A clamp and its manufacturing method and use method

A technology of clamps and clamps, applied in the direction of pipe supports, pipes/pipe joints/pipes, hose connection devices, etc., can solve the problem of difficult to control the clamping force, the increase of the relative force, the failure of clamps, etc. problems, to achieve the effect of improving production efficiency, improving stability, and speeding up the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be described in further detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are only descriptive and do not limit the scope of protection of the present invention.

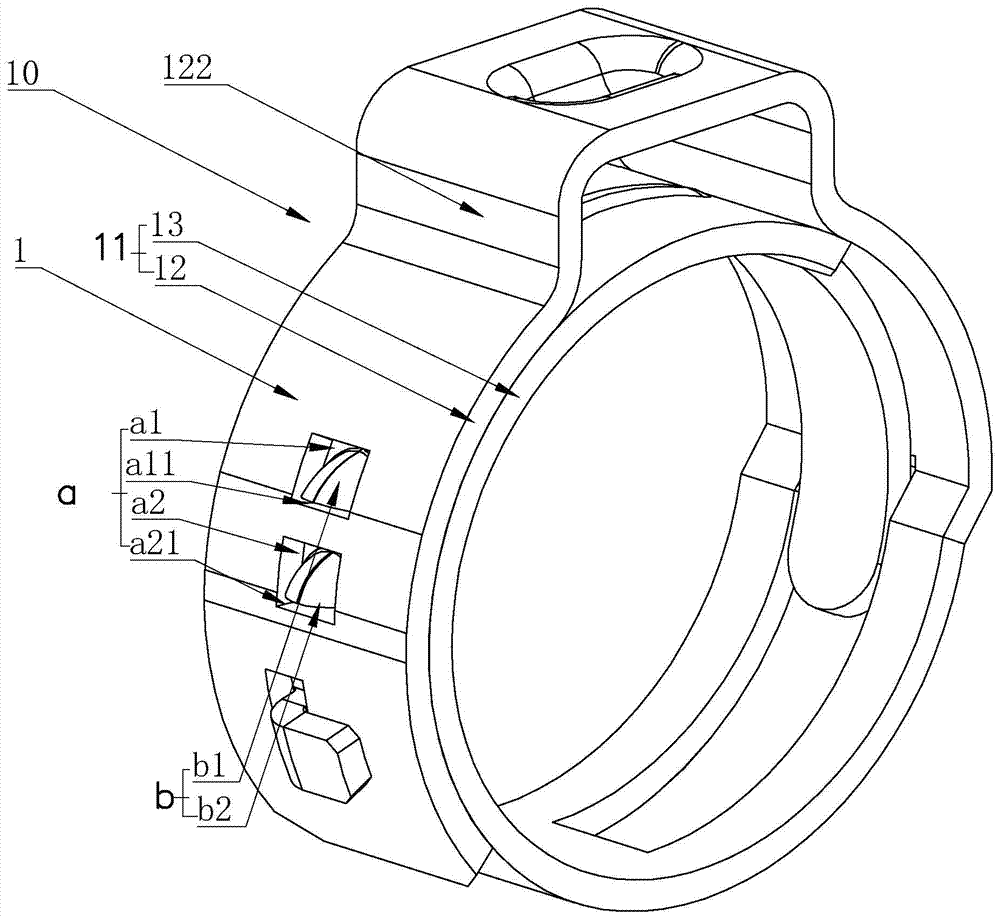

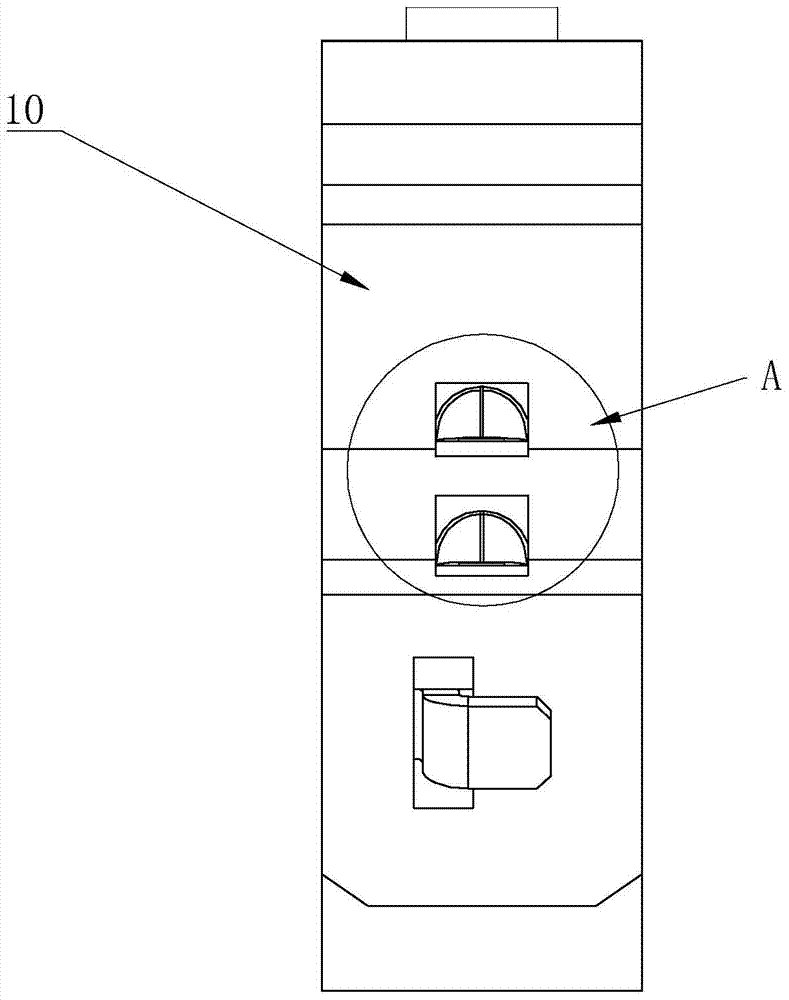

[0036] Such as Figure 1 to Figure 4 As shown, specific examples of clamp products:

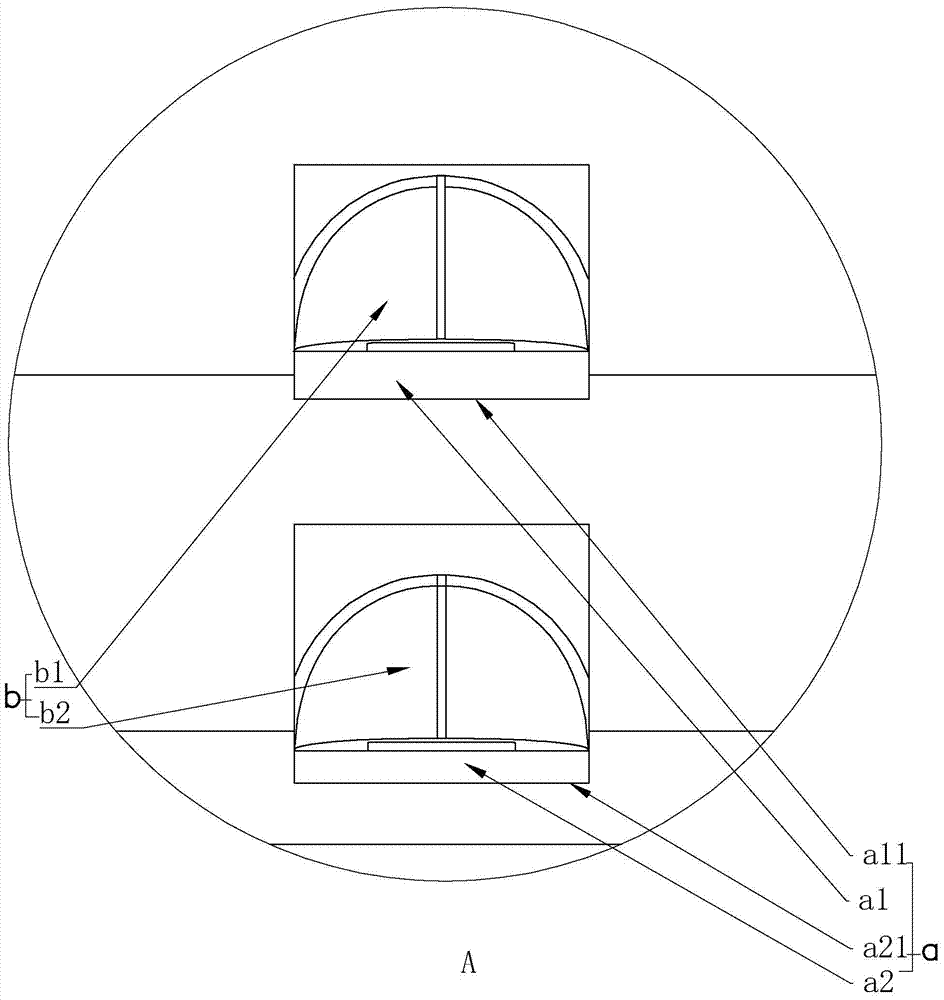

[0037] Such as figure 1 , Figure 4 As shown, a clamp includes a clamp band 1 which is crimped to form a clamp body 10 with a sleeve area 101. The clamp body 10 is sleeved on the pipe fitting, and the sleeve area 101 is for inserting the pipe fitting. The clamp body 10 forms an overlapping portion 11, and the overlapping portion 11 includes an outer belt body 12 and an inner belt body 13. The sleeved area 101 includes a long axis 2 and a short axis 3.

[0038] Such as figure 2 , image 3 As shown, the outer belt body 12 is provided with a clamping notch a (it should be noted here that the clamping notch a can be set as a through hole or a blind hole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com