Rail-spliced type automatic seedbed moving system

An automatic moving and splicing technology, applied in application, cultivation, agriculture, etc., can solve the problems of low supply rate of high-quality seedlings, low degree of intelligent control, backward seedling technology, etc., and achieve low operating and management costs, simplified The effect of designing structure and saving manpower, material and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

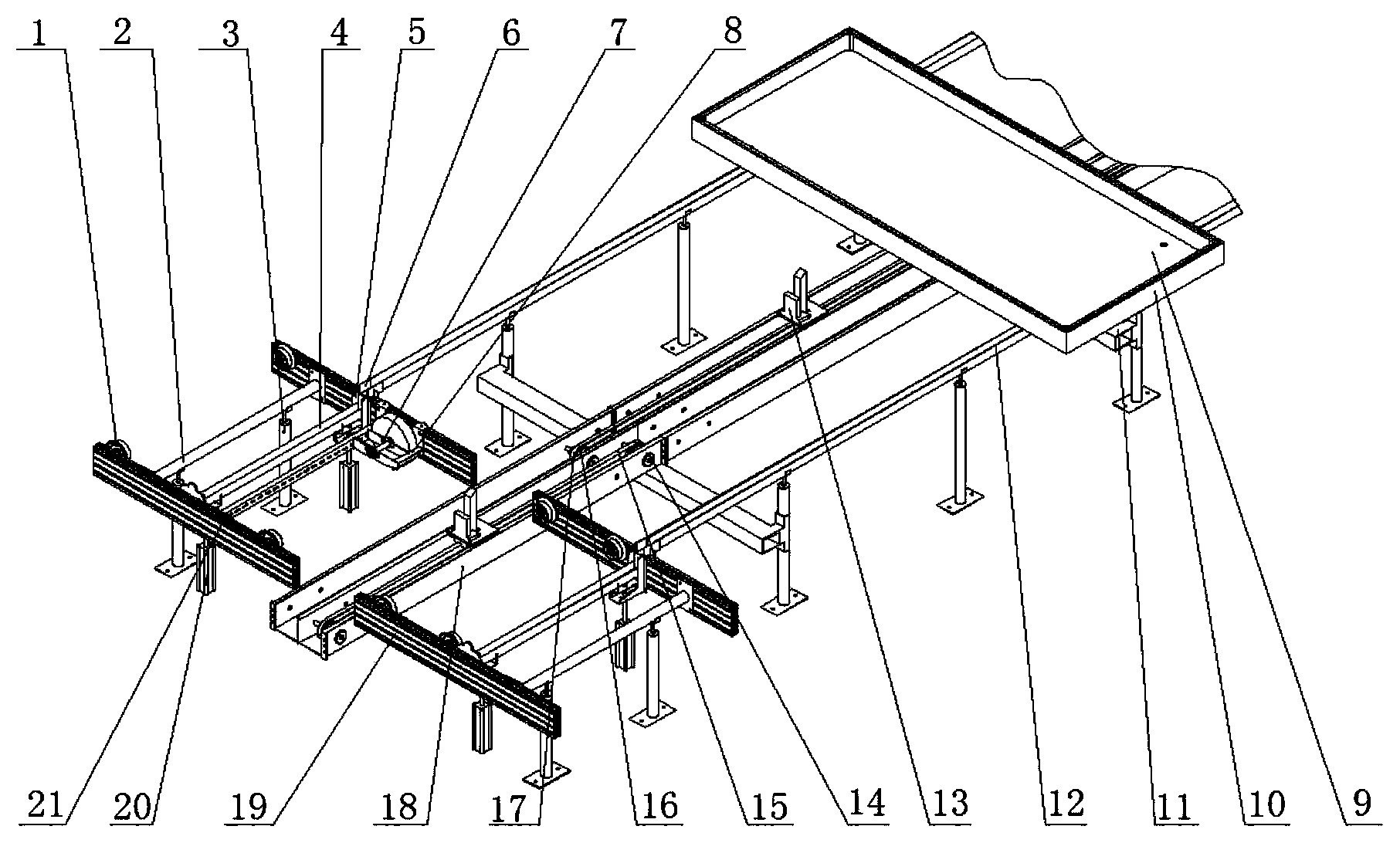

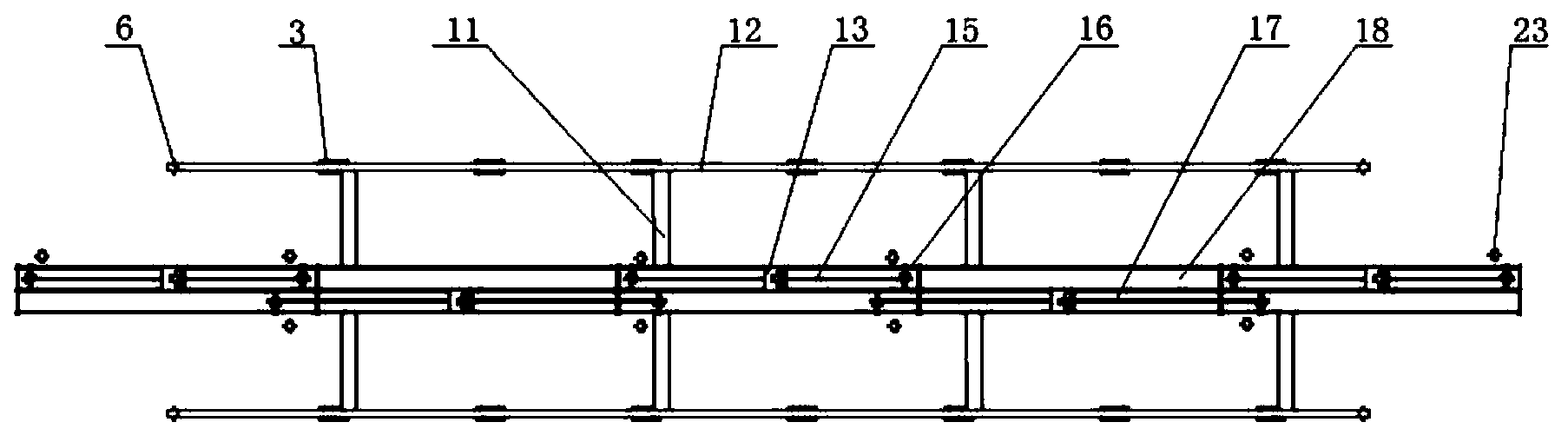

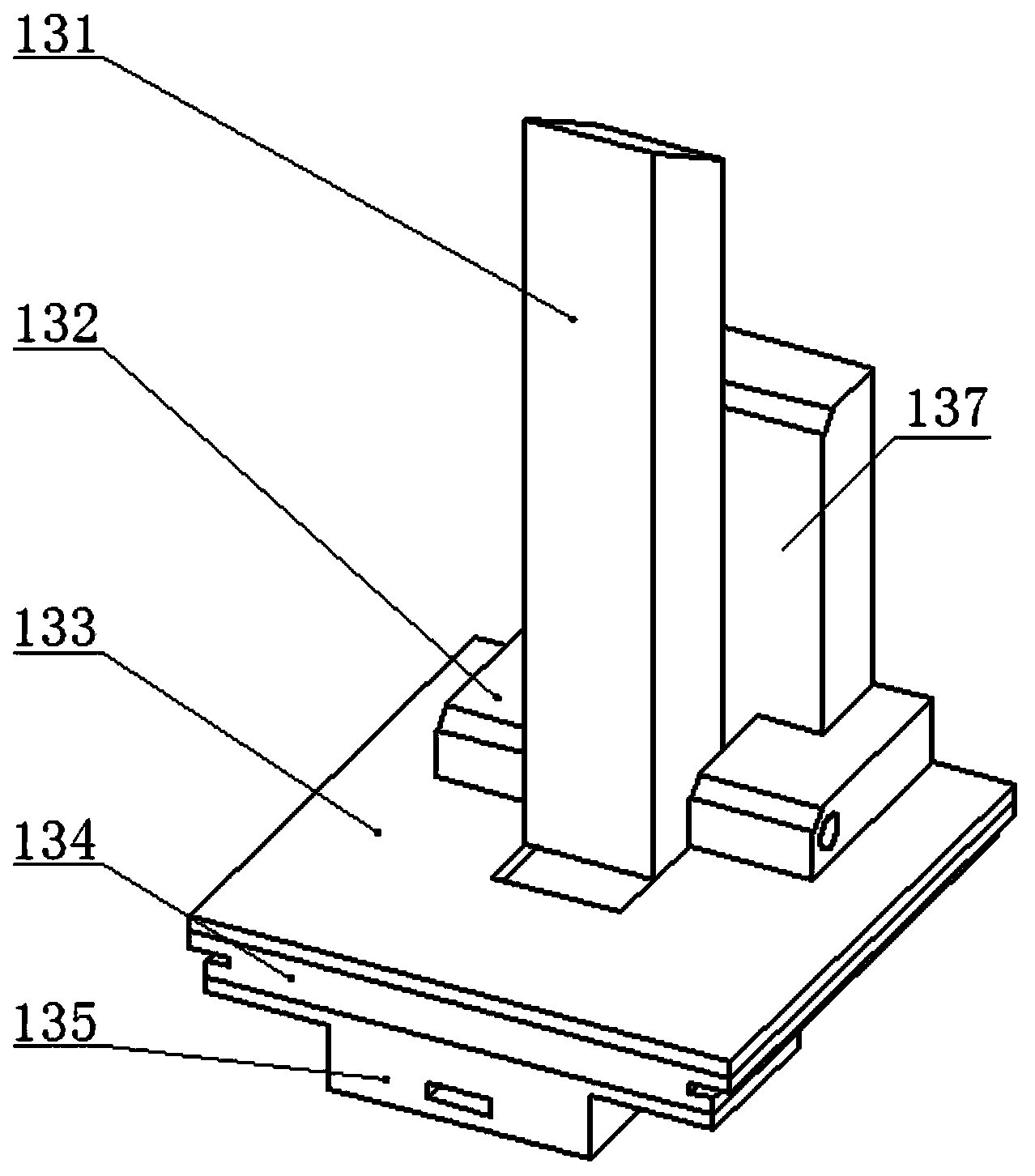

[0062] A track splicing type automatic moving seedbed system, such as figure 1 As shown, it includes an inlet unit, an outlet unit, a cultivation unit, a single seedbed and a sensor positioning device. The inlet unit and the outlet unit are respectively located at the front and rear ends of the cultivation unit. The inlet unit and the outlet unit have the same structure, including the longitudinal sliding track of the seedbed and the The driving device 7 for driving the sliding of the single seedbed; the cultivation unit includes the lateral sliding track of the seedbed, the chain track frame 18 and the pushing device arranged on the chain track frame 18 to push the single seedbed to move; the single seedbed passes through the longitudinal sliding track of the seedbed of the inlet unit It enters the lateral sliding track of the seedbed of the cultivation unit, and after the cultivation is completed, it is moved out from the longitudinal sliding track of the seedbed of the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com