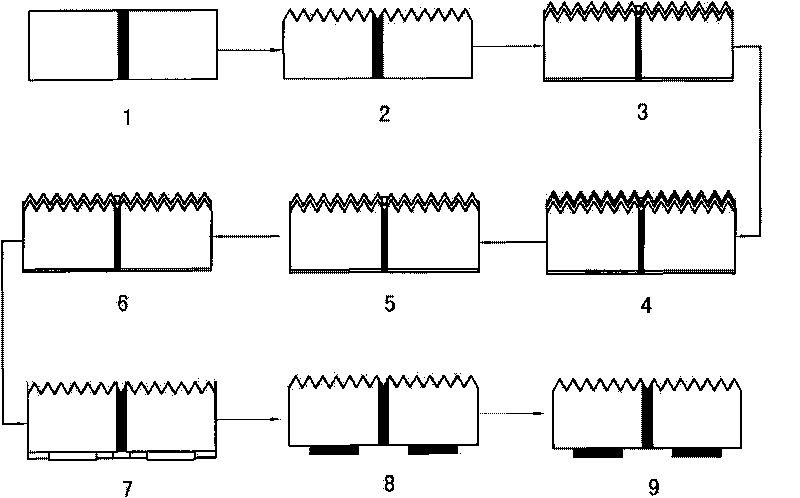

Method for preparing hidden-type emitter silicon solar cells

A silicon solar cell, concealed technology, used in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of reducing the effective light-receiving area of the battery, reducing the output current of the collector, and increasing the series resistance of the emitter, and achieves easy industrial automation. The effect of production, reducing wiring resistance and increasing collector current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] 1. Laser drilling on a 125mm×125mm p-type silicon wafer with a hole density of 0.5hole / mm 2 .

[0034] 2. Cleaning, polishing, removing radiation damage and texturing of silicon wafers.

[0035] Use the following steps to clean and remove impurities on the silicon wafer:

[0036] 1) Wash the surface of the silicon wafer several times with deionized water to remove large impurity particles on the surface of the silicon wafer.

[0037] 2) Ultrasonic cleaning several times with detergent, and then rinse several times with a large amount of hot and cold deionized water to remove the grease on the surface of the silicon wafer.

[0038] 3) Boil the silicon wafer with concentrated sulfuric acid until white smoke is emitted to remove pollutants on the surface of the silicon wafer.

[0039] The corrosion time of the texturizing corrosive solution is 30 minutes. After the texturing is finished, rinse several times alternately with a large amount of hot and cold deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com