Patents

Literature

36 results about "Cobalt sulphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

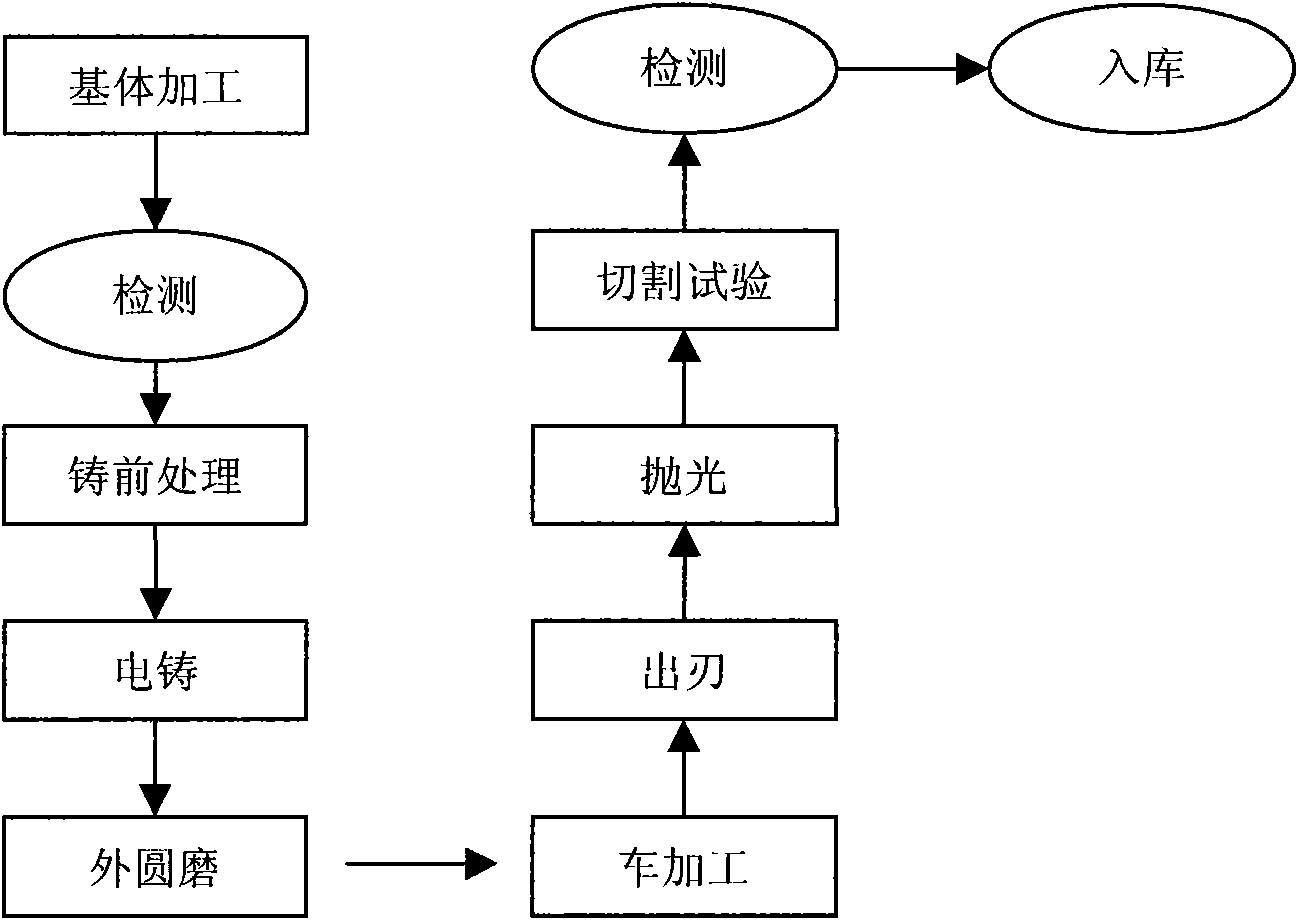

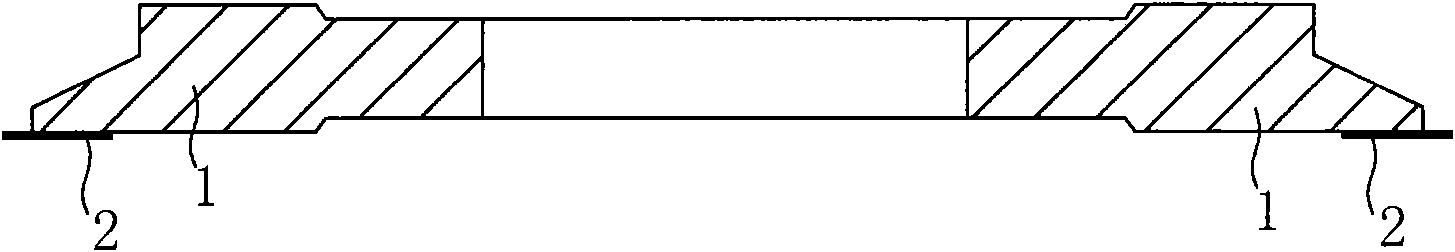

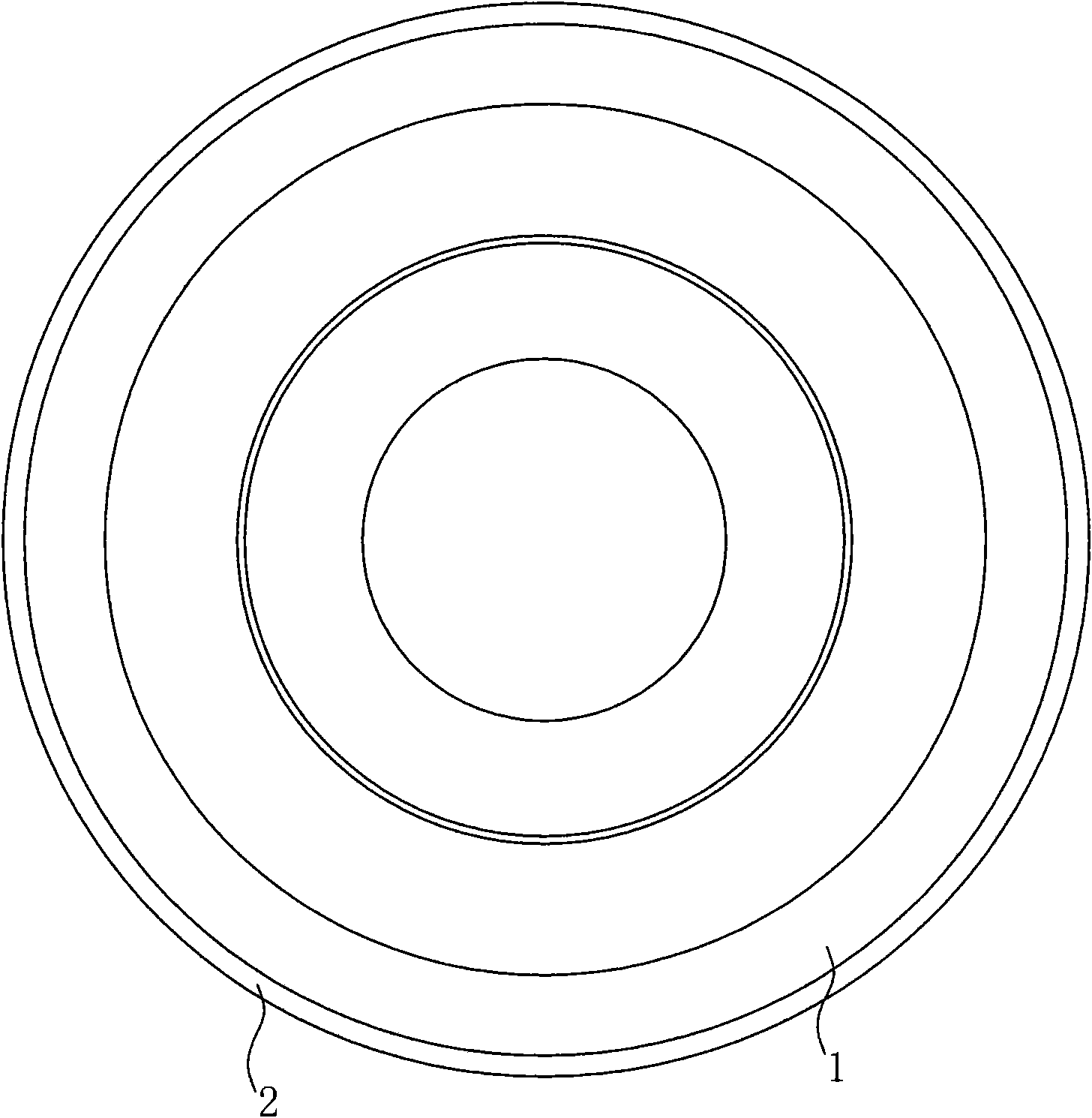

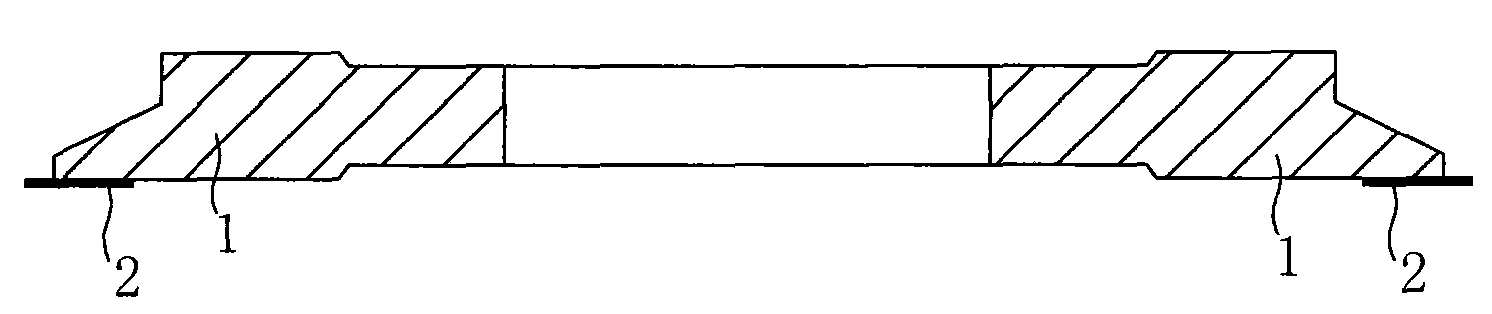

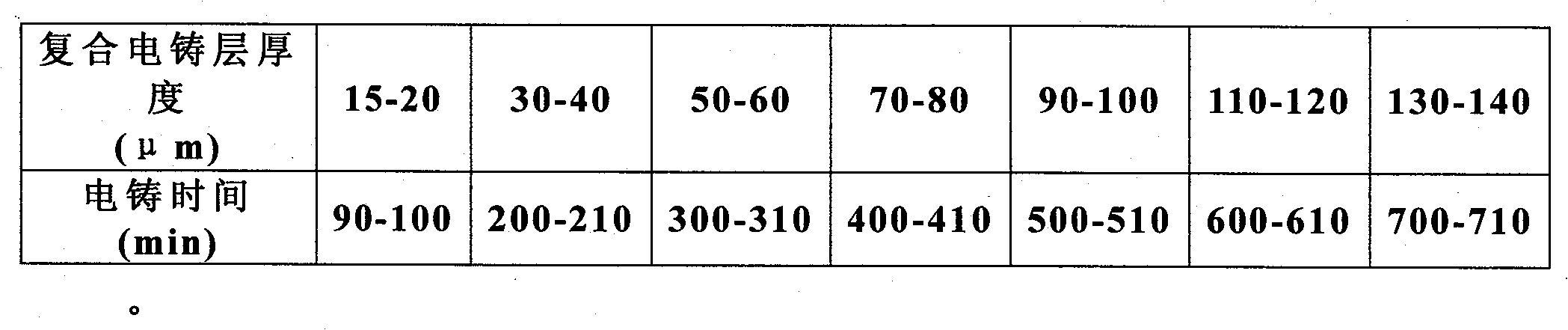

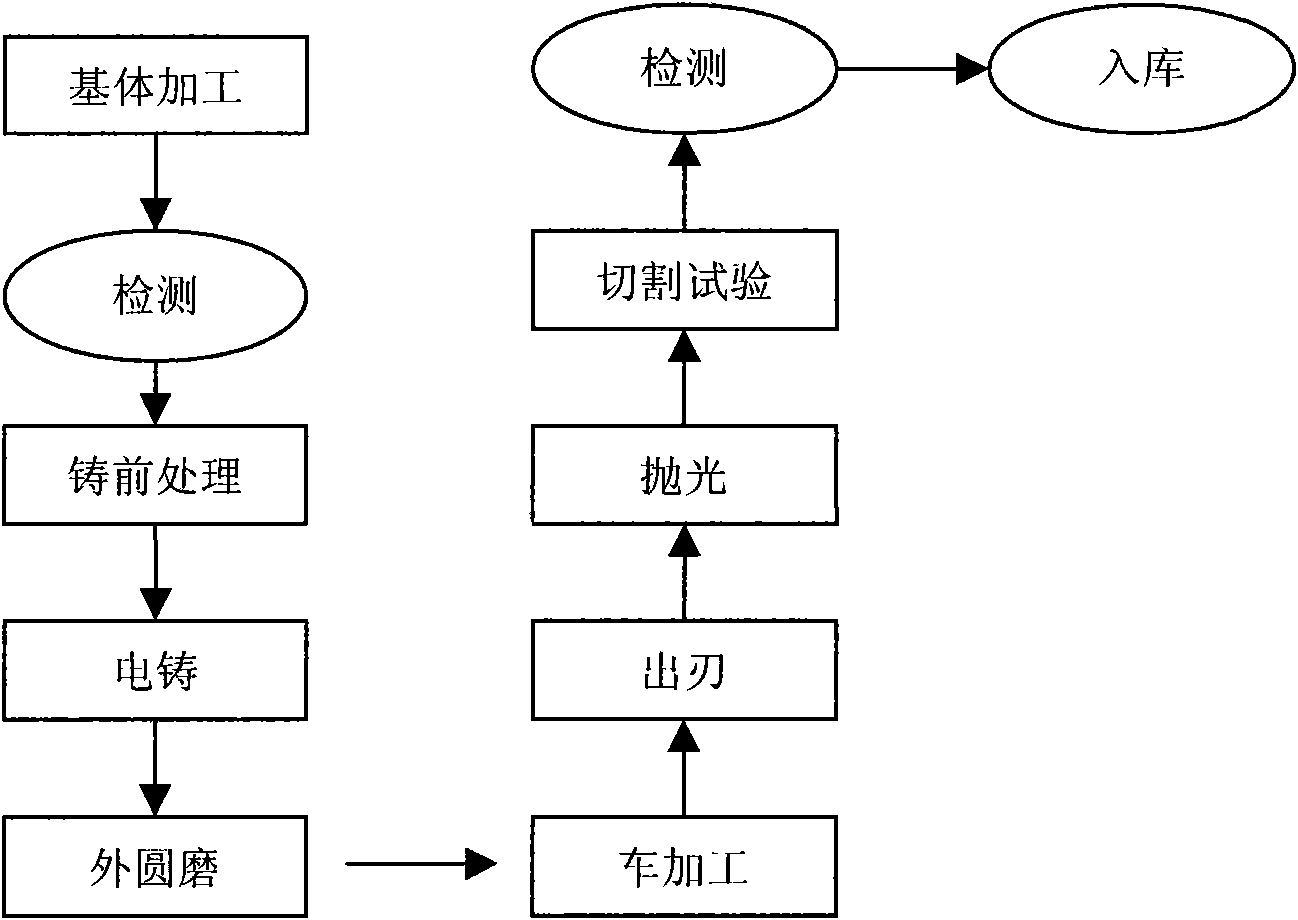

Diamond grinding wheel for cutting silicon crystal circle and preparation method thereof

ActiveCN101633158AHigh strengthImprove rigidityGrinding devicesGrinding machinesNumerical controlCobalt sulphate

The invention discloses a diamond grinding wheel for cutting a silicon crystal circle and a preparation method thereof. The method comprises the following steps: (1) preprocessing an aluminum alloy basal body; (2) configuring electroforming liquid: configuring the electroforming liquid according to the weight ratio of (38-43):(15-20):(43-57):(50-180):(4-8) of nickel sulphate, cobalt sulphate, deionized water, a diamond grinding material and a suspending agent; fully stirring evenly and obtaining the electroforming liquid; (3) carrying out insulation processing on the aluminum alloy basal body obtained in the step (1), putting the aluminum alloy basal body into the electroforming liquid, electroforming in an ultrasonic field, evenly precipitating the diamond grinding material in the electroforming liquid and metal on the basal body together and obtaining a grinding wheel blank body with a compound electroforming layer; and (4) taking out the grinding wheel blank body completing electroforming, and carrying out accurate processing on the grinding wheel blank body on a numerical control grinder and a numerical control lathe respectively according to the accuracy requirements of the required basal body and the required cutting edge. The diamond grinding wheel obtained by the invention meets the ultrathin and superfine technical conditions and also has favorable strength and rigidity.

Owner:赛尔科技(如东)有限公司

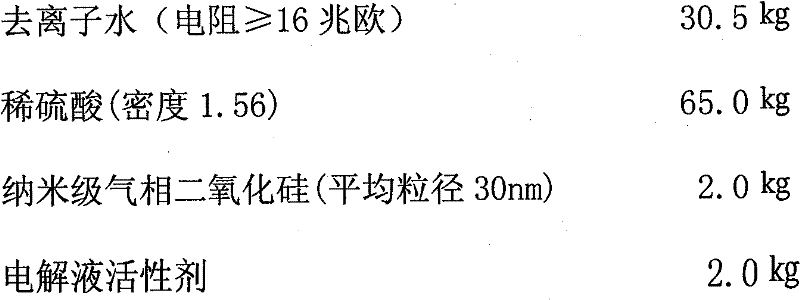

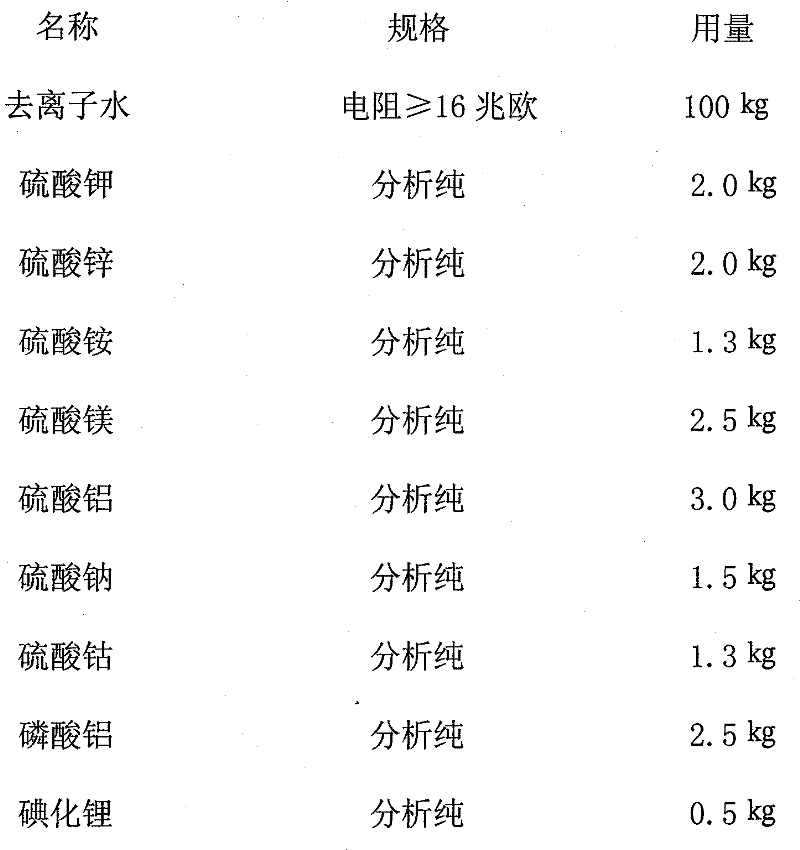

Electrolyte of lead-acid battery and preparation method thereof

ActiveCN101685884AGood dispersionImprove stabilityFinal product manufactureLead-acid accumulators constructionDispersityActive agent

The invention relates to an electrolyte of lead-acid battery and preparation method thereof. The electrolyte comprises the following raw materials by parts by weight: 20-40 parts of deionized water, 62-68 parts of dilute sulphuric acid, 1.5-2.5 parts of nano aerosol and 2-2.5 parts of electrolyte active agent; wherein the electrolyte active agent is formed by analytically pure potassium sulphate,zinc sulphate, ammonium sulphate, magnesium sulphate, aluminium sulphate, sodium sulphate, cobalt sulphate, aluminium phosphate and lithium iodide in certain ratio; and multiple micro elements are added into the electrolyte, so that the nano silicon oxide particles have favourable dispersity, the prepared electrolyte has no sedimentation, flocculation or layering for a long time, and meantime service life and environmental performance of battery can be effectively improved.

Owner:深圳市夺标环保技术有限公司

Metal alloy electroplating liquid

The invention discloses a metal alloy electroplating liquid. The metal alloy electroplating liquid is composed of the following raw material components in parts: 30-40 parts of copper sulphate, 30-50 parts of aluminium sulphate, 50-60 parts of copper chloride, 50-60 parts of nickel hydroxide, 20-30 parts of cobalt sulphate, 30-40 parts of cobalt chloride, 10-15 parts of iron sulphate, 30-35 parts of ferrous chloride, 50-58 parts of cuprous oxide, 16-18 parts of hydrochloric acid, 15-20 parts of acetic acid, 3-4 parts of Tween-60, 4-5 parts of sodium hydroxyethyl sulfonate, 5-6 parts of allyl polyethenoxy ether, 6-7 parts of polyethylene glycol, 3-4 parts of ammonium lauryl sulphate, 5-8 parts of sodium lauryl sulphate and 200-300 parts of deionized water. The metal alloy electroplating liquid is good in stability, the surface of a plated film is high in brightness and smoothness, the flexibility of a plated layer is obviously improved, and the defects of burrs, roughness and the like on the outer surface of a plated part are basically eliminated.

Owner:梁胜光

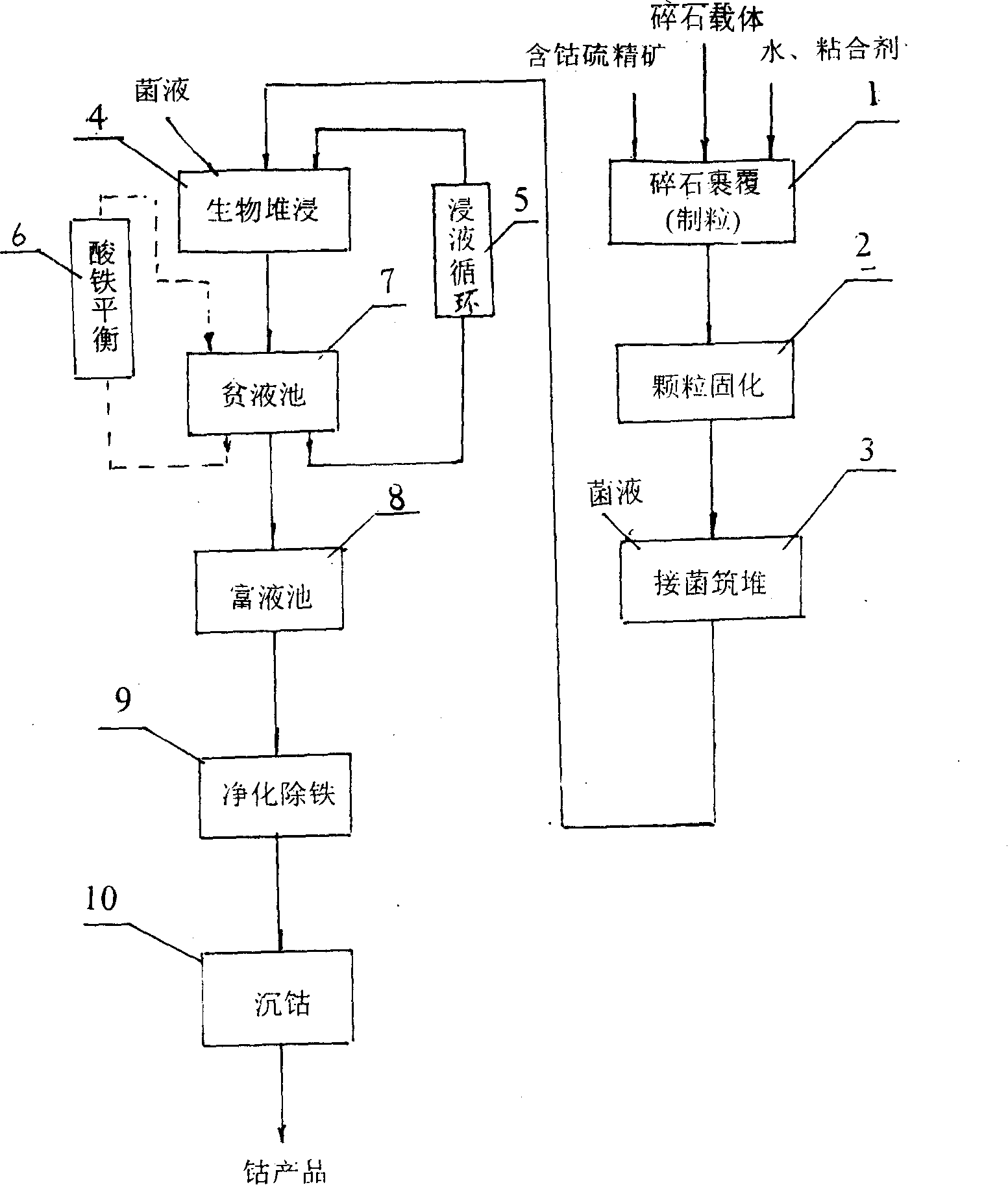

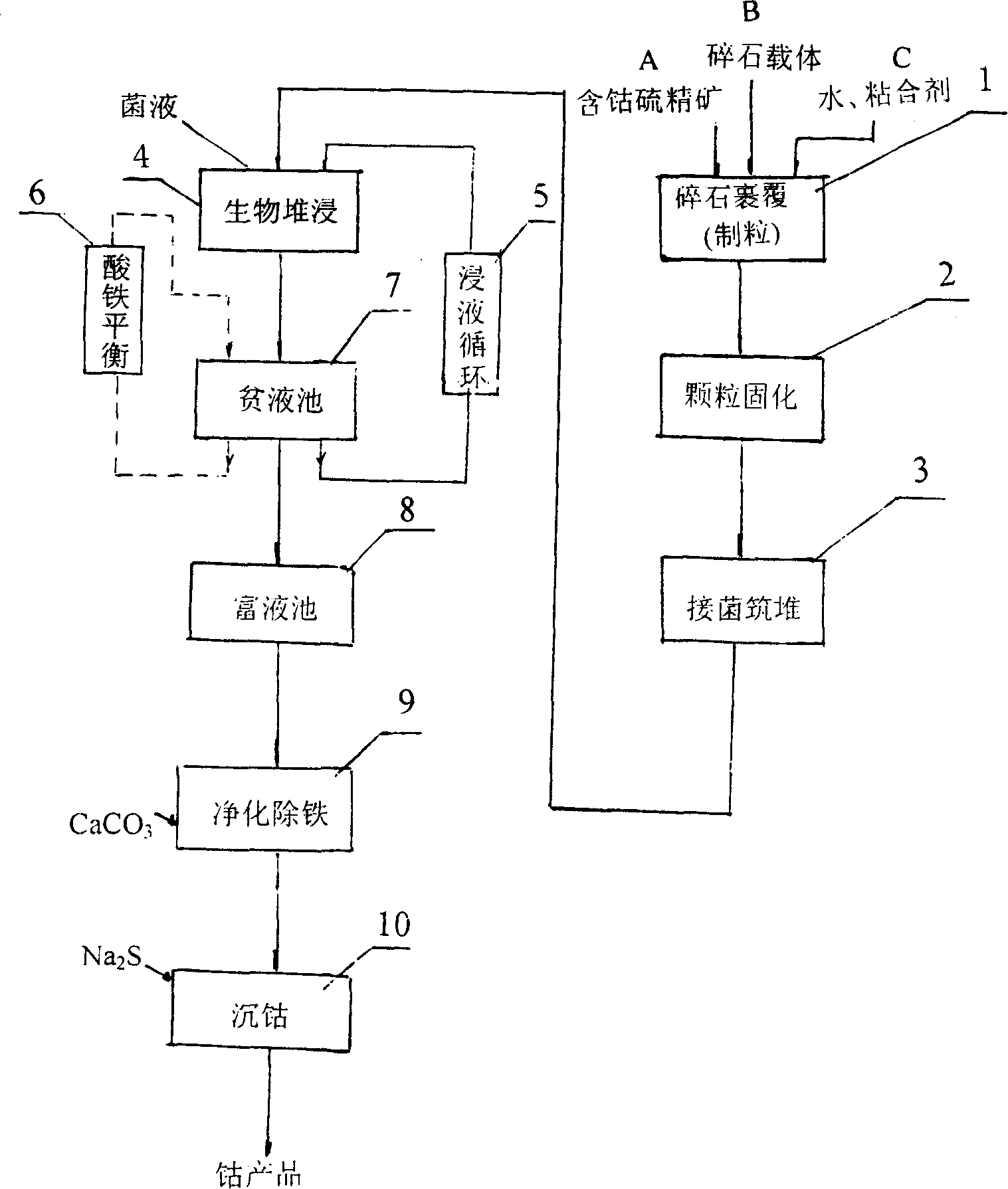

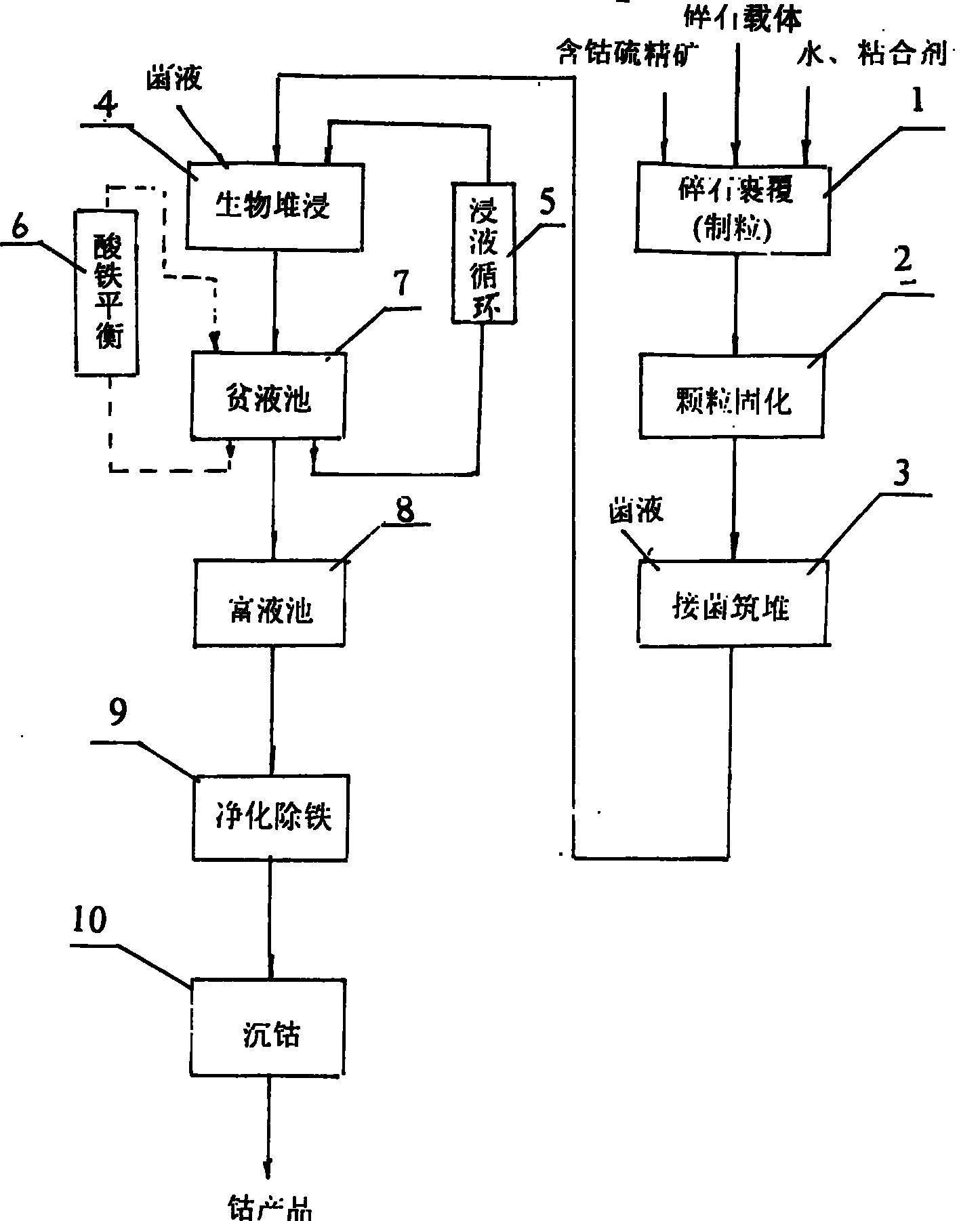

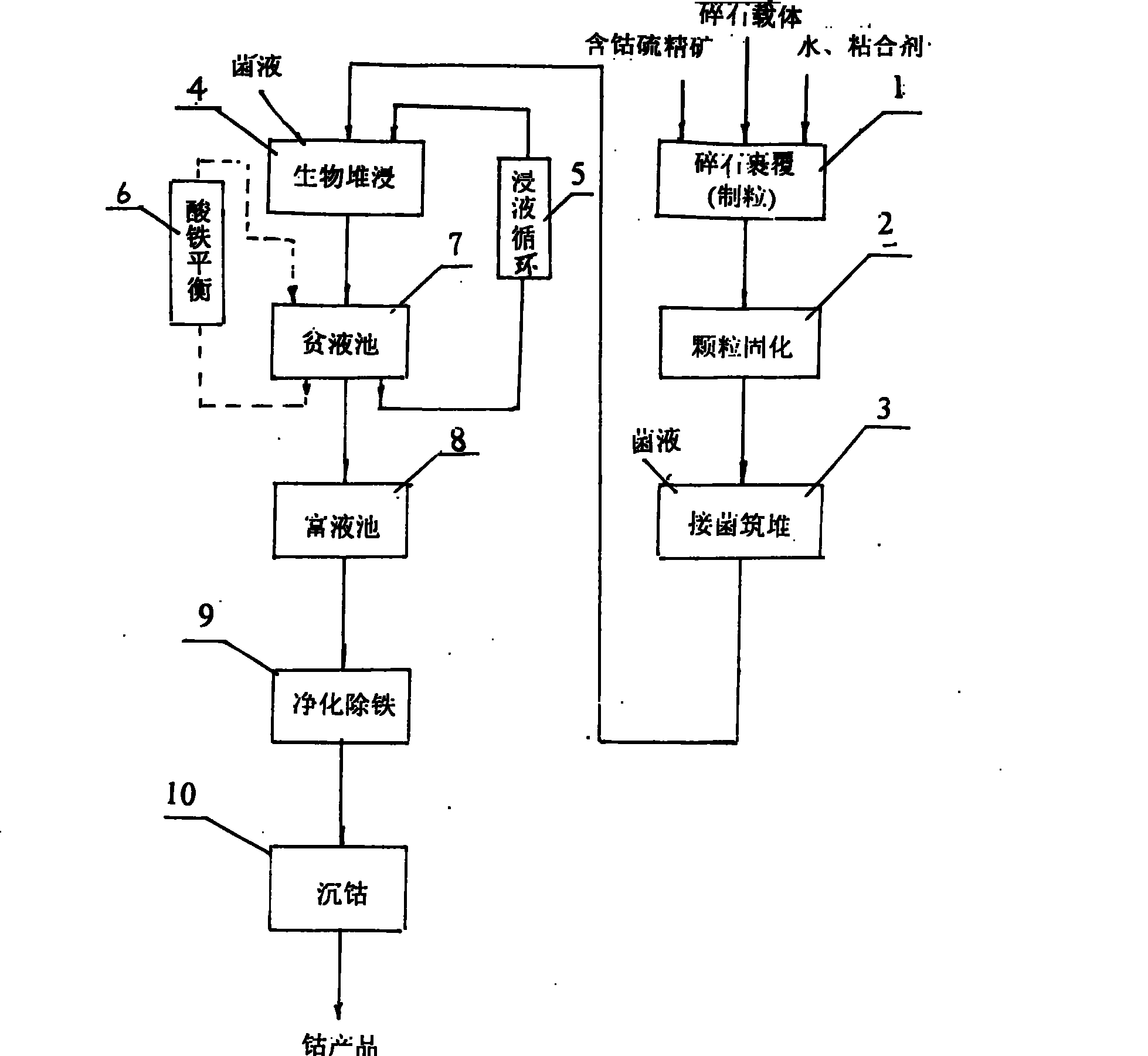

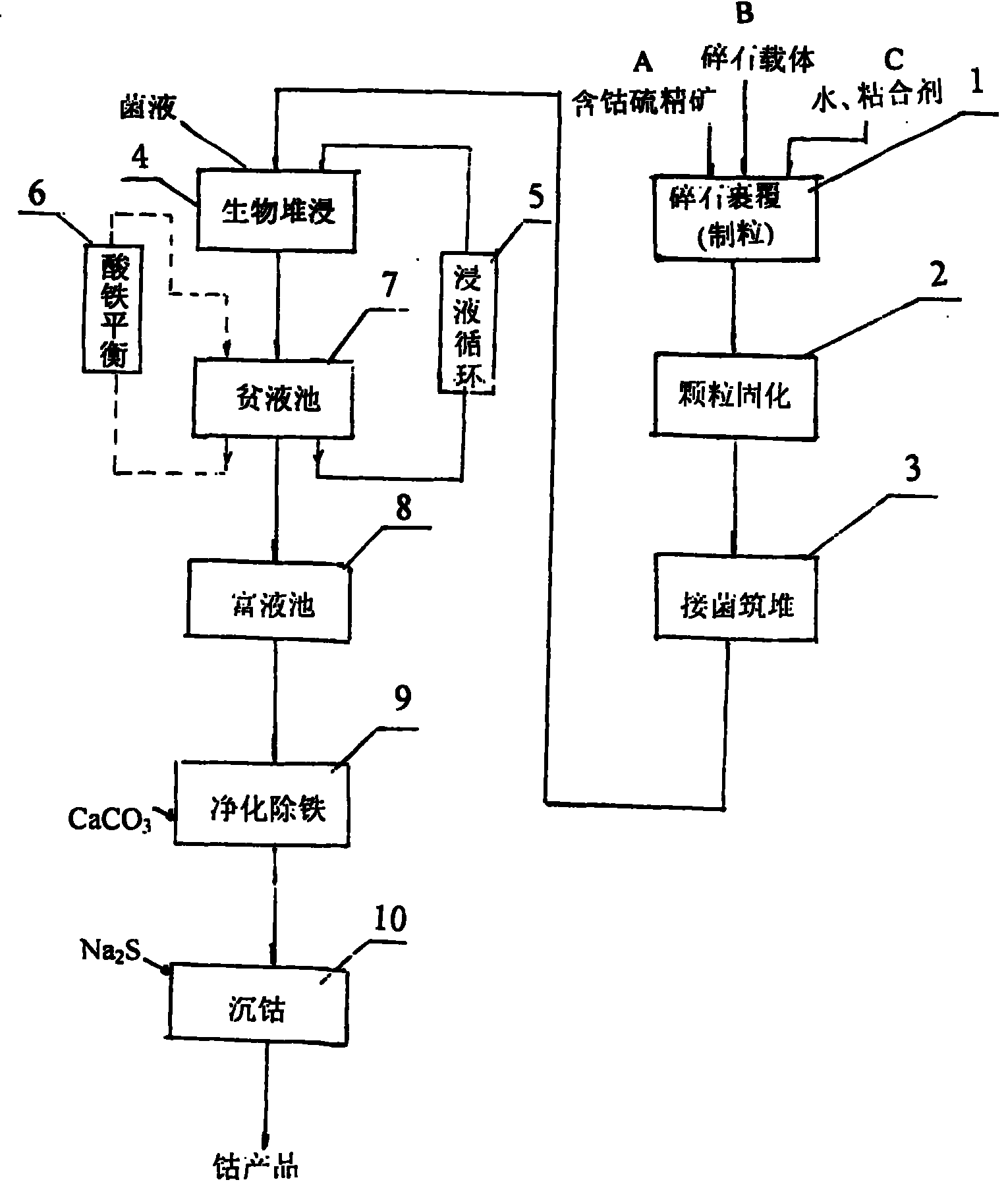

Mesophilic acidophilic bacteria and biological heap leaching technique for low-grade cobalt-containing sulfur concentrate

InactiveCN101191122AEfficient recyclingLow investment costBacteriaProcess efficiency improvementThiobacillus ferrooxidansCobalt sulphate

The invention relates to mesophilic acidophilic bacteria and a biological heap leaching technology for low-grade cobaltiferous sulfide ore concentrates. The mesophilic acidophilic bacteria have a name of Thiobacillus ferrooxidans Retech V and a collection registration number of CCTCC NO: M202039, and has been stored and collected in China Center for Type Culture Collection (in Wuhan University). The biological heap leaching technology is that: mineral grains which are suitable for biological heap leaching are obtained after coating of crushed stones and solidification of the mineral grains of the low-grade cobaltiferous sulfur-bearing ore concentrates. Cobalt sulphates are obtained through procedures of embankment, heap leaching and trickling by adoption of bacteria with two different growth temperatures, lixivium circulation, purification and deferrization of cobalt pregnant solution, cobalt settlement and so on of the mineral grains. The temperature of 10 to 55 DEG C, the PH value of 1.2 to 1.8 and the adequate Fe concentration of a storage yard in a heap leaching system during the leaching out process are favorable for activity of leaching bacteria. The invention has the advantages of capability of fully utilizing low-grade cobaltiferous sulfide ore resources in old mines, improvement of comprehensive utilization level of mines, conservation of cost, and improvement of profit. The invention is applied in developing cobaltiferous sulfide ore resources in remote areas.

Owner:有研资源环境技术研究院(北京)有限公司

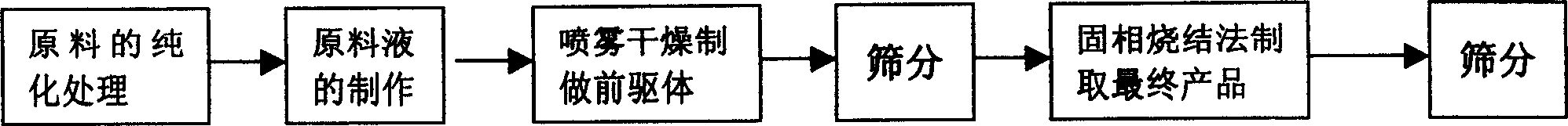

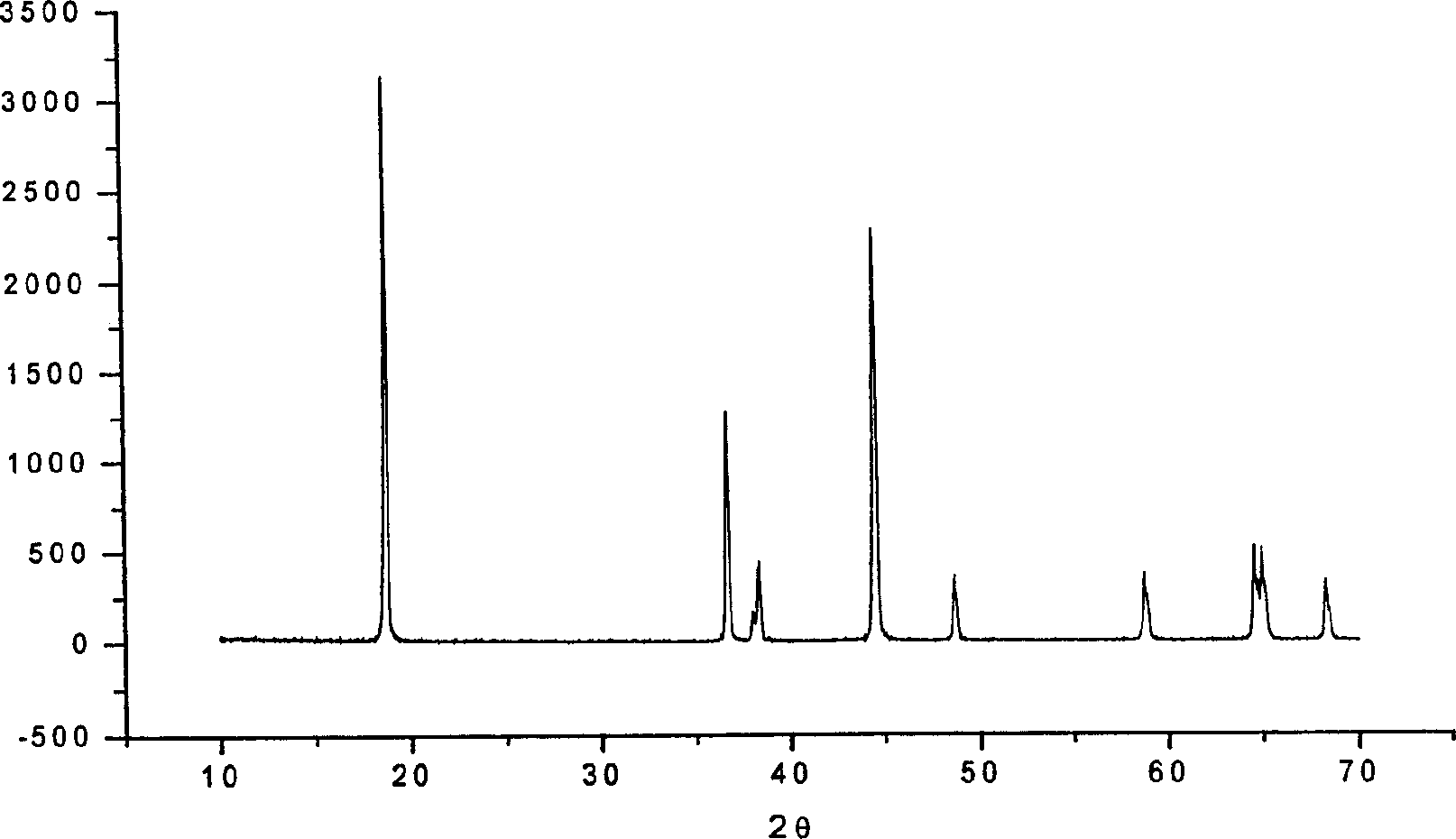

Anode material--lithium nickelate cobalt for lithium ion battery and preparation method thereof

InactiveCN1567620AReduce dosageReduce consumptionElectrode manufacturing processesLithium compoundsLithium chlorideNickel salt

The invention is a method of preparing lithium ion cell anode material-nickel cobalt acid lithium, and its characteristic: in the proportion of its formula, A-group matters: water-soluble lithium salt which is one of the lithium chloride, lithium sulphate, lithium nitrate and lithium acetate, water cobalt salt which is one of the cobalt chloride, cobalt sulphate, cobalt nitrate and cobalt acetate, and water nickel salt which is one of the nickel chloride, nickel sulphate, nickel nitrate and nickel acetate, the molar ratio of the three matters is 1.00-1.1 : 0.2-0.3 : 0.8-0.7; B-group matters: complexant is one of the oxalic acid, tartaric acid, citric acid, succinic acid, malonic acid, and maleic acid; the molar ratio of A to B is 1.0 : 0.6 -0.8; C-group polymers: gelatin, modified starch and polyvinyl alcohol. The beneficial effects: it can effectively reduce cost and the made LiNi1-yCoyO2 has the advantages of both LiCoO2 and LiNiO2, i.e. easy to synthesize, stable-property, high-specific capacity (higher than that of LiCoO2 by above 20%), etc. Additionally, because the use of Co is reduced, thus it reduces the environmental pollution. Therefore, LiNi1-yCoyO2 has a great hope of becoming the preferred substitute for LiCoO2, and its market demand is quite considerable.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD

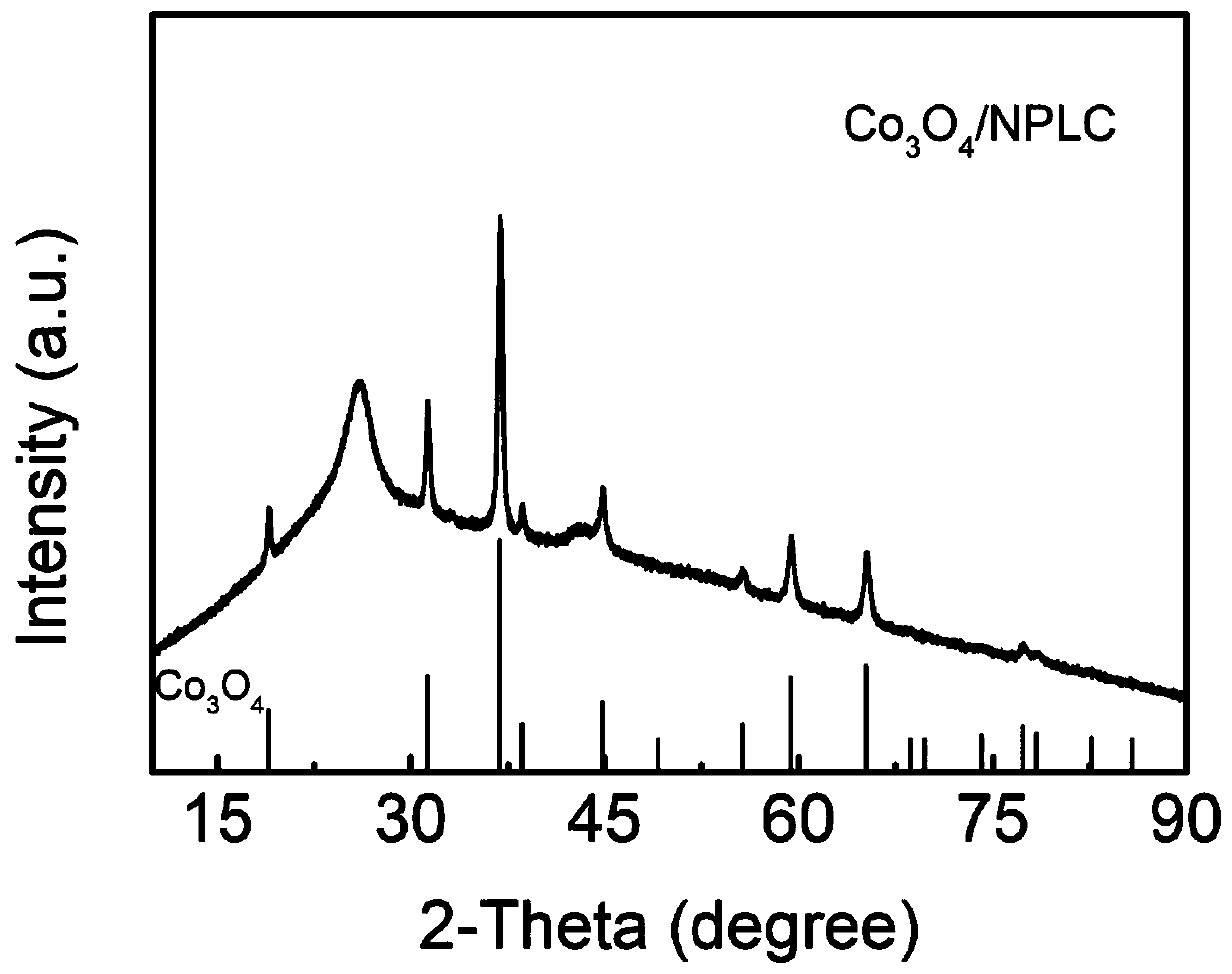

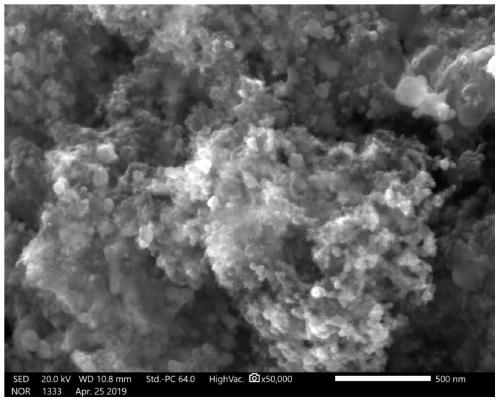

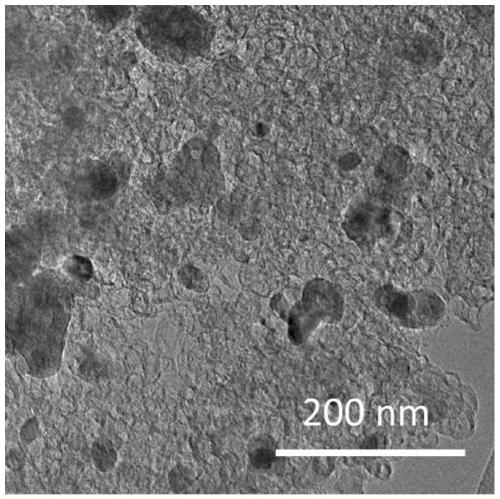

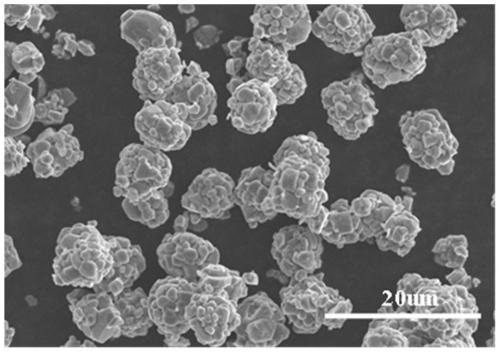

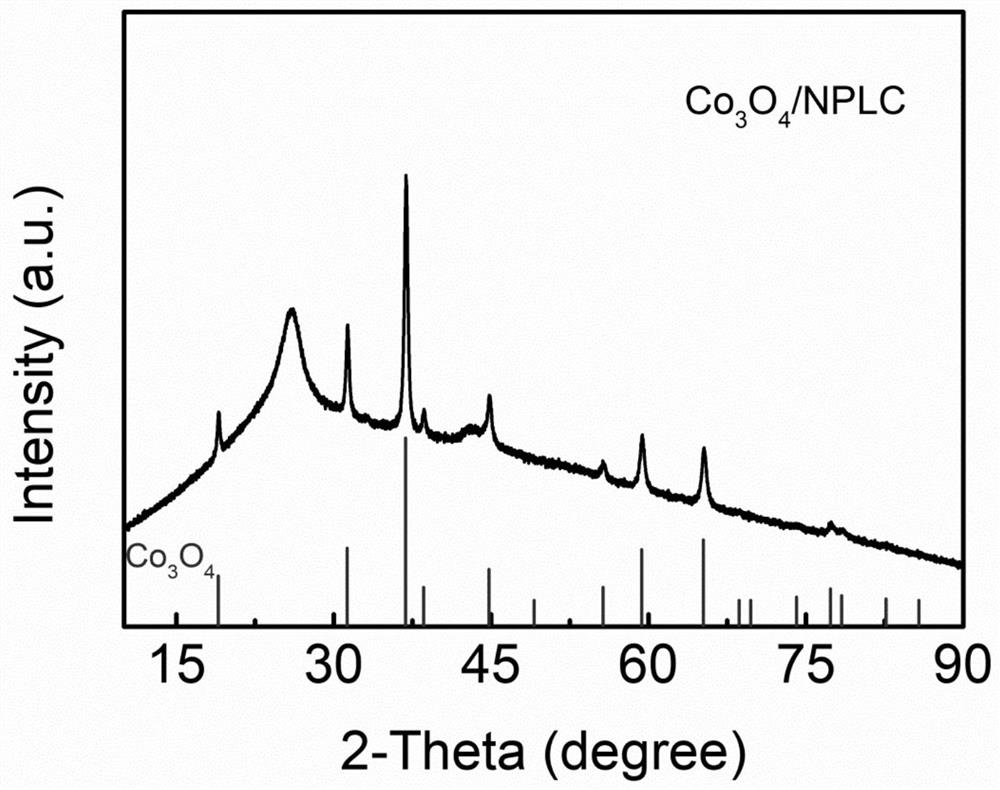

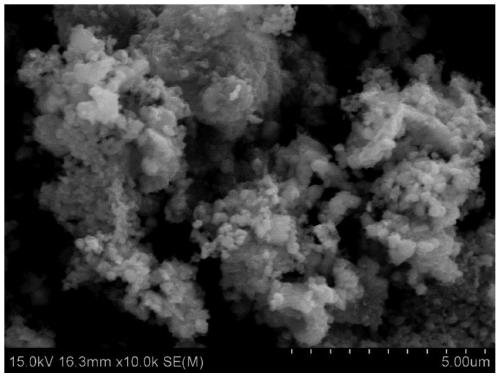

Two-step preparation method of nitrogen-doped carbon-loaded cobaltosic oxide particle catalyst

The invention relates to the field of energy materials, and discloses a two-step preparation method of a nitrogen-doped carbon-loaded cobaltosic oxide particle catalyst in order to solve the problemsthat in the high-temperature pyrolysis process, carbon atoms can reduce cobaltosic oxide, and the number of active components is reduced. The preparation method comprises the following steps: adding acobalt source and a nitrogen source into deionized water, adding a carbon source after complete dissolution, and carrying out uniform ultrasonic dispersion; reacting the prepared solution under the condition of 170-190 DEG C; sequentially carrying out suction filtration and drying on the obtained sample at room temperature; and uniformly grinding the obtained sample, and carrying out high-temperature pyrolysis in argon to obtain a finished product. Biomass carbon source glucose and derivatives thereof, urea and cobalt sulfate are used as precursors, nitrogen-doped carbon-loaded cobaltosic oxide is prepared through two steps of hydrothermal-pyrolysis, the problem that cobaltosic oxide is reduced in the pyrolysis process is effectively reduced, and the number of active sites on the surfaceof the catalyst is ensured.

Owner:HANGZHOU DIANZI UNIV

High-voltage agglomerated lithium cobalt oxide material, preparation method and application thereof

PendingCN111370677ABlock direct contactIncrease capacityCell electrodesSecondary cellsCobalt sulphateLithium

The invention discloses a preparation method of a high-voltage agglomerated lithium cobalt oxide material. The method comprises the following steps: doping a certain amount of a source compound of a doping element D during preparation of primary sintered lithium cobalt oxide; preparing primary sintered lithium cobalt oxide particles with an agglomeration-like structure, forming a coating layer onthe surfaces of the primary sintered lithium cobalt oxide particles by taking a cobalt source B and an additive E as coating agents, and finally sintering and crushing to obtain the lithium cobalt oxide material with the agglomeration-like structure. The doping element D is at least one of Ti, Mg, Ni, La, Zr, Y, Nb and Al. The cobalt source B is at least one of cobaltosic oxide, cobalt hydroxide,cobalt carbonate and cobalt sulfate. The additive E is at least one of a Ti compound, a Mg compound and an Al compound. The lithium cobalt oxide material disclosed by the invention is of an agglomeration-like structure formed by tightly fusing primary particles, the particle size distribution is uniform, the fluidity is good, a coating layer is tight and uniform, and the lithium cobalt oxide material has excellent rate capability and cycle performance under a high-voltage condition.

Owner:JIANGMEN KANHOO IND

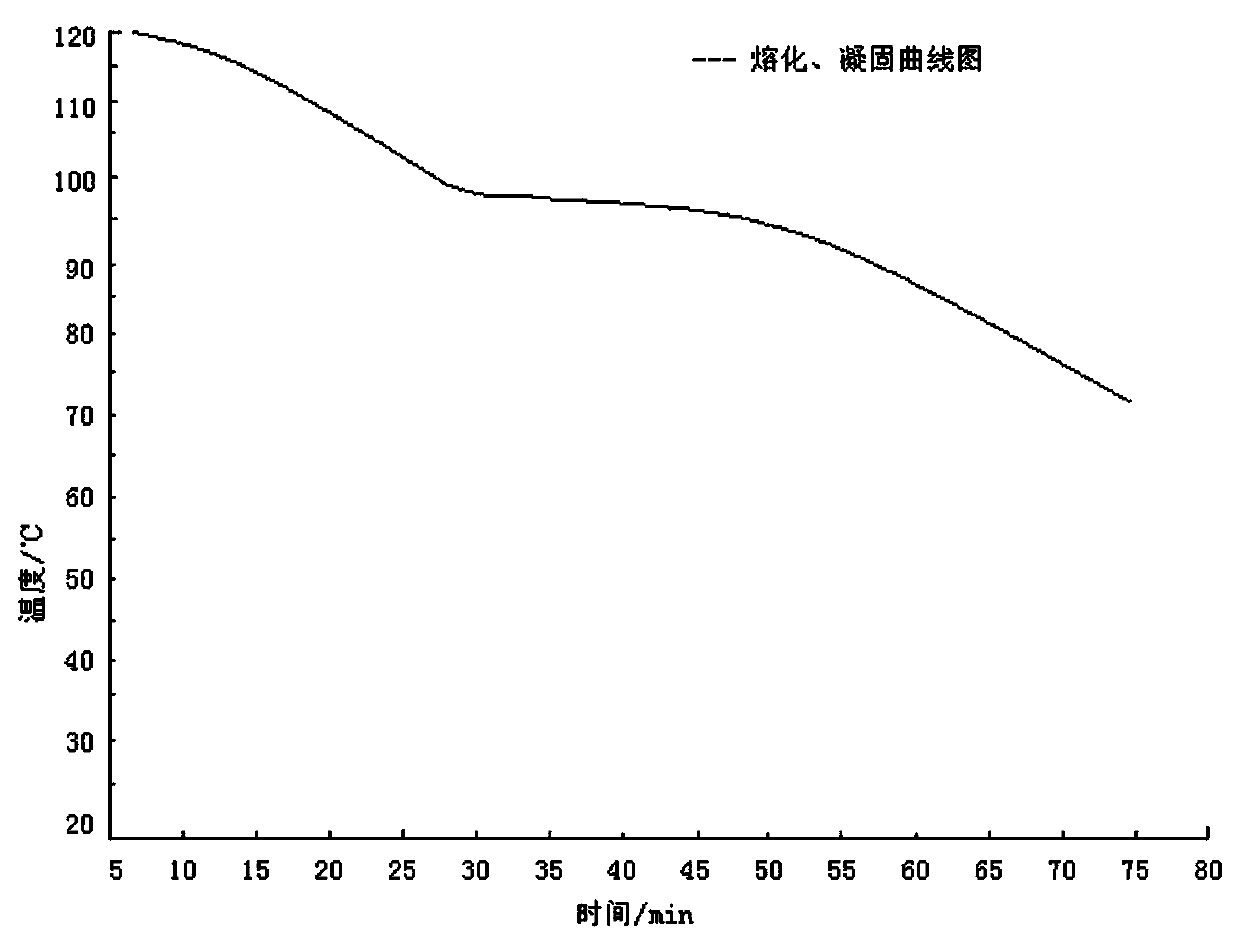

High-temperature inorganic nano phase change energy storage material and preparation method thereof

InactiveCN103468217ASimple processLow costHeat proofingHeat-exchange elementsCobalt sulphateInorganic salts

The invention discloses a high-temperature inorganic nano phase change energy storage material and a preparation method thereof, and belongs to the technical field of building low carbon and energy saving. The inorganic nano energy storage material is formed by taking silica gel, titanium oxide and manganese dioxide powder which are hydrolyzed by ethyl orthosilicate Si(OC2H5)4, tetrabutyl titanate Ti(OC2H5)4 and manganous nitrate Mn(NO3)2 as a nano rubber power wall material, taking cobaltous sulfate heptahydrate CoSO4.7H2O as a core material, and encapsulating the nano inorganic salt hydrate phase change core material with the nano rubber power wall material. The phase change temperature is 96.8 DEG C, and the energy storage material is suitable for serving as a thermal insulation and heat preservation material of a high-temperature drying room.

Owner:贵州中益能新材料科技有限公司

Gluconic acid cobalt and method of preparing the same

InactiveCN101153006APromote absorptionEasy to produceCarboxylic acid salt preparationSolubilitySodium bicarbonate

Gluconic cobalt and the production method relate to a cobalt-containing organic compound, gluconic cobalt, suitable for pharmaceutical intermediates and the production method. The present invention aims to solve the problem that the current domestic and foreign markets have no gluconic cobalt. The chemical formula is C12H22CoO14. In the production method, the cobalt sulphate and sodium bicarbonate are respectively dissolved in water to prepare saturated solution; the saturated solution is filtered and refined; the mixture reacts in a reactor; the reaction temperature is controlled at 80 DEG C; after one hour, the mixture is arranged in another container to be statically laid for 12 hours; the following process comprises the centrifugal separation, washing, drying, crushing, and screening. The chemical reaction formula is 5CoSO4question mark 7H2O+10NaHCO3arrow 2CoCO3question mark 3Co(OH)2+5Na2SO4+8CO2. Then the prepared alkali cobalt carbonate and glucose acid react in the reactor for one hour at a temperature between 70 and 100 DEG C; the products are then arranged in a crystallization slot for crystallization, drying and crushing. The present invention has the advantages of easy solubility in water and simple production process.

Owner:栾广胜

High power silicon crystal electrolyte and its preparation method

ActiveCN100382376CIncrease capacityExtend your lifeLead-acid accumulatorsConductive materialCobalt sulphateLithium hydroxide

Owner:浙江天地之光电池制造有限公司

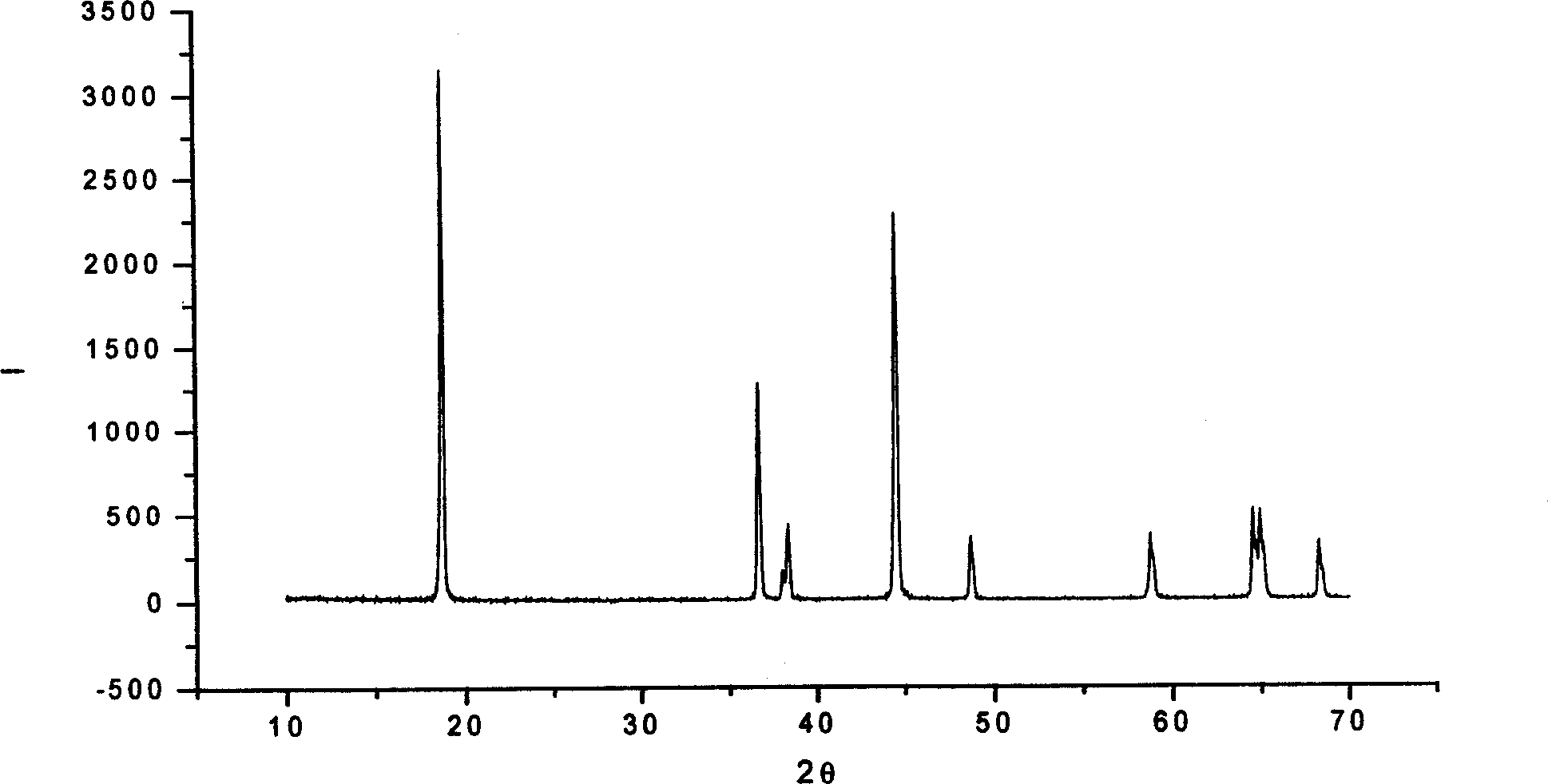

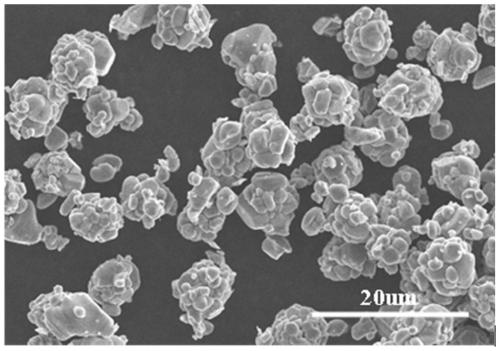

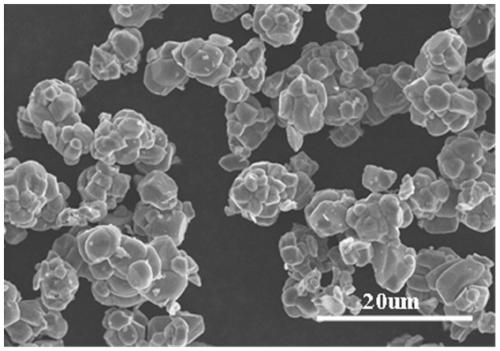

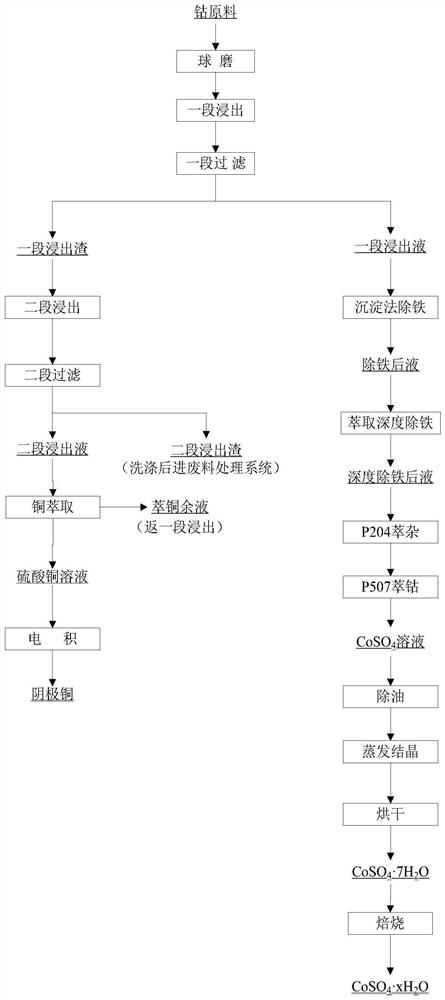

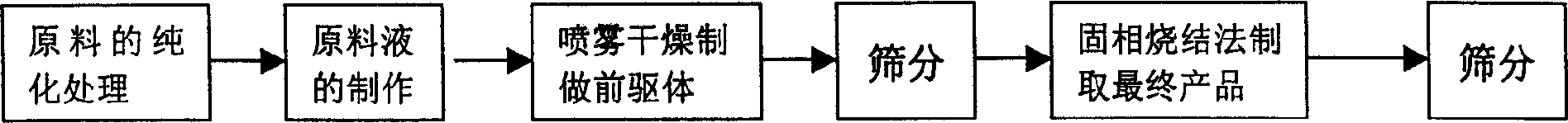

A kind of production method of battery grade cobalt sulfate crystal

ActiveCN109518005BReduce difficultyImprove the operating environmentPolycrystalline material growthProcess efficiency improvementSlagElectrical battery

The invention discloses a production method of battery-grade cobalt sulfate crystals. The steps are as follows: (1) pretreatment: crushing cobalt-containing raw materials and ball milling to form pulp; (2) two-stage leaching: adding acid and reducing agent to the pulp Carry out two stages of leaching; (3) Precipitation method for iron removal: add oxidant and neutralizer to one stage of leachate, control a certain temperature and pH value to form iron slag, and remove Fe in one stage of leachate; (4) Extraction depth for iron removal: Use the extraction method to remove a small amount of Fe in the liquid after iron removal to achieve the purpose of deep Fe removal; (5) P204 extraction of impurities and P507 extraction of cobalt (6) evaporation crystallization and roasting dehydration to obtain CoSO 4 ·xH 2 O crystals. The invention does not need to use hydrochloric acid, improves the operating environment and reduces the anti-corrosion requirements for equipment, and at the same time reduces the difficulty of wastewater treatment; the two-stage leaching process can reduce the burden of the precipitation iron removal process and the P204 impurity extraction process, and at the same time Raw materials are greatly saved.

Owner:赣州寒锐新能源科技有限公司

Anode material--lithium nickelate cobalt preparation method for lithium ion battery

InactiveCN1255889CReduce dosageReduce consumptionElectrode manufacturing processesLithium compoundsNickel saltLithium chloride

The invention is a method of preparing lithium ion cell anode material-nickel cobalt acid lithium, and its characteristic: in the proportion of its formula, A-group matters: water-soluble lithium salt which is one of the lithium chloride, lithium sulphate, lithium nitrate and lithium acetate, water cobalt salt which is one of the cobalt chloride, cobalt sulphate, cobalt nitrate and cobalt acetate, and water nickel salt which is one of the nickel chloride, nickel sulphate, nickel nitrate and nickel acetate, the molar ratio of the three matters is 1.00-1.1 : 0.2-0.3 : 0.8-0.7; B-group matters: complexant is one of the oxalic acid, tartaric acid, citric acid, succinic acid, malonic acid, and maleic acid; the molar ratio of A to B is 1.0 : 0.6 -0.8; C-group polymers: gelatin, modified starch and polyvinyl alcohol. The beneficial effects: it can effectively reduce cost and the made LiNi1-yCoyO2 has the advantages of both LiCoO2 and LiNiO2, i.e. easy to synthesize, stable-property, high-specific capacity (higher than that of LiCoO2 by above 20%), etc. Additionally, because the use of Co is reduced, thus it reduces the environmental pollution. Therefore, LiNi1-yCoyO2 has a great hope of becoming the preferred substitute for LiCoO2, and its market demand is quite considerable.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD

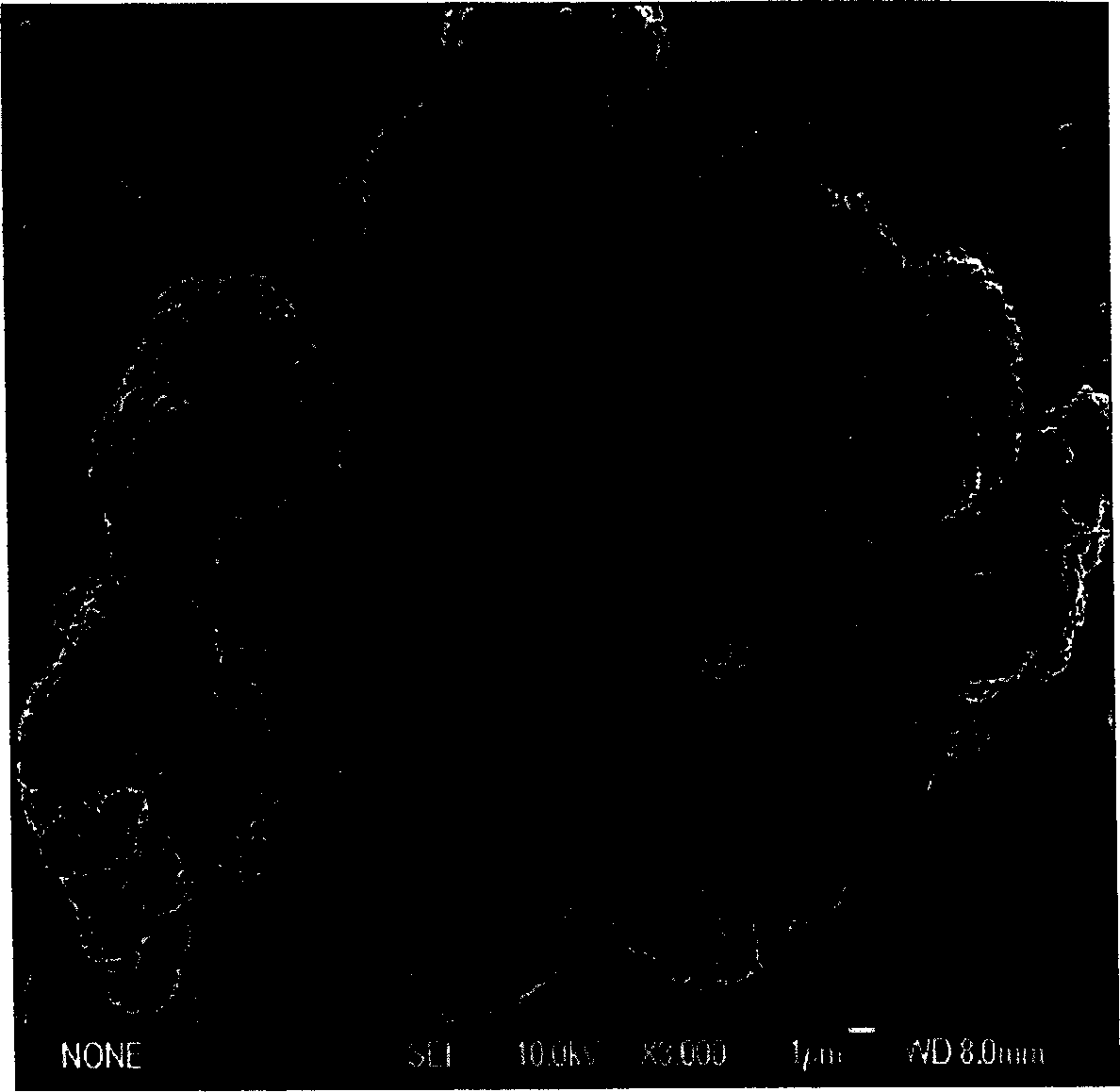

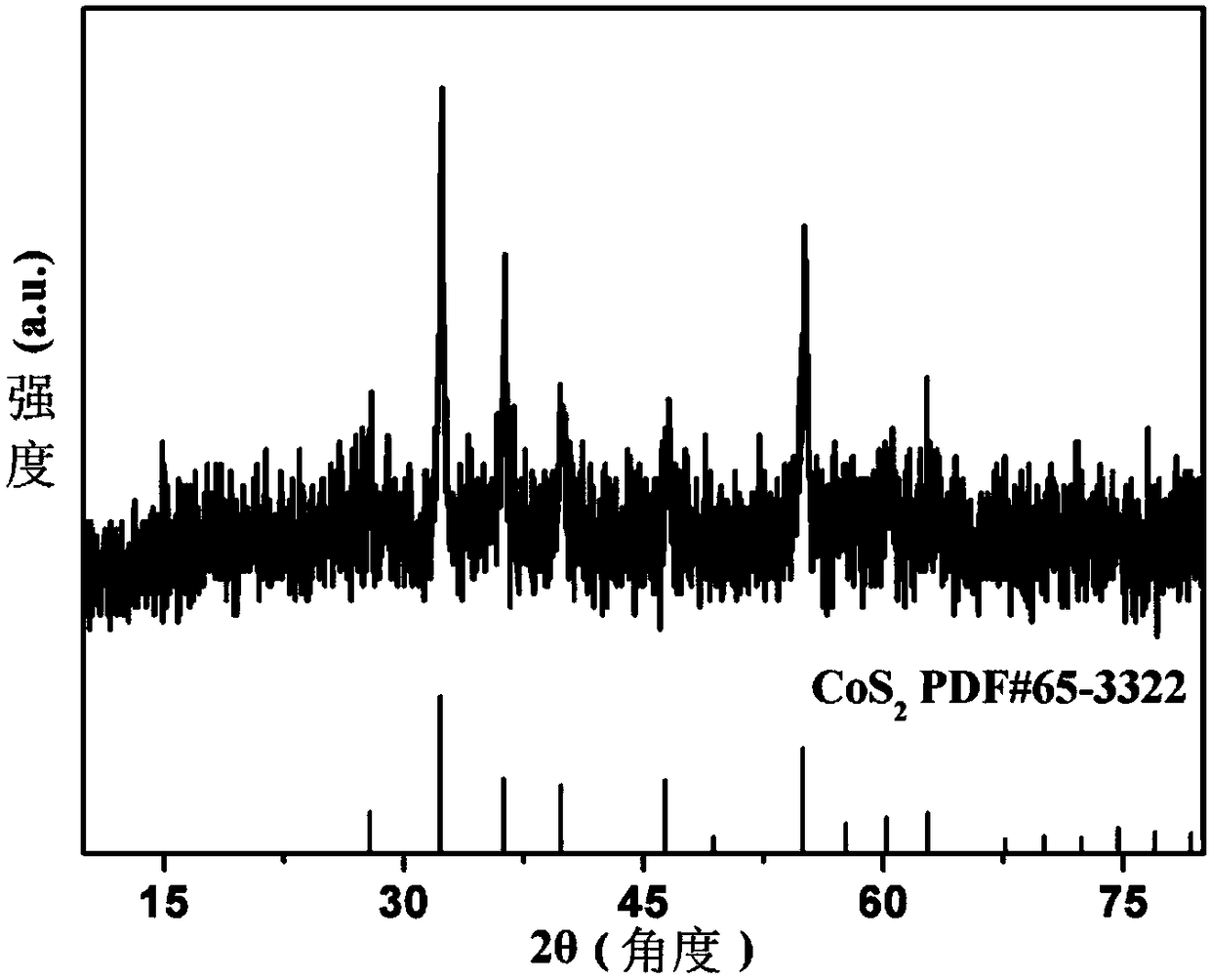

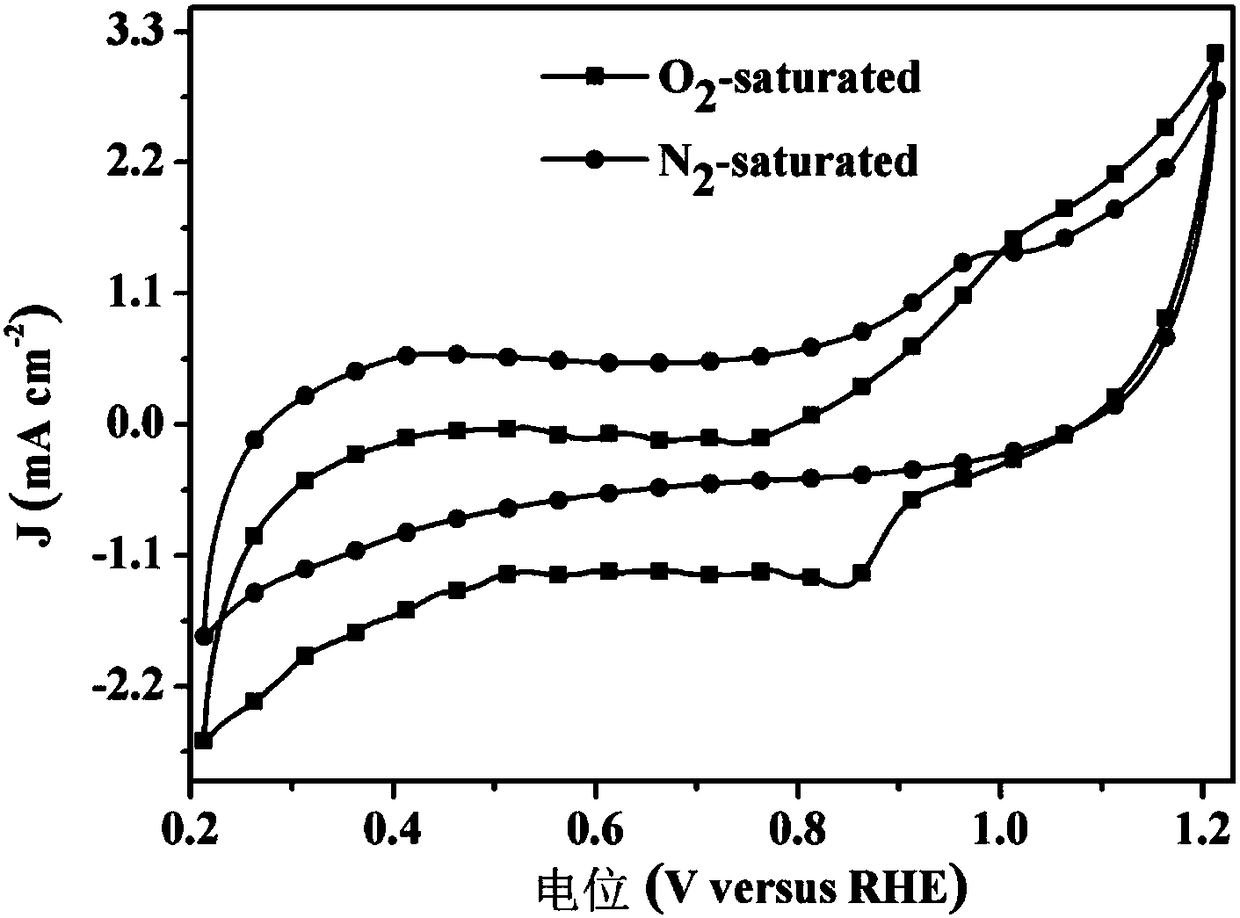

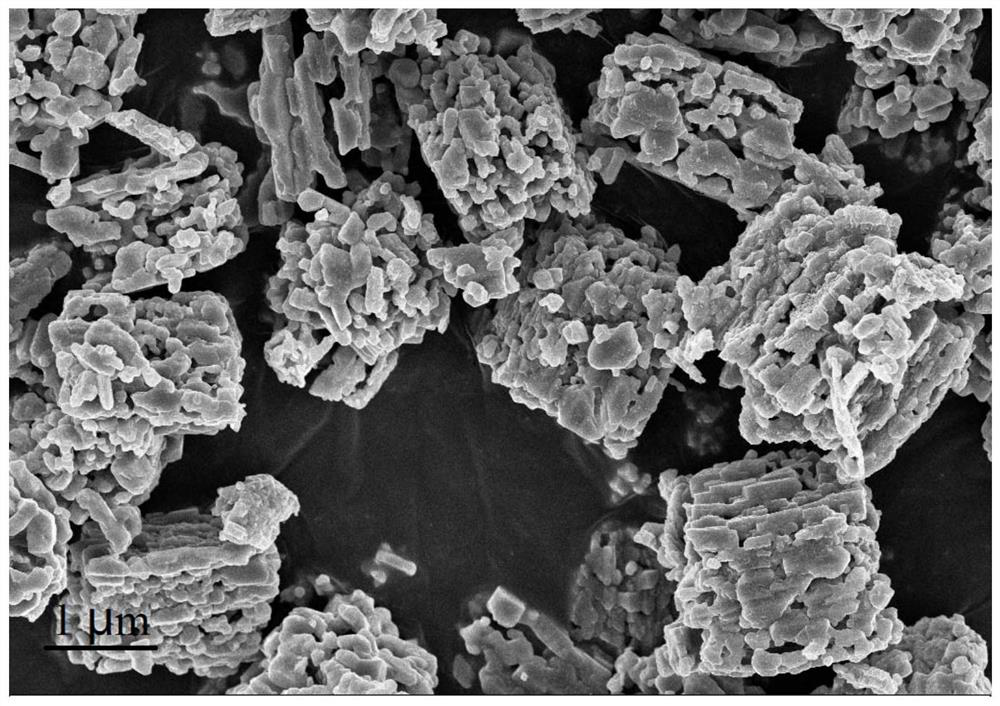

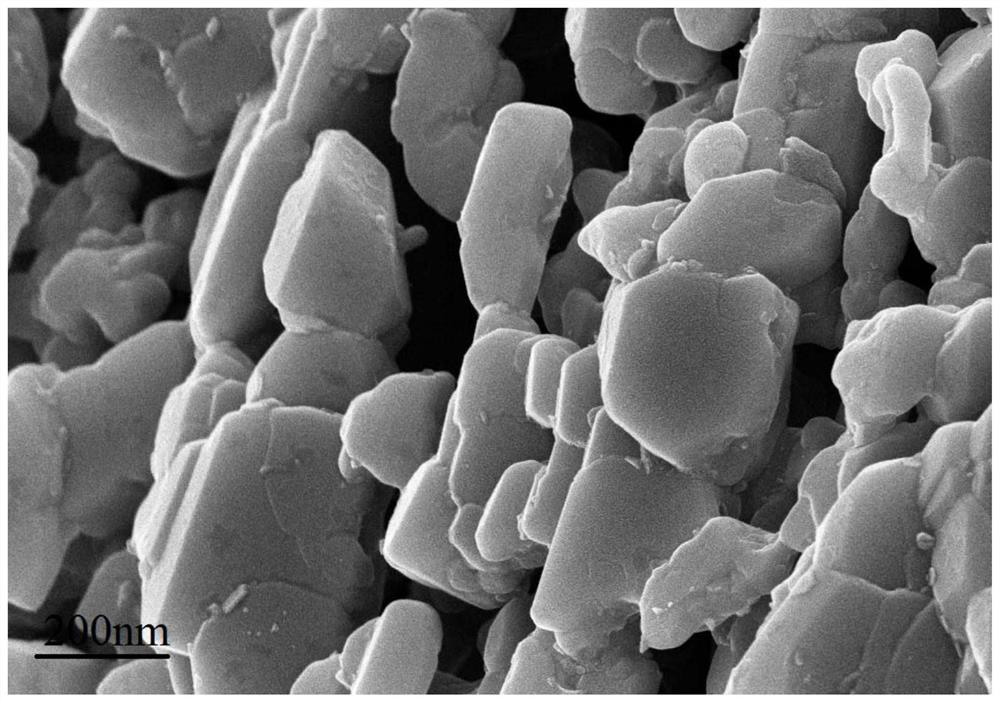

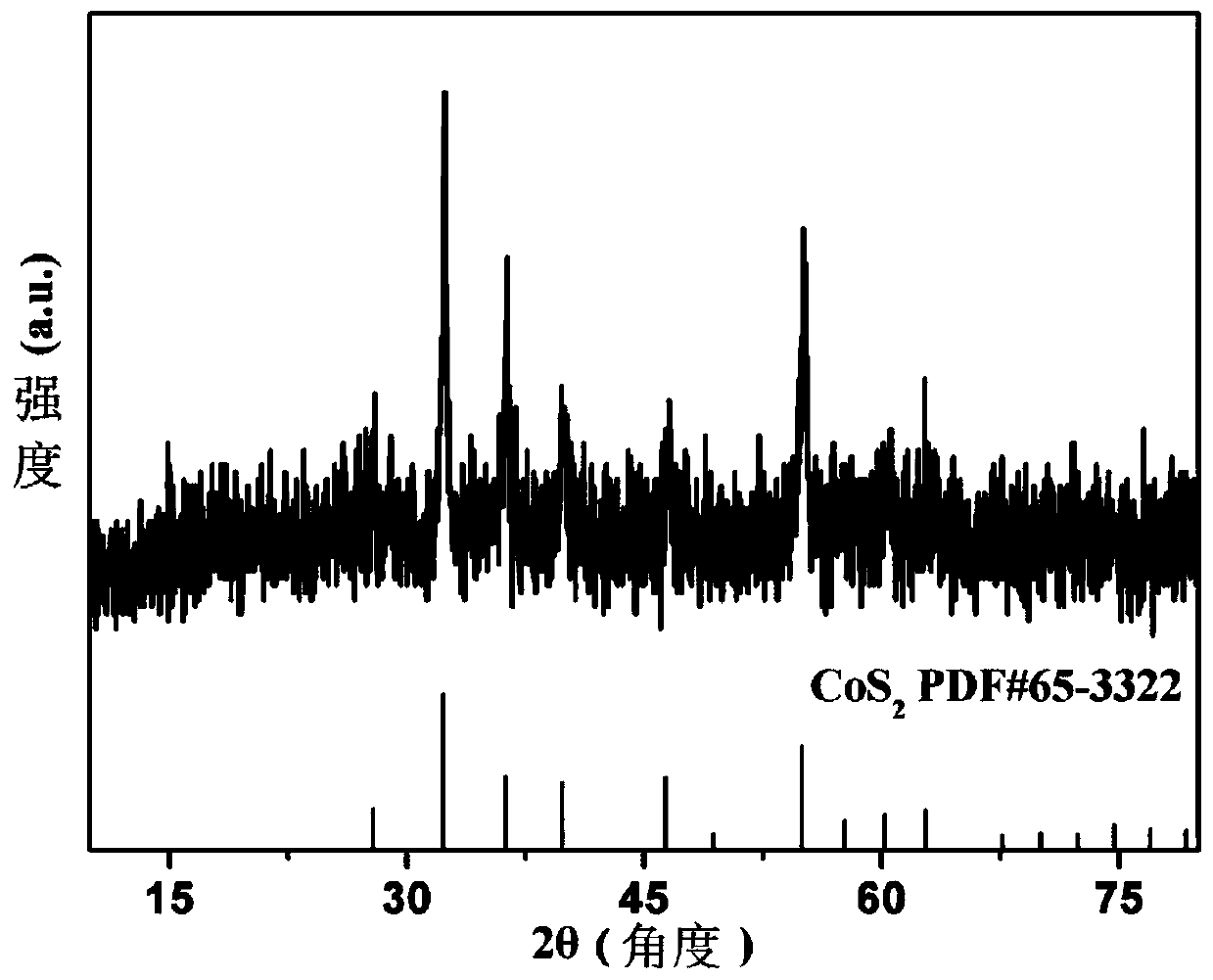

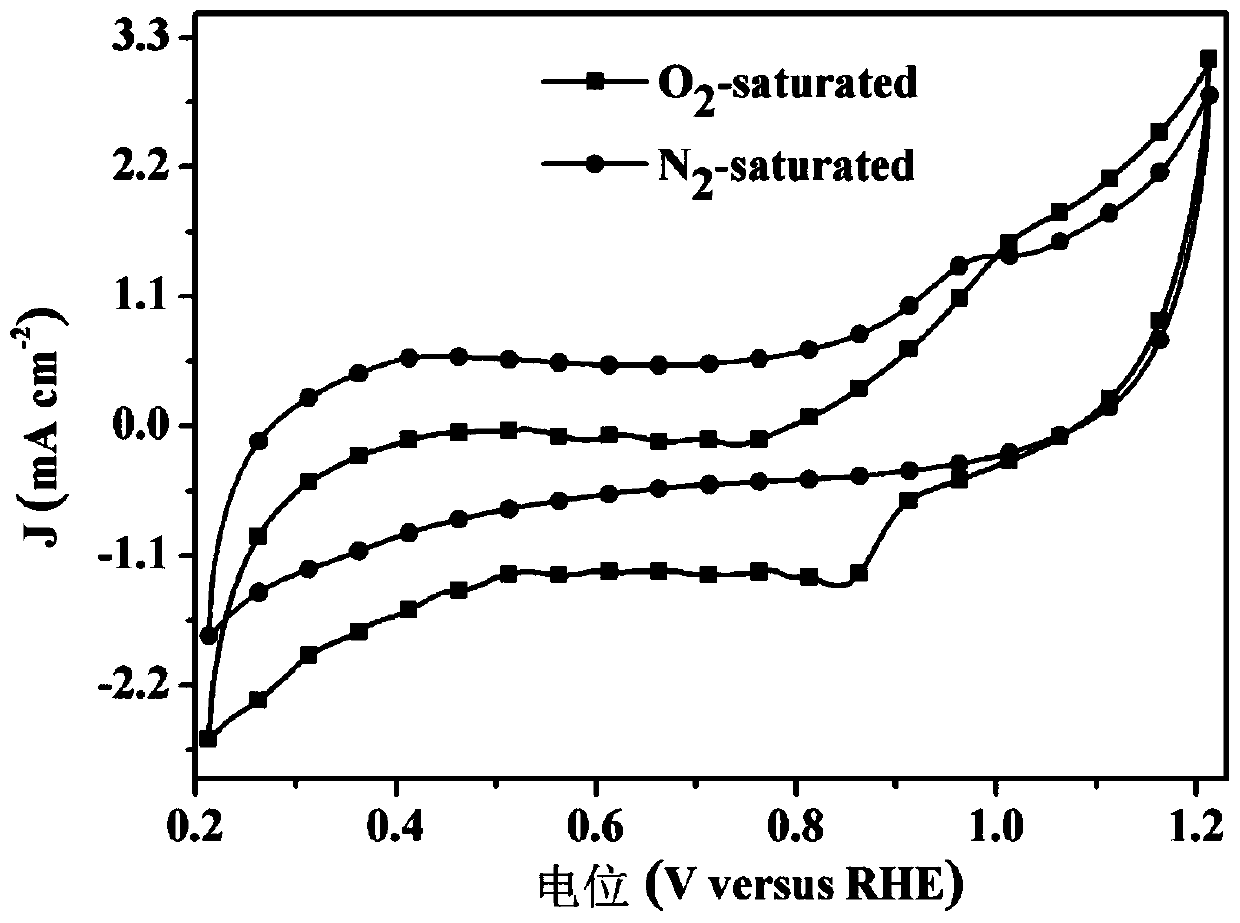

Preparation method of graphene-supported cobalt disulphide oxygen reduction catalyst and application thereof

InactiveCN108134103AThe process is simple and convenientMild reaction conditionsCell electrodesHigh current densitySulfide

The invention relates to a preparation method of a graphene-supported cobalt disulphide oxygen reduction catalyst. The preparation method comprises the following specific preparation steps: (1) reacting, namely, dissolving cobalt sulphate and sodium thiosulphate into deionized water, adding sulphur powder into a mixed solution, and then performing mixed reaction on the mixed solution and a graphene oxide dispersing liquid; (2) separating, namely, cooling after the reaction is completed, performing centrifugal washing and drying on obtained solid precipitate, and finally obtaining the graphene-supported cobalt disulphide oxygen reduction catalyst. According to the preparation method, the graphene-supported cobalt disulphide oxygen reduction catalyst is prepared through a one-step hydrothermal method; a preparation process is simple and safe; reaction conditions are mild and controllable, low in cost and short in period. The invention also discloses application of the catalyst to an oxygen reduction reaction, and the catalyst shows high current density and good oxygen reduction kinetics. According to the preparation method of the graphene-supported cobalt disulphide oxygen reductioncatalyst, a platinum-based catalyst with high cost and scarce resources is replaced by a transition metal sulphide, so that the cost of a fuel battery is reduced to a great extent.

Owner:UNIV OF JINAN

Diamond grinding wheel for cutting silicon crystal circle and preparation method thereof

ActiveCN101633158BHigh strengthImprove rigidityGrinding devicesGrinding machinesCobalt sulphateCnc grinding

The invention discloses a diamond grinding wheel for cutting a silicon crystal circle and a preparation method thereof. The method comprises the following steps: (1) preprocessing an aluminum alloy basal body; (2) configuring electroforming liquid: configuring the electroforming liquid according to the weight ratio of (38-43):(15-20):(43-57):(50-180):(4-8) of nickel sulphate, cobalt sulphate, deionized water, a diamond grinding material and a suspending agent; fully stirring evenly and obtaining the electroforming liquid; (3) carrying out insulation processing on the aluminum alloy basal bodyobtained in the step (1), putting the aluminum alloy basal body into the electroforming liquid, electroforming in an ultrasonic field, evenly precipitating the diamond grinding material in the electroforming liquid and metal on the basal body together and obtaining a grinding wheel blank body with a compound electroforming layer; and (4) taking out the grinding wheel blank body completing electroforming, and carrying out accurate processing on the grinding wheel blank body on a numerical control grinder and a numerical control lathe respectively according to the accuracy requirements of the required basal body and the required cutting edge. The diamond grinding wheel obtained by the invention meets the ultrathin and superfine technical conditions and also has favorable strength and rigidity.

Owner:赛尔科技(如东)有限公司

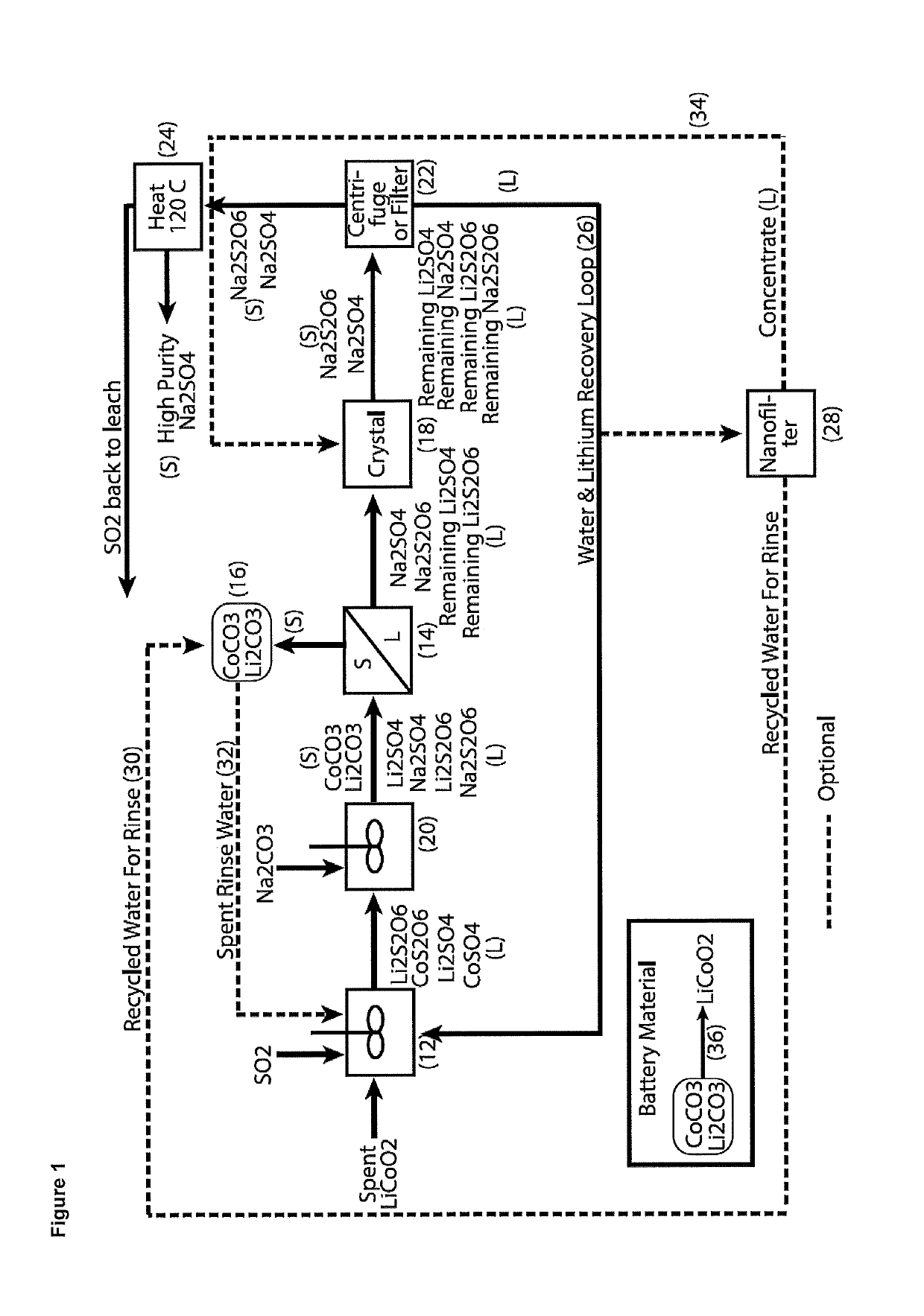

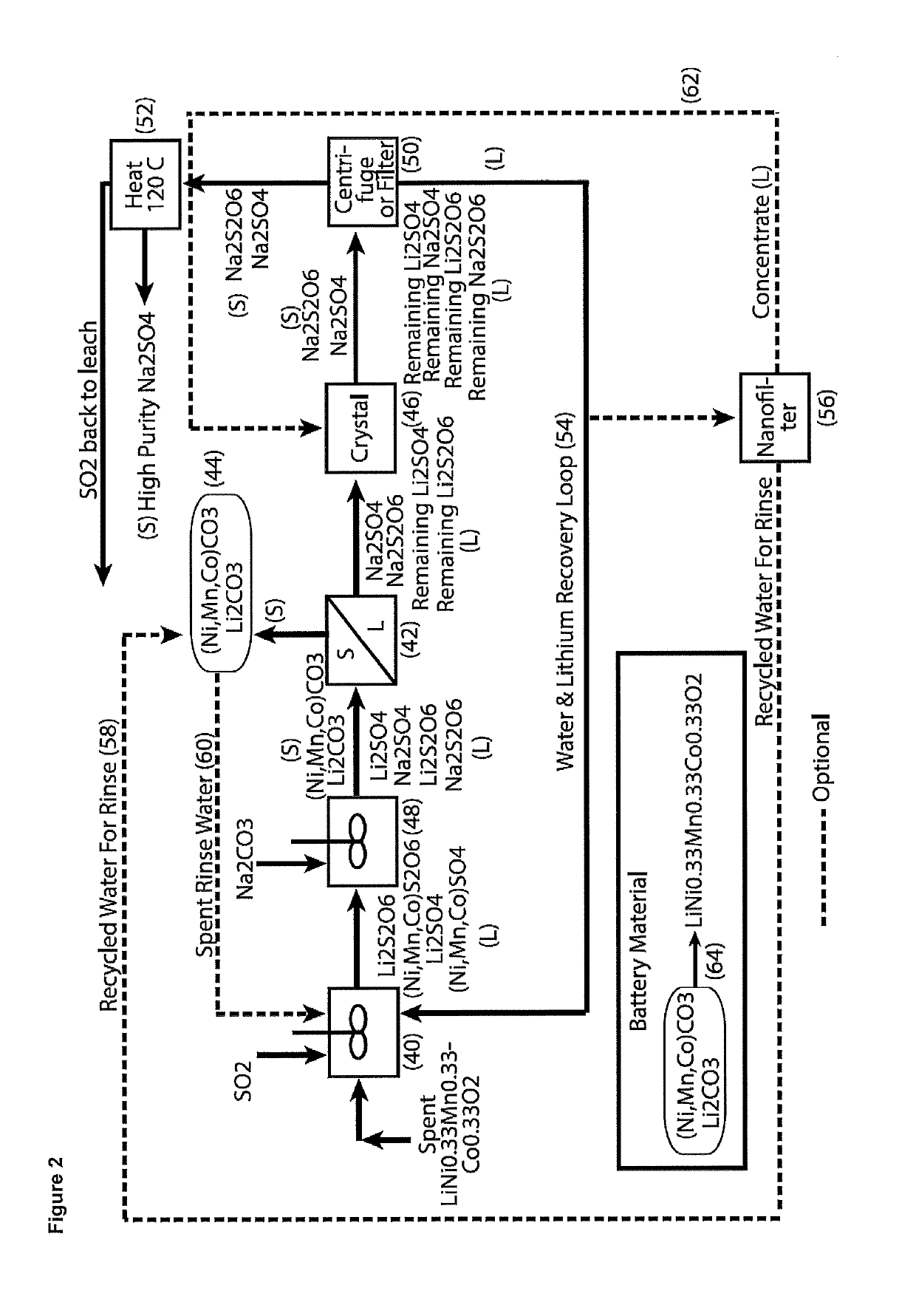

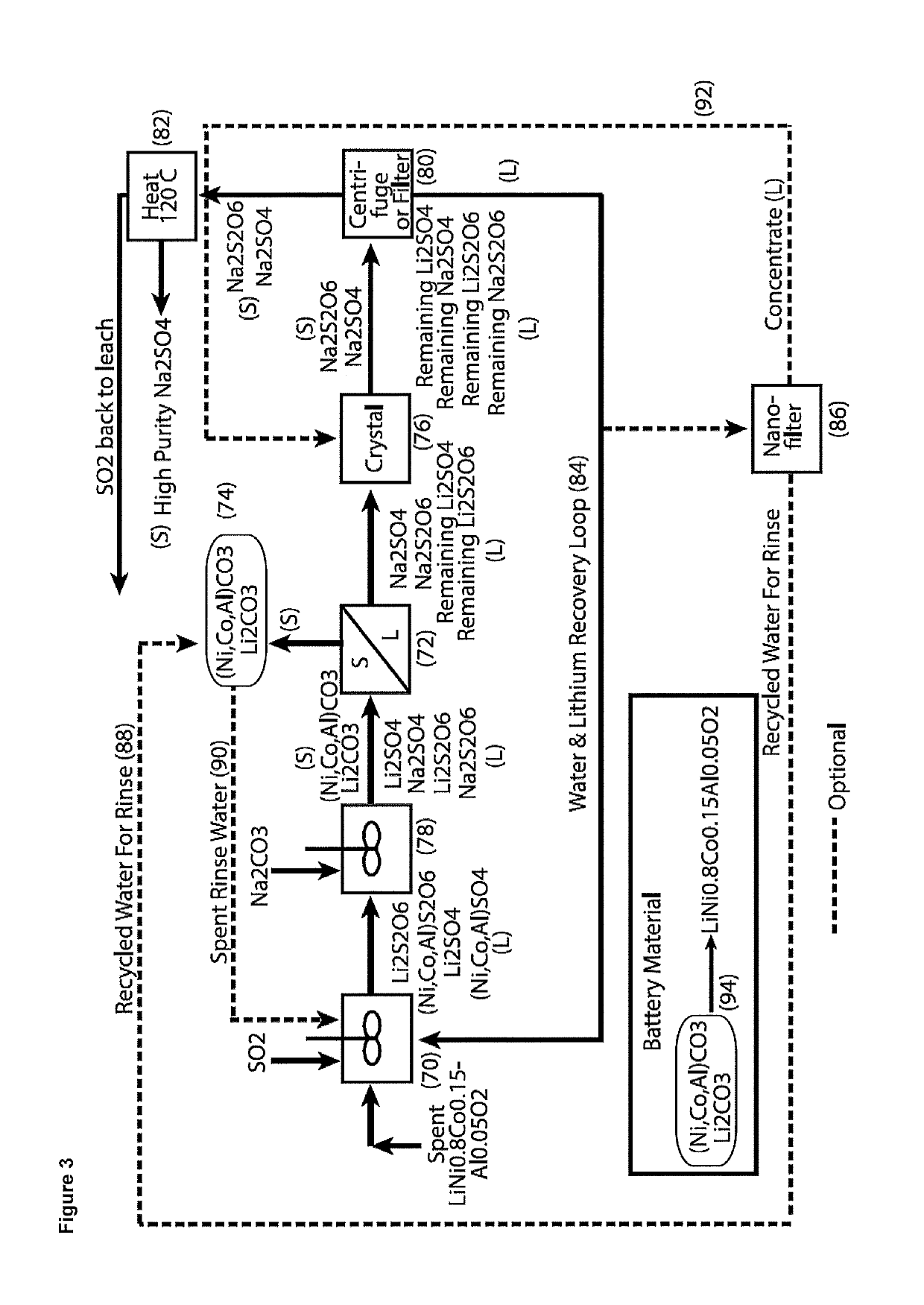

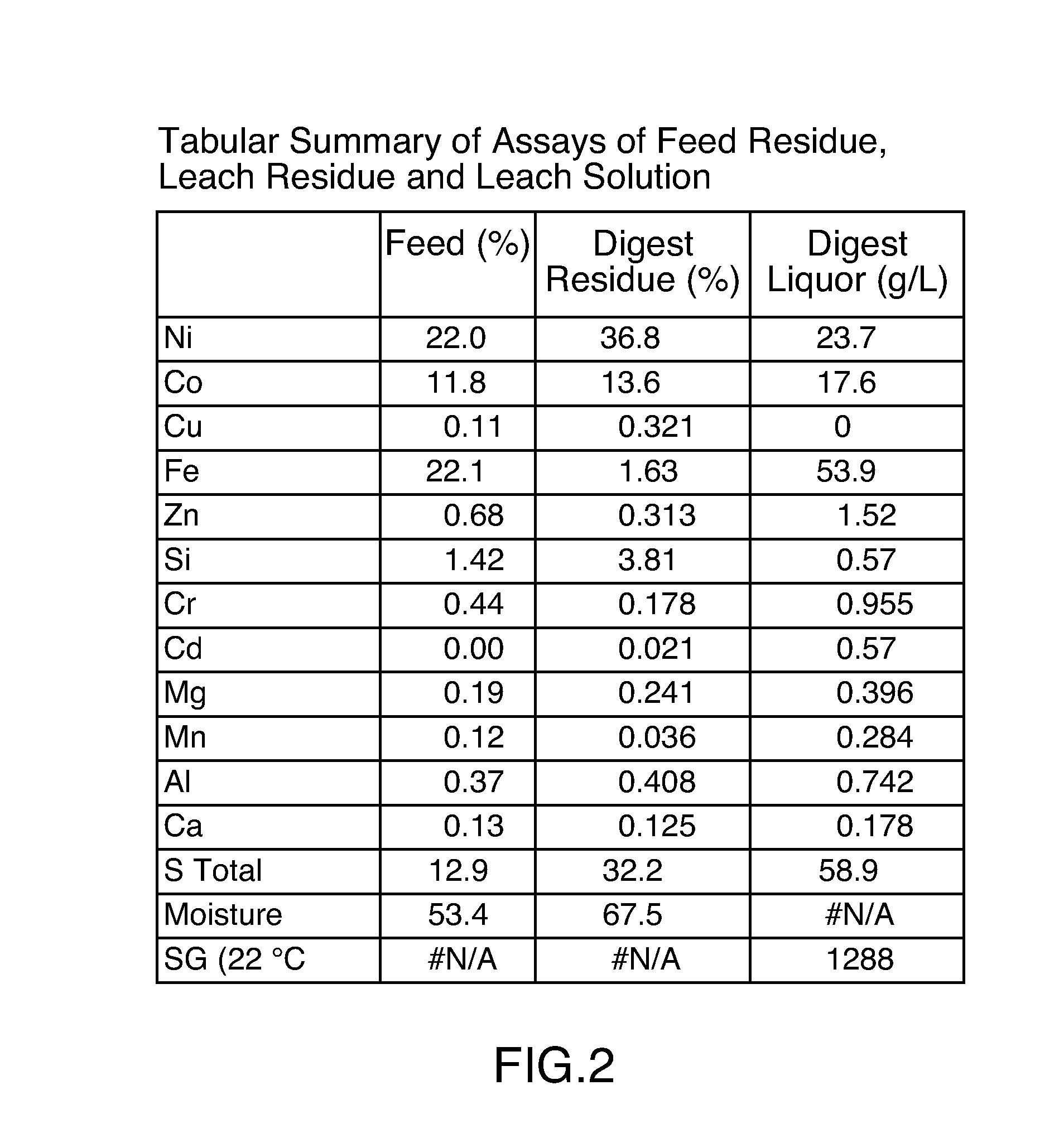

Processing of cobaltous sulphate/dithionate liquors derived from cobalt resource

ActiveUS10308523B1Thiosulfates/dithionites/polythionitesWaste accumulators reclaimingDithionateCobalt(II) hydroxide

A process for water removal and / or recycling of sodium sulphate and / or sodium dithionate containing liquors derived from processing a cobalt resource derived from components of lithium ion batteries comprising steps of deriving from the cobalt resource a solution containing cobalt sulphate and cobalt dithionate, precipitation of cobalt as cobaltous carbonate or cobaltous hydroxide followed by removal thereof from the liquor, crystallization of sodium sulphate and sodium dithionate and removal of the resulting crystals, followed by heating of the crystals to anhydrous sodium sulphate, sulphur dioxide and water and then separating the anhydrous sodium sulphate.

Owner:ROCHER MANGANESE INC

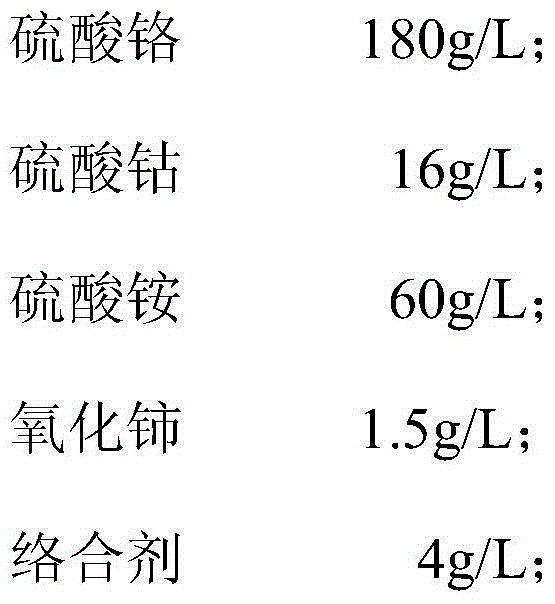

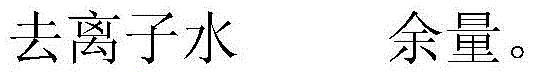

Rare-earth-cerium-chromium-cobalt electroplating solution and electroplating method thereof

The invention discloses a rare-earth-cerium-chromium-cobalt electroplating solution and an electroplating method thereof. The rare-earth-cerium-chromium-cobalt electroplating solution comprises 80-160 g / L of chromium sulfate, 20-80 g / L of cobalt sulphate, 0.1-10 g / L of cerium oxide, 4-60 g / L of formic acid, 80-120 g / L of sodium hypophosphite, and 1-10 g / L of a brightener. A certain amount of rare earth cerium is added into the rare-earth-cerium-chromium-cobalt electroplating solution, the electric current efficiency and dispersion performance are obviously improved. The electroplated layer is compact and uniform and has excellent combination and corrosion resistance.

Owner:无锡杨市表面处理科技有限公司

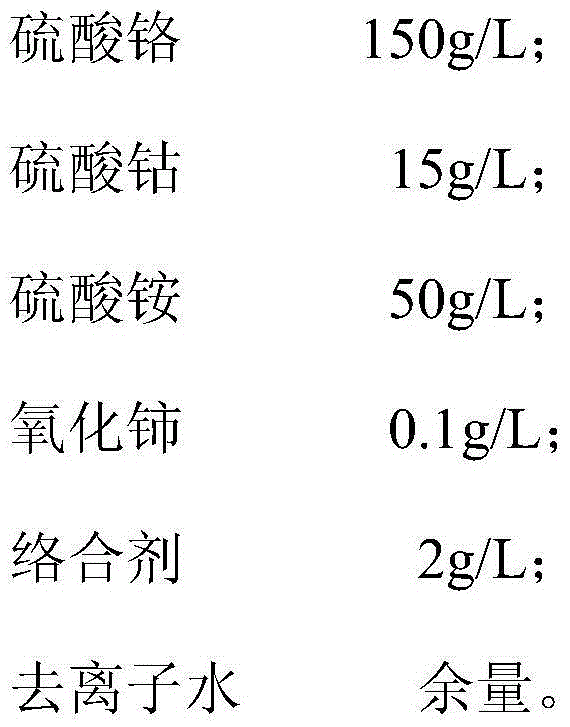

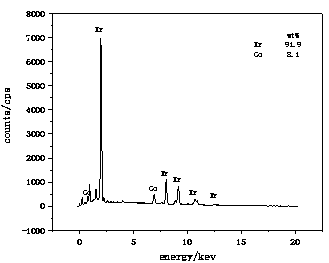

Polyhedral cobalt iridium nano particle electrolytic hydrogen evolution catalyst and plating solution formula and preparation method thereof

ActiveCN110453256ASimple deposition processSize is easy to controlElectrode shape/formsIridiumBenzotriazole

The invention discloses a polyhedral cobalt iridium nano particle electrolytic hydrogen evolution catalyst and a plating solution formula and a preparation method thereof. The cobalt iridium nano particles have octahedral and octahedral structures, the particle size is 10-250 nm, the chemical components of cobalt and iridium in the particles are uniformly distributed, the iridium content is 45-95wt%, the catalytic hydrogen evolution performance tower fresnel slope of the catalyst is 30-40 mV / decade. The plating solution formula of the catalyst is that the cobalt salt is 5-200 mmol / L of cobaltsulfamate and 1-100 mmol / L of cobalt sulfamate; the iridium salt is 10-150 mmol / L of hexa-bromo-iridium (IV) acid sodium and 1-100 mmol / L of hexa-bromo-iridium (III) acid sodium; the conductive saltis 0.1-500 mmol / L of sodium bromide and 0.1-100 mmol / L of sodium chloride; the complexing agent is 1-20 mmol / L of triammonium citrate and 1-10 mmol / L of sodium tetraborate l; and the other additives are 1-10 mmol / L of benzotriazole, 1-10 mmol / L of thiourea and 1-5 mmol / L of sodium dodecyl benzene sulfonate. The preparation method is prepared by an electrochemical deposition process, is high in efficiency and can be applied to the surface preparation of a conductive substrate with a complicated shape, and the size of the nano particles and the components of the nano particles are controllable;in addition, the catalytic performance is high, and the stability is high.

Owner:CHANGZHOU UNIV

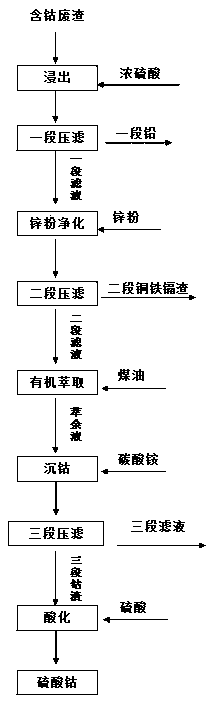

Method for preparing cobalt sulphate from zinc smelting cobalt-containing waste residues

InactiveCN109182770AIncrease consumptionIncrease costCobalt sulfatesProcess efficiency improvementRaffinateImpurity

The invention discloses a method for preparing cobalt sulphate from zinc smelting cobalt-containing waste residues. The method comprises the following steps of: preparing cobalt sulphate from zinc smelting cobalt-containing waste residues by a method of combining zinc powder replacement with extraction; adding quantitative zinc powder to remove copper-iron-cadmium impurities in leaching liquor; adding an organic reagent into obtained second-stage filtrate to extract to obtain extracting liquor and raffinate; adding ammonium carbonate into the raffinate to perform cobalt precipitation, whereinpercentage content of cobalt in the cobalt residues is 80%; and dissolving and acidifying three-stage cobalt residues obtained by filter-pressing with sulphuric acid to finally obtain a cobalt sulphate solution. The method is low in cost, is simple in process flow, and percentage content of cobalt in the cobalt residues is high, so that high-value comprehensive utilization for zinc smelting cobalt-containing waste residues is realized.

Owner:常宁市华兴冶化实业有限责任公司

Electrolyte of lead-acid battery and preparation method thereof

InactiveCN101685884BGood dispersionImprove stabilityFinal product manufactureLead-acid accumulators constructionDispersityEnvironmental resistance

The invention relates to an electrolyte of lead-acid battery and preparation method thereof. The electrolyte comprises the following raw materials by parts by weight: 20-40 parts of deionized water, 62-68 parts of dilute sulphuric acid, 1.5-2.5 parts of nano aerosol and 2-2.5 parts of electrolyte active agent; wherein the electrolyte active agent is formed by analytically pure potassium sulphate, zinc sulphate, ammonium sulphate, magnesium sulphate, aluminium sulphate, sodium sulphate, cobalt sulphate, aluminium phosphate and lithium iodide in certain ratio; and multiple micro elements are added into the electrolyte, so that the nano silicon oxide particles have favourable dispersity, the prepared electrolyte has no sedimentation, flocculation or layering for a long time, and meantime service life and environmental performance of battery can be effectively improved.

Owner:深圳市夺标环保技术有限公司

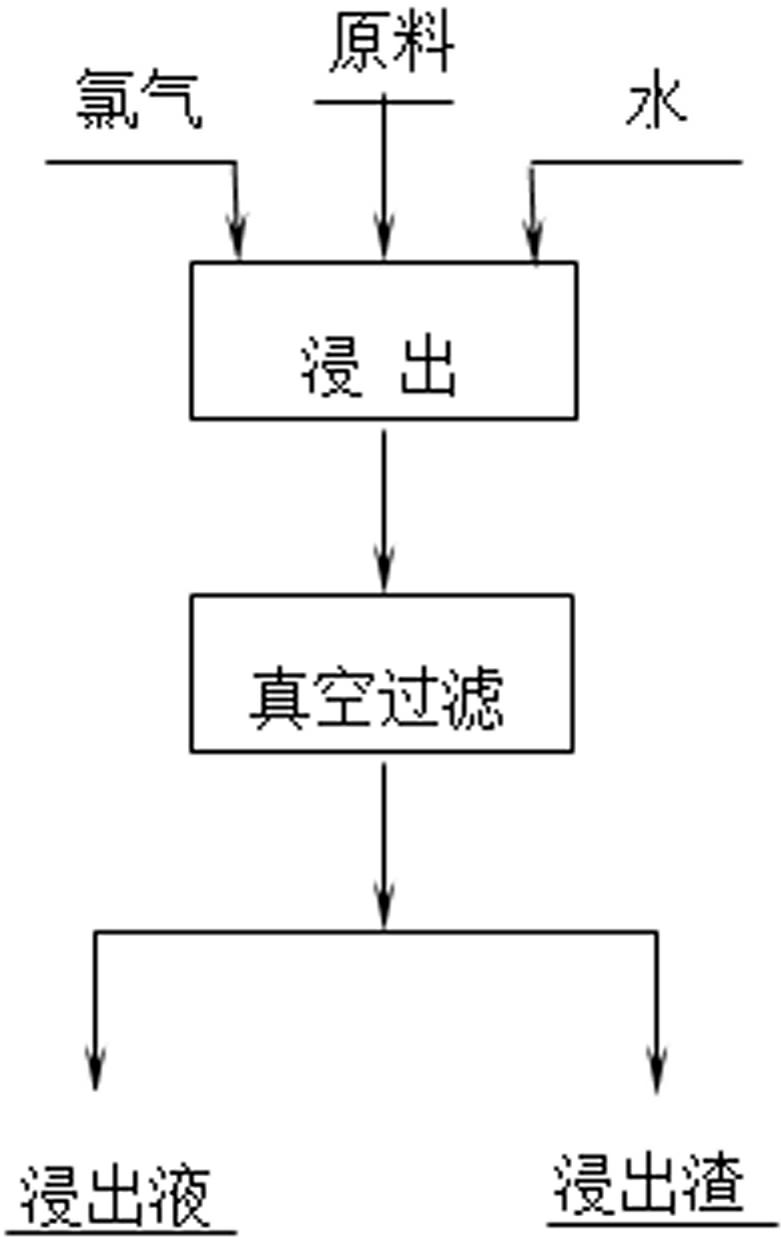

Chlorination leaching method of laterite sulfurized precipitate

InactiveCN102634655AFast chemical reactionReduce energy consumptionProcess efficiency improvementCobalt sulphatePregnant leach solution

The invention relates to a chlorination leaching method of laterite sulfurized precipitate. Chlorination leaching is utilized to obtain the metallic-nickel-enriched turnover liquid which can directly enter the nickel production system. The technological process comprises the following steps: (1) mixing the laterite sulfurized precipitate and water in a mass ratio of (2-6):1, and introducing chlorine gas of which the pressure is 0.1-0.5Mpa; and (2) control of leaching of chlorine gas: the liquid-to-solid ratio is controlled at (2-6):1, the leaching temperature is 70-80 DEG C, the leaching potential is 450-480mv, the leaching time is 2-4 hours, and the leaching stock solution is a copper-bearing 30-50 g / L water solution. The invention obtains a nickel-cobalt sulphate solution of which the nickel content is greater than 90%: more than 90% of nickel and cobalt in the laterite sulfurized precipitate are leached and enter the solution, and valuable metals in the residues are comprehensively recycled, thereby promoting the recycling of waste ores.

Owner:JINCHUAN GROUP LIMITED

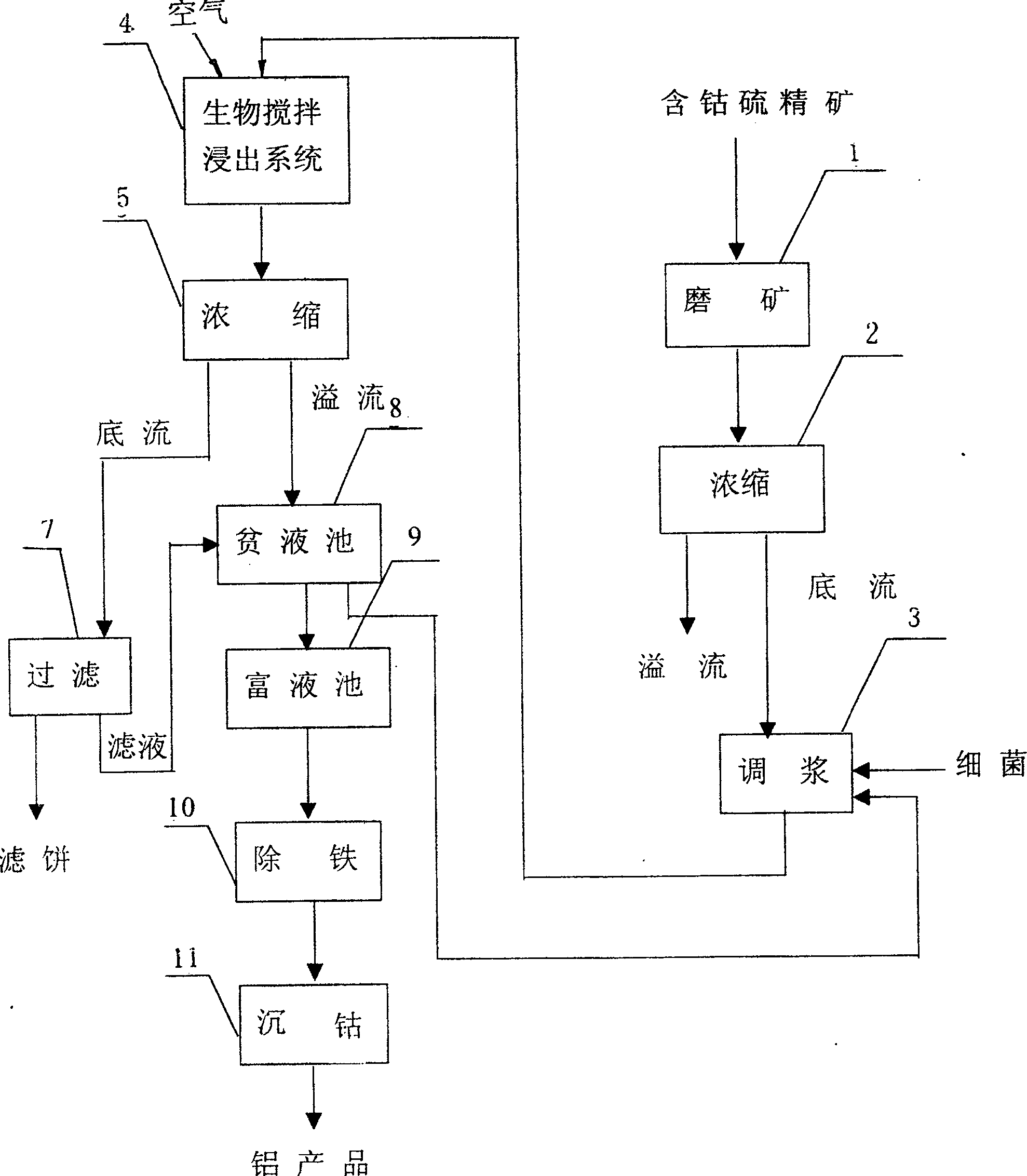

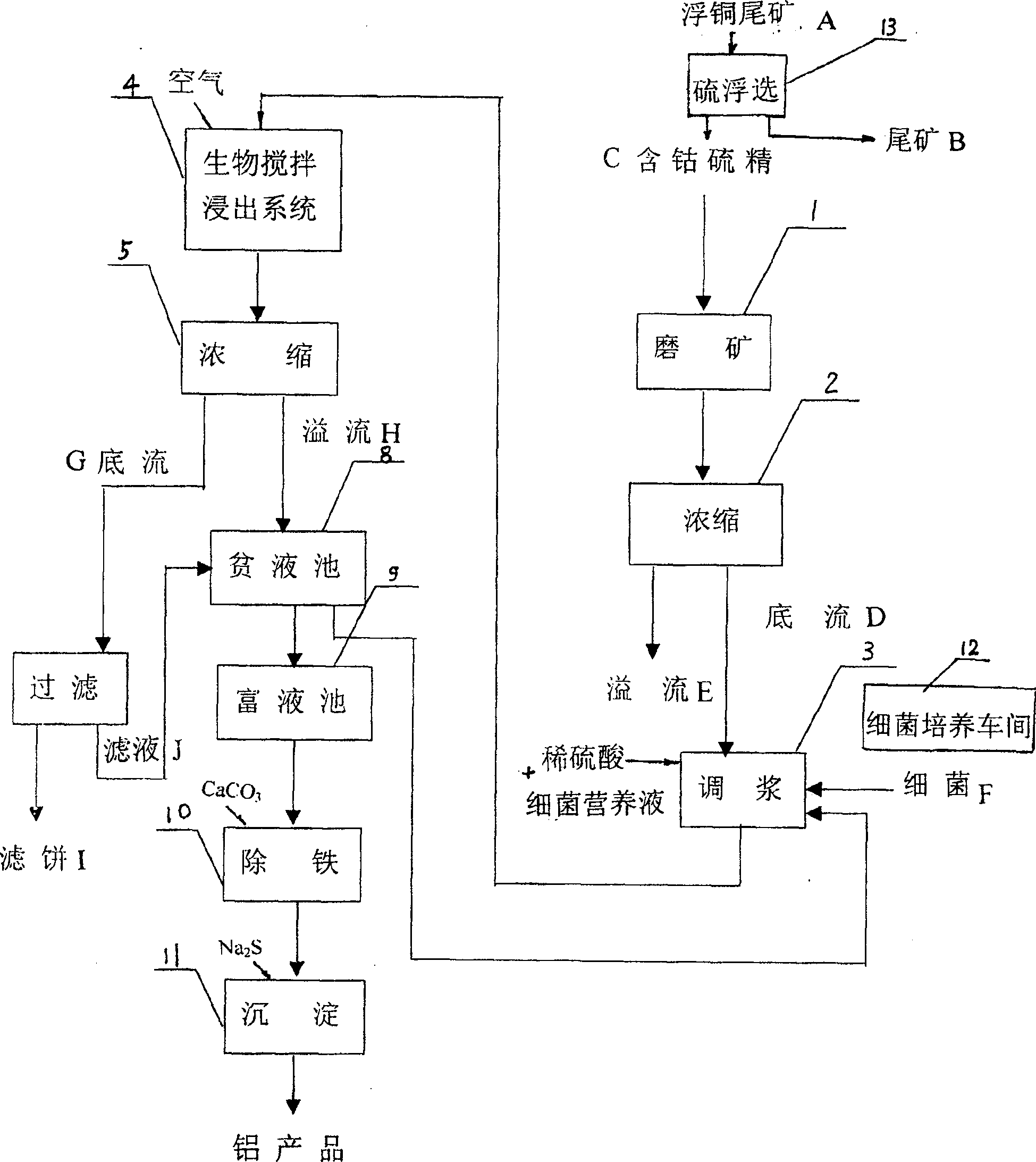

Biological stirring cobalt-dipping technique for concentrate containing cobalt and sulfur

InactiveCN100537799CFast leachingEfficient recyclingMicroorganismsProcess efficiency improvementCobalt sulphateSulfur

Owner:有研资源环境技术研究院(北京)有限公司

A two-step method for preparing a nitrogen-doped carbon-supported cobalt tetroxide particle catalyst

The invention relates to the field of energy materials, and discloses a two-step method for preparing a nitrogen-doped carbon-supported cobalt tetroxide particle catalyst for the problem that carbon atoms will reduce cobalt tetroxide during high-temperature pyrolysis to reduce the number of active components. It includes the following preparation steps: add cobalt source and nitrogen source to deionized water, add carbon source after being completely dissolved, and ultrasonically disperse evenly; react the above-mentioned solution at 170~190°C; suction filtration and drying in sequence; the obtained samples were ground evenly and subjected to high-temperature pyrolysis in argon to obtain finished products. The present invention uses biomass carbon source glucose and its derivatives, urea and cobalt sulfate as precursors, and prepares nitrogen-doped carbon-loaded tricobalt tetroxide through two steps of hydrothermal-pyrolysis, effectively reducing the problem of tricobalt tetroxide being reduced during the pyrolysis process, The number of active sites on the catalyst surface is guaranteed.

Owner:HANGZHOU DIANZI UNIV

Cobalt-titanium film-forming agent, aluminum material and surface coating treatment method of aluminum material

InactiveCN112725782AImprove corrosion resistanceStrong adhesionMetallic material coating processesCobalt sulphateSodium tungstate dihydrate

The invention relates to a cobalt-titanium film-forming agent, an aluminum material and a surface coating treatment method of the aluminum material. The cobalt-titanium film-forming agent is used for pretreating the surface of the aluminum material and comprises the following components of, in terms of 1000 parts by weight, 5-50 parts of cobalt sulfate, 2-20 parts of potassium fluotitanate, 2-10 parts of hydrofluoric acid, 2-10 parts of sodium tungstate and the balance water. A film layer formed by the cobalt-titanium film-forming agent is good in corrosion resistance and strong in adhesive force, and is particularly suitable for being used as a coating treatment bottom layer; when the film-forming agent is applied to aluminum material treatment, the film-forming agent can be used in a soaking and spraying mode, and water washing is not needed, so that water is saved, inconvenience caused by using water is avoided, and the film-forming agent is thus very convenient to use; and the film-forming agent is free of chromium ions and other heavy metal which damage the environment, and is of a green, energy-saving and environment-friendly product.

Owner:SHENZHEN CHANGHONGTAI TECH CO LTD

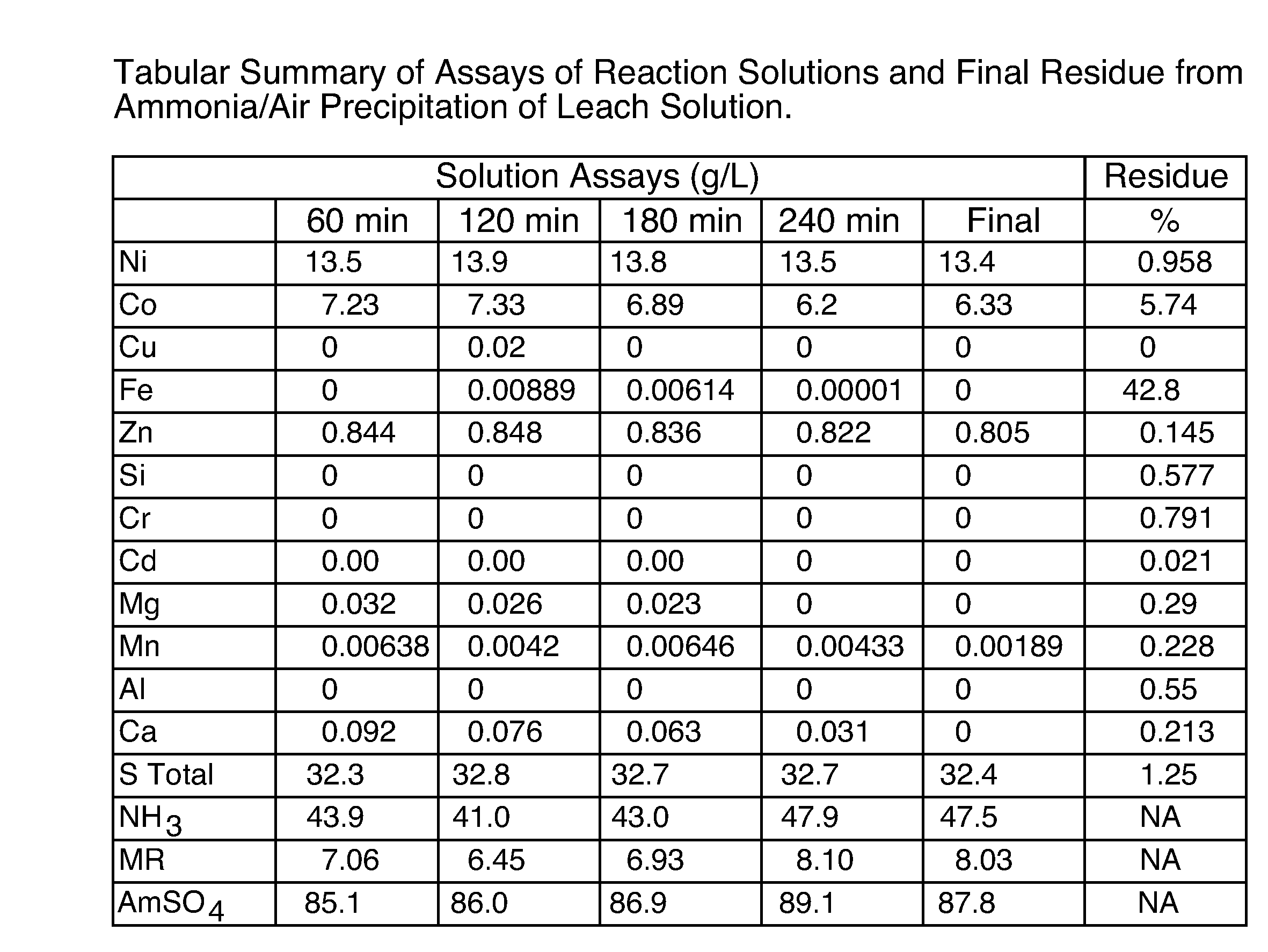

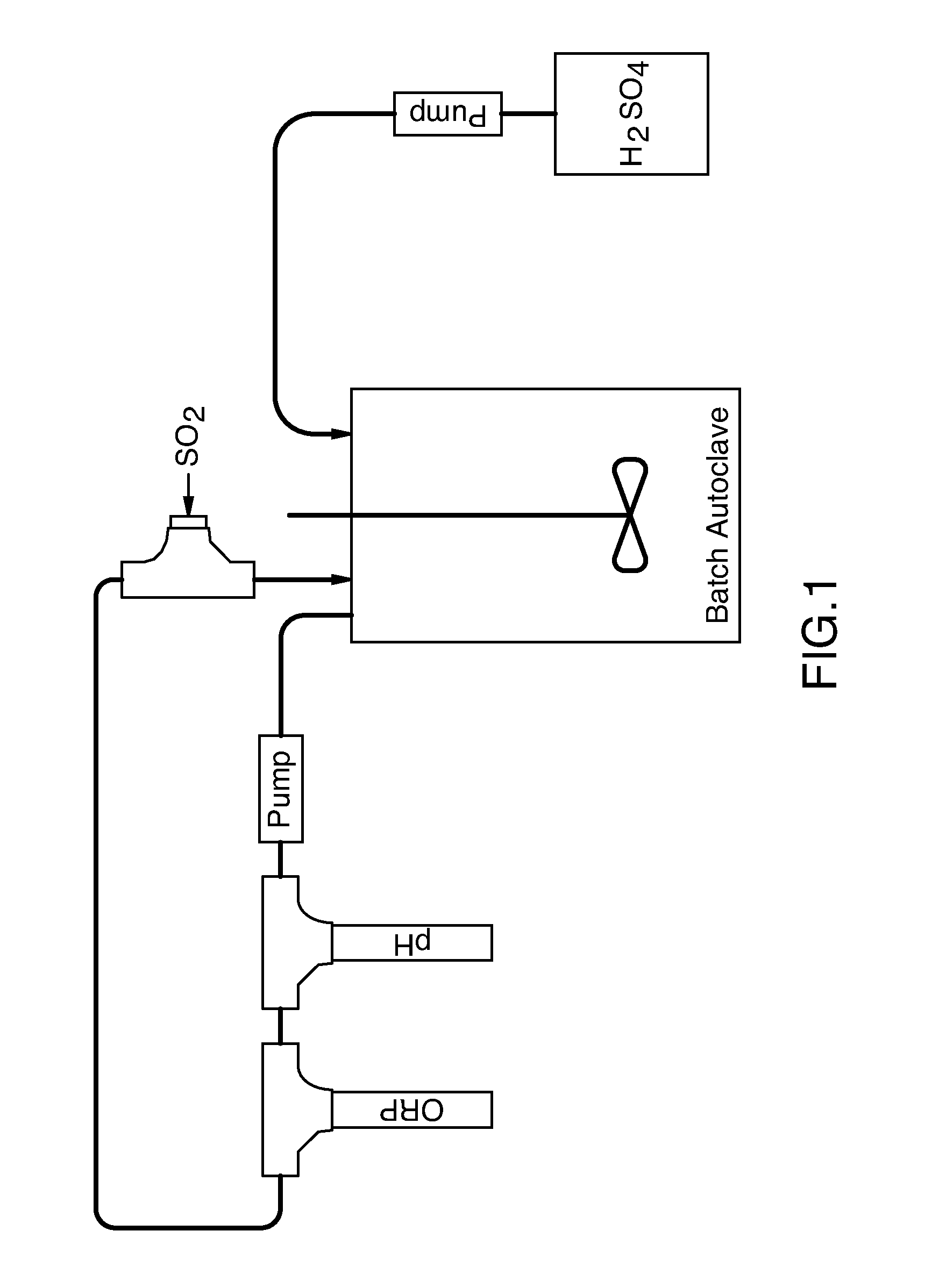

Recovering Metal Values from a Metalliferrous Material

A method of treating a metalliferrous material source is provided. The metalliferrous material source includes at least one of nickel sulphide and cobalt sulphide, and also includes iron sulphide. The metalliferrous material source is leached with a preliminary leachant in a leaching zone to effect production of a preliminary leach product including a preliminary leach solution and a preliminary leach solid residue. The preliminary leachant includes an aqueous solution comprising ammonia and ammonium sulphate. The preliminary leach solution includes at least one of dissolved nickel comprising material and dissolved cobalt comprising material. The preliminary leach solid residue includes: (i) at least one of nickel sulphide and cobalt sulphide, (ii) at least one of other nickel comprising material and other cobalt comprising material, and (iii) other iron comprising material. At least a fraction of the preliminary leach solid residue is separated from the preliminary leach product such that a metalliferrous material is provided, wherein the metalliferrous material includes at least a fraction of the separated preliminary leach solid residue. At least a fraction of the metalliferrous material is leached with an aqueous solution including dissolved sulphuric acid and dissolved sulphur dioxide in a leaching zone so as to effect production of an operative leach product including a leachate component and a solid residue component, wherein the leachate component includes nickel sulphate, cobalt sulphate, and iron sulphate, and wherein the solid residue component includes at least one of nickel sulphide and cobalt sulphide. At least a fraction of the solid residue component is separated from the operative leach product to provide a recovered solid residue component. The recovered solid residue component is recycled to the preliminary leaching zone.

Owner:SHERRITT INTERNATIONAL

Synthesis method of a high-performance lithium-rich manganese-based cathode material with a cubic structure

ActiveCN107845789BImprove lithium battery performanceSimple processCell electrodesSecondary cellsCobalt sulphateManganese sulphate

The invention discloses a synthetic method of a high-performance lithium-rich manganese-based cathode material having a cube structure. The method comprises the following steps: dissolving cobalt sulphate, nickel sulfate and manganese sulfate in deionized water, and adding an alkalescence pH buffering agent to form a solution A; dissolving a double-carbon compound in ethanol to form a solution B;mixing the solution A and the solution B, employing a hydrothermal method for synthesizing a precursor of the cathode material having the cube structure; filtering the precursor, washing the precursor, drying the precursor, and calcining the material to obtain the high-performance lithium-rich manganese-based cathode material having the cube structure. The high-performance lithium-rich manganese-based cathode material takes cobalt sulphate, nickel sulfate, and manganese sulfate as metal sources, the double-carbon compound is taken as a precipitating agent, lithium acetate or sodium acetate istaken as the pH buffering agent, and the hydrothermal method is employed for synthesizing the cathode material having the cube structure. The method has the advantages of simple process and low cost,and the synthesized cathode material having the cube structure has excellent lithium-ion battery performance.

Owner:SUZHOU YOULION BATTERY INC

Preparation method and application of a graphene-supported cobalt disulfide oxygen reduction catalyst

InactiveCN108134103BThe preparation process is simple and safeThe reaction conditions are mild and controllableCell electrodesPtru catalystOxygen reduction reaction

Owner:UNIV OF JINAN

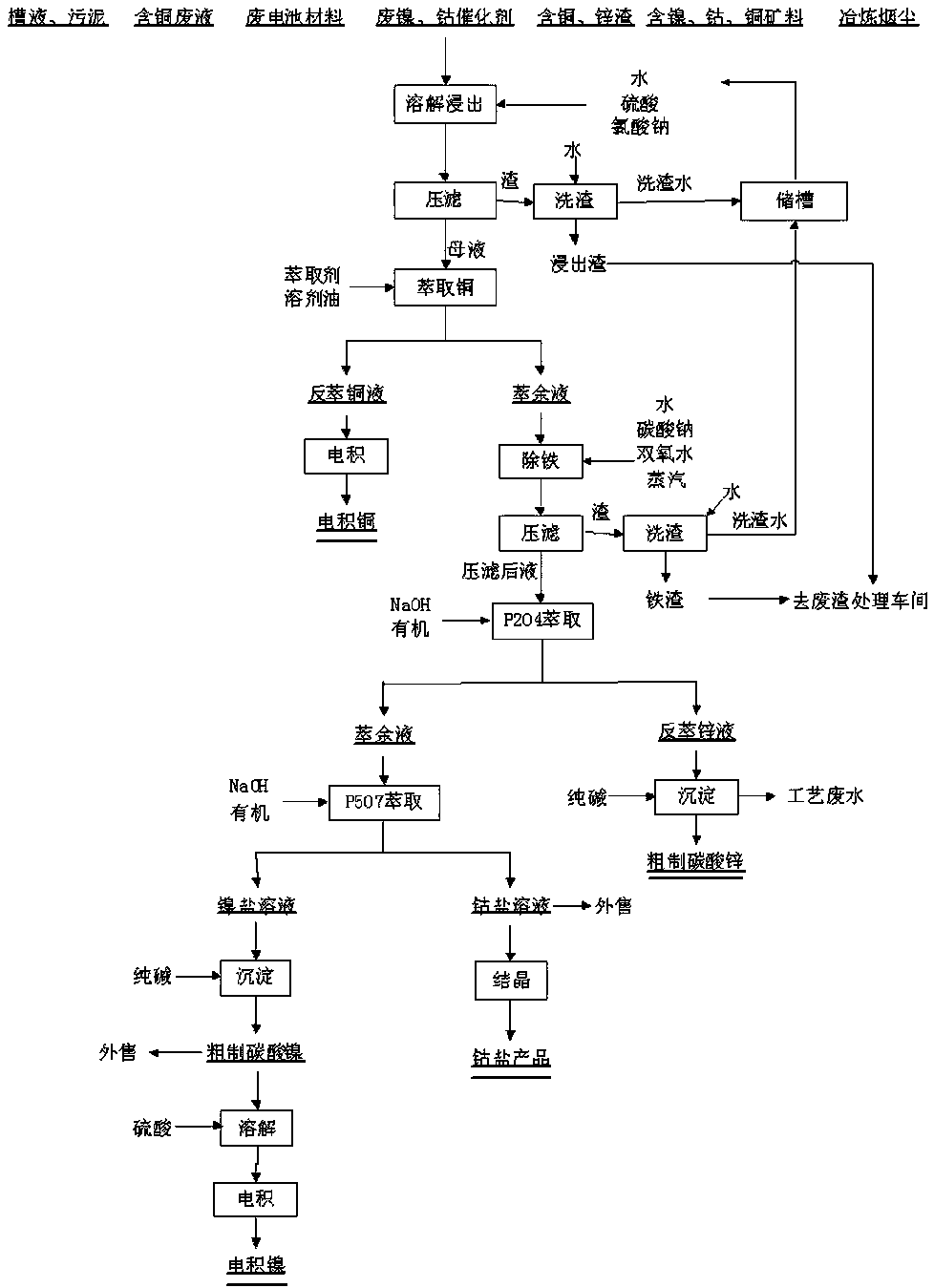

Method for recovering copper, zinc, cobalt and nickel from various waste materials containing ferrous metals

The invention discloses a method for recycling copper, zinc, cobalt and nickel from various kinds of nonferrous metal containing waste. The method comprises the steps that nonferrous metal containing dead catalysts, waste battery materials and other waste raw materials are subjected to leaching dissolution by adding acid and an oxidizing agent, a solution containing nickel, cobalt, copper and zinc is subjected to copper extraction after filter pressing, and reverse extraction is carried out on the copper solution for electro deposited copper production; and P204 extraction is carried out after the raffinate is subjected to deironing treatment, reverse extraction galvanizing zinc is obtained, a zinc carbonate product is obtained through settlement and roughening, P507 nickel and cobalt separation is carried out on the raffinate, and a cobalt salt solution and a nickel salt solution are obtained and used for producing cobalt sulphate, nickel carbonate, electrolytic nickel and other products. Leaching residues and deironining slag obtained after filter pressing are dissolved and enter a waste slag removal treatment workshop for sintering treatment.

Owner:ZHEJIANG XINSHIDAI ZHONGNENG RECYCLING TECH CO LTD

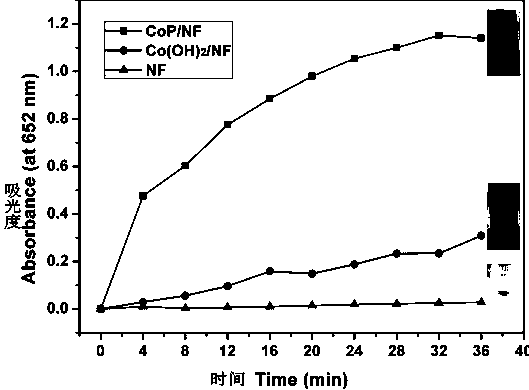

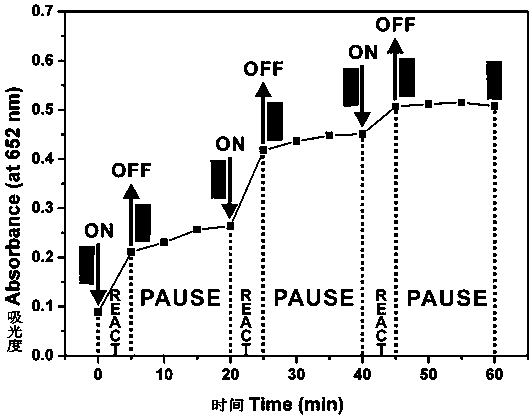

Application of integrated COP nanosheet arrays as monolithic peroxidase-like enzymes

ActiveCN107376961BIncrease surface areaIncrease profitPhysical/chemical process catalystsColor/spectral properties measurementsCobalt sulphatePeroxidase

The invention belongs to the technical field of analogue enzymes, and relates to preparation of an analogue peroxidise, in particular to preparation and application of an integrated CoP nano-flake array serving as an integrated analogue peroxidise. A preparation method for the integrated CoP nano-flake array serving as the integrated analogue peroxidise comprises the following steps: performing pre-treatment to obtain pure nickel foam, then dissolving cobalt sulphate and urea as a solution, adding the nickel foam into the solution, performing a hydrothermal reaction to obtain a Co(OH)2 nano-flake array-modified foam nickel compound, and performing high-temperature phosphating to obtain the integrated CoP / NF integrated analogue peroxidise. The invention also discloses the application of the product to visual detection of hydrogen peroxide. According to the preparation method, the integrated analogue peroxidise is prepared by utilizing porous nickel foam as a supporting body, the surface area and the utilization rate of an analogue enzyme are effectively improved, a reaction process can be controlled, on-demand taking is realized, and a quenching agent is not required. The integrated analogue peroxidise can also be recycled and reused conveniently, and the integrated analogue peroxidise has an excellent reutilization effect.

Owner:JIANGSU UNIV

Green lubricating oil used for ships

InactiveCN108753423ALow toxicityGood application effectLubricant compositionCobalt sulphateBenzoyl peroxide

The invention discloses a green lubricating oil used for ships. The green lubricating oil comprises, by weight, 10 parts of perfluorocapylic acid, 12 parts of isopropanol, 12 parts of benzoyl peroxide, 18 parts of isopropyl acrylate, 4 parts of acetic ester, 4 parts of cobalt sulphate calcium carbonate, 4 parts of benzoyl peroxide, 24 parts of benzoyl peroxide, 12 parts of methyl triethoxysilane,12 parts of methyl cellulose, 12 parts of antimony oxide, 12 parts of methyl silicone oil, and 10 parts of p-dioctyldiphenylamine. Mutual cooperation of the ingredients of the green lubricating oil isachieved; the green lubricating oil is low in toxicity, excellent in smearing effect, and long in using time.

Owner:张彩萍

Mesophilic acidophilic bacteria and biological heap leaching technique for low-grade cobalt-containing sulfur concentrate

InactiveCN101191122BEfficient recyclingLow investment costBacteriaProcess efficiency improvementThiobacillus ferrooxidansCobalt sulphate

The invention relates to mesophilic acidophilic bacteria and a biological heap leaching technology for low-grade cobaltiferous sulfide ore concentrates. The mesophilic acidophilic bacteria have a name of Thiobacillus ferrooxidans Retech V and a collection registration number of CCTCC NO: M202039, and has been stored and collected in China Center for Type Culture Collection (in Wuhan University). The biological heap leaching technology is that: mineral grains which are suitable for biological heap leaching are obtained after coating of crushed stones and solidification of the mineral grains ofthe low-grade cobaltiferous sulfur-bearing ore concentrates. Cobalt sulphates are obtained through procedures of embankment, heap leaching and trickling by adoption of bacteria with two different growth temperatures, lixivium circulation, purification and deferrization of cobalt pregnant solution, cobalt settlement and so on of the mineral grains. The temperature of 10 to 55 DEG C, the PH value of 1.2 to 1.8 and the adequate Fe concentration of a storage yard in a heap leaching system during the leaching out process are favorable for activity of leaching bacteria. The invention has the advantages of capability of fully utilizing low-grade cobaltiferous sulfide ore resources in old mines, improvement of comprehensive utilization level of mines, conservation of cost, and improvement of profit. The invention is applied in developing cobaltiferous sulfide ore resources in remote areas.

Owner:有研资源环境技术研究院(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com