Patents

Literature

1749results about How to "Reduce scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

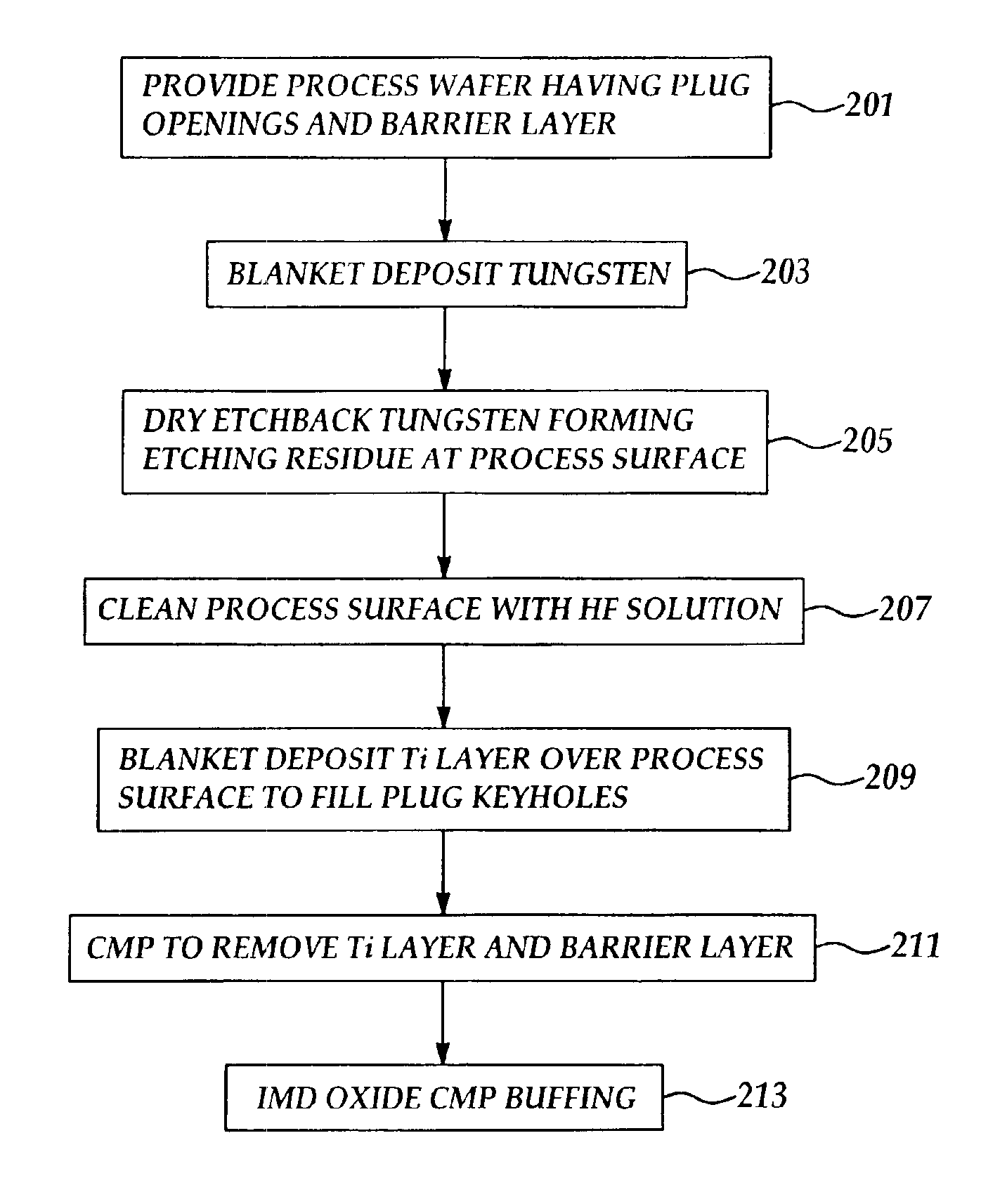

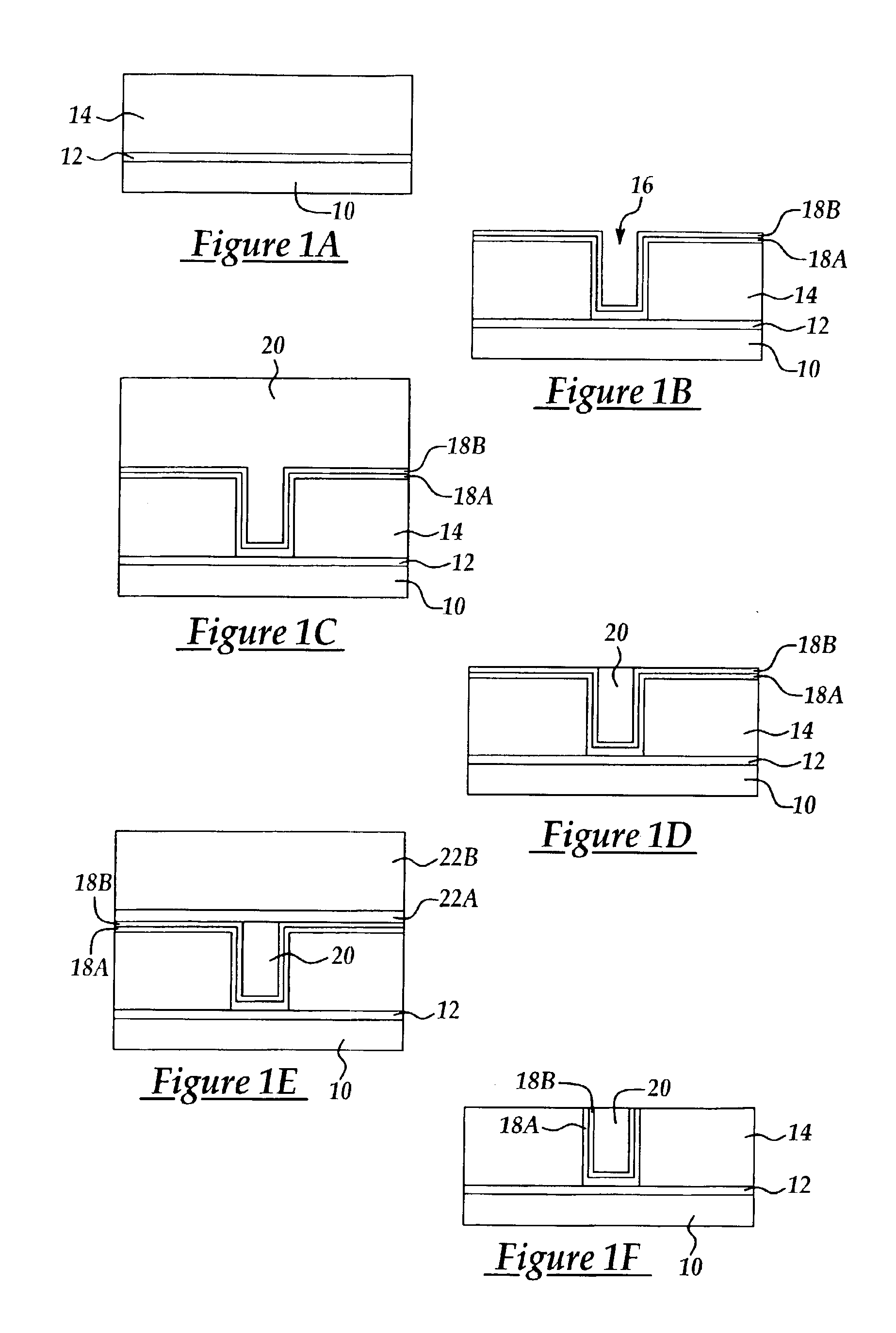

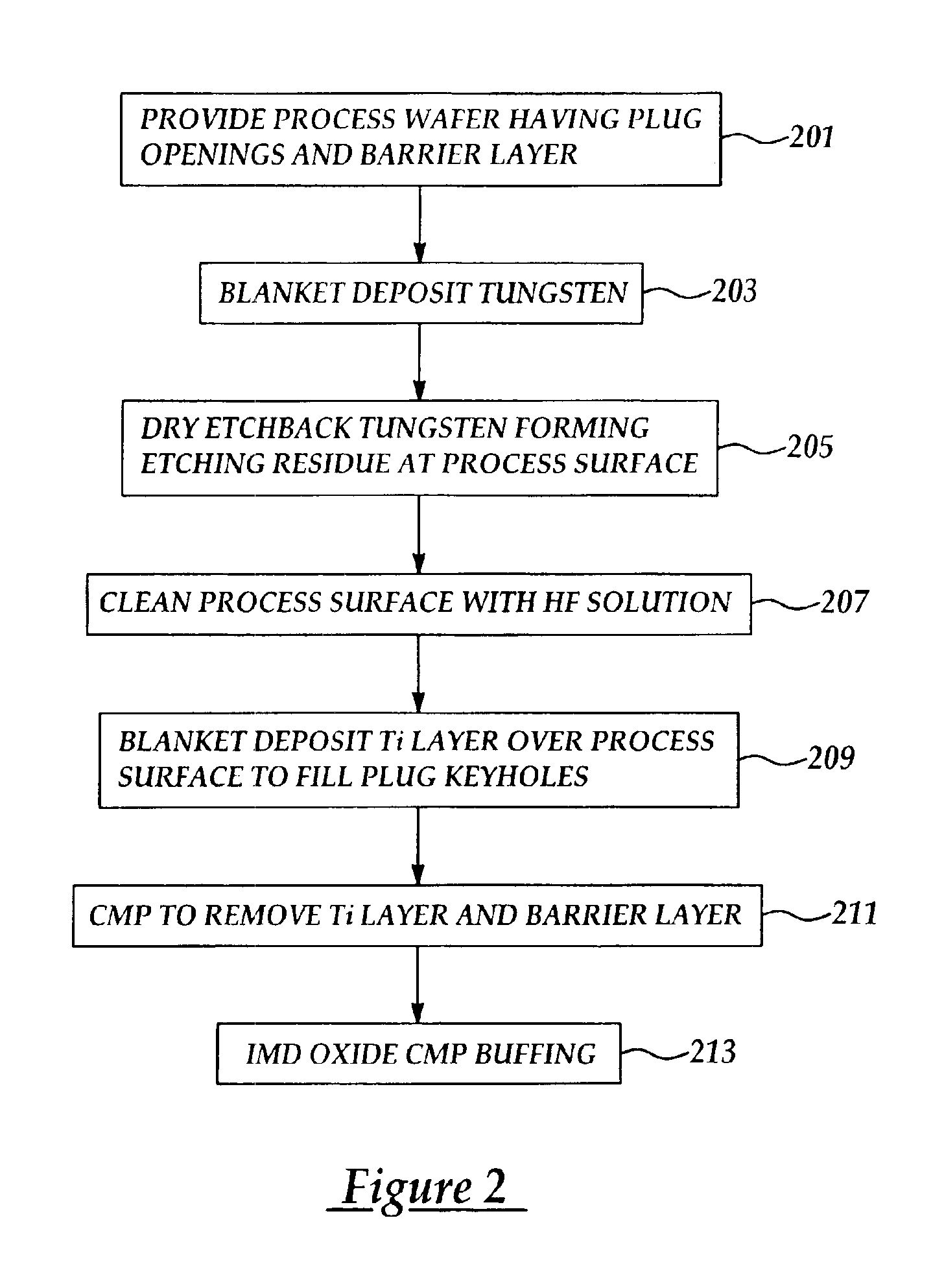

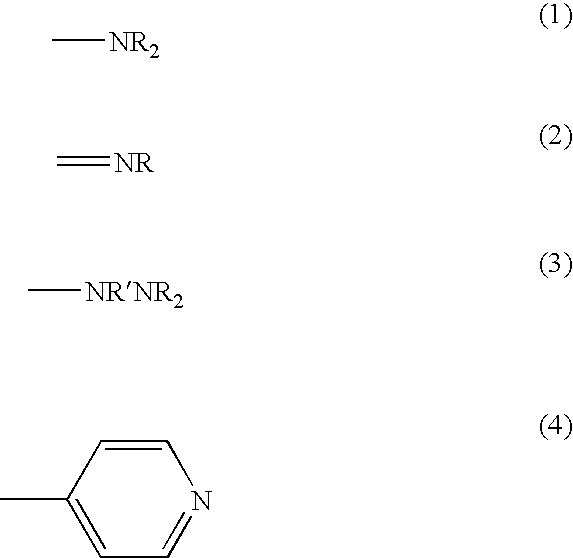

Method of removing metal etching residues following a metal etchback process to improve a CMP process

InactiveUS6936544B2Reduce scratchesSemiconductor/solid-state device manufacturingElectrostatic cleaningHydrofluoric acidCompound (substance)

A method for reducing wafer surface scratching in a metal CMP process including providing a semiconductor wafer having a process surface comprising a blanket deposited metal layer; dry etching in an etchback process comprising a fluorine containing etching chemistry to remove at least a portion of the metal layer forming a metal and fluorine containing etching residue at the process surface; cleaning the process surface with a hydrofluoric acid (HF) containing cleaning solution; and carrying out a subsequent metal chemical mechanical polishing (CMP) process.

Owner:TAIWAN SEMICON MFG CO LTD

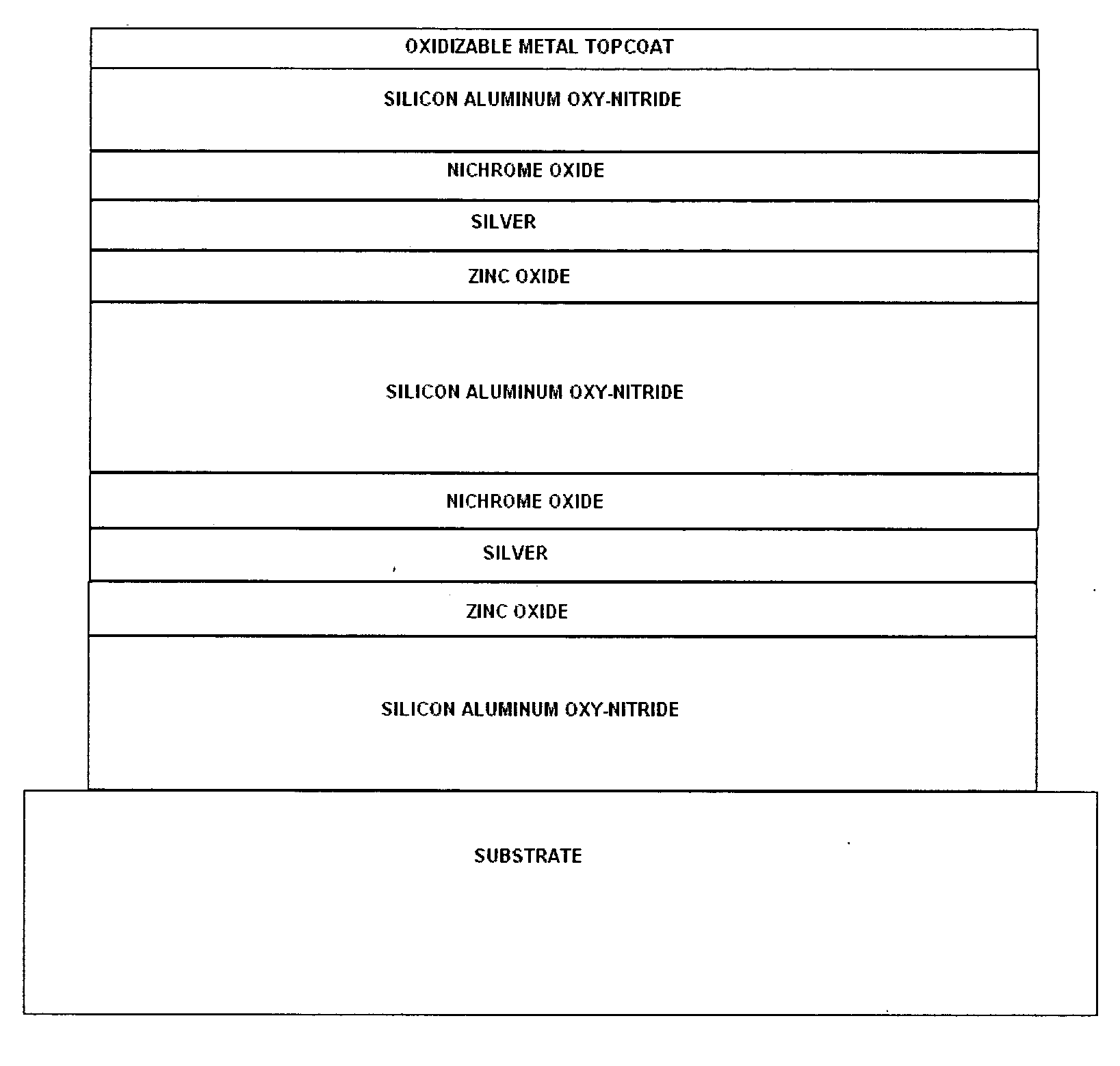

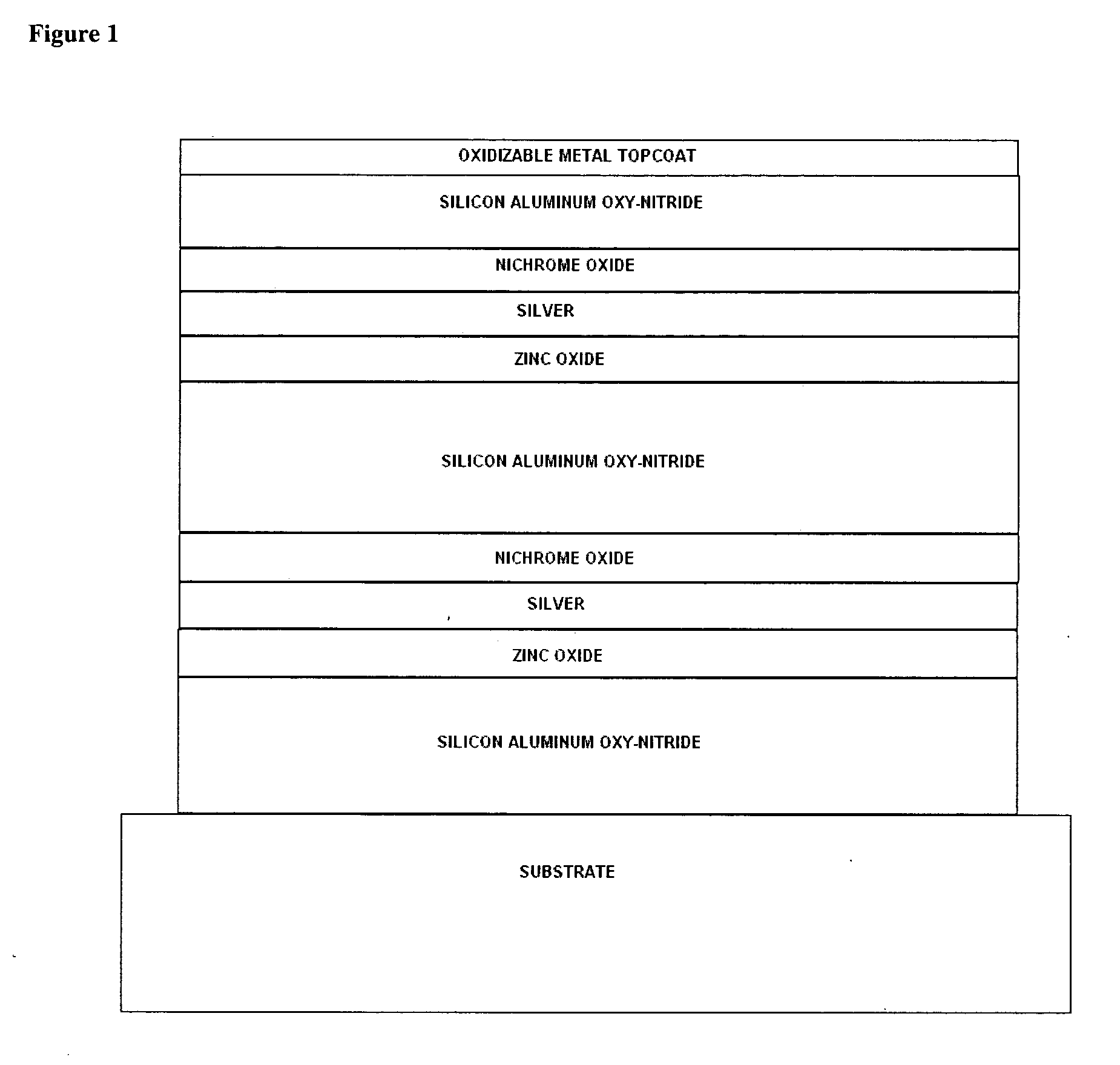

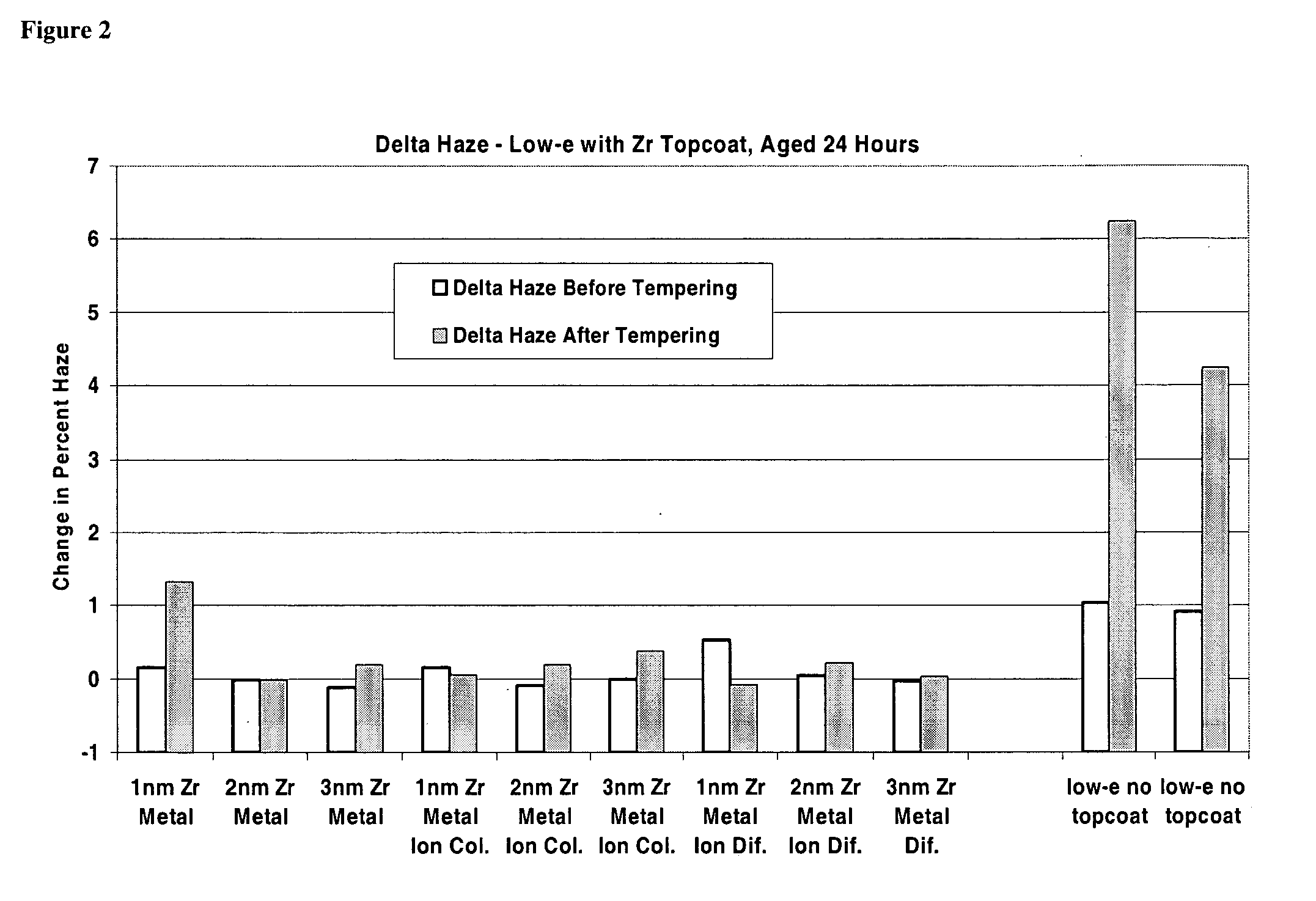

Air oxidizable scratch resistant protective layer for optical coatings

InactiveUS20060134436A1Reduce harmSolve the lack of durabilitySolid state diffusion coatingGlass/slag layered productsMetal alloyOptical coating

The present invention provides a scratch protecting layer comprising a metal, metal alloy, metal compound or an intermetallic layer deposited on an air contacting surface. The scratch protecting layer is typically from 1 to 3 nanometers thick and not optically absorbing after oxidation occurs. This layer is initially deposited in a primarily unoxidized or un-nitrided state. Full oxidation of the metal, metal alloy, metal compound or intermetallic layer occurs within several days after exposure to air. The scratch protection layer can be 2 to 5 nanometers thick if the layer is exposed to a plasma, electrical discharge or ion beam comprising a reactive gas such as oxygen or nitrogen.

Owner:AGC FLAT GLASS NORTH AMERICA INC

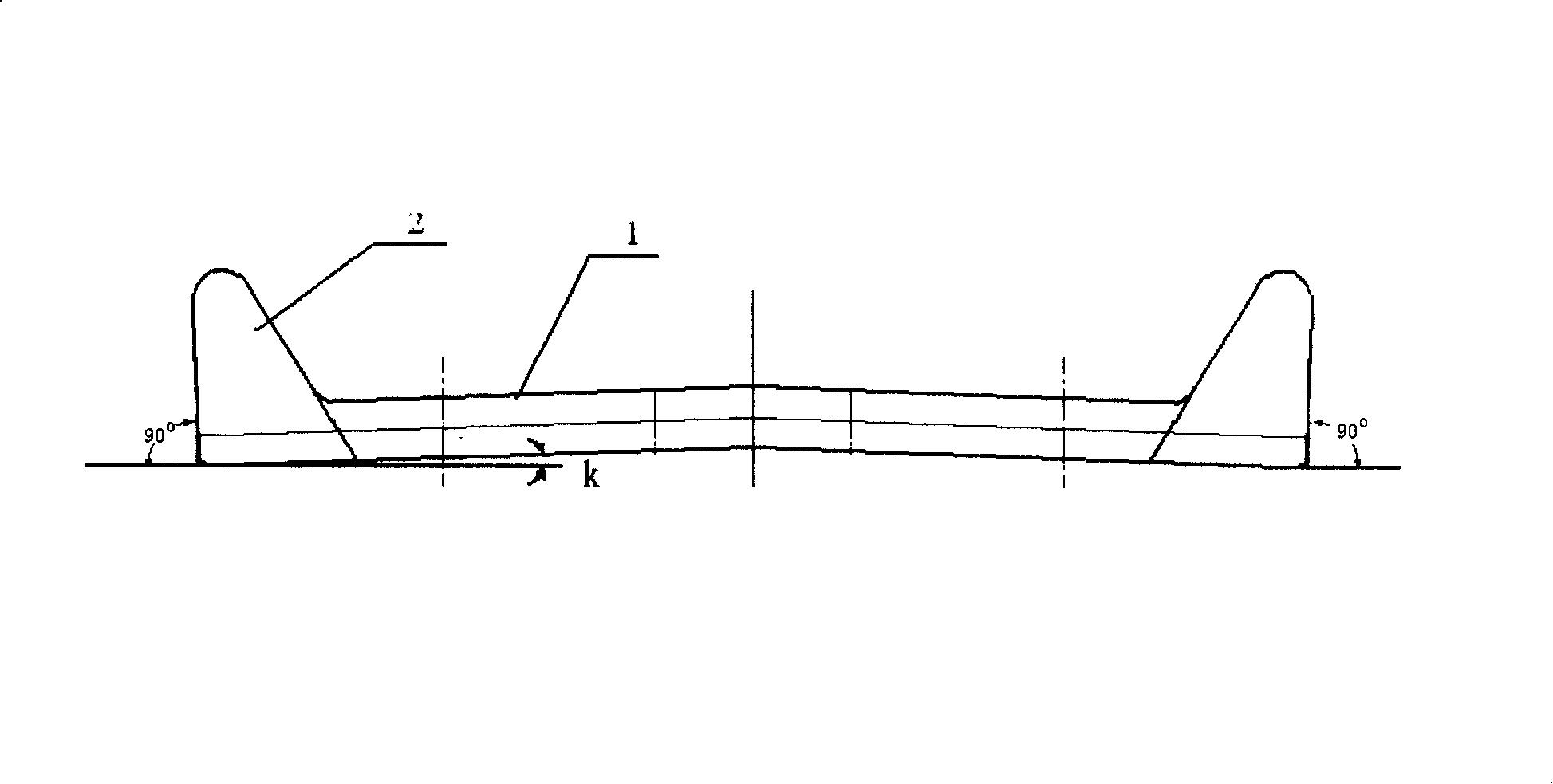

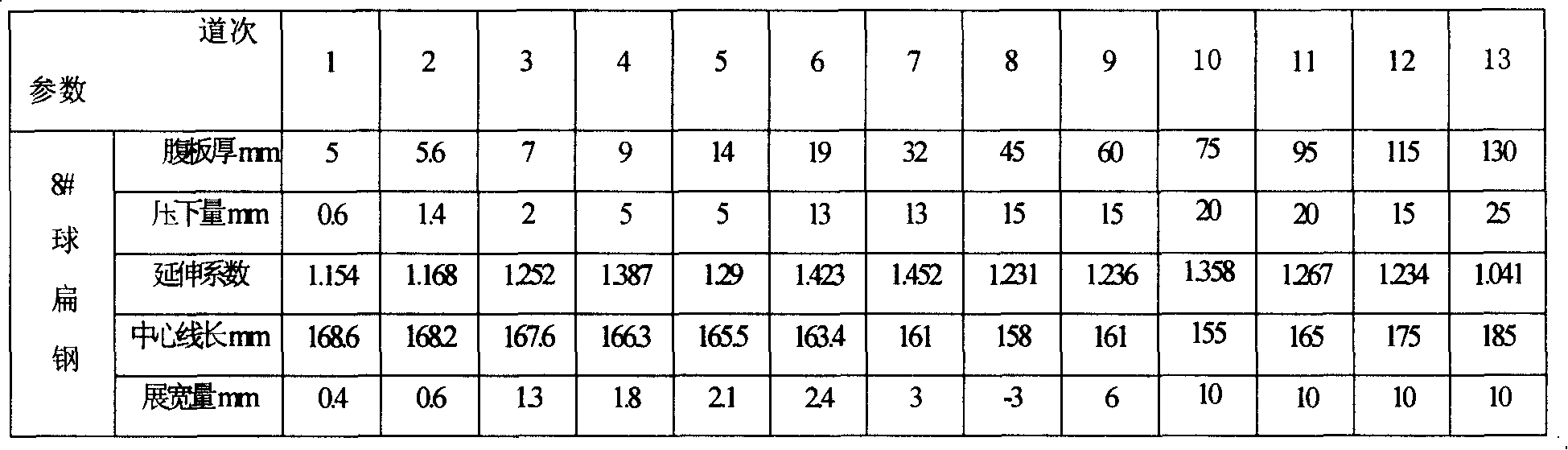

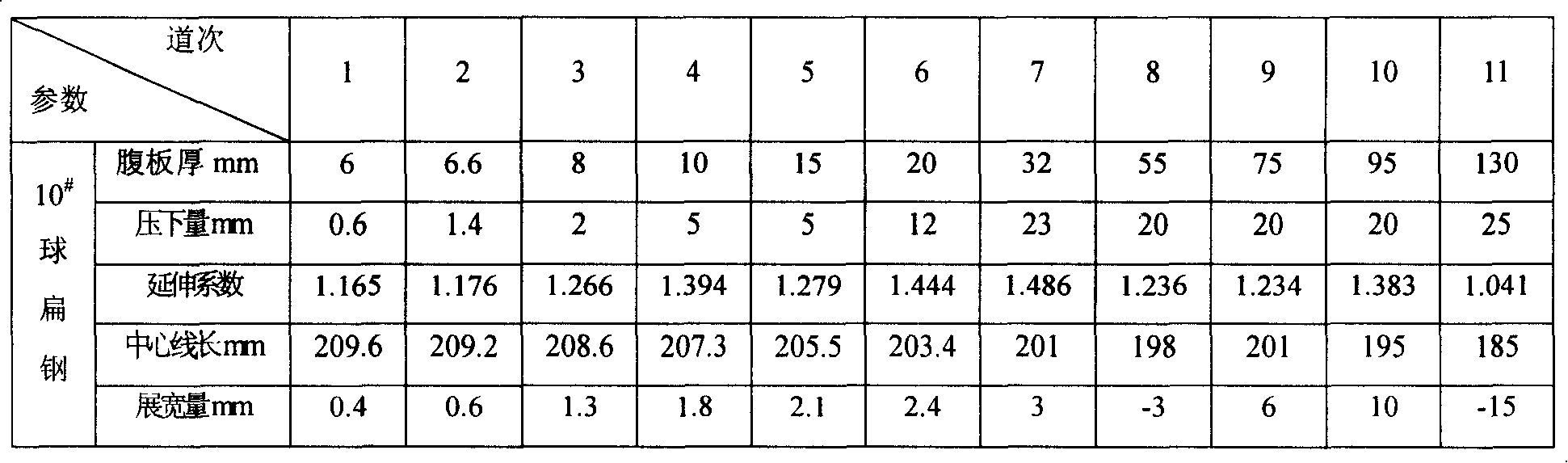

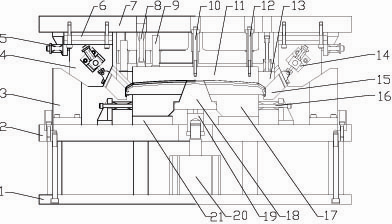

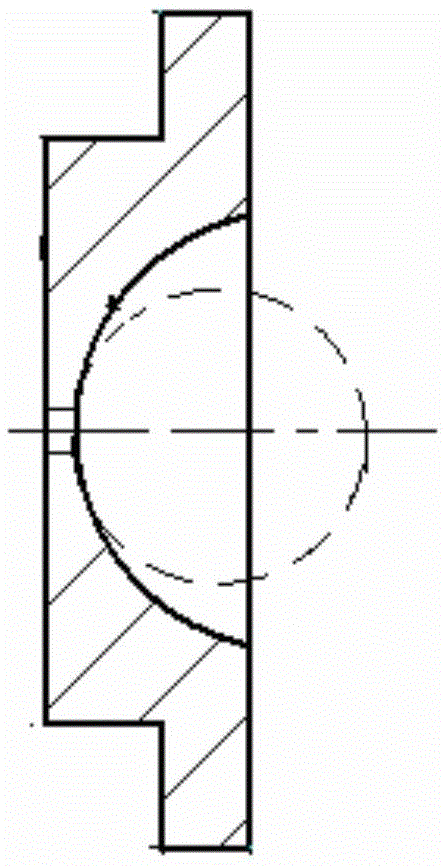

Bulb steel production technology

InactiveCN101190442ASmall fluctuations in section sizeSmall fluctuations in the size of the arcRollsMetal rolling arrangementsIron productionCompression ratio

The invention discloses a ball flat iron production technique, comprising steps of billet, heating, symmetrical rolling, straightening and dissection. The invention is characterized in that the dissection process is carried out after the processes of symmetric rolling and straightening; hole shapes in all the passages of a rolling mill are constituted by two ball flat iron hole shapes which are symmetrically identical. By adopting the technique of symmetric rolling, the invention solves the problems that existing large and medium rolling mills can not produce small ball flat irons with symmetrical rolling and dissection technology. The invention has the advantages of the small size fluctuation of profiles when producing, particularly the small size fluctuation of width, thickness, ball filling and the lower arc of the ball flat iron, rollers subject to uniform forces, easy control in rolling process, greatly reducing the scraping, the rolling mark and the waves of the product by 50% to 70%, improving the quality of the product, enlarging the types of rolled products, leading large profiled bar rolling mill to produce small ball flat iron, enlarging the profile of the billet, large corresponding compression ratio, improving the comprehensive performance of the products, etc.

Owner:ANGANG STEEL CO LTD

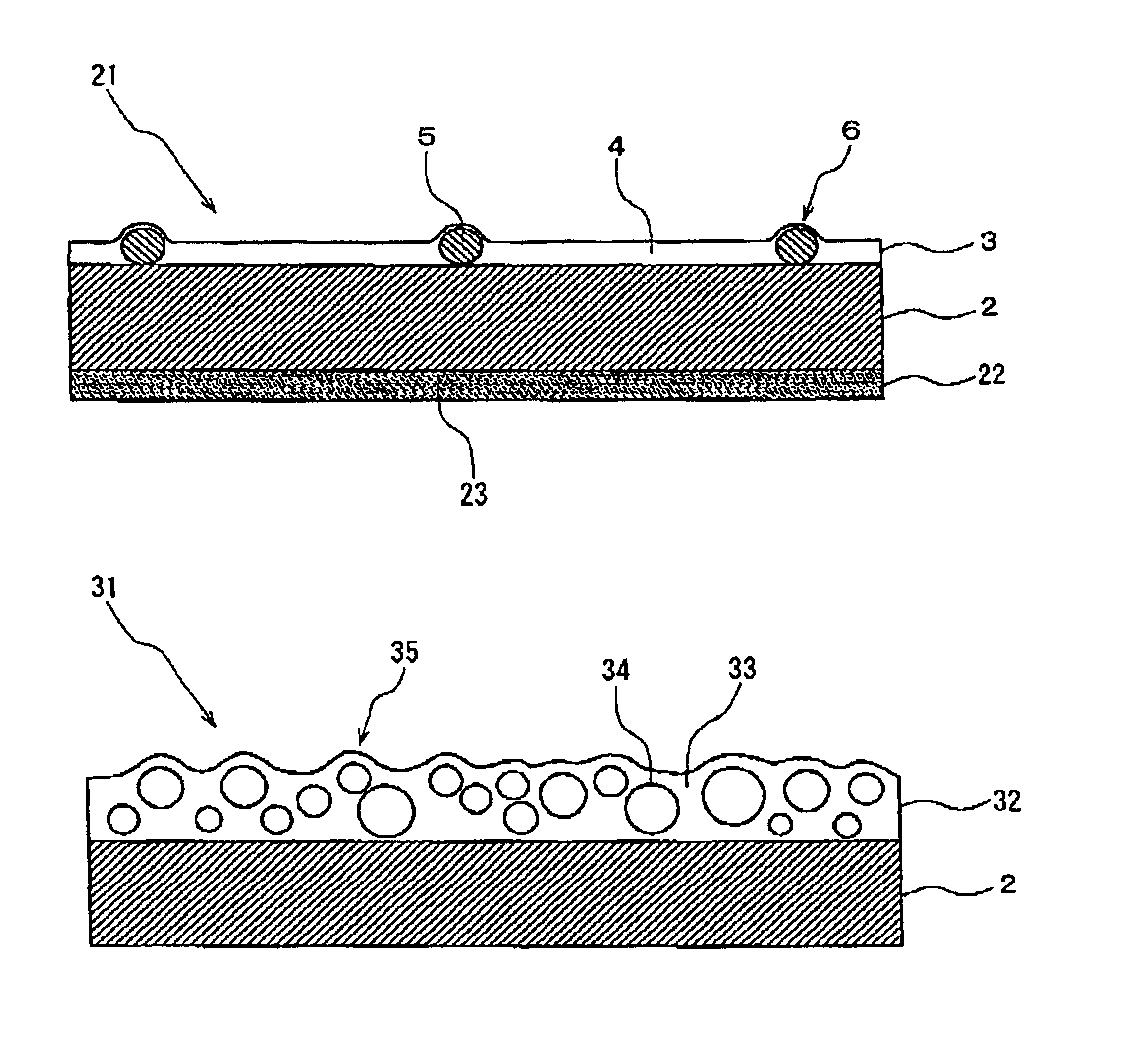

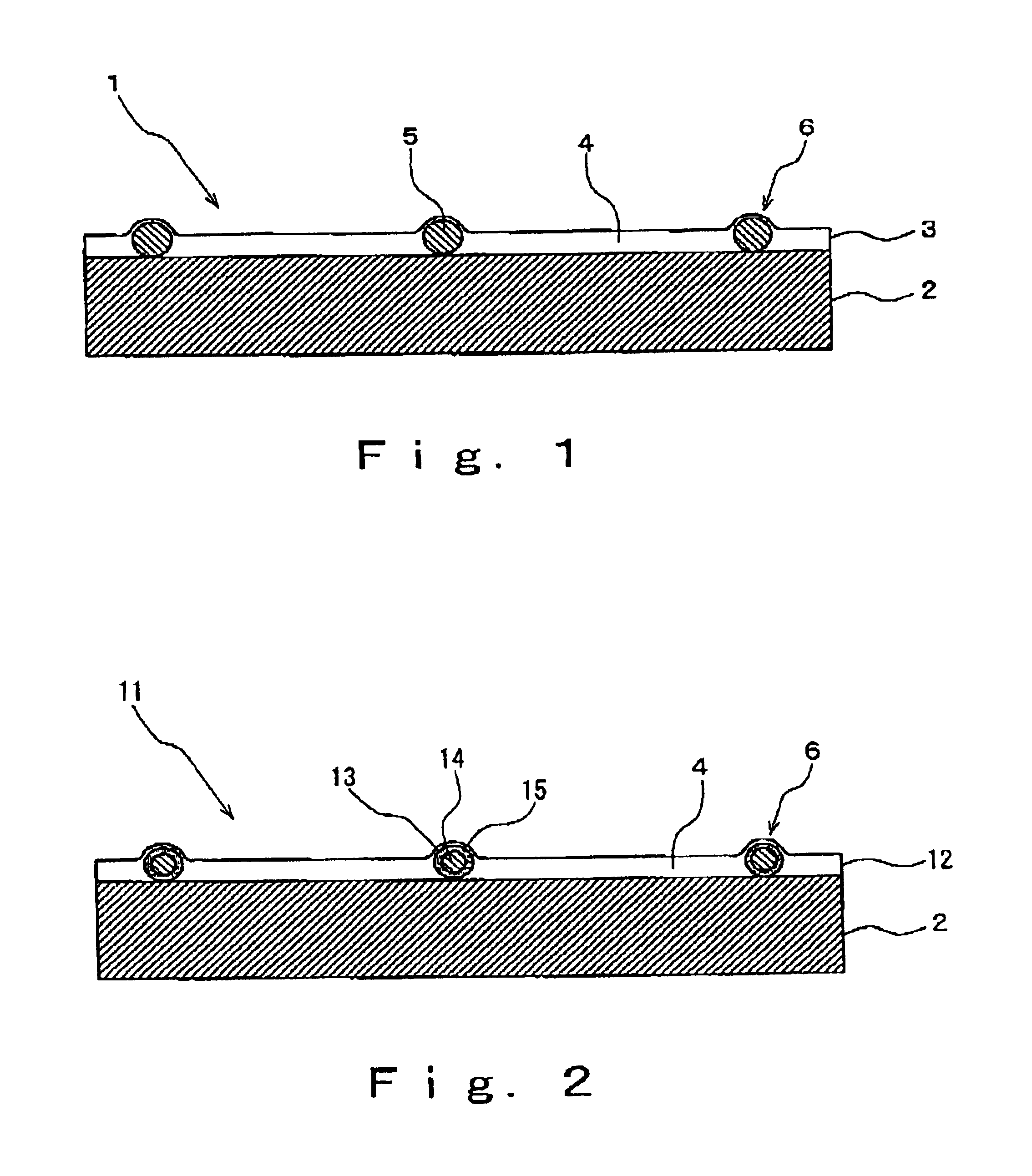

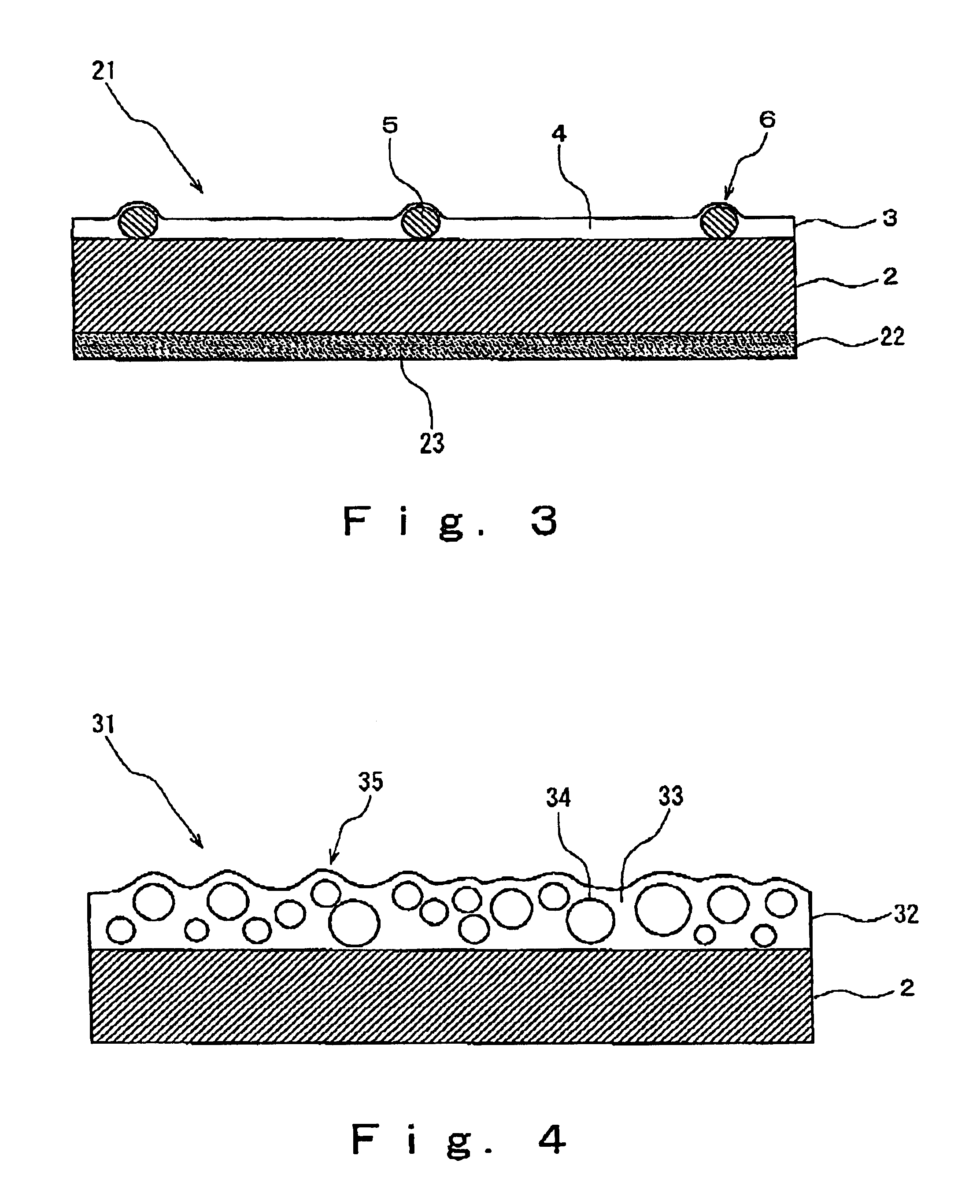

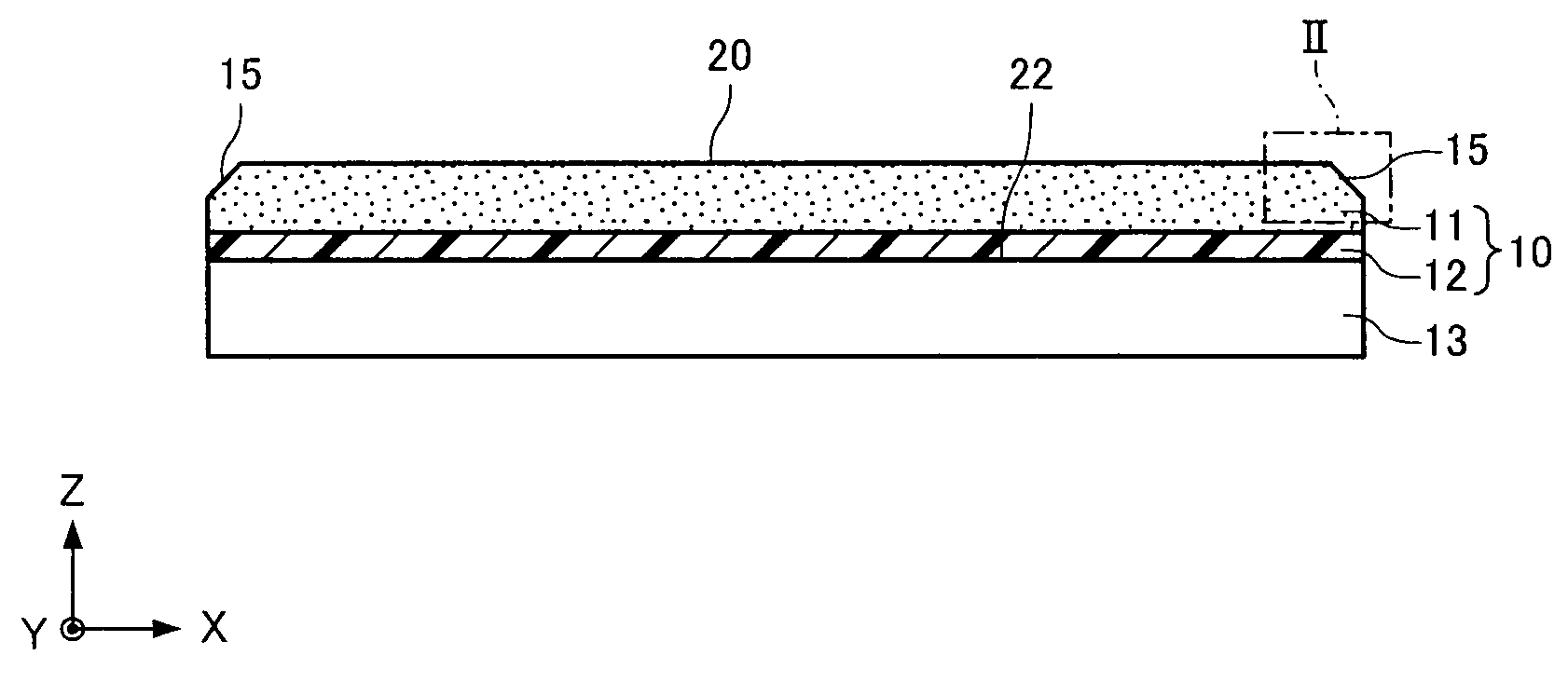

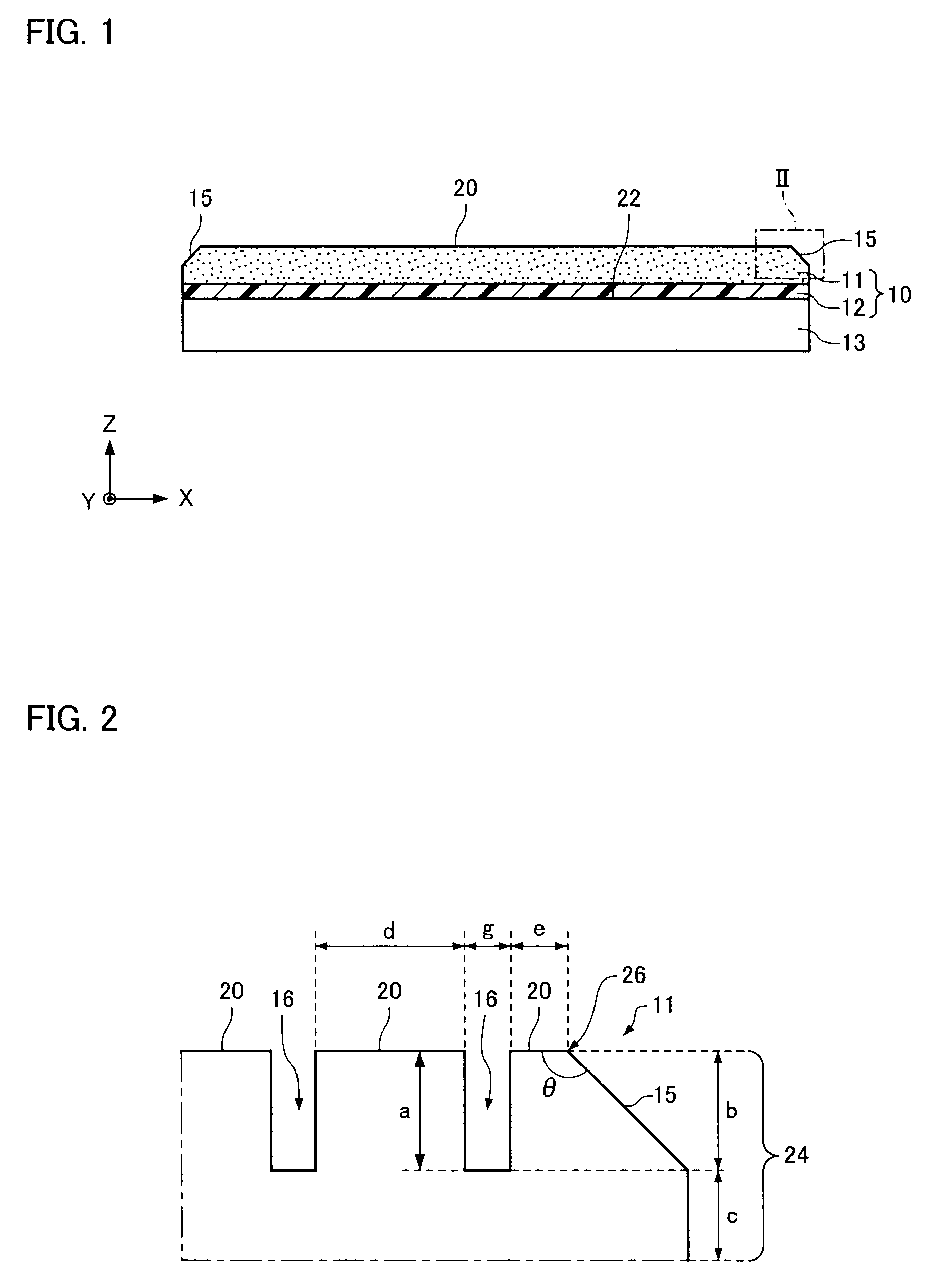

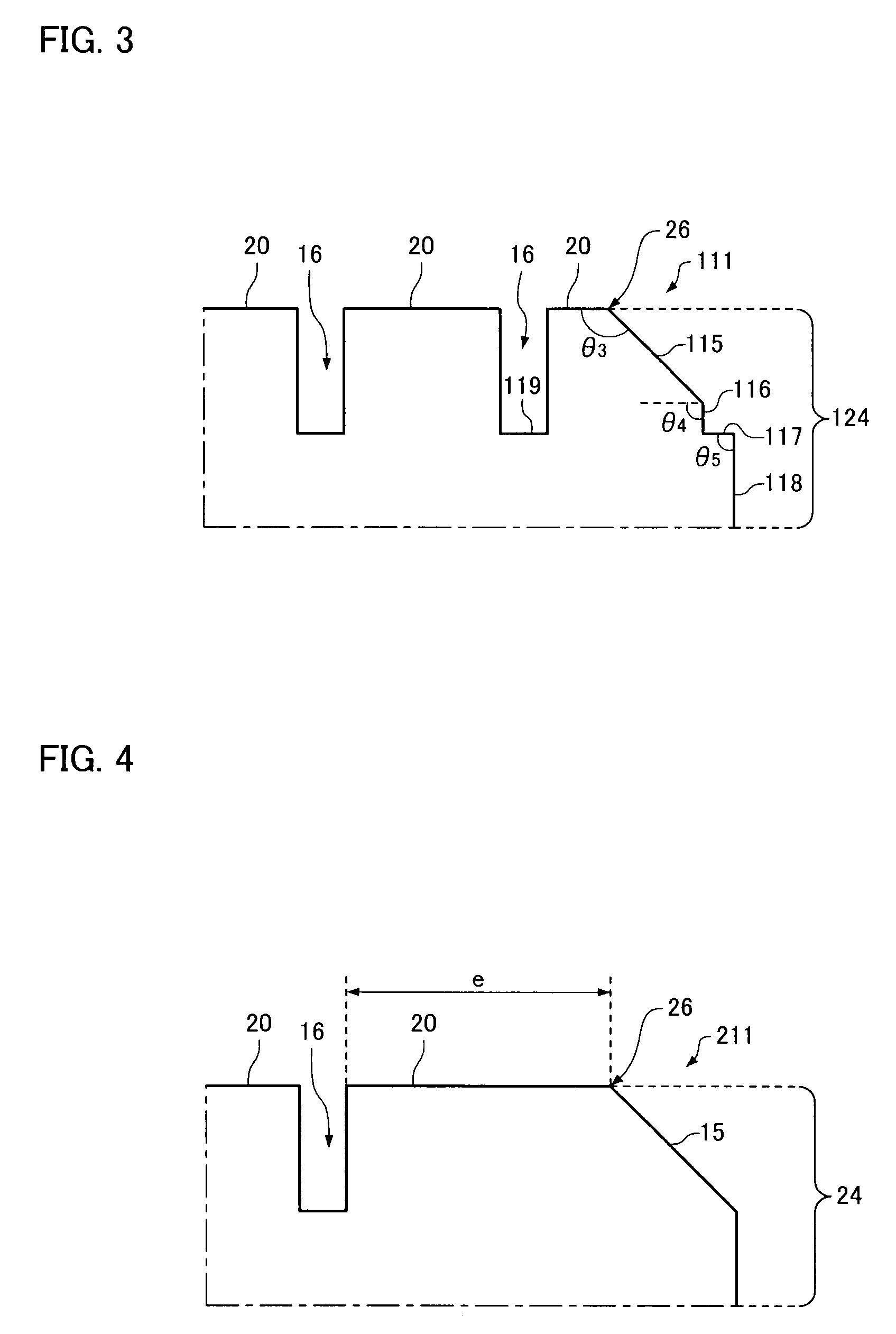

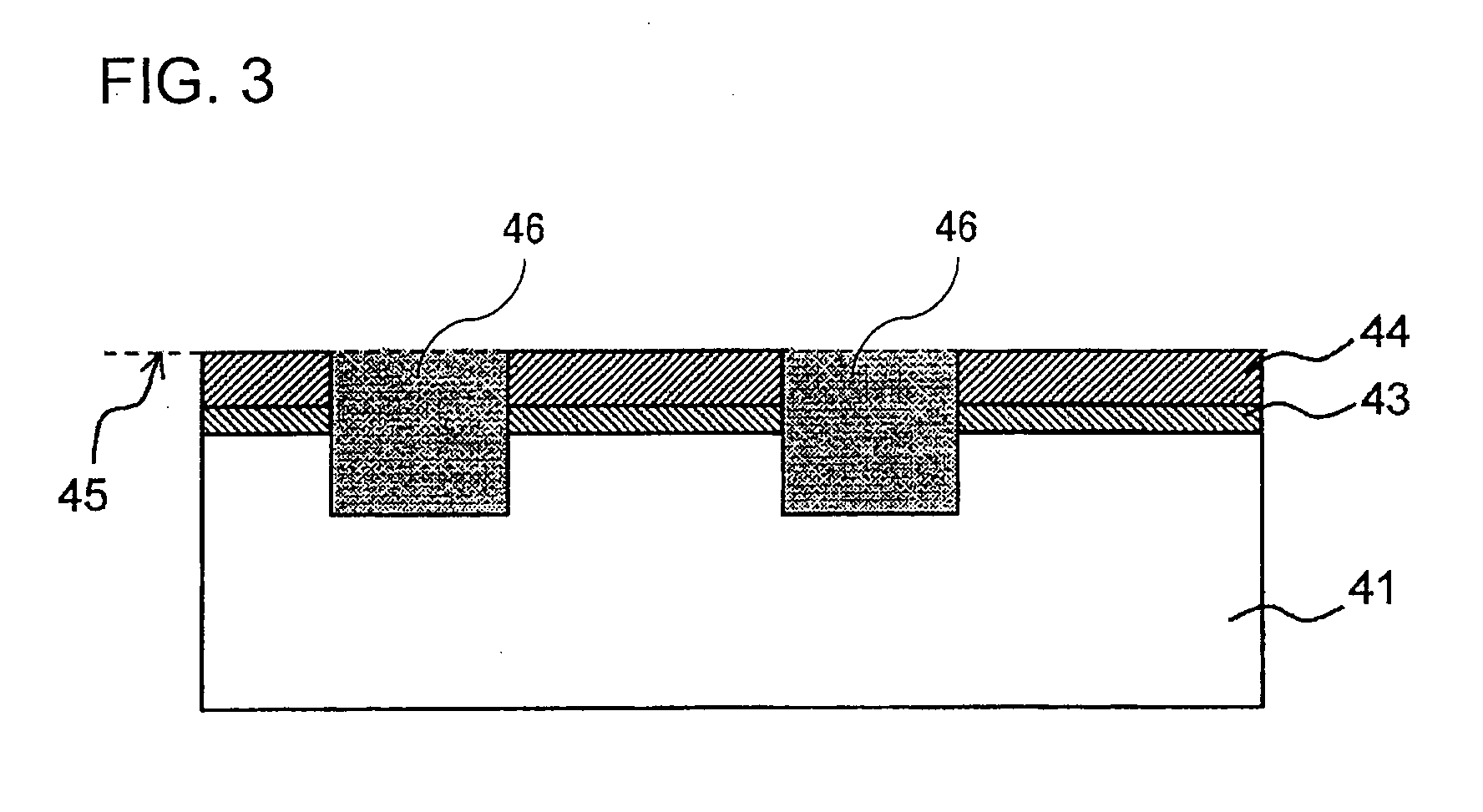

Reflection sheet and backlight unit using the same

InactiveUS6906761B2Increase brightnessReduce lossesMechanical apparatusPlanar/plate-like light guidesElastomerEngineering

A reflection sheet which can prevent scratches on a back face of an optical waveguide plate, and a backlight unit capable of attempting the improvement of brightness and the uniformization of the brightness using the reflection sheet. The reflection sheet includes a substrate sheet made of a white synthetic resin and a scratchproof layer overlaid to the front face side of this substrate sheet, wherein the scratchproof layer has flexible protrusions on its front face in a substantially uniform manner. The scratchproof layer includes a binder and beads dispersed in the binder. Flexible elastomer material which constitutes the beads is preferably flexible polyurethane or a silicone rubber.

Owner:KEIWA INCORPORATED

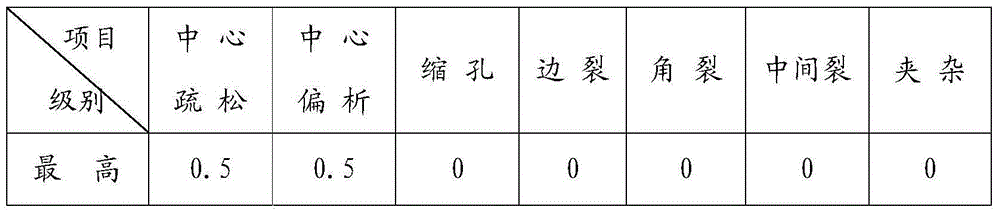

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots, and the provided preparation method of a large-size aluminum alloy ingot solves the problem of easy cracking during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO. flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials are smelted, sequentially adding a zirconium composite salt and magnesium ingots as well as smelting and refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the ingot prepared by using the method is 500-600mm, the width is 1,600mm, and the length is 1,500-2,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 65 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

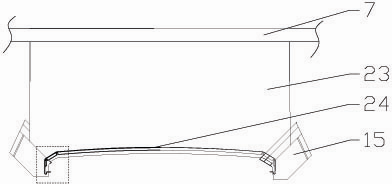

Refrigerator door shell end bending die

ActiveCN101983794AAvoid concentrationReduce defects such as damageShaping toolsCustomer requirementsEngineering

Owner:滁州市科创模具制造有限公司

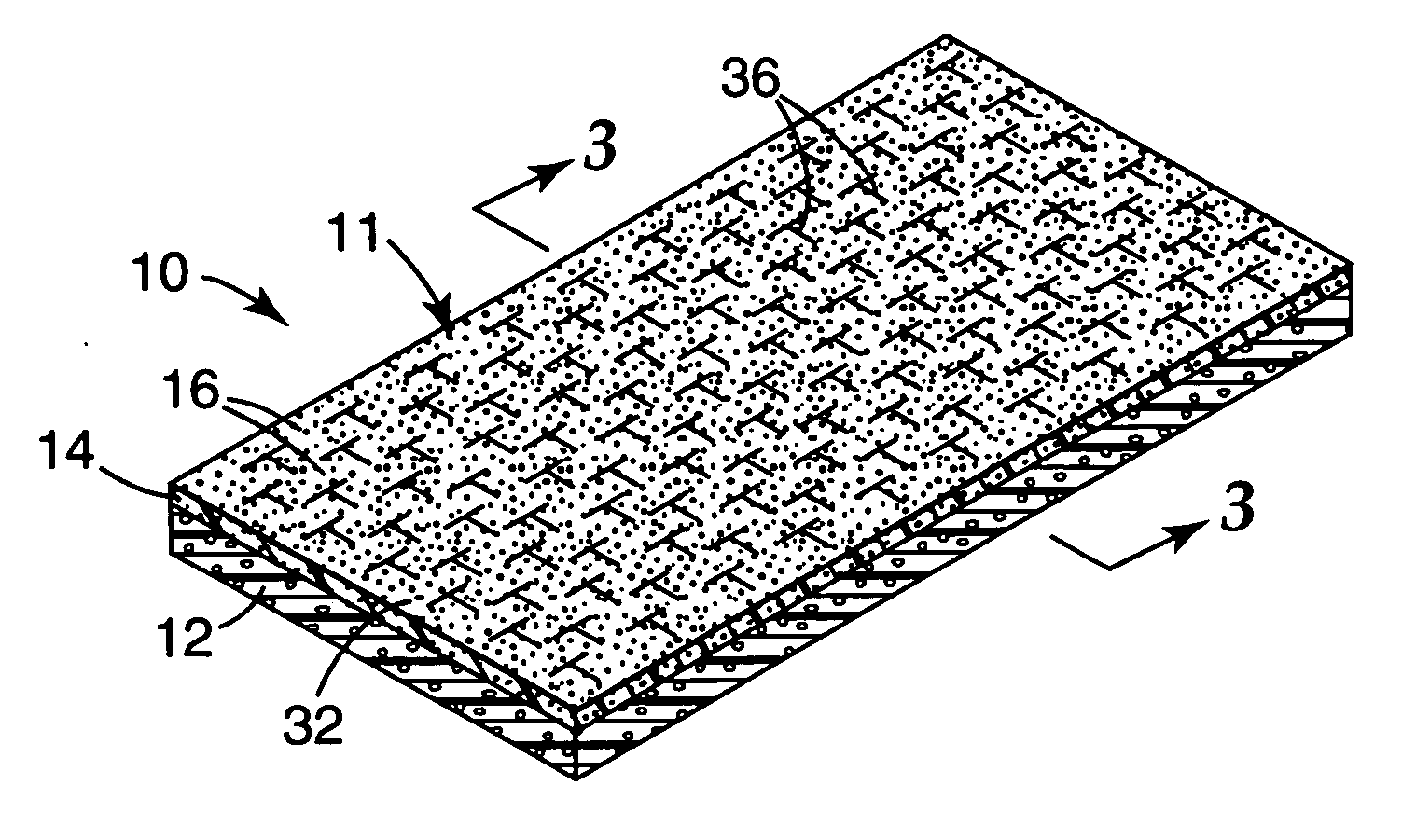

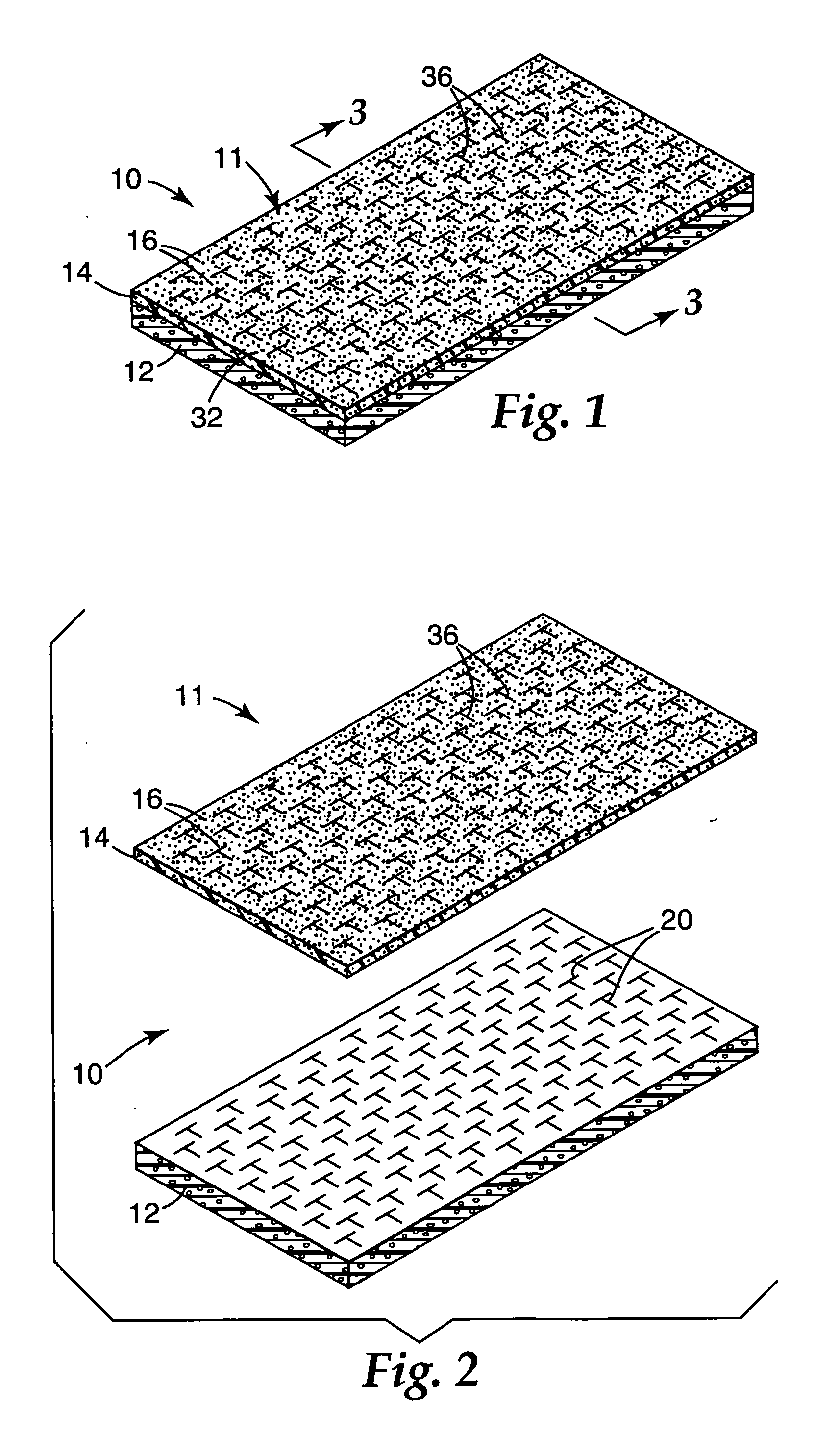

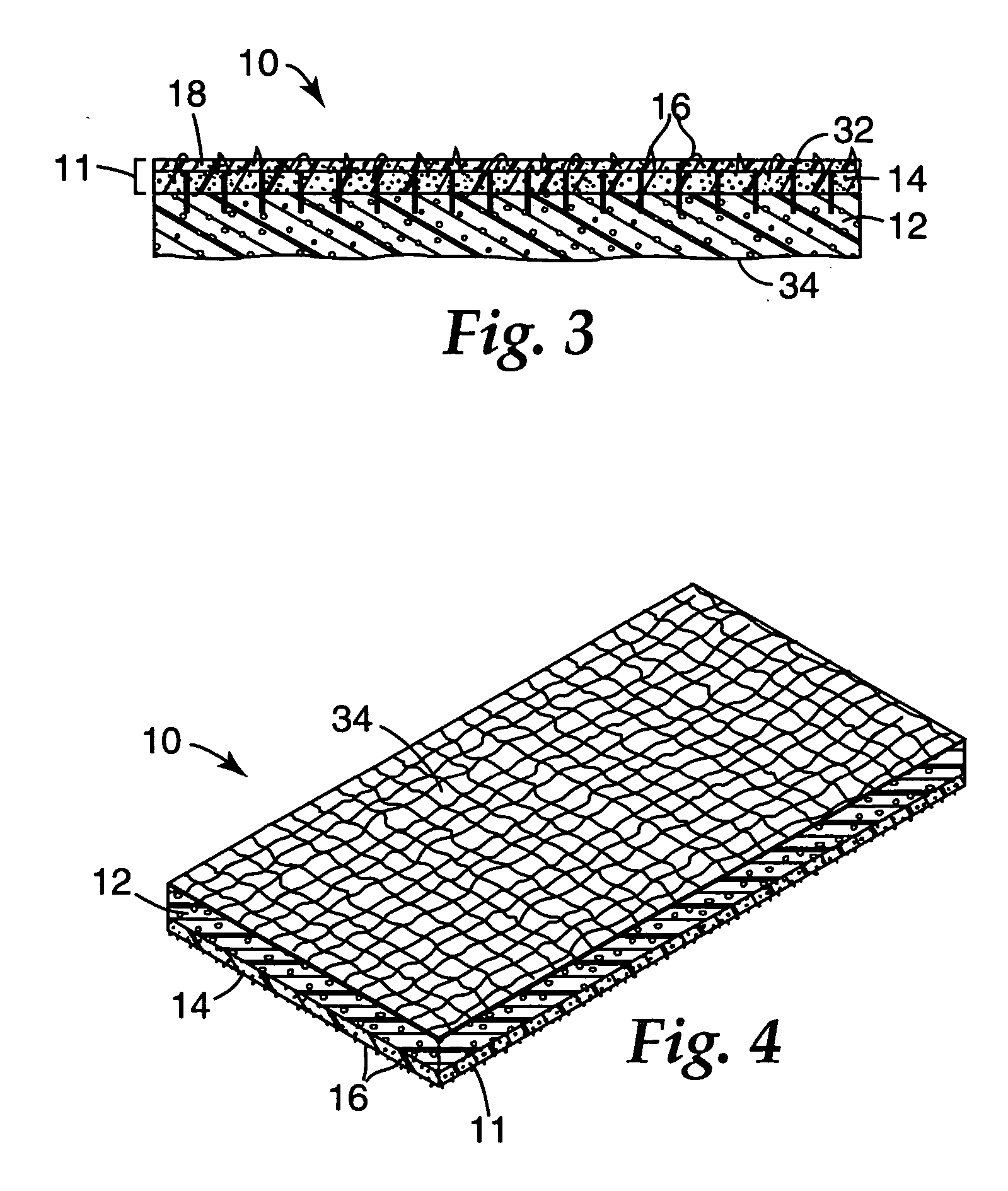

Flexible abrasive article and method of making

A flexible hand-held abrasive article includes a conformable backup pad having opposed major surfaces, a backing layer affixed to one surface of the backup pad, the backing layer containing a plurality of biaxially oriented openings, and abrasive particles arranged on the backing layer, thereby defining an abrasive surface. A method of making such an abrasive article is also disclosed. The abrasive article may also comprise a backing layer containing a plurality of biaxially oriented slits with abrasive particles arranged at least one surface of the backing layer.

Owner:3M INNOVATIVE PROPERTIES CO

Dry film lubricant used for metal parts

The invention discloses a dry film lubricant used for metal parts, which comprises the following components in percentage by weight: 10-55% of soli lubricant, 4-10% of wear-resistant additive, 0.2-5% of dispersant, 2-6% of antioxidant, 0.5-2.5% of magnetic additive and 35-80% of adhesive base body. Compared with the prior art, the dry film lubricant has high wear-resistant performance and low scratch on friction surfaces. The dry film lubricant can be applied in the permanent lubrication of various mechanical metal parts, the initial running-in of pistons, cams, cylinders and like, the repairing of the parts of railway vehicles, aircrafts, ships and like, the fretting wear protection of steel rope shock absorber, mine elevator and bridge steel rope and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

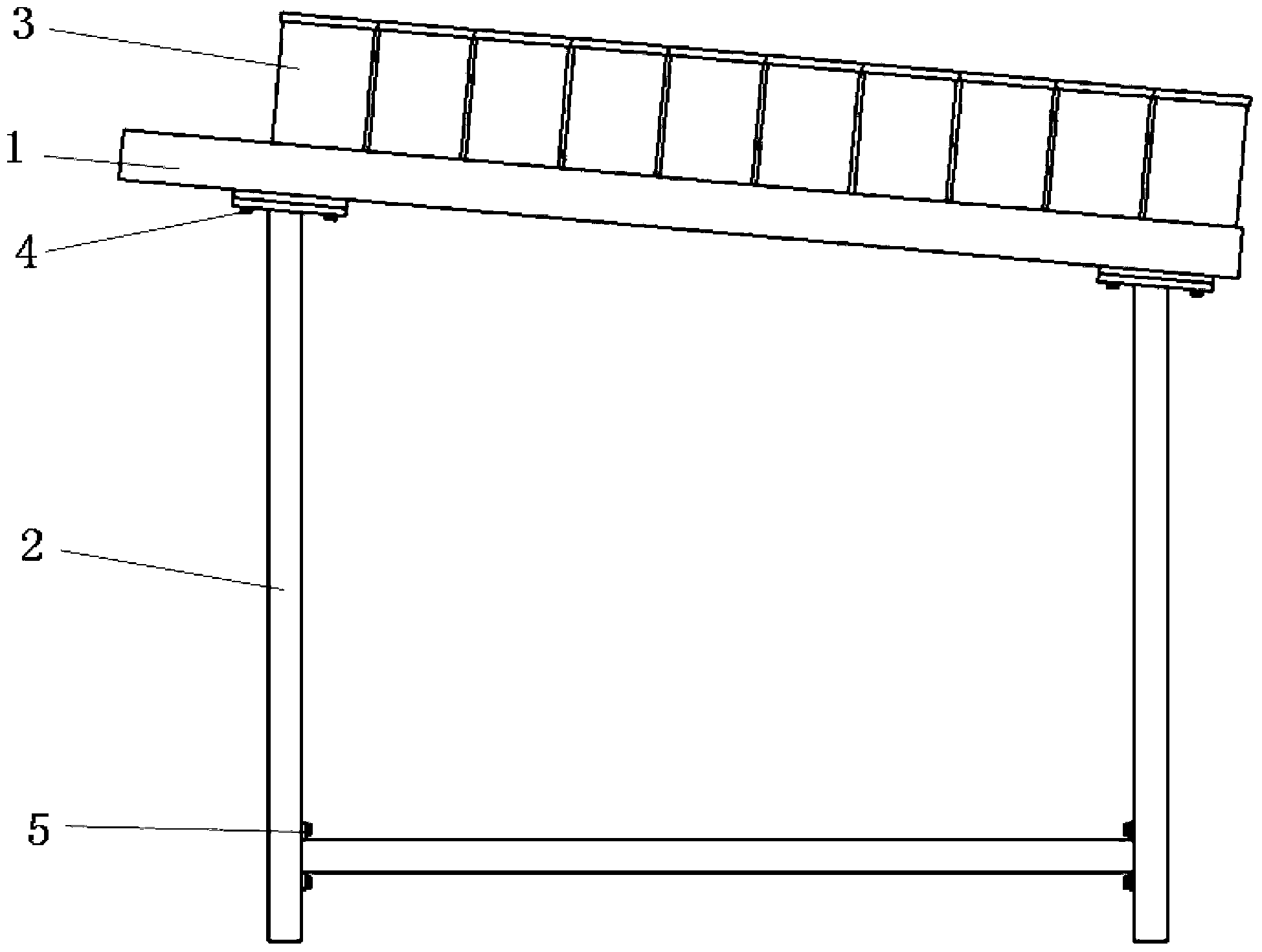

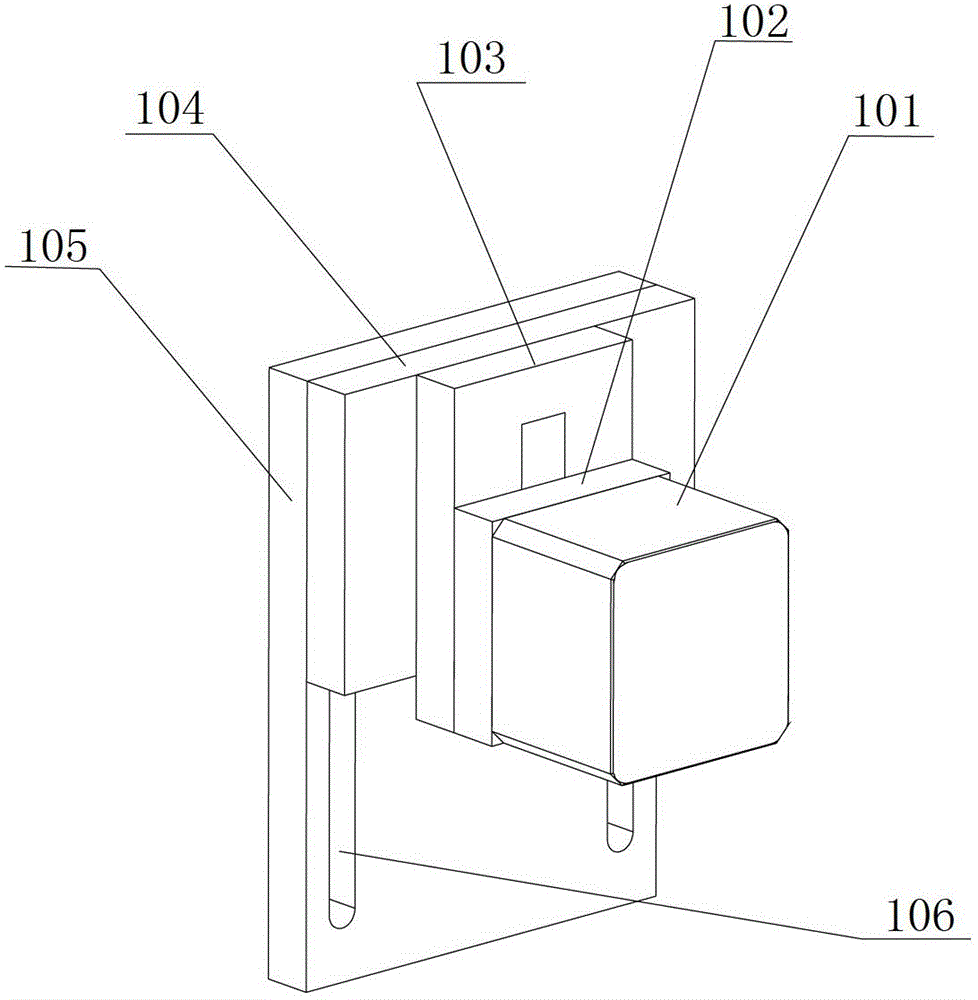

Educational toy suite

InactiveCN105194884AEasy to installEasy to disassembleDollsElectrical appliancesTablet computerEngineering

The invention relates to the technical field of computer vision recognition processing and provides an educational toy suite. The educational toy suite comprises a support, a helmet detector and a base plate, the support is installed on the base plate, and the helmet detector is installed on the support; a first groove is formed in the upper portion of the base plate; the bottom of the support is provided with a protrusion, the protrusion is installed in the first groove, a second groove and a third groove are formed in the top of the support, and the second groove is used for storing a tablet computer; the helmet detector is installed in the third groove. By means of the educational toy suite, the image acquisition scope of a camera of the tablet computer is expanded, the visual angle is enlarged, great interactivity is achieved, game experience is more vivid, the educational toy suite is helpful for alleviating asthenopia, harm to eyes is lowered, operational ability of children is improved, the children are promoted to make progress continuously, intelligence is developed, enjoyment is improved, the educational toy suite is more convenient to carry, move, install and detach, the cost is saved, and maintenance is facilitated.

Owner:SHANGHAI PUTAO TECH CO LTD

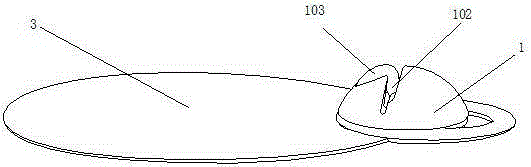

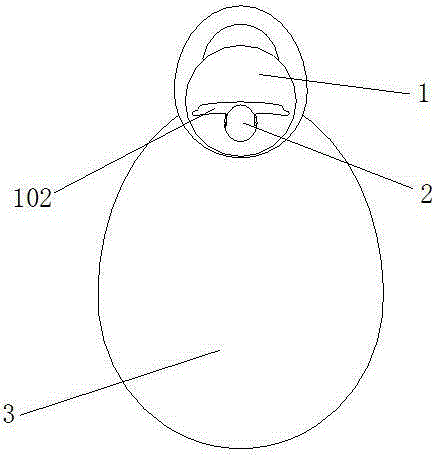

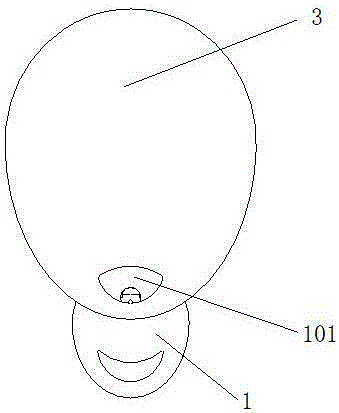

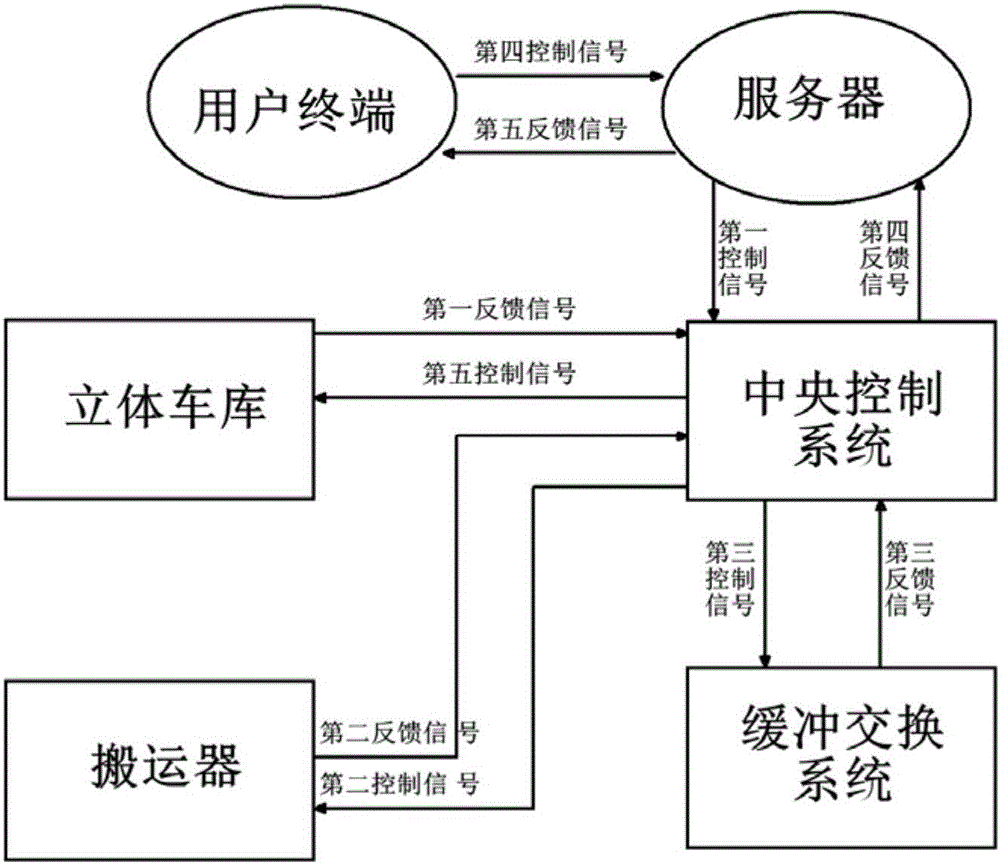

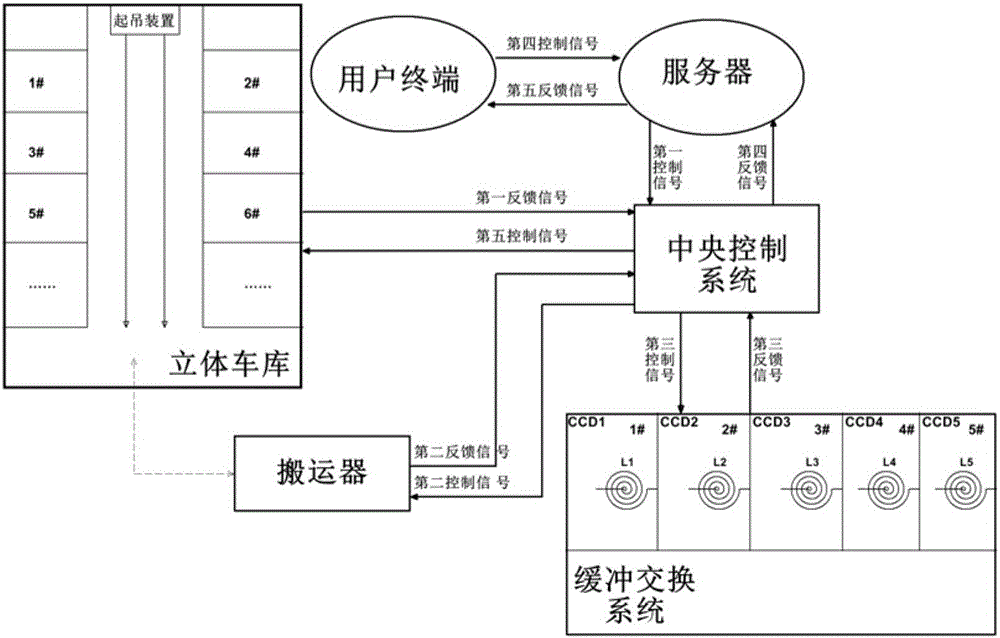

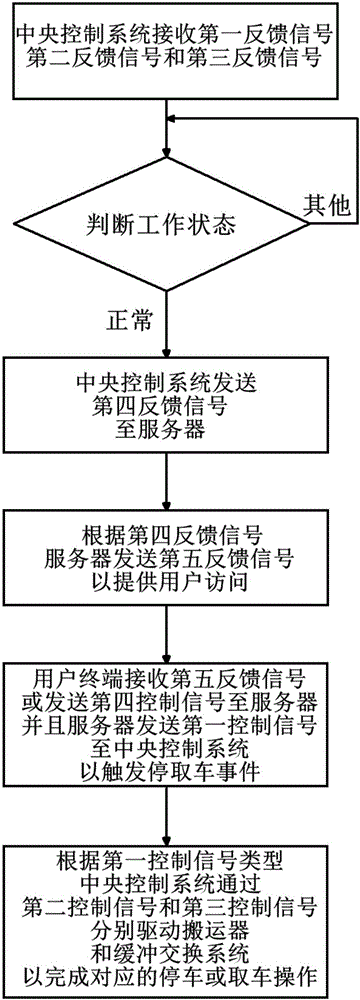

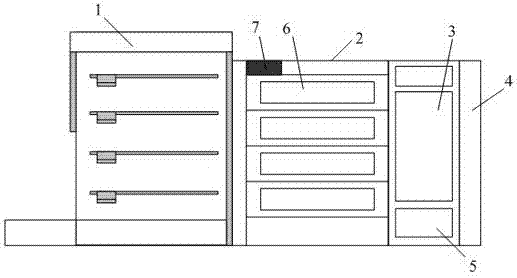

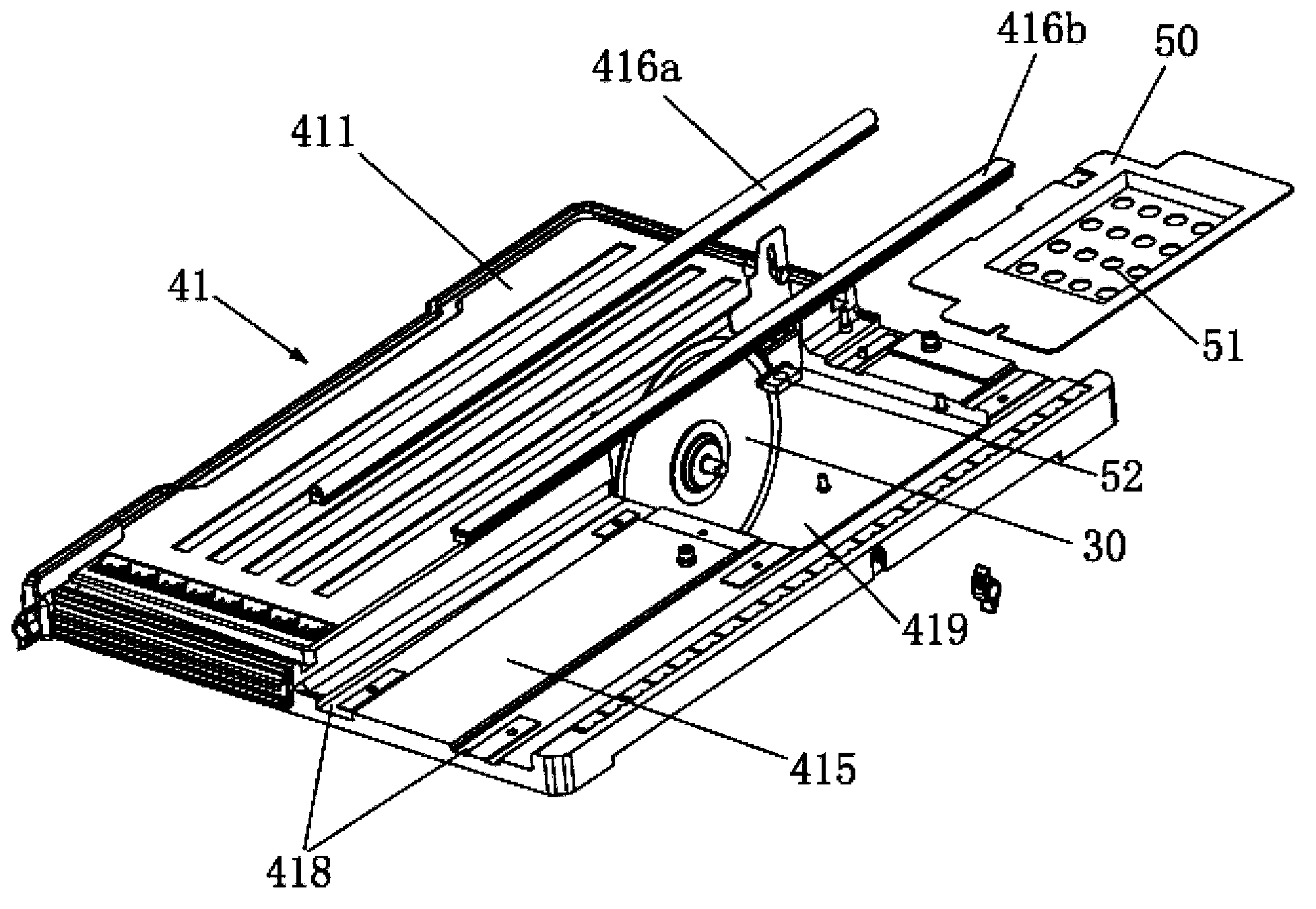

Stereo garage intelligent transfer carrying system and method thereof

InactiveCN105909025AReduce the difficulty of parking and picking up the carReduce processing difficultyIndication of parksing free spacesTransmissionSystems designControl system

The invention provides a stereo garage intelligent transfer carrying system and a method thereof, and relates to the technical field of stereo garage signal and system design. The system and the method aim at solving the technical problems of the existing stereo garage that the waiting time during car storage or car taking is long; cars to be stored or taken easily generate collision and scratching, and the like. The stereo garage intelligent transfer carrying system mainly comprises a central control system, a server, a user terminal, a carrier and a buffer exchange system, wherein the buffer exchange system comprises a buffer exchange region, a camera and a geomagnetic coil; the buffer exchange region is used for transferring the cars to be stored or taken; and the camera and the geomagnetic coil are arranged in the buffer exchange region. The system and the method are used for designing stereo garage signals and systems.

Owner:四川聚达机电有限公司

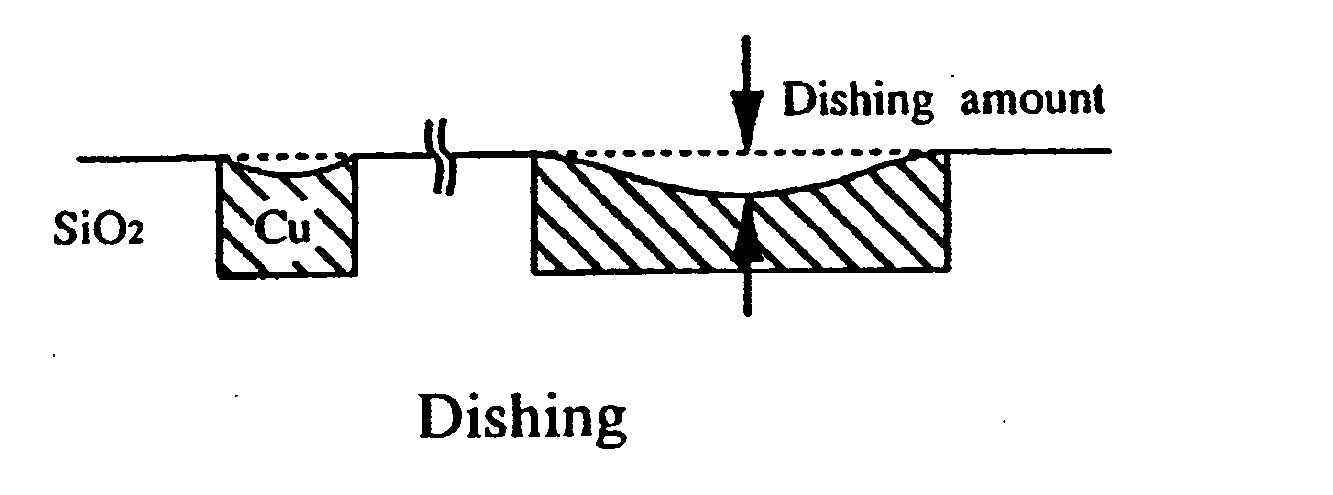

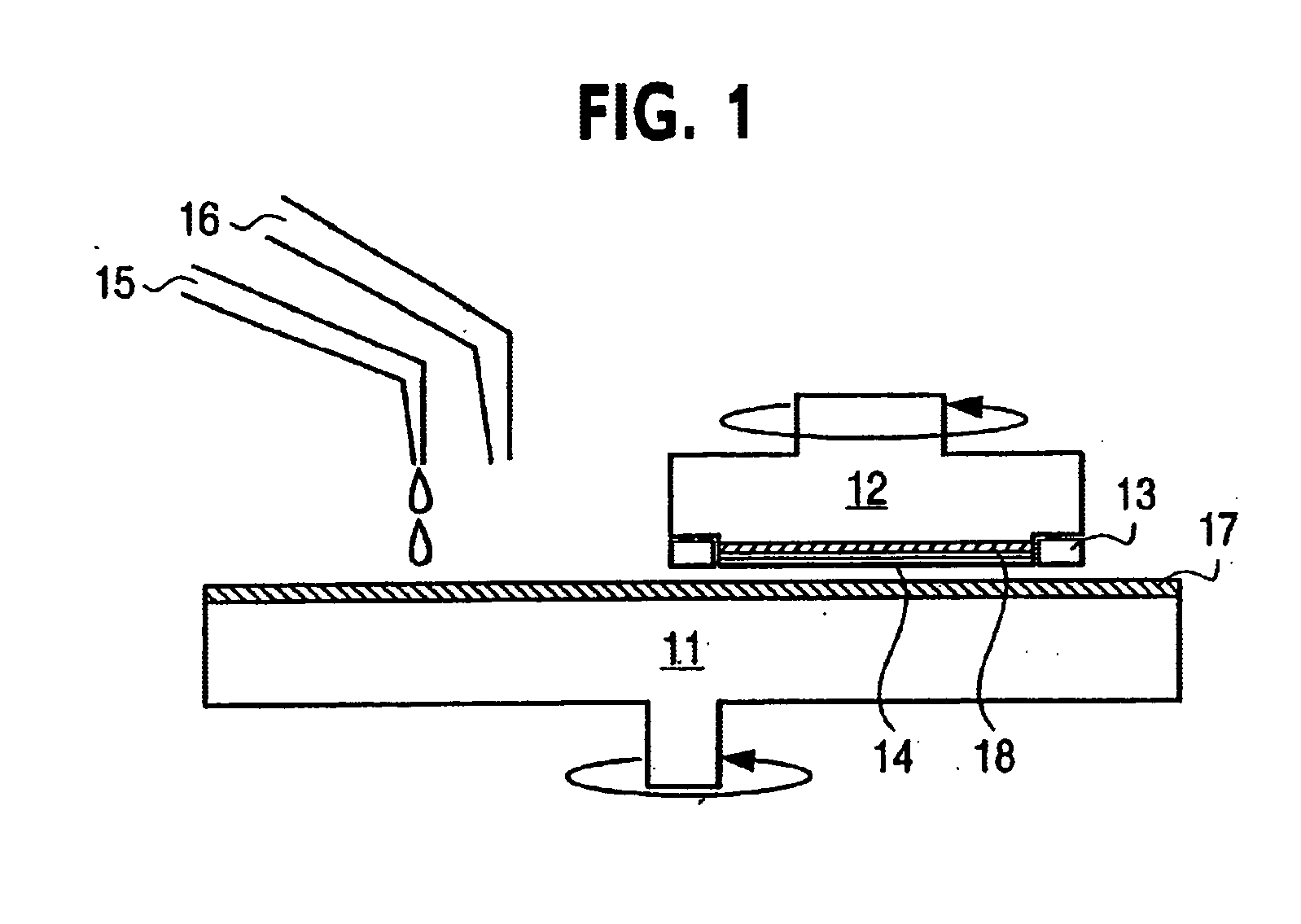

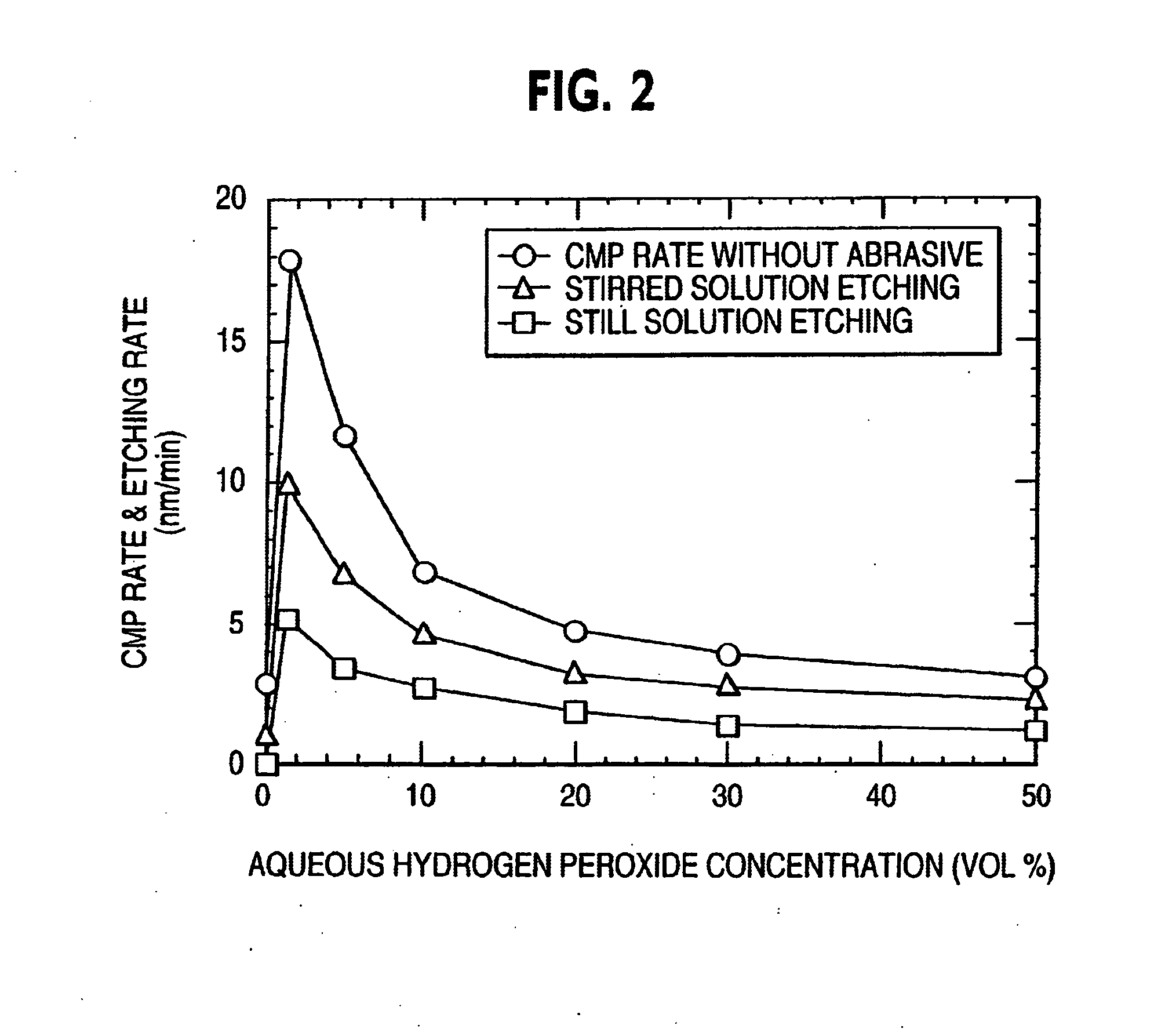

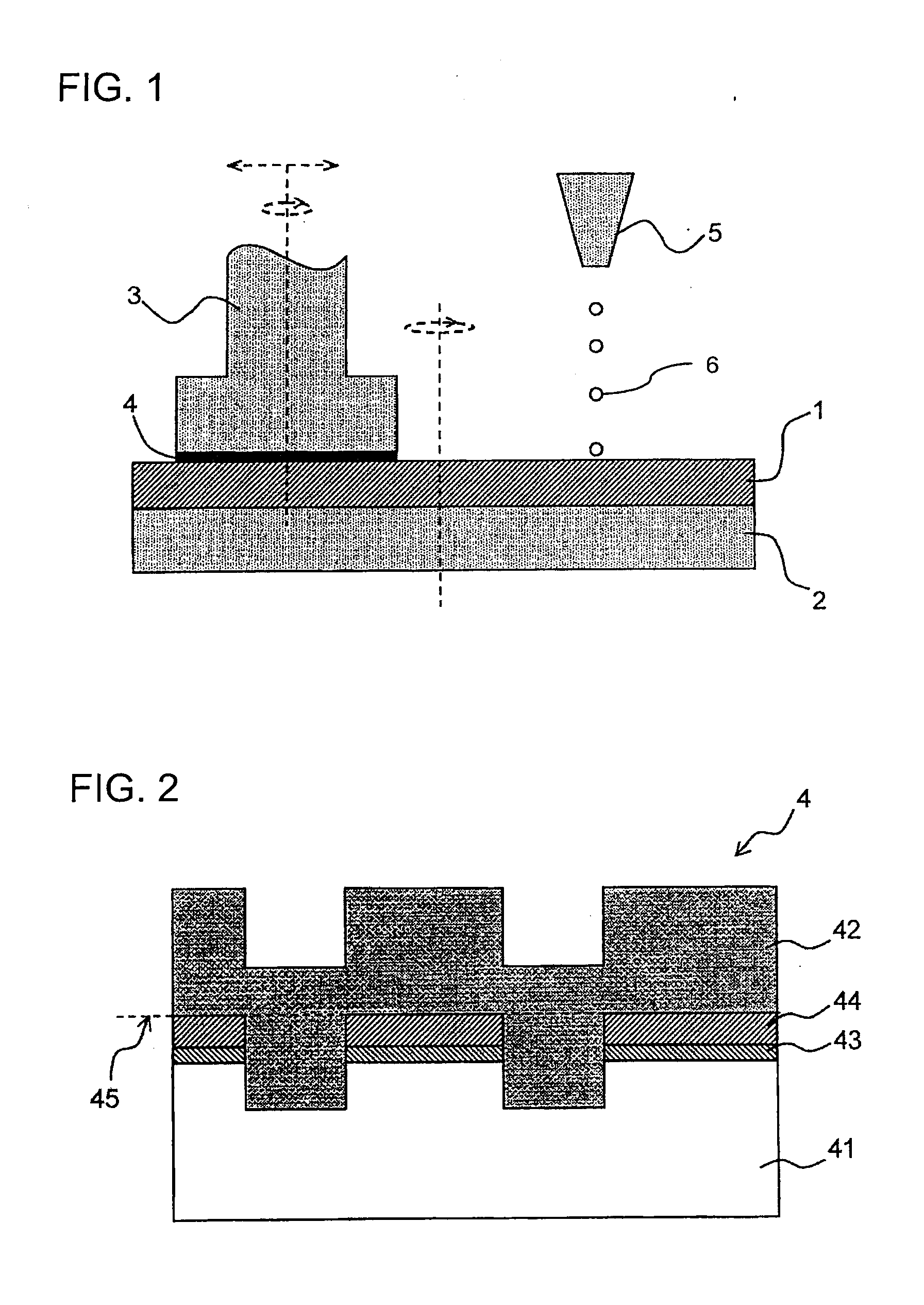

Polishing method

InactiveUS20050074967A1Process controlImprove throughputOther chemical processesSemiconductor/solid-state device manufacturingEngineeringSlurry

A polishing technique wherein scratches, peeling, dishing and erosion are suppressed, a complex cleaning process and slurry supply / processing equipment are not required, and the cost of consumable items such as slurries and polishing pads is reduced A metal film formed on an insulating film comprising a groove is polished with a polishing solution containing an oxidizer and a substance which renders oxides water-soluble, but not containing a polishing abrasive.

Owner:RENESAS ELECTRONICS CORP

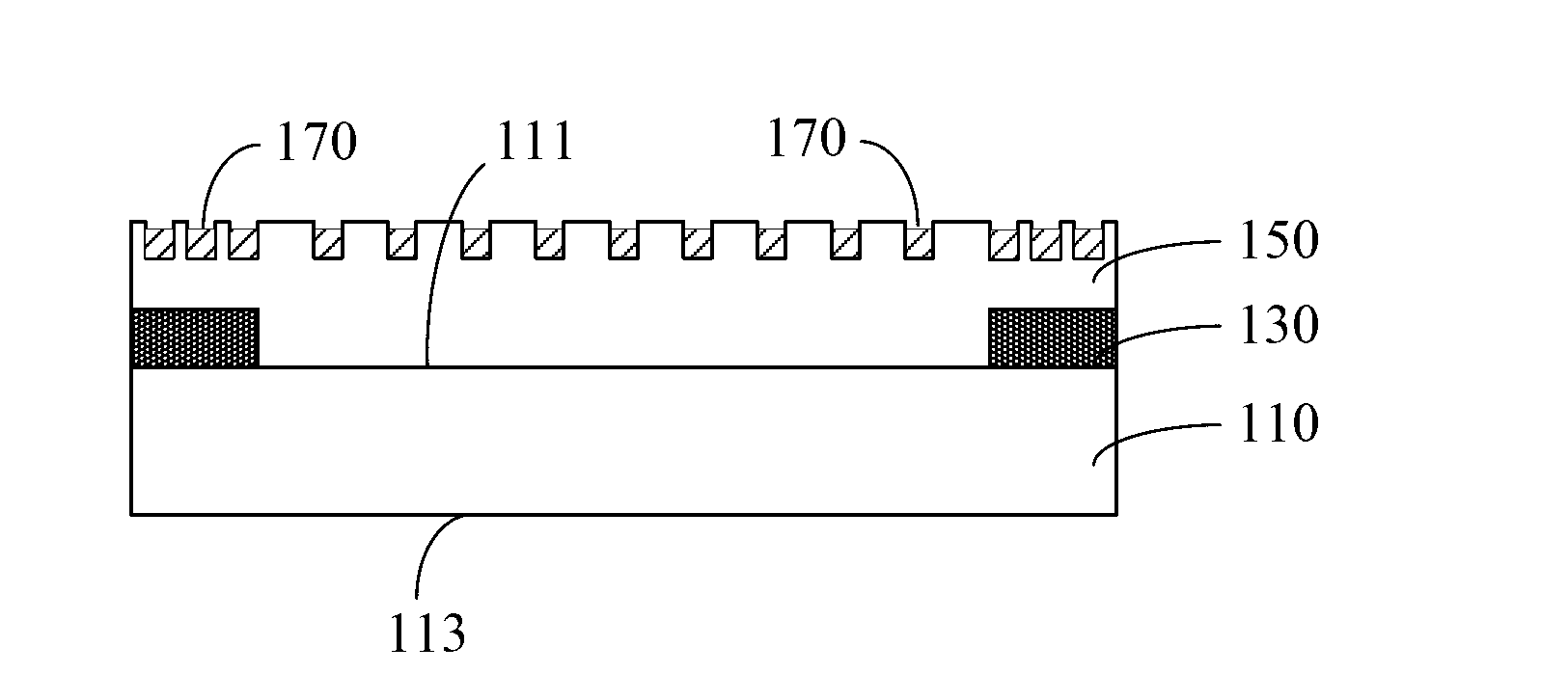

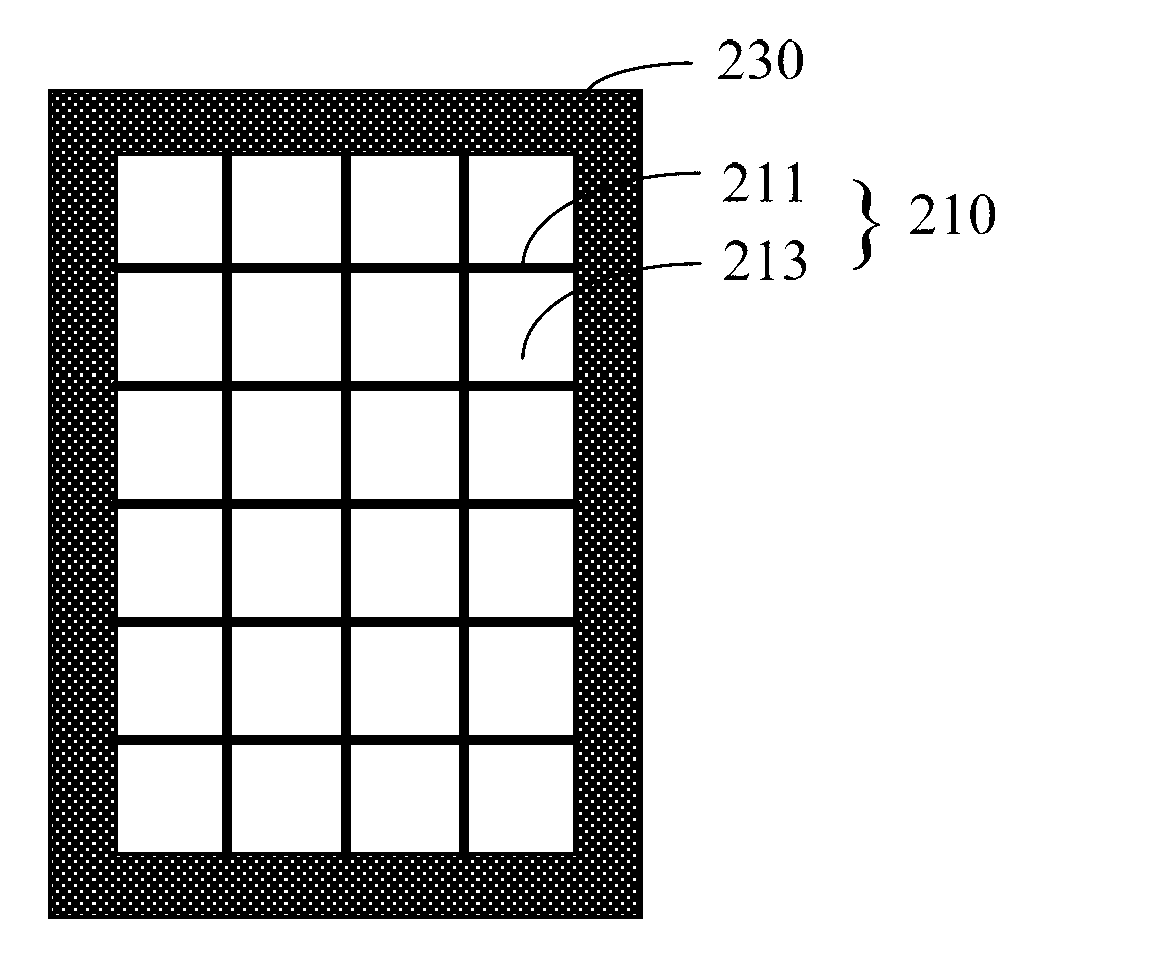

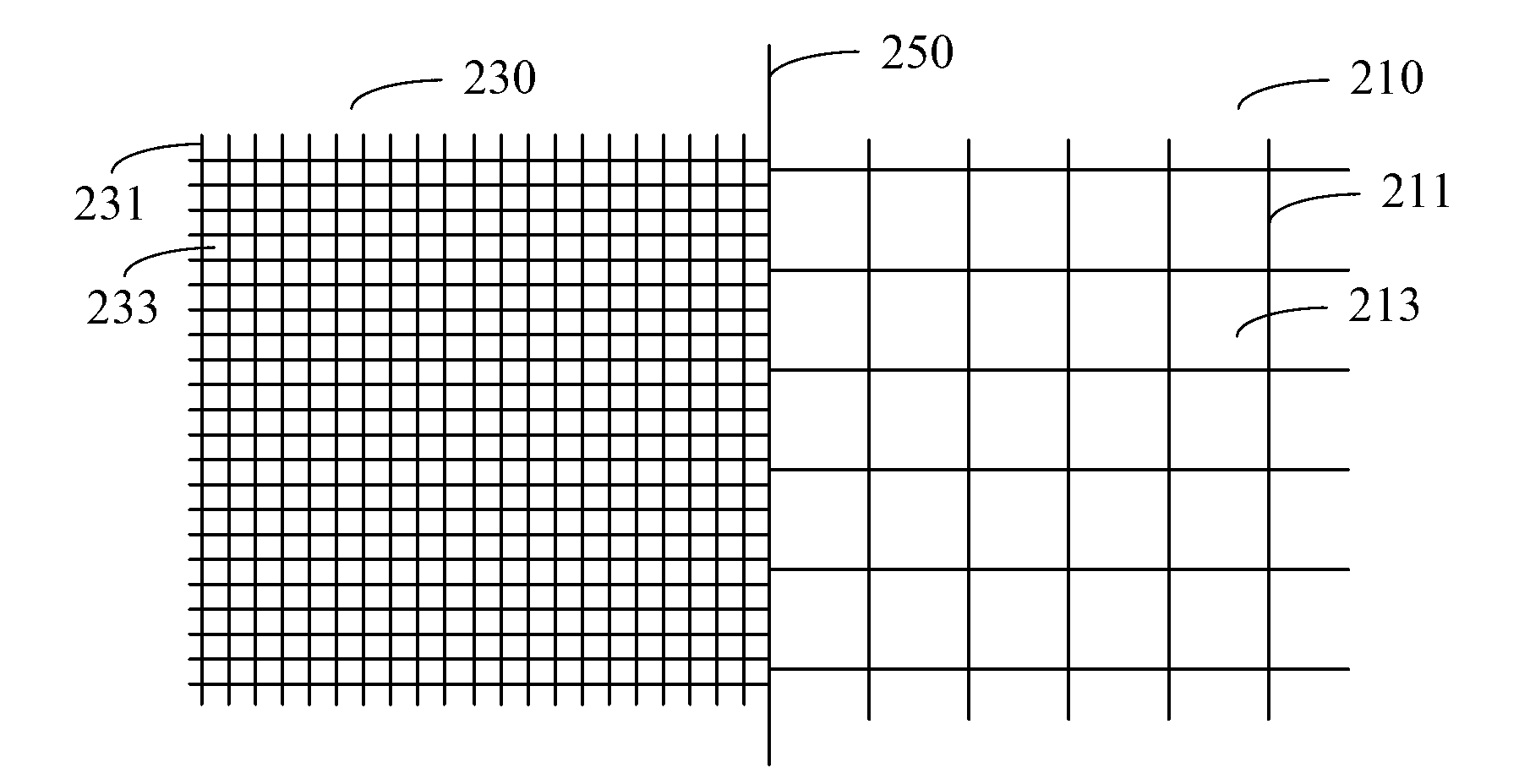

Capacitive touch screen

ActiveCN103164100AReduce scratchesReduce coverage areaInput/output processes for data processingScratchingEngineering

The invention discloses a capacitive touch screen. A conductive groove is arranged in the surface of the touch screen, scratching of conductive materials in the use process of the capacitive touch screen is reduced, due to the groove structure, covering areas of the conductive materials are reduced, resistance is reduced, and production cost is reduced.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Aluminum and aluminum alloy material polishing solution

The invention provides a polishing fluid for aluminum and aluminum alloy materials which includes grinding material, surface active agent, oxidizer, pH regulator, brightener and de-ionized water. The weight percentage of each component is as follows: 10 to 40 percent of grinding material, 0.01 to 0.6 percent of surface active agent, 0.5 to 10 percent of oxidizer, 1 to 6 percent of pH regulator, 1 to 15 percent of brightener and the rest is the de-ionized water; the pH value of the polishing fluid is 8 to 10; the polishing fluid can be used for the surface polishing process on the aluminum and aluminum alloy materials, can effectively reduce the surface scuffing of the aluminum alloy materials after being polished, reduce the surface coarseness of the aluminum alloy materials after being polished and improve the processing quality of the aluminum alloy materials; besides, the polishing fluid has the advantages of fastening the polishing speed, not corrupting the devices, having a high use property, and the like. The polishing fluid can also be used to stop the problems of generating alkaline fog and ammonia gas during the processing process and optimize the working environment.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Chemical mechanical polishing pad

ActiveUS20090209185A1Reduce scratchExcellent durabilityAbrasion apparatusSemiconductor/solid-state device manufacturingChemical-mechanical planarizationEngineering

Owner:JSR CORPORATIOON

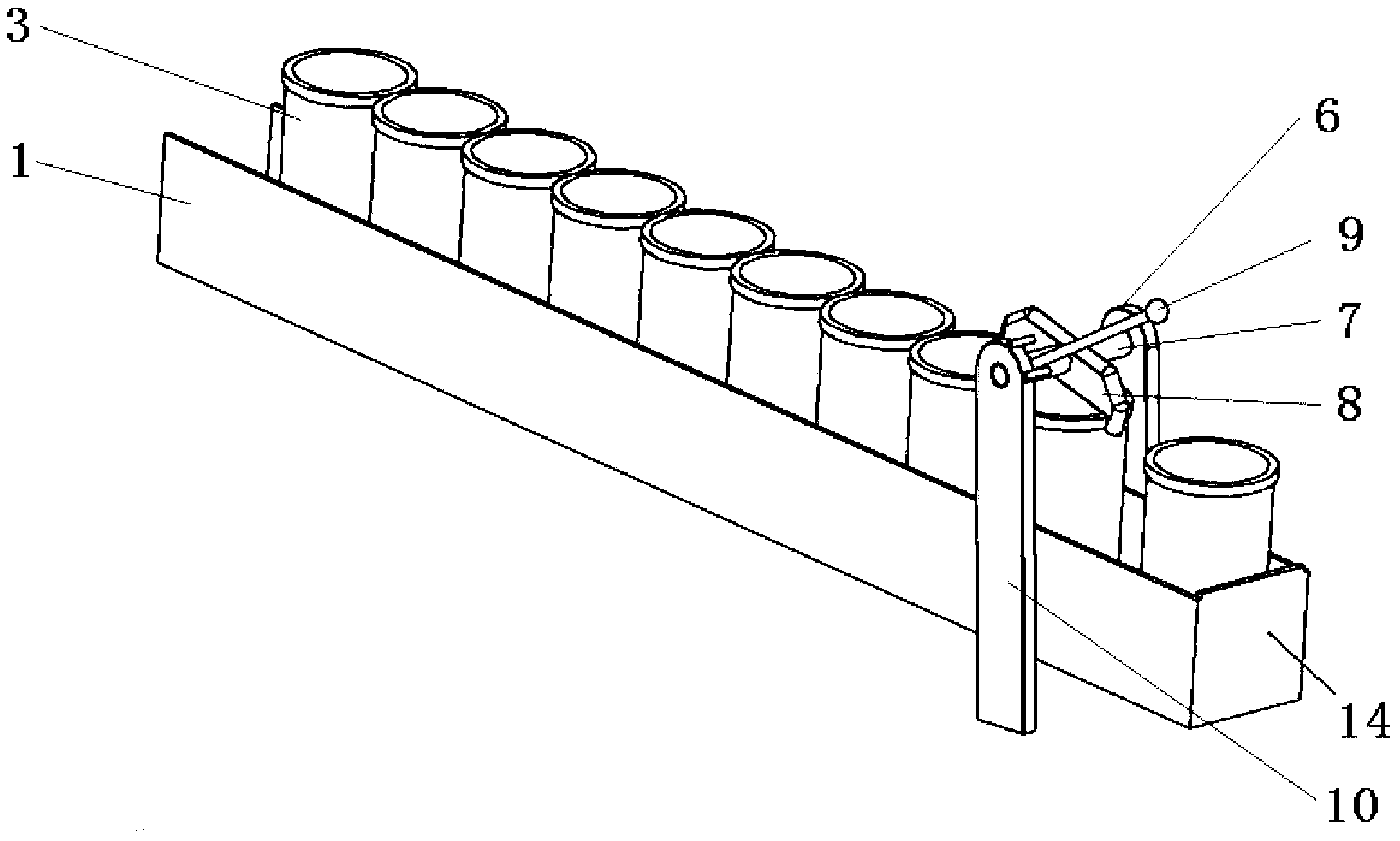

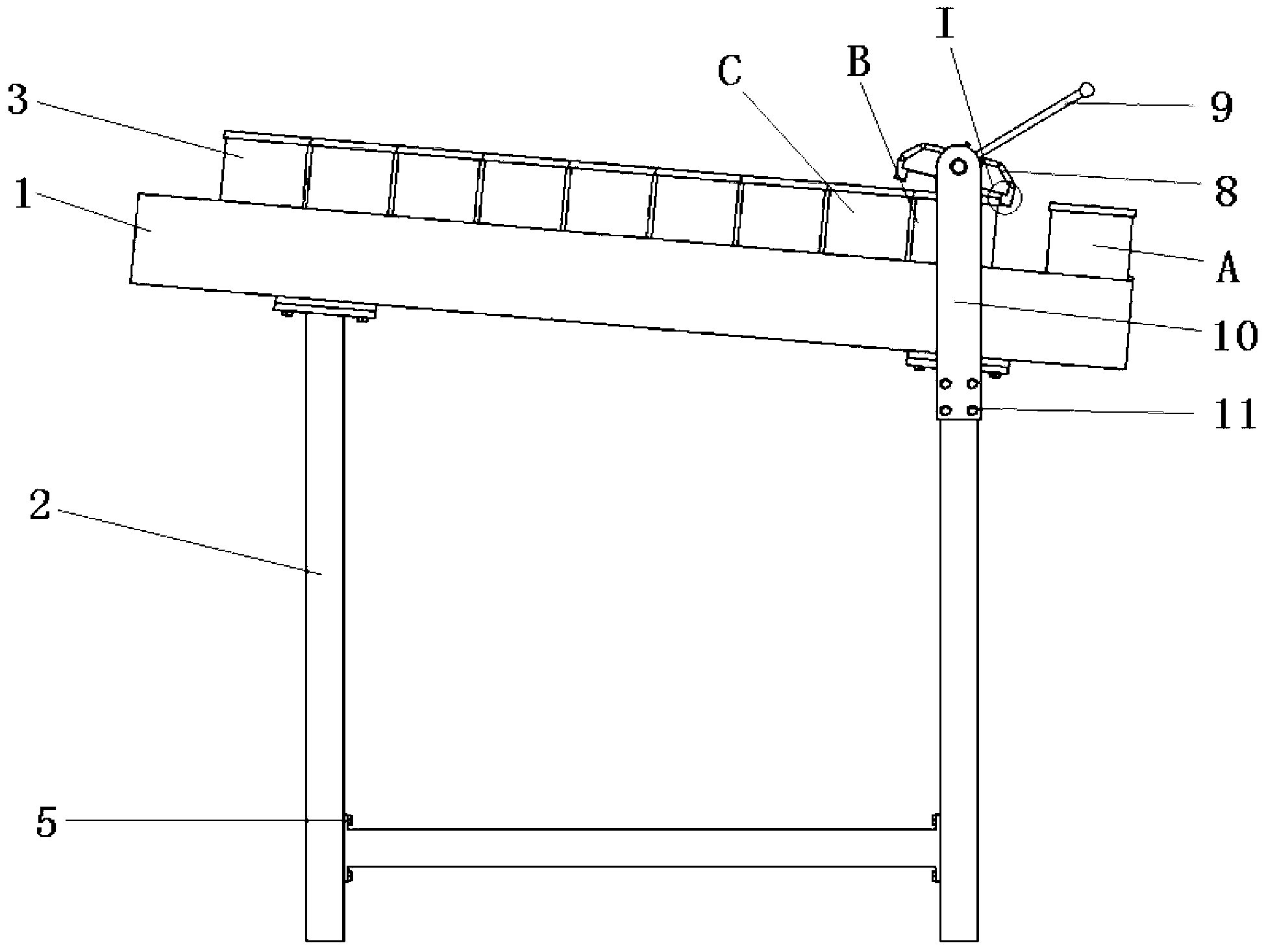

Material loading support with slide

The invention discloses a material loading support with a slide. The material loading support comprises the inclined slide. A baffle for preventing cylindrical material tank sleeves from falling is arranged at a slide terminal. The material loading support further comprises a separating device used for separating the first two cylindrical material tank sleeves of a cylindrical material tank sleeve queue and arranged above the slide. In addition, the slide can be arranged into a slide group. Terminals of slides in the slide group are provided with baffles for preventing cylindrical materials from falling, and separating devices for separating first two cylindrical materials of cylindrical material queues in the slides are arranged above the slide group. By means of the material loading support, a head cylindrical material tank sleeve required to be taken at the head end of the cylindrical material tank sleeve queue can be separated from a second cylindrical material tank sleeve conveniently, and the head cylindrical material tank sleeve is taken conveniently and is labor-saving. During taking of the head cylindrical material tank sleeve, the taken head cylindrical material tank sleeve does not contact the second cylindrical material tank sleeve, and scratch on the surfaces of the cylindrical material tank sleeves is reduced. The material loading support is simple in structure, low in cost and easy to popularize.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

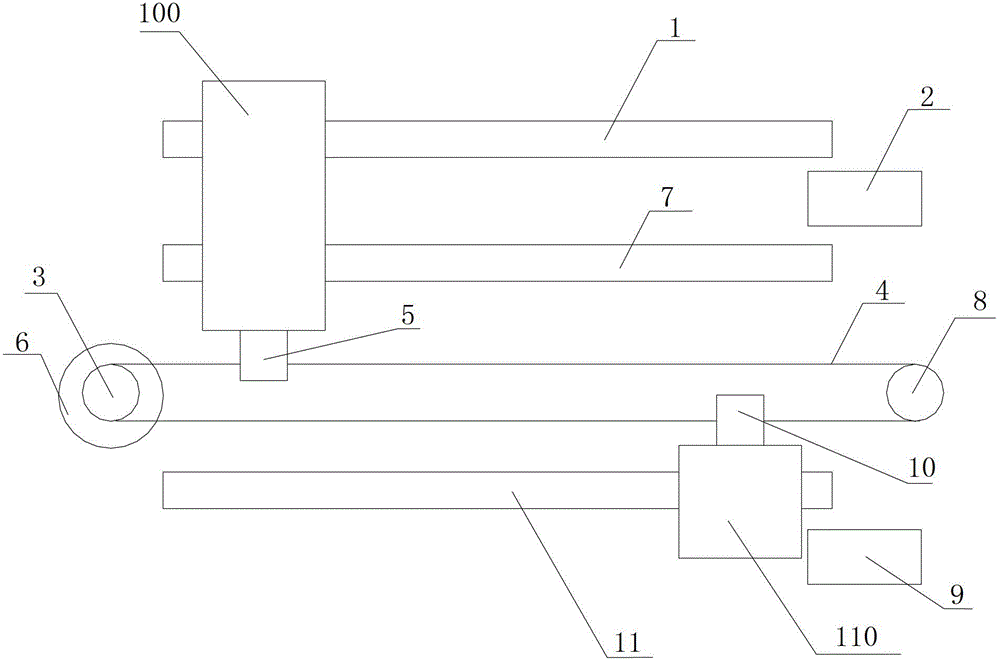

Alternated plate feeding device

InactiveCN102745459ARealize clamping and conveyingCompact structureConveyorsReciprocating motionEngineering

The invention discloses an alternated plate feeding device, which comprises a conveyor belt, at least two plate clamping mechanisms and a slide rail, wherein the conveyor belt comprises a plurality of working sections arranged in parallel, and at least two of all the working sections have opposite conveying directions; the plate clamping mechanisms are fixedly connected to different working sections; and the slide rail is used for bearing reciprocating motion of the plate clamping mechanisms. The alternated plate feeding device does not slip during clamping; and the feeding distance can be conveniently calculated through the conveying distance of the conveyor belt, so that the feeding precision is greatly promoted. In the optimal technical scheme, a first plate clamping mechanism and a second plate clamping mechanism are adopted, so that idle travel is avoided in the feeding process, uninterrupted feeding is realized, and the feeding efficiency is greatly improved; and only one clamping part is required in one feeding stroke, so that the surface of a material is scratched little. The device has the advantages of convenience in control, high feeding precision, little surface scratch, high feeding efficiency and the like.

Owner:ZHEJIANG UNIV

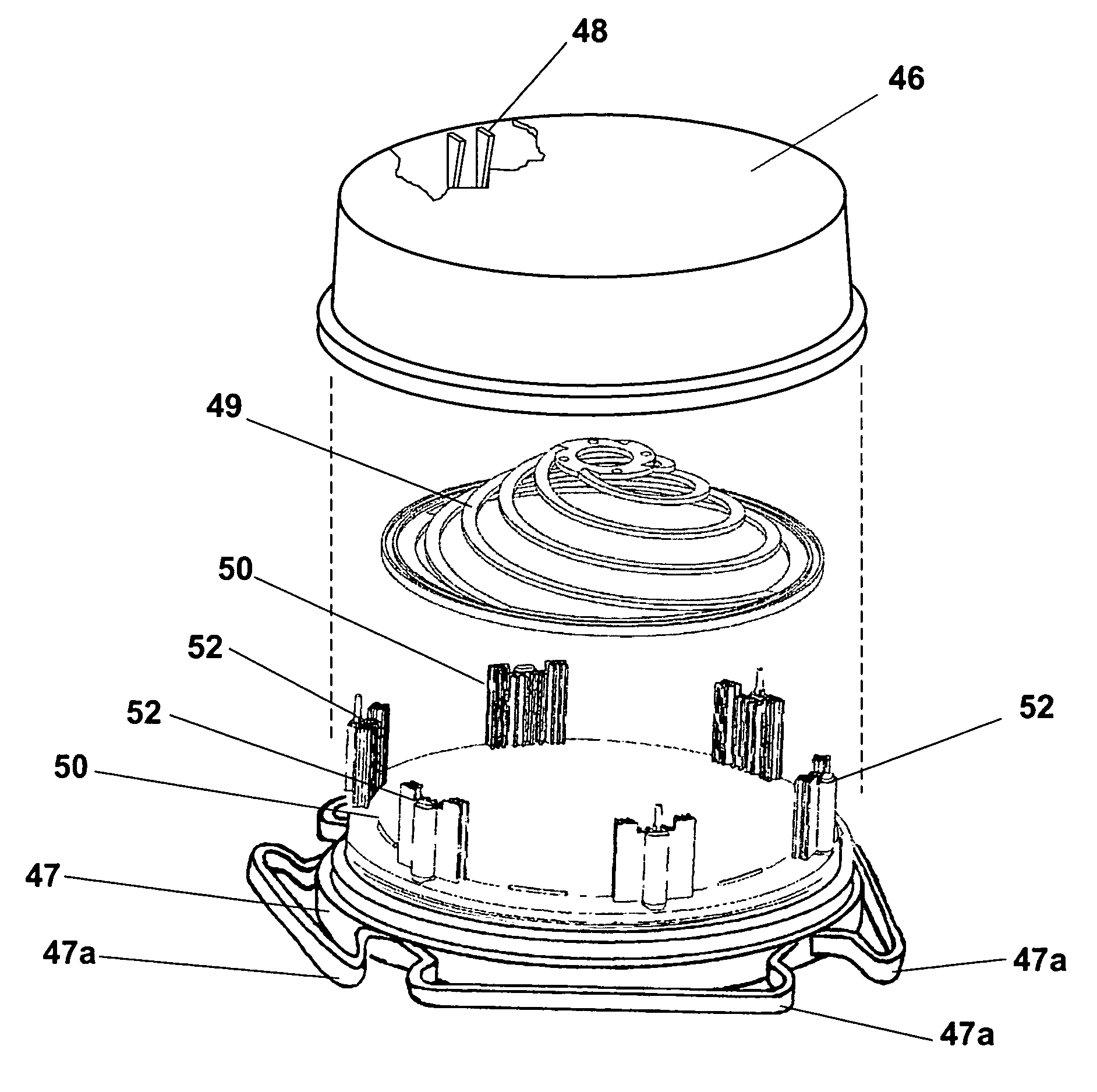

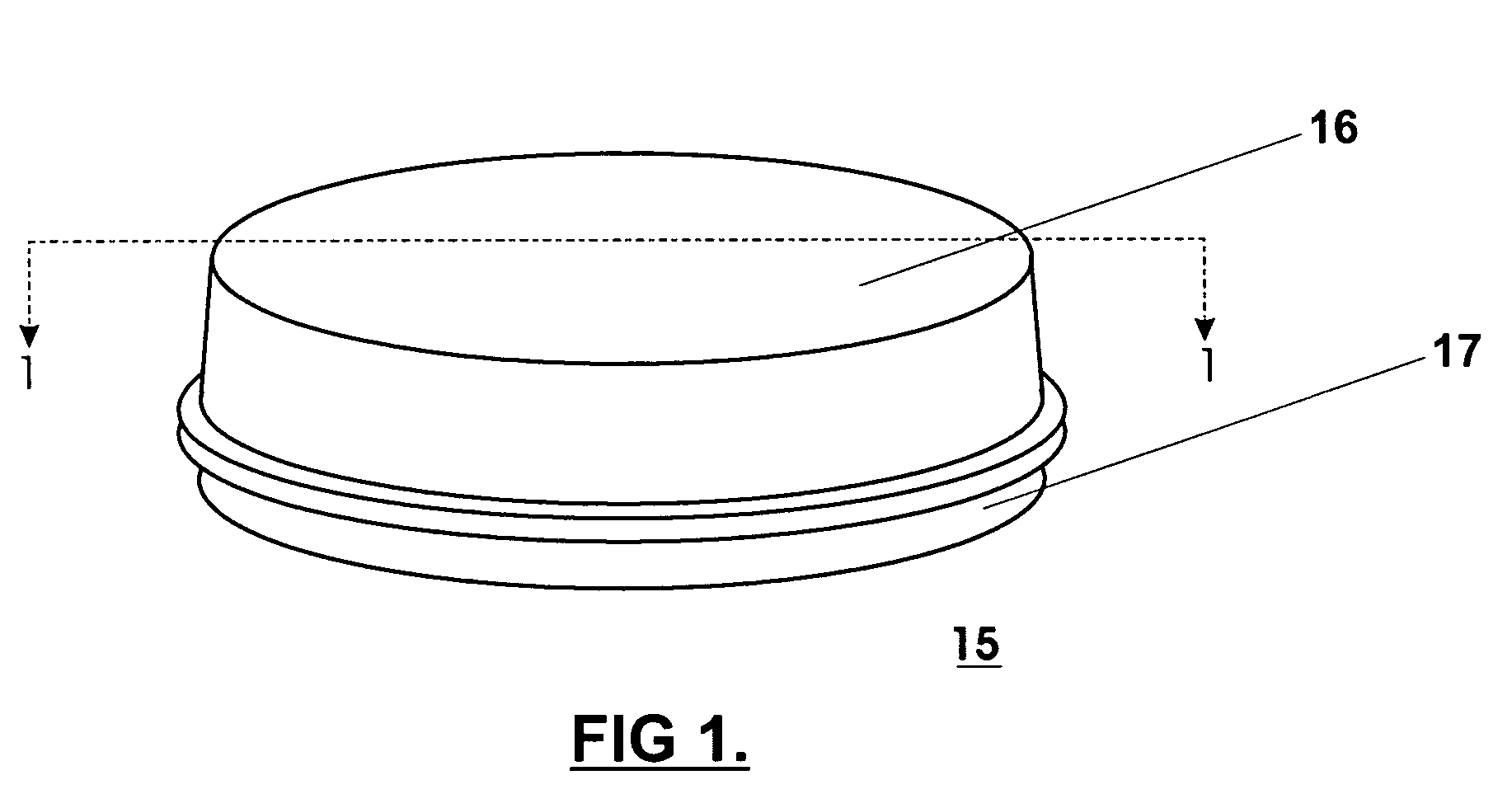

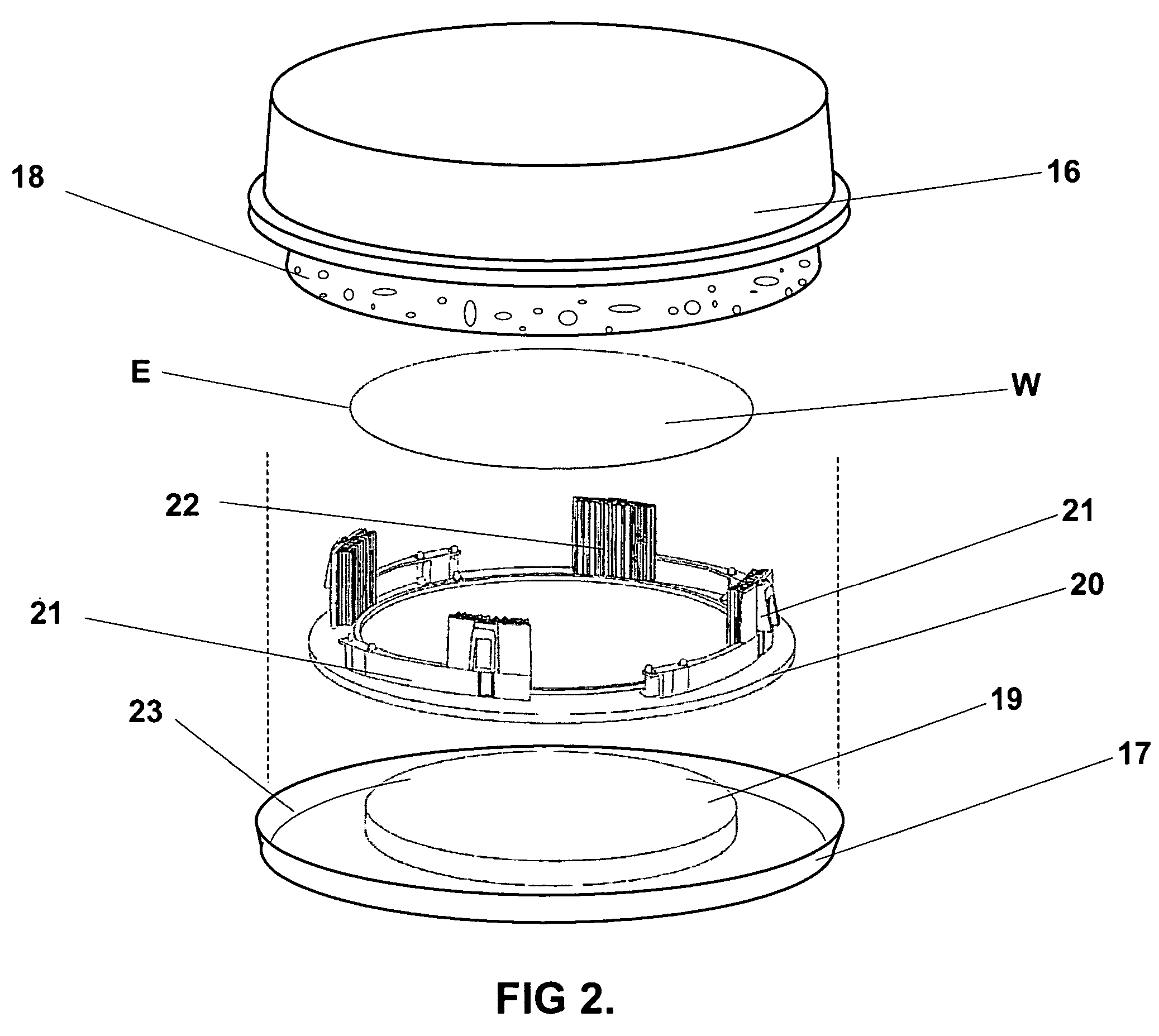

Integrated circuit wafer packaging system and method

InactiveUS7578392B2Reduce yieldReduce scratchesInternal framesSemiconductor/solid-state device manufacturingQuality assuranceMulti method

A packaging system, hereinafter referred to as the Critical Packaging System, relates to critical issues that associate with sensitive articles such as IC wafers before, during and after shipment phases. The system employs a choice of two or more specialty designed containers, and any one selected design having choices of two or more methods by which to avoid, reduce and / or eliminate wafer damage from breakage, scratches and / or corrosion during shipment phases. For the purpose of maximizing product yield during packaging phases a special apparatus is used to insert wafers within containers without scratch damage. The following programs are used in packaging: (1) Quality Assurance / Certification, (2) Critical Factor Monitoring, and (3) a Recycle and Refurbish Program. These programs are specifically designed to achieve new levels of product yields, reduce product cost, and landfill impact.

Owner:CONVEY INC

Chemical mechanical polishing aqueous dispersion, chemical mechanical polishing method, and kit for preparing chemical mechanical polishing aqueous dispersion

ActiveUS20090165395A1Improved yield and productivityPolish rate be decreasePigmenting treatmentOther chemical processesCompound (substance)Materials science

A chemical mechanical polishing aqueous dispersion includes (A) abrasive grains having a pore volume of 0.14 ml / g or more, and (B) a dispersion medium.

Owner:JSR CORPORATIOON

System and method for producing damping polyurethane CMP pads

InactiveUS20090062414A1Simplifying and facilitating overall fabrication processSacrificing foaming characteristicGrinding devicesLapping toolsCarbamateTriol

A solid product formed by polymerizing a urethane prepolymer in the presence of a curative has a Bashore rebound that is less than about 38%. Preferably, the urethane prepolymer is an aliphatic isocyanate polyether prepolymer and the curative includes an aromatic diamine and a triol. To form a microcellular polyurethane material, the urethane prepolymer is frothed with inert gas, in the presence of a surfactant, then cured. The polyurethane can by employed to form highly damping CMP pads that have low rebound and can dissipate irregular energy and stabilize polishing to yield improved uniformity and less dishing.

Owner:PRAXAIR TECH INC

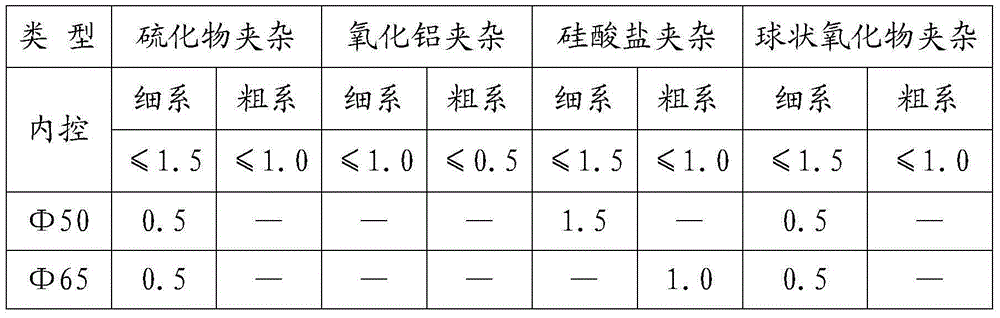

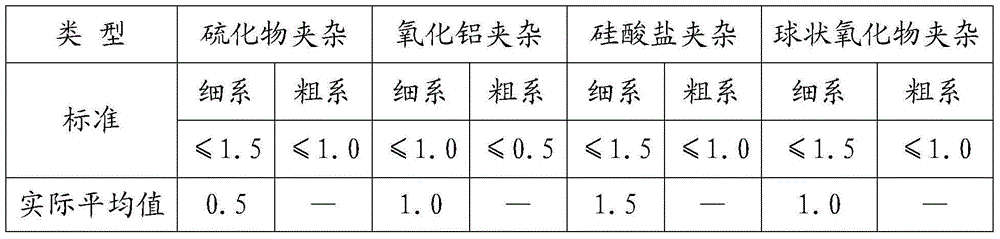

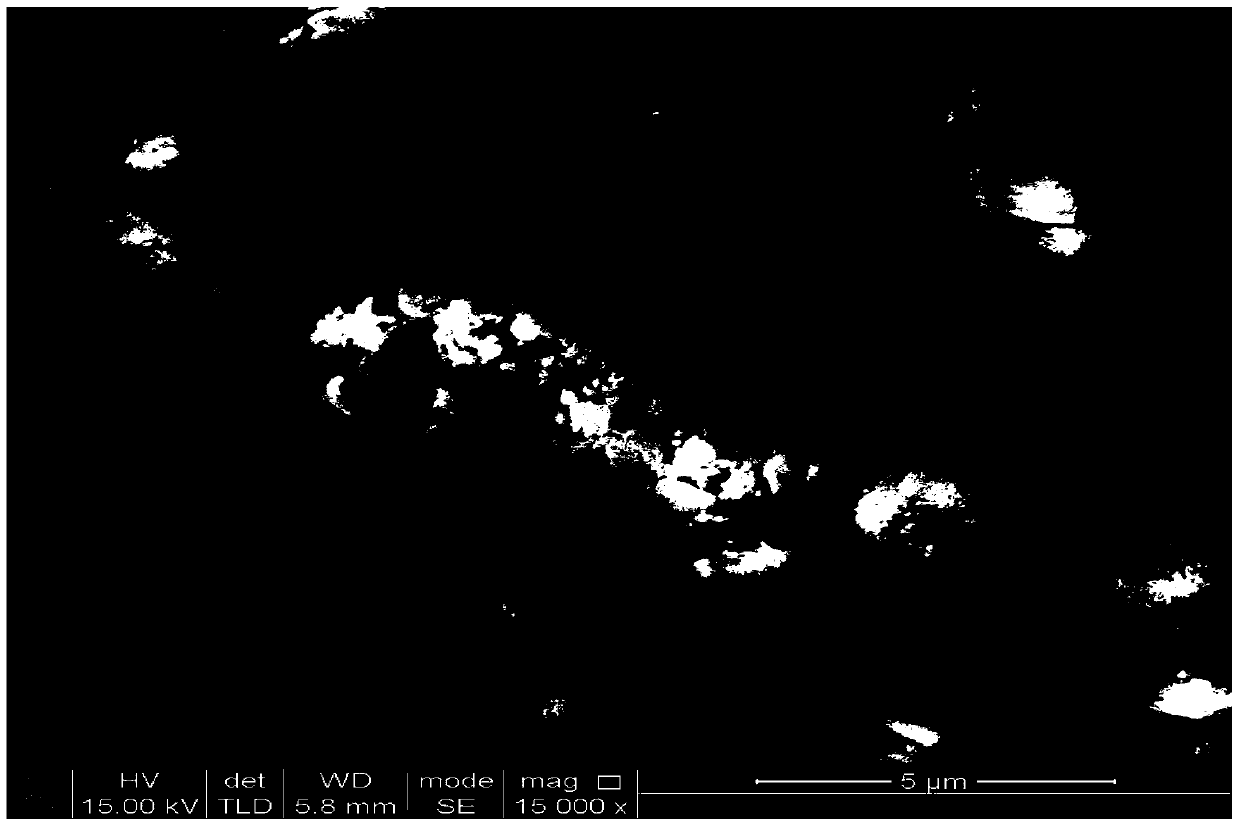

Method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb

InactiveCN105200349AImprove corrosion resistanceReduce hardnessManufacturing convertersProcess efficiency improvementChemical compositionSmelting process

The invention discloses a method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb, wherein the method comprises the following steps: 1) reasonably determining the chemical composition and the inclusion control level of round steel 09CrCuSb; 2) determining the revolving furnace smelting process and N, H and O gas contents; 3) formulating an appropriate continuous casting secondary cooling schedule to make a casting blank keep away from a cracking temperature in a straightening zone, reasonably adopting crystallizer cooling water parameters and vibration negative slip parameters, and controlling casting blank surface cracks; and 4) determining a reasonable heating schedule and a rolling process, choosing low temperature for fast sintering, and reasonably distributing materials, so as to reduce enrichment of Cu elements on the steel surface and avoid the round steel from generating star-shaped cracks; and by controlling the rhythm of steel rolling, avoiding scratches of the round steel surface. By adding alloy elements such as Cr, Cu and Sb, a passivation film is formed on the steel surface; by formulating reasonable smelting, continuous casting and steel rolling processes, the round steel composition is effectively ensured, corrosion resistance can conform to relevant standards and requirements; and through the process, generation of the cracks of the copper-containing steel is avoided.

Owner:TIANJIN IRON & STEEL GRP

Polishing solution containing ceric oxide powder/colloid silicon dioxide mixed abrasive and preparing process thereof

ActiveCN103992743AImprove removal rateImprove surface qualityPolishing compositions with abrasivesSilica particleCerium(IV) oxide

The invention relates to a chemically mechanical polishing solution and a preparation process thereof, and particularly to a polishing solution containing a ceric oxide powder / colloid silicon dioxide mixed abrasive and a preparing process thereof. The polishing solution containing the mixed abrasive is simple in preparing process, practical and prone to production. Raw materials of the polishing solution comprise 3-10% of ceric oxide powder having a particle size of 100-2000 nm, 5-50% of colloid silicon dioxide having a particle size of 10-200 nm, and 0.001-0.5% of a dispersing agent, with the balance being water. The polishing solution is prepared by selecting a container, adding the colloid silicon dioxide solution, adding the ceric oxide powder, stirring uniformly, adding the dispersing agent and the water to the required volume, and stirring uniformly. The ceric oxide powder and the colloid silicon dioxide of different particle sizes are adopted as the abrasive. In the polishing solution, the smaller silicon dioxide particles decrease scratches, pits, and other defects so as to improve the surface quality, and the larger ceric oxide particles obtain a high removing rate.

Owner:杰明纳微电子股份有限公司 +1

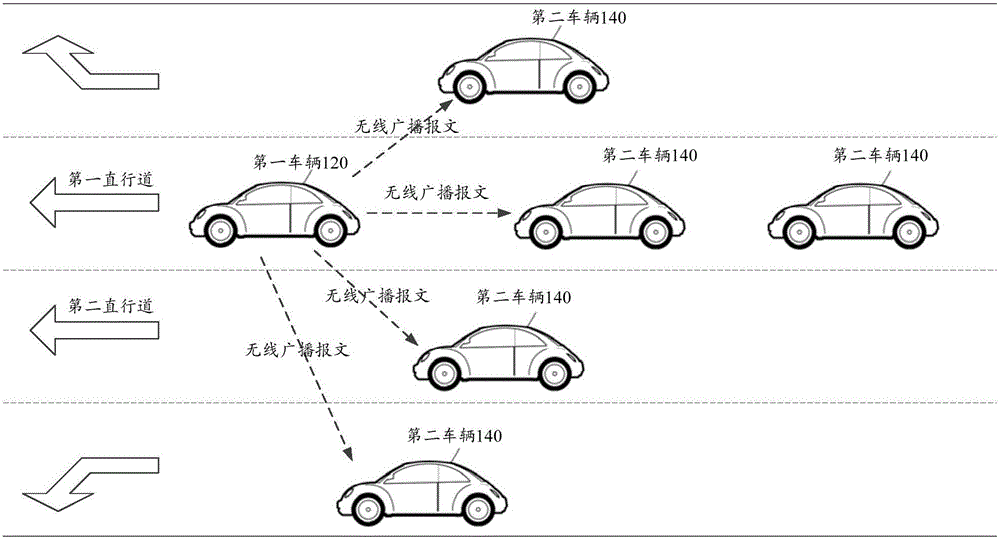

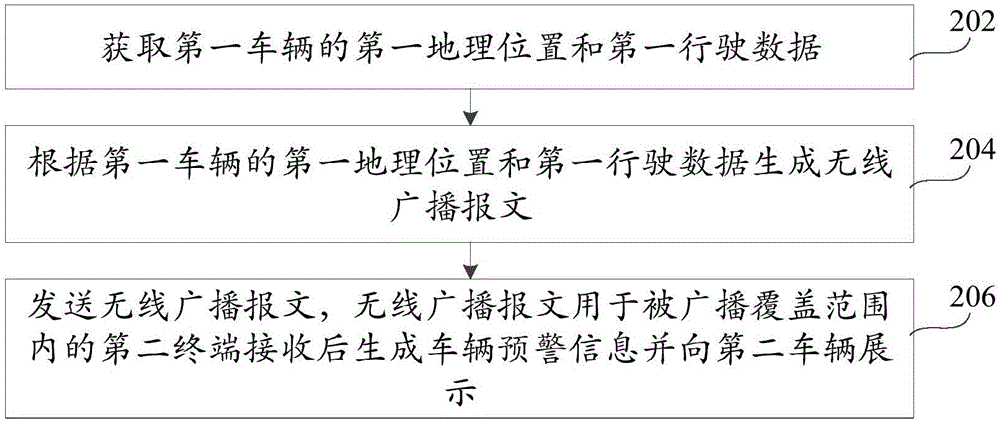

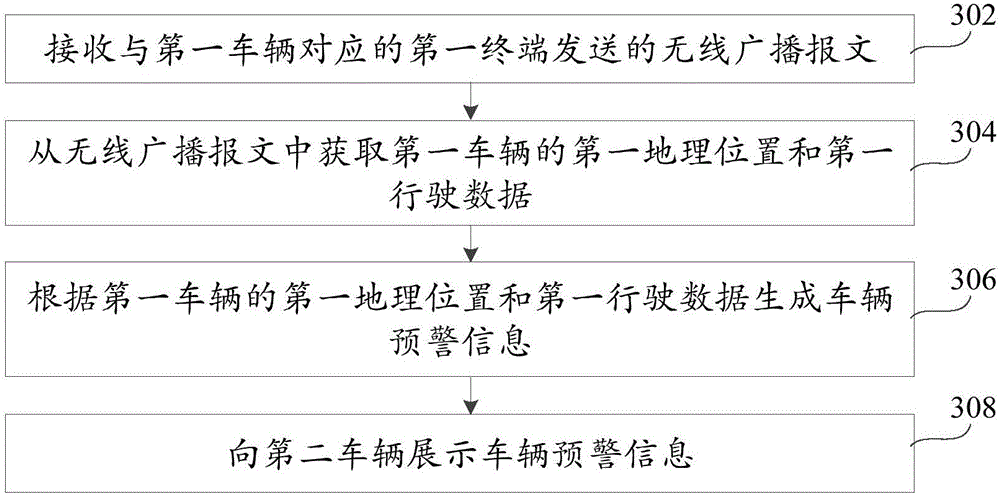

Vehicle communication method, vehicle communication device and vehicle communication system

ActiveCN105788321AKnow driving intentions in timeReduce rear-end collisionRoad vehicles traffic controlTransmissionRear-end collisionDriver/operator

The invention discloses a vehicle communication method, a vehicle communication device and a vehicle communication system, and belongs to the field of intelligent transportation. The method comprises the steps of receiving a wireless radio message sent by a first terminal corresponding to a first vehicle, acquiring a first geographical location and first driving data of the first vehicle in the wireless radio message, generating vehicle warning information according to the first geographical location and the first driving data of the first vehicle, and displaying the vehicle warning information to a second vehicle. The problem that the drivers of vehicles around cannot get the driving intention of the driver of the current vehicle in time under the condition that the driver forgets to use the signal lamps of the vehicle or that the driver has no time to use the signal lamps under emergency or that the vision is poor in a rainy, snowy, frosty or foggy environment or that the signal lamps are damaged is solved. Therefore, the drivers of vehicles around cannot get the driving intention of the driver of the current vehicle in time, and the occurrence of rear-end collision, scratch and accidents is reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

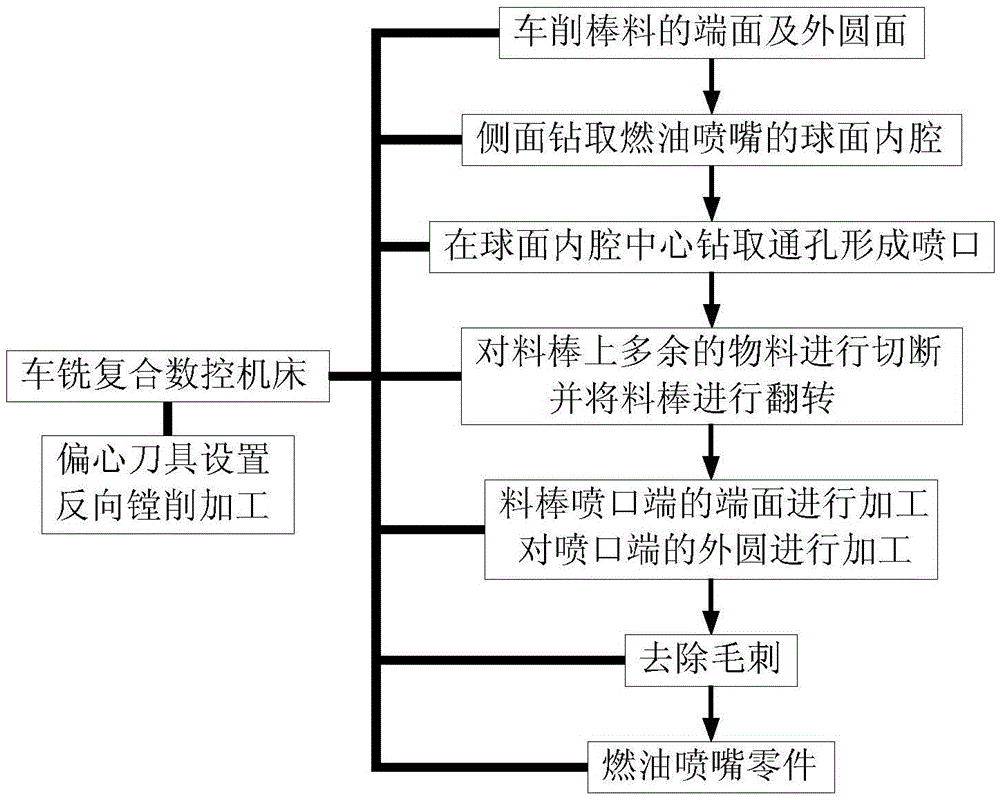

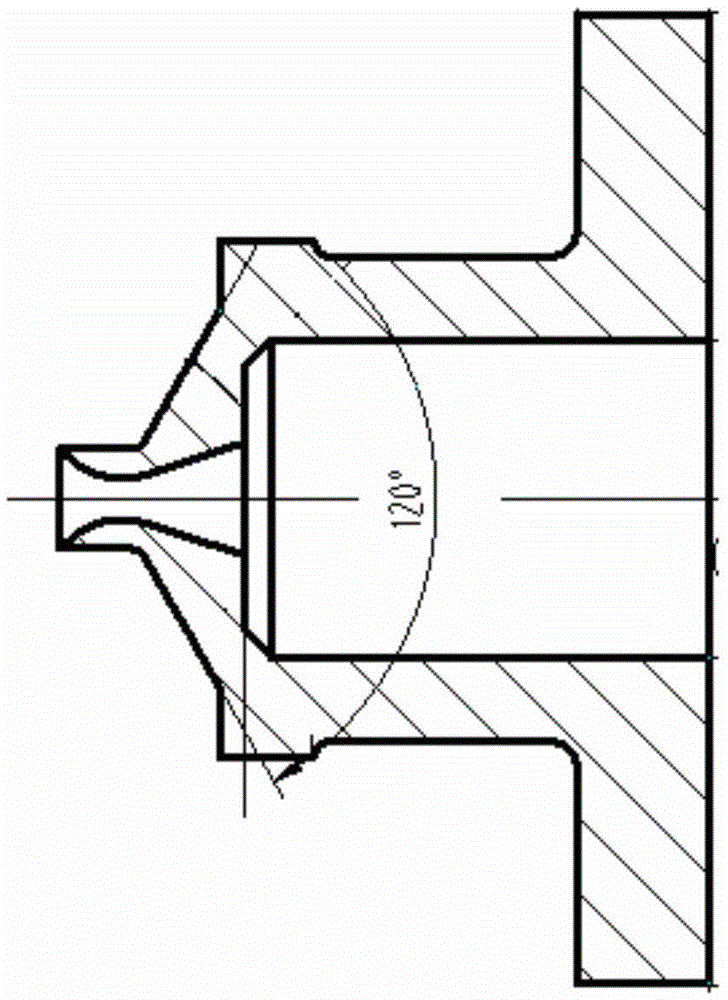

Machining control method for aero-engine fuel nozzle part

ActiveCN105458626AReduce manufacturing costImprove rigidityAircraft componentsTest performanceAviation

The invention discloses a machining control method for an aero-engine fuel nozzle part. A turn-mill combination numerical control machine tool is adopted for carrying out one-time clamping on a bar, and machining in all procedures is carried out; the bar is clamped, the end face and the outer circle face of the bar are turned, a spherical inner cavity of a fuel nozzle is drilled in the side face of the bar, and a through hole is drilled in the center of the spherical inner cavity to form a nozzle; the outer circle face of the machined bar is clamped, residual materials on the bar are cut off, and the bar is turned over; the outer circle face of the turned-over bar is clamped, the end face of the nozzle end of the bar is machined, and the outer circle of the nozzle end is machined; and burrs are removed, and the fuel nozzle part is obtained. The rigidity of a tool is increased through the eccentric structure of the tool, and the cost of the tool is reduced. The reverse boring technology is adopted, chip discharging is facilitated, pulling and scratching caused by scrap iron to an oil spray hole are reduced, and it is guaranteed that the flow test performance parameters of the nozzle are qualified. The machining control method is suitable for machining control over nozzle parts of various aero-engines and auxiliary power device engines.

Owner:CHINA HANGFA SOUTH IND CO LTD

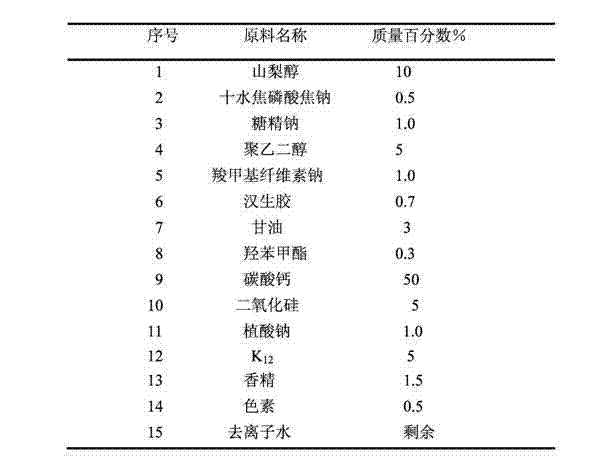

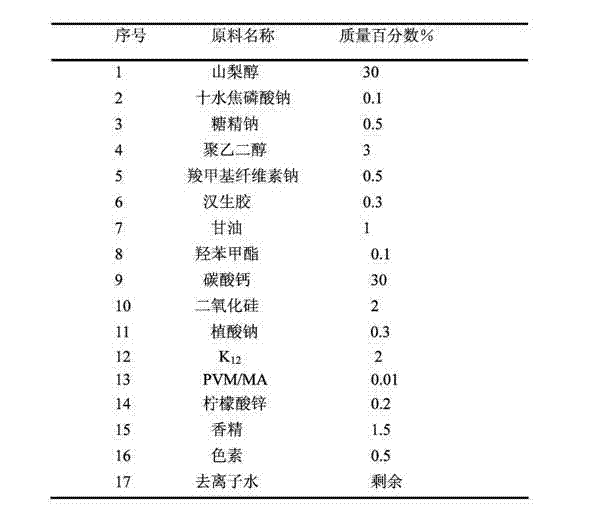

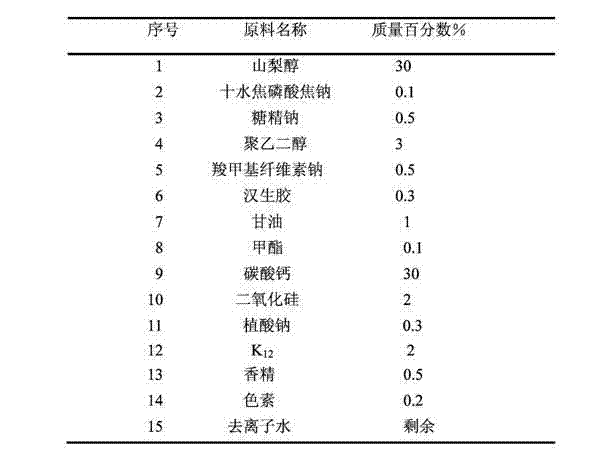

Whitening toothpaste suitable for evening and combined whitening toothpaste suitable for morning and evening

ActiveCN102512335AReduces tooth enamel scratchesImprove whitening effectCosmetic preparationsToilet preparationsMoisturizerToothpaste

The invention discloses whitening toothpaste suitable for evening and combined whitening toothpaste suitable for morning and evening. The combined whitening toothpaste suitable for the morning and the evening is composed of whitening toothpaste suitable for morning and the whitening toothpaste suitable for the evening; and the toothpaste suitable for cleaning in the evening comprises a moisturizer, a rubbing agent, a thickening agent, pyrophosphate, phytate, a poly(vinyl methylether) / malaic anhydride copolymer and zinc citrate. According to different oral cavity environments in the morning and the evening, different antibacterial factors are added; and an organic decontamination agent of the phytate is added into the toothpaste suitable for the morning and composite active factors of PVM / MA (Poly(Vinyl Methylether) / Malaic Anhydride) and the zinc citrate are added into the toothpaste suitable for the evening, so as to achieve the effects of simultaneously resisting bacteria, removing dental plaques and whitening at day and night. Meanwhile, silicon dioxide is prepared to replace one part of calcium carbonate, so that the scratches of tooth enamels, caused by the rubbing agent, are reduced while the effects of decontaminating and whitening are achieved.

Owner:广州舒客实业有限公司

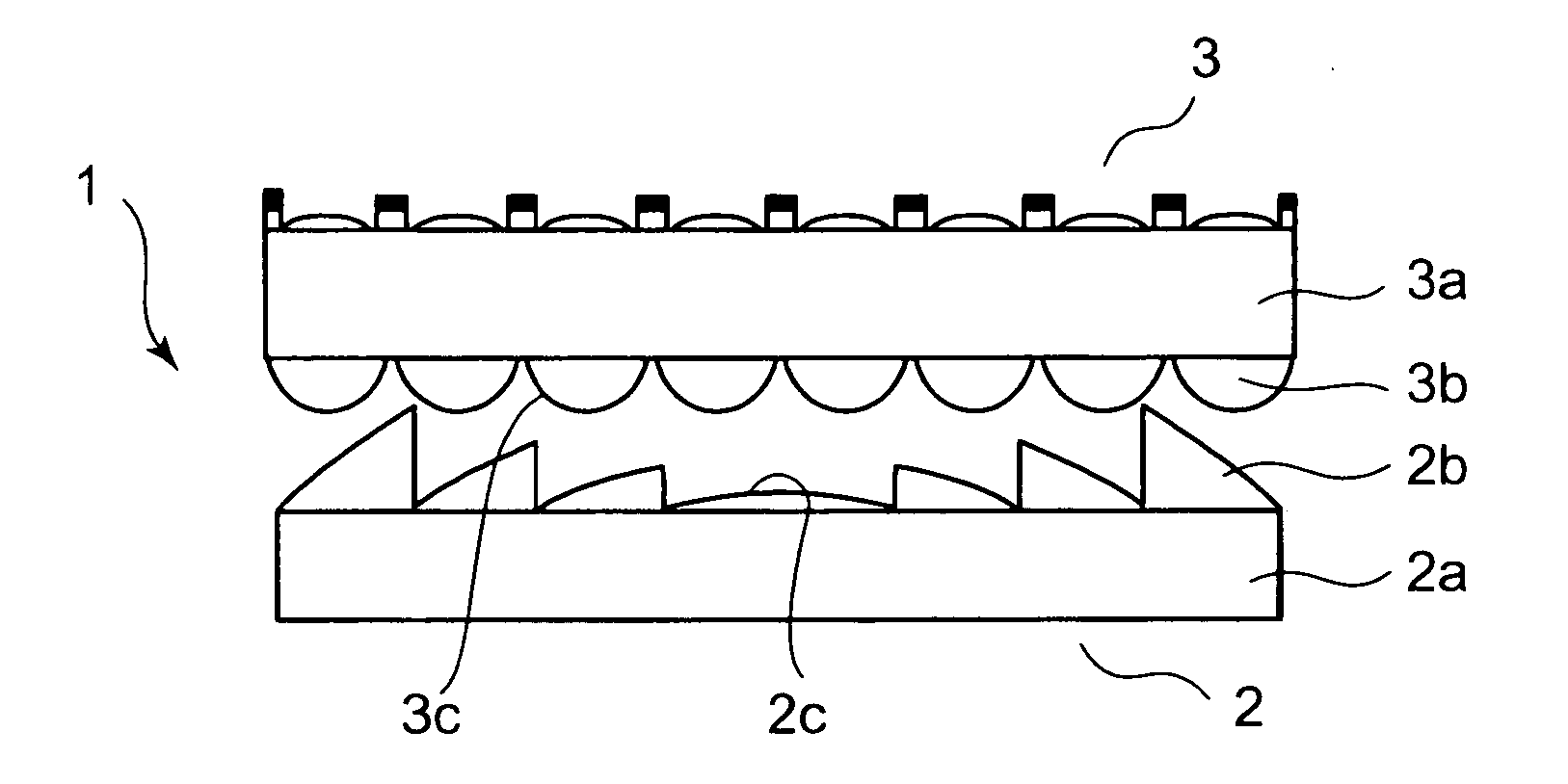

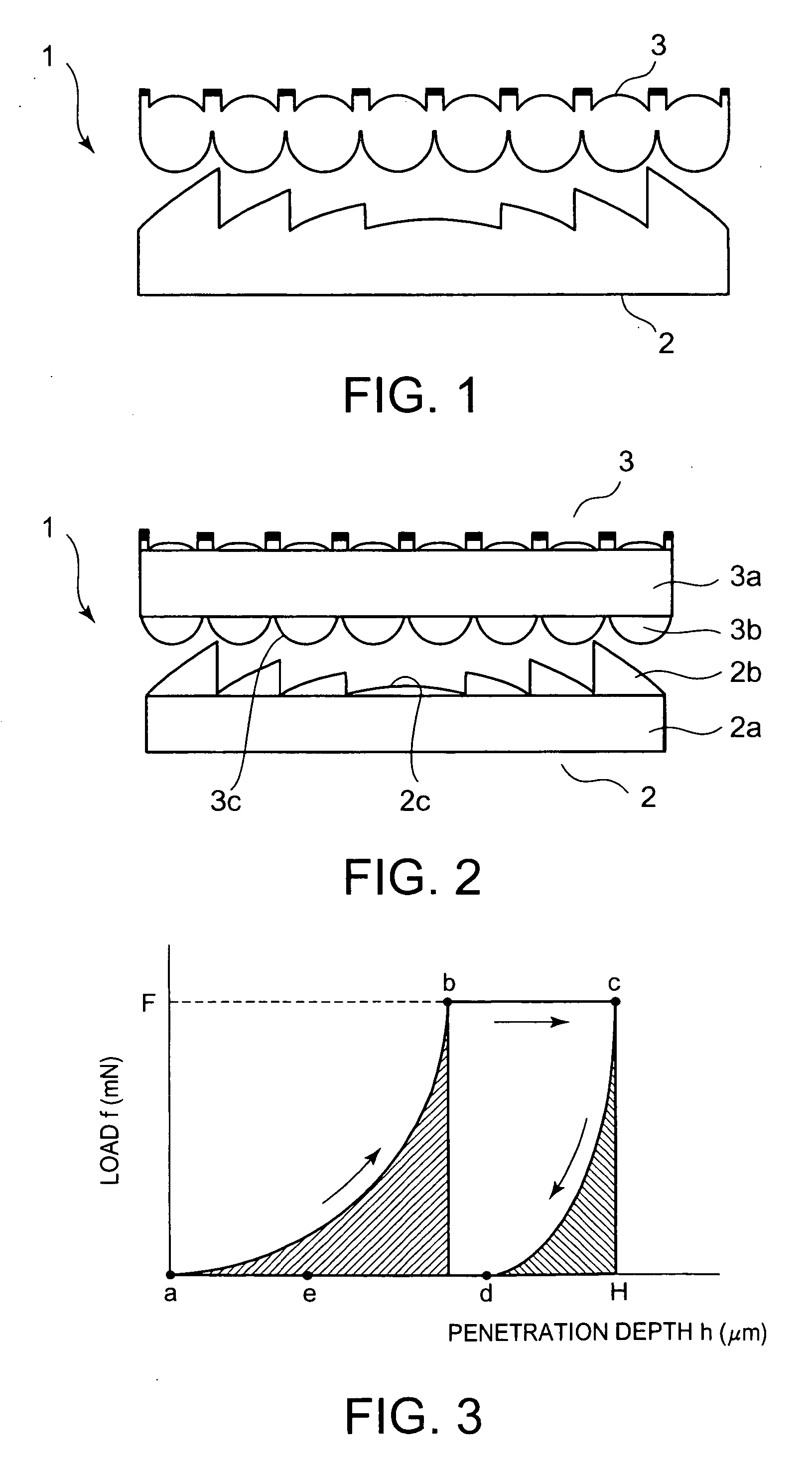

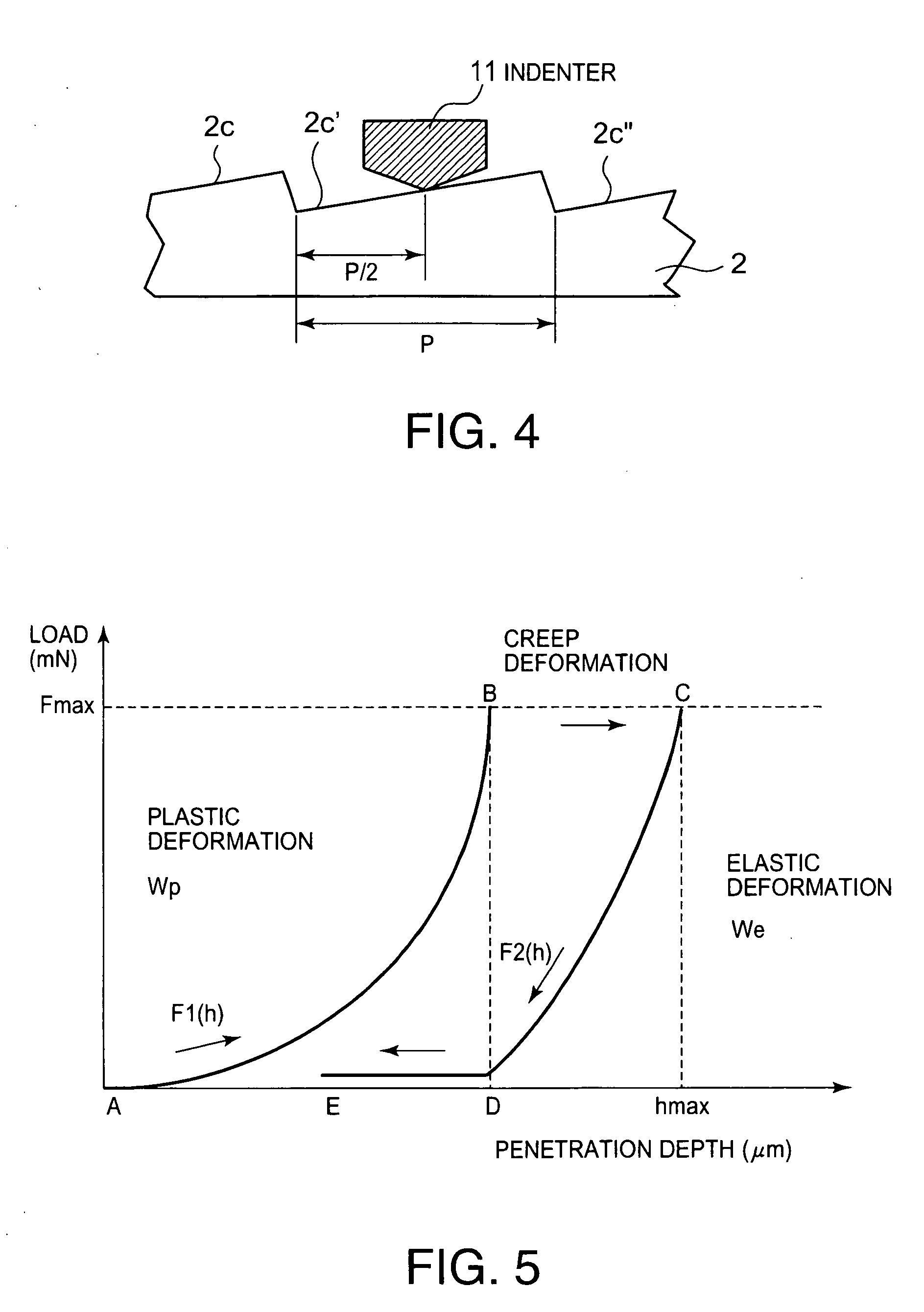

Lens sheet for screen

ActiveUS20060187545A1Trend downImprove dimensional stabilitySynthetic resin layered productsProjectorsHardnessPhysics

There are provided a lens sheet for a screen, which is highly stable by virtue of a reduced tendency toward warping, lifting and the like of the lens caused by external humidity and, at the same time, has a suppressed tendency toward friction between lenses during transport as a screen, and a resin composition for constituting the lens sheet. The lens sheet is used in combination with other lens sheet and comprises one or at least two layers. When the layer in contact with the above other lens is formed of a thermoplastic resin, the universal hardness of the thermoplastic resin composition is brought to a range of 31.0 to 42.0 N / mm2.

Owner:DAI NIPPON PRINTING CO LTD

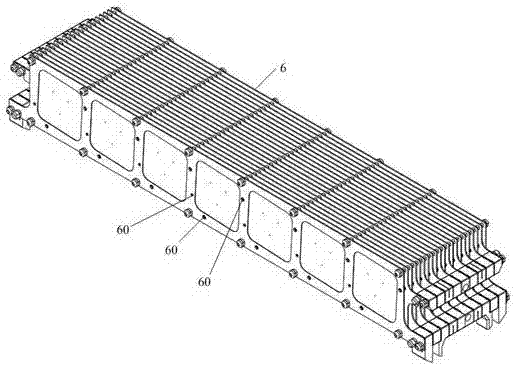

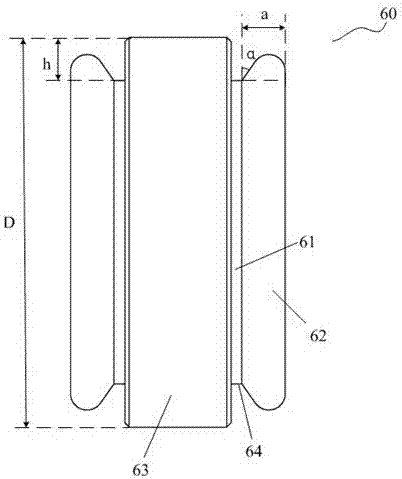

Coating equipment and method for tube-type PERC solar cells

ActiveCN107287579AReduce depthReduce gap sizeFinal product manufactureChemical vapor deposition coatingSilanesSolar cell

The invention discloses coating equipment for tube-type PERC solar cells. The coating equipment comprises a wafer loading region, a furnace body, a gas cabinet, a vacuum system, a heating system, a control system and a graphite boat; the gas cabinet is provided with a first gas pipeline for introducing silane, a second gas pipeline for introducing ammonia, a third gas pipeline for introducing trimethylaluminum, a fourth gas pipeline for introducing laughing gas and a fifth gas pipeline for introducing methane; the graphite boat is used for loading or unloading a silicon wafer; before being used or after being coated many times, the graphite boat needs to be subjected to pretreatment comprising the steps: drying the graphite boat; and coating at least one layer of silicon carbide film on the surface of the dried graphite boat. Correspondingly, the invention further discloses a coating method for tube-type PERC solar cells. By using the coating equipment and method, the pretreatment step of the graphite boat is simplified, the consumption of the silicon wafer is reduced, the silicon wafer is prevented from being scratched, and the EL yield of the cells is increased.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +1

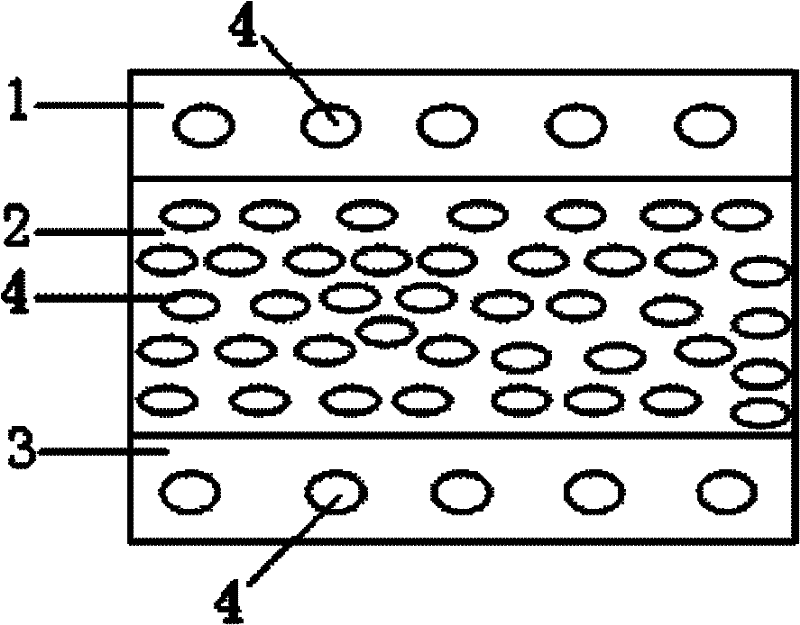

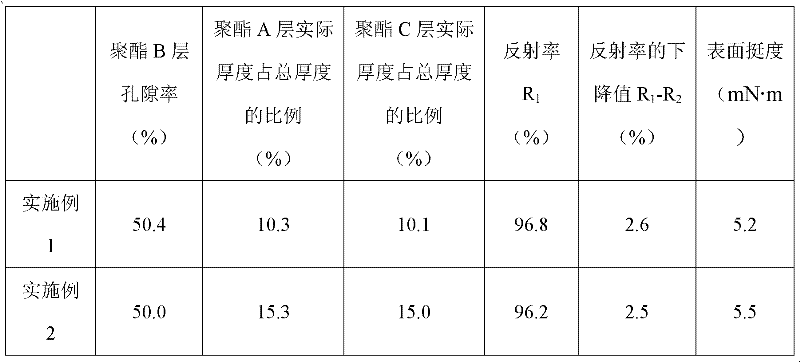

High-reflection and high-stiffness light reflecting film

The invention discloses a high-reflection and high-stiffness light reflecting film which comprises a pore-containing polyester layer B, wherein at least one polyester layer A and at least one polyester layer C are also respectively arranged at two sides of the polyester layer B, and the porosity of the polyester layer B is 50-80%; pores are arranged at inner parts of both the polyester layer A and the polyester layer C, and the porosities of the polyester layer A and the polyester layer C are respectively 5-20%; and the thicknesses of the polyester layer A and the polyester layer C are respectively 10-25% of the total thickness of the reflecting film. In the invention, high stiffness is obtained while high reflection of the reflecting film is realized through adjusting the pore content and the thickness of respective structural layers of the reflecting film, and the high stiffness and the high reflection are beneficial to using and processing in the later period. In the invention, as the high stiffness is obtained while high reflection of the reflecting film is realized, scratches and crease loss of the reflecting film in the processing process are reduced, the processing yield of the reflecting film is increased, the assembly difficulty of a backlight source is reduced, and the production efficiency is increased; and the invention is suitable for a reflecting film.

Owner:WUHAN KINGBULL ECONOMIC DEV

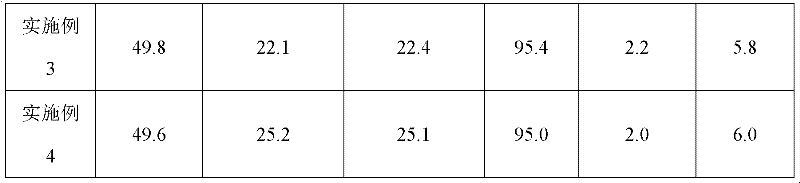

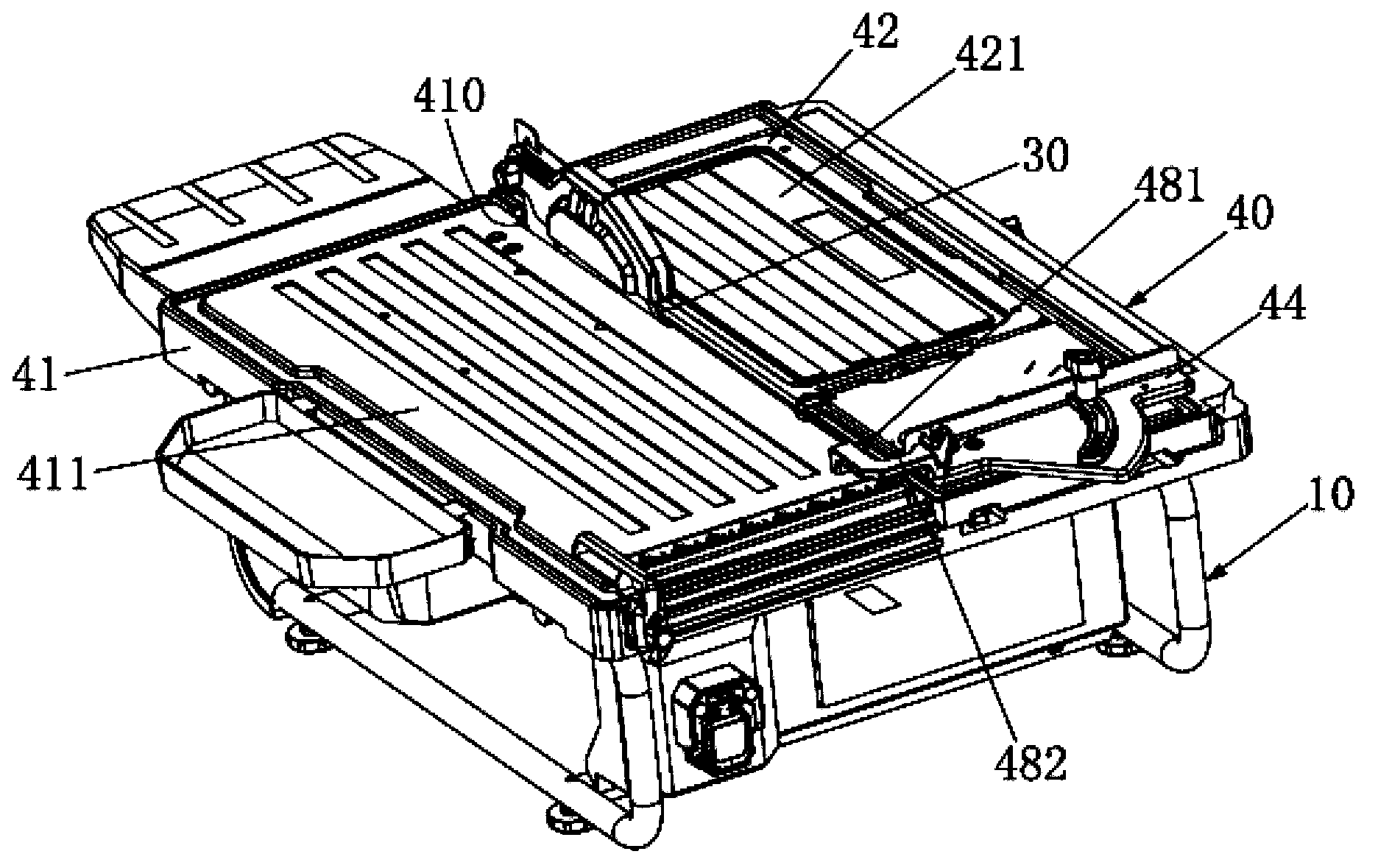

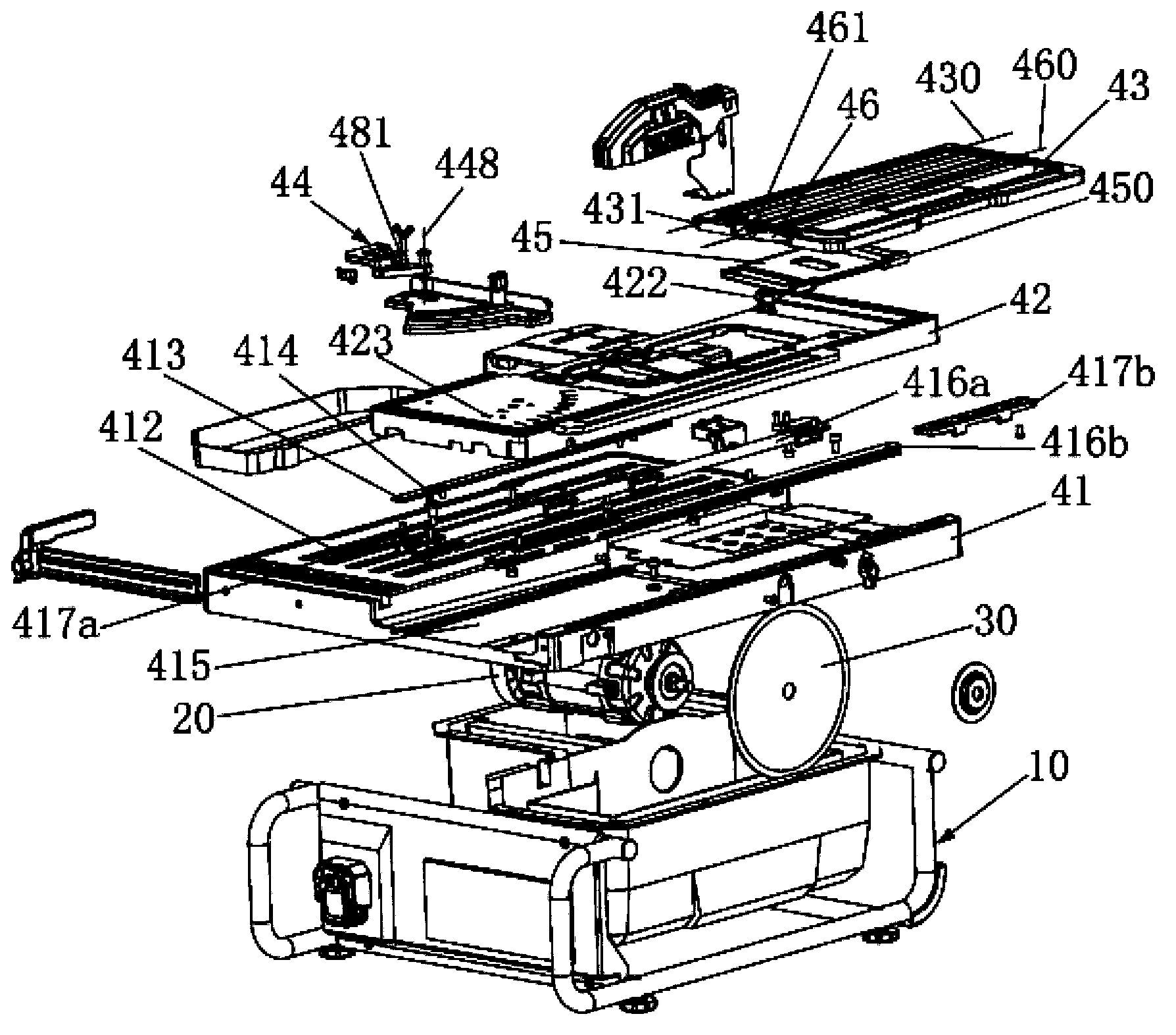

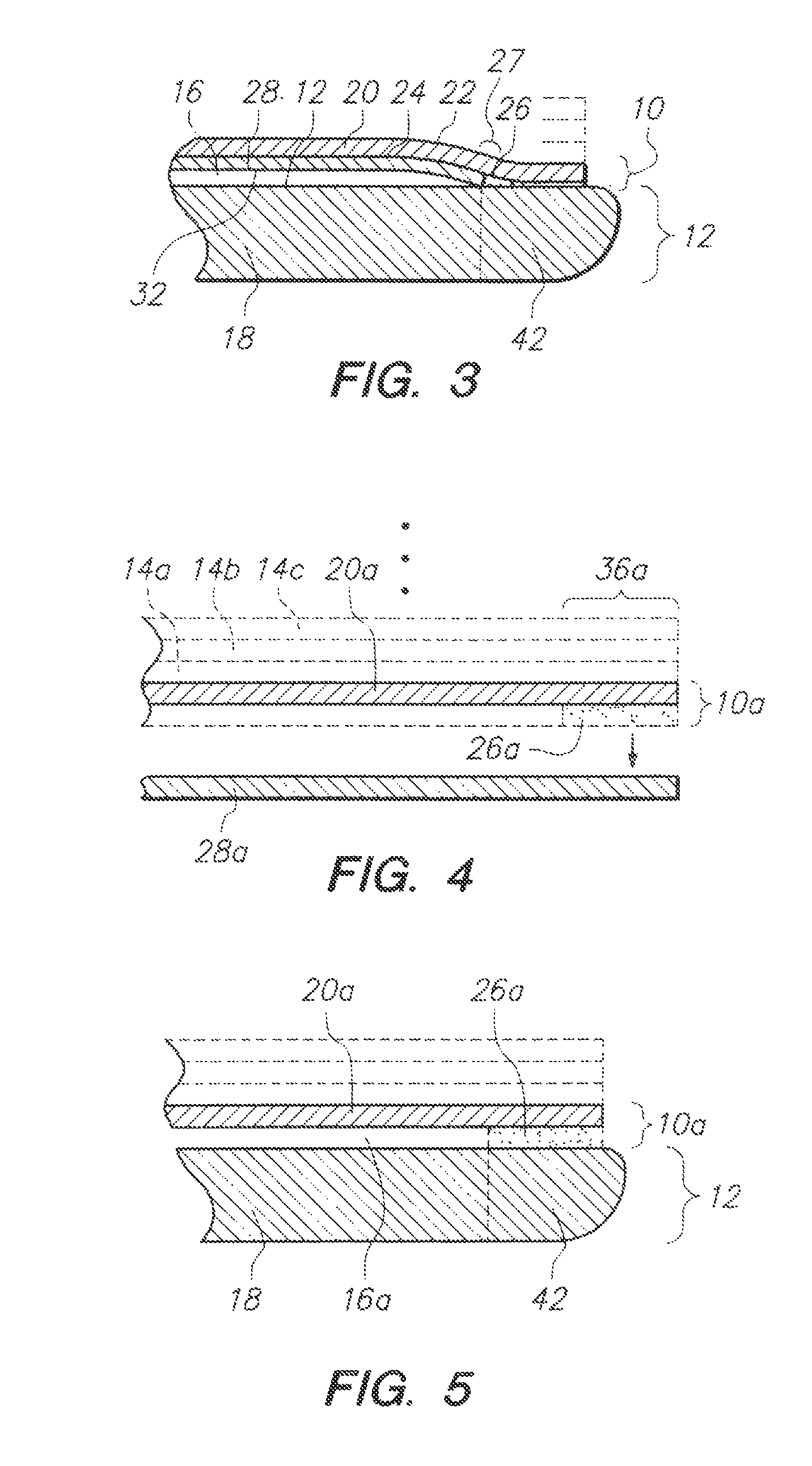

Stone cutter

ActiveCN104275749AReduce scratchesImprove straightnessWorking accessoriesStone-like material working toolsSTONE CUTTEREngineering

A tile cutting machine comprises a base, a motor accommodated in the base, a blade driven to rotate by the motor, and a working table supported on the base, wherein the working table comprises a fixed working table fixedly mounted to the base. A movable working table is slidably mounted to the fixed working table in a sliding direction parallel to a plane of the blade. The movable working table comprises a pivoting plate pivotally mounted to the movable working table about a pivoting axis parallel to the plane where the blade is located and a fence assembly mounted to the movable working table. The tile cutting machine can effectively enhance the ability to produce straight and / or square cuts.

Owner:NANJING CHERVON IND

Silicon slice glazed surface scuffing control method

InactiveCN101367189AReduce scratchesImprove surface qualityPolishing machinesSemiconductor/solid-state device manufacturingSilicon chipRevolutions per minute

The invention provides a method for controlling the scuffing of the polishing surface of a silicon chip. The method comprises the following steps: the silicon chips are pasted on polishing discs of a polishing machine; the polishing discs are fixed on a polishing head of the polishing machine; the pressure of the polishing machine and the rotational speeds of the upper polishing disc and the lower polishing disc are controlled; and polishing solution is injected to the polishing discs and between the silicon chips. The method has the improved aspects: the polishing solution comprises a grinding material, a penetrating agent, a lubricant, a PH regulator, a surfactant, a chelon and deionized water; the pressure of the polishing machine is controlled below 50 kilopascal; the rotational speed of the upper polishing disc is controlled below 60 revolutions per minute; and the rotational speed of the lower polishing disc is controlled below 60 revolutions per minute. The method can effectively reduce the scuffing of the surface of the polishing silicon chip, simultaneously ensure high removing velocity of polishing the silicon chip, has low production cost and is suitable for the requirement of scale production.

Owner:JIANGSU HAIXUN IND GROUP SHARE

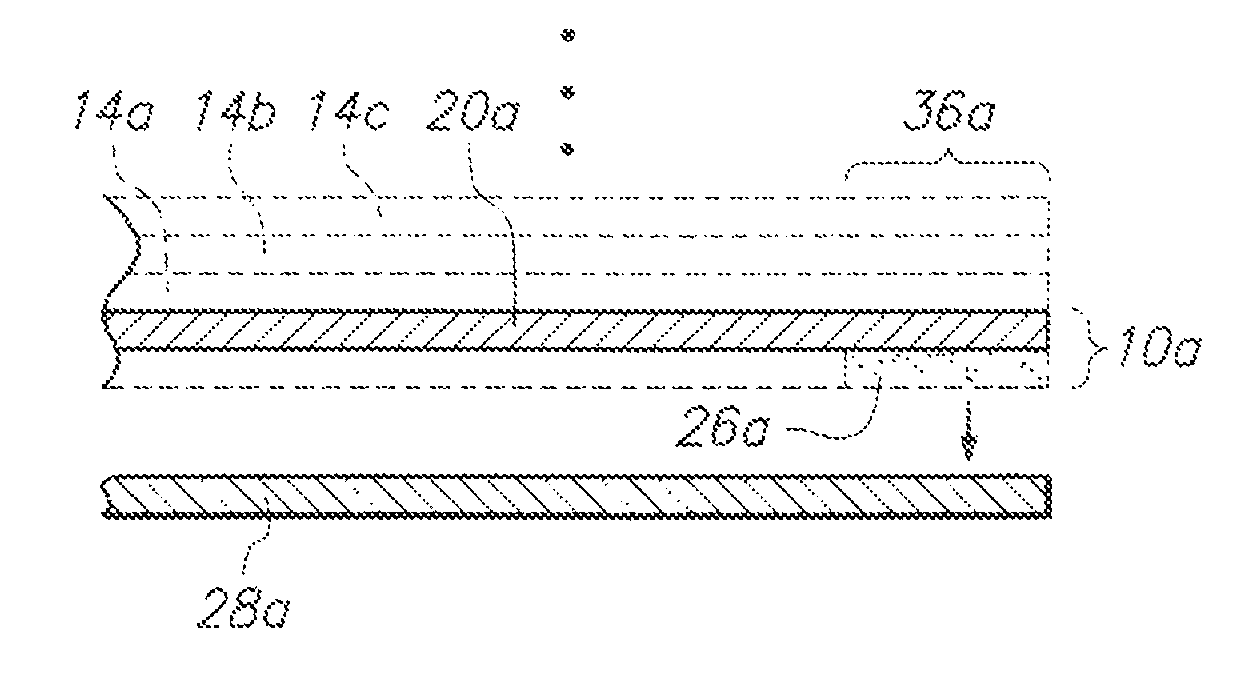

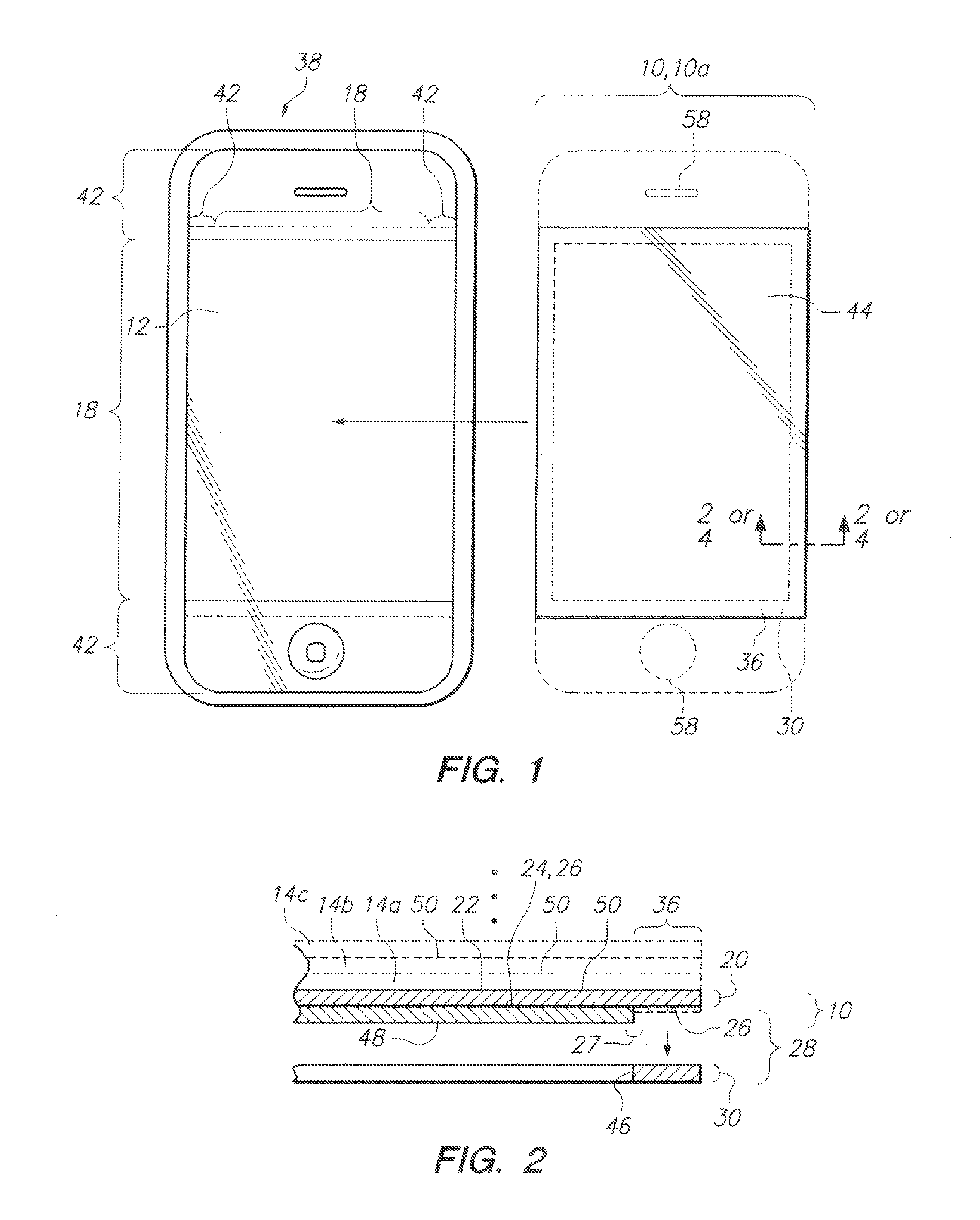

Touch screen shield

ActiveUS9274625B2Promote formationStay flexibleMechanical working/deformationMagnetic/electric field screeningAir bearingEngineering

A shield that is attachable to a touch sensitive screen is disclosed. The shield may be attached to the touch sensitive screen only at its outer peripheral portion. An air gap is enclosed between the shield and the touch sensitive screen to form a planar air bearing. The shield preferably does not touch the active area of the touch sensitive screen when the user is not touching the shield but only viewing the touch sensitive screen through the shield. This mitigates unwanted optical artifacts such as trapped air bubbles, Newton rings and chromatic interference while maintaining the sensitivity of the touch sensitive screen.

Owner:RACING OPTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com