Cable laying take-up and pay-off device and using method thereof

A retractable device and cable laying technology, applied in the direction of cable laying equipment, etc., can solve the problems of low efficiency, hanging cables, high labor intensity, etc., and achieve the effects of saving construction labor, improving construction efficiency, and strong power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

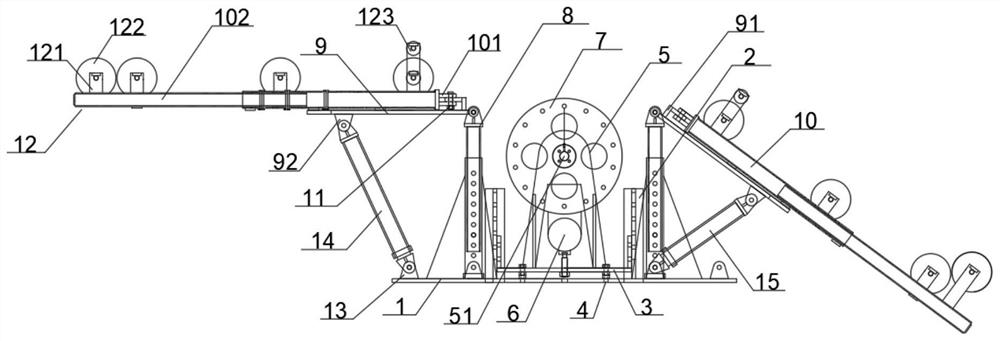

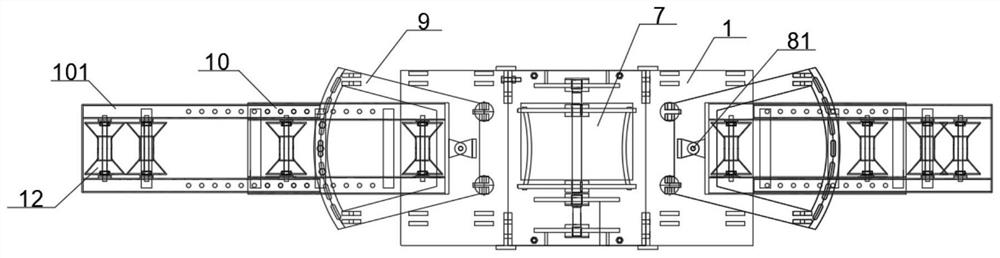

[0029] refer to figure 1 , this embodiment discloses a cable laying and retracting device and its use method, including a base 1, a fixing frame 2, a mounting plate 3, a screw rod 4, a mounting frame 5, an air hoist 6, a roller 7, and a height adjustment sleeve 8. Bracket 9, cantilever frame 10, limit pin shaft 11, roller assembly 12, second fixed seat 13, first angle sleeve 14, second angle sleeve 15.

[0030] refer to figure 1 , the upper end of the central position of the base 1 is provided with a mounting plate 3, and the upper end of the mounting plate 3 is provided with through holes matching the screw mandrel 4, and the lower ends of a plurality of screw mandrels 4 are fixedly connected to the base 1 through the through holes; The upper end of 1 is located at the periphery of mounting plate 3 and is fixedly connected with fixing frame 2 .

[0031] In this embodiment, several through holes are opened on both sides of the upper end of the fixing frame 2 .

[0032] refe...

Embodiment 2

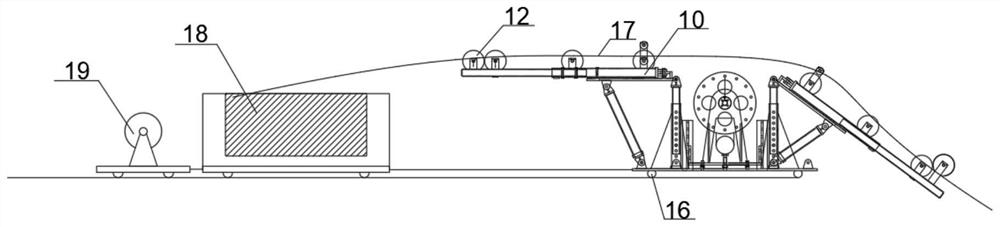

[0045] Embodiment 2, the difference between this embodiment and Embodiment 1 is that, refer to Figure 5 , the cantilever frame 10 is lifted and the telescopic frame 102 is stretched out at the same time, so that the height of the cable 17 on the telescopic frame 102 is slightly higher than the height of the hanging cable hook 20, and the cable 17 is placed in the cable hook 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com