Diamond grinding wheel for cutting silicon crystal circle and preparation method thereof

A diamond grinding wheel and silicon wafer technology, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems that affect cutting quality and cutting efficiency, the strength and stiffness of the grinding wheel cannot be guaranteed, and the swing can be shortened. The effect of reducing processing time, reducing chipping and serpentine cutting, and improving cutting accuracy

Active Publication Date: 2011-01-05

赛尔科技(如东)有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the traditional flat cutting grinding wheel has fatal shortcomings: when the grinding wheel reaches a certain thickness (such as 0.015mm) and precision (thickness tolerance ± 0.002mm), the grinding wheel cannot guarantee the strength and rigidity required for efficient cutting. Vibration, chipping, or even breakage occurs during cutting, which seriously affects the cutting quality and cutting efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

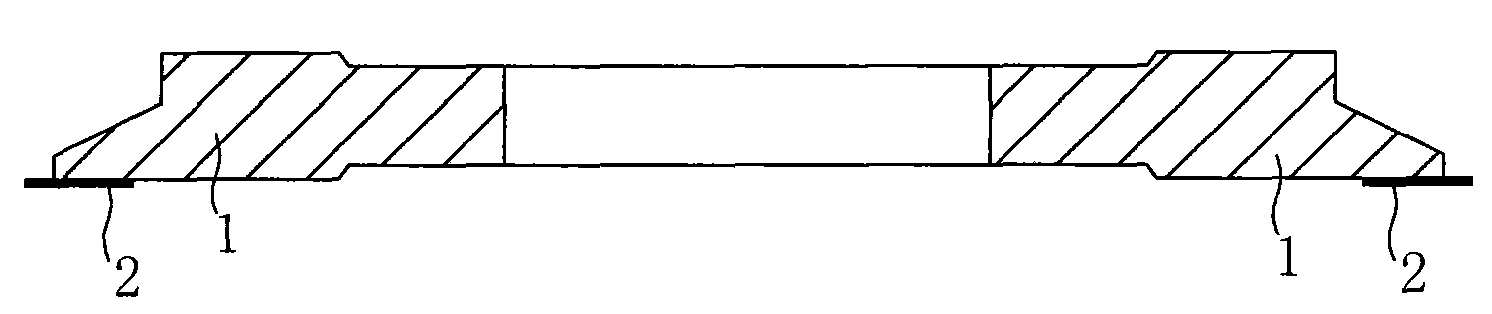

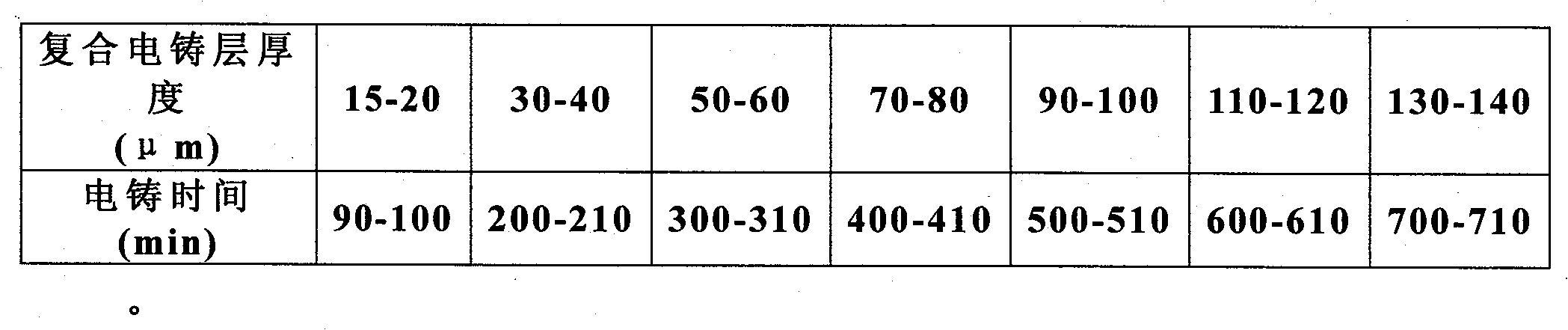

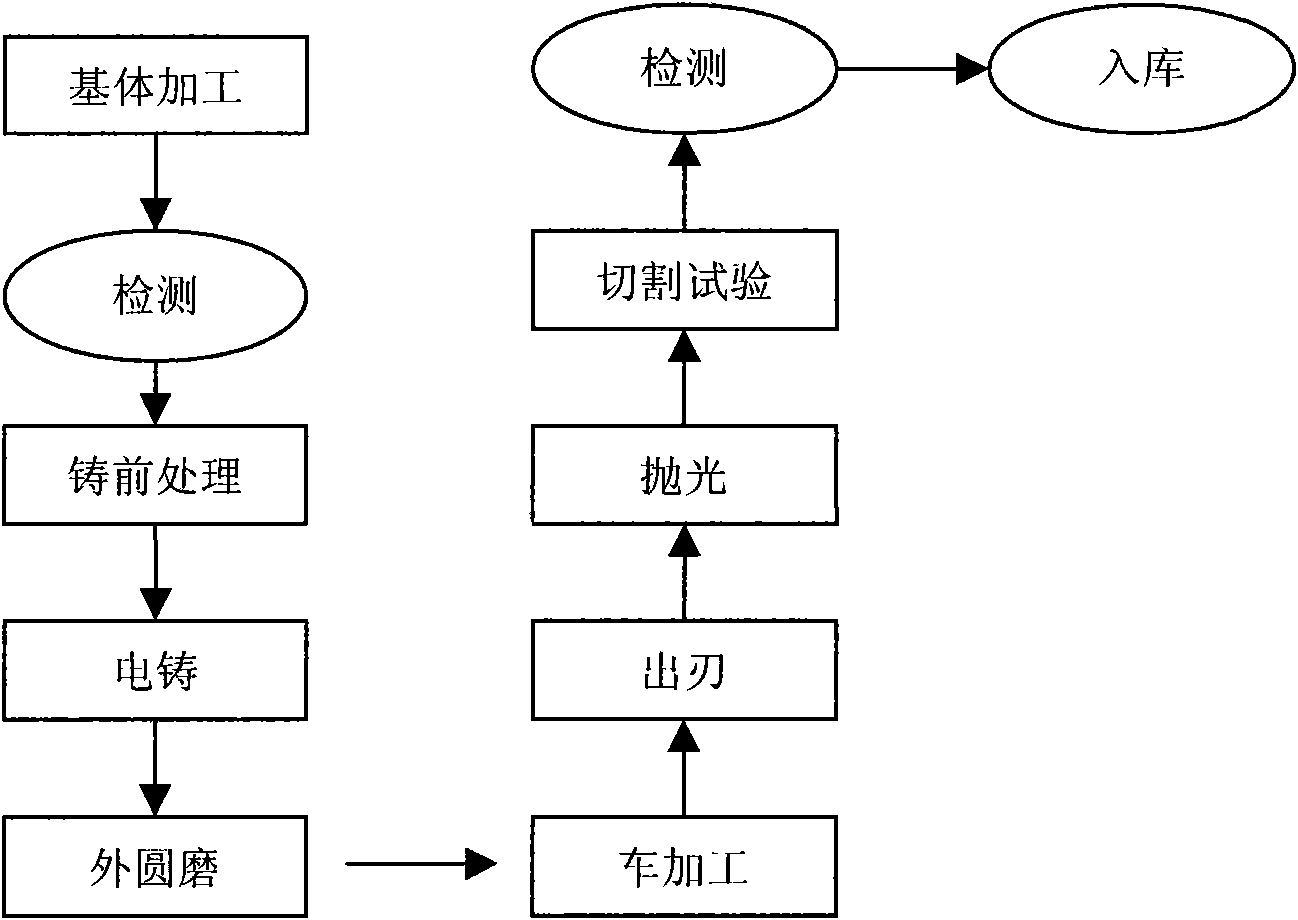

The invention discloses a diamond grinding wheel for cutting a silicon crystal circle and a preparation method thereof. The method comprises the following steps: (1) preprocessing an aluminum alloy basal body; (2) configuring electroforming liquid: configuring the electroforming liquid according to the weight ratio of (38-43):(15-20):(43-57):(50-180):(4-8) of nickel sulphate, cobalt sulphate, deionized water, a diamond grinding material and a suspending agent; fully stirring evenly and obtaining the electroforming liquid; (3) carrying out insulation processing on the aluminum alloy basal bodyobtained in the step (1), putting the aluminum alloy basal body into the electroforming liquid, electroforming in an ultrasonic field, evenly precipitating the diamond grinding material in the electroforming liquid and metal on the basal body together and obtaining a grinding wheel blank body with a compound electroforming layer; and (4) taking out the grinding wheel blank body completing electroforming, and carrying out accurate processing on the grinding wheel blank body on a numerical control grinder and a numerical control lathe respectively according to the accuracy requirements of the required basal body and the required cutting edge. The diamond grinding wheel obtained by the invention meets the ultrathin and superfine technical conditions and also has favorable strength and rigidity.

Description

Diamond grinding wheel for cutting silicon wafer and preparation method thereof technical field The invention relates to a silicon wafer cutting tool and a preparation method thereof, in particular to a diamond grinding wheel for cutting a silicon wafer and a preparation method thereof. Background technique Wafer (such as silicon wafer) cutting belongs to the field of high-tech processing, and the market is huge. The requirements for cutting tools are: thin thickness, good strength, and high precision. Experts in the field of superhard materials have long regarded wafer cutting grinding wheels as one of the main development directions for the development of superhard material tools. However, the traditional flat cutting grinding wheel has fatal shortcomings: when the grinding wheel reaches a certain thickness (such as 0.015mm) and precision (thickness tolerance ± 0.002mm), the grinding wheel cannot guarantee the strength and rigidity required for efficient cutting. Vibrat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24D18/00B24B27/06C25D1/00

Inventor 冉隆光王凯平

Owner 赛尔科技(如东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com