Patents

Literature

4222results about How to "Not easy to loose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

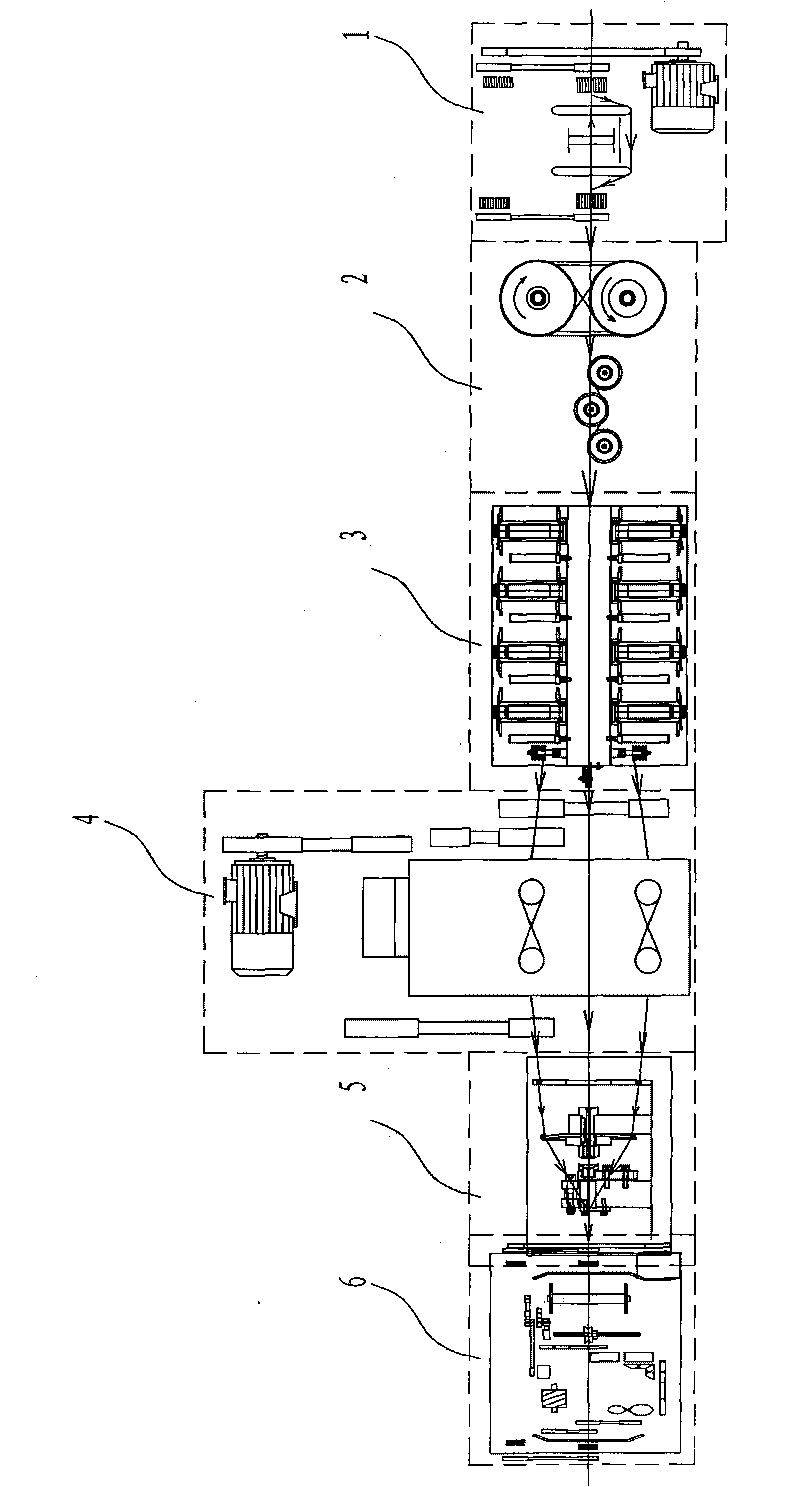

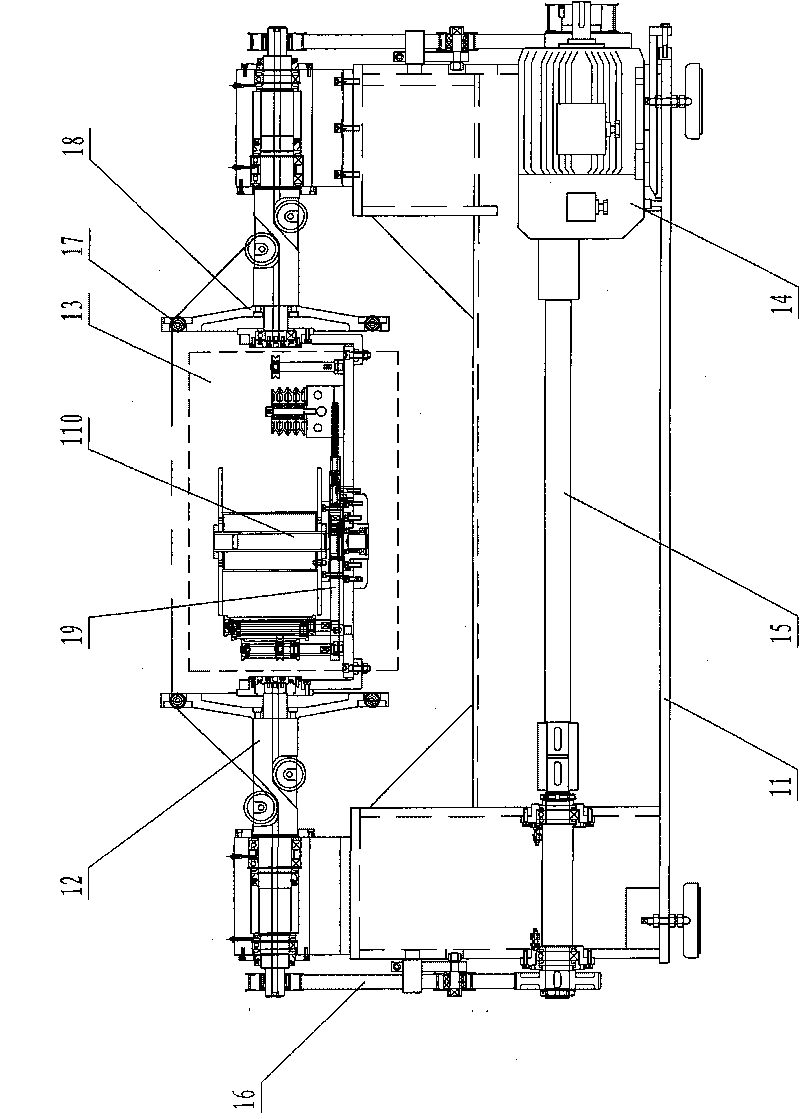

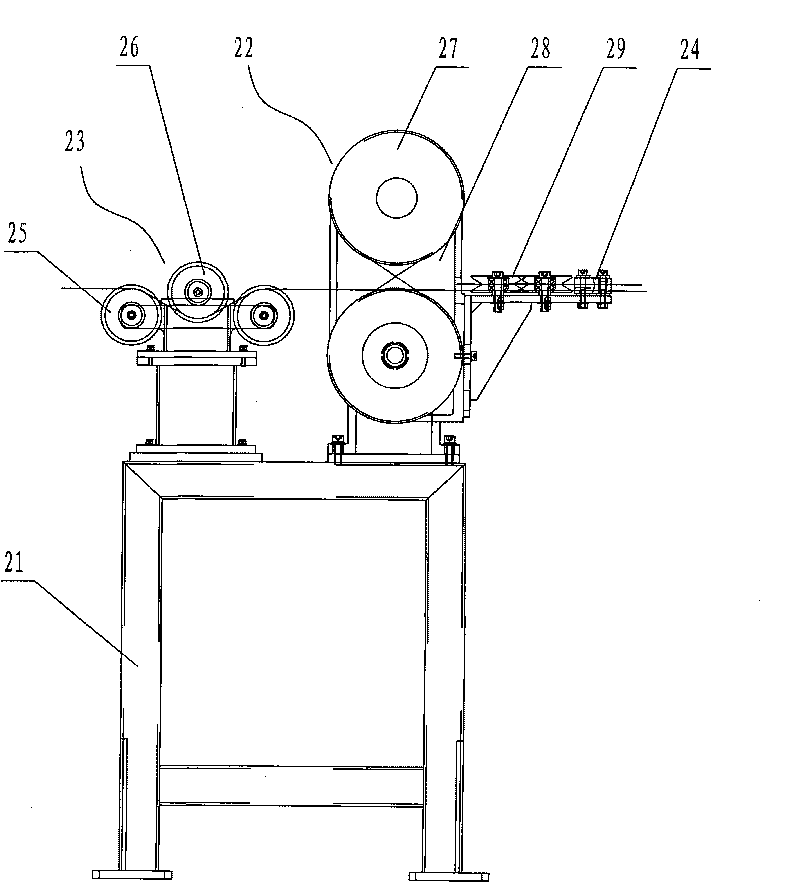

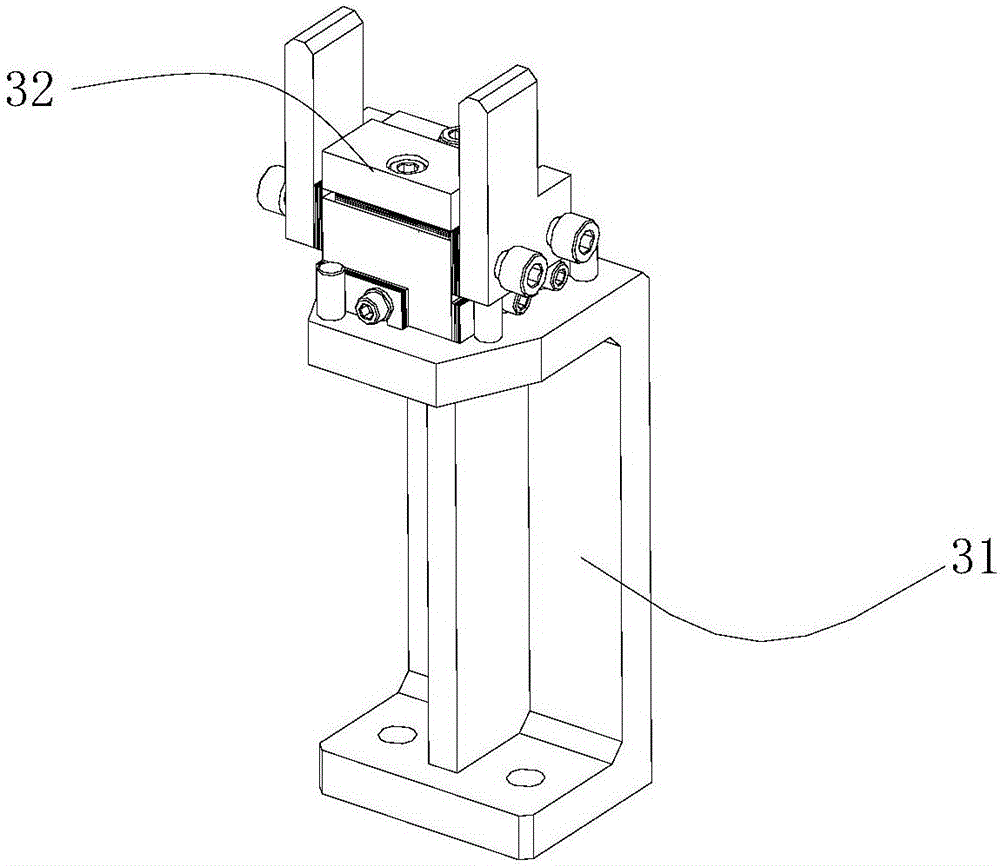

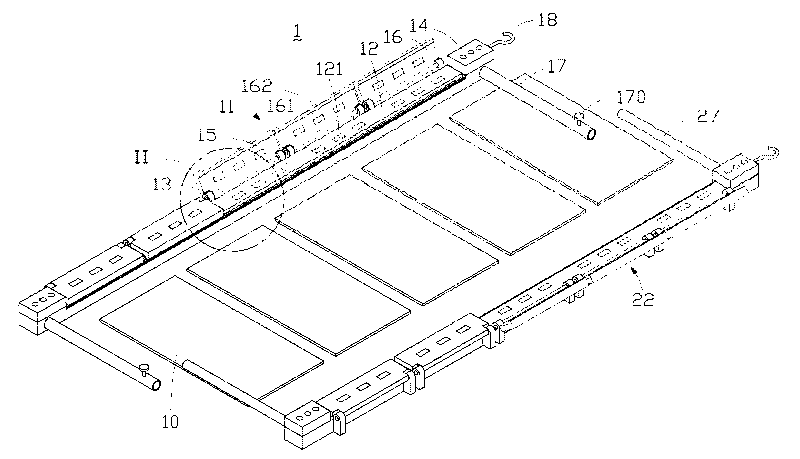

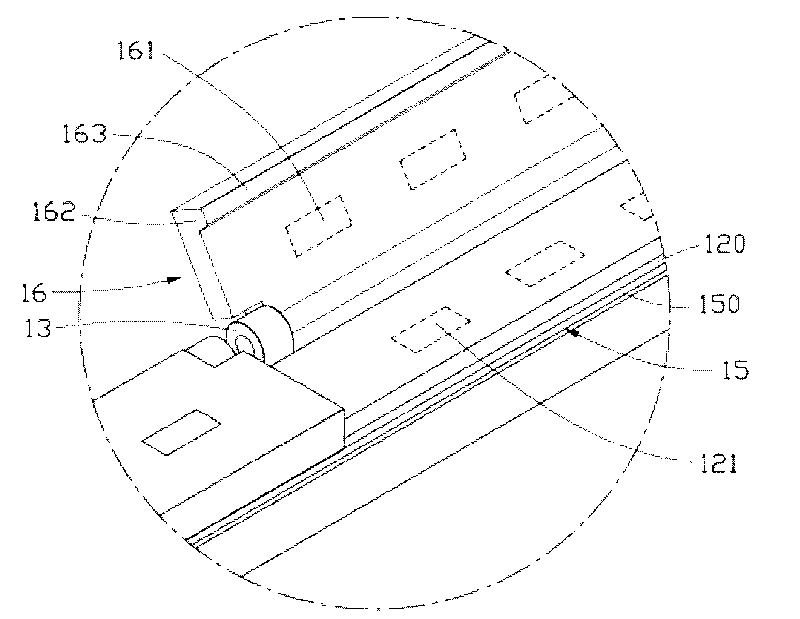

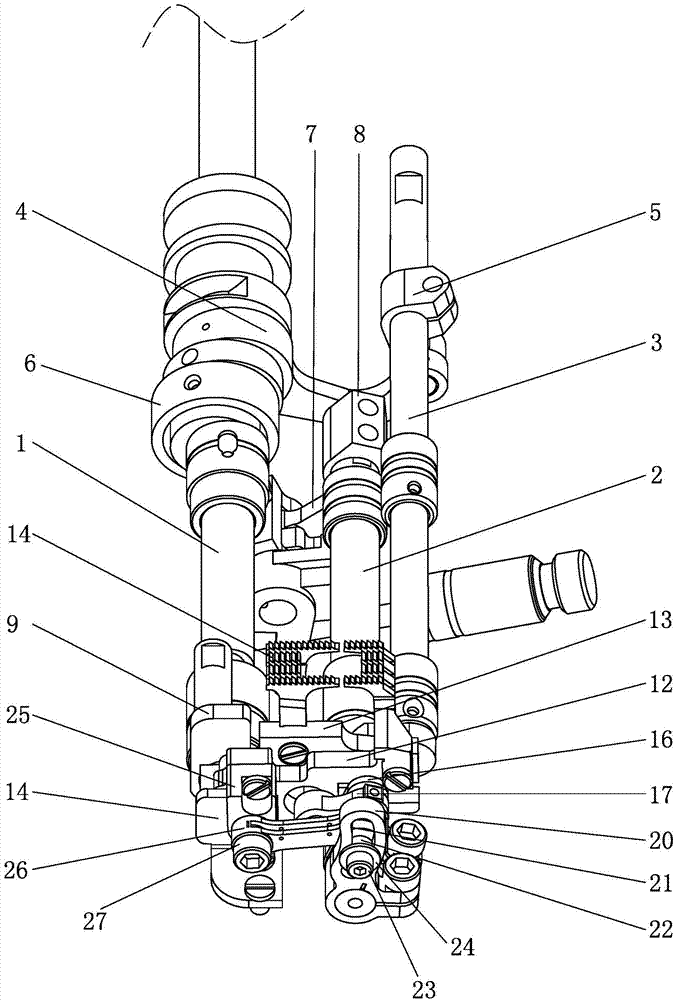

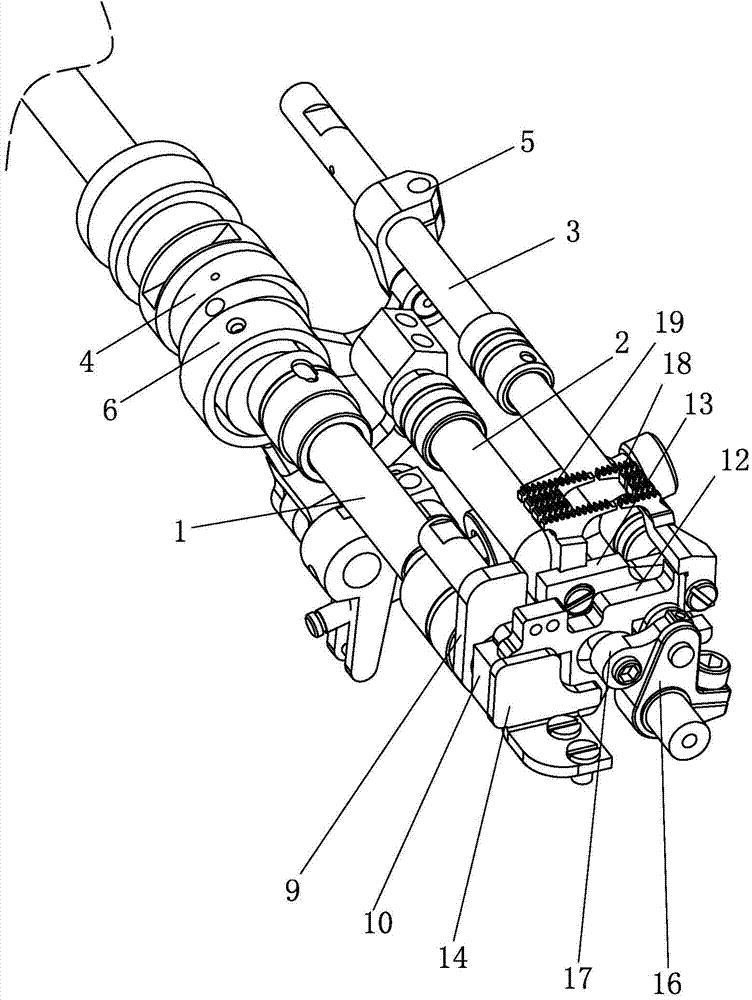

Double twisting rope laying machine

The invention discloses a double twisting rope laying machine which comprises a core wire laying machine, a core wire tension mechanism, a surface wire laying mechanism, a single wire pre-twisting machine, a wire collecting mechanism and a wire-rewinding machine arranged sequentially, wherein the core wire tension mechanism comprises a broken wire detecting device, a wire roller, a tension control device and a tension detecting device; the core wire output tension is detected by the tension detecting device, and if the tension exceeds a set tension range, the core wire output tension is adjusted by the tension control device to realize accurate control of the core wire laying tension; and the single wire pre-twisting machine comprises a motor, a transmission component and a plurality of groups of rotor components which are arranged at the front surface and the back surface of a stand. Through the rotation of each group of rotor components, the single wire pre-twisting process is realized and the single wire stress is eliminated, thereby being favorable to twisting and forming, and finally, the twisted cords have good straightness, stable residual torsion and high product quality and is difficult to loose; and the specifications of the producible cords are 3+9+15*0.22, 3+9+15*0.175 and 0.25+(6+12)*0.22.

Owner:江苏泰隆机电科技有限公司

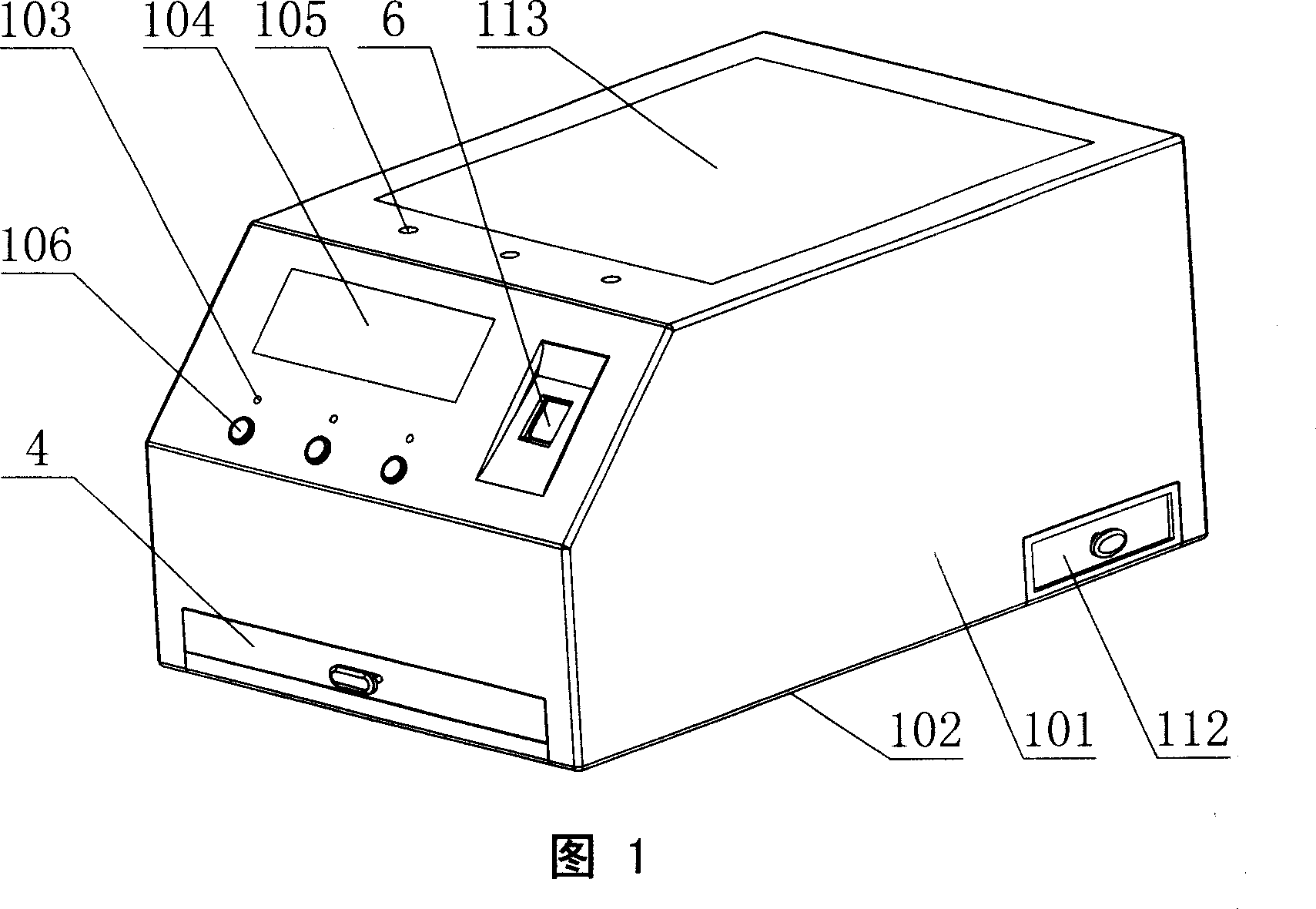

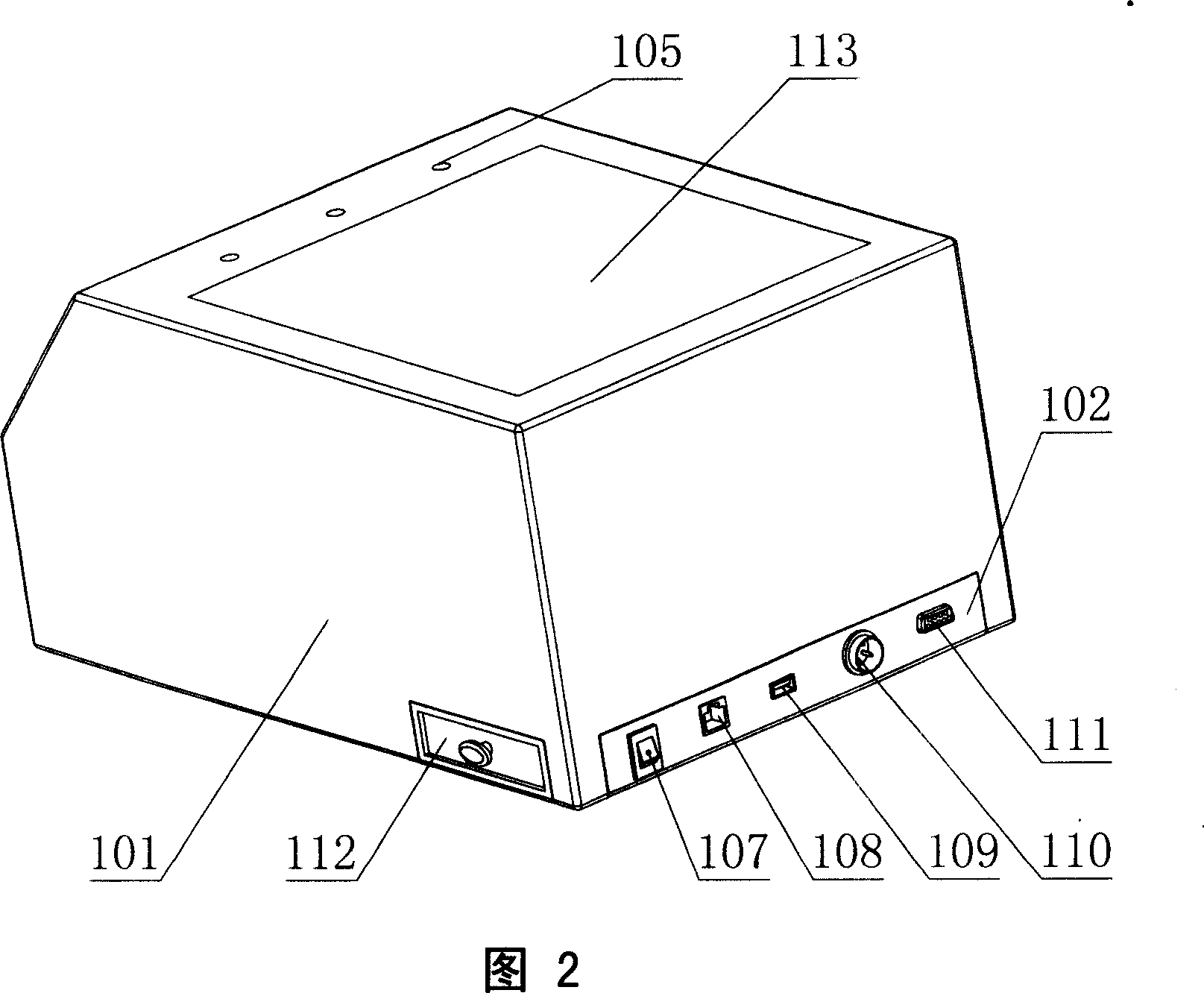

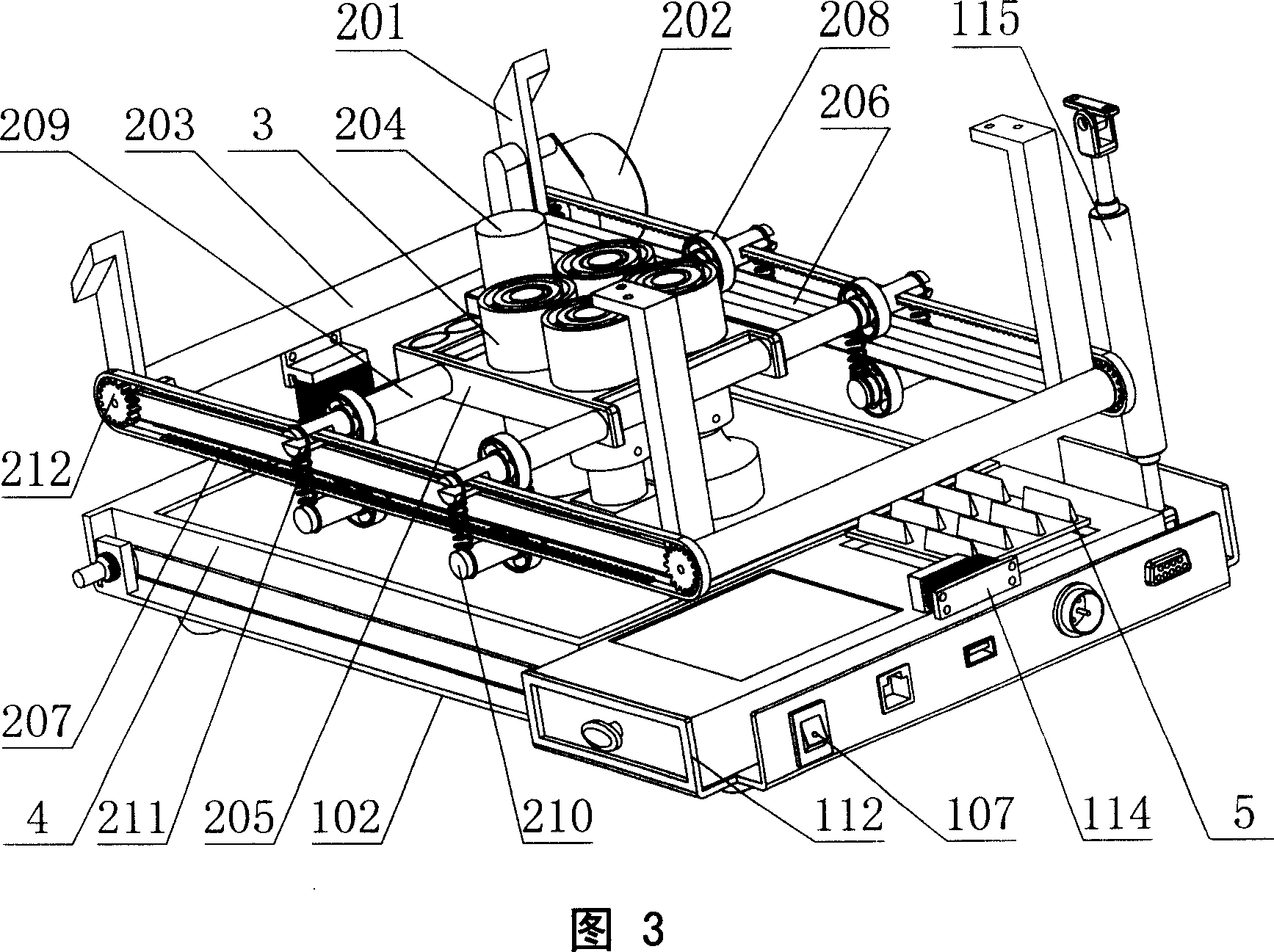

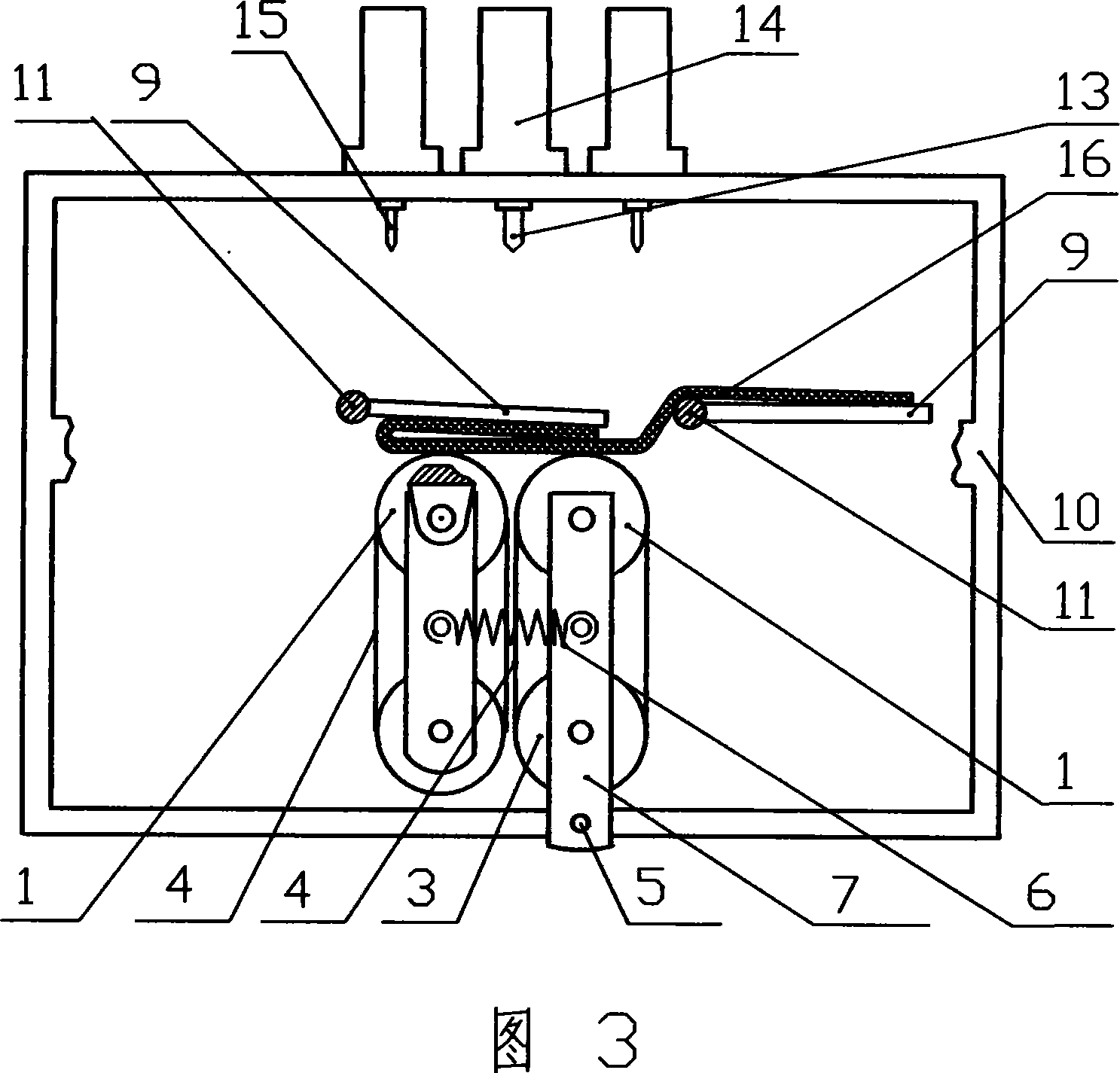

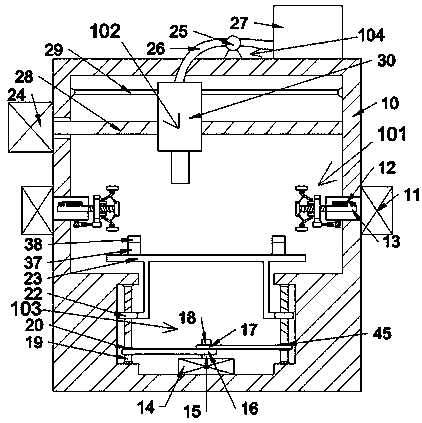

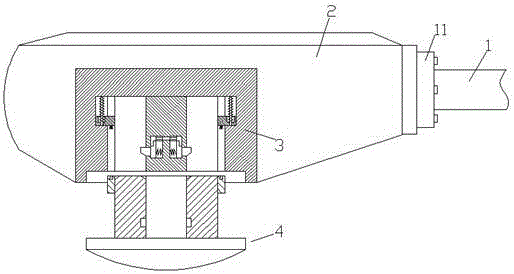

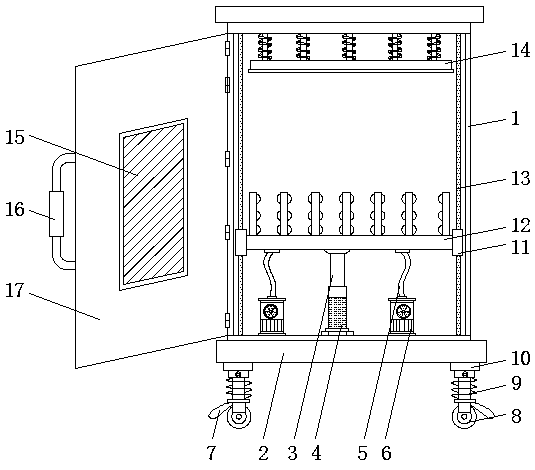

Remote-network signature apparatus

InactiveCN1948020APrevent illegal openingImprove securityStampingHydraulic cylinderElectromagnetic lock

A remote network seal-affixing device able to automatically affix seal under the control of remote signal and with high safety is composed of a box consisting of upper cover, main body, hydraulic cylinder, interface and electromagnetic lock, a sealing moving unit, a sealing holder, a document bearing tray, a seal destroyer, a recognizer, a projector, a camera head, and a control circuit.

Owner:张立安

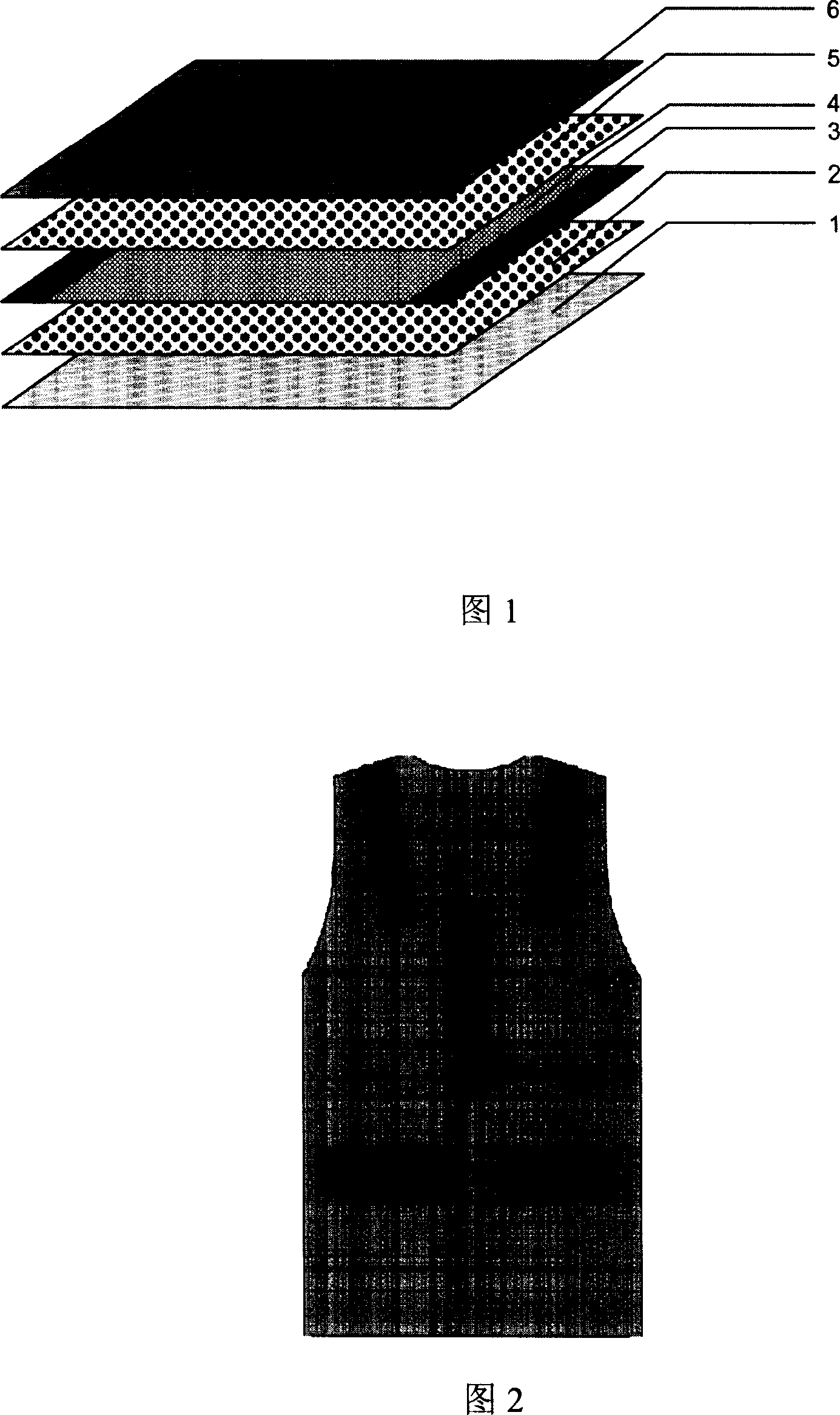

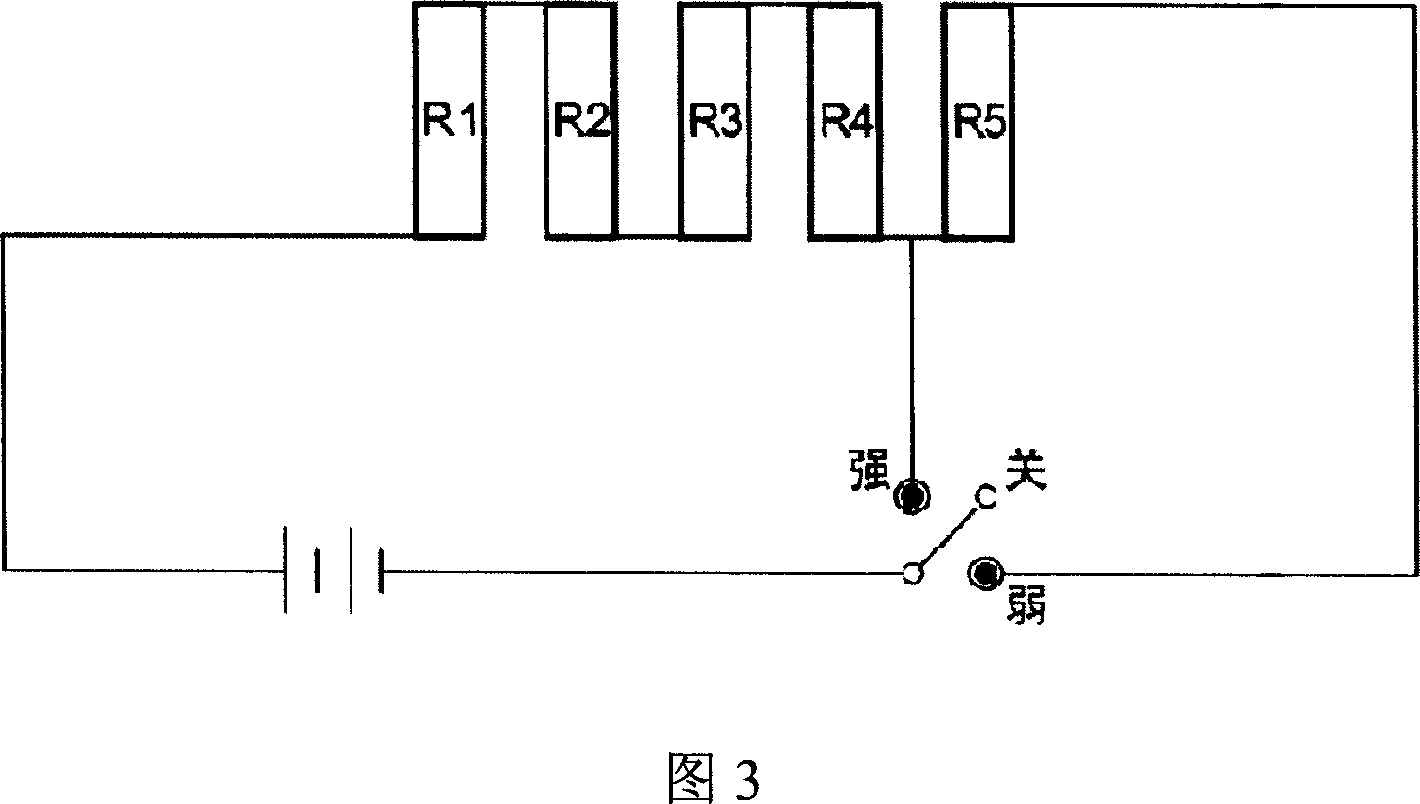

Far infrared flexible surface heating element with high emissivity

The invention discloses one high emission rate infrared flexible heating element, which comprises heat conductive isolation distribution layer, heat melt glue network film A, electrode, heating part, heat melt glue film B and isolation layer with each parts combined into one part by glue and sealing types. The invention also discloses the heating element main process and property and its process method.

Owner:DONGHUA UNIV +1

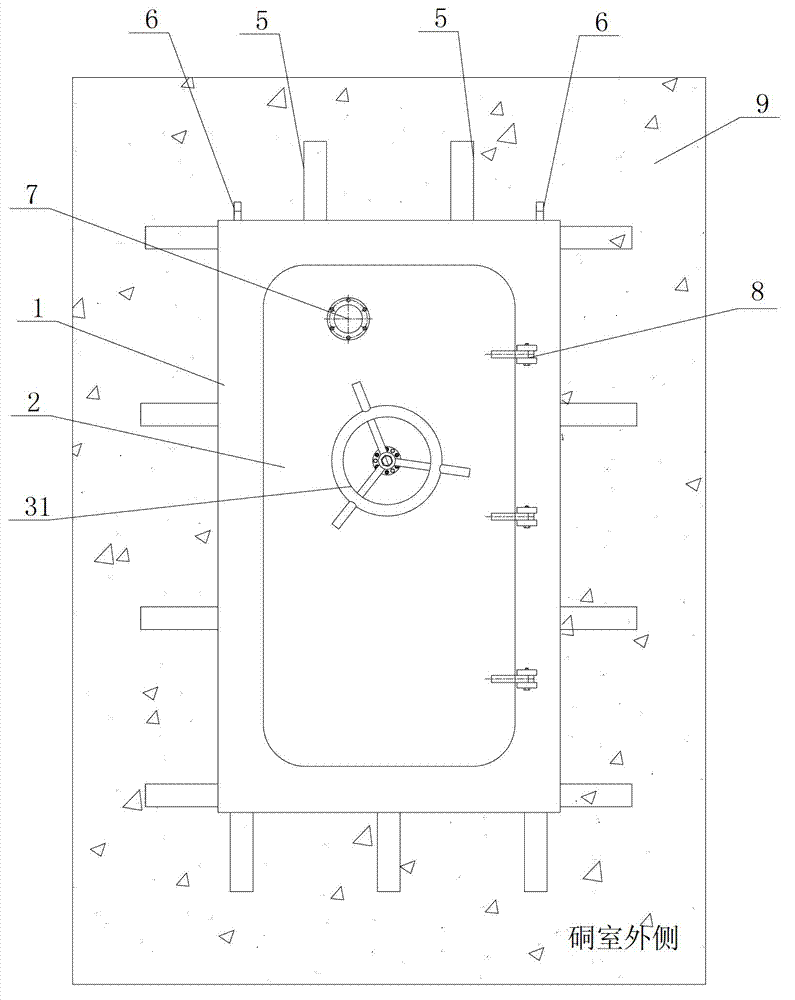

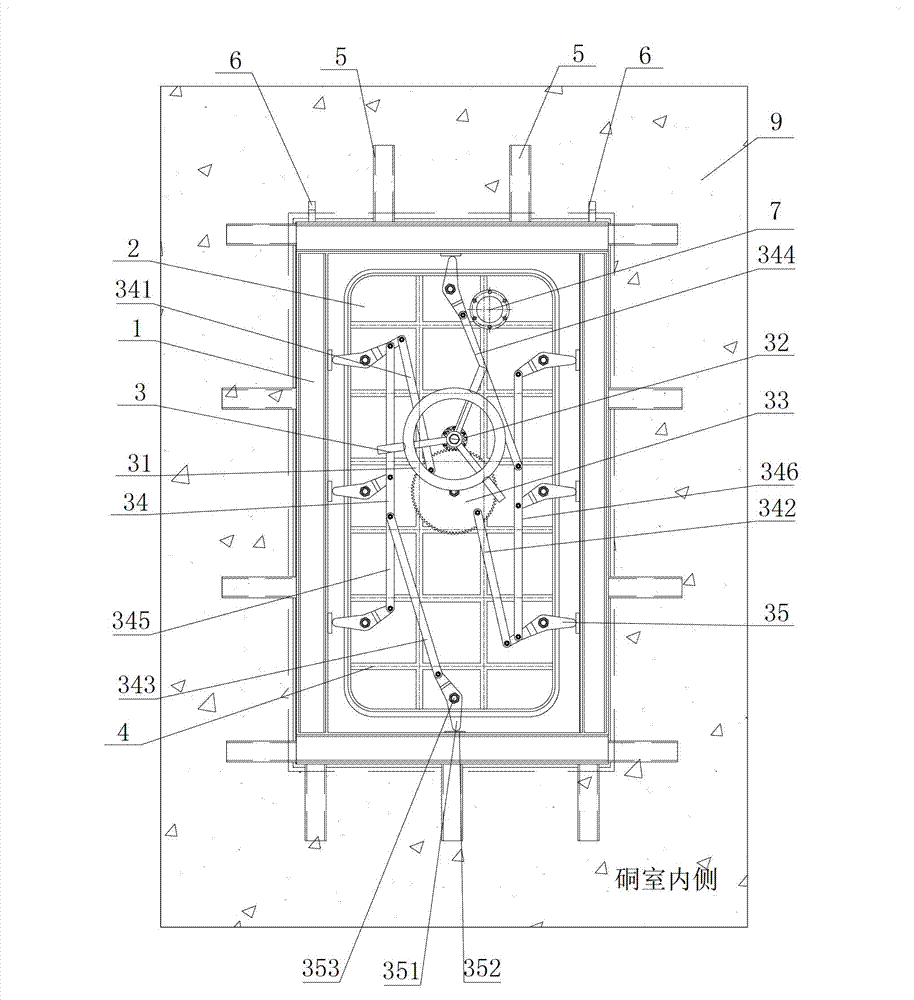

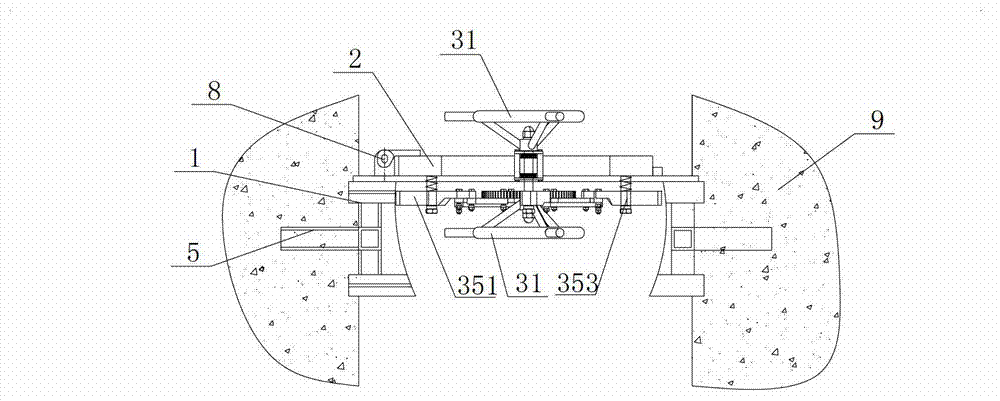

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

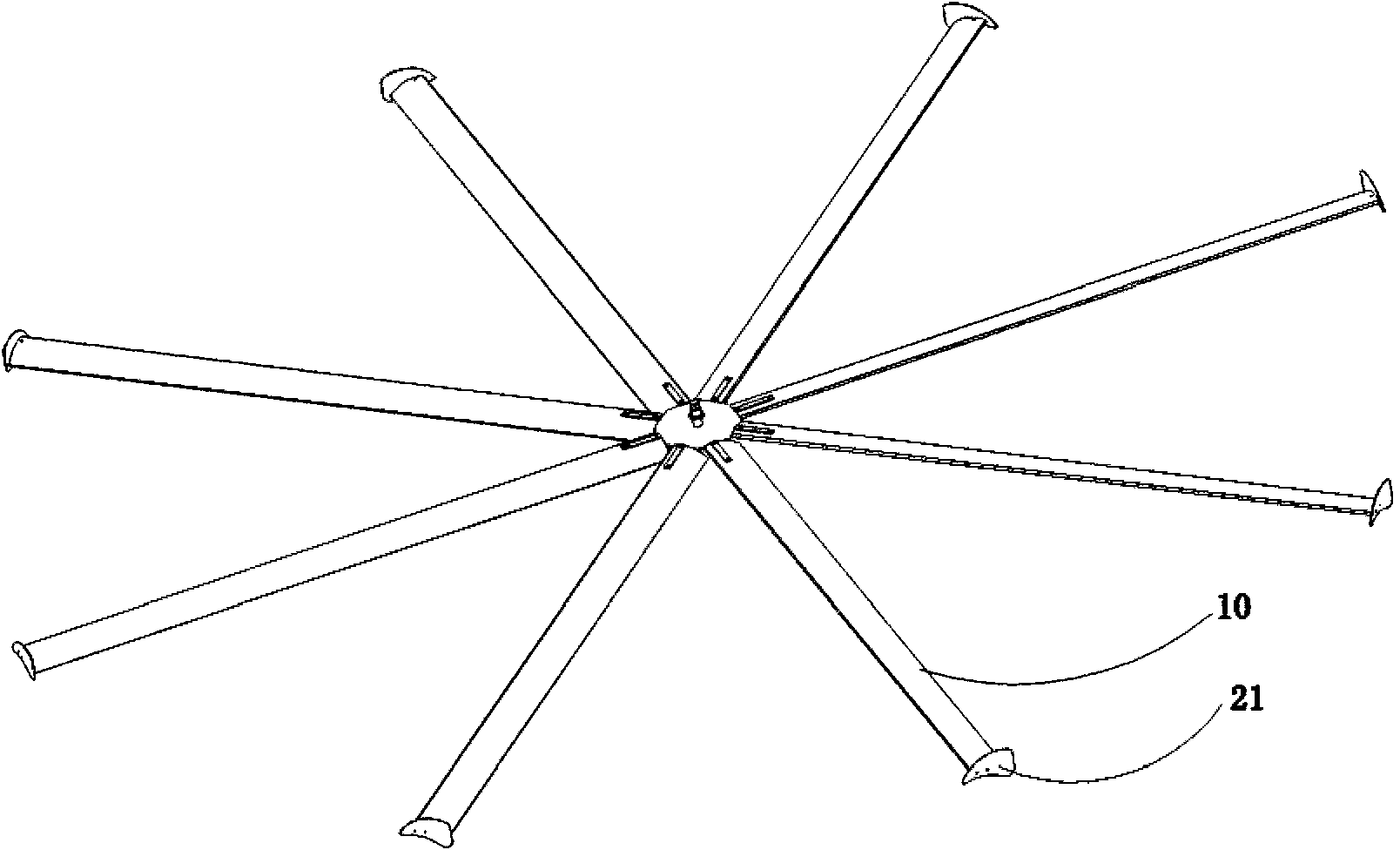

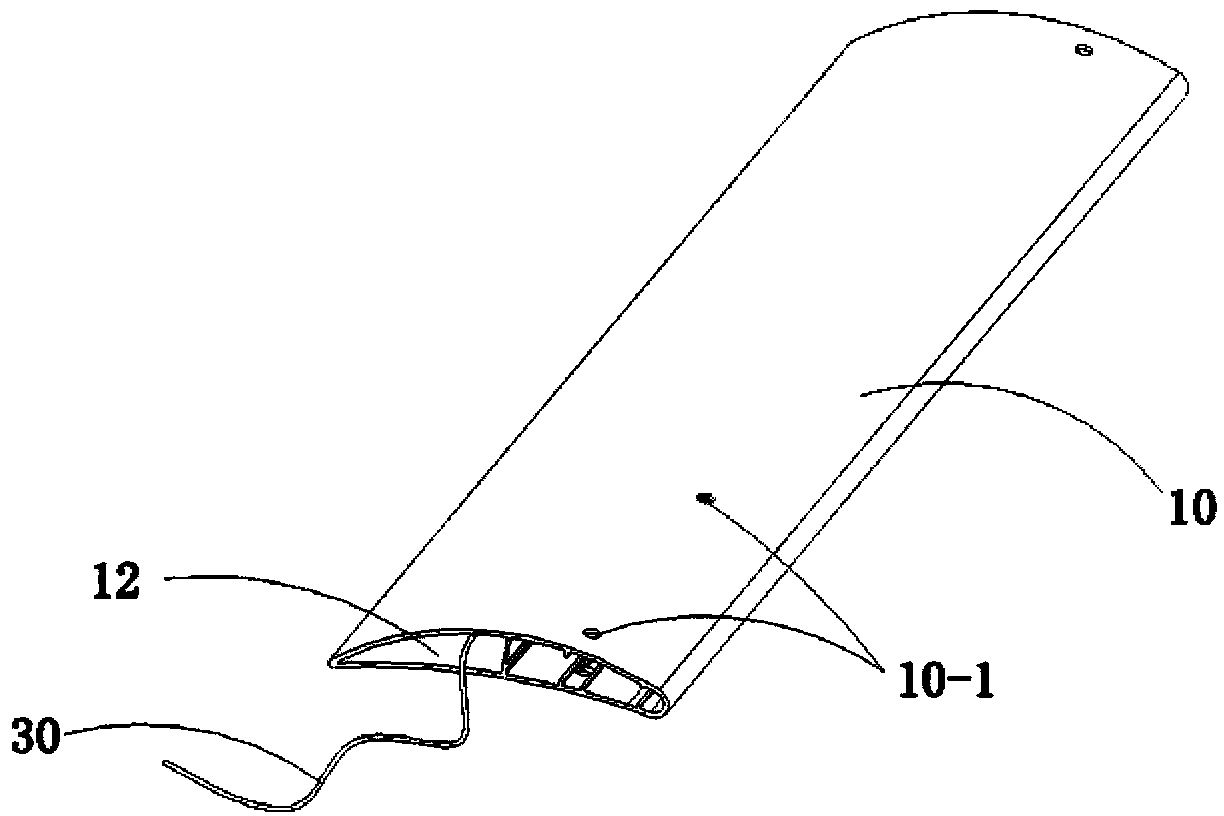

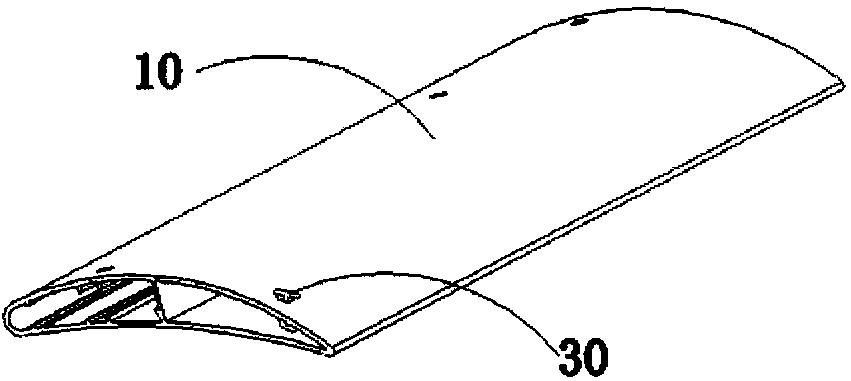

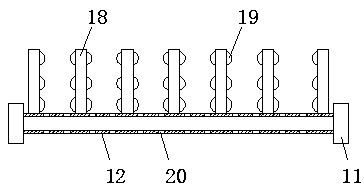

Fan blade

The invention relates to a fan blade which is provided with a fan blade body, wherein the fan blade body is strip-shaped and is hollow inside, the cavity is extended in the length direction of the fan blade body and penetrates through two ends of the fan blade body. The fan blade is characterized in that a plurality of pairs of ribs are arranged on the upper and lower sides of the head part of the fan blade body in the cavity and are provided with notches, all notches are opposite to form a clamping space capable of clamping plate-like bodies, and the fan blade body is provided with a plurality of installation through holes on the upper and lower wall surfaces of the position of the clamping space. According to the invention, the clamping space is used for clamping the plate-like fan blade frame, and the fan blade is tightly fastened by a bolt penetrating through the installation through hole and is hard to loose; furthermore, the fan blade is simple in structure and high in safety degree.

Owner:CHENZHOU ZHIZAO TECH CO LTD

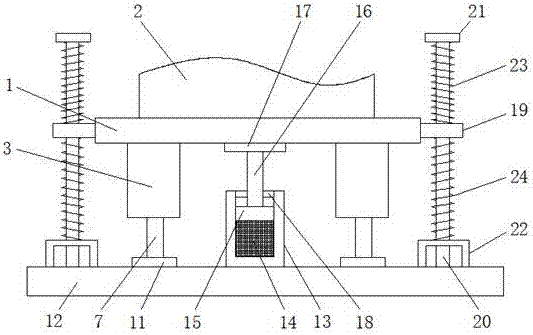

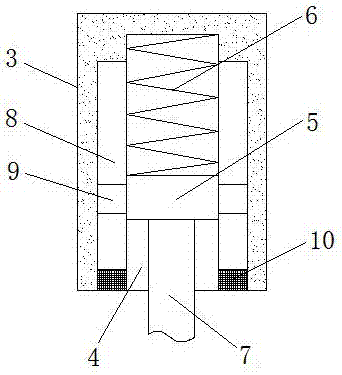

Compressor base

InactiveCN107035657AGood shock absorptionNot easy to loosePositive displacement pump componentsPositive-displacement liquid enginesPistonWork performance

The invention provides a compressor base, and relates to the field of compressors. The compressor base comprises a supporting plate, the top of the supporting plate is fixedly connected with the bottom of a compressor body, shock absorbers are fixedly installed at the four corners of the bottom of the supporting plate, holes are formed inside the shock absorbers, and pressing blocks are arranged inside the holes. According to the compressor base, a first spring, the pressing blocks, a pressing rod, hydraulic oil, a piston, a buffer rod, a guide rod, a second spring and a third spring are arranged, and the surface of the guide rod is sleeved with the second spring and the third spring, so that the supporting plate moves under the effect of the pressing rod and the pressing blocks, the effect of the buffer rod and the piston and the effect of the second spring and the third spring, well buffering and damping on the compressor body are achieved, the compressor body is not likely to loosen, noise increase cannot be caused, the working performance of the compressor body is not influenced.

Owner:浙江商业机械厂有限公司

Yoga rod and manufacturing method thereof

The invention discloses a yoga rod which comprises an outer cover and a core rod arranged in the outer cover. The outer cover is of a hollow cylindrical structure, the core rod is nested in the outer cover, and the outer cover is in interference fit with the core rod. The invention further discloses a method for manufacturing the yoga rod. The yoga rod and the manufacturing method for the yoga rod are provided. The yoga rod manufactured through the method is simple in structure and attractive in appearance; the manufacturing process is simple, work efficiency is greatly improved, and work cost is lowered.

Owner:PINGHU SHENGROUDE PLASTIC IND CO LTD

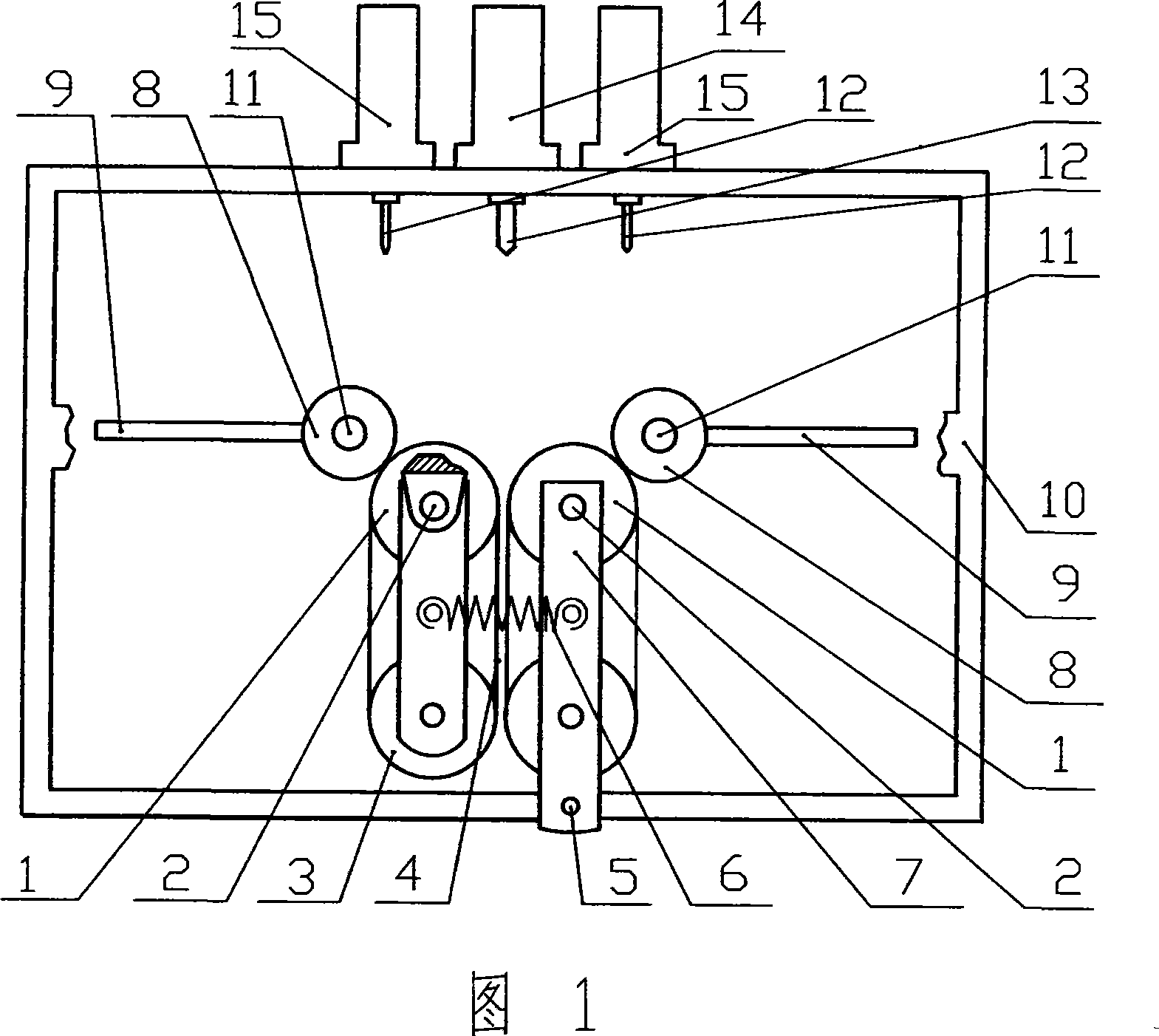

Plastic bag folding press

InactiveCN101134377ANot easy to looseNot easy to damagePaper-makingBox making operationsPlastic bagEngineering

The plastic bag folding machine includes one frame, two turnover boards, two pinching rolls, one inserting and folding board, and elastic pinching roll connecting unit. Its folding process includes the following steps: turning the two turnover boards successively toward the pinching roll by 180 deg to fold the plastic bag, shifting the inserting and folding board downwards to insert the folded plastic bag into between the pinching rolls until passing through the gap between two pinching rolls and to further fold the plastic bag. The present invention has high work efficiency.

Owner:王秀来

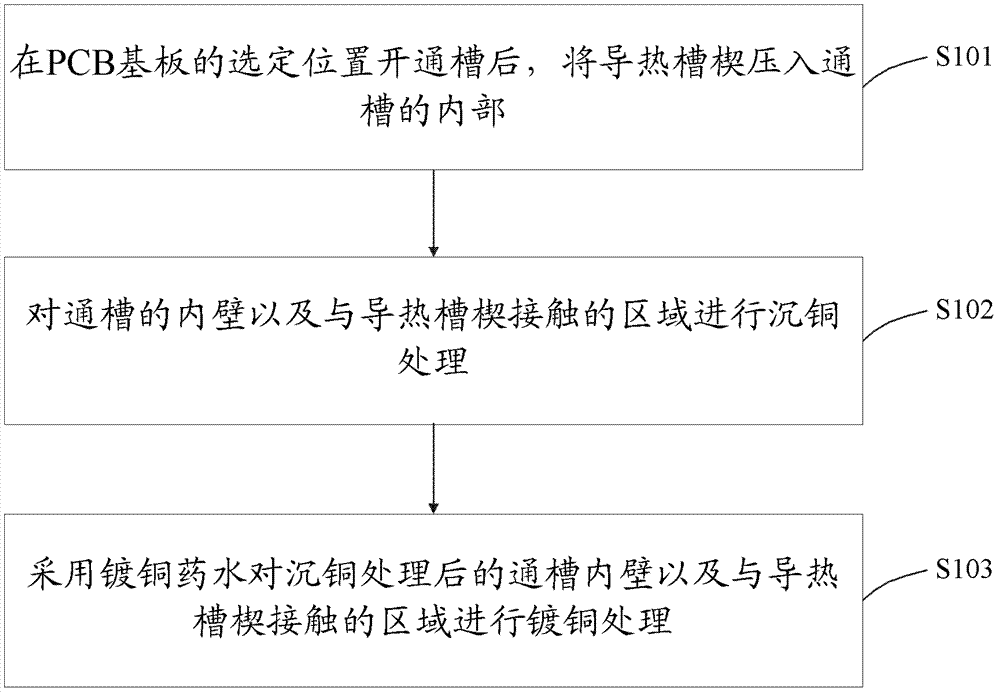

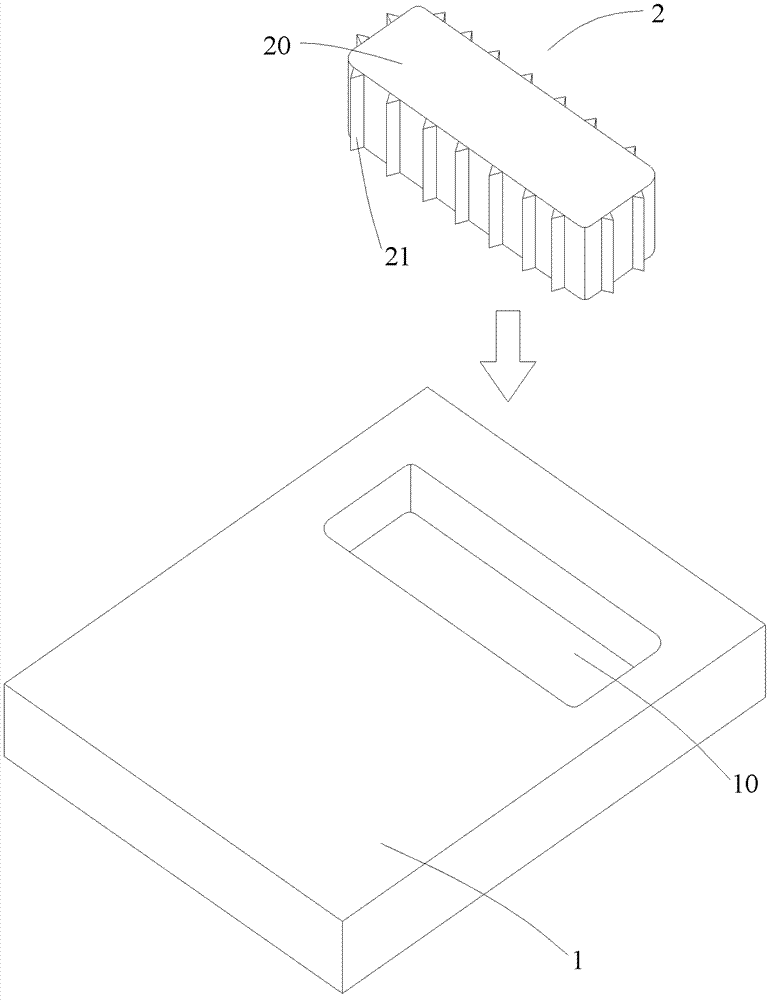

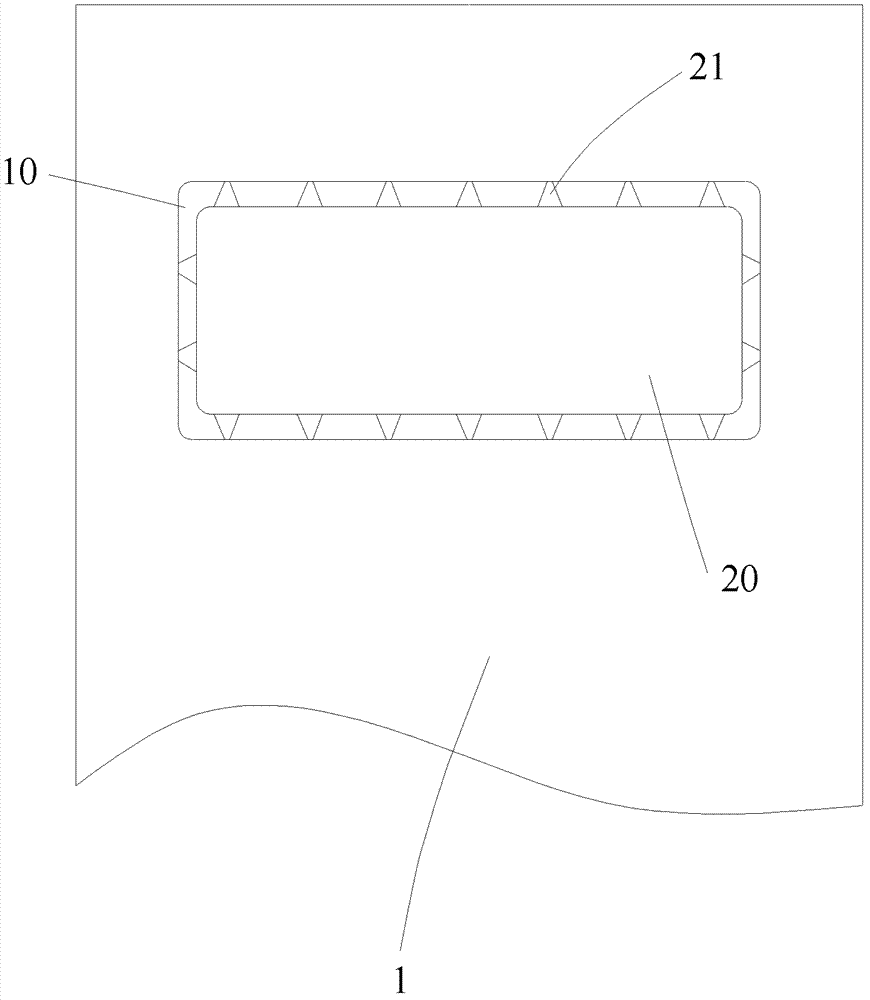

Press-in type high thermal conductive printed circuit board (PCB) and manufacture method thereof

ActiveCN103096638AShort processMake electrical connectionsPrinted circuit assemblingState of artCopper plating

The invention relates to the technical field of printed wiring board manufacture, in particular to a press-in type high thermal conductive printed circuit board (PCB) and manufacture method of the press-in type high thermal conductive PCB. The press-in type high thermal conductive PCB and the manufacture method of the press-in type high thermal conductive PCB are mainly used for solving the problems in the prior art that the connection between a press-in copper block and a PCB base plate is not firm, and looseness and even falling off of the press-in copper block is easy to happen in copper deposition and electroplating. The manufacture method of the press-in type high thermal conductive PCB comprises the steps: a through groove is formed in a chosen position of the PCB base board, a heat conductive slot wedge is pressed inside the through groove, copper deposition is conducted to the inner wall of the through groove and the contact area of the inner wall of the through groove and the heat conductive slot wedge, and copper plating is conducted to the inner wall of the through groove and the contact area of the inner wall of the through groove and the heat conductive slot wedge after copper deposition through copper plating liquid medicine. By means of the press-in type high thermal conductive PCB and the manufacture method of the press-in type high thermal conductive PCB, the technological process in high thermal conductive PCB manufacture is shortened, and the heat conductive slot wedge in a completed PCB is not easy to loosen.

Owner:NEW FOUNDER HLDG DEV LLC +1

Novel self-adaptive earmuff

ActiveCN105392080ANot easy to dropIncrease elasticityIntra aural earpiecesCharging attachments/accumulatorsEarmuffsEngineering

Owner:ZHONGMING DONGGUAN ELECTRONICS

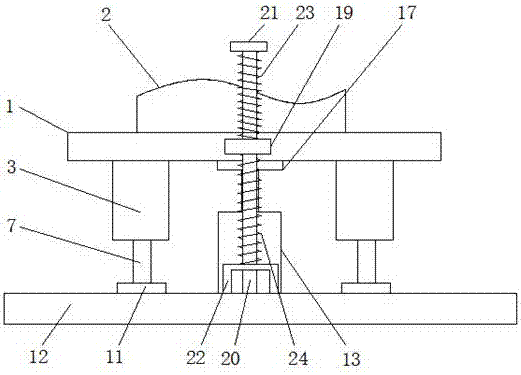

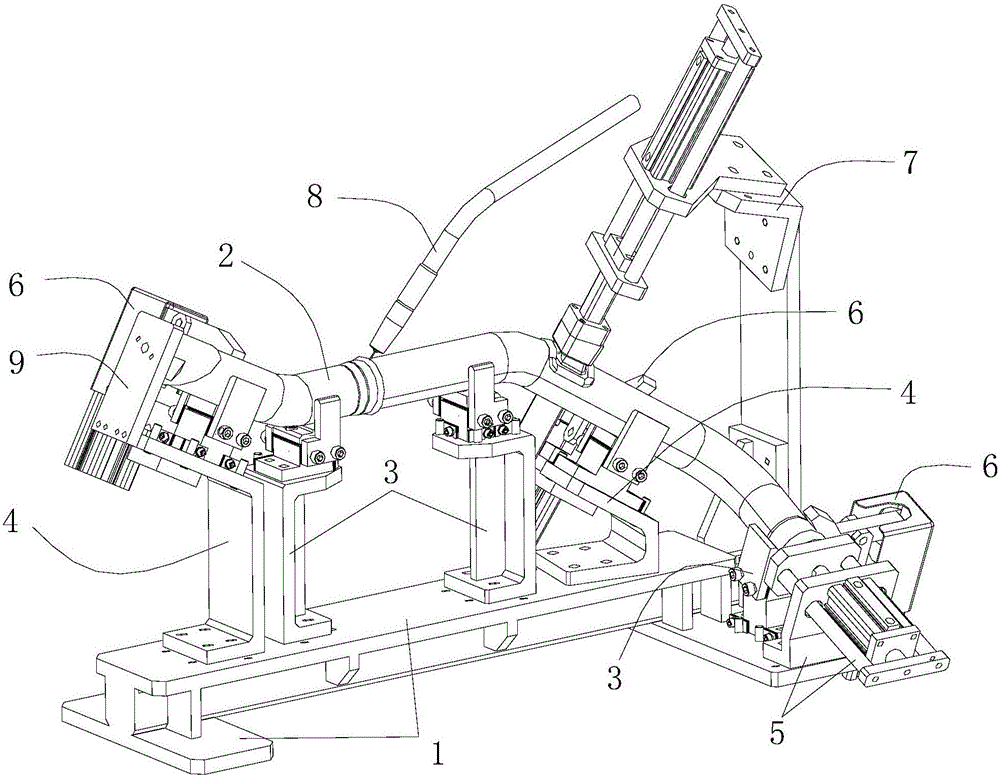

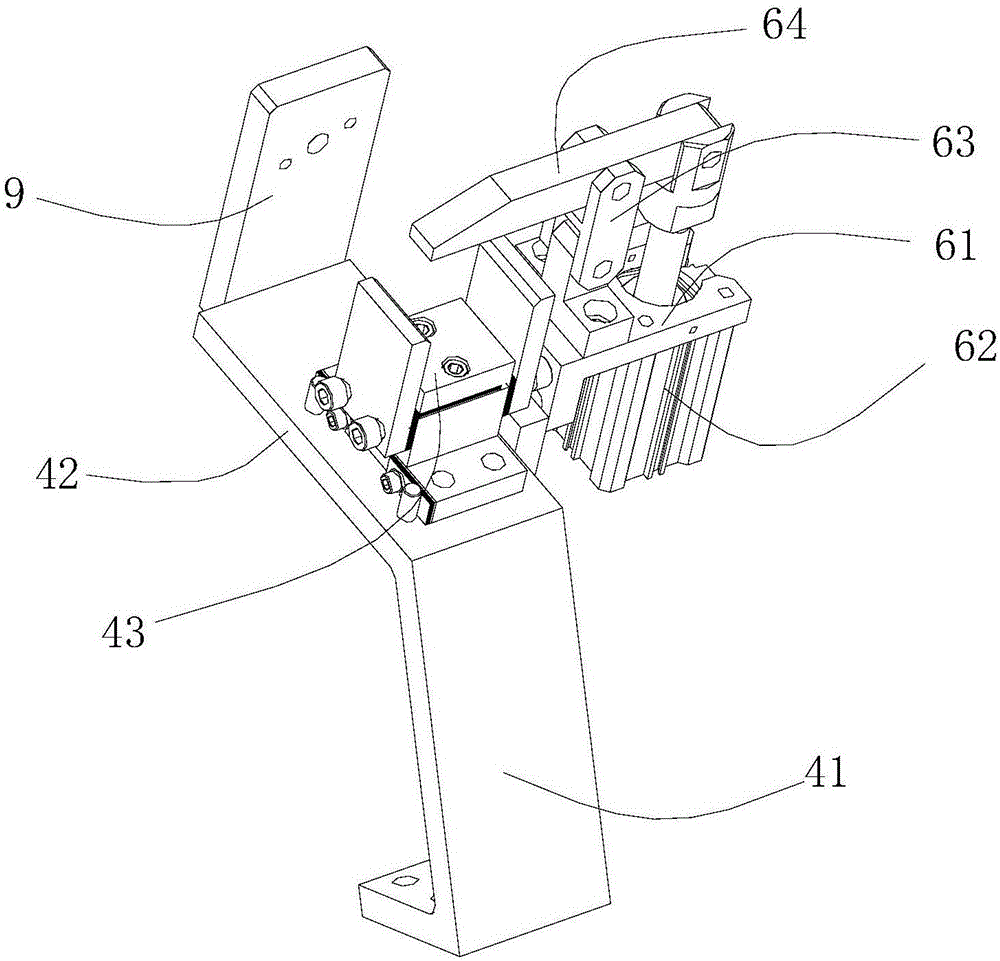

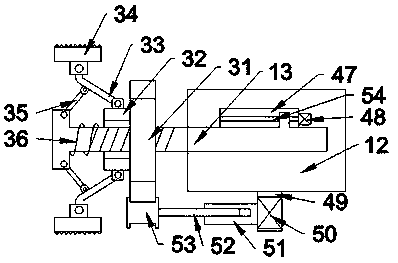

Welding device for special-shaped bent pipe

ActiveCN106514106APrecise positioningNot easy to moveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding device for a special-shaped bent pipe. The special-shaped bent pipe is installed on a working platform. The special-shaped bent pipe comprises a plurality of horizontal sections and a plurality of oblique sections. The horizontal sections are parallel to the working platform. An included angle is formed between each oblique section and the working platform. The welding device for the special-shaped bent pipe comprises at least one first supporting mechanism used for supporting the horizontal sections, at least one second supporting mechanism for supporting the oblique sections, a limiting mechanism used for limiting the movable end of the special-shaped bent pipe, at least one first clamping mechanism for clamping the special-shaped bent pipe, and a second clamping mechanism for clamping the middle portion of the special-shaped bent pipe. The welding device is simple in structure, the special-shaped bent pipe is clamped and positioned, looseness and displacement are not likely to happen, the welding precision of the special-shaped bent pipe is effectively guaranteed, welding application of a welding machine is facilitated, the welding and assembling efficiency is improved, welding errors are reduced, and the welding quality of products is improved.

Owner:景和智能制造(广东)有限公司

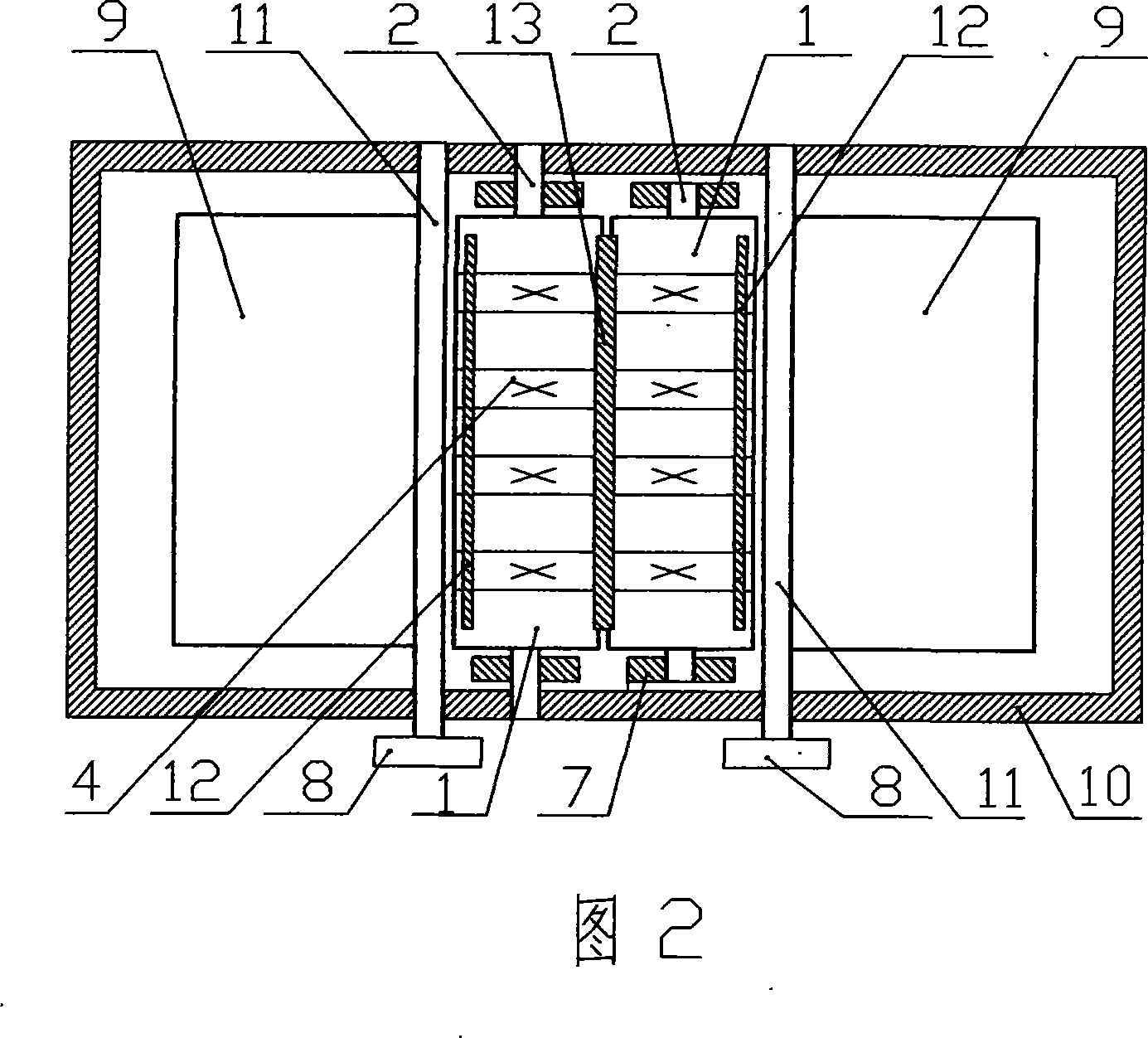

Electroplating clamp for printed circuit board (PCB)

ActiveCN101713094ANot easy to looseAvoid damageElectrolysis componentsEngineeringPrinted circuit board

The invention provides an ultrathin magnetic fixed type electroplating clamp for a printed circuit board (PCB), which is used for clamping the PCB. The electroplating clamp for the PCB comprises a first clamping part, wherein the first clamping part comprises a main body and a clamping cover; the main body comprises a first magnet; the clamping cover comprises a second magnet; and the first magnet and the second magnet mutually attract to enable the main body and the clamping cover to together clamp the edge of the PCB. The electroplating clamp for the PCB of the invention can prevent electroplated components from being damaged, can increase the electroplating uniformity and can improve the production efficiency.

Owner:SHENZHEN WUZHU TECH

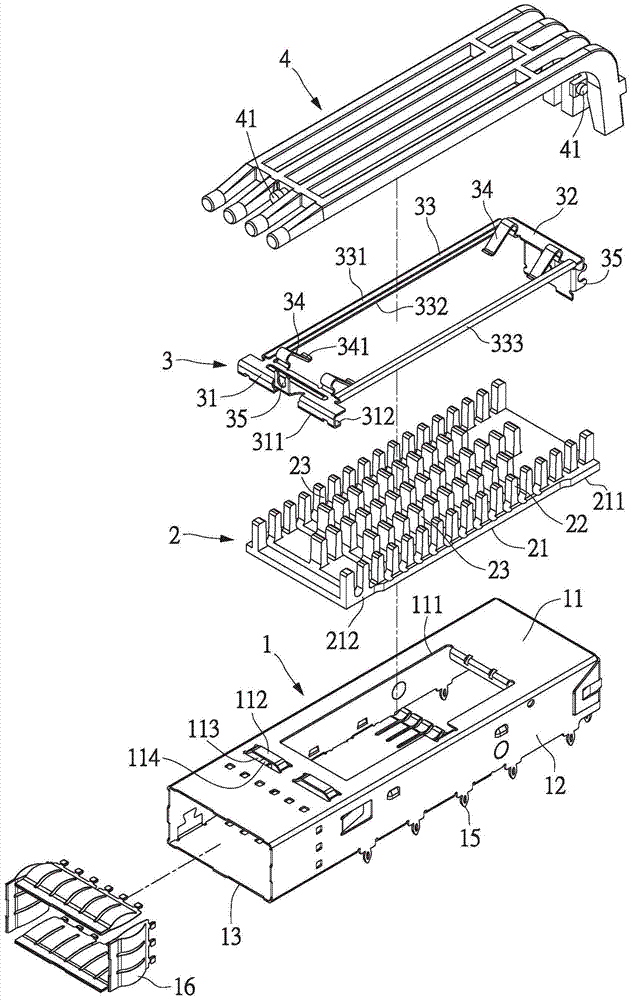

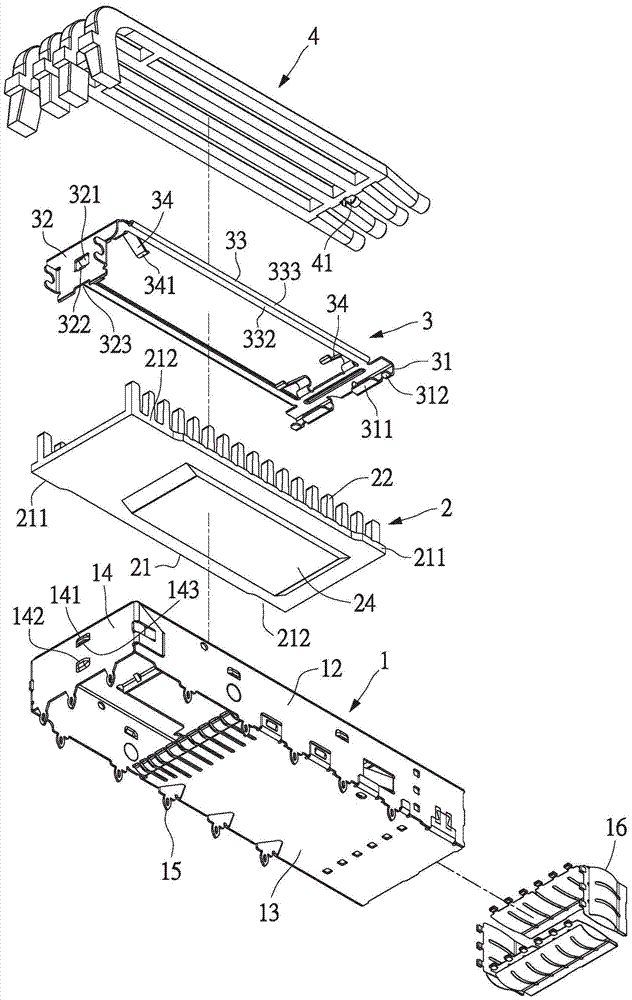

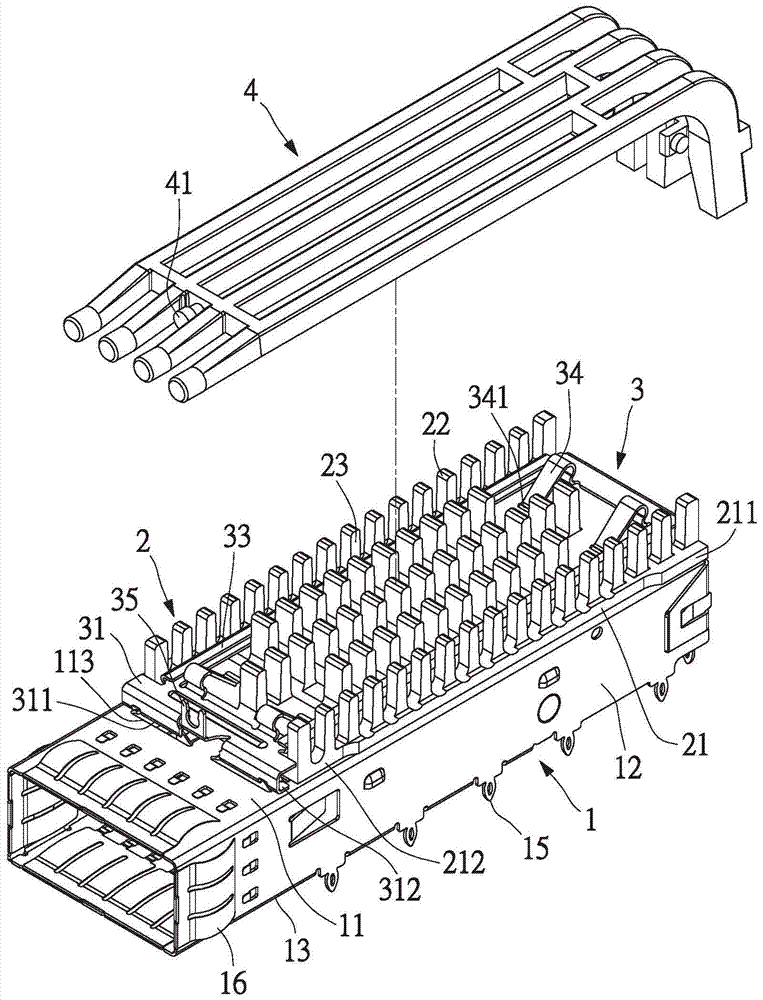

Connector housing heat radiation structure

ActiveCN106990488ANot easy to looseImprove shielding effectCoupling light guidesCooling/ventilation/heating modificationsHeat sinkRadiation

A connector housing heat radiation structure comprises a housing, a heat radiating plate and a buckling member. The first end of the buckling member is buckled and fixed with the top plate of the housing by means of a first tongue plate and a buckling plate, thereby reducing area of an opening on the top plate, and realizing relatively high EMI shielding effect. Two connecting arms of the buckling member penetrate through grooves in the heat radiating plate. Width of the heat radiation plate is not limited, and heat radiation area of the heat radiating plate can be increased. The second end of the buckling member is provided with a second tongue plate which is inserted into a bump at the back cover of the housing. Furthermore through making the abutting end of the second end abut against a backstop part, no easy loosening of the buckling member is realized. The buckling cannot be damaged in bearing pressing by a certain external force.

Owner:NEXTRONICS ENG CORP

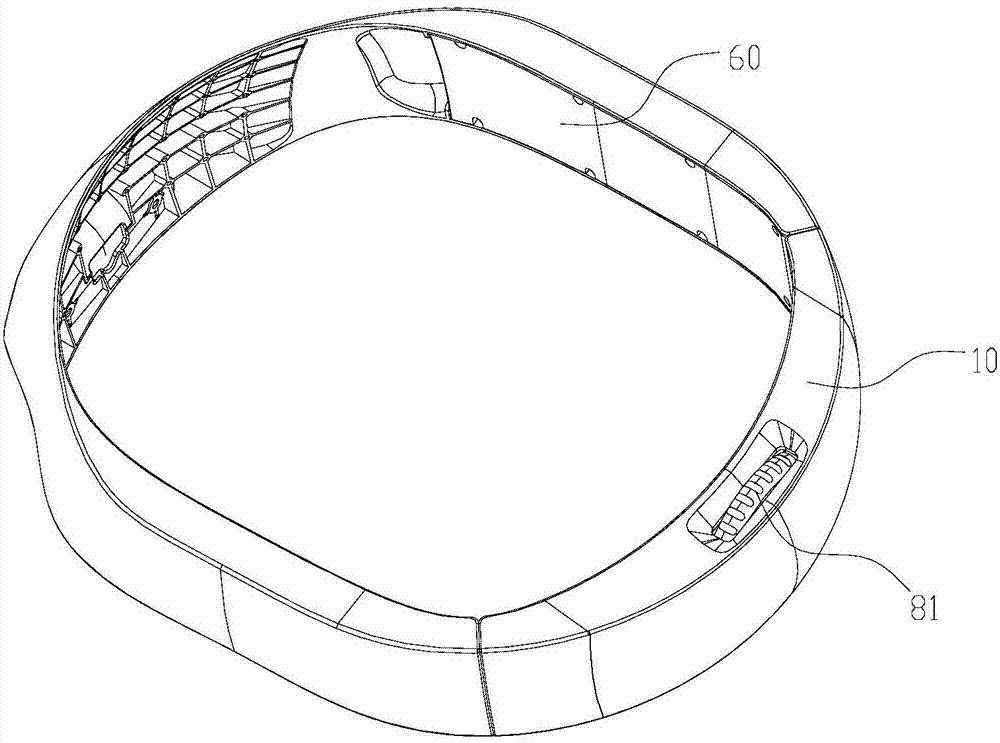

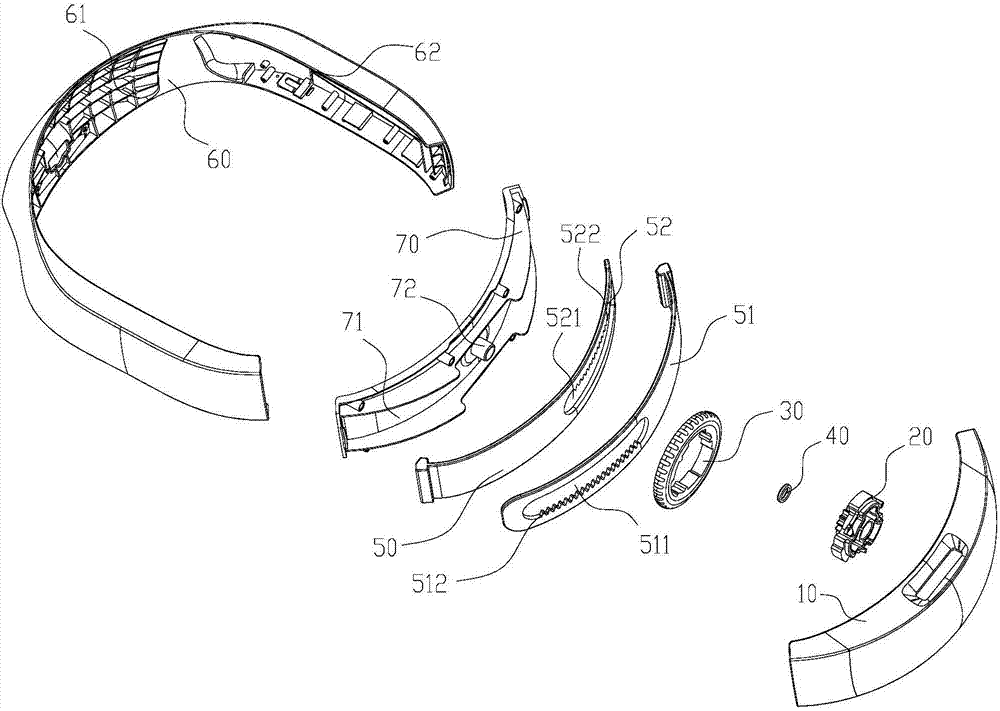

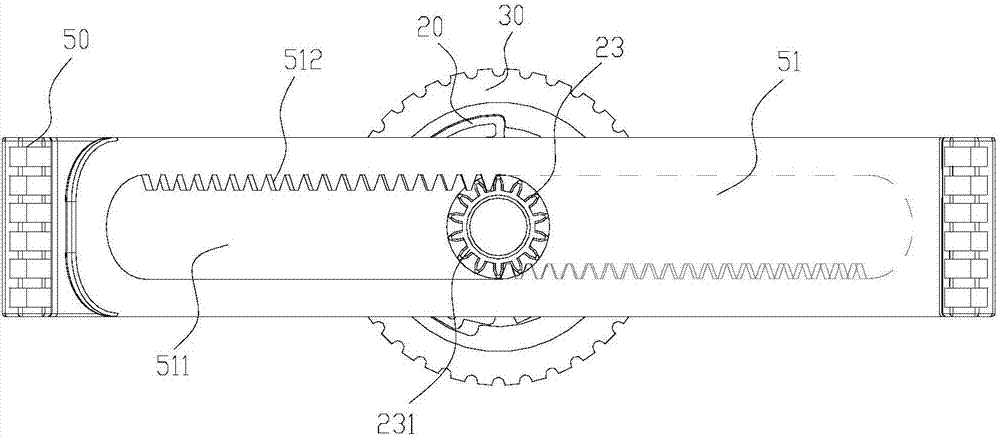

Head belt adjusting device for video glasses, head belt and video glasses

ActiveCN107076995AStable positionReduce sizeMachine supportsDetails for portable computersMechanical engineeringLinkage concept

The invention provides a head belt adjusting device for video glasses, a head belt and video glasses, wherein the head belt adjusting device comprises the components of a mounting seat (10) which is provided with an inner ratchet wheel (11); a linkage member (20) which is mounted on the mounting seat (10) and is provided with a transmission part (23) and at least one spacing part (21) with elasticity, wherein at least one spacing part (21) abuts against ratchet teeth (111); a dial wheel (30) which drives the linkage member (20) to rotate, the ratchet wheel (30) is provided with a disengagement part (31), wherein the dial wheel (30) rotates to one side, the disengagement part (31) abuts against the spacing part (21) so that the spacing part (21) is disengaged from locking to the inner ratchet wheel (11), when the dial wheel (30) rotates to the other side, the spacing part (21) rotates along the inner ratchet wheel (11); and a transmission mechanism (50) which is in transmission matching with the transmission part (23), wherein the linkage member (20) is used for driving the transmission mechanism (50) and drives the head belt to be expanded or folded.

Owner:SZ DJI TECH CO LTD

Sewing machine feeding mechanism

ActiveCN104775236ANot easy to looseSimple structureWork-feeding meansControl theoryDifferential motion

The invention belongs to the technical field of sewing machines and particularly relates to a sewing machine feeding mechanism. A feed lifting crank is arranged at the front end of a lower main shaft. Sliding blocks are fixedly arranged on the lower main shaft. Feed lifting sliding blocks are arranged on the feed lifting shaft. Sliding grooves are formed in the left ends and the right ends of a differential motion tooth frame and a main cloth feeding tooth frame. The sliding blocks and the feed lifting sliding blocks are arranged in the sliding grooves in the two ends of the differential motion tooth frame and the two ends of the main cloth feeding tooth frame. Tooth frame blocking plates are arranged on the front sides of the sliding blocks. The tooth frame blocking plates are in contact connection with the differential motion tooth frame. A first differential motion crank fixed on a differential motion shaft is arranged on the front side of the differential motion tooth frame. The feed lifting crank, the tooth frame blocking plate, the first differential motion crank and the feed lifting shaft press and limit the main cloth feeding tooth frame and the differential motion tooth frame. The first differential motion crank is connected with the main cloth feeding tooth frame through a differential motion connecting rod. Differential motion teeth are arranged on the differential motion tooth frame. Cloth feeding teeth are arranged on the main cloth feeding tooth frame. By two-end clamping limiting, the differential motion tooth frame cannot be loosened even after long-time using.

Owner:JACK SEWING MASCH CO LTD

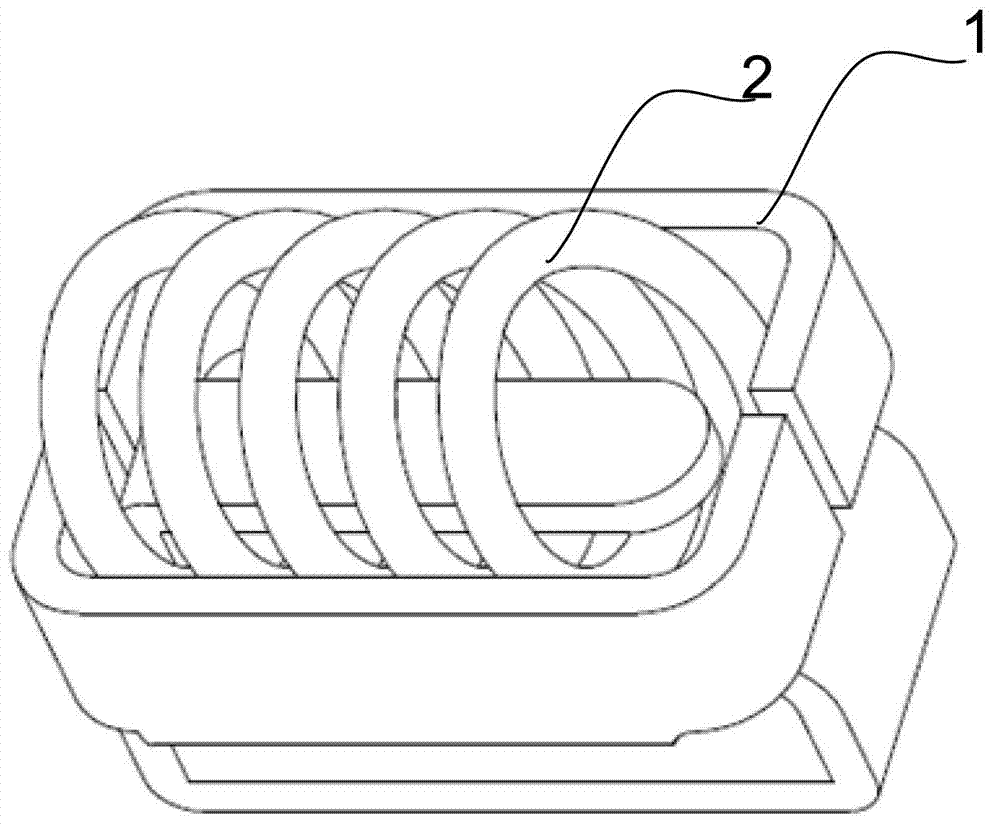

Conductive terminal, circuit board with same and plate-to-plate connector

InactiveCN102810782AIncrease touch pointsReliable contactCoupling contact membersFixed connectionsBoard-to-board connectorEngineering

An embodiment of the invention discloses a conductive terminal, a circuit board with the same and a plate-to-plate connector. The conductive terminal comprises a substrate and a spring contact; the substrate comprises a closed end and an open end, and a fixed rib extending out of the closed end points to the open end; two sides of the opened end can be bent and closed after the spring contact is sleeved on the rib; the spring contact comprises a unit ring which is formed by spirally surrounding a spring wire along an oblique elliptical trace and then spirally winding along an axis in two directions; and the periphery of the unit ring of the spring contact electrically contacts the circuit board connected with the conductive terminal. The closed end and the open end form a placing area of the conductive terminal, so that the conductive terminal is difficult to loose even if electronic and electric equipment shakes or vibrates. The spring contact is provided with multiple contact points, so that the conductive terminal is ensured to reliably be in contact with the circuit board and a contact circuit.

Owner:深圳市簧中簧电子有限公司

Automatic packer of steel pipe

InactiveCN102633011AEasy to operateReduce labor intensityBundling machine detailsEngineeringPipe support

The invention relates to an automatic packer of a steel pipe, comprising a machine seat, a steel pipe support, a fixing arm, an overturning arm and an overturning driving mechanism, wherein the steel pipe support is arranged at the middle part of the machine seat, the fixing arm is vertically arranged on the machine seat on one side of the steel pipe support, the overturning arm is arranged on the machine seat on the other side of the steel pipe support, the lower end of the overturning arm is rotatably arranged on the machine seat through a swinging shaft, the swinging shaft of the overturning arm is driven by the overturning driving mechanism at the lower part of the machine seat, and a pressing mechanism is arranged on the fixing arm and is also arranged on the overturning arm. The automatic packer disclosed by the invention is designed scientifically and reasonably, overcomes the defects of wasting time and labor in a traditional manual binding manner, has the advantages of high automatic degree and efficiency, low labor strength, low possibility of baling off and attractive appearance, completely liberates an operator from a complex operation of packing the steel pipes and also has higher innovativeness.

Owner:天津市友发德众钢管有限公司

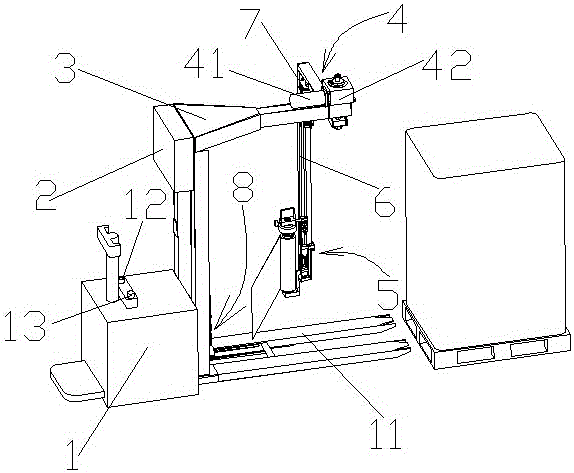

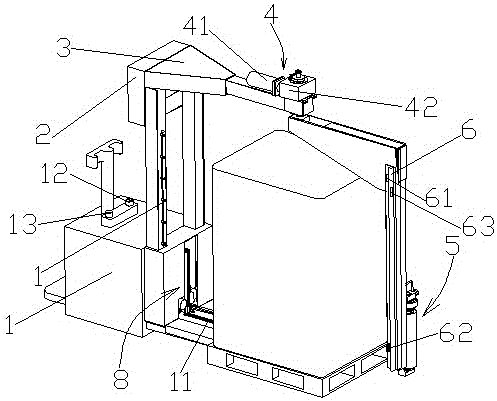

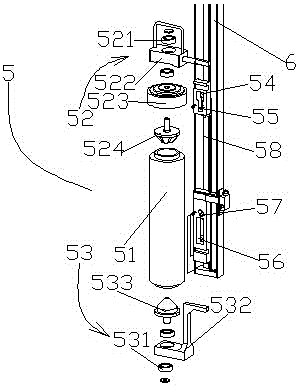

Mobile film winding machine

PendingCN105775196AControllable tensionIncrease profitWrapping material feeding apparatusWeb rotation wrappingWinding machineMotor drive

The invention discloses a mobile film winding machine which comprises a forklift body, an electric cabinet, a fixed support frame, a rotating mechanism, a film tension control mechanism, a film up-and-down moving frame, a film up-and-down moving motor and a film cutting and pressing mechanism, wherein the rotating mechanism is arranged at the tail end of the fixed support frame; the film up-and-down moving frame is movably arranged on the fixed support frame; the film tension control mechanism is arranged on the film up-and-down moving frame; the film up-and-down moving motor drives the film up-and-down moving frame to rise and fall; and the film cutting and pressing mechanism is arranged on the fixed support frame. According to the mobile film winding machine, a mobile forklift is adopted, a film is rotated upwards and wound around cargo through the rotating mechanism and a lifting mechanism, the winding efficiency is high, and the use of the mobile film winding machine is not limited and is convenient; manual operation is not needed, so that the labor intensity of workers is low, and the labor cost is saved; the film tension is controllable, the packing effect is better, and the cargo cannot become loose easily; the cargo does not need to be rotated, so that a great amount of electric energy is saved; and meanwhile, the height of the cargo is detected through photoelectricity, the utilization ratio of the film is high, and the use cost of the film is low.

Owner:北京小棉医药有限公司

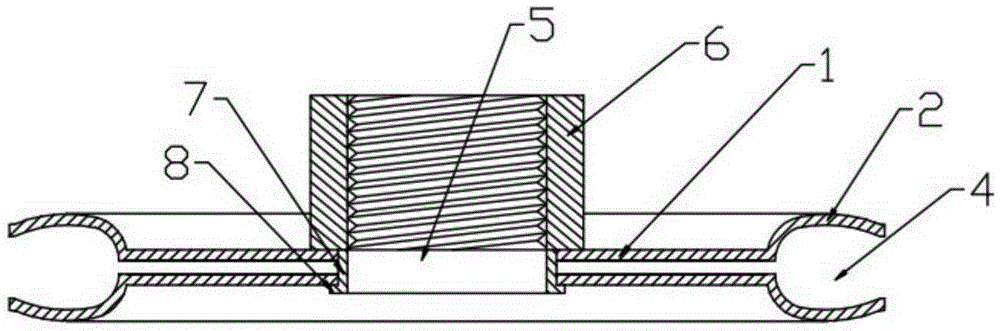

Pipe bus connector

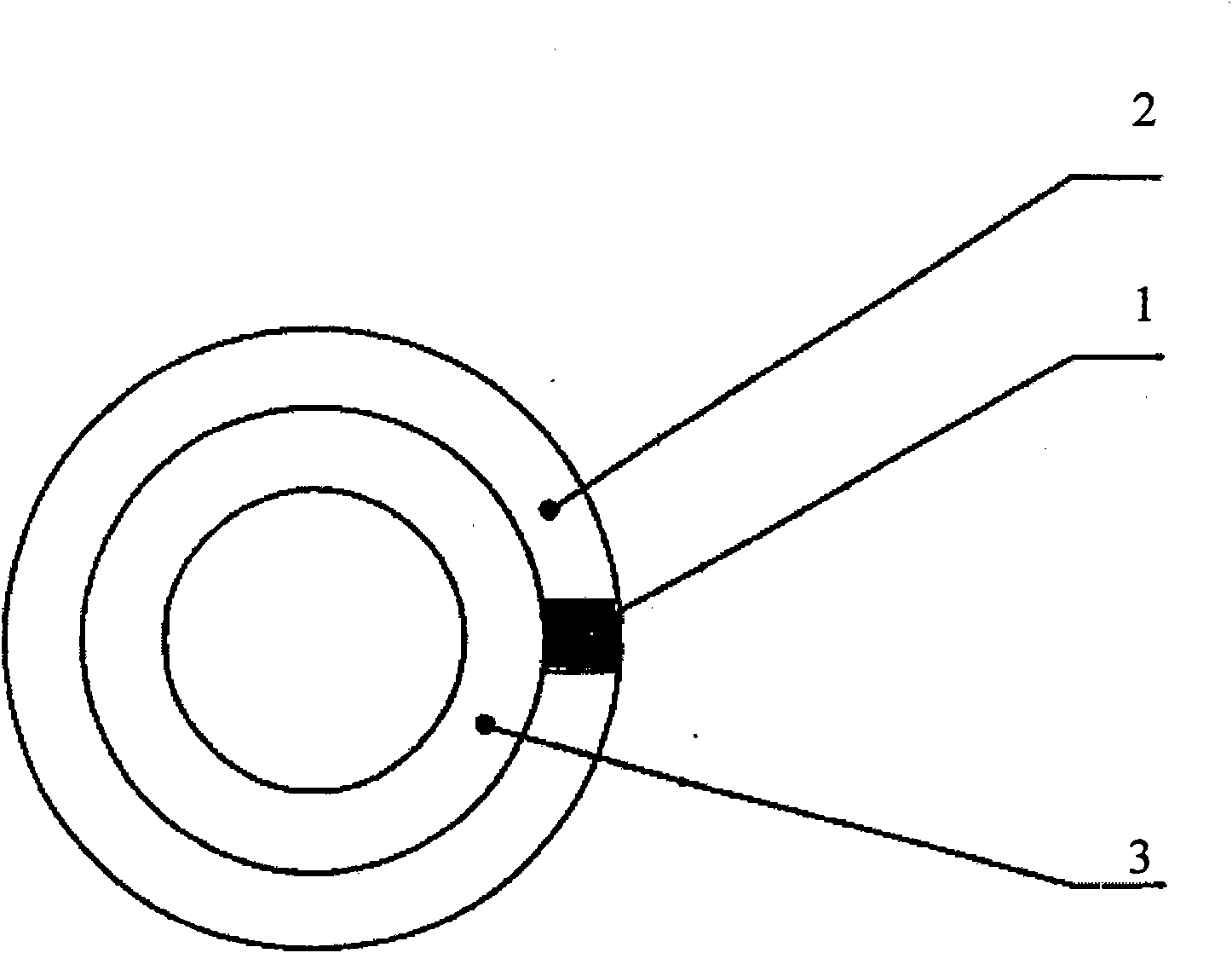

ActiveCN101615729ANot easy to looseImprove stabilitySoldered/welded conductive connectionsClamped/spring connectionsElectrical resistance and conductanceElectrical conductor

The invention discloses a pipe bus connector, which is used for connecting copper, aluminum or alloy buses and is a conductive sleeve (2) made of the same material as a bus conductor (3), wherein the conductive sleeve (2) is sleeved at a bus connecting part, the peripheral wall of the conductive sleeve is provided with an axial opening (1), the inside diameter of the conductive sleeve (2) is matched with the outside diameter of the bus conductor (3), and the axial opening (1) is welded by solder made of a the same material as the bus conductor (3) to ensure that the bus connecting part is closely connected with the conductive sleeve (2) into a whole. The pipe bus connector has the advantages of simple structure, small contact resistance, direct welding of the opening of the conductive sleeve, no clearance, no steam entering, good insulating effect, difficult influence by outside, and firm welded junction.

Owner:罗志昭 +1

Rust removing and paint spraying device for metal pipes

InactiveCN111167655AEasy to holdNot easy to looseGrinding drivesGrinding machinesMetallurgyElectric machinery

The invention discloses a rust removing and paint spraying device for metal pipes. The rust removing and paint spraying device for the metal pipes comprises a rust removing and paint spraying machinebody arranged on the ground; the rust removing and paint spraying machine body is provided with a fixing rod and a first threaded rod which can be used for installing the rust removing and paint spraying device; a clamping device and a lifting platform are arranged in the rust removing and paint spraying machine body; the clamping device comprises second motors which are symmetrically arranged outside the left side wall and the right side wall; and the lifting platform comprises a third motor which is arranged on the lower portion of the inside of the rust removing and paint spraying machine body. The lifting platform is controlled by the third motor, the metal pipes with different diameters on rollers are collinear with the clamping device, and the clamping effect on the metal pipes is good; and a rust removing device can make a rust removing sheet be in full contact with the metal pipes, and therefore the rust removing effect on the metal pipes is improved; and the metal pipes can besubjected to paint spraying treatment after rust removing is completed, and the production efficiency of the metal pipes is improved.

Owner:PAN AN AIKEN MECHANICAL EQUIP CO LTD

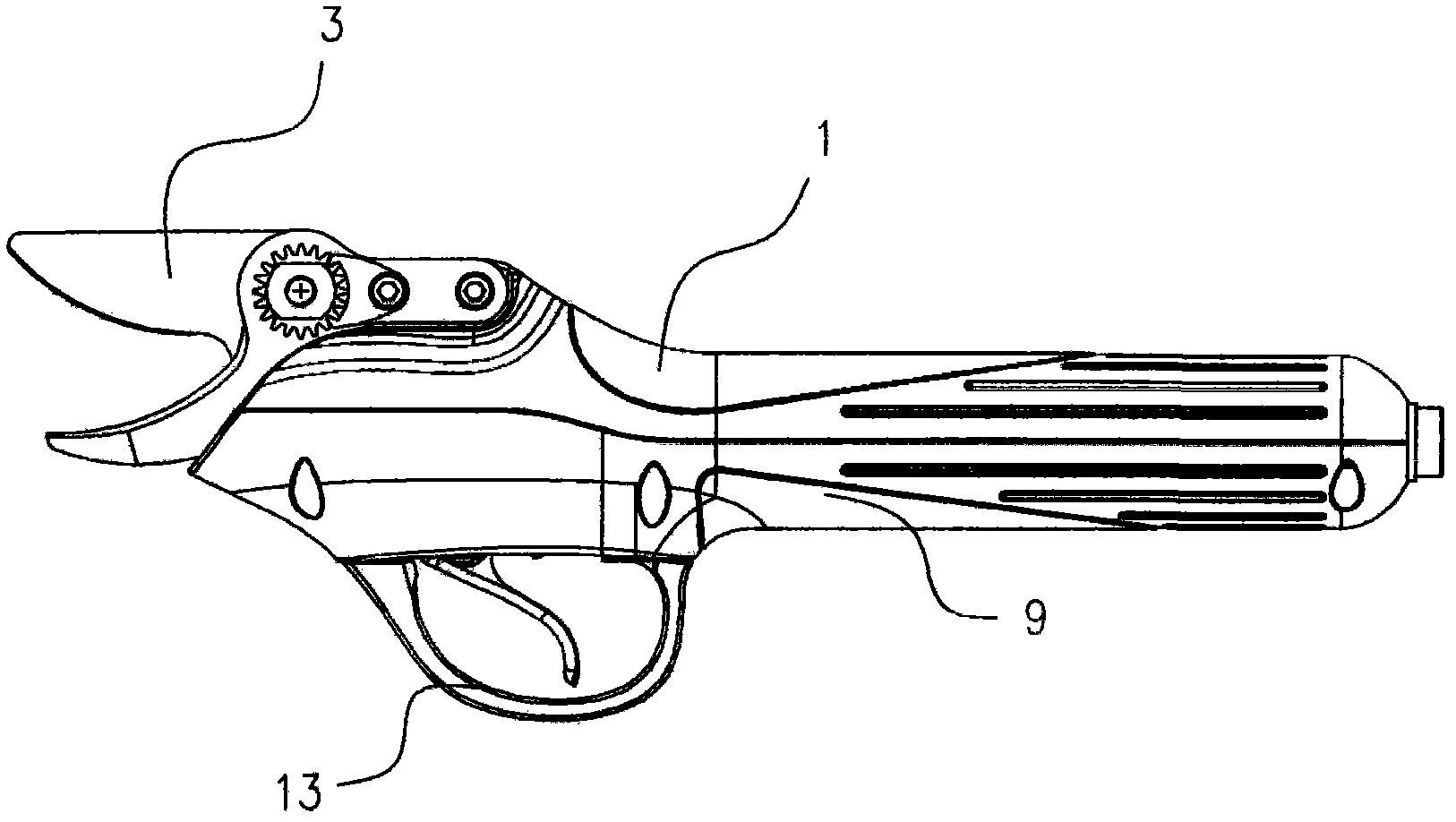

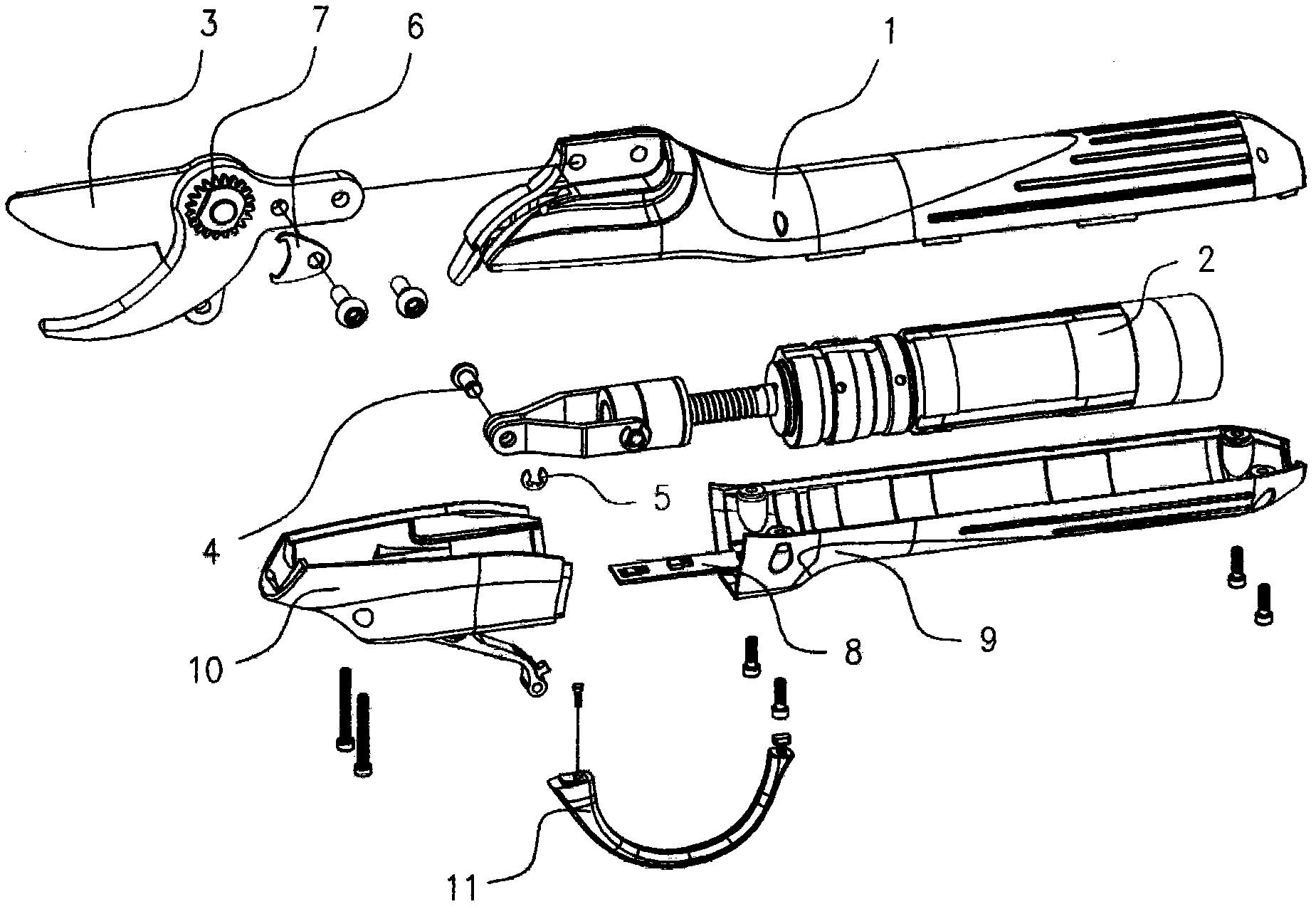

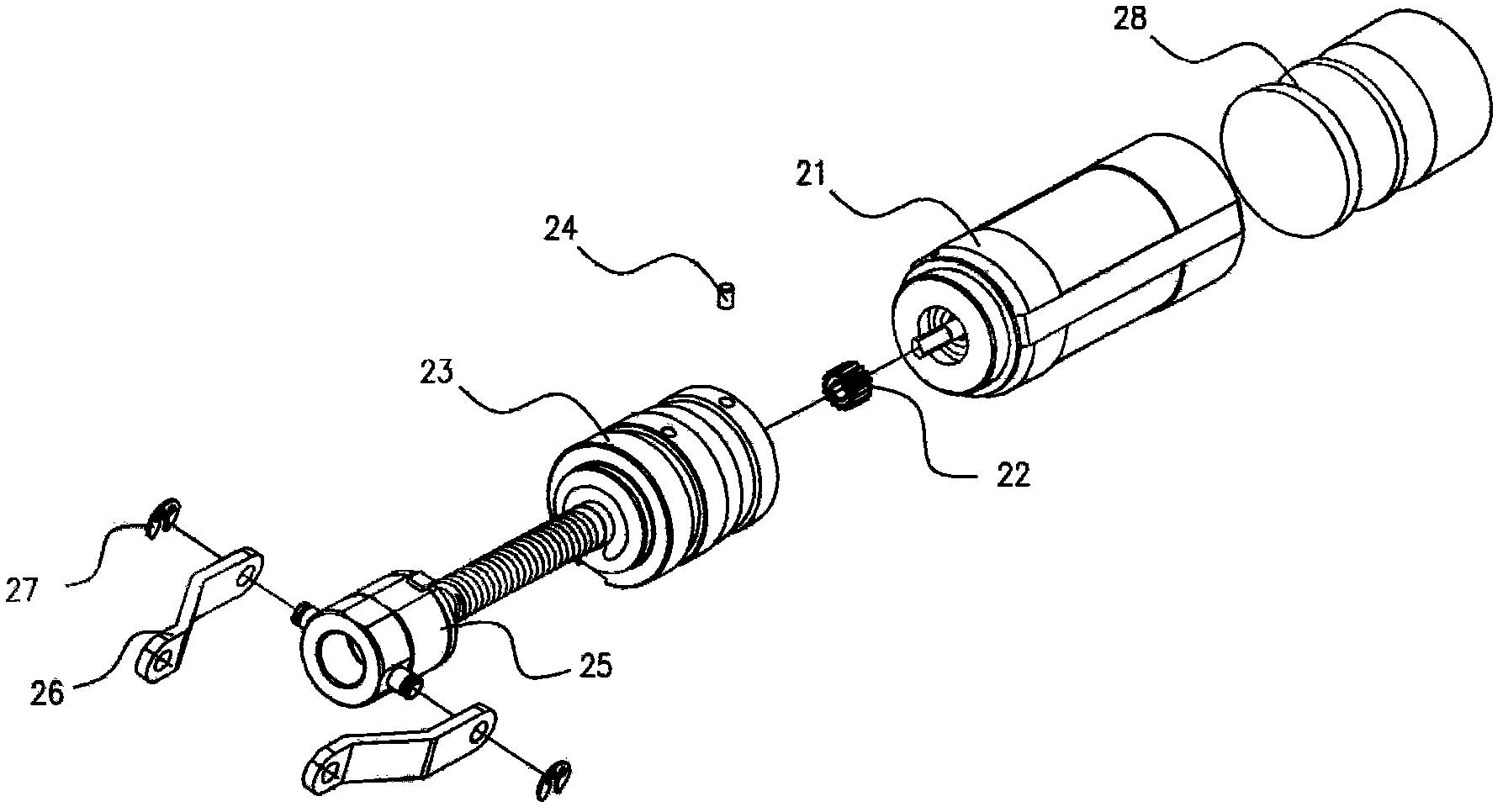

Novel motor-driven garden shears

InactiveCN102907268AExtended service lifeStable installation clearanceCuttersCutting implementsBrushless motorsMotor drive

The invention relates to motor-driven tools, and in particular relates to a pair of novel motor-driven garden shears. The novel motor-driven garden shears comprise an upper machine shell, a lower machine shell, a cutter head part and a switch part, wherein the cutter head part is fixed on the upper machine shell; the switch part is fixed on the lower machine shell; an anti-rotating locking piece is arranged on the cutter head part; the anti-rotating locking piece is matched with a transmission gear which is used for connecting two cutter blades; the upper machine shell and the lower machine shell are internally provided with a motor controller and transmission mechanism; the motor controller and transmission mechanism comprises a circuit controller, a direct-current brushless motor, a planet wheel speed reducing box and a ball screw rod mechanism which are connected together; the circuit controller is positioned at the rear side of the direct-current brushless motor; the ball screw rod mechanism is arranged at the front side of the planet wheel speed reducing box; the front end of the ball screw rod mechanism is fixedly provided with two connecting plates; and the connecting plates are fastened on two sides of the connecting plates by clamping rings. The novel motor-driven garden shears adopt a backpack type lithium battery as a power supply, the power supply can be connected or disconnected by a battery switch, the equipment motor is started, and a trigger can be pulled by holding equipment, so that work is performed.

Owner:方培锵

LED street lamp capable of being quickly and stably installed

ActiveCN106704938AReduce stepsImplement automatic lockingMechanical apparatusOutdoor lightingEngineeringLED lamp

The invention discloses an LED street lamp capable of being quickly and stably installed. The LED street lamp comprises a lamp body, a mounting base fixed in the lamp body, and a lamp rod arranged at the tail end of the right side of the lamp body; an LED lamp module is arranged below the mounting base; a placing cavity is formed in the mounting base; first chutes are symmetrically formed in the inner walls of left and right two sides of the placing cavity; second chutes are formed in one sides, far from the placing cavity, of the tops of the first chutes; slide blocks and guide rods slidingly matched and connected with the slide blocks are arranged in the second chutes; the inner sides of the slide blocks extend into the first chutes for slide matching; elastic clamping pieces are arranged at the bottoms of the slide blocks in the first chutes; a lock insertion rod for downwards extending is arranged on the top wall in the placing cavity; left and right symmetric slide cavities are formed in the lower side in the lock insertion rod; a separation plate is arranged between the slide cavities on the left and right two sides; third chutes are respectively formed in the top of each slide cavity; and locking push blocks are arranged in the slide cavities. The LED street lamp is simple in structure, reasonable in design and convenient to install and dismount, reduces the staff climbing time and operation, is high in installation stability, and is not liable to generate looseness.

Owner:XINGHUI LIGHTING ENG GRP

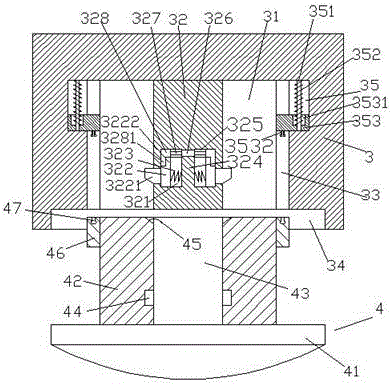

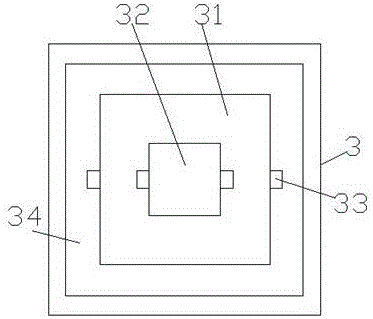

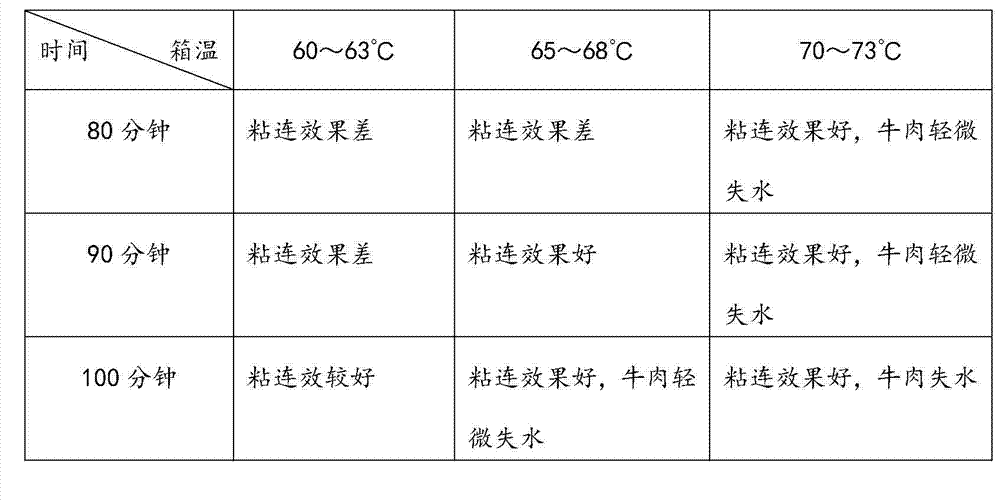

Pork and beef combined bacon and production method thereof

The invention discloses a pork and beef combined bacon and a production method thereof. The combined bacon is prepared from the following raw materials in parts by weight: 290 to 320 parts of streaky pork, 340 to 370 parts of foreslope beef, 35 to 65 parts of foreslope pork (lean pork), 205 to 235 parts of ice water and accessories. The combined bacon is prepared from raw meat by pretreatment, accessory injection, tumbling, die filling, digestion, drying, smudging, quick freezing, slicing and packing. The combined bacon has a good adhesion effect, is difficult to loosen, can be applied to various cooking modes such as frying, baking, steaming and instant boiling, is tender and delicious and balances various nutrients, and customers can enjoy unique flavor of blending multiple kinds of meat.

Owner:名佑(福建)食品有限公司

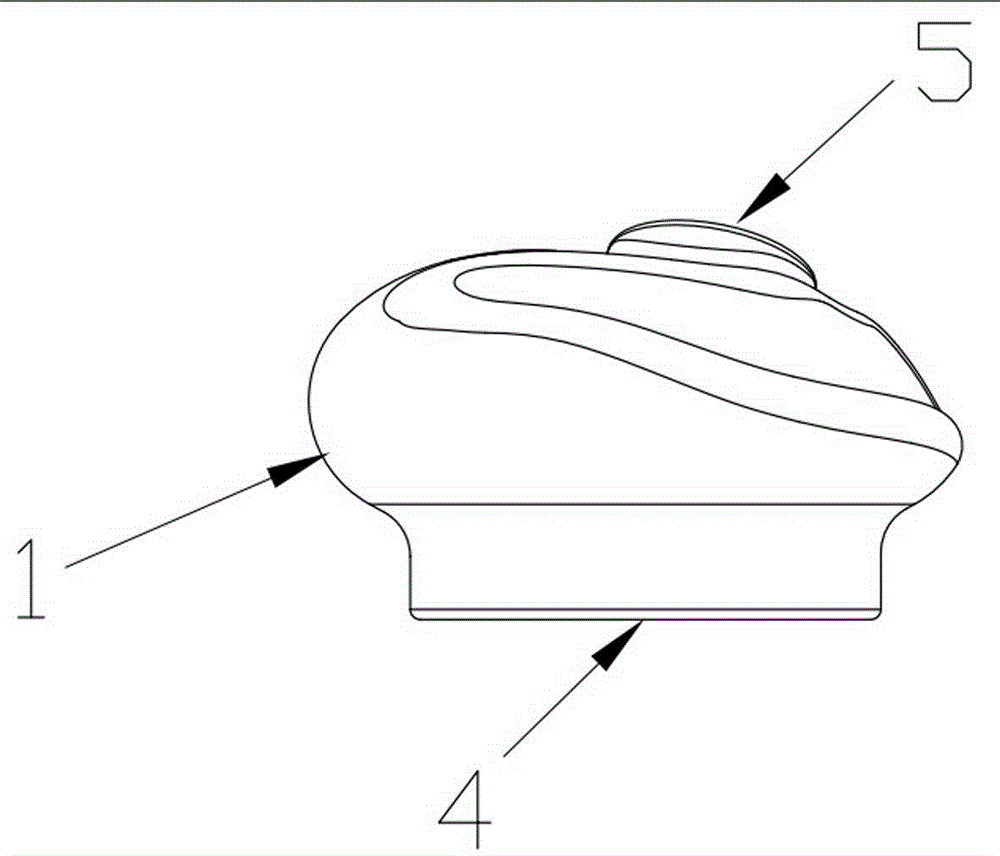

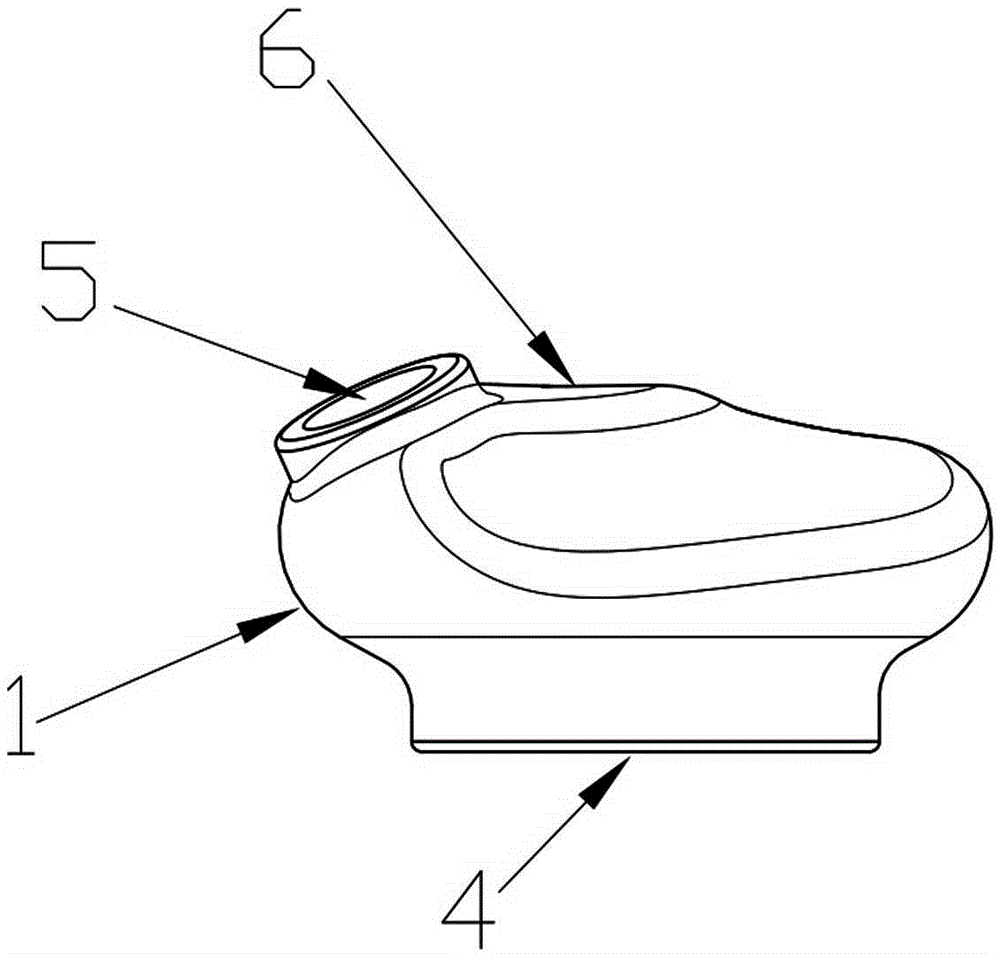

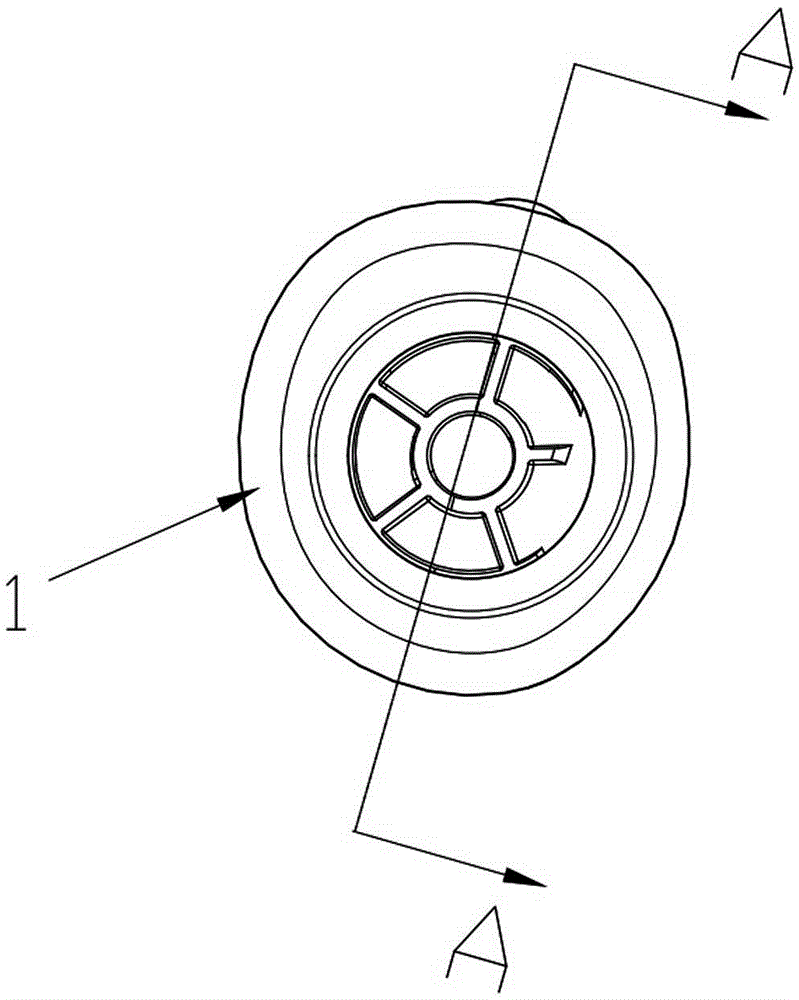

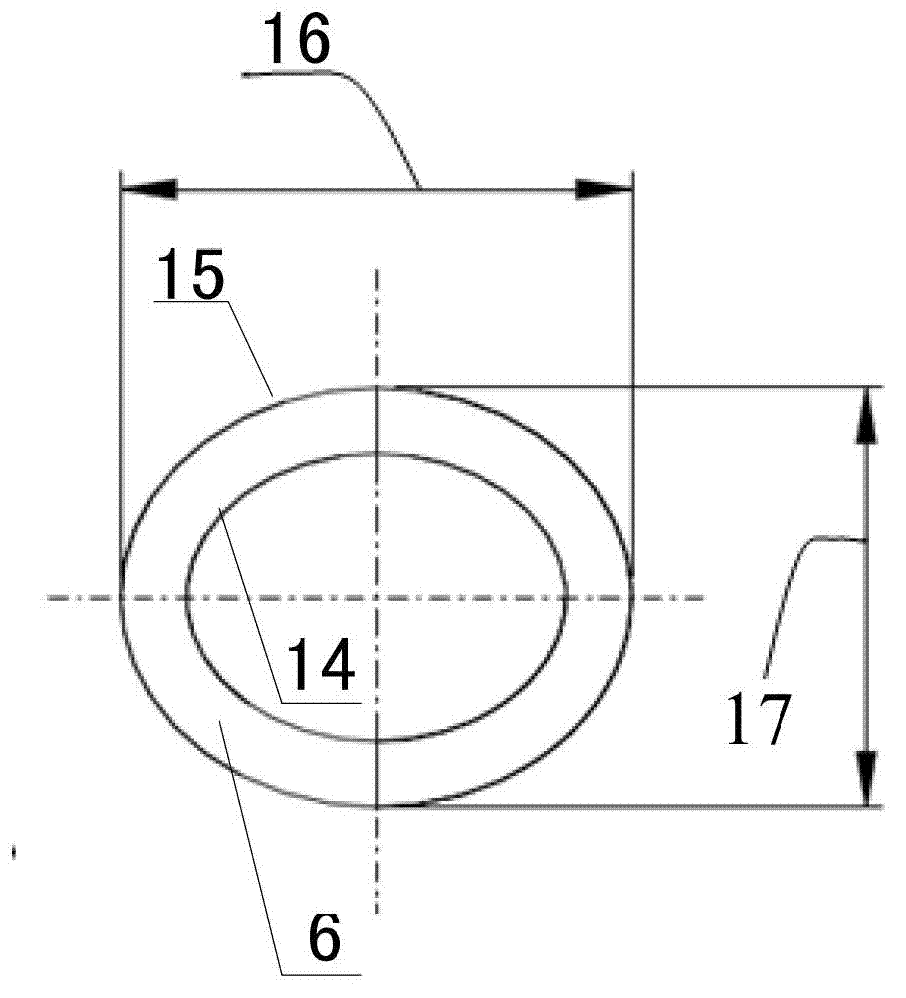

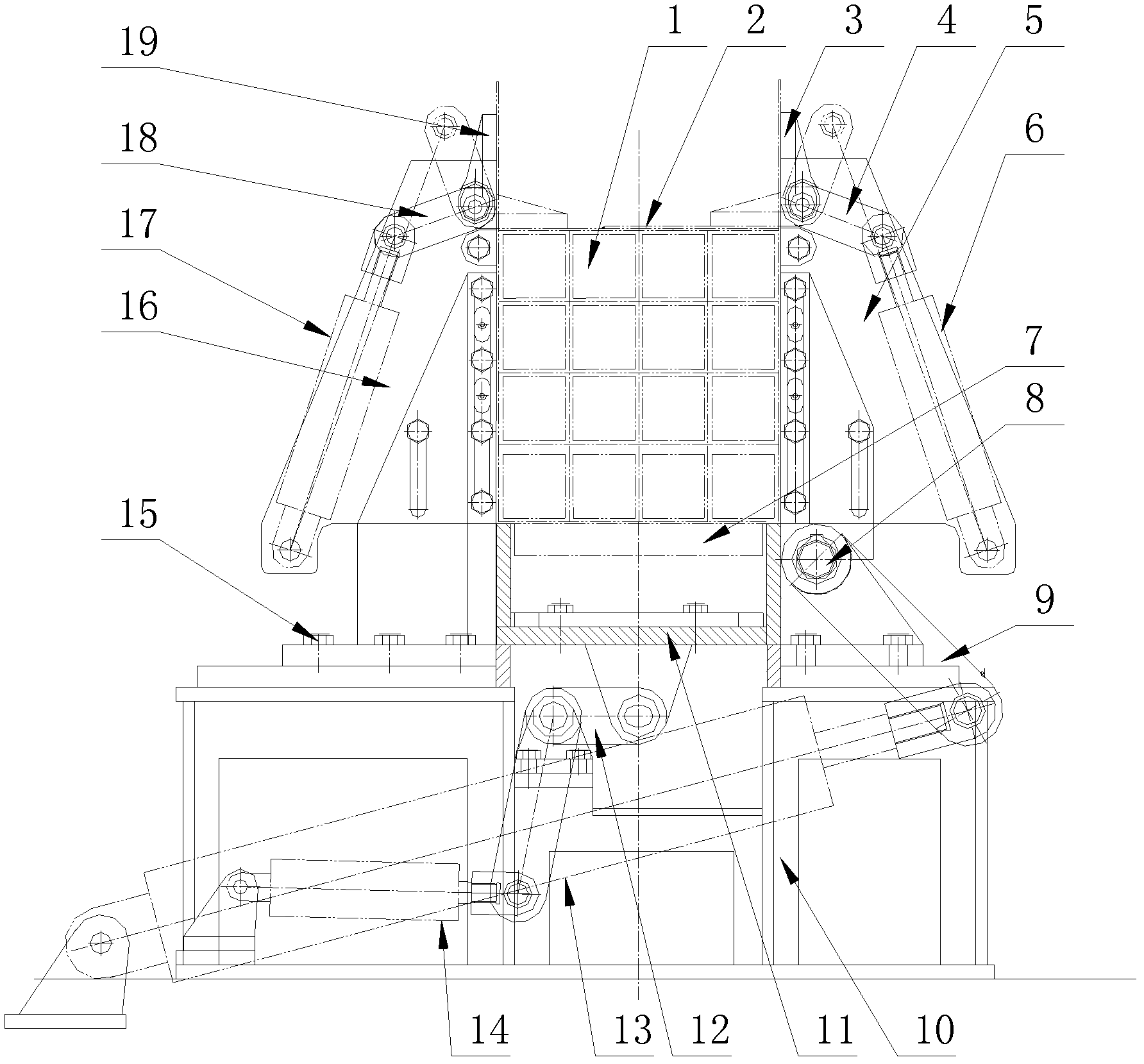

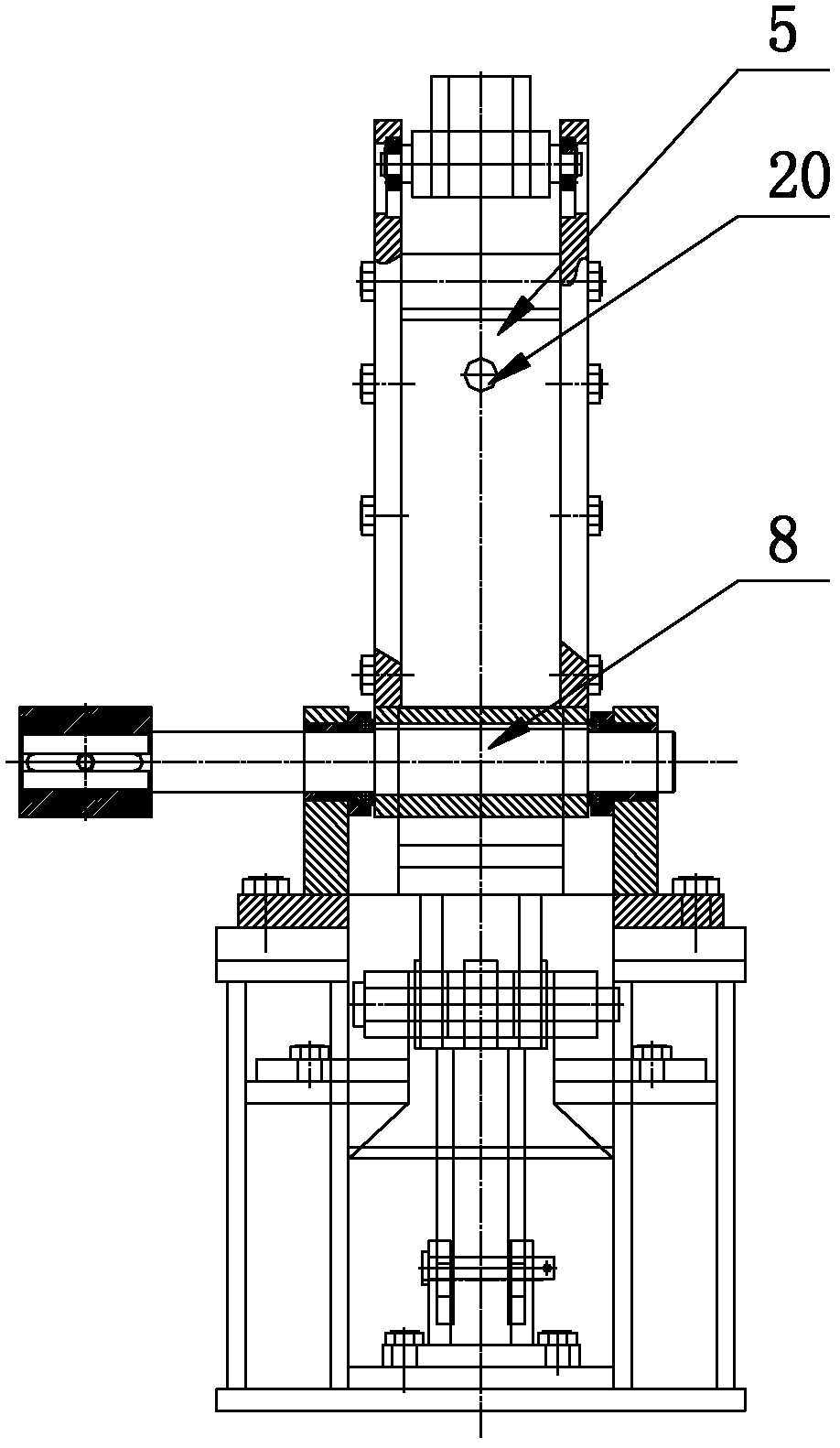

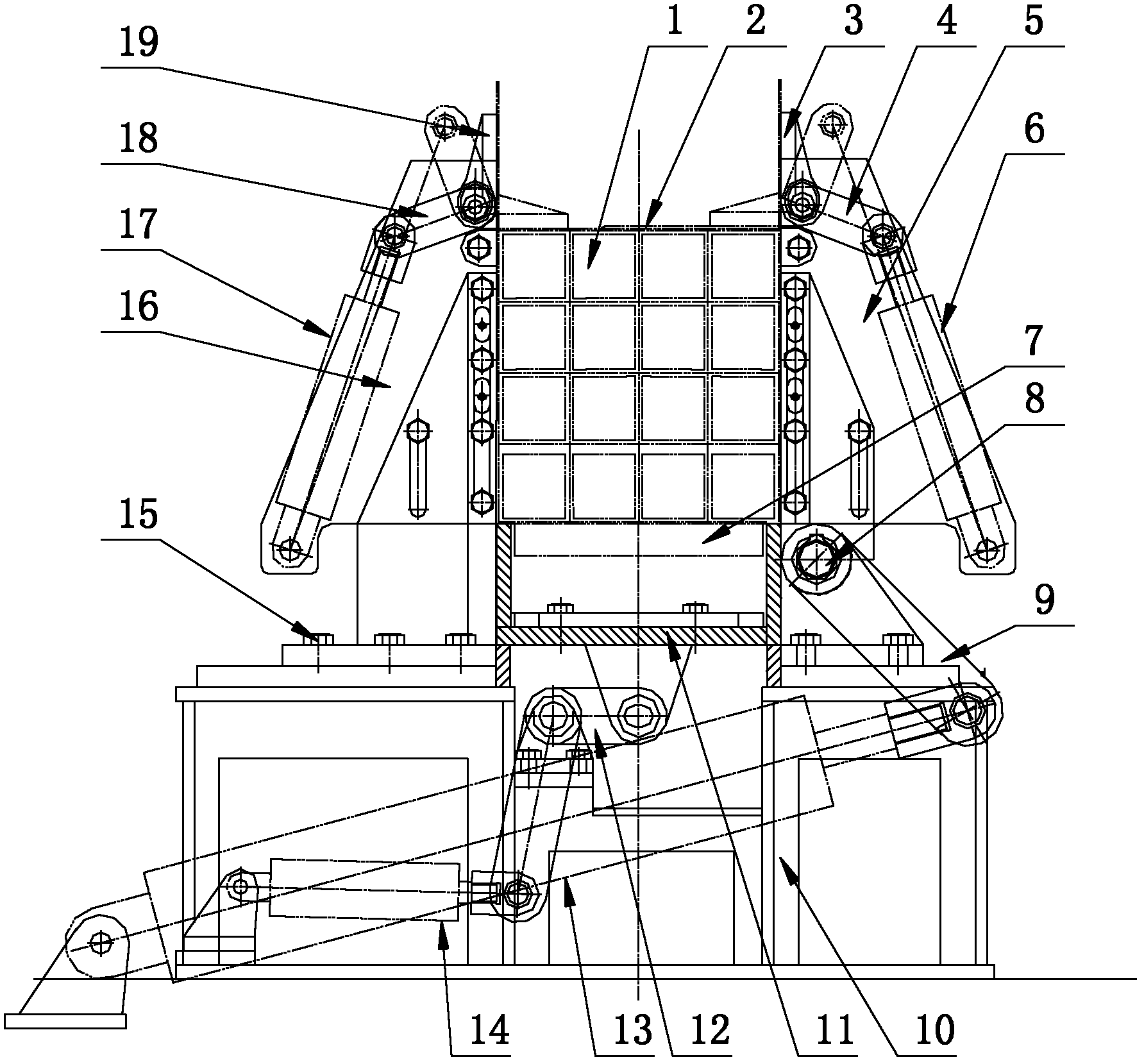

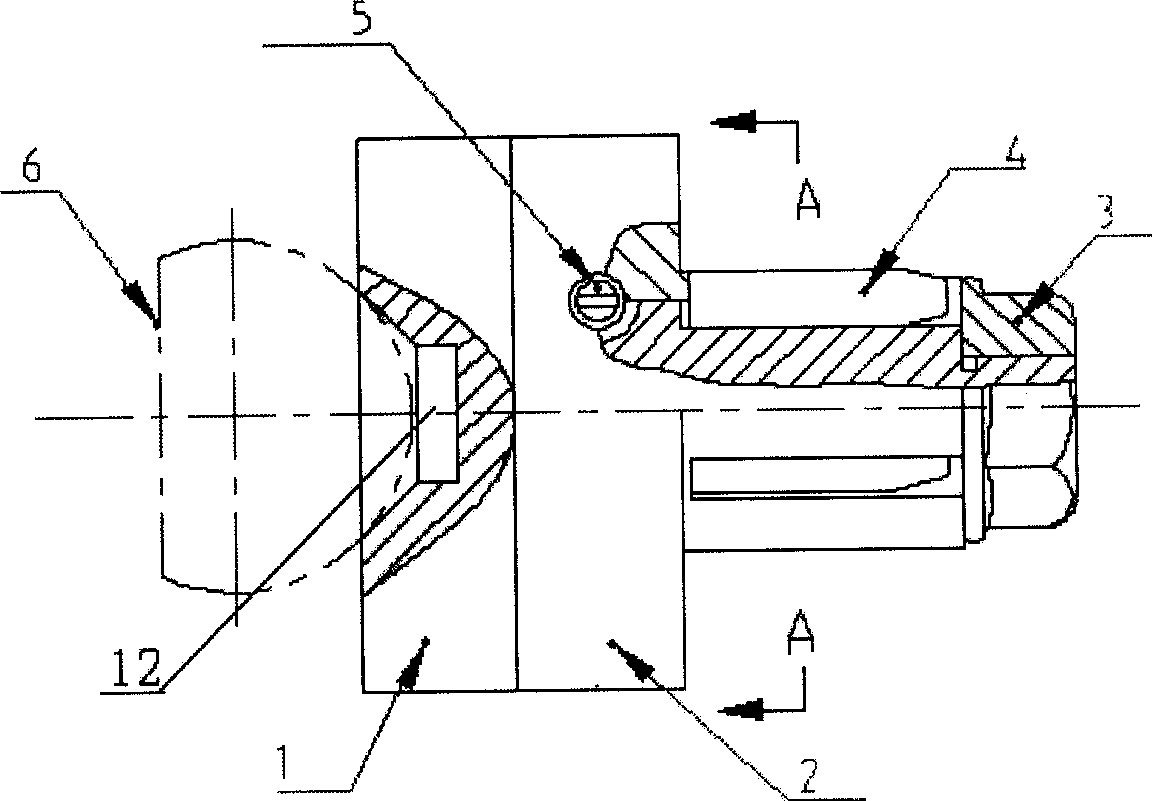

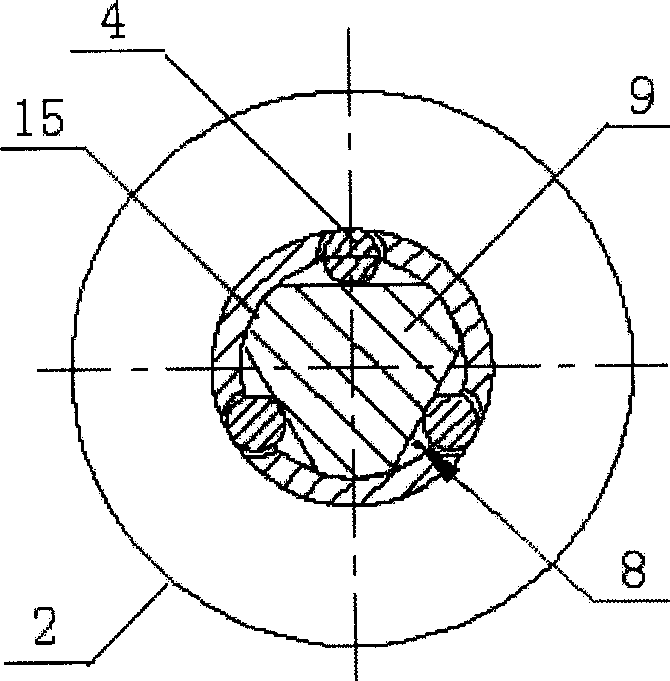

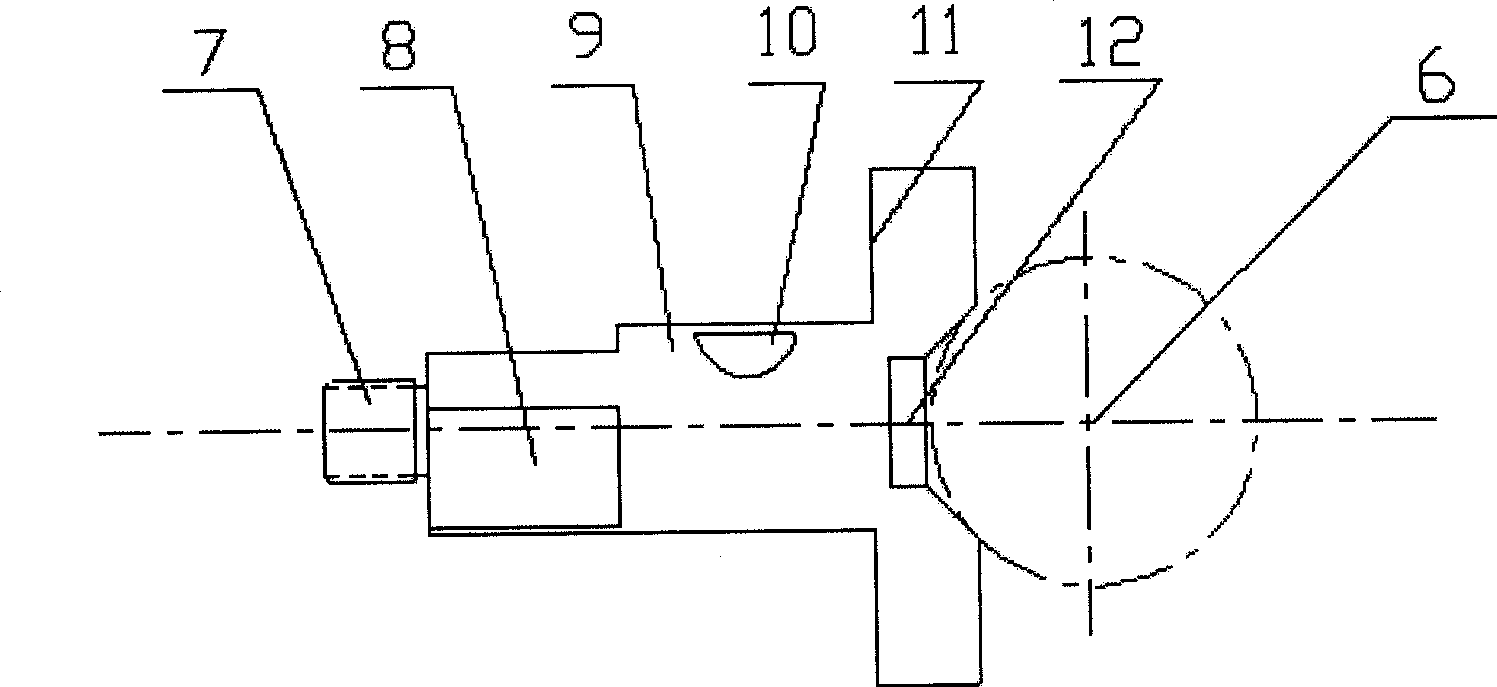

Self-locking auto-centering target ball mounting seat

ActiveCN101446481AReduce installation errorsNot easy to looseUsing optical meansElectromagnetic wave reradiationSelf lockingLaser

The invention discloses a self-locking auto-centering target ball mounting seat used for mounting the target ball of a laser tracer; the inner wall circle of a locating central hole (15) of the sleeve (2) of the target ball seat is provided with needle roller slots (14) which are at least arranged in trisection and used for arranging a needle roller (4); at least one cross surface of the coaxial direction of a locating guide column (9) is a polygon; and the coaxial squeezing surface (8) on each side is corresponding to one needle roller (4) assembled in the needle roller slot (14). As squeezing force is generated to the needle roller when the central saddle of the target ball is rotated, the needle roller is led to move outwards to squeeze and clamp a measured hole, so as to automatically lock and fix the target ball mounting seat, thus realizing the excellent tight static matching between the guide column of the central saddle and the measured hole. The target ball automatically centered in the central saddle of the target ball is led to be automatically positioned to the center of the mounting hole and be able to reduce the mounting error of the target ball mounting seat. The invention is suitable for measuring the mounting holes with the hole tolerance less than IT12 and the diameter between 10mm and 50mm.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

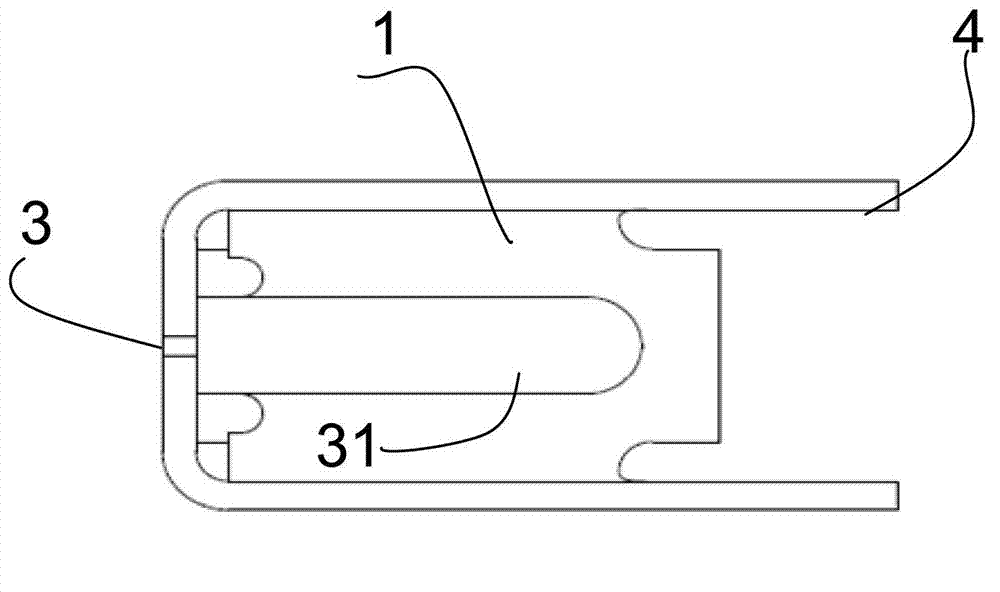

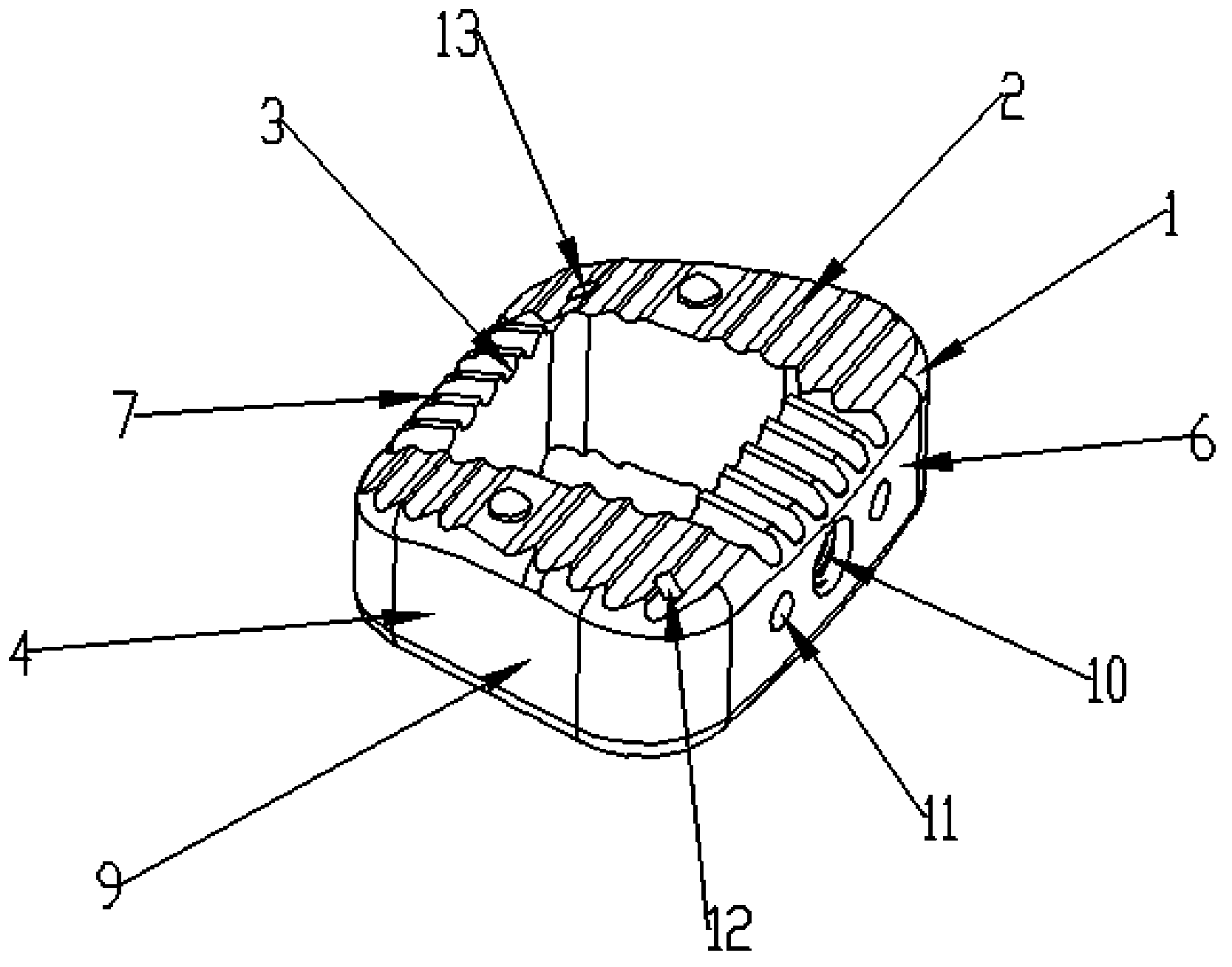

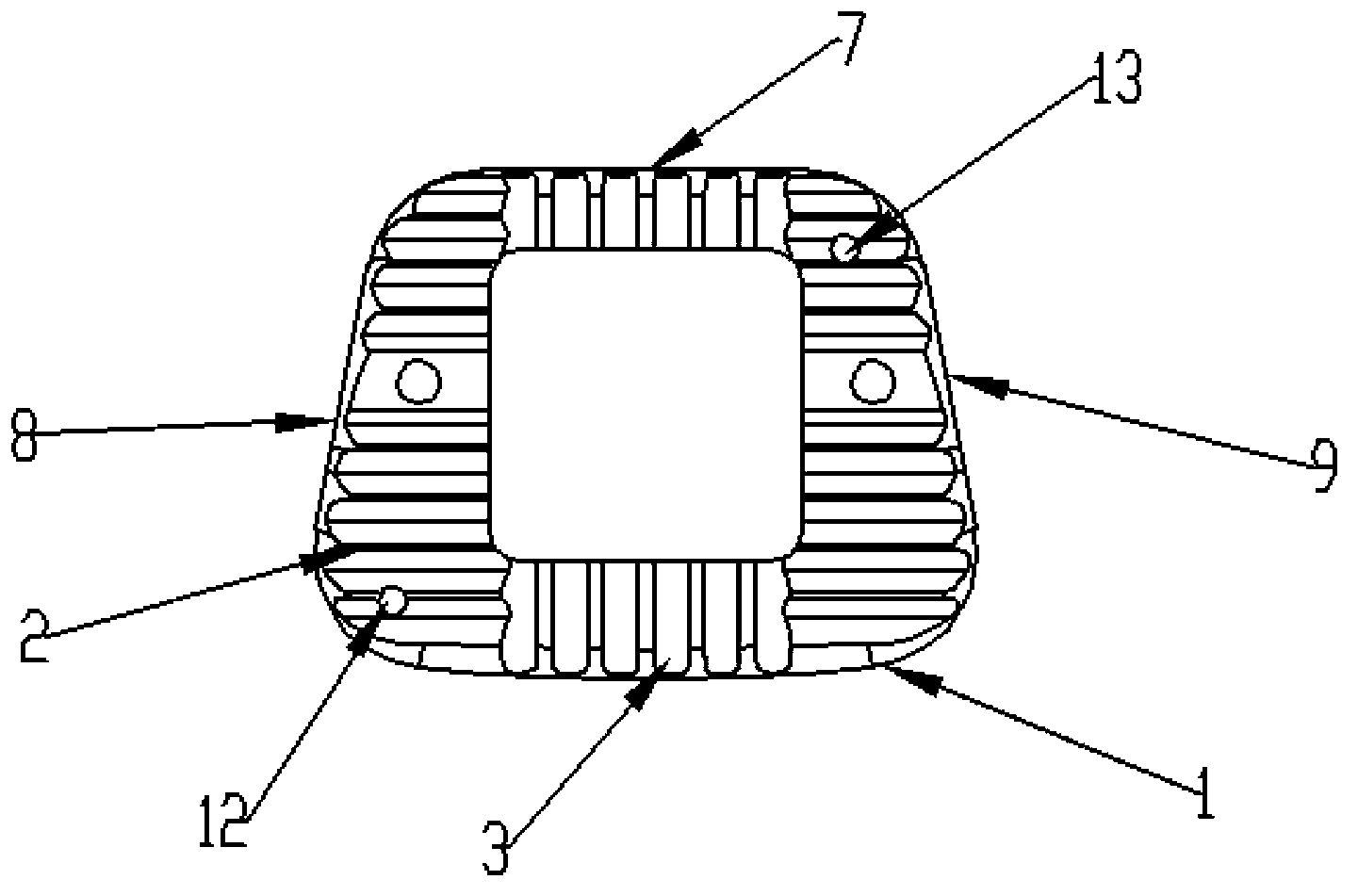

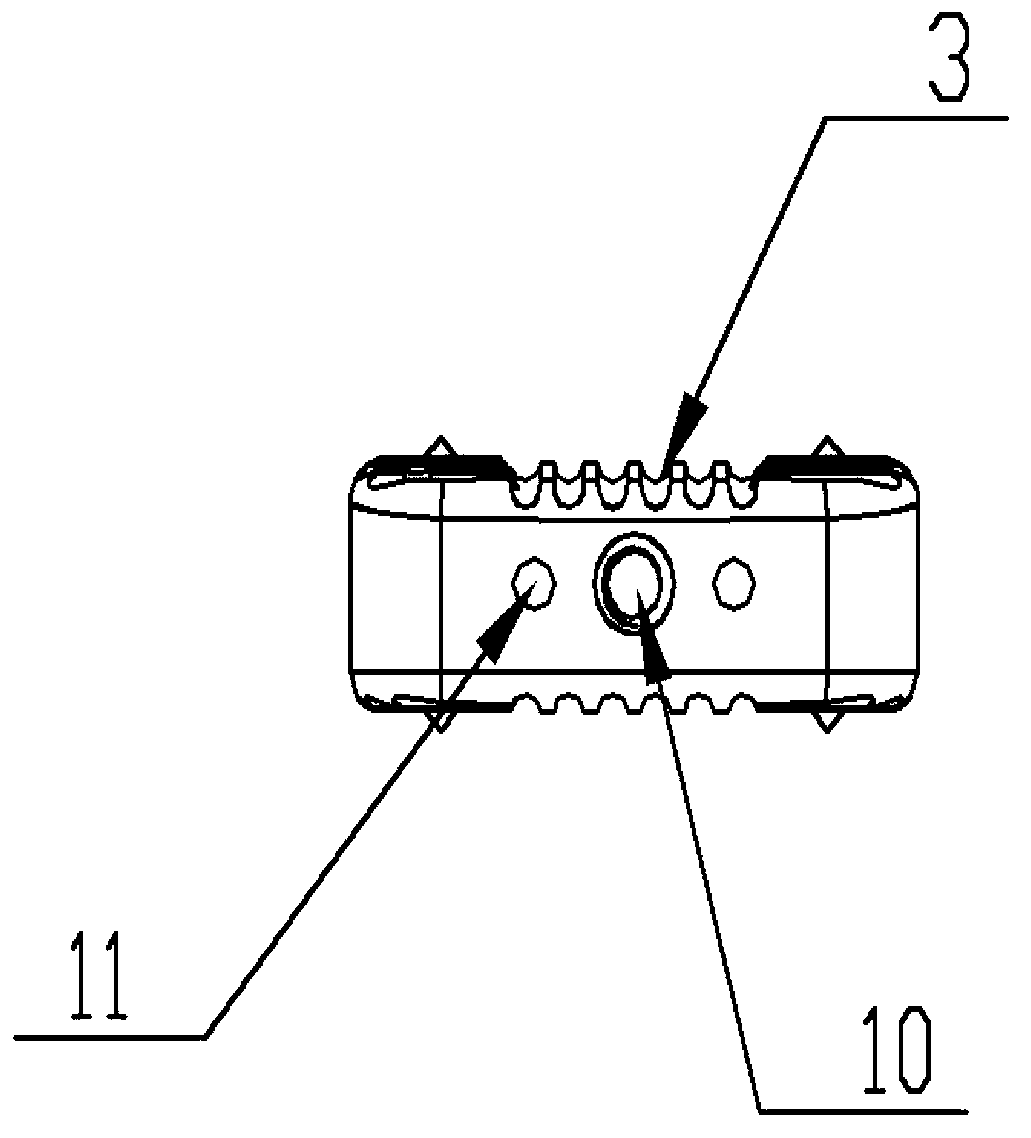

Anterior cervical interbody fusion cage

InactiveCN103300947AEnsure safe implantationPromote bone fusionInternal osteosythesisSpinal implantsSpinal cageGynecology

The invention discloses an anterior cervical interbody fusion cage which comprises a main body and a development needle arranged on the main body, wherein the main body is a hollow tetrahedron; the cross section of the hollow periphery of the tetrahedron is ladder-shaped; the cross section of the hollow inner circumference of the tetrahedron is square or rectangular; the main body comprises a front wall, a rear wall, a left side wall and a right side wall; and the front wall is connected with the rear wall through the left side wall and the right side wall. The shape of the main body confirms to the anatomic form of the cervical intervertebral disc of a normal human body; while the safe implantation is ensured, the main body can be in tight contact with end plates of an upper cervical vertebral body and a lower cervical vertebral body under the compression state to create a good condition for bone fusion; and the cross section of the hollow inner circumference of the main body is square or rectangular, so that the contact surface of the main body and the end plates of the cervical vertebral bodies is increased to the greatest extent, the bone implementation amount is increased, and the fusion is speeded up.

Owner:广州聚生生物科技有限公司

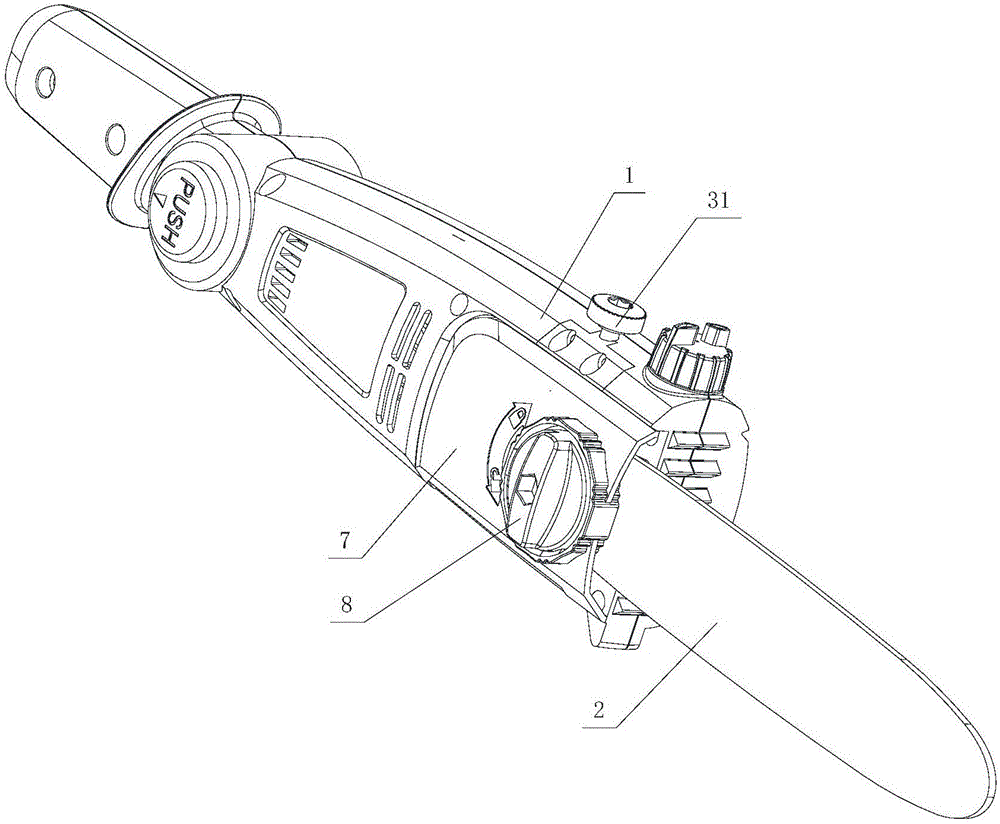

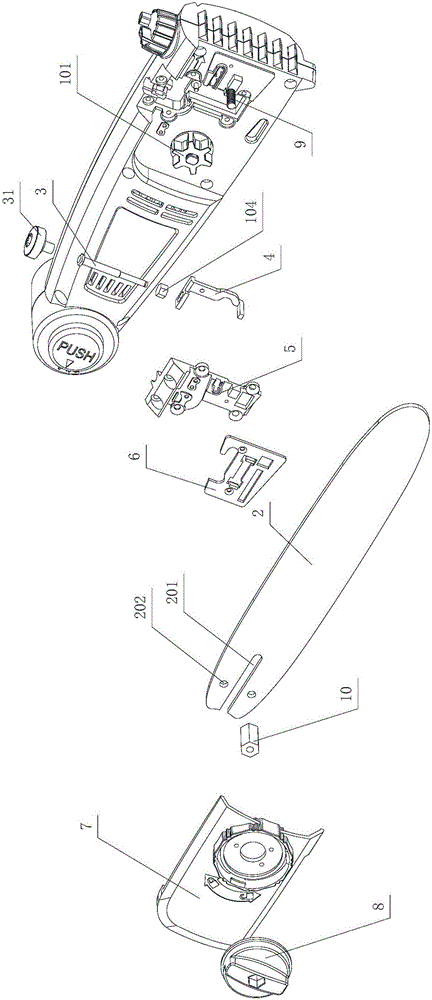

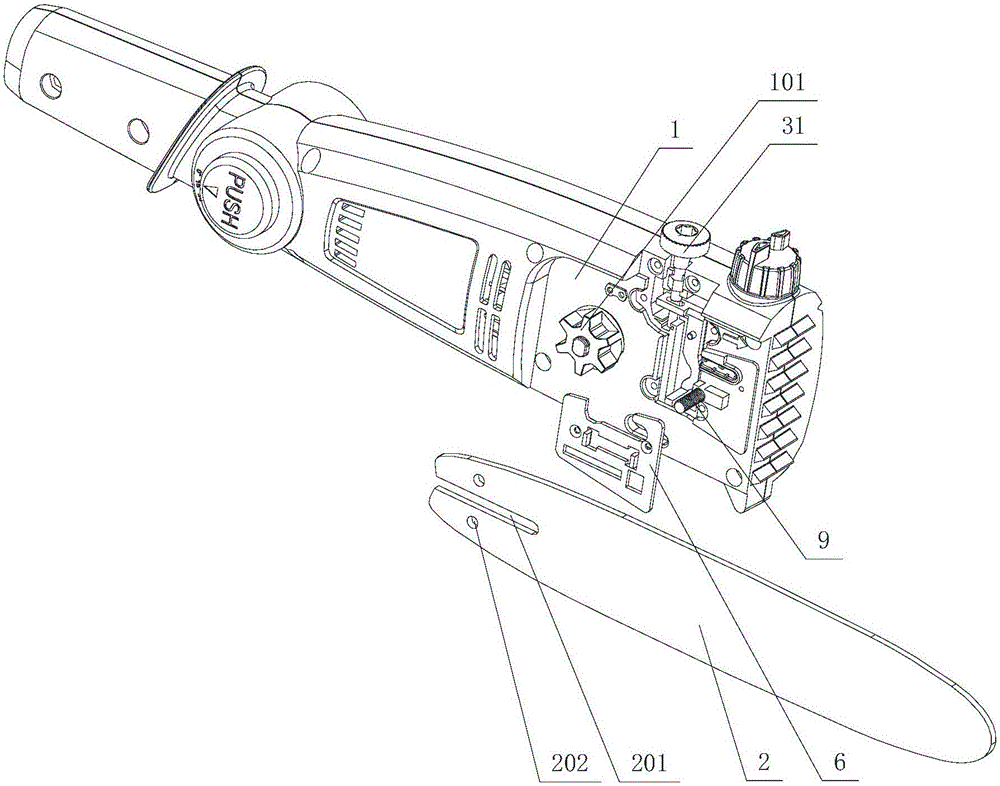

Chain tensioning mechanism of chain saw and assembly method of chain saw with such mechanism

The invention provides a chain tensioning mechanism of a chain saw. The chain tensioning mechanism comprises a housing, a chain saw guide plate, an adjusting bolt and a lever; a driving chain wheel is arranged in the housing; the chain saw guide plate is in slide fit with the housing, and a sliding direction of the chain saw guide plate is perpendicular to and intersects an axis of the driving chain wheel; the adjusting bolt is in threaded connection with the housing, and an axis of the adjusting bolt forms an included angle with the sliding direction of the chain saw guide plate; the lever is rotationally mounted in the housing; a head portion of the lever is connected with the adjusting bolt, while a tail portion of the lever is connected with the chain saw guide plate; and when the adjusting bolt is tightened, the lever pushes the chain saw guide plate to move towards a side far away from the driving chain wheel. Meanwhile, the present invention also provides an assembly method of a chain saw. The chain tensioning mechanism of the chain saw provided by the present invention is simple and compact in structure, convenient to operate, good in tensioning effect and reliability, and not prone to slip, thereby greatly improving the safety.

Owner:NINGBO ENERGY POWER TOOLS

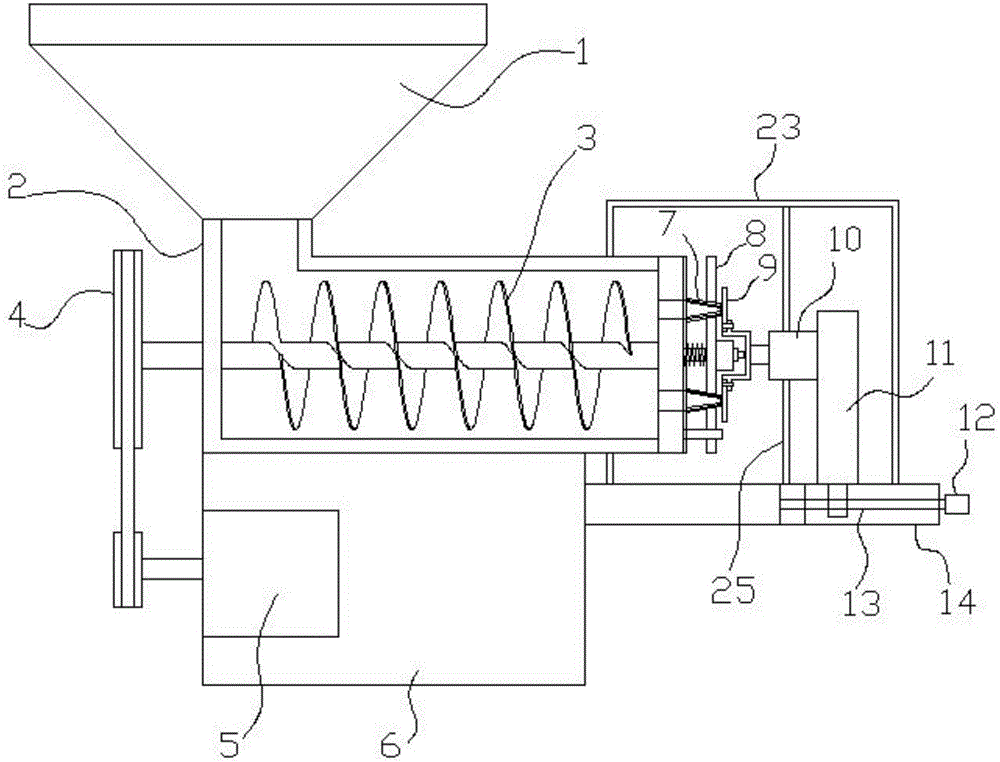

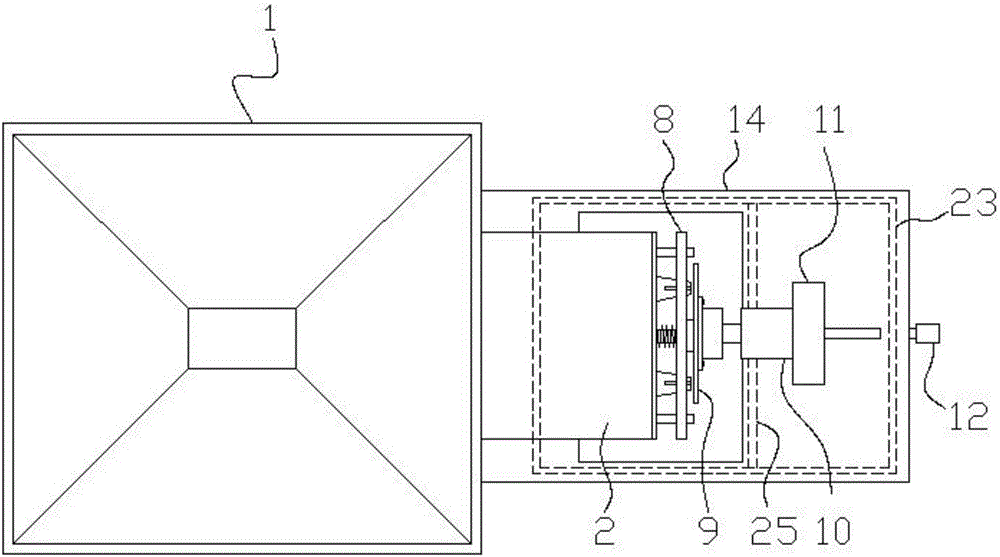

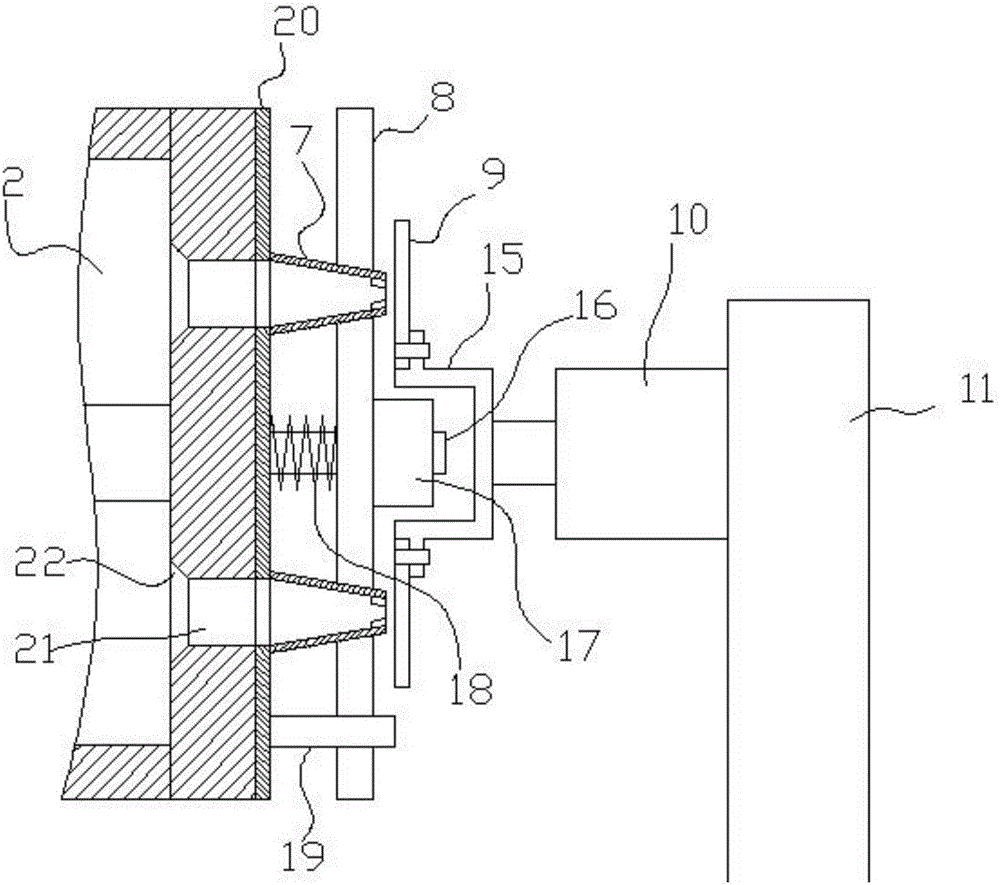

Extrusion cutting type multi-particle size adjustable granulating machine

ActiveCN106622022ALarge adjustment rangeEasy to adjustGranulation in rotating dishes/pansGranulation by material expressionPropellerAgricultural engineering

The invention discloses an extrusion cutting type multi-particle size adjustable granulating machine. The extrusion cutting type multi-particle size adjustable granulating machine comprises a stirring cylinder, wherein the stirring cylinder is arranged on a base, a spiral propeller is arranged in the stirring cylinder, and a material inlet hopper is arranged at the upper end of the stirring cylinder; the spiral propeller is connected with a propelling motor; a granulating disc is arranged at the front end of the stirring cylinder; conical granulating sleeves are uniformly arranged on the granulating disc, and are sheathed on an adjusting disc; a cutting tool disc is arranged at the front end of each conical granulating sleeve, and is fixedly arranged on a fixed disc; the fixed disc is connected with a cutting motor, and the cutting motor is arranged on a slide base; the slide base is connected with a screw rod in a bracket, and the bracket is connected with the base; an adjusting rotary button is arranged at the front end of the screw rod; each conical granulating sleeve is in a conical sleeve shape, and adjusting grooves are uniformly arranged at the front end of each conical granulating sleeve; mounting grooves are arranged on the inner walls of both sides of each adjusting groove; an arc-shaped movable plate is arranged in each mounting groove; outlet tool blades are uniformly arranged on the inner wall of the front end of each conical granulating sleeve. The extrusion cutting type multi-particle size adjustable granulating machine has the advantages that the quick and high-efficiency granulating function is realized, the granulating size can be adjusted, the adjusting range is wide, and the flexibility and convenience in use are realized.

Owner:湖南康易达绿茵科技有限公司

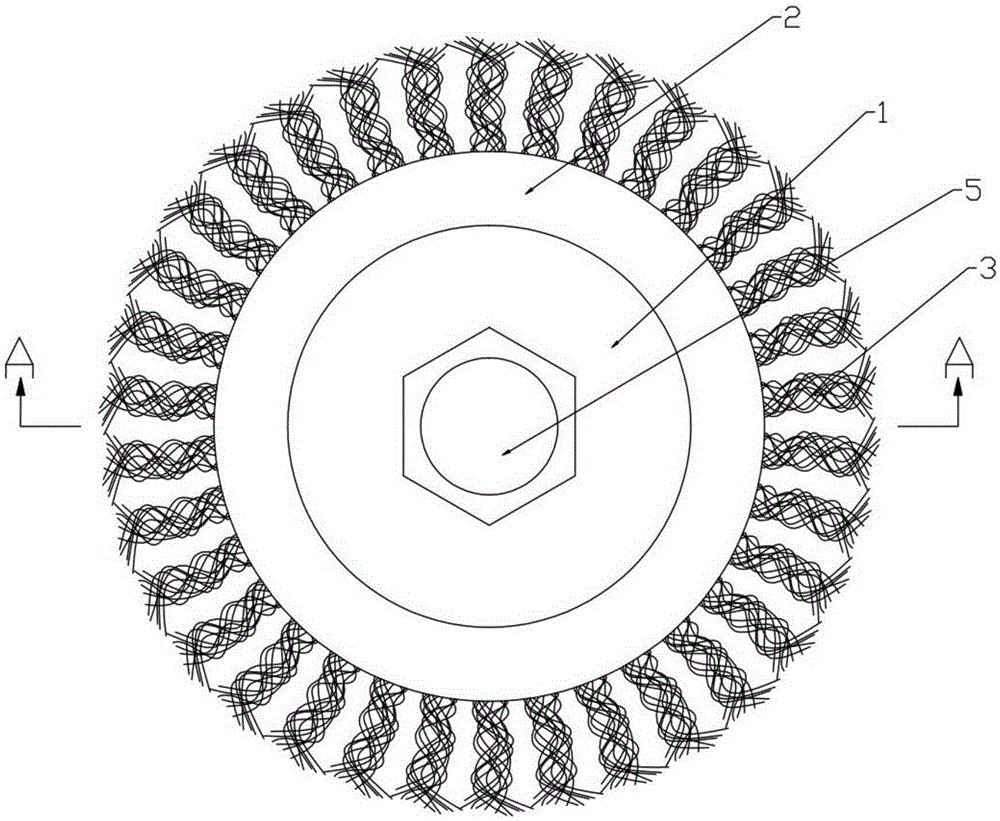

Metal wire polishing wheel

InactiveCN105415212ALight in massReduce quality problemsFlexible-parts wheelsMetallic material coating processesAlloy substrateEngineering

The invention provides a metal wire polishing wheel. The metal wire polishing wheel comprises an upper clamping plate and a lower clamping plate. A plurality of metal wire beams are installed between the edge parts of the upper clamping plate and the lower clamping plate in a central symmetrical mode. A fastener is installed between through holes of the upper clamping plate and the lower clamping plate. A longitudinal installation hole is formed in the middle of the fastener and internally provided with an internal thread. Both the upper clamping plate and the lower clamping plate are divided into the annular sunk parts in the middles and the annular protruding parts at the edges. The annular protruding part of the upper clamping plate and the annular protruding part of the lower clamping plate are symmetrical and form an annular installation groove of the metal wire beams. The metal wire beams are formed by twisting a plurality of metal wires made from an aluminum alloy composite material. The aluminum alloy composite material comprises an aluminum alloy substrate and a ceramic layer arranged on the surface of the aluminum alloy substrate through laser cladding. The metal wire polishing wheel is compact and firm in structure, convenient to install and use and good in thermal conductivity, heat dispersion, mechanical property and usability.

Owner:NINGBO DAHUA GRINDING WHEEL

Transferring box for amorphous silicon membrane solar cell modules

InactiveCN107719882ARealize the height adjustment functionEasy to fixShock-sensitive articlesContainers to prevent mechanical damageHydraulic cylinderAmorphous silicon

The invention discloses a transferring box for amorphous silicon membrane solar cell modules. The transferring box comprises a box body, a hydraulic cylinder is arranged at the bottom of an inner cavity of the box body, a containing plate is connected to the top end of the hydraulic cylinder through a hydraulic rod, clamping plates distributed at equal intervals are arranged on the containing plate, and elastic protrusions are arranged on the inner walls of the clamping plates; and dust collectors are arranged at the positions, close to the two sides of the hydraulic cylinder, of the interiorof the box body, and the dust collectors are connected with the containing plate through dust collection pipes. The transferring box is simple in structure and convenient to use, a large number of solar cell modules can be clamped more firmly at a time, and the transferring efficiency is high; the elastic protrusions are arranged on the inner walls of the clamping plates, and therefore the solar cell modules can be clamped more firmly, and mutual collision, fracture and damage of the solar cell modules in the transporting process are avoided; and the hydraulic cylinder is arranged at the bottom of the inner cavity of the box body, the height adjusting function of the containing plate can be achieved, and the solar cell modules with different lengths can be transferred.

Owner:江阴艾能赛瑞能源科技有限公司

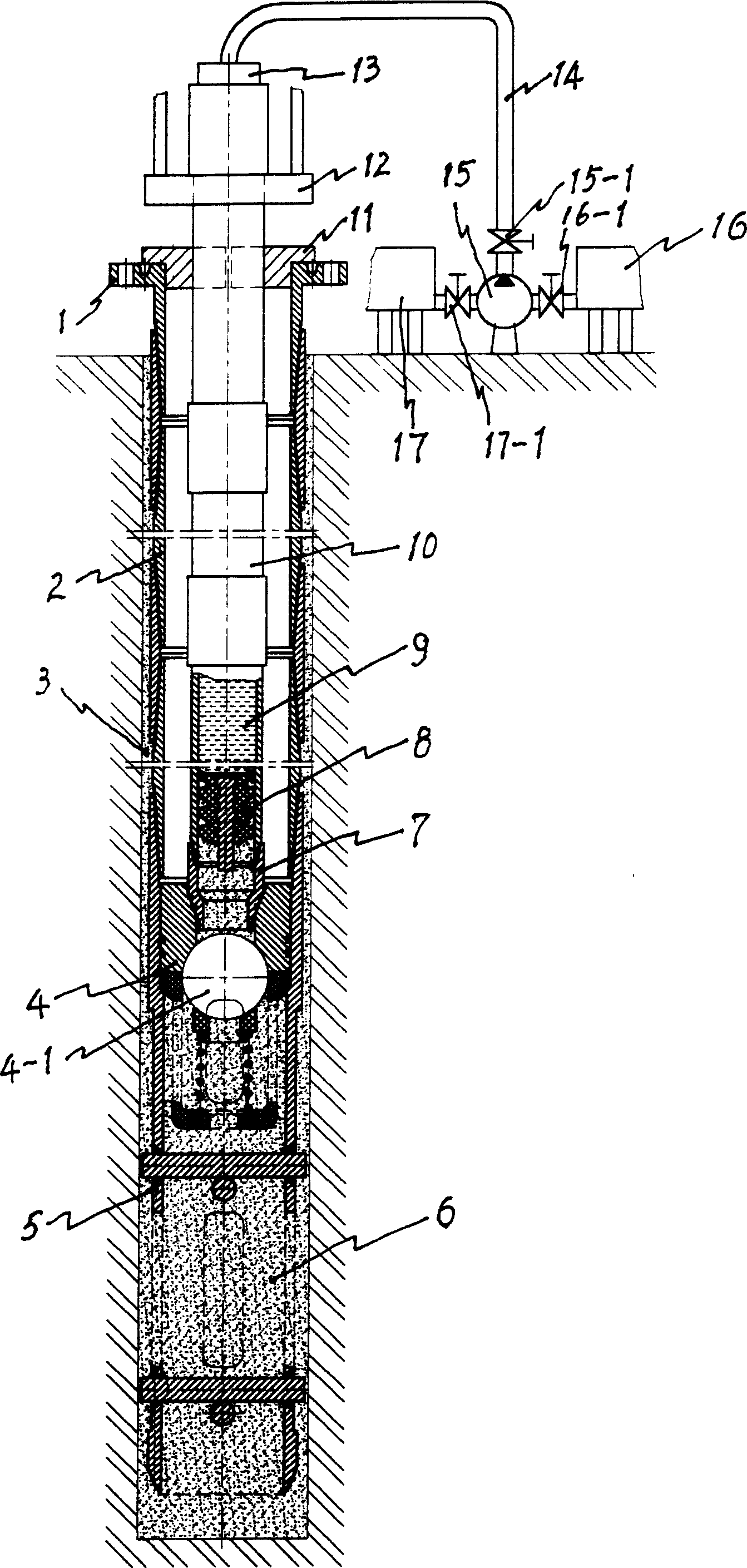

A fixation method for underground gas storage well bore

InactiveCN1837672AFirmly condensedAvoid pollutionContainer filling methodsContainer discharging methodsFixation methodPollution

The invention relates to a method for fixing underground gas storage well cylinder, which comprises a well cylinder whose bottom has a one-way valve and a fixing bracket inside the basic well; a irrigating device for mounting insertion tube and modulating the cement via the cement pump, insertion tube, and one-way valve to fill cement into the cylinder and the well wall; then removing the irrigating device; and waiting the cement be solidified. The invention can avoid pollution on the inner chamber of well cylinder, to eliminate the washing process. And it can improve the safety and service life of well cylinder.

Owner:自贡力源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com