Patents

Literature

77results about How to "With recycling function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

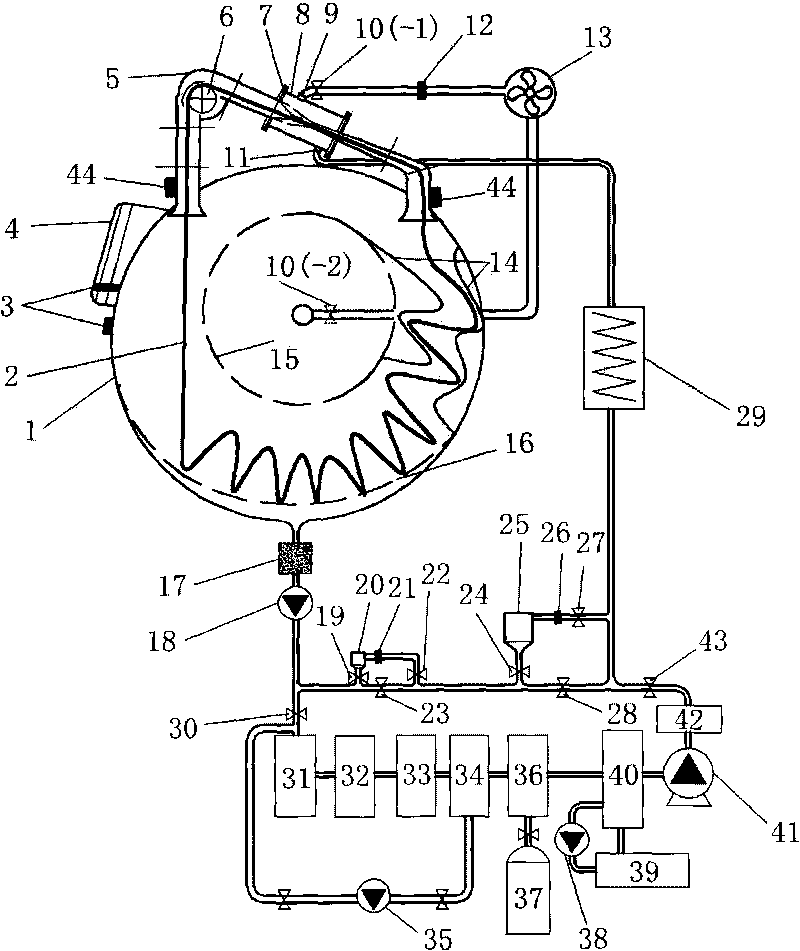

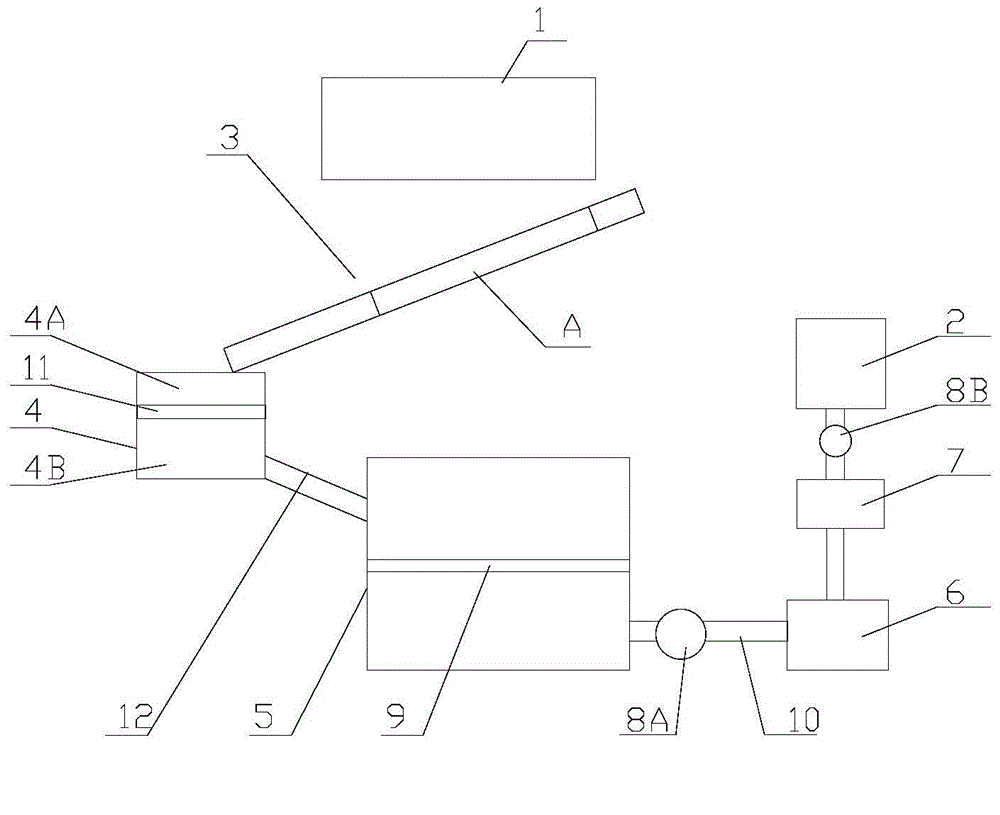

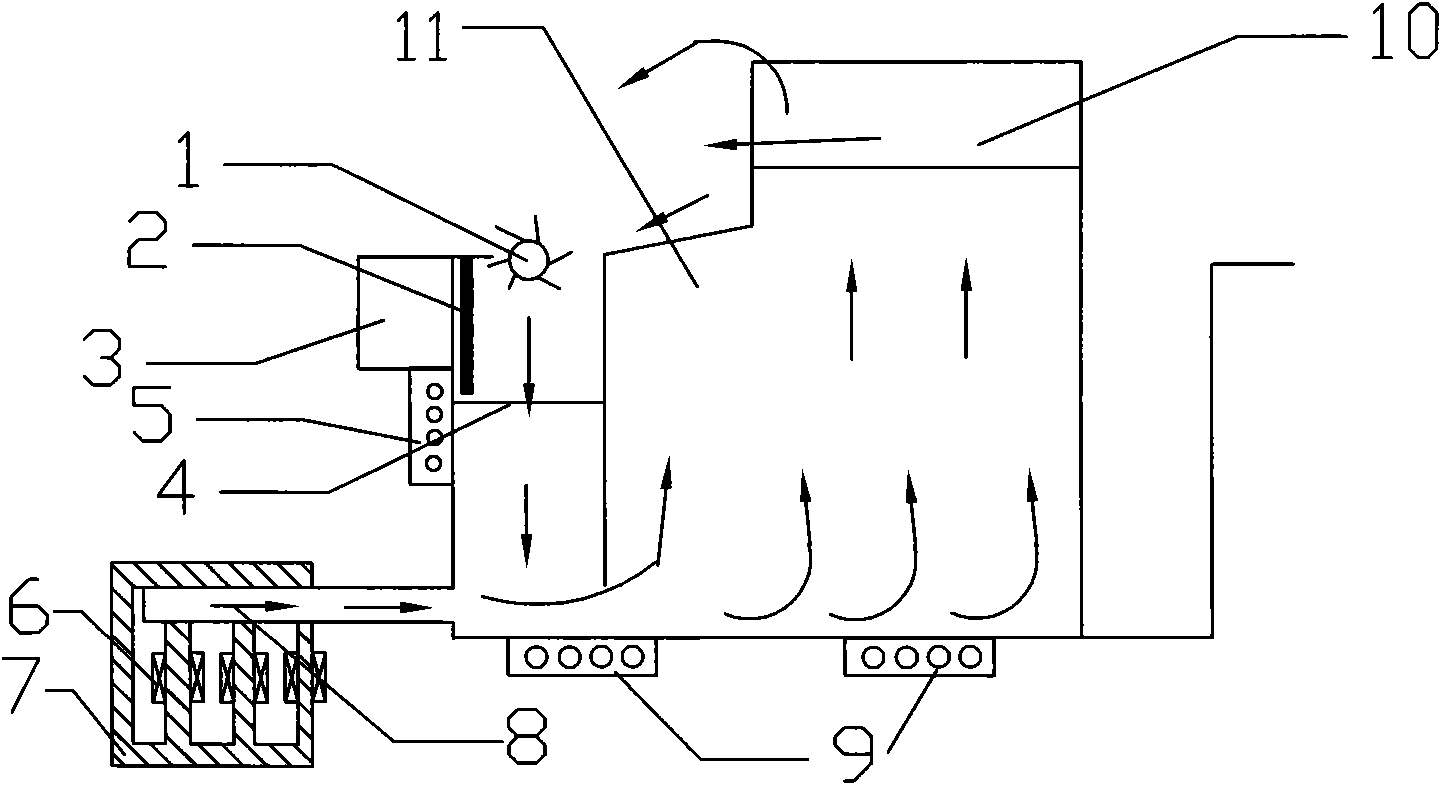

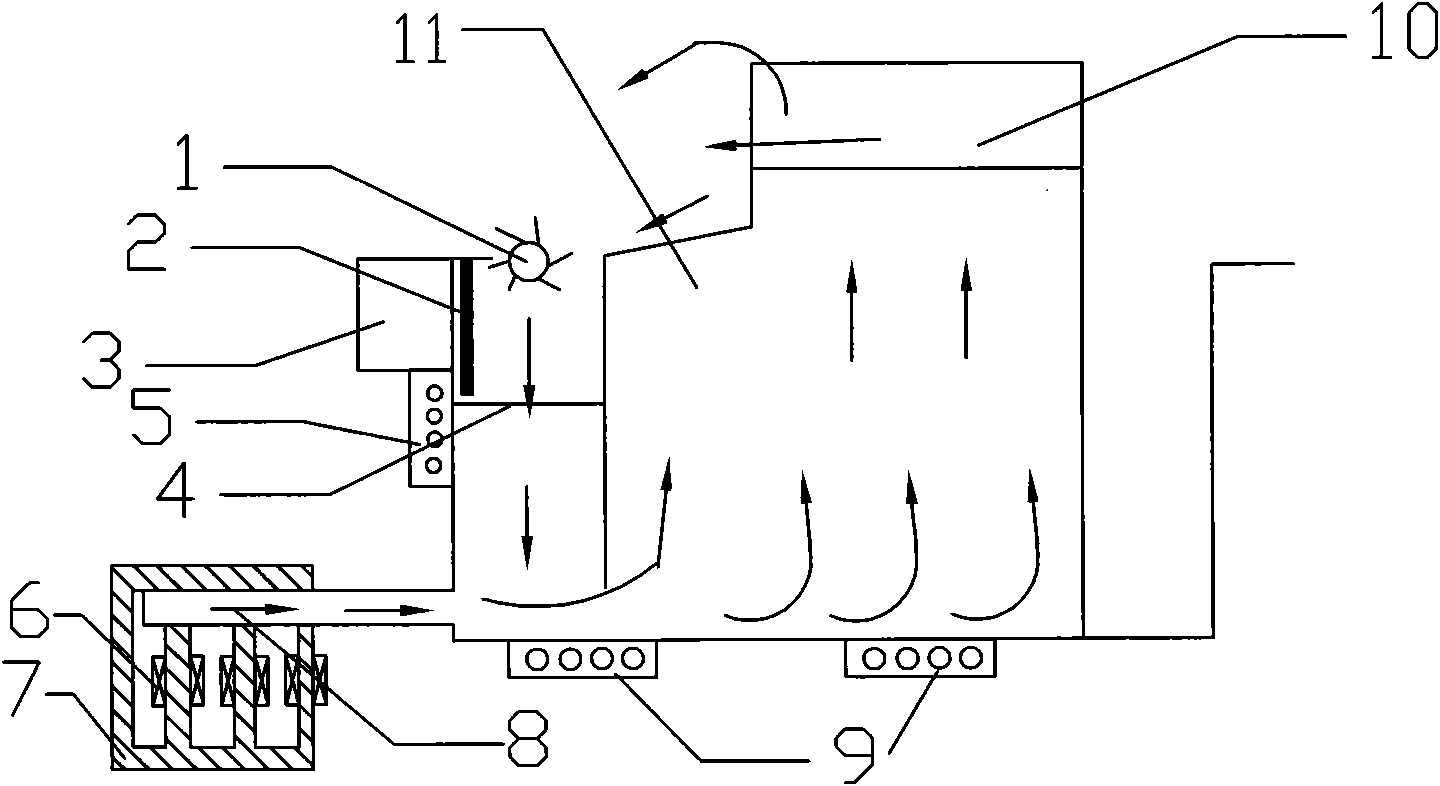

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

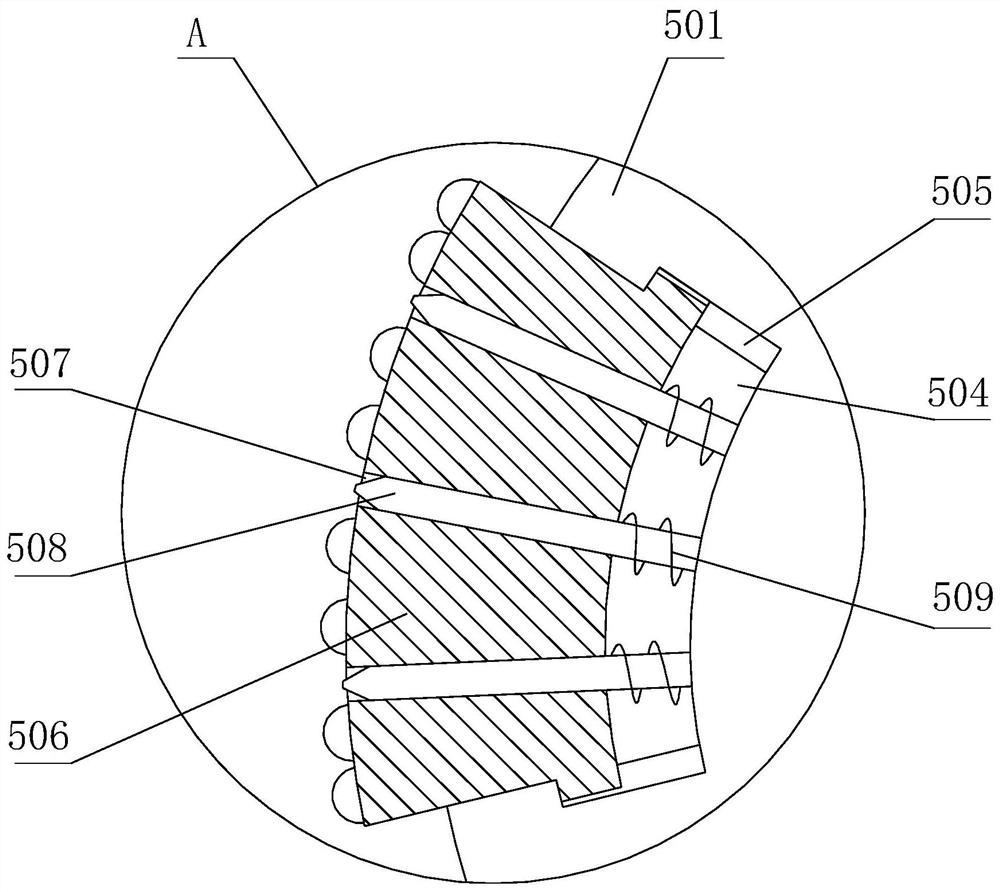

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

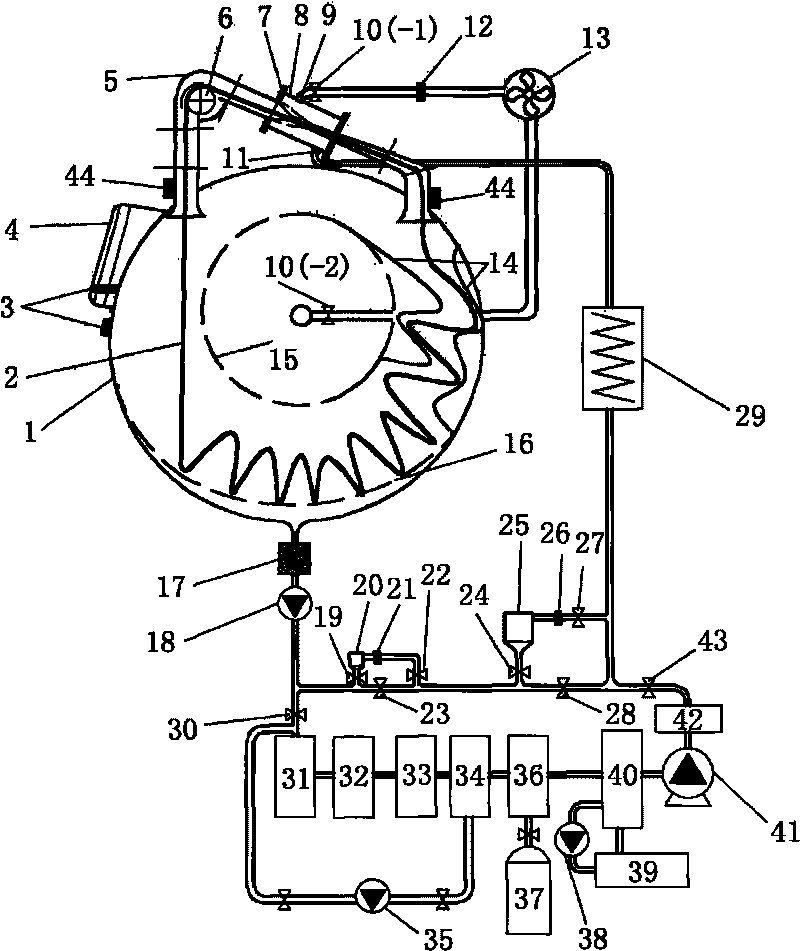

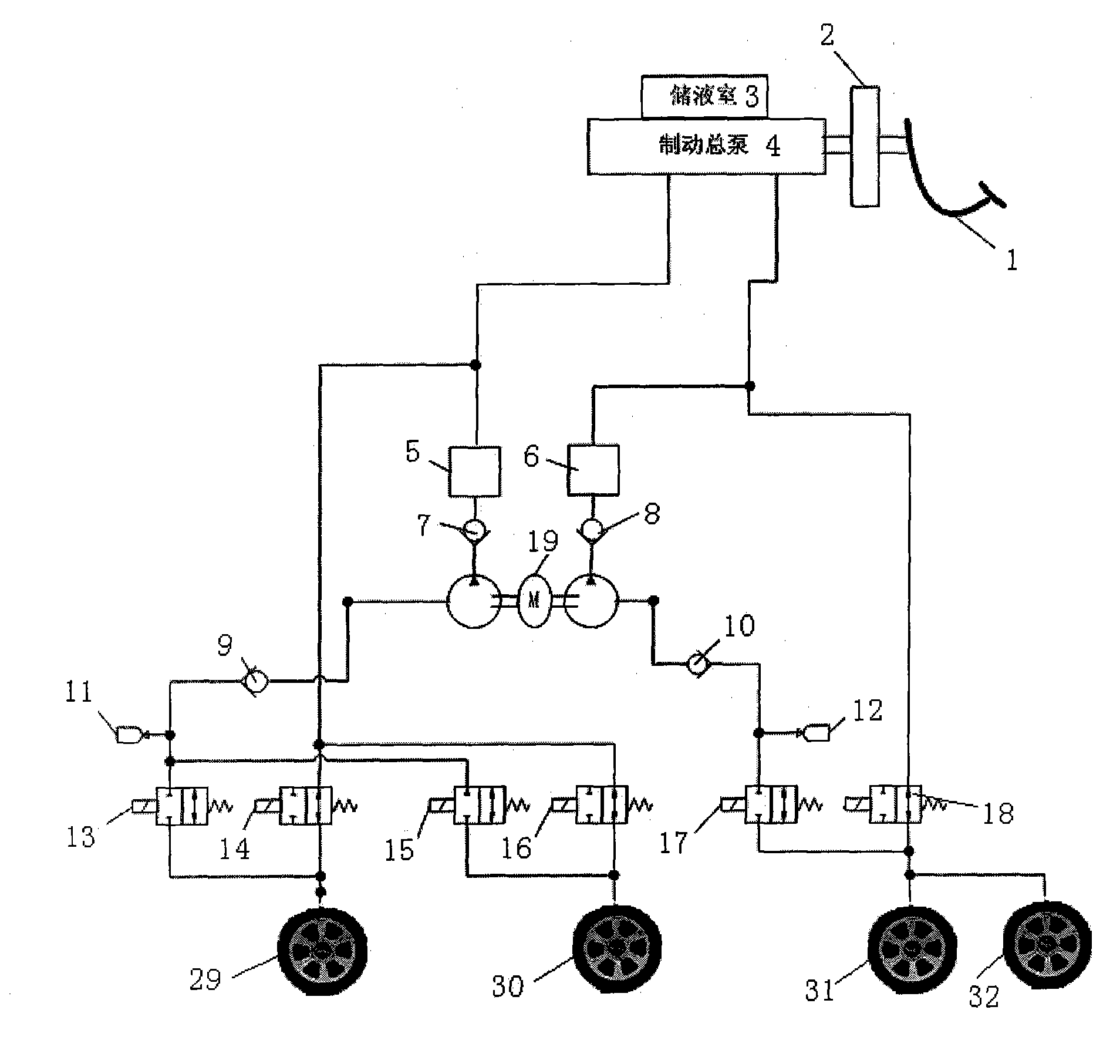

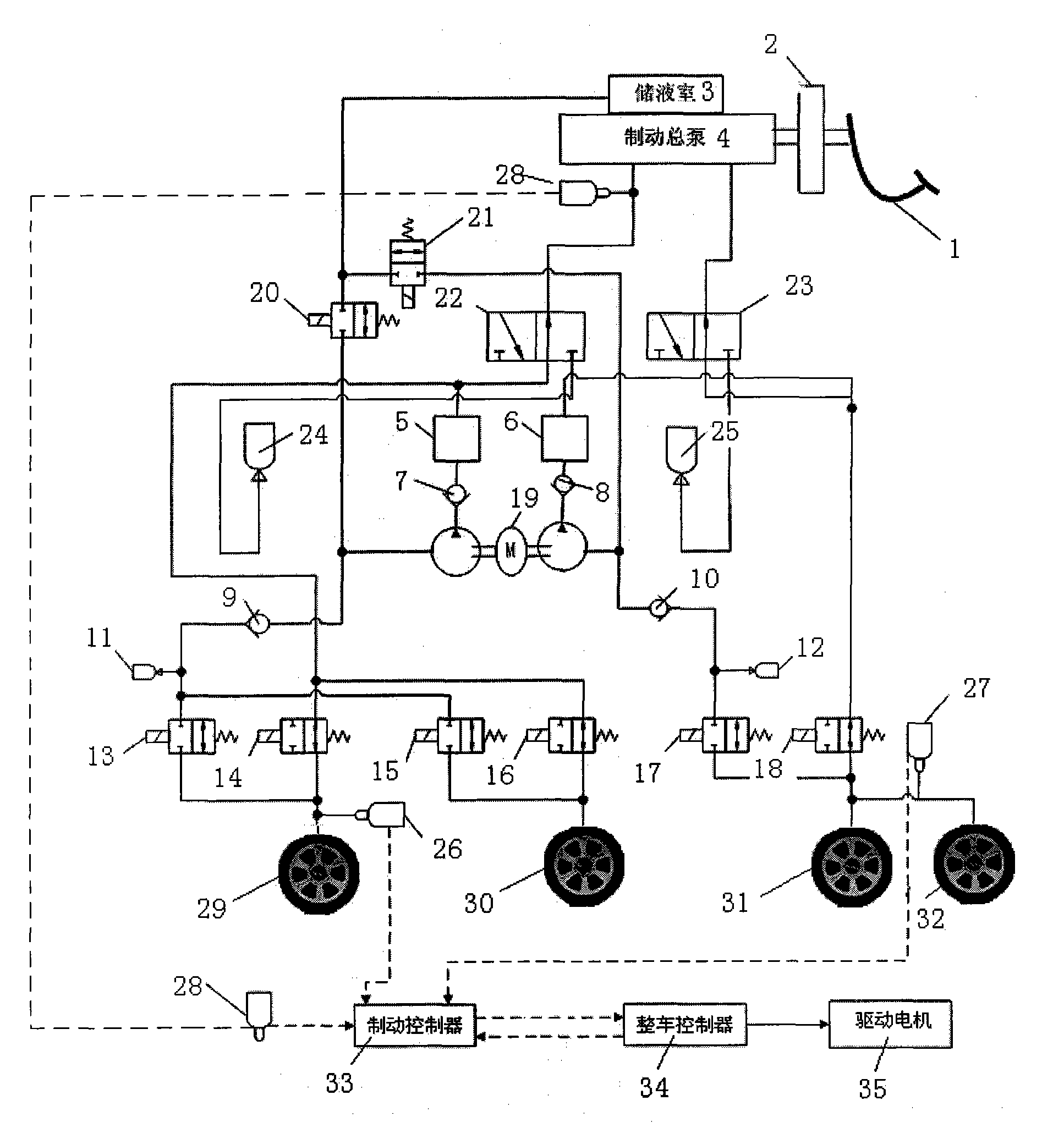

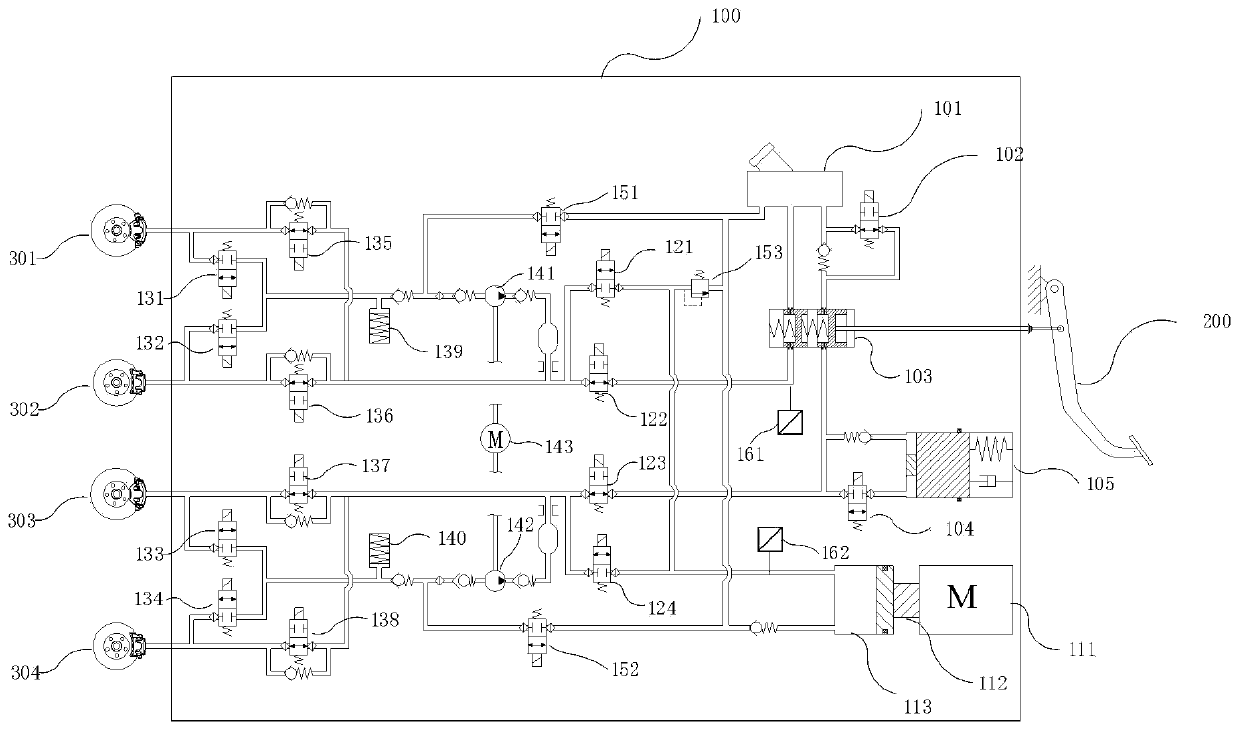

Hydraulic braking system of four-wheel driven electric vehicle

ActiveCN101941430AWith recycling functionRealize the recycling functionBraking action transmissionDriving safetyDriving range

The invention discloses a hydraulic braking system of a four-wheel driven electric vehicle. Based on the conventional hydraulic braking system, the system has the following characteristics that: 1, a selector valve and a master cylinder brake pressure sensor are arranged in front of a high-pressure damper on a brake pipeline led out of a master brake pump, a pipeline is connected from an outlet of the selector valve, and a medium pressure energy accumulator is arranged; another selector valve is arranged in front of the high-pressure damper on another brake pipeline, a pipeline is connected from the outlet of the selector valve, and a medium pressure energy accumulator is arranged; 2, two pipelines are led out of a liquid storage chamber and communicated with two one-way valves, and a switching electromagnetic valve is arranged on the pipeline; and 3, a wheel cylinder brake pressure sensor is connected at a left front wheel cylinder and a right rear wheel cylinder respectively. The system can ensure the same feeling of brake pedal as that of the conventional hydraulic braking system; the braking energy recovery efficiency reaches the maximum; and an ABS function can also be realized; and the driving safety is ensured and the driving range of an electrically-propelled vehicle is widened.

Owner:TSINGHUA UNIV

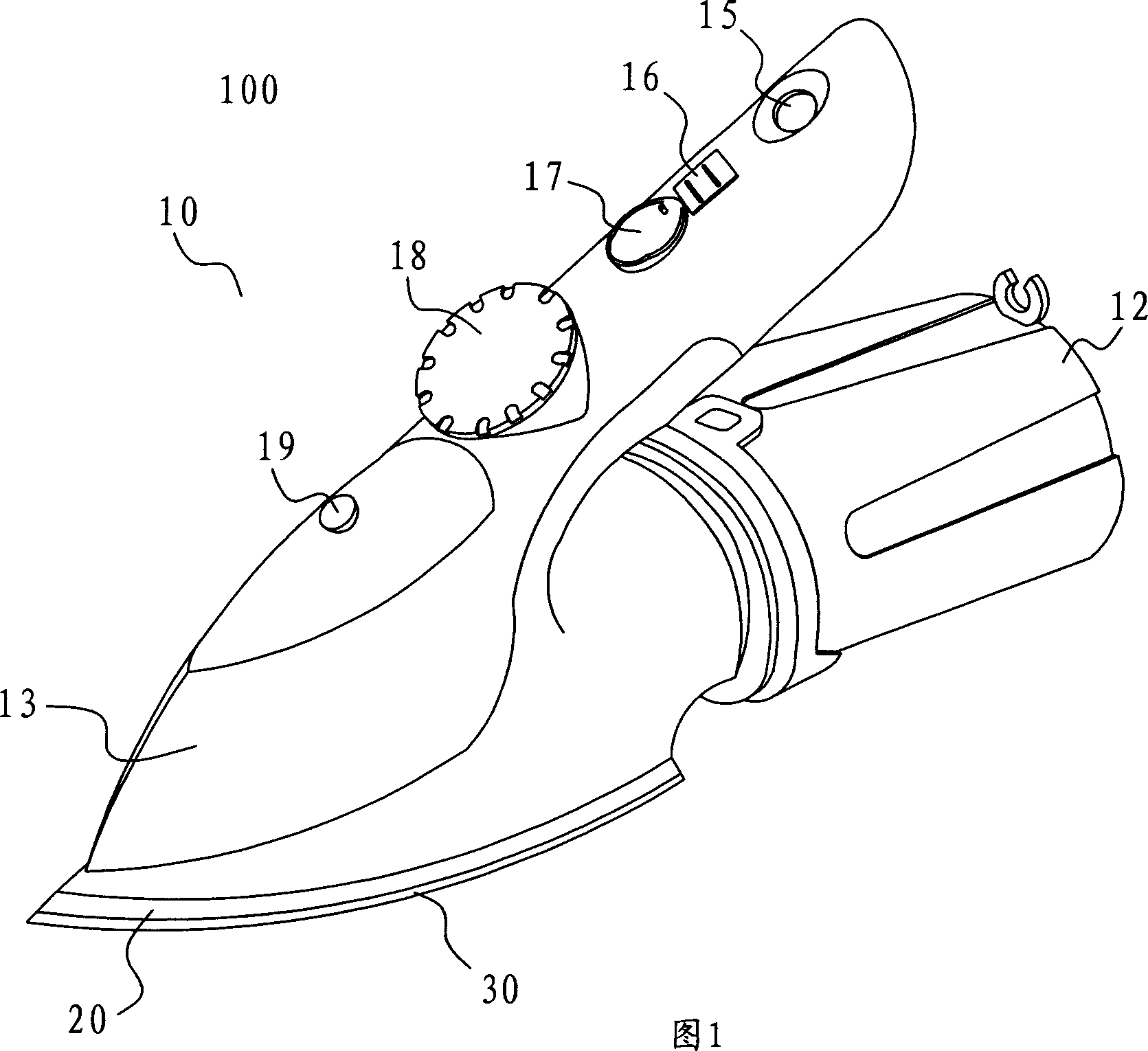

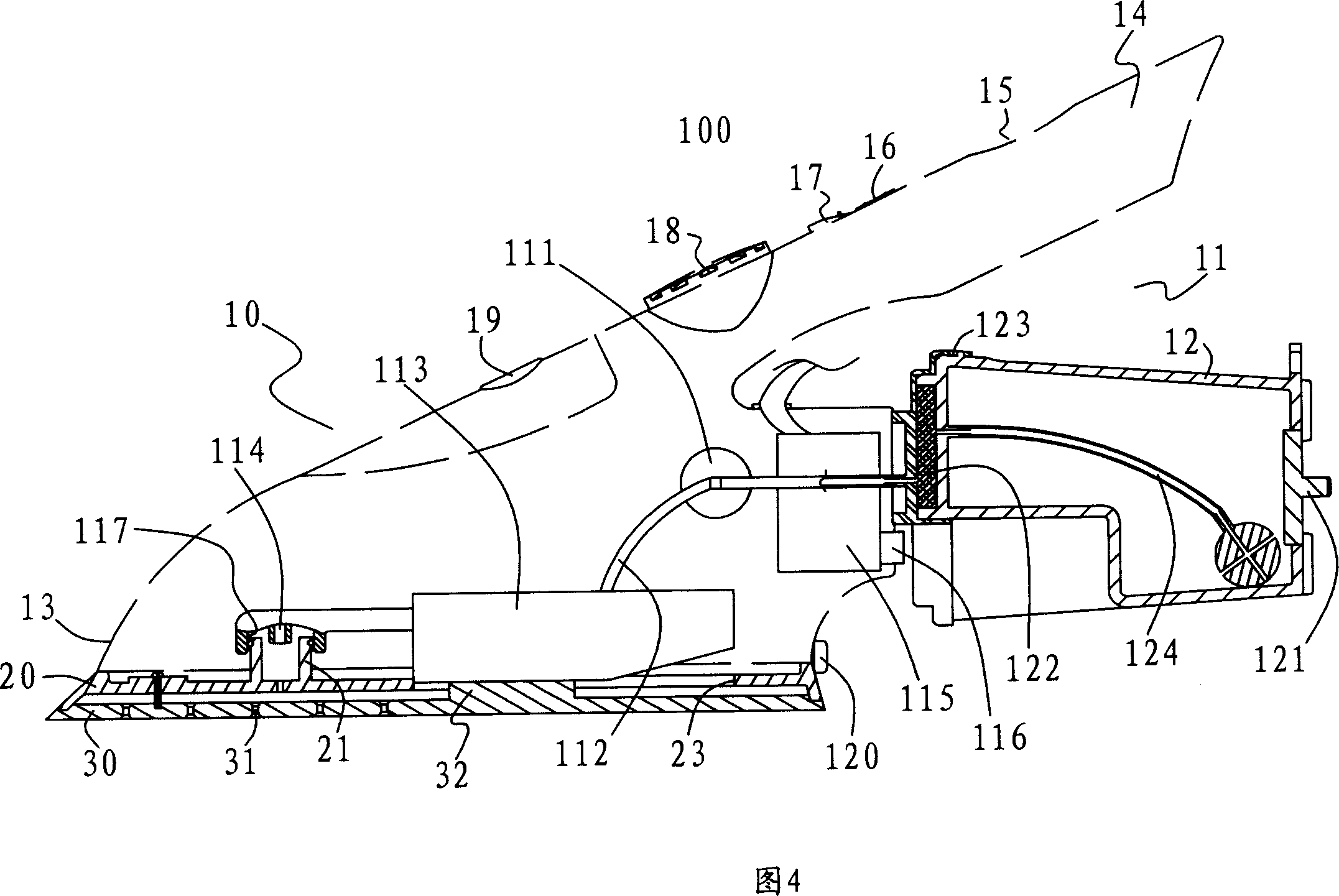

Steam cleaner

InactiveCN1981944ASimple structureWith recycling functionIroning apparatusTextiles and paperEngineeringVacuum cleaner

A steam cleaner has a main body consisting of a casing and a water supply system comprising liquid cylinder, pipeline with filter and heater for evaporating said liquid to obtain steam, a selective constant-pressure block aided switch for controlling the generation of high-temp steam, a connector, and a steam spraying- recovering head.

Owner:吴连宝

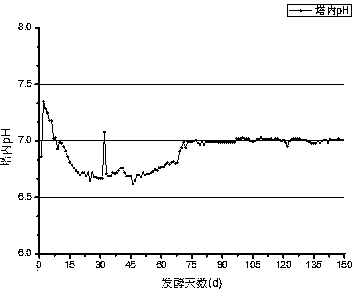

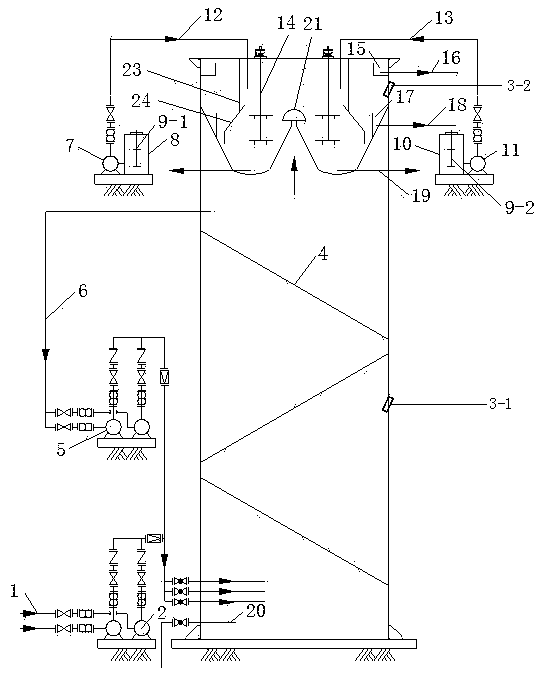

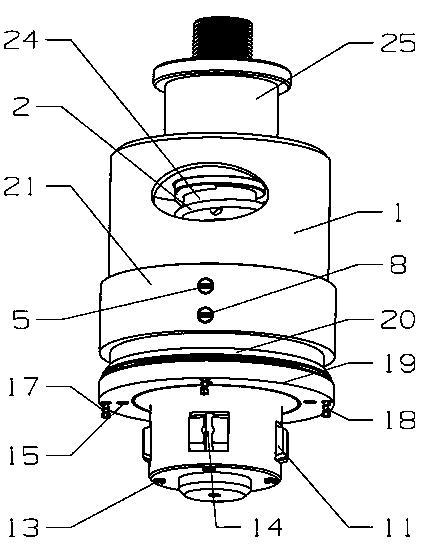

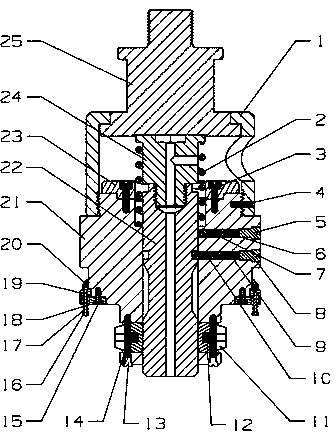

Anaerobic fermentation device with struvite recycling function and fermentation acid production method thereof

ActiveCN104003596AWith recycling functionEfficient recyclingBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeStruvite Crystals

The invention discloses an anaerobic fermentation device with a struvite recycling function. The anaerobic fermentation device comprises a tank body, wherein the tank body is internally provided with a sludge internal circulation structure and a struvite recycling structure; the sludge internal circulation structure comprises an internal circulation tube, an internal circulation pump and a sludge inlet tube; the struvite recycling structure comprises a basin-shaped structure, an inverted funnel-shaped structure, a stirring machine, an alkali liquid input device and a magnesium source liquid input device and various discharge tubes. According to a method for utilizing the anaerobic fermentation device with the struvite recycling function to ferment to produce acid, the pH value is stabilized and the nitrogen and the phosphorus in a fermented liquid are recycled by controlling the sludge feeding amount and the circulation amount every day. According to the anaerobic fermentation device with the struvite recycling function and the fermentation acid production method disclosed by the invention, the pH value in the anaerobic fermentation process is stable, the fermentation efficiency is high, the nitrogen and the phosphorus in the fermented liquid can be effectively removed, and then struvite crystal with relatively high purity can be collected, so that the method is an economic and efficient sludge treatment method and has good social and economic benefits.

Owner:SUZHOU UNIV OF SCI & TECH

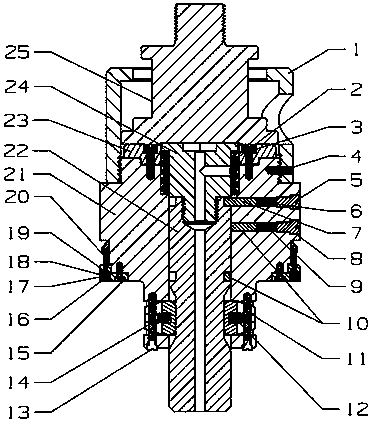

Underwater steel wire rope operation equipment with releasing and withdrawing functions

The invention relates to underwater steel wire rope operation equipment with releasing and withdrawing functions. The underwater steel wire rope operation equipment is characterized by comprising a main sleeve, the upper end of the main sleeve is connected with a connecting sleeve, the connecting sleeve is connected with a top joint in a sleeving manner, a mandrel is mounted in a center through hole of the main sleeve, the upper end of the mandrel is connected with a mandrel cap and sleeved with a mandrel spring, the upper end and the middle of the mandrel are provided with an upper pin slot and a lower pin slot, an upper radial spring pin and a lower radial spring pin are arranged in the middle of the main sleeve and used for matching with the upper and lower pin slots, a lower neck bush is arranged at the lower end of the main sleeve, square slots are formed in the periphery of the lower neck sleeve, elastic locking blocks are disposed in the square slots, and the rear ends of the elastic locking blocks are matched with the outer peripheral surface of the lower end of the mandrel and grooves formed in the middle-lower portion of the mandrel respectively to realize springing out or retracting of the elastic locking blocks. The underwater steel wire rope operation equipment is compact in structure and reasonable in arrangement; axial movement opportunity and distance of the mandrel can be controlled accurately to realize connection and disconnection with the underwater equipment; the equipment is simple to mount and demount, reliable in connection and convenient to use and operate.

Owner:KINGDREAM PLC CO +1

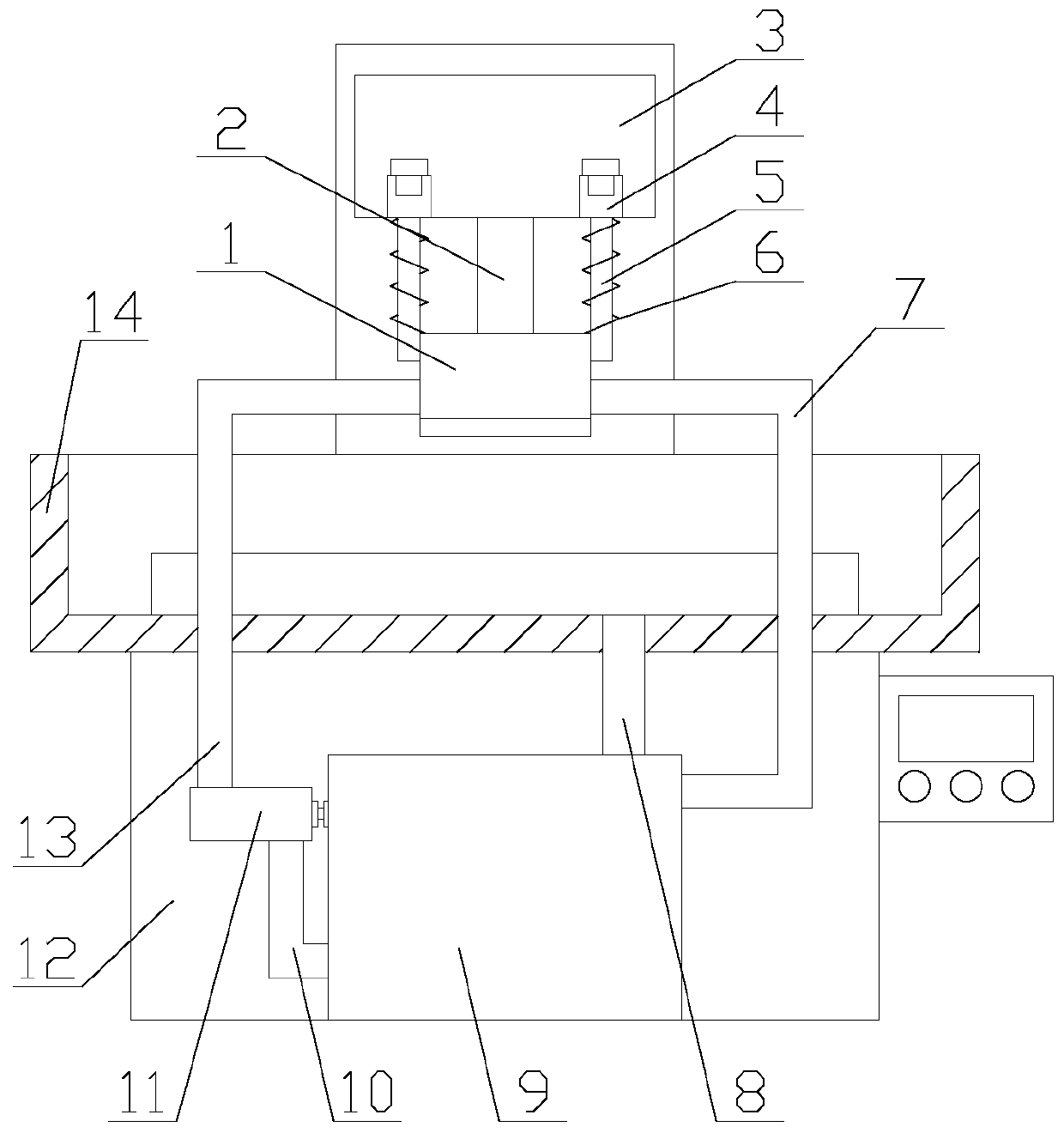

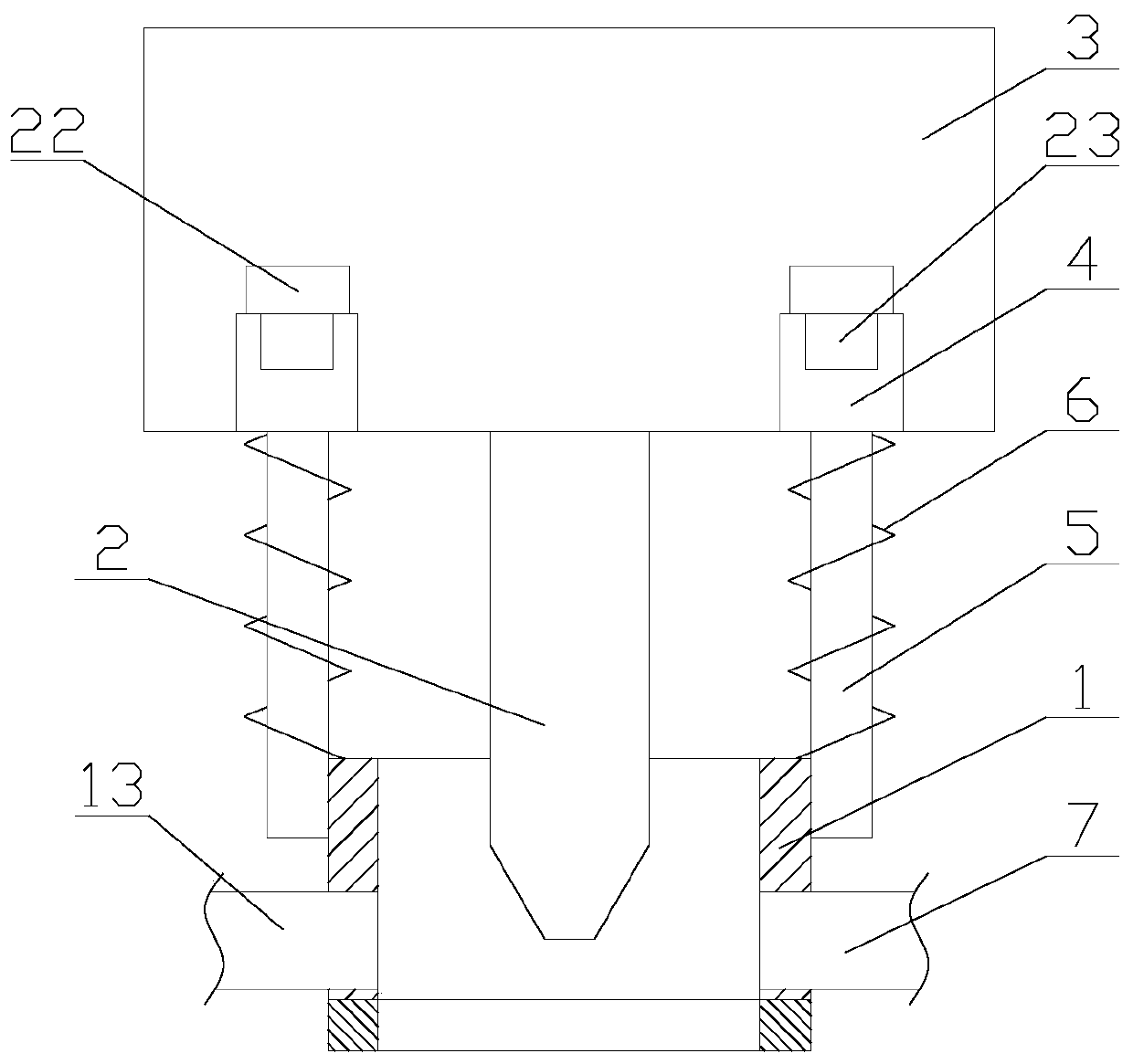

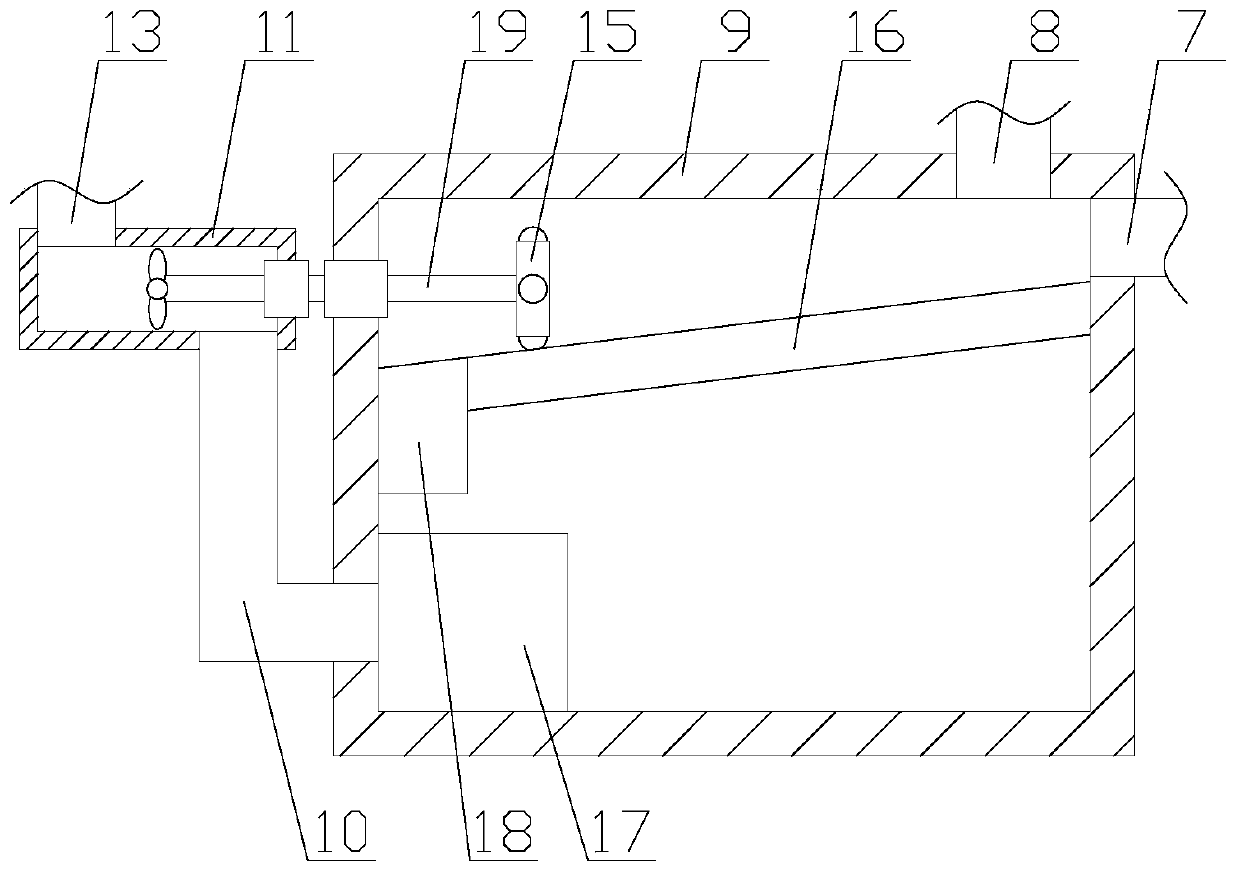

Vegetable drug juice extracting device for biological pharmacy

The invention discloses a vegetable drug juice extracting device for biological pharmacy. The vegetable drug juice extracting device for the biological pharmacy comprises a device base. The device base is provided with a juice collection box and a residue collection box in a sliding manner. One end of the device base is provided with a vertical plate. The middle portion of the vertical plate is provided with a controller. The upper portion of the vertical plate is provided with a feeding oil cylinder. The feeding oil cylinder coordinates with a feeding push head. The feeding push head is in sliding fit with a feeding square cylinder. The upper portion of the feeding square cylinder is connected with a feeding cylinder. The upper portion of the feeding cylinder is provided with a charging motor. The end portion of the feeding square cylinder is provided with a dividing device. The end portion of the feeding square cylinder coordinates with a conveying channel. The conveying channel is connected with a juice pressing cylinder. The juice pressing cylinder is internally provided with a juice pressing push head in a sliding manner. The vegetable drug juice extracting device for the biological pharmacy is easy to operate, convenient to control, capable of rapidly extracting vegetal juice and conveying the juice to the position of the next treating working procedure and high in automation degree and has a vegetal residue recovering function.

Owner:袁兴文

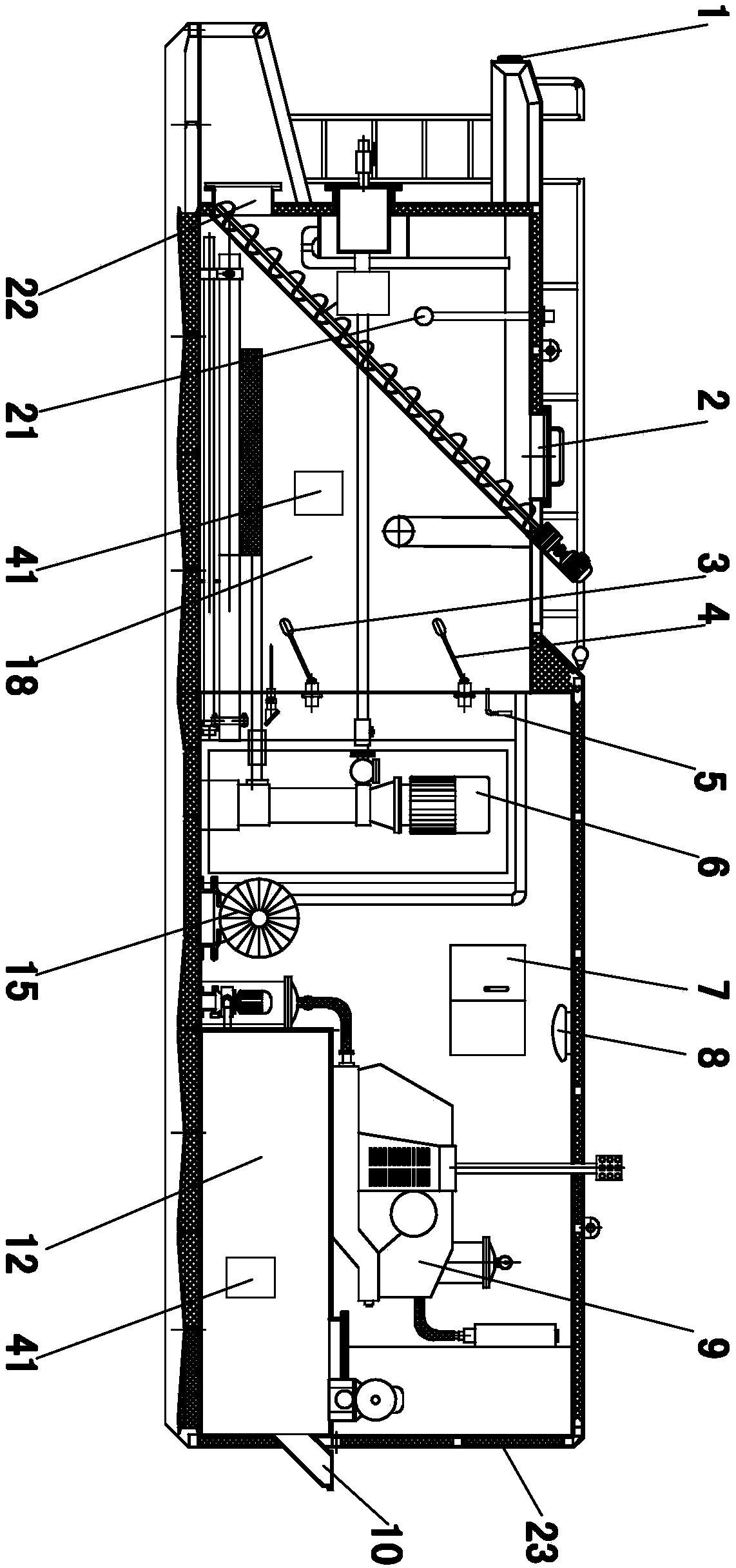

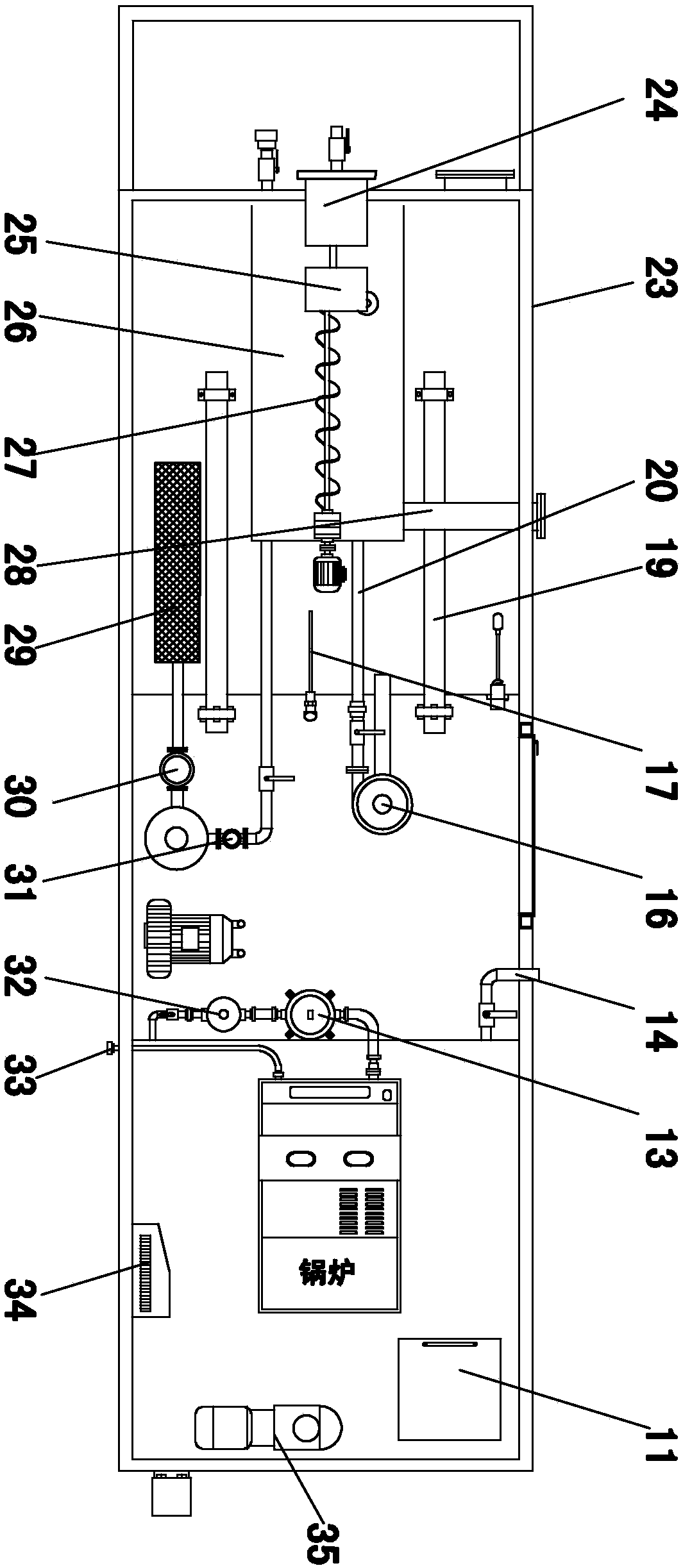

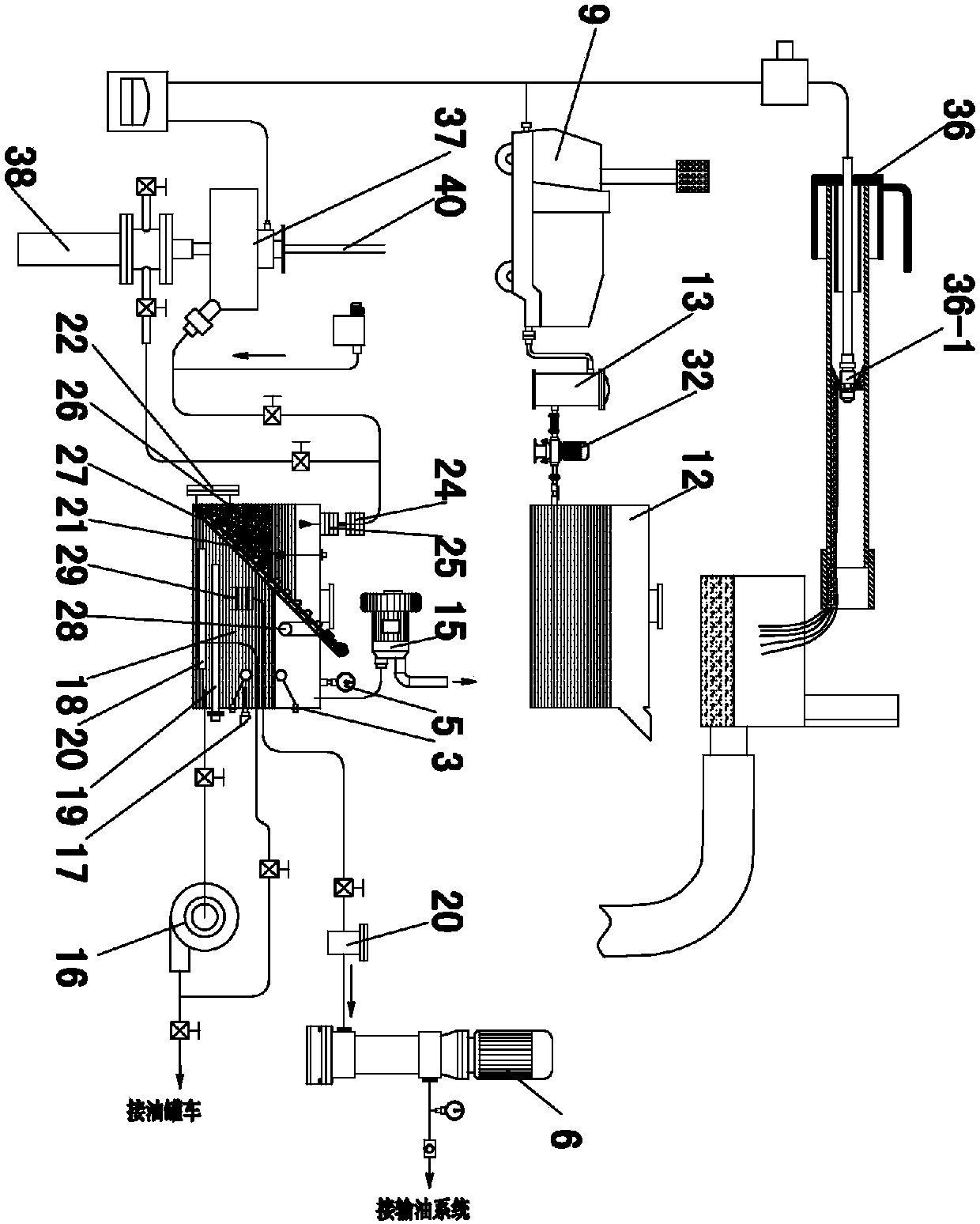

Integral apparatus for cleaning work

An integral apparatus for cleaning work belongs to the technical field of petrochemical equipment and can effectively solve a problem of well field environment pollution due to water containing oil dirt during the well repairing work. An outlet of a solid-liquid separator communicates with an inlet of an oil-water separator; the other end of a high-pressure hot water joint communicates with a first nozzle of an oil pipe inner wall cleaner via a pipeline, or the other end of the high-pressure hot water joint communicates with an oil removing and cleaning mechanism; and an inlet of the solid-liquid separator communicates with a well mouth and the oil removing and cleaning mechanism. Cleaning effect for an oil pumping rod or an oil pipe can be improved, so the oil pumping rod or the oil pipecan reach a work standard after being cleaned; the water containing oil dirt can be recycled after being processed, so transportation time and cost can be reduced; environment protection requirementsfor onsite work can be met; cleaning work can be achieved; and a problem of environmental pollution of well repairing work can be solved, so the integral apparatus for cleaning work is an environment-protective innovation product being favorable for the nation and the people.

Owner:DAQING KEFENG GASOLINEEUM TECH DEV

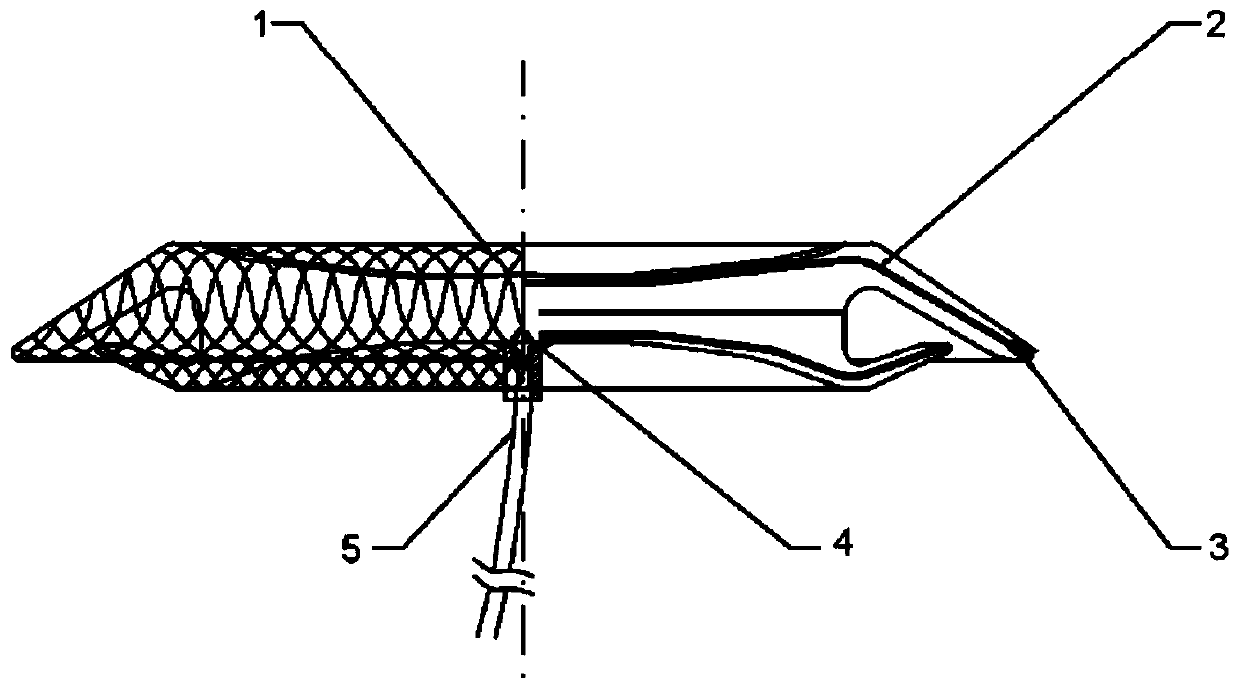

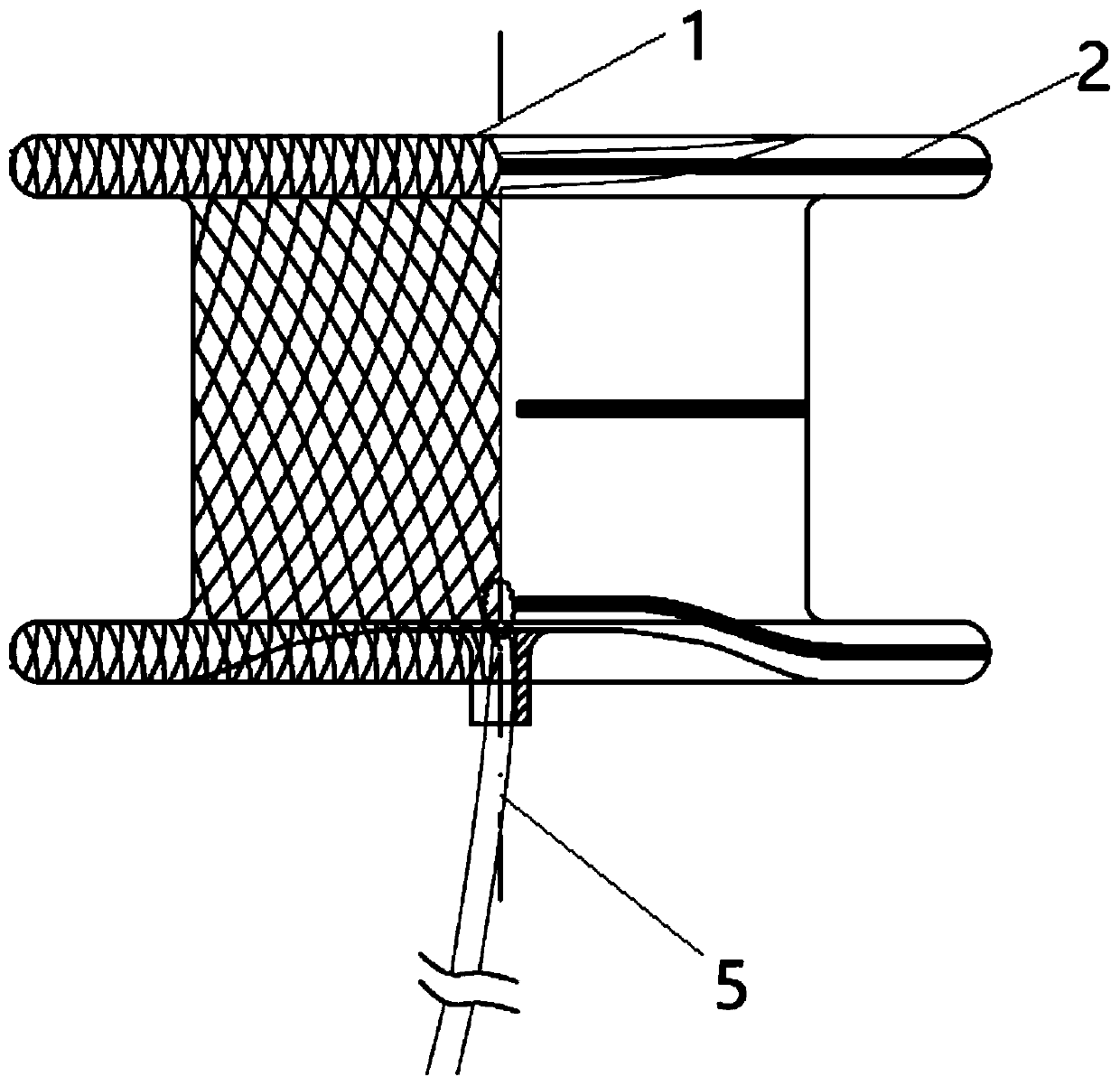

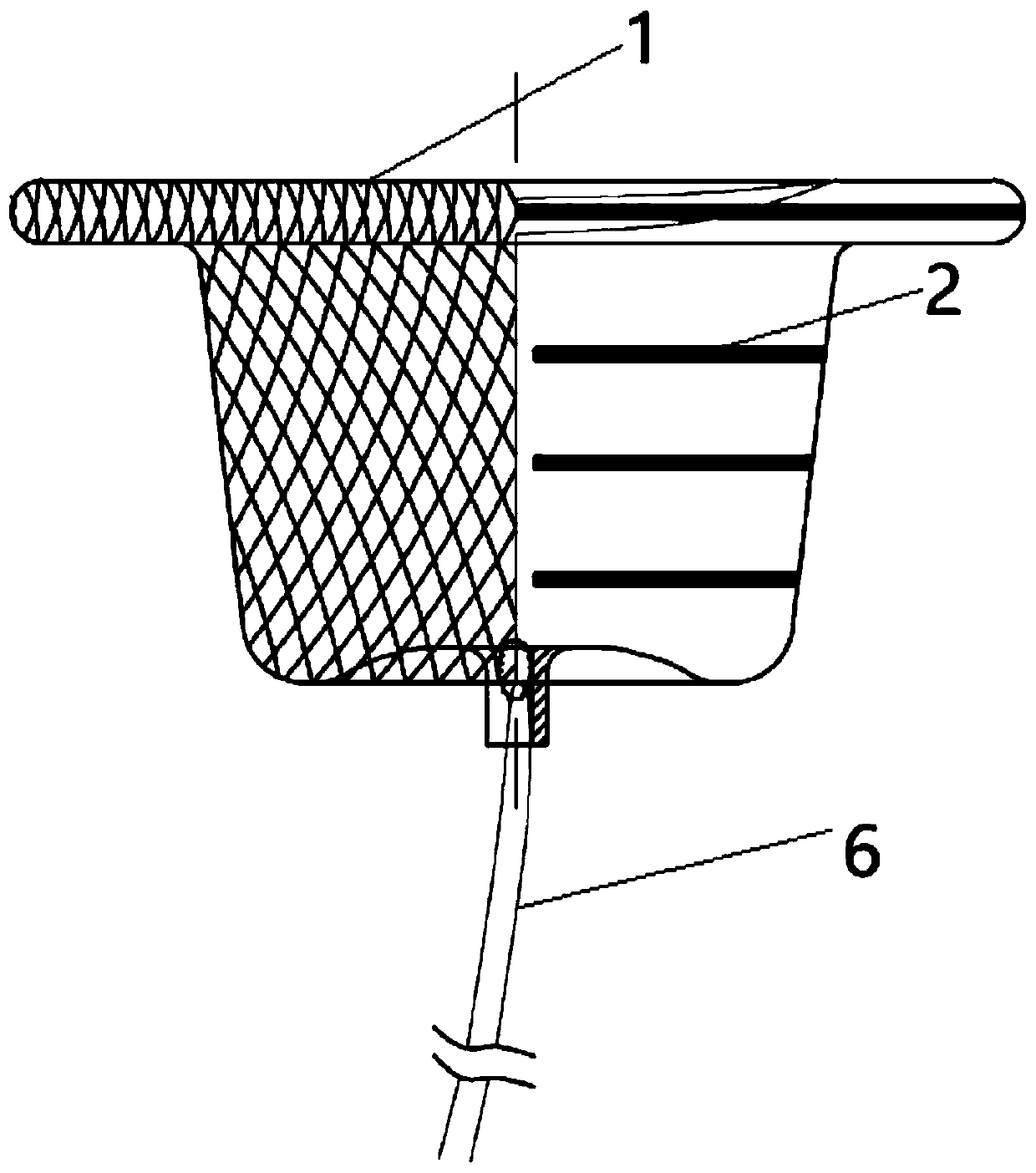

Parachute design biodegradable occluder

The invention provides a parachute design biodegradable occluder. The end close to a human body is defined as a near end, and the end away from the human body is defined as a far end; the occluder ischaracterized in that the occluder includes an occluder support internally arranged with a flow-choking membrane, and a forming ring with changeable states; and the occluder support, the flow-chokingmembrane and the forming ring are made from macromolecule polymer materials having biodegradable properties in biological tissue. The occluder is made from the biodegradable polymer materials, so thatthe occluder can be decomposed or absorbed by human tissue after a period of time in the human tissue, defect parts can be finally formed by the self tissue of the human body, therefore, occlusion without foreign matters can be realized, and the benefits are particularly obvious for children.

Owner:SHANGHAI SHAPE MEMORY ALLOY

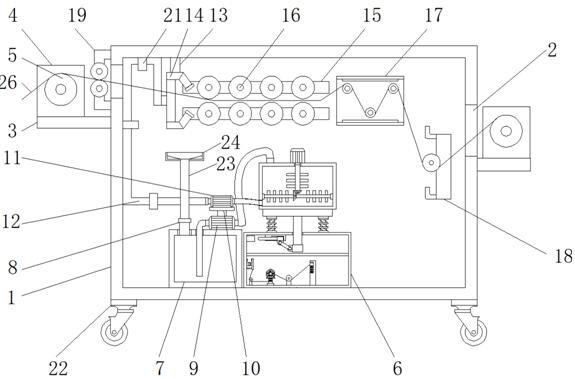

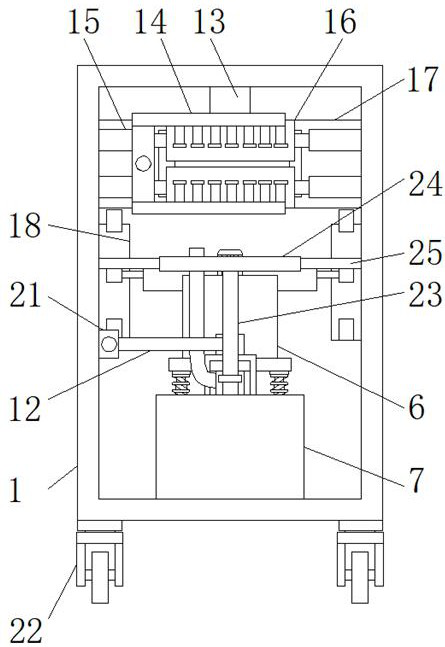

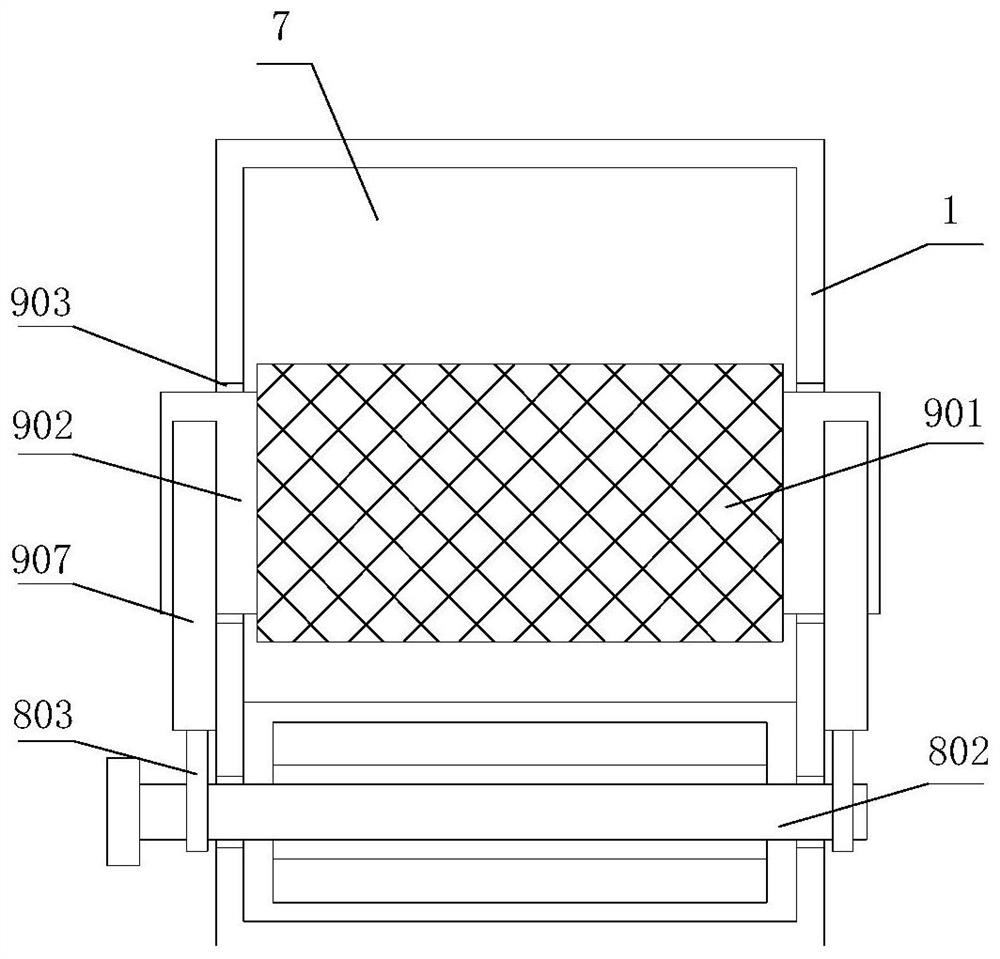

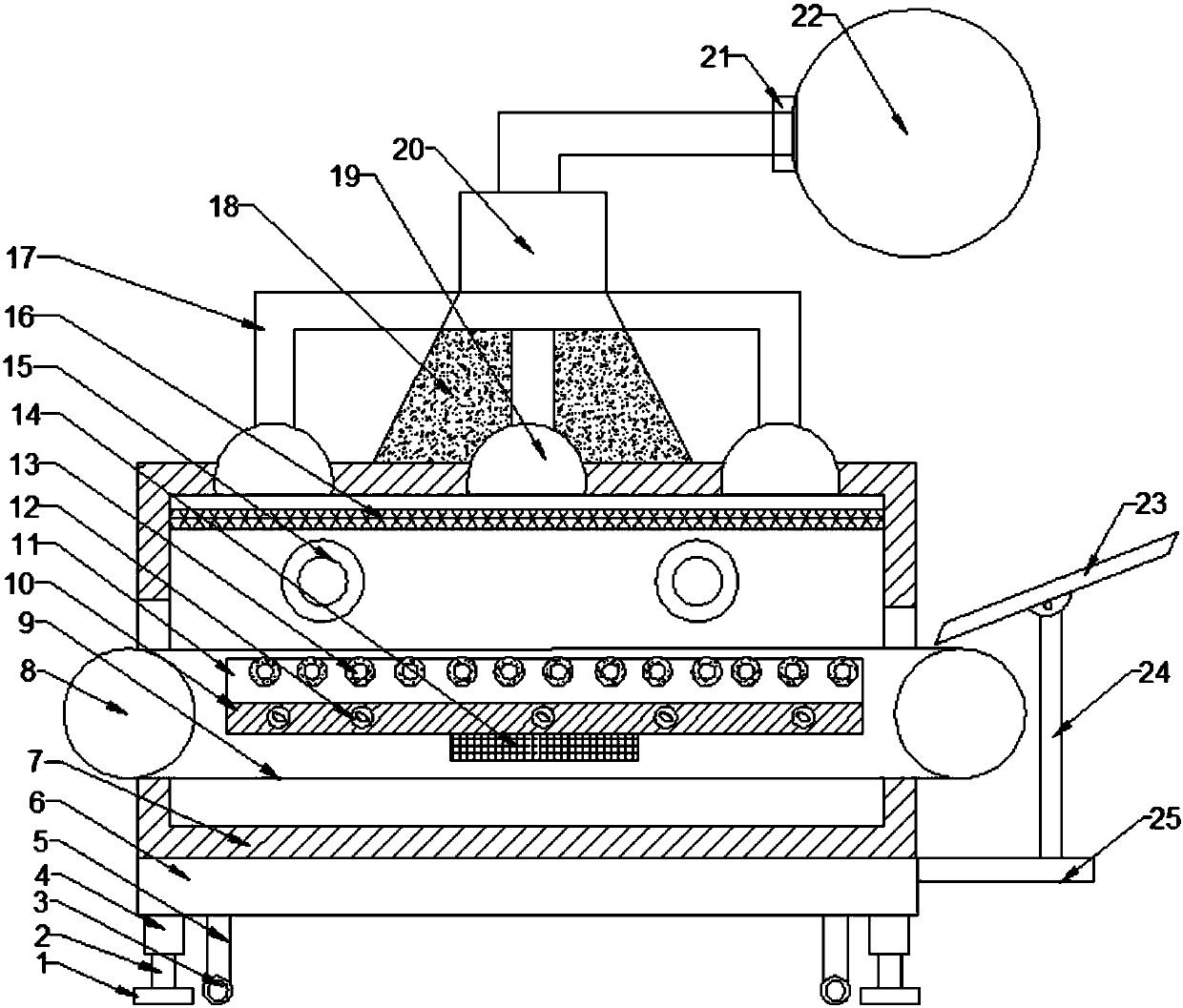

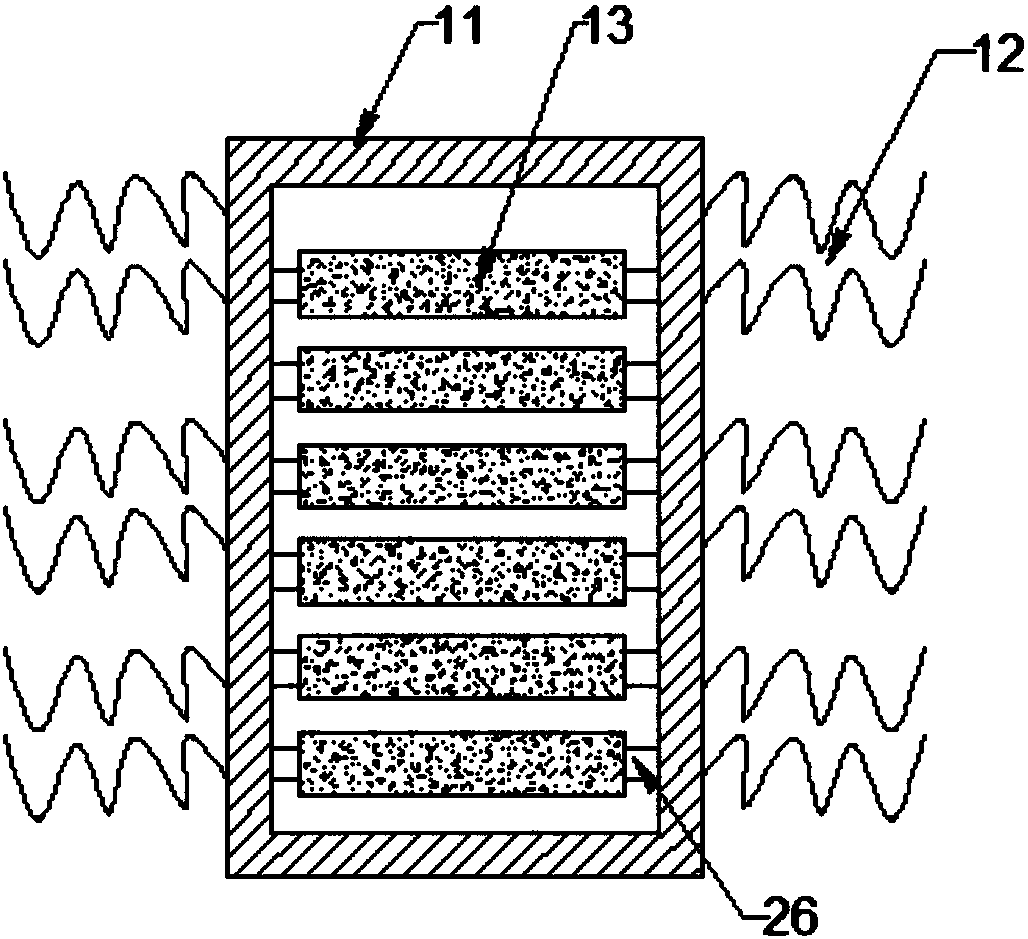

Printing and dyeing device for textile with automatic feeding structure

PendingCN111636161AGood drying effectWith tension adjustment functionMechanical cleaningPressure cleaningPolymer chemistryEngineering

The invention relates to the technical field of printing and dyeing, in particular to a printing and dyeing device for textile with an automatic feeding structure. The printing and dyeing device comprises a box body. The upper portion of the left side and the upper portion of the right side of the box body are each provided with an opening. The positions, located under the openings, of the left side and the right side of the box body are each fixedly provided with a carrier plate. The front side and the rear side of the top end of each carrier plate are each fixedly provided with a baffle. Dyes can be automatically supplemented in the printing and dyeing process, the dye amount is kept at a constant value, there is no need to manually observe the dye storage amount and supplement the dyesregularly, dust and impurities can be removed from textile fabrics before printing and dyeing, the printed and dyed textile fabrics can be dried through a drying device, the printing and dyeing devicehas a tension degree adjusting function and a dye recovery function, it is avoided that sprayed dyes drip to be wasted, the dyes can be stirred to be prevented from uneven composition distribution, and the printing and dyeing device can be conveniently moved according to needs and is worthy of popularization and use.

Owner:嘉兴程熙纺织品有限公司

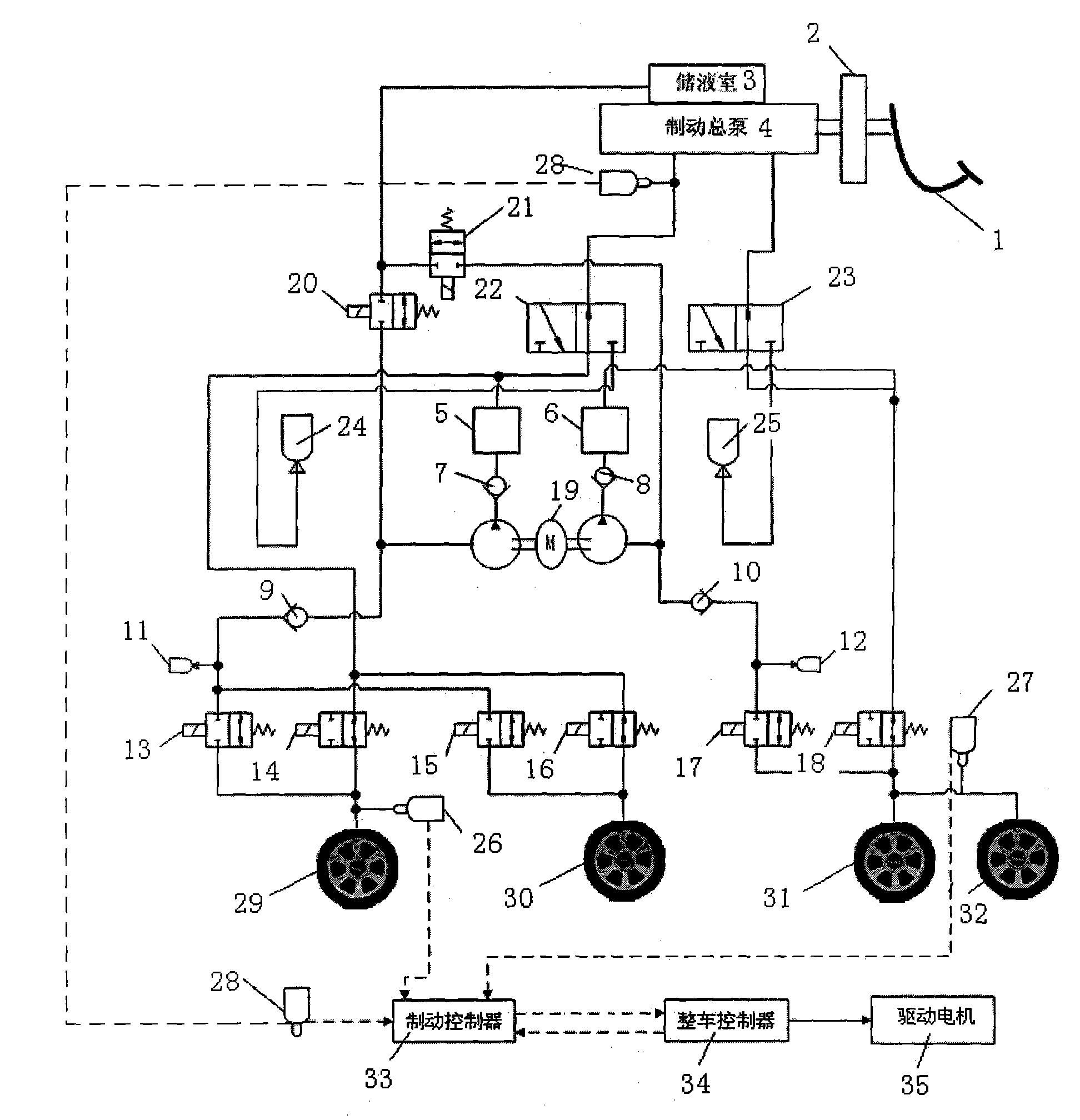

Electronic hydraulic brake boosting system

InactiveCN111086495AWith recycling functionSolve the problem of volume lossBraking action transmissionControl theoryBrake fluid

The invention provides an electronic hydraulic brake boosting system, which relates to the field of automobile braking. The electronic hydraulic brake boosting system comprises an electronic hydraulicbrake boosting system body, a brake pedal, a first brake wheel cylinder, a second brake wheel cylinder, a third brake wheel cylinder and a fourth brake wheel cylinder. The electronic hydraulic brakeboosting system, the brake pedal, the first brake wheel cylinder, the second brake wheel cylinder, the third brake wheel cylinder and the fourth brake wheel cylinder are matched for use, therefore, the system has an electric brake backup function, a mechanical brake backup function, an anti-lock control function, a brake fluid recycling function, an active pressure module protection function and apedal feedback feeling changing function.

Owner:TIANJIN TRINOVA AUTOMOTIVE TECH CO LTD

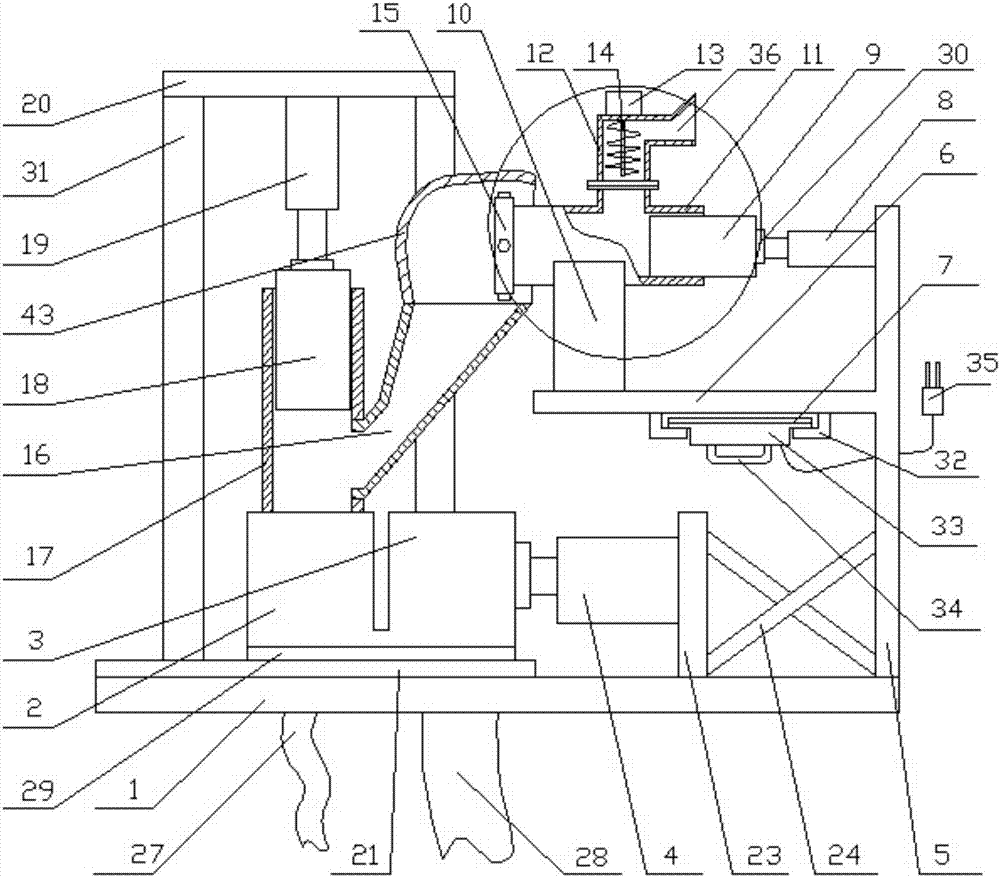

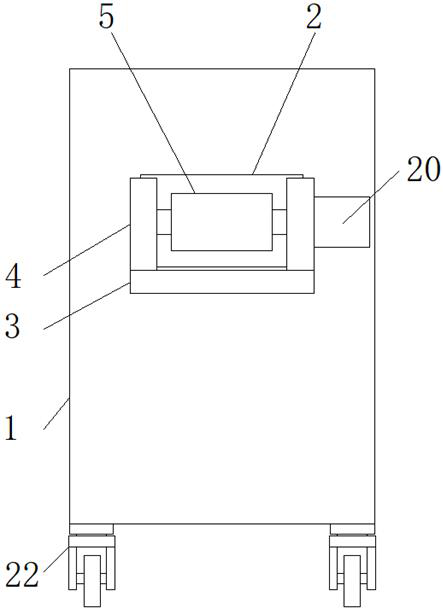

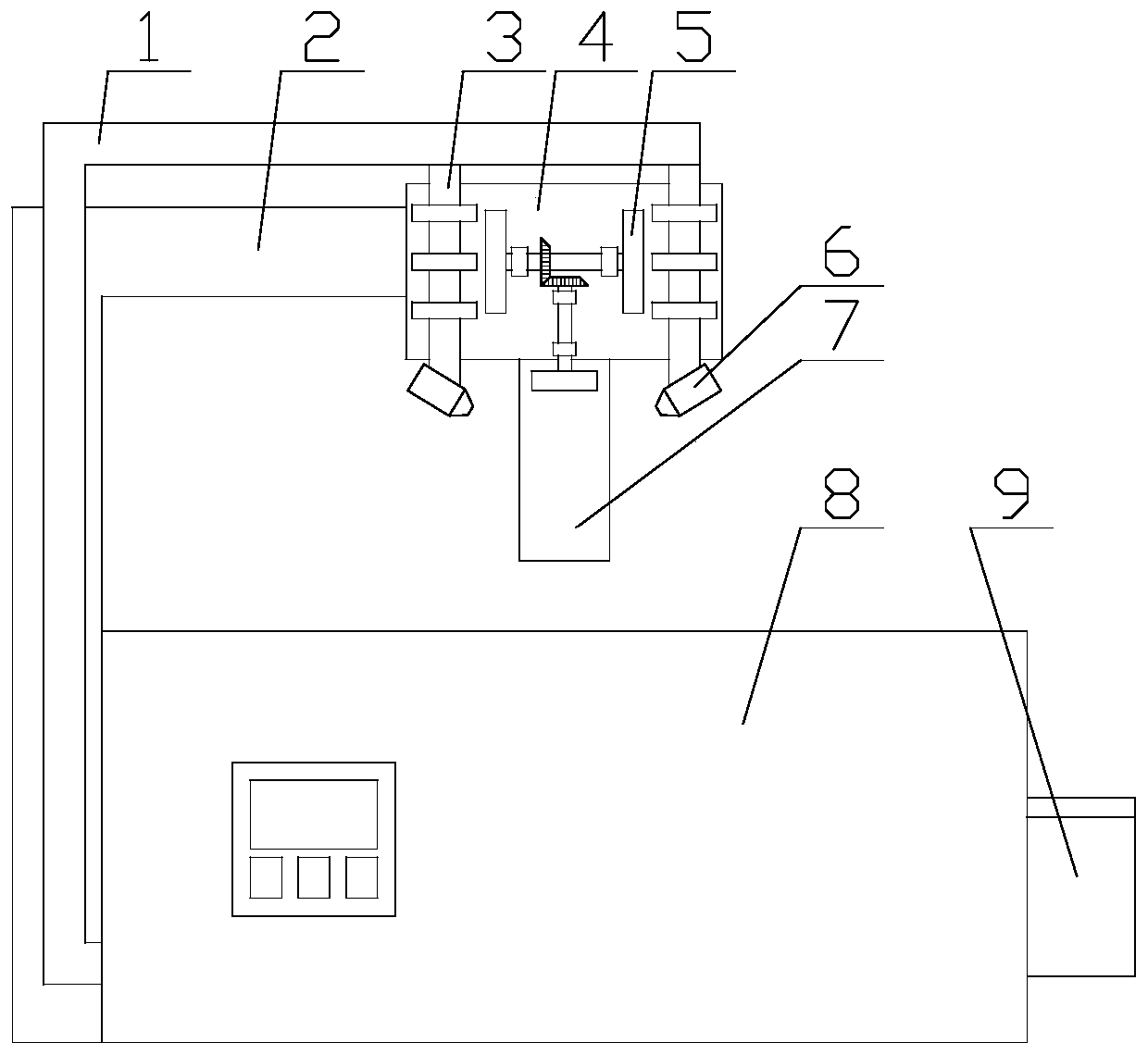

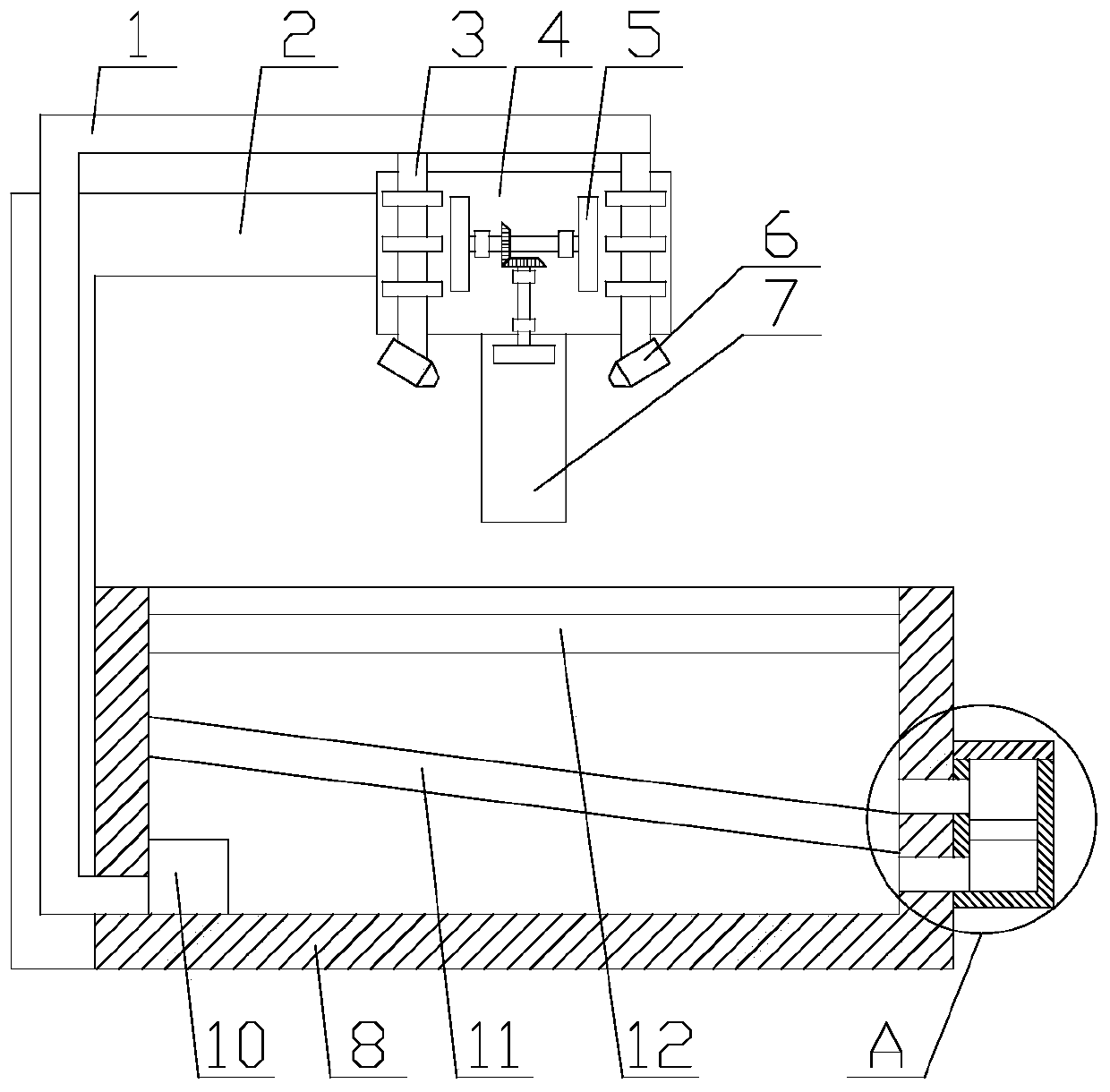

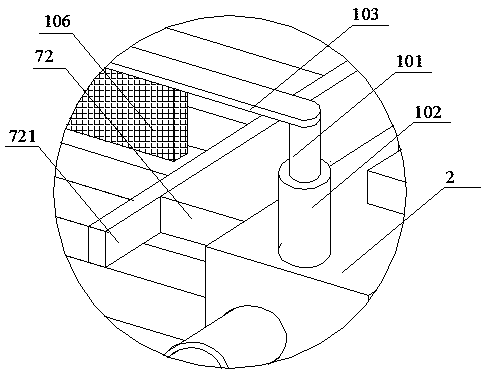

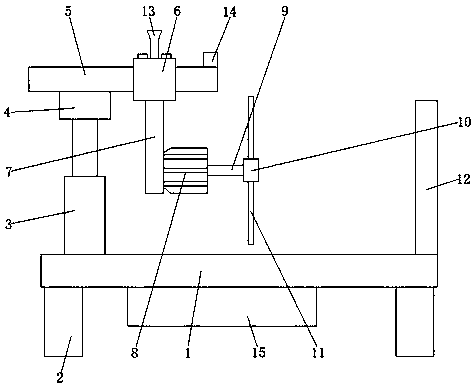

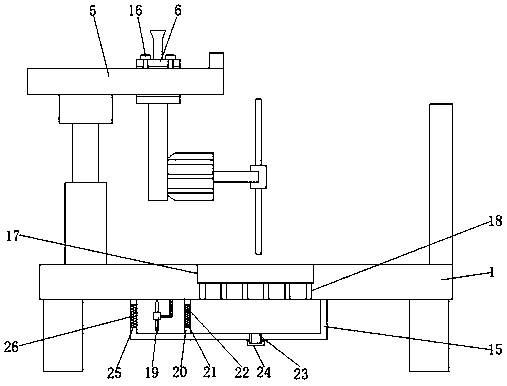

Numerical control milling machine with cutting fluid recycling function

InactiveCN111251060AWith recycling functionAchieve recyclingMilling cuttersMilling equipment detailsNumerical controlMilling cutter

The invention relates to a numerical control milling machine with a cutting fluid recycling function. The numerical control milling machine comprises a base, a power device, a milling cutter, a bracket and a supporting mesh, and further comprises a circulation mechanism and a heat dissipation mechanism, wherein the circulation mechanism comprises a first communication pipe, a second communicationpipe, a purifying box, a filter screen, a guide plate, a power pump, a pipeline, two heat conduction pipes and two nozzles, and the heat dissipation mechanism comprises a first drive shaft, a second drive shaft, a first gear, a second gear, a friction disk and two fan blades. According to the numerical control milling machine with the cutting fluid recycling function, by means of the circulation mechanism, the cutting fluid can be recovered, recycling of the cutting fluid is realized, and production cost of the numerical control milling machine is reduced; and by means of the heat dissipationmechanism, temperature of the cutting fluid is reduced, lubricating effect of the cutting fluid is improved, and working reliability of the numerical control milling machine is improved.

Owner:深圳市迅成科技有限公司

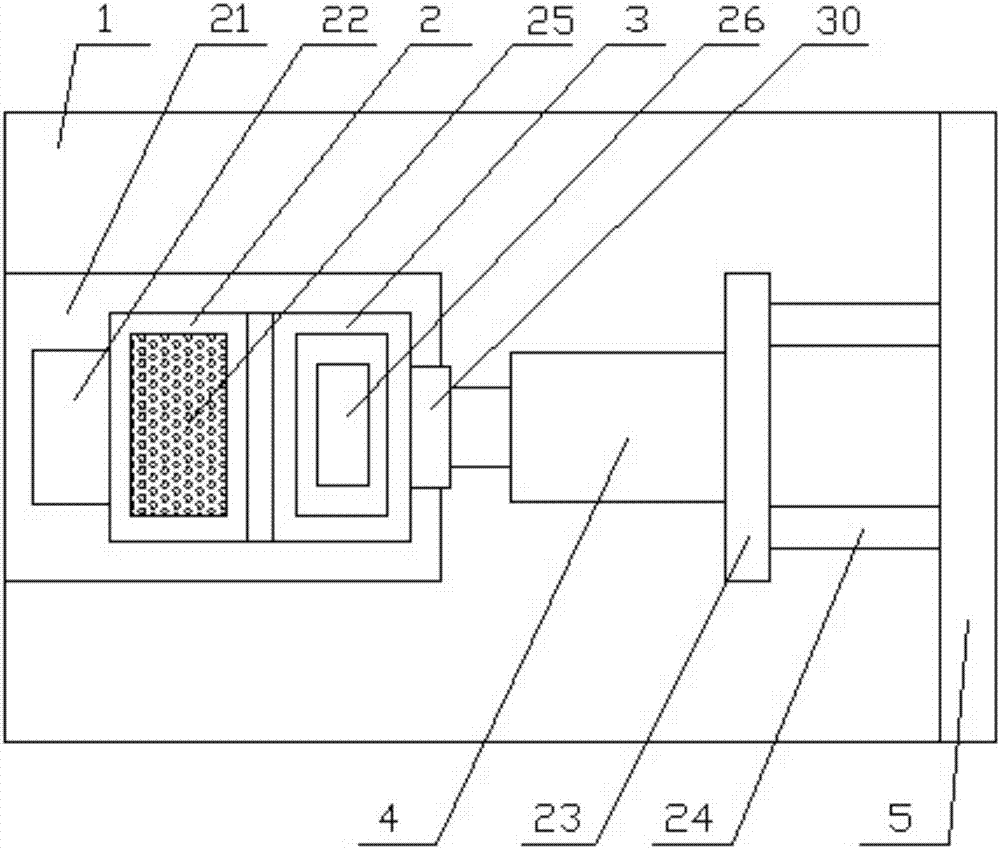

Efficient numerical control machine tool with cooling liquid recovery function

ActiveCN110814855AWith recycling functionImprove cooling effectBoring/drilling componentsMaintainance and safety accessoriesPropellerProcessing accuracy

The invention relates to an efficient numerical control machine tool with a cooling liquid recovery function. The efficient numerical control machine tool comprises a power device, a base, a drill bit, a machining groove, a cooling mechanism and a recovery mechanism. The cooling mechanism comprises a support sleeve, a storage box, a fourth pipeline, a first pipeline, a power pump, a third pipeline, a power cylinder and two support assemblies; the recovery mechanism comprises a second pipeline, a filter net, a collection groove, a screw propeller, a driving shaft, a rotating disc and at least two knocking blocks; and each support assembly comprises a fixed sleeve, a lifting rod, a spring, a limiting block and a touch switch. In the efficient numerical control machine tool with the cooling liquid recovery function, the cooling effect of cooling liquid is improved through the cooling mechanism, the machining precision of the numerical control machine tool is improved, cooling liquid is recovered through the recovery mechanism, and the production cost of the numerical control machine tool is reduced.

Owner:湖南九五精机有限责任公司

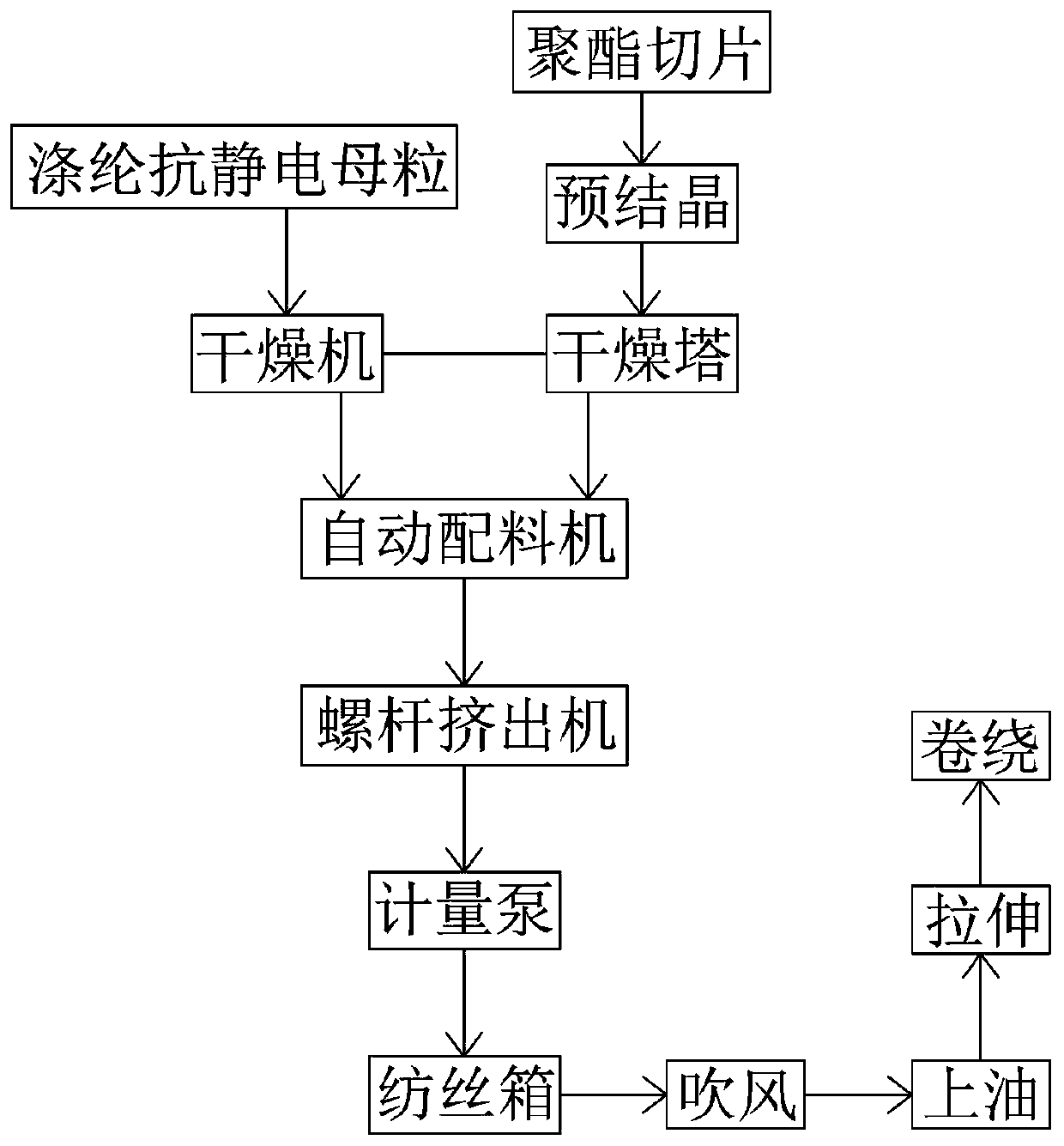

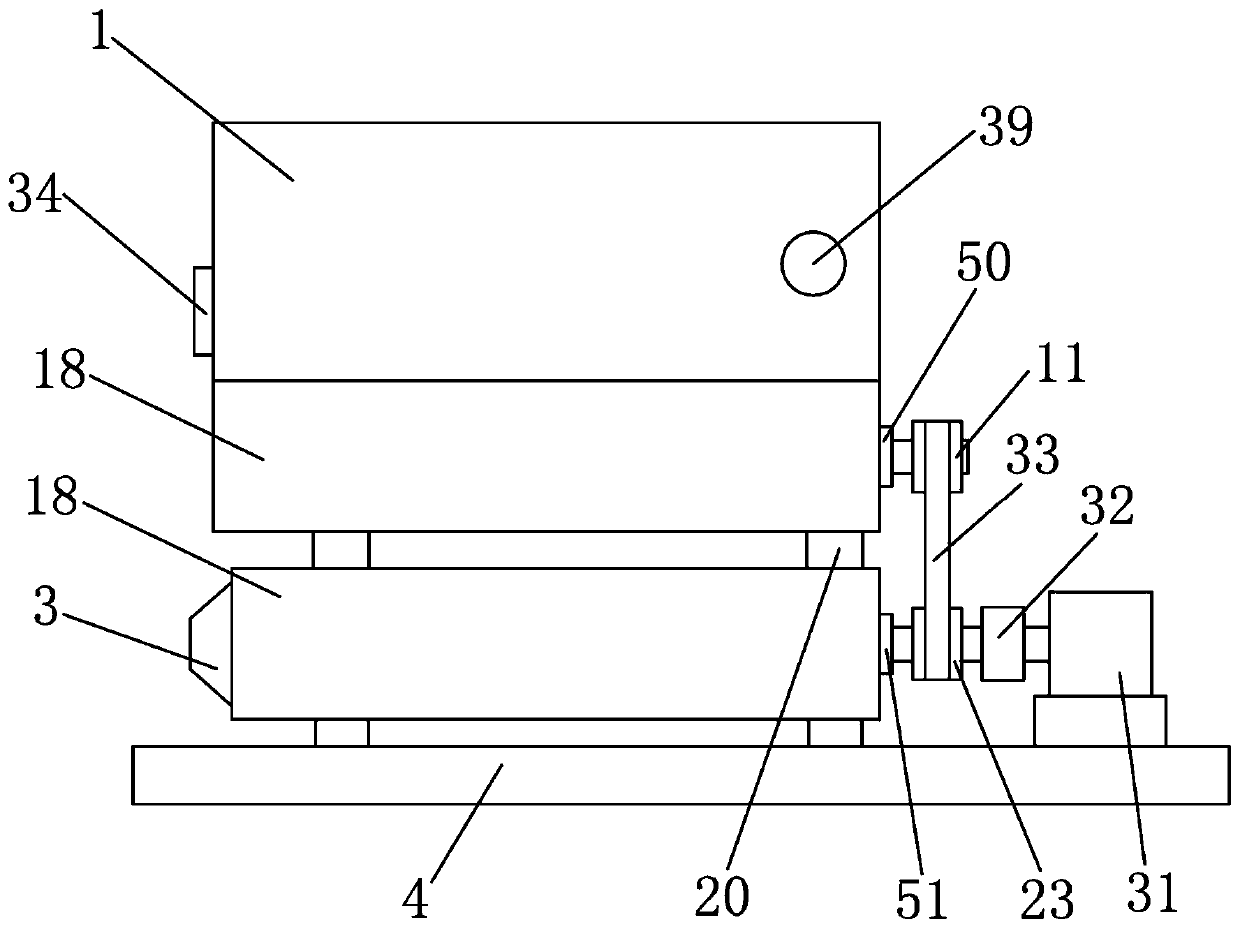

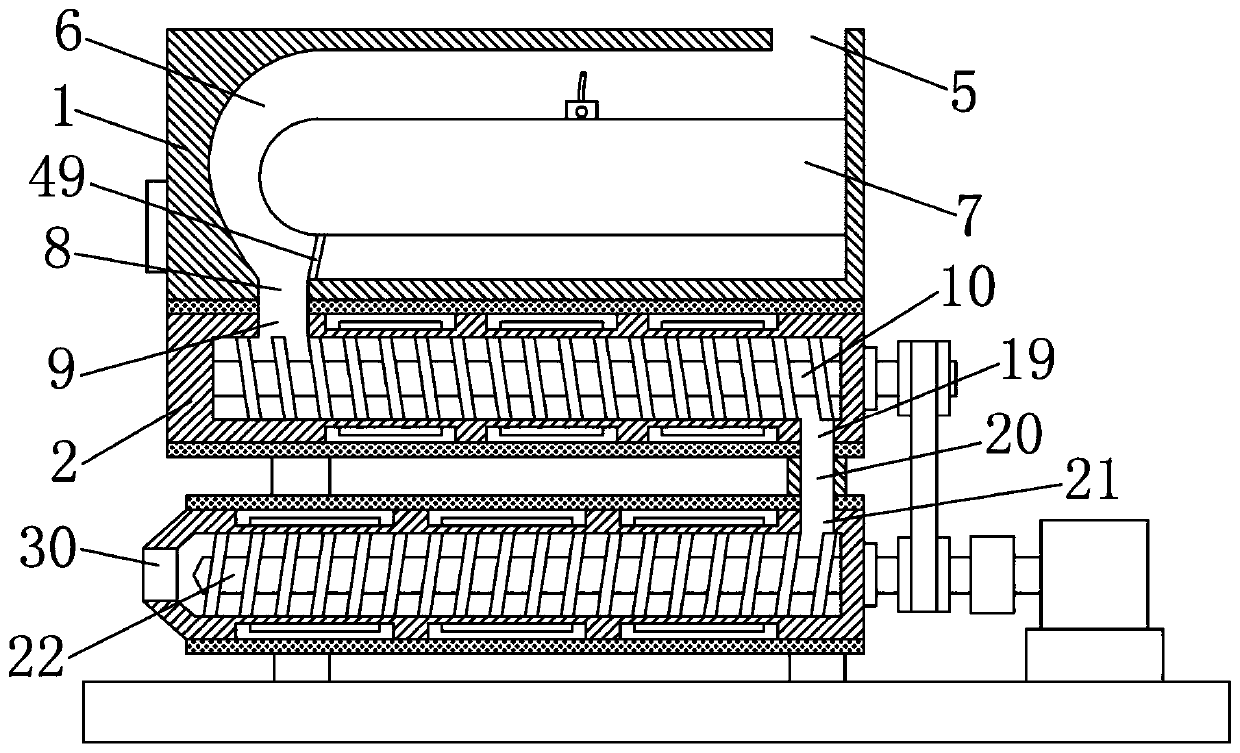

Production process of cyclic regeneration antistatic fiber

ActiveCN110952155AThe process is simple and easyGood antistaticElectroconductive/antistatic filament manufactureSpinning solution de-aeratingChemistryPolyester

The invention discloses a production process of a cyclic regeneration antistatic fiber, and belongs to the technical field of fiber preparation. The production process comprises the following steps ofraw material pretreatment, raw material mixing, melt preparation, implementation of a filament forming work procedure, air blowing treatment, oiling treatment, stretching treatment and winding treatment. Polyester antistatic master batches and polyester chips are used as raw materials; the prepared fiber has a cyclic regeneration function and an excellent antistatic property; the antistatic effect cannot be weakened or disappear as time goes on; and the prepared fiber can be used as a novel green environment-friendly material. The production process has the advantages that simplicity, convenience, easy implementation and no pollution are realized; the proportioning quantity of the polyester antistatic master batches is small; no influence is caused on the existing production process of the cyclic regeneration fiber; and good market prospects are realized.

Owner:浙江佳人新材料有限公司

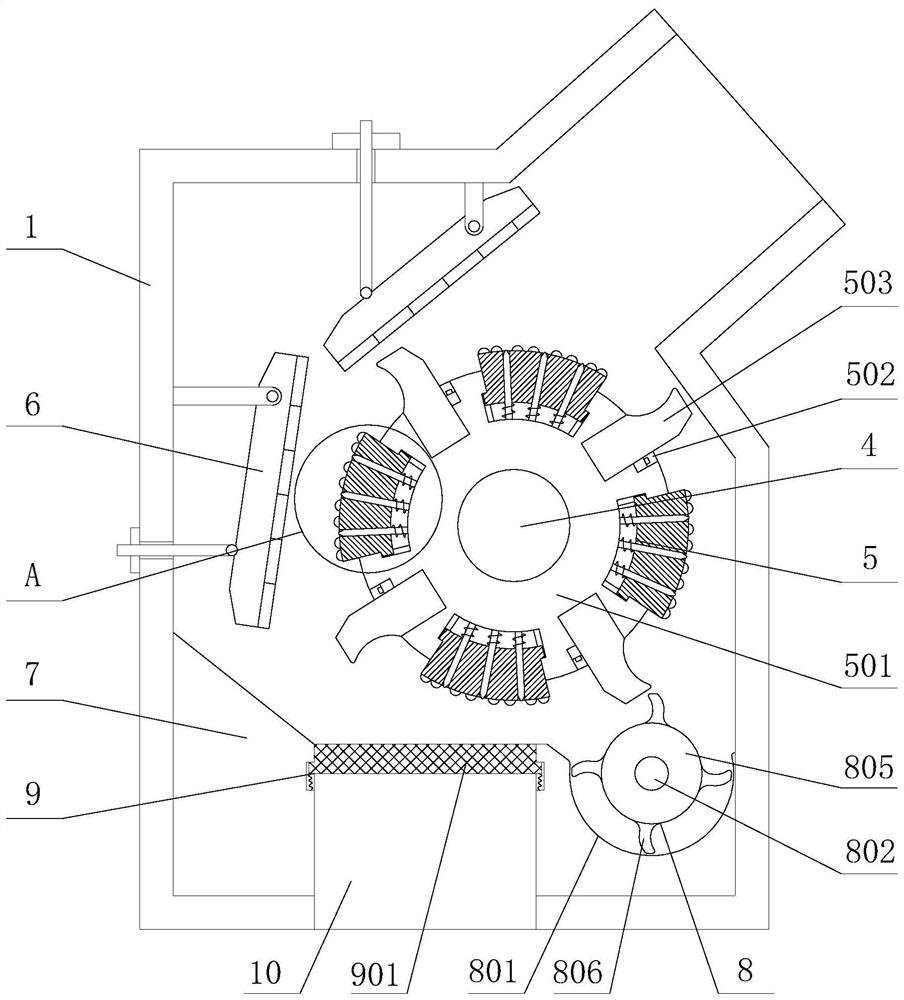

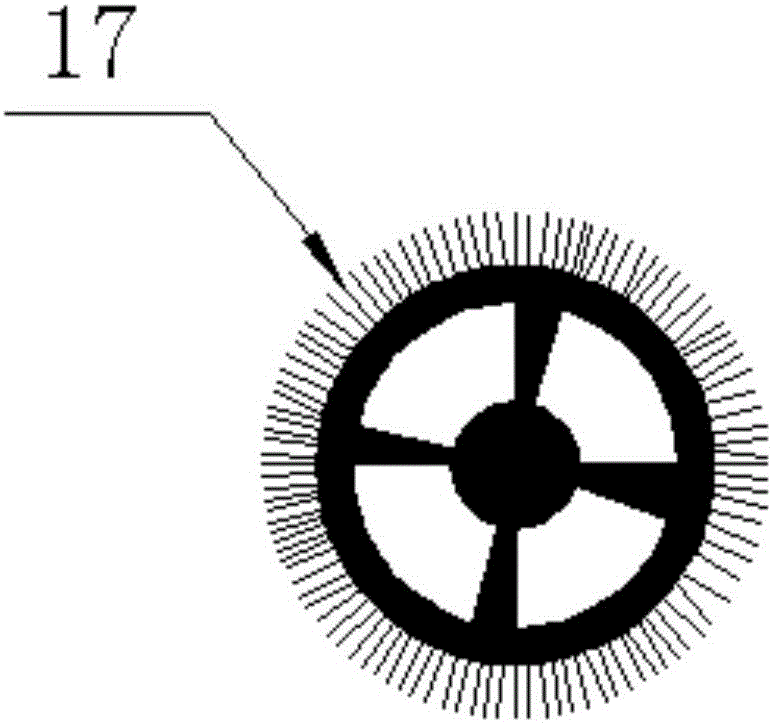

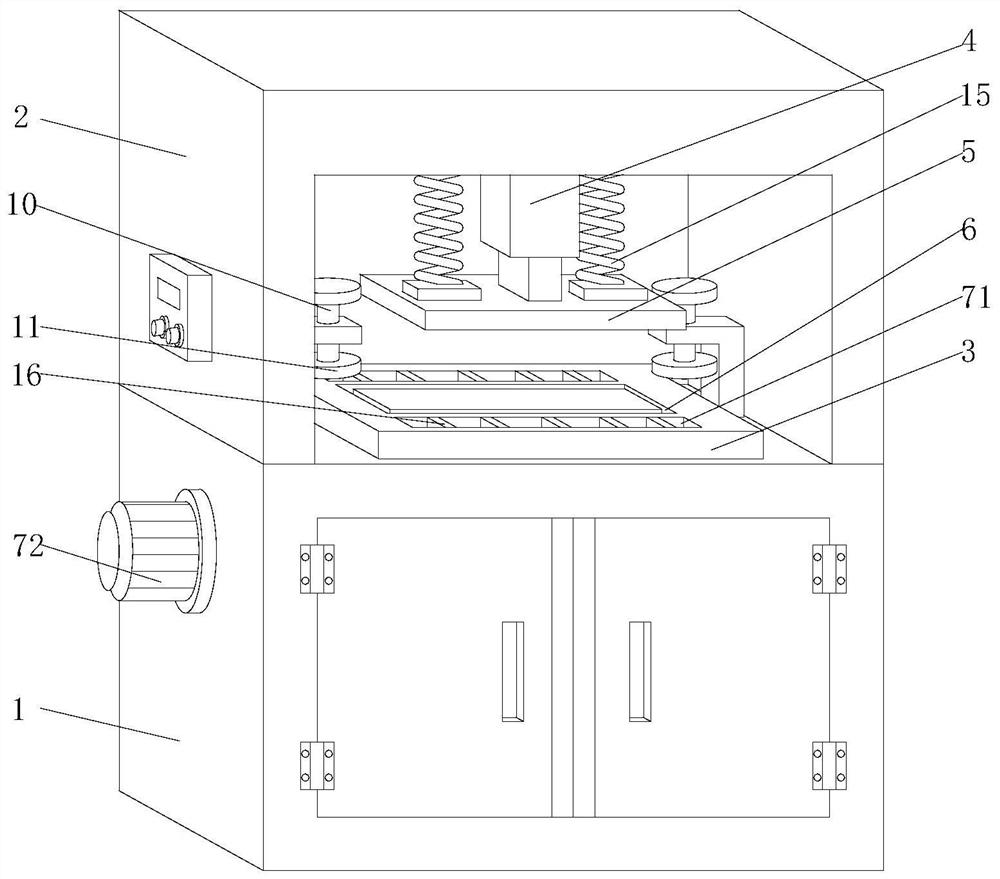

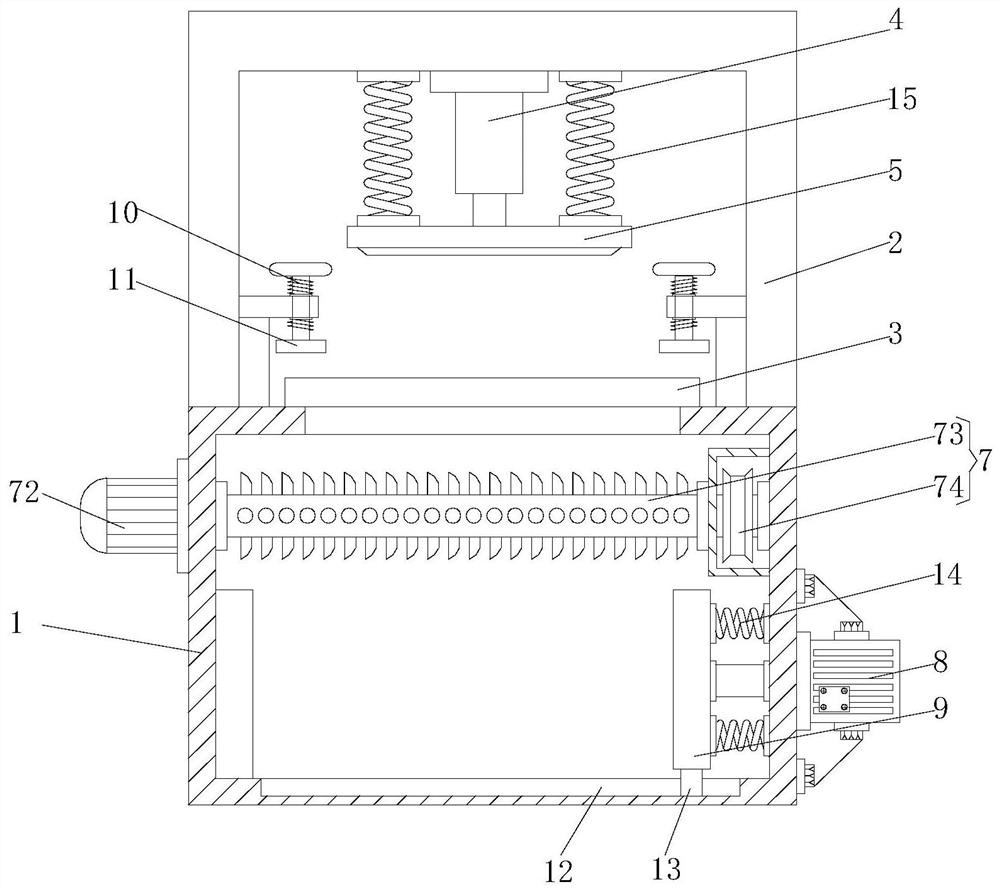

Multi-stage rock-soil crushing device with recovery function

InactiveCN113210073AImprove crushing efficiencyPracticalGrain treatmentsSoil scienceElectric machinery

The invention relates to the technical field of rock-soil crushing, in particular to a multi-stage rock-soil crushing device with a recovery function, and aims to solve the technical problems that part of existing rock-soil crushing devices are low in crushing efficiency; part of existing crushing devices are difficult to recover rock soil which is not completely crushed; and in the using process of part of existing crushing devices, filter screens are prone to being blocked, and the filtering effect is poor. In order to solve the technical problems, the invention provides the multi-stage rock-soil crushing device with the recovery function, which comprises a machine shell. A motor is fixedly connected to the front end of the outer wall of the machine shell. The multi-stage rock-soil crushing device with the recovery function is composed of a crushing mechanism, a recovery mechanism and a filtering mechanism. Rock soil is thrown to the surface of an impact plate through cooperation of the centrifugal force generated in the rotating process of a rotating sleeve and compression springs, then the rock soil rebounds to the surface of a crushing plate and is crushed through cooperation of crushing rods, compression springs drive the crushing plate to pop out the rock soil after being pressed, and repeated crushing is conducted in the process, so that the overall crushing efficiency of the equipment is improved.

Owner:QUZHOU UNIV

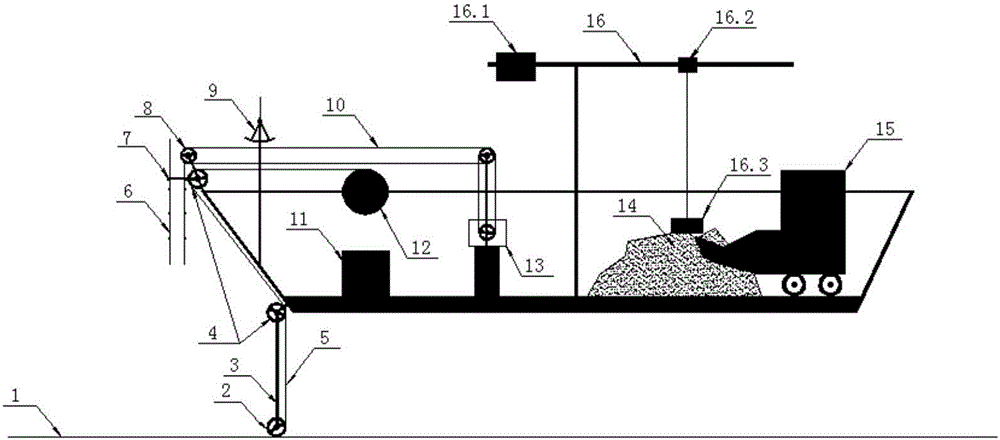

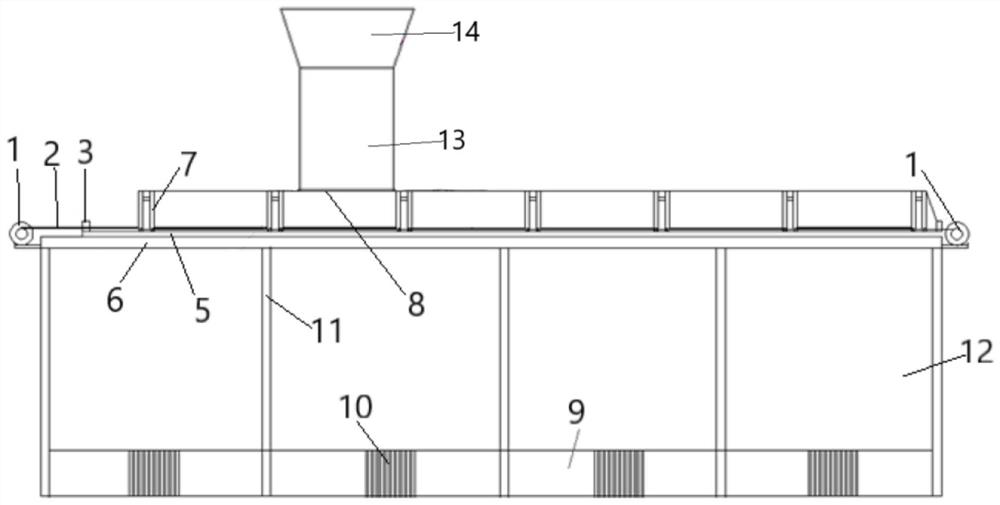

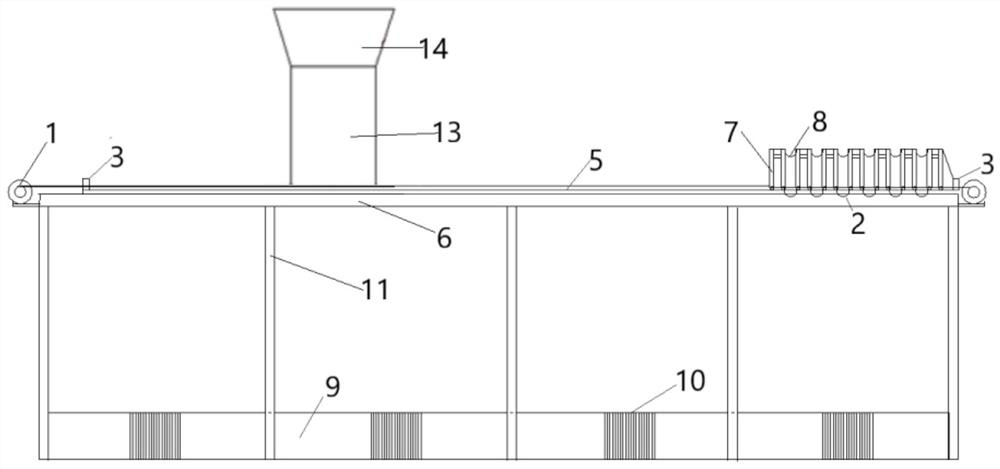

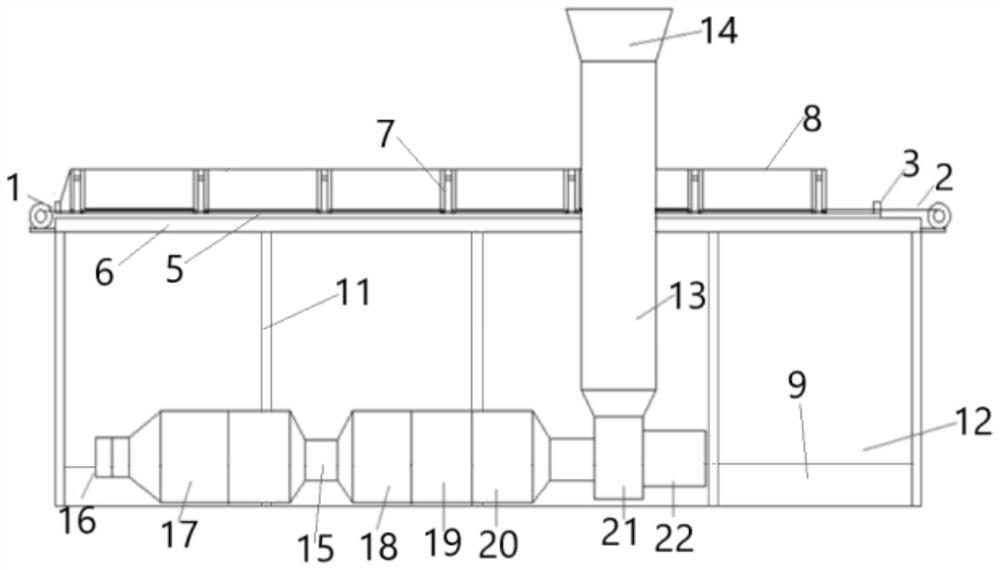

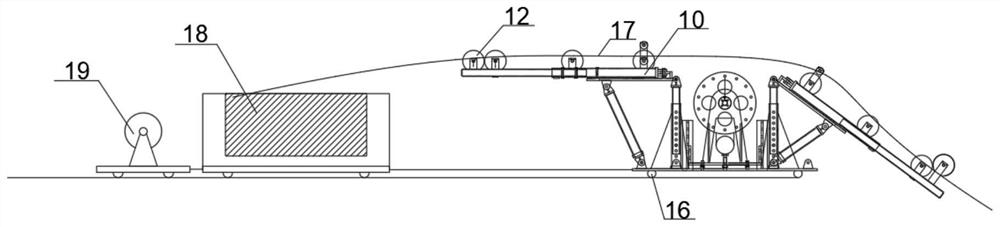

Cover treatment method for reducing release of river-lake sediment pollutants

InactiveCN106430868AHigh degree of mechanizationFast constructionSludge treatmentHydraulic engineering apparatusPollutantEngineering

The present invention discloses a cover treatment method for reducing the release of river-lake sediment pollutants. According to the cover treatment method, the paving system of a cover film (5) and the conveying system of a filler (14) are arranged on a ship, wherein the paving system of the cover film (5) is characterized in that the coiled cover film (5) is placed on a film coiling drum (12) and one end of the cover film (5) is covered on the river-lake bottom surface sequentially through two guide wheels (4) and a paving wheel (2), and the conveying of the filler (14) is characterized in that the filler is placed on a conveying belt (10) through a crane (16) or a forklift (15), the filler (14) is conveyed to a material guide drum (6) through the rotating of a rolling wheel (8) and then is sprinkled on the cover film (5) covered on the river-lake bottom surface, and the power source of the conveying belt is completed by making the power motor (11) sequentially drive a motor (13) and the rolling wheel (8). The cover treatment method of the present invention is suitable for the river-lake water regions with different depths, and has advantages of rapid construction, good quality, and significant environmental benefits.

Owner:NORTHEAST NORMAL UNIVERSITY

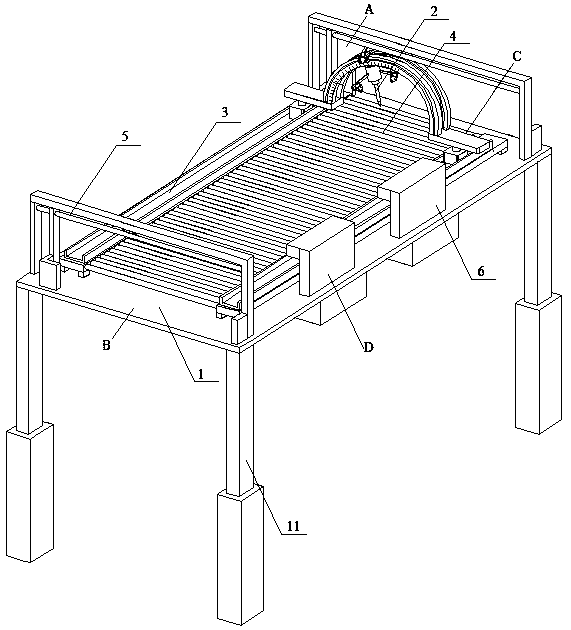

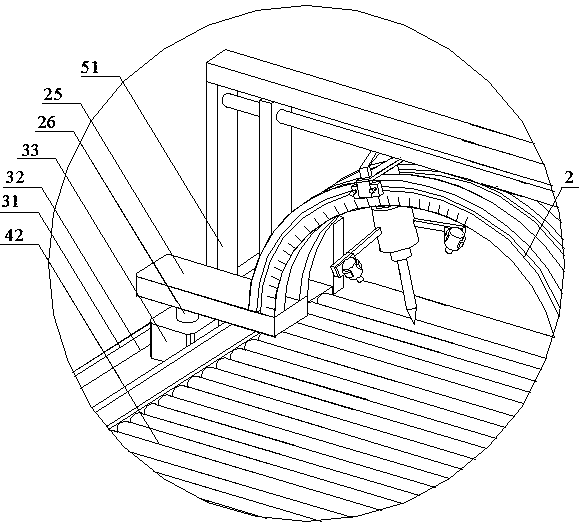

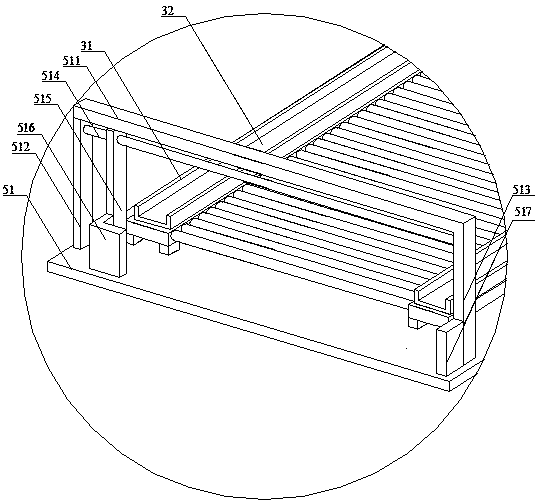

High stability perforating device with furniture panel scrap recycling function

InactiveCN109397391AWith recycling functionWith angle guide functionStationary drilling machinesTransfer mechanismMachining

The invention discloses a high stability perforating device with a furniture panel scrap recycling function, and relates to the field of panel machining devices. The high stability perforating devicewith the furniture panel scrap recycling function comprises an operating table, a panel transfer mechanism and a multi-angle drilling mechanism crossing the panel transfer mechanism. A drill bit of the multi-angle drilling mechanism can do semi-circular motion on the panel transfer mechanism and the drilling is always towards the center of the semi-circular motion track, and at least one scrap recycling mechanism is arranged on the outer side of the length direction of the panel transfer mechanism. The scrap recycling mechanisms comprise scrap adsorption pipelines located on the operating table and scrap recycling boxes located on the bottom of the operating table. Fans are arranged in the scrap adsorption pipelines, and the suction inlets of the scrap adsorption pipelines are arranged towards the panel transfer mechanism. Through holes are formed in the operating table, and the discharge outlets of the scrap adsorption pipelines communicate with the scrap recycling boxes through the through holes. The high stability perforating device with the furniture panel scrap recycling function can prevent scrap from accumulating.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

Paint room with paint spraying waste gas treatment system

InactiveCN111889291AAvoid spreadingAffect physical and mental healthDispersed particle separationSpray boothsEnvironmental engineeringWinch

The invention relates to a paint room with a paint spraying waste gas treatment system. The paint room comprises a room body for paint spraying, a centrifugal fan and a waste gas treatment system, andthe room body introduces paint waste gas into the waste gas treatment system through the centrifugal fan. The waste gas treatment system comprises a waste gas introduction inlet, a waste gas treatment box and a gas discharge channel. The room body comprises a ceiling capable of being opened or closed. The ceiling comprises two parallel H-shaped steel pieces and several sets of trusses, the H-shaped steel pieces are provided with I-steel guide rails in the same direction as the H-shaped steel pieces, the several sets of trusses are perpendicular to the H-shaped steel pieces and provided with rollers capable of sliding along the I-steel guide rails, ceiling canvas is arranged between the adjacent trusses, two ends of the H-shaped steel pieces are provided with winches for driving the trusses to slide, the winches on the same H-shaped steel piece have opposite rotating directions, and the H-shaped steel pieces are further provided with limiting baffles for preventing the trusses from falling. The paint room is simple and reliable, avoids environmental pollution and bodily injury, and is environmentally friendly and practical.

Owner:CHINA FIRST METALLURGICAL GROUP +1

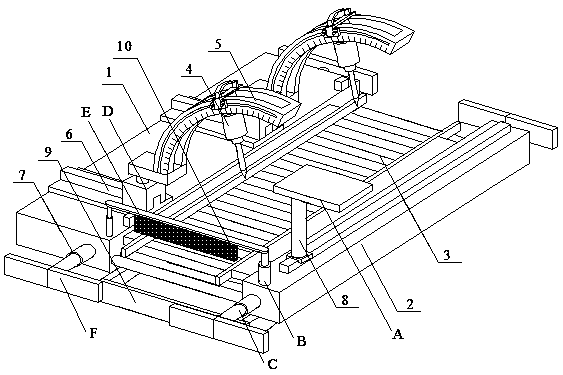

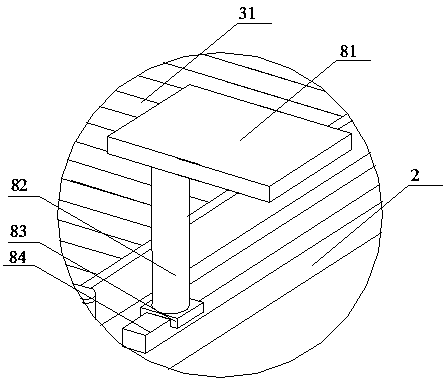

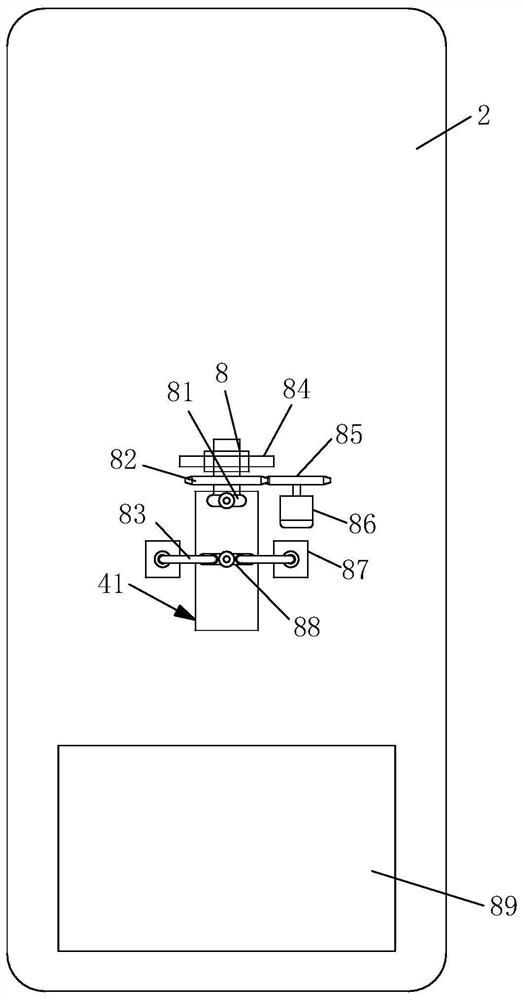

Multifunctional high-efficiency intensive furniture board machining device

InactiveCN109551572AWith recycling functionHigh processing stabilityStationary drilling machinesReciprocating motionEngineering

The invention discloses a multifunctional high-efficiency intensive furniture board machining device. The multifunctional high-efficiency intensive furniture board machining device comprises a first working table and a second working table, and further comprises a plate conveying mechanism, a drilling mechanism, an arc-shaped guide mechanism, a sliding mechanism, a plate limiting mechanism and anexternal packing treatment mechanism, wherein the plate conveying mechanism is arranged between the first working table and the second working table, and a plate is conveyed along the length directions of the first working table and the second working table; the drilling mechanism is suspended above the plate conveying mechanism, and the drilling angle of a drill bit of the drilling mechanism canbe adjusted; the arc-shaped guide mechanism is arranged on the end surface of the first working table; the arc-shaped guide mechanism can do horizontal reciprocating motion in the width direction of the first working table through the sliding mechanism; the plate limiting mechanism comprises a horizontal transverse limiting mechanism and a horizontal longitudinal limiting mechanism; the external packing treatment mechanism comprises a sucker assembly which is horizontally arranged and a rotating rod which is arranged at the bottom of the sucker assembly. The multifunctional high-efficiency intensive furniture board machining device has the functions of multi-angle drilling, external packaging treatment and waste recovery, and meanwhile, the board machining stability is high, and the machining quality is good.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

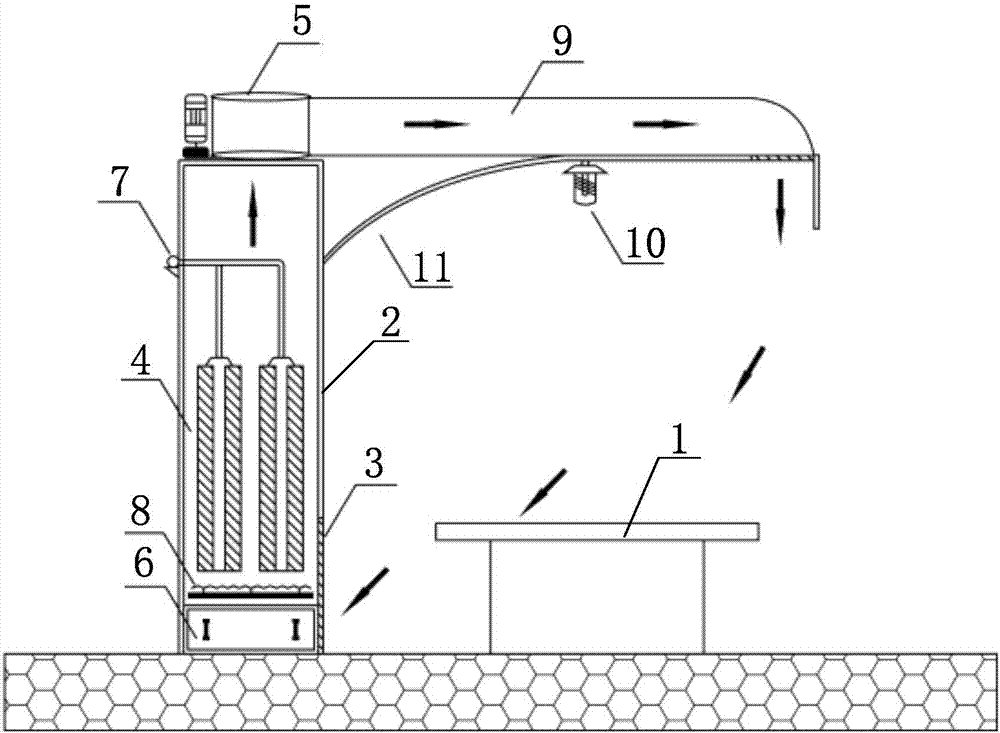

Grinding room with recycling function

InactiveCN107350972AFeel cool to workDamage to healthDispersed particle filtrationGrinding/polishing safety devicesAir pollutionSurface grinding

The invention discloses a grinding room with a recycling function. The grinding room comprises a grinding platform. A dust suction recycling pipe is arranged beside the grinding platform. A dust suction opening is formed in the side face, close to the grinding platform, of the dust suction recycling pipe. A cloth bag filtering device is arranged in the dust suction recycling pipe. A pulse air pipe is connected to the top of the cloth bag filtering device. An outlet of the dust suction recycling pipe is connected with a suction opening of an exhaust fan. An air outlet of the exhaust fan is connected with an air return pipeline. The air return pipeline is horizontally arranged and provided with an air outlet. A dust storage bin is arranged below the cloth bag filtering device. By the adoption of the grinding room, large-concentration dust generated during the surface grinding operation and deep machining of components can be sucked away and collected in a concentrated manner, air is recycled, the air is exhausted indoors after the dust is removed, the purified air is recycled to the grinding room, workers do not need to wear masks when working in the grinding room, the problem of the emission pollution existing in traditional grinding can be solved, and the air pollution and the harm to the body health of the workers are avoided.

Owner:成都漆彩之星环保科技有限公司

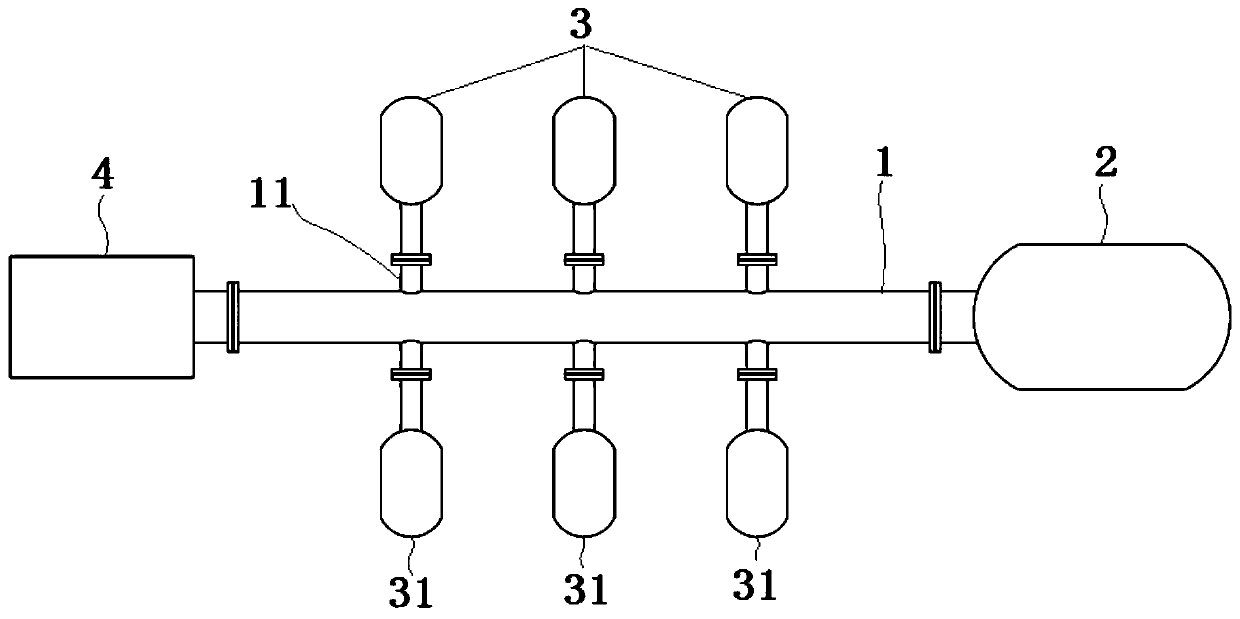

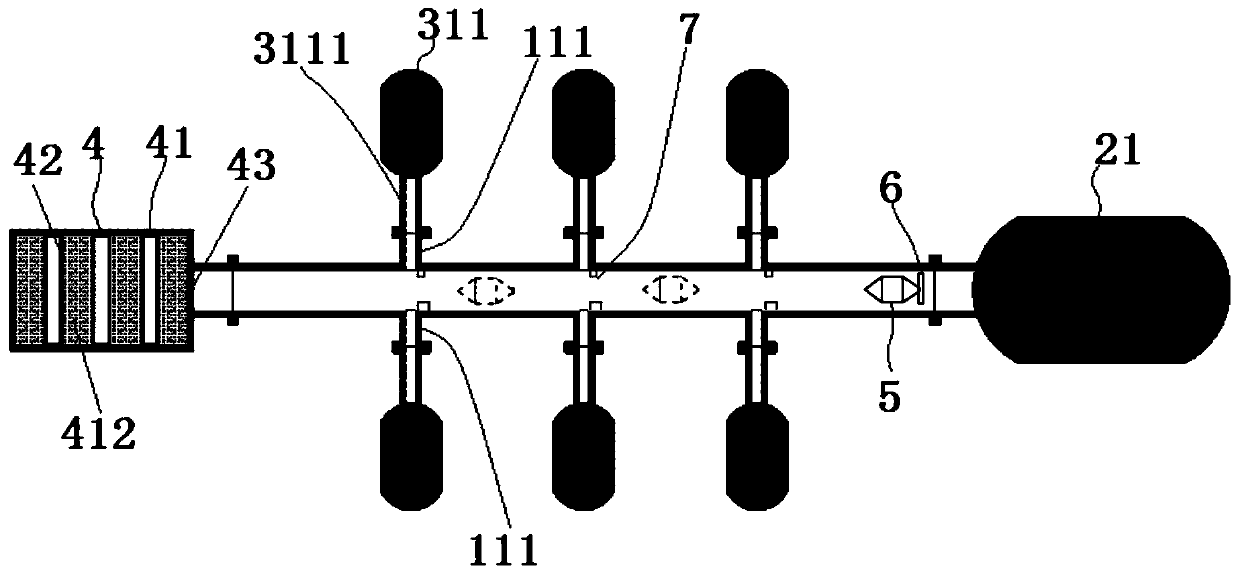

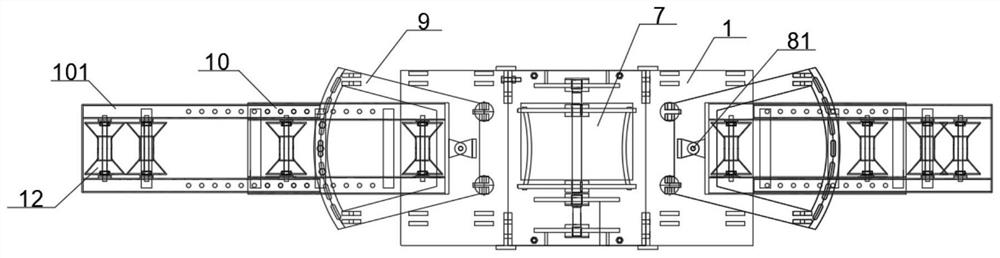

Continuous moving body acceleration system for strong impact test and working method thereof

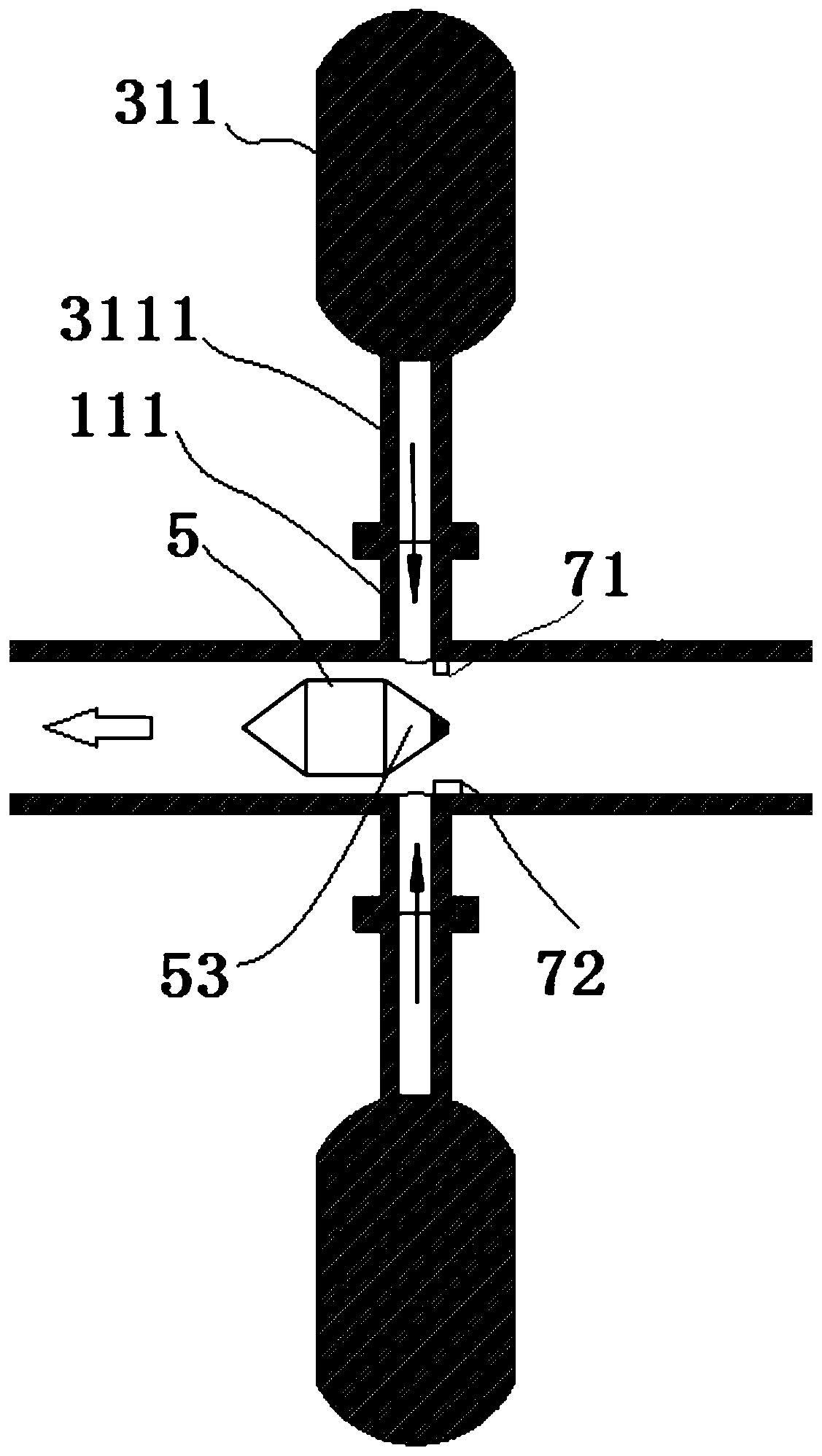

ActiveCN109855832AImprove accuracyImprove acceleration performanceCompressed gas gunsShock testingWorking setEngineering

The invention discloses a moving body continuous acceleration system for a strong impact test and a working method thereof. The system comprises a moving body high-speed motion pipeline, a primary pneumatic acceleration device, a secondary pneumatic acceleration device, a moving body recovery device and a moving body arranged in the moving body high-speed motion pipeline. An air outlet of the primary pneumatic acceleration device is communicated with an initial pipe orifice of the moving body high-speed motion pipeline to drive the moving body pneumatically so as to obtain an initial speed ofhigh-speed movement in the moving body high-speed motion pipeline. An air outlet of the secondary pneumatic acceleration device is communicated with the body of the moving body high-speed motion pipeline to drive the moving body pneumatically multiple times so as to realize acceleration and high-speed movement in the moving body high-speed motion pipeline. The moving body recovery device is used for recycling a moving body ejected from the moving body high-speed motion pipeline. According to the invention, the moving body can be accelerated continuously in the strong impact test and thus the high-speed movement of the moving body in the moving body high-speed motion pipeline is realized; and the acceleration effect is good.

Owner:XIAN TECHNOLOGICAL UNIV

Powder metallurgy dust removing device

InactiveCN107838127AWith collection functionWith recycling functionDirt cleaningCleaning using gasesEngineeringConveyor belt

The invention discloses a dust removal device for powder metallurgy, which comprises a support device and a dust removal device; a conveyor belt is interspersed in the middle of the inner cavity of the dust removal box; cavity, and set on the inner side of the conveyor belt, a vibrator is fixed under the supporting plate, and a roller bracket is set above the supporting plate; the material retaining screen is set on the upper side of the inner cavity of the dust removal box; The lower end of the machine is connected with the dust suction hood through the dust suction pipe, and the dust suction hood is equidistantly arranged on the upper end of the dust removal box. On the top, it has the function of blowing the powder on the blank to facilitate separation; the upper end of the exhaust fan is provided with a collection bag through the dust suction pipe, which has the function of collecting and recycling the powder dust; the device has a simple manufacturing process and is practical. Strong performance and good dust removal effect.

Owner:WUXI WASHING MACHINERY FACTORY

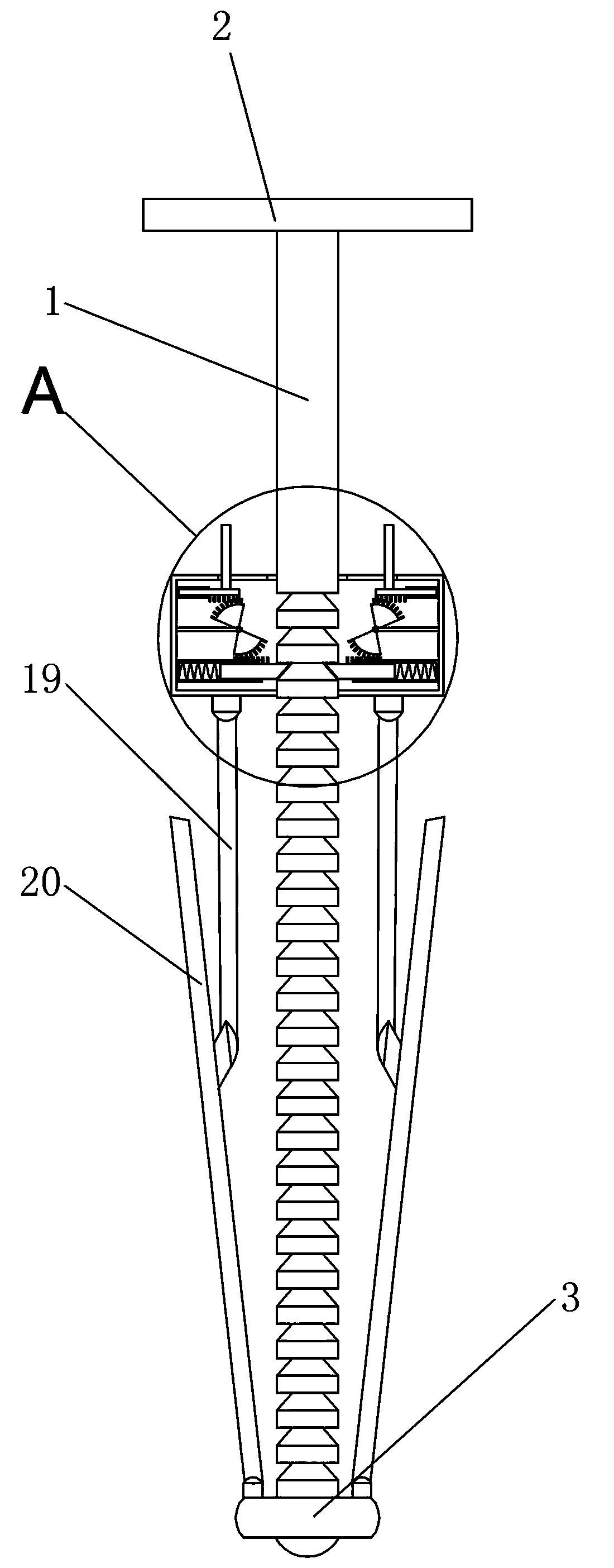

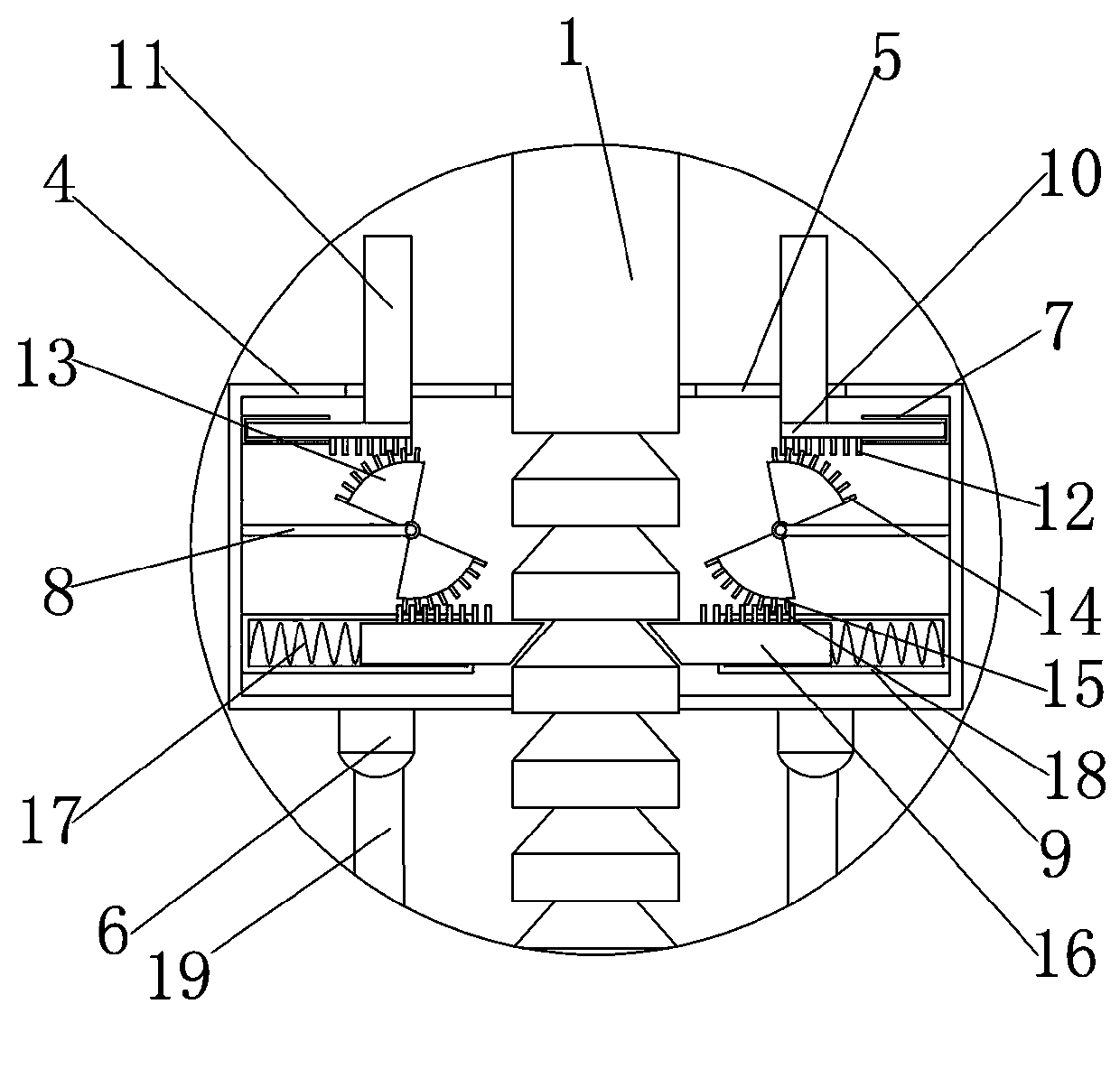

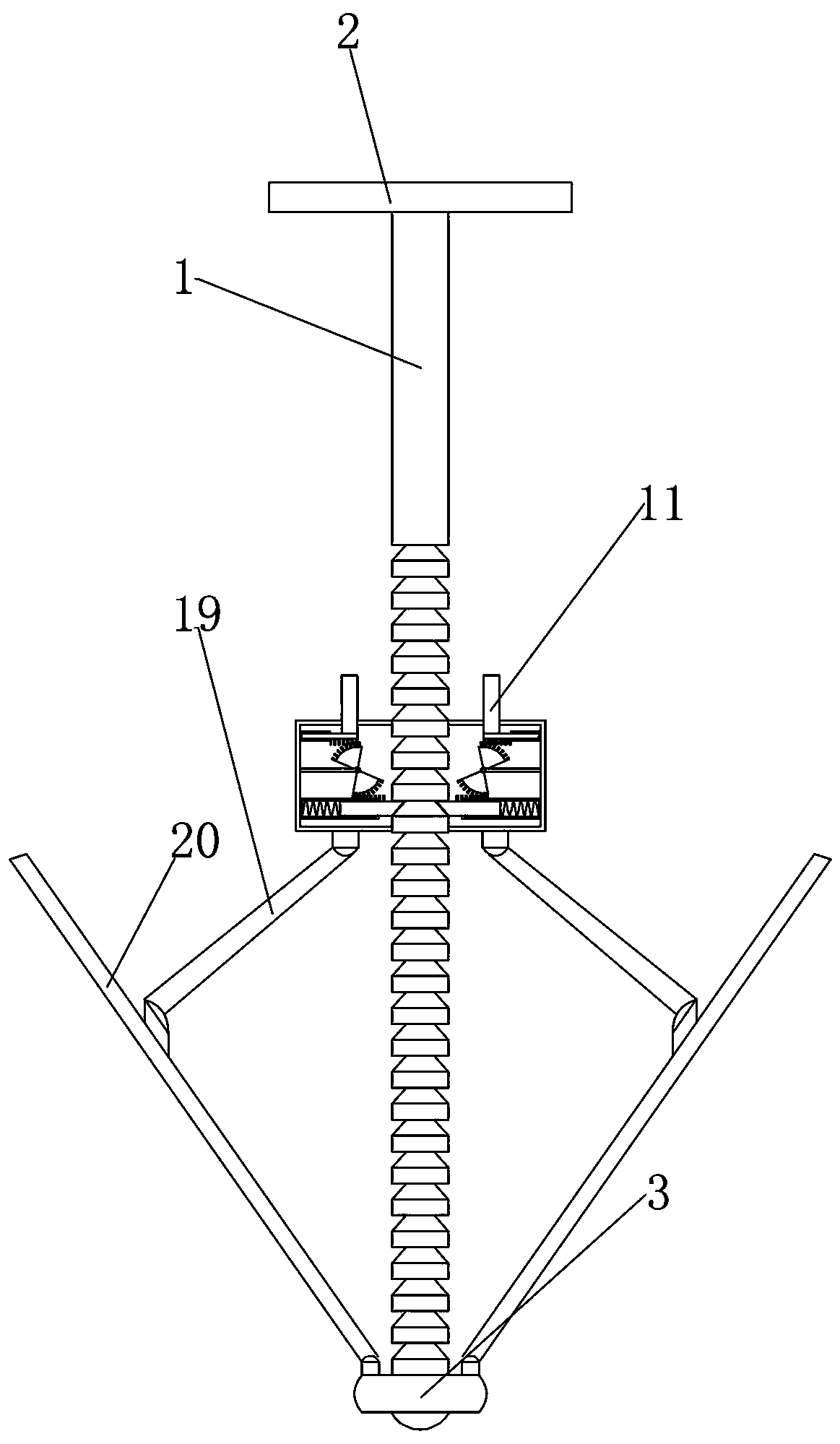

Soil slope fixing device

InactiveCN110984196AEasy to fixFixed effects influenceExcavationsBulkheads/pilesSoil scienceStructural engineering

The invention discloses a soil slope fixing device. The soil slope fixing device is primarily composed of a cylindrical long rod, a control box, moving rods, a bayonet lock, a spring and a transmission plate. According to the device, the second moving rod and the third moving rod can be unfolded according to an actual need, so that the contact range between the soil slope fixing device and a surrounding soil body is improved and the soil body fixing effect is improved. After the moving rods are unfolded at certain angles, the angles can be fixed by means of the bayonet lock, so that a condition that the fixing effect is affected as the angles shrink due to the pressure of the surrounding soil body is prevented. Meanwhile, the soil slope fixing device has a recovery function and can be usedcircularly.

Owner:JIAXING UNIV

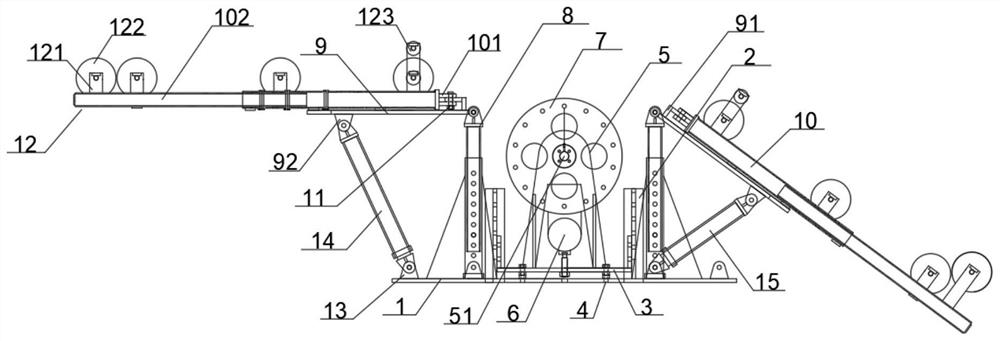

Cable laying take-up and pay-off device and using method thereof

ActiveCN113788369AAvoid manual unloadingPowerfulApparatus for laying cablesEngineeringStructural engineering

Owner:HUAINAN MINING IND GRP

Machine tool with lubricating oil recycling function

ActiveCN104924149AWith recycling functionImprove recycling efficiencyMaintainance and safety accessoriesSlagFuel tank

The invention provides a machine tool with a lubricating oil recycling function. The machine tool comprises a rack, a machining mechanism, an oil storage tank, an oil and slag separating screen plate, a slag collecting tank, an oil collecting tank, a lubricating oil filter, a recycling tank, a first suction pump and a second suction pump. The machining mechanism is mounted on the rack, and the oil storage tank can convey lubricating oil to the machining mechanism; the oil and slag separating screen plate is mounted on the rack in an inclining manner and is located under the machining mechanism; and a plurality of screen holes are formed in the oil and slag separating screen plate; the slag collecting tank is mounted at the lower end of the oil and slag separating screen plate, and the oil collecting tank is mounted on one side, close to the ground, of the oil and slag separating screen plate; a first screen net is arranged in the oil collecting tank, and an output pipe is arranged on the oil collecting tank; the output pipe is communicated with an oil inlet end of the lubricating oil filter; and the oil outlet end of the lubricating oil filter is communicated with the recycling tank, and the oil storage tank is communicated with the recycling tank through the second suction pump. Lubricating oil is circularly utilized, lubricating oil cost is saved, and the problem of waste oil draining is solved.

Owner:蚌埠中知知识产权运营有限公司

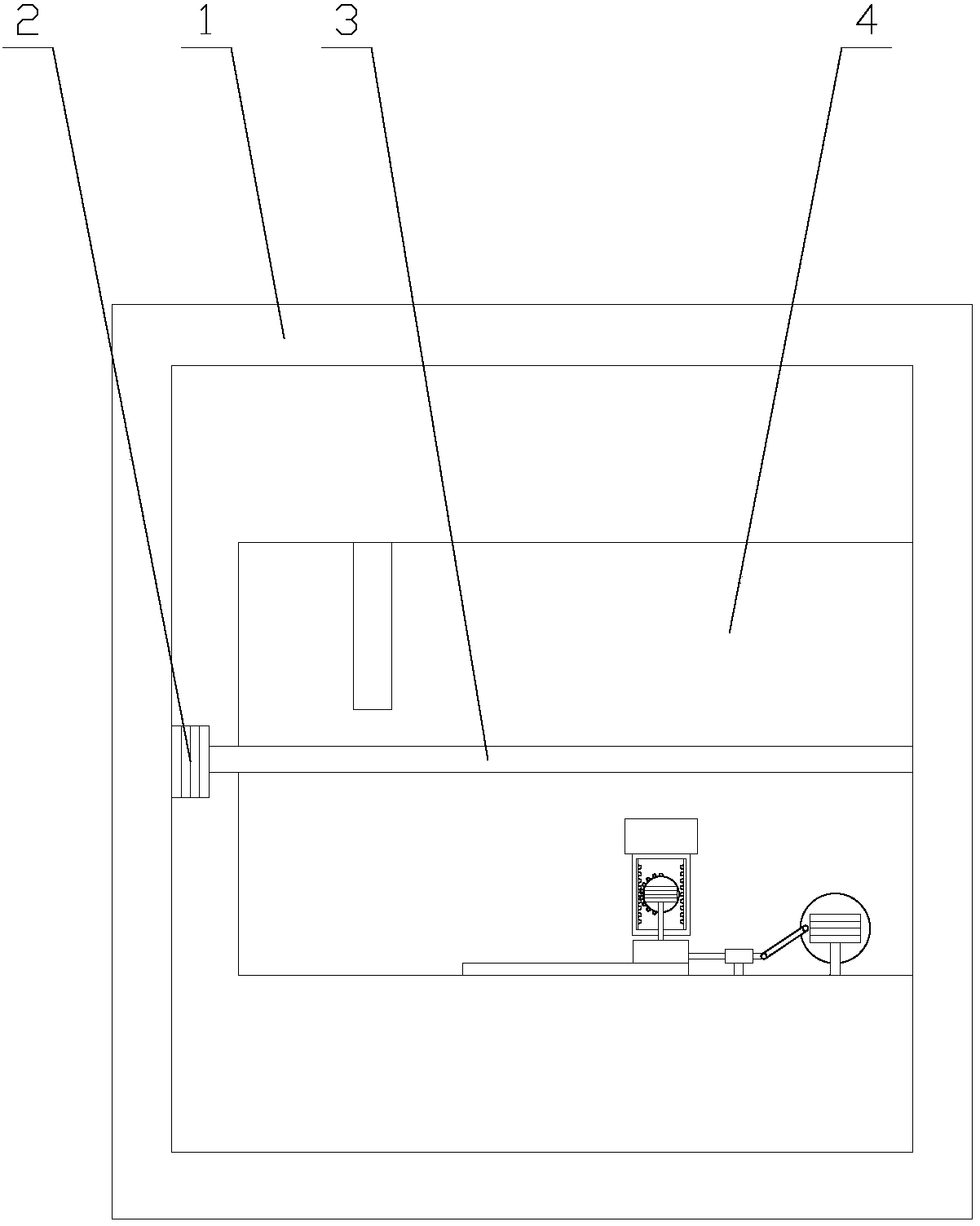

Production equipment of intelligent optical fiber preforming bar with recovery function

InactiveCN107804966AWith recycling functionImprove practicalityGlass making apparatusEngineeringRecovery function

The invention relates to production equipment of an intelligent optical fiber preforming bar with a recovery function. The production equipment comprises a shell; the shell is internally provided witha first motor, a target bar and a reaction chamber; the reaction chamber is internally provided with a cleaning mechanism and a moving mechanism; the moving mechanism comprises a lifting assembly anda moving assembly; and the lifting assembly comprises a blast lamp, a moving frame, a second motor, a semi-gear, a connecting rod and two racks. According to the intelligent optical fiber preformingbar with the recovery function, residues on the target bar are cleaned away by the cleaning mechanism, and compared with a traditional cleaning mechanism, the cleaning mechanism is wider in cleaning angle and better in cleaning effect; and a nonuniform part of a dust-like porous stock bar is filled by the moving mechanism, and compared with a traditional moving mechanism, the moving mechanism is more stable and precise during lifting and horizontal moving, so that the dust-like porous stock bar is more precisely filled by using the blast lamp, and the practicability of the production equipmentof the optical fiber preforming bar is greatly improved.

Owner:深圳市中科智诚科技有限公司

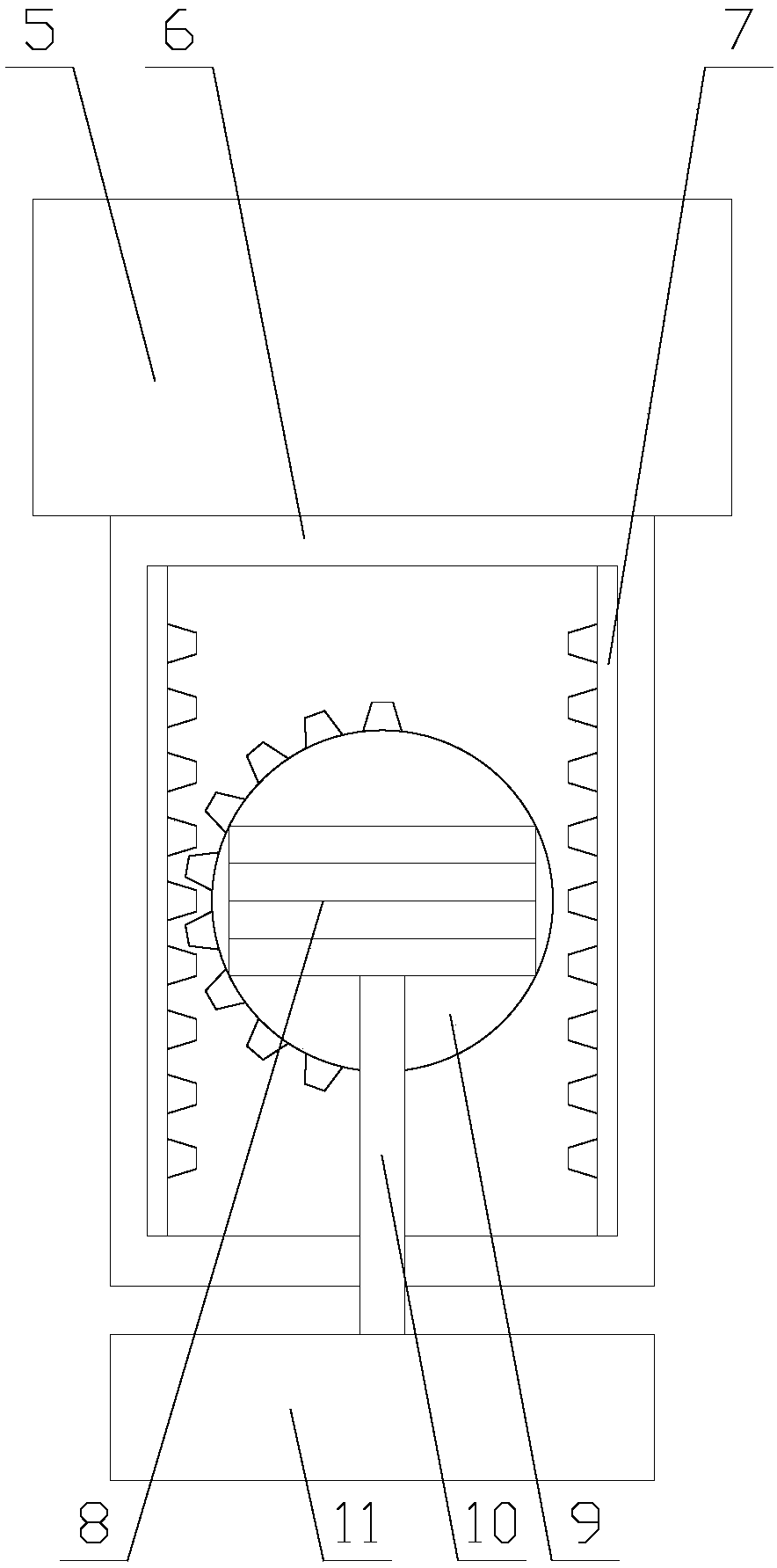

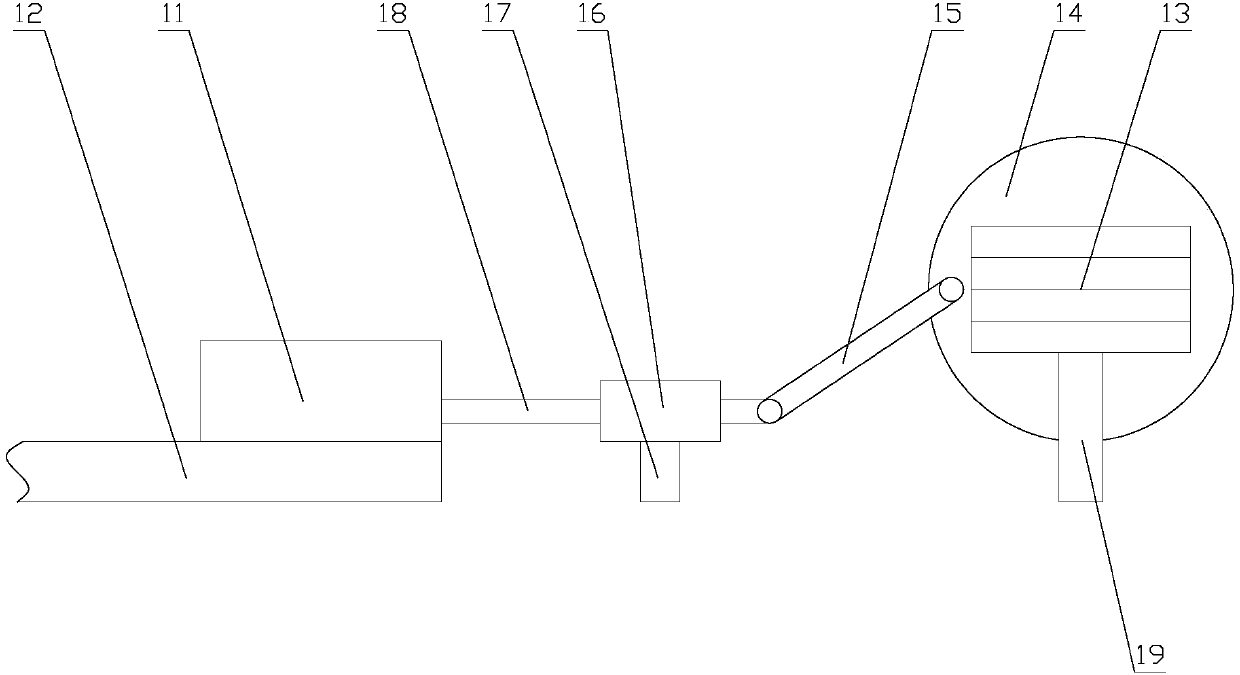

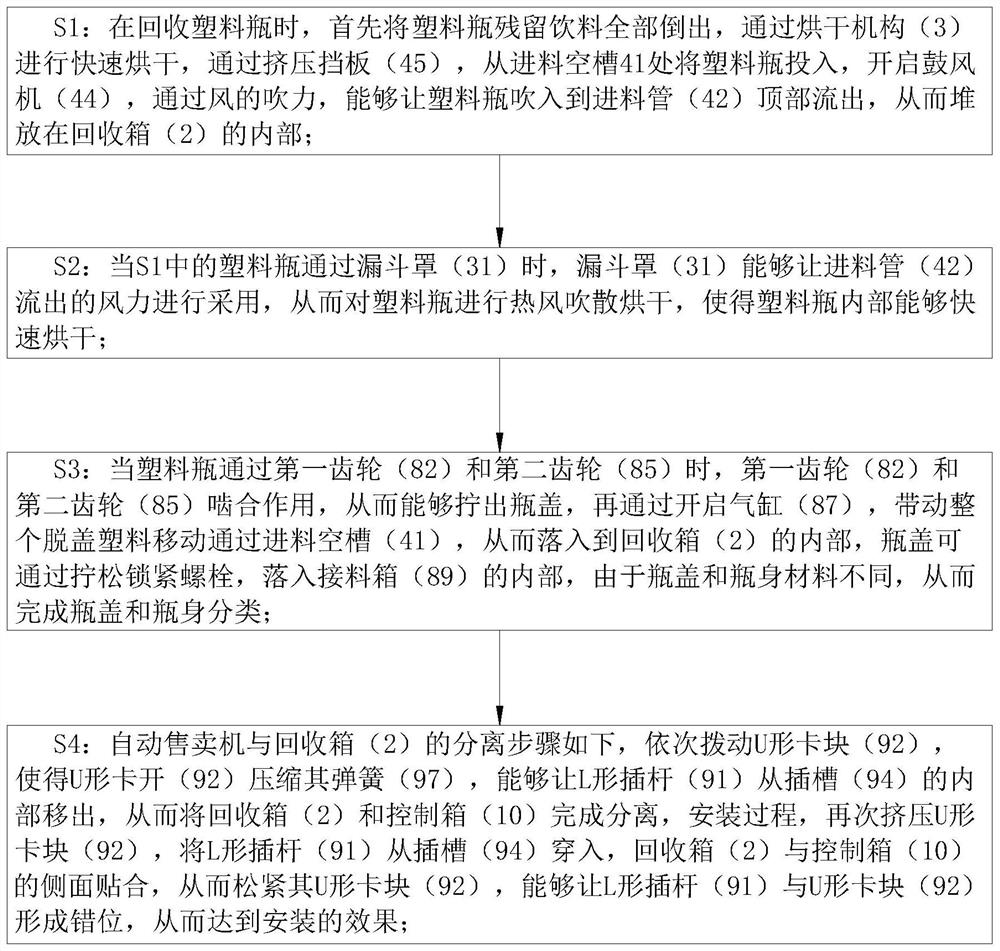

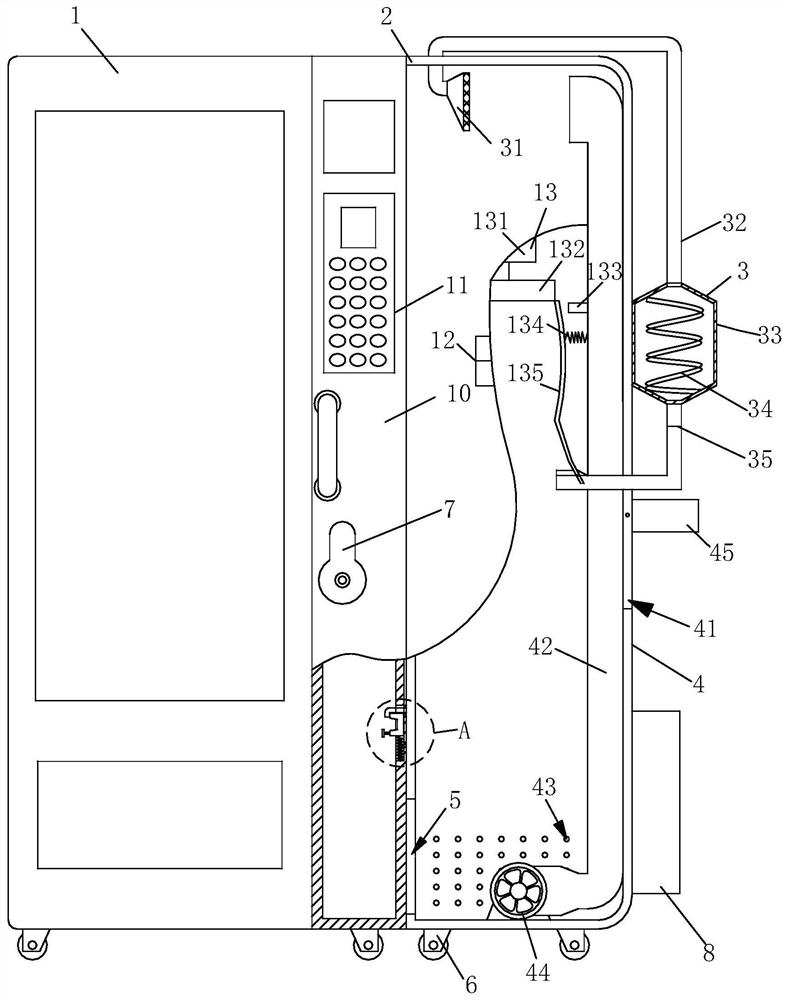

Waste plastic bottle classification and recovery method

InactiveCN111824625AWith plastic bottle recycling functionWith recycling functionBottle/container closurePower operated devicesProcess engineeringAir blower

The invention relates to the field of plastic recovery, and particularly relates to a waste plastic bottle classification and recovery method. A vending machine body, a control box, a recovery box, adrying mechanism, a feeding mechanism and an automatic classification mechanism are included, wherein the drying mechanism is connected to the top of the side face of the recovery box; the feeding mechanism is connected into the recovery box and comprises a feeding pipe, an air blower and a baffle; the inner bottom of the recovery box is connected with the air blower; an outlet of the air blower is connected with the feeding pipe; the outer side wall of the feeding pipe is connected with the inner side face of the recovery box; the side faces, attached to each other, of the feeding pipe and the recovery box are provided with feeding empty grooves correspondingly; and the tops of the feeding empty grooves are rotationally connected with the baffle through hinges. The vending machine with the plastic bottle recovery function has the beneficial effects that materials can be put from the low position and start to fall from the inner top of the recovery box, and the internal volume of the recovery box is sufficiently stored and utilized.

Owner:唐杰

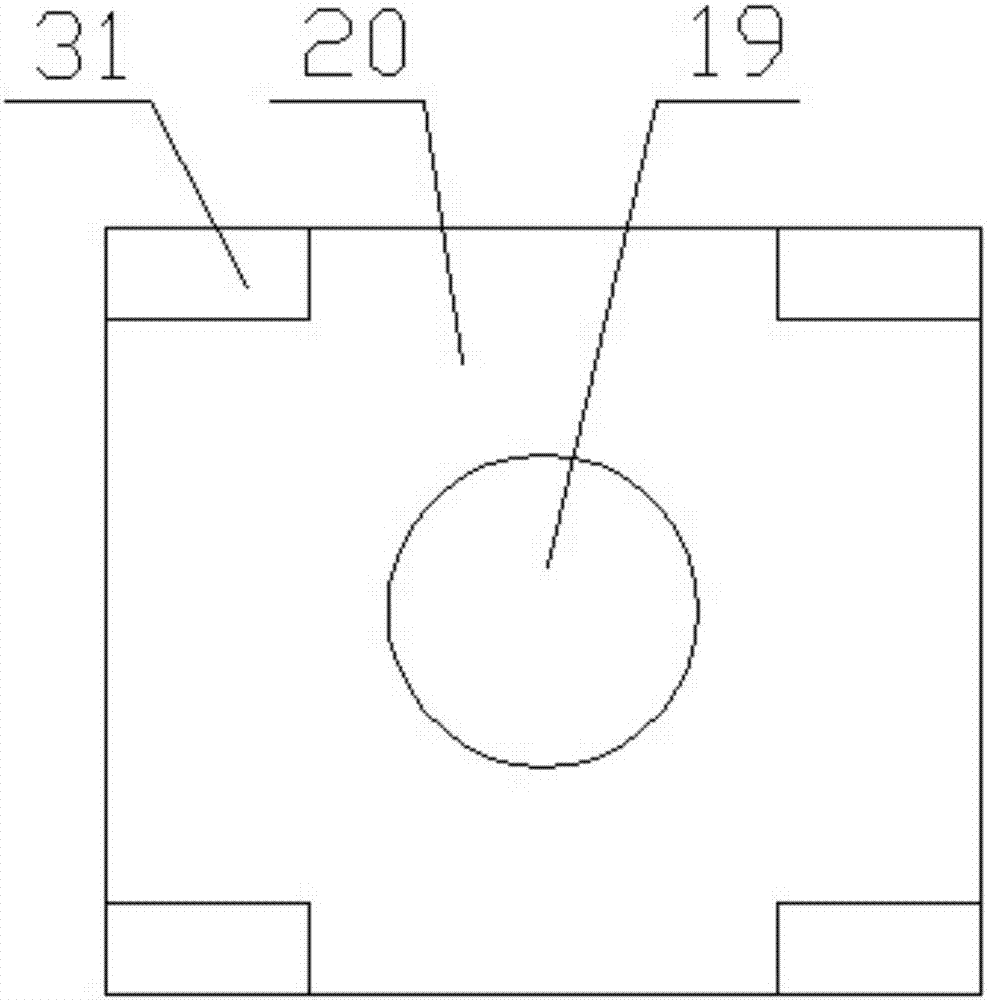

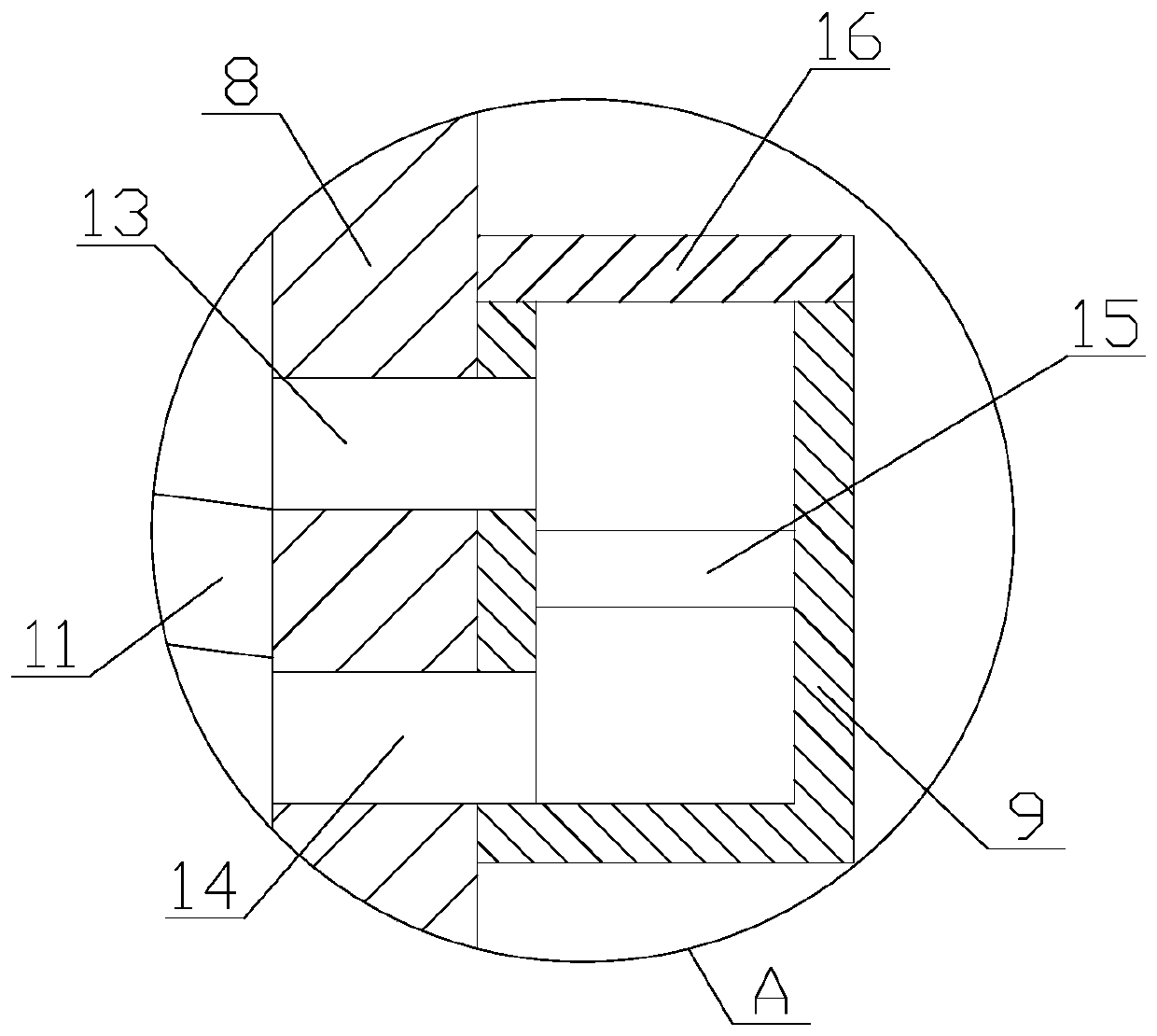

Electromagnetic pump wave crest generator with function of recovering welding flux

InactiveCN102056422ASimple structureNovel and reasonable designPrinted circuit assemblingMetal working apparatusEngineeringThree-phase

The invention disclose an electromagnetic pump wave crest generator with a function of recovering welding flux, comprising the wave crest generator and a welding flux recovery unit, wherein the wave crest generator comprises a wave crest inner container and an actuating mechanism, the welding flux recovery unit is internally embedded on the wave crest generator; the actuating mechanism is a three-phase asynchronous inductive electromagnetic pump arranged at the bottom of the wave crest inner container, the outer side of a wave crest sprayer arranged on the wave crest inner container is communicated with the ditch of three-phase asynchronous inductive electromagnetic pump via a side runner, the interior of the wave crest inner container and the ditch of the three-phase asynchronous inductive electromagnetic pump are communicated via a main runner, the main runner and the side runner are communicated to form a circulation channel for the welding flux to flow; and an electric heater is arranged at the outer side of the bottom of the bottom side runner. The invention has the advantages of simple structure, novel and reasonable design, low cost, simplicity for operation, more functions, high utilization ratio of the welding flux, power saving and the like, and can be used for effectively solving the defects and deficiencies of high electric energy consumption and environmental pollution and the like in traditional wave crest welding machines.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

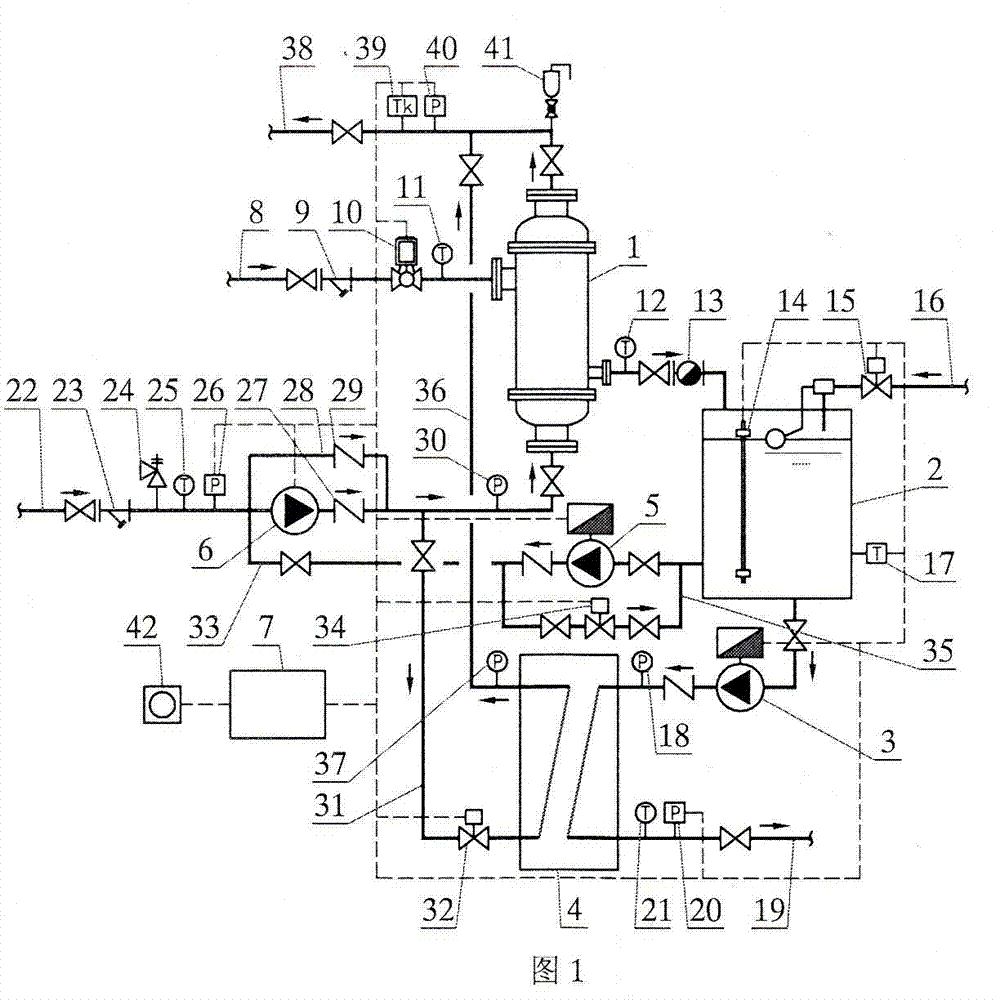

Recycling efficient energy-saving steam-water heat exchange station

InactiveCN104848321AImprove utilization efficiencyWith waste heat utilizationLighting and heating apparatusSpace heating and ventilation detailsEngineeringCirculating pump

The invention discloses a recycling efficient energy-saving steam-water heat exchange station. The recycling efficient energy-saving steam-water heat exchange station is mainly composed of a steam heat exchanger, a condensate water recycling and storing box, a recycling variable frequency pump, a condensate water heat exchanger, a water filling variable frequency pump, a circulating pump and a control cabinet. The steam heat exchanger and the condensate water heat exchanger are arranged in a parallel-connection manner; and a first-time outlet of the steam heat exchanger is provided with a connecting pipe, and the steam heat exchanger is connected with the condensate water recycling and storing tank; a water conveying pipe is arranged at the bottom of the condensate water recycling and storing tank and is connected with a second-time inlet of the condensate water heat exchanger; a second-time outlet of the condensate water heat exchanger is connected with a condensate water recycling pipe, and the recycling variable frequency pump is arranged on the water conveying pipe, connected with the condensate water heat exchanger, of the condensate water recycling and storing tank; and a first pressure sensor is arranged on the condensate water recycling pipe. The recycling efficient energy-saving steam-water heat exchange station has the beneficial effects that the function of utilizing and recycling steam condensate water waste heat is achieved, and therefore the utilization efficiency of steam heat exchange is improved; and energy saving and emission reduction are achieved, and meanwhile the heating cost is reduced.

Owner:高天红

Cut-off equipment with recovering function for filter material processing

InactiveCN109927099AWith recycling functionMetal working apparatusBiochemical engineeringMaterials processing

The invention provides cut-off equipment with a recovering function for filter material processing and relates to the field of filter materials. The cut-off equipment with the recovering function forfilter material processing comprises a cut-off equipment working plate. Supporting legs are fixedly connected to two sides of the lower surface of the cut-off equipment working plate, an electric pushrod is fixedly connected to the left side of the upper surface of the cut-off equipment working plate, and a fixed block is fixedly connected to the end, far away from the cut-off equipment working plate, of the electric push plate. According to the cut-off equipment with the recovering function for filter material processing, by arranging a fan matched with an obstructing plate and an isolatingnet, the cut-off equipment for filter material processing has the recovering function by means of a groove and a recovery hole, so that the problem of waste of resources is solved effectively as the cut-off equipment for filter material processing for cutting off a filter material generates some residues in a filter material cut-off process and the current cut-off equipment for filter material processing cannot recycle the residues in a centralized manner.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

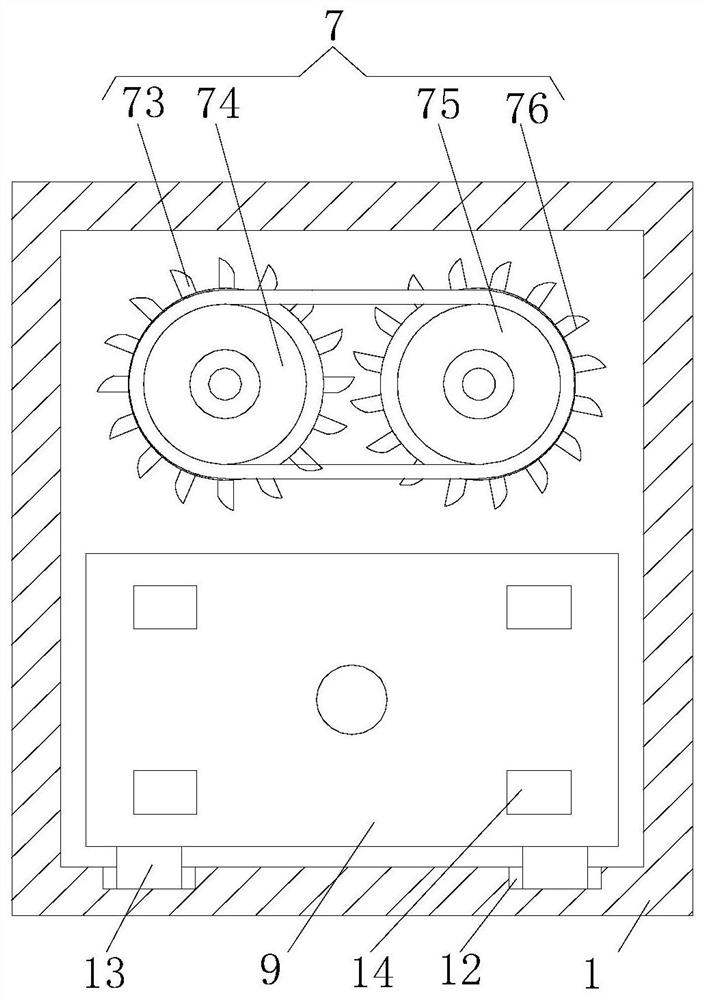

Textile fabric edge cutting device with waste recovery function

InactiveCN112538749AWith recycling functionEasy to transportSevering textilesGrain treatmentsElectric machineryStructural engineering

The invention provides a textile fabric edge cutting device with a waste recycling function. The textile fabric edge cutting device comprises a box body, a support is connected to the top of the box body in a bolted mode, a containing plate is connected to the center of the top of the box body in a bolted mode, and an electric telescopic rod is connected to the center of the top of an inner cavityof the support in a bolted mode. Through cooperation of through grooves, a user can conveniently convey waste into the box body, random discarding of the waste is avoided, and cleanliness and tidiness of a work site are guaranteed; through cooperation of a motor, a driving source is provided for rotation of a first smashing roller; through cooperation of the first smashing roller, a first belt wheel can be driven to rotate; through cooperation of the first belt wheel, a second belt wheel and a second smashing roller can be driven to rotate; and through cooperation of the second smashing roller and the first smashing roller, the waste can be smashed. Resource waste is reduced, ecological environment protection is facilitated, and the problem that most of traditional edge cutting devices for the textile fabric do not have the waste recycling function is solved.

Owner:WUJIANG KESHIDA TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com