Patents

Literature

346results about How to "Reduce width size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

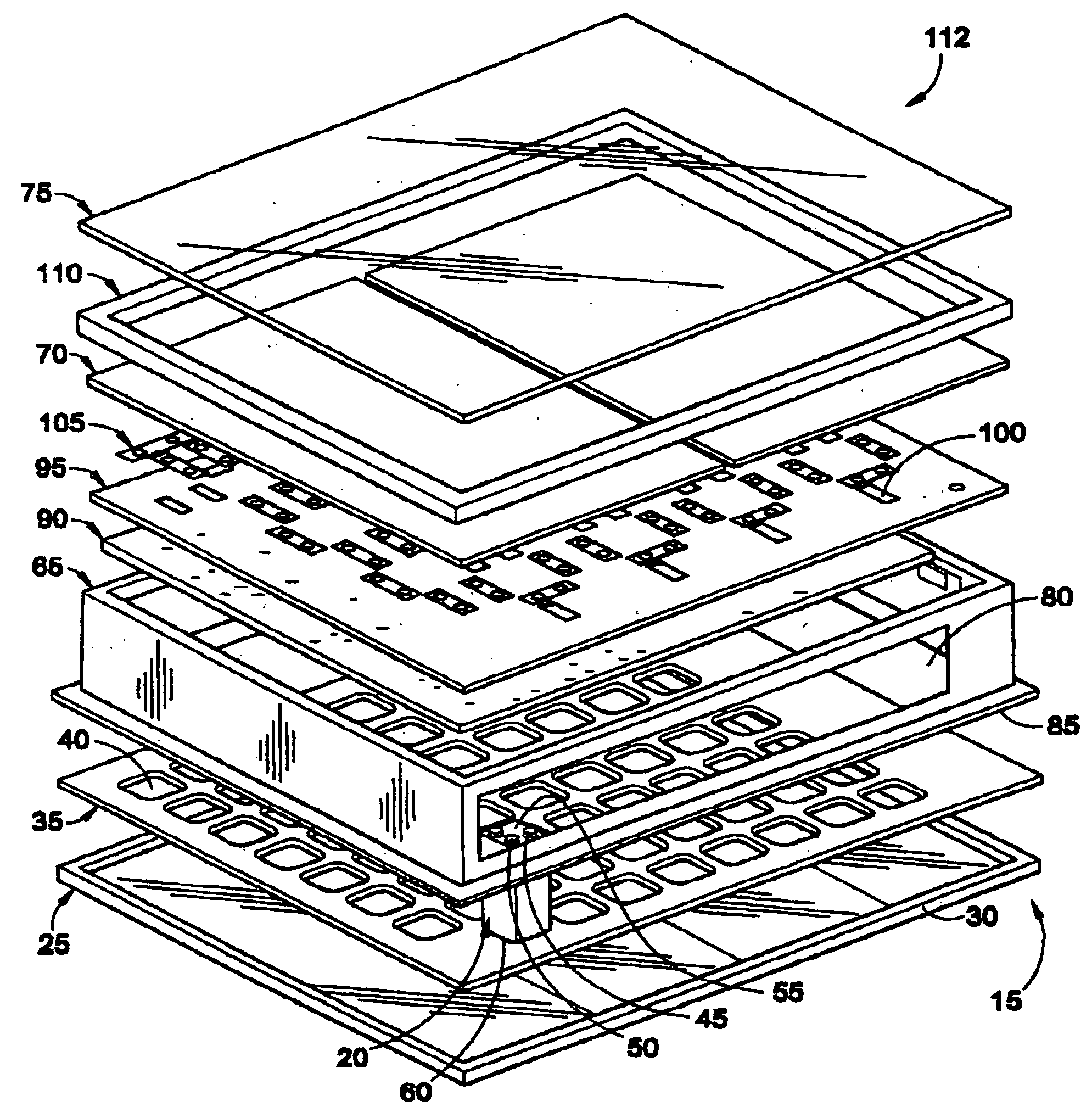

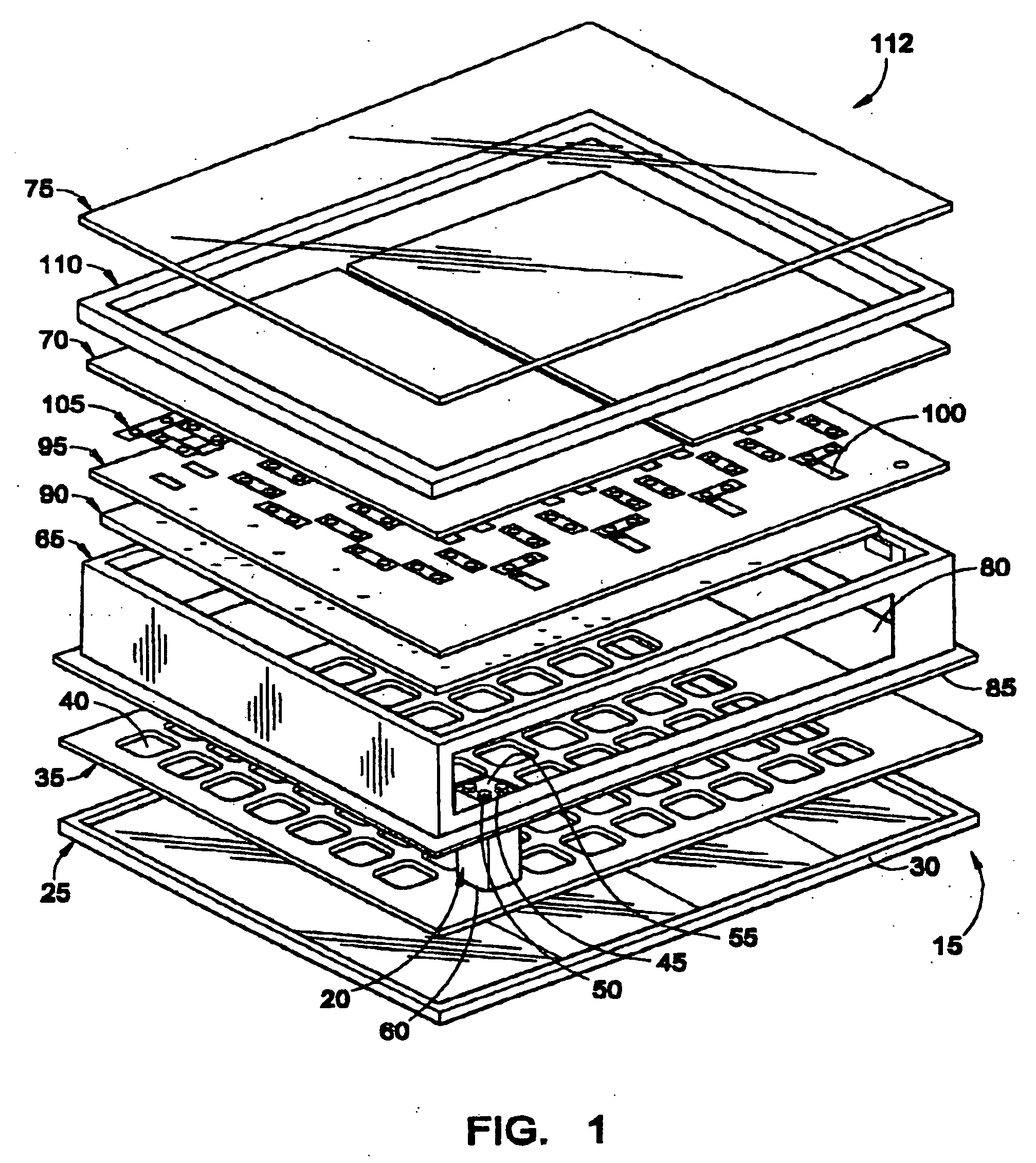

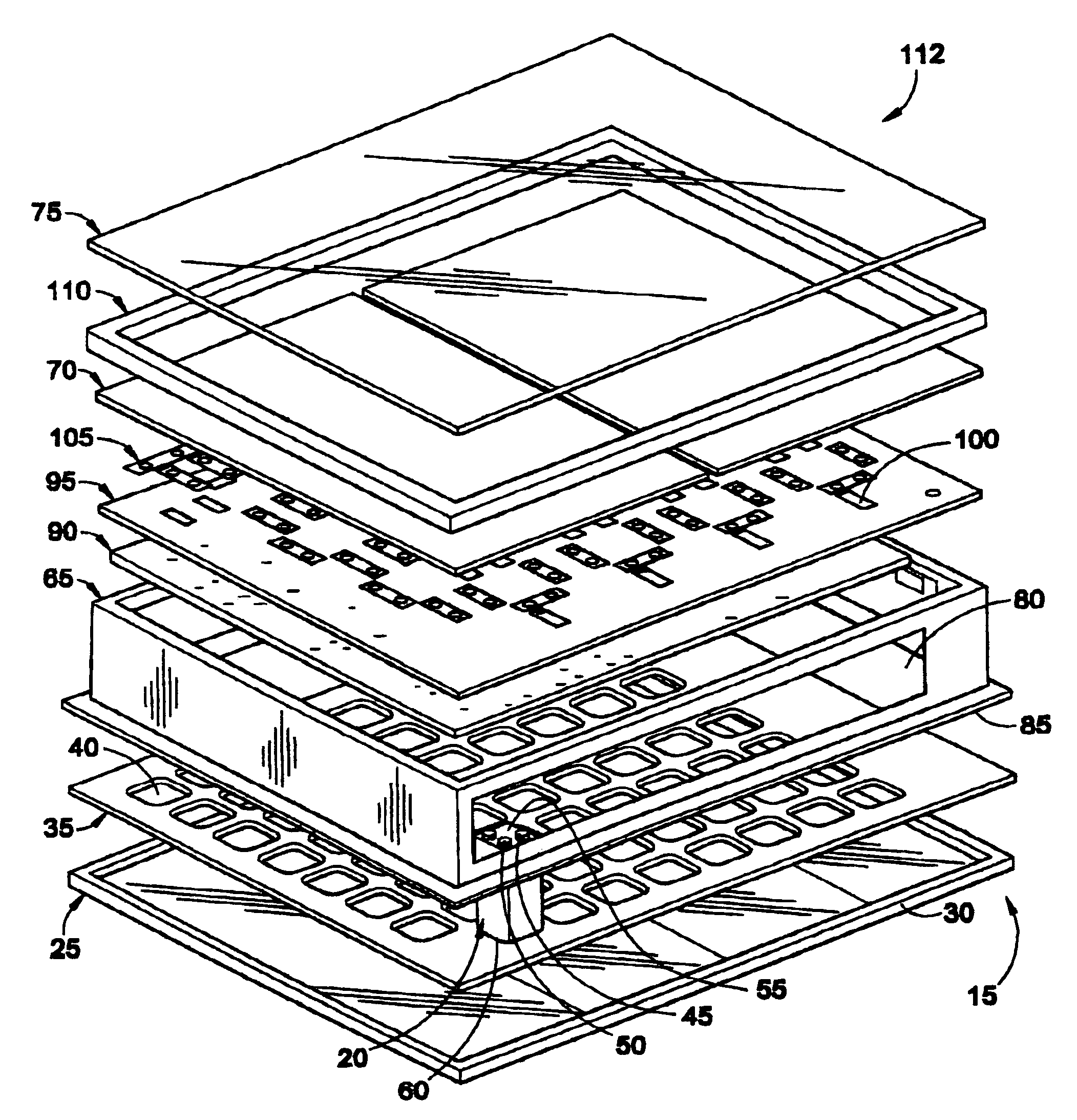

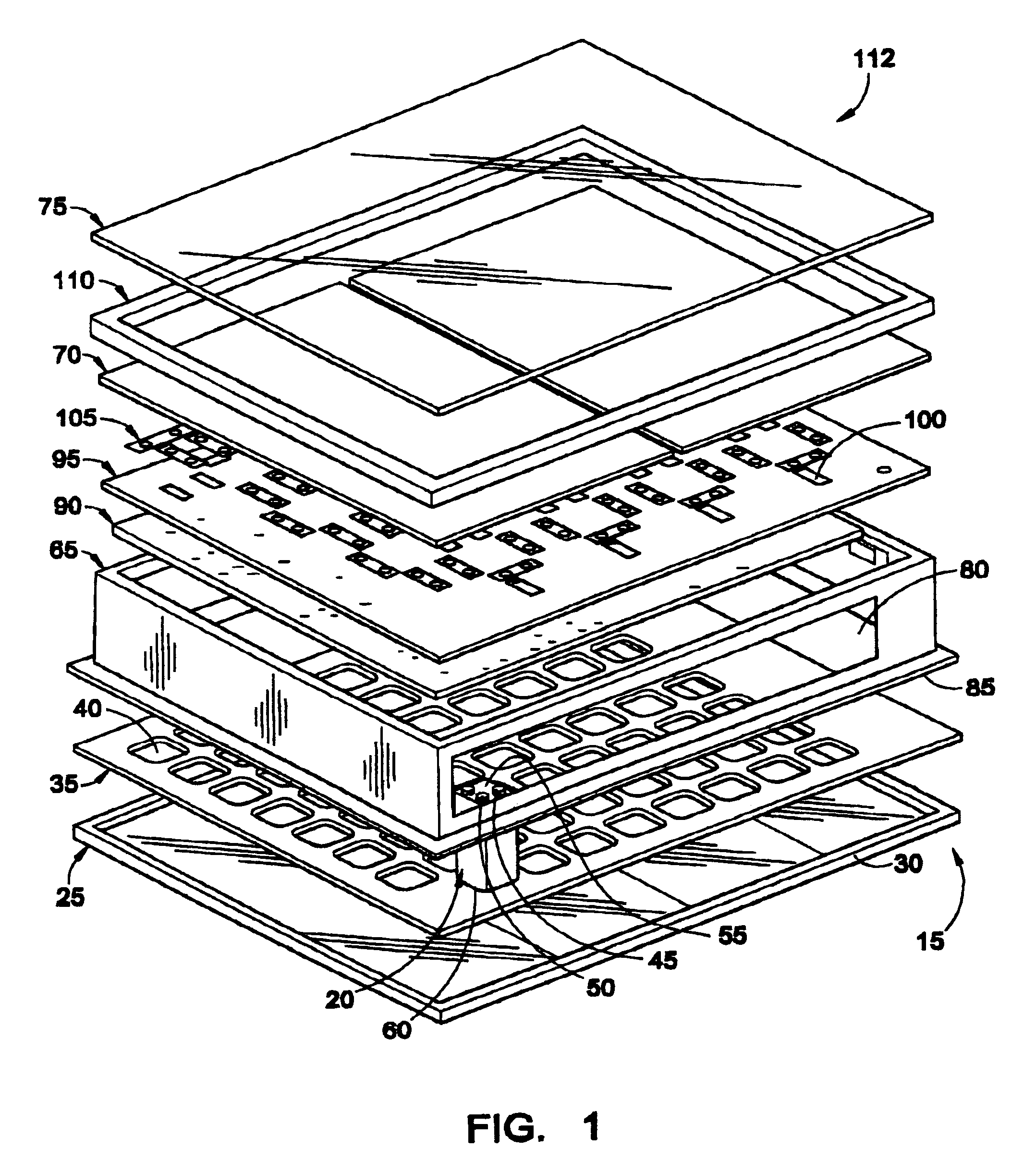

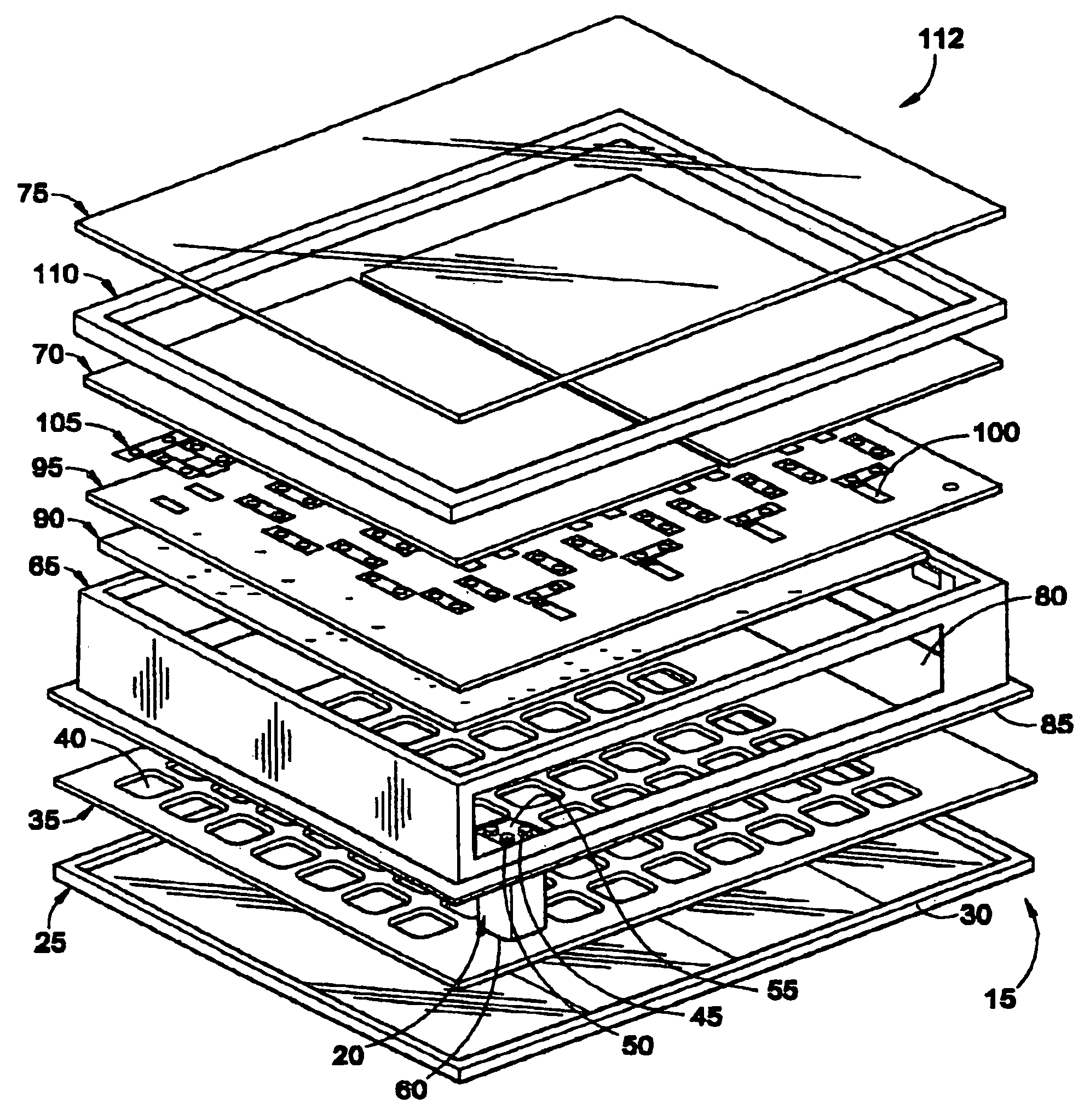

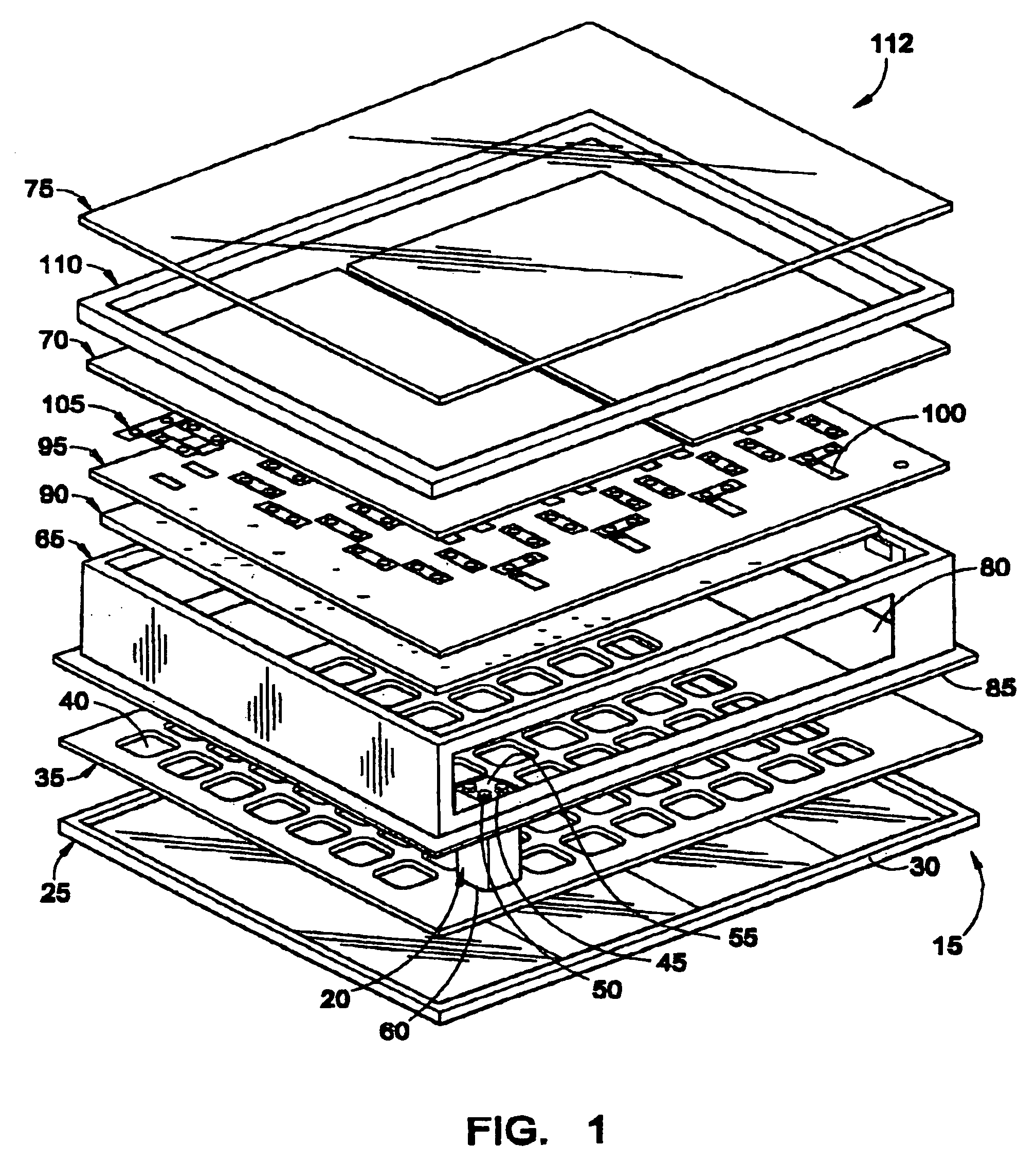

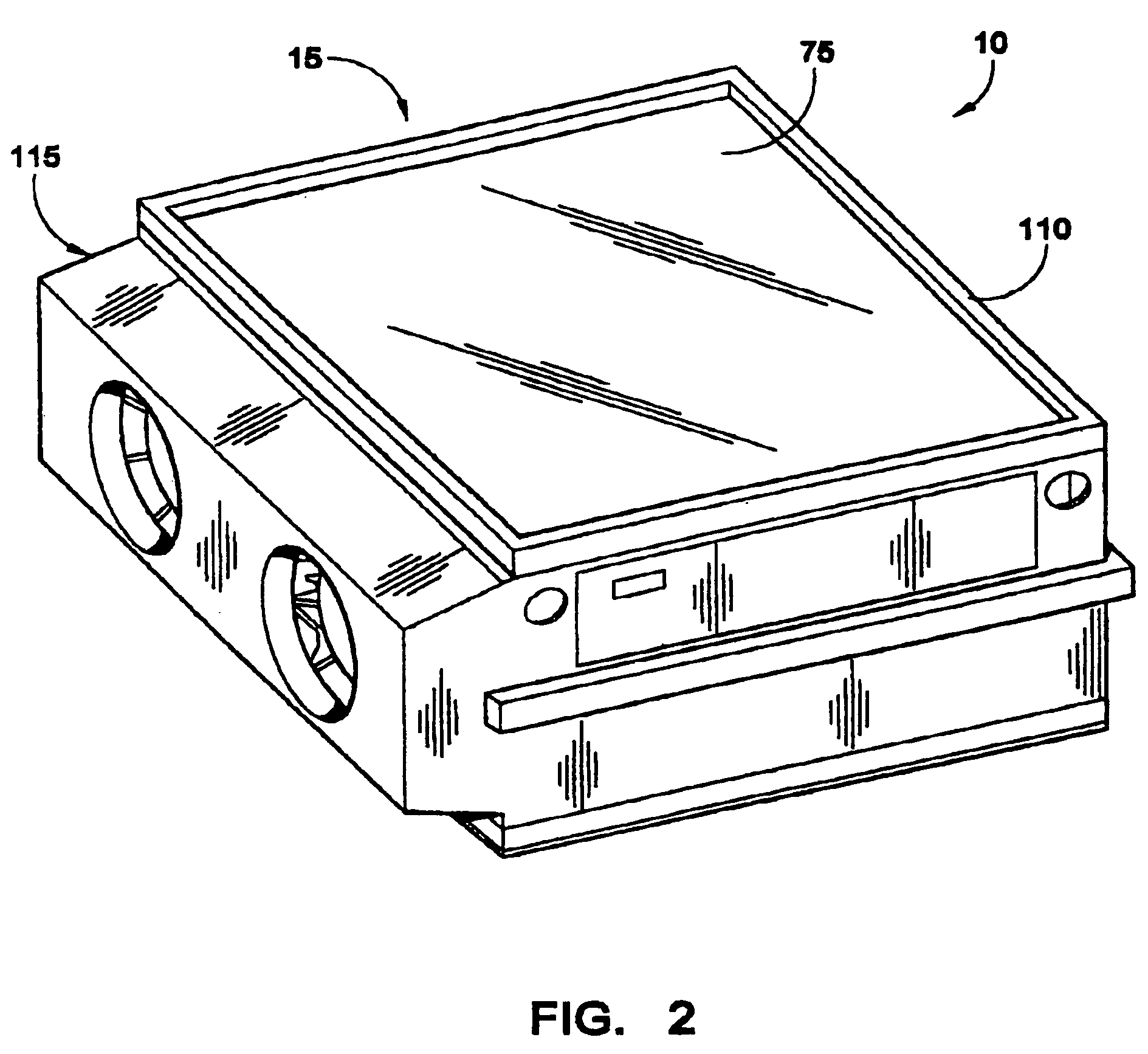

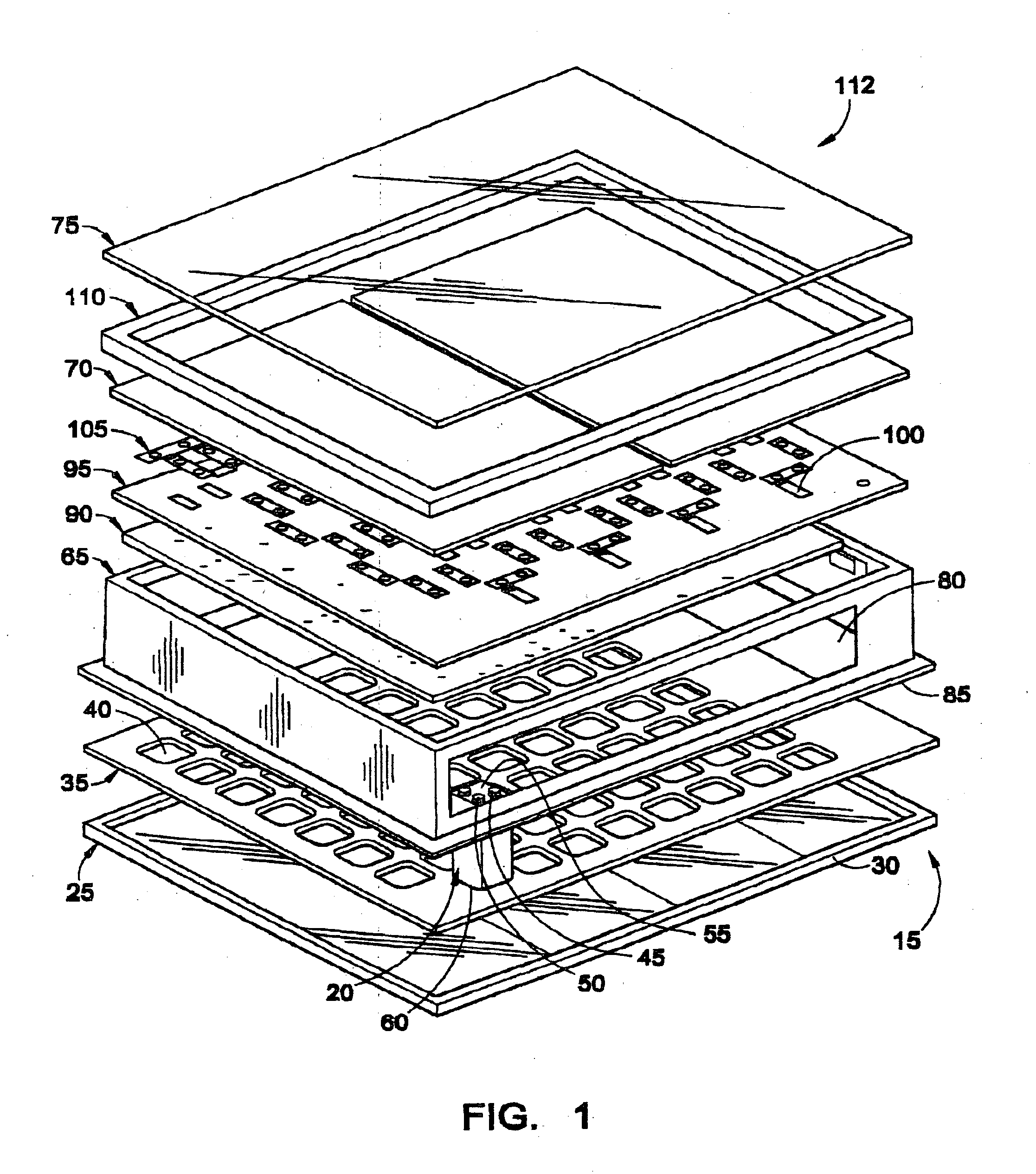

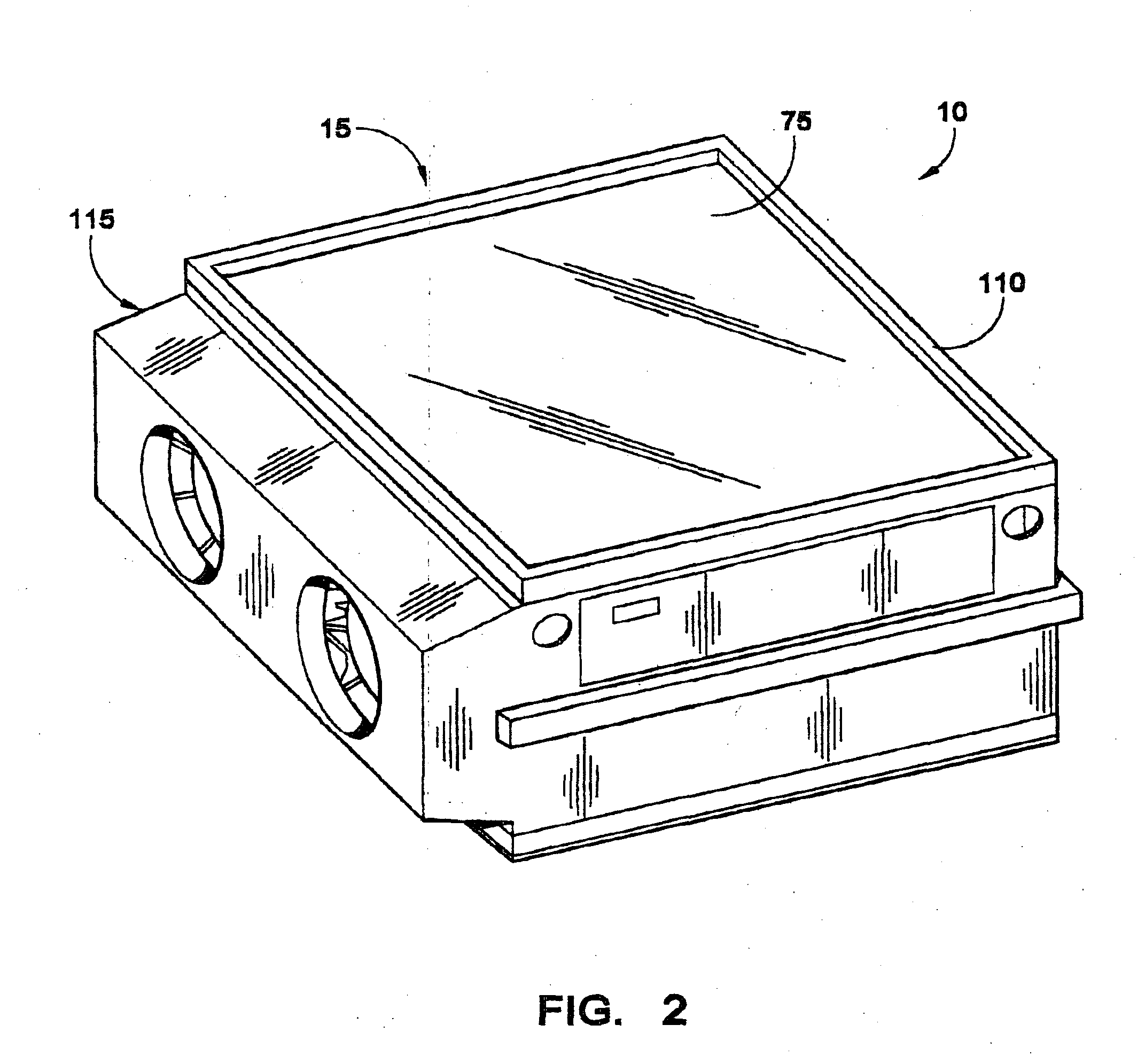

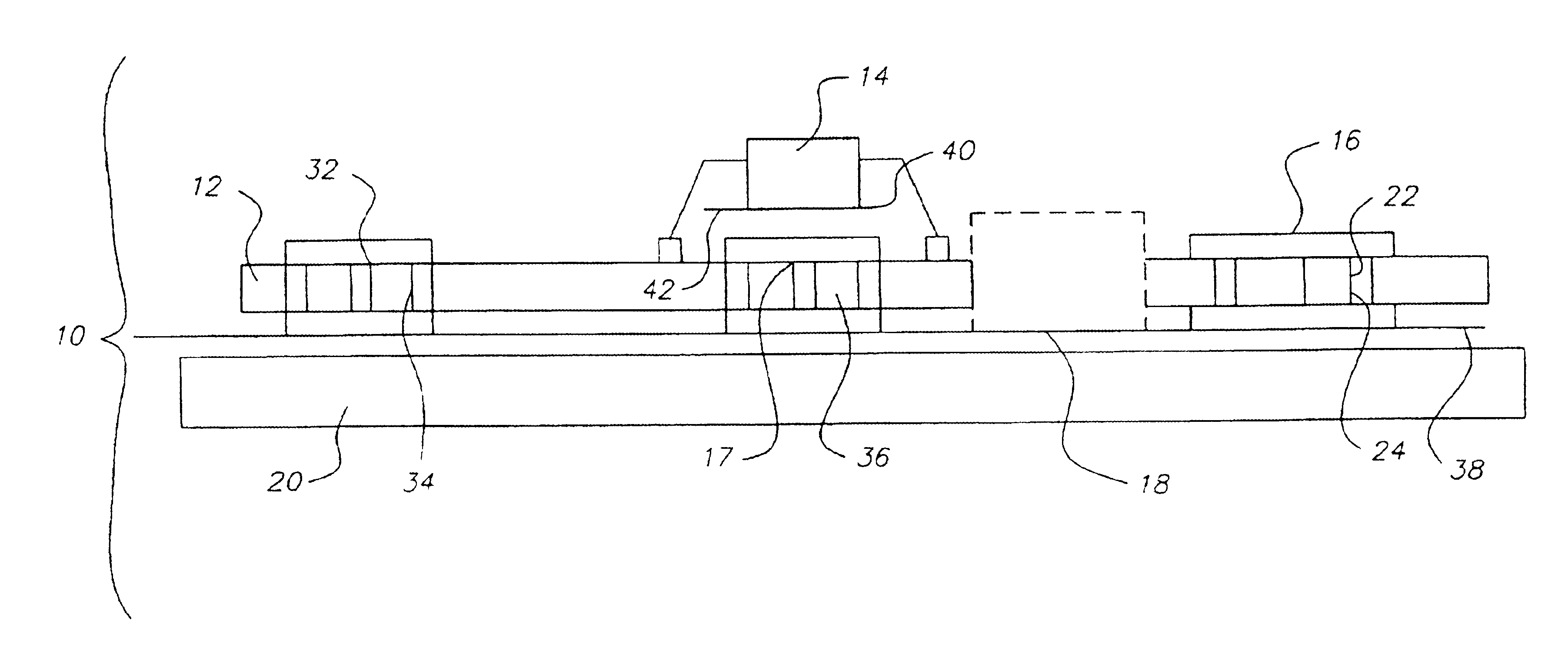

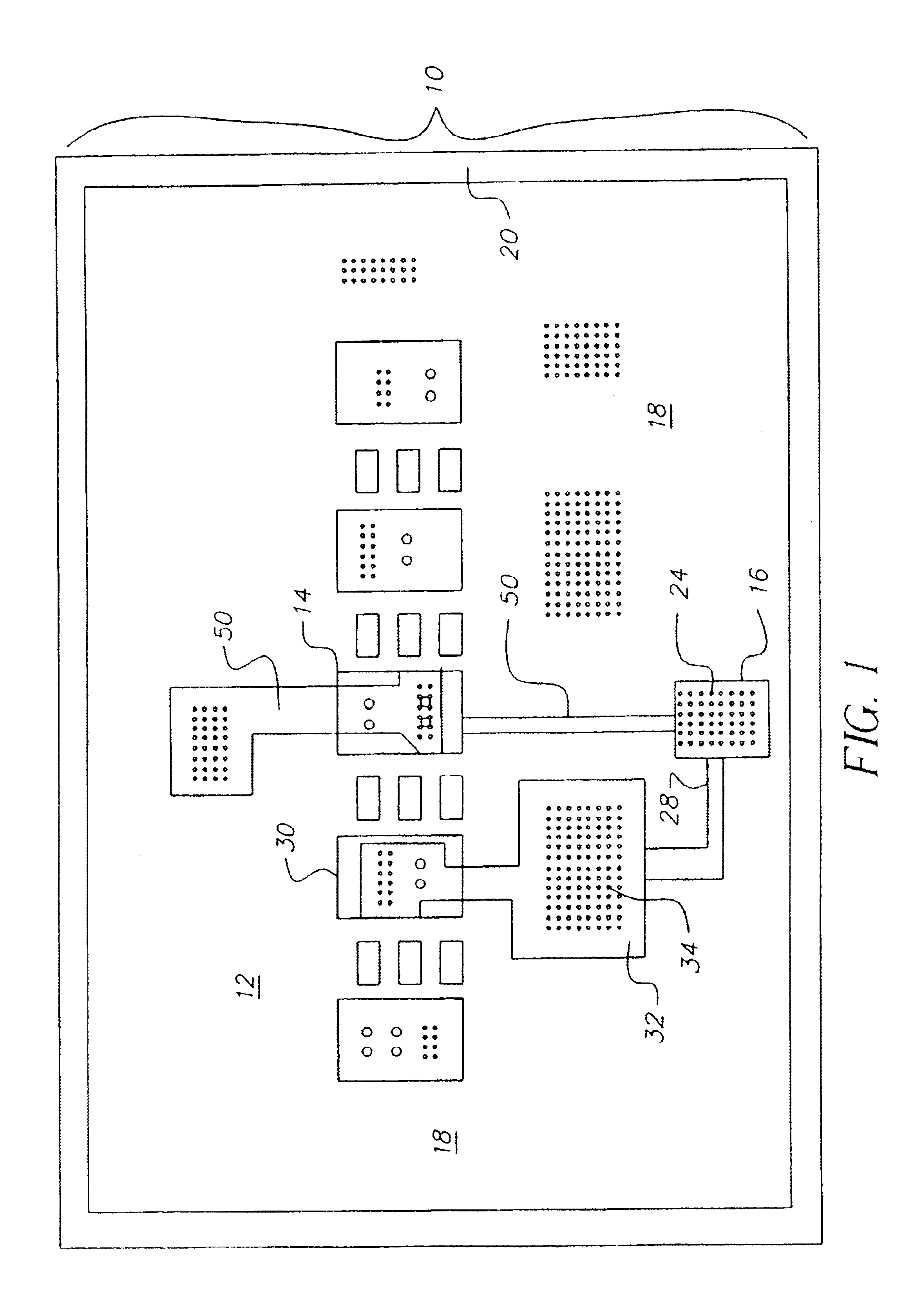

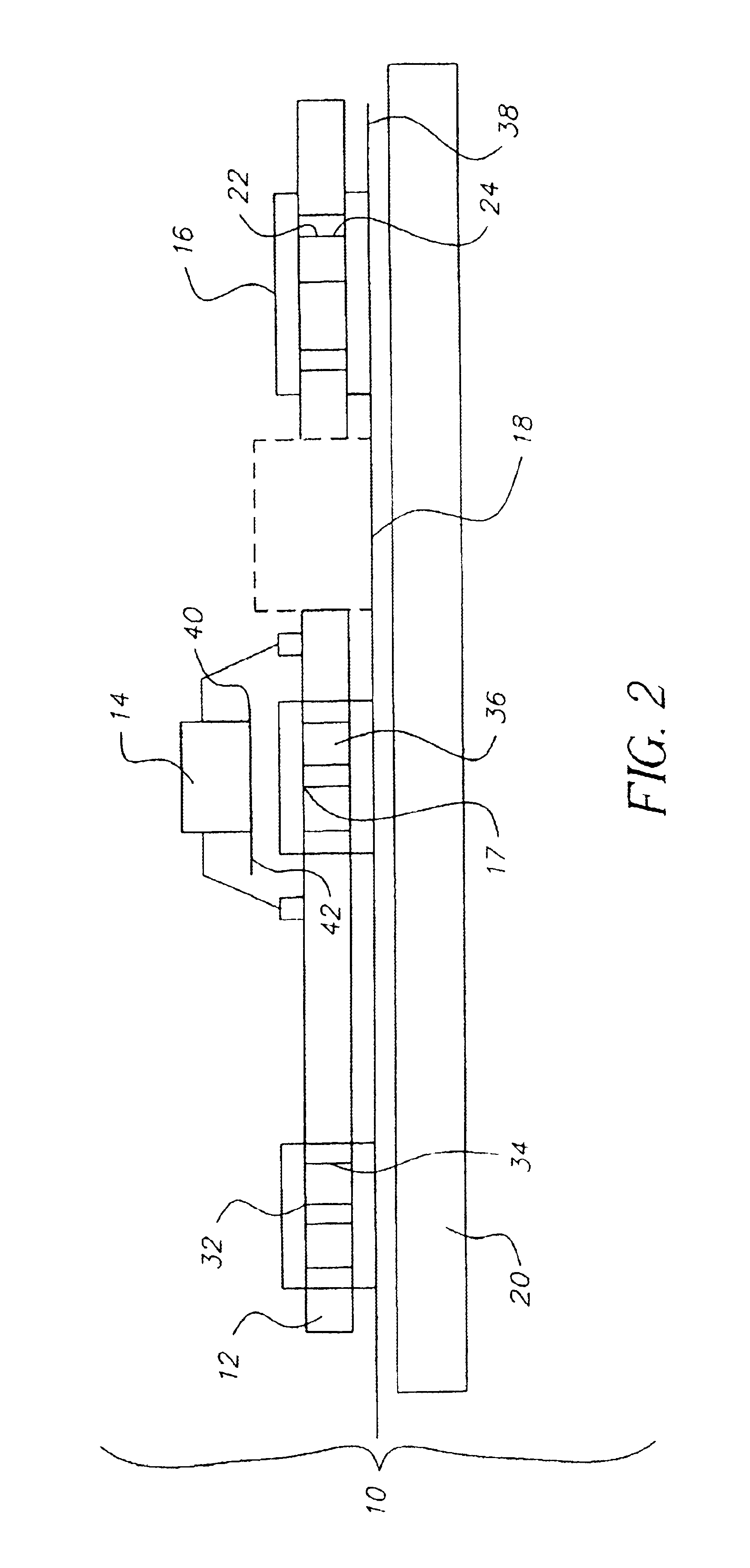

High-power ultracapacitor energy storage pack and method of use

InactiveUS20050041370A1Prolong lifeDischarge safetyCapacitor terminalsCapacitor housing/encapsulationElectrical batterySupercapacitor

An ultracapacitor energy storage cell pack includes an ultracapacitor assembly having a plurality of series connected ultracapacitors and balancing resistors, each balancing resistor connected in parallel with each ultracapacitor to automatically balance each ultracapacitor over time, thereby automatically over time discharging the ultracapacitors of the ultracapacitor assembly; an enclosure to enclose and protect the ultracapacitor assembly; a controller for the ultracapacitor assembly; and one or more temperature sensors to monitor temperature of the ultracapacitor assembly and coupled to the controller.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

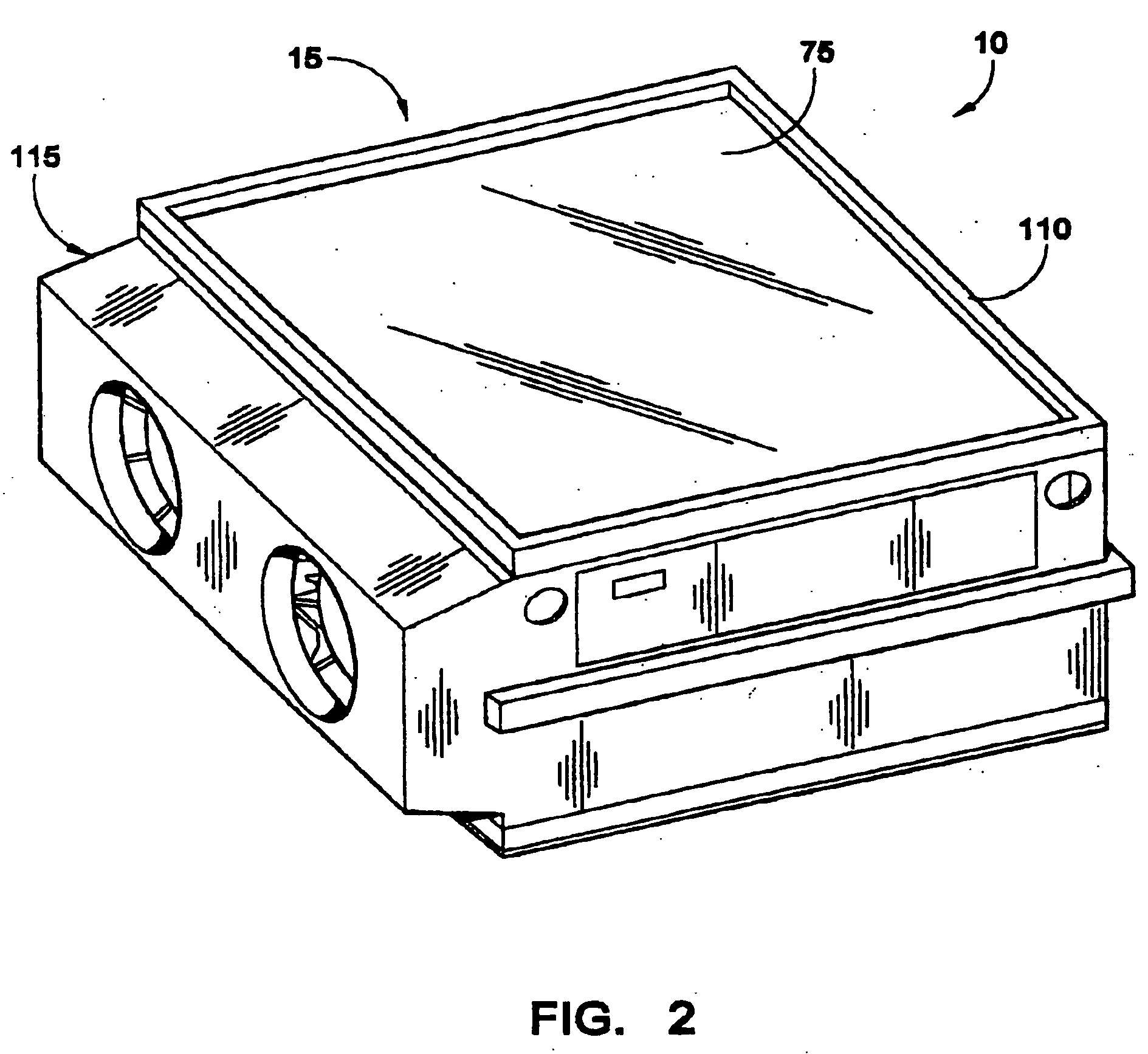

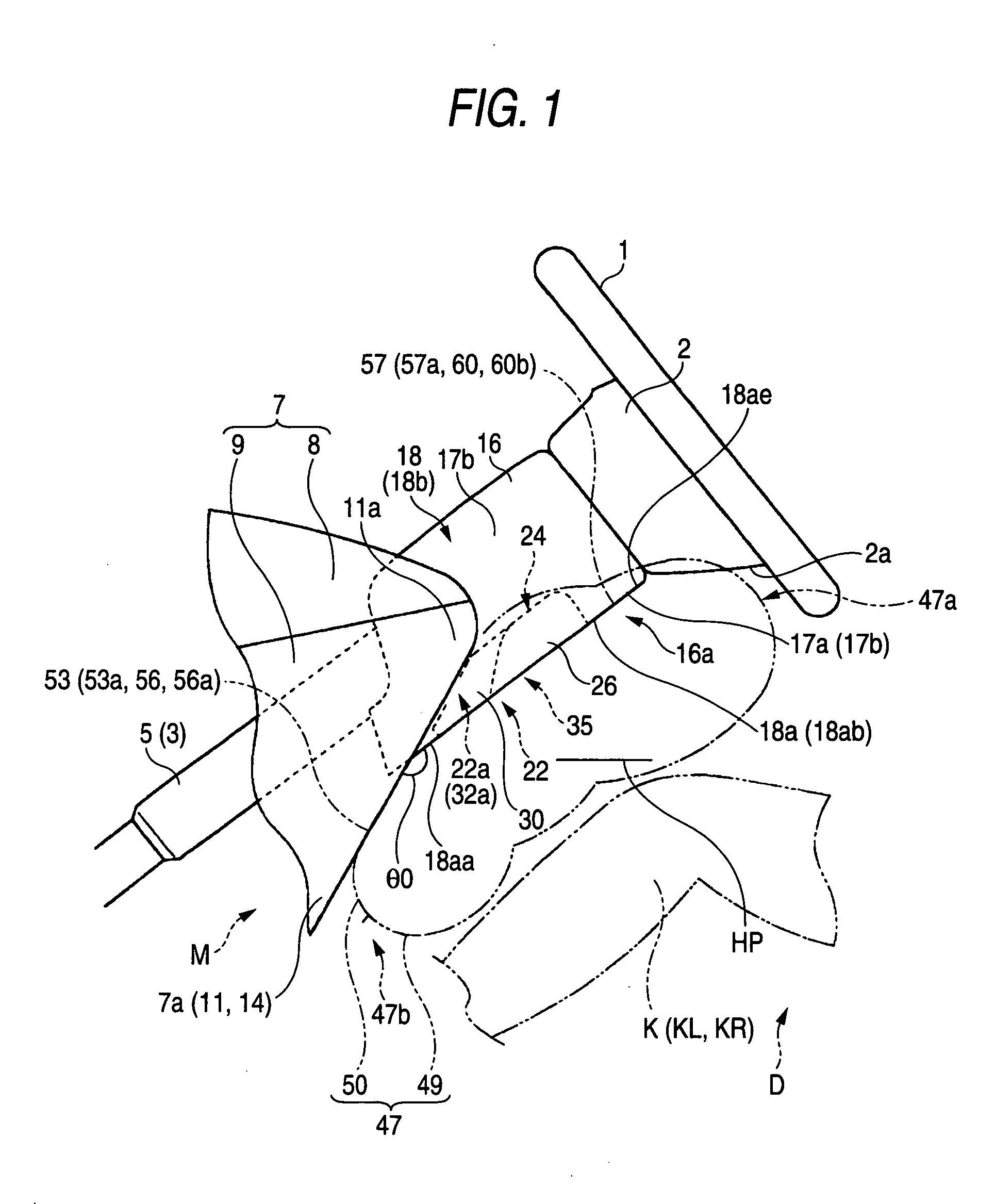

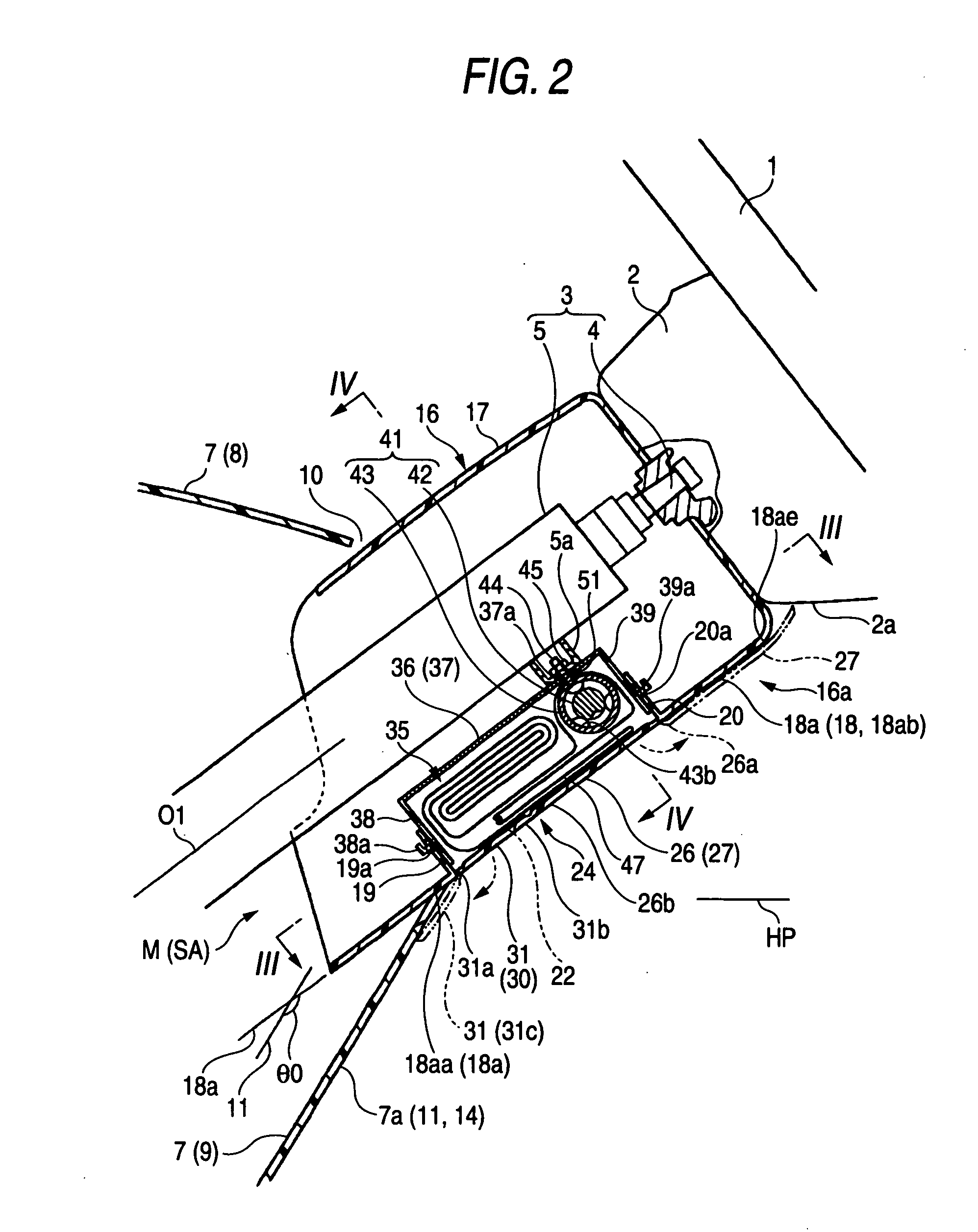

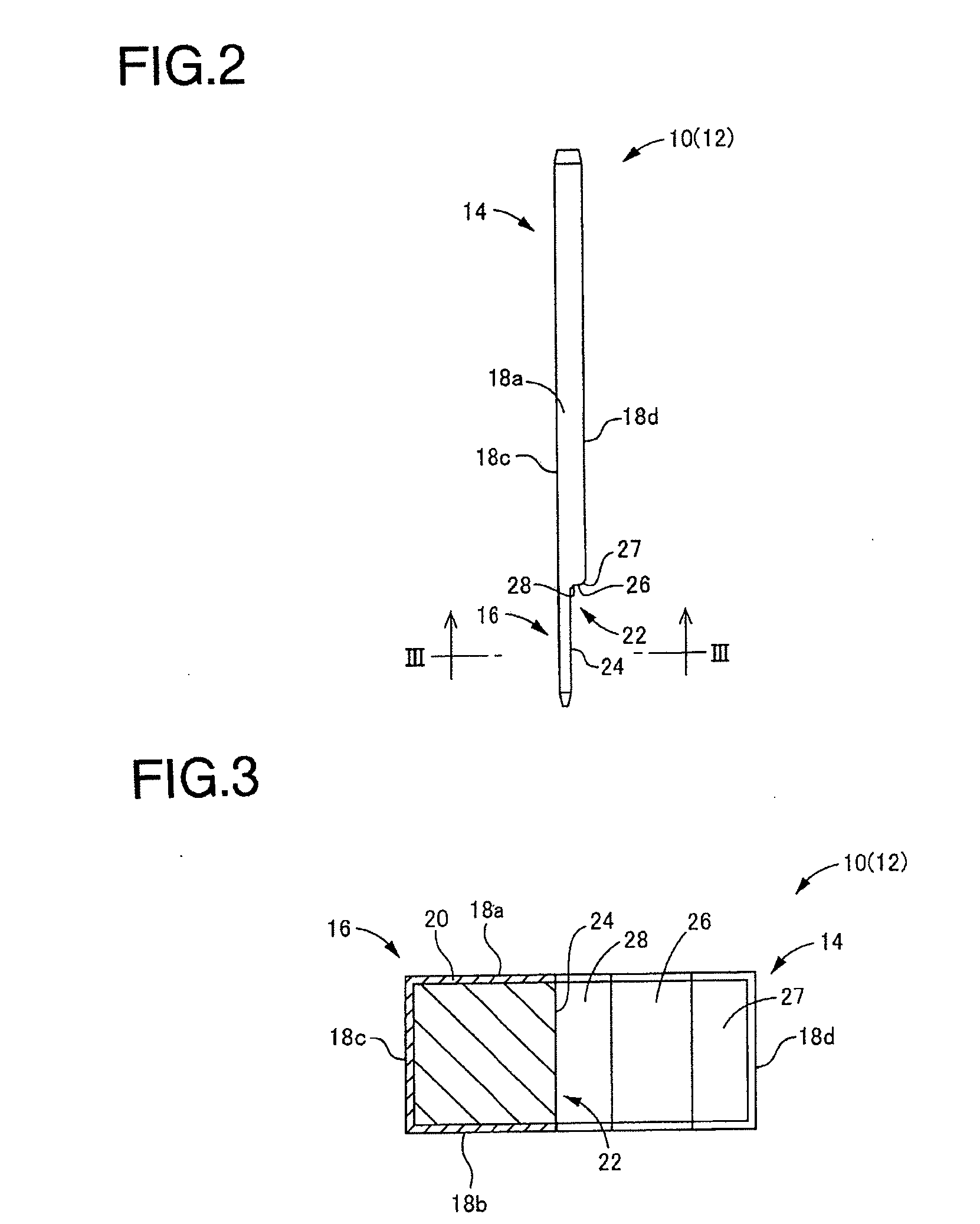

Knee-protecting airbag device

InactiveUS20080116669A1Reduce horizontal widthReduce width sizePedestrian/occupant safety arrangementEngineeringSurface plate

A knee-protecting airbag device is configured so that a folded airbag is accommodated and held in an accommodation part at the side of a lower portion in a column cover. An outer peripheral wall at completion of inflation of the airbag includes a driver-side wall portion and a column-sidewall portion. At the completion of inflation of the airbag, the column-side wall portion covers a bottom surface of a periphery of the accommodation part of the column cover, and areas of a panel surface, which are located at both left and right sides of the column cover from below the column cover. A front-side portion and a rear-side portion of the column-side wall portion are set so that at the completion of inflation of the single airbag, the intersection angle between a front surface of the front-side part and a front surface of the rear-side part is substantially equal to the intersection angle between the panel surface and a bottom surface of the column cover protruded from the panel surface.

Owner:TOYODA GOSEI CO LTD

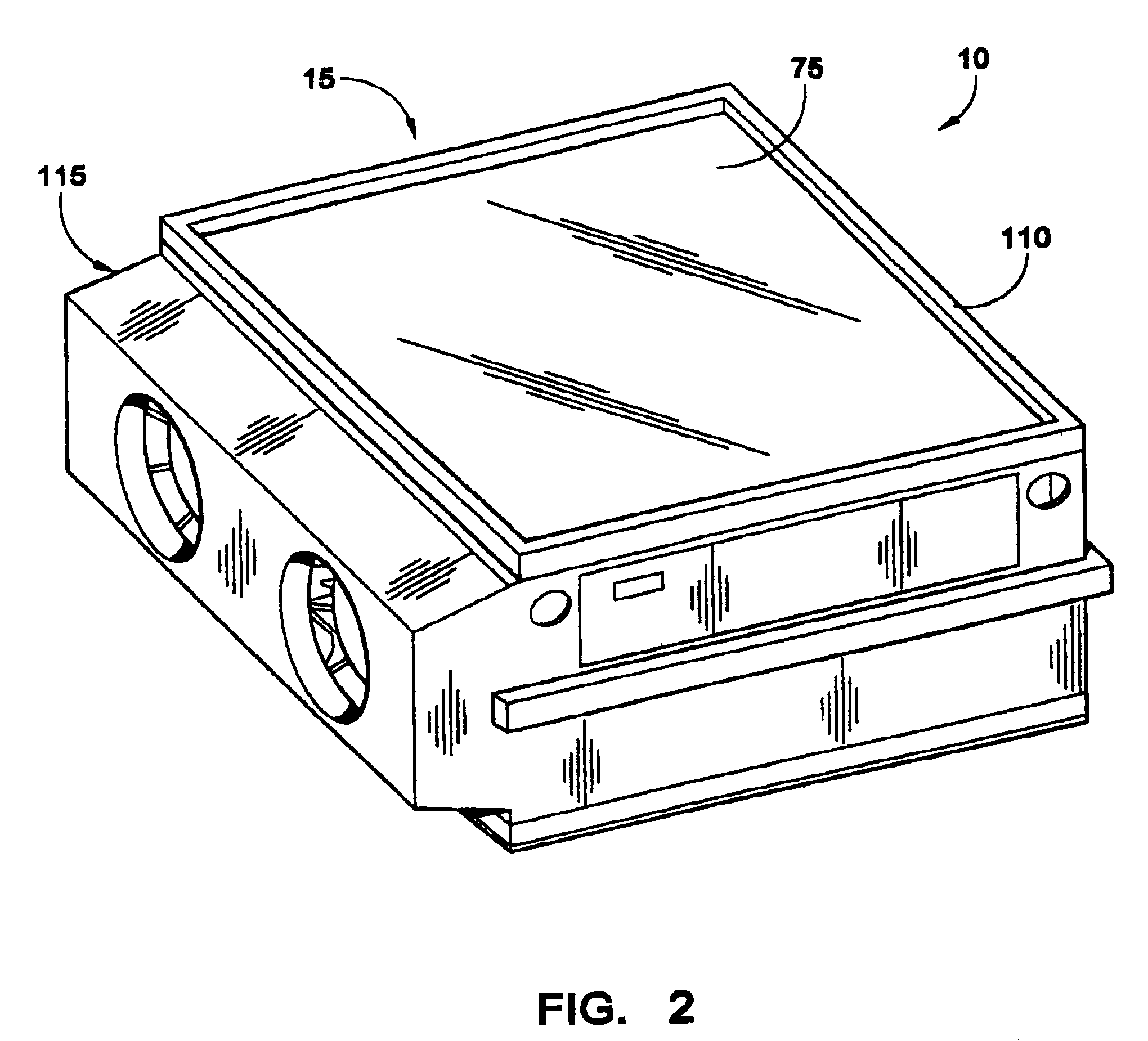

High-power ultracapacitor energy storage pack and method of use

InactiveUS7085112B2Assures balanceReduce width sizeElectric devicesCapacitor terminalsElectrical batteryVoltage sensor

An ultracapacitor energy storage cell pack includes an ultracapacitor assembly including a plurality of parallel ultracapacitors and balancing resistors in series; an enclosure for the ultracapacitor assembly; a controller; one or more temperature sensors; a pack voltage sensor; a GFI sensor; one or more cooling fans carried by the enclosure; an on / off relay coupled to the ultracapacitor assembly and the controller, the on / off relay activated by the controller during normal operation of the ultracapacitor assembly and deactivated by the controller when the GFI sensor detects a ground fault interrupt condition, the one or more temperature sensors detect an over-temperature condition, or the pack voltage sensor detects an over-voltage condition; and a pre-charge resistor and a pre-charge relay coupled to the ultracapacitor assembly and the controller, and activated by the controller to cause the pre-charge resistor to limit pack charge current until the ultracapacitor assembly reaches a minimum voltage.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON +1

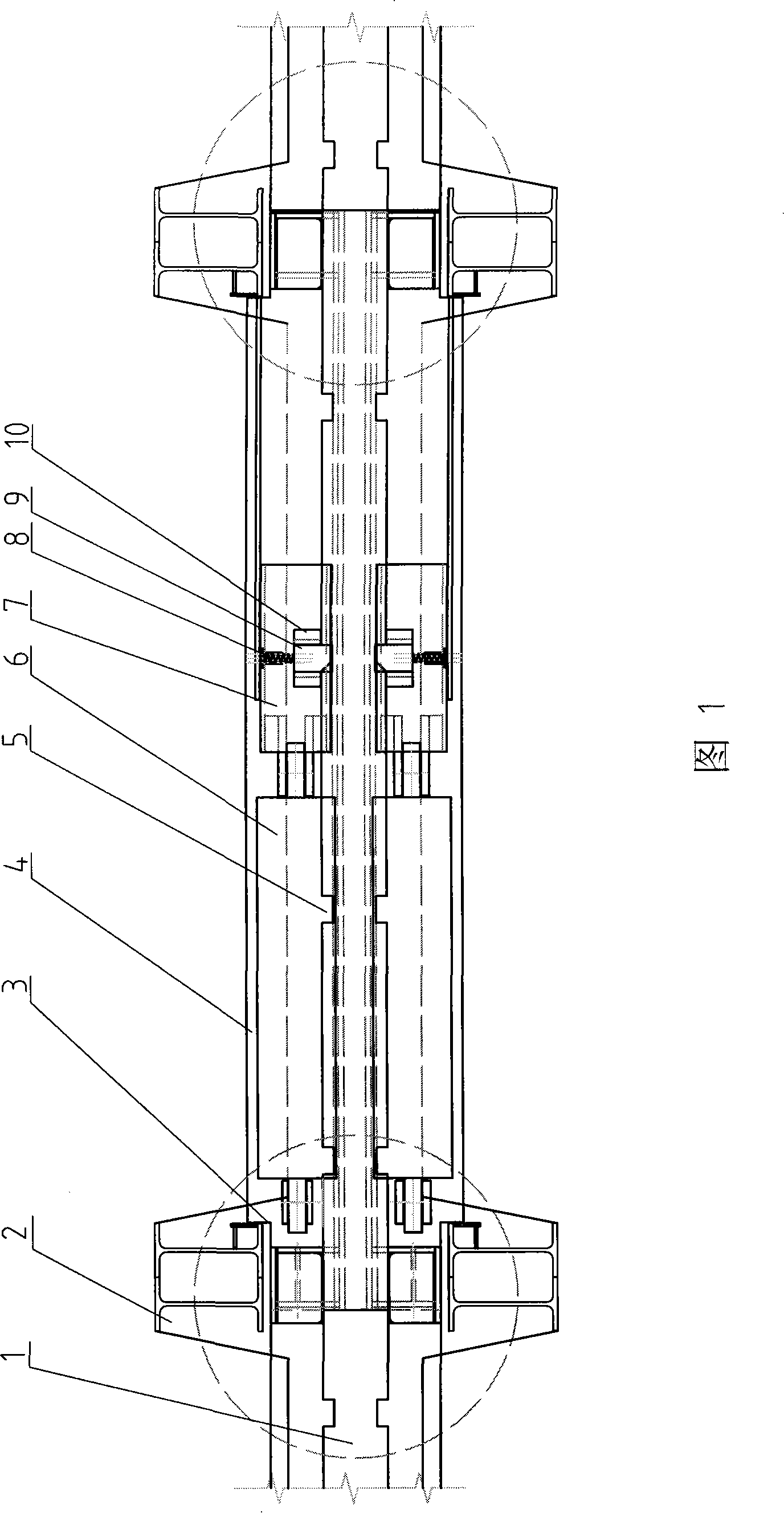

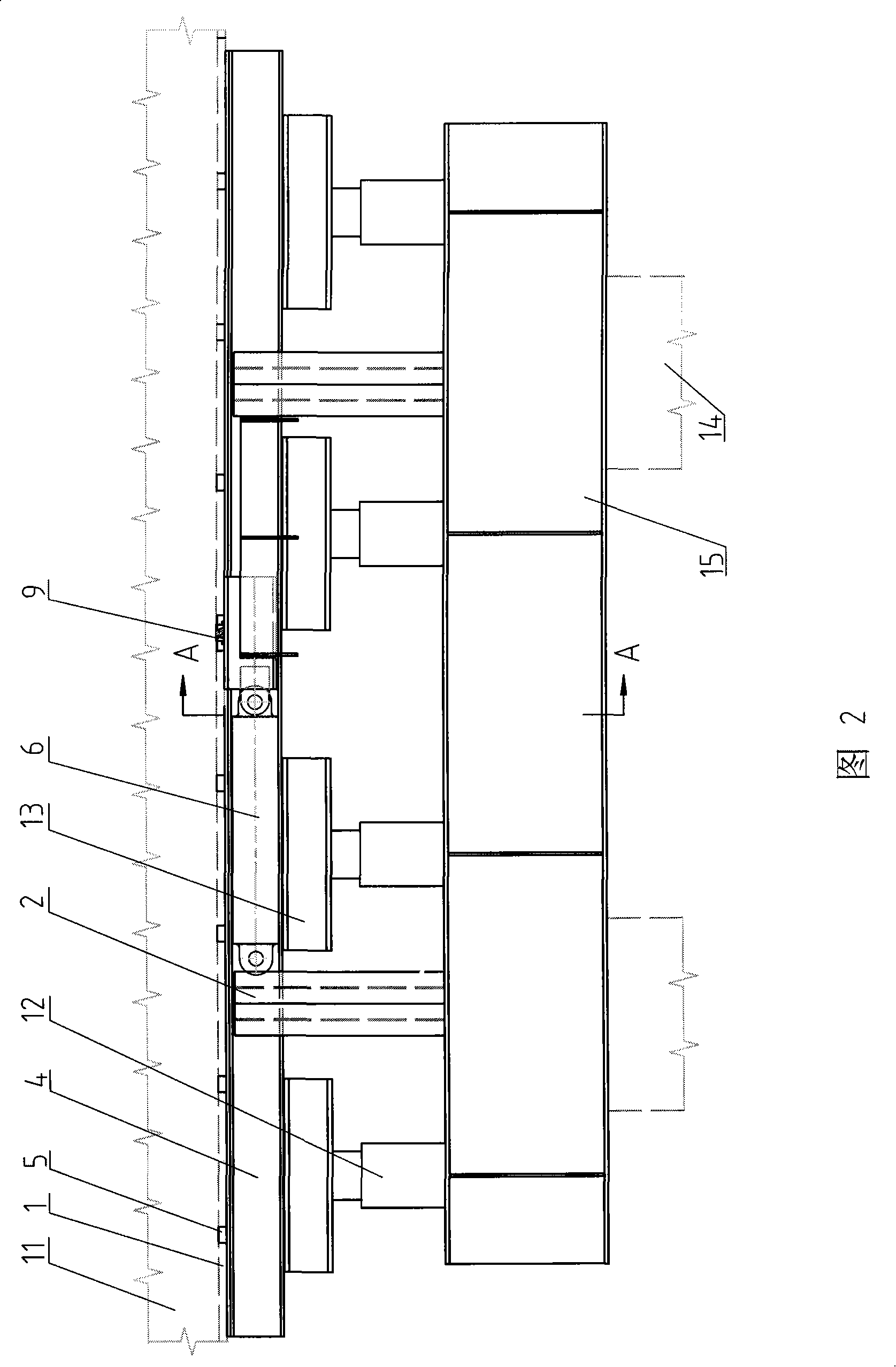

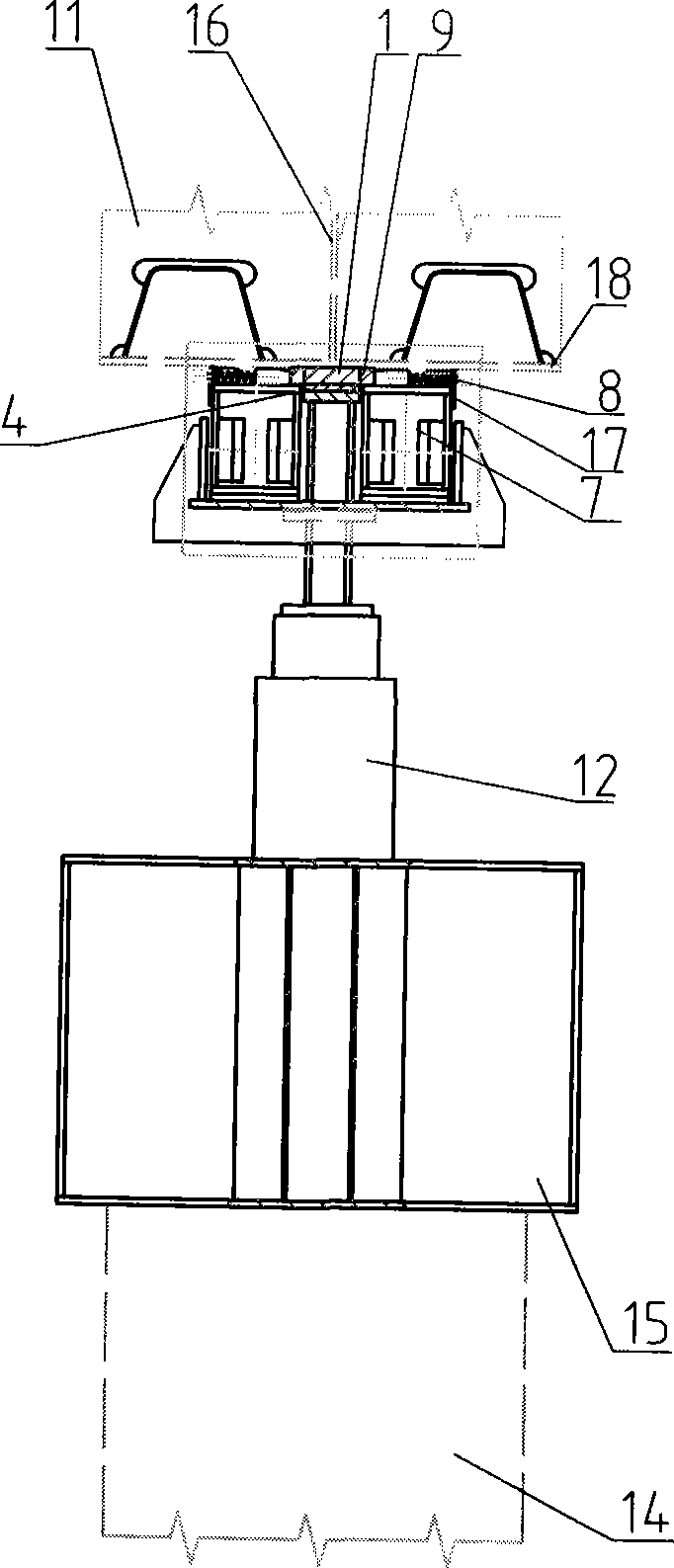

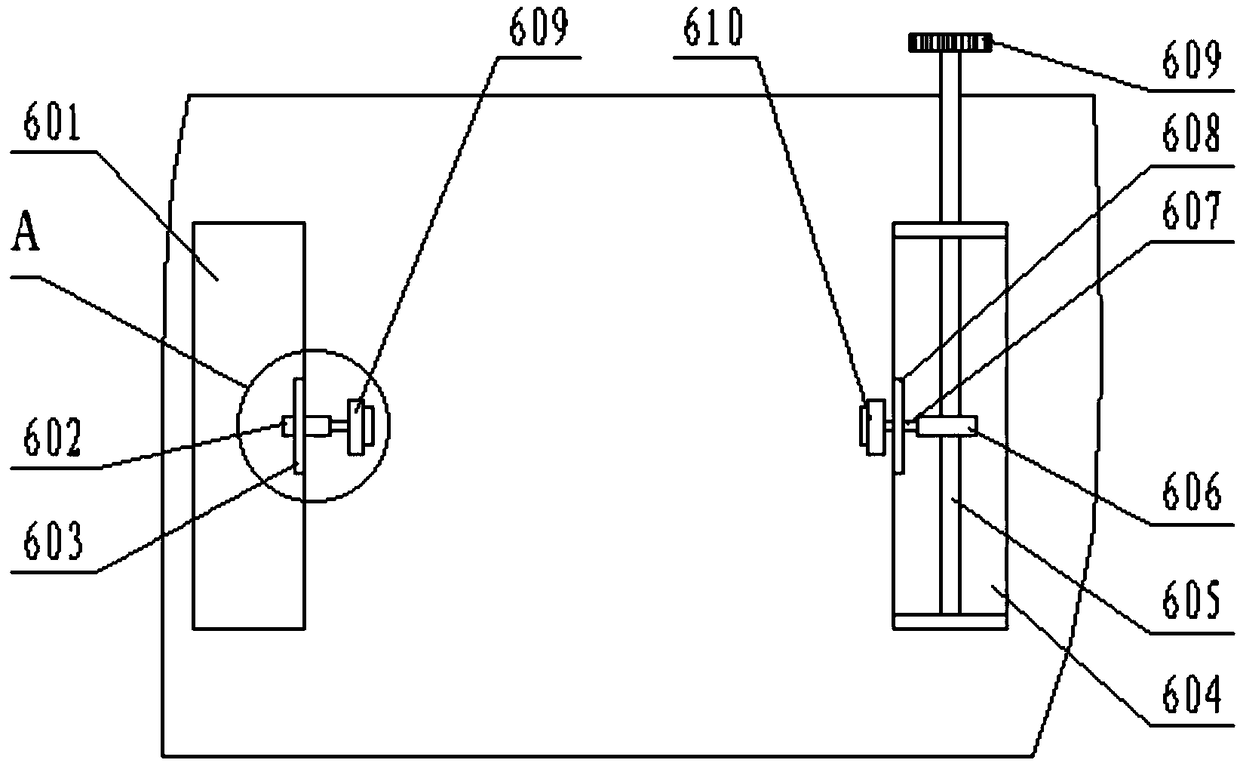

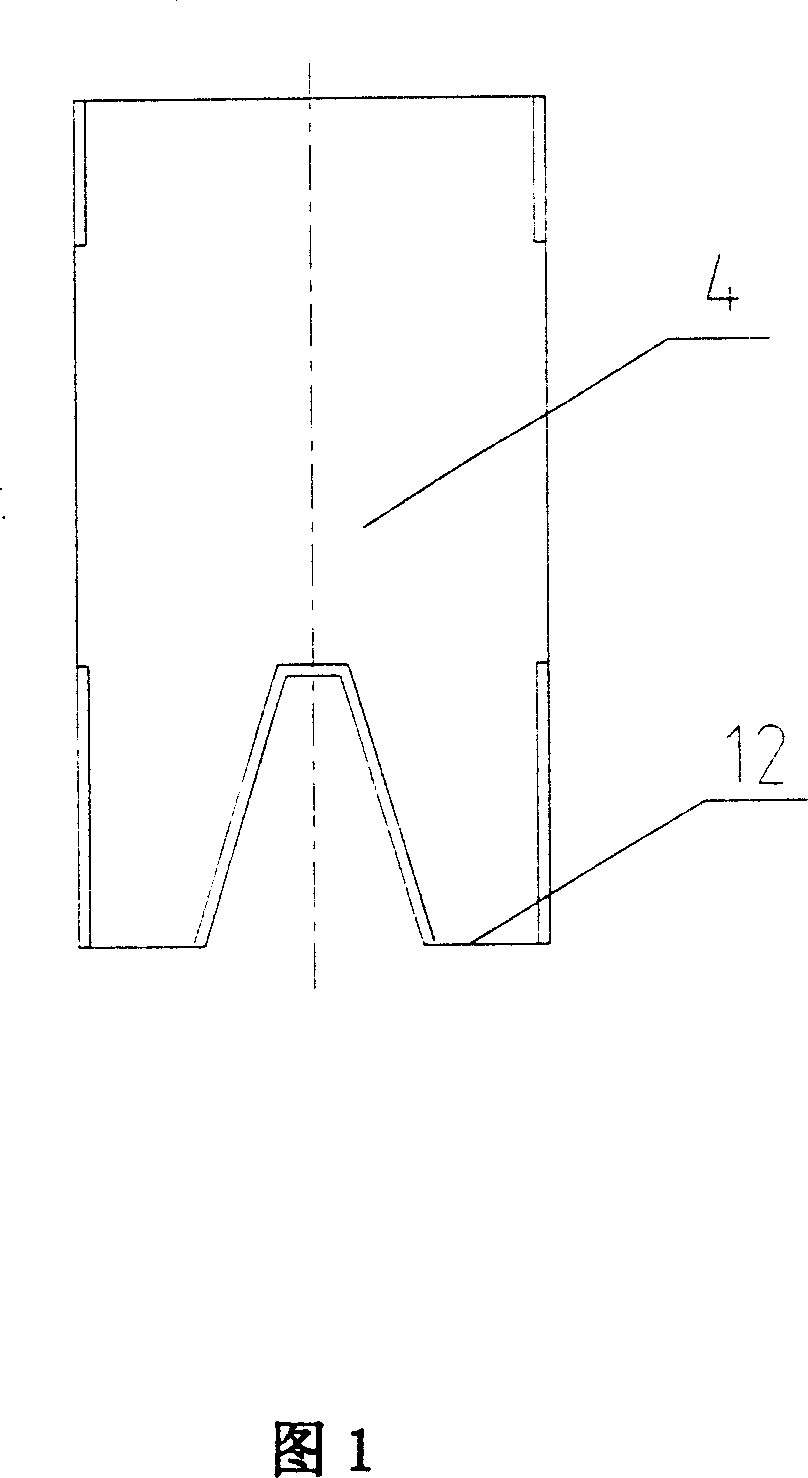

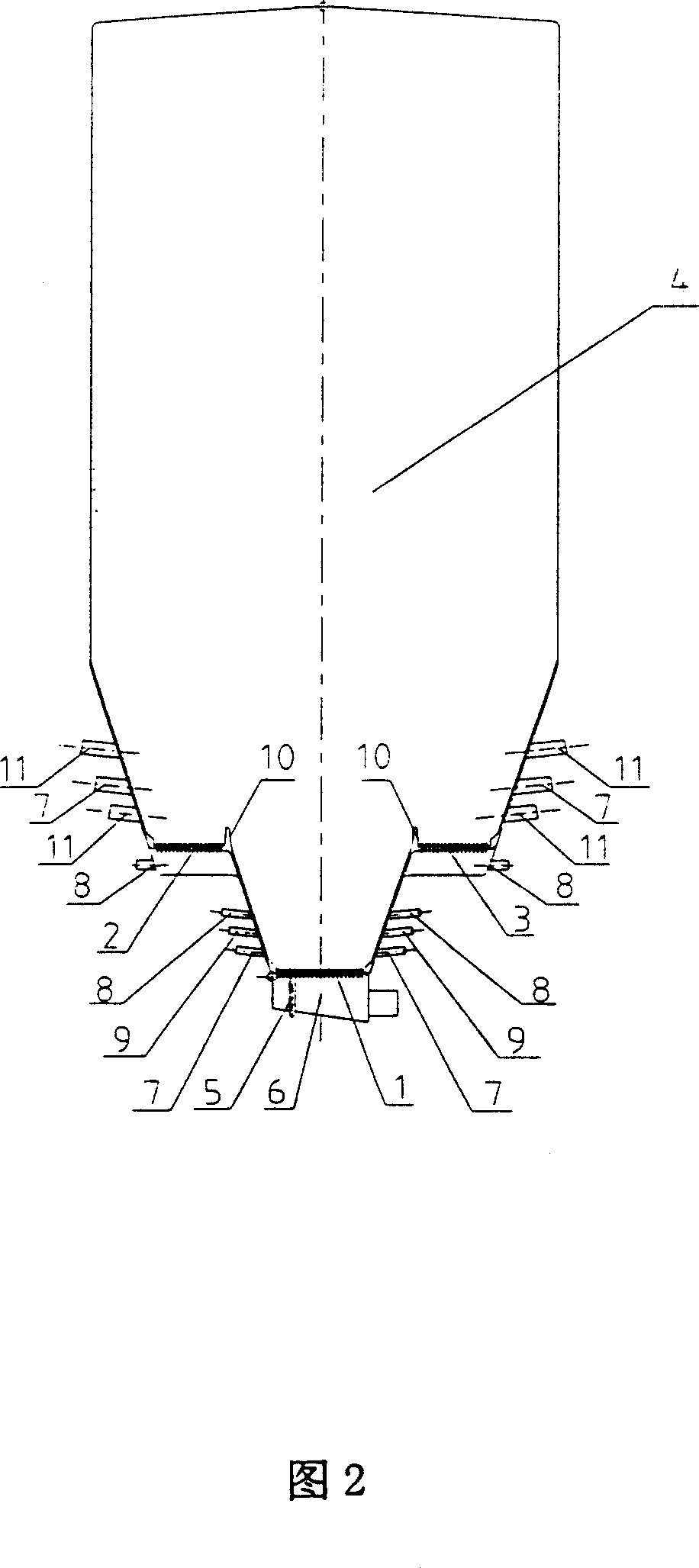

Method for construction of multi-point integral top pulling steel case beam

ActiveCN101250855AReduce width sizeImprove work efficiencyBridge erection/assemblyBridge materialsBridge engineeringPiston rod

The invention discloses a construction method of a multi-point whole incremental launching steel box girder, which belongs to the field of bridge engineering. The construction method uses a dental plate with a tooth socket, which is arranged on a steel box girder and a guiding beam web plate, a jacking force is supplied by an incremental launching jack, wherein a piston rod of the incremental launching jack is equipped with a slider, on which a spinous block with an inclined plane and a control spring are arranged, the inclined plane is arranged on the side of the incremental launching jack, the steel box girder and the guiding beam are applied with the jacking force through the push travel of the incremental launching jack, and the spinous block withdraws from the tooth socket during the return to enter into a next push travel. The construction method also supplies the support and adjusts the elevation of corresponding points through lifting-up the jack, simultaneously the incremental launching jack and the upper portion of the incremental launching jack are all equipped with a displacement sensor and a pressure sensor to collect information, thereby controlling an incremental launching process. The construction method has less consumption of steel material, a support reaction and a thrust force are capable of being controlled, and the problem of the rotation angle of the steel box girder is capable of being excellently solved.

Owner:SHANDONG LUQIAO GROUP

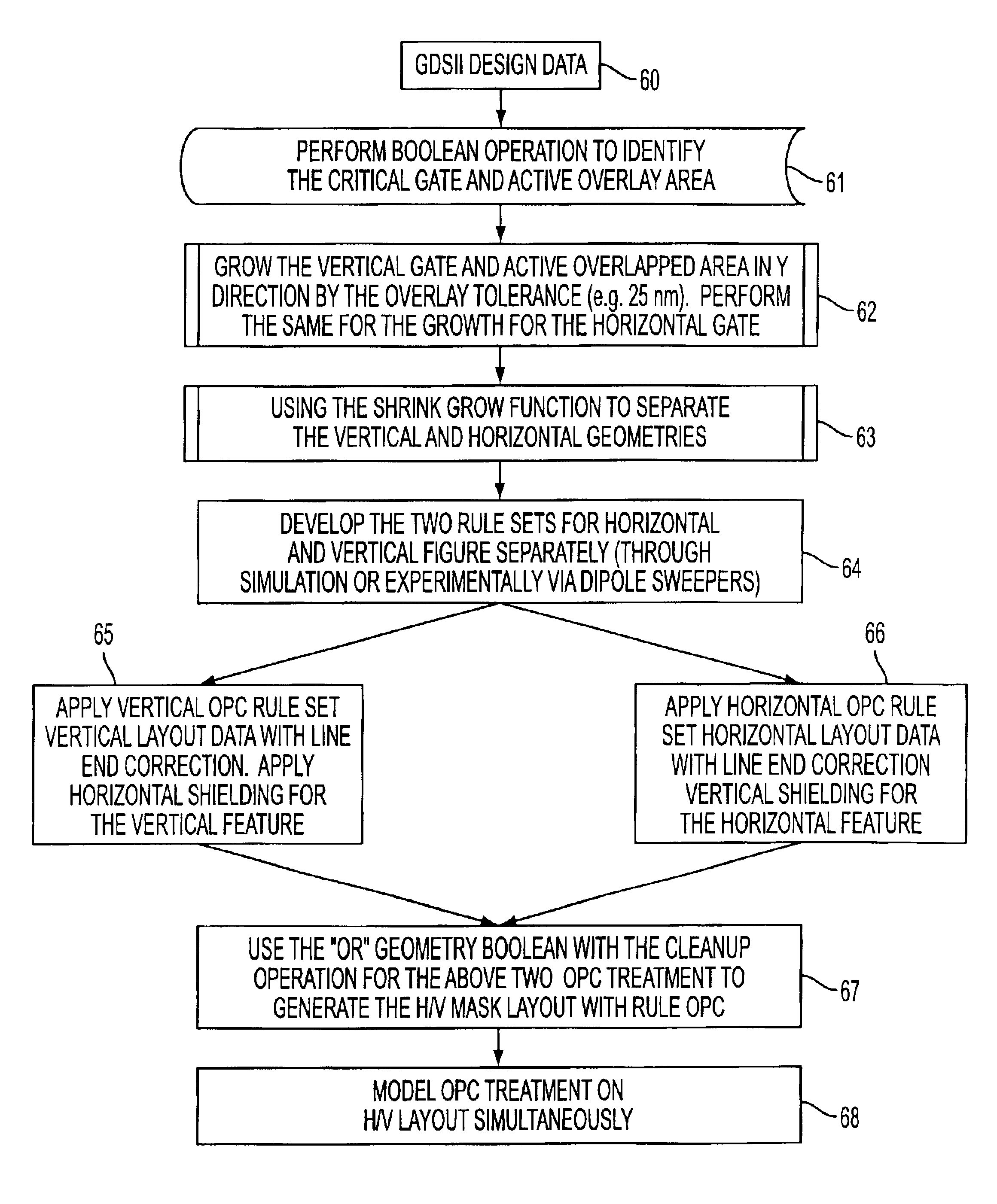

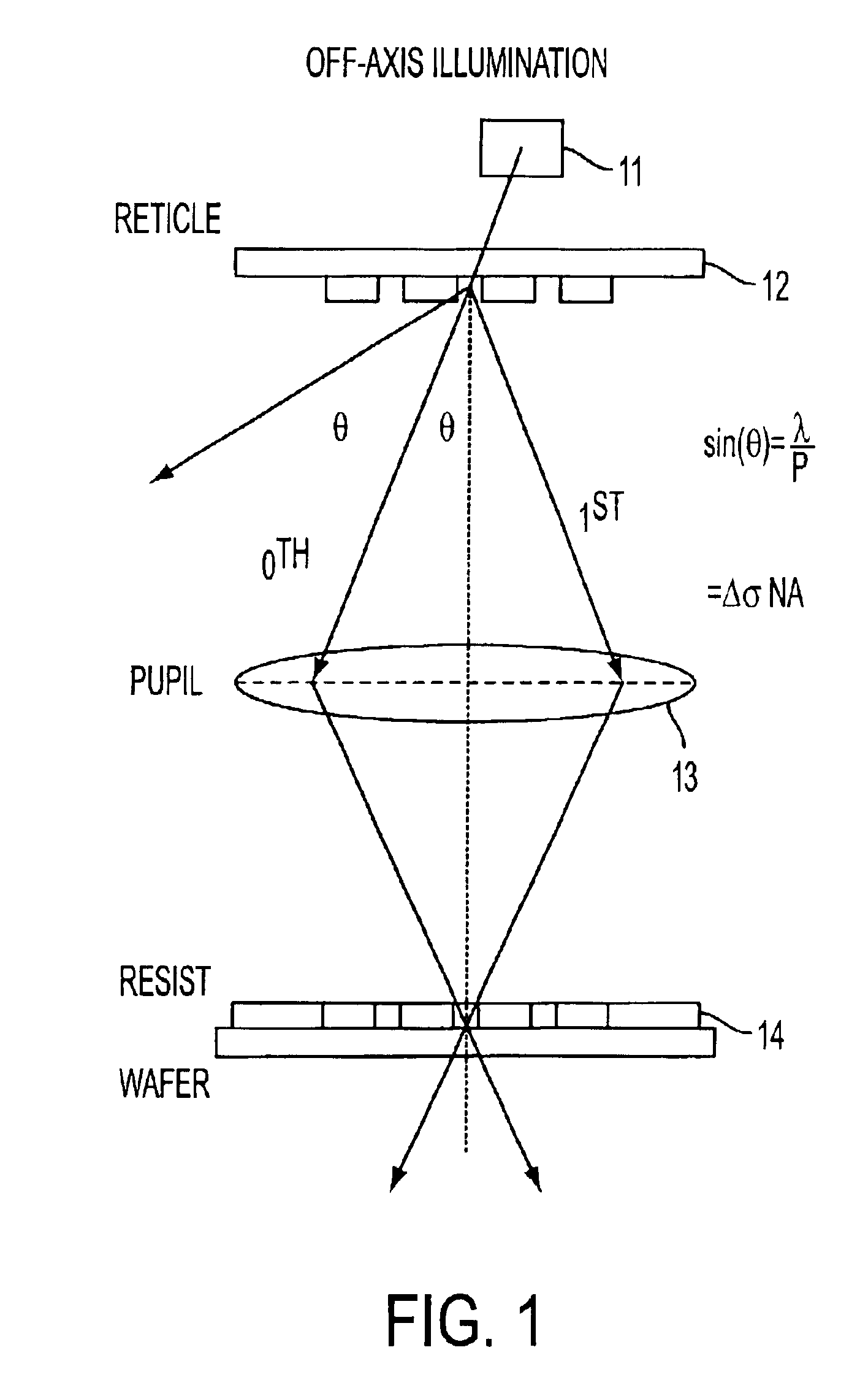

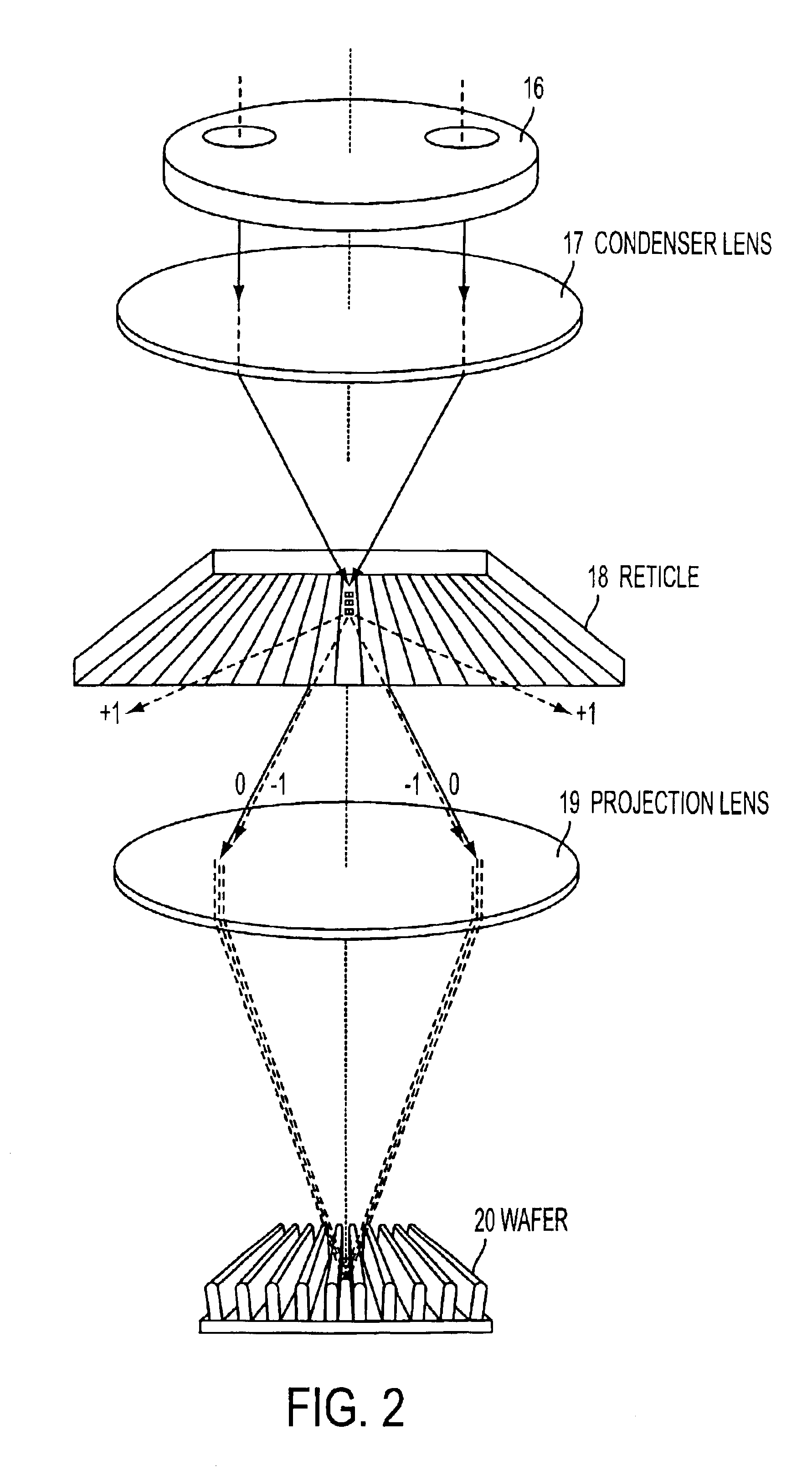

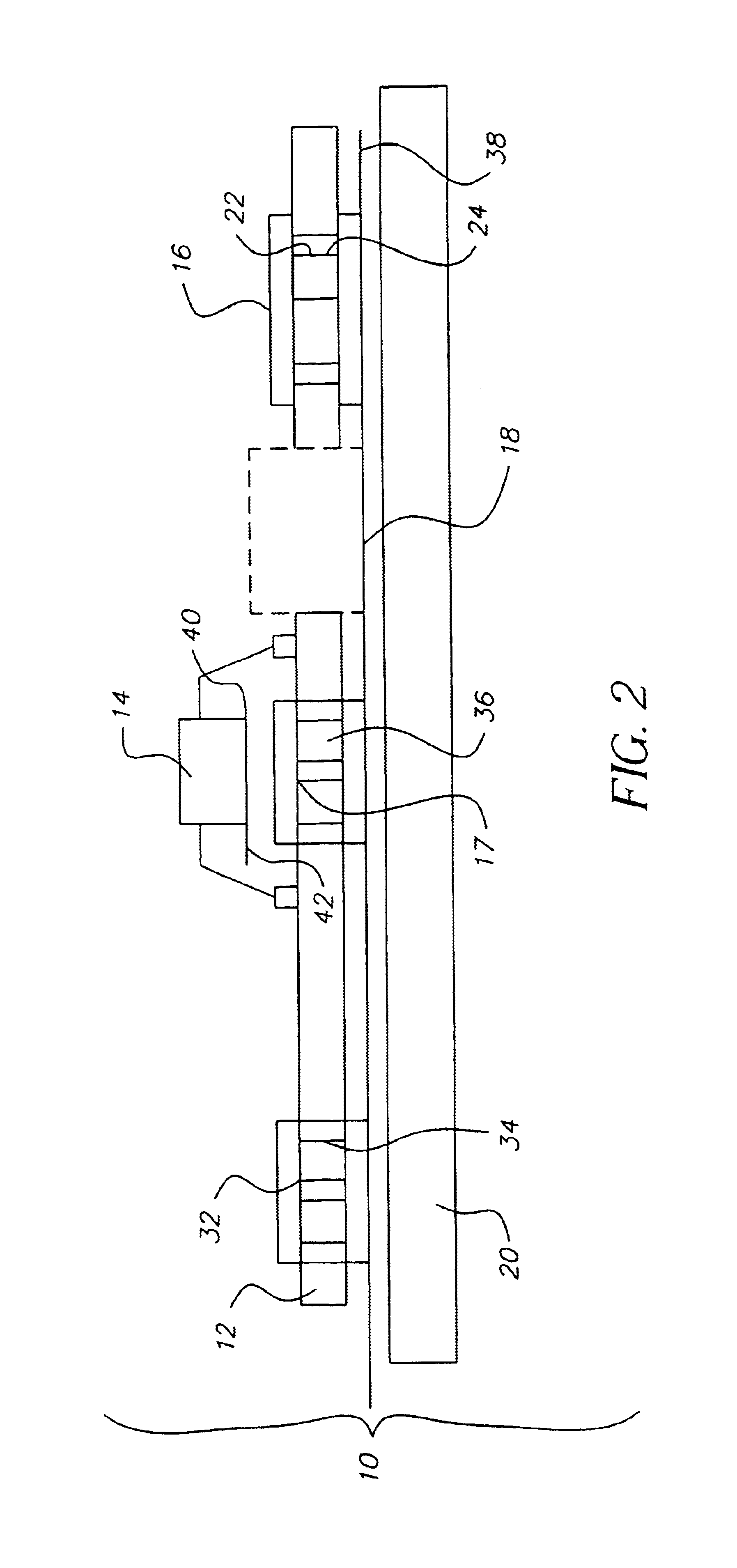

Method and apparatus for performing rule-based gate shrink utilizing dipole illumination

ActiveUS6915505B2Reduction of gate lengthShorten the lengthSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhysicsDipole

A method of printing a gate pattern on a substrate comprising the steps of: identifying at least one area in the pattern in which one of the gate features overlays one of the active regions; reducing a width dimension of the one of the gate features at the location which the one of the gate features overlays the one of the active regions; extracting the gate features from the pattern; decomposing the gate features into a vertical component mask and a horizontal component mask; and illuminating the vertical component mask and the horizontal component mask utilizing dipole illumination.

Owner:ASML NETHERLANDS BV

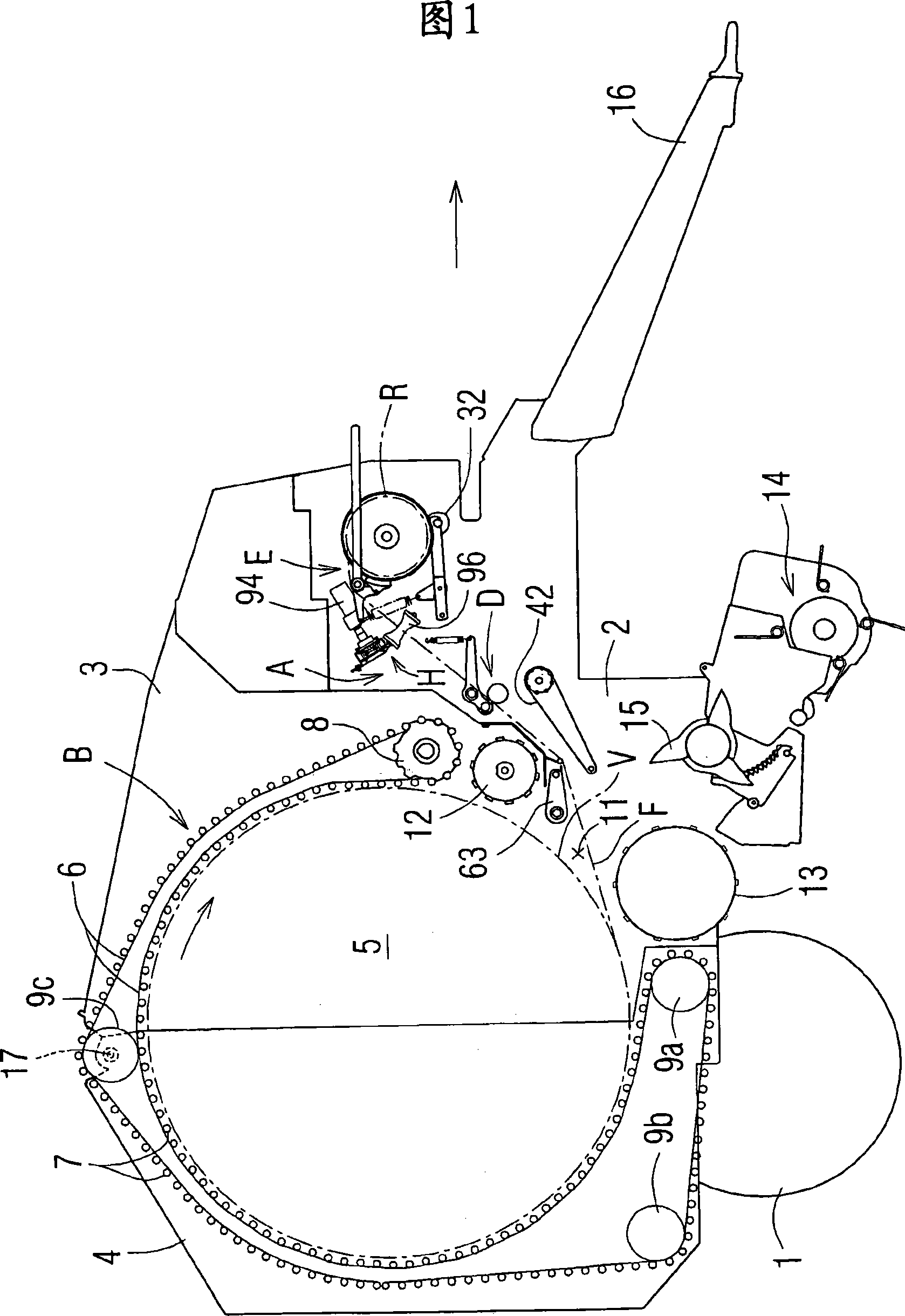

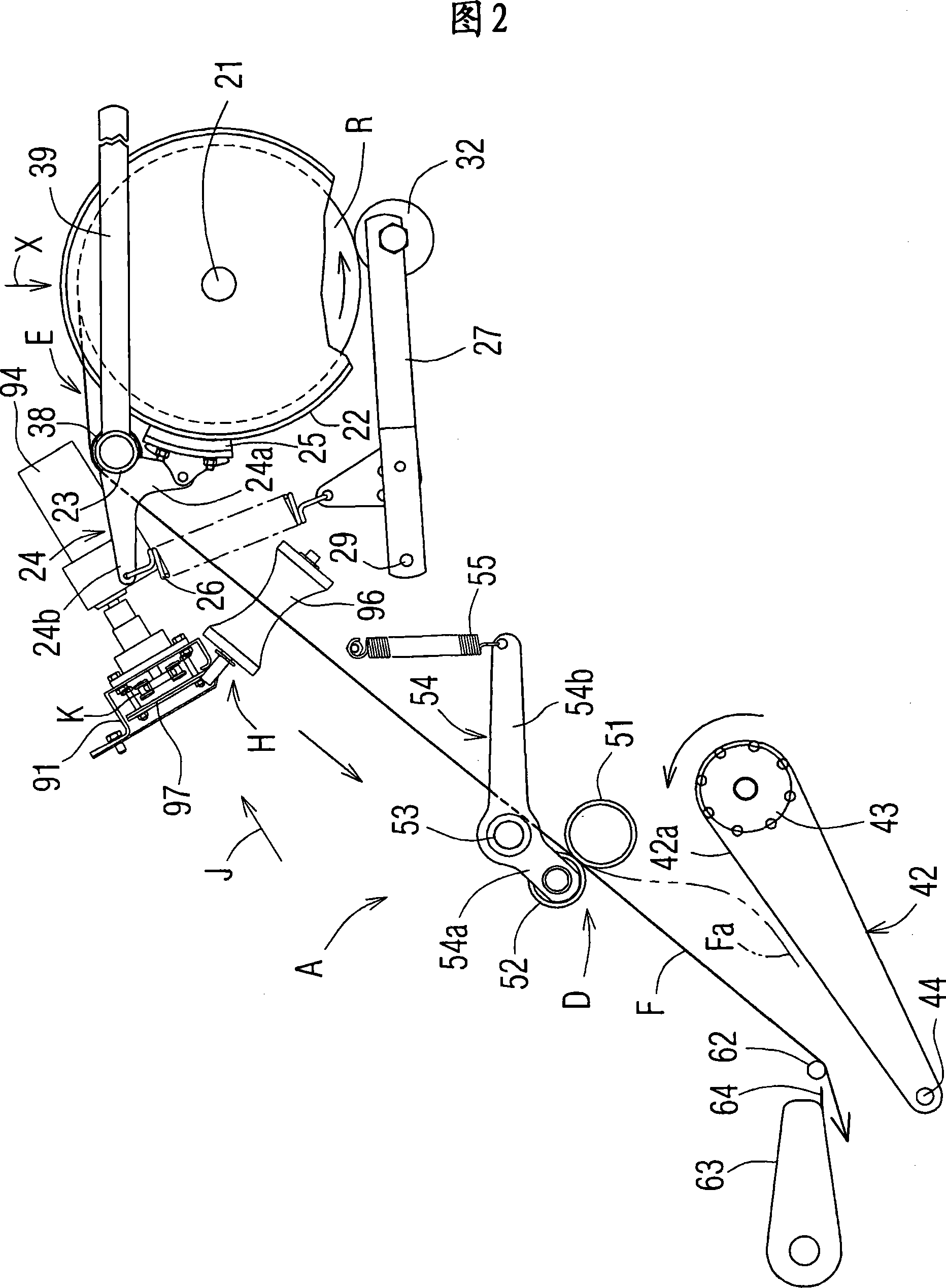

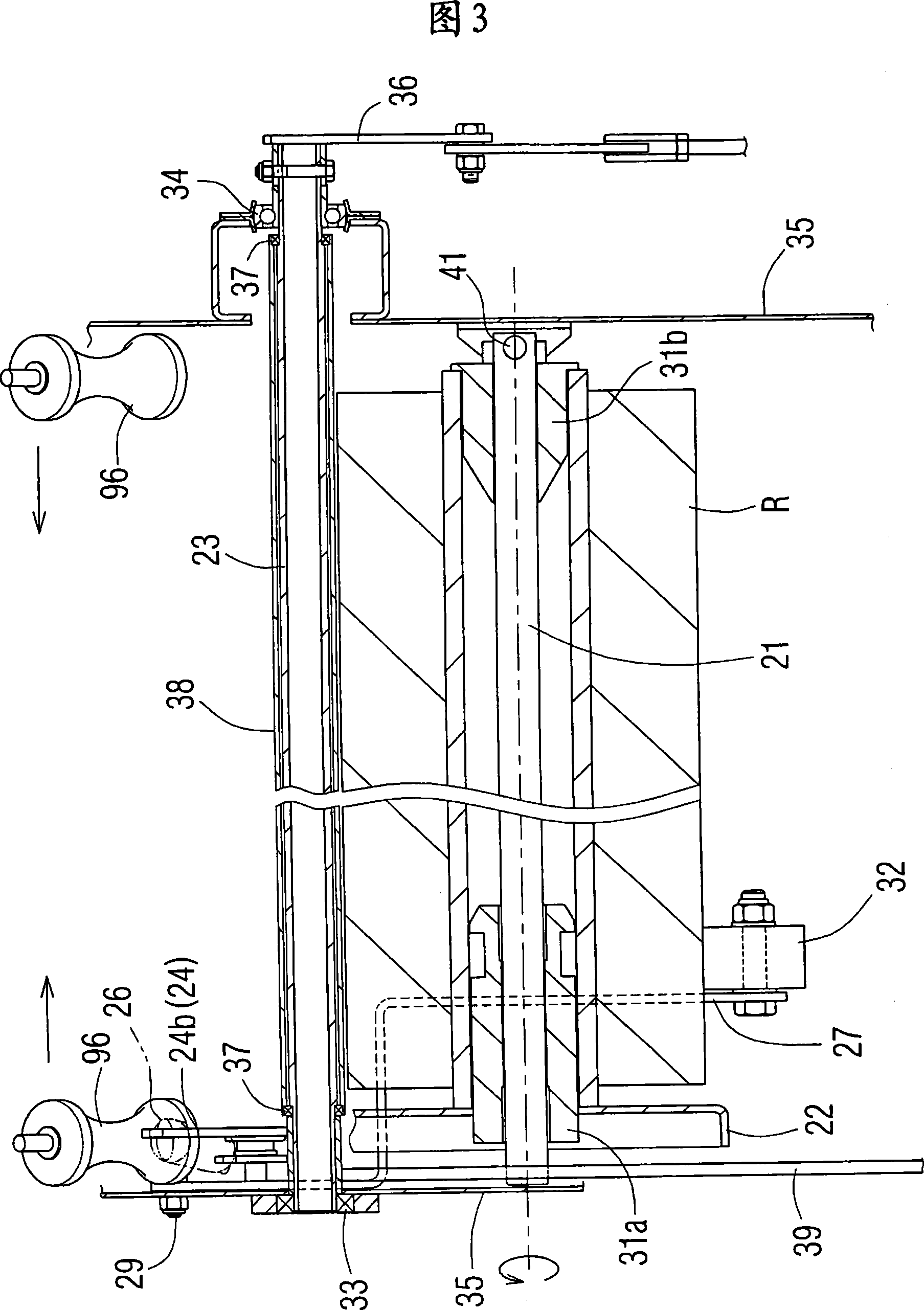

Film letting-off device for roll baler, and method for winding film on rolled bale

ActiveCN101096228ANo damageEliminate damageWrapping material feeding apparatusBalingEngineeringMechanical engineering

Owner:德佳达有限公司

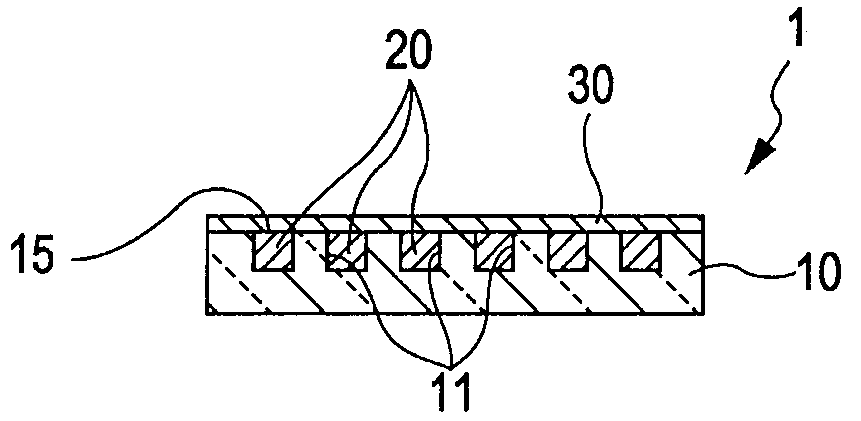

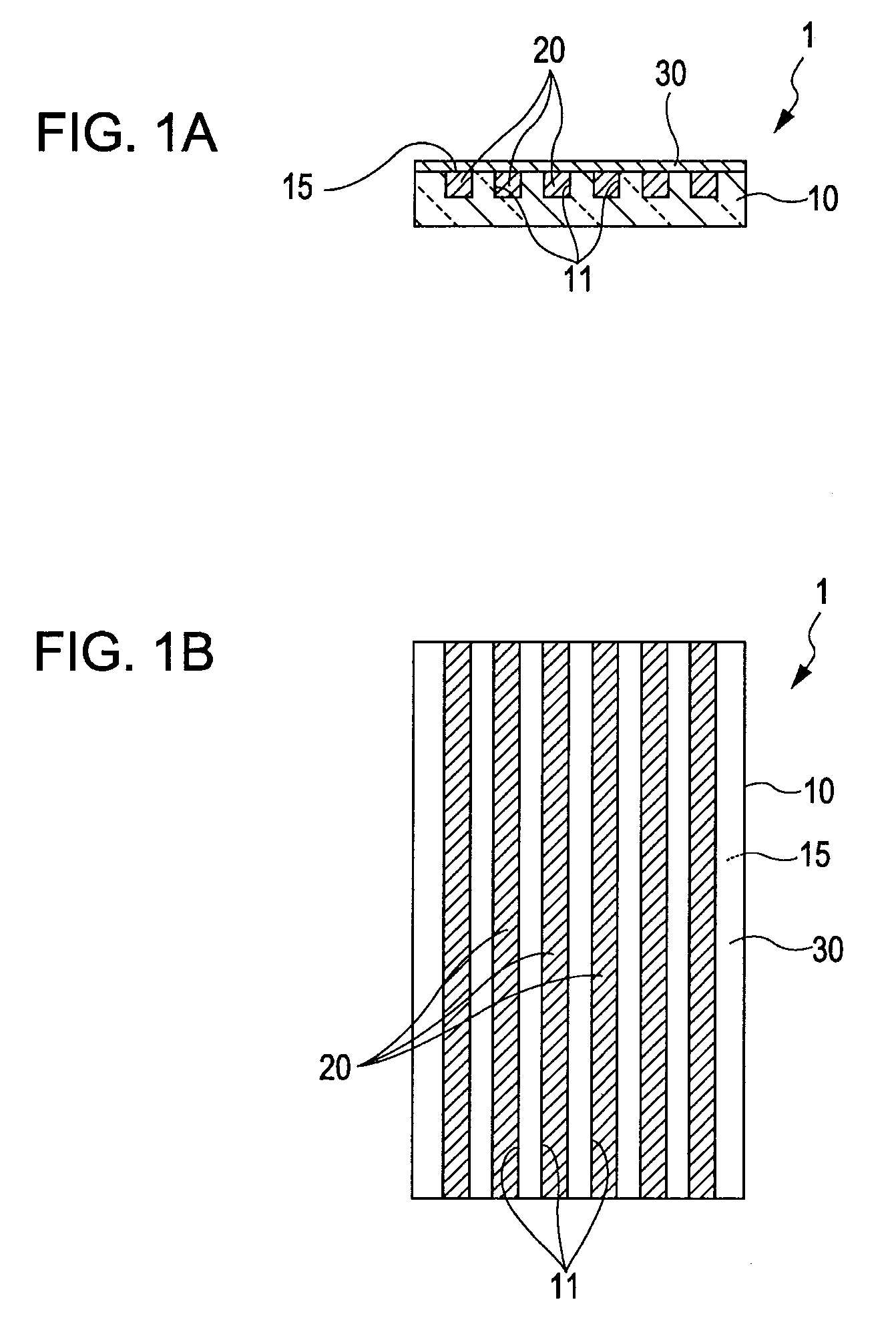

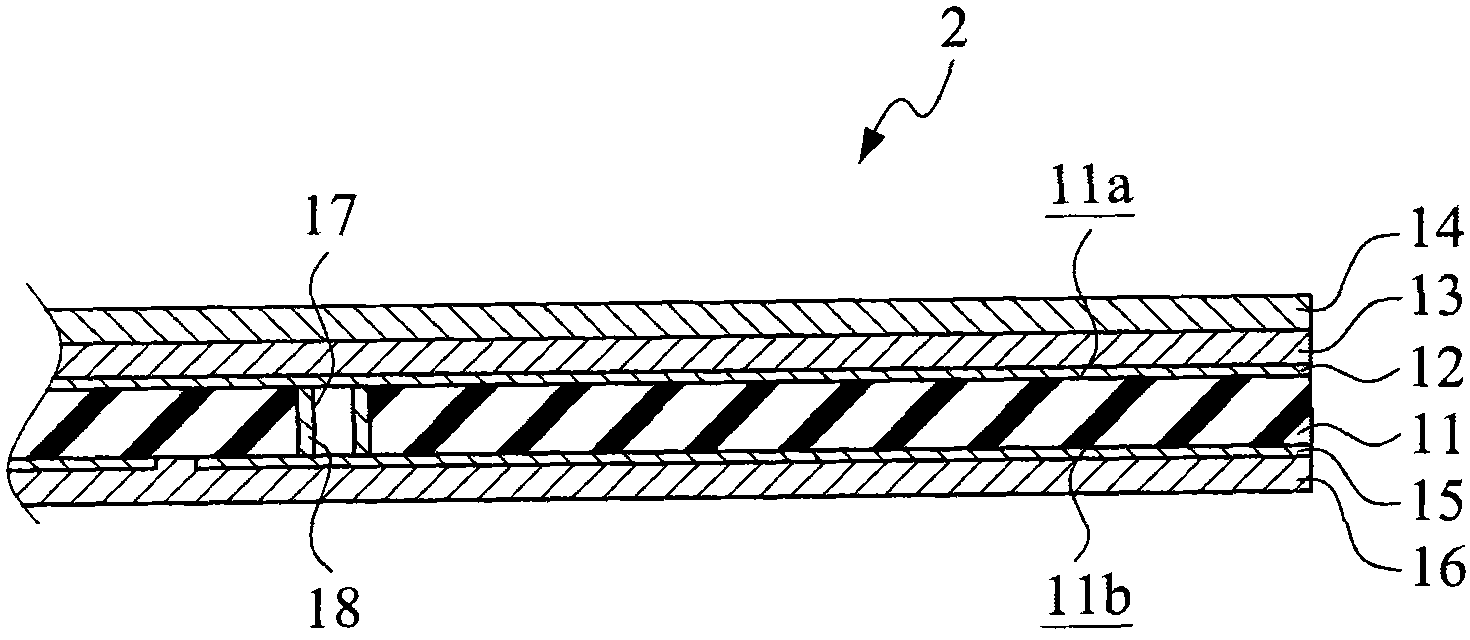

Wire grid type polarization element, manufacturing method thereof, liquid crystal device, and projection type display apparatus

InactiveUS20090027773A1High transmittanceHigh qualityOptical articlesPolarising elementsEngineeringLiquid crystal devices

There is provided a wire grid type polarization element equipped with a plurality of lines of metal grid on a translucent substrate. A plurality of lines of groove like concave portions are formed on the substrate, and the metal grid is embedded in the plurality of lines of groove like concave portions.

Owner:SEIKO EPSON CORP

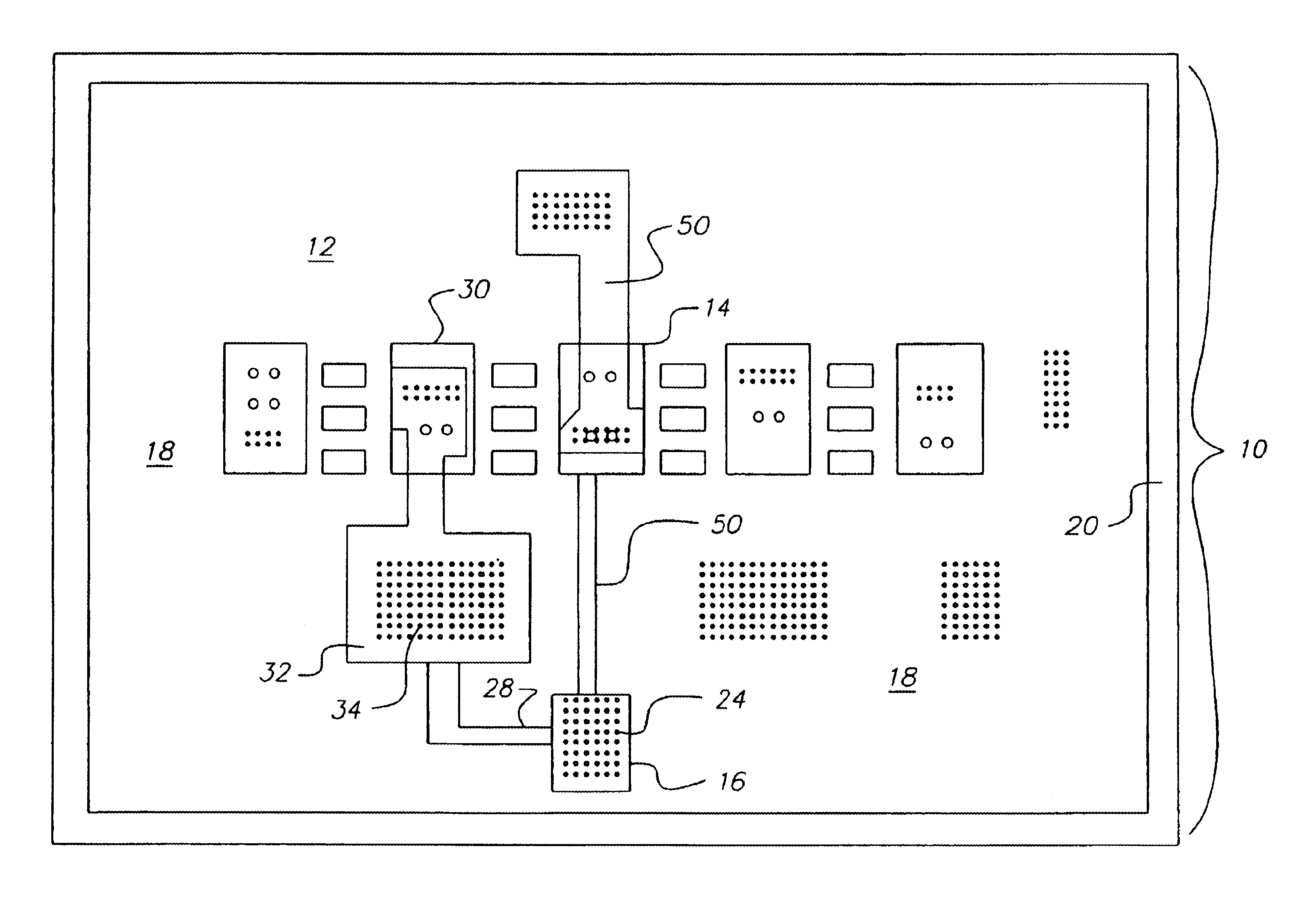

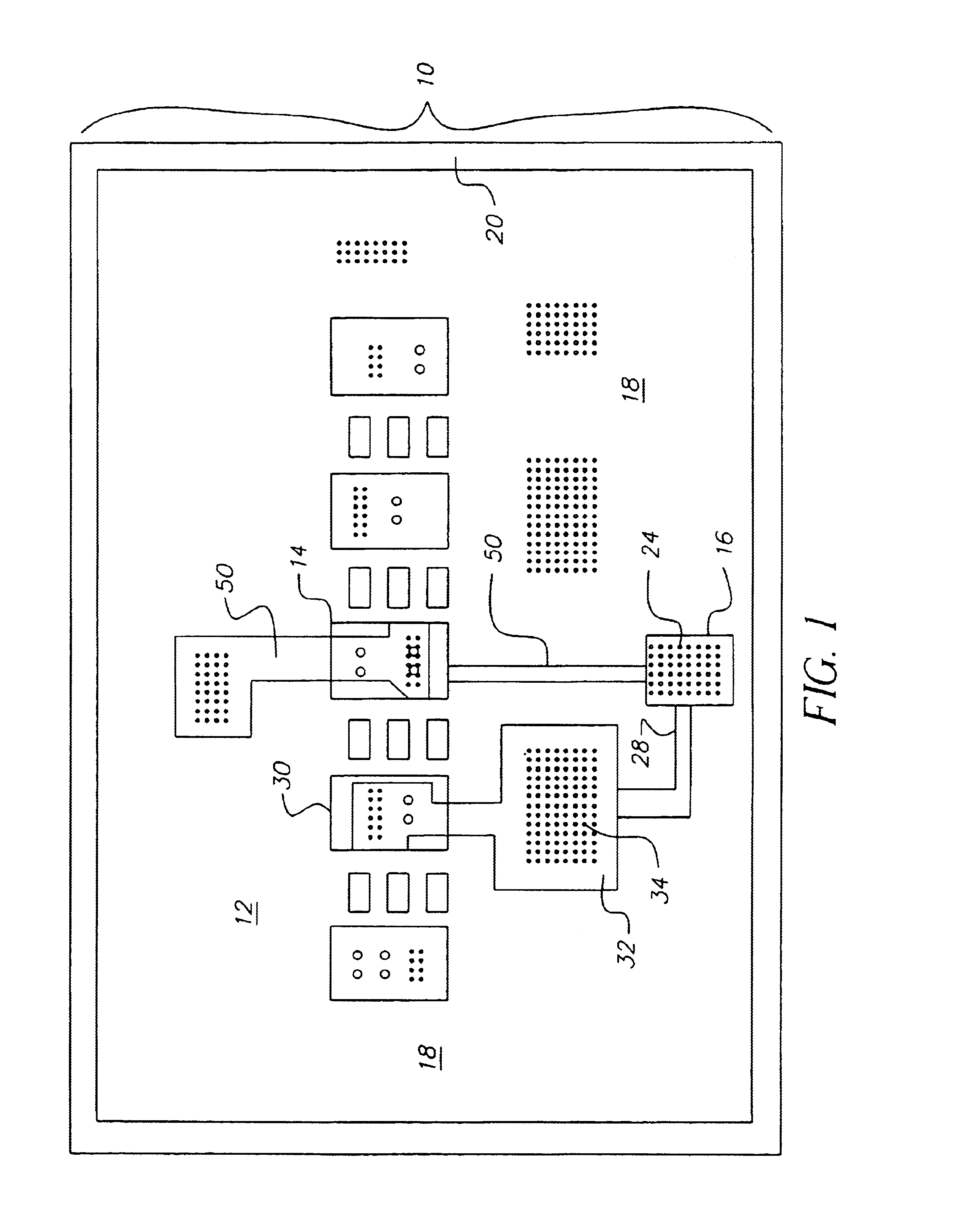

Densely packed electronic assemblage with heat removing element

InactiveUS6930885B2Lower operating temperatureLower junction temperatureSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringHeat sink

A densely packed electronic assemblage has a substrate medium for supporting at least one heat generating component and means for reducing the temperature of the at least one heat generating component. A heat sink cooperates with the at least one heat removing element for reducing heat of the heat generating component by absorbing heat from the at least one heat generating component.

Owner:APPLE INC

High-power ultracapacitor energy storage pack and method of use

InactiveUS7218489B2Reduce width sizeProlong lifeCapacitor terminalsCapacitor housing/encapsulationSupercapacitorEngineering

An ultracapacitor energy storage cell pack includes an ultracapacitor assembly having a plurality of series connected ultracapacitors and balancing resistors, each balancing resistor connected in parallel with each ultracapacitor to automatically balance each ultracapacitor over time, thereby automatically over time discharging the ultracapacitors of the ultracapacitor assembly; an enclosure to enclose and protect the ultracapacitor assembly; a controller for the ultracapacitor assembly; and one or more temperature sensors to monitor temperature of the ultracapacitor assembly and coupled to the controller.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

High-Power Ultracapacitor Energy Storage Pack and Method of Use

InactiveUS20070002518A1Reduce width sizeEfficient packagingProtecting/adjusting hybrid/EDL capacitorCapacitor terminalsInterconnectionEngineering

An ultracapacitor energy storage cell pack including an ultracapacitor assembly including a plurality of ultracapacitors in series; a plurality of interconnections for mechanically and electrically interconnecting the ultracapacitors; and a plurality of balancing resistors, each balancing resistor in parallel with each ultracapacitor to form a resistor divider network that automatically discharges and equalizes each ultracapacitor over time, thereby balancing the ultracapacitors of the ultracapacitor assembly, and each balancing resistor directly mechanically and electrically connected to an associated interconnection.

Owner:ISE

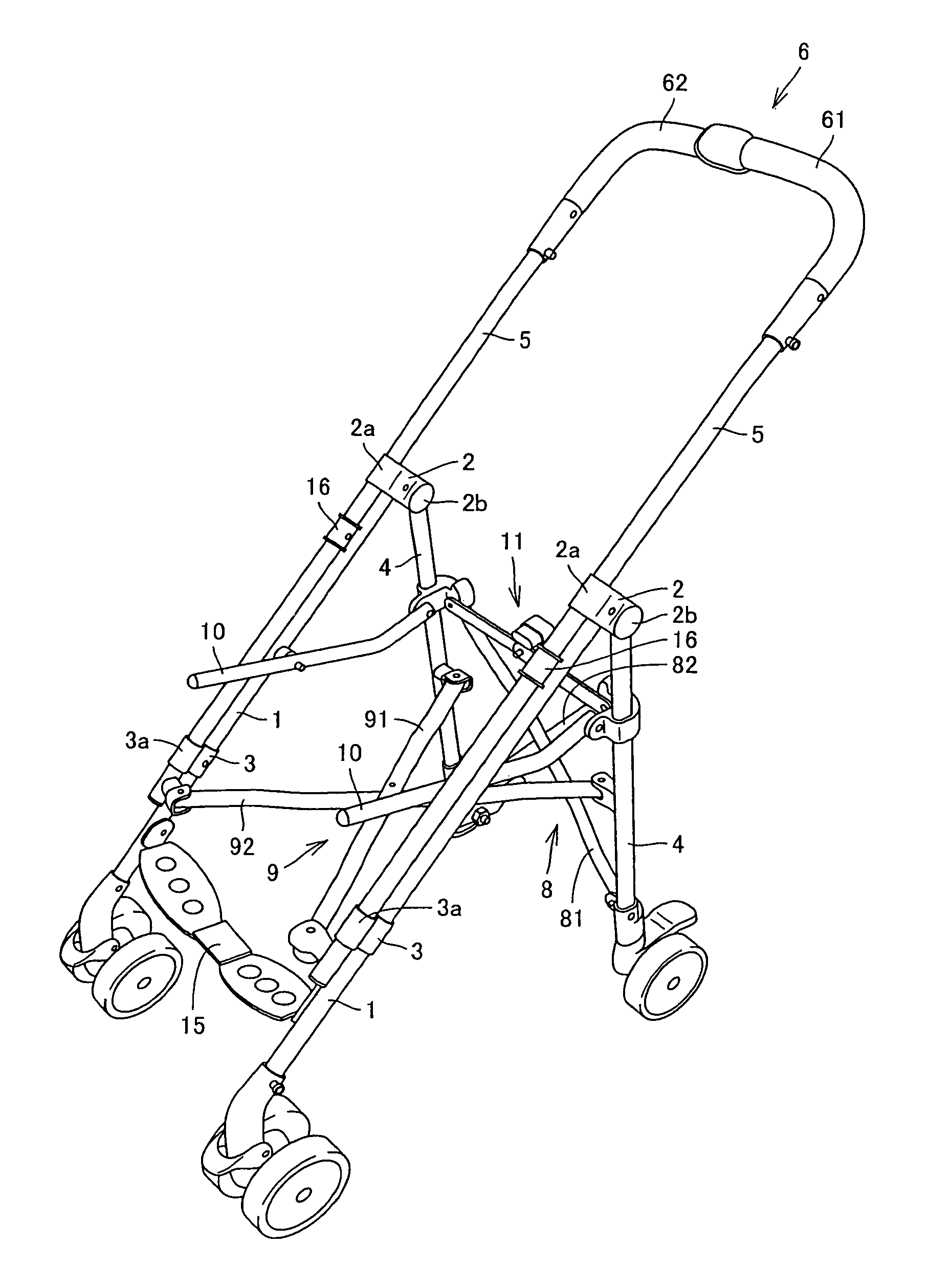

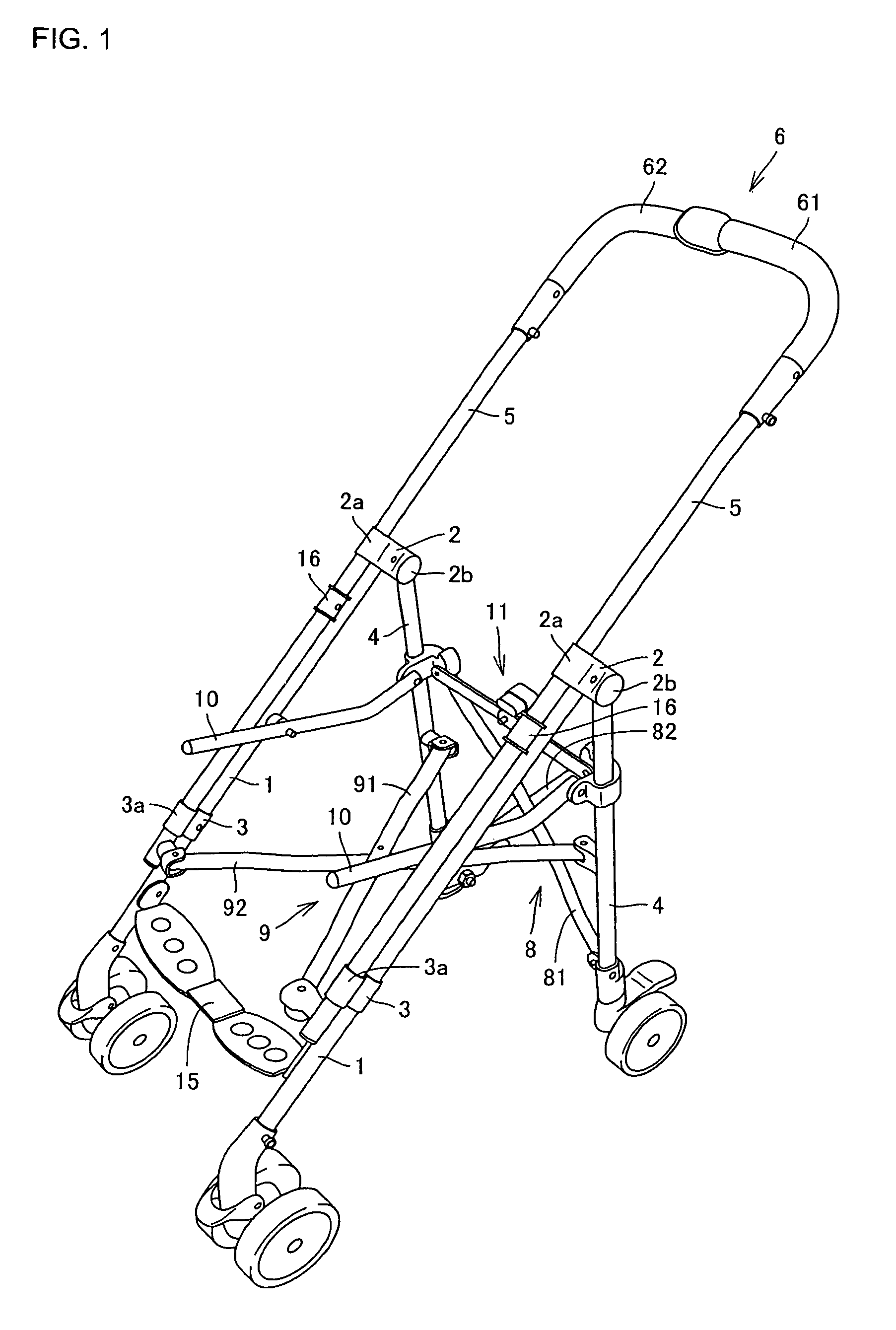

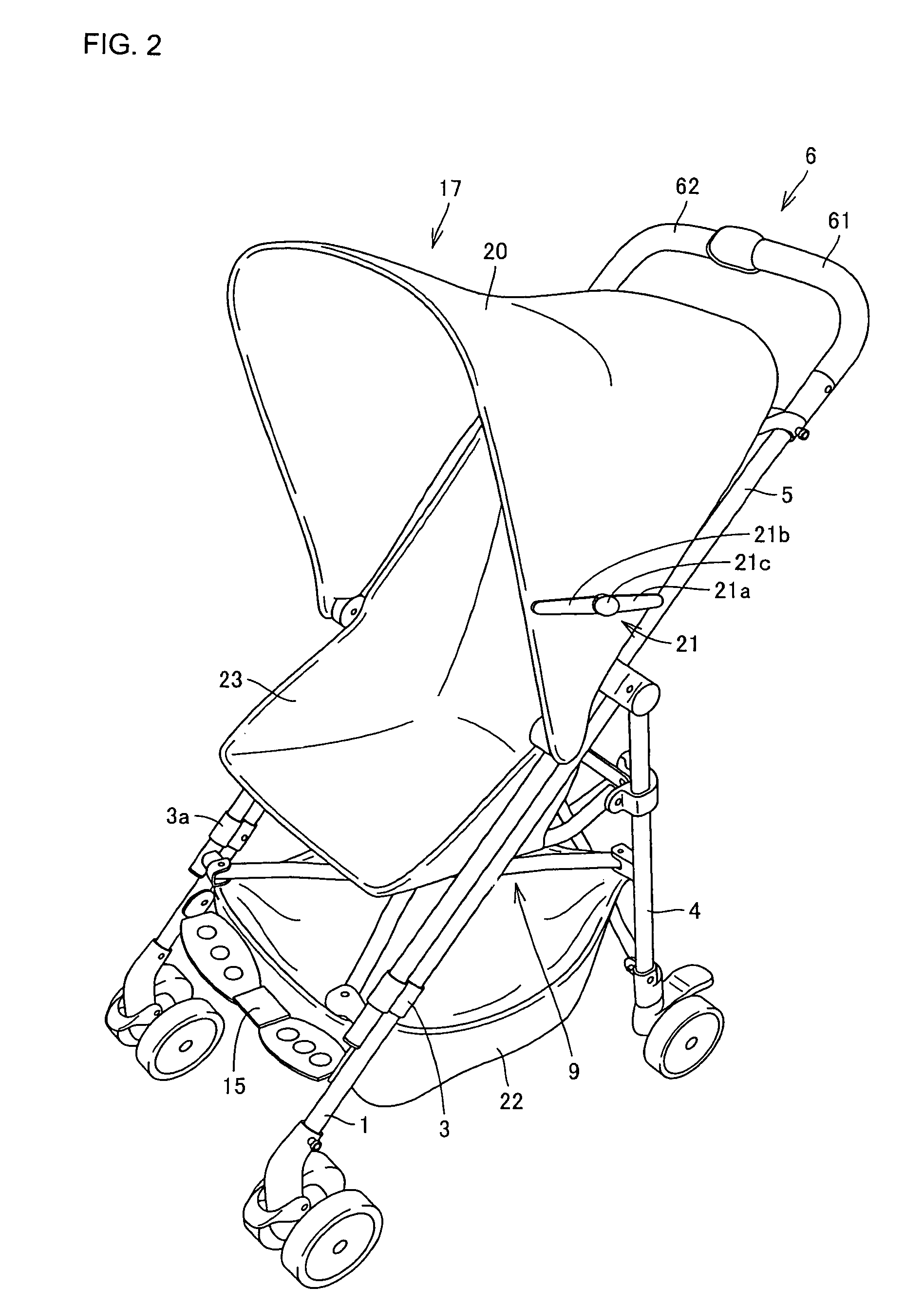

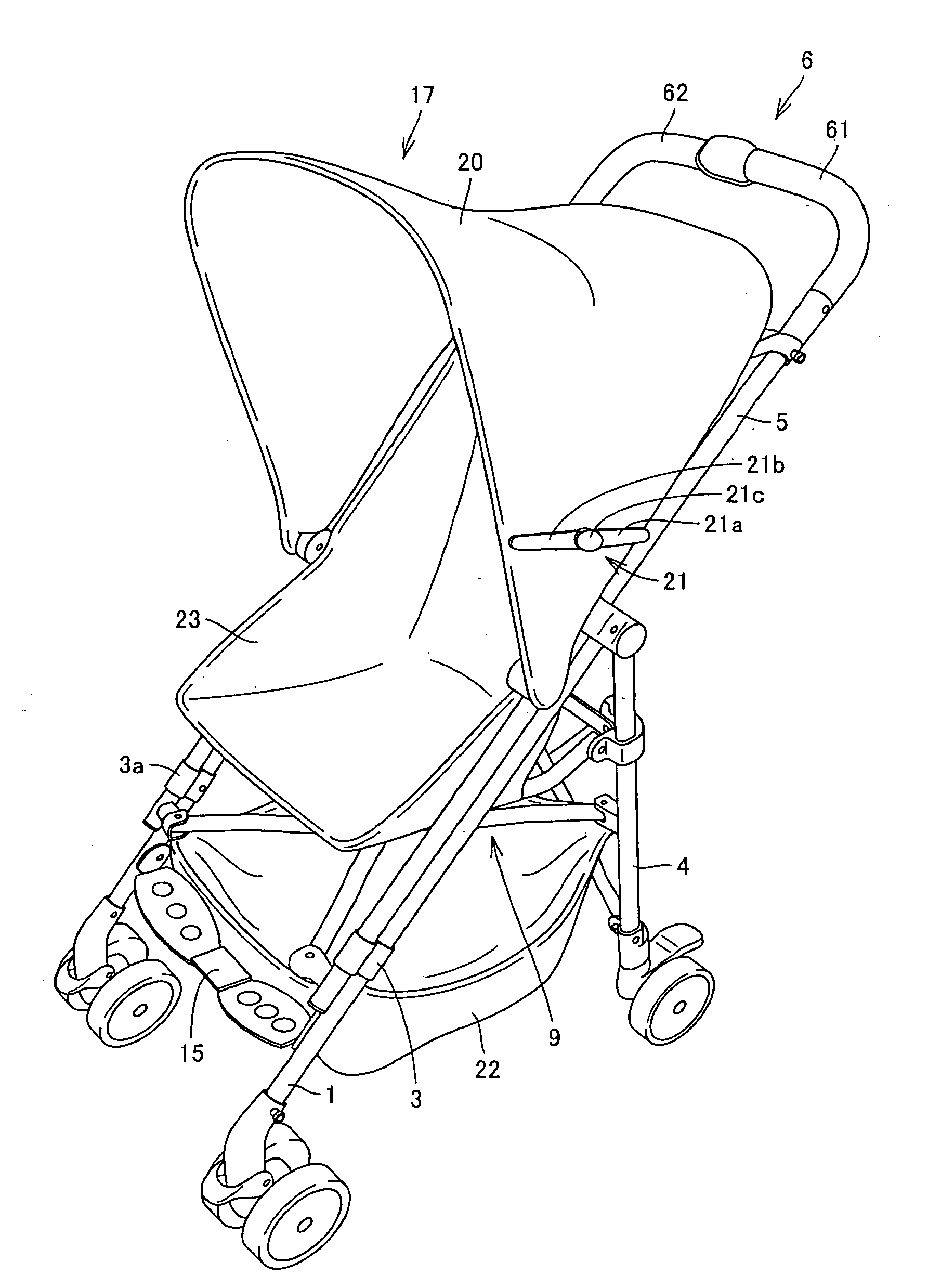

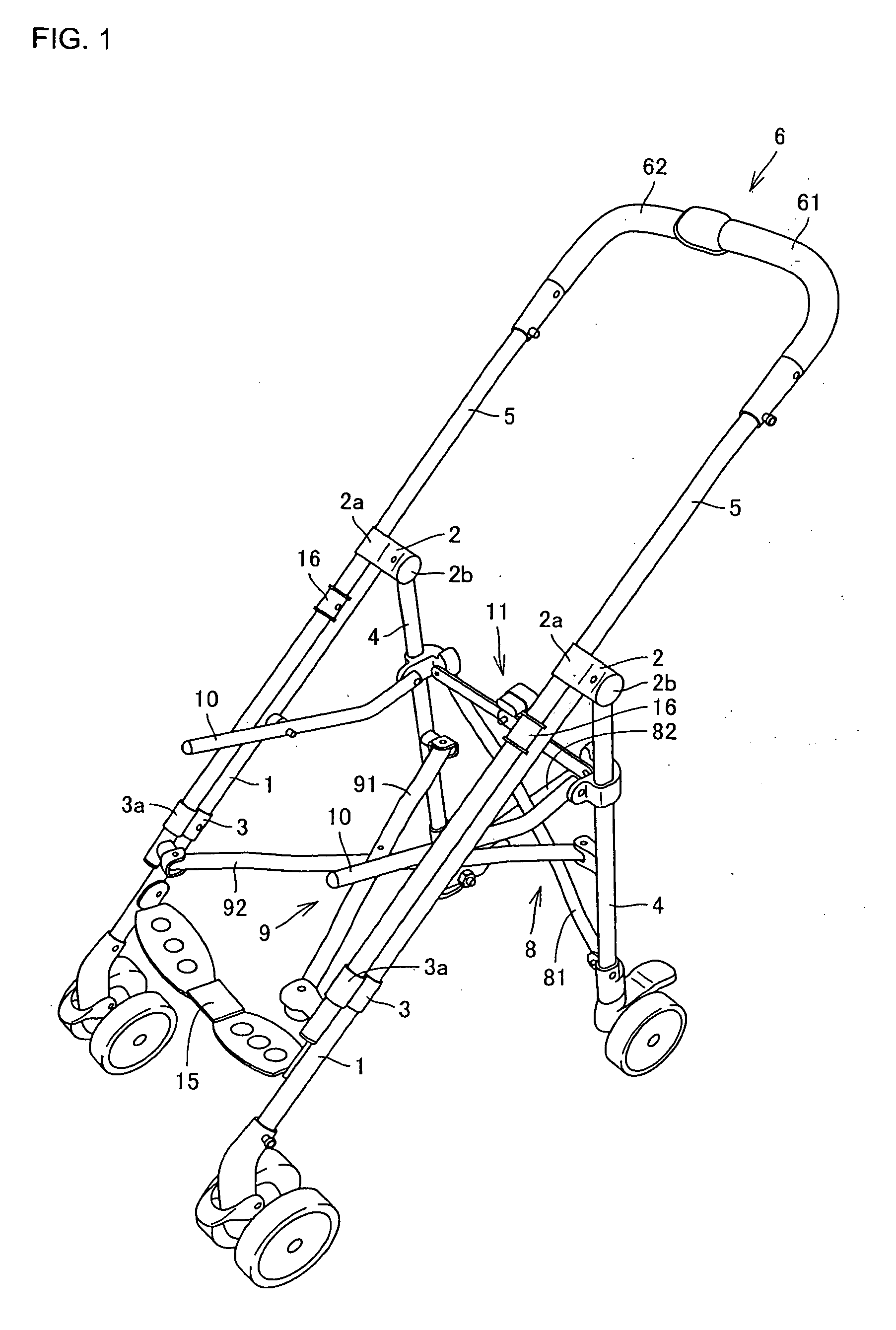

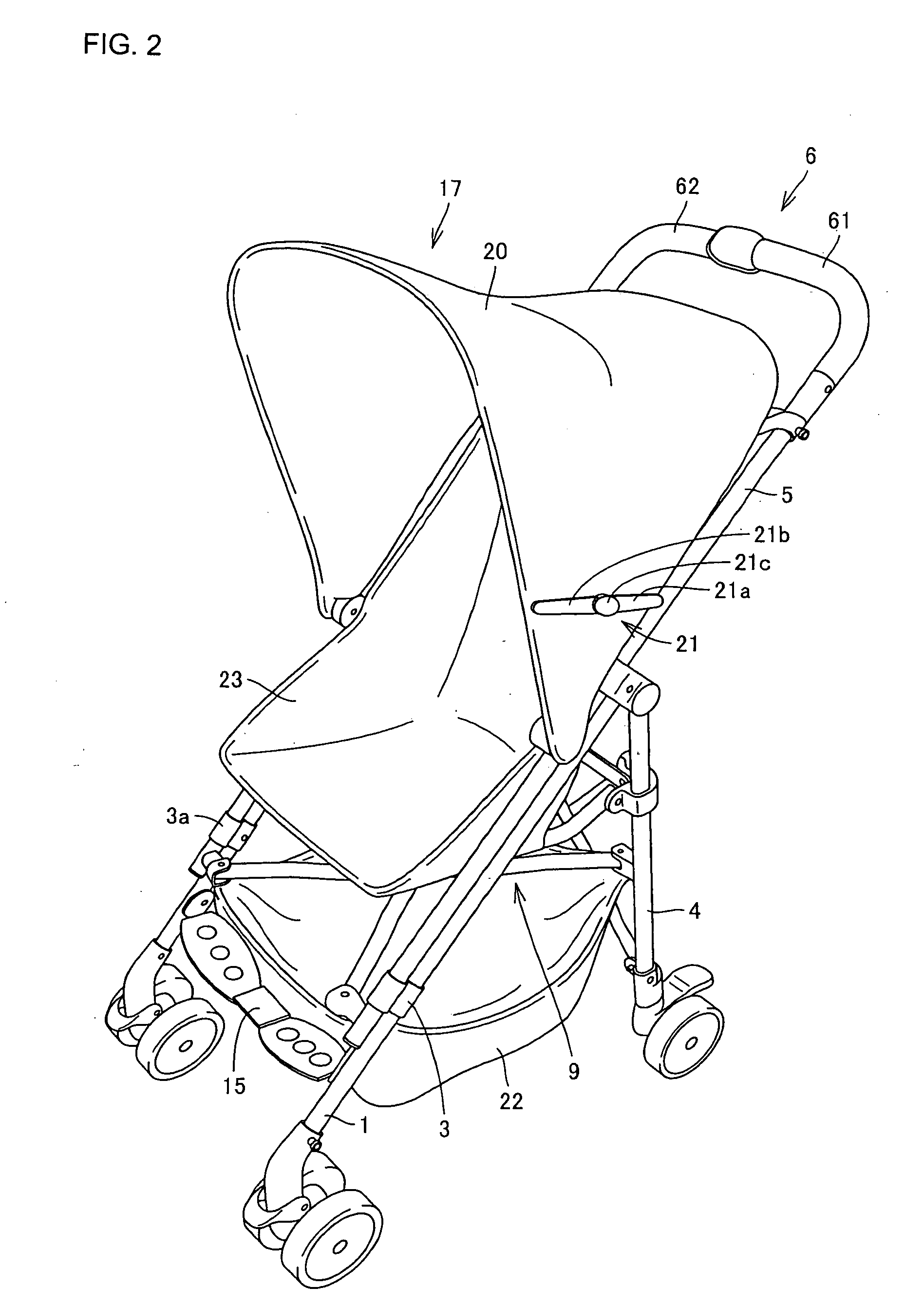

Foldable pushcart and foldable baby carriage

InactiveUS8066300B2Small sizeSimple structureCarriage/perambulator accessoriesCarriage/perambulator with single axisIntermediate regionElectrical and Electronics engineering

A baby carriage includes: a pair of front legs; a pair of connecting members; a pair of guide sleeves respectively fixed to intermediate regions of the pair of front legs, a pair of rear legs having their upper ends pivotally connected to the connecting members, respectively; a pair of push bars slidably held by the pair of connecting members and the pair of guide sleeves, respectively; a pair of slide members provided slidably on upper regions of the pair of rear legs, respectively; a back cross member having its upper end pivotally connected to the pair of slide members and its lower end pivotally connected to respective lower regions of the pair of rear legs; and a bottom cross member having its front end pivotally connected to respective lower ends of the pair of push bars, and its rear end pivotally connected to respective intermediate regions of the pair of rear legs.

Owner:APRICA CHILDRENS PROD

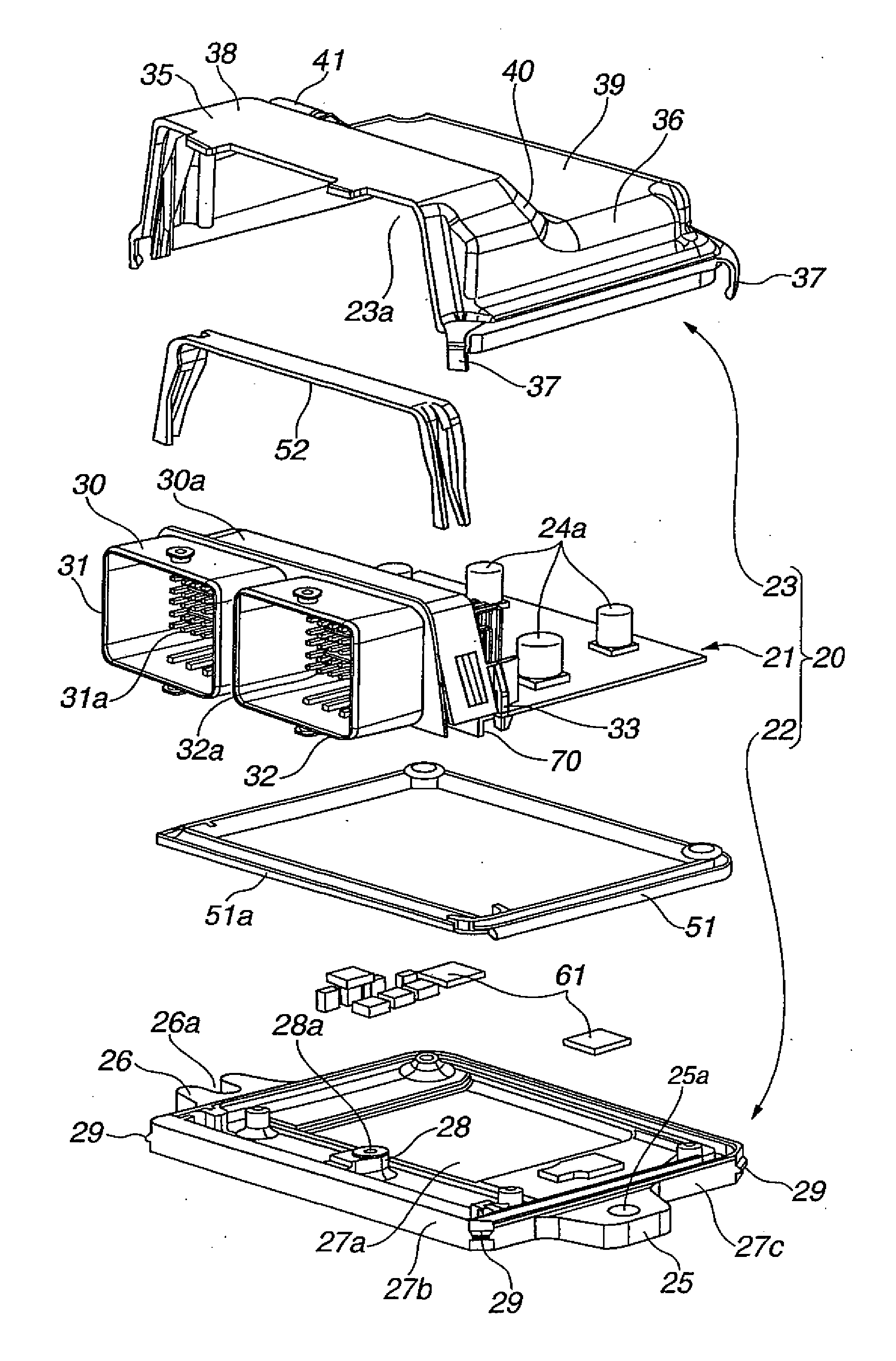

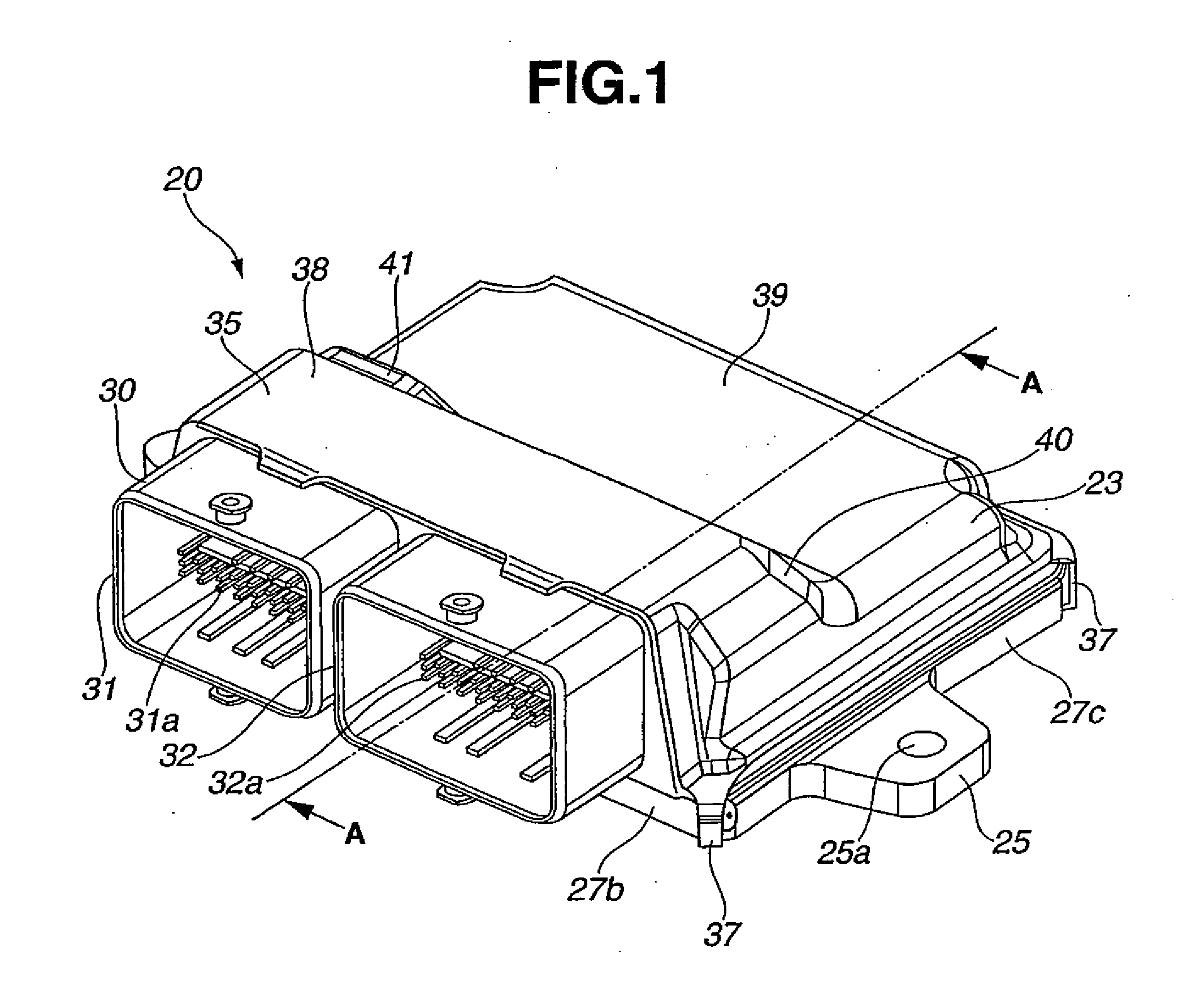

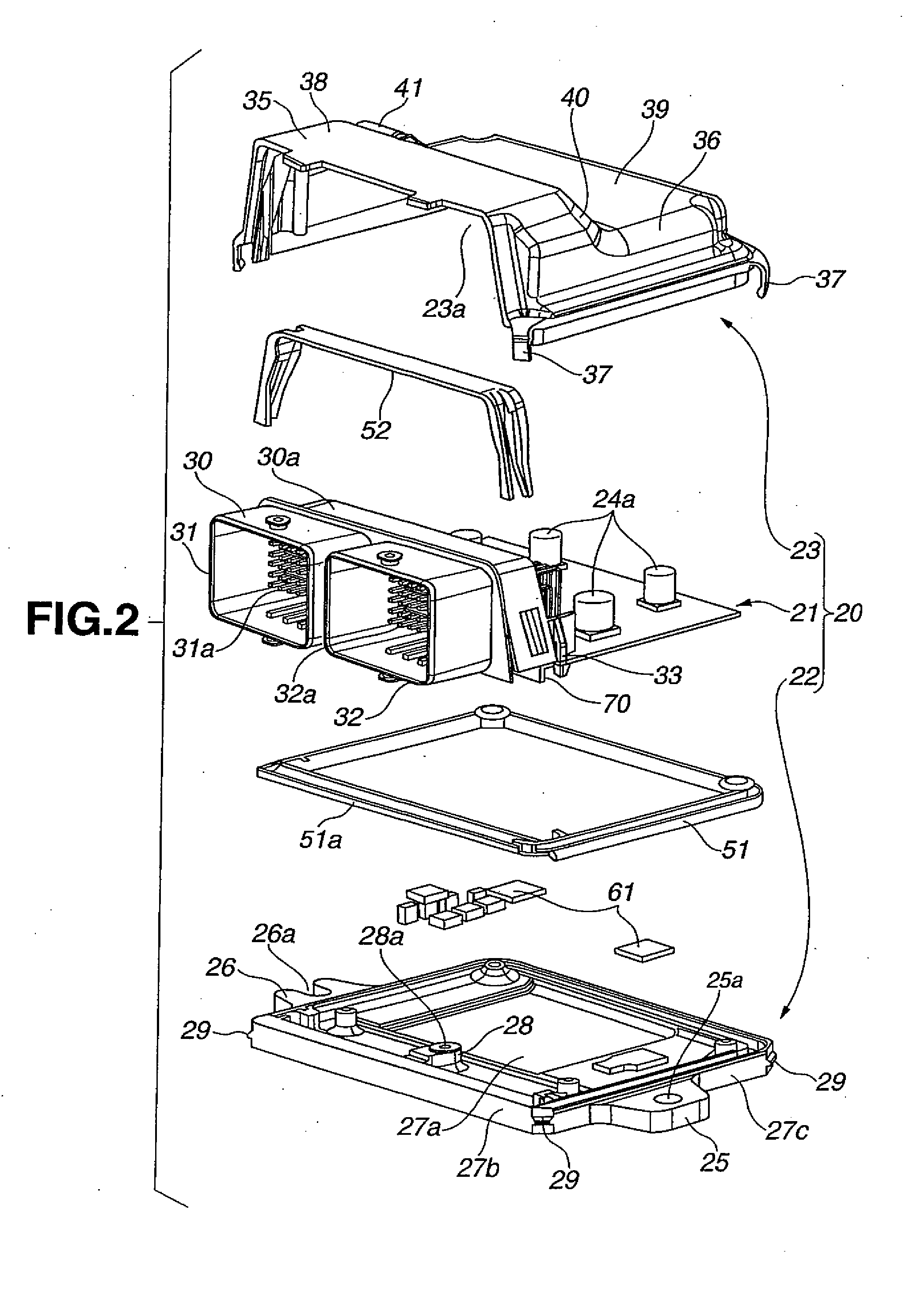

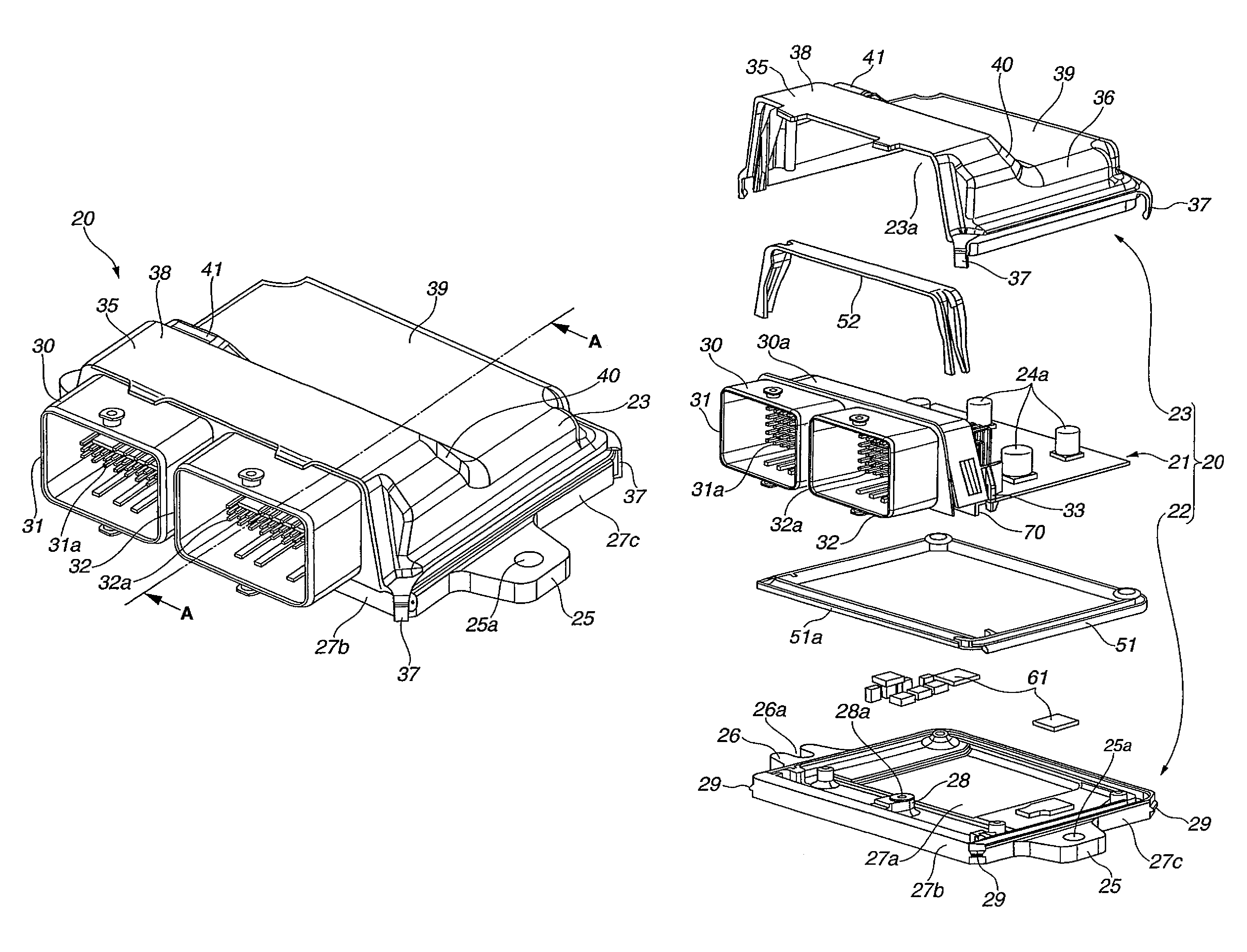

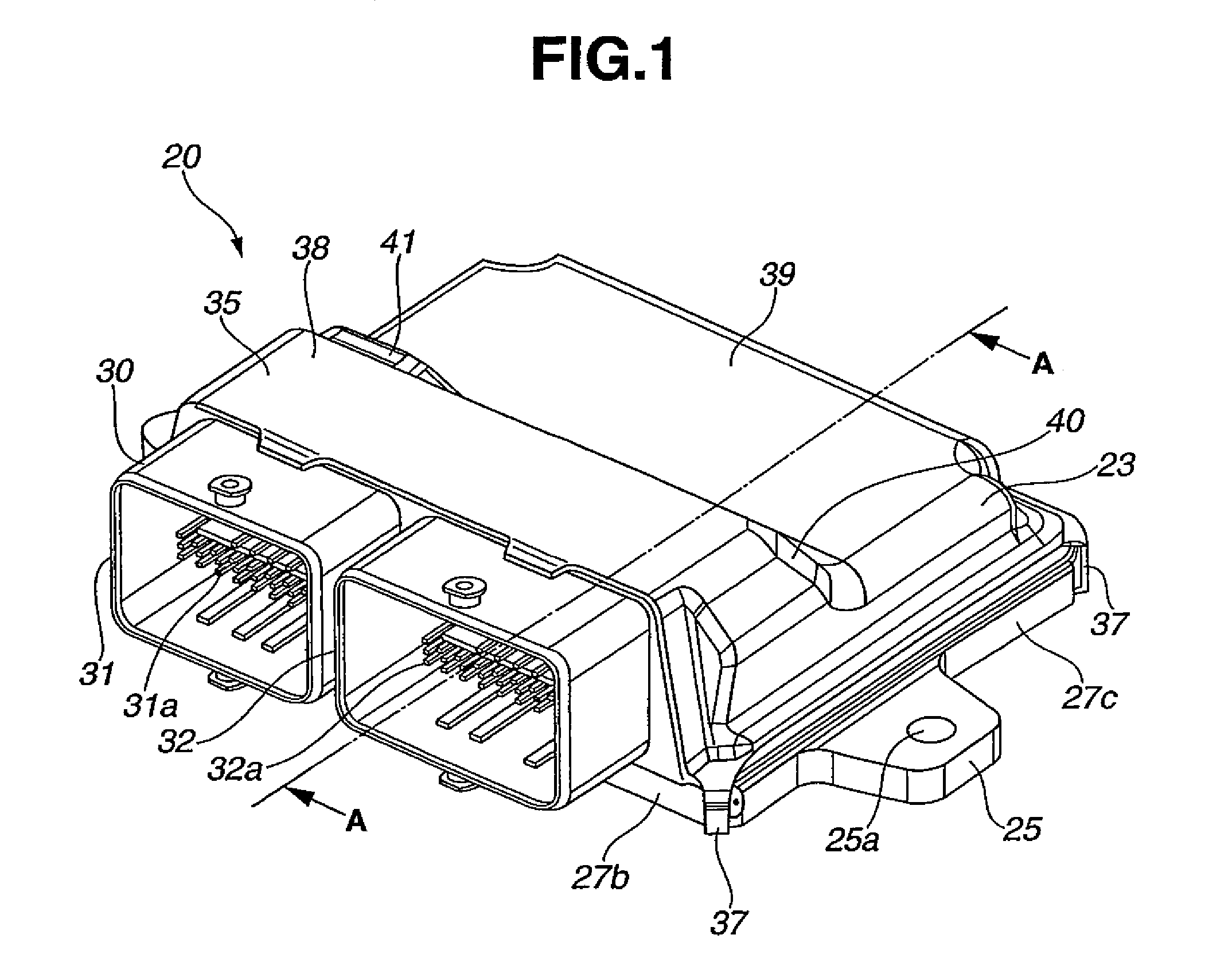

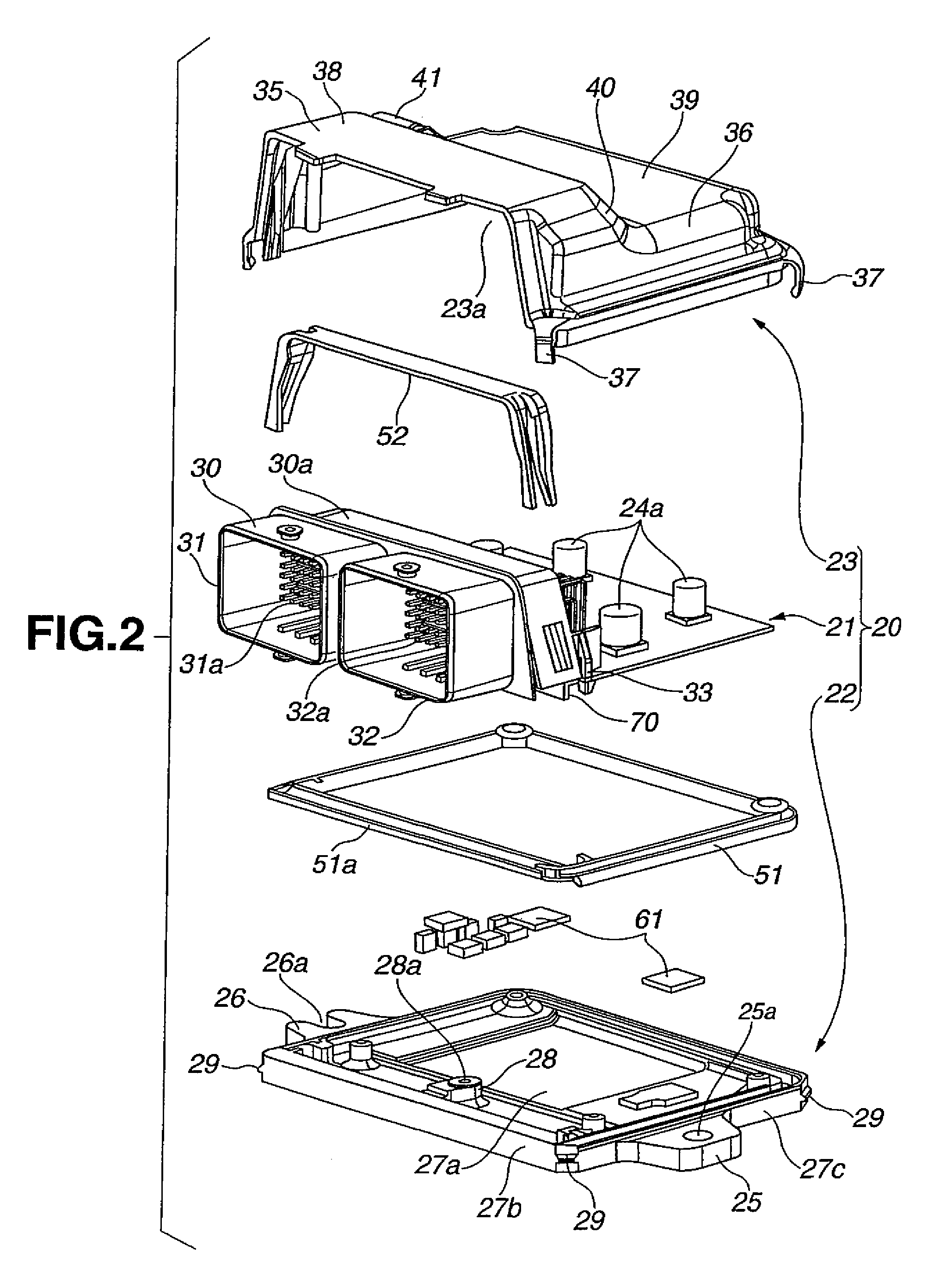

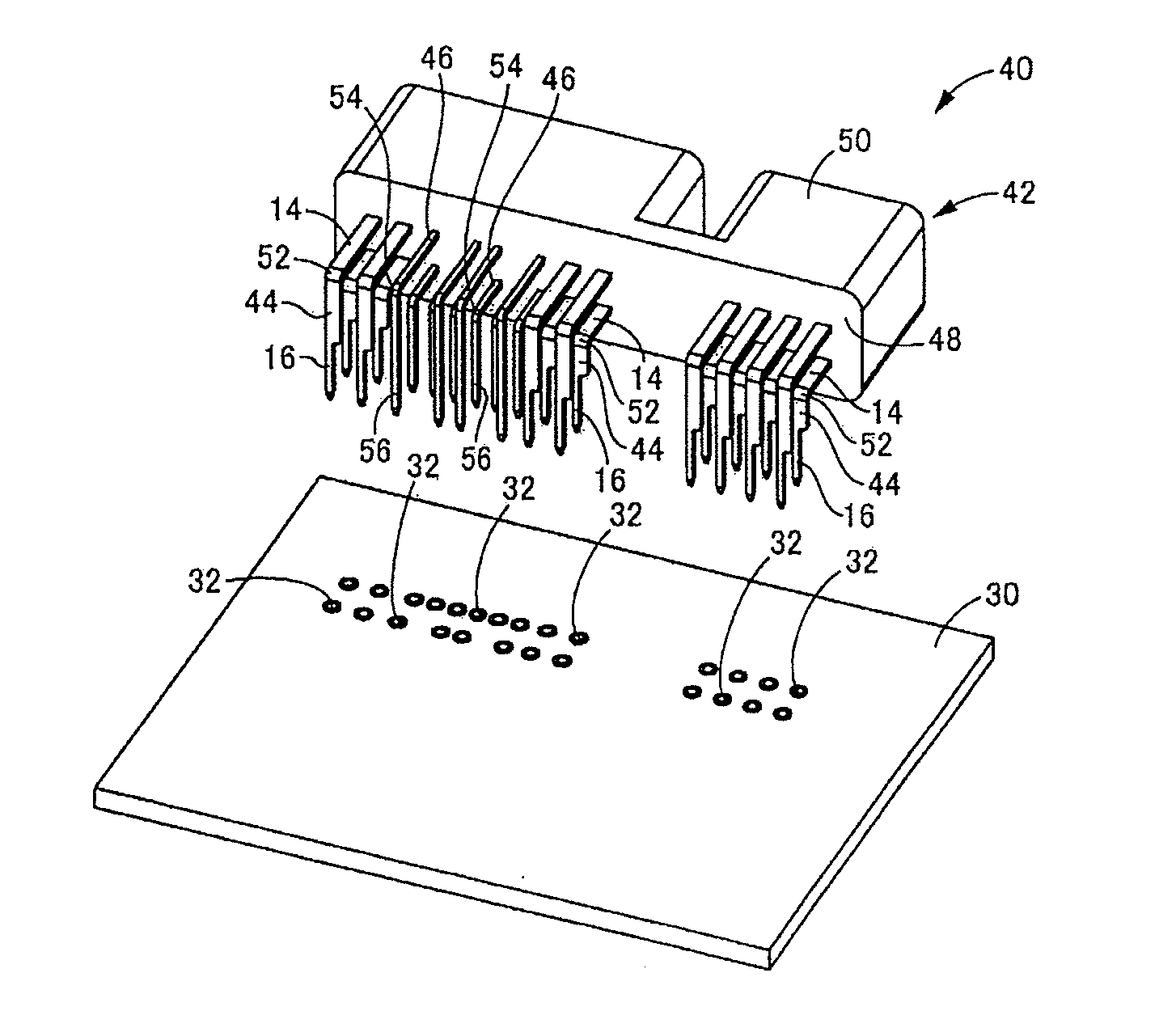

Electronic control device

ActiveUS20140080329A1Enhance salt damage resistanceReduce width dimensionCouplings bases/casesSupport structure mountingEngineeringConnector Pin

Owner:HITACHI ASTEMO LTD

Electrical assemblage and method for removing heat locally generated therefrom

InactiveUS6882537B2Lower operating temperatureLower junction temperatureSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringHeat sink

Owner:APPLE INC

Electronic control device

ActiveUS9093776B2Reduce in quantityReduce adverse effectsCouplings bases/casesSupport structure mountingEngineeringElectrical and Electronics engineering

Owner:HITACHI ASTEMO LTD

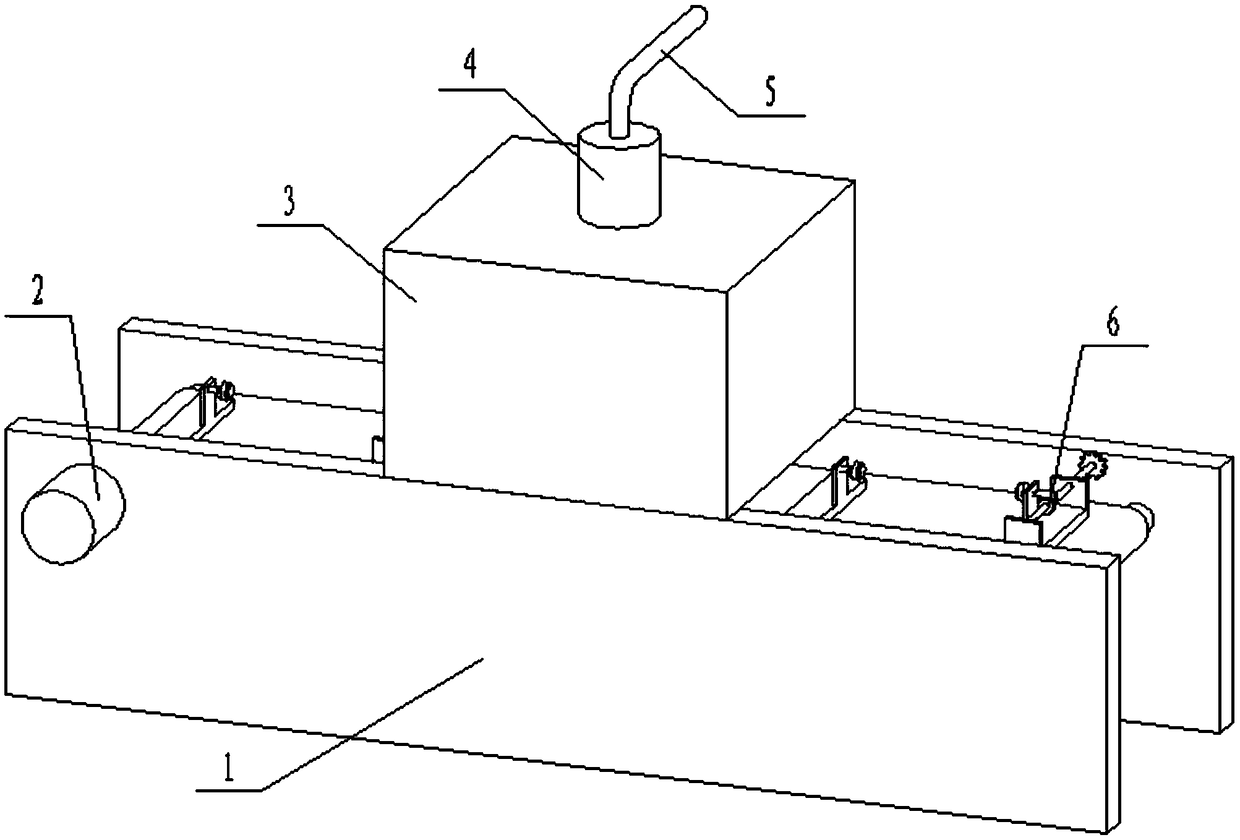

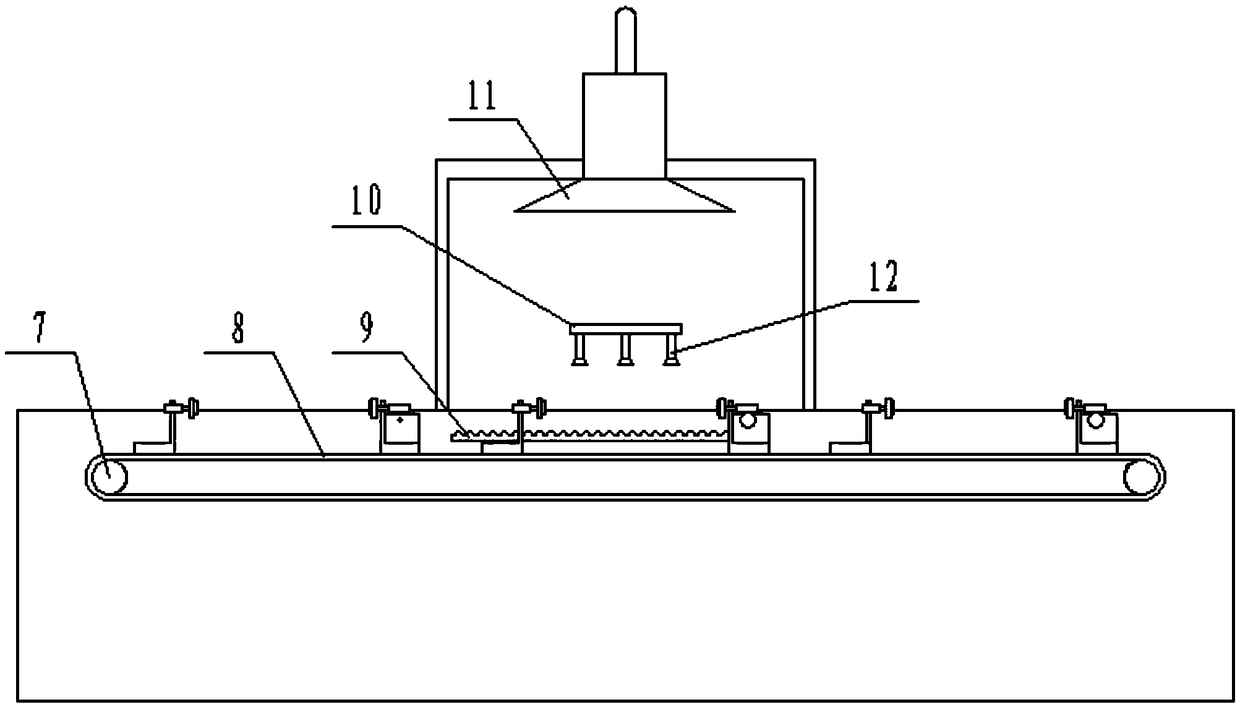

Environment-friendly building pipe paint spraying device

ActiveCN108654877ARealize automatic deliveryRealize automatic paintingSpraying apparatusEngineeringExhaust pipe

The invention discloses an environment-friendly building pipe paint spraying device. The environment-friendly building pipe paint spraying device comprises a rack, a conveying motor is arranged on oneside of the rack, a toothed bar is arranged on one side of the inner wall of the rack, a conveying roller is arranged in the rack, the conveying roller is fixedly connected with the conveying motor,a conveying belt is arranged on the outer side of the conveying roller, a clamping mechanism is arranged on the surface of the conveying belt, a box body is arranged at the upper end of the rack, an air suction pump is arranged at the upper end of the box body, the air suction pump communicates with the box body, the exhaust end of the air suction pump is provided with an exhaust pipe connected with a water box, a bearing plate is arranged in the box body, and a nozzle is arranged at the bottom of the bearing plate. The device has the beneficial effects that automatic conveying and automatic paint spraying of pipes can be achieved, the paint spraying effect is good, the efficiency is high, in the paint spraying process, paint mist generated by paint spraying can be absorbed, and the phenomenon that due to paint mist drifting, the health of an operator is affected is avoided.

Owner:杨智萍

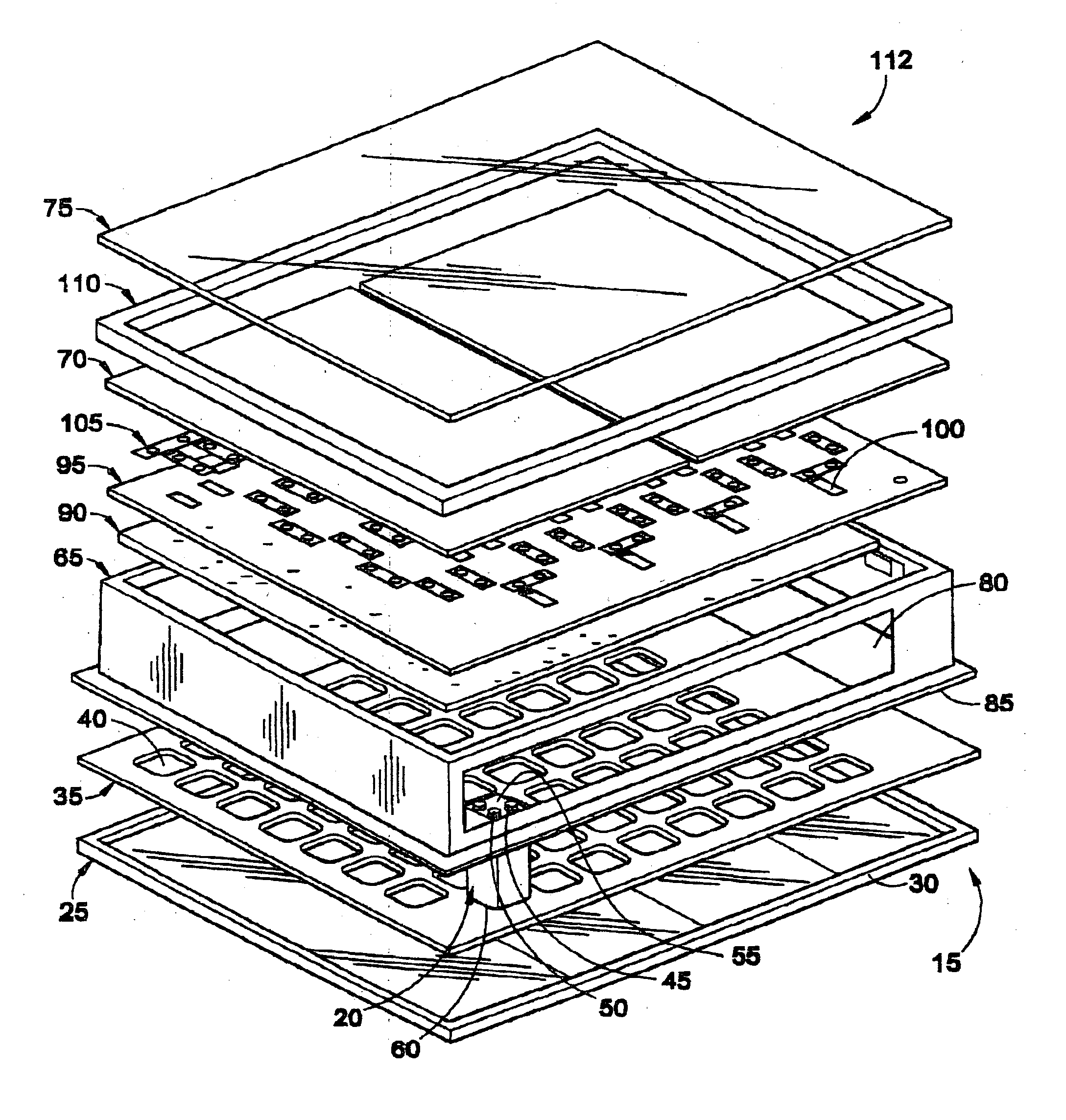

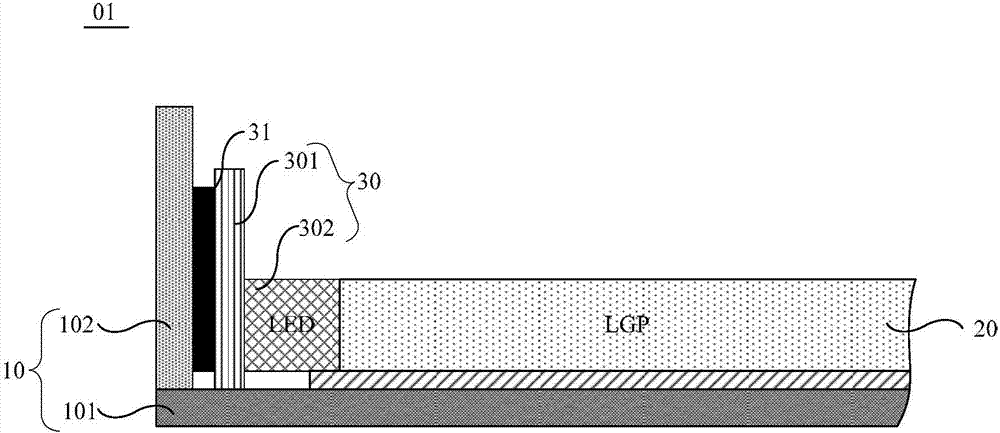

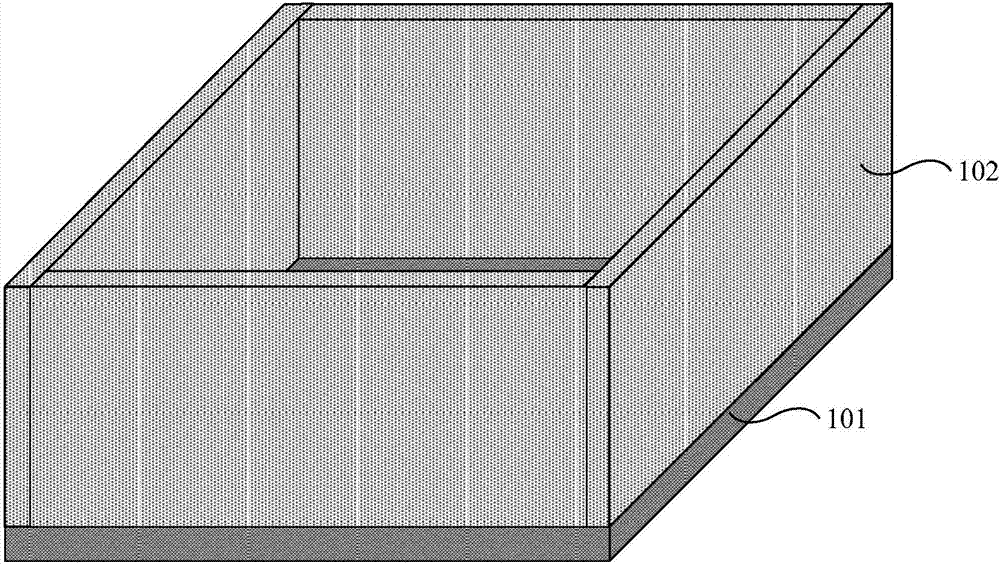

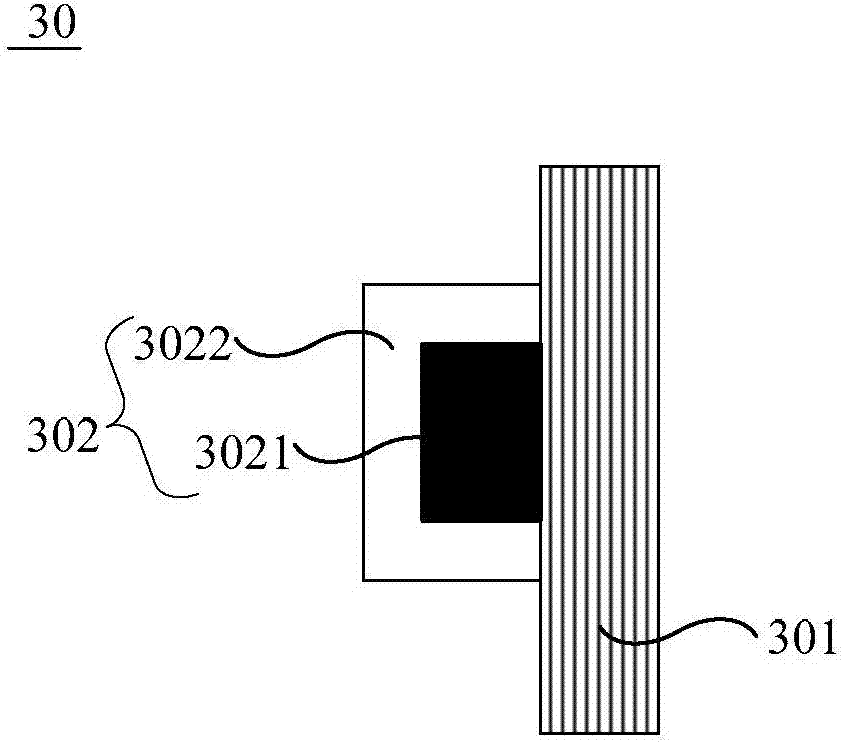

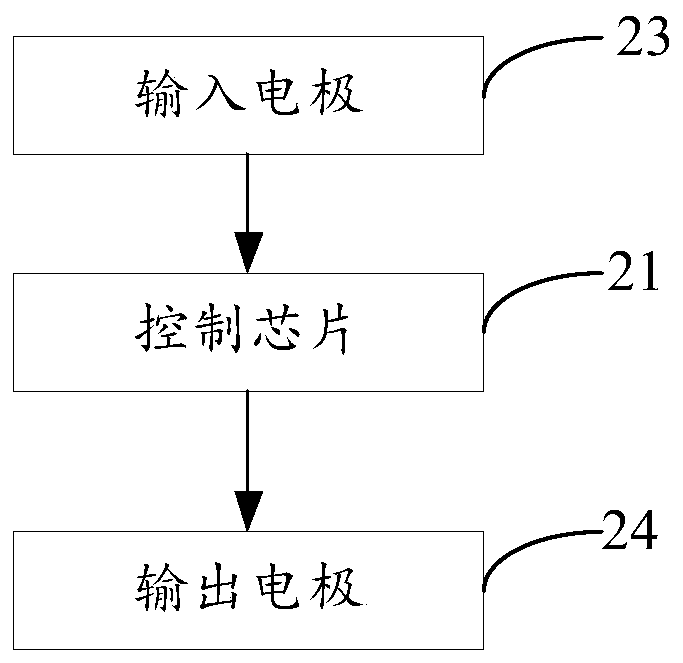

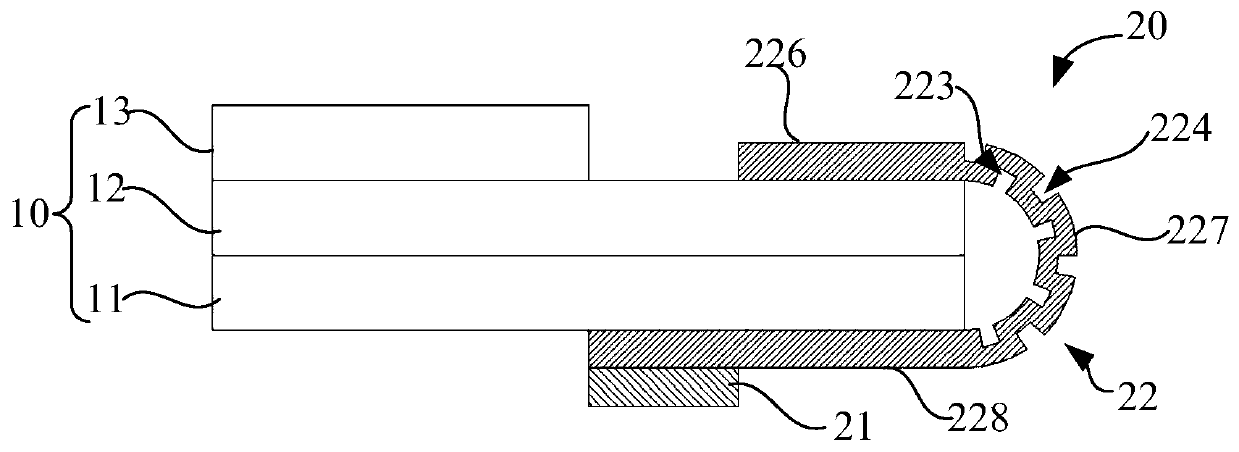

Backlight module and display device

InactiveCN107247364AReduce widthReduce width sizePlanar/plate-like light guidesNon-linear opticsLight guideDisplay device

An embodiment of the invention relates to the technical field of display, provides a backlight module and a display device and aims to narrow the backlight module. The backlight module comprises a back plate, the back plate comprises a bottom plate and a plurality of side plates perpendicular to the bottom plate, the side plates are in sequential end-to-end connection around the bottom plate, and the bottom plate and the side plates form a storage space. The backlight module further comprises a light guide plate and a light source, and the light source is positioned on a light incidence surface of the light guide plate which is positioned in the storage space. The light source comprises a base plate and a light emitting device on the base plate, the base plate is parallelly mounted on one of the side plates, and a light emergence surface of the light emitting device is opposite to the light incidence surface of the light guide plate. The backlight module is used for providing a backlight source for a display panel.

Owner:BOE TECH GRP CO LTD +1

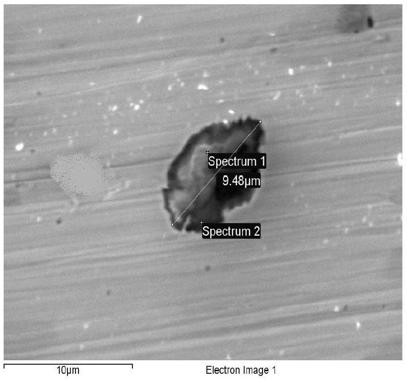

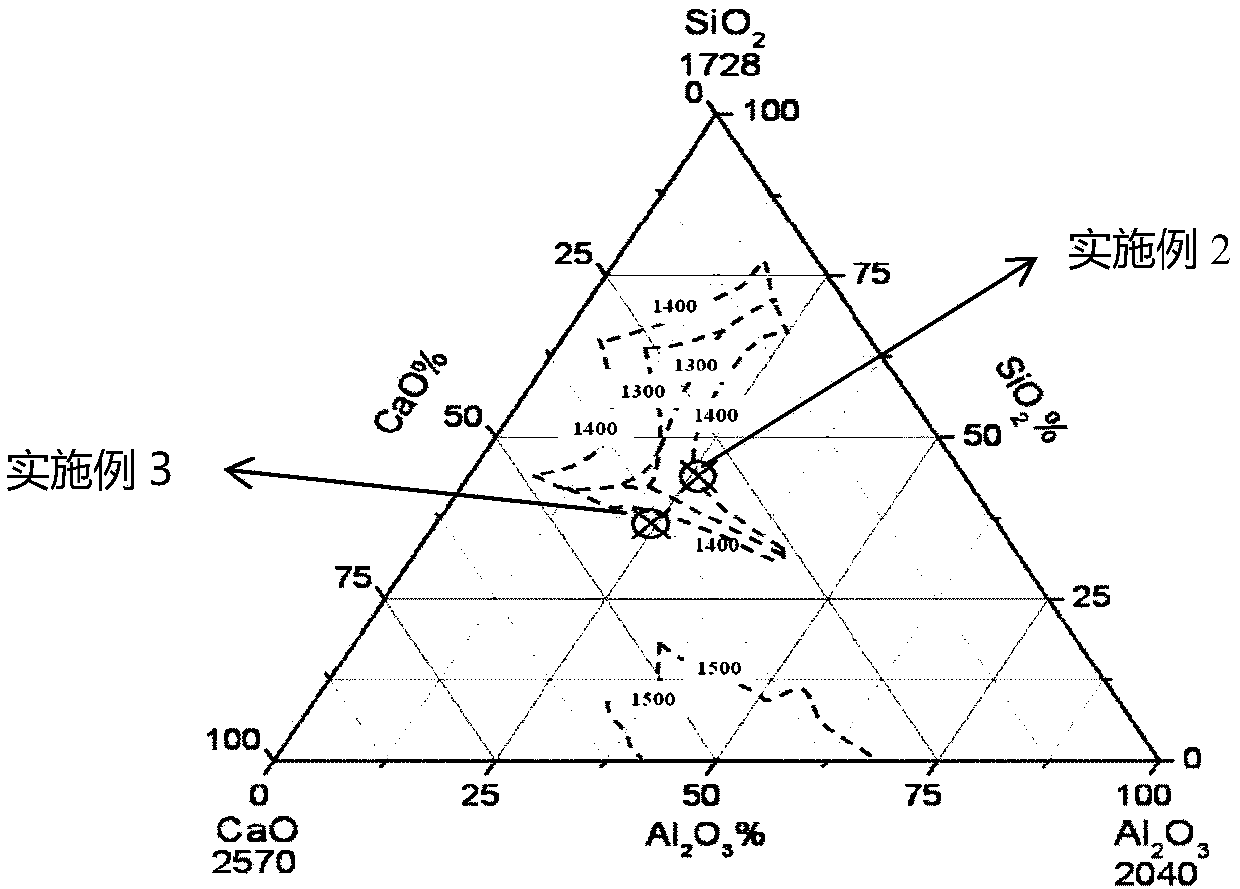

Smelting process for controlling spring steel inclusions

ActiveCN109097518ARelieve pressureFully integratedManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

The invention discloses a smelting process for controlling spring steel inclusions. The smelting process comprises the following steps of (1) KR molten iron desulfurization pretreatment, (2) BOF top-bottom double combined flowing converter smelting, (3) LF furnace refining, (4) RH furnace refining and (5) continuous casting process, wherein the mass fraction of S is controlled to be below 0.005% after molten iron is processed by the step (1); the step (3) is carried out by high-purity silicon carbide for diffusion deoxidation, and the refining slag alkalinity is controlled to be 0.6-0.9; a lowalkalinity slag process is adopted in the step (4), and the final slag alkalinity is 0.5-0.7; and it is ensured that a molten steel contact part is free of aluminum in the step (5), a double electromagnetic stirring process is adopted in a secondary cooling zone and a casting blank solidification end zone, and a central carbon segregation index is controlled to be below 1.15. The smelting processadopts molten iron pretreatment, converter catching carbon, refining low alkali slag, continuous casting protective pouring and special refractory materials. Through the control over the oxygen potential of molten steel, the inclusion form and the central carbon segregation, the spring drawing performance is improved, and the spring fatigue limit is increased.

Owner:NANJING IRON & STEEL CO LTD

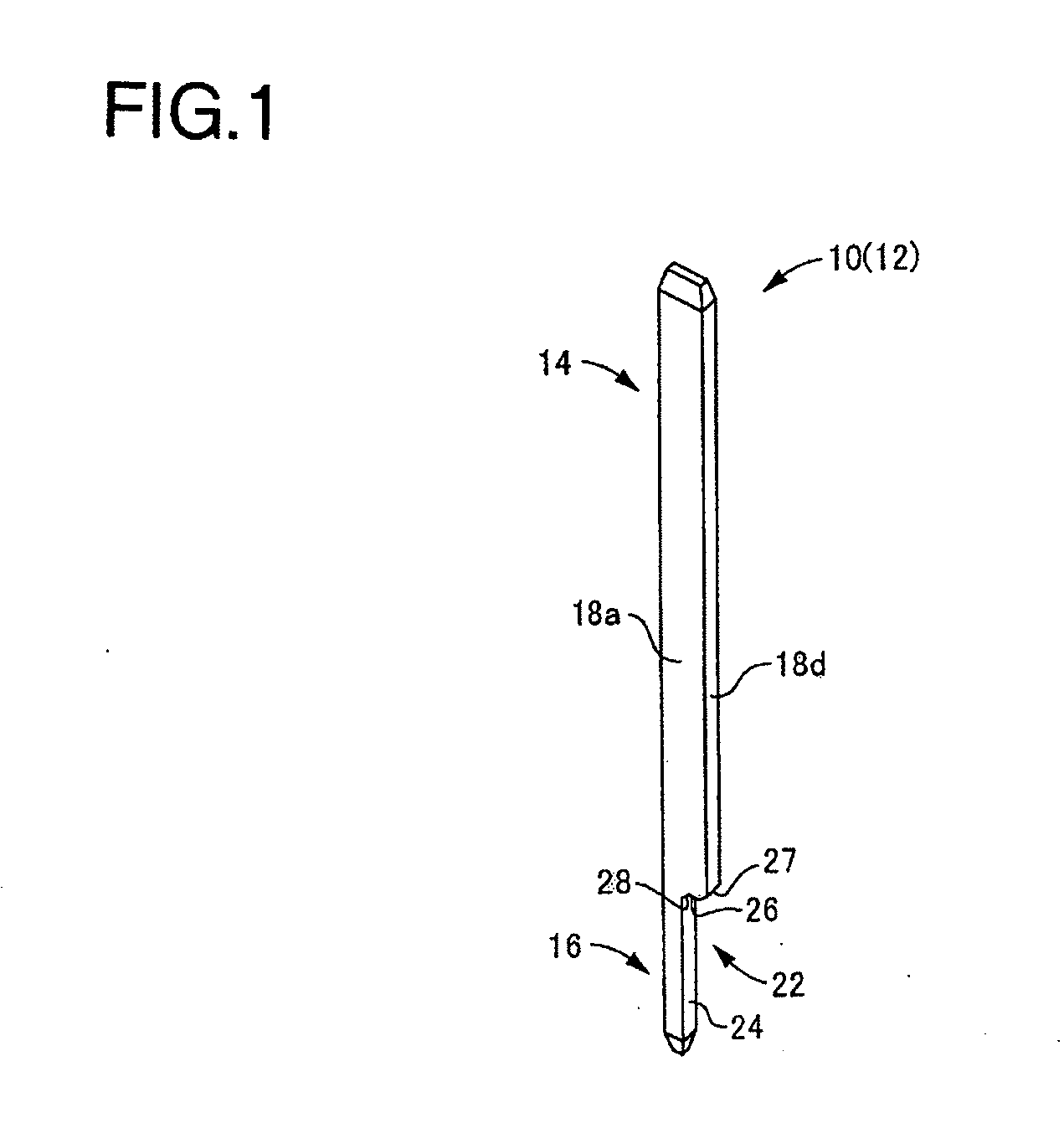

Printed circuit board terminal and printed circuit board connector having the same

ActiveUS20110111609A1Sufficient solder wettabilitySmall sizeContact member manufacturingSoldered/welded conductive connectionsEngineeringPrinted circuit board

A printed circuit board terminal includes a rectangular metal wire rod having a substantially rectangle cross-section. One longitudinal end portion of the printed circuit board terminal includes an insertion portion that is configured to be inserted into a through hole provided in a printed circuit board and soldered. A conducting metal plated layer is provided on an entire surface of the rectangular metal wire rod. One marginal portion of the insertion portion, which faces a long side direction of the rectangle cross-section, is removed to reduce a dimension in the long side direction corresponding to a width direction.

Owner:SUMITOMO WIRING SYST LTD

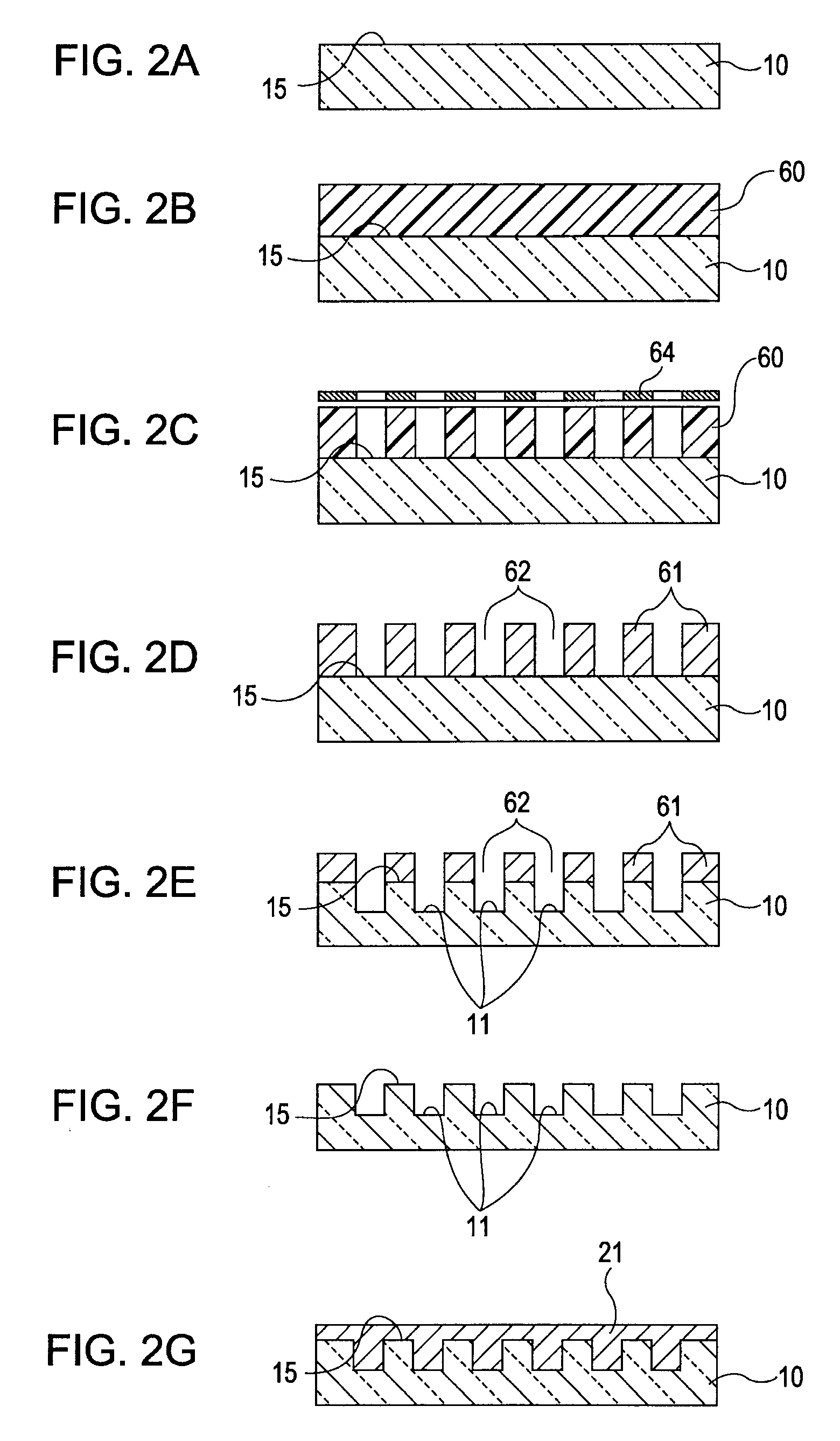

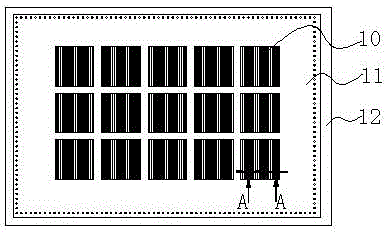

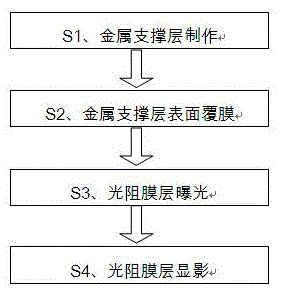

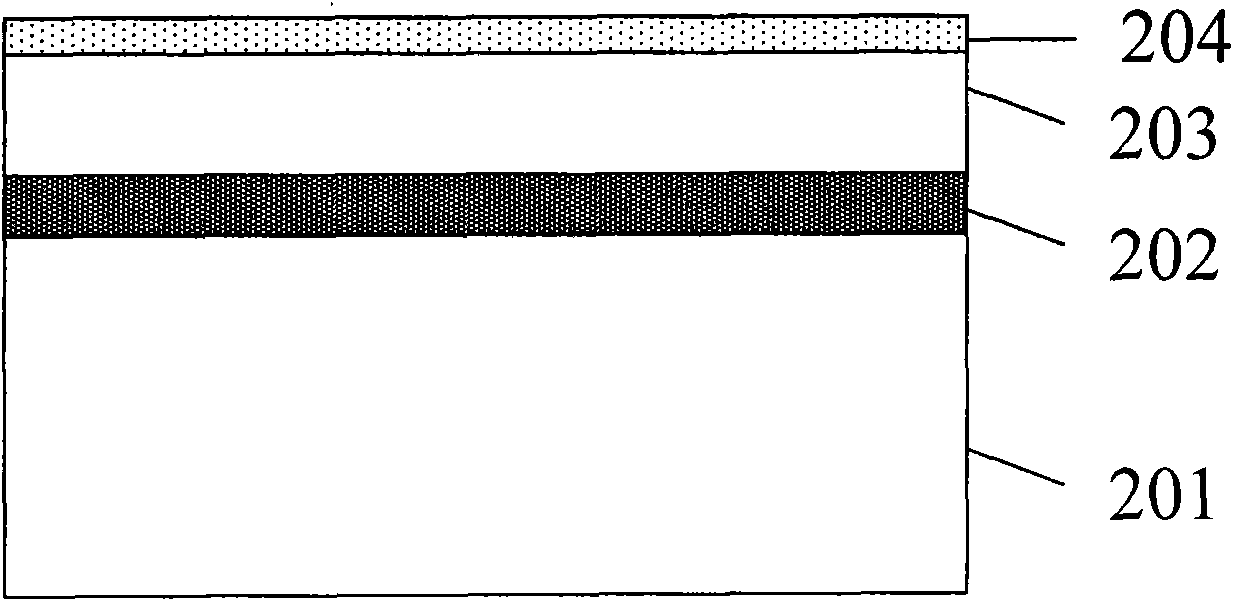

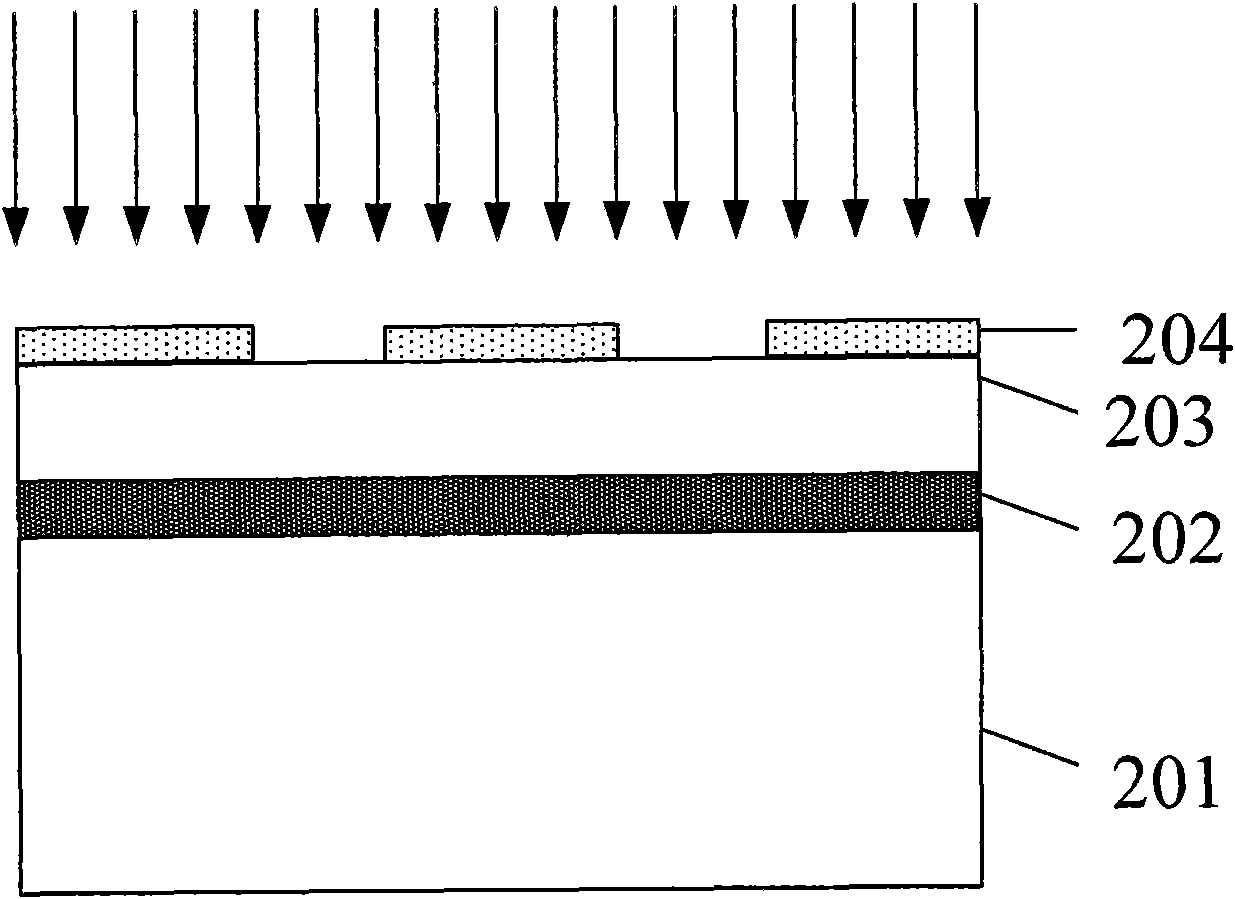

Method for manufacturing magnetic mask plate for coating by evaporation

InactiveCN105063553AReduce width sizeHigh resolutionVacuum evaporation coatingSolid-state devicesImage resolutionEvaporation

The invention discloses a method for manufacturing a mask plate. The method is completely different from an existing etching process, and includes the steps that 1, a metal supporting layer is manufactured; 2, the surface of the metal supporting layer is covered with a film; 3, the light-blocking film layer is subjected to exposure; and 4, the light-blocking film layer is developed. According to the magnetic mask plate manufactured through the method, the organic mask layer of the mask plate can be quite thin, the width of an opening is further made smaller, and therefore the finally formed magnetic mask plate can be subjected to coating by evaporation to form OLED products of higher resolution ratios.

Owner:KUN SHAN POWER STENCIL

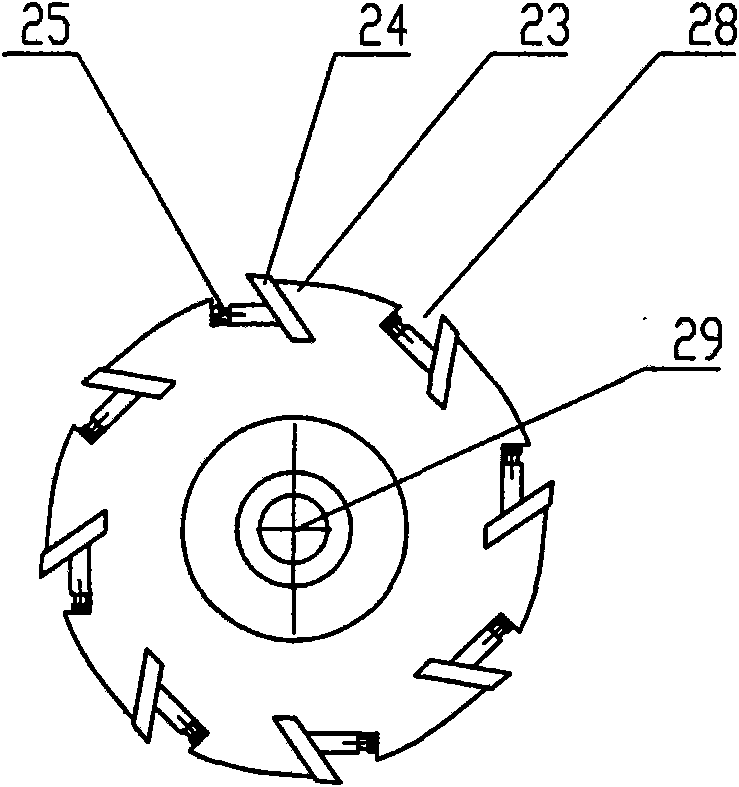

Arranging method of layered fluidization air distribution plate of fluidized bed boiler

ActiveCN1948831AImprove mixing conditionsRealize large-scaleFluidized bed combustionApparatus for fluidised bed combustionAir volumeCombustion

The invention adopts a multi-layer arrangement method of a fluidized-bed boiler bottom air-feeding plates and the integral hearth bottom consists of three independent air-feeding plates. One air-feeding plate is disposed in the lowerest part of the hearth and on the above air-feeding plate are overlaid the other air-feeding plates, so as to realize the step charging, the step air-supply and the fractional combustion of the recirculating fluidized-bed boiler. By regulating the blast volume and the fuel flow of each air-feeding plate, the uniform combustion and air-supply of the boiler can be realizer.

Owner:SHANGHAI BOILER WORKS

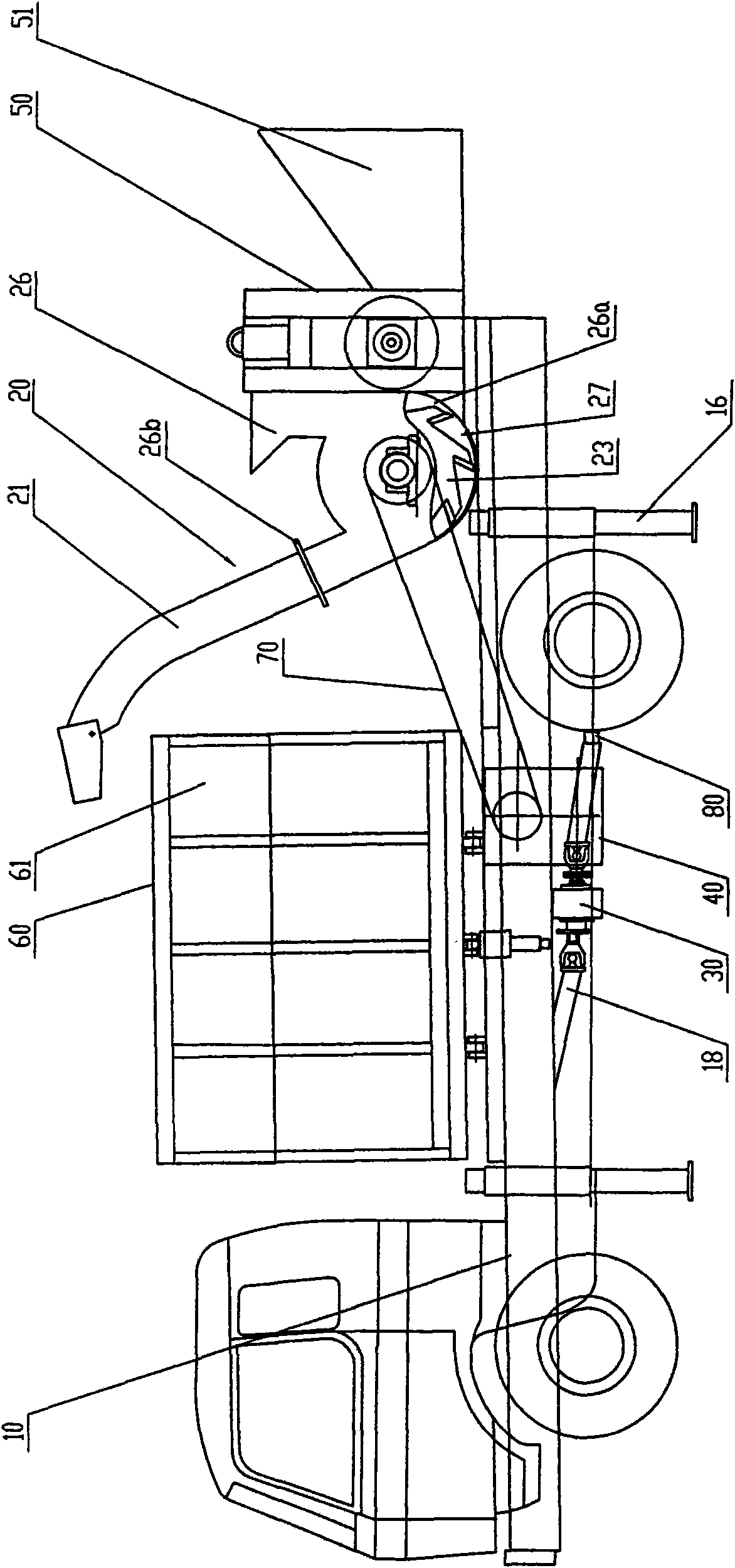

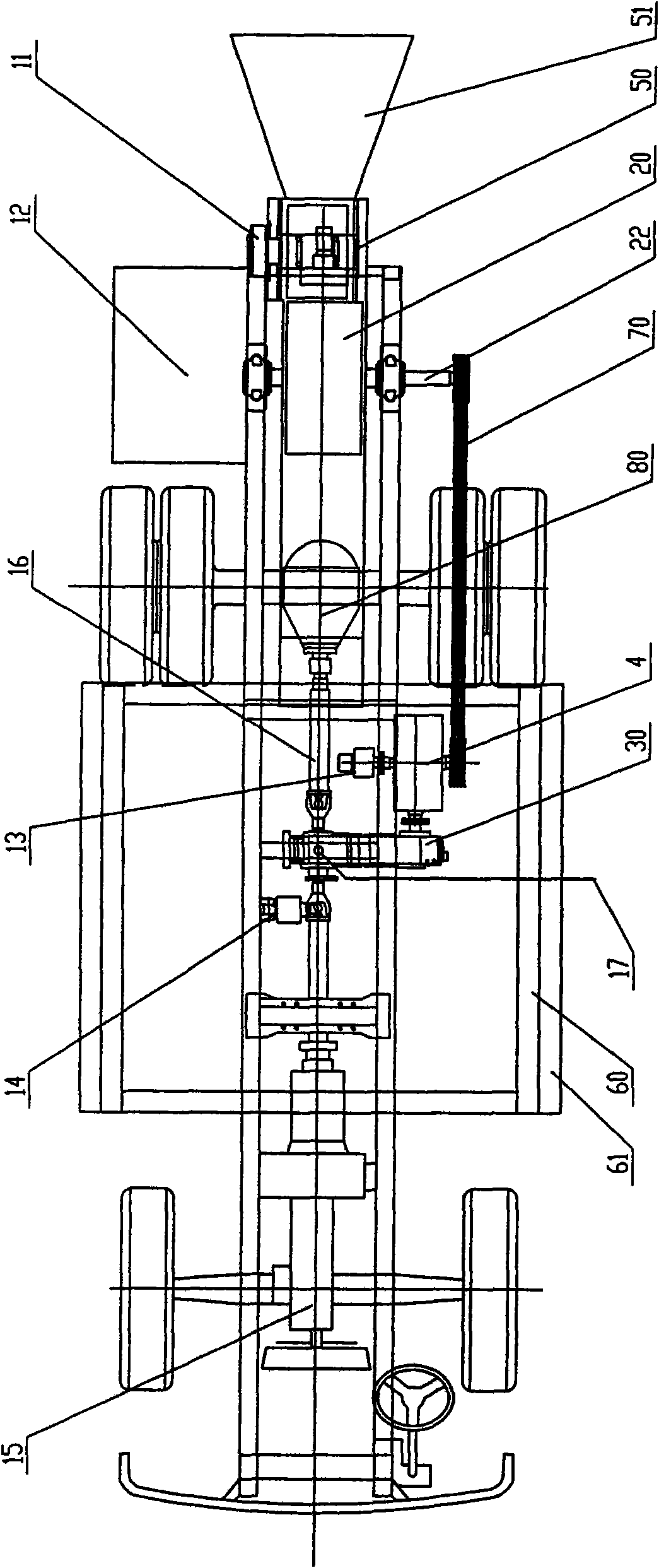

Branch crushing vehicle

The invention relates to a branch crushing vehicle. The vehicle comprises a chassis, a transmission shaft, a power distributor, a gear case, a material storage bin, a belt transmission mechanism, a crusher, a hydraulic valve, a hydraulic pump, a hydraulic motor, an engine, a rear axle and support legs, wherein the engine, the hydraulic pump, the power distributor, the gear case and the rear axle are fixed on the lower side of the chassis of the vehicle; the crusher and the material storage bin are arranged above the chassis of the vehicle; the transmission shaft is connected with an output shaft of a gear box of the engine and an input shaft of the power distributor, and a first output shaft of the power distributor is connected with a transmission input shaft of the gear case; and both ends of a transmission output shaft of the gear case are in transmission connection with the belt transmission mechanism and the hydraulic pump respectively, the belt transmission mechanism and the hydraulic pump are in transmission connection with a cutter head shaft and a feeding roller of the crusher respectively, and a second output shaft is connected with the rear axle. The vehicle has the advantages that: branches are crushed at any time and in any place, the conveying efficiency is improved, and the operating cost is lowered; because the milling mode is adopted for cutting, the crushing efficiency is high; and the occupied area is small, and the vehicle hardly affects traffic when working.

Owner:NANJING AGRICULTURAL UNIVERSITY

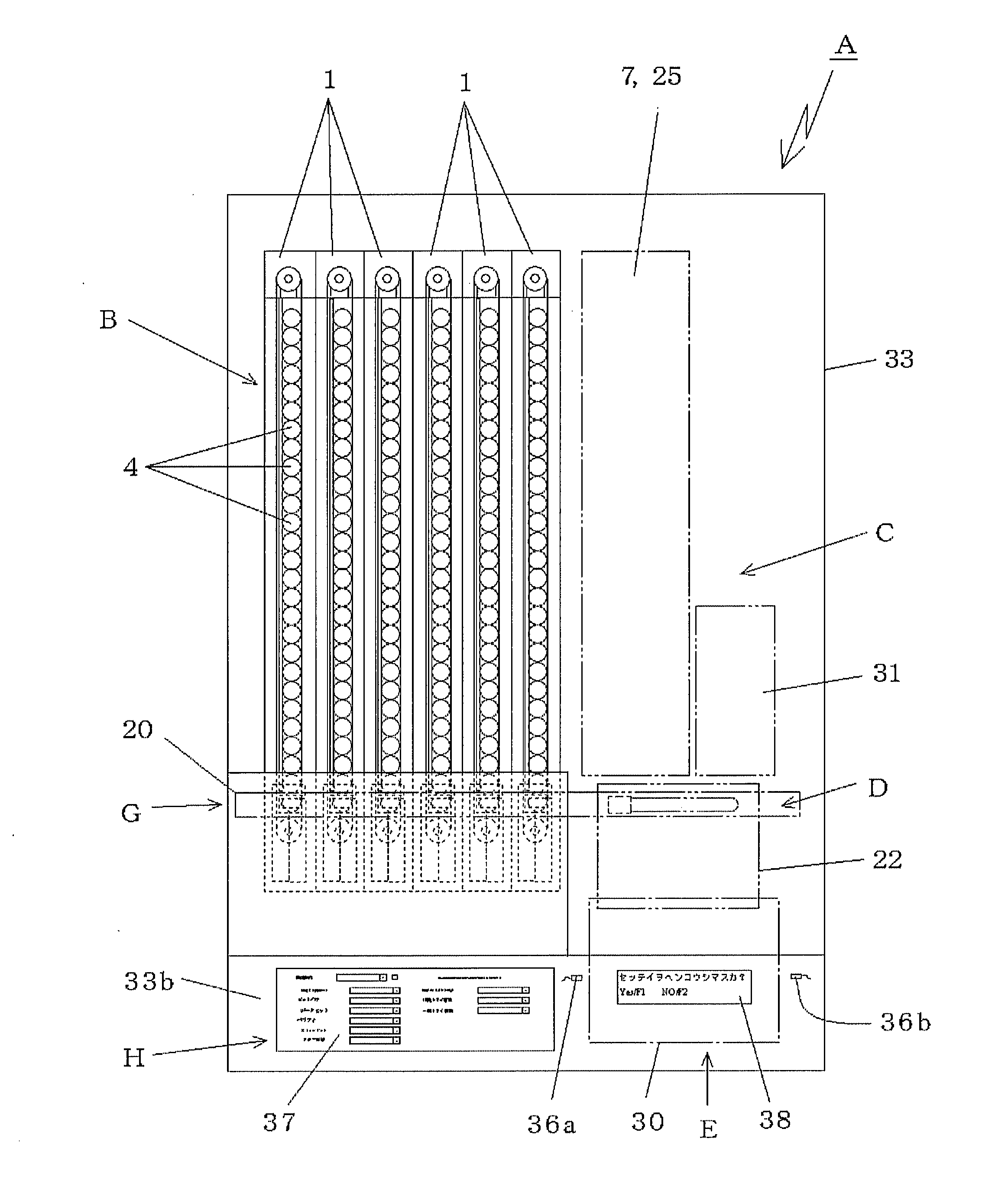

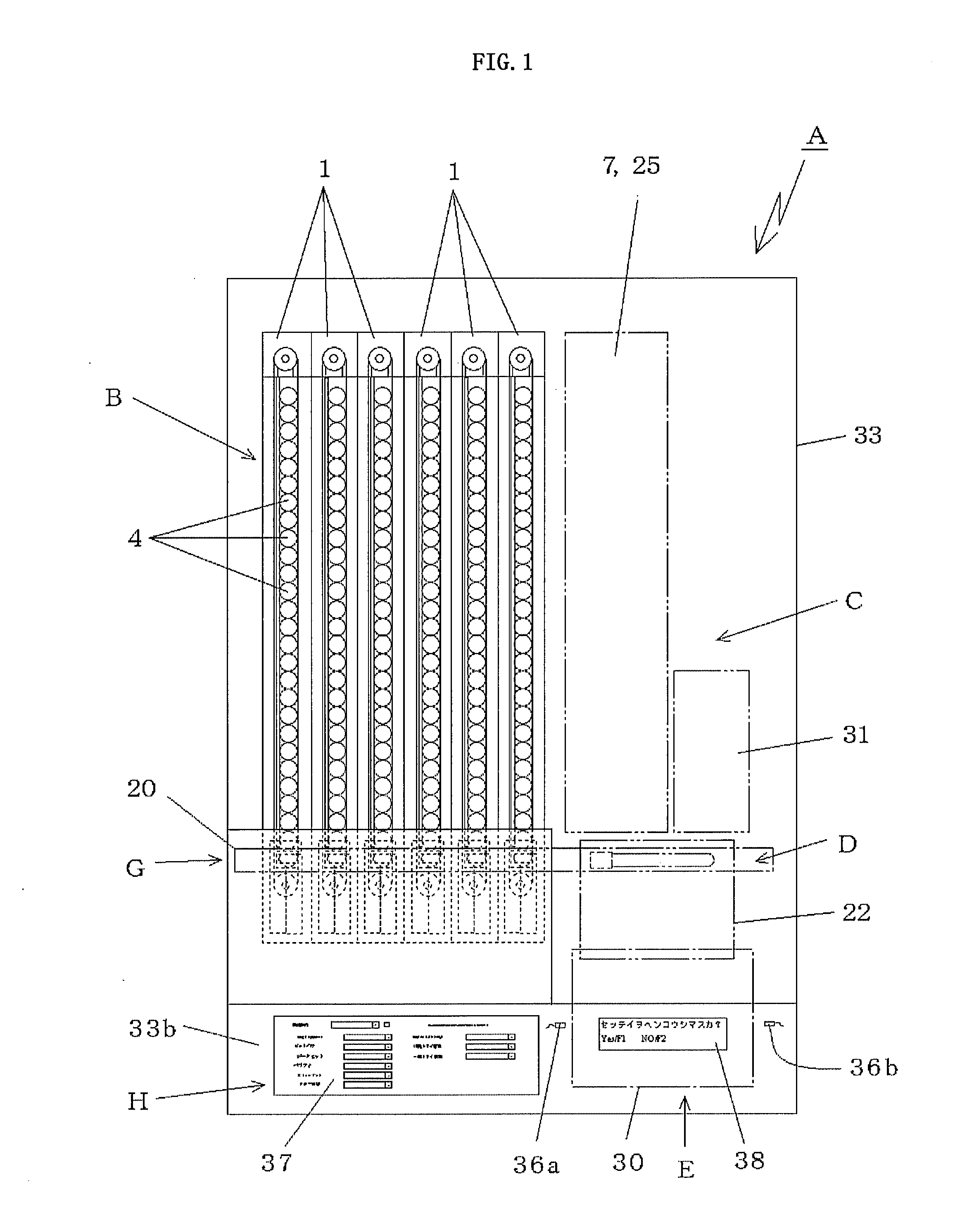

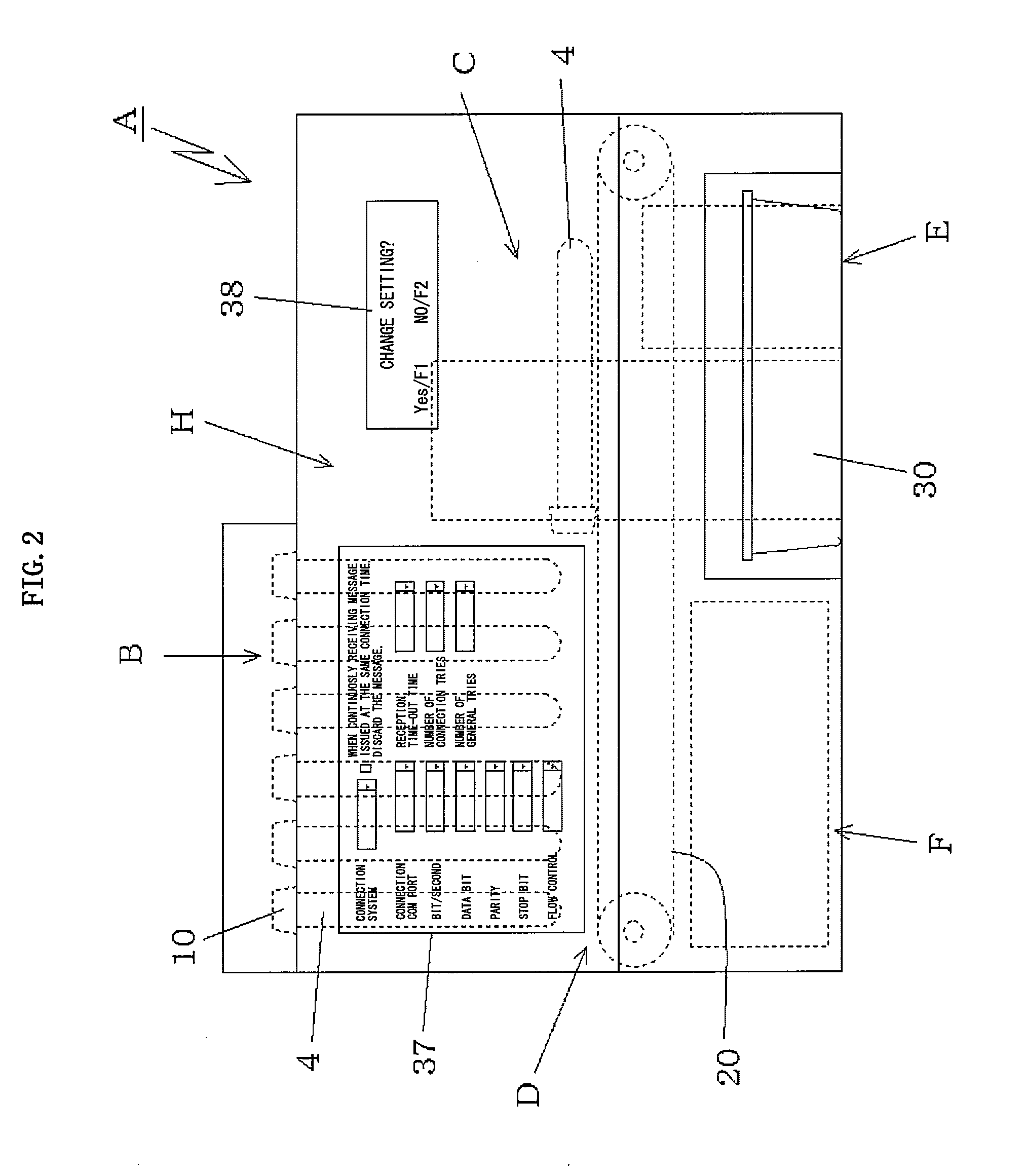

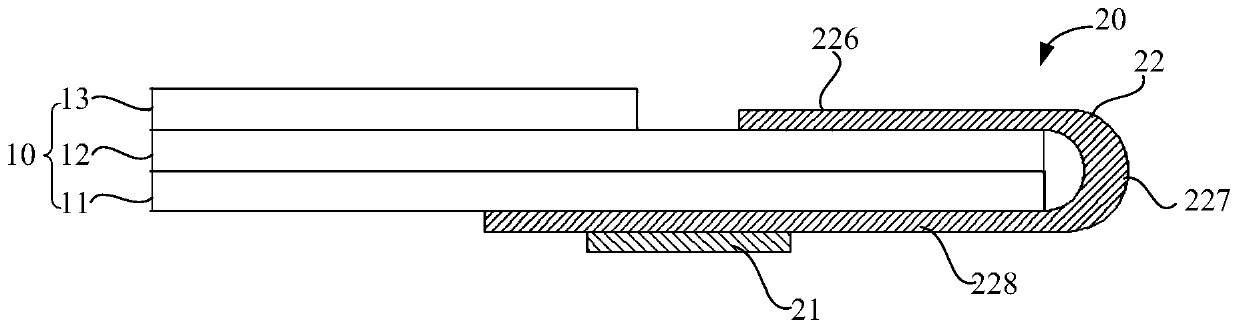

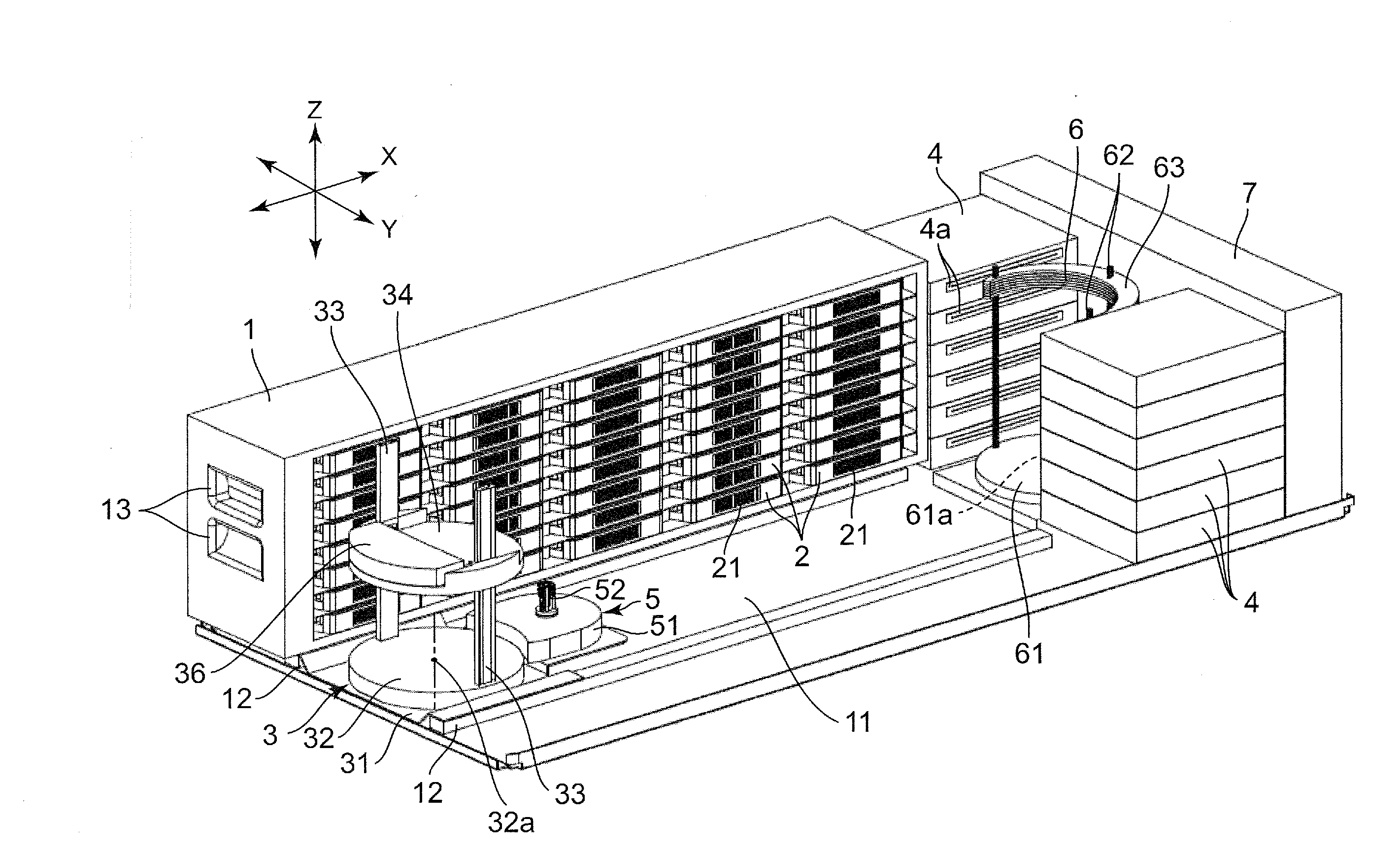

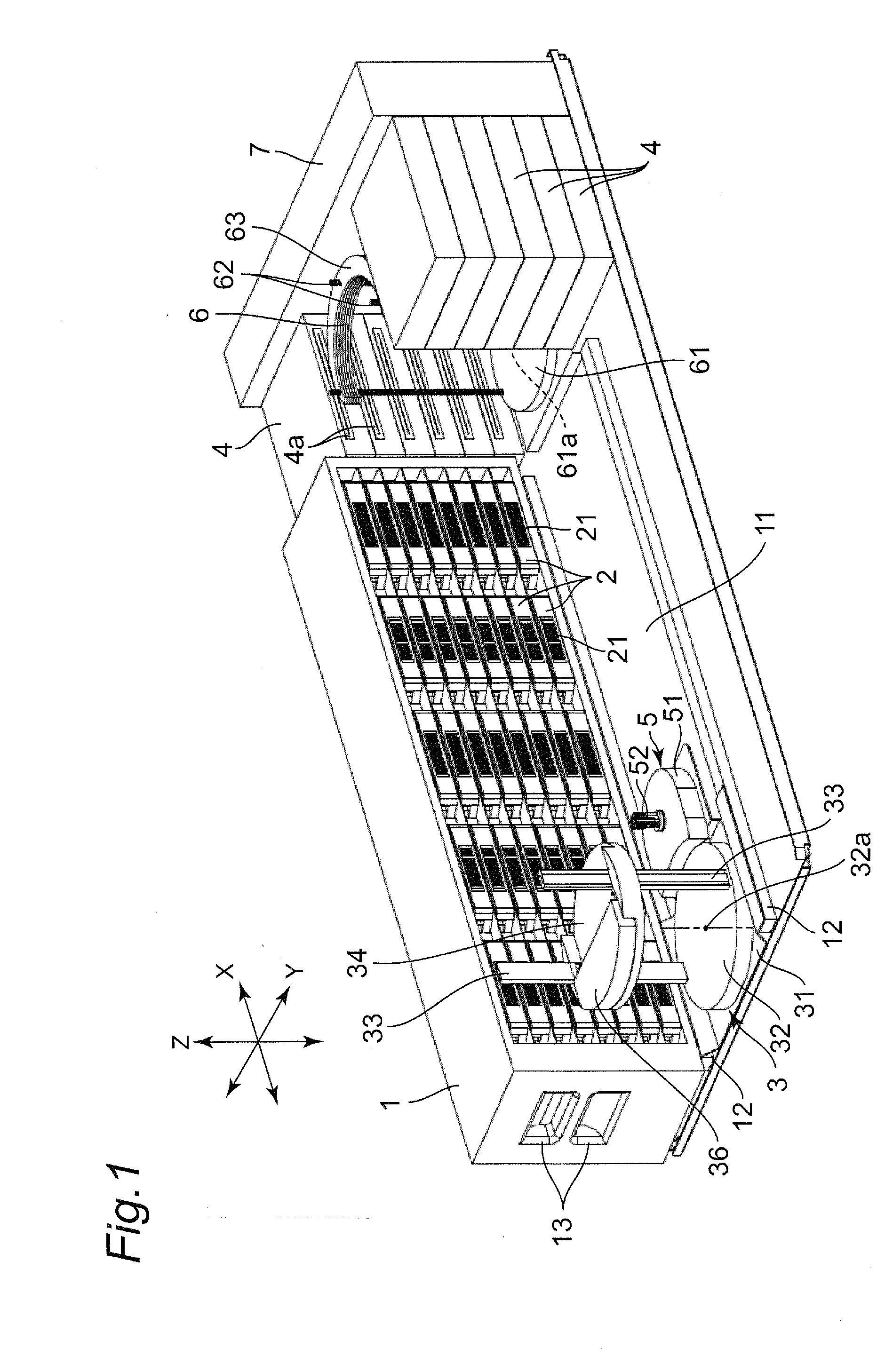

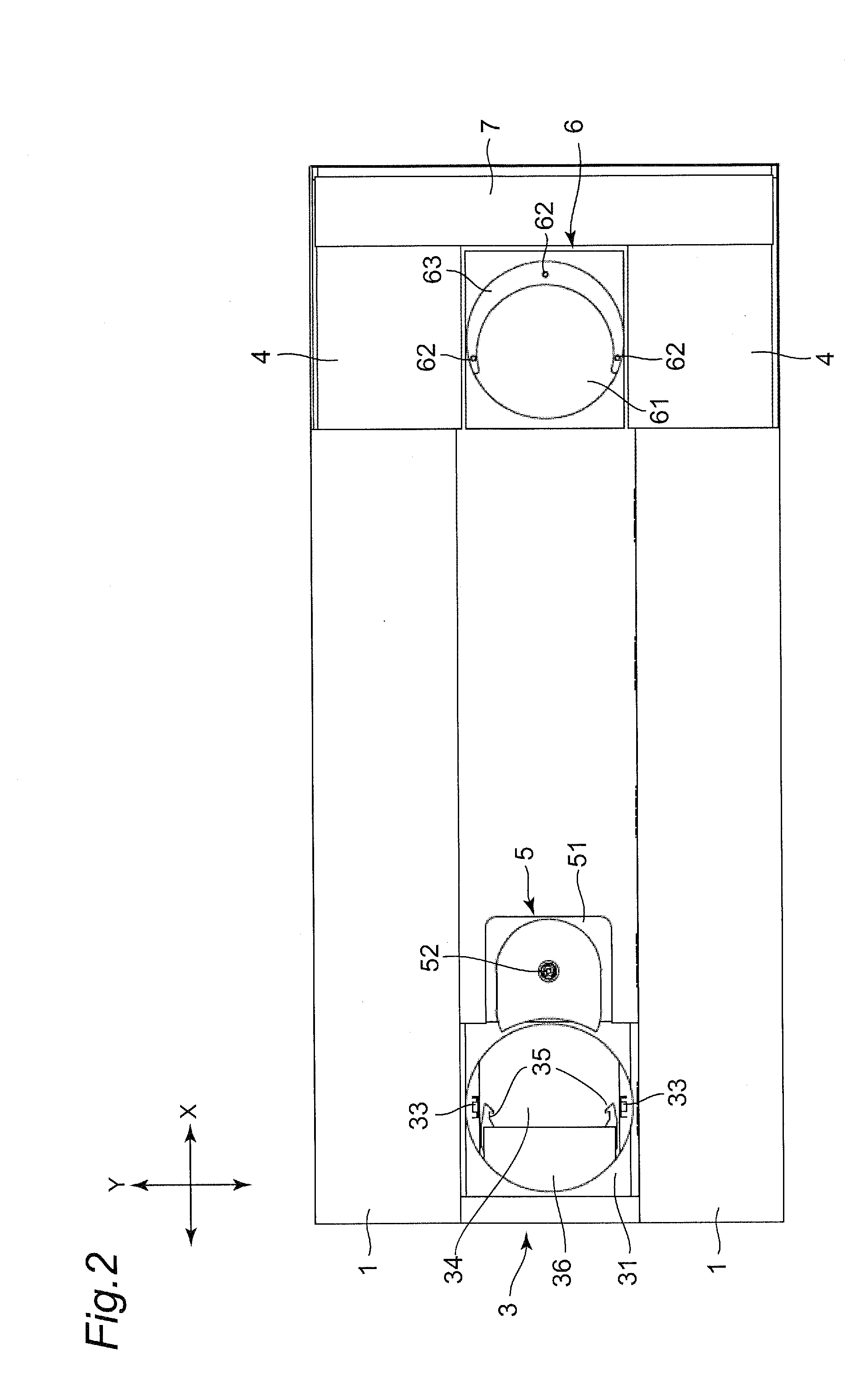

Blood collection tube storage box and blood collection tube preparing apparatus

InactiveUS20110173927A1Reduce width sizePharmaceutical product form changeSolid materialBlood Collection TubeMedicine

Provided is a blood collection tube preparing apparatus which is simple, downsized, portable, capable of being easily placed on a desk or the like, excellent in responding to an emergency such as a disaster, and capable of preparing various kinds of blood collection tubes depending on a blood collection instruction from a doctor. A blood collection tube holding member is arranged along one transferring belt and between a forward-side transferring belt and a backward-side transferring belt of the one transferring belt, and lower end surfaces of a cap of a blood collection tube is supported on upper end surfaces of the blood collection tube holding member and the forward-side transferring belt. The forward-side transferring belt applies a transferring force to the blood collection tube through the cap. Further, the members constituting a storage box are accommodated in one module, and the storage box is detachably mounted onto a mounting portion of an apparatus main body. Further, the storage box is in the form of module, and hence an operation in the case of failure or during maintenance is significantly facilitated.

Owner:AFC MINNESOTA

Foldable pushcart and foldable baby carriage

InactiveUS20090102163A1Small sizeSimple structureCarriage/perambulator accessoriesCarriage/perambulator with single axisEngineeringIntermediate region

A baby carriage includes: a pair of front legs; a pair of connecting members; a pair of guide sleeves respectively fixed to intermediate regions of the pair of front legs, a pair of rear legs having their upper ends pivotally connected to the connecting members, respectively; a pair of push bars slidably held by the pair of connecting members and the pair of guide sleeves, respectively; a pair of slide members provided slidably on upper regions of the pair of rear legs, respectively; a back cross member having its upper end pivotally connected to the pair of slide members and its lower end pivotally connected to respective lower regions of the pair of rear legs; and a bottom cross member having its front end pivotally connected to respective lower ends of the pair of push bars, and its rear end pivotally connected to respective intermediate regions of the pair of rear legs.

Owner:APRICA CHILDRENS PROD

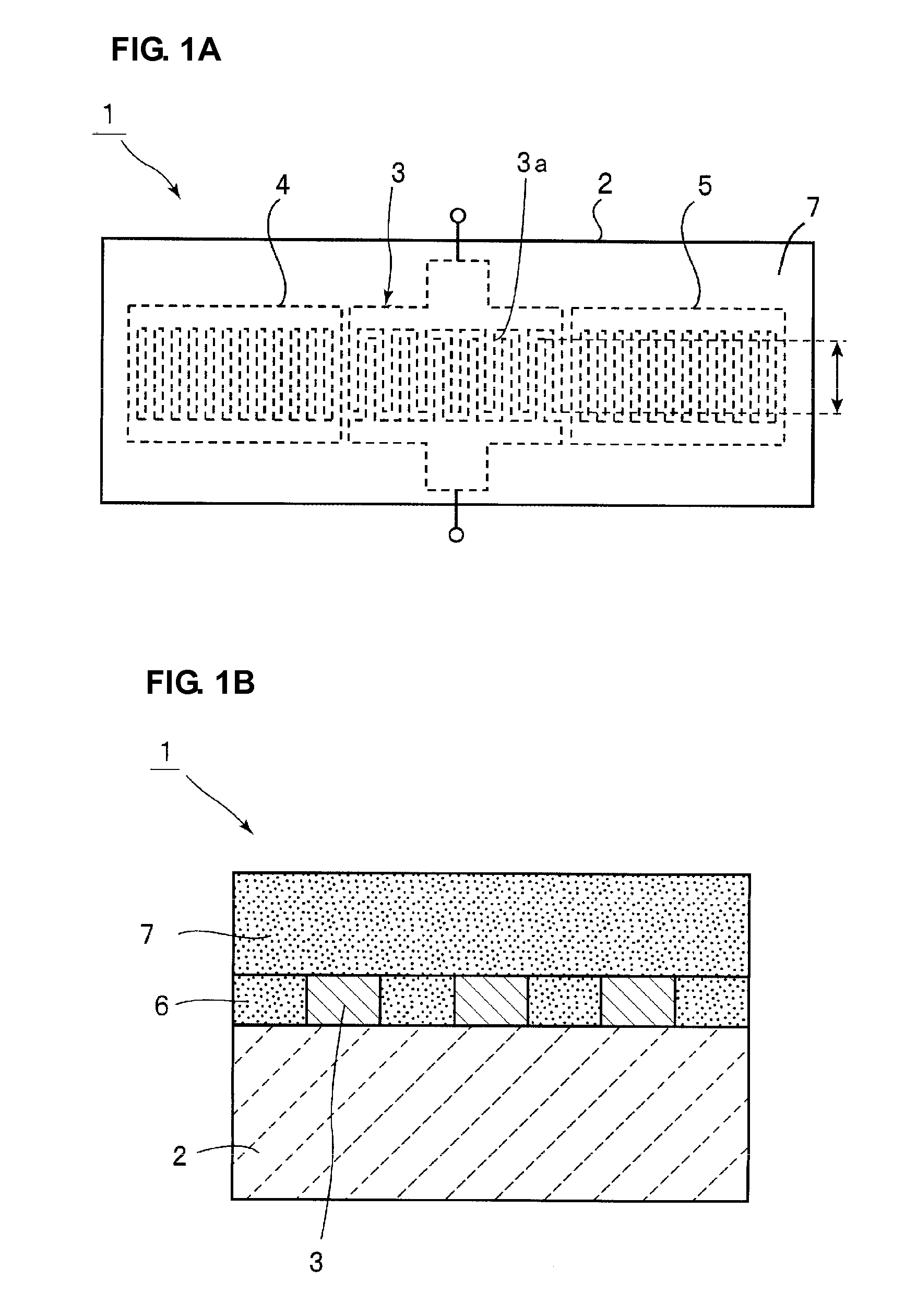

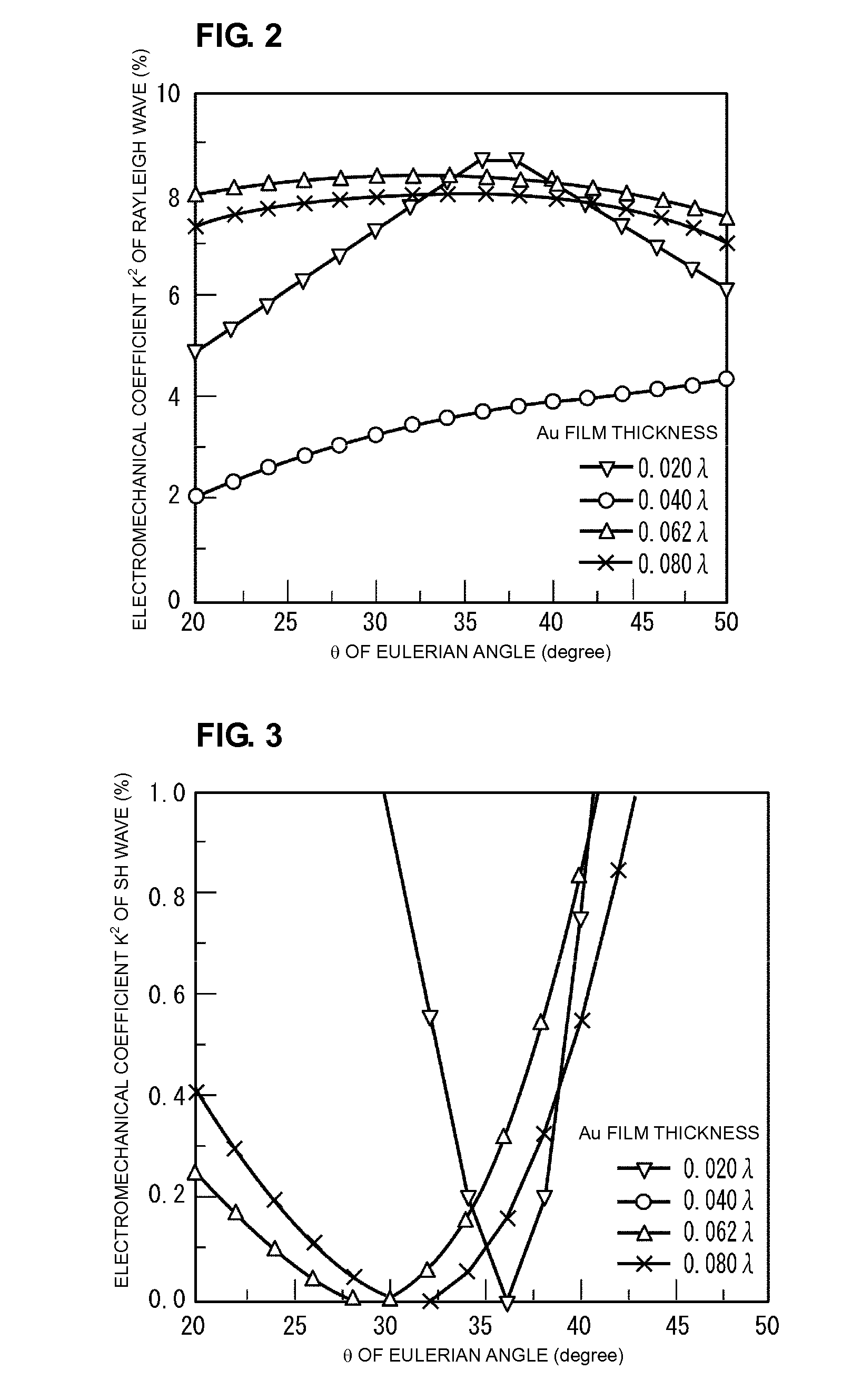

Surface acoustic wave device

ActiveUS20090009028A1Reduce lossReduce width sizeImpedence networksPiezoelectric/electrostriction/magnetostriction machinesRayleigh waveEuler angles

A surface acoustic wave device utilizing a Rayleigh wave includes a LiNbO3 substrate having Euler angles of (0°±5°, 0±5°, 0°±10°), an electrode which is disposed on the LiNbO3 substrate and which includes an IDT electrode primarily including Au, a first silicon oxide film disposed in a region other than the region in which the above-described electrode is disposed, the first silicon oxide film having a film thickness substantially equal to the thickness of the above-described electrode, and a second silicon oxide film arranged to cover the electrode and the first silicon oxide film, wherein the film thickness of the electrode is in the range of about 0.062λ to about 0.14λ, where λ represents the wavelength of a surface acoustic wave, and θ of the above-described Euler angles of (0°±5°, 0±5°, 0°±10°) is in the range satisfying the following Formula (1):θ=31.72−206.92×exp (−1×TAu / 0.0138) Formula (1)where TAu is a value of Au electrode film thickness normalized with the wavelength λ.

Owner:MURATA MFG CO LTD

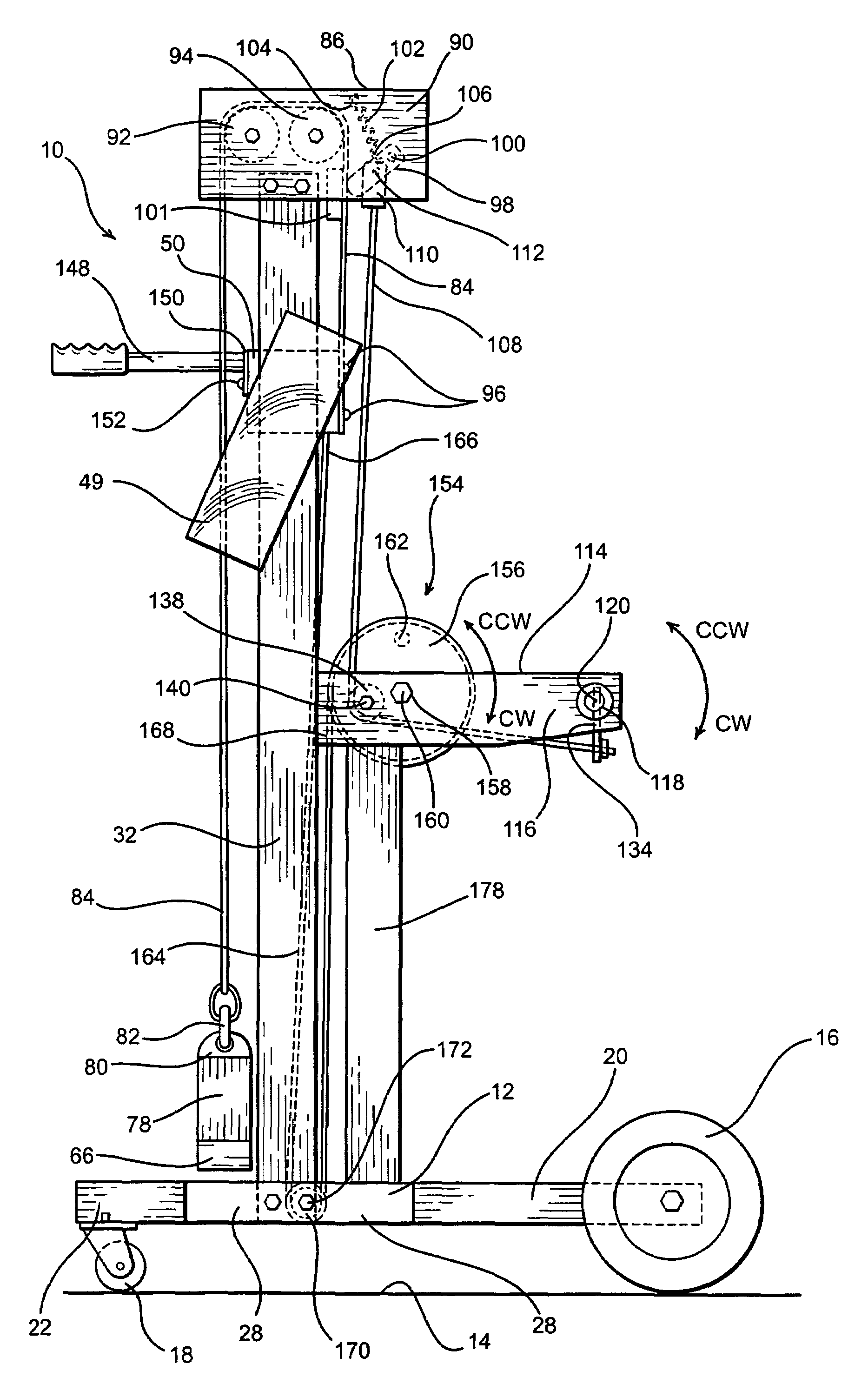

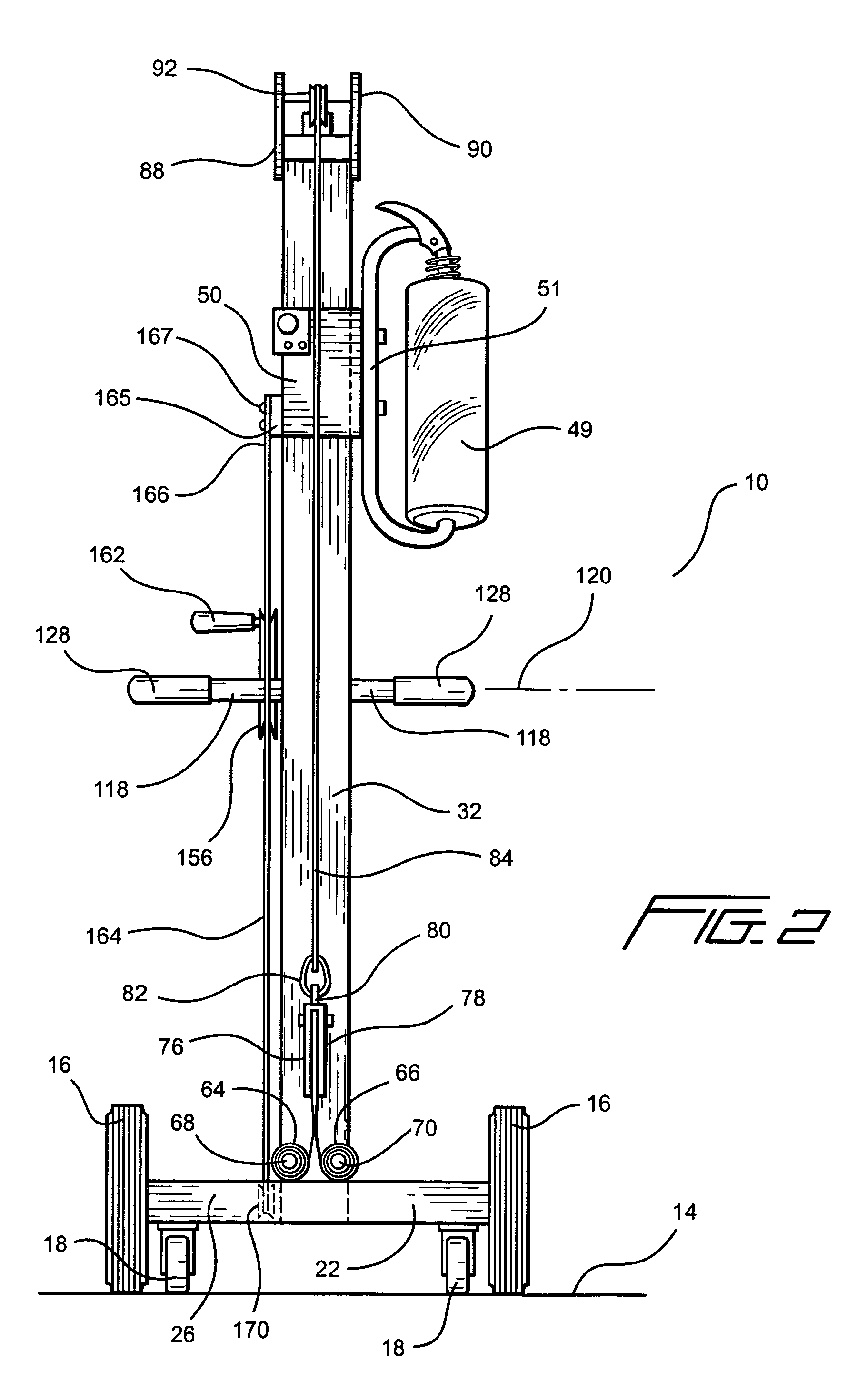

Film wrapping apparatus with negator spring biasing members

InactiveUS7051492B2Reduced overall height dimensionReduce width sizeWeb rotation wrappingBinding material applicationEngineeringPlastic film

A portable plastic film wrapping system comprises a push-cart having a vertical mast member mounted thereon, and a film roll carriage is vertically movable along the mast member. The film roll carriage is operatively connected to negator spring members by a film roll carriage lift cable, and a holding pawl mechanism is adapted to be movable between ENGAGED and DISENGAGED positions with respect to the film roll carriage lift cable. When the holding pawl mechanism is moved to its DISENGAGED position, the negator spring members cause the film roll carriage to be vertically elevated, whereas when the holding pawl mechanism is disposed at its ENGAGED position, movement of the film roll carriage lift cable, and the film roll carriage, is effectively prevented. The film roll carriage can also be controllably moved in both upward and downward directions so as to achieve bottom-to-top, as well as top-to-bottom, wrapping modes of operation upon palletized loads.

Owner:ILLINOIS TOOL WORKS INC

Flexible circuit board and manufacturing method thereof, display device and mobile terminal

ActiveCN110536542AReduce footprint widthReduce border widthPrinted circuit detailsPrinted circuit aspectsFlexible circuitsDisplay device

The invention provides a flexible circuit board and a manufacturing method thereof, a display device and a mobile terminal. The flexible circuit board comprises a body and a bending portion arranged on one side of the body. The bending portion is bent along a bending line relative to the body. The bending portion comprises a flexible substrate and a conductive layer. The conductive layer is arranged on the flexible substrate, a first stress groove is arranged in one side surface, facing the flexible substrate, of the conductive layer, a second stress groove is arranged in the other side surface of the conductive layer, and the first stress groove and the second stress groove extend along a direction parallel to a bending line. By using the display device and the mobile terminal of the flexible circuit board, an occupied width of the flexible circuit board can be reduced by bending the bending portion of the flexible circuit board so that frame widths of the display device and the mobile terminal are reduced, and a narrow frame design is realized.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Disc device

ActiveUS20130263162A1Increase in size of apparatus can be suppressedConveying time can be reducedRecord information storageRecord carrier contruction detailsMechanical engineeringOptical disc

A disc device which takes out a disc stored in a magazine and conveys the disc to any disc drive, in which the magazine comprises a tray which stores a plurality of discs, and a case which has a substantially rectangular parallelepiped shape and which stores the tray. The case has an opening at front face into which the tray can be inserted into or taken out therefrom. The tray has an outer shape being substantially rectangular in planar view. The tray is provided with cut portions formed at corner portions positioned on the back side of the case being cut off. The disc device further comprises a picker which holds the tray and draws out the tray from the case. The picker rotates the tray when the cut portion passes through the opening.

Owner:PANASONIC CORP

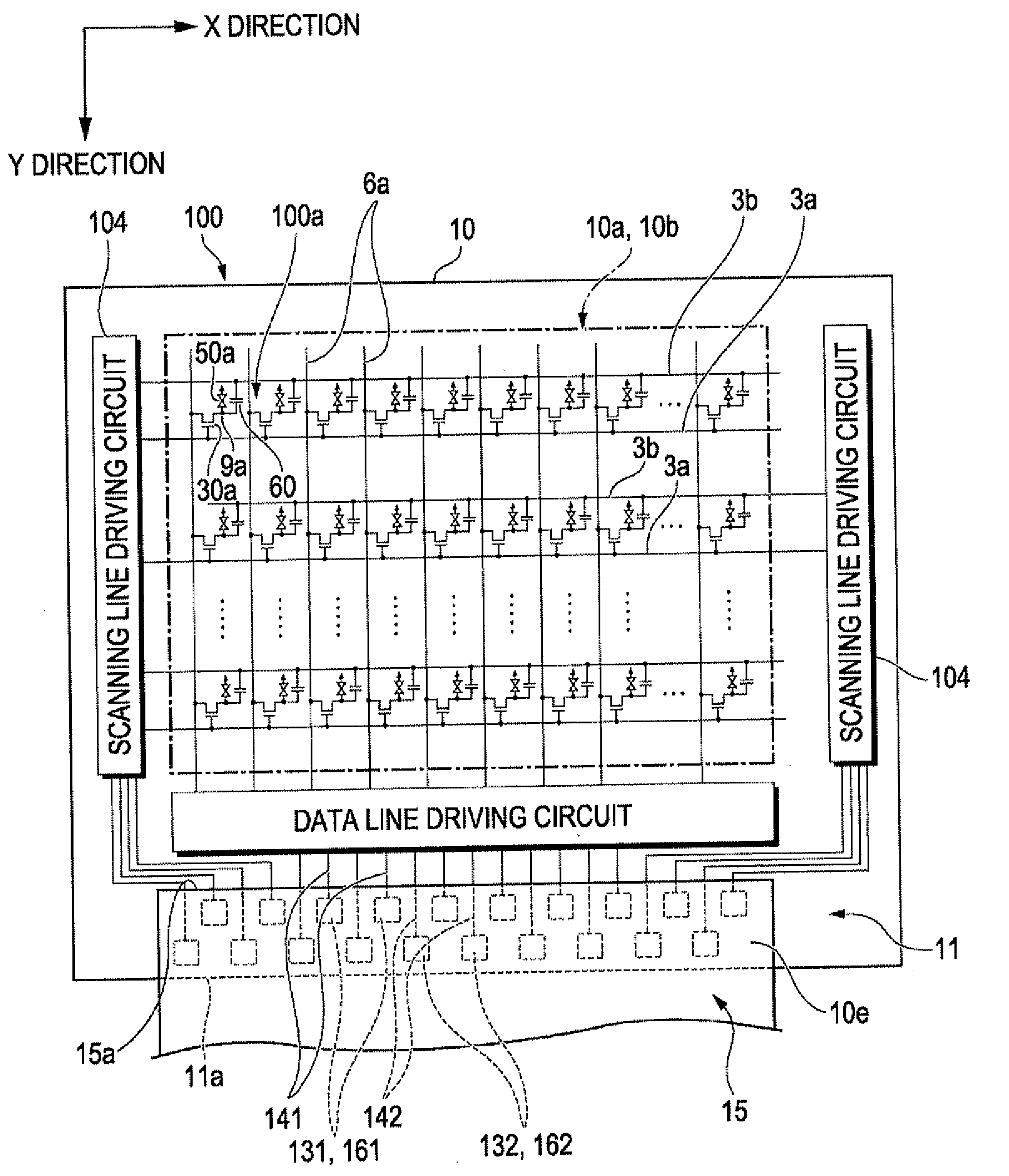

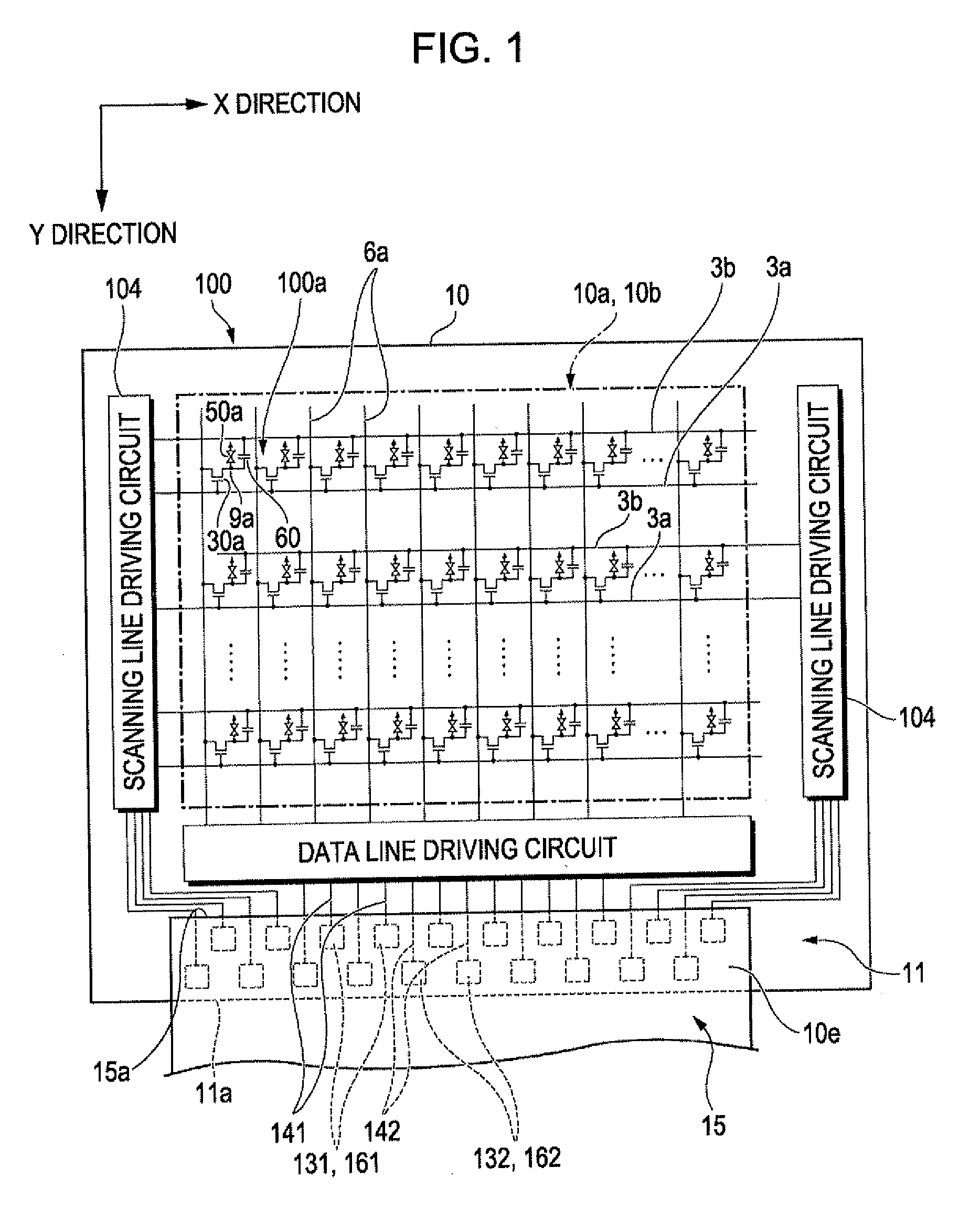

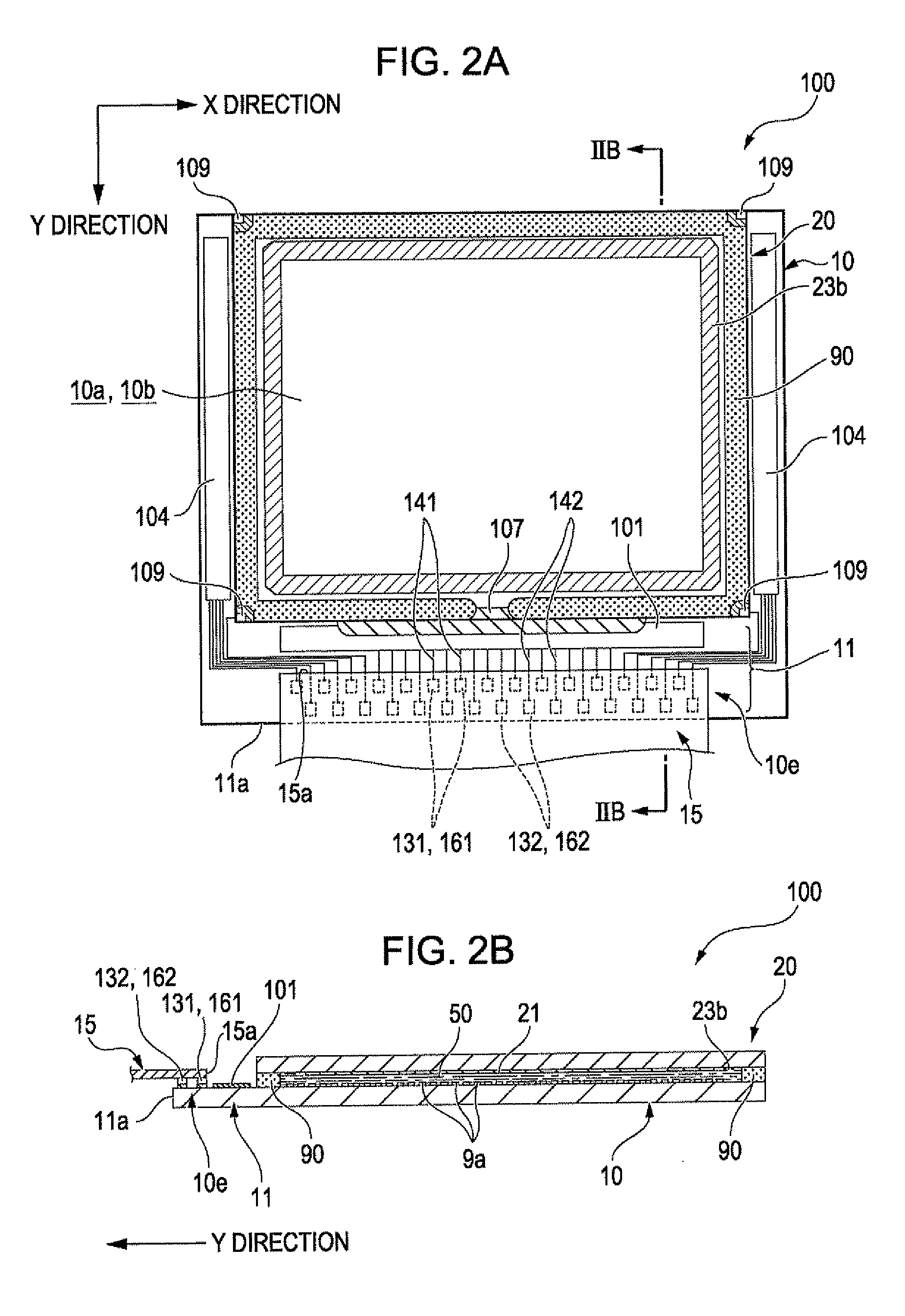

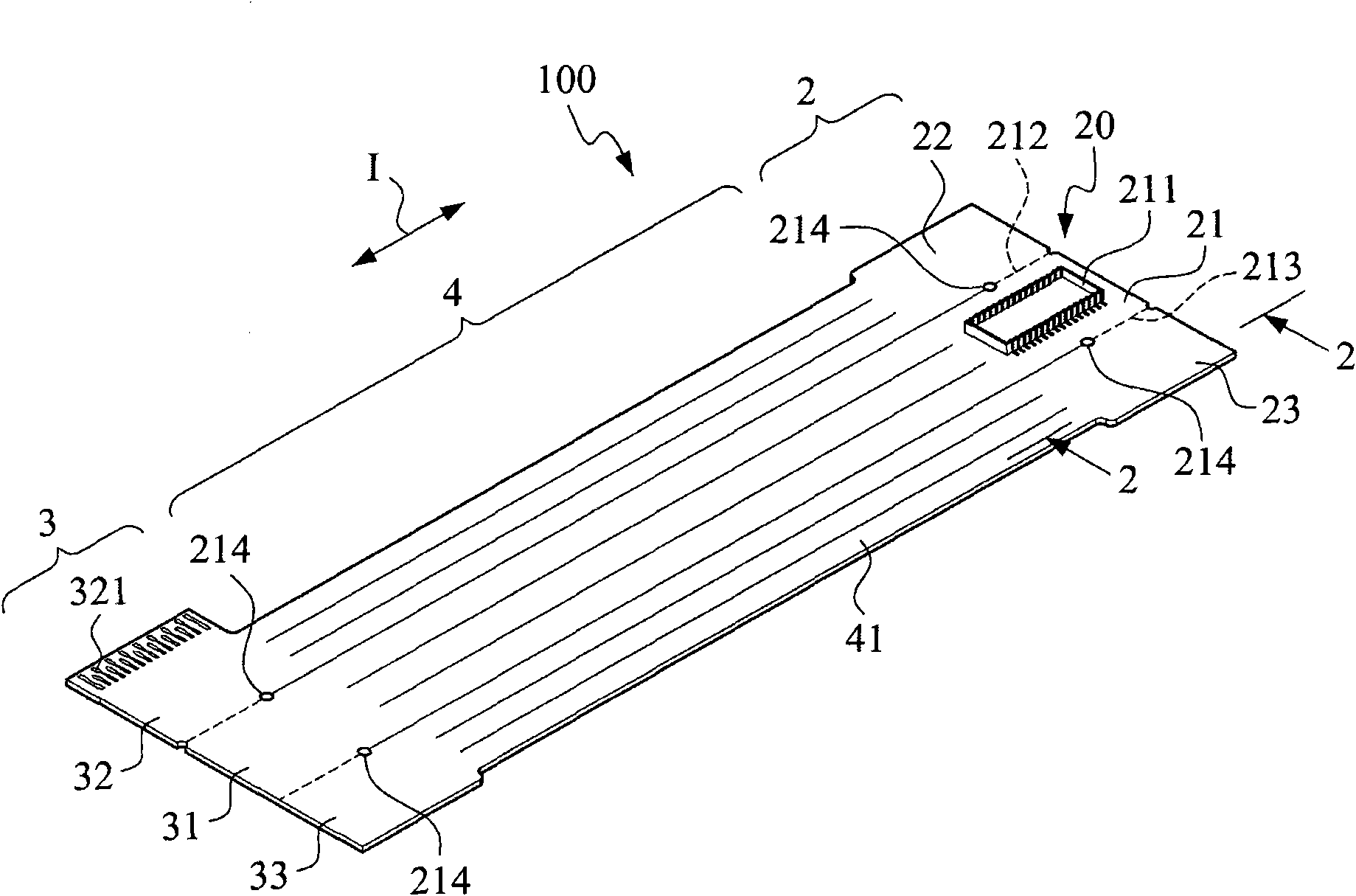

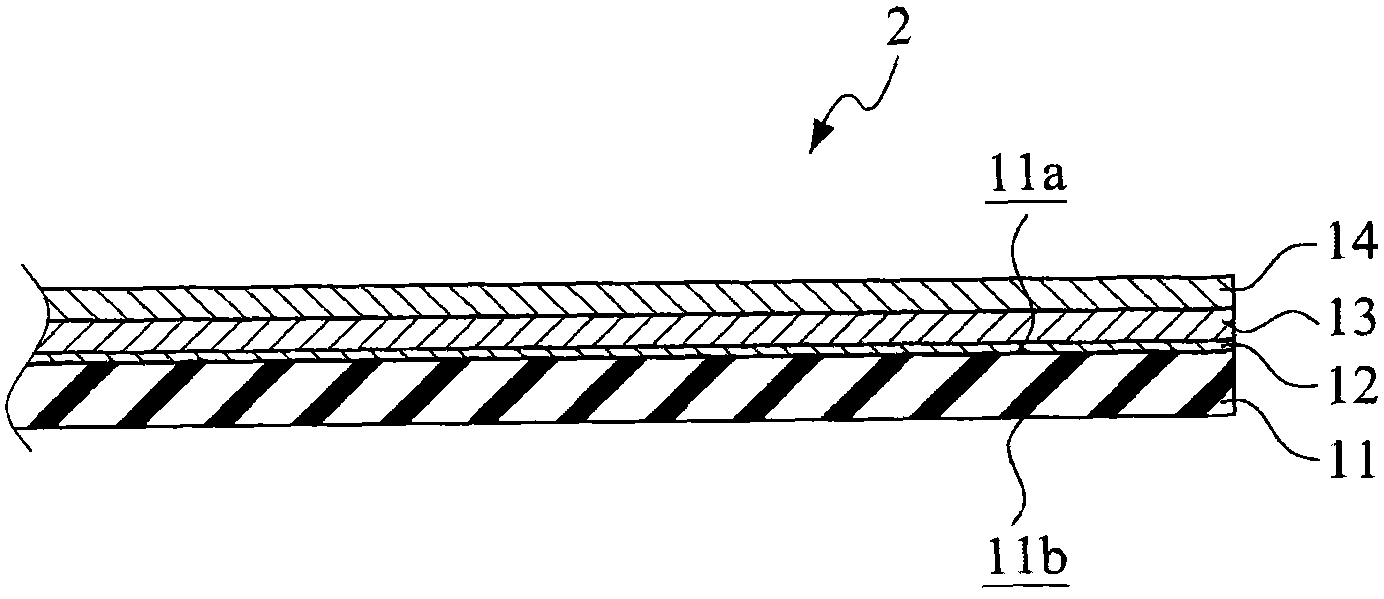

Mounting structure and electro optical device

ActiveUS20090225268A1Reliable electrical connectionIncrease the number ofDischarge tube luminescnet screensFinal product manufactureElectricity

Owner:SEIKO EPSON CORP

Fascicular flexible circuit busbar wire

ActiveCN102044310AReduce width sizeEasy to pass throughFlat/ribbon cablesFixed connectionsFlexible circuitsBusbar

The invention discloses a fascicular flexible circuit busbar wire. A flexible substrate comprises at least one cluster zone, at least one first connecting zone is formed at one end of the cluster zone, and at least one second connecting zone is formed at the other end of the cluster zone; both of the first connecting zone and the second connecting zone or one of the first connecting zone and the second connecting zone comprise an overlay structure; the flexible substrate can be in a single-sided board structure or a double-sided board structure and also can comprise an electromagnetic shielding layer; and a selected position in the cluster zone is rolled and bundled into a fascicular structure by using a rolling and bundling structure, and the rolling and bundling structure can be made of a shielding material, an insulating material or a combined shielding and insulating material.

Owner:ADVANCED FLEXIBLE CIRCUITS

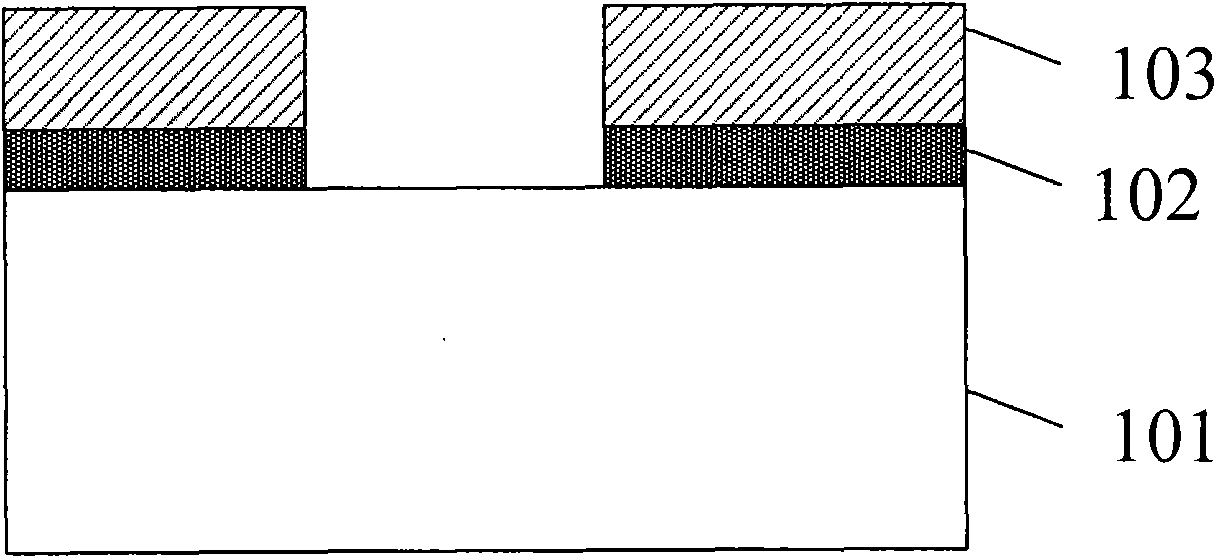

Manufacturing method of shallow groove isolation structure

InactiveCN101908500AImprove device integrationHighly integratedSemiconductor/solid-state device manufacturingPhotoresistSilicon nitride

The invention provides a manufacturing method of a shallow groove isolation structure, which is used for manufacturing the shallow groove isolation structure. A silicon-on-insulator orderly comprises a silicon substrate layer, an oxidation buried layer and a monocrystalline silicon top layer. The manufacturing method of the shallow groove isolation structure comprises the following steps of: depositing a layer of silicon dioxide and silicon nitride on the monocrystalline silicon top layer to serve as a hard screening layer, coating photoresist and exposing for development, etching the hard screening layer by means of dry etching, removing the residual photoresist, and exposing the position on the monocrystalline silicon top layer for manufacturing the shallow groove isolation structure; and performing oxygen ion implantation from upward side of the monocrystalline silicon top layer and annealing at high temperature to form a silicon dioxide isolation zone on the monocrystalline silicon top layer. The manufacturing method of the shallow groove isolation structure provided by the invention is not required to perform silicon dioxide deposition and chemical mechanical polishing to the shallow groove and can improve the component integration level so as to enhance the integration level, simplify the manufacturing flow and reduce the cost.

Owner:GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com