Flexible display panel and manufacturing method thereof and flexible display device

A flexible display and manufacturing method technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of quality degradation of flexible display devices, short-circuiting of conductive film layers, and easy cracking, etc. The probability of small cracks or even breakage, the effect of preventing short circuits, preventing or even failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further illustrate the flexible display panel, the manufacturing method thereof, and the flexible display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

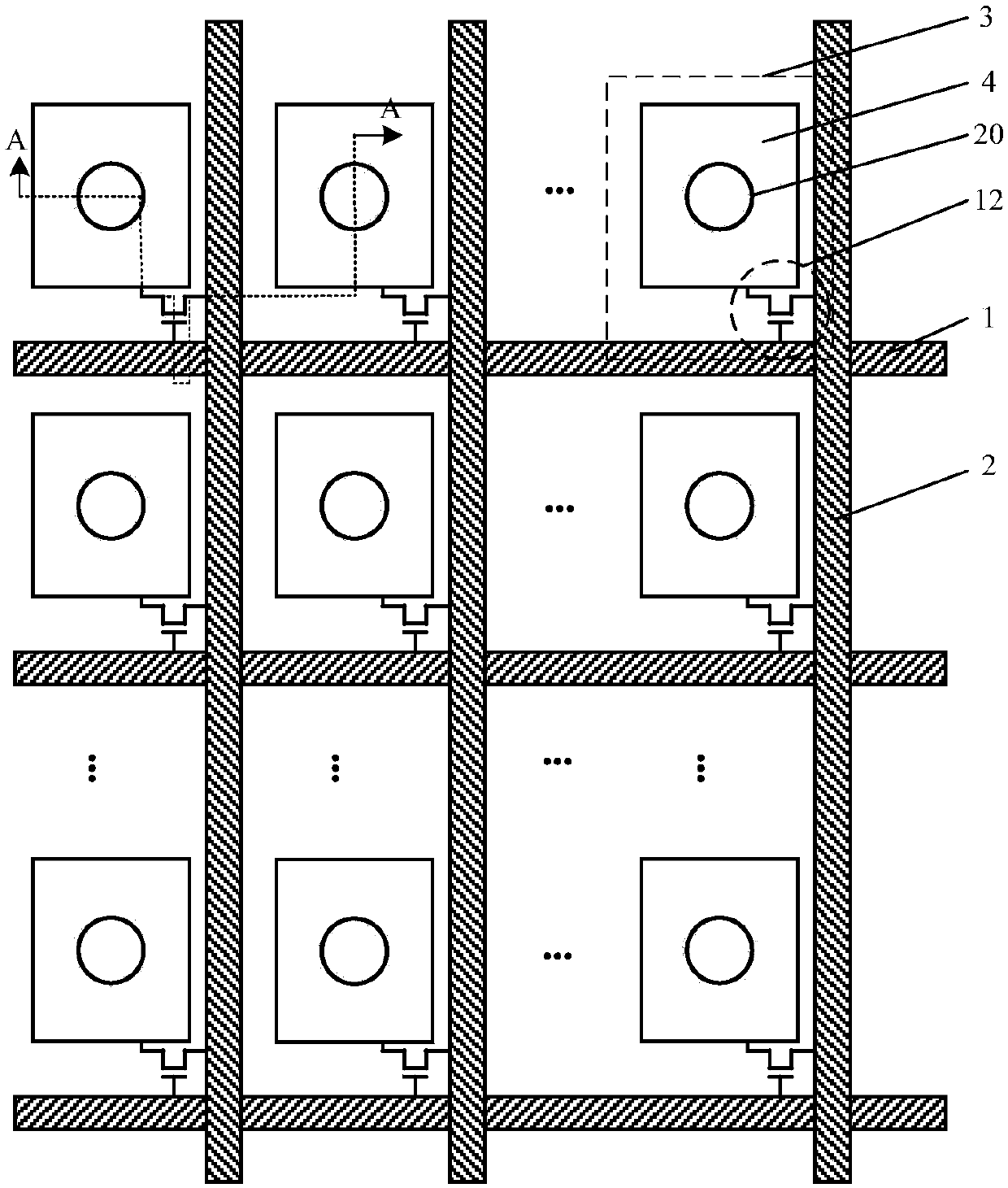

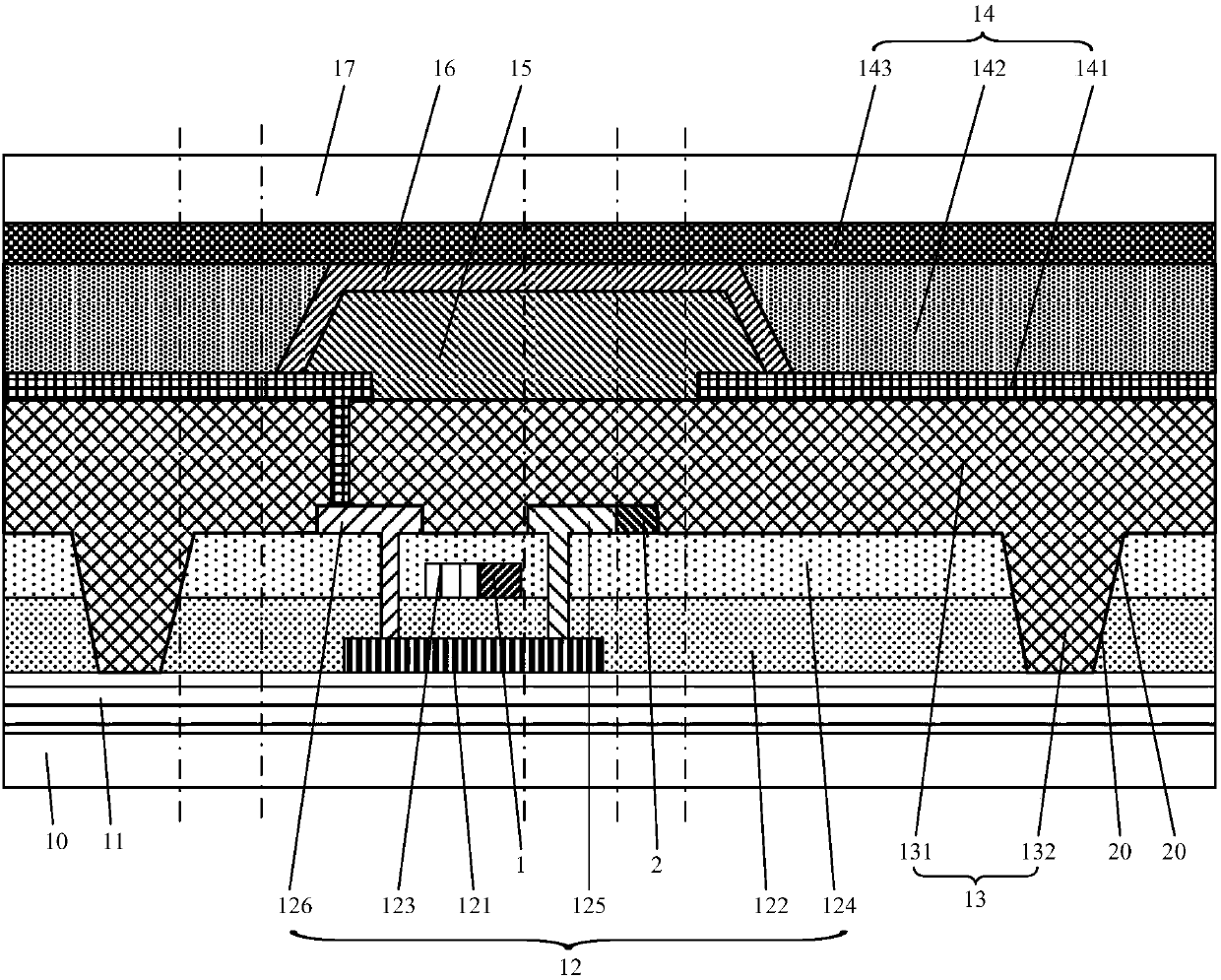

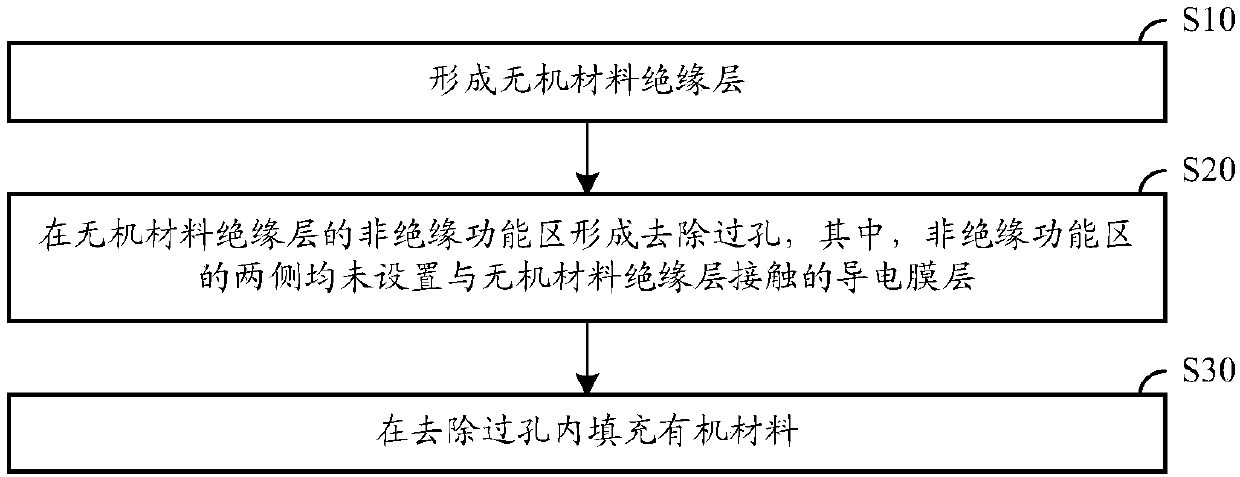

[0049] see figure 1 and figure 2 The flexible display panel provided by the embodiment of the present invention includes an insulating layer of inorganic material, the insulating layer of inorganic material includes a non-insulating functional area, and a removal via hole for removing the insulating layer of inorganic material in the functional area of the non-insulating layer is provided in the non-insulating functional area , removing the filling of the organic material in the via hole; wherein, no conductive film layer in contact with the insulating layer of the inorganic material is provided on both sides of the non-insulating functional area.

[0050] For an example, please continue to figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com