Patents

Literature

191results about How to "Reduce coverage area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

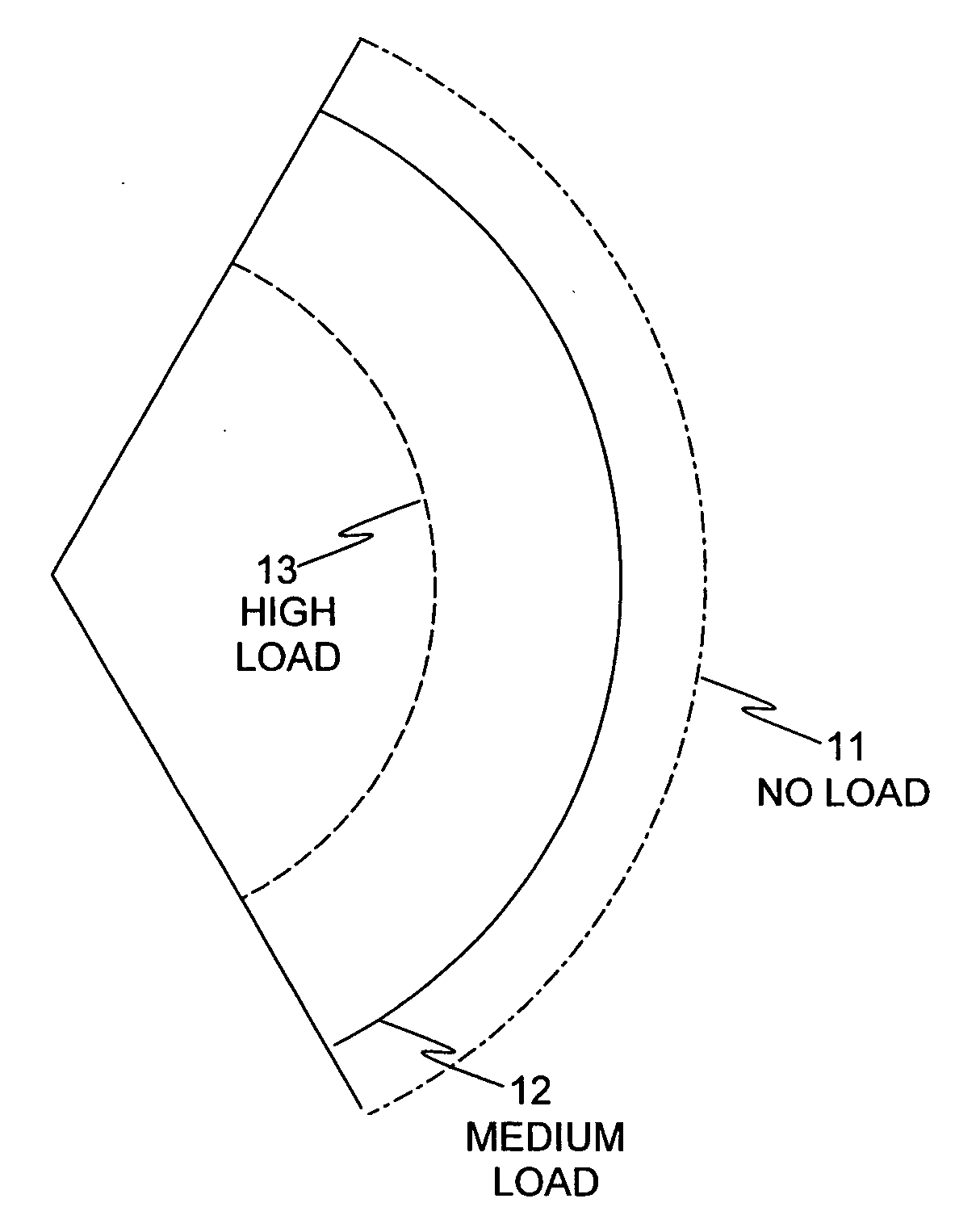

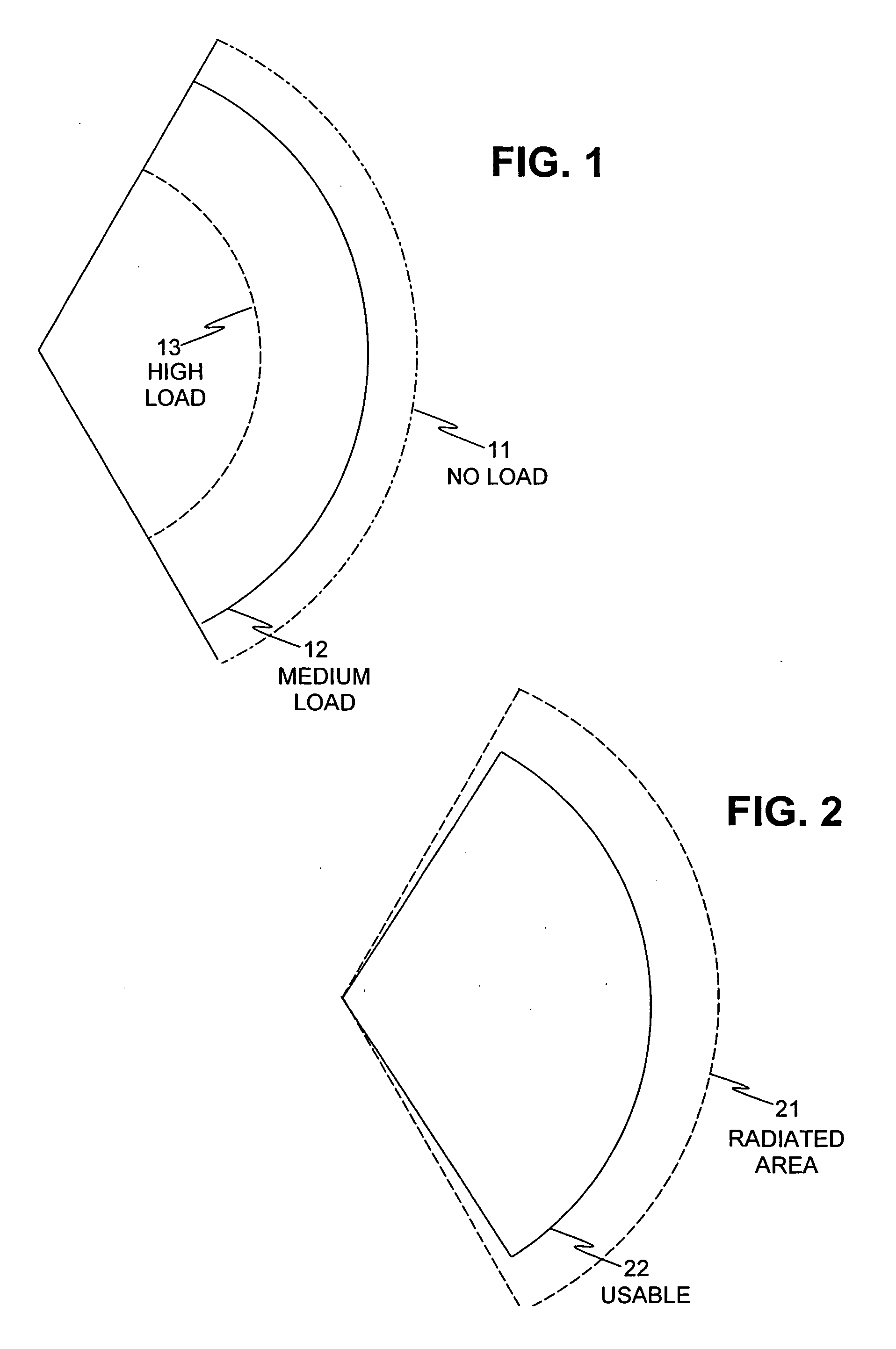

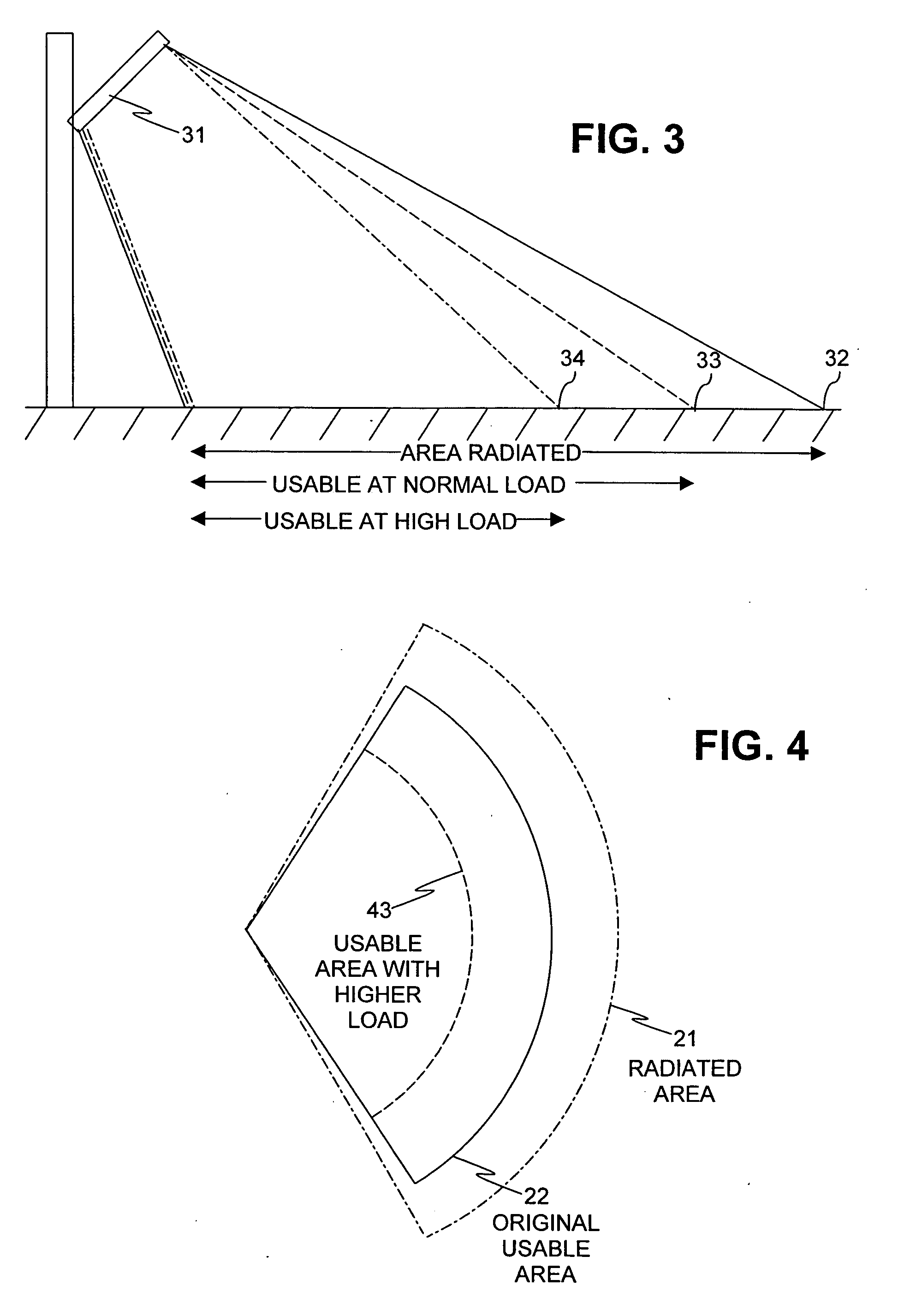

Interference control in CDMA networks

InactiveUS20060068849A1Decrease interferenceIncrease capacitySubstation equipmentRadio/inductive link selection arrangementsCdma networksRadiation pattern

It is proposed to decrease the interference in a CDMA network by automatically adapting the radiation pattern, and thereby the coverage areas, of a cell to the service coverage area without operator intervention. This will increase the overall capacity of the network, because a fully loaded cell generates less interference to neighboring cells and hence leaves more capacity in those cells. It will avoid coverage holes in case certain cells become highly loaded such that their coverage area shrinks (“cell breathing”). In an embodiment of the invention, the radiation pattern is adapted by changing the down-tilt of the antenna.

Owner:LUCENT TECH INC

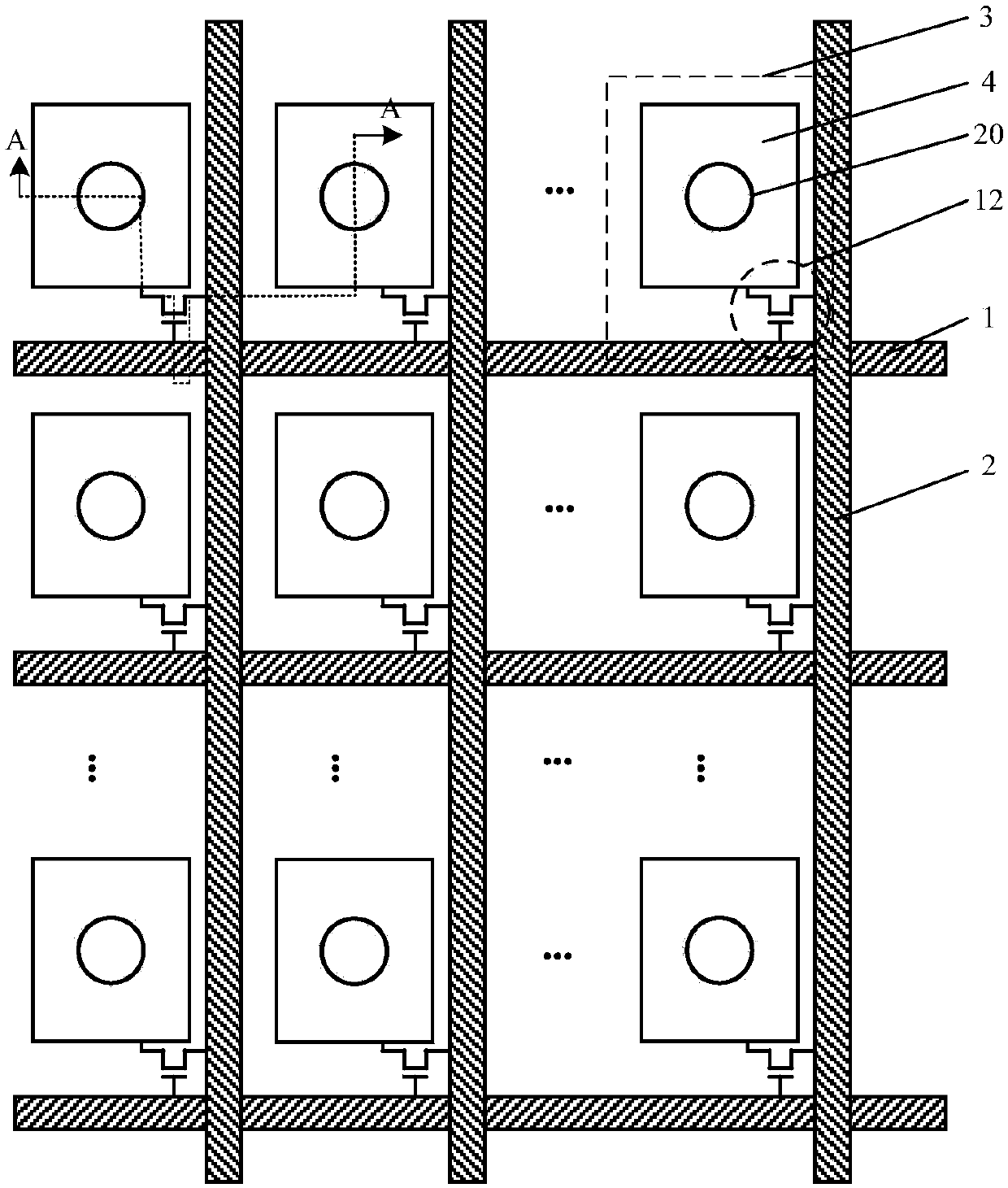

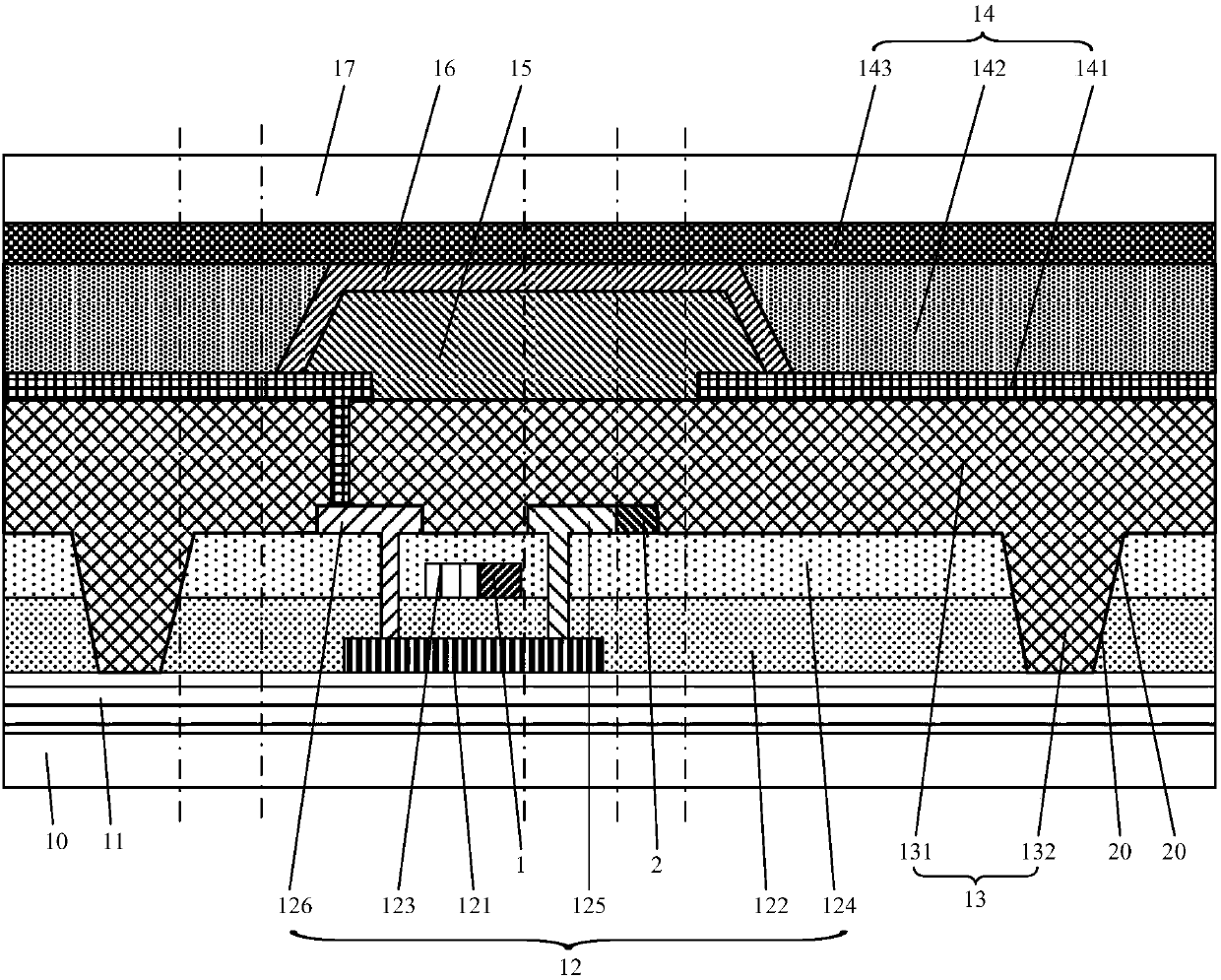

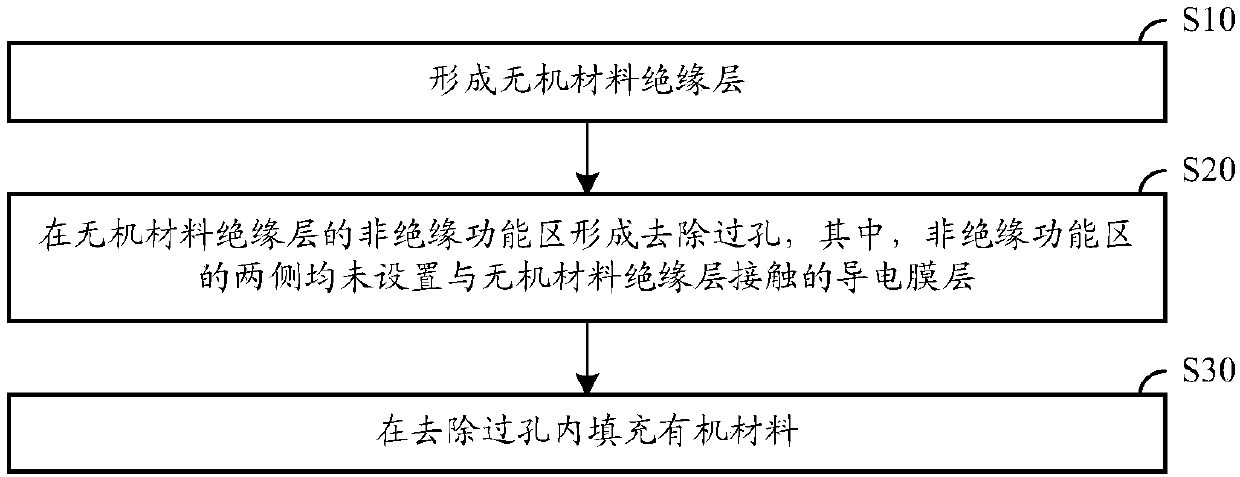

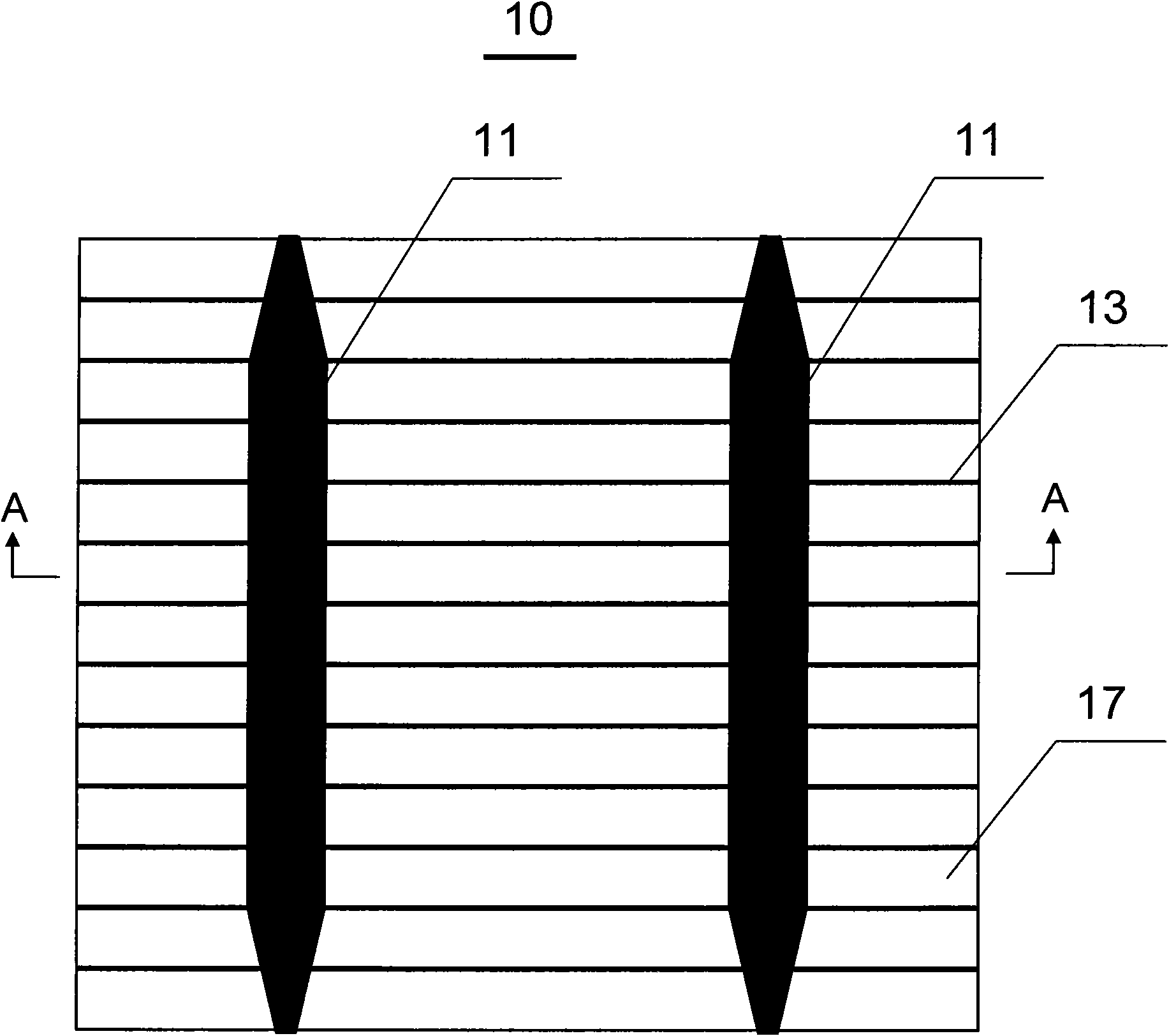

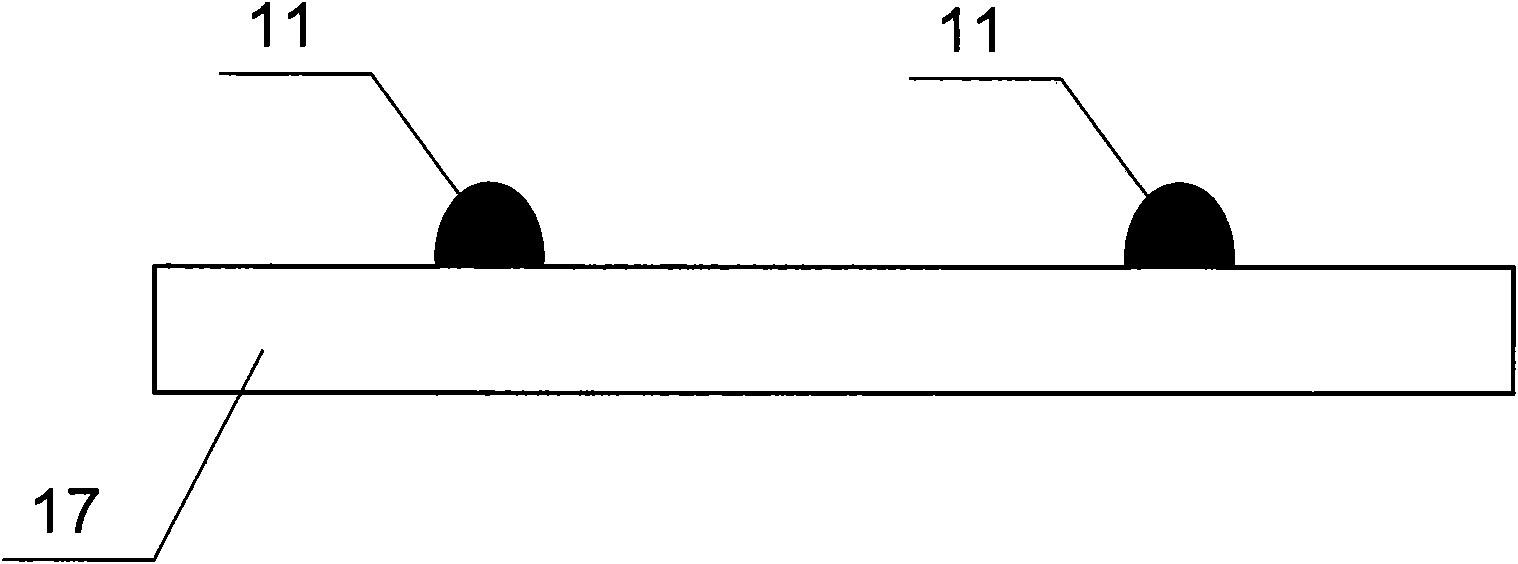

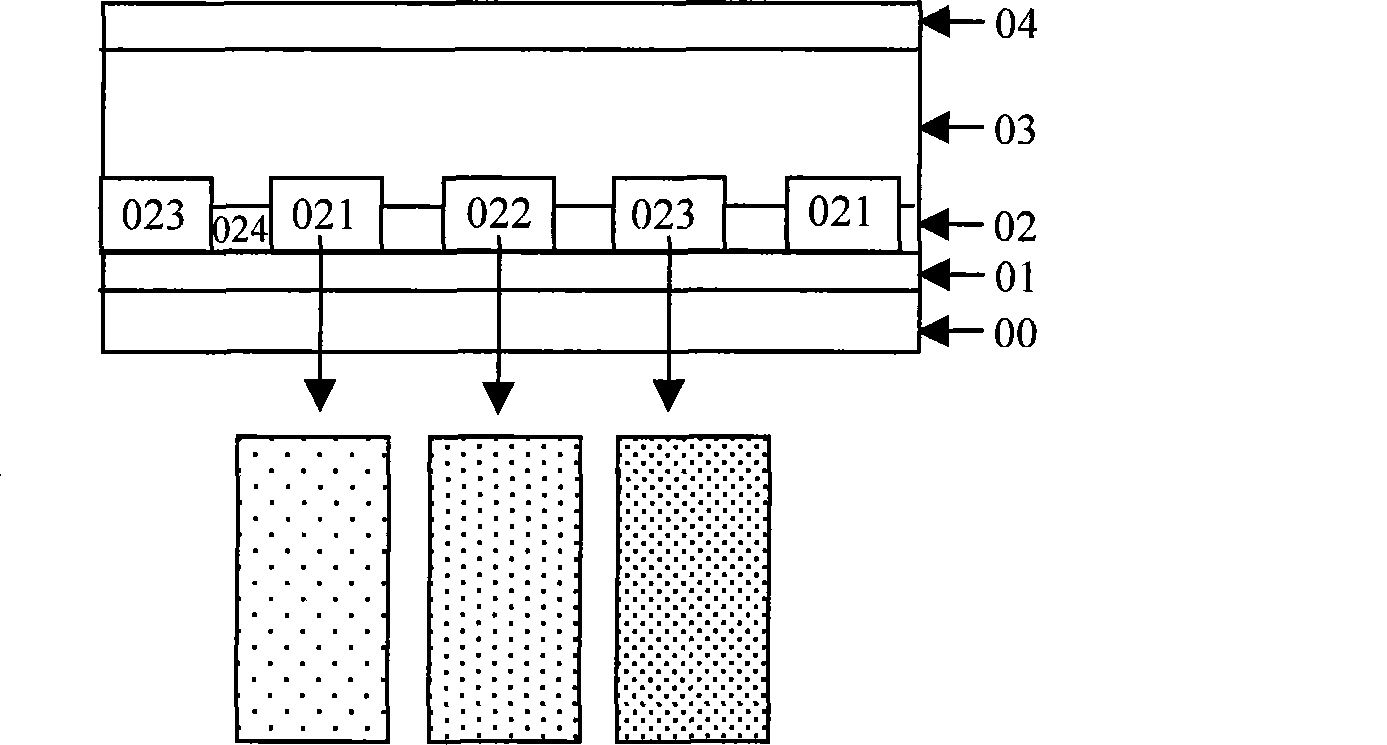

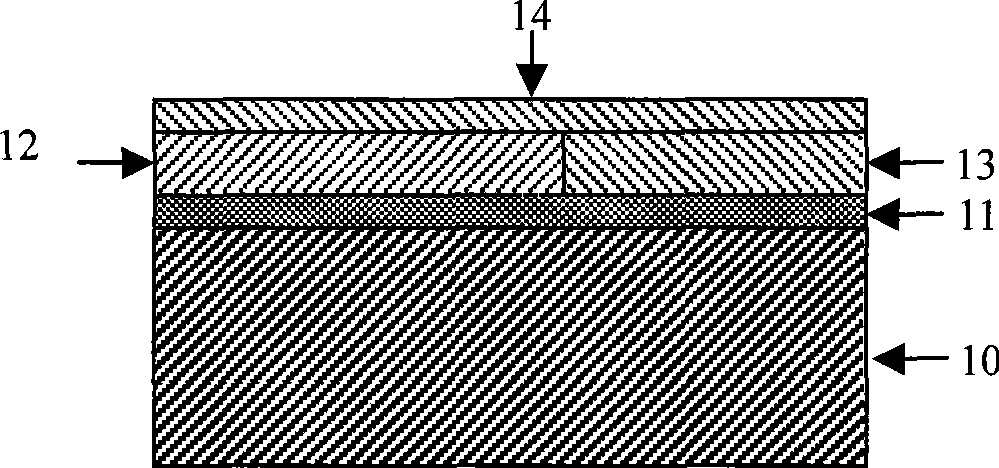

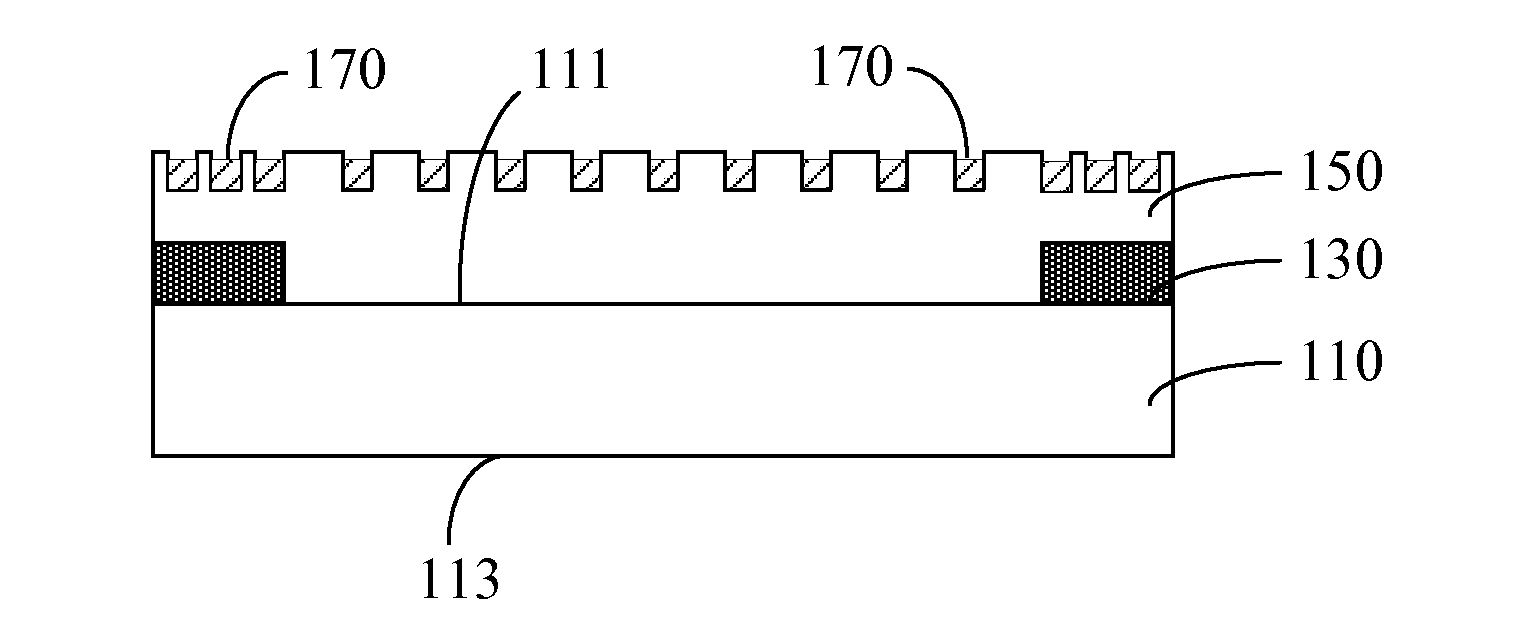

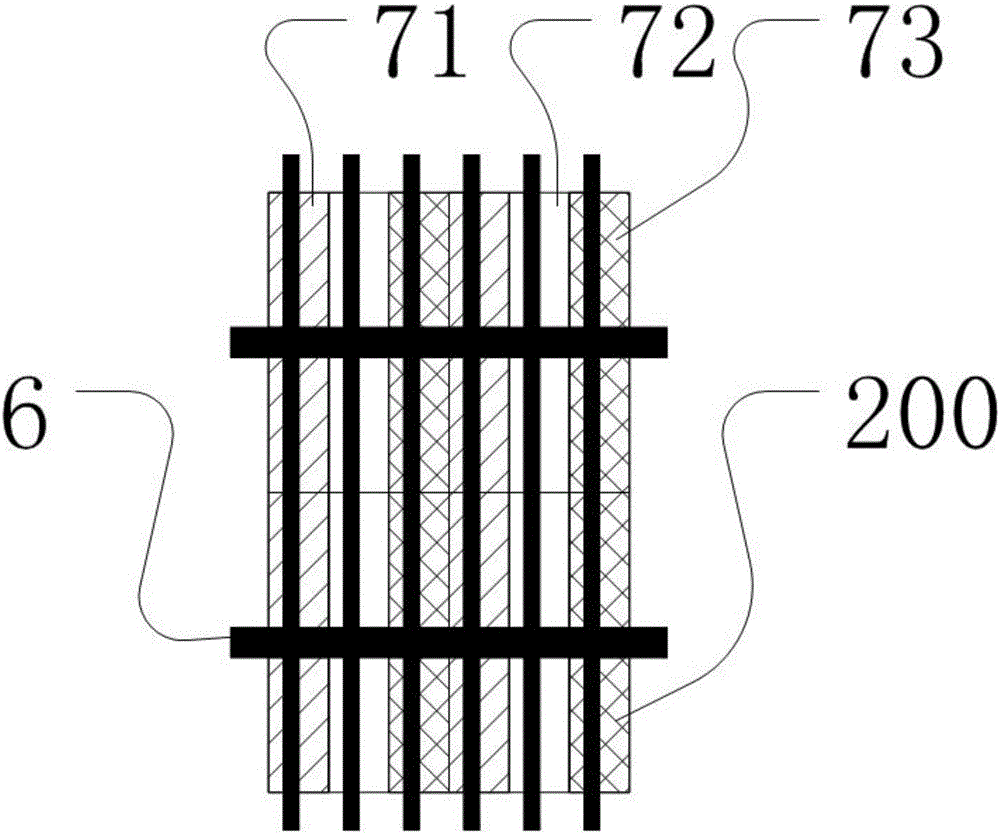

Flexible display panel and manufacturing method thereof and flexible display device

PendingCN107658333AReduce coverage areaImprove bending resistanceFinal product manufactureSolid-state devicesInorganic materialsFlexible display

The invention discloses a flexible display panel and a manufacturing method thereof and a flexible display device, and relates to the technical field of display. Quality declining and even failure ofthe flexible display device caused by cracks and even fractures of an inorganic material insulating layer because of the stress can be prevented. The flexible display panel comprises the inorganic material insulating layer. The inorganic material insulating layer comprises a non-insulating functional area. The non-insulating functional area is internally provided with removing through holes for removing the inorganic material insulating layer in the non-insulating functional area so as to remove the organic material filled in the through holes. The two sides of the non-insulating functional area are not provided with a conductive film layer contacted with the inorganic material insulating layer. The coverage area of the inorganic material insulating layer can be reduced without influencingthe insulation function of the inorganic material insulating layer, and the removing through holes are filled by using the organic material so that the probability of the cracks and even the fractures of the inorganic material insulating layer can be reduced, and quality declining and even failure of the flexible display device can be prevented.

Owner:BOE TECH GRP CO LTD

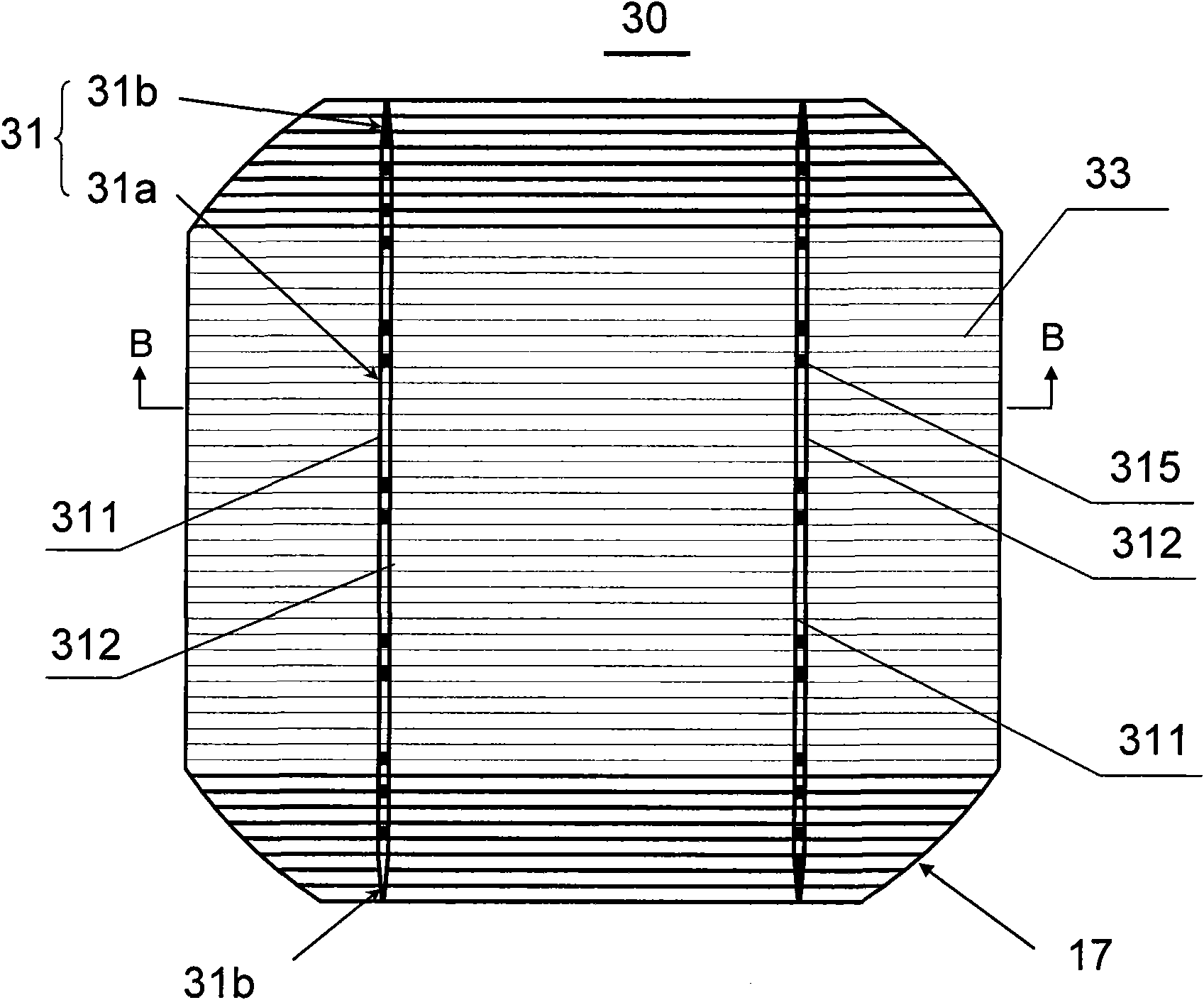

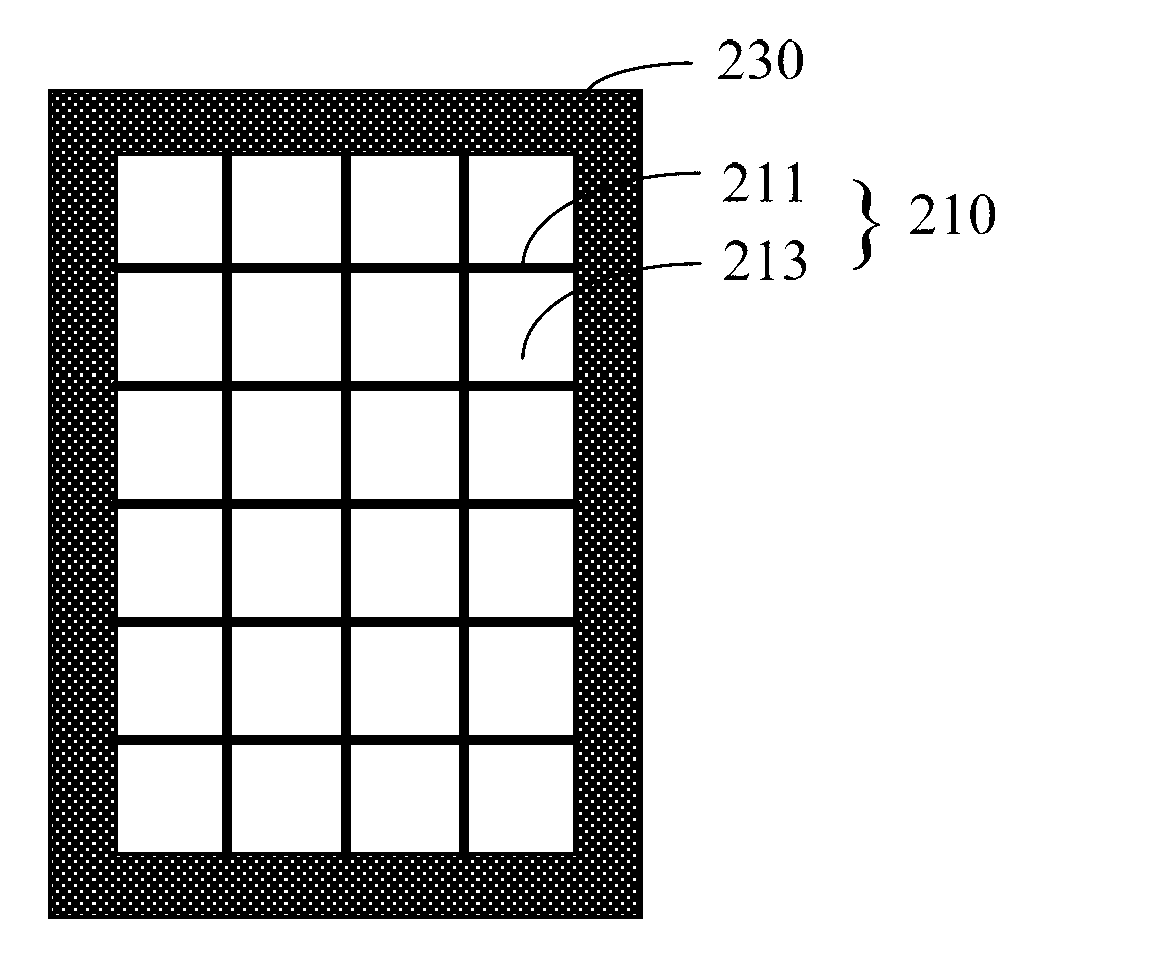

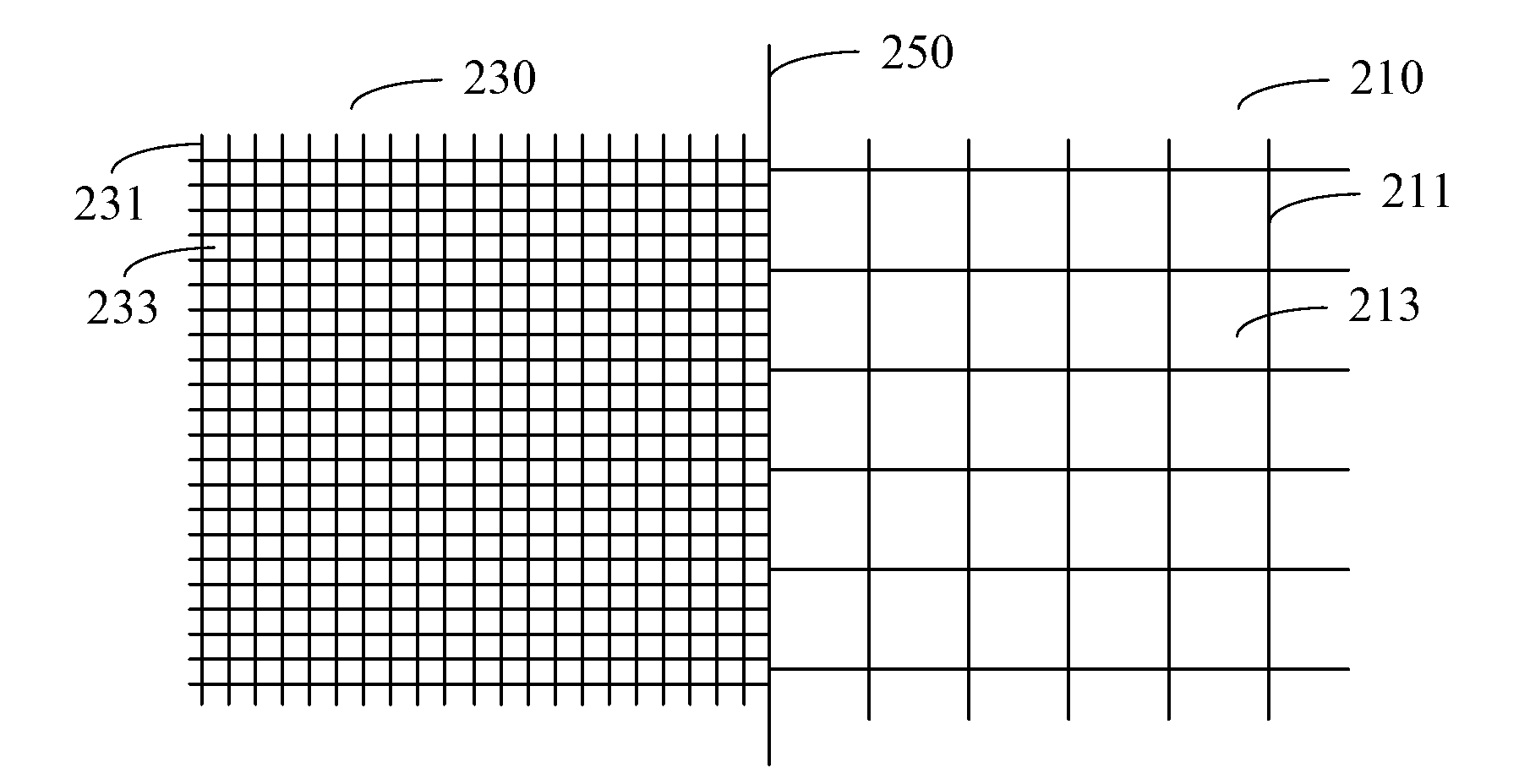

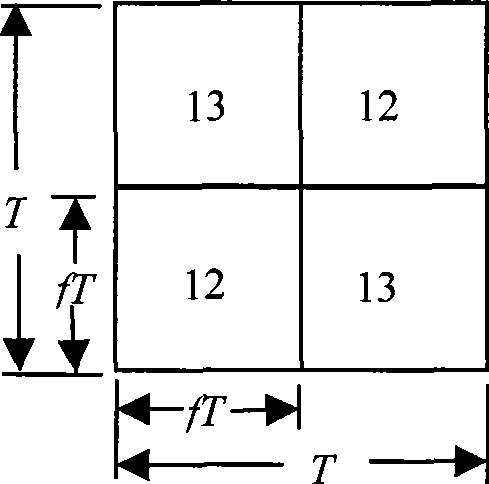

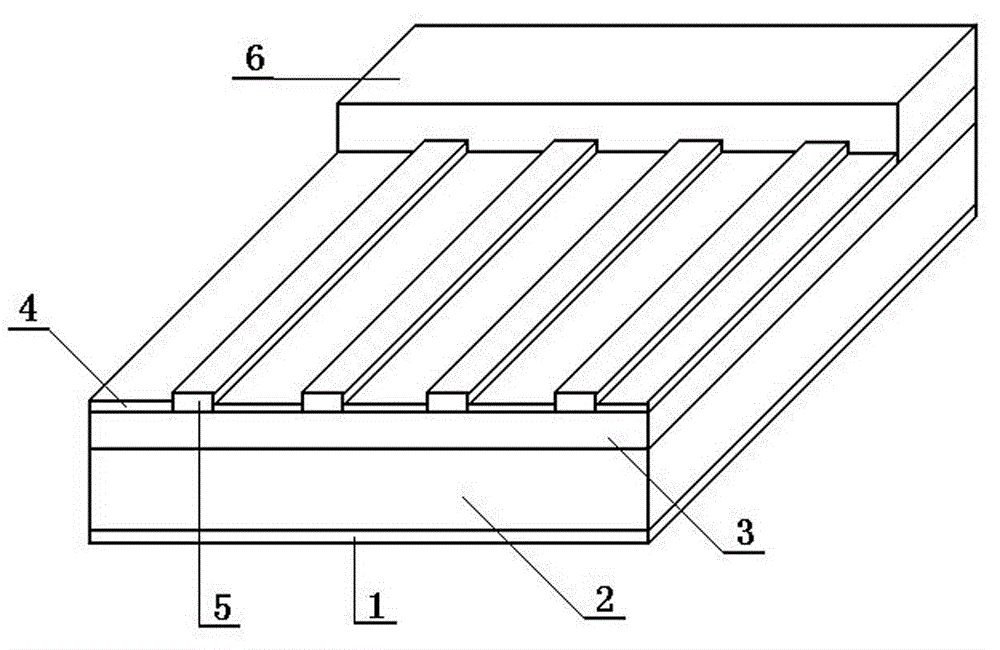

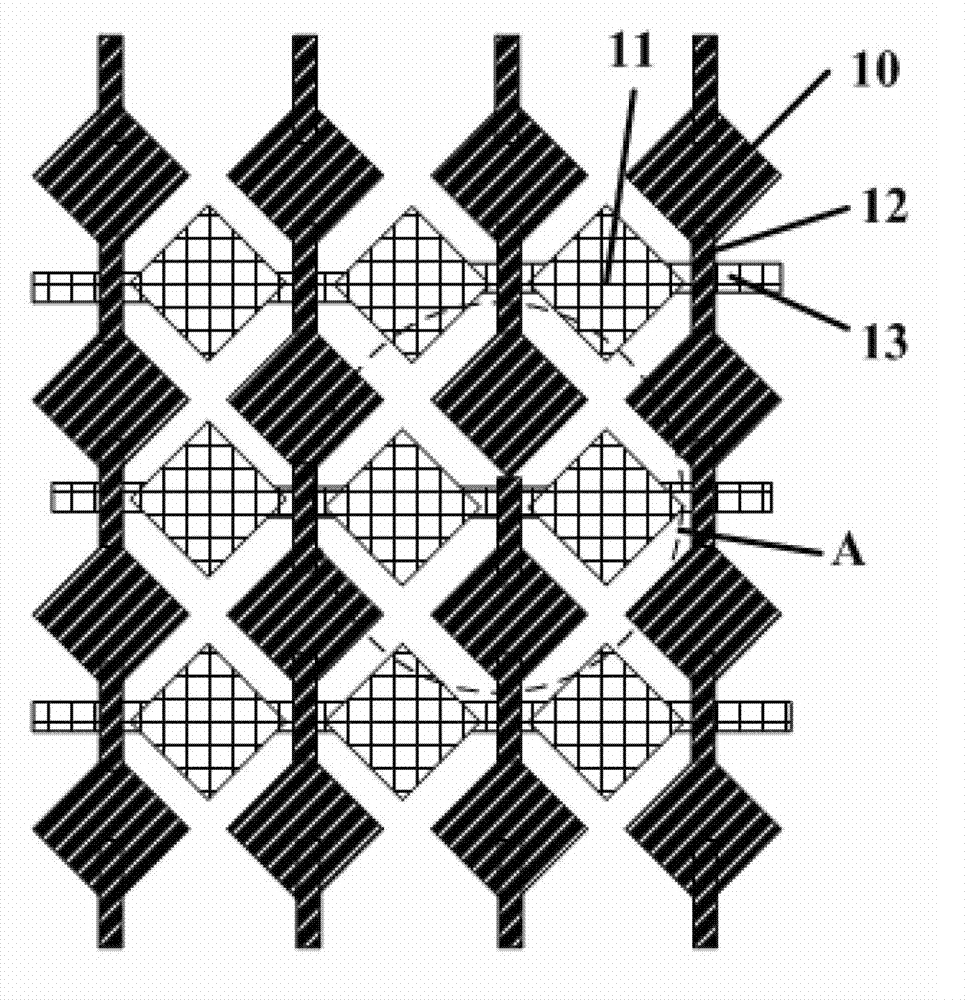

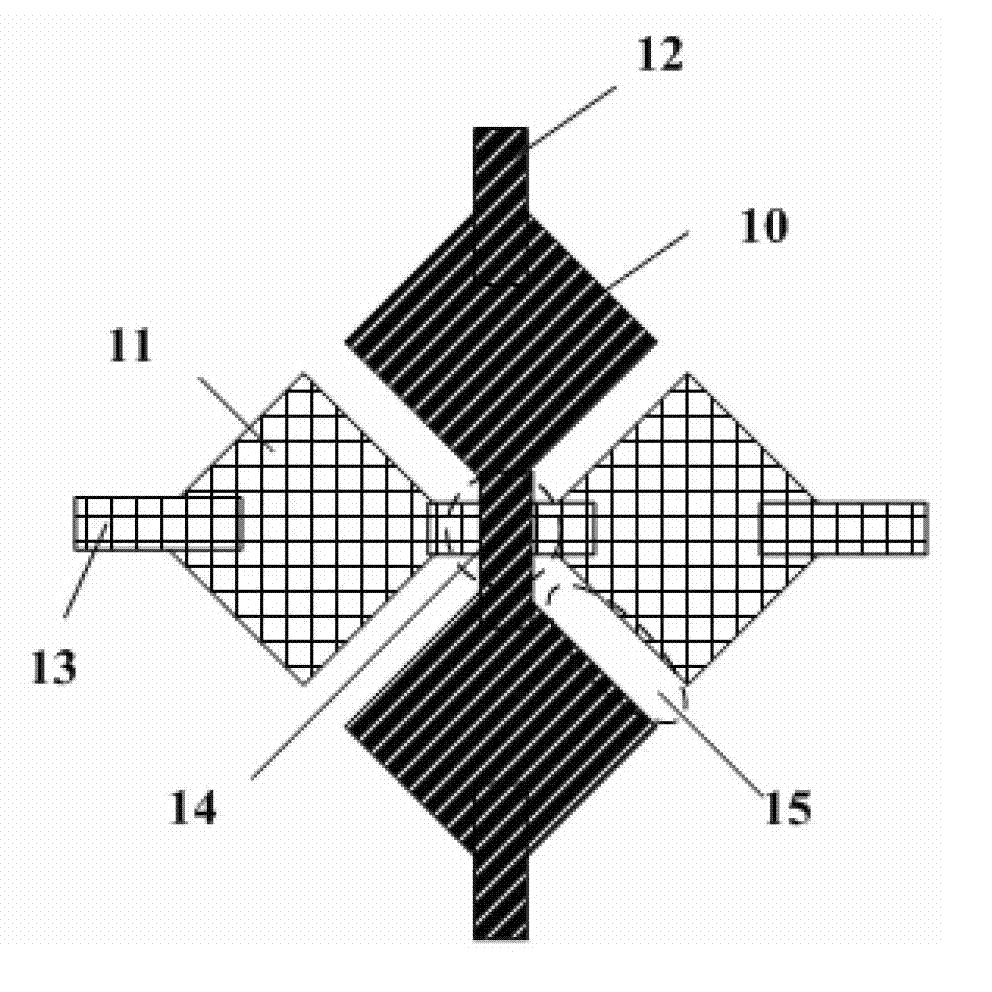

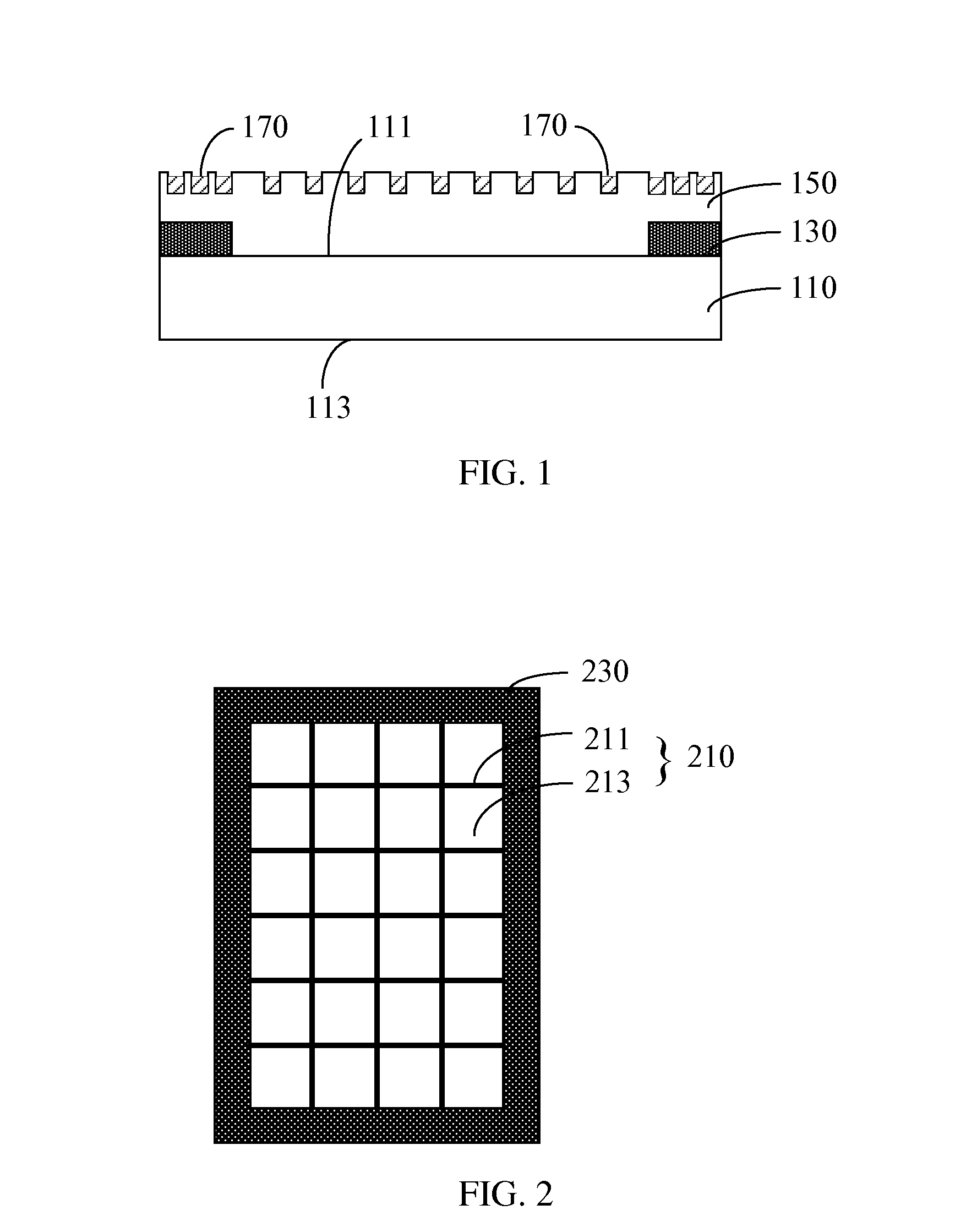

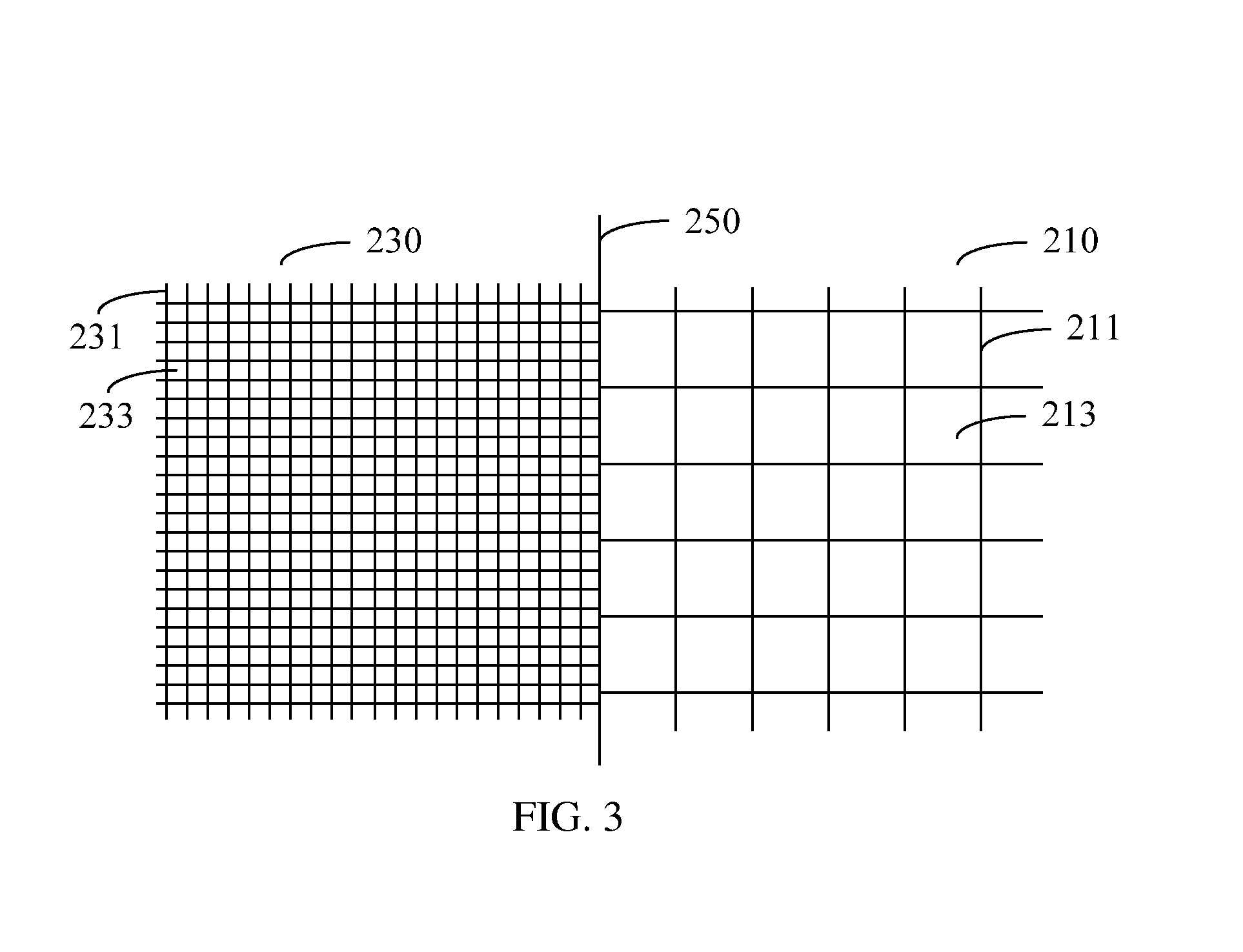

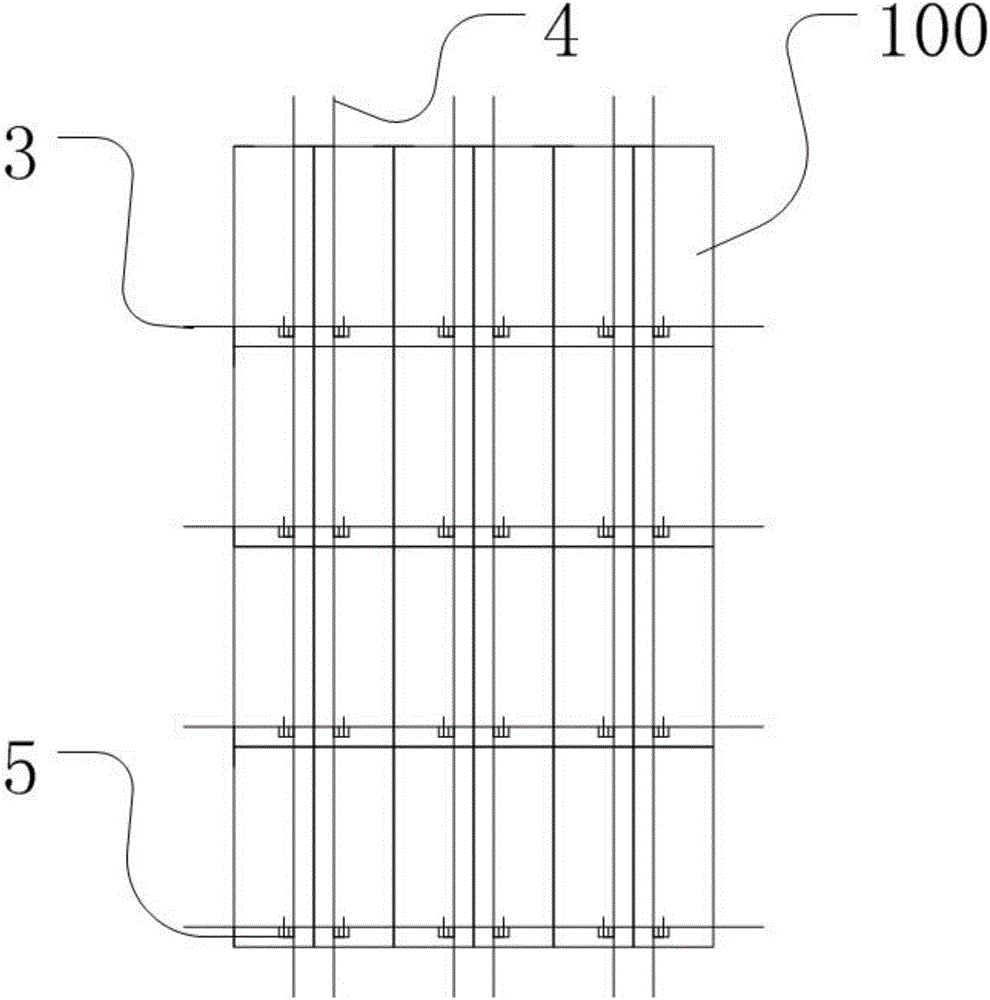

Solar cell, screen printing plate and solar cell module thereof

InactiveCN101826569AReduce stressReduce contact areaPhotovoltaic energy generationSemiconductor devicesScreen printingInterconnector

The invention discloses a solar cell, a screen printing plate and a solar cell module thereof, belonging to the technical field of photovoltaics. The solar cell of the invention comprises a cell substrate and an electrode, wherein the electrode is arranged on the substrate; the electrode comprises a main grid line; the construction of the line area of the main grid line is in a structure comprising at least one thin grid line to reduce the contact area between the main grid line and the substrate; the screen pringting plate provided by the invention is used for manufacturing the electrode of the solar cell of the invention by screen printing; and meshes for composing and forming the main grid line of the electrode are arranged on the screen printing plate. The solar cell module provided by the invention comprises a plurality of the solar cells provided by the invention. The solar cell and the solar cell module have low cost, and because the compound area between the metal electrode and the silicon in the cell structure is reduced, the conversion efficiency is improved, the output power of the module is increased, and in addition, the reliability after an interconnector is welded with a cell plate is good.

Owner:WUXI SUNTECH POWER CO LTD

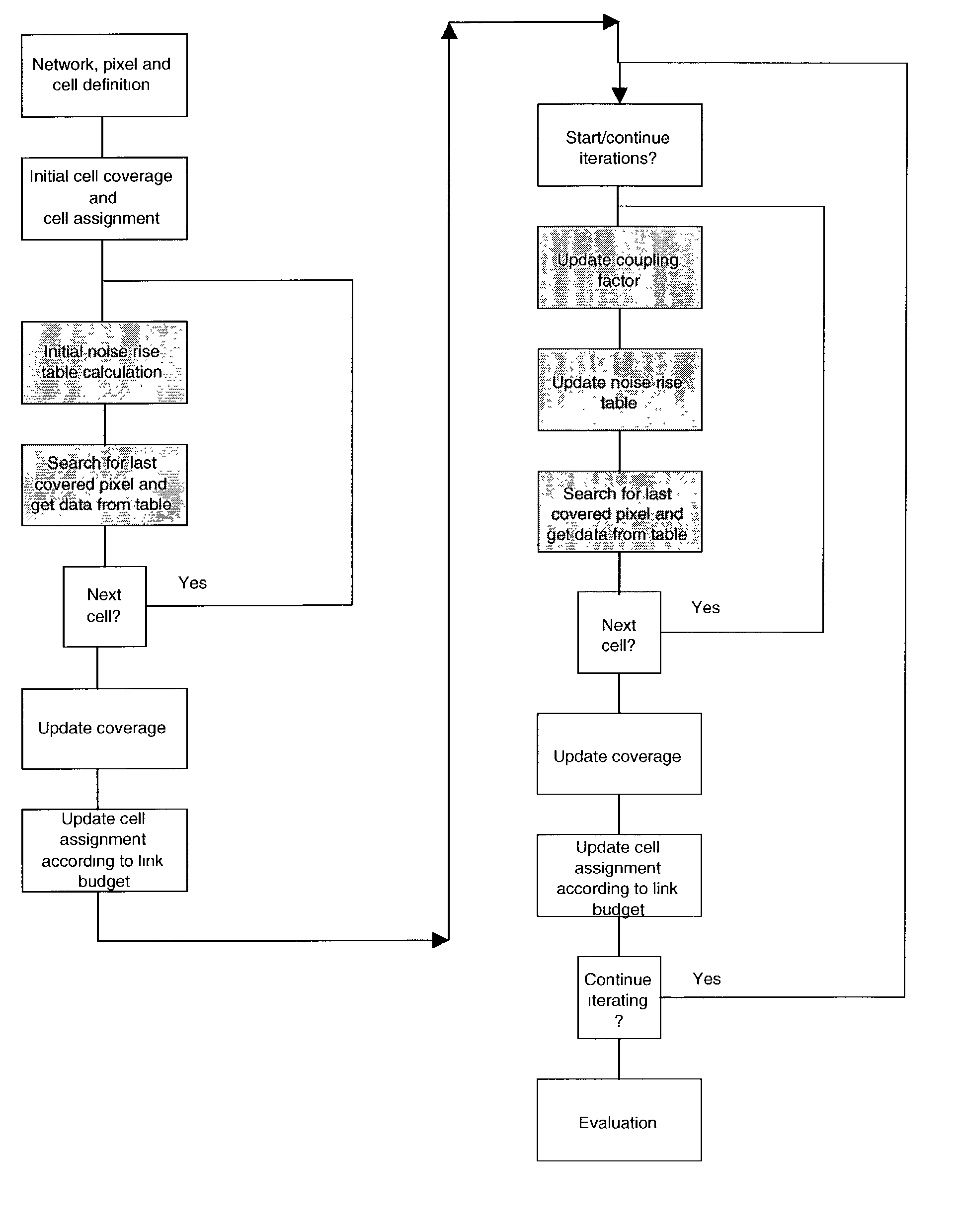

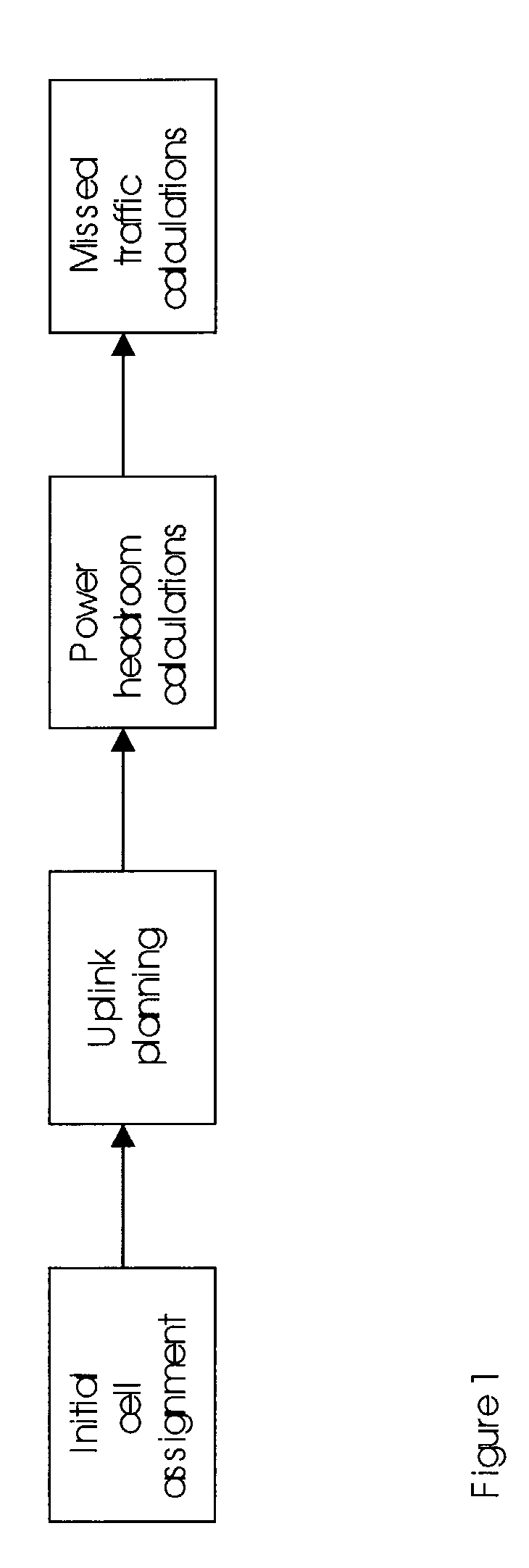

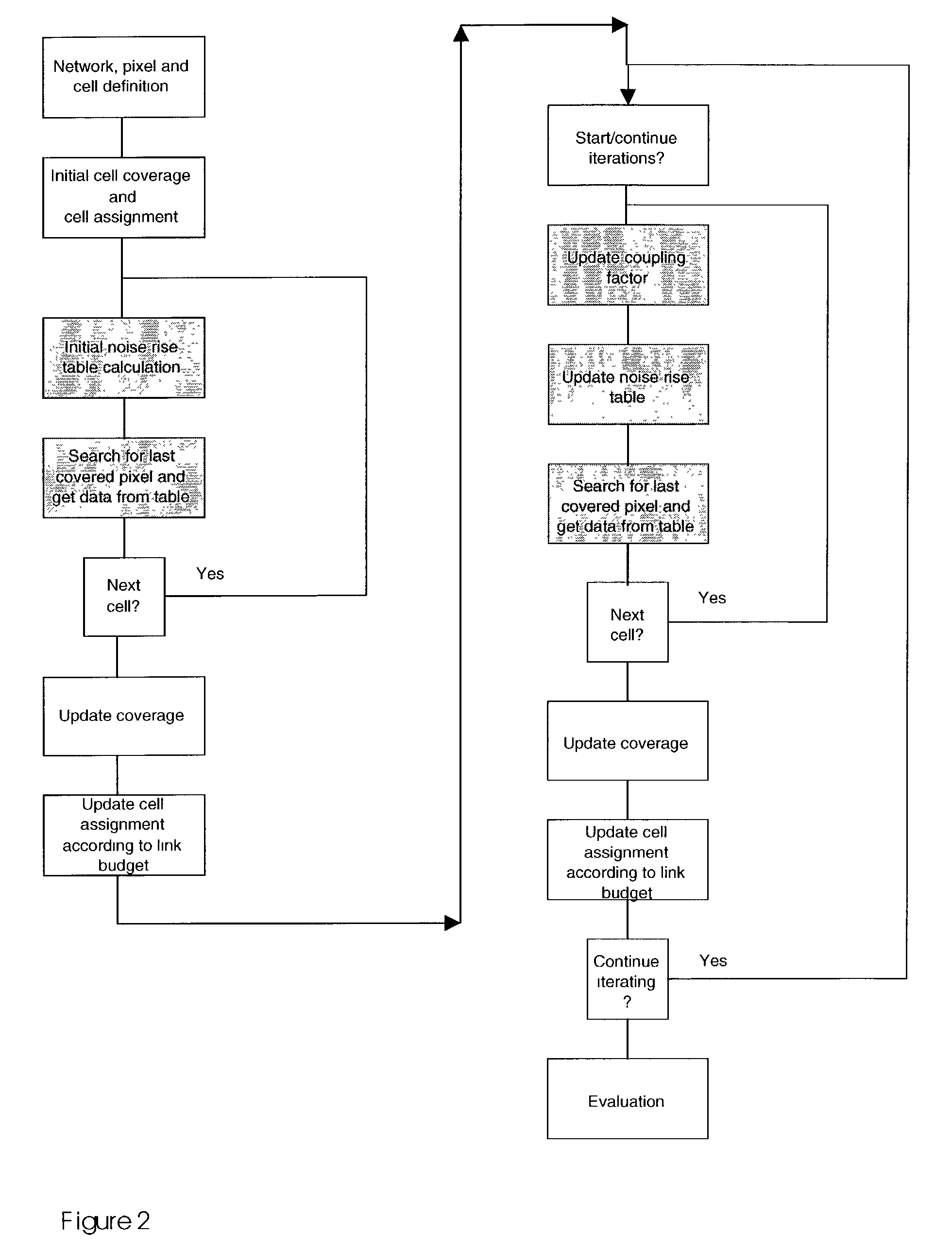

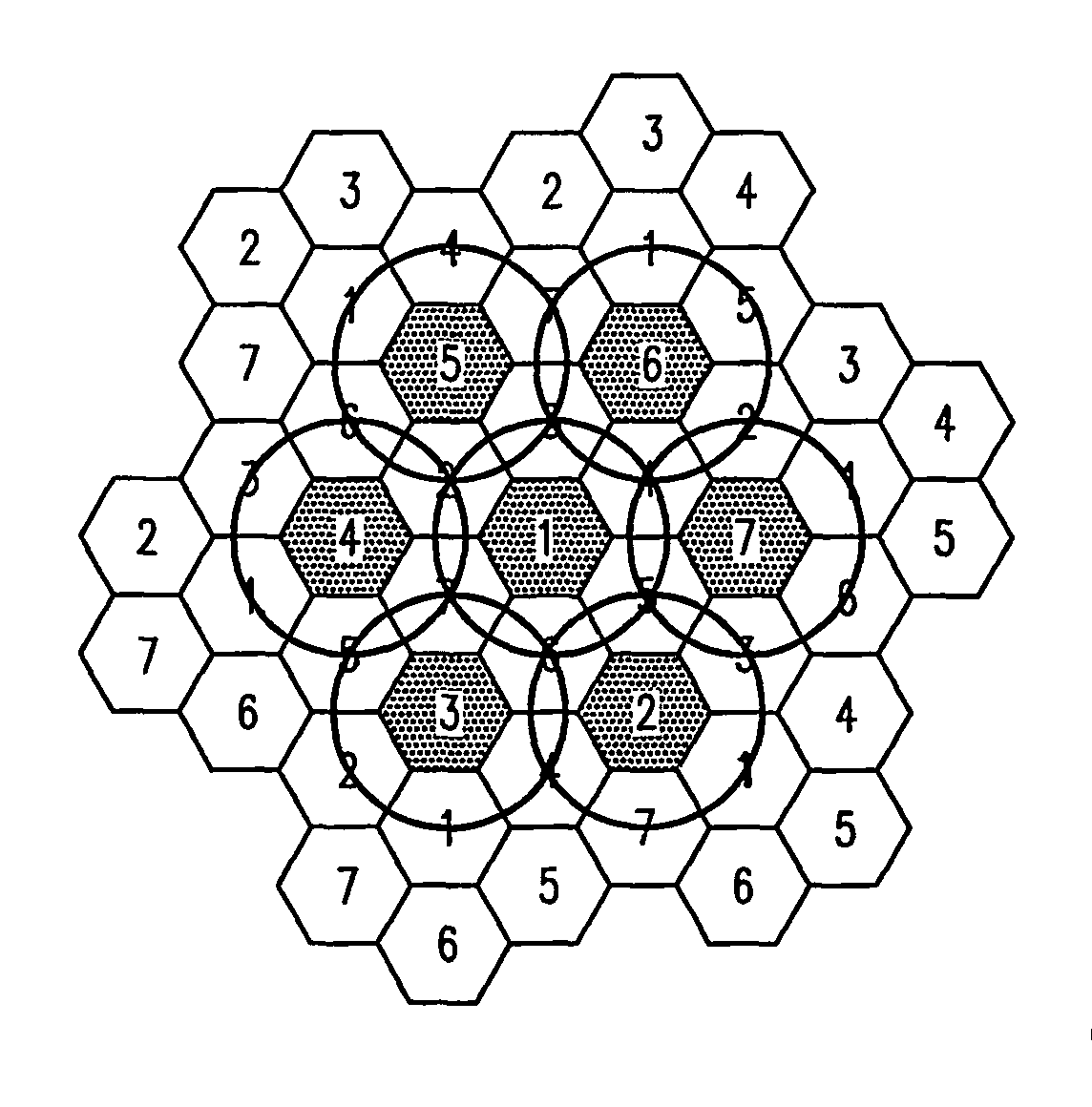

Method and system for planning and evaluation of CDMA radio networks

InactiveUS20030087641A1Small coverage areaNoise riseRadio/inductive link selection arrangementsNetwork planningRadio networksTelecommunications

Method and system for the planning and / or evaluation of radio networks, especially CDMA radio networks. The service area of a radio network is divided into pixels after which for each pixel a probability is determined whether it is covered by a cell of the radio network. To account for cell breathing due to traffic changes, the planning involves the calculation of a link budget for each pixel and of a noise rise for each cell.

Owner:KONINK KPN NV

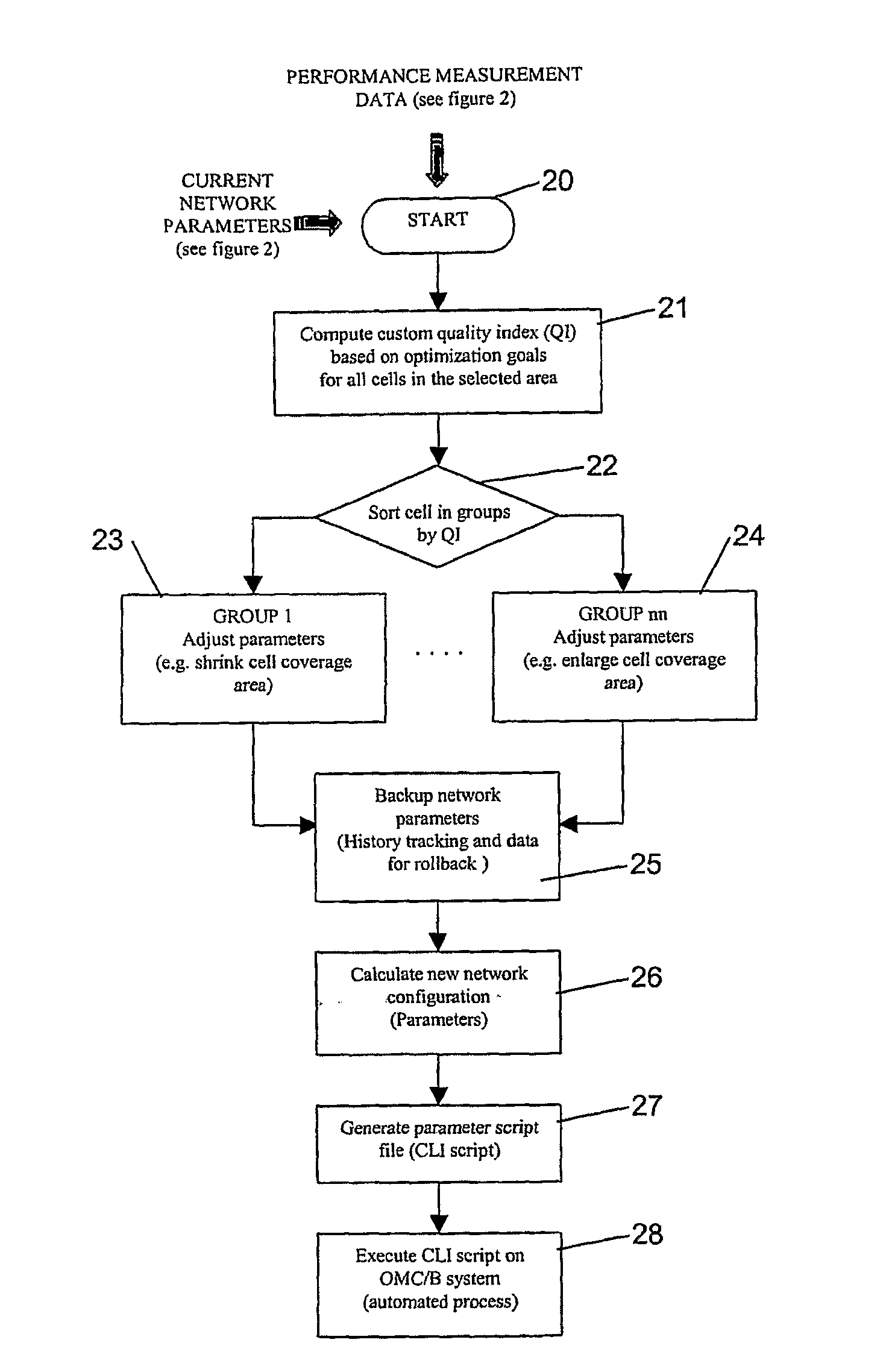

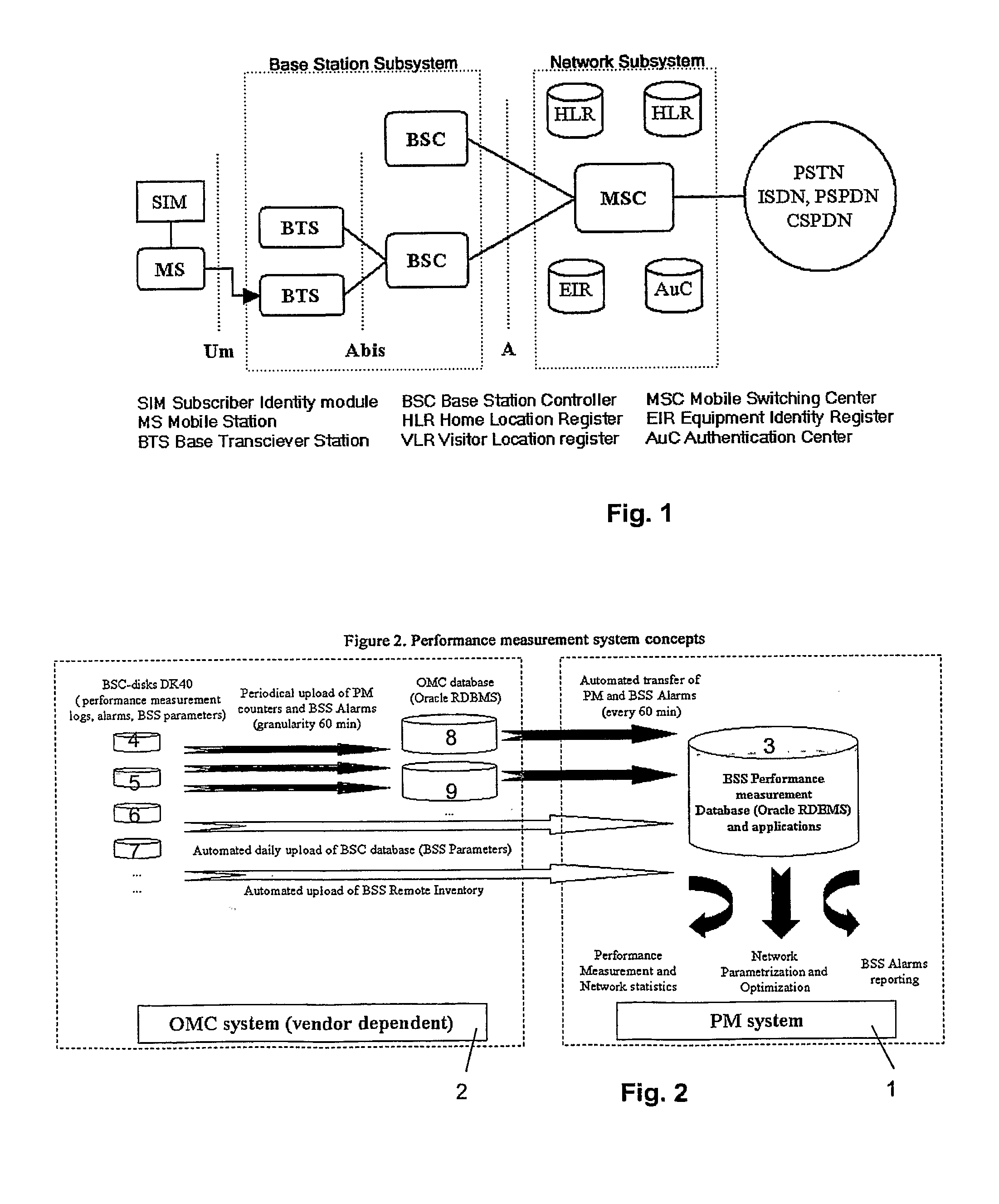

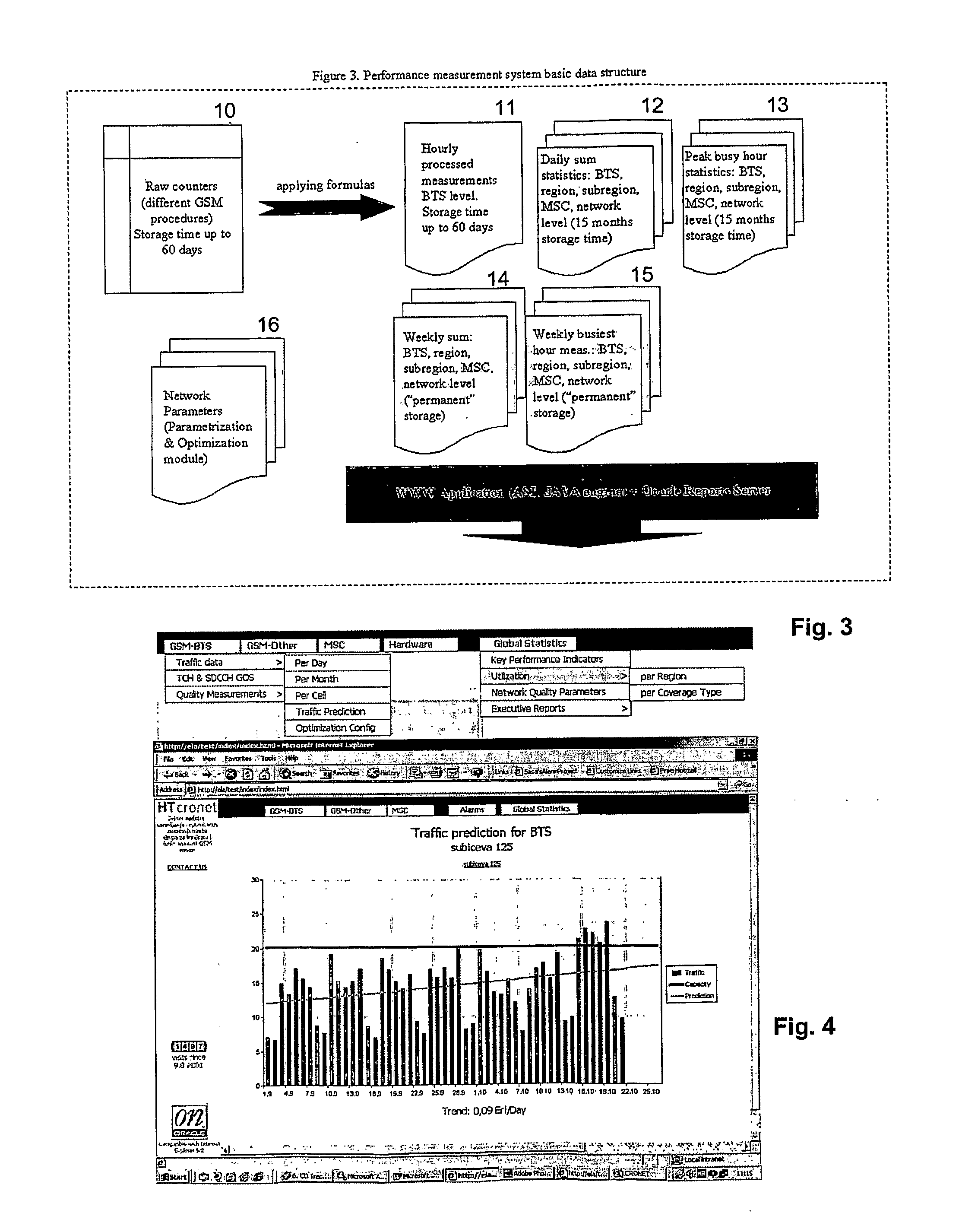

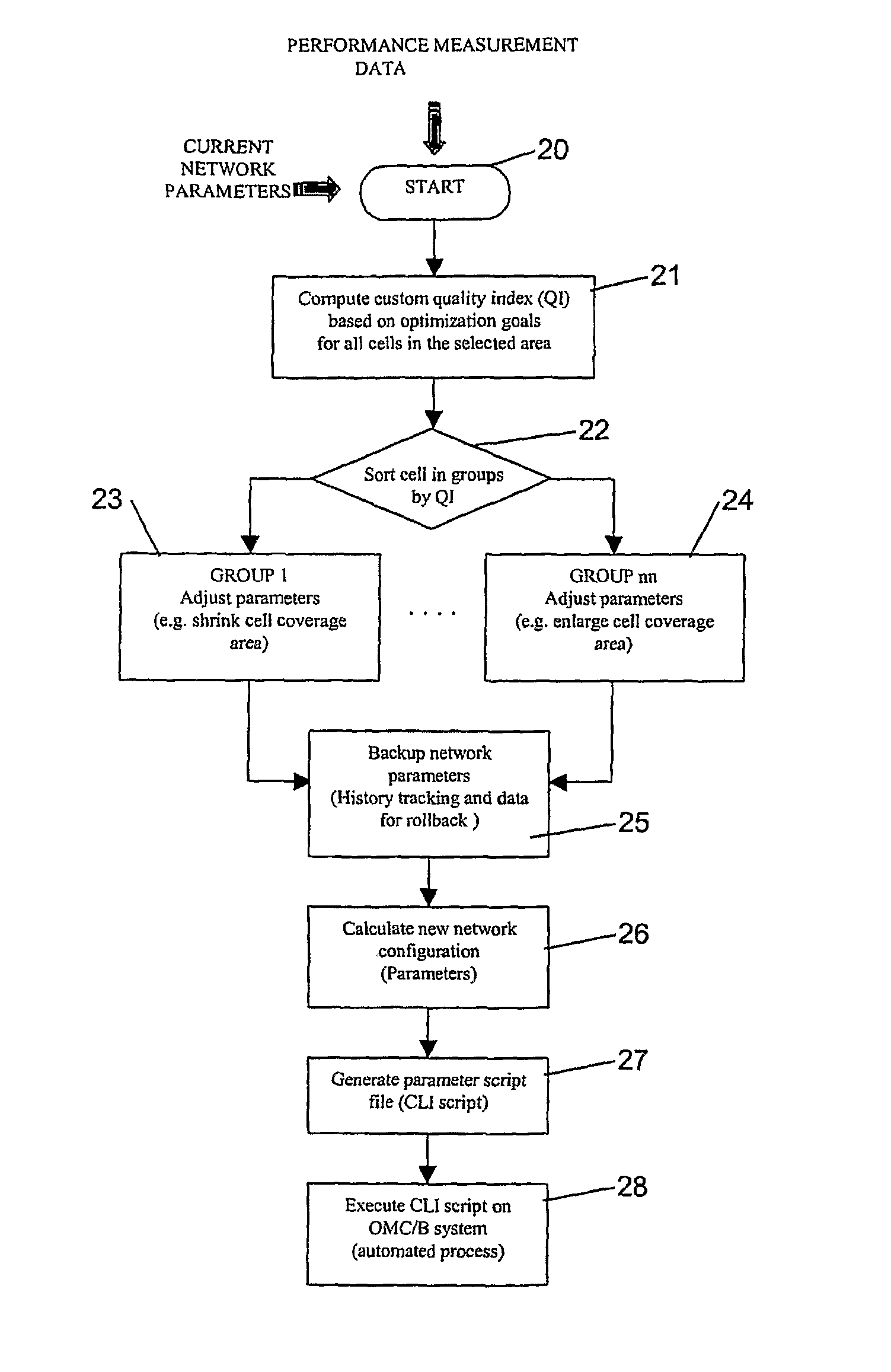

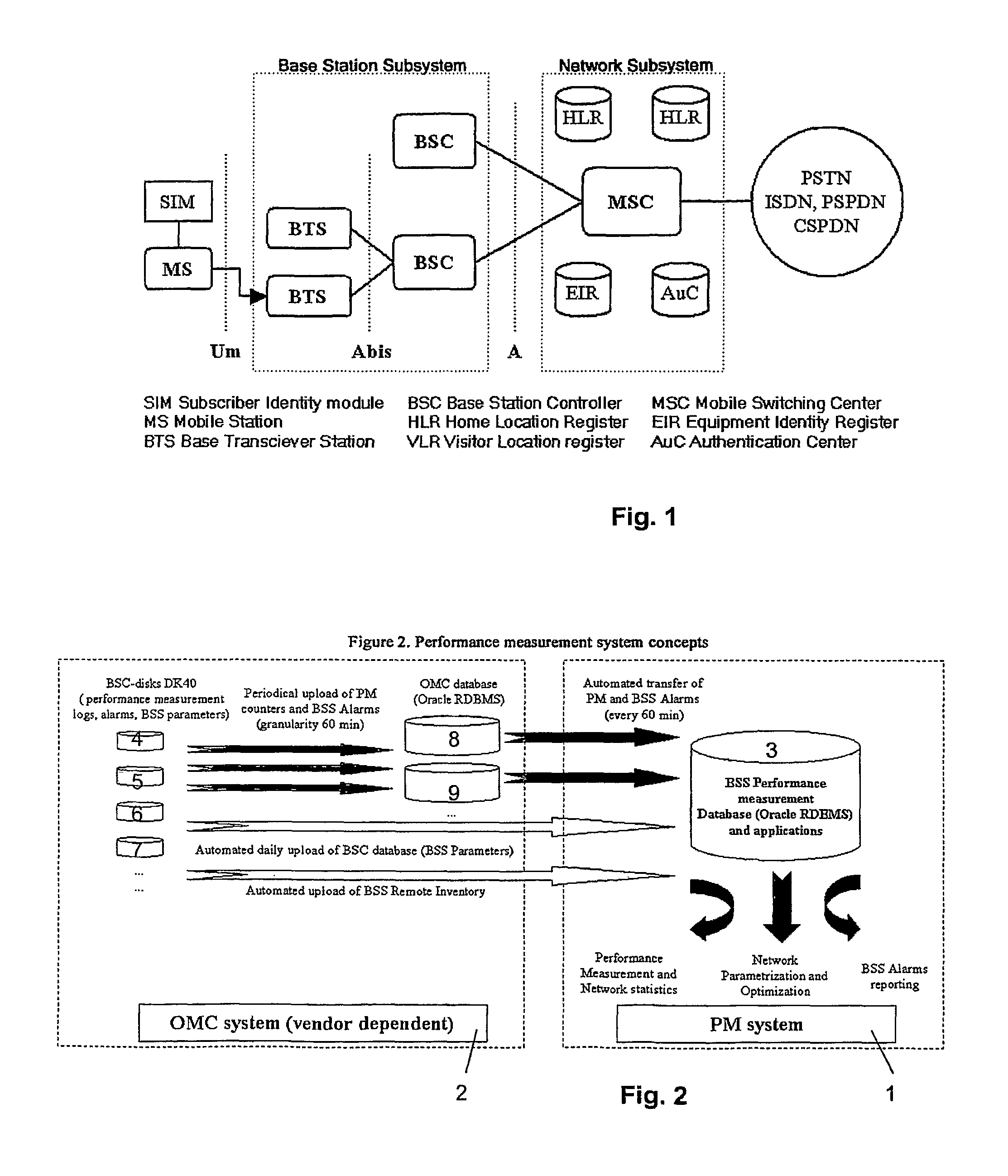

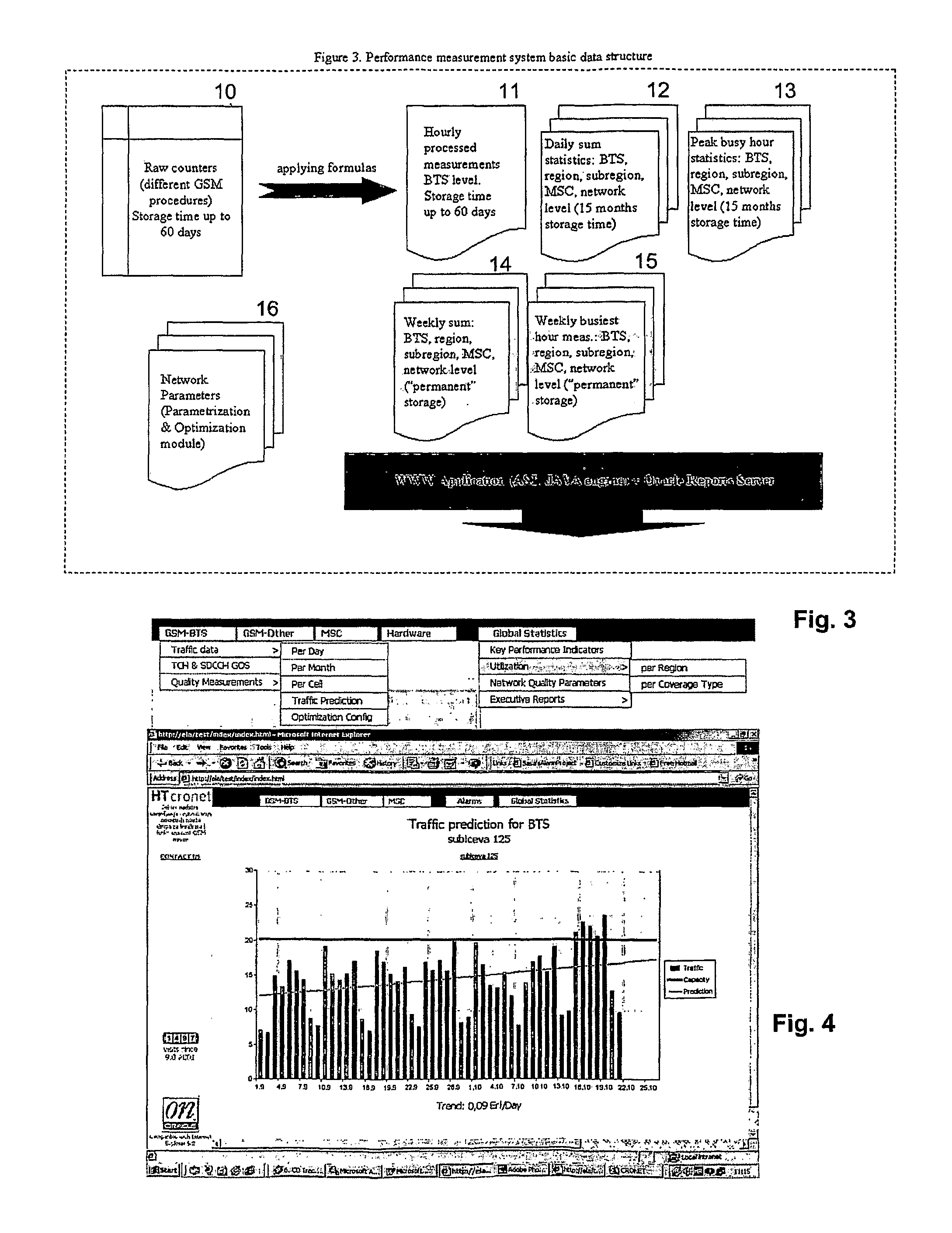

Base Station System Performance Measurement System in a GSM Radio Communication Network

ActiveUS20110014925A1Expand coverageReduce coverage areaSubstation equipmentTransmissionQuality of serviceResource consumption

The invention relates to a system an a method for self optimizing a radio communication network comprising a plurality of radio cells, the system means for monitoring the network resource consumption and quality parameters individually for each cell, and means for distributing the network traffic dynamically between neighboring radio cells in order to maintain satisfactory quality of service in each radio cell.

Owner:T MOBILE HRATSKA D O O

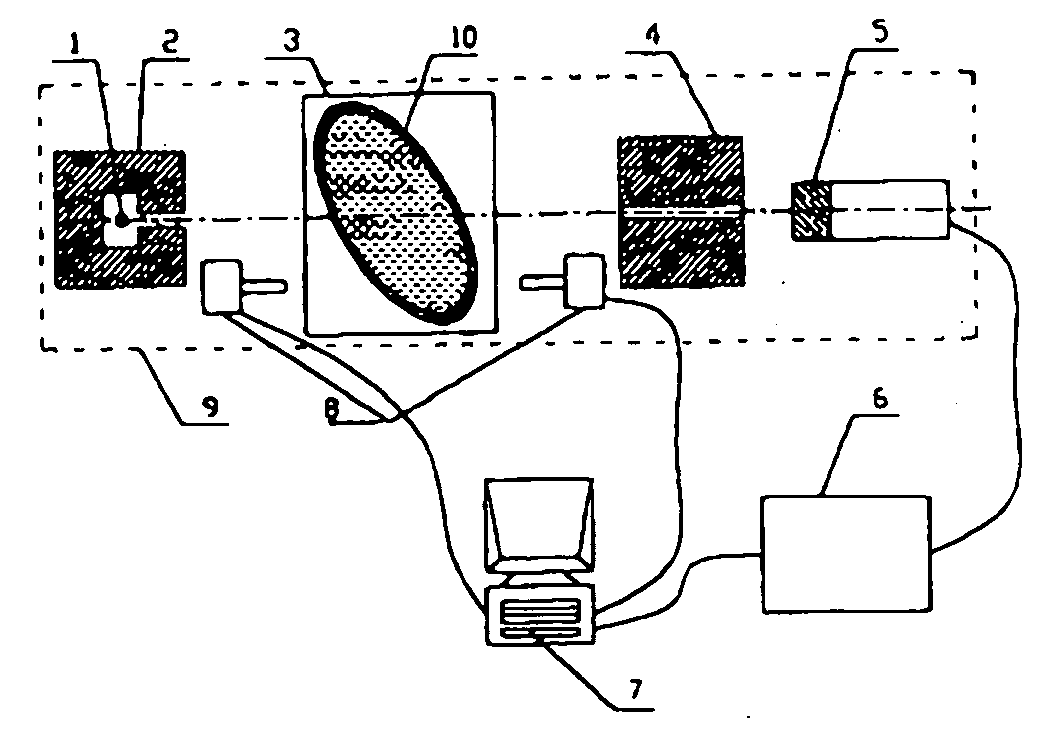

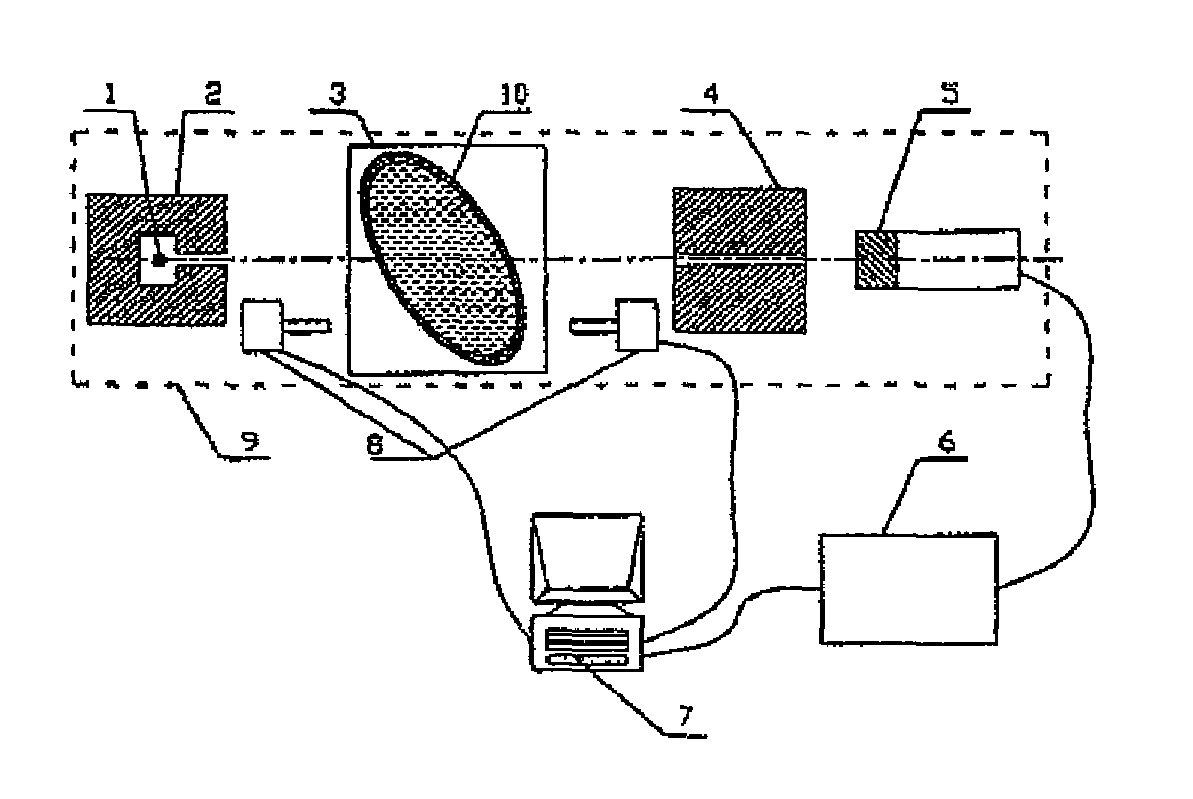

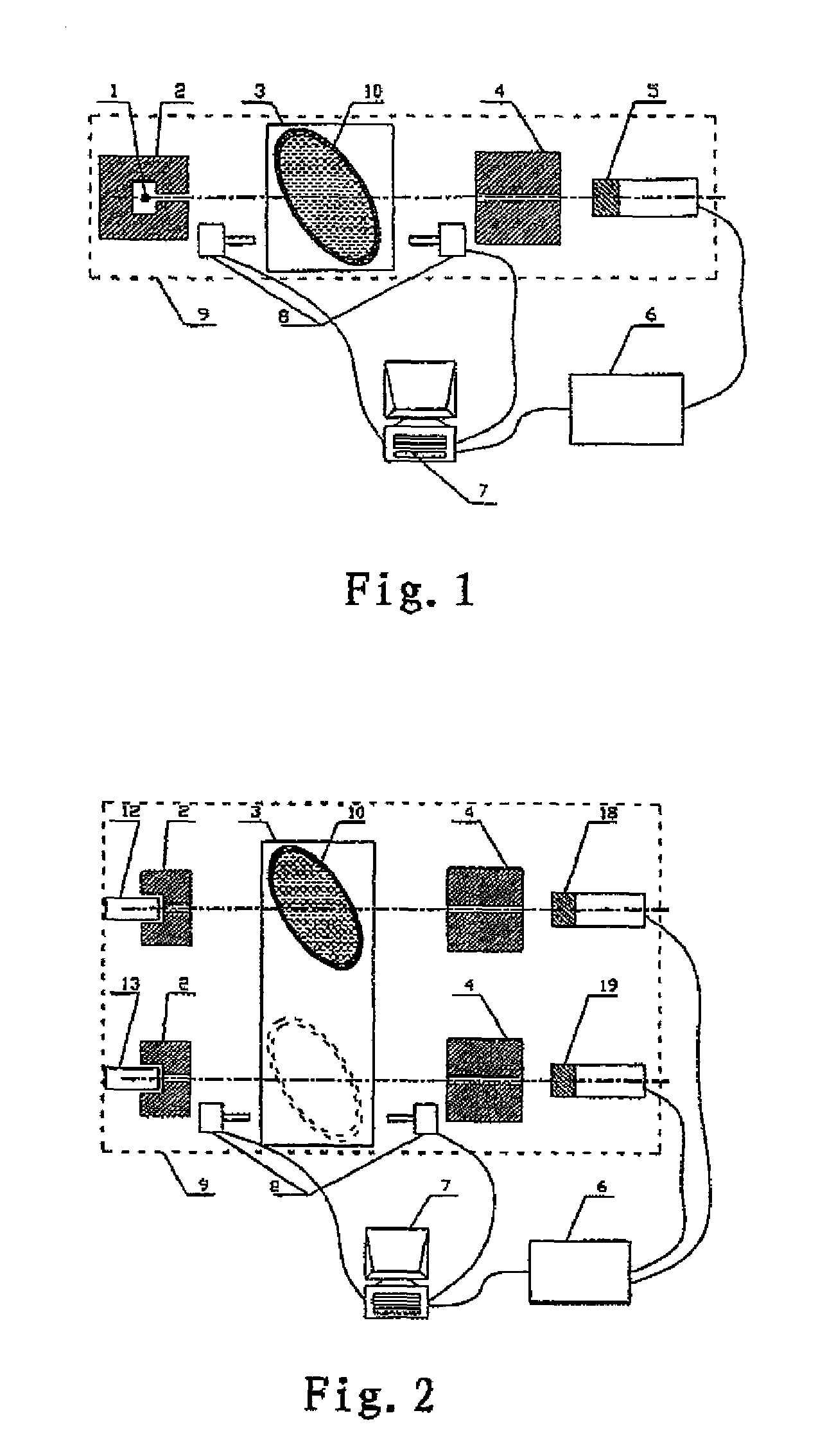

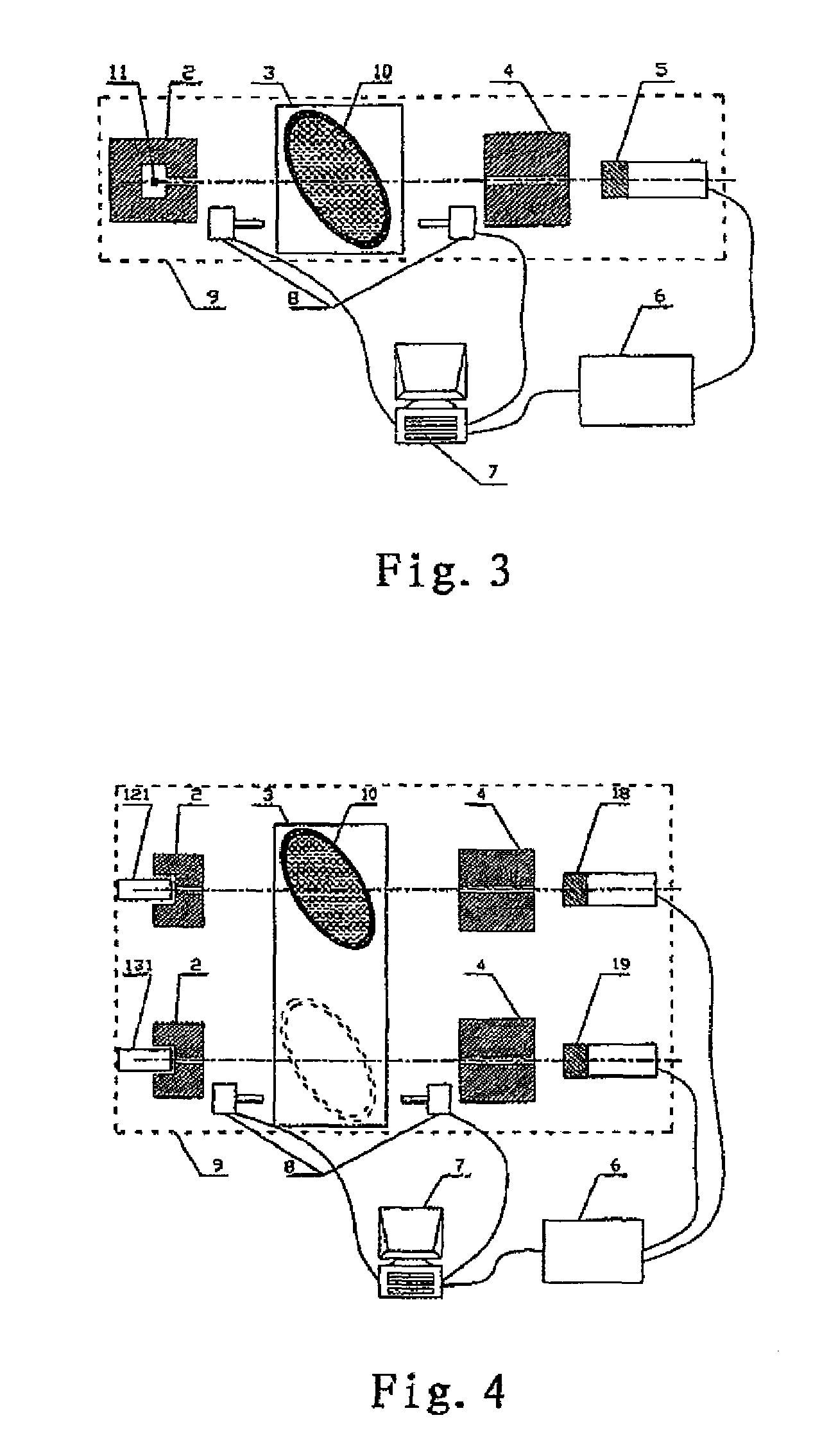

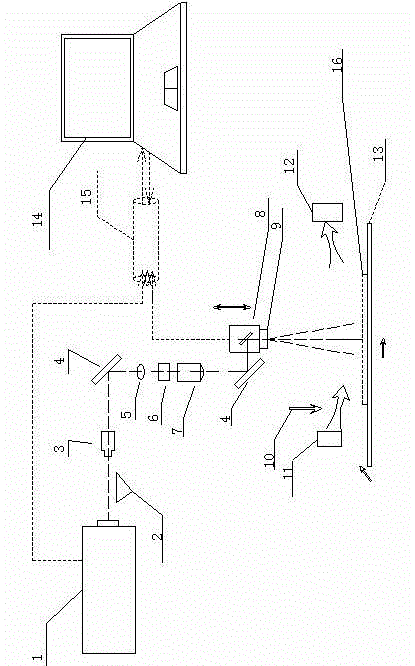

Method and an apparatus for liquid safety-detection with a radiation source

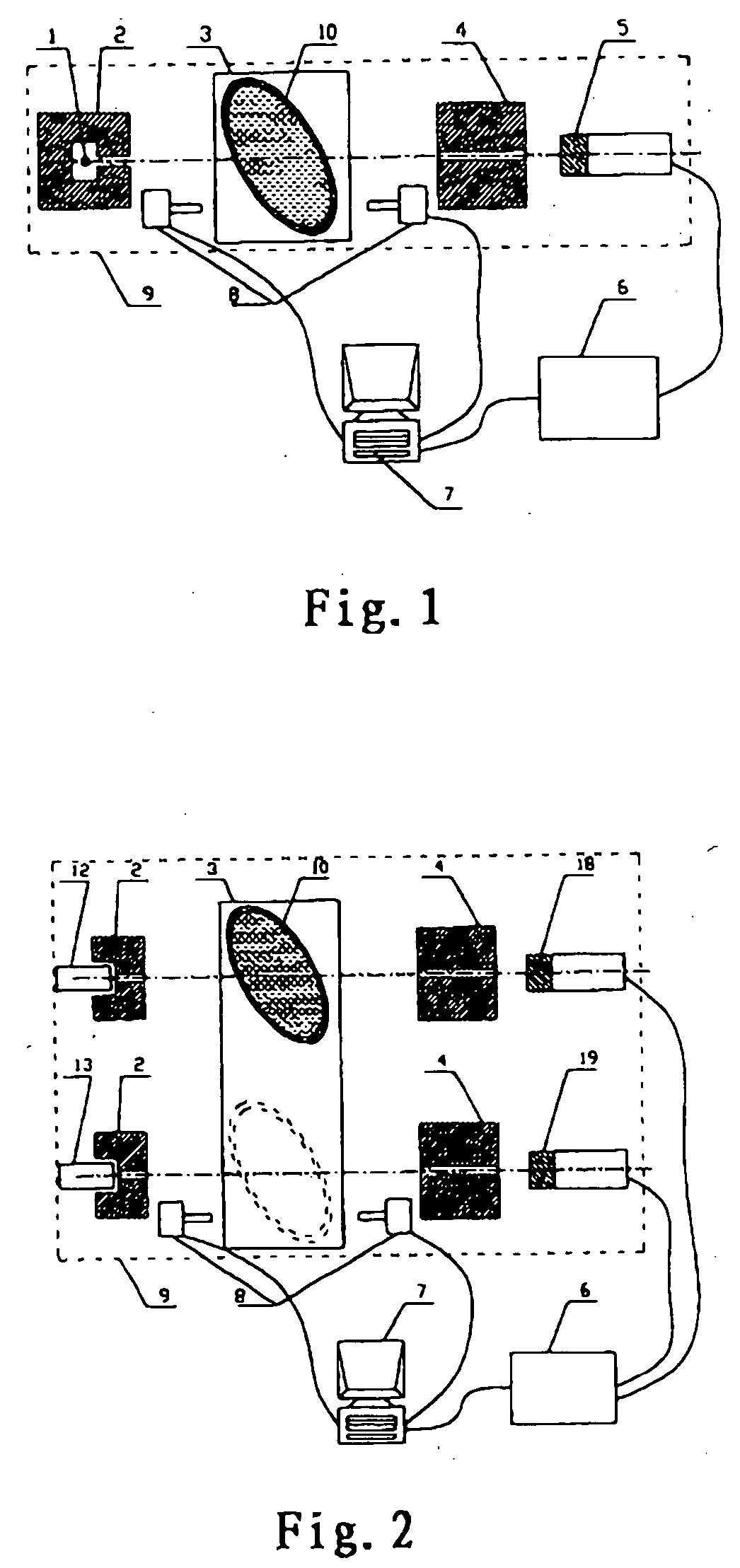

ActiveUS20060115044A1Reduce coverage areaImprove accuracyGirdersJoistsInterference resistanceData acquisition

A method and an apparatus for liquid safety-detection with a radiation source relate to a radiation detecting technology field. The main steps of the method of the invention are: an article to be detected being conveyed into an operation zone within a radiation shield field; the ray emitted from a radiation source passing through the article to be detected, and being received by a detector; the detector transmitting the received ray signal to a data collector; the data collector amplifying and forming the ray signal, and transmitting such data and the data collected by thickness measuring probing heads to a data processing computer; and the data processing computer processing the two groups of data to derive the density and atomic number of the detected liquid, comparing the result with the densities and atomic numbers of dangerous articles in a existing database, and displaying the detected information of the detected article. Comparing to the prior art, the invention is not subjected to the affection of the outside package of an article and has great anti-interference, and has the features of small volume, high accuracy of detection, easy shielding, and high use safety and reliability.

Owner:TSINGHUA UNIV +1

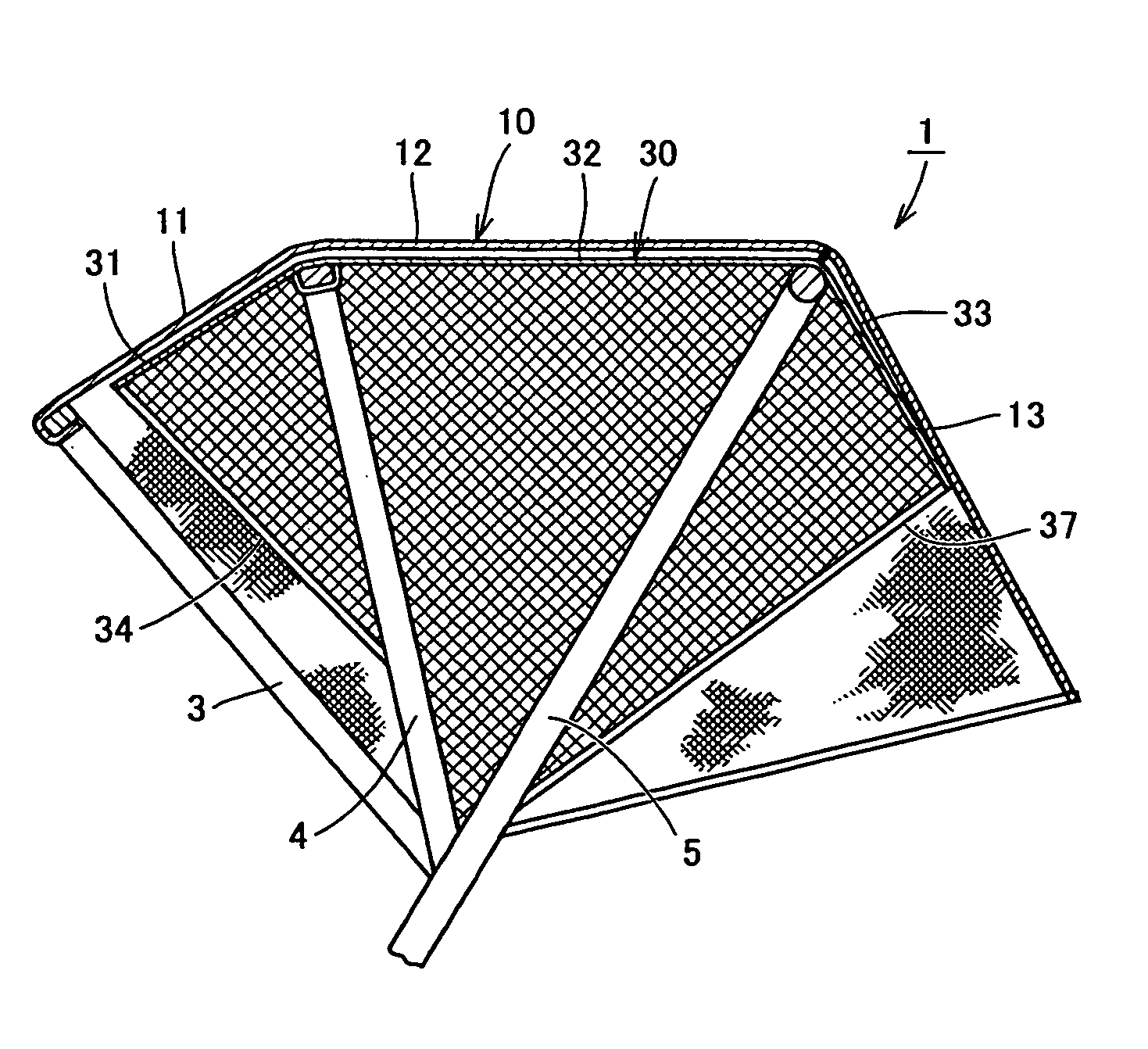

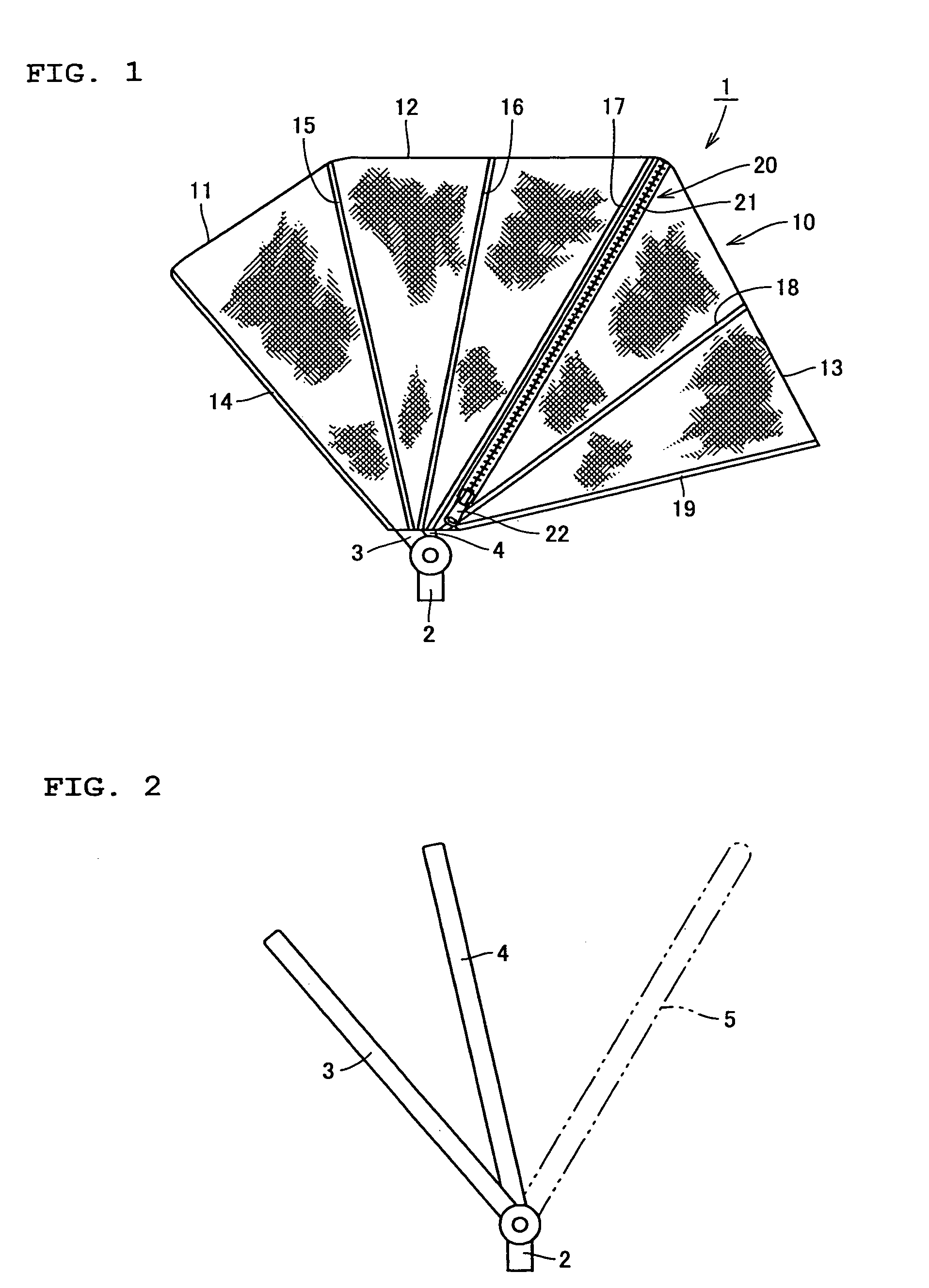

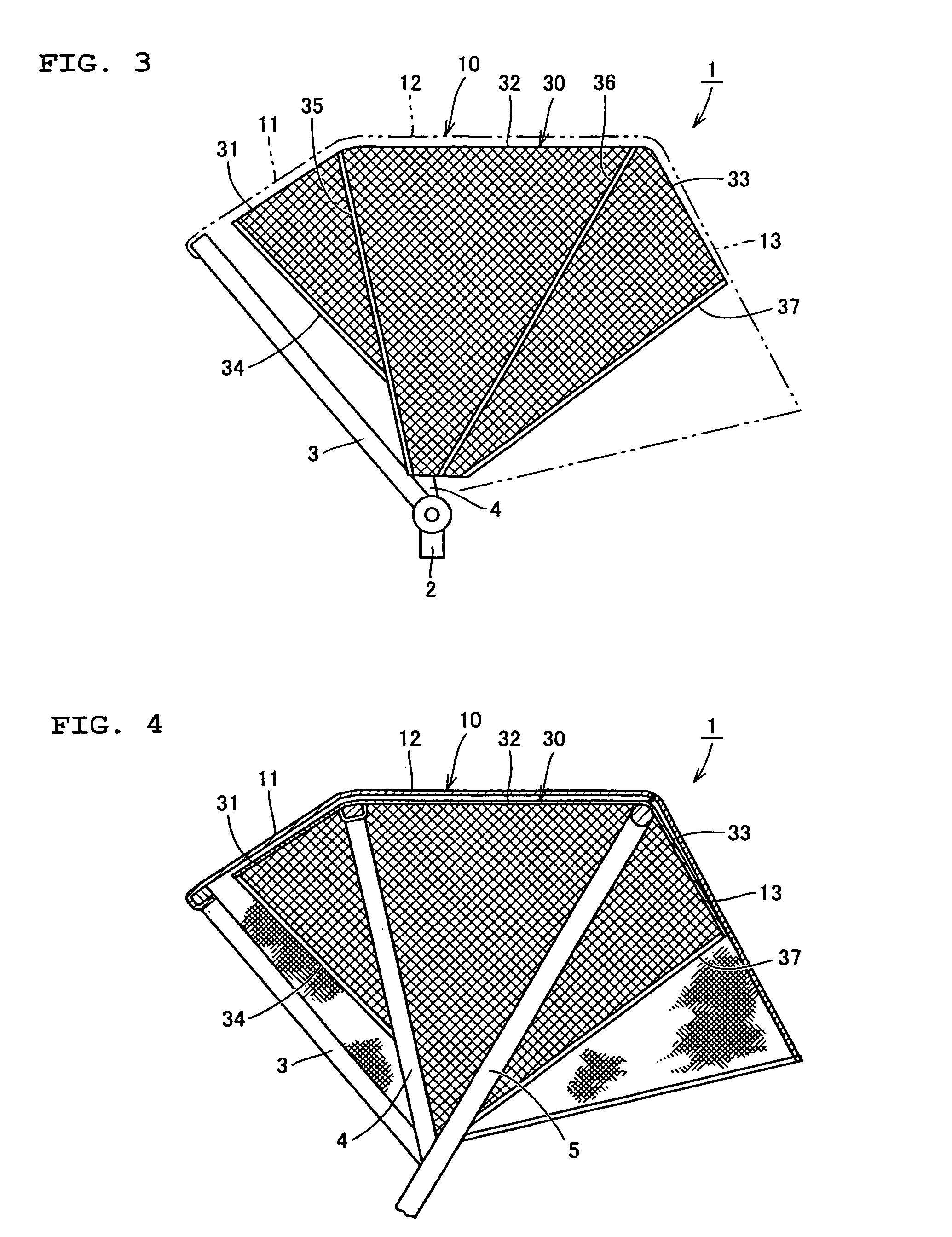

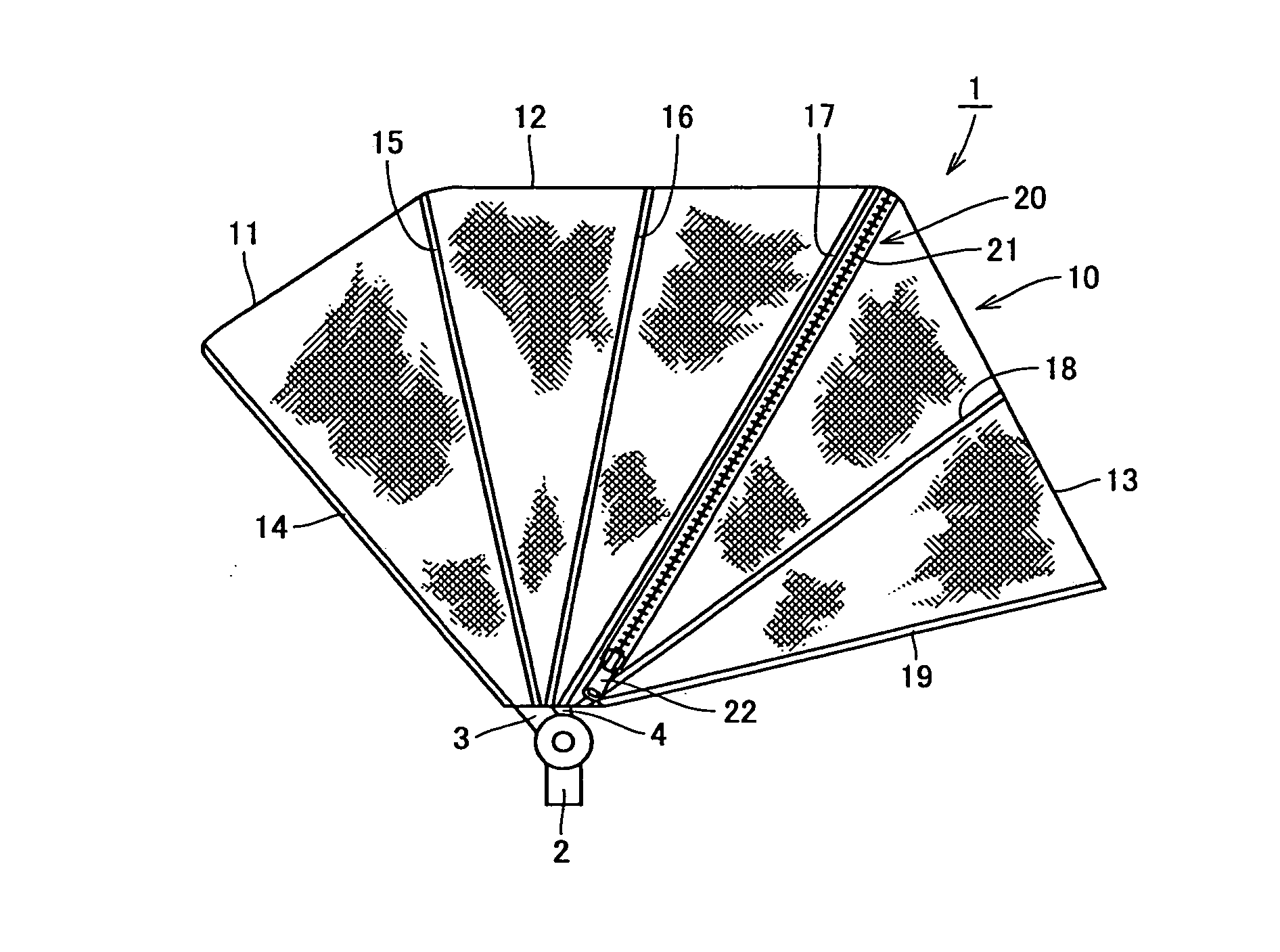

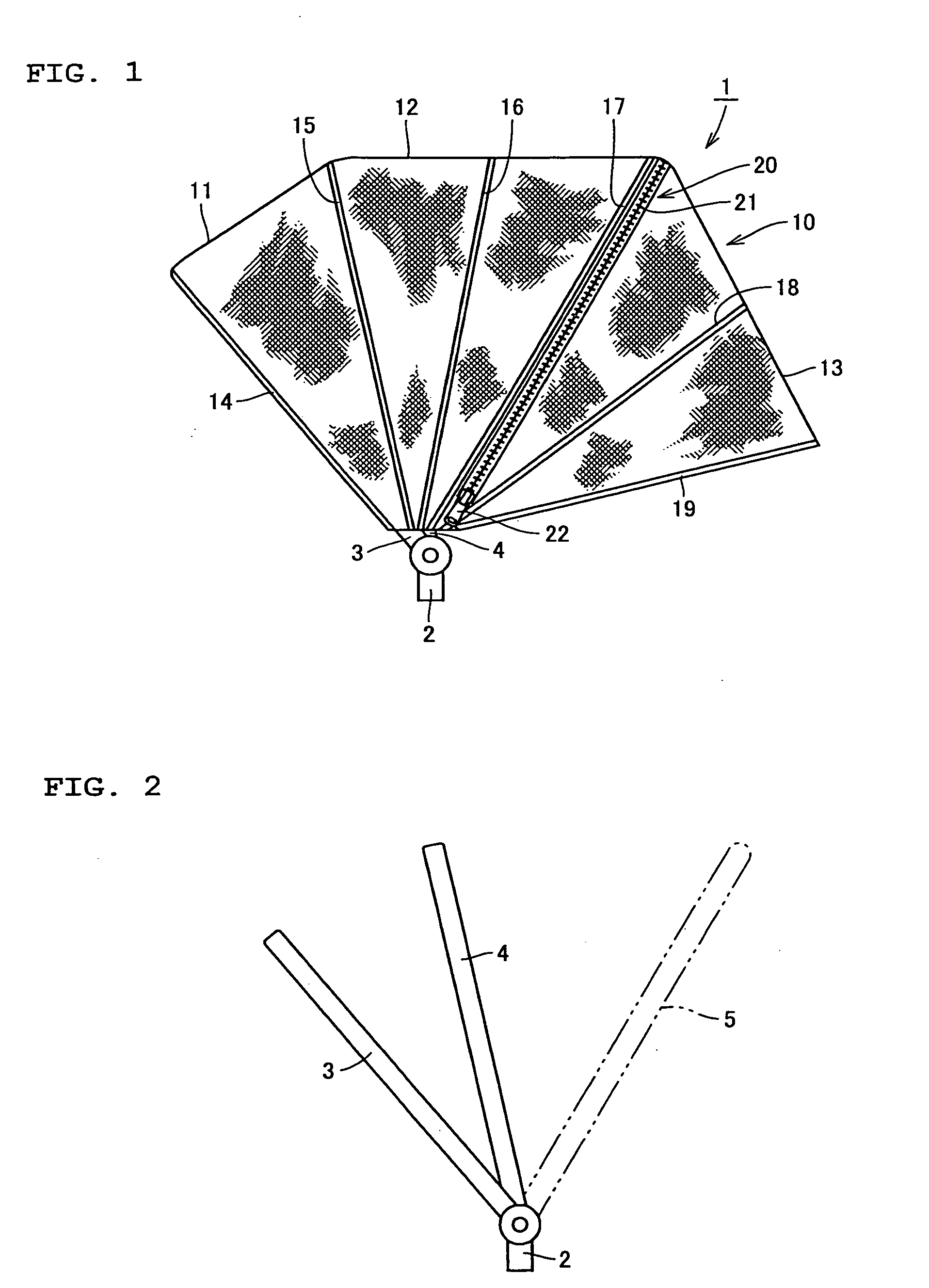

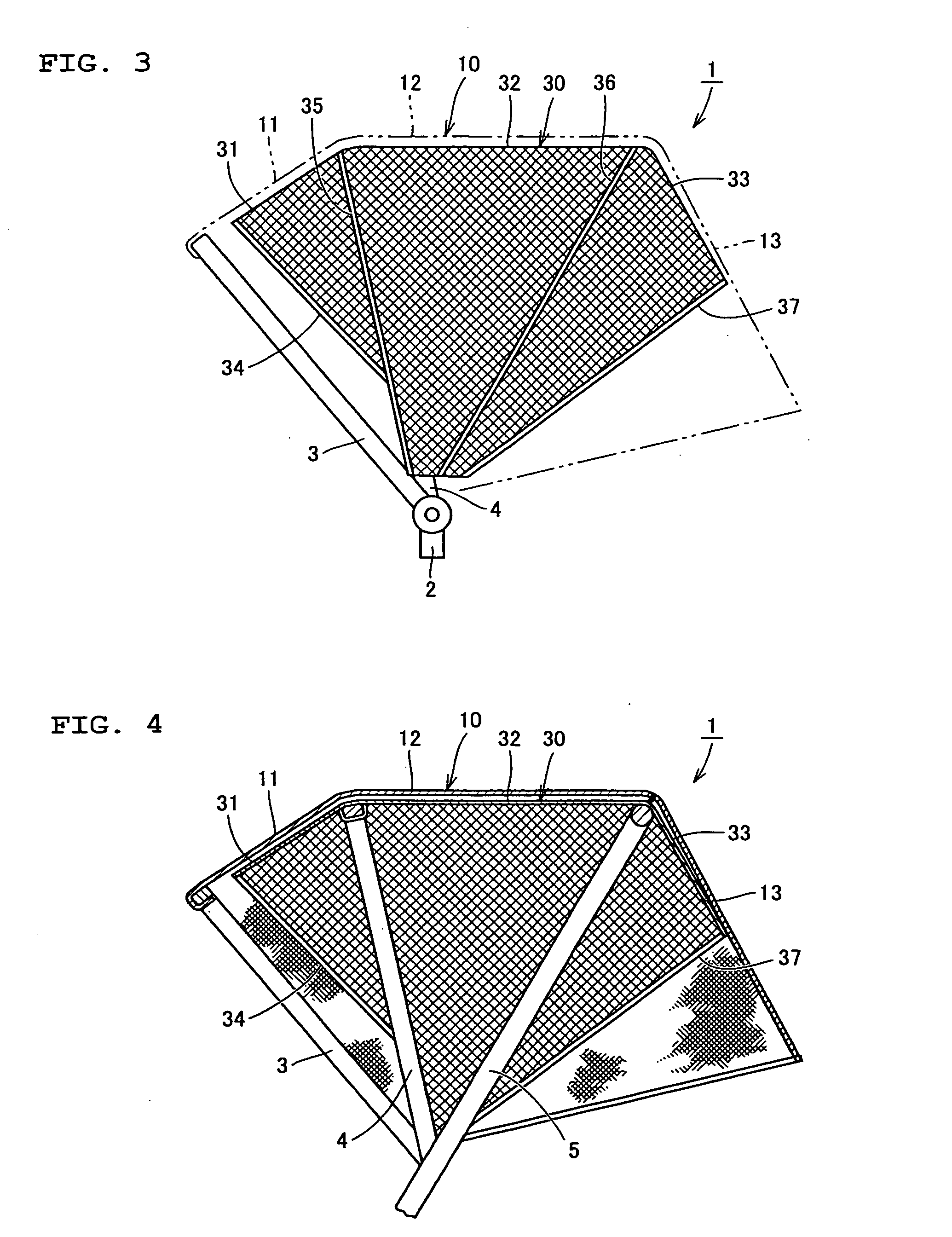

Baby-care implement provided with hood

InactiveUS7118173B2Improve shadingImprove breathabilityCarriage/perambulator accessoriesTents/canopiesEngineeringMechanical engineering

Owner:APRICA CHILDRENS PROD

Capacitive touch screen

ActiveCN103164100AReduce scratchesReduce coverage areaInput/output processes for data processingScratchingEngineering

The invention discloses a capacitive touch screen. A conductive groove is arranged in the surface of the touch screen, scratching of conductive materials in the use process of the capacitive touch screen is reduced, due to the groove structure, covering areas of the conductive materials are reduced, resistance is reduced, and production cost is reduced.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

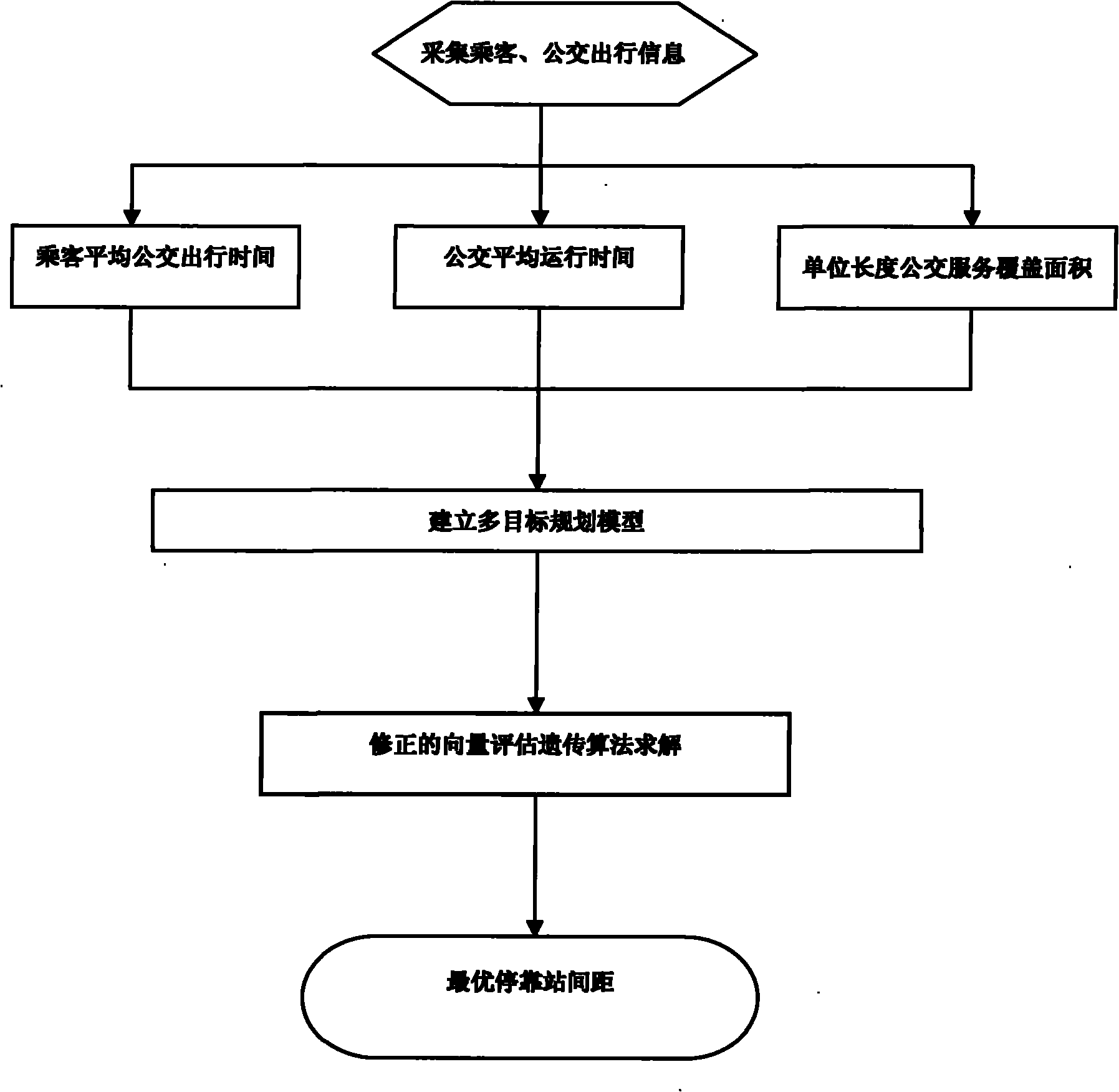

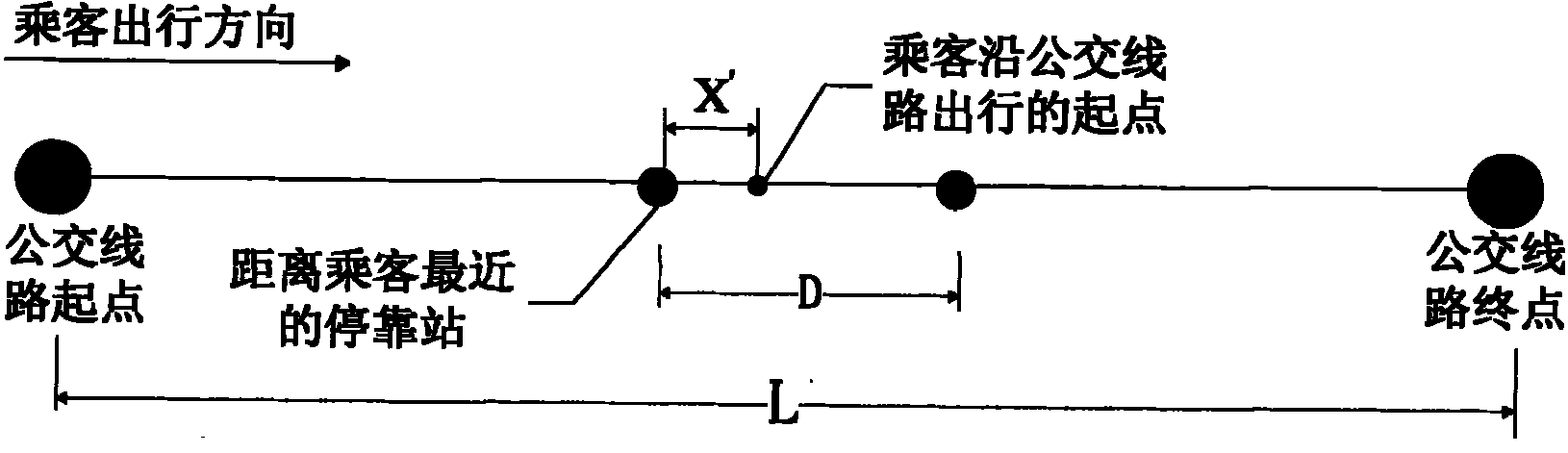

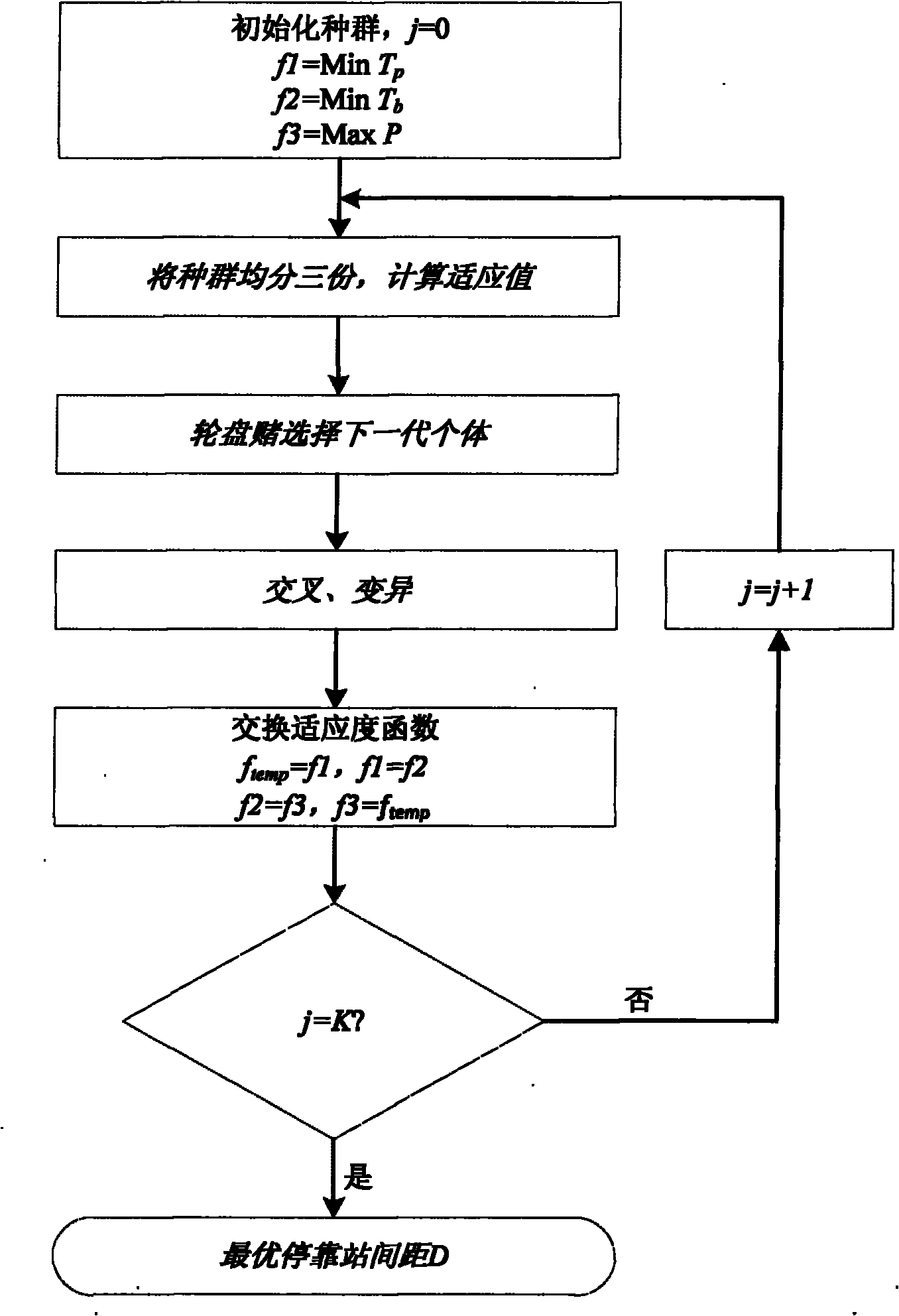

Method for setting stop stations of urban bus line

InactiveCN101944288AImprove rationalityImprove accuracyRoad vehicles traffic controlGenetic algorithmRunning time

The invention discloses a method for setting stop stations of an urban bus line, relating to the technical field of urban bus programming. The method comprises the following steps of: establishing a multi-target programming model through the functional relation between the setting of the bus stop stations as well as an averaged passenger bus travel time, an averaged bus running time and a unit-length bus service cover area; and solving by adopting a correctional vector estimating genetic algorithm to obtain an optimum bus stop station setting scheme. The method in the invention fully takes the influence of the setting of the bus stop stations on passengers, bus operations and urban bas systems into account and ensures that the cover area of the bus service is as large as possible under the condition of ensuring that the passenger bus travel time and the bus running time are as short as possible. Compared with the prior art, the method greatly improves the setting reasonableness and accuracy of the bus stop stations and has the important significance on the urban bus programming.

Owner:SOUTHEAST UNIV

Base station system performance measurement system in a GSM radio communication network

ActiveUS8185124B2Expand coverageReduce coverage areaSubstation equipmentTransmissionQos quality of serviceResource consumption

The invention relates to a system an a method for self optimizing a radio communication network comprising a plurality of radio cells, the system means for monitoring the network resource consumption and quality parameters individually for each cell, and means for distributing the network traffic dynamically between neighboring radio cells in order to maintain satisfactory quality of service in each radio cell.

Owner:T MOBILE HRATSKA D O O

Method and an apparatus for liquid safety-detection with a radiation source

A method and an apparatus for liquid safety-detection with a radiation source relate to a radiation detecting technology. The main steps of the method of the invention are: conveying an article to be detected into an operation zone within a radiation shield; allowing a ray beam to be emitted from the radiation source, to pass through the article to be detected, and to be received by a detector; transmitting the received ray signal to a data collector by the detector; amplifying and forming the ray signal, and transmitting such data to a data processing computer by the data collector, and transmitting a data collected by thickness measuring probing heads to the data processing computer by the same; and processing a data from the data collector and a data from the thickness measuring probing heads to derive the density and atomic number of the detected liquid, comparing a result with the densities and atomic numbers of dangerous articles in a existing database, and displaying the detected information of the detected article, by the data processing computer. Comparing to the prior art, the invention is not subjected to the affection of the outside package of an article and has great anti-interference, and has the features of small volume, high accuracy of detection, easy shielding, and high use safety and reliability.

Owner:TSINGHUA UNIV +1

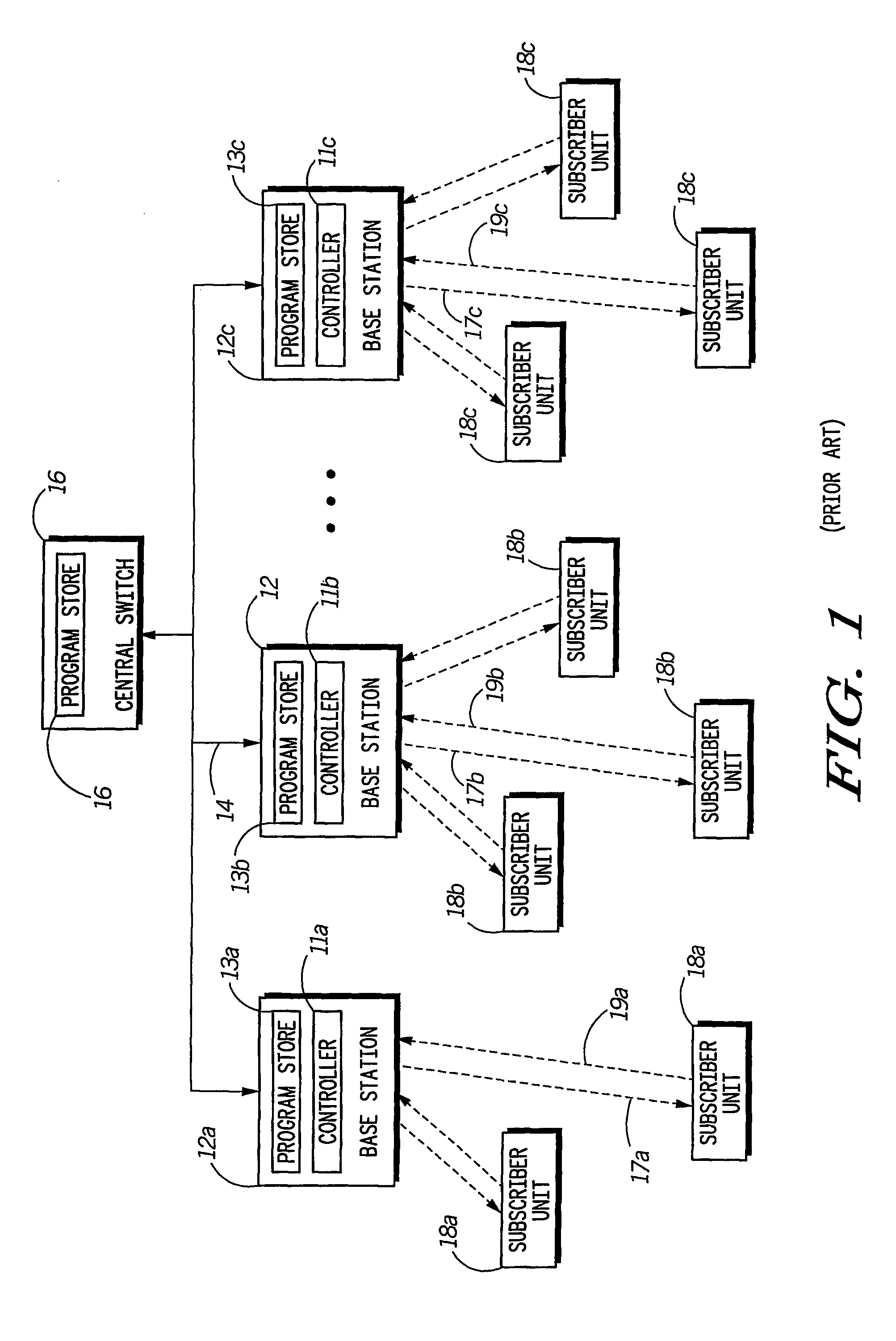

Cellular radio communication systems and methods and equipment for use therein

ActiveUS7783285B2Wide coverageIncreasing output operational power levelPower managementTransmission control/equalisingCellular radioCommunications system

Disclosed is a method of operation for use in a radio communications system comprising a cellular network of base stations and mobile units linked to the base stations. The method comprises detecting that a base station has become isolated from the system, wherein the isolated base station has lost at least one link to other base stations but is still in radio communication with its mobile units and changing an output power level of said isolated base station relative to an output power level of one or more selected co-channel base stations of neighboring cells of the cellular system, whereby the range of communications provided by said isolated base station is changed to a different finite value relative to that provided by the said co-channel base stations.

Owner:MOTOROLA SOLUTIONS INC

Colored filter with grating structure

ActiveCN101546003AImprove light energy utilizationReduce coverage areaOptical filtersNon-linear opticsLuminous energyLight filter

The invention discloses a colored filter with a grating structure, which mainly comprises a substrate, a black matrix, a color filter layer, a protective layer and an ITO conducting film and is characterized in that the substrate is covered with a dielectric layer, the refractive index of the dielectric layer is larger than 1.65, the color filter layer is an embedded submicron grating which consists of a metal layer and a low-index dielectric layer, the metal layer is arranged at one side close to the substrate, the low-index dielectric layer is arranged at one side far from the substrate, and the refractive index of dielectric material is smaller than 1.65; and grating units of different colors are obtained by different grating structural parameters. The invention is based on the submicron embedded metal grating structure, has same transmitted spectrum characteristic under TE and TM polarized lights, has high utility rate of luminous energy, improves the purity of output light and can be manufactured in super large breadth.

Owner:SUZHOU UNIV +1

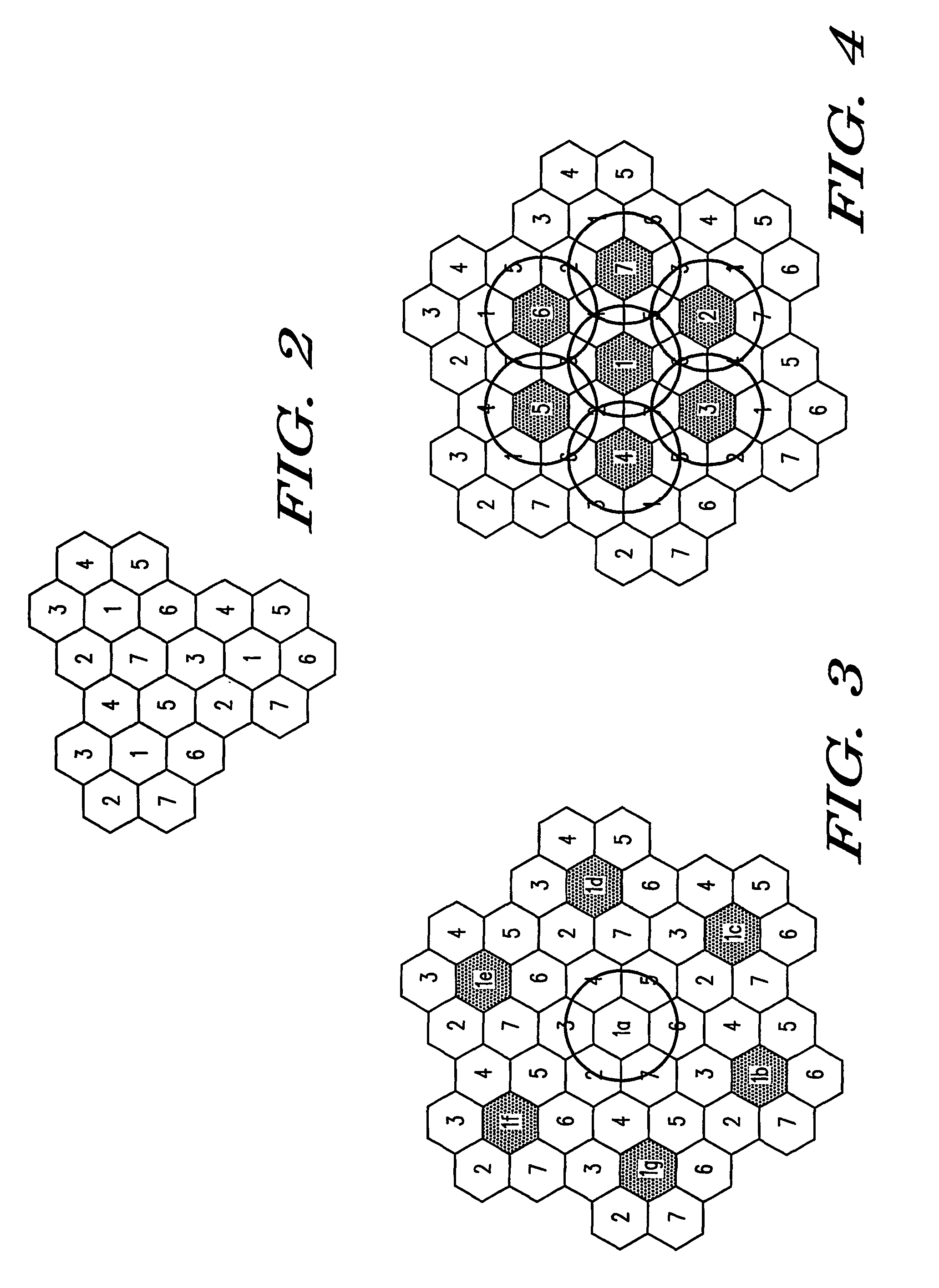

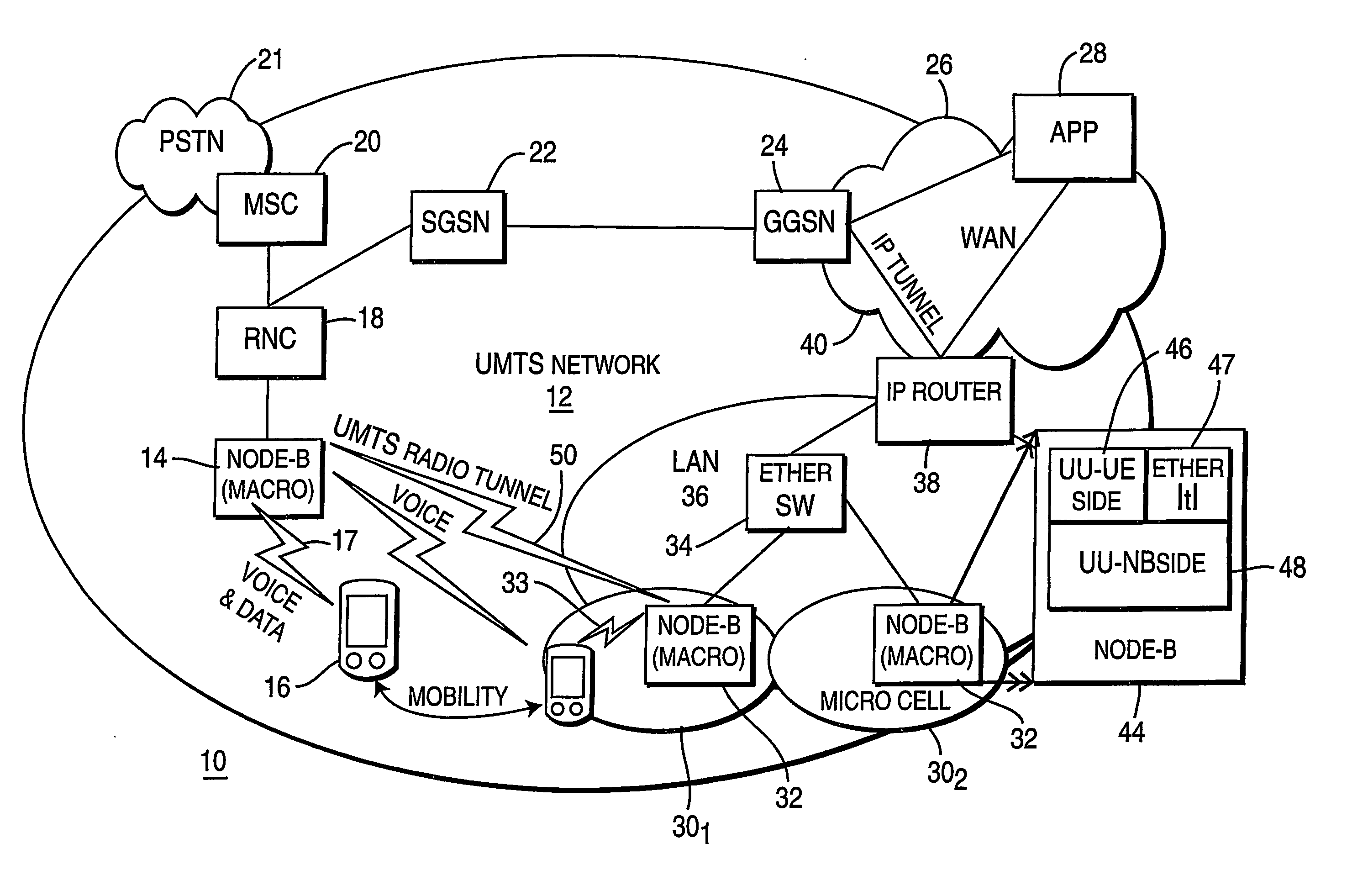

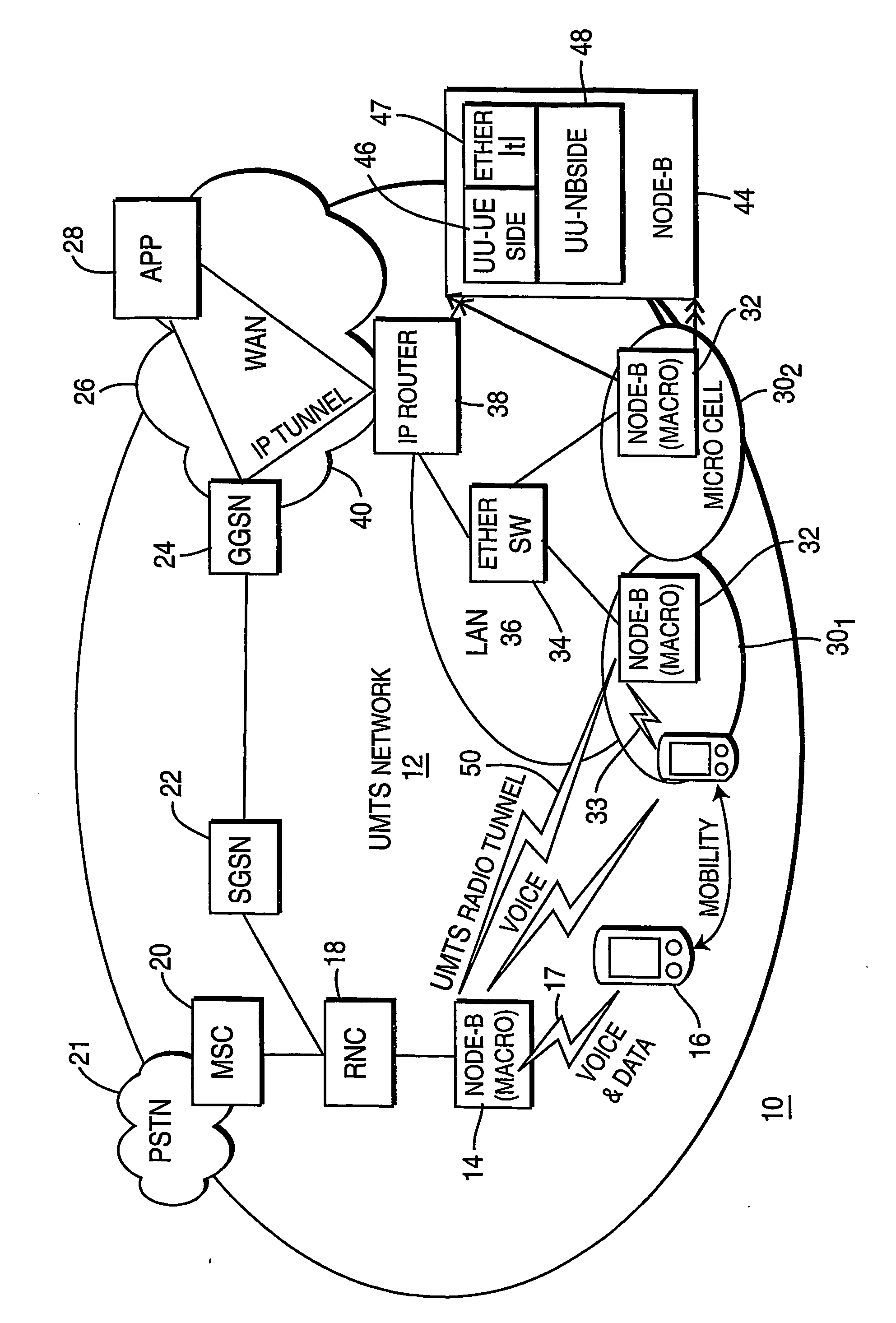

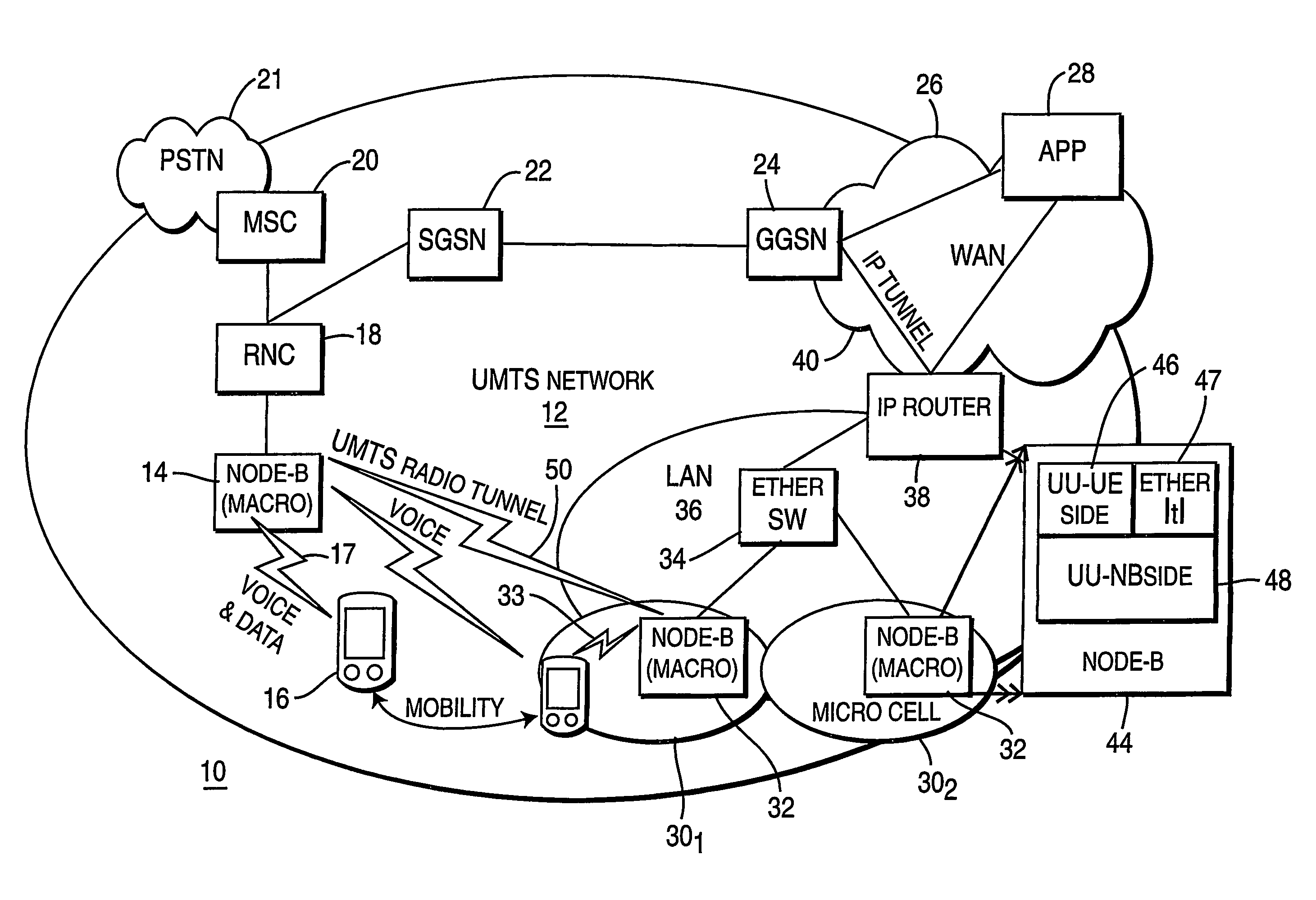

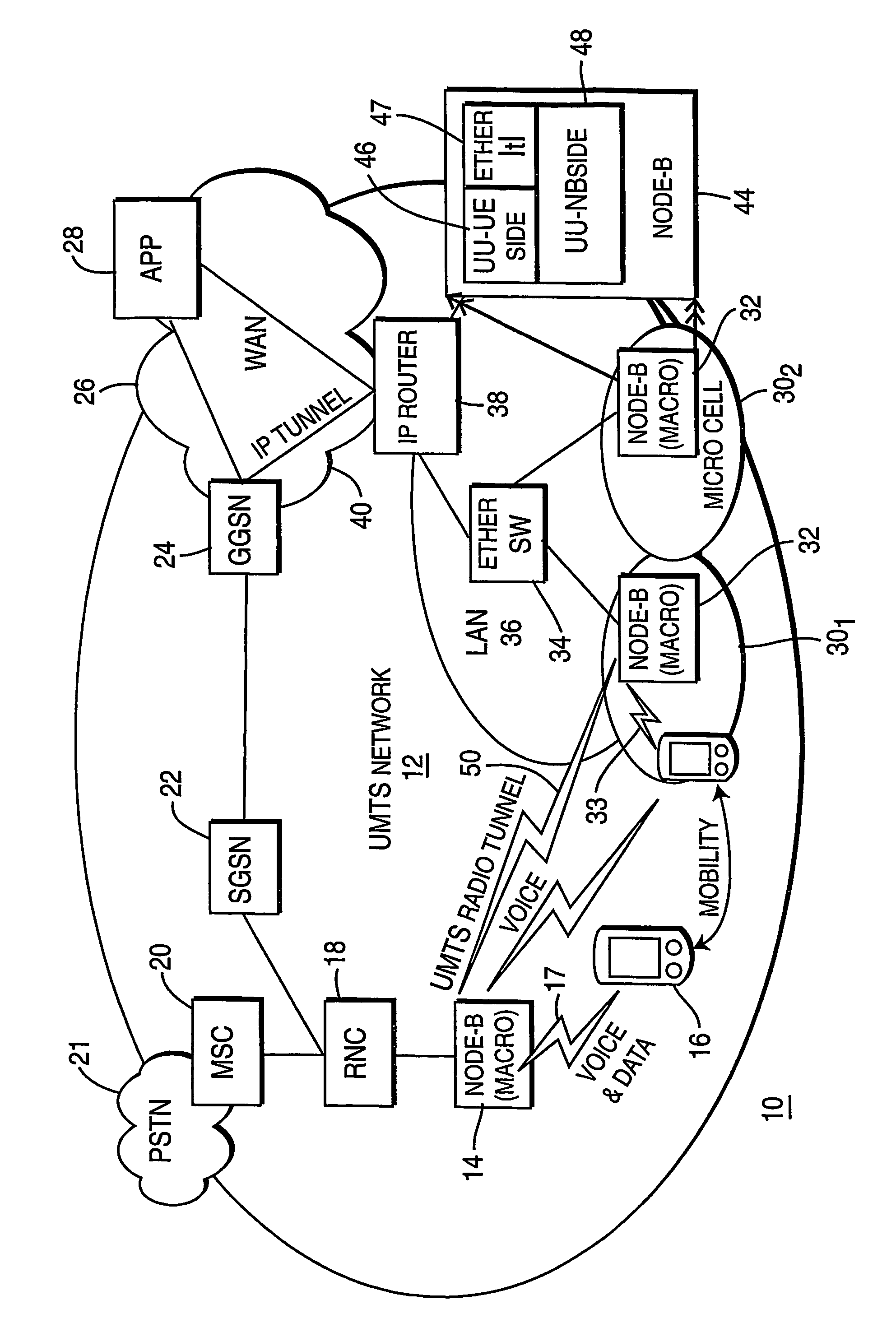

Overlay micro cell structure for universal mobile telephone system network

ActiveUS20060154668A1Increase capacityLow costNetwork topologiesConnection managementTelecommunications linkCommunications system

A wireless telephony communications system includes at least one macro cell for communicating both voice and data with a mobile communications device across a first wireless link and at least one micro cell for communicating data with the mobile communications device across a second wireless communication link. Each micro cell communicates signaling information through the macro cell via a wireless link to a control element that manages the micro cells. Using a wireless link to communicate signaling between each micro cell and the control element in the UMTS system eliminates the need for a wired back haul link, thereby reducing access costs.

Owner:THOMSON LICENSING SA

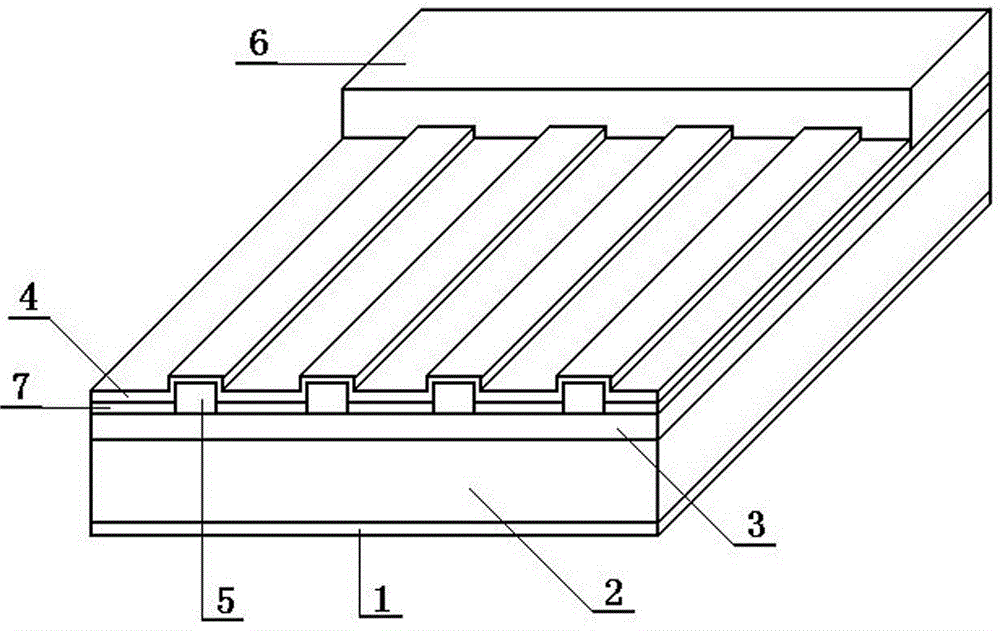

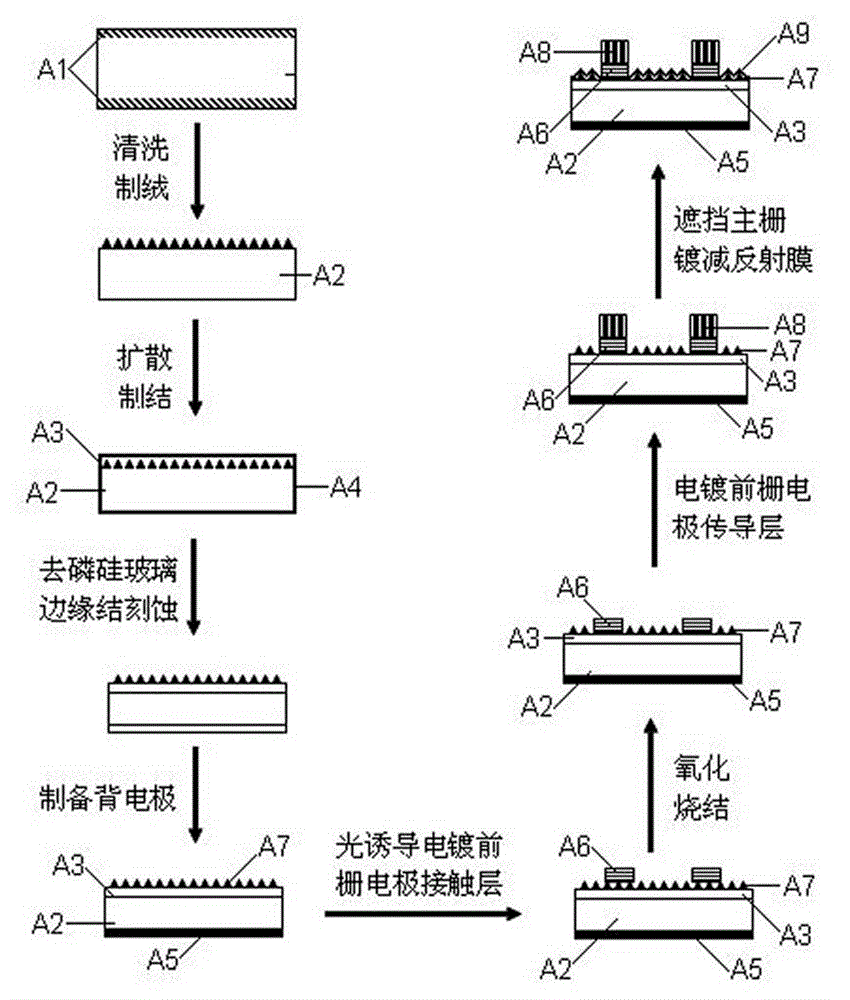

Crystalline silicon solar cell with high-photoelectric conversion efficiency and manufacturing method thereof

InactiveCN102881732AReduce shadow lossTightly boundFinal product manufactureSemiconductor devicesOhmic contactCrystalline silicon

The invention discloses a crystalline silicon solar cell with high-photoelectric conversion efficiency and a manufacturing method thereof. The cell comprises a crystalline silicon P-N node substrate, a back electrode and a front gate electrode, wherein the back electrode is in ohmic contact with the P area of the crystalline silicon P-N node substrate; the front gate electrode is in ohmic contact with the N area of the crystalline silicon P-N node substrate; the front gate electrode is wrapped under the antireflection layer and comprises a SiO2 layer and an antireflection layer; the SiO2 layer is positioned on the surface of the N area of the crystalline silicon P-N node substrate; and the antireflection layer is arranged on the SiO2 layer. The manufacturing method comprises a cleaning and flocking step, a diffusing and knotting step, a phosphorus-washing and etching step, a back electrode-preparing step, a photoinduced front gate electrode electroplating step, an oxidizing and sintering step, a front gate electrode electroplating step and an antireflection layer preparing step. The photoinduced front gate electrode electroplating step and the oxidizing and sintering step are adopted, so that the cell has the characteristics of simple production process, high efficiency, low cost, low front gate electrode shade loss of the solar cell, low contact resistance and body resistance, uneasiness in line breaking of the thin front gate electrode, low cell surface reflectivity and high photoelectric conversion efficiency.

Owner:YUNNAN UNIV

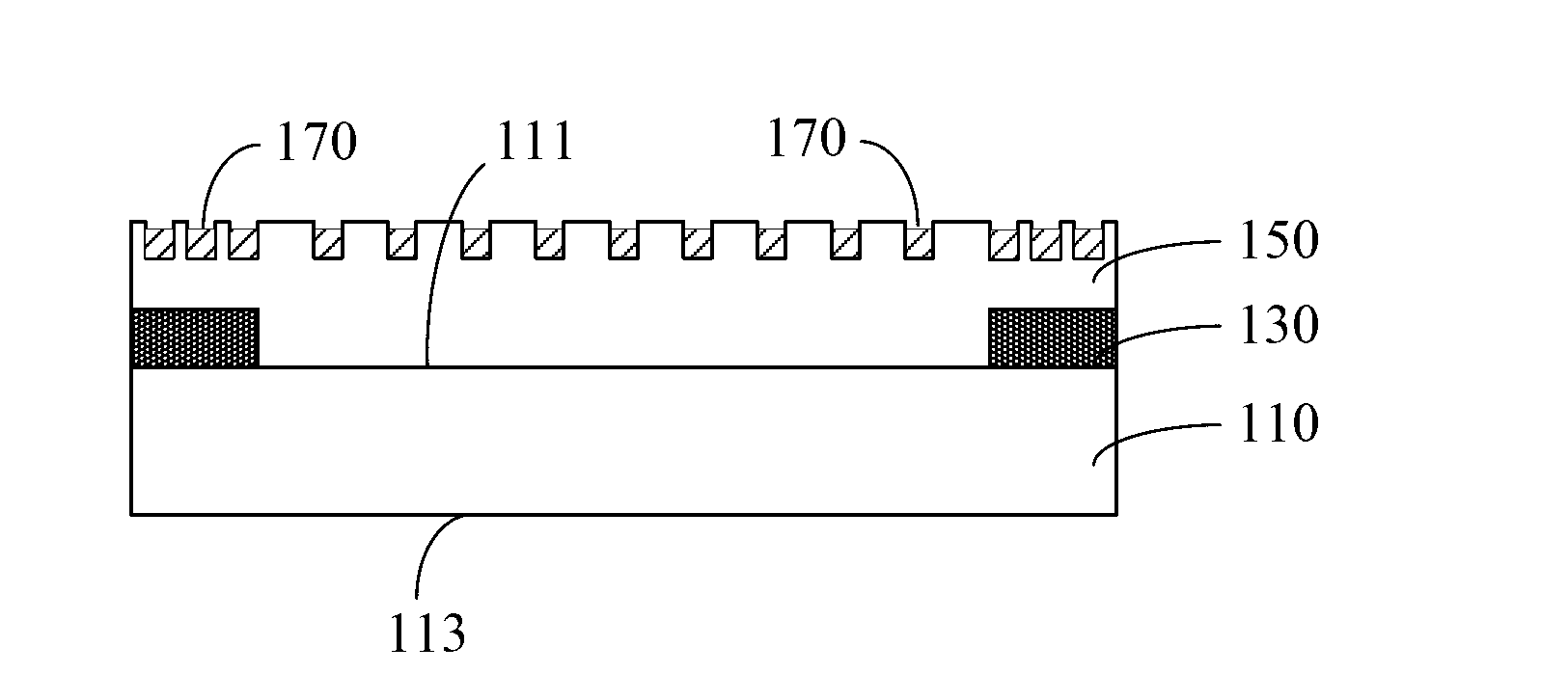

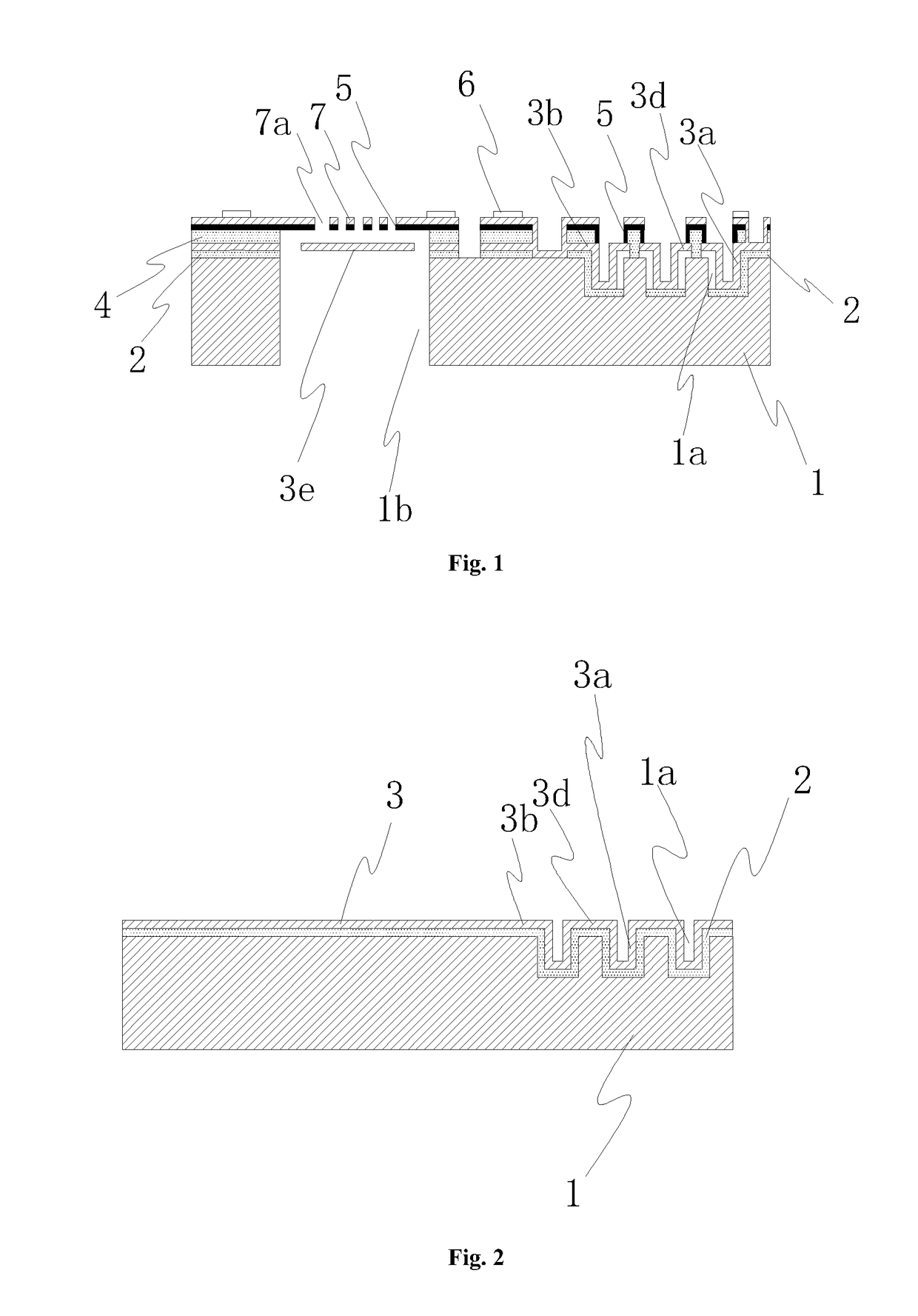

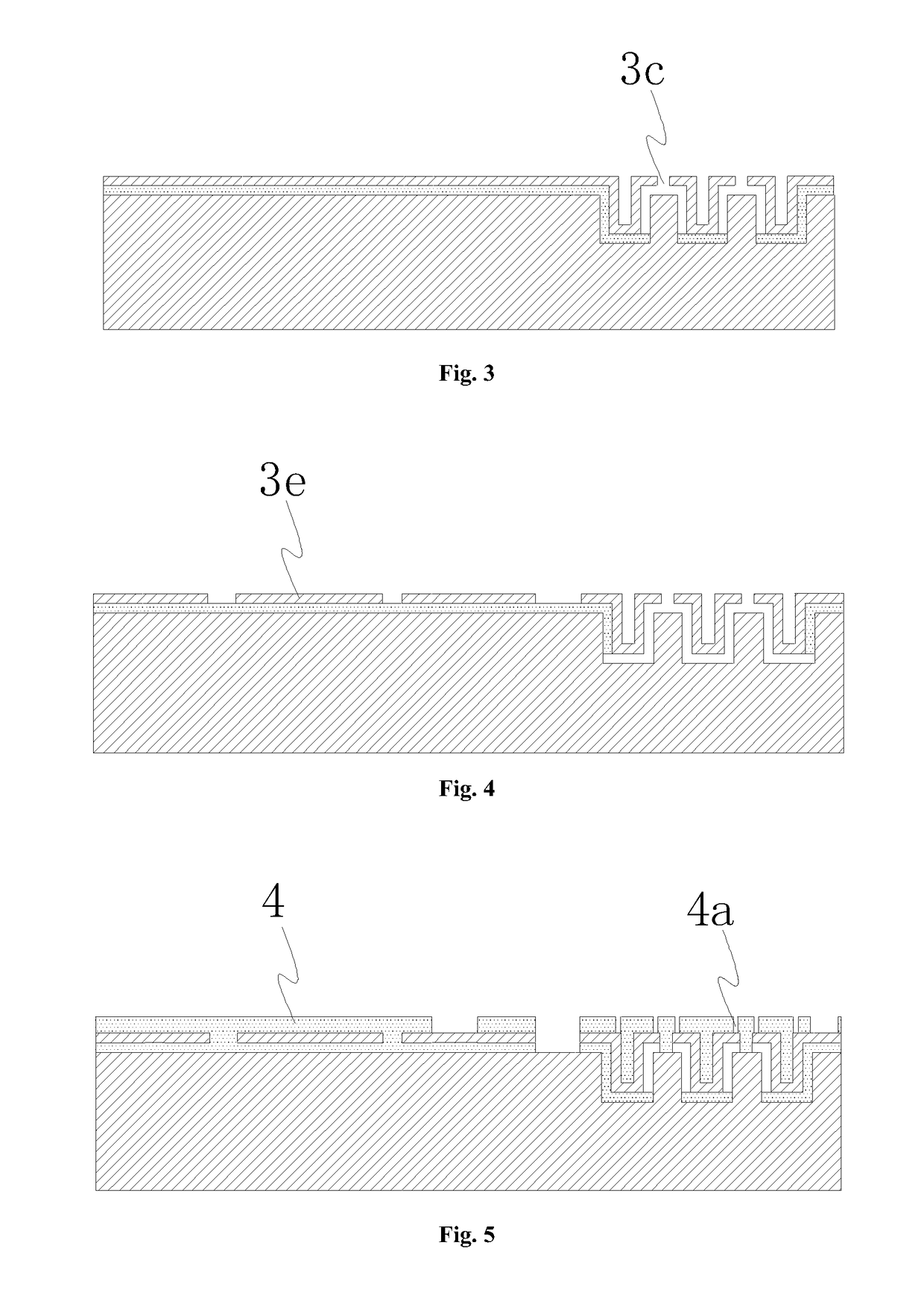

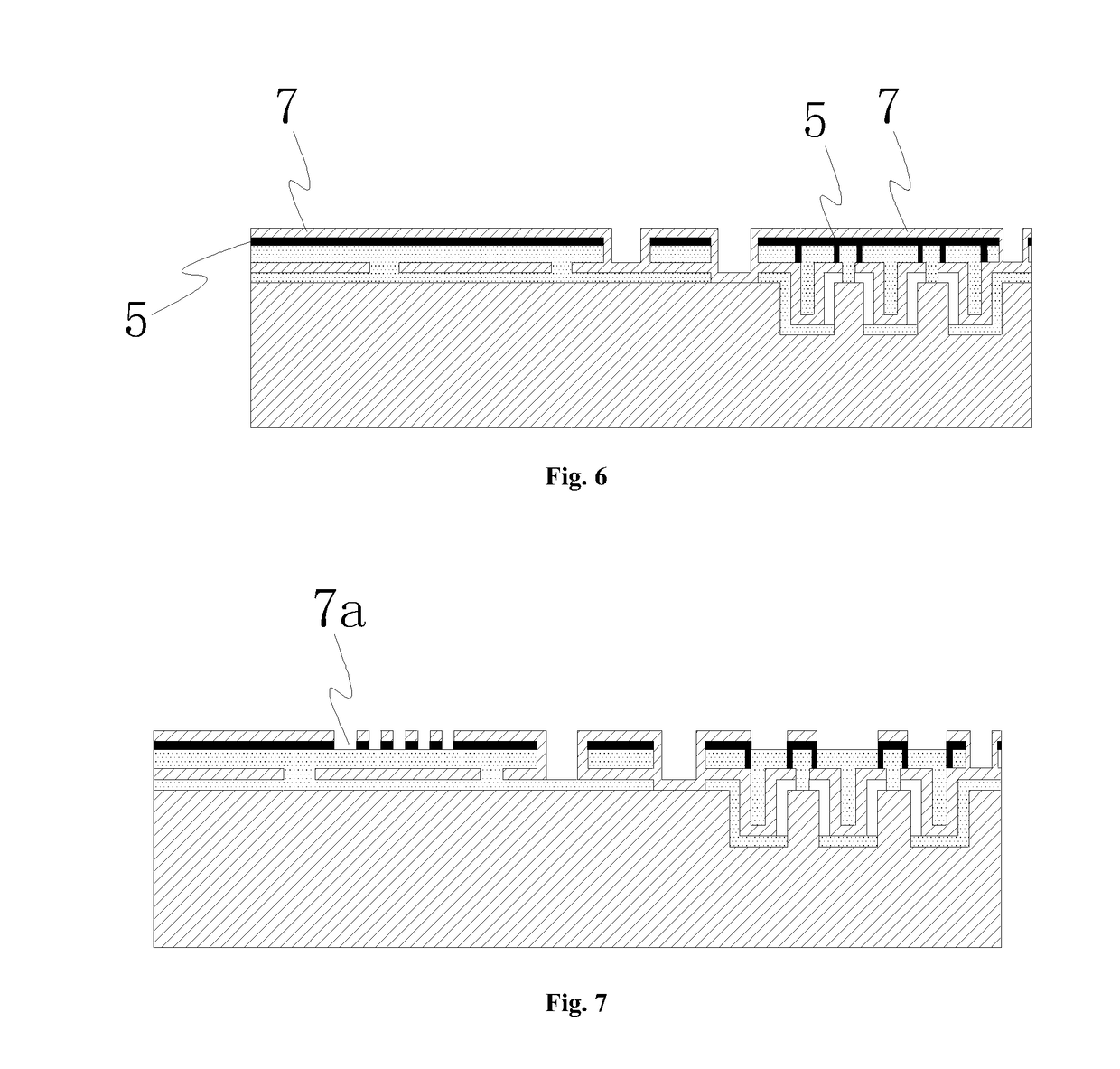

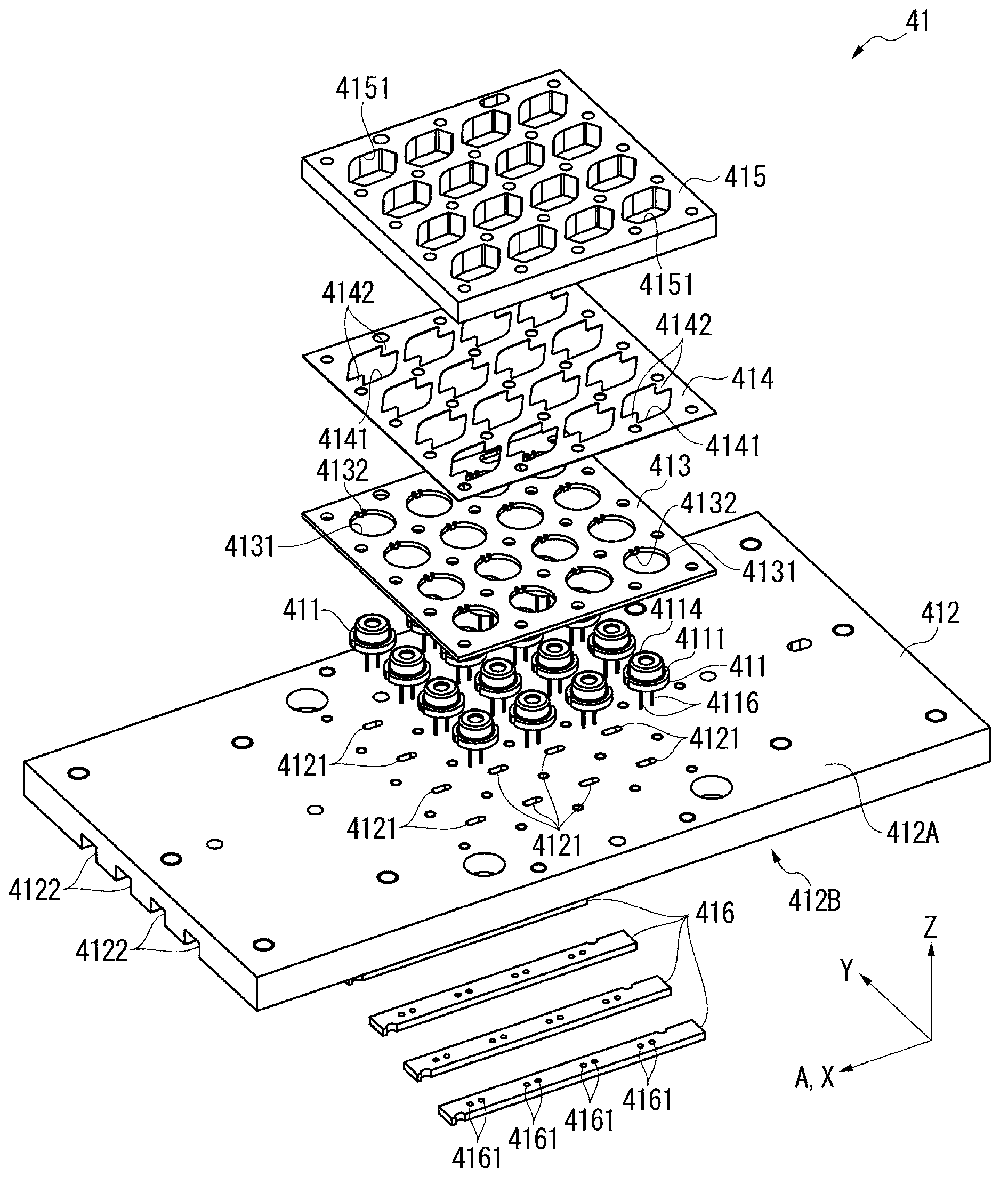

Acoustic sensor integrated MEMS microphone structure and fabrication method thereof

ActiveUS20180359571A1Small sizeIncrease productivityMicrophonesDecorative surface effectsEngineeringMems microphone

An acoustic sensor integrated MEMS microphone structure and a fabrication method thereof. A diaphragm (3e) and back-pole (7) which forms a condenser structure are formed on a substrate (1) having at least one recessed slot (1a) on the top. A sensitive electrode is formed on the substrate (1), the sensitive electrode comprising a fixed portion (3b) fixed on the substrate (1) via a sacrificial layer (2), and a bending portion (3a) inserted into the recessed slot (1a), wherein the bending portion and the side wall of the recessed slot form the condenser structure. The integrated structure integrates the condenser structure of the microphone and condenser structure of the acoustic sensor on a substrate (1), thereby increasing the integration level thereof and reducing the overall size of the package. Meanwhile, the microphone diaphragm (3e) and the sensitive electrode of the acoustic sensor can be fabricated on a same substrate (1) at the same time, from the same material, and using the same fabricating process to increase production efficiency.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

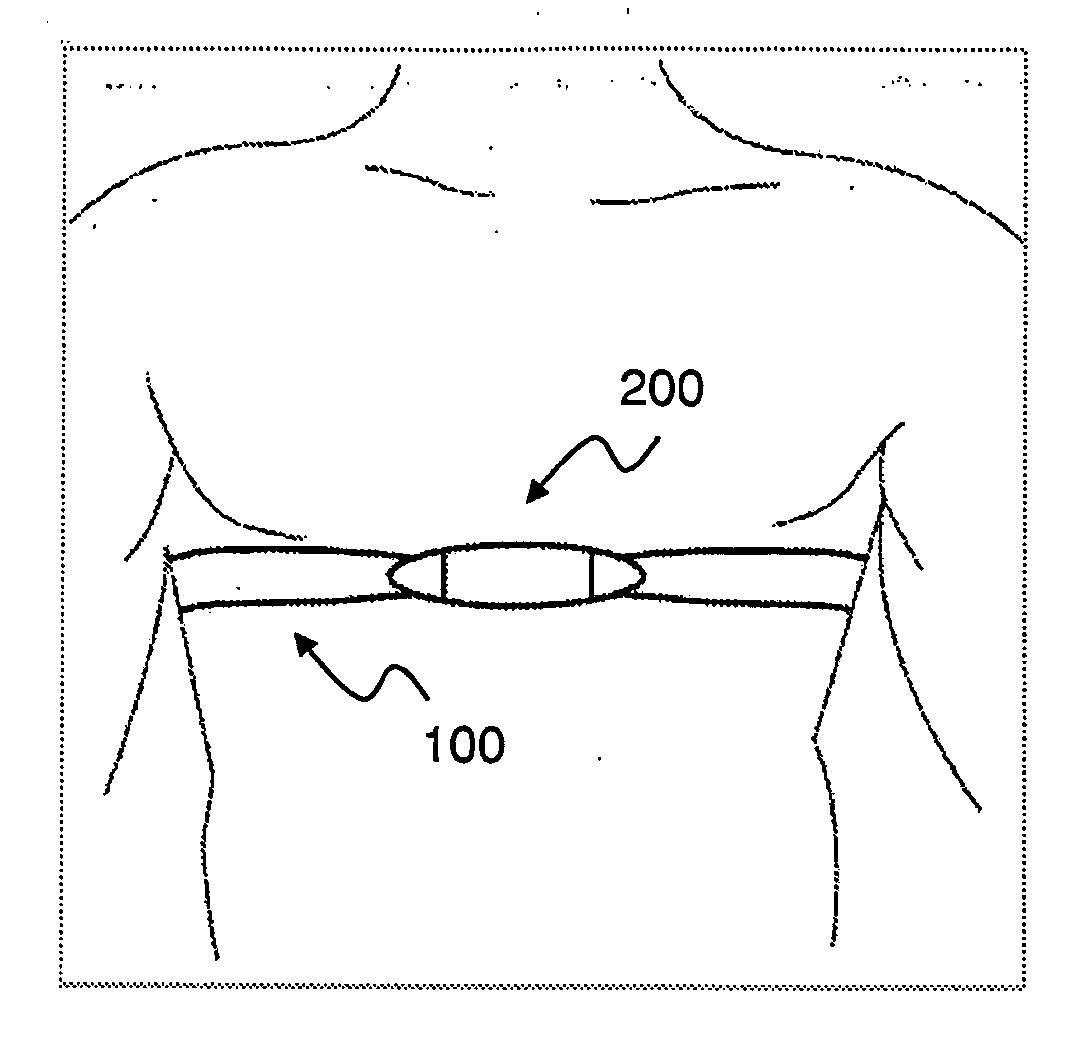

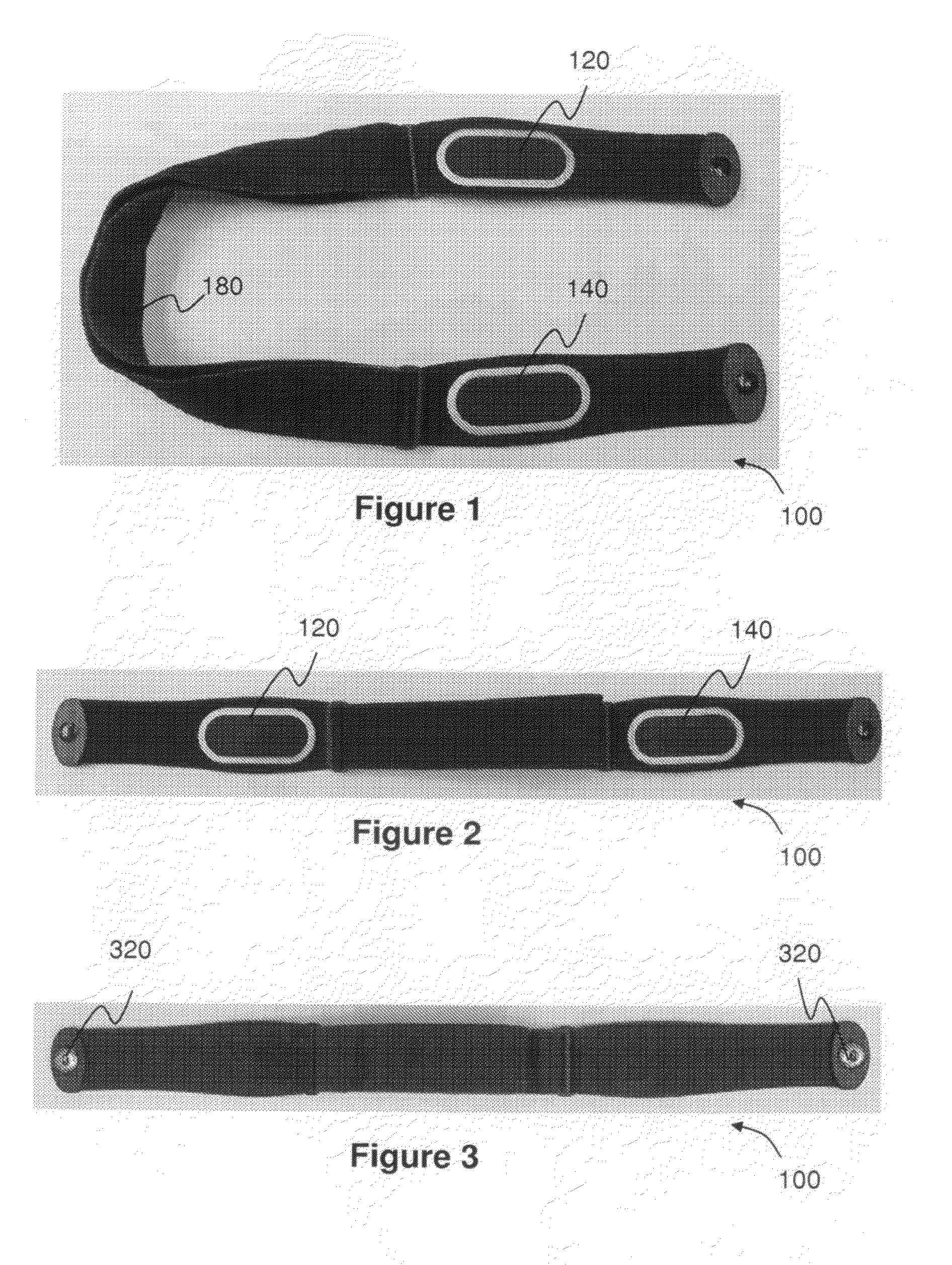

Physilogical signal collection apparatus and performance monitoring apparatus incorporating same

InactiveUS20130131460A1Reduces skin covering areaComfortable to wearElectrocardiographyInertial sensorsSkin contactBiomedical engineering

A physiological signal collection electrode comprises a signal collection pad having a skin contact portion, a signal output pad and an elongate bridging portion interconnecting the signal collection pad and the signal output pad. The signal collection pad, the signal output portion and the bridging portion are integrally moulded of a flexible, conductive and resilient material. The width of the bridging portion is substantially smaller than that of the skin contact portion. A narrowed bridging portion operates to concentrate collected physiological signals collected by the skin contact portion before the signals are output to the signal output pad. An elongate bridging portion reduces skin covering area for better wearer comfort as well as providing better resiliency to the electrode when the bridging portion is extended.

Owner:DAYTON TECH

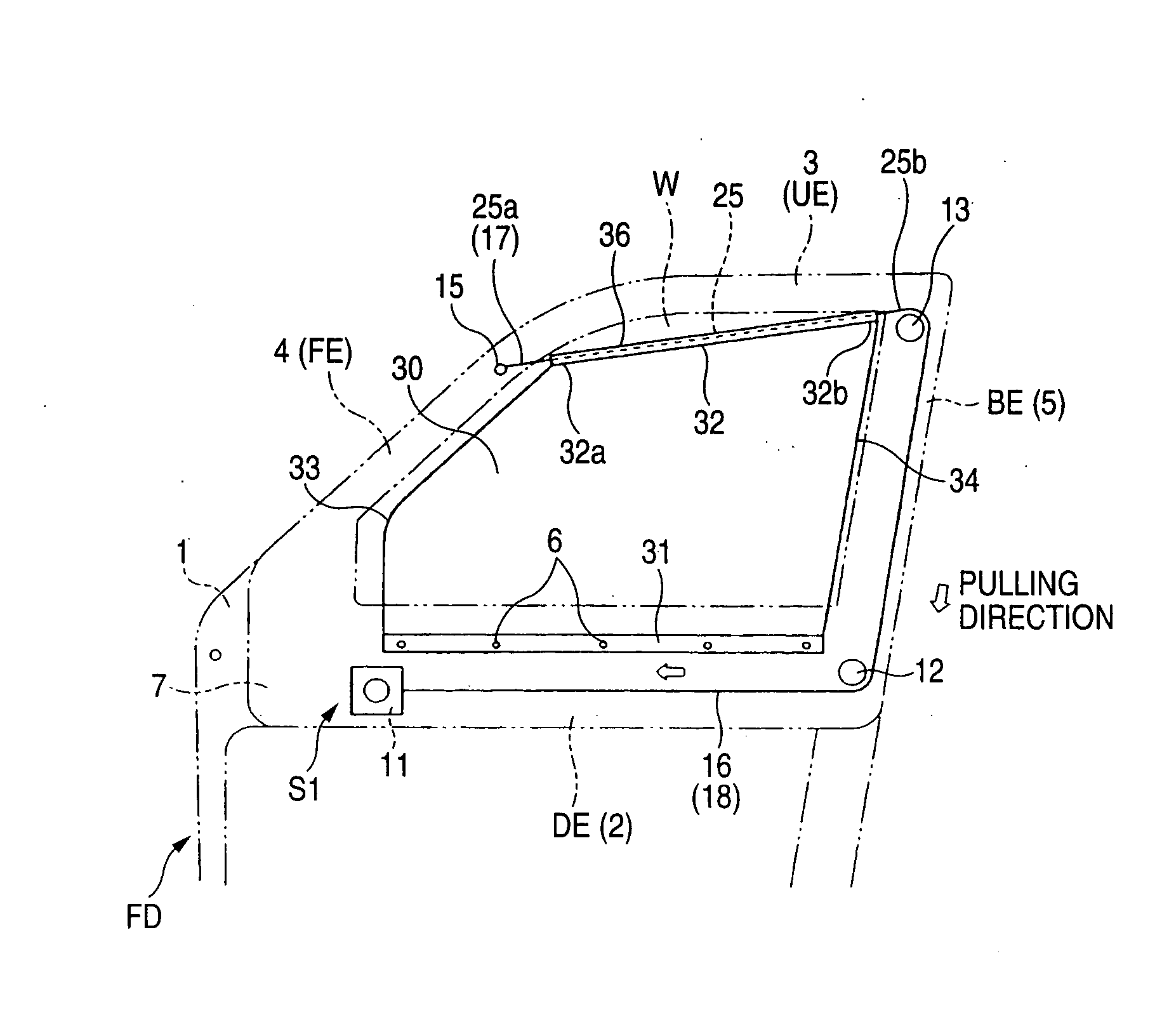

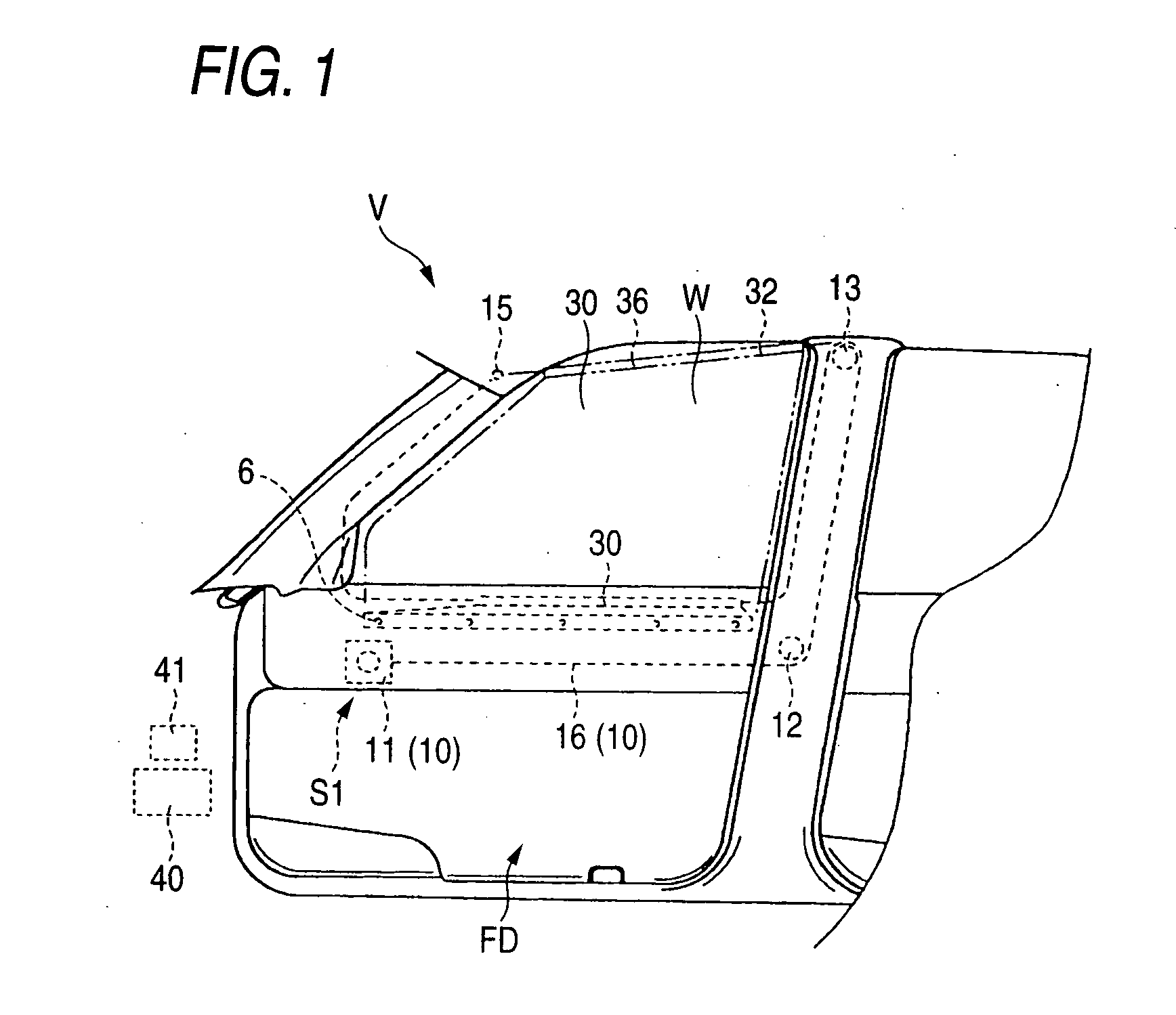

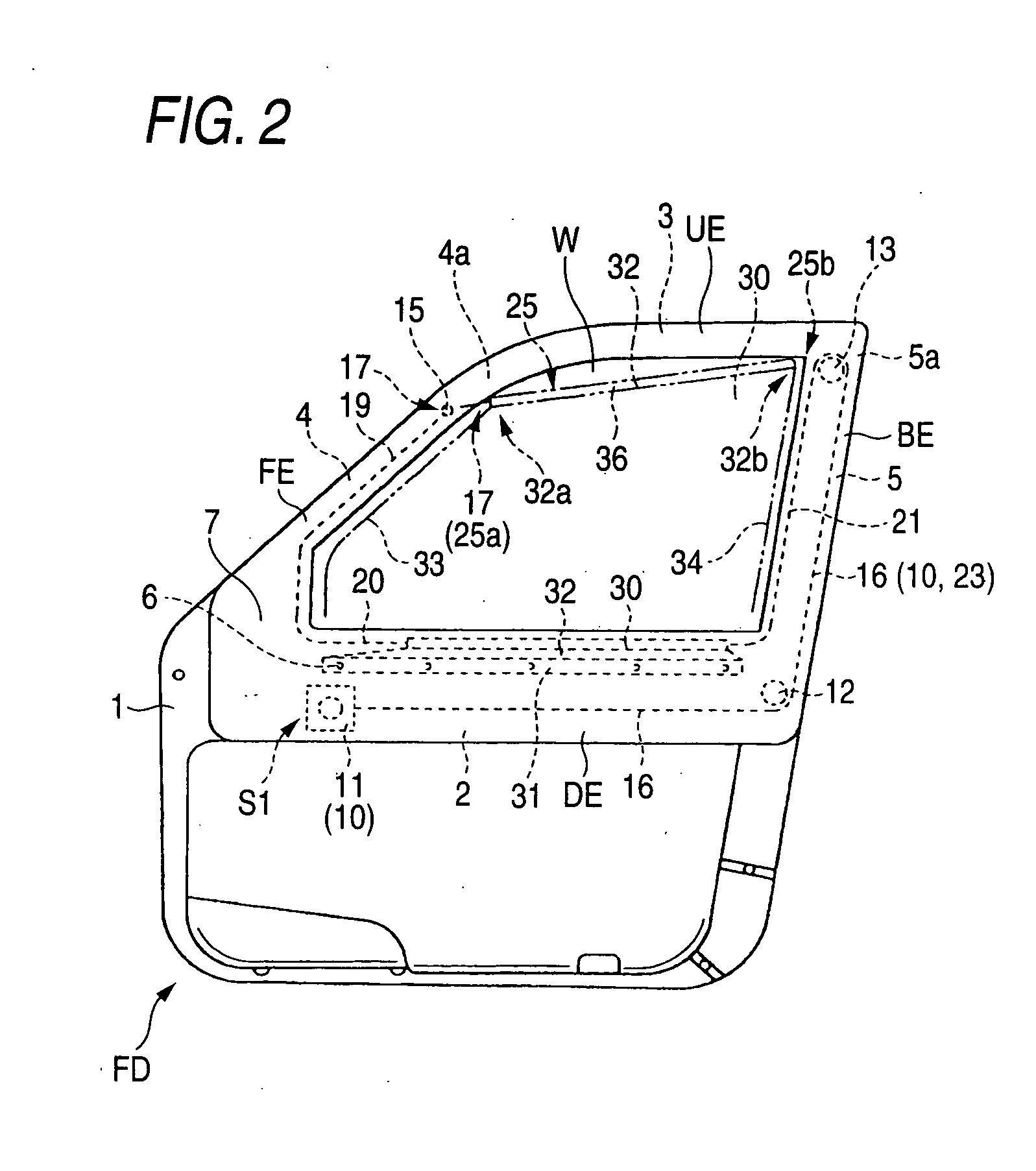

Occupant protection apparatus

InactiveUS20070102126A1Difficulty risePrevent movementWindowsAntiglare equipmentEngineeringMechanical engineering

An occupant protection apparatus includes a cover sheet adapted to be fed out from a peripheral edge of a window of a vehicle, when a pulling unit is activated, so as to cover the window. The pulling unit includes a pulling string having flexibility and a pulling device to which the pulling string is connected so as to be pulled thereby and which is disposed below the window. When the pulling device is activated, the pulling string is pulled such that a portion thereof which extends from a fixed end to where it is supported by a support member becomes a straight line while a portion thereof which is disposed along a lower edge portion of the peripheral edge of the window is caused to rise. The cover sheet includes a passageway portion through which the pulling string is passed on an upper side part thereof and is folded to be accommodated in the window only along the lower edge side of the peripheral edge thereof with the portion of the pulling string which has not yet been activated inserted into the passageway portion so as to be staying therein.

Owner:TOYODA GOSEI CO LTD

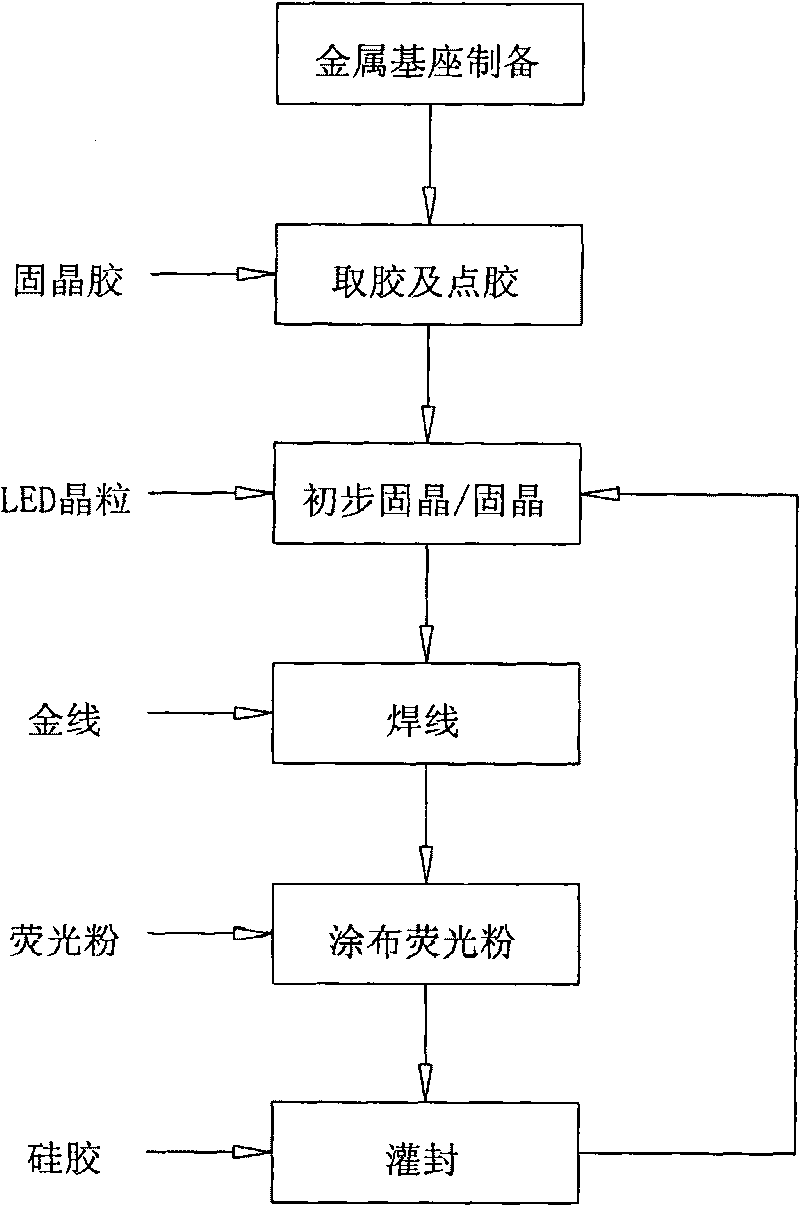

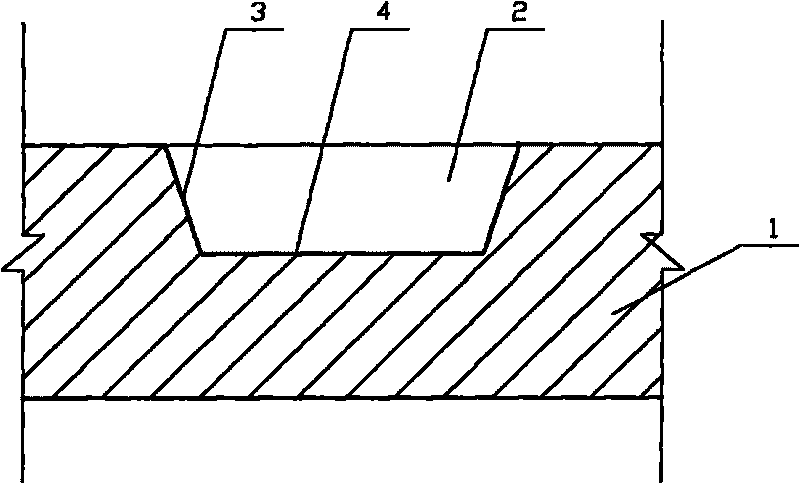

Novel LED die bonding method

The invention relates to a novel LED die bonding method which comprises the steps: firstly, coating a thin layer of die bonding glue on a bottom die bonding surface of a LED crystal particle fixing concave pit with a reflection layer on a metal base; after completion, placing the LED crystal particles at a base die bonding surface dispensed with die bonding glue, compacting and completing primary die bonding, then welding gold thread, coating fluorescent powder, and finally encapsulating by silica gel so as to wholly wrap LED crystal particles in the silica gel, thus completing final die bonding. The traditional LED carry out die bonding by the die bonding glue, while in the invention, only a thin layer of die bonding glue is coated for playing a role of primary die bonding, and finally the die bonding protection is carried out by encapsulating the silica gel. The method does not influence LED solid luminescence, and the light emitted from the periphery thereof is reflected out by the fixing concave pit, thus improving light extraction efficiency.

Owner:SUZHOU ZHONGZE OPTOELECTRONICS TECH

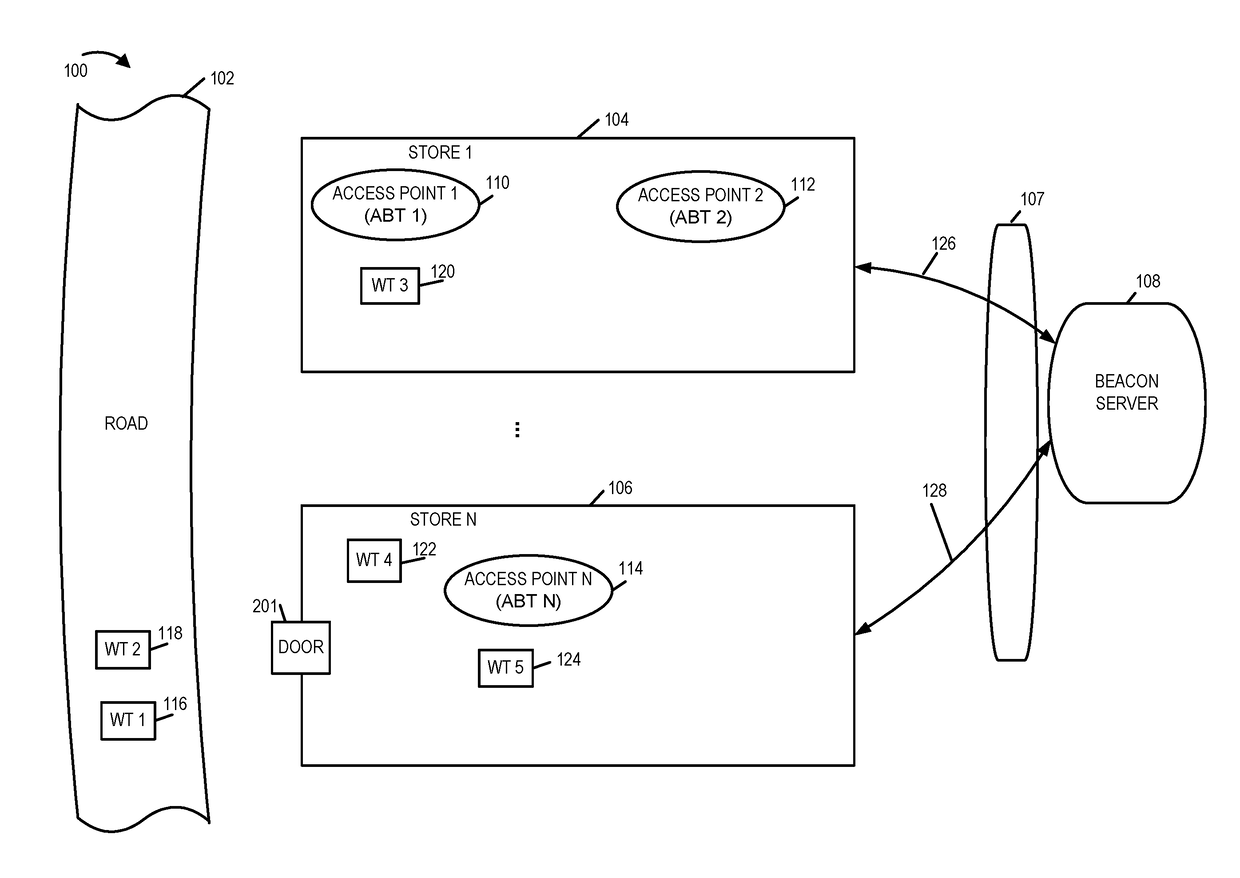

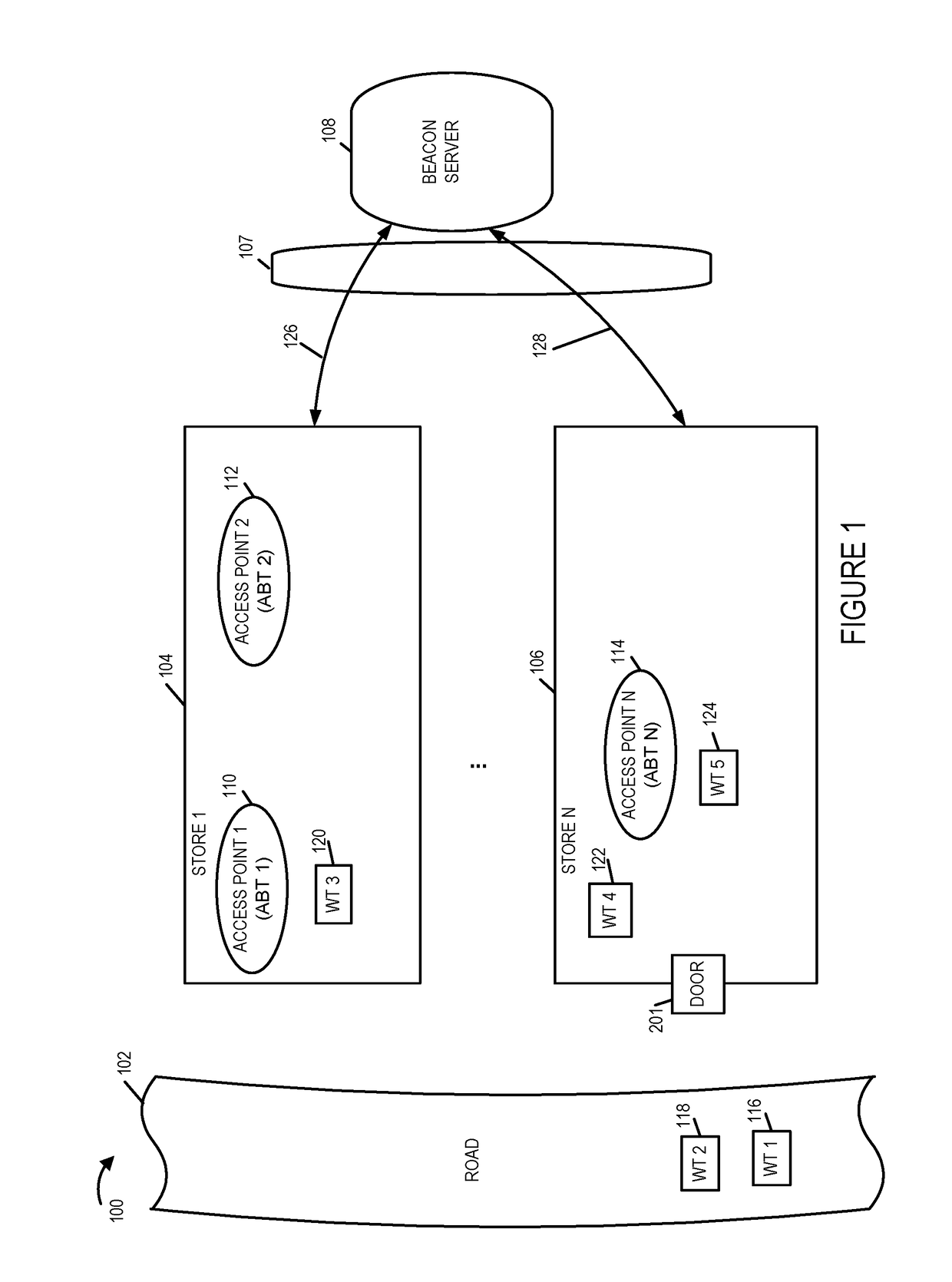

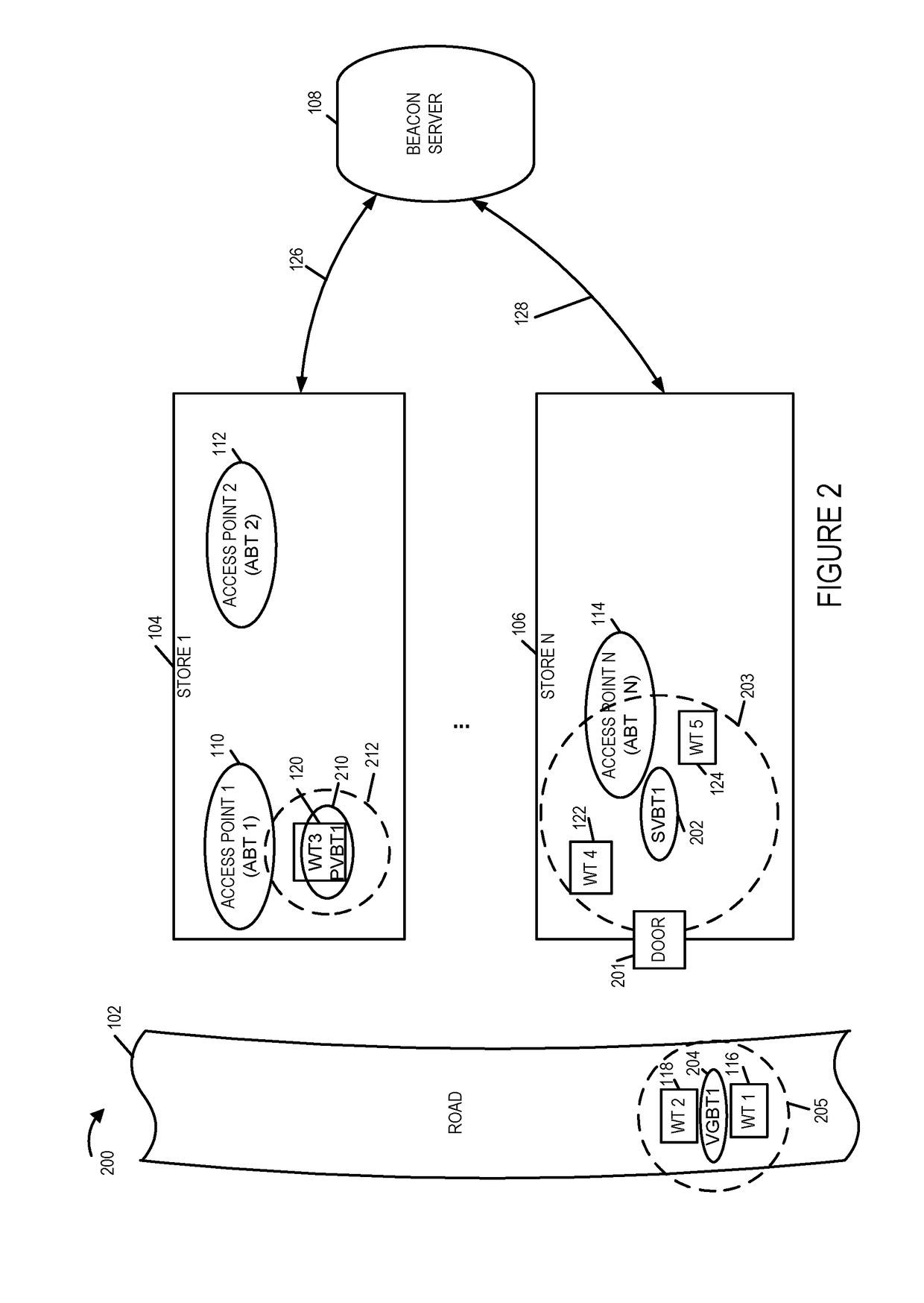

Dynamic virtual beacon methods and apparatus

ActiveUS20170273008A1Easy to updateReduce coverage areaPower managementReceivers monitoringTransmitterHuman–computer interaction

Methods and apparatus relating to use of actual and / or virtual beacons are described. Virtual beacons are virtual in that an actual beacon need not be transmitted but a rather a virtual beacon transmitter at a desired location may be considered to transmit virtual beacons. Beacon transmitter information indicates transmission power and location of actual and virtual beacon transmitters as well as information to be communicated by virtual beacons and is dynamically updated based on device movement, a schedule and / or the locations of devices in a group. Virtual personal beacons, virtual group beacons and virtual scheduled beacons are supported. A virtual personal beacon transmitter location is updated as the location of a device corresponding to the person moves. Reception of a virtual beacon is reported in a message sent to a wireless terminal or a component of the wireless terminal which acts upon receiving an indication of beacon reception.

Owner:JUNIPER NETWORKS INC

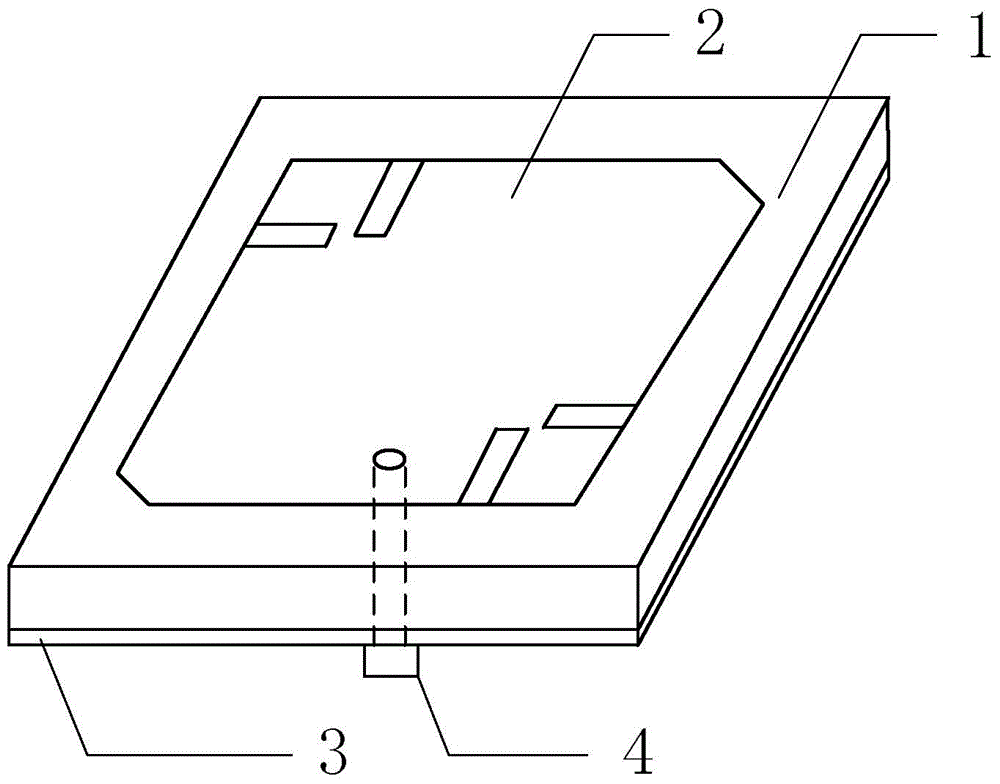

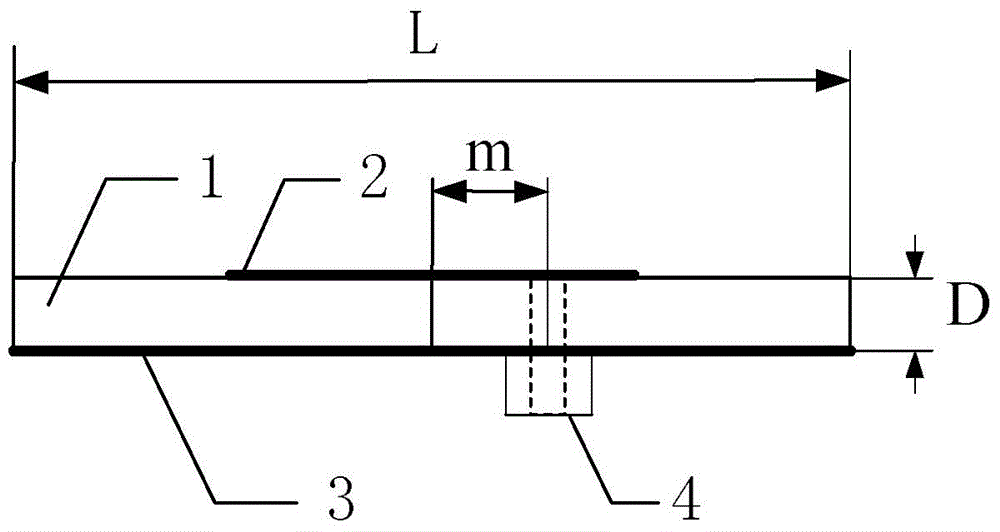

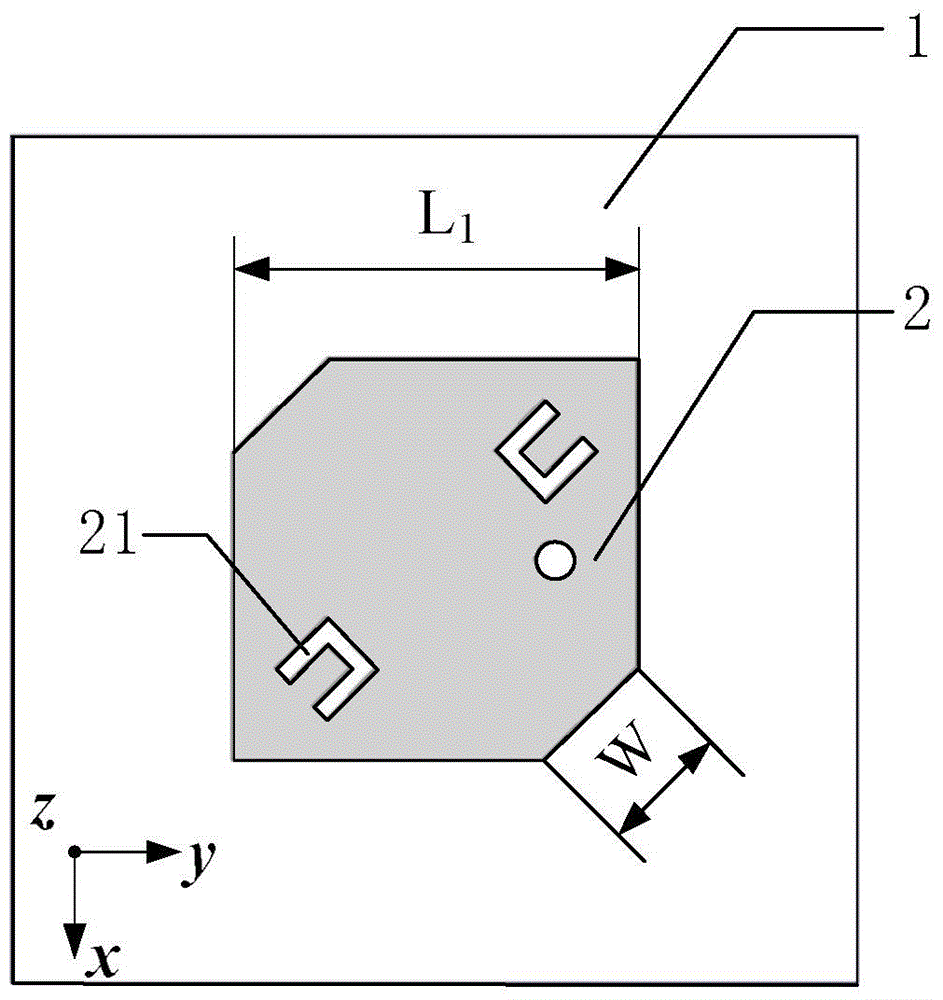

Broadband circularly polarized micostrip antenna

ActiveCN104701628ALower quality factorHigh bandwidthRadiating elements structural formsAntenna earthingsCoaxial lineDielectric slab

The invention discloses a broadband circularly polarized micostrip antenna. The broadband circularly polarized micostrip antenna is used for solving the problem of narrow working band of existing circularly polarized microstrips. The broadband circularly polarized micostrip antenna comprises a dielectric slab (1), a radiating unit (2), a radiating bottom slab (3) and a coaxial cable (4). The upper surface and the lower surface of the dielectric slab (1) are printed with the radiating unit (2) and the radiating bottom slab (3) respectively; the radiating bottom slab (3) is composed of a square patch (33), eight quasi-fractal units (31) and a metal strip (32), wherein the diagonals of the square patch (33) are symmetrically etched with four composite-structured slots (331) and equal-arm L-type slots (332),the eight quasi-fractal units (31) are uniformly distributed outside the square patch (33) and connected through the metal strip (32); along the diagonal without truncated angles of the square patch, the radiating unit (2) is symmetrically etched with two U-type slots (21) with outward openings. The broadband circularly polarized microstrip antenna has the advantages of being broad in band and small in size and can be applied to radio frequency identification, radar and wireless communication.

Owner:XIDIAN UNIV

Baby-care implement provided with hood

InactiveUS20050258673A1Block effectReduce coverage areaCarriage/perambulator accessoriesTents/canopiesEngineeringMechanical engineering

Owner:APRICA CHILDRENS PROD

Overlay micro cell structure for universal mobile telephone system network

ActiveUS8532665B2High bandwidthReduce coverage areaNetwork topologiesConnection managementMobile Telephone ServiceTelecommunications link

A wireless telephony communications system includes at least one macro cell for communicating both voice and data with a mobile communications device across a first wireless link and at least one micro cell for communicating data with the mobile communications device across a second wireless communication link. Each micro cell communicates signaling information through the macro cell via a wireless link to a control element that manages the micro cells. Using a wireless link to communicate signaling between each micro cell and the control element in the UMTS system eliminates the need for a wired back haul link, thereby reducing access costs.

Owner:THOMSON LICENSING SA

Touch screen, touch display device and production method of touch screen

InactiveCN102830841AReduce contact resistanceReduce coverage areaInput/output processes for data processingColor effectElectrical resistance and conductance

The invention discloses a touch screen, a touch display device and a production method of the touch screen. The touch screen comprises first electrodes, second electrodes, second electrode connecting wires, first electrode connecting wires, insulating blocks and a protective layer. The first electrodes, the second electrodes and the second electrode connecting wires are arranged on a first level. The first electrodes and the second electrodes intersect with each other. The second electrode connecting wires connect the adjacent second electrodes at the intersection. The first electrode connecting wires on a second level connect the adjacent first electrodes at the intersection in an overlapping manner. The insulating blocks located between the first electrode connecting wires and the second electrode connecting wires are overlapped with the first electrode connecting wires. The arrangement size of the insulating blocks in the direction of the first electrodes is smaller than the length of each first electrode connecting wire, and the arrangement size of the insulating block in the direction of the second electrodes is not smaller than the width of each first electrode connecting wire. The protective layer is arranged above the structure of the first level, the insulating blocks and the second level. Light transmissivity of the touch screen is improved greatly, macroscopic color effect is improved, and touch resistance between the first electrodes is also reduced.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Capacitive Touch Screen

ActiveUS20140293152A1Reduce conductive materialReduce coverage areaNon-linear opticsInput/output processes for data processingScratchingConductive materials

A capacitive touch screen is disclosed in the present invention, including: a transparent substrate, including a first surface and a second surface opposite to the first surface; a light-shield layer formed on the edge of the first surface of the transparent substrate, which forms a non-visible area; and a transparent polymer layer formed on the first surface, which is opposite to the first surface and covers the light-shield layer, a part of the transparent polymer layer covering the light-transmission area of the transparent substrate forms a sensing area, a surface of that is patterned to form a first meshed conductive trench, which is filled with a conductive material. The defined conductive trench reduces the scratching to the conductive material when the capacitive touch screen is in use, and the use of the trench structure reduces the covering area of the conductive material, the contact resistance and the cost.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

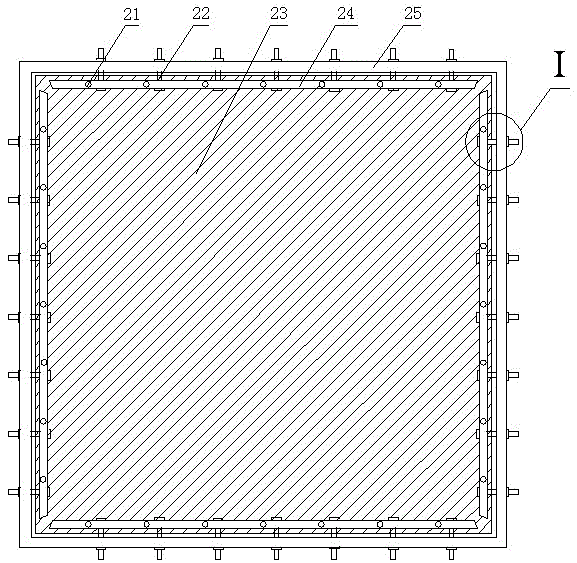

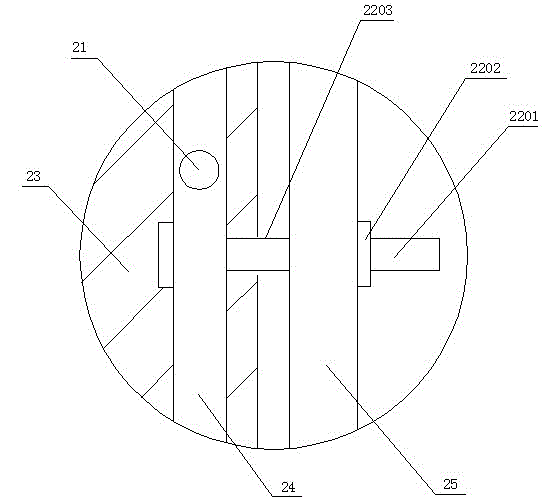

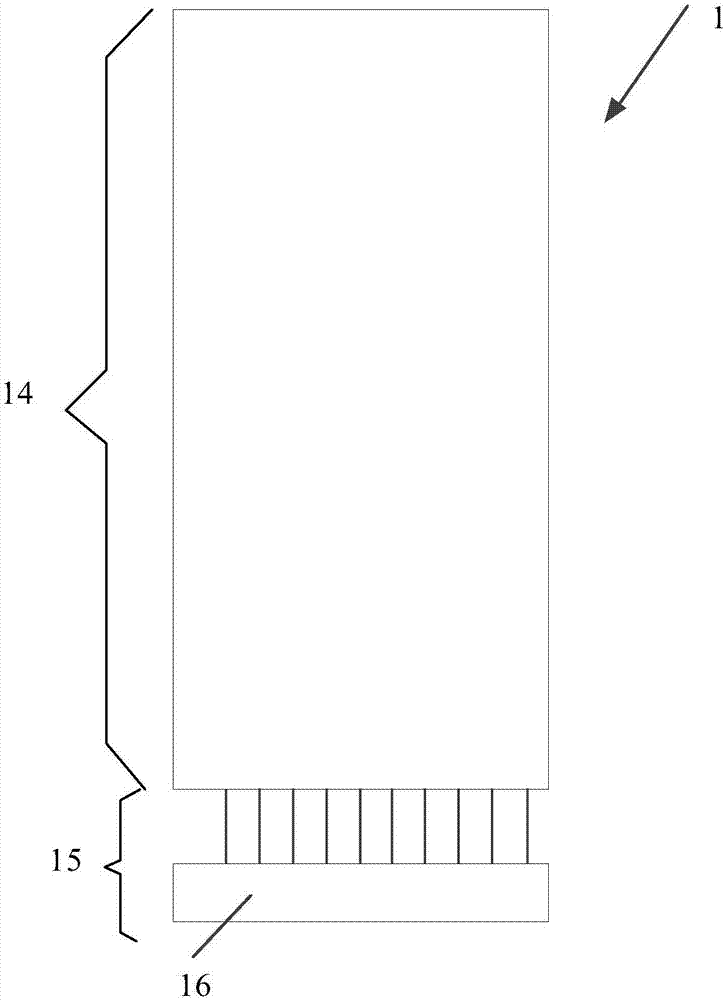

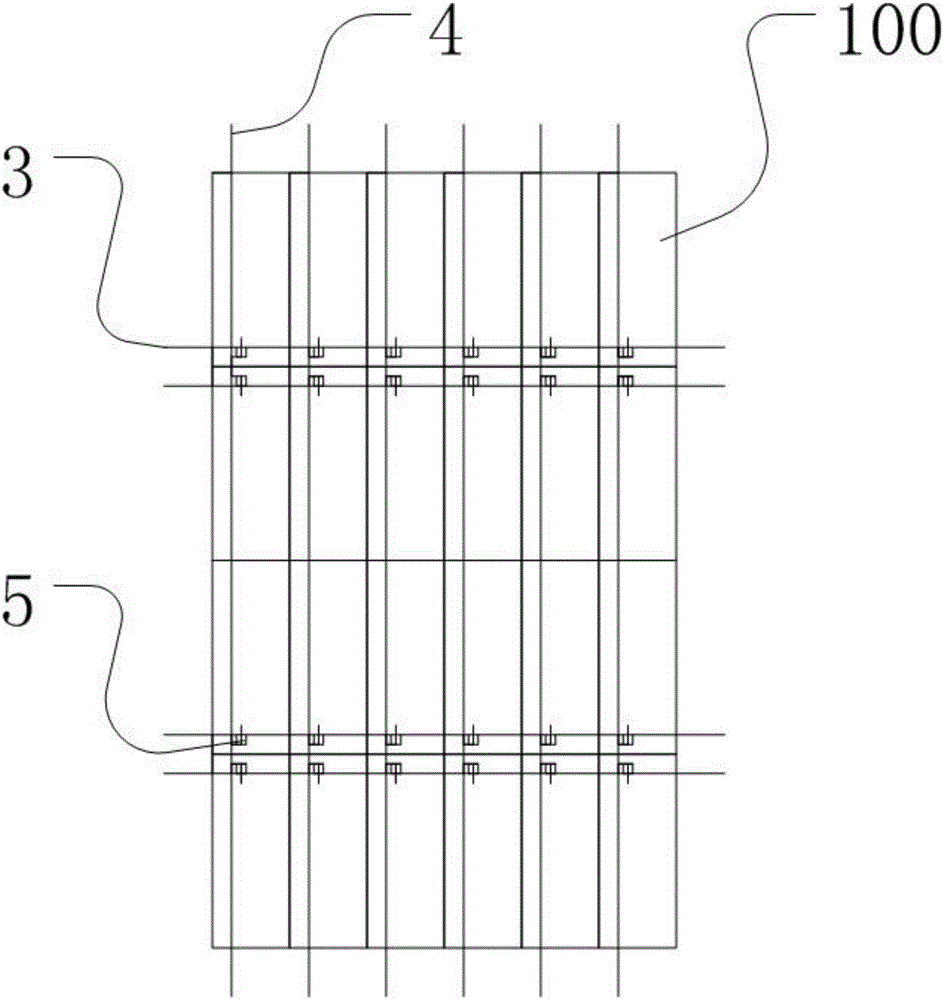

Device and method for manufacturing silicon solar cell electrode printing screen through laser

ActiveCN102717193AIncrease light receiving areaSimple processLaser beam welding apparatusBeam expanderGalvanometer

The invention relates to a device and a method for manufacturing a silicon solar cell electrode printing screen through a laser. The device comprises a laser device (1), wherein the laser emitted by the laser device (1) passes through an optical shutter (2) and a beam expander (3) so as to be incident on the surface of a laser mirror (4); is reflected by the laser mirror (4); sequentially passes through a half-wave plate (5), a Glan prism (6) and a rotary module (7) so as to be incident on the surface of another laser mirror (4); is reflected by the laser mirror (4); and enters into a galvanometer system (8). The laser emitted from the galvanometer system (8) is focused through a focus lens (9) so as to be over against a workpiece to be machined (16) on a platform (13). According to the device and the method for manufacturing the silicon solar cell electrode printing screen through the laser, the service life of the solar cell printing screen can be effectively improved, and the printing quality of a solar cell electrode is improved.

Owner:JIANGYIN DELI LASER EQUIP

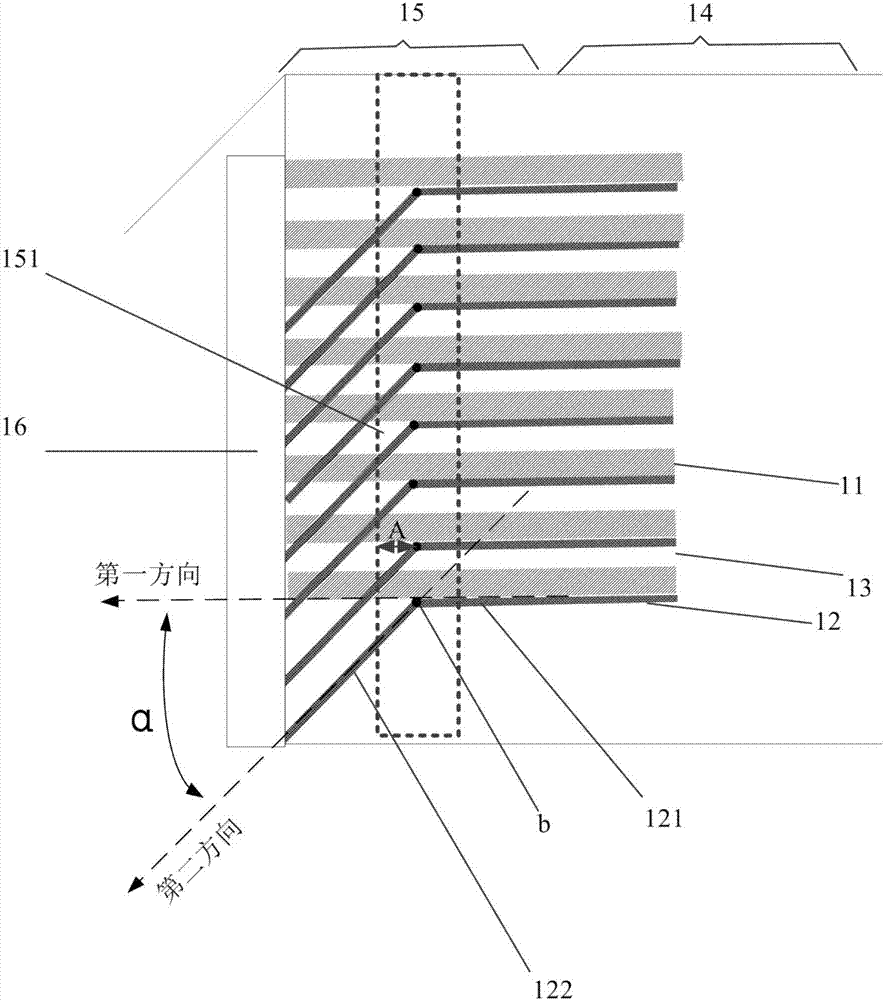

Display panel and display device

ActiveCN107065333AReduce coverage areaImprove transmittanceNon-linear opticsInput/output processes for data processingDisplay deviceTransmittance

The invention provides a display panel and a display device. The display panel includes a display region and a fan-out region. The fan-out region includes a frame sealing glue coating region. The display panel also includes a plurality of first signal lines, a plurality of second signal lines and a driving circuit; the first signal lines and the second signal lines extend from the display region to the fan-out region and are electrically connected to the driving circuit; the first signal lines extend in the first direction and pass through the frame sealing glue coating region; at least one second signal line includes a first section and a second section which are positioned in the fan-out region, the first section and the second section are connected through a first node, the first section extends in the first direction, a projection of the first section and wiring clearance projections of the first signal lines have overlapped portions, the second section extends in the second direction, and a first included angle is formed between the first direction and the second direction. The technical scheme can increase the transmittance of the frame sealing glue, can improve the frame sealing effect, and can reinforce the display panel.

Owner:SHANGHAI AVIC OPTOELECTRONICS

Preparation method of crystalline silicon SE solar cell and crystalline silicon SE solar cell

ActiveCN103681942AReduced series resistanceImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingTunnel kilnWhole body

The invention provides a preparation method of a crystalline silicon SE solar cell. The preparation method comprises the following steps: (S1) the wool making, the dispersion and the phosphorosilicate glass removal treatments are implemented for the surface of a silicon slice; then a silicon nitride antireflection film is plated on the frontal surface of the silicon slice; (S2) one layer of metal mask is covered on the surface of the antireflection film; then bismuth oxide is deposited on the antireflection film by adopting the magnetron sputtering method; (S3) back surface silver conductive paste and back field aluminum paste are printed on the back surface of the silicon slice; the whole body is introduced in a tunnel kiln for sintering; the annealing is implemented after finishing the sintering; (S4) the photoinduction electroplating is implemented on the frontal surface of the silicon slice to obtain the crystalline silicon SE solar cell. The preparation method, provided by the invention, has the advantage of simple process, low cost and capability of realizing large-scale production; the prepared crystalline silicon SE solar cell has the benefits of fine surface electrode grid lines, small covering area, low cell serial connection resistance, increased fill factor, high photoelectric converting efficiency and low cost.

Owner:SHANGHAI BYD

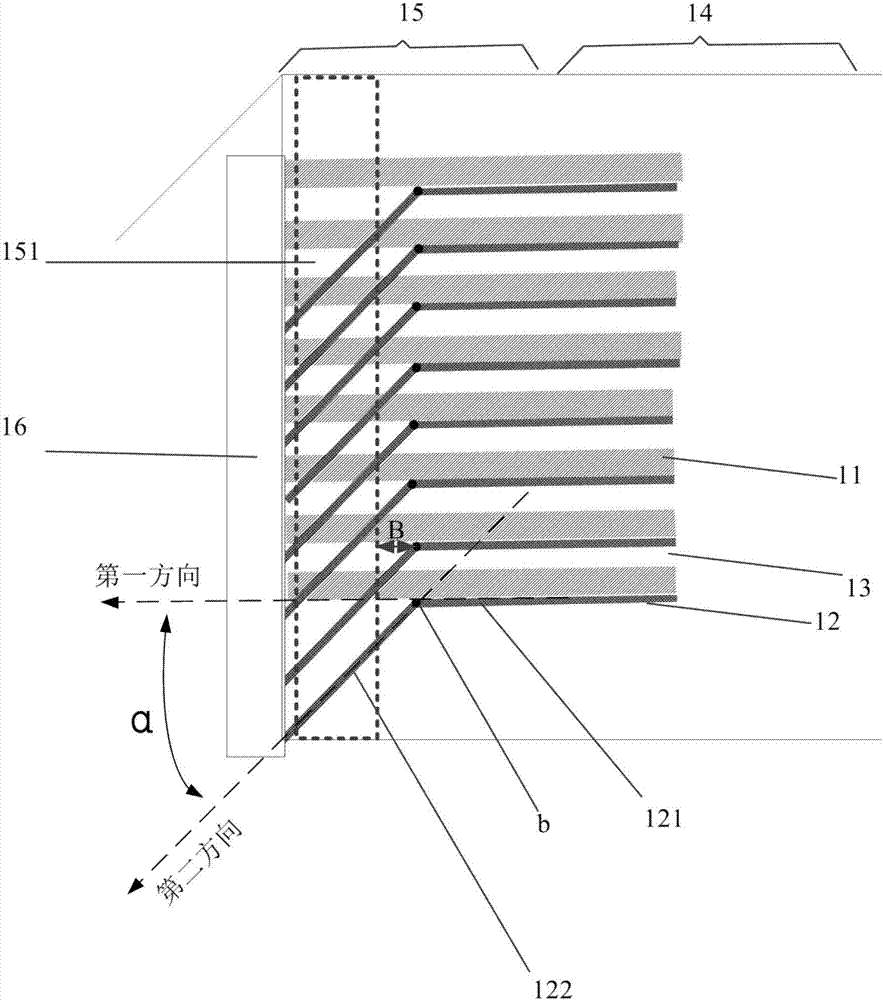

Display panel and display device

InactiveCN106502016AReduce coverage areaIncrease the area of the light-transmitting areaNon-linear opticsEngineeringDisplay device

The invention discloses a display panel and a display device. The display panel comprises a first substrate and a second substrate. The first substrate is provided with a plurality of active switches and conductive wires coupled with the active switches. The active switch corresponding to the Nth conductive wire is arranged opposite to the active switch corresponding to the (N-1)th conductive wire, wherein the Nth conductive wire and the (N-1)th conductive wire are in the same direction and adjacent to each other. The active switch corresponding to the Nth conductive wire and the active switch corresponding to the (N+1)th conductive wire are arranged face to face. The distance between the Nth conductive wire and the (N-1)th conductive wire is smaller than the distance between the Nth conductive wire and the (N+1)th conductive wire. The second substrate is provided with shading layers in the corresponding positions of the Nth conductive wire and the (N-1)th conductive wire. The coverage area of the shading layers can be effectively reduced, the area of light-pervious regions is increased, and the aperture ratio is increased.

Owner:HKC CORP LTD +1

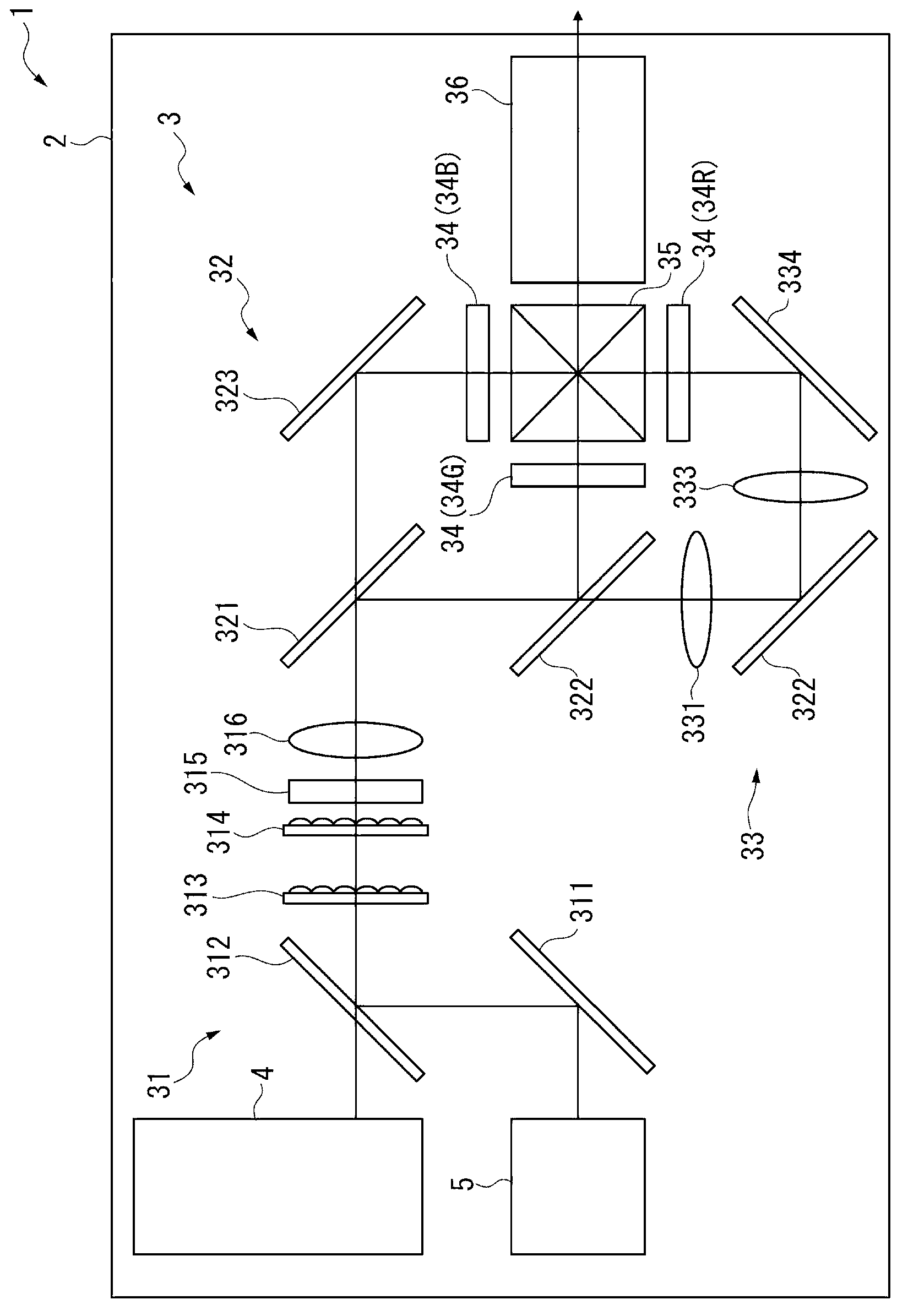

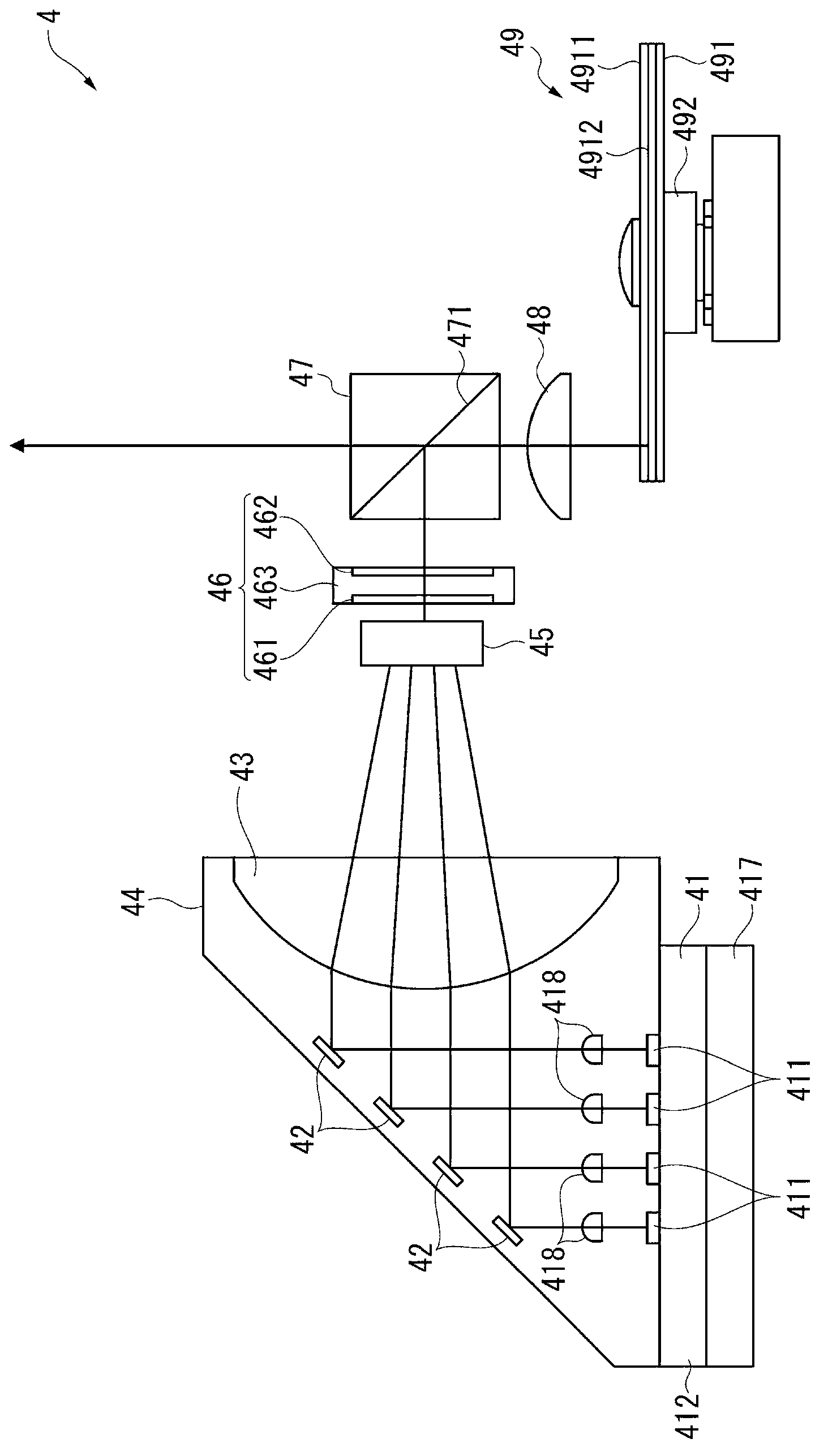

Light source device and projector

ActiveCN102929085AReduce width sizeReduce manufacturing costPoint-like light sourceLighting heating/cooling arrangementsEngineeringLight source

A light source device includes a plurality of solid-state light sources, and a base member on which the plurality of solid-state light sources are provided, wherein each of the solid-state light sources includes a stem on which a light-emitting element is provided and terminals connected to the light-emitting element, and the base member includes a hole portion into which one of the terminals is inserted and a planar portion that is in contact with the stem.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com