Patents

Literature

742results about How to "Prevent dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

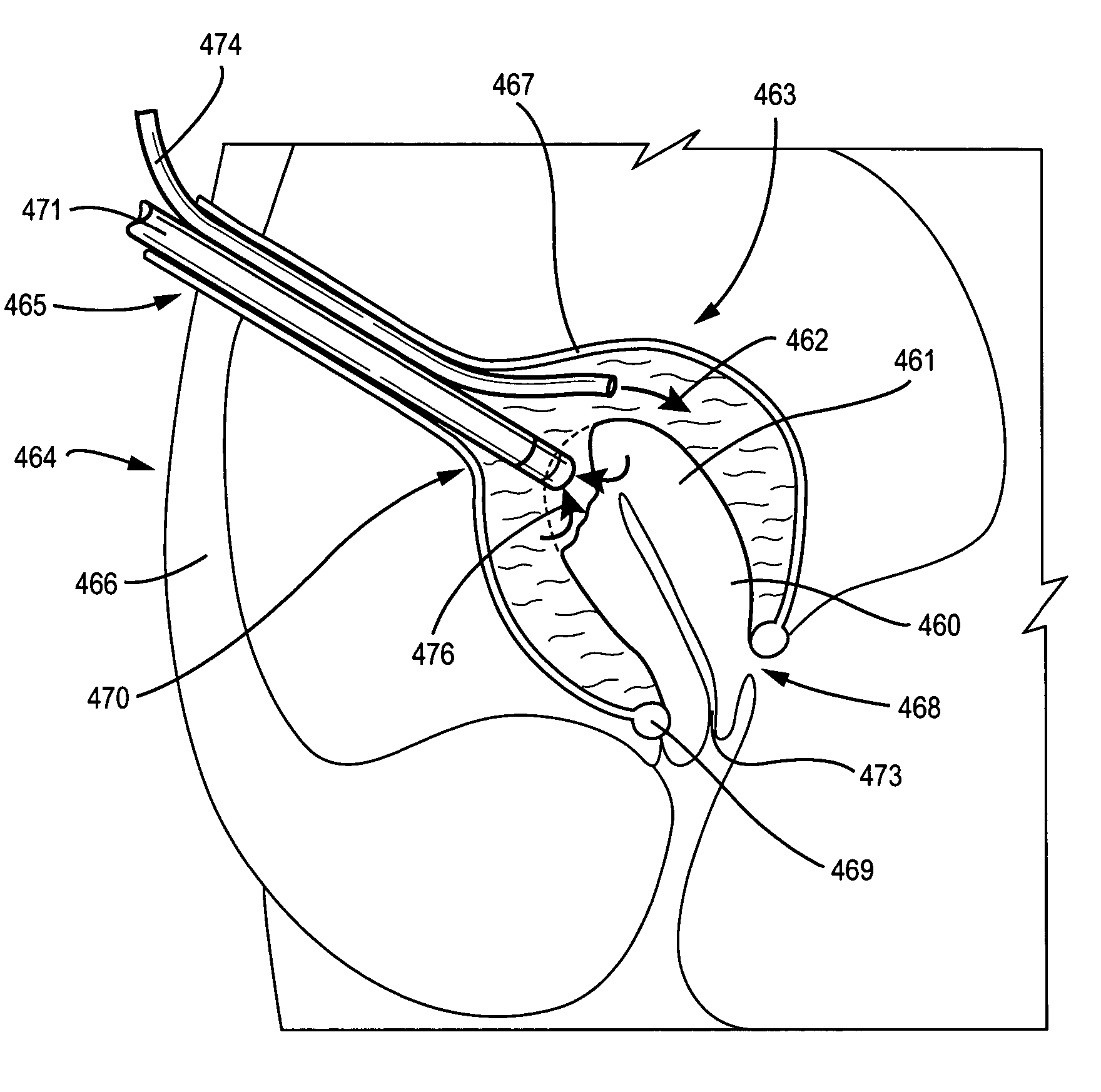

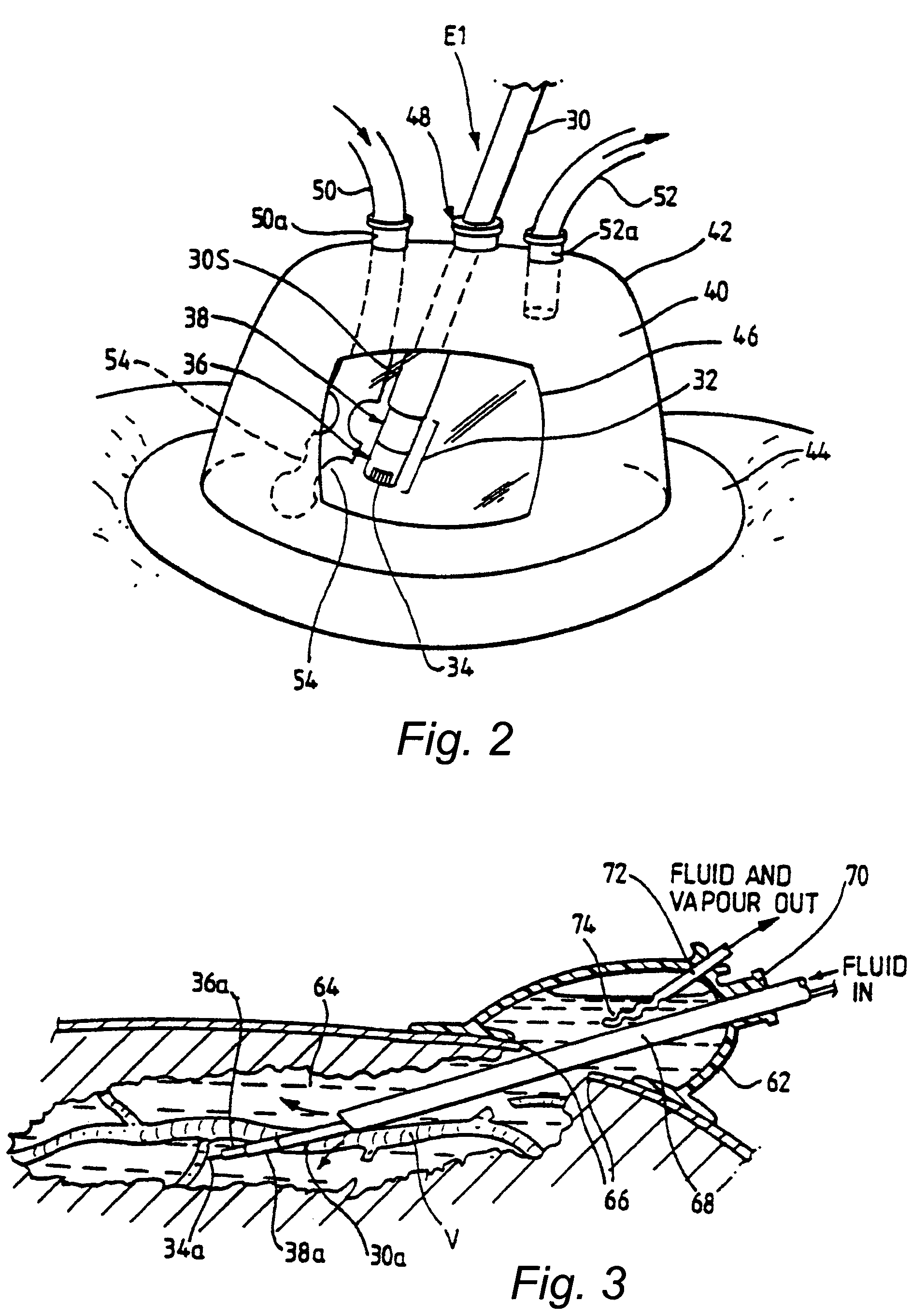

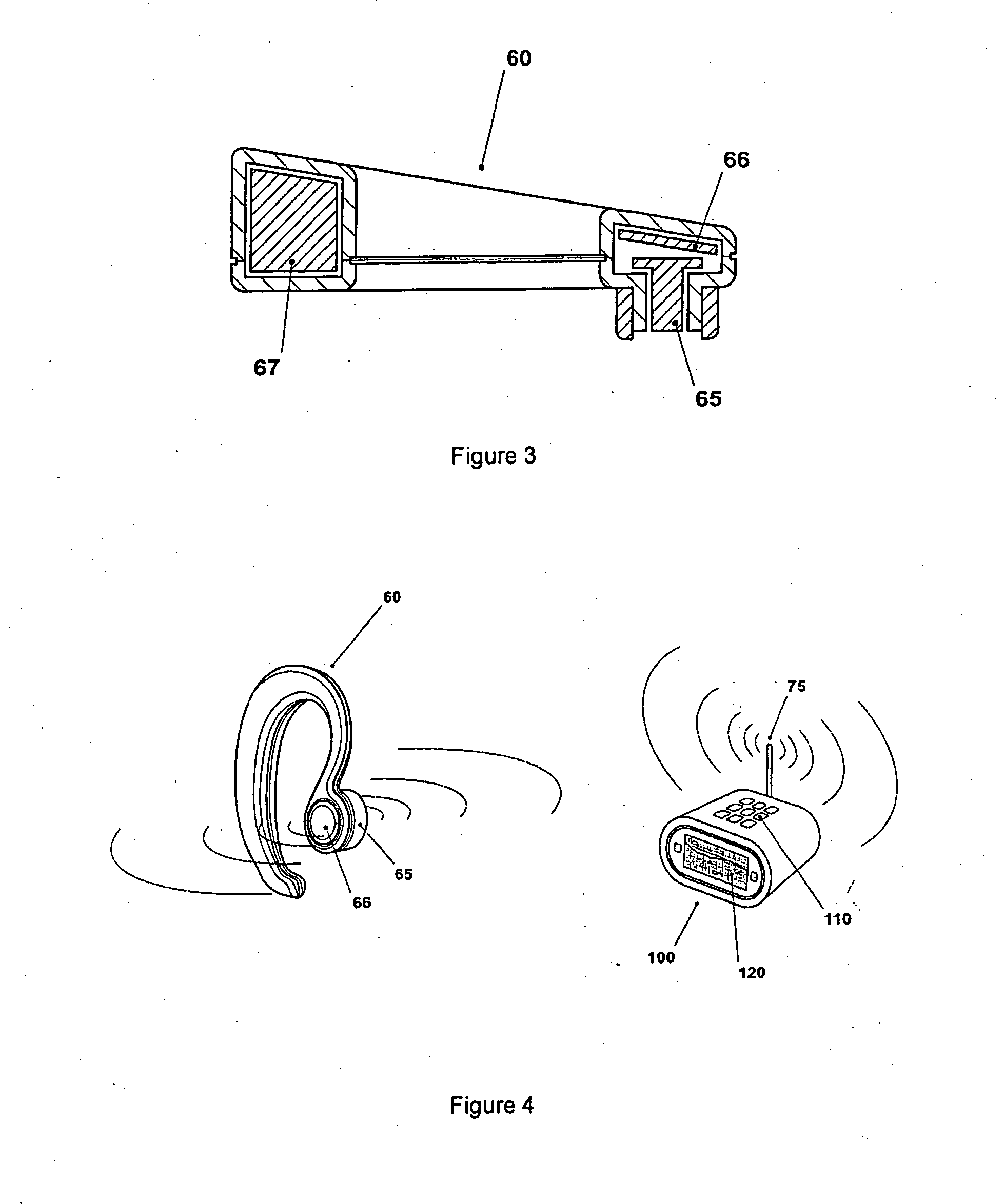

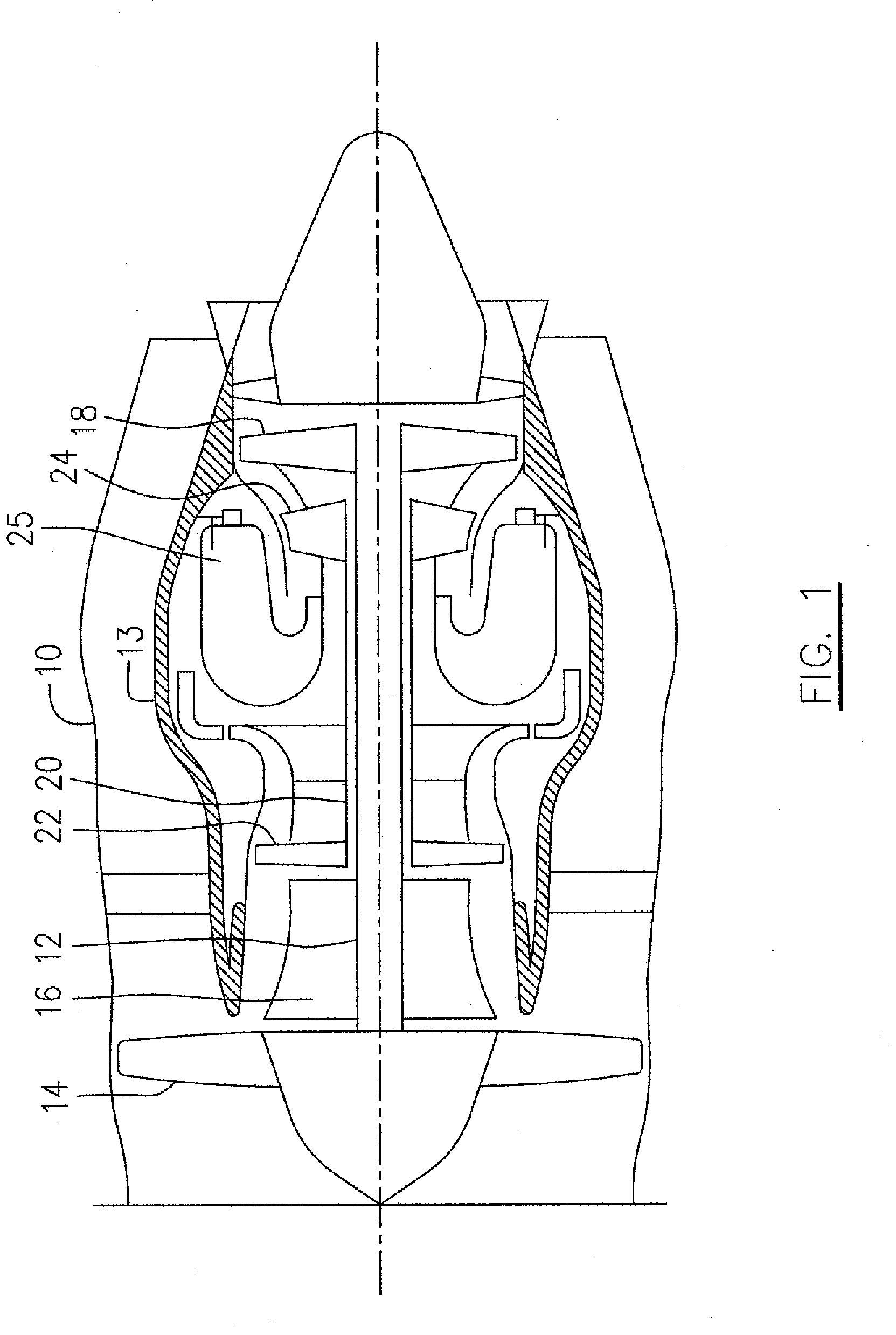

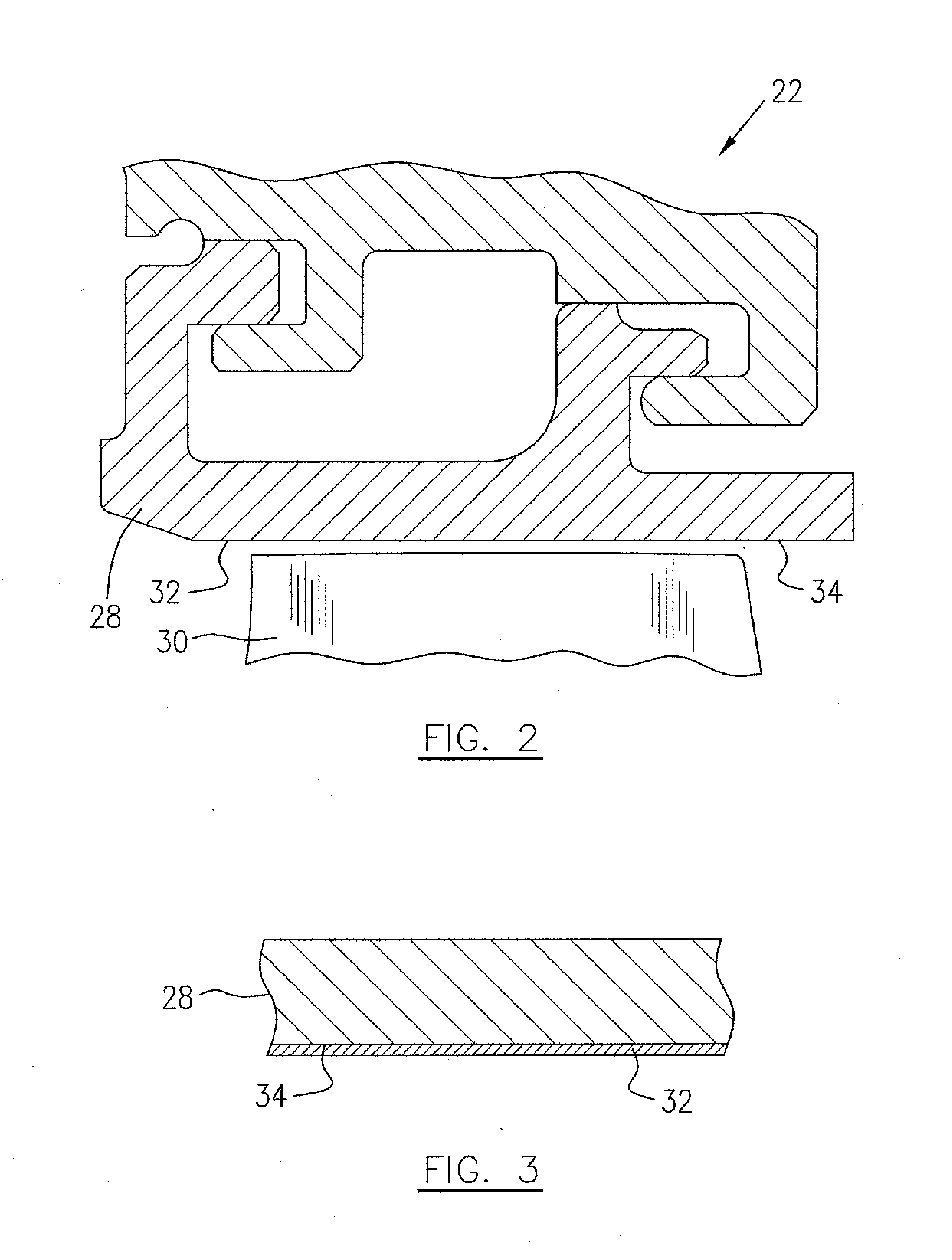

Electrosurgical instrument

InactiveUS7278994B2Lower impedanceReduced effectivenessCannulasDiagnosticsGynecologyPeritoneal cavity

A system and method are disclosed for removing a uterus using a fluid enclosure inserted in the peritoneal cavity of a patient so as to enclose the uterus. The fluid enclosure includes a distal open end surrounded by an adjustable loop, that can be tightened, a first proximal opening for inserting an electrosurgical instrument into the fluid enclosure, and a second proximal opening for inserting an endoscope. The loop is either a resilient band extending around the edge of the distal open end or a drawstring type of arrangement that can be tightened and released. The fluid enclosure is partially inserted into the peritoneal cavity of a patient in a deflated condition and then manipulated within the peritoneal cavity over the body and fundus of the uterus to the level of the uterocervical junction. The loop is tightened around the uterocervical junction, after which the enclosure is inflated using a conductive fluid. The loop forms a pressure seal against the uterocervical junction to contain the conductive fluid used to fill the fluid enclosure. Endoscopically inserted into the fluid enclosure is an electrosurgical instrument that is manipulated to vaporize and morcellate the fundus and body of the uterus. The fundus and body tissue that is vaporized and morcellated is then removed from the fluid enclosure through the shaft of the instrument, which includes a hollow interior that is connected to a suction pump The fundus and body are removed after the uterus has been disconnected from the tissue surrounding uterus.

Owner:GYRUS MEDICAL LTD

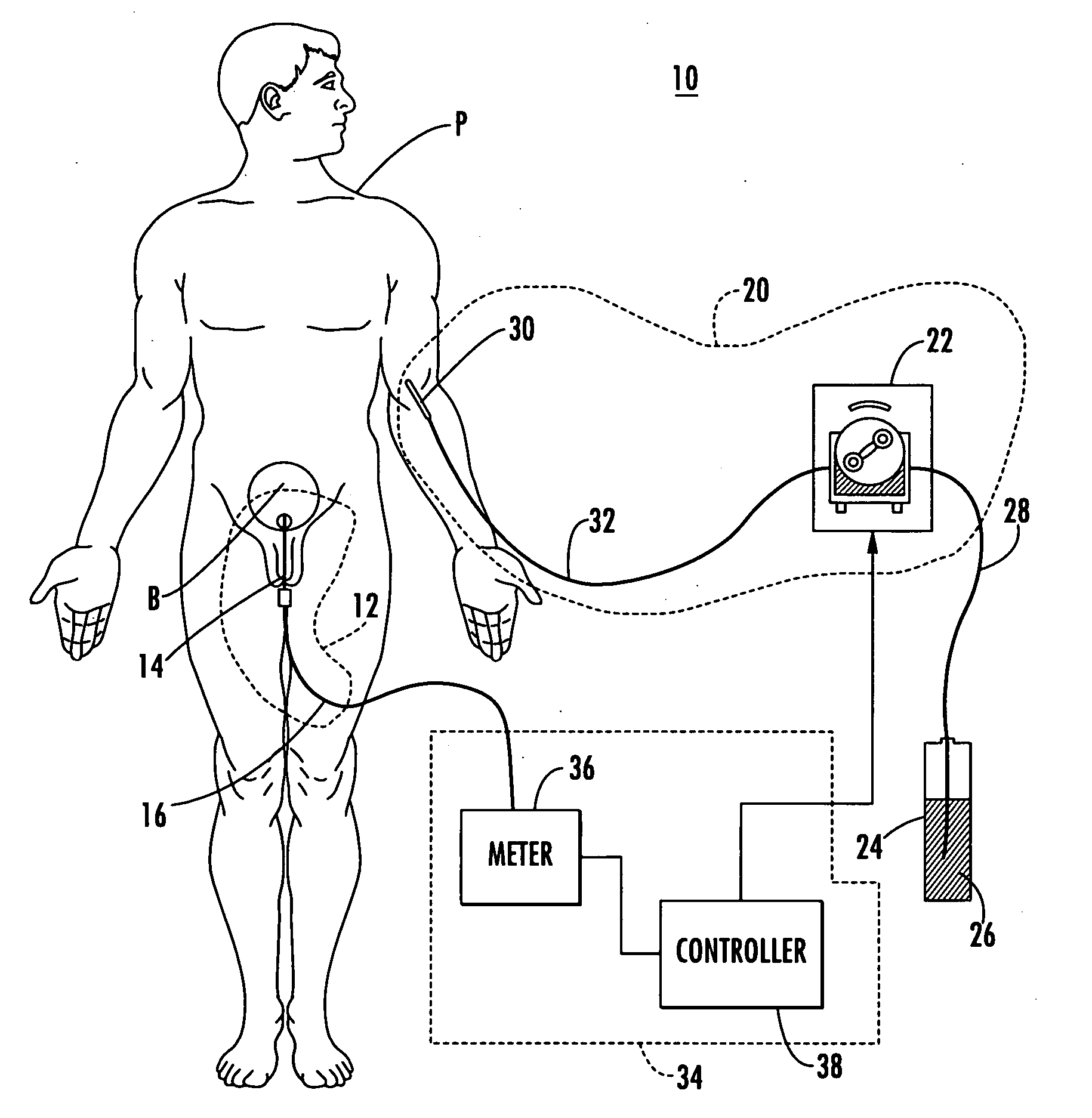

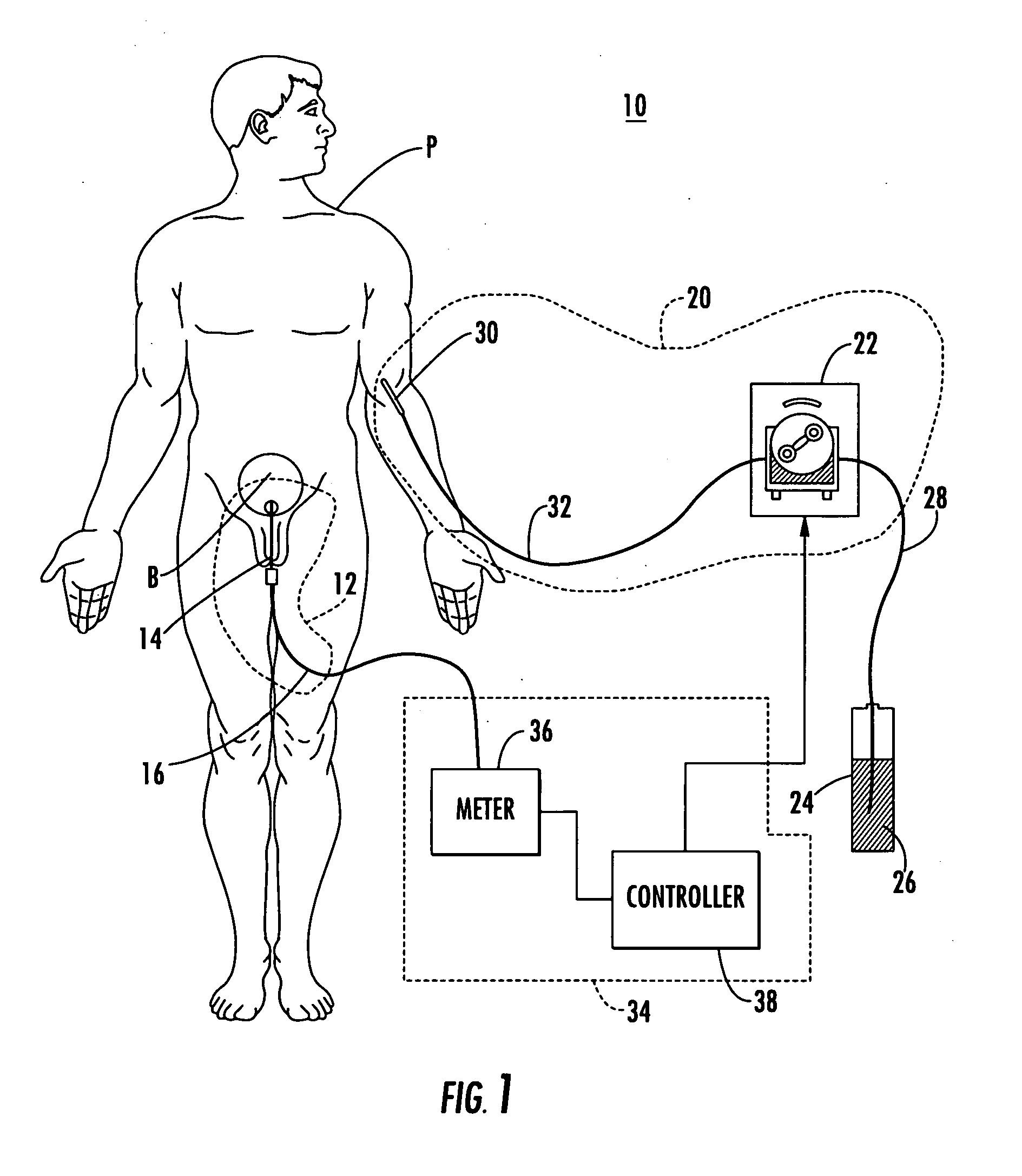

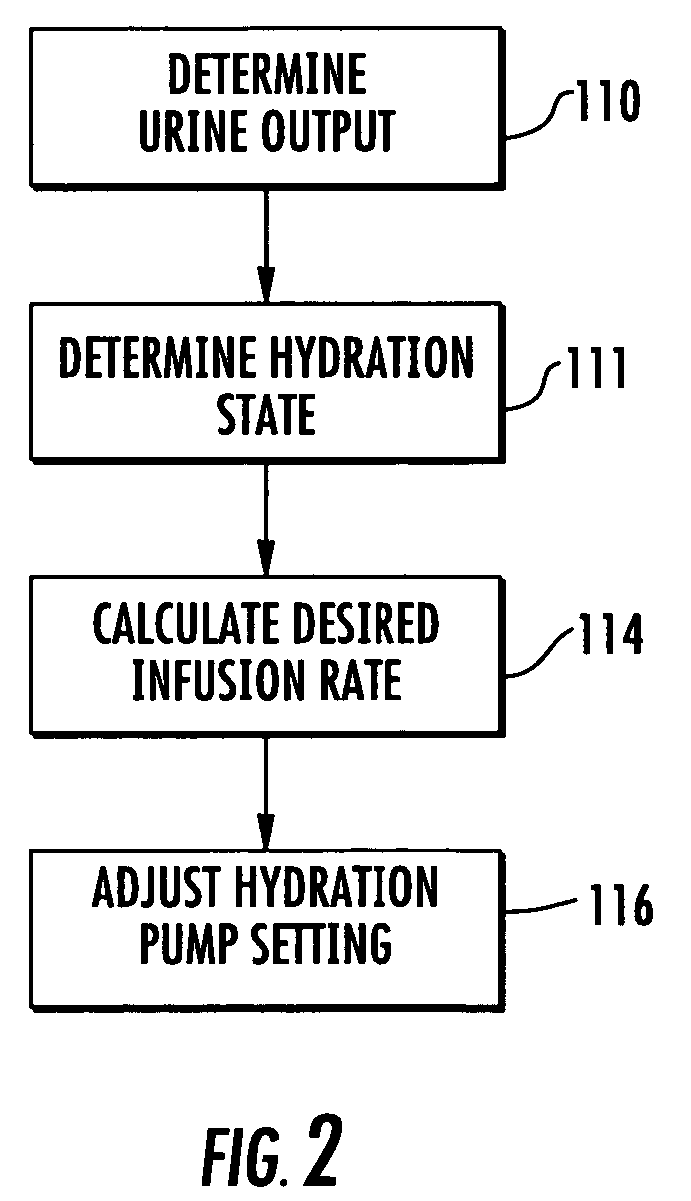

Patient hydration system with abnormal condition sensing

ActiveUS20060235353A1Prevent kidney damagePrevent dehydrationMedical devicesPressure infusionUrine outputIntensive care medicine

A patient hydration system and method wherein hydration fluid is administered to a patient and the patient's urine output is measured either by weight or some other suitable way. A controller is responsive to the patient's urine output measurement and configured to control the infusion rate to hydrate the patient based on the patient's urine output. The controller also detects abnormal patient urine output measurements and initiates corrective action in response.

Owner:MEDICAL SYST

Appetite satiation and hydration beverage

InactiveUS20050276839A1Sufficient nutritional valueAvoid malnutritionBiocideTetrapeptide ingredientsBetaineAdditive ingredient

Appetite satiation and hydrating beverages and methods of delivering appetite satiation ingredients and nutrients are disclosed. According to one embodiment of the invention, the appetite satiationhydrating beverage comprises at least one complex carbohydrate, at least one chelated electrolyte, hoodia gordonii cactus, gymnema sylvestre, betaine and piperine.

Owner:RIFKIN CALMAN H

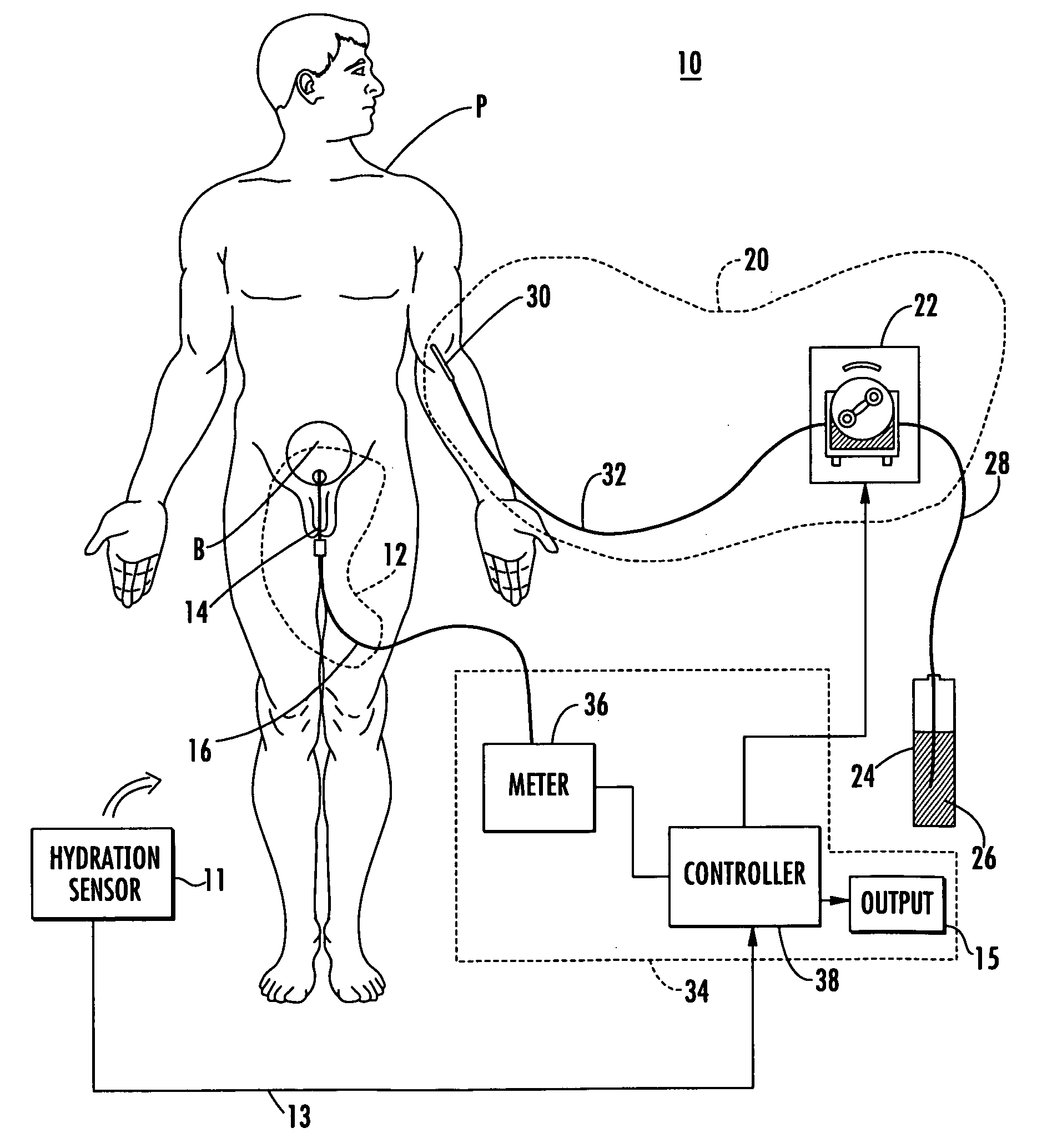

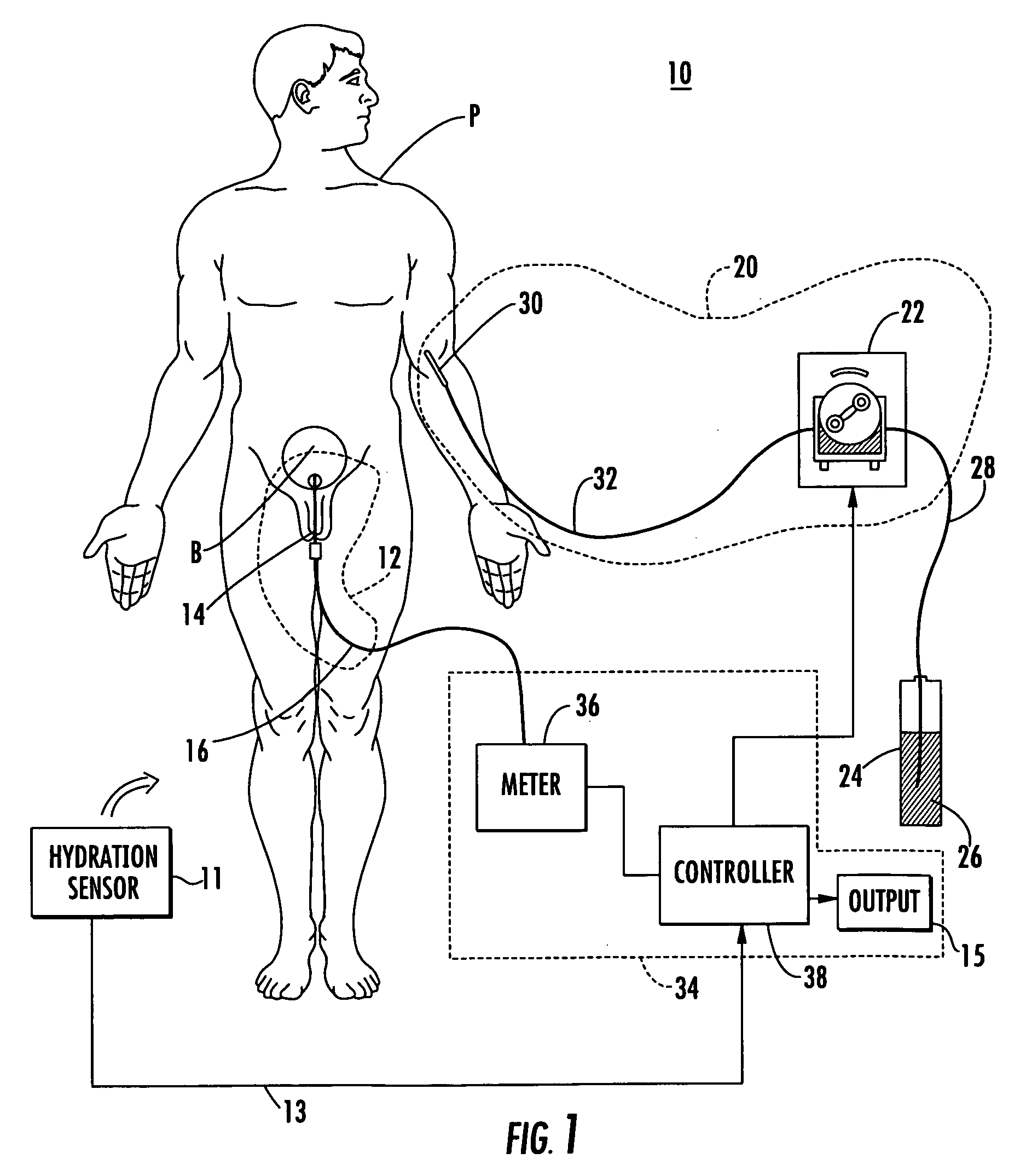

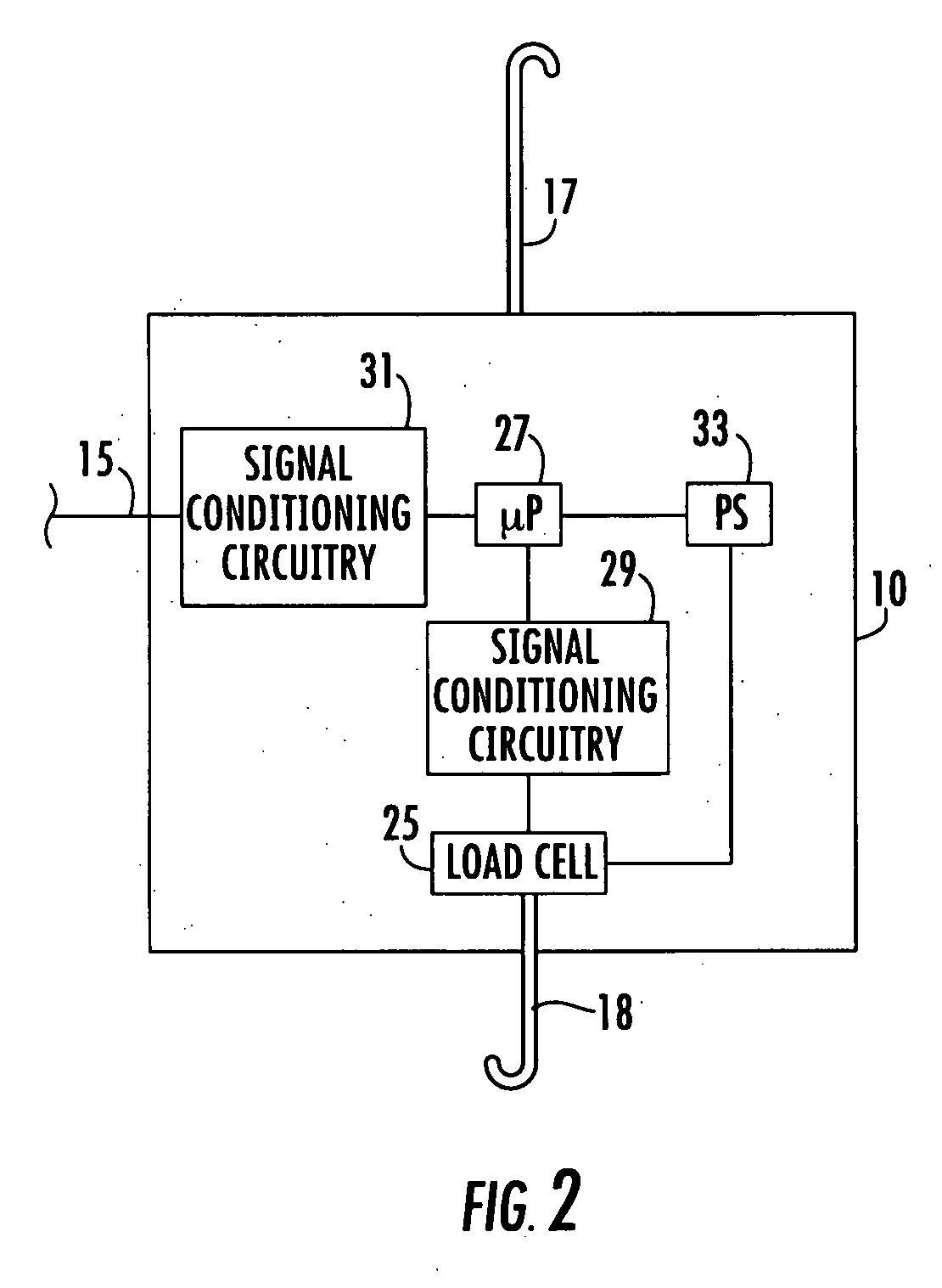

Patient hydration system with hydration state detection

ActiveUS7736354B2Prevent kidney damagePrevent dehydrationMedical devicesPressure infusionMeasurement deviceUrine output

A patient hydration system with a patient urine output measurement device, a hydration fluid administration subsystem, and a controller, responsive to the patient urine output measurement device. The controller is configured to control the hydration fluid administration subsystem to administer hydration fluid to the patient to prevent dehydration of the patient. A hydration sensor is also included to detect at least one patient parameter indicative of the patient's hydration state.

Owner:MEDICAL SYST

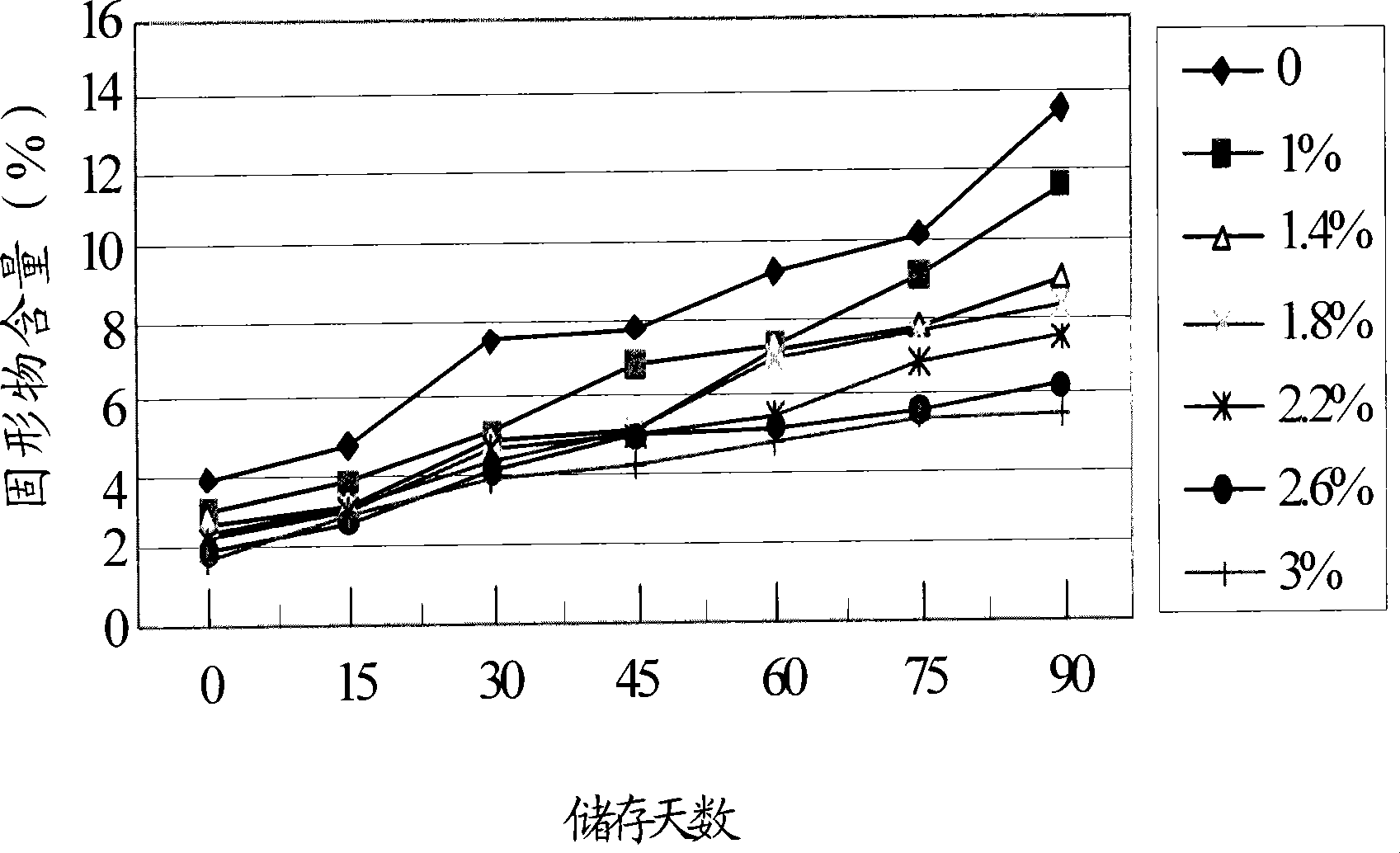

Quick-freezing cooked wheaten food improver and flour, quick-freezing dumpling, noodle and ravioli containing the same

The invention relates to a modifying agent for fast-freezing wheaten food, which contains: (A) 20 to 50 weight portions of sorbierite; (B) at least one kind of 3.5 to 20 weight portions of a thickening agent; (C) at least one kind of 10.2 to 55 weight portions of a flour gluten fortifier; and (D) at least one kind of 10.5 to 38 weight portions of phosphate. A finished product of the fast-freezing wheaten food containing the modifying agent has the skin which is difficult to crack and change color, has good water boiling performance, prolongs freshness period, and has the advantages of bright skin, smooth taste, good elasticity, and no soup turbidness at the same time. And the modifying agent has the advantages of low price and so on.

Owner:ANGELYEAST CO LTD

Chemical etching, cleaning and drying method of single-crystal silicon solar battery and integrated processing machine

InactiveCN101087007AImprove reflective effectAvoid secondary pollutionFinal product manufactureSemiconductor devicesEtchingWater source

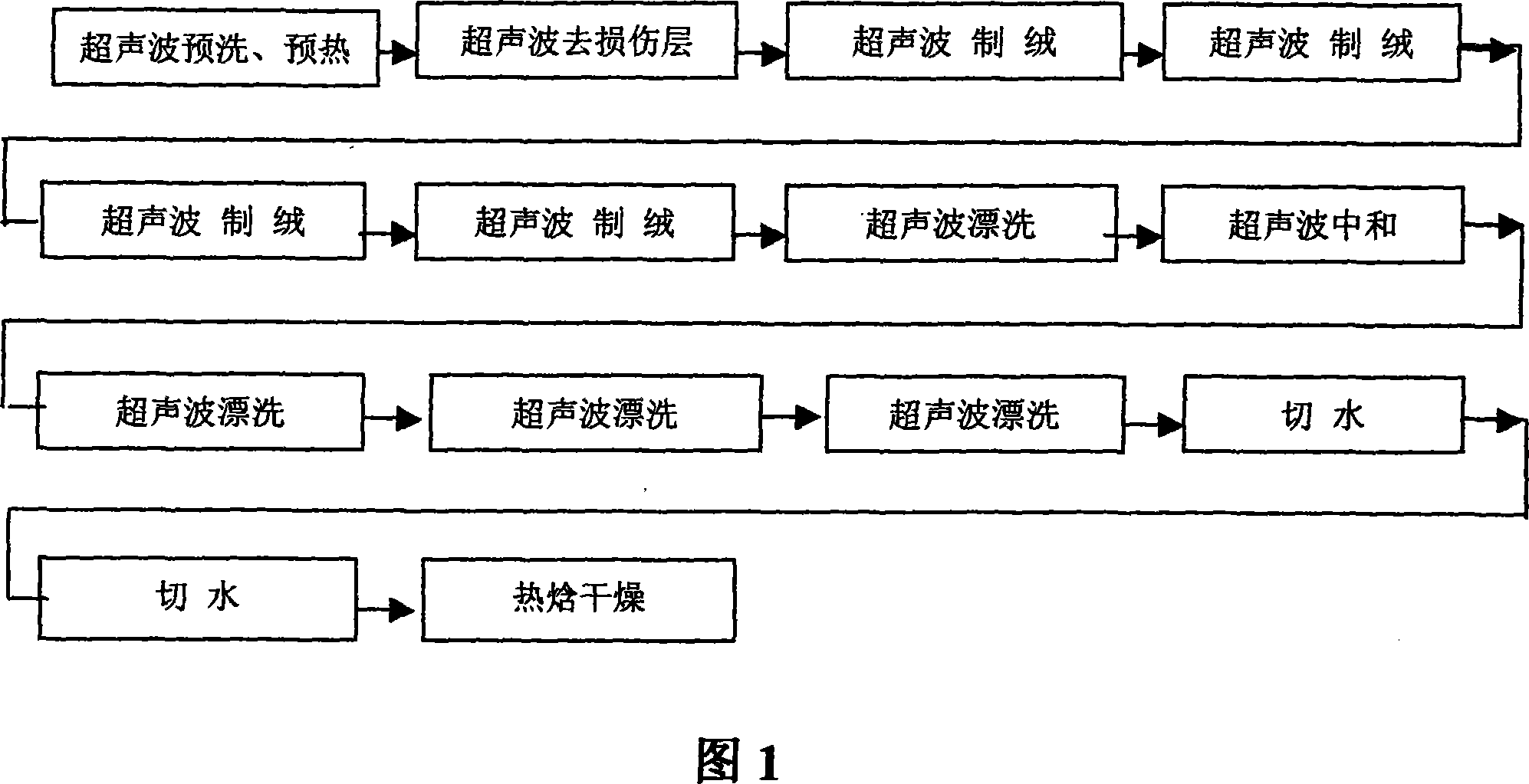

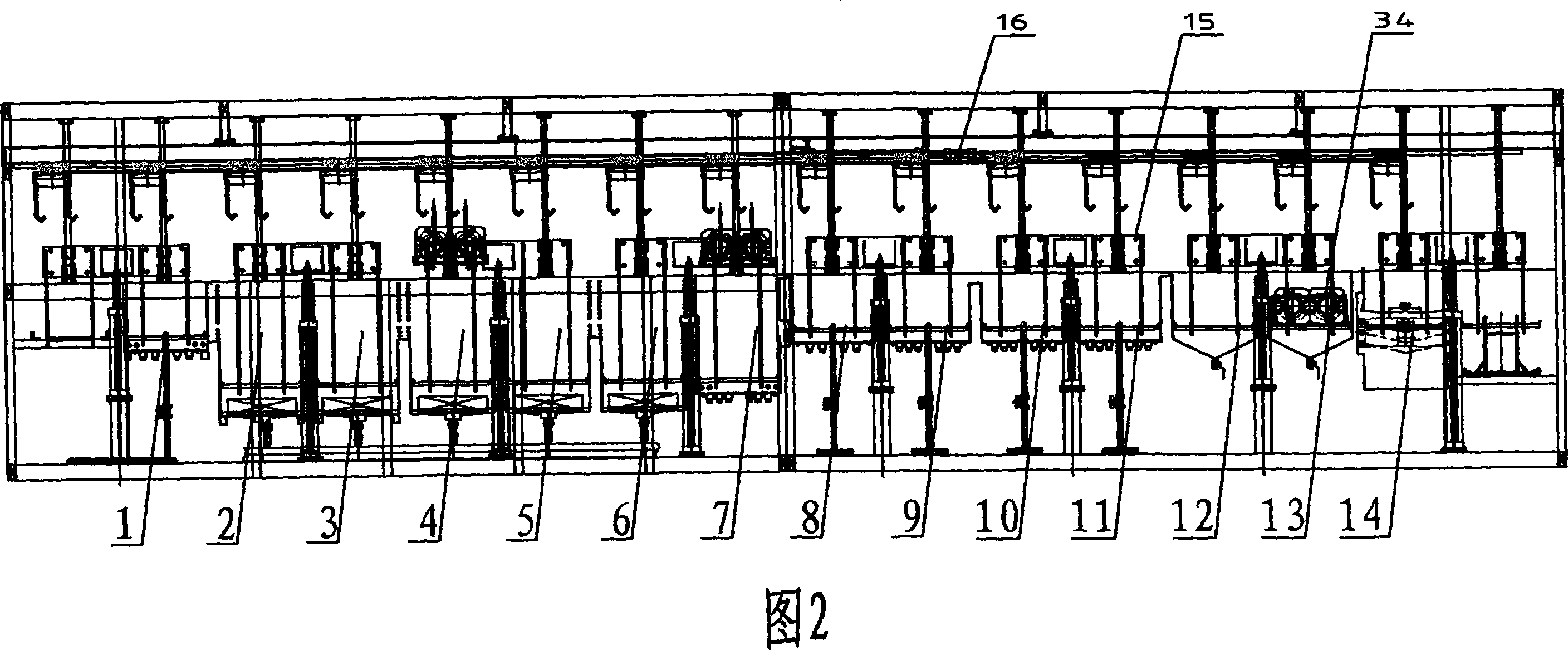

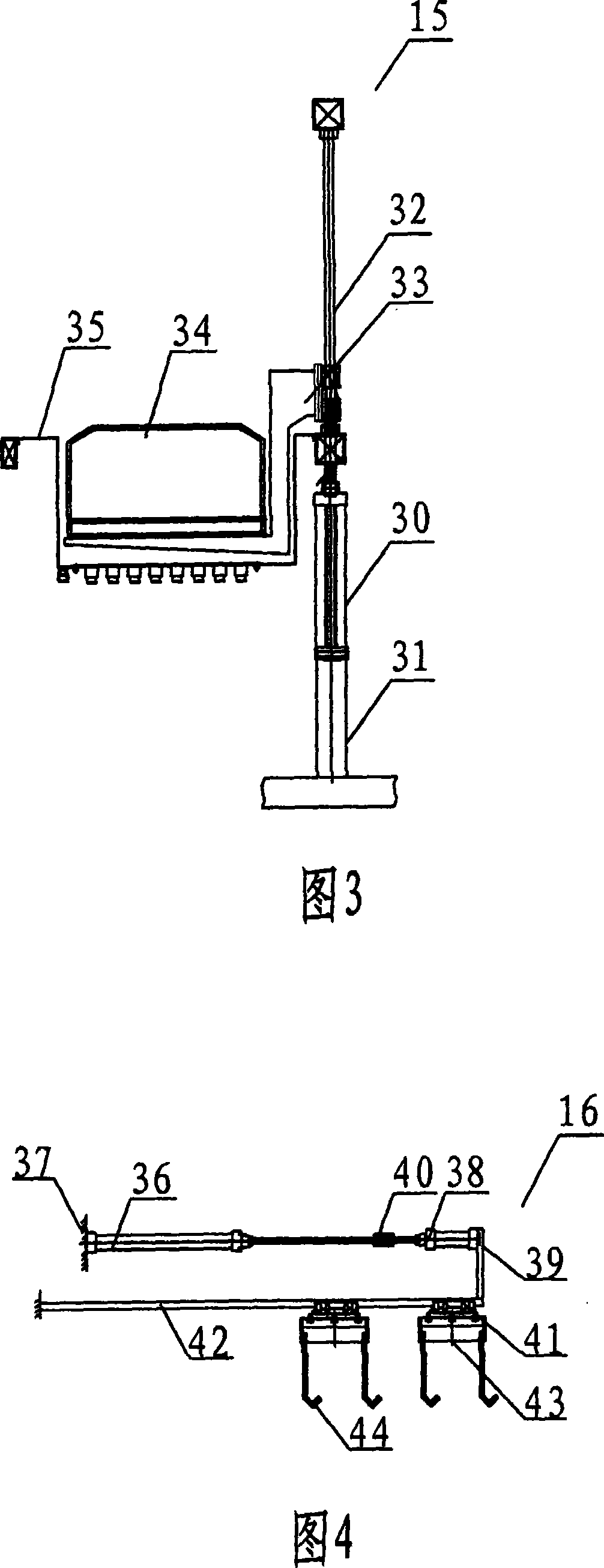

Monocrystalline silicon solaode chemical etching, washing, drying method and integral processor belong to technique field of chemical etching technique and washing. It characterized in that it not only includes water, acid, alkali, but also ultrasonic participates in etching and washing course: it includes following steps: (1) ultrasonic washes and heats in advance, (2) ultrasonic removes damnification layer, (3) ultrasonic makes herbs into wool, (4) ultrasonic rinses, (5) washing with acid to counteract, (6) ultrasonic rinses, (7) cutting water, (8) hot enthalpy to dry. Positive effects of the invention are: adopting ultrasonic to etch and wash, liquid of making wool can be acted with silicon piece, similar coarseness degree can be generated on surface, perfect pyramid pattern can be obtained; it also eliminates kalium, natrium ion from alkalescent solution, and extends service life of silicon piece; pollution can be decreased, energy consumption and water source can be saved greatly, it is a practical invention.

Owner:SHANGHAI MINGXING KAICHENG ULTRASONIC TECH +2

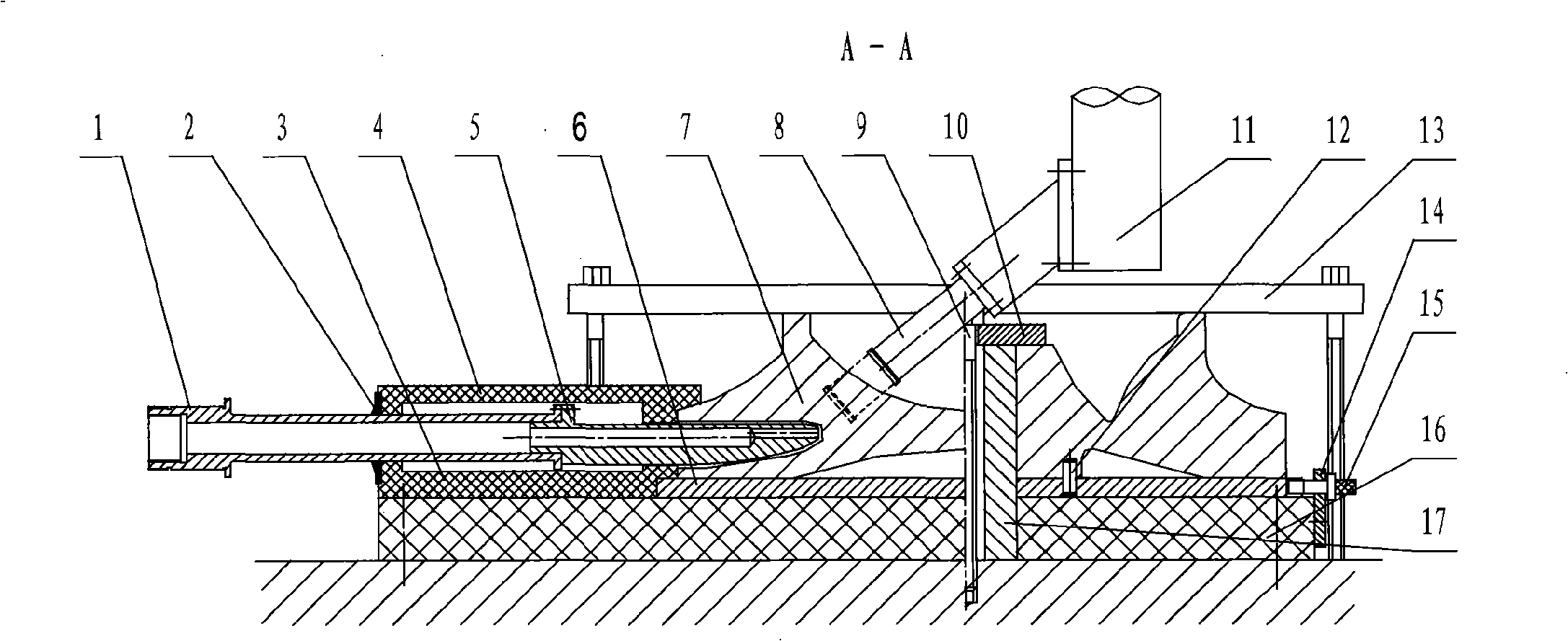

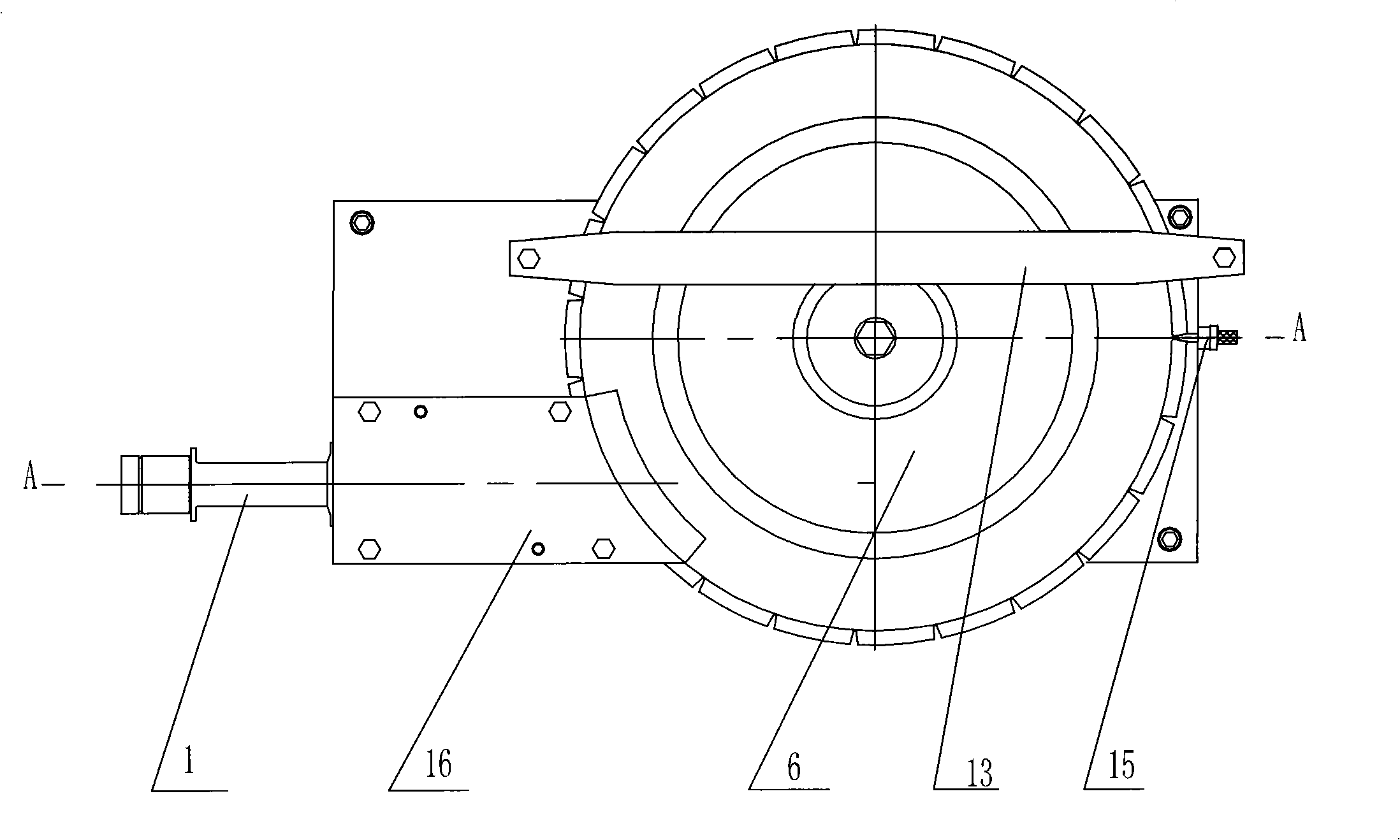

Method for manufacturing three-dimensional flow enclosed-type impeller inter-impeller passage and special clamp thereof

InactiveCN101524805AImprove efficiencyAvoid the phenomenon that is prone to blind spots in processingImpellerEngineering

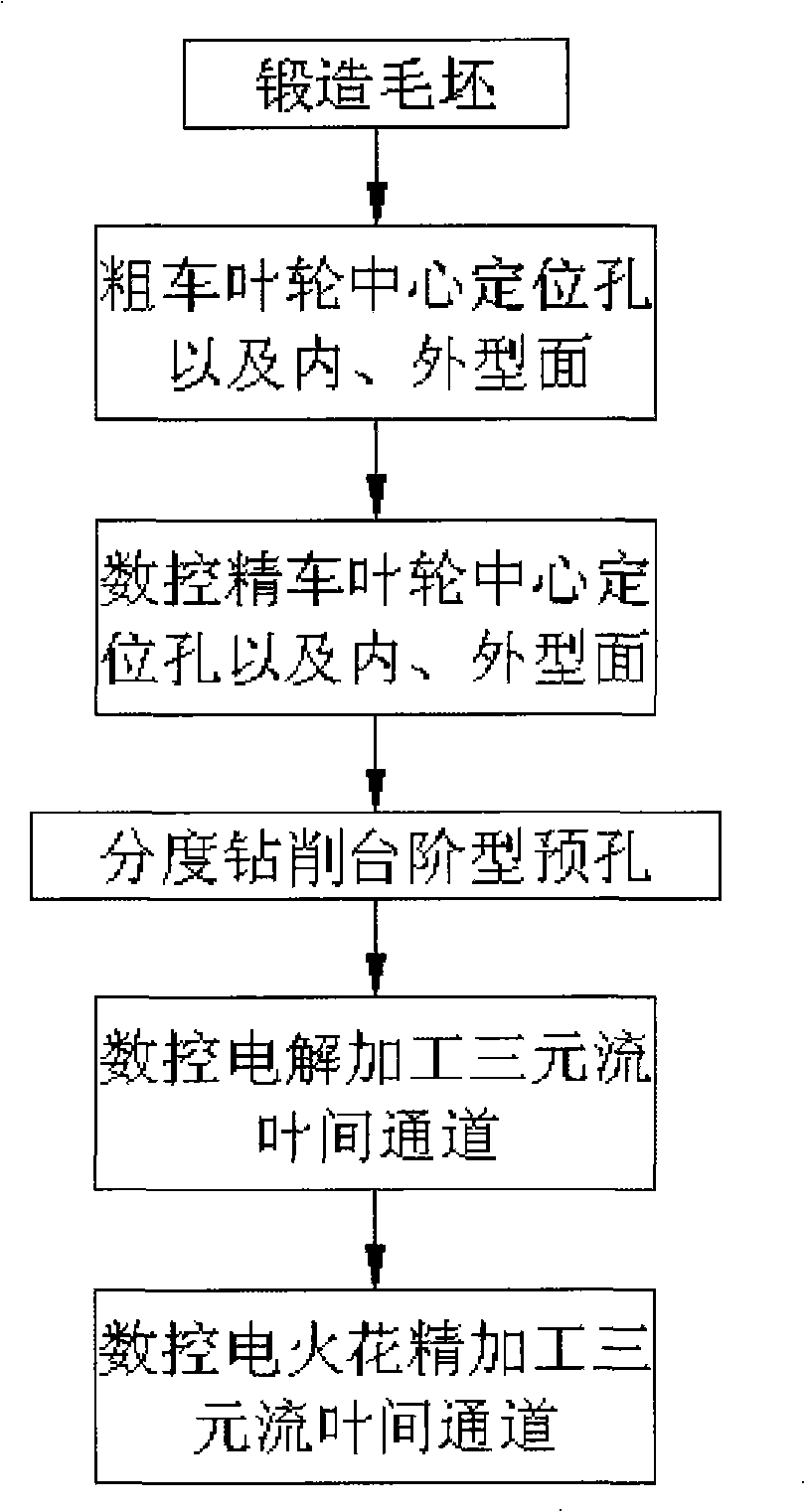

The invention relates to a method for manufacturing a three-dimensional flow enclosed-type impeller inter-impeller passage and a special clamp thereof. A specially designed and manufactured molding or quasi-molding tool cathode is used for numerical control electrolytic processing to remove most remainder, then a specially designed and manufactured molding or quasi-molding tool electrode is used for numerical control electric spark precision processing to achieve the design requirement, thereby the three-dimensional flow enclosed-type impeller inter-impeller passage that can not be processed resulting from interference of numerical control milling cutter and undercutting can be manufactured, besides, the method has the technical and economical characteristics of high precision and efficiency, and low cost compared with the prior three manufacturing methods of integral casting, divided processing rewelding and numerical control milling.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

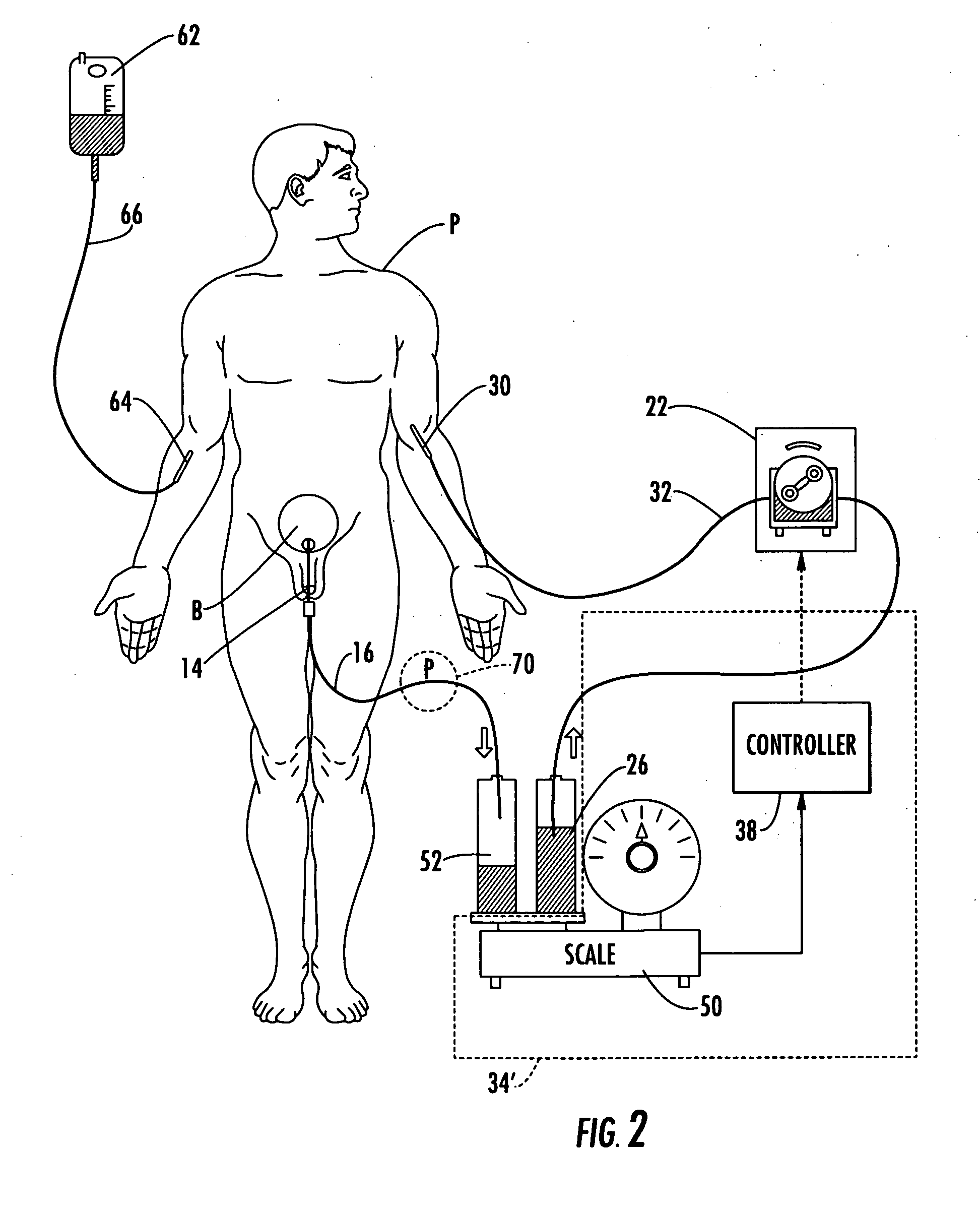

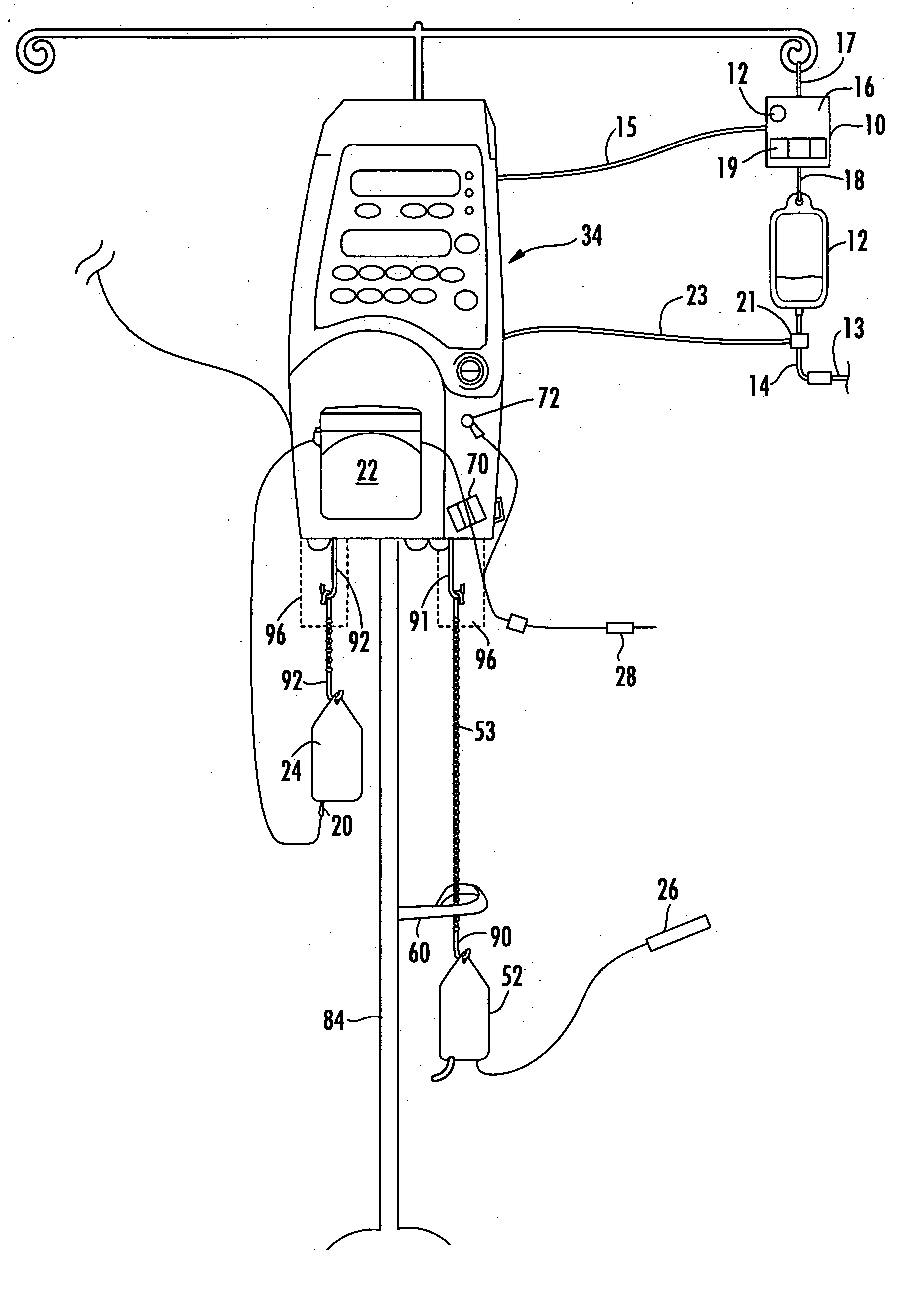

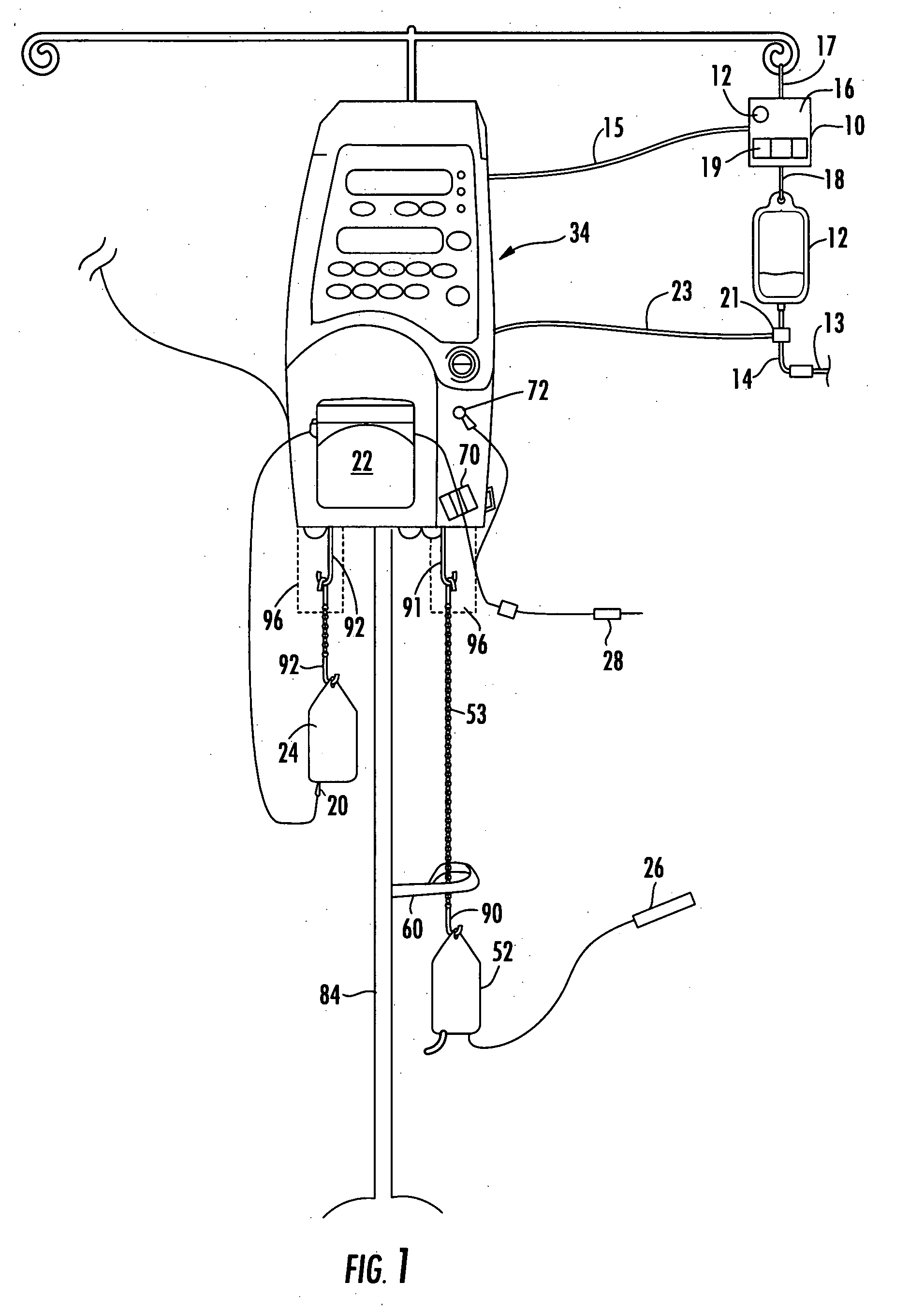

Patient hydration/fluid administration system and method

InactiveUS20080027409A1Prevent kidney damagePrevent dehydrationMedical devicesPressure infusionUrine outputIntensive care medicine

A patient hydration system with a first infusion subsystem for infusing a patient with fluid from a first source and a second infusion subsystem for infusing a patient with fluid from a second source. A urine output measurement subsystem determines the amount of urine output by the patient. A controller is responsive to the first infusion subsystem, the second infusion subsystem, and the urine output measurement subsystem and is configured to control the first infusion subsystem based on the amount of urine output by the patient and / or the amount of infused fluid measured by the second infusion subsystem.

Owner:MEDICAL SYST

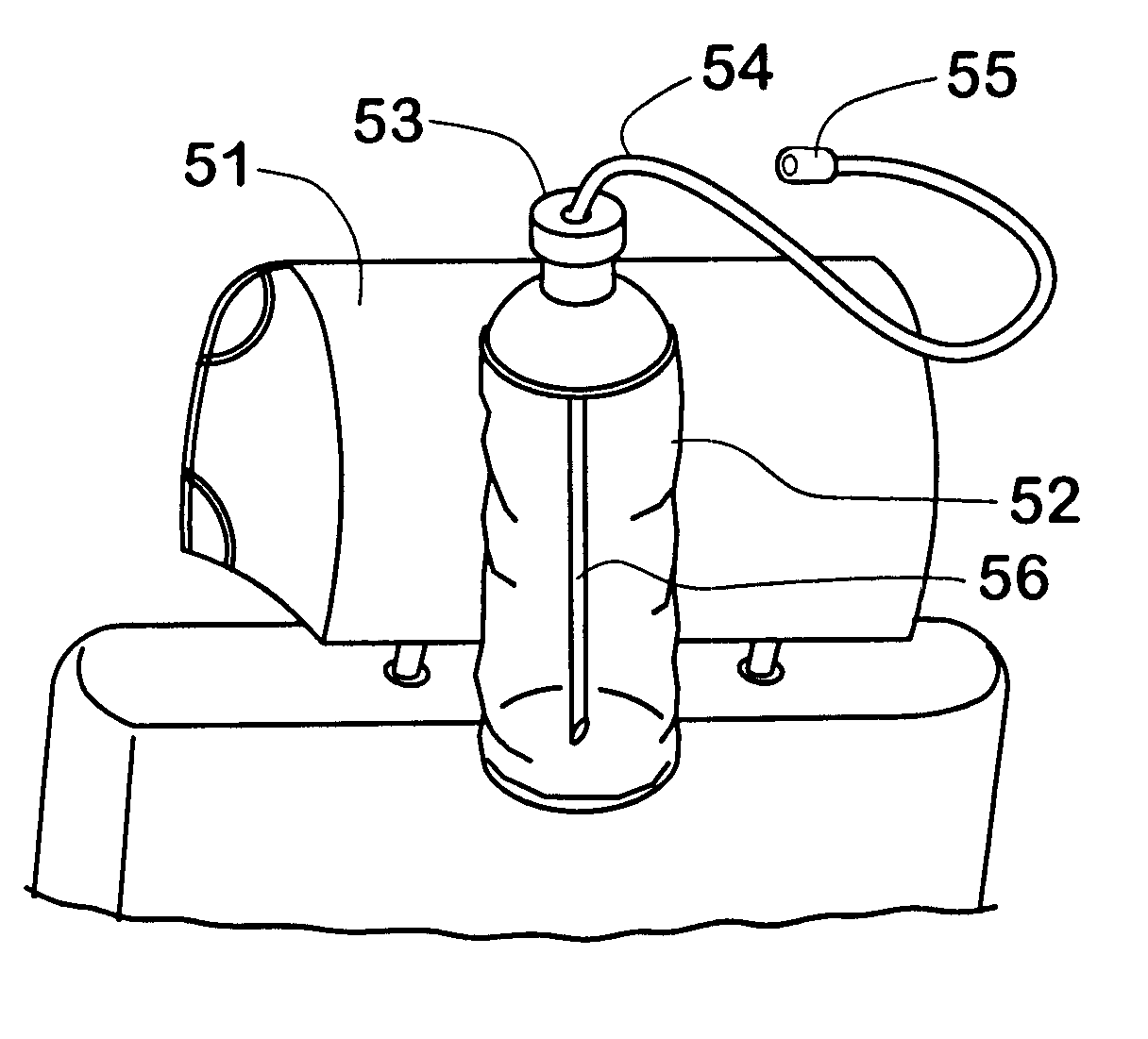

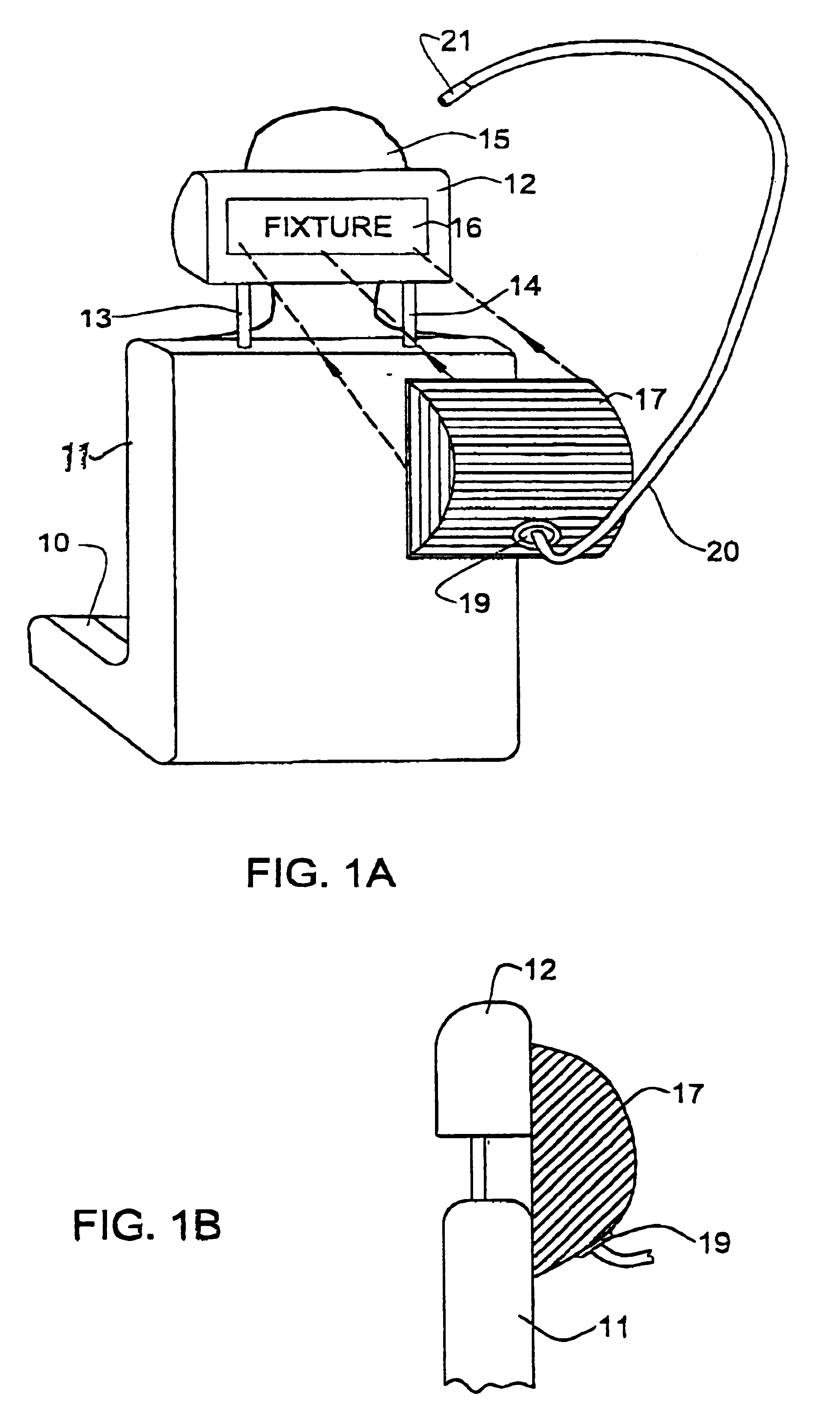

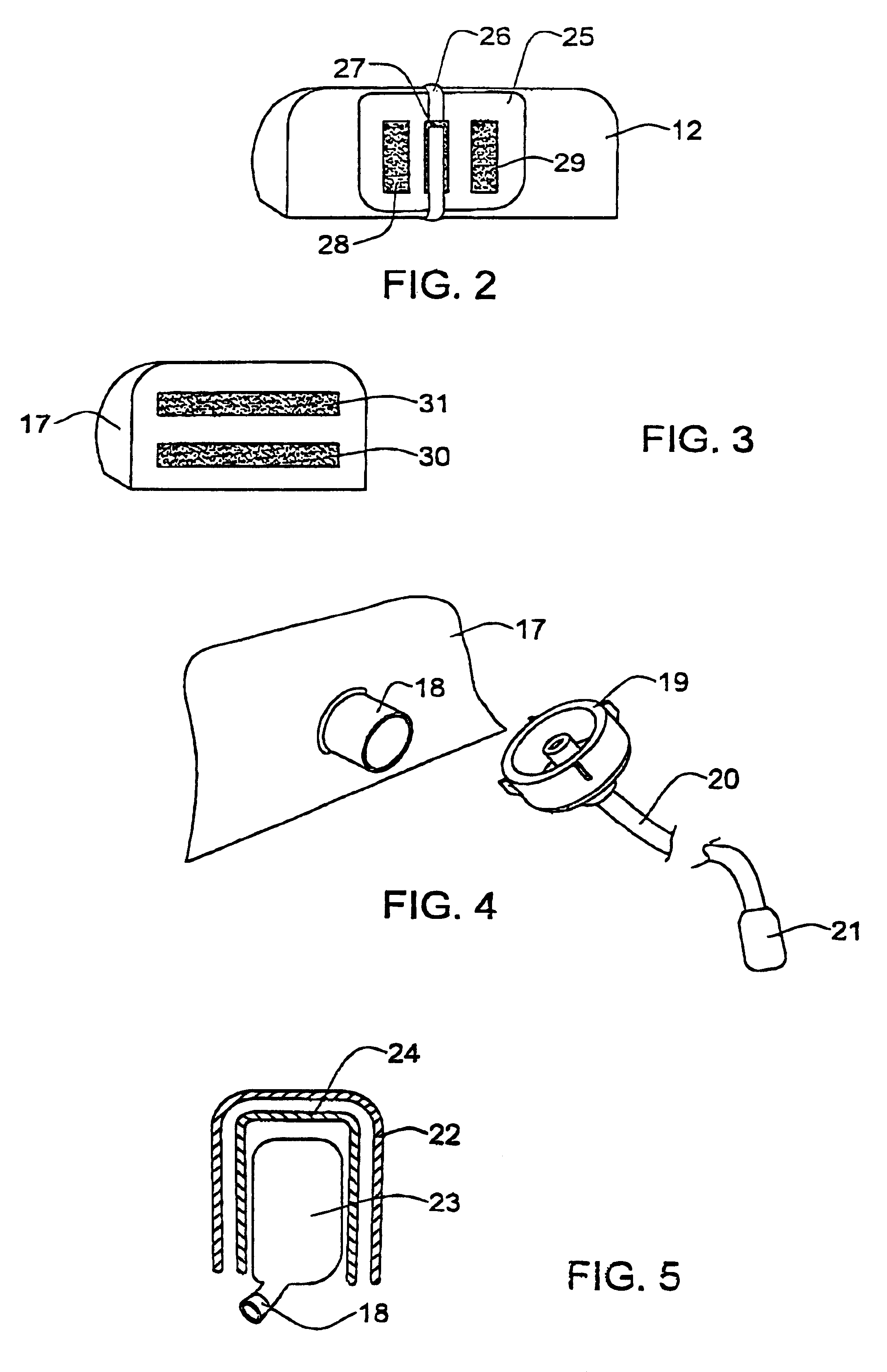

Water-supply pack assembly

InactiveUS6513686B1Quench his thirstPrevent dehydrationVehicle seatsTravelling sacksEngineeringHead holder

A water-supply pack assembly adapted to hitch onto the driver's seat in an automobile, thereby making it possible for the driver to drink water drawn from the supply without having to interrupt his driving activity The assembly includes a fixture attachable to the headrest of the driver's seat and a water-supply pack mountable on the fixture so that it is then behind the back of the seat. A flexible tube extending from the outlet of the supply and terminating in a valved mouthpiece functions as a straw to permit the driver with the mouthpiece in place to suck water from the supply as he drives the vehicle.

Owner:BEN SASSON AMIT

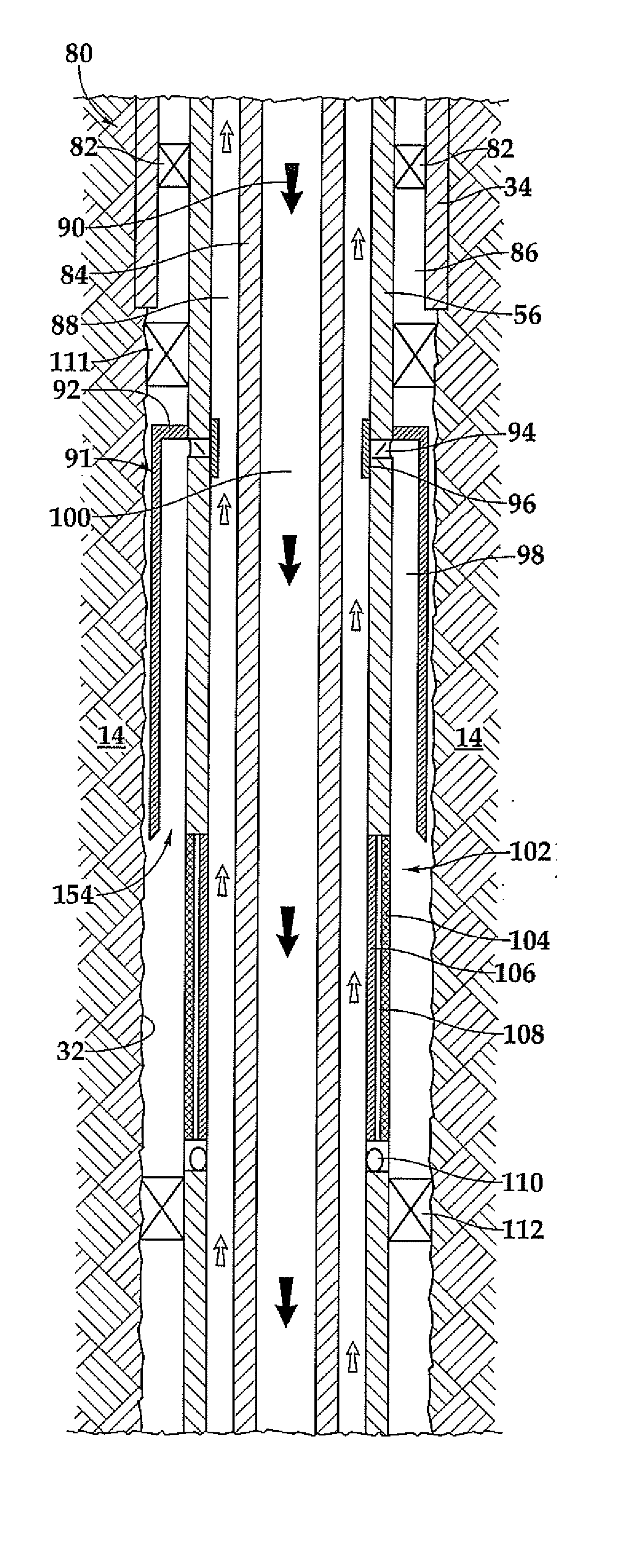

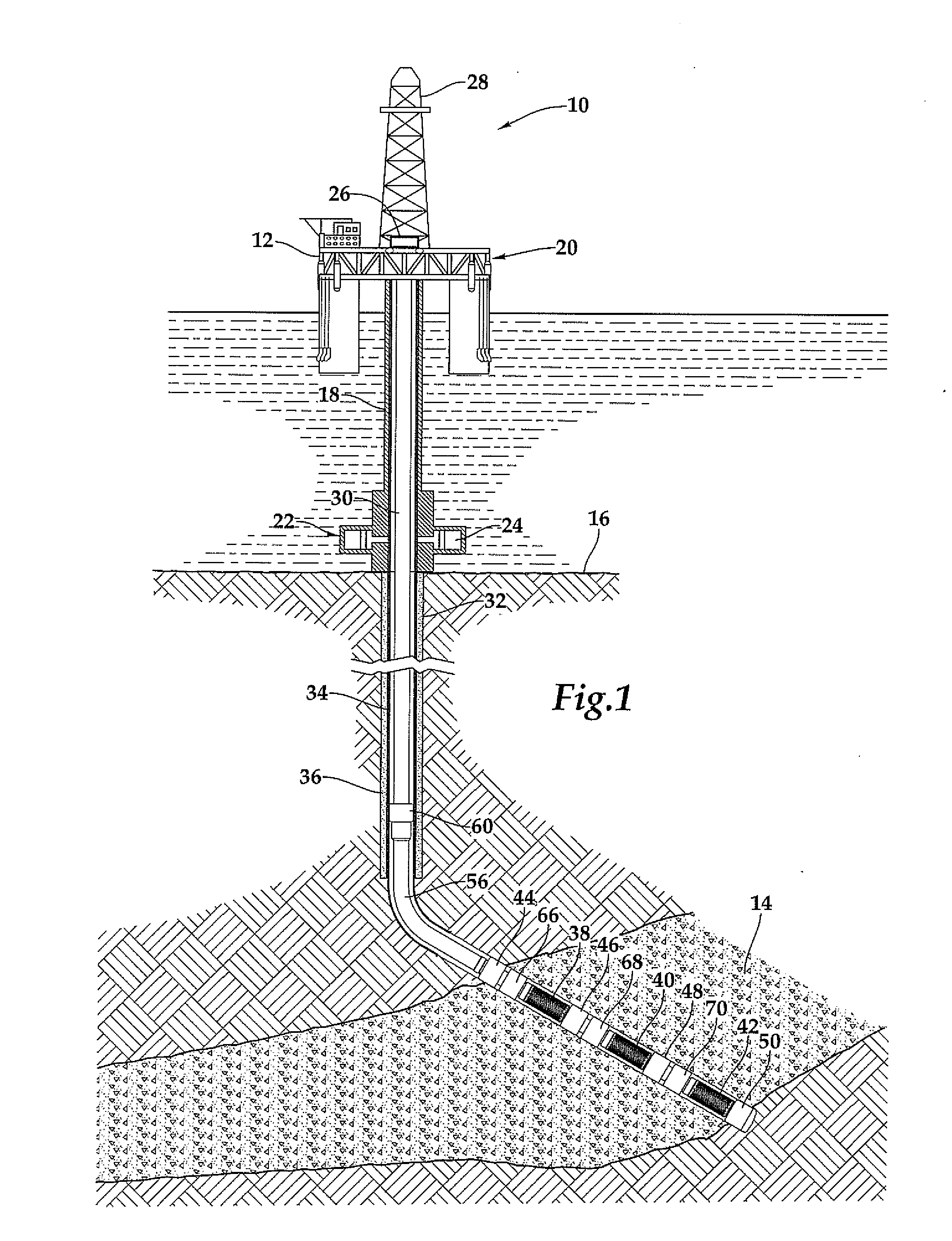

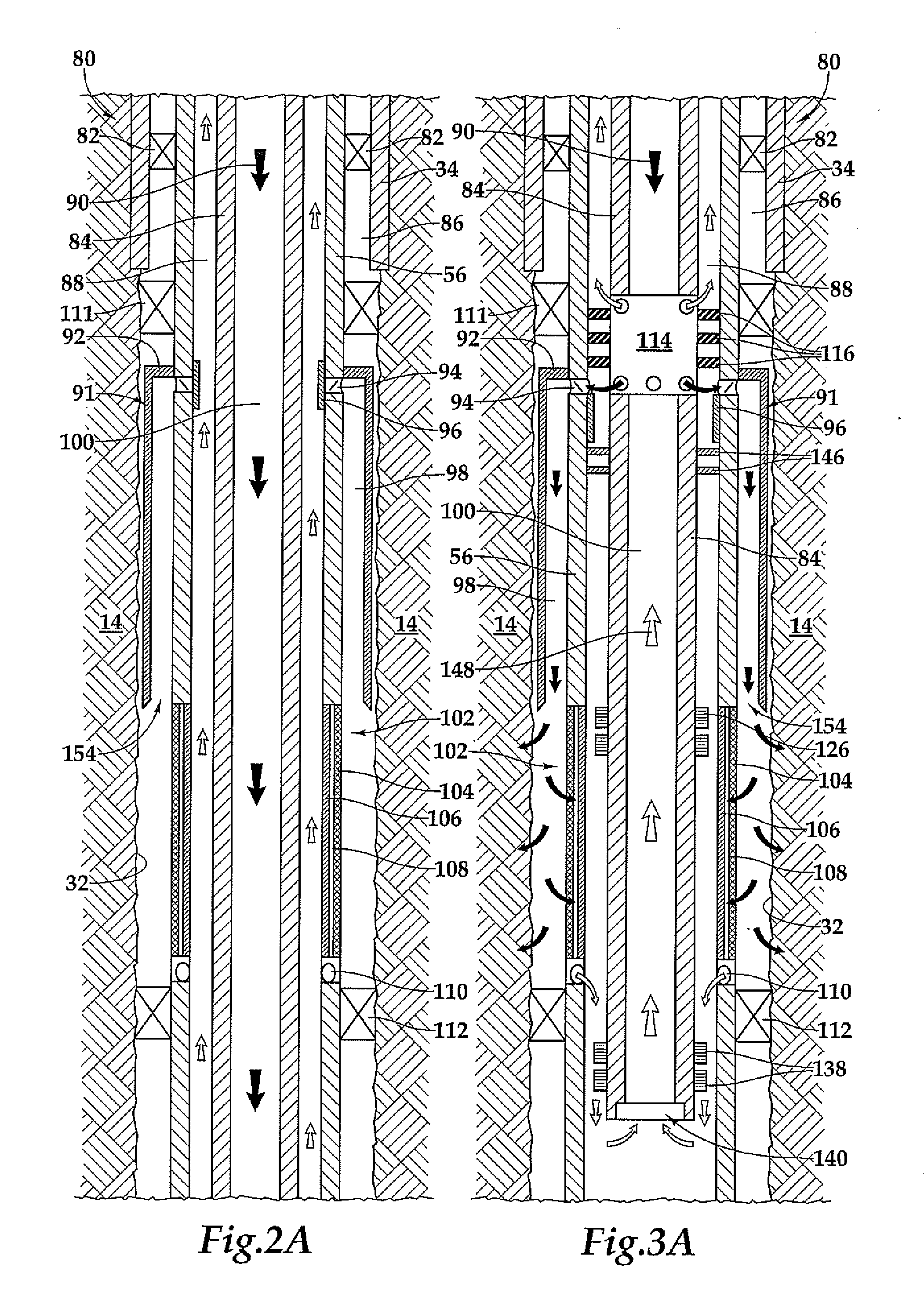

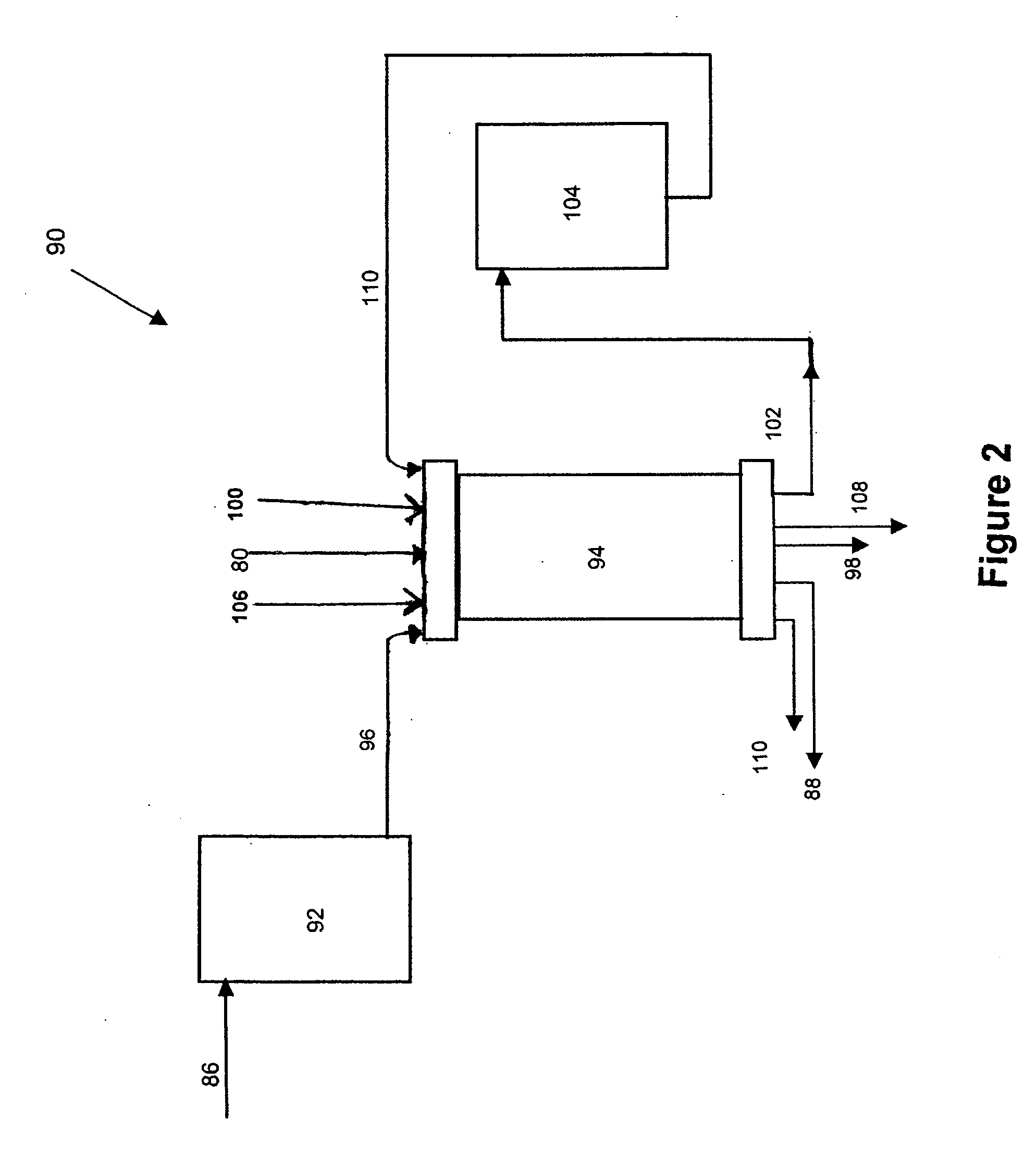

Open Hole Completion Apparatus and Method for Use of Same

ActiveUS20100294495A1Prevent dehydrationFluid removalVibration devicesBiomedical engineeringWellbore

An open hole completion apparatus (80) includes an outer tubing string (56) disposed in an open hole portion of a wellbore (32). The outer tubing string (56) includes a sand control screen (102) and a shrouded closing sleeve (91). An inner tubing string (84) is at least partially disposed within the outer tubing string (56). The inner tubing string (84) includes a crossover assembly (114). The shrouded closing sleeve (91) has a shroud (92) that creates a channel (98) with a portion of the outer tubing string (56) by extending over a fluid port (94) of the shrouded closing sleeve (91) toward the sand control screen (102), such that when a treatment fluid is pumped through the inner tubing string (84), the crossover assembly (114) and the fluid port (94), the treatment fluid is injected into the wellbore (32) remote from the fluid port (94).

Owner:HALLIBURTON ENERGY SERVICES INC

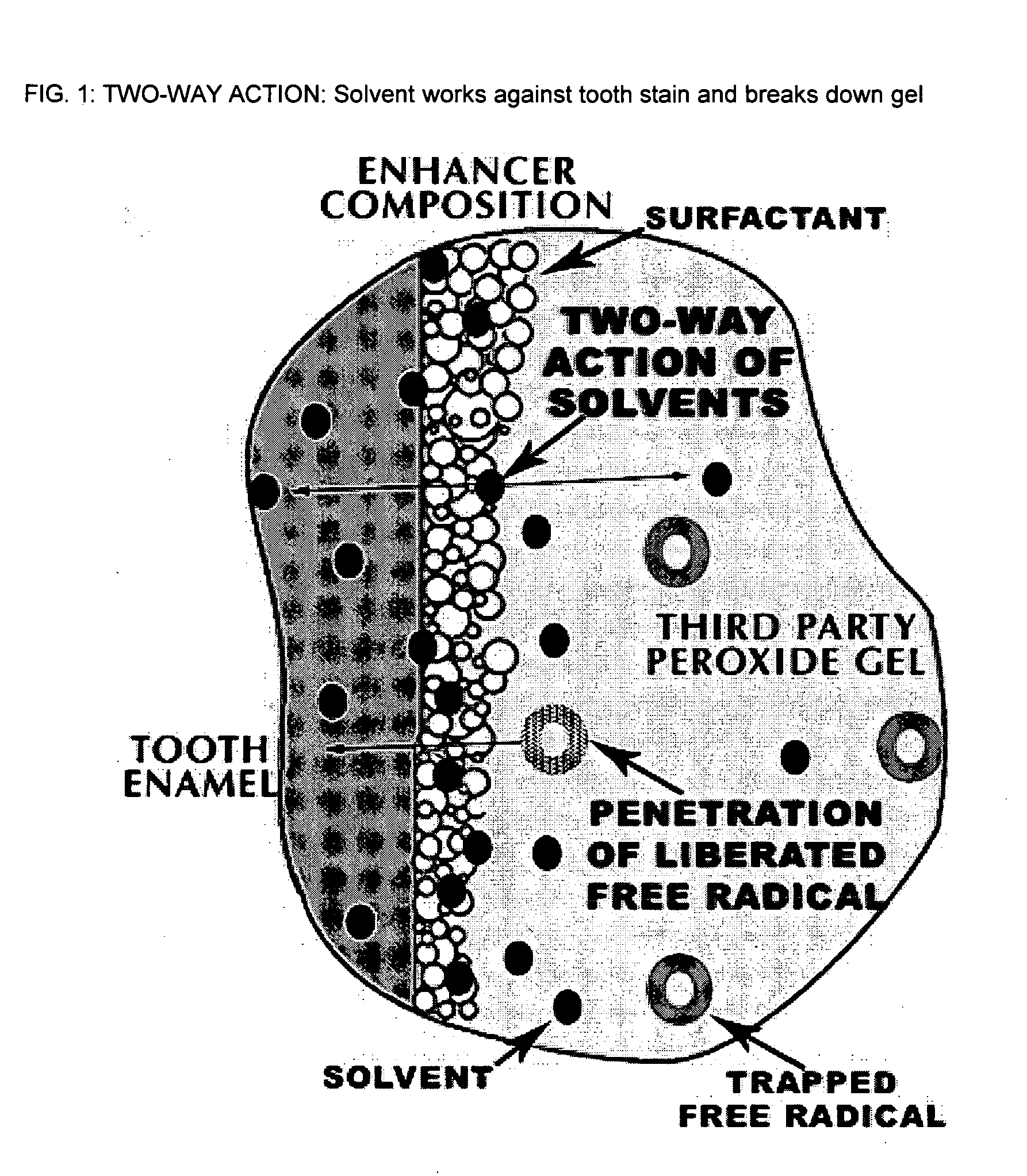

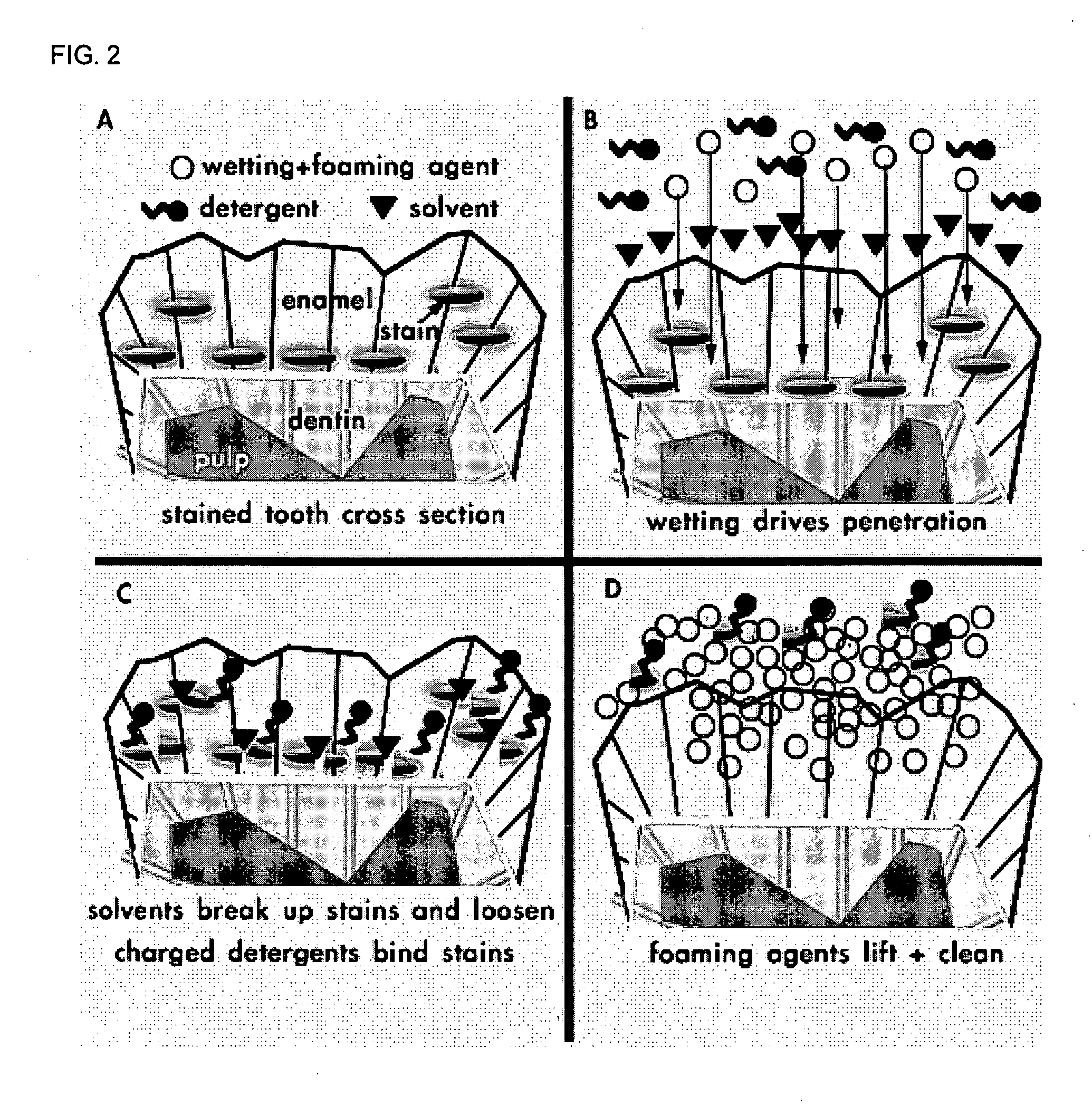

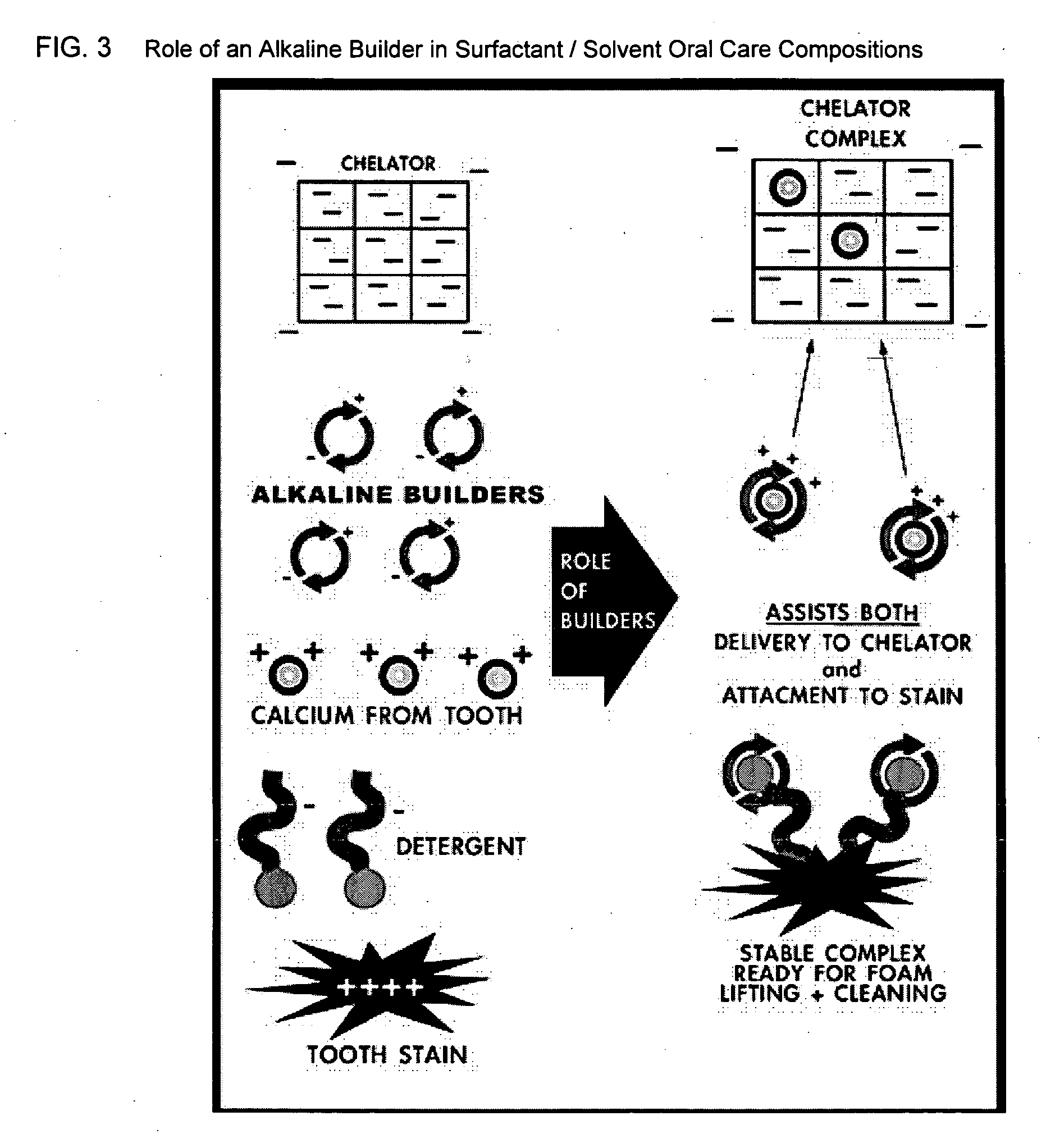

Stand-alone or enhancer composition for oral care

InactiveUS20060198797A1Reduction in associated transient dentinal hypersensitivityConvenient whiteningCosmetic preparationsToilet preparationsSolventBiological tissue

A biological tissue care composition, such as an oral care composition, for enhancing the effects of whitening compositions. A solvent and surfactant is used with an alkaline builder and an optional saponifier. A method of use of such a composition includes use as a tooth cleaning composition. Alternatively the composition may be used as a stand-alone cleaning composition.

Owner:STAIN AWAY

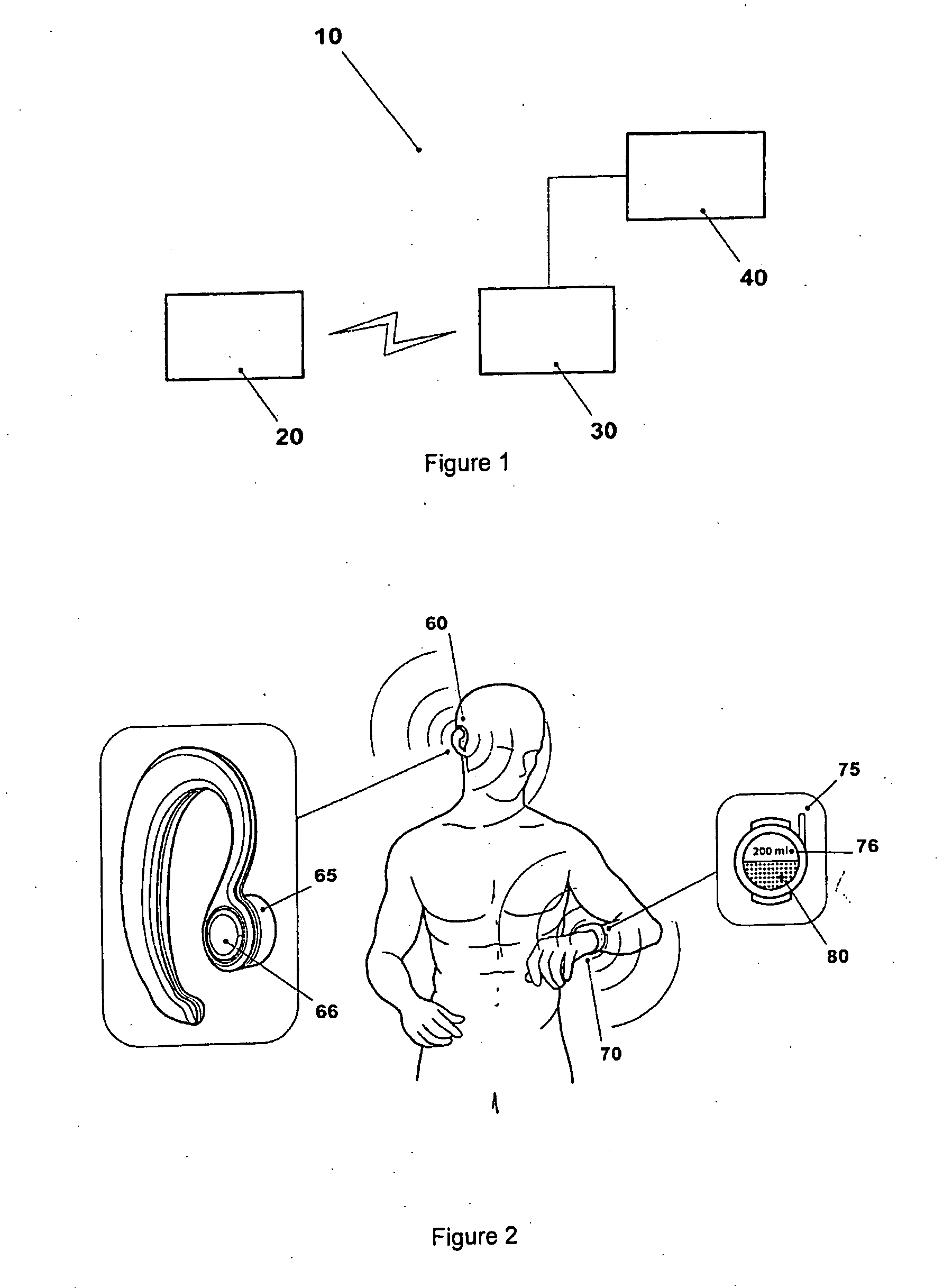

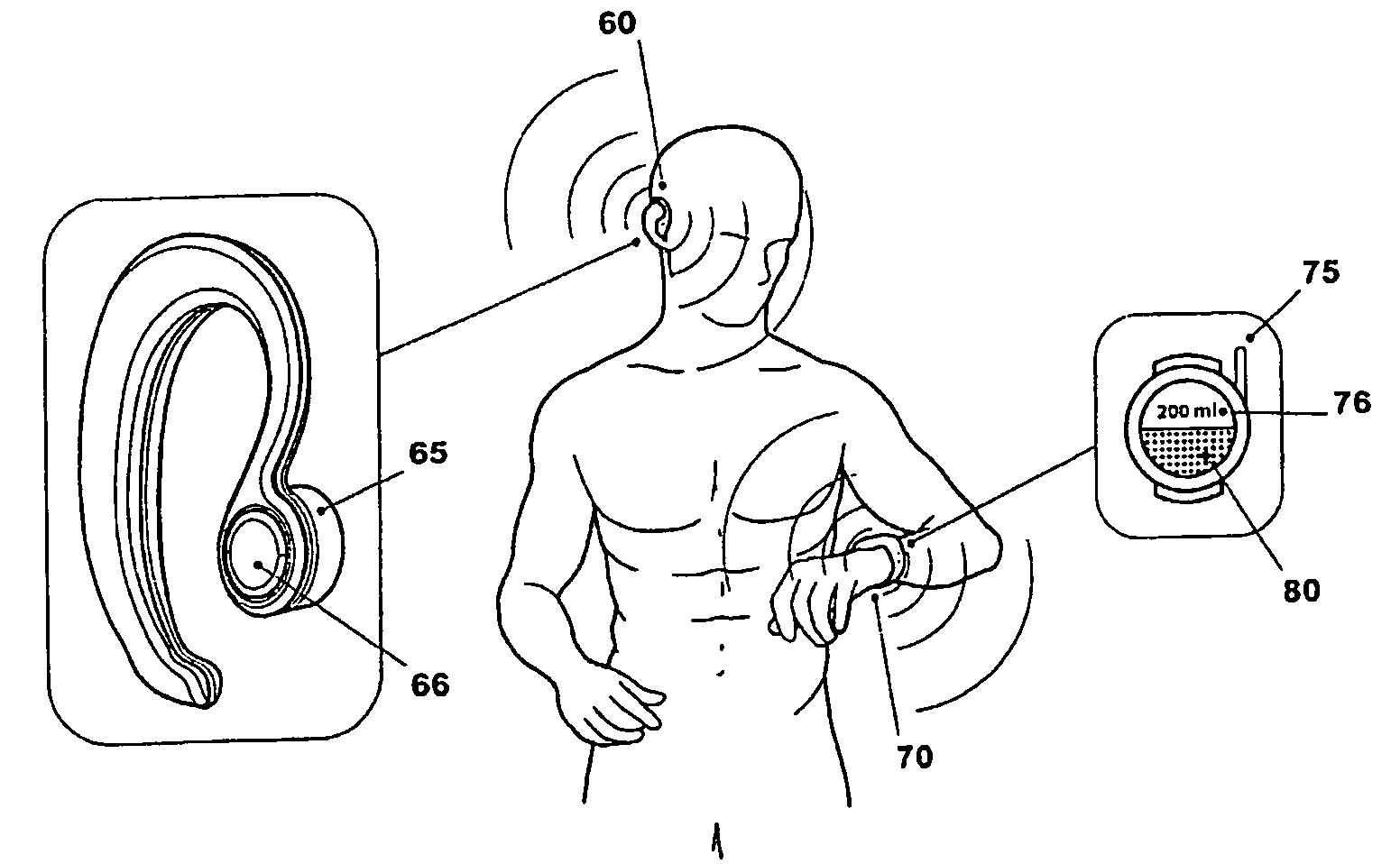

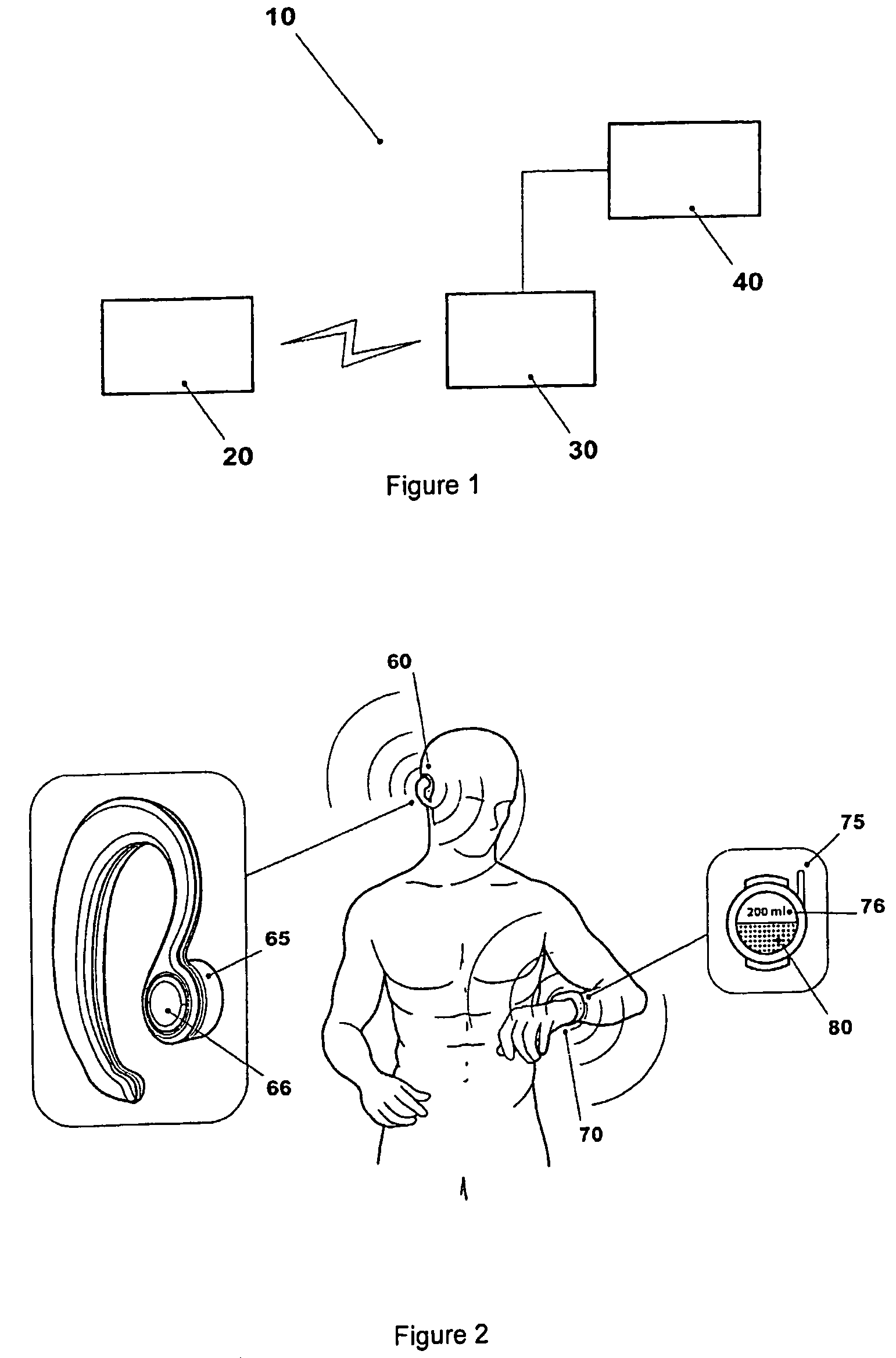

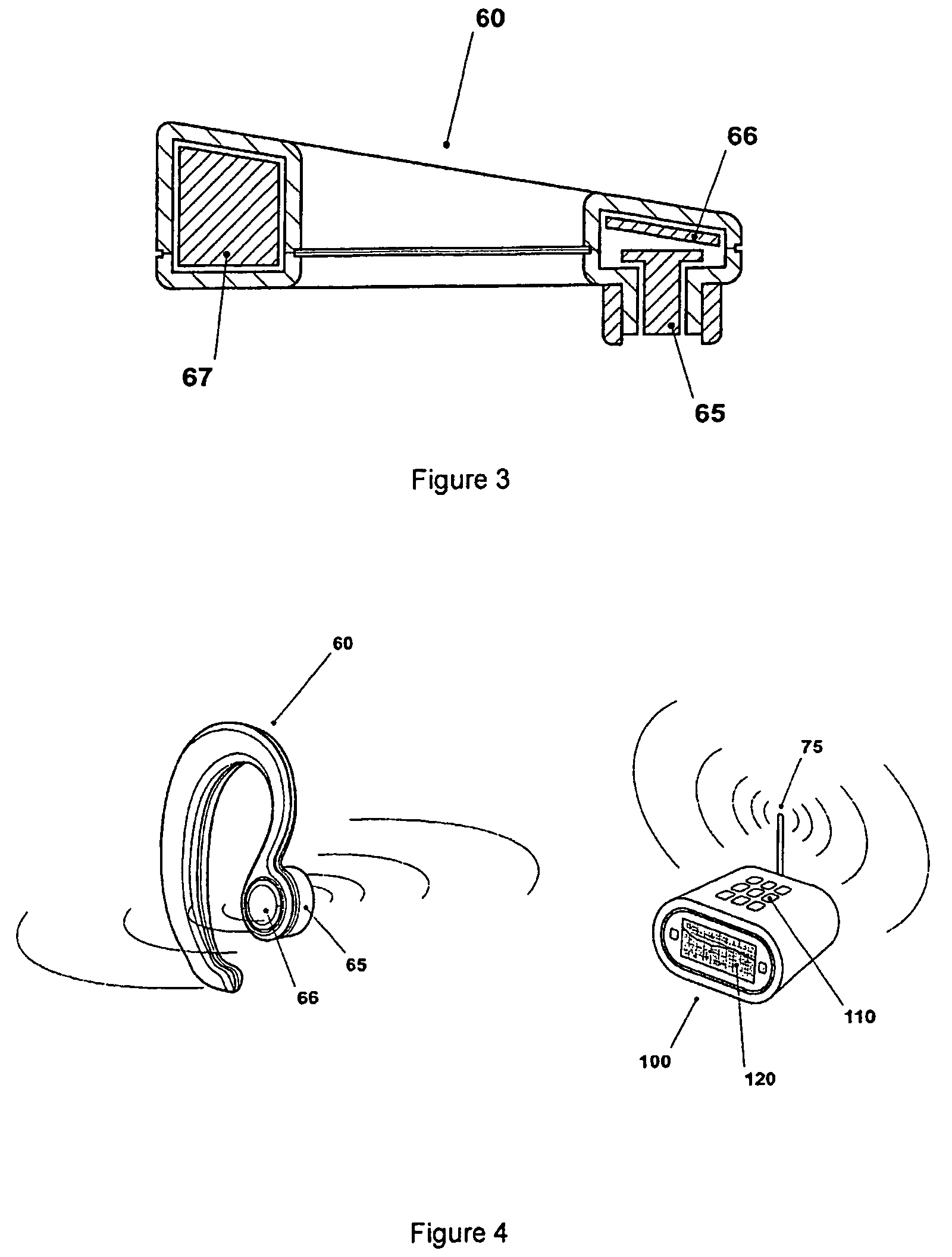

Hydration Monitor

ActiveUS20080234600A1Performance maximizationPrevent dehydrationDiagnostic recording/measuringSensorsMedicineCore temperature

Owner:INOVA DESIGN SOLUTIONS

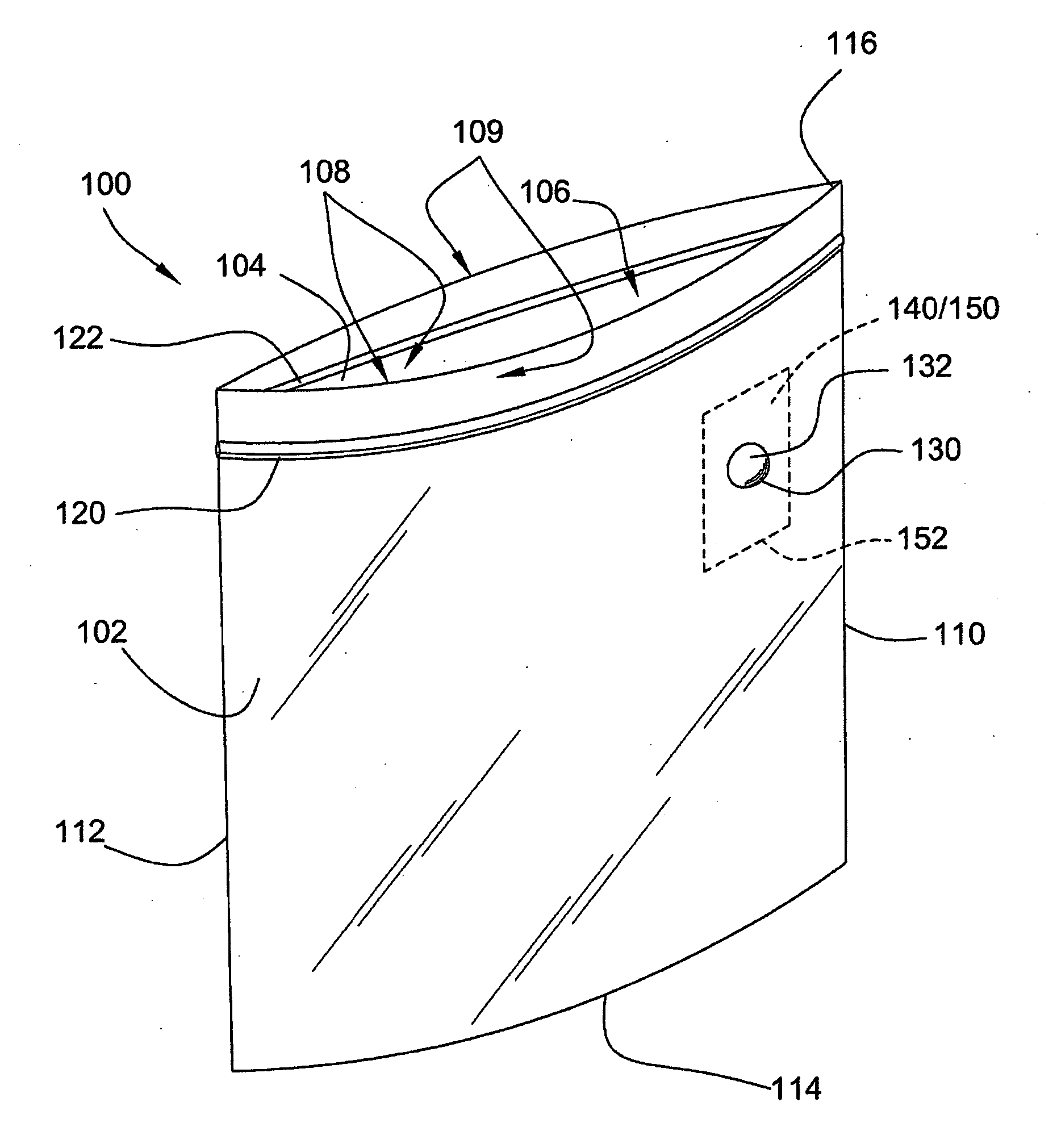

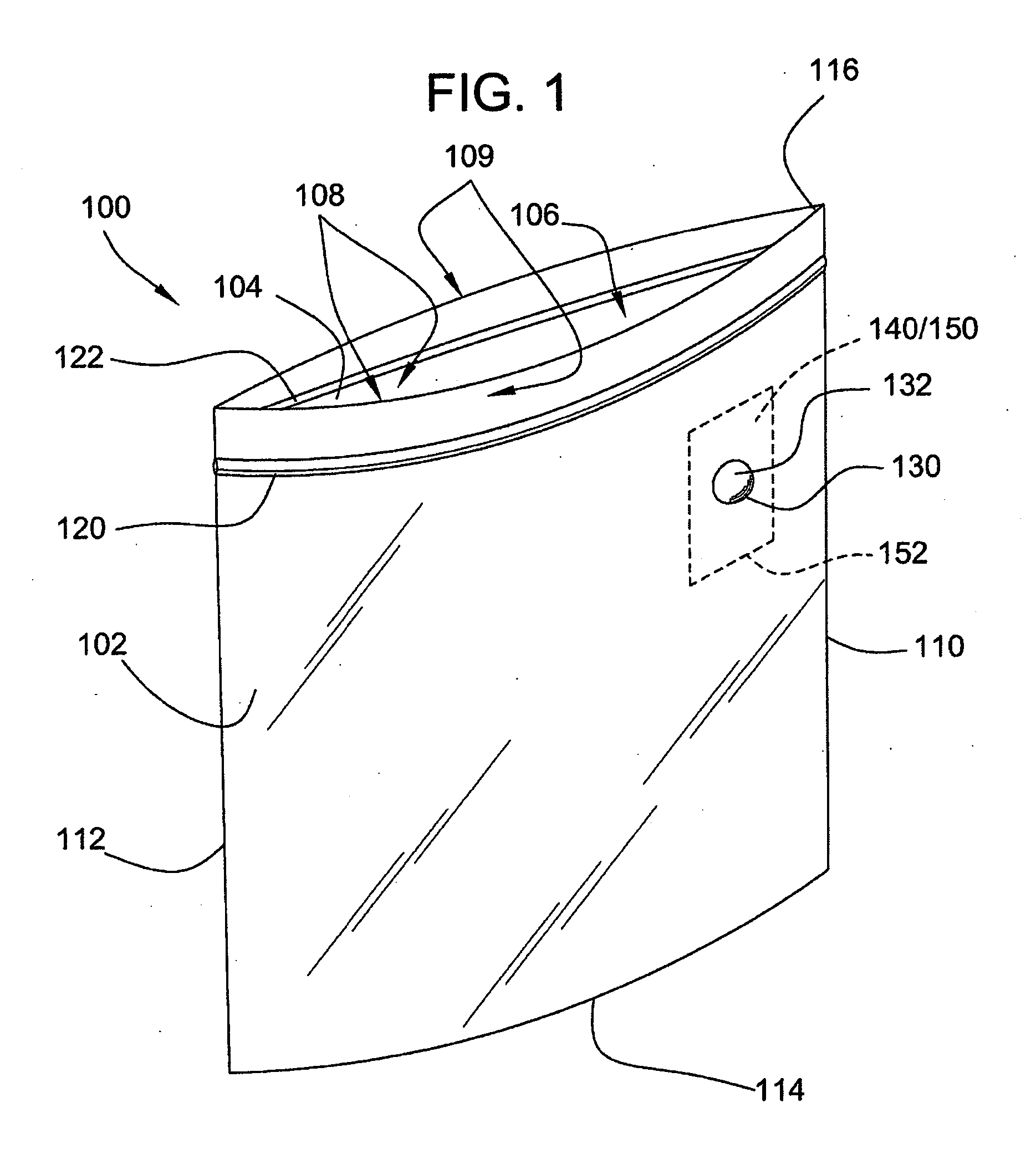

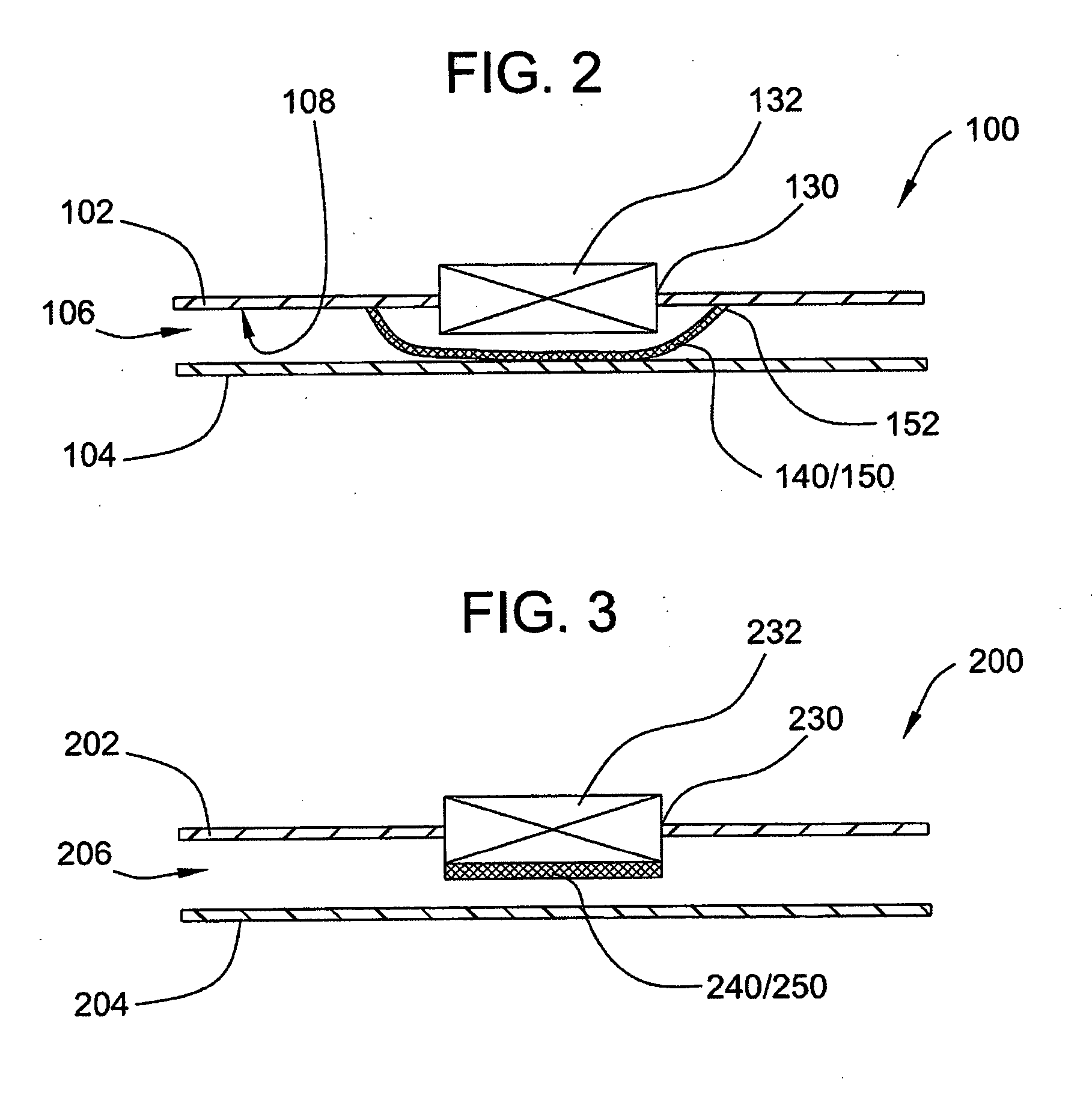

Storage bag

A flexible storage bag for storing food items and the like is provided with a separation material positioned to cover an aperture disposed in and / or a one-way valve element attached to the storage bag. The separation material may be a non-woven material. When latent air remaining in the interior volume of the storage bag is exhausted through the aperture and / or one-way valve element, the air passes through the separation material. The separation material functions to remove liquids that may be entrained in the exhausting air. In an embodiment, the separation material may be treated with a low surface energy substance to improve the liquid removal function. In another embodiment, the separation material may be provided as a plurality of layers or as part of the one-way valve element.

Owner:THE GLAD PROD CO

Preparation method of instant oat flour

InactiveCN104642910AModerate tastePreserve soluble nutrientsFood preparationCelluloseAdditive ingredient

The invention discloses a preparation method of instant oat flour and relates to a preparation method of oat flour. The preparation method comprises the following steps: baking, cleaning, soaking, steaming and cooling oats, serving as raw materials, sequentially; glue milling the oats after pretreatment to prepare oat pulp, carrying out enzymatic hydrolysis, heating, boiling, and killing enzyme; and cooling an enzymolysis liquid, glue milling, homogenizing, drying, sterilizing and packaging a finished product. According to the preparation method disclosed by the invention, with the oats as the raw materials, by virtue of pretreatment, enzymatic hydrolysis technological treatment and spray drying, the instant oat flour which can keep multiple nutritional components and fragrance of oat is prepared; the prepared instant oat flour is moderate in taste, has self flavor of oat, keeps the soluble nutritional components in the oats, is also capable of providing extra plant proteins, fats and soluble dietary fibers and can be directly used for preparing an oat beverage; as macromolecular substances including starch, cellulose and proteins in the oats are hydrolyzed by virtue of an enzyme method, the viscosity of the starch of the oats is lowered, and the problems of water separating, gelation, precipitation and the like caused when the oats are applied to beverages are solved.

Owner:厦门北大泰普食品科技有限公司

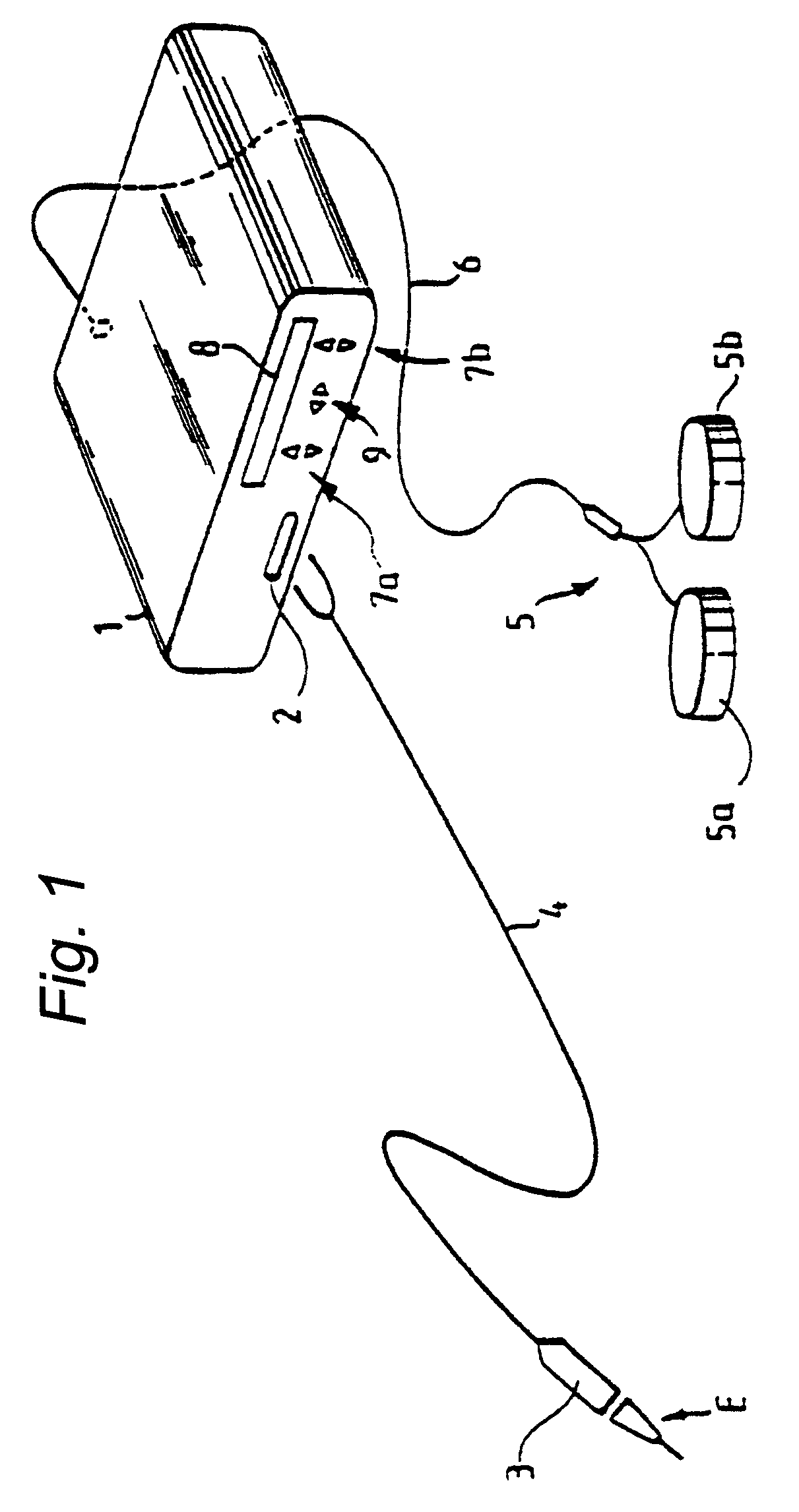

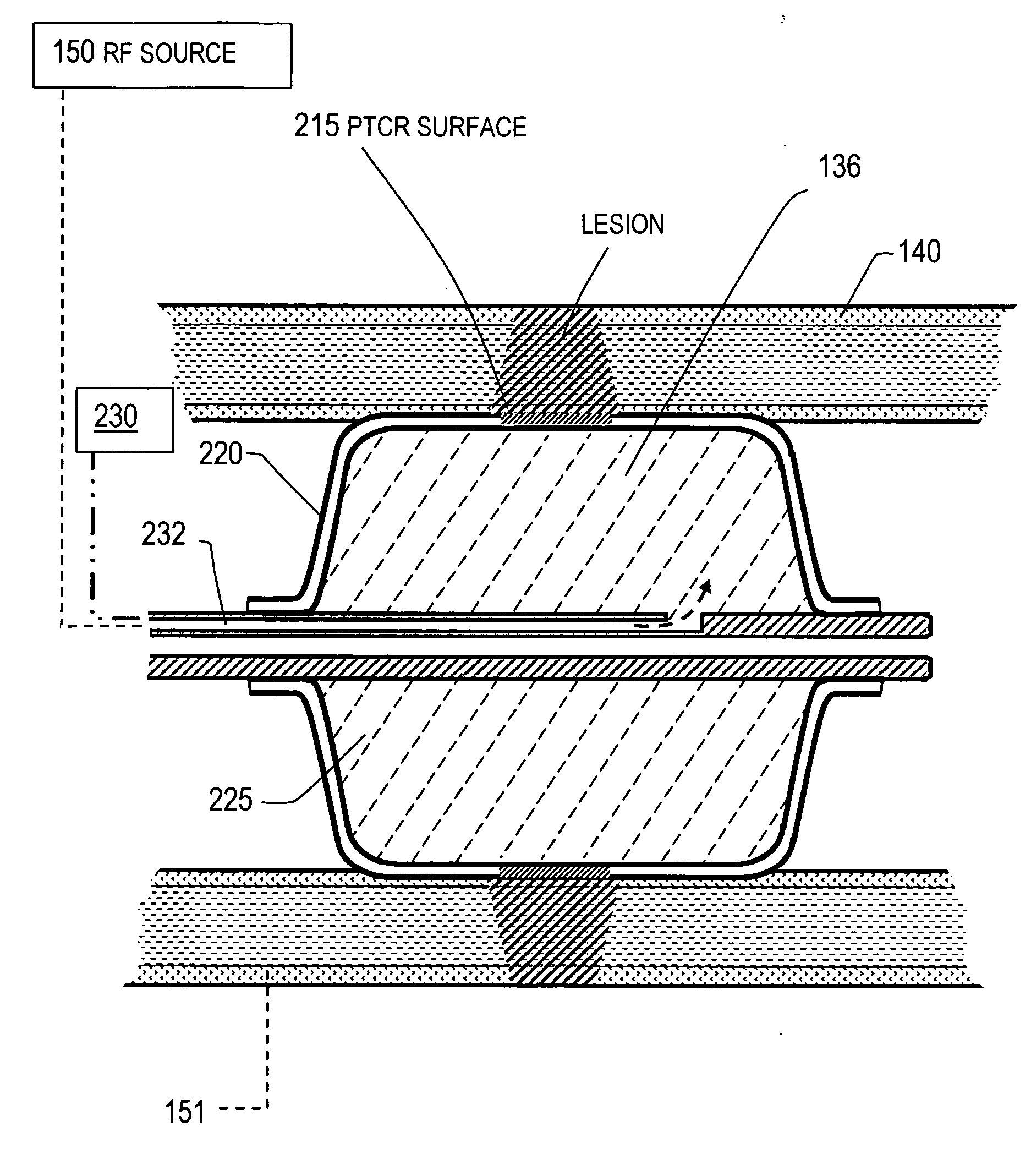

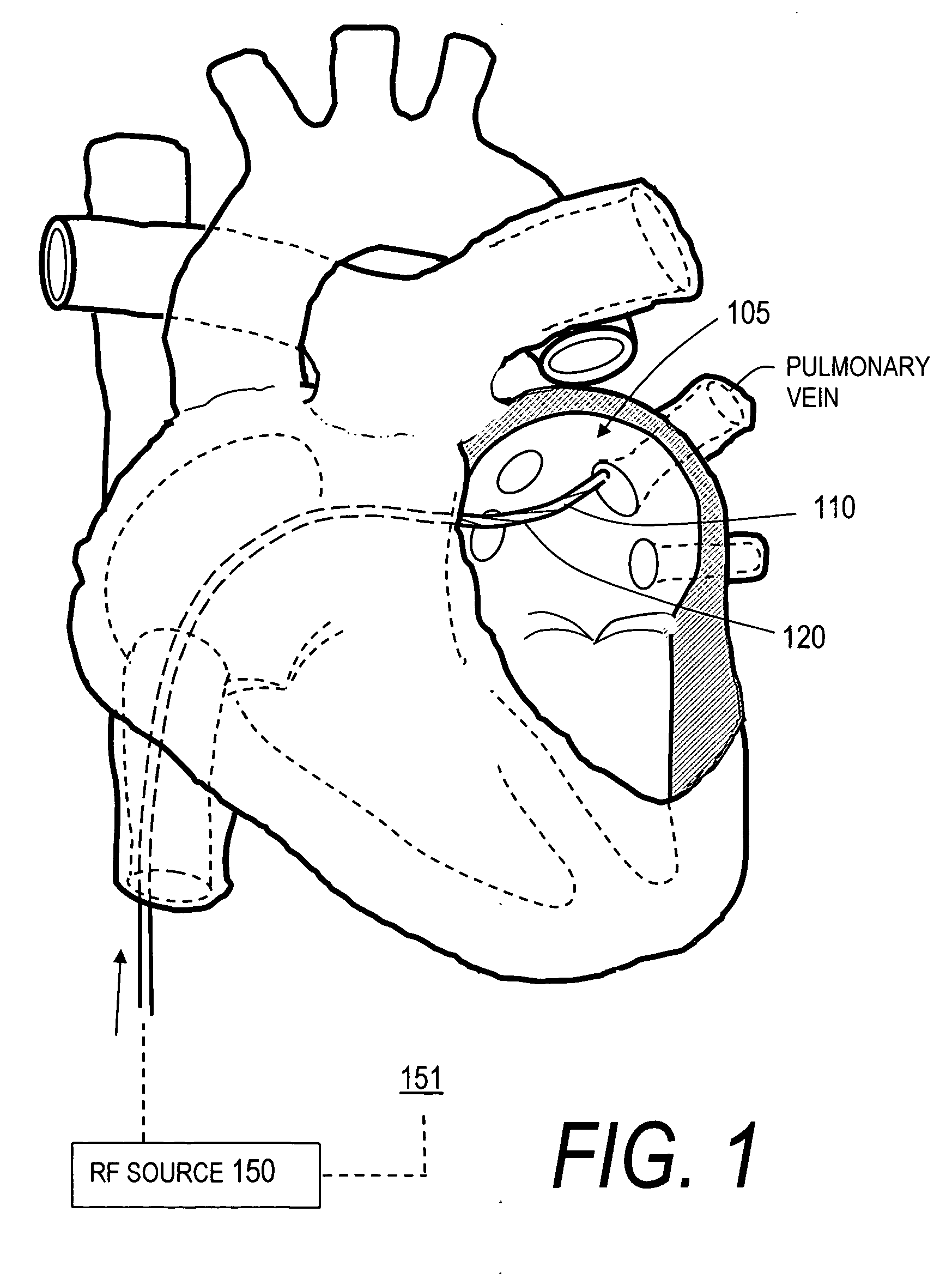

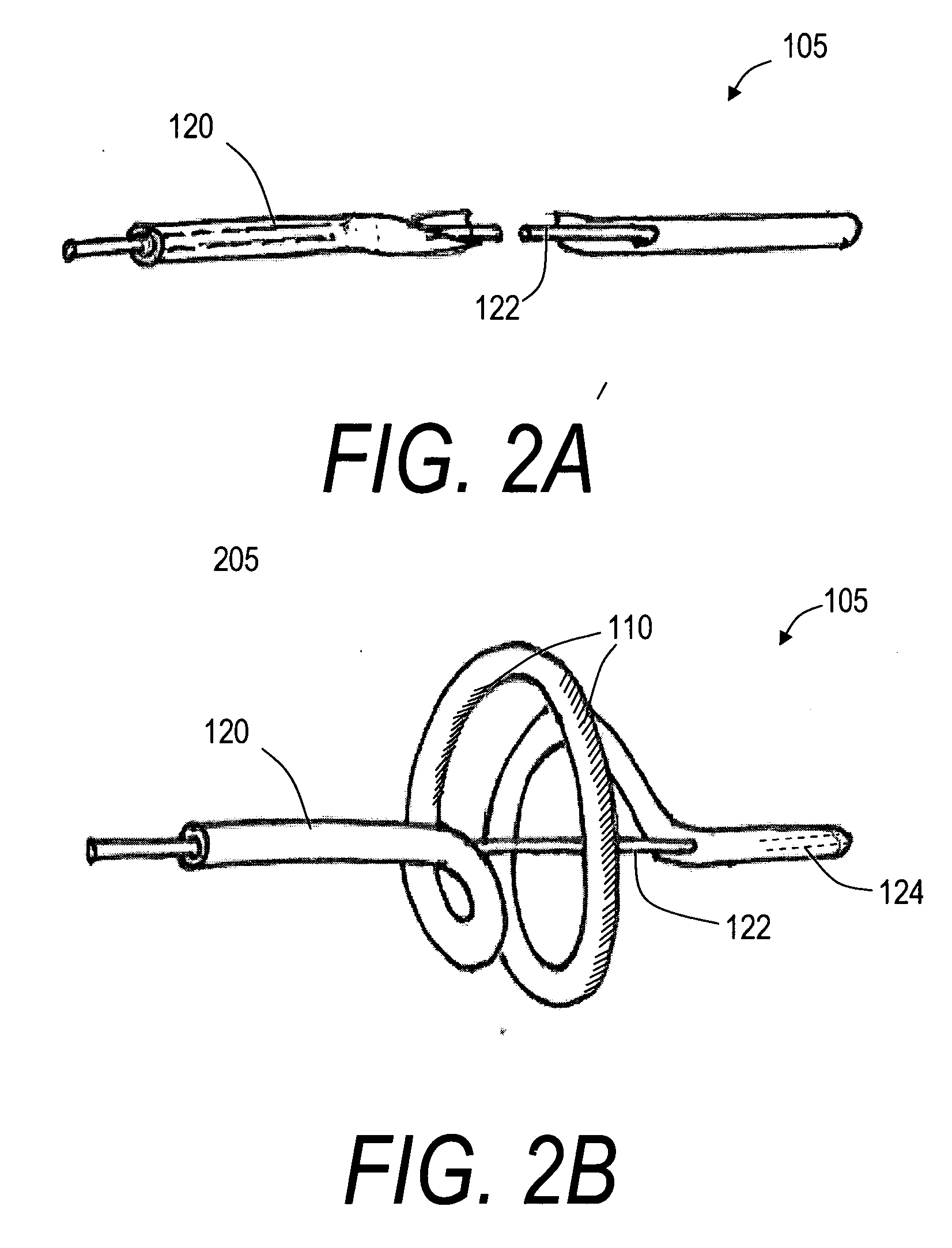

Endovascular catheter and method of use

InactiveUS20060084969A1Inhibit migrationReduce conductanceDiagnosticsSurgical instruments for heatingSurgical departmentIntravascular catheter

An electrosurgical medical device and method for treating cardiac arrhythmias. In one embodiment, an elongate catheter has a distal shaft end or balloon that carries an electrosurgical energy delivery surface comprising at least one electrode with a positive temperature coefficient of resistance (PTCR) surface and / or an electrode with a pressure sensitive variable resistance to provide a smart surface for controlling Rf current flow at the interface of electrosurgical surface and the tissue. The electrosurgical surface then can limit or modulate Rf energy delivery through the surface in response to the temperature of the tissue or the engagement pressure of the surface against the engaged tissue. In operation, the smart electrosurgical surface can prevent arcing at the electrode-tissue interface, and thus control ohmic heating to prevent tissue desiccation, charring and emboli formation.

Owner:TRUCKAI CSABA +1

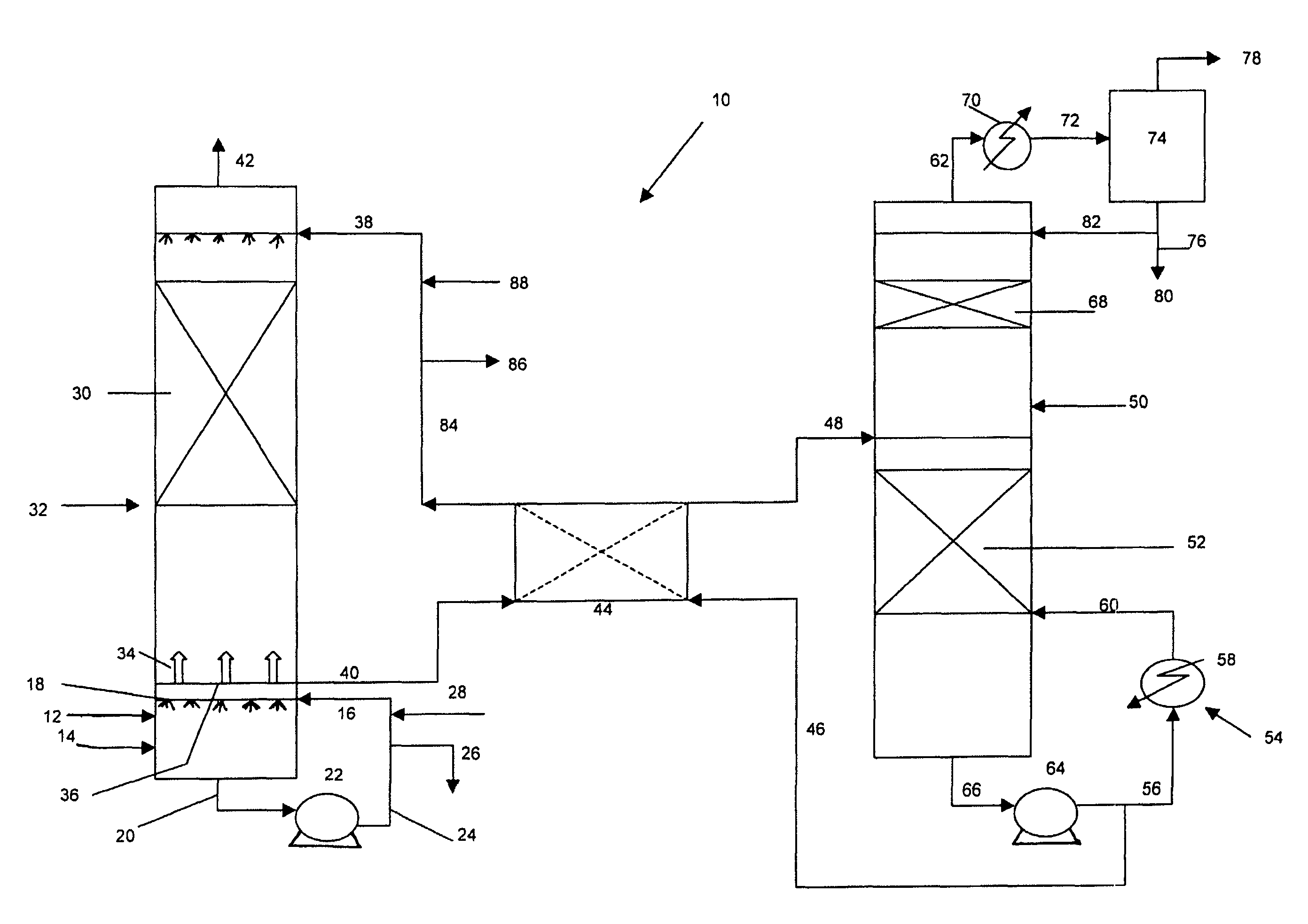

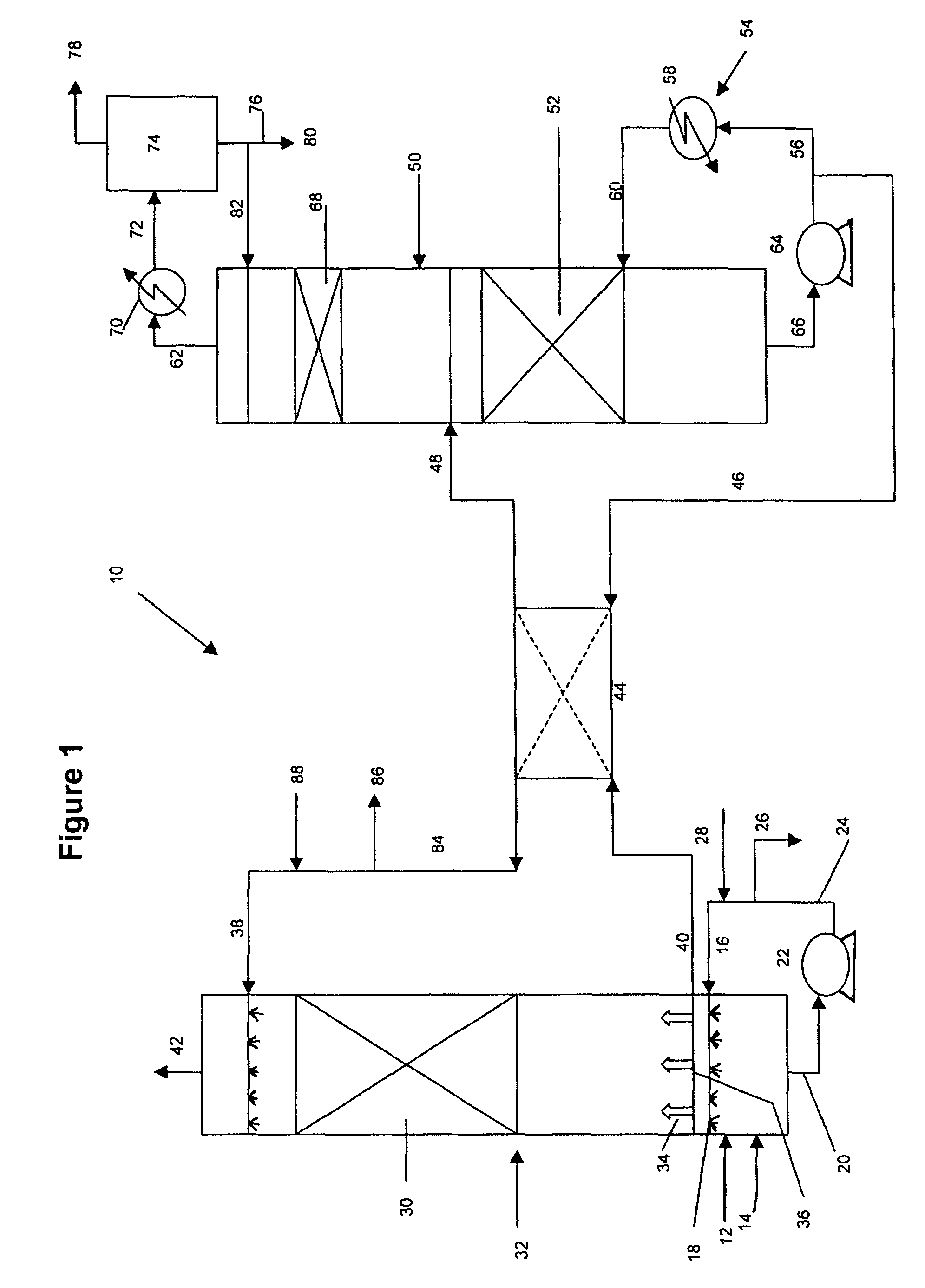

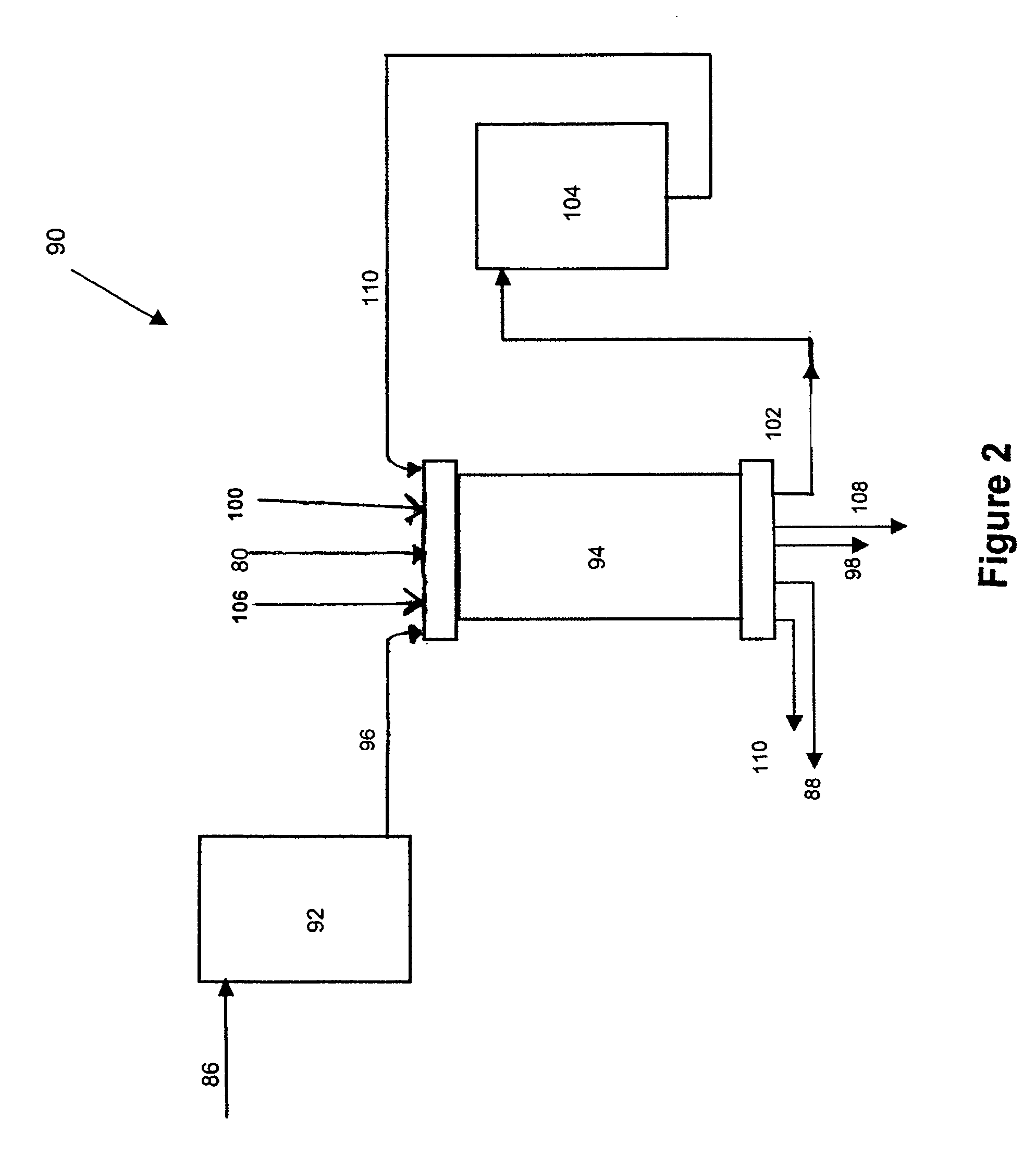

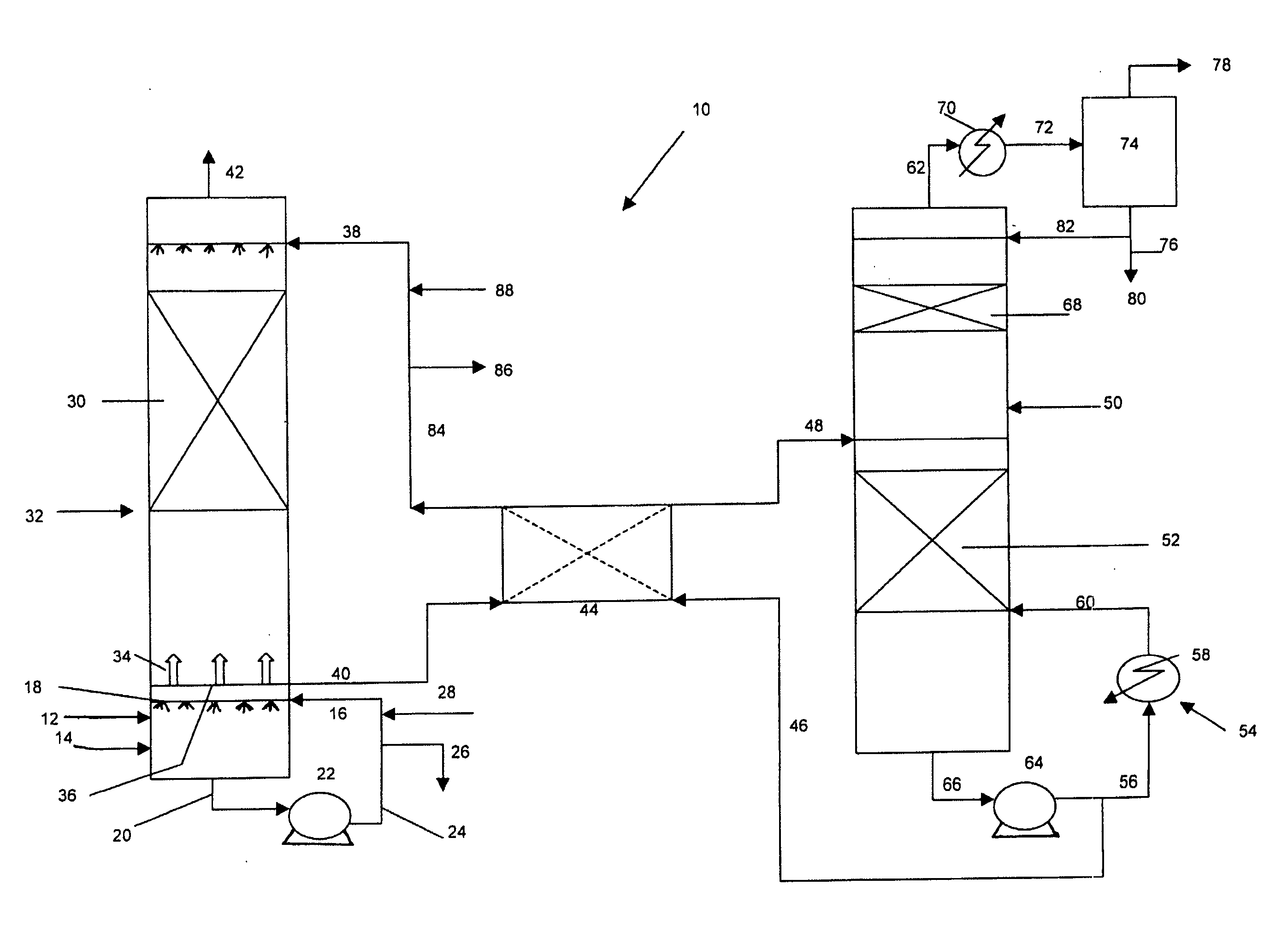

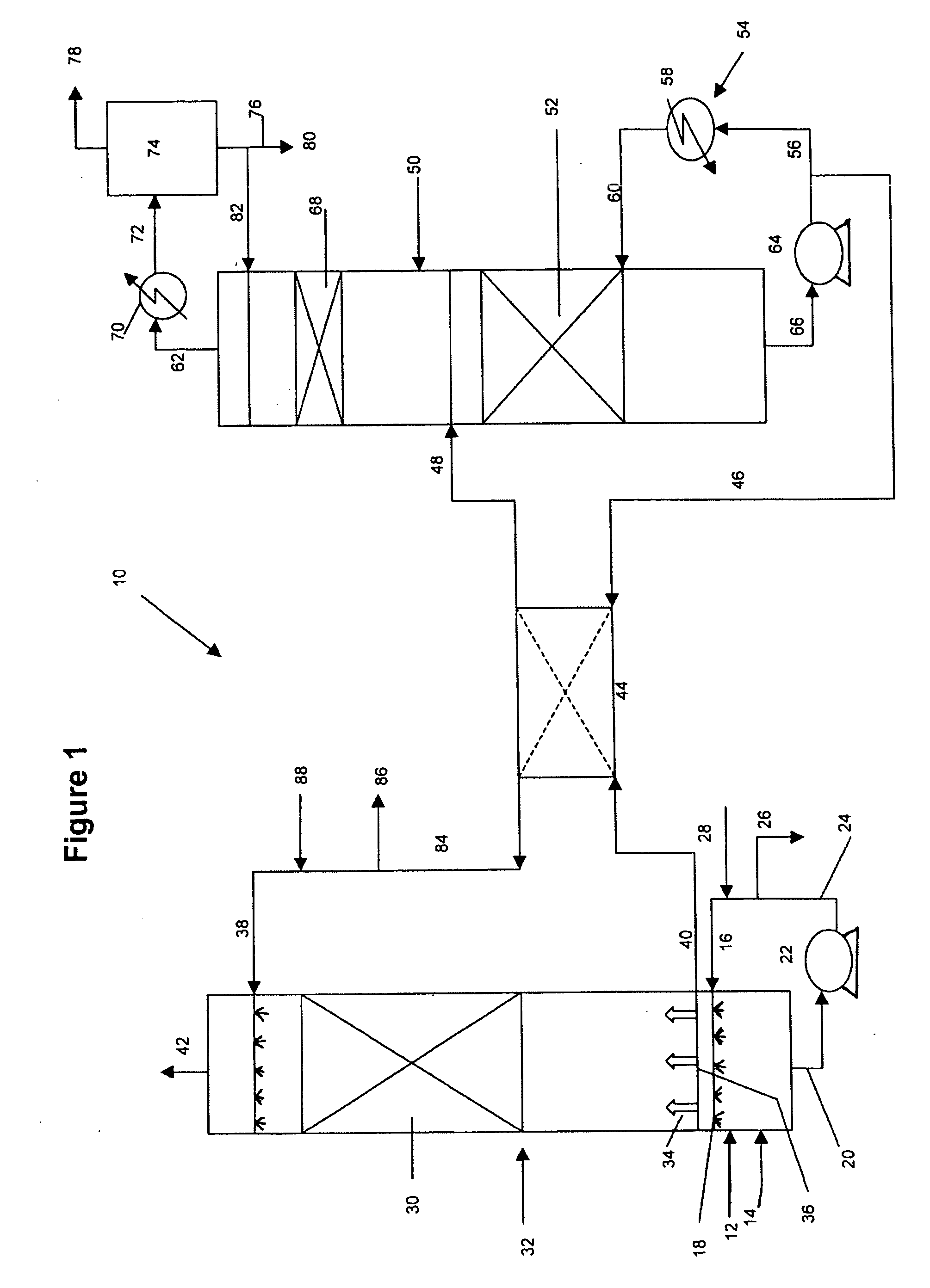

Regeneration of ion exchangers that are used for salt removal from acid gas capture plants

ActiveUS7776296B2Large volumeEfficiently recover the amine after the loading step can be minimizedDispersed particle separationHydrogen sulfidesIon exchangeIon-exchange resin

A process for the removal of an amine capturable gas from a feed gas stream using an amine solvent, the process comprises (a) contacting the feed gas stream with a lean amine solvent to form a rich amine solvent, wherein heat stable salts are present in the rich amine solvent; (b) stripping amine capturable gas from the rich amine solvent to form the lean amine solvent and an overhead reflux stream; (c) periodically contacting at least a portion of one or both of the lean amine solvent and the rich amine solvent with an anion exchange resin to form a first heat stable salt lean amine solvent; (d) periodically regenerating the anion exchange resin, wherein during the regeneration of the anion exchange resin, at least a portion of the reflux stream is used to wash the amine solvent from the anion exchange resin to produce a second heat stable salt lean amine solvent; and, (e) recycling at least a portion of the first and the second heat stable salt lean amine solvent for use in capturing the amine capturable gas from the feed gas.

Owner:SHELL OIL CO

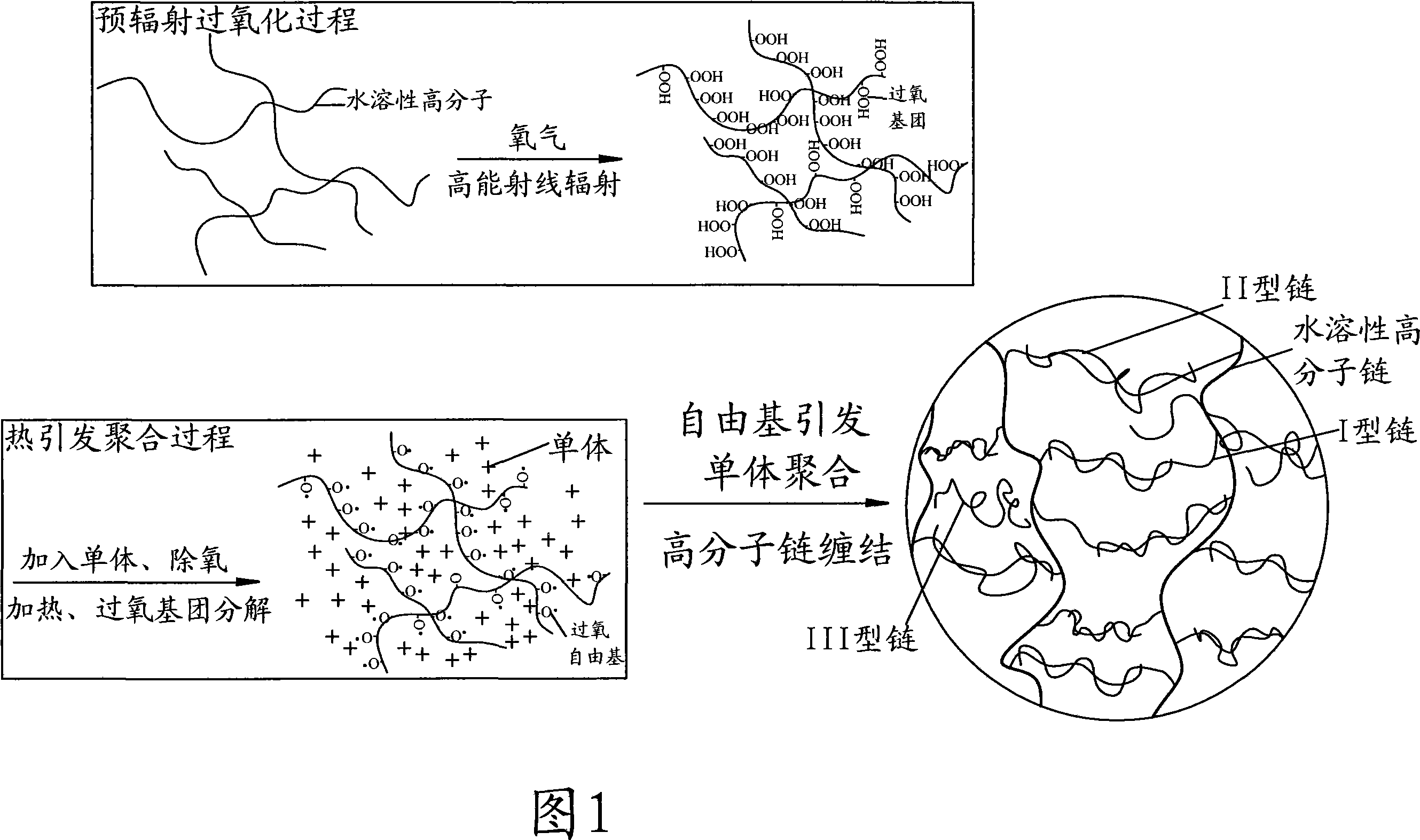

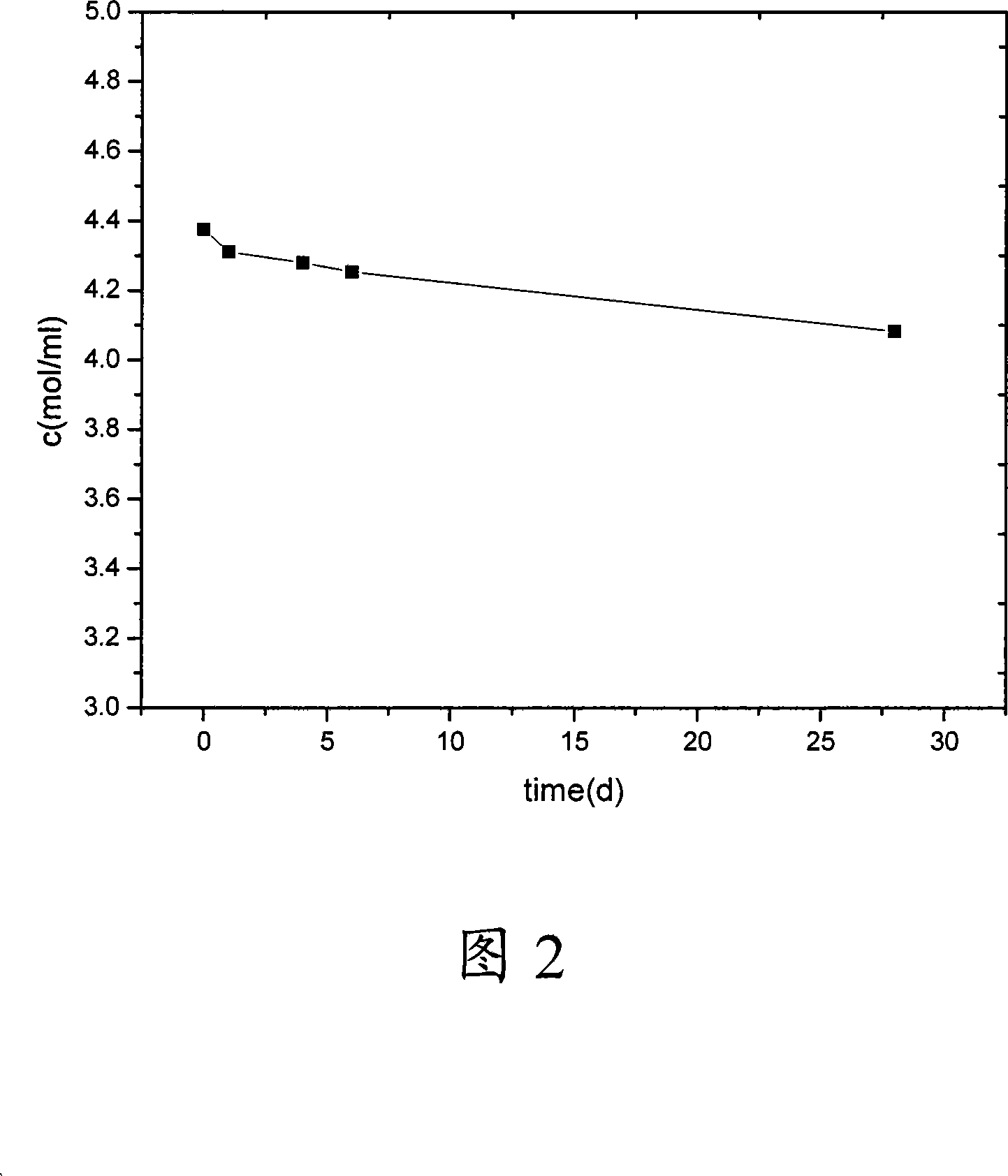

Hydrogel and method for preparing same

The present invention relates to a high strength hydrogel and a preparation method thereof. The method is firstly to perform a pre-irradiation and peroxidation process and then a thermal-initiated polymerization process. The pre-irradiation and peroxidation process is to irradiate the water soluble polymer or the water soluble polymer solution in the nitrogen atmosphere by the high energy radiation source to combine the peroxy group on the polymer chains; and the thermal-initiated polymerization process is to mix solution prepared by the water soluble polymer after initiated with the water soluble monomer or mix the water soluble polymer solution after initiated with the water soluble monomer, and then the product is obtained by deoxidizing and heating the mixture. The preparation method of hydrogel of the invention is simple, and the prepared hydrogel has a high mechanical strength, a wide selecting range of the raw materials, and a high applied cost.

Owner:BEIJING NORMAL UNIVERSITY

Application method of heteropoly acid type catalyst

InactiveCN1390643AImprove catalytic performancePrevent dehydrationPhysical/chemical process catalystsHeteropoly acidSolid acid

A process for improving the acid intensity stability of solid acid catalyst containing heteropoly acid or its salt (0.5-100 wt.%) features that said heteropoly acid or its salt has central atom (P or Si) and coordinating atom chosen from W, Mo and V, and there is water in reaction atmosphere.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

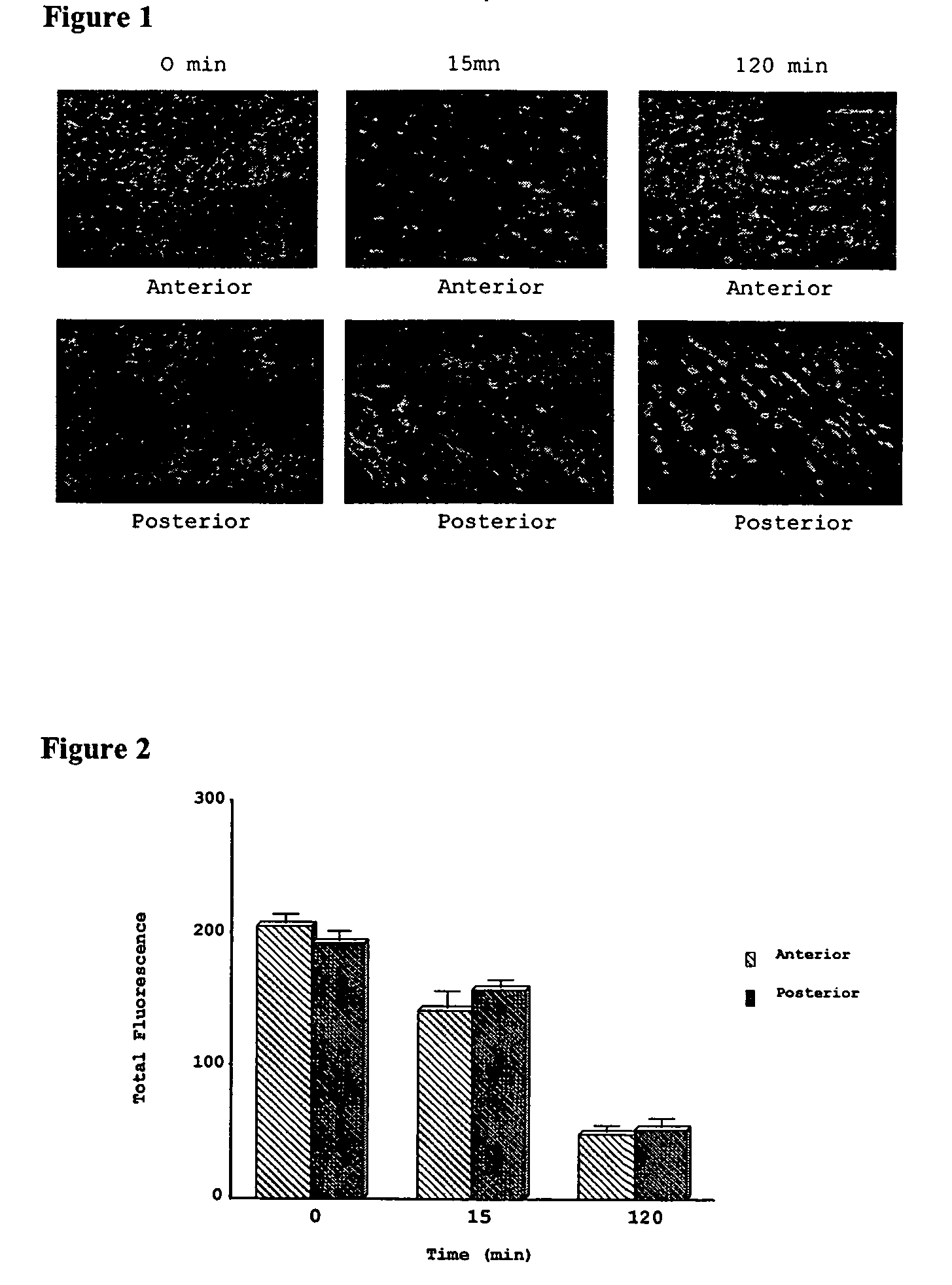

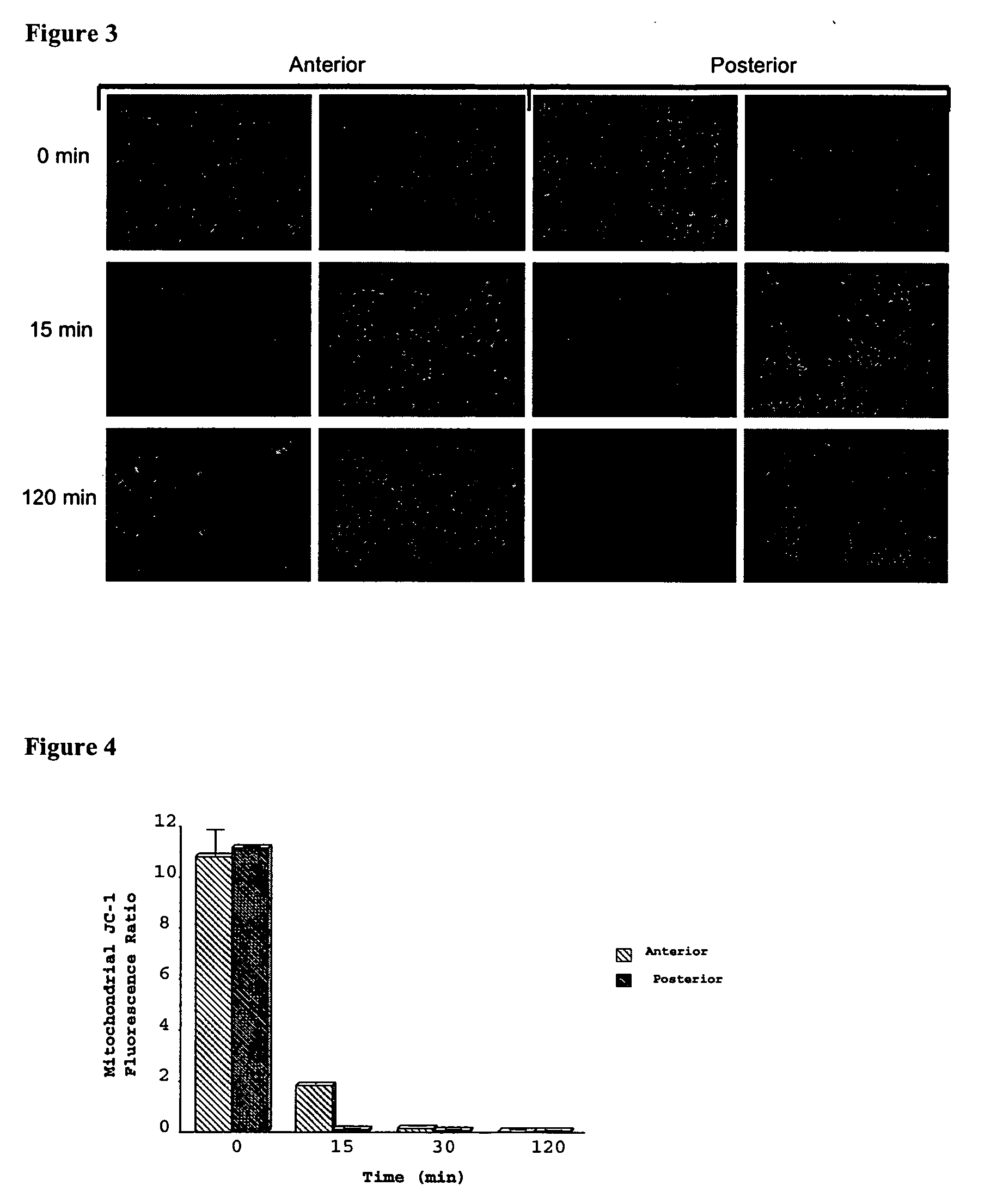

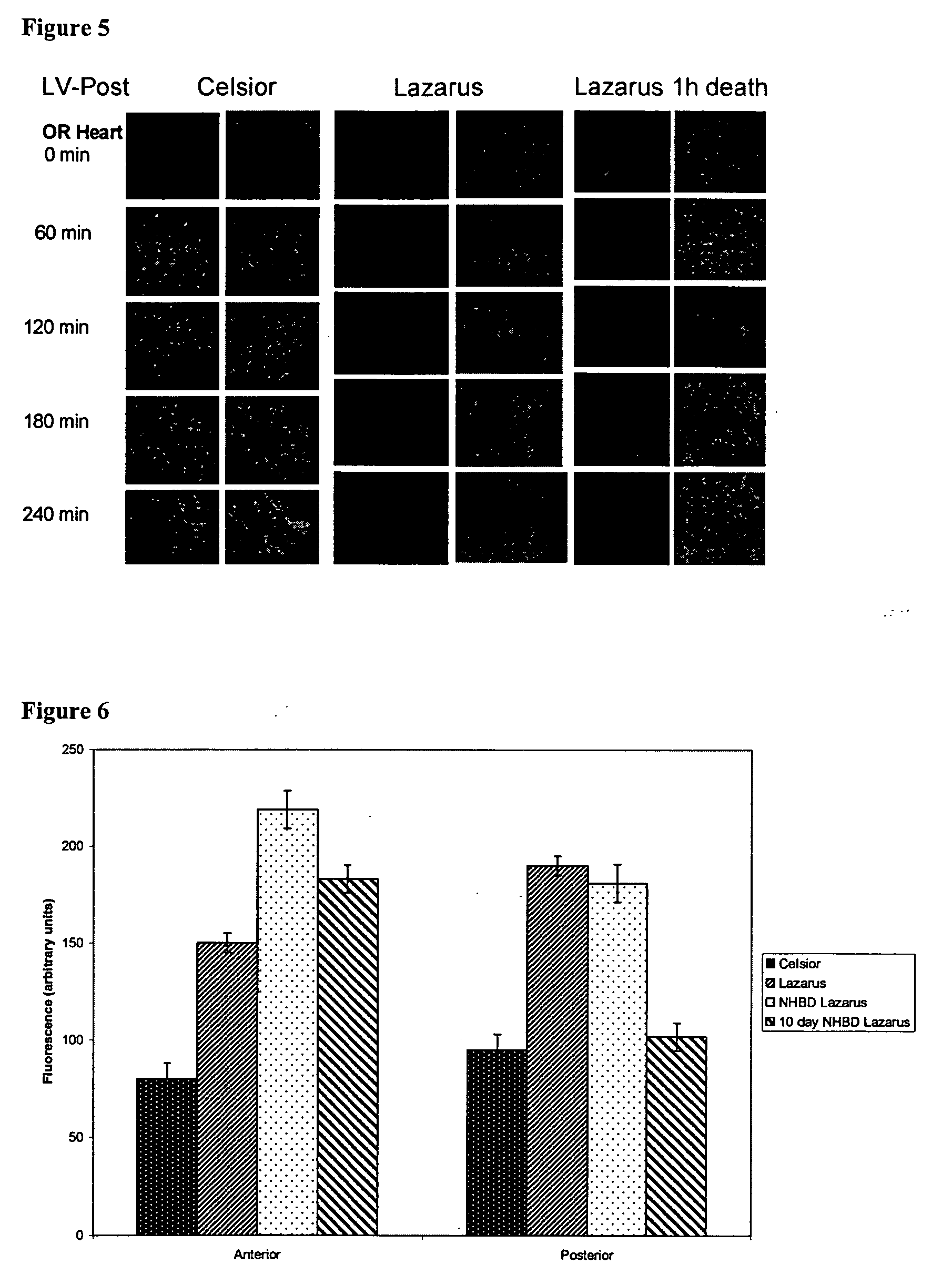

Compositions and methods for tissue preservation

ActiveUS20100151435A1Maintain functional integrityRecovery functionMicrobiological testing/measurementDead animal preservationPotassiumApoptosis

Methods and compositions for resuscitating, storing, and preserving functional integrity of organs and tissues. Metabolic function is maintained by sustaining ATP levels, mitochondrial function, cardiomyocyte contractility, prevention of acidosis, inhibition of induction of apoptosis, maintaining ionontrophy and lusiotrophy by regulating calcium, sodium, potassium and chloride ions.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +1

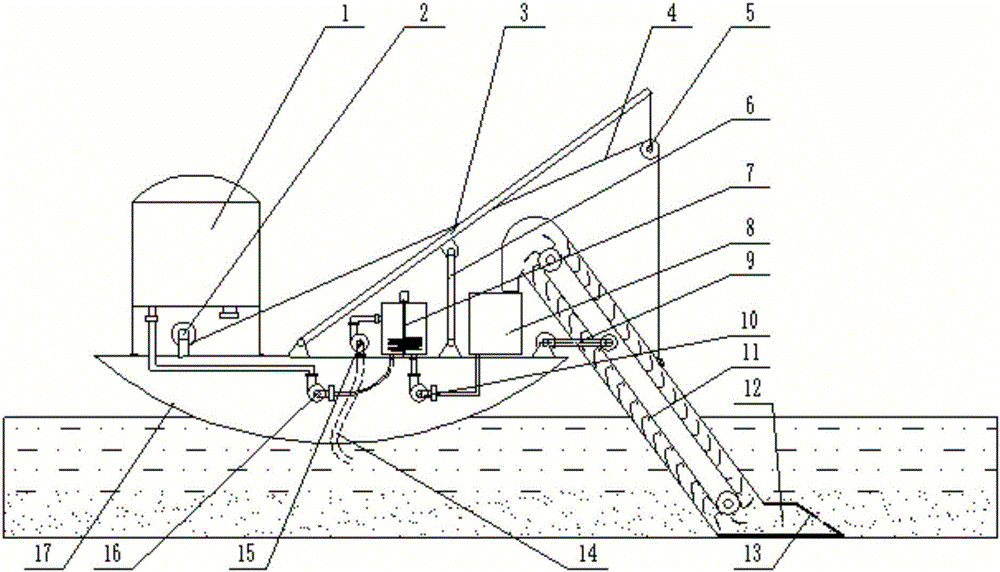

River silt cleaning system

PendingCN106836357AImprove dredging efficiencyAvoid dehydrationSludge treatmentMechanical machines/dredgersGeotechnicsSilt

The invention belongs to the technical field of environmental geotechnics and discloses a river silt cleaning system. The river silt cleaning system comprises a carrier, a silt cleaning device, a mud making device and a mud storage device, wherein the silt cleaning device is fixed on the carrier and goes deep into a river silt seam to clean river silt; the mud making device is connected with the silt cleaning device, smashes the river silt and makes the river silt into mud; the mud storage device is connected with the mud making device and stores the mud. The river silt cleaning system is efficient, convenient, anti-clogging and low in pollution.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

Hydration monitor

ActiveUS8574165B2Performance maximizationLevel of hydration is always safeDiagnostic recording/measuringSensorsMedicineCore temperature

Owner:INOVA DESIGN SOLUTIONS

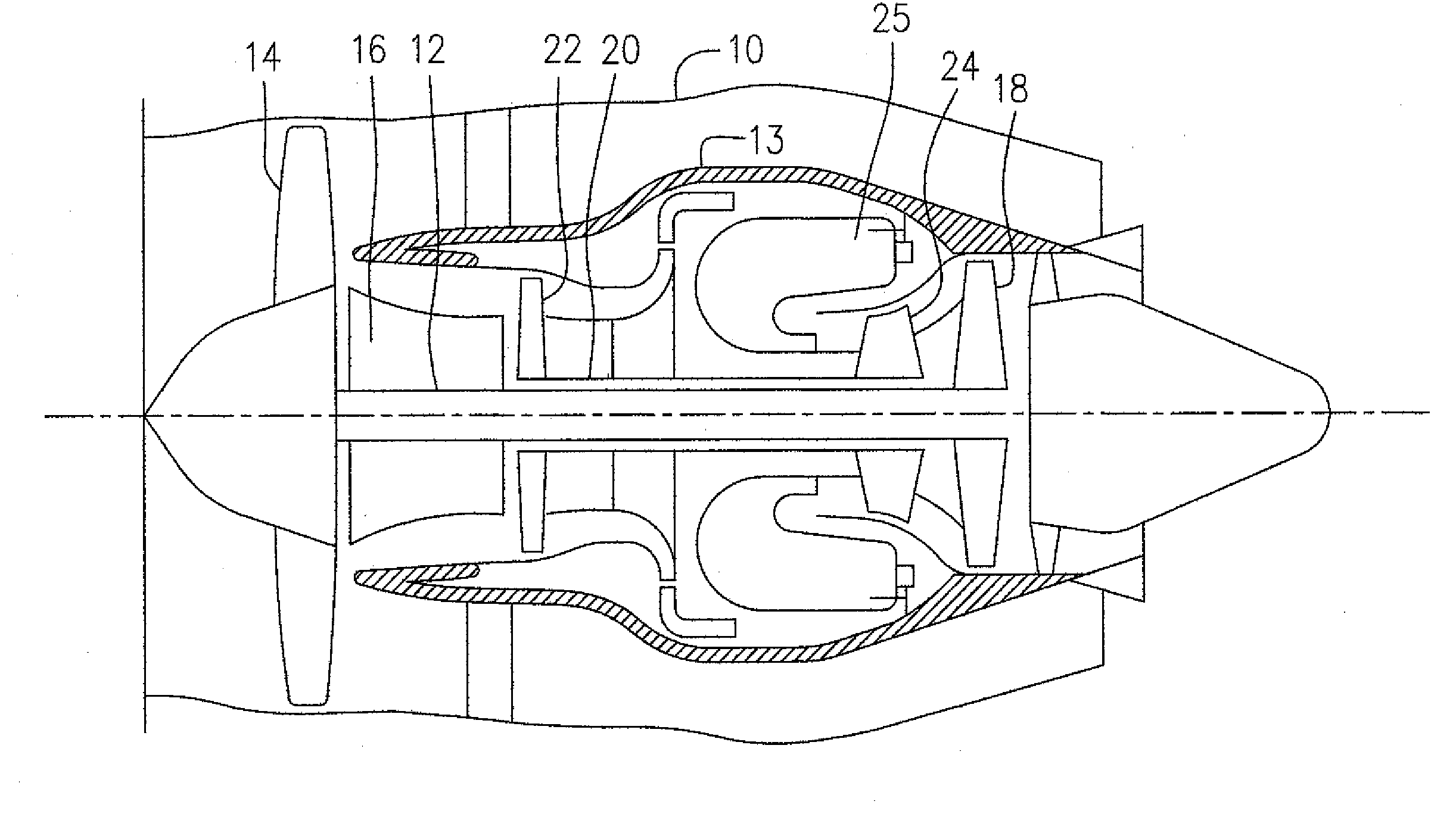

Method for applying abradable coating

InactiveUS20080286459A1Prevent oxidationAvoid decompositionLiquid surface applicatorsPressure inorganic powder coatingTarget surfaceMaterials science

In accordance with one aspect of the invention a process for applying an abradable coating to a component includes cold spraying an abradable coating material in particles towards a target surface of the component.

Owner:PRATT & WHITNEY CANADA CORP

Hydration beverage and method of delivering nutrients

InactiveUS7160565B2Reduce contentIncrease moistureFruit and vegetables preservationVitamin food ingredientsBetaineAdditive ingredient

A composition useful as a hydrating beverage comprising at least one complex carbohydrate, at least one chelated electrolyte, betaine, and piperine. The composition, which may be carbonated or non-carbonated beverage compositions and beverage concentrates adapted for all administration of water, physiologically essential electrolytes and other ingredients to a subject specifically adapted for enhancing hydration; preferably with enhanced absorption after ingestion while at the same time attenuating muscle fatigue and, preferably destroying harmful free radicals.

Owner:BREAKTHRU PRODS

Regeneration of ion exchangers that are used for salt removal from acid gas capture plants

ActiveUS20070213415A1Speed up the processLarge volume of waterDispersed particle separationHydrogen sulfidesRefluxIon exchange

A process for the removal of an amine captureable gas from a feed gas stream using an amine solvent, the process comprises (a) contacting the feed gas stream with a lean amine solvent to form a rich amine solvent, wherein heat stable salts are present in the rich amine solvent; (b) stripping amine captureable gas from the rich amine solvent to form the lean amine solvent and an overhead reflux stream; (c) periodically contacting at least a portion of one or both of the lean amine solvent and the rich amine solvent with an anion exchange resin to form a first heat stable salt lean amine solvent; (d) periodically regenerating the anion exchange resin, wherein during the regeneration of the anion exchange resin, at least a portion of the reflux stream is used to wash the amine solvent from the anion exchange resin to produce a second heat stable salt lean amine solvent; and, (e) recycling at least a portion of the first and the second heat stable salt lean amine solvent for use in capturing the amine captureable gas from the feed gas.

Owner:SHELL OIL CO

Method for artificial dormancy-relieving and early focing culturing

InactiveCN1868256AWide varietyPrevent dehydrationCultivating equipmentsHorticulture methodsAmygdalus persicaDormancy

An accelerative culture method of peach tree by artificially relieving dormancy includes such steps as storing the chosen peach saplings in ditch in the autumn, transplanting in the culture soil contained in perforated plastic bag in the next February, putting them in greenhouse, transplanting in the field in the May, spraying uniconazole every 7 days twice, picking off leaves in the August, forced dormancy in cold storehouse for 40-50 days, transplanting in greenhouse in the October, controlling the temp of florescence to 20-22 deg.C, and fruit growing management.

Owner:傅友 +2

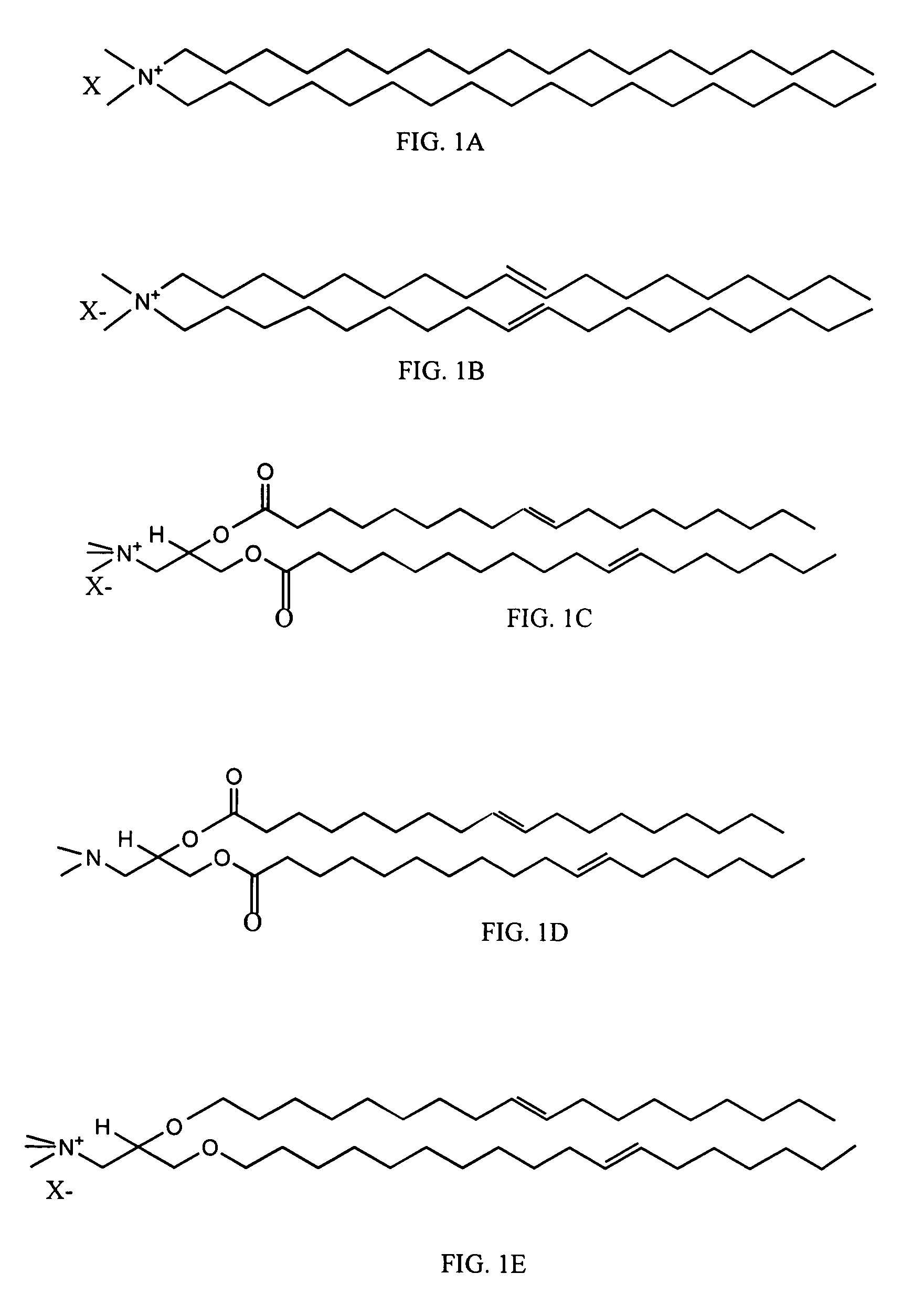

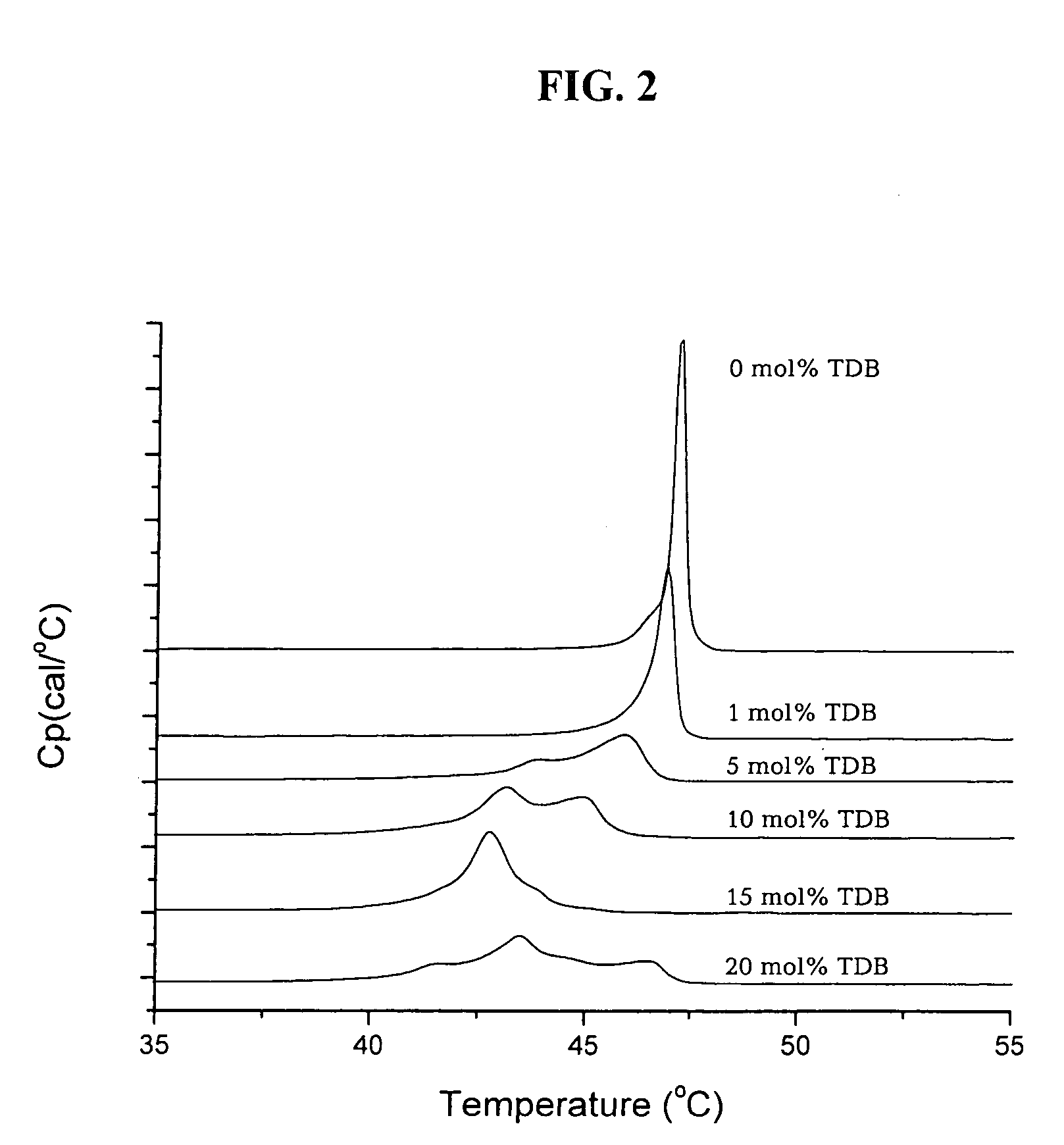

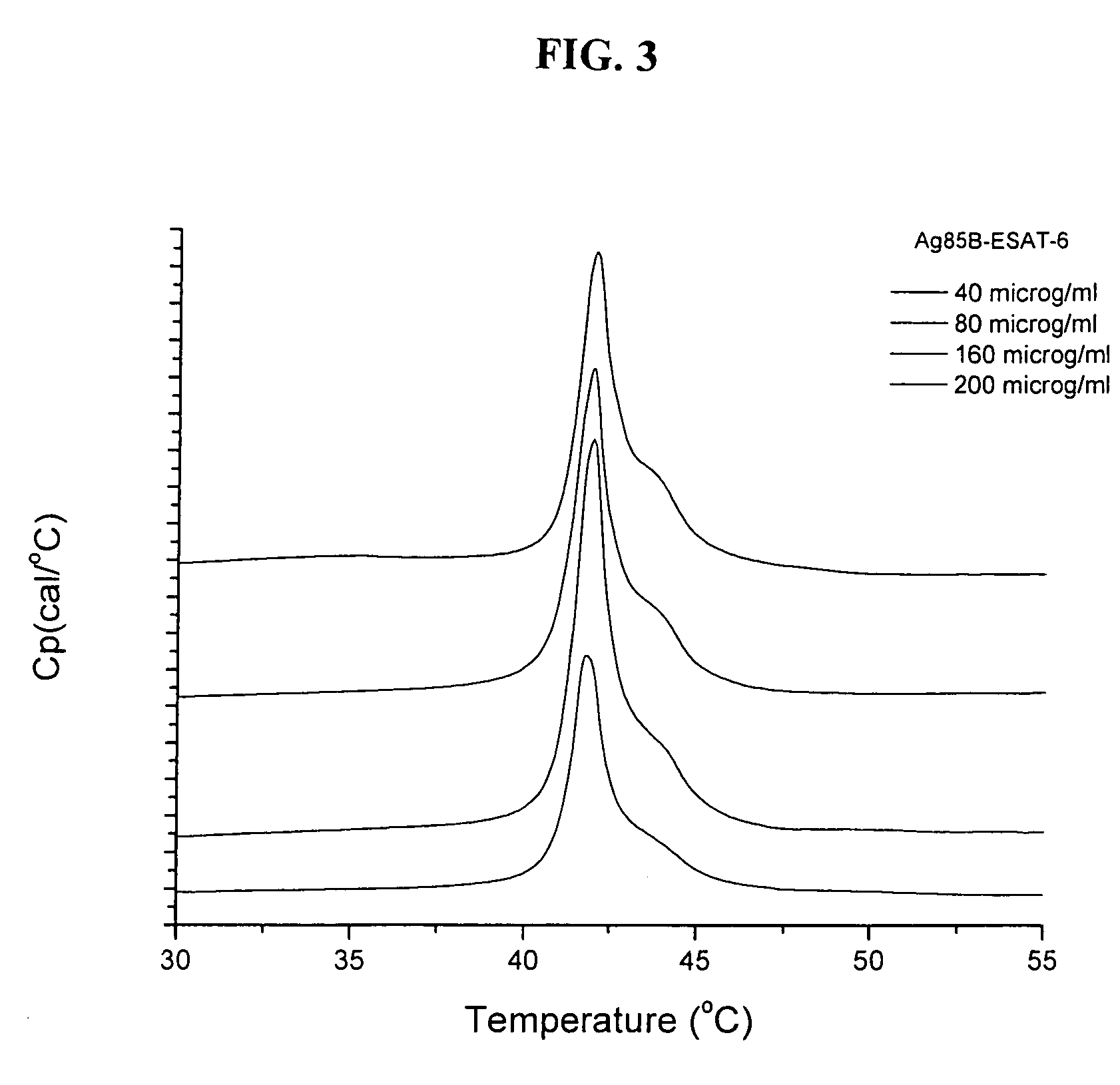

Compositions and methods for stabilizing lipid based adjuvant formulations using glycolipids

ActiveUS7749520B2Increase moisturePrevent dehydrationBacterial antigen ingredientsIn-vivo radioactive preparationsAntigenLipid formation

The present invention relates to liposome formulations that are physically stable. In particular the present invention relates to steric stabilization of cationic liposomes by incorporating glycolipids into the liposomes. The stabilized liposomes can be used either as an adjuvant for antigenic components or as a drug delivery system. In particular the invention relates to vaccines with adjuvants in aqueous media for immunization, where the final product is stable.

Owner:STATENS SERUM INST

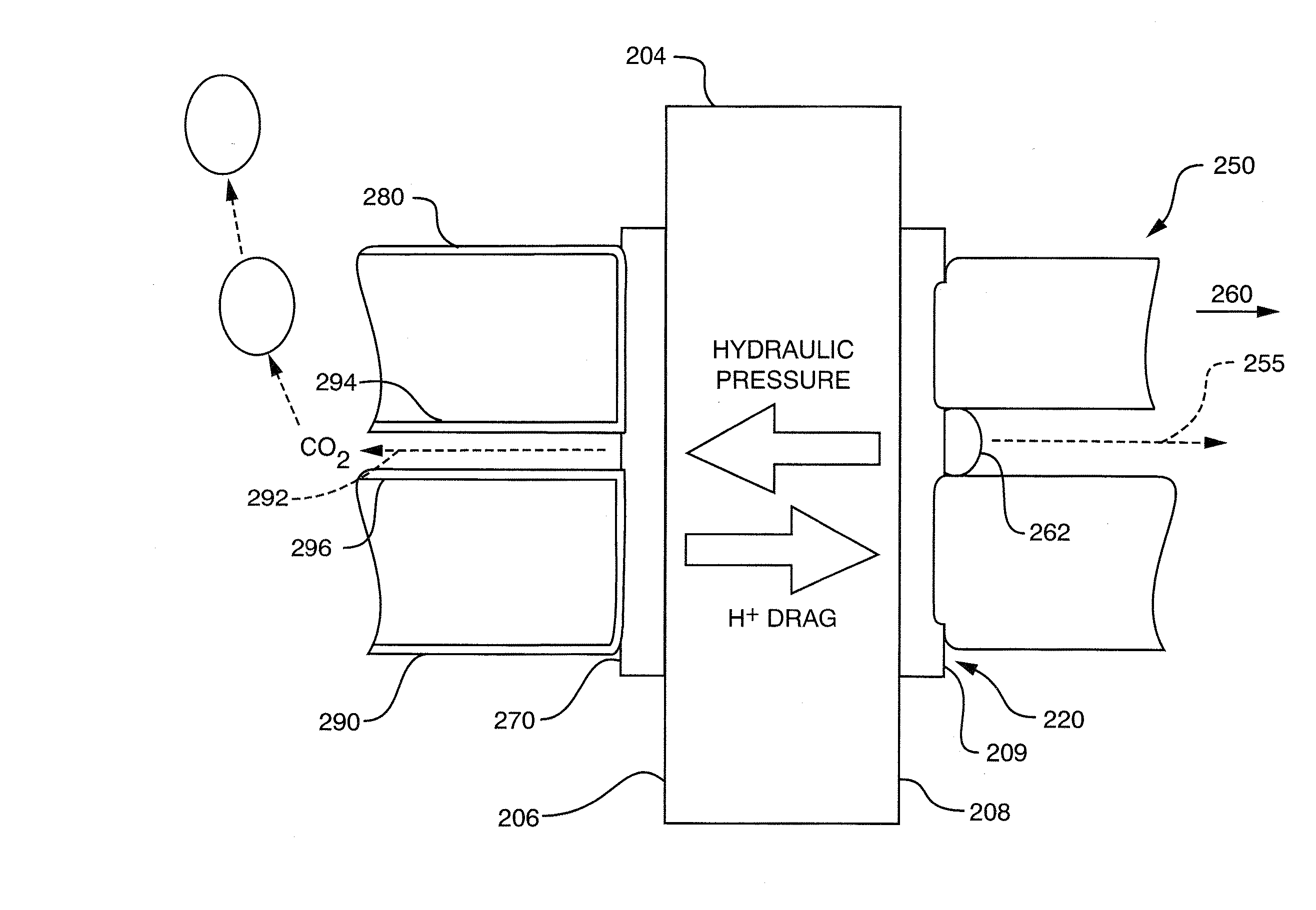

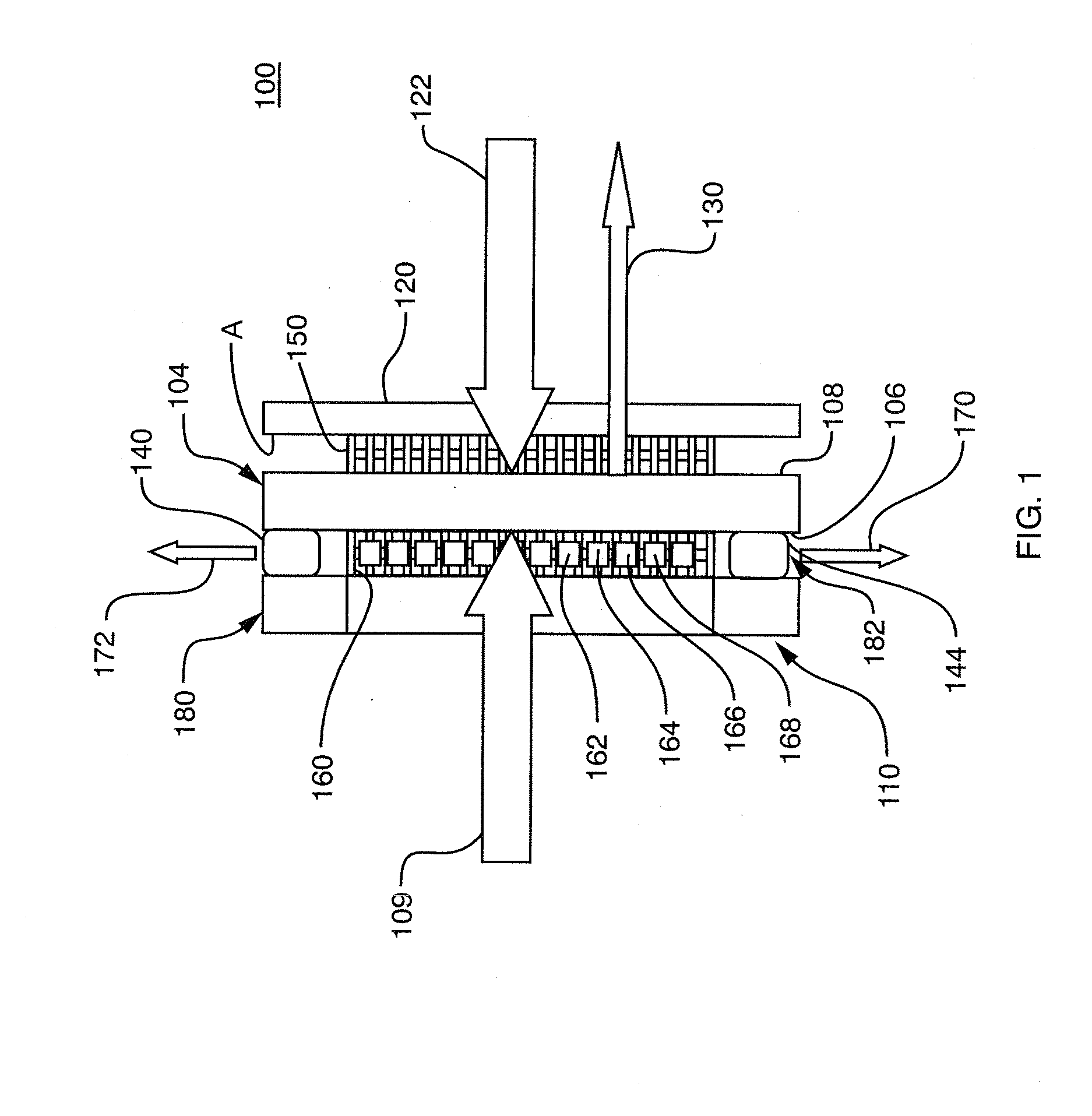

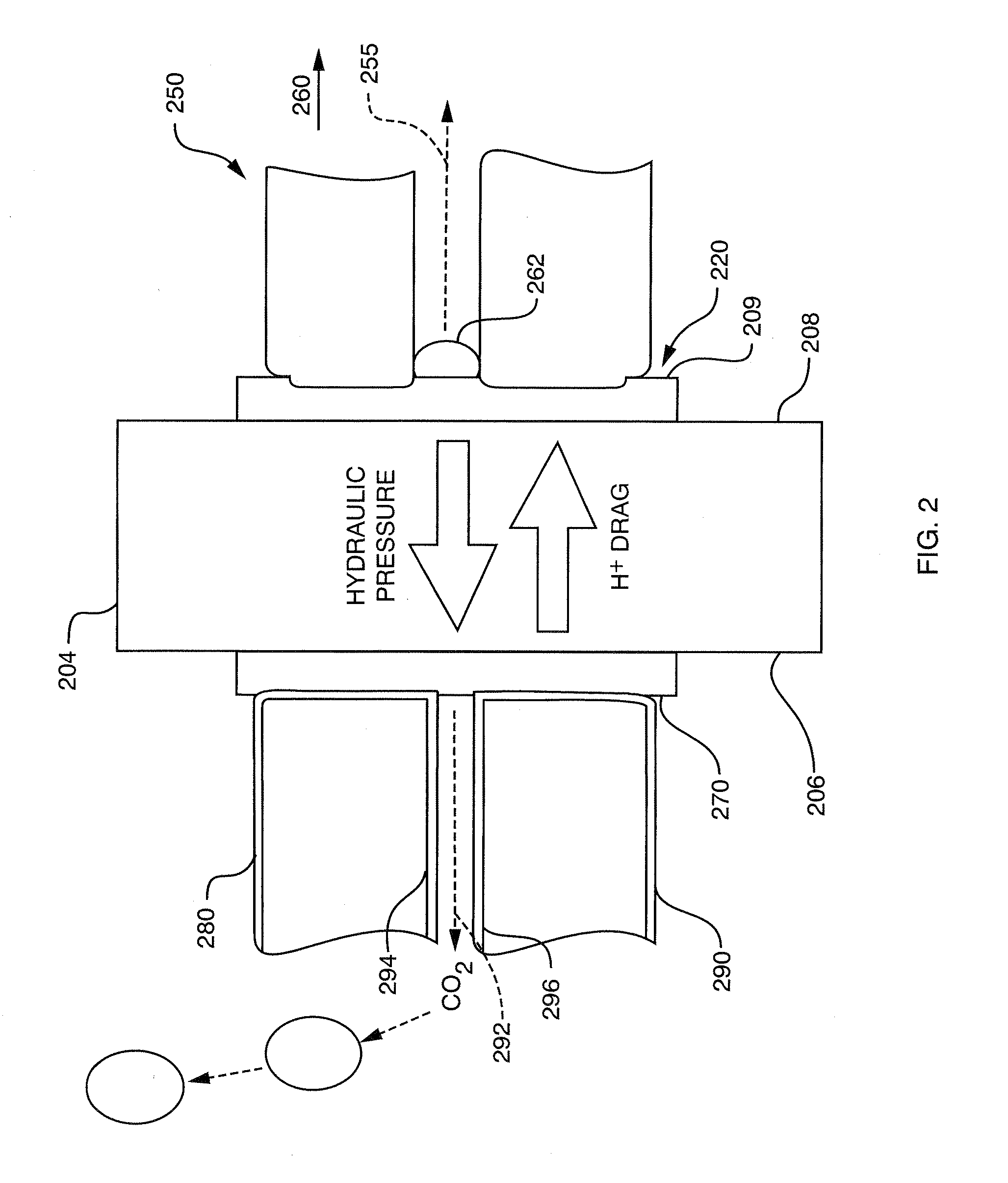

Passive water management techniques in direct methanol fuel cells

InactiveUS20080032182A1Neat, or highly concentrated methanol fuel supplyOvercome disadvantagesWater management in fuel cellsActive material electrodesWater vaporLiquid water

Passive water management techniques are provided in an air-breathing direct oxidation fuel cell system. A highly hydrophobic component with sub-micrometer wide pores is laminated to the catalyzed membrane electrolyte on the cathode side. This component blocks liquid water from traveling out of the cathode and instead causes the water to be driven through the polymer membrane electrolyte to the cell anode. The air-breathing direct oxidation fuel cell also includes a layer of cathode backing and additional cathode filter components on an exterior aspect of the cell cathode which lessen the water vapor escape rate from the cell cathode. The combination of the well laminated hydrophobic microporous layer, the thicker backing and the added filter layer, together defines a cathode structure of unique water management capacity, that enables to operate a DMFC with direct, controlled rate supply of neat (100%) methanol, without the need for any external supply or pumping of water. The cell anode is provided with a hydrophilic backing layer. When the water is driven through the polymer membrane electrolyte from the cell cathode to the cell anode chamber, it is available for the anodic reaction, and any excess water is carried out along CO2 ventilation channels to the outside environment.

Owner:MTI MICROFUEL CELLS

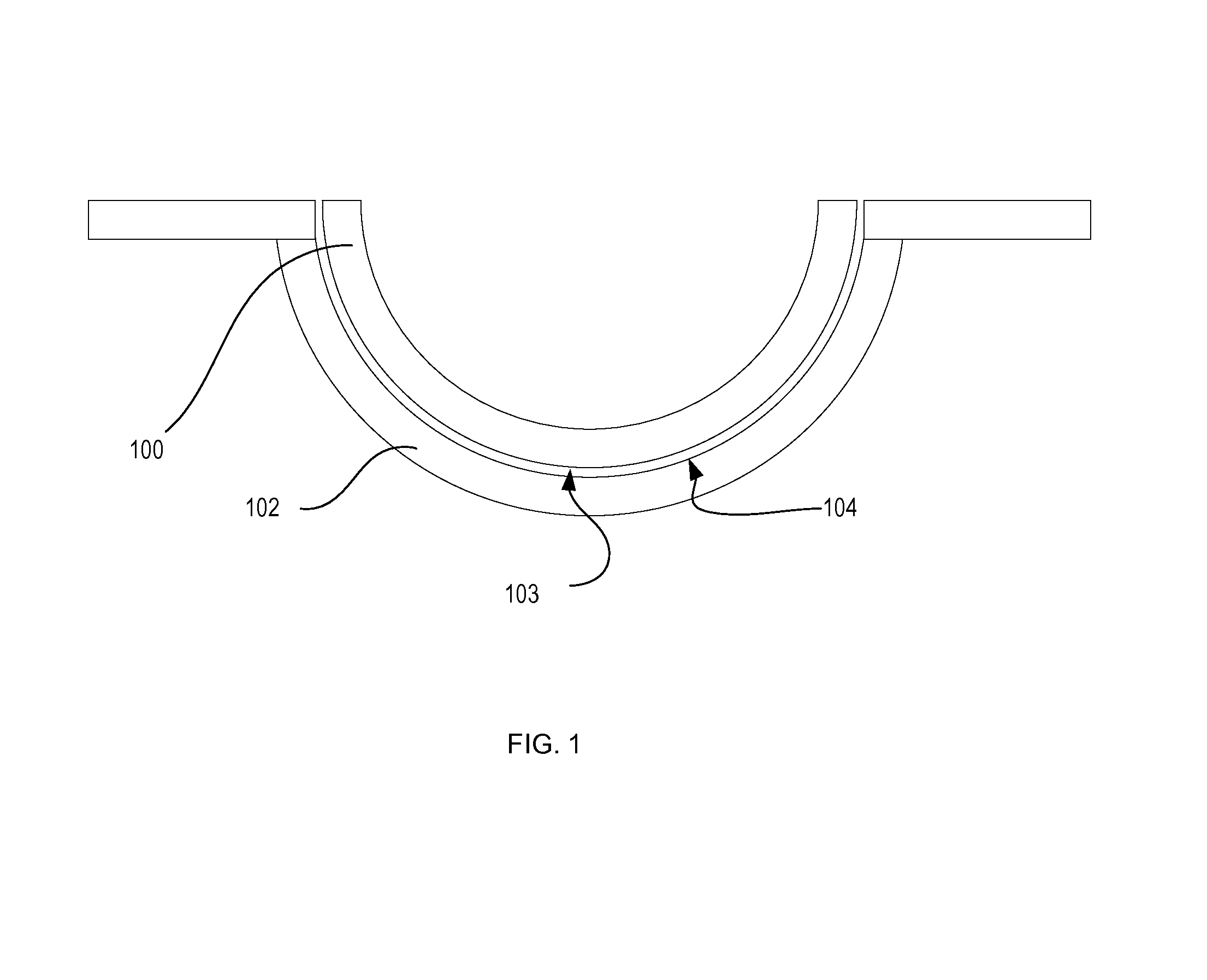

Silicone hydrogels having a structure formed via controlled reaction kinetics

ActiveUS20140031447A1Increasing the thicknessPrevent evaporationCoatingsIntraocular lensBoiling pointDiluent

The present invention relates to a process comprising the steps of reacting a reactive mixture comprising at least one silicone-containing component, at least one hydrophilic component, and at least one diluent to form an ophthalmic device having an advancing contact angle of less than about 80°; and contacting the ophthalmic device with an aqueous extraction solution at an elevated extraction temperature, wherein said at least one diluent has a boiling point at least about 10° higher than said extraction temperature.

Owner:JOHNSON & JOHNSON VISION CARE INC

Dispenser for readily attaching to a role-type toilet-tissue holder and dispensing moist towelettes from a role

InactiveUS7395986B1Good adhesionAvoid disadvantagesFilament handlingDomestic applicationsFacial tissueTowelettes

A dispenser for readily attaching to a roll-type toilet-tissue holder and dispensing moist towelettes from a roll of the moist towelettes. The roll-type toilet-tissue holder is disposed in a wall and has a spindle that is axially spring loaded to facilitate insertion into and removal from the roll-type toilet-tissue holder. The dispenser includes a container. The container contains the roll of the moist towelettes to prevent dehydration thereof prior to dispensing, dispenses the moist towelettes from the roll of the moist towelettes contained in the container, and has the spindle of the roll-type toilet-tissue holder pass freely therethrough and attach to the roll-type toilet-tissue holder so as to allow the container to readily attach to the roll-type toilet-tissue holder.

Owner:HAERING ERNEST L

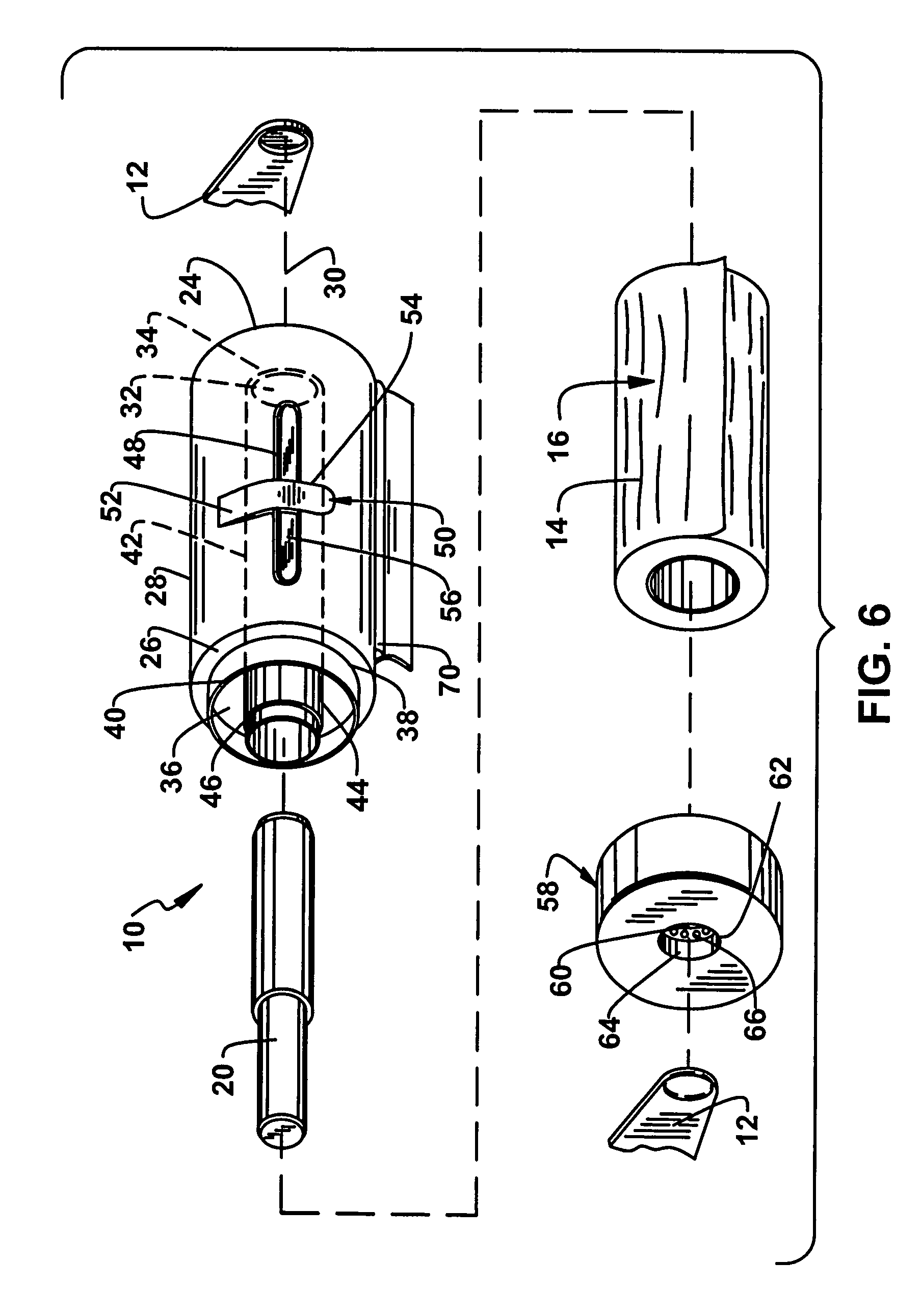

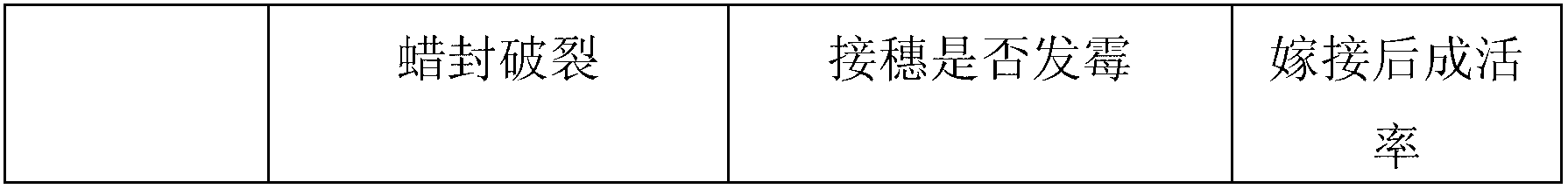

Jujube tree grafting method

A jujube tree grafting method comprises the following steps of (1) preparing jujube tree cion; (2) preparing wax sealing liquid: smelting 100 parts by mass of paraffin wax and 20 to 35 parts by mass of gum rosin at the temperature of 80 to 100 DEG C to obtain the wax sealing liquid; (3) wax sealing and storing the jujube tree cion; (4) processing jujube rootstock: cutting a frozen part on the upper part of the jujube tree rootstock before the grafting, and cutting the top of the rootstock twice; (5) utilizing sugar water to soak the cion; (6) grafting the cion processed in the step (5) onto the jujube tree rootstock processed in the step (4); and (7) binding the jujube tree cion and the jujube tree rootstock. By adopting the technical scheme, the cracks occurred in the long-term storage, transportation and grafting process of the wax-sealed cion can be reduced, the jujube tree cion can be prevented from being dehumidified under the dry air condition and from being mildewed under the situation that the ambient humidity is large, the excessive water loss of the cion under the exposure of the sunshine can be effectively reduced after being grafted, and the grafting survival rate of the jujube tree in extremely cold area can be improved by 22 percent.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com