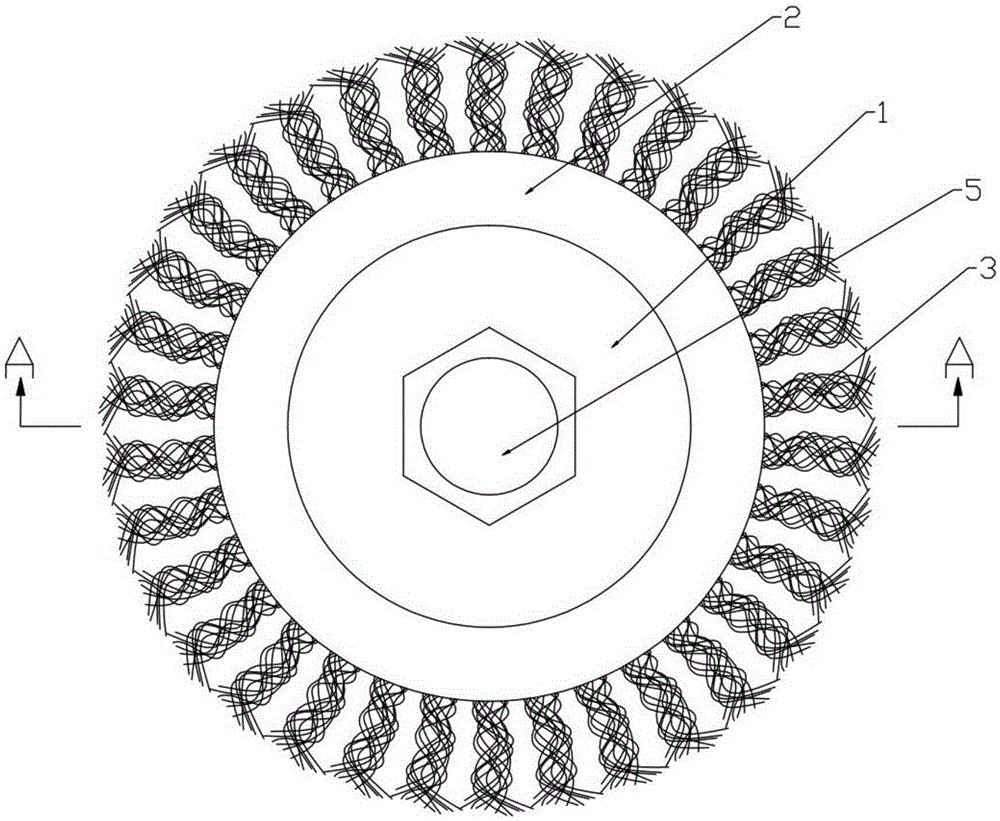

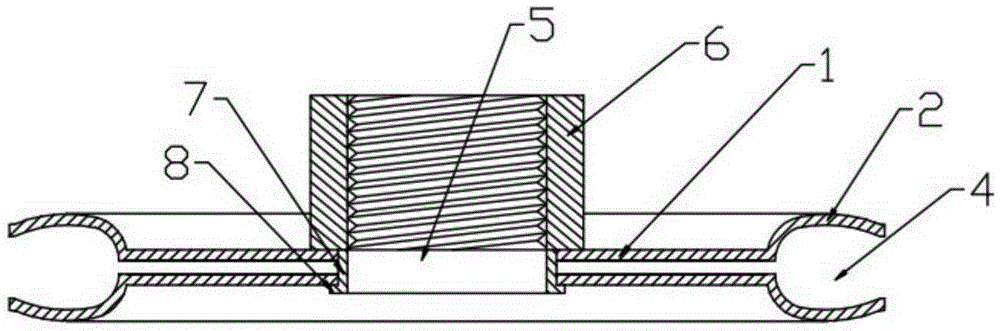

Metal wire polishing wheel

A metal wire and polishing wheel technology, used in the field of grinding and polishing, can solve the problems of easy falling off of metal wire, non-wear-resistant brush wire, short service life, etc., to increase mechanical properties and mechanical properties, fast cooling speed, solid solution The effect of less state impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

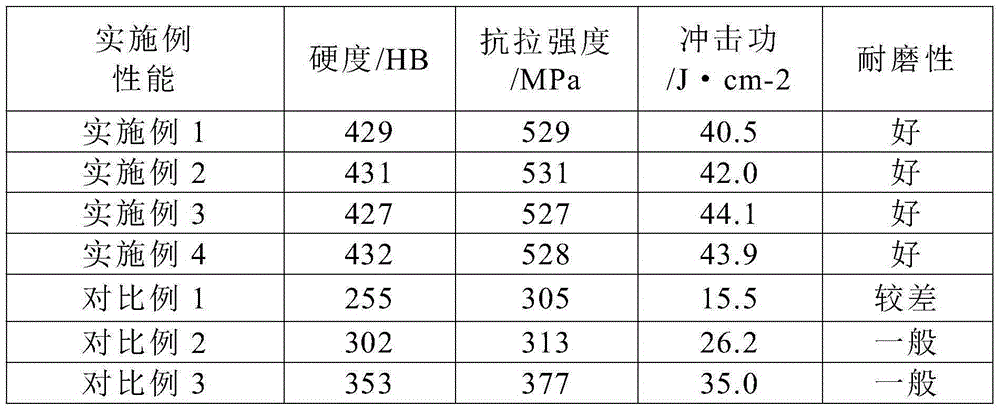

Embodiment 1

[0044] The metal wire in the metal wire bundle in the present invention is made of aluminum alloy composite material, and the aluminum alloy composite material includes an aluminum alloy substrate and a ceramic layer coated on the surface of the aluminum alloy substrate by laser cladding. The preparation process of the aluminum alloy composite material is as follows:

[0045] The surface of the aluminum alloy is first polished with sandpaper, and then a layer of light-absorbing paint is applied to the surface of the aluminum alloy by spraying. The light-absorbing coating includes the following components in mass percentage: 40% TiO 2 , 18% nano Y 2 o 3 , 20% nano-CeO 2 , and the balance is additives such as dispersant and thickener, which can be used commonly.

[0046] Ultrasonicize the carbon nanotubes in ethanol or dichloromethane for 20 minutes to remove the glue, roughen the surface of the carbon nanotubes with 15% v / w sulfuric acid, and then impregnate the carbon nano...

Embodiment 2

[0049] The metal wire in the metal wire bundle in the present invention is made of aluminum alloy composite material, and the aluminum alloy composite material includes an aluminum alloy substrate and a ceramic layer coated on the surface of the aluminum alloy substrate by laser cladding. The preparation process of the aluminum alloy composite material is as follows:

[0050] The surface of the aluminum alloy is first polished with sandpaper, and then a layer of light-absorbing paint is applied to the surface of the aluminum alloy by spraying. The light-absorbing coating includes the following components in mass percentage: 44% TiO 2 , 17% nano Y 2 o 3 , 18% nano CeO 2 , and the balance is additives such as dispersant and thickener, which can be used commonly.

[0051] Ultrasonicize the carbon nanotubes in ethanol or dichloromethane for 24 minutes to remove the glue, roughen the surface of the carbon nanotubes with 16% v / w sulfuric acid, and then impregnate the carbon nano...

Embodiment 3

[0054] The metal wire in the metal wire bundle in the present invention is made of aluminum alloy composite material, and the aluminum alloy composite material includes an aluminum alloy substrate and a ceramic layer coated on the surface of the aluminum alloy substrate by laser cladding. The preparation process of the aluminum alloy composite material is as follows:

[0055] The surface of the aluminum alloy is first polished with sandpaper, and then a layer of light-absorbing paint is applied to the surface of the aluminum alloy by spraying. The light-absorbing coating includes the following components in mass percentage: 47% TiO 2 , 16% nano Y 2 o 3 , 17% nano CeO 2 , and the balance is additives such as dispersant and thickener, which can be used commonly.

[0056] Ultrasonicize the carbon nanotubes in ethanol or dichloromethane for 28 minutes to remove the glue, roughen the surface of the carbon nanotubes with 18% v / w sulfuric acid, and then impregnate the carbon nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com