Solar cell, screen printing plate and solar cell module thereof

A solar cell module, solar cell technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of large thermal stress, cracking, easy generation of fragments, etc., to reduce stress, reduce compounding, and reduce contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

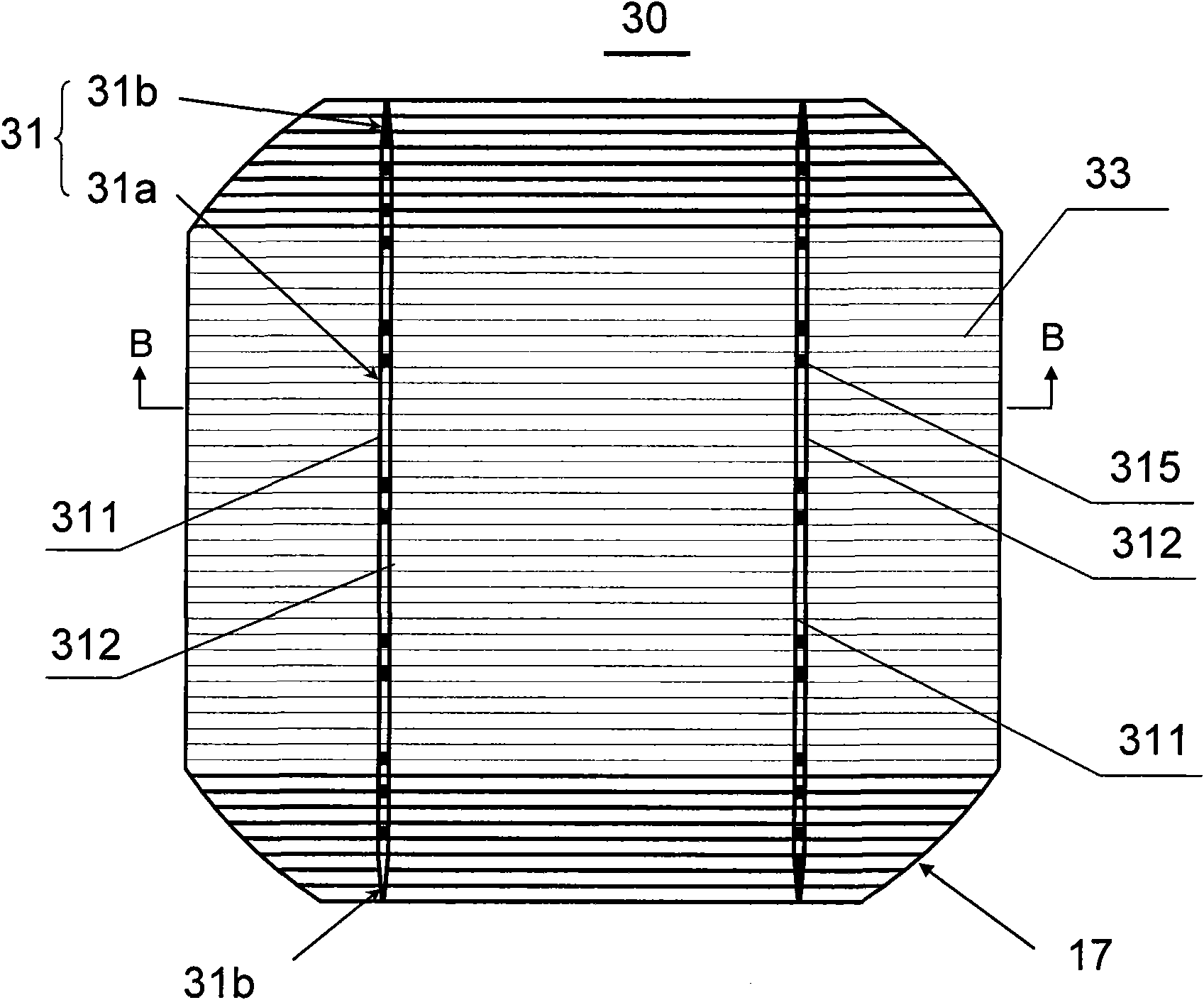

[0040] The following introduces some of the possible embodiments of the present invention, which are intended to provide a basic understanding of the present invention, but are not intended to identify key or decisive elements of the present invention or limit the scope of protection. In the drawings, for the sake of clarity, the thickness of layers or the area of regions may be exaggerated, but as a schematic diagram, it should not be regarded as strictly reflecting the proportional relationship of geometric dimensions. In the drawings, the same reference numerals refer to the same structural parts, and thus their descriptions will be omitted.

[0041] The orientation terms such as up, down, left, right, middle, and horizontal mentioned in this article are defined relative to the orientation of the solar cell shown in the drawings. They are relative concepts and can be used and placed according to the solar cell. vary accordingly.

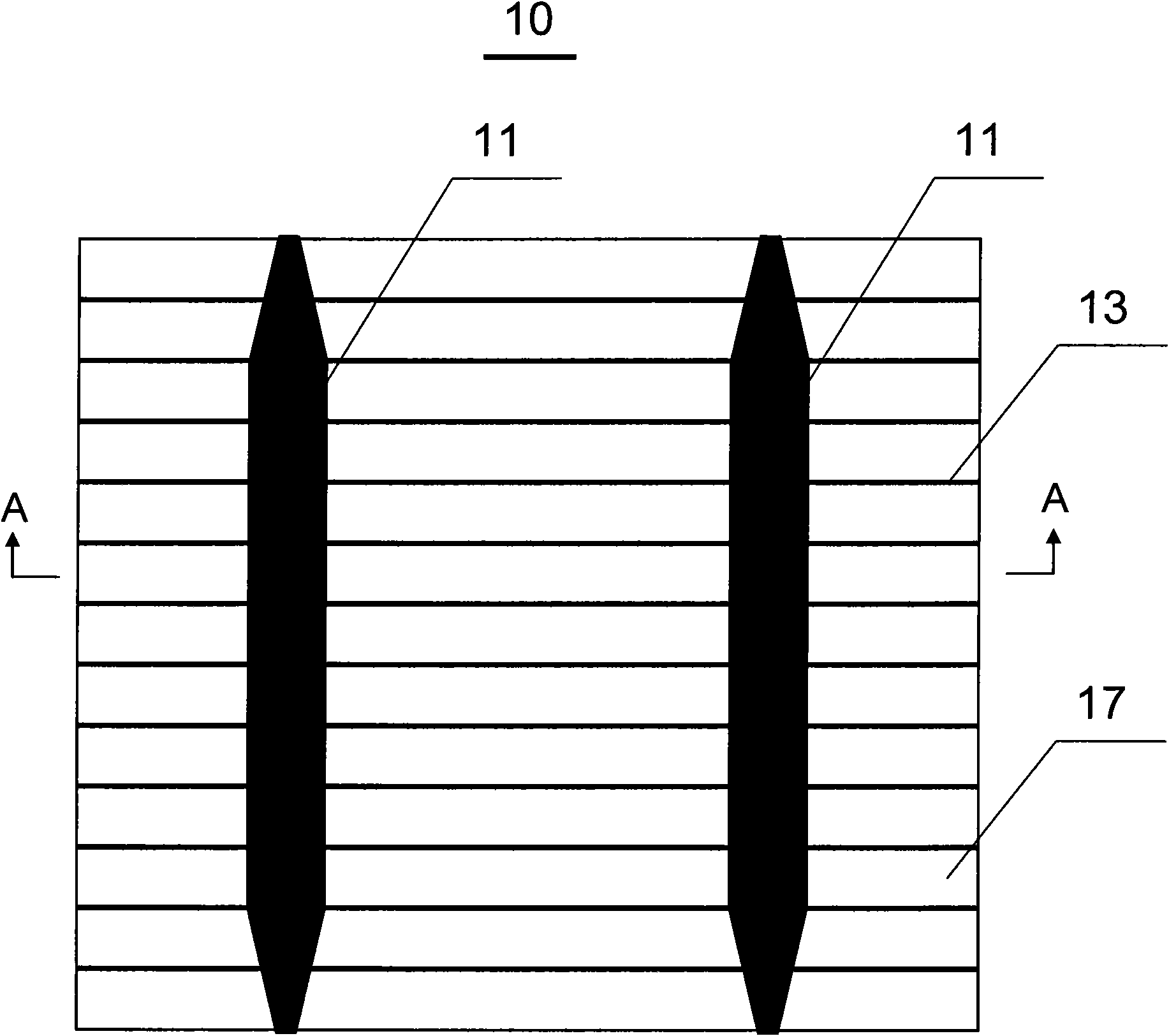

[0042] image 3 Shown is a schematic pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com