Electrolyte of lead-acid battery and preparation method thereof

A lead-acid battery, electrolyte technology, applied in lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. Small and other problems, to achieve good high current charge and discharge, good dispersion, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

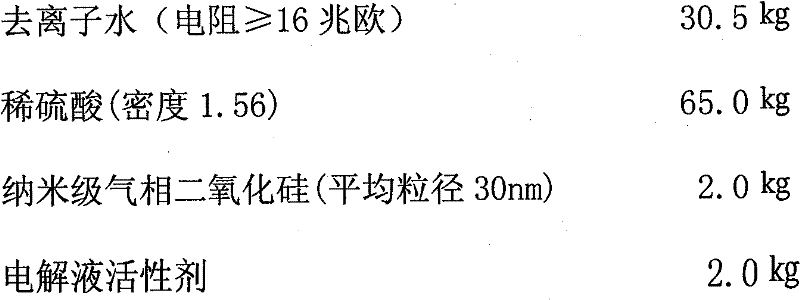

[0006] The electrolyte is prepared according to the following proportions by weight:

[0007]

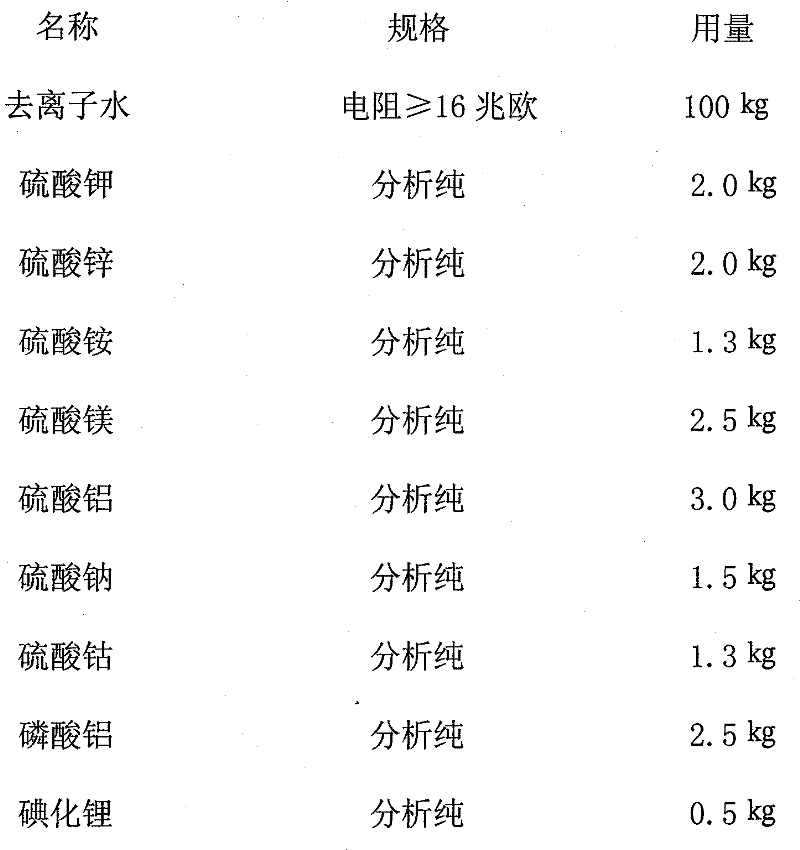

[0008] Among them, the resistance of deionized water is not less than 16 megohms, the density of dilute sulfuric acid solution is 1.5-1.6, the particle size of nano-scale fumed silica is 20-40nm, and the specific surface area is 300m 2 / g or more, the components of the electrolyte active agent and their weight ratios are prepared according to the following ratio:

[0009]

[0010] Follow the steps in the following order, the first step: put 2.0kg potassium sulfate, 2.0kg zinc sulfate, 1.3kg ammonium sulfate, 2.5kg magnesium sulfate, 3.0kg aluminum sulfate, 1.5kg sodium sulfate, 1.3kg cobalt sulfate, 2.5kg aluminum phosphate , 0.5kg lithium iodide was dissolved in 100kg deionized water, and mixed uniformly to obtain an electrolyte activator; the second step: 30.5kg deionized water, 2.0kg nano-scale fumed silica, 2.0kg electrolyte activator, Mix 65.0 kg of dilute sulfuric acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com