Preparation method of tailorable and washable silk floss flocculus

A technology of flakes and silk floss, which is applied in the field of preparation of silk floss flakes, can solve the problems of high processing cost, decreased flexibility and warmth retention, and low production efficiency, and achieve the goals of improving mechanical strength, reducing production cost, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

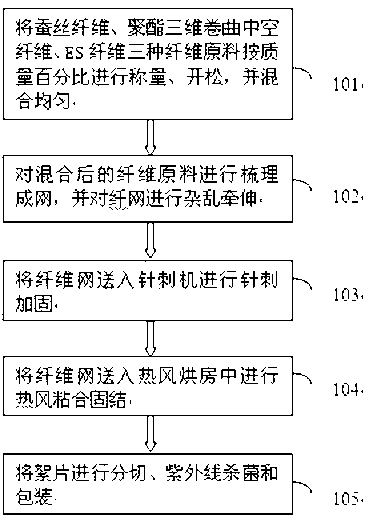

[0028] like figure 1 As shown, the technical solution of the present invention is to provide a kind of preparation method that can be cut, washable silk floss, it is characterized in that comprising following processing steps:

[0029] 1) In step 101, the three fiber raw materials of silk fiber, polyester three-dimensional crimped hollow fiber and ES fiber are weighed and loosened according to the mass percentage, and mixed evenly.

[0030] According to the mass percentage, the composition of the three fibers is: silk fiber 55-80%, polyester three-dimensional crimped hollow fiber 10-35%, ES fiber 5-20%;

[0031] 2) Step 102, combing the mixed fiber raw materials into a web, and performing random drafting on the fiber web;

[0032] 3) Step 103, sending the fiber web into the acupuncture machine for acupuncture reinforcement;

[0033] 4) Step 104, sending the fiber web into a hot air drying room for hot air bonding and consolidation;

[0034] 5) In step 105, the flakes are cu...

example 1

[0037] In the present embodiment, the preparation method of the cutable and washable silk floss flakes is carried out according to the following steps:

[0038] In step 1, the three fibers are weighed, opened, and mixed uniformly according to the following mass percentages. 60% silk refined cotton fiber with a length of 50mm and a fineness of 3.3dtex, 25% polyester three-dimensional crimped hollow fiber with a length of 51mm, and 15% ES fiber with a fineness of 1.95dtex and a length of 38 mm.

[0039] Step 2: Combing the mixed fiber raw materials into a web, and performing random drafting on the fiber web.

[0040] Step 3, sending the fiber web into a needling machine for needling reinforcement, the needling diameter is 0.95 mm, the needling depth is 8 mm, and the needling density is 25 needles / cm2.

[0041] Step 4, sending the fiber web into a hot air drying room for hot air bonding and consolidation. The consolidation process conditions are: hot air temperature 150°C, time...

example 2

[0044] In the present embodiment, the preparation method of the cutable and washable silk floss flakes is carried out according to the following steps:

[0045] In step 1, the three fibers are weighed, opened, and mixed uniformly according to the following mass percentages. 75% silk dry cotton fiber with a length of 62mm, 15% polyester three-dimensional crimped hollow fiber with a fineness of 6.67dtex and a length of 64mm, and 10% ES fiber with a fineness of 1.95dtex and a length of 51 mm.

[0046] Step 2: Combing the mixed fiber raw materials into a web, and performing random drafting on the fiber web.

[0047] Step 3, sending the fiber web into a needling machine for needling reinforcement, the needling diameter is 0.85 mm, the needling depth is 8 mm, and the needling density is 40 needles / cm2.

[0048] Step 4, sending the fiber web into a hot air drying room for hot air bonding and consolidation. The consolidation process conditions are: hot air temperature 150°C, time 55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com