Patents

Literature

37results about How to "Improve far-infrared emissivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

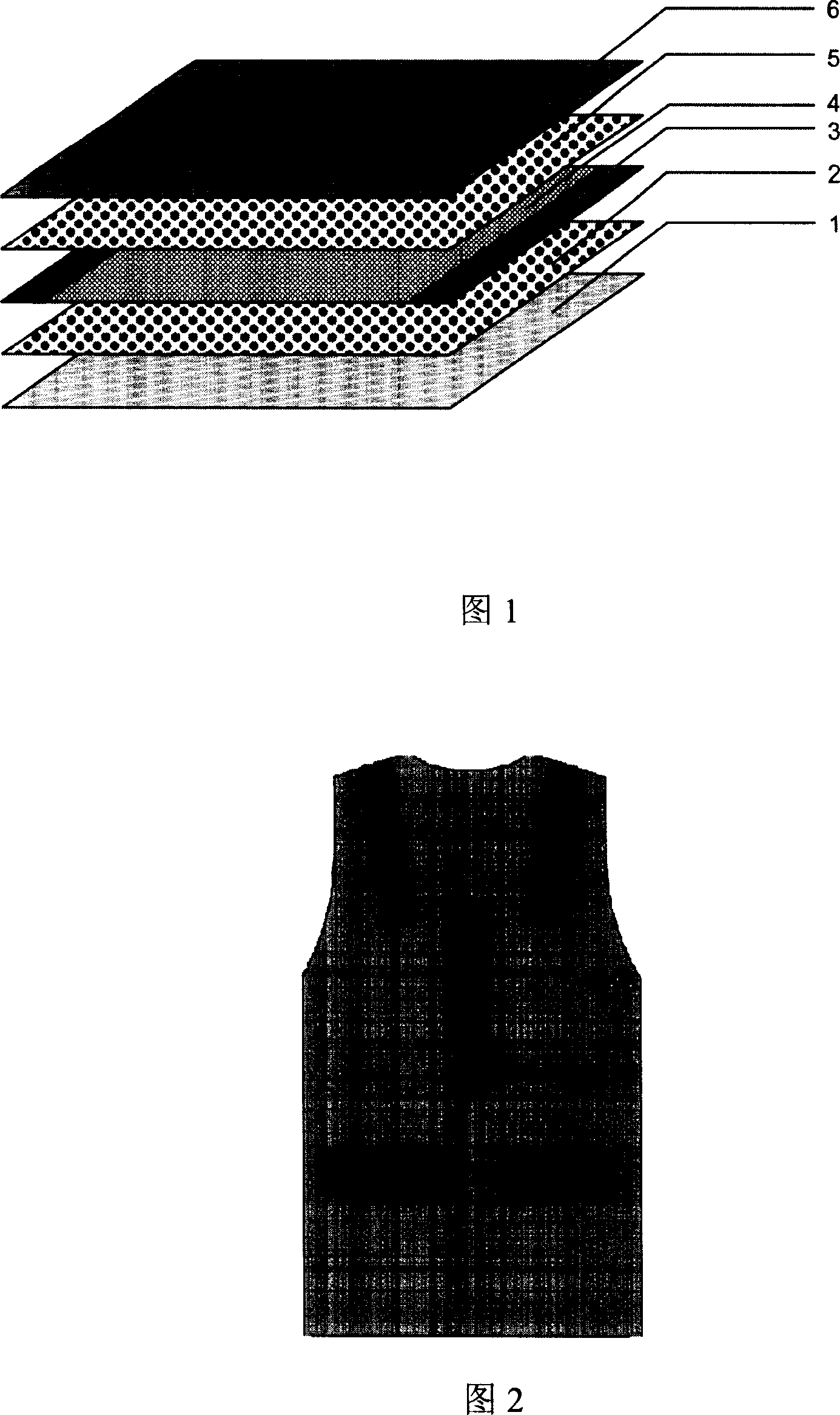

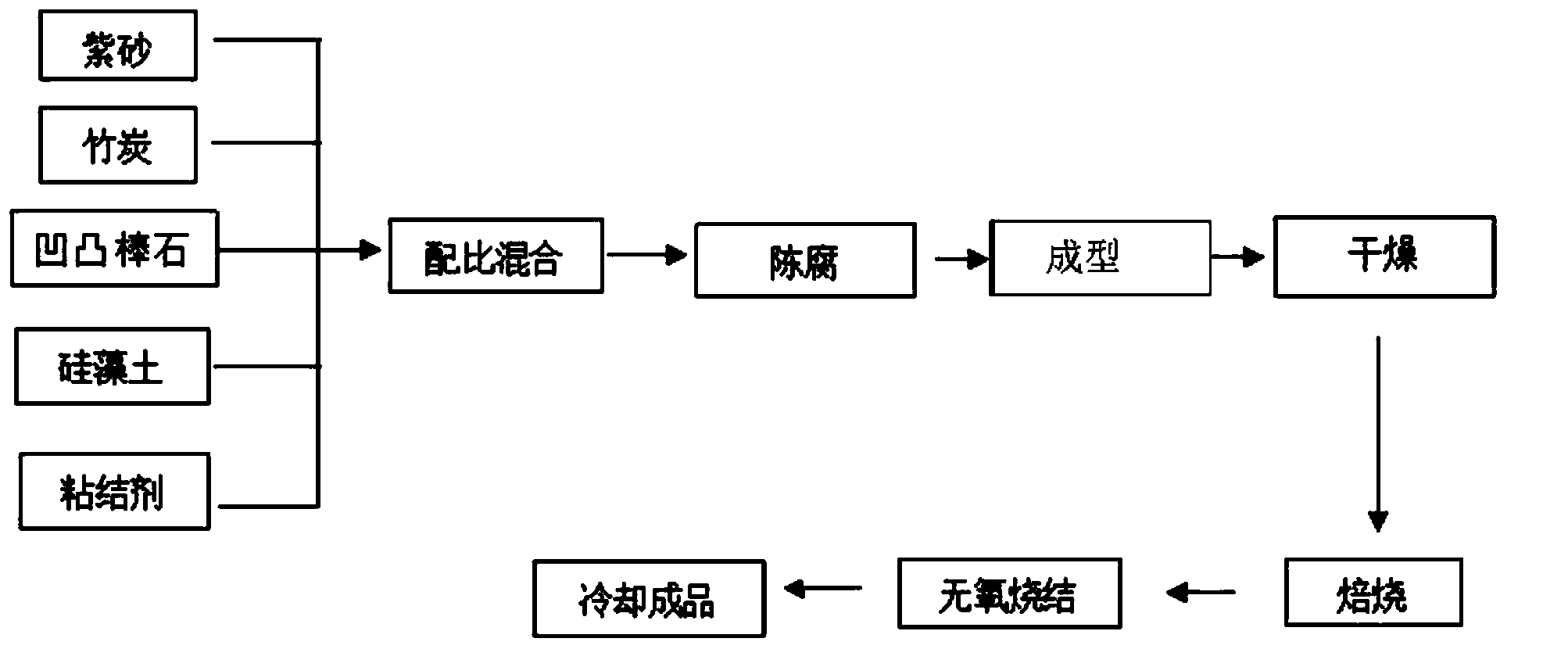

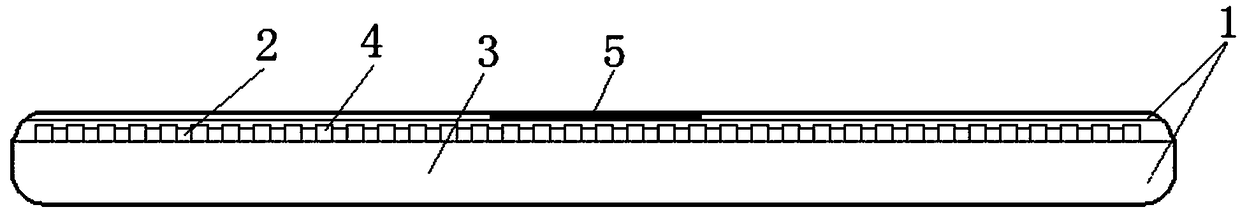

Far infrared flexible surface heating element with high emissivity

The invention discloses one high emission rate infrared flexible heating element, which comprises heat conductive isolation distribution layer, heat melt glue network film A, electrode, heating part, heat melt glue film B and isolation layer with each parts combined into one part by glue and sealing types. The invention also discloses the heating element main process and property and its process method.

Owner:DONGHUA UNIV +1

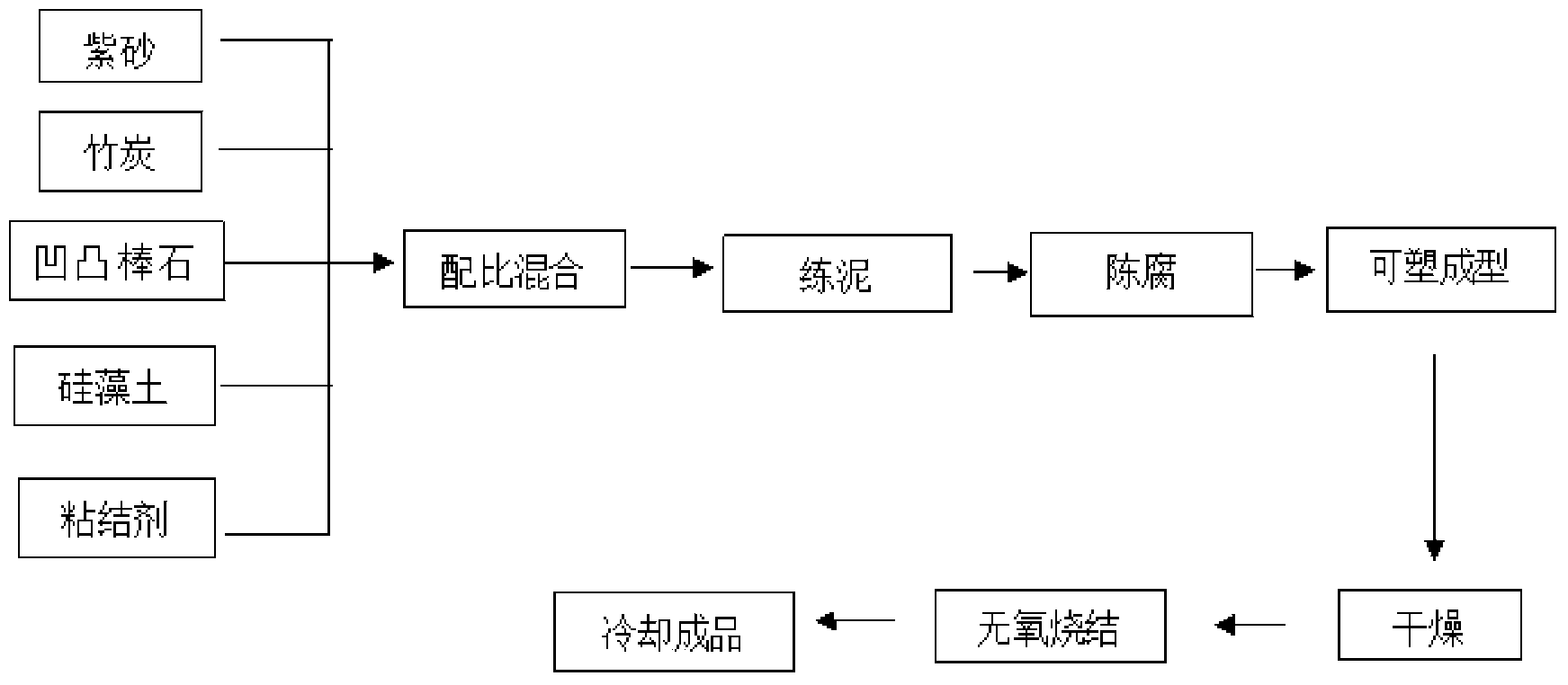

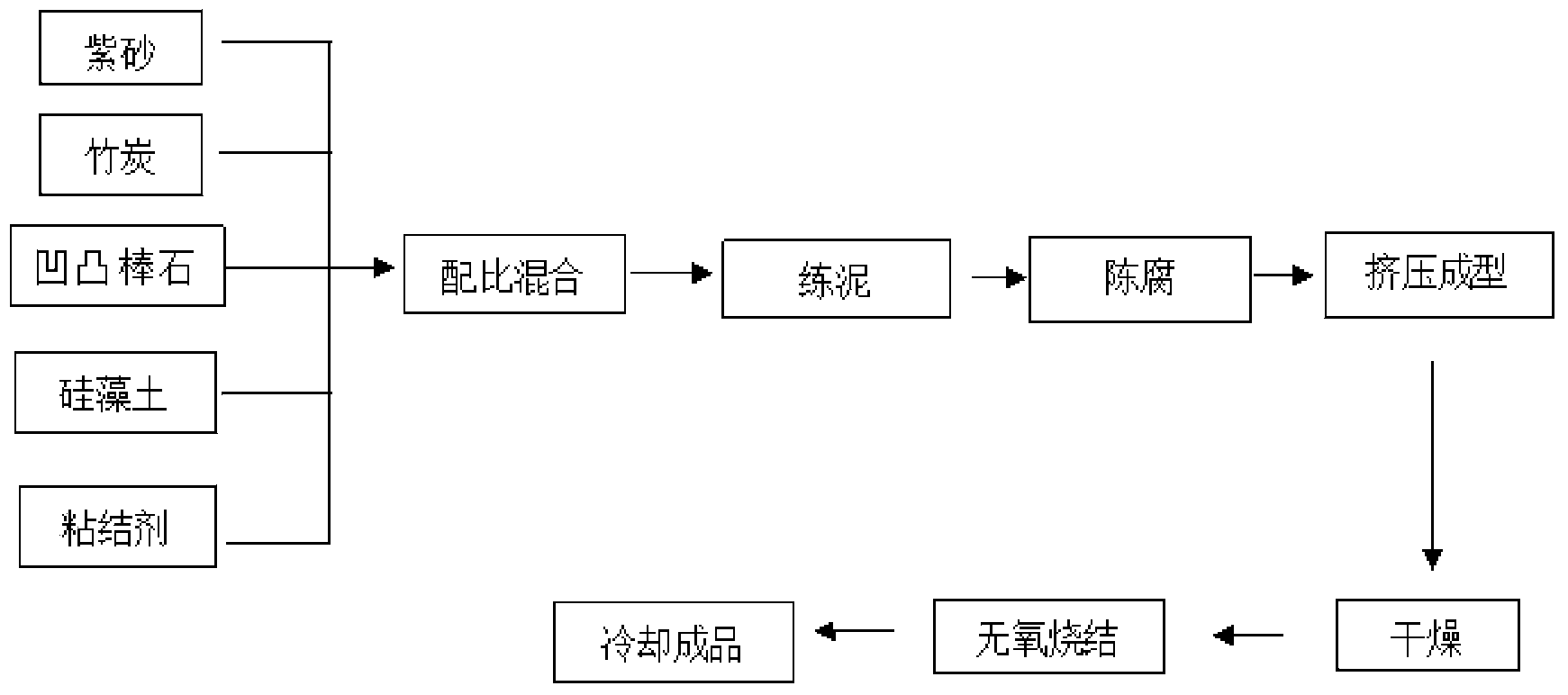

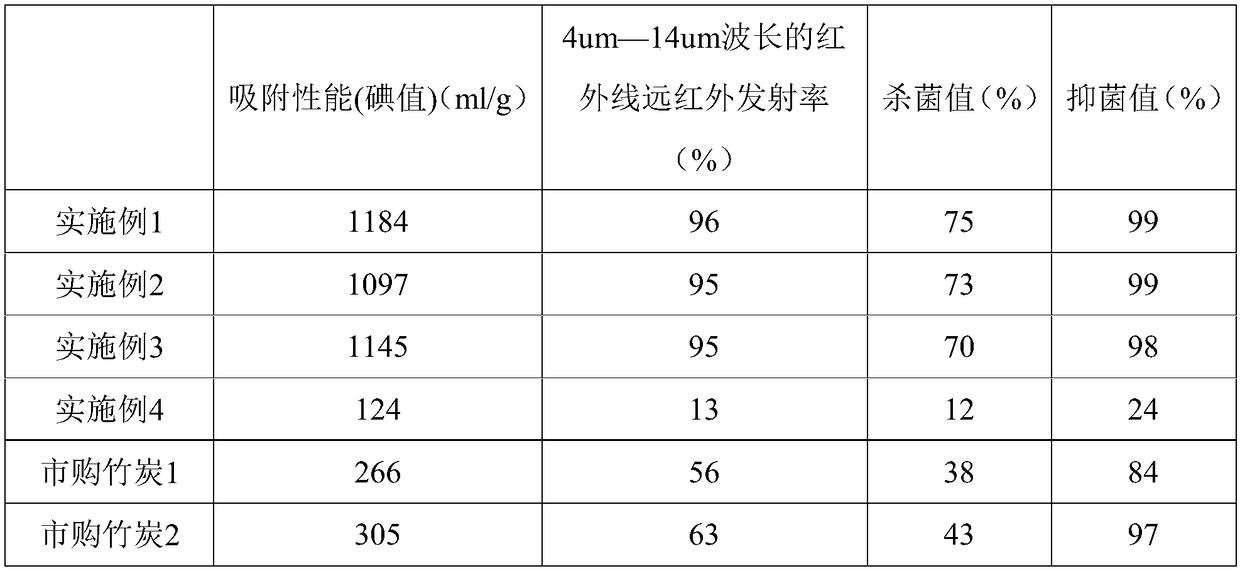

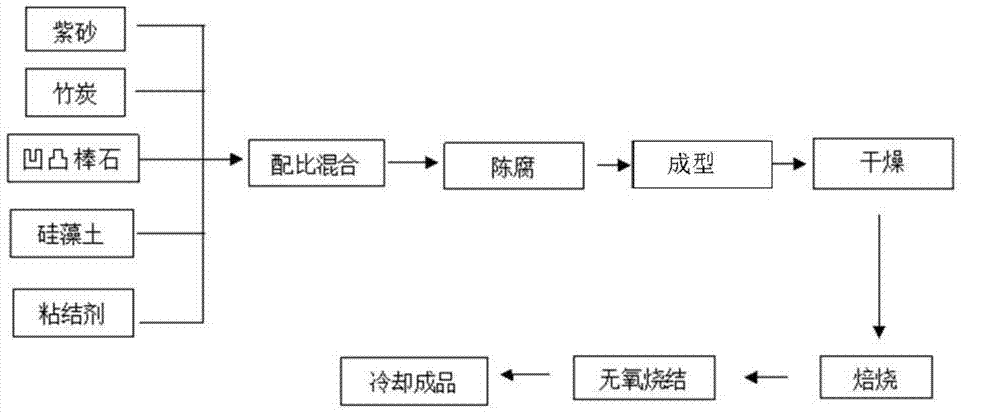

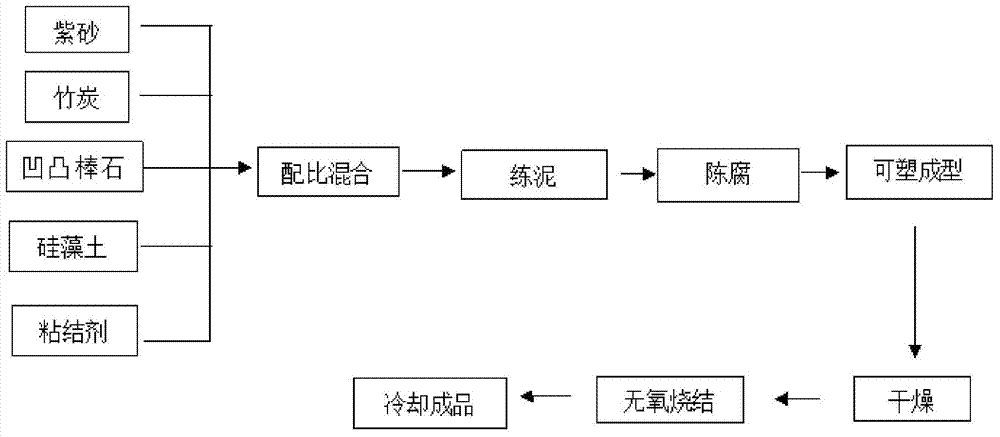

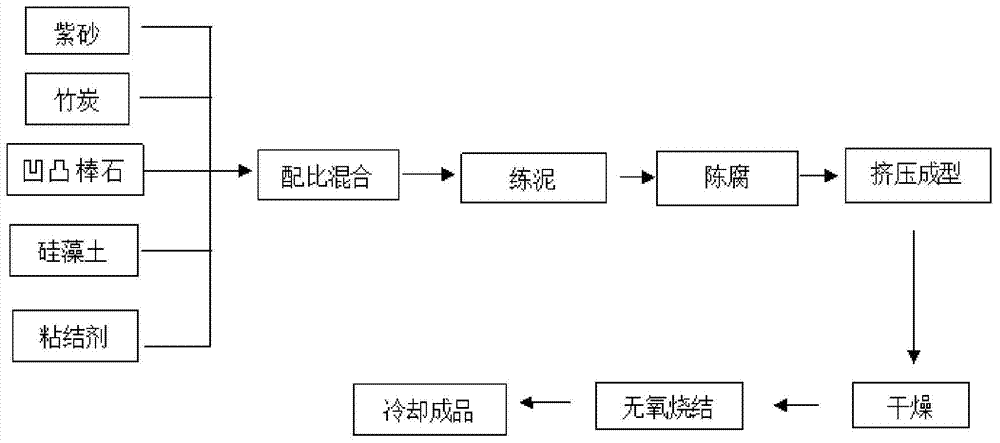

Microcrystal bamboo charcoal purple sand composite pottery material and application thereof

InactiveCN103467066AHigh porosityImprove thermal shock resistanceOther chemical processesCeramicwareHazardous substancePhenol

The invention relates to a microcrystal bamboo charcoal purple sand composite pottery material and application of the microcrystal bamboo charcoal purple sand composite pottery material. The microcrystal bamboo charcoal purple sand composite pottery material is composed of, by weight, 5-40% of microcrystal bamboo charcoal powder, 40-60% of purple sand powder, 10-30% of attapulgite, 5-30% of kieselguhr and 1-5% of binder in a mixing mode. The microcrystal bamboo charcoal purple sand composite pottery material can be used for manufacturing a microcrystal bamboo charcoal purple sand composite pottery, the steps for manufacturing the microcrystal bamboo charcoal purple sand composite pottery are specifically forming, air drying, drying, calcination and cooling, and therefore the microcrystal bamboo charcoal purple sand composite pottery can be obtained. According to the microcrystal bamboo charcoal purple sand composite pottery material and the application of the microcrystal bamboo charcoal purple sand composite pottery material, through different raw material ratios and calcination crafts, the manufactured microcrystal bamboo charcoal pottery after processing is low in firing shrinkage coefficient, high in bending strength and strong in adsorption of formaldehyde, phenol, sulfur dioxide, TVOC and other hazardous substances and can be manufactured into pottery materials of different water adsorption rates as required.

Owner:王萍 +2

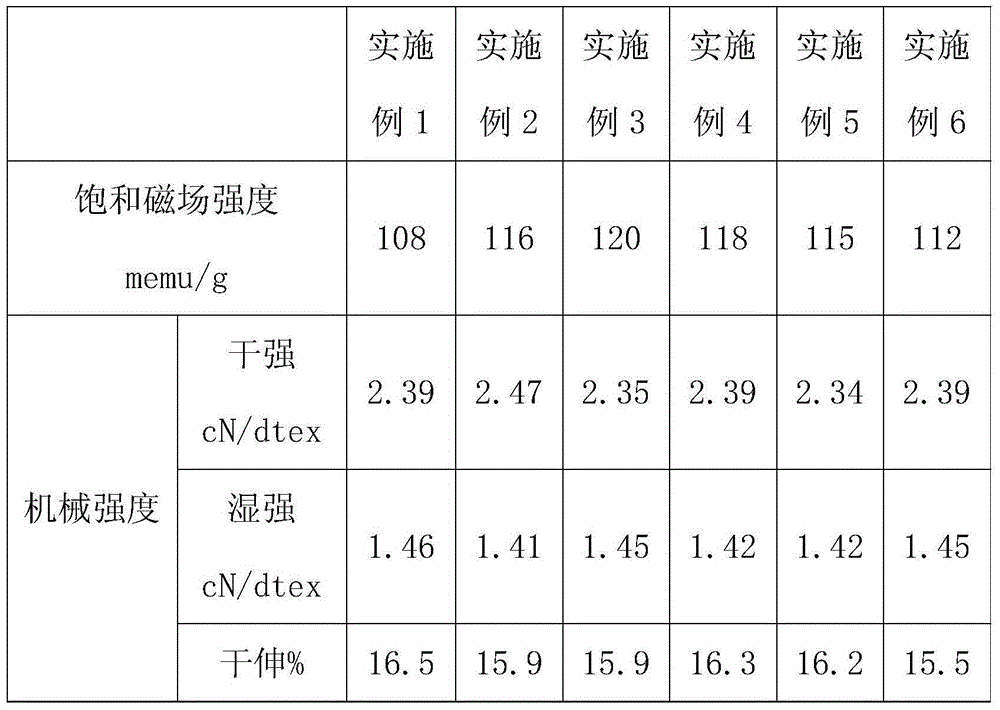

Stone needle polyester fiber and preparation method thereof

ActiveCN108330555AImprove solubilityImprove conductivityElectroconductive/antistatic filament manufactureFilament/thread formingInfraredElectricity

The invention provides stone needle polyester fiber. The content of stone needle micro powder in the fiber is 0.5-5%, and the content of an electric conduction enhancer is 5-10%. The far infrared emission rate of the textile prepared by adopting the stone needle polyester fiber is 92%. The invention further provides a preparation method of the stone needle polyester fiber. The preparation method comprises the step that S1 a stone needle polyester resin section is prepared; in the step 1, the stone needle polyester resin section is prepared from raw materials: 65-70% of polyester high polymer resin section, 5-13% of electric conduction fluid, 0.5-5% of stone needle nano micro powder, 5-10% of electric conduction enhancer and 0.5-1% of dispersing agent. Stone needle in a traditional Chinesemedicine therapy is adopted to serve as a base material and added into the spinning processing process of modern polyester, and thus the prepared fiber has the functions of releasing infrared rays andconducting electricity at the same time.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

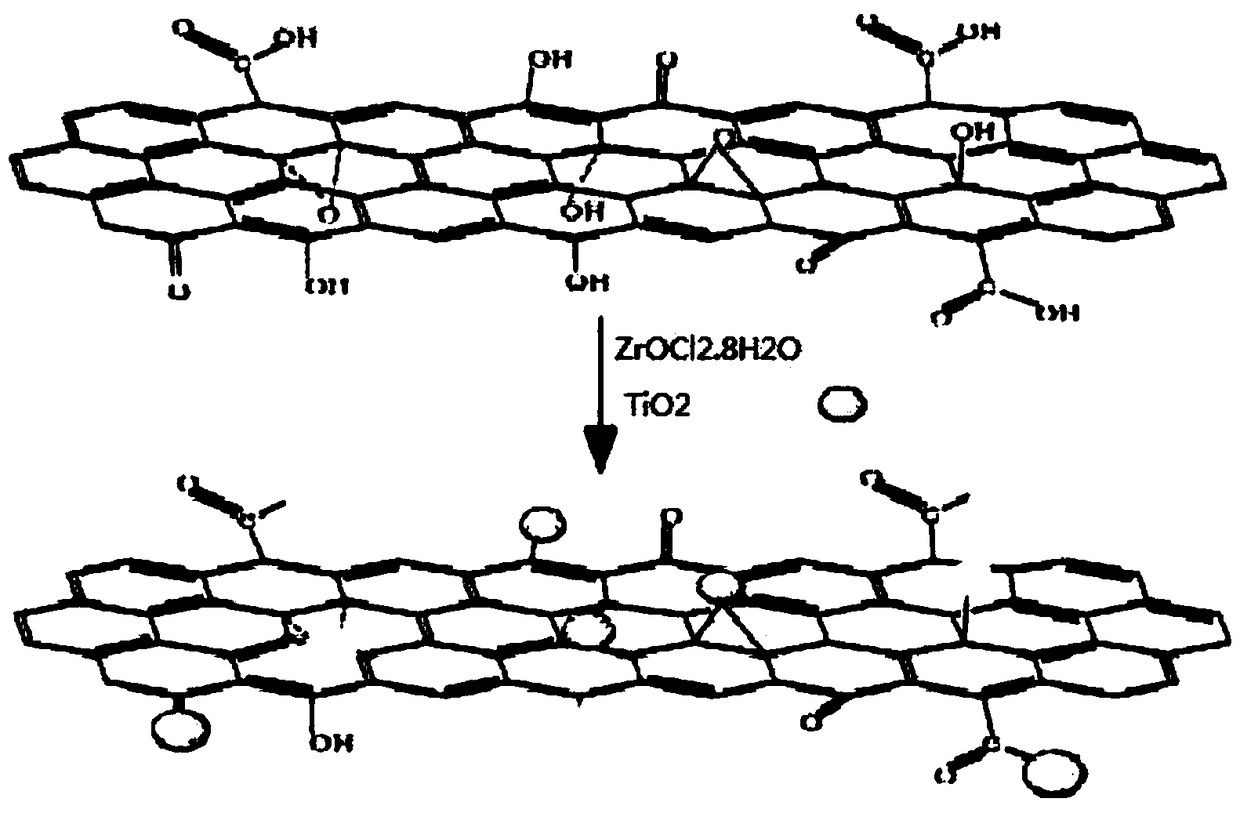

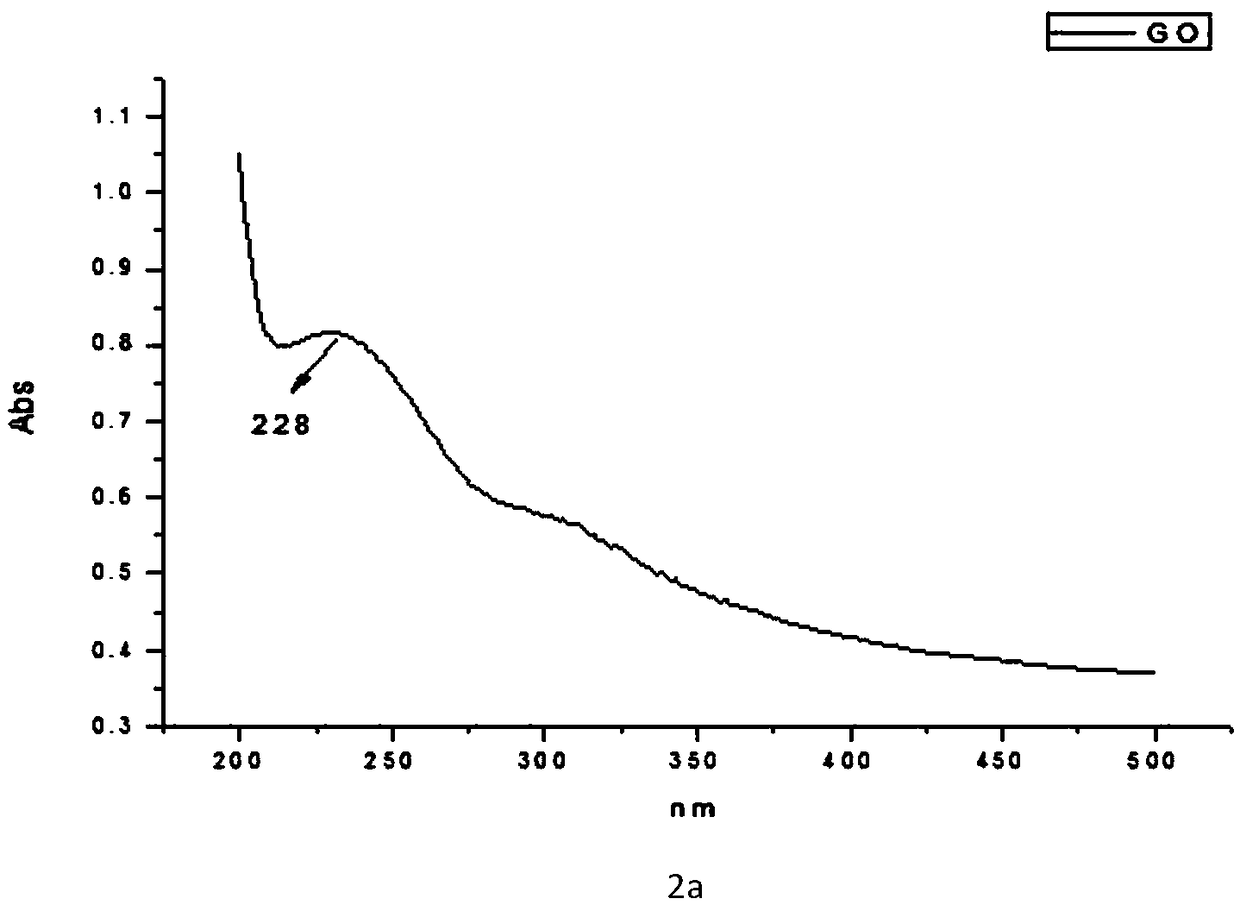

Far infrared textile fabric preparation method

ActiveCN108221363AEasy to operateImprove far-infrared emissivityVegetal fibresEngineeringFar infrared

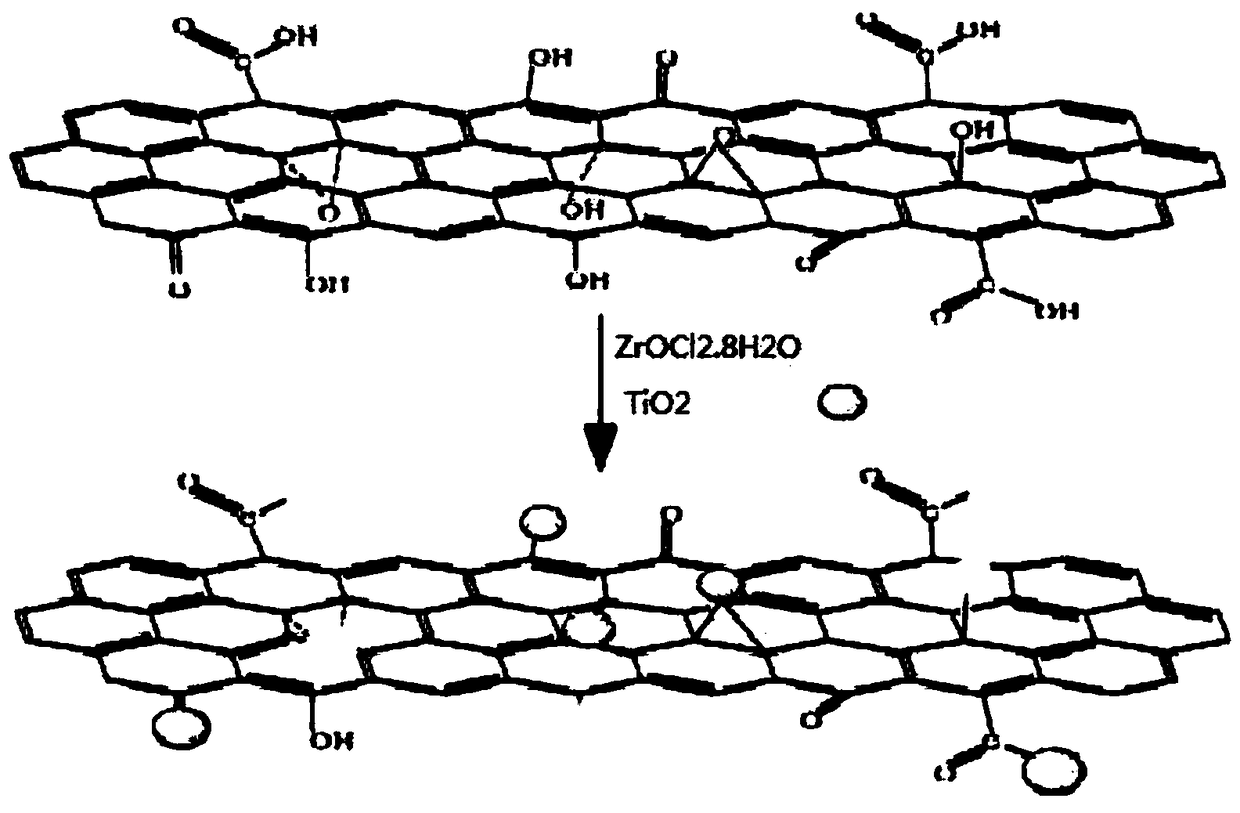

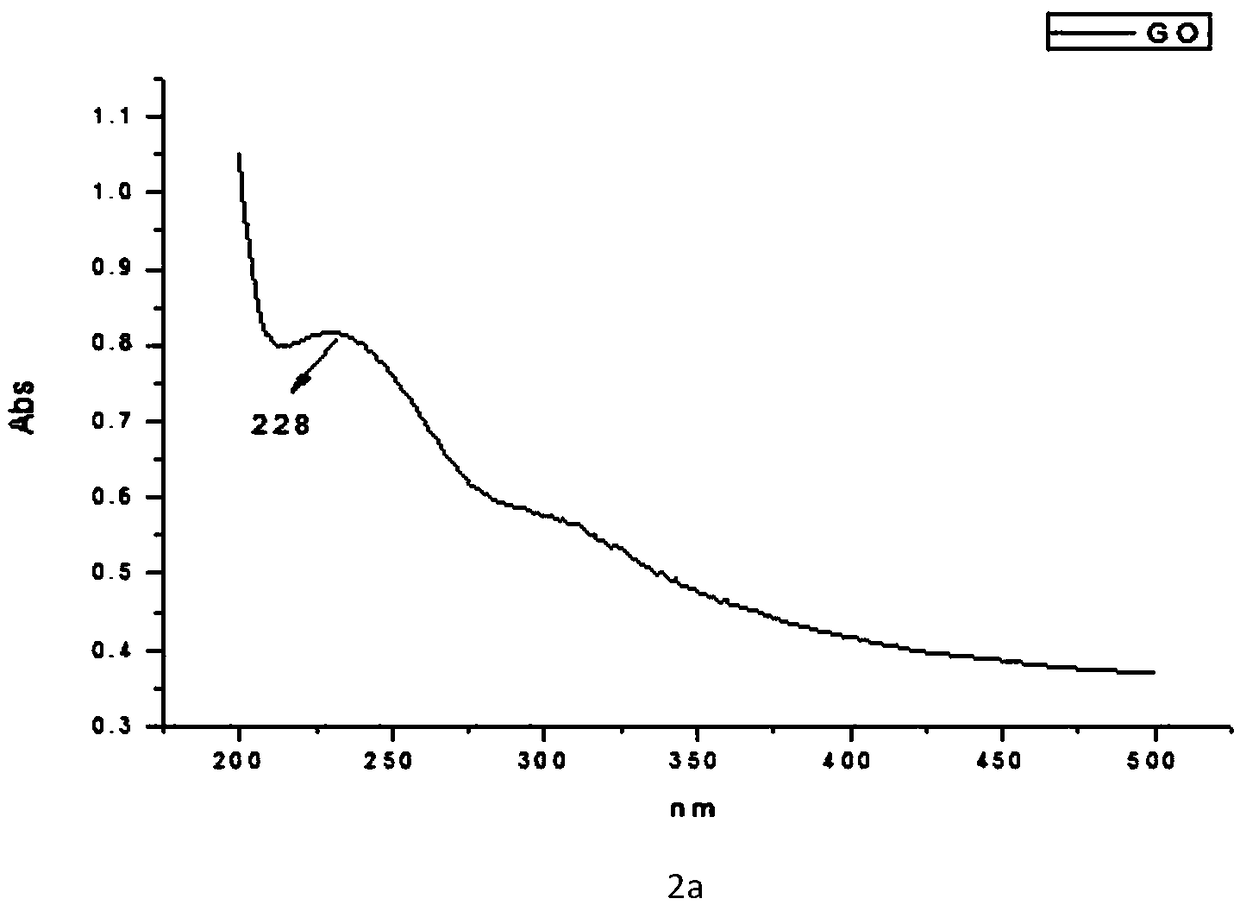

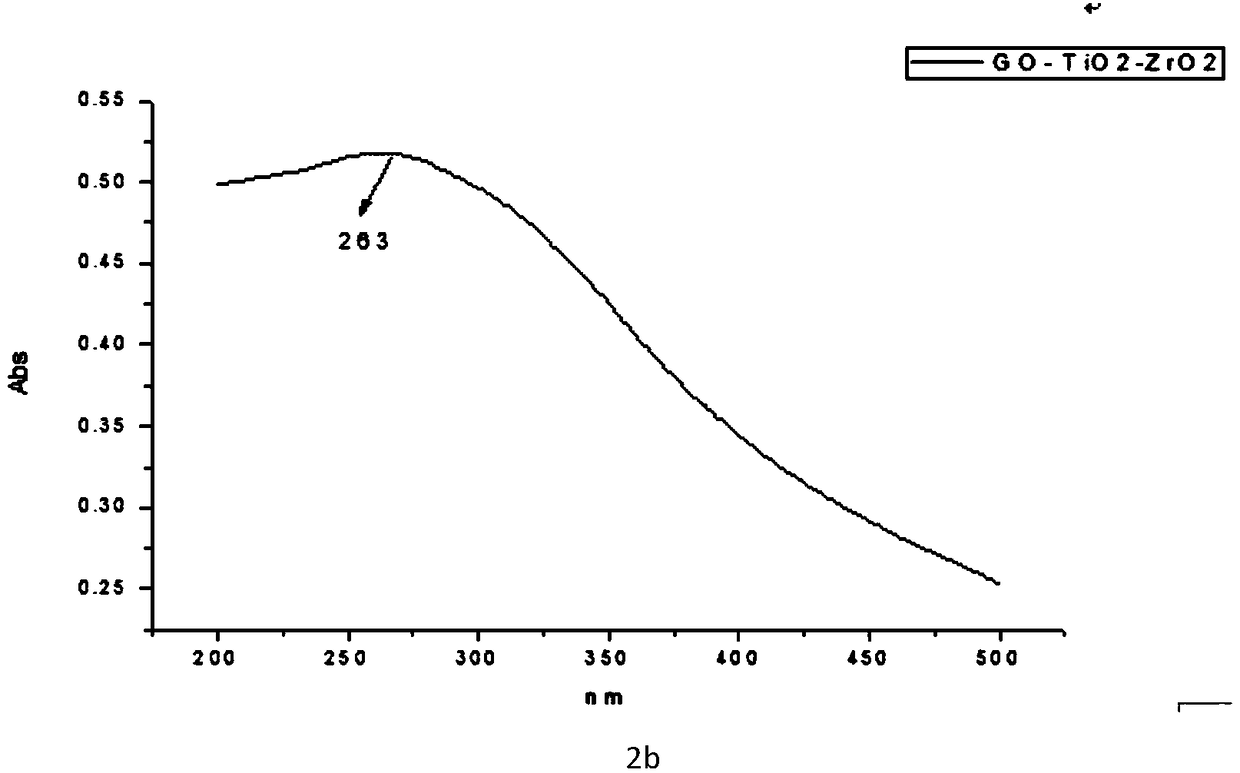

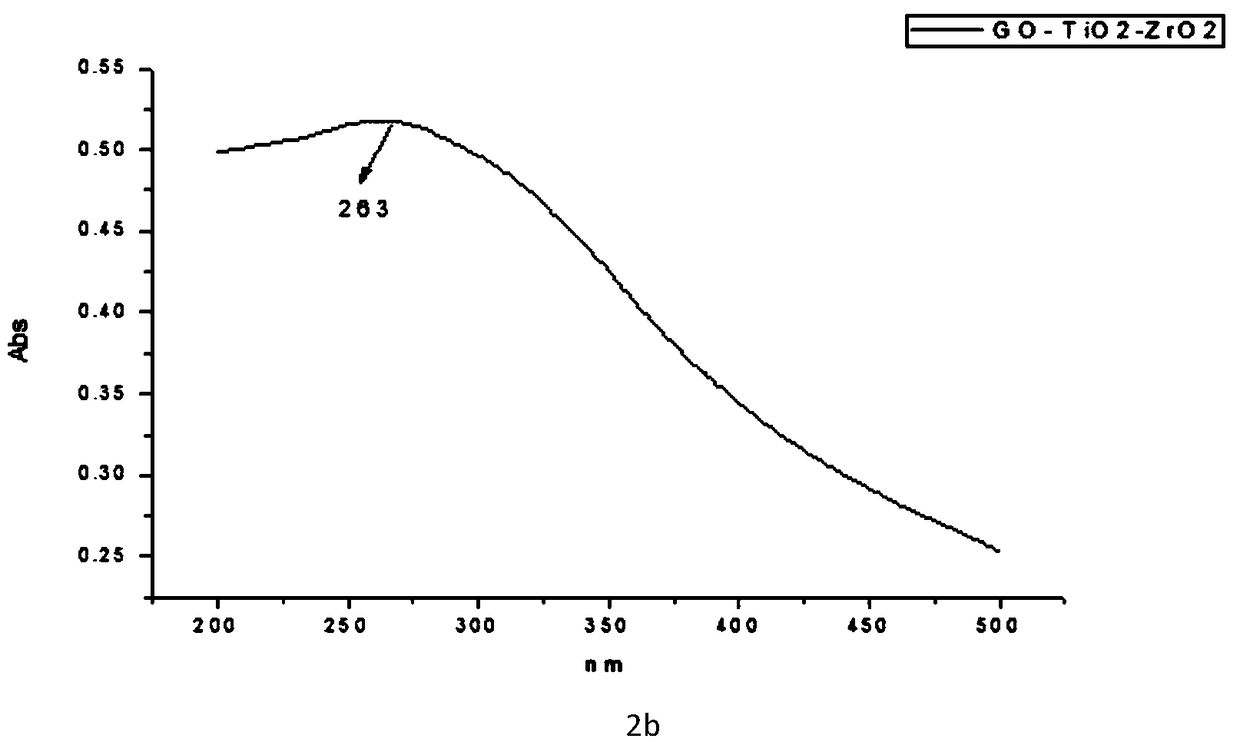

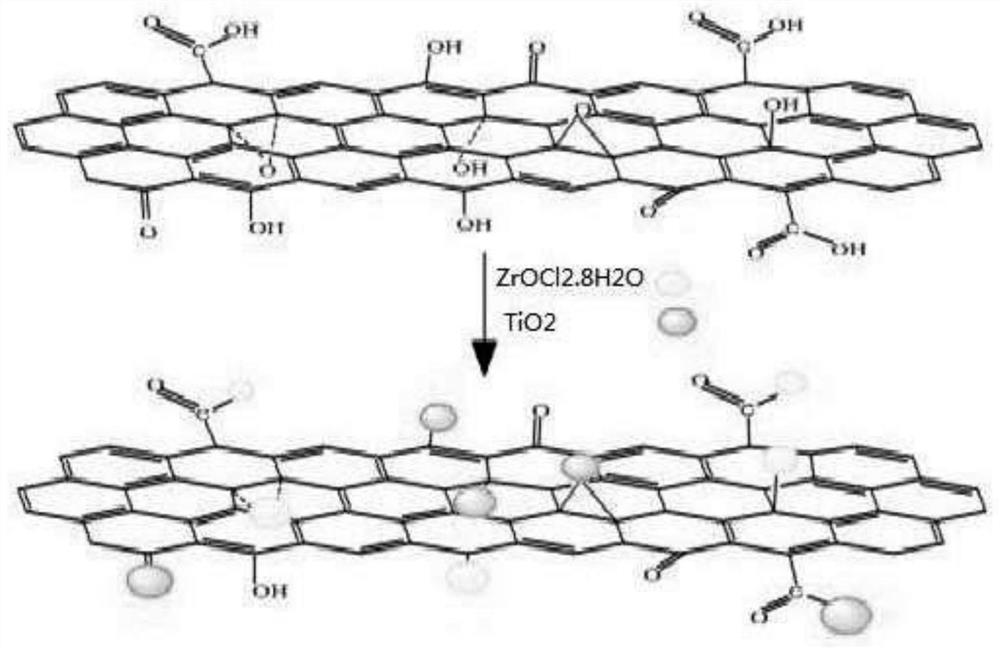

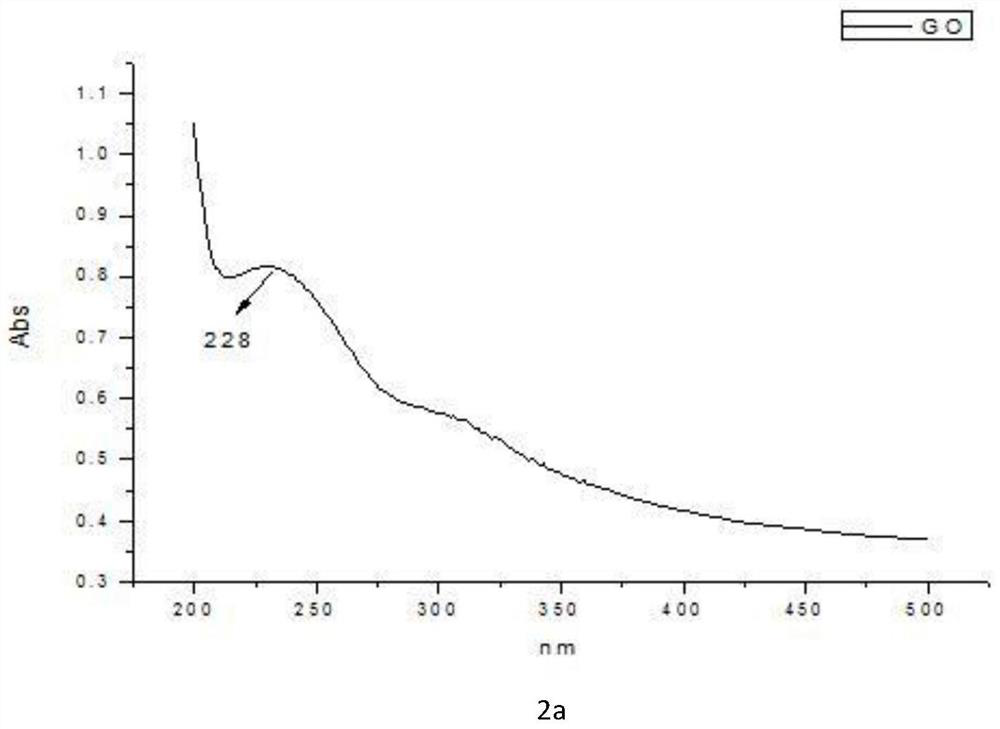

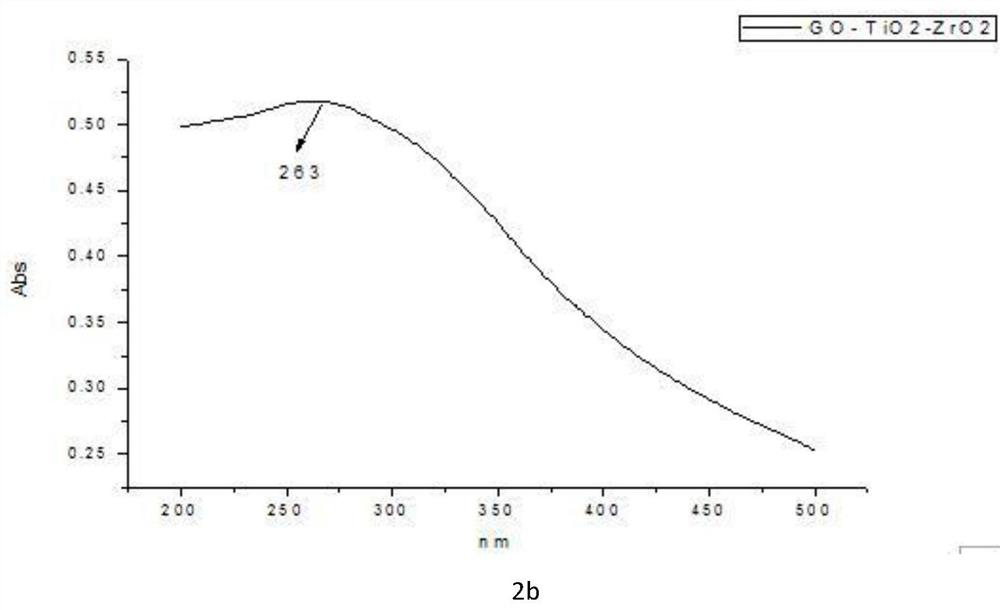

The invention relates to the technical field of textile finishing and specifically relates to a far infrared textile fabric preparation method. The invention further provides a composite material based on GO-TiO-ZrO2, wherein the three materials are connected through chemical bonds, a traditional textile material with far infrared emission and a novel far infrared emitting material graphene oxideare compounded, and then the graphene oxide / titanium dioxide / zirconium dioxide composite material is combined with cotton textiles through a crosslinking effect of waterborne polyurethane in an after-finishing mode; thus, a far infrared emission rate of textiles is improved; furthermore, the composite material has the advantages of simpleness in preparation and low cost.

Owner:HUNAN INSTITUTE OF ENGINEERING

Method for firing high-density bamboo charcoal by using medium-small diameter bamboos

InactiveCN102206498AHigh densityAbundant resourcesBiofuelsSpecial form destructive distillationHigh densityVolumetric Mass Density

The invention relates to a method for firing high-density bamboo charcoal by using medium-small diameter bamboos, comprising the following steps of: selecting a carbonization furnace, such as a multitubular moving bed destructive distillation carbonization furnace and the like which have controllable temperate of different stages of charcoals and achieve the temperature of high-temperature areas at 1000 DEG C and are provided with sealing areas at the lower parts of carbonization furnaces near charcoal outlets, for firing; splitting and cutting a bamboo wood, and then placing into the carbonization furnace; then firing through the steps of smoke drying, pre-carbonization, main carbonization, calcination refining, sealing cooling, charcoal discharging, and the like, wherein the density of the bamboo charcoal reaches 0.9-1.2 g / cm<3>, and application fields are further broadened. Through adopting the method disclosed by the invention to fire the high-density bamboo charcoal, the medium-small diameter bamboos have rich raw materials and short regeneration period; other heat supply sources are almost not needed during firing; and the charcoals can be discharged after 25.5-42 hours; and in addition, the invention has short production period, high production efficiency and outstanding energy saving effect.

Owner:ZHEJIANG FORESTRY ACAD

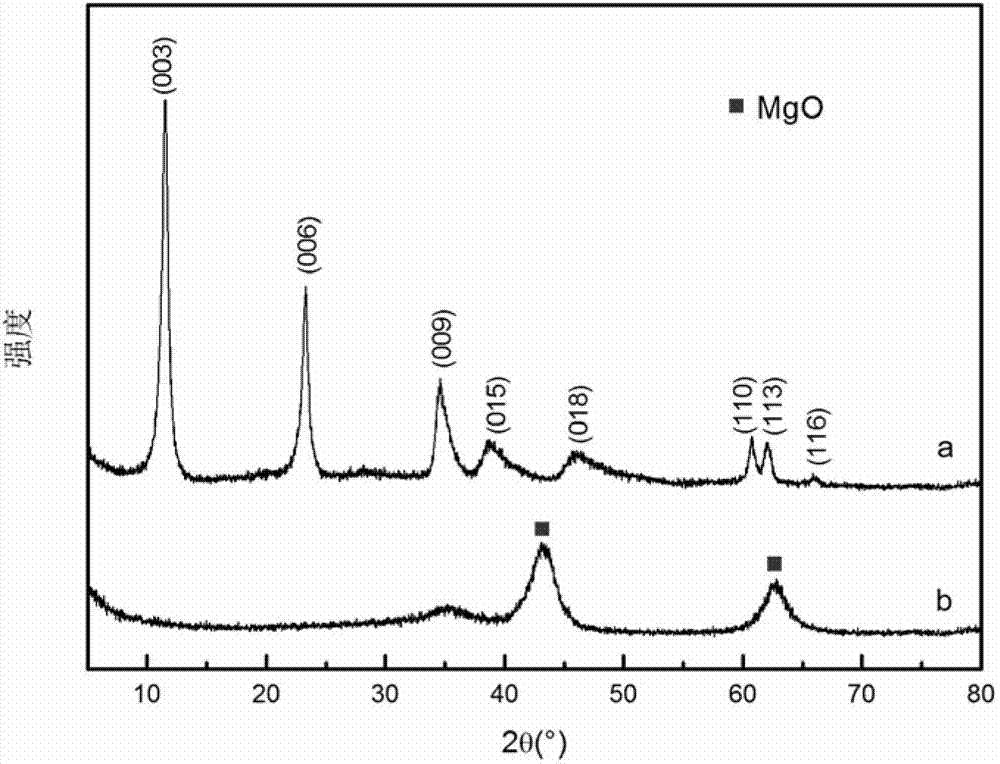

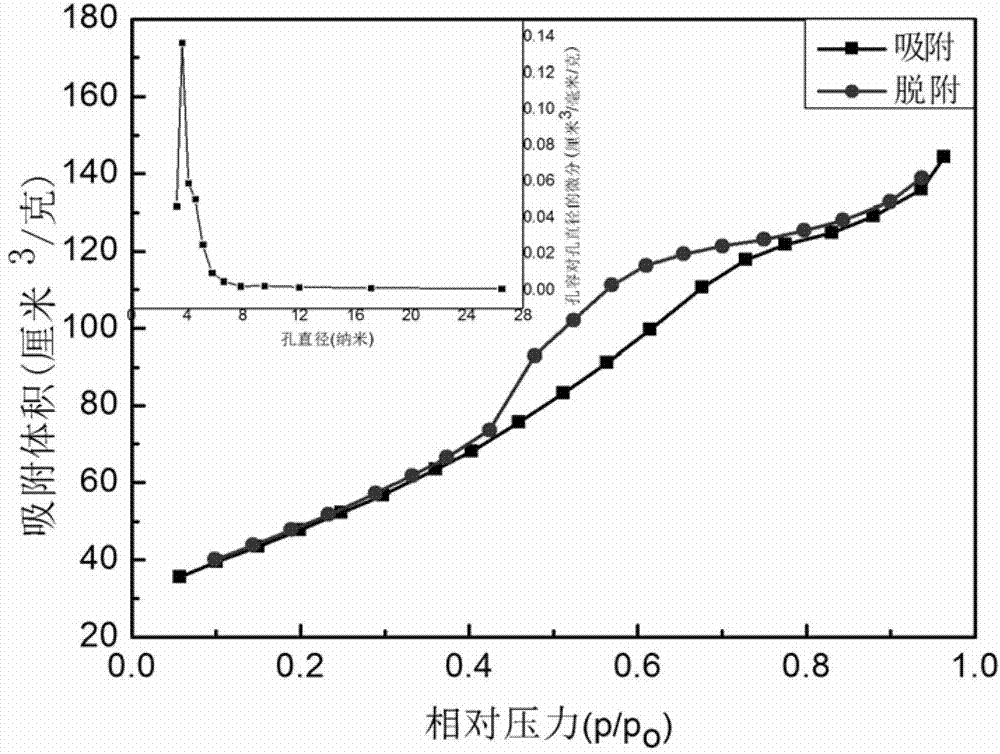

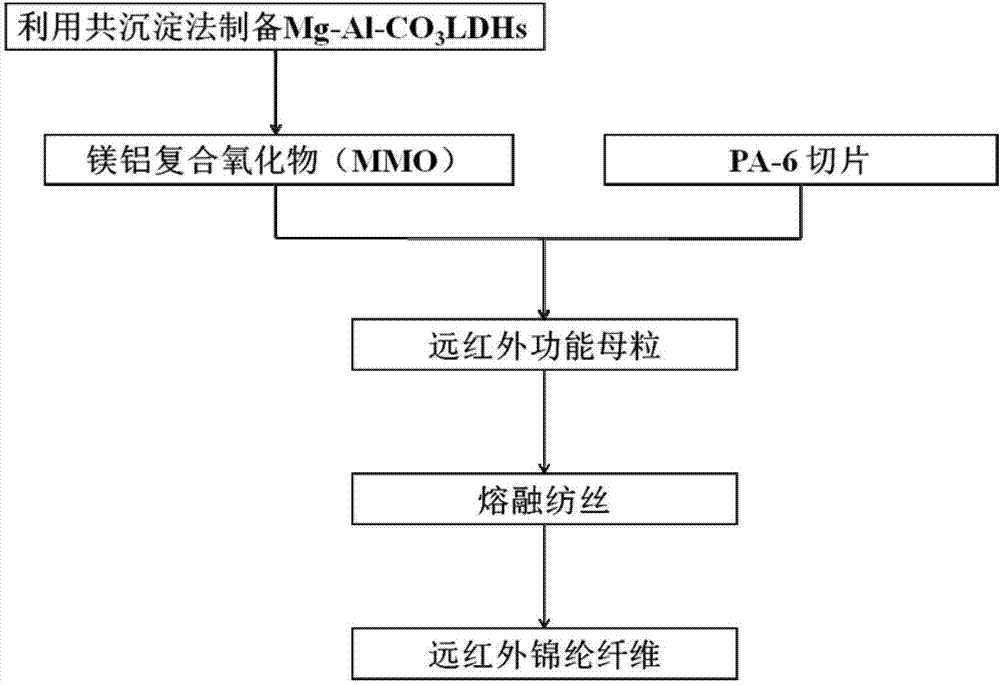

Method for preparing efficient far infrared nylon fibers

InactiveCN102776600AOvercome problemsImprove far-infrared emissivityArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceMagnesium salt

The invention relates to a method for preparing efficient far infrared nylon fibers, comprising the steps of (1) preparing soluble magnesium salt and soluble aluminum salt into a mixed aqueous solution; adding the mixed aqueous solution drop by drop to a NaOH / Na2CO3 solution; and after crystallizing, leaching, washing and drying to obtain Mg-Al-CO3 LDHs; (2) calcinating the Mg-Al-CO3 LDHs at a high temperature to obtain MMO; (3) drying polyamide 6 chips, mixing the polyamide 6 chips with the MMO evenly, blending and granulating to obtain far infrared master-batch chips; and (4) drying the far infrared master-batch chips with forced draught in vacuum, and finally performing melt spinning to obtain the far infrared nylon fibers. The method for preparing the efficient far infrared nylon fibers is simple in preparation process and low in cost; and the prepared far infrared functional nylon fibers are of good mechanical property and excellent far infrared emission rate, can promote human blood circulation and improve immunity, and has good heat-preservation and health care effects.

Owner:DONGHUA UNIV

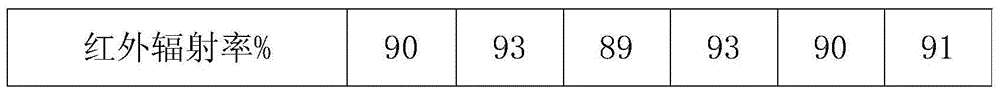

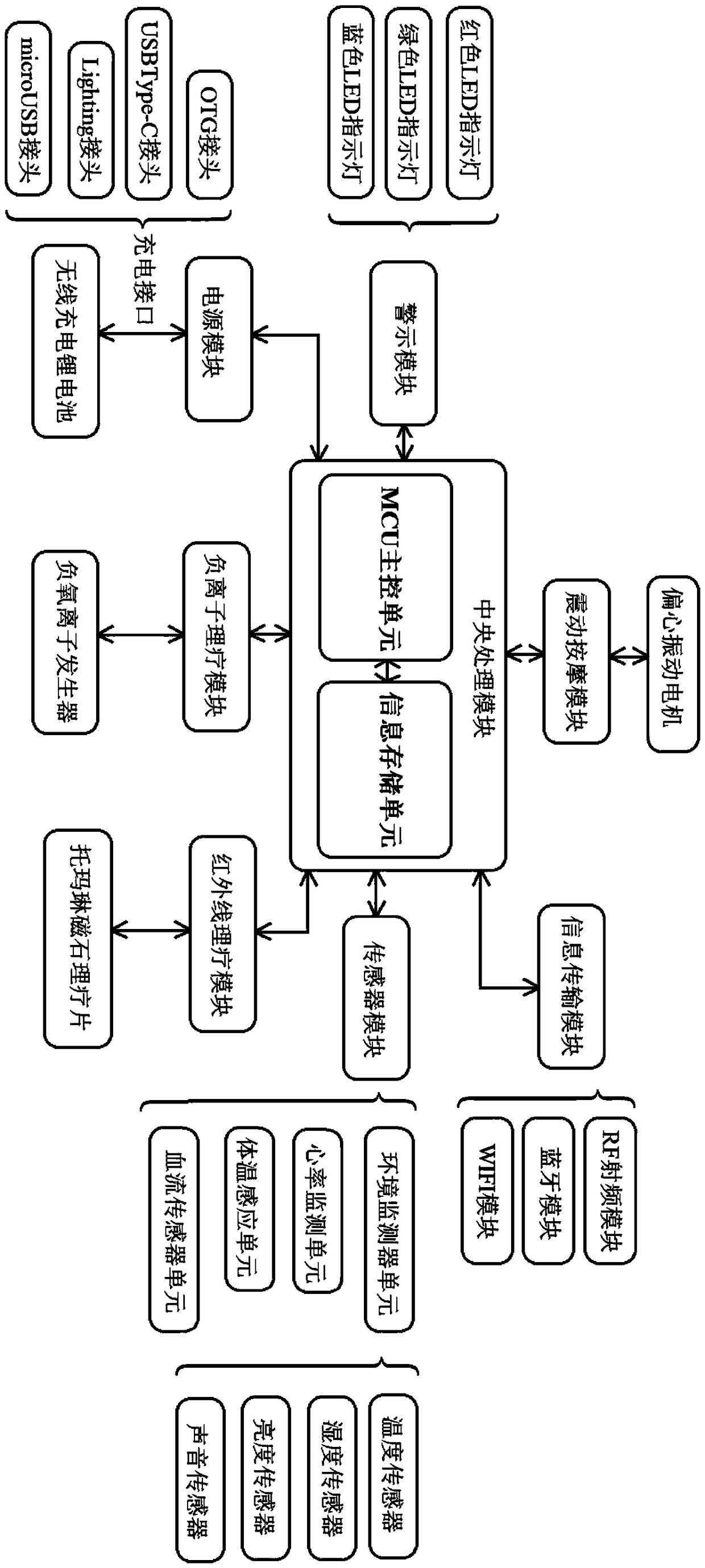

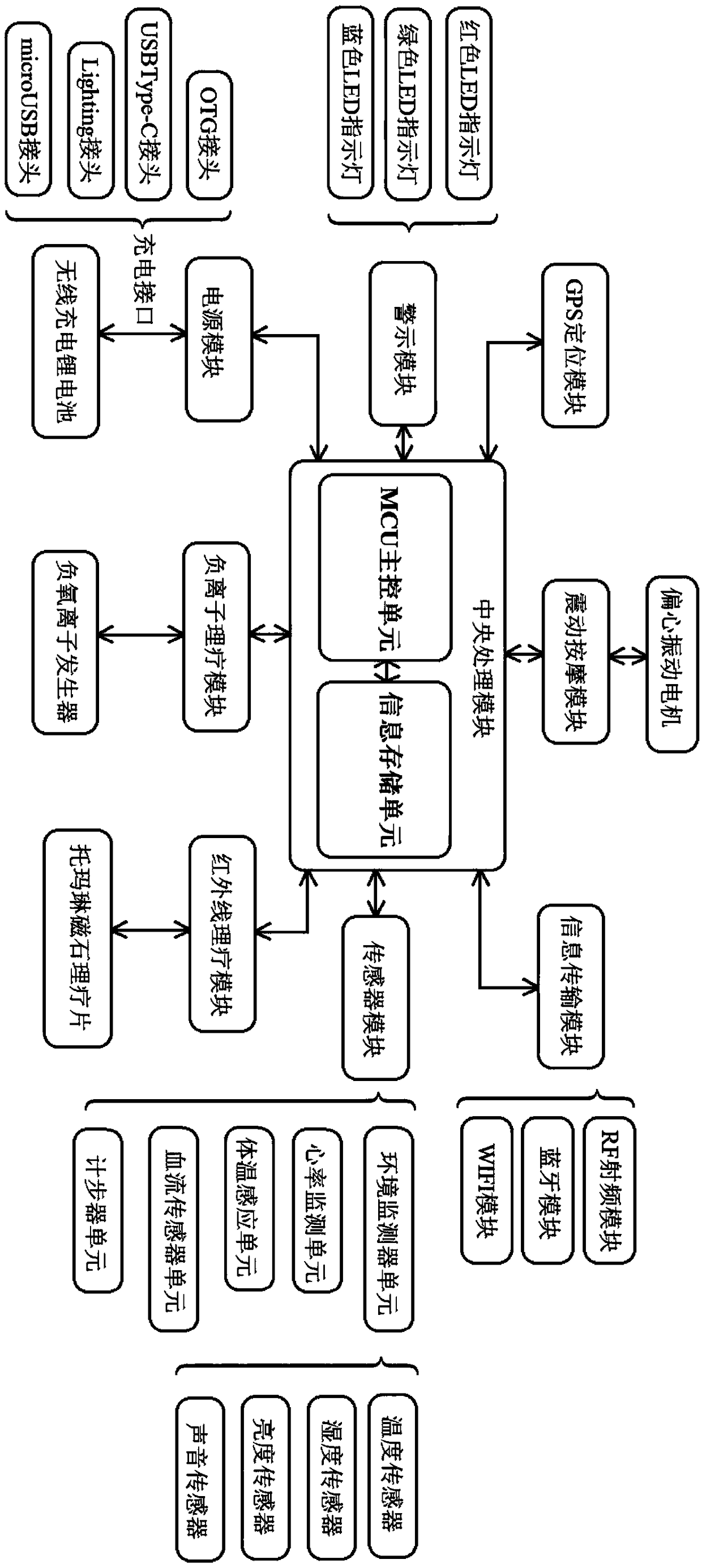

Intelligent protector four-in-one kit with microcirculation physiotherapy function

InactiveCN109011524APromote circulationGuaranteed adsorption effectElectrotherapyVibration massageInfraredInformation transmission

An intelligent protector four-in-one kit with a microcirculation physiotherapy function comprises four protecting sleeves which are made of antibacterial far-infrared microcirculation promoting functional fabric, namely a microcirculation intelligent finger protecting sleeve, a microcirculation intelligent wrist protecting sleeve, a microcirculation intelligent knee protecting sleeve and a microcirculation intelligent ankle protecting sleeve. The antibacterial far-infrared microcirculation promoting functional fabric has advantages absorbing moisture, discharging sweat, keeping warm, realizinga far-infrared and negative-ion radiation function, improving skin state after long-time wearing, improving body microcirculation and realizing body health. An intelligent detecting control chip performs information exchange with a smartphone through a central processing module and an information transmission module. Through a sensor module and an alarm module, sign information of a wearer body is monitored. Furthermore the acquired sign information is analyzed, and an analysis result is compared with an individual body condition of the user. Appropriate physiotherapy recovering is performedon the wearer body through a vibration massage module, an infrared physiotherapy module and a negative ion physiotherapy module, thereby improving body health of the wearer.

Owner:深圳市生物钟健康咨询有限责任公司

Double-layer composite glass magnesium board with high fireproof grade and preparation method of double-layer composite glass magnesium board

The invention discloses a double-layer composite glass magnesium board with a high fireproof grade. The double-layer composite glass magnesium board is characterized by being prepared from the following raw materials in parts by weight: 42-45 parts of light calcined magnesia, 39-41 parts of magnesium chloride hexahydrate, 7-9 parts of forsterite powder, 5-7 parts of tourmaline powder, 4-6 parts of expanded graphite, 1-2 parts of ammonium polyphosphate, 4.5-5 parts of metakaolin, 2.5-3 parts of aluminum dihydrogen phosphate, 1.5-2.5 parts of aluminum silicate fibers, 0.2-0.25 part of a silane coupling agent kh 550, 1.5-2 parts of waterborne polyurethane, 6-8 parts of a 5% polyvinyl alcohol solution, 15-18 parts of thermoplastic phenolic resin, 5-6 parts of 25% urotropine aqueous solution and a proper amount of pure water. According to the double-layer composite glass magnesium board, the forming time is shortened through a modifying process, the process is convenient for industrial control, the components are simple and easily available, and the production efficiency is improved; the prepared glass magnesium board has double-layer effect, is smooth and attractive in surface, high in fireproof grade, safe and non-toxic, and a moisture absorption and deformation problems are solved.

Owner:ANHUI XINRUN NEW MATERIALS

Composite textile finishing agent as well as preparation method and application thereof

The invention relates to the technical field of textile finishing, in particular to a novel far-infrared composite textile finishing agent as well as a preparation method and application thereof. Zirconium and titanium oxides are combined with oxygen-containing functional group of graphene oxide by virtue of chemical bonds, the nano composite modification is performed on the graphene oxide to prepare a GO-TiO2-ZrO2 composite material and a far-infrared textile finishing agent based on the GO-TiO2-ZrO2 composite material, the GO-TiO2-ZrO2 composite material and the far-infrared textile finishing agent based on the GO-TiO2-ZrO2 composite material are applied to the far-infrared finishing of cotton textiles, so that the far-infrared emitting rate of a fabric is increased; and moreover, the composite textile finishing agent is simple to produce and low-cost.

Owner:HUNAN INSTITUTE OF ENGINEERING

Multipurpose glass fibre and magnesium eco-plate and preparation method thereof

InactiveCN104891941AGood dispersionImprove far-infrared emissivitySynthetic resin layered productsGlass/slag layered productsHexamethylenetetraminePhosphate

The invention discloses a multipurpose glass fibre and magnesium eco-plate which is characterized by being prepared from the following raw materials, by weight, 42-45 parts of light calcined magnesia, 40-42 parts of magnesium chloride hexahydrate, 6-7 parts of tourmalinite powder, 0.2-0.25 part of a silane coupling agent kh550, 1.5-2 parts of waterborne polyurethane, 6-8 parts of 5% polyvinyl alcohol solution, 2-3 parts of spent pulping liquor, 7-9 parts of waste glass powder, 4.5-5 parts of metakaolin, 2.5-3 parts of aluminium dihydrogen phosphate, 0.8-1 part of aluminum sulfate, 1-2 parts of vinyltriethoxysilane, 15-18 parts of thermoplastic phenolic resin, 5-6 parts of 25% urotropine aqueous solution, 1.5-2.5 parts of aluminium silicate fibre and a proper amount of pure water. According to the invention, insufficiencies of materials such as artificial marble, ceramic tile, natural stone and the like are overcome. The multipurpose glass fibre and magnesium eco-plate has high heat-resistant and fireproofing grade, is nontoxic, harmless, waterproof and fracture resistant, has high strength and can be applied to interior and exterior walls, decorative sheets, furniture, floor and the like.

Owner:ANHUI XINRUN NEW MATERIALS

Fracture-resistant glass magnesium board containing modifying agents such as EVA emulsion, and preparation method thereof

The invention discloses a fracture-resistant glass magnesium board containing modifying agents such as EVA emulsion. The glass magnesium board is characterized in that the glass magnesium board is prepared from the raw materials of, by weight, 44-46 parts of light-burned magnesium oxide, 38-40 parts of magnesium chloride hexahydrate, 1-2 parts of a crosslinking agent TAC, 9-11 parts of charred wood shavings, 3-5 parts of papermaking black mud, 3-4 parts of EVA emulsion, 4.5-5 parts of metakaolin, 2.5-3 parts of aluminum dihydrogen phosphate, 5-7 parts of tourmaline powder, 0.2-0.25 parts of a silane coupling agents kh550, 1.5-2 parts of waterborne polyurethane, 9-11 parts of a polyvinyl alcohol solution with a concentration of 5%, 15-18 parts of thermoplastic phenolic resin, 5-6 parts of a urotropine water solution with a concentration of 25%, 1.5-2.5 parts of nano-grade zirconia, and an appropriate amount of water. According to the invention, a layer of phenolic resin is finally coated on the surface of a formed board material, such that board corrosion caused by the external environment is reduced. The product is safe and environment-friendly, and has the advantages of convenient construction, high fracture resistance, and high quality.

Owner:ANHUI XINRUN NEW MATERIALS

Novel magnetically-grafted silk fiber and preparation method thereof

The invention discloses a novel magnetically-grafted silk fiber and a preparation method thereof. The method comprises the following steps: cleaning and activating the surface of the silk fiber; putting in a magnetic grafting solution, heating, oscillating and reacting so as to obtain the magnetically-grafted silk fiber. According to the method, a magnetic nanometer material containing iron and silver is dissolved in an acidic salt buffering solution to activate the surface of a magnetic material; by an assistant effect of a triggering agent, the magnetic material is grafted to the surface of the silk fiber. The preparation method has the advantages of increasing the utilization rate of the magnetic material, saving energy, protecting environment and easily achieving industrial production. The prepared silk fiber is good in magnetic property, retains the gloss and soft hand feeling of silk and is good in water washing property.

Owner:HUNAN JICHANG SILK

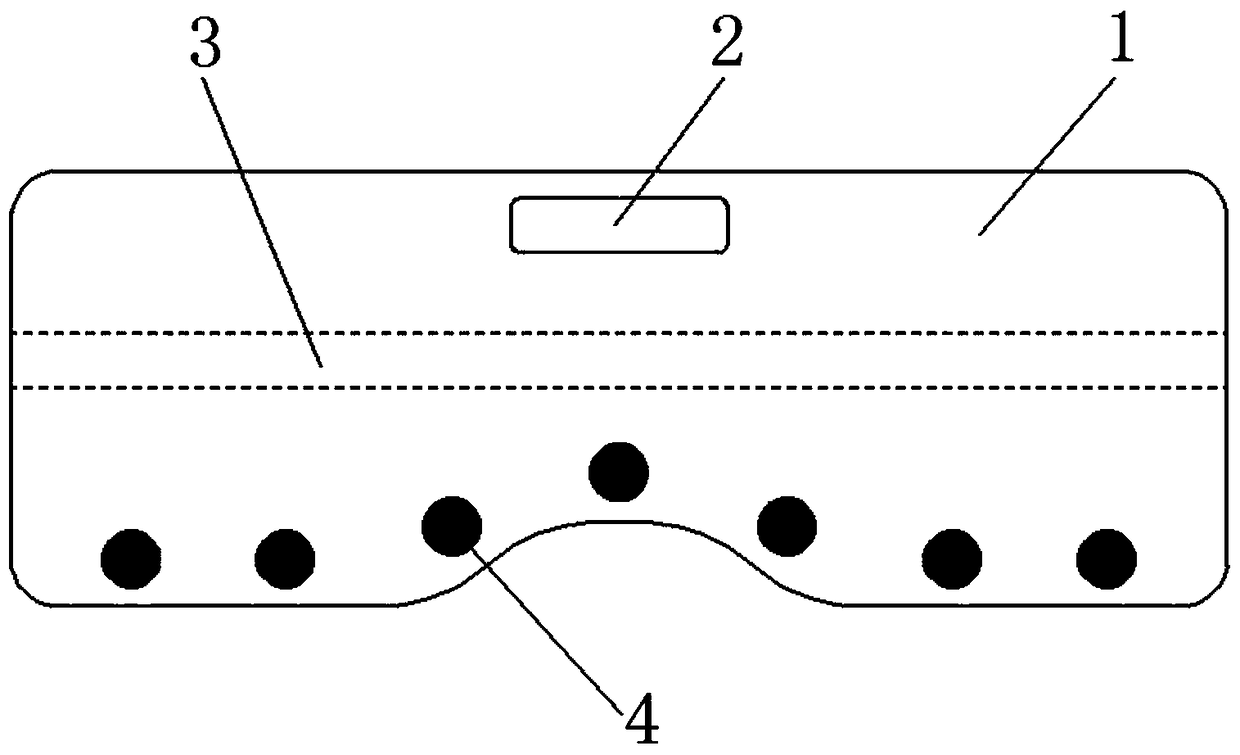

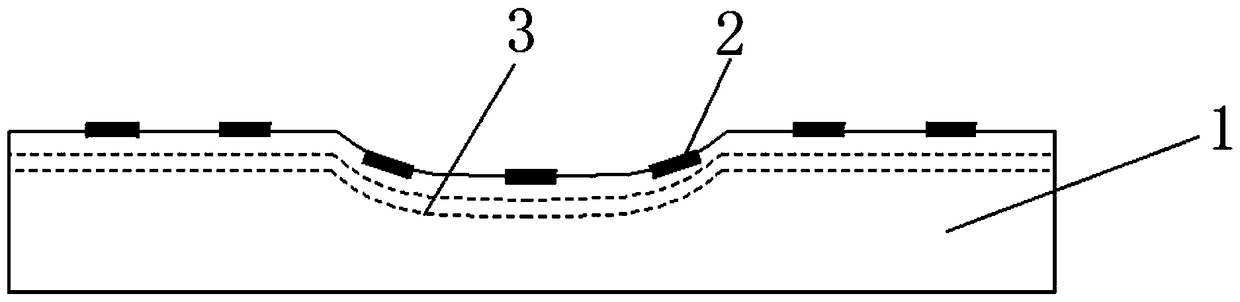

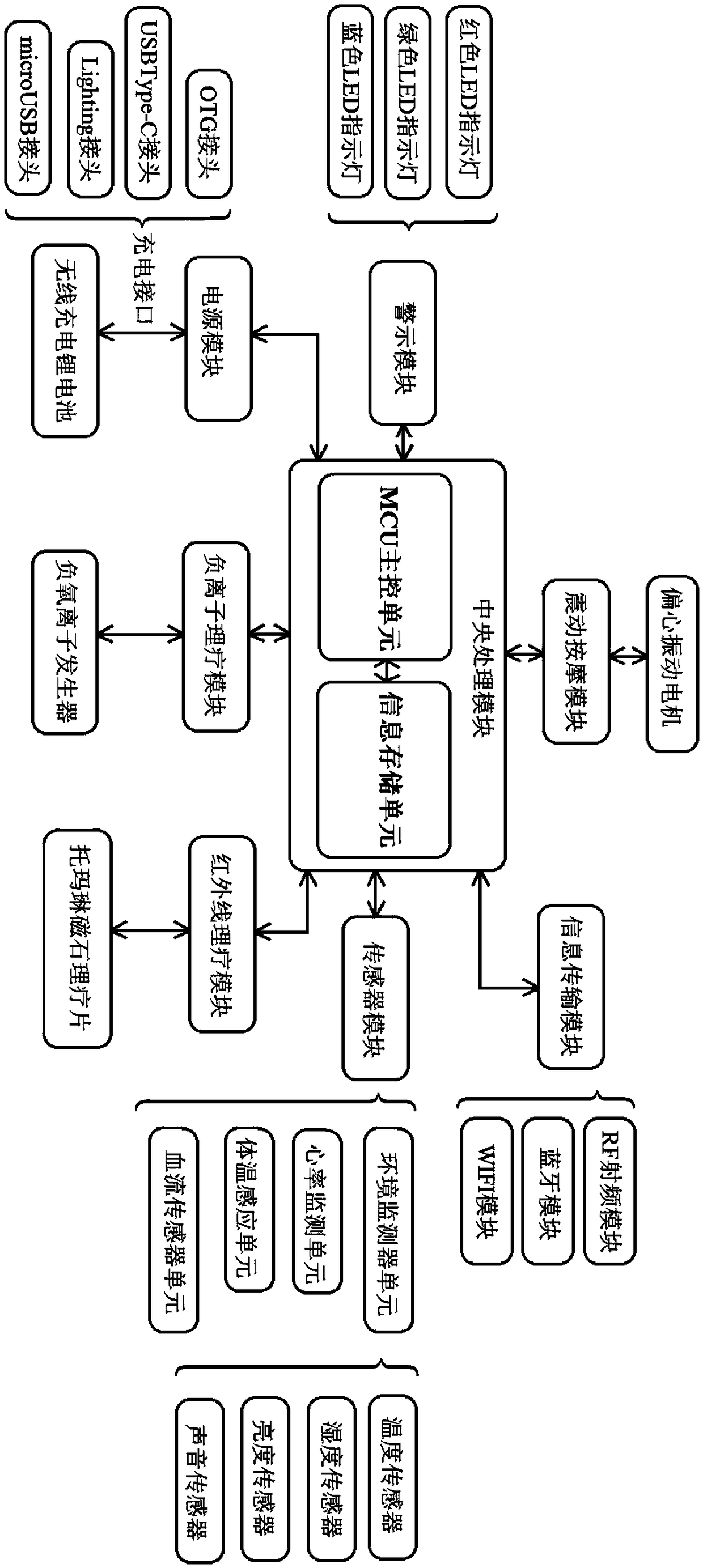

Smart mattress with microcirculation physical therapy function

InactiveCN109090899APromote circulationGuaranteed adsorption effectStuffed mattressesSpring mattressesInfraredPhysical well being

A smart mattress with a microcirculation physical therapy function includes a mattress surface layer made of an antibacterial far-infrared fabric promoting a microcirculation function, and the surfacelayer of a memory sponge is provided with a plurality of hemispherical mushroom heads arranged at intervals. The lower portion of the memory sponge is provided with a high-density sponge. The waist of a mattress body is detachably equipped with a smart detection control chip. The antibacterial far-infrared fabric promoting the microcirculation function has the advantages of moisture absorption and perspiration, heat storage and warmth and far-infrared and negative ion radiation functions and can improve skin condition and body microcirculation after long-term use. The smart detection controlchip exchanges information with a smart phone through a central processing module and an information transmission module, monitors physical sign information of the body of a user, analyzes the collected physical sign information, and compares an analysis result with the personal physical condition of the user. A vibration massage module, an infrared physical therapy module and a negative ion physical therapy module are adopted to conduct appropriate physical therapy recovery on the body of the user. The mattress is favorable for the body health of the user.

Owner:深圳市生物钟健康咨询有限责任公司

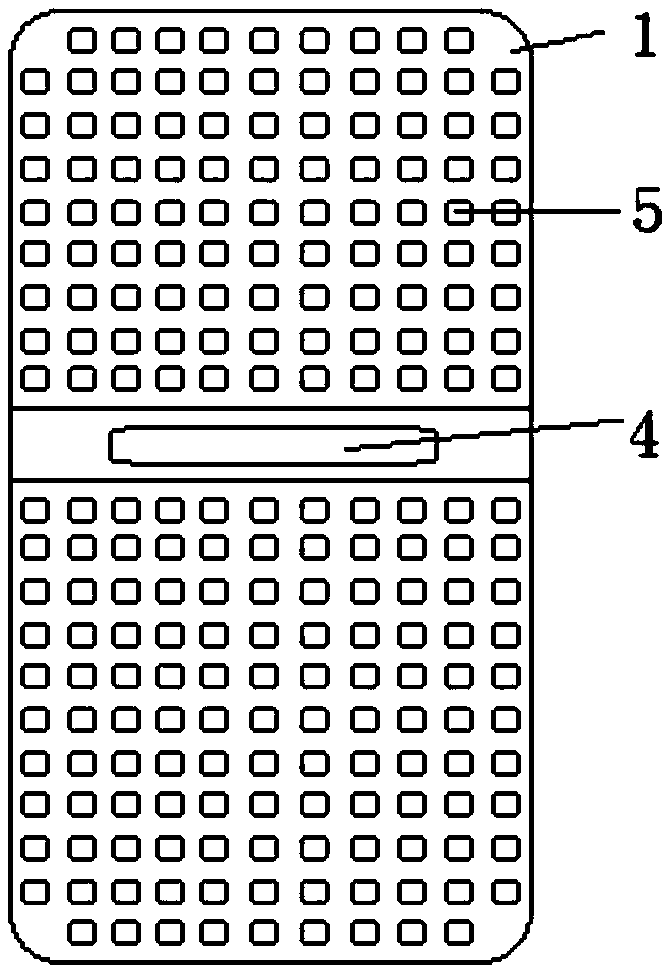

Preparation method of high-infrared emitting ability graphene/MnO2 porous material

InactiveCN107541207AImprove far-infrared emissivityEasy to prepareLuminescent compositionsEmissivityFar infrared

The invention provides a preparation method of a high-infrared emitting ability graphene / MnO2 porous material. The preparation method comprises that graphene and potassium permanganate as raw materials are uniformly dispersed in an aqueous solution by a simple ultrasonic dispersion method and then the graphene / MnO2 porous material is prepared through a hydrothermal reduction reaction. The preparation method has simple processes and is easy to operate. The porous material has infrared emitting ability of 0.94 to 0.98 at 8 to 14 microns, has the advantages of high far-infrared emissivity, stability, environmental friendliness and easy availability of raw materials, can be easily industrialized and has great application potential in the field of far-infrared products.

Owner:墨烯材料科技有限公司

Far-infrared mask base cloth and preparation method thereof

InactiveCN112458623ASimple manufacturing methodEasy to operate and controlCosmetic preparationsToilet preparationsFiberFar infrared

The invention discloses a preparation method of far-infrared mask base cloth. The preparation method characterized by comprising the following steps: S1, preparing a copolymer, S2, preparing functional fibers, and S3, carrying out spunlace forming. The invention further discloses the far-infrared mask base cloth prepared according to the preparation method of the far-infrared mask base cloth. Thefar-infrared mask base cloth disclosed by the invention is high in adsorption capacity and remarkable in antibacterial effect, can release far-infrared rays, promote blood circulation and metabolism and tissue regeneration of cells, and can inhibit melanin precipitation to achieve a whitening effect.

Owner:朱宇

Production method of far infrared composite material

The invention relates to a production method of a far infrared composite material. According to the production method, a far infrared material is produced and compounded from bamboo charcoal and tourmaline, and 50% of bamboo charcoal and 50% of tourmaline are compounded. The production method particularly comprises the following steps: (1) calcining tourmaline at 500-700 DEG C for 1-3 hours; (2) adequately mixing calcined tourmaline with bamboo charcoal according to a formula, and grinding until the particle size of mixed powder reaches 0.1-1 microns; (3) shaping the mixed powder at 90MPa-110MPa, and calcining the mixed powder at 850-1000 DEG C for 1-5 hours at a vacuum environment, so as to obtain calcined substances, wherein the shaped mixed powder has the size of 40-60mm * 7-13mm; and (4) cooling the calcined substances to room temperature, so as to obtain the composite material. The production method has the beneficial effects that the raw materials are easily available, a production process is simple and convenient, the production energy consumption is low, the production process meets environmental requirements, and the cost is low.

Owner:张娣

Intelligent sleeping pillow with microcirculation physiotherapy function

InactiveCN109008506APromote circulationGuaranteed adsorption effectPillowsElectrotherapyInfraredFar infrared

An intelligent sleeping pillow with a microcirculation physiotherapy function comprises a pillow body which is made of antibacterial far-infrared microcirculation promoting functional fabric. The pillow body has a layered structure and is internally provided with memory foam. The surface of the pillow body is provided with a plurality of massage projections which correspond with head acupuncture points. The upper part of the pillow body is provided with an intelligent detecting control chip. The surface of the pillow body is provided with one layer of turmaline. The antibacterial far-infraredmicrocirculation promoting functional fabric has advantages absorbing moisture, discharging sweat, realizing a far-infrared and negative-ion radiation function, improving skin state and improving headmicrocirculation. An intelligent detecting control chip performs information exchange with a smartphone through a central processing module and an information transmission module. The intelligent detecting control chip monitors sign information of a user head, analyzes the acquired sign information and performs comparison with the individual head condition of the user according to an analysis result. The intelligent sleeping pillow performs appropriate physiotherapy recovering on the user head through a vibration massage module, an infrared physiotherapy module and a negative ion physiotherapy module, thereby facilitating health of the user head.

Owner:深圳市生物钟健康咨询有限责任公司

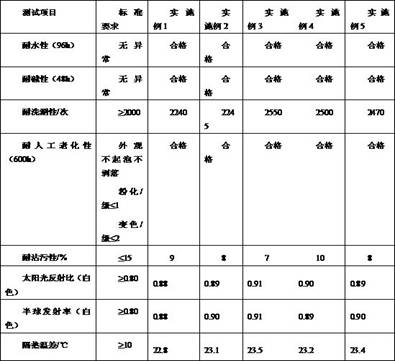

Heat storage and temperature adjustment type reflective heat insulation coating and preparation process thereof

InactiveCN111647349AImprove reflectivityHigh emissivityWax coatingsAntifouling/underwater paintsParaffin waxALLYL SUCROSE

The invention relates to the technical field of coatings, particularly relates to a heat storage and temperature adjustment type reflective heat insulation coating, and further provides a preparationprocess of the coating. The coating specifically comprises an organic silicon emulsion, paraffin / zeolite-polyacrylic acid phase change microcapsules, a high-reflection type material, a heat radiationfiller, a heat insulation functional filler, a wetting dispersant, a mildew-proof antibacterial agent, a thickener, a defoamer, a coalescing agent and deionized water. The heat storage and temperatureadjustment type reflective heat insulation coating has high reflectivity and emissivity, is good in heat insulation effect, can effectively prevent heat conduction, is excellent in heat insulation performance and lasting in heat insulation performance, and automatically adjusts and stabilizes the indoor temperature by utilizing the reversible energy storage and release effects of the phase changemicrocapsules.

Owner:河南宣和钧釉环保材料有限公司

A kind of preparation method of far infrared textile fabric

ActiveCN108221363BEasy to operateImprove far-infrared emissivityVegetal fibresPolymer scienceFar infrared

Owner:HUNAN INSTITUTE OF ENGINEERING

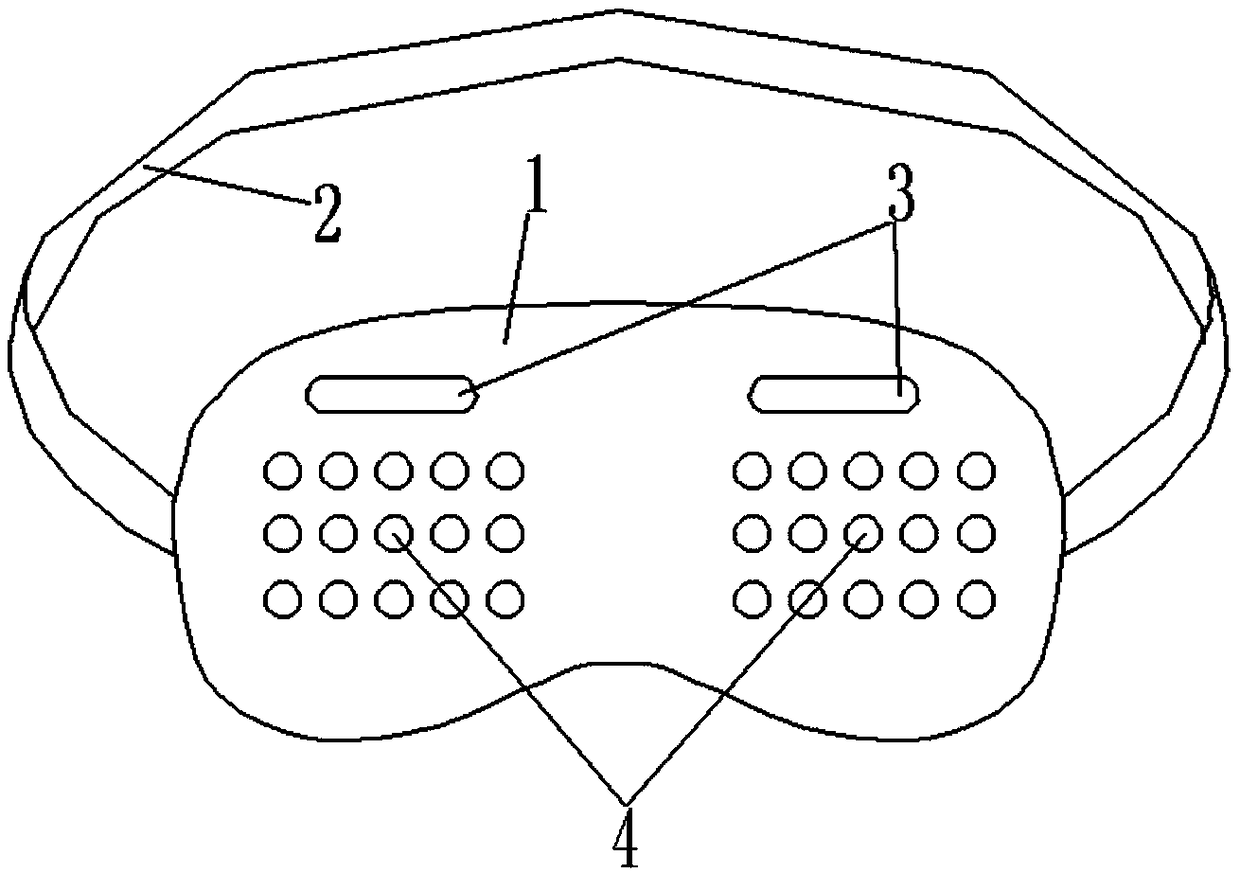

Intelligent eye resting eyeshade with microcirculation physiotherapy function

InactiveCN109009660APromote circulationGuaranteed adsorption effectElectrotherapyVibration massageInfraredInformation transmission

An intelligent eye resting eyeshade with a microcirculation physiotherapy function comprises an eye cover and elastic belts, wherein the eye cover is made of antibacterial far-infrared microcirculation promoting functional fabric. An inner layer is provided with a plurality of massage projections at positions which correspond with eye acupuncture points. An outer layer is provided with an intelligent detecting control chip. The antibacterial far-infrared microcirculation promoting functional fabric has advantages of absorbing moisture, discharging sweat, keeping warm, realizing a far-infraredand negative ion radiating function, improving skin state after long-term wearing, improving body microcirculation and realizing benefit to eyes. The intelligent detecting control chip performs information change with a smartphone through a central processing module and an information transmission module. The intelligent detecting control chip monitors the sign information of the wearer body through a sensor module and an alarm module, analyzes the acquired sign information and performs comparison with the individual body condition of the user. The intelligent eye resting eyeshade performs appropriate physiotherapy recovery on the eyes of a wearer through a vibration massage module, an infrared physiotherapy module and a negative ion physiotherapy module, thereby facilitating eye health ofthe wearer.

Owner:深圳市生物钟健康咨询有限责任公司

High-emissivity negative ion modified graphene heating carbon paste and preparation method thereof

PendingCN114096021ALow costStructurally intactOhmic-resistance electrodesFurnace heating elementsCarbon nanotubeGraphite

The invention discloses high-emissivity negative ion modified graphene heating carbon paste and a preparation method thereof. The high-emissivity negative ion modified graphene heating carbon paste is prepared from the following raw materials in percentage by weight: 15-35% of a binder, 15-35% of a conductive filler, 3-5% of a far infrared emission material, 2-3% of an auxiliary agent and the balance of a solvent. The conductive filler is composed of graphene powder, conductive graphite, conductive carbon black, carbon nanotubes and a silver nanomaterial; and the far infrared emission material is composed of tourmaline, bamboo charcoal powder and infrared emission powder. The production process is simple, the far infrared emissivity is high, and the stability of the heating carbon paste is good. The product can be widely applied to the fields of floor heating, wall heating, warmers, physiotherapy products and the like.

Owner:浙江希维纳米科技有限公司

Manufacturing method of heating carbonaceous down jacket fabric

InactiveCN104775221AImprove breathabilityEnhance downproof performanceSynthetic resin layered productsFibre chemical featuresPerspirationMoisture absorption

The invention provides a manufacturing method of a heating carbonaceous down jacket fabric. Materials adopt carbon smart materials and conducing wires, the heating and temperature rise is fast, no odor and no pollution are generated, the effect is good, meanwhile, the far-infrared emission rate is as high as 90 percent, the blood circulation of the human body can be promoted, the health care effect is achieved, and the adopted nanometer bamboo charcoal knitted fabric has the functions of anti-bacterial deodorizing, peculiar odor adsorption, moisture absorption and sweat perspiration. The air permeability of the whole fabric is good, and the down-proof performance is good.

Owner:ANHUI HONGRUNDA TEXTILE TECH CO LTD

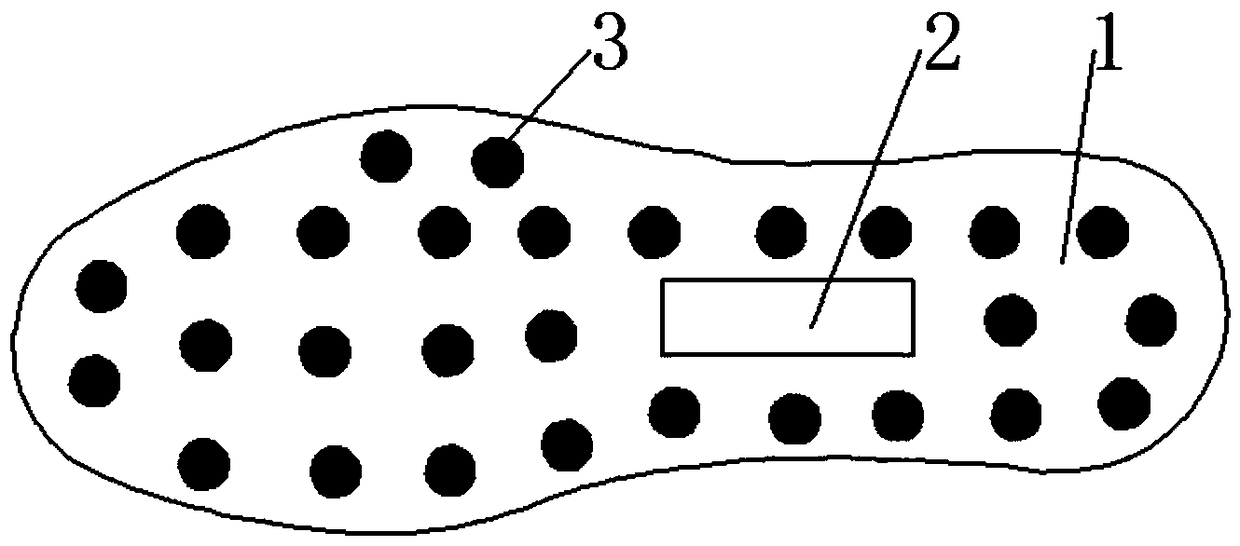

Smart insole with microcirculation physiotherapy function

InactiveCN108903132APromote circulationGuaranteed adsorption effectElectrotherapyInsolesInfraredInformation transmission

The invention discloses a smart insole with a microcirculation physiotherapy function. The smart insole includes an insole body made of anti-bacterial far-infrared microcirculation promoting functional fabric, and an intelligent detection control chip is arranged at the foot arch of the front surface of the insole body. Anti-slip stripes are arranged on the back surface of the insole body, and a physiotherapy piece emitting magnetic therapy waves is arranged on the front surface of the insole body. The anti-bacterial far-infrared microcirculation promoting functional fabric is hygroscopic andsweat-releasing, stores heat, keeps warm, and has far-infrared and negative ion radiation functions. Skin conditions can be improved by long-term wear, foot microcirculation is improved, and foot health is benefitted. The intelligent detection control chip exchanges information with a smart phone through a central processing module and an information transmission module. The physical sign information of feet of a wearer is monitored by a sensor module and a warning module, the collected physical sign information is analyzed, and the analysis result is compared with the personal foot conditionsof a user. Appropriate physiotherapy recovery is performed on the feet of the wearer through a vibration massage module, an infrared physiotherapy module and a negative ion physiotherapy module to contribute to the foot health of the wearer.

Owner:深圳市生物钟健康咨询有限责任公司

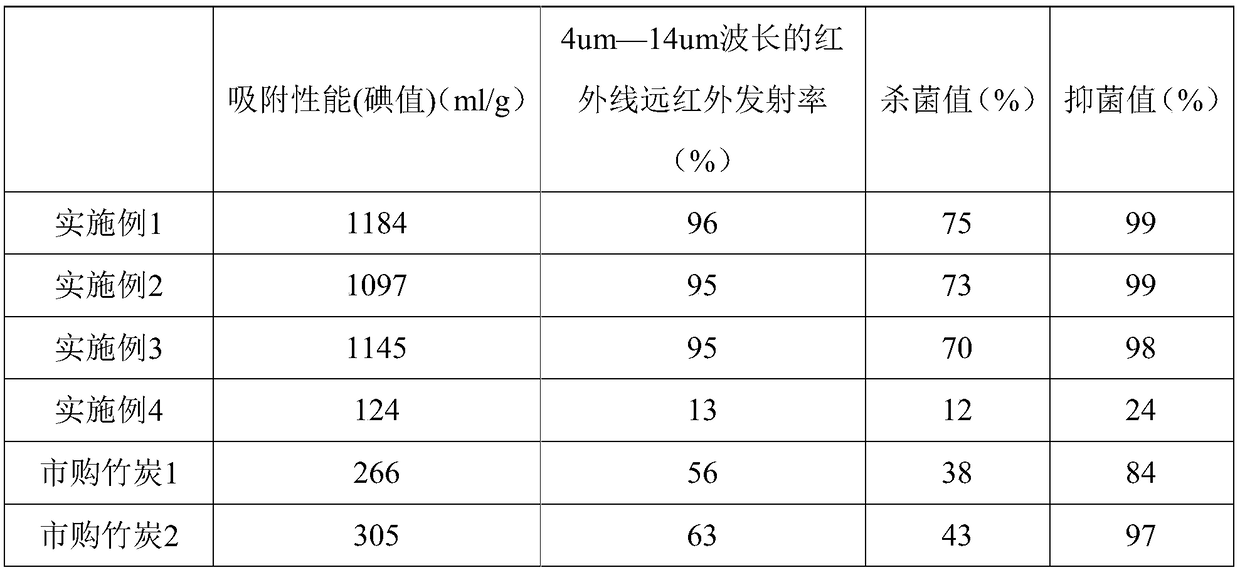

Bamboo charcoal-based far infrared composite material and method for preparing same

The invention discloses a preparation method for charcoal-based far-infrared composite materials, comprising the following steps: (1), the following components are taken as raw materials based on weight percentage: 50%-95% of charcoal, 0.5%-30% of tourmaline, 1-10% of clay and 0.5-20% of maifan stone; (2), all the materials are put into deionized water, then binder is added to the water for ball-mill mixing; (3), the mixture obtained from the step (2) goes through high pressure forming and is then put into a vacuum graphite sintering furnace and calcined in a protective atmosphere of nitrogen;(4), the calcined product obtained from the step (3) is cooled to room temperature to get the charcoal-based far-infrared composite material. The invention also discloses the charcoal-based far-infrared composite material prepared through the method. The charcoal-based far-infrared composite material of the invention has high far-infrared emissivity and is environmental-friendly and healthy.

Owner:ZHEJIANG UNIV

Microcrystal bamboo charcoal purple sand composite pottery material and application thereof

InactiveCN103467066BHigh porosityImprove thermal shock resistanceOther chemical processesCeramicwareHazardous substancePhenol

The invention relates to a microcrystal bamboo charcoal purple sand composite pottery material and application of the microcrystal bamboo charcoal purple sand composite pottery material. The microcrystal bamboo charcoal purple sand composite pottery material is composed of, by weight, 5-40% of microcrystal bamboo charcoal powder, 40-60% of purple sand powder, 10-30% of attapulgite, 5-30% of kieselguhr and 1-5% of binder in a mixing mode. The microcrystal bamboo charcoal purple sand composite pottery material can be used for manufacturing a microcrystal bamboo charcoal purple sand composite pottery, the steps for manufacturing the microcrystal bamboo charcoal purple sand composite pottery are specifically forming, air drying, drying, calcination and cooling, and therefore the microcrystal bamboo charcoal purple sand composite pottery can be obtained. According to the microcrystal bamboo charcoal purple sand composite pottery material and the application of the microcrystal bamboo charcoal purple sand composite pottery material, through different raw material ratios and calcination crafts, the manufactured microcrystal bamboo charcoal pottery after processing is low in firing shrinkage coefficient, high in bending strength and strong in adsorption of formaldehyde, phenol, sulfur dioxide, TVOC and other hazardous substances and can be manufactured into pottery materials of different water adsorption rates as required.

Owner:王萍 +2

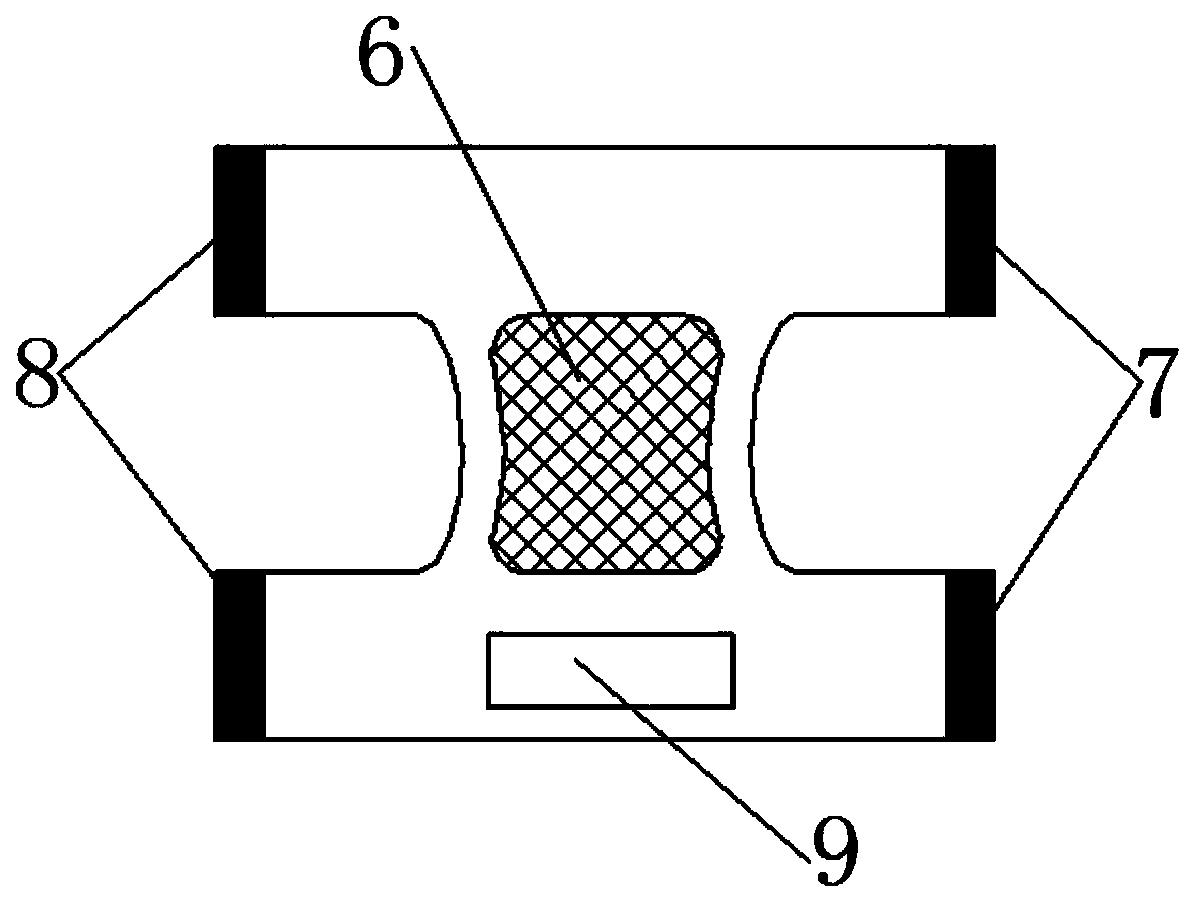

Infrared health care neck protector

InactiveCN109091763AImprove antibacterial propertiesImprove far-infrared emissivityPillowsLight therapyEmissivityMedicine

The invention provides an infrared health care neck protector. The infrared health care neck protector is composed of a lining, a core material and a protection sleeve, wherein the lining is made of the fleece fabric, the core material is composed of a modified phenolic resin adhesive coating layer coated with graphene oxide and an organic cloth substrate, the corresponding adhesive application amount is 2-5 g / m<2>, the coating thickness is 40-50 mu m, and the protection sleeve is provided with an infrared radiation filler filling cavity and is linked with the lining and the core material through buttons. The infrared health care neck protector is advantaged in that the modified phenolic resin adhesive coating layer added with the graphene oxide has wash durability, through adding the graphene oxide, the core material is enabled to have the antibacterial and bacteriostatic effects, an infrared radiation filler has the high far infrared emissivity, under the condition of the normal temperature or body temperature, infrared radiation can be utilized to improve the surface microcirculation of a human body and increase the body surface temperature, the immune function is improved, andthe health benefit is achieved.

Owner:宿迁空天新材料有限公司

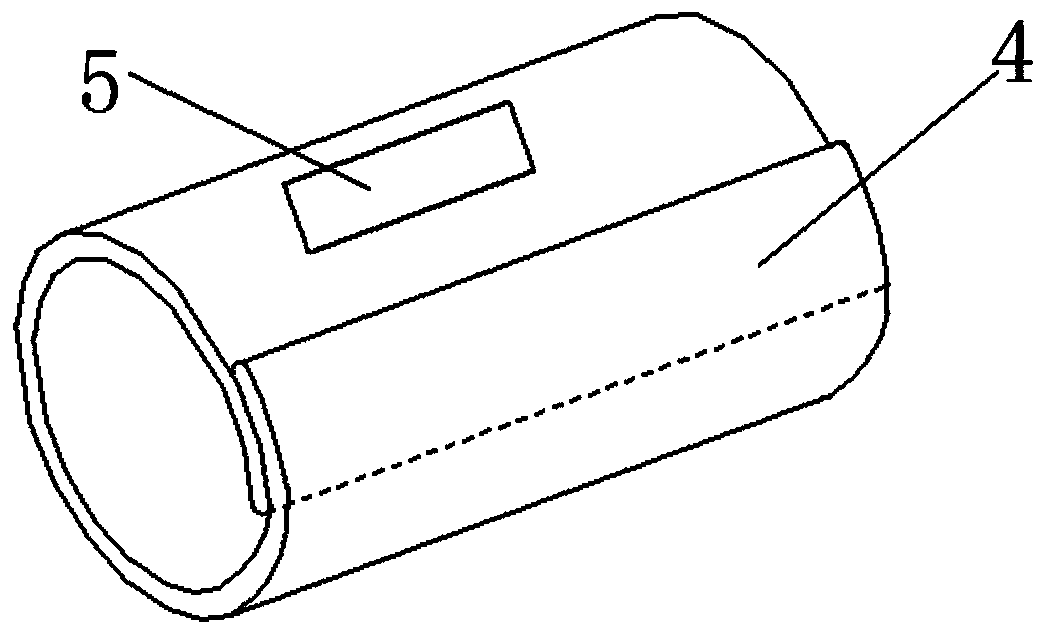

A far-infrared quartz tube applied to a low-temperature non-combustible electronic smoke nebulizer and its preparation method

The invention provides a far-infrared quartz tube applied to a low-temperature non-combustible electronic smog vaporizer. The far-infrared quartz tube is composed of a conductive film layer, a far-infrared coating and a quartz tube connected in sequence; wherein, the far-infrared coating is composed of a far-infrared Infrared coatings are formed. Far-infrared coatings are prepared from the following components by weight: 30-40 parts of pure acrylic emulsion, 2-3 parts of wetting and dispersing agents, 10-15 parts of fillers, 90-100 parts of solvents, film-forming 1-2 parts of auxiliary agent, 40-45 parts of far-infrared powder, 7-10 parts of tin tetrachloride, 3-4 parts of modifier; the conductive film layer is formed by conductive paste, and the conductive paste consists of the following parts by weight It is prepared from the following components: 4-5 parts of sodium carboxymethylcellulose, 80-90 parts of N,N-dimethylacetamide, and 12-18 parts of conductive graphite. The invention also provides a preparation method of the far-infrared quartz tube. The far-infrared quartz tube provided by the invention adopts a far-infrared heating mode and has better heating performance.

Owner:东莞市中科智恒新材料有限公司

Preparation method of high-emissivity far-infrared emission domestic ceramic

PendingCN112374915AReduce erosion and dissolutionImprove far-infrared emissivityClaywaresCeramic glazeGreen body

The invention relates to a far-infrared emission domestic ceramic technology, in particular to a preparation method of high-emissivity far-infrared emission domestic ceramic, which comprises the following steps: taking a domestic ceramic blank, adding far-infrared ceramic powder which accounts for 10-30% of the mass of the domestic ceramic blank, conducting mixing to obtain far-infrared emission ceramic glaze slip, adding the far-infrared emission ceramic glaze slip, ballstone and water into a ball milling tank according to a mass ratio of 1:2.5:1, carrying out ball milling, and conducting sieving with a 100-mesh porous sieve to obtain far-infrared emission ceramic slurry; uniformly smearing the prepared far-infrared emission ceramic slurry on the surface of a ceramic green body accordingto a daily ceramic glazing process to serve as daily ceramic ground glaze, and then putting the coated ceramic green body into a drying furnace to be dried to obtain a ceramic green body coated with far-infrared emission mixed powder; and carrying out surface glaze decoration on the surface of the prepared ceramic blank body, conducting drying, putting the decorated ceramic blank body into a domestic ceramic firing furnace, conducting heating at a heating rate of 5 DEG C / min, conducting heating from room temperature to a temperature of lower than 1250 DEG C, keeping the temperature for 1 hourto 2 hours, and conducting natural cooling to room temperature to obtain the high-emissivity far-infrared domestic ceramic.

Owner:SHAANXI UNIV OF SCI & TECH

Far infrared ceramic glazed brick and preparation method thereof

The invention discloses a far infrared ceramic glazed brick and a preparation method thereof. The preparation method comprises the following steps of: coating the surface of the ceramic glazed brick with a far infrared nano liquid, wherein the far infrared nano-liquid contains medical stone nano-particles. According to the method, the surface of the polished ceramic glazed tile is coated with thefar infrared nano liquid, so that the tile surface effect is better, the surface roughness is reduced, the antifouling property becomes excellent, meanwhile, the ceramic glazed tile has a high far infrared function, and the far infrared normal release rate reaches 93% or above (8-22microm).

Owner:MONALISA GRP CO LTD

Bamboo charcoal-tourmaline far infrared composite material and preparation thereof

The invention discloses a bamboo charcoal-tourmaline far IR composite material. The weight percentage of the formula components thereof are as follows: 40 to 60 percent of bamboo charcoal as well as 40 to 60 percent of tourmaline. The invention also provides a preparation method for the composite material, which comprises the following steps: 1) the tourmaline is calcined for 1 to 3 hours at the temperature between 500 and 700 DEG C; 2) the calcined tourmaline and the bamboo charcoal are fully mixed and grinded according to the formula proportion to lead the granularity of the obtained mixed powder to achieve 0.1 to 1um; 3) the mixed powder is shaped under the pressure between 90 and 110MPa and then calcined for 1 to 5 hours at the temperature between 850 and 1000 DEG C under a vacuum environment to obtain a calcined substance; and 4) the calcined substance is cooled to normal temperature to obtain the composite material. The composite material has the characteristic of high far IR transmission rate.

Owner:SUICHANG WENZHAO BAMBOO CHARCOAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com