Patents

Literature

2276 results about "Silk fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

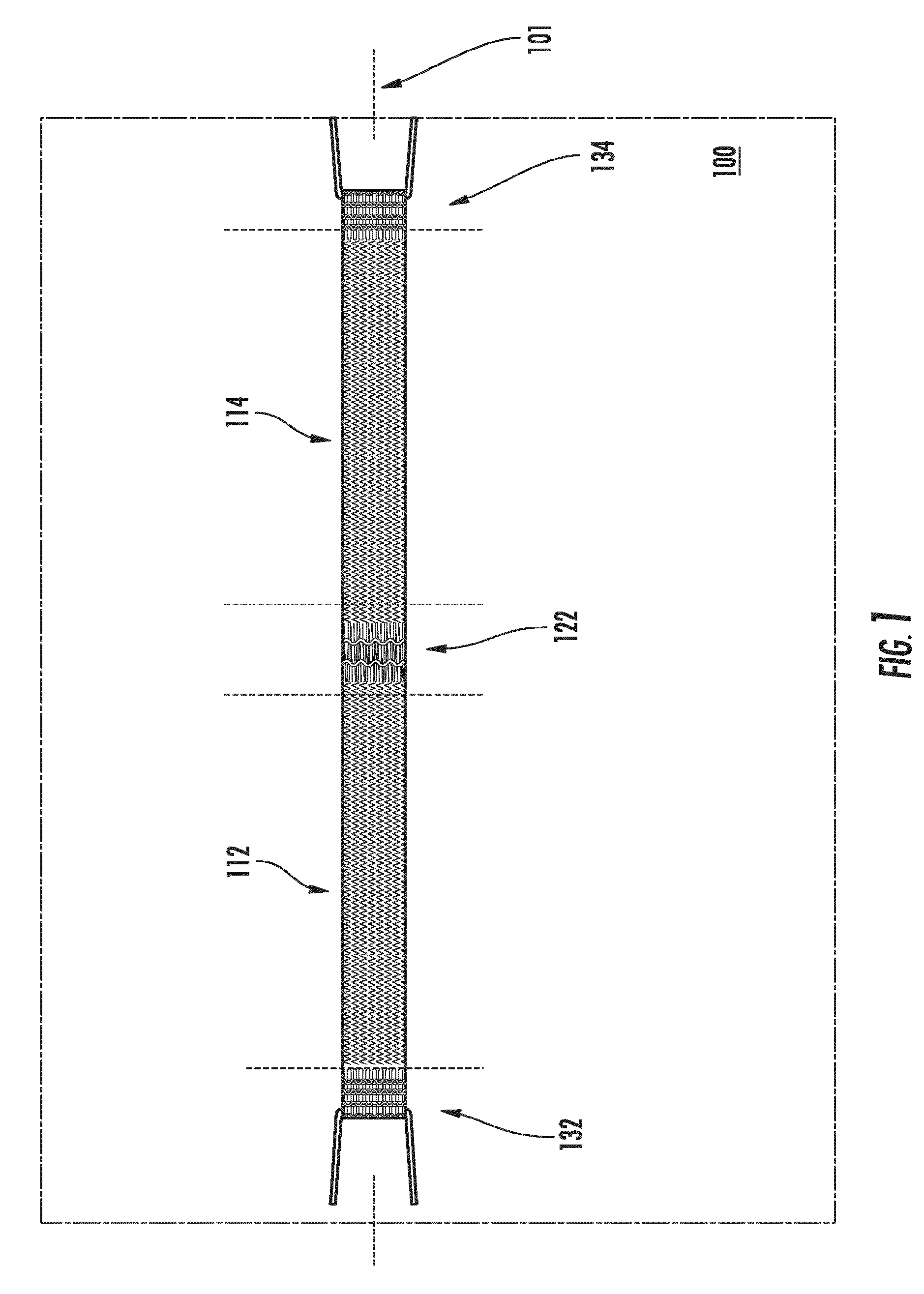

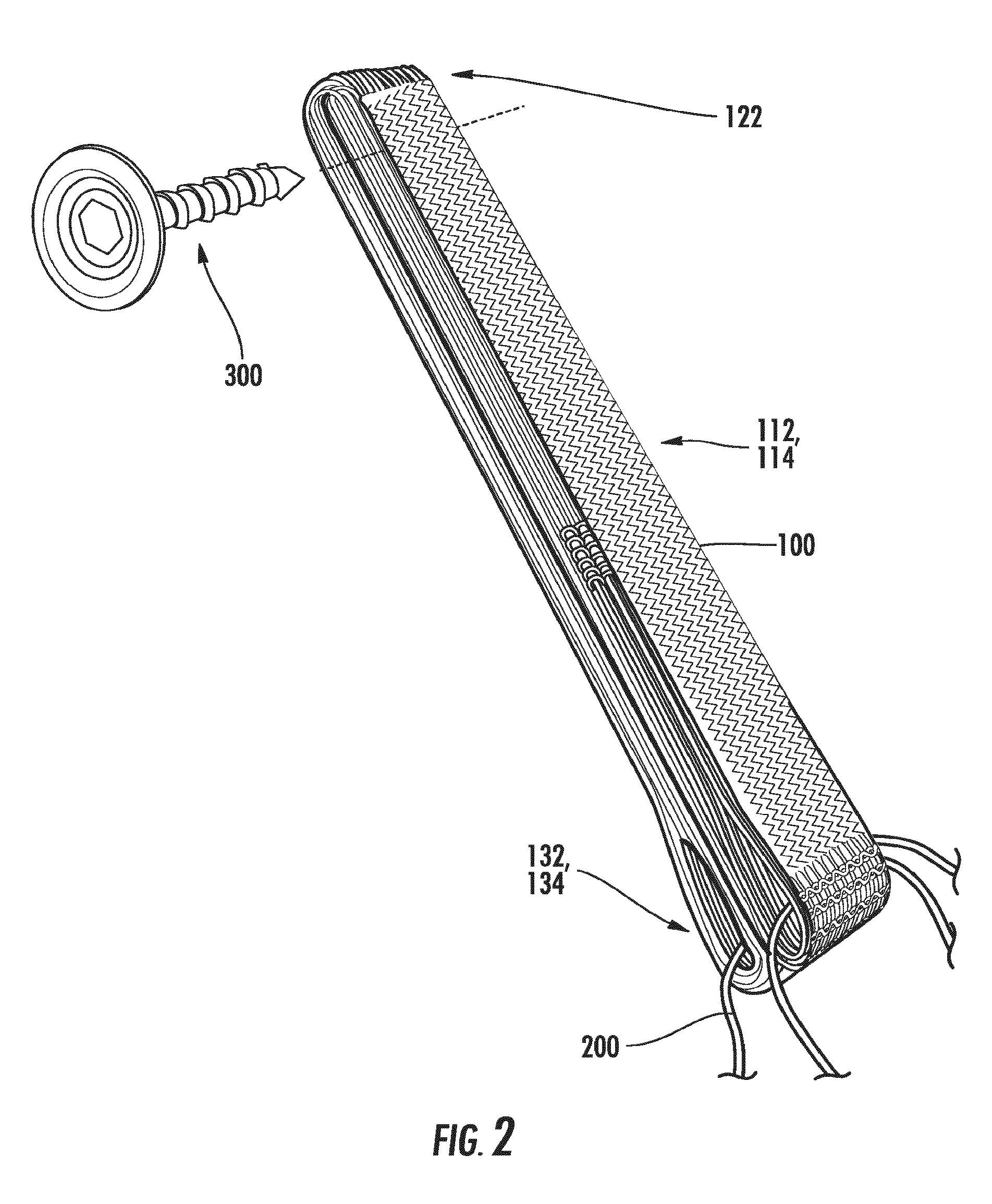

Selectively absorbable/biodegradable, fibrous composite constructs and applications thereof

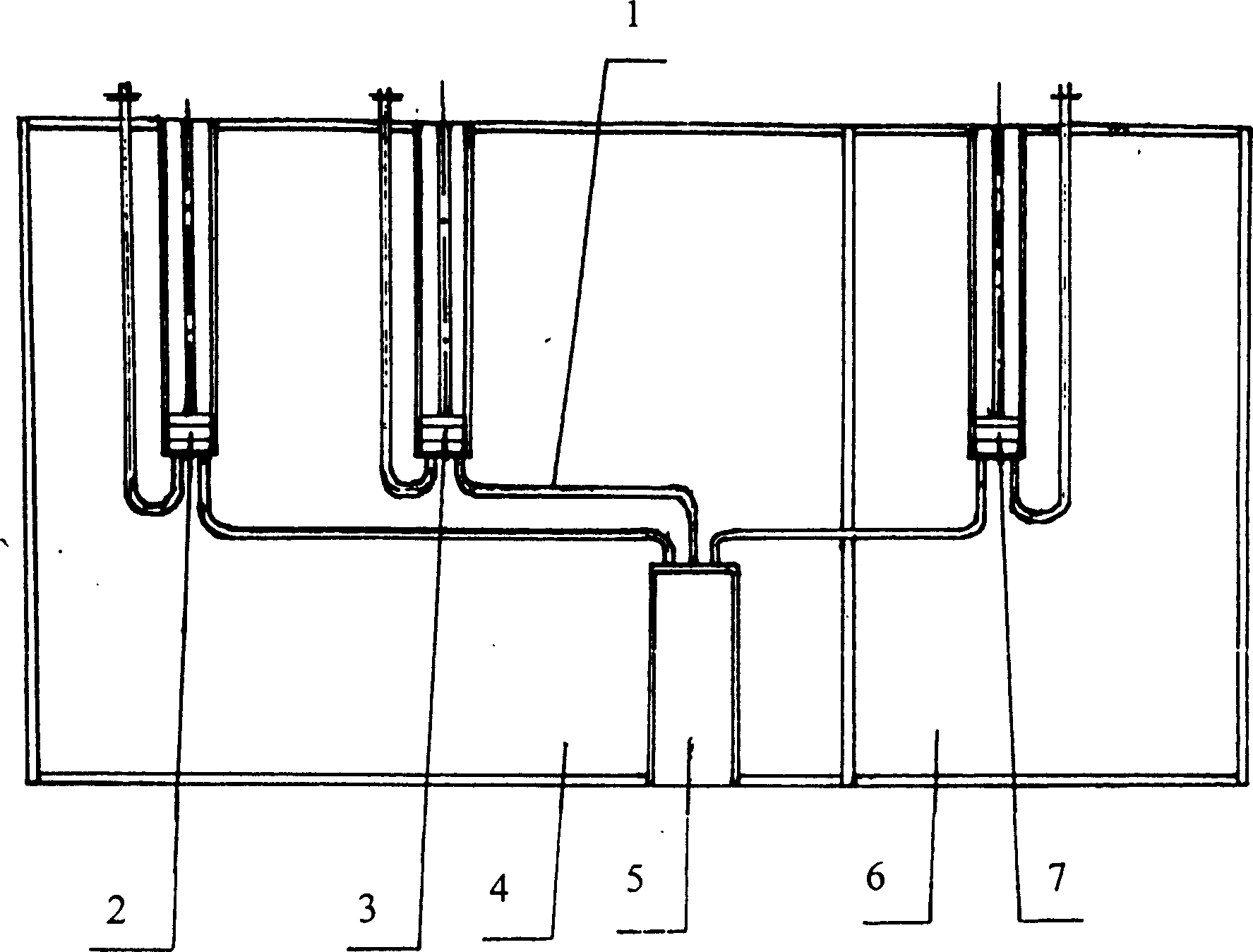

A family of selectively absorbable / biodegradable, fibrous composite constructs includes different combinations of biostable and absorbable / biodegradable yarns assembled as initially interdependent, load-bearing components, transitioning to exhibit independent functional properties during in vivo end-use. The family of constructs consists of two groups, one group is made of fiber-reinforced composites of high compliance, absorbable matrices of segmented polyaxial copolyesters reinforced with multifilament yarn constructs, which are combinations of ultrahigh molecular weight polyethylene fibers and at least one absorbable / biodegradable fiber selected from silk fibers and multifilament yarns made from linear segmented, l-lactide copolyesters and poly (3-hydroxyalkanoates, are useful in orthopedic, maxillofacial, urological, vascular, hernial repair and tissue engineering applications. The second group is made of coated and uncoated, warp-knitted mesh constructs for use in hernial, vascular, and urological tissue repair and tissue engineering.

Owner:POLY MED

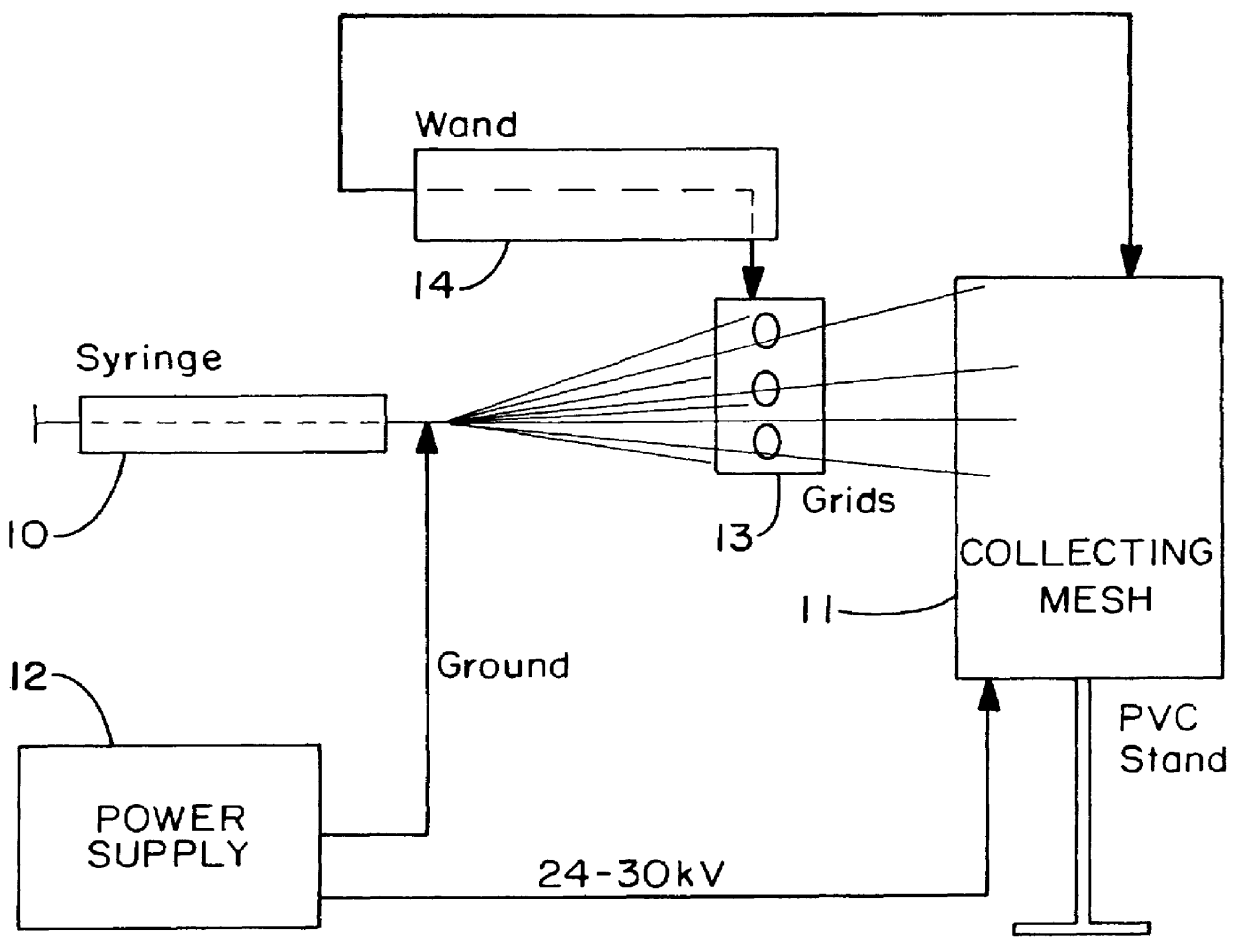

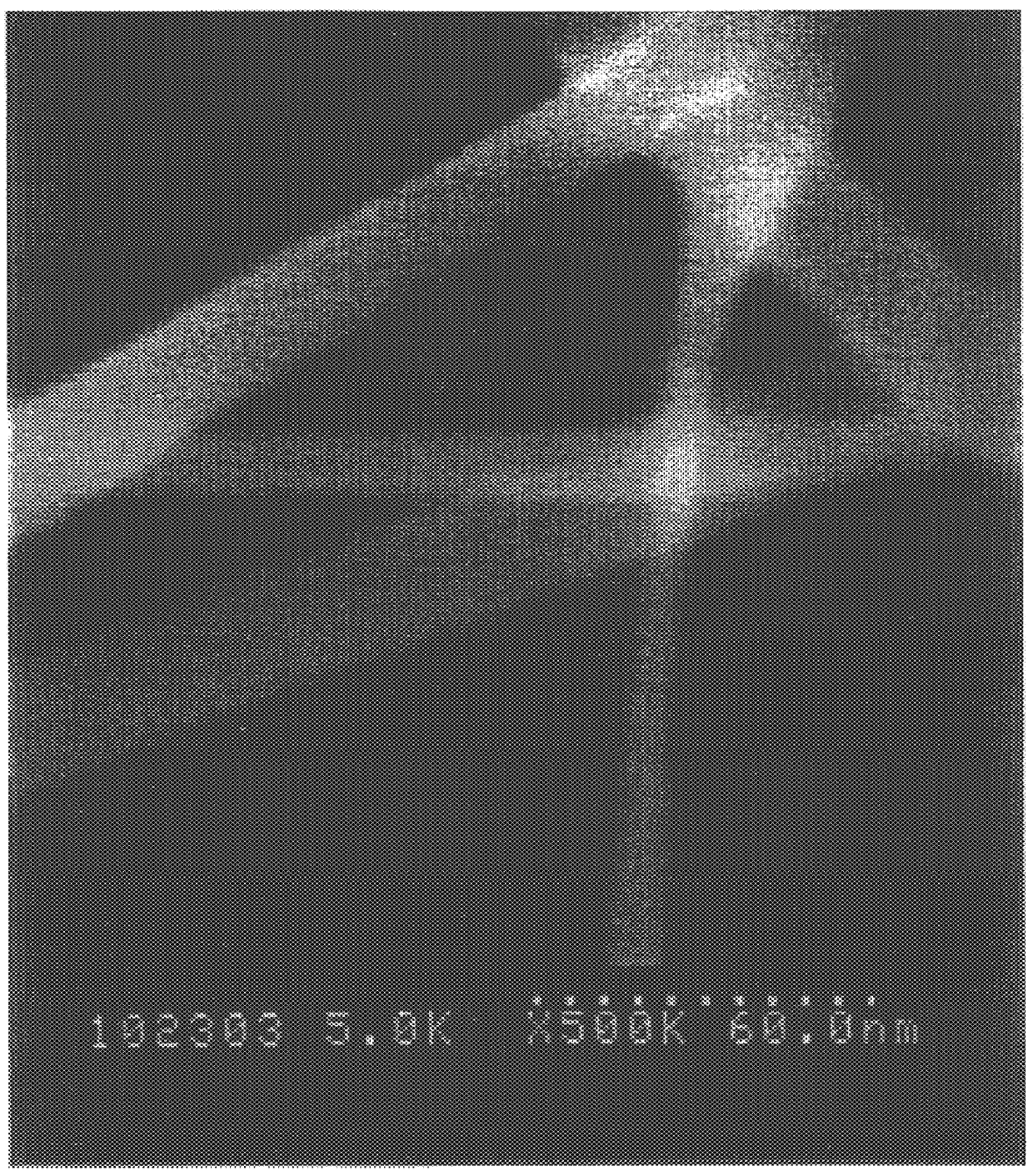

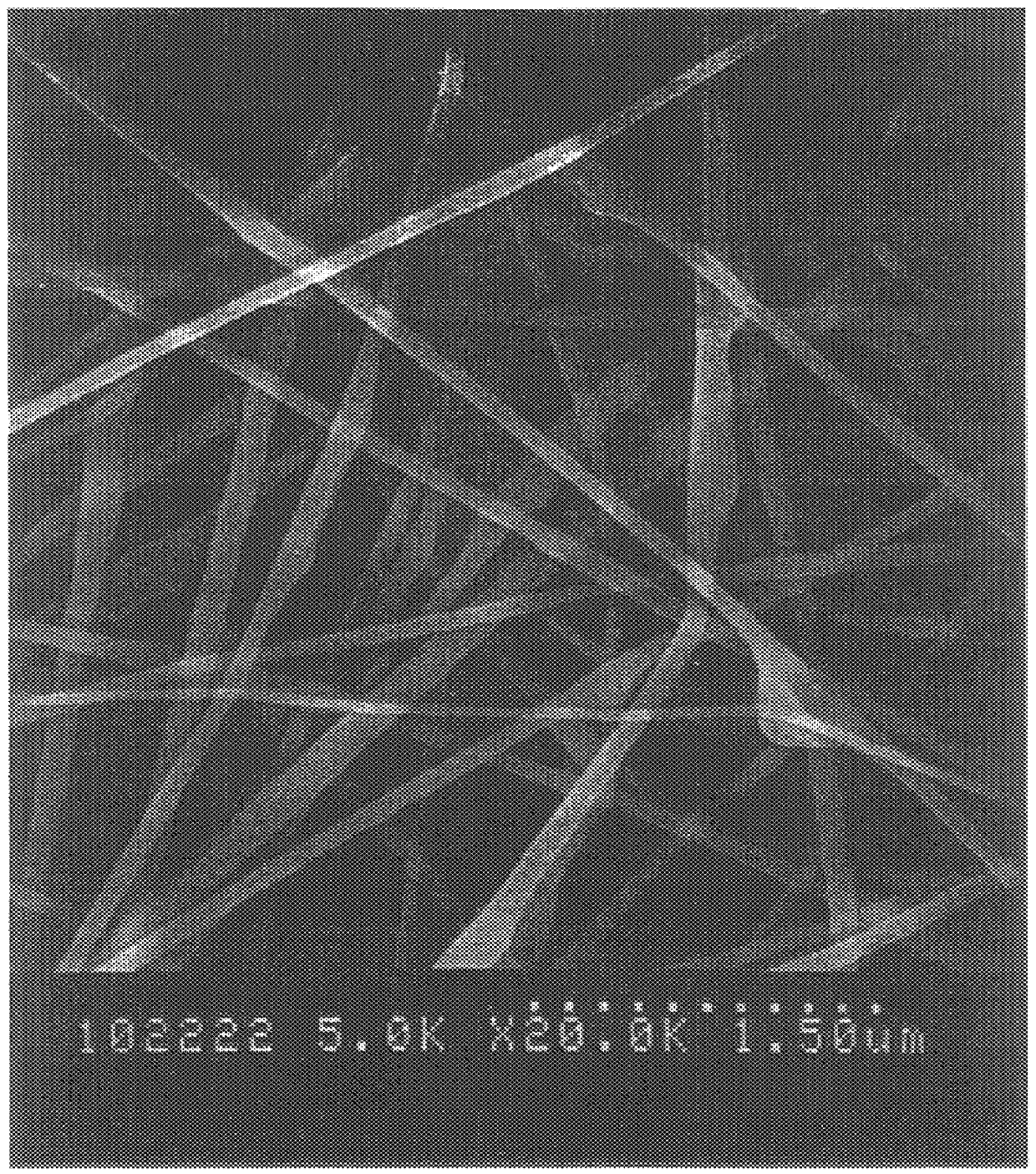

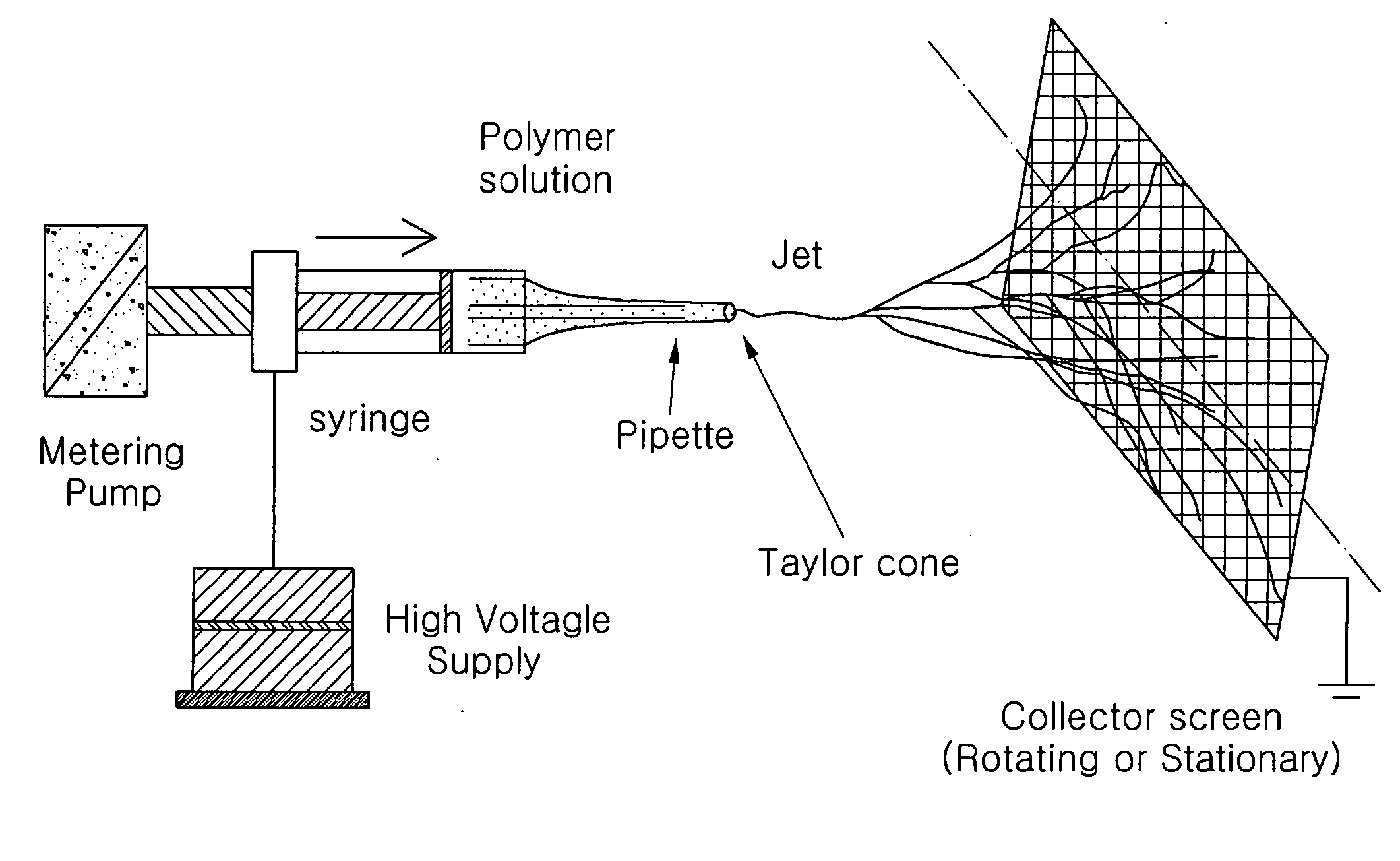

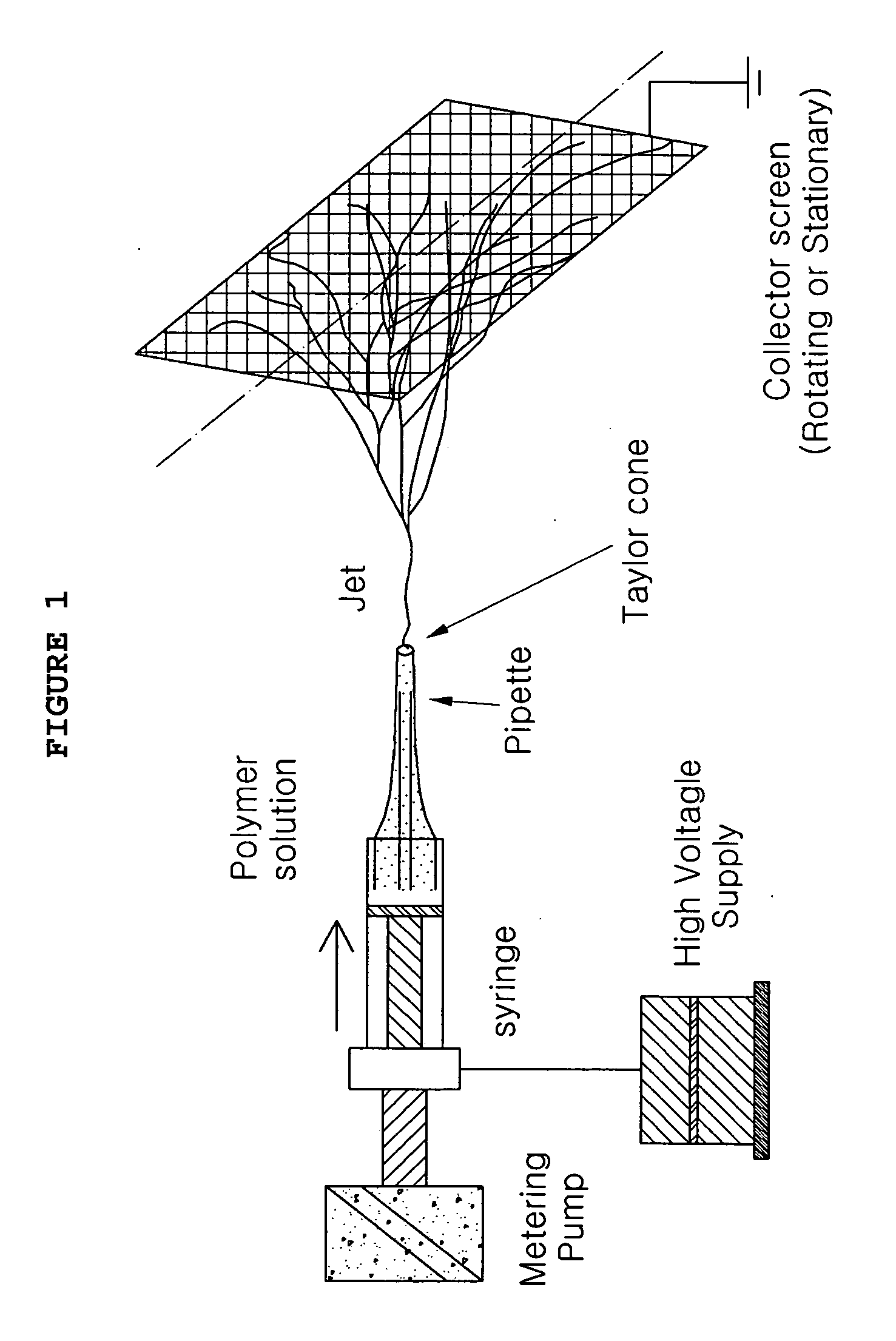

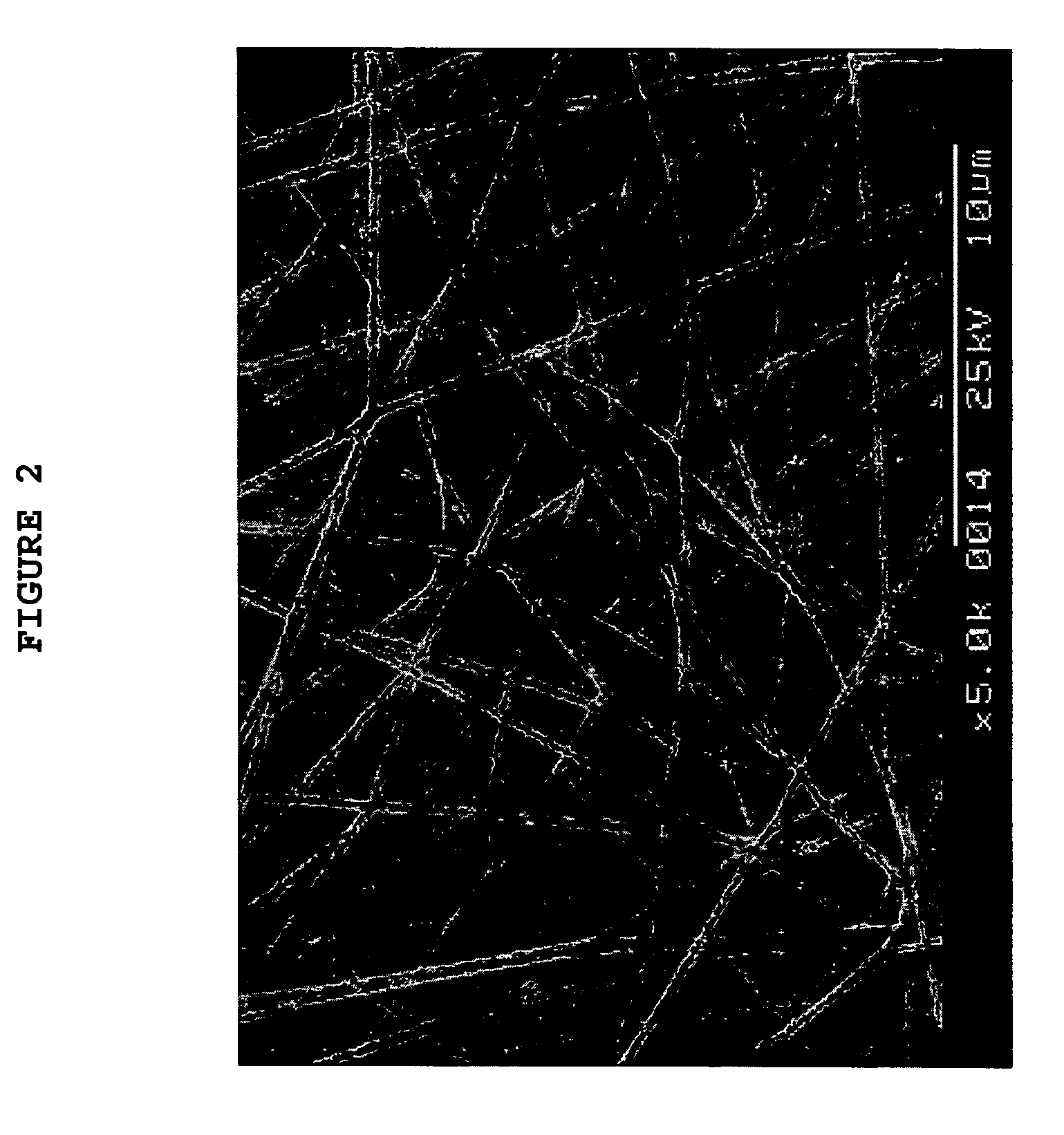

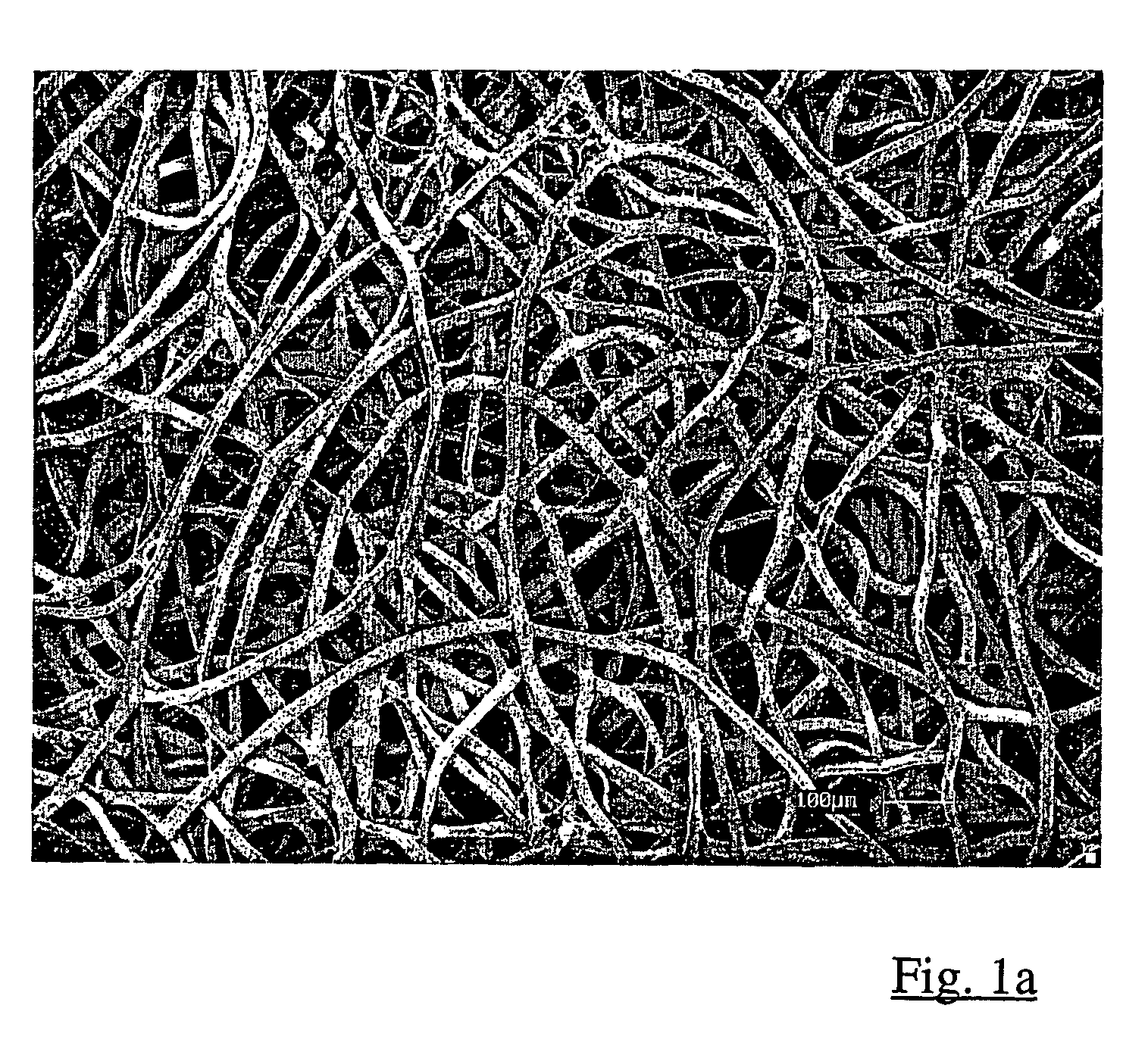

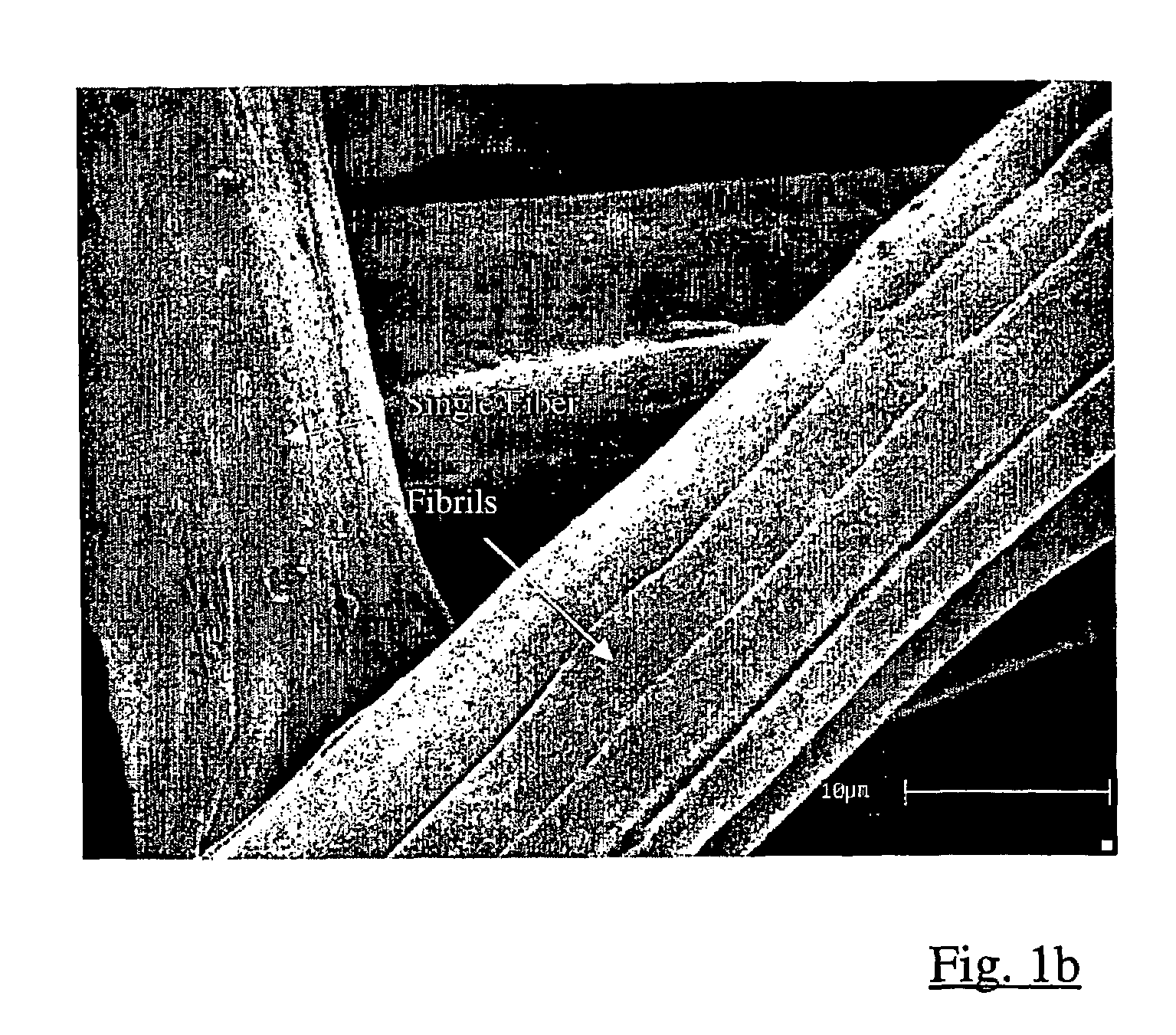

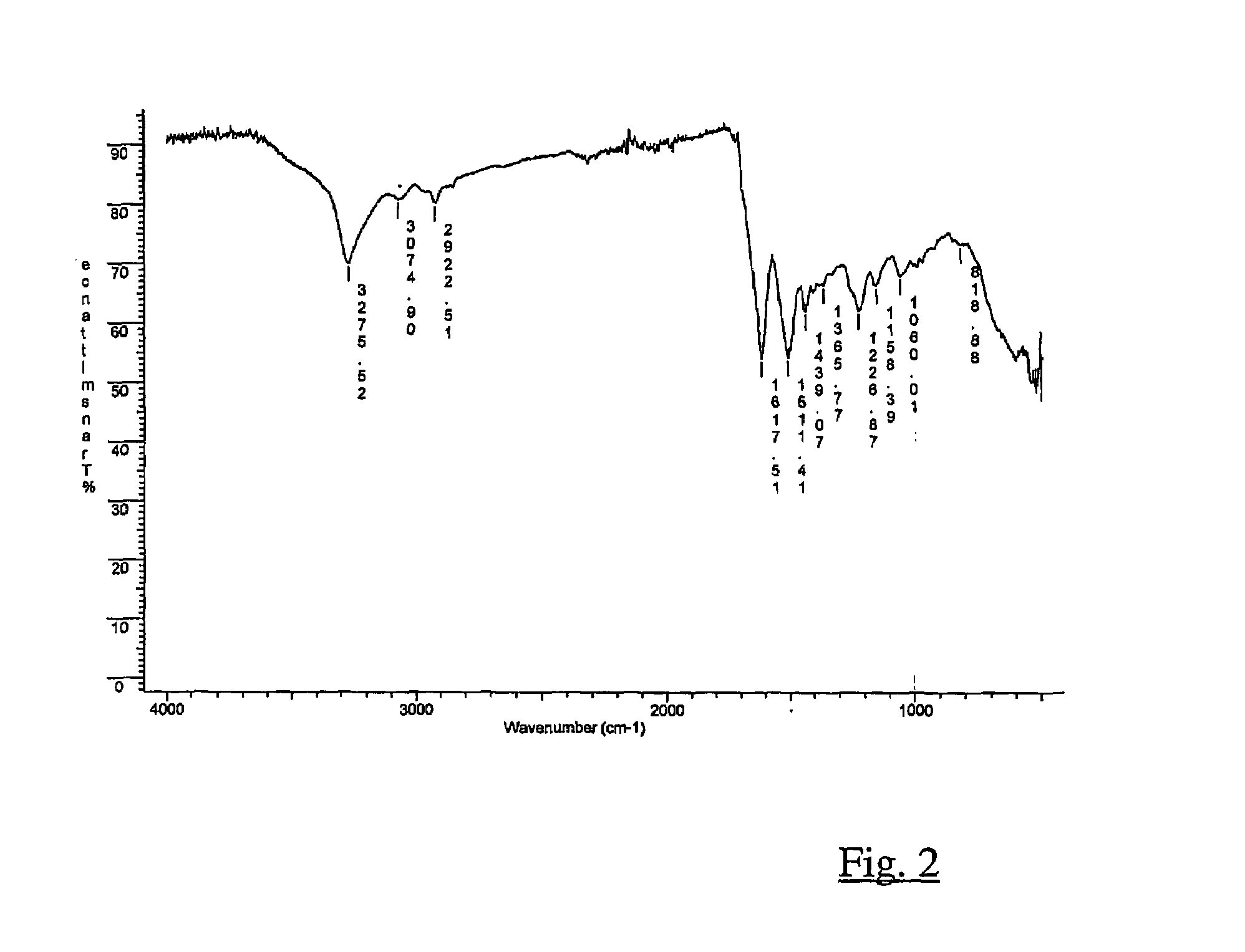

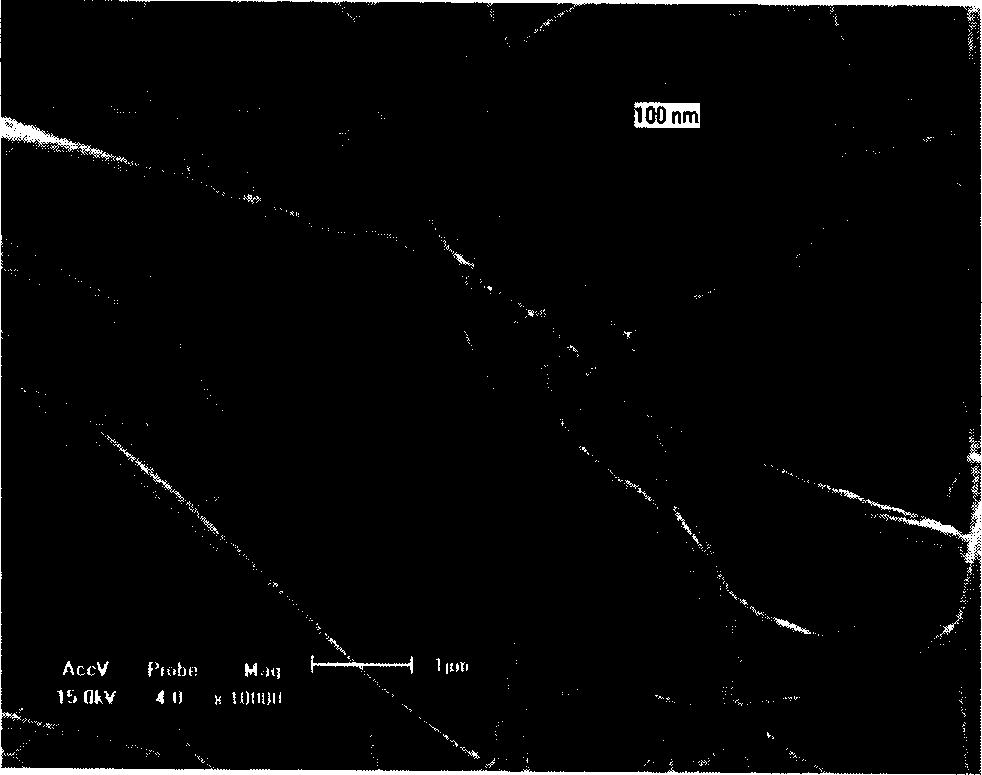

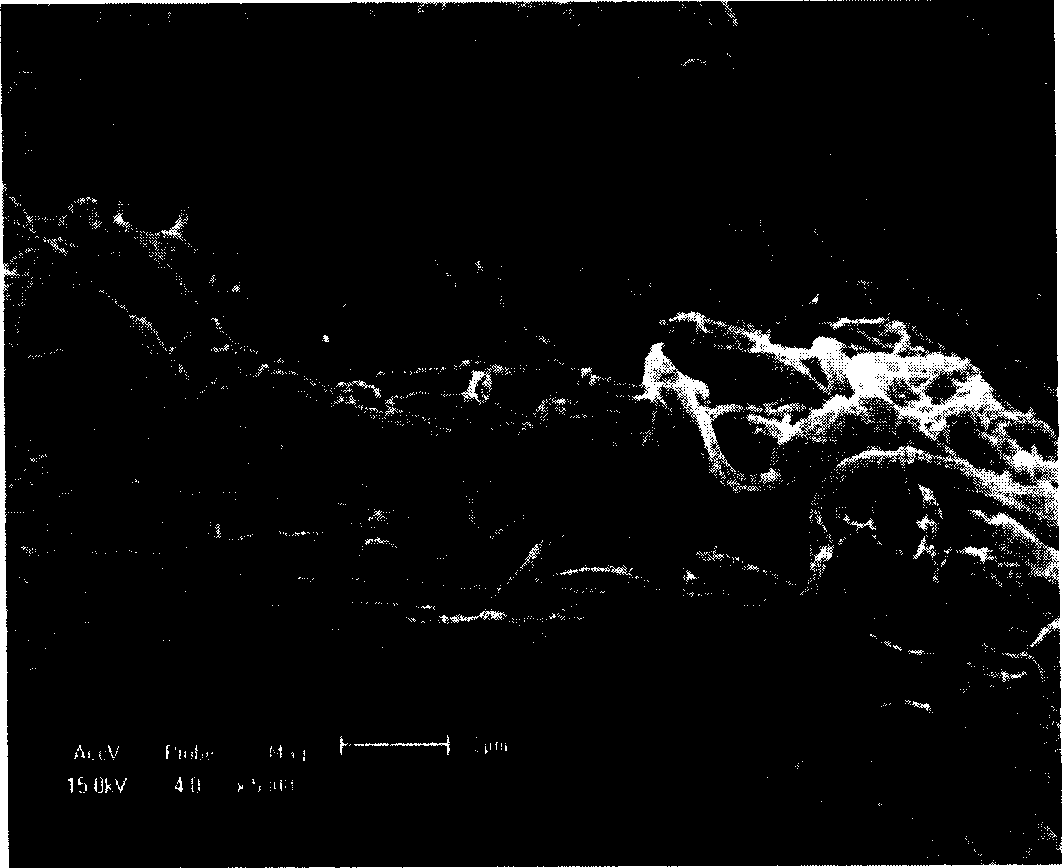

Synthetically spun silk nanofibers and a process for making the same

InactiveUS6110590AMonocomponent fibroin artificial filamentFilament/thread formingBombyx moriNanofiber

A silk nanofiber composite network produced by forming a solution of silk fiber and hexafluroisopropanol, wherein the step of forming is devoid of any acid treatment, where the silk solution has a concentration of about 0.2 to about 1.5 weight percent silk in hexafluroisopropanol, and where the silk is selected from Bombyx mori silk and Nephila clavipes silk; and electrospinning the solution, thereby forming a non-woven network of nanofibers having a diameter in the range from about 2 to about 2000 nanometers.

Owner:THE UNIVERSITY OF AKRON

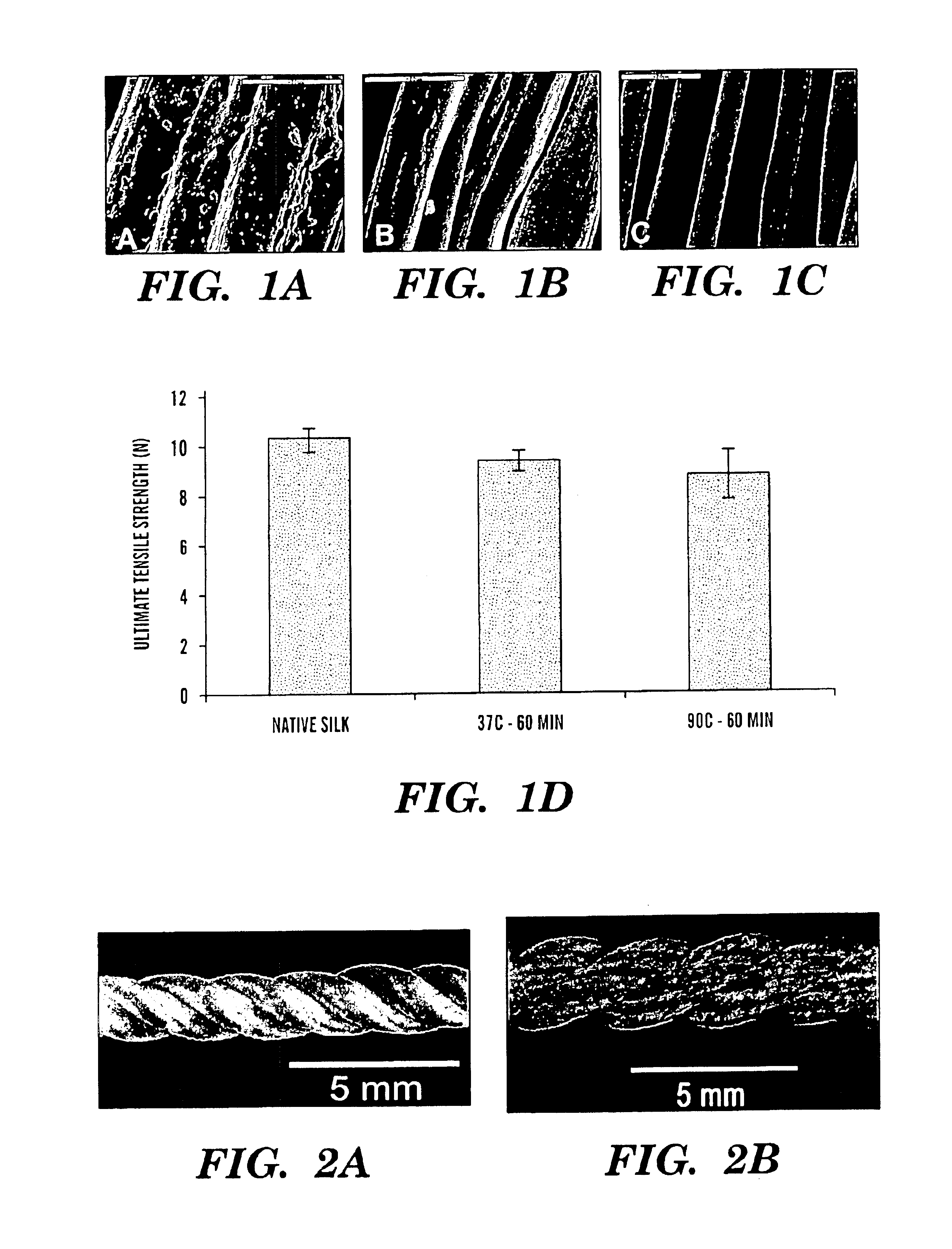

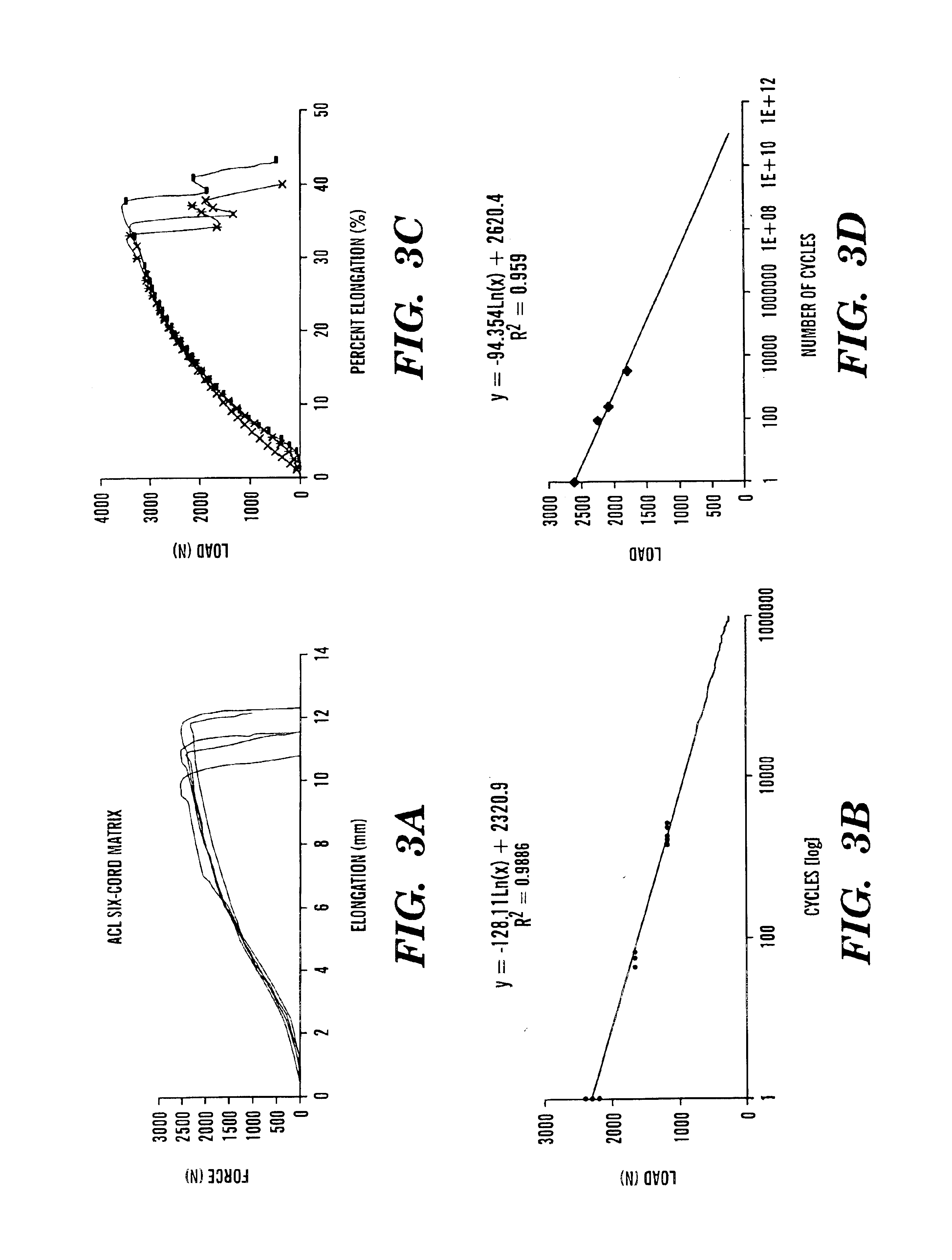

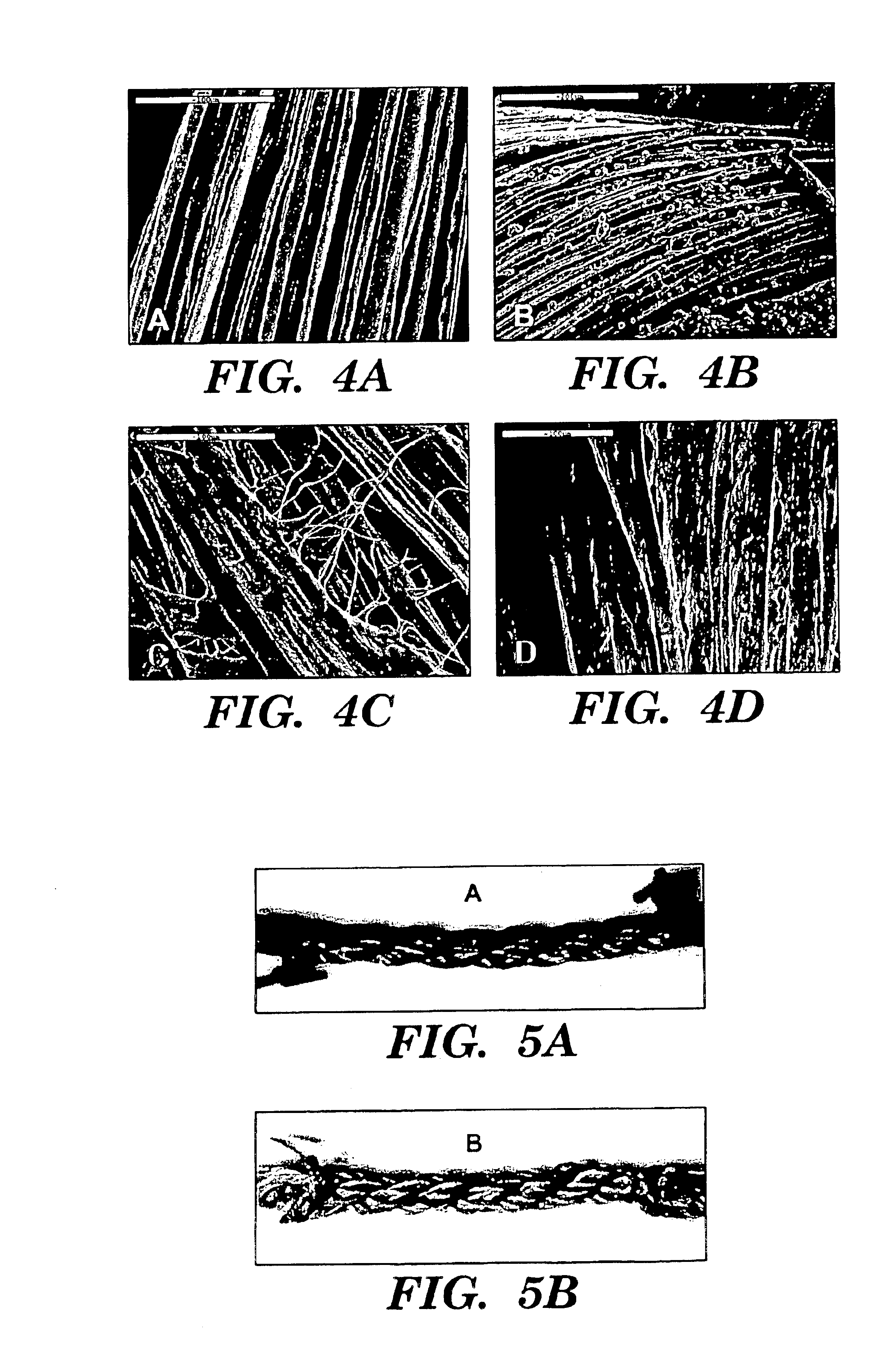

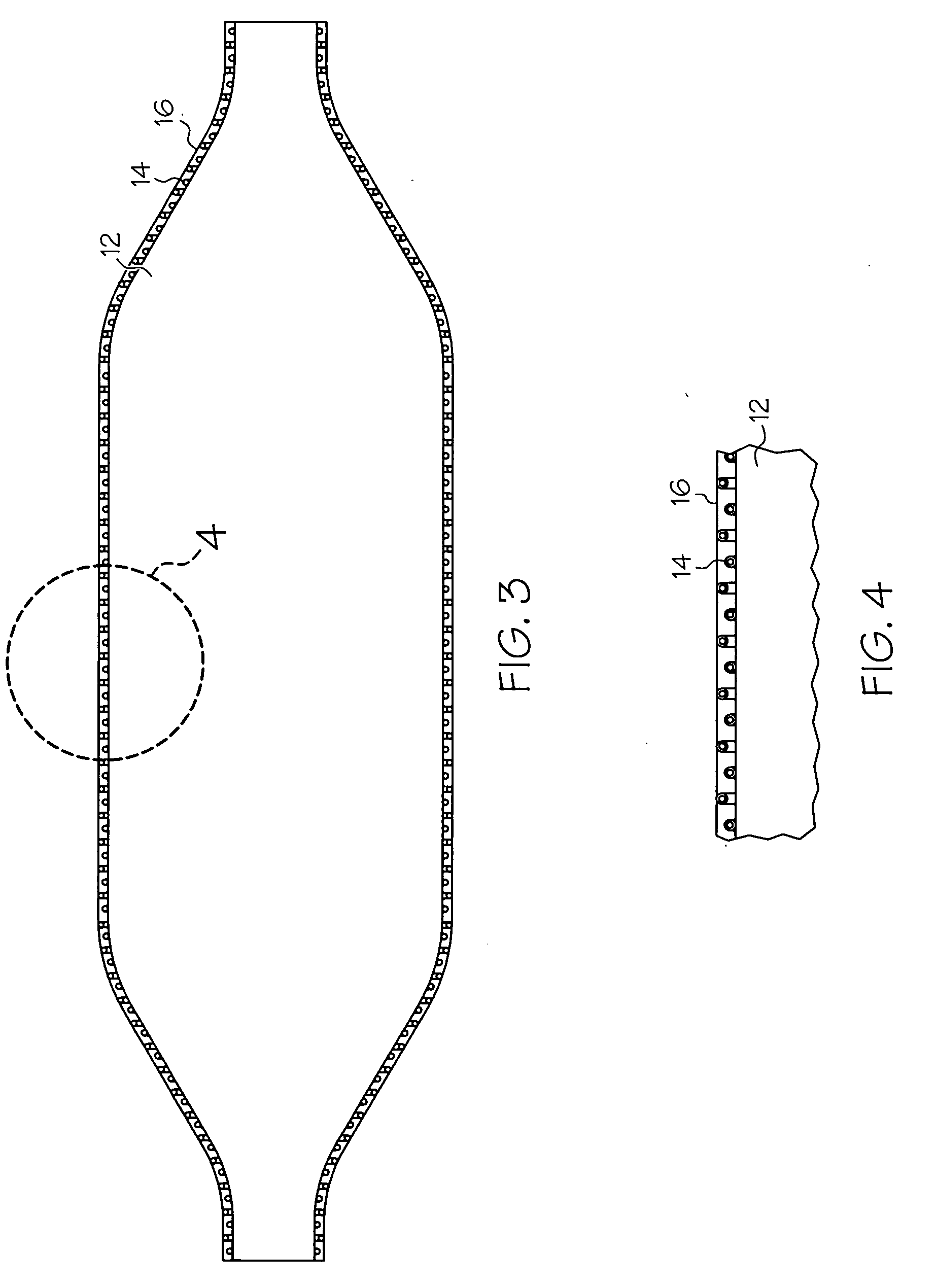

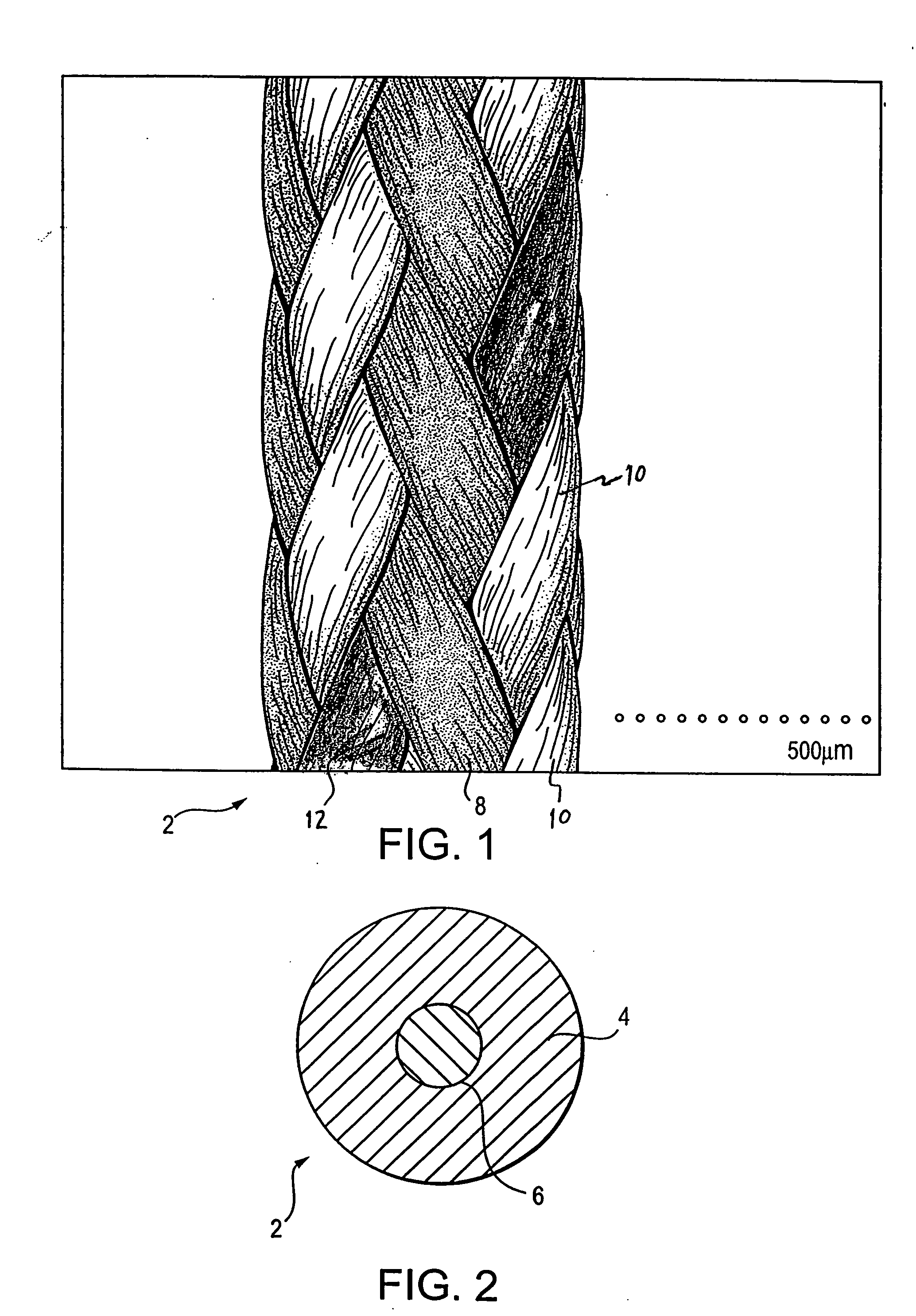

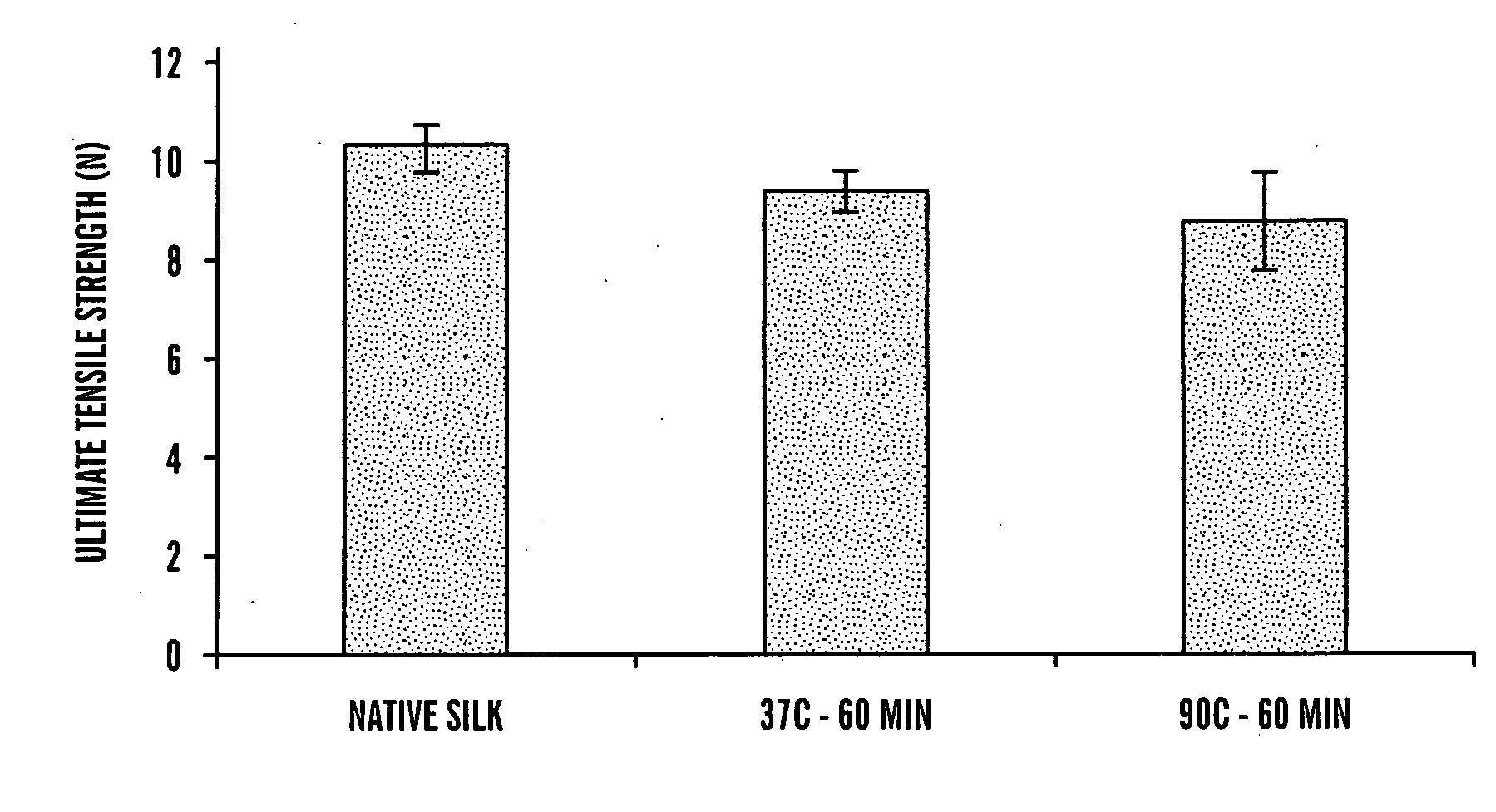

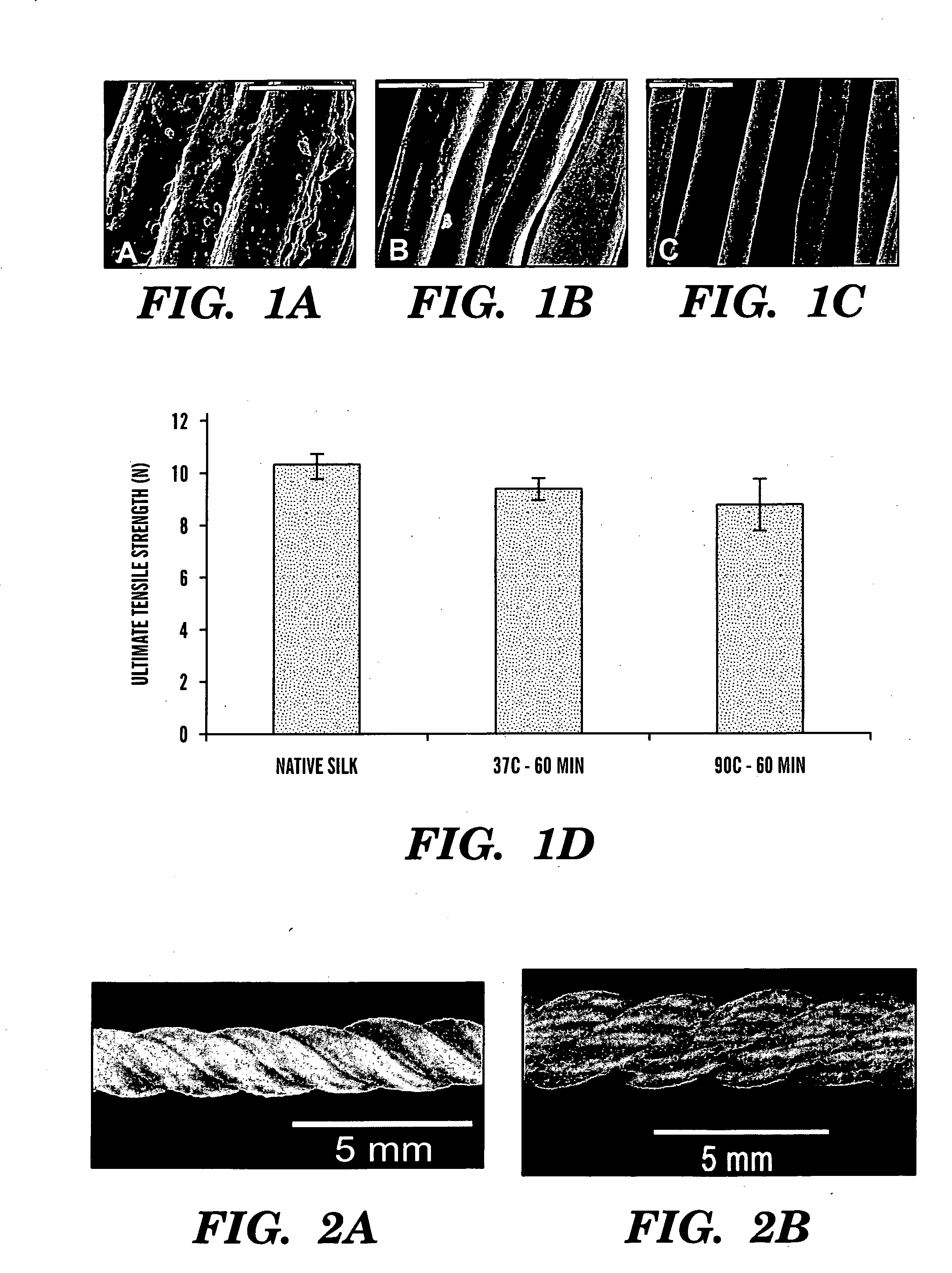

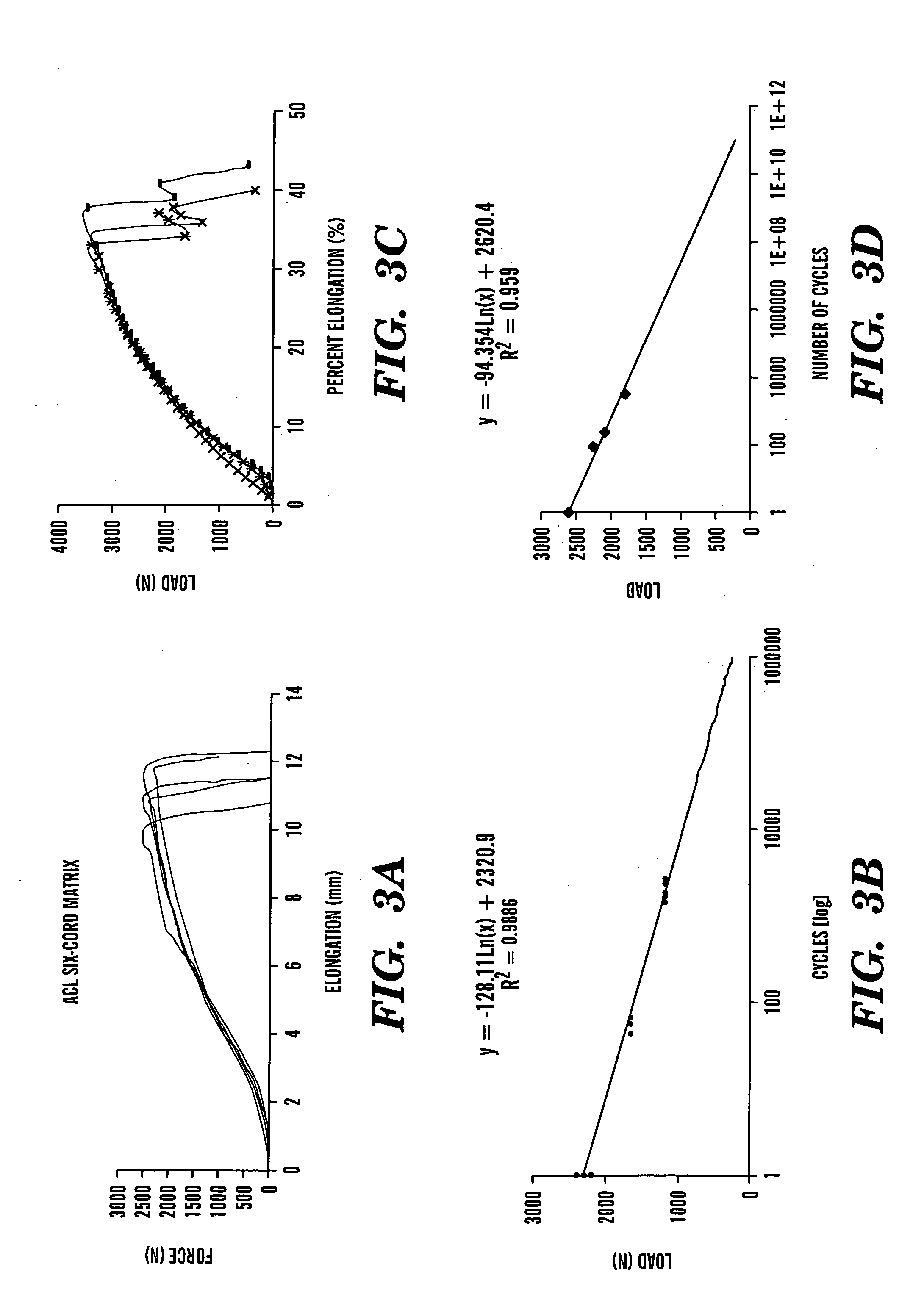

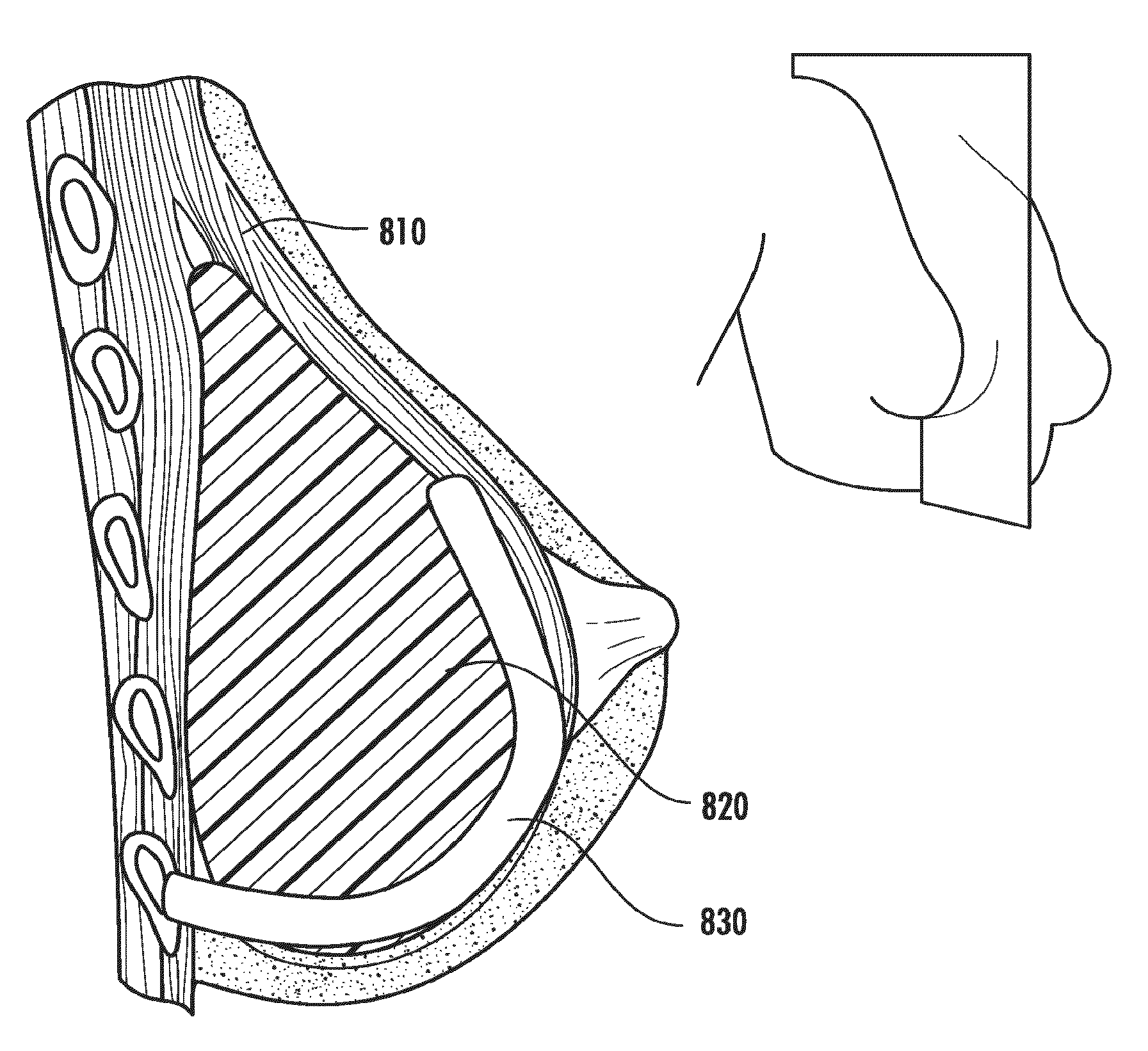

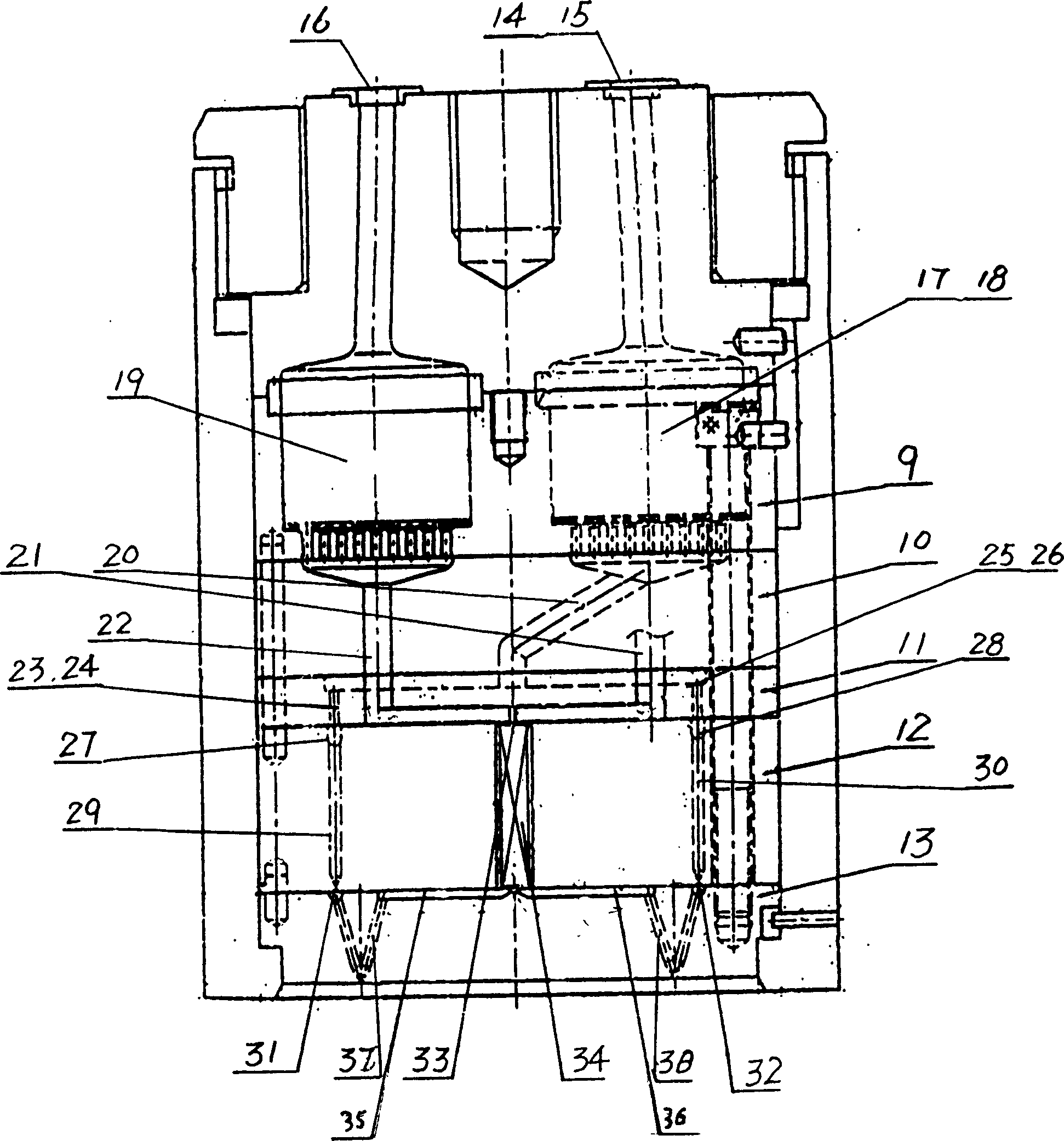

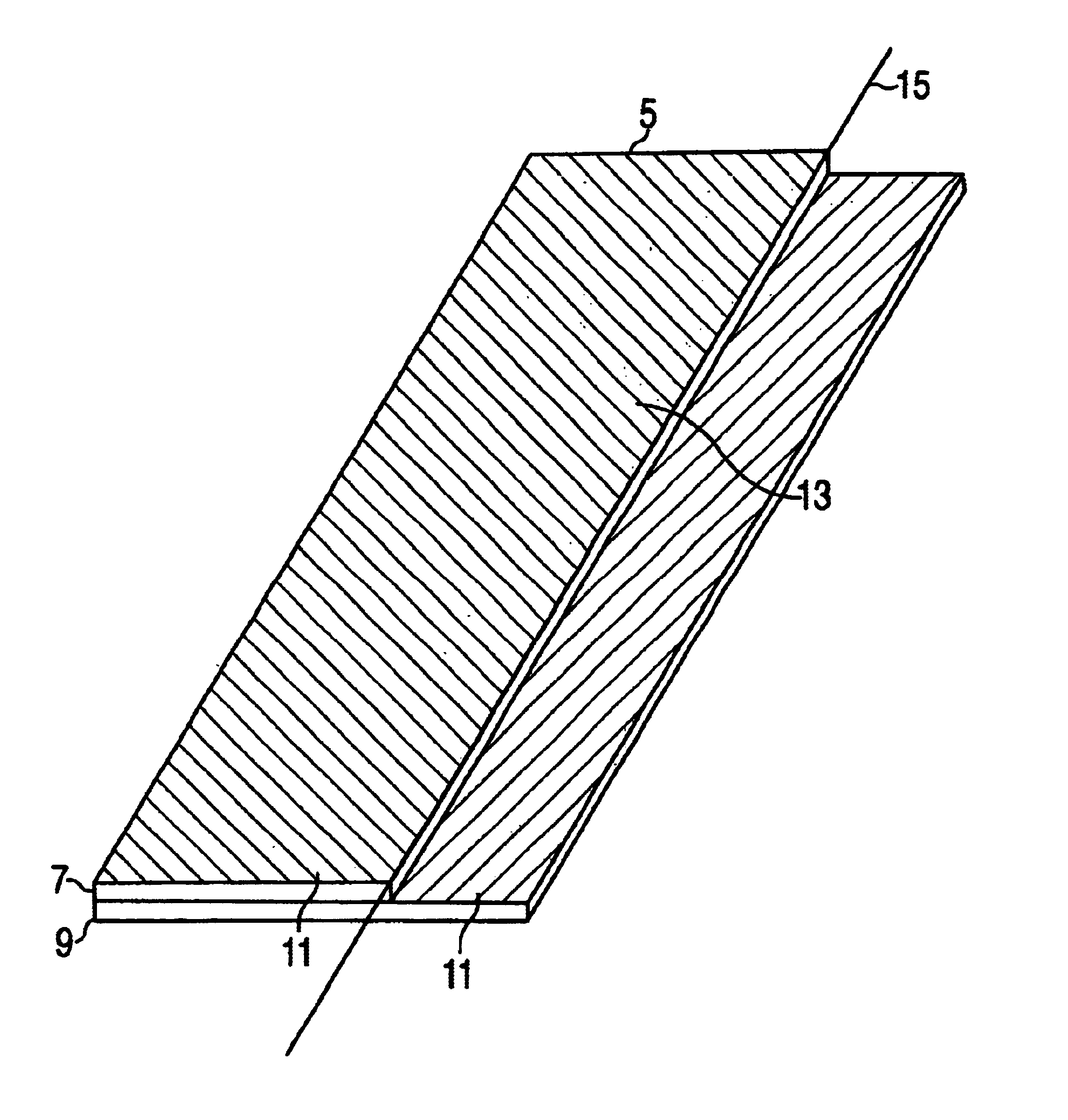

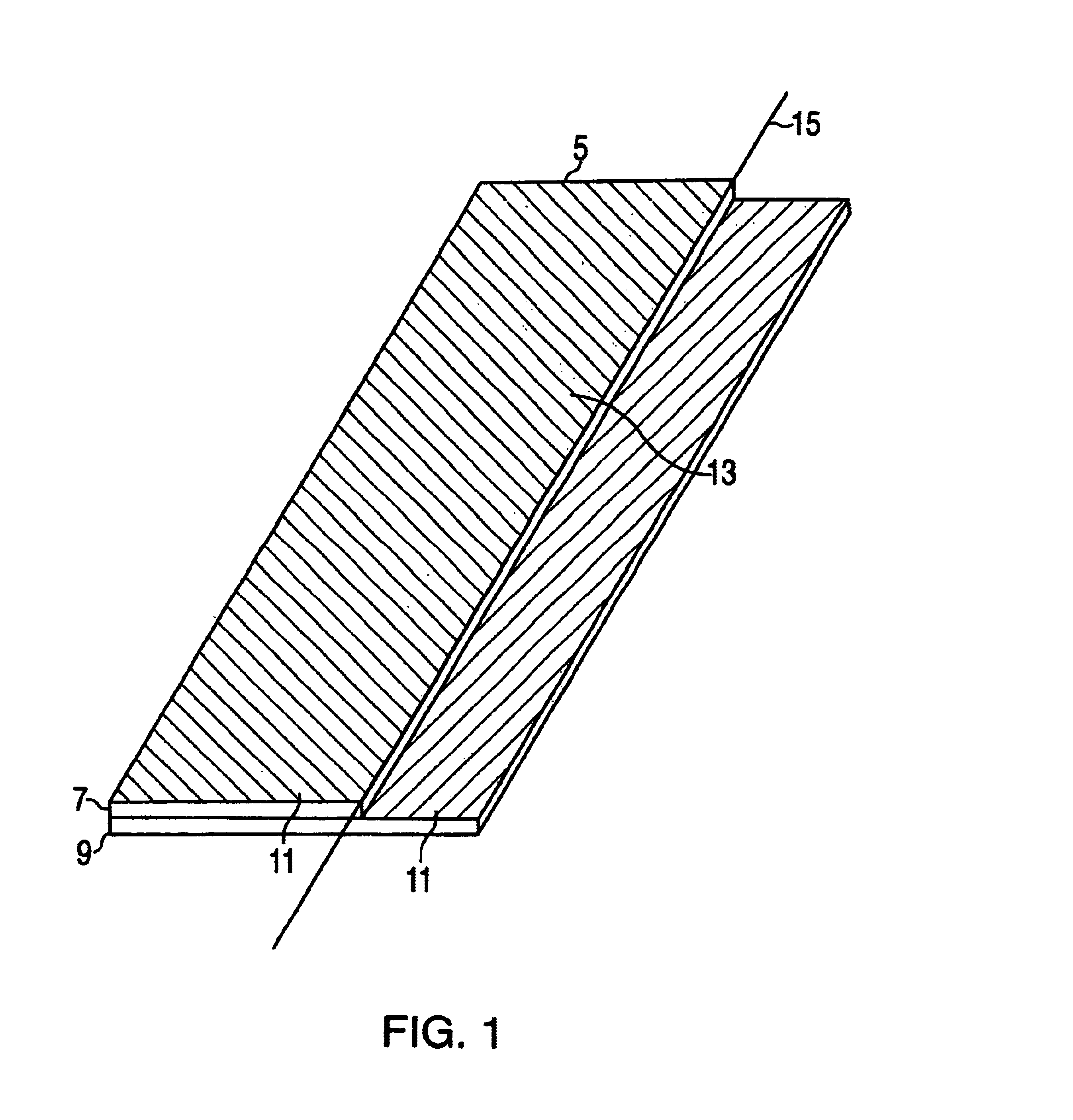

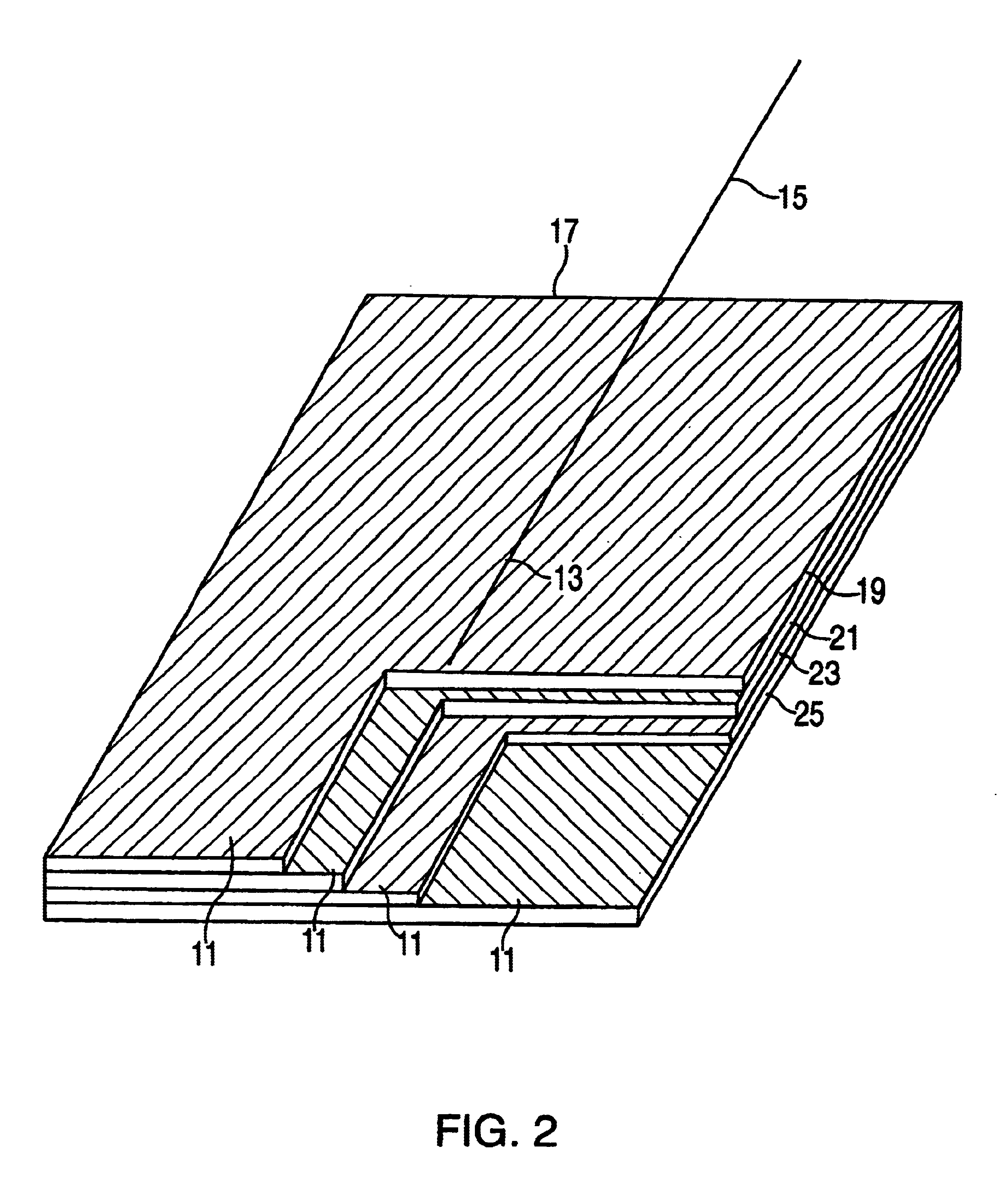

Helically organized silk fibroin fiber bundles for matrices in tissue engineering

InactiveUS6902932B2Immobilised enzymesBioreactor/fermenter combinationsFiber bundleLigament structure

The present invention provides a novel silk-fiber-based matrix having a wire-rope geometry for use in producing a ligament or tendon, particularly an anterior cruciate ligament, ex vivo for implantation into a recipient in need thereof. The invention further provides the novel silk-fiber-based matrix which is seeded with pluripotent cells that proliferate and differentiate on the matrix to form a ligament or tendon ex vivo. Also disclosed is a bioengineered ligament comprising the silk-fiber-based matrix seeded with pluripotent cells that proliferate and differentiate on the matrix to form the ligament or tendon. A method for producing a ligament or tendon ex vivo comprising the novel silk-fiber-based matrix is also disclosed.

Owner:ALLERGAN INC +1

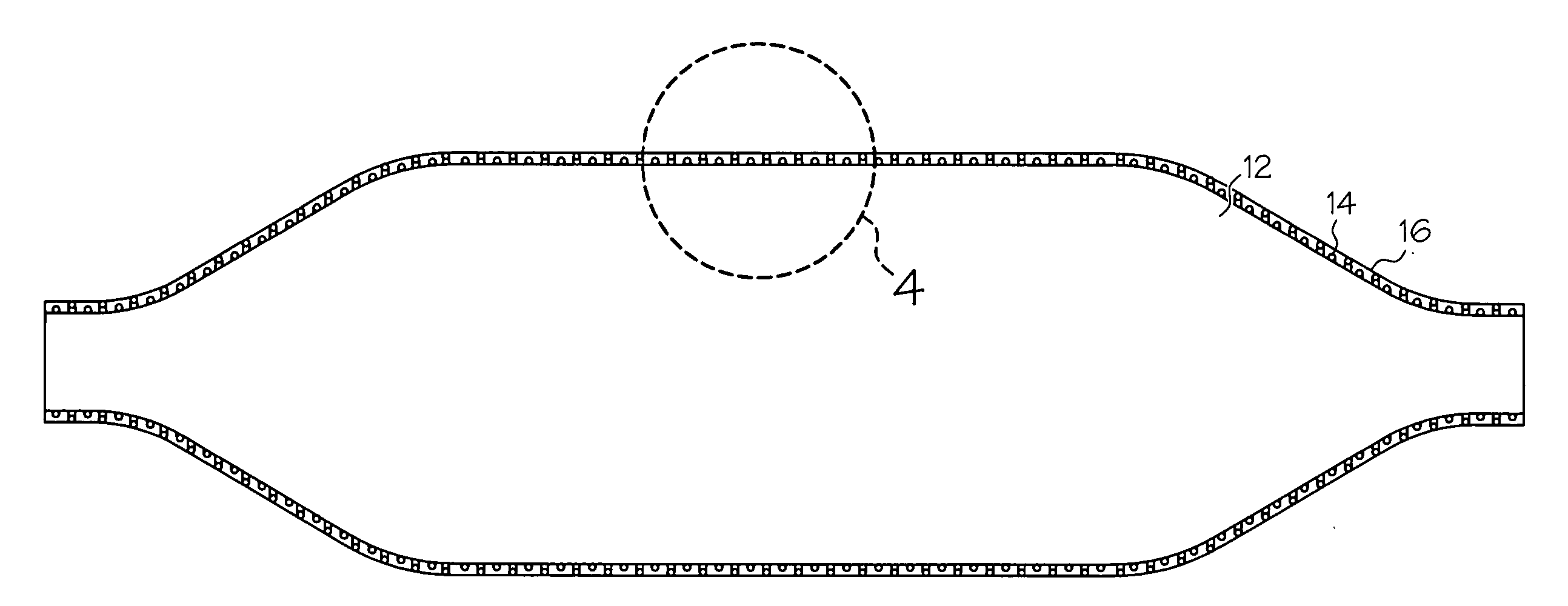

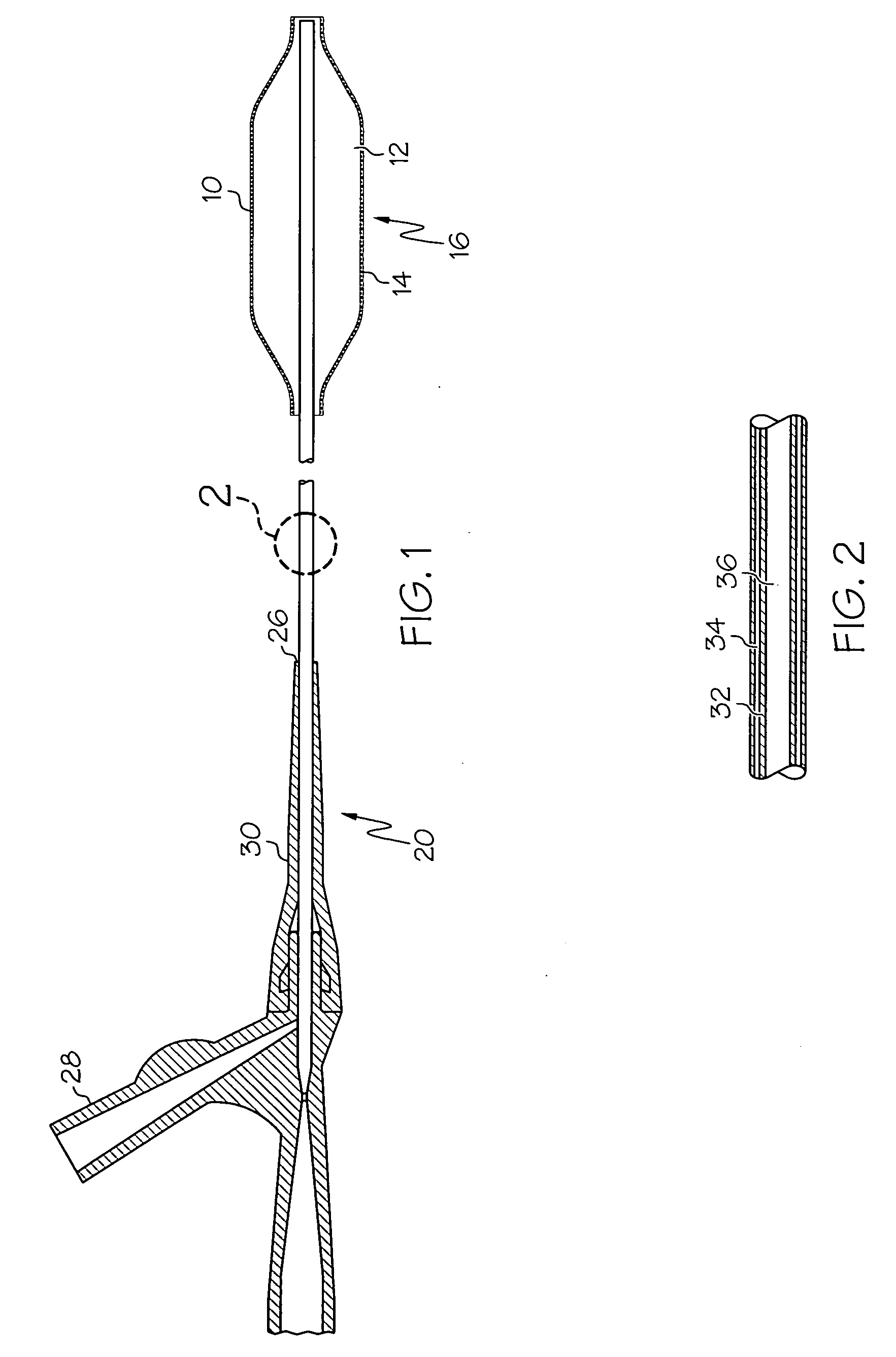

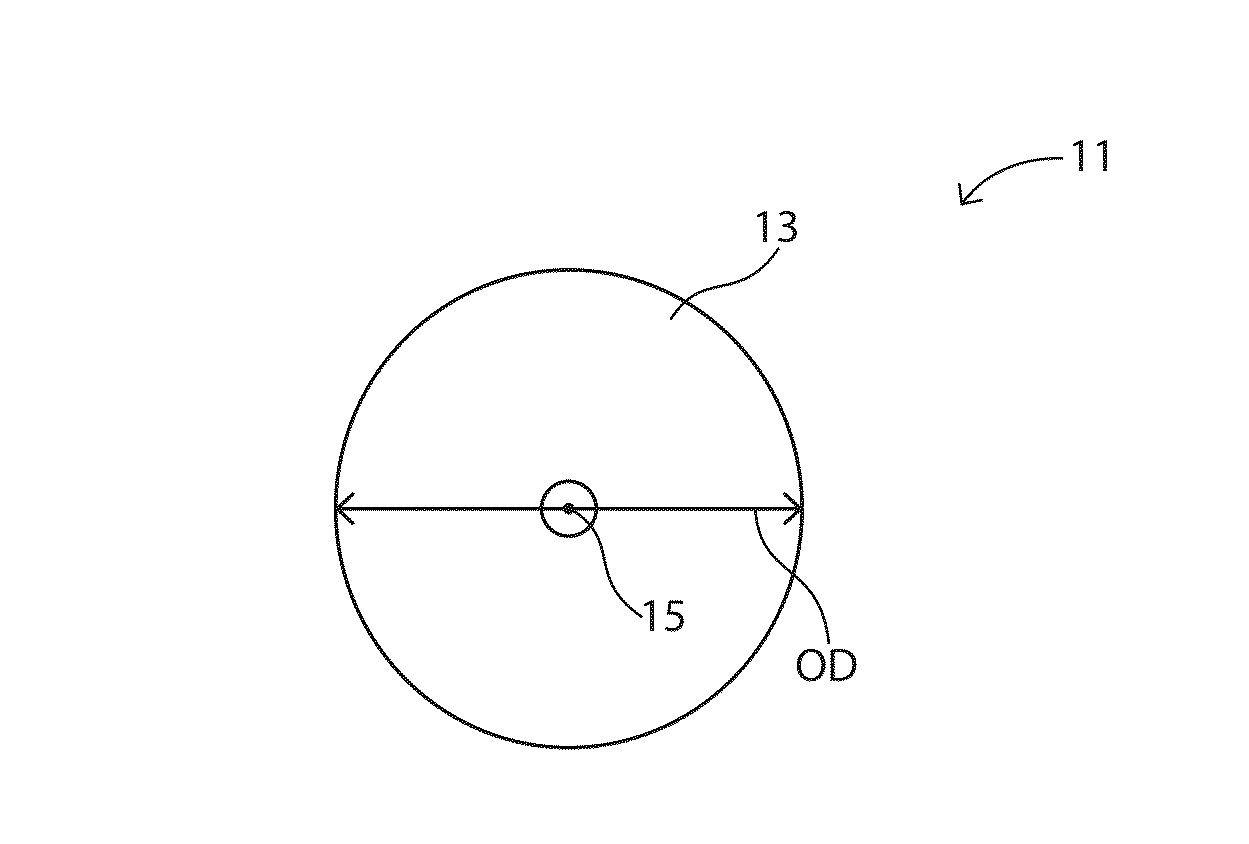

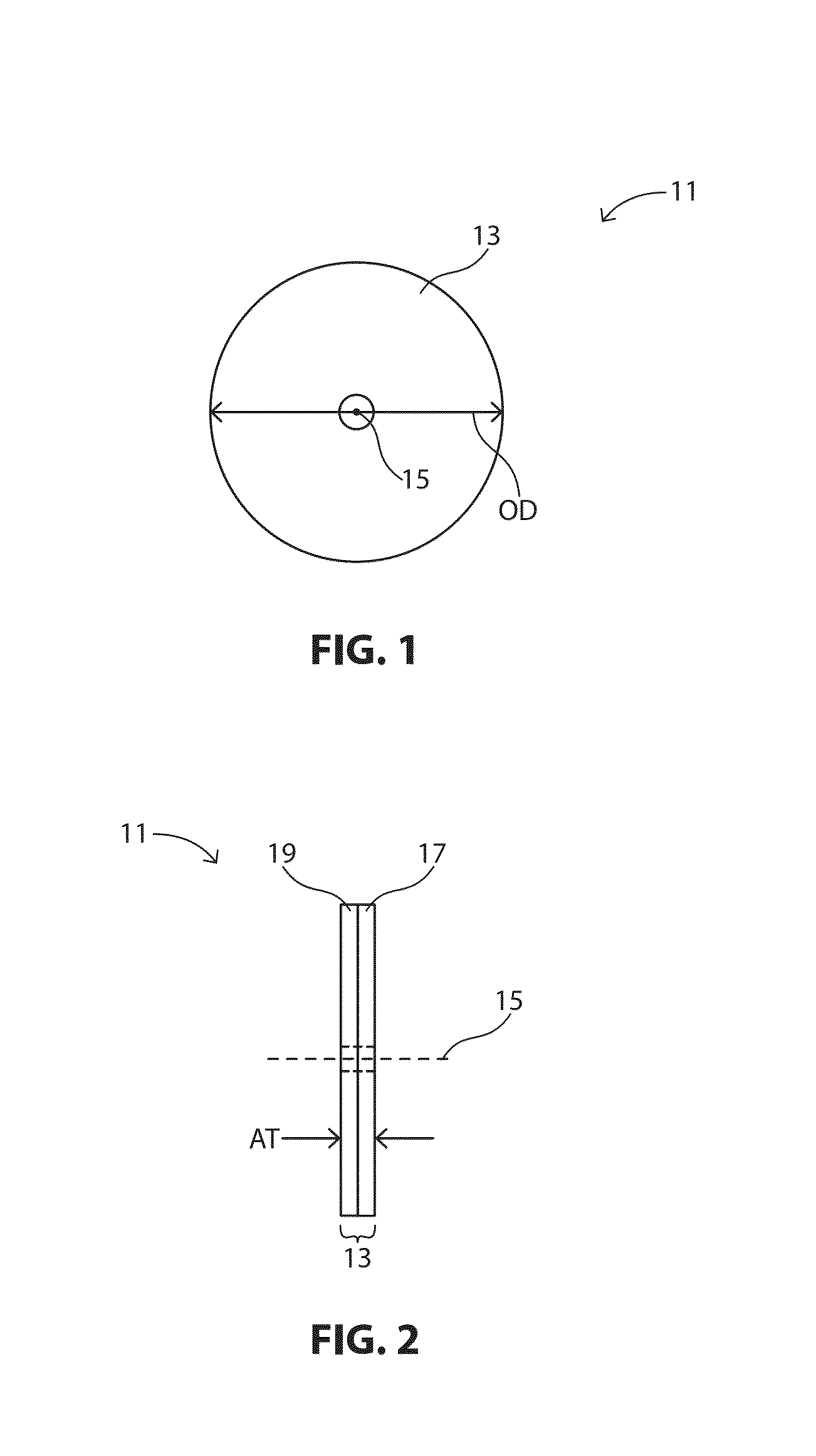

Artificial silk reinforcement of PTCA balloon

InactiveUS20050271844A1Prevent penetrationImprove integrityBalloon catheterPedestrian/occupant safety arrangementMedical deviceBiomedical engineering

A medical device formed from at least one first layer defining the shape of the medical device, the first layer having an inner surface and an outer surface and a web formed with silk fiber provided over at least a portion of the inner surface, the outer surface or both of the first layer.

Owner:BOSTON SCI SCIMED INC

Enhanced ballistic performance of polymer fibers

ActiveUS7964518B1Synthetic resin layered productsPersonal protection gearFiber ChemistryPhysical strength

Ballistic resistant materials having improved strength and lighter weights. More particularly, improved ballistic resistant fabrics produced from drawn, high modulus fibers having a reduced fiber diameter and improved physical strength properties, without changing other properties such as fiber chemistry, binder resin type and binder resin content. The fabrics incorporate low denier per filament monofilament fibers, low denier per filament multifilament fibers, or a combination of low denier per filament monofilament fibers and low denier per filament multifilament fibers in a specialized fabric construction to form fine fiber layers and fabrics having enhanced strength and fiber areal density without altering the fabric weight, or having reduced fabric weight without a corresponding reduction in ballistic performance.

Owner:HONEYWELL INT INC

Nanofibrous nonwoven membrane of silk fibroin for guided bone tissue regeneration and manufacturing method thereof

InactiveUS20060095137A1Easy to controlSimple processMaterial nanotechnologyElectric discharge heatingBone tissueBiocompatibility Testing

The present invention relates to a membrane for guided bone tissue regeneration and, more particularly, to a membrane for guided bone tissue regeneration having a structure that silk fibroin nanofibers obtained by removing sericin from silk fibers are formed as a nonwoven, and a manufacturing method thereof. A membrane for guided bone tissue regeneration according to the present invention has a predetermined strength, biocompatibility, and biodegradability, and may maintain a sustained drug release system, when drugs are added in the manufacturing process. Additionally, a membrane for guided bone tissue regeneration according to the present invention may be modified corresponding to the condition of usage, because a thickness of the membrane may be adjusted by controlling fineness of nanofibers, compactness of nanofibers, and pore size of a multiporous structure may be adjusted, in a nonwoven manufacturing process. A nanofibrous membrane for guided bone tissue regeneration according to the present invention is manufactured by freezing rapidly, drying a silk fibroin solution obtained by removing sericin from silk fibers, and by electrospinning after dissolving the dried silk fibroin in an electrospinning solvent. The membrane according to the present invention has excellent adhesion and air permeability, and is thereby effective in regeneration of damaged periodontal tissues.

Owner:SEOUL NAT UNIV R&DB FOUND

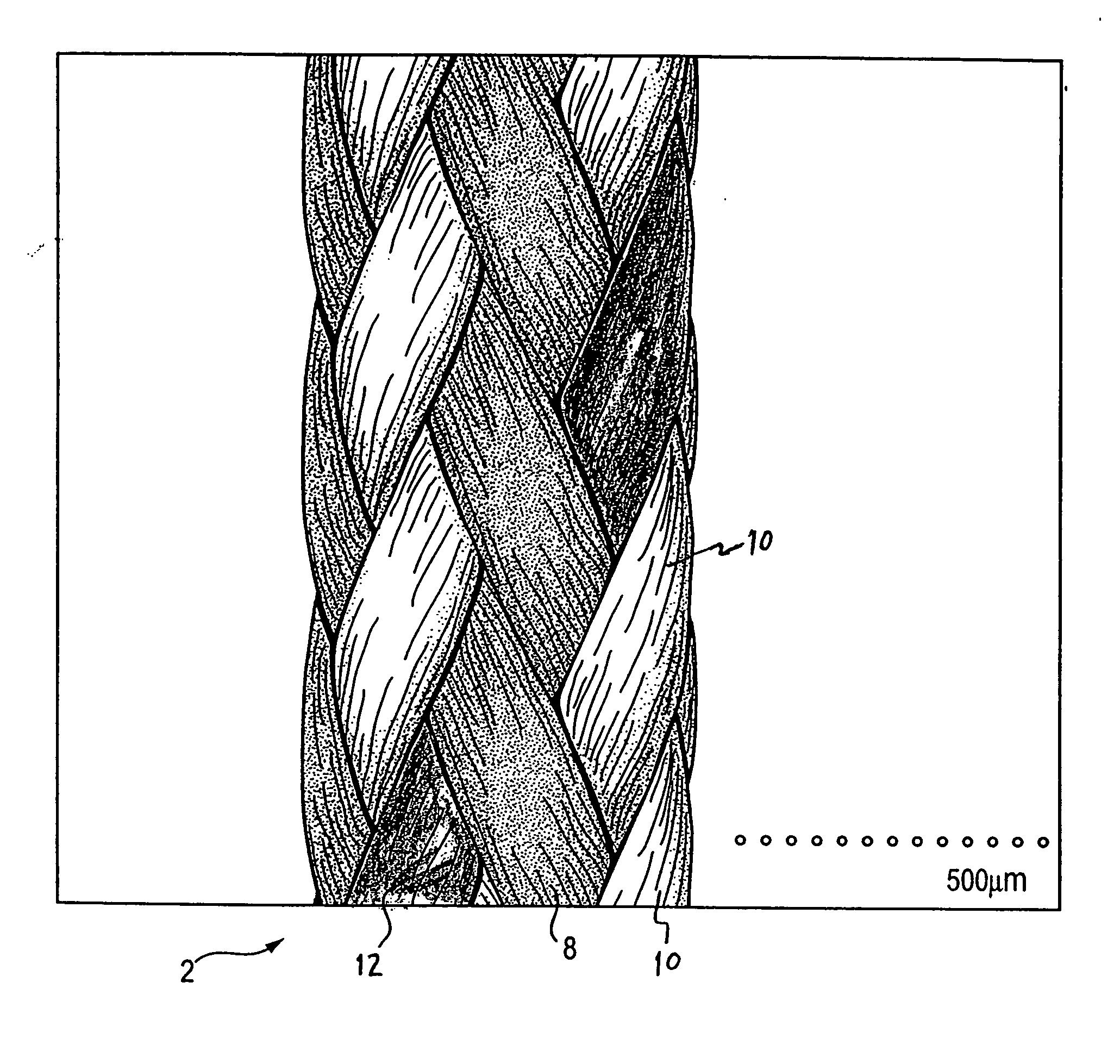

Hemostatic textile

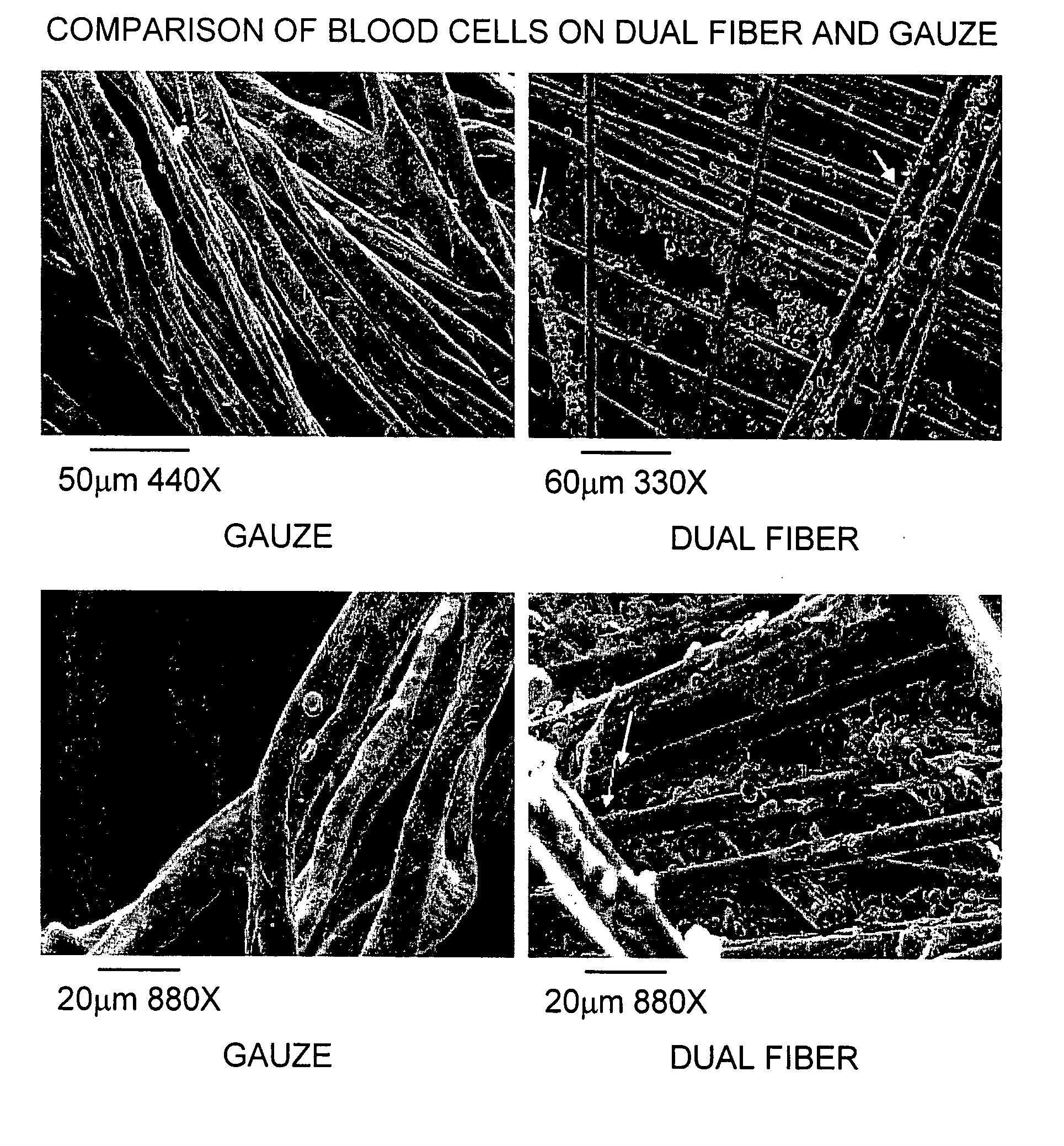

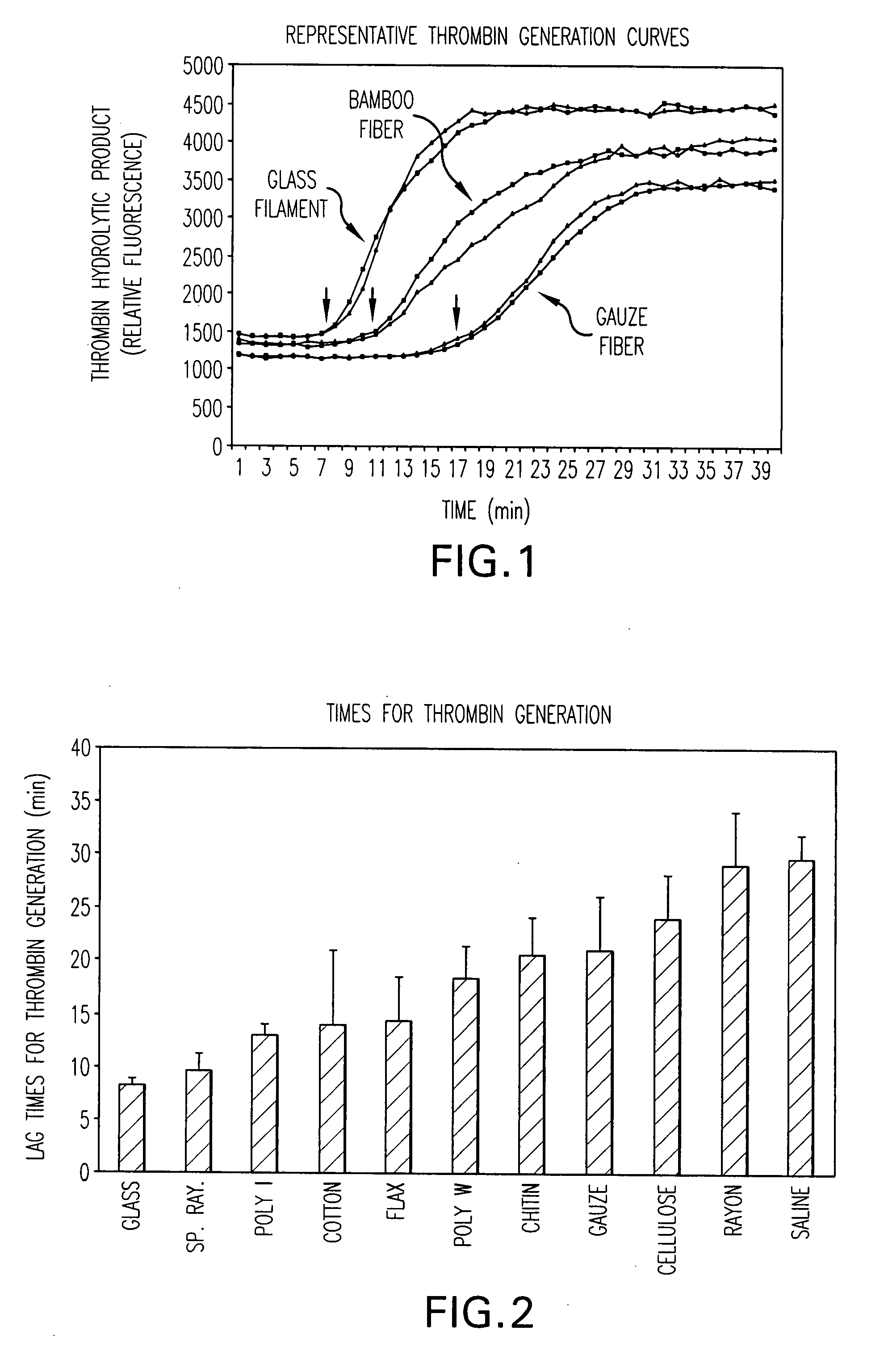

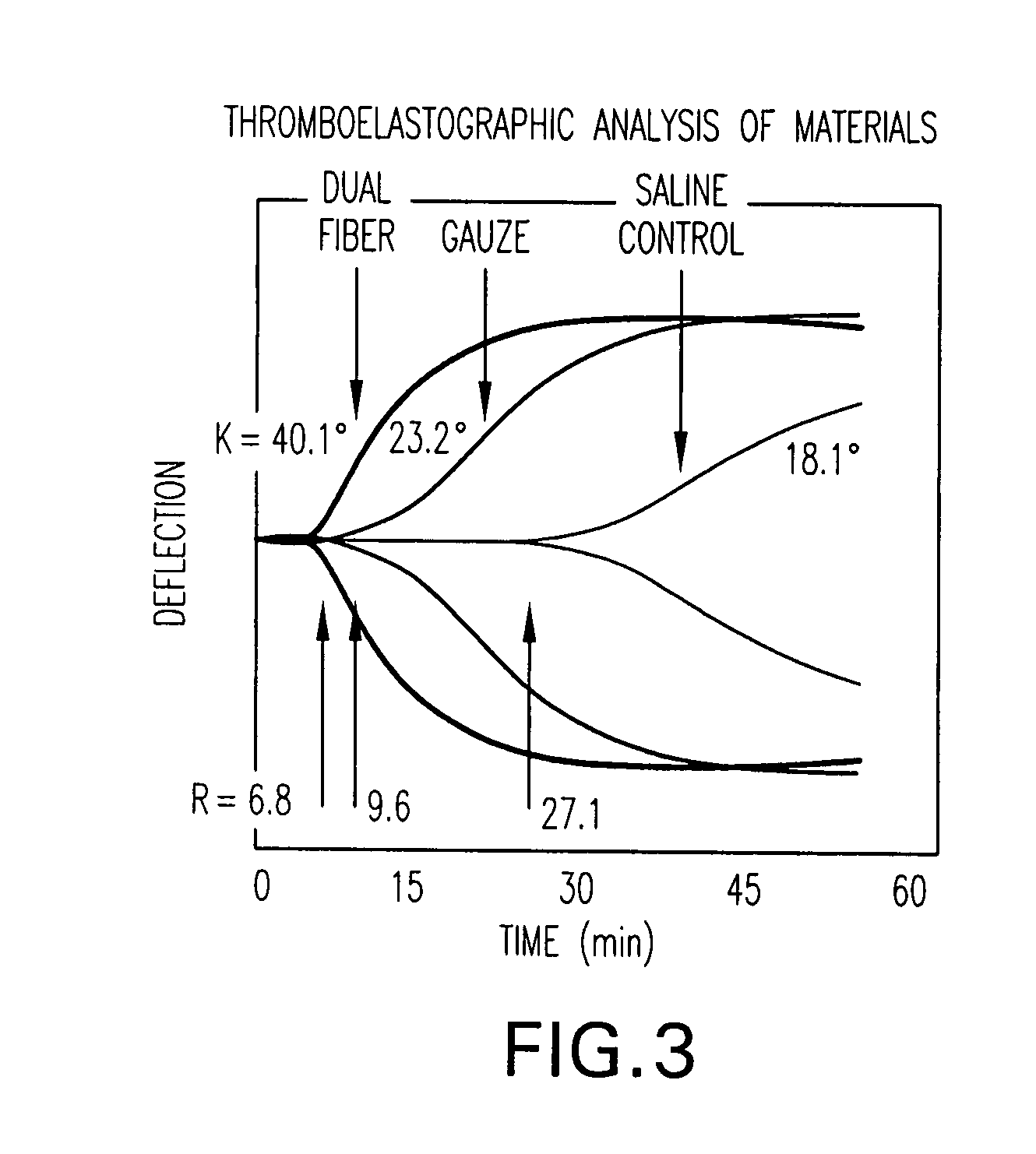

ActiveUS20070160653A1Quick activationNon-adhesive dressingsPeptide/protein ingredientsLactideSisal fiber

The present invention is directed to a hemostatic textile, comprising: a material comprising a combination of glass fibers and one or more secondary fibers selected from the group consisting of silk fibers; ceramic fibers; raw or regenerated bamboo fibers; cotton fibers; rayon fibers; linen fibers; ramie fibers; jute fibers; sisal fibers; flax fibers; soybean fibers; corn fibers; hemp fibers; lyocel fibers; wool; lactide and / or glycolide polymers; lactide / glycolide copolymers; silicate fibers; polyamide fibers; feldspar fibers; zeolite fibers, zeolite-containing fibers, acetate fibers; and combinations thereof; the hemostatic textile capable of activating hemostatic systems in the body when applied to a wound. Additional cofactors such as thrombin and hemostatic agents such as RL platelets, RL blood cells; fibrin, fibrinogen, and combinations thereof may also be incorporated into the textile. The invention is also directed to methods of producing the textile, and methods of using the textile to stop bleeding.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

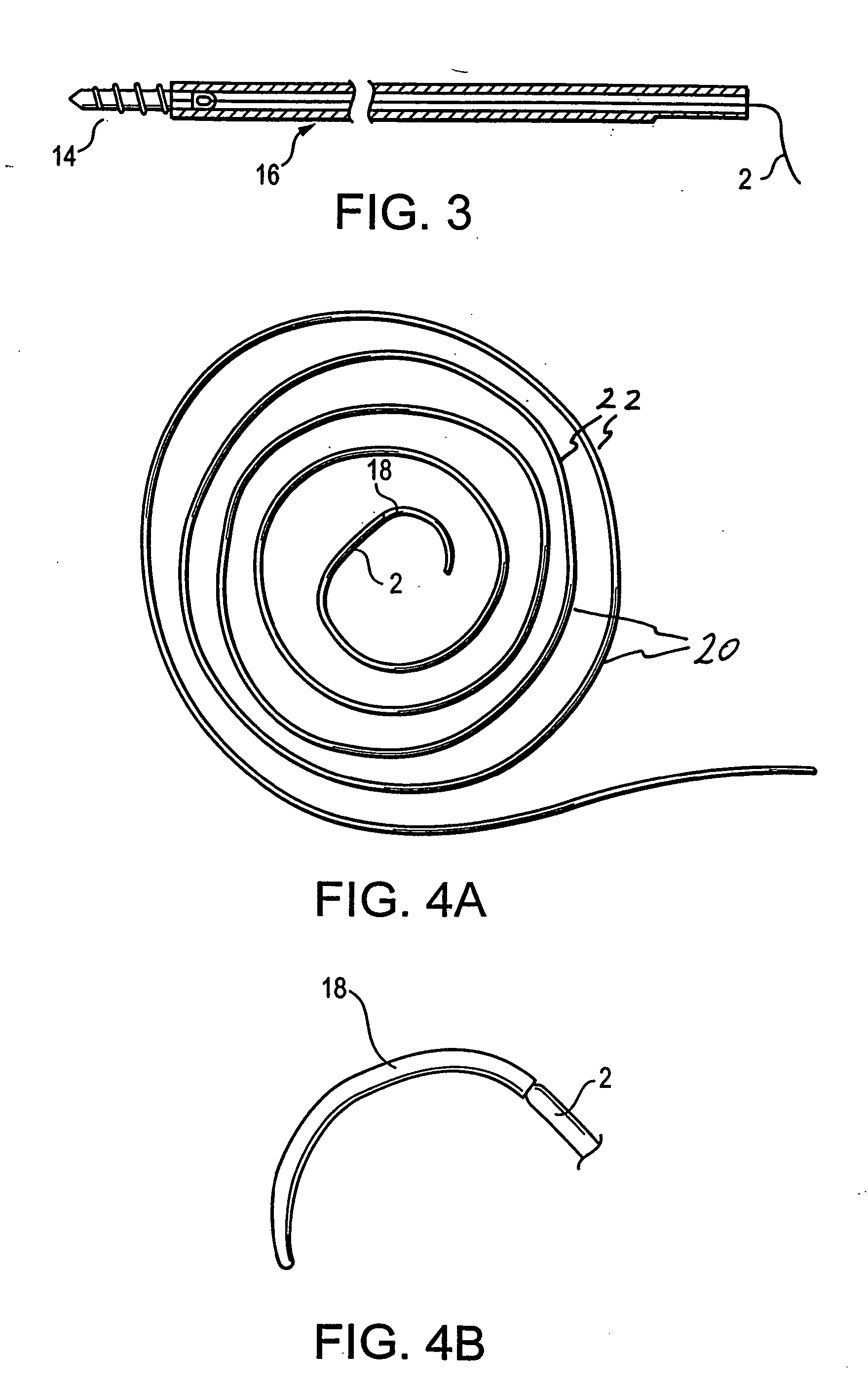

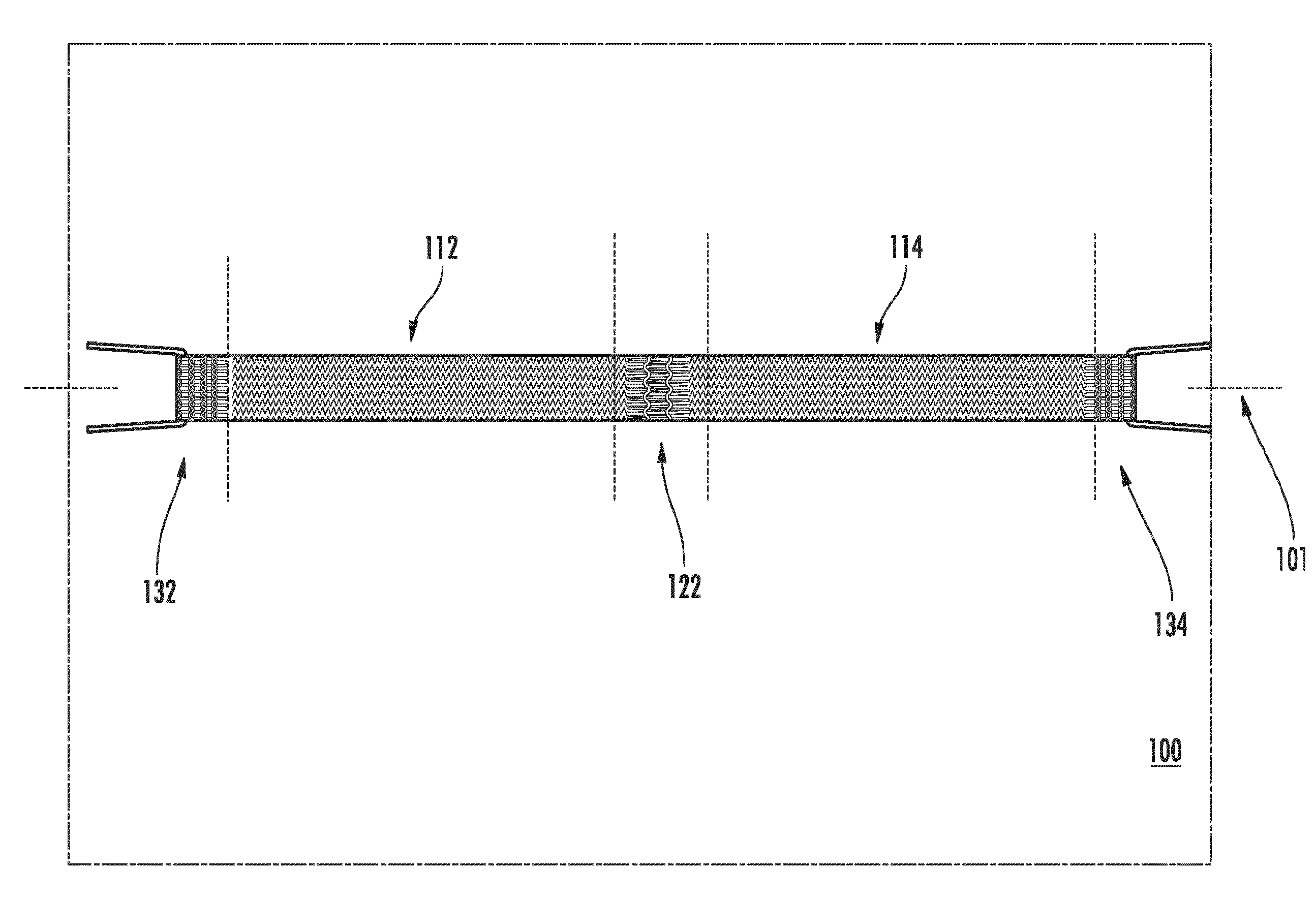

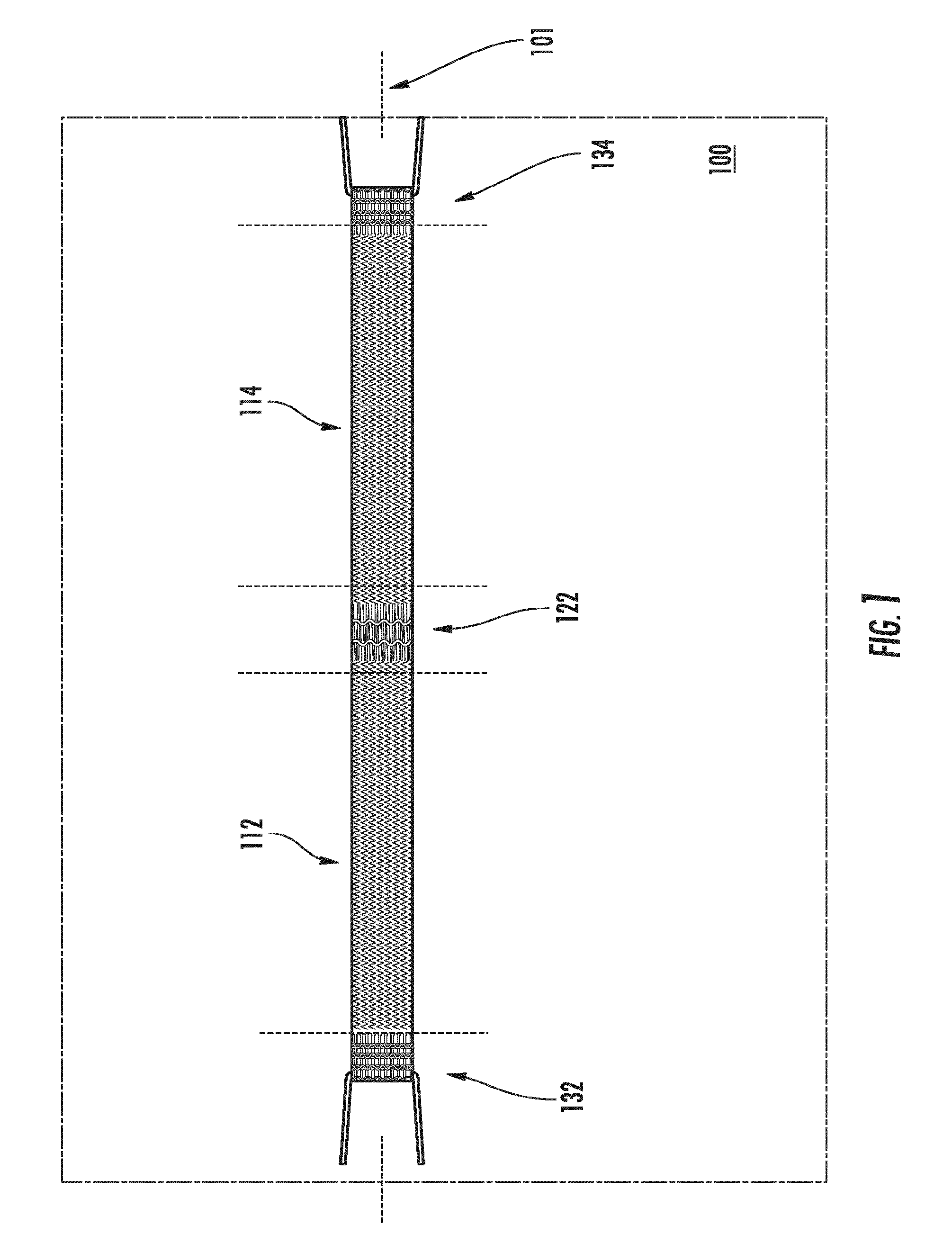

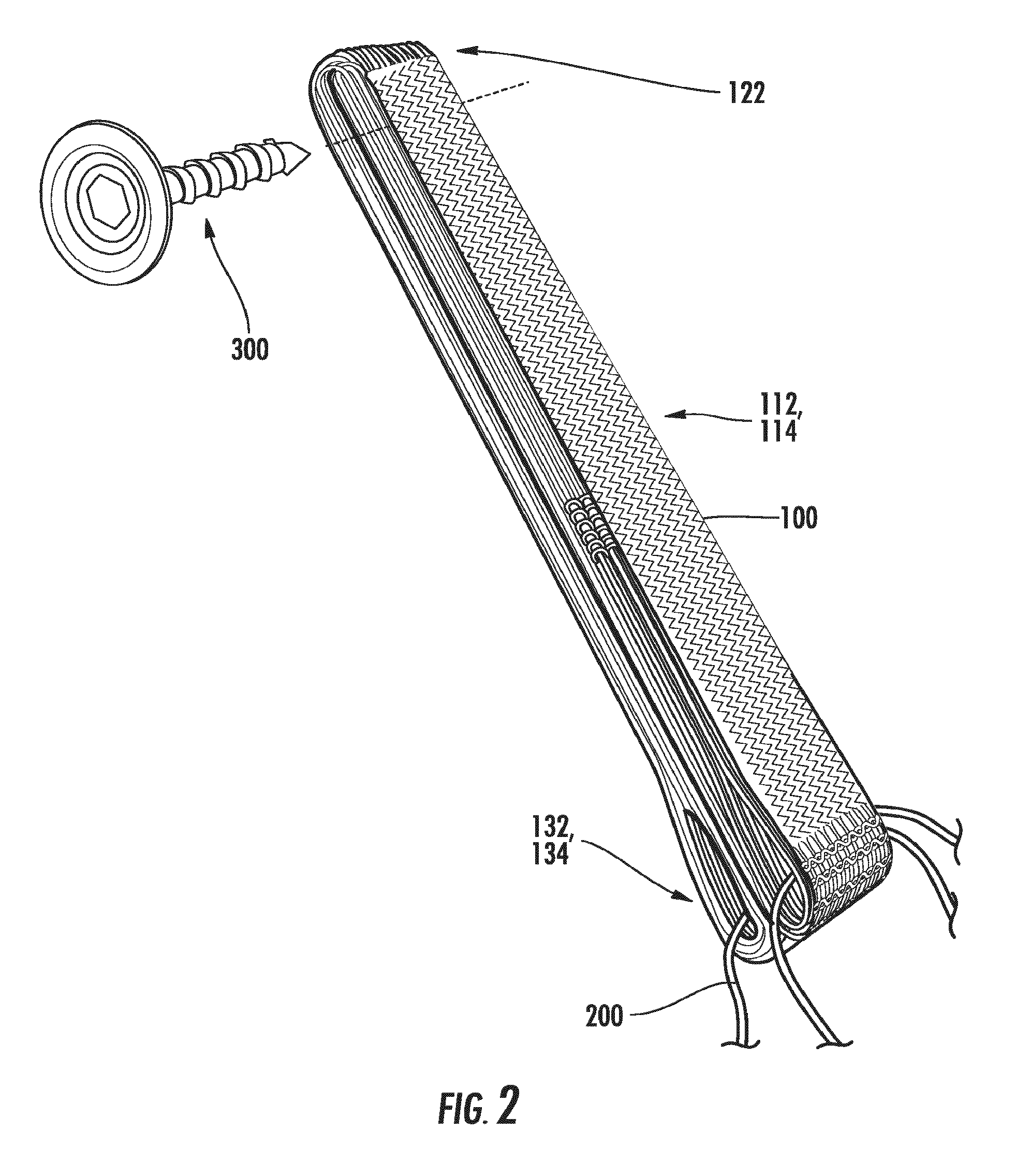

High strength suture with silk trace

InactiveUS20050055051A1High strengthImproved tie down characteristicSuture equipmentsPolyesterSuture anchors

A high strength abrasion resistant surgical suture material with improved tie down characteristics and tissue compliance is color coded for visualization and identification purposes. The suture features a multifilament jacket formed of braided strands of ultra high molecular weight polyethylene and polyester, with silk fibers included in a color contrasting with the other jacket fibers to provide an identifiable trace. In one embodiment, the braided jacket surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a No. 2 size, has the strength of No. 5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle. The identifiable silk trace preferably may be provided along one half of the length of the suture, so that when the suture is loaded onto a suture anchor, for example, the two legs of the length of suture on either side of the suture anchor can be readily distinguished.

Owner:ARTHREX

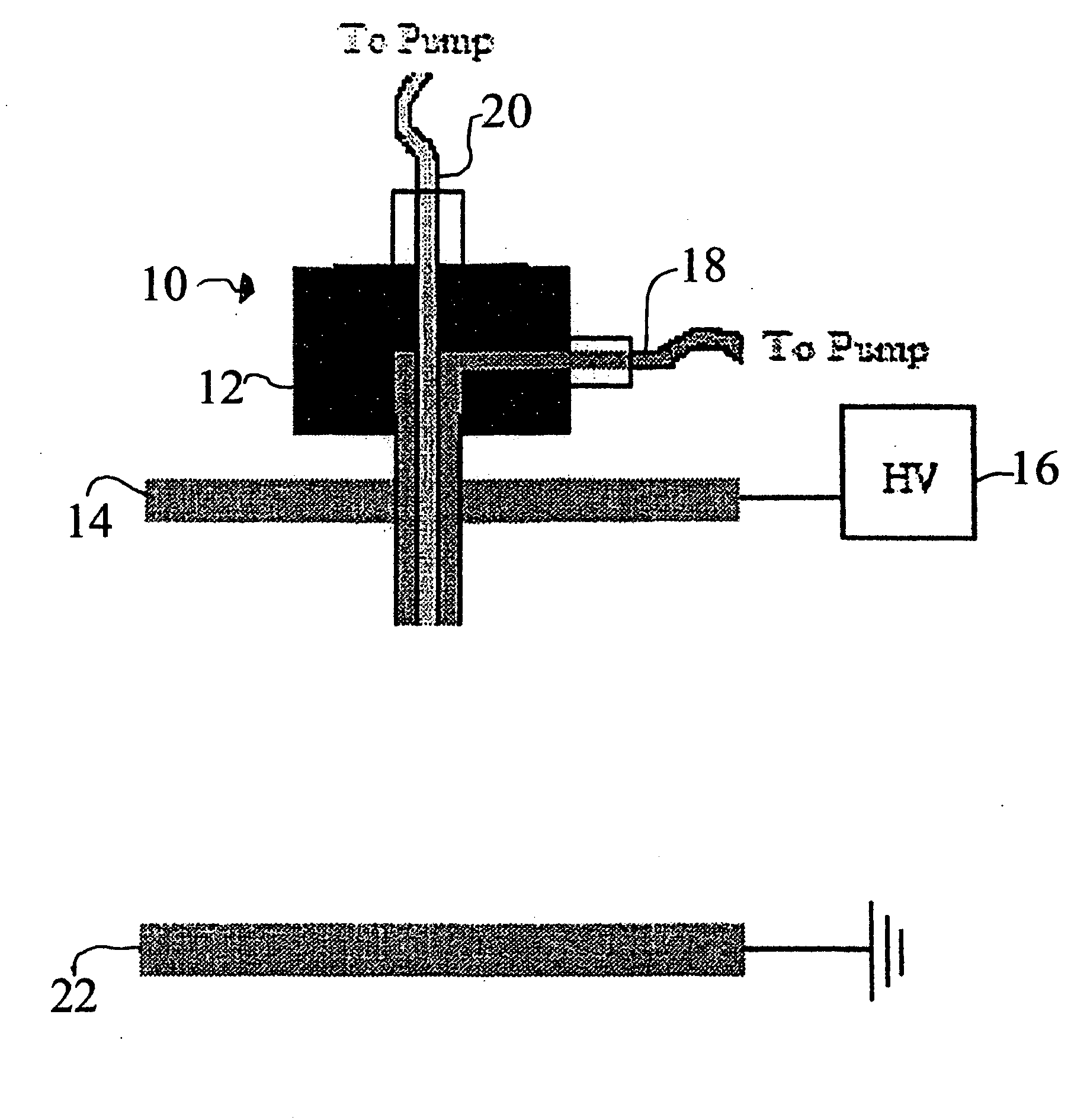

Production of submicron diameter fibers by two-fluid electrospinning process

InactiveUS20060213829A1Conjugated cellulose/protein artificial filamentsElectro-spinningHollow fibreNanowire

Electrospinning of materials that are difficult or impossible to process into nanofibers by conventional fiber-forming techniques or by electrospinning are prepared by an electrospinning procedure which uses an electrospinnable outer “shell” fluid around an inner “core” fluid, which may or may not be electrospinnable, to form nanofibers of the inner core fluid having a core / shell morphology. The resulting shell around the nanofiber can remain in place or be removed during post-processing with the core of the fiber remaining intact. The dual-fluid electrospinning process can produce core fibers having diameters less than 100 nm, insulated nanowires, as well as tough, bio-compatible silk fibers. Alternatively, the core can be removed leaving a hollow fiber of the shell fluid.

Owner:MASSACHUSETTS INST OF TECH

Method for the preparation of a non-woven silk fibroin fabrics

InactiveUS7285637B2Peptide/protein ingredientsMonocomponent fibroin artificial filamentSericinDisulfide bond

A process for producing non-woven silk fiber fabrics comprises the following steps: a) obtaining silk fibroin, for example either from silk cocoons, or silk textiles or waste silk; b) removing the sericin layer covering the silk fibroin fibers, when present; c) breaking the disulfide bonds between heavy (350 kDa) and light (27 kDa) chains of silk fibroin in order to obtain the production of chain fragments which serve as a specific cellular recognition sites promoting the attachment and growth of cells, d) homogenising of the material resulting from step c).

Owner:CONSORZIO PER GLI STUDI UNIVRI

Silk fibroin fiber bundles for matrices in tissue engineering

InactiveUS20050089552A1Increase differentiationEnhance tissue development processBioreactor/fermenter combinationsPeptide/protein ingredientsFiber bundleLigament structure

The present invention provides a novel silk-fiber-based matrix having a wire-rope geometry for use in producing a ligament or tendon, particularly an anterior cruciate ligament, ex vivo for implantation into a recipient in need thereof. The invention further provides the novel silk-fiber-based matrix which is seeded with pluripotent cells that proliferate and differentiate on the matrix to form a ligament or tendon ex vivo. Also disclosed is a bioengineered ligament comprising the silk-fiber-based matrix seeded with pluripotent cells that proliferate and differentiate on the matrix to form the ligament or tendon. A method for producing a ligament or tendon ex vivo comprising the novel silk-fiber-based matrix is also disclosed.

Owner:ALLERGAN INC

Prosthetic device and method of manufacturing the same

InactiveUS20120221105A1Sufficient flexibilityEqually distributedMammary implantsWeft knittingBreast augmentationImplanted device

Owner:ALLERGAN INC

Selectively absorbable/biodegradable, fibrous composite constructs and applications thereof

A family of selectively absorbable / biodegradable, fibrous composite constructs includes different combinations of biostable and absorbable / biodegradable yarns assembled as initially interdependent, load-bearing components, transitioning to exhibit independent functional properties during in vivo end-use. The family of constructs consists of two groups, one group is made of fiber-reinforced composites of high compliance, absorbable matrices of segmented polyaxial copolyesters reinforced with multifilament yarn constructs, which are combinations of ultrahigh molecular weight polyethylene fibers and at least one absorbable / biodegradable fiber selected from silk fibers and multifilament yarns made from linear segmented, l-lactide copolyesters and poly (3-hydroxyalkanoates, are useful in orthopedic, maxillofacial, urological, vascular, hernial repair and tissue engineering applications. The second group is made of coated and uncoated, warp-knitted mesh constructs for use in hernial, vascular, and urological tissue repair and tissue engineering.

Owner:POLY MED

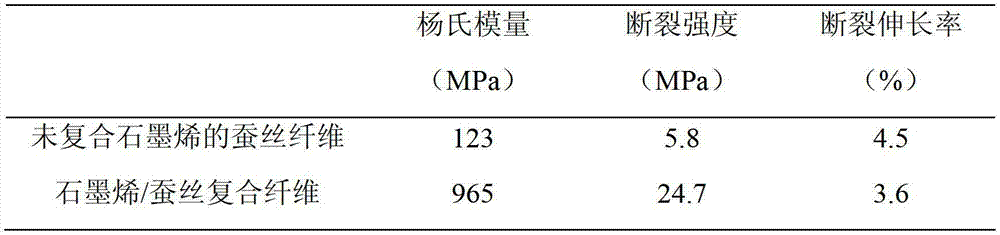

Method for preparing graphene/ silk composite fiber

InactiveCN103173882AHigh strengthImprove toughnessMonocomponent fibroin artificial filamentFilament/thread formingElectrospinningGraphite

The invention provides a method for preparing graphene / silk composite fiber. The method comprises the steps of: oxidizing graphite powder by using acid, and carrying out ultrasonic dispersing and stripping to obtain graphene solution; mixing the obtained graphene solution with degummed silk fibroin and formic acid to obtain spinning solution; and carrying out electrospinning on the spinning solution by an electrostatic spinning device to obtain the graphene / silk composite fiber. The method is simple in preparation technology, can effectively improve the mechanical property of the silk fiber and is easy to popularize and use.

Owner:DALIAN MARITIME UNIVERSITY

Strengthened toughened regenerated silk fibers and preparation method thereof

ActiveCN103572395ASimple preparation processMonocomponent protein artificial filamentAnimal fibresMolar concentrationGraphite oxide

The invention relates to strengthened toughened regenerated silk fibers and a preparation method thereof. The preparation method comprises the following steps of 1, degumming silkworm cocoons, and dissolving the degummed silkworm cocoons to obtain a regenerated silk fibroin aqueous solution, 2, blending a graphene oxide aqueous solution subjected to ultrasonic treatment and the regenerated silk fibroin aqueous solution according to a certain ratio, 3, adding metal-oxide hydrosol into the mixture according to a certain ratio, 4, adding a CaCl2 solution into the mixture obtained by the step 3 to adjust a calcium ion molar concentration to 0.15-0.3mol / L, and sequentially carrying out concentration, 5, carrying out dry spinning on the concentrated solution as a spinning liquid at a room temperature, and 6, after-treating the composite fibers by an ethanol-water solution. The preparation method has simple processes and utilizes the raw materials having wide sources. The treated composite fibers have good strength and good toughness and have breaking strength of 70-380MPa, breaking elongation of 20-150% and breaking energy of 30-100J / g.

Owner:DONGHUA UNIV

Method for preparing colored fabric containing polylactic acid fiber and silk components

InactiveCN102102268AAvoiding paradoxes of decompositionLow costWeft knittingPolymer sciencePolylactic acid

The invention discloses a method for preparing a colored fabric containing polylactic acid fiber and silk components, which comprises the following steps of: dyeing polylactic acid fibers and silk fibers respectively, and weaving into the colored fabric. By the method, the respective advantages of the polylactic acid fibers and silk are fully exerted, high skin affinity is achieved, the cost of areal silk fabric can be reduced, and the prepared fabric has a wide market prospect.

Owner:HENAN LONGDU BIOLOGY TECH

Biomimetic preparation method of high-strength regenerated silk protein fiber

ActiveCN103498210AHigh crystallinityHigh strengthConjugated cellulose/protein artificial filamentsWet spinning methodsMechanical propertyProtein fiber

The invention discloses a biomimetic preparation method of a high-strength regenerated silk protein fiber. The method takes high crystallization degree, high strength, high modulus nano cellulose whiskers with a large length-diameter ratio to simulate the beta-fold microcrystal in the natural silk fiber, then mixes the nano cellulose whiskers with a regenerated silk fibroin solution, and finally prepares the high-strength regenerated silk protein fiber through a wet spinning method. The characteristic that a large amount of hydroxyl groups in the molecular chains of the rigid nano cellulose whiskers can form intermolecular hydrogen bonds with polar groups such as carboxyl groups, amino groups, and the like, in the molecular chains of silk protein is utilized to achieve the structural bionics of the regenerated silk protein fiber, and thus improves the mechanical properties of the regenerated silk protein fiber. The preparation method is simple, and does not pollute the environment. The mechanical properties of the obtained regenerated silk fiber are equal to or even better than those of natural silk, and the regenerated silk fiber has the similar micro-structure and configuration as the natural silk.

Owner:浙江枫翎新材料科技有限公司

Cotton fibers with antibacterial and insect-resisting effects and production method of cotton fibers

InactiveCN104278359AEasy to cleanNot easy to fluffConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCnidium monnieriFatty alcohol

The invention discloses cotton fibers with antibacterial and insect-resisting effects. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 21-24 parts of cotton fibers, 10-12 parts of apocynum venetum fibers, 6-8 parts of silk fibers, 7-9 parts of cashmere fibers, 9-11 parts of pineapple fibers, 4-7 parts of polypropylene fibers, 6-8 parts of taxus chinensis superfine micro-powder, 3-5 parts of ailanthus altissima leaf extracted powder, 1-3 parts of zeolite powder, 1.1-2.3 parts of chitosan, 0.5-0.7 part of magnesium nitride, 0.8-1.4 parts of N,N-dicyanoethylaniline, 5-7 parts of sulfonated castor oil, 15-18 parts of fatty alcohol alkoxy ether, 1-2 parts of mashed garlic, 1.3-2.5 parts of cnidium monnieri cuss, 2.1-3.6 parts of coptis chinensis, 90-95 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-100 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the cotton fibers, the taxus chinensis superfine micro-powder is added into raw materials by adopting an ultrasonic technology and a prepared cotton textile has a very good health effect and a useful pain-relieving effect on tumor patients and female symptoms; furthermore, the other active ingredients are added so that the good clothes properties of sweat absorption, breathability, softness, allergy prevention, easiness of washing, low probability of fuzzing and balling up and the like of natural cotton fibers are maintained, and the cotton fibers have good antibacterial and insect-resisting functions, a good electromagnetic radiation shielding function and the like.

Owner:ANHUI SWAN TECH IND GRP

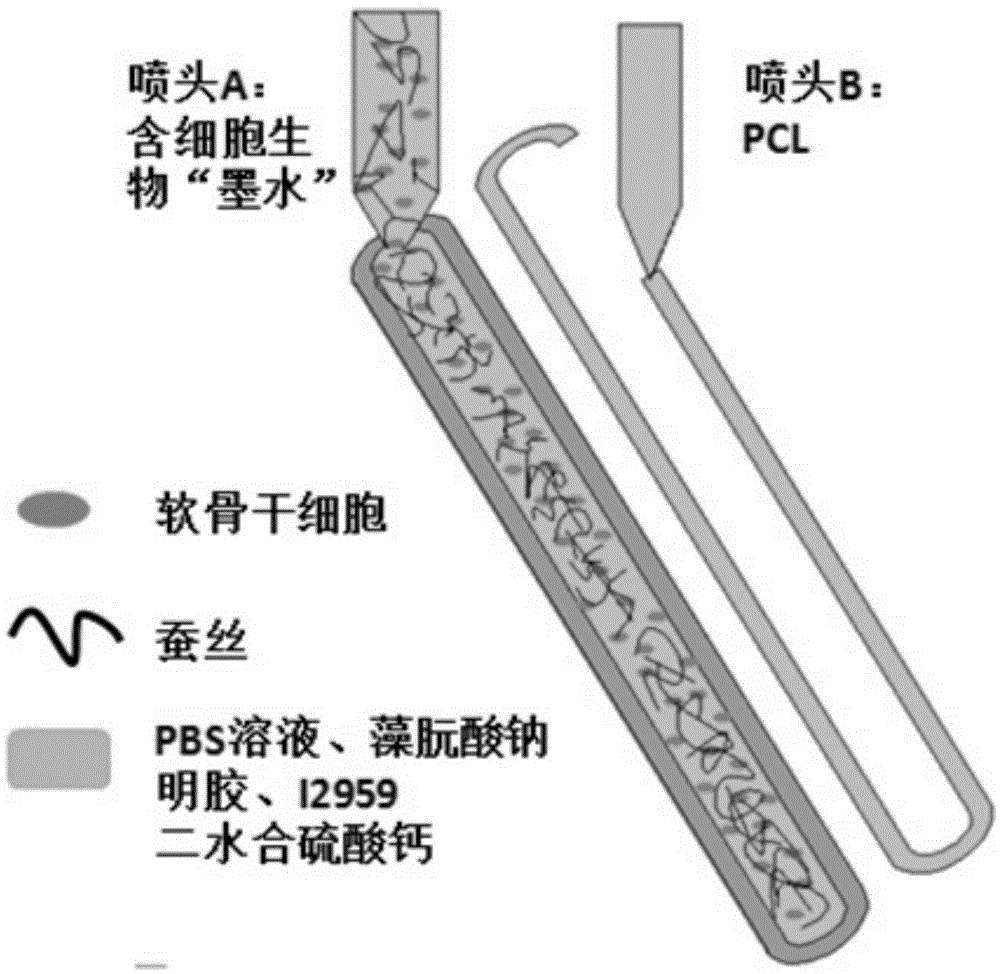

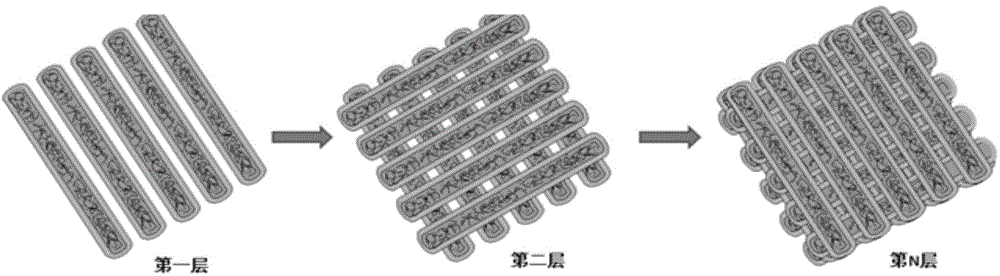

Method for preparing cartilage with high mechanical property based on 3D bioprinting

ActiveCN104399119AImprove mechanical propertiesGood mechanical propertiesProsthesisBiocompatibility TestingBiological materials

The invention provides a method for preparing cartilage with a high mechanical property based on 3D bioprinting. The method comprises the following steps: preparing silk fibers, preparing a gelatin solution, preparing ciological ink containing cells, carrying out 3D cartilage printing, performing cell culture and differentiation on a printed tissue to form the cartilage. The method solves the problems of polarization of 2-dimension culture for cells and high body and surface ratio of cells through the 3D bioprinting technology; sodium alginate and calcium ions form ionic bonds, and gelatin and methacrylic anhydride form covalent bonds, so that the 3D bioprinted cartilage is good in mechanical property and is not easily broken; the gelatin has biocompatibility and degradability of normal biological material hydrogel, has bioactivity, and is good for cell growth and differentiation and realization of cell functions.

Owner:西安博恩生物科技有限公司

High tensile and bend resistant movables cable conductor

InactiveCN101447244AHigh strength and high temperature resistanceHigh strength bending resistanceNon-insulated conductorsInsulated cablesTinningElectrical conductor

The invention discloses a high tensile and bend resistant movable cable conductor. The cable conductor comprises a tensile wire layer positioned in an inner layer and formed by adopting a plurality of strands of aramid silk fiber strands and multiple strands and a conductor layer formed by respectively enwinding a plurality of homocentric tinning annealed copper wires or annealed bare copper wires on the tensile wire layer. The enwinding directions of each layer of tinning annealed copper wires or annealed base copper wires are opposite from inside to outside. The invention can be taken as the conductor of various movable cables; the cables can freely move, have smaller bending radius, and can freely move along with a movable device, and the conductor service life thereof can be improved to tens of times.

Owner:ANHUI HUALING CABLE GRP

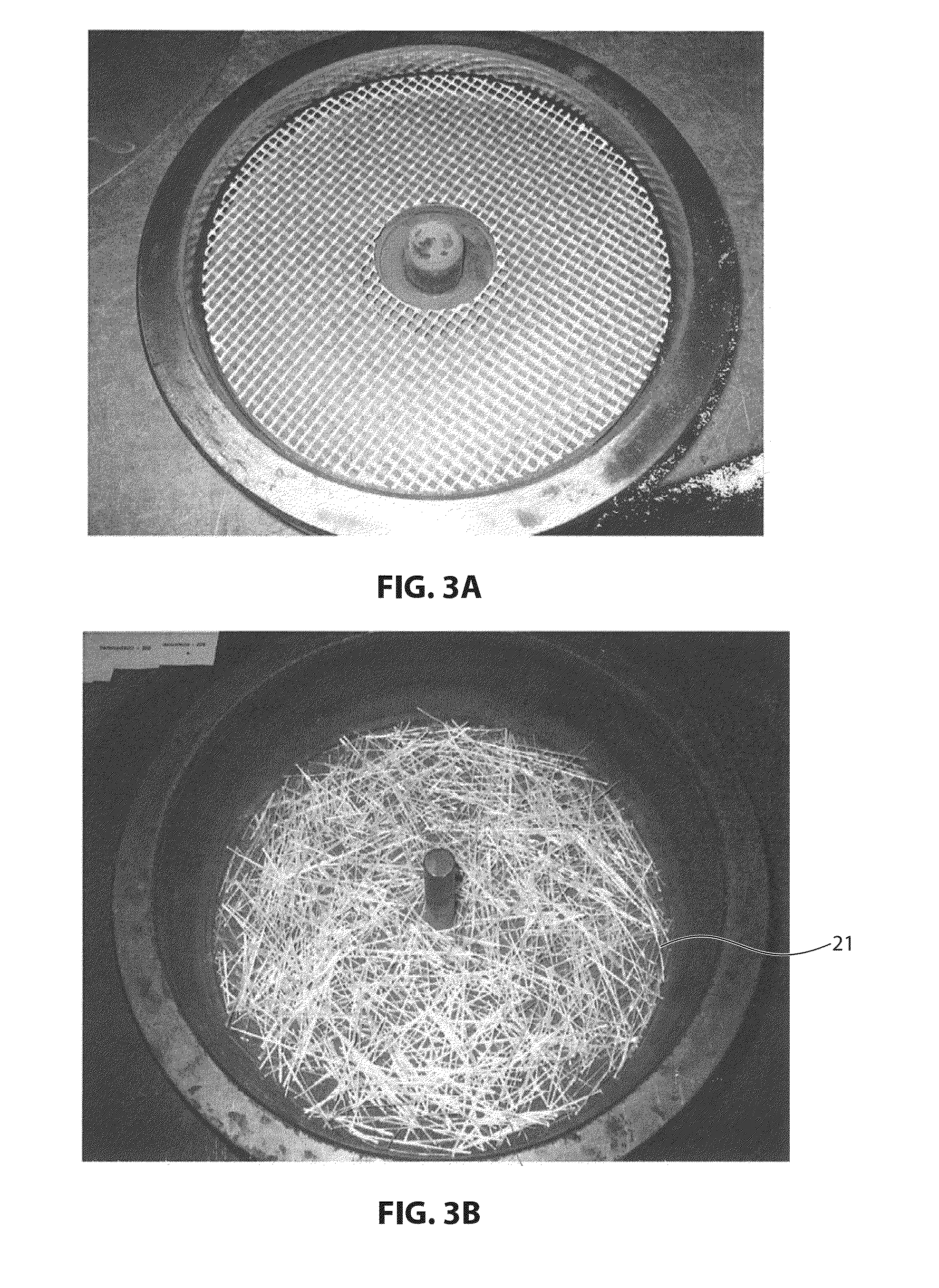

Abrasive article

An abrasive article has an abrasive portion with an organic bond and abrasive particles. The abrasive article has a non-abrasive portion (NAP) mounted to the abrasive portion. The NAP includes molding compound (MC) having chopped strand fibers (CSF). The CSF can be coated with a thermoplastic coating having a loss on ignition (LOI) of at least about 2.4 wt %, and the NAP having no abrasive particles. The NAP can include an MC having no abrasive particles with a MOHS scale hardness of at least about 9. The NAP may include CSF coated with a primary coating and a secondary coating on the primary coating. The NAP may have an outer diameter that is at least half of but not greater than an outer diameter of the abrasive article.

Owner:SAINT GOBAIN ABRASIVES INC +1

Natural nanometer fiber preparation method

InactiveCN1730734ASuitable for a wide rangeControllableMonocomponent fibroin artificial filamentFilament/thread formingSpider ProteinsLaboratory research

The present invention relates to the preparation process of natural nanometer fiber for tissue engineering, air filtering, clothing material and composite reinforced aeronautical and astronautical material, and is especially the preparation process of natural nanometer spider silk fiber and cocoon silk fiber. Through soaking in certain solution and ultrasonic dissociation, natural nanometer fiber of diameter 30-100 nm may be prepared. The prepared natural nanometer fiber may find its wide application in tissue engineering, air filtering, clothing material and composite reinforced aeronautical and astronautical material. The present invention has simple operation, simple equipment, low power consumption and low cost, and is suitable for both lab preparation and industrial production.

Owner:TSINGHUA UNIV

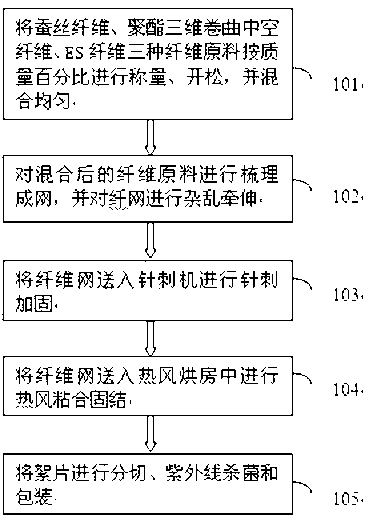

Preparation method of tailorable and washable silk floss flocculus

The invention provides a preparation method of a tailorable and washable silk floss flocculus, which comprises the following steps that 1), three raw fiber materials, namely a silk fiber, a polyester three-dimensional crimp hollow fiber and an ES (Ethylene-Propylene Side By Side) fiber are weighed according to mass percent, opened, and mixed uniformly, wherein the silk fiber is 55-80%, the polyester three-dimensional crimp hollow fiber is 10-35%, and the ES fiber is 5-20%; 2), the mixed raw fiber materials are subjected to carding and web forming, and a fiber web is subjected to disorder drafting; 3), the fiber web is fed into a needling machine for needling reinforcement; 4), the fiber web is fed into a hot air drying room for hot air bonding solidification; and 5), the flocculus is slit, subjected to ultraviolet sterilization and packed. The silk floss flocculus prepared by the method reserves the advantages of lightness, softness, comfortability, health care, heat preservation, breathability and the like of a silk product, and introduces the advantages of the polyester three-dimensional crimp hollow fiber, so that the heat preservation performance and the bulkiness are improved, and the production cost is lowered appropriately.

Owner:XINYUAN COCOON SILK GROUP

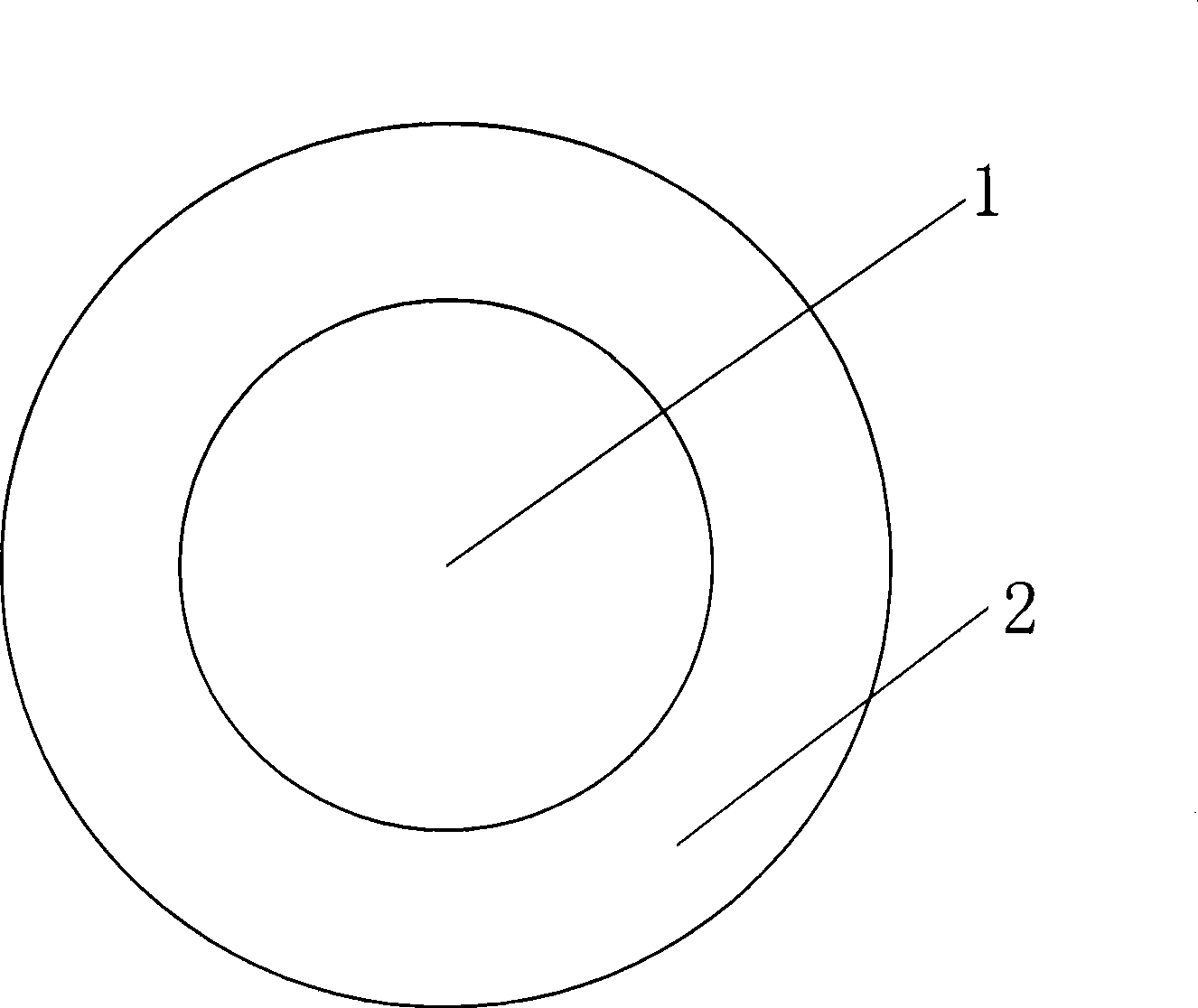

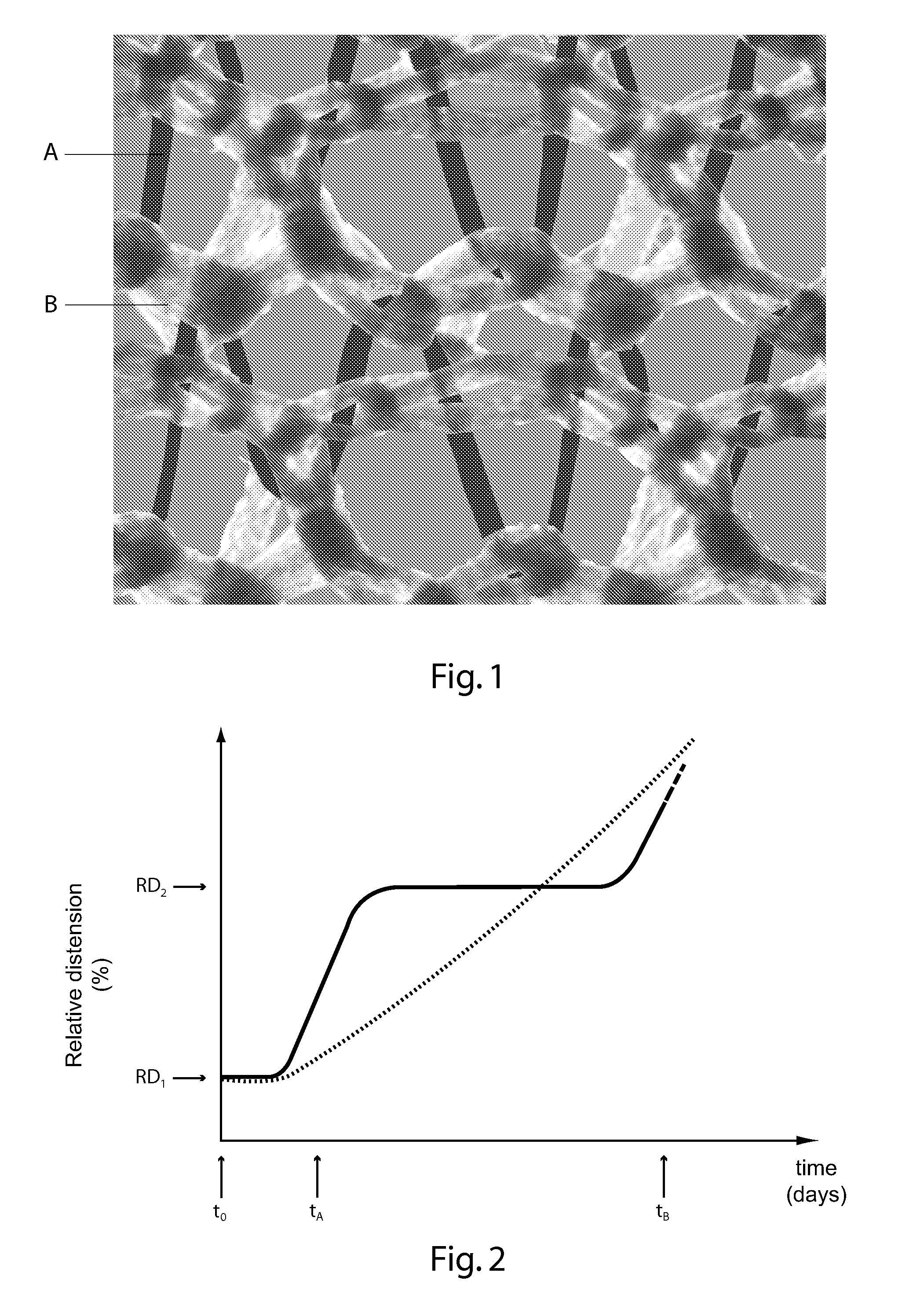

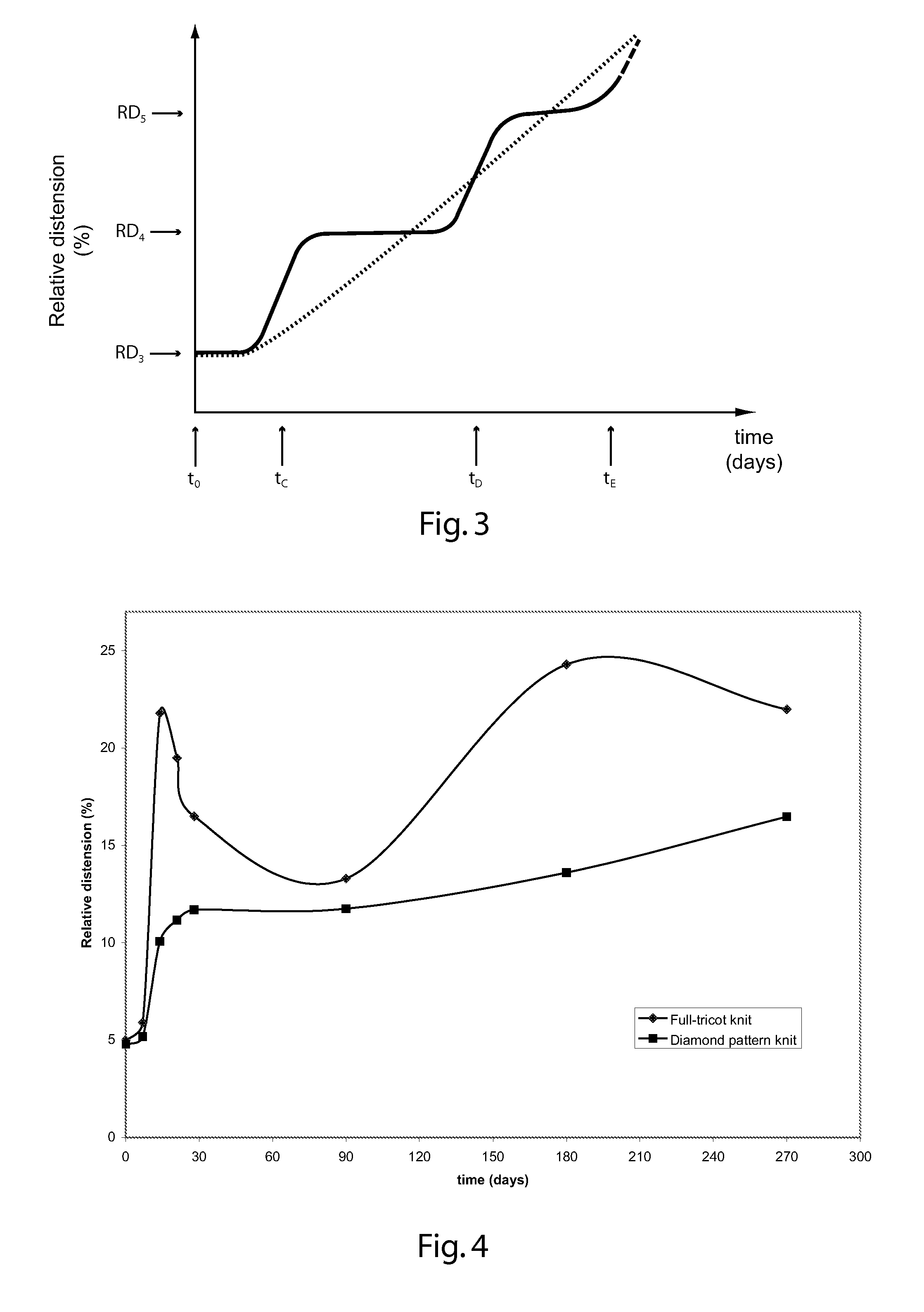

Mesh implant with an interlocking knitted structure

A resorbable polymeric mesh implant is provided for use in the reconstruction of soft tissue defects. The mesh implant is provided with an interlocking knitted structure comprising two or more sets of fibers with different times of degradation, allowing a stepwise increase in the relative distension of the overall mesh over time. The filamentous fibers are knitted together, wherein the filaments of the first set of fibers are interlaced into the filaments of the second set of fibers and at least partly traverse the knit pattern of the second set of fibers such that the filaments of the first set of fibers lock the movement of the part of the mesh formed by the second set of fibers.

Owner:NOVUS SCI

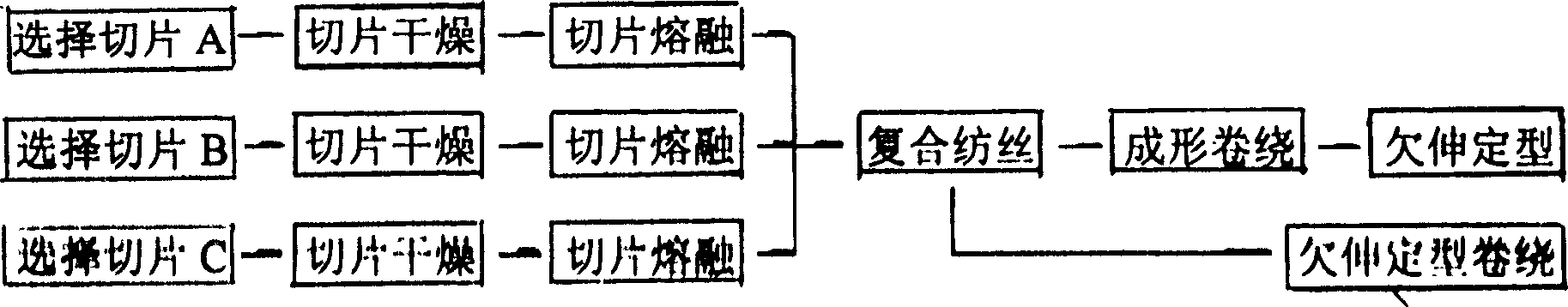

Method for producing three-component self-crimped filament yarn

InactiveCN1676685AFine fiberLow modulusFilament/thread formingConjugated synthetic polymer artificial filamentsEllipseSkin core

This invention is about a kind of producing method of self-curling long filament with superthin structure, with the method of three groups fusing composite spinning. The fibers of the 3 groups are the long fibers with the titer of single fiber 1-6 dtex and the number of pores (12-72)*2. The fibers have at least 7% curling and shrinking percentage after hotly forming and at least 20% curling and shrinking percentage after alkali process. The cross-section of one single fiber is paralleling or eccentric skin-core structural circle, ellipse or snowman. One side of the cross section has fortuitous laminated structure, and the outside fiber ratio is 0.3-0.8 dtex. The producing steps of the self curling long fibers are slice choosing - slice drying - slice fusing - combined spinning - forming curling - drafting to form the shape. By mixing the spinning units and combining the units of big heat shrinking percentage in the paralleling or eccentric skin-core structural way, we can solute the soluble units during the after operation, and separate the outboard fibers of the self curling filaments, making the fibers more slender and modulus smaller. In a word, the curling and shrinking ratio, feeling and amenity have been largely improved.

Owner:SHAOXING GLOBAL CHEM FIBER

Processing technology of super-soft and high-hygroscopicity untwisted yarn textile

InactiveCN103255535AGood flexibilityImprove water absorptionWoven fabricsYarnPolymer scienceCarbon fibers

The invention relates to a processing technology of super-soft and high-hygroscopicity untwisted yarn textile. Raw materials of the untwisted yarn textile comprises warp yarns, weft yarns and water-solubility yarns, wherein the warp yarns are composed of anion polypropylene fibers, bamboo carbon fibers and cotton fibers with the wet to dry weight ratio of 15%:30%:55%, the weft yarns are composed of milk protein fibers, silk fibers and porous superfine moisture-guiding polyester filament yarns with the wet to dry weight ratio of 50%:30%:20%, and the water-solubility yarns are composed of water-solubility vinylon short fibers or water-solubility PVA fibers. After twisting and untwisting processing, a twisting direction and an untwisting direction are opposite, forward-direction twist degree and backward-direction twist degree are the same, and therefore after vinylon dissolving, the cotton fibers are in a single-fiber untwisting state in fur warp yarns, and the textile has high hygroscopicity and softness. The textile can be applied to clothing, home textile, sports goods and medical health care.

Owner:上海正策咨仕信息科技有限公司

Prosthetic device and method of manufacturing the same

InactiveUS20120221104A1Sufficient flexibilityEqually distributedMammary implantsWeft knittingMastopexyBreast augmentation

Owner:ALLERGAN INC

One-way wet-guide quick-drying real silk facing material

InactiveCN101270524ADistinct silk styleSpeed up moisture transferFilament/thread formingWoven fabricsMoisture absorptionEngineering

The invention relates to a unidirectional wicking fast-drying true silk fabric which is characterized in that the front surface of the fabric is two first or three first twill-weave; the back surface corresponding to the front surface is one second or one third twill-weave; the material of the front surface adopts silk with the specification of 15 to111dtex; the material of the back surface adopts ultrathin denier wicking fast-drying terylene DTY long thread with the single thread density of 0.2 to 0.8dtex; the section of the long thread is crisscross; the invention adopts a embedded weaving method for weaving and manufacture. The surface of the fabric obviously assumes the styles of true silk which has fleshy and soft hand feelings as well as excellent moisture absorption and ventilation properties. As the wicking fast-drying terylener is adopted as the back surface of the fabric, the excellent fast-drying property thereof can quicken the wicking speed of the true silk fiber on the front surface after absorbing moisture and simultaneously can not go so far to reveal the defects of hard hand feeling, easy pilling and generating static of the terylener.

Owner:SUZHOU HUACHOU TECH

Composite comprising organic fibers having a low twist multiplier and improved compressive modulus

InactiveUS6851463B1High modulusReduce tire weightSynthetic resin layered productsTyresGramMetallurgy

The present invention provides an improved fiber-reinforced article comprised of at least two plies. Each of the plies comprises (a) rubber and (b) cord made from melt-spinnable, non-metallic, multifilament fibers for which the cord has a twist multiplier of less than or equal to about 375, a stress at 1% strain greater than or equal to about 1.7 grams / denier, and an initial compressive modulus greater than or equal to about 7 grams / denier, and the at least two plies have a fiber orientation angle of greater than or equal to about 23°. The composite is useful as a tire belt in a passenger tire.

Owner:PERFORMANCE FIBERS +1

Biological enzyme process antibacterial and anti-wrinkle finishing method of silk fabric

InactiveCN102677475AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentAnimal fibresCooking & bakingCatalytic oxidation

The invention discloses a biological enzyme process antibacterial and anti-wrinkle finishing method of a silk fabric, belongs to the field of a textile biotechnology, and aims to overcome the defects of high baking temperature, high probability of damage of silk fibers and reduced whiteness in real silk antibacterial and anti-wrinkle treatment of the conventional chemical method and realize enzyme-promoted antibacterial and anti-wrinkle functional modification of a real silk fabric. According to the method, a chitosan natural finishing agent with a primary amine structure is grafted to the surface of the silk fiber by utilizing the catalytic oxidation effect of tyrosinase, so that the antibacterial and anti-wrinkle effects of the silk fabric are improved. The process flow comprises the following steps of: pre-treating the silk fabric; catalyzing grafting modification treatment of chitosan by the tyrosinase; washing; and drying. Through the silk fabric treated by the invention, the antibacterial performance is improved, the wrinkle recovery performance is improved, and the mechanical property and the dyeing performance of the fabric are also improved. Compared with the conventional chemical method, the method has the advantages of adoption of the tyrosinase process for catalysis of the antibacterial and anti-wrinkle treatment process of the real silk, low energy consumption, high efficiency, less pollution and contribution to environmental protection.

Owner:FOSHAN CITY HANHAI YANBU SISTER FLOWER UNDERWEAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com