Device and method for manufacturing silicon solar cell electrode printing screen through laser

A silicon solar cell and printing screen technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems affecting the free electron passage efficiency of solar cells, reducing the conversion efficiency of solar cells, and affecting the conversion efficiency of solar cells. Achieve the effects of reduced coverage area, thin grid line width and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

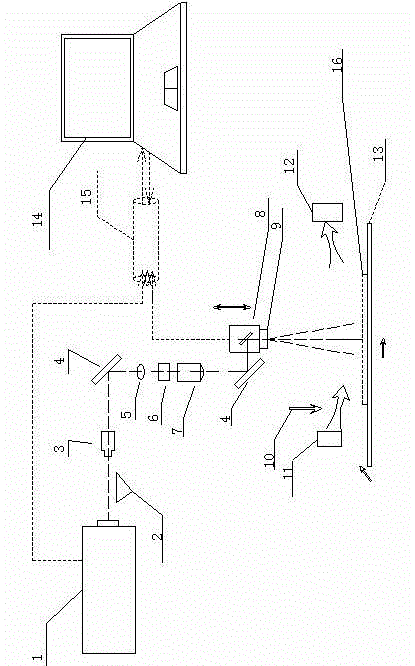

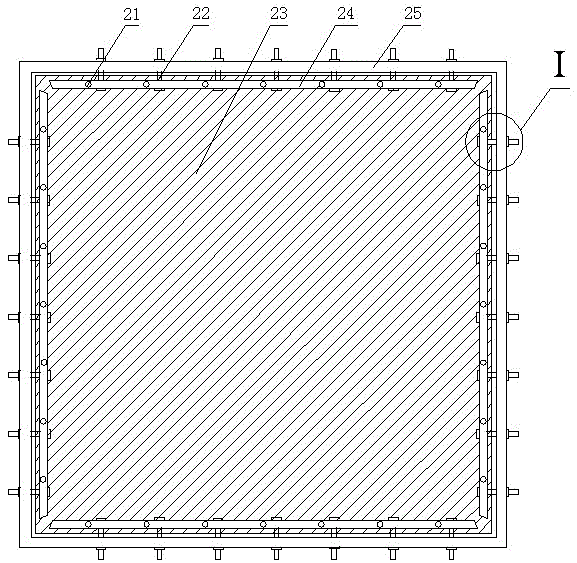

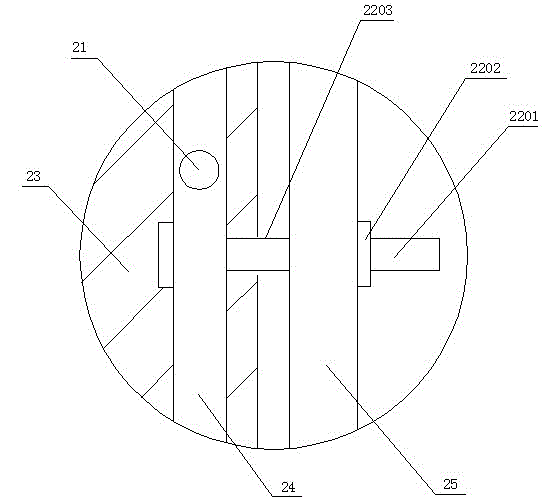

[0028] see Figure 1~3 , the present invention relates to a device and method for making a silicon solar cell electrode printing screen by laser, the device includes a laser 1 (specifically, the laser 1 is a pulse laser with a repetition frequency of 10KHz and above, and the emitted The wavelength of the laser is 196nm~1064nm, and the pulse width action time is 1fs~1ms), the high-frequency pulsed laser emitted by the laser 1 passes through the shutter 2 and the beam expander 3, and then enters the surface of the laser reflector 4. After the reflection of the mirror 4, it is incident on the surface of another laser mirror 4 through the half-wave plate 5, the Glan prism 6 and the rotating module 7 (TREPANNING HEAD), and enters the vibrating mirror after being reflected by the laser mirror 4 System 8, the laser beam emitted from the galvanometer system 8 is focused by the focusing mirror 9 and is facing the workpiece 16 to be processed on the platform 13. A CCD alignment observat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com