Patents

Literature

174results about How to "Speed up the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for optimizing low pneumatic noise of high-speed train head section longitudinal symmetry plane line

ActiveCN101354729AAccelerated aerodynamic noise controlAerodynamic Noise Control ScienceSpecial data processing applications3D modellingNoise controlRailway passenger car

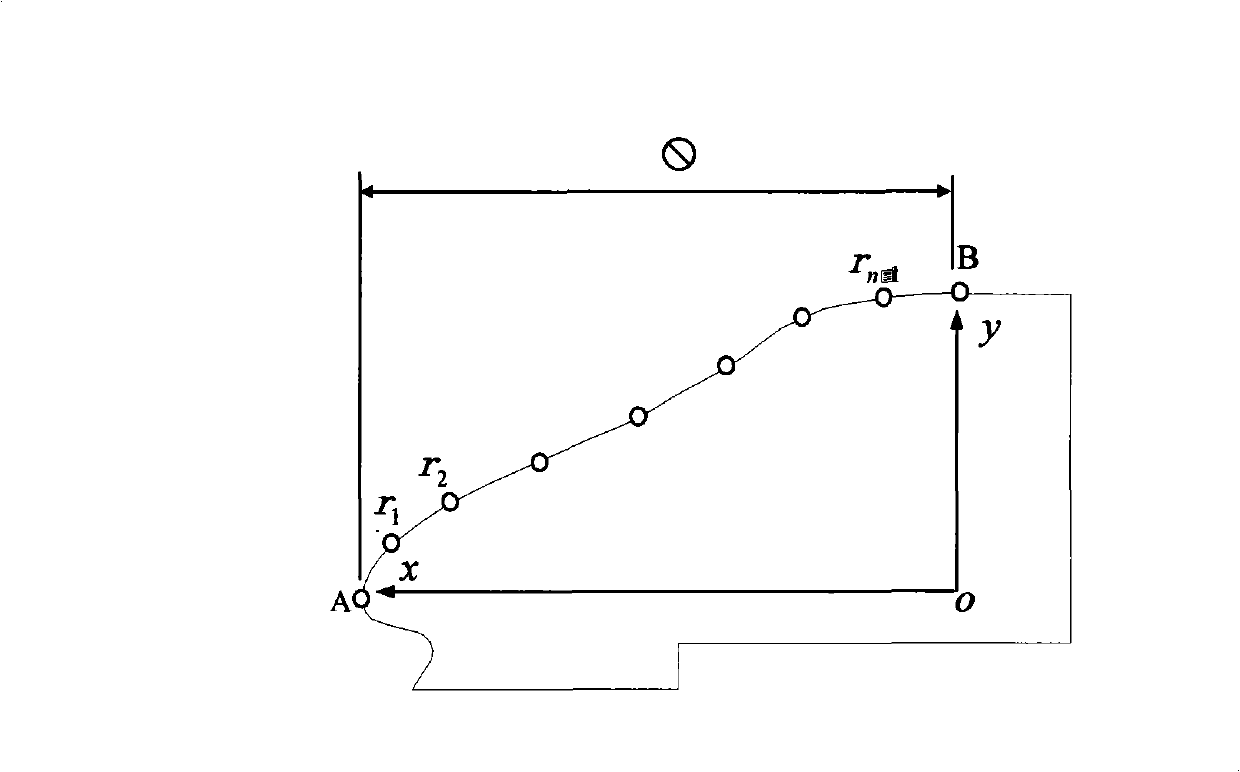

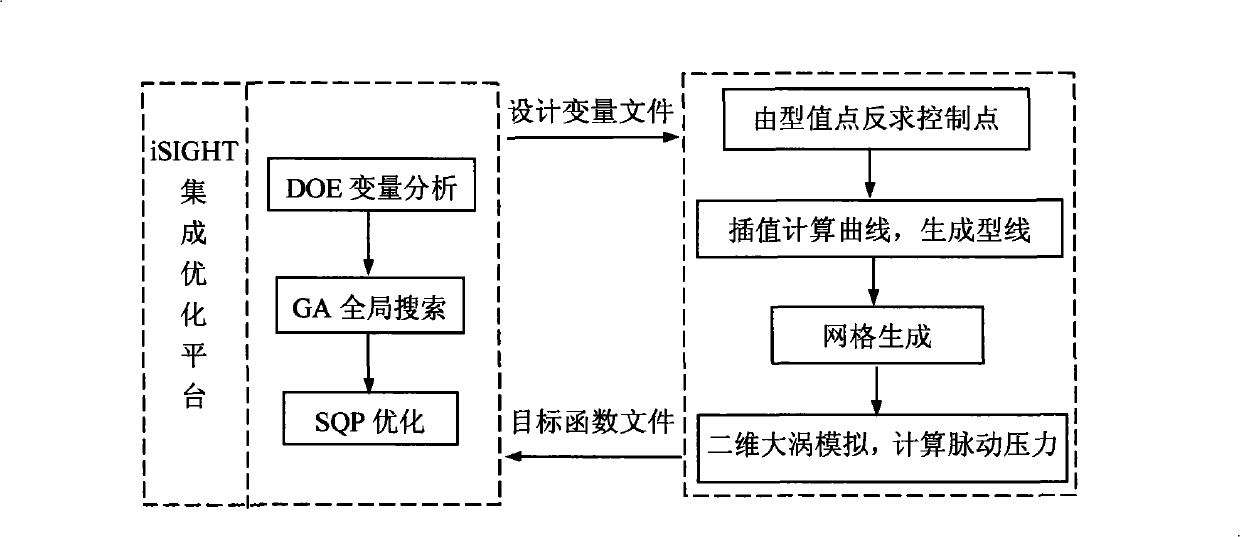

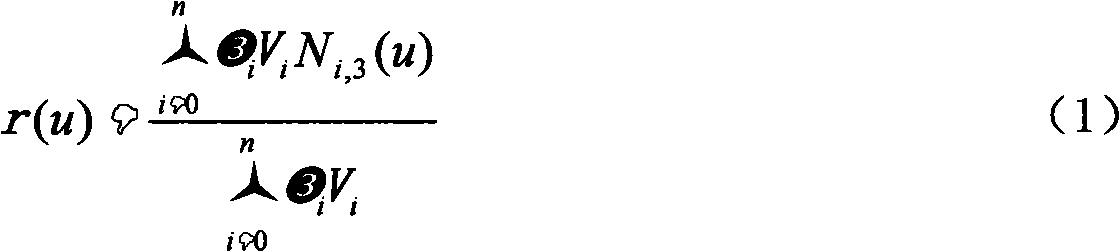

The invention relates to a method for optimizing low aerodynamic noise of molded lines of longitudinal symmetrical surface for the head part of a high-speed train. The molded lines of the longitudinal symmetrical surface for the head part of the high-speed train are basic molded lines for determining the running trend of the whole appearance, wherein the part of the molded line between nose cone points A and transition points B from the train head to the train body is the key part in the molded line design. The invention is the optimized design of the part. The method performs the parameterized model and CFD value calculation on the molded lines of longitudinal symmetrical surface for the head part of a high-speed train by utilizing the NURBS curves, combines the optimized arithmetic to link the change in the aerodynamic performance of the molded line and the adjustment of the geometrical shape, and adjusts the molded lines repeatedly through a flow field computation program and an optimized program, thereby accurately determining the optimal position of the value point of the molded lines of the longitudinal symmetrical surface so that the aerodynamic noise of the head part of the train is reduced to the minimum, lowering the design and the manufacture costs of the aerodynamic noise control of the high-speed train, accelerating the production process of the high-speed train, and making the noise control of the train more scientific.

Owner:CRRC QINGDAO SIFANG CO LTD

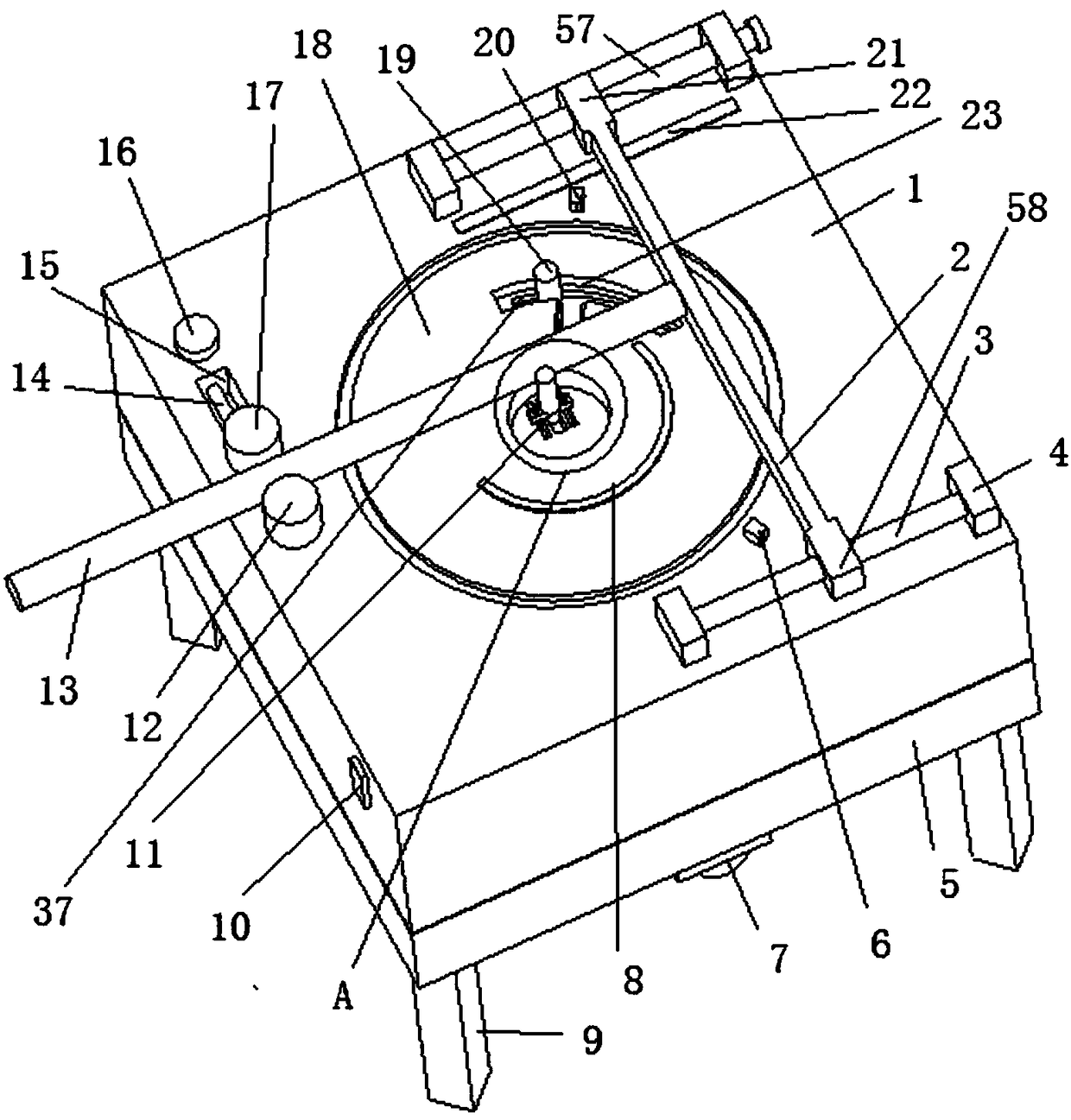

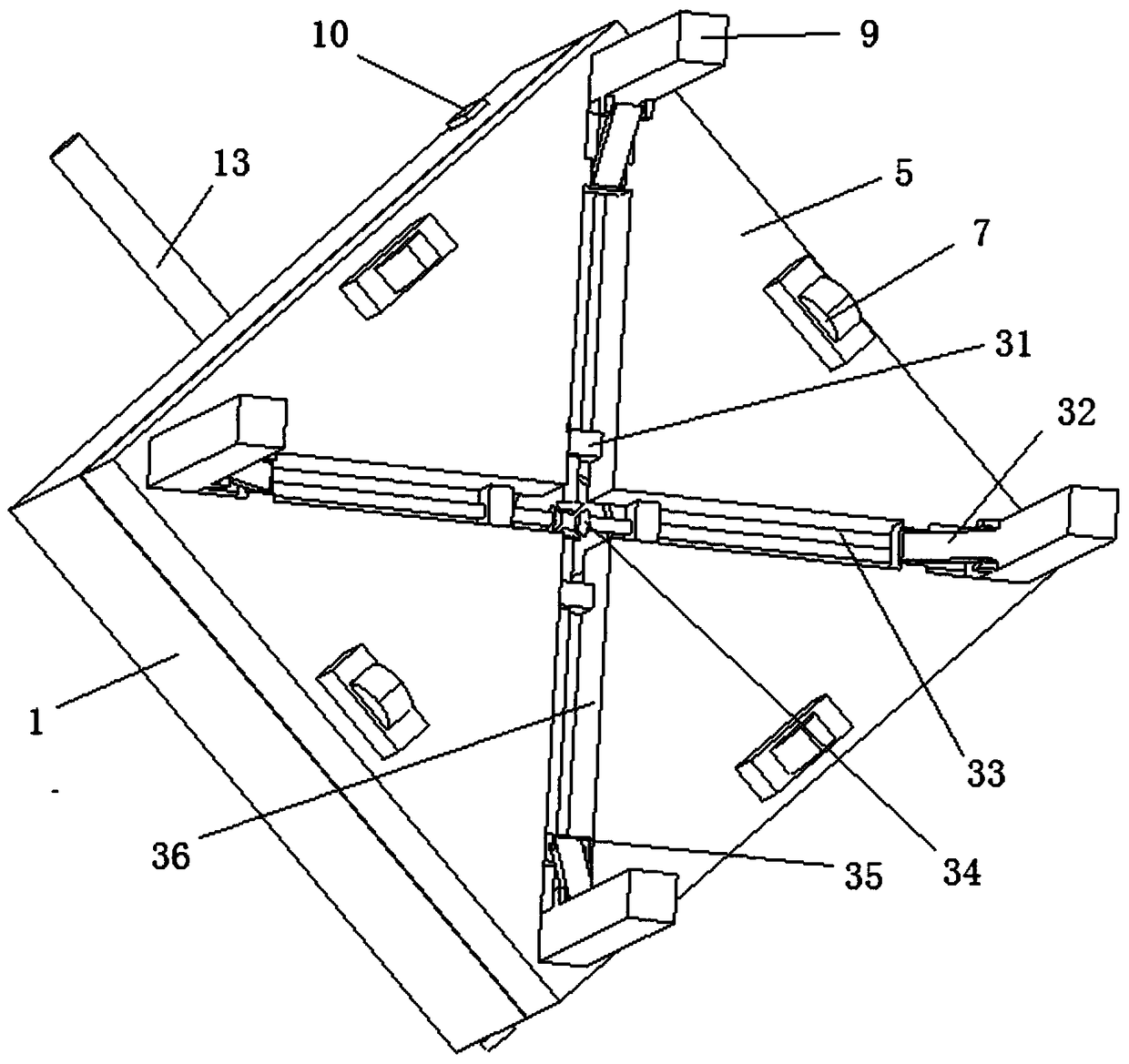

Flexible automatic production system for combined firework

InactiveCN102645135AAccurate and timely deliveryGuarantee quality and efficiencyFireworksFireworksPhotoelectric conversion

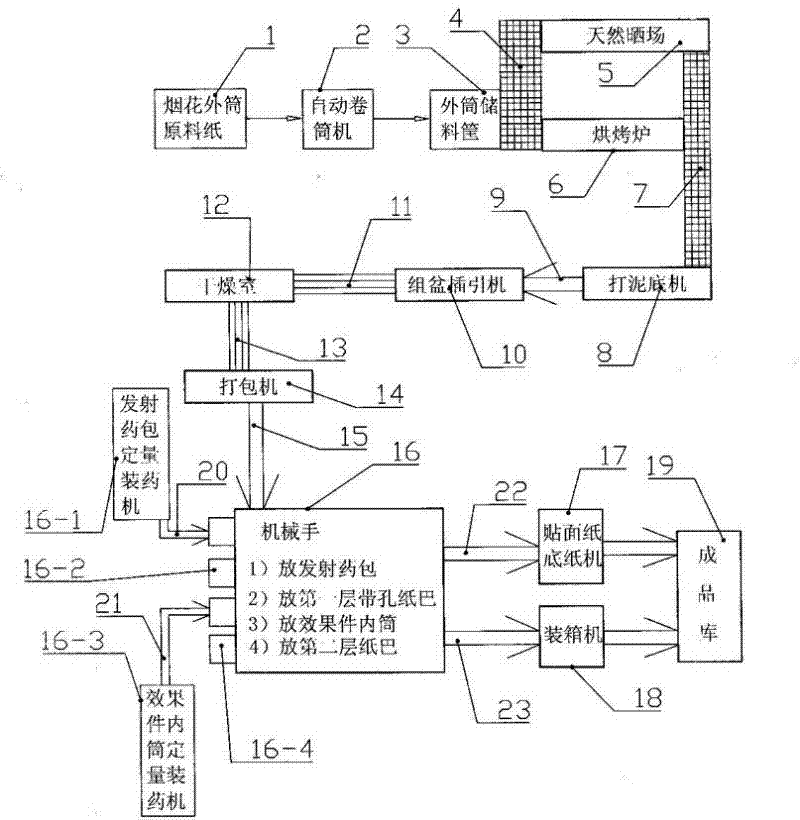

The invention relates to a flexible automatic production system for combined fireworks, which comprises an automatic tube rolling machine, a conveyer, a mud filling machine, a cake assembling and fuse inserting machine, a wrapping machine and a manipulator. The system is characterized in that firstly tubes are rolled through the automatic tube rolling machine and are stored in a tube storage basket, the tubes are fed to the mud filing machine for mud filling, cake assembling and fuse inserting after the tubes are dried, then the tubes are wrapped and reinforced by the wrapping machine, the tubes are righted and fed to the inlet port of the manipulator, propelling charges, effect part tubes, a first paper layer and a second paper layer are sequentially filled into the tubes after cake assembling, face paper and labels are stuck, products are boxed and sealed by a boxing and sealing machine and then the finished products are conveyed by the conveyer to a finished product warehouse; and materials among equipment of the entire system are conveyed by adopting the conveyer, and the loading position and the unloading position of each equipment are provided with photoelectrical conversion switches which are used for controlling the startup and the shutdown of the conveyer. Since the materials in the system are conveyed by the conveyer and the startup and shutdown of the conveyer are controlled by the photoelectric conversion switches, the materials are accurately conveyed in time, the product quality and the production efficiency are guaranteed, and the defects that manual handling in the past is time-consuming and labor-consuming and safety accidents are apt to occur are avoided.

Owner:柳真

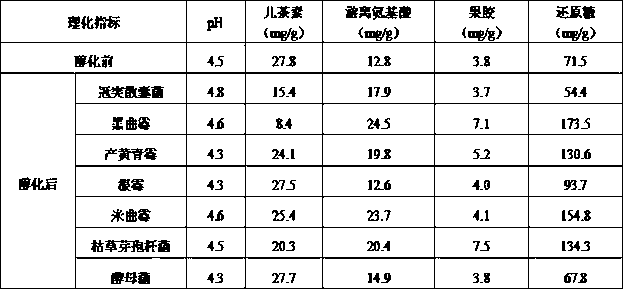

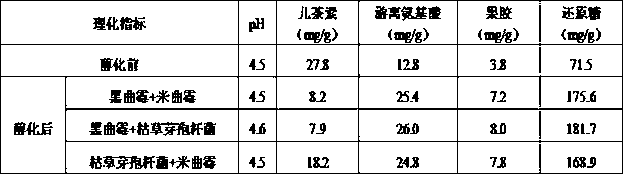

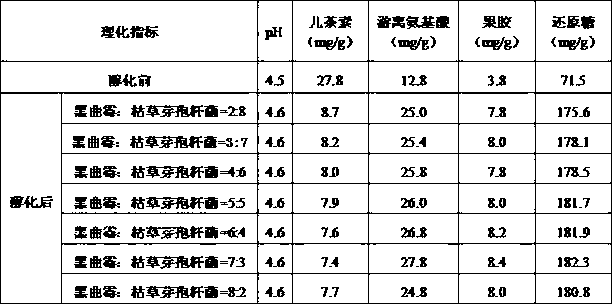

Fast alcoholized dark green tea and preparation method thereof

The invention discloses fast alcoholized dark green tea and a preparation method of the dark green tea. The preparation method comprises the following steps of: converting catechin with bitter taste in the raw dark green tea into theaflavin, thearubigin and theabrownin, degrading cellulose into glucose with sweet taste, converting insoluble pectin into soluble pectin (to increase the thickness of a tea soup), and degrading protein into amino acids with umami taste by adding microorganisms and an enzyme solution into the raw dark green tea under the condition with certain temperature and humidity, and applying chemical action to the resulting product in supplementation, and at last neutralizing partial acidic components with baking soda. The technical problems of long fermentation time and the generation of nauseating and sour smells in dark green tea pile fermentation are solved; the tea made from the dark green tea obtained by the preparation method disclosed by the invention is delicate and mellow in taste, orange red and transparent in tea soup, and rich in stale flavor; and the dark green tea is pretty high in contents such as soluble sugar, theaflavin, thearubigin and amino acid, and can reach the taste effect of old tea more than 5 years in about 4 days.

Owner:湖南省怡清源茶业有限公司

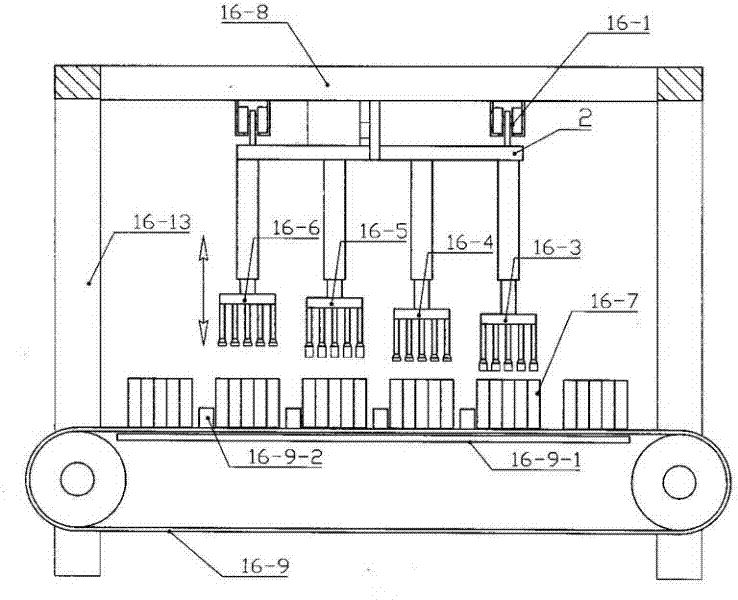

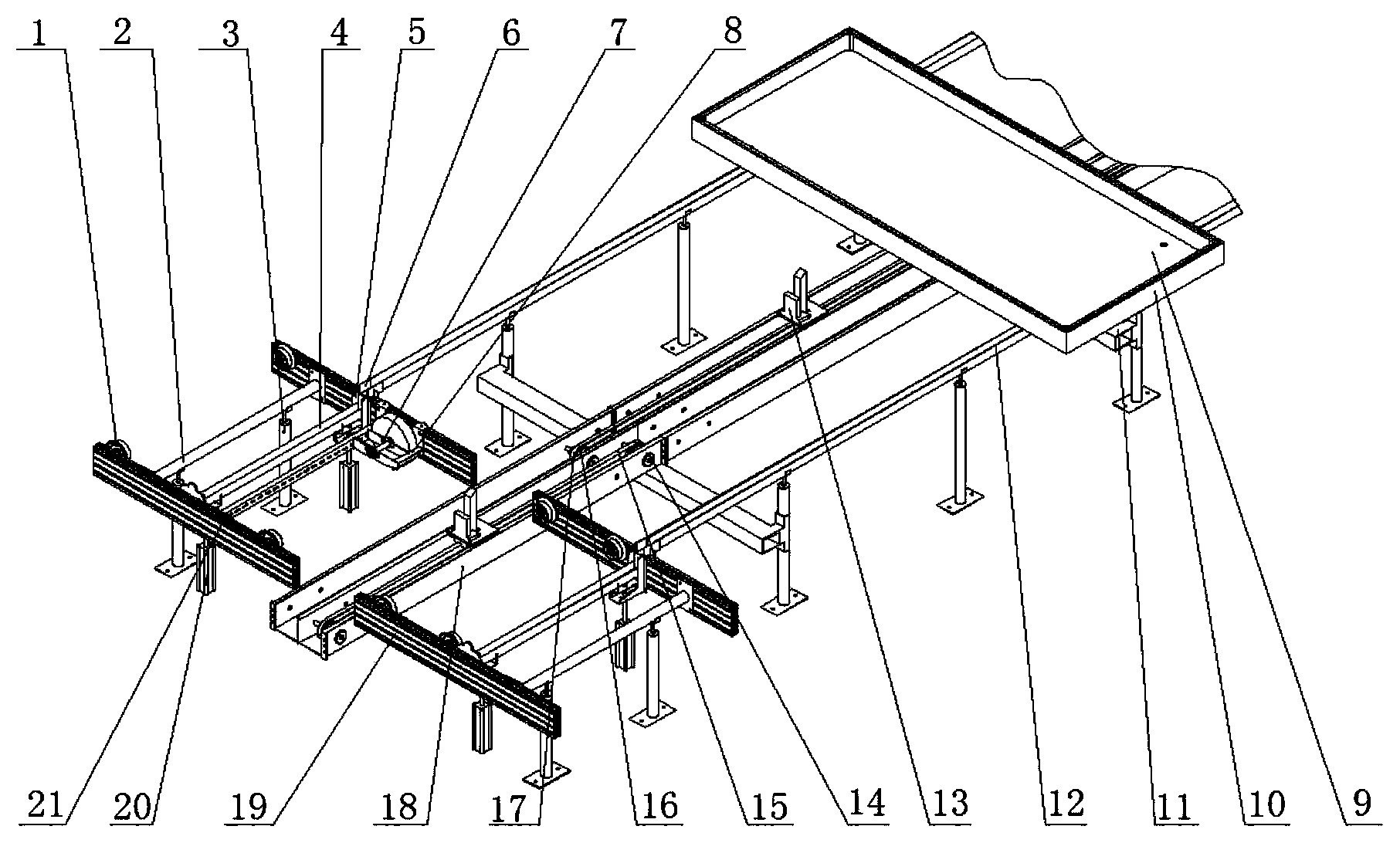

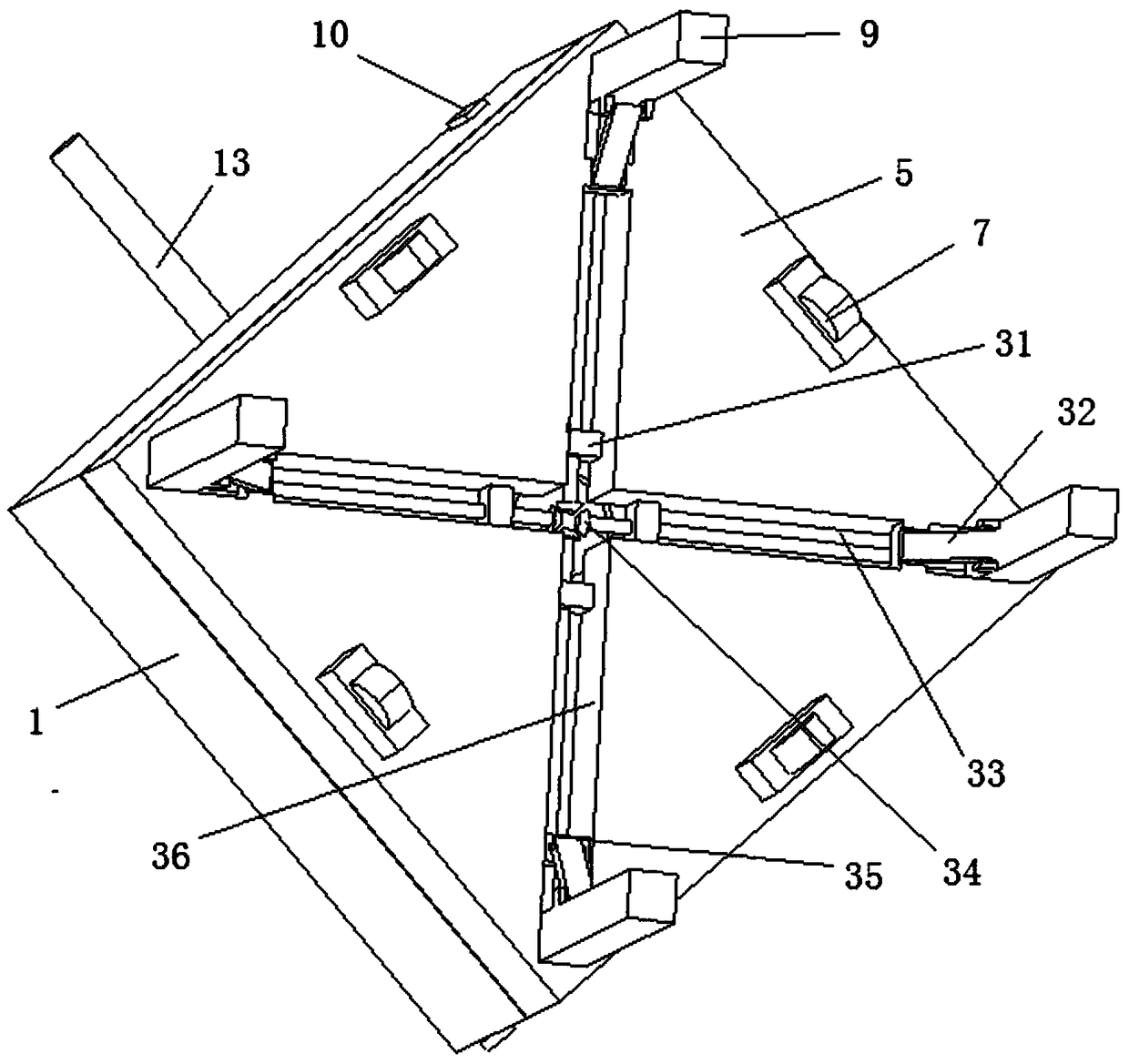

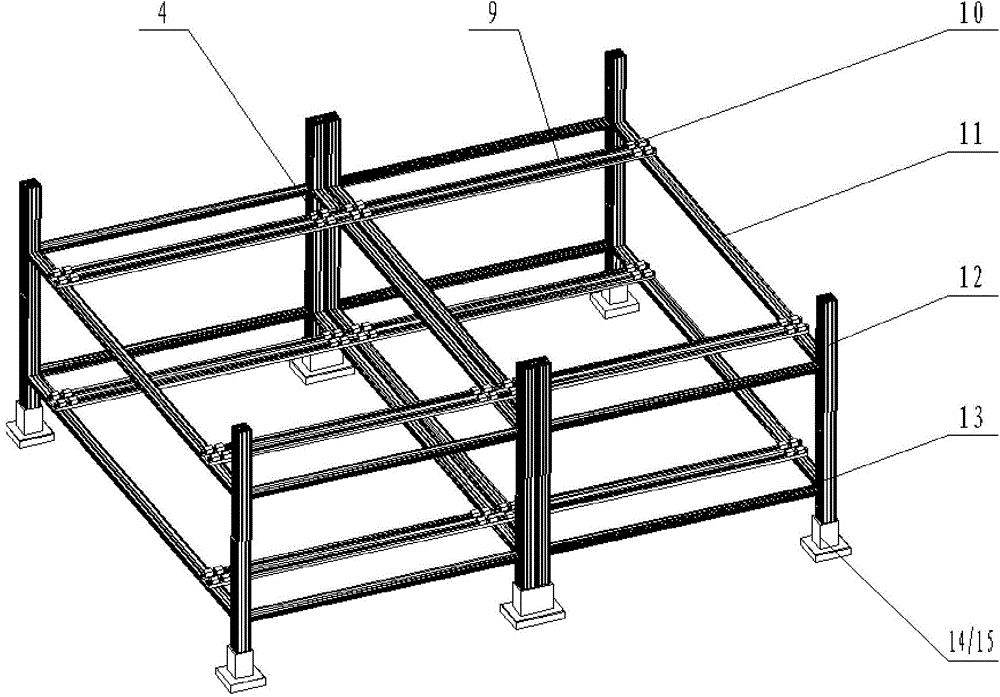

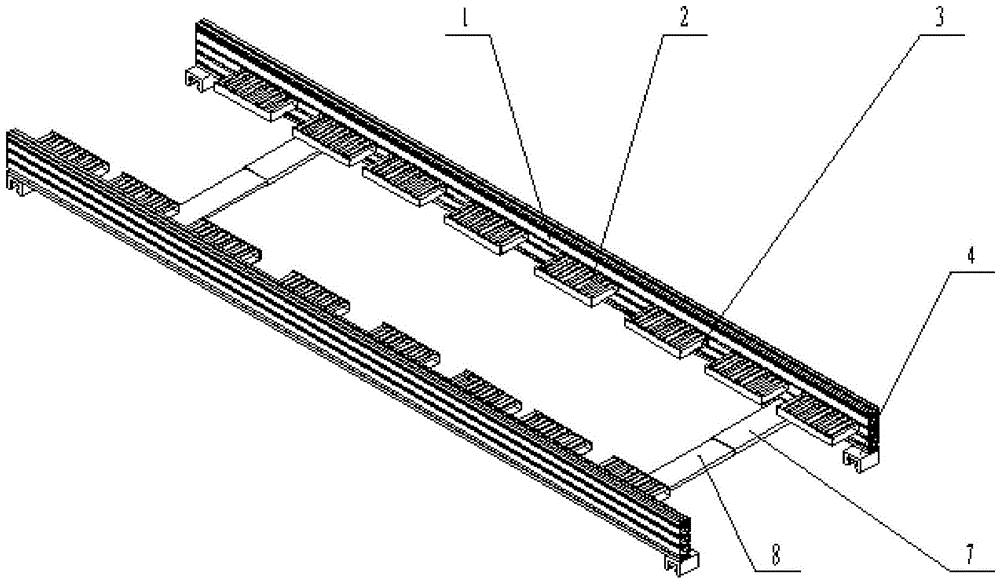

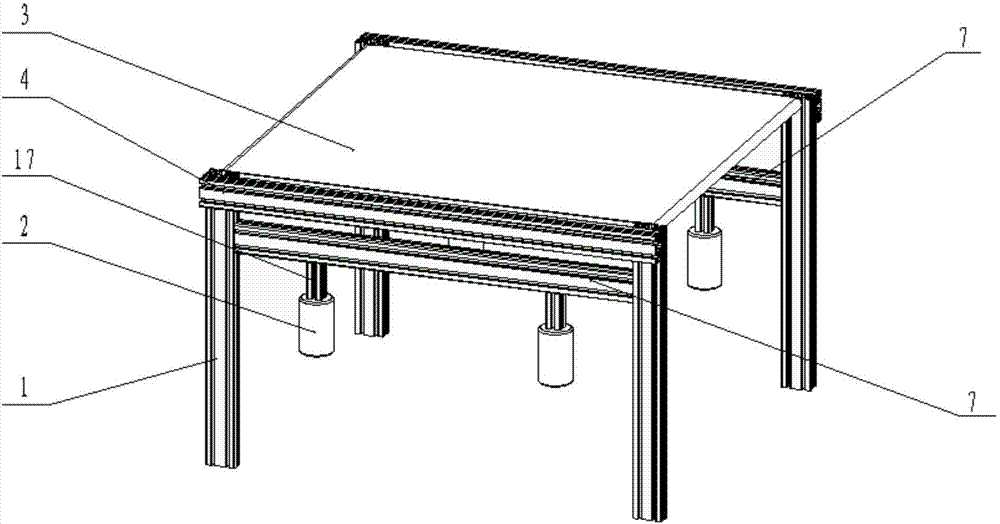

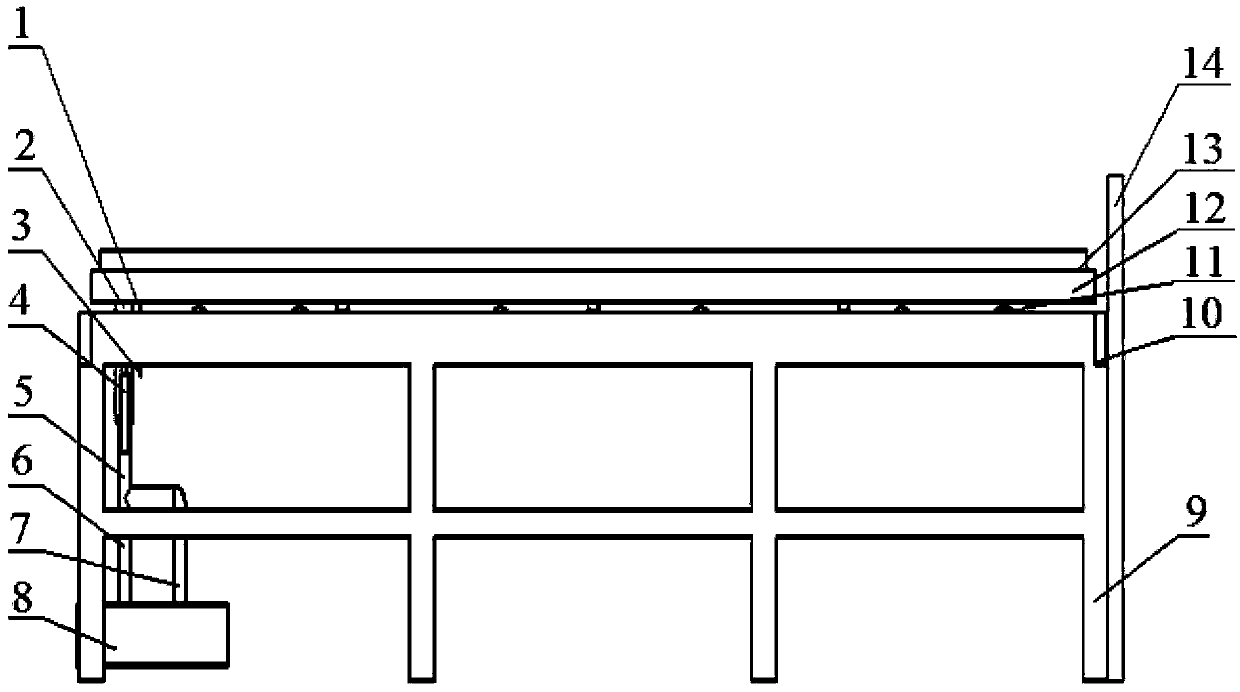

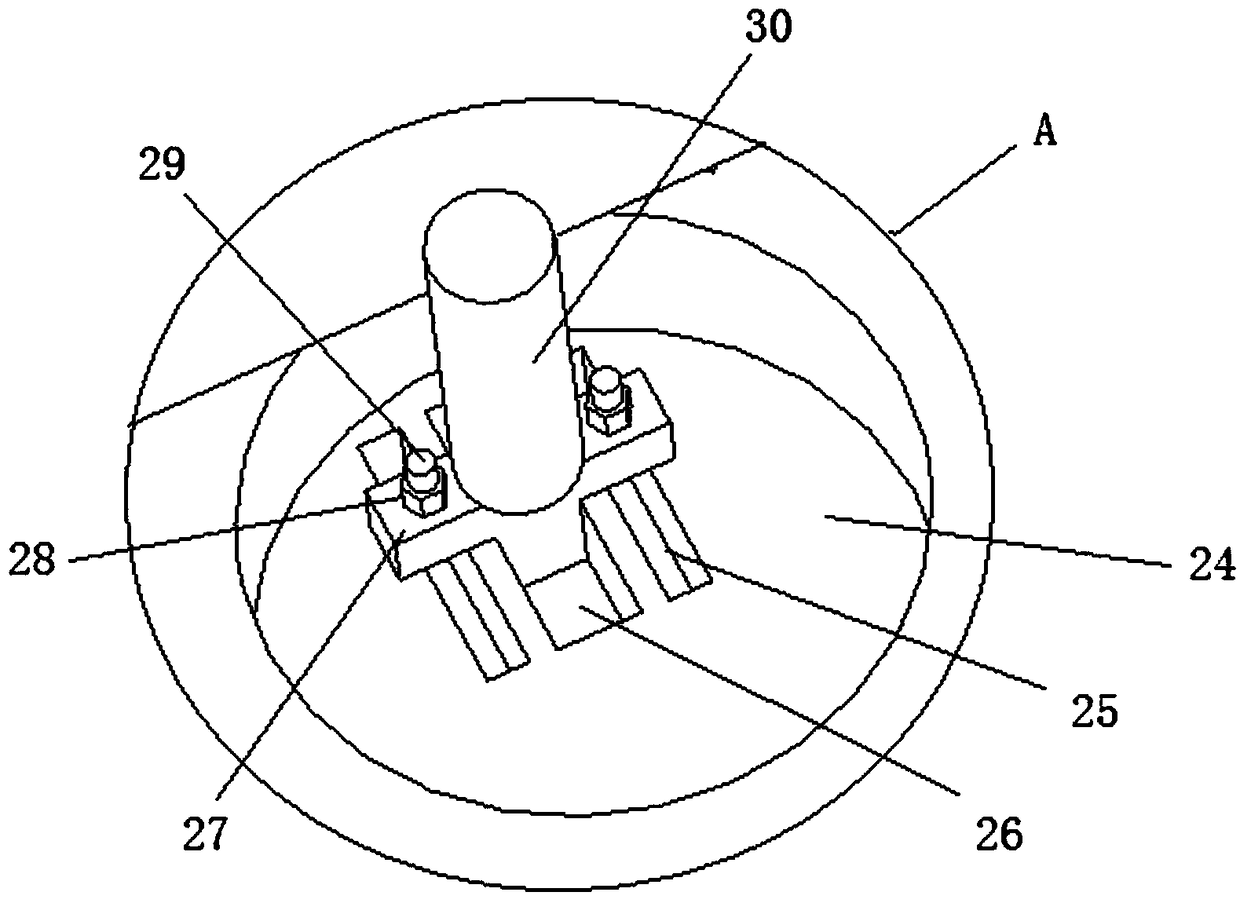

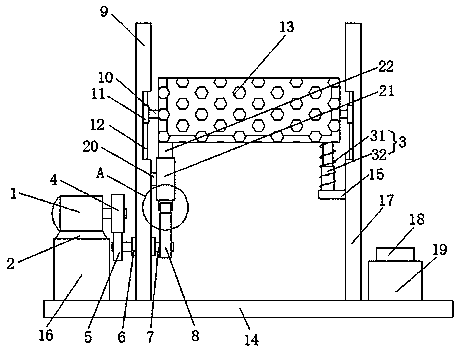

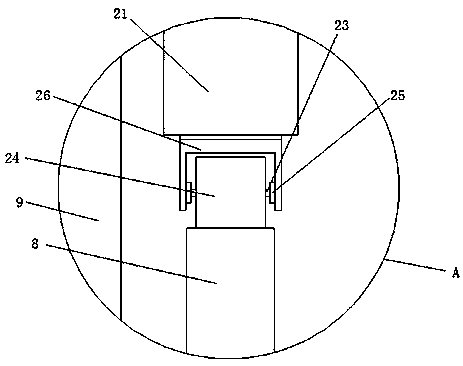

Rail-spliced type automatic seedbed moving system

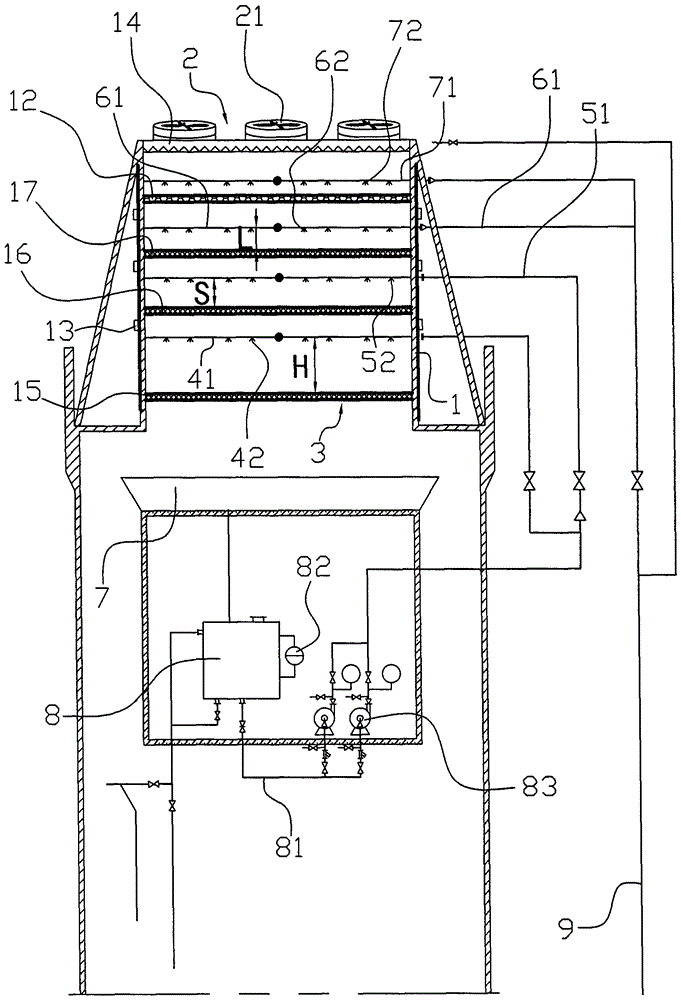

The invention relates to a rail-spliced type automatic seedbed moving system. The rail-spliced type automatic seedbed moving system comprises an inlet unit, an outlet unit, a cultivating unit, a single seedbed and sensing positioning devices, wherein the inlet unit and the outlet unit are arranged at the front and rear ends of the cultivating unit respectively and are identical in structure and both comprise longitudinal seedbed sliding rails and driving devices driving the single seedbed to slide. The cultivating unit comprises transverse seedbed sliding rails, chain rail racks and pushing devices arranged on the chain rail racks to push the single seedbed to move. The single seedbed enters the transverse seedbed sliding rails of the cultivating unit through the longitudinal seedbed sliding rails of the inlet unit and moves out through the longitudinal seedbed sliding rails of the outlet unit after cultivating. The sensing positioning devices are used for positioning the single seedbed. Compared with the prior art, the rail-spliced type automatic seedbed moving system is capable of automatically moving the seedbed to the appointed position and being docked with an auxiliary worktable, and conforms to development trend from a conventional greenhouse to a large plant factory.

Owner:TONGJI UNIV

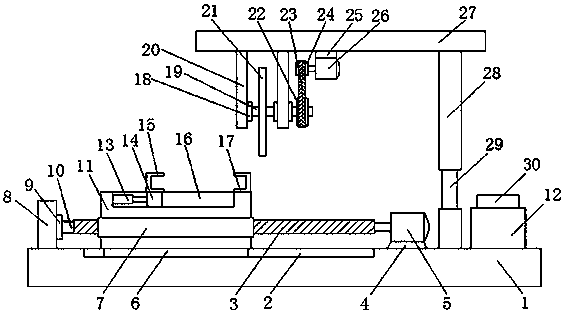

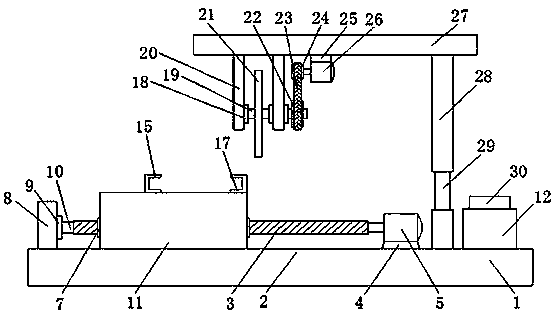

Work method of rebar bending device for building construction

The invention relates to the technical field of buildings, in particular to a work method of a rebar bending device for building construction. The work method involves a first supporting plate, and ashell is arranged at the upper end of the first supporting plate. A rotating plate is arranged at the upper end of a second supporting column, and a T-shaped block is arranged in a sliding groove. A third movable column is arranged at the upper end of the T-shaped block, and T-shaped grooves are symmetrically formed in the upper end of a second supporting plate. An arc-shaped groove is formed in one side of the upper end of the rotating plate, and a second movable column is arranged in the arc-shaped groove. A fixed column is arranged on one side of the upper end of the shell, and a first threaded rod is arranged between a separation plate and a fixed base. A first movable column is arranged at the upper end of a third threaded sleeve, and the upper end of a rotary shaft penetrates the shell to be connected with a first rotary disc. According to the work method, rebars can be bent into different radians, the rebars of different bending lengths can be bent, and the structure is simple;adjustment and use are convenient, the labor efficiency can be reduced, and the production process can be accelerated; and time and labor are saved, and the work method is worthy of use and popularization.

Owner:广东鸿福城建设有限公司

Processing method for colorful mercerized spun-dyed yarns

InactiveCN101580985ASpeed up the production processAdd mercerizing processMercerising of yarns/threads/filamentsDyeing processYarnPulp and paper industry

The invention relates to a processing method for colorful mercerized spun-dyed yarns, which comprises the following steps: cotton dying, namely selecting a certain amount of cotton respectively and dying the cotton with various reference colors; cotton mixing, namely one or more types of cotton which is dyed with the reference colors is mixed with cotton with natural color according to the requirement and the proportion; spinning; mercerization; and yarn dying. In the working procedure of the cotton dying, a small amount of cotton is only dyed with a plurality of specific reference colors, yarns with different color systems can be combined freely by yarn re-dying, and manufacturers can prepare goods more conveniently and purposely, and accelerate the production flow of the spun-dyed yarns; in the working procedure of the cotton mixing, a small amount of the cotton dyed with the reference colors is mixed with a large amount of the cotton with the natural color so as to reduce the phenomena of reducing the spinnability possibly caused by cotton dying, and high count yarns can be spun; the working procedure of yarn dying is added after the spinning work procedure, and the yarns are dyed into various colorful spun-dyed yarns by dying; and the addition of the mercerization work procedures makes the colors of the spun-dyed yarns more colorful.

Owner:WUXI NATURAL GREEN FIBER TECH

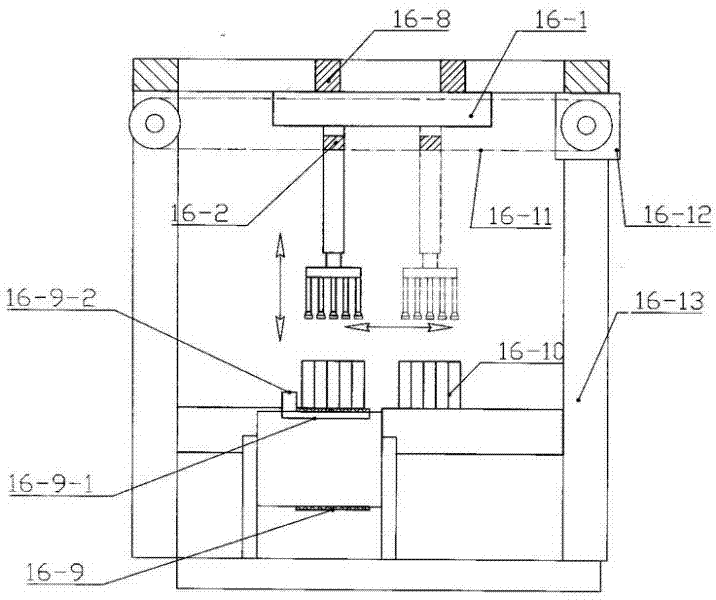

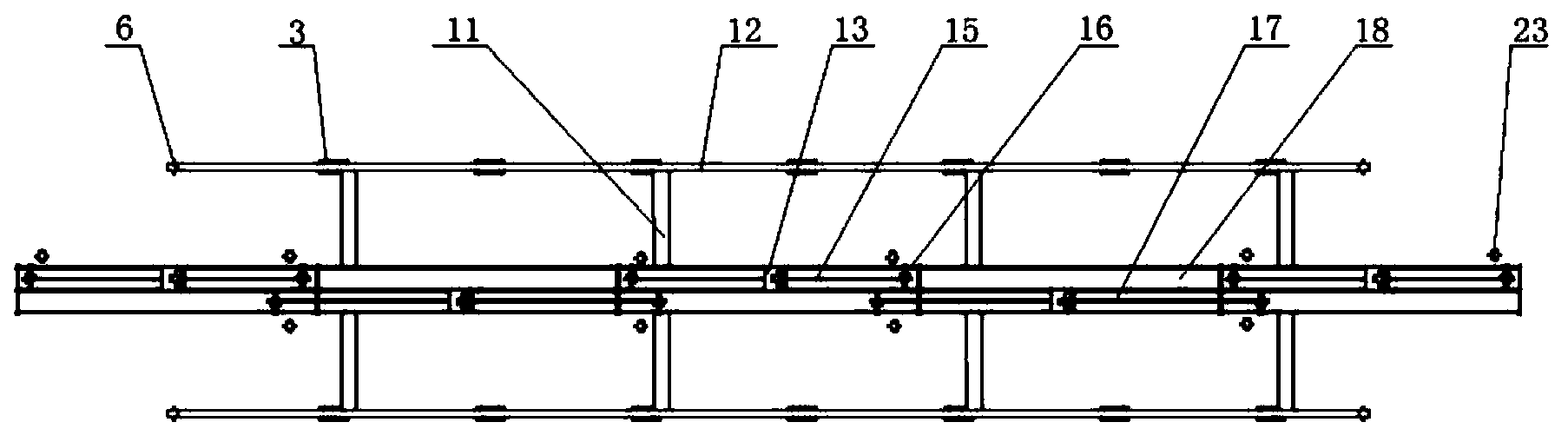

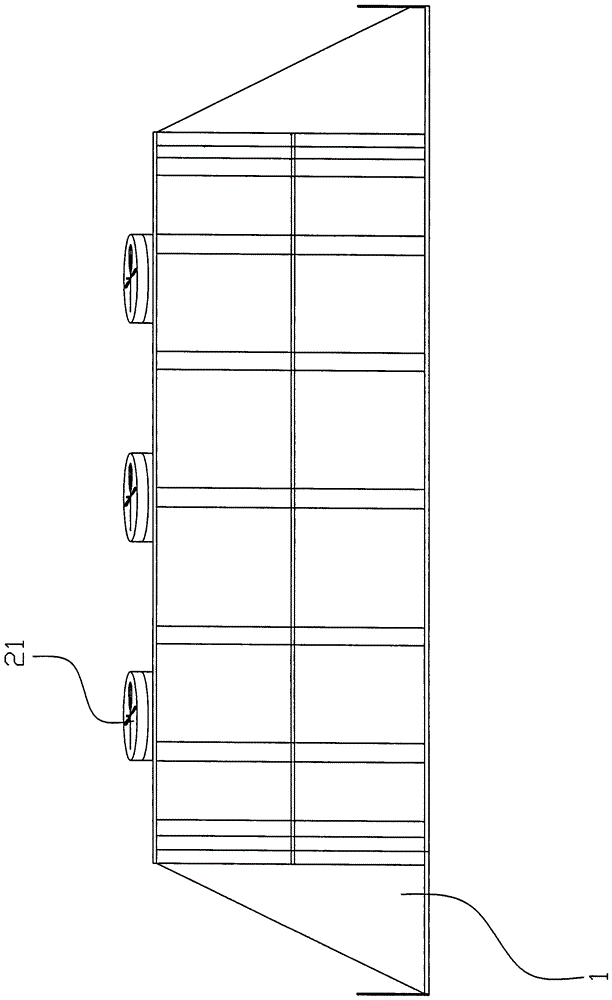

Automatically-moving three-dimensional seedbed system with adjustable light transmittance

InactiveCN104604598AIncrease flexibilityChange footprintSaving energy measuresCultivating equipmentsPlant factoryGreenhouse

The invention relates to an automatically-moving three-dimensional seedbed system with the adjustable light transmittance. The automatically-moving three-dimensional seedbed system comprises a three-dimensional frame body, linear guide rails, seedbed conveying units, single seedbeds and sensing and positioning devices. The linear guide rails are arranged on the three-dimensional frame body in a layered mode through supporting plates. Each seedbed conveying unit comprises two side plates arranged in parallel, wherein the distance between the two side plates is regulated according to the depth by which corresponding interval insertion plate inner plates are inserted into corresponding interval insertion plate outer plates, wheels used for rolling to convey the corresponding single seedbed are arranged on the inner sides of the side plates, and the side plates are connected to the corresponding linear guide rail in a sliding mode through slide blocks. The sensing and positioning devices are arranged on the three-dimensional frame body, the seedbed conveying units and the single seedbeds to position the single seedbeds. Compared with the prior art, the seedbeds can be moved to the assigned seedbed positions, the positions of the seedbeds can be automatically adjusted according to the growth condition of plants, the illumination receiving rate of the seedbeds is increased, and the automatically-moving three-dimensional seedbed system conforms to the tendency that traditional greenhouses are developed towards large-scale plant factories.

Owner:TONGJI UNIV

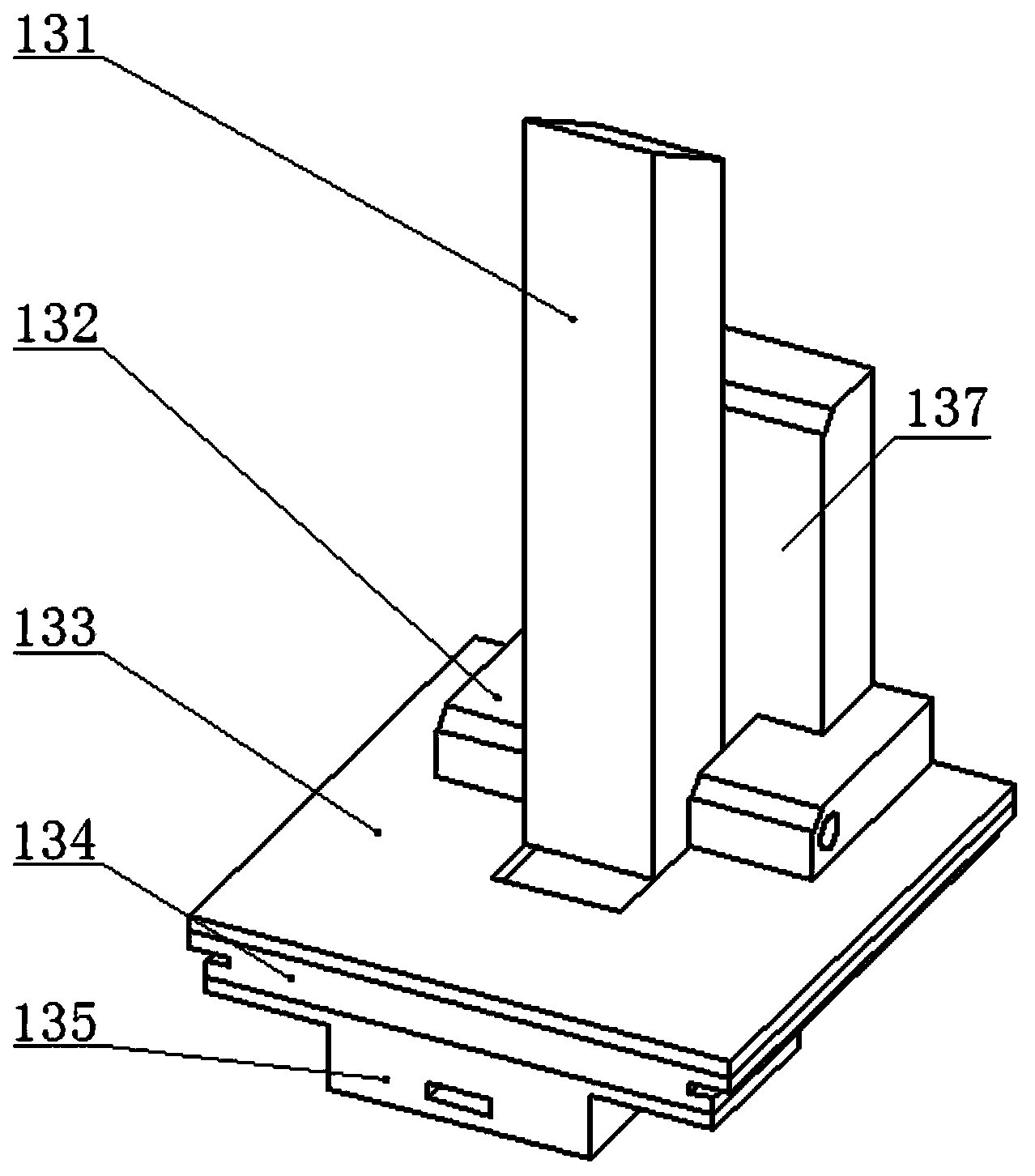

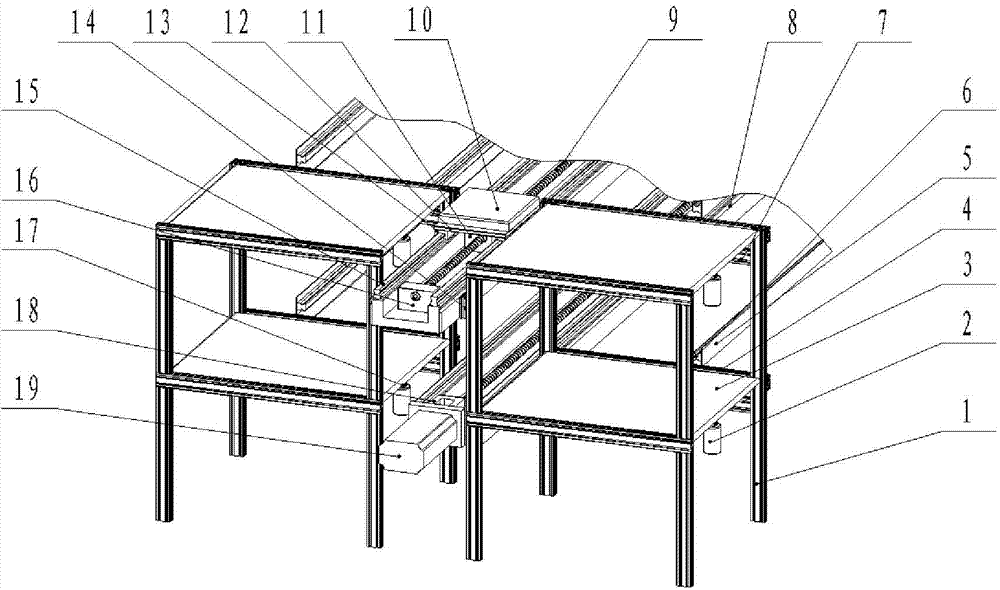

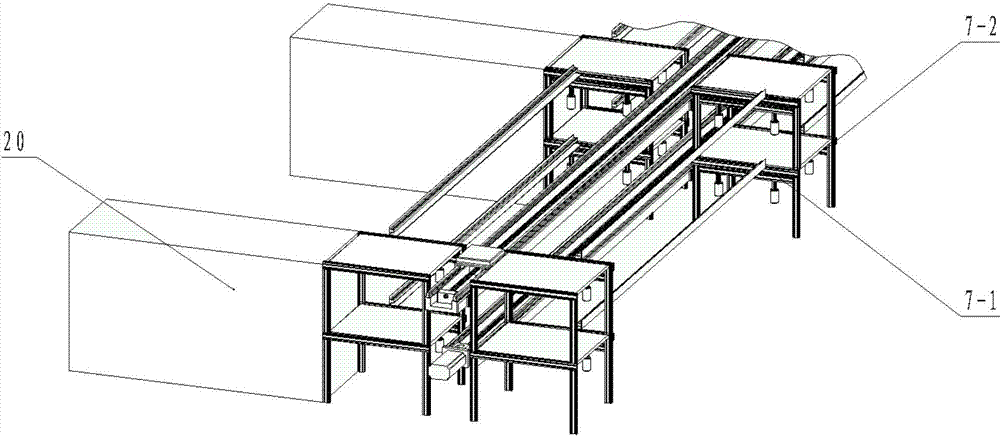

Quick and precise positioning automatic movement three-dimensional seedbed system

InactiveCN104488593AStrong suctionGreat suctionCultivating equipmentsMechanical conveyorsPlant factoryButt joint

The invention relates to a quick and precise positioning automatic movement three-dimensional seedbed system. The system comprises a cultivation unit, a front conveying unit, a rear conveying unit, a single seedbed and a sensor positioning device, wherein the cultivation unit comprises an L-shaped track and a pushing device; the L-shaped track is used for supporting the single seedbed to slide; the pushing device is used for pushing the single seedbed to move transversely on the L-shaped track; the front conveying unit and the rear conveying unit are the same in structure and are arranged at the front and rear ends of the cultivation unit respectively to drive the single seedbed to move longitudinally; the sensor positioning device is arranged on the front conveying unit, the rear conveying unit and the cultivation unit to position the single seedbed; the pushing device is a lead screw device. Compared with the prior art, the system has the advantages that the seedbed can be quickly and accurately positioned and automatically moved to a specific position and can be automatically butt-jointed to an auxiliary working table, the device has good maneuverability, mass production can be modularized according to specific production requirements, the production site can be expanded or saved in the directions of three dimensions, and the system conforms to the trend of development of the conventional greenhouse to a large-sized plant factory.

Owner:TONGJI UNIV

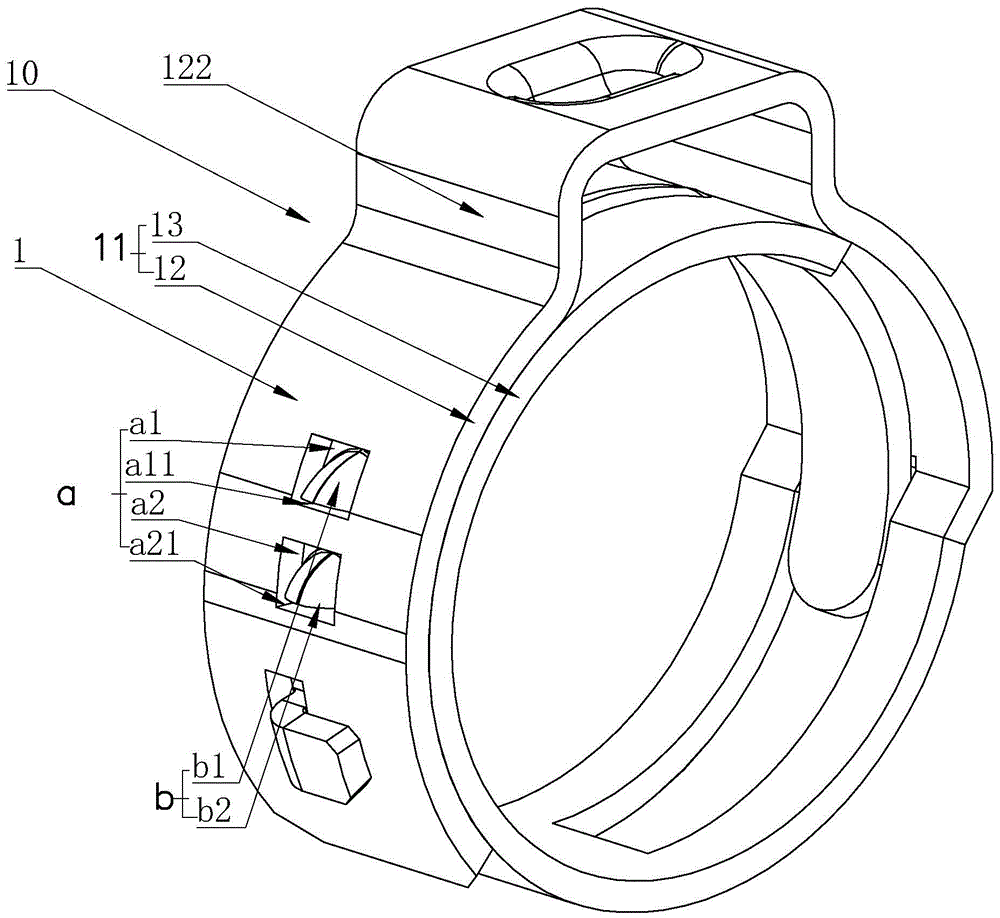

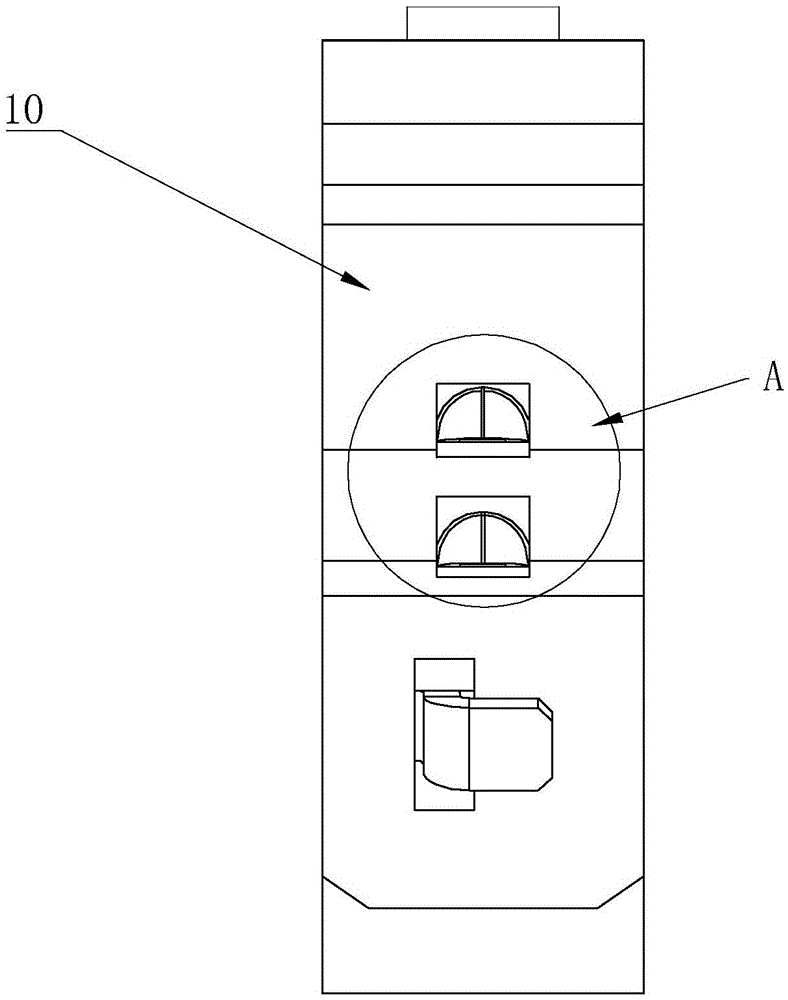

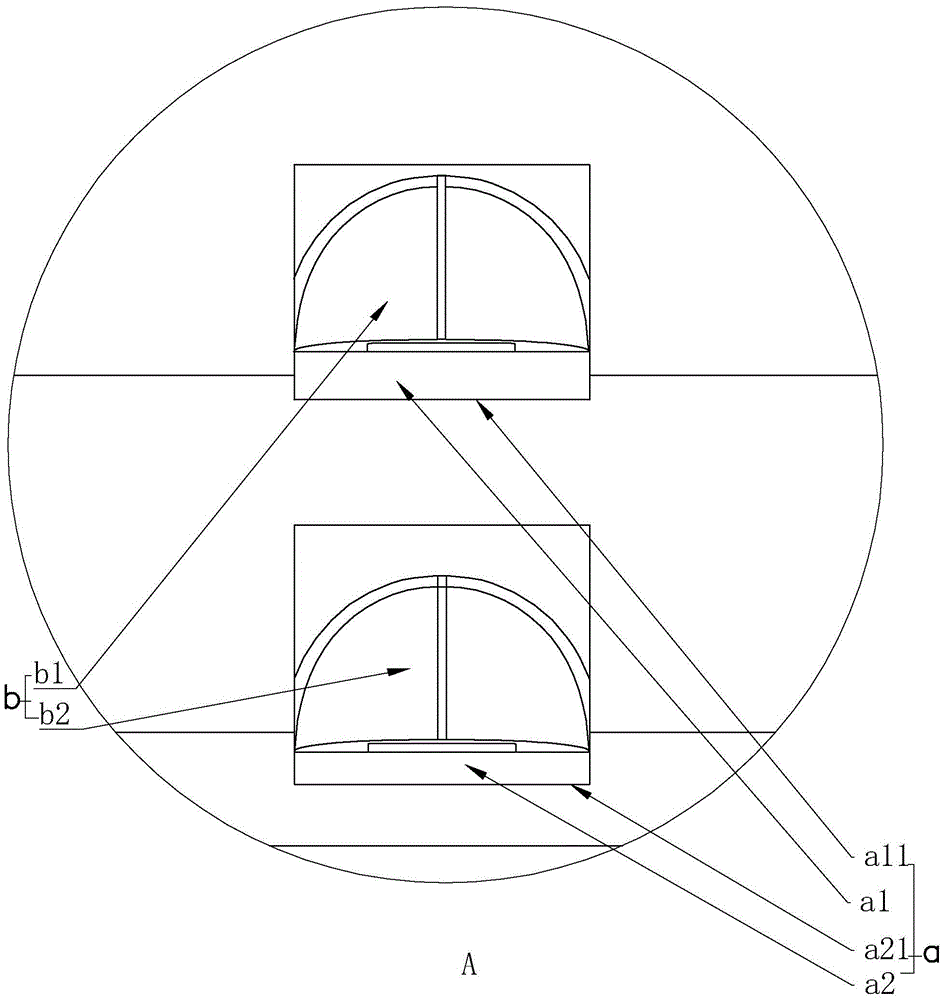

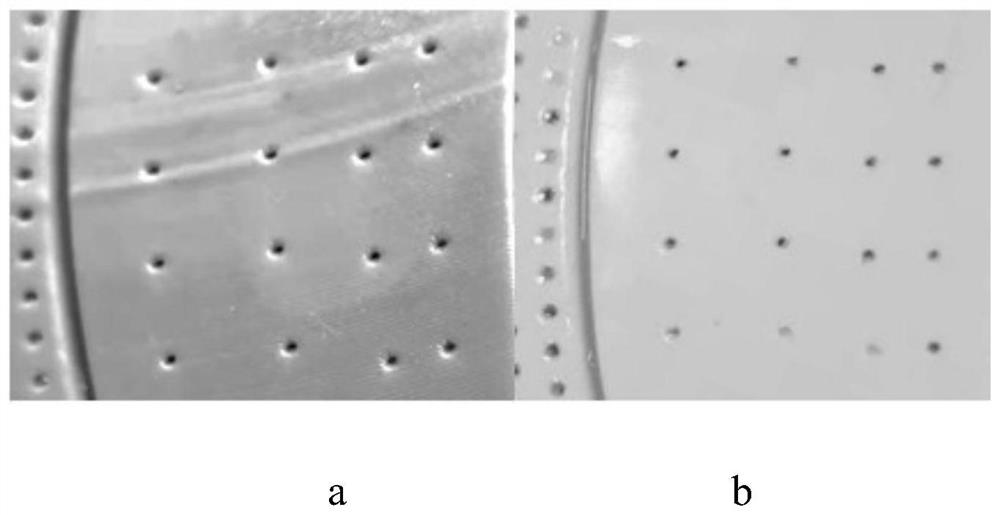

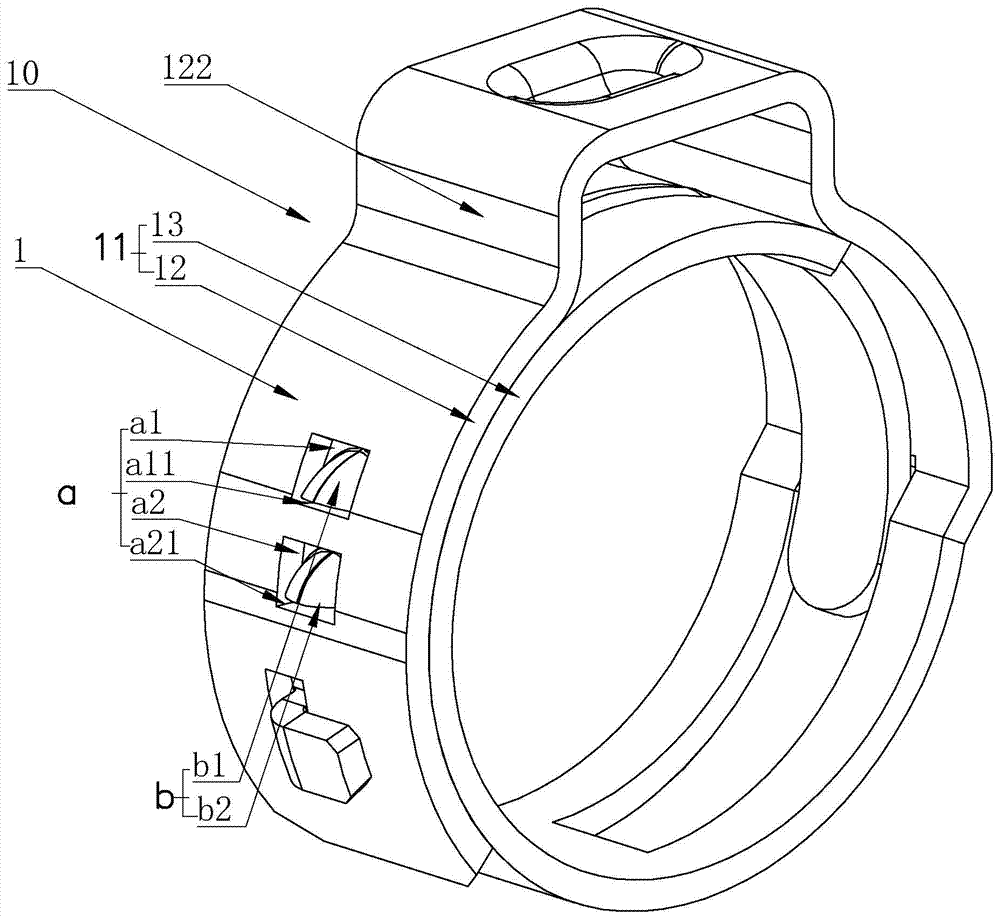

Hoop as well as manufacturing method and use method thereof

ActiveCN105587935APrevent looseningNot easy to loosePipe supportsHose connectionsPipe fittingEngineering

The invention discloses a hoop as well as a manufacturing method and a use method thereof. The hoop comprises a clamping belt, wherein the clamping belt is bent and formed into a hoop body with a sleeving area; the hoop body forms a superposed part; the superposed part comprises an outer-side belt body and an inner-side belt body; and the sleeving area is elliptical. The manufacturing method thereof comprises the following steps: producing a clamping belt at first, and then directly bending and forming the clamping belt into a hoop body with an elliptical sleeving area. The use method thereof comprises the following steps: directly bending and forming a clamping belt into a hoop body with a sleeving area; carrying out pre-forming treatment on the sleeving area and enabling the sleeving area to be elliptical; sleeving a pipe fitting with the hoop body, and enabling the hoop body to form abutting connection with the pipe fitting at a short shaft corresponding to the sleeving area; and further shrinking and clamping the hoop through a hoop clamping tool. The invention aims at providing a hoop; and the hoop has the advantages of being convenient to install, and capable of being effectively pre-fixed on the pipe fitting.

Owner:YUEQING DONGBO ELECTROMECHANICAL

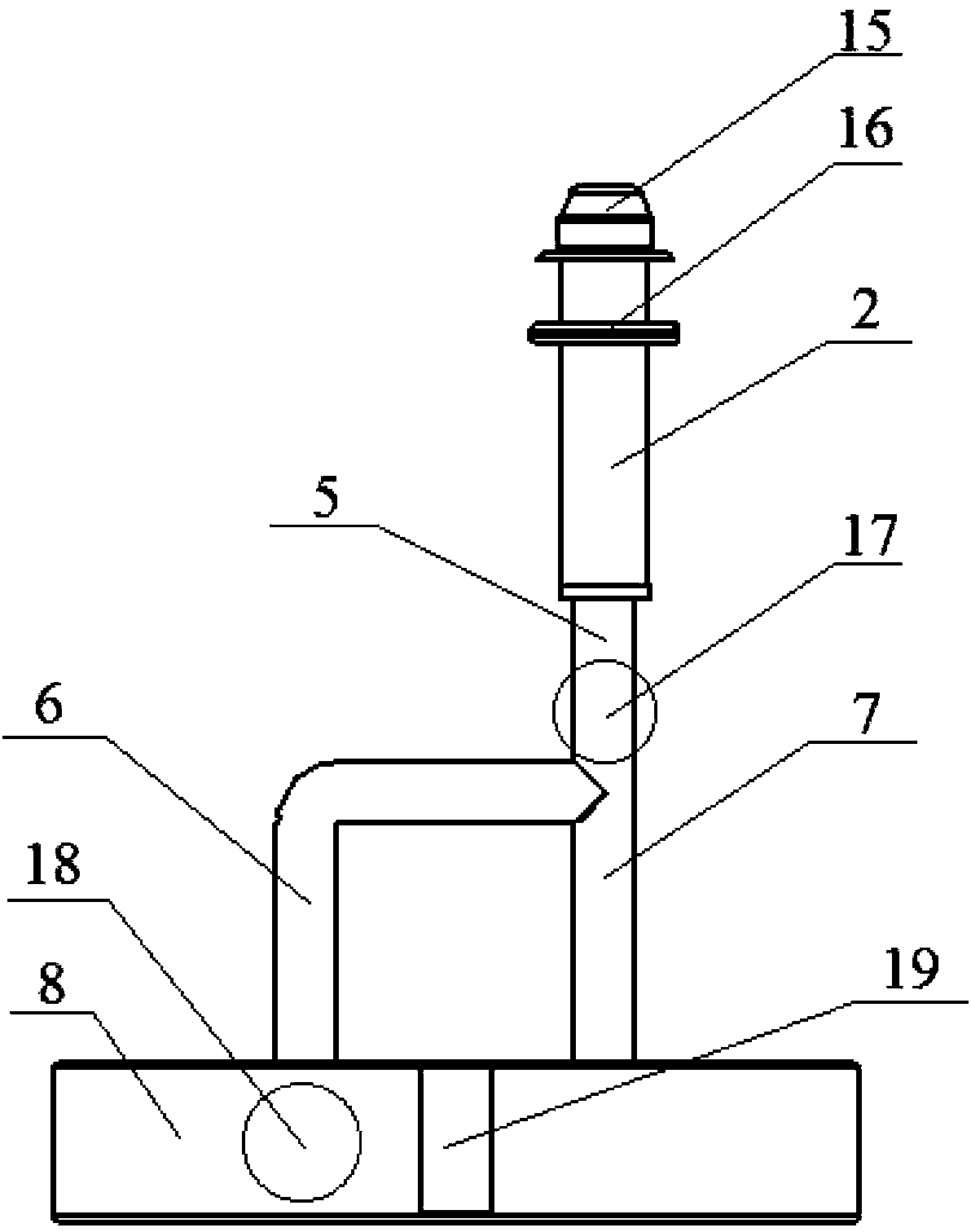

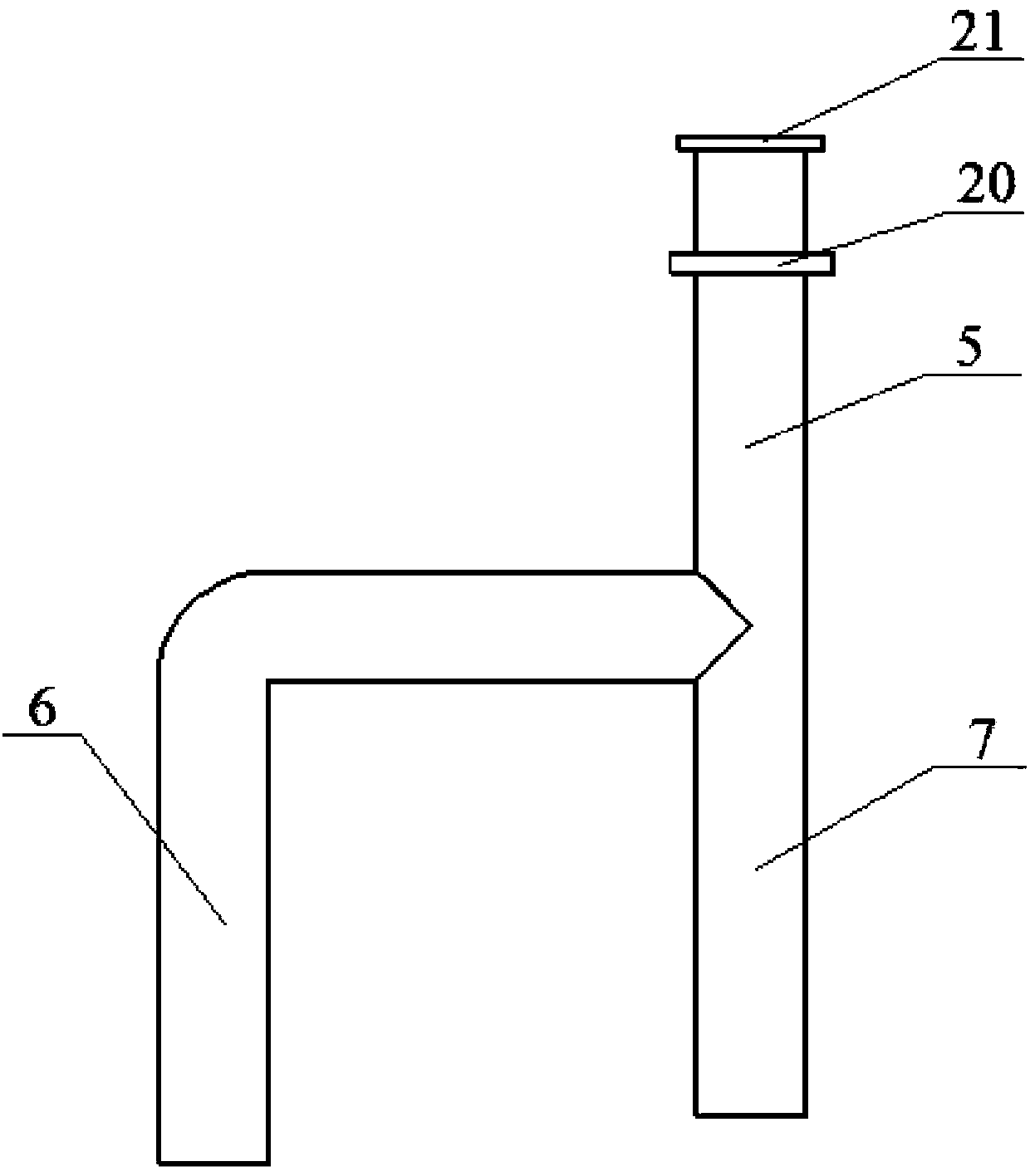

Automatized tide type irrigation device matched with mobile seedling bed

InactiveCN103461036AImprove mobilityImprove work efficiencyClimate change adaptationSaving energy measuresDiseaseGreenhouse

The invention relates to an automatized tide type irrigation device matched with a mobile seedling bed. The automatized tide type irrigation device matched with the mobile seedling bed comprises a mobile seedling bed frame, a single mobile seedling bed connected onto the mobile seedling bed frame in a sliding mode and a seedling tray arranged on the single mobile seedling bed and further comprises a reciprocating motion unit, an irrigation spray head, a connecting top plate, an irrigation pipeline, a storage pond and a magnetic valve. The storage pond is arranged at the middle-lower portion of the mobile seedling bed frame, one end of the irrigation pipeline is inserted into the storage pond, the other end of the irrigation pipeline is connected with the irrigation spray head, the reciprocating motion unit is connected with the irrigation spray head through the connecting top plate and drives the irrigation spray head to move vertically so as to enable the irrigation spray head and the seedling tray to be connected or separated, and the magnetic valve is arranged inside the irrigation pipeline and controls liquid feeding or liquid return of the irrigation pipeline so as to perform tide type irrigation to the seedling tray. Compared with the prior art, the automatized tide type irrigation device matched with the mobile seedling bed is low in cost, simple, convenient, compact in mechanism and long in service life, reduces transmission of diseases and insect pests inside a greenhouse, basically achieves closed automatic regulation and control and achieves the energy-saving, environmental-friendly, accurate and efficient purposes.

Owner:TONGJI UNIV

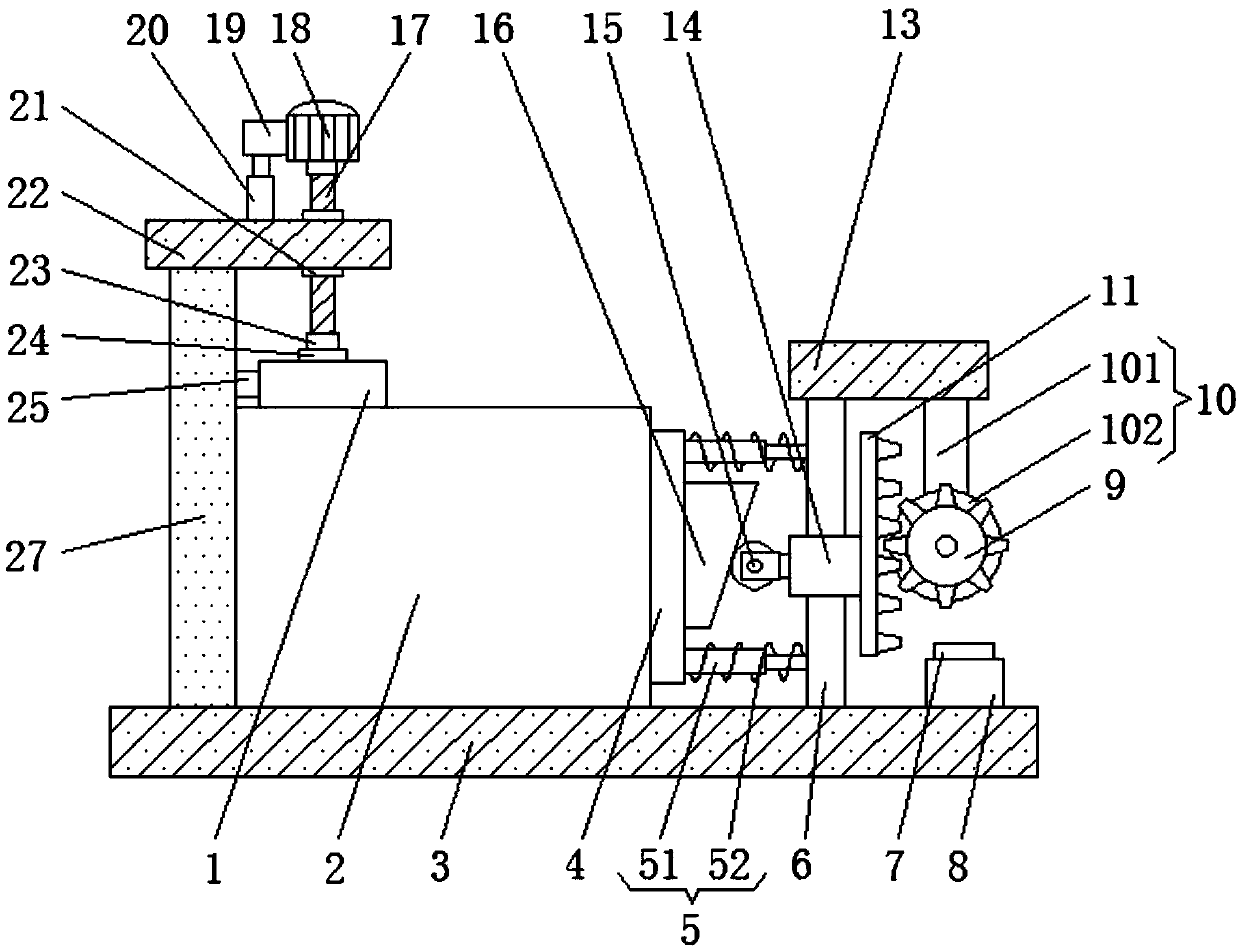

Reinforcement bending device for construction

InactiveCN108435967ASimple structureEasy to adjust and useMetal working apparatusArchitectural engineeringRebar

Owner:郭凤琴

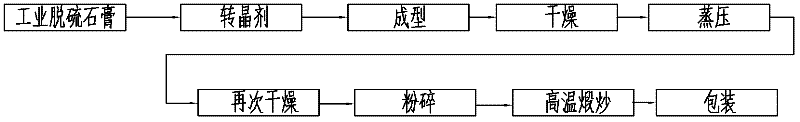

Method for producing alpha type high-strength gypsum powder by using desulfurization gypsum serving as industrial byproduct

InactiveCN102249579APromote sustainable developmentRaw materials are cheap and easy to getMasterbatchLand resources

The invention relates to a method for producing alpha type high-strength gypsum powder by using desulfurization gypsum serving as an industrial byproduct, and belongs to the field of the preparation of inorganic materials. The method is characterized by comprising the following steps of: extruding desulfurization gypsum serving as the industrial byproduct is extruded under the pressure of between 0.5 and 5 MPa to be formed, drying, autoclaving, drying again, crushing, sieving with an 80 to 200-mesh sieve, and calcining at the high temperature of between 120 and 210 DEG C for 30 to 150 minutes to obtain the alpha type high-strength gypsum powder. By the method, a new path is opened up for the comprehensive utilization of the desulfurization gypsum serving as solid waste of the industrial byproduct, and a new simple and low-cost method is also opened up for the preparation of die gypsum and self-leveling masterbatch gypsum by utilizing the industrial desulfurization gypsum, so mineral resources are saved, the occupation of land resources is reduced, and the problem of secondary pollution is solved.

Owner:刘长昕 +1

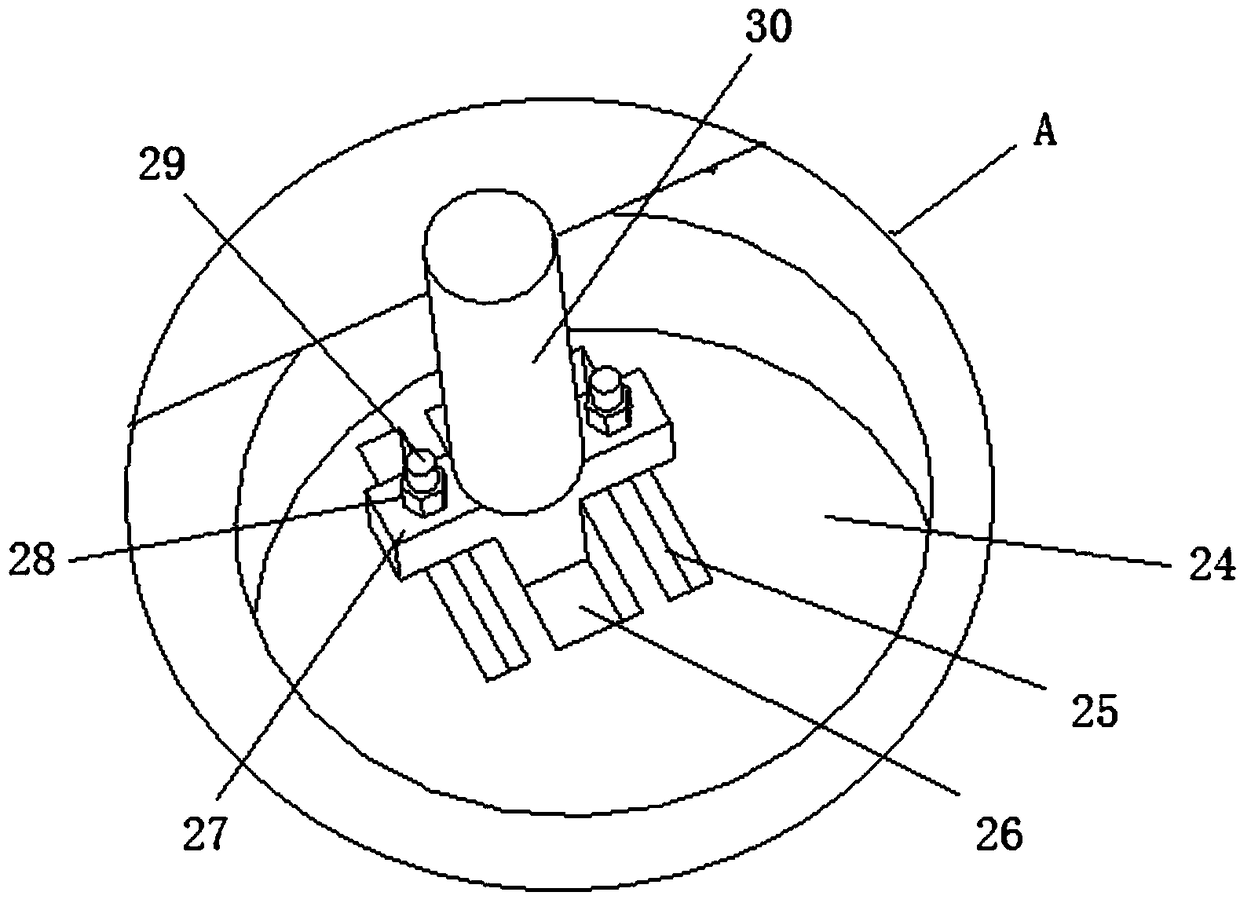

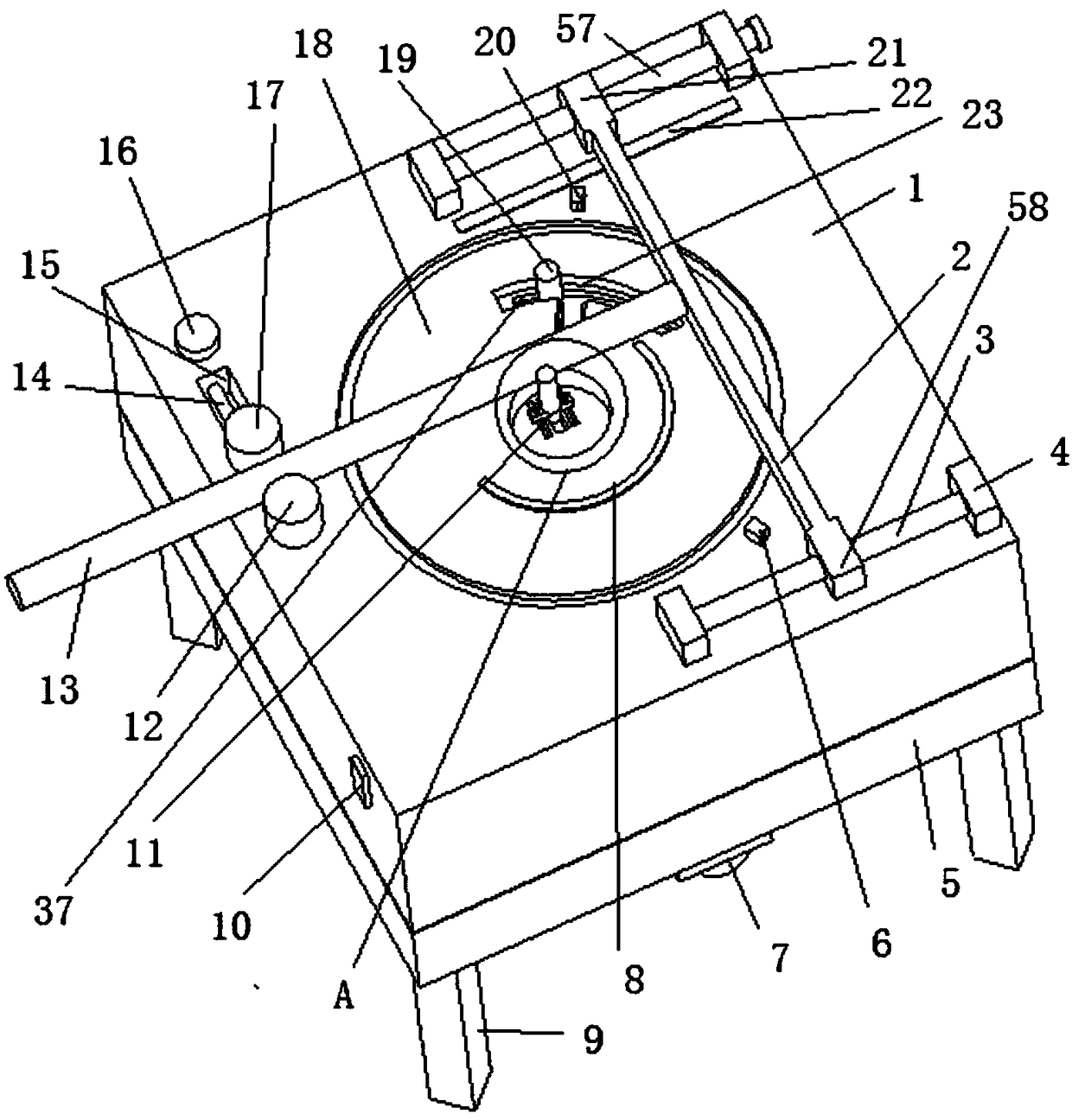

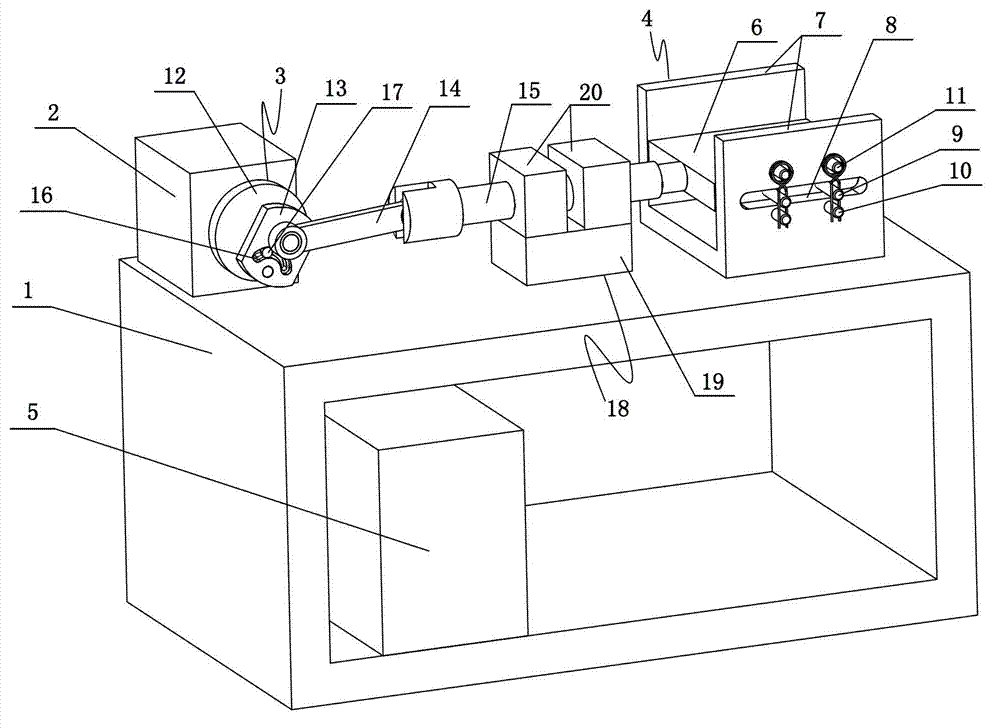

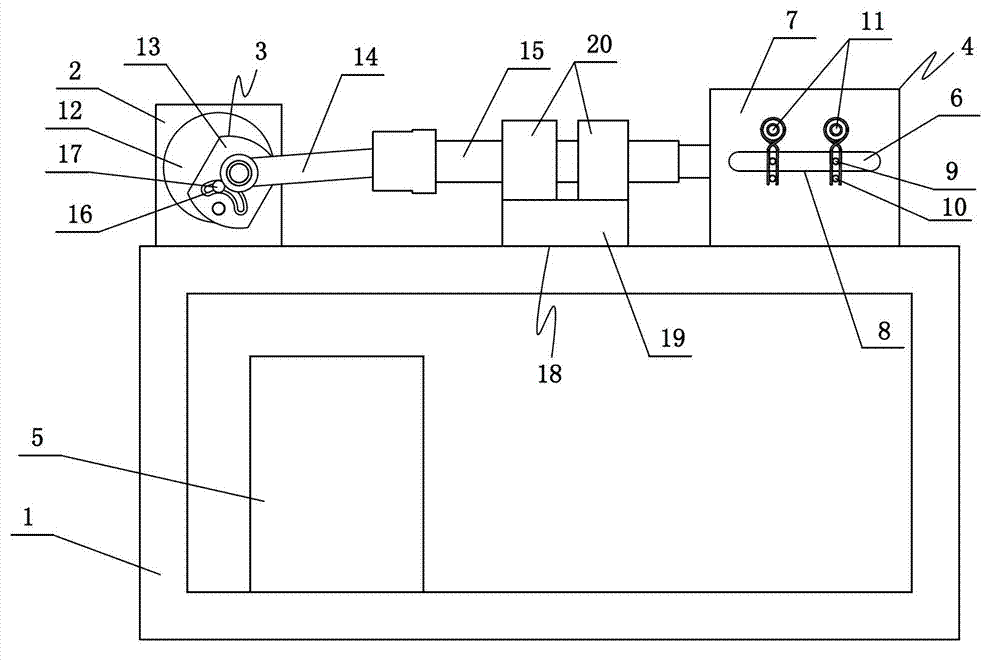

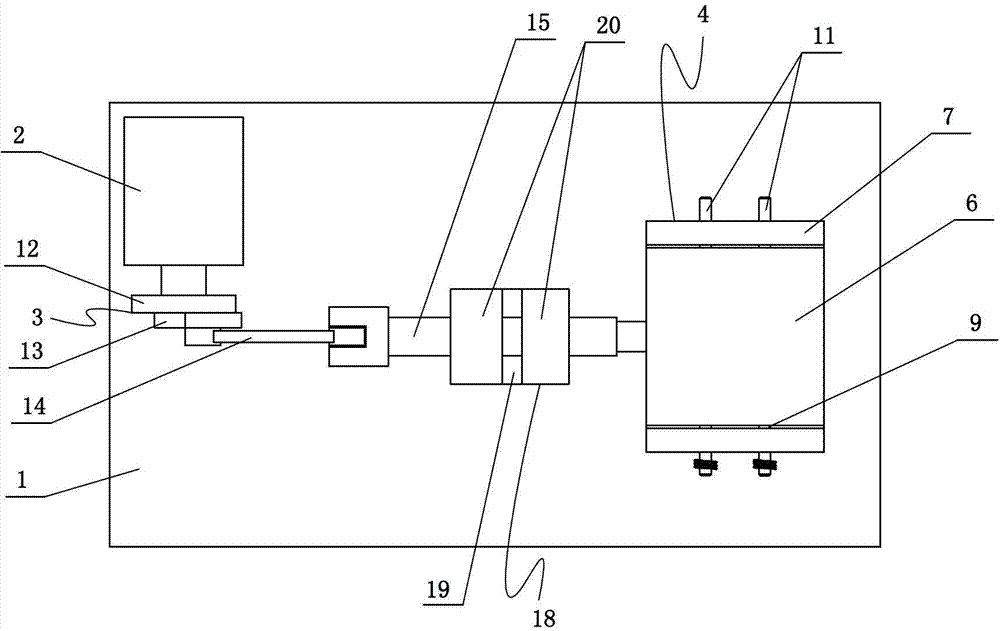

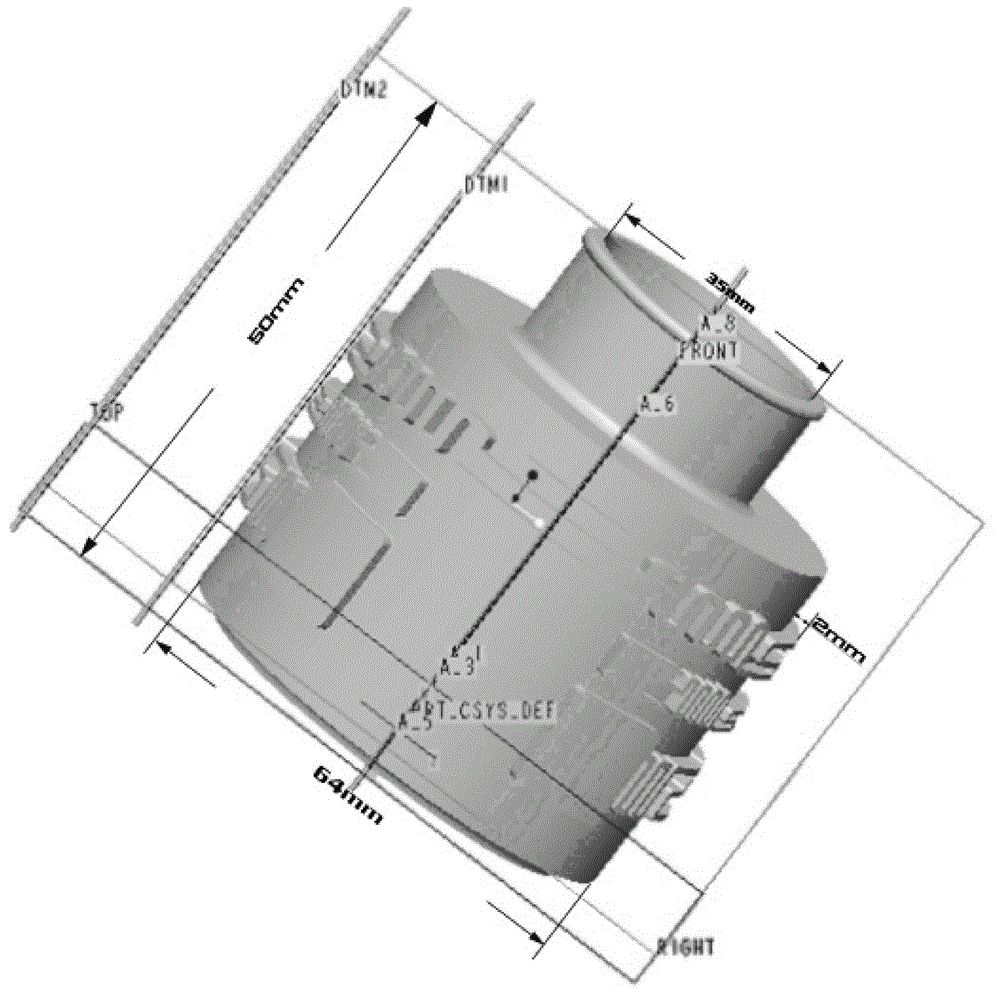

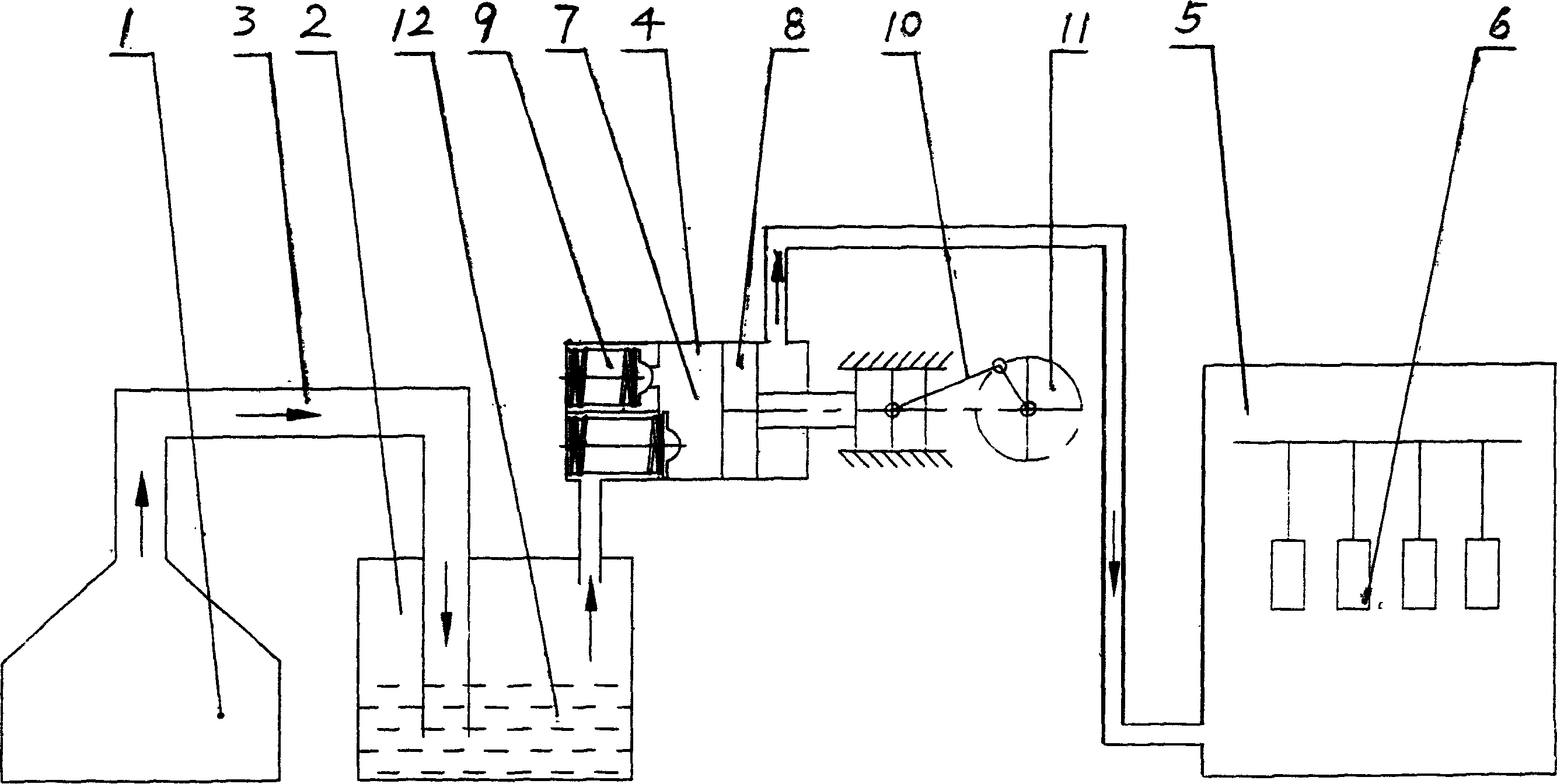

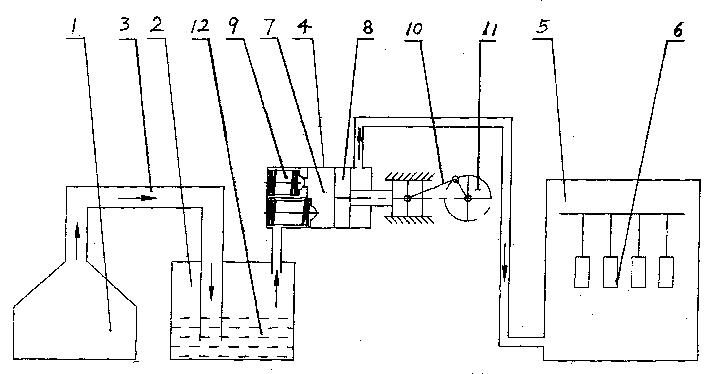

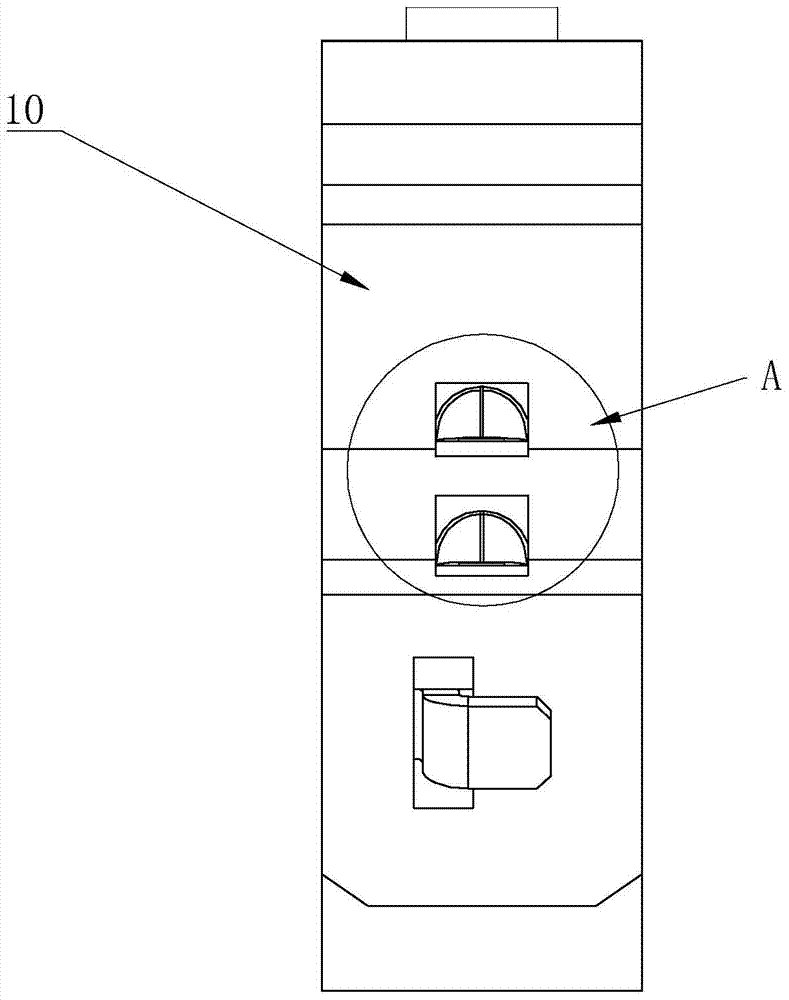

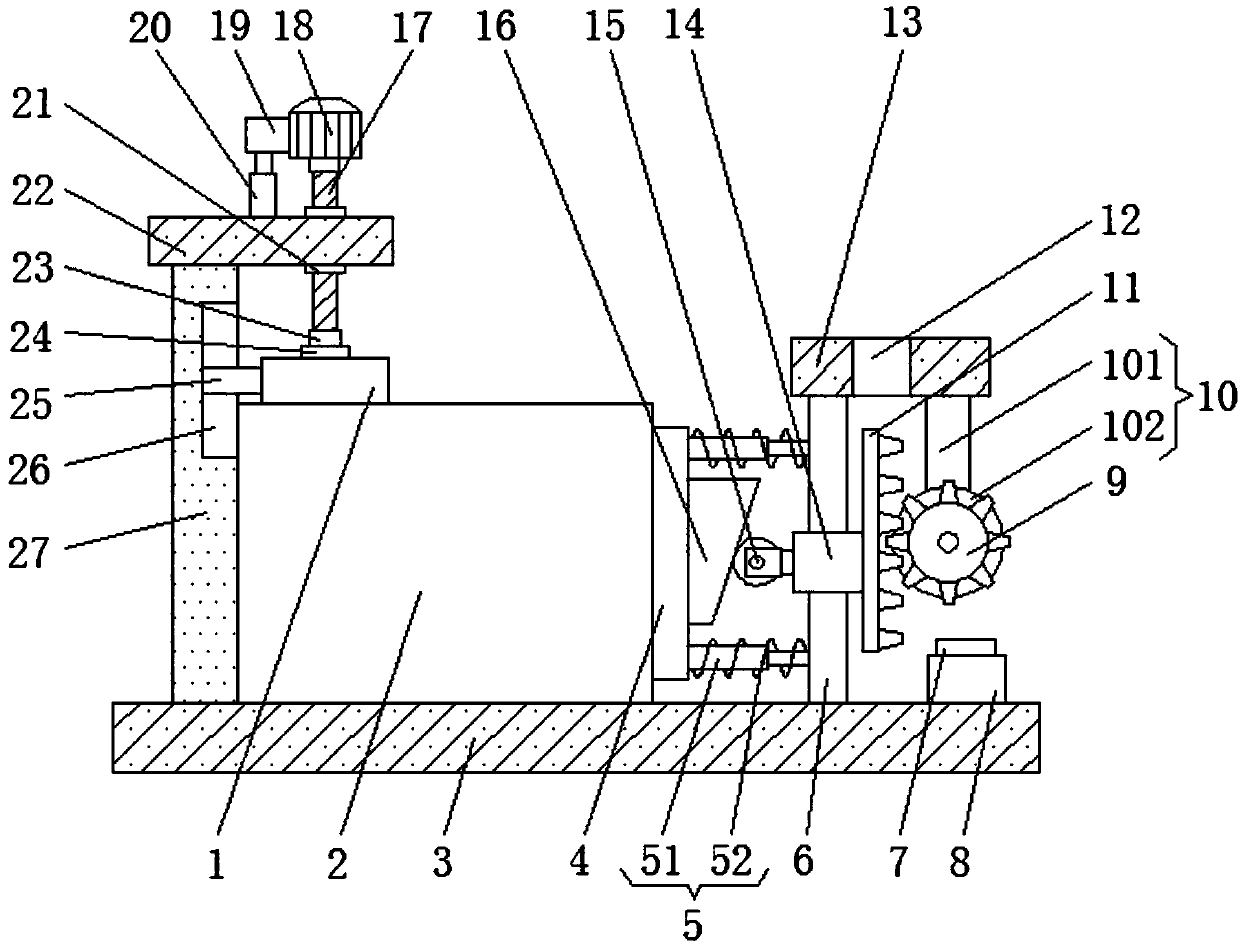

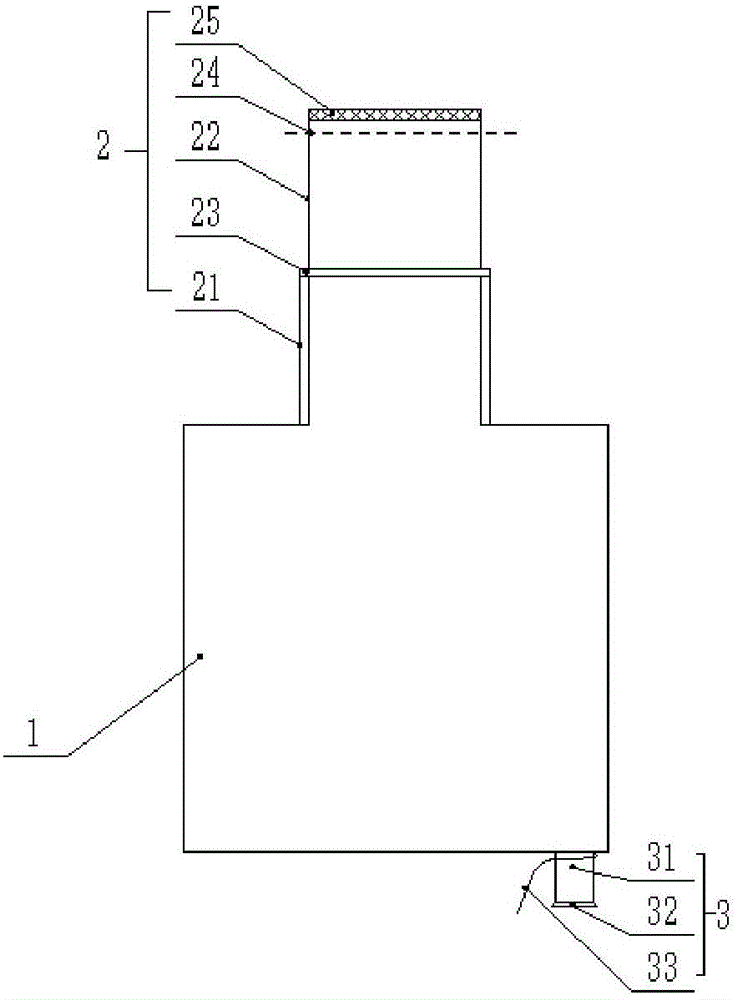

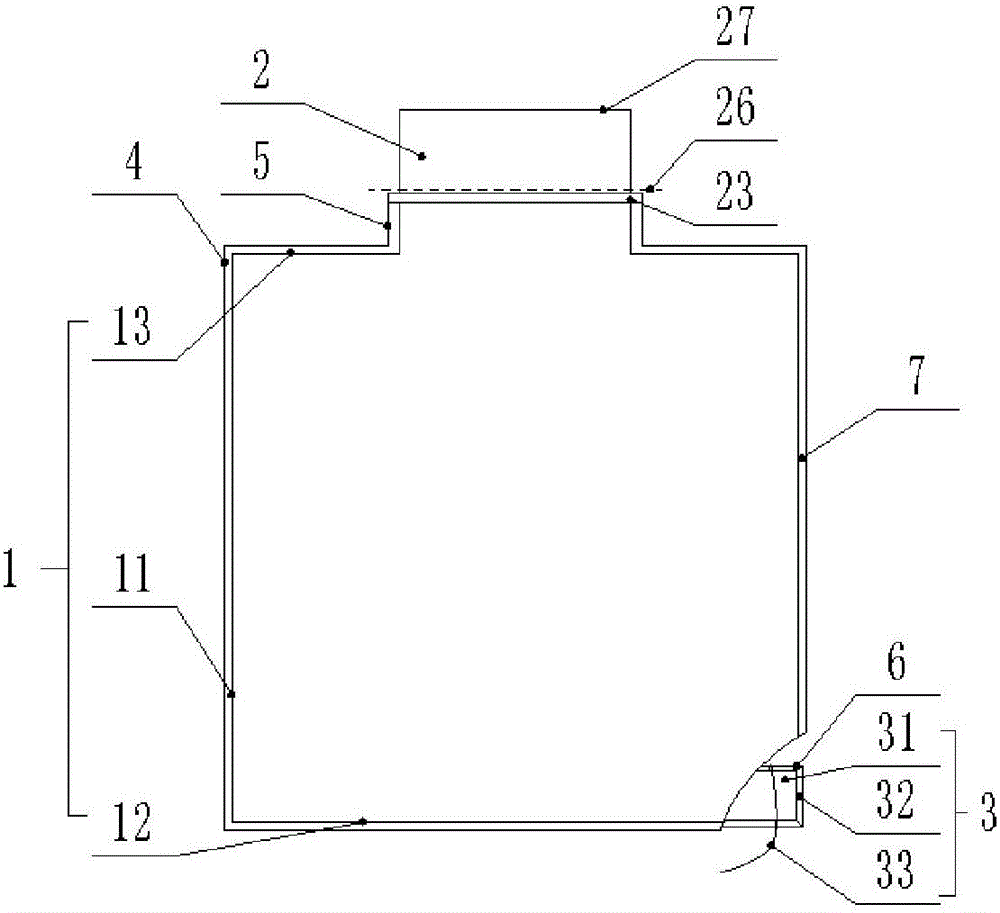

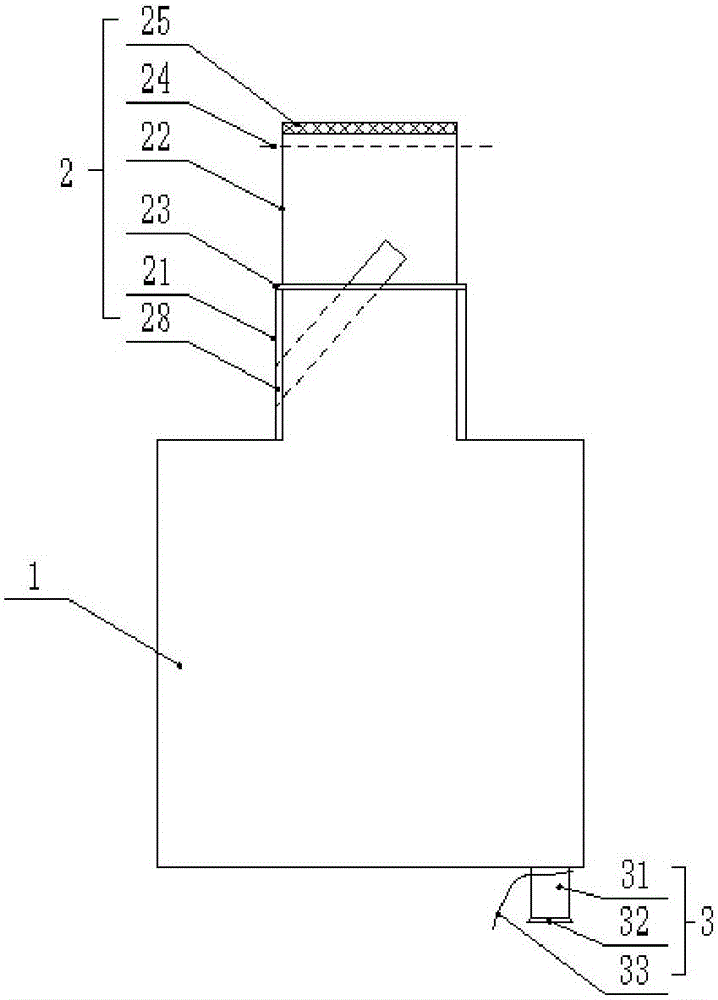

Fatigue testing machine for torsion spring

ActiveCN103091158ASpeed up the production processSimple structureStrength propertiesTest efficiencySlide plate

The invention relates to a fatigue testing machine for a torsion spring. According to the fatigue testing machine, a torsion spring fixture (4) comprises a sliding plate (6) and at least one fixing plate (7), wherein the fixing plates (7) are vertically fixed at the upper end face of a stander (1), and the planes of the fixing plates (7) are vertical to the axis of an output shaft of a motor (2); at least one deflector rod (9) is arranged at one side of the sliding plate (6), close to the fixing plates (7), the middle parts of the deflector rods (9) are connected into sliding chutes (8) in a sliding way, limiting rods (10) in one-to-one correspondence with the deflector rods (9) are arranged on the planes of the fixing plates (7) above the free ends of the deflector rods (9), sleeving rods (11) for sleeving the torsion spring are arranged right below the limiting rods (10) on the planes of the fixing plates (7), the sliding chutes (8) are located between the limiting rods (10) and the sleeving rods (11), and the distances between the limiting rods (10) and the sleeving rods (11) are shorter than the length of a twisted foot of the torsion spring. Compared with the prior art, the fatigue testing machine has the characteristics that the structure is simpler, the parts and components are fewer, the stability is better, the obtained test data is closer to an actual use condition, and the test efficiency is higher.

Owner:NINGBO YONGXIN AUTO COMPONENTS MFG

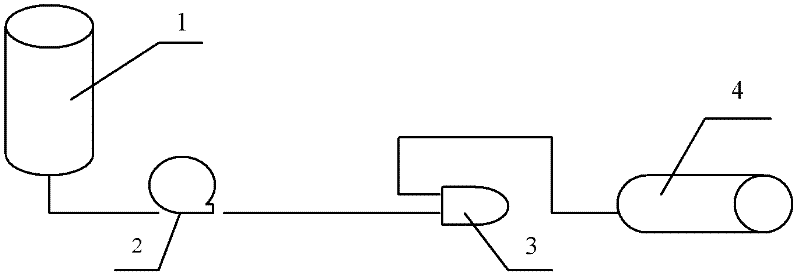

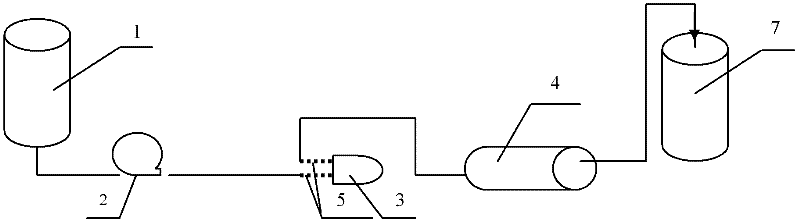

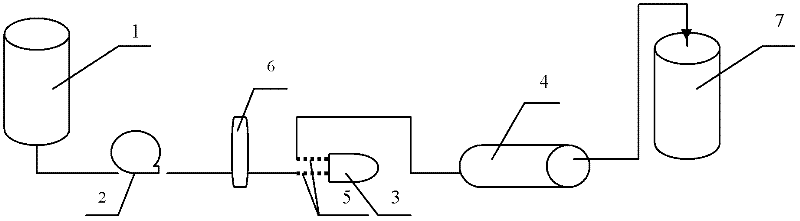

Concentrating device and concentrating method of acarbose destaining solution

InactiveCN102512957AIncreased concentration potencyIncrease drying speedSemi-permeable membranesSugar derivativesEnrichment methodsSpray drying

The invention relates to a concentration device of acarbose destaining solution, which comprises a material tank, a pre-pressurizing device, a pressurizing device and a film device which are connected in sequence by pipelines, wherein the film device is a coil type film. The invention also provides a concentrating method of the acarbose destaining solution. The concentration device and the concentration method can be used in the mass industrialized production, so that the concentration valence of the acarbose destaining solution can be obviously improved, the concentration time of the acarbose destaining solution can be obviously shortened, the production progress can be quickened, the processing amount can be greatly improved, and the speed and the efficiency of the follow-up spray drying can be quickened.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST +1

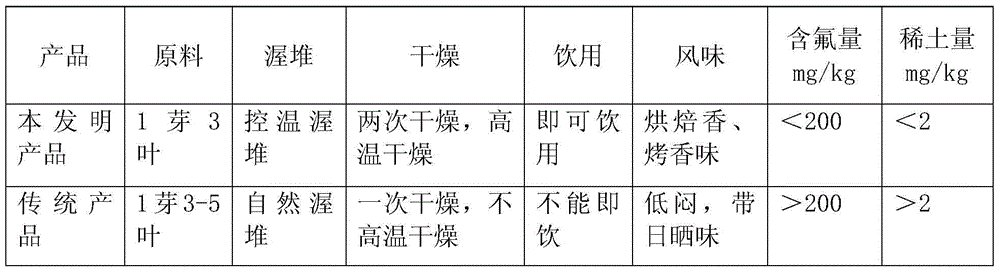

Processing method of dark raw tea

ActiveCN103549049AGuaranteed qualityMeet the needs of quality formationPre-extraction tea treatmentFlavorRare earth

The invention discloses a processing method of dark raw tea. The processing method is based on a conventional processing process of the dark raw tea. The processing method comprises the procedures of picking materials, de-enzyming, primarily kneading, carrying out pile fermentation, secondarily kneading and drying. The picking of the materials is strictly executed by three fresh leaves with one bud; in the procedure of pile fermentation, the piling of the primarily-kneaded leaves lasts for 12-16 hours with the leaf temperature in the primarily-kneaded leaf pile being 48-52 DEG C, and when the leaves are tawny, the coarse smell is eliminated and the fragrant flavor is generated, unpiling and deblocking are carried out for secondary kneading; in the drying procedure, the drying is carried out till the water content is 4-6% and forming the roasted flavor. Therefore, the processing method disclosed by the invention has the advantages that the problem that the contents of fluorine and rare soil in the dark raw tea exceed the standard due to coarseness of the raw materials can be effectively solved; a new product of the dark raw tea is mellow in taste, is not coarse, has the roasted flavor, can realize the instantaneous drinking of the dark raw tea, and is used for processing and pressing the raw tea materials; the produced dark raw tea is an all-new dark raw tea product.

Owner:安化云台山八角茶业有限公司

Printing plate and plate roller integrated flexible plate and 3D rapid molding printing type direct platemaking method and application

The invention provides a printing plate and plate roller integrated flexible plate and 3D rapid molding printing type direct platemaking method. The method comprises the following steps: designing a plate to be printed by utilizing a 3D printing plate making method by using three-dimensional software, and selecting a printing material; and spraying to obtain a printing plate material and images and texts on the printing plate material by using a 3D printing machine to obtain a printing plate and plate roller integrated flexible plate. According to the method, a printing plate and the images and texts in a 3D design image are designed into cylindrical shapes; mounting steps are omitted and troubles and labor are not wasted; the operability and the safety are improved; the bending deformation caused by installation does not occur, and the accuracy and the working efficiency are improved; meanwhile, a compensation step of pre-printing deformation amount is omitted; the antenna images and texts cover the printing plate so that the images and texts, and the printing plate are integrated, and the printing plate and a roller are integrated; the content of the images and texts on the printing plate is determined, and the image and text copying accuracy is improved; and the method can be used for creating a new chapter of a printing plate and plate roller integrated flexible plate platemaking technology, and fills up the national blank.

Owner:TIANJIN HAISHUN PRINTING & PACKAGING

Steel plate cutting device for whole vehicle manufacturing

InactiveCN107900586AControl workEasy to controlWelding/cutting auxillary devicesAuxillary welding devicesSheet steelSlide plate

The invention discloses a steel plate cutting device for whole vehicle manufacturing. The steel plate cutting device for whole vehicle manufacturing comprises a baseplate; a first chute is formed in the upper surface of the baseplate; a first slide block is arranged in the first chute; the upper surface of the first slide block is fixedly connected with the lower surface of a slide plate; a threadcylinder is clamped on the left side surface of the slide plate; a thread column is in threaded connection into the thread cylinder; and the left end of the thread column is fixedly connected with the right end of a first rotating shaft. Through arrangement of the baseplate, the first chute, the first slide block, the slide plate, the thread column, the thread cylinder, a first electric push rod, a second chute, a second slide block, a first pressing plate, a second pressing plate, a first motor, a second motor, a cutting wheel, a control panel and an accumulator, the steel plate cutting device for whole vehicle manufacturing realizes automatic clamping and cutting of steel plates without needing manual reciprocating carrying of the steel plates, so that the physical strength of workersis saved, the production time is saved, and the production progress is accelerated.

Owner:王丽

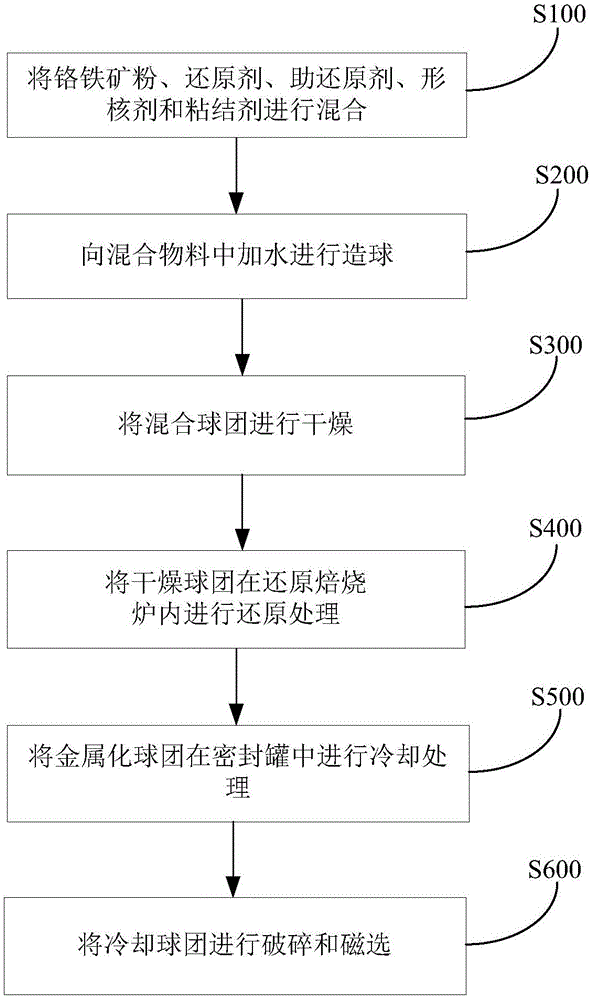

Ferrochrome preparation method

The invention discloses a ferrochrome preparation method. The ferrochrome preparation method comprises the following steps: (1) mixing chromite ore fine, a reducing agent, a reducing assistant, a nucleating agent and a binder to conveniently obtain a mixed material; (2) adding water into the mixed material for pelletizing to conveniently obtain mixed pellets; (3) drying the mixed pellets to conveniently obtain dry pellets; (4) performing reduction treatment of the dry pellets in a reduction roaster to conveniently obtain metallic pellets; (5) cooling down the metallic pellets in a seal pot to conveniently obtain cooled pellets; and (6) performing crushing and magnetic separation of the cooled pellets to conveniently obtain ferrochrome and tailings. The ferrochrome preparation method can effectively utilize chromite powder resource and is low in production cost and simple in process, and chromium in the obtained ferrochrome is high in grade.

Owner:SHENWU TECH GRP CO LTD

Filtering smoked meat products method

InactiveCN1456062AMaintain and improve gradeNo pollution in the processMeat/fish preservationEngineeringSmoke

Owner:王虎坚

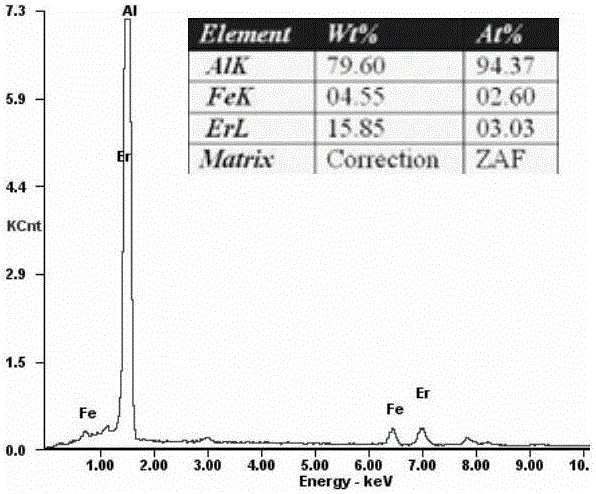

Silicon-based ceramic core slurry and application thereof

ActiveCN112500143AHigh thermal shock resistancePromote absorptionAdditive manufacturing apparatusFoundry mouldsSilicon oxidePhoto curing

The invention discloses a preparation method and application of a silicon-based ceramic core. Mixed slurry obtained according to the mixing ratio is formed by using a photocuring method to obtain a mold core biscuit, the mold core biscuit is degreased and then impregnated with a ceramic slurry, the impregnated mold core biscuit is dried, and the dried mold core biscuit is sintered in an air atmosphere by using a buried powder sintering method to obtain the silicon-based ceramic core. By means of the method, forming of a high-surface-precision silicon-based ceramic core blank can be achieved, the forming precision of the silicon-based ceramic core is improved, the production process of the ceramic core is accelerated, and the forming difficulty of the silicon-based ceramic core of a complexstructure is lowered. Degreasing and sintering treatment are carried out on the mold core biscuit obtained through the photocuring method, dipping lifting treatment is carried out on the mold core biscuit through the silicon oxide inorganic slurry, and the surface precision of the silicon-based ceramic mold core blank can be effectively improved. The method is simple, and the forming difficulty of the silicon-based ceramic mold core with a complex structure is reduced.

Owner:西安国宏天易智能科技有限公司

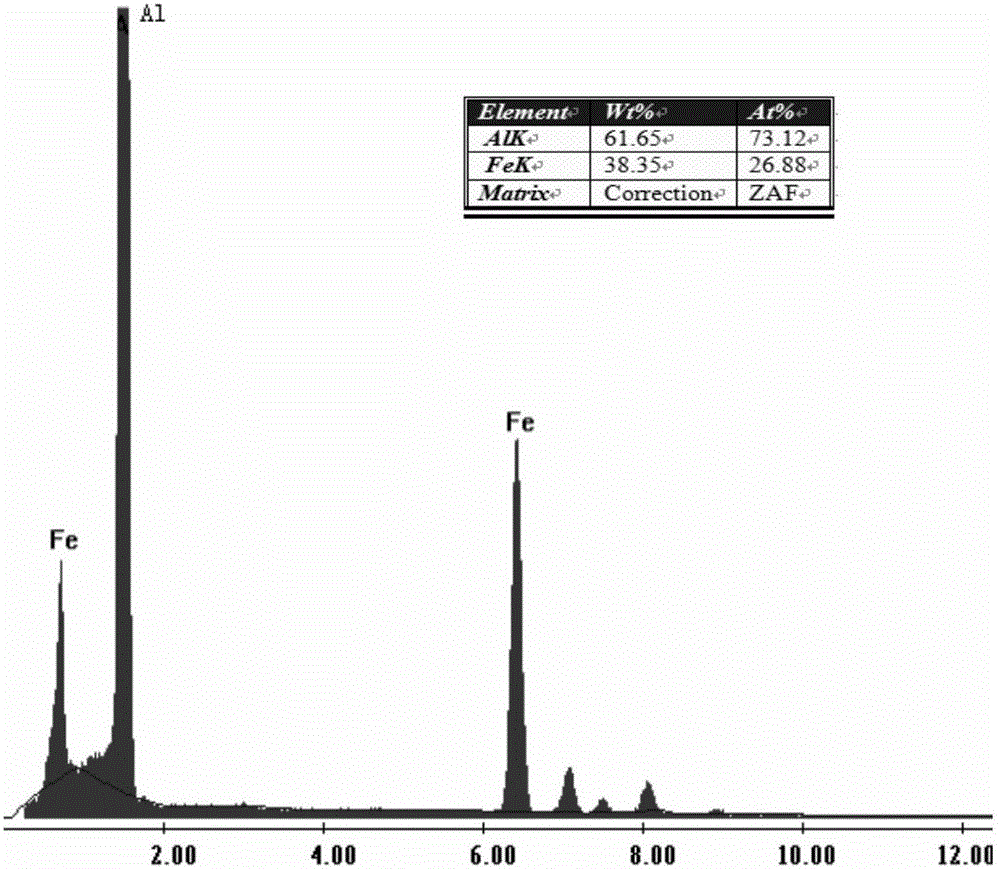

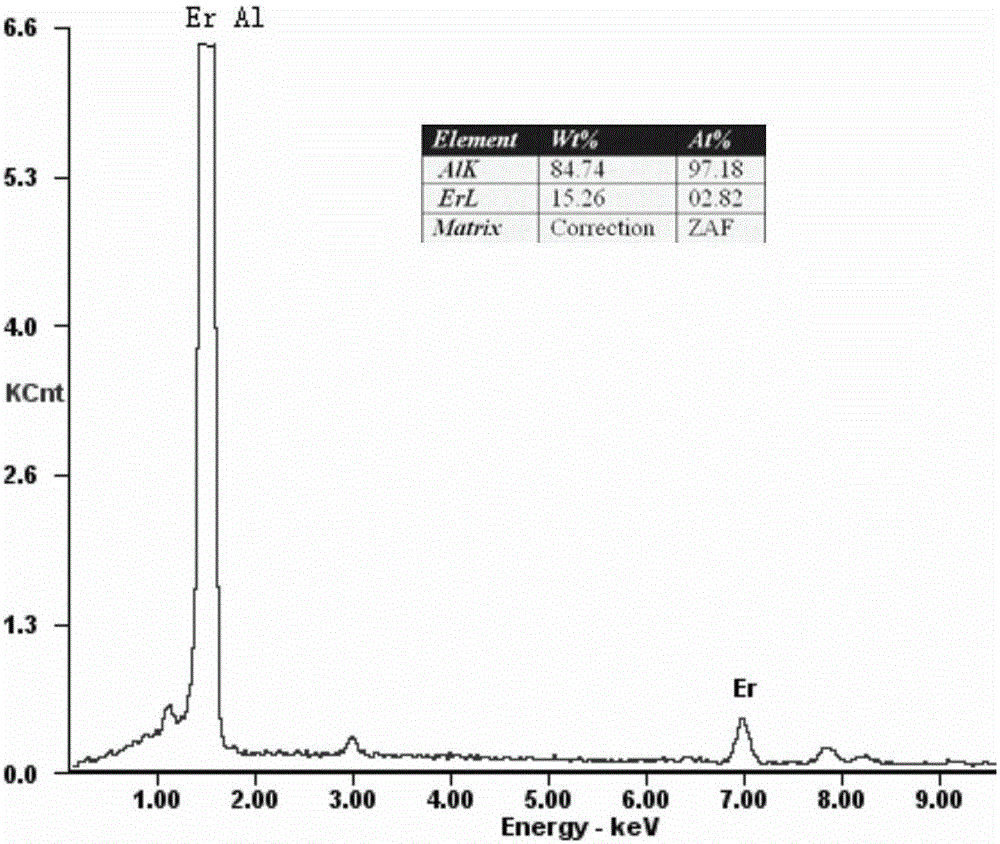

Light high-conductivity and heat-resistant aluminum conductor and preparation method thereof

ActiveCN105734353AImprove conductivityOo fullConductive materialMetal/alloy conductorsElectricityHeat resistance

The invention discloses a light high-conductivity and heat-resistant aluminum conductor and a preparation method thereof. The aluminum conductor is composed of, by weight, 0.035-0.06% of B, 0.1-0.2% of Zr, 0.1-0.3% of Er, inevitable impurities and the balance Al. The technological process comprises the steps of smelting, on-the-spot fast component analyzing, refining, rapid cooling casting, blank annealing, extruding and drawing. The added B element has the refining and modifying effects and mainly has the effect of promoting supersaturated solid solutions containing Zr and Er to separate out Al3(Er and Zr) ternary composite phases; the Al3(Er and Zr) composite phases are nano particles which are coherent with a matrix and have shell-core structures, are dispersed in the aluminum matrix and can greatly improve the electricity conductivity and the heat resistance of the aluminum conductor; the density of obtained monofilaments is smaller than or equal to 2.71 g / cm<3>, the electricity conductivity of the monofilaments is greater than or equal to 62%IACS, the short-time heat-resistance temperature of the monofilaments reaches 230 DEG C, the long-term heat-resistance temperature of the monofilaments reaches 210 DEG C, and the tensile strength of the monofilaments is greater than or equal to 165 MPa; the economic benefits are remarkable, the energy is greatly saved, and the environmental friendliness is high.

Owner:CENT SOUTH UNIV

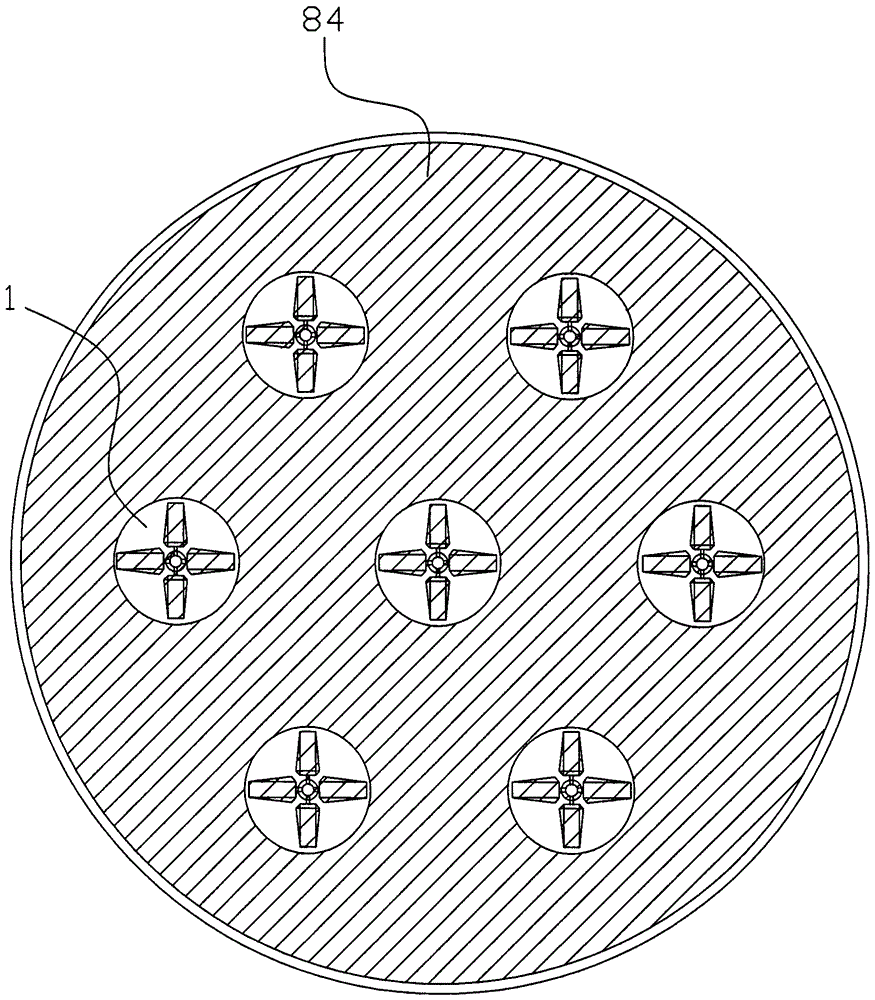

Dust recycling device for high-tower granulation of compound fertilizer

A dust recycling device for high-tower granulation of compound fertilizer comprises a shell and a collection tank. An air outlet is arranged at the upper end of the shell, an exhaust fan is arranged in the air outlet, an air inlet is arranged at the lower end of the shell, a first spraying device, a second spraying device and a third spraying device are sequentially arranged in the shell from bottom to top at intervals, a first filling layer is arranged at the air inlet at the lower end of the shell, a second filling layer is arranged between the first spraying device and the second spraying device, a third filling layer is arranged between the second spraying device and the third spraying device, a fourth spraying device is arranged between the third spraying device and the top surface of an inner cavity of the shell, the collection tank is positioned right below the air inlet and communicated with a circulating tank through a pipeline, the circulating tank is connected with inlets of a first water pipe in the first spraying device and a second water pipe in the second spraying device, and inlets of a third water pipe and a fourth water pipe are connected with a condensing water pipe respectively. The dust recycling device has the advantages of simple structure, convenience in operation and capability of better dissolving and absorbing dust.

Owner:王献

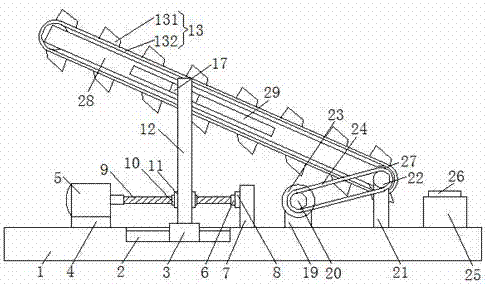

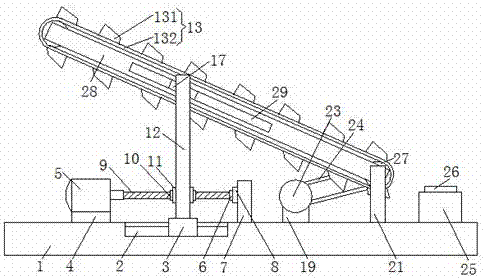

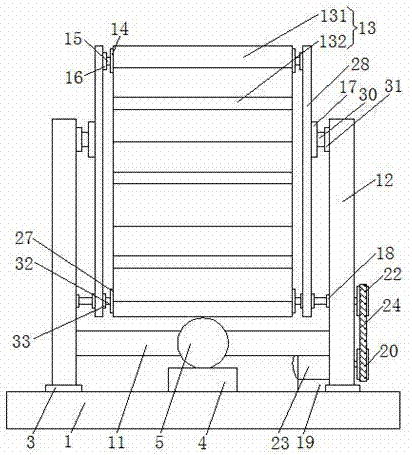

Inclination angle adjustable bucket elevator

The invention discloses an inclination angle adjustable bucket elevator. The bucket elevator comprises a bottom plate. The upper surface of the bottom plate is fixedly connected with the lower surfaces of two first supporting plates. First bearings are clamped onto the opposite surfaces of the two first supporting plates. First rotary shafts are connected to the corresponding first bearings in a sleeved mode. The outer surfaces of the first rotary shafts are sleeved with two second bearings and a first roller. The inclination angle adjustable bucket elevator is provided with first sliding blocks, first sliding grooves, a second motor, a threaded column, a threaded cylinder, second sliding blocks, second sliding grooves, a horizontal plate, a conveying device, a first motor, a driving wheel, a driven wheel, the first rotary shafts and the first roller; when an application environment or an application occasion is changed, the inclination angle of second supporting plates can be adjustedconveniently, convenience is brought to workers during work, and time is saved; accordingly, the production process is accelerated.

Owner:WUXI HENGDA MINE MACHINERY

A clamp and its manufacturing method and use method

ActiveCN105587935BPrevent looseningNot easy to loosePipe supportsHose connectionsEngineeringMinor axis

The invention discloses a clamp and a method for manufacturing and using the clamp. A clamp includes a clamping belt, and the clamping belt is crimped and formed into a clamp body with a sheathing area. The clamp The main body forms an overlapping portion, the overlapping portion includes an outer belt body and an inner belt body, and the sleeve area is elliptical. The manufacturing method first produces a clamping belt, and then directly curls the clamping belt into an elliptical sleeve. Clamp body with setting area; its use method is to directly curl the clamping band into a clamp body with a sleeve area; preform the sleeve area to make it elliptical; set the clamp body on the pipe fitting , so that the clamp body forms a conflicting connection with the pipe fitting at the short axis of the corresponding sleeve area; the clamp is further contracted and clamped by the clamp clamping tool. The object of the present invention is to provide a clamp, which has the advantages of being easy to install and can be effectively pre-fixed on the pipe fitting.

Owner:YUEQING DONGBO ELECTROMECHANICAL

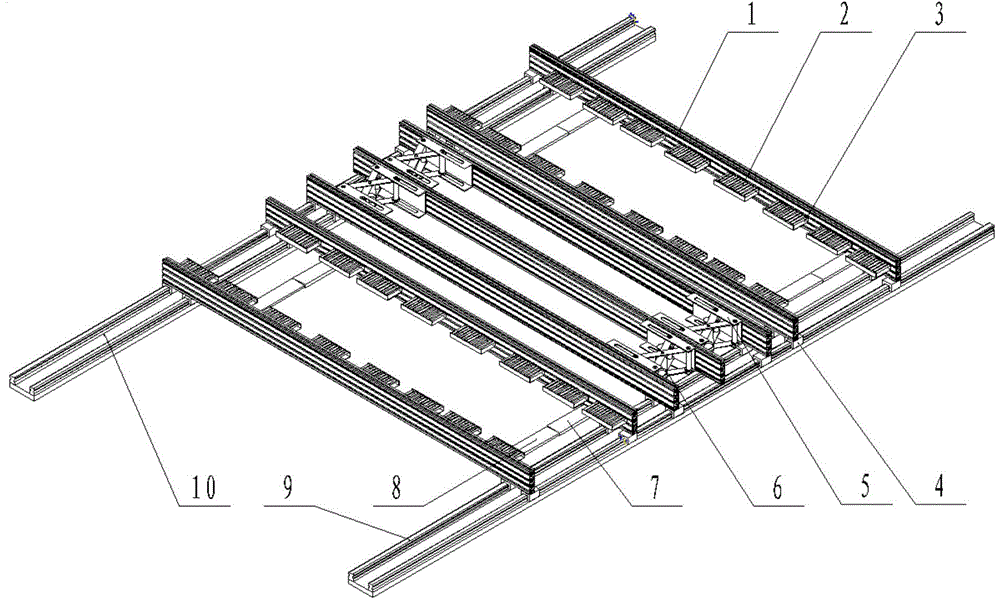

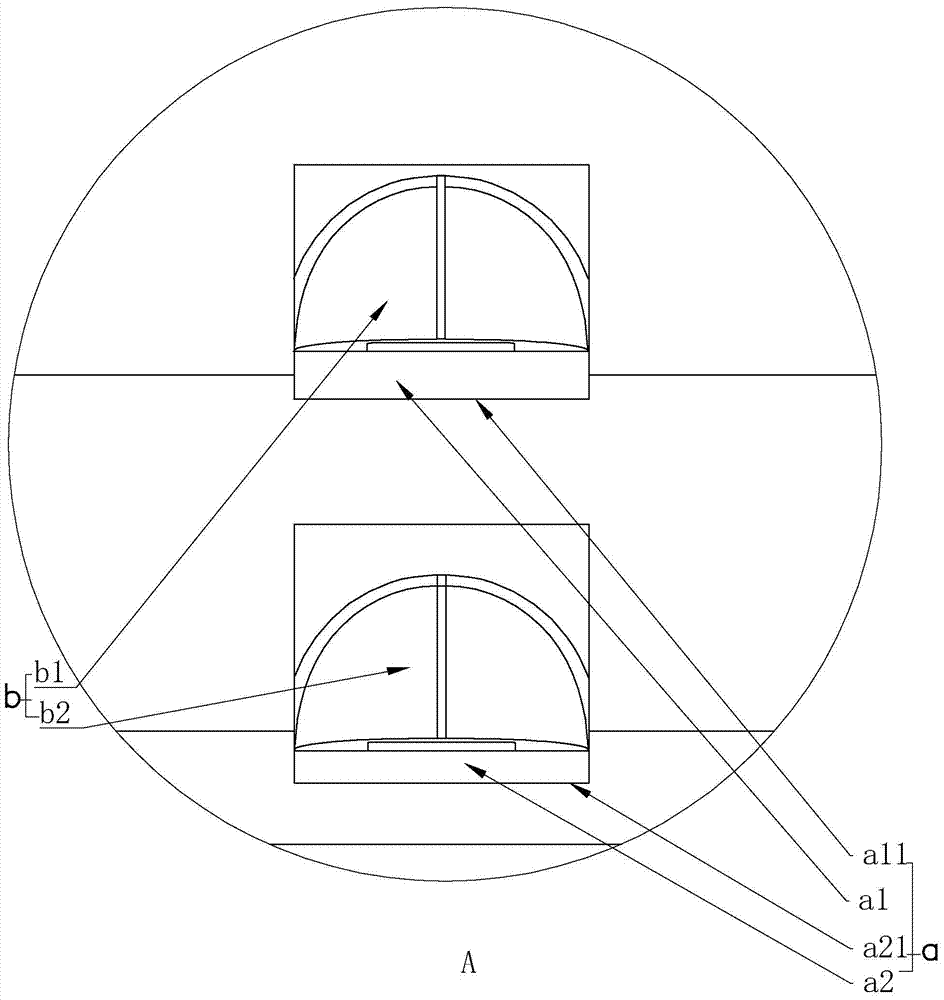

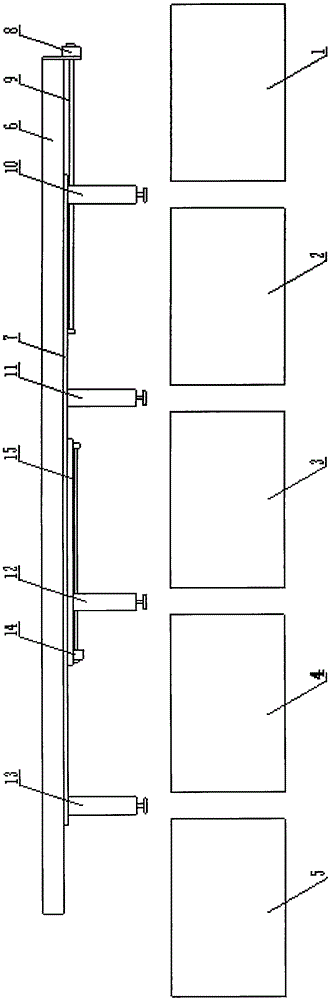

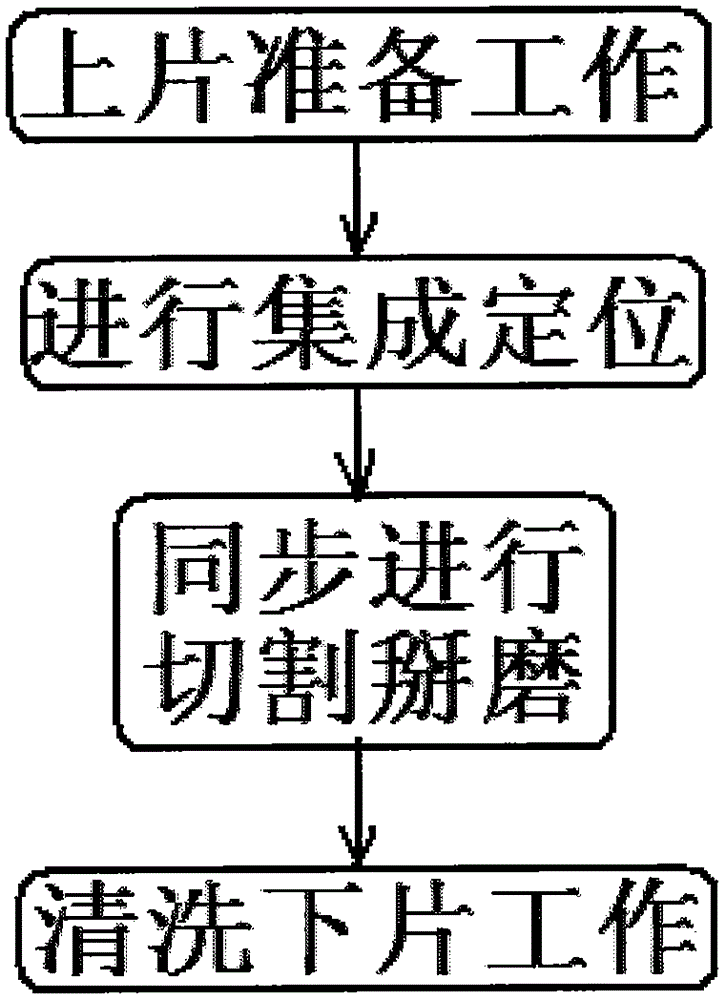

Special-shaped glass remote control cutting, breaking and grinding integrated processing production line and operation method thereof

InactiveCN105598781AHigh precisionImprove edging accuracyEdge grinding machinesGrinding drivesProduction lineRemote control

Provided are a special-shaped glass remote control cutting, breaking and grinding integrated processing production line and an operation method thereof. The processes of cutting, edge breaking, edge grinding and the like are integrated to efficiently process all kinds of special-shaped glass in a fully automatic mode at a time, precision, stability and quickness are achieved, waste is treated by itself, and the performance of the whole machine is excellent. Operation is easy, use is safe and convenient, the rate of finished products reaches up to 99.96%, and production quality and efficiency are greatly improved. Energy saving and environment friendliness are achieved, production cost is reduced by 50%, and the requirements of the production processes and the need of a special-shaped glass deep processing production line for fast development and changes are met. The special-shaped glass remote control cutting, breaking and grinding integrated processing production line is composed of a glass GPS positioning and navigation system, a special-shaped glass remote control cutter, a special-shaped glass remote control edge breaking machine, a special-shaped glass remote control edge grinding machine, a glass remote control cleaning machine, a glass control conveying device, a sensing conveying device, a first servo motor, a first ball screw, a cutting linkage mechanical arm, an edge breaking linkage mechanical arm, an edge grinding linkage mechanical arm and the like.

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

Robot polishing device

InactiveCN107900900AEasy to disassembleEasy to fixGrinding carriagesGrinding bedsEngineeringFuselage

The invention discloses a robot polishing device. The robot polishing device comprises a bottom plate, and the upper surface of the bottom plate is fixedly connected with the lower surface of a supporting plate; the upper surface of the supporting plate is fixedly connected with the lower surface of a first top plate; a threaded barrel is connected to the upper surface of the first top plate in aclamping manner; a threaded pillar is connected in the threaded barrel in a threaded manner; the top end of the threaded pillar is fixedly connected with an output shaft of a first motor; and a body of the first motor is fixedly connected with the right side surface of a first fixed plate. According to the robot polishing device, the threaded pillar, the first motor, a second motor, the threaded barrel, a first pressing plate, a robot polishing device body, a telescopic device, a second pressing plate, a rack, a gear, a sliding sleeve, a roller, a trapezoidal plate, a switch and a storage battery are arranged, so that the robot polishing device body can be moved without the requirement of firstly disassembling bolts, disassembly and fixation are more convenient, time is saved, and the production process is quickened.

Owner:SICHUAN 910 CONSTR ENG CO LTD

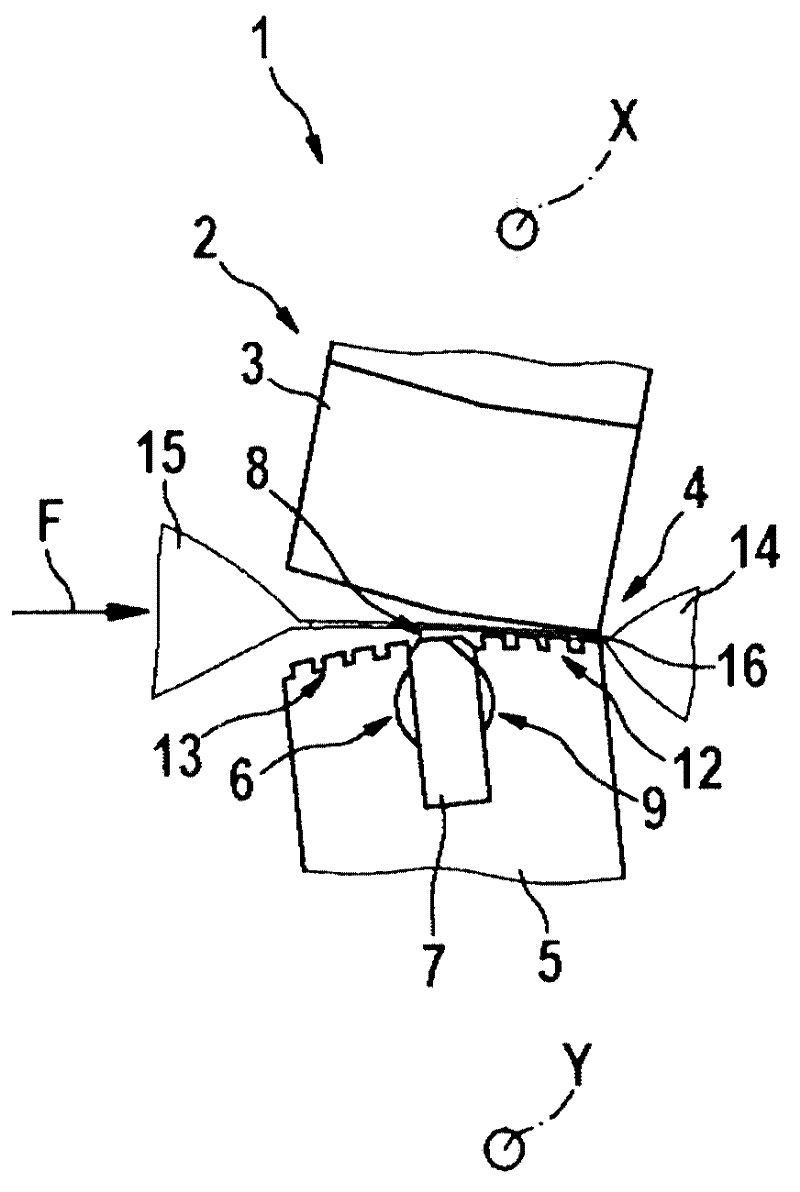

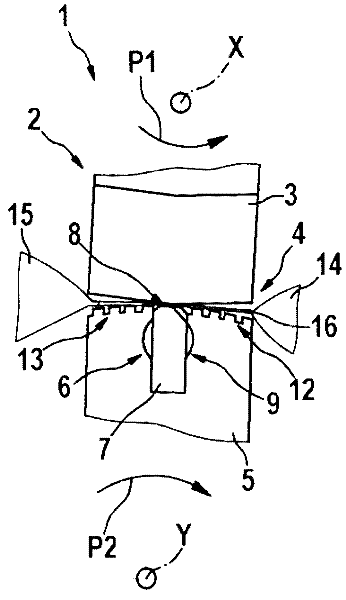

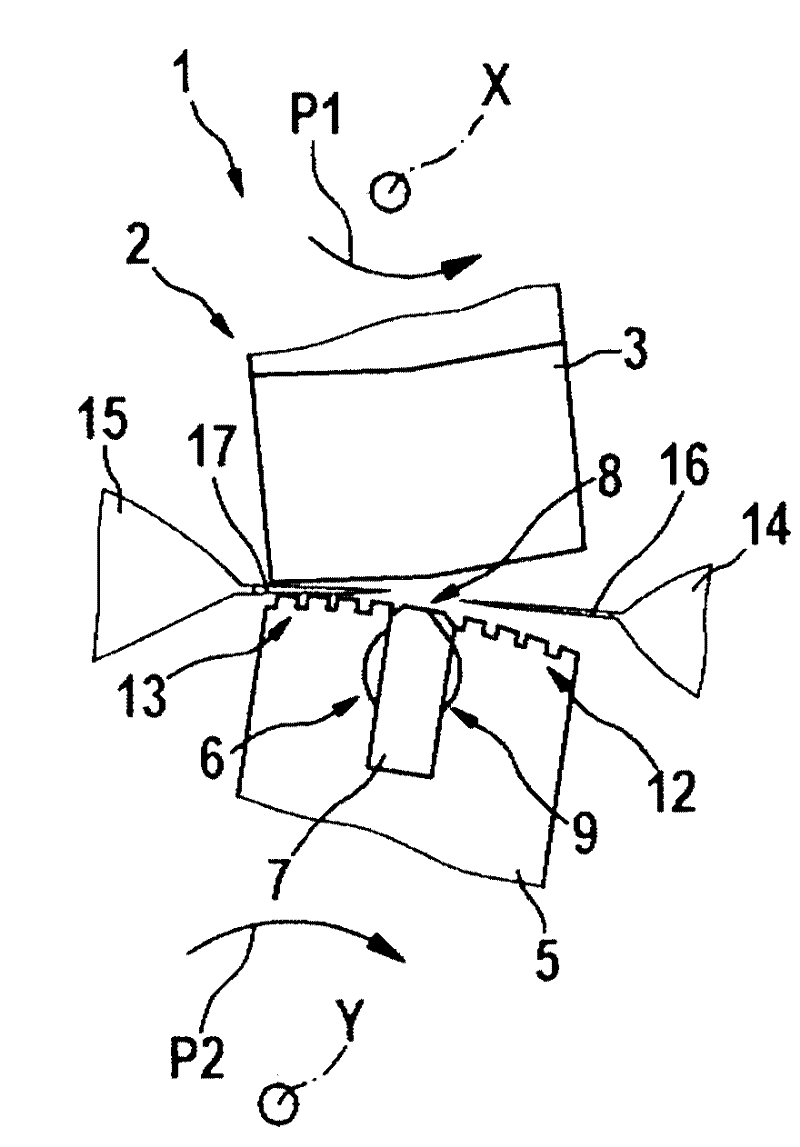

Device and method for welding and separating packaging materials for a package

InactiveCN102548735AExtended service lifeReduced conversion timeWrapper twisting/gatheringEngineeringUltrasonic welding

The invention relates to a device for welding and separating a packaging material (4) for a package, comprising an ultrasonic welding device (2) with a sonotrode (3) and an anvil (5) for sealing the packaging material (4), wherein the sonotrode (3) is rotatable about a first axis of rotation (X) and the anvil (5) is rotatable about a second axis of rotation (Y), and a cutting device (6) with at least one blade (7) for separating the packaging material (4), which device is arranged in the anvil (5), wherein the at least one blade (7) is arranged on the anvil (5) in such a way that a minimum distance (S) between the sonotrode (3) and a cutting edge (8) of the blade (7) is maintained, and so the packaging material (4) can be severed without any contact between the sonotrode (3) and the blade (7).

Owner:ROBERT BOSCH GMBH

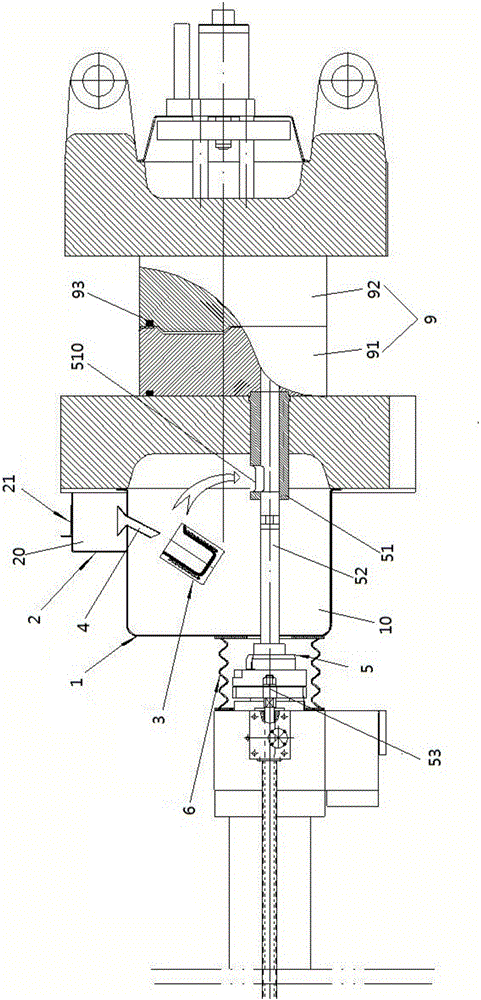

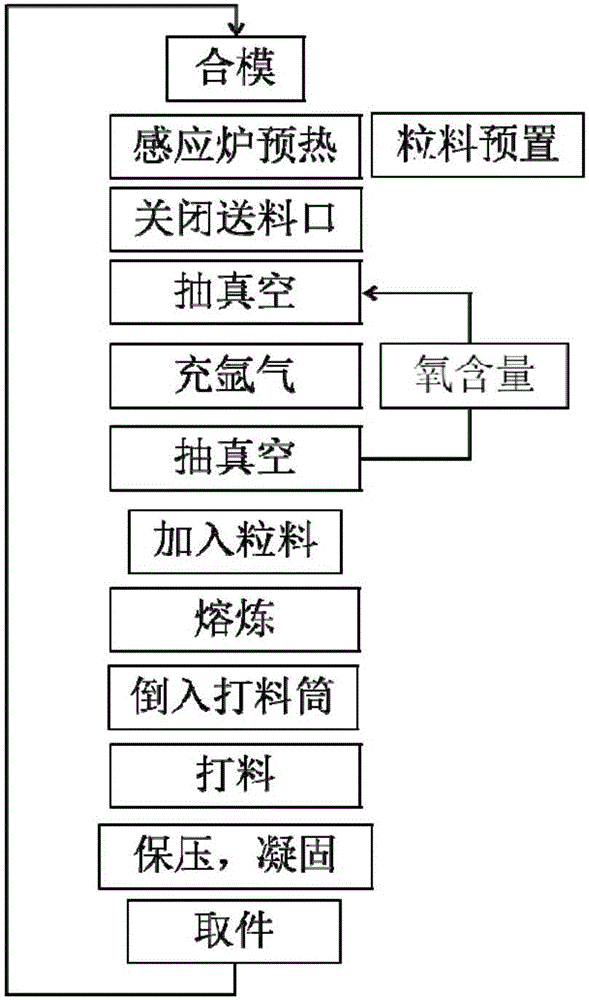

Liquid metal die-casting machine and die-casting method

The invention is applicable to the technical field of vacuum melting die-casting of amorphous alloy and discloses a liquid metal die-casting machine and a die-casting method. The liquid metal die-casting machine comprises a die-casting machine body, a vacuum chamber and a feeding chamber connected onto the vacuum chamber, wherein the vacuum chamber is provided with a vacuum cavity; a heating cup is arranged in the vacuum cavity; the feeding chamber is connected with a feeding door; a heating component is arranged in the feeding door; the vacuum chamber is connected with a vacuumizing device; the liquid metal die-casting machine further comprises a knockout device; the knockout device is used for injecting liquid metal heated by the heating cup into a die-casting die and comprises a knockout cylinder communicating the vacuum chamber and the die-casting die; and one end of the knockout cylinder stretches into the vacuum chamber, and the other end of the knockout cylinder is connected onto the die-casting die. The die-casting method is applicable to the liquid metal die-casting machine. According to the liquid metal die-casting machine and the die-casting method, the product quality and the production efficiency are high, and the production cost is low.

Owner:SHENZHEN LEADWELL TECH CO LTD

Bean sprout peeling device

The invention discloses a bean sprout peeling device. The bean sprout peeling device comprises a bottom plate, wherein the upper surface of the bottom plate is fixedly connected with the lower surfaceof a first supporting plate; a first bearing is connected to the left side surface of the first supporting plate in a clamping manner; a first rotating shaft is connected to the first bearing in a sleeving manner; a first gear and a cam are separately connected to the outer surface of the first rotating shaft in a sleeving manner; the first gear is meshed with a second gear; and the left side surface of the second gear is fixedly connected with an output shaft of a motor. According to the bean sprout peeling device disclosed by the invention, the motor, the first supporting plate, a second supporting plate, a third supporting plate, the first gear, the second gear, the first rotating shaft, the first bearing, a sliding block, the cam, a roller, a second rotating shaft, a second bearing, asliding rod, a sliding sleeve, a mesh screen tank, a sliding groove, a telescopic device, a control panel and an accumulator are arranged, so that the cam is driven by the motor to rotate, and peeling is performed on bean sprouts in the mesh screen tank; and the physical strength of workers is saved, and time is also saved, so that the production process is accelerated.

Owner:WUXI SUYA FOOD CO LTD

IBC (Intermediate Bulk Container) lining bag, intermediate bulk container with lining bag and use method of lining bag

InactiveCN106742822ACause activityEasy to installLarge containersIntermediate bulk containerEngineering

The invention provides an IBC (Intermediate Bulk Container) lining bag, an intermediate bulk container with the lining bag and a use method of the lining bag, and relates to the field of chemical articles. The IBC lining bag comprises a bag body, wherein an opening is formed in the top of the bag body; a feeding part is connected with the opening in a sealed manner; a discharge part is connected with the bottom of the bag body in a sealed manner; the feeding part comprises an outer-layer protection film and an inner-layer storage film from outside to inside in sequence; the top end surface of the outer-layer protection film is wrapped by a first sealing ring; and the top of the inner-layer storage film is directly sealed. The invention further relates to the intermediate bulk container with the lining bag. The IBC lining bag is arranged inside the IBC. The invention further relates to the use method of the lining bag. The use method mainly comprises procedures of charging air and exhausting air through the discharge part. By adopting the technical scheme of the invention, chemical raw materials inside the intermediate bulk container can be rapidly recycled, mounting procedures of the lining bag can be also reduced, and thus the cost can be reduced.

Owner:吴江市科欣包装材料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com