Patents

Literature

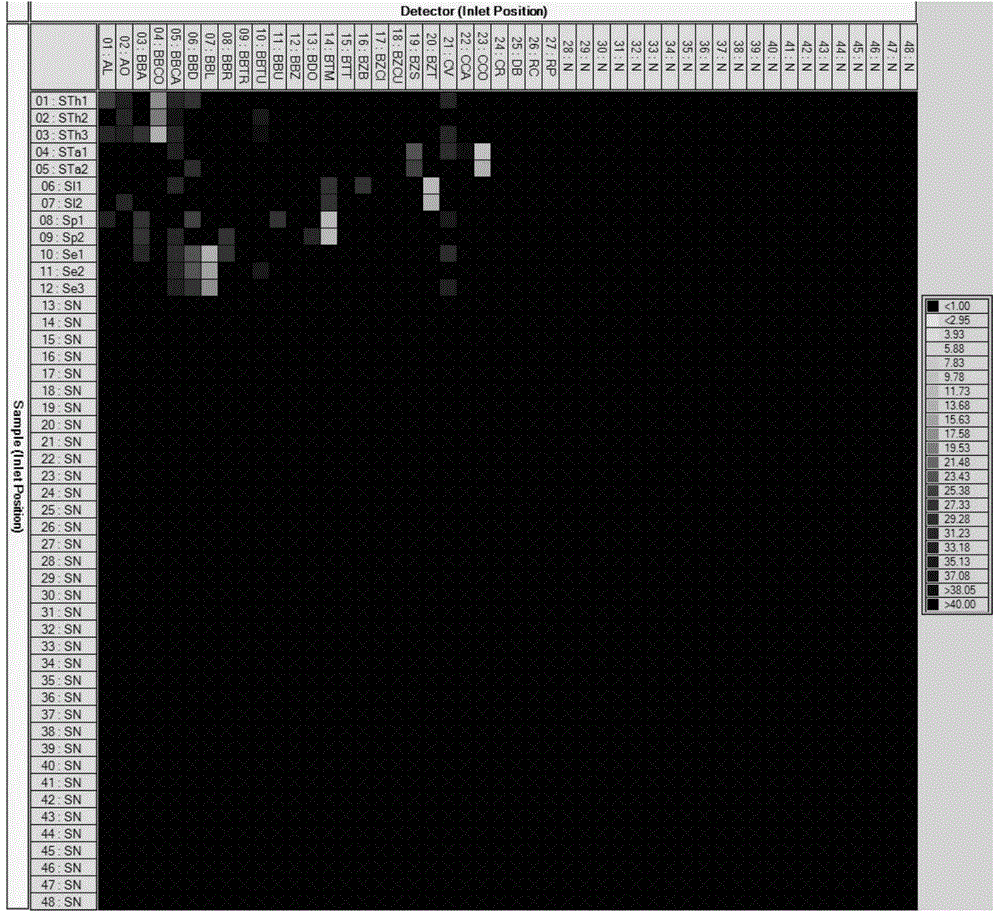

104results about How to "Wide variety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

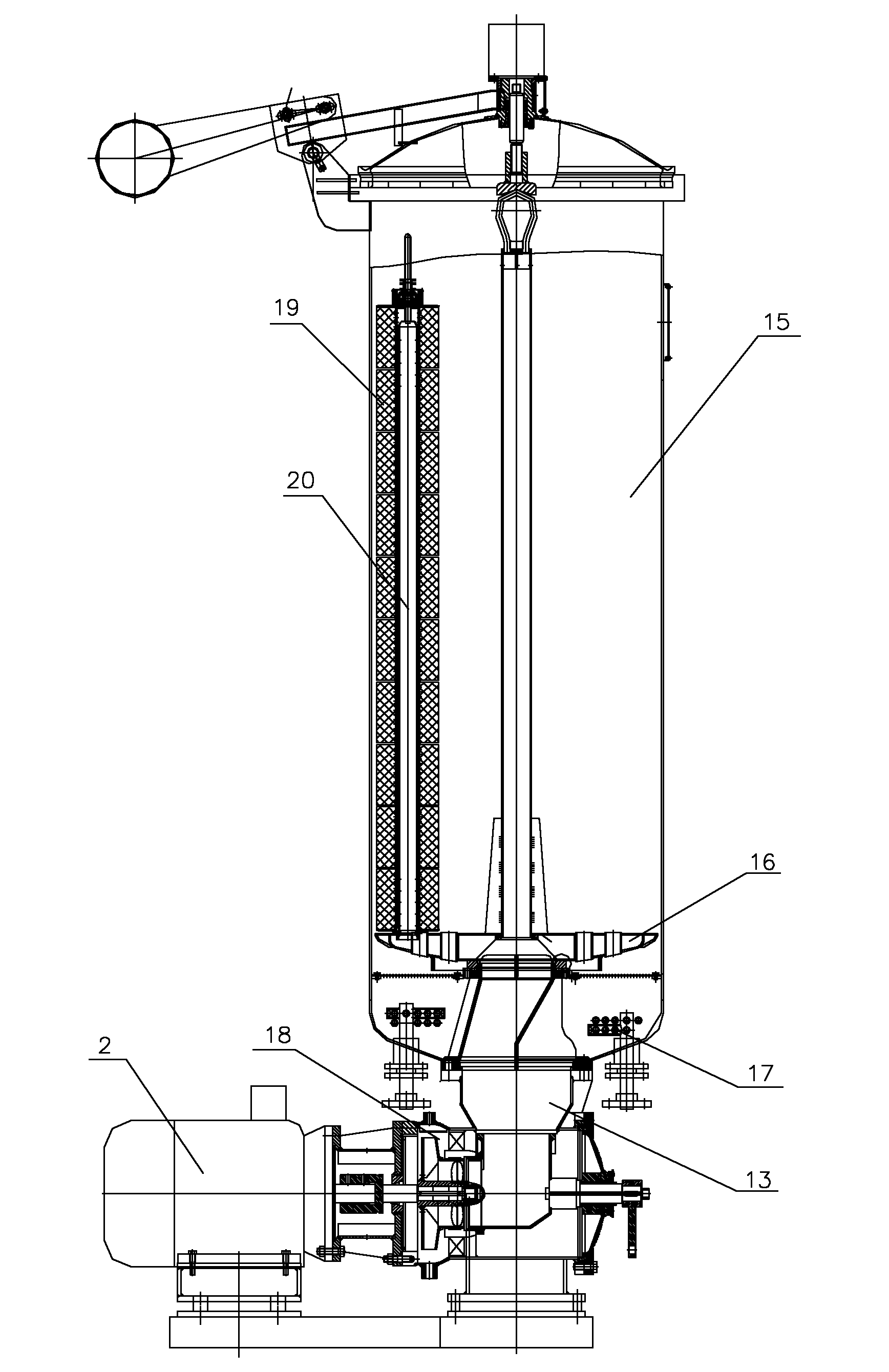

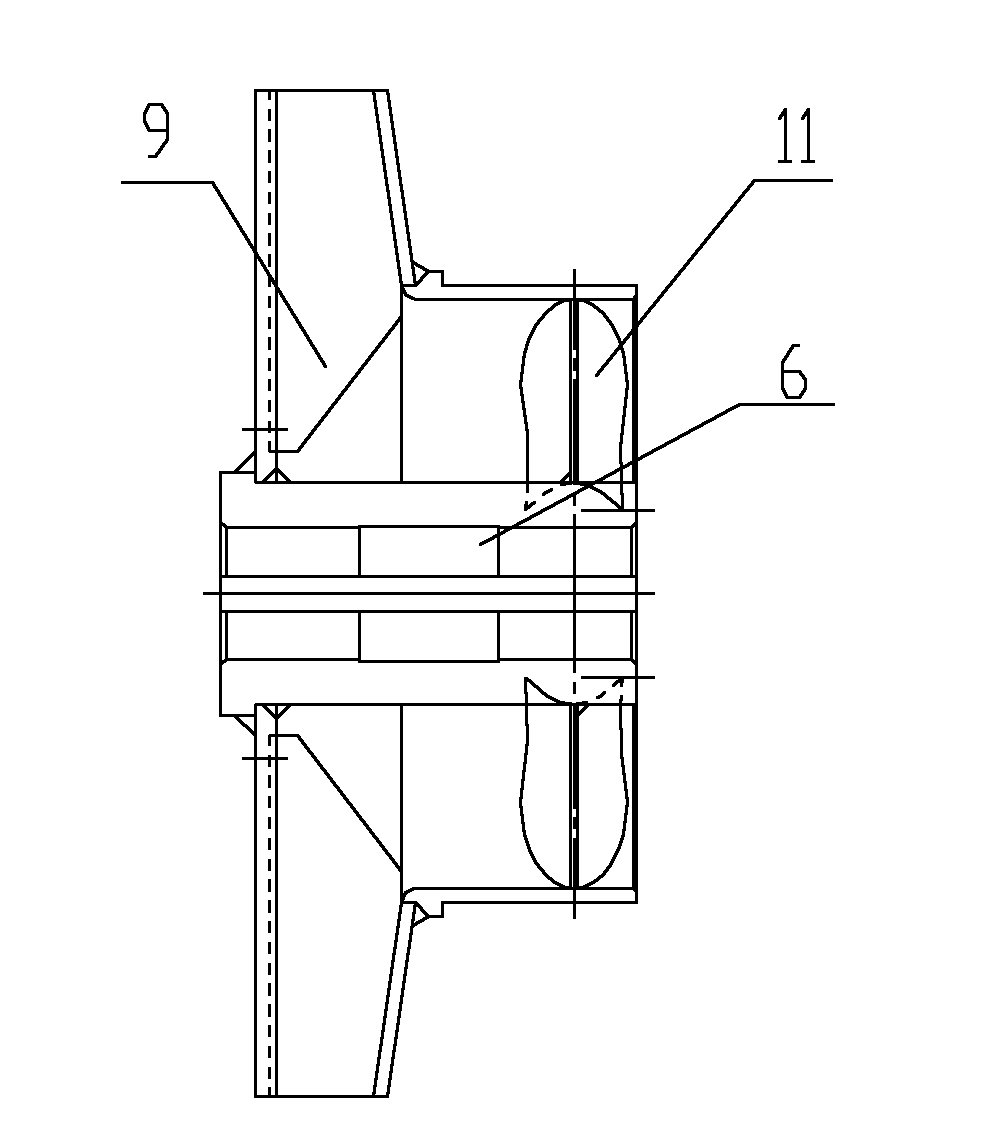

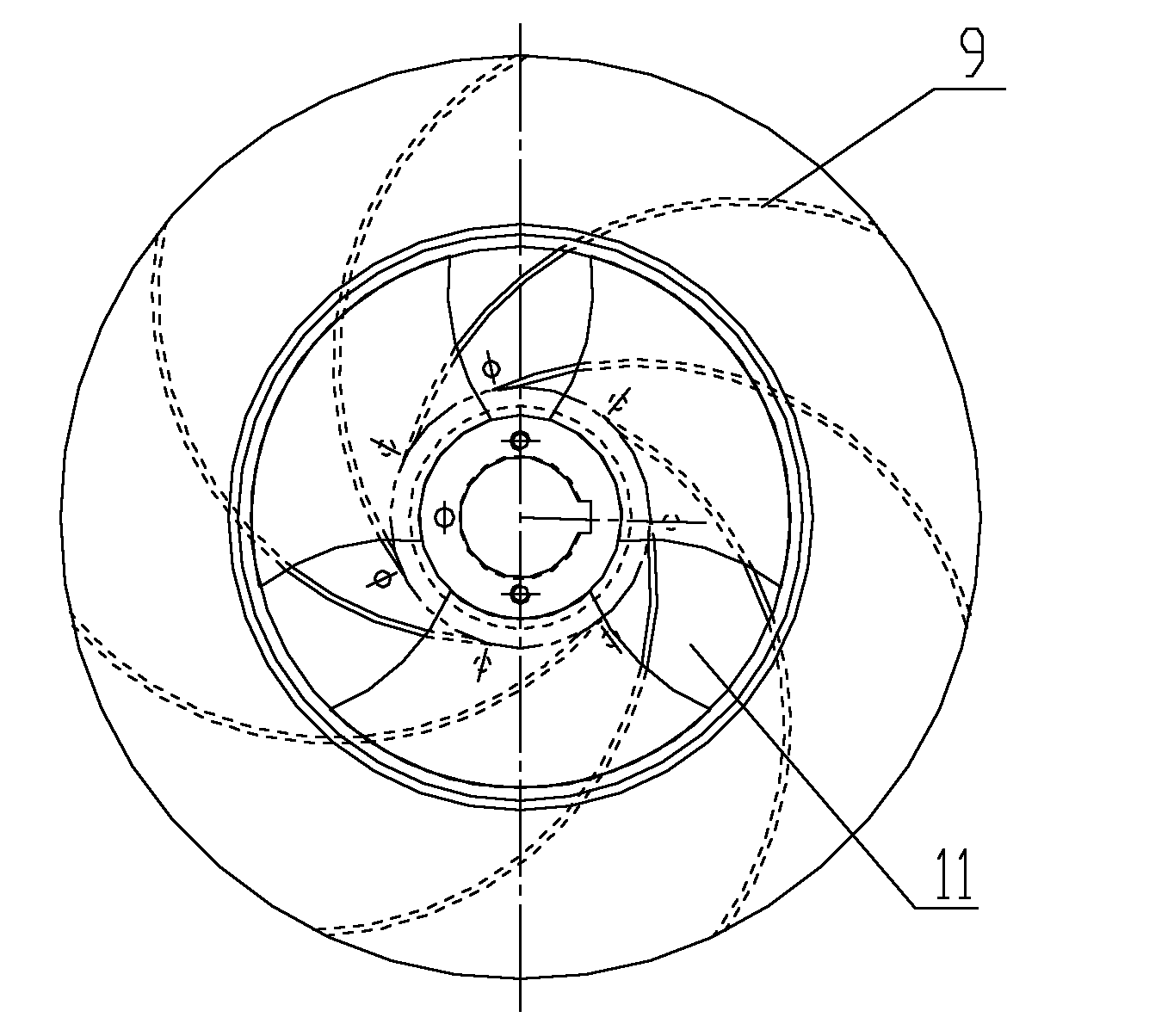

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

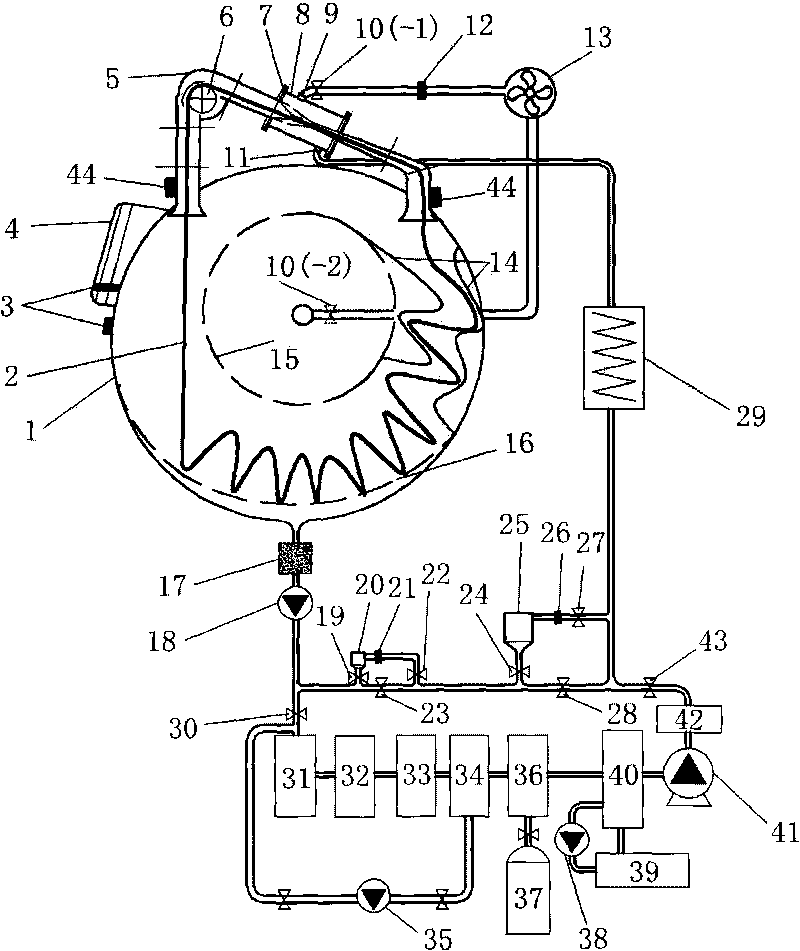

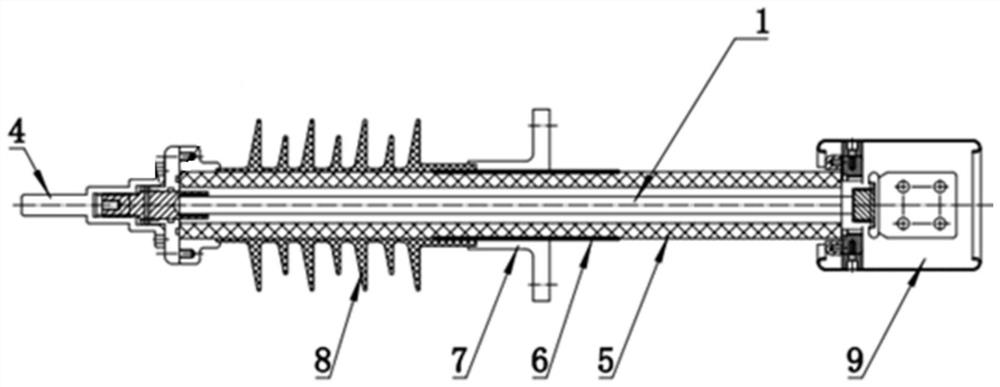

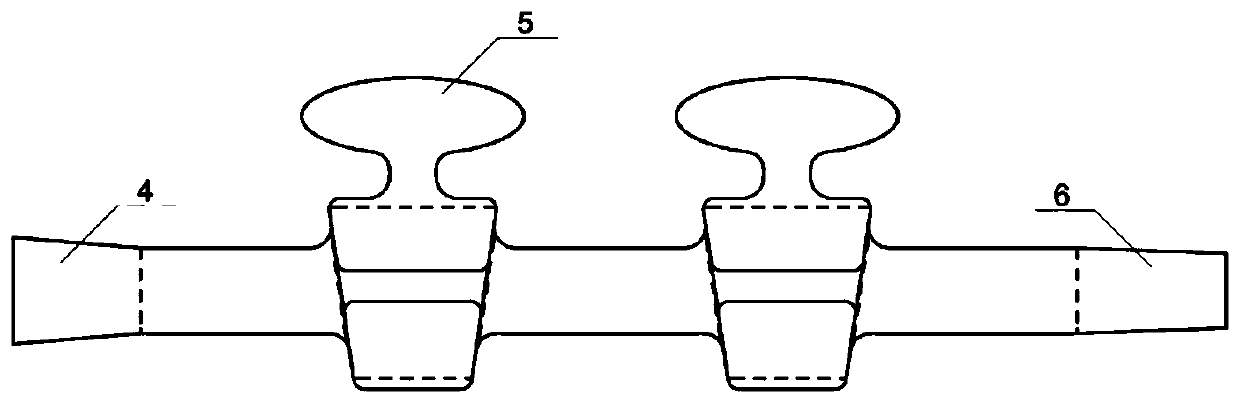

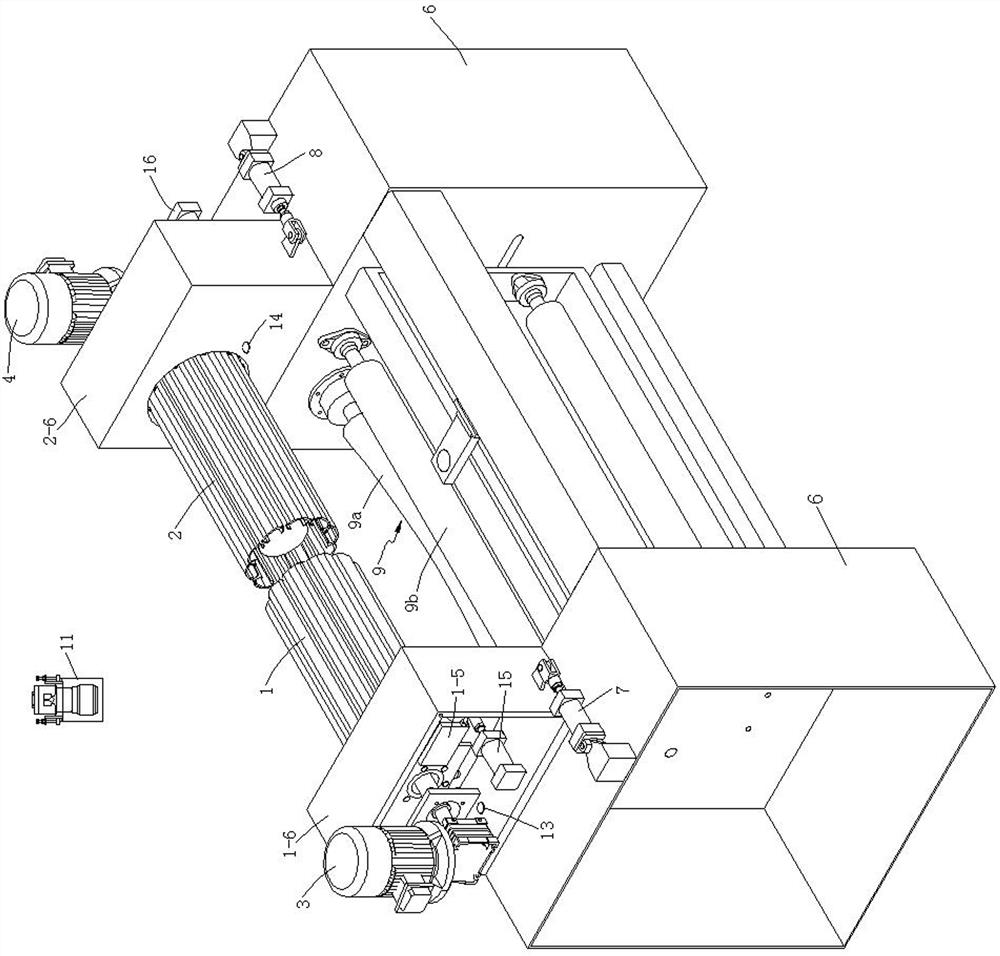

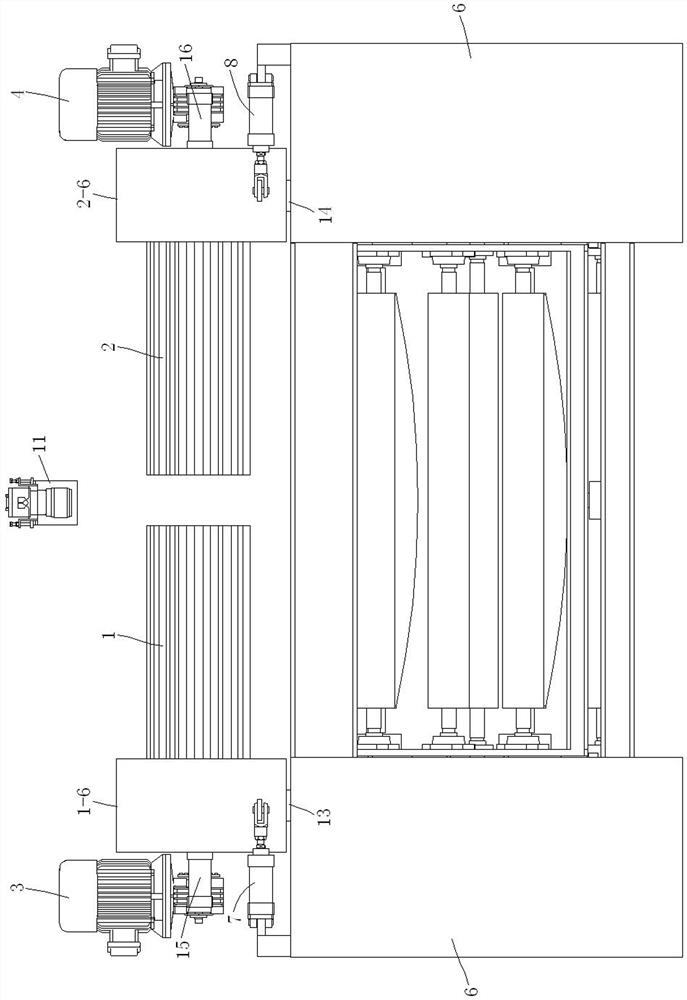

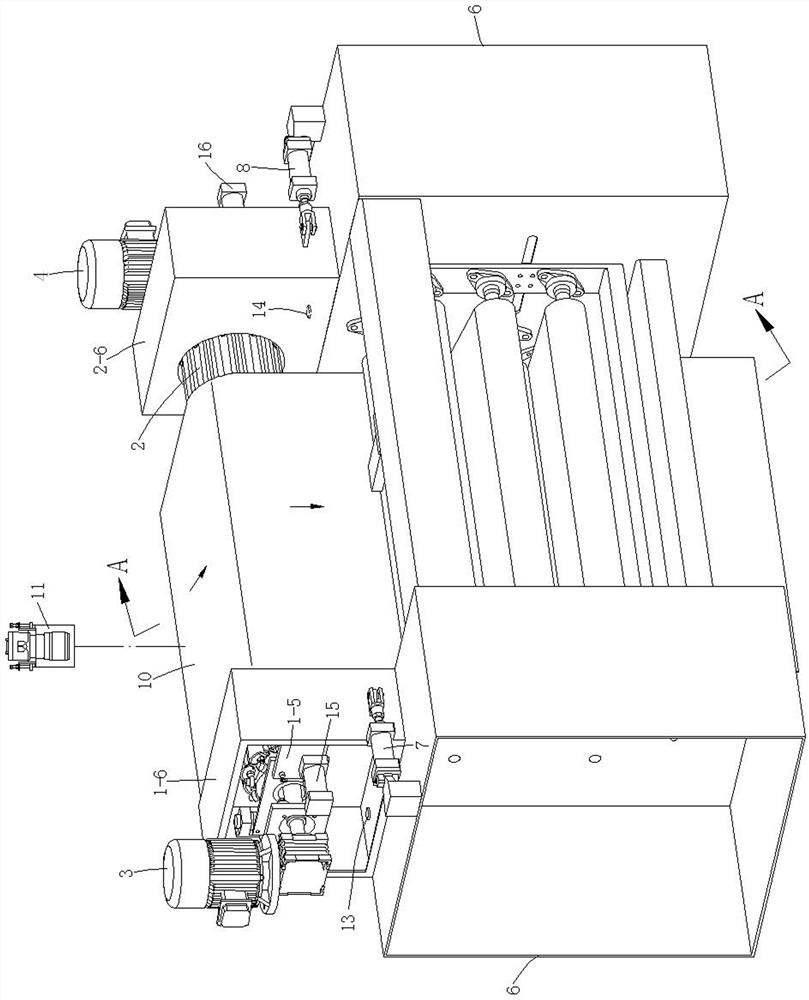

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

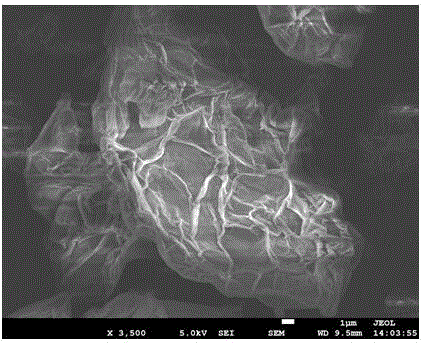

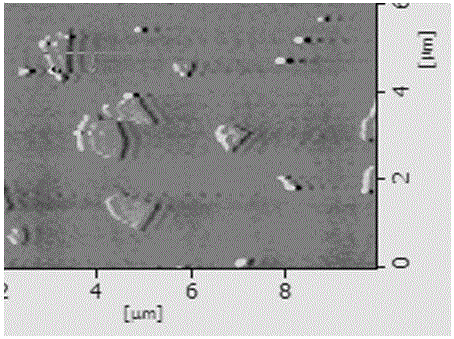

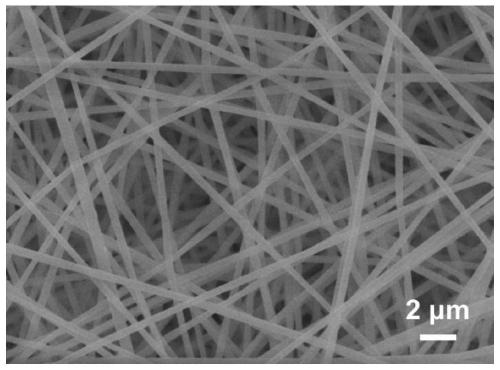

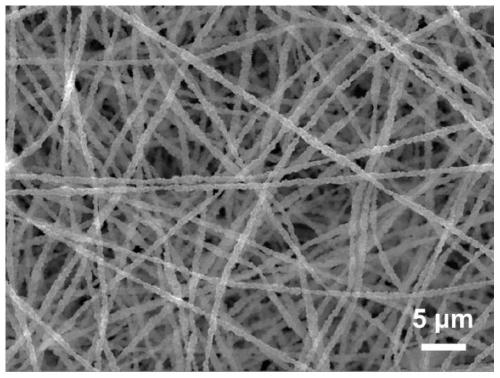

High-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and preparation method thereof

InactiveCN107557894AImprove throughputHigh porosityFatty/oily/floating substances removal devicesUltrasonic/sonic fibre treatmentFiberNanofiber

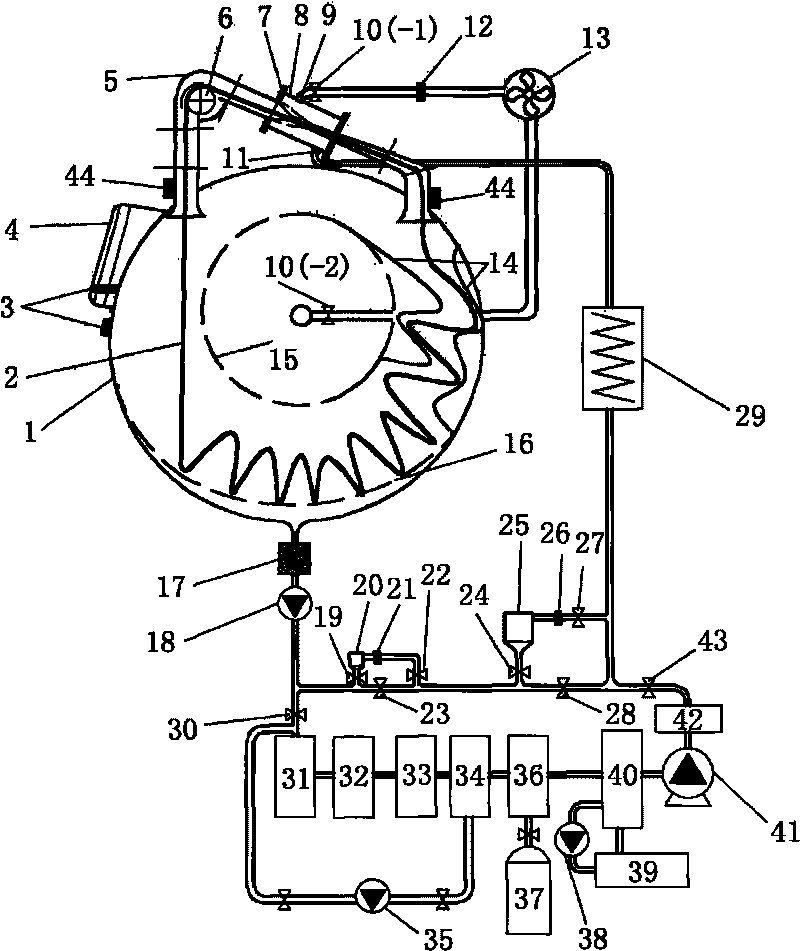

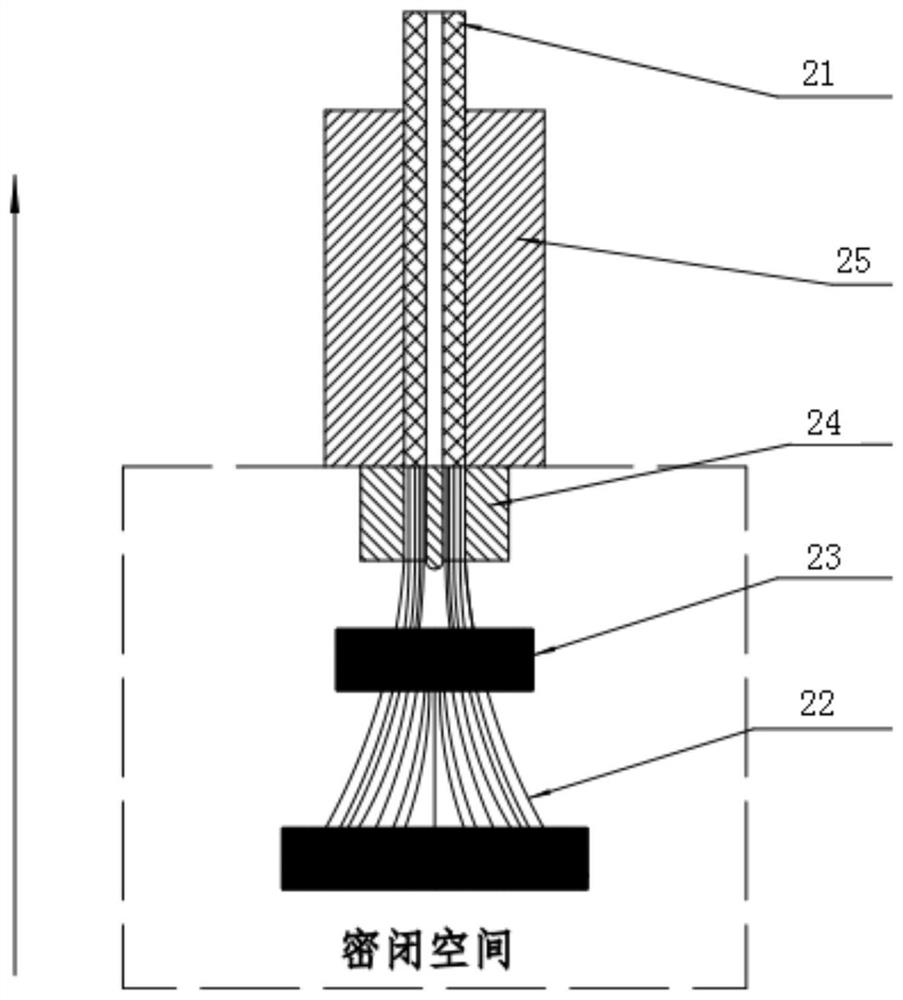

The invention discloses a high-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and a preparation method thereof. The preparation method comprises the following steps: a polymer solution is prepared from a selected polymer, a net is formed through electrostatic direct injection of the polymer solution, a spinneret vibrates in situ by the aid of external force inan electrostatic direct injection process to promote generation of charged droplets, the droplets are subjected to phase separation, and a uniform 2D net-shaped ultrafine nanofiber material is formedon the surface of a receiving substrate and is in a continuous and seamlessly stacked shape; then the obtained material is subjected to surface modification, and the 2D net-shaped ultrafine nanofiberoil-water separation material with selective surface and interface wetting property is obtained. The preparation process is simple, raw material limitations are few, and the net-shaped ultrafine nanofiber oil-water separation material has tiny meshes and good pore channel connectivity and has great application prospect in the fields of oil purification, oil-containing wastewater treatment and thelike.

Owner:DONGHUA UNIV

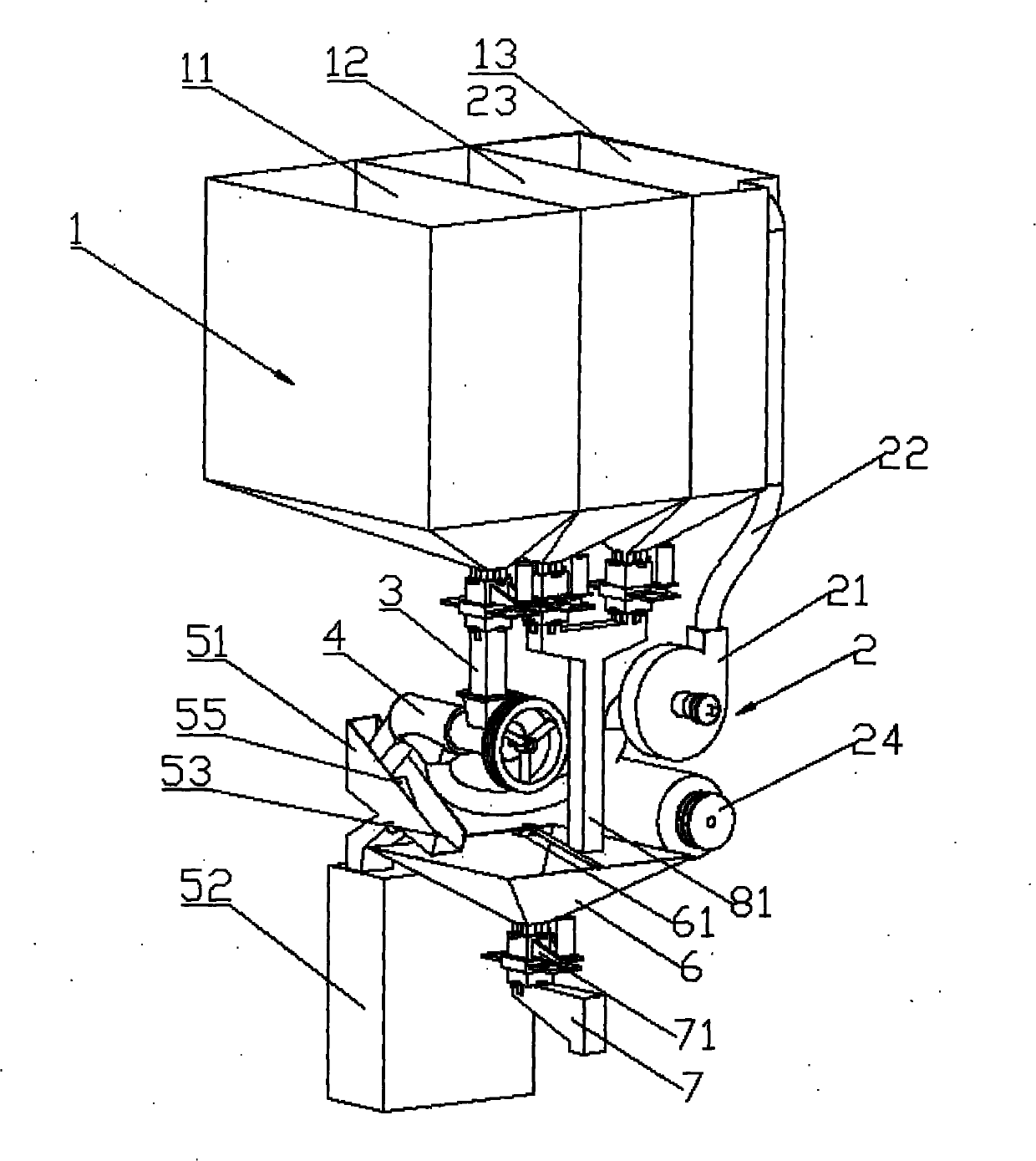

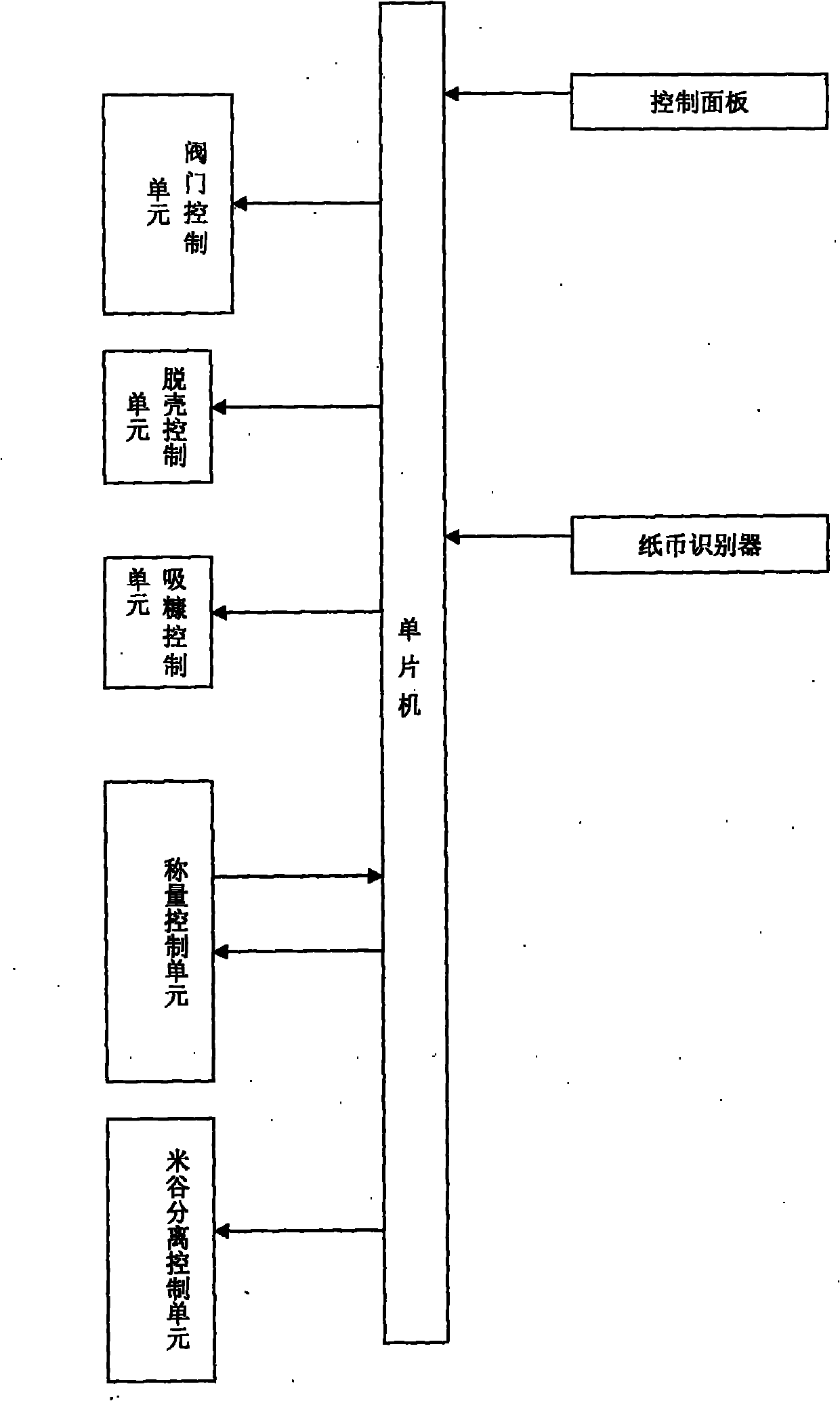

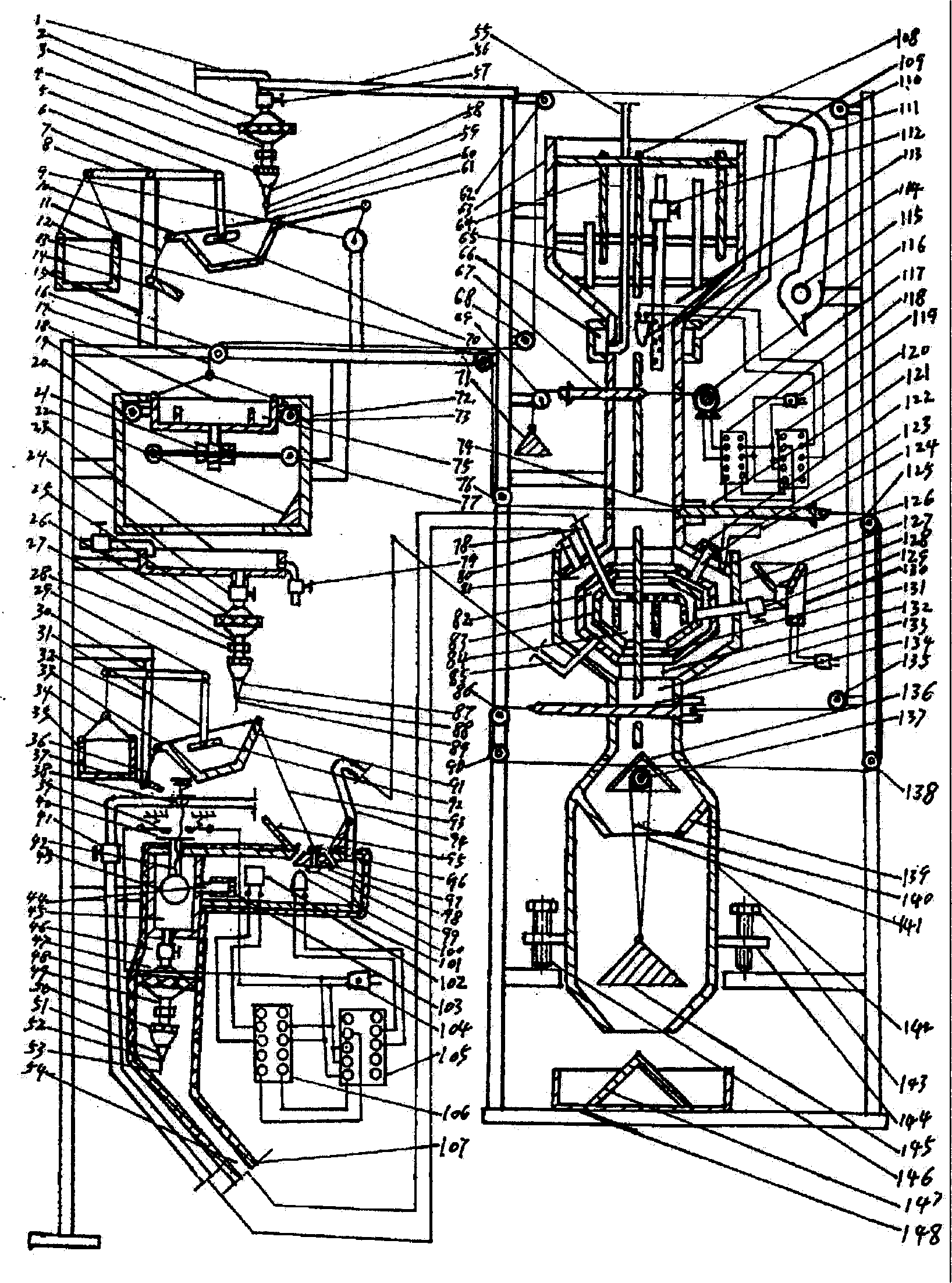

Integrated multi-rice vending machine

InactiveCN102034312AGood effectEasy to operateCoin-freed apparatus detailsApparatus for dispensing discrete articlesAgricultural engineeringDisplay device

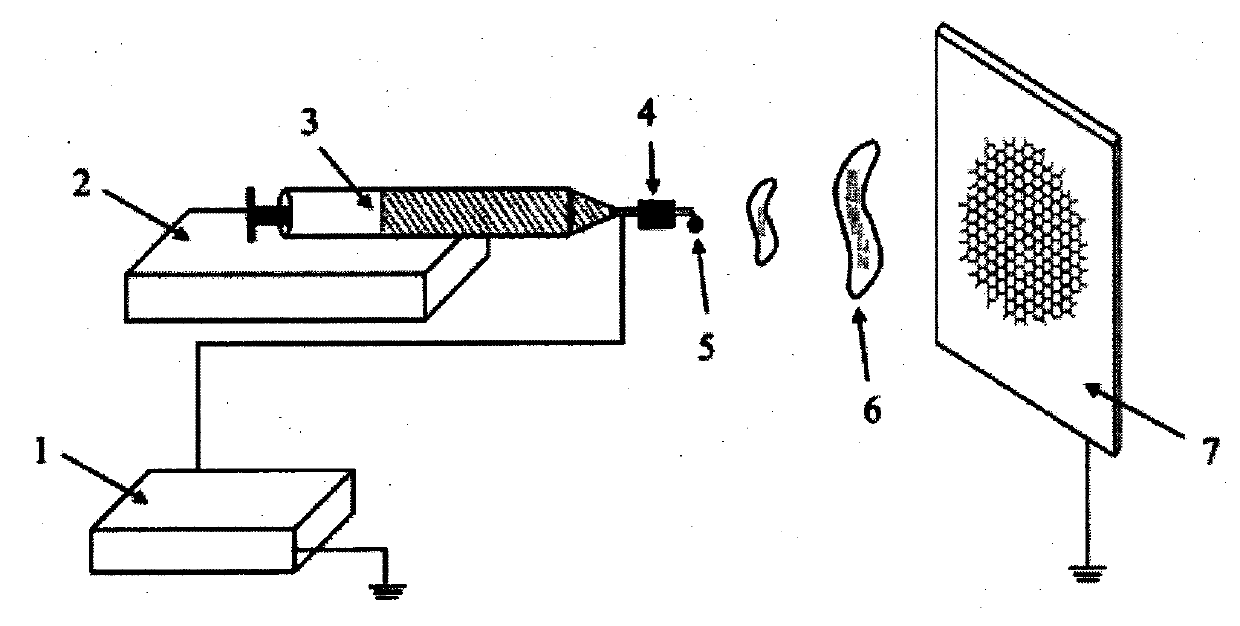

The invention discloses an integrated multi-rice vending machine. The machine comprises a shell, a storage box, a grain grinding device, a weighing device, an electric control device, a grain and rice separator, a bran sucking device, a voice shopping guide device, a digital display device and the like, wherein the storage box is used for storing rice and grains; the electric control device is used for realizing integral automatic running and sale of the grain grinding device and the weighing device; the output control port of the electric control device is connected with the input control ports of the grain grinding device and the weighing device; the storage box is divided into three parts by clapboards for storing polished rice, unpolished rice and unhulled rice respectively; the compartments for storing the polished rice and the unpolished rice are directly communicated with the weighing device in the shell through pipelines; the compartment for storing the unhulled rice is directly communicated with the grain grinding device and the weighing device in the shell through pipelines sequentially; and a rice inlet, an unhulled rice inlet and a rice outlet are formed on the shell. The electric control device is used for automatic integral self-service sale.

Owner:张立天

Method for artificial dormancy-relieving and early focing culturing

InactiveCN1868256AWide varietyPrevent dehydrationCultivating equipmentsHorticulture methodsAmygdalus persicaDormancy

An accelerative culture method of peach tree by artificially relieving dormancy includes such steps as storing the chosen peach saplings in ditch in the autumn, transplanting in the culture soil contained in perforated plastic bag in the next February, putting them in greenhouse, transplanting in the field in the May, spraying uniconazole every 7 days twice, picking off leaves in the August, forced dormancy in cold storehouse for 40-50 days, transplanting in greenhouse in the October, controlling the temp of florescence to 20-22 deg.C, and fruit growing management.

Owner:傅友 +2

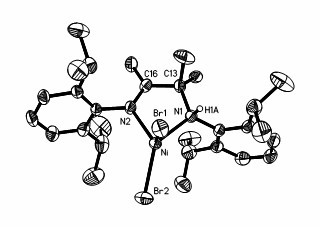

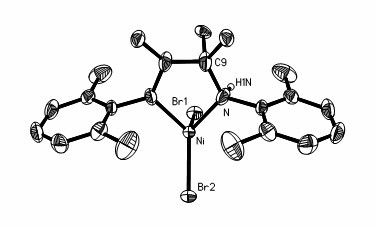

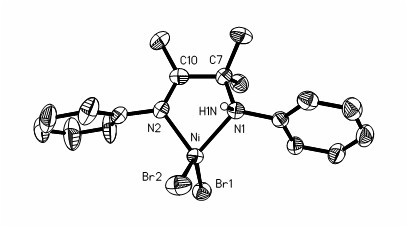

Preparation method and application of amido-imine nickel vinyl polymerization catalyst

ActiveCN102250152AThe synthesis method is simpleRaw materials are cheap and easy to getNickel organic compoundsAnilineBiological activation

The invention discloses a preparation method of an amido-imine nickel catalyst and application of the amido-imine nickel catalyst to catalyzing vinyl polymerization. The complex has the structures of a formula (I) and a formula (II) shown in the specification, wherein R1 is hydrogen or alkyl, R2 is hydrogen or alkyl, R3 is hydrogen or alkyl, R4 is hydrogen or alkyl, and X is halogen. The preparation method of the complex comprises the following steps of: carrying out condensation reaction on a diketone compound and phenylamine through ketoamine to obtain an diimine compound; then reacting with trimethyl aluminum, and hydrolyzing to obtain an amido-imine ligand; finally carrying out coordination reaction on the amido-imine ligand and (DME)NiX2 under the condition without water and oxygen to obtain a nickel complex. The complex disclosed by the invention has a specific ligand replacement structure and can be used for catalyzing the vinyl polymerization under the activation of modified methyl aluminium oxane or alkyl aluminum, showing the characteristics of living polymerization under specific conditions and obtaining the high-molecular-weight narrowly-distributed branched polyethylene.

Owner:SUN YAT SEN UNIV

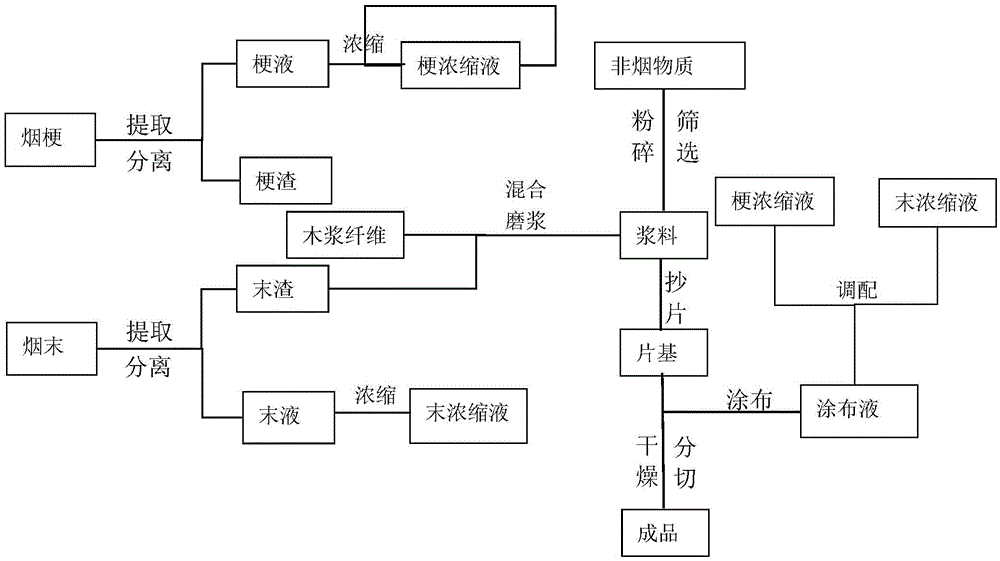

Preparation method and application of functional reconstituted tobacco

ActiveCN105559132AWide varietyKeep the characteristic aromaTobacco preparationChemistryTemperature treatment

The invention discloses a preparation method and application of functional reconstituted tobacco. The preparation method includes the following steps that 1, tobacco waste is subjected to soaking extraction and solid-liquid separation to obtain a tobacco powder extraction solution and tobacco powder dregs; 2, tobacco stems are subjected to soaking extraction and separation to obtain a stem extraction solution and stem dregs; 3, the tobacco powder dregs and stem dreg fibers are mixed, wood pulp fibers are added, and the mixture is prepared into pulp; 4, non-tobacco matter is smashed and screened, the screened non-tobacco matter is added into the pulp, the non-tobacco matter and the pulp are mixed evenly, and the pulp is prepared into a substrate in a papermaking mode; or the screened non-tobacco matter is added into the pulp in the pulp papermaking process; 5, a stem concentrated solution, a tobacco powder concentrated solution and spice are blended to obtain a coating solution; 6, the substrate is coated with the coating solution, dried and sliced to obtain tobacco slices. According to the preparation method, the non-tobacco matter is smashed and then added into the pulp, then papermaking is carried out, high-temperature treatment of the non-tobacco matter is not needed, the preparation method is suitable for many types of raw materials, the characteristic aroma of the non-tobacco matter is kept to the maximum degree, and the quality of the tobacco slices is improved.

Owner:山东瑞博斯烟草有限公司

Multifunctional three layers combined antifog film of polythene for shed

ActiveCN101003720AInhibition and mitigation of diseaseIncrease light intensityOther chemical processesClimate change adaptationAgricultural engineeringCo extrusion

This invention relates to a three-layer multifunctional anti-fogging film of polyethylene. The film has three layers, with the thickness ratio of 3:4:3. All the three layers are based on polyethylene, and the anti-fogging agent is added in the innermost layer. The film is molded by co-extrusion blowing, has good anti-fogging performance and low cost, and can inhibit crop diseases, increase crop illumination intensity, improve crop quality, and increase crop yield.

Owner:白山市喜丰塑业有限公司

Composite material producing extruding-casting, permeating and sintering process and equipment

The technological process of producing composite material includes mixing reinforcing hard phase material, self-lubricating material and self-smelting alloy powder as well as adhesive and flux in certain proportion in a material mixer; pressing into prefabricated block in required shape and setting into stove after natural drying for 24 hr; preheating extruding and casting mold, painting heat resisting paint and stoving; setting the prefabricated block into the mold, stoving and casting with the refined molten metal; and extruding in a extruder to penetrate the molten metal into the interval between reinforcing phase material to obtain the reinforced composite material product.

Owner:丁刚

Moisture-conducting quick-drying weft-knitted fabric and processing technology thereof

PendingCN107354564AStable moisture-wicking functionLow raw material costWeft knittingTextile/flexible product manufactureChemistryProcess engineering

The invention provides a moisture-conducting quick-drying weft-knitted fabric. The fabric can solve the problems that an existing moisture-conducting quick-drying fabric is not washable when treated with a functional additive, is not resistant to high temperature when water-repellent fibers serve as the inner layer, and is expensive and not easy to process when waterproof yarn serves as the inner layer. A grey fabric of the fabric is formed through weft knitting of at least two kinds of yarn different in DPF, wherein the looping area of the yarn, with the minimum DPF, in the at least two kinds of yarn different in DPF on the front side of the grey fabric accounts for 60-100% of the total area of the front side; the looping area or the floating thread area of the yarn, with the maximum DPF, in the at least two kinds of yarn different in DPF on the reverse side of the grey fabric accounts for 60-100% of the total area of the reverse side; the DPF value of the yarn with the maximum DPF is at least 0.3 larger than that of the yarn with the minimum DPF. The invention provides a processing technology of the moisture-conducting quick-drying weft-knitted fabric. The technology comprises the following steps of grey cloth weaving, pre-treatment, dyeing, reduction washing, high-temperature setting, reduction washing and finished product shaping.

Owner:WUXI HANUO TEXTILE TECH

Chilling-free cultivating method of peaches in greenhouse

ActiveCN104429783AWide range of applicable varietiesWide varietyFertilising methodsCultivating equipmentsOperabilityBud

The invention discloses a chilling-free cultivating method of peaches in a greenhouse. Through a series of chilling-free cultivating technological means including the step of promoting flower buds to fully differentiate in advance, the step of spraying nutritional agents, shielding light and closing a plastic shed so as to make leaves fall, the step of spraying dormancy-breaking chemicals, controlling the temperature and promoting flowering, the step of spraying fruit-setting and branch-promoting agents to prevent secondary dormancy, the step of reasonably regulating and controlling the temperature and humidity, the step of manually compensating for light and the step of applying carbon dioxide fertilizer, the mature period of peaches in the greenhouse is greatly brought forward. The method has the advantages of being wide in suitable variety range, high in operability, accurate in regulation and control, high in increased benefit and the like, is suitable for being applied to greenhouse precocity promoting cultivation of most of middle-early ripen peaches with a chilling requirement of 700 hours or fewer in present production, also has quite high guidance significance in regulating the mature period of other northern fruit trees, and makes peaches in the greenhouse ripen as early as possible and appear on the market before the spring festival, the peaches can meet the requirements for the spring festival consumer market and sightseeing and picking, the sale price is several times to ten times or more the price of peaches appearing on the market in April and May, and the benefit increase is quite remarkable.

Owner:廊坊市农林科学院

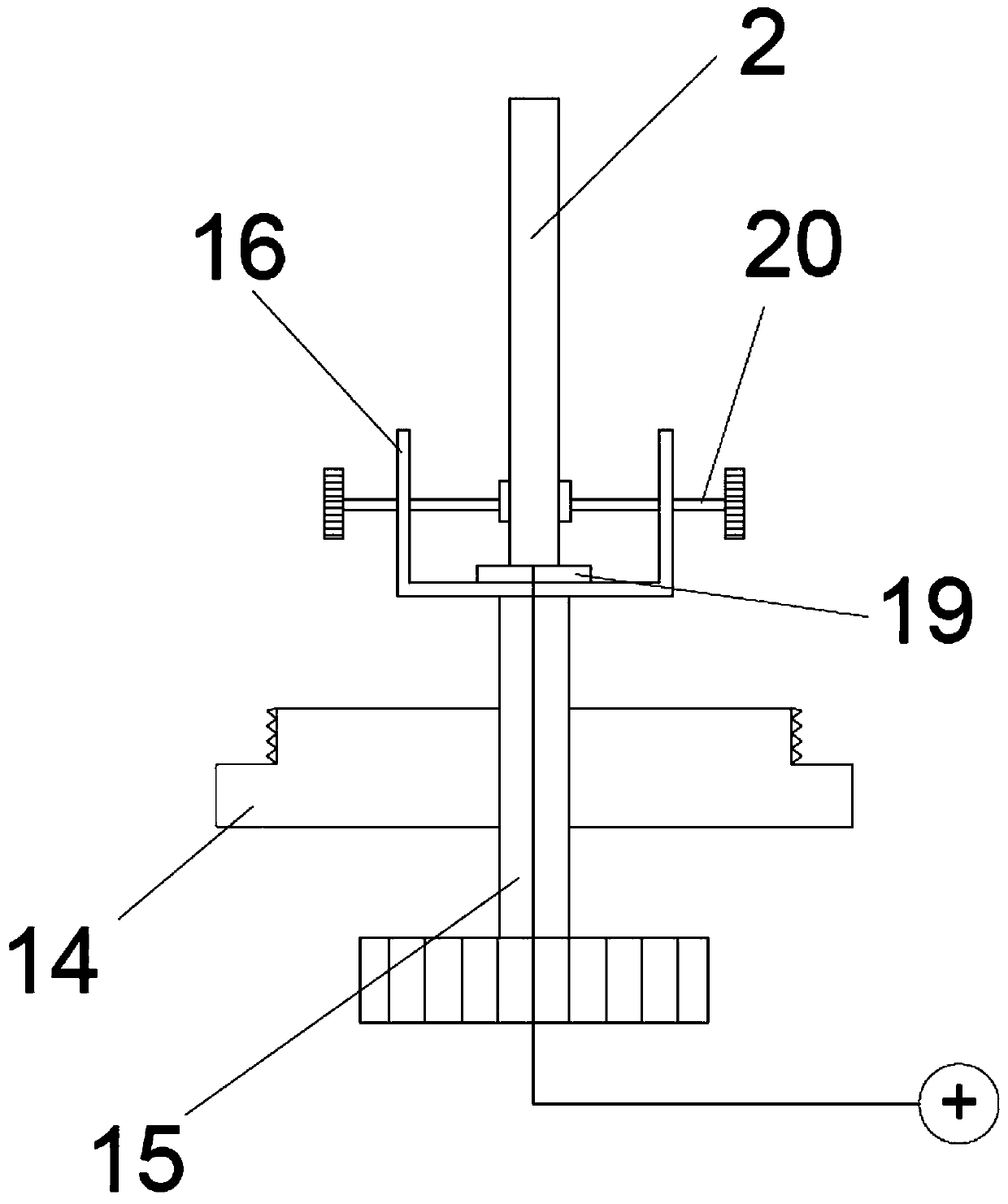

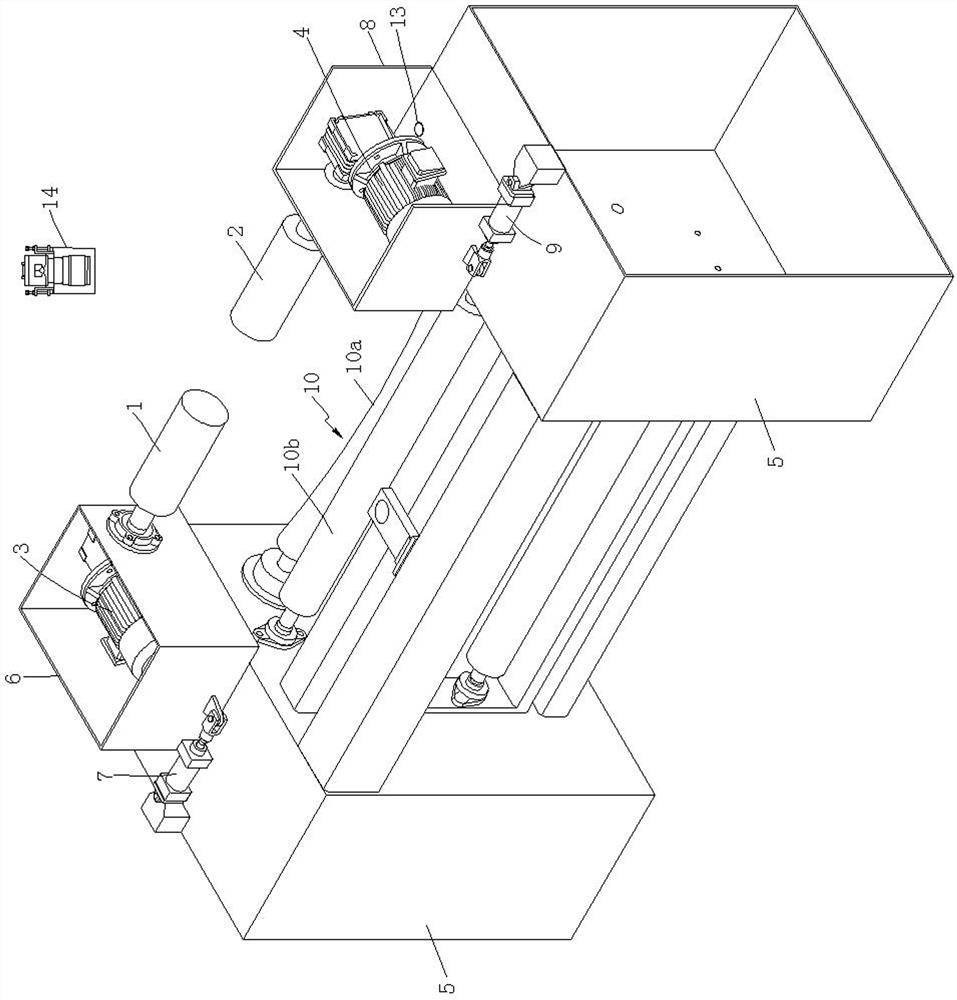

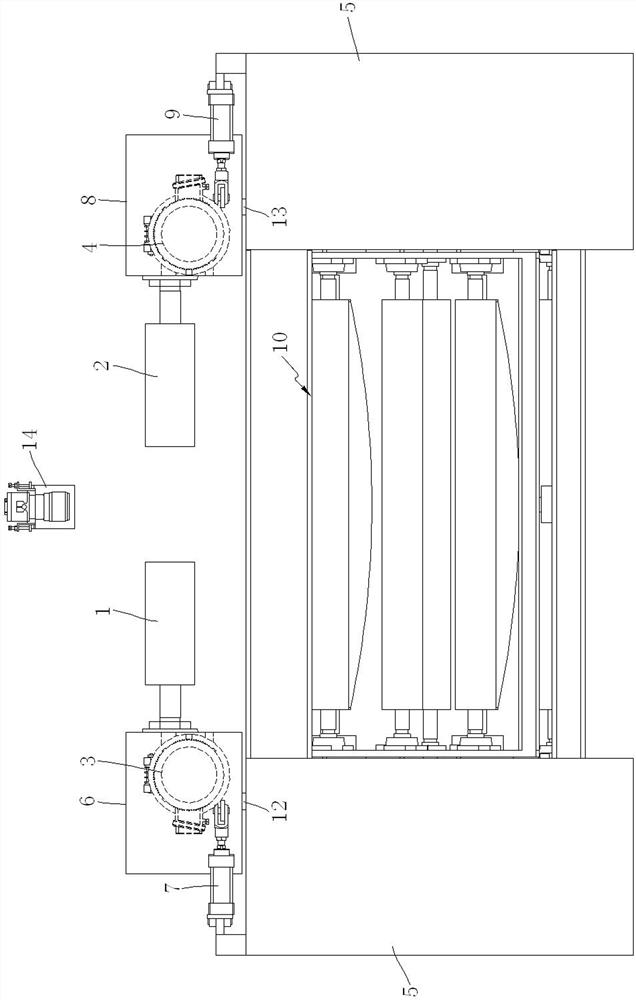

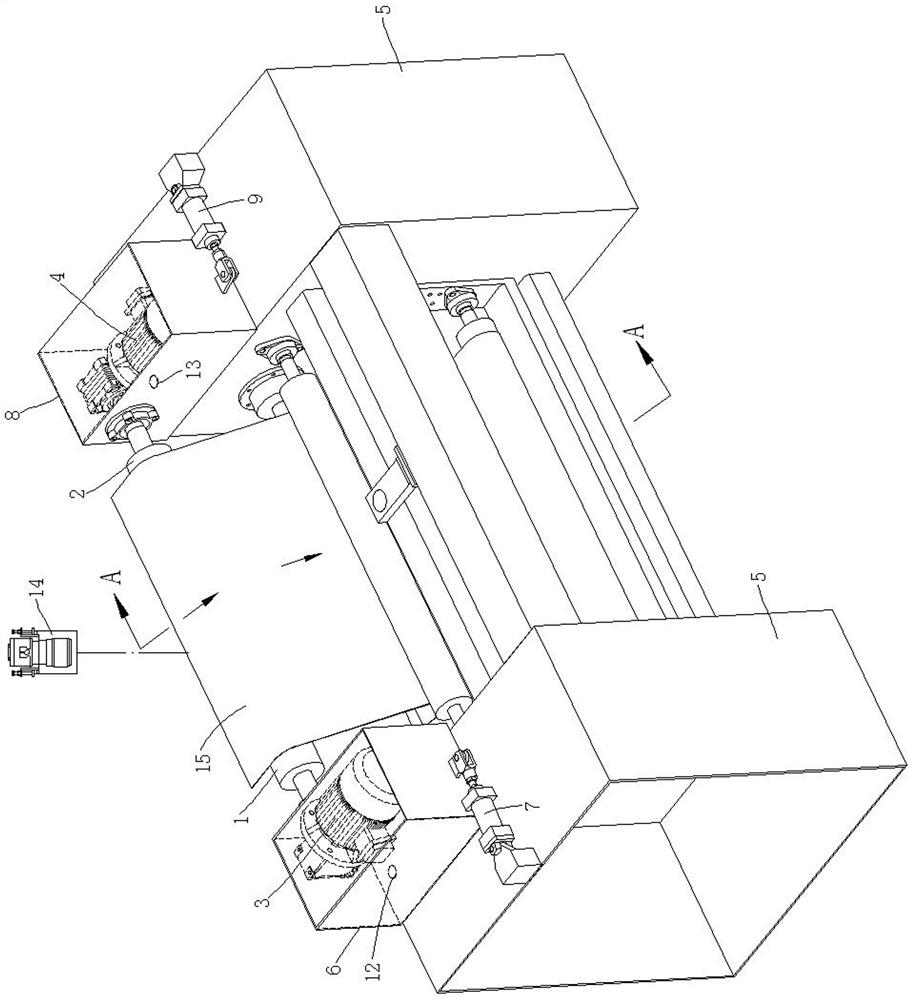

Preparation system and preparation method of nano alloy material

ActiveCN111168077AUniversal applicabilityWide varietyNanotechnologySemiconductor electrodeElectrical connection

The invention discloses a preparation system and preparation method of a nano alloy material, and relates to the technical field of nano material preparation. The preparation system comprises a nano alloy preparation device and a collection device, wherein the nano alloy preparation device consists of a power supply, an electrode, an ablation reaction container and an inert gas source; the collection device comprises a collection box; the inert gas source communicates with the ablation reaction container; the ablation reaction container communicates with the collection box; exhaust holes are formed in the bottom of the collection box; two electrode fixing seats for mounting and fixing electrodes are arranged in the ablation reaction container, the two electrode fixing seats are oppositelyarranged on the inner wall of the ablation reaction container, and the two electrode fixing seats are respectively electrically connected with two poles of the power supply; the electrode is one of apure metal electrode, an alloy electrode and a semiconductor electrode; and a receiving substrate used for receiving and collecting nano materials is arranged inside the collection box. The preparation system and the preparation method have general applicability and wide variety and range for preparing nano alloy materials.

Owner:GUANGDONG UNIV OF TECH

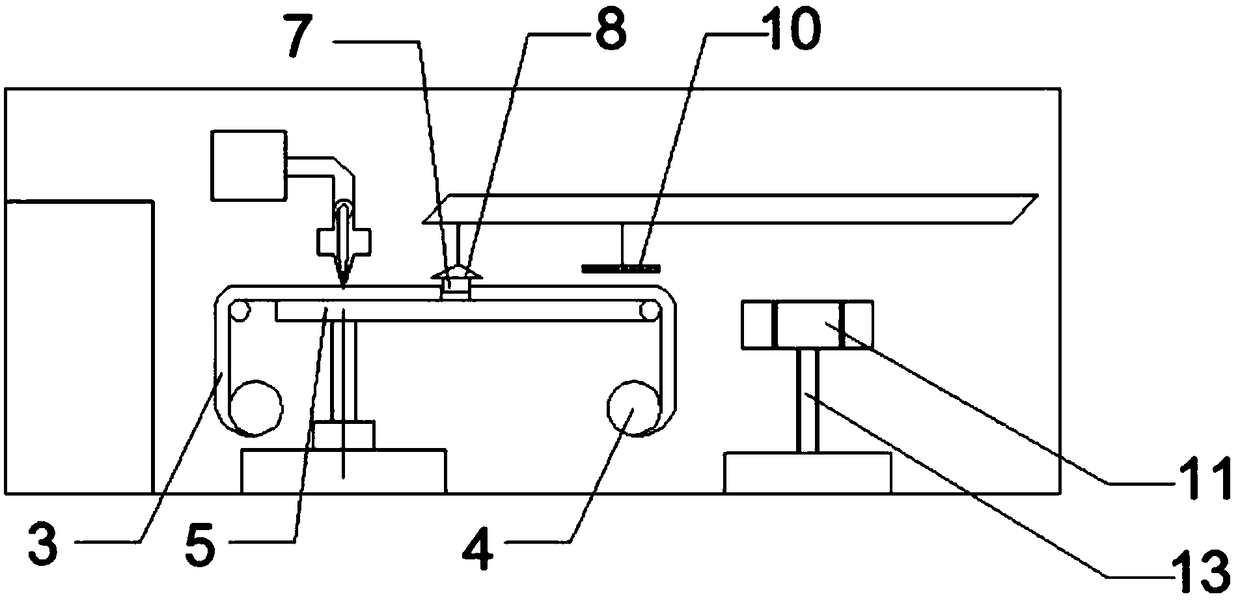

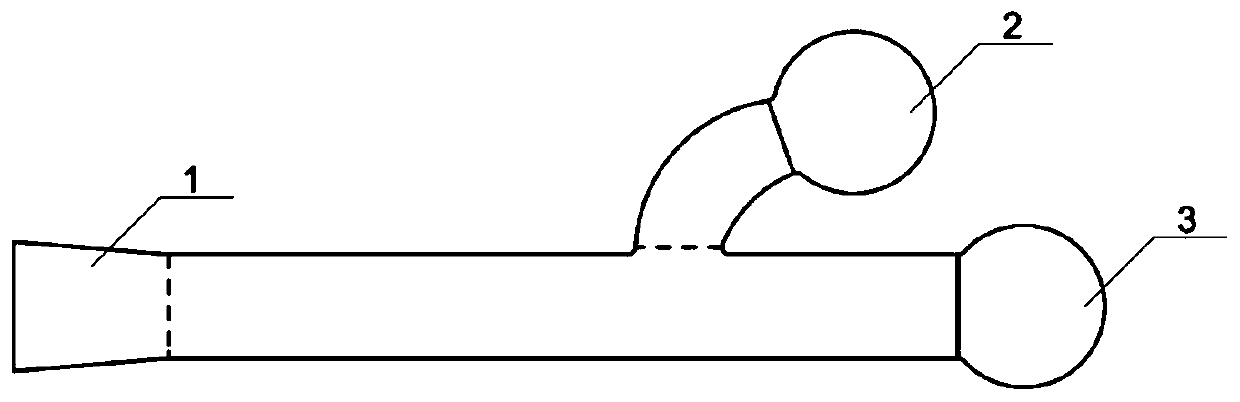

Fabric weft setting or weft setting and pattern setting system and method

PendingCN111851041AImprove the correction effectSolve the big problem of poor adaptabilityInspecting textilesMaterial analysis by optical meansElectric machineryWoven fabric

The invention discloses a fabric weft setting or weft setting and pattern setting system and method. The fabric weft setting or weft setting and pattern setting system comprises a correcting mechanism, a detecting mechanism and a central processing unit. The correcting mechanism comprises a first driving roller wheel, a second driving roller wheel and a plurality of correcting rollers, the first driving roller wheel is driven by a first motor, the second driving roller wheel is driven by a second motor, the multiple correcting rollers are driven by the driving mechanism, the first driving roller wheel is arranged on one side of fabric in the width direction, the second driving roller wheel is arranged on the other side of the fabric in the width direction, and the multiple correcting rollers are arranged in front of the first driving roller wheel and the second driving roller wheel along the fabric running route. The detecting mechanism is arranged in front of and / or behind the first driving roller wheel and the second driving roller wheel along the fabric running route, and the first motor, the second motor, the driving mechanism and the detecting mechanism are controlled by the central processing unit. The first and second driving roller wheels are preferably friction roller wheels with friction surfaces on the periphery. The fabric weft setting or weft setting and pattern setting system and method have the advantages of wide application range of textiles, no damage to fabrics during correction, fast correction response, capability of real-time correction control, high correction precision and good effect.

Owner:CHANGZHOU HONGDA INTELLIGENT EQUIP IND DEV RES INST CO LTD

Sesame oil with functions of blood pressure lowering and health caring

The invention belongs to the technical field of health food, and particularly relates to sesame oil with the functions of blood pressure lowering and health caring. The sesame oil is prepared from the following raw materials in parts by weight: 1400-1500 parts of white sesame seeds, 30-35 parts of pine nuts, 20-30 parts of sunflower seeds, 10-12 parts of oats, 12-15 parts of calendula, 6-8 parts of gardenia, 12-15 parts of lotus leaves, 9-12 parts of gastrodia elata, 6-8 parts of lotus plumule and 12-15 parts of sophora flower bud. The sesame oil is rich in raw materials, pine nut, sunflower seed, oat and other materials improve the edible value of the sesame oil; calendula, gardenia, lotus leaves and other Chinese herbs have the functions of promoting blood circulation and arresting bleeding, clearing heat, reducing internal heat, lowering blood pressure and preventing stroke; a carbon dioxide subcritical extraction technique which has environment-friendly and efficient effects is adopted; the extraction temperature is low; bioactive constituents in the raw materials cannot be destroyed. The sesame oil is high in edible value, is particularly suitable for the middle-aged and old people, can protect the heart and cerebral vessels and has values of popularization and application.

Owner:太和县庄老汉杂粮有限公司

Method for efficiently preparing graphene oxide organic solution

The invention discloses a method for efficiently preparing a graphene oxide organic solution. A target organic solvent is added to a graphene oxide aqueous solution with known concentration, water and the target organic solvent are separated with a solvent replacement method through distillation or fractionation, finally, a graphene oxide organic solution without water is ultrasonically dispersed, and the graphene oxide organic solution is obtained. The method has the advantages that the process is simple and the concentration and variety range of the organic solution is wide.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

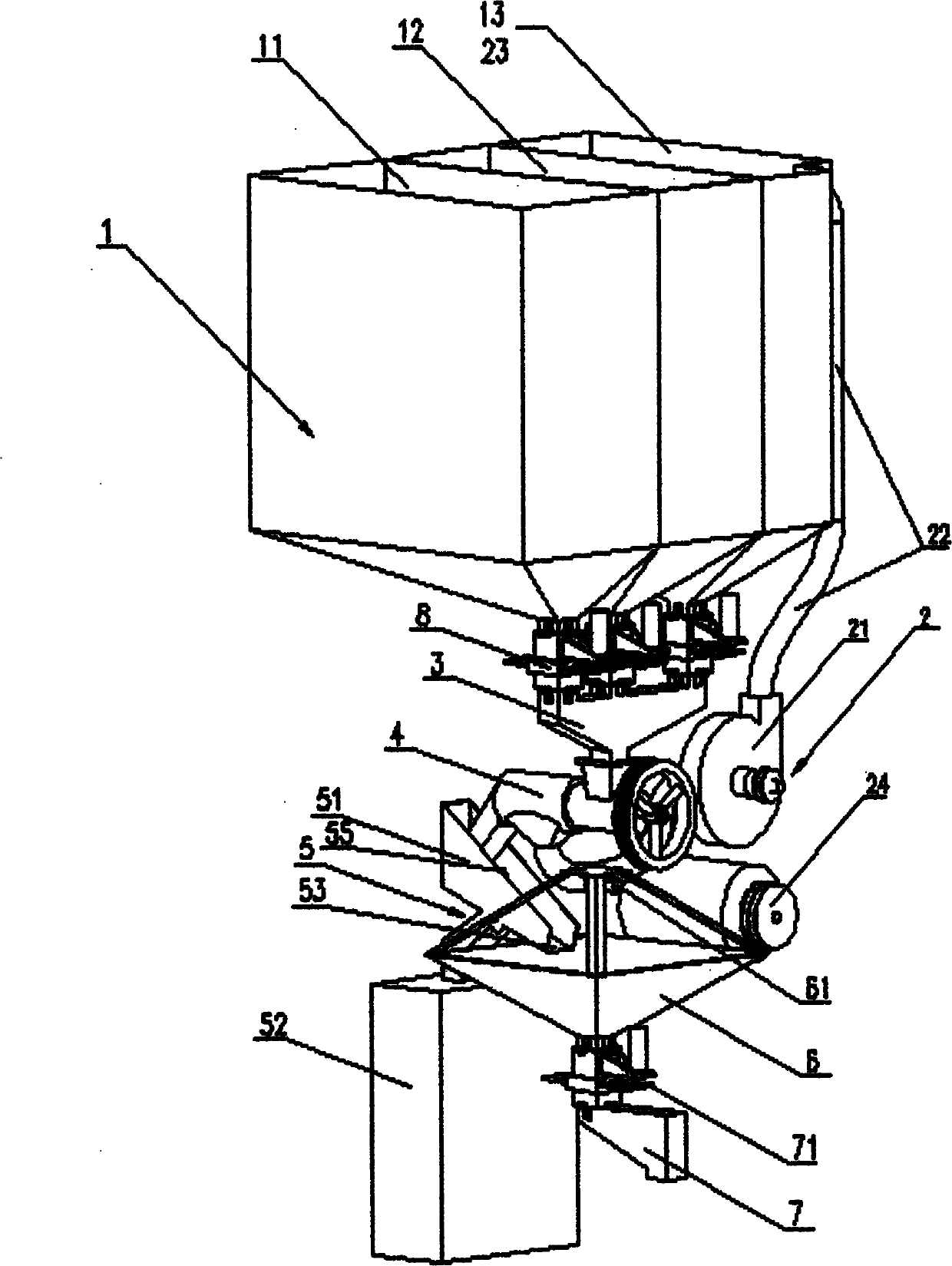

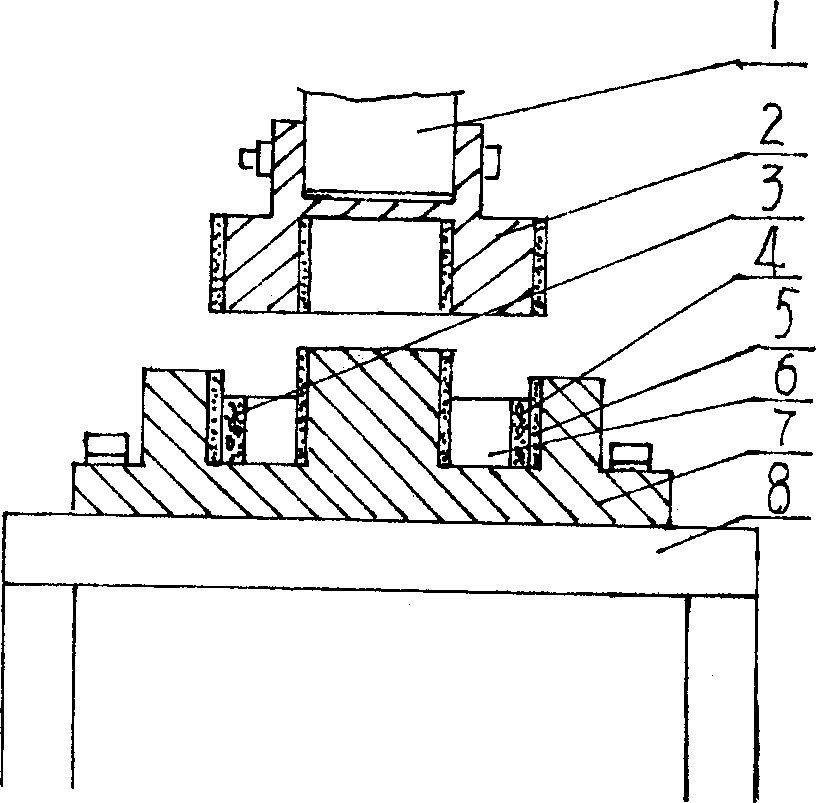

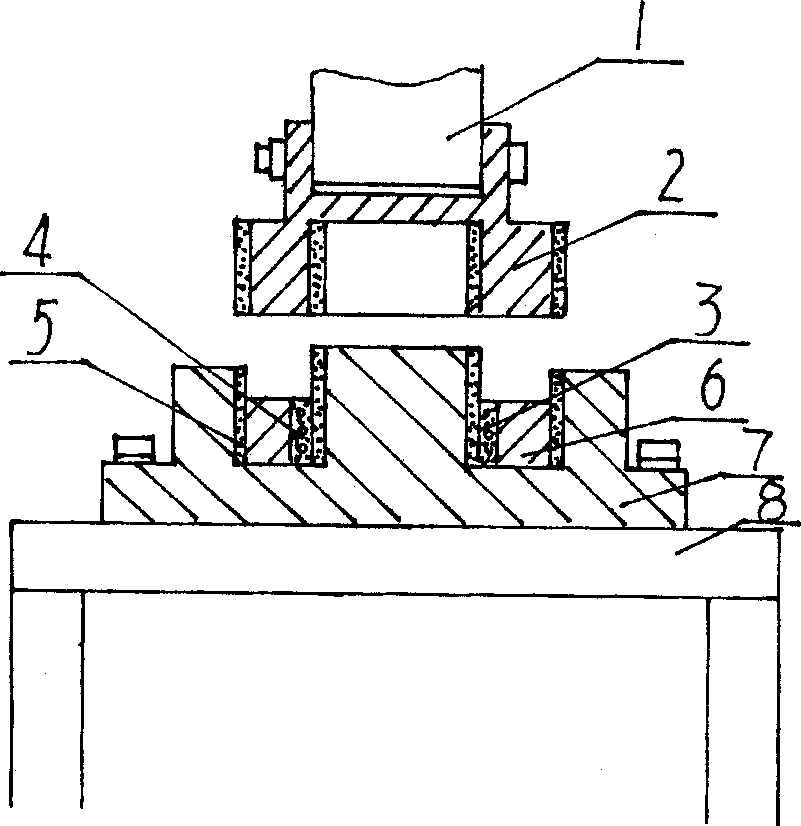

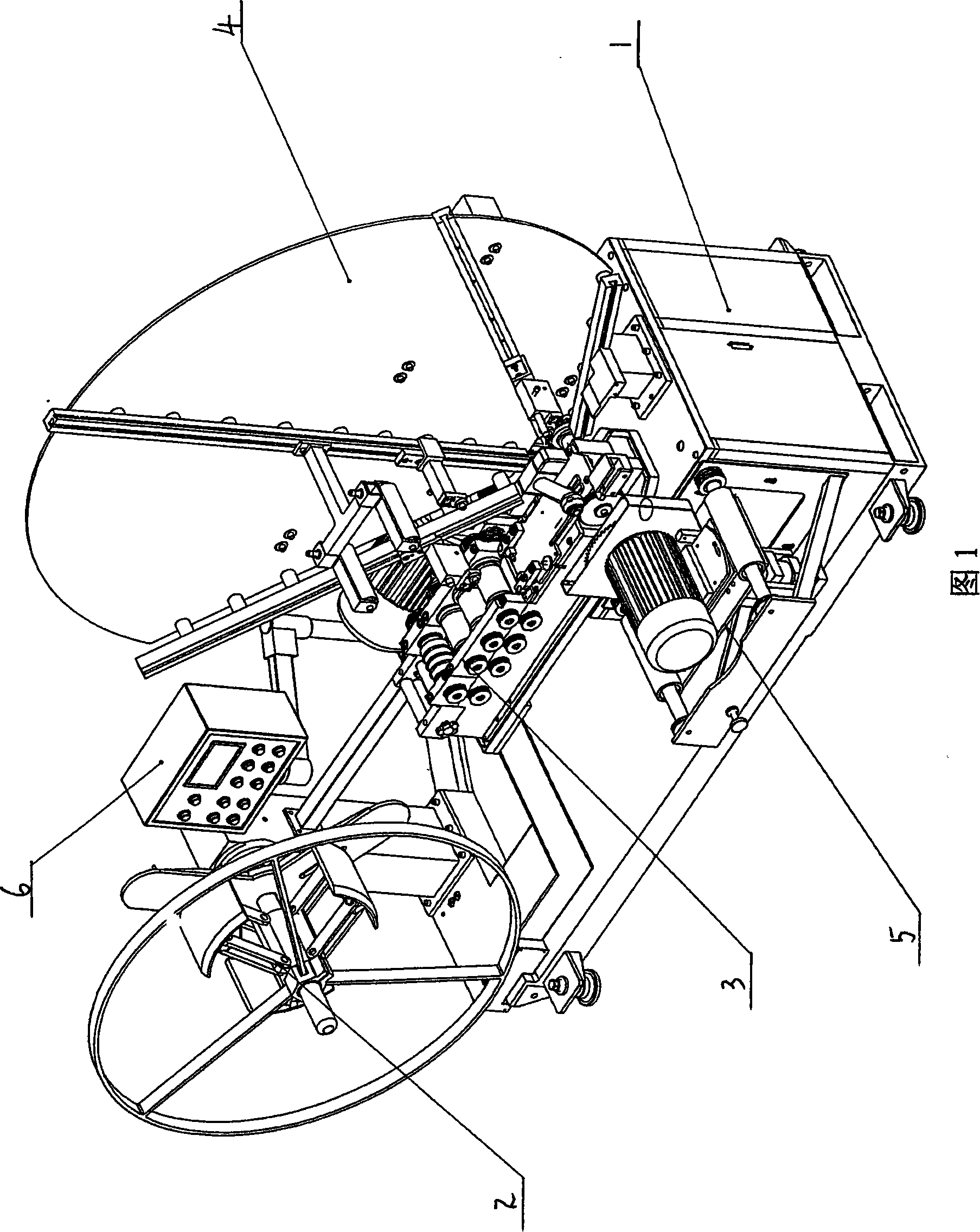

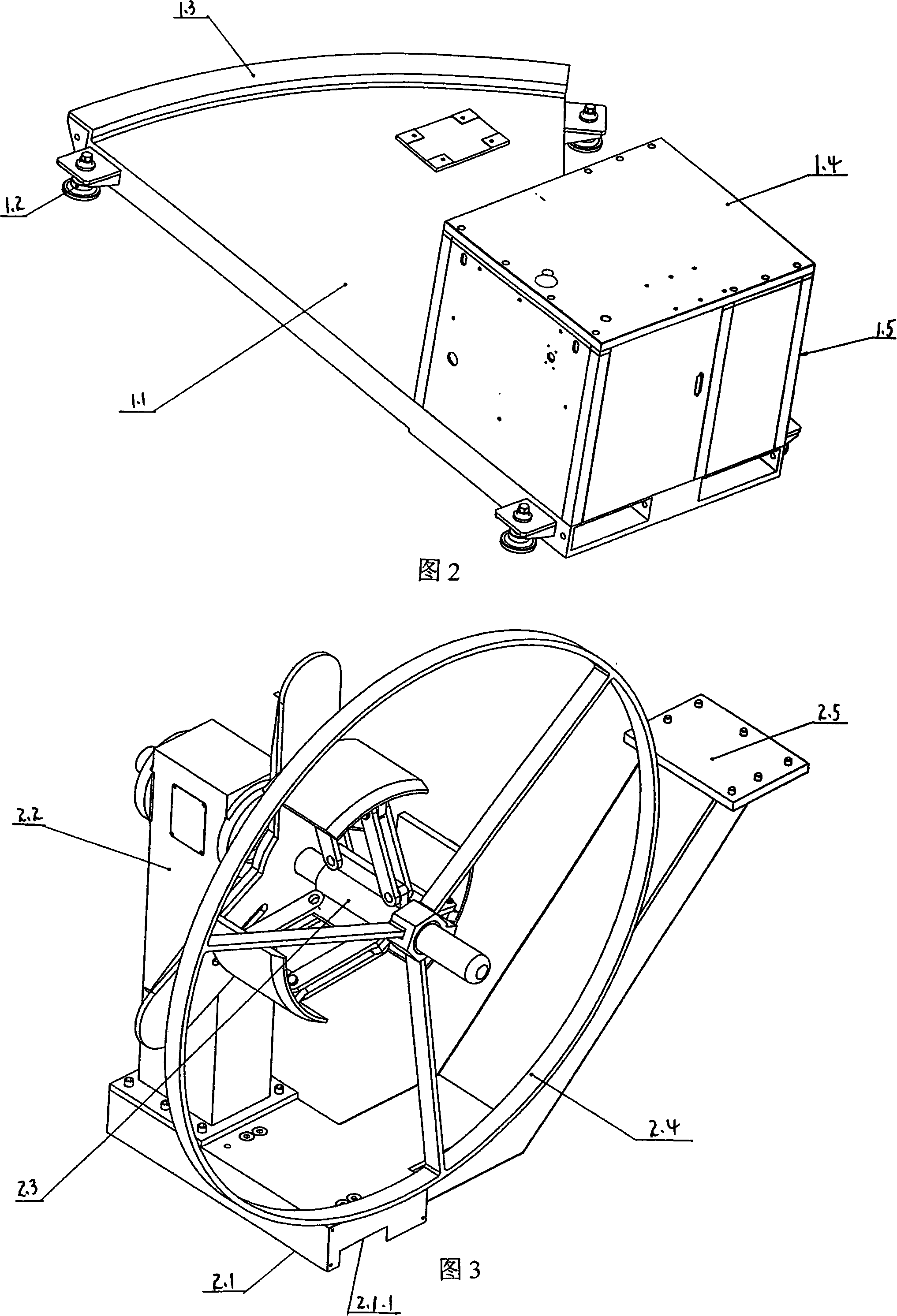

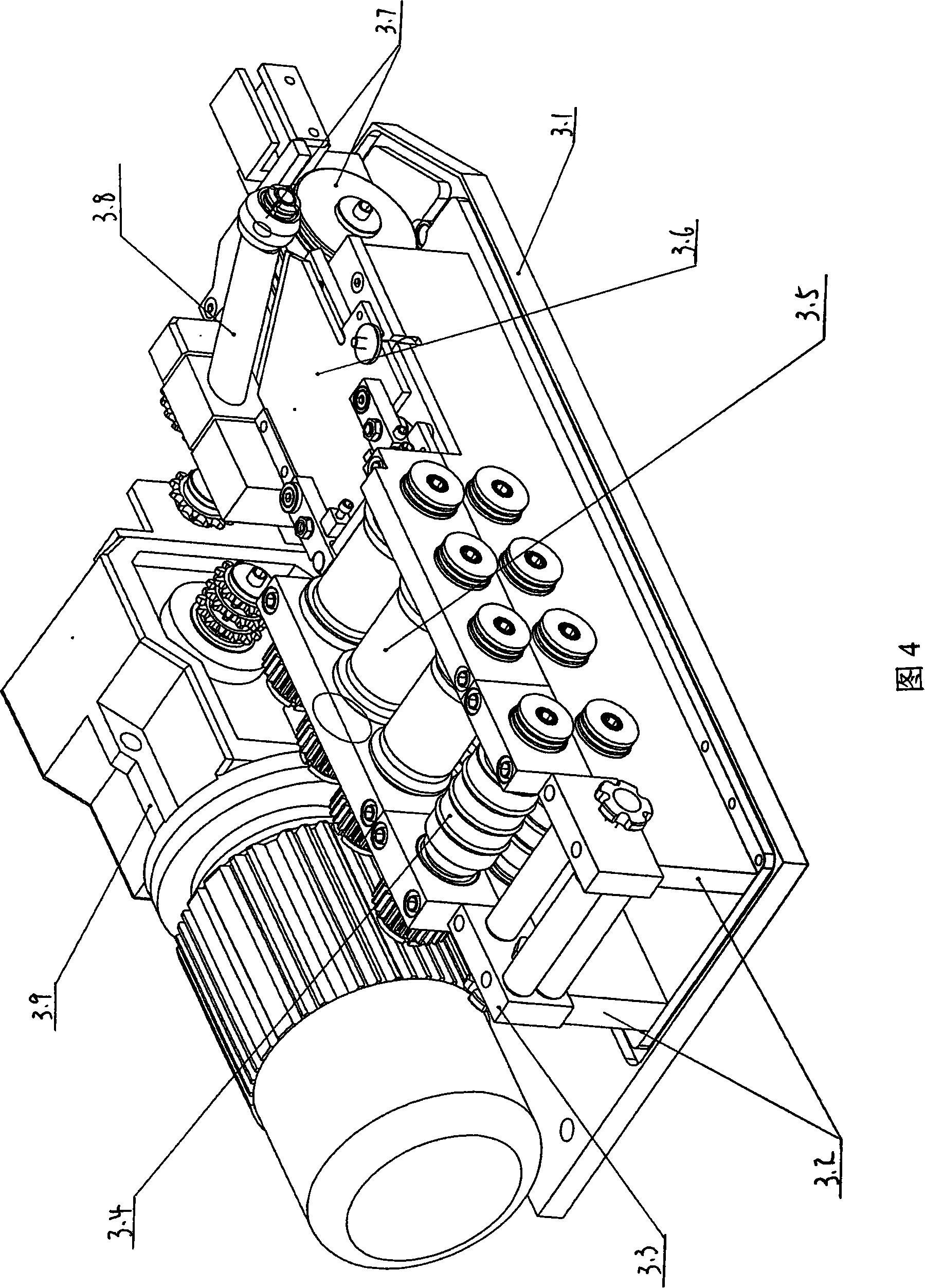

Helical gas pipe forming machines

The invention relates to a novel spiral gas tube forming machine, which is applicable for spiral ducts formed by rolling strip steel roll material along a spiral involute track. The spiral gas tube forming machine comprises a frame (1); a material shelf (2), a lock forming set (3), a mold frame (4) and a cutting machine (5) arranged on the frame (1); and a discharge shelf (7) arranged on the front side of the cutting machine (5); wherein the frame (1) comprises a bottom plate (1.1), level adjusting bases (1.2), material shelf guide rails (1.3) and a platform (1.4); the material shelf (2) comprises a slider (2.1), a pillar (2.2), a main body (2.3) and a connection crank arm (2.5); the lock forming set (4) comprises a bottom plate (3.1), wall plates (3.2), a feed leveling device (3.3), an upper and a lower rib-pressing rollers (3.4), an upper and a lower roller groups (3.5), a discharge guide plate (3.6), an upper and a lower engagement wheels (3.7), and a pressing crank arm (3.8); and the mold frame comprises a support frame (4.1), guide rails (4.2), a template (4.3) and wind pipe baffles (4.5). The spiral gas tube forming machine has the advantages of simple structure, integration of the material shelf and the machine, good lock formability, multi-purpose of the mold frame, synchronous cutting without stopping, high production efficiency and good product quality.

Owner:陶国荣

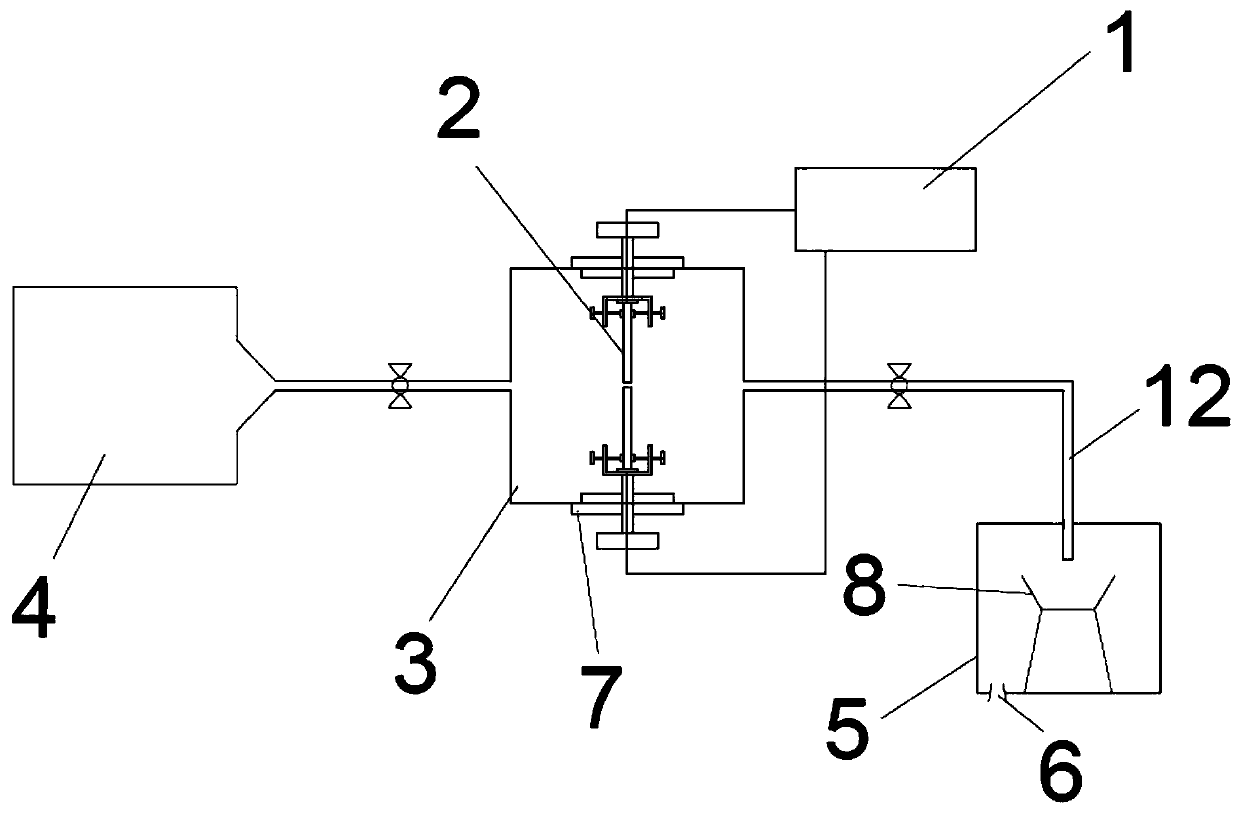

High-temperature pulse flow yarn dyeing machine with ultra low bath ratio and control method thereof

InactiveCN102140743AIncrease exchange frequencyQuick responseTextile treatment machine arrangementsTextile/flexible product manufactureYarnThree level

The invention discloses a high-temperature pulse flow yarn dyeing machine with an ultra low bath ratio and a control method thereof. The yarn dyeing machine comprises a dye vat, a creel, a heat exchange coiler, an adaptive water level monitoring device, a variable frequency motor, a three-level vane pump with an ultra low bath ratio and a dyeing computer. The method comprises the following steps: a time pulse generator in the dyeing computer gives out pulse flow data to a variable frequency motor controller to control the revolving rate of the variable frequency motor according to the set technological process; the variable frequency motor drives the three-level vane pump with an ultra low bath ratio to output dyeing flow in pulse flow type fluctuation; the output dyeing flow carries out adaptive adjustment according to an ideal reference model in the dyeing computer; the adaptive water level monitoring device gives out water-level reference identification information; and according to the information, a water level regulator and the variable frequency motor controller respectively regulate the water level and the variable frequency motor to reach the water level and the pulse flow required by the set technological process. The pulse flow dyeing technology in the invention conforms to the requirement of the minimum consumption of four factors, namely, water, energy, accessory ingredient and time for economical dyeing of ecological environment protection.

Owner:高勋绿色智能装备(广州)有限公司

Foam forming method for completely biological degradable plastic tubleware and drinking ware

The present invention discloses the formulation and foaming formation process of biodegradable starch-base plastic tableware. The tableware is produced with starch as main material, PVA, plasticizer, foaming agent, stuffing and other supplementary material, and through mixing, foaming, formation and surface treatment. The present invention has improved toughness and high temperature water tolerance, and is biodegradable completely.

Owner:胡靖

Water-control timely feeding method

A timing food supply method of water control, which is characterized in that it comprises following steps: voltage stabilizing treatment for water source, adjusting adjustable pore in water outlet, intruding adjusted water with fiber to water collecting vessel for measuring to get water with a certain volume, timing food supply for animals. The invention is characterized in that: timing with a plurality of water control timing device to control different food supply time, the timing food supply can increase the nutrition usage rate and form eating want conditioned reflex which can improve function of alimentary system for animal and promote internal secretion for adsorption and usage to increase weight and improve healthy, and etc.

Owner:韦啟索

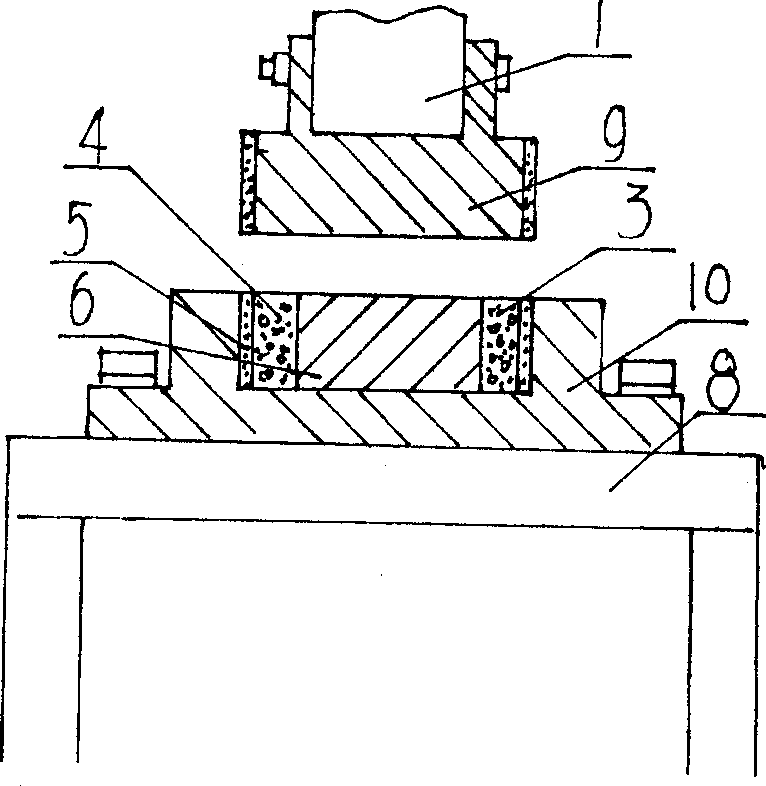

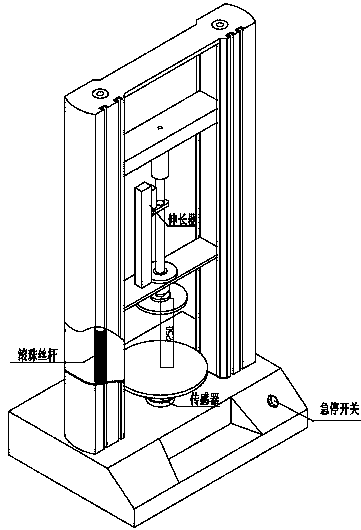

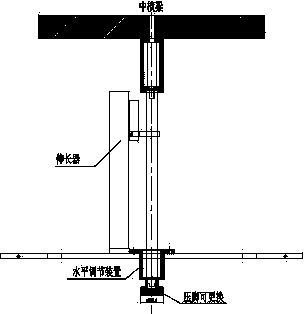

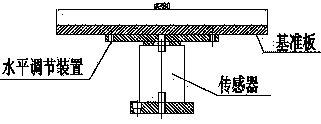

Instrument for automatically testing thickness and compression recovery performance of textile product

ActiveCN104111220AOvercome the limitations of pressurizationAdjustable pressure rangeInspecting textilesUsing mechanical meansConvertersFiber

The invention relates to an instrument for automatically testing the thickness and the compression recovery performance of a textile product. The instrument comprises an instrument main frame (a pedestal, two vertical columns and a middle cross beam), a lengthener (comprising a corresponding horizontal support plate), a series of pressure feet, a sensor, a sample collector, an output interface, output equipment (a computer and a printer), and a software control system, the software control system is utilized to set the pressure and the running speed of the pressure feet in order to automatically determine the thickness, the compression recovery performance and the fiber compression performance of the textile product, test data are automatically output, and a relevant statistical chart is output according to test needs. The instrument utilizes a servo motor to electrically press, the pressure is momentarily captured under a sampling frequency reaching 5000 / s through circuit and software filtering by using a 32 bit ARM controller and a 24 bit highly-precise AD converter, and the motor is controlled by adopting a PID algorithm to increase or decrease the pressure in order to realize a constant pressure; the AC servo motor is decelerated through a synchronous pulley, and is transmitted through a ball screw to drive the pressure feet arranged on the cross beam to downward move, and the speed is (0.01-1000)mm / min; and the position of the cross beam is calculated by acquiring the signal of a 2500 wire motor encoder, and is automatically output to obtain the thickness or the thickness displacement of a sample.

Owner:福建省纤维检验局 +1

Waste emulsified explosive and method for reclaiming matrix thereof

InactiveCN1837162AImprove securityWide varietyExplosive working-up apparatusOil phaseAmmonium nitrate

The invention discloses a waste emulsified explosive and method for reclaiming matrix, which consists of rolling 75-92% of ammonium nitrate, charging 0.05-0.50 of modifier, 2-19% of waste emulsion type explosive and base material, rolling again to remove moisture, charging 1-55 of compound oil phase material, rolling the mixture, charging charging 2-11% of TNT and 2-6% of dried wood powder, rolling and packaging.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

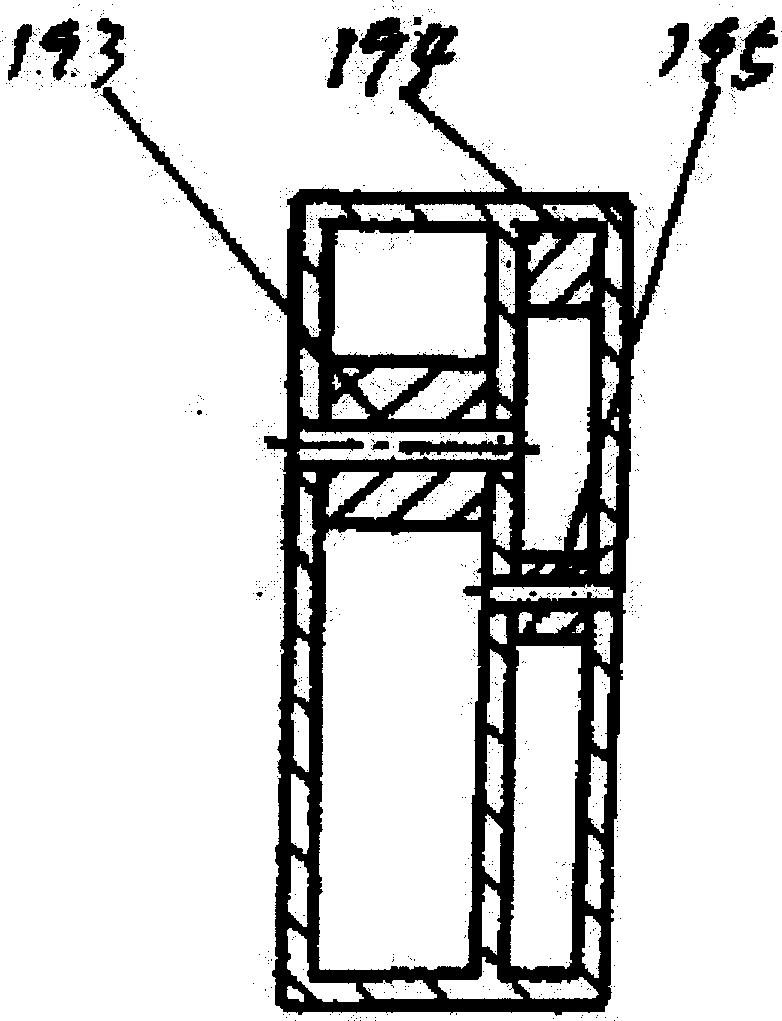

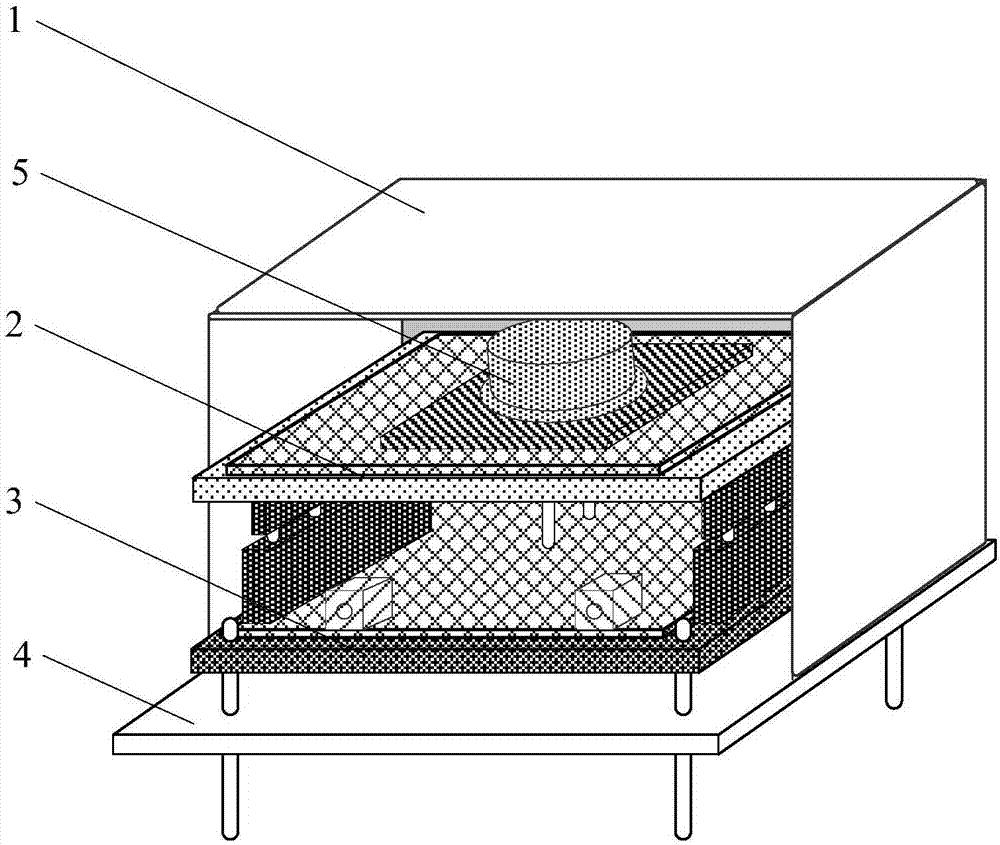

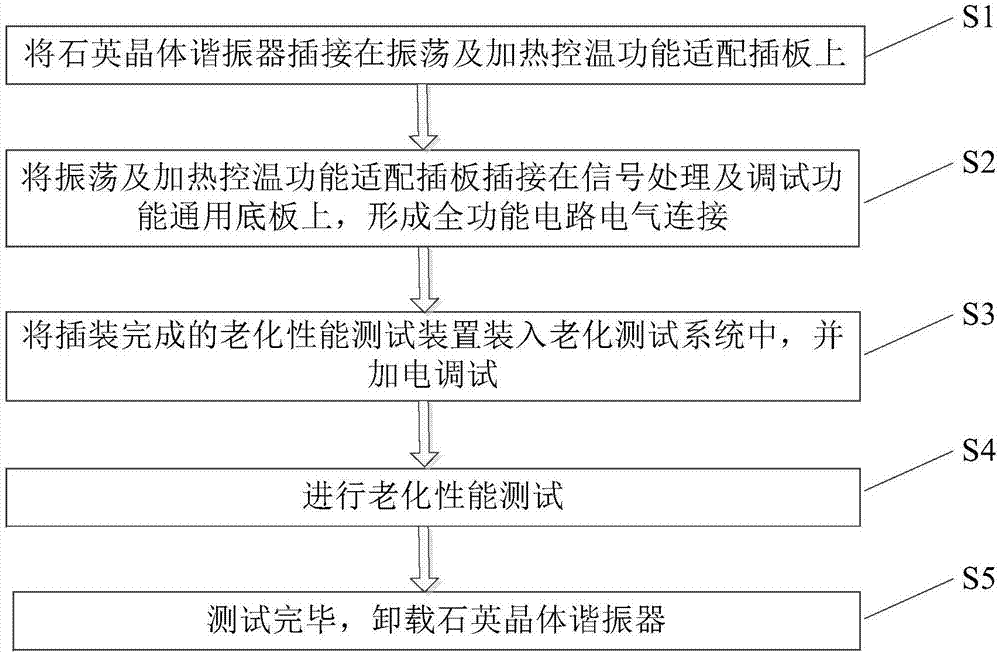

Aging performance test device and method for quartz-crystal resonator

ActiveCN107991561AWide varietyAvoid damageEnvironmental/reliability testsQuartz crystal resonatorControl function

The invention discloses an aging performance test device and method for a quartz-crystal resonator. The aging performance test device for the quartz-crystal resonator comprises a shell with an openingin the bottom, an output switching base at the bottom of the shell, a signal processing and debugging function universal base plate and an oscillating and heating temperature control function adaptive plug board, wherein the signal processing and debugging function universal base plate is located in the shell and fixedly combined with the output switching base; the oscillating and heating temperature control function adaptive plug board is located on the portion, above the signal processing and debugging function universal base plate, in the shell. The aging performance test method comprisesthe steps that the quartz-crystal resonator is plugged in the oscillating and heating temperature control function adaptive plug board; the oscillating and heating temperature control function adaptive plug board is inserted into the signal processing and debugging function universal base plate; the aging performance test device obtained after plug-in mounting is completed is installed in an agingtest system, powered on and debugged; aging performance testing is conducted; the quartz-crystal resonator is dismounted. By means of the aging performance test device and method, the problems are solved that by means of an existing method, the product morphology is damaged, and the product adaptability is poor.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

A kind of high-efficiency high-throughput two-dimensional network ultrafine nanofiber oil-water separation material and its preparation method

InactiveCN107557894BImprove throughputHigh porosityFatty/oily/floating substances removal devicesUltrasonic/sonic fibre treatmentFiberPolymer solution

The invention discloses a high-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and a preparation method thereof. The preparation method comprises the following steps: a polymer solution is prepared from a selected polymer, a net is formed through electrostatic direct injection of the polymer solution, a spinneret vibrates in situ by the aid of external force inan electrostatic direct injection process to promote generation of charged droplets, the droplets are subjected to phase separation, and a uniform 2D net-shaped ultrafine nanofiber material is formedon the surface of a receiving substrate and is in a continuous and seamlessly stacked shape; then the obtained material is subjected to surface modification, and the 2D net-shaped ultrafine nanofiberoil-water separation material with selective surface and interface wetting property is obtained. The preparation process is simple, raw material limitations are few, and the net-shaped ultrafine nanofiber oil-water separation material has tiny meshes and good pore channel connectivity and has great application prospect in the fields of oil purification, oil-containing wastewater treatment and thelike.

Owner:DONGHUA UNIV

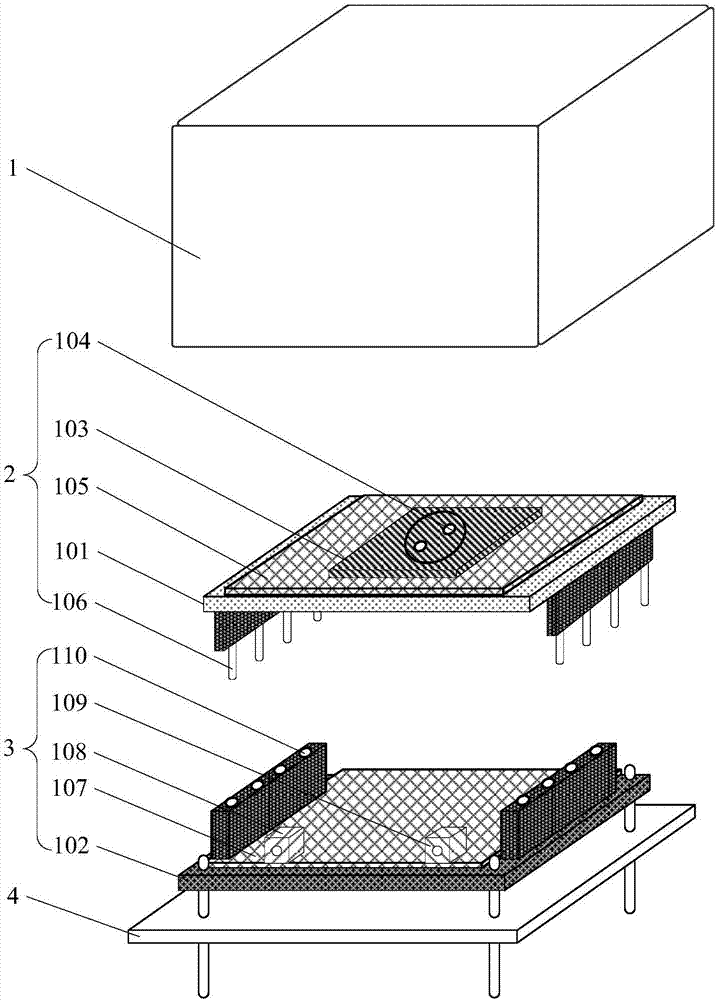

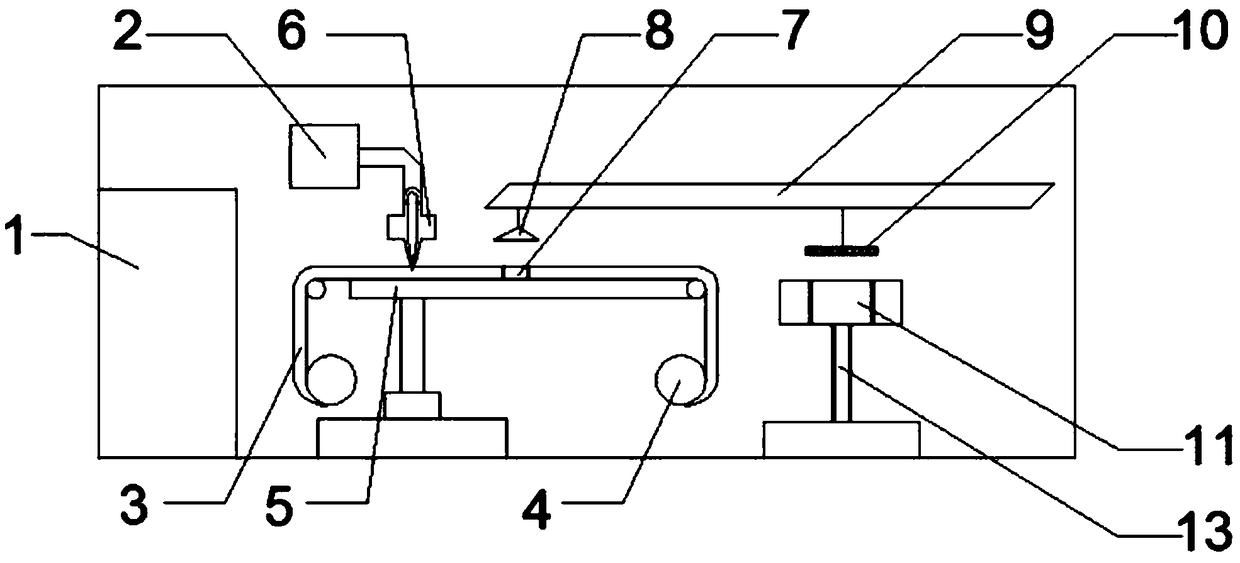

Part manufacturing equipment and method combining laser cutting with electromagnetic welding

ActiveCN108188606AGuaranteed production speedGuarantee product qualityAdditive manufacturing apparatusWelding apparatusControl systemEngineering

The invention discloses part manufacturing equipment and method combining laser cutting with electromagnetic welding. The part manufacturing equipment comprises a laser cutting system, a raw materialconveying and recovery system, a transportation system, an electromagnetic welding system and a control system; the laser cutting system comprises a laser and a cutting platform, and the laser is located over the cutting platform; the raw material conveying and recovery system comprises a raw material reel and a recovery reel, the raw material reel and the recovery reel are located on the two sides of the cutting platform correspondingly, and metal material strips penetrate through the cutting platform and are driven by the recovery reel to move forwards on the cutting platform; the transportation system comprises a three-axis track and a suction cup assembly, and the suction cup assembly can freely move on the three-axis track; and the electromagnetic welding system comprises an electromagnetic coil device and a welding worktable, the electromagnetic coil device can freely move on the three-axis track, and the welding worktable is a lifting table and gradually declines along with increasing of the number of welding layers. According to the part manufacturing equipment and method combining laser cutting with electromagnetic welding, the cost can be reduced, the machining time duration can be shortened, and applicability on parts with various size ranges is good.

Owner:HONG KONG PRODUCTIVITY COUNCIL

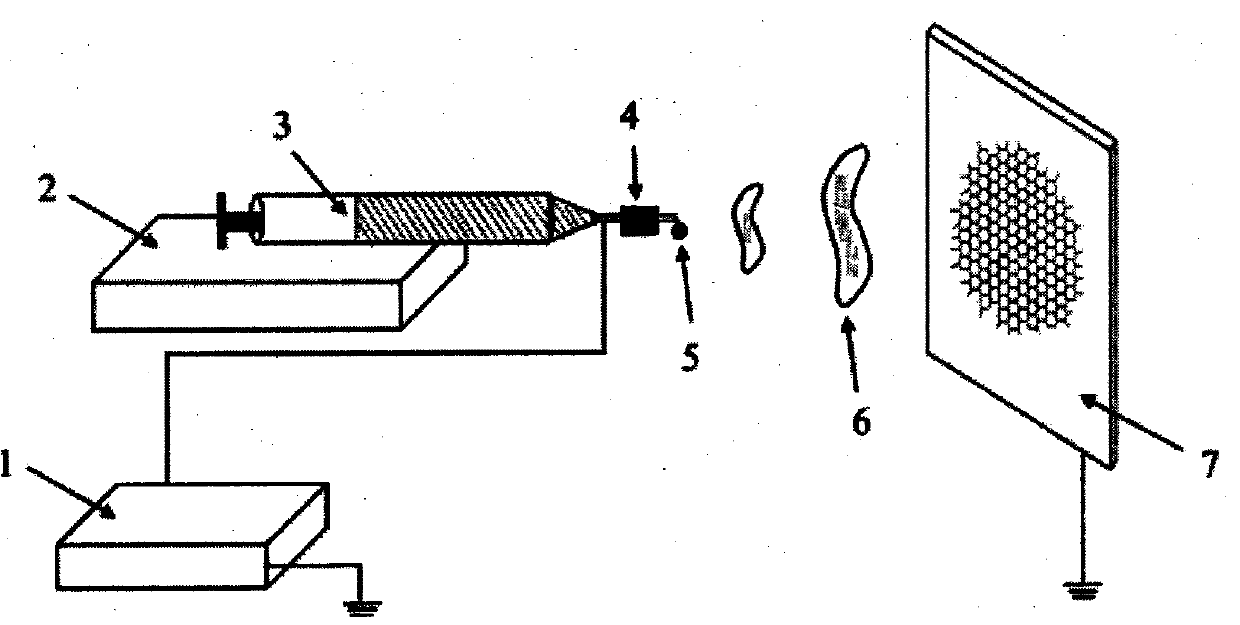

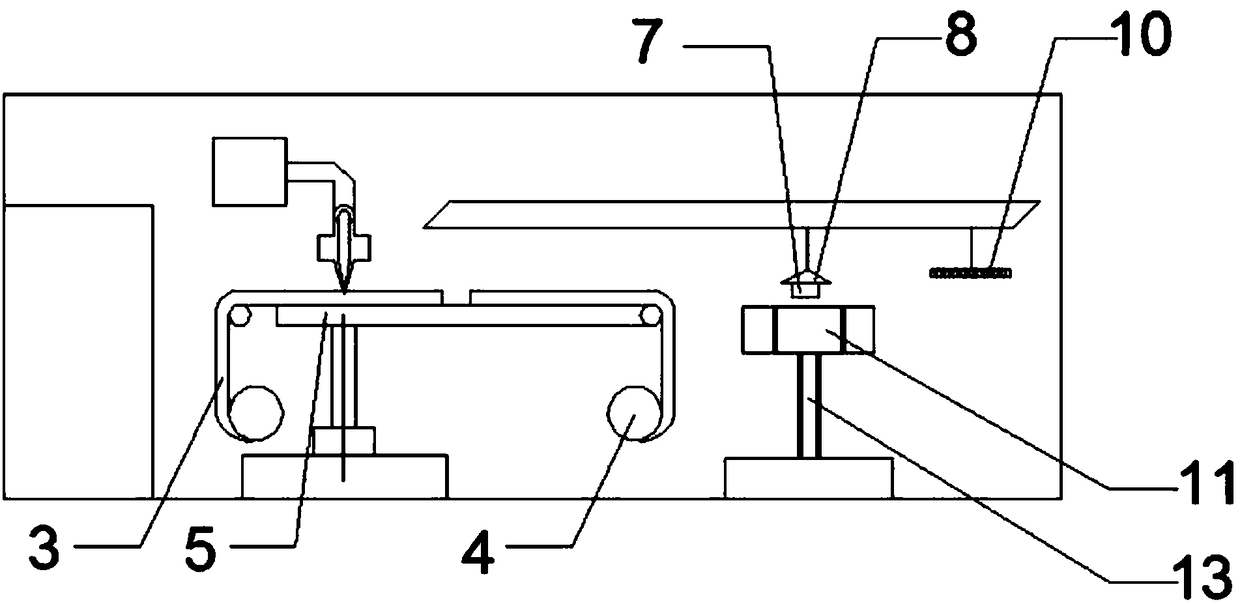

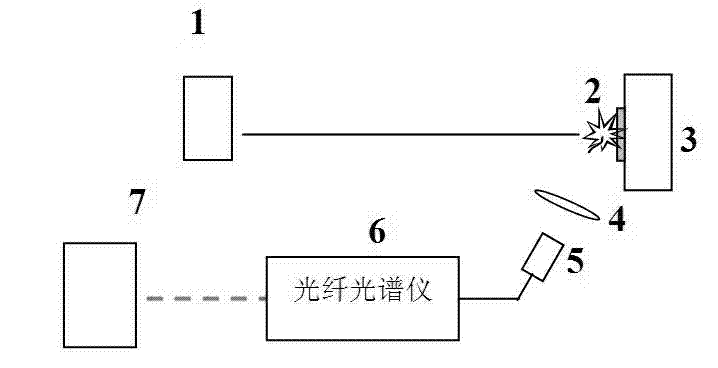

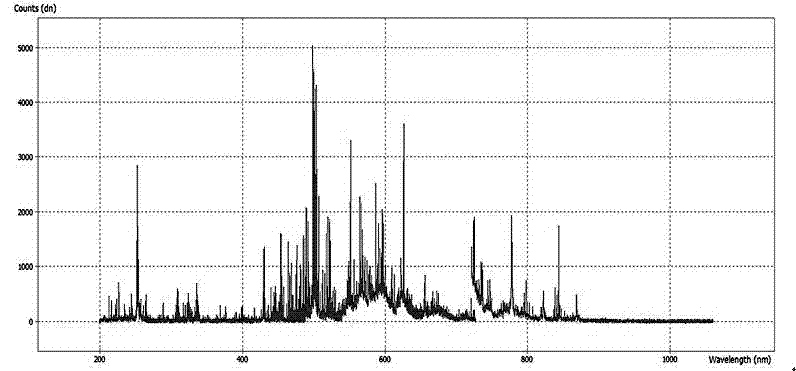

Discrimination method for laser damage on the surface of a film or an optical element and determination device thereof

InactiveCN102226764AImprove discrimination accuracyEliminate false positivesAnalysis by material excitationTest efficiencyFiber

The invention relates to a discrimination method and determination device for laser damage on the surface of a film or an optical element and a determination device therof. The prior art has the disadvantages of strong subjectivity, great working intensity and low testing efficiency. The invention provides a discrimination method for laser damage on the surface of a film or an optical element. According to the method, an operating laser beam carries out monopulse laser irradiation on a sample; if the surface of the sample has no damage, the surface does not produce plasma flash; if the surface is damaged, strong plasma flash is generated the moment the damage appears, and if a photoluminescence peak of an element not being N, O, H or C appears according to analysis of a flash spectrum, appearance of damage can be determined. The invention also discloses a determination device realizing the above-mentioned method. The device comprises a laser generator and a test board and is characterized by further comprising a convergent lens and a fibre-optical probe on the imaging surface of the convergent lens, wherein the fibre-optical probe, a fiber spectrometer and a computer are connected sequentially. According to the invention, high precision in the discrimination is obtained; the discrimination speed is fast; a wide variety of films can be discriminated; the construction of the determination device is simple.

Owner:XIAN TECHNOLOGICAL UNIV

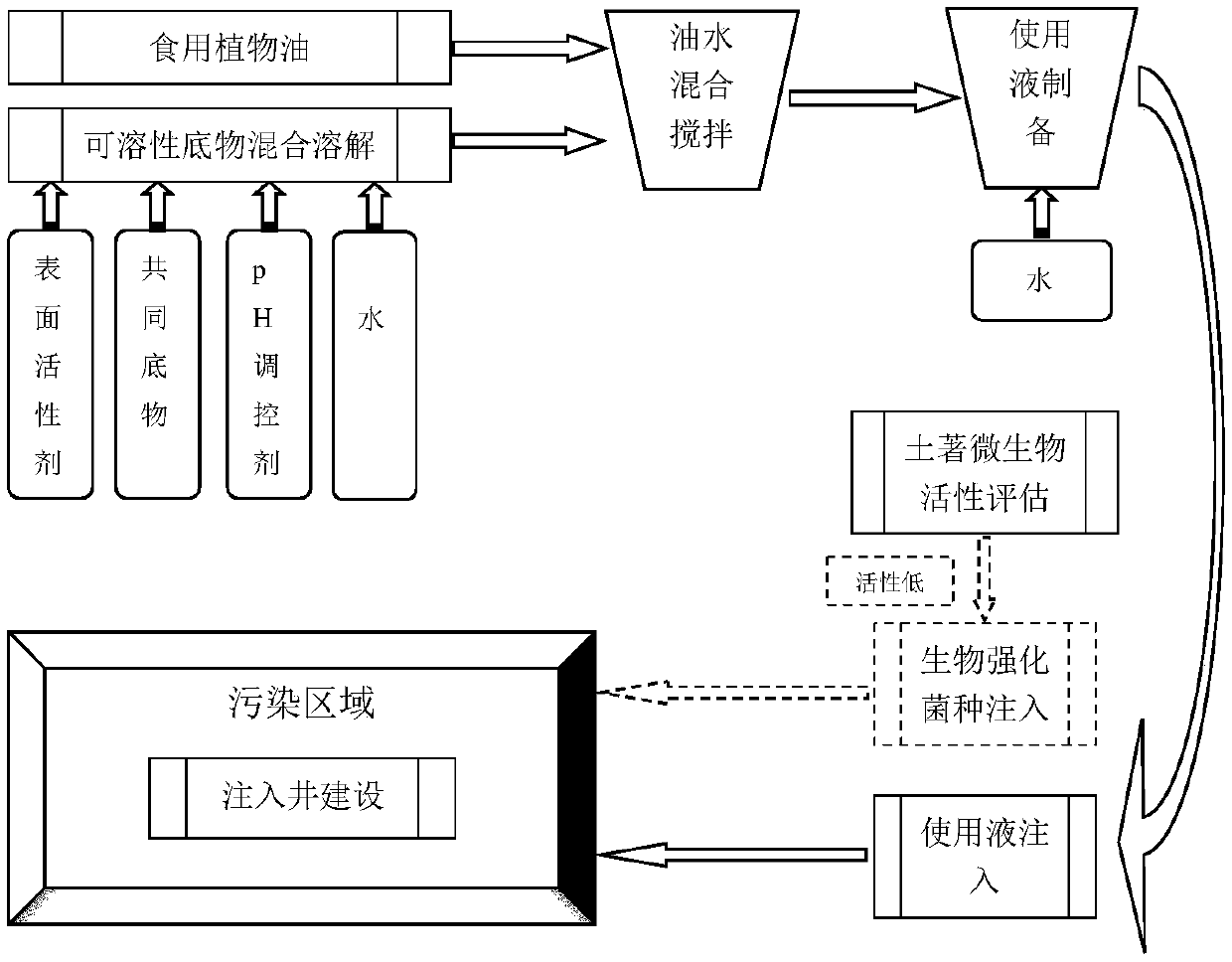

Emulsified vegetable oil as well as preparation method and application thereof

InactiveCN109534517AQuick effectWide varietyWater contaminantsFatty-oils/fats refiningVegetable oilGroundwater remediation

The invention belongs to the technical field of underground water remediation, and particularly relates to emulsified vegetable oil as well as a preparation method and application thereof. The emulsified vegetable oil is prepared from the following components in percentage by weight: 45 to 75 percent of edible vegetable oil, 2 to 12 percent of a surfactant and 20 to 45 percent of water and is alsoprepared from an optional common substrate and / or a pH (Potential of Hydrogen) regulator. The preparation method of the emulsified vegetable oil comprises the following steps of: mixing and dissolving of a soluble substrate, mixing and stirring of oil and water, and the like. An application method of the emulsified vegetable oil comprises the following steps of: injection well building, emulsified oil working solution preparation, indigenous microorganism activity evaluation, emulsified oil working solution injection and the like, thus realizing standardized remediation of chlorinated organicmatter polluted underground water. After the emulsified vegetable oil prepared by the invention is injected, the effect can be quickly obtained and is stable and lasting, and the emulsified vegetableoil can continuously take effect within 3 to 5 years after injecting once and requires no continuous addition for a long term; the technology is reasonable, raw materials are easy to obtain, the costis low, popularization and implementation are easy, and the environmental benefit, the economic benefit and the social benefit are good.

Owner:BEIJING GEOENVIRON ENVIRONMENT RESTORATION CO LTD

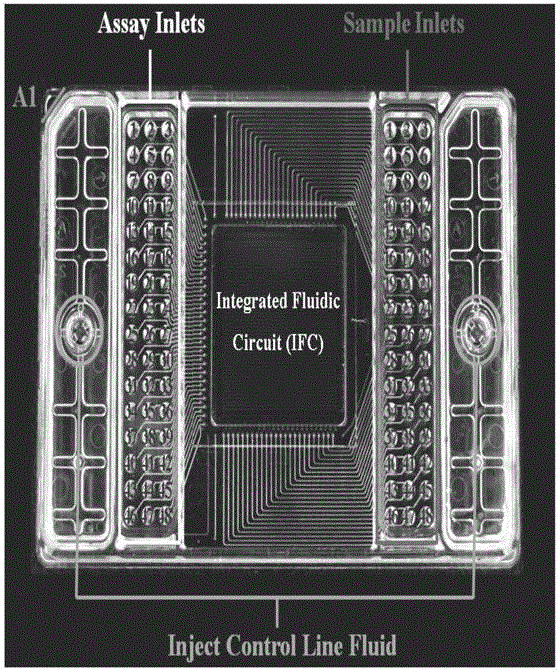

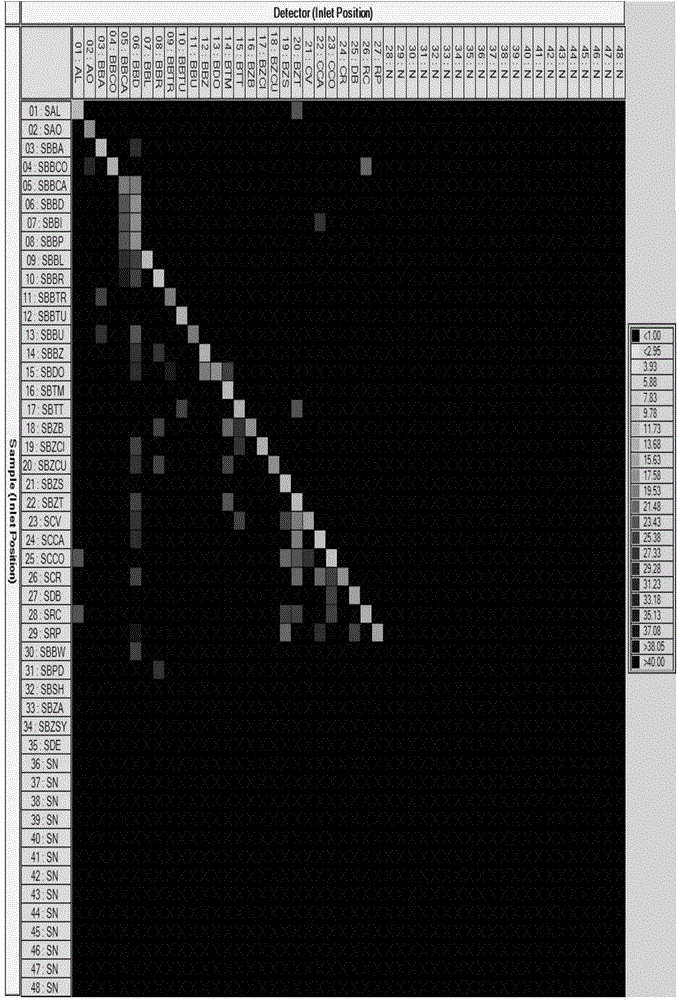

Integrated fluidic chip for identification of fruit fly type and use thereof

ActiveCN104894237AWide varietyMeet needsNucleotide librariesMicrobiological testing/measurementMolecular identificationDiffusion

The invention discloses an integrated fluidic chip for identification of a fruit fly type and a use thereof. The integrated microfluidic chip comprises specific primers for fruit fly type identification and a TaqMan-MGB probe. The invention provides a fruit fly type molecular identification technology utilizing the integrated fluidic chip. A test proves that the integrated microfluidic chip-based molecular identification technology realizes fast identification of a fruit fly type, has good specificity, high flux, a low cost and simple processes, realizes identification of a type of non-adult fruit fly or fruit fly adult residual body, provides a fast identification tool and technology for import and export plant quarantine and nationwide fruit fly epidemic monitoring, effectively prevents invasion and diffusion of dangerous fruit fly, protects agricultural production and ecological safety and promotes trade and economic development in China.

Owner:CHINA AGRI UNIV +1

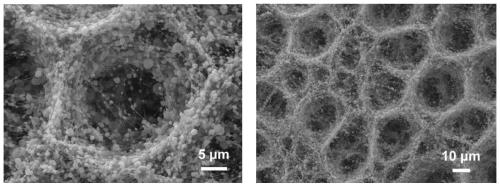

High-specific-surface-area honeycomb-like structure nano fiber material and preparing method thereof

ActiveCN111575917AExcellent one-way moisture directionGood moisture absorption and quick drying effectElectro-spinningNon-woven fabricsSpinningElectrospinning

The invention relates to a high-specific-surface-area honeycomb-like structure nano fiber material and a preparing method thereof. The preparing method comprises the steps that a polymer solution in which a nanoscale metal-organic framework is scattered is subjected to electrostatic spinning, an insulating material subjected to charge eliminating treatment serves as a receiving base material, andthe high-specific-surface-area honeycomb-like structure nano fiber material is prepared; and the finally-prepared material has a certain thickness and is of a three-dimensional honeycomb-like communication hole way structure microcosmically, a hole way is a conical direct-through hole way, the big-end hole diameter of the hole way is 20-100 microns, the small-end hole diameter of the hole way is 5-25 microns, single fiber is in a moniliform shape and is rough and porous, and the specific surface area is 600 m<2> / g. According to the high-specific-surface-area honeycomb-like structure nano fibermaterial and the preparing method thereof, a template is not needed, the nano fiber material with the three-dimensional honeycomb-like communication hole way structure can be prepared through one step, the prepared honeycomb-like structure nano fiber material has the conical direct-through hole way so that water vapor can be rapidly transmitted in an oriented manner in the thickness direction, oriented fiber communicating in the hole way effectively promotes horizontal diffusion of water, and wide application prospects are achieved in the fields of water guiding and dehumidification.

Owner:DONGHUA UNIV

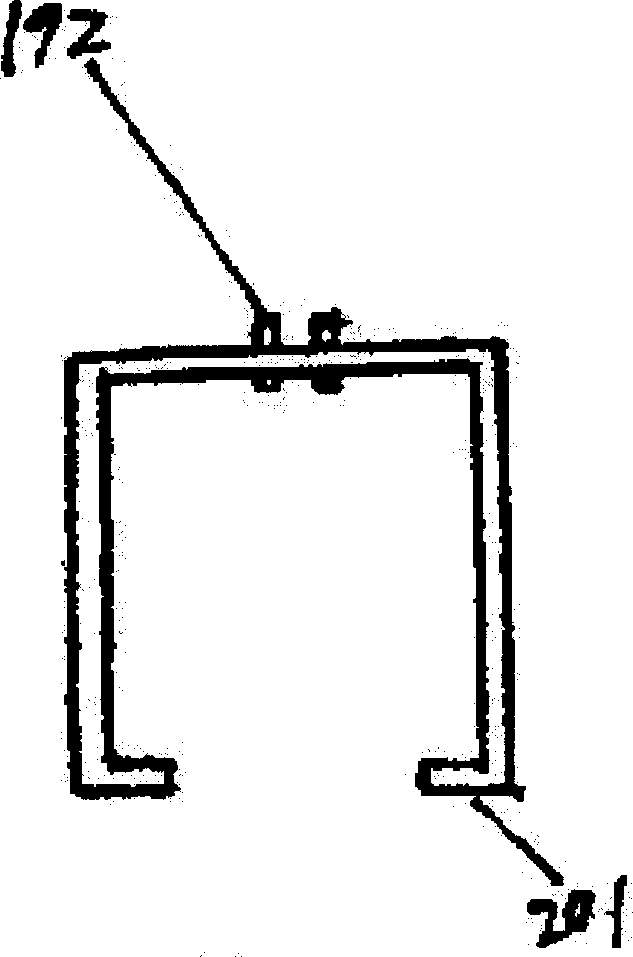

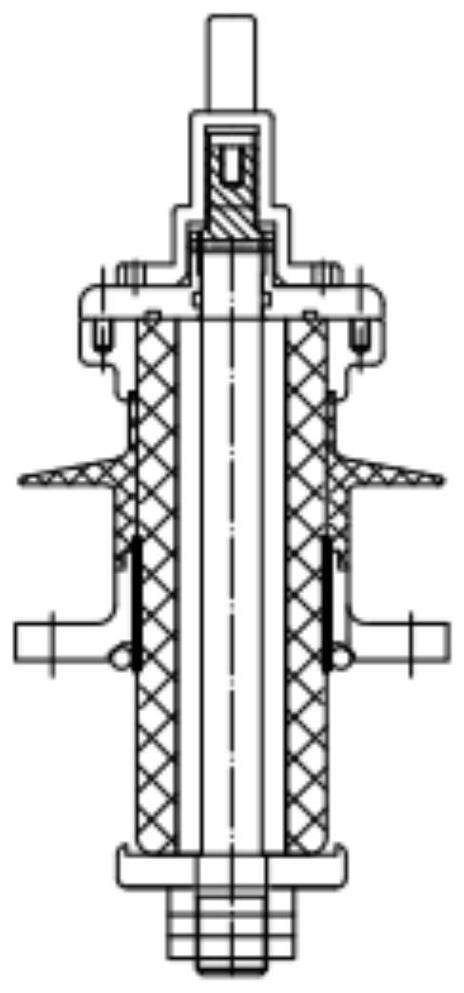

Novel dry-type bush for electric power system

PendingCN112863786AReduce manufacturing costImprove electrical performanceTransformers/inductances coils/windings/connectionsInsulating bodiesEpoxyGlass fiber

The invention discloses a novel dry-type bush for an electric power system. According to the invention, a main insulation core is made of an insulation pipe formed by dipping glass fiber yarns in epoxy resin and conducting pultrude moulding; a semiconductor material is sprayed on the inner cavity wall of the main insulation core, and an equipotential surface is formed on the inner cavity wall of the main insulation core; a current-carrying conducting rod is arranged in the main insulation core in a penetrating manner and is connected with the equipotential surface; a groove is formed in the outer wall of the main insulation core; carbon fibers impregnated with epoxy resin are wound in the groove; a mounting flange is glued on the grounding electrode; a silicon rubber umbrella cover is arranged on the main insulation core; an air end electrode of the grounding electrode is wrapped in the silicon rubber umbrella cover; and a conductive joint and a voltage-sharing ball are respectively installed on two sides of the main insulation core. A wide variety range of bushes can be made in the invention; the voltage levels of the bushes may be in a range of 380V-550kV or higher; the current levels of the bushes may be from several amperes to tens of thousands of amperes; the bushes can be used for an alternating-current power system and a direct-current power system; manufacturing cost is low; and explosion risks are avoided.

Owner:安徽智达电气科技有限公司

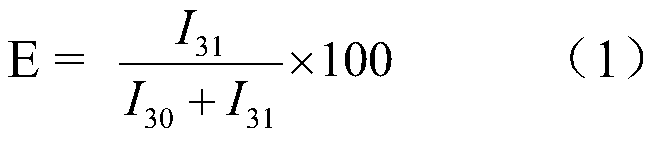

Sample preparation method used for determining abundance of <15>N isotope of nitrite

ActiveCN110763535AWide varietyMeet testing needsPreparing sample for investigationMaterial analysis by electric/magnetic meansNitriteIsotope

The invention relates to a sample preparation method used for determining abundance of a <15>N isotope of nitrite. The sample preparation method comprises the following steps: loading a sample, namelyloading a <15>N-labeled to-be-prepared sample and aqueous solution of a reducing agent into a first bulb of a double bulb reaction tube, and loading an acidic material into a second bulb of the double bulb reaction tube; preparing a <15>NO gas, namely maintaining vacuum degree, and adding the acidic material in the second bulb into the first bulb, so that the <15>NO gas is generated; detecting, namely after the vacuum degree of a pipeline between a vacuum plug valve and a gas isotope ratio mass spectrometer is reduced to be below 2*10<-5>Pa, opening the vacuum plug valve, and introducing the<15>NO gas in the first bulb into the gas isotope ratio mass spectrometer; setting detection parameters of the gas isotope ratio mass spectrometer, detecting a relative intensity when mass numbers are30 and 31, and performing a parallel test for multiple times; and calculating an abundance value of the <15>N isotope. Compared with the prior art, the sample preparation method provided by the invention has the advantages that an operation process is safe and reliable, sample pretreatment time is greatly shortened, economic cost is low and test data accuracy and precision are high.

Owner:SHANGHAI RES INST OF CHEM IND

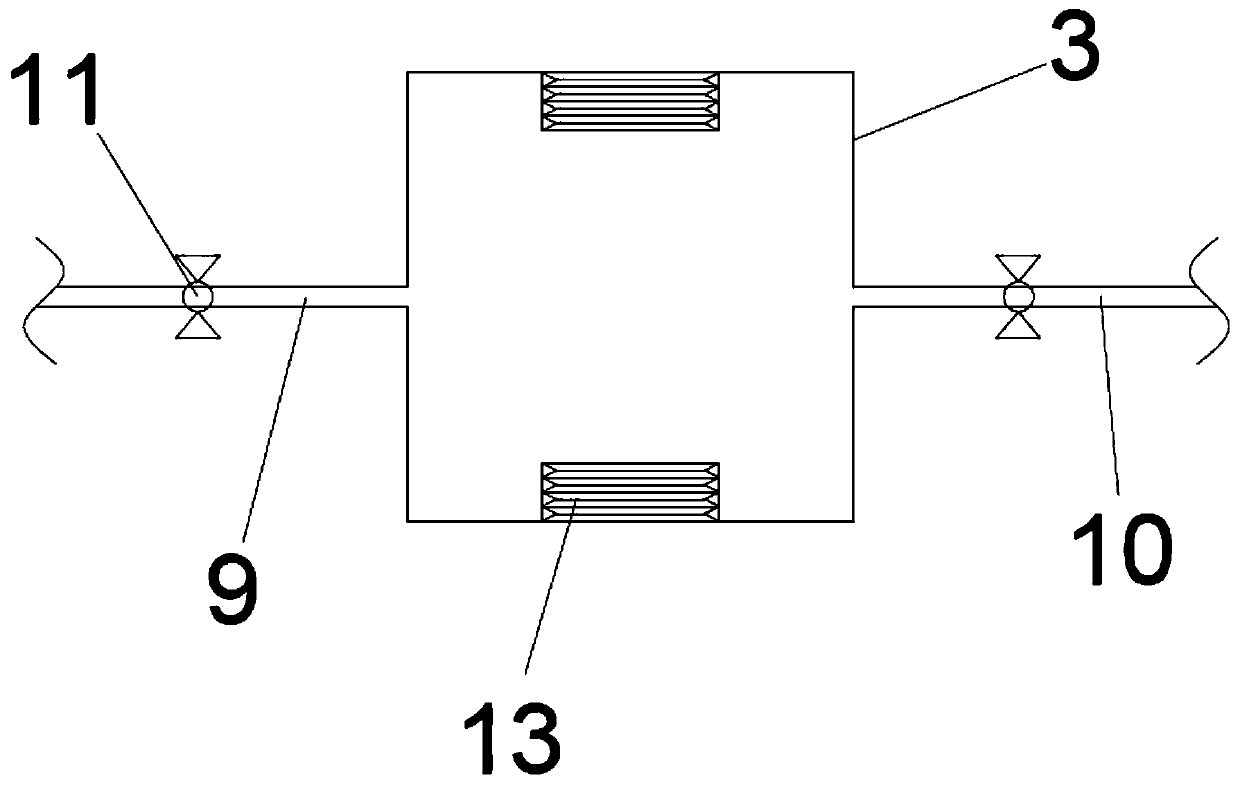

Fabric weft straightening or weft straightening and pattern straightening mechanism and method

PendingCN111826925AGood correction effectCorrect crookednessInspecting textilesStretchingWoven fabricEngineering

The invention discloses a fabric weft straightening or weft straightening and pattern straightening mechanism and method. The fabric weft straightening or weft straightening and pattern straighteningmechanism comprises a correcting mechanism, a detecting mechanism and a central processing unit. The correcting mechanism comprises a first spreading roller, a second spreading roller and multiple correcting rollers. The first spreading roller is driven by a first motor, the second spreading roller is driven by a second motor, and the multiple correcting rollers are driven by a driving mechanism.The first spreading roller is arranged on one side of fabric in the width direction, the second spreading roller is arranged on the other side of the fabric in the width direction, and the multiple correcting rollers are arranged in front of the first spreading roller and the second spreading roller along the fabric running route. The detecting mechanism is arranged in front of and / or behind the first spreading roller and the second spreading roller along the fabric running route. The first motor, the second motor, the driving mechanism and the detecting mechanism are controlled by the centralprocessing unit. According to the fabric weft straightening or weft straightening and pattern straightening mechanism and method, the correction control can be conducted in real time, the correctionresponse speed is high, the fabric is not damaged in the correction process, the use cost is low, the applicable textile variety range is wide, the correction precision is high, and the effect is better.

Owner:CHANGZHOU HONGDA INTELLIGENT EQUIP IND DEV RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com