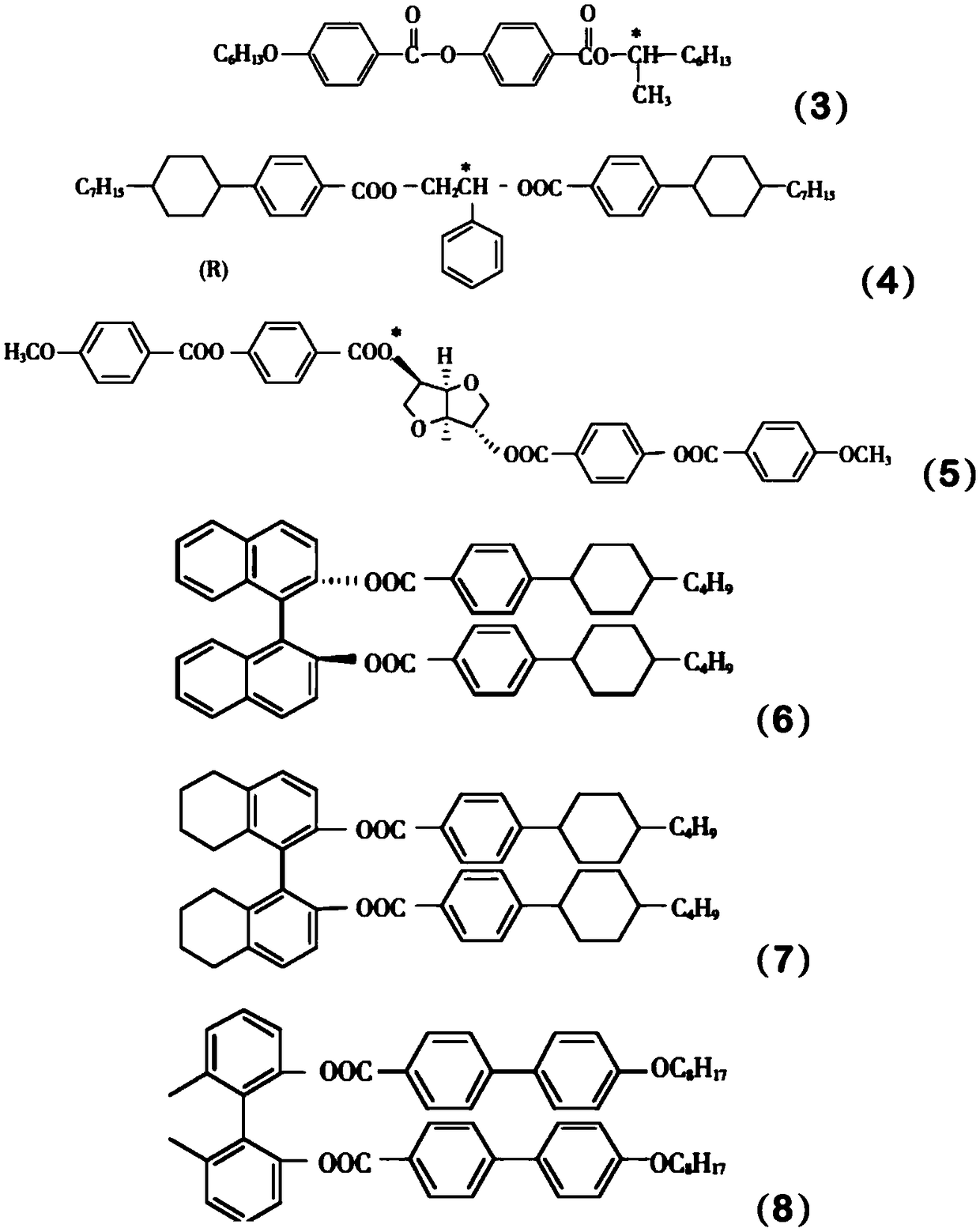

Easy thermal erasing type liquid crystal membrane writing board and preparation method

ActiveCN108717239ABroaden the reflected wave widthLower threshold voltageLiquid crystal compositionsNon-linear opticsLiquid-crystal displayLiquid crystal

The invention relates to the technical field of liquid crystal displaying, in particular to an easy thermal erasing type liquid crystal membrane writing board and a preparation method. The easy thermal erasing type liquid crystal membrane writing board comprises a PET transparent thin membrane with the single side coated with ITO, a liquid crystal thin membrane and a PET non-transparent black thinmembrane with the single side coated with ITO from top to bottom; the sides of conducting layers of the PET transparent thin membrane with the single side coated with the ITO and the PET non-transparent black thin membrane with the single side coated with the ITO are coated with insulating layers. Words written on the easy thermal erasing type liquid crystal membrane writing board can be completely removed under the lower voltage condition; the easy thermal erasing type liquid crystal membrane writing board can be packaged in rolling, and conveniently transported; the erasing and writing temperatures are low, the words can be reserved clearly at 0-4 DEG C, and the words written on the liquid crystal membrane writing board can be completely erased at the temperature between 45-60 DEG C.

Owner:山东蓝贝易书信息科技有限公司

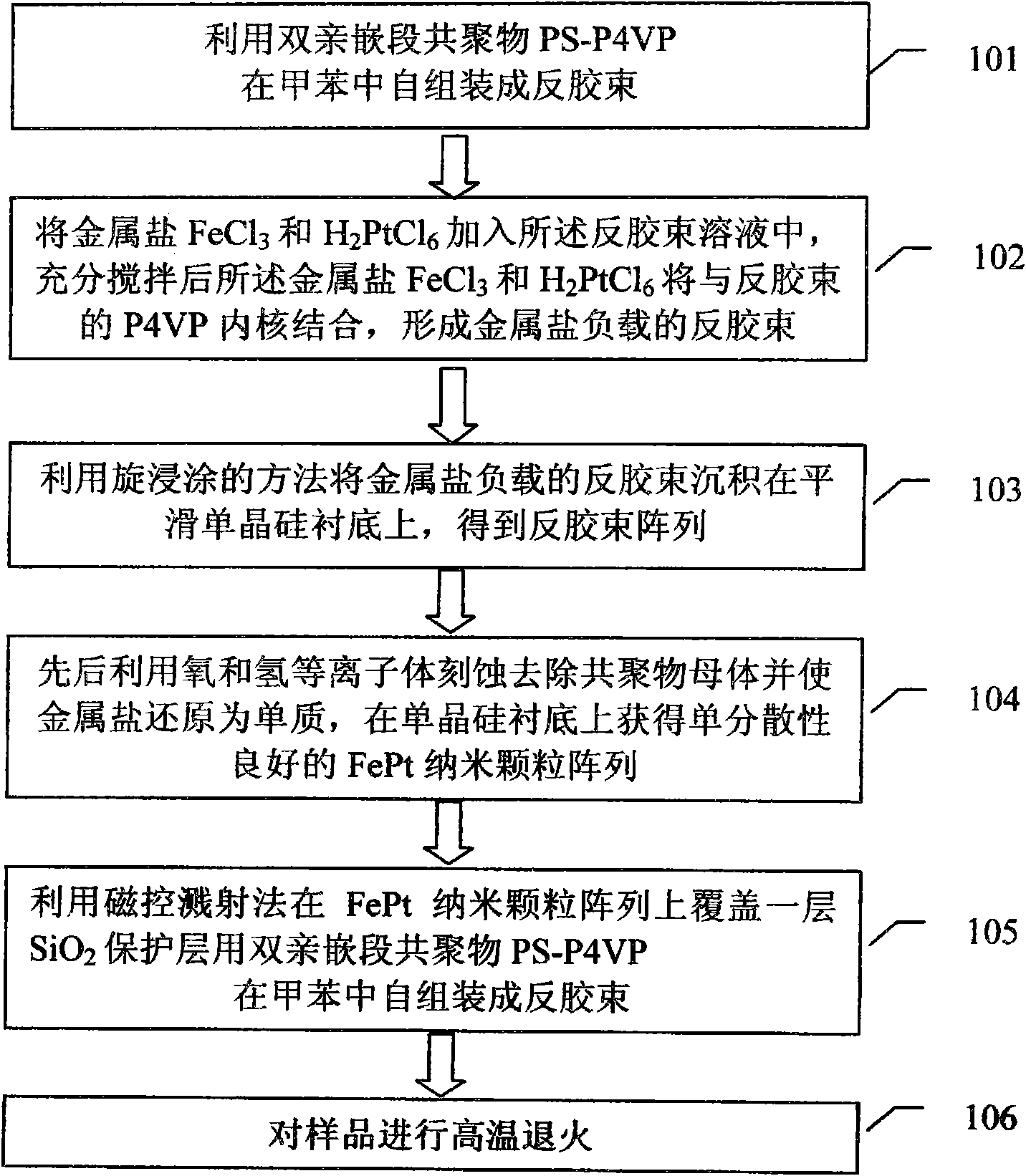

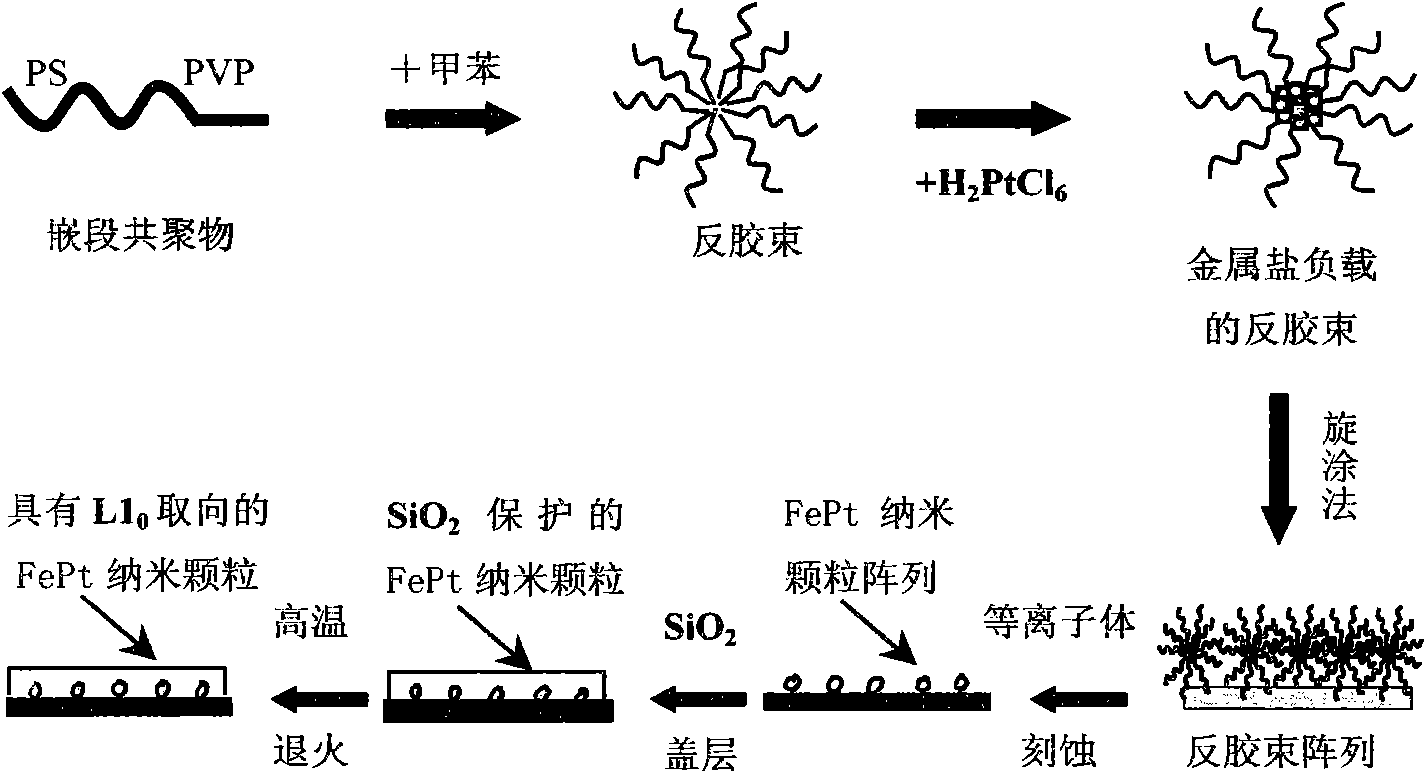

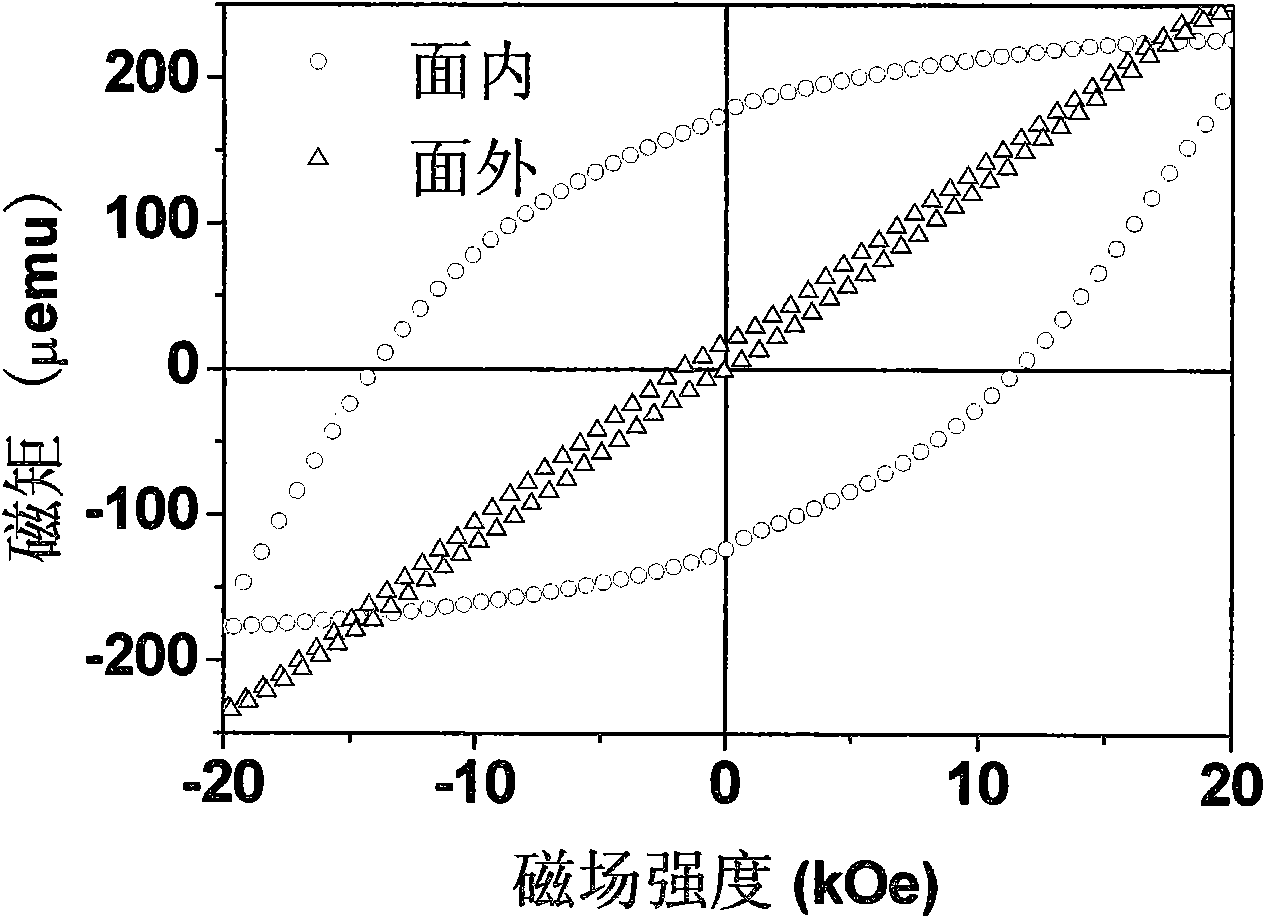

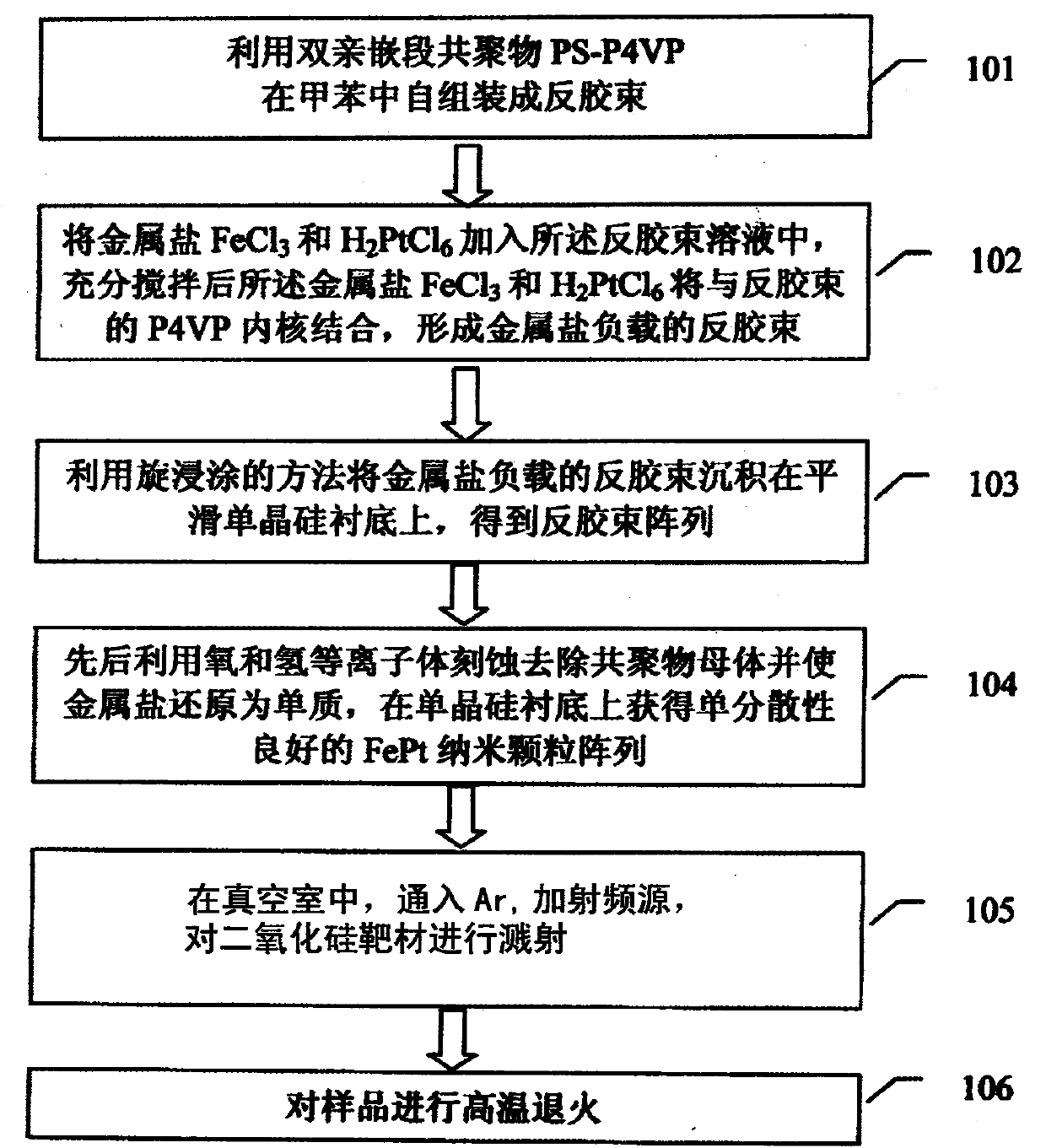

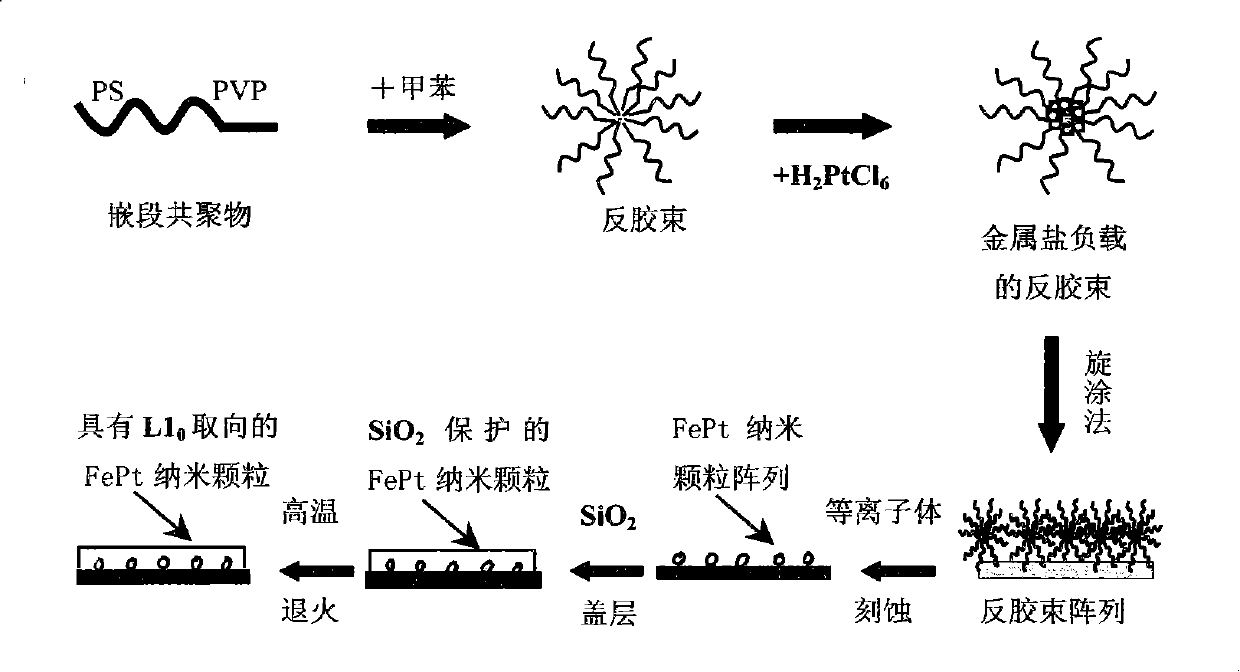

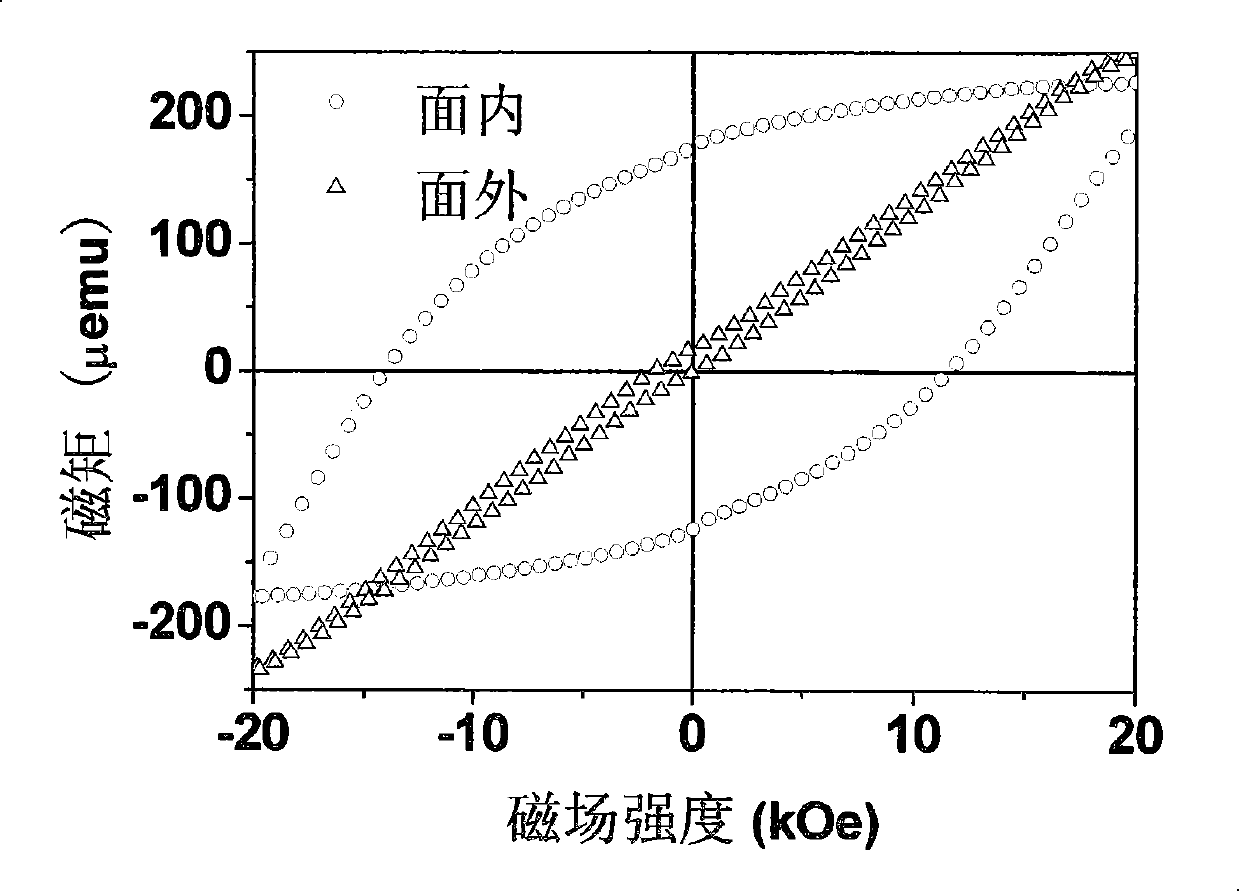

Method for preparing parallel-oriented FePt magnetic nano-composite film

InactiveCN101609743ASmall size dispersionEvenly distributedMagnetic film to substrate applicationMagnetic layersComposite filmCopolymer

The invention discloses a method for preparing a parallel-oriented FePt magnetic nano-composite film, which is characterized by comprising the following steps: 1, utilizing an amphiphilic block copolymer PS-P4VP to self-assemble into a reverse micelle in methylbenzene, and then adding metal salt, namely FeCl3 and H2PtCl6 into reverse micelle solution to form a metal salt supported reverse micelle; 2, utilizing a spin-coating method to obtain a reverse micelle array on a silicon substrate, and obtaining an FePt nano-particle array with good monodispersity through oxygen plasma etching and hydrogen plasma etching; 3, using a magnetic control sputtering method to cover an SiO2 protective layer on the FePt nano-particle array; and 4, performing high-temperature annealing on a sample under protective atmosphere to finish the production of the parallel-oriented FePt magnetic nano-composite film.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

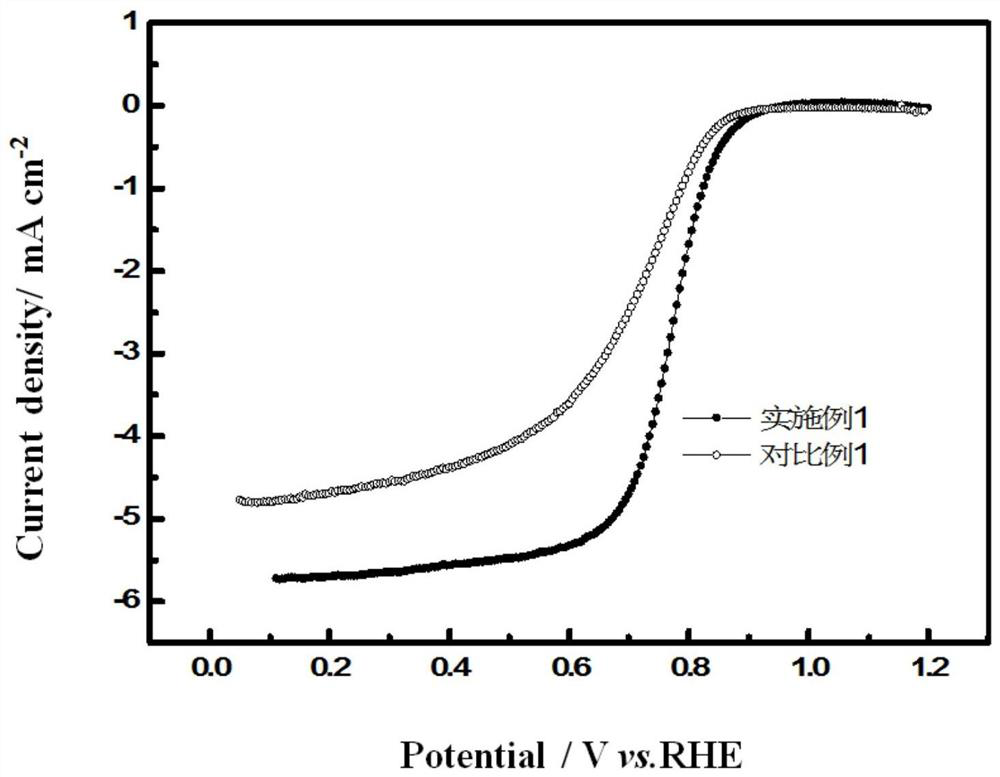

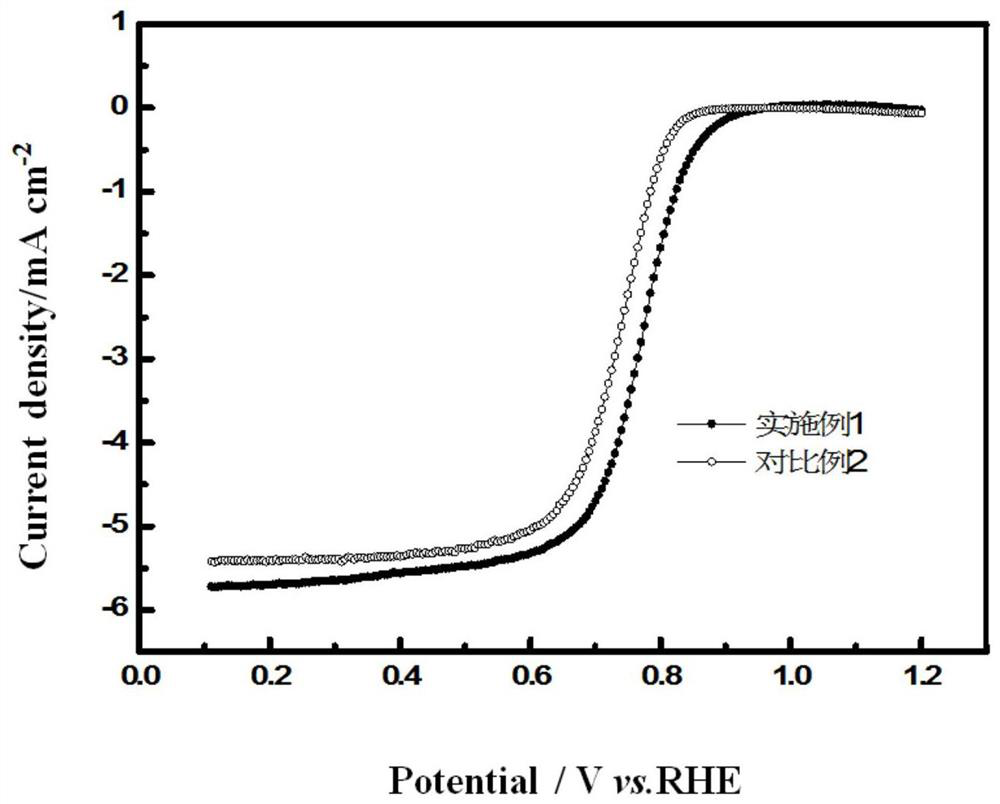

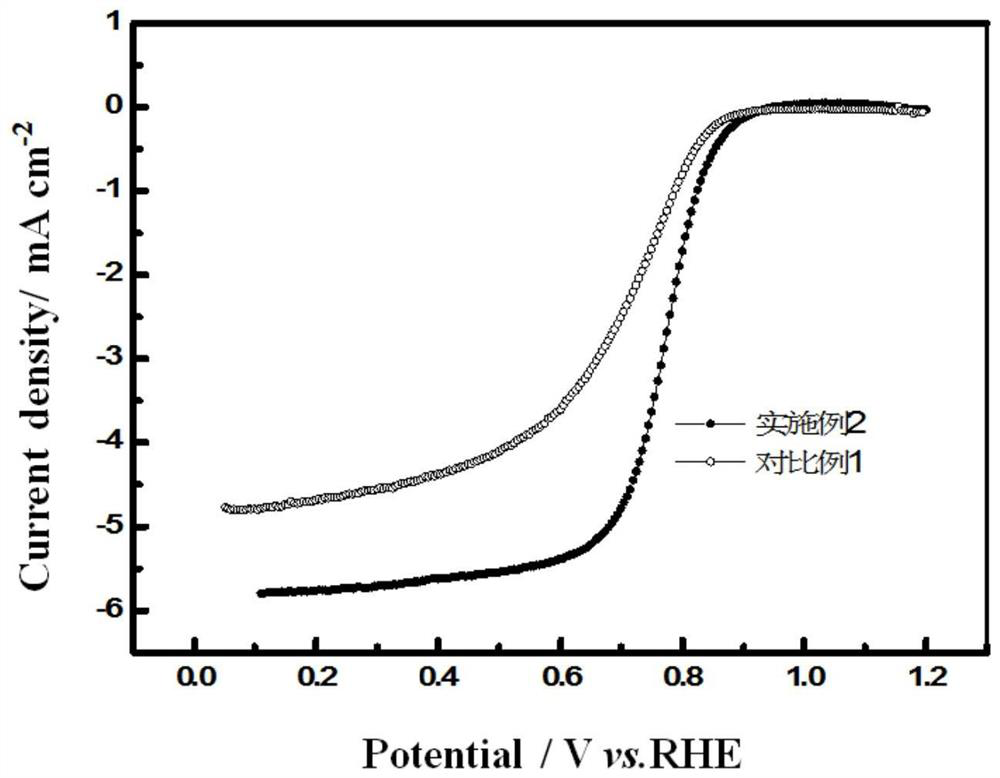

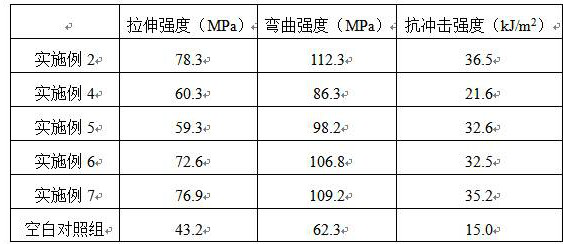

High-activity Co-Ni-Fe co-inlaid non-noble metal catalyst as well as preparation method and application thereof

InactiveCN112691688AHigh activityThere will be no reunionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetallurgy

The invention provides a high-activity Co-Ni-Fe co-inlaid non-noble metal catalyst as well as a preparation method and application thereof. Based on a preparation method of an organic metal framework compound, the high-activity Co-Ni-Fe co-inlaid non-noble metal catalyst is synthesized by optimizing the contents of Co, Ni and Fe. The multi-metal inlaid catalyst has three active sites of Co-N-C, Ni-N-C and Fe-N-C, and after optimization, the Co-Ni-Fe co-inlaid non-noble metal catalyst has no metal agglomeration phenomenon. Besides, due to rich active sites, the catalyst shows excellent electrochemical activity, the half-wave potential in a 0.1 M KOH solution is as high as 0.881 V (vs.RHE), and the half-wave potential in a 0.1 M HCLO4 solution is as high as 0.798 V (vs.RHE), which are far superior to those of a conventional non-noble metal catalyst. The catalyst has a huge application prospect in the aspect of effectively reducing the cost of the proton exchange membrane fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of nano zinc oxide-biomass fiber composite material

InactiveCN112553881AThere will be no reunionImprove qualityUltrasonic/sonic fibre treatmentLight/infra-red/X-rays fibre treatmentNano zinc oxideFibrous composites

The invention discloses a preparation method of a nano zinc oxide-biomass fiber composite material, and belongs to the technical field of inorganic material processing. The method comprises the following steps of (1) nano zinc oxide pretreatment; (2) biomass fiber pretreatment; (3) steam explosion treatment; (4) corona treatment; and (5) cold plasma treatment. According to the preparation method of the nano zinc oxide-biomass fiber composite material, nano zinc oxide and biomass raw materials are treated and effectively combined, so that the finally prepared nano zinc oxide-biomass fiber composite material cannot be agglomerated when being combined with a high polymer, is excellent in dispersity, has good filling characteristics, and can be used for processing and preparation of plastics,castings, rubber and the like to improve the quality of processed products.

Owner:安徽泰龙锌业有限责任公司

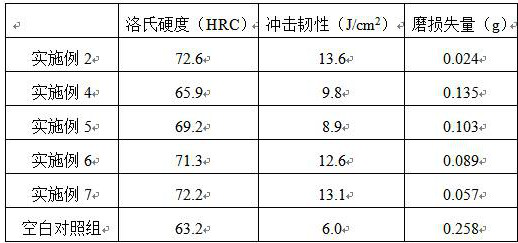

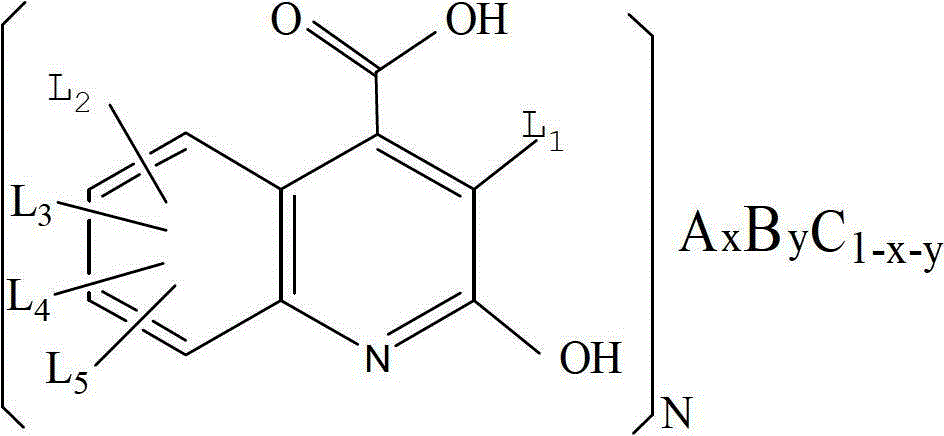

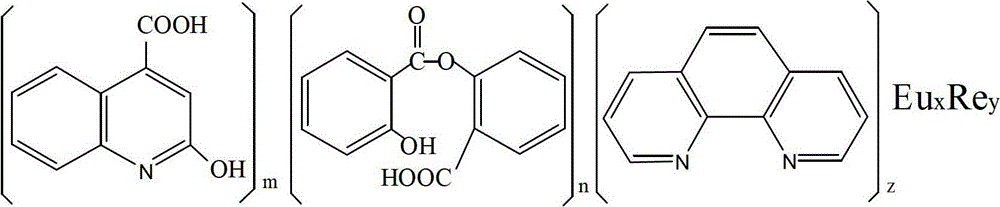

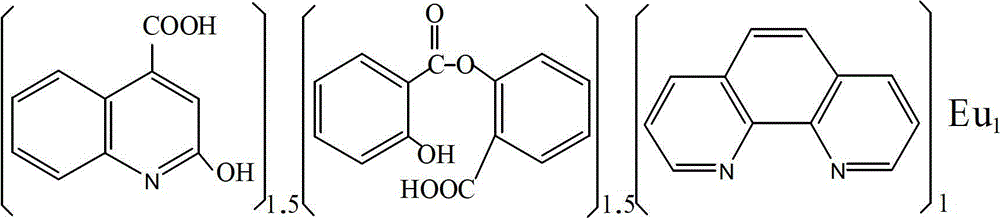

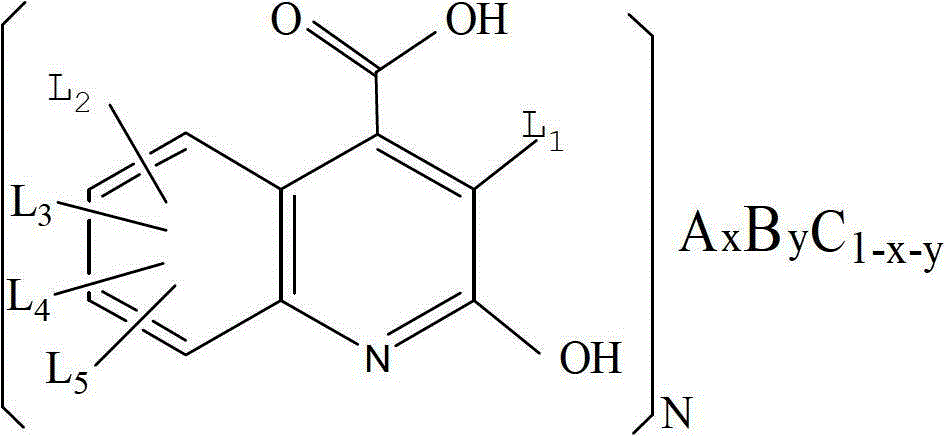

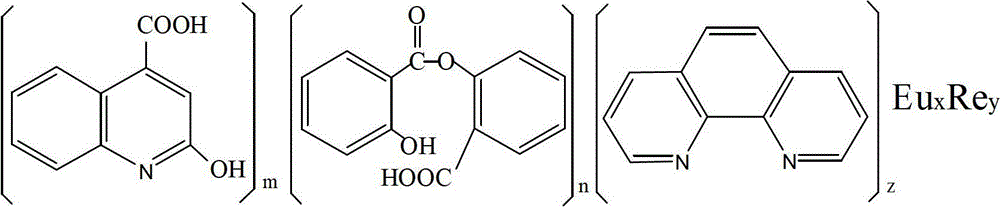

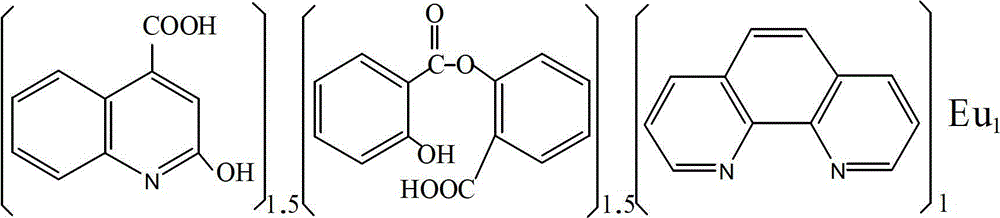

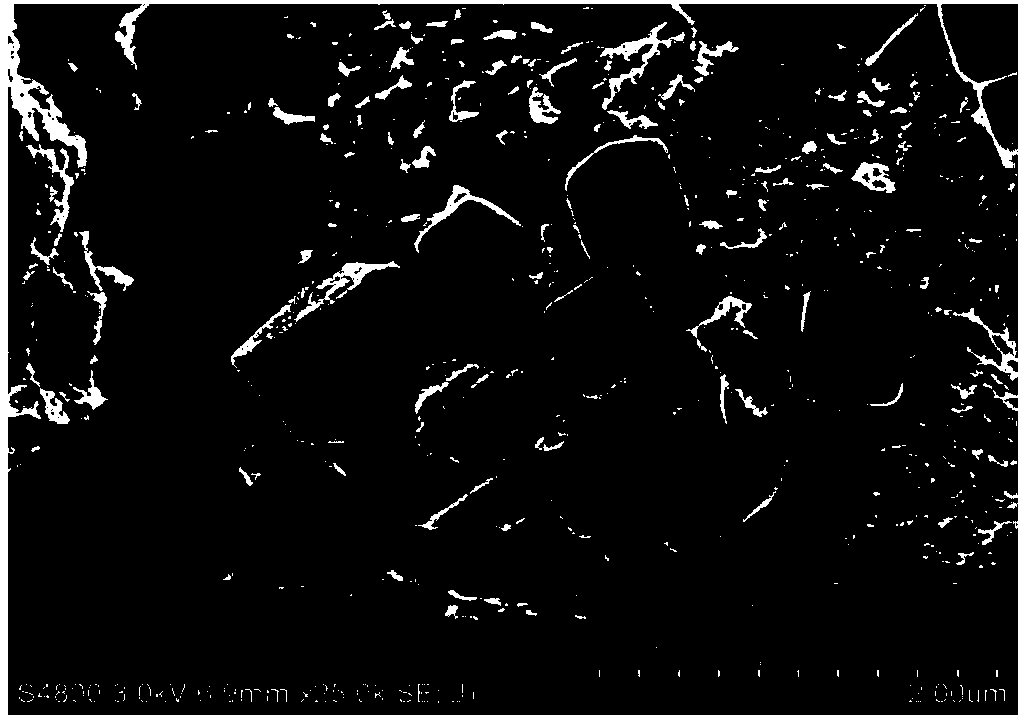

Rare-earth metal compound and synthetic process thereof

ActiveCN103059052AGood dispersionEvenly dispersedGroup 3/13 element organic compoundsLuminescent compositionsHeavy metal compoundRare earth metal compounds

The invention discloses a rare-earth metal compound and a synthetic process thereof. The chemical general formula of the rare-earth metal compound is shown in the specification, wherein x is more than 0, and y is not less than 0; m and n are more than 0, and m+n is equal to 3(x+y); z is equal to x+y; and Re is any of rare-earth metal elements except for Eu. The rare-earth metal compound can serve as a red fluorescent material, and the rare-earth metal compound has good acid resistance properties, alkaline resistance properties and powder dispersibility compared with the red fluorescent material in the prior art.

Owner:CHINA BANKNOTE SECURITY PRINTING TECH RES INST CO LTD +1

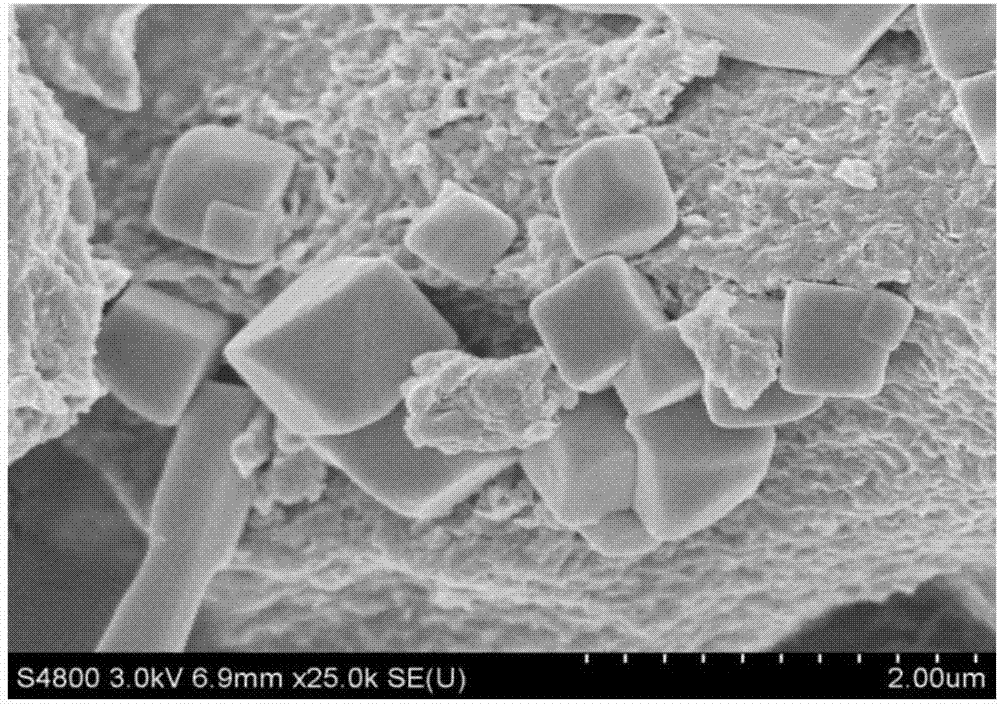

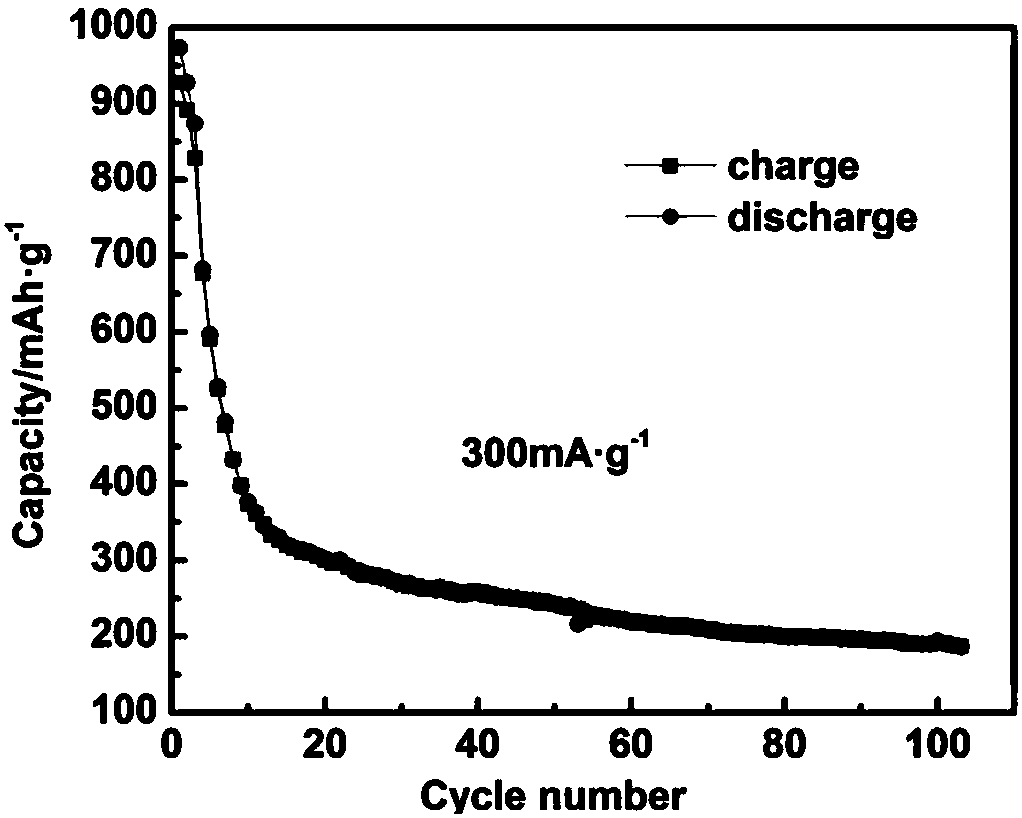

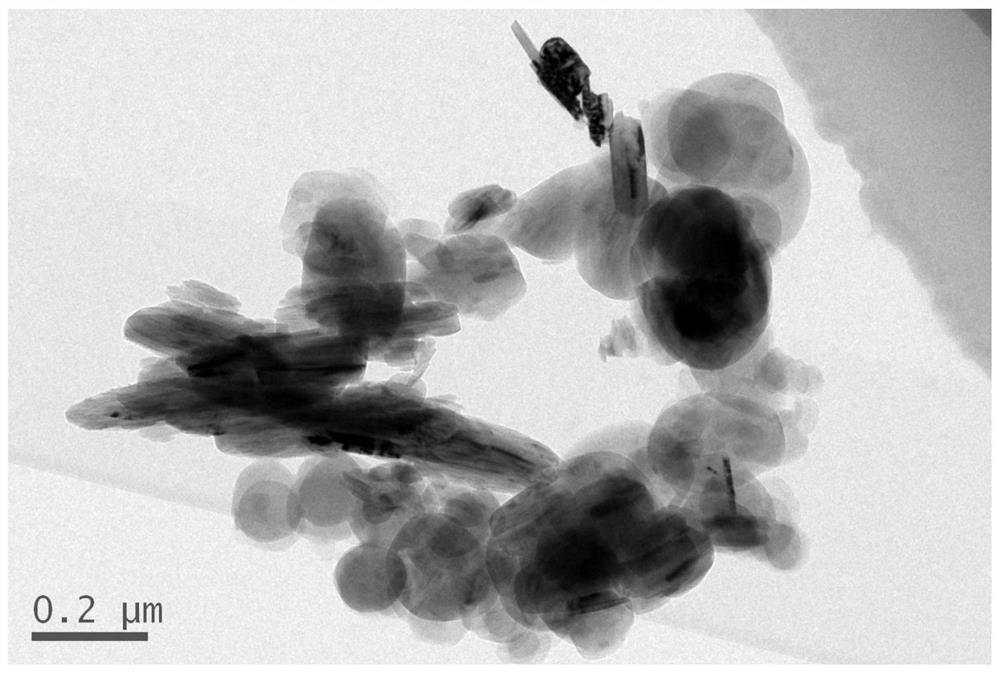

Preparation method of SnS2 sodium-ion battery anode material with cubic structure

ActiveCN107032390AEvenly dispersedHigh crystallinityMaterial nanotechnologyTin compoundsFreeze-dryingSodium-ion battery

The invention discloses a preparation method of a SnS2 sodium-ion battery anode material with a cubic structure. The preparation method comprises steps as follows: 1), sodium thiosulfate is dissolved in deionized water, a solution A is prepared, stannic chloride pentahydrate is dissolved in the equal amount of deionized water, and a solution B is prepared; 2), the solution B is dropwise added to the solution A, a solution C is obtained, hexadecyl trimethyl ammonium chloride is gradually added to the solution C, and a solution D is obtained; 3), the solution D is subjected to ultrasonic oscillation in an ultrasonic generator; 4), pH of the mixed solution D after ultrasonic oscillation treatment is regulated, and a solution E is prepared; 5), the solution E is subjected to a hydrothermal reaction; 6), after the reaction, a precursor is taken out, centrifugally washed with ionized water and anhydrous ethanol and then subjected to freeze drying, and the SnS2 sodium-ion battery anode material with the cubic structure is obtained. The preparation method is low in preparation cost, simple to operate and short in preparation cycle, and the prepared SnS2 sodium-ion battery anode material with the cubic structure has excellent charge-discharge rate performance.

Owner:SHAANXI UNIV OF SCI & TECH

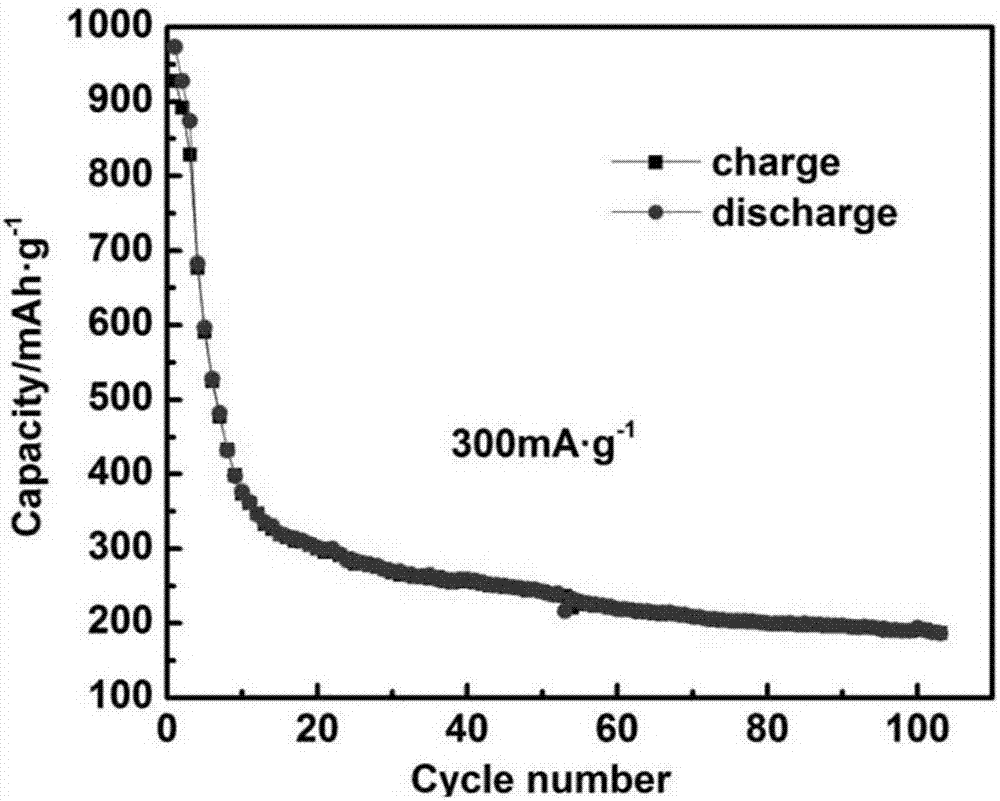

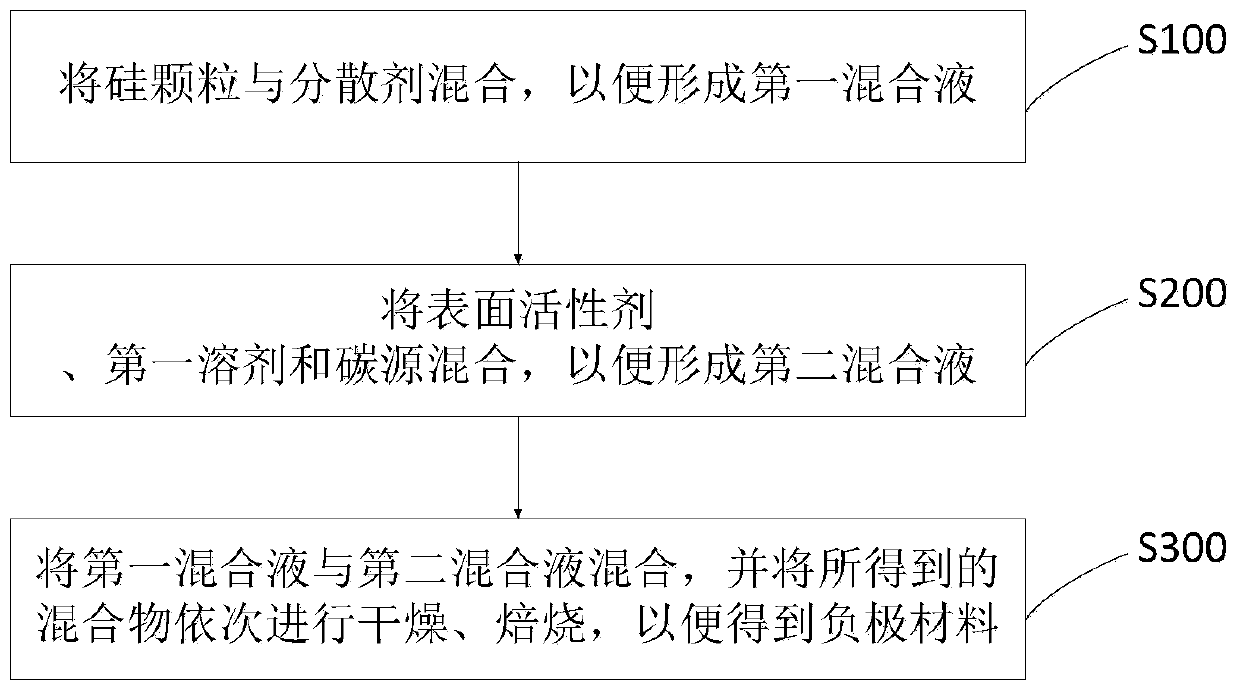

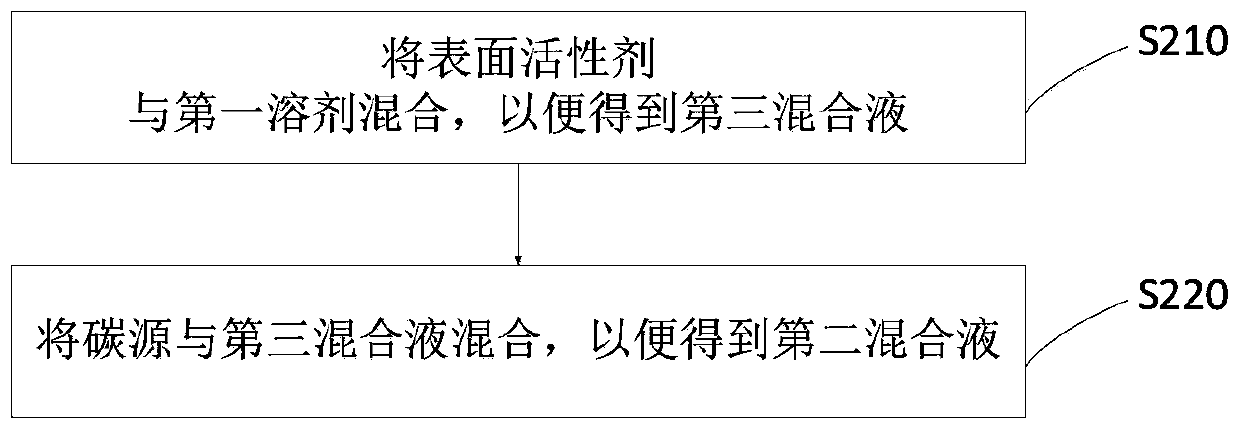

Negative electrode material and preparation method thereof, negative electrode and battery

InactiveCN109786706AStable structureGood electrochemical performanceCell electrodesSecondary cellsSolventSilicon particle

The invention provides a negative electrode material and a preparation method thereof, a negative electrode and a battery, wherein the preparation method of the negative electrode material comprises the following steps: mixing silicon particles with dispersing agent, thereby forming first mixed liquor; mixing surface active agent, first solvent and carbon source together, thereby forming second mixed liquor; mixing the first mixed liquor with the second mixed liquor, further orderly performing drying and roasting for the obtained mixture, thereby obtaining the negative electrode material. Themethod is simple and convenient to operate and easy to realize; and the negative electrode obtained by the method has relatively good first effect, specific capacity and cycle performance.

Owner:ENN GRAPHENE TECH CO LTD

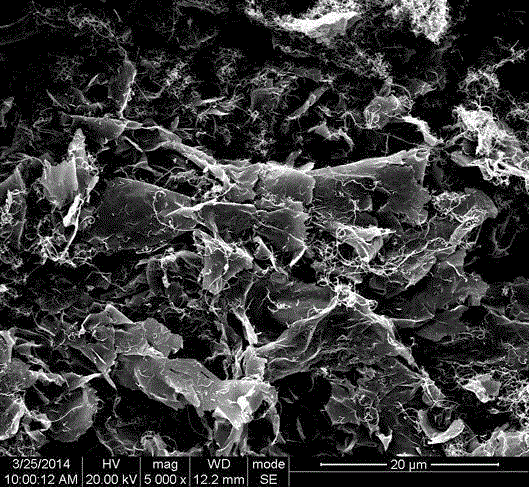

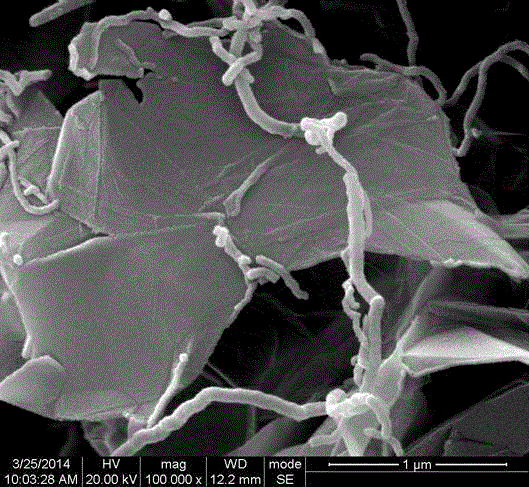

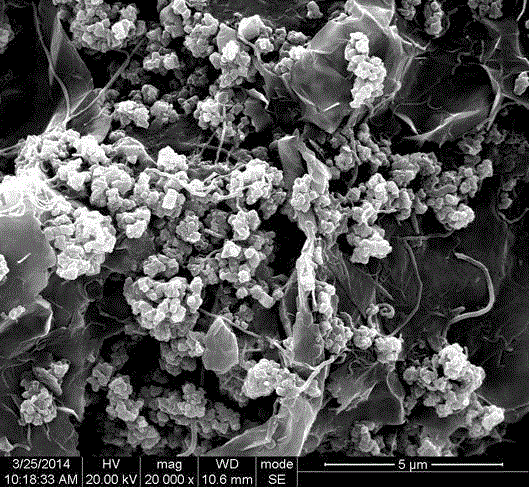

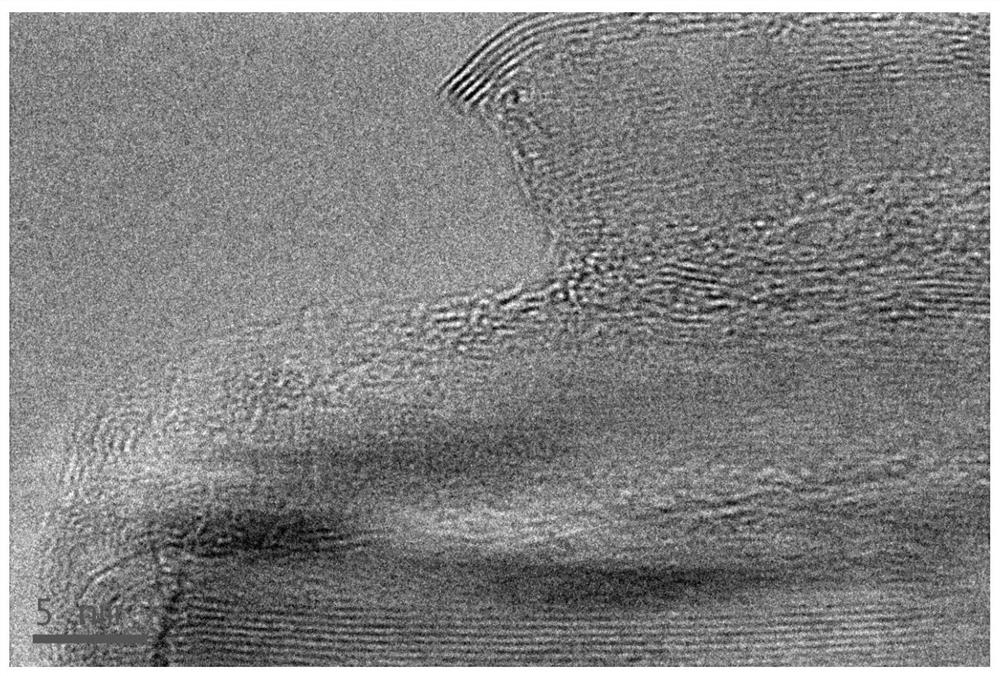

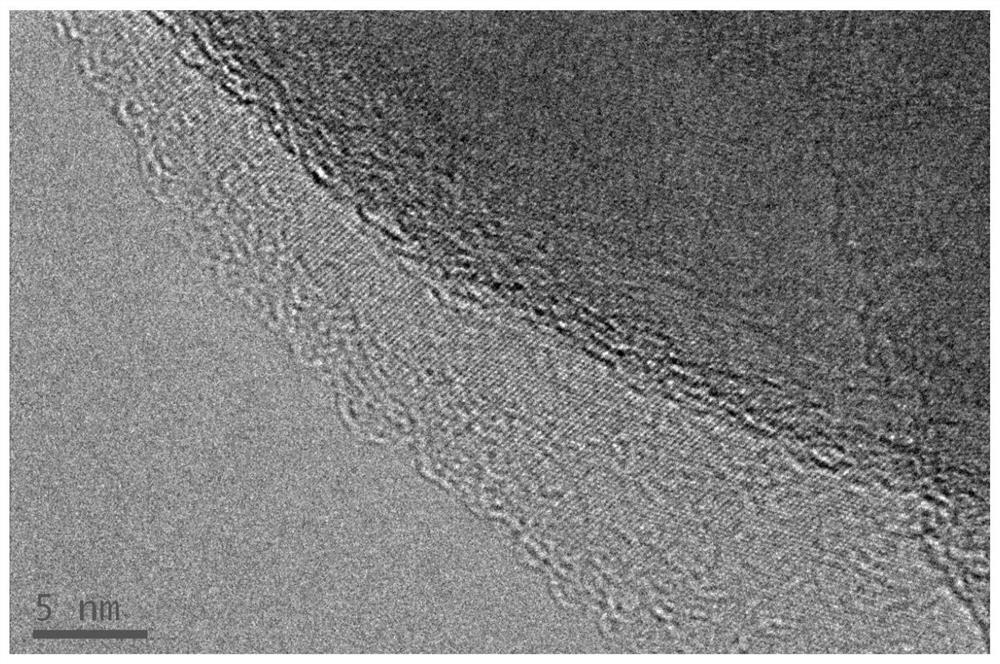

A kind of preparation method of carbon nanotube/graphene composite material

ActiveCN103956498BThere will be no reunionPromote recombinationHybrid capacitor electrodesCell electrodesSlurryLithium-ion battery

The invention discloses a method for preparing a carbon nanotube / graphene composite material, which comprises adding graphene oxide slurry and a surfactant into a single-layer glass reactor and stirring evenly, and then adding the carbon nanotube slurry to obtain a mixed slurry The mixed slurry is dried and crushed; the crushed particles are added to a muffle furnace, expanded in the air, and cooled to normal temperature after reduction treatment to obtain a powdered carbon nanotube / graphene composite material; the powdered composite material and The slurry-like carbon nanotube / graphene composite material was prepared by solvent mixing and ultrasonic vibration. The preparation method provided by the invention has the advantages of simple process, convenient preparation and low energy consumption, and is suitable for large-scale industrial production; the carbon nanotube / graphene composite material prepared by the method has excellent performance and can be used as a conductive additive for lithium-ion batteries , can significantly improve the high-current rapid charge and discharge performance of lithium-ion batteries, and can be used as materials for supercapacitor electrodes and fillers to improve the electrostatic conductivity of paints and coatings.

Owner:江苏宝烯新材料科技有限公司

Method for preparing micron-sized light diffusion core-shell hybrid microspheres through hydrothermal synthesis

InactiveCN113913110AStrong UV Absorbing PropertiesImprove shielding effectDiffusing elementsPolyurea/polyurethane coatingsMicrosphereTransmittance

The invention relates to a method for preparing a micron-sized light diffusion core-shell hybrid microsphere by hydrothermal synthesis. The method comprises the following steps: preparing a polysiloxane microsphere by a simple sol-gel method, and synthesizing by a hydrothermal process by taking the polysiloxane microsphere as a template to obtain the micron-sized light diffusion core-shell hybrid microsphere. According to the invention, the microsphere has a polysiloxane microsphere inner core of 4-6 [mu]m, an outer layer is composed of a nano inorganic compound, the thickness of a shell layer is 50-150 nm, and a series of functionalized microsphere materials can be synthesized through the method; an optical performance test after a film is formed shows that the micron-sized light diffusion core-shell hybrid microsphere has an excellent light diffusion effect and relatively high light transmittance, can be widely used for preparing various light diffusion materials, and can improve the thermal stability of the film-forming resin; and the microsphere preparation method is simple, has great potential application value, and is low in cost, and the preparation process is green and environment-friendly.

Owner:LISHUI UNIV

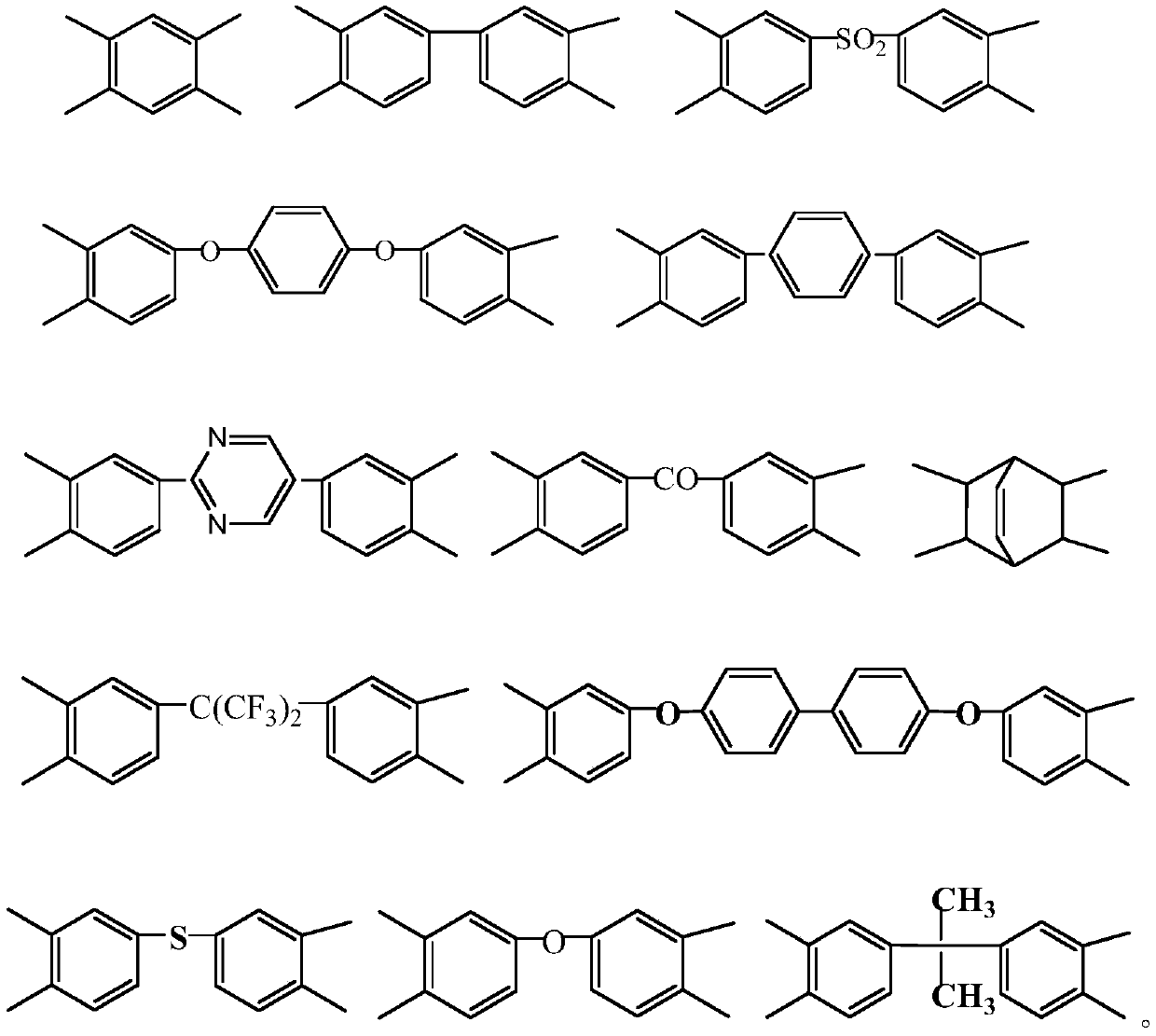

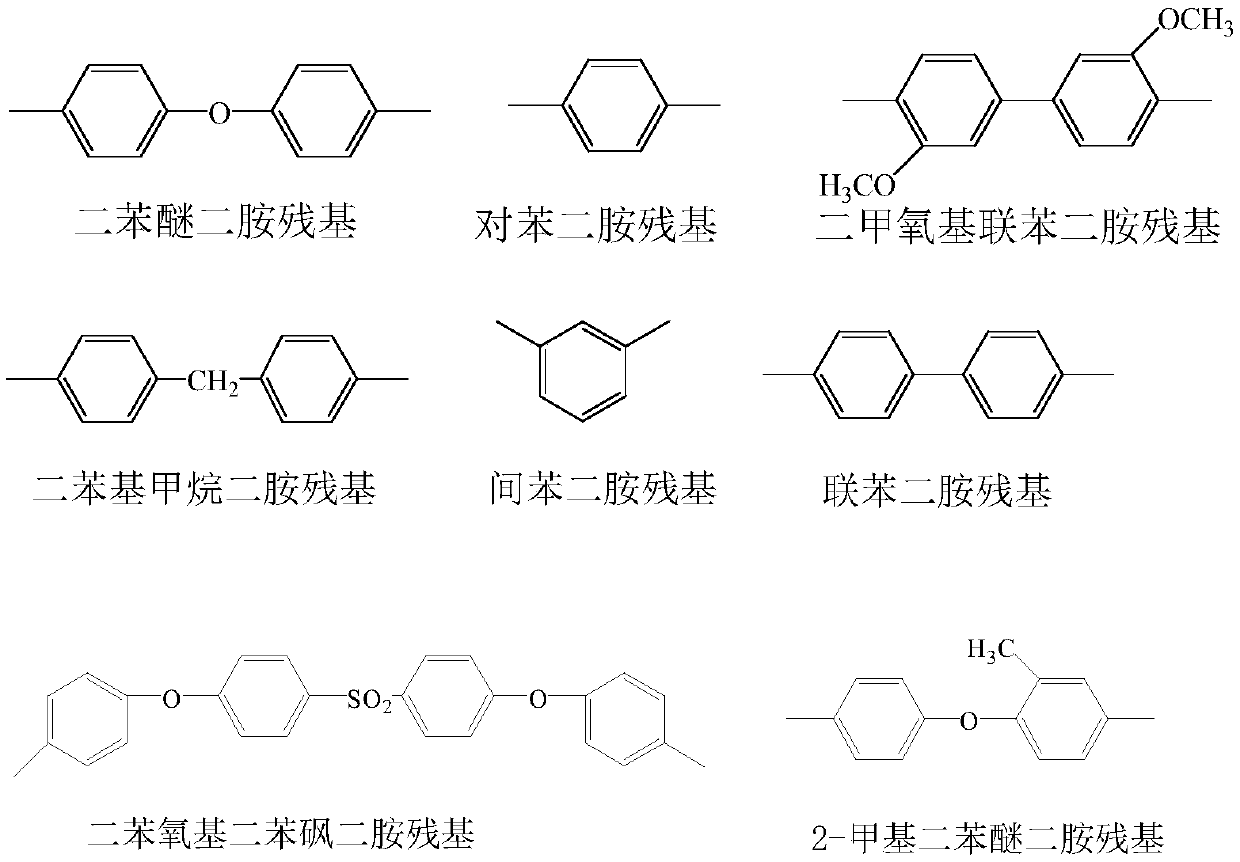

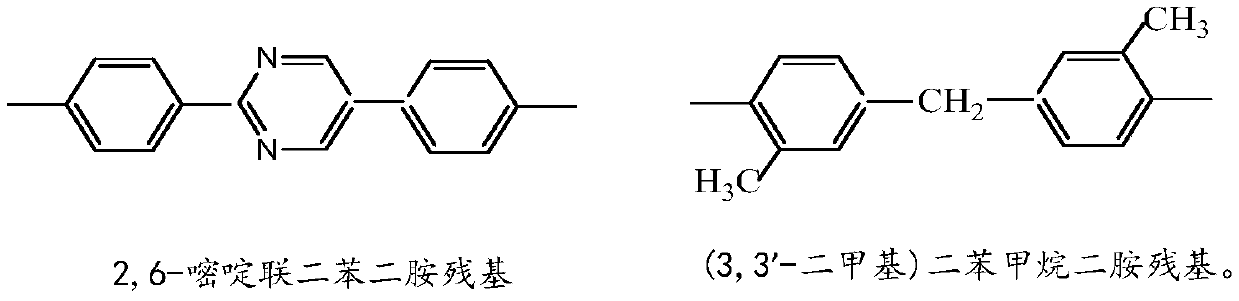

Ultra-short electrospinning polyimide nanofiber and preparing method thereof

ActiveCN110106635AGood orientationGood dispersionSevering textilesFilament/thread formingFiberDispersity

The invention relates to the technical field of ultra-short fiber, in particular to an ultra-short electrospinning polyimide nanofiber and a preparing method thereof. The preparing method of the ultra-short electrospinning polyimide nanofiber includes the steps of preparing a polyamide acid solution, conducting electrostatic spinning to form polyamide acid fiber felt, slitting the polyamide acid fiber felt into strips, conducting heat drawing to form high-orientation polyimide nanofiber bundles, and conducting cutting to form the ultra-short electrospinning polyimide nanofiber, wherein the width of the strips obtained by slitting the polyamide acid fiber felt is 3-8 cm, and the length of the ultra-short electrospinning polyimide nanofiber obtained through cutting is 0.1-2.00 mm. The ultra-short nanofiber even in length distribution can be prepared, and the nanofiber is quite high in dispersity and has potential applicability for preparing carbon fiber composites and flexible honeycombmaterials.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

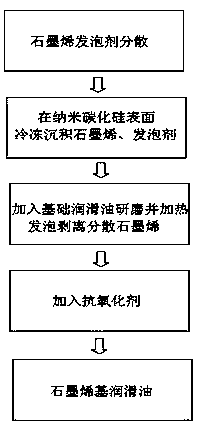

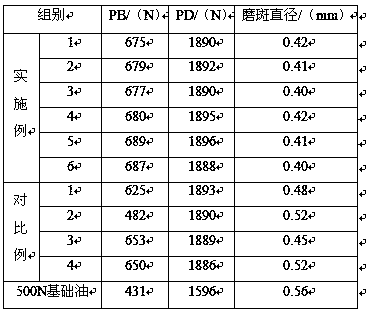

Method for preparing graphene-based lubricating oil by micro-explosion graphene dispersion

InactiveCN111575086AInhibit carbon depositionInhibits varnish formationLubricant compositionNano siliconCarbide silicon

The invention relates to the technical field of modified lubricating oil, and particularly relates to a method for preparing graphene-based lubricating oil by micro-explosion graphene dispersion. Themethod comprises the following steps: uniformly dispersing graphene, a mixed solvent, a dispersing agent and a foaming agent, adding nano silicon carbide for ultrasonic dispersion, freeze-drying, adding base lubricating oil, stirring and dispersing, heating and grinding, then adding an antioxidant, uniformly stirring, and defoaming to obtain the graphene-based lubricating oil. The problem that inthe prior art, the ideal lubricating effect of graphene in lubricating oil is difficult to achieve is solved. The graphene-based lubricating oil prepared through the method has the advantages of beingsmall in friction resistance coefficient, high in heat conductivity coefficient, high in stability and good in compatibility, the friction coefficient is small, so that a good protection effect on mechanical parts is achieved, the heat conductivity coefficient is high, and heat generated in the friction process can be removed in time, and therefore, the service lifetime of the mechanical parts isprolonged.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Method for preparing parallel-oriented FePt magnetic nano-composite film

InactiveCN101609743BSmall size dispersionEvenly distributedMagnetic film to substrate applicationMagnetic layersComposite filmCopolymer

The invention discloses a method for preparing a parallel-oriented FePt magnetic nano-composite film, which is characterized by comprising the following steps: 1, utilizing an amphiphilic block copolymer PS-P4VP to self-assemble into a reverse micelle in methylbenzene, and then adding metal salt, namely FeCl3 and H2PtCl6 into reverse micelle solution to form a metal salt supported reverse micelle; 2, utilizing a spin-coating method to obtain a reverse micelle array on a silicon substrate, and obtaining an FePt nano-particle array with good monodispersity through oxygen plasma etching and hydrogen plasma etching; 3, using a magnetic control sputtering method to cover an SiO2 protective layer on the FePt nano-particle array; and 4, performing high-temperature annealing on a sample under protective atmosphere to finish the production of the parallel-oriented FePt magnetic nano-composite film.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A kind of rare earth metal compound and its synthesis process

ActiveCN103059052BGood dispersionEvenly dispersedGroup 3/13 element organic compoundsLuminescent compositionsState of artRare earth metal compounds

The invention discloses a rare-earth metal compound and a synthetic process thereof. The chemical general formula of the rare-earth metal compound is shown in the specification, wherein x is more than 0, and y is not less than 0; m and n are more than 0, and m+n is equal to 3(x+y); z is equal to x+y; and Re is any of rare-earth metal elements except for Eu. The rare-earth metal compound can serve as a red fluorescent material, and the rare-earth metal compound has good acid resistance properties, alkaline resistance properties and powder dispersibility compared with the red fluorescent material in the prior art.

Owner:CHINA BANKNOTE SECURITY PRINTING TECH RES INST CO LTD +1

Preparation method of high-load antibacterial nanofiber film

InactiveCN112080861AImprove solubilityLarge specific surface areaFilament/thread formingNon-woven fabricsSpinningElectrospinning

The invention relates to the technical field of antibacterial materials, in particular to a preparation method of a high-load antibacterial nanofiber film. The preparation method comprises the following steps that PVC resin is added into a solvent to be dissolved to obtain a PVC solution, wherein the solvent comprises dimethylformamide; the PVC solution is uniformly mixed with a titanium source toobtain a precursor solution of titanium, and the precursor solution of titanium is prepared into a film by adopting an electrostatic spinning method; and nano titanium dioxide is synthesized with rutile phase content of more than 99% from the titanium source on the film by adopting a hydrothermal method to prepare the high-load nanofiber film. According to the preparation method, the loading rateand the loading stability of the nano titanium dioxide on the PVC surface can be effectively improved.

Owner:ZHEJIANG YASHA DECORATION

A kind of preparation method of cubic structure sns2 sodium ion battery negative electrode material

ActiveCN107032390BEvenly dispersedHigh crystallinityMaterial nanotechnologyTin compoundsFreeze-dryingCharge discharge

The invention discloses a preparation method of a SnS2 sodium-ion battery anode material with a cubic structure. The preparation method comprises steps as follows: 1), sodium thiosulfate is dissolved in deionized water, a solution A is prepared, stannic chloride pentahydrate is dissolved in the equal amount of deionized water, and a solution B is prepared; 2), the solution B is dropwise added to the solution A, a solution C is obtained, hexadecyl trimethyl ammonium chloride is gradually added to the solution C, and a solution D is obtained; 3), the solution D is subjected to ultrasonic oscillation in an ultrasonic generator; 4), pH of the mixed solution D after ultrasonic oscillation treatment is regulated, and a solution E is prepared; 5), the solution E is subjected to a hydrothermal reaction; 6), after the reaction, a precursor is taken out, centrifugally washed with ionized water and anhydrous ethanol and then subjected to freeze drying, and the SnS2 sodium-ion battery anode material with the cubic structure is obtained. The preparation method is low in preparation cost, simple to operate and short in preparation cycle, and the prepared SnS2 sodium-ion battery anode material with the cubic structure has excellent charge-discharge rate performance.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of preparation method of carbon/carbon-boron nitride antifriction composite material

ActiveCN109665855BImprove mechanical propertiesImprove friction and wear propertiesFiberBoron carbonitride

The invention discloses a method for preparing a carbon / carbon-boron nitride friction-reducing composite material. The graphitized C / C green body is acidified, washed to neutral to obtain a pretreated C / C green body, and then soaked In a solution containing a modifier, react to obtain a functionalized C / C green body, and then immerse the functionalized C / C green body in the h-BN slurry, and dry to obtain a C / C-BN prefabricated body, C / C-BN prefabricated body is carbonized and densified by carbon source, and graphitized to obtain C / C-BN antifriction composite material; the modifier is selected from silane coupling agent or polyvinyl alcohol (PVA) . The invention adopts the slurry impregnation method firstly to obtain the BN matrix. After functionalizing the C / C body, the BN powder can be effectively introduced into the C / C body during the slurry impregnation process. This method can effectively avoid the damage of carbon fibers and ensure the excellent structural strength of C / C‑BN composites. The obtained C / C‑BN composites have excellent friction and wear properties.

Owner:CENT SOUTH UNIV

A method for preparing hexangular ordered FePt nanometer particle arrays

InactiveCN100465308CEvenly distributedParticle size is easy to controlInductances/transformers/magnets manufactureNanoparticleDip-coating

The process of preparing ordered hexagonal nanometer FePt particle array includes the following steps: 1. self-assembling inverse micelle with amphiphilic block copolymer PS-block-P2VP intoluene; 2. adding metal salts FeCl3 and H2PtCl6 into the inverse micelle solution through stirring for the metal salts FeCl3 and H2PtCl6 to be combined with the P2VP kernel of the inverse micelle to form inverse micelle with supported metal salts; 3. depositing the inverse micelle with supported metal salts onto smooth monocrystalline substrate through dip coating to obtain ordered hexagonal inverse micelle array; and 4. oxygen plasma etching to eliminate copolymer substrate and reduce metal salt into simple substance so as to obtain homogeneous ordered hexagonal nanometer FePt particle array on the monocrystalline substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

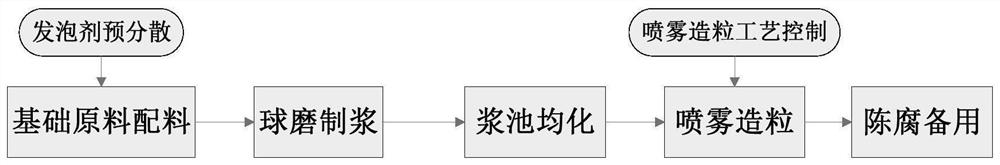

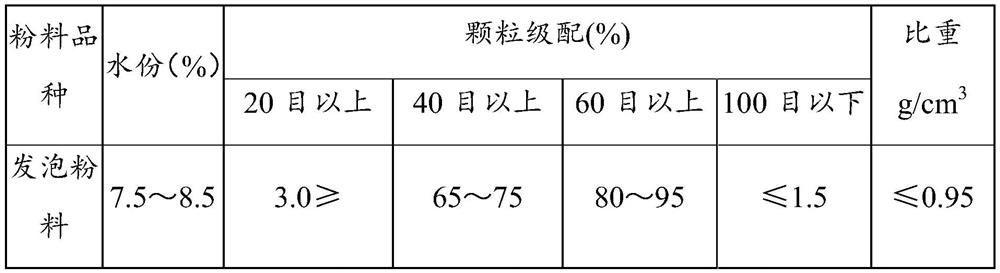

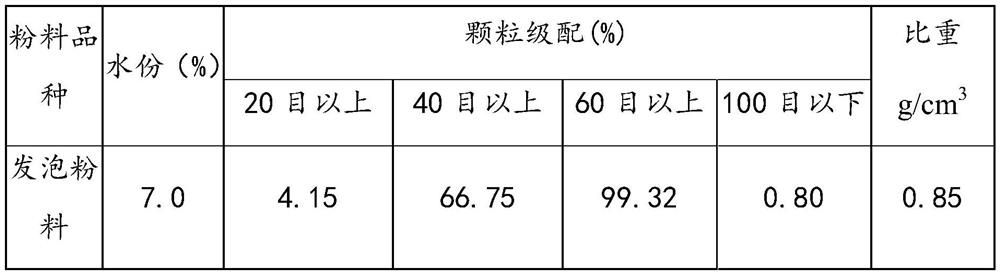

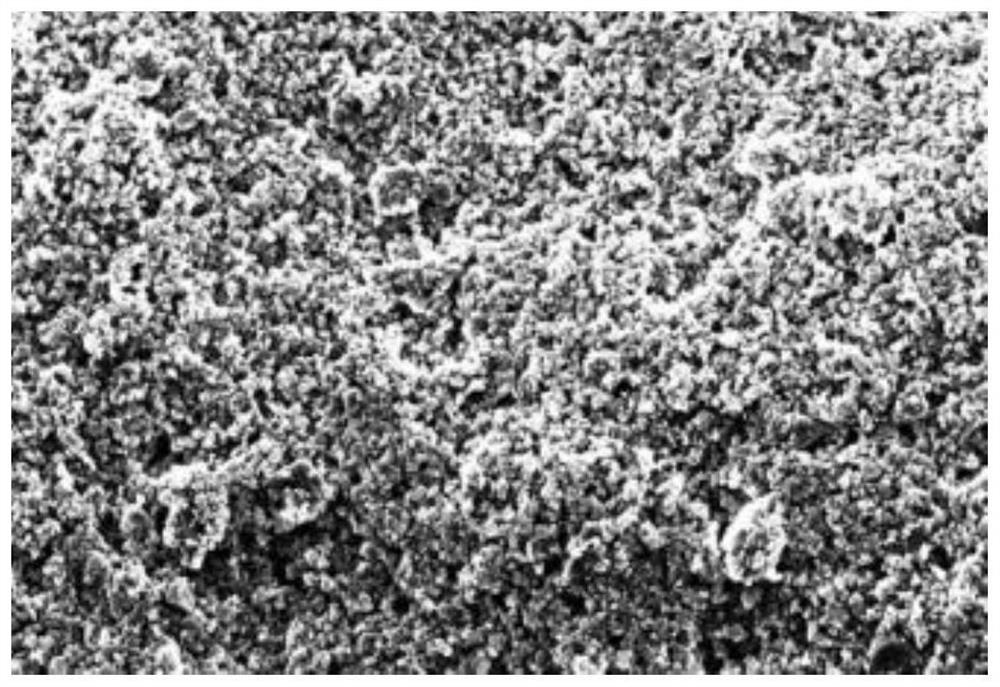

Foaming agent composition, preparation method and application thereof, foamed ceramic wallboard powder and preparation method thereof

ActiveCN110317067BGood dispersionGuaranteed uniformityCeramic shaping apparatusCeramicwareFoaming agentOrganosolv

The invention provides a foaming agent composition, a preparation method and application thereof, a foamed ceramic wallboard powder and a preparation method thereof, and relates to the technical field of ceramic materials. The foaming agent composition of the present invention is mainly prepared from the following raw materials in parts by mass: 90-110 parts of foaming agent, 1-20 parts of polyethyleneimine and / or polyacrylamide, 350-450 parts of water, organic 100-150 parts of solvent and 0.01-1 part of enhancer. The invention can alleviate the problems that the foaming agent micropowder is not easy to disperse, easy to agglomerate the foaming agent micropowder and affect the product quality in the preparation of the existing foamed ceramic wallboard powder, and can improve the dispersion performance of the foaming agent. Powder performance, improve product quality and quality.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +3

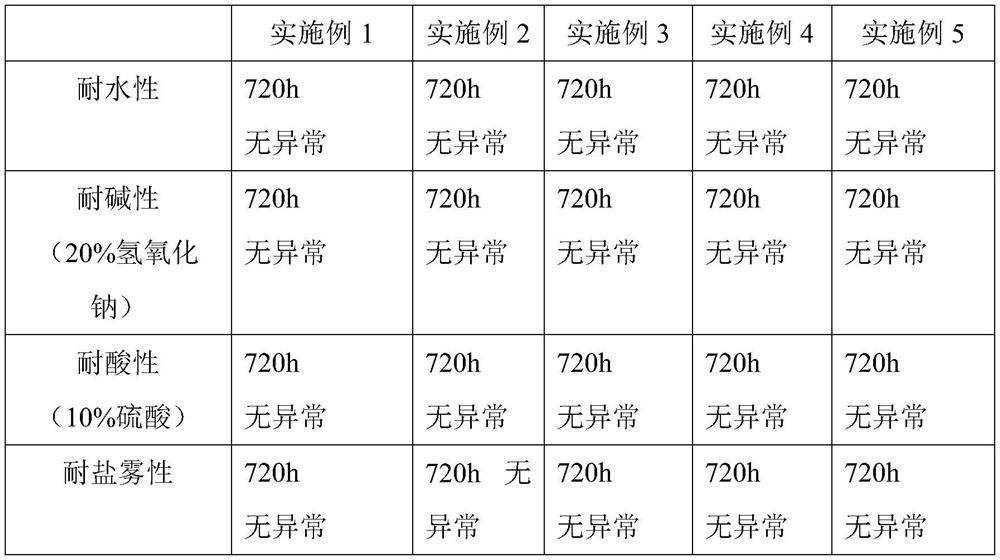

Heat-preservation, heat-insulation, anti-rust and anti-corrosion coating for chassis

PendingCN114806357AImprove water resistanceWith anti-rust functionAnti-corrosive paintsEpoxy resin coatingsEpoxySilicic acid

The invention relates to the field of automobile anti-corrosion materials, in particular to a heat-preservation, heat-insulation, anti-rust and anti-corrosion coating for an automobile chassis, which is prepared by the following steps: step 1, adding 3-6 parts of nano silicon dioxide, 1-2 parts of dispersing agent and 10-15 parts of deionized water, and stirring and uniformly dispersing under high-speed mechanical stirring; the rotating speed of the high-speed mechanical stirring is 1,800 to 2,000 rpm (revolutions per minute); step 2, adding 50-70 parts of acrylic acid modified alkyd resin and 30-40 parts of epoxy resin into the uniform material obtained in the step 1, stably heating the working temperature to 50 + / -5 DEG C, and uniformly stirring at the rotating speed of 600-800rpm; 3, after the mixture in the step 2 is cooled to the room temperature, 0.5-1 part of composite magnesium aluminum silicate and 1-2 parts of dodecanol ester alcohol are added, and the mixture is evenly mixed at the room temperature. According to the paint, the acrylic acid modified alkyd resin and the epoxy resin are used as substrates, the nano silicon dioxide is added for combined use, and the paint adopts multi-component substances for combined use, so that the paint has the functions of heat preservation, heat insulation, rust prevention and corrosion prevention.

Owner:江苏天时新材料科技有限公司

A light-diffusing film for display and its preparation method

ActiveCN104730605BStrong UV Absorbing PropertiesImprove shielding effectDiffusing elementsPolyurea/polyurethane coatingsPhotoluminescenceFluorescence

The invention relates to a light diffusion membrane for display and a preparation method thereof. The light diffusion membrane is obtained by scattering a light diffusant of a core-shell structure in acrylate resin and carrying out ultraviolet light polymerization. Cores of the light diffusant are polysiloxane microballoons, shells of the light diffusant are made of quantum dot hybrid materials of organopolysiloxane zinc oxide, and the micromorphology of the light diffusant is of the inner layer and outer layer core-shell microballoon structure. The partical size of the microballoons ranges form 5mum to 8mum, the thickness of shell layers ranges from 100nm to 400nm, the light diffusant has the obvious photoluminescence phenomenon and presents yellow green fluorescence under an 365nm ultraviolet lamp, and a wave band near the microballoons has adjustability. The light diffusion membrane prepared through the method has an excellent light diffusion effect, the photoluminescence character is also presented in the membrane, and the light diffusion membrane can be used as a novel light diffusion membrane in a liquid crystal display backlight module. The light diffusion membrane is good in mechanical property and ageing-resistant performance and low in cost; the preparation method of the light diffusion membrane is simple, production is easy to expand, and the preparation process is friendly to the environment.

Owner:NANJING BREADY ELECTRONICS CO LTD

Modified bentonite lubricating oil additive and preparation method thereof

InactiveCN111944588AGood cation exchangeImprove uniformityAdditivesSilicon compoundsCalcium borateActive agent

The invention relates to the technical field of lubricating oil additives, in particular to a preparation method of a modified bentonite lubricating oil additive, which comprises the following steps:soaking bentonite in a dilute acid solution, carrying out primary soaking on acid-swelling modified bentonite in a surfactant aqueous solution, and carrying out secondary soaking in a saturated copperchloride solution; finally, carrying out rapid sintering to obtain the bentonite with the nano metal copper inserted between the layers; finally, adding the bentonite, oleic acid, calcium borate, a high-temperature antioxidant and organic molybdenum into a sand mill to be ground and compounded, thereby obtaining the high-temperature-resistant bentonite. According to the preparation method of themodified bentonite lubricating oil additive, the copper ions are attached to the bentonite in advance and then reduced to form the nanoscale copper elementary substance, so that the obtaining difficulty of the nano-copper is reduced, and the preparation method is convenient to apply and popularize. The modified bentonite lubricating oil additive has good antifriction and antiwear properties, has good dispersibility in lubricating oil, and does not cause agglomeration.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Solid electrolyte and preparation method thereof

PendingCN114394831AHigh activityThere will be no reunionLevel indicators by physical variable measurementParaffin waxAdhesive

The invention discloses a solid electrolyte and a preparation method thereof, and relates to the technical field of electrolytes. The solid electrolyte comprises the following components: powder and an adhesive, wherein the mass ratio of the powder to the adhesive is (20-50): (50-80); the powder comprises the following components in percentage by mass: 80%-98% of ZrO2 and 2%-5% of a stabilizer, and the adhesive comprises the following components in percentage by mass: 80%-95% of paraffin, 1%-7% of a first additive and 0.1%-0.8% of a second additive; the preparation method comprises the following steps: mixing 80wt%-98wt% of ZrO2 and 2wt%-5wt% of a stabilizer to obtain powder; carrying out ultrafine treatment on the obtained powder; mixing the powder subjected to the ultrafine treatment with an adhesive, and mixing a mixture obtained after mixing; and after mixing, granulating, injecting, degreasing and sintering to prepare the solid electrolyte. Therefore, the problem of poor thermal shock property of the zirconium oxide tube solid electrolyte in the prior art is solved.

Owner:河北欧禹科技有限公司

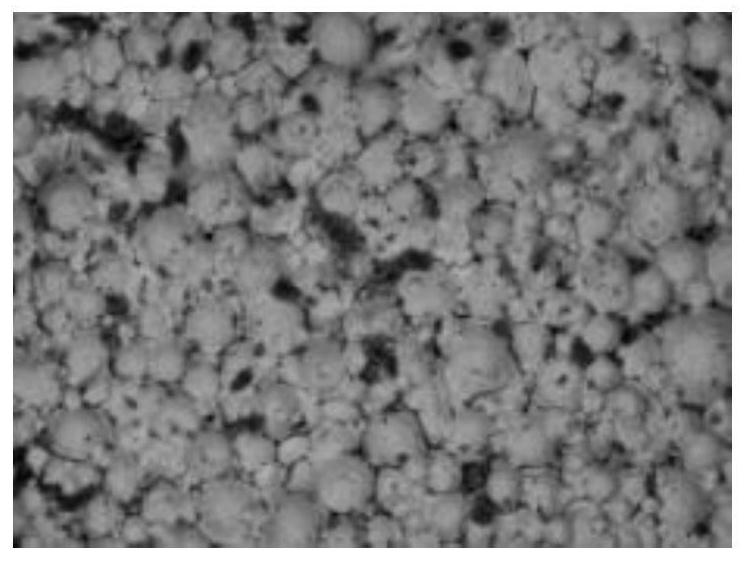

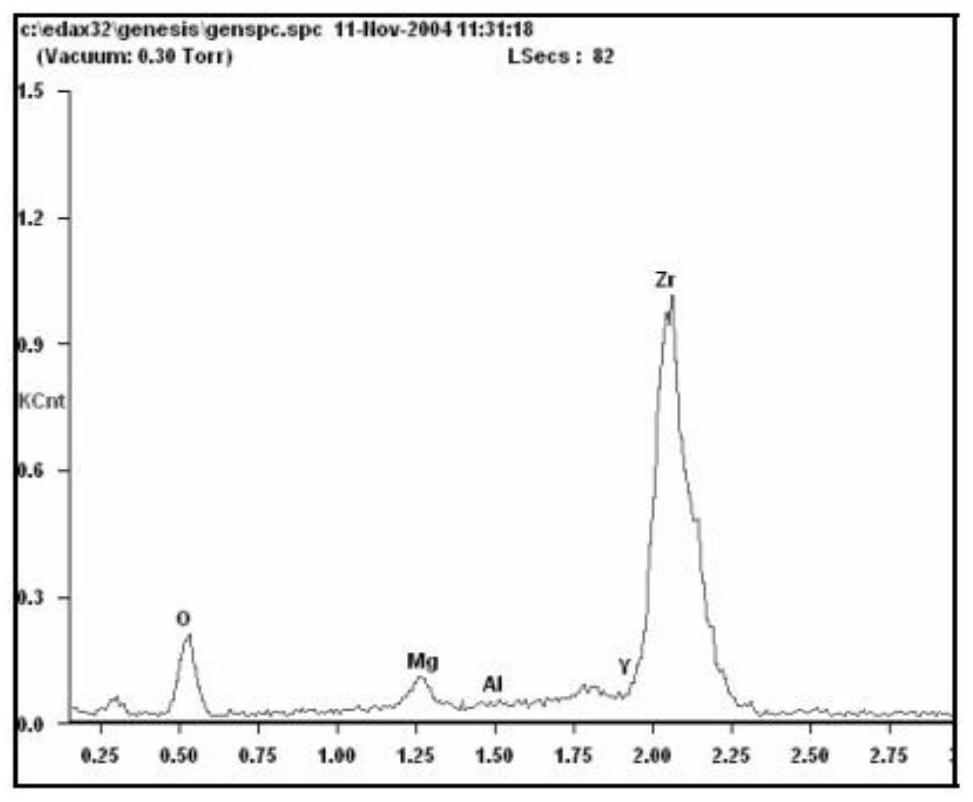

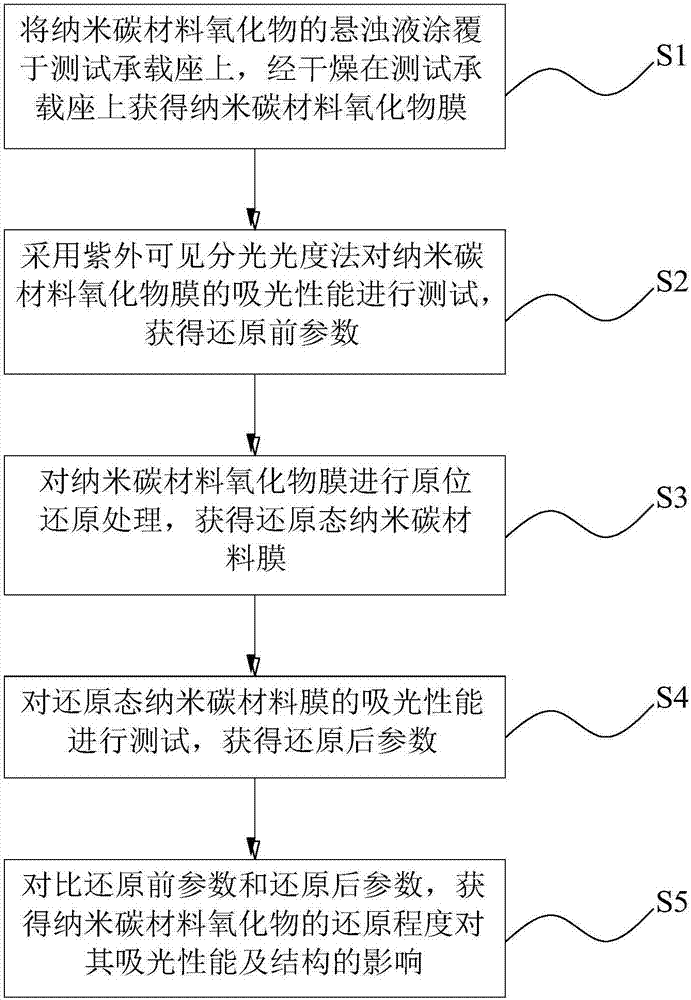

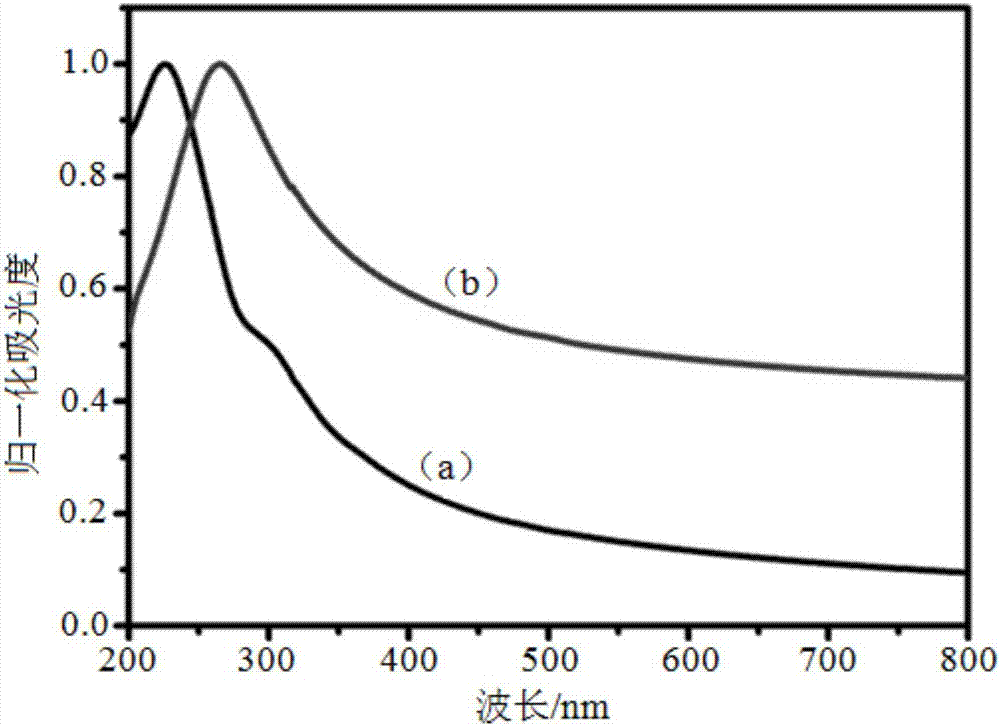

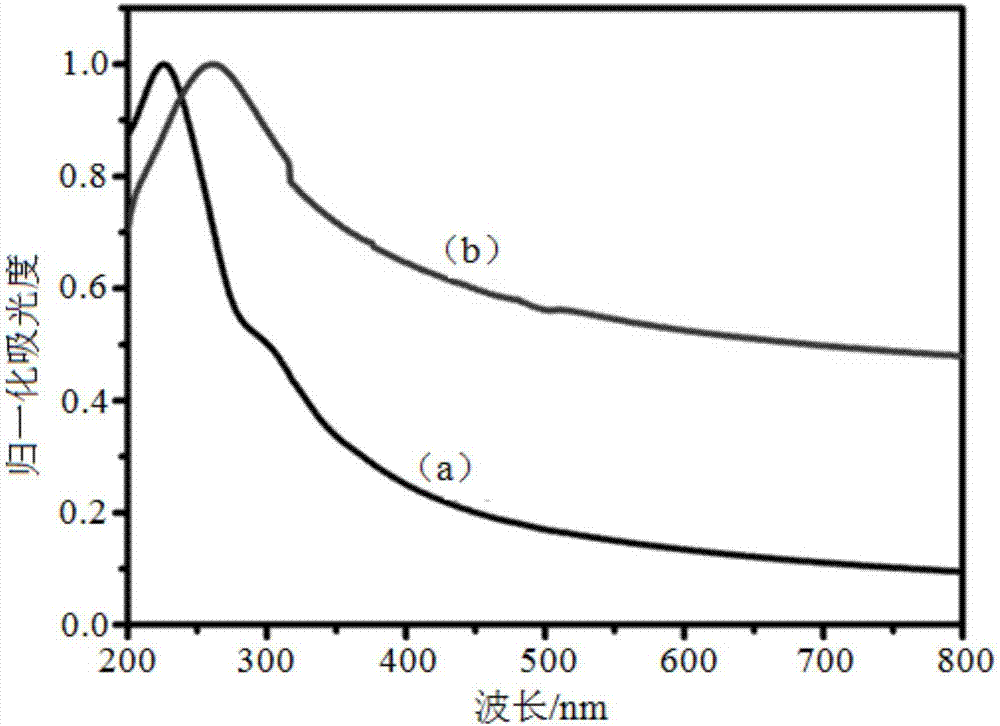

Test method of nanometer carbon material oxides based on ultraviolet-visible spectrophotometry

InactiveCN107202768AControl concentrationControl absorbencyColor/spectral properties measurementsReduction treatmentUv vis absorbance

The invention provides a test method of nanometer carbon material oxides based on ultraviolet-visible spectrophotometry. The method comprises the following steps of coating suspension of the nanometer carbon material oxides onto a test carrying seat to obtain a nanometer carbon material oxide film; performing in-situ reduction treatment to obtain a reducing state nanometer carbon material film; using the ultraviolet-visible spectrophotometry for respectively testing the light absorption performance of the nanometer carbon material film before and after the in-situ reduction treatment; correspondingly obtaining the parameters before the reduction and the parameters after the reduction; comparing the parameters before the reduction and the parameters after the reduction; obtaining the influence of the reduction degree on the light absorption performance and the structure. By using the test method provided by the invention, an interface limitation sample manufacturing method is used, so that the sample to be tested is limited by the interface, so that after the in-situ reduction, the agglomeration phenomenon cannot occur; the long-period stability of the samples of the nanometer carbon material oxides can be maintained, so that the stability and the reliability of the experiment results can be ensured; in addition, great convenience is brought to the test process of the ultraviolet-visible absorption spectrum.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com