Far infrared flexible surface heating element with high emissivity

A heating element and high emissivity technology, applied in textile, composite materials, and electric heating fields, can solve problems such as reduction and increase of heating power, unstable heating resistance value, etc., and achieve stable heating resistance value and improved quality and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] Example 1 Fabrication of a flexible heating element

[0057] 1) Use PAN-based pre-oxidized silk to cut short fibers to a length of 20-30mm, and after spinning into 20-30TEX yarns, weave them into muslins with a warp and weft density of 18-20 / cm. The oxidized silk cloth is carbonized at 1200°C, and then graphitized at 2600°C to obtain a functional carbon fiber heating cloth. The weight per unit area of the cloth is 80-110 g / m 2 , The carbon content is higher than 99%, and the resistance value is 6-100m·Ω.cm.

[0058]2) Select the resistance value, distribution state (series or parallel) and shape size of the heating carbon cloth according to design elements such as heating area, heating power, and power supply voltage. On this basis, determine the placement position of the electrode and the size of the electrode, and then use the metal wire Sew the electrode wire cloth on the surface of the carbon cloth.

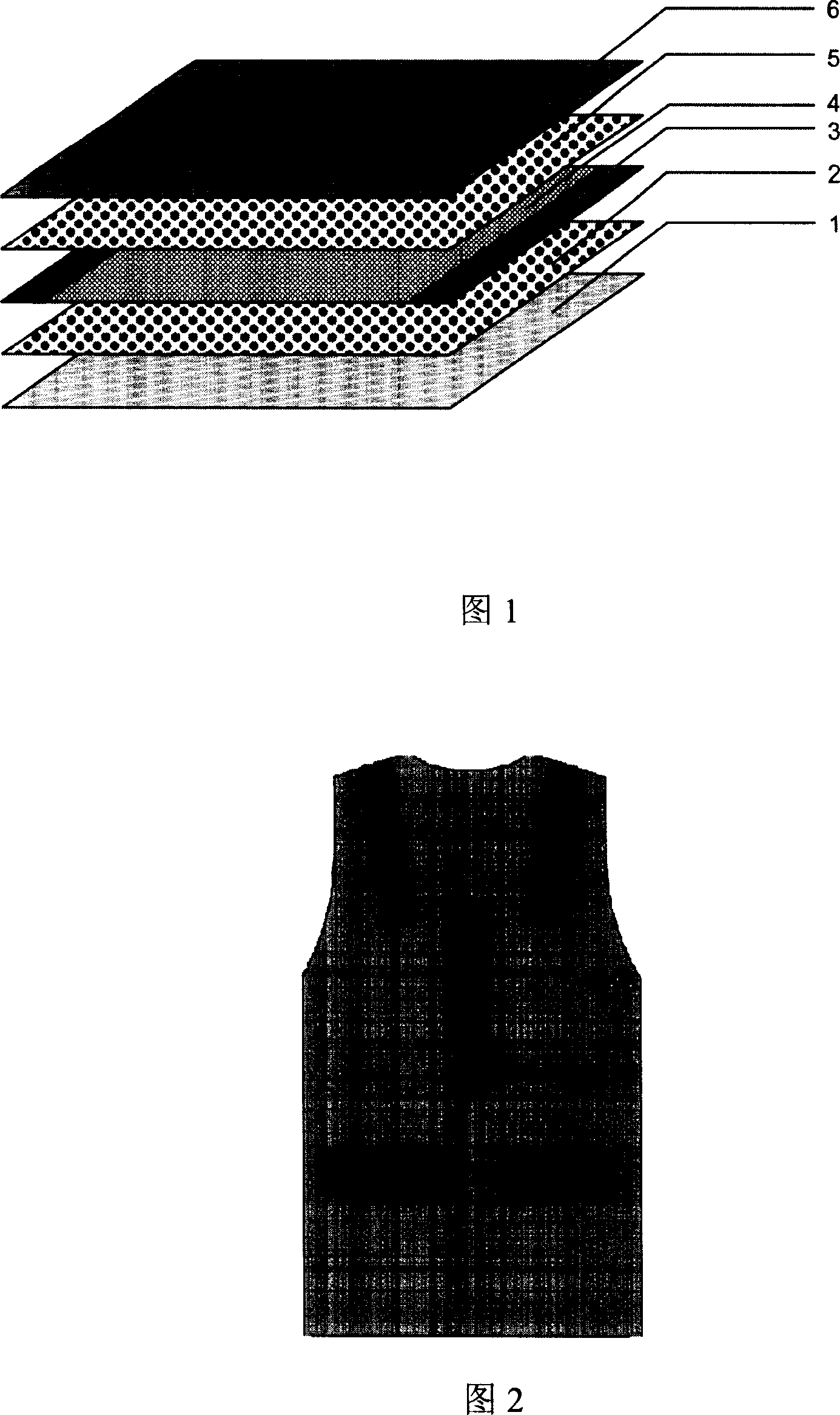

[0059] 3) Lay layers in the following order: heat-conducting...

example 2

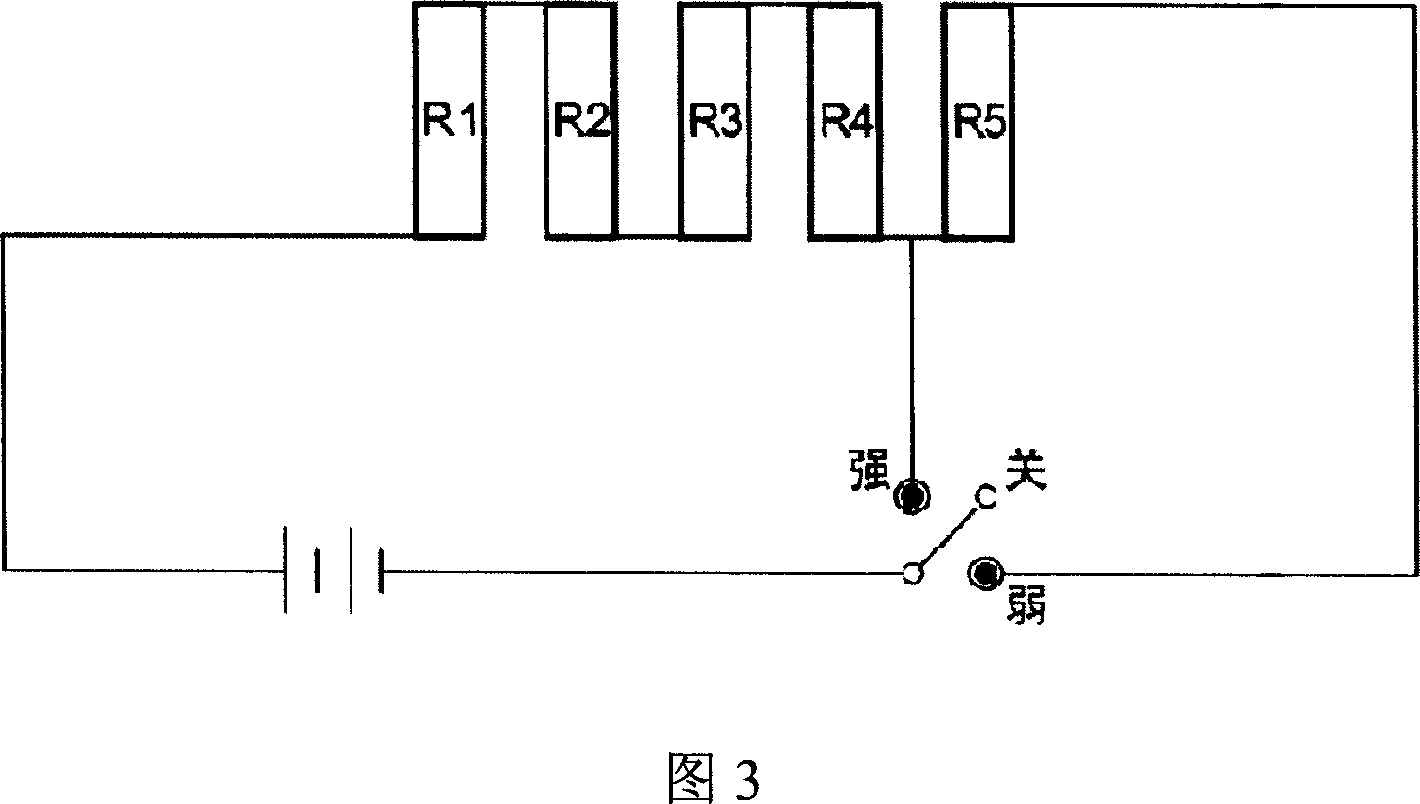

[0062] Example 2 Flexible heating element used in vest

[0063] Use the method of example 1 to make 5 pieces of far-infrared heating sheets, each piece of heating area is 5 cm wide, 15 cm long, and the resistance value is 1.9-2.1 ohms. It is fixed on the shoulder, back, and waist of the human body with sutures (as shown in Figure 2). The heating elements are connected in series with flexible wires, as shown in Figure 3, connected to a 7.4V lithium battery through a two-way switch. When the power is turned on, only the four heating elements on the waist and shoulders generate heat, and the clothes heat up quickly. When the temperature is high, dial Pull the switch manually, the fifth piece (back) heating piece will participate in the work, the resistance will increase, the current will decrease, and it will enter the power-saving and stable working state.

example 3

[0064] Example 3 Flexible heating element applied to electric socks

[0065] Make 2 far-infrared heating sheets with the method of Example 1, wherein one is used for the toes, the heating area is 2 cm wide, 8 cm long, and the resistance value is 1.5-2 ohms, and the other is used for the arch of the foot, and the heating area is 4 cm wide. 5 cm long, with a resistance of 1.5-2 ohms, fix the above-mentioned heating sheets with PU hot melt adhesive and connect them in series, and use flexible wires at both ends to connect with the 3,7V lithium battery fixed at the ankle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com