Patents

Literature

93results about How to "Convenient production work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roadway surrounding rock stress monitoring device based on fiber bragg grating sensing

ActiveCN103454021AUnderstanding Stress SituationsImprove stabilityForce measurement by measuring optical property variationUsing optical meansGratingFiber Bragg grating

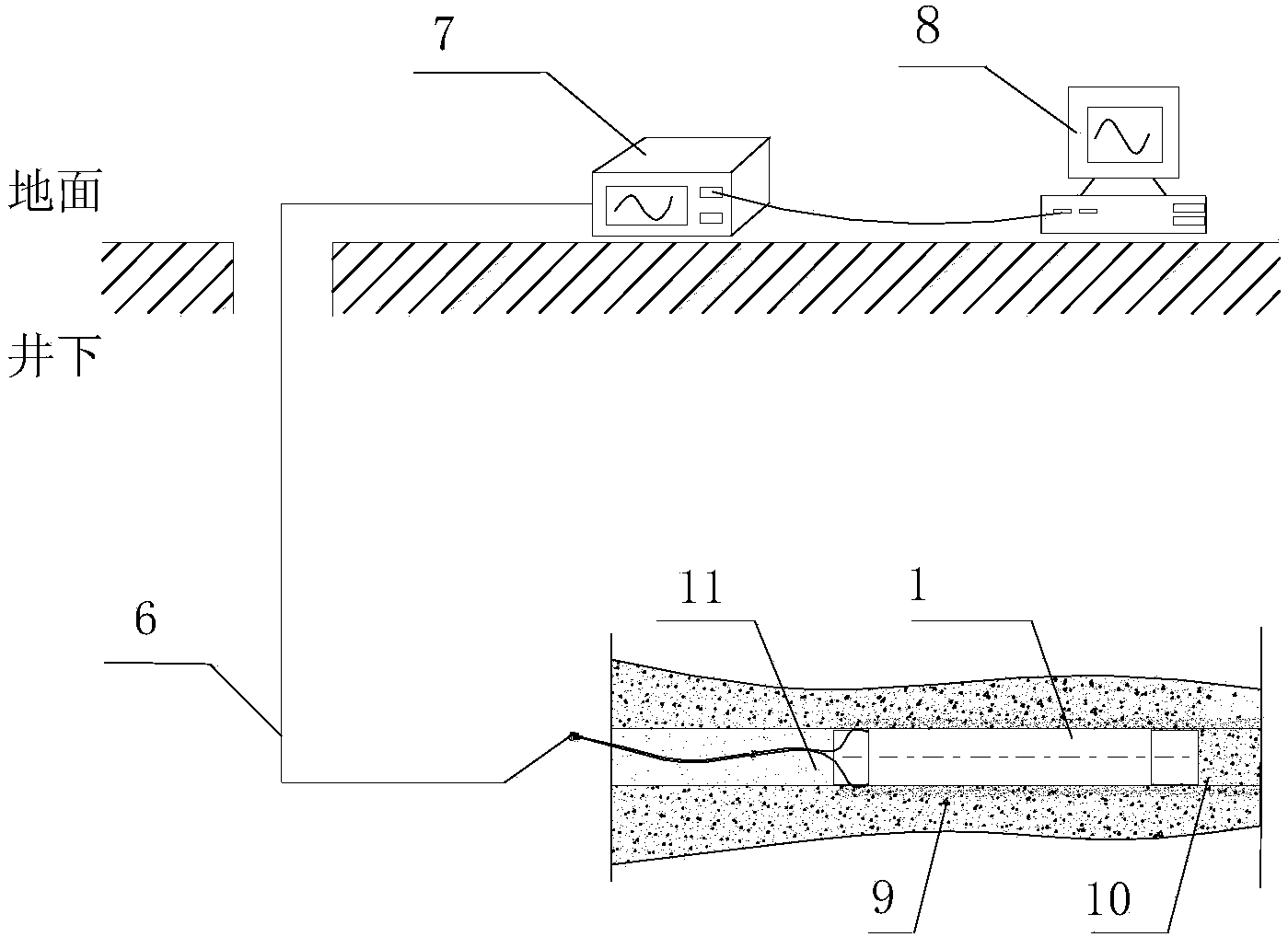

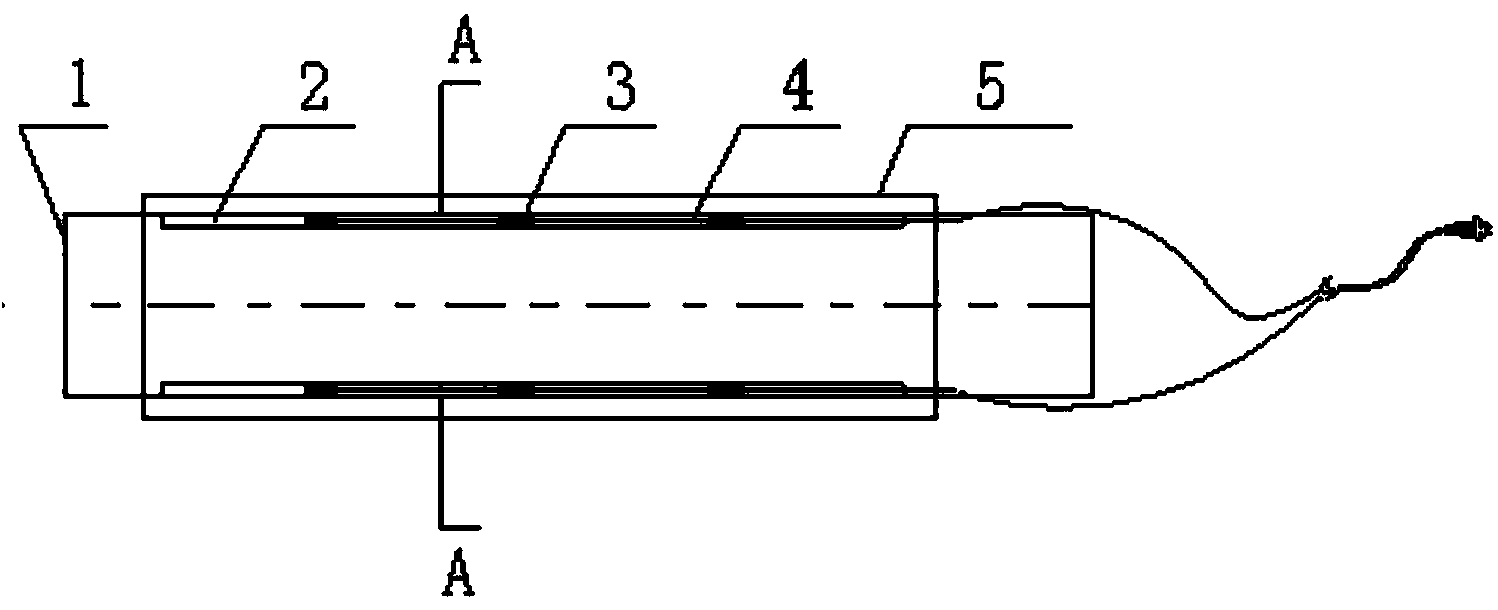

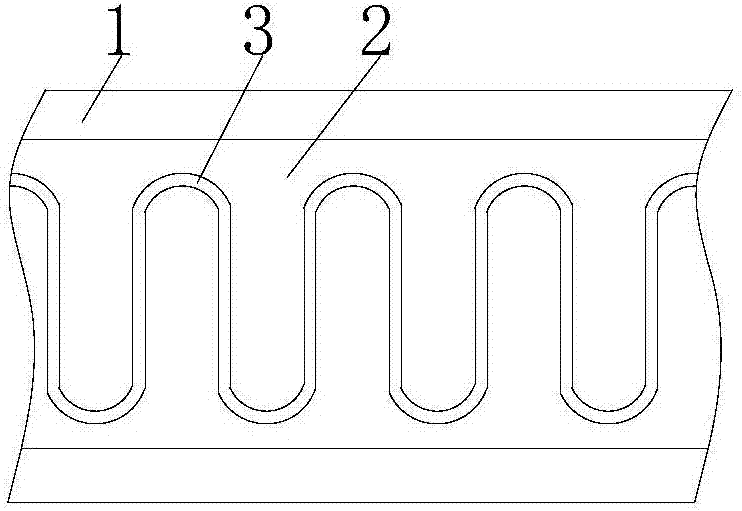

The invention discloses a roadway surrounding rock stress monitoring device based on fiber bragg grating sensing. Grooves are symmetrically carved in a metal rod along the axial center, an FBG set is fixedly installed inside each groove, FBGs serve as sensitive elements, when roadway surrounding rock is deformed, the stress of the surrounding rock will be changed, therefore, force is generated through the metal rod, surface micro-deformation is generated, the grating distances of the FBGs attached to the metal rod are changed along with the metal rod, the center reflection wavelength of the FBGs can be caused to generate drifting, wavelength signals are demodulated into electrical signals through an FBG interrogator, and the stress situations of different sites can be obtained. The roadway surrounding rock stress monitoring device has the advantages that installation is easily achieved, and the roadway surrounding rock stress monitoring device is suitable for wide popularization; power is not required to be supplied to the working face end, and site safety is guaranteed; all-optical measurement and fiber transmission are adopted, and influences of electromagnetic interference are effectively avoided; the temperature error is compensated, and the accuracy is improved; the surrounding rock stress monitoring results can be timely and accurately provided, and guidance on site production and scientific research is facilitated.

Owner:CHINA UNIV OF MINING & TECH

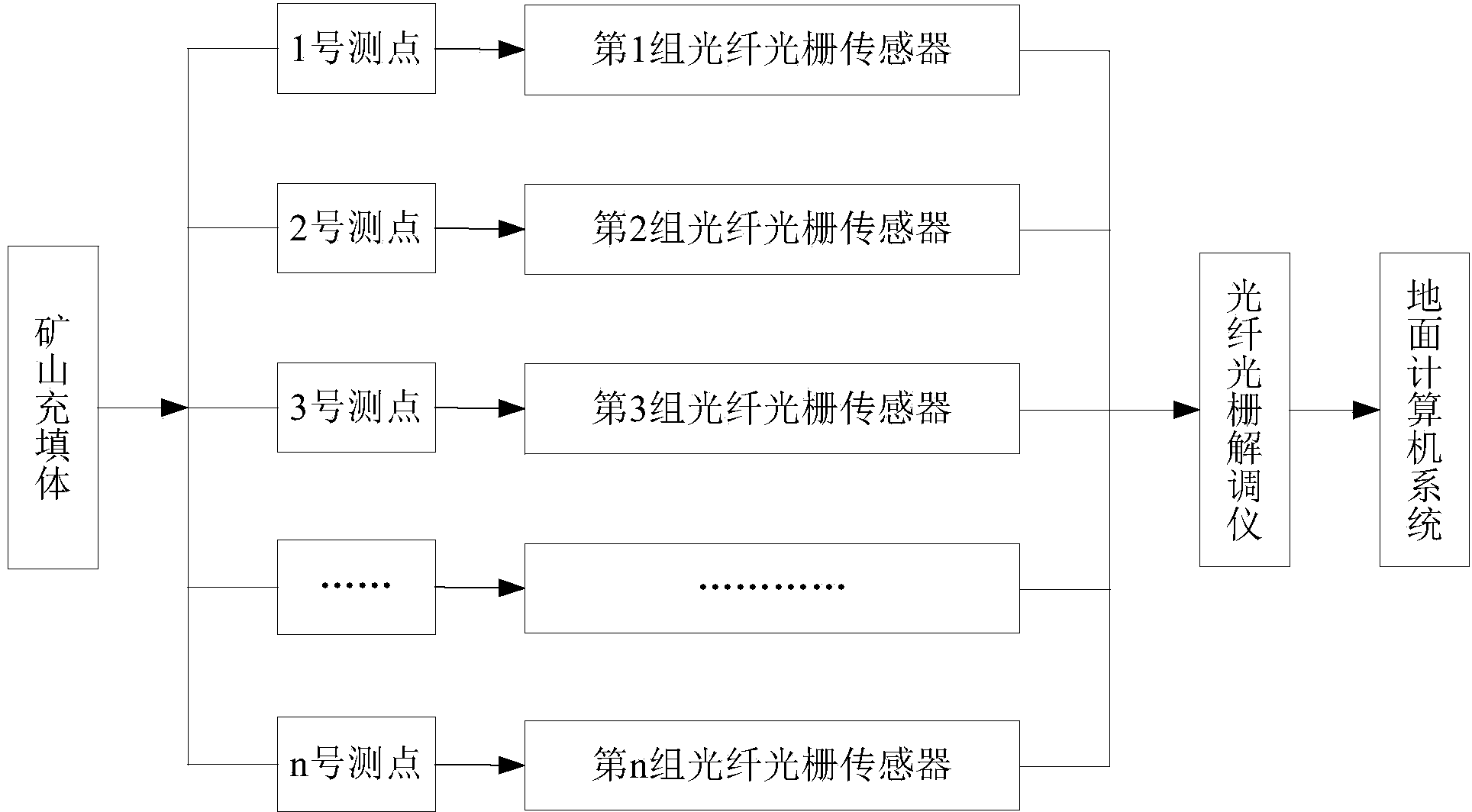

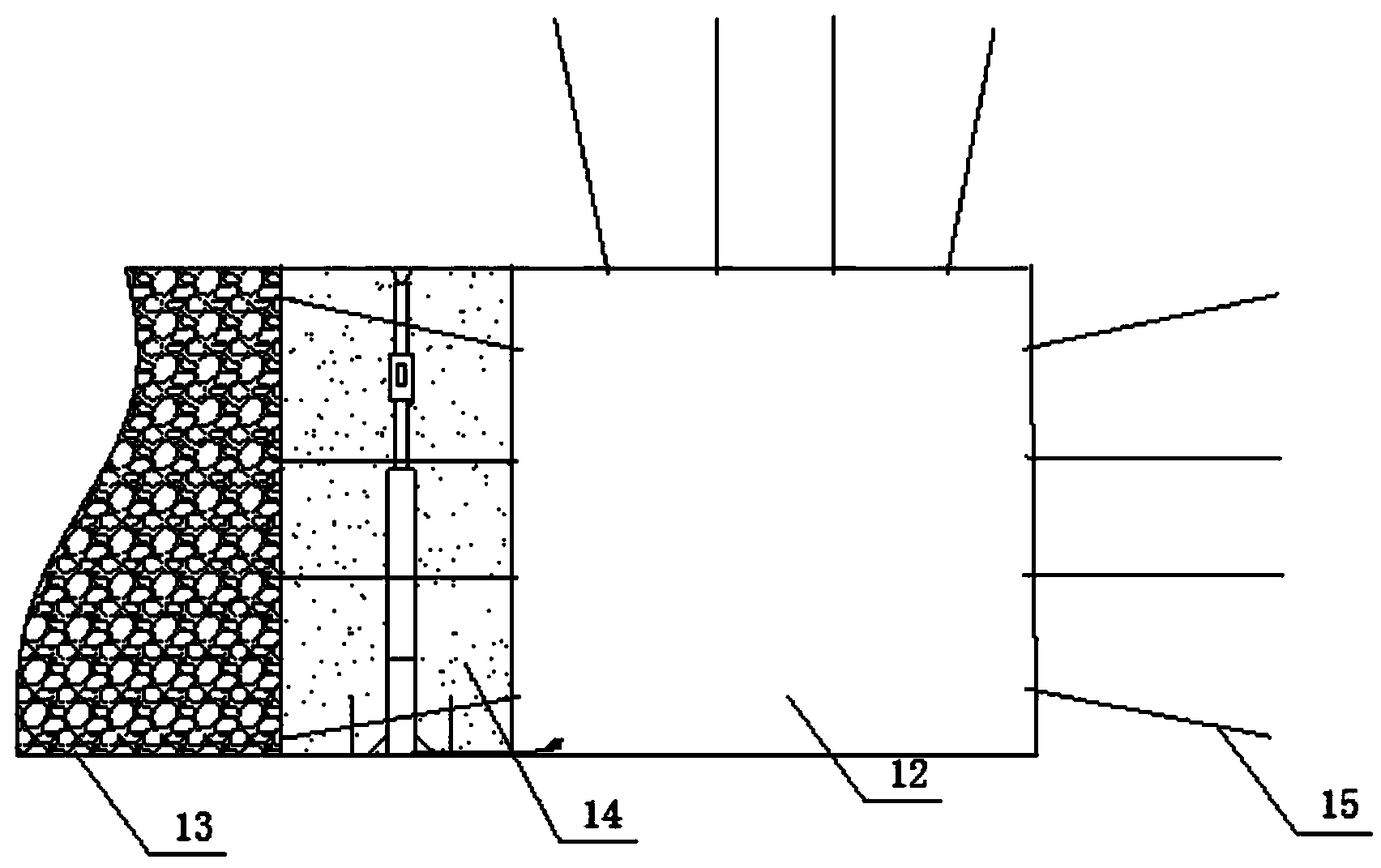

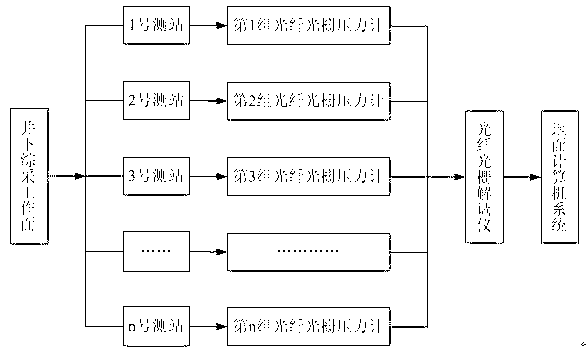

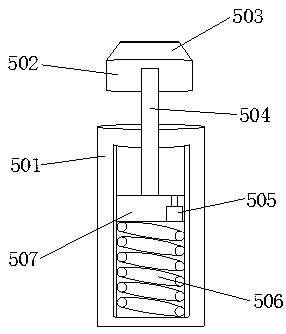

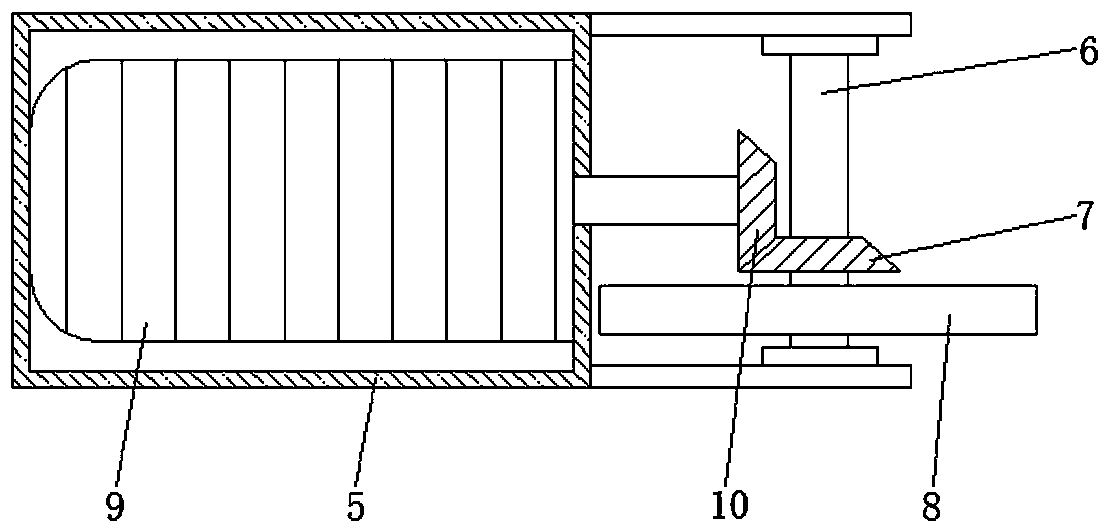

Coal mine paste filler online monitoring system based on optical fiber grating sensing

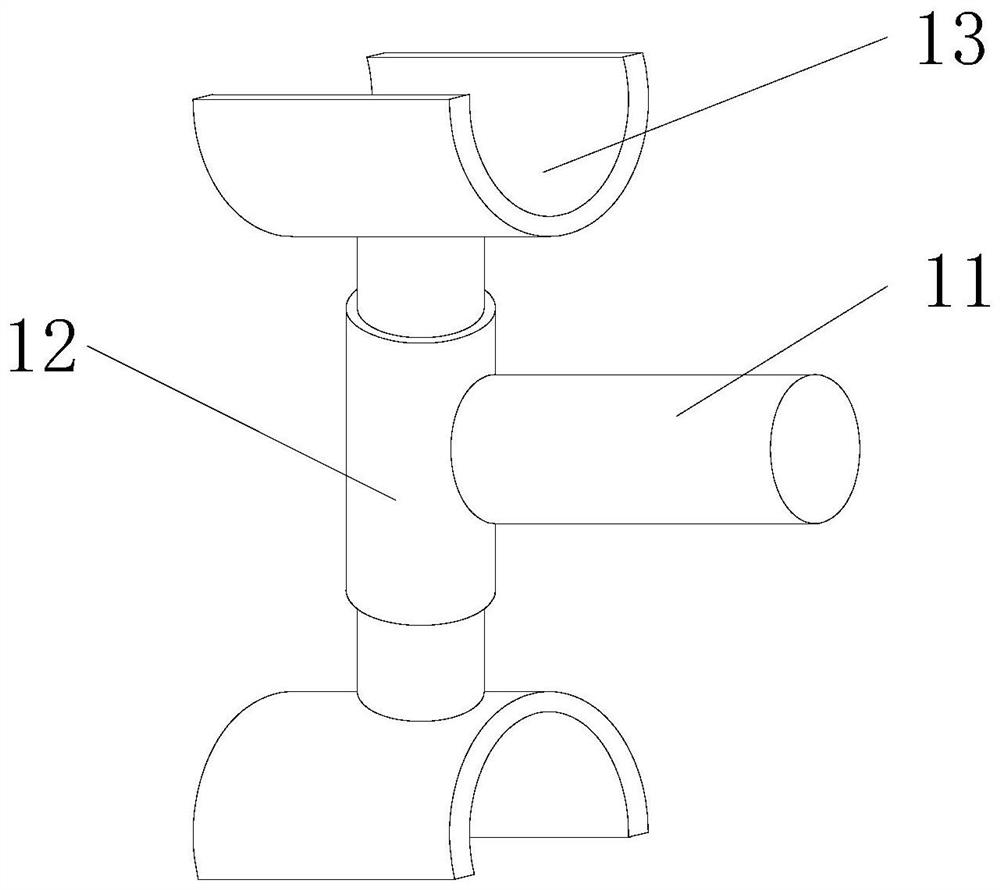

ActiveCN103528731AEquipment installation is simpleSite securityForce measurement by measuring optical property variationUsing optical meansOptical fiber connectorOptical measurements

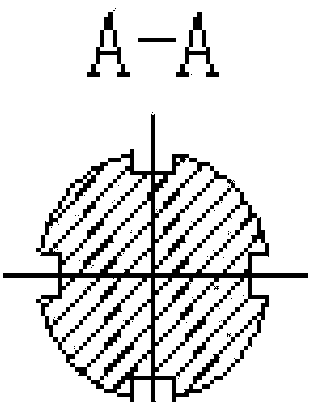

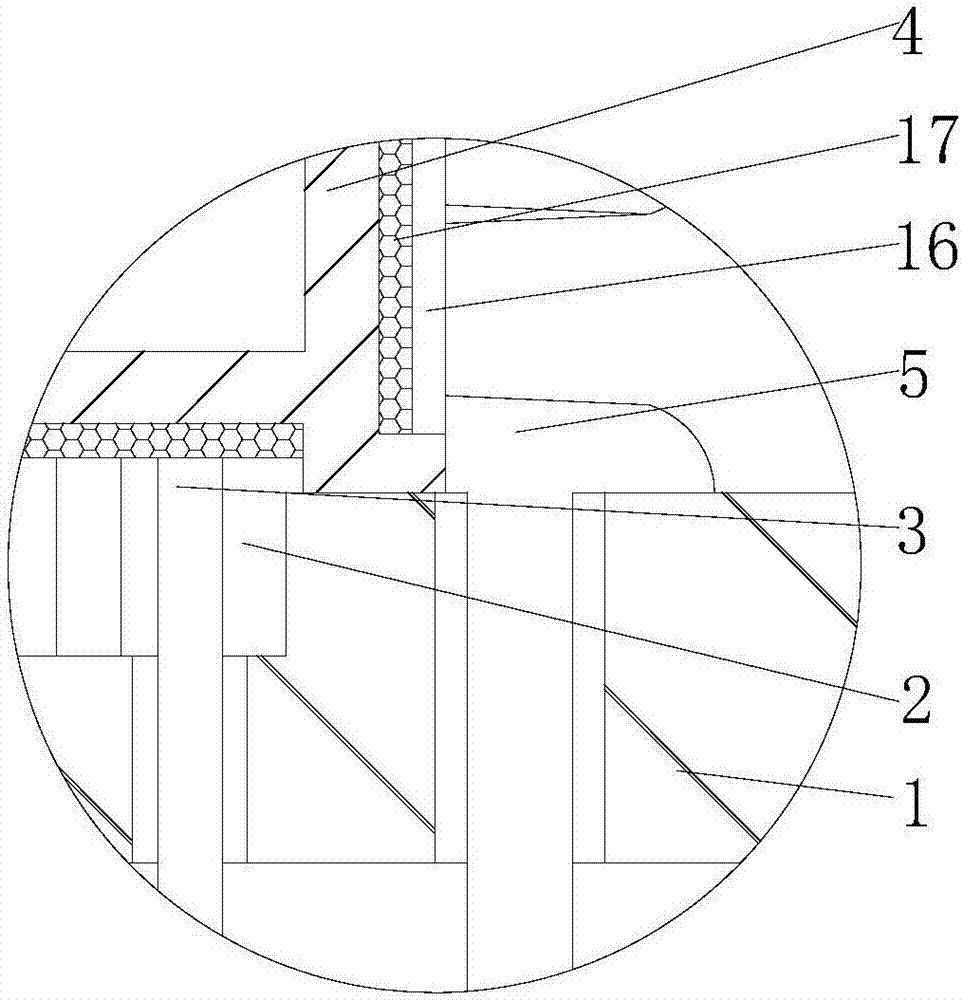

The invention relates to a coal mine paste filler online monitoring system based on optical fiber grating sensing, and belongs to a mine filler online monitoring system. Before space of each measuring point is filled, a supporting rod is fixed to a filling space bottom plate through ground anchors, a telescopic rod telescopically supports a filling space top plate, an optical fiber grating sensor group is mounted in the middle of the telescopic rod, and an optical fiber connector is lead out of the tail part of the supporting rod and connected to a mine optical cable through optical fiber, so that an optical grating monitoring signal is transmitted to an optical fiber grating demodulation instrument; and a demodulated signal is transmitted to a computer system, and a paste filler is subjected to real-time online monitoring and analysis process after the space is filled. The system has the advantages as follows: the equipment installation is simple, and the system is suitable for general popularization; underground power supply is not required, and the scene safety is guaranteed; full-optical measurement and optical fiber transmission are adopted, so that influence of electromagnetic interference is effectively avoided; a temperature compensation optical grating is adopted for compensating temperature errors, so that the monitoring accuracy is improved greatly; and the monitoring result can be timely provided, and guidance of scene production and scientific research is facilitated.

Owner:CHINA UNIV OF MINING & TECH

Combustible gas detector and calibration method thereof

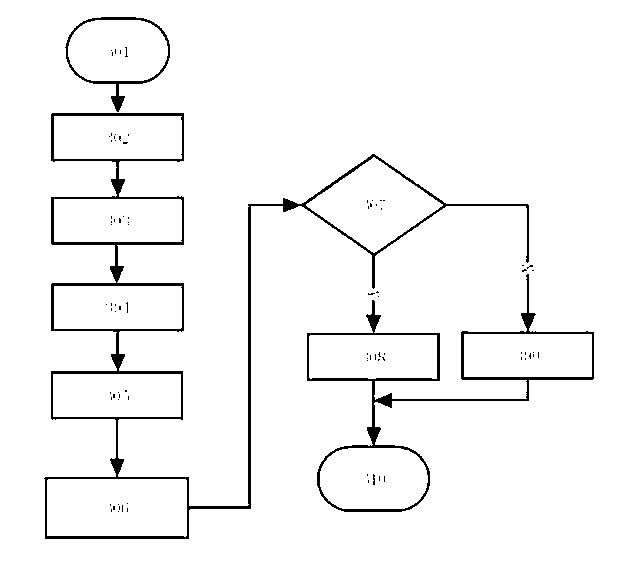

InactiveCN103257157ADesign does not affectLittle influence of temperatureMaterial resistanceControl communicationsComputer module

The invention discloses a combustible gas detector. The combustible gas detector is composed of a power management unit, a main control chip unit, a sensor and an interface circuit unit, an output alarm unit, a V / I conversion circuit unit and a communication circuit unit, wherein the power management unit is connected with the other units and can provide power for the other units; the main control chip unit is connected with the sensor and the interface circuit unit, the communication circuit unit, the output alarm unit and the V / I conversion circuit unit, controls the communication circuit unit to be communicated with an upper computer, carries out digitization on data processed through the sensor and the interface circuit unit, and configures an interface circuit connected with the sensor and the interface circuit unit; and the communication circuit unit, the output alarm unit and the V / I conversion circuit unit are enabled or prohibited through the main control chip unit. The combustible gas detector provided by the invention is connected with an upper computer PC with display and interface operational software through a communication module, the parameter calibration such as internal compensation and gain of the combustible gas detector is realized in an on-line manner through the operation on the software, the detecting precision is less influenced by temperature, and large-scale manufacturing and calibration are conveniently realized.

Owner:镇江恒驰科技有限公司

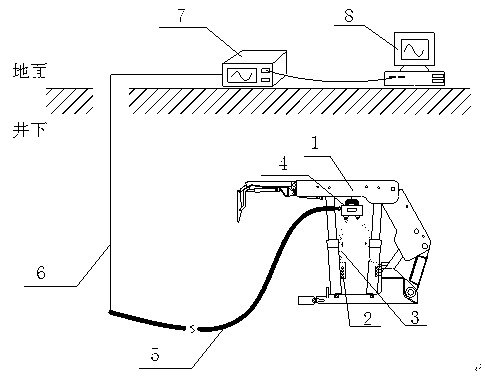

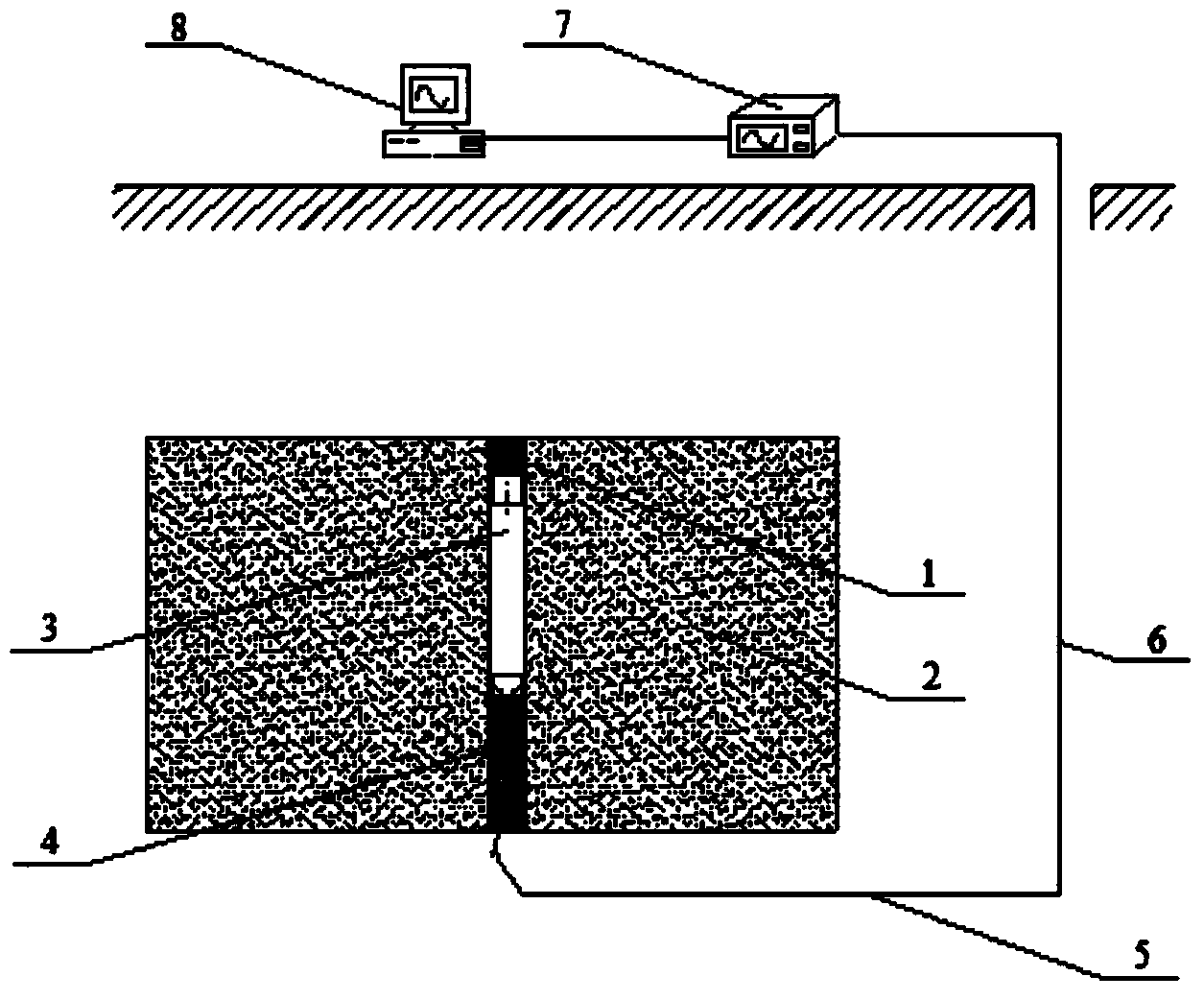

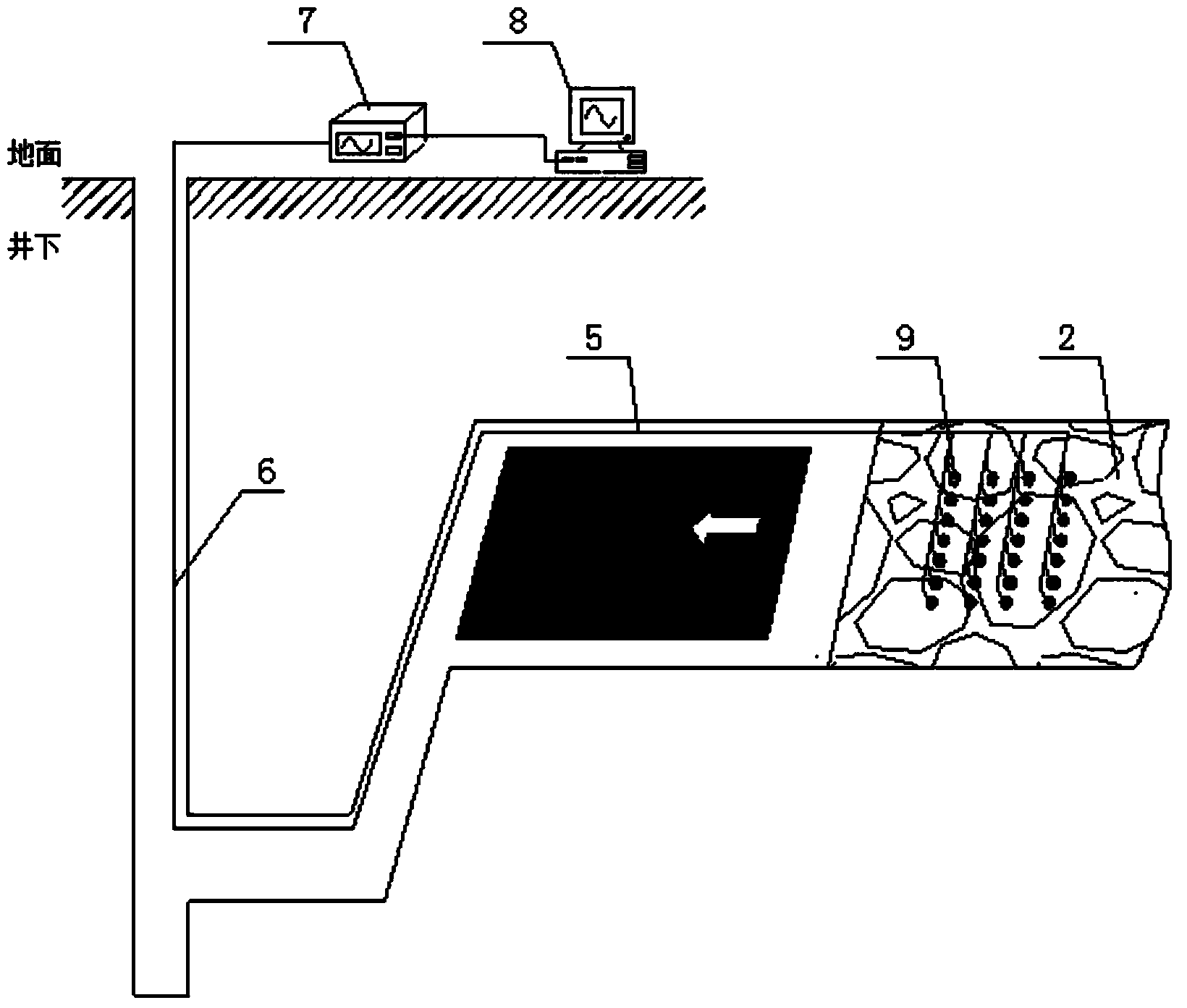

Working face mine pressure on-line monitoring system based on fiber grating sensing

InactiveCN103257009ARealize online monitoringRealize functionForce measurement by measuring optical property variationFiberGrating

The invention belongs to mine pressure on-line monitoring systems, and discloses a working face mine pressure on-line monitoring system based on fiber grating sensing. According to the monitoring system, a plurality of measurement points are selected on a working face in a pit, one monitoring system is installed inside each measurement point, a hydraulic control valve of each monitoring system is installed in a hydraulic support and is connected with a pressure guide hole of an intrinsic safety type fiber grating pressure meter through an oil pipe, an optical signal of the intrinsic safety type fiber grating pressure meter is transmitted to a fiber grating demodulator on the ground through an optical fiber and a mining optical cable, the fiber grating demodulator is demodulated into a digital signal to be transmitted to a computer system, and the computer system carries out real-time monitoring and analysis processing. The working face mine pressure on-line monitoring system based on the fiber grating sensing has the advantages of being simple in installation, adopting full-optical measurement and optical fiber transmission, being capable of effectively avoiding influence of electromagnetic interference, greatly improving monitoring accuracy due to adoption of a temperature compensation grating for compensating a temperature error, and being capable of timely providing a working face mine pressure monitoring and predicting result so as to bring convenience to production and scientific researches of a guidance site.

Owner:CHINA UNIV OF MINING & TECH

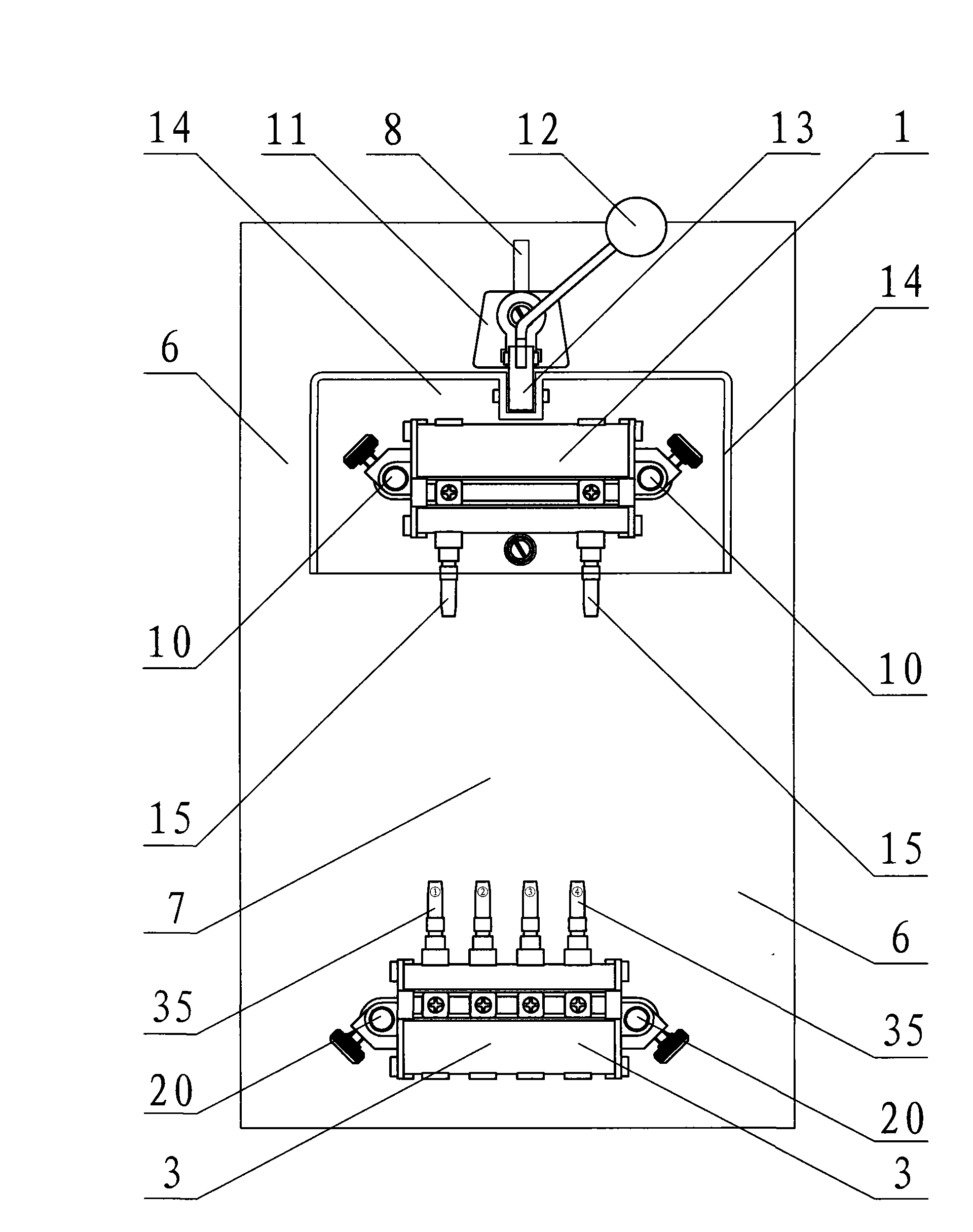

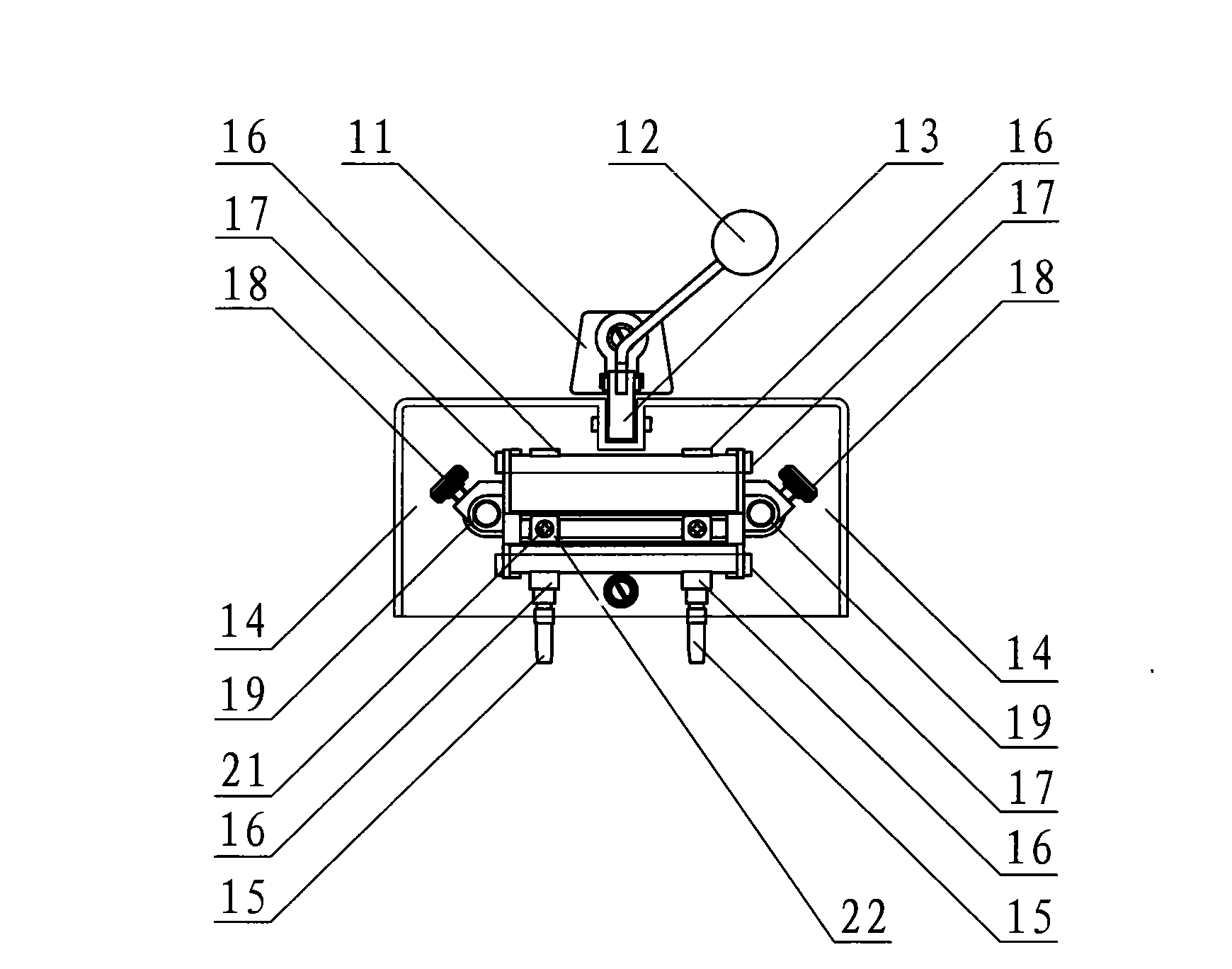

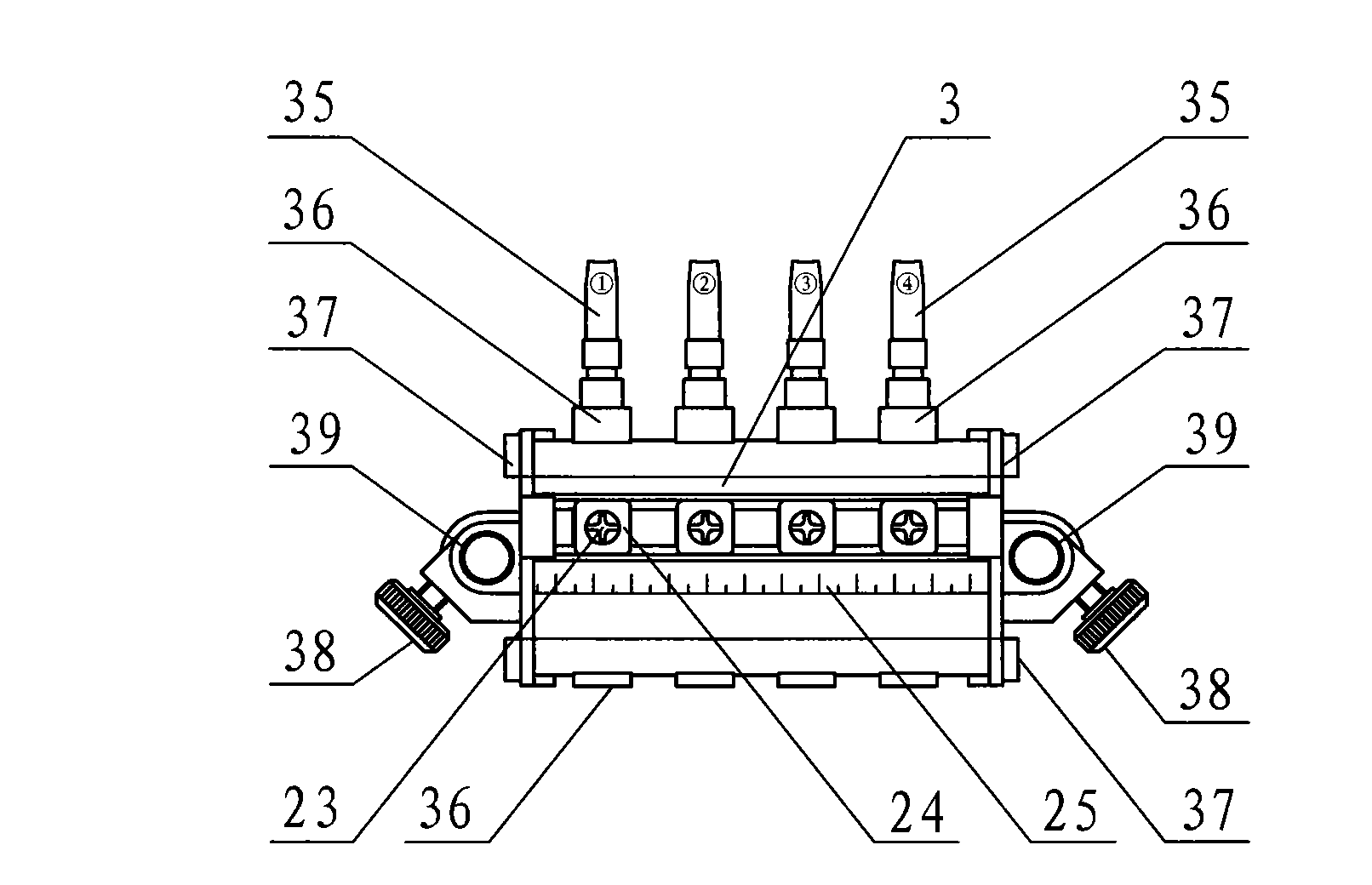

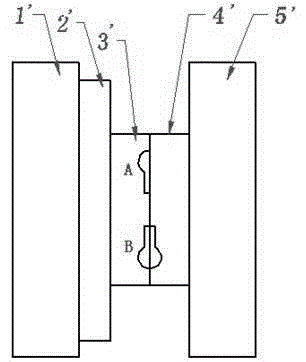

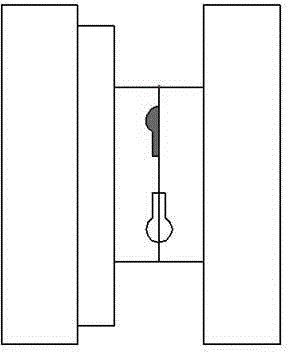

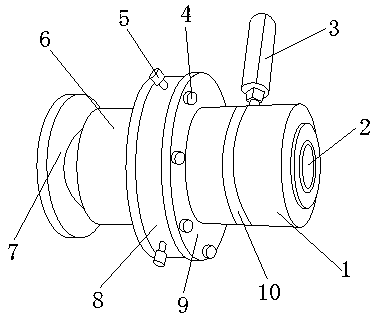

Multifunctional access meter device of single-phase electric energy meter

InactiveCN101634694AConvenient production workFacilitate verification workElectrical measurementsBinding postElectric energy

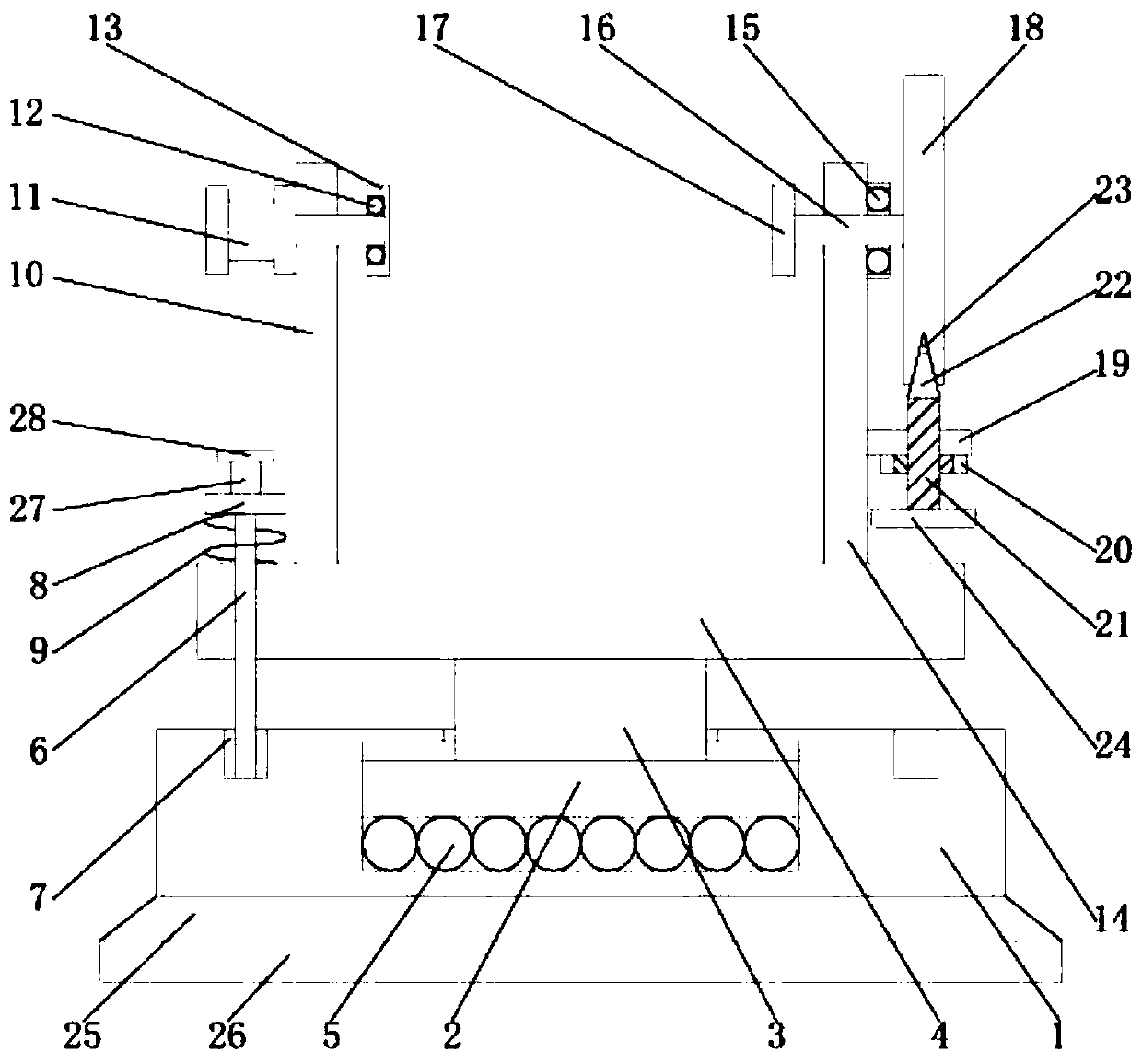

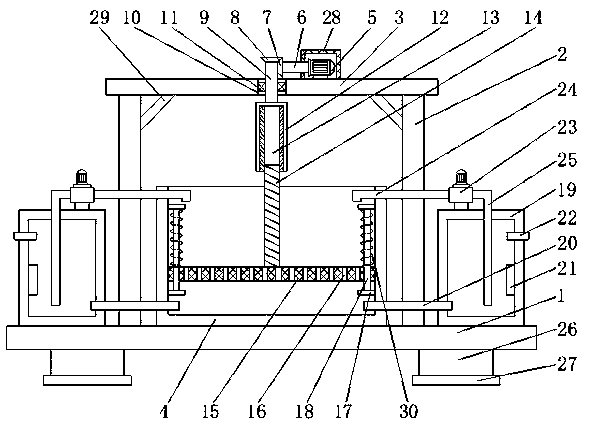

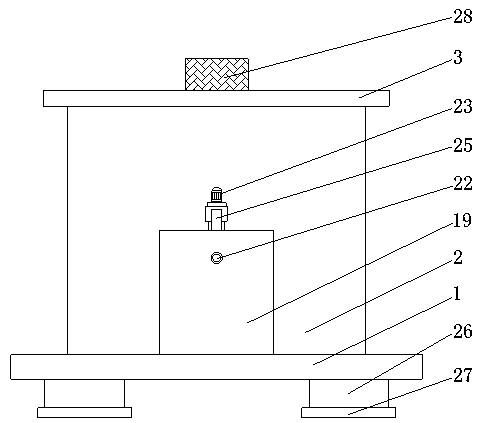

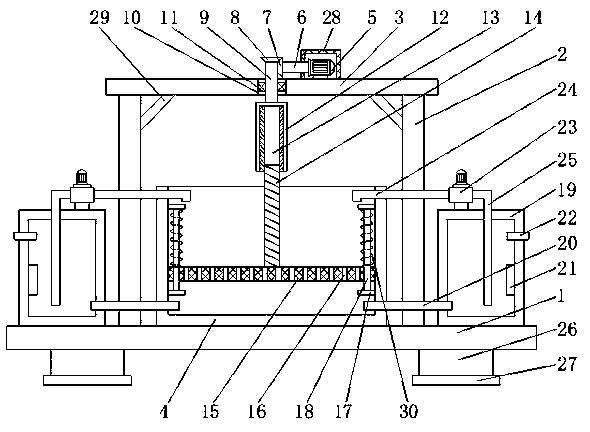

The invention provides a multifunctional access meter device of a single-phase electric energy meter, comprising a substrate, a pressure meter block and an access meter frame; the substrate is provided with a sliding rod; the pressure meter block comprises a mounting plate, a handle base, a handle, a connecting rod, a guide component and two groups of access meter wire columnar components; the handle base is installed on the substrate; one side at the lower end of the handle is movably connected with the handle base; the other side at the lower end of the handle base is movably connected with one end of the connecting rod; the other end of the connecting rod is movably connected with the mounting plate on which a sliding rod is installed; the access meter frame comprises a guide component and four groups of access meter wire columnar components; the guide component comprises a frame body, a sliding barrel, a screw hole, a tapping screw and a transverse guide track; the access meter wire columnar component comprises a slide block, a wiring column and a guide track chute that is clamped to the transverse guide track; the sliding barrel of the pressure meter block is penetrably installed on the sliding rod, and the tapping screw of the pressure meter block is installed on the sliding rod; the sliding barrel of the access meter frame is penetrably installed on the sliding rod, and the tapping screw of the access meter frame is installed on the sliding rod. The device has advantages of skilful conception, fast wiring, convenient use and strong stability.

Owner:ZHENGZHOU WONDER ELECTRICAL POWER +1

Coal mine goaf top plate strain monitoring system and method based on fiber bragg grating sensing

InactiveCN103528732ALong-term strain real-time monitoringPromote safe and efficient miningNon-electrical signal transmission systemsForce measurement by measuring optical property variationFiberGrating

The invention discloses a coal mine goaf top plate strain monitoring system and method based on fiber bragg grating sensing, and belongs to a coal mine top plate strain monitoring system and method. The system comprises a fiber bragg grating demodulation instrument, a monitoring computer, a mining transmission optical cable, a communication optical fiber and tail optical fibers, wherein a plurality of monitoring points are arranged in a goaf top plate; each monitoring point is provided with one fiber bragg grating strain sensor; the sensors in the monitoring points are connected in parallel through the tail optical fibers which access the mining transmission optical cable through optical fibers; the mining transmission optical cable is connected to an input end of the fiber bragg grating demodulation instrument on the ground; an output end of the fiber bragg grating demodulation instrument is connected with the monitoring computer; and the monitoring computer constitutes a fiber bragg grating strain monitoring system of coal mine goaf top plate all-fiber communication. The coal mine goaf top plate strain monitoring system and method based on the fiber bragg grating sensing have the advantages that all-optical measurement and optical fiber transmission are adopted, so that the influence of electromagnetic interference is avoided; equipment does not require power supply, so that essential safety of working face production is ensured; and real-time monitoring and analysis of coal mine goaf top plate strain are realized.

Owner:CHINA UNIV OF MINING & TECH

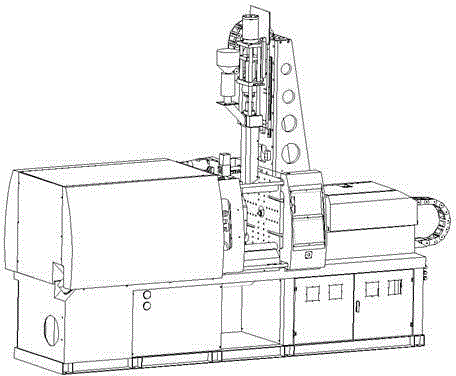

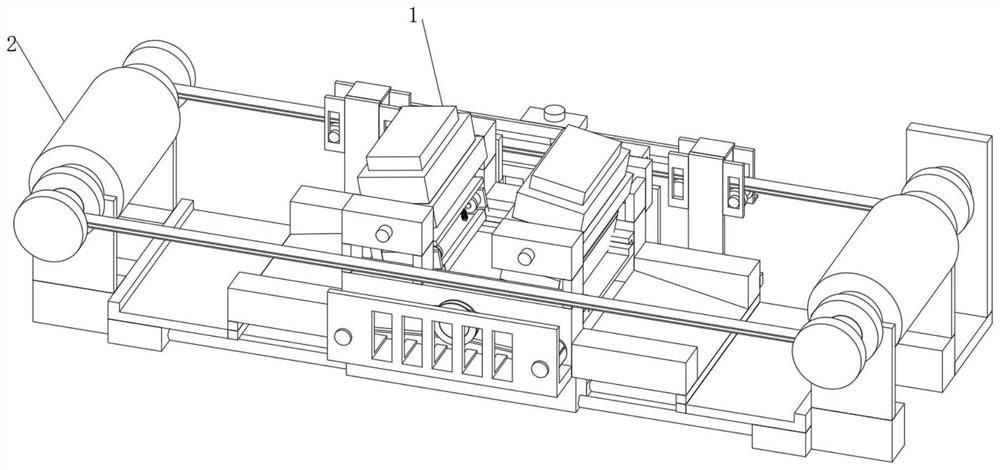

Double-material injection moulding machine and forming method thereof

InactiveCN104476717AHigh precisionEasy to meet requirementsCoatingsElectric controlInjection moulding

The invention provides a double-material injection moulding machine and a forming method thereof. The double-material injection moulding machine is mainly used for the product production of a mixing injection moulding process of a thermoplastic plastic and a thermosetting liquid silica gel. The double-material injection moulding machine comprises a mould closing mechanism, a rotating disc mechanism, a plastic injection mechanism, a liquid silica gel injection moulding mechanism, a plastic baking and feeding mechanism, a mixer, a hydraulic system and an electric control system, wherein the mixer is formed by connecting a dynamic screw rod and a static mixing tube. According to the double-material injection moulding machine, the rotating disc mechanism can rotate a rear mould plate at 180 degrees so as to exchange mould cavities inside a mould, so that the product is processed at a time, high accuracy of a synthetic product is achieved, the requirement of a customer on the product is easily met, and adverse effect generated due to secondary processing is prevented. The double-material injection moulding machine provided by the invention has the advantages of time conservation, convenience for operation and facilitation in production work.

Owner:GUANGZHOU TIANYUAN SILICONE MACHINE TECH

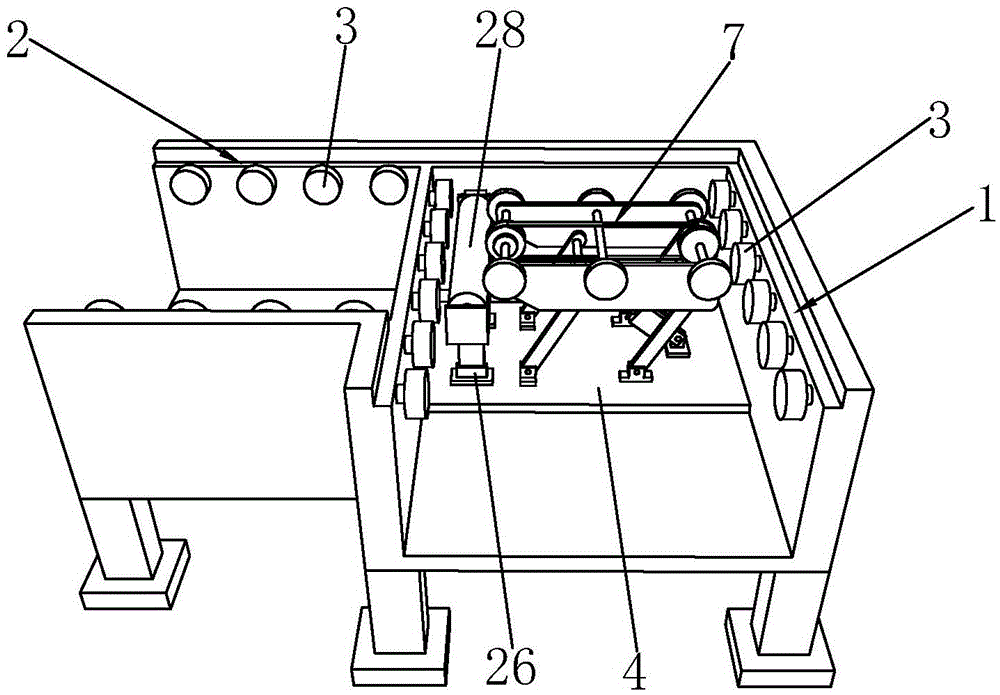

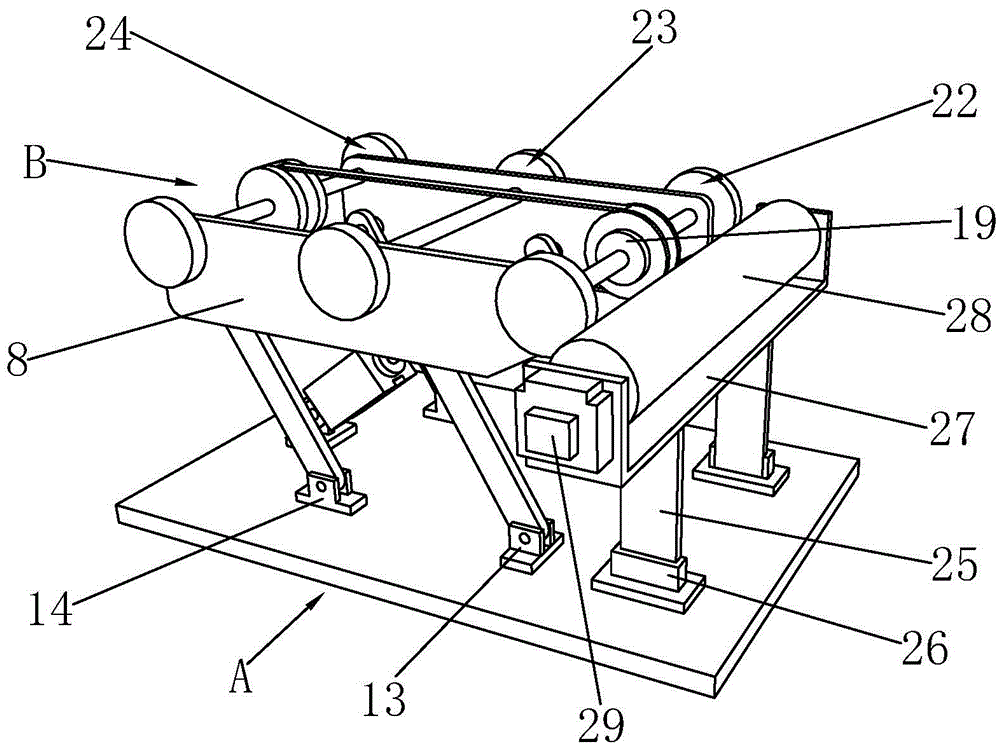

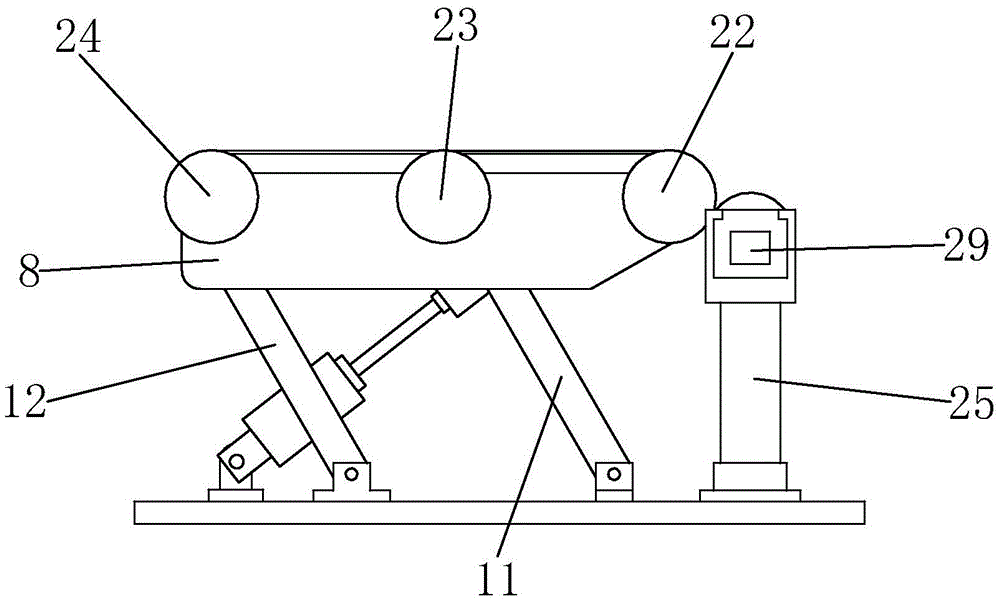

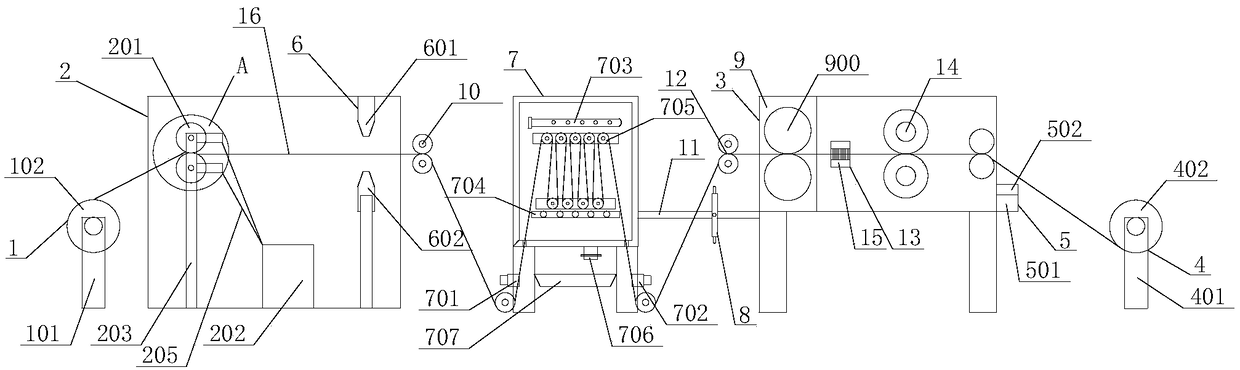

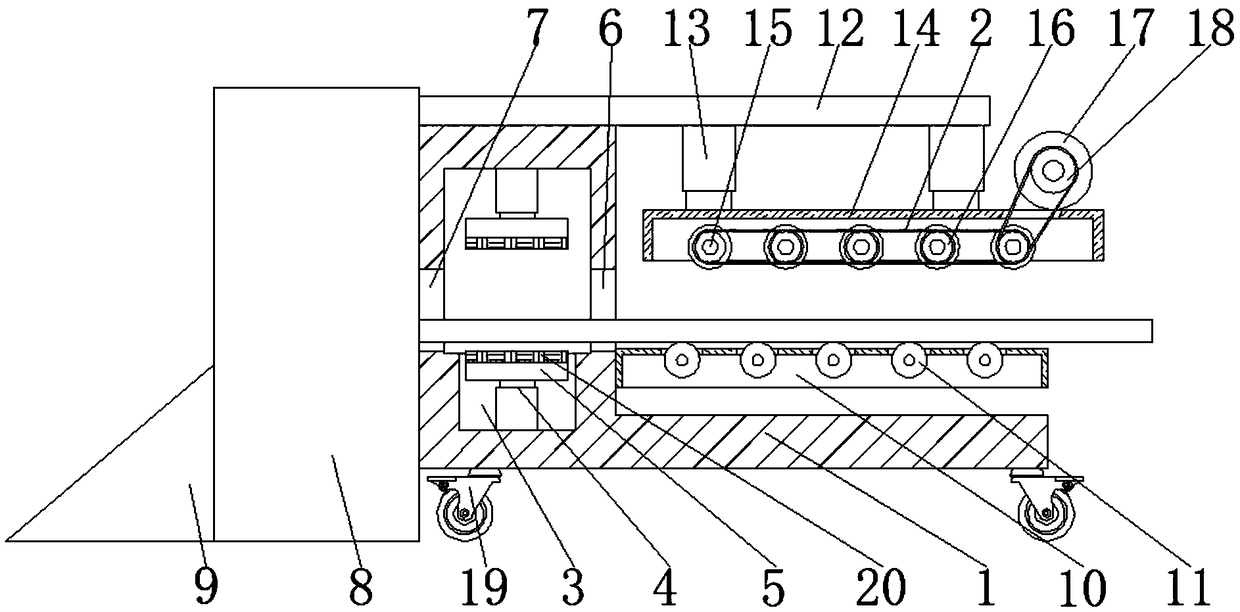

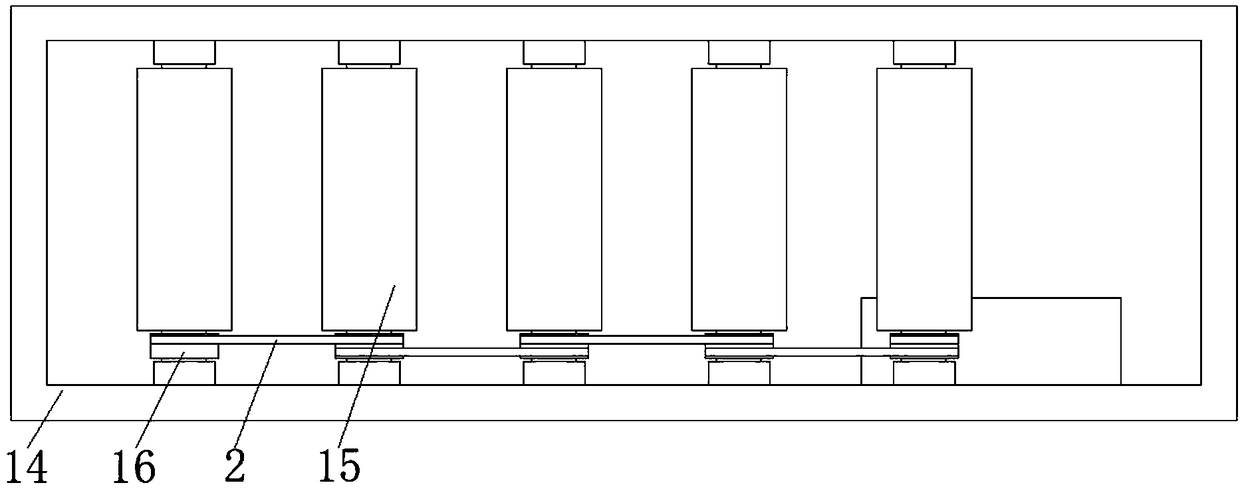

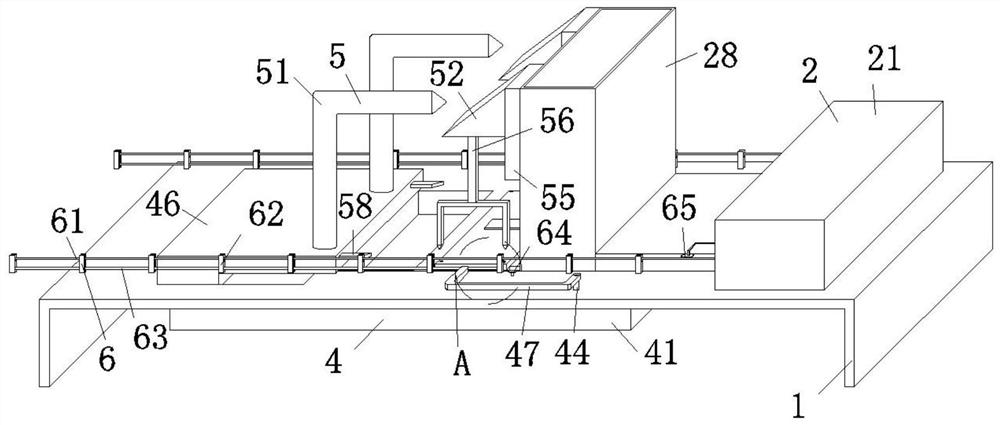

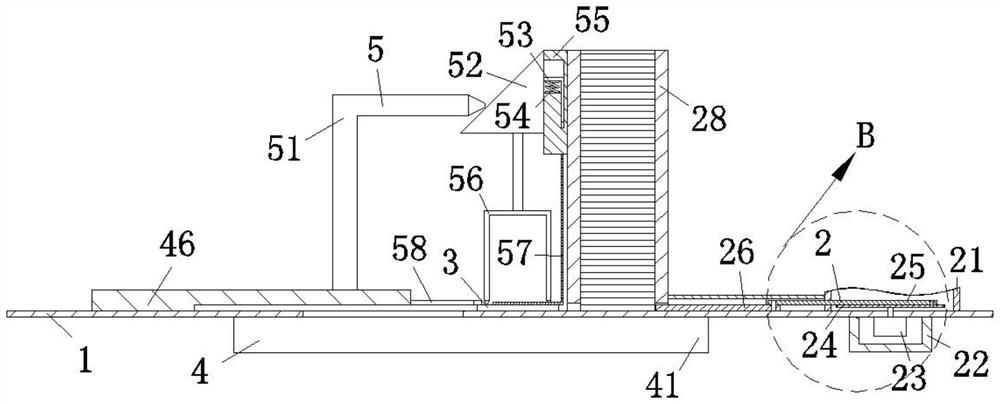

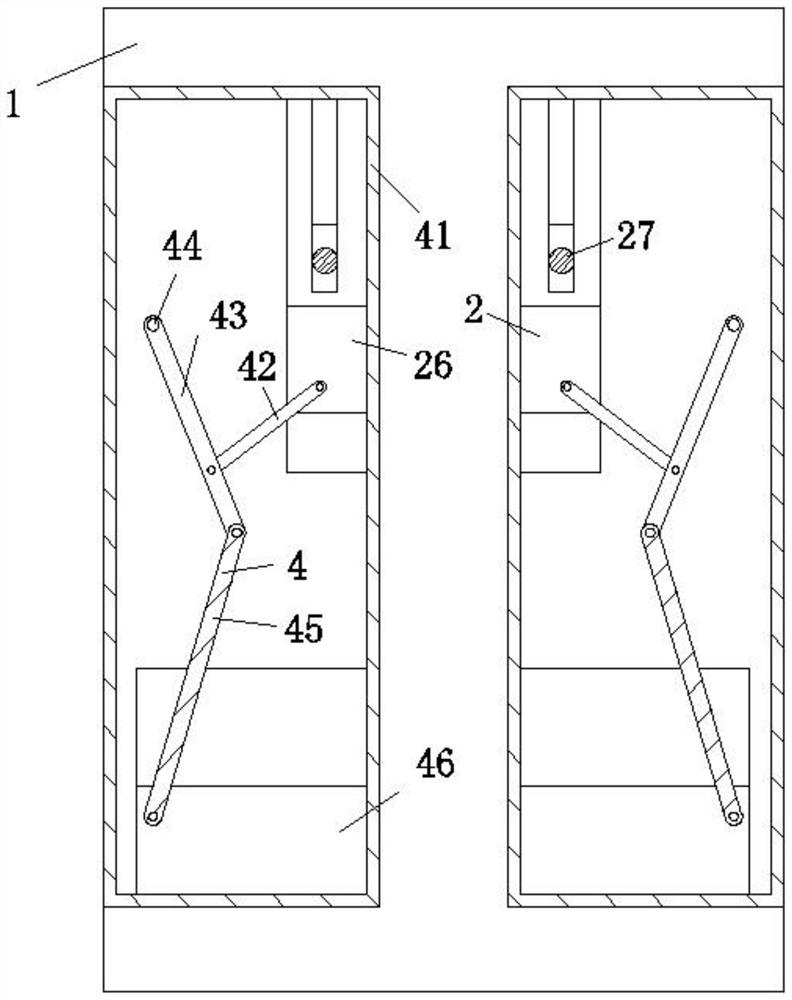

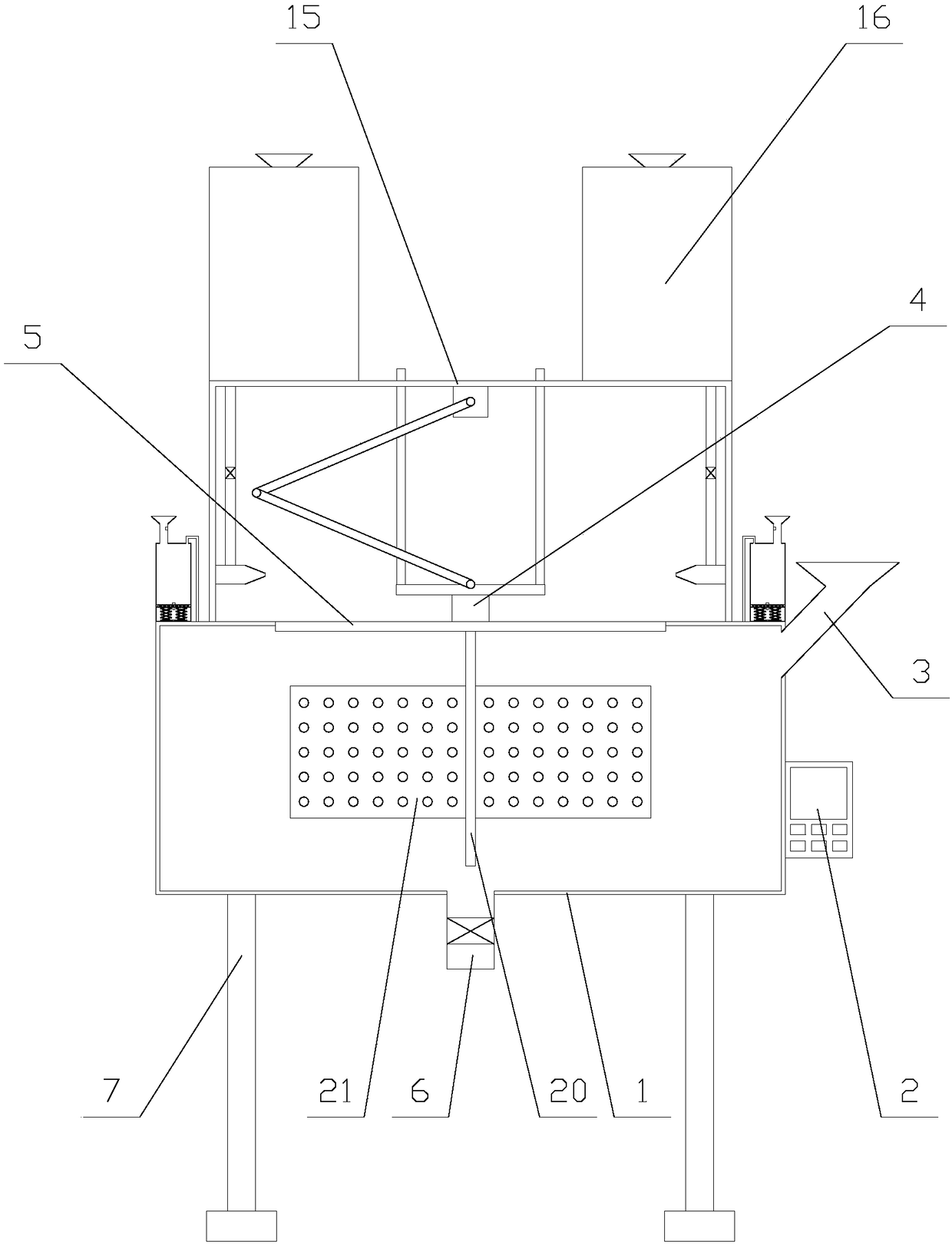

Transferring and conveying device for aluminum plate production line

InactiveCN105460547AImprove connection efficiencyIncrease productivityConveyorsControl devices for conveyorsProduction lineEconomic benefits

The invention discloses a transferring and conveying device for an aluminum plate production line. The transferring and conveying device comprises a first conveying mechanism and a second conveying mechanism, wherein the included angle between the first conveying mechanism and the second conveying mechanism is 90 DEG; the first conveying mechanism is provided with a fixed platform; the fixed platform is provided with a transferring mechanism; the transferring mechanism comprises a driving assembly, a link assembly and a transferring assembly; the transferring assembly is arranged on the link assembly; the link assembly is rotationally connected to the fixed platform; the driving assembly is rotationally connected to the fixed platform and is connected with the link assembly; the fixed platform is provided with a supporting base; and the supporting base is provided with a rotary roller mechanism. The transferring and conveying work among different conveying lines in the aluminum plate production process is finished through the rotary lifting motion of the transferring mechanism, so that the transferring and conveying device is automatic and practical; and the linking efficiency among various aluminum plate production lines is increased, so that the production efficiency is increased, the cost is reduced, and the economic benefit is remarkable.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

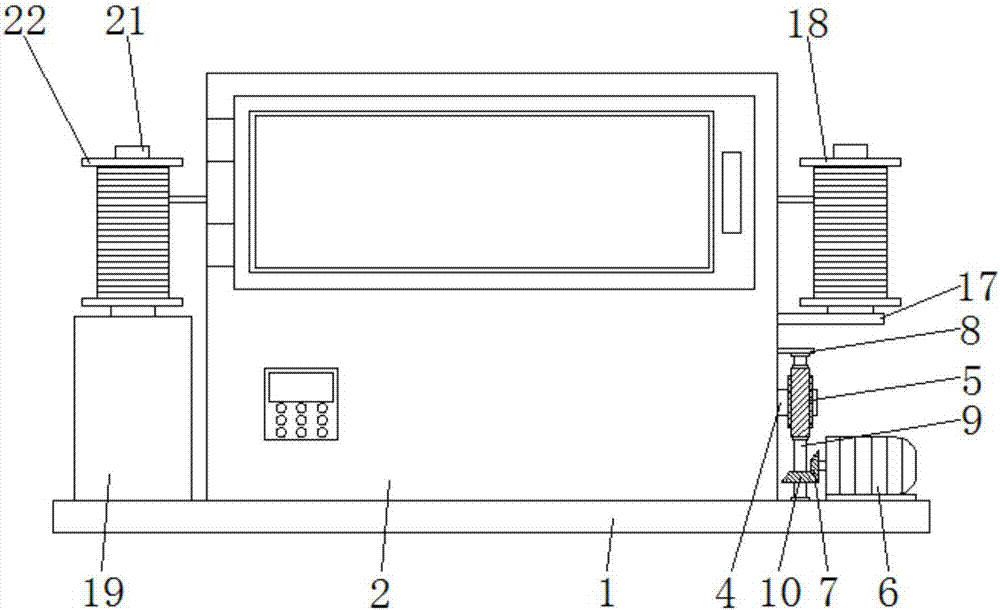

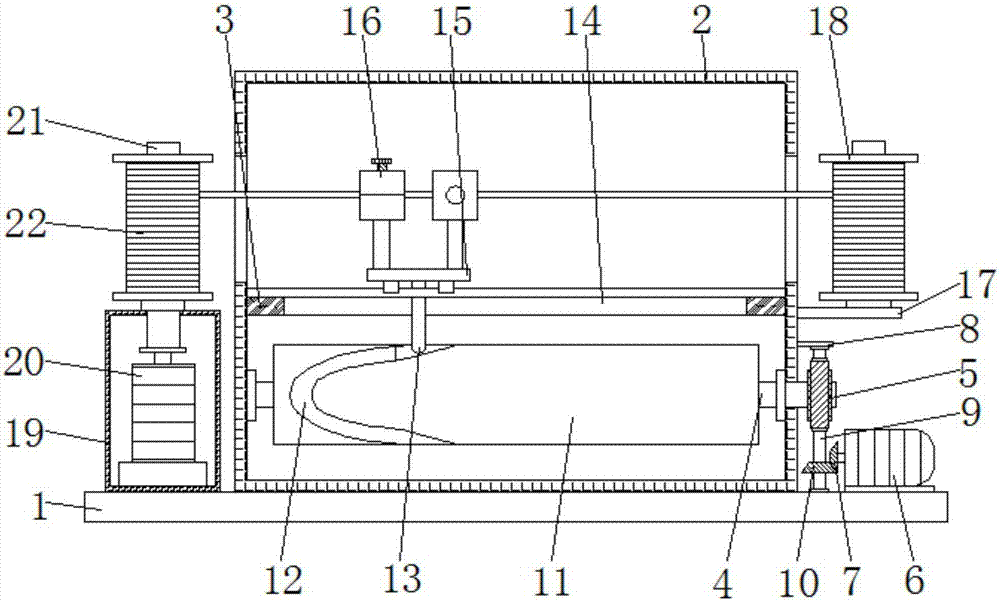

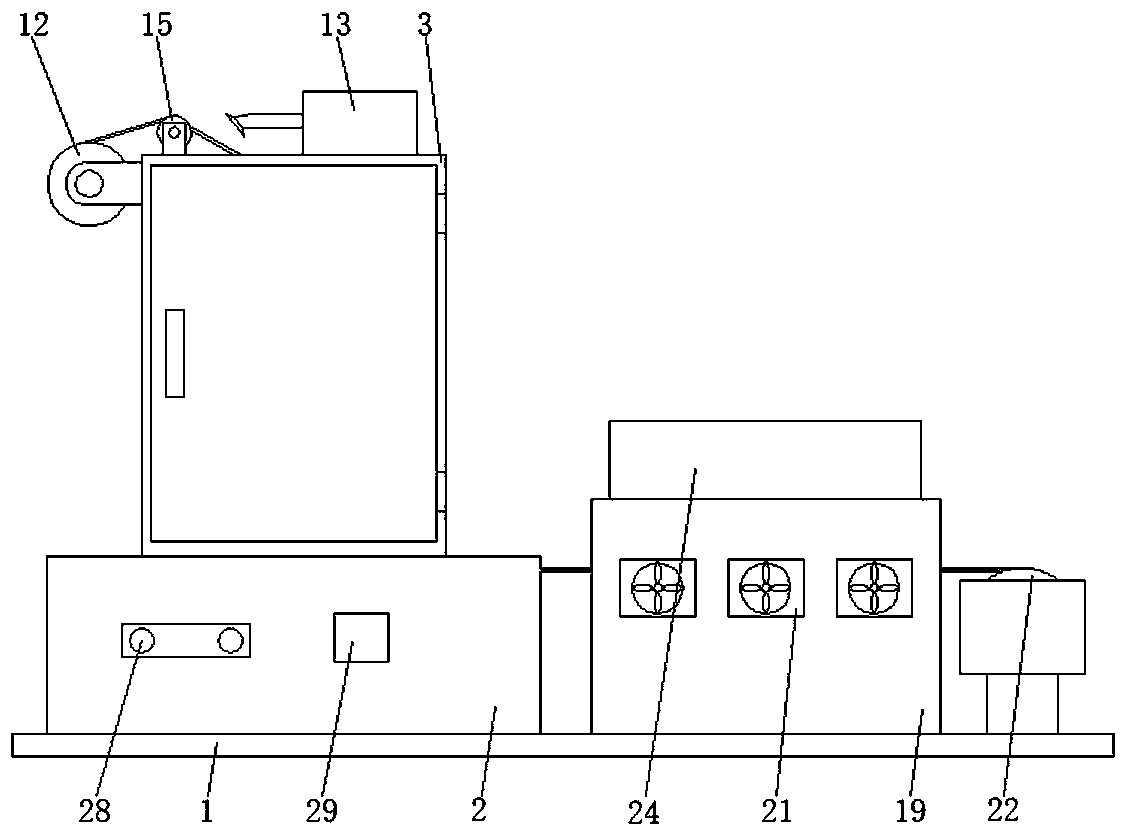

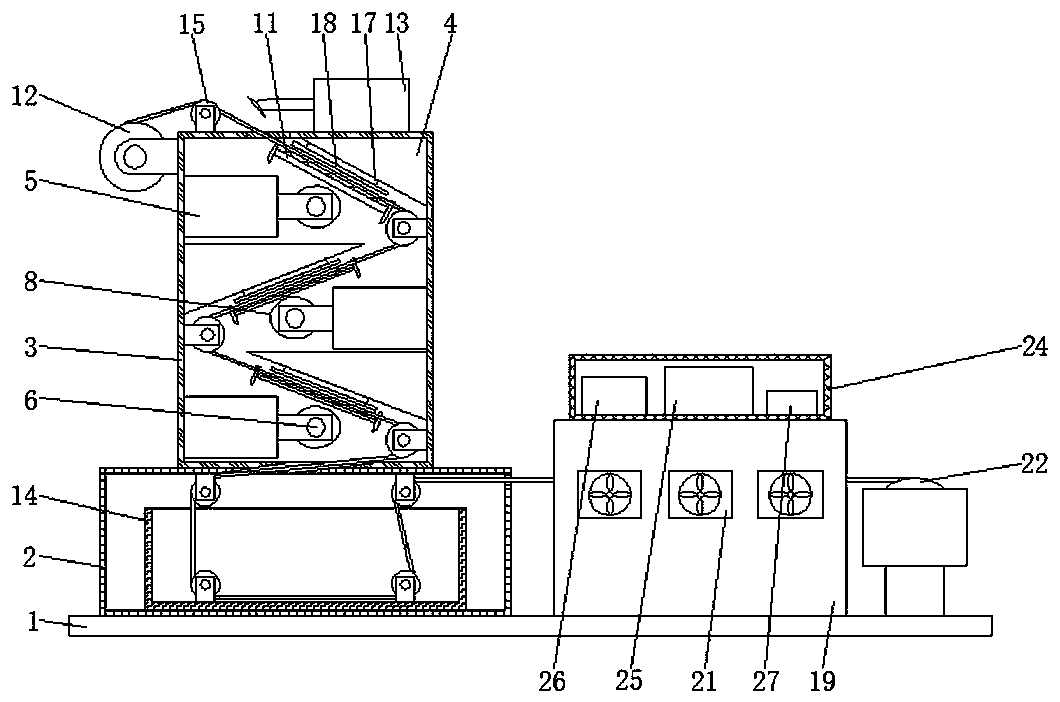

Novel fabric singeing machine

InactiveCN108642782AConvenient production workAvoid scratchesSingeingProgrammable logic controllerElectric machinery

The invention relates to a novel fabric singeing machine. The novel fabric singeing machine comprises a cloth charge mechanism, a singeing mechanism, a cooling mechanism, a cloth discharge mechanism and a control mechanism, wherein the cloth charge mechanism comprises a cloth charge frame and a cloth charge roll, and the cloth charge roll is arranged on the cloth charge frame; the cloth dischargemechanism comprises a cloth discharge frame and a cloth discharge roll, and the cloth discharge roll is arranged on the cloth discharge frame; the singeing mechanism comprises an electrostatic roll and a singeing device; a fire extinguishing box is arranged between the singeing mechanism and the cooling mechanism; the cooling mechanism comprises a cooling device, a dedusting device and a third cloth guide roll; the control mechanism comprises a control panel and an alarming device; the control panel is respectively electrically connected with motors of the cloth charge roll and the cloth discharge roll. The novel fabric singeing machine has the beneficial effect that an acceleration signal of the third cloth guide roll monitored by an acceleration sensor in real time is sensed by a PLC (programmable logic controller), namely monitoring a signal about whether the singed fabric has naps or not, so as to automatically judge whether the fabric is smooth or not, and facilitate the subsequent production.

Owner:广东南豆科技有限公司

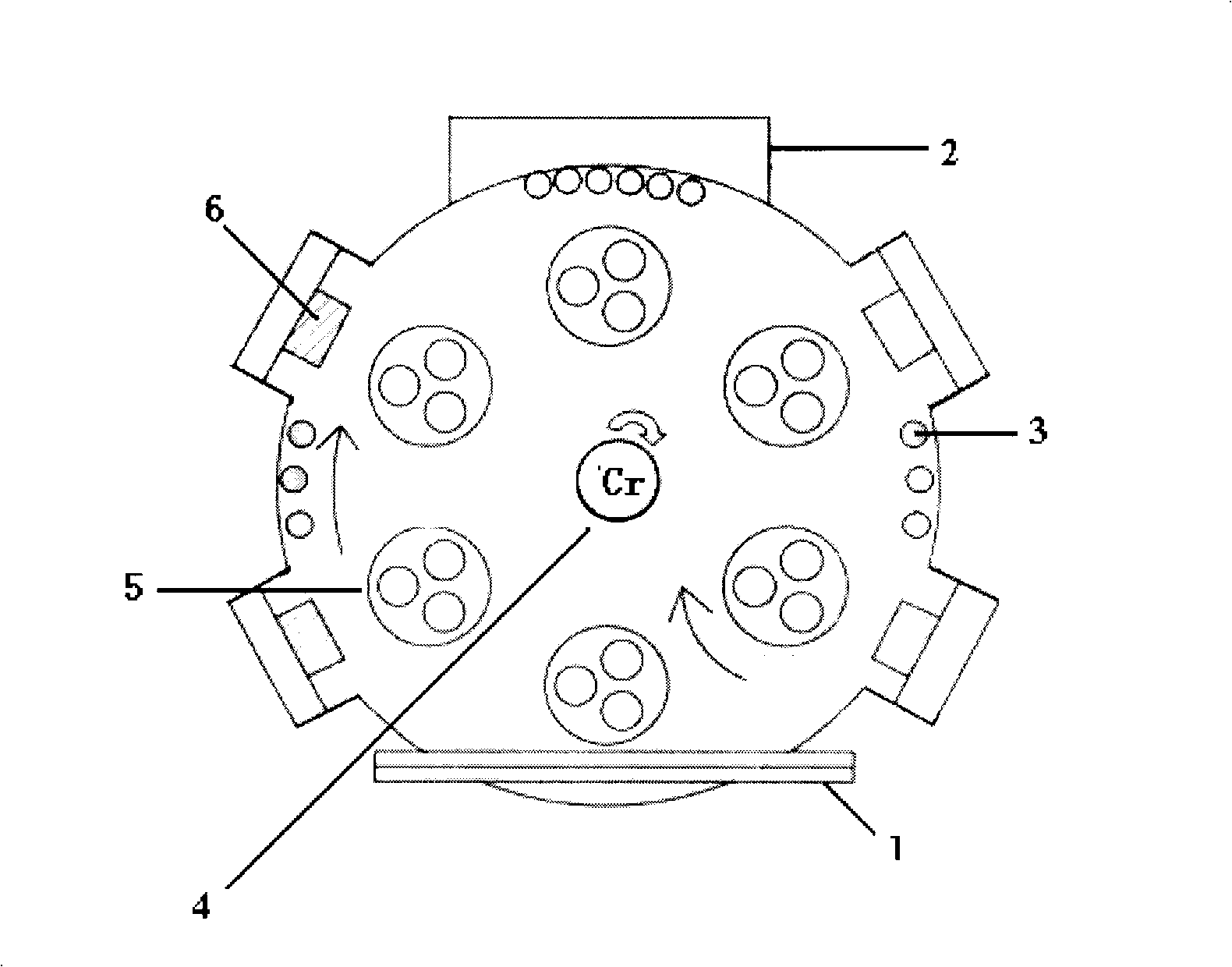

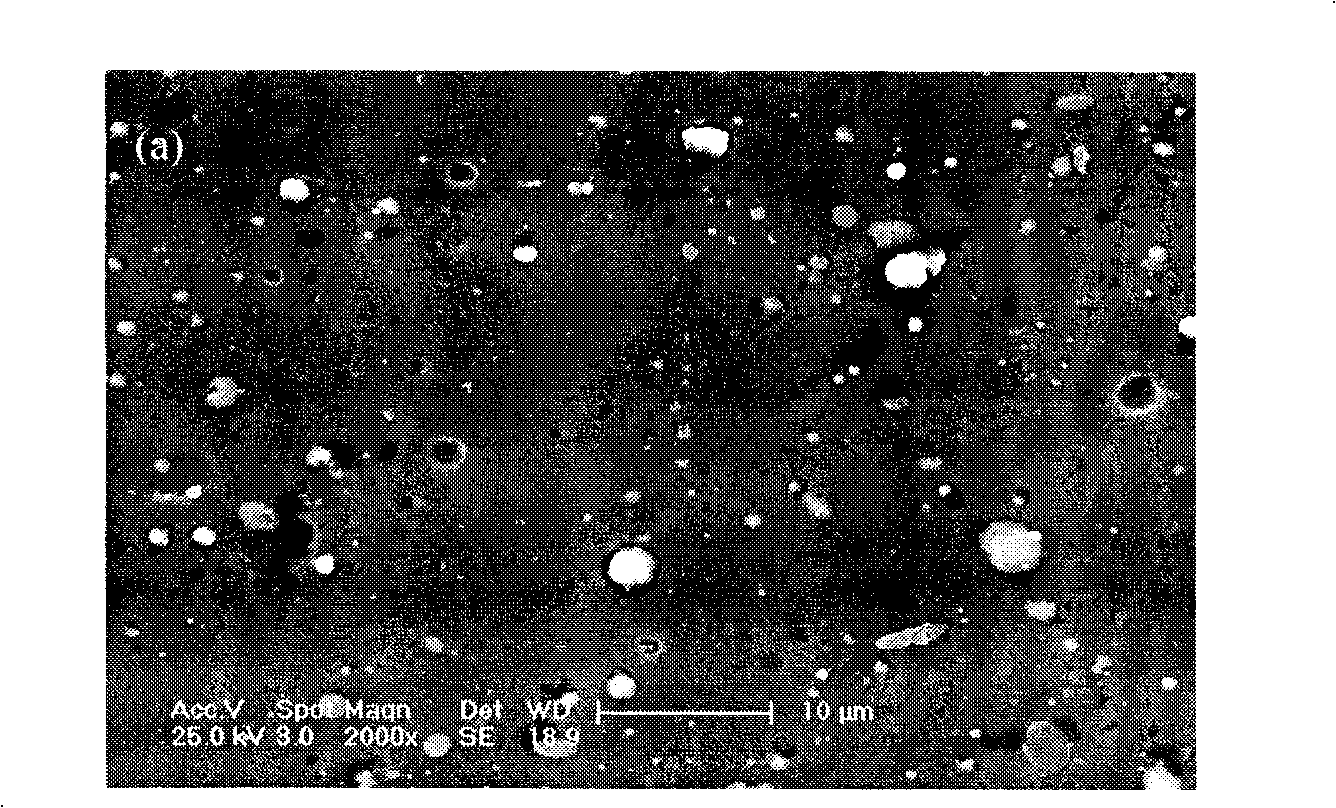

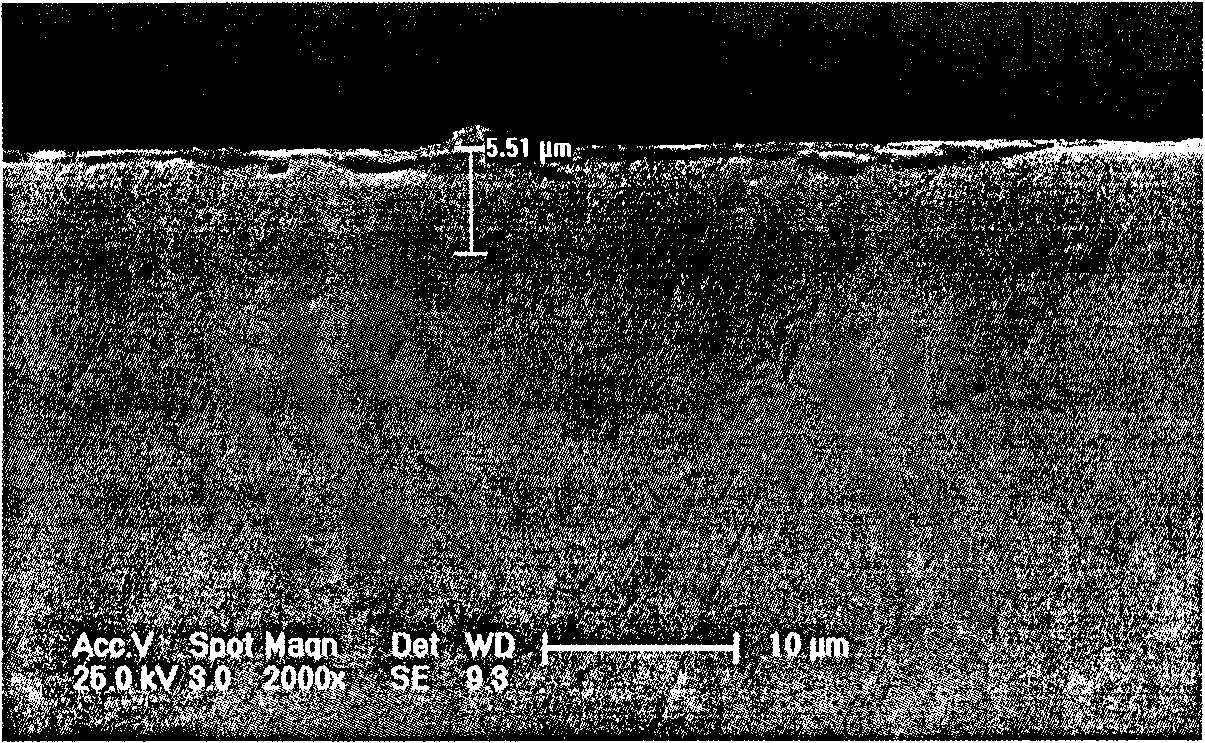

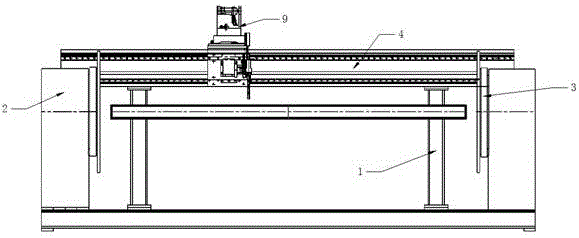

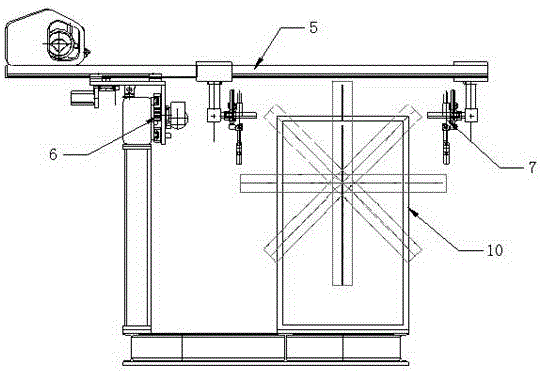

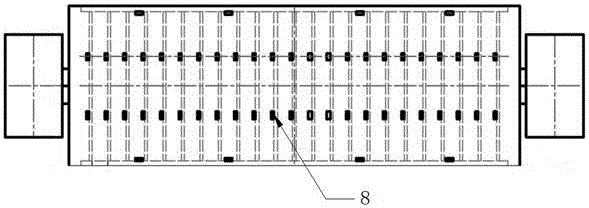

Quick solid-ceramic coating ion plating apparatus

InactiveCN101403101AImprove uniformityAdjustable temperatureVacuum evaporation coatingSputtering coatingVacuum pumpingCeramic coating

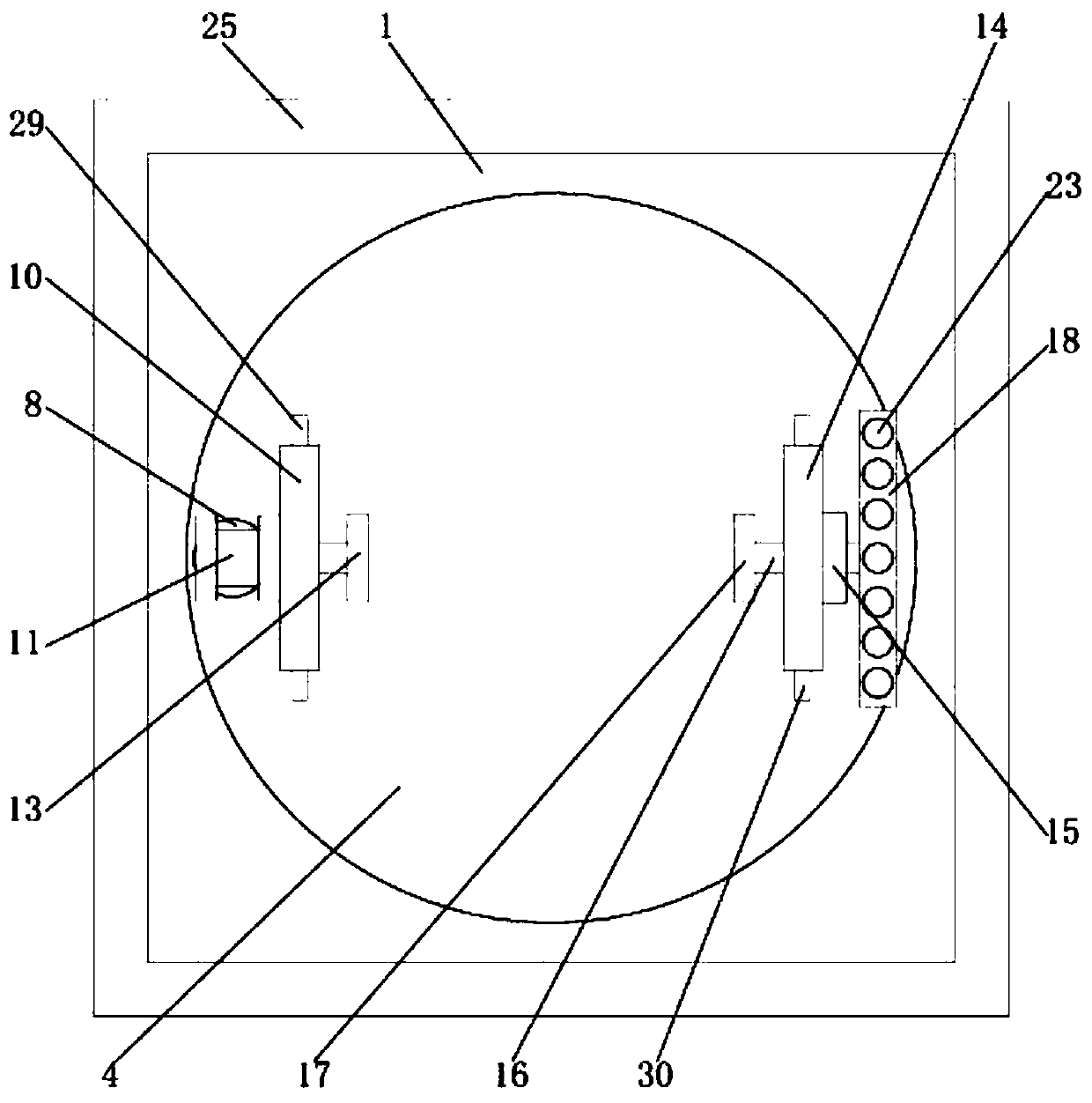

The invention discloses a rapid hard ceramic coating ion plating device which comprises a vacuum chamber formed by a furnace wall, one side of which is provided with a furnace door, and the vacuum chamber is provided with a vacuum pumping port. The interior of the vacuum chamber is provided with round electric arc targets and a high-power cylindrical rotary electric arc target, wherein, the round electric arc targets are divided into 2N rows, N is more than or equal to 1, the round electric arc targets are uniformly distributed on the furnace wall, the high-power cylindrical rotary electric arc target is arranged at the centre of the vacuum chamber, and the space between the round electric arc targets and the central high-power cylindrical electric arc target is an ion plating deposition area, and work supports are distributed in the ion plating deposition area. The device fully utilizes the high ionization rate of the electric arc ion plating technology, greatly improves the deposition efficiency of the ceramic coating and overcomes the defects in the prior art that expensive ion sources need to be added so as to improve adhesive force, etc. The device has the advantages of high film plating efficiency, low film plating cost, convenient operation, and the like. The device can meet the demand of over-thick ceramic coating in industry and has good application prospect in industrial production.

Owner:WUHAN UNIV

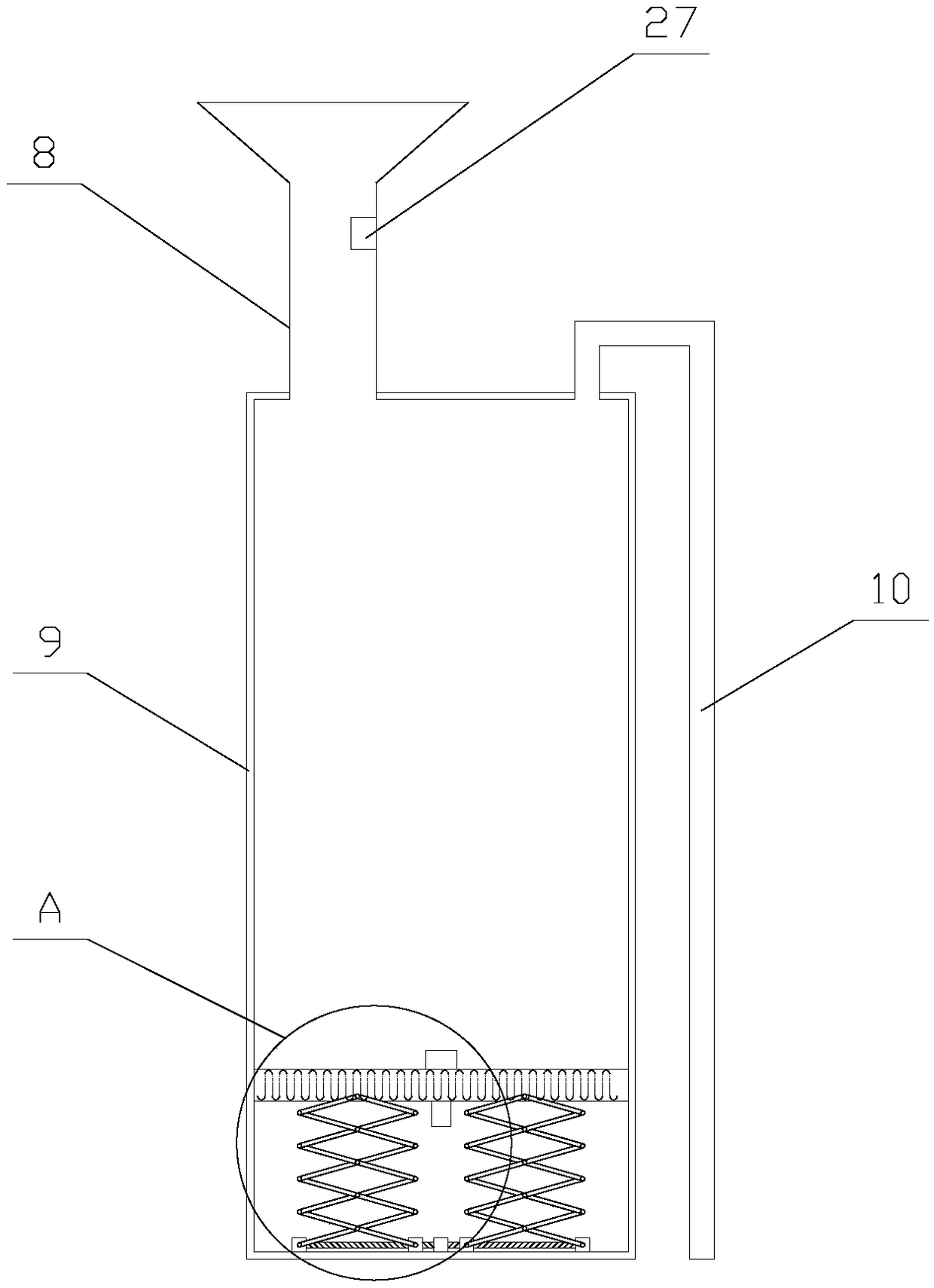

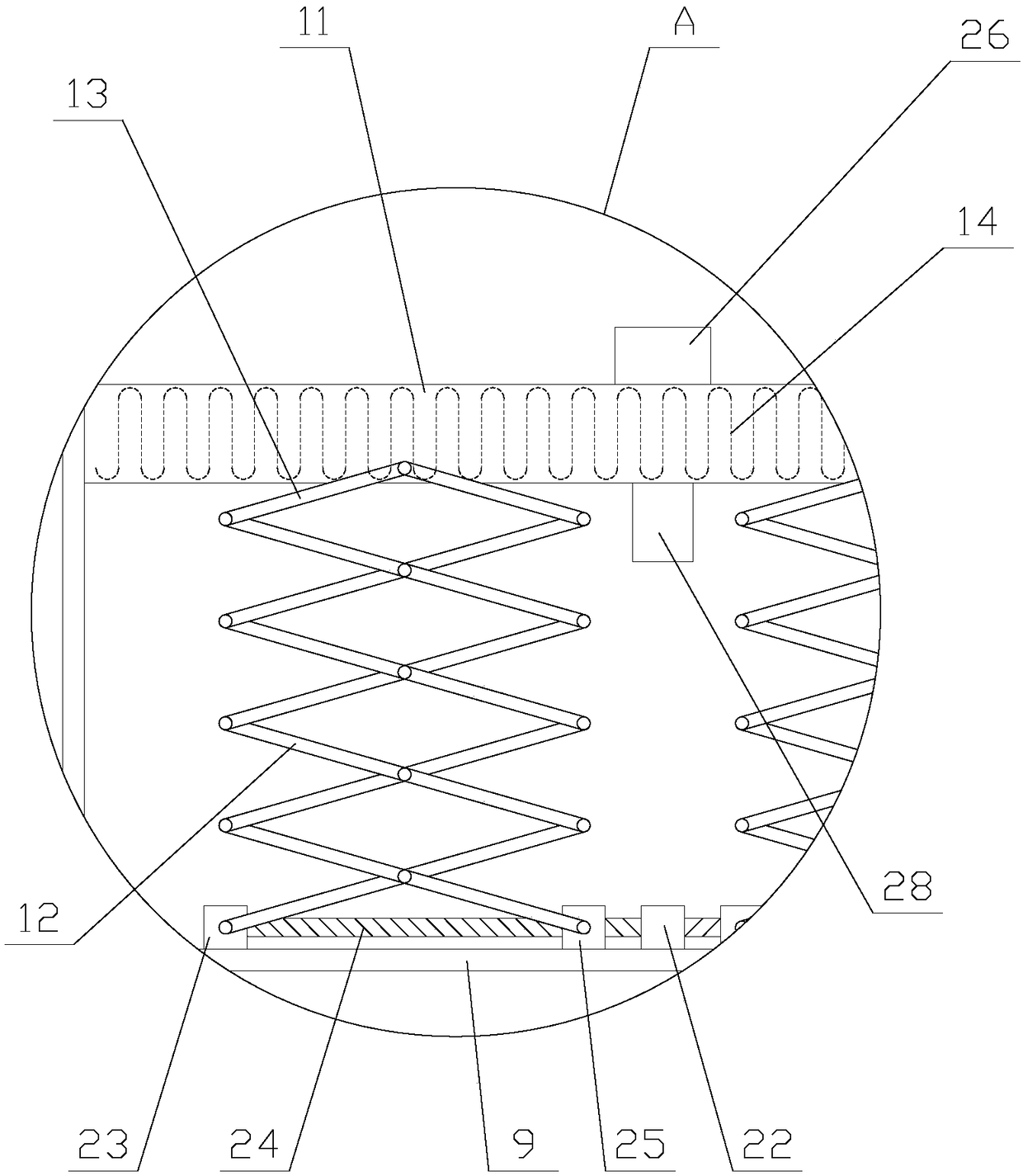

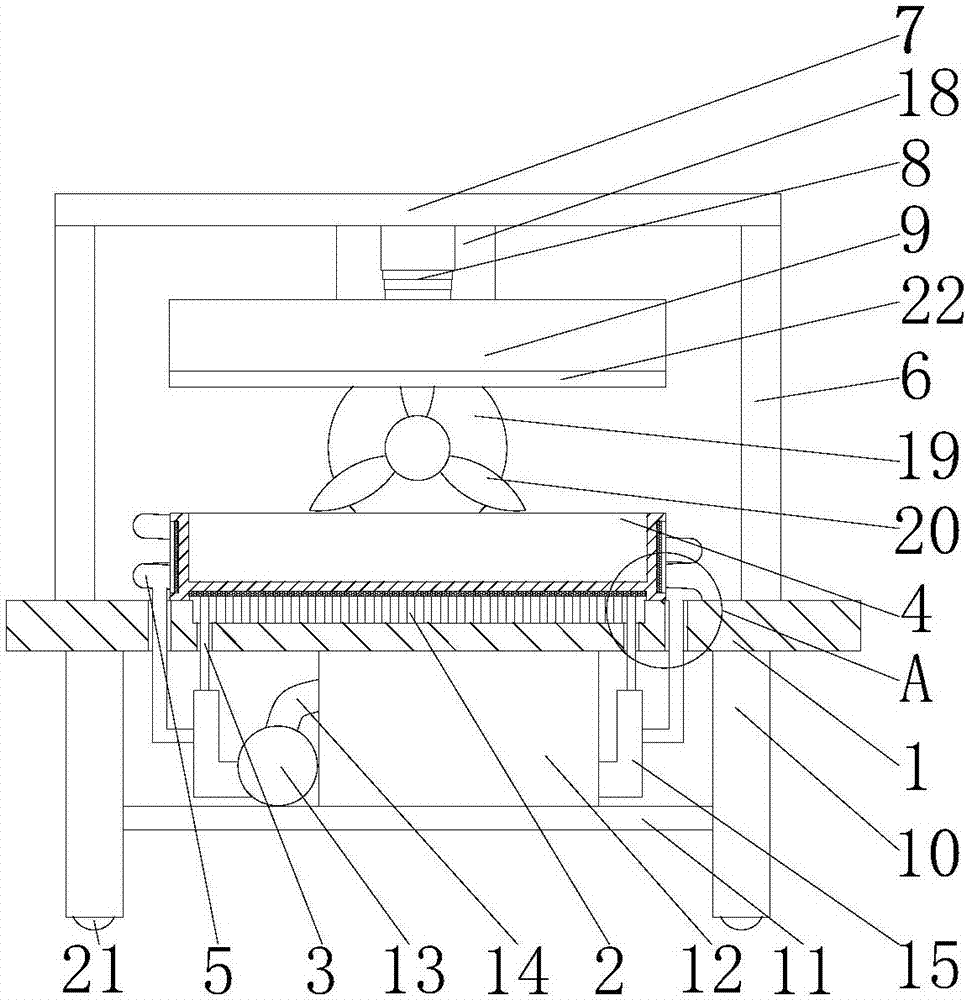

Automatic welding equipment for guard bar

InactiveCN106141548AReasonable designSimple and efficient operationWelding/cutting auxillary devicesAuxillary welding devicesHydraulic pumpIndustrial engineering

The invention discloses a mechanical product, in particular to automatic welding equipment for a guard bar. The automatic welding equipment for the guard bar is characterized in that a fork type supporting arm and supporting upright posts are arranged on a lifter base; a plurality of telescopic oil cylinders are arranged at the inner side of the fork type supporting arm; a lifter tabletop is arranged at the upper end of the fork type supporting arm; a plurality of fixing lug plates are arranged on the fork type supporting arm; the fork type supporting arm is connected with the lifter base and the lifter tabletop through the fixing lug plates; a hydraulic pump is arranged on the lifter base; a hydraulic pump controller is arranged at one side of the lifter base in a connecting manner. The automatic welding equipment has the beneficial effects of reasonable design, simplicity and convenience in operation, high welding quality and short production period of a finished product; labor force of enterprises is greatly reduced; production cost is reduced and production period is shortened, market demand is met, and great convenience is brought to normal production work of the enterprises.

Owner:济南新智数控机械设备有限公司

Feeding device for plate shearing machine

InactiveCN108994377AEfficient transportImprove work efficiencyShearing machinesShearing machine accessoriesEngineeringMaterial transport

The invention discloses a feeding device for a plate shearing machine. The device comprises a rack and a belt, a groove is formed in the bottom of an inner cavity of the rack, the bottom of a groove inner cavity and the top of the inner cavity of the rack are each fixedly connected with a first electric telescopic rod, a fixed plate is fixedly connected to the bottom of each of the first electrictelescopic rods, a feeding opening and a discharging opening are formed in the two sides of the rack, and the plate shearing machine is arranged on the left side of the rack. Through cooperative use of the rack, the belt, the groove, the first electric telescopic rods, the fixed plates, the feeding opening, the discharging opening, the plate shearing machine, a guide plate, a discharging table, afirst roller shaft set, a top plate, a second electric telescopic rod, a protection box, a second roller shaft set, a driven belt disc, a motor and a driving belt disc, efficient and rapid material transport is achieved, a worker does not need to manually carry materials, time and labor are saved, work efficiency is greatly improved, and production cost is reduced.

Owner:宋胜利

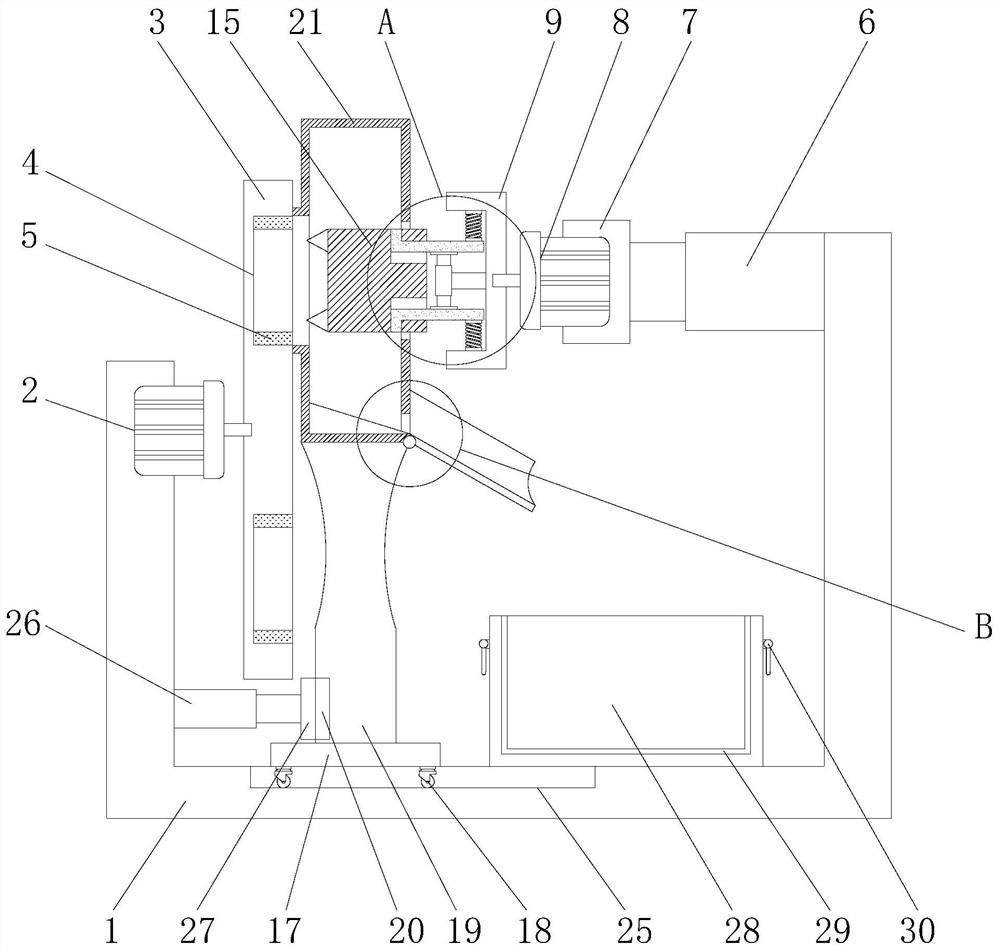

Wiping and dust removing device for flux-cored wires

InactiveCN107877040AWipe dust to achieveQuick and efficient wiping and dust removalWelding/cutting media/materialsSoldering mediaEngineeringFlux-cored arc welding

The invention discloses a wiping and dedusting device for flux-cored welding wire, which comprises a base plate, a box body is fixedly connected to the top of the bottom plate, and a partition plate is fixedly connected to both sides of the inner wall of the box body. Between the two sides of the inner wall and at the bottom of the partition plate, a rotating shaft is rotatably connected with a bearing. One end of the rotating shaft runs through the box and extends to one side of the box. The rotating shaft extends to one side of the box. The outer surface is sheathed with a worm gear, and the invention relates to the technical field of flux cored wire production facilities. The wiping and dust removal device for flux cored wire greatly enhances the dust removal effect, improves the dust removal efficiency very well, and realizes a good wiping and dust removal on the surface of the flux cored wire without spending a lot of time for the production personnel to clean the flux core. The repeated dust removal of the welding wire reduces the workload of the production personnel and realizes the rapid and efficient thorough wiping and dust removal of the flux-cored welding wire.

Owner:WUXI WEI KELAI TECH CO LTD

Novel extrusion forming mould for plastic pipes

The invention discloses a novel extrusion forming mould for plastic pipes. The novel extrusion forming mould for plastic pipes structurally comprises a mold core, an injection molding cavity, an operation handle, bolts, buffers, a connecting pipe, a product tray, a thickened ring, a fastening ring and a rotating shaft. Each buffer is composed of an outer pipe, a collision head, a sound attenuationsleeve, a mandrel, a check valve, a spring and a piston. According to the novel extrusion forming mould for plastic pipes, processing extrusion force borne by the collision heads is converted into and released through work of four cycles of an intake stroke, a compression stroke, an expansion stroke and an exhaust stroke of the pistons; and the springs have a buffering effect, the springs are pressed down in the processing and extruding process of the mold and are recovered into the original shape after extruding is stopped, the elastic property is high, redundant pressure is released, and pressure output is controlled effectively.

Owner:青岛益丰中润塑料机械有限公司

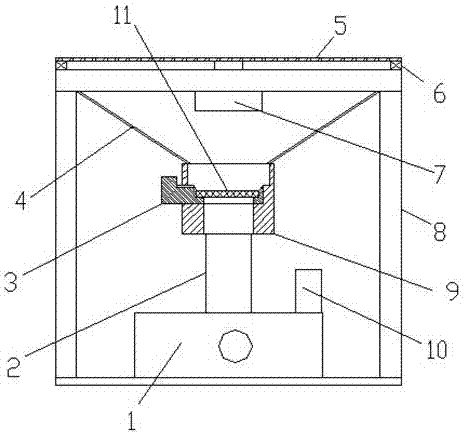

Intelligent precise die device

InactiveCN110153291AMeet production and processing needsSpeed up the production processShaping toolsNon-rotating vibration suppressionEngineeringMechanical engineering

The invention relates to an intelligent precise die device which comprises a bottom plate, wherein a rotary block is arranged in a groove in the top of the bottom plate; a rotary column is fixedly connected with the top of the rotary block; the top of the rotary column penetrates through the bottom plate, extends out of the bottom plate and is fixedly connected with a rotary plate; a ball at the bottom of the rotary block is arranged in the groove in the top of the bottom plate; and a stabilizing rod is movably connected with the left side of the top of the rotary plate. Through mutual cooperation of the rotary block, the rotary column, the rotary plate, the ball, the stabilizing rod, a stabilizing groove, a movable plate, a limiting spring, a first bearing, a second bearing, a rotary rod,a second fixed plate, a rotary disc, a support plate, a nut, a threaded rod, a limiting block and a limiting groove, the intelligent precise die device can conveniently adjust the angle, so that thedie producing and processing demand is better met, the production progress of the precise die is accelerated, and great convenience is brought for die production.

Owner:HEFEI UNIV

Processing method of power cable

InactiveCN110233002AEasy to useAvoid damageApparatus for heat treatmentReduction of cables/conductors sizeElectrical conductorPower cable

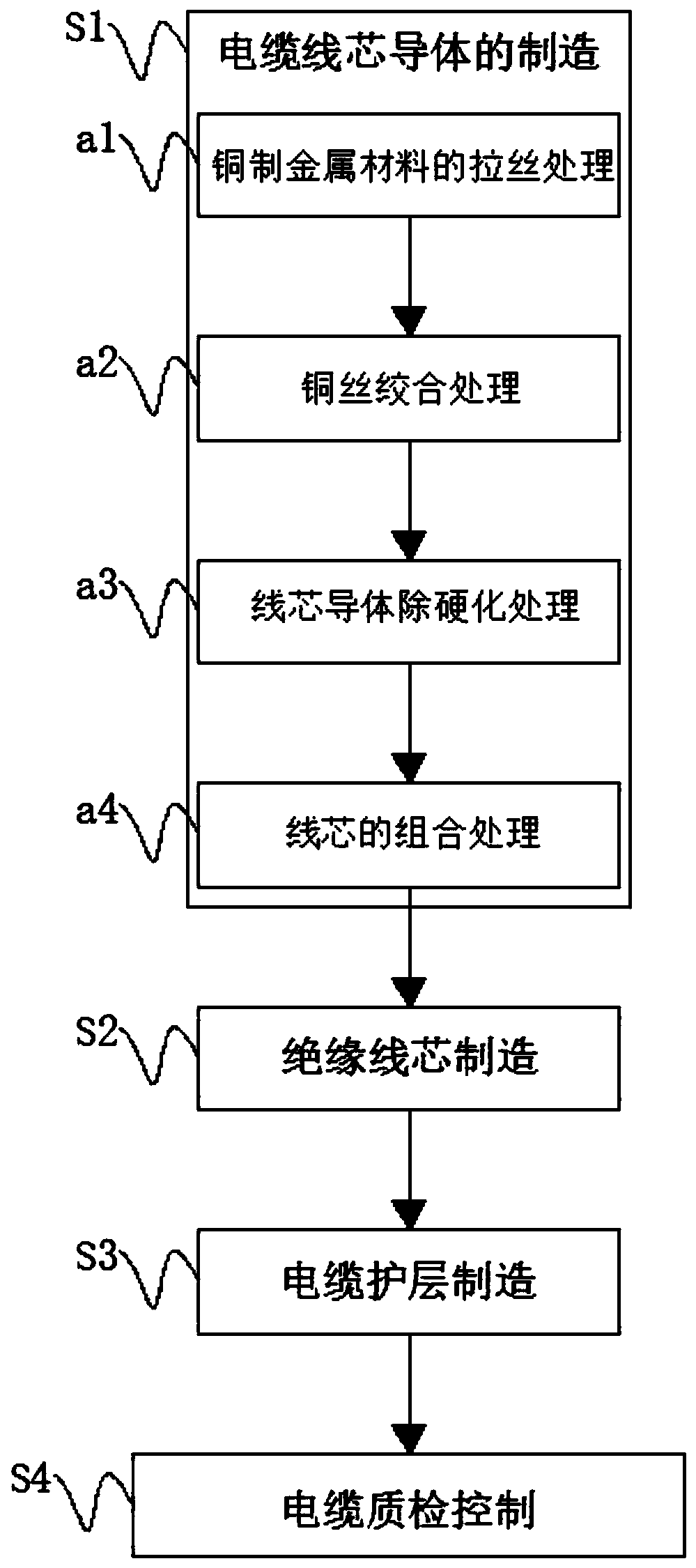

The invention discloses a processing method of a power cable. The processing method specifically comprises the following steps of (S1) manufacturing of a wire core conductor of a cable, namely (a1) wire drawing treatment of a copper metal material, (a2) twisting treatment of copper wires, (a3) hardening removal treatment of the wire core conductor and (a4) combination treatment of a wire core; (S2) manufacturing of an insulated wire core; (S3) manufacturing of a cable sheath; and (S4) quality control of the cable. The invention relates to the technical field of power cable processing. According to the processing method of the power cable, oven heating can be replaced through induction heating on the wire core conductor, the production staff do not need to spend a lot of time to operate andmonitor, the workload of the production staff is reduced, the production efficiency of the cable is greatly improved, the target of quickly and conveniently carrying out good hardening removal treatment on the wire core conductor of the cable is well achieved, and the targets of simplifying the production procedure of the cable and reducing the production cost are achieved, thereby greatly facilitating cable production work of the production staff.

Owner:江苏双花电线电缆有限公司

Cooling tank for rubber production

Owner:席早明

Integrated cleaning and drying equipment for textile cloth and working process thereof

ActiveCN108277600AImprove bindingFast and efficient cleaningSucessive textile treatmentsLiquid/gas/vapor removal by gas jetsElectric machineryEngineering

The invention discloses integrated cleaning and drying equipment for textile cloth and relates to the technical field of production processing equipment for textile cloth. The equipment comprises a baseplate, a cleaning box is fixedly connected to the top of the baseplate, and a beat pounding box is fixedly connected to the top of the cleaning box; a wedge block and a motor box are fixedly connected to the inner wall of the beat pounding box separately, rotation shafts are rotatably connected to one side of the motor box through a supporting rack, and first bevel gears and rotation cams sleevethe rotation shafts from top to bottom in sequence; a motor is fixedly connected to the interior of the motor box. According to the integrated cleaning and drying equipment for the textile cloth anda working process thereof, the cleaning and drying effect is greatly improved, the cleaning and drying efficiency is well improved, production personnel do not need to spend a large amount of time incleaning and drying the textile cloth, the textile cloth is quickly and efficiently subjected to cleaning and drying integrated treatment, and great convenience is provided for production personnel toconduct production work of the textile cloth.

Owner:泉州台商投资区国进信息技术有限公司

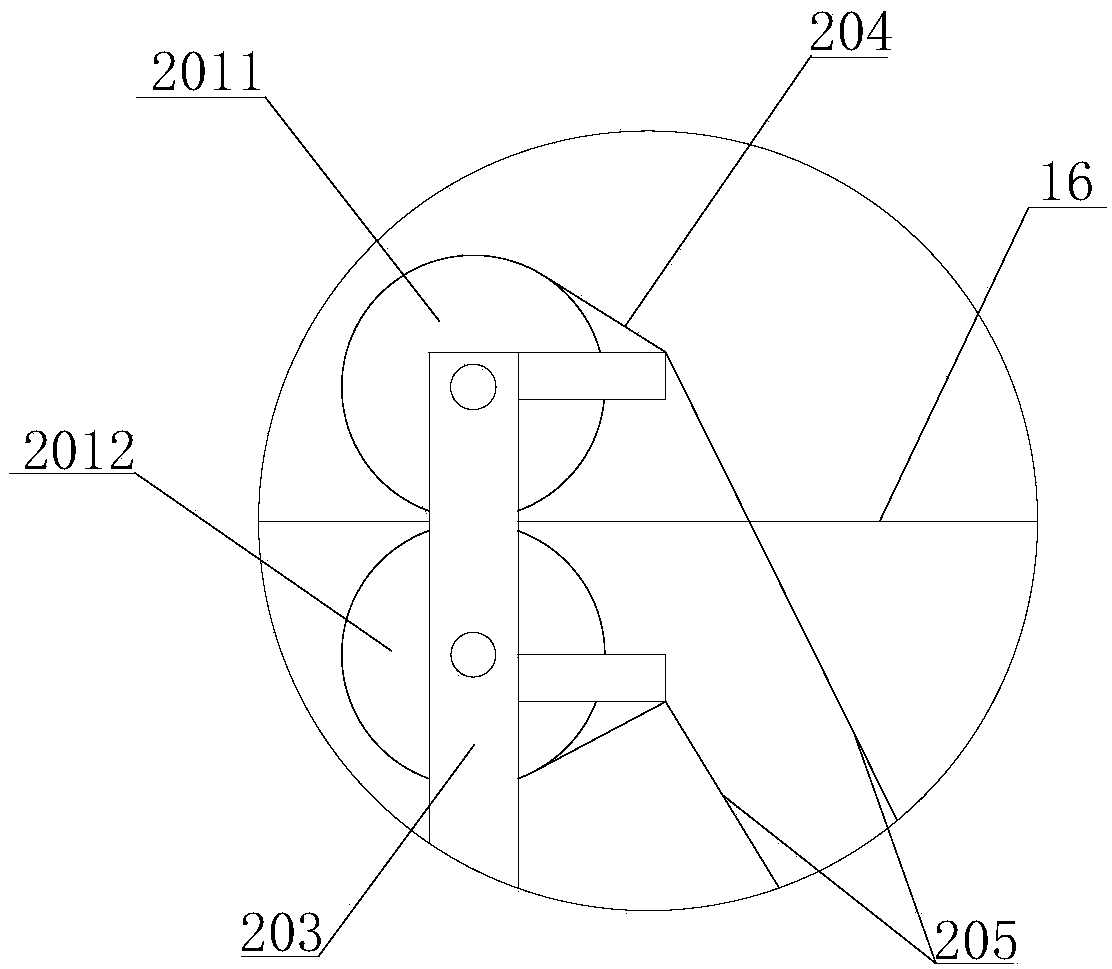

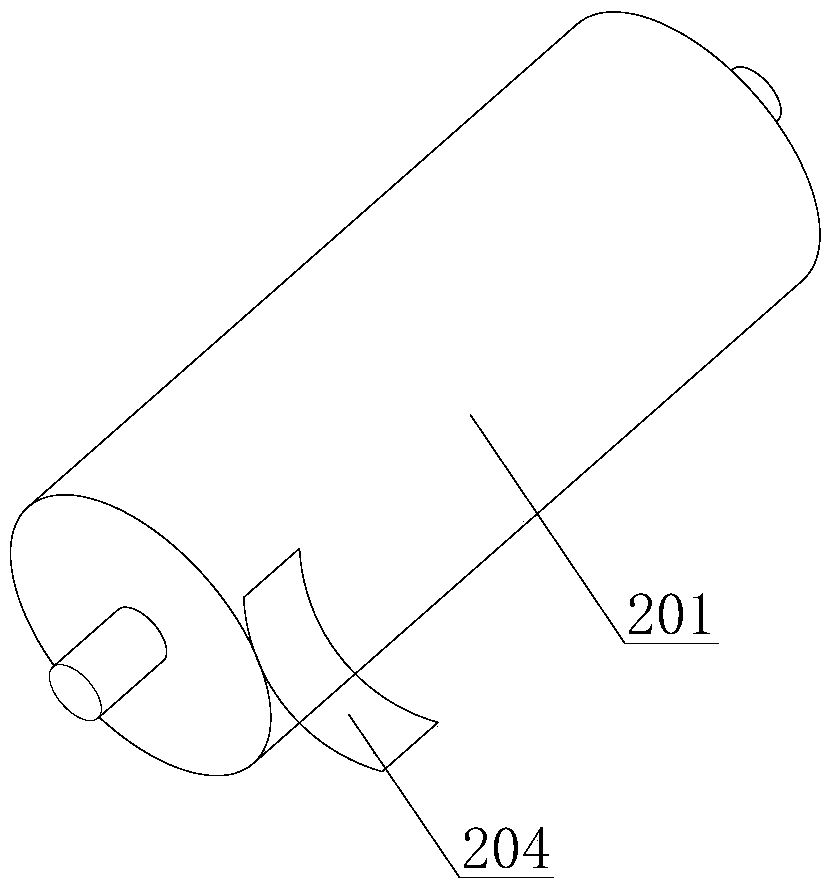

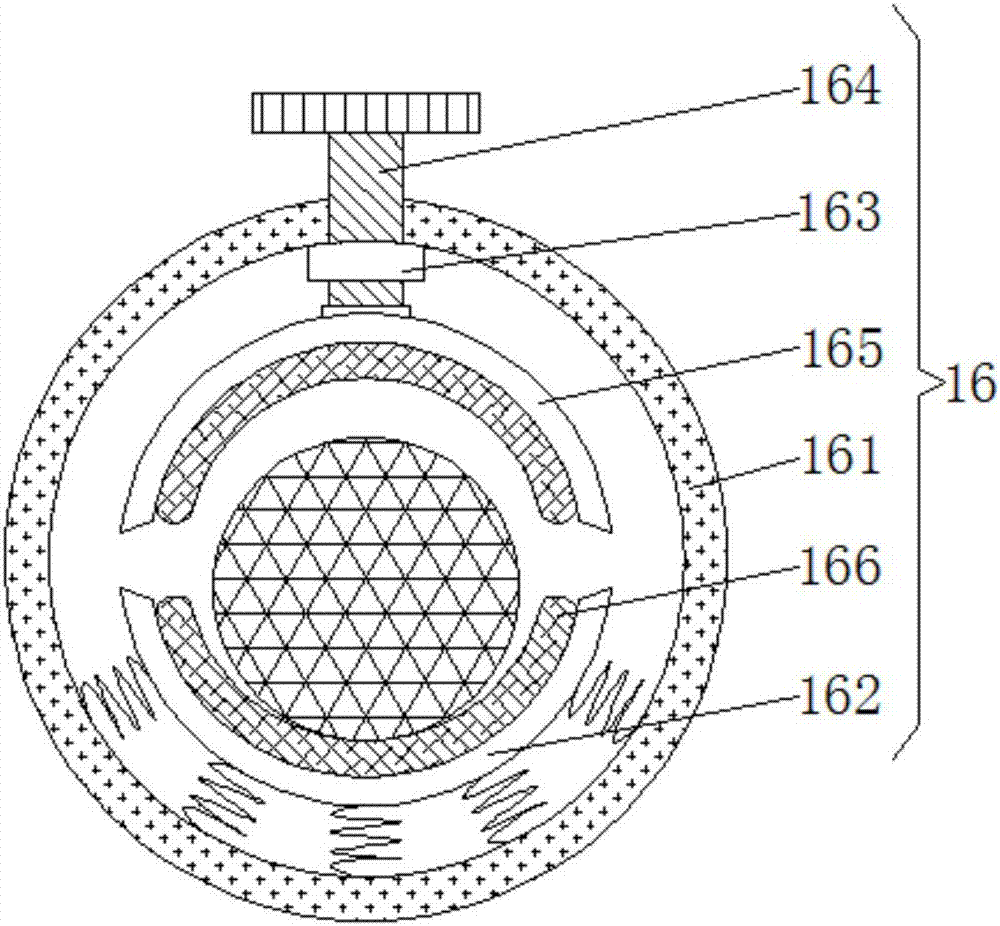

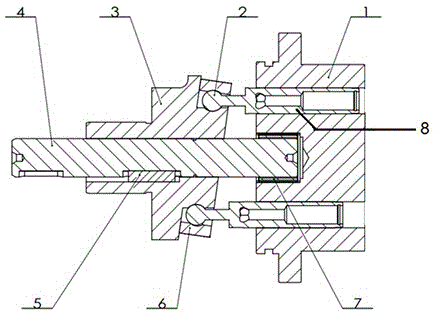

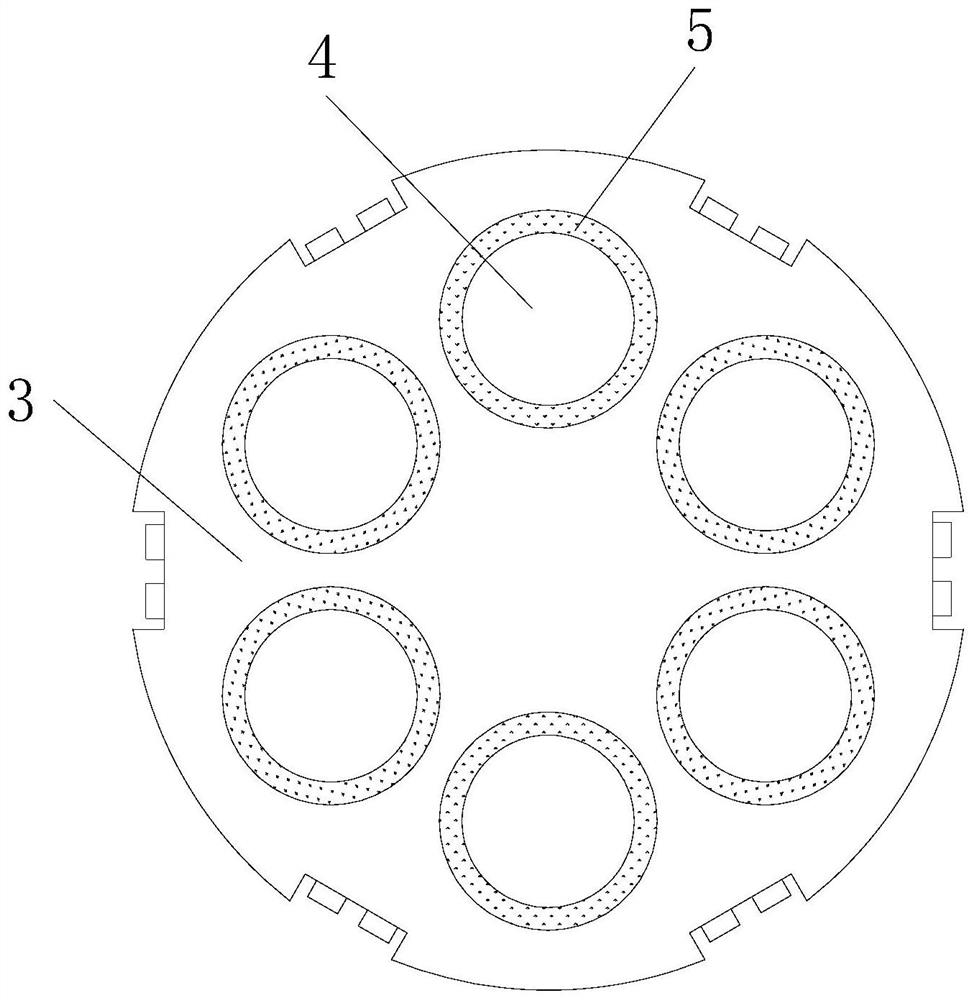

Axial plunger pump

InactiveCN104405606ASimple structureQuality improvementPositive-displacement liquid enginesMulti-cylinder pumpsReciprocating motionCylinder block

The invention discloses an axial plunger pump, which comprises a cylinder body, ball plungers, an inner ring type inclined plate, a main shaft, a flat key, a needle bearing, a plunger retainer ring and a thrust plate, wherein the main shaft penetrates through a central through hole of the inner ring type inclined plate and is connected through the flat key; the connecting end of the main shaft and the cylinder body is connected with the cylinder body through the needle bearing; the plunger retainer ring is arranged on the inner ring type inclined plate and opposite to the inner ring type inclined plate to form an arc-shaped roller path; a plurality of plunger chambers are uniformly arranged on the cylinder body along the circumference; one ball plunger is placed in each plunger chamber; spherical head parts of the ball plungers are embedded into the arc-shaped roller path; the main shaft is rotated to drive the inclined plate to rotate; the ball plungers are subjected to right-and-left piston reciprocating motion under the action of an inclination angle of the inner ring type inclined plate so as to complete oil absorption and oil discharge of the pump.

Owner:ZHEJIANG UNIV +1

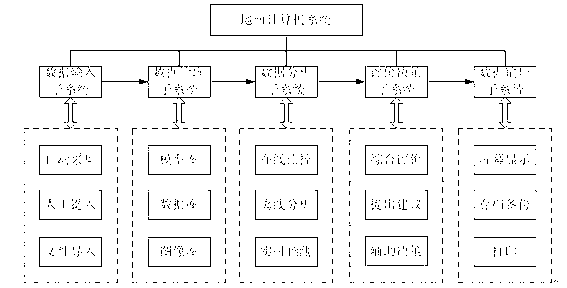

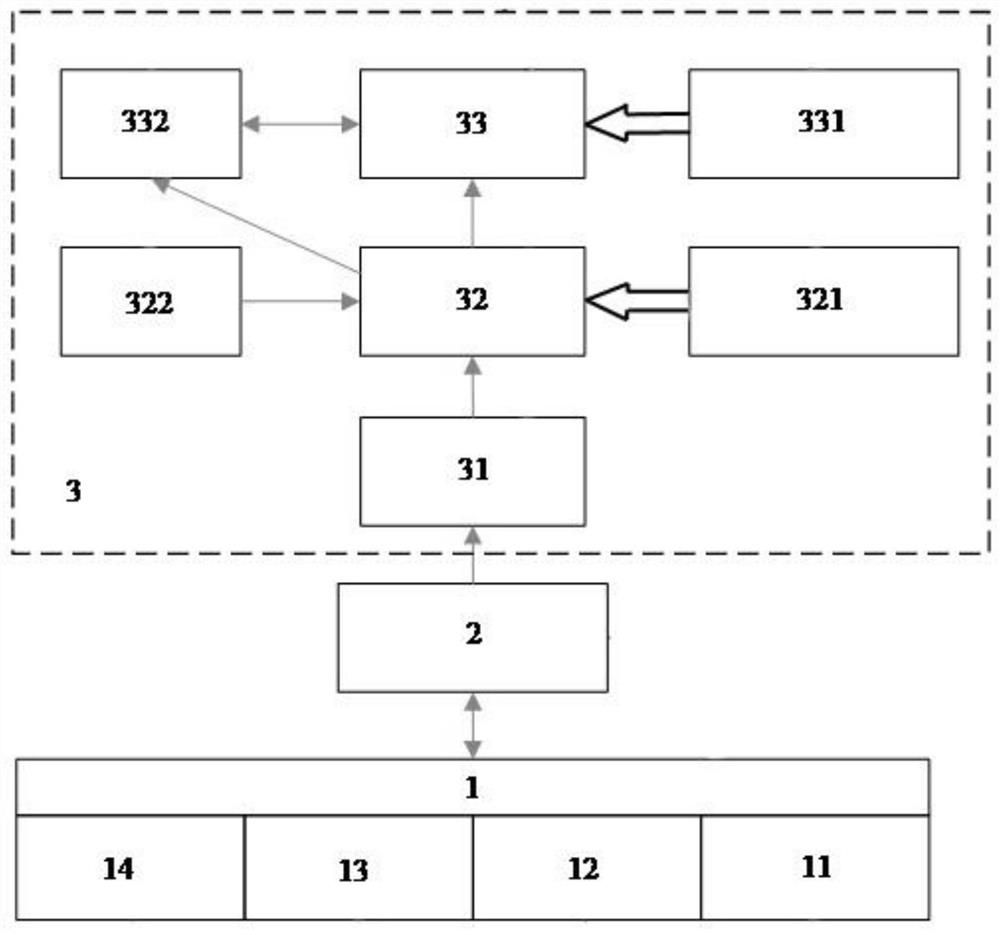

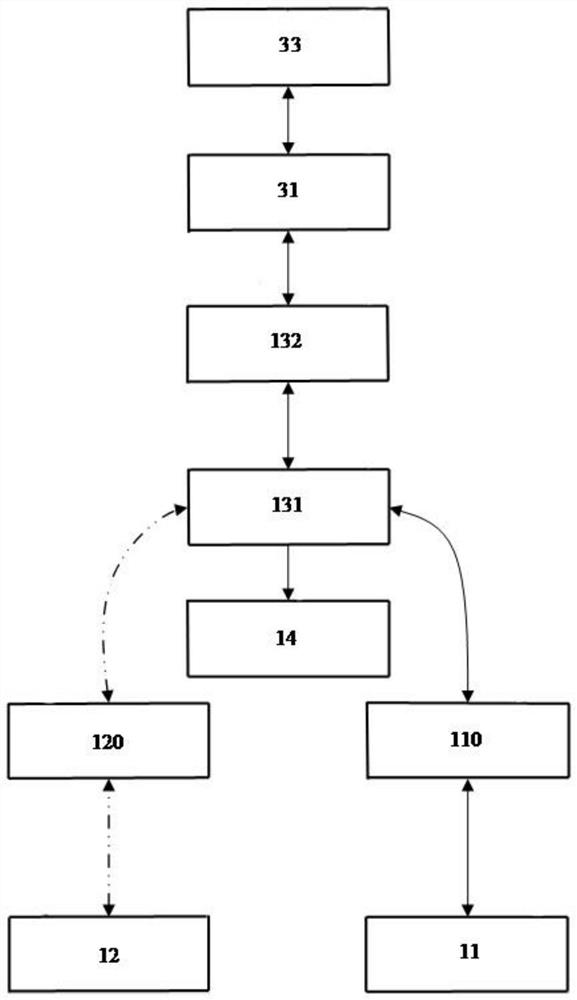

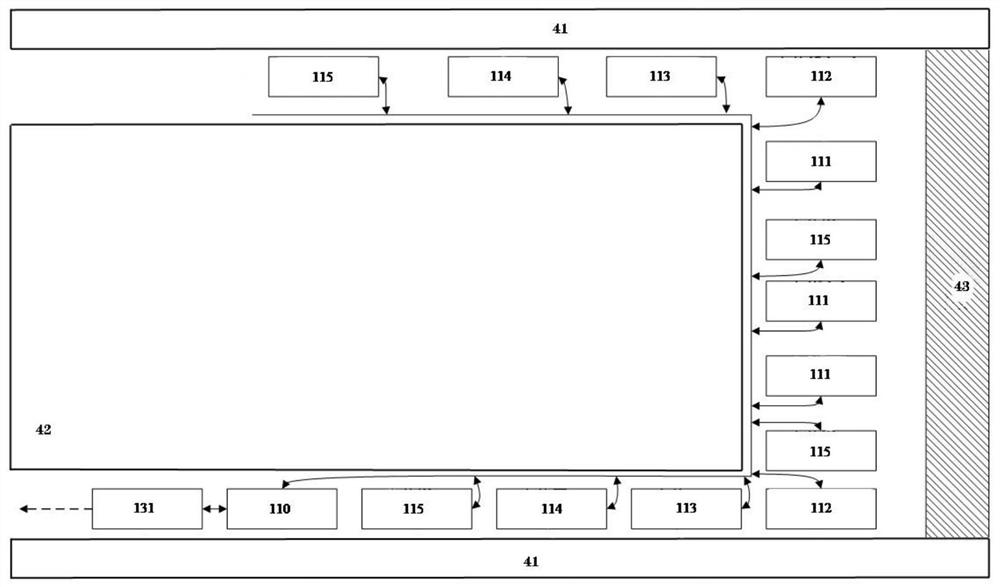

Mine pressure monitoring and analyzing system

The invention relates to the technical field of coal mine monitoring. The invention particularly relates to a mine pressure monitoring and analyzing system. The system comprises a cloud server, the cloud server is in communication connection with a coal mine data center and a remote monitoring center, the coal mine data center is located above a well and is in communication connection with a plurality of underground data acquisition units, the data acquisition units are used for acquiring underground mine pressure monitoring data, and the remote monitoring center is used for remote analysis and processing. According to the mine pressure monitoring system, the Internet of Things technology and the cloud platform technology are utilized, stable collection of underground mine pressure monitoring data is achieved, the scattered mine pressure monitoring data can be integrated, and data flow transmission from the underground coal mine to a remote monitoring center is achieved.

Owner:CCTEG COAL MINING RES INST +1

Rotary and environment-friendly negative pressure adsorption dust-free workbench

InactiveCN107414747AConvenient production workProtect environmental healthWork benchesCleaning using gasesCircular discSuction stress

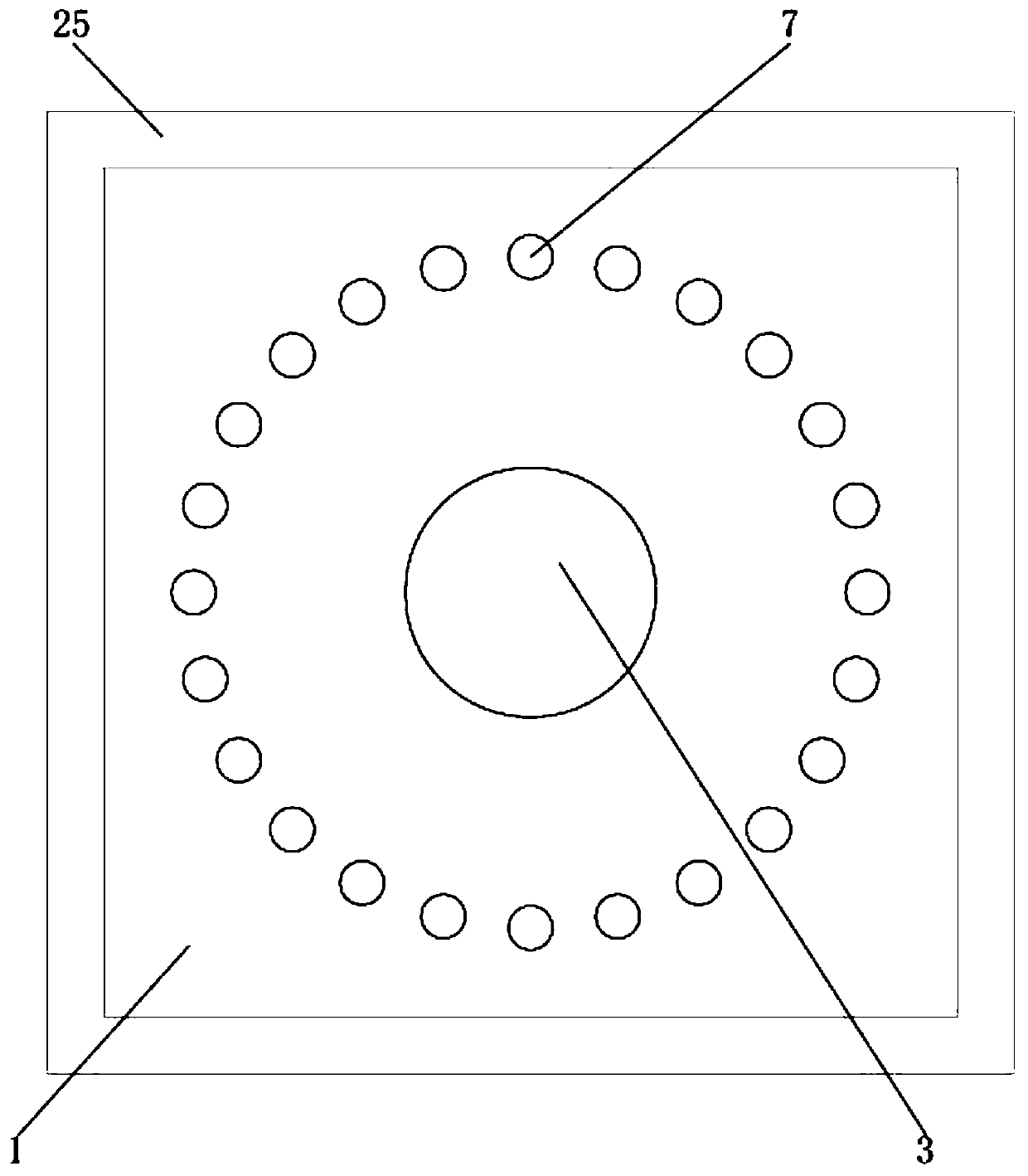

The invention discloses a rotary and environment-friendly negative pressure adsorption dust-free workbench. The rotary and environment-friendly negative pressure adsorption dust-free workbench comprises a supporting frame, a round plate, a rotary driving device and an air exhauster. The rotary driving device is arranged on the supporting frame, and the top output end of the rotary driving device is connected with the bottom of the round plate. A tapered seal shell located below the round plate and the rotary driving device is arranged in the supporting frame. Air ventilation holes are formed in the round plate in a manner of ring arrays. A connecting sleeve is arranged at the bottom of the tapered seal shell, a push plate is arranged on one side of the connecting sleeve in a manner of transverse insertion, a stepped hole is formed in the push plate, a filter screen is arranged in the stepped hole, and a pipeline is arranged between the bottom of the connecting sleeve and an air inlet of the air exhauster for connection. By the way, the rotary driving device is utilized to drive the round plate to rotate, the air ventilation holes in the round plate generate downward suction through the air exhauster, and debris and dust particles on the round plate are sucked into the lower tapered seal shell.

Owner:TAICANG WANG YU MACHINERY TECH CO LTD

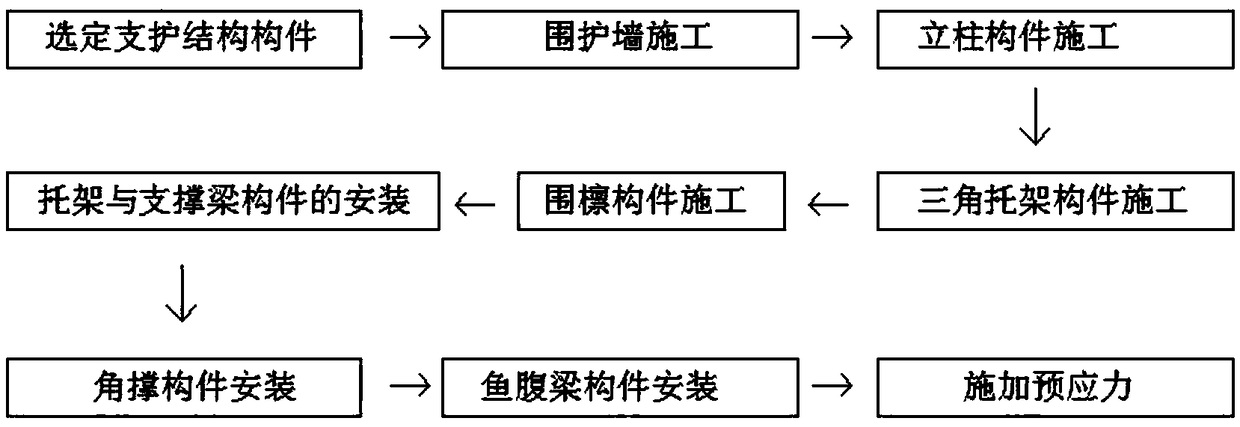

Prefabricated support structure construction process based on prestressed fish-belly beam support technology

The invention provides a prefabricated support structure construction process based on prestressed fish-belly beam support technology, comprising the steps of selecting support structural members, constructing an enclosure wall, constructing column members, constructing triangular carrier members, mounting round purlin members, mounting carriers and support beam members, mounting angle brace members, mounting fish-belly members, mounting fish-belly beam members and applying prestress. The prestressed fish-belly beam support technology is used herein to manufacture the prefabricated support structure; rigidity and stability of the whole prefabricated support structure can be improved; construction site space can be enlarged; other production in a foundation pit is facilitated; the process herein also has the advantages of short construction period. Energy consumption is greatly reduced; pretreatment of the triangular carrier members helps improve post-mounting stability of triangular carriers; a better positioning reference environment is provided for the round purlin mounting in subsequent steps; therefore, mounting precision and structural stability of the whole prefabricated support structure can be improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Bearing bush cutting device capable of facilitating waste collection

ActiveCN112643392AReduce wasted personnel and wasted timeEasy to recyclePositioning apparatusMaintainance and safety accessoriesSlide plateWaste material

The invention discloses a bearing bush cutting device capable of facilitating waste collection. The bearing bush cutting device comprises a base and a bottom plate; a first motor is fixed to the inner side wall of the base; and an output shaft of the first motor is fixedly connected with a machining rotary disc through a coupler. According to the bearing bush cutting device capable of facilitating waste collection, a waste collecting box is arranged on one side of the machining rotary disc, so that the waste generated by machining falls into the waste collecting box, slides out of the waste collecting box along a sliding block and a sliding plate and finally enters a waste storage box. The bearing bush cutting device facilitates waste collection, a bearing bush can generate a large quantity of waste materials during cutting work, the waste materials are easy to collect and cannot be splashed, the surface of a cutting operation table cannot be messy, manual cleaning is not needed, the development concept of full-automatic development of bearing bush production work is inherited, unnecessary personnel waste and time waste are reduced, bearing bush waste recycling work is facilitated, the waste materials can be recycled conveniently, and great convenience is brought to bearing bush cutting work.

Owner:安徽科达汽车轴瓦有限公司

Mask production equipment and production method thereof

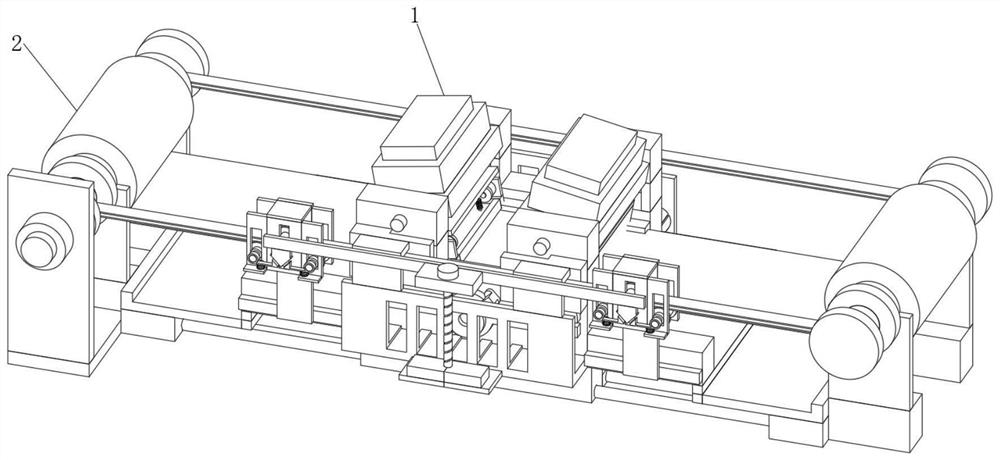

InactiveCN113183504AFacilitate automated production workRealize automatic feeding processDomestic articlesProtective garmentReciprocating motionProcess engineering

The invention relates to the technical field of protective articles, in particular to mask production equipment and a production method thereof. The mask production equipment comprises a base, a driving structure, a mask body, a linkage structure, a dispensing structure and a line pulling structure. The driving structure is utilized to realize reciprocating motion, so that the mask body is pushed to slide, the subsequent mask body is continuously subjected to dispensing and line connection, the automatic production work of a mask is greatly facilitated, the working efficiency is greatly improved, and the linkage structure is used for being matched with the driving structure to drive the dispensing structure to do reciprocating motion, so that the line connection work of the mask body is achieved, the production efficiency of the mask body is greatly improved, and the line pulling structure is utilized to transmit a pull rope, so that the automatic line feeding work is facilitated, the production work of the mask body is greatly facilitated, and human resources are saved.

Owner:乐红辉

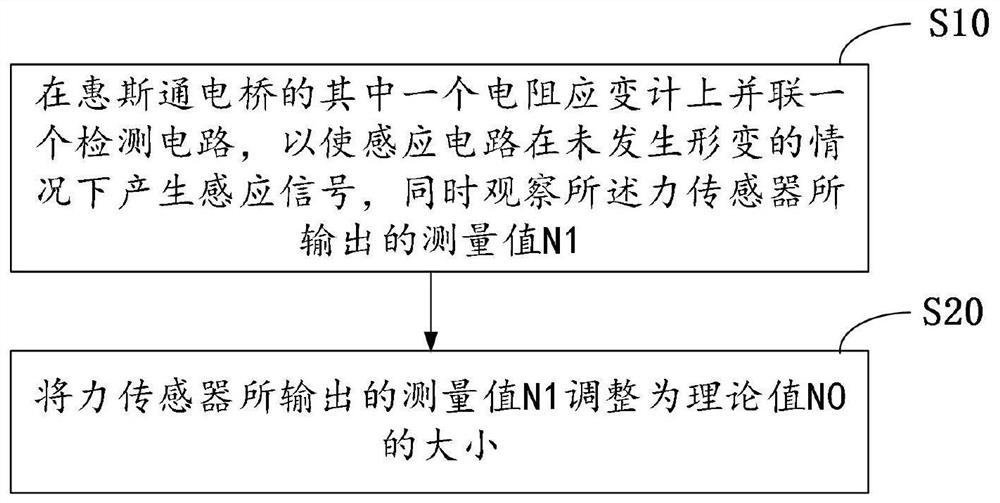

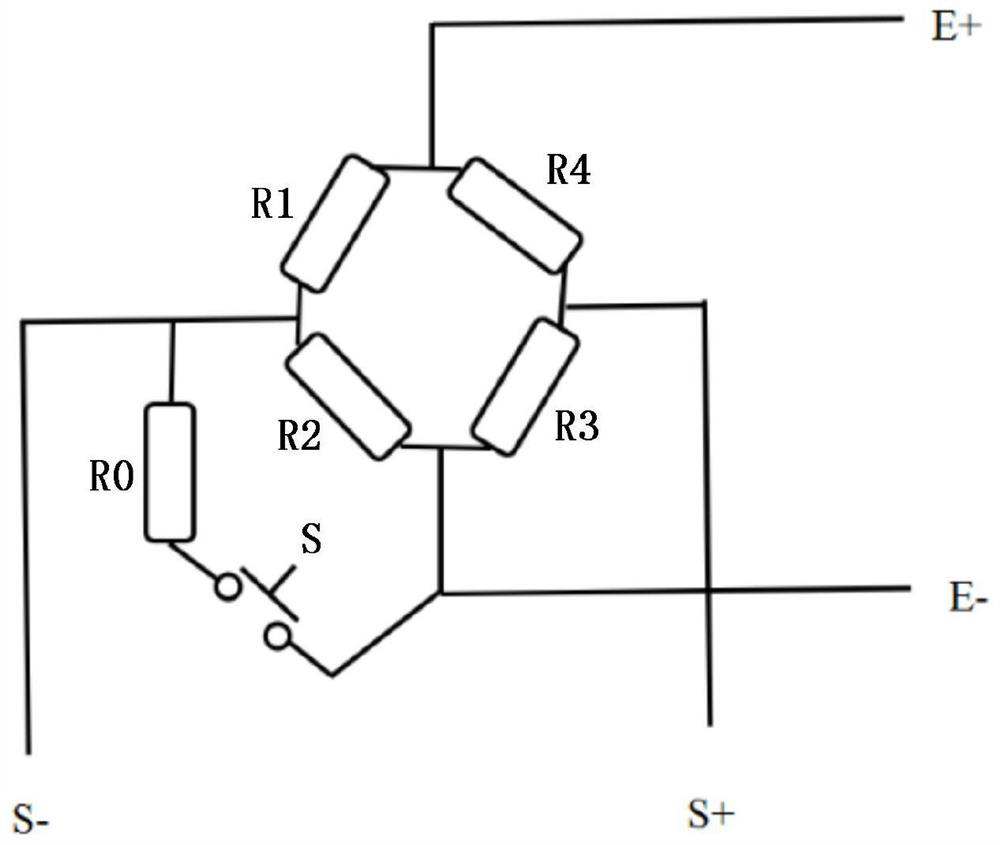

Calibration method for force sensor

InactiveCN112284613AReduce calibration errorConvenient production workForce/torque/work measurement apparatus calibration/testingElectrical resistance and conductanceClassical mechanics

The invention relates to the technical field of sensors, and discloses a calibration method for a force sensor. The force sensor comprises an induction circuit which can generate an induction signal according to the deformation degree. The calibration method comprises the following steps that a calibration circuit is connected to one resistance strain gauge of the Wheatstone bridge in parallel, sothat the induction circuit generates an induction signal under the condition that deformation does not occur, and meanwhile a measurement value N1 output by the force sensor is observed, wherein under the condition that the resistance value of the calibration circuit is known, the theoretical value output by the force sensor is N0; and the measured value N1 output by the force sensor is adjustedto be the theoretical value N0. According to the calibration method for the force sensor provided by the invention, the force sensor can be calibrated under the condition of simulating full-scale output by accurately controlling the resistance value of the calibration circuit, so that the calibration error can be effectively reduced, the calibrated sensor is more accurate, and great convenience isbrought to production work.

Owner:深圳市鑫精诚科技有限公司

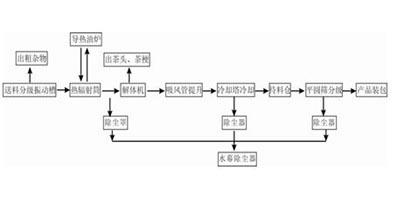

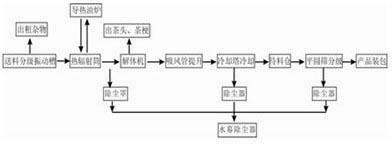

Broken tea refined processing technique

InactiveCN102599281AAvoid cokingStop evaporationPre-extraction tea treatmentProduction lineCooling tower

The invention relates to a broken tea refined processing technique. Equipment used in the broken tea refined processing technique comprises feeding grading vibration grooves, a drying system, a disintegration machine, a suction pipe, a cooling tower, an automatic tapping device and a dust removal system. The broken tea refined processing technique is characterized in that tealeaves enter the disintegration machine to be disintegrated so as to remove tea heads and tea stalks after entering a heat radiation cylinder of the drying system to be dried and dust removed through the feeding grading vibration grooves, then the disintegrated tealeaves enter the cooling tower to be cooled through the suction pipe, and finally the cooled tealeaves enter a flat and round sieve to be graded and packaged. An automatic production line is provided for the tealeaves from impurity removal, drying, dust removal, disintegration, grading to packaging, so that the production efficiency is improved, the working environment is improved, and the grade of the tealeaves is improved.

Owner:HUNAN LONGZHOU TEA IND

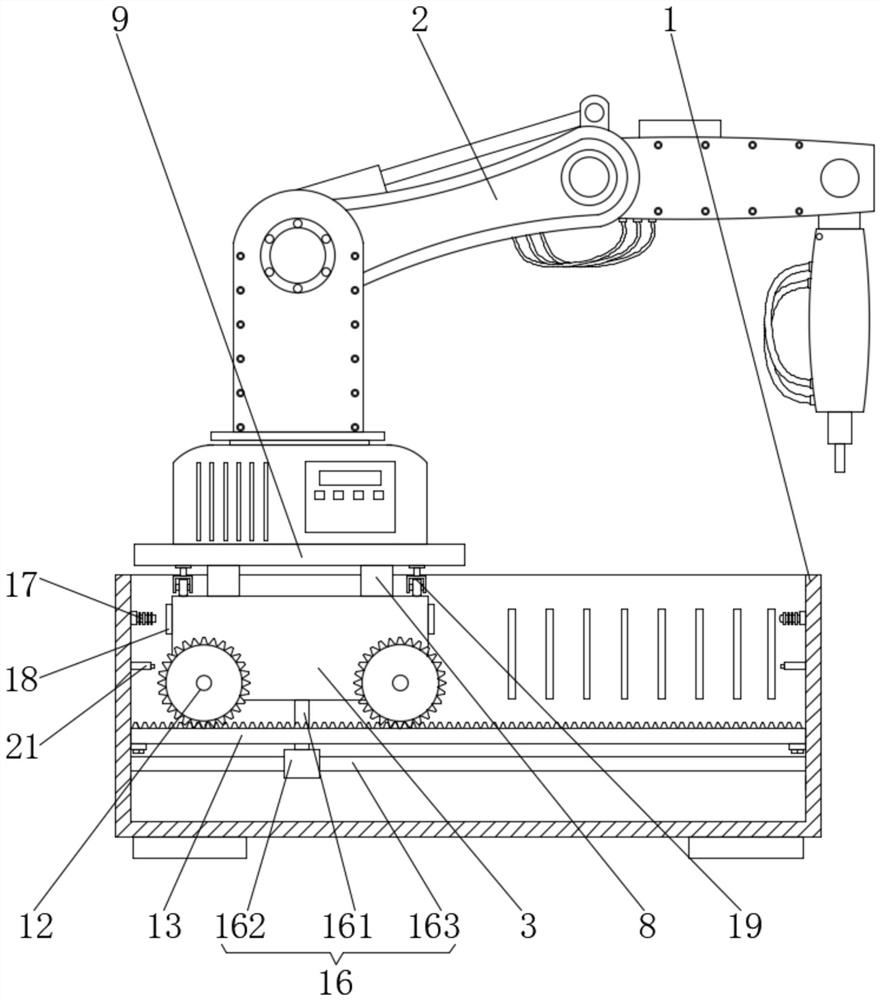

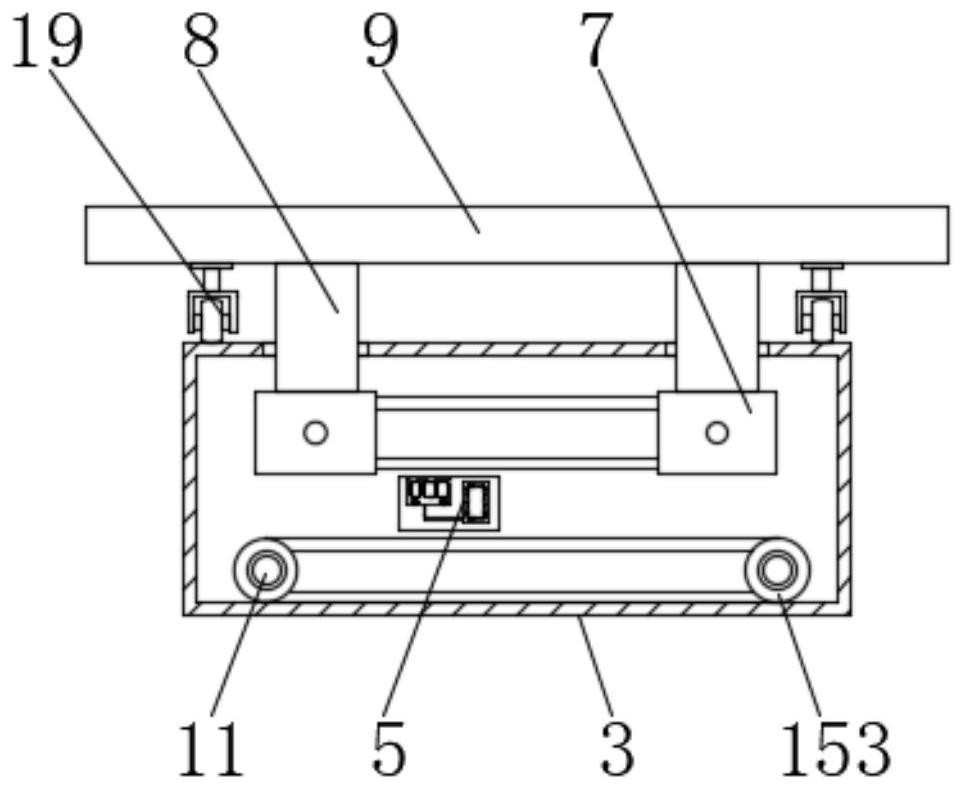

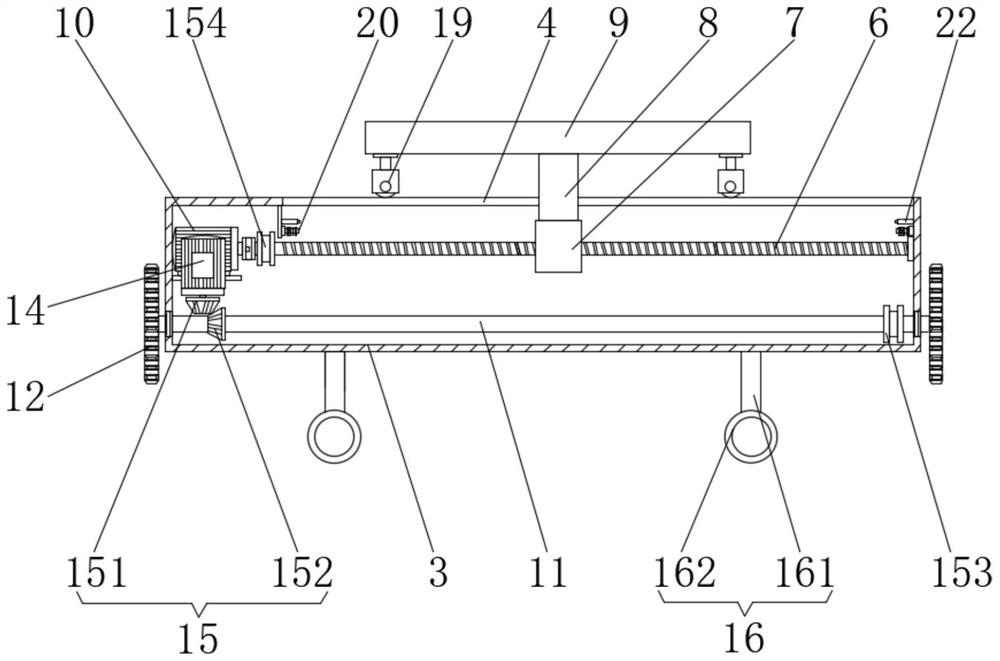

Multidirectional adjustable welding mechanical arm structure and using method thereof

PendingCN112936239AExpand the scope of workImprove adjustabilityProgramme-controlled manipulatorEngineeringScrew thread

The invention relates to the technical field of welding equipment, in particular to a multidirectional adjustable welding mechanical arm structure and a using method thereof. The multidirectional adjustable welding mechanical arm structure comprises a shell, a mechanical arm body, a box body and a processor, through grooves are formed in the two sides of the top of the box body in a penetrating mode, and screw rods are rotationally connected to the two sides of the interior of the box body; and the surface of each screw rod is in threaded connection with a moving block, the top of each moving block is in bolted connection with a supporting column, and the top end of each supporting column is in bolted connection with a fixing plate. The position of the mechanical arm can be adjusted in the left-right direction and the front-back direction, the working range of the mechanical arm is expanded, the adjustability of the mechanical arm structure is improved, convenience is brought to the production work, and the problems that most of the existing welding mechanical arms are fixed to the same position, the mechanical arms can only rotate in situ, the working range of the mechanical arm is limited due to the fact that the position of the mechanical arm cannot be adjusted in the left-right direction or the front-back direction are solved.

Owner:丁斌

Color bean curd machine convenient for cleaning

InactiveCN108617797AQuality assuranceQuantitative control of the amount addedCheese manufactureCleaning using liquidsSprayerEngineering

The invention relates to a color bean curd machine convenient for cleaning. The color bean curd machine comprises a mixing box, a controller, a soybean milk pipe, a first motor, a sealing plate, a cleaning mechanism, a discharging pipe, a plurality of support legs and a plurality of feeding mechanisms. The feeding mechanism comprises a feeding pipe, a material box and a material conveying pipe. The material box is internally provided with a feeding component. The feeding component comprises a driving component, a feeding plate and two telescopic components. The telescopic component comprises atelescopic frame and two first connecting rods. The cleaning mechanism comprises a shielding can and two water tanks. The shielding can is internally provided with a lifting component, a lifting plate and two cleaning components. The cleaning component comprises a sprayer and a water pipe. The color bean curd machine convenient for cleaning is capable of, through the feeding mechanisms, adding vegetable juice solution with a moderate pH value to the mixing box, and guaranteeing the quality of produced bean curd, in addition, enabling a stirring plate to be lifted to the exterior of the mixingbox through the cleaning mechanism, spraying water solution to clean through the sprayers, and removing residual solution on the stirring plate. The follow-up production work is convenient, and the practicability of the device is improved.

Owner:永春辛德环保科技有限公司

Efficient heat dissipation device for mold

InactiveCN107322981AEfficient, fast and comprehensive heat dissipationNo shrinkagePressesEngineering

The invention discloses an efficient heat dissipation device for a mold. The device comprises a workbench; a deep groove is formed in the top of the workbench; first condensing pipes are arranged in an inner cavity of the deep groove; a lower mold is fixedly connected at the top of the workbench and located on the surface of the deep groove; second condensing pipes are arranged on the surface of the lower mold; supporting columns are fixedly connected at the top of the workbench and located on two sides of the lower mold; a supporting plate is fixedly connected at the tops of the supporting columns; and an electric telescopic rod is fixedly connected at the front end of the bottom of the supporting plate. With the device, through matched use of the workbench, the deep groove, the first condensing pipes, the lower mold, the second condensing pipes, a condensate box, a water pump, a hose, two-way pipes and grooves, efficient, quick and comprehensive heat dissipation can be performed on the mold, the defects such as local shrinkage cavities, uneven shrinkage, looseness and the like of a product can be avoided, the percent of pass and the quality of the product are increased, the production cost is reduced, and the production progress is accelerated.

Owner:张家港华翊电工有限公司

Manufacturing and forming method for rotor punching sheet of servo motor

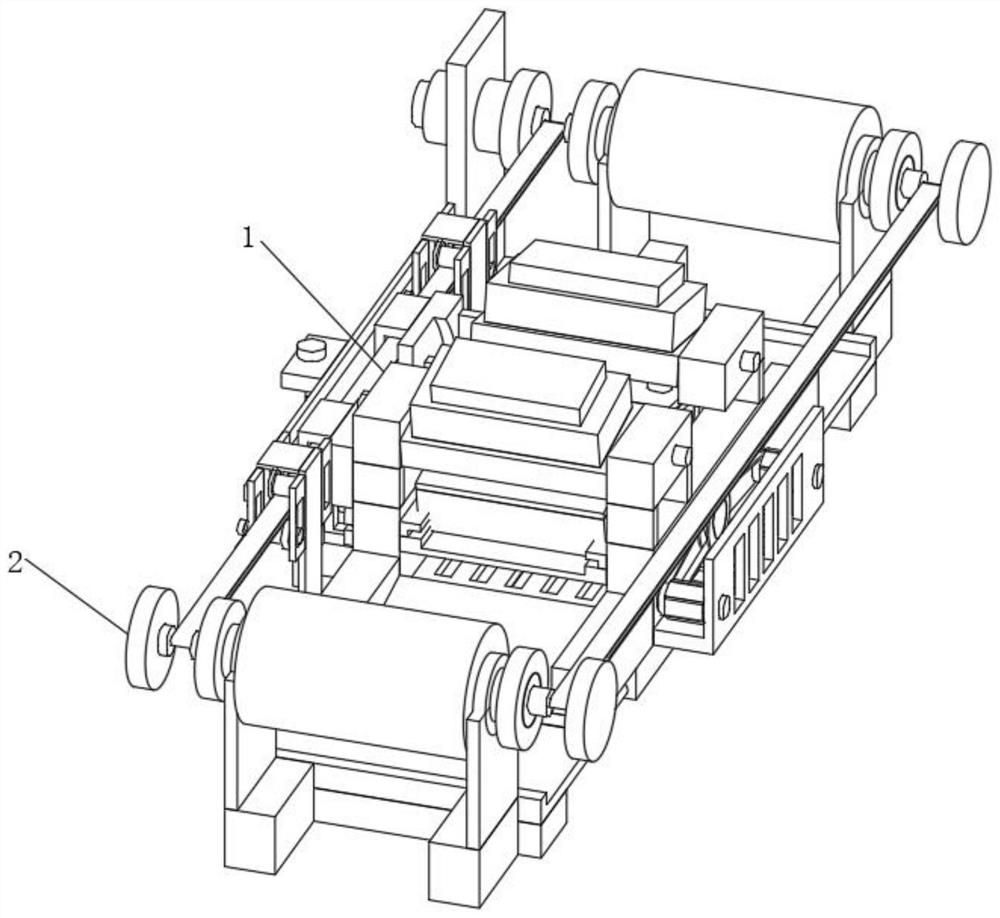

PendingCN114583905AConvenient stamping production workEfficient production purposeManufacturing stator/rotor bodiesConveyor partsPunchingIndustrial engineering

The invention discloses a servo motor rotor punching sheet manufacturing and forming method which comprises a stamping production structure, the side end position of the stamping production structure is connected with an adjusting feeding structure in a limiting mode, and the stamping production structure comprises a first stamping part, a transmission inclined guide part and a second stamping part. The conveying inclined guide part is arranged at the bottom of the inner end of the stamping production structure, one side of the upper end of the conveying inclined guide part is fixedly connected with the first stamping part, and the other side of the upper end of the conveying inclined guide part is fixedly connected with the second stamping part. According to the manufacturing and forming method for the rotor punching sheet of the servo motor, the purpose of manufacturing and forming the rotor punching sheet of the servo motor at the inner end is achieved through the arrangement of a pressing production structure.

Owner:蔡义强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com