Test method of nanometer carbon material oxides based on ultraviolet-visible spectrophotometry

A nano-carbon material and spectrophotometry technology, applied in the measurement of color/spectral properties, etc., can solve the problems of limited rGO application field, poor dispersion, difficult absorption peaks, etc., to achieve convenient testing process, ensure stability and reliability, and maintain long-term stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

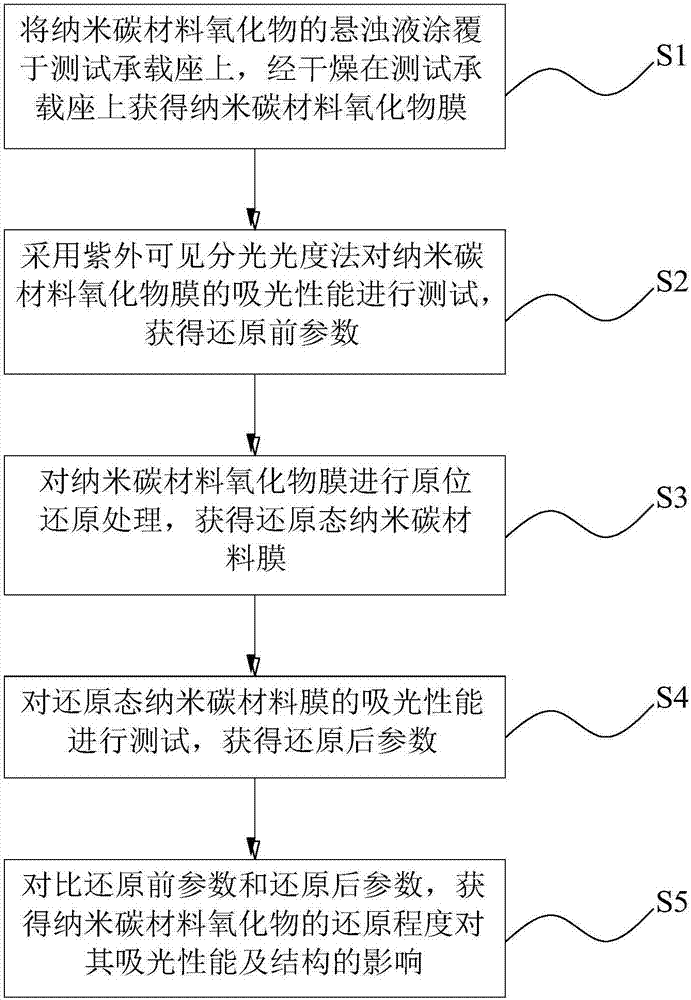

[0031] figure 1 It is a flow chart of the steps of the testing method of nano-carbon material oxide based on UV-visible spectrophotometry according to Example 1 of the present invention.

[0032] Specific reference figure 1 , according to the testing method of the nano-carbon material oxide based on ultraviolet-visible spectrophotometry of the present embodiment specifically includes the following steps:

[0033] Step S1 , coating the suspension of carbon nanomaterial oxide on the test support base, and drying the nano carbon material oxide film on the test support base.

[0034] In the present embodiment, the nano-carbon material oxide specifically selects graphene oxide (hereinafter referred to as GO); generally, the amount of GO on the control test bearing seat is 1.7×10 -2 mg / cm 2 ~0.6mg / cm 2 That is, specifically, 0.3mL-1.5mL of GO suspension with a concentration of 0.04mg / mL-4mg / mL can be used, and after drying, a GO film in which GO is the above-mentioned content ca...

Embodiment 2

[0049] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between Example 2 and Example 1 is that in step S1, the concentration of the GO suspension is 0.50 mg / mL, and the volume is 0.6 mL; in step S3, the GO film is placed in an oven, and controlled The temperature was maintained at 200° C. for 1 h to obtain an rGO film; the rest was described in Example 1.

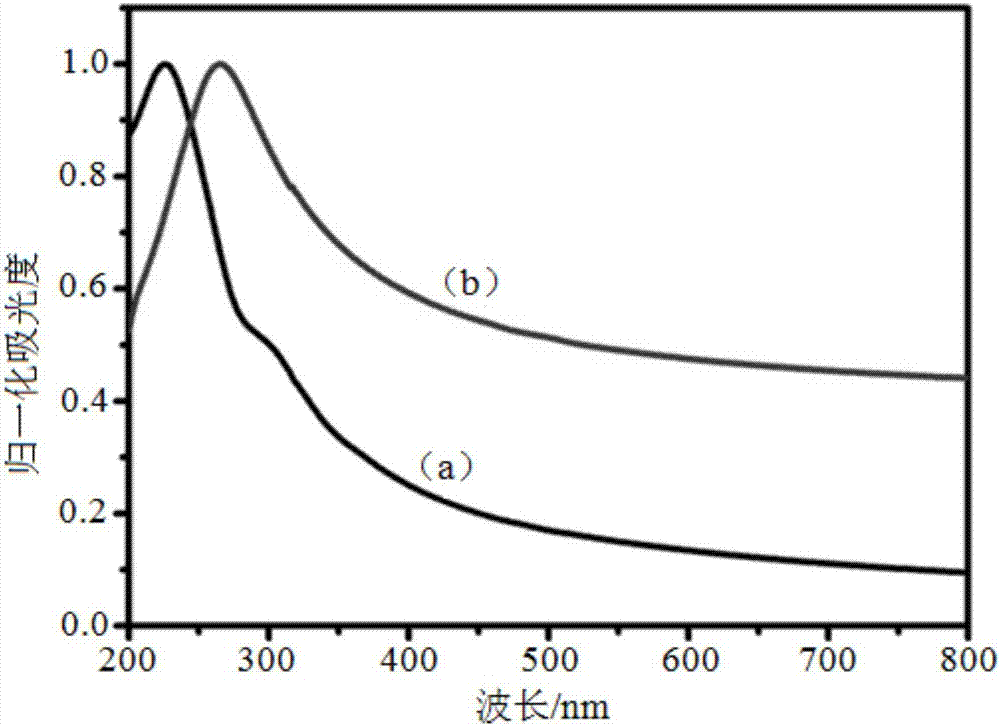

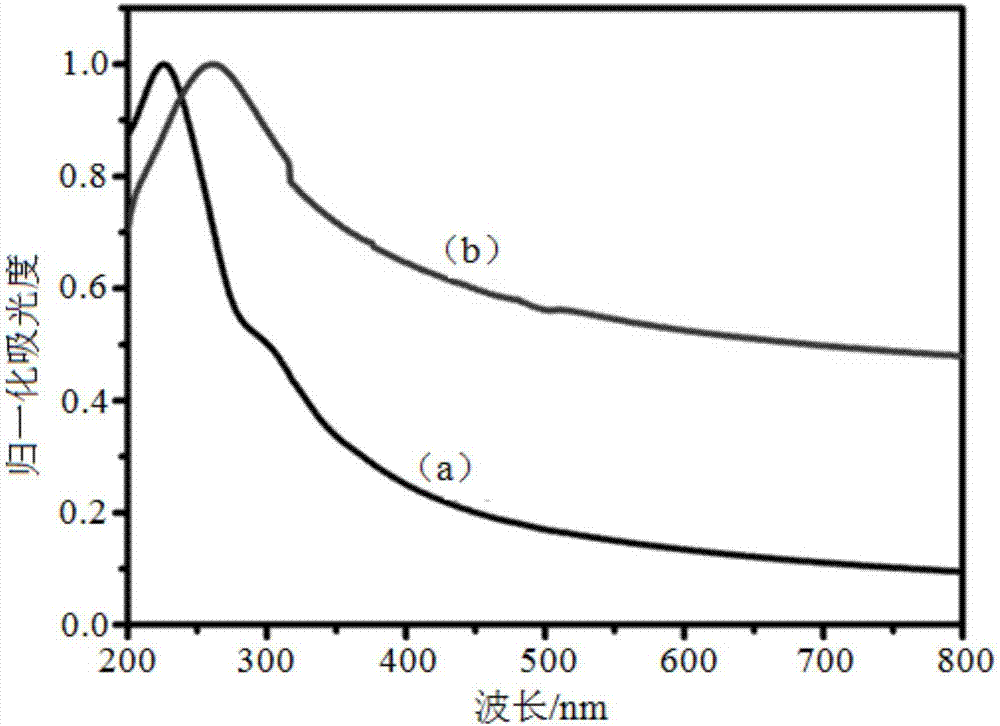

[0050] In this example, the UV-visible absorption spectra of GO before and after the in situ reduction reaction are as follows: image 3 shown. from image 3 It can be seen in (a) that the π-π* transition absorption peak before the reaction in the curve (a) red-shifts from 225.8nm to the 261.92nm of the π-π* transition absorption peak in the (b) curve after the reaction, and the reaction greater than 239nm The absorption intensity is also enhanced compared with that before the reaction, indicatin...

Embodiment 3

[0053] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between Example 3 and Example 1 is that in step S1, the dosage of GO is 0.15 mg, 0.3 mg, 0.6 mg and 2 mg respectively, corresponding to the concentration of 0.5 mg / mL and 1 mg / mL respectively from 300 μL and 2mg / mL GO suspension and 1mL of 2mg / mL GO suspension; the rest are described in Example 1.

[0054] In this example, since the addition of 300 μL is difficult to effectively spread the GO in the GO suspension with a concentration of 1 mg / mL and 2 mg / mL, this operational problem is overcome by continuing to add solvent.

[0055] This shows that the method for testing nano-carbon material oxides based on ultraviolet-visible spectrophotometry according to this embodiment can also realize the control of the concentration of the sample to be tested and the strength of the absorption spectrum signal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com