A kind of preparation method of carbon nanotube/graphene composite material

A carbon nanotube and composite material technology, which is applied in the directions of hybrid capacitor electrodes, electrical components, electrochemical generators, etc., can solve the problem of not being able to improve the high-current charging and discharging performance of lithium-ion battery materials - rate performance, expensive, messy Stacking distribution and other issues, to achieve high current fast charge and discharge performance, weaken van der Waals force, and improve electronic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

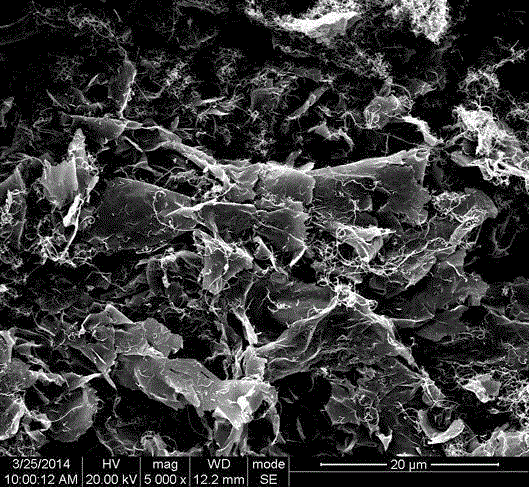

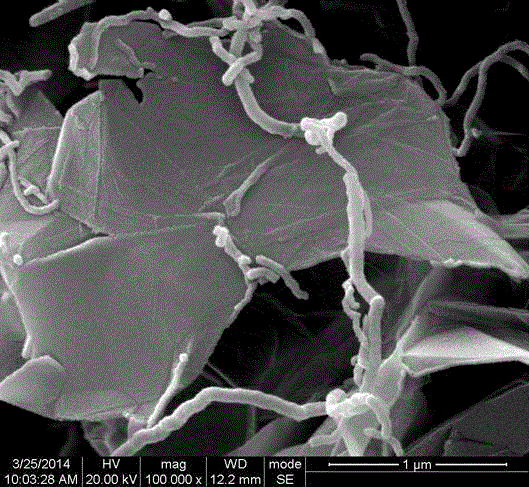

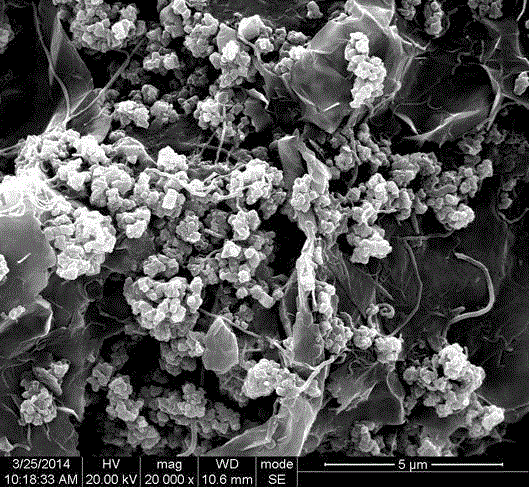

Image

Examples

Embodiment 1

[0033] Example 1: A preparation method of carbon nanotube / graphene composite material, it comprises the following steps:

[0034]S1. Mixing: Add the graphene oxide slurry with a solid content of 50% into a single-layer glass reactor, add polyvinylpyrrolidone, stir mechanically for 25 minutes to make it evenly mixed, and then add the carbon nanotube slurry with a solid content of 50% Add in the reaction kettle, continue to stir for 25min to obtain a mixed slurry; the weight ratio of the graphene oxide slurry, carbon nanotube slurry, and polyvinylpyrrolidone is 1:1:0.01; the diameter of the carbon nanotube is 50nm, and the length is 5μm;

[0035] S2. Pulverization: place the above mixed slurry in an oven at 90°C for drying until the water content is 5%, and pulverize the dried solid with a pulverizer so that the particle size of the pulverized particles is 74 μm;

[0036] S3. Preparation of powdered carbon nanotube / graphene composite material:

[0037] Heat the muffle furnac...

Embodiment 2

[0038] Example 2: A preparation method of carbon nanotube / graphene composite material, it comprises the following steps:

[0039] S1. Mixing: Add the graphene oxide slurry with a solid content of 40% into a single-layer glass reactor, add sodium dodecylsulfonate, and stir it mechanically for 35 minutes to make it evenly mixed, and then add the carbon dioxide slurry with a solid content of 40% The nanotube slurry was added into the reactor, and the stirring was continued for 35min to obtain a mixed slurry; the weight ratio of the graphene oxide slurry, carbon nanotube slurry, and sodium dodecylsulfonate was 20:20:0.01; The diameter of the carbon nanotubes is 42nm and the length is 6 μm;

[0040] S2. Pulverization: place the above mixed slurry in an oven at 110°C for drying until the water content is 4%, and pulverize the dried solid with a pulverizer so that the particle size of the pulverized particles is 65 μm;

[0041] S3. Preparation of powdered carbon nanotube / graphene ...

Embodiment 3

[0043] Example 3: A preparation method of carbon nanotube / graphene composite material, it comprises the following steps:

[0044] S1. Mixing: Add the graphene oxide slurry with a solid content of 35% into a single-layer glass reactor, add hexadecyltrimethylammonium chloride, stir mechanically for 28 minutes to make it evenly mixed, and then mix the slurry with a solid content of 30% The carbon nanotube slurry of % is added in the reactor, continues to stir 30min, obtains mixed slurry; The weight ratio of described graphene oxide slurry, carbon nanotube slurry, cetyltrimethylammonium chloride is 8 :10:0.01; the diameter of the carbon nanotube is 30nm, and the length is 10 μm;

[0045] S2. Pulverization: place the above-mentioned mixed slurry in an oven at 100°C for drying until the water content is 3%, and pulverize the dried solid with a pulverizer so that the particle size of the pulverized particles is 60 μm;

[0046] S3. Preparation of powdered carbon nanotube / graphene c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com