Heat storage and temperature adjustment type reflective heat insulation coating and preparation process thereof

A reflective thermal insulation coating, heat storage and temperature regulation technology, applied in the field of coatings, can solve the problems of few composite phase change thermal insulation coatings, difficult to have both, avoid drastic changes in side and surface temperature, prevent heat conduction, and improve the The effect of heat storage and energy release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

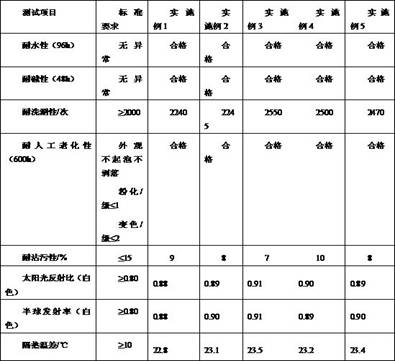

Examples

Embodiment 1

[0053] The heat-storage and temperature-adjustable reflective heat-insulating coating of this embodiment is made of the following raw materials in parts by weight:

[0054] 200 parts of silicone emulsion;

[0055] 30 parts of paraffin / zeolite-polyacrylic acid phase change microcapsules;

[0056] High reflective material 80 parts;

[0057] 50 parts of thermal radiation filler;

[0058] 100 parts of thermal insulation functional filler;

[0059] Wetting and dispersing agent 2 parts;

[0060] 1 part of anti-mildew and antibacterial agent;

[0061] 5 parts of thickener;

[0062] 4 parts of defoamer;

[0063] 15 parts of film-forming aids;

[0064] 100 parts of deionized water;

[0065] The paraffin / zeolite-polyacrylic acid phase change microcapsule uses zeolite as the phase change material carrier, paraffin wax as the phase change material, and polyacrylic acid as the modified capsule skin of the phase change microcapsule;

[0066] The high reflective material is rutile t...

Embodiment 2

[0090] The heat-storage and temperature-adjustable reflective heat-insulating coating of this embodiment is made of the following raw materials in parts by weight:

[0091] 300 parts of silicone emulsion;

[0092] 70 parts of paraffin / zeolite-polyacrylic acid phase change microcapsules;

[0093] High reflective material 150 parts;

[0094] Heat radiation filler 100 parts;

[0095] 150 parts of thermal insulation functional filler;

[0096] Wetting and dispersing agent 5 parts;

[0097] 3 parts of anti-mildew and antibacterial agent;

[0098] 10 parts of thickener;

[0099] 8 parts of defoamer;

[0100] 25 parts of film-forming aids;

[0101] 150 parts of deionized water;

[0102] The paraffin / zeolite-polyacrylic acid phase change microcapsule uses zeolite as the phase change material carrier, paraffin wax as the phase change material, and polyacrylic acid as the modified capsule skin of the phase change microcapsule;

[0103] The high reflective material is rutile tit...

Embodiment 3

[0127] The heat-storage and temperature-adjustable reflective heat-insulating coating of this embodiment is made of the following raw materials in parts by weight:

[0128] 250 parts of silicone emulsion;

[0129] 55 parts of paraffin / zeolite-polyacrylic acid phase change microcapsules;

[0130] High reflective material 110 parts;

[0131] 75 parts of thermal radiation filler;

[0132] 125 parts of thermal insulation functional filler;

[0133] Wetting and dispersing agent 3.5 parts;

[0134] 2 parts of anti-mildew and antibacterial agent;

[0135] 7.5 parts of thickener;

[0136] 6 parts of defoamer;

[0137] 20 parts of film-forming aids;

[0138] 125 parts of deionized water;

[0139] The paraffin / zeolite-polyacrylic acid phase change microcapsule uses zeolite as the phase change material carrier, paraffin wax as the phase change material, and polyacrylic acid as the modified capsule skin of the phase change microcapsule;

[0140] The high reflective material is ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com